Mitsubishi Electronics MSZ-FH06NA, MSZ-FH09NA, MSZ-FH12NA, MSZ-FH15NA, MSZ-FH18NA User Manual

...Page 1

INDOOR UNIT

INDOOR UNIT

SERVICE MANUAL

Models

MSZ-FH06NA

MSZ-FH09NA

Revision D:

• MSZ-FH06NA and MSZ-FH18NA2 have been

added.

Please void OBH683 REVISED EDITION-C.

No. OBH683

REVISED EDITION-D

MSZ-FH12NA

MSZ-FH15NA

MSZ-FH18NA

MSZ-FH18NA2

Outdoor unit service manual

MUZ-FH·NA(H) Series (OBH684)

MXZ-C•NA,NAHZ Series (OCH573)

CONTENTS

1. TECHNICAL CHANGES ··································· 3

2. PART NAMES AND FUNCTIONS ····················· 4

3. SPECIFICATION ················································ 5

4. OUTLINES AND DIMENSIONS ························ 6

5. WIRING DIAGRAM ············································ 7

6. REFRIGERANT SYSTEM DIAGRAM ··············· 8

7. SERVICE FUNCTIONS ····································· 9

8. MICROPROCESSOR CONTROL ····················11

9. TROUBLESHOOTING ····································· 20

10. DISASSEMBLY INSTRUCTIONS ···················· 32

PARTS CATALOG (OBB683)

NOTE:

RoHS compliant products have <G> mark on the spec name plate.

Page 2

Use the specifi ed refrigerant only

OBH683D

Never use any refrigerant other than that specified.

Doing so may cause a burst, an explosion, or fire when the unit is being used, serviced, or disposed of.

Correct refrigerant is specified in the manuals and on the spec labels provided with our products.

We will not be held responsible for mechanical failure, system malfunction, unit breakdown or accidents caused by

failure to follow the instructions.

Revision A:

• 3. SPECIFICATION has been modified.

(The value of the disconnect switch for MSZ-FH15NA has been modified.)

• 8. MICROPROCESSOR CONTROL has been modified.

• 9. TROUBLESHOOTING has been modified.

Revision B:

• 4. OUTLINE AND DIMENSIONS has been modified.

(The length of the connect pipes has been modified.)

• Some descriptions have been modified.

Revision C:

• MSZ-FH18NA has been added.

Revision D:

• MSZ-FH06NA and MSZ-FH18NA2 have been added.

2

Page 3

1

OBH683D

MSZ-FH09NA

MSZ-FH12NA

MSZ-FH15NA

1. New model

MSZ-FH18NA

1. New model

MSZ-FH06NA

MSZ-FH18NA2

1. New model

TECHNICAL CHANGES

3

Page 4

2

OBH683D

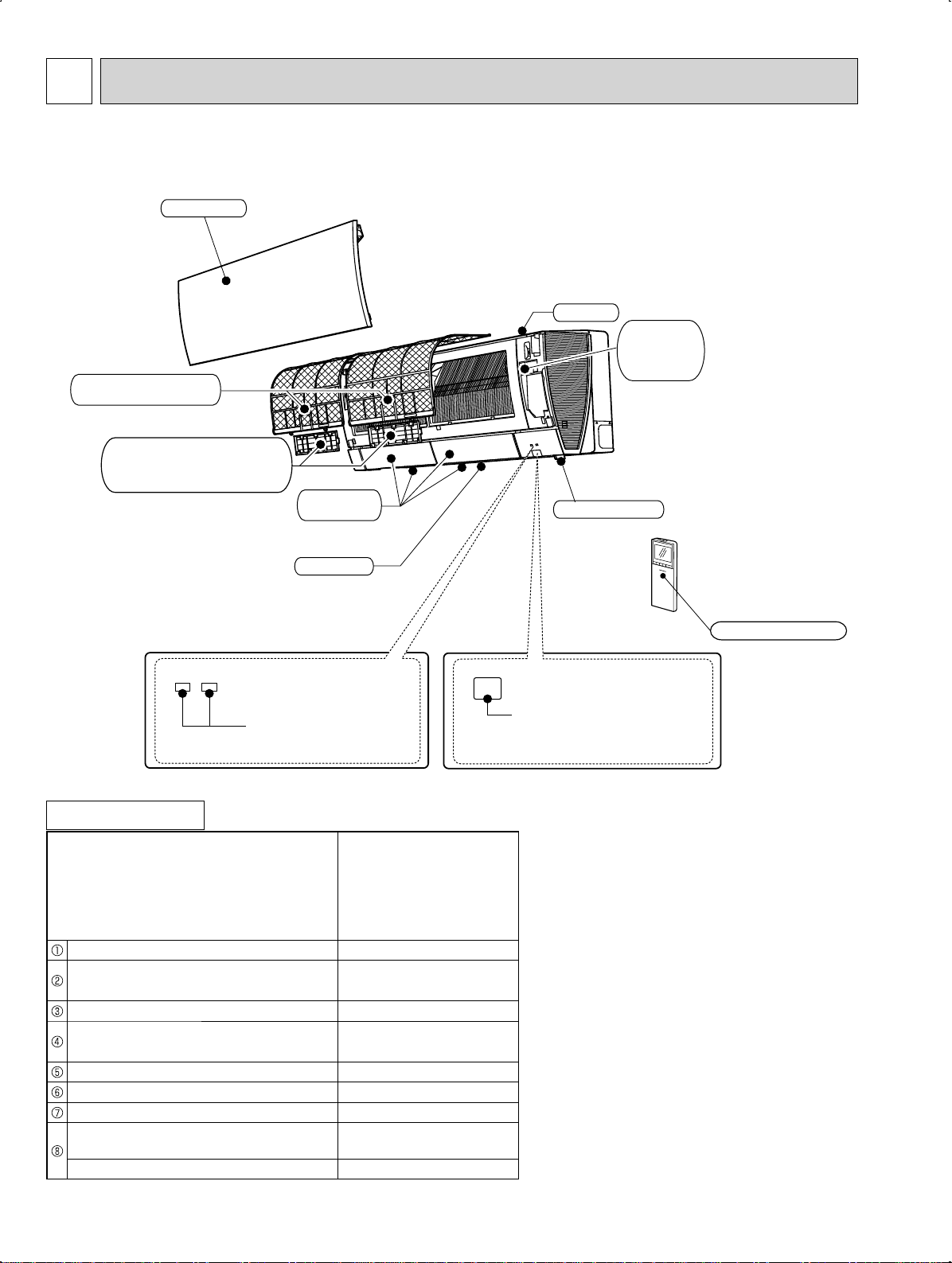

PART NAMES AND FUNCTIONS

MSZ-FH06NA MSZ-FH09NA MSZ-FH12NA MSZ-FH15NA MSZ-FH18NA MSZ-FH18NA2

Front panel

Air inlet

Emergency

operation

switch

Air filter

(Nano platinum filter)

Air cleaning filter

(Electrostatic anti-allergy

enzyme filter and deodorizing fiter)

Horizontal

vane

i-see SENSOR

Air outlet

Operation indicator lamp

ACCESSORIES

MSZ-FH06NA

MSZ-FH09NA

Model

Installation plate 1

Attachment screws for the installation

plate 4 × 25 mm

Remote controller holder 1

Screw for the remote controller holder

3.5 × 16 mm (Black)

Battery (AAA) for the remote controller 2

Wireless remote controller 1

Felt tape (For left or left-rear piping) 1

Air cleaning fi lter

(Electrostatic anti-allergy enzyme fi lter)

Air cleaning fi lter (Deodorizing fi lter) 1

MSZ-FH12NA

MSZ-FH15NA

MSZ-FH18NA

MSZ-FH18NA2

Remote controller

Remote control receiving

section

5

2

1

4

Page 5

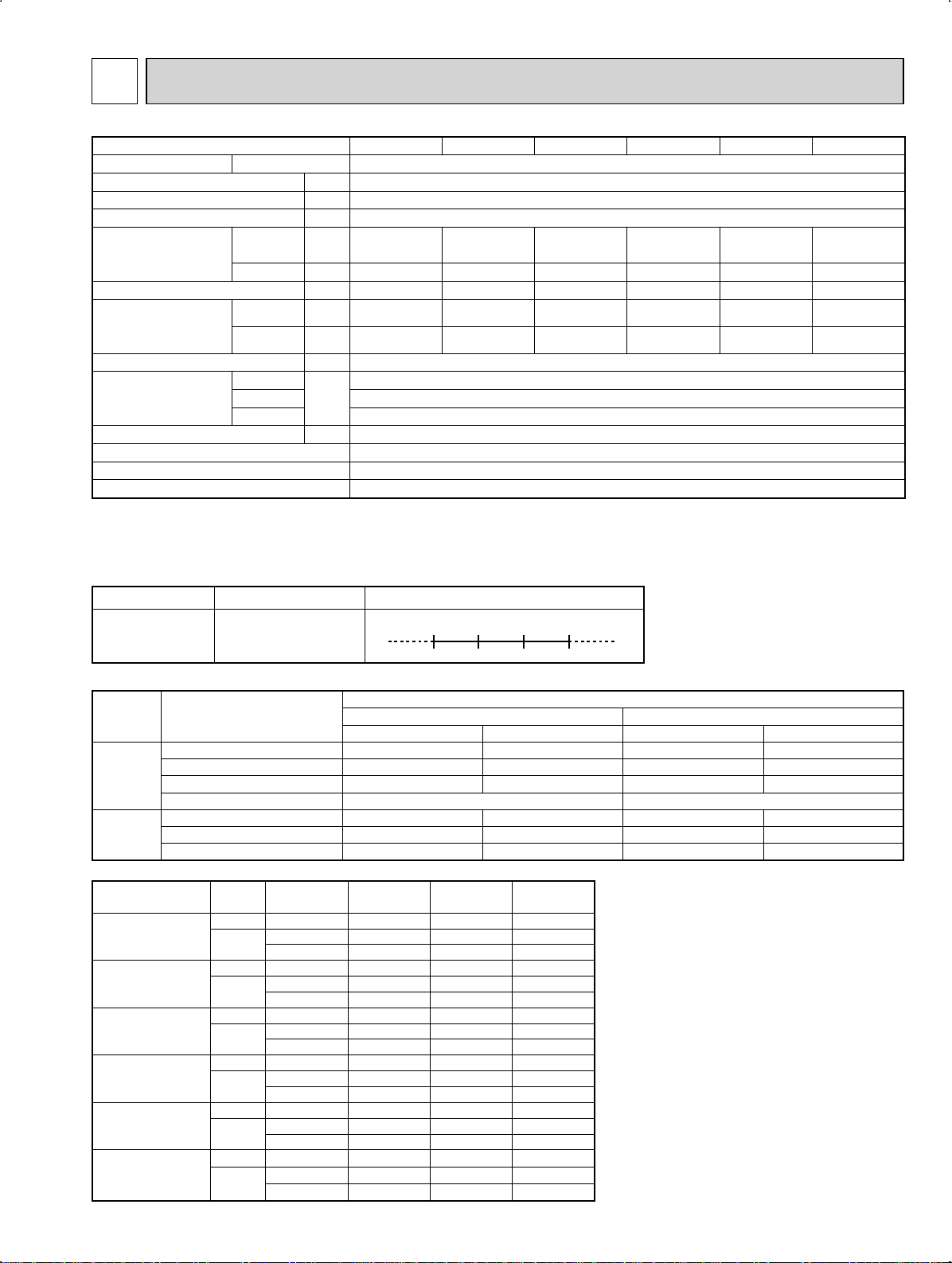

3

OBH683D

SPECIFICATION

Indoor unit model

Power supply V, phase, Hz 208/230 , 1 , 60

Disconnect switch A 15

Min. circuit ampacity A 1.0

Fan motor F.L.A 0.67

Airfl ow

Super high - High Med. - Low - Quiet

Moisture removal pt./h 0.2 0.6 1.9 4.0 5.1 4.8

Sound level

Super high - High Med. - Low - Quiet

Cond. drain connection O.D. in. 5/8

Dimensions

Weight Ib. 29

External fi nish Munsell 1.0Y 9.2/0.2

Remote controller Wireless type

Control voltage (by built-in transformer) 12 - 24 VDC

NOTE: Test conditions are based on AHRI 210/240.

