SPLIT-TYPE, AIR CONDITIONERS

SPLIT-TYPE, HEAT PUMP AIR CONDITION

NOTE: • This service Manual covers only change points.

SERVICE MANUAL

Wireless type

Models

MSC-07RV MSC-09RV MSC-12RV -

MSC-07RV MSC-09RV MSC-12RV -

MSC-07RV MSC-09RV MSC-12RV -

MSC-07RV MSC-09RV MSC-12RV -

MSC-07RV MSC-09RV MSC-12RV -

MSC-07RV MSC-09RV MSC-12RV -

Multi system type

MSC-07RV MSC-09RV MSC-12RV -

Inverter controlled multi system type

(WH)

(WH)

(WH)

(WH)

(WH)

(WH)

(WH)

(WH)

(WH)

(WH)

(WH)

(WH)

(WH)

(WH)

(WH)

(WH)

(WH)

(WH)

(WH)

(WH)

(WH)

· MU-07RV -

· MU-09RV -

· MU-12RV -

· MU-07RV -

· MU-09RV -

· MU-12RV -

· MU-07RV -

· MU-09RV -

· MU-12RV -

· MUH-07RV -

· MUH-09RV -

· MUH-12RV -

· MUH-07RV -

· MUH-09RV -

· MUH-12RV -

· MUH-07RV -

· MUH-09RV -

· MUH-12RV -

· MUX-10RV -

· MUX-18RV -

· MUX-24RV -

· MXZ-18RV -

Please refer to the Service Manual OB227 REVISED

EDITION-B for unchanged contents.

• Please refer to the following service manual when the

outdoor unit is the under mentioned model.

MXZ-32SV- : OB254

MXZ-18TV- : OB280

MUX-19/20/25TV- : OB284

• Please void OB252 REVISED EDITION-B.

E1

E1

E1

No. OB252

REVISED EDITION-C

E2E2

E2E2

E2E2

E3E3

E3E3

E3E3

E4E4

E4E4

E4E4

E2E2

E2E2

E2E2

E3E3

E3E3

E3E3

E4E4

E4E4

E4E4

E2E2

E2E2

E2E2

E2

MSC-07RV MSC-09RV MSC-12RV -

E4

E4

E4

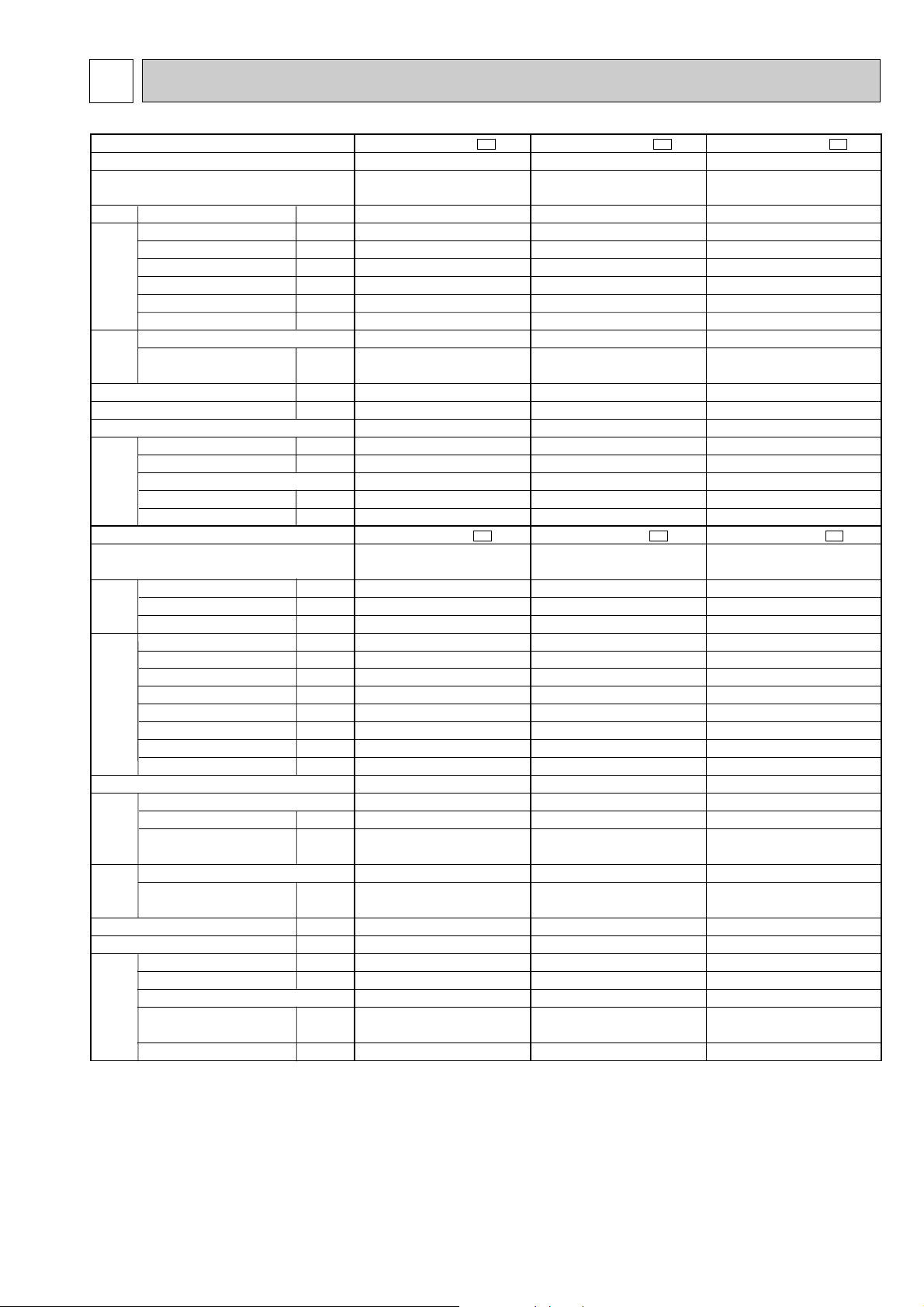

CONTENTS

1. TECHNICAL CHANGES ····································3

2. PART NAMES AND FUNCTIONS······················8

3. SPECIFICATION···············································11

4. WIRING DIAGRAM ··········································13

5. REFRIGERANT SYSTEM DIAGRAM··············15

6. MICROPROCESSOR CONTROL ····················16

7. TROUBLESHOOTING······································16

8. PARTS LIST ·····················································27

REVISION

Page

Part name

E02 504 426 ➔ E02 141 083 REMOTE CONTROLLER HOLDER

Model

MSC-07/09/12RV-

E1

MSC-07/09/12RV-

E2

MSC-07/09/12RV-

E2

P27

Part number

P27 REMOTE CONTROLLER

E02 141 083 ➔ E02 504 426

Parts numbers have been partially modified.

1

1

2

3

4

5

6

7

8

9

10

11

12

13

The specifications of Indoor and Outdoor fan motor.

The data of Med. and Low speed are added to Indoor fan motor

specification

✼

✼The data value of indoor fan motor does not change if the indoor

unit is connected to a multi-type outdoor unit.

Remote controllers of COOL ONLY or COOL & HEAT

type are outdoor unit accessory.

Remote controller is included as an indoor unit accessory.

Two-way common remote controller

Two-way (using dip switch) remote controller

The specification of electronic control P.C. board is

compatible with remote controllers of COOL ONLY

and COOL & HEAT type.

Indoor electronic control P.C. board has changed

for two-way remote controller.

Indoor electronic control P.C. board has changed

for two-way remote controller.

Microprocessor programing flow has changed.

Electronic control P.C. board for E3 is interchangeable

with the one for E2 (except for MSC-12RV).

(New P.C. board) Indoor electronic control P.C. board has

changed.

Earth wire from the board is fixed to the electrical box with screw.

The shape of connector CN211 has changed. Indoor electronic

control P.C. board has been connected with

Power monitor, receiver P.C. board using connector.

When fan speed is set to"Auto", initial temperature difference

specitying changing fan speed has been improved in order to

reach the set temperature faster than E1, E2, and E3.

The mark of terminal block has changed. Terminal block for E4 is

interchangeable with the ones for E1, E2 and E3.

Winding resistance and shape of fan motor have changed.

Fan motor for E4 is not interchangeable with the ones for E1,

E2 and E3 except for MSC-12RV.

Fan motor rubber mount has changed because the shape of

fan motor was changed.

