Page 1

SPLIT-TYPE,AIR CONDITIONERS

SERVICE MANUAL

Multi system type

Models

No. OB284

MUX-19TV MUX-20TV MUX-25TV -

E1

E1

E1

CONTENTS

1. TECHNICAL CHANGES ····································2

2. PART NAMES AND FUNCTIONS······················2

3. INDOOR/OUTDOOR

CORRESPONDENCE TABLE ···························3

4. SPECIFICATION·················································3

5. NOISE CRITERIA CURVES······························ 6

6. OUTLINES AND DIMENSIONS························ 7

7. WIRING DIAGRAM ············································9

8. REFRIGERANT SYSTEM DIAGRAM··············10

MUX-19TV MUX-20TV MUX-25TV -

This manual describes technical data of outdoor unit.

For indoor unit refer to the service manuals No.OB227 REVISED EDITION-B and OB252 REVISED EDITION-A of corresponding models.

E1

E1

E1

9. PERFORMANCE CURVES······························14

10. TROUBLESHOOTING ······································26

11. DISASSEMBLY INSTRUCTIONS·····················32

12. PARTS LIST······················································35

13. OPTIONAL PARTS ···········································37

Page 2

1

TECHNICAL CHANGES

MUX-19TV MUX-20TV MUX-25TV -

New models

2

E1

E1

E1

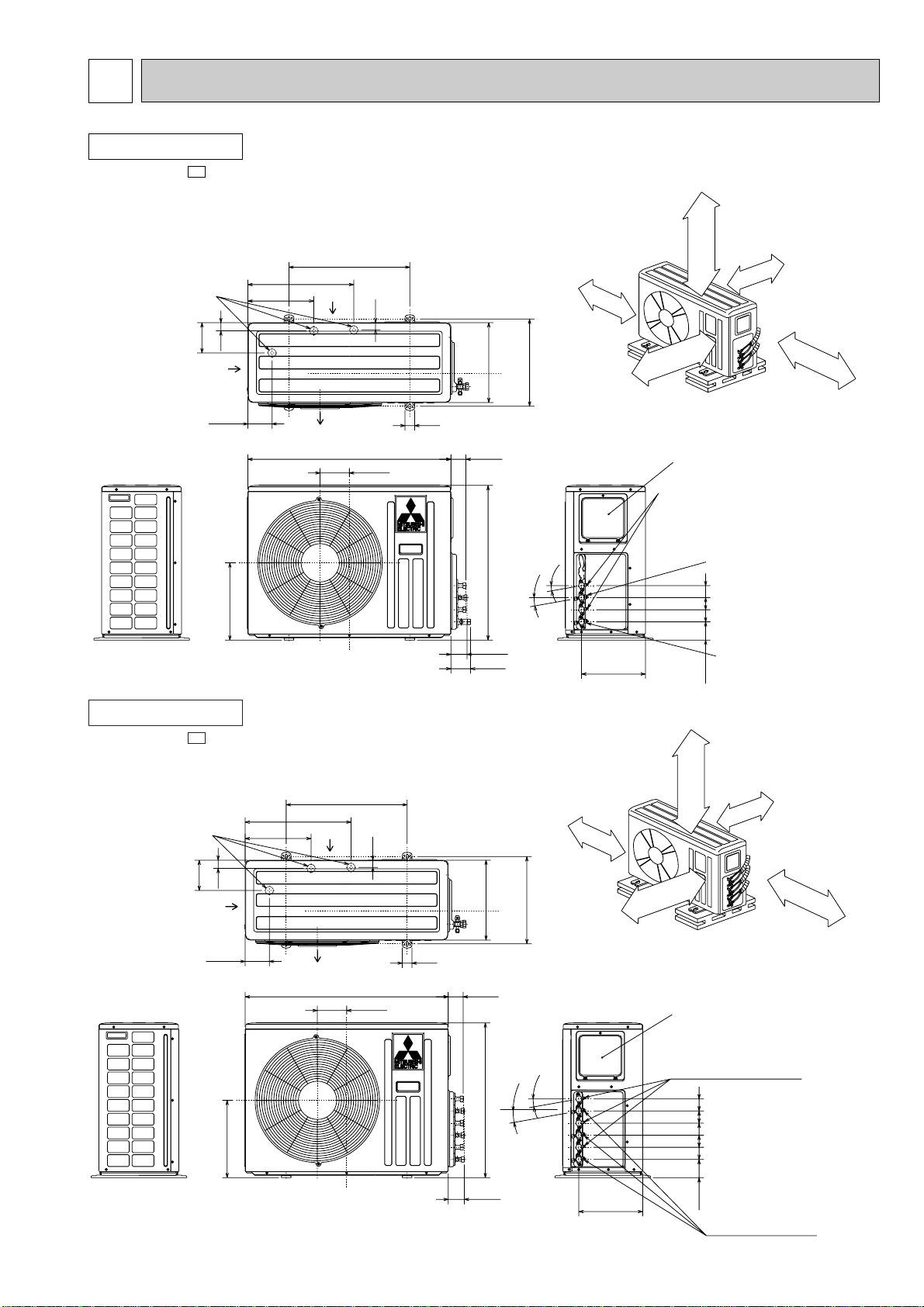

PART NAMES AND FUNCTIONS

OUTDOOR UNIT

MUX-19TV MUX-20TV MUX-25TV -

E1

E1

E1

Air inlet

(Back and side)

Piping

Drainage hose

Air outlet

2

Page 3

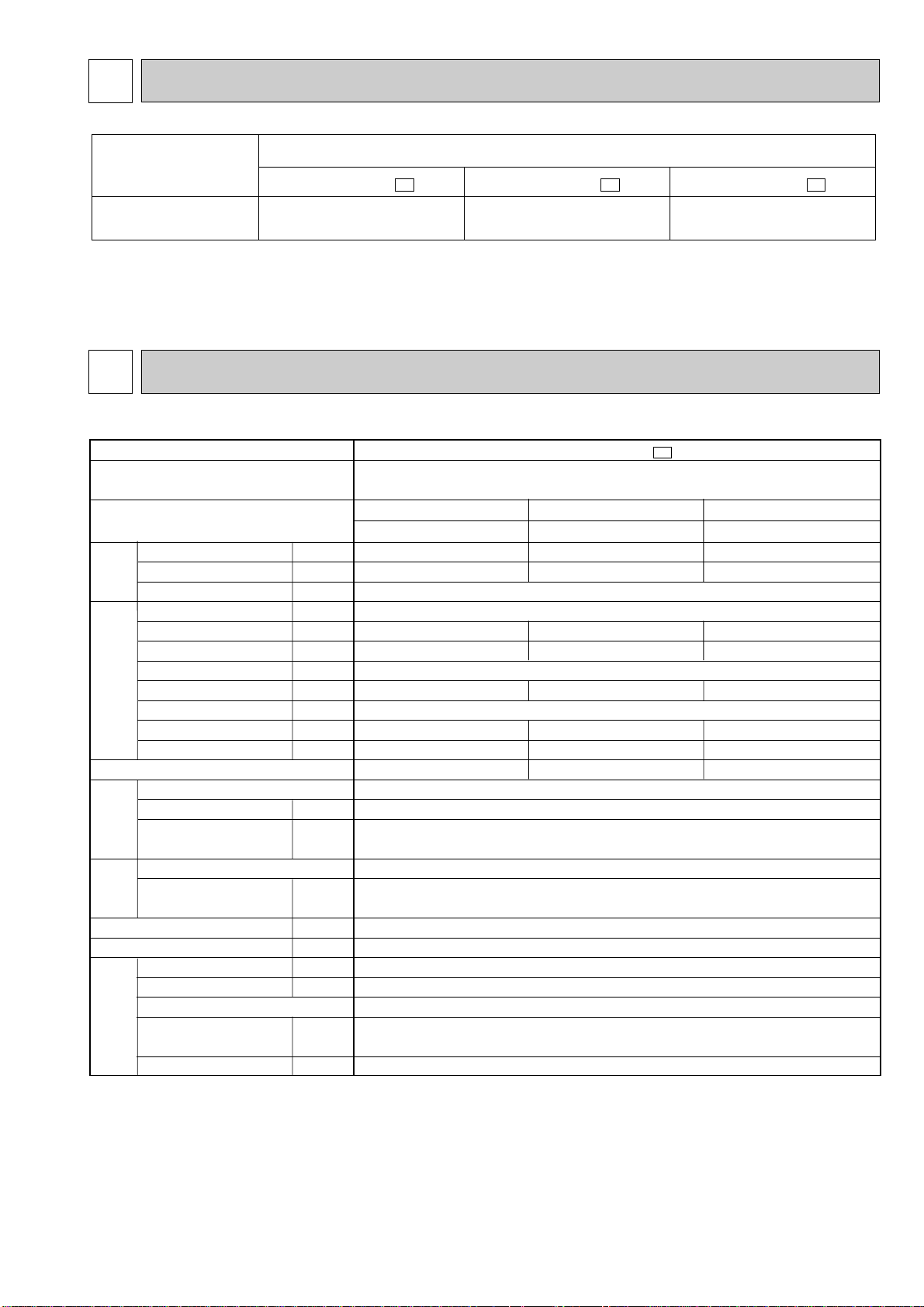

3

❈There is no combination other than this table.

MUX-19TV-

E1

MUX-20TV-

E1

MUX-25TV-

E1

Combination of the

connectable indoor units

OUTDOOR UNIT

A:07, B:12 A:09, B:09, C:09 A:12, B:12

Outdoor model

Capacity

Dehumidification

Outdoor air flow

Power outlet

Running current

Power input

Auxiliary heater

Power factor

Starting current

Compressor motor current

Fan motor current

Model

Output

Winding

resistance(at20:)

Model

Winding

resistance(at20:)

Dimensions WOHOD

Weight

Sound level

Fan speed

Fan speed regulator

Refrigerant filling

capacity(R22)

Refrigerating oil (Model)

kW

R/h

K /h

A

A

W

A(kW)

%

A

A

A

W

"

"

mm

kg

dB

rpm

kg

cc

Opetate 1 unit

A

3.5

1.6

6.01

1,280

92.6

5.68

0.33

2.65

Opetate 2 unit

A+B

3.5+2.2

1.6+0.8

8.94

2,005

97.5

8.37

0.57

2.74

MUX-19TV -

E1

Single phase

230V, 50Hz

Opetate 1 unit

B

2.2

0.8

Hi:2,460 / Lo:1,920

15

3.33

745

—

97.3

45.6

3.00

0.33

2.82

RH220VHAT (Room A) / RH135VHAT (Room B)

1,050 / 650

C-R 2.13/4.18

C-S 3.91/5.76

RA6V60-DA

WHT-BLK 90 BKL-YLW 54

BLK-RED 146

840✕640✕330

63

52

High:730 / Low:580

2

Room A : 0.87

Room B :1.0

520(MS56) / 300(MS56)

Compressor

Electrical

data

Fan

motor

Special

remarks

Capacity

Coefficient of performance(C.O.P)

Outdoor unit power supply

Indoor unit No.

INDOOR / OUTDOOR CORRESPONDENCE TABLE

4

NOTE: Test conditions are based on ISO 5151.

SPECIFICATION

Cooling : Indoor DB27°C / WB19°C

Outdoor DB35°C / WB(24°C)

3

Page 4

Outdoor model

Capacity

Dehumidification

Outdoor air flow

Power outlet

Running current

Power input

Auxiliary heater

Power factor

Starting current

Compressor motor current

Fan motor current

Model

Output

Winding

resistance(at20:)

Model

Winding

resistance(at20:)

Dimensions WOHOD

Weight

Sound level

Fan speed

Fan speed regulator

Refrigerant filling

capacity(R22)

Refrigerating oil (Model)

kW

R/h

K /h

A

A

W

A(kW)

%

A

A

A

W

"

"

mm

kg

dB

rpm

kg

cc

Opetate 1 unit

A

2.5

1.1

3.43

775

98.2

3.10

0.33

3.09

Opetate 1 unit

B or C

2.7

1.2

4.23

965

99.2

3.90

0.33

2.70

Opetate 2 unit

A+B or A+C

2.4+2.7

0.9+1.2

7.56

1,740

99.9

6.99

0.57

2.82

Opetate 3 unit

A+B+C

2.4+1.75✕2

0.9+0.3✕2

7.79

1,785

99.6

7.22

0.57

3.12

MUX-20TV -

E1

Single phase

230V, 50Hz

Opetate 2 unit

B+C

1.75✕2

0.3✕2

High: 2,460 / Low: 1,920

15

4.36

1,000

—

99.7

40

4.03

0.33

3.27

RH140VHAT (Room A) / RH174VHAT (Room B,C)

700/800

C-R 4.03/3.30

C-S 5.71/5.80

RA6V60-DA

WHT-BLK 90 BLK-YLW 54

BLK-RED 146

840✕640✕330

62

52

High: 730 / Low: 580

2

Room A : 0.8

Room B,C : 0.96

300(MS56) / 300(MS56)

Compressor

Electrical

data

Fan

motor

Special

remarks

Capacity

Coefficient of performance(C.O.P)

Outdoor unit power supply

Indoor unit No.

