Page 1

Global LCD Panel Exchange Center

12.1” SVGA

www.panelook.com

TENTATIVE

All information in this technical data sheet is tentative

and subject to change without notice.

TECHNICAL SPECIFICATION

D006L

D121S-L01

Melco Display Technology Inc.

Date: Jun.19,’06

MDTI Confidential (1/22) D121S-L01_02_00

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 2

Global LCD Panel Exchange Center

CONTENTS

No. Item Page

-- COVER 1

-- CONTENTS 2

www.panelook.com

1 APPLICATION 3

2 OVERVIEW 4

3 ABSOLUTE MAXIMUM RATINGS 5

4 ELECTRICAL CHARACTERIST ICS 5, 6, 7

5 INTERFACE PIN CONNECTIO N 8, 9

6 INTERFACE TIMING 10, 11, 12, 13

7 BLOCK DIAGRAM 14

8 MECHANICAL SPECIFICATION 15, 16

9 OPTICAL CHARACT ERISTICS 17, 18

10 RELIABILITY TEST CONDITION 19

11 HANDLING PRECAUTIONS FOR TFT-LCD MODULE 20, 21, 22

MDTI Confidential (2/22) D121S-L01_02_00

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 3

Global LCD Panel Exchange Center

1. APPLICATION

This specification applies to color TFT-LCD module, D006L / D121S-L01.

These specification papers are the proprietary product of Melco Display Technology Inc. (“MDTI”)

and include materials protected under copyright of MDTI. No part of this document may be

reproduced in any form or by any means without the express written permission of MDTI.

MDTI does not assume any liability for infringement of patents, copyrights or other intellectual

property rights of third parties by or arising from use of a product specified in this document. No

license, express, implied or otherwise, is granted under any patents, copyrights or other

intellectual property rights of MDTI or of others.

MDTI classifies the usage of the TFT-LCD module as follows. Please confirm the usage before using

www.panelook.com

the product.

(1) Standard Usage

(2) Special Usage

(3) Specific Usage

The product specified in this document is designed for “Standard Usage” unless otherwise specified

in this document. If customers intend to use the product for applications other than those specified

for “Standard Usage”, they should contact MDTI sales representative in adva nce.

Computers, office equipment, factory automation equipment, test and measurement

equipment, communications, transportation equipment(automobiles, ships, trains, etc.),

provided, however, that operation is not influenced by TFT-LCD directly.

Medical equipment, safety equipment, transportation equipment, provided, however, that

TFT-LCD is necessary to its operation.

Cockpit Equipment, military systems, aerospace equipment, nuclear reactor control

systems, life support systems and any othe r equipment. MDTI should make a con tract

that stipulate apportionment of responsibilities between MDTI and our customer.

MDTI has been making continuous effort to improve the reliability of its products. Customers

should implement sufficient reliability design of their application equipments such as redundant

system design, fail-safe functions, anti-failure features.

MDTI assumes no responsib ility for any da mage resulting from the use of the product that does not

comply with the instructions and the precautions specified in this document.

MDTI Confidential (3/22) D121S-L01_02_00

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 4

Global LCD Panel Exchange Center

2. OVERVIEW

D006L / D121S-L01 is 12.1” col or TFT- LCD (Th in Fi lm Tran sistor Liqui d Cr ystal Di splay) modul e

composed of LCD panel, driver ICs, control circuit, and backlight unit.

By applyi ng 6 bit digi tal data, 800 × 600, 262 K-col or images ar e displayed on the 12.1” diagon al

screen. Input power voltage is single 3.3V or 5.0V for LCD driving.

The type of data and c ontrol sig nals are dig ital and transmi tted via CM OS interf ace per Typ. 40

MHz clock cycle.

Inverter for backlight is not included in this module. General specifications are summarized in the

following table:

ITEM SPECIFICATION

Display Area (mm)

Number of Dots 800 × 3 (H) × 600 (V)

www.panelook.com

246.0(H) × 184.5(V)

(12.106-inch diagonal)

Pixel Pitch (mm) 0.3075 (H) × 0.3075 (V)

Color Pixel Arrangement RGB vertical stripe

Display Mode Normally white TN

Number of Color 262 K

Brightness (cd/m2) 400

Wide Viewing Angle Technology Optical compensation film

Surface Treatment Antiglare and hard-coating 3H

Viewing Angle (CR ≥ 10) -65∼65° (H) -75~45° (V)

Electrical Interface CMOS

Optimum Viewing Angle(Contrast ratio) 6 o’clock

Module Size (mm) 280.0 (W) × 210.0 (H) × 12.0 (D)

Module Mass (g) 720

Backlight Unit CCFL, 2-tube s, edge-light, replaceab le

Characteristic value without any note is typical value.

MDTI Confidential (4/22) D121S-L01_02_00

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 5

Global LCD Panel Exchange Center

www.panelook.com

3. ABSOLUTE MAXIMUM RATINGS

ITEM SYMBOL MIN. MAX UNIT

Power Supply Voltage for LCD VCC 0 6.0 V

Logic Input Voltage VI -0.3 6.5 V

Lamp Voltage VL 0 2000 Vrms

Lamp Current IL 0 18 mArms

Lamp Frequency FL -- 80 kHz

Operation Temperature(Panel)

Operation Temperature(Ambient)

Storage Temperature

Note 1,2)

Note 2)

T

Note 2)

T

T

op(Panel)

op(Ambient)

stg

-20 70 °C

-20 70 °C

-20 80 °C

[Note]

1) Measured at the center of active area and at the center of panel back surface

2) Top,Tstg ≤ 40°C : 90%RH max. without condensation

Top,Tstg > 40°C : Absolute humidity shall be less than t he value of 90%RH at 40 °C without

condensation.