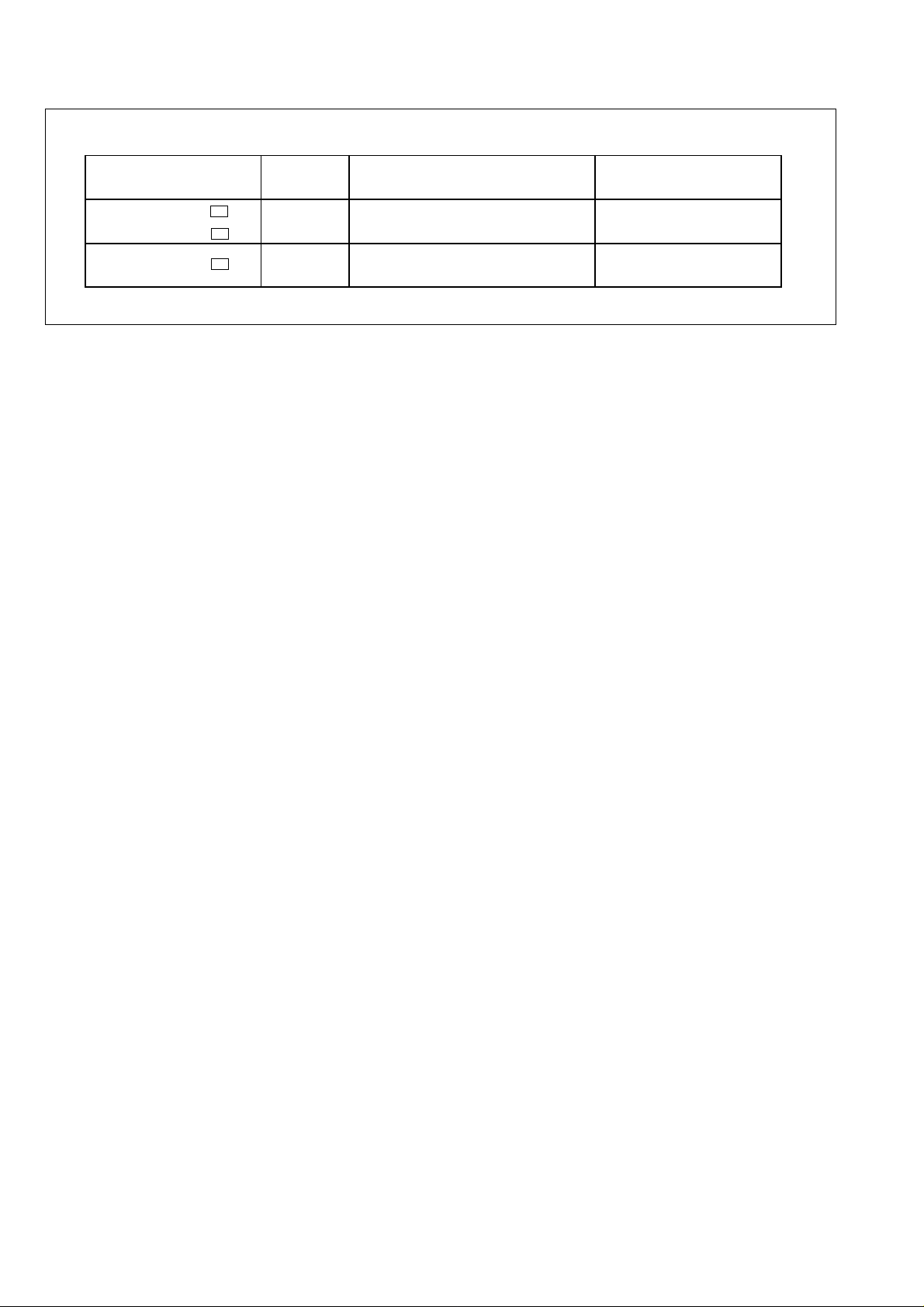

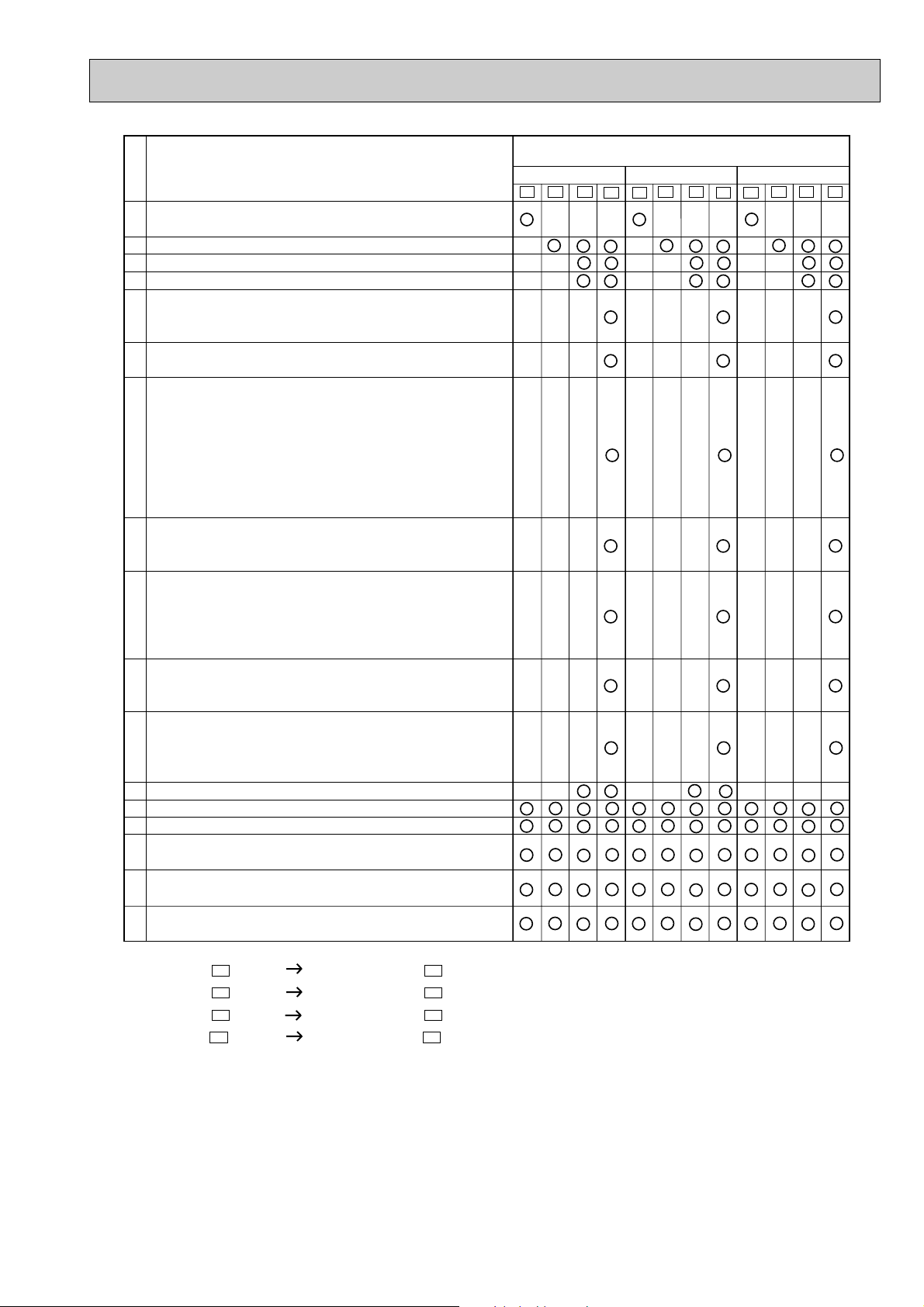

Circle shows the change point of the model.

Change point

No.

MSC-07RV-

E1

E2

E3

MSC-09RV-

E1

E2

E3

MSC-12RV-

E1

E2

E3

E4

E4

E4

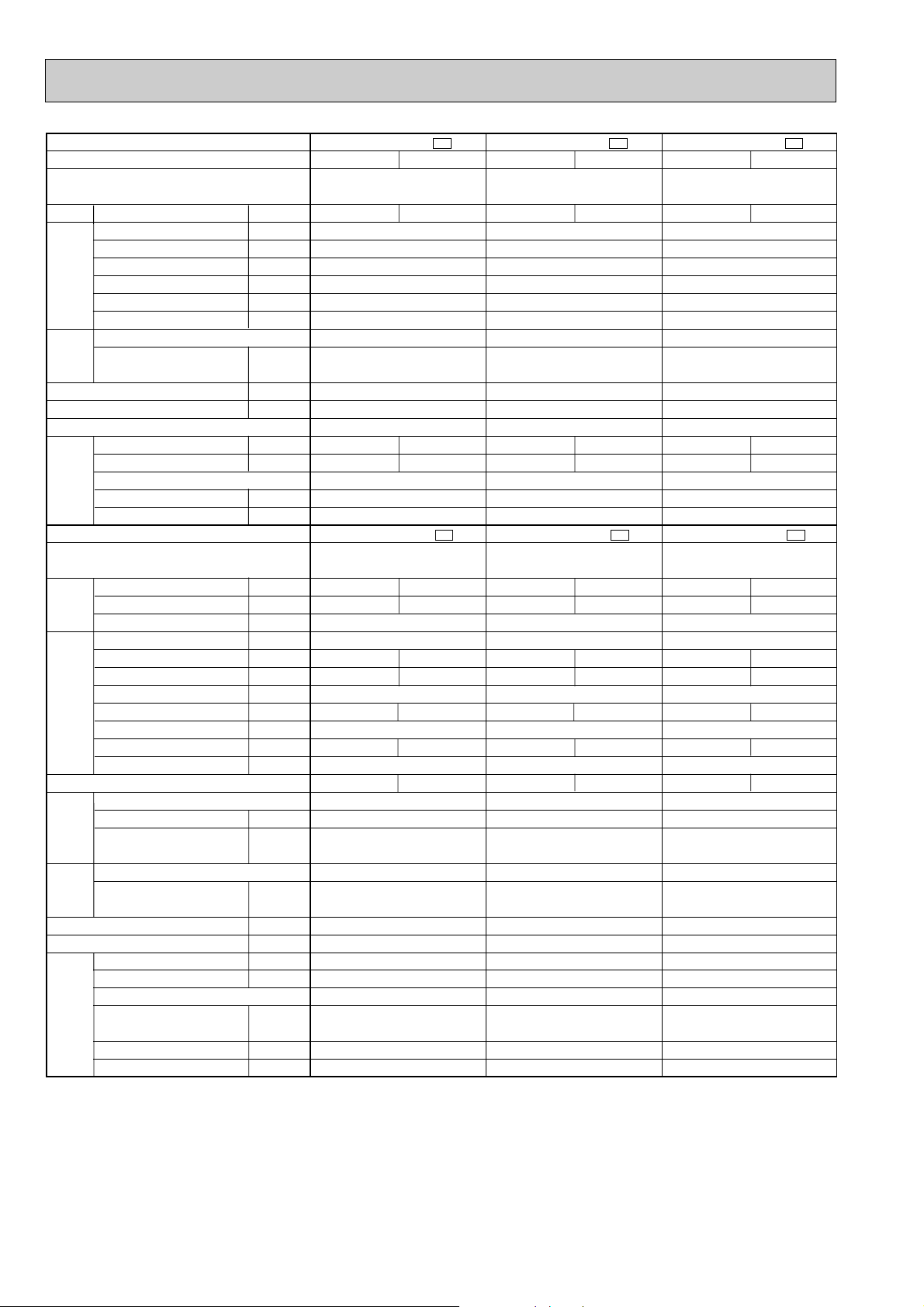

TECHNICAL CHANGES

3

1

2

3

4

5

6

7

8

9

10

11

12

13

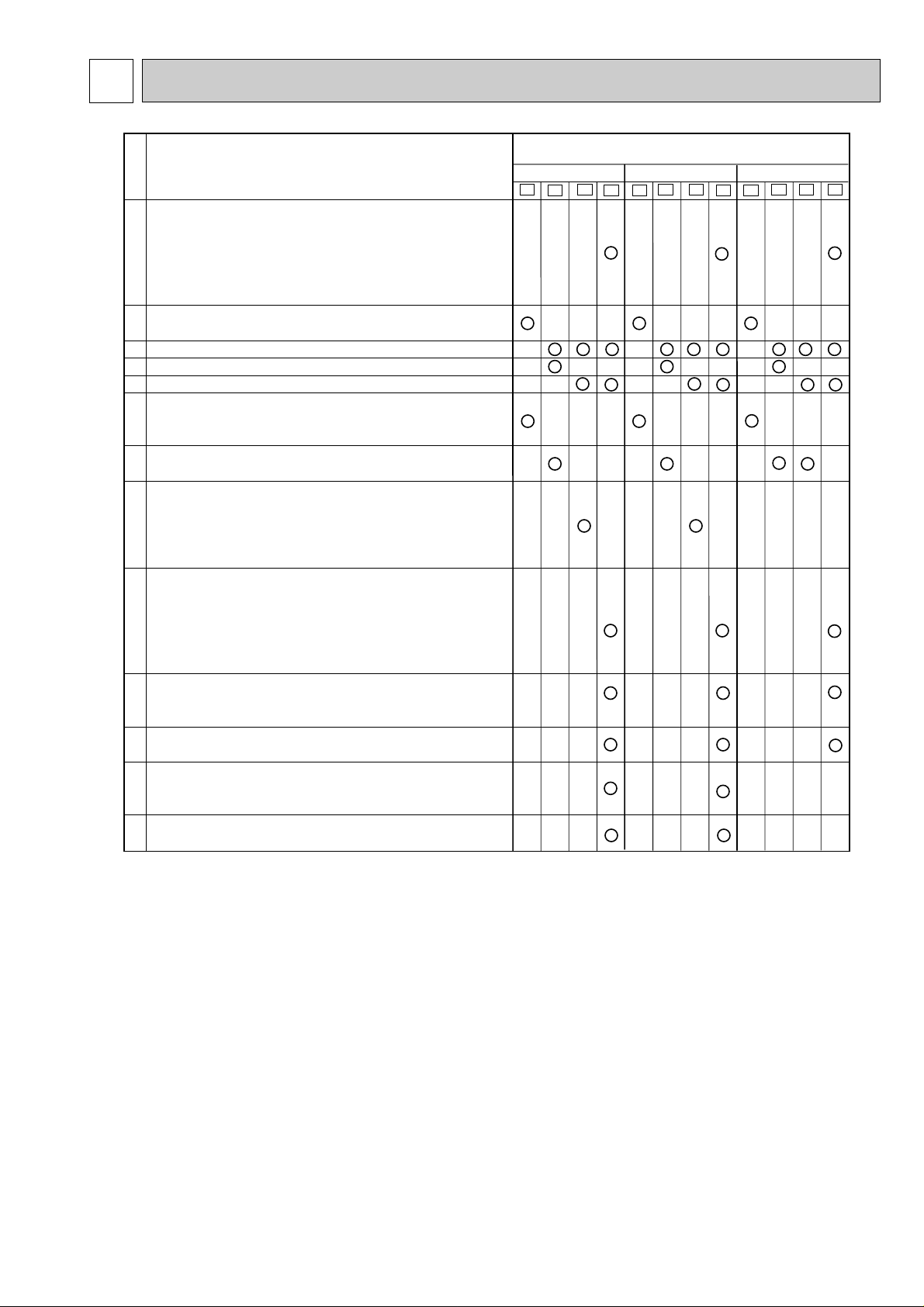

Remote controller of COOL ONLY type is outdoor unit accessory.

Remote controller is included as an indoor unit accessory.

Compressor contactor (52C) has changed. Compressor

contactor for E2,E3,E4 are interchangeable with the ones for E1.

Compressor has changed. Compressors for E3 and E4 are not

interchangeable with the ones for E1 and E2.

Compressor capacitor has changed. Due to different shape,

compressor capacitor for E4 is not interchangeable with the

ones for E1, E2 and E3.

Fuse has been removed.

Wiring diagram has changed because fuse was removed.

The shape of propeller fan has changed. The number of

propeller fan has changed from four to three. Propeller fan for E4

is not interchangeable with the ones for E1, E2 and E3.

The shape, diameter of axis and fan speed of fan motor have

changed. Fan motor for E4 is not interchangeable with the ones

for E1, E2 and E3.

Fan motor capacitor has changed. 1.5+➔ 2.0+

Fan motor capacitor for E4 is not interchangeable with the

ones for E1, E2 and E3(MU-12RV only).

Refrigerant filing capacity has changed. 0.85kg➔ 0.80kg

The method of troubleshooting for outdoor unit has changed.

The repairing procedure when outdoor unit does not stop

has been added to troubleshooting.

Circle shows that change points apply to the models.

Change point

No.

MU-07RV-

E1

E2

E3

MU-09RV-

E1

E2

E3

MU-12RV-

E1

E2

E3

E4

E4

E4

4

No.