COOL Dry

(Wet)

HEAT Dry CFM

Cooling dB(A)

Heating dB(A)

W

D 9-3/16

H 12 (+ 11/16)

CFM

in.

MSZ-FH06NA MSZ-FH09NA MSZ-FH12NA MSZ-FH15NA MSZ-FH18NA MSZ-FH18NA2

381- 304 - 221 - 167 - 137

(328 - 261 - 190 - 143 - 117)

437 - 325 - 225 - 167 - 140 437 - 325 - 225 - 167 - 140 454 - 325 - 225 - 167 - 140 497 - 394 - 317 - 254 - 201 514 - 394 - 317 - 254 - 201 514 - 394 - 317 - 254 - 201

40 - 36 - 29 - 23 - 20 40 - 36 - 29 - 23 - 20 41 - 36 - 29 - 24 - 21 44 - 39 - 35 - 31 - 27 44 - 39 - 35 - 31 - 27 47 - 39 - 35 - 31 - 27

42 - 36 - 29 - 24 - 20 42 - 36 - 29 - 24 - 20 42 - 36 - 29 - 24 - 21 46 - 39 - 34 - 29 - 25 46 - 39 - 34 - 29 - 25 46 - 39 - 34 - 29 - 25

381- 304 - 221 - 167 - 137

(328 - 261 - 190 - 143 - 117)

398 - 304 - 221 - 167 - 137

(342 - 261 - 190 - 143 - 117)

411 - 355 - 304 - 262 - 225

(354 - 305 - 261 - 225 - 194)

36-7/16

437 - 355 - 304 - 262 - 225

(376 - 305 - 261 - 225 - 194)

459 - 355 - 304 - 262 - 225

(395 - 305 - 261 - 225 - 194)

3-1. OPERATING RANGE

(1) POWER SUPPLY

Rated voltage Guaranteed voltage (V)

Indoor unit

208/230 V

1 phase

60 Hz

Min. 187

208 230 Max. 253

(2) OPERATION

Intake air temperature (°F)

Mode Condition

Standard temperature 80 67 95 —

Cooling

Heating

Maximum temperature 90 73 115 —

Minimum temperature 67 57 14 —

Maximum humidity 78% —

Standard temperature 70 60 47 43

Maximum temperature 80 67 75 65

Minimum temperature 70 60 -13 -14

DB WB DB WB

Indoor Outdoor

3-2. OUTLET AIR SPEED AND COVERAGE

Model Mode Function

MSZ-FH06NA

MSZ-FH09NA

MSZ-FH12NA

MSZ-FH15NA

MSZ-FH18NA

MSZ-FH18NA2

HEAT Dry 437 19.5 29.8

COOL

HEAT Dry 437 19.5 29.8

COOL

HEAT Dry 454 20.3 31.0

COOL

HEAT Dry 497 22.2 33.8

COOL

HEAT Dry 514 23.0 34.9

COOL

HEAT Dry 514 23.0 34.9

COOL

Airfl ow

(CFM)

Dry 381 17.0 26.1

Wet 328 14.6 22.5

Dry 381 17.0 26.1

Wet 328 14.6 22.5

Dry 398 17.8 27.3

Wet 342 15.3 23.5

Dry 411 18.3 28.0

Wet 354 15.7 24.1

Dry 437 19.5 29.8

Wet 376 16.7 25.6

Dry 459 20.5 31.2

Wet 395 17.6 27.0

Air speed

(ft./s)

Coverage

5

(ft.)

● The air coverage is the figure up to the

position where the air speed is 1 ft./s,

when air is blown out horizontally from

the unit properly at the High speed

position.

The coverage should be used only

as a general guideline since it varies

according to the size of the room and

furniture arranged inside the room.

Page 6

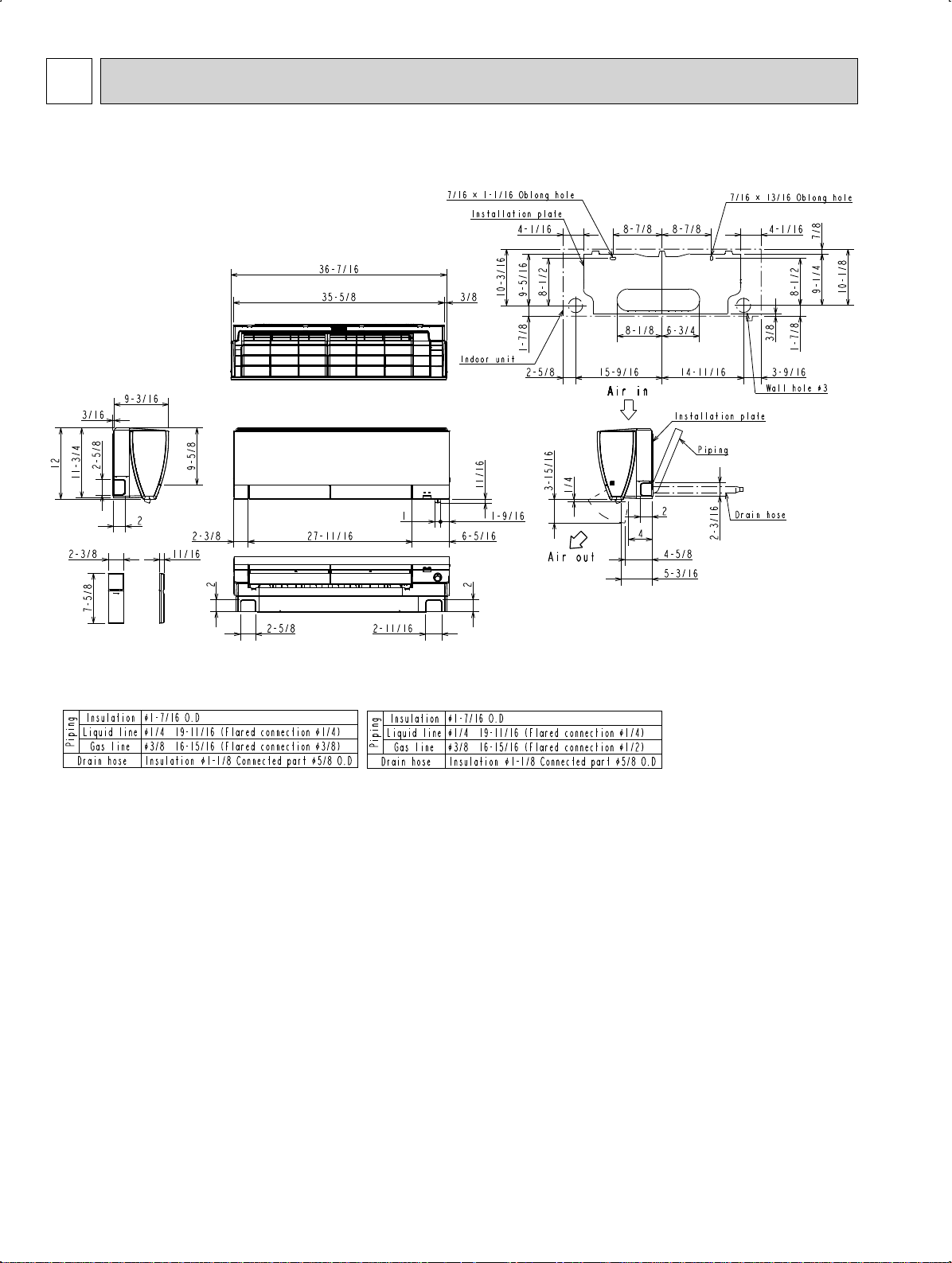

4

OBH683D

MSZ-FH06NA MSZ-FH09NA MSZ-FH12NA MSZ-FH15NA MSZ-FH18NA MSZ-FH18NA2

OUTLINES AND DIMENSIONS

Unit: inch

(MSZ-FH06/09/12NA)

(MSZ-FH15/18NA/18NA2)

