Mitsubishi MUZ-A09NA, MUZ-A12NA, MUZ-A15NA, MUZ-A17NA, MUZ-A24NA Service Manual

...

SPLIT-TYPE, HEAT PUMP AIR CONDITIONERS

OUTDOOR UNIT

HFC

utilized

R410A

SERVICE MANUAL

Wireless type

Models

No. OB451

MUZ-A09NA MUZ-A09NAMUZ-A12NA MUZ-A12NAMUZ-A15NA MUZ-A15NAMUZ-A17NA MUZ-A17NAMUZ-A24NA MUZ-A24NAMUY-A15NA

MUY-A17NA

MUY-A24NA

MUZ-A09NA MUY-A15NA

MUZ-A12NA MUY-A17NA

MUZ-A15NA

CONTENTS

1. TECHNICAL CHANGES ····································2

2. PART NAMES AND FUNCTIONS······················5

3. SPECIFICATION·················································6

4. OUTLINES AND DIMENSIONS·······················10

5. WIRING DIAGRAM···········································11

6. REFRIGERANT SYSTEM DIAGRAM··············15

7. DATA·································································17

8. ACTUA TOR CONTROL····································30

9. SERVICE FUNCTIONS ····································31

10. TROUBLESHOOTING ······································31

11. DISASSEMBLY INSTRUCTIONS·····················59

12. PARTS LIST······················································66

12-1. PARTS LIST ·············································66

12-2. RoHS PARTS LIST··································72

13. OPTIONAL PARTS ·························BACK PAGE

Indoor unit service manual

MSZ-A•NA Series (OB450)

U1

U1

U1

U1

U1

NOTE:

This service manual describes technical data of the outdoor units.

RoHS compliant products have <G> mark on the spec name plate.

For servicing of RoHS compliant products, refer to the PARTS

LIST (RoHS compliant).

TM

1

Refrigeration

oil

Refrigerant

New refrigerant

R410A

HFC-32: HFC-125 (50%:50%)

Pseudo-azeotropic refrigerant

Not included

A1/A1

72.6

-60.5

225.82

3.995

Non combustible

0

1730

From liquid phase in cylinder

Possible

Incompatible oil

Non

Non

Previous refrigerant

R22

R22 (100%)

Single refrigerant

Included

A1

86.5

-41.4

136.34

2.772

Non combustible

0.055

1700

Gas phase

Possible

Compatible oil

Light yellow

Non

Refrigerant

Composition (Ratio)

Refrigerant handling

Chlorine

Safety group (ASHRAE)

Molecular weight

Boiling point (°F)

Steam pressure [77°F](PSIG)

Saturated steam density [77°F](lb/ft

3

)

Combustibility

ODP w1

GWP w2

Refrigerant charge method

Additional charge on leakage

Kind

Color

Smell

w1:Ozone Destruction Parameter : based on CFC-11

w2 :Global Warmth Parameter : based on CO

2

TECHNICAL CHANGES

MUZ09UN ➔ MUZ-A09NA

MUZ12UN ➔ MUZ-A12NA

MUH15TN ➔ MUZ-A15NA

MUH17TN ➔ MUZ-A17NA

MUH24WN ➔ MUZ-A24NA

MU15TN ➔ MUY-A15NA

MU17TN ➔ MUY-A17NA

MU24WN ➔ MUY-A24NA

1. Outdoor unit model has been changed.

2. Control method between indoor and outdoor unit has been changed.

3. Refrigerant has been changed. (R22 ➔ R410A)

4. Fan motor has been changed. (AC ➔ DC)

5. Compressor has been changed. (AC ➔ DC)

INFORMATION FOR THE AIR CONDITIONER WITH R410A REFRIGERANT

• This room air conditioner adopts HFC refrigerant (R410A) which never destroys the ozone layer.

• Pay particular attention to the following points, though the basic installation procedure is same as that for R22 air

conditioners.

1 As R410A has working pressure approximate 1.6 times as high as that of R22, some special tools and piping parts/

materials are required. Refer to the table below.

2 Take sufficient care not to allow water and other contaminations to enter the R410Arefrigerant during storage and

installation, since it is more susceptible to contaminations than R22.

3 For refrigerant piping, use clean, pressure-proof parts/materials specifically designed for R410A. (Refer to 2. Refrigerant

piping.)

4 Composition change may occur in R410A since it is a mixed refrigerant. When charging, charge liquid refrigerant to prevent

composition change.

2

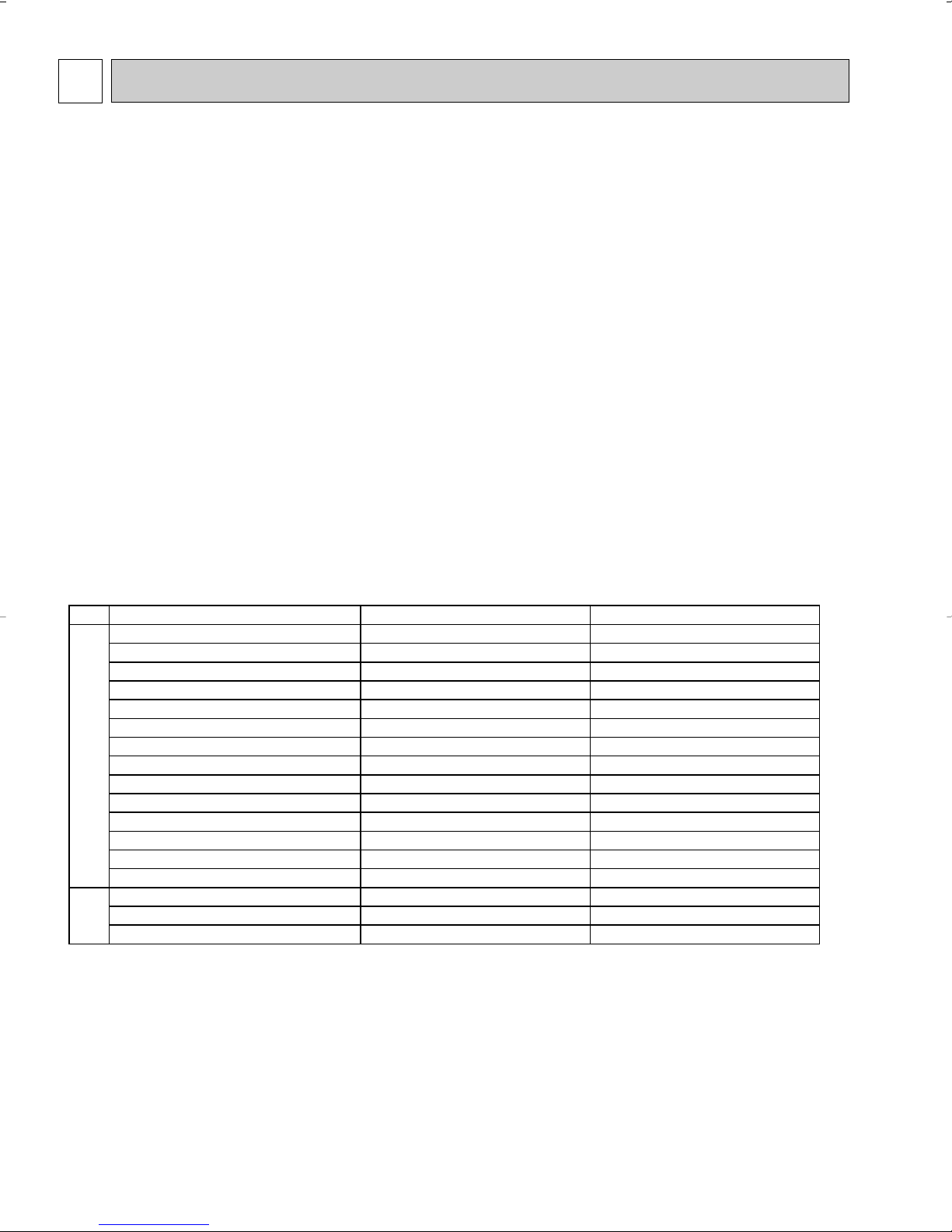

1.Tools dedicated for the air conditioner with R410A refrigerant

New Specification Current Specification

The incompatible refrigeration oil easily separates from

refrigerant and is in the upper layer inside the suction muffler.

Raising position of the oil back hole enables to back the

refrigeration oil of the upper layer to flow back to the

compressor.

Since refrigerant and refrigeration oil are compatible each,

refrigeration oil goes back to the compressor through the

lower position oil back hole.

Compressor

Suction muffler

Oil back hole

refrigeration oil

Refrigerant

Compressor

Suction muffler

Oil back hole

refrigeration oil /Refrigerant

Compressor

-22 -4 14 32 50 68

86

104 122 140

-73

0

73

145

218

290

363

435

508

580

(PSIG)

R410A

R22

Conversion chart of refrigerant temperature and pressure

Saturated liquid pressure

(°F)

The following tools are required for R410A refrigerant. Some R22 tools can be substituted for R410A tools.

R410A tools

Gauge manifold

Charge hose

Gas leak detector

Torque wrench

Can R22 tools be used?

No

No

No

Yes

No 1/2in. and 5/8in.

Flare tool

Flare gauge

Vacuum pump

adapter

Electronic scale for

refrigerant charging

No : Not Substitutable for R410A Yes : Substitutable for R410A

Yes

New

New

New

Description

R410A has high pressures beyond the measurement range of existing

gauges.

Hose material have been changed to improve the pressure resistance.

Dedicated for HFC refrigerant.

1/4in. and 3/8in.

Clamp bar hole has been enlarged to reinforce the spring strength in the tool.

Provided for flaring work (to be used with R22 flare tool).

Provided to prevent the back flow of oil. This adapter enables you to use

vacuum pumps.

It is difficult to measure R410A with a charging cylinder because the

refrigerant bubbles due to high pressure and high-speed vaporization

3

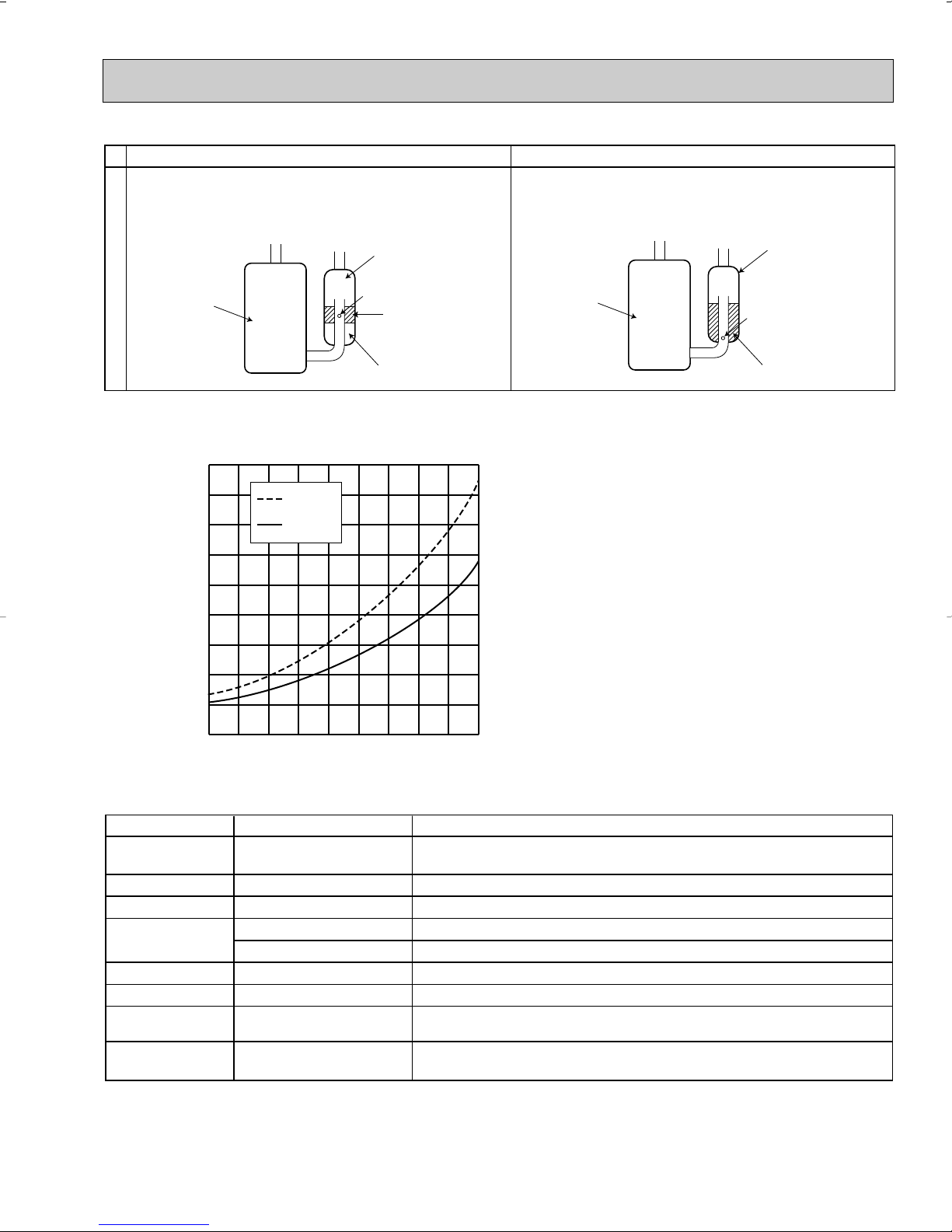

R410A

Pipe diameter

inch

1/4

3/8

1/2

5/8

17 (11/16)

22 (7/8)

26 (1-1/32)

29 (1-5/32)

Dimension of flare nut

R22

mm(in)

17 (11/16)

22 (7/8)

24 (15/16)

27 (1-1/16)

2.Refrigerant piping

Wall thickness (in)

Outside diameter(in)

1/4

3/8

1/2

5/8

0.0315

0.0315

0.0315

0.0394

Heat resisting foam plastic

Specific gravity 0.045 Thickness 0.315 in

Insulation material

Electronic scale for refrigerant charging

Outdoor unit

Refrigerant gas

cylinder

operating valve

Refrigerant gas cylinder

for R410A with siphon

Refrigerant (liquid)

Service port

Gauge manifold

valve (for R410A)

Union

Liquid pipe

Gas pipe

Stop valve

Indoor unit

Charge hose (for R410A)

1 Specifications

Use the copper or copper-alloy seamless pipes for refrigerant that meet the following specifications.

2 Flaring work and flare nut

Flaring work for R410A pipe differs from that for R22 pipe.

For details of flaring work, refer to Installation manual “FLARING WORK”.

3.Refrigerant oil

Apply the special refrigeration oil (accessories: packed with indoor unit) to the flare and the union seat surfaces.

4.Air purge

• Do not discharge the refrigerant into the atmosphere.

Take care not to discharge refrigerant into the atmosphere during installation, reinstallation, or repairs to the refrigerant

circuit.

• Use the vacuum pump for air purging for the purpose of environmental protection.

5.Additional charge

For additional charging, charge the refrigerant from liquid phase of the gas cylinder.

If the refrigerant is charged from the gas phase, composition change may occur in the refrigerant inside the cylinder and the

outdoor unit. In this case, ability of the refrigeration cycle decreases or normal operation can be impossible. However,

charging the liquid refrigerant all at once may cause the compressor to be locked. Thus, charge the refrigerant slowly.