NOTE: Test conditions are based on ISO 5151.

Cooling : Indoor DB27°C / WB19°C

Outdoor DB35°C / WB(24°C)

4

Page 5

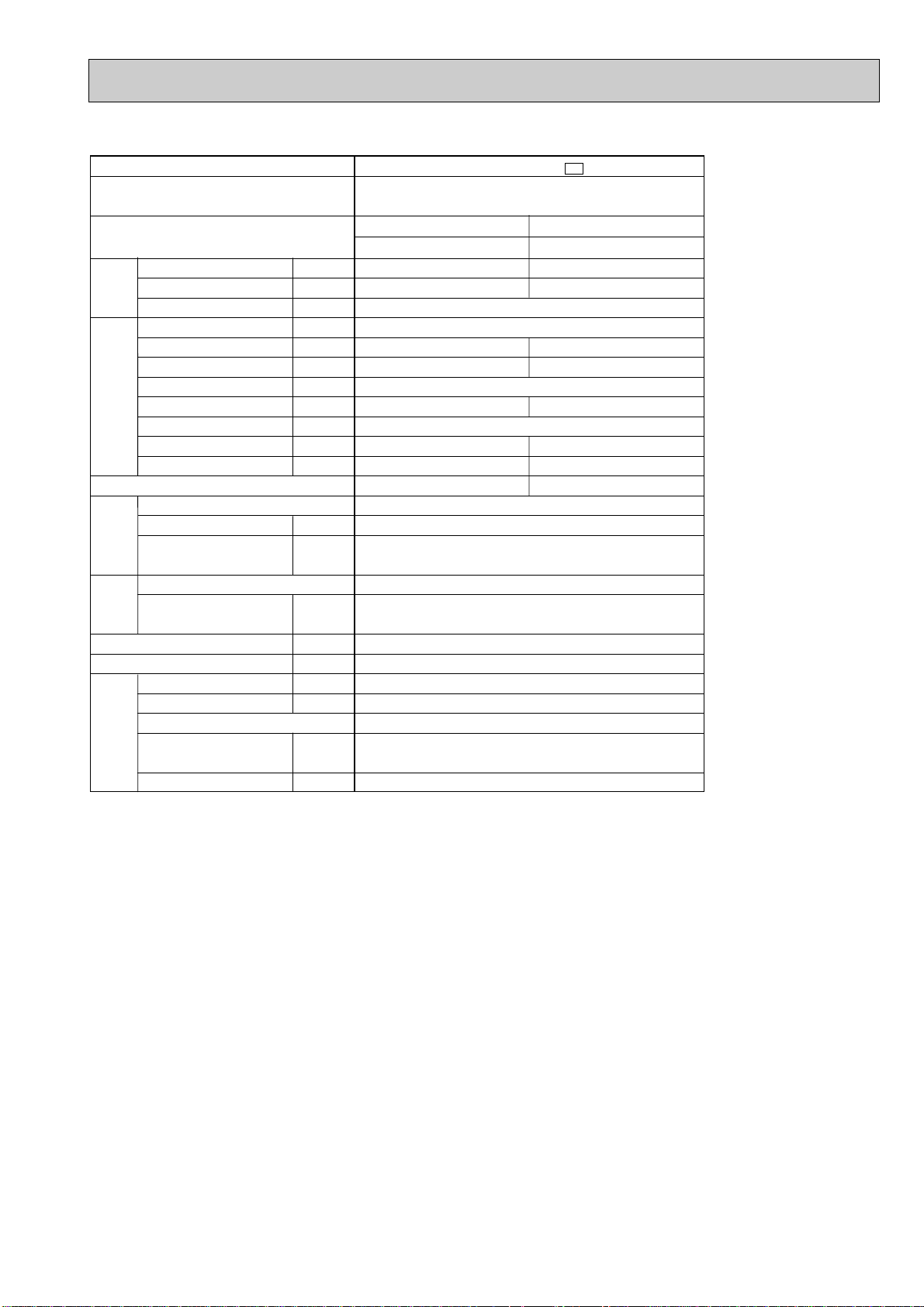

Outdoor model

Outdoor unit power supply

Indoor unit No.

Capacity

Dehumidification

Outdoor air flow

Capacity

Power outlet

Running current

Power input

Auxiliary heater

Power factor

Electrical

data

Starting current

Compressor motor current

Fan motor current

kW

R/h

K /h

A

A

W

A(kW)

%

A

A

A

Coefficient of performance(C.O.P)

Model

Output

Winding

Compressor

resistance(at20:)

Model

Winding

Fan

motor

resistance(at20:)

Dimensions WOHOD

Weight

Sound level

Fan speed

W

"

"

mm

kg

dB

rpm

Fan speed regulator

Refrigerant filling

Special

remarks

capacity(R22)

Refrigerating oil (Model)

kg

cc

NOTE: Test conditions are based on ISO 5151.

Cooling : Indoor DB27°C / WB19°C

Outdoor DB35°C / WB(24°C)

MUX-25TV -

Single phase

230V, 50Hz

Opetate 1 unit

A or B

3.5

1.6

High:2,760 / Low:1,920

6.11

1,350

96.1

5.79

0.32

2.52

RH231VHAT✕2

1,100✕2

C-R 2.13

C-S 3.91

RA6V60-EA

WHT-BLK 67 BLK-YLW 75

BLK-RED 73

840✕640✕330

High: 810 / Low: 580

Room A: 0.9

Room B: 0.9

520(MS56) / 520(MS56)

25

—

56

65

54

E1

Opetate 2 unit

A+B

3.5✕2

1.6✕2

12.42

2,760

96.6

11.81

0.61

2.46

2

5

Page 6

NOISE CRITERIA CURVES5

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

TERESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

Test conditions.

Cooling :DB35: WB24:

High

SPEED

52

SPL(dB(A)) LINE

MUX-19TV - E1

MUX-20TV - E1

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

TERESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

Test conditions.

Cooling :DB35: WB24:

