Page 1

Page 2

Introduction

This manual covers the items required for maintaining the MITSUBISHI CNC M800/M80/E80 Series.

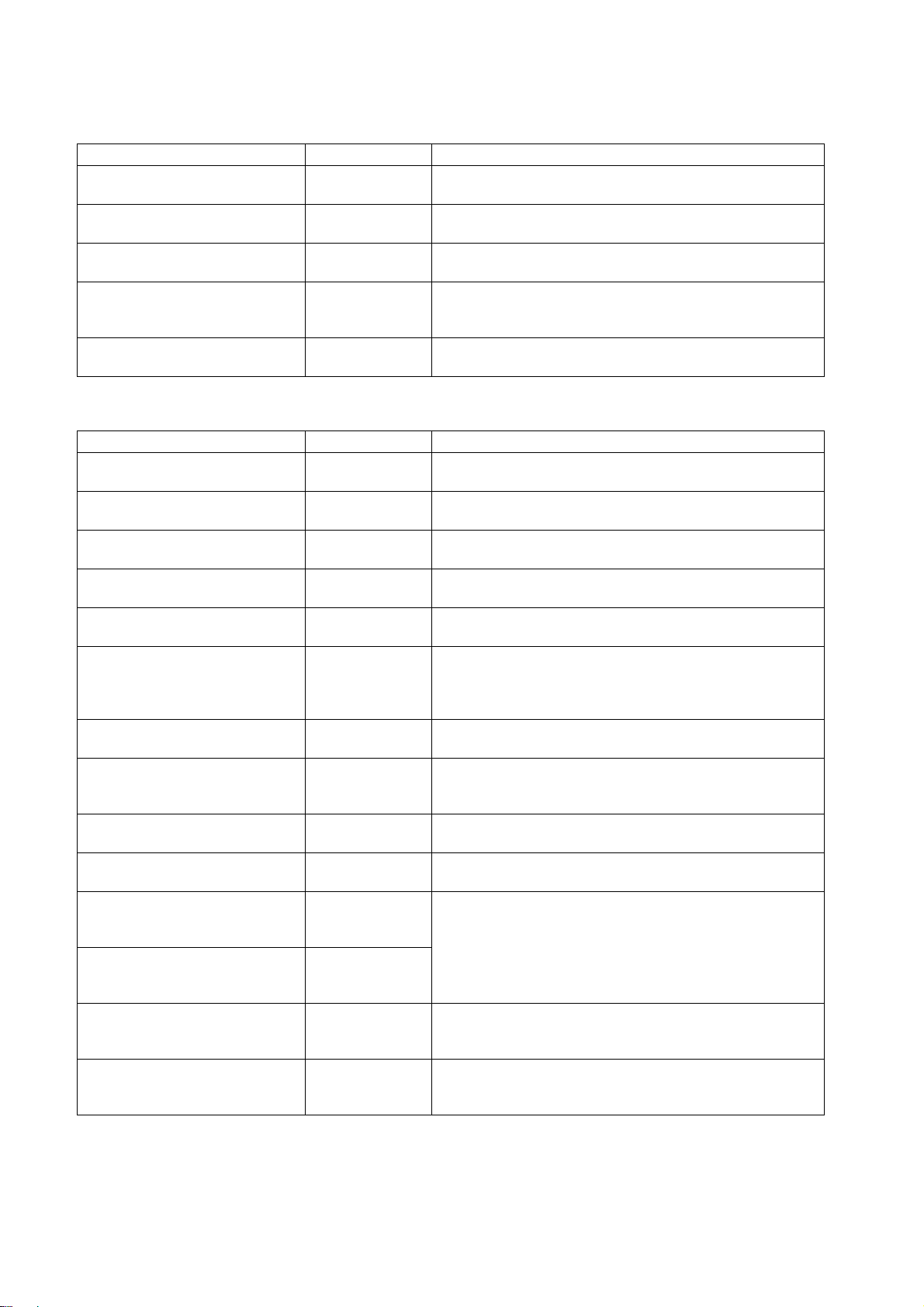

Supported models are as follows:

Supported models Abbreviations in this manual

M800W Series M850W, M830W

M800S Series M850S, M830S

M80W Series M80W

M80 Series M80 TypeA, M80 TypeB

E80 Series E80 TypeA, E80 TypeB

Abbreviations in this manual are as follows:

Abbreviations Supported models

M800, M800 Series M800W Series/M800S Series

M80, M80 Series M80W Series/M80 Series

M800/M80, M800/M80 Series M800W Series/M800S Series/M80W Series/M80 Series

M8, M8 Series M800W Series/M800S Series/M80W Series/M80 Series/E80 Series

Read this manual thoroughly and understand the product's functions and performance before starting to use.

The unit names, cable names and various specifications are subject to change without notice. Please confirm these before

placing an order.

Be sure to keep this manual always at hand.

The following screens described in this manual are the screens for Mitsubishi Electric's display unit.

If the display unit you are using is not manufactured by Mitsubishi, please contact the machine tool builder.

CAUTION

For items described as "Restrictions" or "Usable State" in this manual, the instruction manual issued by the

machine tool builder (MTB) takes precedence over this manual.

Items not described in this manual must be interpreted as "not possible".

This manual is written on the assumption that all the applicable functions are included. Some of them, however,

may not be available for your NC system. Refer to the specifications issued by the machine tool builder before

use.

Refer to the manuals issued by the machine manufacturer for each machine tool explanation.

Some screens and functions may differ depending on the NC system (or its version), and some functions may

not be possible. Please confirm the specifications before use.

Do not connect NC system to the Internet-connected network.

To maintain the safety of the NC system against unauthorized access from external devices via the network,

take appropriate measures.

In this manual, the following abbreviations might be used.

MTB: Machine tool builder

Also refer to the manuals on "Manual List" as necessary.

Page 3

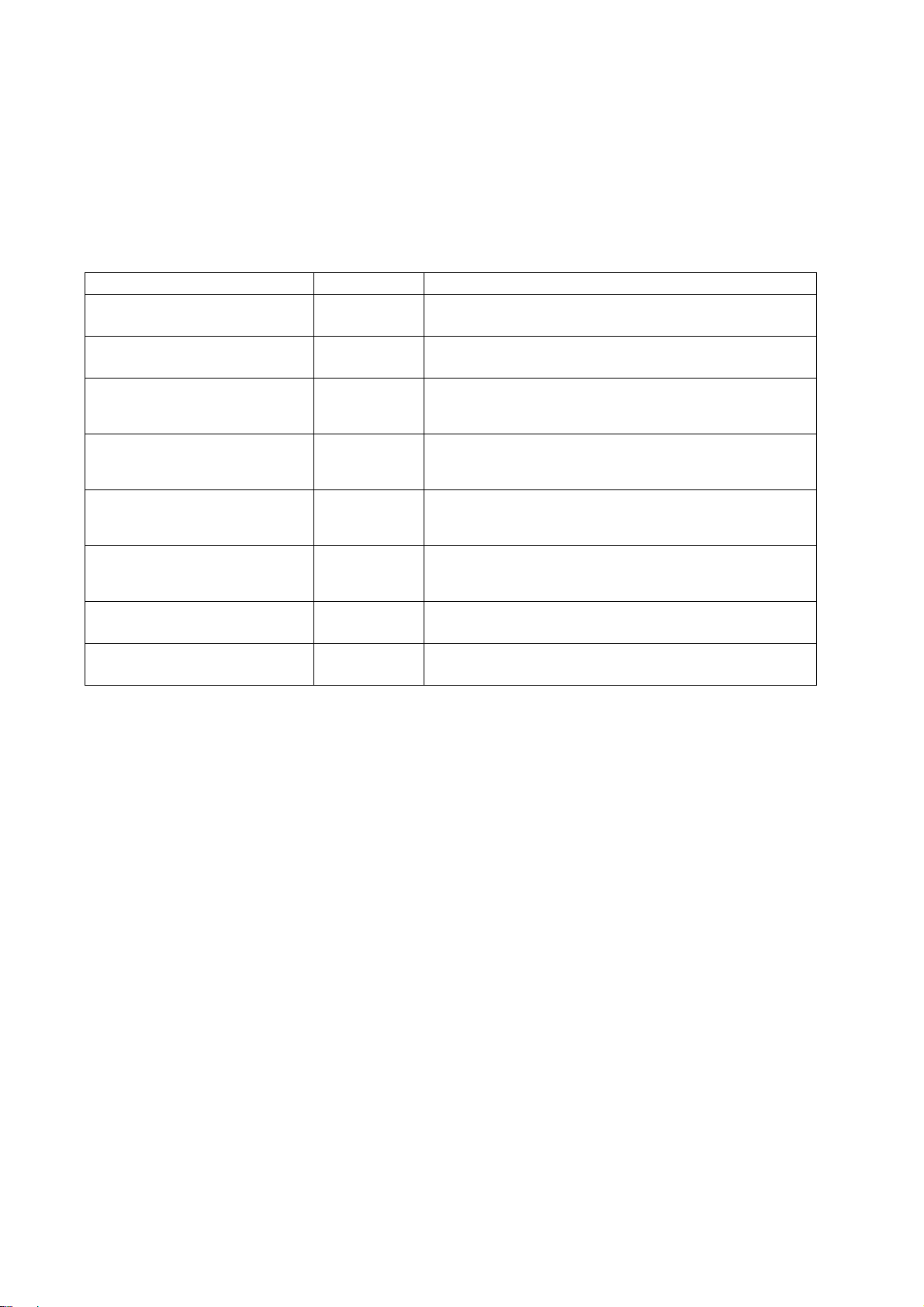

Manual List

Manuals related to M800/M80/E80/C80 Series are listed as follows.

These manuals are written on the assumption that all optional functions are added to the targeted model.

Some functions or screens may not be available depending on the machine or specifications set by MTB. (Confirm the

specifications before use.)

The manuals issued by MTB take precedence over these manuals.

