Page 1

Page 2

Page 3

MELDAS is a registered trademark of Mitsubishi Electric Corporation.

Other company and product names that appear in this manual are trademarks or

registered trademarks of the respective companies.

Page 4

Page 5

Introduction

This manual is the alarm/parameter guide required to use the MITSUBISHI CNC

MULTI-AXIS,MULTI-PART SYSTEM M700L/M700LV/M70L Series.

This manual is prepared on the assumption that your machine is provided with all of the MITSUBISHI

CNC MULTI-AXIS,MULTI-PART SYSTEM M700L/M700LV/M70L Series functions. Confirm the

functions available for your NC before proceeding to operation by referring to the specification issued by

the machine tool builder.

Notes on Reading This Manual

(1) This manual explains general parameters as viewed from the NC.

For information about each machine tool, refer to manuals issued from the machine tool builder.

If the descriptions relating to "restrictions" and "allowable conditions" conflict between this manual

and the machine tool builder's instruction manual, the later has priority over the former.

(2) This manual is intended to contain as much descriptions as possible even about special operations.

The operations to which no reference is made in this manual should be considered impossible.

(3) The "special display unit" explained in this manual is the display unit incorporated by the machine

tool builder, and is not the MELDAS standard display unit.

(4) Some functions are unavailable depending on the machine model.

Caution

If the descriptions relating to the "restrictions" and "allowable conditions" conflict between this

manual and the machine tool builder’s instruction manual‚ the latter has priority over the former.

The operations to which no reference is made in this manual should be considered

"impossible".

This manual is complied on the assumption that your machine is provided with all optional

functions. Confirm the functions available for your machine before proceeding to operation by

referring to the specification issued by the machine tool builder.

In some NC system versions‚ there may be cases that different pictures appear on the screen‚

the machine operates in a different way or some function is not activated.

Page 6

Page 7

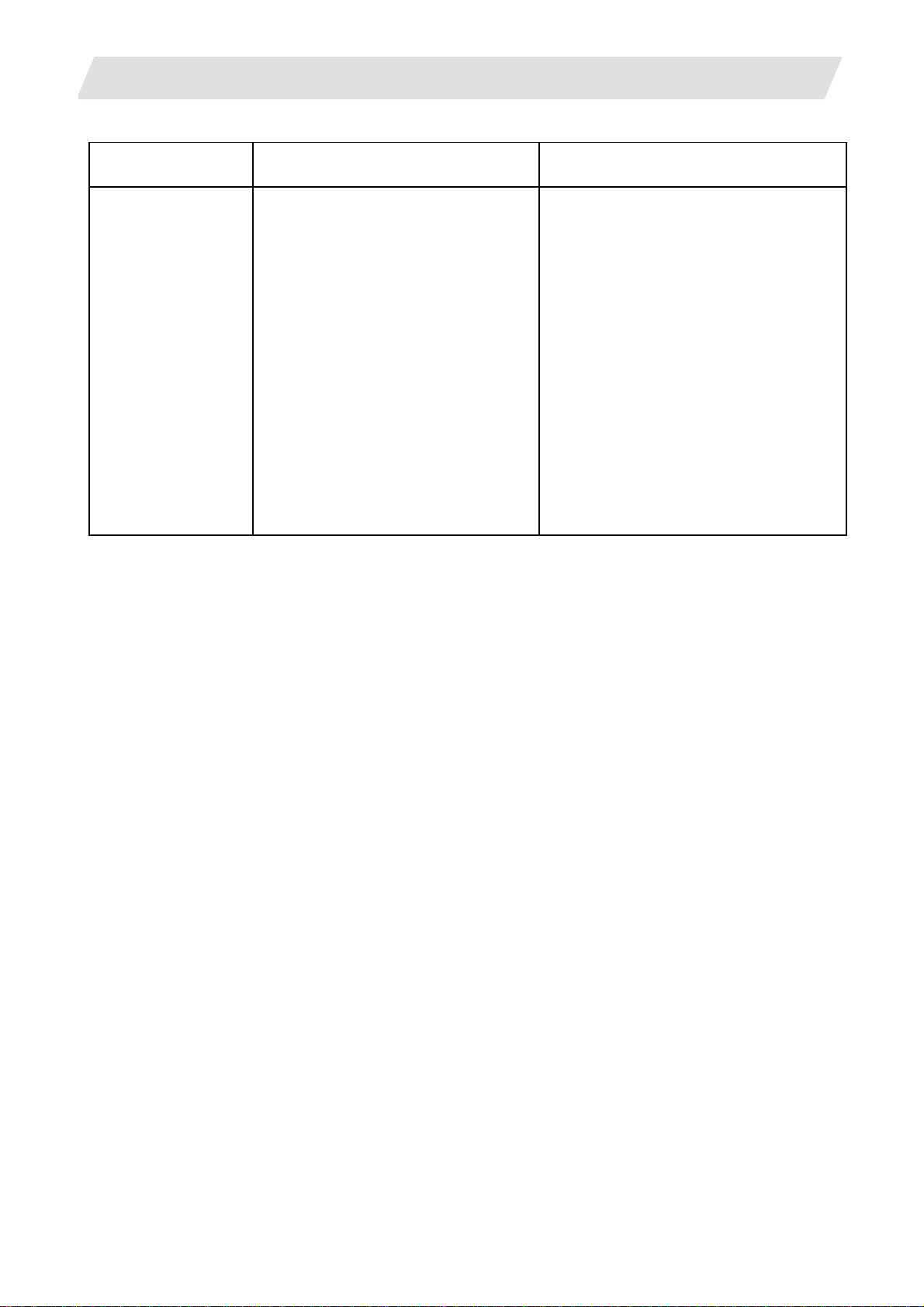

Precautions for Safety

Always read the specifications issued by the machine tool builder, this manual, related manuals and attached

documents before installation, operation, programming, maintenance or inspection to ensure correct use.

Understand this numerical controller, safety items and cautions before using the unit.

This manual ranks the safety precautions into "DANGER", "WARNING" and "CAUTION".

DANGER

When the user may be subject to imminent fatalities or major injuries if handling is

mistaken.

WARNING

CAUTION

Note that even items ranked as "

case, important information that must always be observed is described.

Not applicable in this manual.

Not applicable in this manual.

When the user may be subject to fatalities or major injuries if handling is mistaken.

When the user may be subject to injuries or when physical damage may occur if

handling is mistaken.

CAUTION", may lead to major results depending on the situation. In any

DANGER

WARNING

1. Items related to product and manual

If the descriptions relating to the "restrictions" and "allowable conditions" conflict between this

manual and the machine tool builder's instruction manual‚ the latter has priority over the former.

The operations to which no reference is made in this manual should be considered impossible.

This manual is complied on the assumption that your machine is provided with all optional

functions. Confirm the functions available for your machine before proceeding to operation by

referring to the specification issued by the machine tool builder.

In some NC system versions‚ there may be cases that different pictures appear on the screen‚

the machine operates in a different way on some function is not activated.

2. Items related to faults and abnormalities

If the battery low alarm is output, save the machining programs, tool data and parameters to an

input/output device, and then replace the battery. If the BATTERY alarm occurs, the machining

programs, tool data and parameters may be damaged. After replacing the battery, reload each

data item.

CAUTION

[Continued on next page]

Page 8

CAUTION

3. Items related to maintenance

Do not replace the battery while the power is ON.

Do not short-circuit, charge, heat, incinerate or disassemble the battery.

Dispose of the spent battery according to local laws.

4. Items related to servo parameters and spindle parameters

Do not adjust or change the parameter settings greatly as operation could become unstable.

In the explanation on bits, set all bits not used, including blank bits, to "0".

[Continued]

Page 9

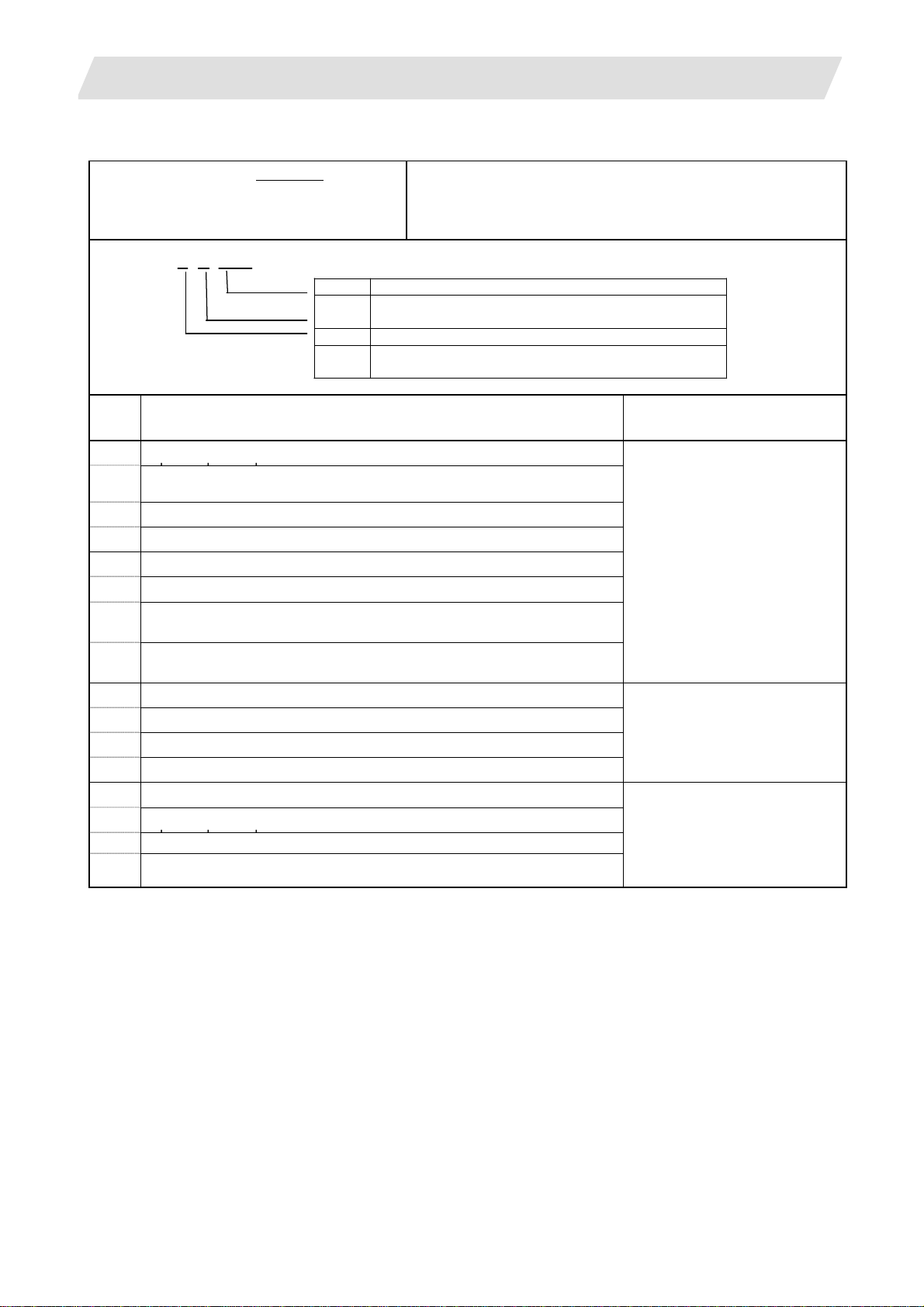

Disposal

(Note) This symbol mark is for EU countries only.

This symbol mark is according to the directive 2006/66/EC Article 20 Information for endusers and Annex II.

Your MITSUBISHI ELECTRIC product is designed and manufactured with high quality materials and

components which can be recycled and/or reused.

This symbol means that batteries and accumulators, at their end-of-life, should be disposed of

separately from your household waste.

If a chemical symbol is printed beneath the symbol shown above, this chemical symbol means that the

battery or accumulator contains a heavy metal at a certain concentration. This will be indicated as

follows:

Hg: mercury (0,0005%), Cd: cadmium (0,002%), Pb: lead (0,004%)

In the European Union there are separate collection systems for used batteries and accumulators.