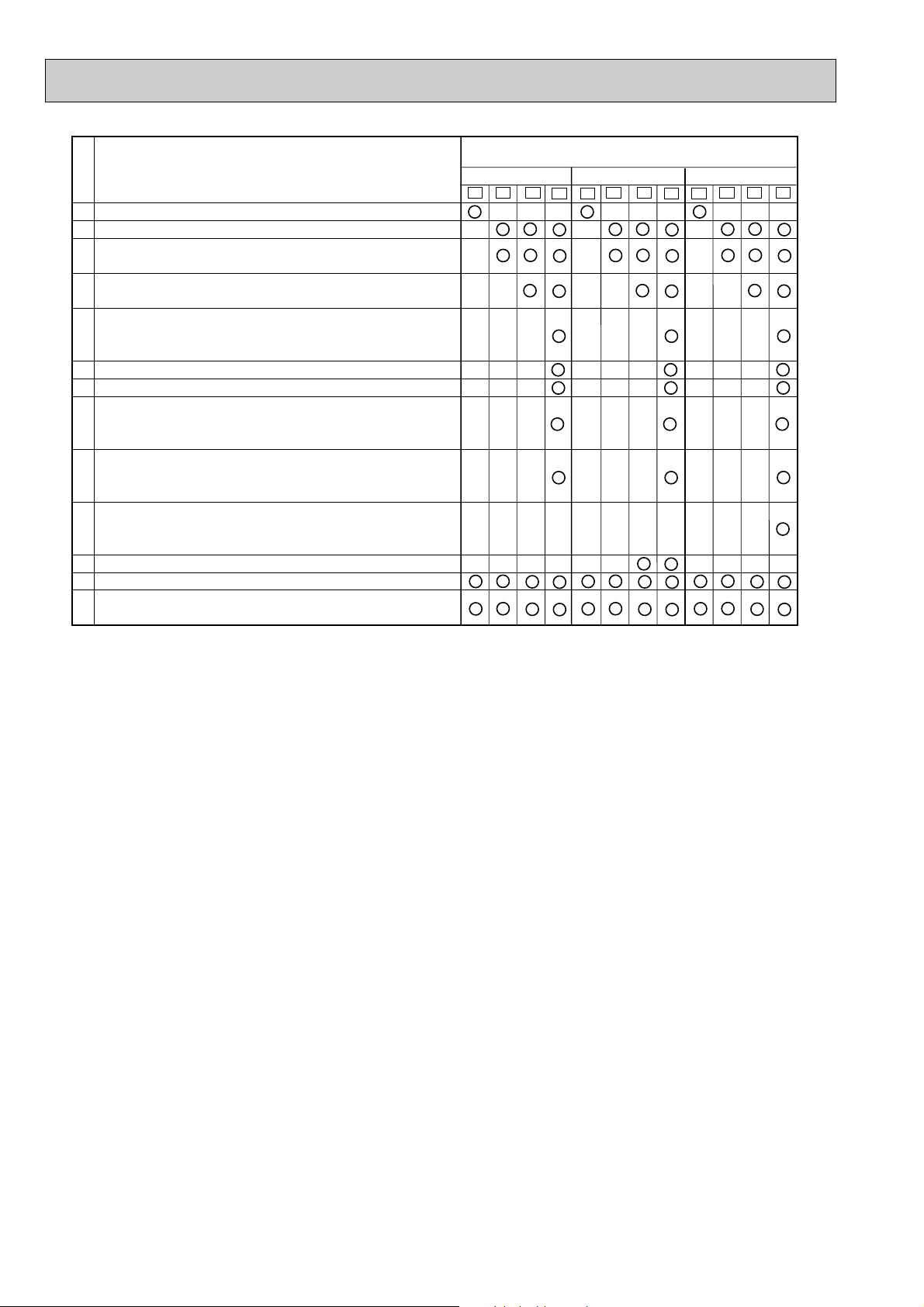

Remote controller of COOL & HEAT type is outdoor unit

1

accessory.

Remote controller is included as an indoor unit accessory.

2

Accumulator has been removed.

3

Compressor has changed.

4

Compressor capacitor has changed. Due to different

shape, compressor capacitor for E4 is not interchangeable

5

with the ones for E1,E2 and E3.

The mark of terminal block has changed. Terminal block

6

for E4 is interchangeable with the ones for E1, E2 and E3.

Deicer P.C. board has changed. Jumper wire of compulsory

defrosting mode has changed.

Jumper wire for defrost setting has changed.

(JPC-JPE➔JRF-JRG) (Refer to page 26.)

7

The defrosting intervals which are changed by setting a short

circuit are the same as E1, E2, and E3.

Deicer P.C. board for E4 is not interchangeable with the

ones for E1, E2 and E3.

Wiring diagram has changed according to the following

reasons; the shape of connectors CN711 and CN661 has

8

changed and R.V. coil relay (X62) has changed into SSR (SR62).

X62 has changed into SR62 in Example of Operation

time chart in HEAT operation.

9

Compared to E1, E2, and E3, no change has been made about

the operational condition for defrosting and tne control system of

R.V. coil (timing of switching on/off).

The shape of propeller fan has changed. The number of

propeller fan has changed from four to three. Propeller

10

fan for E4 is not interchangeable with the ones for E1,E2, and E3.

The shape and diameter of axis of fan motor have changed.

The shape of connector has changed.

11

Fan motor and connector for E4 are not interchangeable

with those for E1, E2 and E3.

Refrigerant filling capacity has changed. 0.80kg➔ 0.85kg

12

The method of checking serial signal error for E4 has been added.

13

The method of troubleshooting for outdoor unit has changed.

14

The method for checking thermistor has been added to

15

troubleshooting.

The method for checking 4-way valve has been added to

16

troubleshooting.

The repairing procedure when outdoor unit does not stop has

17

been added to troubleshooting.

Change point

(JP607-R853➔JPDS-JPSG)

Circle shows that change points apply to the models.

MUH-07RV-

E1

E2

E3

E4

MUH-09RV-

E1

E2

E3

E4

MUH-12RV-

E1

E2

E3

E4

MUX-10RV MUX-18RV MUX-24RV MXZ-18RV -

E1

E1

E1

E1

MUX-10RV MUX-18RV MUX-24RV MXZ-18RV -

E2

E2

E2

E2

1. Remote controller is unprovided as the outdoor unit accessory.

5

COOL ONLY

COOL

& HEAT

TWO-WAY

REMOTE CONTROLLER

Model

MS-07/09/12RV-

E1

MSH-07/09/12RV-

E1

MS-07/09/12RV-

E2

MSH-07/09/12RV-

E2

✕

✕

✕

✕

w

w When HEAT mode is selected

by the remote controller of

COOL & HEAT type, the unit

will operate in FAN mode.

TWO-WAY

DIP switch

✕

MS-07/09/12RV-

E3

MSH-07/09/12RV-

E3

MS-07/09/12RV-

E4

MSH-07/09/12RV-

E4

✕

✕

Reference

162

19

58

Wireless remote controller

MSC-07RV MSC-09RV MSC-12RV MU-07RV MU-09RV MU-12RV MUH-07RV MUH-09RV MUH-12RV -

E1

E1

E1

E1

E1

E1

E1

E1

E1

MSC-07RV MSC-09RV MSC-12RV MU-07RV MU-09RV MU-12RV MUH-07RV MUH-09RV MUH-12RV -

E2

E2

E2

E2

E2

E2

E2

E2

E2

COOL ONLY REMOTE CONTROLLER TWO-WAY REMOTE CONTROLLER

COOL&HEAT REMOTE CONTROLLER TWO-WAY REMOTE CONTROLLER

1. Both of COOL ONLY and COOL & HEAT remote controller are unified into a two-way remote controller.

2. FAN mode operation is available in COOL ONLY unit. In this case the set room temperature

will be displayed on the remote controller, however, the room temperature can not be controlled by remote controller button.

HEAT operation is available in only HEAT & COOL type unit.

MSC-07RV MSC-09RV MSC-12RV -

E2

E2

E2

MSC-07RV MSC-09RV MSC-12RV -

E3

E3

E3

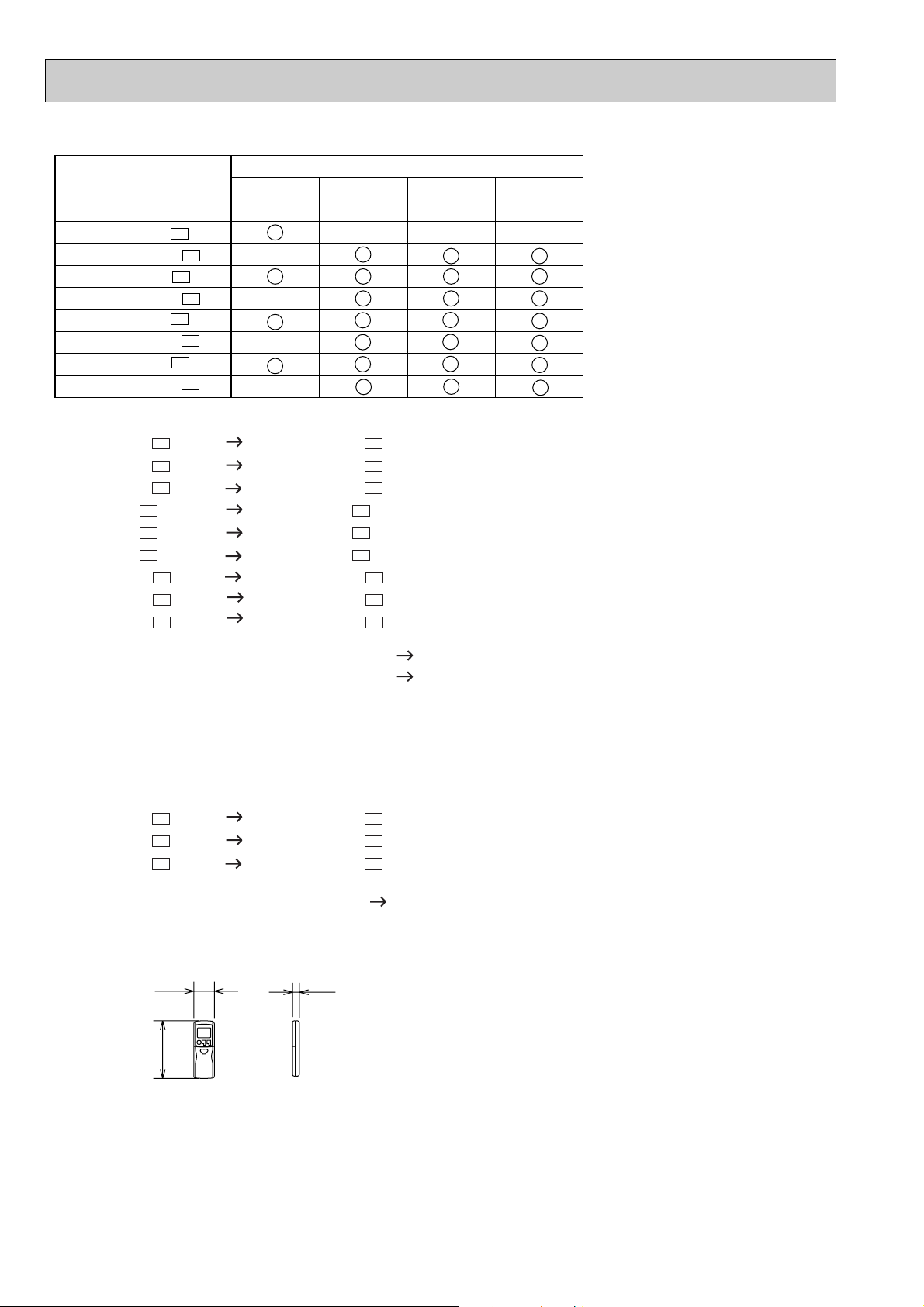

TWO-WAY REMOTE CONTROLLER TWO-WAY DIP SWITCH REMOTE CONTROLLER

• Outlines and dimensions have been changed.

6

• The way of remodelling individual operation of P.C Board of remote controller has changed.

No. 1 unit

No. 2 unit

No. 3 unit

No. 4 unit

1 unit operation

No modification

–

–

–

2 units operation

Same as at left

Solder J1

–

–

3 units operation

Same as at left

Same as at left

Solder J2

–

4 units operation

Same as at left

Same as at left

Same as at left

Solder both J1 and J2

A maximum of 4 indoor units with wireless remote controllers can be used in a room.

In this case, to operate each indoor unit individually by each remote controller, P.C. boards of remote controller must be

modified according to the number of the indoor unit.

How to modify the remote controller P.C. board

Remove batteries before modification.

The board has a print as shown below :

NOTE : For remodelling, take out the bat-

teries and press the

OPERATE/STOP(ON/OFF)button

twice or 3 times at first.

After finish remodelling, put back

the batteries then press the

RESET button.

The P.C. board has the print “J1” and “J2”. Solder “J1” and “J2” according to the number of indoor unit as shown

in Table 1. After modification, press the RESET button.

Table 1

REMOTE CONTROLLER (How to set the type)

This remote controller setting needs to be switched according to the type of air conditioner (COOL & HEAT or COOL

ONLY).

