Page 1

HOW TO OBTAIN FTO DIAGNOSTIC INFORMATION

There are many ways to obtain the diagnostic information from your fto, you will find in this

guide the specialist equipment that can be used .

You will also find in this guide the most common code errors and a way to read them without

the use of one of the specialist diagnostic tools.

The FTO's engine ECU monitors everything from sensors to injectors, solenoid valves to

ignition. If it notices a problem, it records this in the form of a diagnostic code. A Mitsubishi

dealer equipped with the right MUT-II diagnostic setup is capable of accessing these codes.

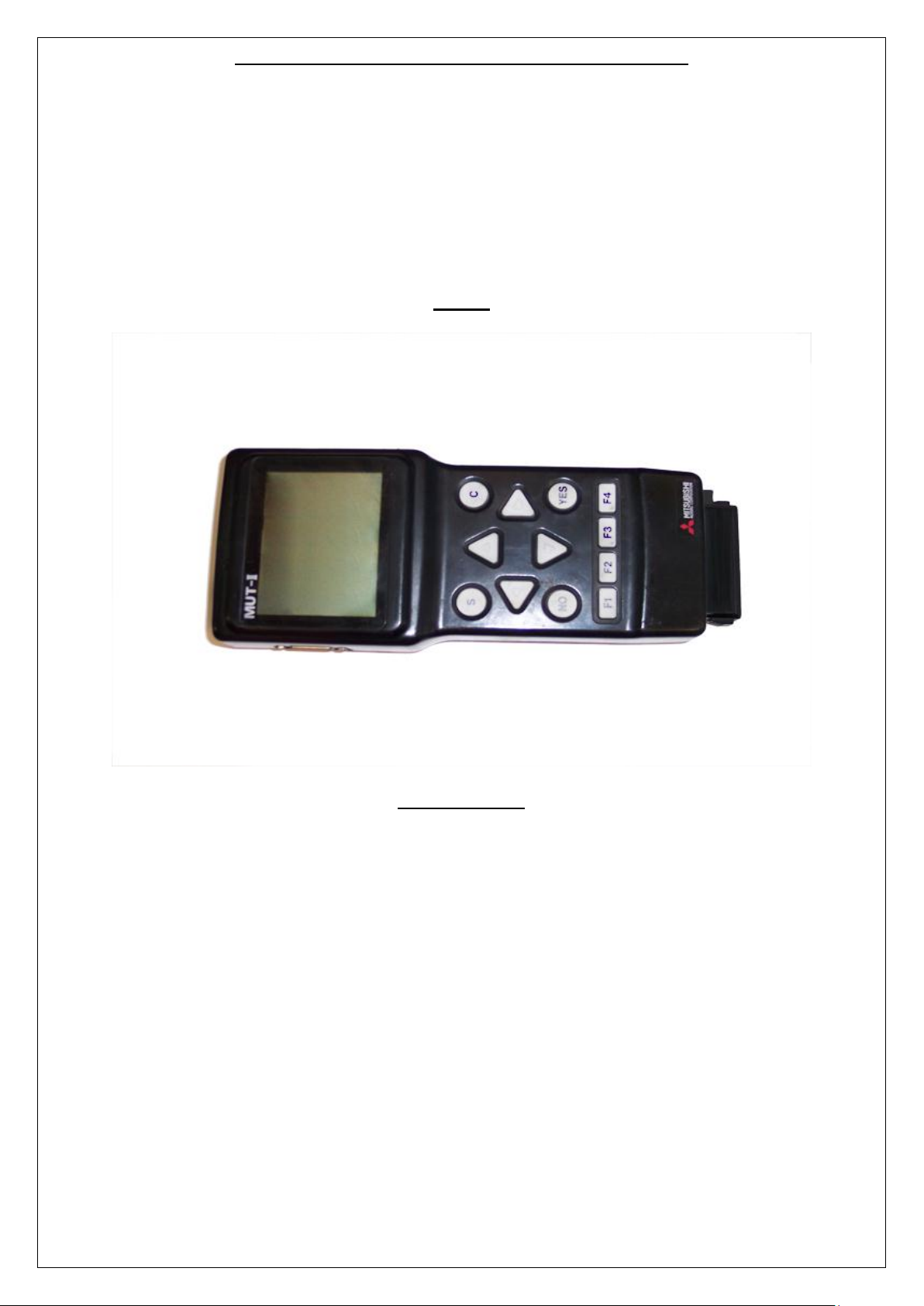

MUT-II

DESCRIPTION

The MUTII Tester is offered to the aftermarket in the same specification that is currently

supplied to MITSUBISHI franchised dealers. The MUTII can complete coverage all of

MITSUBISHI car systems past and present coupled with the knowledge that the

developments will continue well into the future .