Please, dispose of batteries and accumulators correctly at your local community waste collection/

recycling centre.

Please, help us to conserve the environment we live in!

Page 10

Page 11

CONTENTS

I Explanation of Alarms

1. Errors During Operation ............................................................................................. 1

1.1 Operation Alarms....................................................................................................................1

1.2 Operation Warning ...............................................................................................................19

2. Stop Codes................................................................................................................. 20

3. Servo/Spindle Alarms(S)........................................................................................... 24

3.1 Servo Errors(s01/S03/S04) ..................................................................................................24

3.1.1 MDS-D/DH Series..........................................................................................................24

3.1.2 Intelligent Servo motor HS Series..................................................................................47

3.2 Initial Parameter Errors (S02)...............................................................................................50

3.3 Parameter Errors (S51)........................................................................................................52

3.4 Servo Warnings (S52)..........................................................................................................53

3.4.1 MDS-D/DH Series..........................................................................................................53

3.4.2 Intelligent Servo motor HS Series..................................................................................57

4. MCP Alarms ............................................................................................................... 58

4.1 MCP Alarms .........................................................................................................................58

4.2 MCP Warnings .....................................................................................................................67

5. Messages Related to System ................................................................................... 69

5.1 System Alarms .....................................................................................................................69

5.2 System Warnings .................................................................................................................75

6. Alarms Related to User PLC..................................................................................... 78

7. Program Errors.......................................................................................................... 84

II User Parameters

1. Control Parameter....................................................................................................... 1

2. Axis Parameters .......................................................................................................... 6

3. Setup Parameter.......................................................................................................... 7

Page 12

III Machine Parameters

1. Basic Specifications Parameters ............................................................................... 1

1.1 Base Axis Parameters............................................................................................................1

1.2 Base System Parameters.......................................................................................................4

1.3 Base Common Parameters ..................................................................................................12

1.3.1 Analog interface parameter............................................................................................32

2. Axis Specification Parameters ................................................................................. 35

3. Zero Point Return Parameters (Reference Position Return).................................. 48

4. Servo Parameters...................................................................................................... 51

4.1 List of Parameters (MDS-D/DH Series)................................................................................51

4.2 Supplement (MDS-D/DH Series)..........................................................................................95

4.2.1 D/A Output No................................................................................................................95

4.2.2 Electronic Gears.............................................................................................................96

4.2.3 Lost Motion Compensation.............................................................................................97

4.3 List of Parameters (Intelligent Servomotor)..........................................................................98

4.4 Supplement (Intelligent Servomotor)..................................................................................111

4.4.1 Command polarity ........................................................................................................111

4.4.2 Limitations to electronic gear setting value ..................................................................111

4.4.3 Intelligent Servomotor D/A Output Function.................................................................112

5. Spindle Parameters................................................................................................. 115

5.1 Spindle NC Parameters......................................................................................................115

5.2 Spindle Parameters............................................................................................................131

5.3 Supplement.........................................................................................................................174

5.4 Spindle-Type Servo Parameters.........................................................................................175

6. PLC Constants......................................................................................................... 176

6.1 PLC Constants....................................................................................................................176

6.2 PLC Integrated Timer .........................................................................................................177

6.3 PLC Counter.......................................................................................................................177

6.4 PLC Constants....................................................................................................................178

6.5 Selecting the PLC Bit..........................................................................................................178

7. Custom Variables .................................................................................................... 181

8. Macro List................................................................................................................. 182

9. Position Switch Parameter ..................................................................................... 185

10. Machine Error Compensation............................................................................... 188

10.1 Function Outline................................................................................................................188

10.2 Setting Compensation Data..............................................................................................191