If the setting is incorrect, the air conditioner does not operate normally. Therefore, check if the setting corresponds to

the type of air conditioner. If it does not, correct the setting as shown below.

Slide switch

Type

The position

of the slide

switch

COOL ONLYCOOL & HEAT

7

Installation plate

Installation plate fixing screw 4 o 25 mm

Remote controller mounting hardware

Fixing screw for 3 3.5 o 16 mm

Battery (AAA) for remote controller

Felt tape (Used for left or left-rear piping)

Deodorizing filter

Air cleaning filter

Wireless remote controller

Drain socket: MUH type

Drain cap: MUH type

1

1

2

1

5

1

2

2

1

1

1

<Indoor unit>

Installation plate

Installation plate fixing screw 4 o 25 mm

Remote controller mounting hardware

Fixing screw for 3 3.5 o 16 mm

Battery (AAA) for remote controller

Wireless remote controller

Felt tape (Used for left or left-rear piping)

Deodorizing filter

Air cleaning filter

Drain socket

Drain cap

1

2

1

5

1

2

2

1

1

1

1

<Indoor unit>

<Outdoor unit: MUH type><Outdoor unit>

9

0

1

1

2

3

4

5

6

7

8

0

1

1

2

3

4

5

6

7

8

9

• How to replace batteries

Insert the negative pole

of the batteries first.

Check if the polarity of

the batteries are correct.

HEAT

/FAN

/

RESET button

HEAT

/FAN

/

Weak batteries may cause the remote controller malfunction.

In this case, replace the batteries to operate the remote controller normally.

1 Remove the front lid and insert batteries.

2 Press the RESET button.

Then re-attach the front lid.

NOTE : If the RESET button is not pressed, the remote controller may not operate correctly.

2

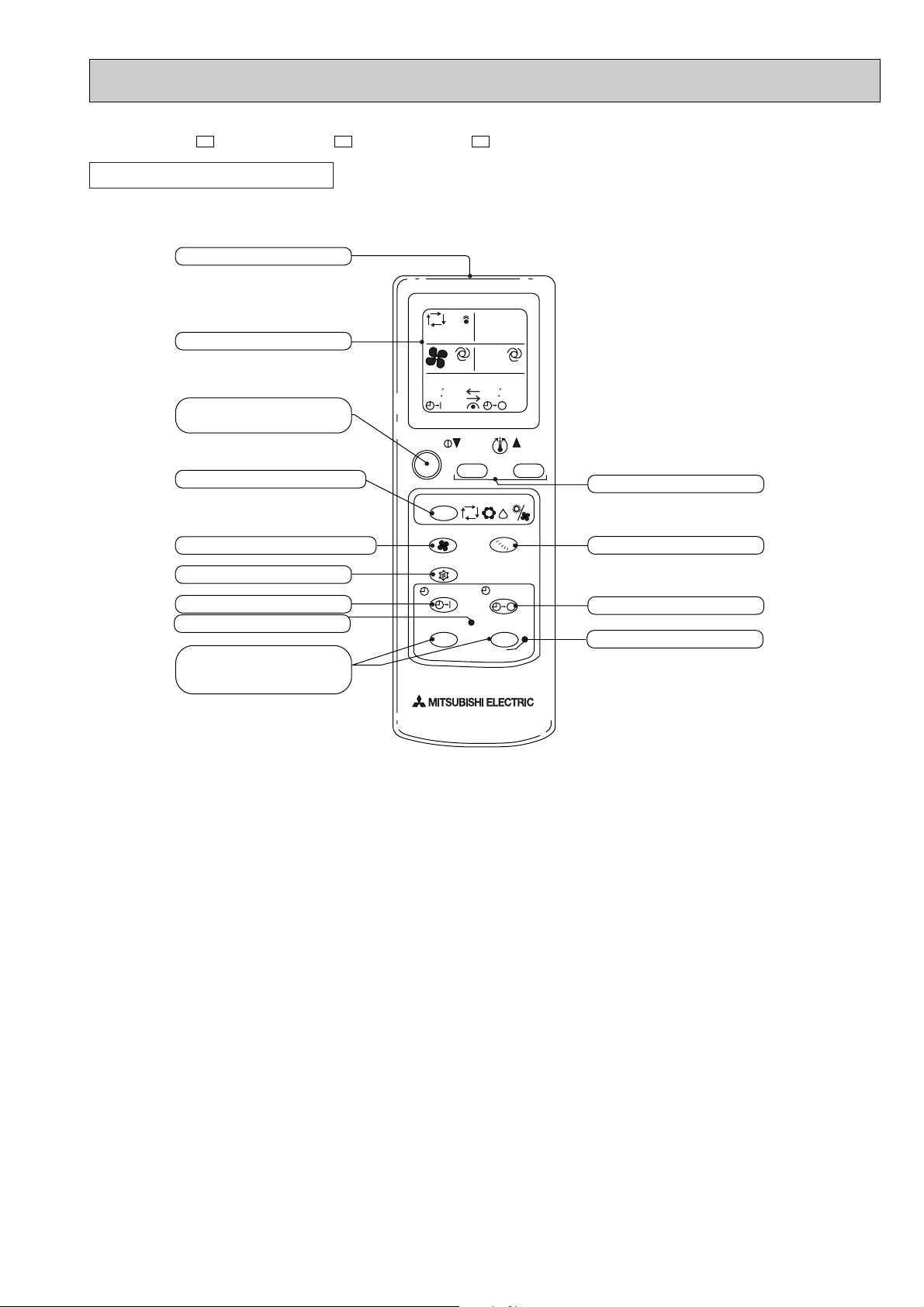

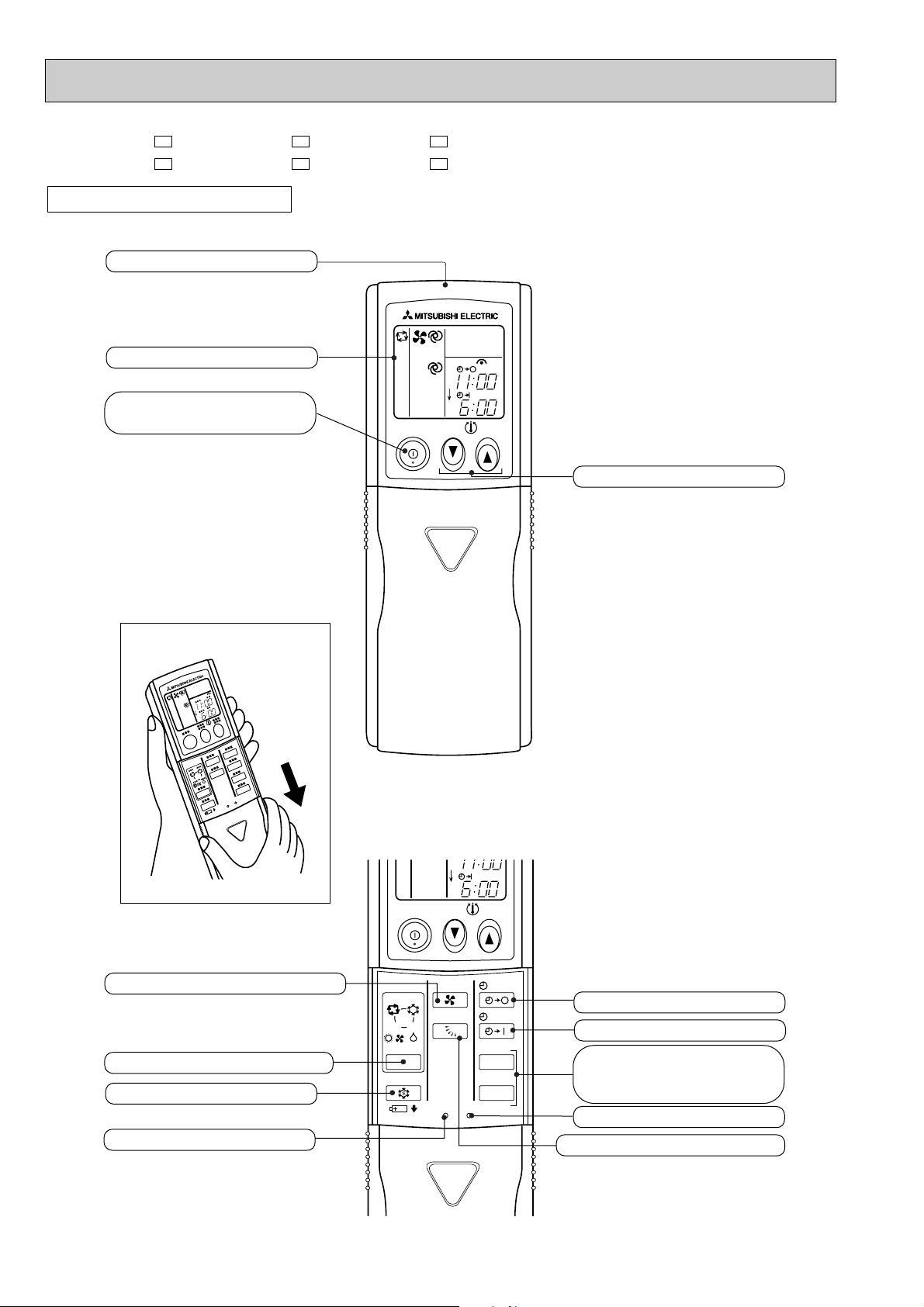

PART NAMES AND FUNCTIONS

ACCESSORIES

MSC-07RV - • MU-07RV MSC-09RV - • MU-09RV MSC-12RV - • MU-12RV MSC-07RV - • MUH-07RV MSC-09RV - • MUH-09RV MSC-12RV - • MUH-12RV -

MSC-07RV - • MU-07RV MSC-09RV - • MU-09RV MSC-12RV - • MU-12RV MSC-07RV - • MUH-07RV MSC-09RV - • MUH-09RV MSC-12RV - • MUH-12RV MSC-07RV - • MU-07RV MSC-09RV - • MU-09RV MSC-12RV - • MU-12RV MSC-07RV - • MUH-07RV MSC-09RV - • MUH-09RV -

E1E1

E1E1

E1E1

E1E1

E1E1

E1E1

MSC-12RV - • MUH-12RV MSC-07RV - • MU-07RV MSC-09RV - • MU-09RV MSC-12RV - • MU-12RV MSC-07RV - • MUH-07RV MSC-09RV - • MUH-09RV MSC-12RV - • MUH-12RV -

E2E2

E2E2

E2E2

E2E2

E2E2

E2E2

E3E3

E3E3

E3E3

E3E3

E3E3

E3E3

E4E4

E4E4

E4E4

E4E4

E4E4

E4E4

8

MSC-07RV - MSC-09RV - MSC-12RV -

Signal transmitting section

Operation display section

OPERATE /STOP

(ON /OFF)button

OPERATION SELECT button

FAN SPEED CONTROL button

ON-TIMER button

CLOCK SET button

HR. button

MIN. button

(TIME SET button)

TEMPERATURE buttons

VANE CONTROL button

OFF-TIMER button

RESET button

ON/OFF TOO

WARM

TOO

COOL

HR. MIN.

CLOCK

RESET

CLOCK

MODE

FAN

VANE

START

STOP

ECONO COOL button

ECONO COOL

I FEEL

COOL DRY

HEAT/FAN

6 00 1

1 00

AM

PM

REMOTE CONTROLLER

E2E2E2

9

MSC-07RV - MSC-09RV - MSC-12RV MSC-07RV - MSC-09RV - MSC-12RV -

REMOTE CONTROLLER

Signal transmitting section

E3E3E3

E4E4E4

Operation display section

OPERATE /STOP

(ON /OFF)button

Open the front lid.

ON/OFF

TOO

WARM

PM

AM

TOO

COOL

TEMPERATURE buttons

FAN SPEED CONTROL button

OPERATION SELECT button

ECONO COOL button

RESET button

TOO

ON/OFF

WARM

COOL

DRY

FAN

VANE

RESET

I FEEL

HEAT

/FAN

/

MODE

ECONO COOL

10

CLOCK

CLOCK

PM

AM

TOO

COOL

STOP

START

HR.

MIN.