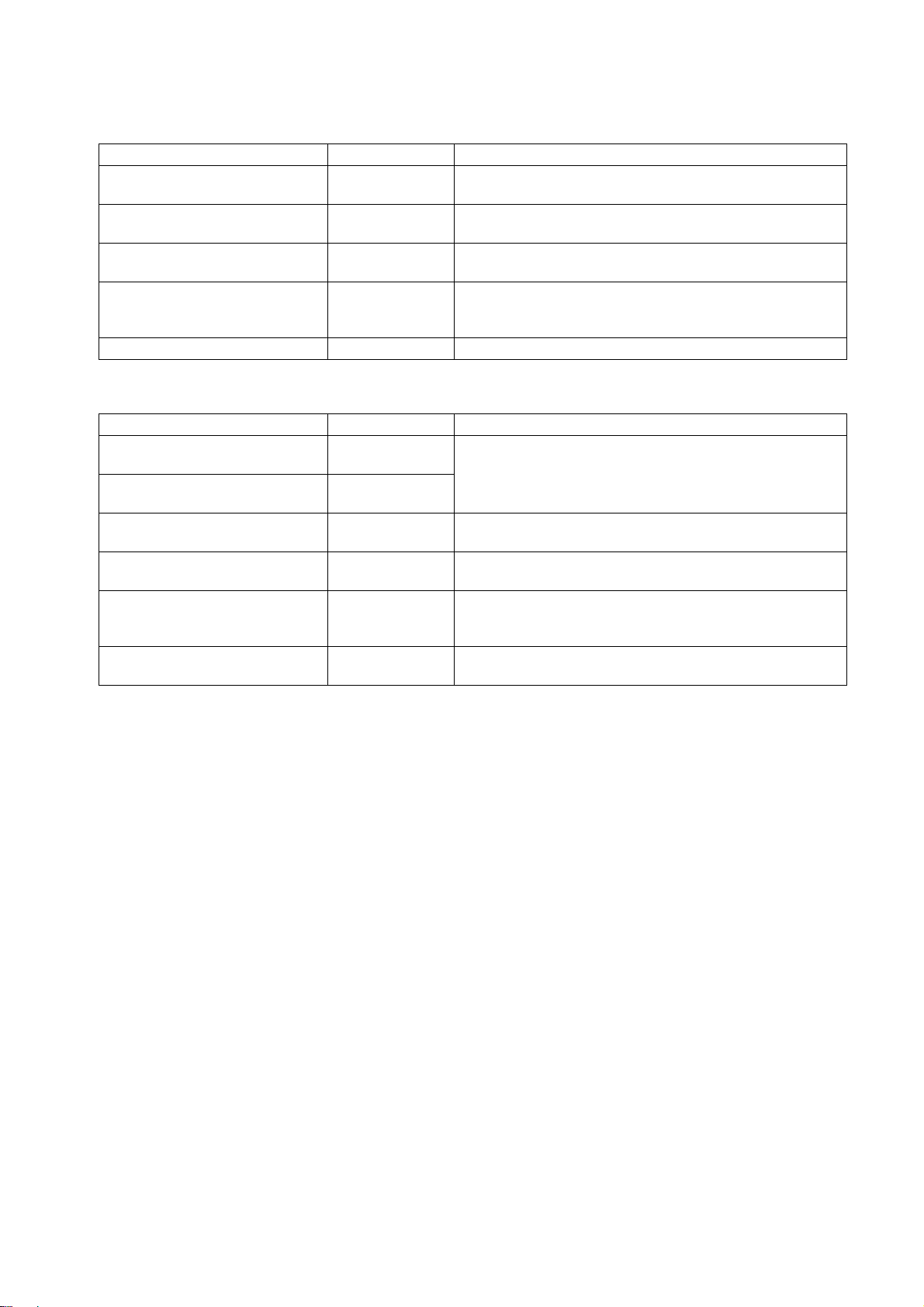

Manual IB No. Purpose and Contents

M800/M80/E80 Series

Instruction Manual

C80 Series

Instruction Manual

M800/M80/E80/C80 Series

Programming Manual

(Lathe System) (1/2)

M800/M80/E80/C80 Series

Programming Manual

(Lathe System) (2/2)

M800/M80/E80/C80 Series

Programming Manual

(Machining Center System) (1/2)

M800/M80/E80/C80 Series

Programming Manual

(Machining Center System) (2/2)

M800/M80/E80 Series

Alarm/Parameter Manual

C80 Series

Alarm/Parameter Manual

IB-1501274

IB-1501453

IB-1501275

IB-1501276

IB-1501277

IB-1501278

IB-1501279

IB-1501560

Operation guide for NC

Explanation for screen operation, etc.

Operation guide for NC

Explanation for screen operation, etc.

G code programming for lathe system

Basic functions, etc.

G code programming for lathe system

Functions for multi-part system, high-accuracy function, etc.

G code programming for machining center system

Basic functions, etc.

G code programming for machining center system

Functions for multi-part system, high-accuracy function, etc.

Alarms

Parameters

Alarms

Parameters

Page 4

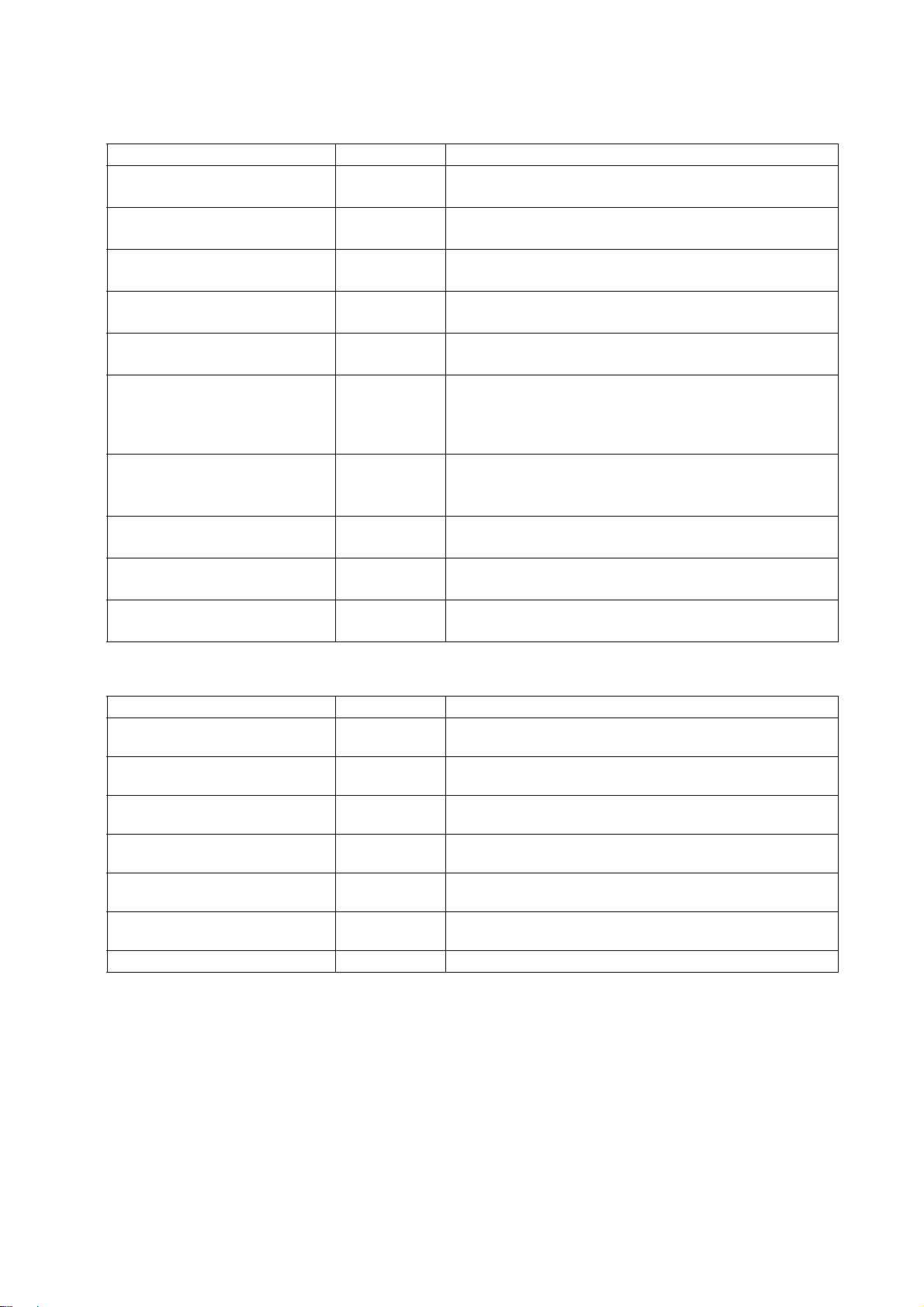

Manuals for MTBs (NC)

Manual IB No. Purpose and Contents

M800/M80/E80/C80 Series

Specifications Manual (Function)

M800/M80/E80/C80 Series

Specifications Manual (Hardware)

M800W/M80W Series

Connection and Setup Manual

M800S/M80/E80 Series

Connection and Setup Manual

C80 Series

Connection and Setup Manual

M800/M80/E80 Series

PLC Development Manual

M800/M80/E80 Series

PLC Programming Manual

M800/M80/E80/C80 Series

PLC Interface Manual

M800/M80/E80 Series

Maintenance Manual

C80 Series

Maintenance Manual

IB-1501505

IB-1501506

IB-1501268

IB-1501269

IB-1501452

IB-1501270

IB-1501271

IB-1501272

IB-1501273

IB-1501454

Model selection

Outline of various functions

Model selection

Specifications of hardware unit

Detailed specifications of hardware unit

Installation, connection, wiring, setup (startup/adjustment)

Detailed specifications of hardware unit

Installation, connection, wiring, setup (startup/adjustment)

Detailed specifications of hardware unit

Installation, connection, wiring, setup (startup/adjustment)

Electrical design

I/O relation (assignment, setting, connection), field network

Development environment (PLC on-board, peripheral

development environment), etc.

Electrical design

Sequence programming

PLC support functions, etc.

Electrical design

Interface signals between NC and PLC

Cleaning and replacement for each unit

Other items related to maintenance

Cleaning and replacement for each unit

Other items related to maintenance

Manuals for MTBs (drive section)

Manual IB No. Contents

MDS-E/EH Series

Specifications Manual

MDS-E/EH Series

Instruction Manual

MDS-EJ/EJH Series

ecifications Manual

Sp

MDS-EJ/EJH Series

Instruction Manual

MDS-EM/EMH Series

Specifications Manual

MDS-EM/EMH Series

Instruction Manual

DATA BOOK IB-1501252 Specifications of servo drive unit, spindle drive unit, motor, etc.

IB-1501226 Specifications for power supply regeneration type

IB-1501229 Instruction for power supply regeneration type

IB-1501232 Specifications for regenerative resistor type

IB-1501235 Instruction for regenerative resistor type

IB-1501238

IB-1501241 Instruction for multi-hybrid, power supply regeneration type

Specifications for multi-hybrid, power supply regeneration

type

Page 5

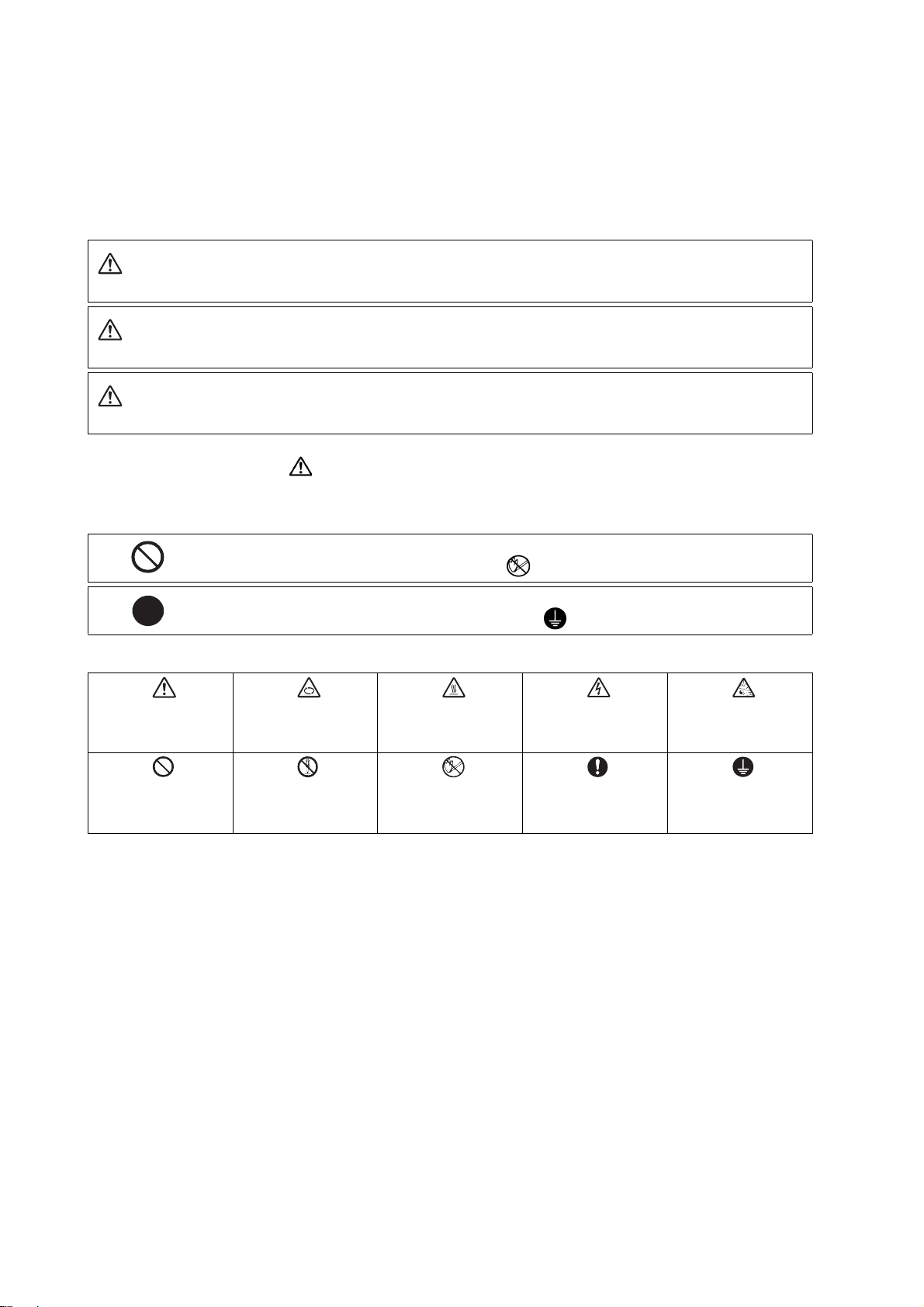

Manuals for MTBs (Others)