High

SPEED

54

SPL(dB(A)) LINE

MUX-25TV - E1

6

Page 7

6

500

840 61.7

264.2

10°

10°

Service panel

Open as a rule

500mm or more if

the front and both

sides are open

100mm or more

200mm or more if

there are obstacles

to both sides

Open as a rule

500mm or more if the back,

both sides and top are open

350mm or more

100mm or more

B UNIT

A UNIT

Gas refrigerant

pipe joint

Refrigerant pipe

(flared) {9.52

Gas refrigerant

pipe joint

Refrigerant pipe

(flared) {12.7

Liquid refrigerant

pipe joint

Refrigerant pipe

(flared) {6.35

66.2

80.7

121.3

40

438.4

Air in

Air out

Air in

272.9

100.3

125.6

319.8

34

330

640

360.6

75.8

505050

Drainage

3hoies {33

}

}

OUTLINES AND DIMENSIONS

OUTDOOR UNIT

MUX-19TV-

E1

Unit: mm

OUTDOOR UNIT

MUX-20TV-

E1

Drainage

3hoies {33

125.6

Air in

34

100.3

319.8

272.9

438.4

Air in

Air out

500

40

840 61.7

121.3

330

640

66.2

7

100mm or more

360.6

Open as a rule

500mm or more if the back,

both sides and top are open

10°

10°

}

}

}

264.2

Service panel

Liquid refrigerant

pipe joint

Refrigerant pipe

(flared) {6.35

C UNIT

B UNIT

A UNIT

5050505050

75.8

Unit: mm

Open as a rule

500mm or more if

the front and both

sides are open

100mm or more

200mm or more if

there are obstacles

to both sides

350mm or more

Gas refrigerant

pipe joint

Refrigerant pipe

(flared) {9.52

Page 8

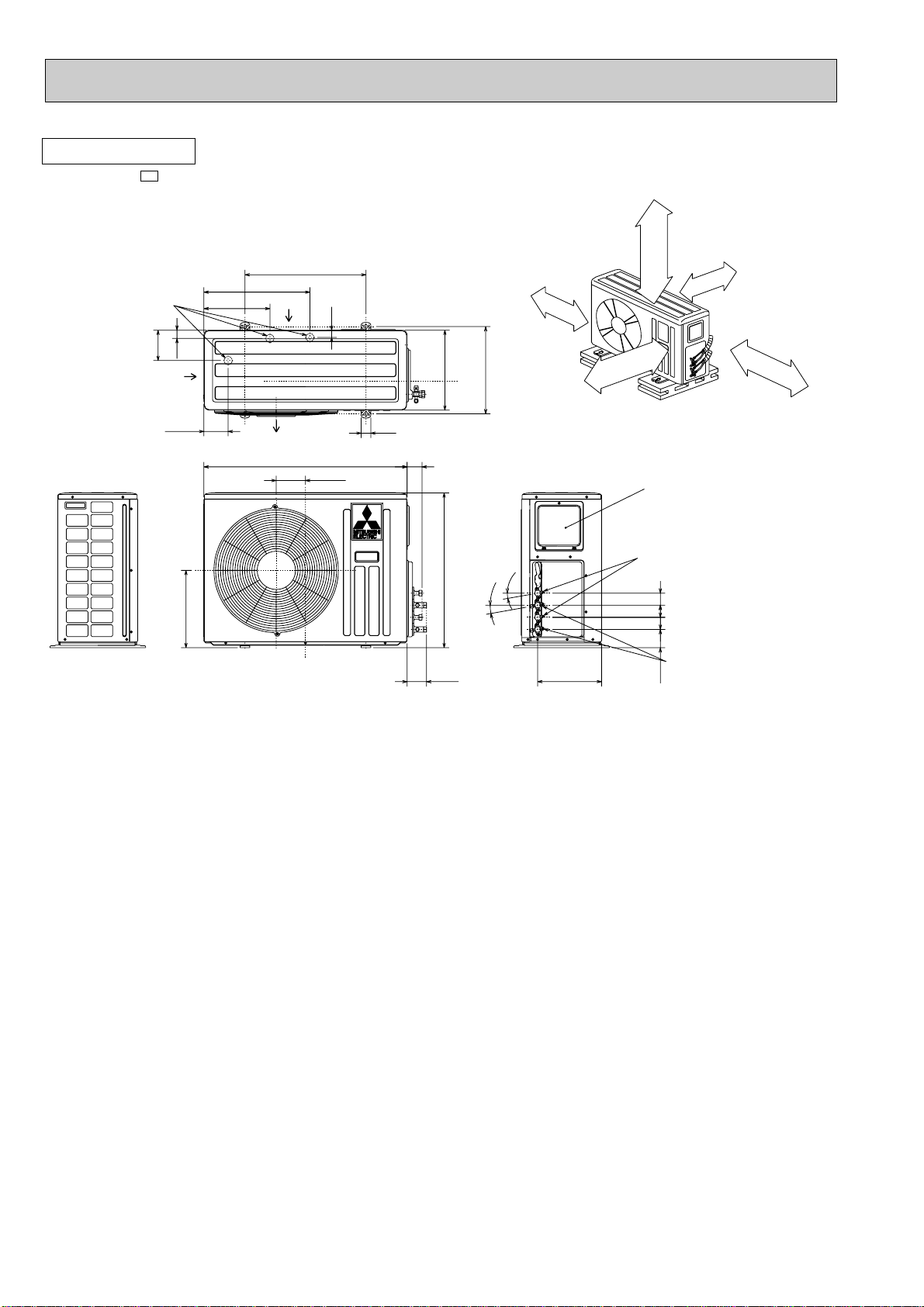

OUTDOOR UNIT

MUX-25TV-

E1

Drainage

3hoies {33

125.6

Air in

34

100.3

319.8

272.9

500

438.4

Air in

Air out

840 61.7

121.3

Unit: mm

Open as a rule

500mm or more if

the front and both

sides are open

100mm or more

100mm or more

330

360.6

Open as a rule

500mm or more if the back,

40

640

both sides and top are open

10°

10°

B UNIT

}

A UNIT

}

Service panel

Liquid refrigerant

pipe joint

Refrigerant pipe

(flared) {6.35

505050

200mm or more if

there are obstacles

to both sides

350mm or more

80.7

264.2

Gas refrigerant

pipe joint

75.8

Refrigerant pipe

(flared) {12.7

8

Page 9

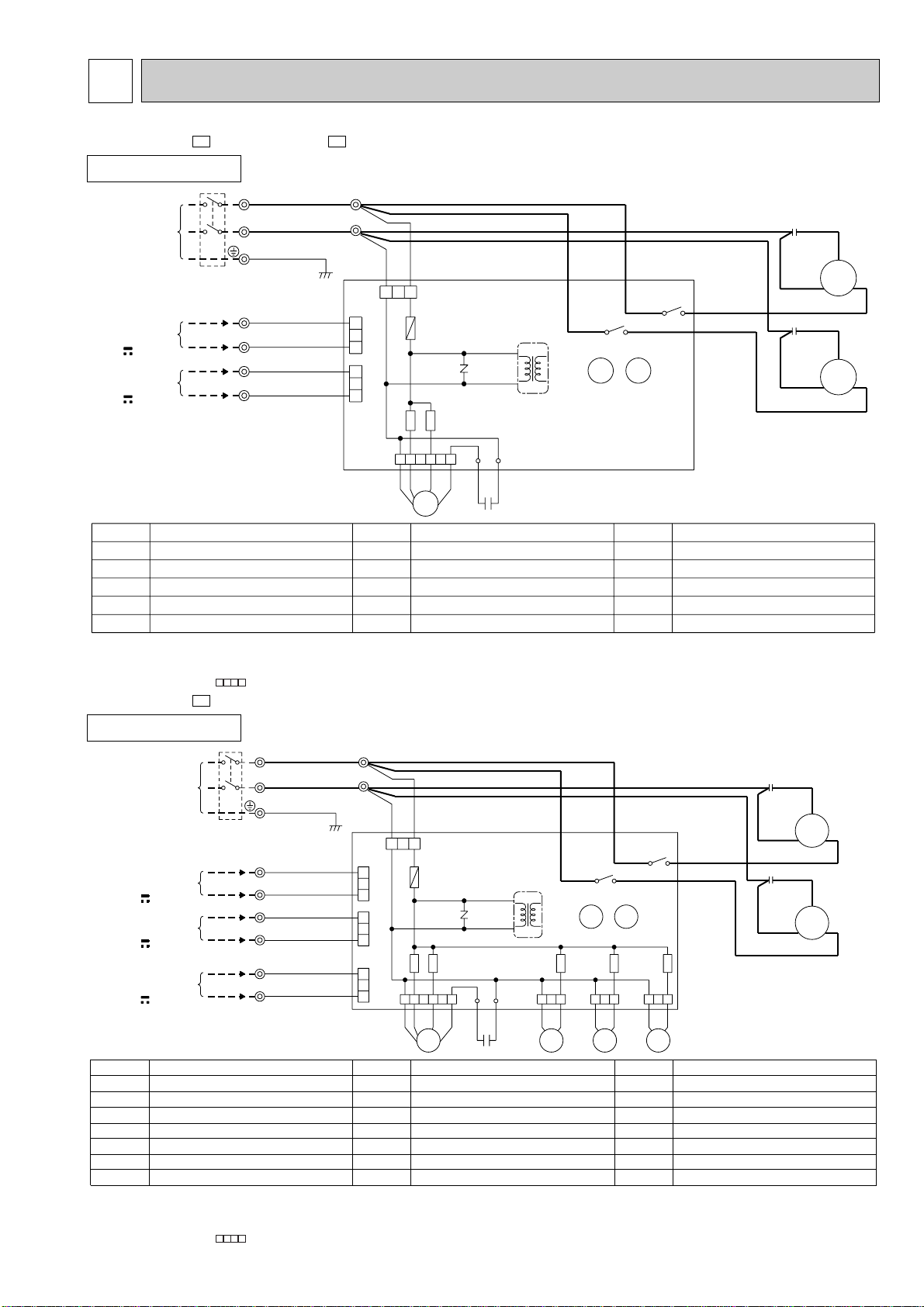

7

1

2

3

123

2

1

3

(3.15A)

RED

RED

NR61

T61

1

2

43

43

C61

LD1

WHT

WHT

OUTDOOR CONTROL PC BOARD

BRN

BLU

BRN

BLU

BRN

X522

X521

BLK

SR862

SR861

LD2

RED

BLK

YLW

WHT

652341

BRN

BLU

BLU

TB4

CN91

CN90

TB2

X521X522

F61

CN73 CN71

TO INDOOR

UNIT B

CONNECTING

12V

PE

CIRCUIT BREAKER

GRN/YLW

ORN

BLU

YLW

BLU

RED

RED

TO INDOOR

UNIT A

CONNECTING

12V

1

2

C2

C1

RC

S

CR

S

MC2

MF61

MC1

BLK

TB1

POWER SUPPLY

~/N

230V

50Hz

1

2

L

N

SYMBOL

C1

C2

C61

F61

MC1

SYMBOL

MC2

MF61

NR61

SR861

SR862

SYMBOL

TB1

TB2~TB4

T61

X521

X522

NAME

COMPRESSOR CAPACITOR (MC1)

COMPRESSOR CAPACITOR (MC2)

FAN MOTOR CAPACITOR

FUSE (3.15A)

COMPRESSOR (INNER PROTECTOR)

NAME

COMPRESSOR (INNER PROTECTOR)

FAN MOTOR (INNER PROTECTOR)

SURGE ABSORBER

FAN MOTOR RELAY

FAN MOTOR RELAY

NAME

TERMINAL BLOCK

TERMINAL BLOCK

TRANSFORMER

COMPRESSOR CONTACTOR (MC1)

COMPRESSOR CONTACTOR (MC2)

1

2

3

1

2

3

123

2

1

3

(3.15A)

123123123

RED

RED

21R421R3

NR61

T61

1

2

43

43

C61

LD1

WHT

WHT

OUTDOOR CONTROL PC BOARD

BRN

BLU

BRN

BLU

BRN

BLU

BLU

X522

X521

BLK

SR865

SR866

SR863

SR862

SR861

LD2

RED

BLK

YLW

WHT

652341

BRN

BLU

BLU

TB4

CN86

CN85

CN81

CN91

CN90

TB3

TB2

X521

BLU

BLU

X522

BLU

BLU

21RB

F61

CN74 CN73 CN71

TO INDOOR

UNIT B

CONNECTING

12V

PE

CIRCUIT BREAKER

GRN/YLW

WHT

BLU

ORN

BLU

YLW

BLU

RED

RED

TO INDOOR

UNIT A

CONNECTING

12V

1

2

1

2

C2

C1

RC

S

CR

S

MC2

TO INDOOR

UNIT C

CONNECTING

12V

MF61

MC1

BLK

TB1

POWER SUPPLY

~/N

230V

50Hz

1

2

L

N

SYMBOL

C1

C2

C61

F61

MC1

MC2

MF61

SYMBOL

NR61

SR861

SR862

SR863

SR865

SR866

TB1

SYMBOL

TB2~TB4

T61

X521

X522

21RB

21R3

21R4

NAME

COMPRESSOR CAPACITOR (MC1)

COMPRESSOR CAPACITOR (MC2)

FAN MOTOR CAPACITOR

FUSE (3.15A)

COMPRESSOR (INNER PROTECTOR)

COMPRESSOR (INNER PROTECTOR)

FAN MOTOR (INNER PROTECTOR)

NAME

SURGE ABSORBER

FAN MOTOR RELAY

FAN MOTOR RELAY

RELAY (21RB)

RELAY (C) (21R4)

RELAY (B) (21R3)

TERMINAL BLOCK

NAME

TERMINAL BLOCK

TRANSFORMER

COMPRESSOR CONTACTOR (MC1)

COMPRESSOR CONTACTOR (MC2)

SOLENOID COIL

SOLENOID COIL (B)

SOLENOID COIL (C)

WIRING DIAGRAM

MUX-19TV - MUX-25TV -

OUTDOOR UNIT

MODELS WIRING DIAGRAM

E1E1

NOTE:1. About the outdoor side electric wiring refer to the outdoor unit electric wiring diagram for servicing.

MUX-20TV -

OUTDOOR UNIT

NOTE:1. About the outdoor side electric wiring refer to the outdoor unit electric wiring diagram for servicing.