4

2

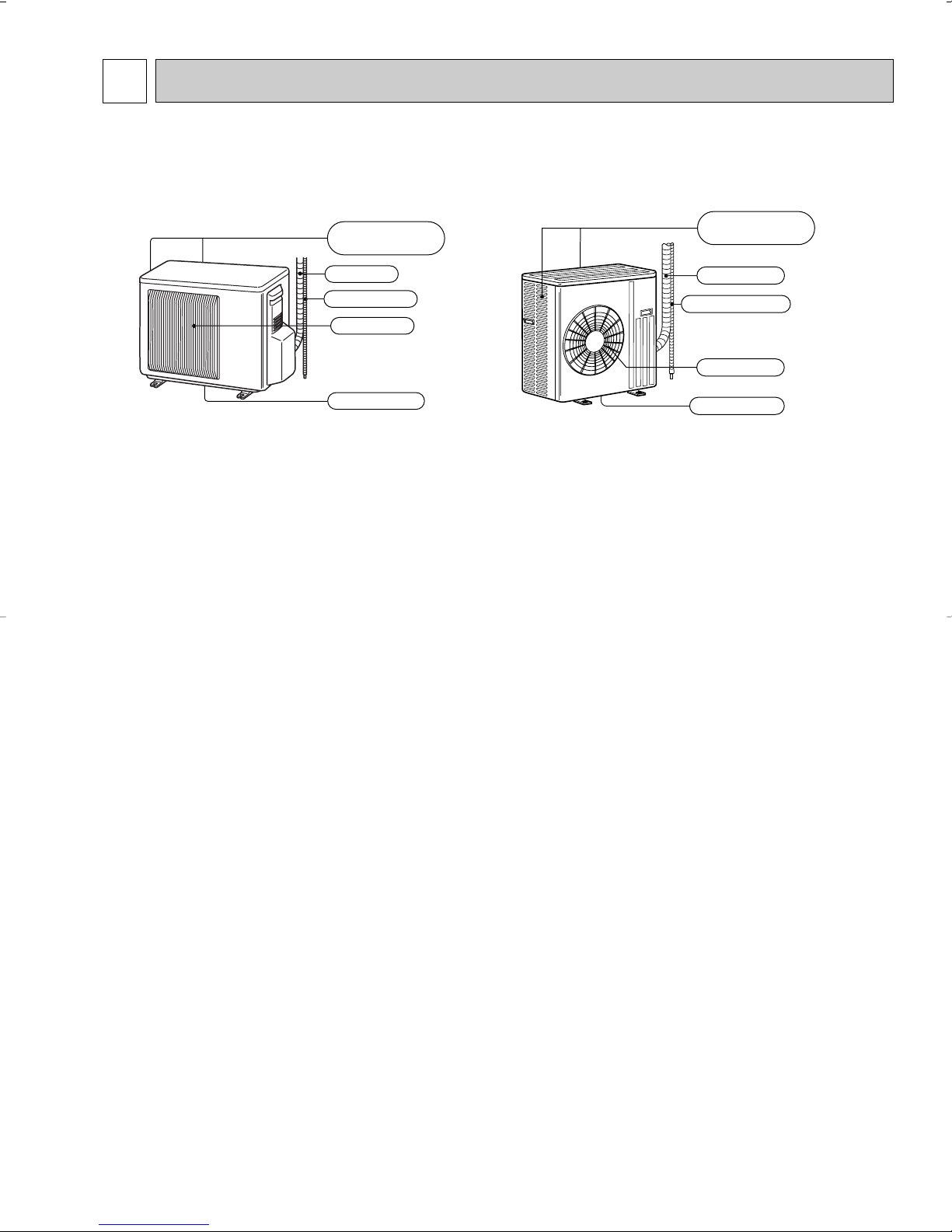

Air outlet

Drain outlet

Piping

Drain hose

Air inlet

(back and side)

Piping

Air outlet

Drain hose

Drain outlet

Air inlet

(back and side)

PART NAMES AND FUNCTIONS

MUZ-A09NA MUZ-A15NA MUY-A15NA

MUZ-A12NA MUZ-A17NA MUY-A17NA

MUZ-A24NA

MUY-A24NA

5

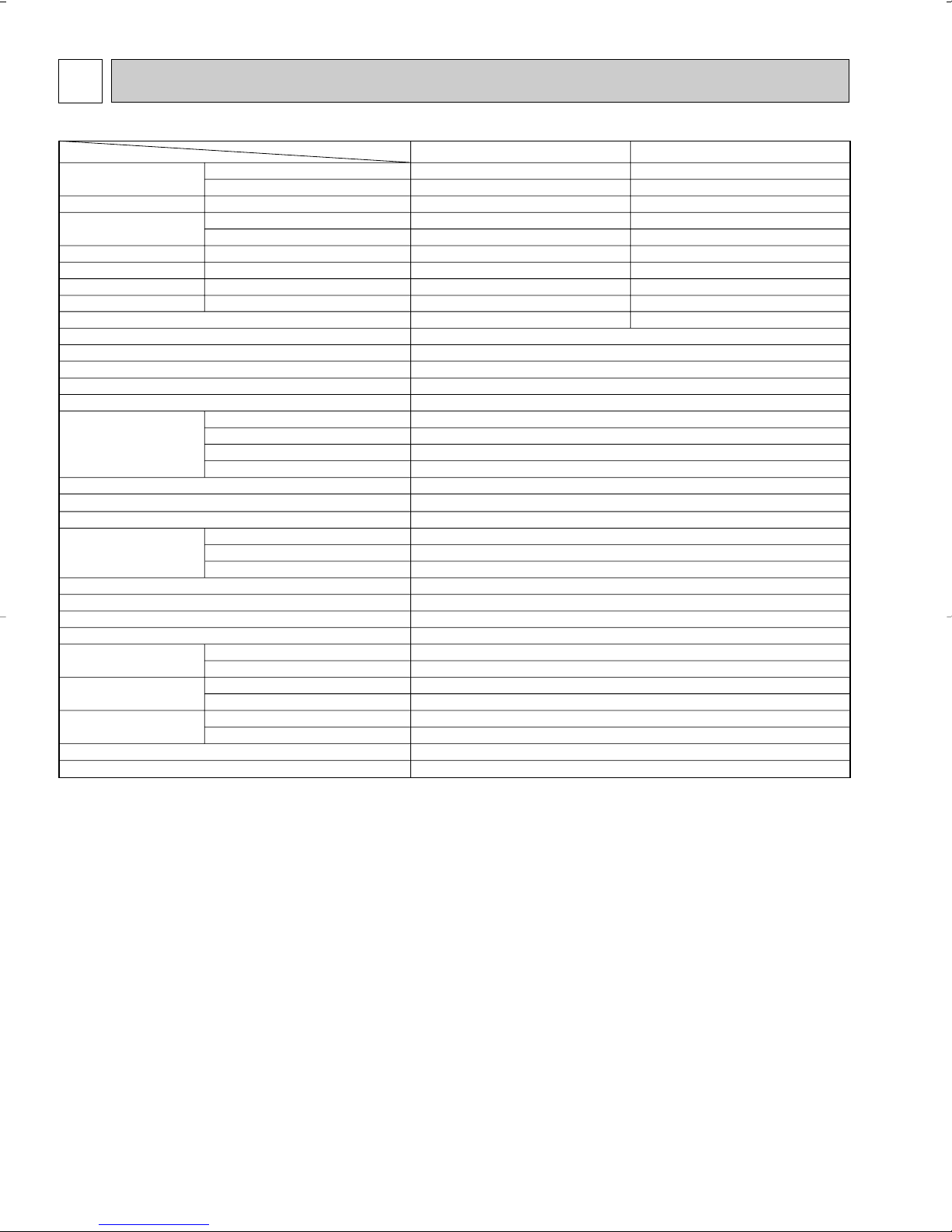

3

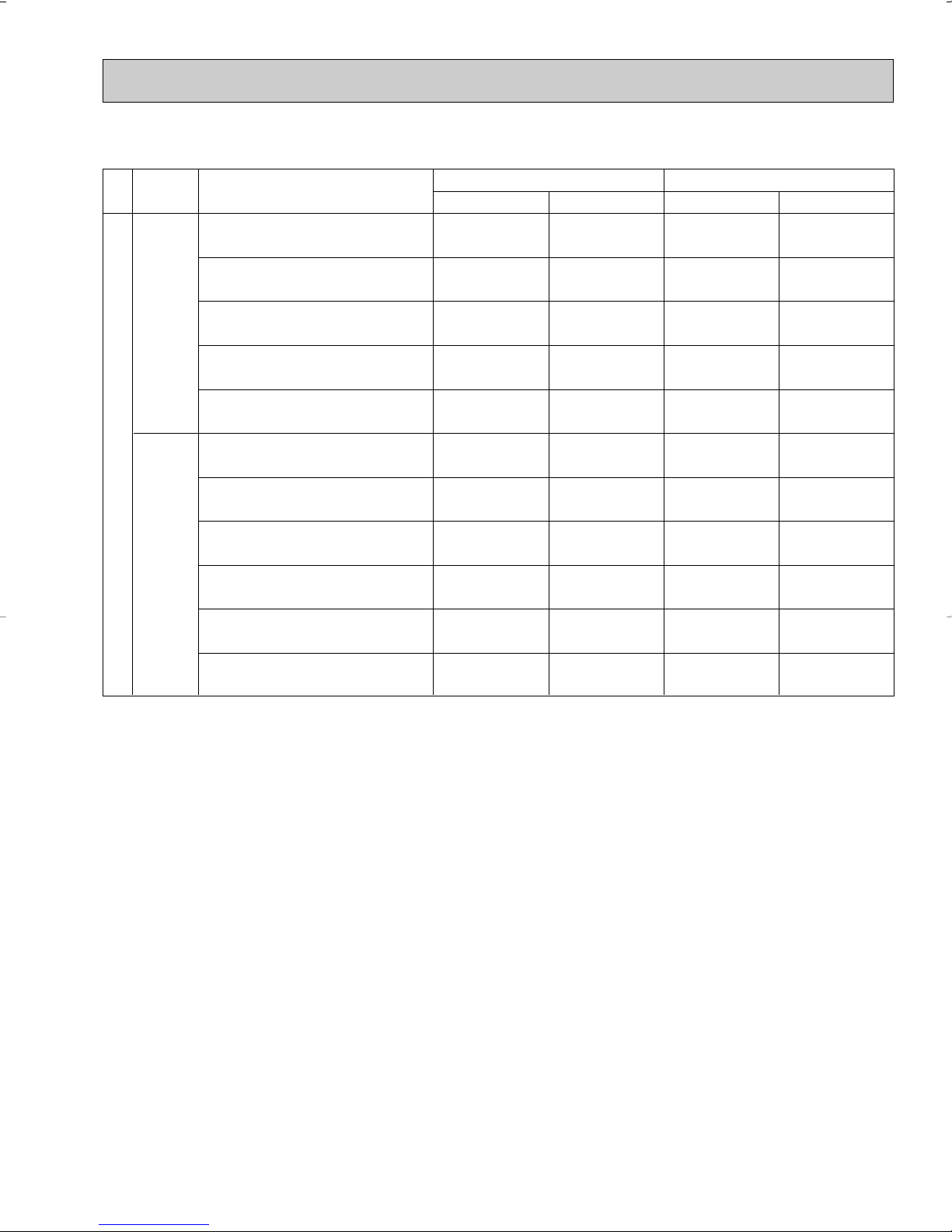

Item

Model

MSZ-A12NA

Capacity

Rated(Minimum~Maximum)

Capacity Rated

Power consumption

Rated(Minimum~Maximum)

Power consumption Rated

EER [SEER]

HSPF IV(V)

COP

OUTDOOR UNIT MODEL

External finish

Power supply

Max. fuse size (time delay)

Min. circuit ampacity

Fan motor

Compressor

Refrigerant control

Sound level

Defrost method

Dimensions

Weight

REMOTE CONTROLLER

Control voltage (by built-in transformer)

REFRIGERANT PIPING

Refrigerant pipe size

(Min. wall thickness)

Connection method

Between the indoor

& outdoor units

Refrigerant charge (R410A)

Refrigerating oil (Model)

Btu/h

Btu/h

Btu/h

W

W

W

V, phase, Hz

A

A

F.L.A

R.L.A

L.R.A

dB(A)

in.

in.

in.

Ib.

in.

in.

ft.

ft.

cc.

Munsell 3Y 7.8/1.1

208/230, 1, 60

15

12

0.52

KNB092FPAH

0.49

7.8

9.2

Liner expansion valve

48

Reverse cycle

31-1/2

11-1/4

21-5/8

82

Wireless type

12-24V DC

Not supplied

1/4 (0.0315)

3/8 (0.0315)

Flared

Flared

40

65

2lb.5oz.

320 (NE022)

9,000 (5,500~9,000)

10,900 (5,200~12,600)

7,700

690 (390~690)

860 (350~1,100)

880

13.0 [17.0]

8.2 (6.7)

3.71

12,000 (5,700~12,000)

13,600 (5,200~13,600)

8,300

1,170 (395~1,170)

1,160 (350~1,160)

930

10.3 [17.0]

8.2 (6.7)

3.44

MUZ-A09NA MUZ-A12NA

❈1 ❈3

❈1

❈1

❈2

❈1

❈1

❈2

Cooling

Heating 47

Heating 17

Cooling

Heating 47

Heating 17

Cooling

Heating

Heating

MSZ-A09NA

Model

Winding resistance (at 68˚F) Ω

W

D

H

Liquid

Gas

Indoor

Outdoor

Height difference

Piping length

❈1

❈1

❈4

SPECIFICATION

NOTE : Test conditions are based on ARI 210/240.

❈1 : Rating conditions (cooling) — Indoor : 80˚FDB, 67˚FWB, Outdoor : 95˚FDB, (75˚FWB) Rated frequency: A09:50Hz A12:76Hz

❈2 : (heating) — Indoor : 70˚FDB, 60˚FWB, Outdoor : 17˚FDB, 15˚FWB Maximum frequency: A09:71Hz A12:76Hz

(heating) — Indoor : 70˚FDB, 60˚FWB, Outdoor : 47˚FDB, 43˚FWB Rated frequency: A09:61Hz A12:76Hz

6

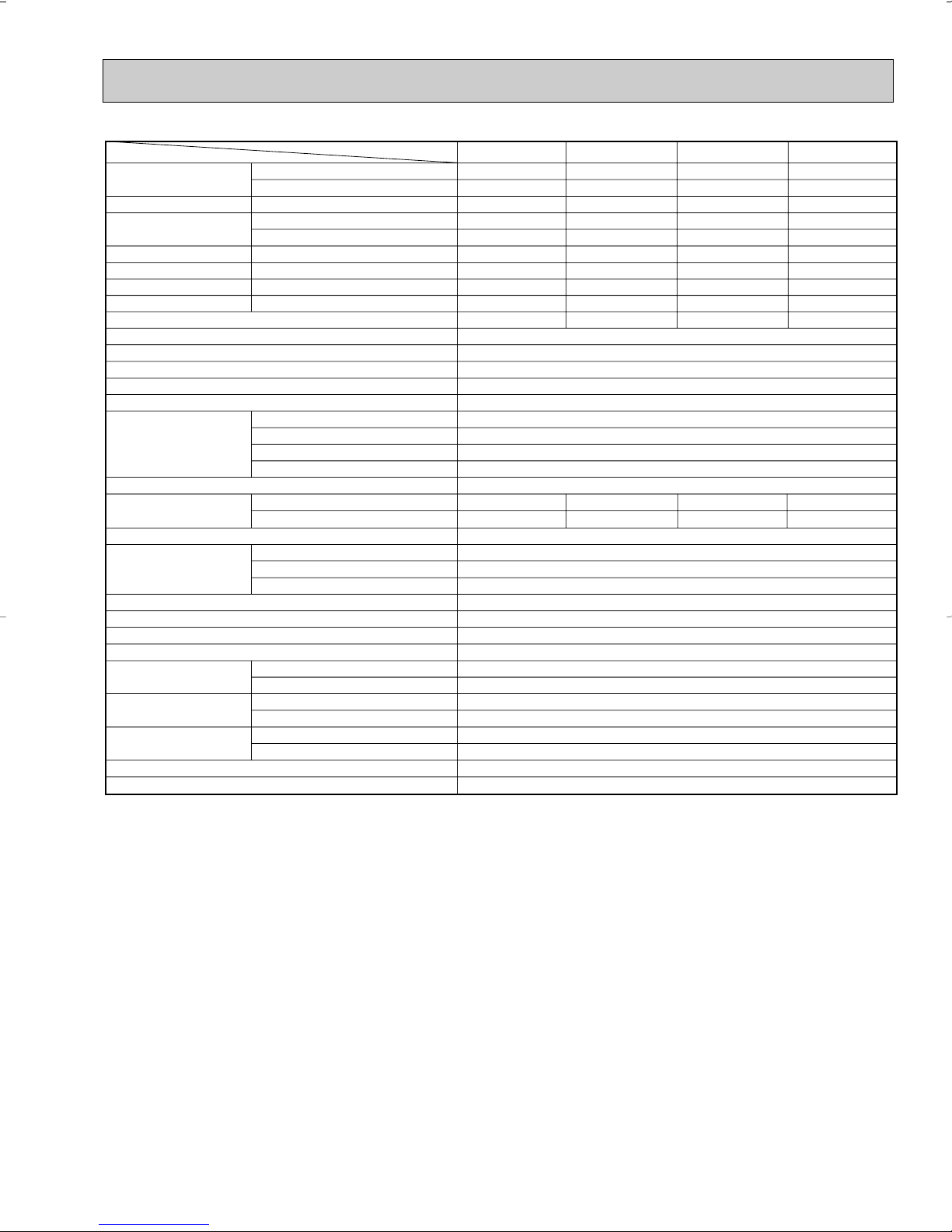

Item

Model

Capacity

Rated(Minimum~Maximum)

Capacity Rated

Power consumption

Rated(Minimum~Maximum)

Power consumption Rated

EER [SEER]

HSPF IV(V)

COP

OUTDOOR UNIT MODEL

External finish

Power supply

Max. fuse size (time delay)

Min. circuit ampacity

Fan motor

Compressor

Refrigerant control

Sound level dB(A)

Defrost method

Dimensions

Weight

REMOTE CONTROLLER

Control voltage (by built-in transformer)

REFRIGERANT PIPING

Refrigerant pipe size

(Min. wall thickness)

Connection method

Between the indoor

& outdoor units

Refrigerant charge (R410A)

Refrigerating oil (Model)

Btu/h

Btu/h

Btu/h

W

W

W

V, phase, Hz

A

A

F.L.A

R.L.A

L.R.A

in.

in.

in.