10.3 Example in Using a Linear Axis as the Base Axis............................................................193

10.4 Example in Using a Rotation Axis as the Base Axis.........................................................196

11. Absolute Position Setting..................................................................................... 197

Page 13

I Explanation of Alarms

Page 14

Page 15

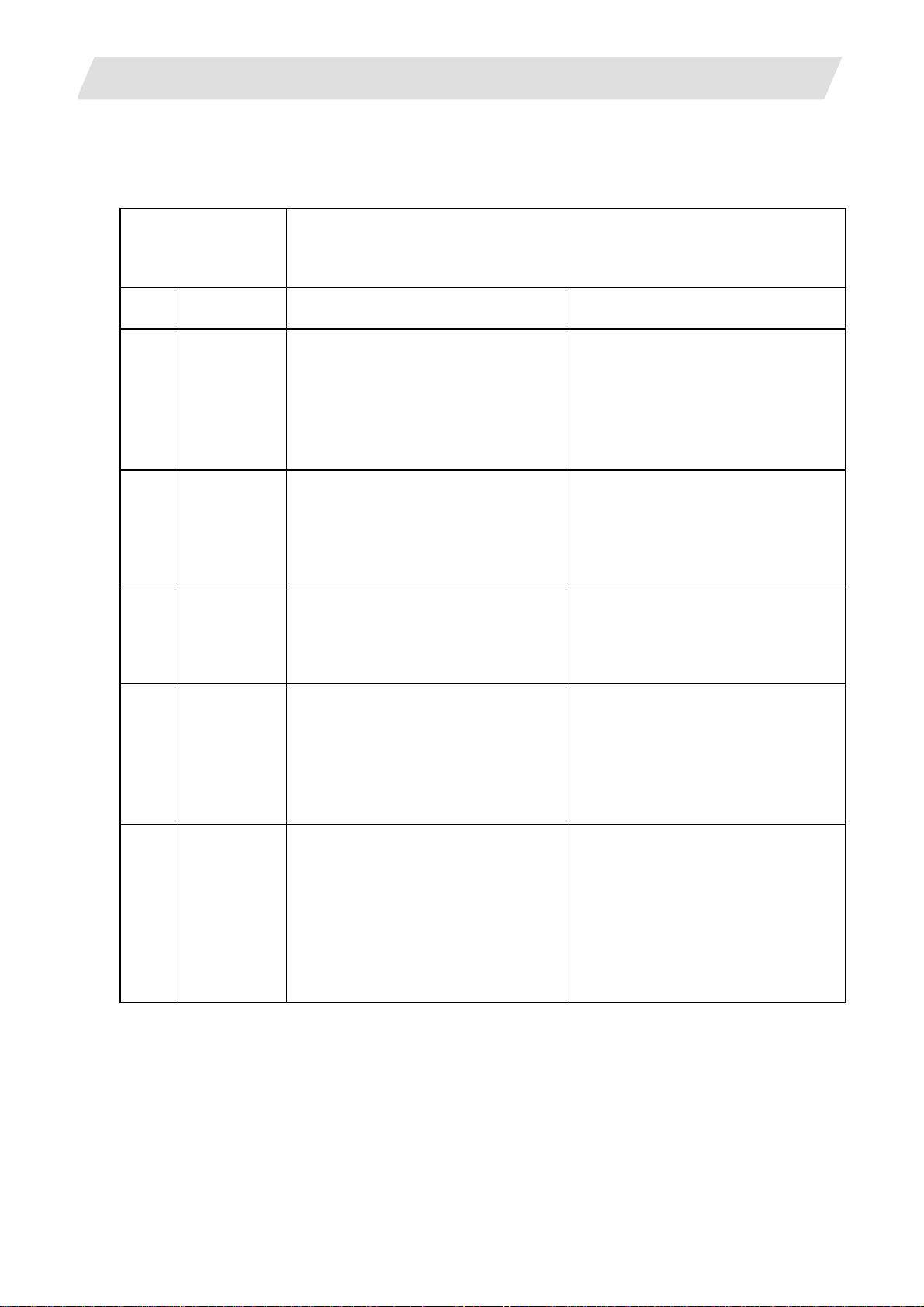

1. Errors During Operation

1. Errors During Operation

1.1 Operation Alarms

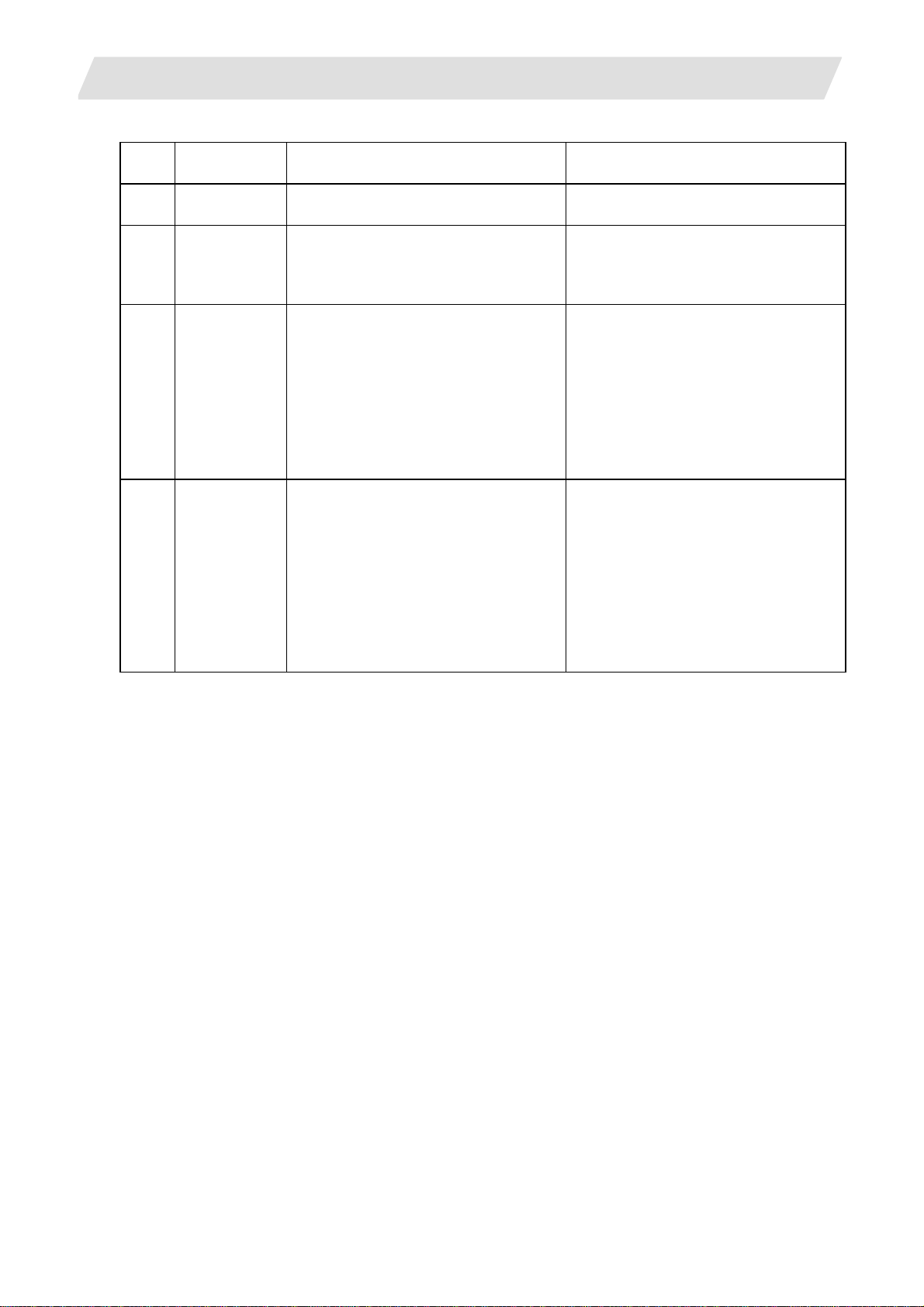

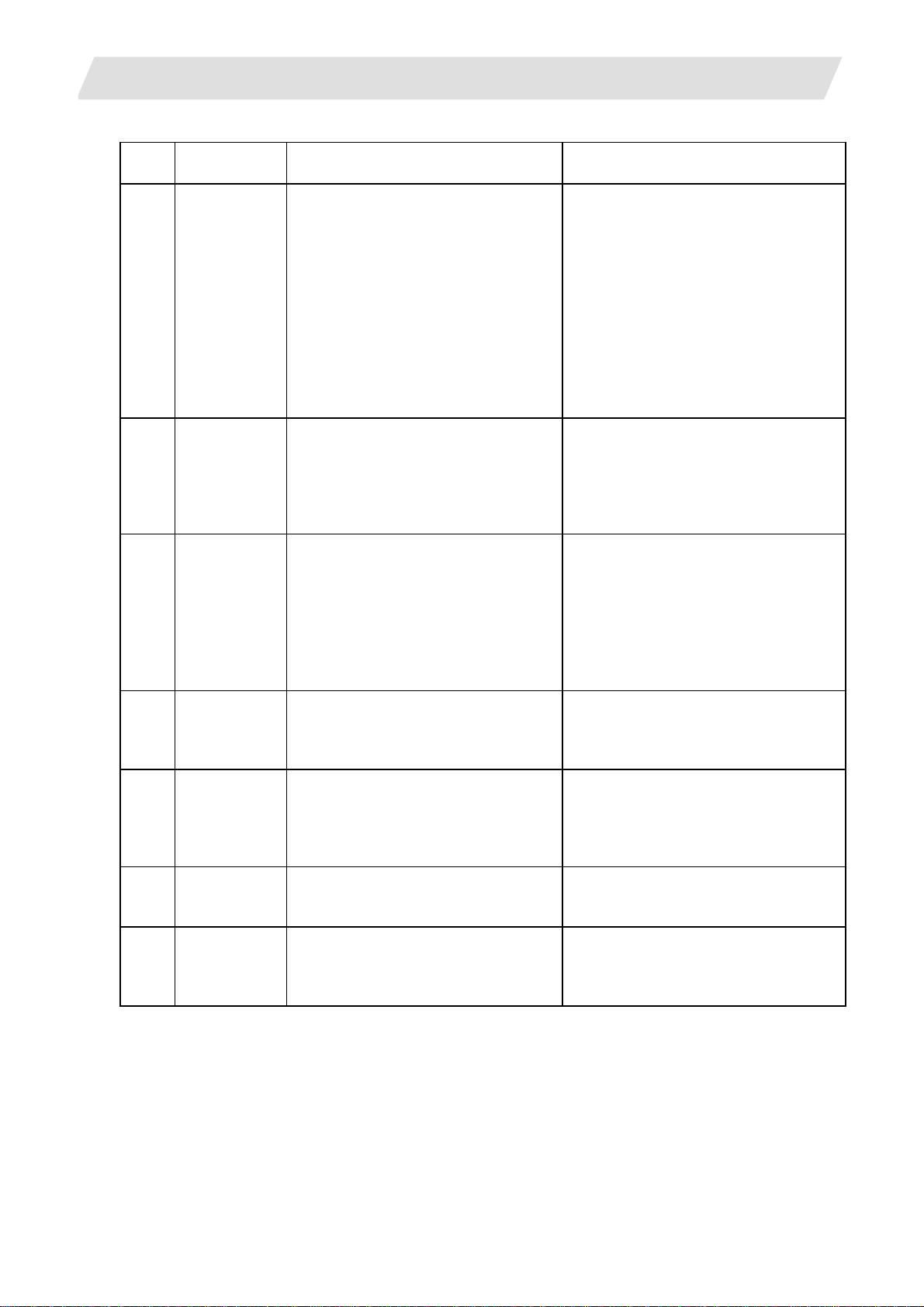

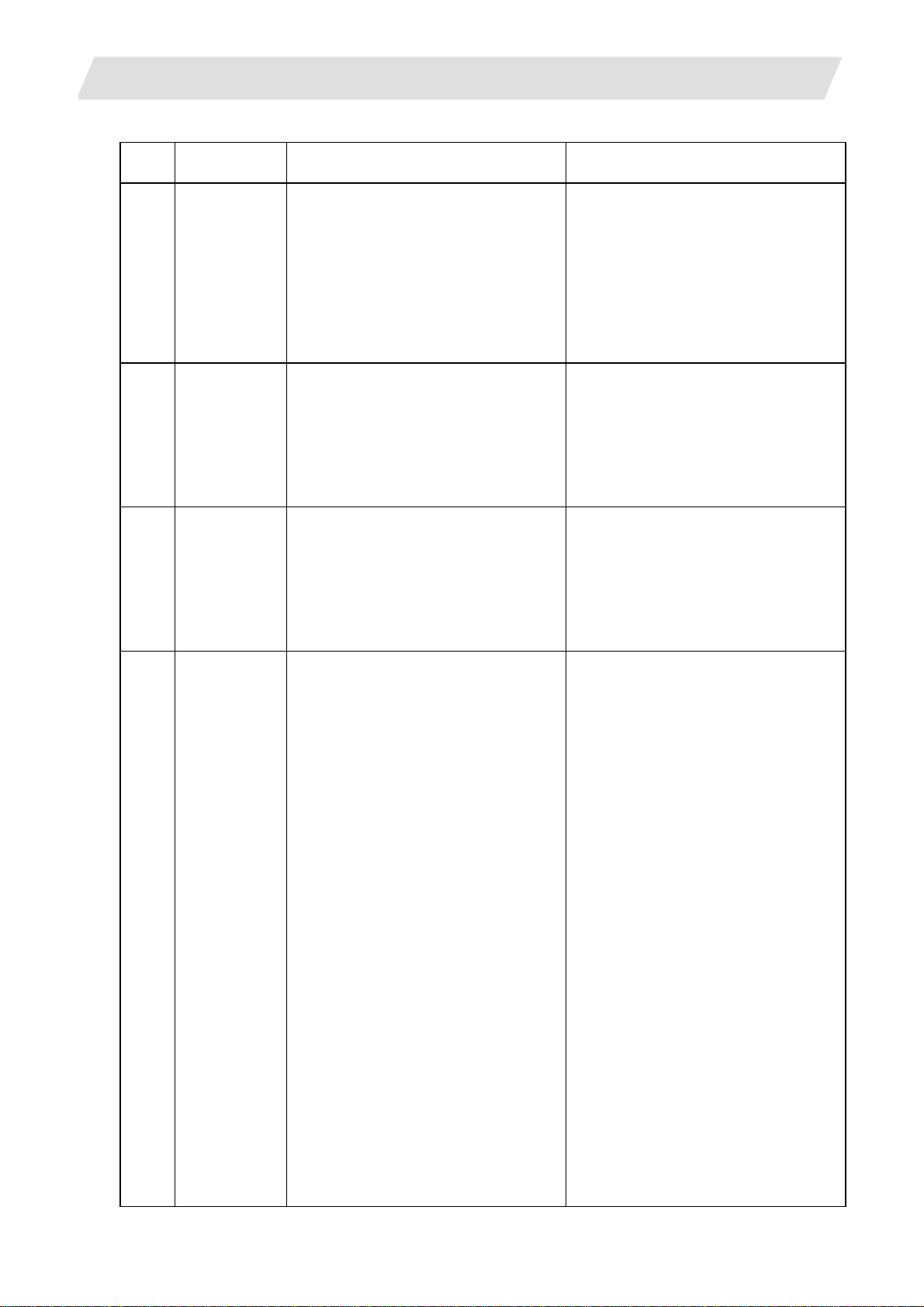

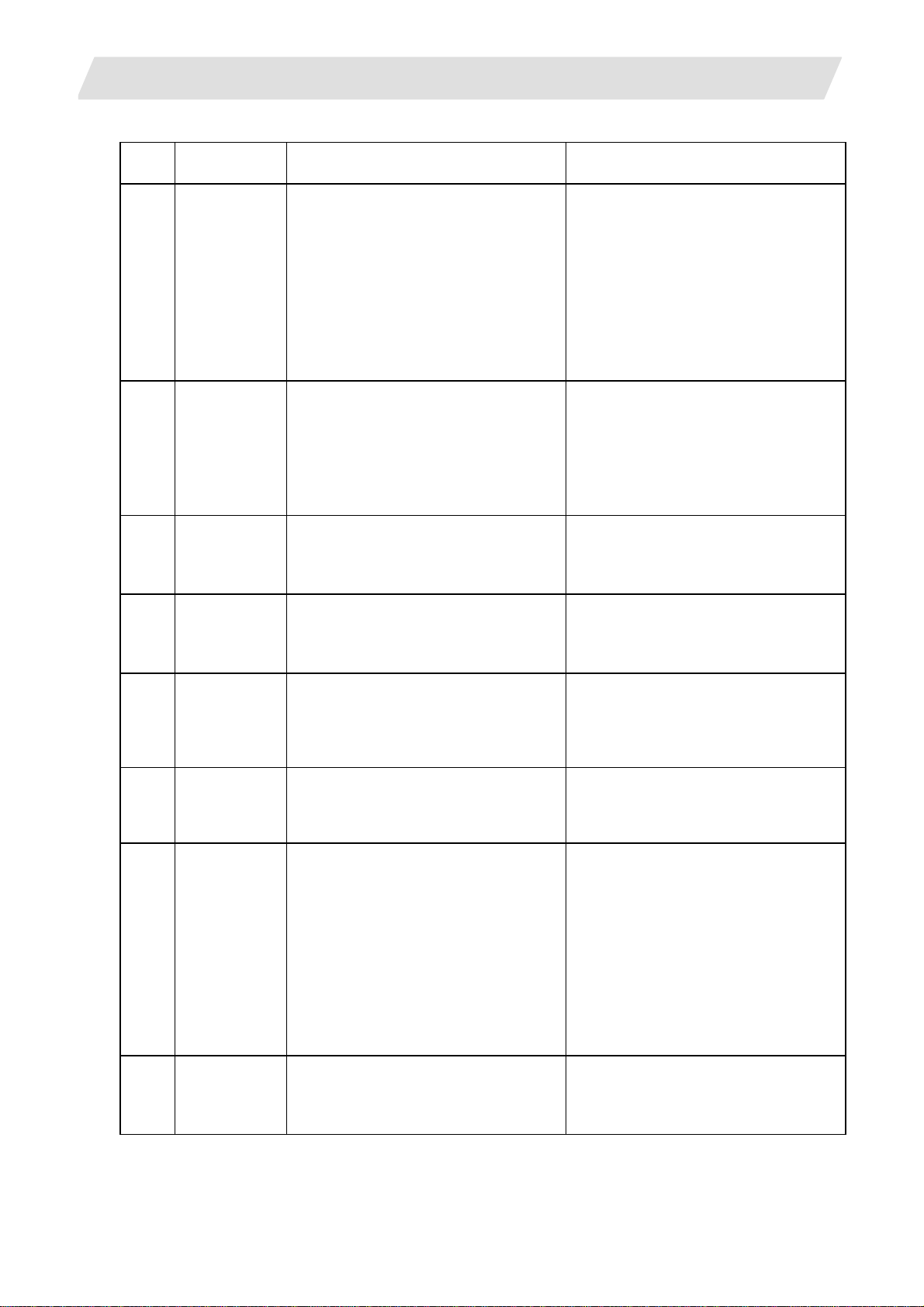

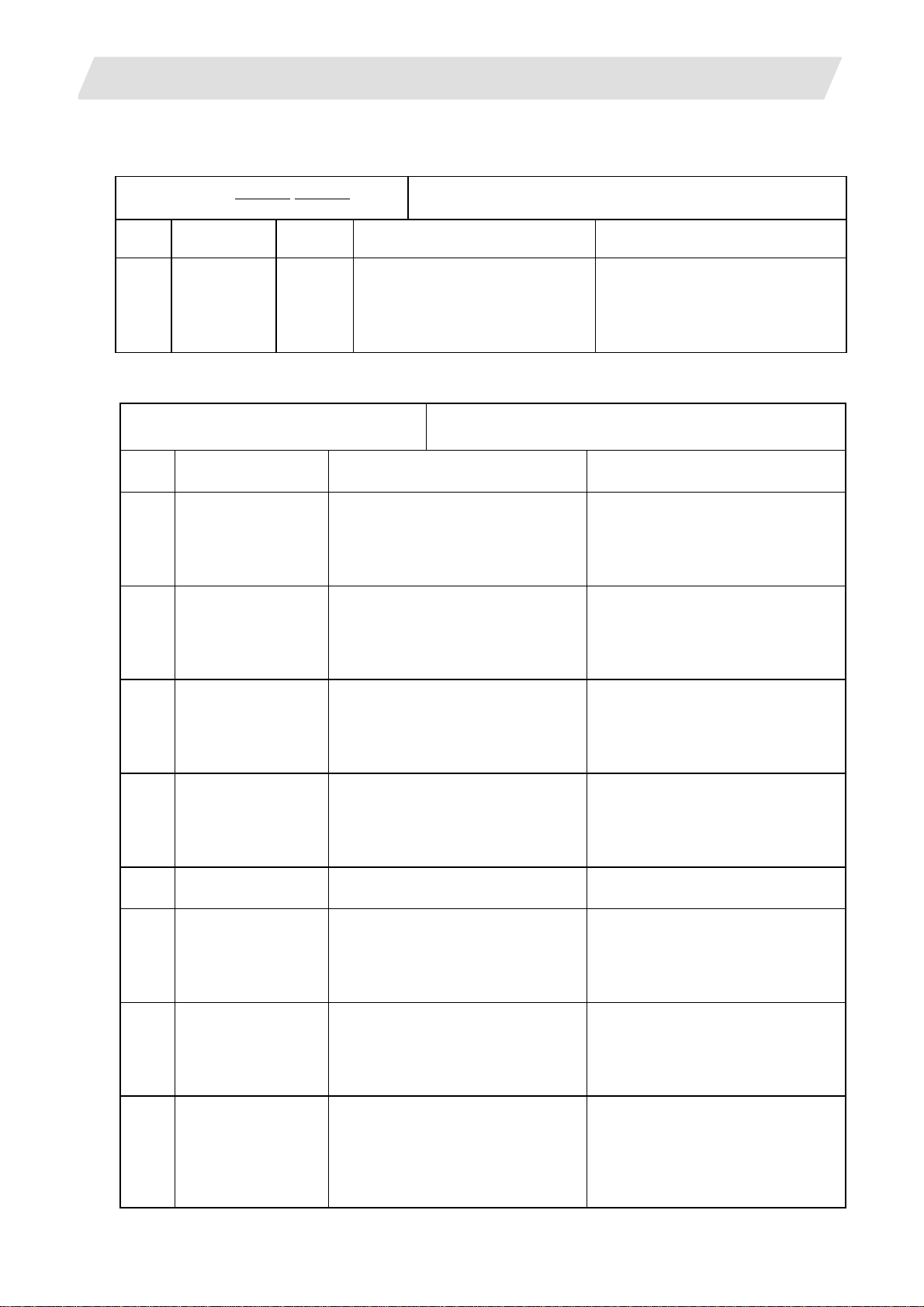

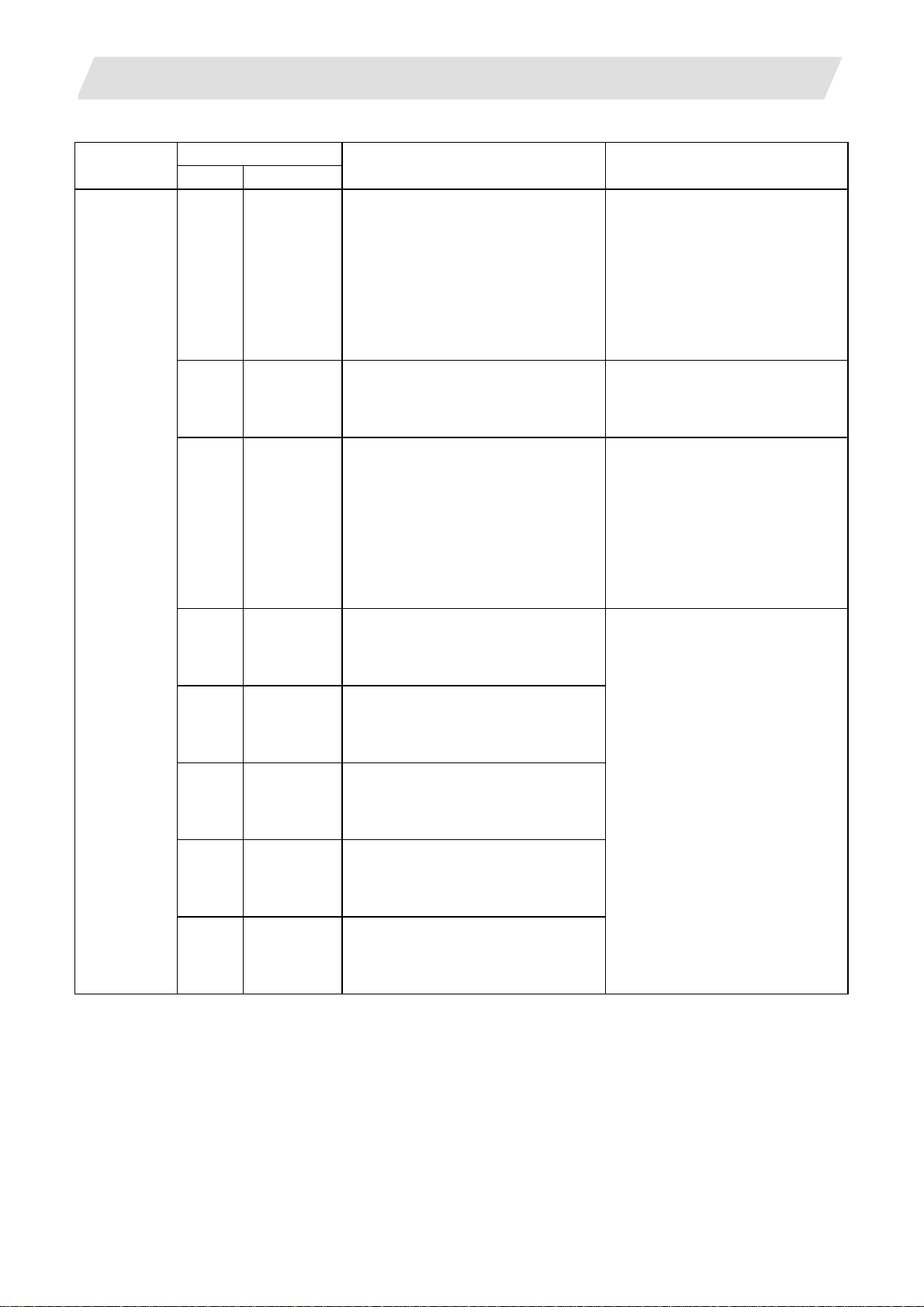

(1) Class: M01 Operation errors

1.1 Operation Errors (M01)

M01 Message

Error

No.

0001 Dog overrun

0002 Some ax

0003 Reference

0004 External

0005 Internal

Message Details Remedy

does not pass

Z phase

point return

illegal

interlock axis

exists

interlock axis

exists

Alarms resulting from incorrect operation by the operator during NC operation

and alarms resulting from the machine fault are displayed.

The numbers given in the table can be referred to on the Alarm list screen

(Diagnosis group).

• When the spindle returned to the

reference point, the near-point

detecting limit switch was not

stopped by the dog but it overran the

dog instead.

• One of the axes did not pass the

Z-phase of the detector on the initial

return of the machine to the reference

point after the power was turned ON.

• When returning manually to the

reference point, the direction of the

return differs from the axis movement

direction which has been designated

by the AXIS SELECTION key.

• The external interlock function has

been activated (the input signal is

"OFF"), and one of the axes is

interlocked as a result.

• An internal interlock status is

established.

• Increase the length of the near-point

dog.

• Reduce the speed at which the

spindle returns to the reference

point.

(Note) This error may not occur

depending on the system.

• Move the machine by an amount

equivalent to one or more rotations

of the detector in the reverse

direction to that of the reference

point, and proceed with reference

point return again.

• An AXIS SELECTION key

corresponding to the wrong direction

has been selected. The error is

released by feeding the axis in the

correct direction.

• Since the interlock function has been

activated, it must first be released

before operation is resumed.

• Check the sequence on the machine

side.

• Check for breakage in the interlock

signal wire.

• Since the servo "OFF" function has

been activated, it must first be

released.

• An axis for which axis removal is

valid has been commanded. Carry

out the correct operation.

• The manual skip is designated in the

same direction as when this turned

ON. Carry out the correct operation.

