Page 1

Page 2

Page 3

MELDAS and MELSEC are registered trademarks of Mitsubishi Electric Corporation.

Microsoft®and Windows®are either registered trademarks or trademarks of Microsoft Corporation in the United

States and/or other countries.

Intel®, Pentium® and Celeron® are either trademarks or registered trademarks of Intel Corporation and its

subsidiaries in the United States and other countries.

Other company and product names that appear in this manual are trademarks or registered trademarks of the

respective company.

Page 4

Page 5

Introduction

CAUTION

This manual describes the specifications of MITSUBISHI CNC M700V Series.

To safely use this CNC unit, thoroughly study the "Precautions for Safety" on the next page before use.

Details described in this manual

At the beginning of each item, a table indicating it's specification according to the model.

○ : Standard

△ : Optional

□ : Selection

☆ : Planning

The items that are not described in this manual must be interpreted as "not possible".

This manual is written on the assumption that all option functions are added.

Some functions may differ or some functions may not be usable depending on the NC system (software)

version.

General precautions

(1) When the contents of this manual is updated, the version (A, B, ...) on the cover will be incremented.

Page 6

Page 7

Precautions for Safety

DANGER

WARNING

CAUTION

DANGER

WARNING

CAUTION

Always read this manual, related manuals and attached documents before installation, operation,

programming, maintenance or inspection to ensure correct use. Under stand all the conditions described in

this manual before using the unit. We rank the safety precautions into "DANGER", "WARNING" and

"CAUTION" for the manuals issued by Mitsubishi, including this manual.

When there is a great risk that the user could be subject to fatalities or serious injuries if handling

is mistaken.

When the user could be subject to fatalities or serious injuries if handling is mistaken.

When the user could be subject to injuries or when physical damage could occur if handling is

mistaken.

Note that even items ranked as " CAUTION", may lead to major results depending on the situation. In

any case, important information that must always be observed is described.

Not applicable in this manual.

Not applicable in this manual.

1. Items related to product and manual

The items that are not described in this manual must be interpreted as "not possible".

This manual is written on the assumption that all option functions are added.

Some functions may differ or some functions may not be usable depending on the NC system (software)

version.

2. Items related to start up and maintenance

Follow the power specifications (input voltage range, frequency range, momentary power failure time

range) described in this manual.

Follow the environment conditions (ambient temperature, humidity, vibration, atmosphere) described in

this manual.

Follow the remote type machine contact input/output interface described in this manual. (Connect a

diode in parallel with the inductive load or connect a protective resistor in serial with the capacitive load,

etc.)

If the parameter is used to set the temperature rise detection function to invalid, overheating may occur,

thereby disabling control and possibly resulting in the axes running out of control, which in turn may

result in machine damage and/or bodily injury or destruction of the unit. It is for this reason that the

detection function is normally left "valid" for operation.The parameter for the temperature rise detection

function will be validated forcibly when the NC unit is turned ON.

Page 8

Page 9

Disposal

(Note) This symbol mark is for EU countries only.

This symbol mark is according to the directive 2006/66/EC Article 20 Information for endusers and Annex II.

Your MITSUBISHI ELECTRIC product is designed and manufactured with high quality materials and

components which can be recycled and/or reused.

This symbol means that batteries and accumulators, at their end-of-life, should be disposed of

separately from your household waste.

If a chemical symbol is printed beneath the symbol shown above, this chemical symbol means that the

battery or accumulator contains a heavy metal at a certain concentration. This will be indicated as

follows:

Hg: mercury (0,0005%), Cd: cadmium (0,002%), Pb: lead (0,004%)

In the European Union there are separate collection systems for used batteries and accumulators.

Please, dispose of batteries and accumulators correctly at your local community waste collection/

recycling centre.

Please, help us to conserve the environment we live in!

Page 10

Page 11

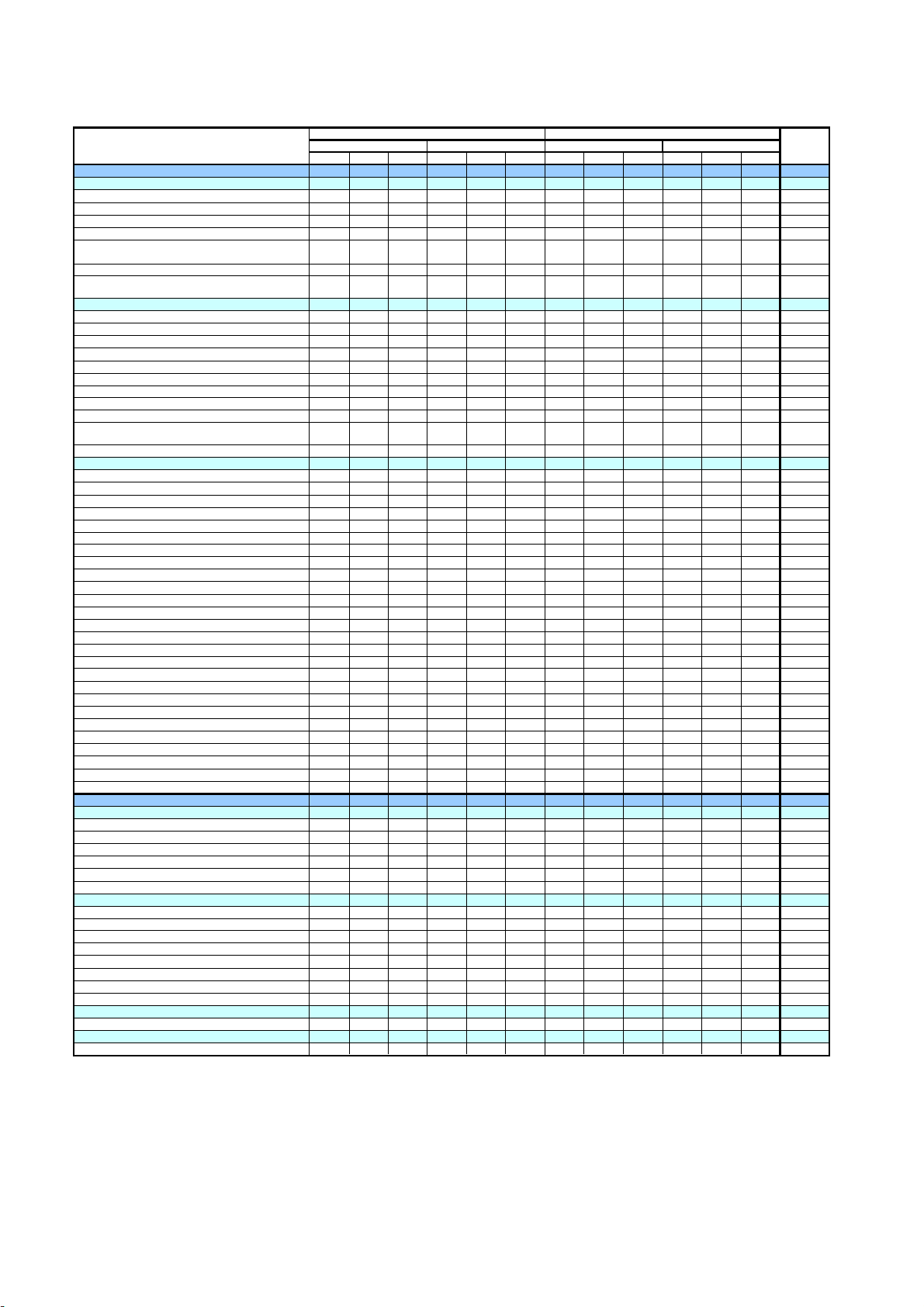

CONTENTS

I General Specifications (M700VW Series)

1 System Basic Configuration Drawing.. ....................................... ... ... .... ...................................... .......... I - 1

2 General Connection Diagram................................................................................................................. I - 3

2.1 For 10.4-type Display Unit ....................................... ...................................... .... ... ... ..........................I - 4

2.2 For 15-type Display Unit .......................................... ...................................... .... ... ... ..........................I - 5

3 List of Configuration............................................................................................................................... I - 7

3.1 List of Units.............................................................. ... ... ... .... ... ... ... ....................................................I - 8

3.2 Durable Parts....................................................... .... ...................................... .... ... ... ........................I - 11

3.3 Replacements.......................................................... ... ....................................... ... ... ... .....................I - 11

3.4 List of Cables.......................... .... ...................................... .... ... ... ... .................................................. I - 12

4 Environment Conditions ...................................................................................................................... I - 15

5 Hardware Specifications ...................................................................................................................... I - 19

5.1 Control Unit.......................................................... .... ... ... ....................................... ... ........................I - 20

5.2 Display Unit............................. .... ... ... ... ....................................... ... .... ... ........................................... I - 34

5.3 Keyboard Unit............................. ... ... ... ....................................... ... .... ... ........................................... I - 44

5.4 Operation Panel I/O Unit...................... .... ... ... ... ....................................... ... ... .... .............................. I - 47

5.5 Hard Disk Unit.................................................................................................................................. I - 60

5.6 Remote I/O Unit............................. ... ....................................... ... ... .... ... ........................................... I - 63

5.7 Scan I/O Unit.............. ....................................... ... .... ... ....................................... ... ... ........................I - 69

5.8 External Power Supply Unit .............................................................................................................I - 80

5.9 Manual Pulse Generator..................................................................................................................I - 84

5.10 Synchronous Feed Encoder ..........................................................................................................I - 86

5.11 Expansion Unit and Expansion Card ............................................................................................. I - 87

5.11.1 Expansion unit ........... ... .... ... ... ....................................... ... ... .... ... ........................................... I - 87

5.11.2 Expansion card (PROFIBUS-DP)........................... .... ... ... ... ....................................... ... ... .... . I - 88

5.11.3 Expansion card (CC-Link). ... ... ... ....................................... ... .... ... ........................................... I - 89

5.12 Expansion I/O Card........................................................................................................................ I - 91

5.13 Handy Terminal.............................................................................................................................. I - 98

5.14 Precautions for Use of Commercially Available CF Cards..... ... ... ................................................I - 102

5.15 Precautions for Use of USB devices............................................................................................ I - 103

II General Specifications (M700VS Series)

1 System Basic Configuration Drawing.. ....................................... ... ... .... ...................................... ......... II - 1

2 General Connection Diagram................................................................................................................ II - 3

2.1 Without Touch Panel...................... ... ... .... ... ... ... ... ....................................... ... .... ... ............................II - 4

2.2 With Touch Panel.............................................................................................................................. II - 5

3 List of Configuration.............................................................................................................................. II - 7

3.1 List of Units.......................... ....................................... ... ... .... ............................................................II - 8

3.2 Durable Parts....................................................... .... ...................................... .... ... ... .......................II - 11

3.3 Replacements.......................................................... ... ....................................... ... ... ... ....................II - 11

3.4 List of Cables.......................... .... ...................................... .... ... ... ... ................................................. II - 12

4 Environment Conditions ..................................................................................................................... II - 15

5 Hardware Specifications ..................................................................................................................... II - 19

5.1 Control Unit.......................................................... .... ... ... ....................................... ... .......................II - 20

5.2 Display Unit............................. .... ... ... ... ....................................... ... .... ... .......................................... II - 31

5.3 Keyboard Unit............................. ... ... ... ....................................... ... .... ... .......................................... II - 34

5.4 Operation Panel I/O Unit...................... .... ... ... ... ....................................... ... ... .... ............................. II - 40

5.5 Remote I/O Unit............................. ... ....................................... ... ... .... ... .......................................... II - 51

5.6 Scan I/O Unit.............. ....................................... ... .... ... ....................................... ... ... .......................II - 57

5.7 External Power Supply Unit ............................................................................................................II - 68

5.8 Manual Pulse Generator.................................................................................................................II - 71

5.9 Synchronous Feed Encoder ........................................................................................................... II - 73

5.10 Precautions for Use of Commercially Available CF Cards............................................................II - 74