OFF-TIMER button

ON-TIMER button

HR. button

MIN. button

(TIME SET button)

CLOCK SET button

VANE CONTROL button

3

Indoor model

Function

Indoor unit power supply

Air flow(High/Med. /Low )

Power outlet

Running current

Power input

Power factor

Starting current

Fan motor current

Model

Winding

resistance(at20:)

Dimensions WOHOD

Weight

Air direction

Sound level(High/Med. /Low )

Fan speed (High/Med. /Low )

Fan speed regulator

Thermistor RT11(at25:)

Thermistor RT12(at25:)

Outdoor model

Capacity

Dehumidification

Outdoor air flow

Power outlet

Running current

Power input

Auxiliary heater

Power factor

Starting current

Compressor motor current

Fan motor current

Model

Output

Winding

resistance(at20:)

Model

Winding

resistance(at20:)

Dimensions WOHOD

Weight

Sound level

Fan speed

Fan speed regulator

Refrigerant filling

capacity(R22)

Refrigerating oil (Model)

K /h

A

A

W

%

A

A

"

mm

kg

dB

rpm

k"

k"

kW

R/h

K /h

A

A

W

A(kW)

%

A

A

A

W

"

"

mm

kg

dB

rpm

kg

cc

MSC-07RV -

E4

Single phase

220-240V,50Hz

10

0.17

35

93.6-85.8

—

0.17

WHT-BLK 413

BLK-RED 334

850O278O191

9

5

3

10

10

MU-07RV -

E4

Single phase

220-240V,50Hz

10

—

2.77-2.71

0.21-0.22

RH-130VGCT

650

C-R 4.18

C-S 5.76

RA6V23-FC

WHT-BLK 353

BLK-RED 321

780o540o255

32

44-45

710-760

1

0.80

300 (MS56 )

Cooling

474/384 /294

RC4V19-LA

36/31 /26

950/790 /640

2.2

0.8

1620-1752

2.98-2.93

645-675

98.4-96.0

19

3.24-3.10

MSC-09RV -

E4

Single phase

220-240V,50Hz

10

0.17

35

RC4V19-LA

WHT-BLK 413

BLK-RED 334

850O278O191

9

5

3

10

10

MU-09RV -

E4

Single phase

220-240V,50Hz

10

—

RH-140VGCT

700

C-R 4.03

C-S 5.71

RA6V23-FC

WHT-BLK 353

BLK-RED 321

780o540o255

32

44-45

710-760

1

0.80

300 (MS56 )

Cooling

474/384 /294

93.6-85.8

—

0.17

36/31 /26

950/790 /640

2.5

1.1

1620-1752

3.43-3.28

745-775

98.7-98.5

20

3.22-3.06

0.21-0.22

3.21-3.09

MSC-12RV -

E4

Single phase

220-240V,50Hz

10

0.19

40

RC4V19-GA

WHT-BLK 375

BLK-RED 294

850O278O191

10

5

3

10

10

MU-12RV -

E4

Single phase

220-240V,50Hz

1.6

1848-1980

10

—

96.1-91.3

35

RH-220VHAT

1050

C-R 2.13

C-S 3.91

RA6V33-DC

WHT-BLK 301

BLK-RED 332

780o540o255

34

49

810-840

1

0.88

520 (MS56)

Cooling

588/468 /360

95.7-87.7

—

0.19

39/34 /29

1020/850 /690

3.5

6.01-6.16

1270-1350

5.72-5.84

0.29-0.33

2.67-2.52

Electrical

data

Fan

motor

Special

remarks

Compressor

Electrical

data

Fan

motor

Special

remarks

Capacity

Coefficient of performance(C.O.P)

Outdoor unit power supply

Capacity

ww

ww

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

SPECIFICATION

NOTE: Test conditions are based on ISO 5151.

Cooling : Indoor DB27°C WB19°C

Indoor-Outdoor piping length 5m

w Reference value

Outdoor DB35°C WB24°C

11

Indoor model

Function

Indoor unit power supply

Air flow(High/Med. /Low )

Power outlet

Running current

Power input

Power factor

Starting current

Fan motor current

Model

Winding

resistance(at20:)

Dimensions WOHOD

Weight

Air direction

Sound level(High/Med. /Low )

Fan speed(High/Med. /Low )

Fan speed regulator

Thermistor RT11(at25:)

Thermistor RT12(at25:)

Outdoor model

Capacity

Dehumidification

Outdoor air flow

Power outlet

Running current

Power input

Auxiliary heater

Power factor

Starting current

Compressor motor current

Fan motor current

Model

Output

Winding

resistance(at20:)

Model

Winding

resistance(at20:)

Dimensions WOHOD

Weight

Sound level

Fan speed

Fan speed regulator

Refrigerant filling

capacity(R22)

Refrigerating oil (Model)

Thermistor RT61(at0:)

K /h

A

A

W

%

A

A

"

mm

kg

dB

rpm

k"

k"

kW

R/h

K /h

A

A

W

A(kW)

%

A

A

A

W

"

"

mm

kg

dB

rpm

kg

cc

k"

MSC-07RV -

E4

Single phase

220-240V,50Hz

10

0.17

35

93.6-85.8

—

0.17

RC4V19-LA

WHT-BLK 413

BLK-RED 334

850O278O191

9

5

3

10

10

MUH-07RV -

E4

Single phase

220-240V,50Hz

1620-1752

10

—

25

0.21-0.22

RH-130VGCT

650

C-R 4.18

C-S 5.76

RA6V23-FB

WHT-BLK 353

BLK-RED 321

788o540o255

33

47

710-760

1

0.85

300 (MS56)

33.18

Cooling

474/384 /294

36/31 /26

950/790 /640

2.2

0.8

3.13-3.03

675-715

98.0-98.3

2.92-2.81

3.10-2.93

Heating

504/414 /336

35/30 /26

1000/850 /710

2.5

—

2.98-2.88

645-685

98.4-99.1

2.77-2.66

3.68-3.47

MSC-09RV -

E4

Single phase

220-240V,50Hz

10

0.17

35

93.6-85.8

—

0.17

RC4V19-LA

WHT-BLK 413

BLK-RED 334

850O278O191

9

5

3

10

10

MUH-09RV -

E4

Single phase

220-240V,50Hz

1620-1752

10

—

25

0.21-0.22

RH-165VGCT

800

C-R 3.30

C-S 5.80

RA6V23-FB

WHT-BLK 353

BLK-RED 321

780o540o255

33

47

710-760

1

0.85

300 (MS56)

33.18

Cooling

474/384 /294

36/31 /26

950/790 /640

2.5

1.1

3.93-3.83

845-885

97.7-96.3

3.72-3.61

2.84-2.72

Heating

504/414 /336

35/30 /26

1000/850 /710

3.1

—

4.13-3.93

885-905

97.4-95.9

3.92-3.71

3.37-3.30

MSC-12RV -

E4

Single phase

220-240V,50Hz

10

0.19

40

95.7-87.7

—

0.19

RC4V19-GA

WHT-BLK 375

BLK-RED 294

850O278O191

10

5

3

10

10

MUH-12RV -

E4

Single phase

220-240V,50Hz

1656-1758

10

—

35

0.29-0.32

RH-220VHAT

1050

C-R 2.13

C-S 3.91

RA6V33-DB

WHT-BLK 301

BLK-RED 332

780o540o255

38

49

810-840

1

1.19

520 (MS56)

33.18

Cooling

588/468 /360

39/34 /29

1020/850 /690

3.4

1.6

5.56-5.71

1180-1260

96.5-91.9

5.27-5.39

2.79-2.62

Heating

642/516 /402

39/34 /29

1100/920 /750

4.0

—

5.76-5.91

1220-1310

96.3-92.4

5.47-5.59

3.17-2.96

Electrical

data

Fan

motor

Special

remarks

Compressor

Electrical

data

Fan

motor

Special

remarks

Capacity

Coefficient of performance(C.O.P)

Outdoor unit power supply

Capacity

ww

ww

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

w

NOTE: Test conditions are based on ISO 5151.

Cooling : Indoor DB27°C WB19°C Heating : Indoor DB20°C

Indoor-Outdoor piping length 5m

Outdoor DB35°C WB24°C Outdoor DB 7°C / WB 6°C

w Reference value

12

4

SYMBOL

TB

T11

SYMBOL

NR11

RT11

RT12

SR141

SYMBOL

C11

F11

MF

MV

NAME

NAME NAME

INDOOR FAN CAPACITOR

FUSE(3.15A)

INDOOR FAN MOTOR(INNER FUSE)

VANE MOTOR

VARISTOR

ROOM TEMPERATURE THERMIST OR

INDOOR COIL THERMISTOR

SOLID STATE RELAY

TERMINAL BLOCK

TRANSFORMER

CIRCUIT BREAKER

SR141

C11

RED

WHT

3

6

5

BRN

YLW

GRY

BLK

4

3

2

1

MF

121

CN

1

3

5

111

CN

112

CN

RT12

RT11

NR11

T11

TRANS

F11

ELECTRONIC CONTROL P.C. BOARD

CN211

TAB12

CN201

3

2

1

CN202

2

1

151

CN

5

5

BRN

RED

BLU

WHT

BLK

BLU

BRN

TB

L

3

N

2

1

12V

TO OUTDOOR

UNIT

CONNECTING

POWER

SUPPLY

CORD

~/N 220-240V

50Hz

GRN/YLW

POWER MONITOR,

RECEIVER

P.C.BOARD

REMOTE

CONTROLLER

MV

FOR

MUH OR

MXZ TYPE

FOR

MU OR

MUX TYPE

12V

PE

LD103

101

CN

GRN

WIRING DIAGRAM

MSC-07RV MSC-09RV MSC-12RV -

E4

E4

E4

INDOOR UNIT

MODELS WIRING DIAGRAM

NOTE:1. About the outdoor side electric wiring refer to the outdoor unit electric wiring diagram for servicing.

2. Use copper conductors only. (For field wiring)

3. Symbols below indicate.

/: Terminal block, : Connector

13

SG79J412H01

MU-07RV MU-09RV MU-12RV -

E4

E4

E4

OUTDOOR UNIT

FROM

INDOOR UNIT

CONNECTING

POWER SUPPLY

~/N

220-240V

50Hz

MODELS WIRING DIAGRAM

TB2

2

WHT

1

PE

TB1

L

N

BLK

BRN

BLU

GRN/YLW

12V

CIRCUIT BREAKER

NO

52C

52C

COM

BRN

WHT

WHT

C2

DSAR

C1

WHT

BLU

RED

RED

BLK

1

2

3

WHT

BLK

RED

C

MC

S

R

MF

SYMBOL

C1

C2

DSAR

NOTE:1. About the indoor side electric wiring refer to the indoor unit electric wiring diagram for servicing.

COMPRESSOR CAPACITOR

OUTDOOR FAN CAPACITOR

SURGE ABSORBER

2.Use copper conductors only. (For field wiring)

3. Symbols below indicate.

/: Terminal block, : Connector

MUH-07RV MUH-09RV MUH-12RV -

OUTDOOR UNIT

FROM

INDOOR UNIT

CONNECTING

12V

POWER SUPPLY

~/N

220-240V

50Hz

NAME

E4

E4

E4

MODELS WIRING DIAGRAM

CIRCUIT BREAKER

SYMBOL

TB1,TB2

TB2

3

N

TB1

L

N

PE

MC

MF

RED

BLK

BRN

BRN

BLU

NAME NAME

COMPRESSOR(INNER PROTECTOR)

OUTDOOR FAN MOTOR(INNER FUSE)

TERMINAL BLOCK

21S4

RT61

DSAR

BLU

1

2

3

F61

TAB20

CN661

CN730

T61

52C

4

CN721

NR61

3

DEICER P.C.BOARD

C1

GRN/YLW

SR62

RED

BLK

SYMBOL

52C

SR61

WHT

S

COMPRESSOR CONTACTOR

VG79B132H01

MF

CN711

WHT

1

BLK

2

RED

3

C65

C

MC

R

SYMBOL

C1

COMPRESSOR CAPACITOR

C65

DSAR

F61

MC

NOTE:1. About the indoor side electric wiring refer to the indoor unit electric wiring diagram for servicing.

OUTDOOR FAN CAPACITOR

SURGE ABSORBER

FUSE(2A)

COMPRESSOR(INNER PROTECTOR)

2.Use copper conductors only. (For field wiring)

3. Symbols below indicate.

/: Terminal block, : Connector

NAME

SYMBOL

MF

NR61

RT61

SR61, SR62

T61

NAME NAME

OUTDOOR FAN MOTOR(INNER FUSE)

VARISTOR

DEFROST THERMISTOR

SOLID STATE RELAY

TRANSFORMER

14

SYMBOL

TB1,TB2

21S4

52C

TERMINAL BLOCK

R.V. COIL

COMPRESSOR CONTACTOR

SG79B111H01

5

REFRIGERANT SYSTEM DIAGRAM

MSC-07RV - MSC-07RV MSC-09RV - MSC-09RV -

Unit:mm

E4E3

E4E3

MUH-07RV - MUH-07RV MUH-09RV - MUH-09RV -

E4E3

E4E3

INDOOR UNIT

Indoor

heat

exchanger

Room temperature

thermistor

RT11

Indoor coil

thermistor

RT12

Refrigerant pipe [ 9.52

(with heat insulator)

Flared connection

Flared connection

Refrigerant pipe [6.35

(with heat insulator)

MSC-12RV - MSC-12RV -

OUTDOOR UNIT

4-way valve

Muffler

Stop valve

(with service

port)

Strainer

Stop valve

E4E3

Capillary tube

[3.0x[1.4x600(MUH-07)

[3.0x[1.4x550(MUH-09)

Strainer

Check valve

Defrost

thermistor

RT61

Compressor

Capillary tube

[3.0x[1.6x600(MUH-07)

[3.0x[1.6x400(MUH-09)

Refrigerant flow in cooling

Refrigerant flow in heating

Outdoor

heat

exchanger

Capillary tube

[3.0x[1.4x800 (2 pcs)

R.V. coil

heating ON

cooling OFF

MUH-12RV - MUH-12RV -

Unit:mm

E4E3

INDOOR UNIT

Indoor

heat

exchanger

Room temperature

thermistor

RT11

Indoor coil

thermistor

RT12

Refrigerant pipe [12.7

(with heat insulator)

Flared connection

Flared connection

Refrigerant pipe [6.35

(with heat insulator)

4-way valve

Muffler

Stop valve

(with service port)

Strainer

Stop valve

Strainer

Compressor

Capillary tube

[3.0x[1.6x700

Check

valve

OUTDOOR UNIT

Defrost

thermistor

RT61

Capillary tube

[3.0x[1.8x300

R.V. coil

heating ON

cooling OFF

Refrigerant flow in cooling

Refrigerant flow in heating

Outdoor

heat

exchanger

Capillary tube

[3.0x[1.4x500(2pcs)

15

6

RED

BLK

YLW

GRY

BRN

WHT

FUSE

WHTRED

BLK

MAIN

AUX.