I - 1

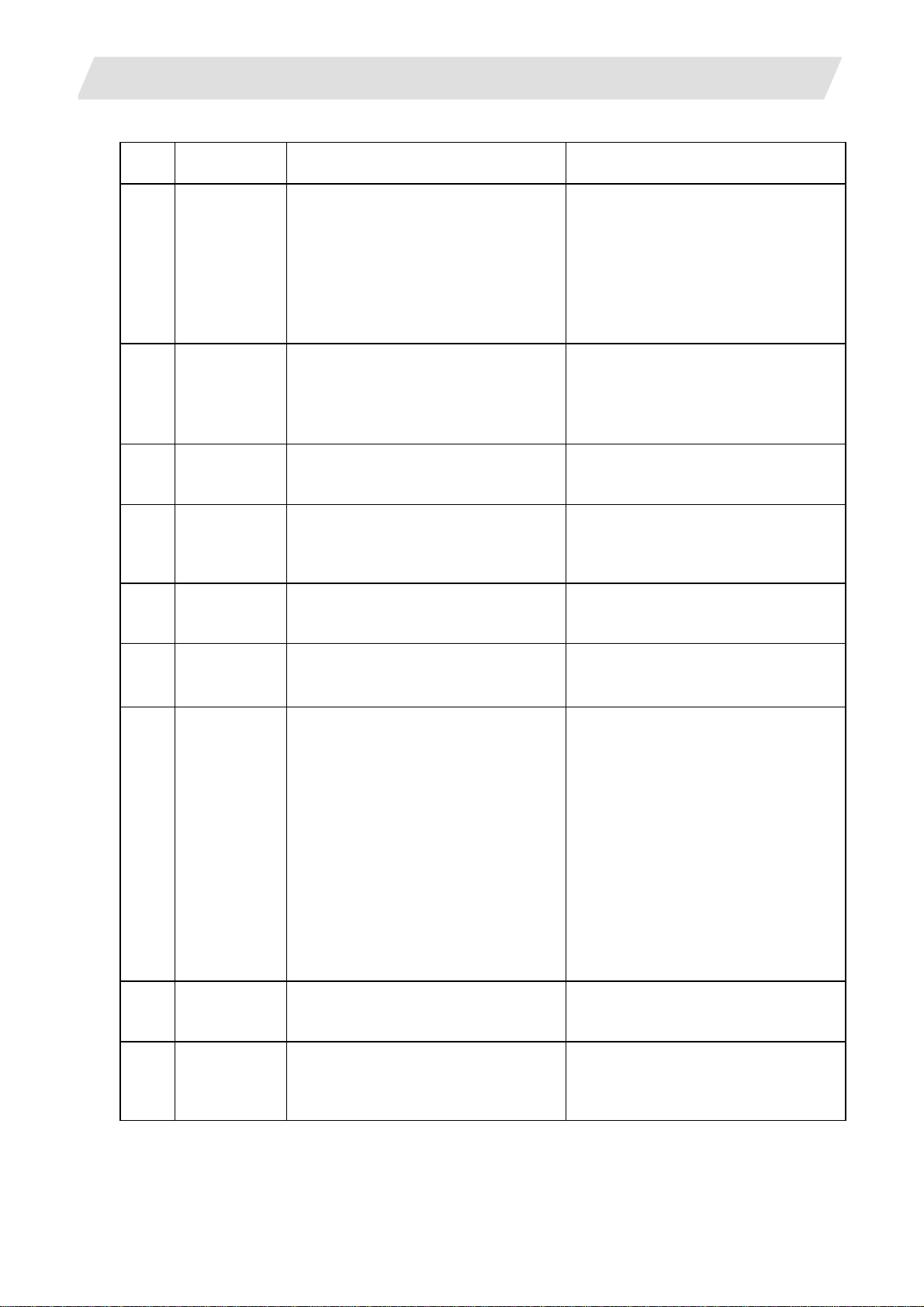

Page 16

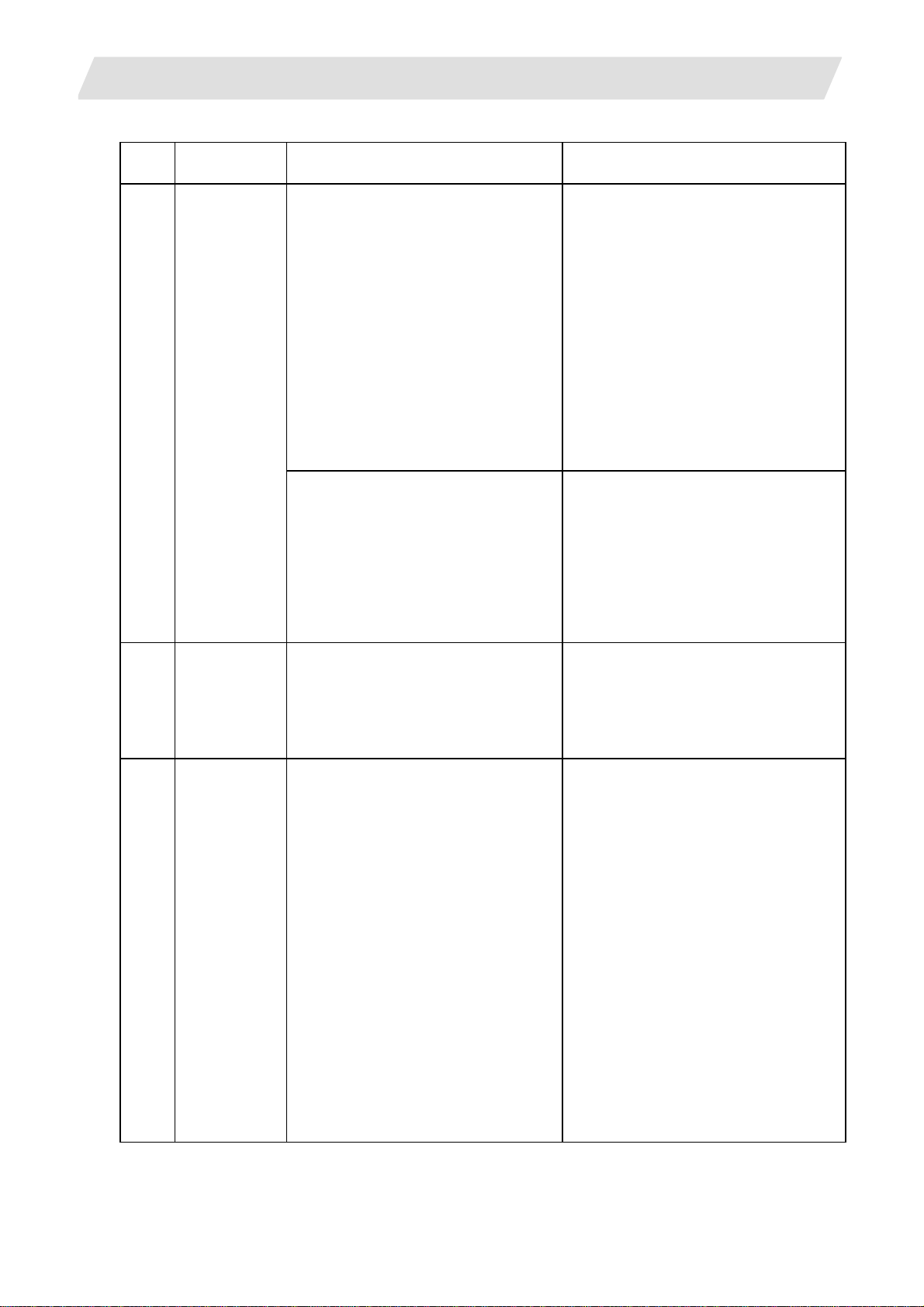

1. Errors During Operation

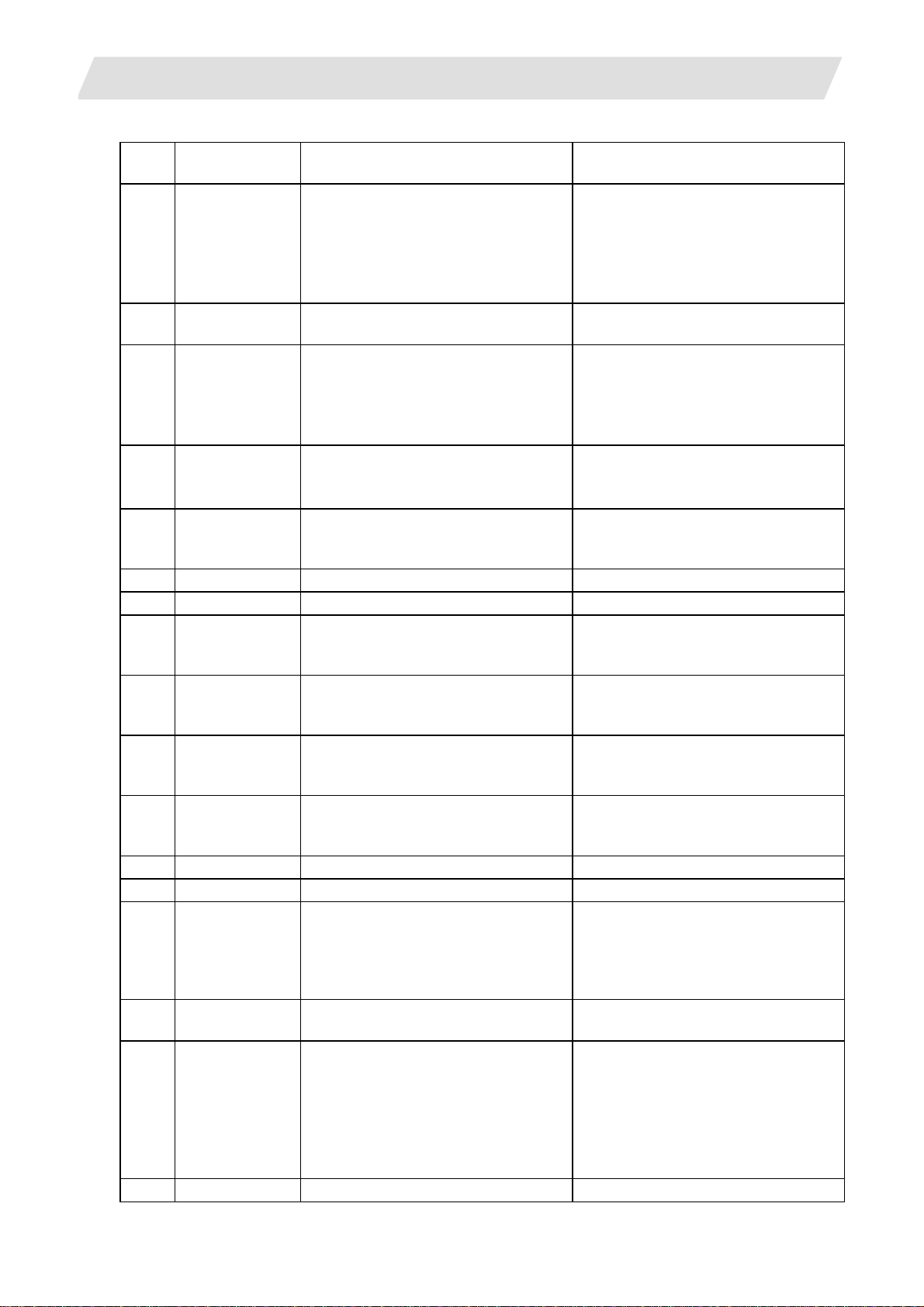

Error

No.

0006 H/W stroke

0007 S/W stroke

0008 Chuck/

0009 Ref point

0010 R-pnt ret invld

0011 Door open

0012 Auto zero pt

0024 R-pnt ret invld

0025 R-pnt ret invld

Message Details Remedy

end axis

exists

end axis

exists

tailstock

barrier valid

return not

completed

at tool retract

signal ON

init not valid

at abs pos

alm

at zero pt ini

1.1 Operation Errors (M01)

• The stroke end function is activated

(the input signal is "OFF") and one of

the axes is in the stroke-end status.

• The stored stroke limit I or II function

has been activated.

• The chuck/tail-stock barrier function

was valid, and the stroke end

occurred on an axis.

• When return to the 1st reference

point had not been completed, return

to the 2nd reference point was

executed.

• The operation mode was changed to

the reference point return mode

while in the tool retract return mode.

• The door open signal is being input. • Close the door.

• When initializing the absolute

position, the machine zero point is at

a position exceeding the pushing

point.

• The Basic specification parameter

"1011 abson" is not set to "2".

• The Absolute position set parameter

manual zero point initialization mode

is valid.

• The Absolute position set parameter

"1205 No stopper" is set to "1".

• The reference point return signal

was input while the absolute position

detection alarm was occurring.

• The reference point return signal

was input while carrying out zero

point initialization of the absolute

position detection system.

• Since the stroke end limit switch has

been activated (the stroke end status

has been established), move the

machine in reverse by operating it

manually.

• Check for breakage or disconnection

in the stroke end signal wire.

• Check for a failure in the limit switch.

• Since the machine is in the stroke

end status, move it in reverse by

operating it manually.

• Reset the stored stroke limit in the

parameters.

• After resetting the alarm by resetting

the NC, move the machine in the

reverse direction.

• Execute return to the 1st reference

point again.

• Select an operation mode other than

the reference point return mode.

• Turn OFF the door open signal

(Y488).

• Reset the Absolute position

parameter "1202 Ref position offset"

and the Zero (Reference) point

return parameters "2113 to 2116

#1_rfp to #4_rfp" and "2107 dir(–)"

so that the pushing point is not

exceeded.

• Set the Basic specification parameter

1 "1011 abson" to "2".

• If the Absolute position set parameter

manual zero point initialization mode

is valid, turn the NC power ON again.

• Set the Absolute position set

parameter "1205 No stopper" to "0".

• After the absolute position detection

alarm is released, return to reference

point can be made.

• Carry out reference point return after

the zero point initialization is

completed.