Page 12

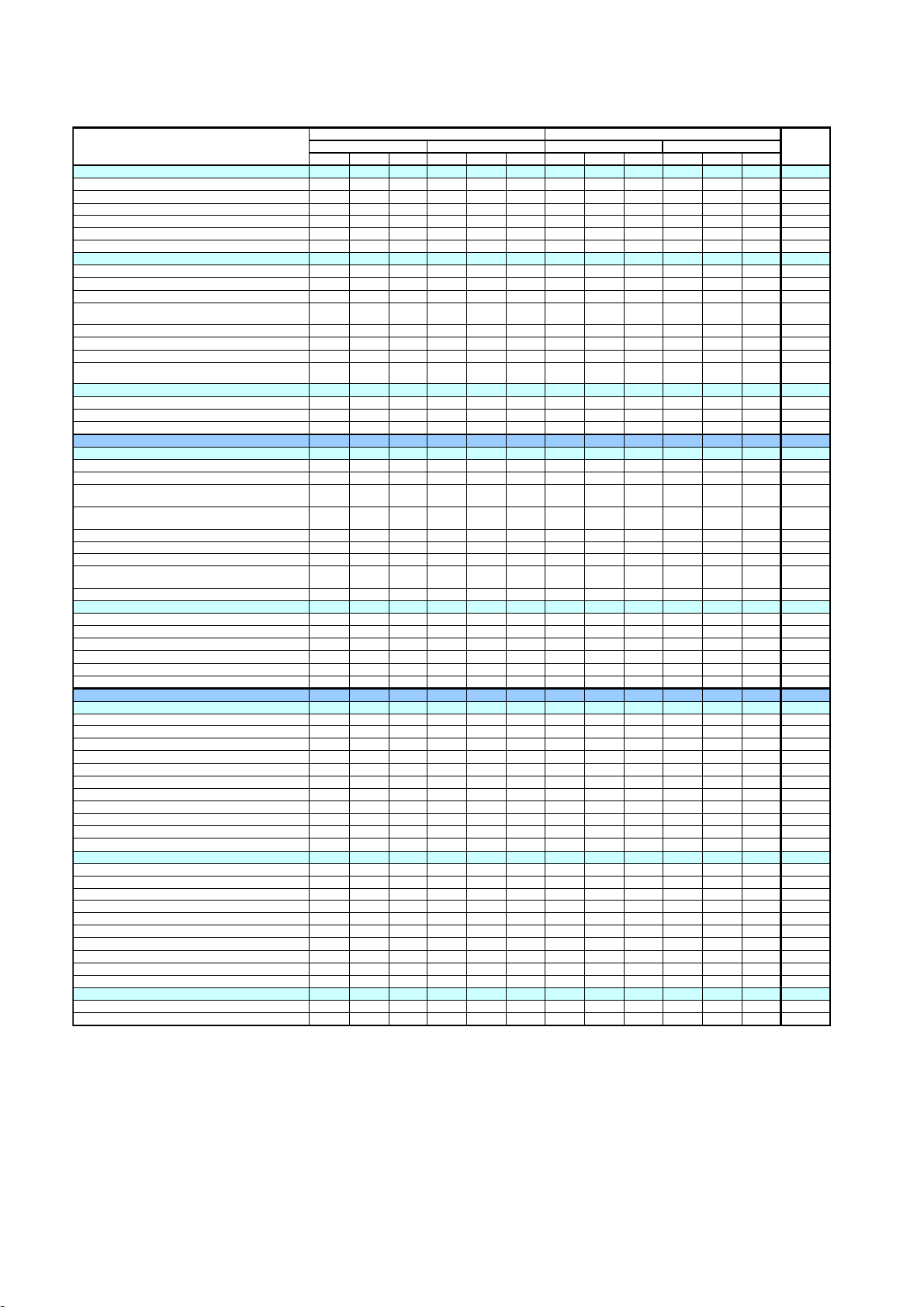

III Functional Specifications

W

M720VS M730VS M750VS M720VS M730VS M750VS

1. Cont ro l axes III - 1

1.1 Cont rol axes III - 2

1.1.1 Number of basic control axes (NC axes)

○ 3○ 3○ 3○ 2○ 2○ 2○ 3○ 3○ 3○ 2○ 2○

2III - 2

1.1.2 Max. number of axes

(

)

12 16 16 12 16 16 12 16 16 12 16 16 III - 2

(

)

6 16 16 12 16 16 6 16 16 12 16 16 III - 2

1.1.2.2 Max. number of spindles 444466444466III - 2

1.1.2.3 Max. number of PLC axes 666666666666III - 2

1.1.3 Max. number of auxiliary axes 466466000000III - 3

1.1.4 Max. number of PLC indexing axes 466466466466III - 3

1.1.5 Number of simulta neous co ntouring

448448448448III - 3

1.1.6 Max. number of NC axes in a part system 688688688688III - 3

1.2 Cont rol part system III - 4

1.2.1 Standard number of part systems 111111111111III - 4

1.2.2 Max. number of part systems

○1○2○2○2○4○4○1○2○2○2○4○

4III - 4

1.3 Control axes and operation modes III - 4

1. 3. 1 T a pe (RS - 23 2C in pu t ) m o de

○○○○○○○○○○○○

III - 4

1.3.2 Memor y m ode

○○○○○○○○○○○○

III - 4

1.3.3 MDI mode

○○○○○○○○○○○○

III - 4

1.3.4 High - s peed progr am se r ver mode

(CF card in control unit)

III - 5

1.3.4. 1 CF Card in Contro l Unit

△△△△△△

――――――III - 5

1.3.5 Fron t IC ca r d mode

△△△△△△△△△△△△

III - 5

1.3.6 Hard disk mode

△△△△△△

――――――III - 6

2. Input co mmand III - 7

2.1 Data incremen t III - 8

2.1.1 Least command increment III - 8

2.1.1. 1 Least comman d inc r em ent 1µ m

○○○○○○○○○○○○

III - 8

2.1.1. 2 Least comman d inc r em ent 0.1µm

△△△△△△△△△△△△

III - 8

2.1.1. 3 Least comman d inc r em ent 0.01µm( 10nm) ―

△△

―

△△

―

△△

―

△△

III - 8

2.1.1. 4 Least comman d inc r em ent 0.001µm( 1nm) ―

△△

―

△△

―

△△

―

△△

III - 9

2.1.2 Least cont r ol increm ent III - 10

2.1.2. 1 Least control increm ent 0.01μm(10nm)

○○○○○○○○○○○○

III - 10

2.1.2. 2 Least control increm ent 0.001μm(1nm) ―

△△

―

△△

―

△△

―

△△

II

I - 10

2.1.3 Indexing increment

○○○○○○○○○○○○

III - 10

2.2 Unit system III - 11

2.2.1 Inch /Metric c hangeover

△△△△△△△△△△△△

III - 11

2.2.2 Input comma n d incr em ent tenfold

○○○

―――

○○○

―――III - 12

2.3 Prog ram for mat III - 13

2.3.1 Program f ormat III - 13

2.3.1. 1 For mat 1 f or Lathe ―――

○○○

―――

○○○

III - 13

2.3.1. 2 For mat 2 f or Lathe ―――

○○○

―――

○○○

III - 13

2.3.1. 3 Special for m at for lathe ―――

○○○

―――

○○○

III - 13

2.3.1. 4 For m at 1 for Ma c hining cent er

○○○

―――

○○○

―――III - 13

2.3.1. 5 For m at 2 for Ma c hining cent er (M2 form at)

○○○

―――

○○○

―――III - 13

2.3.1. 6 MITSUBISHI CNC special form at ―――

○○○

―――

○○○

III - 13

2.4 Com mand value III - 14

2.4.1 Decimal point input I,II

○○○○○○○○○○○○

III - 14

2.4.2 Absolute /I nc r eme ntal comm and

○○○○○○○○○○○○

III - 15

2. 4. 3 Dia m eter /R ad ius de s ign a t i on ―――

○○○

―――

○○○

III - 17

3. Posit ioni ng/I nterp olat i on III - 19

3.1 Posi t ioning III - 20

3.1.1 Positioning

○○○○○○○○○○○○

III - 20

3.1.2 Unidirectional positioning

△△△

―――

△△△

―――III - 21

3.2 Linear/Circular interpolation III - 23

3.2.1 Line ar i nterp ol atio n

○○○○○○○○○○○○

III - 23

(

)

○○○○○○○○○○○○

III - 24

3.2.3 Helical inter polati on

△△△△△△△△△△△△

III - 26

3.2.4 Spiral/C onical i nterpola tion

△△△

―――

△△△

―――III - 29

3.2.5 Cylindrical interpolation

△△△△△△△△△△△△

III - 32

3.2.6 Polar coordinate interpolation

△△△△△△△△△△△△

III - 34

3.2.7 Milling interpolati on ―――

△△△

―――

△△△

III - 35

3.2.8 Hypot heti c al a x is interpolation

△△△

―――

△△△

―――III - 36

3.3 Cur ve int erpolation III - 37

3.3.2 Exponential interpolation

△△△△△△△△△△△△

III - 37

3.3.3 Spline interpolation

△△△

―――

△△△

―――III - 39

3.3.4 NURBS interpolation ―

△△

――――

△△

―――III - 40

3.3.5 3-dimensional circular interpolation ―

△△

――――

△△

―――III - 41

○

: Standard △: Option ☆: Plan □: Sel ect ion

Class

M7 00V W Serie s M700V S Series

Page

M syst em L systemM system L system

MITSUBISHI CNC M700V Series Specifications List

M720VWM730VWM750VWM720VWM730VWM750V

NC axes + Spindles + PLC axes

1.1.2. 1 Ma x. numb er of NC axes

in tot al for all t h e part systems

control axes

3.2.2 Circular in terpo la tio n

Ce nter /Ra diu s de s ignation

Page 13

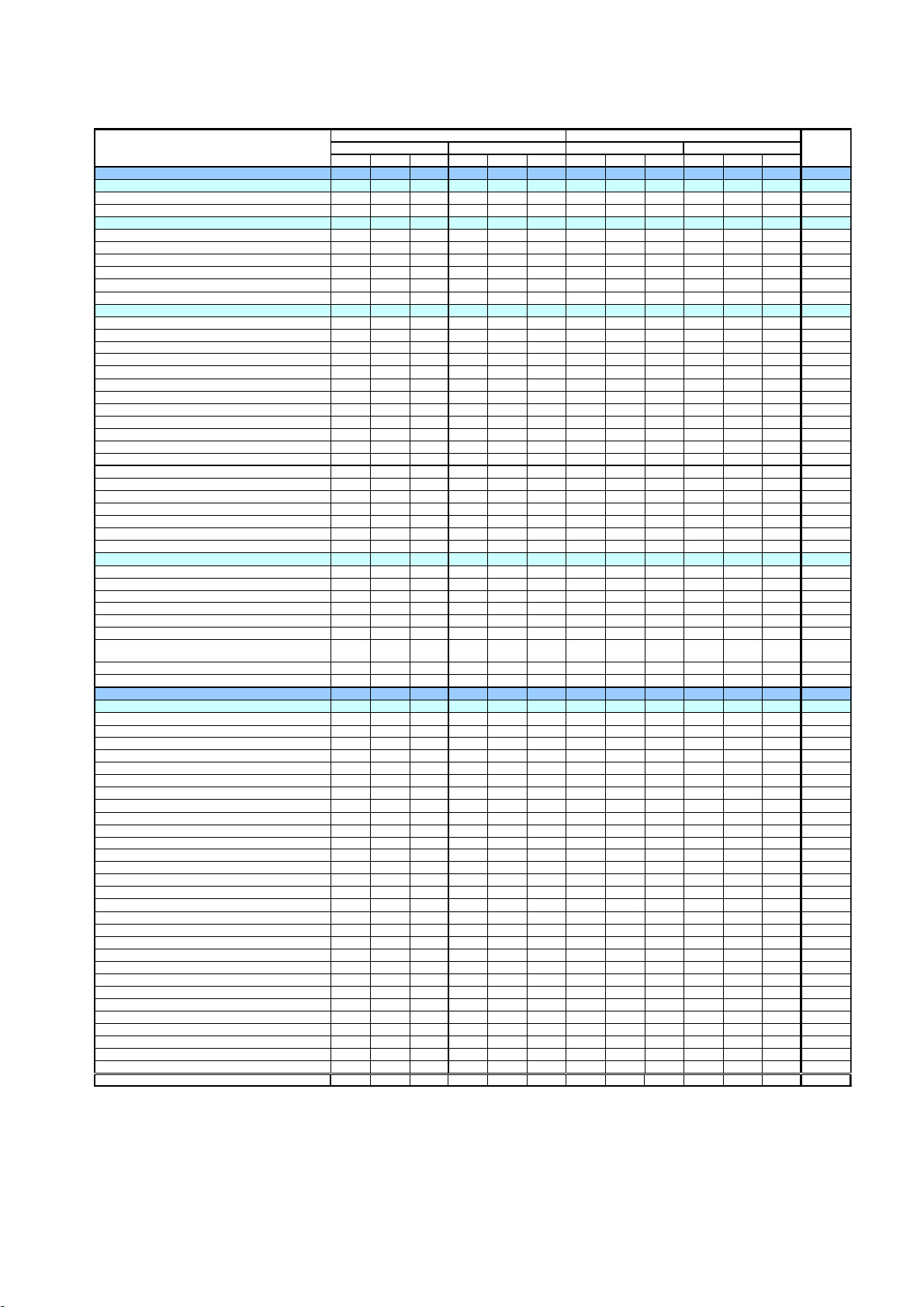

M720VWM730VWM750VWM720VWM730VWM750V

W

M720VS M730VS M750VS M720VS M730VS M750VS

4. Feed III - 43

4.1 Fee d rate III - 44

4.1.1 Rapi d traver s e r ate (m/min) 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 II I - 44

4.1.2 Cutting feed r ate (m/min) 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 III - 45

4.1.3 Manual feed r ate (m/min) 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 III - 47

4.1.4 Rotar y ax i s c om m and speed te nfold

○○○○○○○○○○○○

III - 47

4.2 Feed rate input methods III - 48

4.2.1 Feed per minute

○○○○○○○○○○○○

III - 48

4.2.2 Feed per r evolution

△△△○○○△△△○○○

III - 50

4.2. 3 In vers e ti me feed

△△△

―――

△△△

―――III - 51

4.2.4 F 1-di git feed

○○○○○○○○○○○○

III - 52

4.2.5 Manual speed comm and

△△△△△△△△△△△△

III - 53

4.3 Ov erride III - 54

4.3.1 Rapi d traver s e override

○○○○○○○○○○○○

III - 54

4.3.2 Cutting feed ov err ide

○○○○○○○○○○○○

III - 54

4.3.3 2nd cut ting feed over r ide

○○○○○○○○○○○○

III - 54

4.3.4 Override canc el

○○○○○○○○○○○○

III - 55

4.4 Acceleratio n/Deceler at ion III - 56

4.4.1 Automatic acceleration/deceleration

○○○○○○○○○○○○

III - 56

4.4.2 Rapi d traverse constan t inc lination

○○○○○○○○○○○○

III - 58

△△△

―――

△△△

―――III - 61

4.5 Thread cut t in g III - 63

4.5.1 Thread cutting

(

)