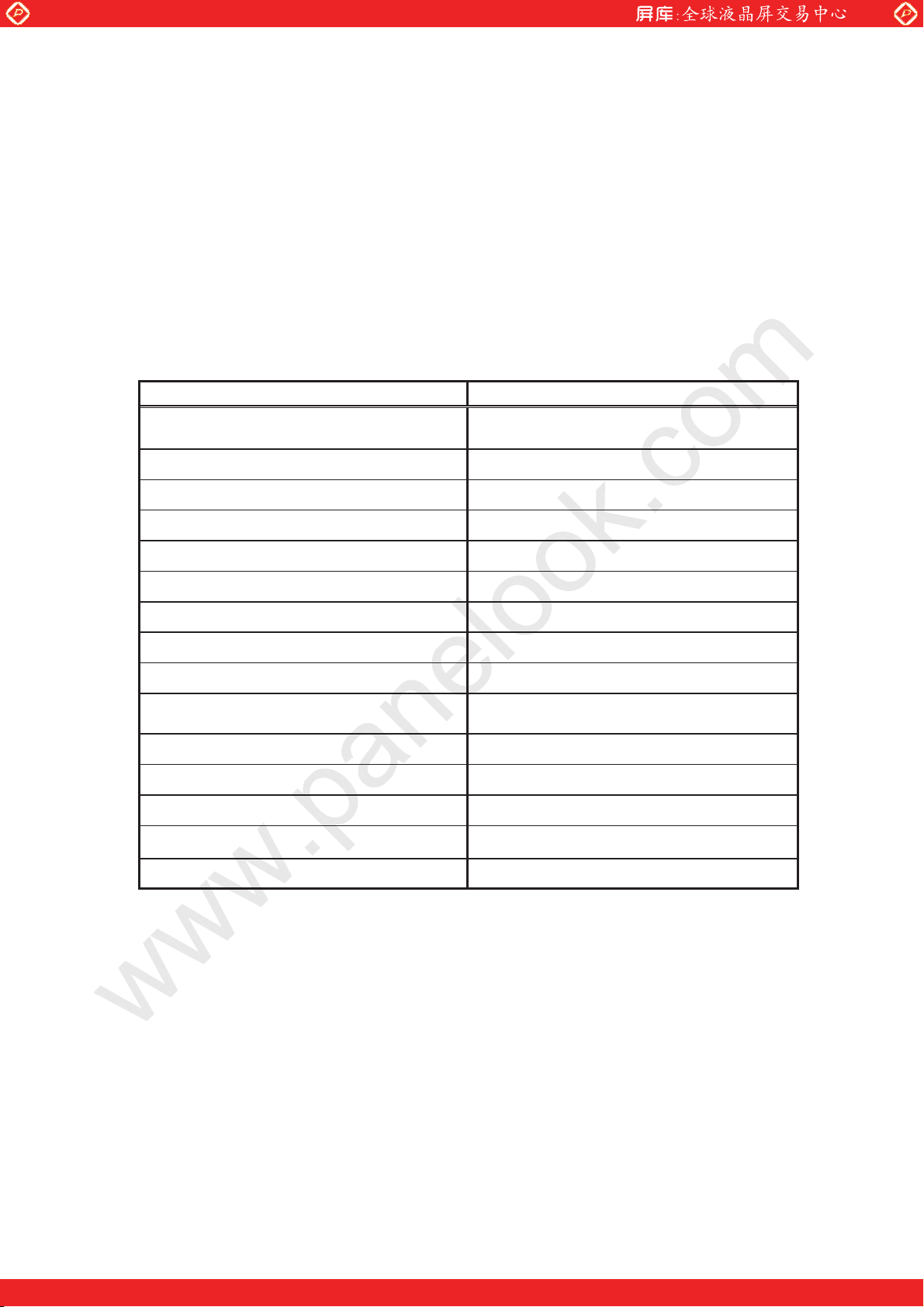

4. ELECTRICAL CHARACTERISTICS

(1) TFT-LCD Ambient temperature: Ta = 25℃

ITEM SYMBOL MIN. TYP. MAX. UNIT Remarks

Power Supply

Voltage for LCD

Power Supply

Current for LCD

3.3V pow e red VCC 3.0 3.3 3 .6 V

5.0V pow e red VCC 4.5 5.0 5 .5 V

3.3V powered ICC -- 340 500 mA

5.0V powered ICC -- 220 340 mA

*1)

*1)

*2)

*2)