6

Page 7

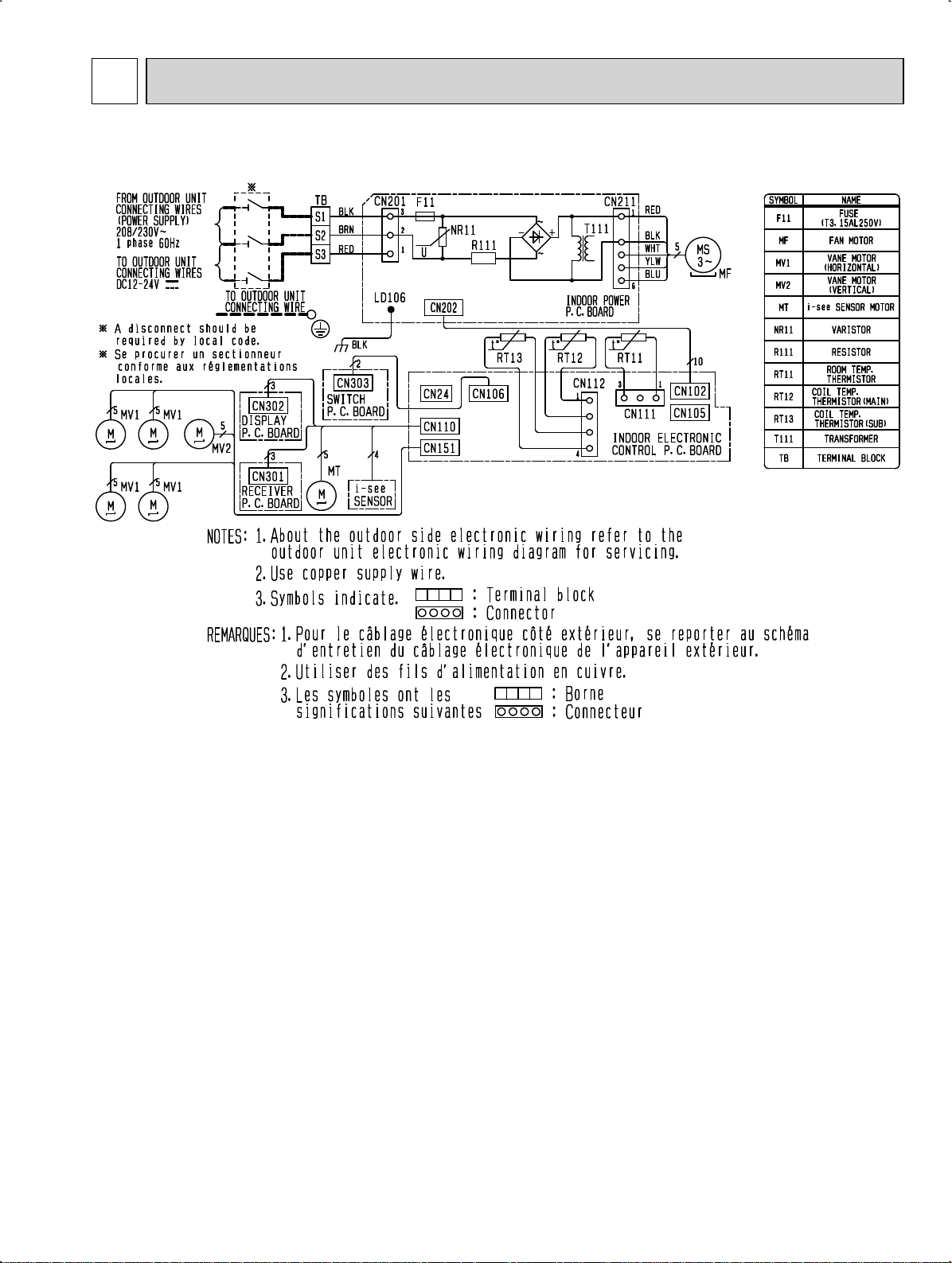

5

OBH683D

MSZ-FH06NA MSZ-FH09NA MSZ-FH12NA MSZ-FH15NA MSZ-FH18NA MSZ-FH18NA2

WIRING DIAGRAM

7

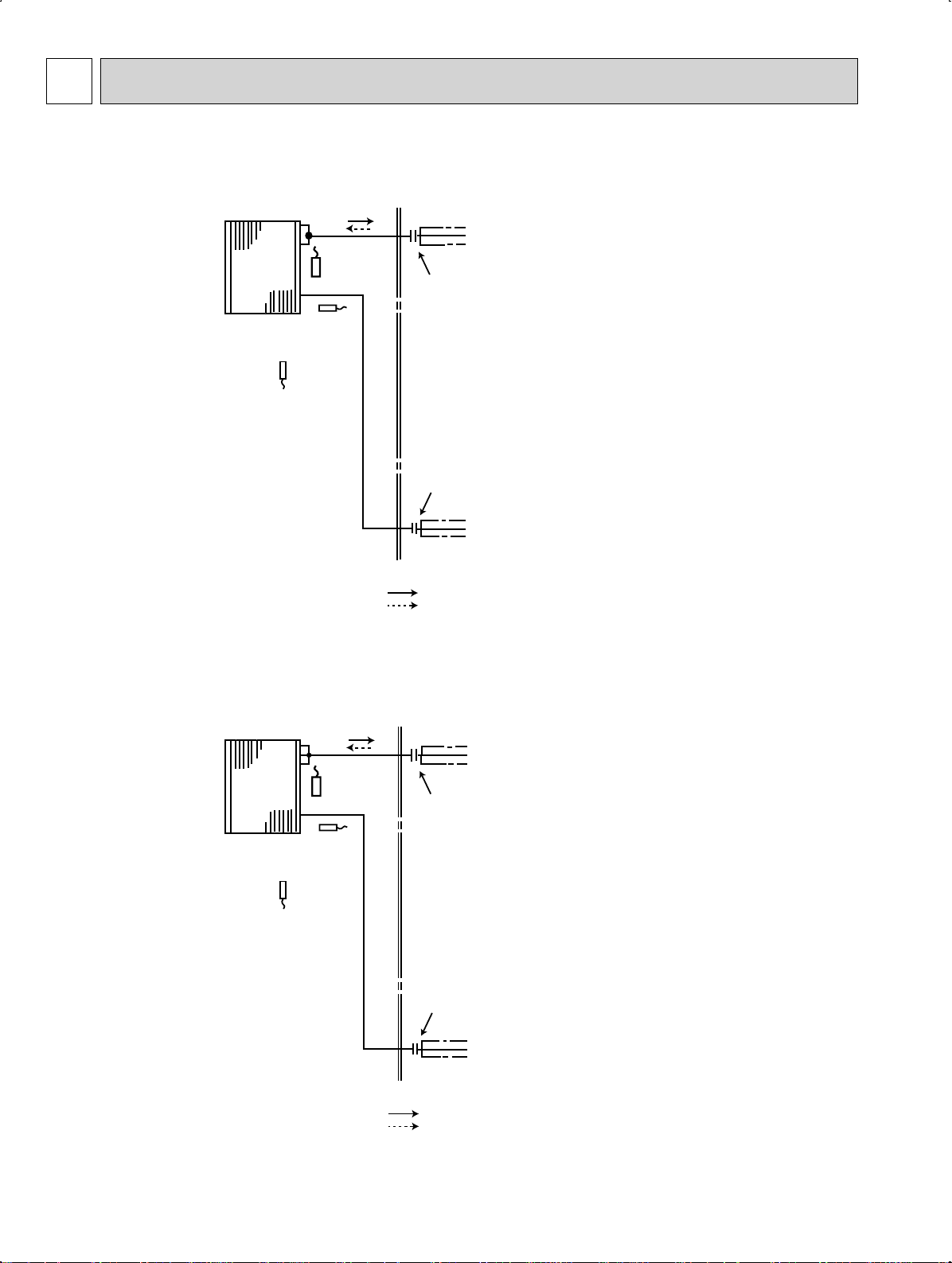

Page 8

Indoor

heat

exchanger

Flared connection

Room temperature

thermistor

RT11

Flared connection

Refrigerant pipe ø3/8 (ø9.52)

(with heat insulator)

Refrigerant pipe ø1/4 (ø6.35)

(with heat insulator)

Indoor coil

thermistor

RT12 (main)

Indoor coil

thermistor

RT13 (sub)

Refrigerant flow in cooling

Refrigerant flow in heating

6

Indoor

heat

exchanger

Flared connection

Room temperature

thermistor

RT11

Flared connection

Refrigerant pipe ø1/2 (ø12.7)

(with heat insulator)

Refrigerant pipe ø1/4 (ø6.35)

(with heat insulator)

Indoor coil

thermistor

RT12 (main)

Indoor coil

thermistor

RT13 (sub)

Refrigerant flow in cooling

Refrigerant flow in heating

OBH683D

REFRIGERANT SYSTEM DIAGRAM

MSZ-FH06NA MSZ-FH09NA MSZ-FH12NA

Unit: inch (mm)

MSZ-FH15NA MSZ-FH18NA MSZ-FH18NA2

8

Page 9

7

OBH683D

SERVICE FUNCTIONS

MSZ-FH06NA MSZ-FH09NA MSZ-FH12NA MSZ-FH15NA MSZ-FH18NA MSZ-FH18NA2

7-1. TIMER SHORT MODE

For service, the following set time can be shortened by bridging JPG and JPS on the electronic control P.C. board.

(Refer to 9-7.)

Set time: 3 minutes → 3 seconds (It takes 3 minutes for the compressor to start operation. However, the starting time is

shortened by bridging JPG and JPS.)

7-2. HOW TO SET REMOTE CONTROLLER EXCLUSIVELY FOR A PARTICULAR INDOOR UNIT

A maximum of 4 indoor units with wireless remote controllers can be used in a room.

To operate the indoor units individually with each remote controller, assign a number to each remote controller according

to the number of the indoor unit.

This setting can be set only when all the following conditions are met:

• The remote controller is powered OFF.

• Weekly timer is not set.

• Weekly timer is not being edited.

(1) Hold down

(2) Press

Each press of

(3) Press

After you turn the breaker ON, the remote controller that first sends a signal to an indoor unit will be regarded as the

remote controller for the indoor unit.

Once they are set, the indoor unit will only receive the signal from the assigned remote controller afterwards.

button on the remote controller for 2 seconds to enter the pairing mode.

button again and assign a number to each remote controller.

button advances the number in the following order: 1 → 2 → 3 → 4.

button to complete the pairing setting.

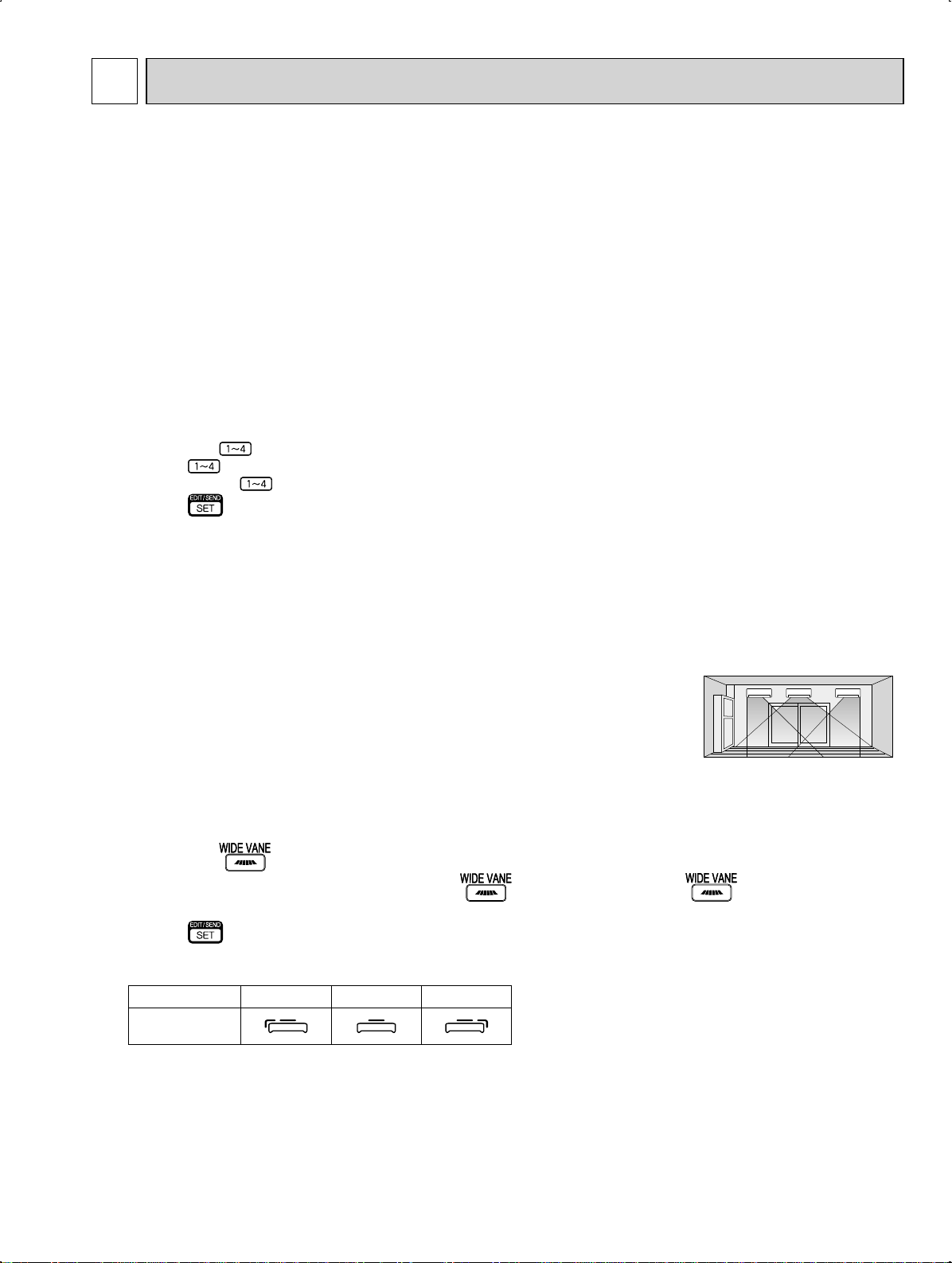

7-3. SETTING THE INSTALLATION POSITION

Be sure to set the remote controller according to the installed position of the indoor unit.

Installation position:

Left: Distance to objects (wall, cabinet, etc.) is less than 50 cm to the left

Center: Distance to objects (wall, cabinet, etc.) is more than 50 cm to the left and right

Right: Distance to objects (wall, cabinet, etc.) is less than 50 cm to the right

The installation position can be set only when all the following conditions are met:

• The remote controller is powered OFF.

• Weekly timer is not set.

• Weekly timer is not being edited.

(1) Hold down

(2) Select the target installation position by pressing

positions in order: center → right → left.)

(3) Press

button on the remote controller for 2 seconds to enter the position setting mode.

button. (Each press of the button displays the

button to complete the position setting.

(Left)(Center)(Right)

Installation position Left Center Right

Remote controller

display

9

Page 10

7-4. AUTO RESTART FUNCTION

OBH683D

When the indoor unit is controlled with the remote controller, the operation mode, the set temperature, and the fan speed

are memorized by the indoor electronic control P.C. board. “AUTO RESTART FUNCTION” automatically starts operation in

the same mode just before the shutoff of the main power.

Operation

If the main power has been cut, the operation settings remain.

After the power is restored, the unit restarts automatically according to the memory.

(However, it takes at least 3 minutes for the compressor to start running.)

How to disable “AUTO RESTART FUNCTION”

Turn off the main power for the unit.

Cut the jumper wire to JR77 on the indoor electronic control P.C. board. (Refer to 9-7.)

Indoor electronic control

P.C. board

CN110CN151

BZ

JR77

NOTE:

• The operation settings are memorized when 10 seconds have passed after the indoor unit was operated with the remote

controller.

• If main power is turned OFF or a power failure occurs while AUTO START/STOP timer is active, the timer setting is can-

celled.

• If the unit has been off with the remote controller before power failure, the auto restart function does not work as the

power button of the remote controller is OFF.

• To prevent breaker OFF due to the rush of starting current, systematize other home appliance not to turn ON at the same

time.

• When some air conditioners are connected to the same supply system, if they are operated before power failure, the

starting current of all the compressors may flow simultaneously at restart.