△△△○○○△△△○○○

III - 63

4.5.2 Variable lead th r ead cutt ing ―――

○○○

―――

○○○

III - 64

4.5.3 Sync hr onous tapping (w ith dig ital I/F sp indle) III - 66

4.5.3. 1 Synchr onous tapp ing cycle

△△△△△△△△△△△△

III - 66

4.5.3. 2 Pecking tap ping cy c le

△△△☆☆☆△△△☆☆☆

III - 68

4.5.3. 3 De ep-hole ta pping cy c le

△△△

―――

△△△

―――III - 70

4.5.4 Chamf er ing ―――

○○○

―――

○○○

III - 72

4.5.6 Circular thread cutting ―――

△△△

―――

△△△

III - 73

4.5.8 High - s peed synchronou s t apping

△△△△△△△△△△△△

III - 74

4.6 Manu al feed III - 75

4.6.1 Manual rapid traverse

○○○○○○○○○○○○

III - 75

4.6.2 Jog fe ed

○○○○○○○○○○○○

III - 76

4.6.3 Incremental feed

○○○○○○○○○○○○

III - 77

4.6.4 Hand le feed

○○○○○○○○○○○○

III - 78

4.6.5 Manual feed r ate B

○○○○○○○○○○○○

III - 79

4.6.6 Manual feed r ate B surfac e speed control

△△△

―――

△△△

―――III - 80

4.7 Dwell III - 81

4.7.1 Dwe ll (Time-based design ation)

○○○○○○○○○○○○

III - 81

5. Prog r am me mory/edit ing II I - 83

5.1 Memory ca pacity III - 84

5.1.1 Memor y c apacity (num ber of program s st or ed) III - 84

5.1.1. 1 15KB[40m ] (64 pr ogram s )

○○○○○○○○○○○○

III - 84

5.1.1. 2 30KB[80m ] (128 progr am s )

△△△△△△△△△△△△

III - 84

5.1.1. 3 60KB[160m] (200 pr ogr ams )

△△△△△△△△△△△△

III - 84

5.1.1. 4 125KB[320m] (200 pr ograms)

△△△△△△△△△△△△

III - 84

5.1.1. 5 230KB[600m] (400 pr ograms)

△△△△△△△△△△△△

III - 84

5.1.1. 6 500KB[1280m] (1000 programs ) ―

△△

―

△△

―

△△

―

△△

III - 84

5.1.1. 7 1000KB [2560 m ] (10 00 program s ) ―

△△

―

△△

―

△△

―

△△

II

I - 85

5.1.1. 8 2000KB [5120 m ] (10 00 program s ) ―

△△

―

△△

―

△△

―

△△

III - 85

5.2 Edi t in g III - 86

5.2.1 Progr am editi ng

○○○○○○○○○○○○

III - 86

5.2.2 Back gr ound editing

○○○○○○○○○○○○

III - 87

5.2.3 Buffer correction

○○○○○○○○○○○○

III - 88

○

: Standard △: Option ☆: Plan □: Sel ect ion

Class

M7 00V W Serie s M700V S Series

Page

M syst em L systemM system L system

after interpolation

acceleration/deceleration

4.4.3 Rapi d traverse constan t inc lination m ulti - s tep

acceleration/deceleration

Lead/ Thread number designation

Page 14

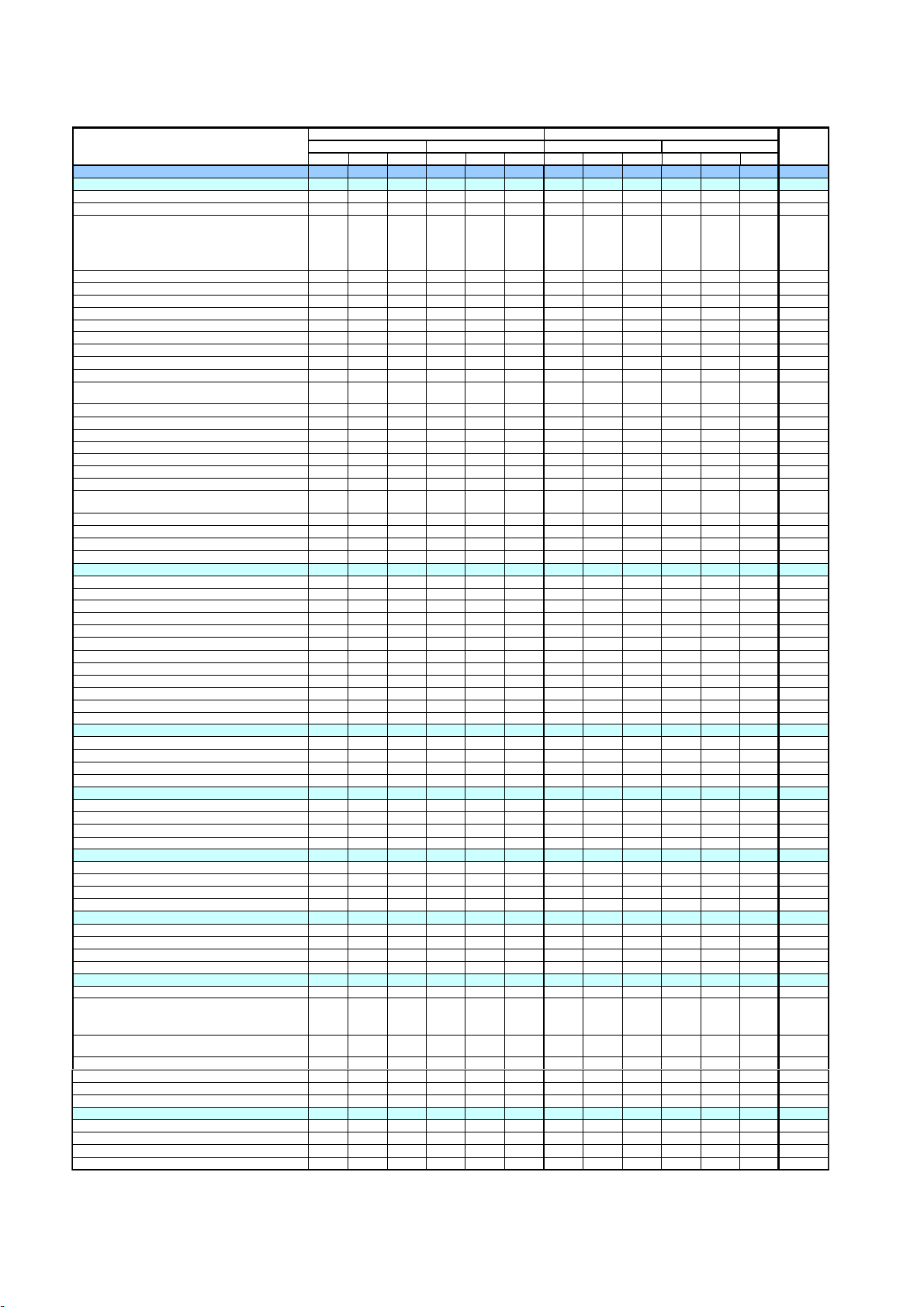

M720VWM730VWM750VWM720VWM730VWM750V

W

M720VS M730VS M750VS M720VS M730VS M750VS

6. Oper ation and dis pla y III - 89

6.1 Str uctur e of op eration/display panel III - 90

6.1.1 Color display(8.4-type LCD TFT) ――――――

□□□□□□

III - 90

6.1.2 Color display(10.4-type LCD TFT) ――――――

□□□□□□

III - 90

6.1.3 Color display(10.4-type LCD TFT/WindowsXPe)

□□□□□□

――――――III - 90

6.1.4 Color display(15-type LCD TFT/WindowsXPe)

□□□□□□

――――――III - 90

6.1.5 Color touch-panel display

(10.4-type LCD TFT/WindowsXPe)

□□□□□□

――――――III - 90

6.1.6 Color touch-panel display(10.4-type LCD TFT) ――――――

□□□□□□

III - 90

6.1.7 Color touch-panel display

)

□□□□□□

――――――III - 90

6.2 Operation methods and functions III - 91

6.2. 1 O p er ati on i npu t

○○○○○○○○○○○○

III - 91

6.2.2 Absolute value/Incremental value setting

○○○○○○○○○○○○

III - 91

6.2. 5 Dis p layed pa r t sys t e m sw itc h

○○○○○○○○○○○○

III - 92

6.2.6 Menu list

○○○○○○○○○○○○

III - 92

6.2.7 Display switch by operation mode

○○○○○○○○○○○○

III - 92

6.2.8 External signal display switch

○○○○○○○○○○○○

III - 92

6.2.10 Scr een saver, ba c k light OFF

○○○○○○○○○○○○

III - 93

6.2.11 Param eter/Operati on guidance

○○○○○○○○○○○○

III - 93

6.2.12 Alarm gu idance

△△△△△△△△△△△△

III - 93

6.2.13 Machining program in put mistake

g

△△△△△△△△△△△△

III - 94

6.2.15 Scr een Capture

------○○○○○○

III - 94

6.3 Dis pl ay methods an d contents III - 95

6.3.1 Status display

○○○○○○○○○○○○

III - 95

6.3.2 Clock display

○○○○○○○○○○○○

III - 95

6.3. 3 O p er ati on s c r e en dis pl ay

○○○○○○○○○○○○

III - 95

6.3.4 Prepar ati on s creen d is play

○○○○○○○○○○○○

III - 96

6.3. 5 E dit s c r e en di s pl ay

○○○○○○○○○○○○

III - 96

6.3.6 Diagnosis screen display

○○○○○○○○○○○○

III - 96

6.3. 7 M ain tena nce s c r een di s pla y

○○○○○○○○○○○○

III - 96

6.3.8 Additional languages III - 97

6.3.8. 1 J a panese

○○○○○○○○○○○○

III - 97

6.3.8. 2 Engli s h

○○○○○○○○○○○○

III - 97

6.3.8. 3 German

△/□△/□△/□△/□△/□△/□△/□△/□△/□△/□△/□△/□

III - 97

6.3.8. 4 Itali an

△/□△/□△/□△/□△/□△/□△/□△/□△/□△/□△/□△/□

III - 97

6.3.8. 5 Fr ench

△/□△/□△/□△/□△/□△/□△/□△/□△/□△/□△/□△/□

III

- 97

6.3.8. 6 Spani s h

△/□△/□△/□△/□△/□△/□△/□△/□△/□△/□△/□△/□

III - 97

6.3.8. 7 C hinese III - 97

6.3. 8.7.1 Tradit ional Chine s e c hara c ters

△/□△/□△/□△/□△/□△/□△/□△/□△/□△/□△/□△/□

III - 97

6.3. 8.7.2 S im plif ied Chinese char acters

△/□△/□△/□△/□△/□△/□△/□△/□△/□△/□△/□△/□

III - 97

6.3.8. 8 Korean

△/□△/□△/□△/□△/□△/□△/□△/□△/□△/□△/□△/□

III

- 98

6.3.8. 9 Portugu ese

△/□△/□△/□△/□△/□△/□△/□△/□△/□△/□△/□△/□

III - 98

6.3.8. 10 H ungarian

△/□△/□△/□△/□△/□△/□△/□△/□△/□△/□△/□△/□

III - 98

6.3.8. 11 D utch

△/□△/□△/□△/□△/□△/□△/□△/□△/□△/□△/□△/□

III

- 98

6.3.8.12 Swedish

△/□△/□△/□△/□△/□△/□△/□△/□△/□△/□△/□△/□

III - 98

6.3.8.13 Turkish

△/□△/□△/□△/□△/□△/□△/□△/□△/□△/□△/□△/□

III - 98

6.3.8.14 Polish

△/□△/□△/□△/□△/□△/□△/□△/□△/□△/□△/□△/□

III - 98

6.3.8. 15 R ussi an

△/□△/□△/□△/□△/□△/□△/□△/□△/□△/□△/□△/□

III

- 98

6.3.8. 16 C z ec h

△/□△/□△/□△/□△/□△/□△/□△/□△/□△/□△/□△/□

III - 98

7. Inpu t /Outpu t f un ct ions an d d evice s III - 99

7.1 Inpu t /Outpu t data III - 100

7.1.1 Machining program input/output

○○○○○○○○○○○○

III - 100

7.1.2 Tool offset data input/output

○○○○○○○○○○○○

III - 100

7.1.3 Common variable input/output

○○○○○○○○○○○○

III - 100

7.1.4 Parameter input/output

○○○○○○○○○○○○

III - 100

7.1.5 Hist or y data ou tput

○○○○○○○○○○○○

III - 100

7.1.7 System configuratio n d ata ou tput

○○○○○○○○○○○○

III - 100

7.2 Inpu t /Outpu t I/ F III - 101

7.2.1 RS-232C I/F

○○○○○○○○○○○○

III - 101

7.2.2 IC card I/F III - 101

7.2.2.1 I/F for IC car d in control unit

○○○○○○

――――――III - 101

7.2.2. 2 Fr ont IC c ar d I/ F

○○○○○○○○○○○○

III - 101

7.2.3 Ethernet I/F

○○○○○○○○○○○○

III - 102

7.2. 4 Har d dis k I /F

△△△△△△

――――――III - 102

7.2.5 Floppy Disk I/F

△△△△△△

――――――III - 102

7.2. 6 US B m em or y I/F [u p t o 2GB y te ]