Test function:

Read faulty code

Clear faulty code

Data stream

Activate state

Programming and coding control unit

Component test

Data stream

Page 2

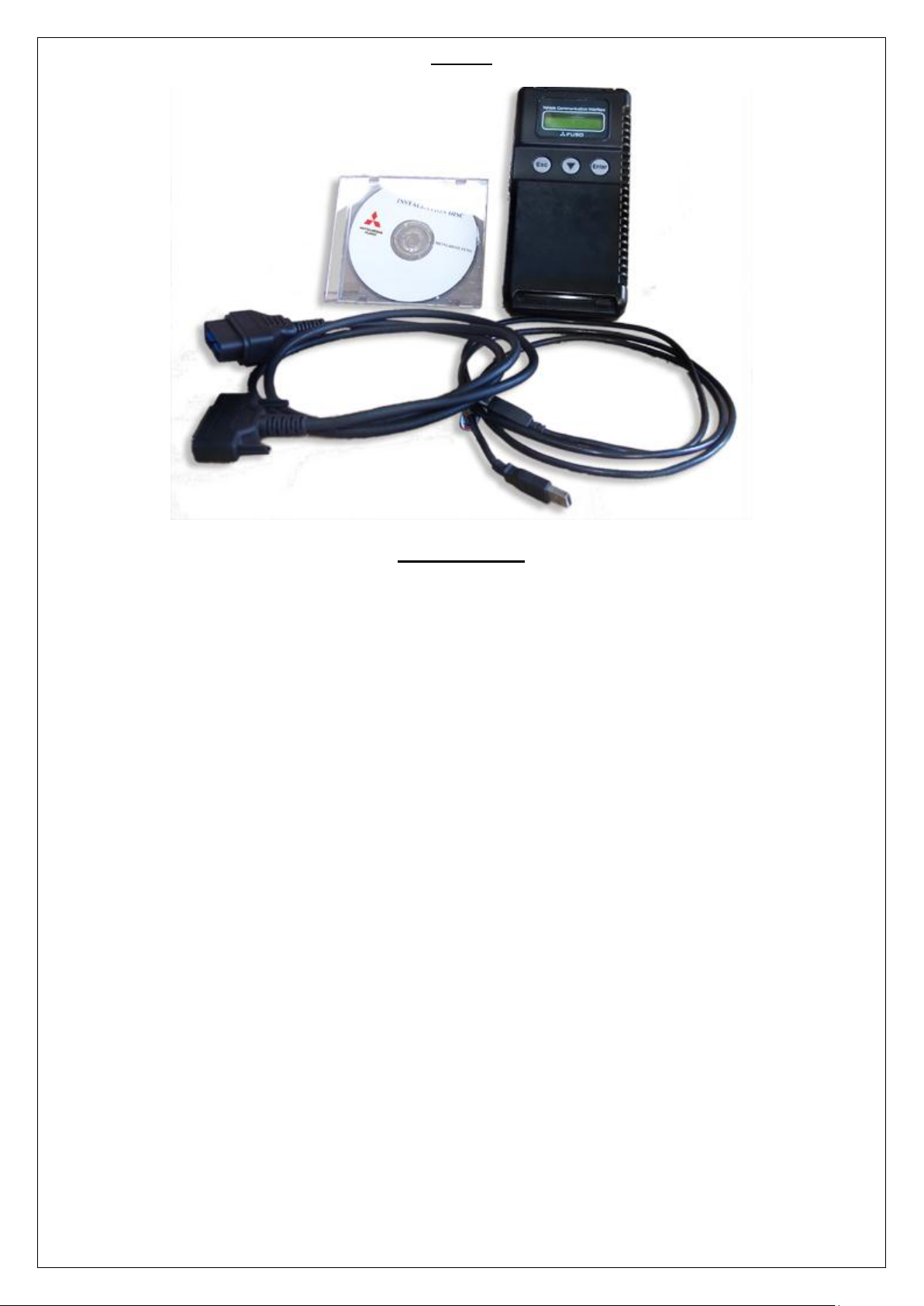

MUT III

DESCRIPTION

In accordance with releasing new products that introduce can communications systems,

mmc has developed the mut-iii as a next generation diagnosis tester for servicing these new

and future vehicles.

A personal computer (pc) is connected to the mut iii unit and used as a system¡¦s control

terminal, and communicates with a vehicle ecu through the v.c.i.. In addition to being able to

handle all diagnosis functions covered by the conventional mut-ii tester, the mut-iii system

can display data as easy-to-understand diagrams and graphs on a large screen of the pc.

Unlike the mut-ii, the mut-iii can retain data on all vehicles, from old to new models,

classified according to destination in the pc¡¦s hard disk. This eliminates the awkward but

essential job with the mut-ii, of switching the data list (communications protocol data and

diagnosis item list database) by replacing the rom pack with another according to the vehicle

model and year model.

New functions that make use of the advantages of the pc are also being developed. For

example, the workshop manual viewer is a useful function for mechanics as they no longer

have to carry around a thick manual and search for relevant pages while working on a

vehicle. The workshop manual viewer is currently available for certain vehicle models, and

allows users to retrieve the pages containing the failure code for a particular problem at the

push of a button.

Page 3

EVO SCAN

DESCRIPTION

To use evo scan You will require a potable pc, fto obd lead and evo scan software

Display and record engine data onto your PC at the highest speeds ever seen. High Speed

Data logging - 200 data items per second!