Ib.

in.

in.

ft.

ft.

cc.

16,200 (3,100~16,200)

–

–

2,070 (210~2,070)

–

–

7.8 [16.0]

–

–

16,200 (3,100~16,200)

20,100 (3,400~20,900)

13,000

2,070 (210~2,070)

2,150 (250~2,330)

1,740

7.8 [16.0]

8.2 (6.7)

2.74

15,000 (3,100~15,000)

18,000 (3,400~20,900)

13,000

1,690 (210~1,690)

1,790 (250~2,330)

1,740

8.9 [16.0]

8.2 (6.7)

2.95

50

51

50

—

52

53

52

—

15,000 (3,100~15,000)

–

–

1,690 (210~1,690)

–

–

8.9 [16.0]

–

–

❈1 ❈3

❈1

❈1

❈2

❈1

❈1

❈2

Cooling

Heating 47

Heating 17

Cooling

Heating 47

Heating 17

Cooling

Heating

Heating

Model

Winding resistance (at 68°F) "

Cooling

Heating

W

D

H

Liquid

Gas

Indoor

Outdoor

Height difference

Piping length

MSZ-A15NA MSY-A15NA MSZ-A17NA MSY-A17NA

MUZ-A15NA MUY-A15NA MUZ-A17NA MUY-A17NA

❈1

❈1 ❈1

❈4

Munsell 3Y 7.8/1.1

208/230, 1, 60

15

14

0.52

SNB130FPDH

0.45

10.1

12.0

Liner expansion valve

Reverse cycle

31-1/2

11-1/4

21-5/8

88

Wireless type

12-24V DC

Not supplied

1/4 (0.0315)

1/2 (0.0315)

Flared

Flared

40

65

2lb.7oz.

450 (NE022)

NOTE : Test conditions are based on ARI 210/240.

❈1 : Rating conditions (cooling) — Indoor : 80˚FDB, 67˚FWB, Outdoor : 95˚FDB, (75˚FWB) Rated frequency: A15:77Hz A17:89Hz

❈2 : (heating) — Indoor : 70˚FDB, 60˚FWB, Outdoor : 17˚FDB, 15˚FWB Maximum frequency: A15:93Hz A17:93Hz

(heating) — Indoor : 70˚FDB, 60˚FWB, Outdoor : 47˚FDB, 43˚FWB Rated frequency: A15:78Hz A17:88Hz

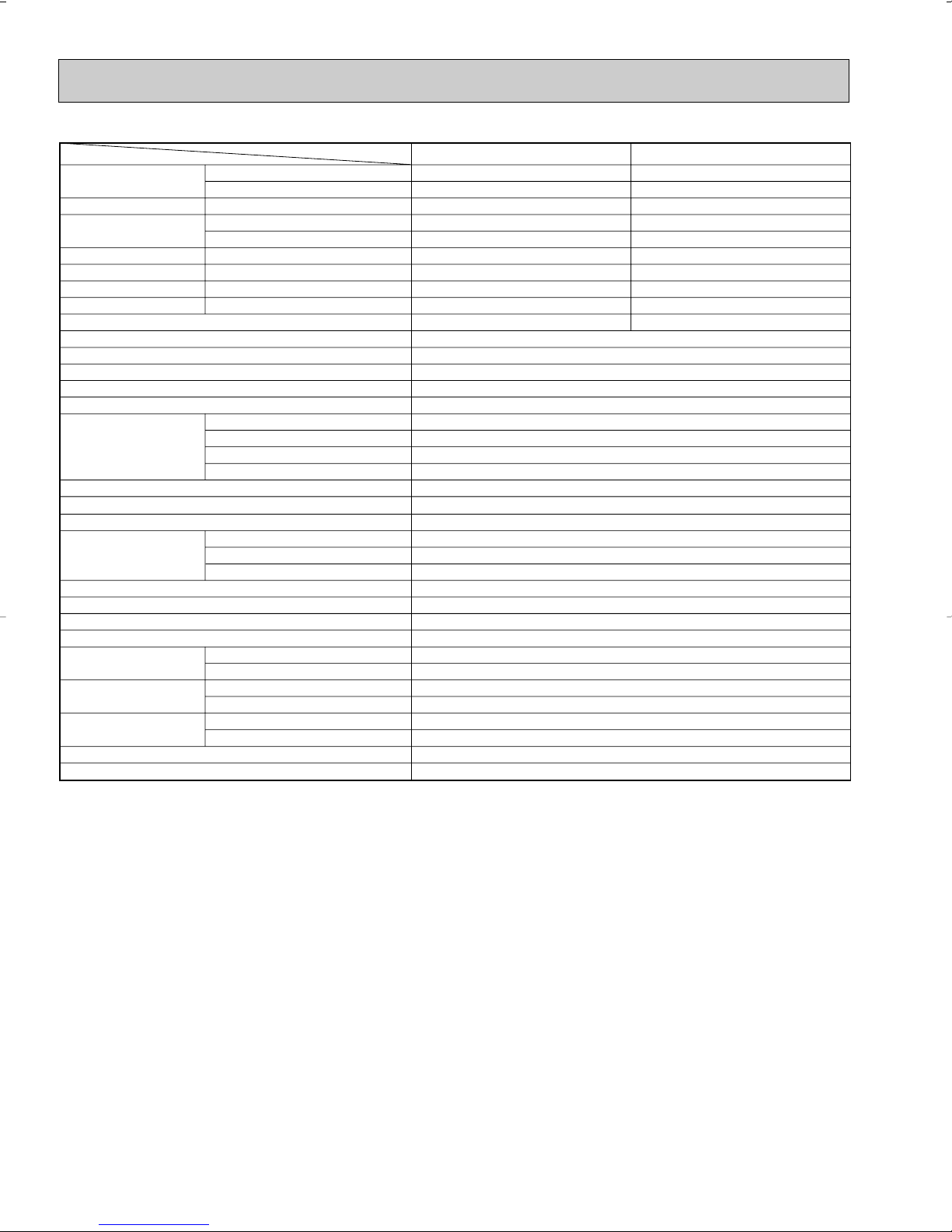

7

Item

Model

MSY-A24NA

Capacity

Rated(Minimum~Maximum)

Capacity Rated

Power consumption

Rated(Minimum~Maximum)

Power consumption Rated

EER [SEER]

HSPF IV(V)

COP

OUTDOOR UNIT MODEL

External finish

Power supply

Max. fuse size (time delay)

Min. circuit ampacity

Fan motor

Compressor

Refrigerant control

Sound level

Defrost method

Dimensions

Weight

REMOTE CONTROLLER

Control voltage (by built-in transformer)

REFRIGERANT PIPING

Refrigerant pipe size

(Min. wall thickness)

Connection method

Between the indoor

& outdoor units

Refrigerant charge (R410A)

Refrigerating oil (Model)

Btu/h

Btu/h

Btu/h

W

W

W

V, phase, Hz

A

A

F.L.A

R.L.A

L.R.A

dB(A)

in.

in.

in.

Ib.

in.

in.

ft.

ft.

cc.

Munsell 3Y 7.8 1.1

208/230, 1, 60

20

17

0.93

SNB130FPDH

0.45

10.1

16.0

Liner expansion valve

55

Reverse cycle

33-1/16

13

33-7/16

128

Wireless type

12-24VDC

Not supplied

1/4 (0.0315)

5/8 (0.0394)

Flared

Flared

50

100

4lb.

450 (NE022)

22,000 (4,400~22,000)

23,200 (3,600~24,400)

15,200

2,880 (290~2,880)

2,350 (260~2,570)

1,960

7.6 [16.0]

8.2 (6.7)

2.89

22,000 (4,400~22,000)

—

—

2,880 (290~2,880)

—

—

7.6 [16.0]

—

—

❈1 ❈3

❈1

❈1

❈2

❈1

❈1

❈2

Cooling

Heating 47

Heating 17

Cooling

Heating 47

Heating 17

Cooling

Heating

Heating

MSZ-A24NA

MUZ-A24NA MUY-A24NA

Model

Winding resistance (at 68˚F) Ω

W

D

H

Liquid

Gas

Indoor

Outdoor

Height difference

Piping length

❈1

❈1

❈4

NOTE : Test conditions are based on ARI 210/240.

❈1 : Rating conditions (cooling) — Indoor : 80˚FDB, 67˚FWB, Outdoor : 95˚FDB, (75˚FWB) Rated frequency: 110Hz

❈2 : (heating) — Indoor : 70˚FDB, 60˚FWB, Outdoor : 17˚FDB, 15˚FWB Maximum frequency: 108Hz

(heating) — Indoor : 70˚FDB, 60˚FWB, Outdoor : 47˚FDB, 43˚FWB Rated frequency: 101Hz

8

Test condition

SEER

(Cooling)

HSPF

(Heating)

ARI

Mode

"A" Cooling Steady State

at rated compressor Speed

"B-2" Cooling Steady State

at rated compressor Speed

"B-1" Cooling Steady State

at minimum compressor Speed

Low ambient Cooling Steady State

at minimum compressor Speed

Intermediate Cooling Steady State

At Intermediate compressor Speed

❈5

Standard Rating-Heating

at rated compressor Speed

Low temperature Heating

at rated compressor Speed

Max temperature Heating

at minimum compressor Speed

High temperature Heating

at minimum compressor Speed

Frost Accumulation

at rated compressor Speed

Test

Indoor air condition Outdoor air condition

Dry bulb

Wet bulb

Dry bulb

Wet bulb

80

80

80

80

80

70

70

70

70

70

70

67

67

67

67

67

60

60

60

60

60

60

Frost Accumulation

at Intermediate compressor Speed

❈5

95

82

82

67

87

47

17

62

47

35

35

(75)

(65)

(65)

(53.5)

(69)

43

15

56.5

43

33

33

❈5 : At Intermediate compressor Speed

=("Cooling rated compressor speed" - "minimum compressor speed") / 3 + "minimum compressor speed".

(Unit : [˚F])

❈3, ❈4

9

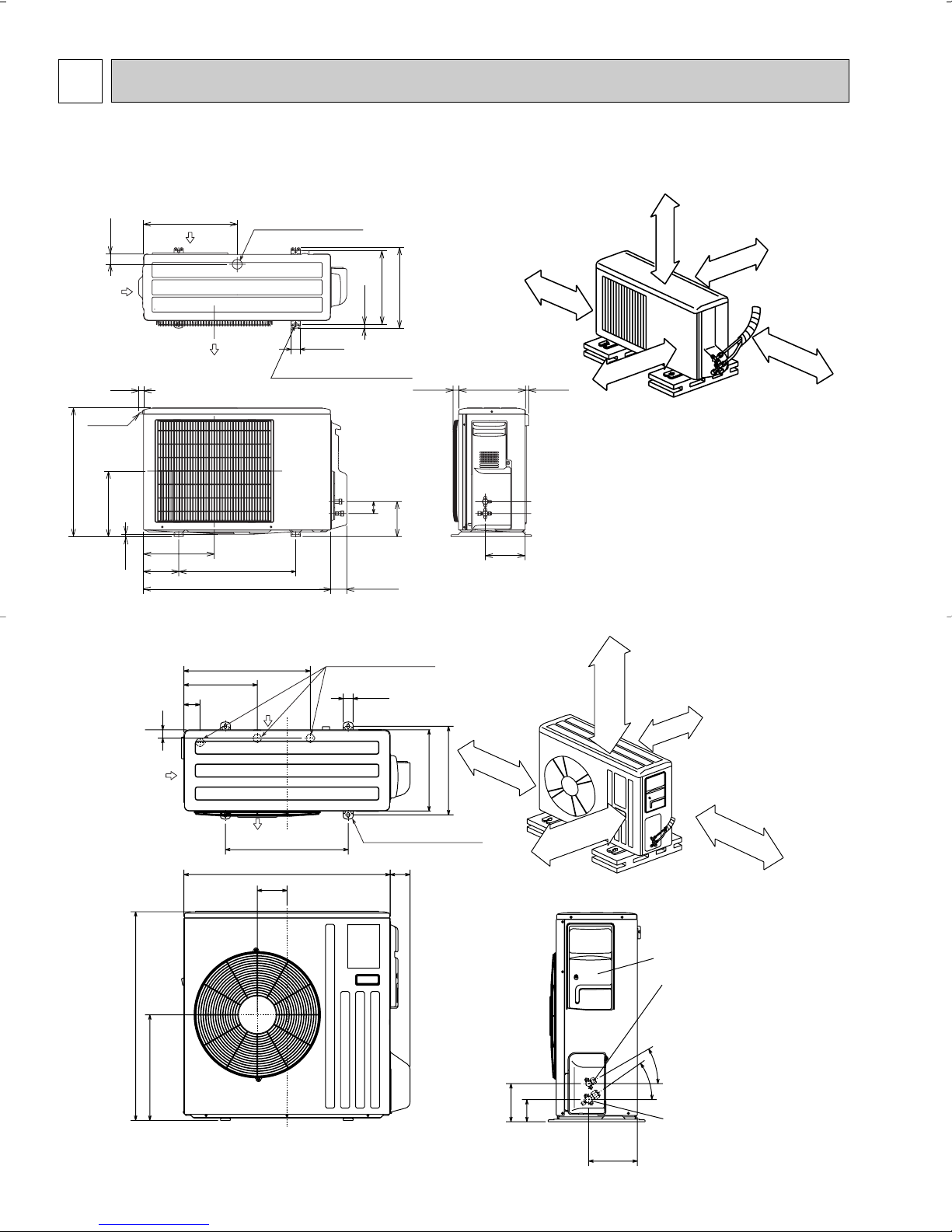

4

Liquid pipe :1/4 (flared)

Gas pipe :3/8 (flared) · · · MUZ-A09/12NA

:1/2 (flared) · · · MUZ-A15/17NA, MUY-A15/17NA

6-23/32

2

5-7/8

2-23/32

1-3/4

15-3/4

12 ~ 12-3/4

13-9/16

11/16

1-9/16

7/8

21-5/8

11-1/32

13/32

31-1/2

19-11/16

5-15/16

11-29/32

17/3229/32 11-1/4

Air in

handle

Air in

Air out

2- 3/8 o 13/16 Oval hole

Drainage hole [ 1-5/8

{

REQUIRED SPACE

Basically open 4inch or more

without any obstruction in front

and on both sides of the unit.