Manual No. Purpose and Contents

GOT2000 Series User’s Manual

(Hardware)

GOT2000 Series User’s Manual

(Utility)

GOT2000 Series User’s Manual

(Monitor)

GOT2000 Series Connection

Manual (Mitsubishi Electric

Products)

GT Designer3 (GOT2000) Screen

Design Manual

■ For M800/M80/E80 Series

Manual No. Purpose and Contents

GOT2000/GOT1000 Series CC-Link

Communication Unit User's Manual

GX Developer Version 8 Operating

Manual (Startup)

GX Developer Version 8 Operating

Manual

GX Converter Version 1 Operating

Manual

GX Works2 Installation Instructions BCN-P5999-0944

GX Works2 Version 1 Operating

Manual (Common)

GX Works2 Version 1 Operating

Manual (Simple Project)

GX Works2 Version 1 Operating

Manual (Simple Project, Function

Block)

GX Works3 Installation Instructions BCN-P5999-0391

MELSEC-Q CC-Link System Master/

Local Module User’s Manual

GOT2000 Series Connection

Manual (Non-Mitsubishi Electric

Products 1)

GOT2000 Series Connection

Manual (Non-Mitsubishi Electric

Products 2)

GOT2000 Series Connection

Manual (Microcomputers, MODBUS/

Fieldbus Products, Peripherals)

GT SoftGOT2000 Version1

Operating Manual

SH-081194

SH-081195

SH-081196 Outline of each monitor function of GOTs

SH-081197

SH-081220

IB-0800351

SH-080372E

SH-080373E

IB-0800004E

SH-080779ENG

SH-080780ENG

SH-080984ENG

SH-080394E

SH-081198ENG

SH-081199ENG

SH-081200ENG

SH-081201ENG

Outline of hardware such as part names, external dimensions,

installation, wiring, maintenance, etc. of GOTs

Outline of utilities such as screen display setting, operation

method, etc. of GOTs

Outline of connection types and connection method between

GOT and Mitsubishi Electric connection devices

Outline of screen design method using screen creation

software GT Designer3

Explanation for handling CC-Link communication unit (for

GOT2000 series/GOT1000 series)

Explanation for system configuration, installation, etc. of PLC

development tool GX Developer

Explanation for operations using PLC development tool GX

Developer

Explanation for operations using data conversion tool GX

Converter

Explanation for the operating environment and installation

method of GX Works2

Explanation for the system configuration of GX Works2 and

the functions common to Simple project and Structured project

such as parameter setting, operation method for the online

function

Explanation for methods for such as creating and monitoring

programs in Simple project of GX Works2

Explan

Explanation for the operating environment and installation

Explanation for system configuration, installation, wiring, etc.

Explanation for connection types and connection method

Explanation for connection types and connection method

Explanation for system configuration, screen configuration

ation for methods for such as creating function blocks,

pasting function blocks to sequence programs, and operating

FB library in Simple project of GX Works2

method of GX Works3

of master/local modules for CC-Link system

between GOT and other company's devices

between GOT and microcomputers, MODBUS/fieldbus

products, peripherals

and operation method of monitoring software GT

SoftGOT2000

Page 6

■ For C80 Series

Manual No. Purpose and Contents

MELSEC iQ-R Module Configuration

Manual

MELSEC iQ-R CPU Module User’s

Manual (Startup)

MELSEC iQ-R CPU Module User’s

Manual (Application)

QCPU User’s Manual (Hardware

Design, Maintenance and

Inspection)

GX Works3 Operating Manual SH-081215 Outline of functions, programming, etc.

Reference Manual for MTBs

Manual No. Purpose and Contents

M800/M80 Series Smart safety

observation Specification manual

C80 Series Smart safety observation

Specification manual

M800/M80 Series CC-Link (Master/

Local) Specification manual

M800/M80 Series PROFIBUS-DP

Specification manual

M800/M80 Series Interactive cycle

insertion (Customization)

Specification manual

M800/M80 Series EtherNet/IP

Specifications manual

SH-081262

SH-081263

SH-081264

SH-080483

BNP-C3072-022

BNP-C3077-022

BNP-C3072-089 Explanation for CC-Link

BNP-C3072-118 Explanation for PROFIBUS-DP communication function

BNP-C3072-121-

0003

BNP-C3072-263 Explanation for EtherNet/IP

Outline of system configuration, specifications, installation,

wiring, maintenance, etc.

Outline of specifications, procedures before operation,

troubleshooting, etc. for CPU module

Outline of memory, functions, devices, parameters, etc. for

CPU module

Outline of specifications, necessary knowledge to configure

the system and maintenance-related descriptions for Q series

CPU module, etc.

Explanation for smart safety observation function

Explanation for interactive cycle insertion

Page 7

Page 8

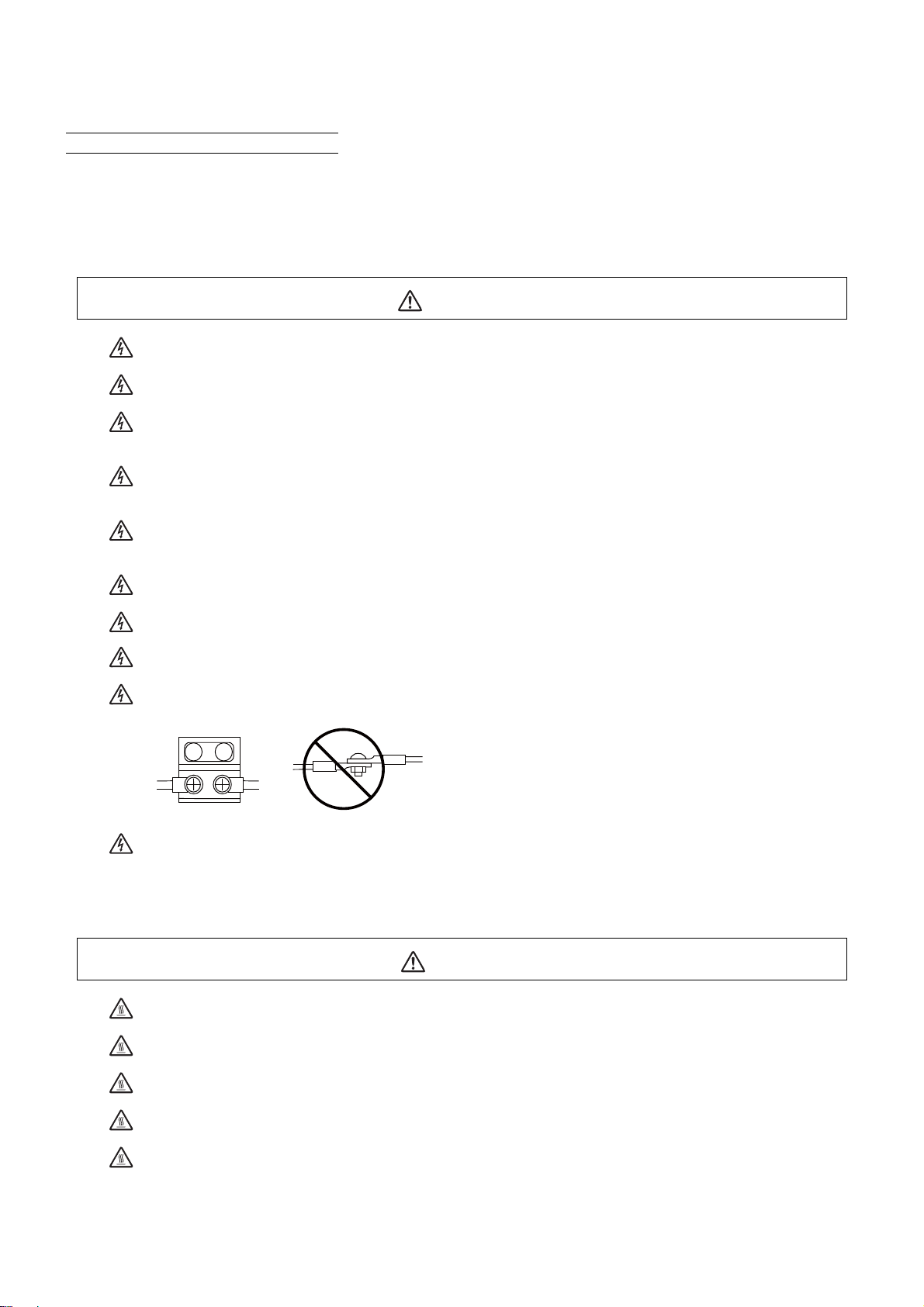

Precautions for Safety

Always read the specifications issued by the MTB, this manual, related manuals and attached documents before installation,

operation, programming, maintenance or inspection to ensure correct use. Understand this numerical controller, safety items

and cautions before using the unit.

This manual ranks the safety precautions into "DANGER", "WARNING" and "CAUTION".

DANGER

When the user may be subject to imminent fatalities or major injuries if handling is mistaken.

WARNING

When the user may be subject to fatalities or major injuries if handling is mistaken.

CAUTION

When the user may be subject to bodily injury or when physical damage may occur if handling is mistaken.

Note that even items ranked as " CAUTION", may lead to major results depending on the situation. In any case, important

information that must always be observed is described.

The following signs indicate prohibition and compulsory.

This sign indicates prohibited behavior (must not do).

For example, "Keep fire away" is indicated by .

This sign indicates a thing that is critical (must do).

For example, "it must be grounded" is indicated by .

The meaning of each pictorial sign is as follows.

CAUTION

Prohibited

CAUTION rotate ob-

ject

Disassembly is pro-

hibited

CAUTION HOT

KEEP FIRE AWAY

Danger Electric

shock risk

General instruction

Danger explosive

Earth ground

Page 9

For Safe Use

MITSUBISHI CNC is designed and manufactured solely for applications to machine tools to be used for industrial purposes.