Permissive Input Ripple Voltage VRP -- -- 100 mVp-p VCC = +3.3V/5.0 V

Logic Input

Voltage

High VIH 2.0 -- 5.5 V

Low VIL 0 -- 0.8 V

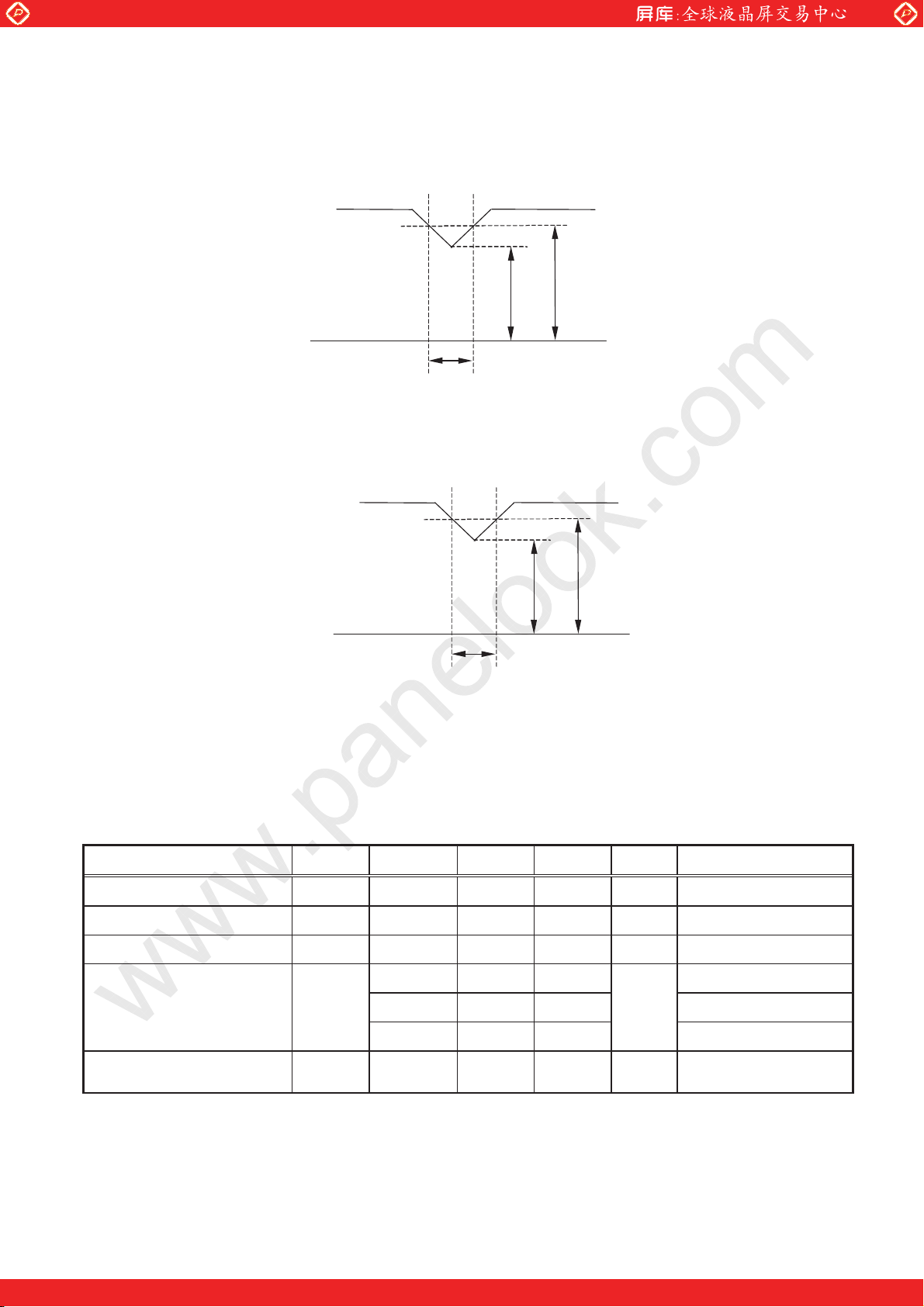

*1) Power and signals sequence:

t1 ≤ 10 ms 200 ms ≤ t4

0 < t2 ≤ 50 ms 200 ms ≤ t5

0 < t3 ≤ 50 ms 0 ≤ t6

VCC

LCD Power Supply

Logic Signal

0.9VCC

data

0.1VCC

0.9VCC

0.1VCC

0.1VCC

t2

t1

Backlight

Backlight Power Supply

t5 t6

data: RGB DATA, DCLK, HD, VD, DENA

t3

t4

MDTI Confidential (5/22) D121S-L01_02_00

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 6

Global LCD Panel Exchange Center

VCC-dip conditions:

(a) 3.3 V powered

1) When 2.7 V

2) When VCC < 2. 7 V

VCC-dip conditions should also follow the power and signals sequence.

(b) 5.0V powered

1) When 4.2 V

2) When VCC < 4. 2 V

VCC-dip conditions should also follow the power and signals sequence.

www.panelook.com

≤ VCC < 3.0 V, t d ≤ 10 ms

VCC

3.0V

2.7V

td

≤ VCC < 4.5 V, t d ≤ 10 ms

VCC

4.5V

4.2V

td

*2) Typical current condition:

64-gray-bar pattern

600 line mode

VCC = +3.3 V / 5.0 V, f

=37.9kHz, fV=60.3Hz, f

H

= 40MHz

CLK

(2) Backlight

Ta = 25℃

ITEM

SYMBOL

MIN. TYP. MAX. UNIT Remarks

Lamp Voltage VL -- 540 -- Vrms IL = 12.0 mArms

Lamp Current IL 6.0 12.0 14.0 mArms

Lamp Frequency FL 30 -- 60 kHz

* 2), *6)

*3)

1000 -- -- Ta = 25°C

Starting Lamp Voltage VS

1200 -- -- Ta = 0°C

1290 -- --

Lamp Life Time LT 50,000 -- -- h

Vrms

Ta = -20°C

* 4),*5)

IL = 12.0 mArms,

Continuous operation

MDTI Confidential (6/22) D121S-L01_02_00

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 7

Global LCD Panel Exchange Center

[Note]