If your car has faulty sensors, and is displaying a Check Engine Light (CEL) on your

dashboard, you can use Evo Scan to read and identify Diagnostic Trouble Codes

(DTCs) You will be able to Read and Clear DTCs for heaps of protocols such as EvoX,

SST, ABS, AYC, ACD, SSMII, OBDII, EVOX CAN, OBDII

CAN.(SAE/ISO/KWP2000)

Record and Display air/fuel ratios and engine timing values on the colourful Map Tracer

Graph with pin point precision.

You can easily customise the gauges and layout to suit your own style and preferences.

Make your own awesome gauges using the easy built-in gauge designer.

Chart your vehicle data in real time or slice and dice the logs afterwards.

Page 4

ALTERNATIVE METHOD OF CODE READING

The first step is to remove the panel underneath

the steering wheel. This simply requires the

removal of four screws. Note that the bonnet

release cable and lever will still be connected to

this panel - just drop the panel down and keep it

out of the way.

Now if you crawl under there, you will notice an

interface socket on the left hand side, about level

with the bottom left screw you removed a moment

ago. You can click on the image (right) to

enlarge...

This is the location of the diagnosis connector and

where a MUT-II, MUT-III or EVO SCAN unit can be

connected.

The picture is oriented to the rear of the

vehicle. the strange circular thing in the centre

of the frame is simply the alarm's glass

breakage sensor.

As noted before, we must earth No. 1

terminal on this connector. The pin in

question is the bottom right one in the picture

- highlighted.

All we have to do is ground out this pin by

using a single cable. With the engine ignition

switch on, the computer will flash the engine

warning light to indicate any stored diagnostic

code(s).

At the back of the diagnostic plug, it was clear

to see that the relevant pin was connected to

an easily accessible lead (grey with red stripe)

on this 1995 GPX, but can be a different

colour on some other FTOs.

a standard patch connector was used to

attach an extra wire to the relevant lead (see

image to right, highlighted).

Now it is simply a matter of grounding out the

permanent diagnostic lead stowed under the

dash.

DISCLAIMER: DO NOT ATTEMPT ANY WIRING MODIFICATIONS YOURSELF WITHOUT (A)

CHECKING THE CONNECTIONS, WIRE COLOURS, ETC. ON YOUR OWN VEHICLE, AND (B)

KNOWING WHAT YOU ARE DOING. I TAKE NO RESPONSIBILITY FOR ANY COOKED WIRING,

ECUS OR ANYTHING ELSE YOU MAY FEEL LIKE PLAYING WITH. ANY WORK DONE ON YOUR

OWN VEHICLE IS DONE SO AT YOUR OWN RISK...

STEP 1

Earth No. 1 terminal (diagnostic control terminal) of the diagnostic connector.

STEP 2

Turn on the ignition switch.

Page 5

WHAT DOES THE ECU DIAGNOSTIC CODE LOOK LIKE WHEN IT IS

DISPLAYED?

The light you need to look at on the speedo cluster is the engine management warning light

shown below:

The light will flash in a sequence very similar to Morse code.

This diagnostic code 31would be shown by:;

blinking the engine warning light for 3 long flashes and 1 short flash.

If no codes are currently stored, it will simply flash continually, once per second.

I assume that if more than one code is stored, it will display each one in a repeating

sequence, eg. 31, 52, 64, 31, 52, 64...

To clear the codes, simply disconnect the car battery for 20 seconds or so.

Page 6

GEARBOX ECU CODE READING

NO

ENGINE CODE

NO

GEARBOX CODE

11

Oxygen Sensor

15

Oil temperature sensor

12

Air Flow Sensor

22

Input shaft speed sensor

13

Intake air temperature sensor

23

Output shaft speed sensor

14

Throttle position sensor

31

Low and reverse solenoid valve

15

ISC Motor Position Sensor

32

Under drive and reverse solenoid valve

21

Engine coolant temperature sensor

33

Second solenoid valve

22

Crank angle sensor

34

Overdrive solenoid valve

23

Camshaft position sensor

35

Reduction solenoid valve

24

Vehicle speed sensor

36

Damper clutch control solenoid valve

25

BARO Sensor

52

Damper clutch control solenoid valve

31

Detonation sensor

32

Vacuum sensor

36

Ignition Timing Adjustment Signal

39

Oxygen Sensor

41

Injector system

42

Fuel Pump

43

EGR

44

Ignition coil and power transistor unit

(Cylinder 1 & 4)

52

Ignition coil and power transistor unit

(Cylinder 2 & 5)

53

Ignition coil and power transistor unit

(Cylinder 3 & 6)

55

Idle Air Control Valve/Servo Valve

Position Sensor

61

Communications wire with A/T-ECU

62

Intake air control valve position sensor

64

Alternator FR terminal

71

Vacuum control solenoid valve (TCL)

72

Ventilation control solenoid valve (TCL)

For the tiptronic gear box codes watch the flashes of the 'N' on the dash board. The

first part of the code is represented by long flashes while the second part is

represented by short flashes. For example, if we take error code 23 (Output shaft

speed sensor), you would see 2 long flashes followed by 3 short ones.

COMMON ERROR CODES

Loading...

Loading...