FUSE

MICROPROCESSOR CONTROL

MSC-07RV - MU-07RV - MUH-07RV MSC-09RV - MU-09RV - MUH-09RV MSC-12RV - MU-12RV - MUH-12RV -

E4E4E4

E4E4E4

E4E4E4

6-1. 11-1. COOL ( ) OPERATION

1. Indoor fan speed control

Indoor fan operates continuously at the set speed by FAN SPEED CONTROL button regardless of thermostat’s OFF-ON.

In Auto the fan speed is as follows.

MSC-07RV - MSC-07RV - MSC-07RV MSC-09RV - MSC-09RV - MSC-09RV MSC-12RV - MSC-12RV - MSC-12RV -

E3E2E1

E3E2E1

E3E2E1

Initial temperature difference

Fan speed

Room temperature minus set temperature : 2 degrees or more································High

Room temperature minus set temperature : Between 1 and 2 degrees····················Med.

Room temperature minus set temperature : less than 1 degree································Low

MSC-07RV MSC-09RV MSC-12RV -

E4

E4

E4

Initial temperature difference

Fan speed

Room temperature minus set temperature : 1.7 degrees or more·····························High

Room temperature minus set temperature : Between 1 and 1.7 degrees·················Med.

Room temperature minus set temperature : less than 1 degree································Low

Difference between room

temperature and set temperature during operation

4 deg.

1 deg.

2 deg.

1.7 deg.

Difference between room

temperature and set temperature during operation

3 deg.

1.7 deg.

1 deg.

7

TROUBLESHOOTING

7-1. Trouble criterion of main parts

E4

MSC-07RV MSC-09RV MSC-12RV -

Part name

Indoor fan

motor(MF)

INNER FUSE

136I3 CUT OFF

Outdoor fan

motor(MF)

INNER FUSE

163I3 CUT OFF

MU-07RV -

E4

MU-09RV -

E4

MU-12RV -

Motor part

WHT-BLK

BLK-RED

WHT-BLK

BLK-RED

E4

MUH-07RV -

E4

MUH-09RV -

E4

MUH-12RV -

E4

E4

E4

Check method and criterion Figure

Measure the resistance between the terminals with a tester.

(Coil wiring temperature10°C ~ 30°C)

Color of

lead wire

WHT-BLK

BLK-RED

MSC-07/09RV-

396 ~ 430Ω

320 ~ 348Ω

Normal

E4

MSC-12RV-

396 ~ 430Ω

320 ~ 348Ω

E4

Measure the resistance between the terminals with a tester.

(Coil wiring temperature –10°C ~ 40°C)

Color of

lead wire

Color of

lead wire

MU-07/09RV-

311 ~ 381

283 ~ 347

MUH-07/09RV-

311 ~ 381

283 ~ 347

Normal

E4

Ω

Ω

Normal

E4

Ω

Ω

MU-12RV-

265 ~ 325

292 ~ 359

MUH-12RV-

265 ~ 325

292 ~ 359

E4

Ω

Ω

E4

Ω

Ω

Abnormal

Open or short-circuit

Abnormal

Open or short-circuit

Abnormal

Open or

short-circuit

16

When OPERATION INDICATOR lamp flashes 3-time.

Indoor fan motor doesn’t operate.

A

Check of indoor fan motor

Turn OFF the power supply.

Check connector CN211 visually.

No

Re-connect the lead wires.

Are lead wires connected?

Disconnect lead wires from connector CN211 on indoor electronic control P.C. board.

Measure resistance between lead wires No.1 and No.5 and then No.3 and No.5.

Yes

Is resistance 0 (short circuit) or ∞ (open circuit)?

Yes ( 0 or ∞ )

Repair or replace the indoor fan motor.

Is soldered point of the connector

correctly soldered?

Turn ON the power supply. Stop it if the unit oper-

ate. Insert screwdriver into air outlet to rotate

indoor fan motor slowly for 1 revolution or over, and

No

(others)

measure voltage No.2(+) and No.3(-) on CN121.

No

Does voltage repeat 0V DC and 5V DC?

Replace the indoor electronic control P.C. board.

Yes

No

Re-solder it.

Yes

Indoor unit operates by pressing the EMERGENCY OPERATION switch, but doesn’t operate with the remote controller.

Check of remote controller and receiver P.C. board

B

wCheck the remote controller is exclusive for this air conditioner.

Switch on the remote controller.

Is LCD display on the remote controller displayed?

Yes

Remove batteries, then set them back and

press the RESET button. Check if the unit

operates with the remote controller.

Does the unit operate with the

remote controller?

Yes

Ok

Measure the voltage between receiver P.C. board connector CN302

No.3

No

(not clear)

No

(–)

and No.5

Replace the batteries.

Turn on a radio to AM and press switch on

the remote controller.

Is noise heard from radio?

Yes

Are there any fluorescent lights of

inverter or rapid-start type within

the range of 1m?

No

MSC-07/09/12RV- , ,

MSC-07/09/12RV-

(+)

when the remote controller button is pressed.

Is the voltage approx. 4V DC?

Replace the receiver P.C. board.

E4

No(5V or 0V DC)

No

Yes

Yes

Replace the remote controller.

• Re-install the unit away from lights.

• Attach a filter on receiving part.

E3E2E1

Replace the indoor electronic control

P.C. board.

17

The unit doesn’t operate with the remote controller.

Also, the OPERATION INDICATOR lamp doesn’t light up by pressing the EMERGENCY OPERATION switch.

Check of indoor electronic control P.C. board

C

Check the both “parts side” and “pattern

side” of indoor electronic control P.C.

board visually.

Turn OFF the power supply.

Remove indoor fan motor connector CN211 and

vane motor connector CN151 from the indoor electronic

control P.C. board and turn ON the power supply.

Does the unit operate with the remote controller?

Does the OPERATION INDICATOR lamp light up

by pressing the EMERGENCY OPERATION switch?

Yes

Turn OFF the

power supply.

Be sure to check both resistances.

Replace the vane

motor.

Yes

Is winding

resistance of

vane motor 0 "?

Is winding

resistance of

fan motor 0 "?

Yes

Replace the fan

motor.

No

No

No

Turn OFF the

power supply.

Be sure to check both fuse

and varistor in any case.

Replace the fuse.

Yes

Is fuse(F11) blown?

Is varistor(NR11) burnt?

Yes

Replace the varistor.

No

Replace the indoor

electronic control

P.C. board.

No

18

Compressor and / or outdoor fan motor doesn’t operate.

Yes

Is there 220-240V AC

between 1–2 on the outdoor

terminal block (TB2)?

Compressor

doesn't operate.

Operate the unit in COOL mode by pressing the

EMERGENCY OPERATION switch.

3-minute time delay works.

Test run operation operates for 30 minutes.

Outdoor fan motor

doesn't operate.

Check the power supply, and

rectify the connecting wire.

Check the indoor electronic

control P.C. board, and rectify

the indoor and outdoor

connecting wire.

Start

No

No

Yes

Is there 220-240V AC between L–N

on the outdoor terminal block (TB1)?

Is the switch SW2-2 on the

indoor electronic control

P.C. board set to MU type?

No

Change the switch SW-2-2

on the indoor electronic control

P.C. board to MU type.

Yes

Is there 220-240V AC between L–N

on the outdoor terminal block (TB1)?

Is there 12V DC between

1–2 on the outdoor

terminal block (TB2)?

No

Check the indoor electronic

control P.C. board, and rectify

the indoor and outdoor

connecting wire.

Yes

Is there 220-240V AC between COM

on the compressor contactor (52C) and

N on the outdoor terminal block (TB1)?

Yes

Check the compressor and

compressor contactor, and

rectify the connecting wire.

Replace the compressor

contactor (52C).

No

Yes

Is there 220-240V AC between COM

on the compressor contactor (52C) and

N on the outdoor terminal block(TB1)?

Yes

Check the outdoor fan motor

and outdoor fan capacitor,

and rectify the connecting wire.

No

Check the power supply, and

rectify the connecting wire.

Replace the compressor

contactor (52C).

No

E1

E2

E3

MU-07/09/12RV- , ,

Is fuse "F" (2A) blown?

No

Replace the fuse "F" (2A).

Yes

D

Check of outdoor unit

<MU-07/09/12RV>

19

Compressor and / or outdoor fan motor doesn’t operate.

Yes

Compressor

doesn't operate.

Yes

Yes

Is there 220-240V AC between

3 on the compressor contactor

(52C) and N on the outdoor

terminal block (TB1)?

Operate the unit in COOL or HEAT mode by pressing the

EMERGENCY OPERATION switch.

3-minute time delay works.

Test run operation operates for 30 minutes.

Outdoor fan motor

doesn't operate.

No

Rectify the indoor and

outdoor connecting wire.

Rectify the connecting wire.

Check the compressor and compressor

capacitor, and rectify the connecting wire.

Start

Yes

Is there 220-240V AC between 4

on the compressor contactor (52C) and

TAB20 on the deicer P.C. board?

Is there 220-240V AC between L–N

on the outdoor terminal block (TB1)?

Replace the

deicer P.C. board.

Replace the

deicer P.C. board.

No

No

Yes

Yes

No

Check the outdoor fan motor

and rectify the connecting

wire.

Is there 220-240V AC between 4 on

the compressor contactor (52C) and

TAB 20 on the deicer P.C. board?

Replace the

deicer P.C. board.

No

Yes

Rectify the indoor and

outdoor connecting wire.

Rectify the connecting wire.

Is there 220-240V AC between L–N

on the outdoor terminal block (TB1)?

No

No

Is the switch SW2-2 on the

indoor electronic control

P.C. board set to MUH type?

No

Change the switch SW-2-2

on the indoor electronic control

P.C. board to MUH type.

Yes

+

–

Is there 5V DC between J8 –J9

(MUH-07/09/12RV- , , )/

J205 –J101 (MUH-07/09/12RV- )

on the deicer P.C. board?

+

–

E1

E2

E3

E4

+

–

Is there 5V DC between J8 –J9

(MUH-07/09/12RV- , , )/

J205 –J101 (MUH-07/09/12RV- )

on the deicer P.C. board?

+

–

E1

E2

E3

E4

D

Check of outdoor unit

<MUH-07/09/12RV>

20

E

How to check mis-wiring and serial signal error

Outdoor unit does not work.

Start

Turn OFF the power supply(indoor/outdoor unit).

w 1 Set the switch(SW2-2) on indoor electronic control P.C. board to

MU or MUX type, when the outdoor unit is MU or MUX type.

If the setting is MUH or MXZ type, the unit does not work.

w 2 Short circuit of JPG and JPS on the indoor electronic control

P.C. board enables self -check to be displayed in 3 seconds.

Is the outdoor unit "MUH or MXZ" type?

Yes

•Turn ON the power supply(indoor/outdoor unit).

•Press once EMERGENCY OPERATION switch.

3 min. later, what self-check result is

displayed on OPERATION INDICATOR

lamp on indoor unit?

w 2

Mis-wiring is indicated.

No

Serial signal error is indicated.

(0.5-sec. ON, 2.5-sec. OFF)

Set the switch(SW2-2) on the indoor electronic

control P.C. board to MU or MUX type.

Does the unit operate?

Refer to the

"Instruction of

troubleshooting."

(0.5-sec. ON, 0.5-sec. OFF)

Make them sure.

Yes

Is this mis-wiring, poor contact,

or disconnection of wire?