2. Use copper conductors only. (For field wiring)

3. Symbols below indicate.

/: Terminal block, : Connector

E1

MODEL WIRING DIAGRAM

2. Use copper conductors only. (For field wiring)

3. Symbols below indicate.

/: Terminal block, : Connector

9

VG79B082H01

VG79B081H01

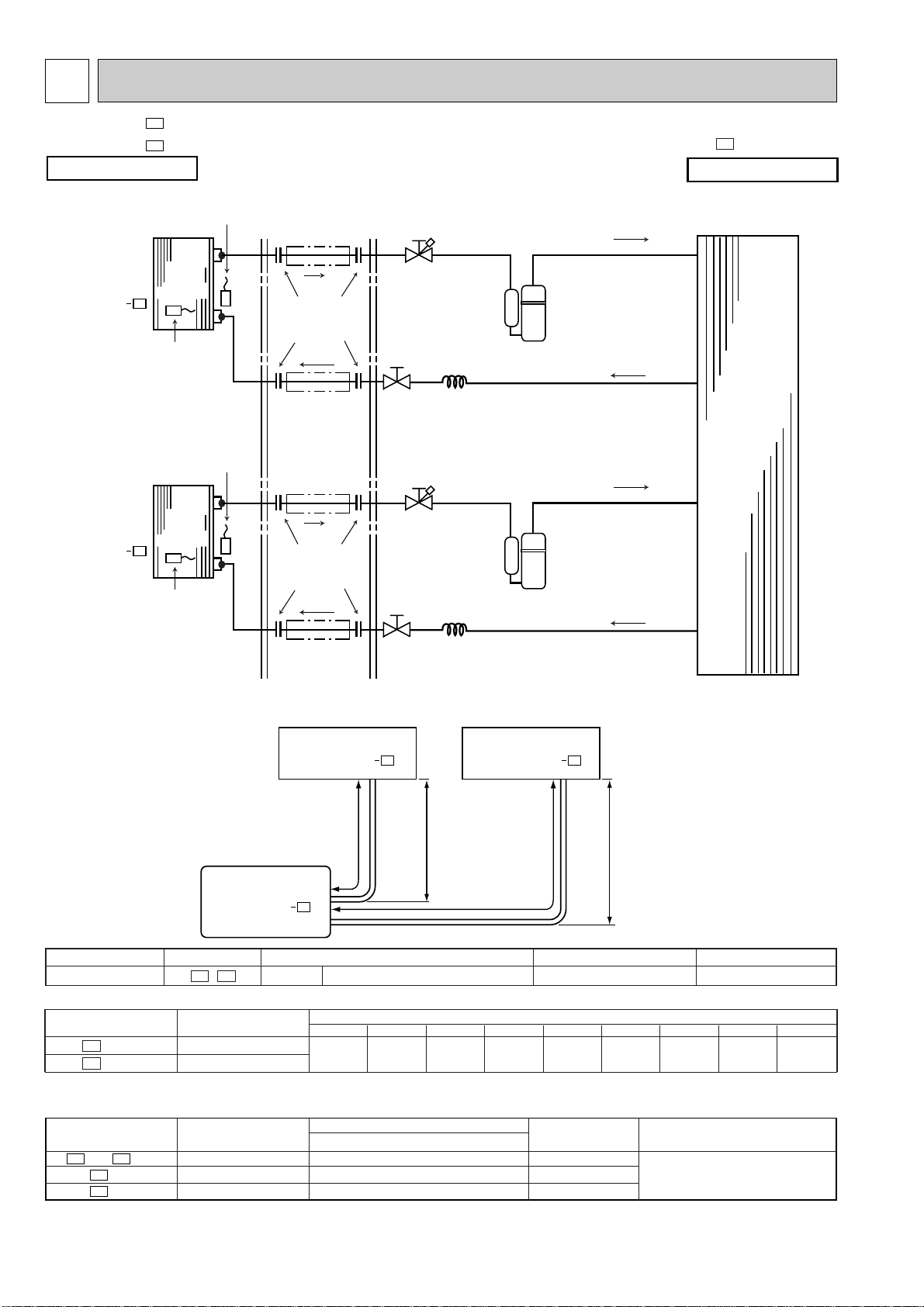

Page 10

8

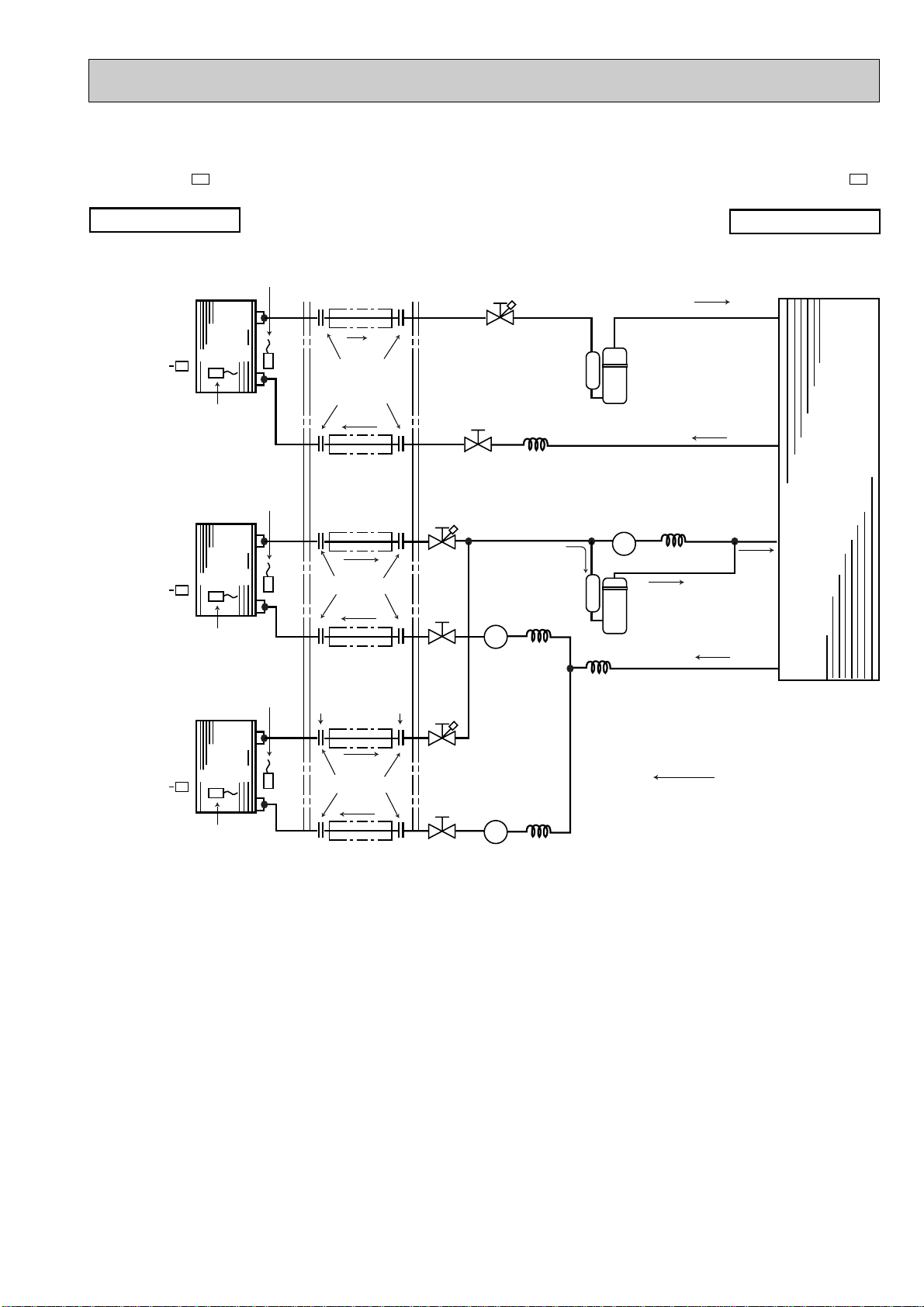

REFRIGERANT SYSTEM DIAGRAM

MSC-07RVMSC-12RV-

INDOOR UNIT

UNIT A

MSC-12RV

MSC-07RV

E3

UNIT B

E3

E3

E3

Indoor

heat

exchanger

Indoor coil

thermistor

RT12

Indoor

heat

exchanger

Room

temperature

thermistor

RT11

Room

temperature

thermistor

RT11

Refrigerant pipe

{12.7

(With insulation)

Flared connection

Refrigerant pipe

{6.35

(With insulation)

Refrigerant pipe

{9.52

(With insulation)

Flared connection

Stop valve

with service port

Stop valve

Capillary tube

{

Stop valve

with service port

3.0 ✕{1.6 ✕ 660

Compressor(MC1)

MUX-19TV-

OUTDOOR UNIT

E1

Outdoor

heat

exchanger

Unit: mm

Indoor coil

thermistor

RT12

Refrigerant pipe

{6.35

(With insulation)

Stop valve

Capillary tube

{

3.0 ✕{1.4 ✕ 810

Compressor(MC2)

MAX. REFRIGERANT PIPING LENGTH & MAX. HEIGHT DIFFERENCE

Max. limits

MUX-19TV

UNIT No.

,

Outdoor unit

BA

Indoor unit B

MSC-07RV

E1

L

E3

LLHH

Additional piping max. length 15m

Pipe length

15m

Indoor unit A

MSC-12RV

E3

Height difference (H)

10m

ADDITIONAL REFRIGERANT CHARGE (R22:g)

A

B

UNIT

UNIT

Outdoor unit

precharged (g)

870

1,000

7m

0 153045607590105120

8m 9m 10m 11m 12m 13m 14m 15m

Refrigerant piping length (one way)

PIPING PREPARATION

1 Table below shows the specifications of pipes commercially available.

UNIT No. Pipe

BA

and UNIT For liquid 6.35 8 mm

B

UNIT For gas 9.52 8 mm

A

UNIT For gas 12.7 8 mm

2 Ensure that the 2 refrigerant pipes are well insulated to prevent condensation.

3 Refrigerant bending radius must be 10cm or more.

Outside diameter Insulation

mm thickness

10

No. of bends

10

Insulation material

Heat resisting foam plastic

0.045 specific gravity

Page 11

Unit: mm

MSC-09RV-

INDOOR UNIT

UNIT A

MSC-09RV

MSC-09RV

E3

UNIT B

E3

E3

Indoor

heat

exchanger

Indoor coil

thermistor

RT12

Indoor

heat

exchanger

Indoor coil

thermistor

RT12

Room

temperature

thermistor

RT11

Room

temperature

thermistor

RT11

Room

temperature

thermistor

RT11

Refrigerant pipe

{9.52

(With insulation)

Flared connection

Refrigerant pipe

{6.35

(With insulation)

Refrigerant pipe

{9.52

(With insulation)

Flared connection

Refrigerant pipe

{6.35

(With insulation)

Refrigerant pipe

{9.52

Stop valve

with service port

Stop valve

Stop valve

with service port

Stop valve

Solenoid valve

21R3

{

Capillary tube

{

3.0✕{1.4 ✕ 450

Capillary tube

3.0✕{1.6 ✕ 900

Compressor(MC1)

Solenoid valve

21RB

Capillary tube

{

3.0✕{1.6 ✕ 1,000

Compressor(MC2)

Capillary tube

{

3.0✕{1.8 ✕ 450

MUX-20TV-

E1

OUTDOOR UNIT

Outdoor

heat

exchanger

UNIT C

MSC-09RV

E3

Indoor

heat

exchanger

Indoor coil

thermistor

RT12

Flared connection

Refrigerant pipe

{6.35

(With insulation)

Stop valve

with service port

Solenoid valve

21R4

Stop valve

Capillary tube

{

3.0✕{1.6 ✕ 900

Refrigerant flow

11

Page 12

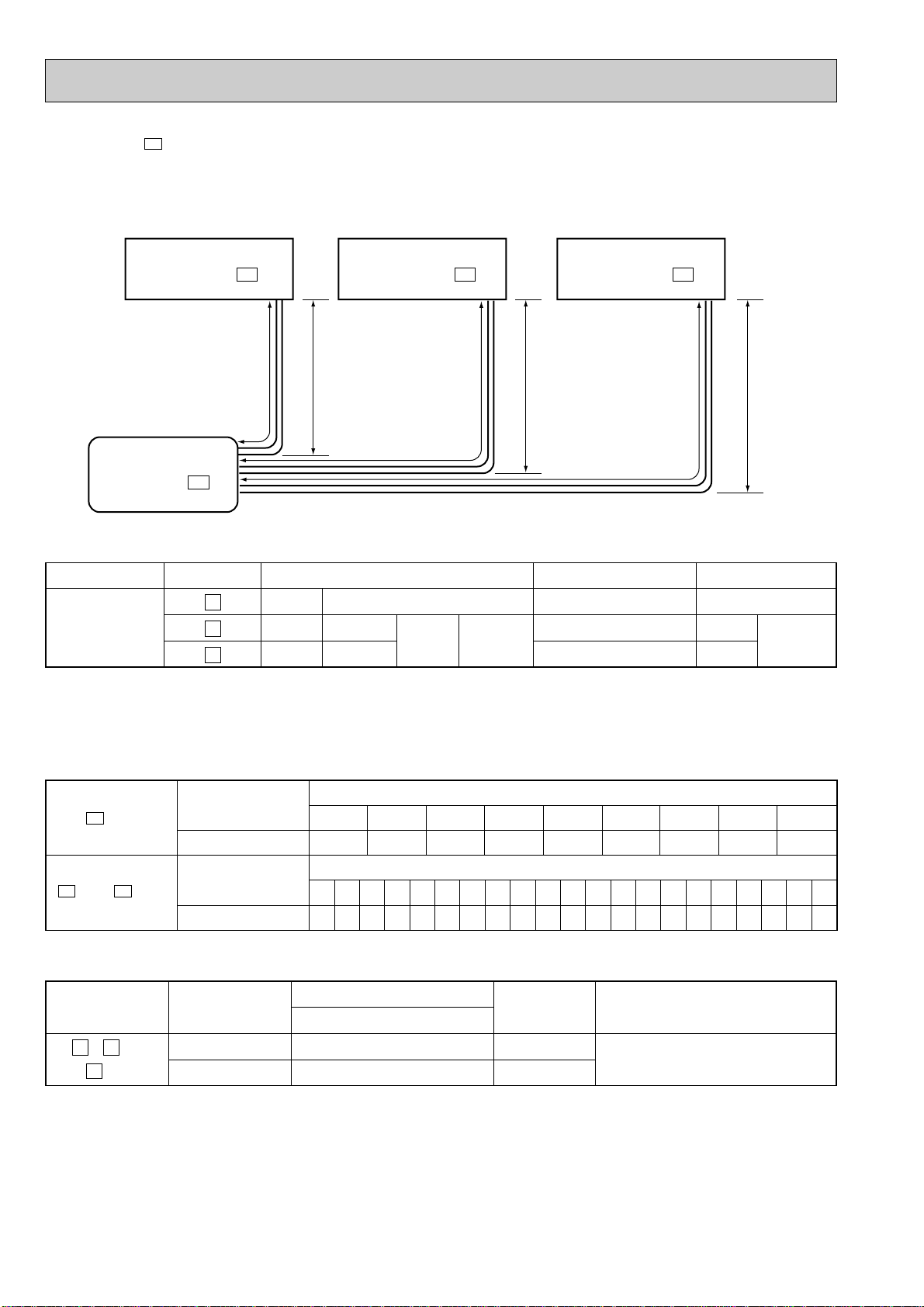

LC

Indoor unit C

MSC-09RV - E3

HL

B HLA

H

Indoor unit B

MSC-09RV - E3

Indoor unit A

MSC-09RV - E3

Outdoor unit

MUX-20TV - E1

MUX-20TV-

7m

0

10m011m1012m2013m3014m4015m5016m6017m7018m8019m9020m

100

21m

110

22m

120

23m

130

24m

140

25m

150

26m

160

27m

170

28m

180

29m

190

30m

200

8m

15

9m

30

10m4511m

60

12m7513m

90

14m

105

15m

120

Refrigerant piping length (one way)

A

unit

Refrigerant piping length (one way, 2 unit total)

Outdoor unit

precharged (g)

800

Outdoor unit

precharged (g)

960

B

unit + C unit

E1

MAX.REFRIGERANT PIPING LENGTH & MAX. HEIGHT DIFFERENCE

Max.

limits

UNIT No.