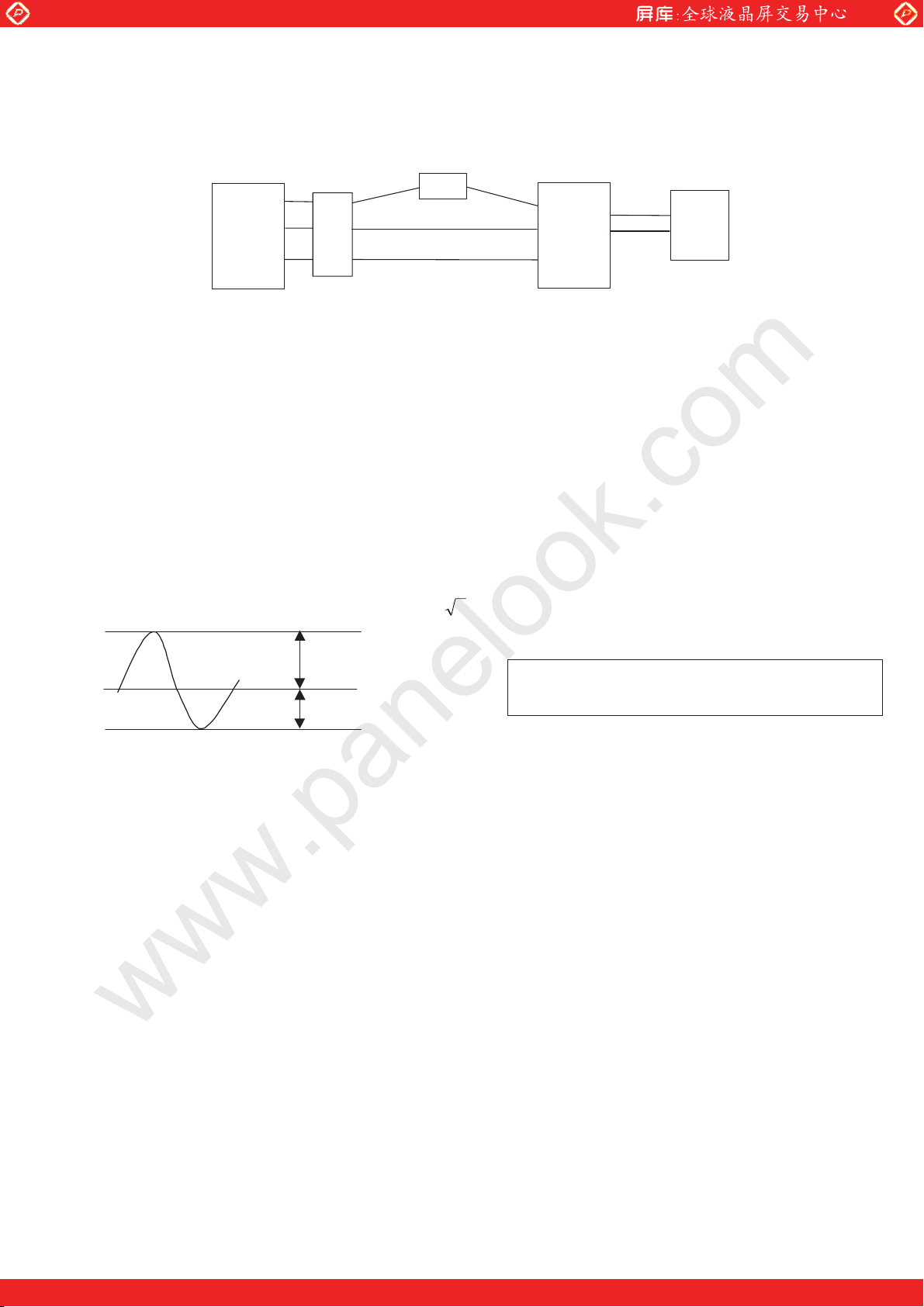

*1)Please use synchronous inverter.

*2) Lamp Current measurement method (The current meter is inserted in low voltage line.)

www.panelook.com

A

Inverter

Power

Supply

LCD

Module

CTL

CTH

CTH

*3) Lamp frequency of inverter may produce interferenc e with horizontal synchronous frequency,

and this may cause horizontal beat on the display. Therefore, please adjust lamp frequency, and

keep inverter as far from module as possible or use electronic shielding between inverter and

module to avoid the interference.

*4) Lamp life time is defined as the time either when the brightness becomes 50% of the initial

value, or when the starting lamp voltage does not meet the value specified in this ta ble.

*5) The life time of the backlight depends on the ambient temperature. The life time will decrease

under low/high temperature.

*6) Please use the inverter which has symmetrical current wave form as follows,

The degree of unbalance: less than 10%

The ratio of wave height: less than

±10%

2

I

PH

I

PL

CURRENT WAVE FORM

IPH: High side peak

I

: Low side peak

PL

The degree of unbalance = |IPH - IPL| / Irms

The ratio of wave height = I

(or IPL) / Irms

PH

100(%)

×

MDTI Confidential (7/22) D121S-L01_02_00

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 8

Global LCD Panel Exchange Center

5. INTERFACE PIN CONNECTION

(1) CN 1(INTERFACE SIG NAL)

Used connector: DF9B-41P-1V(32) (Hirose)

Correspon ding connector: DF9B-41S-1V (Hirose)

Pin No. Symbol Function

1 GND Signal ground

2 DCLK Clock signal for sampling catch data signal

3 GND Signal ground

4 HD Horizontal sync signal

5 VD Vertical sync signal

6 GND Signal ground

7 GND Signal ground

8 GND Signal ground

9 R0 RED data signa l(LSB)

10 R1 RED data signal

11 R2 RED data signal

12 GND Signal ground

13 R3 RED data signal

14 R4 RED data signal

15 R5 RED data signal(MSB)

16 GND Signal ground

17 GND Signal ground

18 GND Signal ground

19 G0 GREEN data signal(LSB)

20 G1 GREEN data s ignal

21 G2 GREEN data s ignal

22 GND Signal ground

23 G3 GREEN data s ignal

24 G4 GREEN data s ignal

25 G5 GREEN data signal(MSB)

26 GND Signal ground

27 GND Signal ground

28 GND Signal ground

29 B0 BLUE data signal (LSB)

30 B1 BLUE data signal

31 B2 BLUE data signal

32 GND Signal ground

33 B3 BLUE data signal

34 B4 BLUE data signal

35 B5 BLUE data signal(MSB)

36 GND Signal ground

37 DENA Data enable signal(to settle the viewing area)

38 GND Signal ground

39 VCC +3.3 / 5.0 V Power supply

40 VCC +3.3 / 5.0 V Power supply

41

SC Scan direct ion control.(Low:Norm al, High:Reverse)

www.panelook.com

*)The shielding case is connected with GND.