I - 2

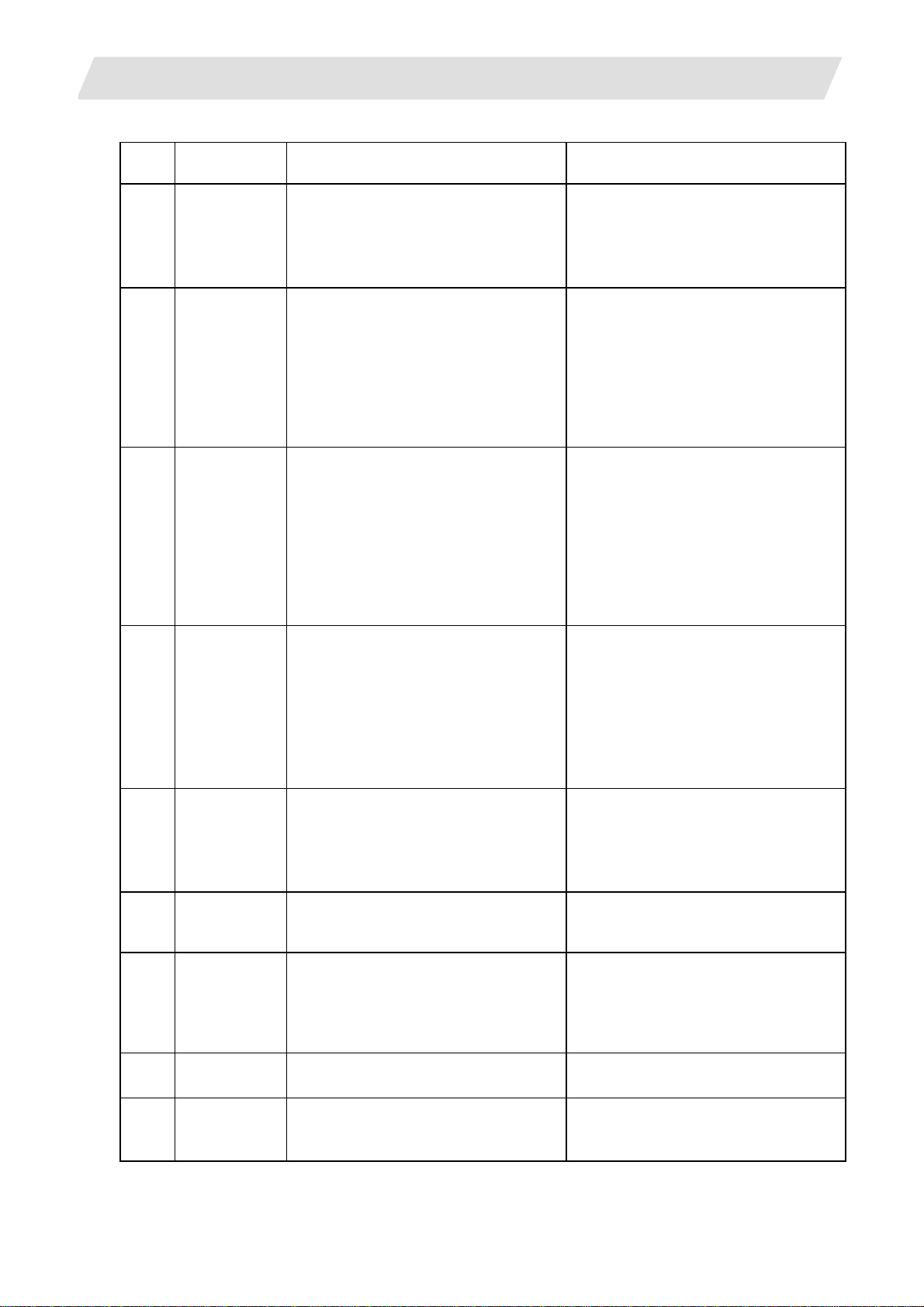

Page 17

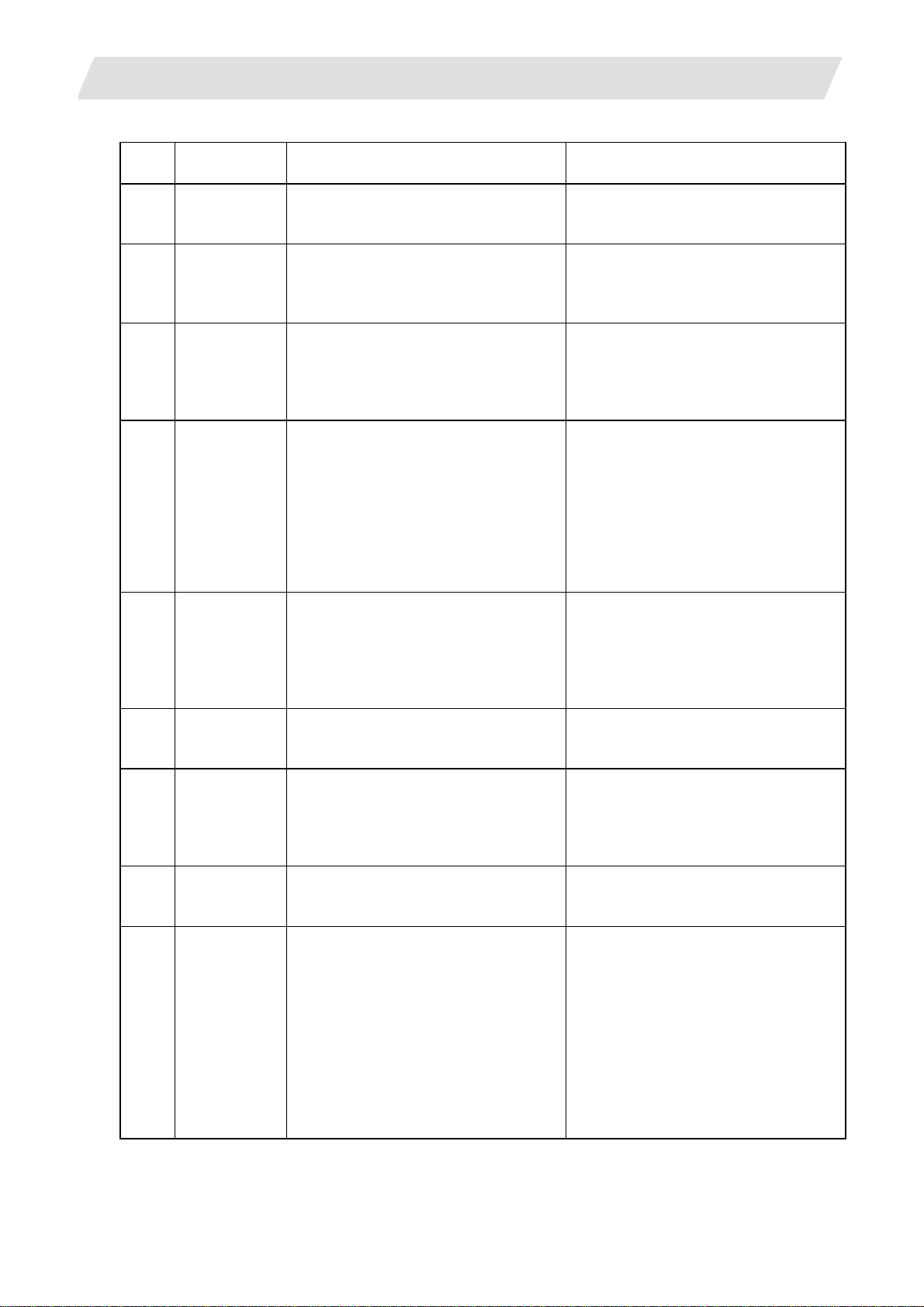

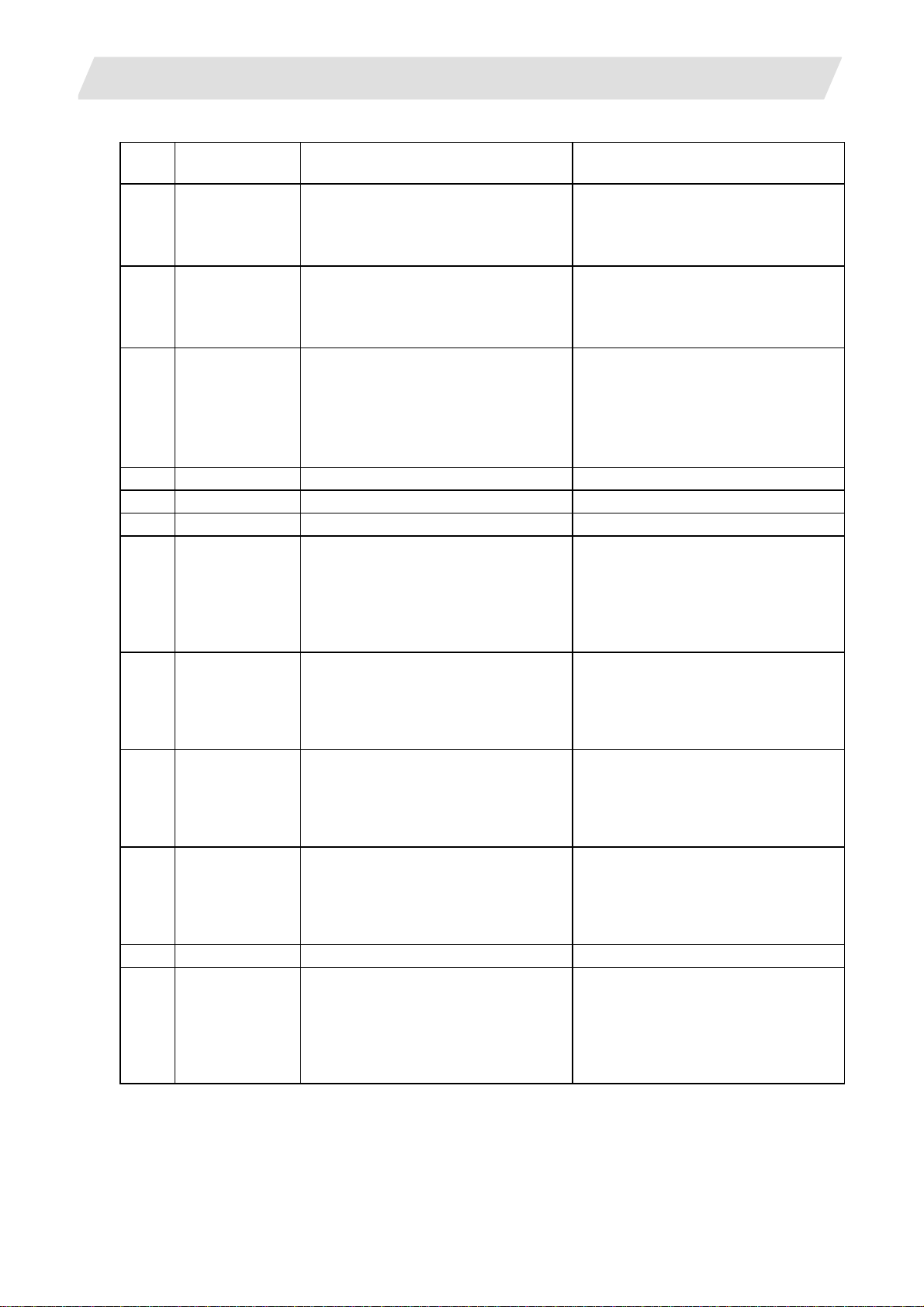

1. Errors During Operation

Error

No.

0101 Ope mode

0102 Cutting

0103 External feed

0105 Spindle stop • The spindle was stopped when the

0106 Handle feed

0107 Spindle

0108 Fixed pnt

0109 Block start

0110 Cutting block

Message Details Remedy

non-selected/

dupli.

override zero

rate zero

ax No. illegal

rotation

speed over

mode feed ax

illegal

interlock

start interlock

• No operation mode is selected, or

two or more operation modes are

selected.

• The "CUTTING FEED OVERRIDE"

switch on the machine operation

panel is set to "0".

• The "MANUAL FEEDRATE" switch

on the machine operation panel has

been set to "0" when the machine is

in the JOG mode and automatic dry

run mode.

synchronous feed command was

input.

• An axis which does not exist in the

specifications has been designated

for handle feed.

• The handle feed axis has not been

selected.

• The spindle speed has exceeded the

clamp speed of the axis when the

thread cutting command was issued.

• An axis not defined in the specifications was designated during fixed

point mode feed.

• The fixed point mode feedrate is

illegal.

• An interlock signal which locks the

block start has been input.

• An interlock signal which locks the

cutting block start has been input.

1.1 Operation Errors (M01)

• Check for breakage in the input

mode signal wire.

• Check for a failure in the MODE

SELECT switch.

• Check the sequence program.

• The error is released by setting the

“CUTTING FEED OVERRIDE”

switch to any position except “0”.

• If the “CUTTING FEED OVERRIDE”

switch has been set to any position

except “0”, check whether the signal

wire has been short-circuited.

• Check the sequence program.

• The error is released by setting the

"MANUAL FEEDRATE" switch on

the machine operation panel to any

position except "0".

• If the "MANUAL FEEDRATE" switch

has been set to any position except

"0", check whether the signal wire

has been short-circuited.

• Check the sequence program.

• Rotate the spindle. Establish the dry

run mode unless a workpiece is

being cut.

• Check for disconnection in the

spindle encoder cable.

• Check the connections of the spindle

encoder connectors.

• Check the spindle encoder pulse.

• Check for breakage in the handle

feed axis selection signal wire.

• Review the sequence program.

• Check the number of axes listed in

the specifications.

• Reduce the commanded spindle

speed.

• Check the fixed point mode feed axis

selection signal wire and fixed point

mode feedrate wire for breakage.

• Check the fixed point mode feed

specifications.

• Check the sequence program.

• Cancel the block start interlock signal.

• Check the sequence program.

• Cancel the cutting block start interlock

signal.