No

1. Turn OFF the power supply(indoor/outdoor unit) and disconnect indoor and outdoor connecting wire on indoor side.

2. Short-circuit between indoor terminal block N and 3.

3. Turn ON the power supply(indoor unit) and press once EMERGENCY OPERATION switch.

Is there 20V DC between both ends of

R132 on indoor electronic control P.C.

board ?

( By tester, the stylus is between 0 ~ 20V. )

Yes

•Turn OFF the power supply(indoor unit).

•Connect ON indoor and outdoor connecting wire.

Turn ON the power supply(outdoor unit).

No

Replace the indoor electronic

control P.C. board.

No

Yes

w1

Ok

Is the outdoor unit "MUH" type?

Yes

Is there 220-240V AC between outdoor

terminal block L-N (TB1)?

Is there 5V DC between J8 - –J9 + (MUH-07/09/12RV- , , )/

J205 + –J101 - (MUH-07/09/12RV- ) on the deicer P.C. board?

Turn ON the power supply(indoor unit).

During EMERGENCY OPERATION,

is there 10V DC between both ends

of R601?

(By tester, the stylus is between 5 ~10V)

Replace the deicer P.C. board.

Yes

E4

Yes

Yes

No

No

E2

E1

E3

No

Refer to T Check of mis-wiring

or mis-piping.

Check the outdoor power supply,

power supply cord and

connection.

No

Replace the deicer P.C. board.

Make the wiring between CN730

on the deicer P.C. board and

outdoor terminal block correct.

21

Compressor and / or outdoor fan motor doesn’t stop.

V

Check of outdoor unit

Start

Turn OFF the power supply.

After 1 minute, turn ON

power supply again.

Does compressor or

outdoor fan motor stop?

Yes

Ok

No

<MU-07/09/12RV>

Is there 12V DC between

1–2 on the outdoor

terminal block (TB2)?

Yes

Replace the indoor

electoronic control

P.C. board.

Compressor and / or outdoor fan motor doesn’t stop.

V

Check of outdoor unit

Start

Turn OFF the power supply.

After 1 minute, turn ON

power supply again.

<MUH-07/09/12RV>

Is there 220-240V AC between COM on

No

the compressor contactor (52C) and N on

the outdoor terminal block (TB1)?

Rectify the connecting wire.

No

Yes

Replace the compressor

contactor(52C).

Does compressor stop?

Yes

Ok

Does outdoor fan motor stop?

Yes

Ok

Is there 220-240V AC between 3 on

No

the compressor contactor (52C) and N on

the outdoor terminal block (TB1)?

Yes

Replace the

deicer P.C. board.

No

Replace the

deicer P.C. board.

No

Rectify the connecting wire.

22

When OPERATION INDICATOR lamp flashes 6-time.

Thermistors in the outdoor unit are abnormal.

W

Check of outdoor thermistor

Start

Defrost thermistor (RT61)

Measure

Turn OFF the

power supply.

resistance

between CN 661

1 and 2.

<MUH-07/09/12RV>

Does the resistance

of thermistor have

the characteristics ?

No

Replace the

thermistor.

Re-connect CN661.

Turn ON the power

Yes

supply and press

the EMERGENCY

OPERATION

switch.

Replace the deicer P.C.

Does the unit operate

10 minutes or more?

❈ Defective contact of the connector is considered.

Unit operates COOL mode even if it is set to HEAT mode.

w First, measure the resistance of R.V. coil to confirm it is disconnected or is not short-circuit.

Check of R.V. coil

X

<MUH-07/09/12RV>

Turn ON the power supply and operate

the indoor unit in HEAT mode by pressing

the EMERGENCY OPERATION switch.

board.

No

Yes

Ok ❈

After 3 minutes, does the unit

operate in COOL mode?

Yes

Is there 220-240V AC

between CN7211 – 2 on the

deicer P.C. board?

Yes

Replace the R.V. coil.

No

Ok

No

Replace the

deicer P.C. board

23

After 3 minutes, does the unit

operate in HEAT mode?

Ok

No

Is there 220-240V AC

between CN7211 – 2 on the

deicer P.C. board?

Replace the

deicer P.C. board.

Yes

Yes

Yes

No

Replace the R.V. coil.

Turn ON the power supply and operate

the indoor unit in COOL mode by pressing

the EMERGENCY OPERATION switch.

Unit operates HEAT mode even if it is set to COOL mode.

w First, measure the resistance of R.V. coil to confirm it is disconnected or is not short-circuit.

Check of R.V. coil

X

<MUH-07/09/12RV>

24

TEST POINT DIAGRAM AND VOLTAGE

MSC-07RV MSC-09RV MSC-12RV -

E4

E4

E4

Indoor electronic control P.C. board

Power supply input

220-240V AC

}

CN201

Fuse(F11) 250V AC 3.15A

Fan motor power supply

}

Varistor (NR11)

CN111

Room temperature

thermistor (RT11)

CN112

Indoor coil

thermistor (RT12)

12V

DC

5V

DC

}

+

}

JPGND

J205

+

CN302

R132

CN121

Timer short mode point

(JPS, JPG)

Emergency operation switch

Vane motor power supply

(CN151)

SW2 (Refer to page 121 of

OB227 REVISED EDITION-B.)

1 sets the Auto restart function

ON/ OFF.

2 switches over MU and MUX

type/ MUH and MXZ type.

P.C.board

0~20V DC

Resistance(k")

25

MUH-07RV MUH-09RV MUH-12RV -

E4

E4

E4

Outdoor deicer P.C. board

CN711

Outdoor fan motor

220-240V AC

}

CN721

R.V. coil

220-240V AC

}

5V DC

J205

J101

Power supply input

220-240V AC

}

NR61

Varistor

F61

Fuse

2A/250V

R601

+

5~10VDC

}

--

Defrost interval

time short pin

(JPDS, JPSG)

(Refer to page 5.)

Jumper wire for

change in

}

CN661 1-2

Defrost thermistor RT61

+

--

}

defrost setting

(JRF,JRG)

(Refer to page

5.)

12V DC

J204

+

J101

--

26

8 PARTS LIST

MSC-07RV - (WH) MSC-07RV - (WH) MSC-07RV - (WH) MSC-07RV - (WH)

MSC-09RV - (WH) MSC-09RV - (WH) MSC-09RV - (WH) MSC-09RV - (WH)

MSC-12RV - (WH) MSC-12RV - (WH) MSC-12RV - (WH) MSC-12RV - (WH)

8-1. INDOOR UNIT STRUCTURAL PARTS

8-2. ACCESSORY AND

E4E3E2E1

E4E3E2E1

E4E3E2E1

REMOTE CONTROLLER

1 (W1)

11

2

3

10

9 (W2)

4

8 (W2)

5

6

(W1) These figures show about MSC-12RV.

(W2) Refer to OB227 REVISED EDITION-B 16. OPTIONAL PARTS. (See page 184 )

7 (W1)

12

MSC-07RV MSC-09RV MSC-12RV -

E2

E2

E2

13

MSC-07RV MSC-09RV MSC-12RV -

E4E3

E4E3

E4E3

8-1. INDOOR UNIT STRUCTURAL PARTS

Symbol

No.

Part No.

E02 409 234

1

E02 411 234

E02 409 976

2

E02 424 000

3

E02 409 067

4

E02 424 010

5

E02 408 142

6

E02 408 100

7

E02 410 100

8

9

E02 409 975

10

E02 408 970

11

Part Name

BOX(WH)

BOX(WH)

CORNER BOX (LEFT)

FRONT PANEL(WH)

SCREW CAP(WH)

GRILLE(WH)

CATCH

AIR FILTER

AIR FILTER

DEODORIZING FILTER

AIR CLEANING FILTER

CORNER BOX (RIGHT)

INSTALLATION PLATE

in Wiring

Diagram

MSC-07RV-

E1

(WH)

(WH)

1

1

1

2

1

3

2

1

1

1

1

8-2. ACCESSORY AND REMOTE CONTROLLER

E02 141 083

12

E02 527 083

E02 504 426

13

E02 583 426

REMOTE CONTROLLER HOLDER

REMOTE CONTROLLER HOLDER

REMOTE CONTROLLER

REMOTE CONTROLLER

11

Q'ty/unit

E3

E2

(WH)

1

1

1

1

1

1

2

2

1

1

3

3

2

2

1

1

1

1

1

1

1

1

E4

1

1

1

2

1

3

2

1

1

1

1

E1

1

1

1

2

1

3

2

1

1

1

1

E3

E2

(WH)(WH)(WH)(WH)

1

1

1

1

1

1

2

2

1

1

3

3

2

2

1

1

1

1

1

1

1

1

11

MSC-09RV-

1

1

1

1

1

1

1

1

E4

1

1

1

2

1

3

2

1

1

1

1

1

1

MSC-12RV-

E1

E2

(WH)(WH)(WH)

1

1

1

1

1

1

2

2

1

1

3

3

2

2

1

1

1

1

1

1

1

1

11

1

E3

(WH)

1

1

1

2

1

3

2

1

1

1

1

1

1

Remarks

E4

(WH)

1

1

1

Including No.4,5,6

2

2PCS/SET

1

3

3PCS/SET

2

1

MAC-1800DF

1

MAC-1300FT

1

1

1

1

27

Part No.

No.

Part Name

18

19

20

INDOOR HEAT EXCHANGER

INDOOR HEAT EXCHANGER

INDOOR HEAT EXCHANGER

UNION(GAS)

UNION(GAS)

UNION(LIQUID)

1

1

1

{9.52

{12.7

{6.35

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

E02 001 504

E02 408 702

E02 409 235

E02 409 040

E02 409 041

E02 127 382

E02 336 385

E02 408 034

E02 424 452

E02 504 452

E02 583 452

E02 691 452

E02 425 452

E02 505 452

E02 584 452

E02 692 452

E02 426 452

E02 506 452

E02 693 452

E02 408 303

E02 693 303

E02 408 308

E02 151 300

E02 665 300

E02 424 375

E02 691 375

E02 151 505

E02 665 505

E02 408 307

E02 408 302

E02 408 509

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

SLEEVE BEARING

DRAIN HOSE

NOZZLE (WH)

VANE UPPER (WH)

VANE LOWER (WH)

FUSE

VARISTOR

VANE MOTOR SUPPORT SET

ELECTRONIC CONTROL P.C.BOARD

ELECTRONIC CONTROL P.C.BOARD

ELECTRONIC CONTROL P.C.BOARD

ELECTRONIC CONTROL P.C.BOARD

ELECTRONIC CONTROL P.C.BOARD

ELECTRONIC CONTROL P.C.BOARD

ELECTRONIC CONTROL P.C.BOARD

ELECTRONIC CONTROL P.C.BOARD

ELECTRONIC CONTROL P.C.BOARD

ELECTRONIC CONTROL P.C.BOARD

ELECTRONIC CONTROL P.C.BOARD

VANE MOTOR

VANE MOTOR

ROOM TEMPERATURE THERMISTOR

INDOOR FAN MOTOR

INDOOR FAN MOTOR

TERMINAL BLOCK

TERMINAL BLOCK

FAN MOTOR RUBBER MOUNT

FAN MOTOR RUBBER MOUNT

INDOOR COIL THERMISTOR

LINE FLOW FAN

BEARING MOUNT

3.15A

AUTO RESTART

AUTO RESTART

AUTO RESTART

AUTO RESTART

AUTO RESTART

AUTO RESTART

AUTO RESTART

AUTO RESTART

AUTO RESTART

AUTO RESTART

AUTO RESTART

RC4V19RC4V19-

2PCS/SET

2PCS/SET

F11

NR11

MV

MV

RT11

MF

MF

TB

TB

RT12

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

Symbol

in Wiring

Diagram

Q'ty/unit

Remarks

MSC-07RV

MSC-09RV MSC-12RV

E1

E2

E3

E1

E2

E3

E1

E2

E3

(WH)

(WH)

(WH)

(WH)(WH)(WH)

(WH)(WH)(WH)(WH)

(WH)

(WH)

E4

E4

E4

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

E02 408 620

E02 410 620

E02 515 620

E02 151 666

E02 155 666

E02 151 667

MSC-07RV - (WH) MSC-07RV - (WH) MSC-07RV - (WH) MSC-07RV - (WH)

MSC-09RV - (WH) MSC-09RV - (WH) MSC-09RV - (WH) MSC-09RV - (WH)

MSC-12RV - (WH) MSC-12RV - (WH) MSC-12RV - (WH) MSC-12RV - (WH)

8-3. INDOOR UNIT ELECTRICAL PARTS

AND FUNCTIONAL PARTS

SLEEVE

BEARING

1

3

4

17

16

15

2

14

ROOM TEMPERATURE

THERMISTOR

11

12

10

13

8-4. INDOOR UNIT HEAT EXCHANGER

18 (W)

19

20

E4E3E2E1

E4E3E2E1

E4E3E2E1

5

FUSE

6

VARISTOR

8

7

9

(W)These figures show about MSC-12RV.