△△△△△△○○○○○○

III - 102

7.3 Com pu t er link III - 103

7.3. 1 Com p uter l ink B

△△△△△△△△△△△△

III - 103

7.4 Others III - 104

7.4.1 Handy terminal connection

△△△△△△

――――――III - 104

○

: Sta

ndard △: Option ☆: Plan □: Selection

Class

M7 00V W Series M7 0 0V S S eries

Page

M syst em L systemM system L system

(15-type LCD TF T/ WindowsXP e

check warnin

Page 15

M720VWM730VWM750VWM720VWM730VWM750V

W

M720VS M730VS M750VS M720VS M730VS M750VS

8. Spin dle , Tool an d Mis cella ne ous func t io ns III - 105

8.1 Spi nd le funct ions (S ) III - 106

8. 1. 1 S pin dl e co ntrol function s III - 106

8.1.1. 1 Spindl e digit al I/F

○○○○○○○○○○○○

III - 107

8.1.1. 2 Spindl e analog I/F

○○○○○○○○○○○○

III - 107

8.1.1. 3 Co il switch

○○○○○○○○○○○○

III - 107

8.1.1.4 Autom atic c oil switch

○○○○○○○○○○○○

III - 107

8.1.1. 5 Encoder input I/F

△△△△△△△△△△△△

III - 108

8.1.2 S code output

○○○○○○○○○○○○

III - 110

8.1.3 Const ant surface speed con trol

△△△△△△△△△△△△

III - 111

8.1.4 Spindle override

○○○○○○○○○○○○

III - 113

8.1.5 Multiple-spindle control III - 114

8.1.5. 1 Mu ltiple-spindle cont r ol I ―――

△△△

―――

△△△

III - 115

8.1.5. 2 Mu ltiple-spindle cont r ol II

△△△△△△△△△△△△

III - 115

8.1.6 Spindle orientation

○○○○○○○○○○○○

III - 116

(Sp

)

△△△△△△△△△△△△

III - 118

8.1.8 Spindle sync hronization III - 119

8.1.8. 1 Spindl e s y nchr onization I ―――

△△△

―――

△△△

III - 119

8.1.8. 2 Spindl e s y nchr onization II ―――

△△△

―――

△△△

III - 120

8.1.9 Tool spindle synchronization I (Polygon) III - 121

8.1.9. 1 Tool spindle sync hr onizatio n I A

(Spindle-Spindle, Polygon)

―――

△△△

―――

△△△

III - 121

8.1.9. 2 Tool spindle sync hr onizatio n I B

(Spindle-Spindle, Polygon)

―――

△△△

―――

△△△

III - 122

8.1.9. 3 Tool spindle sync hr onizatio n I C

(Spindle-NC axis, Polygon)

―――

△△△

―――

△△△

III - 123

8.1.10 Tool spindl e syn c hr onizatio n II (H obbing) ―――

△△△

―――

△△△

III - 124

8. 2 Tool fun c ti ons (T) III - 126

8.2.1 Tool functi ons ( T comma n d)

○○○○○○○○○○○○

III - 126

8.3 Miscellaneou s f un ct ions (M ) III - 127

8.3.1 Misc ellaneous fu nctions

○○○○○○○○○○○○

III - 127

8.3.2 Multiple M codes in 1 block

○○○○○○○○○○○○

III - 127

8.3.3 M code independent output

○○○○○○○○○○○○

III - 128

8.3.4 Misc ellaneous fu nction finish

○○○○○○○○○○○○

III - 129

8.3.5 M code output during ax is trav eling ―――

△△△

―――

△△△

III - 130

8.4 2nd miscellaneous functions (B) III - 131

8.4.1 2nd misc ellaneous fun c tions

○○○○○○○○○○○○

III - 131

9. Tool compen sa t ion III - 133

9. 1 Tool lengt h/Tool posit ion III - 134

9.1.1 Tool length compensation

○○○○○○○○○○○○

III - 134

9. 1. 2 T o ol po s i t i on offs et

○○○

―――

○○○

―――III - 137

9.1.3 Tool compensation for additional axes ―――

○○○

―――

○○○

III - 137

9.2 Tool radius III - 138

9.2.1 Tool radius compensation

○○○

―――

○○○

―――III - 138

9.2.2 3-dimensional tool radius compensation

△△△

―――

△△△

―――III - 141

9.2.3 Tool nose radius compensation (G 40/41/42) ―――

○○○

―――

○○○

III - 143

9.2.4 Auto m atic decis ion of n os e r adius

)

―――

○○○

―――

○○○

III - 144

r

○○○○○○○○○○○○

III - 144

9. 3 Tool offs et amoun t III - 145

9.3.1 Number of tool offset sets III - 145

9.3.1. 1 20 sets ―――

○○○

―――

○○○

III - 145

9.3.1. 2 40 sets

○○○

―――

○○○

―――III - 145

9.3.1. 3 80 sets ―――

△△△

―――

△△△

III - 145

9.3.1. 4 200 sets

△△△

―――

△△△

―――III - 145

9.3.1. 5 400 sets

△△△

―――

△△△

―――III - 146

9.3.1. 6 999 sets ―

△△

――――

△△

―――III - 146

9.3.2 Offset memory III - 147

9.3.2. 1 Tool shape/ wear off se t amount

○○○○○○○○○○○○

III - 147

○

: Standard △: Option ☆: Plan □: Sel ect ion

Class

M7 00V W Serie s M700V S Series

Page

M syst em L systemM system L system

8.1.7 Spindle po s ition contro l

compens a t i on di r e c t i on (G46/40

9.2.5 Tool radius compensation diamete

designation

ind le/C ax i s c ontr o l

Page 16

M720VWM730VWM750VWM720VWM730VWM750V

W

M720VS M730VS M750VS M720VS M730VS M750VS

10. Co ordin at e system III - 151

10.1 Coordinate system type and setting III - 152

10.1.1 Machine coor dinate system

○○○○○○○○○○○○

III - 153

10.1.2 Coo r dinate system sett i ng

○○○○○○○○○○○○

III - 154

10.1.3 Aut om atic coor dinate system setting

○○○○○○○○○○○○

III - 156

10.1.4 Wor k piece coordi n ate sys tem selec tio n III - 157

(

)

○○○○○○○○○○○○

III - 157

10.1.4. 2 E x tende d work piece coordi nate sy s tem

selection (48 sets) G54.1P1 to P48

△△△△△△△△△△△△

III - 159

10.1.4. 3 E x tende d work piece coordi nate sy s tem

selection (96 sets) G54.1P1 to P96

―

△△

――――

△△

―――III - 159

10.1.5 External workpiece c oordinate offset

○○○○○○○○○○○○

III - 160

10.1.6 Wor k piece coordi n ate sys tem pres et (G9 2.1)

△△△△△△△△△△△△

III - 161

10.1.7 Local coordinat e s ystem

○○○○○○○○○○○○

III - 162

10.1.8 Coo r dinate sys tem for rotary ax is

○○○○○○○○○○○○

III - 164

10.1.9 Plane selectio n

○○○○○○○○○○○○

III - 165

10.1.10 Or igin set/Origin canc el

○○○○○○○○○○○○

III - 166

10.1.11 Co unter set

○○○○○○○○○○○○

III - 168

10.2 Return III - 169

10.2.1 Manual ref er ence p os iti on r eturn

○○○○○○○○○○○○

III - 169

10.2.2 Aut om atic 1st refe re n c e position re turn

○○○○○○○○○○○○

III - 170

10.2.3 2nd , 3rd, 4th r eference posi tion r eturn

○○○○○○○○○○○○

III - 172

10.2.4 Refer ence pos iti on c heck

○○○○○○○○○○○○

III - 174

10.2.5 Absolut e position detec tion

△△△△△△△△△△△△

III - 175

10.2.6 Tool ex c hange posit i on return

○○○○○○○○○○○○

III - 176

11. O perati on sup port functions III - 177

11.1 Prog ram control III - 178

11.1.1 Optiona l b lock skip

○○○○○○○○○○○○

III - 178

11.1.2 Optiona l b lock skip addition

△△△△△△△△△△△△

III - 178

11.1.3 Single block

○○○○○○○○○○○○

III - 179

11.2 Prog ram test III - 180

11.2.1 Dry r un

○○○○○○○○○○○○

III - 180

11.2.2 Machine lock

○○○○○○○○○○○○

III - 180

11.2.3 Misc ellaneou s func tio n loc k

○○○○○○○○○○○○

III - 181

11.2.4 Gra phic che c k III - 182

11.2.4. 1 Graphic check

△△△△△△△△△△△△

III - 182

11.2.4. 2 3D sol id pr ogram c hec k

△△△☆☆☆☆☆☆☆☆☆

III - 183

11.2.5 Gra phic trac e

△△△△△△△△△△△△

III - 183

11.2.6 Machining time co mputatio n

○○○○○○○○○○○○

III - 184

11.3 Program searc h/ st art/stop III - 185

11.3.1 Progr am sea r c h

○○○○○○○○○○○○

III - 185

11.3.2 Sequence number s e arch

○○○○○○○○○○○○

III - 185

11.3.3 Verific ati on stop

△

△△△△△△△△△△△

III - 186

11.3.4 Progr am rest ar t

△△△△△△△△△△△△

III - 187

11.3.5 Aut om atic operat ion start

○○○○○○○○○○○○

III - 188

11.3.6 NC reset

○○○○○○○○○○○○

III - 188

11.3.7 Feed hold

○○○○○○○○○○○○

III - 189

11.3.8 Searc h & Star t

○○○○○○○○○○○○

III - 189

11.4 Int erru pt op eration III - 190

11.4.1 Manual interruption

○○○○○○○○○○○○

III - 190

11.4.2 Aut om atic operat ion handle interruption

○○○○○○○○○○○○

III - 191

11.4.3 Manual absolute s witch

○○○○○○○○○○○○

III - 192

11.4.4 Thre ad cutt ing cycle ret ract ―――

△△△

―――

△△△

III - 194

11.4.5 Tapping retract

○○○○○○○○○○○○

III - 195

11.4.6 Manual numerical va lue com ma nd

○○○○○○○○○○○○

III - 196

11.4.7 Arbitrary r ev erse ru n

△△△

―――

△△△

―――III - 197

11.4.8 MDI interrup tion

○○○○○○○○○○○○

III - 198

○○○○○○○○○○○○

III - 199

11.4.10 Simult aneous operation of JOG and

○○○○○○○○○○○○

III - 200

11.4.11 Re ference position re tr act

○○○○○○○○○○○○

III - 200

11.4.12 Tool retrac t and retur n ―

△△

――――

△△

―――III - 201

11.4.13 Skip retrac t

△△△☆☆☆△△△☆☆☆

III - 202

11.4.14 PLC inter r uptio n

△△△△△△△△△△△△

III - 202

○

: Standard △: Option ☆: Plan □: Sel ect ion

Class

M7 00V W Series M7 00V S Series

Page

M sys t em L systemM system L system

10.1.4. 1 Workp iece c oor dinate system selection

11.4.9 Simulta neous oper ati on o f manual and

automatic modes

handle modes

6 sets

Page 17

M720VWM730VWM750VWM720VWM730VWM750V

W

M720VS M730VS M750VS M720VS M730VS M750VS

12. Program support functions III - 203

12.1 Machining method support functions III - 204

12.1.1 Progr am III - 204

12.1.1. 1 Subpr o gr am co ntrol

○

8 layers

○

III - 204

12.1.1. 2 Figure rota tion

△△△

―――

△△△

―――III - 206

12.1.1. 3 Scali ng

△△△

―

☆☆△△△

―

☆☆

III - 208

12.1.1.4 Axis nam e switch ―――

○○○

―――

○○○

III - 209

12.1.2 Macro program III - 210

12.1.2. 1 U s er m ac r o

△

y

III - 210

12.1.2. 2 M achin e tool builder m ac r o

△△△△△△△△△△△△

III - 213

12.1.2.3 Macr o inte r r uptio n

△△△△△△△△△△△△

III - 214

12.1.2. 4 Varia b le com m and III - 216

12 .1.2.4 .1 1 00 sets

○○○○○○○○○○○○

III - 217

12 .1.2.4 .2 2 00 sets

△△△△△△△△△△△△

III - 217

12 .1.2.4 .3 3 00 sets

△△△△△△△△△△△△

III - 217

12 .1.2.4 .4 6 00 sets

△△△△△△△△△△△△

III - 217

12 .1.2.4 .5 7 00 sets

△△△△△△△△△△△△

III - 217

12.1.2.4.6 (50 + 50× num ber of part sys tems) s ets ―

○○○○○

―

○○○○○

III - 217

12.1.2.4.7 (100+100×number of part systems) sets ―

△△△△△

―

△△△△△

III - 217

12.1.2.4.8 (200+100×number of part systems) sets ―

△△△△△

―

△△△△△

III - 217

12.1.2.4.9 (500+100×number of part systems) sets ―

△△△△△

―

△△△△△

III - 218

12.1.2.4.10 (6 00+ 100×number of part systems)