I - 3

Page 18

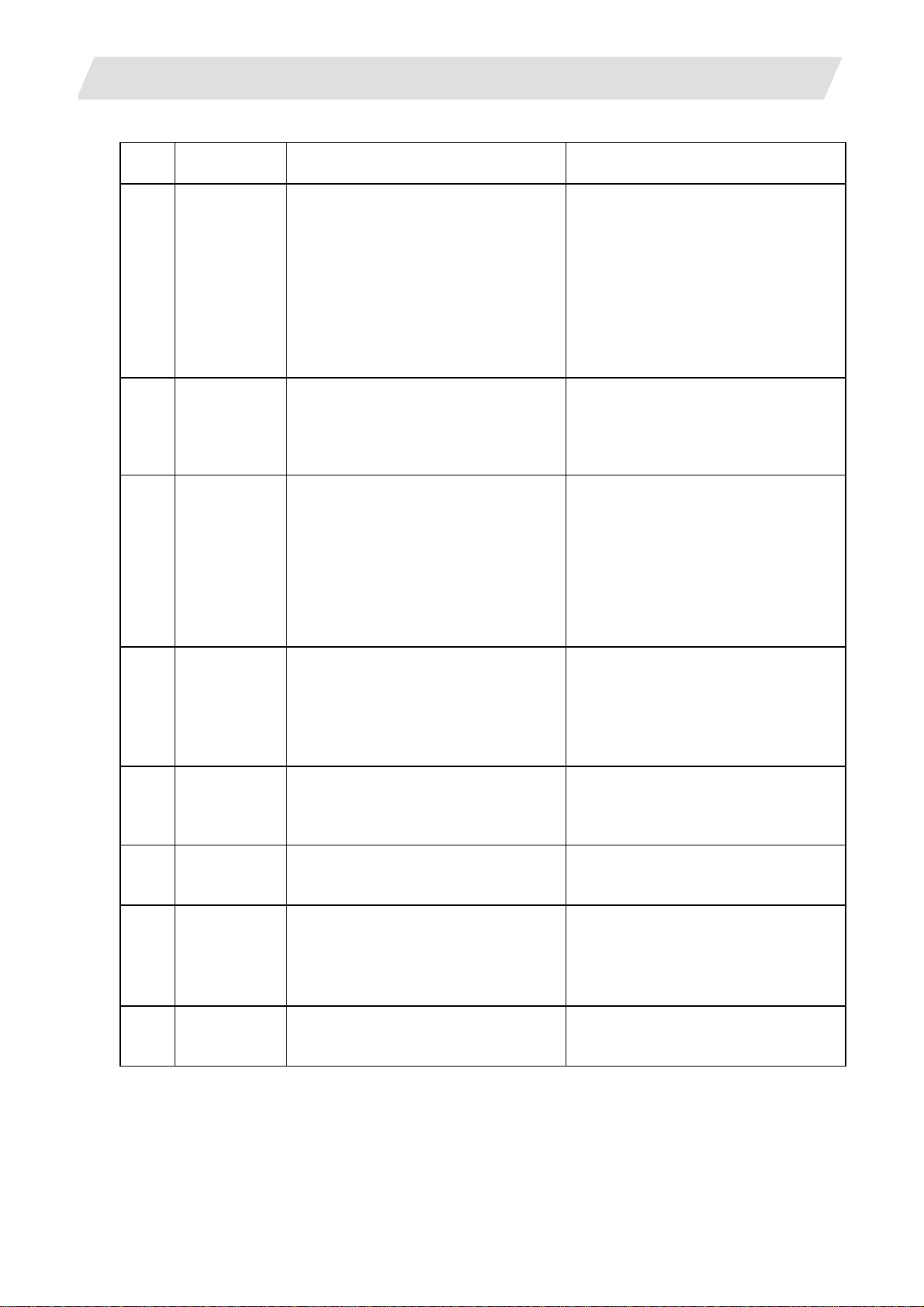

1. Errors During Operation

Error

No.

0115 In reset

1001 Selected ax

1003 Mov cmnd at

1004 S-impos/

Message Details Remedy

process

used as cross

ax

s-impos/

synch ilgl

synch

command

illegal

• Starting was attempted during the

reset process.

• The feed axis selected in manual

operation is being used by the cross

machining command issued by a

different system.

• A machine value command was

issued to a superimposing axis, or a

movement command was issued to

a slave axis.

• Synchronous tapping cycle

command was issued to an axis

relating to control axis

superimposition or arbitrary axis

superimposition control.

• A superimposition command was

issued to an axis under

synchronization control.

• A synchronization command was

issued to an axis under

superimposition control.

• A superimposition command, having

three or more levels, was issued.

• A synchronization command, having

two or more levels, was issued.

1.1 Operation Errors (M01)

• Restart after the reset process is

completed.

• Reset or return the selected feed

axis to the basic definition axis for

the cross machining command.

• Check the machining program.

• Check the parameter setting values.

• Check the machining program.

I - 4

Page 19

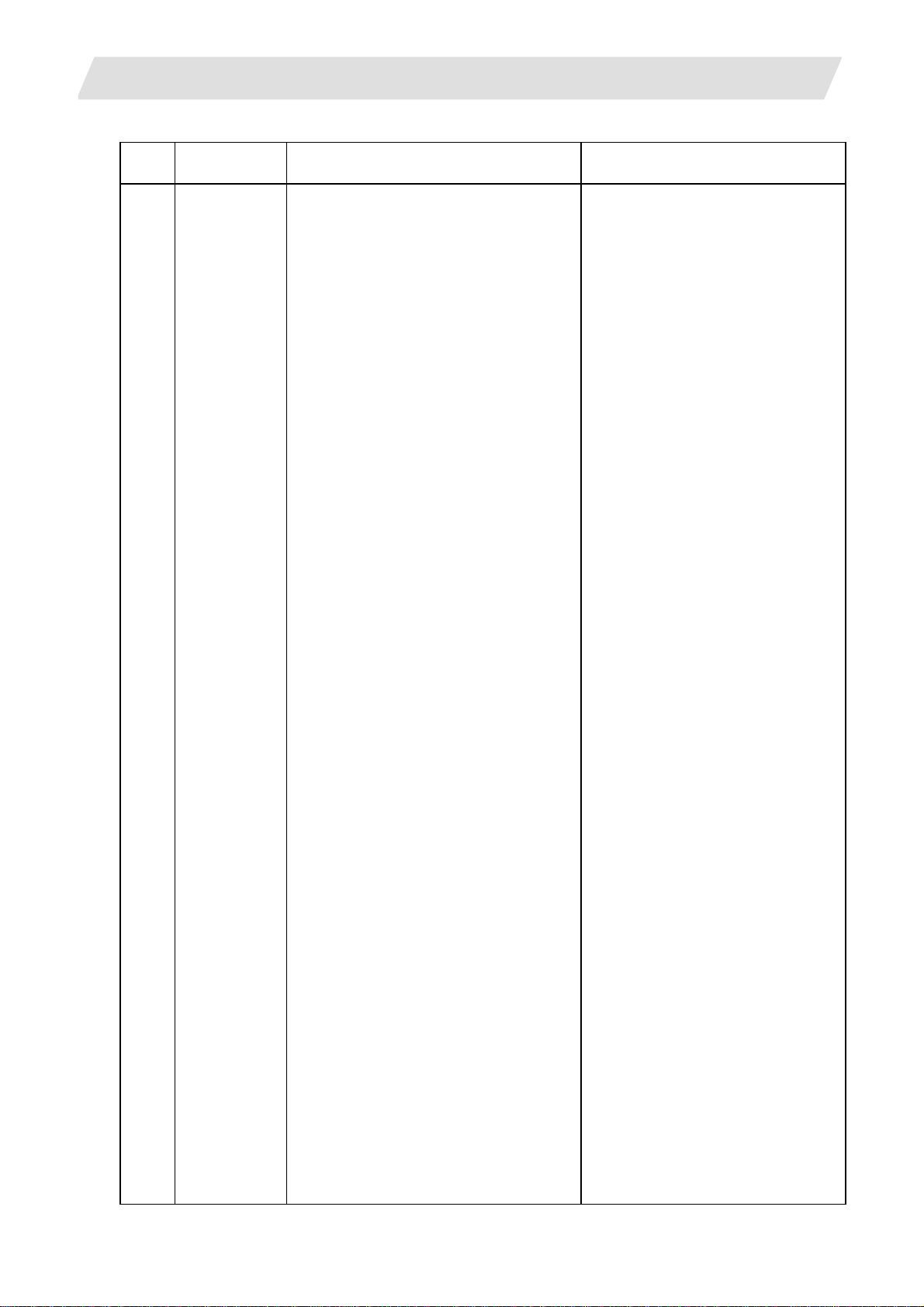

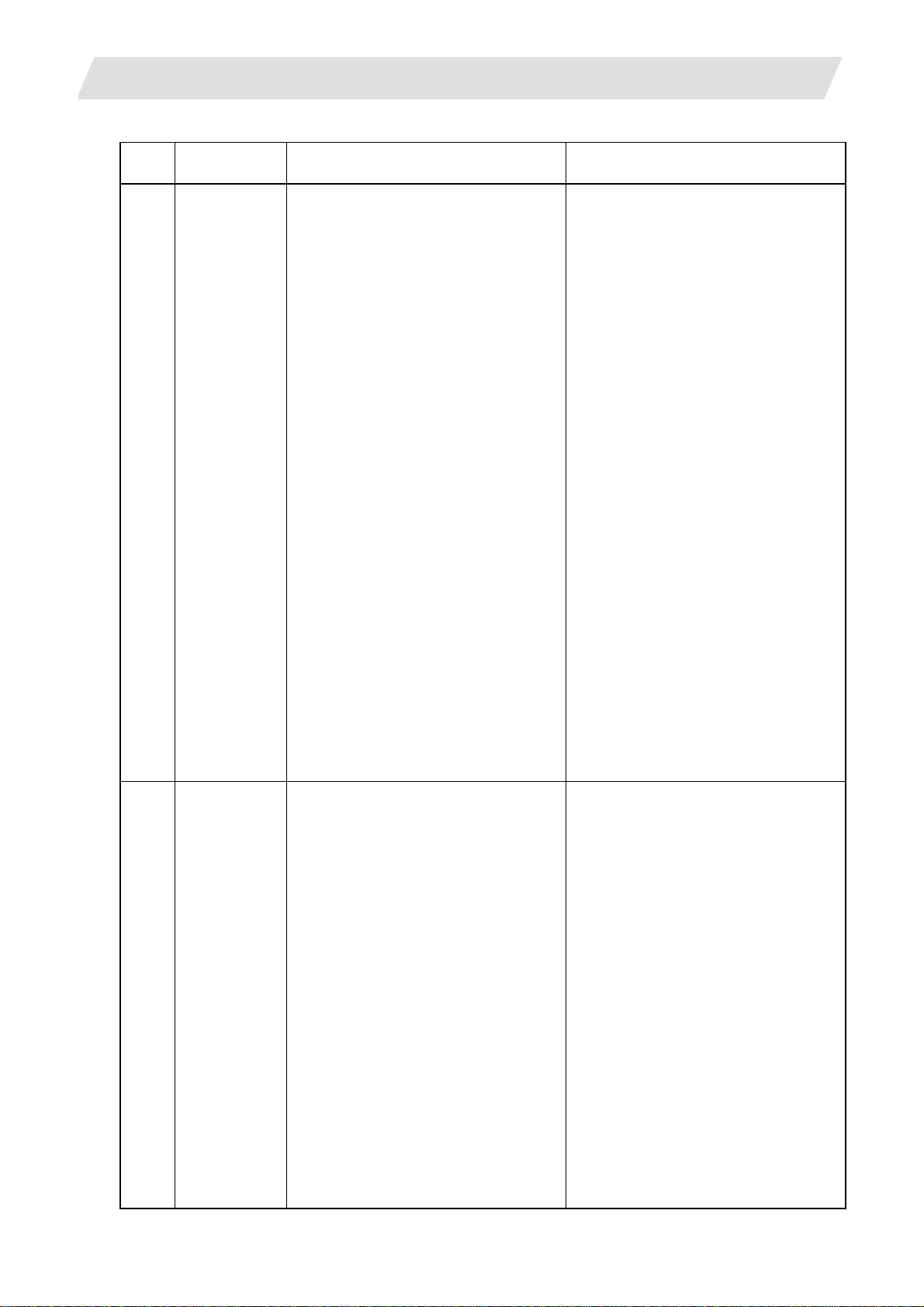

1. Errors During Operation

Error

No.