14 in.

or m

ore

8 in

. o

r m

o

re

4 in.

or more

4

in

. o

r m

o

re

Open two sides of left,

right, or rear side.

30-

3

5-

6-1/28

3-17/32

7-25/32

1-9/16

20-9/32

11-25/32

2-19/32

2

14-3/16

33-7/16

16-15/16

19-11/16

3-3/16

4-25/32

33-1/16

Open as a rule

20inch or more if

the front and both

sides are open

4inch or more

8inch or more if

there are obstacles

to both sides

Open as a rule

20inch or more if the back,

both sides and top are open

1

4

in

. o

r m

o

re

4

in

. o

r m

o

re

Air in

Air out

13

Service panel

Gas refrigerant

pipe joint

Refrigerant pipe

(flared) [5/8

Liquid refrigerant

pipe joint

Refrigerant pipe

(flared) [1/4

Drainage hole [ 1-5/8

4-3/8 o 13/16 Oval hole

REQUIRED SPACE

Air in

OUTLINES AND DIMENSIONS

MUZ-A09NA MUZ-A12NA MUZ-A15NA

MUZ-A17NA MUY-A15NA MUY-A17NA

Unit: inch

MUZ-A24NA MUY-A24NA

10

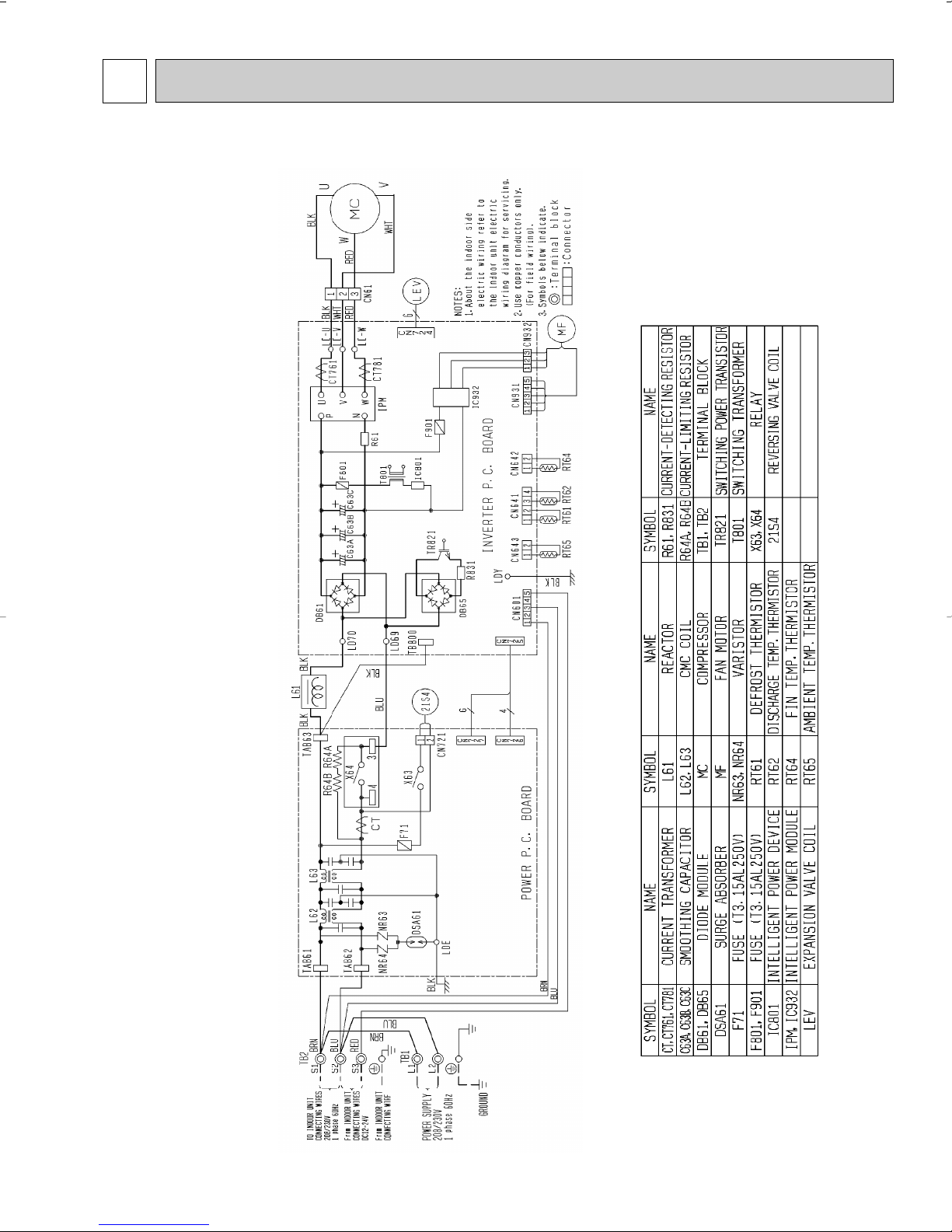

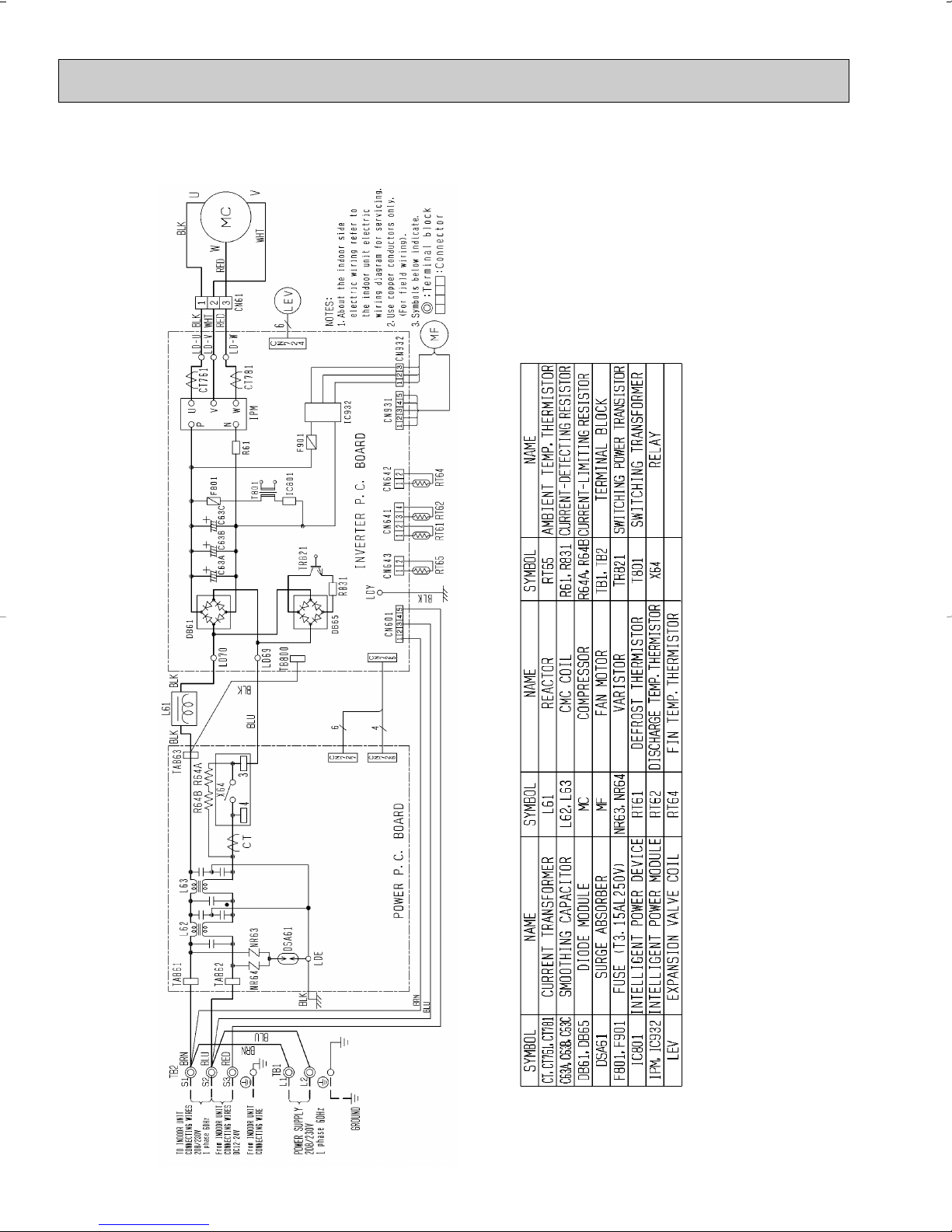

5

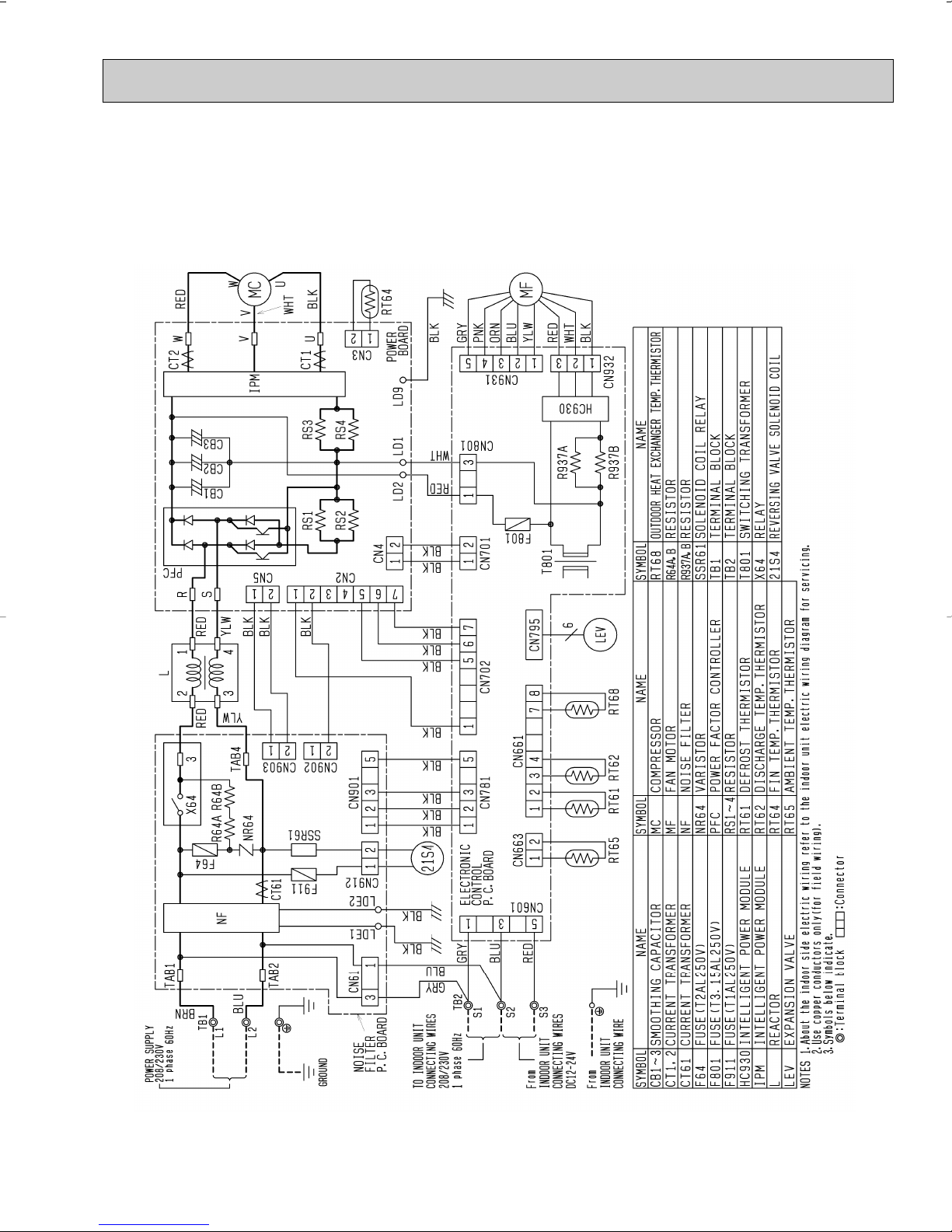

MUZ-A09NA MUZ-A12NA MUZ-A15NA MUZ-A17NA

WIRING DIAGRAM

11

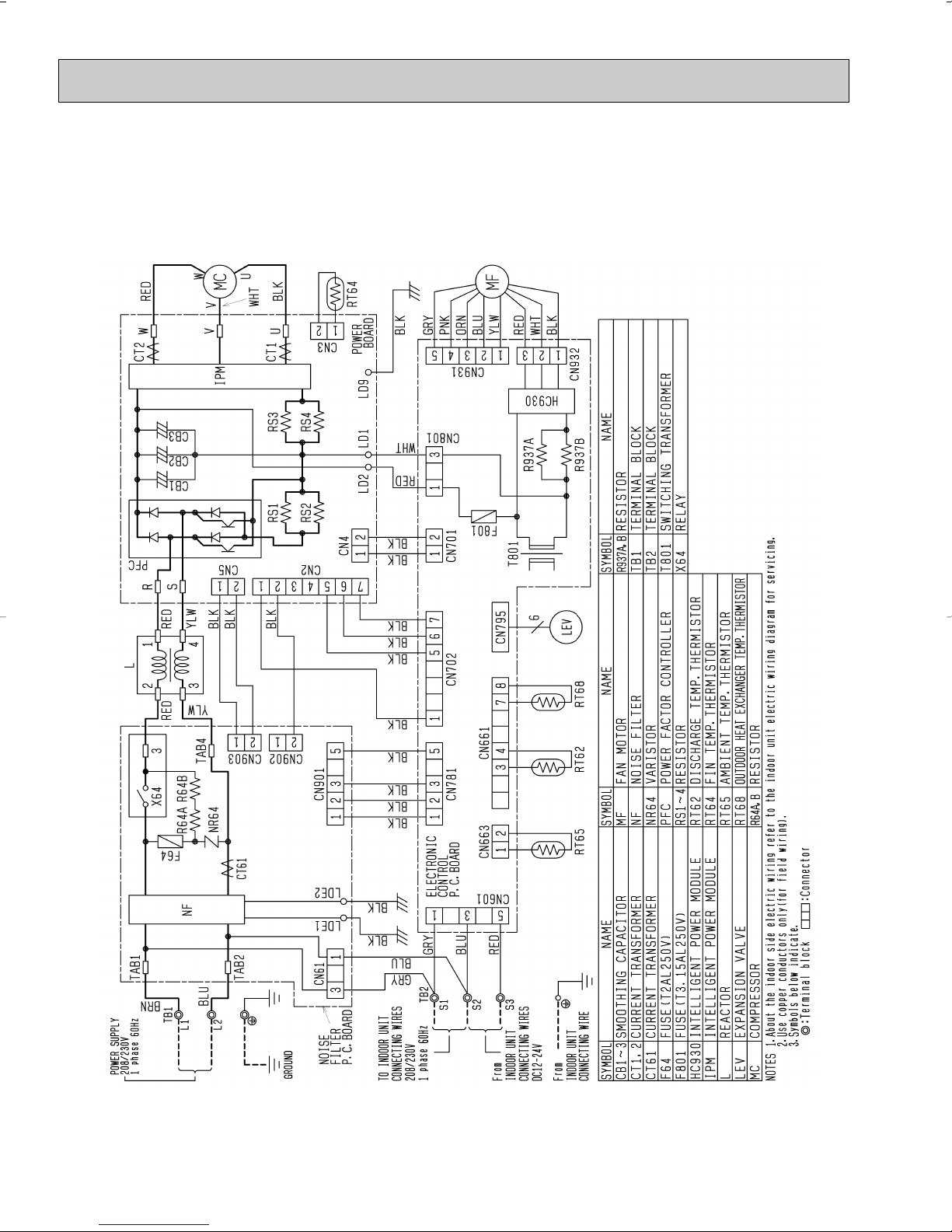

MUY-A15NA MUY-A17NA

12

MUZ-A24NA

13

MUY-A24NA

14

6

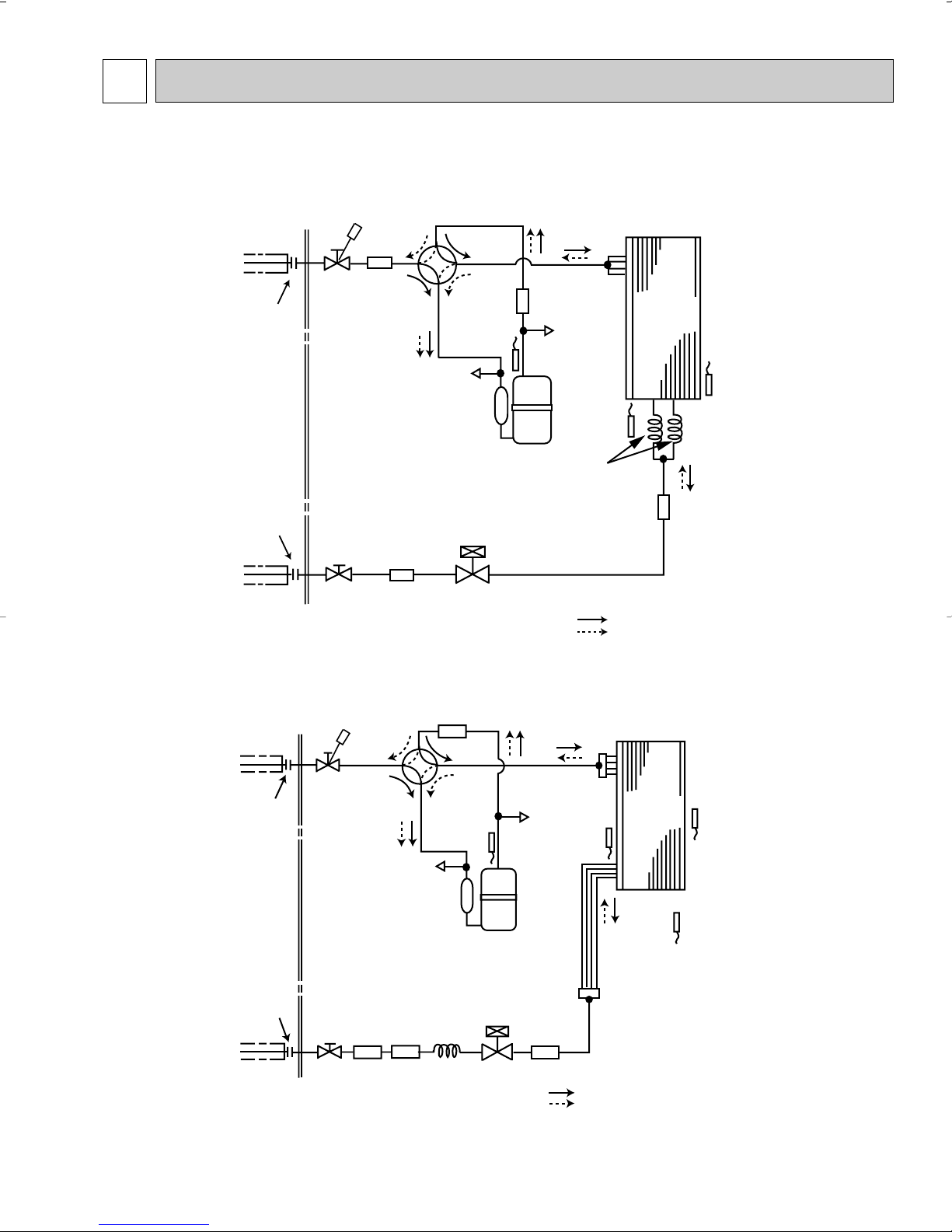

Outdoor

heat

exchanger

Flared connection

Defrost

thermistor

RT61

Discharge

temperature

thermistor

RT62

Service

port

Service

port

Flared connection

Stop valve

(with strainer)

Stop valve

(with service port)

Refrigerant flow in cooling

Compressor

4-way valve

Refrigerant flow in heating (MUZ)

Refrigerant pipe [3/8 (MUZ-A09/12)

[1/2 (MUZ-A15/17,MUY-A15/17)

(with heat insulator)

Refrigerant pipe [1/4

(with heat insulator)

R.V. coil

heating ON

cooling OFF

Strainer

#100

Capillary tube

O.D. 0.118 o I.D. 0.071

o 23-5/8

(

[3.0 o [1.8 o 600

)

Expansion

valve

Ambient

temperature

thermistor

RT65

Muffler

Muffler

Muffler

Outdoor

heat

exchanger

Flared connection

Defrost

thermistor

RT61

Service

port

Service

port

Discharge

temperature

thermistor

RT62

Flared connection

Stop valve