Do not use this product in any applications other than those specified above, especially those which are substantially influential on the public interest or which are expected to have significant influence on human lives or properties.

1. Items related to prevention of electric shocks

WARNING

Do not open or remove the front cover while the power is ON or during operation. The high voltage terminals

and charged sections are exposed, and this could result in electric shocks.

Do not remove the front cover even when the power is OFF, except for the wiring works or periodic inspections. The inside of the controller and drive unit are charged, and this could result in electric shocks.

Always wait at least 15 minutes after turning the power OFF. Then, check the voltage with a tester, etc., before wiring works, inspections or connecting with peripheral devices. Failure to observe this could result in

electric shocks.

Earth ground the controller, drive unit and motor according to the local laws. (In Japan, ground the 200V

Series input products with Class C or higher protective grounding and the 400V Series input with Class D

or higher protective grounding.)

All wiring works, maintenance and inspections must be carried out by a qualified technician. Failure to observe this could result in electric shocks. Contact your nearby Service Center for replacing parts and servicing.

Wire the controller, drive unit and motor after installation. Failure to observe this could result in electric

shocks.

Do not operate the switches with wet hands. Failure to observe this could result in electric shocks.

Do not damage, apply excessive stress, place heavy things on or sandwich the cables. Failure to observe

this could result in electric shocks.

Insulate the power lead using a fixed terminal block. Failure to observe this could result in electric shocks.

Before starting maintenance or inspections, turn the main circuit power and control power both OFF. Wait

at least fifteen minutes until the CHARGE lamp turns OFF, and then confirm that the input and output voltage are zero using a tester, etc. Failure to observe this could lead to electric shocks.

2. Items related to prevention of fire

Install the controller, drive unit, motor and regenerative resistor on non-combustible material. Installation

directly on or near combustible materials could result in fires.

If any malfunction in the unit is observed, shut off the power at the unit’s power supply side. Continuous

flow of large current could result in fires.

Install an appropriate no fuse breaker (NFB) and contactor (MC) on the power input section of the drive unit

and configure the sequence that shuts the power off upon drive unit’s emergency stop or alarm.

When a breaker is shared for multiple power supply units, the breaker may not function upon short-circuit

failure in a small capacity unit. Do not share a breaker for multiple units as this is dangerous.

CAUTION

Incorrect wiring and connections could cause the devices to damage or burn.

Page 10

3. Items related to prevention of bodily injury or property damage

DANGER

When transporting or installing a built-in IPM spindle or linear servomotor, be careful so that your hand or

property is not trapped in the motors or other metal objects. Also keep the devices with low magnetic tolerance away from the product.

CAUTION

Do not apply voltages to the connectors or terminals other than voltages indicated in the connection and

setup manual for the controller or specifications manual for the drive unit. Failure to observe this could

cause bursting, damage, etc.

Incorrect connections could cause the devices to rupture or damage, etc. Always connect the cables to the

indicated connectors or terminals.

Incorrect polarity (+ -) could cause the devices to rupture or damage, etc.

Persons wearing medical devices, such as pacemakers, must stay away fro m th is un it. The e lect roma gne tic

waves could adversely affect the medical devices.

Fins on the rear of the unit, regenerative resistor and motor, etc., may be hot during operation and for a

while after the power has been turned OFF. Do not touch or place the parts and cables, etc. close to these

sections. Failure to observe this could result in burns.

Do not enter the machine’s movable range during automatic operation. Keep your hands, feet or face away

from the spindle during rotation.

4. Other items

Always follow the precautions below as well. Incorrect handling could result in faults, injuries or electric shocks, etc.

(1) Product and manual

CAUTION

For items described as "Restrictions" or "Usable State" in this manual, the instruction manual issued by

the machine tool builder (MTB) takes precedence over this manual.

Items not described in this manual must be interpreted as "not possible"

This manual is written on the assumption that all the applicable functions are included. Some of them, however, may not be available for your NC system. Refer to the specifications issued by the machine tool builder before use.

Refer to the manuals issued by the machine manufacturer for each machine tool explanation.

Some screens and functions may differ depending on the NC system (or its version), and some functions

may not be possible. Please confirm the specifications before use.

Do not connect NC system to the Internet-connected network.

To maintain the safety of the NC system against unauthorized access from external devices via the network,

take appropriate measures.

(2) Transportation and installation

CAUTION

Correctly transport the products according to the mass.

Use motor’s suspension bolts to transport the motor itself. Do not use it to transport the motor after installation onto the machine.

Do not stack the products exceeding the indicated limit.

Do not hold the cables, shaft or encoder when transporting the motor.

Page 11

CAUTION

Do not transport the controller or drive unit by suspending or holding the connected wires or cables.

Do not hold the front cover when transporting the unit, or the front cover could come off, causing the unit

to drop.

Install on a non-combustible place where the unit's or motor's mass can be withstood according to the instruction manual.

The motor does not have a complete water-proof (oil-proof) structure. Do not allow oil or water to contact

or enter the motor. Prevent the cutting chips from being accumulated on the motor as they easily soak up

oil.

When installing the motor facing upwards, take measures on the machine side so that gear oil, etc., will not

enter the motor shaft.

Do not remove the encoder from the motor. (The encoder installation screw is treated with sealing.)

Do not allow foreign matters, especially, conductive foreign matters such as screws or metal chips, or combu stibl e forei g n matt ers suc h as oil , to en ter the co ntroll er, drive unit or motor. Failure to observe this could

result in rupture or damage.

Do not get on the product or place heavy objects on it.

Provide prescribed distance between the controller/drive unit and inner surface of the control panel/other

devices.

Do not install or operate the controller, drive unit or motor that is damaged or has missing parts.

Take care not to cut hands, etc. with the heat radiating fins or metal edges.

Do not block the intake/outtake ports of the motor with the cooling fan.

Install the controller’s display section and operation board section on the spot where cutting oil will not

reach.

The controller, drive unit and motor are precision devices, so do not drop or apply thumping vibration and

strong impacts on them.

Store and use the units according to the environment conditions indicated in each specifications manual.

When disinfectants or insecticides must be used to treat wood packaging materials, always use methods

other than fumigation (for example, apply heat treatment at the minimum wood core temperature of 56 °C

for a minimum duration of 30 minutes (ISPM No. 15 (2009))).

If products such as units are directly fumigated or packed with fumigated wooden materials, halogen substances (including fluorine, chlorine , bromi ne and i o dine) c ontained in fumes may contribute to the erosion

of the capacitors. When exporting the products, make sure to comply with the laws and regulations of each

country.

Do not use the products in conjunction with any components that contain halogenated flame retardants

(bromine, etc). Failure to observe this may cause the erosion of the capacitors.

Securely fix the motor to the machine. The motor could come off during operation if insecurely fixed.

Always install the motor with reduction gear in the designated direction. Failure to observe this could result

in oil leaks.

Always install a cover, etc., over the shaft so that the rotary section of the motor cannot be touched during

motor rotation.

When installing a coupling to the servomotor shaft end, do not apply impacts by hammering, etc. The encoder could be damaged.

Use a flexible coupling when connecting with a ball screw, etc., and keep the shaft core deviation smaller

than the tolerable radial load of the shaft.

Do not use a rigid coupling as an excessive bending load may be applied on the shaft and could cause the

shaft to break.

Do not apply a load exceeding the tolerable level onto the motor shaft. The shaft or bearing could be damaged.

Before using this product after a long period of storage, please contact the Service Center.

Page 12

Following the UN recommendations, battery units and batteries should be transported based on the inter-

RA

RA

COM COM

Control

output

signal

Drive unit

Control

output

signal

Drive unit

(24VDC) (24VDC)

national regulations such as those determined by International Civil Aviation Organization (ICAO), International Air Transport Association (IATA), International Maritime Organization (IMO) and U.S. Department of

Transportation (DOT).

Install the unit in a place which can withstand its weight.

(3) Items related to wiring

Correctly wire this product. Failure to observe this could result in motor runaway, etc.

Do not install a phase advancing capacitor, surge absorber or radio noise filter on the output side of the

drive unit.

Correctly connect the output side (terminal U, V, W). The motor will not run properly if incorrectly connected.

Always install an AC reactor per each power supply unit.

Always install an appropriate breaker per each power supply unit. A breaker cannot be shared for multiple

power supply units.

Do not directly connect a commercial power supply to the motor. Failure to observe this could result in

faults.

When using an inductive load such as relays, always connect a diode in parallel to the load as a noise

countermeasure.

When using a capacitive load such as a lamp, always connect a protective resistor serially to the load to

suppress rush currents.

Do not mistake the direction of the surge absorption diode to be installed on the DC relay for the control

output signal. If mistaken, the signal will not be output due to fault in the drive unit, and consequently the

protective circuit, such as emergency stop, could be disabled.

CAUTION

CAUTION

Do not connect or disconnect the connection cables between each unit while the power is ON.

Do not connect or disconnect the PCBs while the power is ON.

Do not pull the cables when connecting/disconnecting them.

Securely tighten the cable connector fixing screw or fixing mechanism. The motor could come off during

operation if insecurely fixed.

Always treat the shield cables indicated in the Connection Manual with grounding measures such as cable

clamps.

Separate the signal wire from the drive line or power line when wiring.

Use wires and cables whose wire diameter, heat resistance level and bending capacity are compatible with

the system.

Ground the device according to the requirements of the country where the device is to be used.

Wire the heat radiating fins and wires so that they do not contact.