Therefore, the special counter-measures are required to prevent the main voltage-drop or the rush of the starting current

by adding to the system that allows the units to start one by one.

10

Page 11

8

OBH683D

MICROPROCESSOR CONTROL

MSZ-FH06NA MSZ-FH09NA MSZ-FH12NA MSZ-FH15NA MSZ-FH18NA MSZ-FH18NA2

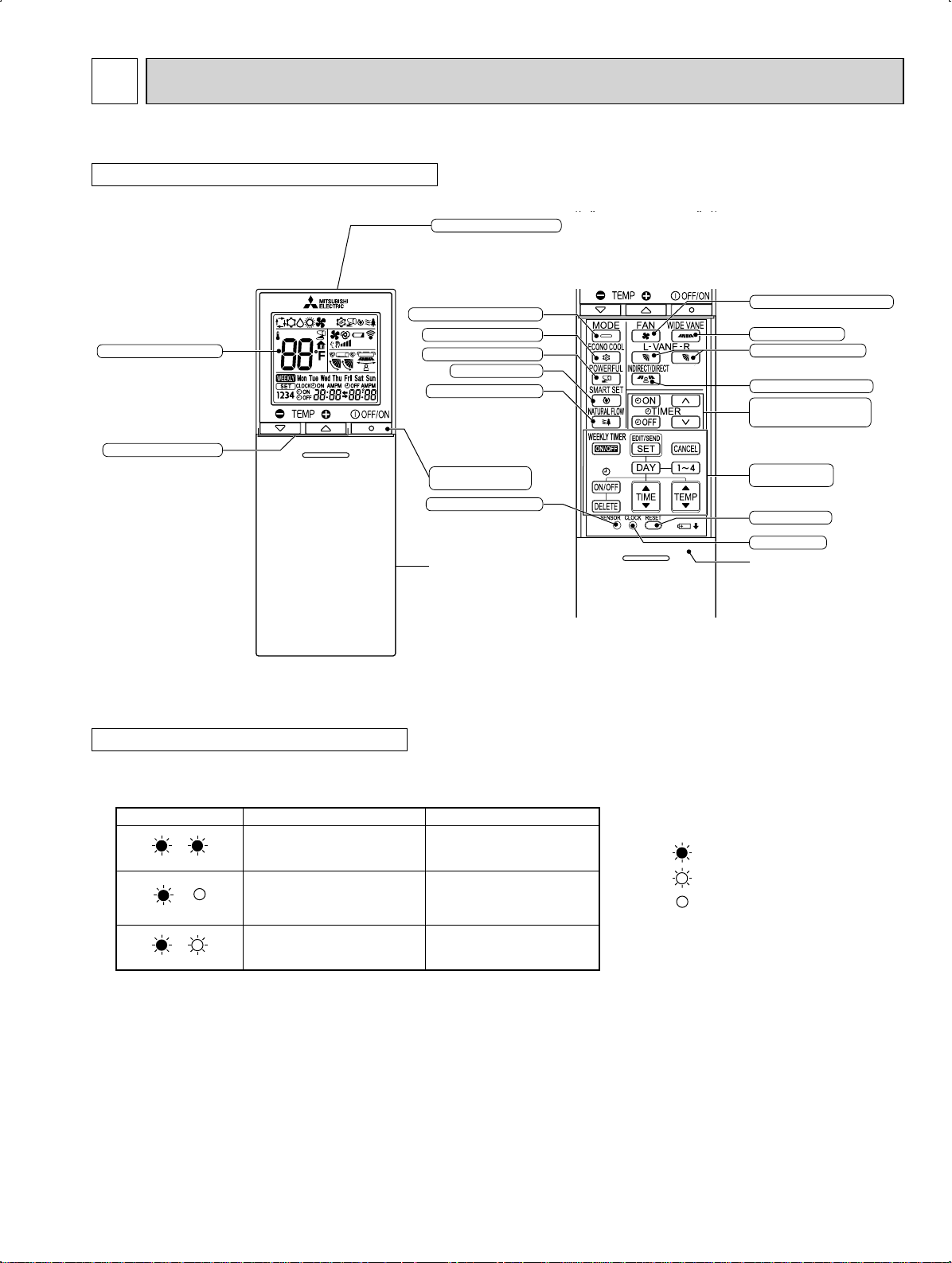

WIRELESS REMOTE CONTROLLER

Signal transmitting section

Distance of signal :

About 20 ft. (6 m)

Beep(s) is (are) heard from

the indoor unit when the

signal is received.

FAN SPEED CONTROL button

WIDE VANE button

VANE CONTROL button

INDIRECT/DIRECT button

TIME, TIMER set buttons

FORWARD button

BACKWARD button

WEEKLY TIMER

set buttons

RESET button

CLOCK button

Lid

Slide the lid down

to open the remote

controller. Slide it down

further to get to the

weekly timer buttons.

Operation display section

TEMPERATURE buttons

OPERATION SELECT button

ECONO COOL button

POWERFUL button

SMART SET button

NATURAL FLOW button

STOP/OPERATE

(OFF/ON) button

SENSOR (i-see) button

Indication of

remote controller

model is on back

NOTE: Last setting will be stored after the unit is turned OFF with the remote controller. Indoor unit receives the signal of the

remote controller with beeps.

INDOOR UNIT DISPLAY SECTION

Operation Indicator lamp

The operation indicator at the right side of the indoor unit indicates the operation state.

•The following indication applies regardless of shape of the indication.

Indication Operation state Room temperature

The unit is operating to

reach the set temperature.

The room temperature is

approaching the set temperature.

Standby mode (only during

multisystem operation)

About 4°F (2°C) or more

away from set temperature

About 2 to 4°F (1 to 2°C)

from set temperature

—

Lighted

Blinking

Not lighted

11

Page 12

8-1. COOL ( ) OPERATION

OBH683D

(1) Press STOP/OPERATE (OFF/ON) button. OPERATION INDICATOR lamp of the indoor unit turns on with a beep tone.

(2) Select COOL mode with OPERATION SELECT button.

(3) Press TEMPERATURE buttons TEMP

The setting range is 61 - 88°F (16 - 31°C).

1. Coil frost prevention

The compressor operational frequency is controlled by the temperature of the indoor heat exchanger to prevent the coil

from frosting.

When the temperature of indoor heat exchanger becomes too low, the coil frost prevention mode works.

The indoor fan operates at the set speed and the compressor stops. This mode continues until the temperature of indoor

heat exchanger rises.

2. Low outside temperature operation

When the outside temperature is lower, low outside temperature operation starts, and the outdoor fan slows or stops.

or button to select the desired temperature.

8-2. DRY ( ) OPERATION

(1) Press STOP/OPERATE (OFF/ON) button. OPERATION INDICATOR lamp of the indoor unit turns on with a beep tone.

(2) Select DRY mode with OPERATION SELECT button.

(3) The set temperature is determined from the initial room temperature.

1. Coil frost prevention

Coil frost prevention works the same way as that in COOL mode. (8-1.1.)

2. Low outside temperature operation

Low outside temperature operation works the same way as that in COOL mode. (8-1.2.)

8-3. FAN ( ) OPERATION

(1) OPERATION INDICATOR lamp of the indoor unit turns on with a beep tone.

(2) Select FAN mode with OPERATION SELECT button.

(3) Select the desired fan speed. When AUTO, it becomes Low.

Only indoor fan operates.

Outdoor unit does not operate.

8-4. HEAT ( ) OPERATION

(1) Press STOP/OPERATE (OFF/ON) button.

OPERATION INDICATOR lamp of the indoor unit turns on with a beep tone.

(2) Select HEAT mode with OPERATION SELECT button.

(3) Press TEMPERATURE buttons TEMP

The setting range is 61 - 88°F (16 - 31°C).

1. Cold air prevention control

When the compressor is not operating or is starting, and the temperature of indoor heat exchanger and/or the room temperature is low or when defrosting is being done, the indoor fan will stop or rotate in Very Low speed.

2. High pressure protection

The compressor operational frequency is controlled by the temperature of the indoor heat exchanger to prevent the condensing pressure from increasing excessively.

When the temperature of indoor heat exchanger becomes too high, the high pressure protection works.

The indoor fan operates following the cold air prevention control. This mode continues until the temperature of indoor

heat exchanger falls.

3. Defrosting

Defrosting starts when the temperature of outdoor heat exchanger becomes too low.

The compressor stops once, the indoor/outdoor fans stop, the 4-way valve reverses, and the compressor re-starts.

This mode continues until the temperature of outdoor heat exchanger rises or the fixed time passes.

or button to select the desired temperature.

8-5. AUTO CHANGE OVER ··· AUTO MODE OPERATION

Once desired temperature is set, unit operation is switched automatically between COOL and HEAT operation.

Mode selection

(1) Initial mode

When unit starts the operation with AUTO operation from OFF:

• If the room temperature is higher than the set temperature, operation starts in COOL mode.

• If the room temperature is equal to or lower than the set temperature, operation starts in HEAT mode.

(2) Mode change

COOL mode changes to HEAT mode when about 15 minutes have passed with the room temperature 2°F (1°C) below

the set temperature.

HEAT mode changes to COOL mode when about 15 minutes have passed with the room temperature 2°F (1°C) above

the set temperature.

12

Page 13

8-6. AUTO VANE OPERATION

OBH683D

1. Horizontal vane

(1) Vane motor drive

These models are equipped with a stepping motors for the horizontal vanes. The rotating direction, speed, and angle

of the motor are controlled by pulse signals (approximately 12 V) transmitted from indoor microprocessor.

(2) The horizontal vane angle and mode change as follows by pressing VANE CONTROL (

AUTO 1 2 5 SWING43

NOTE: The right and left horizontal vanes set to the same level may not align perfectly.

(3) Positioning

To confirm the standard position, the vane move until it touches the vane stopper. Then the vane is set to the selected angle.

Confirming of standard position is performed in the following cases:

(a) When the operation starts or finishes (including timer operation).

(b) When the test run starts.

(c) When standby mode (only during multi system operation) starts or finishes.

(4) VANE AUTO (

In VANE AUTO mode, the microprocessor automatically determines the vane angle to make the optimum room temperature distribution.

) mode

) button.

In COOL and DRY operation

Vane angle is fixed to Horizontal position.

Horizontal

position

(5) STOP (operation OFF) and ON TIMER standby

In the following cases, the horizontal vane returns to the closed position.

(a) When STOP/OPERATE (OFF/ON) button is pressed (POWER OFF).

(b) When the operation is stopped by the emergency operation.

(c) When ON TIMER is ON standby.

(6) Dew prevention

During COOL or DRY operation with the vane angle at Angle 4 or 5 when the compressor cumulative operation time

exceeds 1 hour, the vane angle automatically changes to Angle 3 for dew prevention.

(7) SWING (

By selecting SWING mode with VANE CONTROL button, the horizontal vanes swing vertically.

When COOL, DRY or FAN mode is selected, only the upper vane swings.

(8) Cold air prevention in HEAT operation

The horizontal vane position is set to upward.

NOTE: When 2 or more indoor units are operated with multi outdoor unit, even if any indoor unit turns thermostat off,

(9) ECONO COOL (

When ECONO COOL button is pressed in COOL mode, set temperature is automatically set 4°F (2°C) higher by the

microprocessor. However, the temperature on the LCD screen on the remote controller is not changed. Also the horizontal vane swings in various cycle.

SWING operation makes you feel cooler than set temperature. So, even though the set temperature is higher, the air

conditioner can keep comfort. As a result, energy can be saved.

To cancel this operation, select a different mode or press one of the following buttons in ECONO COOL operation:

ECONO COOL, VANE CONTROL, POWERFUL or NATURAL FLOW button.

) mode

this control does not work in the indoor unit.

) operation (ECONOmical operation)

In HEAT operation

Vane angle is fixed to Angle 4.

4

13

Page 14

(10) POWERFUL (

OBH683D

The air conditioner automatically adjusts the fan speed and the set temperature, and operates the POWERFUL mode.