MDTI Confidential (8/22) D121S-L01_02_00

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 9

Global LCD Panel Exchange Center

(2)CN 2(BACKLIGHT)

Backlight-side connector: BHR-04 VS-1 (JST)

Inverter-side connector: SM04(4.0)B-BHS-1 (JST)

Pin No. Symbol Function

[Note] VBLH - VBLL = VL

www.panelook.com

1, 2 CTH VBL H (High vo ltage)

4 CTL VBLL (Low voltage)

MDTI Confidential (9/22) D121S-L01_02_00

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 10

Global LCD Panel Exchange Center

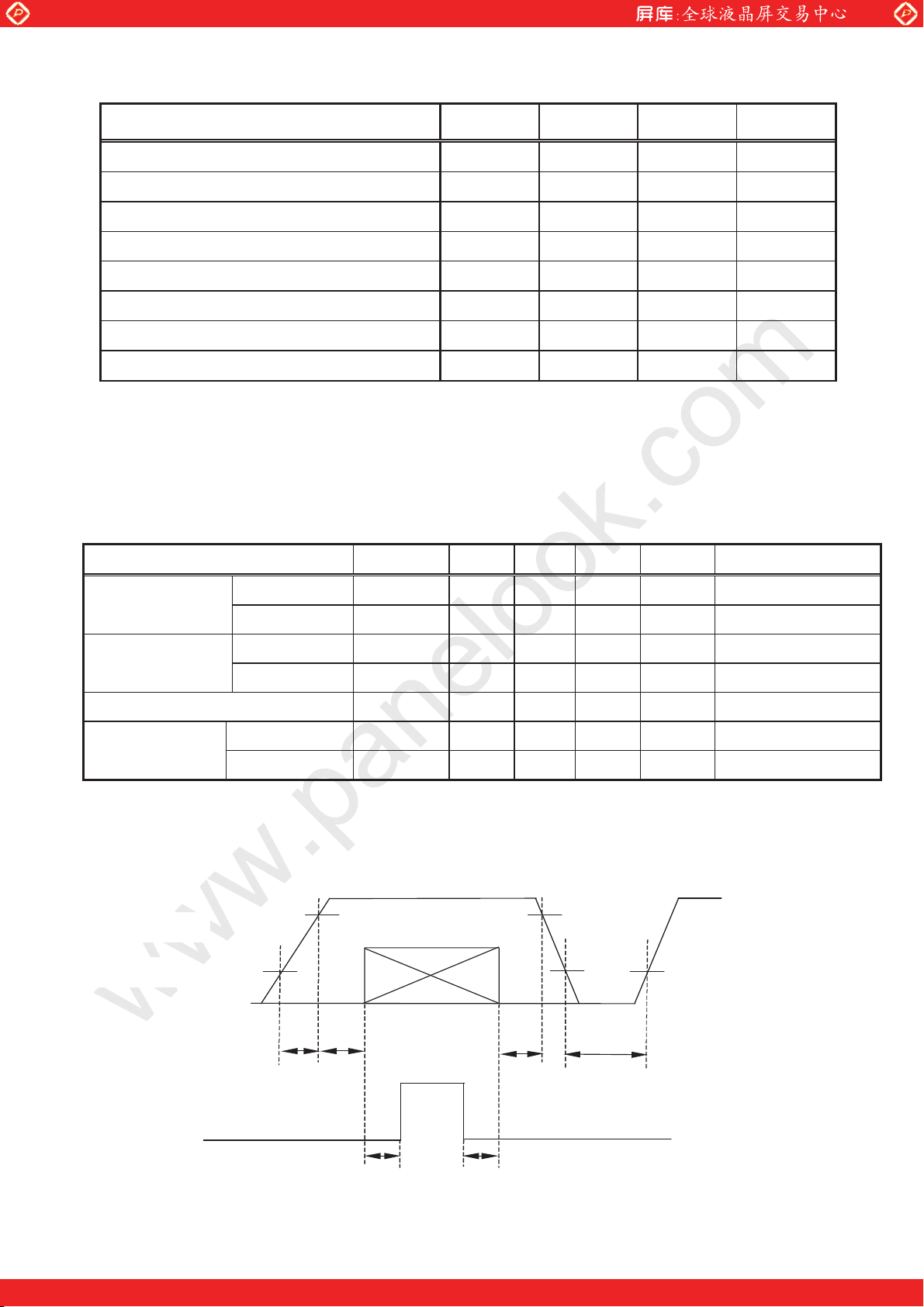

6. INTERFACE TIMING

(1) Timing Specifications

ITEM SYMBOL MIN TYP MAX UNIT

www.panelook.com

DCLK

DATA

(R,G,B,DENA,

HD, VD)

DENA

HD

Frequency f

Period t

Low Width t

High Width t

Set up time t

Hold time t

Horizontal Active Time t

Horizontal Front Porch t

Horizontal Back Porch t

Vertical Active Tim e t

Vertical Front Porch t

Vertical Back Porch t

Frequency f

Period t

Low Width t

CLK

CLK

WCL

WCH

DS

DH

HA

HFP

HBP

VA

VFP

VBP

H

H

WHL

35 40 42 MHz

23.8 25 28.6 ns

10 -- -- ns

10 -- -- ns

4 -- -- ns

4 -- -- ns

800 800 800 t

0 40 -- t

10 216 -- t

600 600 600 t

1 1 -- t

2 27 -- t

CLK

CLK

CLK

H

H

H

35.2 37.9 39.2 kHz

25.5 26.4 28.4 μs

2 128 -- t

CLK

VD

Frequency f

Period t

Low Width t

V

V

WVL

55 60 64.2 Hz

15.6 16.7 18.2 ms

1 4 -- t

H

[Note]

1) DATA is latched at fall edge of DCLK in this specification.

2) Polarities of HD and VD are negative in this s pecification.

3) DENA (Data Enable) should always be positive polarity as shown in the timing specification.

4) DCLK should appear during all invalid period, and HD should appear during invalid pe riod of

frame cycle.