Page 13

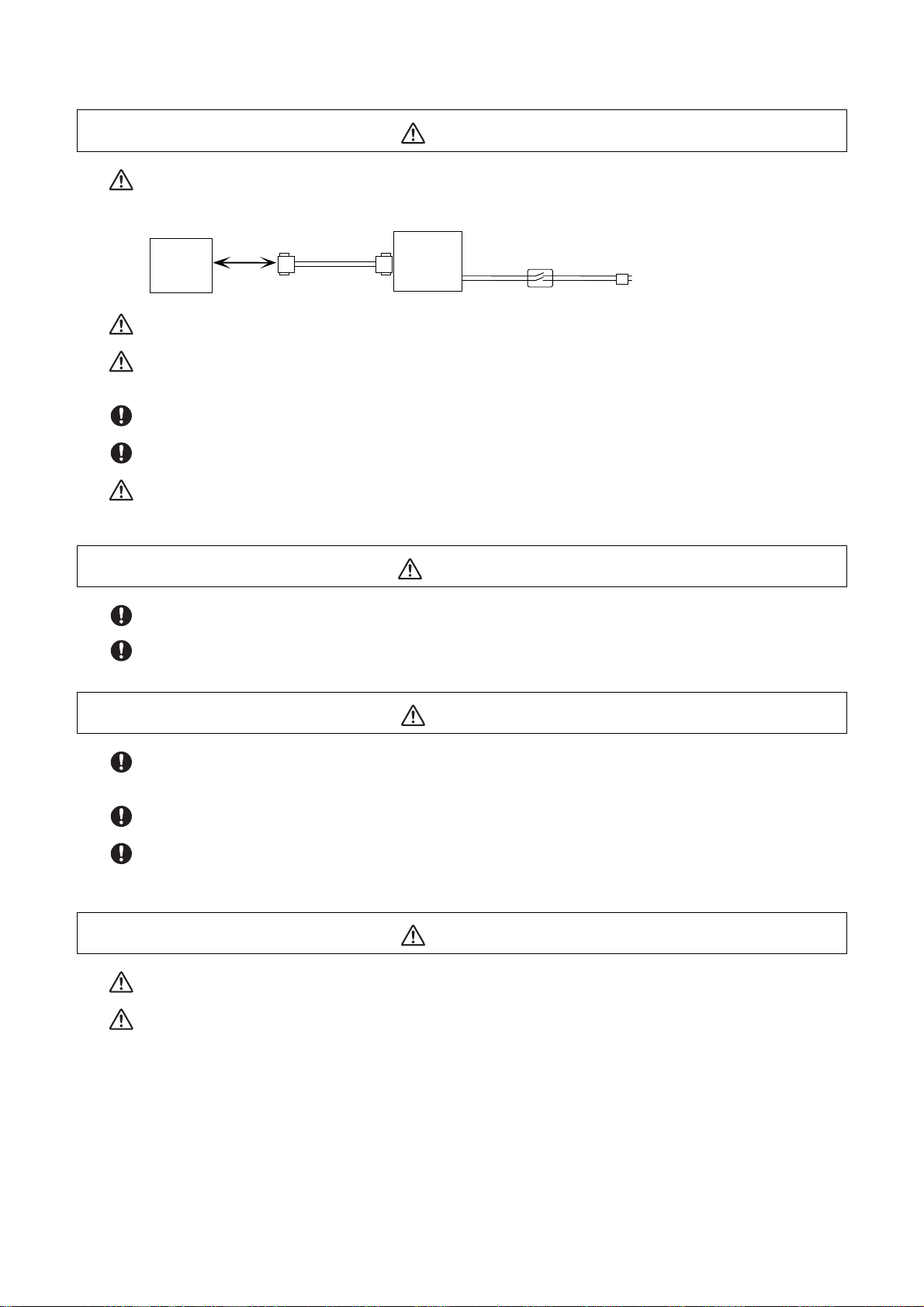

CAUTION

When using the RS-232C device as a peripheral device, caution must be paid for connector connection/disconnection. Always use a double-OFF type AC power supply switch on the device side, and connect/disconnect the connector with the AC power supply on the device side OFF.

(4) Set up

NC unit

RS-232C

Using a stabilized power supply without overcurrent protection may cause the unit's failure due to miswiring of 24V.

12V, 5V, and 3.3V output from connectors are to supply the power for dedicated peripheral devices. Do not

use for other equipment to supply the power since we do not guarantee the NC operation by voltage down

or noise sneaking.

When using an inductive load such as a relay, always connect a diode in parallel to the load to prevent a

counter-electromotive force.

When the rush current exceeds the maximum output current, always connect a protective resistor serially

to the load to suppress rush currents.

The wires from the surge absorber should be connected without extensions.

Device

Switch

AC socket

WARNING

Do not cancel the emergency stop before confirming the basic operation.

Always set the stored stroke limit. Failure to set this could result in collision with the machine end.

If the battery low warning is issued, save the machining programs, tool data and parameters in an input/

output device, and then replace the battery. When the battery alarm is issued, the machining programs, tool

data and parameters may be destroyed. Reload the data after replacing the battery.

Do not adjust the spindle when possible risks associated with adjustment procedures are not thoroughly

taken into consideration.

Be careful when touching spindle's rotating section, or your hand may be caught in or cut.

(5) Adjustments

Check and adjust programs and each parameter before starting operation. Failure to observe this could result in unpredictable operations depending on the machine.

Do not make drastic adjustments or changes as the operation could become unstable.

CAUTION

CAUTION

Page 14

(6) Usage

CAUTION

Install an external emergency stop circuit so that the operation can be stopped and the power turns OFF

immediately when unforeseen situation occurs. A contactor, etc., is required in addition to the shutoff function mounted in the controller.

Turn OFF the power immediately if any smoke, abnormal noise or odor is generated from the controller,

drive unit or motor.

Only a qualified technician may disassemble or repair this product.

Do not alter.

Use a noise filter, etc. to reduce the effect of electromagnetic disturbances in the case where electromagnetic disturbances could adversely affect the electronic devices used near the drive unit.

Use the drive unit, motor and each regenerative resistor with the designated combination. Failure to observe this could result in fires or faults.

The combination of the motor and drive unit that can be used is determined. Be sure to check the models

of motor and drive unit before test operation.

The brakes (electromagnetic brakes) mounted in the servomotor are used for the purpose of holding, and

must not be used for normal braking. Also, do not run the motor with the motor brake applied. Motor brake

is used for the purpose of holding.

For the system running via a timing belt, install a brake on the machine side so that safety can be ensured.

Be sure to confirm SERVO OFF (or READY OFF) when applying the electromagnetic brake. Also, be sure to

confirm SERVO ON prior to releasing the brake.

When using the DC OFF type electromagnetic brake, be sure to install a surge absorber on the brake terminal.

Do not connect or disconnect the cannon plug while the electromagnetic brake’s power is ON. The cannon

plug pins could be damaged by sparks.

After changing programs/parameters, or after maintenance/inspecti o n, alw ays ca r ry out a test o perat i on before starting actual operation.

Use the power that are complied with the power specification conditions (input voltage, input frequency,

tolerable time for instantaneous power interruption) indicated in each specifications manual.

When making encoder cables, do not mistake connection. Failure to observe this could result in malfunction, runaway or fire.

Surge absorber to be selected varies depending on input power voltage.

Always keep the touchscreen surface clean. When it gets dirty, remove the dirt immediately. Do not perform

any operation on the dirty touchscreen.

Pay close attention to the sequence operation when carrying out forced data setting (forced output) in the

I/F diagnosis screen during machine operation.

Page 15

(7) Troubleshooting

MBR EMG

Motor

Electromagnetic

brake

Shut off with motor

brake control output

Shut off with CNC brake

control PLC output

24VDC

Use a motor with electromagnetic brakes or

establish an external brake mechanism for the

purpose of holding; this serves as countermeasures for possible hazardous situation

caused by power failure or product fault.

Use a double circuit structure for the electromagnetic brake's operation circuit so that the

brakes will activate even when the external

emergency stop signal is issued.

The machine could suddenly restart when the power is restored after an instantaneous power failure, so

stay away from the machine. (Design the machine so that the operator safety can be ensured even if the

machine restarts.)

To secure the absolute position, do not shut off the servo drive uni t’s control p ower supp ly when i ts ba tter y

voltage drops (warning 9F) in the servo drive unit side.

If the battery voltage drop warning alarm occurs in the controller side, make sure to back up the machining

programs, tool data and parameters, etc. with the input/output device before replacing the battery. Depending on the level of voltage drop, memory loss could have happened. In that case, reload all the data backed

up before the alarm occurrence.

CAUTION

(8) Maintenance, inspection and part replacement

Periodically back up the programs, tool data and parameters to avoid potential data loss. Also, back up

those data before maintenance and inspections.

When replacing the battery on the controller side, the machining programs, tool data and parameters

should be backed up with the input/output device beforehand. In case the memory is damaged in replacing

the batteries, reload all the data backed up before replacing the battery.

The electrolytic capacitor’s capacity will drop due to deterioration. To prevent secondary damage due to

capacitor's faults, Mitsubishi recommends the electrolytic capacitor to be replaced approx. every five years

even when used in a normal environment. Contact the Service Center for replacements.

Never perform a megger test (measure the insulation resistance) of the drive unit. Failure to observe this

could lead to faults.

Do not replace parts or devices while the power is ON.

Do not short-circuit, charge, overheat, incinerate or disassemble the battery.

There may be a unit filled with substitute Freon in the heat radiating fins of the 37kW or smaller unit. Be

careful not to break the heat radiating fins during maintenance or replacement.

Connect the encoder (CN2/CN3) immediately after the installation of the servo drive unit. In addition, when

a battery box is used, immediately connect to the BTA/BTB connector. (prevention of absolute position data

lost)

Replace the batteries with new ones immediately after the battery voltage drop alarm (9F) has been output.

CAUTION

Replace the batteries while applying the drive unit’s control power.

Replace the batteries with new ones that are in their recommended use period.

Wrong connection may cause liquid leakage, heat generation and/or explosion.

Do not mix new batteries with used ones or mix different types of batteries.

Page 16

(9) Disposal

CAUTION

Take the batteries and backlights for LCD, etc., off from the controller, drive unit and motor, and dispose of

them as general industrial wastes.

Do not alter or disassemble controller, drive unit, or motor.

Collect and dispose of the spent batteries and the backlights for LCD according to the local laws.

Dispose the spent cooling fan according to local laws.

(10) General precautions

To explain the details, drawings given in the instruction manual, etc., may show the unit with the cover

or safety partition removed. When operating the product, always place the cover or partitions back to

their original position, and operate as indicated in the instruction manual, etc.

Page 17

Page 18

Treatment of waste

The following two laws will apply when disposing of this product. Considerations must be made to each law.

The following laws are in effect in Japan. Thus, when using this product overseas, the local laws will have a

priority. If necessary, indicate or notify these laws to the final user of the product.

(1) Requirements for "Law for Promotion of Effective Utilization of Resources"

(a) Recycle as much of this product as possible when finished with use.

(b) When recycling, often parts are sorted into steel scraps and electric parts, etc., and sold to scrap

contractors. Mitsubishi recommends sorting the product and selling the members to appropriate

contractors.

(2) Requirements for "Law for Treatment of Waste and Cleaning"

(a) Mitsubishi recommends recycling and selling the pr oduct when n o longer needed a ccording to item

(1) above. The user should make an effort to reduce waste in this manner.

(b) When disposing a product that cannot be resold, it shall be treated as a waste product.

(c) The treatment of industrial waste must be commissioned to a licensed industrial waste treatment

contractor, and appropriate measures, including a manifest co ntrol, must be taken.

(d) Batteries correspond to "primary batteries", and must be disposed of according to local disposal

laws.

Page 19

Page 20

Disposal

(Note) This symbol mark is for EU countries only.

This symbol mark is according to the directive 2006/66/EC Article 20 Information for endusers and Annex II.

Your MITSUBISHI ELECTRIC product is designed and manufactured with high quality materials and

components which can be recycled and/or reused.

This symbol means that batteries and accumulators, at their end-of-life, should be disposed of

separately from your household waste.

If a chemical symbol is printed beneath the symbol shown above, this chemical symbol means that the

battery or accumulator contains a heavy metal at a certain concentration. This will be indicated as

follows:

Hg: mercury (0,0005%), Cd: cadmium (0,002%), Pb: lead (0,004%)

In the European Union there are separate collection systems for used batteries and accumulators.

Please, dispose of batteries and accumulators correctly at your local community waste collection/

recycling centre.

Please, help us to conserve the environment we live in!

Page 21

Page 22

Trademarks

MELDAS, MELSEC, EZSocket, EZMotion, iQ Platform, MELSEC iQ-R, MELSOFT, GOT, CC-Link, CC-Link/LT,

CC-Link IE, CC-Link IE/field, EcoMonitorLight and SLMP are either trademarks or registered trademarks of

Mitsubishi Electric Corporation in Japan and/or other countries.

Ethernet is a registered trademark of Xerox Corporation in the United States and/or other countries.

Microsoft®, Windows®, SQL Server® and Access® are either trademarks or registered trademarks of Microsoft

Corporation in the United States and/or other countries.

SD logo and SDHC logo are either registered trademarks or trademarks of LLC.

UNIX is a registered trademark of The Open Group in the United States and/or other countries.

Intel® and Pentium® are either trademarks or registered trademarks of Intel Corporation in the United States and/or

other countries.

MODBUS® is either a trademark or a registered trademark of Schneider Electric USA, Inc. or the affiliated

companies in Japan and/or other countries.

EtherNet/IP is a trademark of Open DeviceNet Vendor Association,Inc.

PROFIBUS-DP and PROFINET are either trademarks of Profibus International.