The POWERFUL mode is cancelled automatically 15 minutes after operation starts, or when POWERFUL button

is pressed once again within 15 minutes after operation starts. The operation mode returns to the mode prior to

POWERFUL operation. POWERFUL mode also is cancelled, when the STOP/OPERATE (OFF/ON), ECONO COOL,

FAN SPEED CONTROL, NATURAL FLOW or SMART SET button is pressed within 15 minutes after operation starts, or

operation mode is changed.

2. Vertical vane

(1) Vane motor drive

These models are equipped with a stepping motor for the vertical vane. The rotating direction, speed, and angle of

the motor are controlled by pulse signals (approximately 12 V) transmitted from microprocessor.

(2) The vertical vane angle and mode change as follows by pressing WIDE VANE CONTROL button.

(3) Positioning

) operation

12345

(SWING)

To confirm the standard position, the vane moves until it touches the vane stopper. Then the vane is set to the select-

ed angle.

Confirming of standard position is performed in the following cases:

(a) STOP/OPERATE (OFF/ON) button is pressed (POWER ON).

(4) SWING ( ) MODE

By selecting SWING mode with WIDE VANE CONTROL button, the vertical vane swings horizontally. The remote

controller displays “

”. Swing mode is cancelled when WIDE MODE CONTROL button is pressed once again.

8-7. TIMER OPERATION

1. How to set the time

(1) Check that the current time is set correctly.

NOTE: Timer operation will not work without setting the current time. Initially “12:00 AM” blinks at the current time

display of TIME MONITOR, so set the current time correctly with CLOCK button.

How to set the current time

(a) Press the CLOCK button.

(b) Press the TIME SET buttons (

• Each time FORWARD button ( ) is pressed, the set time increases by 1 minute, and each time BACKWARD

button ( ) is pressed, the set time decreases by 1 minute.

• Pressing those buttons longer, the set time increases/decreases by 10 minutes.

(c) Press the CLOCK set button.

(2) Press STOP/OPERATE (OFF/ON) button to start the air conditioner.

(3) Set the time of timer.

ON timer setting

(a) Press ON TIMER button(

(b) Set the time of the timer using TIME SET buttons ( and ).

OFF timer setting

(a) Press OFF TIMER button ( ) during operation.

(b) Set the time of the timer using TIME SET buttons (

and ) to set the current time.

) during operation.

Each time FORWARD button ( ) is pressed, the set time increases by 10 minutes: each time BACKWARD

ton (

2. To release the timer

To release ON timer, press ON TIMER button ( ).

To release OFF timer, press OFF TIMER button(

TIMER is cancelled and the display of set time disappears.

) is pressed, the set time decreases by 10 minutes.

).

and ).

but-

14

Page 15

PROGRAM TIMER

OBH683D

• OFF timer and ON timer can be used in combination. The set time that is reached first will operate first.

• “ ” and “ ” display shows the order of OFF timer and ON timer operation.

(Example 1) The current time is 8:00 PM.

The unit turns off at 11:00 PM, and on at 6:00 AM.

(Example 2) The current time is 11:00 AM.

The unit turns on at 5:00 PM, and off at 9:00 PM.

NOTE: If the main power is turned OFF or a power failure occurs while ON/OFF timer is active, the timer setting is can-

celled. As these models are equipped with an auto restart function, the air conditioner starts operating with timer

cancelled when power is restored.

8-8. WEEKLY TIMER OPERATION

• A maximum of 4 ON or OFF timers can be set for individual days of the week.

• A maximum of 28 ON or OFF timers can be set for a week.

E.g. : Runs at 75°F (24°C) from waking up to leaving home,

and runs at 81°F (27°C) from getting home to going to

bed on weekdays.

Runs at 81°F (27°C) from waking up late to going bed

early on weekends.

75°F (24°C)

81°F (27°C)

81°F (27°C)

PM 5:30AM 6:00 AM 8:30 PM 10:00

PM 9:00PM 8:00

NOTE:

• The simple ON/OFF timer setting is available while the weekly timer is on. In this case, the ON/OFF timer has priority over the

weekly timer; the weekly timer operation will start again after the simple ON/OFF timer is complete.

• When the weekly timer is set, temperature can not be set to 50°F (10°C).

• The weekly timer operation and SMART SET operation cannot be used together.

15

Page 16

1. How to set the weekly timer

OBH683D

* Make sure that the current time and day are set correctly.

(1) Press button to enter the weekly timer setting mode.

blinks.

*

(2) Press

and buttons to select setting day and number.

E.g. : [Mon Tue ... Sun]

and [1] are selected.

Pressing selects the day of

the week to be set.

* All days can be selected.

Pressing selects

the setting number.

(3) Press , , and buttons to set ON/OFF, time, and temperature.

E.g. : [ON], [AM 6:00] and

[75°F (24°C)] are

selected.

Pressing

selects ON/OFF timer.

Pressing

deletes timer setting.

* Hold down the button to change the time quickly.

* The temperature can be set between 61°F and 88°F (16°C and 31°C) at weekly timer.

Pressing

adjusts the time.

Pressing

adjusts the temperature.

Press and buttons to continue setting the timer for other days and/or numbers.

(4) Press

button to complete and transmit the weekly timer setting.

* which was blink-

ing goes out, and the

current time will be

displayed.

NOTE:

• Press

button to transmit the setting information of weekly timer to the indoor unit. Point the remote controller toward the

indoor unit for 3 seconds.

• When setting the timer for more than one day of the week or one number,

setting. Press

• Press

button to enter the weekly timer setting mode, and press and hold button for 5 seconds to erase all weekly

button once after all the settings are complete. All the weekly timer settings will be saved.

button does not have to be pressed per each

timer settings. Point the remote controller toward the indoor unit.

16

Page 17

2. Checking weekly timer setting

(5) Press

OBH683D

•When the weekly timer is ON, the day of the week whose timer setting is complete, will light.

button to turn the weekly timer ON. ( lights.)

Press

NOTE:

The saved settings will not be cleared when the weekly timer is turned OFF.

2. Checking weekly timer setting

(1) Press button to enter the weekly timer setting mode.

*

(2) Press

(3) Press

NOTE:

When all days of the week are selected to view the settings and a different setting is included among them, will be

displayed.

button again to turn the weekly timer OFF. ( goes out.)

blinks.

or buttons to view the setting of the particular day or number.

button to exit the weekly timer setting.

8-9. i-see CONTROL ( ) MODE

In the i-see control mode, the room temperature is controlled based on the sensible temperature.

(1)

Press SENSOR button with a thin instrument during COOL, DRY, HEAT and AUTO mode to activate i-see control mode ( ).

The default setting is “active”.

(2) Press SENSOR button again to activate ABSENCE DETECTION (

(3) Press SENSOR button again to release i-see control mode.

ABSENCE DETECTION (

This function automatically changes the operation to energy-saving operation when nobody is in the room.

(1) To activate this function, press SENSOR button until

i-see control mode.

(2) Press SENSOR button again to release ABSENCE DETECTION.

NOTE:

Any person at the following places cannot be detected:

• Along the wall on which the air conditioner is installed

• Directly under the air conditioner

• Where any obstacle, such as furniture, is between the person and the air conditioner

A person may not be detected in the following situations:

• Room temperature is high.

• A person wears heavy clothes and his/her skin is not exposed.

• A heating element of which temperature changes signifi cantly is present.

• Some heat sources, such as a small child or pet, may not be sensed.

• A heat source and the air conditioner are more than 20 ft. (6 m) apart.

• A heat source does not move for a long time.

)

appears on the operation display of the remote controller during the

).

17

Page 18

8-10. INDIRECT/DIRECT MODE

OBH683D

The INDIRECT/DIRECT mode offers fi nely-tuned operation by locating where an occupant is in the room.

(1) Press INDIRECT/DIRECT button during COOL, DRY, HEAT or AUTO mode to activate INDIRECT/DIRECT mode.

This mode is only available when the i-see control mode is effective.

(2) Each press of INDIRECT/DIRECT button changes INDIRECT/DIRECT in the following order:

(INDIRECT) (DIRECT) (OFF)

(INDIRECT) : An occupant will be less exposed to direct airfl ow.

(DIRECT) : Mainly the vicinity of an occupant will be air-conditioned.

NOTE:

• Horizontal and vertical airfl ow directions will be automatically selected.

• If you still feel uncomfortable with the air direction determined by the INDIRECT mode, adjust the air direction manually.

• Cancelling the i-see control mode automatically cancels the INDIRECT/DIRECT mode.

INDIRECT/DIRECT mode is also cancelled when the VANE or WIDE VANE buttons is pressed.

• Do not touch the i-see SENSOR. This may cause malfunction of the i-see SENSOR.

8-11. NATURAL FLOW ( ) OPERATION

In NATURAL FLOW operation, air fl ow will become more like natural wind. An occupant will not be directly exposed to the

air fl ow and feel more comfortable.

(1) Press NATURAL FLOW button during COOL or FAN mode to start NATURAL FLOW operation.

(2) Press NATURAL FLOW button again to cancel NATURAL FLOW operation.

• NATURAL FLOW operation is also cancelled when the POWERFUL or ECONO COOL button is pressed.

NOTE: As the fan speed changes constantly during NATURAL FLOW operation, the sound of air fl ow, wind velocity and air fl ow

temperature also change. This is not a malfunction.

8-12. SMART SET ( ) OPERATION

1. How to set SMART SET operation

(1) Press STOP/OPERATE (OFF/ON) button.

(2) Select COOL, HEAT or ECONO COOL mode.

(3) Press SMART SET button.

(4) Set the temperature, fan speed, and airfl ow direction for SMART SET operation.

NOTE:

• SMART SET operation cannot be selected during DRY or AUTO mode operation.

• The setting range of HEAT mode SMART SET operation is 50°F (10°C) and 61 - 88°F (16 - 31°C).

• 2 groups of setting can be saved. (One for COOL/ECONO COOL, one for HEAT)

• SMART SET operation and the weekly timer operation cannot be used together.

2. How to cancel operation

• Press SMART SET button again.

• SMART SET operation can also be cancelled by pressing OPERATION SELECT button to change the operation mode.

The same setting is select from the next time by simply pressing SMART SET button.

18

Page 19

8-13. EMERGENCY/TEST OPERATION

OBH683D

In the case of test run operation or emergency operation, use

EMERGENCY OPERATION switch on the right side of the indoor unit.

Emergency operation is available when the remote controller is missing

or has failed, or when the batteries in the remote controller are running

down. The unit will start and OPERATION INDICATOR lamp will light up.

The first 30 minutes of operation is the test run operation. This operation is for servicing. The indoor fan runs at High speed and the temperature control does not work.

After 30 minutes of test run operation, the system shifts to

EMERGENCY COOL/HEAT MODE with a set temperature of 75°F (24°C).

The fan speed shifts to Medium.

The coil frost prevention works even in the test run or the emergency

operation.

In the test run or emergency operation, the horizontal vane operates in

VANE AUTO ( ) mode.

Emergency operation continues until EMERGENCY OPERATION

switch is pressed once or twice or the unit receives any signal from the

remote controller. In the latter case, normal operation will start.

NOTE: Do not press EMERGENCY OPERATION switch during normal

operation.

Operation mode COOL/HEAT

Set temperature 75°F (24°C)

Fan speed Med.

Horizontal vane Auto

The operation mode is indicated by the Operation

Indicator lamp as following

Operation Indicator lamp

EMERGENCY COOL

EMERGENCY HEAT

STOP

↓

↓

Lighted

Not lighted

Emergency

operation switch

(E.O. SW)

8-14. 3-MINUTE TIME DELAY OPERATION

When the system turns OFF, compressor will not restart for 3 minutes as 3-minute time delay function operates to protect

compressor from overload.

8-15. Changing temperature indication (°F/°C)

• The preset unit is °F.

• °F → °C: Press RESET button while the TEMPERATURE buttons are pressed.

• °C → °F: Press RESET button or remove the batteries .

Press RESET button gently

using a thin instrument.

19

Page 20

Lead wiring

Connector housing

<Incorrect>

<Correct>

9

OBH683D

TROUBLESHOOTING

MSZ-FH06NA MSZ-FH09NA MSZ-FH12NA MSZ-FH15NA MSZ-FH18NA MSZ-FH18NA2

9-1. CAUTIONS ON TROUBLESHOOTING

1. Before troubleshooting, check the following

1) Check the power supply voltage.