―

△△△△△

―

△△△△△

III - 218

12.1.3 Fix ed c y cle III - 219

12.1.3.1 Fix ed cycle for drilli ng

○○○○○○○○○○○○

III - 220

12.1.3. 2 Fixed cycle for drilli ng ( Type I I) ―――

○○○

―――

○○○

III - 225

12.1.3. 3 Special fix ed cycle

△△△

―――

△△△

―――III - 226

12.1.3. 4 Fixed cycle for tur ning mac hining ―――

○○○

―――

○○○

III - 230

12.1.3. 5 C ompound type fix ed c y c le for turnin g

g

―――

△△△

―――

△△△

III - 236

12.1.3. 6 C ompound type fix ed c y c le for turnin g

)

―――

△△△

―――

△△△

III - 246

12.1.3.7 Small-diameter deep-hole drillin g c y c le

△△△

―――

△△△

―――III - 247

12.1.4 Mirr or image III - 248

12.1.4. 1 M i rror image by param eter setting

○○○○○○○○○○○○

III - 248

12.1.4.2 Mirror im age by ex ternal in put

○○○○○○○○○○○○

III - 248

12.1.4. 3 M i rror image by G code

○○○

―――

○○○

―――III - 249

12.1.4. 4 M i rror image f or facing t ool posts ―――

△△△

―――

△△△

III - 250

12.1.4.5 T cod e m ir r or im age fo r facin g tool po s ts ―――

△△△

―――

△△△

III - 251

12.1.5 Coordin ate sy s tem operatio n III - 252

12.1.5. 1 C oordinat e r otation by pr ogr am

△△△

―――

△△△

―――III - 252

12.1.5. 2 C oordinat e r otation by par am eter

△△△

―――

△△△

―――III - 254

12.1.5. 3 3-di m ens ional coordinate con v er s ion

△△△

―――

△△△

―――III - 255

12.1.6 Dimension input III - 257

12.1.6. 1 C orner c ham fering/Cor ner R

△△△△△△△△△△△△

III - 257

12.1.6. 2 Linear angle com m and

△△△△△△△△△△△△

III - 263

12.1.6. 3 Geomet r i c c om m and

△△△○○○△△△○○○

III - 264

12.1.6. 4 Pola r coordinate c om m and

△△△

―――

△△△

―――III - 268

12.1.7 Axis control III - 269

12.1.7. 1 C hopping III - 269

12 .1.7.1 .1 C ho p pi n g

△△△△△△△△△△△△

III - 269

12.1.7.2 Normal line cont r ol

△△△

―――

△△△

―――III - 271

12.1.7. 3 C ircul ar c utting

△△△

―――

△△△

―――III - 272

12.1.8 Mult i-par t system cont r ol III - 273

p

―

○○○○○

―

○○○○○

III - 273

12.1.8. 2 Start point des ignat ion ti m ing

―

○○○○○

―

○○○○○

III - 274

12.1.8. 3 M i x ed sy nc hr onizatio n c o ntrol ―――

△△△

―――

△△△

III - 276

12.1.8. 5 C ontrol axis s y nc hronization ac r oss

―――

△△△

―――

△△△

III - 277

12.1.8. 6 Bala nc e c ut ―――

△△△

―――

△△△

III - 278

12.1.8. 7 C ommo n m em or y for part system s ―――

○○○

―――

○○○

III - 279

12.1.8. 8 2-pa rt s ystem synchr onous thread cut ting ―――

△△△

―――

△△△

III - 280

12.1.8. 9 M ul ti-part system program m anagement ―

○○○○○

―

○○○○○

III - 282

12.1.9 Dat a input by pr ogr am III - 284

12.1.9. 1 Parameter input by pr ogram

△△△△△△△△△△△△

III - 284

12.1.9. 2 C ompens ati on data input by program

△△△△△△△△△△△△

III - 285

12.1.10 Machining modal III - 287

12.1.10.1 Tapping mode

○○○○○○○○○○○○

III - 287

12.1 .10.2 C u tting mode

○○○○○○○○○○○○

III - 288

○

: Standard △: Option ☆: Plan □: Sel ect ion

Class

M7 00V W Series M7 00V S Series

Page

M sys t em L systemM system L system

8 layers○8 layers○8 layers○8 layers○8 layers○8 layers○8 layers○8 layers○8 layers○8 layers○8 layers

△

4 la

4 layers

sets

machinin

machining (Type II

12.1.8. 1 Timing synchronizat ion bet ween

art systems

synchronizat ion

part systems

ers△4 layers△4 layers△4 layers△4 layers△4 layers△4 layers△4 layers△4 layers△4 layers△4 layers

Page 18

M720VWM730VWM750VWM720VWM730VWM750V

W

M720VS M730VS M750VS M720VS M730VS M750VS

12.2 Machining accuracy sup po rt f unctions III - 289

12.2.1 Aut om atic cor ner ov er r ide

○○○○○○○○○○○○

III - 289

12.2.2 Deceleration c hec k III - 291

12.2.2.1 Exact stop check mode

○○○○○○○○○○○○

III - 292

12.2.2. 2 E x ac t stop ch ec k

○○○○○○○○○○○○

III - 292

12.2.2. 3 E r r or detect ion

○○○○○○○○○○○○

III - 293

12.2.2. 4 P r ogr amm able in-position ch ec k

○○○○○○○○○○○○

III - 293

12.3 Hi gh - spee d an d h ig h-accu racy fun ct ions III - 294

12.3.1 Hig h- s peed mac hining mode I (G5P1 )

△

16.8△16.8△16.8 ―――△16.8△16.8△16.8 ―――III - 294

12.3.2 Hig h- s peed mac hining mode II (G5P2)

△

67.5△151△151 ―――△67.5△151△151 ―――I II - 296

12.3.3 Hig h- s peed high-acc urac y control 1 (G5.1Q1)△16.8△33.7△33.7 ―――△16.8△33.7△33.7 ―――III - 298

12.3.4 Hig h- s peed high-acc urac y control 2

)

△

67.5△151△151 ―――△67.5△151△151 ―――I II - 299

12.3.5 Hig h- ac c urac y c ontrol1(G6 1.1/G08)

△△△

―――

△△△

―――III - 302

12.3.6 Hig h- ac c urac y s pline int er polation1(G61.2)

△△△

―――

△△△

―――III - 306

12.3.8 SSS con trol

△△△

―――

△△△

―――III - 307

12.3.9 Hig h- ac c urac y ac c eleration /decelerat ion

△△△

―――

△△△

―――III - 308

12.4 Programming support functions III - 309

12.4.1 Playback

△△△△△△△△△△△△

III - 309

12.4.3 Simple progr ammi ng

△△△△△△△△△△△△

III - 309

12.4.4 G cod e guidance

△△△△△△△△△△△△

III - 309

13. Machine accu racy compensat i on III - 311

13.1 Static accuracy compensa t io n III - 312

13.1.1 Back lash co m pensation

○○○○○○○○○○○○

III - 312

13.1.2 Memor y - type pitch error com pensat ion

△△△△△△△△△△△△

III - 313

13.1.3 Memory-type relative position error

△△△△△△△△△△△△

III - 314

p

△△△△△△△△△△△△

III - 315

13.1.5 Circular er r or r adius c om pensatio n

△△△△△△△△△△△△

III - 315

13.1.6 Ball scre w thermal expansion c om pensation

△△△△△△△△△△△△

III - 316

13.1.7 Machine rotation cent er error c om pensatio n ―

△△

――――

△△

―――III - 318

p

△△△△△△△△△△△△

III - 320

13.1.9 Two- way pitch err or c om pensation

△△△△△△△△△△△△

III - 321

13.2 Dynamic accuracy compensat ion III - 322

13.2.1 Smooth hig h- gain (S HG) control

○○○○○○○○○○○○

III - 322

13.2.2 Dua l feedb ac k

○○○○○○○○○○○○

III - 324

13.2.3 Lost mo tion compensati on

○○○○○○○○○○○○

III - 325

13.2.4 OMR II (Bac k lash with filter)

△△△△△△△△△△△△

III - 325

13.2.6 OMR - FF

△△△△△△△△△△△△

III - 326

13.2.7 Dist ance- c oded reference positio n detect ion

△△△△△△△△△△△△

III - 328

14. Automation support functions III - 329

14.1 Measur ement III - 330

14.1.1 Skip III - 330

14.1.1. 1 S k ip

△△△△△△△△△△△△

III - 330

14.1.1. 2 M u ltipl e-step skip

△△△△△△△△△△△△

III - 332

14.1.1. 4 P LC s k ip

△△△△△△△△△△△△

III - 333

14.1.1. 5 S peed change sk ip

△△△△△△△△△△△△

III - 333

14.1.2 Aut om atic to ol lengt h m eas urem ent

△△△△△△△△△△△△

III - 335

14.1.3 Manual tool lengt h m easur em ent 1

△△△△△△△△△△△△

III - 338

14.1.4 Manual tool lengt h m easur em ent 2

△△△△△△△△△△△△

III - 340

14.1.5 Wor k piece co or dinat e offse t measur em ent ―――

△△△

―――

△△△

III - 342

14.1.6 Wor k piece pos itio n m eas urem ent

△△△

―――

△△△

―――III - 343

14.1.7 Rotation me as ur ement

△△△

―――

△△△

―――III - 346

14.2 Tool life ma nagement III - 347

14.2.1 Tool life manage m ent I II - 347

14.2.1. 1 Tool li fe management I

△△△△△△△△△△△△

III - 347

14.2.1. 2 Tool li fe management II

△△△△△△△△△△△△

III - 347

14.2.2 Number of tool lif e m anagement set s III - 348

14.2.2. 1 80 sets ―――

△△△

―――

△△△

III - 349

14.2.2. 2 200 sets

△△△

―――

△△△

―――III - 349

14.2.2. 3 400 sets

△△△

―――

△△△

―――III - 349

14.2.2. 4 600 sets

△△△

―――

△△△

――

―III - 349

14.2.2. 5 800 sets

△△△

―――

△△△

―――III - 349

14.2.2. 6 1000 sets

△△△

―――

△△△

―――III - 349

14.3 Oth ers III - 350

14.3.1 Progr amma ble cur r ent limitation

△△△△△△△△△△△△

III - 350

14.3.2 Aut o power off

○○○○○○○○○○○○

III - 351

Page

M sys t em L systemM system L system

○

: Standard △: Option ☆: Plan □: Sel ect ion

Class

M7 00VW Seri es M700V S S eries

(G5P10000

time constant extension

compensation

13.1.4 External machine coord inate syst e m

com

13.1.8 Positio n- dependent gr adually incr easing-type

backlash com

ensation

ensation

Page 19

M720VWM730VWM750VWM720VWM730VWM750V

W

M720VS M730VS M750VS M720VS M730VS M750VS

15. Saf ety and mainte nance III - 353

15.1 Safety switches III - 354

15.1.1 Emer gency s top

○○○○○○○○○○○○

III - 354

15.1.2 Data pr otect ion key

○○○○○○○○○○○○

III - 354

15.2 Di splay f or ensuri ng safe t y III - 354

15.2.1 NC warning

○○○○○○○○○○○○

III - 354

15.2.2 NC al a rm

○○○○○○○○○○○○

III - 355

15.2.3 Operation stop cause

○○○○○○○○○○○○

III - 355

15.2.4 Emer gency s top cause

○○○○○○○○○○○○

III - 355

15.2.5 Thermal dete c ti on

○○○○○○○○○○○○

III - 356

15.2.6 Bat tery alar m /wa rnin g

○○○○○○○○○○○○

III - 357

15.3 Protection III - 358

15.3.1 Stroke end (Over trav el)

○○○○○○○○○○○○

III - 358

15.3.2 Sto r ed s troke li m it III - 358

15.3.2. 1 Stored strok e limit I /I I

○○○○○○○○○○○○

III - 359

15.3.2. 2 Stored strok e limit I B

△△△△△△△△△△△△

III - 361

15.3.2. 3 Stored strok e limit I IB

△△△△△△△△△△△△

III - 362

15.3.2. 4 Stored strok e limit I C

△△△△△△△△△△△△

III - 362

15.3.3 Stroke chec k before travel

△△△

―――

△△△

―――III - 363

15.3.4 Chuck/Tailstock bar r ier chec k ―――

○○○

―――

○○○

III - 364

15.3.5 Interlock

○○○○○○○○○○○○

III - 365

15.3.6 External decelerat ion

○○○○○○○○○○○○

III - 365

15.3.8 3D Machine I nterferen ce check ―

☆☆

―――――――――III - 366

15.3.9 Door inter lock III - 367

15.3.9. 1 D oor interlo c k I

○○○○○○○○○○○○

III - 367

15.3.9. 2 D oor interlo c k II

○○○○○○○○○○○○

III - 369

15.3.10 Parameter lock

○○○○○○○○○○○○

III - 370

15.3.11 Program pr o tecti on (Edi t lock B, C)

○○○○○○○○○○○○

III - 370

15.3.12 Program di s play lock

○○○○○○○○○○○○

III - 371

15.3.13 Saf ety observa tion

△△△△△△△△△△△△

III - 371

15.3.14 Vertical axis pull-up

○○○○○○○○○○○○

III - 372

15.4 Maintenance and troubleshooting III - 373

15.4.1 Oper atio n hi s tory

○○○○○○○○○○○○

III - 373

15.4.2 Data sam p ling

○○○

○○○○○○○○○

III - 373

15.4.3 NC da ta back up

○○○○○○○○○○○○

III - 374

15.4.4 MELDA SNET III - 374

15.4.4. 1 M achine tool builder netw or k s y s tem

△△△△△△△△△△△△

III - 374

15.4.4. 2 Anshi n- net serv ice

△△△△△△△△△△△△

III - 375

15.4.5 Serv o automatic tuning

)