A

B

C

LA

LB

LC

Pipe length

15m

15m

15m

L

B

+

LC

Total

30m

Height difference (H)

10m

10m

10m

Note: The length of piping to individual units (A,B,C) should not exceed 10 meters.

If units B and C are linked, the maximum combined length of piping should not exceed 15 meters.

ADDITIONAL REFRIGERANT CHARGE (R22:g)

PIPING PREPARATION

1Table below shows the specifications of pipes commercially available.

UNIT No.

BA

, and

C

unit

Pipe

For liquid

For gas

Outside diameter

mm

6.35

9.52

Insulation

thickness

8mm

8mm

No. of bends

10

10

10

Insulation material

Heat resisting foam plastic

0.045 specific gravity

Total

15

2Ensure that the 2 refrigerant pipes are well insulated to prevent condensation.

3Refrigerant bending radius must be 10cm or more.

12

Page 13

MSC-12RV-

E3

MUX-25TV-

E1

Unit: mm

INDOOR UNIT

UNIT A

MSC-12RV

MSC-12RV

E3

UNIT B

E3

Room

temperature

thermistor

RT11

Indoor

heat

exchanger

Indoor coil

thermistor

RT12

Room

temperature

thermistor

RT11

Indoor

heat

exchanger

Indoor coil

thermistor

RT12

Refrigerant pipe

{12.7

(With insulation)

Flared connection

Refrigerant pipe

{6.35

(With insulation)

Refrigerant pipe

{12.7

(With insulation)

Flared connection

Refrigerant pipe

{6.35

(With insulation)

Stop valve

with service port

Stop valve

Capillary tube

{

Stop valve

with service port

Stop valve

Capillary tube

{

Compressor(MC1)

3.0 ✕{1.6 ✕ 550

Compressor(MC2)

3.0 ✕{1.6 ✕ 600

OUTDOOR UNIT

Outdoor

heat

exchanger

MAX. REFRIGERANT PIPING LENGTH & MAX. HEIGHT DIFFERENCE

Max. limits

MUX-25TV

UNIT No.

BA

,

Outdoor unit

MSC-12RV

E1

L

Indoor unit B

E3

LLHH

Additional piping max. length 10m

Pipe length

15m

Indoor unit A

MSC-12RV

E3

Height difference (H)

10m

ADDITIONAL REFRIGERANT CHARGE (R22:g)

A

B

UNIT

UNIT

Outdoor unit

precharged (g)

900

900

7m

0 153045607590105120

8m 9m 10m 11m 12m 13m 14m 15m

Refrigerant piping length (one way)

PIPING PREPARATION

1 Table below shows the specifications of pipes commercially available.

UNIT No. Pipe

BA

and UNIT

For liquid 6.35 8 mm Heat resisting foam plastic

For gas 12.7 8 mm 0.045 specific gravity

2 Ensure that the 2 refrigerant pipes are well insulated to prevent condensation.

3 Refrigerant bending radius must be 10cm or more.

Outside diameter Insulation

mm thickness

13

No. of bends

10

Insulation material

Page 14

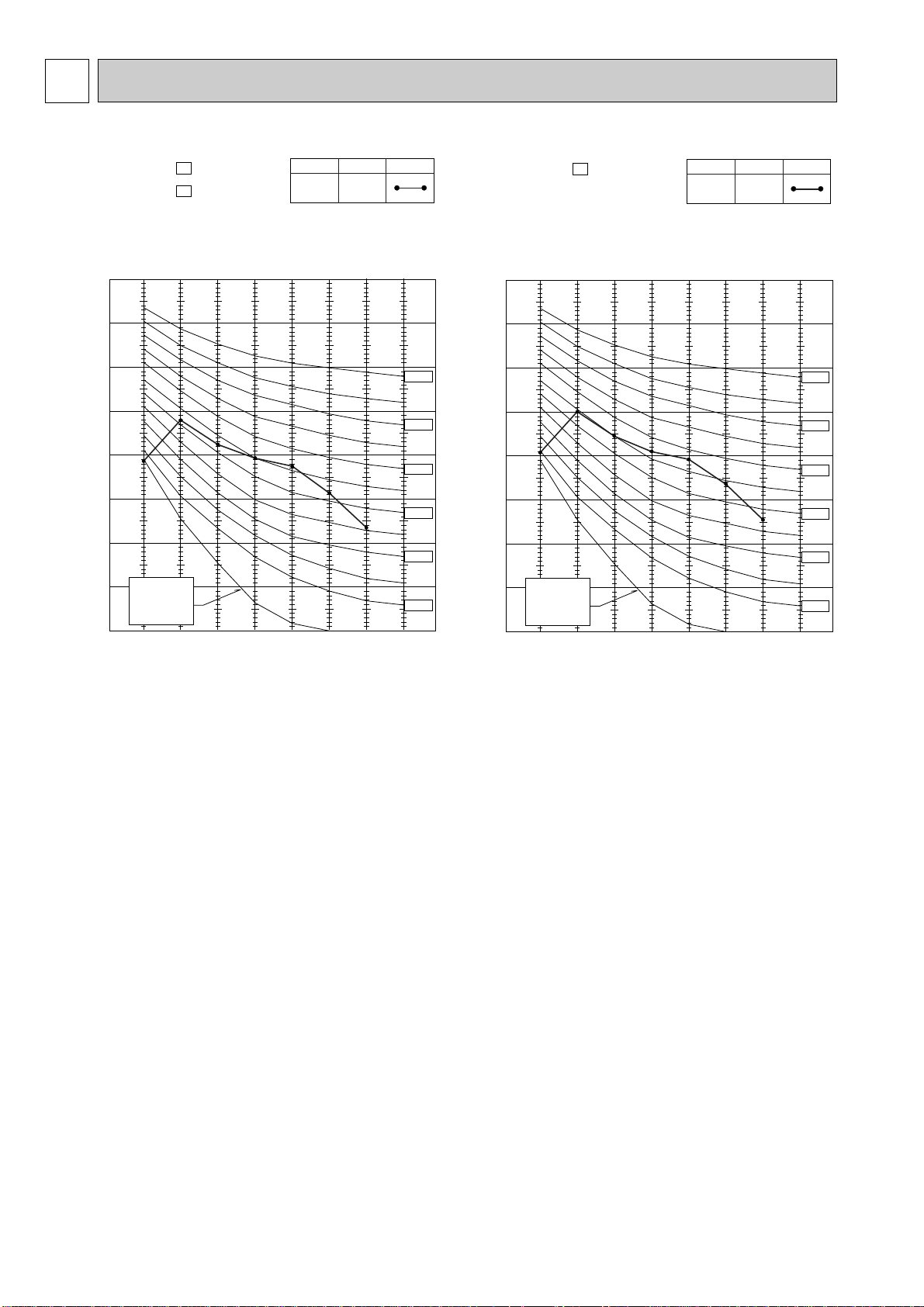

9

0.8

0.7

0.6

0.5

0.4

0.3

(kgf/F•G)(MPa•G)

Outdoor low pressure (kgf/F•G)

7

6

5

4

3

8

0.7

0.6

0.5

0.4

0.3

(kgf/F•G)(MPa•G)

Outdoor low pressure (kgf/F•G)

6

5

4

3

7

Outdoor unit current (A)

Outdoor unit current (A)

Single operation (Unit A) Single operation (Unit B)

0.7

0.6

0.5

0.4

0.3

0.2

(kgf/F•G)(MPa•G)

Outdoor low pressure (kgf/F•G)

6

5

4

3

2

7

Outdoor unit current (A)

Single operation (Unit A or B)

7

6

3

4

3

2

7

6

4

5

3

8

4

5

0.8

PERFORMANCE CURVES

MSC-07RV MSC-09RV MSC-12RV -

E3

MUX-19TV -

E3

MUX-20TV -

E3

MUX-25TV -

E1

E1

E1

9-1-1.CAPACITY AND THE INPUT CURVES

(ONE INDOOR UNIT WITH ONE OUTDOOR UNIT)

8.9

11.6

8.2

10.6

7.4

9.6

8.7

6.7

7.8

6.0

6.9

5.4

Indoor air WB temperature

difference (deg.)

MUX-19TV- E1

MUX-19TV- E1

(MSC-12RV- E3 )

(MSC-07RV- E3 )

10.2

9.3

8.5

7.7

6.9

6.1

MUX-20TV- E1

(Single unit A)

(MSC-09RV- E3 )

11.2

10.6

10.2

9.3

8.4

7.5

6.6

MUX-20TV- E1

(MSC-09RV- E3 )

(Single unit B or C)

9.6

8.7

7.8

6.9

MUX-25TV- E1

(MSC-12RV- E3 )

11.6

9-1-2.OUTDOOR LOW PRESSURE AND OUTDOOR UNIT CURRENT

COOL operation

① Both indoor and outdoor unit are under same temperature/humidity condition.

Dry-bulb temperature Relative humidity (%)

20

25

30

➁ Air flow should be set at MAX.

MUX-19TV-

E1

50

60

70

MUX-25TV-

E1

14

Page 15

MUX-20TV-

(kgf/F•G)(MPa•G)

Outdoor low pressure (kgf/F•G)

0.8

8

0.7

7

0.6

6

0.5

5

0.4

4

0.3

3

E1

Single operation (Unit A)

4

3

Outdoor unit current (A)

2 2

(kgf/F•G)(MPa•G)

Outdoor low pressure (kgf/F•G)

0.8

8

0.7

7

0.6

6

0.5

5

0.4

4

0.3

3

Single operation (Unit B or C)

6

5

4

3

Outdoor unit current (A)

15

Page 16

PERFORMANCE DATA

INDOOR INDOOR

21 25 27 30

DB(;) WB(;)

Q SHC SHF INPUT Q SHC SHF INPUT Q SHC SHF INPUT Q SHC SHF INPUT

CAPACITY : 2.2 kW INPUT(Total=Indoor+Outdoor) : 780 W SHF : 0.74

OUTDOOR DB(;)

21

21

22

22

22

24

24

24

24

26

26

26

26

26

28

28

28

28

28

30

30

30

30

30

32

32

32

32

32

18

20

18

20

22

18

20

22

24

18

20

22

24

26

18

20

22

24

26

18

20

22

24

26

18

20

22

24

26

2.59

2.70

2.59

2.70

2.81

2.59

2.70

2.81

2.95

2.59

2.70

2.81

2.95

3.04

2.59

2.70

2.81

2.95

3.04

2.59

2.70

2.81

2.95

3.04

2.59

2.70

2.81

2.95

3.04

1.45

1.19

1.55

1.29

1.01

1.76

1.51

1.23

0.94

1.96

1.72

1.46

1.18

0.85

2.17

1.94

1.68

1.42

1.09

2.38

2.16

1.91

1.65

1.34

2.59

2.37

2.13

1.89

1.58

0.56

0.44

0.60

0.48

0.36

0.68

0.56

0.44

0.32

0.76

0.64

0.52

0.40

0.28

0.84

0.72

0.60

0.48

0.36

0.92

0.80

0.68

0.56

0.44

1.00

0.88

0.76

0.64

0.52

624

655

624

655

679

624

655

679

710

624

655

679

710

749

624

655

679

710

749

624

655

679

710

749

624

655

679

710

749

2.48

2.59

2.48

2.59

2.71

2.48

2.59

2.71

2.84

2.48

2.59

2.71

2.84

2.95

2.48

2.59

2.71

2.84

2.95

2.48

2.59

2.71

2.84

2.95

2.48

2.59

2.71

2.84

2.95

1.39

1.14

1.49

1.24

0.97

1.68

1.45

1.19

0.91

1.88

1.65

1.41

1.14

0.83

2.08

1.86

1.62

1.36

1.06

2.28

2.07

1.84

1.59

1.30

2.48

2.27

2.06

1.82

1.53

0.56

0.44

0.60

0.48

0.36

0.68

0.56

0.44

0.32

0.76

0.64

0.52

0.40

0.28

0.84

0.72

0.60

0.48

0.36

0.92

0.80

0.68

0.56

0.44

1.00

0.88

0.76

0.64

0.52

655

694

655

694

722

655

694

722

749

655

694

722

749

788

655

694

722

749

788

655

694

722

749

788

655

694

722

749

788

2.38

2.51

2.38

2.51

2.64

2.38

2.51

2.64

2.77

2.38

2.51

2.64

2.77

2.90

2.38

2.51

2.64

2.77

2.90

2.38

2.51

2.64

2.77

2.90

2.38

2.51

2.64

2.77

2.90

1.33

1.10

1.43

1.20

0.95

1.62

1.40

1.16

0.89

1.81

1.61

1.37

1.11

0.81

2.00

1.81

1.58

1.33

1.05

2.19

2.01

1.80

1.55

1.28

2.38

2.21

2.01

1.77

1.51

0.56

0.44

0.60

0.48

0.36

0.68

0.56

0.44

0.32

0.76

0.64

0.52

0.40

0.28

0.84

0.72

0.60

0.48

0.36

0.92

0.80

0.68

0.56

0.44

1.00

0.88

0.76

0.64

0.52

686

710

686

710

741

686

710

741

772

686

710

741

772

811

686

710

741

772

811

686

710

741

772

811

686

710

741

772

811

2.29

2.42

2.29

2.42

2.53

2.29

2.42

2.53

2.68

2.29

2.42

2.53

2.68

2.82

2.29

2.42

2.53

2.68

2.82

2.29

2.42

2.53

2.68

2.82

2.29

2.42

2.53

2.68

2.82

1.28

1.06

1.37

1.16

0.91

1.56

1.36

1.11

0.86

1.74

1.55

1.32

1.07

0.79

1.92

1.74

1.52

1.29

1.01

2.10

1.94

1.72

1.50

1.24

2.29

2.13

1.92

1.72

1.46

0.56

0.44

0.60

0.48

0.36

0.68

0.56

0.44

0.32

0.76

0.64

0.52

0.40

0.28

0.84

0.72

0.60

0.48

0.36

0.92

0.80

0.68

0.56

0.44

1.00

0.88

0.76

0.64

0.52

718

741

718

741

772

718

741

772

811

718

741

772

811

835

718

741

772

811

835

718

741

772

811

835

718

741

772

811

835

COOL operation (230V)