5) t

HFP

+ t

HBP

≥ 20 t

CLK

MDTI Confidential (10/22) D121S-L01_02_00

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 11

Global LCD Panel Exchange Center

V

V

K

V

V

K

f

f

V

(2) Timing Chart

www.panelook.com

a. Pixel Timing Chart

DCL

DATA

(R,G,B),

DENA, HD , V D

b. Horizontal Timing Chart

DCL

DATA

Invalid Data Invalid Data

(R,G,B)

t

HFP

t

HBP

t

CLK

t

WCH

t

DS

First Data

1 2 799 8003

t

WCL

2.0

0.8

t

DH

2.0

0.8

t

HA

Last Data

DENA

HD

c. Vertical Timing Chart

HD

LINE DATA

t

VFP

DENA

D

tH=1/

H

t

WHL

Invalid Data Invalid Data

t

VBP

t

WVL

12 5996003

t

VA

tV=1/

V

MDTI Confidential (11/22) D121S-L01_02_00

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 12

Global LCD Panel Exchange Center

(3) Color Dat a Assignment

www.panelook.com

INPUT DATA

COLOR

R5 R4 R3 R2 R1 R0 G5 G4 G3 G2 G1 G0 B5 B4 B3 B2 B1 B0

MSB LSB MSB LSB MSB LSB

R DATA G DATA B DATA

BLACK 00 0 0 000000000 0 0 000

RED(63) 11 1 1 110000000 0 0 000

GREEN(63) 0 0 0 0 001111110 0 0 000

BASIC BLUE(63) 00 0 0 000000001 1 1 111

COLOR CYAN 00 0 0 001111111 1 1 111

MAGENTA 11 1 1 110000001 1 1 111

YELLOW 11 1 1 111111110 0 0 000

WHITE 11 1 1 111111111 1 1 111

RED(1) 00 0 0 010000000 0 0 000

RED(2) 00 0 0 100000000 0 0 000

RED

RED(62) 11 1 1 100000000 0 0 000

RED(63) 11 1 1 110000000 0 0 000

GREEN(1) 0 0 0 0 000000010 0 0 000

GREEN(2) 0 0 0 0 000000100 0 0 000

GREEN

GREEN(62) 0 0 0 0 001111100 0 0 000

GREEN(63) 0 0 0 0 001111110 0 0 000

BLUE(1) 00 0 0 000000000 0 0 001

BLUE(2) 00 0 0 000000000 0 0 010

BLUE

BLUE(62) 00 0 0 000000001 1 1 110

BLUE(63) 00 0 0 000000001 1 1 111

[Note]

1) Definition of gray scale

Color (n) --- n indicates gray scale level.

Higher n means brighter level.

2) Data

1:High, 0: Low

MDTI Confidential (12/22) D121S-L01_02_00

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 13

Global LCD Panel Exchange Center

(4) Display Position and Scan Direction

D(X,Y) shows the data number of input signal for LCD panel signal processing PCB.

SC:Low SC:High

www.panelook.com

D(1,1) D(800,1)

D(1,600)

D(800,600)

CN2

D(800,600) D(1,600)

CN2

D(800,1) D(1,1)

MDTI Confidential (13/22) D121S-L01_02_00

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 14

Global LCD Panel Exchange Center

7. BLOCK DIAGRAM

Timing signal

Display data

Timing

Converter

www.panelook.com

G1

G2

TFT-LCD

Power

Drivers(gate)

I/F Connector

Power

Supply

Circuit

G600

S1

S2

Drivers(source)

CCFL

S2399

S2400

CN2

1

2

4

MDTI Confidential (14/22) D121S-L01_02_00

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 15

Global LCD Panel Exchange Center

8. MECHANICAL SPECIFICATIONS

(1) Front Side

www.panelook.com

MDTI Confidential (15/22) D121S-L01_02_00

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

(Unit: mm)

www.panelook.com

Page 16

Global LCD Panel Exchange Center

(2) Rear Side

www.panelook.com

1) Tolerance is ±0.5mm unless noted.

2) Except for thickness of PET film

MDTI Confidential (16/22) D121S-L01_02_00

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

(Unit:mm)