2) Check the indoor/outdoor connecting wire for miswiring.

2. Take care of the following during servicing

1) Before servicing the air conditioner, be sure to turn OFF the main unit first with the remote controller, and then after

confirming the horizontal vane is closed, turn OFF the breaker and/or disconnect the power plug.

2) Be sure to turn OFF the power supply before removing the front panel, the cabinet, the top panel, and the P.C. board.

3) When removing the P.C. board, hold the edge of the board with care NOT to apply stress on the components.

4) When connecting or disconnecting the connectors, hold the connector housing. DO NOT pull the lead wires.

3. Troubleshooting procedure

1) Check if the OPERATION INDICATOR lamp on the indoor unit is flashing ON and OFF to indicate an abnormality.

To make sure, check how many times the OPERATION INDICATOR lamp is flashing ON and OFF before starting serv-

ice work.

2) Before servicing, check that the connector and terminal are connected properly.

3) When the electronic control P.C. board seems to be defective, check the copper foil pattern for disconnection and the

components for bursting and discoloration.

4) When troubleshooting, Refer to 9-2, 9-3 and 9-4.

4. How to replace batteries

Weak batteries may cause the remote controller malfunction.

In this case, replace the batteries to operate the remote controller normally.

Remove the front lid and insert batteries.

Then reattach the front lid.

Press RESET button with a thin instrument, and

then use the remote controller.

NOTE: 1. If RESET button is not pressed, the remote controller may not operate correctly.

2. This remote controller has a circuit to automatically reset the microcomputer when batteries are replaced.

This function is equipped to prevent the microcomputer from malfunctioning due to the voltage drop caused by the

3. Do not use the leaking batteries.

battery replacement.

Insert the negative pole of the

batteries first. Check if the polarity

of the batteries is correct.

RESET button

20

Page 21

9-2. FAILURE MODE RECALL FUNCTION

OBH683D

Outline of the function

This air conditioner can memorize the abnormal condition which has occurred once.

Even though LED indication listed on the troubleshooting check table (9-4.) disappears, the memorized failure details can

be recalled.

1. Flow chart of failure mode recall function for the indoor/outdoor unit

Operational procedure

Setting up the failure mode recall function

Judgment of indoor/outdoor abnormality

Releasing the failure mode recall function

The cause of abnormality cannot be found because the abnormality does not recur.

Turn ON the power supply.

<Preparation of the remote controller>

While pressing both OPERATION SELECT button and

controller at the same time, press RESET button.

First, release RESET button.

Hold down the other 2 buttons for another 3 seconds. Make sure that the indicators

on the LCD screen shown in the right fi gure are all displayed. Then release the but-

tons.

Press STOP/OPERATE (OFF/ON) button of the remote controller (the set temperature is

displayed) with the remote controller headed towards the indoor unit.

Does the left lamp of the OPERATION INDICATOR lamp on the indoor unit blink at the interval of

0.5 seconds?

Blinks: Either indoor or outdoor unit is abnormal.

Beep is emitted at the same timing as the

blinking of the left lamp of OPERATION

INDICATOR lamp. 2

Before blinking, does the left lamp of

OPERATION INDICATOR lamp stay ON for 3

seconds?

When it stays ON for 3 seconds (without beep):

The outdoor unit is abnormal.

The indoor unit is abnormal.

Check the blinking pattern, and identify the abnormal point by referring to the

indoor unit failure mode table. (Refer to 9-2.2)

Make sure to check at least 2 consecutive blinking cycles.

Release the failure mode recall function by the following procedures.

Turn OFF the power supply and turn it ON again.

Press RESET button of the remote controller.

button on the remote

TEMP

1

1 Regardless of normal or abnormal condition,

a short beep is emitted once the signal is

received.

No

(OFF)

Yes

(Blinks)

Yes

No

2

Indoor unit is normal.

But the outdoor unit might be abnormal because there are some abnormalities that cannot be recalled with this way.

Check if outdoor unit is abnormal according to the detailed outdoor unit

failure mode recall function.

NOTE: It takes up to 1 minute to indicate the outdoor unit abnormality.

Even if the OPERATION INDICATOR lamp is not lighting, keep

checking at least 1 minute or longer.

The outdoor unit is abnormal.

Check the blinking pattern, and identify the abnormal point by referring

to the outdoor unit failure mode table. (Refer to outdoor unit service

manual.)

Make sure to check at least 2 consecutive blinking cycles.

3

Repair the failure parts.

Deleting the memorized abnormal condition

After repairing the unit, recall the failure mode again according to "Setting up the failure mode recall

function" mentioned above.

Press STOP/OPERATE (OFF/ON) button of the remote controller (the set temperature is displayed)

with the remote controller headed towards the indoor unit.

Press EMERGENCY OPERATION switch so that the memorized abnormal condition is deleted.

Release the failure mode recall function according to "Releasing the failure mode recall function" men-

tioned above.

NOTE: 1. Make sure to release the failure mode recall function after it is set up, otherwise the unit cannot operate properly.

2. If the abnormal condition is not deleted from the memory, the last abnormal condition is kept memorized.

2. Blinking pattern when the indoor unit is abnormal:

2.5-second OFF

ON

OFF

3.Blinking pattern when the outdoor unit is abnormal:

2.5-second OFF 3-second ON

ON

OFF

Blinking at 0.5second interval

Repeated cycle Repeated cycle

Beeps

No beep Beeps

Repeated cycle

2.5-second OFF

Blinking at 0.5second interval

Blinking at 0.5second interval

Beeps

2.5-second OFF 3-second ON

Repeated cycle

No beep Beeps

Repeated cycle

Beeps

21

Blinking at 0.5second interval

Repeated cycle

Page 22

2. Indoor unit failure mode table

OBH683D

The left lamp of

the OPERATION

INDICATOR lamp

Not lighted Normal — —

1-time fl ash every

0.5-second

2-time fl ash

2.5-second OFF

3-time fl ash

2.5-second OFF

11-time fl ash

2.5-second OFF

12-time fl ash

2.5-second OFF

Abnormal point

(Failure mode)

Room temperature

thermistor

Indoor coil

thermistor

Serial signal

Indoor fan motor

Indoor control

system

Condition Remedy

The room temperature thermistor short or

open circuit is detected every 8 seconds during operation.

The indoor coil thermistor short or open circuit

is detected every 8 seconds during operation.

The serial signal from outdoor unit is not received for a maximum of 6 minutes.

The rotational frequency feedback signal is

not emitted for 12 seconds after the indoor fan

motor is operated.

It cannot properly read data in the nonvolatile

memory of the indoor electronic control P.C.

board.

Refer to the characteristics of the room temperature

thermistor (9-7.).

Refer to the characteristics of the main indoor coil thermistor, the sub indoor coil thermistor (9-7.).

Refer to 9-6.

signal error".

Refer to 9-6.

Replace the indoor electronic control P.C. board.

"How to check miswiring and serial

"Check of indoor fan motor".

NOTE: Blinking patterns of this mode differ from the ones of TROUBLESHOOTING CHECK TABLE (9-4.).

3. Operation check on i-see SENSOR

While recalling the failure details, set the temperature to 66°F (19°C) to perform the simple check on the i-see SENSOR.

Place your hand over the i-see SENSOR, and the buzzer will beep at 1 second intervals. (Normal detection temperature

range is 93 to 102°F (34 to 39°C).)

If the buzzer does not beep, check for disconnection of the connectors.

Set the temperature to 73°F (23°C) to exit the simple check mode on the i-see SENSOR.

The left lamp of

the OPERATION

INDICATOR lamp

6-time fl ash i-see SENSOR

Abnormal point

(Failure mode)

Condition Remedy

Poor contact in i-see SENSOR wiring

Failure in loading corrected data of i-see

SENSOR

Check for disconnection of the connectors.

22

Page 23

9-3. INSTRUCTION OF TROUBLESHOOTING

OBH683D

Start

"Test Run operation" means the

operation within 30 minutes after EMERGENCY OPERATION

switch is pressed.

If blinking of OPERATION INDICATOR lamp cannot be checked,

it can be checked with failure

mode recall function.

Indoor unit operates.

Outdoor unit

does not operate.

Outdoor unit

operates only

in Test Run

operation.

Check room

temperature

thermistor.

Refer to 9-7.

"Test point

diagram and

voltage".

Outdoor unit

does not

operate even

in Test Run

operation.

Refer to "How

to check

inverter/compressor".

Indoor unit operates.

Outdoor unit does

not operate normally.

Unit does not

operate normal operation

in COOL or

HEAT mode.

Refer to

"Check of R.V.

coil".

Indoor unit does

not receive the

signal from remote controller.

Indoor unit

operates, when

EMERGENCY

OPERATION

switch is pressed.

Refer to 9-6.

"Check of remote

controller and

indoor electronic

control P.C. board".

LEFT lamp of the OPERATION INDICATOR lamp is

fl ashing ON and OFF.

Indoor unit does

not operate, when

EMERGENCY

OPERATION

switch is pressed.

1. Check indoor/outdoor connecting wire.

(Check if the power is

supplied to the indoor

unit.)

2. Refer to 9-6. "Check

of indoor P.C. board

and indoor fan motor".

Refer to outdoor unit service manual.

LEFT lamp

Flash on and

off at 0.5-second intervals

Cause:

Indoor/Outdoor

unit

• Miswiring or

trouble of

serial signal

Refer to 9-6.

"How to

check miswiring and

serial signal

error".

LEFT lamp

2-time fl ash

Cause:

Indoor unit

• Trouble

of room

temperature

/ indoor coil

thermistor

Check room

temperature

thermistor

and indoor

coil thermistor. Refer to

9-7. "Test

point diagram

and voltage".

LEFT lamp

3-time fl ash

Cause:

Indoor unit

• Trouble of

indoor fan

motor

Refer to 9-6.

"Check of

indoor fan

motor".

LEFT lamp

4-time fl ash

Cause:

Indoor unit

• Trouble

of indoor

unit control

system

Replace the

indoor electronic control

P.C. board.

23

LEFT lamp

5-time fl ash

Cause:

Outdoor unit

• Outdoor

power

system

abnormality

Refer to

"How to

check

inverter/compressor".

LEFT lamp

6-time fl ash

Cause:

Outdoor unit

• Trouble of

thermistor in

outdoor unit

Refer to

"Check of

outdoor thermistors".

LEFT lamp

7-time fl ash

Cause:

Outdoor unit

• Trouble of

outdoor control system

Replace the

inverter P.C.

board or

the outdoor

electronic

control P.C.

board.

LEFT lamp

14-time fl ash

or more

Cause:

Outdoor unit

• Other abnormality

Check "Flow

chart of the

detailed

outdoor unit

failure mode

recall function."

Page 24

9-4. TROUBLESHOOTING CHECK TABLE

OBH683D

Before taking measures, make sure that the symptom reappears for accurate troubleshooting.

When the indoor unit has started operation and detected an abnormality of the following condition (the first detection after the

power ON), the indoor fan motor turns OFF and OPERATION INDICATOR lamp flashes.

• The following indicator applies regardless of shape of the indication.

OPERATION INDICATOR

Lighted

Blinking

Not lighted

Abnormal

No.

1

point

Miswiring

or serial

signal

LEFT lamp fl ashes.

0.5-second ON

0.5-second OFF

Operation indicator lamp Symptom Condition Remedy

Refer to 9-6.

The serial signal from the outdoor unit is not

received for 6 minutes.

•

miswiring and serial signal error".

"How to check

Indoor coil

thermistor

2

Room temperature

thermistor

Indoor fan

3

motor

Indoor con-

4

trol system

Outdoor

5

power system

Outdoor

6

thermistors

Outdoor

7

control system

Other ab-

8

normality

LEFT lamp fl ashes.

2-time fl ash

2.5-second OFF

LEFT lamp fl ashes.

3-time fl ash

2.5-second OFF

LEFT lamp fl ashes.

4-time fl ash

2.5-second OFF

LEFT lamp fl ashes.

5-time fl ash

2.5-second OFF

LEFT lamp fl ashes.

6-time fl ash

2.5-second OFF

LEFT lamp fl ashes.