MSC-07RV - (Single) : MUX-19TV -

E1E3

NOTE Q :Total capacity (kW) SHF :Sensible heat factor

SHC :Sensible heat capacity (kW) INPUT :Total power input (W)

16

Page 17

PERFORMANCE DATA

INDOOR INDOOR

35 40 46

DB(;) WB(;)

Q SHC SHF INPUT Q SHC SHF INPUT Q SHC SHF INPUT

CAPACITY : 2.2 kW INPUT(Total=Indoor+Outdoor) : 780 W SHF : 0.74

OUTDOOR DB(;)

21

21

22

22

22

24

24

24

24

26

26

26

26

26

28

28

28

28

28

30

30

30

30

30

32

32

32

32

32

18

20

18

20

22

18

20

22

24

18

20

22

24

26

18

20

22

24

26

18

20

22

24

26

18

20

22

24

26

2.16

2.27

2.16

2.27

2.40

2.16

2.27

2.40

2.53

2.16

2.27

2.40

2.53

2.66

2.16

2.27

2.40

2.53

2.66

2.16

2.27

2.40

2.53

2.66

2.16

2.27

2.40

2.53

2.66

1.21

1.00

1.29

1.09

0.86

1.47

1.27

1.06

0.81

1.64

1.45

1.25

1.01

0.75

1.81

1.63

1.44

1.21

0.96

1.98

1.81

1.63

1.42

1.17

2.16

1.99

1.82

1.62

1.38

0.56

0.44

0.60

0.48

0.36

0.68

0.56

0.44

0.32

0.76

0.64

0.52

0.40

0.28

0.84

0.72

0.60

0.48

0.36

0.92

0.80

0.68

0.56

0.44

1.00

0.88

0.76

0.64

0.52

764

796

764

796

827

764

796

827

858

764

796

827

858

889

764

796

827

858

889

764

796

827

858

889

764

796

827

858

889

1.98

2.11

1.98

2.11

2.24

1.98

2.11

2.24

2.38

1.98

2.11

2.24

2.38

2.51

1.98

2.11

2.24

2.38

2.51

1.98

2.11

2.24

2.38

2.51

1.98

2.11

2.24

2.38

2.51

1.11

0.93

1.19

1.01

0.81

1.35

1.18

0.99

0.76

1.50

1.35

1.17

0.95

0.70

1.66

1.52

1.35

1.14

0.90

1.82

1.69

1.53

1.33

1.10

1.98

1.86

1.71

1.52

1.30

0.56

0.44

0.60

0.48

0.36

0.68

0.56

0.44

0.32

0.76

0.64

0.52

0.40

0.28

0.84

0.72

0.60

0.48

0.36

0.92

0.80

0.68

0.56

0.44

1.00

0.88

0.76

0.64

0.52

811

835

811

835

874

811

835

874

897

811

835

874

897

928

811

835

874

897

928

811

835

874

897

928

811

835

874

897

928

1.83

1.96

1.83

1.96

2.09

1.83

1.96

2.09

2.24

1.83

1.96

2.09

2.24

2.35

1.83

1.96

2.09

2.24

2.35

1.83

1.96

2.09

2.24

2.35

1.83

1.96

2.09

2.24

2.35

1.02

0.86

1.10

0.94

0.75

1.24

1.10

0.92

0.72

1.39

1.25

1.09

0.90

0.66

1.53

1.41

1.25

1.08

0.85

1.68

1.57

1.42

1.26

1.04

1.83

1.72

1.59

1.44

1.22

0.56

0.44

0.60

0.48

0.36

0.68

0.56

0.44

0.32

0.76

0.64

0.52

0.40

0.28

0.84

0.72

0.60

0.48

0.36

0.92

0.80

0.68

0.56

0.44

1.00

0.88

0.76

0.64

0.52

842

881

842

881

905

842

881

905

936

842

881

905

936

967

842

881

905

936

967

842

881

905

936

967

842

881

905

936

967

COOL operation (230V)

MSC-07RV - (Single) : MUX-19TV -

E1E3

NOTE Q :Total capacity (kW) SHF :Sensible heat factor

SHC :Sensible heat capacity (kW) INPUT :Total power input (W)

17

Page 18

PERFORMANCE DATA

INDOOR INDOOR

21 25 27 30

DB(;) WB(;)

Q SHC SHF INPUT Q SHC SHF INPUT Q SHC SHF INPUT Q SHC SHF INPUT

CAPACITY : 3.5 kW INPUT(Total=Indoor+Outdoor) : 1320W SHF : 0.67

OUTDOOR DB(;)

21

21

22

22

22

24

24

24

24

26

26

26

26

26

28

28

28

28

28

30

30

30

30

30

32

32

32

32

32

18

20

18

20

22

18

20

22

24

18

20

22

24

26

18

20

22

24

26

18

20

22

24

26

18

20

22

24

26

4.11

4.29

4.11

4.29

4.46

4.11

4.29

4.46

4.69

4.11

4.29

4.46

4.69

4.83

4.11

4.29

4.46

4.69

4.83

4.11

4.29

4.46

4.69

4.83

4.11

4.29

4.46

4.69

4.83

2.02

1.59

2.18

1.76

1.29

2.51

2.10

1.65

1.17

2.84

2.44

2.01

1.55

1.01

3.17

2.79

2.37

1.92

1.40

3.50

3.13

2.72

2.30

1.79

3.82

3.47

3.08

2.67

2.17

0.49

0.37

0.53

0.41

0.29

0.61

0.49

0.37

0.25

0.69

0.57

0.45

0.33

0.21

0.77

0.65

0.53

0.41

0.29

0.85

0.73

0.61

0.49

0.37

0.93

0.81

0.69

0.57

0.45

0.49

0.37

0.53

0.41

0.29

0.61

0.49

0.37

0.25

0.69

0.57

0.45

0.33

0.21

0.77

0.65

0.53

0.41

0.29

0.85

0.73

0.61

0.49

0.37

0.93

0.81

0.69

0.57

0.45

0.49

0.37

0.53

0.41

0.29

0.61

0.49

0.37

0.25

0.69

0.57

0.45

0.33

0.21

0.77

0.65

0.53

0.41

0.29

0.85

0.73

0.61

0.49

0.37

0.93

0.81

0.69

0.57

0.45

0.49

0.37

0.53

0.41

0.29

0.61

0.49

0.37

0.25

0.69

0.57

0.45

0.33

0.21

0.77

0.65

0.53

0.41

0.29

0.85

0.73

0.61

0.49

0.37

0.93

0.81

0.69

0.57

0.45

1056

1109

1056

1109

1148

1056

1109

1148

1201

1056

1109

1148

1201

1267

1056

1109

1148

1201

1267

1056

1109

1148

1201

1267

1056

1109

1148

1201

1267

3.94

4.11

3.94

4.11

4.31

3.94

4.11

4.31

4.52

3.94

4.11

4.31

4.52

4.69

3.94

4.11

4.31

4.52

4.69

3.94

4.11

4.31

4.52

4.69

3.94

4.11

4.31

4.52

4.69

1.93

1.52

2.09

1.69

1.25

2.40

2.02

1.59

1.13

2.72

2.34

1.94

1.49

0.98

3.03

2.67

2.28

1.85

1.36

3.35

3.00

2.63

2.21

1.74

3.66

3.33

2.97

2.57

2.11

1109

1175

1109

1175

1221

1109

1175

1221

1267

1109

1175

1221

1267

1333

1109

1175

1221

1267

1333

1109

1175

1221

1267

1333

1109

1175

1221

1267

1333

3.78

3.99

3.78

3.99

4.20

3.78

3.99

4.20

4.41

3.78

3.99

4.20

4.41

4.62

3.78

3.99

4.20

4.41

4.62

3.78

3.99

4.20

4.41

4.62

3.78

3.99

4.20

4.41

4.62

1.85

1.48

2.00

1.64

1.22

2.31

1.96

1.55

1.10

2.61

2.27

1.89

1.46

0.97

2.91

2.59

2.23

1.81

1.34

3.21

2.91

2.56

2.16

1.71

3.52

3.23

2.90

2.51

2.08

1162

1201

1162

1201

1254

1162

1201

1254

1307

1162

1201

1254

1307

1373

1162

1201

1254

1307

1373

1162

1201

1254

1307

1373

1162

1201

1254

1307

1373

3.64

3.85

3.64

3.85

4.03

3.64

3.85

4.03

4.27

3.64

3.85

4.03

4.27

4.48

3.64

3.85

4.03

4.27

4.48

3.64

3.85

4.03

4.27

4.48

3.64

3.85

4.03

4.27

4.48

1.78

1.42

1.93

1.58

1.17

2.22

1.89

1.49

1.07

2.51

2.19

1.81

1.41

0.94

2.80

2.50

2.13

1.75

1.30

3.09

2.81

2.46

2.09

1.66

3.39

3.12

2.78

2.43

2.02

1214

1254

1214

1254

1307

1214

1254

1307

1373

1214

1254

1307

1373

1412

1214

1254

1307

1373

1412

1214

1254

1307

1373

1412

1214

1254

1307

1373

1412

COOL operation (230V)

MSC-12RV - (Single) : MUX-19TV -

E1E3

NOTE Q :Total capacity (kW) SHF :Sensible heat factor

SHC :Sensible heat capacity (kW) INPUT :Total power input (W)

18

Page 19

PERFORMANCE DATA

INDOOR INDOOR

35 40 46

DB(;) WB(;)

Q SHC SHF INPUT Q SHC SHF INPUT Q SHC SHF INPUT

CAPACITY : 3.5 kW INPUT(Total=Indoor+Outdoor) : 1320W SHF : 0.67

OUTDOOR DB(;)