www.panelook.com

Page 17

Global LCD Panel Exchange Center

www.panelook.com

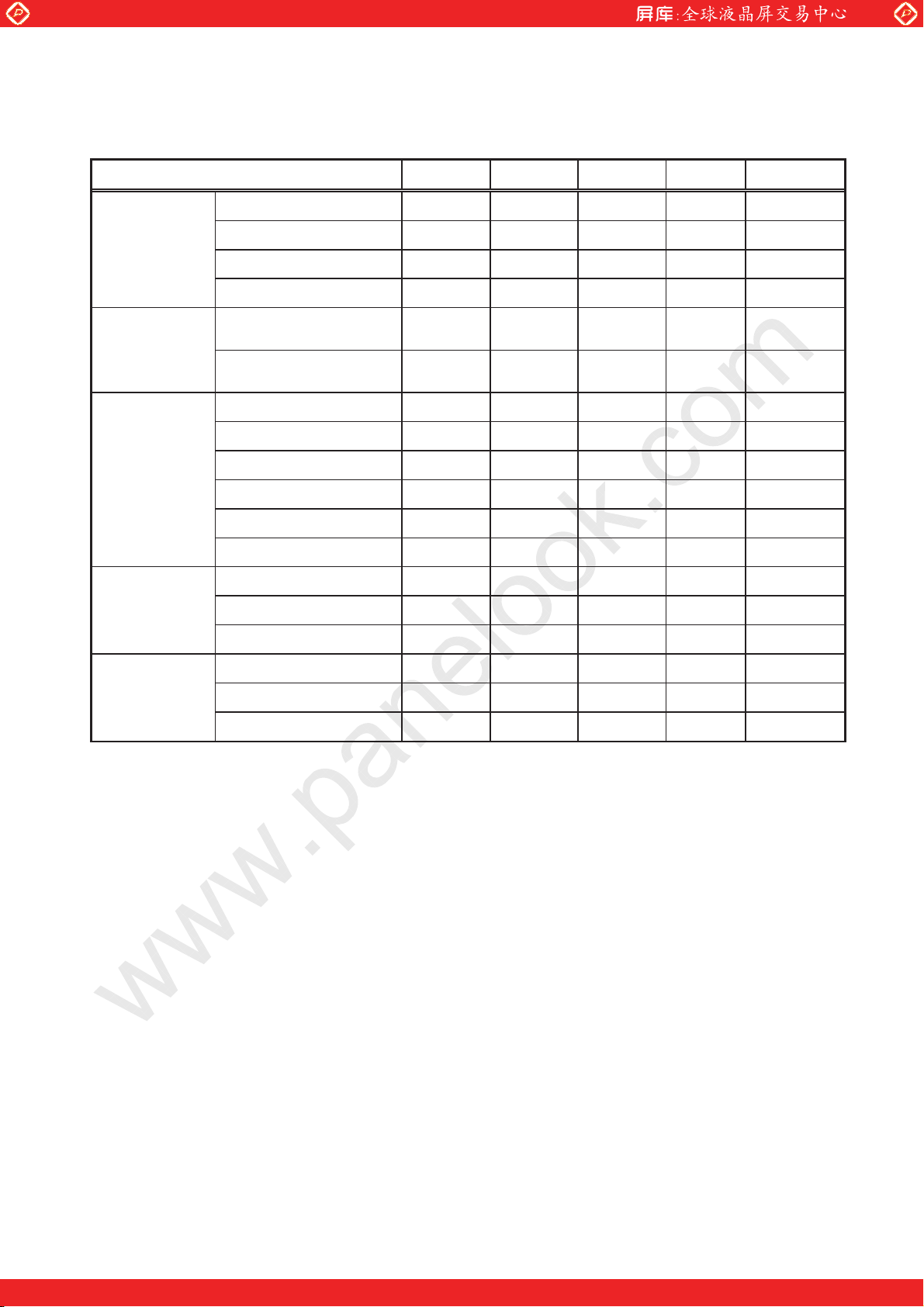

9. OPTICAL CHARACTERISTICS

Ta=25°C, VCC=3.3V / 5.0V, Input Signals: Typ. Values shown in Section 6

ITEM SYMBOL CONDITION MIN TYP MAX UNIT Remarks

Contrast Ratio CR θ = φ = 0° 350 500 -- --

Luminance Lw θ = φ = 0° 250 400 -- cd/m

Luminance Uniformity ΔLw θ = φ = 0° -- -- 30 % *1)*4)*6)

Response Time tr θ = φ = 0° -- 10 -- ms

Horizontal φ -50∼50 -65∼65 -- °

Viewing

Angle

Vertical θ

Horizontal φ -65∼65 -80∼80 -- °

Vertical θ

Image sticking tis 2 h -- -- 2 s

Red Rx 0.556 0.586 0.616

Color Green Gx 0.300 0.330 0.360

Coordinates Gy θ = φ = 0° 0.525 0.555 0.585 --

Blue Bx 0.138 0.168 0.198

White Wx 0.302 0.332 0.362

tf θ = φ = 0° -- 30 -- ms

CR ≥ 10

-40∼30 -75∼45 -- °

CR ≥ 5

-50∼40 -80∼55 -- °

Ry 0.310 0.340 0.370

By 0.167 0.197 0.227

Wy 0.337 0.367 0.397

*1)*2)*6)

2

*1)*3)*6)

*1)*5)*6)

*1)*5)*6)

*1)*6)

*1)*6)

*1)*6)

*1)*6)

*7)

*1)*6)

[Note]

These items are measured using CS1000(MINOLTA) for color coordinates, EZContrast(ELDIM) for

viewin g angle and CS1000 or BM- 5A ( TOPC ON) f o r ot he r s u nde r th e dar k r oo m c o nd it io n ( n o ambi en t

light) after more than 30 minutes from turning on the lamp unless noted.

Condition: IL = 12.0 mArms, FL=55kHz

*1) Definition of Contrast Ratio

CR=ON (White) Luminance / OFF(Black) Luminance: measurement point 5 (center point)

shown in a figure below

*2) Definition of Luminance and Luminance Uniformity

Lw= ON (White) Luminance: measurement point 5 (center point) shown in a figure below

ΔLw=[Lw(MAX)/Lw(MIN)-1] × 100

200

(1, 1)

150

300

450

400

1

3

600

2

5

4

(800, 600)

*3) Definition of Luminance

Lw= ON (White) Luminance

MDTI Confidential (17/22) D121S-L01_02_00

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 18

Global LCD Panel Exchange Center

*4) Definition of Luminance Uniformity

ΔLw=[Lw(MAX)/Lw(MIN)-1] × 100

*5) Definition of Response Time

White

Luminance

www.panelook.com

90%90%

tr

*6) Definition of Viewing Angle( θ , φ)

10%10% Black

tf

*7) Image sticking:

Continuously display the test pattern shown in the figure below for two-hours. Then display a

completely white screen. The previous image shall not persist more than two seconds a t 25°C.

Cols 398-402

White

Area

Rows 298-302

Black

Lines

TEST PATTERN FOR IMAGE STICKING TEST

MDTI Confidential (18/22) D121S-L01_02_00

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 19

Global LCD Panel Exchange Center

www.panelook.com

10. RELIABILITY TEST CONDITION

(1) Temp e rature and Humi dity

TEST ITEM CONDITIONS

HIGH TEMPERATURE

HIGH HUMIDITY OPERATIO N

HIGH TEMPERATURE OP ERATION 70°C, 240 h

LOW TEMPERAT URE OPERATION -20°C, 240 h

HIGH TEMPERATURE ST ORAGE 80°C, 240 h

LOW TEMPERATURE STORAGE -20°C, 240 h

THERMAL SHOCK

(2) Shock & Vibration

ITEM CONDITIONS

40°C, 90%RH, 240h

(No condensation)

BETWEEN -20°C (1h) and 8 0°C(1h),

100 CYCLES

Shock level: 1470m/s2(150G)

SHOCK Waveform: half sinusoidal wave, 2ms

(NON-OPERATION) Number of shocks: one shock input in each direction of three mutually

perpendicular axes for a total of six shock inputs

Vibration level: 9.8m/s2 (1.0G)

Waveform: sinusoida l

VIBRATION Frequency range: 5 to 500Hz

(NON-OPERATION) Frequency sweep rate: 0.5 octave /min

Duration: one sweep from 5 to 500 Hz in each of three mutually

perpendicular axis(each x,y,z axis: 1 hour, total 3 hours)

(3) Judgment standard

The judgment of the above tests should be made as follow:

Pass: Norma l display image, no dam age of the display function. (ex. no line defect)

Partial transformation of the module parts should be ignored.