8-3. INDOOR UNIT ELECTRICAL PARTS AND FUNCTIONAL PARTS

8-4. INDOOR UNIT HEAT EXCHANGER

28

MU-07RV - MU-07RV - MU-07RV - MU-07RV MU-09RV - MU-09RV - MU-09RV - MU-09RV MU-12RV - MU-12RV - MU-12RV - MU-12RV -

8-5. OUTDOOR UNIT STRUCTURAL PARTS

12

1

2

3

11

E4E3E2E1

E4E3E2E1

E4E3E2E1

10

9

Part number that is circled is not shown in the illustration.

Symbol

No.

E02 336 630

1

E02 336 232

2

E02 336 521

3

E02 437 900

E02 589 900

E02 438 900

4

E02 408 900

E02 141 900

E02 594 900

E02 336 506

5

E02 075 506

E02 339 290

6

E02 340 290

E02 339 661

7

E02 340 661

E02 339 662

8

E02 336 245

9

E02 339 233

10

E02 440 233

E02 336 515

11

E02 336 297

12

E02 339 936

13

E02 412 936

Part No.

Part name

OUTDOOR HEAT EXCHANGER

CABINET

GRILLE(OUT)

COMPRESSOR

COMPRESSOR

COMPRESSOR

COMPRESSOR

COMPRESSOR

COMPRESSOR

COMPRESSOR RUBBER SET

COMPRESSOR RUBBER SET

BASE

BASE

STOP VALVE(GAS)

STOP VALVE(GAS)

STOP VALVE(LIQUID)

SERVICE PANEL

BACK PANEL

BACK PANEL

MOTOR SUPPORT

TOP PANEL

CAPILLARY TUBE

CAPILLARY TUBE

in Wiring

Diagram

MC

MC

MC

MC

MC

MC

4

6 75

8

Q'ty/unit

MU-12RV-MU-07RV- MU-09RV-

E1

E2

E3

E4

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

E2

E3

E4

1

1

1

1

1

1

1

1

1

1

1

1

E1

1

1

1

1

E2

E3

1

1

1

1

1

1

1

E1

1

1

1

1

1

3

3

3

3

3

3

3

3

3

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

3

3

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Remarks

E4

1

1

1

RH-135VGCT

RH-130VGCT

RH-145VGCT

RH-140VGCT

RH-231VHAT

RH-220VHAT

1

3RUBBERS/SET

3RUBBERS/SET

3

1

{9.52

{12.7

1

{6.35

1

1

1

1

1

{3.0x{1.4x600

{3.0x{1.6x600

1

29

1

2

3

4

5

6

7

8

9

E02 336 501

E02 665 501

E02 437 301

E02 676 301

E02 439 301

E02 677 301

E02 095 350

E02 661 351

E02 664 351

E02 085 353

E02 694 353

E02 079 353

E02 696 353

E02 437 374

E02 466 375

E02 438 374

E02 001 340

E02 466 340

E02 095 382

E02 128 383

PROPELLER FAN

PROPELLER FAN

OUTDOOR FAN MOTOR

OUTDOOR FAN MOTOR

OUTDOOR FAN MOTOR

OUTDOOR FAN MOTOR

OUTDOOR FAN CAPACITOR

OUTDOOR FAN CAPACITOR

OUTDOOR FAN CAPACITOR

COMPRESSOR CAPACITOR

COMPRESSOR CAPACITOR

COMPRESSOR CAPACITOR

COMPRESSOR CAPACITOR

TERMINAL BLOCK

TERMINAL BLOCK

TERMINAL BLOCK

COMPRESSOR CONTACTOR

COMPRESSOR CONTACTOR

FUSE

SURGE ABSORBER

RA6V23RA6V23RA6V33RA6V33-

1.5+ /440V AC

1.5+ /440V AC

2.0+ /440V AC

25+ /440V AC

25+ /440V AC

30+ /440V AC

30+ /440V AC

3P

3P

2P

250V/ 2A

MF

MF

MF

MF

C2

C2

C2

C1

C1

C1

C1

TB1

TB1

TB2

52C

52C

F

DSAR

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

No.

Part No.

Part name

Remarks

Symbol

in Wiring

Diagram

Q'ty/unit

MU-12RV-MU-07RV- MU-09RV-

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

E1

E2

E3

E1

E2

E3

E1

E2

E3

E4

E4

E4

E02 408 426

10

REMOTE CONTROLLER

11

1

MU-07RV - MU-07RV - MU-07RV - MU-07RV MU-09RV - MU-09RV - MU-09RV - MU-09RV MU-12RV - MU-12RV - MU-12RV - MU-12RV 8-6. OUTDOOR UNIT

8-7. REMOTE CONTROLLER

ELECTRICAL PARTS AND

FUNCTIONAL PARTS

MU-07RV MU-09RV MU-12RV -

E3E2E1

E3E2E1

E3E2E1

2

6

5

E4E3E2E1

E4E3E2E1

E4E3E2E1

10

1

MU-07RV MU-09RV MU-12RV -

3

E4

E4

E4

4

8-6. OUTDOOR UNIT ELECTRICAL PARTS AND FUNCTIONAL PARTS

Part numbers that are circled are not shown in the illustration.

8-7. REMOTE CONTROLLER

30

No.

Part No.

Remarks

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

E02 440 630

E02 442 630

E02 336 232

E02 336 521

E02 164 900

E02 589 900

E02 128 900

E02 593 900

E02 141 900

E02 594 900

E02 336 506

E02 075 506

E02 339 290

E02 340 290

E02 339 661

E02 340 661

E02 139 662

E02 444 961

E02 336 245

E02 440 233

E02 336 515

E02 442 515

E02 336 297

E02 159 936

E02 156 936

E02 339 936

E02 441 936

E02 412 936

E02 134 937

E02 134 936

E02 442 936

E02 154 642

OUTDOOR HEAT EXCHANGER

OUTDOOR HEAT EXCHANGER

CABINET

GRILLE(OUT)

COMPRESSOR

COMPRESSOR

COMPRESSOR

COMPRESSOR

COMPRESSOR

COMPRESSOR

COMPRESSOR RUBBER SET

COMPRESSOR RUBBER SET

BASE

BASE

STOP VALVE(GAS)

STOP VALVE(GAS)

STOP VALVE(LIQUID)

4-WAY VALVE

SERVICE PANEL

BACK PANEL

MOTOR SUPPORT

MOTOR SUPPORT

TOP PANEL

CAPILLARY TUBE

CAPILLARY TUBE

CAPILLARY TUBE

CAPILLARY TUBE

CAPILLARY TUBE

CAPILLARY TUBE

CAPILLARY TUBE

CAPILLARY TUBE

CHECK VALVE

RH-135VGHT

RH-130VGCT

RH-174VGHT

RH-165VGCT

RH-231VHAT

RH-220VHAT

3RUBBERS/SET

3RUBBERS/SET

{9.52

{12.7

{6.35

{3.0x{1.4x800

{3.0x{1.4x500

{3.0x{1.4x600

{3.0x{1.4x550

{3.0x{1.6x600

{3.0x{1.6x400

{3.0x{1.6x700

{3.0x{1.8x300

1

1

1

1

3

1

1

1

1

1

1

1

1

2

1

1

1

MC

MC

MC

MC

MC

MC

1

1

1

1

3

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

3

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

3

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

3

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

3

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

3

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

3

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

3

1

1

1

1

1

1

1

1

2

1

1

1

Symbol

in Wiring

Diagram

Part name

Remarks

Q'ty/unit

MUH-12RV-MUH-07RV- MUH-09RV-

1

1

1

1

3

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

3

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

3

1

1

1

1

1

1

1

1

2

1

1

1

E1

E2

E3

E1

E2

E3

E1

E2

E3

E4

E4

E4

MUH-07RV - MUH-07RV - MUH-07RV - MUH-07RV MUH-09RV - MUH-09RV - MUH-09RV - MUH-09RV MUH-12RV - MUH-12RV - MUH-12RV - MUH-12RV -

8-8. OUTDOOR UNIT STRUCTURAL PARTS

13

1

2

3

Part numbers that are circled are not shown in the illustration.

12

4 6 75

E4E3E2E1

E4E3E2E1

E4E3E2E1

11

10

8

9

31

1

2

3

4

5

6

7

8

9

10

11

E02 336 501

E02 665 501

E02 440 301

E02 671 301

E02 442 301

E02 672 301

E02 085 353

E02 694 353

E02 079 353

E02 696 353

E02 440 451

E02 679 451

E02 699 451

E02 128 383

E02 437 374

E02 466 375

E02 440 374

E02 697 374

E02 289 310

E02 697 310

E02 440 310

E02 699 310

E02 440 490

E02 095 382

E02 085 385

PROPELLER FAN

PROPELLER FAN

OUTDOOR FAN MOTOR

OUTDOOR FAN MOTOR

OUTDOOR FAN MOTOR

OUTDOOR FAN MOTOR

COMPRESSOR CAPACITOR

COMPRESSOR CAPACITOR

COMPRESSOR CAPACITOR

COMPRESSOR CAPACITOR

DEICER P.C. BOARD

DEICER P.C. BOARD

DEICER P.C. BOARD

SURGE ABSORBER

TERMINAL BLOCK

TERMINAL BLOCK

TERMINAL BLOCK

TERMINAL BLOCK

DEFROST THERMISTOR

DEFROST THERMISTOR

DEFROST THERMISTOR

DEFROST THERMISTOR

R. V. COIL

FUSE

VARISTOR

RA6V23RA6V23RA6V33RA6V3325+ /440V AC

25+ /440V AC

30+ /440V AC

30+ /440V AC

3P

3P

2P

2P

250V 2A

MF

MF

MF

MF

C1

C1

C1

C1

DSAR

TB1

TB1

TB2

TB2

RT61

RT61

RT61

RT61

21S4

F61

NR61

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

E02 430 426

E02 440 704

E02 444 704

E02 440 705

12

13

14

REMOTE CONTROLLER

DRAIN SOCKET

DRAIN SOCKET

DRAIN CAP

1

1

2

1

1

2

1

1

2

1

2

1

2

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

2

121

2

1

2

1

2

No.

Part No.

Remarks

Symbol

in Wiring

Diagram

Part name

2PCS/SET

Q'ty/unit

MUH-12RV-MUH-07RV- MUH-09RV-

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

E1

E2

E3

E1

E2

E3

E1

E2

E3

E4

E4

E4

MUH-07RV - MUH-07RV - MUH-07RV - MUH-07RV MUH-09RV - MUH-09RV - MUH-09RV - MUH-09RV MUH-12RV - MUH-12RV - MUH-12RV - MUH-12RV -

8-9. OUTDOOR UNIT

ELECTRICAL PARTS AND

8-10. ACCESSORY AND

REMOTE CONTROLLER

FUNCTIONAL PARTS

MUH-07RV MUH-09RV MUH-12RV -

E3E2E1

E3E2E1

E3E2E1

8

76

2

E4E3E2E1

E4E3E2E1

E4E3E2E1

12

13

1

MUH-07RV MUH-09RV MUH-12RV -

E4

E4

E4

3

4

5

8-9. OUTDOOR UNIT ELECTRICAL PARTS AND FUNCTIONAL PARTS

Part numbers that are circled are not shown in the illustration.

8-10. ACCESSORY AND REMOTE CONTROLLER

14

32

MUX-10RV - MUX-10RV -

No.

Part No. Part Name Remarks

MUX-10RV-

Symbol

in Wiring

Diagram

Q'ty / unit

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

OUTDOOR FAN CAPACITOR

COMPRESSOR CAPACITOR

OUTDOOR HEAT EXCHANGER

TOP PANEL

CABINET

OUTER NOZZLE

SERVICE PANEL

SEPARATOR

COMPRESSOR

BASE ASSEMBLY

STOP VALVE (GAS)

STOP VALVE (LIQUID)

CAPILLARY TUBE

([3.0O[1.6O1200)

SOLENOID VALVE

CAPILLARY TUBE

([3.0O[1.4O1900)

SOLENOID VALVE

BYPASS VALVE SOLENOID COIL

SOLENOID COIL (B)

SOLENOID COIL (A)

MOTOR SUPPORT

PROPELLER FAN

TERMINAL BLOCK

TERMINAL BLOCK

COMPRESSOR CONTACTOR

OUTDOOR FAN MOTOR

OVERCURRENT RELAY

RELAY

TERMINAL BLOCK

FUSE

1

1

1

1

1

1

1

1

1

1

2

2

1

1

1

2

1

1

1

1

1

1

2

2

1

1

2

1

2

1

1

1

1

1

1

1

1

1

1

2

2

1

1

1

2

1

1

1

1

1

1

2

2

1

1

2

1

2

1.5+440V AC

17+440V AC

KH-134VLL

[9.52

[6.35

[3.0O[1.6O1000

L N

RA6V22-

G4F11123T

2,1,2,1

2A 250V

C2

C1

MC

21R

21R2

21R1

TB