○○○○○○○○○○○○

III - 376

15.4.6 Aut om atic back up

○○○○○○○○○○○○

III - 377

15.4.7 Sys tem setup

○○○○○○○○○○○○

III - 378

16. Drive system III - 379

16.1 Servo/Spindle III - 380

16.1.1 Feed ax is III - 380

16.1.1. 1 M D S - D- V 1/D - V 2 (200V) III - 380

16.1.1.1.1 Servo motor: HF**-A48 (260kp/rev)

□□□□□□□□□□□□

III - 380

16.1.1.1.2 Servo motor: HF**-A51 (1000kp/rev)

□□□□□□□□□□□□

III - 380

16.1.1.1.3 S ervo moto r: HF **- A 74 (16000kp/rev)

□□□□□□□□□□□□

III - 380

16.1.1.1.4 Servo motor: HP**-A51 ( 1000kp/rev)

□□□□□□□□□□□□

III - 380

16 .1.1.1 .5 Ser vo mot o r: H P**- A74 ( 1 60 0 0kp/r ev)

□□□□□□□□□□□□

III - 380

16.1.1. 2 M D S - DH-V 1/DH-V2 ( 400V) III - 380

16.1.1.2.1 Servo motor: HF**-A48 (260kp/rev)

□□□□□□□□□□□□

III - 380

16.1.1.2.2 Servo motor: HF-H**-A51 (1000kp/rev)

□□□□□□□□□□□□

III - 380

16.1.1.2.3 Servo motor: HF-H**-A74 (16000kp/rev)

□□□□□□□□□□□□

III - 381

16.1.1.2.4 Servo motor: HP-H**-A51 (1000kp/rev)

□□□□□□□□□□□□

III - 381

16.1.1.2.5 Servo motor: HP-H**-A74 (16000kp/rev)

□□□□□□□□□□□□

III - 381

16.1.1. 3 MDS-D- S V J 3 (200V) III - 381

16.1.1.3.1 Servo motor: HF**-A48(260kp/rev)

□□□□□□□□□□□□

III - 381

16.1.1.3.2 Servo motor: HF**-A51(1000kp/rev)

□□□□□□□□□□□□

III - 381

16.1.1.3.3 Servo motor: HF-KP**JW04(260kp/rev)

□□□□□□□□□□□□

III - 381

16.1.2 Spindle III - 382

16.1.2. 1 MDS-D- S P ( 200V)

□□□□□□□□□□□□

III - 382

16.1.2. 2 MDS-DH-S P (4 00V )

□□□□□□□□□□□□

III - 382

16.1.2. 3 MDS-D- S P J 3 (200V)

□□□□□□□□□□□□

III - 382

16.1.3 Auxiliary ax is III - 382

16.1.3. 1 Indexing /P os itioning ser vo:MR - J 2-CT

□□□□□□

――――――III - 382

16.1.3.1.1 Servo motor: HC-SF/HC-RF (16kp/rev)

□□□□□□

――――――III - 382

16.1.3.1.2 Servo motor: HA-FF/HC-MF (8kp/rev)

□□□□□□

――――――III - 382

16.1.4 Power supply III - 383

16.1.4.1 Power supply: MDS-D - CV (200V)

□□□□□□□□□□□□

III - 383

16.1.4. 2 Pow er s upply: MDS-D H- CV (400V )

□□□□□□□□□□□□

III - 383

16.1.4. 3 AC reactor f or power s upply

□□□□□□□□□□□□

III - 383

○

: Standard △: Option ☆: Plan □:

Select ion

Class

M7 00V W Serie s M700V S Series

Page

M syst em L systemM system L system

16.1.4.4 Gro und plat e

□□□□□□□□□□□□

III - 383

(Need separ ate PC S/W

Page 20

M720VWM730VWM750VWM720VWM730VWM750V

W

M720VS M730VS M750VS M720VS M730VS M750VS

17. Machine support functions III - 385

17.1 PLC III - 386

17.1.1 Built-i n PL C pr oc ess ing mode

○○○○○○○○○○○○

III - 386

17.1.2 PLC funct ions III - 387

17.1.2. 1 B uilt-in PLC basic functi on

○

*In d ex

qualifi-

cation is

available.

○

*Index

qualifi-

cation is

available.

○

*Index

qualifi-

cation is

available.

○

*Index

qualifi-

cation is

available.

○

*Index

qualifi-

cation is

available.

○

*Index

qualifi-

cation is

available.

○

*Index

qualifi-

cation is

available.

○

*Index

qualifi-

ca ti on is

available.

○

*Index

qualifi-

cation is

available.

○

*Index

qualifi-

cation is

available.

○

*Index

qualifi-

cation is

available.

○

*Index

qualifi-

cation is

available.

III - 387

17.1.2. 2 P LC ex clusive instr uc tion

○○○○○○○○○○○○

III - 388

17.1.3 PLC s upport func tions III - 393

17.1.3. 1 Alarm m es s age display

○○○○○○○○○○○○

III - 393

17.1.3. 2 Operator mes s age display

○○○○○○○○○○○○

III - 393

17.1.3. 3 M e m or y sw itch (PL C sw itch) III - 393

17 .1.3.3 .1 PLC switc h 3 2 -point

○○○○○○○○○○○○

III - 393

17 .1.3.3 .2 PLC switc h 6 4 -point

△△△△△△△△△△△△

III - 393

17.1.3. 4 Load m eter display

○○○○○○○○○○○○

III - 394

17.1.3. 5 Us er PLC version display

○○○○○○○○○○○○

III - 394

17.1.3. 6 M u lti-ladd er pr ogram regist er and

○○○○○○○○○○○○

III - 394

17.1.3. 7 Ladder pro gr am wr iti ng during RUN

○○○○○○○○○○○○

III - 394

17.1.3. 8 P LC protecti on

○○○○○○○○○○○○

III - 395

17.1.4 Built-i n PL C c apacity

○

42000○42000○42000○42000○42000○42000○42000○42000○42000○42000○42000○42000 III - 395

17.1.5 Machine contact i nput/output I/F

○○○○○○○○○○○○

III - 396

17.1.6 Lad der moni tor

○○○○○○○○○○○○

III - 402

17.1.7 PLC development III - 402

17.1.7. 1 On-board development

○○○○○○○○○○○○

III - 402

17.1.7. 2 M ELSEC development tool

)

○○○○○○○○○○○○

III - 402

17.1.8 PLC param eter III - 403

17.1.8. 1 P LC c onstant (15 0 point s )

○○○○○○○○○○○○

III - 403

17.1.8. 2 P LC c onstant extensi on (Up to 7 55 point s )

○○○○○○○○○○○○

III - 403

17.1.10 Pallet pr ogr am re gis trat ion

△△△

―――

△△△

―――III - 404

17.2 Machine construction III - 405

17.2.1 Serv o OFF

○○○○○○○○○○○○

III - 405

17.2.2 Axis detac hment

△△△△△△△△△△△△

III - 406

17.2.3 Sync hr onous contr ol

△△△△△△△△△△△△

III - 408

17.2.4 Inc lined axis contro l ―――

△△△

―――

△△△

III - 411

17.2.5 Positio n sw itch

○24○24○24○24○24○24○24○24○24○24○24○

24 I II - 412

17.2.7 Index tabl e ind exing

○○○○○○○○○○○○

III - 413

17.2.8 Auxiliary ax is co ntrol (J 2- CT)

△△△△△△

――――――III - 414

17.2.9 Tool length compensation along th e tool axis ―

△△

――

☆

―

△△

――

☆

III - 415

17.2.10 Tool handle fee d & interrupti on ―

△△

――

☆

―

△△

――

☆

III - 416

17.2.11 Tool cen ter coor dinat e dis play ――

△

――

☆

――

△

――

☆

III - 416

17.2.12 Tool cen ter point contr ol ――

△

――

☆

――

△

――

☆

II

I - 417

17.2.13 Inclined surface machining command ――

☆

――

☆

――

☆

――

☆

III - 419

17.3 PLC operation III - 420

17.3.1 Arbitrary feed in ma nual mode

○○○○○○○○○○○○

III - 420

17.3.2 Circ ular feed in ma nual mode

△△△△△△△△△△△△

III - 421

17.3.3 PLC ax is con tr ol

△△△△△△△△△△△△

III - 424

17.3.5 PLC ax is indexing

△△△△△△△△△△△△

III - 425

17.4 PLC interface III - 427

17.4.1 CNC co n trol signal

○○○○○○○○○○○○

III - 427

17.4.2 CNC status s ignal

○○○○○○○○○○○○

III - 428

17.4.3 PLC windo w

△△△△△△△△△△△△

III - 431

17.4.4 External searc h

△△△△△△△△△△△△

III - 432

17.5 Machine contact I/O III - 433

17.5.1 Additional DI/D O (DI :32/DO: 32)

□□□□□□□□□□□□

III - 433

17.5.2 Additional DI/D O (DI :64/DO: 64)

□□□□□□□□□□□□

III - 433

17.5.3 Remote I/O 32/32

□□□□□□□□□□□□

III - 433

17.5.4 Remote I/O 64/48

□□□□□□□□□□□□

III - 433

17.6 External PLC link III - 434

17.6.1 External PLC link II (Bus c onnection ) III - 434

17.6.1. 2 M ELSEC- Q series

☆☆☆☆☆☆□□□□□□

III - 434

17.6.3 CC-Link (M aster/Slav e)

☆☆☆☆☆☆□□□□□□

III - 434

17.6.4 PROFIBUS - DP ( M as ter)

☆☆☆☆☆☆

――――――III - 441

17.7 Installing S/W for machine tools III - 442

17.7.1 Cust om ization(NC Designer)

△△△△△△△△△△△△

III - 442

17.7.1. 1 Customization data storage capacit y

[MByte]

depending

on hard

disk

space

depending

on hard

disk

space

depending

on hard

disk

space

depending

on hard

disk

space

depending

on hard

disk

space

depending

on hard

disk

space

666666

III - 443

17.7.1. 2 Customization wor k piece d ata si ze

]

666666666666

III - 443

17.7.2 User - def ined key

○○○○○○○○○○○○

III - 444

○

: Standard △: Option ☆: Plan □: Selection

Class

M7 00V W Series M7 0 0V S S eries

Page

M syst em L systemM system L system

17.7.3 EZSocket I /F (Need se para te PC S/W)

○○○○○○○○○○○○

III - 444

17.7.4 APLC r elease ( Need s eparat e P C S /W )

△△△△△△△△△△△△

III - 444

17.7.5 Cust om A P I library ( Need separate PC S/W )

○○○○○○○○○○○○

III - 445

17.8 Others III - 446

17.8.1 Credit sys tem

△△△△△△△△△△△△

III - 446

17.8.2 CNC Remot e Operat ion Tool III - 446

17.8.2. 1 N C M ONITO R ( Need sepa rate PC S/W)

○○○○○○○○○○○○

III - 446

17.8.2. 2 N C E x plorer ( Need separate PC S/W )