Stop valve

(with service port)

Capillary tube

Refrigerant flow in cooling

Compressor

4-way valve

Refrigerant flow in heating

Refrigerant pipe [5/8

(with heat insulator)

Refrigerant pipe [1/4

(with heat insulator)

LEV

R.V. coil

heating ON

cooling OFF

Muffler

#100

Strainer

#100

Receiver

Outdoor heat

exchanger

temperature

thermistor

RT68

Ambient

temperature

thermistor

RT65

Strainer

#100

O.D. 0.142 o I.D. 0.094

o 1-31/32

(

[3.6 o [2.4 o 50

)

REFRIGERANT SYSTEM DIAGRAM

MUZ-A09NA MUZ-A15NA MUY-A15NA

MUZ-A12NA MUZ-A17NA MUY-A17NA

Unit:inch

MUZ-A24NA

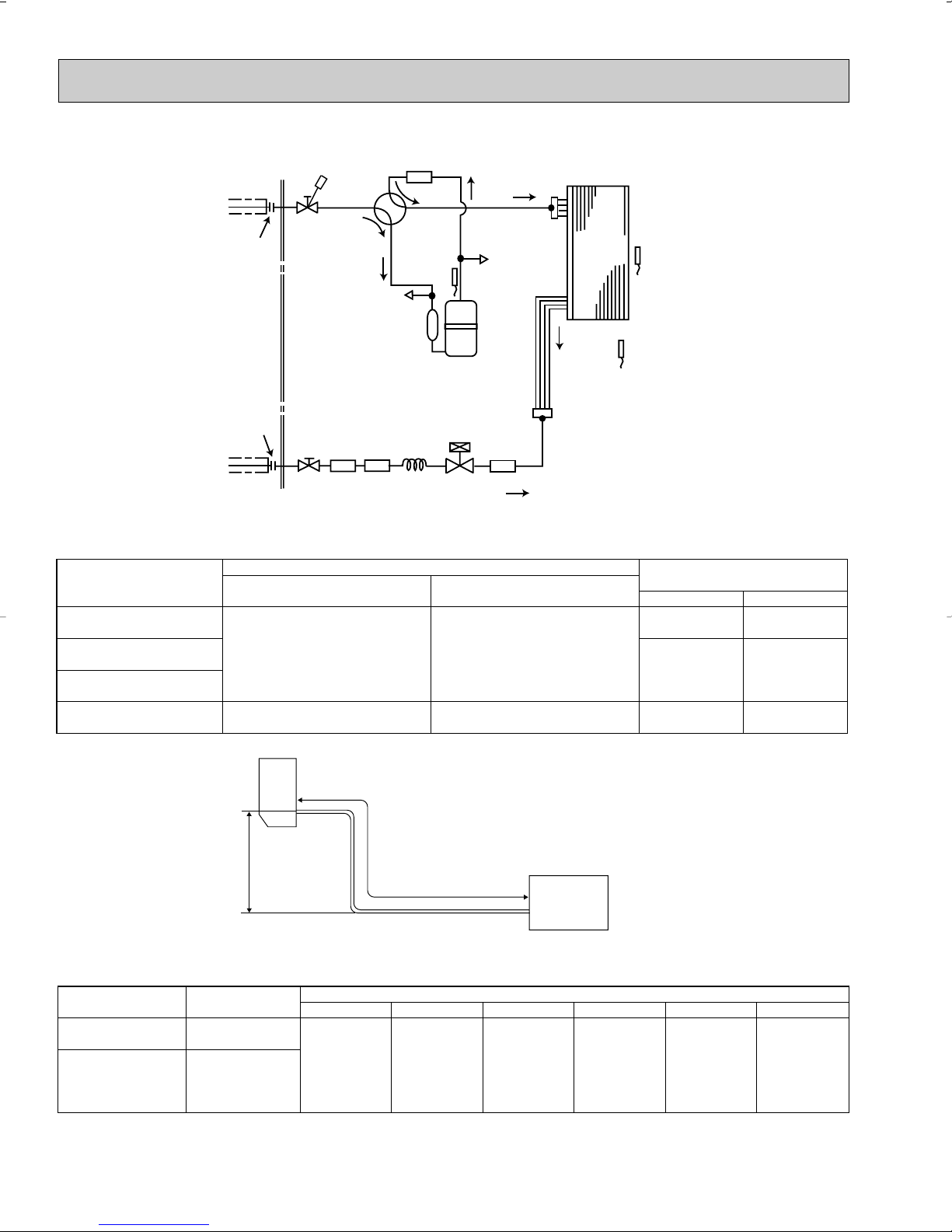

15

Max. length

A

Max. Height

difference

B

Indoor

unit

Outdoor unit

Max. length

A

Max. Height difference

B

Model

Gas

Liquid

3/8

1/4

1/2

1/4

5/8

40

50

65

100

1/4

Piping size O.D : in

Refrigerant piping : ft

MUZ-A09NA

MUZ-A12NA

MUZ-A15NA

MUY-A15NA

MUZ-A17NA

MUY-A17NA

MUZ-A24NA

MUY-A24NA

MUY-A24NA

Outdoor

heat

exchanger

Flared connection

Discharge

temperature

thermistor

RT62

Flared connection

Stop valve

Stop valve

(with service port)

Capillary tube

Refrigerant flow in cooling

Compressor

Service

port

Service

port

4-way valve

Refrigerant pipe [5/8

(with heat insulator)

Refrigerant pipe [1/4

(with heat insulator)

LEV

Muffler

#100

Strainer

#100

Receiver

Outdoor heat

exchanger

temperature

thermistor

RT68

Ambient

temperature

thermistor

RT65

Strainer

#100

O.D. 0.142 o I.D. 0.094

o 1-31/32

(

[3.6 o [2.4 o 50

)

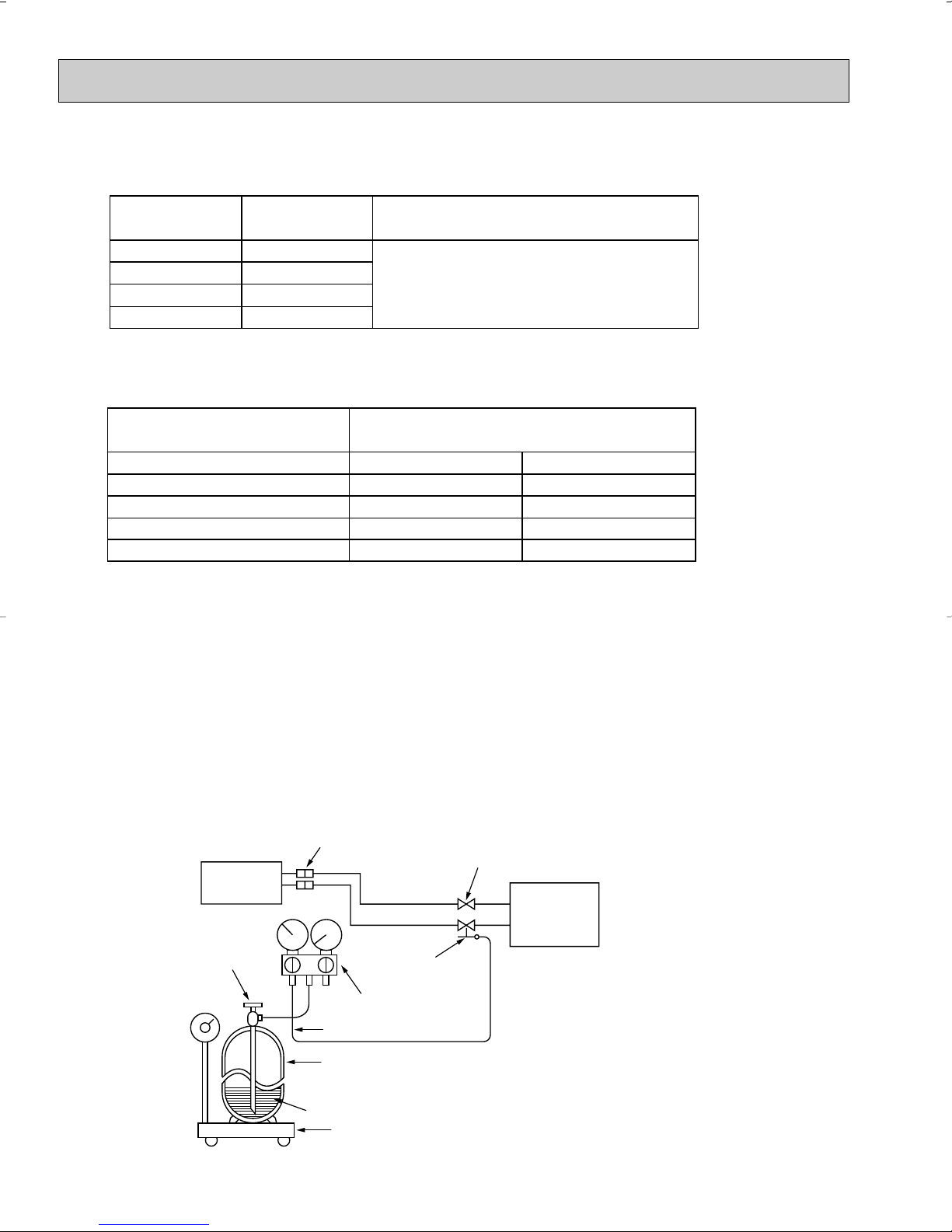

Outdoor unit

precharged

3025 50

Model

Refrigerant piping length (one way) : ft

40

60 65

2lb.5oz.

2lb.7oz.

0 1.62 4.86 11.34 12.968.10

MUZ-A09NA

MUZ-A12NA

MUZ-A15NA

MUY-A15NA

MUZ-A17NA

MUY-A17NA

Calculation : Xoz. = 1.62/ 5oz./ ft o (Refrigerant piping length (ft)-25)

MAX. REFRIGERANT PIPING LENGTH and MAX. HEIGHT DIFFERENCE

Unit:inch

ADDITIONAL REFRIGERANT CHARGE (R410A:oz.)

Refrigerant piping exceeding 25ft. requires additional refrigterant charge according to the calculation.