21

21

22

22

22

24

24

24

24

26

26

26

26

26

28

28

28

28

28

30

30

30

30

30

32

32

32

32

32

18

20

18

20

22

18

20

22

24

18

20

22

24

26

18

20

22

24

26

18

20

22

24

26

18

20

22

24

26

3.43

3.61

3.43

3.61

3.82

3.43

3.61

3.82

4.03

3.43

3.61

3.82

4.03

4.24

3.43

3.61

3.82

4.03

4.24

3.43

3.61

3.82

4.03

4.24

3.43

3.61

3.82

4.03

4.24

1.68

1.33

1.82

1.48

1.11

2.09

1.77

1.41

1.01

2.37

2.05

1.72

1.33

0.89

2.64

2.34

2.02

1.65

1.23

2.92

2.63

2.33

1.97

1.57

3.19

2.92

2.63

2.29

1.91

0.49

0.37

0.53

0.41

0.29

0.61

0.49

0.37

0.25

0.69

0.57

0.45

0.33

0.21

0.77

0.65

0.53

0.41

0.29

0.85

0.73

0.61

0.49

0.37

0.93

0.81

0.69

0.57

0.45

0.49

0.37

0.53

0.41

0.29

0.61

0.49

0.37

0.25

0.69

0.57

0.45

0.33

0.21

0.77

0.65

0.53

0.41

0.29

0.85

0.73

0.61

0.49

0.37

0.93

0.81

0.69

0.57

0.45

0.49

0.37

0.53

0.41

0.29

0.61

0.49

0.37

0.25

0.69

0.57

0.45

0.33

0.21

0.77

0.65

0.53

0.41

0.29

0.85

0.73

0.61

0.49

0.37

0.93

0.81

0.69

0.57

0.45

1294

1346

1294

1346

1399

1294

1346

1399

1452

1294

1346

1399

1452

1505

1294

1346

1399

1452

1505

1294

1346

1399

1452

1505

1294

1346

1399

1452

1505

3.15

3.36

3.15

3.36

3.57

3.15

3.36

3.57

3.78

3.15

3.36

3.57

3.78

3.99

3.15

3.36

3.57

3.78

3.99

3.15

3.36

3.57

3.78

3.99

3.15

3.36

3.57

3.78

3.99

1.54

1.24

1.67

1.38

1.04

1.92

1.65

1.32

0.95

2.17

1.92

1.61

1.25

0.84

2.43

2.18

1.89

1.55

1.16

2.68

2.45

2.18

1.85

1.48

2.93

2.72

2.46

2.15

1.80

1373

1412

1373

1412

1478

1373

1412

1478

1518

1373

1412

1478

1518

1571

1373

1412

1478

1518

1571

1373

1412

1478

1518

1571

1373

1412

1478

1518

1571

2.91

3.12

2.91

3.12

3.33

2.91

3.12

3.33

3.57

2.91

3.12

3.33

3.57

3.75

2.91

3.12

3.33

3.57

3.75

2.91

3.12

3.33

3.57

3.75

2.91

3.12

3.33

3.57

3.75

1.42

1.15

1.54

1.28

0.96

1.77

1.53

1.23

0.89

2.00

1.78

1.50

1.18

0.79

2.24

2.02

1.76

1.46

1.09

2.47

2.27

2.03

1.75

1.39

2.70

2.52

2.29

2.03

1.69

1426

1492

1426

1492

1531

1426

1492

1531

1584

1426

1492

1531

1584

1637

1426

1492

1531

1584

1637

1426

1492

1531

1584

1637

1426

1492

1531

1584

1637

COOL operation (230V)

MSC-12RV - (Single) : MUX-19TV -

E1E3

NOTE Q :Total capacity (kW) SHF :Sensible heat factor

SHC :Sensible heat capacity (kW) INPUT :Total power input (W)

19

Page 20

PERFORMANCE DATA

INDOOR INDOOR

21 25 27 30

DB(;) WB(;)

Q SHC SHF INPUT Q SHC SHF INPUT Q SHC SHF INPUT Q SHC SHF INPUT

CAPACITY : 2.5 kW INPUT(Total=Indoor+Outdoor) : 810W SHF : 0.70

OUTDOOR DB(;)

21

21

22

22

22

24

24

24

24

26

26

26

26

26

28

28

28

28

28

30

30

30

30

30

32

32

32

32

32

18

20

18

20

22

18

20

22

24

18

20

22

24

26

18

20

22

24

26

18

20

22

24

26

18

20

22

24

26

2.94

3.06

2.94

3.06

3.19

2.94

3.06

3.19

3.35

2.94

3.06

3.19

3.35

3.45

2.94

3.06

3.19

3.35

3.45

2.94

3.06

3.19

3.35

3.45

2.94

3.06

3.19

3.35

3.45

1.53

1.23

1.65

1.35

1.02

1.88

1.59

1.28

0.94

2.12

1.84

1.53

1.21

0.83

2.35

2.08

1.79

1.47

1.10

2.59

2.33

2.04

1.74

1.38

2.82

2.57

2.30

2.01

1.66

0.52

0.40

0.56

0.44

0.32

0.64

0.52

0.40

0.28

0.72

0.60

0.48

0.36

0.24

0.80

0.68

0.56

0.44

0.32

0.88

0.76

0.64

0.52

0.40

0.96

0.84

0.72

0.60

0.48

0.52

0.40

0.56

0.44

0.32

0.64

0.52

0.40

0.28

0.72

0.60

0.48

0.36

0.24

0.80

0.68

0.56

0.44

0.32

0.88

0.76

0.64

0.52

0.40

0.96

0.84

0.72

0.60

0.48

0.52

0.40

0.56

0.44

0.32

0.64

0.52

0.40

0.28

0.72

0.60

0.48

0.36

0.24

0.80

0.68

0.56

0.44

0.32

0.88

0.76

0.64

0.52

0.40

0.96

0.84

0.72

0.60

0.48

0.52

0.40

0.56

0.44

0.32

0.64

0.52

0.40

0.28

0.72

0.60

0.48

0.36

0.24

0.80

0.68

0.56

0.44

0.32

0.88

0.76

0.64

0.52

0.40

0.96

0.84

0.72

0.60

0.48

648

680

648

680

705

648

680

705

737

648

680

705

737

778

648

680

705

737

778

648

680

705

737

778

648

680

705

737

778

2.81

2.94

2.81

2.94

3.08

2.81

2.94

3.08

3.23

2.81

2.94

3.08

3.23

3.35

2.81

2.94

3.08

3.23

3.35

2.81

2.94

3.08

3.23

3.35

2.81

2.94

3.08

3.23

3.35

1.46

1.18

1.58

1.29

0.98

1.80

1.53

1.23

0.90

2.03

1.76

1.48

1.16

0.80

2.25

2.00

1.72

1.42

1.07

2.48

2.23

1.97

1.68

1.34

2.70

2.47

2.21

1.94

1.61

680

721

680

721

749

680

721

749

778

680

721

749

778

818

680

721

749

778

818

680

721

749

778

818

680

721

749

778

818

2.70

2.85

2.70

2.85

3.00

2.70

2.85

3.00

3.15

2.70

2.85

3.00

3.15

3.30

2.70

2.85

3.00

3.15

3.30

2.70

2.85

3.00

3.15

3.30

2.70

2.85

3.00

3.15

3.30

1.40

1.14

1.51

1.25

0.96

1.73

1.48

1.20

0.88

1.94

1.71

1.44

1.13

0.79

2.16

1.94

1.68

1.39

1.06

2.38

2.17

1.92

1.64

1.32

2.59

2.39

2.16

1.89

1.58

713

737

713

737

770

713

737

770

802

713

737

770

802

842

713

737

770

802

842

713

737

770

802

842

713

737

770

802

842

2.60

2.75

2.60

2.75

2.88

2.60

2.75

2.88

3.05

2.60

2.75

2.88

3.05

3.20

2.60

2.75

2.88

3.05

3.20

2.60

2.75

2.88

3.05

3.20

2.60

2.75

2.88

3.05

3.20

1.35

1.10

1.46

1.21

0.92

1.66

1.43

1.15

0.85

1.87

1.65

1.38

1.10

0.77

2.08

1.87

1.61

1.34

1.02

2.29

2.09

1.84

1.59

1.28

2.50

2.31

2.07

1.83

1.54

745

770

745

770

802

745

770

802

842

745

770

802

842

867

745

770

802

842

867

745

770

802

842

867

745

770

802

842

867

COOL operation (230V)

MSC-09RV - (Single Room A) : MUX-20TV -

E1E3

NOTE Q :Total capacity (kW) SHF :Sensible heat factor

SHC :Sensible heat capacity (kW) INPUT :Total power input (W)

20

Page 21

PERFORMANCE DATA

INDOOR INDOOR

35 40 46

DB(;) WB(;)

Q SHC SHF INPUT Q SHC SHF INPUT Q SHC SHF INPUT

CAPACITY : 2.5 kW INPUT(Total=Indoor+Outdoor) : 810W SHF : 0.70

OUTDOOR DB(;)

21

21

22

22

22

24

24

24

24

26

26

26

26

26

28

28

28

28

28

30

30

30

30

30

32

32

32

32

32

18

20

18

20

22

18

20

22

24

18

20

22

24

26

18

20

22

24

26

18

20

22

24

26

18

20

22

24

26

2.45

2.58

2.45

2.58

2.73

2.45

2.58

2.73

2.88

2.45

2.58

2.73

2.88

3.03

2.45

2.58

2.73

2.88

3.03

2.45

2.58

2.73

2.88

3.03

2.45

2.58

2.73

2.88

3.03

1.27

1.03

1.37

1.13

0.87

1.57

1.34

1.09

0.81

1.76

1.55

1.31

1.04

0.73

1.96

1.75

1.53

1.27

0.97

2.16

1.96

1.74

1.50

1.21

2.35

2.16

1.96

1.73

1.45

0.52

0.40

0.56

0.44

0.32

0.64

0.52

0.40

0.28

0.72

0.60

0.48

0.36

0.24

0.80

0.68

0.56

0.44

0.32

0.88

0.76

0.64

0.52

0.40

0.96

0.84

0.72

0.60

0.48

0.52

0.40

0.56

0.44

0.32

0.64

0.52

0.40

0.28

0.72

0.60

0.48

0.36

0.24

0.80

0.68

0.56

0.44

0.32

0.88

0.76

0.64

0.52

0.40

0.96

0.84

0.72

0.60

0.48

0.52

0.40

0.56

0.44

0.32

0.64

0.52

0.40

0.28

0.72

0.60

0.48

0.36

0.24

0.80

0.68

0.56

0.44

0.32

0.88

0.76

0.64

0.52

0.40

0.96

0.84

0.72

0.60

0.48

794

826

794

826

859

794

826

859

891

794

826

859

891

923

794

826

859

891

923

794

826

859

891

923

794

826

859

891

923

2.25

2.40

2.25

2.40

2.55

2.25

2.40

2.55

2.70

2.25

2.40

2.55

2.70

2.85

2.25

2.40

2.55

2.70

2.85

2.25

2.40

2.55

2.70

2.85

2.25

2.40

2.55

2.70

2.85

1.17

0.96

1.26

1.06

0.82

1.44

1.25

1.02

0.76

1.62

1.44

1.22

0.97

0.68

1.80

1.63

1.43

1.19

0.91

1.98

1.82

1.63

1.40

1.14

2.16

2.02

1.84

1.62

1.37

842

867

842

867

907

842

867

907

932

842

867

907

932

964

842

867

907

932

964

842

867

907

932

964

842

867

907

932

964

2.08

2.23

2.08

2.23

2.38

2.08

2.23

2.38

2.55

2.08

2.23

2.38

2.55

2.68

2.08

2.23

2.38

2.55

2.68

2.08

2.23

2.38

2.55

2.68

2.08

2.23

2.38

2.55

2.68

1.08

0.89

1.16

0.98

0.76

1.33

1.16

0.95

0.71

1.49

1.34

1.14

0.92

0.64

1.66

1.51

1.33

1.12

0.86

1.83

1.69

1.52

1.33

1.07

1.99

1.87

1.71

1.53

1.28

875

915

875

915

940

875

915

940

972

875

915

940

972

1004

875

915

940

972

1004

875

915

940

972

1004

875

915

940

972

1004

COOL operation (230V)

MSC-09RV - (Single Room A) : MUX-20TV -

E1E3

NOTE Q :Total capacity (kW) SHF :Sensible heat factor

SHC :Sensible heat capacity (kW) INPUT :Total power input (W)

21

Page 22

PERFORMANCE DATA

INDOOR INDOOR

21 25 27 30

DB(;) WB(;)

Q SHC SHF INPUT Q SHC SHF INPUT Q SHC SHF INPUT Q SHC SHF INPUT

CAPACITY : 2.7 kW INPUT(Total=Indoor+Outdoor) : 1000W SHF : 0.69

OUTDOOR DB(;)