○○○○○○○○○○○○

III - 446

execution

(GX Deve loper

[MByte

Page 21

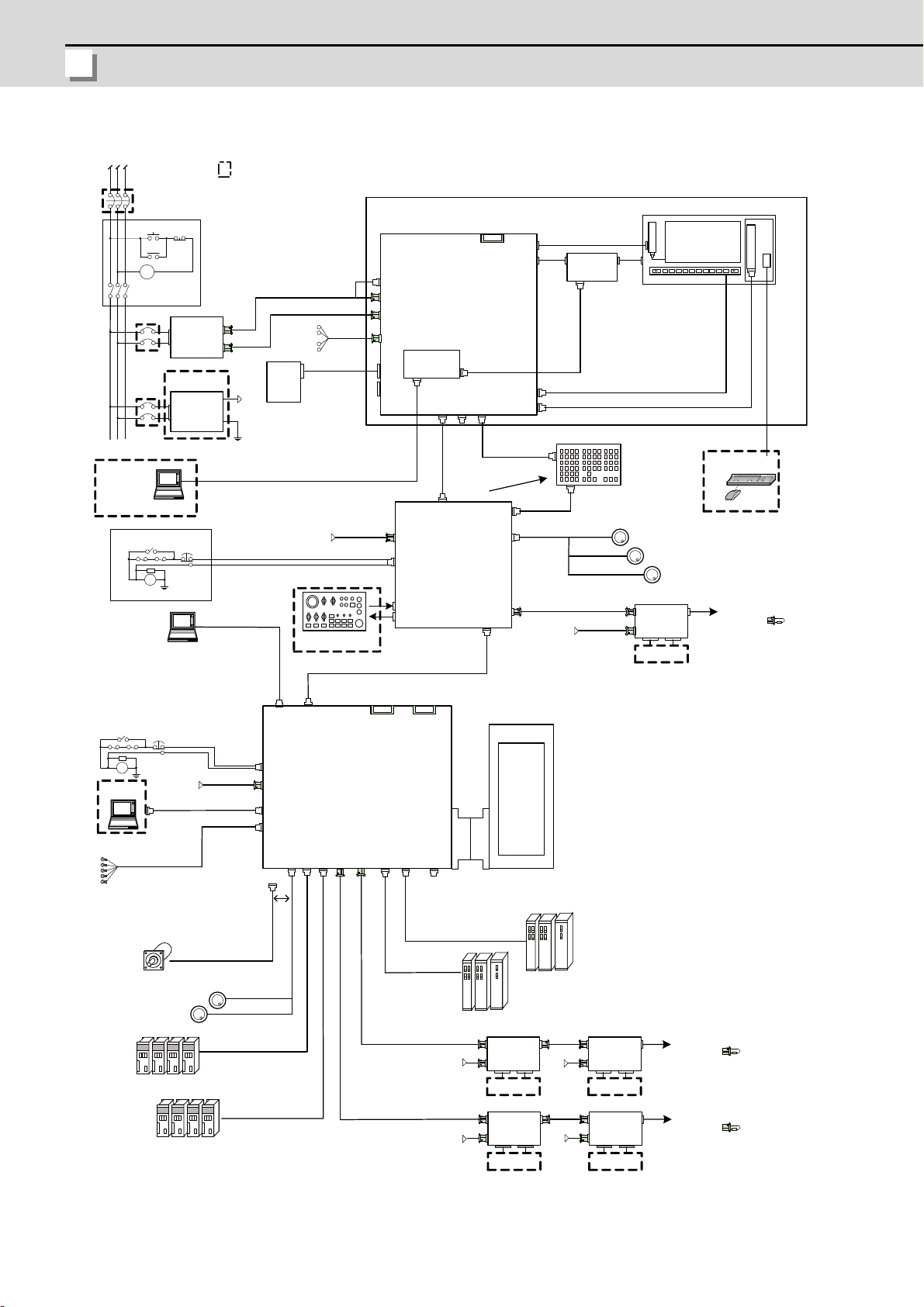

I General Specifications

(M700VW Series)

Page 22

Page 23

I - 1

1

System Basic

Configuration Drawing

Page 24

I General Specifications (M700VW Series)

MITSUBISHI CNC

Motor group

Auxiliary axis

Servo/Spindle

drive unit

MR-J2-CT/CT4 Series

Auxiliary axis Servo

drive unit

Manual pulse generator

Manual pulse penerator

Expansion unit

Control unit

Display unit

Keyboard unit

Remote I/O unit

Synchronous

feed encoder

Remote I/O unit

Operation panel

I/O unit

MDS-D/DH/DM Series

MDS-D-SVJ3/SPJ3 Series

Expansion card

Hard disk unit

(Note) For the drive unit configuration, refer to the Instruction Manual of the drive unit you use.

I - 2

Page 25

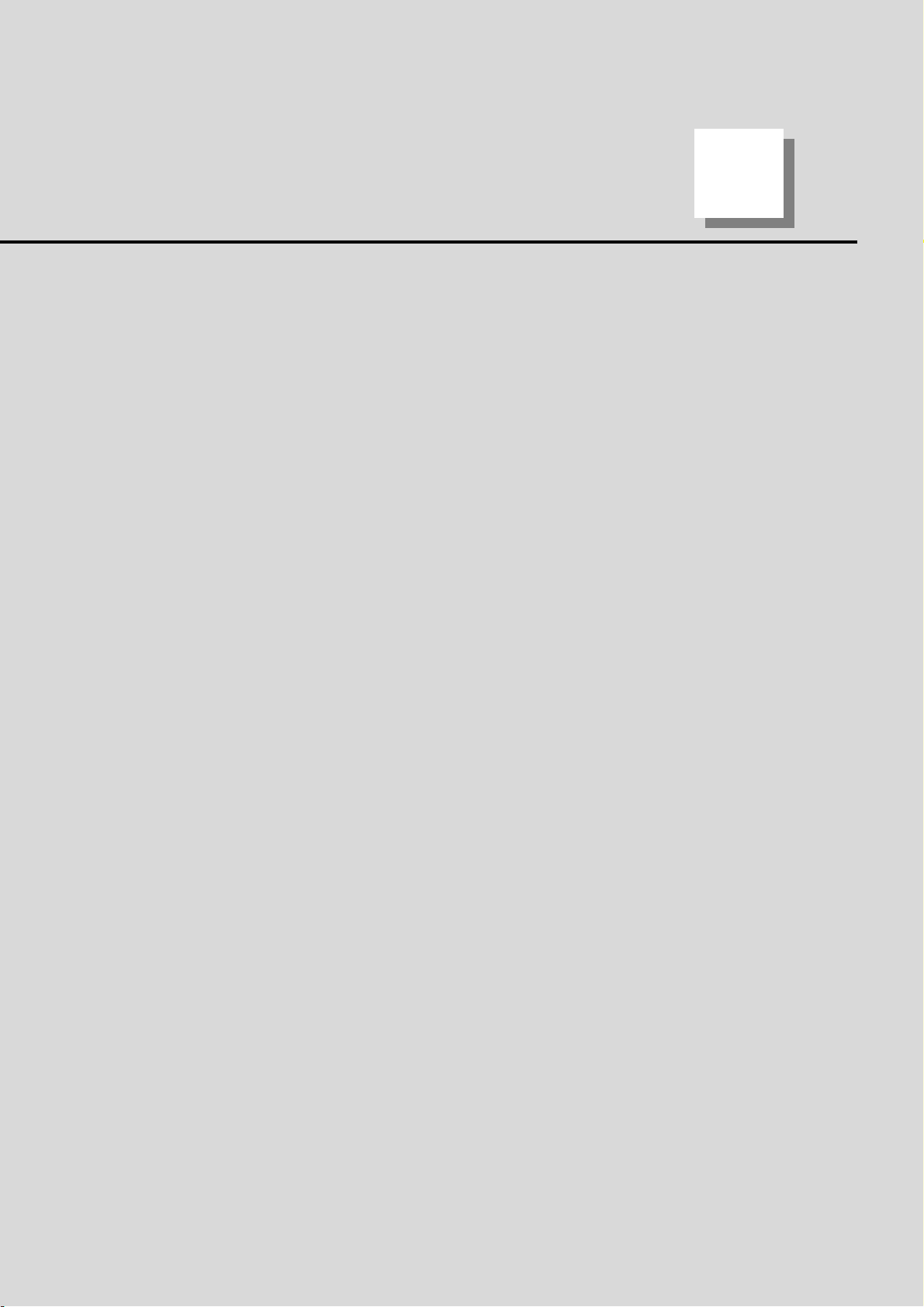

I - 3

2

General Connection

Diagram

Page 26

I General Specifications (M700VW Series)

MITSUBISHI CNC

2.1 For 10.4-type Display Unit

24Vdc

RIO1

DCIN

RIO2

FCUA-R211

/SH41

24Vdc

RIO1

DCIN

RIO2

SV1

LAN1

CF

OPT1

EXT-CON

SV2

SIO×2

RIO1

Slot1

OPI

LAN(user)

EMG

24Vdc

RIO1

DCIN

RIO2

FCUA-R211

/SH41

24Vdc

RIO1

DCIN

RIO2

MC

RST

ON OFF

MC

DCOUT

ON/OFF

ACIN

CP

PD2 7

DCOUT

FG

ACIN

DCIN

CF01

HDD

INV

LVDS

MC

24Vdc

F110

24Vdc

RA

FG

FG

EMG

F070

G171

DCIN

CF24

EMG

MENUKEY

MPG

RIO3

F020/F021/F022

Mouse

USB1USB2

FRONT_OUT

PC Keyboard

ON

G170

ON/OFF

F120

HDD

CF25

USB

HN273/274

RIO2

LAN

PCLAN

DX101

24Vdc

RIO1

DCIN

RIO2

Remote I/O unit

Machine I/O

24Vdc

F070

DCIN

F040/F041

MPG/

ENC

SIO

G018

FCU7-KB021/KB022/KB041/KB045

<G290>

<G291>

<G301>

SKIP

F023/F024

(Max: 20m)

(5V)

F034/F035

SH21

SH21

F120

(5V/12V )

F070

<G990>

F140

RA

FG

EMG

<G485>

FCU7-MU031/041

FCU7-MA041

FCU7-EX891

G395/G396/G380

OPT 2

FCUA-R211/SH41

FCUA-R211/SH41

FCU7-

DX670/671/770/771

CG3x

G031/G0 3 2

G020/G021/G022

NCRST

SDIO

FCUA -DX1xx

FCUA -DX1xx

FCUA -DX1xx

FCUA -DX1xx

G395/G396/G380

FCUA-R211/SH41

CP

HN012

SIO

USB

CF

FCU7-HD002-001

TPOUT

OFF

OPI

(NFB)

MDS-D/DH/SVJ3/SPJ3

MDS-D/DH/SVJ3/SPJ3

MDS-C/CH/SVJ2/SPJ2

MDS-C/CH/SVJ2/SPJ2

FCUA-R030

FCU7-DA646-11/31

Skip signal input

Machine I/O Machine I/O

RS232C

Remote I/O unit

Machine I/O Machine I/O

10.4-type LCD

24VDC stabilized

power supply

Backlight inverter

Machine operation

panel

OT release SW

RS232C

device

Dotted lines indicate the sections prepared by the machine tool builder.

PCMCIA slot

Keyboard unit

Can be added onto

back of keyboard

CNC control unit

Expansion Unit

Spindle/Servo drive units

Operation panel

I/O unit

Synchronous feed

encoder

Manual pulse

generator

10.4-type Display unit

Spindle/Servo drive units

Spindle/Servo drive units

Spindle/Servo drive units

Remote I/O unit

Remote I/O unit

Remote I/O unit

No-fuse breaker

The name with brackets <>

indicates the cable for the unit.

To the next remote I/O

or terminator

Menu key

PC Board

MI-CM15-M5A

HN273 : with touch panel function

HN274 : without touch panel function

Hard disk unit

Can be added onto

back of keyboard

To the next remote I/O

or terminator

device

To the next remote I/O

or terminator

Manual pulse

generator

OT release SW

I - 4

(Note) As for drive units, only the brief diagram is given here. Refer to the drive unit's manual for details.

Page 27

M700V Series Specifications Manual

2 General Connection Diagram

2.2 For 15-type Display Unit

24Vdc

RIO1

DCIN

RIO2

FCUA-R211

/SH41

24Vdc

RIO1

DCIN

RIO2

SV1

LAN1

CF

OPT1

EXT-CON

SV2

SIO×2

RIO1

Slot1

OPI

LAN(user)

EMG

24Vdc

RIO1

DCIN

RIO2

FCUA-R211

/SH41

24Vdc

RIO1

DCIN

RIO2

MC

RST

ON OFF

MC

DCOUT

ON/OFF

ACIN

CP

PD2 7

DCOUT

FG

ACIN

DCIN

CF01

HDD

INV

LVDS

MC

24Vdc

F110

24Vdc

RA

FG

FG

EMG

F070

G171

DCIN

CF24

EMG

MENUKEY

MPG

RIO3

F020/F021/F022

Mouse

USB1USB2

FRONT_OUT

PC Keyboard

ON

G170

ON/OFF

F120

HDD

CF25

USB

RIO2

LAN

PCLAN

DX101

24Vdc

RIO1

DCIN

RIO2

24Vdc

F070

DCIN

F040/F041

MPG/

ENC

SIO

G018

FCU7-KB021/KB022/KB041/KB045

<G290>

<G291>

<G301>

SKIP

F023/F024

(Max: 20m)

(5V)

F034/F035

SH21

SH21

F120

(5V/12V )

F070

F140

RA

FG

EMG

FCU7-MU031/041

FCU7-MA041

FCU7-EX891

G395/G396/G380

OPT 2

FCUA-R211/SH41

FCUA-R211/SH41

FCU7-

DX670/671/770/771

CG3x

G031/G0 3 2

G020/G021/G022

NCRST

SDIO

FCUA -DX1xx

FCUA -DX1xx

FCUA -DX1xx

FCUA -DX1xx

G395/G396/G380

FCUA-R211/SH41

CP

HN012

SIO

USB

CF

FCU7-HD002-001

TPOUT

OFF

OPI

(NFB)

MDS-D/DH/SVJ3/SPJ3

MDS-D/DH/SVJ3/SPJ3

MDS-C/CH/SVJ2/SPJ2

MDS-C/CH/SVJ2/SPJ2

FCUA-R030

LVDS I/F

SET

<G483>

<G092-A>

HN241

<G420>

MI-CM15-M5A

FCU7-DA636-11/31

Remote I/O unit

Machine I/O

Skip signal input

Machine I/O Machine I/O

RS232C

Remote I/O unit

Machine I/O Machine I/O

15-type LCD

24VDC stabilized

power supply

Backlight inverter

Machine operation

panel

OT release SW

RS232C

device

Dotted lines indicate the sections prepared by the machine tool builder.