7-time fl ash

2.5-second OFF

LEFT lamp fl ashes.

14-time fl ash or more

2.5-second OFF

Indoor unit and

outdoor unit do

not operate.

The indoor coil or the room temperature thermistor is short or open circuit.

The rotational frequency feedback signal is

not emitted during the indoor fan operation.

It cannot properly read data in the nonvolatile

memory of the indoor electronic control P.C.

board.

It consecutively occurs 3 times that the compressor stops for overcurrent protection or

start-up failure protection within 1 minute after

start-up.

The outdoor thermistors short or open circuit

during the compressor operation.

It cannot properly read data in the nonvolatile

memory of the inverter P.C. board or the outdoor electronic control P.C. board.

An abnormality other than above mentioned

is detected.

Refer to the characteristics of

•

indoor coil thermistor, and the

room temperature thermistor

(9-7.).

Refer to 9-6. "Check of in-

•

door fan motor".

Replace the indoor electronic

•

control P.C. board.

Refer to "How to check of in-

•

verter/compressor".

Refer to outdoor unit service

manual

Check the stop valve.

•

Refer to "Check of outdoor

•

thermistor".

Refer to outdoor unit service

manual.

Replace the inverter P.C. board

•

or the outdoor electronic control

P.C. board.

Refer to outdoor unit service

manual.

Check the stop valve.

•

Check the 4-way valve.

•

Check the abnormality in detail

•

using the failure mode recall

function for outdoor unit.

Outdoor

9

control system

LEFT lamp lights up.

Outdoor unit

does not operate

It cannot properly read data in the nonvolatile

memory of the inverter P.C. board or the outdoor electronic control P.C. board.

24

Check the blinking pattern of

•

the LED on the inverter P.C.

board or the outdoor electronic

control P.C. board.

Page 25

9-5. TROUBLE CRITERION OF MAIN PARTS

OBH683D

MSZ-FH06NA MSZ-FH09NA MSZ-FH12NA MSZ-FH15NA MSZ-FH18NA MSZ-FH18NA2

Part name Check method and criterion Figure

Room temperature

thermistor (RT11)

Indoor coil thermistor

(RT12, RT13)

Measure the resistance with a tester.

Refer to 9-7. "Test point diagram and voltage", "Indoor electronic control P.C.

board", for the chart of thermistor.

Indoor fan motor (MF)

Vane motor (MV1)

(HORIZONTAL)

Vane motor (MV2)

(VERTICAL)

i-see SENSOR MOTOR

(MT)

Check 9-6. "Check of indoor fan motor".

Measure the resistance between the terminals with a tester.

(Temperature: 50 - 86°F (10 - 30°C))

Color of the lead wire Normal

RED - SKY

262

- 328 Ω

Measure the resistance between the terminals with a tester.

(Temperature: 50 - 86°F (10 - 30°C))

Color of the lead wire Normal

RED - SKY

219

- 273 Ω

Measure the resistance between the terminals with a tester.

(Temperature: 50 - 86°F (10 - 30°C))

Color of the lead wire Normal

RED - BLK

262

- 328 Ω

SKY

SKY

RED

SKY

SKY

RED

BLK

BLK

RED

ROTOR

SKY

ROTOR

SKY

ROTOR

BLK

SKY

SKY

BLK

25

Page 26

9-6. TROUBLESHOOTING FLOW

OBH683D

A Check of indoor fan motor

The indoor fan motor error has occurred, and the indoor fan does not operate.

Turn OFF the power supply.

Is there any foreign matter that interferes

the rotation of the line fl ow fan?

Yes

Remove the foreign matter and

adjust the line fl ow fan.

Is there 294/325 VDC

between CN211

and (–) ?

Replace the indoor power

P.C. board.

(+)

No

Yes

No

Yes

Pay enough attention to the high voltage on the fan motor connector CN211.

Turn ON the power supply, wait 5 seconds or more, and then press

EMERGENCY OPERATION switch.

Measure the supply voltage as follows within 12 seconds after EMERGENCY OPERATION switch is pressed.

If more than 12 seconds passes, turn OFF the power supply and turn it

ON again, then measure the voltage.

<Indoor power P.C. board>

1. Measure the voltage between CN211 (+) and (–).

2. Measure the voltage between CN211

<Indoor electronic control P.C. board>

3. Measure the voltage between CN102 (+) and JPG (GND)(–).

If more than 12 seconds passes after EMERGENCY OPERATION switch

is pressed, the voltage measured at 2. above goes 0 VDC although the

indoor P.C. board is normal.

Does the voltage between CN211

(–) on the power P.C. board

(+) and

rise to the range of 3 to 6 VDC within

12 seconds after EMERGENCY

OPERATION switch is pressed?

No

Does the voltage between CN102

(+) and JPG (GND)(–) on the indoor

electronic control P.C. board fall to

2 V or less within 12 seconds after

EMERGENCY OPERATION switch is

pressed?

Yes

No

(+) and (–).

Replace the indoor fan motor.

Replace the indoor electronic

control P.C. board.

The indoor fan motor error has occurred, and the indoor fan repeats "12-second ON and 30-second OFF" 3 times, and then stops.

Measure the voltage between CN211

rotating.

(+) and (–) while the fan motor is

Replace the indoor power P.C.

board.

Yes

(Unchanged)

Is it unchanged holding

0 or 15 VDC?

Yes

(Unchanged)

Replace the indoor fan motor.

Is it unchanged holding

0 or 5 VDC?

26

No

(Changed)

No

(Changed)

Measure the voltage CN102 (+)

and JPG (GND)(–) on the indoor

electronic control P.C board when

the fan motor is rotating.

Replace the indoor

electronic control P.C.

board.

Page 27

B Check of remote controller and indoor electronic control P.C. board

OBH683D

Check if the remote controller is exclusive for this air conditioner.

Press STOP/OPERATE (OFF/ON)

button on the remote controller.

Is LCD display on the remote

controller visible?

Yes

Remove the batteries, then set them

back and press RESET button.

(Refer to 9-1.4.)

Check if the unit operates with the

remote controller.

Does the unit operate with the

remote controller?

Yes

OK

No

(Not clear)

No

Replace the batteries. (Refer to 9-1.4.)

Assign a number of remote controller.

(Refer to 7-2.)

Check if the unit operates with the

remote controller.

Does the unit operate with

the remote controller ?

Yes

OK

No

1 Look at the image of the signal transmitting section of

the remote controller through the monitor of a digital

camera or a camera phone. It is normal if the LED of

the signal transmitting section lights up when the STOP/

OPERATE (OFF/ON) button on the remote controller is pressed. However, it may be diffi cult to see the

illuminated LED of the signal transmitting section with a

smartphone camera.

2 If the inverter fl uorescent light is turned on when the

room is cool, the unit may have diffi culty receiving the

signal from the remote controller or may not be able to

operate with it; if the inverter fl uorescent light is turned

on when the room is warm, the unit may be able to

operate with the remote controller.

Turn ON a radio to AM and press STOP/

OPERATE (OFF/ON) button on the

remote controller.

Is noise heard from radio?

Are there any fl uorescent lights

of inverter or rapid-start type

within the range of 3.28 ft.?

1

Yes

No

No

Yes

2

Replace the remote controller.

• Reinstall the unit away from lights.

• Attach a fi lter on receiving part.

Measure the voltage between receiver P.C. board connector CN301 No.1(-) and No.3(+)

when the remote controller button is pressed.

Yes

Is the voltage approximately 4 VDC - 5 VDC?

No

Replace the receiver P.C. board.

Replace the indoor electronic

control P.C. board.

27

Page 28

C Check of indoor P.C. board and indoor fan motor

OBH683D

Turn OFF the power supply.

Remove indoor fan motor connector CN211

from indoor power P.C. board and vane

motor connector CN151 from the indoor

electronic control P.C. board and turn ON

the power supply.

Does the unit operate with the remote

controller?

Does OPERATION INDICATOR lamp light

up by pressing EMERGENCY OPERATION

switch?

No

Yes

Measure the resistance of indoor fan

motor.

Refer to 9-5.

Measure the resistance of the vane

motor coil.

Refer to 9-5.

Short circuit:

Replace the indoor fan motor.

Short circuit:

Replace the vane motor and the indoor

electronic control P.C. board.

Turn OFF the power supply.

Check both “parts side” and “pattern

side” of the indoor power P.C. board

visually.

Measure the resistance of the i-see

SENSOR MOTOR coil. Refer 9-5.

Replace the varistor (NR11)

and fuse (F11). 3

Yes

Are the varistor (NR11)

burnt and the fuse (F11)

blown?

Be sure to check both the fuse

and the varistor in any case.

Is the fuse (F11) blown

only?

Yes

Measure the resistance between

(+) and (-) of indoor fan

CN211

motor connector.

Is the resistance 1MΩ or more?

Replace the fuse (F11).

1, 2

Yes

Short circuit:

Replace the i-see SENSOR MOTOR and

the indoor electronic P.C. board.

No

No

1. The fan motor connector's lead wire is red,

whereas

2. Connect "+" of the tester to fan motor connector's

resistance cannot be measured properly.

3. Please replace the fuse after removing the indoor

power P.C. board from the electrical box.

Replace the fuse (F11) and the

indoor fan motor.

3

is black.

lead wire, and “-” to lead wire, otherwise the

3No

Indoor electronic

control P.C. board

Indoor power

P.C. board

CN211

Measure the resistance of

resistor (R111) on the indoor

power P.C. board.

Fuse (F11)

GND(JPG)

Varistor

(NR11)

CN102

R111

Is the resistance of

resistor (R111) approximately

3.9 Ω ?

Yes

Is there approximately 5 VDC between

5 V (+) and JPG (GND) (-) of the

indoor electronic control P.C. board?

Is there approximately 12 VDC

between 12 V (+) and JPG (GND) (-)

of the indoor electronic control P.C.

board?

No

Is connector CN102 on the

indoor electronic control P.C.

board or lead wires disconnected?

Replace the indoor electronic control P.C. board.

No

No

Yes

28

Replace the indoor

power P.C. board and

the indoor fan motor.

Replace the indoor fan motor.

Yes

Connect the connector or repair disconnection.

Page 29

D How to check miswiring and serial signal error

OBH683D

Turn OFF the power supply.

NOTE: Refer to the outdoor unit service manual.

Is there rated voltage in the power supply?

Turn ON the power supply.

Is there rated voltage between the outdoor terminal block S1 and S2?

Press EMERGENCY OPERATION switch once.

Does the left lamp of OPERATION INDICATOR

lamp light up? <Confi rmation of the power to

the indoor unit>

Is serial signal error indicated 6 minutes later?

Turn OFF the power supply.

Check once more if the indoor/outdoor

B

connecting wire is not miswiring.

Bridge the outdoor terminal block S2 and

1

S3.

Turn ON the power supply.

Is the bus-bar voltage of the inverter P.C. board normal?

(Refer to "TEST POINT DIAGRAM AND VOLTAGE" in the outdoor service manual.)

Yes

Yes

Yes

Yes

A

Yes

No

No

No

1. Miswiring may damage indoor electronic control P.C.

3. Be sure to check this within 3 minutes after turning ON.

Check the power supply.

No

Check the wiring.

Is there any miswiring,

poor contact, or wire

disconnection of the

indoor/outdoor connecting wire?

board during the operation.

Be sure to confi rm the wiring is correct before the opera-

tion starts.

After 3 minutes, LED blinks 6 times. Even when the

inverter P.C. board is normal, LED blinks 6 times after 3

minutes.

No

No

Check of power supply.

(Refer to the outdoor

service manual.)

Yes

Correct them.

Does the LED on the inverter P.C. board repeat

"3.6-second-OFF and 0.8-second-ON quick blinking"?

Turn OFF the power supply.

Remove the bridge between the outdoor terminal block S2 and S3.

Turn ON the power supply.

Is there rated voltage between the indoor terminal block S1 and S2?

<Confi rmation of power voltage>

Is there amplitude of 10 to 20 VDC between the indoor terminal block

S2 and S3? <Confi rmation of serial signal>

Yes

A

• Reinstall

• Attach a fi lter

No

either the unit

or the light

away from

each other.

on remote

control receiving section

of the indoor

unit.