21

21

22

22

22

24

24

24

24

26

26

26

26

26

28

28

28

28

28

30

30

30

30

30

32

32

32

32

32

18

20

18

20

22

18

20

22

24

18

20

22

24

26

18

20

22

24

26

18

20

22

24

26

18

20

22

24

26

3.17

3.31

3.17

3.31

3.44

3.17

3.31

3.44

3.62

3.17

3.31

3.44

3.62

3.73

3.17

3.31

3.44

3.62

3.73

3.17

3.31

3.44

3.62

3.73

3.17

3.31

3.44

3.62

3.73

1.62

1.29

1.74

1.42

1.07

2.00

1.69

1.34

0.98

2.25

1.95

1.62

1.27

0.86

2.51

2.22

1.89

1.56

1.16

2.76

2.48

2.17

1.85

1.45

3.01

2.75

2.44

2.13

1.75

0.51

0.39

0.55

0.43

0.31

0.63

0.51

0.39

0.27

0.71

0.59

0.47

0.35

0.23

0.79

0.67

0.55

0.43

0.31

0.87

0.75

0.63

0.51

0.39

0.95

0.83

0.71

0.59

0.47

0.51

0.39

0.55

0.43

0.31

0.63

0.51

0.39

0.27

0.71

0.59

0.47

0.35

0.23

0.79

0.67

0.55

0.43

0.31

0.87

0.75

0.63

0.51

0.39

0.95

0.83

0.71

0.59

0.47

0.51

0.39

0.55

0.43

0.31

0.63

0.51

0.39

0.27

0.71

0.59

0.47

0.35

0.23

0.79

0.67

0.55

0.43

0.31

0.87

0.75

0.63

0.51

0.39

0.95

0.83

0.71

0.59

0.47

0.51

0.39

0.55

0.43

0.31

0.63

0.51

0.39

0.27

0.71

0.59

0.47

0.35

0.23

0.79

0.67

0.55

0.43

0.31

0.87

0.75

0.63

0.51

0.39

0.95

0.83

0.71

0.59

0.47

800

840

800

840

870

800

840

870

910

800

840

870

910

960

800

840

870

910

960

800

840

870

910

960

800

840

870

910

960

3.04

3.17

3.04

3.17

3.32

3.04

3.17

3.32

3.48

3.04

3.17

3.32

3.48

3.62

3.04

3.17

3.32

3.48

3.62

3.04

3.17

3.32

3.48

3.62

3.04

3.17

3.32

3.48

3.62

1.55

1.24

1.67

1.36

1.03

1.91

1.62

1.30

0.94

2.16

1.87

1.56

1.22

0.83

2.40

2.13

1.83

1.50

1.12

2.64

2.38

2.09

1.78

1.41

2.89

2.63

2.36

2.05

1.70

840

890

840

890

925

840

890

925

960

840

890

925

960

1010

840

890

925

960

1010

840

890

925

960

1010

840

890

925

960

1010

2.92

3.08

2.92

3.08

3.24

2.92

3.08

3.24

3.40

2.92

3.08

3.24

3.40

3.56

2.92

3.08

3.24

3.40

3.56

2.92

3.08

3.24

3.40

3.56

2.92

3.08

3.24

3.40

3.56

1.49

1.20

1.60

1.32

1.00

1.84

1.57

1.26

0.92

2.07

1.82

1.52

1.19

0.82

2.30

2.06

1.78

1.46

1.10

2.54

2.31

2.04

1.74

1.39

2.77

2.55

2.30

2.01

1.68

880

910

880

910

950

880

910

950

990

880

910

950

990

1040

880

910

950

990

1040

880

910

950

990

1040

880

910

950

990

1040

2.81

2.97

2.81

2.97

3.11

2.81

2.97

3.11

3.29

2.81

2.97

3.11

3.29

3.46

2.81

2.97

3.11

3.29

3.46

2.81

2.97

3.11

3.29

3.46

2.81

2.97

3.11

3.29

3.46

1.43

1.16

1.54

1.28

0.96

1.77

1.51

1.21

0.89

1.99

1.75

1.46

1.15

0.79

2.22

1.99

1.71

1.42

1.07

2.44

2.23

1.96

1.68

1.35

2.67

2.47

2.20

1.94

1.62

920

950

920

950

990

920

950

990

1040

920

950

990

1040

1070

920

950

990

1040

1070

920

950

990

1040

1070

920

950

990

1040

1070

COOL operation (230V)

MSC-09RV - (Single Room B or C) : MUX-20TV -

E1E3

NOTE Q :Total capacity (kW) SHF :Sensible heat factor

SHC :Sensible heat capacity (kW) INPUT :Total power input (W)

22

Page 23

PERFORMANCE DATA

INDOOR INDOOR

35 40 46

DB(;) WB(;)

Q SHC SHF INPUT Q SHC SHF INPUT Q SHC SHF INPUT

CAPACITY : 2.7 kW INPUT(Total=Indoor+Outdoor) : 1000W SHF : 0.69

OUTDOOR DB(;)

21

21

22

22

22

24

24

24

24

26

26

26

26

26

28

28

28

28

28

30

30

30

30

30

32

32

32

32

32

18

20

18

20

22

18

20

22

24

18

20

22

24

26

18

20

22

24

26

18

20

22

24

26

18

20

22

24

26

2.65

2.78

2.65

2.78

2.94

2.65

2.78

2.94

3.11

2.65

2.78

2.94

3.11

3.27

2.65

2.78

2.94

3.11

3.27

2.65

2.78

2.94

3.11

3.27

2.65

2.78

2.94

3.11

3.27

1.35

1.08

1.46

1.20

0.91

1.67

1.42

1.15

0.84

1.88

1.64

1.38

1.09

0.75

2.09

1.86

1.62

1.34

1.01

2.30

2.09

1.85

1.58

1.27

2.51

2.31

2.09

1.83

1.54

0.51

0.39

0.55

0.43

0.31

0.63

0.51

0.39

0.27

0.71

0.59

0.47

0.35

0.23

0.79

0.67

0.55

0.43

0.31

0.87

0.75

0.63

0.51

0.39

0.95

0.83

0.71

0.59

0.47

0.51

0.39

0.55

0.43

0.31

0.63

0.51

0.39

0.27

0.71

0.59

0.47

0.35

0.23

0.79

0.67

0.55

0.43

0.31

0.87

0.75

0.63

0.51

0.39

0.95

0.83

0.71

0.59

0.47

0.51

0.39

0.55

0.43

0.31

0.63

0.51

0.39

0.27

0.71

0.59

0.47

0.35

0.23

0.79

0.67

0.55

0.43

0.31

0.87

0.75

0.63

0.51

0.39

0.95

0.83

0.71

0.59

0.47

980

1020

980

1020

1060

980

1020

1060

1100

980

1020

1060

1100

1140

980

1020

1060

1100

1140

980

1020

1060

1100

1140

980

1020

1060

1100

1140

2.43

2.59

2.43

2.59

2.75

2.43

2.59

2.75

2.92

2.43

2.59

2.75

2.92

3.08

2.43

2.59

2.75

2.92

3.08

2.43

2.59

2.75

2.92

3.08

2.43

2.59

2.75

2.92

3.08

1.24

1.01

1.34

1.11

0.85

1.53

1.32

1.07

0.79

1.73

1.53

1.29

1.02

0.71

1.92

1.74

1.51

1.25

0.95

2.11

1.94

1.74

1.49

1.20

2.31

2.15

1.96

1.72

1.45

1040

1070

1040

1070

1120

1040

1070

1120

1150

1040

1070

1120

1150

1190

1040

1070

1120

1150

1190

1040

1070

1120

1150

1190

1040

1070

1120

1150

1190

2.24

2.40

2.24

2.40

2.57

2.24

2.40

2.57

2.75

2.24

2.40

2.57

2.75

2.89

2.24

2.40

2.57

2.75

2.89

2.24

2.40

2.57

2.75

2.89

2.24

2.40

2.57

2.75

2.89

1.14

0.94

1.23

1.03

0.80

1.41

1.23

1.00

0.74

1.59

1.42

1.21

0.96

0.66

1.77

1.61

1.41

1.18

0.90

1.95

1.80

1.62

1.40

1.13

2.13

1.99

1.82

1.62

1.36

1080

1130

1080

1130

1160

1080

1130

1160

1200

1080

1130

1160

1200

1240

1080

1130

1160

1200

1240

1080

1130

1160

1200

1240

1080

1130

1160

1200

1240

COOL operation (230V)

MSC-09RV - (Single Room B or C) : MUX-20TV -

E1E3

NOTE Q :Total capacity (kW) SHF :Sensible heat factor

SHC :Sensible heat capacity (kW) INPUT :Total power input (W)

23

Page 24

PERFORMANCE DATA

INDOOR INDOOR

21 25 27 30

DB(;) WB(;)

Q SHC SHF INPUT Q SHC SHF INPUT Q SHC SHF INPUT Q SHC SHF INPUT

CAPACITY : 3.5 kW INPUT(Total=Indoor+Outdoor) : 1390W SHF : 0.67

OUTDOOR DB(;)

21

21

22

22

22

24

24

24

24

26

26

26

26

26

28

28

28

28

28

30

30

30

30

30

32

32

32

32

32

18

20

18

20

22

18

20

22

24

18

20

22

24

26

18

20

22

24

26

18

20

22

24

26

18

20

22

24

26

4.11

4.29

4.11

4.29

4.46

4.11

4.29

4.46

4.69

4.11

4.29

4.46

4.69

4.83

4.11

4.29

4.46

4.69

4.83

4.11

4.29

4.46

4.69

4.83

4.11

4.29

4.46

4.69

4.83

2.02

1.59

2.18

1.76

1.29

2.51

2.10

1.65

1.17

2.84

2.44

2.01

1.55

1.01

3.17

2.79

2.37

1.92

1.40

3.50

3.13

2.72

2.30

1.79

3.82

3.47

3.08

2.67

2.17

0.49

0.37

0.53

0.41

0.29

0.61

0.49

0.37

0.25

0.69

0.57

0.45

0.33

0.21

0.77

0.65

0.53

0.41

0.29

0.85

0.73

0.61

0.49

0.37

0.93

0.81

0.69

0.57

0.45

0.49

0.37

0.53

0.41

0.29

0.61

0.49

0.37

0.25

0.69

0.57

0.45

0.33

0.21

0.77

0.65

0.53

0.41

0.29

0.85

0.73

0.61

0.49

0.37

0.93

0.81

0.69

0.57

0.45

0.49

0.37

0.53

0.41

0.29

0.61

0.49

0.37

0.25

0.69

0.57

0.45

0.33

0.21

0.77

0.65

0.53

0.41

0.29

0.85

0.73

0.61

0.49

0.37

0.93

0.81

0.69

0.57

0.45

0.49

0.37

0.53

0.41

0.29

0.61

0.49

0.37

0.25

0.69

0.57

0.45

0.33

0.21

0.77

0.65

0.53

0.41

0.29

0.85

0.73

0.61

0.49

0.37

0.93

0.81

0.69

0.57

0.45

1112

1168

1112

1168

1209

1112

1168

1209

1265

1112

1168

1209

1265

1334

1112

1168

1209

1265

1334

1112

1168

1209

1265

1334

1112

1168

1209

1265

1334

3.94

4.11

3.94

4.11

4.31

3.94

4.11

4.31

4.52

3.94

4.11

4.31

4.52

4.69

3.94

4.11

4.31

4.52

4.69

3.94

4.11

4.31

4.52

4.69

3.94

4.11

4.31

4.52

4.69

1.93

1.52

2.09

1.69

1.25

2.40

2.02

1.59

1.13

2.72

2.34

1.94

1.49

0.98

3.03

2.67

2.28

1.85

1.36

3.35

3.00

2.63

2.21

1.74

3.66

3.33

2.97

2.57

2.11

1168

1237

1168

1237

1286

1168

1237

1286

1334

1168

1237

1286

1334

1404

1168

1237

1286

1334

1404

1168

1237

1286

1334

1404

1168

1237

1286

1334

1404

3.78

3.99

3.78

3.99

4.20

3.78

3.99

4.20

4.41

3.78

3.99

4.20

4.41

4.62

3.78

3.99

4.20

4.41

4.62

3.78

3.99

4.20

4.41

4.62

3.78

3.99

4.20

4.41

4.62

1.85

1.48

2.00

1.64

1.22

2.31

1.96

1.55

1.10

2.61

2.27

1.89

1.46

0.97

2.91

2.59

2.23

1.81

1.34

3.21

2.91

2.56

2.16

1.71

3.52

3.23

2.90

2.51

2.08

1223

1265

1223

1265

1321

1223

1265

1321

1376

1223

1265

1321

1376

1446

1223

1265

1321

1376

1446

1223

1265

1321

1376

1446

1223

1265

1321

1376

1446

3.64

3.85

3.64

3.85

4.03

3.64

3.85

4.03

4.27

3.64

3.85

4.03

4.27

4.48

3.64

3.85

4.03

4.27

4.48

3.64

3.85

4.03

4.27

4.48

3.64

3.85

4.03

4.27

4.48

1.78

1.42

1.93

1.58

1.17

2.22