PCMCIA slot

Keyboard unit

Can be added onto

back of display unit

CNC control unit

Expansion Unit

Spindle/Servo drive units

Operation panel

I/O unit

Synchronous feed

encoder

Manual pulse

generator

Spindle/Servo drive units

Spindle/Servo drive units

Spindle/Servo drive units

Remote I/O unit

Remote I/O unit

Remote I/O unit

No-fuse breaker

The name with brackets <>

indicates the cable for the unit.

To the next remote I/O

or terminator

Menu key

PC Board

Hard disk unit

Can be added onto

back of keyboard

To the next remote I/O

or terminator

device

To the next remote I/O

or terminator

Manual pulse

generator

OT release SW

15-type Display unit

HN241 : Touch panel I/F card

(Note) As for drive units, only the brief diagram is given here. Refer to the drive unit's manual for details.

I - 5

Page 28

I - 6

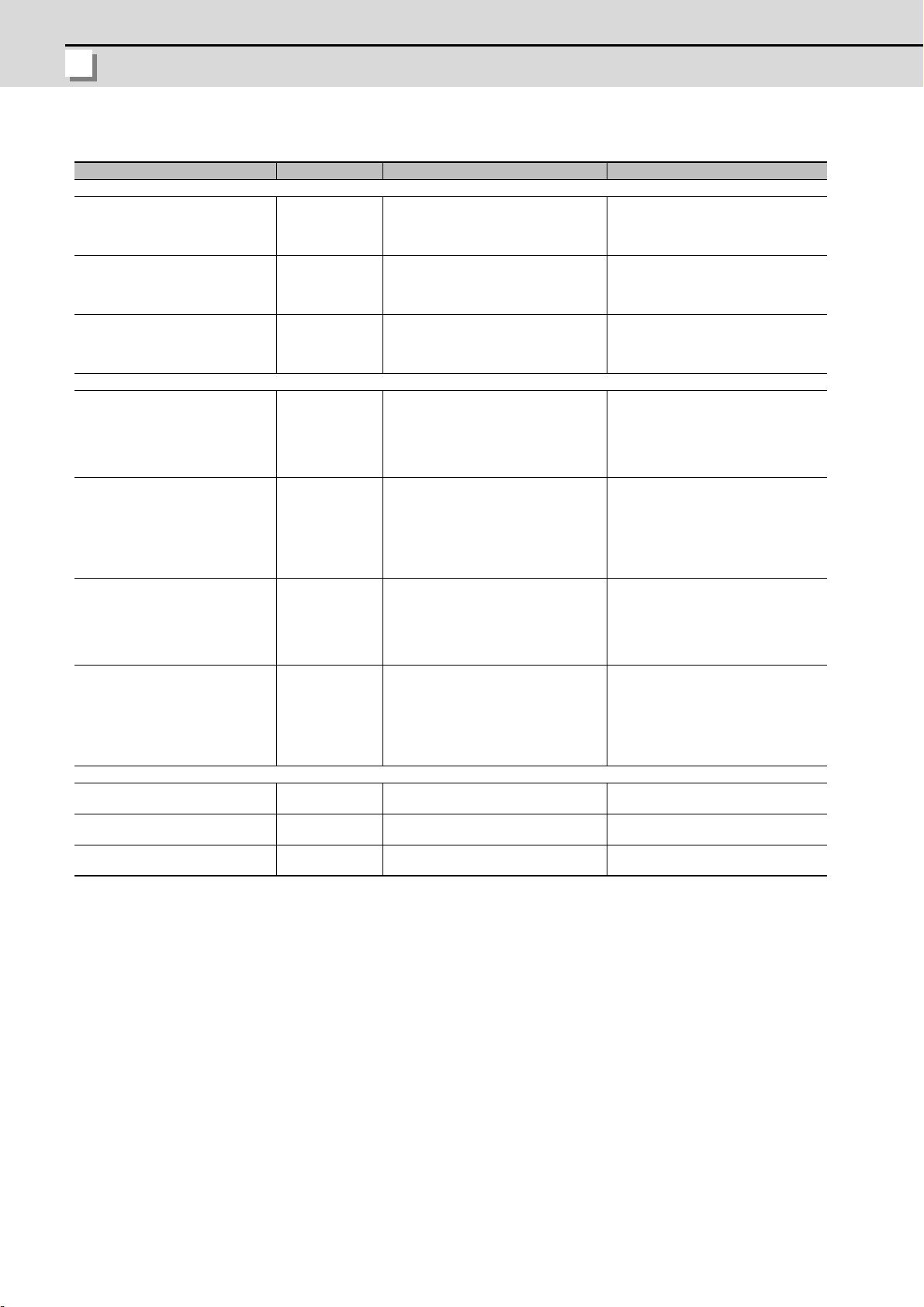

Page 29

I - 7

3

List of Configuration

Page 30

I General Specifications (M700VW Series)

MITSUBISHI CNC

3.1 List of Units

Classification Type Components Remarks

[Control unit]

NC functions

For 720VW

NC functions

For 730VW

NC functions

For 750VW

[Display unit]

10.4-type color TFT

(VGA:640*480)

Panel computer

10.4-type color TFT touch panel

(VGA:640*480)

Panel computer

15-type color TFT

(XGA:1024*768)

Panel computer

15-type color TFT touch panel

(XGA:1024*768)

Panel computer

[Keyboard unit]

Keyboard Clear keys for 8.4-type display

unit

Keyboard Clear keys for 8.4-type display

unit

Keyboard Clear keys for 10.4-type

display unit

FCU7-MU031

FCU7-MU041

FCU7-MA041

FCU7-DA646-11

FCU7-DA646-31

FCU7-DA636-11

FCU7-DA636-31

FCU7-KB021

FCU7-KB022

FCU7-KB041

Main control card

Base card

Power supply card

LED card

Main control card

Base card

Power supply card

LED card

Main control card

Base card

Power supply card

LED card

LCD panel

Backlight inverter

Menu keys

Inverter cable

LCD cable

Backlight cable

LCD panel

Backlight inverter

Menu keys

Inverter cable

LCD cable

Backlight cable

Touch panel

LCD panel

Backlight inverter

Menu keys

Inverter cable

LCD cable

Backlight cable

LCD panel

Backlight inverter

Menu keys

Inverter cable

LCD cable

Backlight cable

Touch panel

Escutcheon, key switch

G290 cable

Escutcheon, key switch

G290 cable

Escutcheon, key switch

G290 cable

Export Trade Control Ordinance an d Foreign

Trade Ordinance noncompliant unit

Export Trade Control Ordinance an d Foreign

Trade Ordinance noncompliant unit

Export Trade Control Ordinance an d Foreign

Trade Ordinance compliant unit

PCMCIA II card I/F is normally equipped with

the display unit

PCMCIA II card I/F is normally equipped with

the display unit

PCMCIA II card I/F is normally equipped with

the display unit

PCMCIA II card I/F is normally equipped with

the display unit

ONG layout for machining center

ONG layout for lathe

ABC layout

I - 8

Page 31

M700V Series Specifications Manual

3 List of Configuration

Classification Type Components Remarks

[Operation panel I/O unit]

Base card

DI 24V/0V common input

DO Sink output

DI 24V/0V common input

DO Source output

DI 24V/0V common input

DO Sink output

DI 24V/0V common input

DO Source output

[Hard Disk Unit]

External memory device FCU7-HD002-1

[Remote I/O unit]

24V/0V common input + Sink output FCUA-DX100 RX311

24V/0V common input + Sink output FCUA-DX110 RX311+RX321-1

24V/0V common input + Sink output

+ Analog output

24V/0V common input + Sink output

+ Analog input/output

24V/0V common input + Source output FCUA-DX101 RX312

24V/0V common input + Source output FCUA-DX111 RX312+RX322-1

24V/0V common input + Source output +

Analog output

24V/0V common input + Source output +

Analog input/output

FCU7-DX670

FCU7-DX671

FCU7-DX770

FCU7-DX771

FCUA-DX120 RX311+RX321

FCUA-DX140 RX311+RX341

FCUA-DX121 RX312+RX322

FCUA-DX141 RX312+RX341

Mounting bracket

G301 cable

G310 cable

Terminator (R-TM)

Base card

Mounting bracket

G301 cable

G310 cable

Terminator (R-TM)

Base card

Add-on card

Mounting bracket

G301 cable

G310 cable

Terminator (R-TM)

Base card

Add-on card

Mounting bracket

G301 cable

G310 cable

Terminator (R-TM)

Hard disk

Mounting plate,

cushioning rubber

F140 cable (50cm)

DI: 32-points 24V/0V common type

DO: 32-points sink type (output 60mA)

Output insulation type

Display-main body relay I/F

MPG:3ch

Emergency stop input

Remote I/O 1ch (160 points/160 points)

DI: 32-points 24V/0V common type

DO: 32-points sink type (output 60mA)

Output insulation type

Display-main body relay I/F

MPG:3ch

Emergency stop input

Remote I/O 1ch (160 points/160 points)

DI: 64-points 24V/0V common type

DO: 64-points sink type (output 60mA)

Output insulation type

Display-main body relay I/F

MPG:3ch

Emergency stop input

Remote I/O 1ch (128 points/128 points)

DI: 64-points 24V/0V common type

DO: 64-points sink type (output 60mA)

Output insulation type

Display-main body relay I/F

MPG:3ch

Emergency stop input

Remote I/O 1ch (128 points/128 points)

DI: 32-points 24V/0V common type

(photo coupler insulation)

DO: 32-points sink type (non-insulation)

Number of occupied stations: 1

DI: 64-points 24V/0V common type

(photo coupler insulation)

DO: 48-points sink type (non-insulation)

Number of occupied stations: 2

DI: 64-points 24V/0V common type

(photo coupler insulation)

DO: 48-points sink type (non-insulation)

AO: 1 point

Number of occupied stations: 2

DI: 32-points 24V/0V common type

(photo coupler insulation)

DO: 32-points sink type (non-insulation)

AI: 4 points

AO: 1 point

Number of occupied stations: 2

DI: 32-points 24V/0V common type

(photo coupler insulation)

DO: 32-points source type (non-insulation)

Number of occupied stations: 1

DI: 64-points 24V/0V common type

(photo coupler insulation)

DO: 48-points source type (non-insulation)

Number of occupied stations: 2

DI: 64-points 24V/0V common type

(photo coupler insulation)

DO: 48-points source type (non-insulation)

AO: 1 point

Number of occupied stations: 2

DI: 32-points 24V/0V common type

(photo coupler insulation)

DO: 32-points source type (non-insulation)

AI: 4 points

AO: 1 point

Number of occupied stations: 2

I - 9

Page 32

I General Specifications (M700VW Series)

MITSUBISHI CNC

Classification Type Components Remarks

[Scan I/O card]

Sink type HR347 HR347

Source type HR357 HR357

[External power supply unit]

External power supply with power supply

ON/OFF function

External power supply with power supply

ON/OFF function

[Manual pulse generator]

5V Manual pulse generator UFO-01-2Z9

12V Manual pulse generator HD60 HD60

[Encoder]

Synchronous feed encoder OSE1024-3-15-68 OSE1024-3-15-68

[Expansion Unit]

Expansion unit x 1slot FCU7-EX891

[Expansion Card]

PROFIBUS-DP FCU7-HN571 HN571 PROFIBUS-DP x 1ch

CC-Link FCU7-HN576 HN576 CC-Link x 1ch

CC-Link FCU7-HN577 HN577 CC-Link x 2ch

PD25

PD27

Power supply card

Case set

Power supply card

Case set

UFO-01-2Z9

(Produced by NIDEC NEMICON)

HR891

Mounting plate, case set

Scan DI/DO = 64 points/64 points

DI/DO = 32 points/32 points

Scan DI/DO = 64 points/64 points

DI/DO = 32 points/32 points

Input 200VAC

Output 24VDC (3A)

Input 200 to 400VAC

Output 24VDC (8A)

Input 5VDC

100pulse/rev

Input 12VDC

25pulse/rev

Input 5VDC

1024pulse/rev

One expansion card HN5xx can be mounted

additionally.

(Note 1) Operation panel I/O unit can be mounted on the back side of the keyboard unit.

(Note 2) DI: Digital input signals, DO: Digital output signals, AI: Analog input signals, AO: Analog output

signals

I - 10

Page 33

M700V Series Specifications Manual

3 List of Configuration

3.2 Durable Parts

Battery for control unit and display unit Q6BAT

Backlight for FCU7-DA646-11/31 104LHS49

Backlight for FCU7-DA636-11/31 AA-L5902174G01

Touch panel protective sheet for FCU7-DA646-31 BN939B036G51

Touch panel protective sheet for FCU7-DA636-31 BN939B060G61

Control unit cooling fan 109P0412H731

Display unit cooling fan MMF-06G24DS-RP2

3.3 Replacements

Protection fuse LM40

Front memory interface card CF-700 USB-PC-CARD

Durable parts Part type

Replacements Part type

I - 11

Page 34

I General Specifications (M700VW Series)

MITSUBISHI CNC

3.4 List of Cables

Type Application