Oracle® is a registered trademark of Oracle Corporation, the subsidiaries, or the affiliated companies in the United

States and /or other countries.

VNC is a registered trademark of RealVNC Ltd. in the United States and other countries.

Other company and product names that appear in this manual are trademarks or registered trademarks of the

respective companies.

Page 23

Page 24

本製品の取扱いについて

( 日本語 /Japanese)

本製品は工業用 ( クラス A) 電磁環境適合機器です。販売者あるいは使用者はこの点に注意し、住商業環境以外で

の使用をお願いいたします。

Handling of our product

(English)

This is a class A product. In a domestic environment this product may cause radio interference in which case the

user may be required to take adequate measures.

본 제품의 취급에 대해서

( 한국어 /Korean)

이 기기는 업무용 (A 급 ) 전자파적합기기로서 판매자 또는 사용자는 이 점을 주의하시기 바라며 가정외의 지역에

서 사용하는 것을 목적으로 합니다 .

Page 25

Page 26

Contents

1 System Basic Configuration ....................................................................................................................... 1

1.1 System Basic Configuration Drawing ....................................................................................................................... 2

1.2 General Connection Diagram ................................................................................................................................... 4

1.2.1 General Connection Diagram [M800W] ........................................................................................................... 4

1.2.2 General Connection Diagram [M80W] ............................................................................................................. 7

1.2.3 General Connection Diagram [M800S] .......................................................................................................... 10

1.2.4 General Connection Diagram [M80]............................................................................................................... 11

1.2.5 General Connection Diagram [E80] ............................................................................................................... 13

1.3 How to Check the System Configuration ................................................................................................................ 14

1.3.1 System Configuration Screen ........................................................................................................................ 14

1.3.2 Option Display Screen ................................................................................................................................... 17

1.4 Each Unit Status Display ........................................................................................................................................ 18

1.4.1 Control Unit .................................................................................................................................................... 18

1.4.2 Personal Computer Unit................................................................................................................................. 21

1.4.3 Operation Panel I/O Unit................................................................................................................................ 22

1.4.4 Remote I/O Unit ............................................................................................................................................. 25

1.4.5 Communication Expansion Unit ..................................................................................................................... 27

1.4.5.1 CC-Link Expansion Unit ....................................................................................................................... 27

1.4.5.2 PROFIBUS-DP Expansion Unit............................................................................................................ 28

1.4.5.3 CC-Link IE Field ................................................................................................................................... 29

1.4.5.4 EtherNet/IP........................................................................................................................................... 30

1.4.6 7-segment LEDs on the Control Unit ............................................................................................................. 31

1.4.6.1 Normal State Display............................................................................................................................ 31

1.4.6.2 Error Display at NC Startup.................................................................................................................. 31

1.4.6.3 Display when an Alarm Occurs ............................................................................................................ 32

2 Daily Maintenance and Periodic Maintenance ........................................................................................ 41

2.1 Daily Maintenance .................................................................................................................................................. 43

2.1.1 Touchscreen .................................................................................................................................................. 43

2.1.2 Escutcheon .................................................................................................................................................... 43

2.2 Periodic Maintenance ............................................................................................................................................. 44

2.2.1 List of Durable Parts....................................................................................................................................... 44

2.2.2 List of Replacing Parts ................................................................................................................................... 44

2.2.3 Durable Parts Replacement ........................................................................................................................... 45

2.2.3.1 Control Unit Battery .............................................................................................................................. 45

2.2.3.2 Personal Computer Unit Cooling Fan................................................................................................... 47

2.2.4 Replacing Fuse .............................................................................................................................................. 48

3 Maintenance of the Drive Unit................................................................................................................... 51

3.1 Periodic Inspections................................................................................................................................................ 52

3.2 Durable Parts.......................................................................................................................................................... 53

3.3 Adding and Replacing Units and Parts ................................................................................................................... 54

3.3.1 MDS-E/EH Series .......................................................................................................................................... 54

3.3.1.1 Replacing the Drive Unit....................................................................................................................... 54

3.3.1.2 Replacing the Unit Fan......................................................................................................................... 55

3.3.1.3 Replacing the Battery ........................................................................................................................... 57

3.3.2 MDS-EJ/EJH Series....................................................................................................................................... 60

3.3.2.1 Replacing the Drive Unit....................................................................................................................... 60

3.3.2.2 Replacing the Unit Fan......................................................................................................................... 60

3.3.2.3 Replacing the Battery ........................................................................................................................... 66

3.3.3 MDS-EM/EMH Series .................................................................................................................................... 69

3.3.3.1 Replacing the Drive Unit....................................................................................................................... 69

3.3.3.2 Replacing the Fan Unit......................................................................................................................... 70

3.3.3.3 Replacing the Battery ........................................................................................................................... 71

4 Failure Diagnosis ....................................................................................................................................... 75

4.1 Introduction ............................................................................................................................................................. 76

4.2 Failure Diagnosis Procedure .................................................................................................................................. 76

4.3 Diagnosis Based on the Alarm ............................................................................................................................... 77

4.3.1 How To Check the Alarm Information ............................................................................................................ 77

4.3.2 Alarm History.................................................................................................................................................. 79

4.3.3 Alarm Message Details .................................................................................................................................. 81

4.4 Diagnosis Based on the I/F Diagnosis Screen ....................................................................................................... 82

Page 27

4.4.1 I/F Diagnosis Screen...................................................................................................................................... 82

4.4.1.1 Displaying the PLC Device Data ........................................................................................................... 84

4.4.1.2 Carrying Out Modal Output ................................................................................................................... 85

4.4.1.3 Carrying Out One-shot Output .............................................................................................................. 86

4.4.2 List of Devices for PLC Uses ......................................................................................................................... 87

4.5 Diagnosis Based on the Self Diagnosis Screen ..................................................................................................... 88

4.5.1 Self Diagnosis Screen.................................................................................................................................... 88

4.6 Diagnosis Based on the Data Sampling Screen..................................................................................................... 93

4.7 Diagnosis Based on the Drive Monitor Screen ....................................................................................................... 94

4.7.1 Drive Monitor Screen (Servo Unit) ................................................................................................................. 94

4.7.2 Drive Monitor Screen (Spindle Unit)............................................................................................................... 99

4.7.3 Drive Monitor Screen (Power Supply Unit) .................................................................................................. 104

4.7.4 Drive Monitor Screen (Synchronous Error) .................................................................................................. 106

4.7.5 Clearing the Alarm History on Drive Monitor Screen ................................................................................... 107

4.8 NC Memory Diagnosis Screen ............................................................................................................................. 108

4.9 Safety Observation Screen................................................................................................................................... 110

4.9.1 Safety Observation Screen (Configuration Diagnosis)................................................................................. 110

4.9.2 Safety Observation Screen (Signal Monitor)................................................................................................ 112

4.9.3 Safety Observation Screen (Drive Monitor) ................................................................................................. 114

4.9.4 Safety Observation Screen (Version Display).............................................................................................. 117

4.10 Servo Diagnosis Screen ..................................................................................................................................... 118

4.11 Diagnosis Data Collection Setting ...................................................................................................................... 121

4.11.1 Starting the Data Collection ....................................................................................................................... 123

4.11.2 Stopping the Data Collection.............................................................................................

4.11.3 Clearing the Collected Data ....................................................................................................................... 124

4.11.4 Referring to the Collected Data.................................................................................................................. 124

4.11.5 Display Delay Function for Communication Errors and Servo/Spindle Alarms .......................................... 127

4.12 Application Error Detection ................................................................................................................................. 128

4.13 IP Address Resetting Procedure at Disabled Network Communication [M800W/M80W Series Only]............... 129

4.13.1 Connectable Control Unit IP Address List Screen ..................................................................................... 129

4.13.2 Resetting Procedure .................................................................................................................................. 130

4.13.3 Message..................................................................................................................................................... 131

4.14 Field Network Diagnostics Function ................................................................................................................... 132

4.14.1 Diagnosis Procedure.................................................................................................................................. 133

4.14.1.1 Statistical Information in Packet Transmission and Reception..........................................................133

4.14.1.2 Protocol-Specific Information ............................................................................................................ 135

4.14.2 Diagnosis Command.................................................................................................................................. 136

4.14.2.1 Clearing Statistical Information of Packet Transmission and Reception ........................................... 136

4.14.2.2 Error Code List .................................................................................................................................. 137

......................... 123

5 Troubleshooting....................................................................................................................................... 139

5.1 Troubleshooting .................................................................................................................................................... 140

5.1.1 Possible Causes of Trouble ......................................................................................................................... 141

6 Replacing Each Unit ................................................................................................................................ 143

6.1 Data Backup and Restoration............................................................................................................................... 144

6.1.1 All Backup .................................................................................................................................................... 145

6.1.2 All Restoration.............................................................................................................................................. 147

6.2 Control Unit........................................................................................................................................................... 149

6.3 Display Unit........................................................................................................................................................... 151

6.4 Personal Computer Unit ....................................................................................................................................... 156

6.5 Keyboard Unit ....................................................................................................................................................... 157

6.6 Operation Panel I/O Unit....................................................................................................................................... 164

6.7 Remote I/O Unit .................................................................................................................................................... 166

6.8 Function Expansion Unit....................................................................................................................................... 168

6.8.1 Encoder (Manual Pulse Generator) I/F Expansion Unit [M800W/M80W] .................................................... 168

6.8.2 Functional Safety Expansion Unit [M80] ...................................................................................................... 169

6.9 Communication Expansion Unit............................................................................................................................ 170

6.10 Built-in Disk of the Display Unit........................................................................................................................... 172

6.11 SD Card .............................................................................................................................................................. 173

6.12 USB memory ...................................................................................................................................................... 174

6.13 MITSUBISHI CNC Machine Operation Panel ..................................................................................................... 175