• Turn OFF inverter-controlled lighting

equipment.

• Turn OFF the power supply and then

turn ON again.

• Press EMERGENCY OPERATION

switch.

Is serial signal

error indicated 6

minutes later?

B

3

Yes

Yes

Yes

Is there 2 VDC or less between CN202 (+)

and JPG (GND)(-) on the indoor electronic

control P.C. board?

Yes

Is there 2 VDC or less between

CN202A (+) and JPG (GND)(-)

on the indoor electronic control P.C.

board?

Replace the indoor power

P.C. board.

No

No Yes No

No

(Lighted

or not

lighted)

No

No

Replace the indoor electronic control P.C. board.

29

Replace the inverter P.C. board . 2

2. Be careful of the residual voltage of

smoothing capacitor.

Check the wiring

If there are any errors of the indoor/outdoor connecting wire:

such as the damage of the wire, intermediate connection,

and/or poor contact to the terminal block, replace the indoor/

outdoor connecting wire.

Is there 2 VDC or less between

CN202

the indoor electronic control P.C.

board?

(+) and JPG (GND)(-) on

Yes

Page 30

E Electromagnetic noise enters into TV sets or radios

OBH683D

Is the unit grounded?

Yes

Is the distance between the antennas

and the indoor unit within 9.91 ft. (3m),

or is the distance between the antennas

and the outdoor unit within 9.91 ft. (3m)?

No

Is the distance between the TV sets or radios and the indoor unit within 3.28 ft.

or is the distance between the TV sets or

radios and the outdoor unit within

9.91 ft.

(3m)

?

No

Are the antennas damaged?

Is the coaxial cable damaged?

Is there any poor contact in the antenna wiring?

No

Is the indoor/outdoor connecting wire

of the air conditioner and the wiring of

the antennas close?

No

(1m)

No

Yes

,

Yes

Yes

Yes

Ground the unit.

Extend the distance between the antennas and

the indoor unit, and/or the antennas and the

outdoor unit.

Extend the distance between the TV sets and/or

radios and the indoor unit, or the TV sets or

radios and the outdoor unit.

Replace or repair the antenna.

Replace or repair the coaxial cable.

Extend the distance between the indoor/outdoor

connecting wire of the air conditioner and the wiring of the antennas.

Even if all of the above conditions are fulfi lled, the electromagnetic noise may enter, depending on the electric fi eld strength

or the installation condition (combination of specifi c conditions such as antennas or wiring).

Check the following before asking for service.

1. Devices affected by the electromagnetic noise

TV sets, radios (FM/AM broadcast, shortwave)

2. Channel, frequency, broadcast station affected by the electromagnetic noise

3. Channel, frequency, broadcast station unaffected by the electromagnetic noise

4. Layout of:

indoor/outdoor unit of the air conditioner, indoor/outdoor wiring, ground wire, antennas, wiring from antennas, receiver

5. Electric fi eld intensity of the broadcast station affected by the electromagnetic noise

6. Presence or absence of amplifi er such as booster

7. Operation condition of air conditioner when the electromagnetic noise enters in

1) Turn OFF the power supply once, and then turn ON the power supply. In this situation, check for the electromagnetic

noise.

2) Within 3 minutes after turning ON the power supply, press STOP/OPERATE (OFF/ON) button on the remote controller for power ON, and check for the electromagnetic noise.

3) After a short time (3 minutes later after turning ON), the outdoor unit starts running. During operation, check for the

electromagnetic noise.

4) Press STOP/OPERATE (OFF/ON) button on the remote controller for power OFF, when the outdoor unit stops but the

indoor/outdoor communication still runs on. In this situation, check for the electromagnetic noise.

30

Page 31

9-7. TEST POINT DIAGRAM AND VOLTAGE

OBH683D

Indoor power P.C. board, Indoor electronic control P.C. board, Receiver board, Display board, Switch board

MSZ-FH06NA MSZ-FH09NA MSZ-FH12NA MSZ-FH15NA MSZ-FH18NA MSZ-FH18NA2

Indoor power P.C. board

Connector

Terminal Block

(CN201)

5 VDC

GND

Fuse (F11) Varistor (NR11)

Indoor fan motor

(CN211)

(+)0 or 15 VDC

(+)3-6 VDC

15 VDC

(–) GND (high-

voltage DC)

294/325 VDC

Resistor (R111)

Connector to indoor

electronic control

P.C. board (CN202)

Indoor electronic control P.C. board

Room temperature

thermistor RT11 (CN111)

Connector cable (CN24)

Display board

CN110

~ pin

Receiver board

(CN301)

~ pin

, , ,

,

i-see SENSOR

MOTOR MT

i-see SENSOR

pin

~ pin

12 VDC

5 VDC

12 VDC

Room temperature thermistor (RT11)

Indoor coil thermistor (RT12, RT13)

Resistance (kΩ)

32

50 68 86 104 122 140

Temperature (°F)

Connector to indoor

power P.C. board

(CN102)

CN151

Vane motor MV1

(horizontal)

Vane motor MV2

(vertical)

26

~ pin

~ pin

Emergency operation switch (E.O.SW) (SW1)

Indoor coil thermistor

RT12, RT13 (CN112)

Switch board

31

Interface

(CN105)

GND

Timer short

mode point

JPG JPS

(Refer to 7-1.)

To disable "Auto restart

function" cut the Jumper

wire to JR77. (Refer to 7-4.)

Page 32

10

OBH683D

DISASSEMBLY INSTRUCTIONS

<"Terminal with locking mechanism" Detaching points>

The terminal which has the locking mechanism can be detached as shown below.

There are 2 types (Refer to (1) and (2)) of the terminal with locking mechanism.

The terminal without locking mechanism can be detached by pulling it out.

Check the shape of the terminal before detaching.

(1) Slide the sleeve and check if there is a locking lever or not. (2) The terminal with this connector has the

Sleeve

locking mechanism.

Locking lever

Slide the sleeve.

Pull the terminal while

pushing the locking

lever.

Hold the sleeve, and

pull out the terminal

slowly.

Connector

10-1. MSZ-FH06NA MSZ-FH09NA MSZ-FH12NA MSZ-FH15NA MSZ-FH18NA

MSZ-FH18NA2

NOTE: Turn OFF the power supply before disassembly.

OPERATING PROCEDURE PHOTOS

1. Removing the panel

(1) Remove the horizontal vanes.

Removal procedure

Unlock the upper and lower vanes as shown

in using a thin instrument.

Then, remove the horizontal vanes in the

direction of .

Unlock

Photo 1

Front panel

Horizontal vanesHorizontal vanes

(2) Remove the front panel. Remove the screw caps of

the under panel. Remove the screws of the under

panel.

(3) Pull out the right top corner of the right panel and

remove the right panel.

(4) Pull out the left bottom corner of the left panel and

remove the left panel.

(5) Unhook the lower part

remove the under panel.

Upper and

lower vanes

of the under panel and

Photo 2

32

Left panel

Screws of the panels

Screws of the under panel

Right panel

Under panel

Page 33

OPERATING PROCEDURE PHOTOS

OBH683D

2. Removing the indoor electrical box

(1) Remove the panels (Refer to 1.) and the right corner

box.

(2) Remove the screw of the V.A. clamp and V.A. clamp.

(3) Remove the screw of the electrical cover and the

electrical cover.

(4) Disconnect following connectors:

<Indoor electronic control P.C. board>

CN151 (Vane motor)

<Indoor power P.C. board>

CN211 (Indoor fan motor)

CN110 (DISPLAY AND i-see SENSOR ASSEMBLY)

(5) Remove DISPLAY AND i-see SENSOR ASSEMBLY.

(6) Remove the screw of conduit cover and the conduit

cover.

(7) Remove the screw of conduit plate, the conduit plate

and the indoor/outdoor connecting wire.

(8) Remove the ground wire connected to the indoor heat

exchanger from the electrical box.

(9) Remove the screw fixing the electrical box, then

the upper catch of the electrical box, and

pull out the electrical box.

When installing the electrical box, pass the lead

wire from the fan motor through

(Photo 4) so that it will not be pinched under the

electrical box.

(Photo 10) and

Photo 3

Photo 4

Ground wire

Ground wire

Upper catch

Electrical box

Screw of

the electrical cover

Screw of

the V.A. clamp

DISPLAY AND i-see

SENSOR ASSEMBLY

Lead wire holder

Indoor power

P.C. board

Catch of the DISPLAY AND

i-see SENSOR ASSEMBLY

Photo 5

Screw of the

conduit cover

Indoor electronic

control P.C. board

Screw of

the electrical box

Screw of

the terminal block

Screw of the

conduit plate

33

Page 34

OPERATING PROCEDURE PHOTOS

OBH683D

3. Removing the indoor power P.C. board, the

switch board, the display board, the receiver

board and the indoor electronic control P.C.

board

(1) Remove the panels (Refer to 1.) and the right corner

box.

(2) Remove the indoor electrical box (Refer to 2.).

(3) Remove the ground wire connected to the electrical

box from the indoor power P.C. board.

(4) Disconnect the following connectors:

<Indoor electronic power P.C. board>

CN106 (Switch board)

CN201 (Terminal block)

CN202 (To the indoor electronic control P.C. board)

(5) Remove the lead wire holder.

(6) Remove the indoor power P.C. board.

(7) Disconnect the following connectors:

<Indoor electronic control P.C. board>

CN111 (Room temperature thermistor)

CN112 (Indoor coil thermistor)

(8) Unhook the catches of the DISPLAY AND i-see

SENSOR ASSEMBLY from the electrical box (right

side).

(9) Unhook the catch of the rear cover of the DISPLAY

AND i-see SENSOR ASSEMBLY, and open the rear

cover.

Remove the display P.C. board and the receiver P.C.

board.

(10)

Open the switch panel and remove the switch P.C.

board.

Photo 6

Catch of the DISPLAY AND

i-see SENSOR ASSEMBLY

Photo 7

Receiver P.C. board

Display P.C. board

34

Page 35

OPERATING PROCEDURE PHOTOS

OBH683D

4. Removing the nozzle assembly

(1) Remove the panels (Refer to 1.) and the right corner

box.

(2) Remove the indoor/outdoor connecting wire (Refer to

2.).

(3) Remove the electrical cover (Refer to 2.).

(4) Disconnect the following connector:

<Indoor electronic control P.C. board>

CN151 (Vane motor)

(5) Remove the DISPLAY AND i-see SENSOR

ASSEMBLY.

(6) Pull out the drain hose from the nozzle assembly and

remove the nozzle assembly.

(7) Remove the vane motors (Refer to 5, 6.).

5. Removing the vertical vane motor

(1) Remove the nozzle assembly (Refer to 4.)

(2) Remove the screw of the vertical vane motor unit, and

pull out the vertical vane motor unit.

(3) Remove the screws of the vertical vane motor unit

cover.

(4) Disconnect the connector from the vertical vane

motor.

(5) Remove the vertical vane motor from the vertical

motor unit cover.

Photo 8

Screw of the vertical

vane motor unit

Screws of the vane

motor unit cover

Photo 9

Screws of the

horizontal vane motor unit

6. Removing the horizontal vane motor

(1) Remove the nozzle assembly (Refer to 4.).

(2) Remove the screws of the horizontal vane motor unit,

and pull out the horizontal vane motor unit.

(3) Remove the screws of the horizontal vane motor.

(4) Disconnect the connector from the horizontal vane

motor.

(5) Remove the horizontal vane motor from the horizontal

vane motor unit.

Screws of the horizontal

vane motor

Screws of the

horizontal vane

motor

35

Page 36

OPERATING PROCEDURE PHOTOS

OBH683D

7. Removing the indoor fan motor, the indoor coil

thermistor and the line flow fan

(1) Remove the panels (Refer to 1.) and the right corner

box.

(2) Remove the indoor electronic control P.C. board

holder, the electrical box and the nozzle assembly.

(3) Remove the screws fixing the motor bed.

(4) Release the hooks of the water cut and remove the

water cut.

(5) Loosen the screw fixing the line flow fan.

(6) Remove the motor bed together with the indoor fan

motor and the motor band.

(7) Release the hooks of the motor band and remove the

motor band. Pull out the indoor fan motor.