16

7DATA

Model

Indoor air Outdoor intake air DB temperature(˚F

)

71

67

63

71

67

63

71

67

63

71

67

63

71

67

63

11.0

10.4

9.8

14.7

13.9

13.1

18.4

17.4

16.4

19.8

18.8

17.7

27.0

25.5

24.0

6.4

7.4

8.3

8.5

9.9

11.0

9.5

11.3

12.8

10.3

12.2

13.8

13.4

16.1

18.3

0.61

0.58

0.55

1.04

0.98

0.94

1.50

1.42

1.35

1.84

1.74

1.66

2.56

2.42

2.30

10.3

9.7

9.1

13.7

13.0

12.1

17.2

16.2

15.2

18.5

17.5

16.4

25.2

23.8

22.2

5.9

6.9

7.7

7.9

9.2

10.2

8.9

10.5

11.9

9.6

11.4

12.8

12.5

15.0

17.0

0.67

0.64

0.61

1.14

1.08

1.04

1.65

1.56

1.50

2.02

1.91

1.83

2.81

2.66

2.55

9.7

9.0

8.5

12.9

12.0

11.3

16.1

15.0

14.1

17.4

16.2

15.2

23.7

22.0

20.7

5.6

6.4

7.1

7.4

8.5

9.5

8.3

9.8

11.0

9.0

10.5

11.9

11.7

13.9

15.8

0.72

0.69

0.66

1.23

1.17

1.12

1.77

1.69

1.61

2.17

2.07

1.98

3.02

2.88

2.75

9.0

8.4

7.7

12.0

11.2

10.3

15.0

14.0

12.8

16.2

15.1

13.9

22.0

20.5

18.8

5.2

5.9

6.5

6.9

7.9

8.7

7.8

9.1

10.0

8.4

9.8

10.8

10.9

12.9

14.4

0.76

0.73

0.70

1.29

1.24

1.19

1.87

1.79

1.72

2.29

2.19

2.11

3.18

3.05

2.94

8.3

7.7

7.0

11.0

10.3

9.4

13.8

12.8

11.7

14.9

13.9

12.6

20.2

18.8

17.2

4.8

5.5

5.9

6.4

7.3

7.9

7.1

8.3

9.2

7.7

9.0

9.9

10.1

11.9

13.1

0.79

0.77

0.73

1.35

1.30

1.24

1.94

1.88

1.79

2.38

2.30

2.19

3.31

3.20

3.05

IWB

(˚F)

75 85 95 105 115

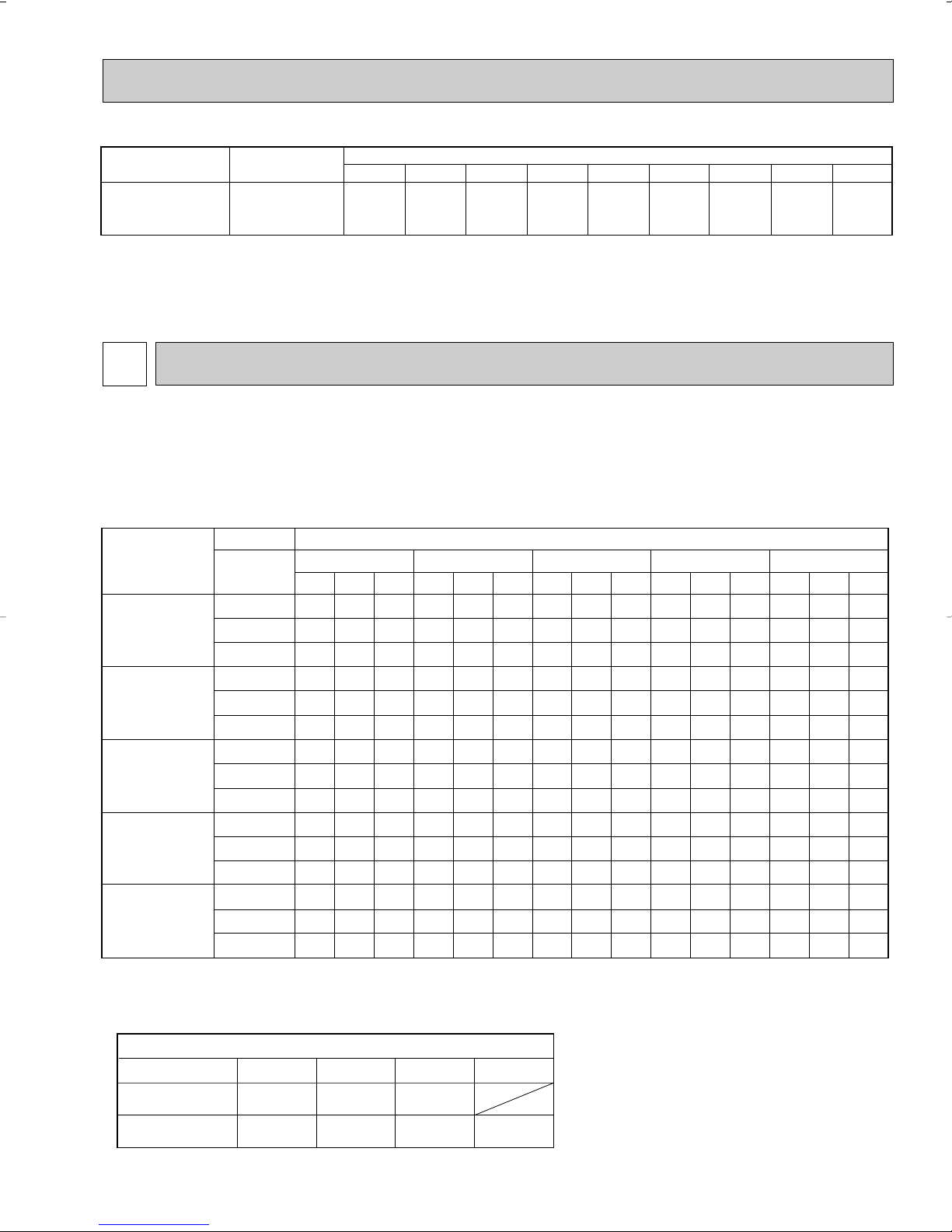

NOTE 1. IWB : Intake air wet-bulb temperature

TC : Total Capacity (x10

3

Btu/h), SHC : Sensible Heat Capacity (x10

3

Btu/h)

TPC : Total Power Consumption (kW)

2. SHC is based on 80˚F of indoor intake air DB temperature.

TC SHC

TPC TC SHC

TPC

TC SHC

TPC

TC SHC TPC

TC SHC

TPC

MSZ-A09NA

MSZ-A12NA

MSY-A15NA

MSY-A17NA

MSY-A24NA

MSZ-A15NA

MSZ-A17NA

MSZ-A24NA

Refrigerant piping length (one way : ft.)

1.0

25 (std.)

40

65

1.0

MSZ-A09/12/15/17NA

MSY-A15/17NA

MSZ-A24NA

MSY-A24NA

Model

0.954

0.95

0.878

0.878

100

0.713

50 60 70 80 90 100

Model

MUZ-A24NA

MUY-A24NA

Refrigerant piping length (one way) : ft

Outdoor unit

precharged

4lb. 0 1.08 3.24 5.40 7.56 9.72 11.88 14.04 16.20

25 30 40

Calculation : Xoz. = 1.08/ 5oz./ ft o (Refrigerant piping length (ft)-25)

NOTE : Refrigerant piping exceeding 25ft. requies additional refrigerant charge according to the calculation.

MUZ-A09NA MUZ-A12NA MUZ-A15NA

MUZ-A17NA MUZ-A24NA

MUY-A15NA MUY-A17NA MUY-A24NA

7-1. PERFORMANCE DATA

1) COOLING CAPACITY

2) COOLING CAPACITY CORRECTIONS

17

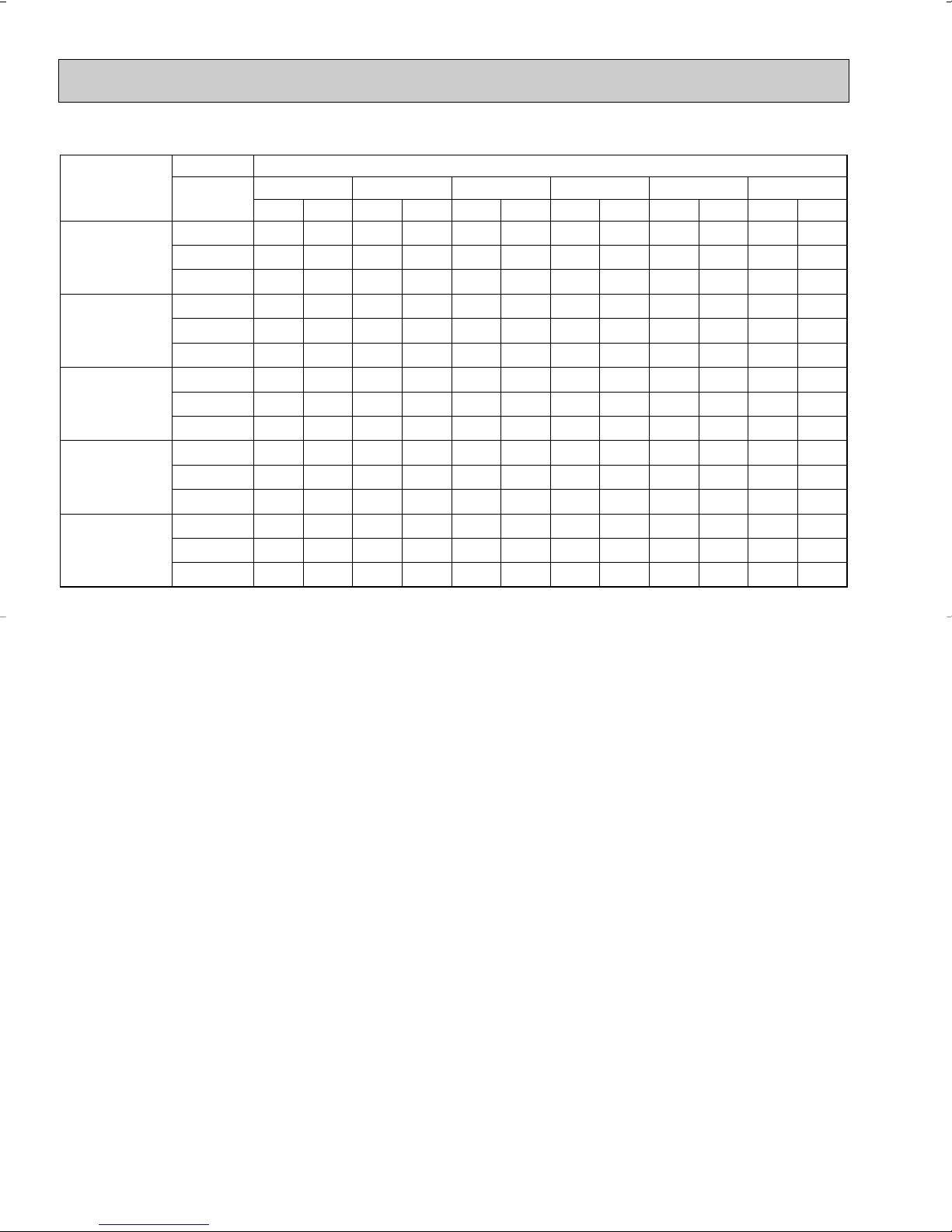

3) HEATING CAPACITY

Model

Indoor air Outdoor intake air WB temperature(˚F

)

75

70

65

75

70

65

75

70

65

75

70

65

75

70

65

6.3

6.7

6.9

7.9

8.4

8.6

10.4

11.1

11.3

11.7

12.4

12.7

13.5

14.3

14.6

0.64

0.62

0.59

0.86

0.84

0.80

1.33

1.29

1.24

1.60

1.55

1.48

1.75

1.69

1.62

7.9

8.2

8.6

9.9

10.2

10.7

13.1

13.5

14.1

14.6

15.1

15.8

16.8

17.4

18.2

0.75

0.74

0.71

1.02

0.99

0.96

1.57

1.53

1.48

1.88

1.84

1.77

2.06

2.01

1.94

9.4

9.6

10.0

11.8

12.0

12.4

15.6

15.9

16.5

17.4

17.8

18.4

20.1

20.5

21.2

0.84

0.82

0.80

1.13

1.10

1.07

1.75

1.70

1.66

2.10

2.04

1.99

2.29

2.23

2.17

10.6

10.9

11.2

13.3

13.6

14.0

17.6

18.0

18.5

19.6

20.1

20.7

22.6

23.2

23.9

0.88

0.86

0.84

1.19

1.16

1.13

1.83

1.79

1.75

2.20

2.15

2.10

2.41

2.35

2.29

11.0

11.2

11.6

13.7

14.0

14.4

18.1

18.5

19.1

20.2

20.7

21.3

23.3

23.9

24.6

0.89

0.88

0.85

1.21

1.18

1.15

1.86

1.83

1.77

2.24

2.19

2.13

2.44

2.40

2.33

12.4

12.7

13.0

15.5

15.8

16.2

20.5

21.0

21.4

22.9

23.4

23.9

26.4

27.0

27.6

0.93

0.91

0.89

1.25

1.23

1.21

1.93

1.90

1.86

2.32

2.28

2.24

2.54

2.49

2.44

IDB

(˚F)

15 25 35 43 45 55

MSZ-A09NA

MSZ-A12NA

MSZ-A15NA

MSZ-A17NA

MSZ-A24NA

NOTE: 1. IDB : Intake air dry-bulb temperature

TC : Total Capacity (x10

3

Btu/h)

TPC : Total Power Consumption (kW)

2. Above data is for heating operation without any frost.

TC TPC TC TPC TC TPC TC TPC TC TPC TC TPC

How to operate with fixed operational frequency of the compressor.

1. Press the EMERGENCY OPERATION switch on the front of the indoor unit, and select either EMERGENCY COOL mode

or EMERGENCY HEAT mode before starting to operate the air conditioner.

2. The compressor starts up.

The operational frequency of the compressor.

3. The fan speed of the indoor unit is High.

4. This operation continues for 30minutes.

5. In order to release this operation, press the EMERGENCY OPERATION switch twice or once, or press any button on the

remote controller.