Page 28

1

1

IB-1501273-F

System Basic Configuration

Page 29

M800/M80/E80 Series Maintenance Manual

1 System Basic Configuration

1System Basic Configuration

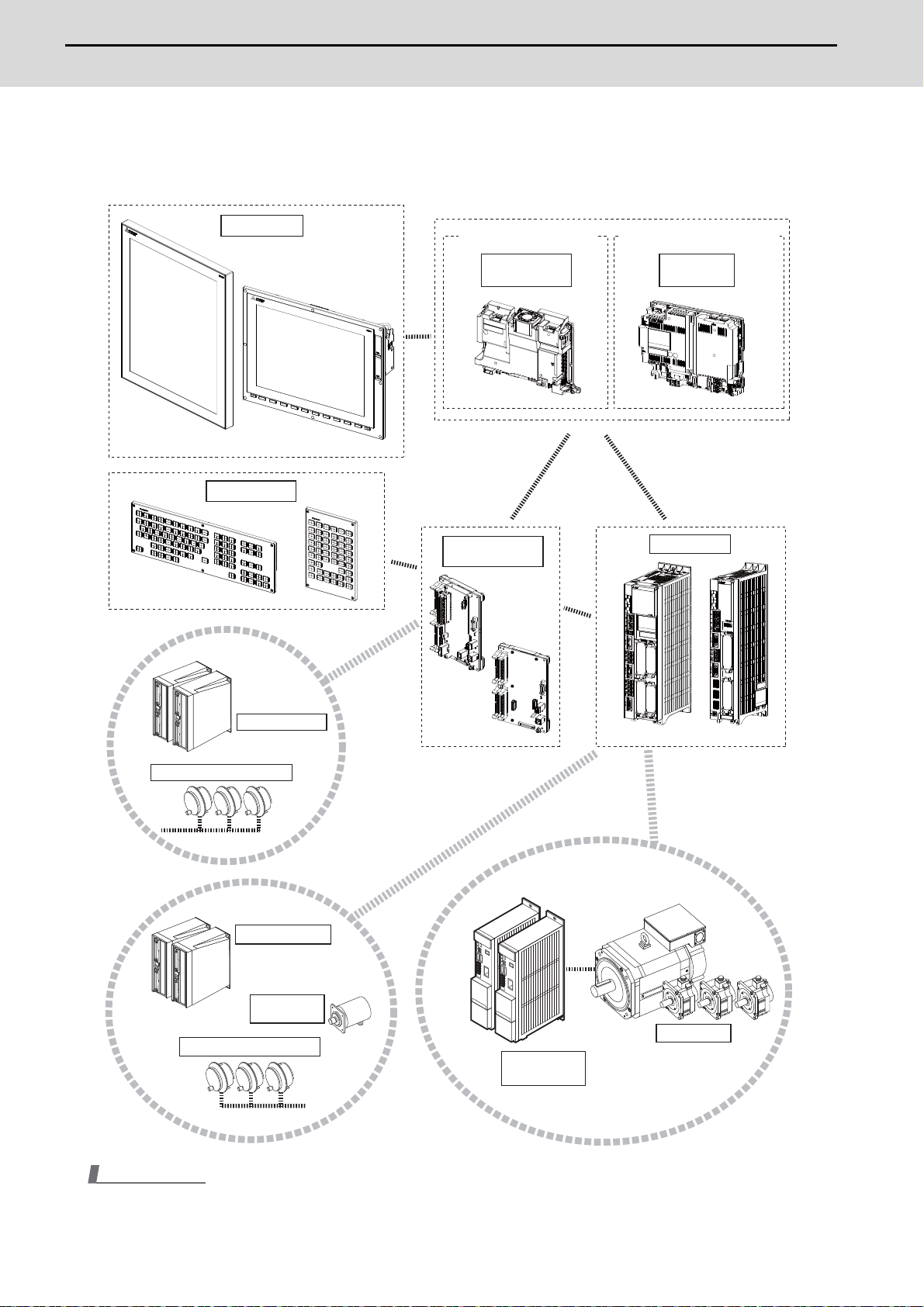

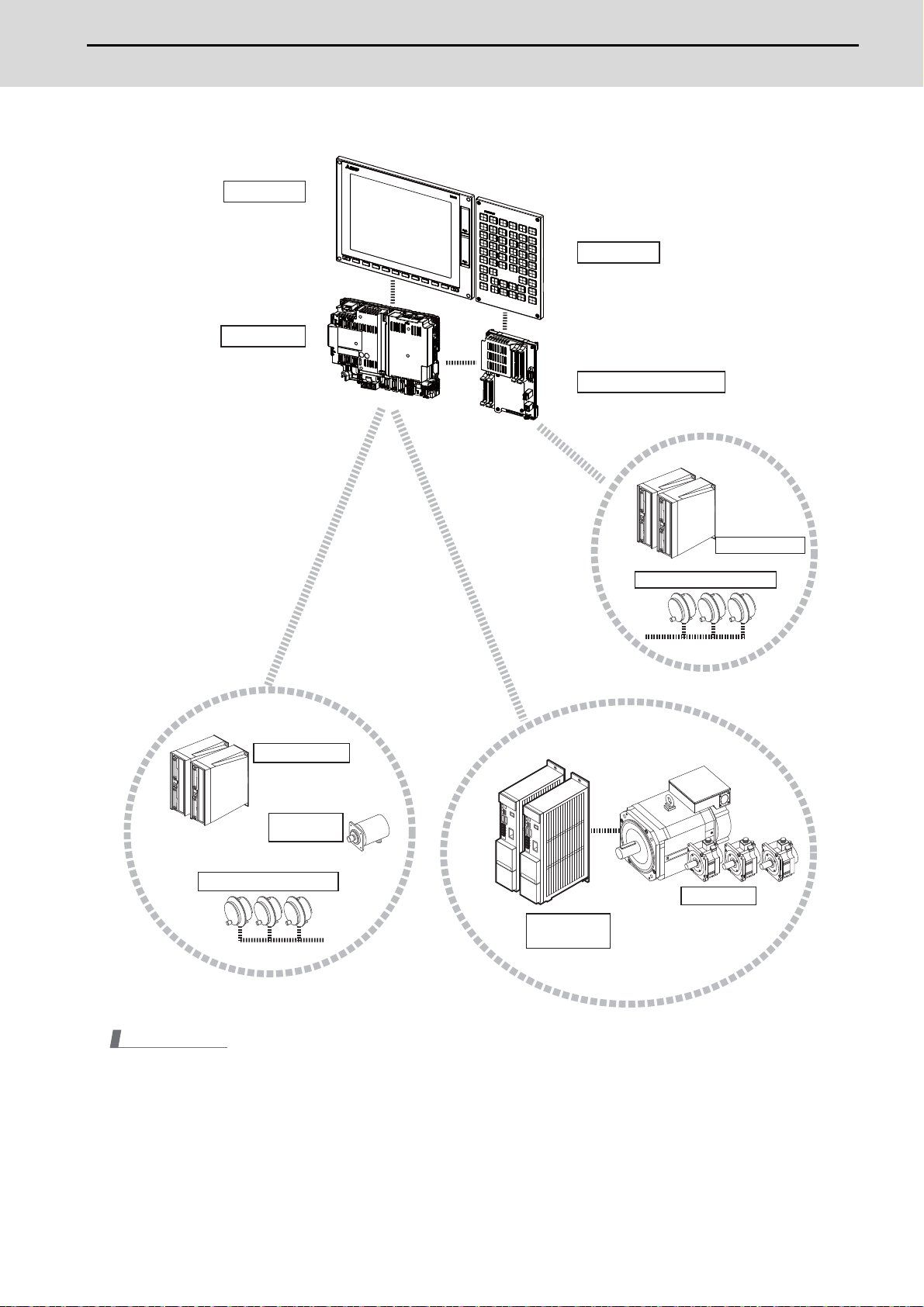

1.1 System Basic Configuration Drawing

For M800W/M80W

Display unit

Keyboard unit

Windows-based display non-Windows-based display

Personal

computer unit

Operation panel

I/O unit

Grahpic

control unit

Control unit

Remote I/O unit

Manual pulse penerator

Remote I/O unit

Synchronous

feed encoder

Manual pulse generator

M800W M80W

Motor group

Servo/Spindle

drive unit

Note

(1) For the drive unit configuration, refer to the drive unit's manual.

IB-1501273-F

2

Page 30

M800/M80/E80 Series Maintenance Manual

1 System Basic Configuration

For M800S/M80/E80

Display unit

(Control unit is added onto

back of display unit.)

Control unit

Keyboard unit

(Operation panel I/O unit is added

onto back of keyboard unit.)

Operation panel I/O unit

Remote I/O unit

Manual pulse penerator

Remote I/O unit

Synchronous

feed encoder

Manual pulse generator

Note

(1) For the drive unit configuration, refer to the drive unit's manual.

Motor group

Servo/Spindle

drive unit

3

IB-1501273-F

Page 31

M800/M80/E80 Series Maintenance Manual

1 System Basic Configuration

SIO

1ch:J030

2ch:J031

2ch

RS232C

SKIP

RIO2

SD

RIO3

GDI

LAN

J303

Network

FCU8-EX56x

J100

SD

FCU8-DX2xx/DX6xx

/DX4xx

RIO1

DCIN

J070/071

(EcoMonitor)

OPTH1

OPTH2

J395/J396

J395/J396

EMG

J120

Max. 8 points

J070/071

J070/071

J210

DI:CJ31/33

DO:CJ32/34

RIO1

DCIN

RIO2

DI:CJ31/33

DO:CJ32/34

RIO1

DCIN

RIO2

J350/351

J350/351

J070/071

J070/071

J210

DI:CJ31/33

DO:CJ32/34

RIO1

DCIN

RIO2

DI:CJ31/33

DO:CJ32/34

RIO1

DCIN

RIO2

J350/351

J350/351

(R2-TM)

(R2-TM)

FG

5V:J023/J024/J025

12V:J020/J021/J022

L1 L2

L3

(NFB)

DCOUT

FG

ACIN

CP

MC

ON OFF

MC

MC

J350/351

J350/351

J350/351

J350/351

FCU8-EX54x

EXT1

EXT3

G430

device

Skip signal input

Communication

expansion unit

Control unit

Max. 32 units for each port

Remote I/O unit

Remote I/O unit

Remote I/O unit

Remote I/O unit

24VDC

Energy measuring units

Drive units

Stored in control unit

To the next

remote I/O or

terminator

connector

To the next

remote I/O or

terminator

connector

Emergency

stop switch

SD

memory

card

24VDC24VDC

24VDC24VDC

Machine

control

relay/contact

Machine

control

relay/contact

24VDC

Manual pulse

generator (5V/12V)

Machine operation

panel made by the

machine tool builder

Dotted lines indicate the sections prepared by the machine tool builder.

<> Angle brackets indicates attached cable of unit.

No-fuse breaker

24VDC stabilized

power supply

Function

expansion unit

(Note 1)

Handy terminal

FCU8-EX56x

FCU8-EX54x

FCU8-MA041/MU042

MA041:M850W

MU042:M830W

RIO8

AIO

J026/J027

J220

EXT2

EXT4

RIO4

RIO6

RIO7

RIO5

Communication

expansion unit

Function

expansion unit

Analog input : 4 points

Analog output : 2 points

Manual pulse

generator (5V)

J120

ON/OFF

CFAST

CFast

LVDS1

USB2-1

USB2-2

FCU8-PC231

LAN

J303

MENUKEY

RIO3EXT

ON

OFF

G170

MPG

INV

RS232C

USB-RS232C

GDI

KEYUSB

RIO3

J303

NCKB

KEYUSB

J210

J291

J210

LVDS2

SD

DCIN

J070/071

EMG

USB

USB3-2

USB3-1

USB2-4

USB2-3

USB2-6

USB2-5

FCU8-DX2xx/DX6xx/DX4xx

CJ71

FCU8-CF001-001

DCIN

J070/071

Network

CG31

CG32

FCU8-DX830/837

CG33

CG34

SDI

Max. 8 points

DI:CJ31/33

DO:CJ32/34

RIO1

DCIN

RIO2

J350/351

J350/351

(R2-TM)

J210

FCU8-KB92x

FCU8-KB941/KB931

<G460>

24VDC

MITSUBISHI CNC Machine Operation Panel

Emergency

stop switch

Personal computer unit

device

conversion

24VDC

USB memory

24VDC

Remote I/O unit

24VDC

Operation panel I/O unit

Safety signal input

DX830:

No safety signal input

DX837:

With safety signal input

Stored in

personal computer unit

CFast unit

(Safety signal input is

DX837 only.)

To the next remote I/O

or terminator connector

Added onto back of

display unit

SD

memory

card

24VDC

Machine

control

relay/contact

Backlight

I/F PCB

FCU8-KB04x/KB083

<G402>

<J09x>

USB

SD

<J292>

<J190>

<J290>

<J081>

<J420>

Keyboard unit

(Note 2)

15-type LCD

with touch panel

Display unit

Menukey

FCU8-DU181-34

1.2 General Connection Diagram

1.2.1 General Connection Diagram [M800W]

Windows-based display (15-type)

(Note 1) For information on how to connect the drive unit, refer to the drive unit's manual.

(Note 2) When using a keyboard unit, install the operation panel I/O unit on the back of the keyboard unit.