Fail: No disp lay image, damage of the display function. (ex. line defect)

MDTI Confidential (19/22) D121S-L01_02_00

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 20

Global LCD Panel Exchange Center

www.panelook.com

11. HANDLING PRECAUTIONS FOR TFT-LCD MODULE

Please pay attention to the followings in handling TFT-LCD products;

(1) ASSEMBLY PRECAUTION

a. Please use the mounting hole on the module in installing and do not bending or wrenching

LCD in assembling. And please do not drop, bend or twist LCD module in handling.

b. Please de sign display housing in accordance with the following guide lines.

(a) Housing case must be designed carefully so as not to put stresses on LCD all sides and not

to wrench module. The stresses may cause non-uniformity even if there is no

non-uniformity statically.

(b) Keep sufficient clearance between LCD module back surface and housing when the LCD

module is mounted. Approximately 1.0mm of the clearance in the design is recommended

taking into account the tolerance of LCD module thickness and mounting structure height

on the housing.

(c) Whe n some parts, suc h as, FPC cable and ferr ite plate, are in stalled u nderneath the LCD

module, still sufficient clearance is required, such as 0.5mm. This clearance is, especially, to

be reconsidered when the additional pa rts are implemented for EMI countermeasure.

(d) Design the inverter location and connector position carefully so as not to give stress to

lamp cable, or not to interface the LCD module by the lamp cable.

(e) Keep sufficient clearance between LCD module and the others parts, such as inverter and

speaker so as not to interface the LCD module. Approximately 1.0mm of the clearance in

the design is recommended.

(f) To avoid local elevation/decrease of temperature, considering location of heating element,

heat release, thermal design should be d one.

c. Please do not push or scratch LCD panel surface with anything hard. And do not soil LCD

panel surface by touching with bare hands. (Polarizer film, surface of LCD panel is easy to be

flawed.)

d. Please do not press any parts on the rear side such as source TCP, gate TCP, control circuit

board and FP Cs during handling LCD module. If pressing rear part is unavoidable, handle the

LCD module with care not to damage them.

e. Please wipe off LCD panel surface with absorbent cotton or soft cloth in case of it being soiled.

f. Please wipe off drops of adhesives like saliva and water on LCD panel surface immediately.

They might dama ge to cause panel surface variation and color change.

g. Please do not take a LCD module to pieces and reconstruct i t. Resolving and reconstructing

modules may cause them not to work well.

h. Please do not touch metal frames with bare hands and soiled gloves. A color change of the

metal frames can happen during a long preservation of soiled LCD modules.

MDTI Confidential (20/22) D121S-L01_02_00

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 21

Global LCD Panel Exchange Center

i. Please handle metal frame carefully to avoid getting hurt because edge of metal frame is very

sharp.

j. Please pay attention to handling lead wire of backlight so that it is not tugged in connecting

with inverter.

k. Please connect the metal frame of LCD module to GND in order to minimize the effect of

external noise and EMI.

l. Be su re to connect the cables and the connecters correctly.

(2) OPERATING PRECAUTIONS

a. Please be sure to turn off the power supply before connecting and disconnecting signal input

cable.

b. Please do not change variable resistance settings in LCD module. They are adjusted to the

www.panelook.com

most suitable value. If they are changed, it might happen LCD does not satisfy the

characteristics specification.

c. LCD backlight takes longer time to become stable of radiation characteristics in low

temperature than in room temperature.

d. The interface signal speed is very high. Please pay attention to transmission line design and

other high speed signal precautions to satisfy signal specification.

e. A condensation might happen on the surface and inside of LCD module in case of sudden

change of ambient temperature.

f. Please pay attention not to display the same pattern for very long time. Image might stic k on

LCD. Even if image sticking happens, it may dis appear as the operation time proceeds.

g. Please obey the same sa fe ins tructions as ones being prepared for ordinary electronic products.

(3) PRECAUTIONS WITH ELECTROSTATICS

a. This LCD module use CMOS-I C on circ uit board and TFT- LCD panel, and so it is easy to be

affected by electrostatics. Please be careful with electrostatics by the way of your body

connecting to the ground and so on.

b. Please remove protection film very slowly from the surface of LCD module to prevent from

electrostatics occurrence.

(4) STORAGE PRECAUTIONS

a. Please do not leave the LCDs in the environment of high humidity and high temperature such

as 60°C90%RH.

b. Please do not leave the LCDs in the environment of low temperature; below -20°C.

MDTI Confidential (21/22) D121S-L01_02_00

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 22

Global LCD Panel Exchange Center

(5) SAFETY PRECAUTIONS

a. When you waste damaged or unnecessary LCDs, it is recommended to crush LCDs into piec es

and wash them off with solvents such as acetone and ethanol, which should later be burned.

b. If any liquid leaks out of a dam aged glass cel l and comes i n contact wi th the hands, wash o ff

thoroughly with soap and water.

c. Be sure to turn off the power sup ply when inserting or d isconnectin g the cable .

d. Inverter should be designed carefully so as not to keep working in case of detecting over

current or open circuit on the lamp.

(6) OTHERS

a. A strong incident light into LCD panel might cause display characteristics changing inferior

www.panelook.com

because of polarizer film, color filter, and other materials becoming inferior. Please do not

expose LCD module direct sunlight and st rong UV rays.

b. Please pay attention to a panel side of LCD module not to contact with other materials in

preserving it alone.

c. For the packaging box, please pay attention to the followings;

(a) Packaging box and inner case for LCD are designed to protect the LCDs from the damage

or scratching during transportation. Please do not open except picking LCDs up from the

box.

(b) Please do not pile them up more than 5 boxes. (They are not designed so.) And please do not

turn over.

(c) Please handle packaging box with care not to give them sudden shock and vibrations. And

also please do not throw them up.

(d) Packaging box a nd inner case for LCDs are made of cardboard. So please pay attent ion not

to get them wet. (Such like keeping them in high humidity or wet place can occur getting

them wet.)

MDTI Confidential (22/22) D121S-L01_02_00

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Loading...

Loading...