18

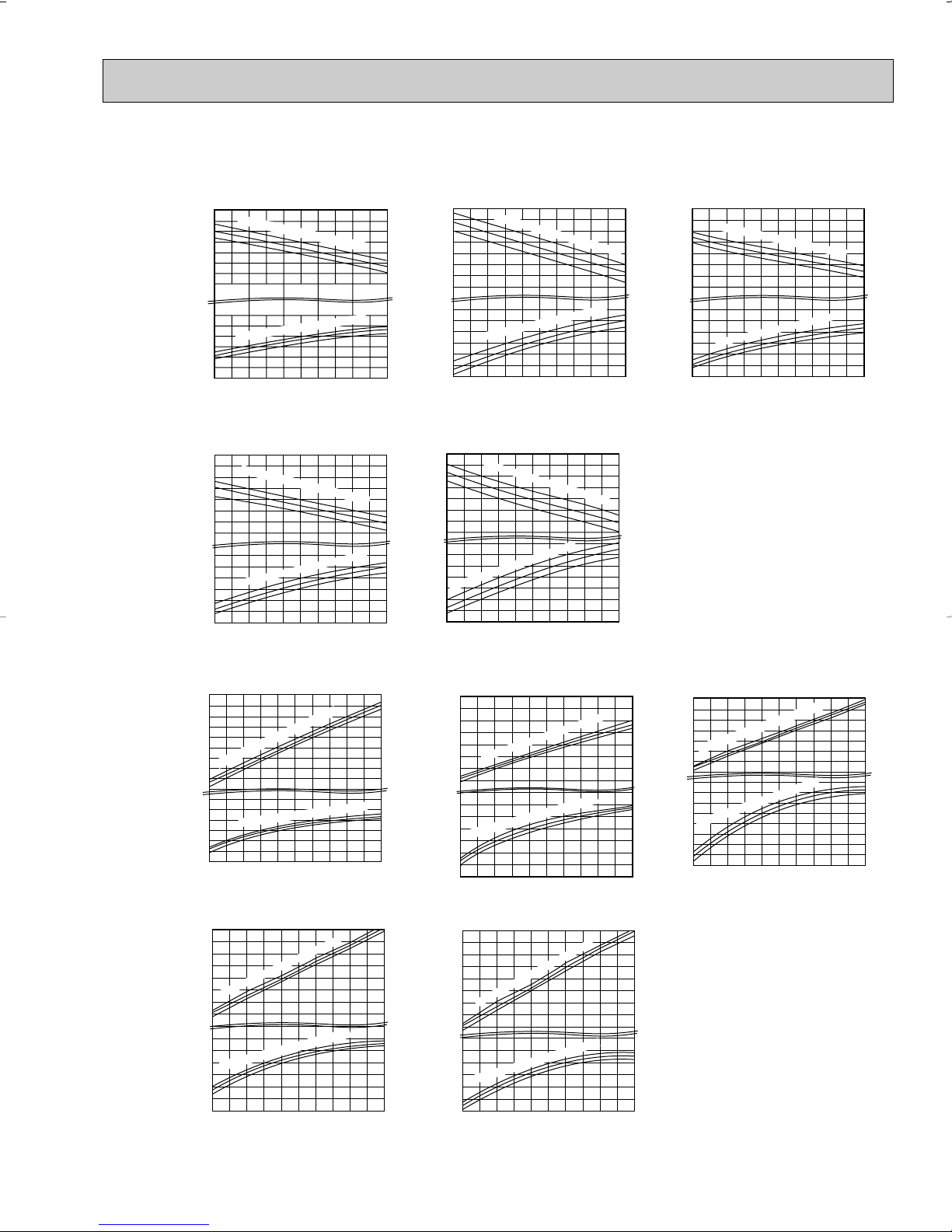

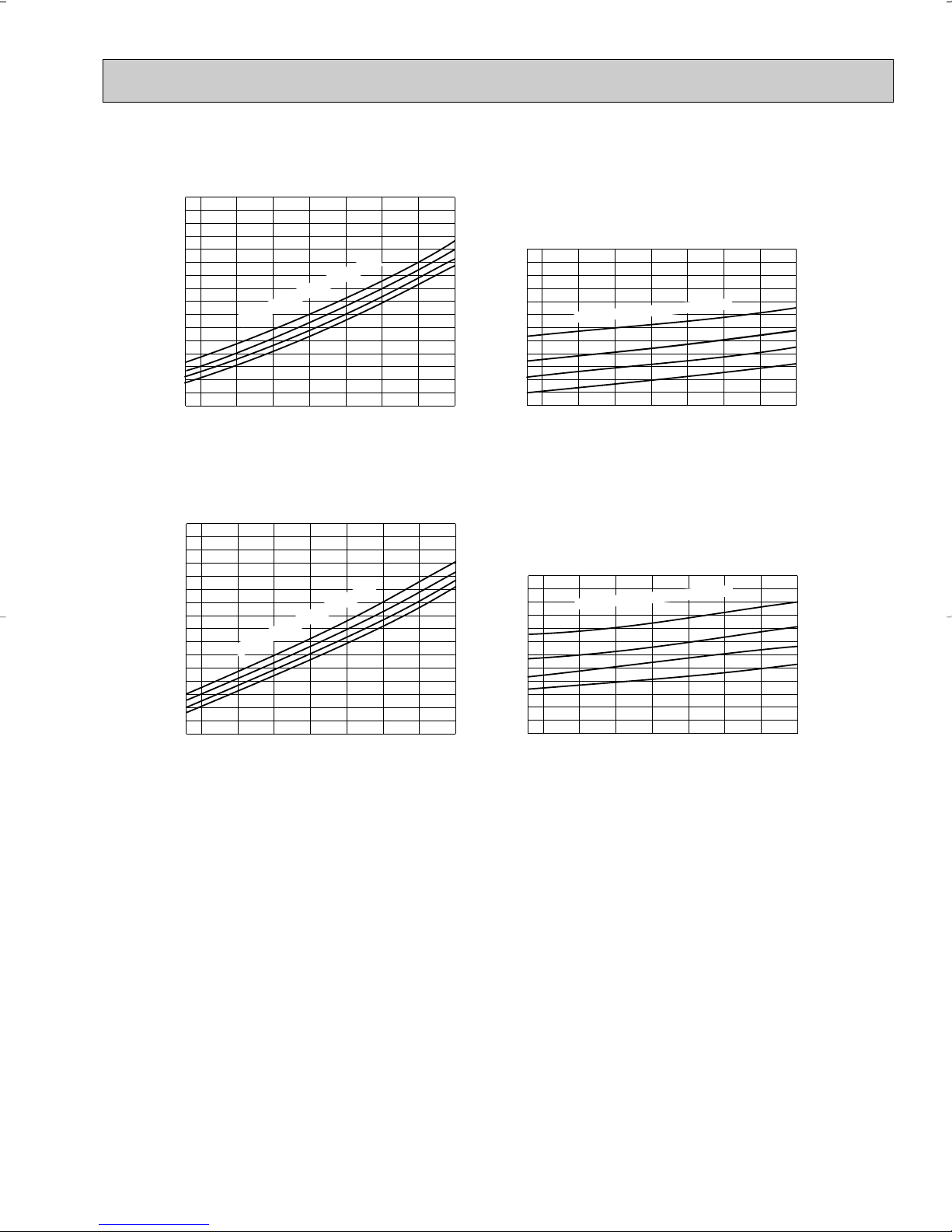

7-2. PERFORMANCE CURVE

65

70

75

75

70

65

Total power consumption

(kW)

Total capacity

( ✕10

3

Btu/h)

Outdoor intake air WB temperature (°F)

= 307CFM

Airflow

12

14

10

8

9

11

13

15

7

1.0

15 25 35 45 55

0.8

0.6

0.7

0.9

In

d

o

o

r in

ta

k

e

a

ir D

B

te

m

p

e

ra

tu

re

(

°F

)

In

d

o

o

r in

ta

ke

a

ir D

B

te

m

p

e

ra

tu

re

(

°F

)

65

70

75

75

70

65

20

12

8

16

22

18

10

14

In

d

o

o

r in

ta

k

e

a

ir D

B

te

m

p

e

ra

tu

re

(

°F

)

= 318CFM

Airflow

15 25 35 45 55

Outdoor intake air WB temperature (°F)

1.3

0.8

0.9

1.0

1.1

1.2

Indoor intake air DB temperature (

°F)

Total power consumption

(kW)

Total capacity

( ✕10

3

Btu/h)

65

70

75

75

70

65

Outdoor intake air WB temperature (°F)

= 381CFM

Airflow

18

22

24

14

10

1.8

1.9

1.7

15 25 35 45 55

1.5

1.3

1.4

1.6

I

n

d

o

o

r

in

t

a

k

e

a

ir

D

B

t

e

m

p

e

r

a

t

u

r

e

(

°

F

)

Indoor intake air D

B tem

perature (

°F)

Total power consumption

(kW)

Total capacity

( ✕10

3

Btu/h)

65

70

75

75

70

65

24

20

12

16

I

n

d

o

o

r

in

t

a

k

e

a

ir

D

B

t

e

m

p

e

r

a

t

u

r

e

(

°

F

)

= 381CFM

Airflow

15 25 35 45 55

Outdoor intake air WB temperature (°F)

2.4

1.4

1.6

1.8

2.0

2.2

Indoor intake air DB temperature (

°F)

Total power consumption

(kW)

Total capacity

( ✕10

3

Btu/h)

65

70

75

75

70

65

28

26

24

22

16

14

20

18

2.6

1.6

Indoor intake air DB temperature (

°F)

= 431CFM

Airflow

15 25 35 45 55

Outdoor intake air WB temperature (°F)

1.8

2.0

2.2

2.4

Indoor intake air DB temperature (°F)

Total power consumption

(kW)

Total capacity

( ✕10

3

Btu/h)

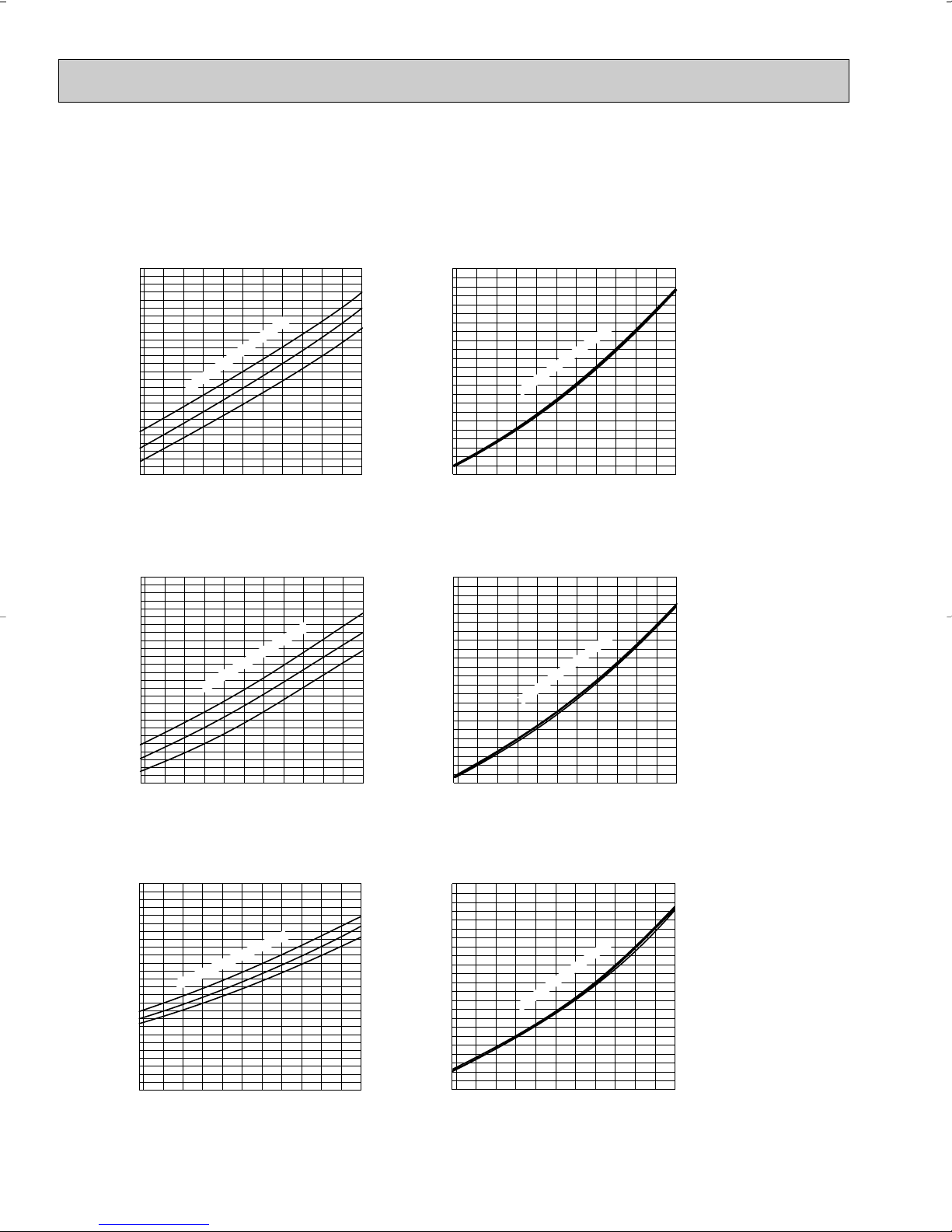

71

67

63

71

67

63

Outdoor intake air DB temperature (°F)

SHF at rating condition = 0.71

= 275CFM

Airflow

6

8

7

9

10

11

12

0.9

65 75 85 95 105 115

0.7

0.6

0.8

In

d

o

o

r

in

ta

k

e

a

ir W

B

te

m

p

e

r

a

tu

r

e

(

°

F

)

Indoor intake air WB temperature (

°F)

0.5

0.4

Total power consumption

(kW)

Total capacity

( ✕10

3

Btu/h)

71

67

63

71

67

63

24

22

20

18

12

16

14

2.5

2.3

2.1

1.9

1.7

1.5

In

d

o

o

r in

ta

k

e

a

ir W

B

te

m

p

e

ra

tu

re

(

°F

)

In

do

or in

ta

ke air W

B

te

m

pe

ra

tu

re (

°F

)

SHF at rating condition = 0.65

= 342CFM

Airflow

65 75 85 95 105 115

Outdoor intake air DB temperature (°F)

Total power consumption

(kW)

Total capacity

( ✕10

3

Btu/h)

71

63

67

71

63

67

27

29

23

19

25

21

17

3.1

2.9

2.7

2.5

2.3

2.1

Indoor intake air W

B

tem

perature (

°F)

Indoor intake air WB temperature (

°F)

SHF at rating condition = 0.63

= 385CFM

Airflow

65 75 85 95 105 115

Outdoor intake air DB temperature (°F)

Total power consumption

(kW)

Total capacity

( ✕10

3

Btu/h)

71

67

63

71

67

63

15

13

9

11

1.4

1.3

1.2

1.1

1.0

0.9

Indoor intake air WB temperature (

°F)

In

d

oo

r in

ta

k

e

a

ir W

B

te

m

pe

ra

tu

re

(

°F

)

SHF at rating condition = 0.70

= 318CFM

Airflow

65 75 85 95 105 115

Outdoor intake air DB temperature (°F)

Total power consumption

(kW)

Total capacity

( ✕10

3

Btu/h)

71

67

63

71

67

63

22

18

10

14

2.2

2.0

1.8

1.6

1.4

1.2

In

d

o

o

r in

ta

k

e

a

ir W

B

te

m

p

e

ra

tu

re

(

°

F

)

In

d

o

or in

ta

ke

a

ir W

B

te

m

p

e

ra

tu

re (

°F

)

SHF at rating condition = 0.65

= 342CFM

Airflow

65 75 85 95 105 115

Outdoor intake air DB temperature (°F)

Total power consumption

(kW)

Total capacity

( ✕10

3

Btu/h)

Cooling

MSZ-A09NA MSZ-A12NA

MSZ-A15NA MSY-A15NA

Heating

MSZ-A17NA MSY-A17NA

MSZ-A09NA

MSZ-A24NA MSY-A24NA

MSZ-A12NA

MSZ-A15NA

MSZ-A17NA

This value of frequency is not the same as the actual frequency in operating. Refer to 7-6 and 7-7 for the relationships

between frequency and capacity.