Note

(1) For the connection of MITSUBISHI CNC machine operation panel, refer to "M800W/M80W Series Connection and Set-

up Manual".

IB-1501273-F

4

Page 32

M800/M80/E80 Series Maintenance Manual

1 System Basic Configuration

SIO

1ch:J030

2ch:J031

2ch

RS232C

SKIP

RIO2

SD

RIO3

GDI

LAN

J303

Network

FCU8-EX56x

J100

SD

FCU8-DX2xx/DX6xx

/DX4xx

RIO1

DCIN

J070/071

(EcoMonitor)

OPTH1

OPTH2

J395/J396

J395/J396

EMG

J120

Max. 8 points

J070/071

J070/071

J210

DI:CJ31/33

DO:CJ32/34

RIO1

DCIN

RIO2

DI:CJ31/33

DO:CJ32/34

RIO1

DCIN

RIO2

J350/351

J350/351

J070/071

J070/071

J210

DI:CJ31/33

DO:CJ32/34

RIO1

DCIN

RIO2

DI:CJ31/33

DO:CJ32/34

RIO1

DCIN

RIO2

J350/351

J350/351

(R2-TM)

(R2-TM)

FG

5V:J023/J024/J025

12V:J020/J021/J022

L1 L2

L3

(NFB)

DCOUT

FG

ACIN

CP

MC

ON OFF

MC

MC

J350/351

J350/351

J350/351

J350/351

FCU8-EX54x

EXT1

EXT3

G430

device

Skip signal input

Communication

expansion unit

Control unit

Max. 32 units for each port

Remote I/O unit

Remote I/O unit

Remote I/O unit

Remote I/O unit

24VDC

Energy measuring units

Drive units

Stored in control unit

To the next

remote I/O or

terminator

connector

To the next

remote I/O or

terminator

connector

Emergency

stop switch

SD

memory

card

24VDC24VDC

24VDC24VDC

Machine

control

relay/contact

Machine

control

relay/contact

24VDC

Manual pulse

generator (5V/12V)

Machine operation

panel made by the

machine tool builder

Dotted lines indicate the sections prepared by the machine tool builder.

<> Angle brackets indicates attached cable of unit.

No-fuse breaker

24VDC stabilized

power supply

Function

expansion unit

(Note 1)

Handy terminal

FCU8-EX56x

FCU8-EX54x

FCU8-MA041/MU042

MA041:M850W

MU042:M830W

RIO8

AIO

J026/J027

J220

EXT2

EXT4

RIO4

RIO6

RIO7

RIO5

Communication

expansion unit

Function

expansion unit

Analog input : 4 points

Analog output : 2 points

Manual pulse

generator (5V)

J120

ON/OFF

CFAST

CFast

LVDS1

USB2-1

USB2-2

FCU8-PC231

LAN

J303

MENUKEY

RIO3EXT

ON

OFF

G170

MPG

INV

RS232C

USB-RS232C

GDI

KEYUSB

RIO3

J303

NCKB

KEYUSB

J210

J291

J210

LVDS2

SD

DCIN

J070/071

EMG

USB

USB3-2

USB3-1

USB2-4

USB2-3

USB2-6

USB2-5

FCU8-DX2xx/DX6xx/DX4xx

CJ71

FCU8-CF001-001

DCIN

J070/071

Network

CG31

CG32

FCU8-DX830/837

CG33

CG34

SDI

Max. 8 points

DI:CJ31/33

DO:CJ32/34

RIO1

DCIN

RIO2

J350/351

J350/351

(R2-TM)

J210

FCU8-KB92x

FCU8-KB941/KB931

<G460>

24VDC

MITSUBISHI CNC Machine Operation Panel

Emergency

stop switch

Personal computer unit

device

conversion

24VDC

USB memory

24VDC

Remote I/O unit

24VDC

Operation panel I/O unit

Safety signal input

DX830:

No safety signal input

DX837:

With safety signal input

Stored in

personal computer unit

CFast unit

(Safety signal input is

DX837 only.)

To the next remote I/O

or terminator connector

Added onto back of

display unit

SD

memory

card

24VDC

Machine

control

relay/contact

Backlight

I/F PCB

<J09x>

<J292>

<J190>

<J290>

<G195>

<J420>

FCU8-EP201-2

USB

SD

PCUSB

19-type LCD

Side memory I/F unit

wth touch panel

Display unit

FCU8-DU191-75

FCU8-DU192-75

Windows-based display (19-type)

(Note 1) For information on how to connect the drive unit, refer to the drive unit's manual.

(1) For the connection of MITSUBISHI CNC machine operation panel, refer to "M800W/M80W Series Connection and Set-

Note

up Manual".

5

IB-1501273-F

Page 33

M800/M80/E80 Series Maintenance Manual

1 System Basic Configuration

SIO

1ch:J030

2ch:J031

2ch

RS232C

SKIP

RIO2

SD

RIO3

GDI

LAN

J303

Network

FCU8-EX56x

J100

SD

FCU8-DX2xx/DX6xx

/DX4xx

RIO1

DCIN

J070/071

(EcoMonitor)

OPTH1

OPTH2

J395/J396

J395/J396

EMG

J120

Max. 8 points

J070/071

J070/071

J210

DI:CJ31/33

DO:CJ32/34

RIO1

DCIN

RIO2

DI:CJ31/33

DO:CJ32/34

RIO1

DCIN

RIO2

J350/351

J350/351

J070/071

J070/071

J210

DI:CJ31/33

DO:CJ32/34

RIO1

DCIN

RIO2

DI:CJ31/33

DO:CJ32/34

RIO1

DCIN

RIO2

J350/351

J350/351

(R2-TM)

(R2-TM)

FG

5V:J023/J024/J025

12V:J020/J021/J022

L1 L2

L3

(NFB)

DCOUT

FG

ACIN

CP

MC

ON OFF

MC

MC

J350/351

J350/351

J350/351

J350/351

FCU8-EX54x

EXT1

EXT3

G430

device

Skip signal input

Communication

expansion unit

Control unit

Max. 32 units for each port

Remote I/O unit

Remote I/O unit

Remote I/O unit

Remote I/O unit

24VDC

Energy measuring units

Drive units

Stored in control unit

To the next

remote I/O or

terminator

connector

To the next

remote I/O or

terminator

connector

Emergency

stop switch

SD

memory

card

24VDC24VDC

24VDC24VDC

Machine

control

relay/contact

Machine

control

relay/contact

24VDC

Manual pulse

generator (5V/12V)

Machine operation

panel made by the

machine tool builder

Dotted lines indicate the sections prepared by the machine tool builder.

<> Angle brackets indicates attached cable of unit.

No-fuse breaker

24VDC stabilized

power supply

Function

expansion unit

(Note 1)

Handy terminal

FCU8-EX56x

FCU8-EX54x

FCU8-MA041/MU042

MA041:M850W

MU042:M830W

RIO8

AIO

J026/J027

J220

EXT2

EXT4

RIO4

RIO6

RIO7

RIO5

Communication

expansion unit

Function

expansion unit

Analog input : 4 points

Analog output : 2 points

Manual pulse

generator (5V)

J070/071

DI:CJ31/33

DO:CJ32/34

RIO1

DCIN

RIO2

<J09x>

USB_F

SDC_F

USB_B

SDC_B

<J08x>

FCU8-GC211

RIO3EXT

RS232C

CJ71

FCU8-DX730

CG31

MPG

CG32

NCKB

CG33

CG34

LAN1

J303

Network

LAN2

J303

J210

G402

J210

EMG

DCIN

J070/071

LCD

MENUKEY

TP

BL

FRONT

ENC

ON

OFF

CJ71

J010

SIO

FCU8-DX2xx/DX6xx/DX4xx

max. 29 units

J170

<J421>

RIO1

J210

FCU8-KB92x

FCU8-KB941/KB931

<G460>

24VDC

MITSUBISHI CNC Machine Operation Panel

24VDC

Remote I/O unit

(Note 2)

Emergency

stop switch

Graphic control unit

device

24VDC

24VDC

Operation panel I/O unit

Menu key

Display unit

Memory mediums

Front memory I/F card

Keyboard unit

(Note 3)

FCU8-KB04x/083

<J421>

10.4-type:FCU8-DU141-31

15-type:FCU8-DU181-31

Non-Windows-based display (10.4-type/15-type)

I/O unit.

(Note 1) For information on how to connect the drive unit, refer to the drive unit's manual.

(Note 2) When connecting a remote I/O unit to the 3rd RIO channel, insert it between the control unit and operation panel

(Note 3) There is no need to connect a terminator R2-TM to the graphic control unit.

Note

(1) For the connection of MITSUBISHI CNC machine operation panel, refer to "M800W/M80W Series Connection and Set-

IB-1501273-F

up Manual".

6

Page 34

M800/M80/E80 Series Maintenance Manual

1 System Basic Configuration

SIO

1ch:J030

2ch:J031

2ch

RS232C

SKIP

RIO2

SD

RIO3

GDI

LAN

J303

Network

FCU8-EX56x

J100

SD

FCU8-DX2xx/DX6xx

/DX4xx

RIO1

DCIN

J070/071

(EcoMonitor)

OPTH1

OPTH2

J395/J396

J395/J396

EMG

J120

Max. 8 points

J070/071

J070/071

J210

DI:CJ31/33

DO:CJ32/34

RIO1

DCIN

RIO2

DI:CJ31/33

DO:CJ32/34

RIO1

DCIN

RIO2

J350/351

J350/351

J070/071

J070/071

J210

DI:CJ31/33

DO:CJ32/34

RIO1

DCIN

RIO2

DI:CJ31/33

DO:CJ32/34

RIO1

DCIN

RIO2

J350/351

J350/351

(R2-TM)

(R2-TM)

FG

5V:J023/J024/J025

12V:J020/J021/J022

L1 L2

L3

(NFB)

DCOUT

FG

ACIN

CP

MC

ON OFF

MC

MC

J350/351

J350/351

J350/351

J350/351

FCU8-EX54x

EXT1

EXT3

G430

device

Skip signal input

Communication

expansion unit

Control unit

Max. 32 units for each port

Remote I/O unit

Remote I/O unit

Remote I/O unit

Remote I/O unit

24VDC

Energy measuring units

Drive units

Stored in control unit

To the next

remote I/O or

terminator

connector

To the next

remote I/O or

terminator

connector

Emergency

stop switch

SD

memory

card

24VDC24VDC

24VDC24VDC

Machine

control

relay/contact

Machine

control

relay/contact

24VDC

Manual pulse

generator (5V/12V)

Machine operation

panel made by the

machine tool builder

Dotted lines indicate the sections prepared by the machine tool builder.

<> Angle brackets indicates attached cable of unit.

No-fuse breaker

24VDC stabilized

power supply

Function

expansion unit

(Note 1)

Handy terminal

FCU8-MU044

RIO4/M

BTBOX

J120

ON/OFF

CFAST

CFast

LVDS1

USB2-1

USB2-2

FCU8-PC231

LAN

J303

MENUKEY

RIO3EXT

ON

OFF

G170

MPG

INV

RS232C

USB-RS232C

GDI

KEYUSB

RIO3

J303

NCKB

KEYUSB

J210

J291

J210

LVDS2

SD

DCIN

J070/071

EMG

USB

USB3-2

USB3-1

USB2-4

USB2-3

USB2-6

USB2-5

FCU8-DX2xx/DX6xx/DX4xx

CJ71

FCU8-CF001-001

DCIN

J070/071

Network

CG31

CG32

FCU8-DX830/837

CG33

CG34

SDI

Max. 8 points

DI:CJ31/33

DO:CJ32/34