MSZ-A24NA

19

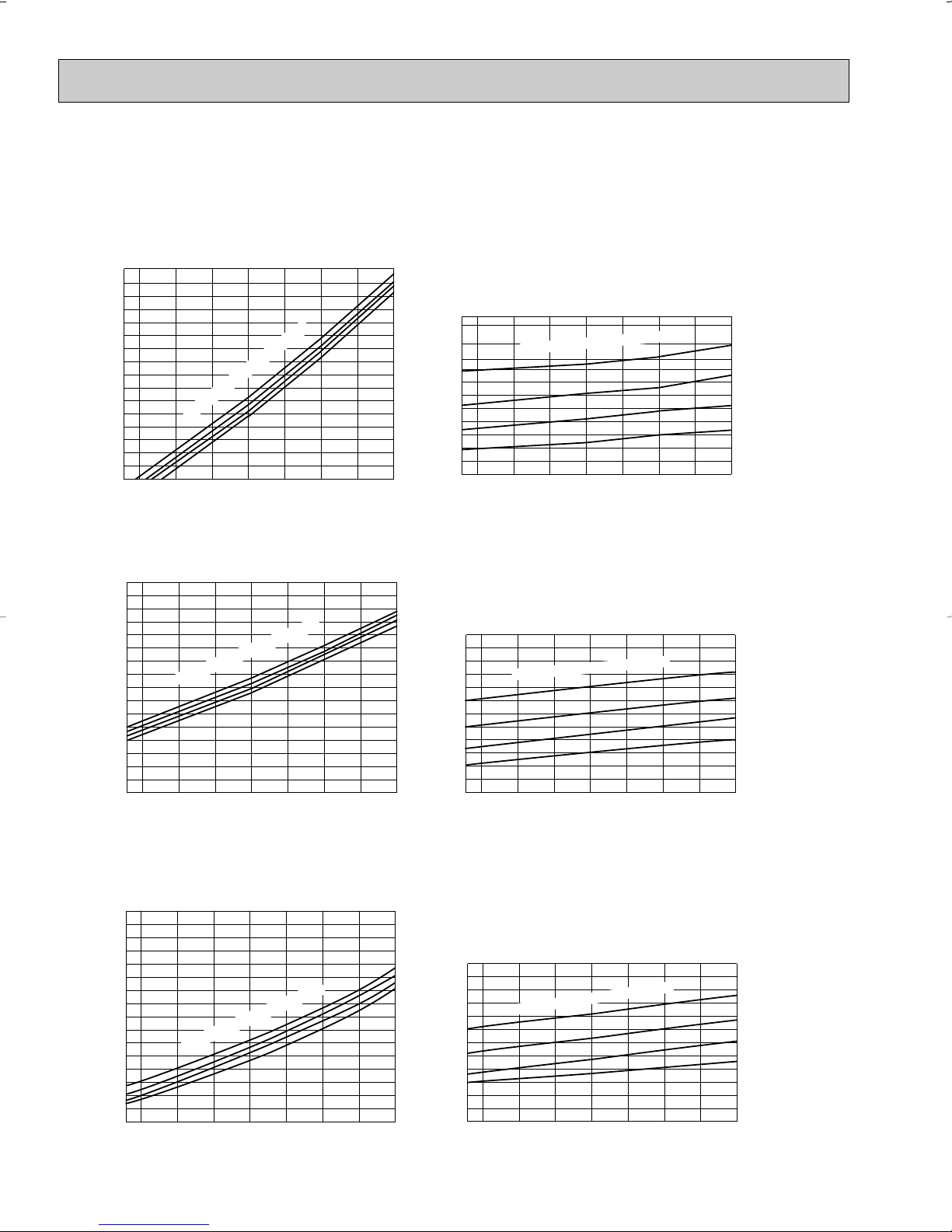

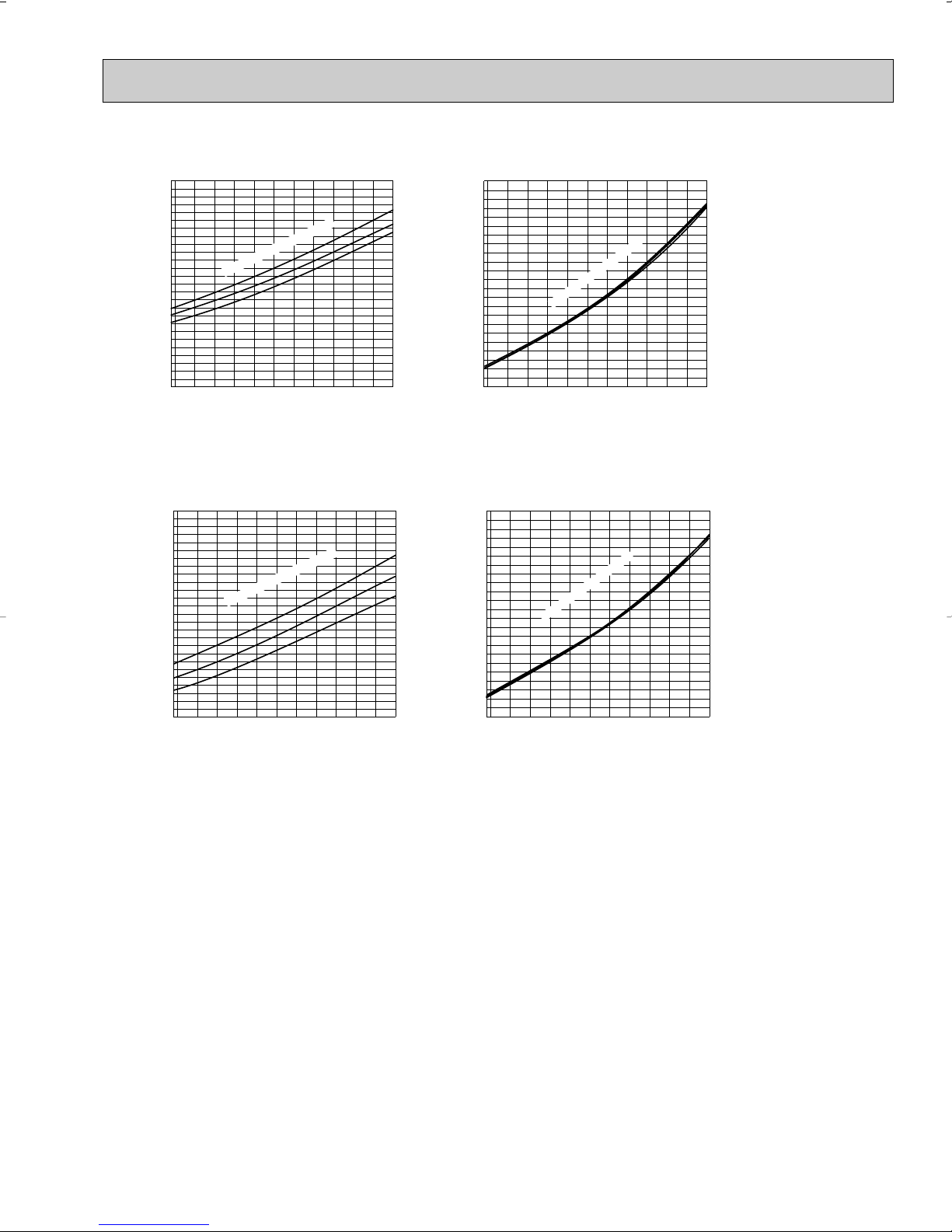

7-3. Condensing pressure

68 70 75 80 85 90 95 100 105

(°F)

110

115

120

125

130

135

140

145

150

155

160

165

170

(PSIG)

Condensing pressure

86

80

75

70

Suction pressure

Outdoor ambient temperature

Indoor DB temperature (

°F)

(PSIG)

86

80

75

70

68 70 75 80 85 90 95 100 105

(°F)

260

280

300

320

340

360

380

400

420

Indoor DB temperature (

°F)

Outdoor ambient temperature

68 70 75 80 85 90 95 100 105

(°F)

90

95

100

105

110

115

120

125

130

135

140

145

150

(PSIG)

Condensing pressure

86

80

75

70

Suction pressure

Outdoor ambient temperature

Indoor DB temperature (

°F)

(PSIG)

86

80

75

70

68 70 75 80 85 90 95 100 105

(°F)

180

220

260

300

340

380

420

460

500

Indoor D

B

tem

perature (

°F

)

Outdoor ambient temperature

68 70 75 80 85 90 95 100 105(°F)

80

85

90

95

100

105

110

115

120

125

130

135

140

(PSIG)

Condensing pressure

86

80

75

70

Suction pressure

Outdoor ambient temperature

Indoor DB temperature (°F)

(PSIG)

86

80

75

70

68 70 75 80 85 90 95 100 105(°F)

260

300

340

380

420

460

500

540

580

Indoor DB temperature (

°F)

Outdoor ambient temperature

Cooling

Data is based on the condition of indoor humidity 50%.

Air flow should be set to High speed.

MSZ-A09NA

MSZ-A12NA

MSZ-A15NA

MSY-A15NA

20

68 70 75 80 85 90 95 100 105(°F)

70

75

80

85

90

95

100

105

110

115

120

125

130

(PSIG)

Condensing pressure

86

80

75

70

Suction pressure

Outdoor ambient temperature

Indoor DB temperature (

°F)

(PSIG)

86

80

75

70

68 70 75 80 85 90 95 100 105(°F)

260

300

340

380

420

460

500

540

580

Indoor D

B tem

perature (

°F

)

Outdoor ambient temperature

MSZ-A17NA

(PSIG)

Condensing pressure

86

80

75

70

68 70 75 80 85 90 95 100 105(°F)

80

85

90

95

100

105

110

115

120

125

130

135

140

Suction pressure

Outdoor ambient temperature

Indoor DB temperature (

°F)

(PSIG)

86

80

75

70

68 70 75 80 85 90 95 100 105(°F)

260

300

340

380

420

460

500

540

580

Indoor DB temperature (

°F)

Outdoor ambient temperature

MSY-A17NA

MSZ-A24NA

MSY-A24NA

21

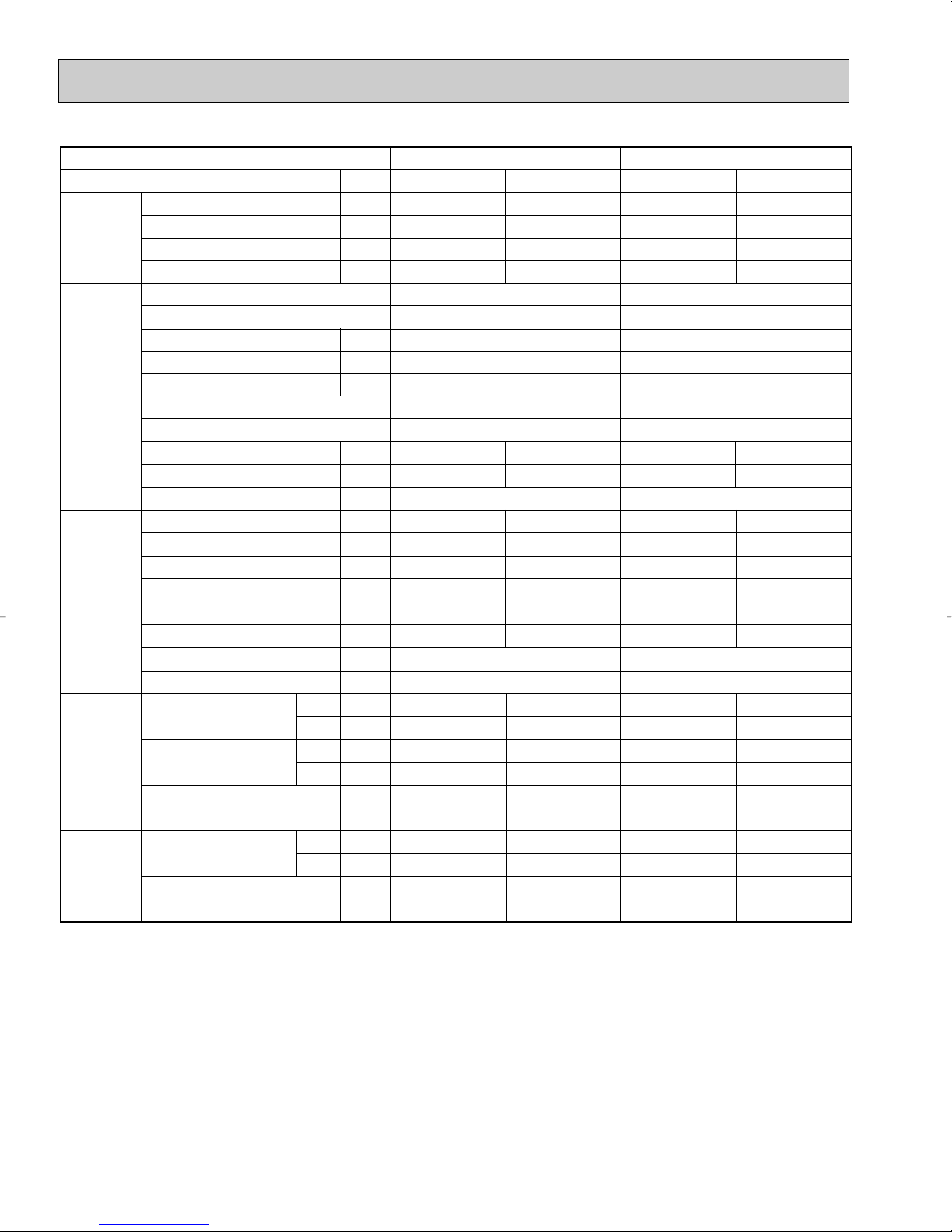

Heating

75

70

65

(PSIG) (PSIG)

Condensing pressure

Outdoor ambient temperature

14 20 25 30 35 40 45 50 55 60 65 70(°F)

340

320

300

280

260

240

360

380

400

440

420

460

480

Indoor DB temperature(

°F)

75

70

65

Suction pressure

Outdoor ambient temperature

14 20 25 30 35 40 45 50 55

58Hz

58Hz

60 65 70(°F)

70

60

80

90

100

110

120

130

140

150

160

170

In

d

o

o

r D

B

te

m

p

e

ra

tu

re

(

°

F

)

75

70

65

(PSIG) (PSIG)

Condensing pressure

Outdoor ambient temperature

14 20 25 30 35 40 45 50 55 60 65 70(°F)

260

220

180

140

100

300

340

380

460

420

500

540

580

620

In

d

o

o

r D

B

te

m

p

e

ra

tu

re

(°

F

)

75

70

65

Suction pressure

Outdoor ambient temperature

14 20 25 30 35 40 45 50 55

58Hz

58Hz

60 65 70(°F)

70

60

50

80

90

100

110

120

130

140

150

160

In

d

o

o

r

D

B

te

m

p

e

ra

tu

re

(

°

F

)

75

70

65

(PSIG) (PSIG)

Condensing pressure

Outdoor ambient temperature

14 20 25 30 35 40 45 50 55 60 65 70(°F)

340

320

300

280

260

240

360

380

400

440

420

460

480

Indoor DB temperature(

°F)

75

70

65

Suction pressure

Outdoor ambient temperature

14 20 25 30 35 40 45 50 55

58Hz

58Hz

60 65 70(°F)

70

60

80

90

100

110

120

130

140

150

160

170

In

d

o

o

r D

B

te

m

p

e

ra

tu

re

(

°

F

)

Data is based on the condition of outdoor humidity 75%.

Air flow should be set to High speed.

Data is for heating operation without any frost.

MSZ-A09NA

MSZ-A12NA

MSZ-A15NA

22

MSZ-A17NA

75

70

65

(PSIG) (PSIG)

Condensing pressure

Outdoor ambient temperature

14 20 25 30 35 40 45 50 55 60 65 70(°F)

260

220

180

140

100

300

340

380

460

420

500

540

580

620

In

d

o

o

r D

B

te

m

p

e

ra

tu

re

(°

F

)

75

70

65

Suction pressure

Outdoor ambient temperature

14 20 25 30 35 40 45 50 55

58Hz

58Hz

60 65 70(°F)

70

60

50

80

90

100

110

120

130

140

150

160

In

d

o

o

r D

B

te

m

p

e

ra

tu

re

(

°

F

)

75

70

65

(PSIG) (PSIG)

Condensing pressure

Outdoor ambient temperature

14 20 25 30 35 40 45 50 55 60 65 70(°F)

280

260

240

220

200

300

320

340

380

360

400

420

440

460

In

d

o

o

r D

B

te

m

p

e

ra

tu

re

(°

F

)

75

70

65

Suction pressure

Outdoor ambient temperature

14 20 25 30 35 40 45 50 55

58Hz

60 65 70(°F)

70

60

50

80

90

100

110

120

130

140

150

160

In

d

o

o

r D

B

te

m

p

e

ra

tu

re

(

°

F

)

58Hz

MSZ-A24NA

23

7-4. STANDARD OPERATION DATA

Capacity

SHF

Input

Rated frequency

Indoor unit

Power supply (V, phase, Hz)

Input

Fan motor current

Aux. heater current

Outdoor unit

Power supply (V, phase, Hz)

Input

Comp. current

Fan motor current

Condensing pressure

Suction pressure

Discharge temperature

Condensing temperature

Suction temperature

Comp. shell bottom temp

Ref. pipe length

Refrigerant charge (R410A)

Intake air temperature

Discharge air temperature

Fan speed (High)

Airflow (High)

Intake air temperature

Fan speed

Airflow

Unit

Btu / h

—

kW

Hz

kW

A

A

kW

A

A

PSIG

PSIG

˚F

˚F

˚F

˚F

ft.

—

˚F

˚F

˚F

˚F

rpm

CFM

˚F

˚F

rpm

CFM

Cooling

9,000

0.71

0.690

50

0.674

2.80 / 2.53

363

144

145

107

55

140

80

67

57

56

1,080

275 (Wet)

95

–

840

1,094

Cooling

12,000

0.70

1,170

76

1.149

5.08 / 4.59

395

124

169

112

54

163

80

67

56

54

1,220

318 (Wet)

95

–

840

1,094

Heating

10,900

–

0.860

61

0.844

3.63 / 3.28

368

109

153

108

37

147

70

60

105

71

1,080

307

47

43

840

1,094

Heating

13,600

–

1,160

76

1.139

5.03 / 4.54

393

103

164

113

35

158

70

60

108

72

1,220

353

47

43

840

1,094

DB

WB

DB

WB

DB

WB

Item

Model

Total

Electrical

circuit

Refrigerant

circuit

Indoor

unit

Outdoor

unit

MSZ-A09NA

MSZ-A09NA

208/230, 1, 60

0.016

0.18 / 0.16

–

MUZ-A09NA

208/230, 1, 60

0.37 / 0.34

25

2lb.5oz.

MSZ-A12NA

MSZ-A12NA

208/230, 1, 60

0.021

0.23 / 0.21

–

MUZ-A12NA

208/230, 1, 60

0.37 / 0.34

25

2lb.5oz.

24

Loading...

Loading...