1005 Illegal G114.n

Message Details Remedy

command

• The G114.n command was issued in

G114.n mode

(When multiple spindle

synchronization set is disabled)

• G114.n was issued while spindle

synchronization instruction was being

issued from PLC. Or spindle

synchronization was instructed from

PLC during G114.n (when multiple

spindle synchronization set is

disabled).

• G113D command was issued to a

spindle other than the synchronous

spindle (when multiple spindle

synchronization set is enabled).

• G114.1 or G114.2 was commanded at

the same time as G113 command

(when multiple spindle synchronization

set is enabled).

• G114.1, G114.2, or spindle

synchronization instruction from PLC

was issued to the syncronous spindle

that is already under spindle

synchronization control (when multiple

spindle synchronization set is

enabled).

• G114.1, G114.2 or spindle

synchronization instruction from PLC

was issued to the basic spindle that is

already in G114.3, G114.2. (when

multiple spindle synchronization set is

enabled).

• When spindle synchronization is

controlled from PLC (using the data set

in R register), the data set in R register

is illegal.

• When spindle synchronization is

controlled from PLC (using the

previously commanded spindle

synchronization command data), the

spindle synchronization control signal

was turned ON without commanding

spindle synchronization (G114.1) after

power ON.

• When spindle synchronization is

controlled from PLC (using the

previously commanded spindle

synchronization (hobbing) command

data), and when the G20/G21 mode in

the previous command is different from

the G20/G21 mode in restoration, the

spindle synchronization control signal

has been turned ON.

1.1 Operation Errors (M01)

• Review the program.

• Check the ladder program.

(When multiple spindle

synchronization set is disabled)

I - 5

Page 20

1. Errors During Operation

Error

No.

1006 Thread

1007 Tap cycle

1008 Teaching

1009 In teaching

1010 No spec:

1011 Teaching

1012 Spindle

1013 C ax commnd

Message Details Remedy

cutting

synchro error

command

illegal

speed illegal

data setting

Teaching

invalid at mirr

image

detached

invalid at

hobbing

• When the thread cutting cycle/

compound thread cutting cycle was

started while the thread cutting

spindle rotation speed automatic

change was selected, the difference

of the automatically changed

command spindle rotation speed

and the spindle actual rotation

speed was not within the tolerable

error width for the spindle rotation

speed automatic change.

• A tap cycle synchronization

command was issued to a related

axis during spindle synchronous

control, tool-spindle control I, II or

III, or peripheral axis synchronous

control.

• The spindle synchronization control

or tool-spindle control I, II or III

was commanded to a spindle in tap

cycle synchronization.

• A tap cycle or tap cycle synchronization command was issued to a

master spindle in spindle

superimposition control.

• A tap cycle synchronization (tap

spindle zero point return type)

command was issued to a

superimposition spindle during

spindle superimposition control.

• The feedrate calculated during

teaching in intersystem

synchronous mode is illegal.

• The set No. (TGSET) was

designated while making settings on

the screen.

• The teaching mode signal was

turned ON though it was not included

in the specifications.

• The teaching command was issued

during the mirror image.

• Use of a spindle cut off with the

spindle cutoff signal was attempted.

• An automatic movement command

was issued to the C axis during the

tool-spindle synchronization control

(hobbing) mode.

1.1 Operation Errors (M01)

• Readjust the Spindle parameters.

• Make sure that the spindle speed

clamp command is not issued in the

machining program.

• Review the machining program.

• Follow the teaching procedure again

from the beginning.

• Stop the setting of the position

control variables on the screen.

• Check the specifications.

• Cancel the teaching mode signal.

• Check the machining program.

• Check the machining program.

• Check the spindle changeover

sequence.

• Check the machining program.

I - 6

Page 21

1. Errors During Operation

Error

No.

1014 GB spindle

1015 GB spindle

1016 GB spindle

1017 G128/G129

1018 G128/G129

Message Details Remedy

synchro

signal OFF

type error

connection

illegal

axis posn

illegal

command

illegal

• A forward run, reverse run,

orientation or C-axis servo ON

command was issued to the

reference spindle while the G/B

spindle synchronization signal was

OFF.

• The G/B spindle synchronization

signal was turned OFF during a

forward run, reverse run, orientation

or C-axis servo ON command.

• A spindle (analog spindle) not

serially connected was used for the

master spindle or G/B spindle.

• The master spindle's spindle NC

parameter "3032 smcp_no" setting

value is larger than the G/B spindle

setting value.

• The master spindle's spindle drive

unit and G/B spindle's spindle drive

unit are not connected to the same

MCP card (QX722 or QX721).

During the axis movement

synchronous superimposition

command (G128, G129):

• The master axis moved from the

direction of the synchronous

superimposition completion

position.

• The distance between the master

axis and synchronous

superimposition axis is already within

the relative distance.

• When commanding with DDBS, the

synchronous superimposing axis is

not within the end position from the

synchronous superimposition start

position.

• During the axis movement

synchronous superimposition

command (G128, G129), a

command with which the

synchronous superimposing axis

exceeds the synchronous

superimposition completion position

was issued.

1.1 Operation Errors (M01)

• Check the ladder program.

• Check the parameters.

• Change the analog spindle to a

serially connected spindle.

• Check smcp_no.

• Check the connection of the spindle

drive unit and MCP card.

• Check the program.

• Check the details designated for the

DDBS conditions.

• Check the program.

I - 7

Page 22

1. Errors During Operation

Error

No.

1019 G128 axis

1020 G128 axis

1021 GB SP sync:

1022 GB SP sync:

1023 GB SP sync:

1024 Sub-part

1025 Crss mach ilgl

Message Details Remedy

locked

locked

Phase mem

sgnl ilgl

Phase set

sgnl ilgl

Z phase not

pass

system call

illegal

at sub-sys

call

During the axis movement

synchronous superimposition

command (G128, G129):

• When the synchronous

superimposition mode was started,

the synchronous superimposing

axis or master axis was moving.

• When the synchronous

superimposition mode was

completed, the synchronous

superimposing axis or master axis

was moving.

• During the axis movement

synchronous superimposition

command (G128, G129), the

synchronous superimposing axis

was in the machine lock or interlock

state.

• The G/B spindle synchronization

phase memory signal was turned

ON while the master spindle or G/B

spindle was rotating.

• The G/B spindle synchronization

phase memory signal was turned ON

while the G/B spindle

synchronization signal was OFF.

• The G/B spindle synchronization

phase alignment signal was turned

ON while the master spindle or G/B

spindle was stopped.

• When the G/B spindle

synchronization phase memory

signal was ON, the master spindle

or G/B spindle’s Z-phase was not

passed.

• A subsystem command was issued

for a system that was not in the

subsystem operation mode.

• The subsystem was started or

stopped with the cross command

when the basic axis configuration

was not established.

1.1 Operation Errors (M01)

• Check the program.

• This will be canceled when the

synchronous superimposition axis or

reference axis is stopped.

• Check the program.

• Check the ladder program.

• Check the ladder program.

• Check the ladder program.

• Check the ladder program.

• Check the machining program.

I - 8

Page 23

1. Errors During Operation

Error

No.

1026

1027 C-surface ctrl

1028 GB SP sync:

Message Details Remedy

Other function

command

disabled during

spindle/C axis

control

invld at taping

Cancel sgnl

illegal

• C axis selection command for

Spindle/C axis control was issued

while "Spindle synchronization",

"Tool spindle synchronization I",

"Tool spindle synchronization II",

"Synchronous tapping cycle" or

"Spindle orientation" was being

commanded.

• "Spindle synchronization", "Tool

spindle synchronization I", "Tool

spindle synchronization II",

"Synchronous tapping cycle" or

"Spindle orientation" command was

issued while C axis was being

selected.

• When deceleration stop position is

set as absolute position from the C

axis zero point (Z phase passed

position), C axis command was

issued after power ON without

passing the spindle's Z phase.

• The constant surface speed

command was issued to a spindle in

the tap cycle/synchronous tap cycle,

or a tap cycle/synchronous tap cycle

command was issued to a spindle in

the constant surface speed control.

The G/B spindle synchronization

temporary cancel signal was turned

ON/OFF when the master spindle and

G/B spindle were in one of the

following modes.

• During rotation (when not stopped)

• During tap cycle synchronization

mode

• During spindle synchronization

mode

• During tool-spindle synchronization

I (polygon machining) mode

• During tool-spindle synchronization

II (hobbing) mode

• During spindle superimposition

mode

• During spindle C axis control C axis

mode

• During orientation/indexing

1.1 Operation Errors (M01)

• Check the C axis's servo ON

sequence.

Automatic operation is disabled, but

this operation error can be released by

manually moving the axis during C

axis's servo ON state.

Manually move the axis to let the phase

Z be passed and switch to servo OFF

to cancel this error. Switch the C axis to

servo ON again, and then, the zero

point can be established.

• Issue only one of the commands.

• Review the ladder program.

I - 9

Page 24

1. Errors During Operation

Error

No.

1100 Sub-system

1101 Axis change

1102 Spindle cond

1103 G156

1104 Prphral/

1105 Collision

1106 Spindle synch

1107 Now feed rate

1108 SP clamped

Message Details Remedy

start not

possible

not possible

check time

exceed

command at

illegal system

synchro ax

No. ilgl

detect cmnd

illegal

phase calc ilgl

clamped

at

superimpose

tap

• A sub-system that can be started is

not remaining when the sub-system

is called.

• When the arbitrary axis exchange

command was issued, the declared

axis was in a status unable to be

exchanged.

• In the spindle status check function,

the designated spindle did not reach

the designated speed, and

exceeded the designated check

time.

• The random superimposition

command was issued from an

external source including

superimposing axes or random

superimposition master axes. Or the

random superimposition cancel

command was issued from an

external source including the

random superimposing axes.

• When setting the axis No. for the

peripheral axis synchronous control,

the slave axis and master axis were

set to the same number, or a number

that does not exist in the system was

set.

• The collision detection function

(G161) was commanded from

several systems.

• The spindle synchronization phase

alignment command was issued

while the spindle synchronization

phase calculation request signal was

valid.

• The commanded feedrate exceeded

the clamp speed set in the

parameters.

• When a tap cycle or synchronous tap

cycle was commanded to a

superimposing axis, the actual

rotation speed of the superimposing

spindle exceeded the spindle clamp

speed.

• The synchronous tap cycle was

commanded when a rotation

command was not input for the

master spindle or superimposing

spindle.

1.1 Operation Errors (M01)

• Check the program.

(Focus on process timing)

• Check the program.

(Focus on process timing)

• Check the program.

• Check the machining program.

• Check the ladder circuit.

• Check the machining program.

• Check the machining program.

• Check the ladder circuit.

• Check the machining program.

• Check the program.

I - 10

Page 25

1. Errors During Operation

Error

No.

1109 Base SP

1110 Ax exchange

1111 Now ax

1112 Mirror image

1113 T-leng meas

1114 Tool No. not

1115 Compen ax

1116 Sensor No.

Message Details Remedy

C-surface

invld at tap

not possible

detached or

servo off

command

illegal

ax not retn

(TLM2)

found (TLM2)

illegal (TLM2)

not specified

(TLM2)

• A constant surface speed command

was issued to the master spindle

when the tap cycle or synchronous

tap cycle was being executed with

the superimposing spindle.

• During constant surface speed

control of the master spindle, the tap

cycle or synchronous tap cycle

command was issued to the

superimposing spindle.

• An arbitrary axis exchange

command for which axis exchange is

not possible or an arbitrary axis

exchange return command was

issued.

• The movement command following

the arbitrary axis superimposition

command, a movement command

following the superimposition/

synchronization control, or a

movement command following the

peripheral axis synchronization

control was issued during the axis

removal mode or during servo OFF.

• The mirror image was turned ON for

a superimposition/synchronous axis

or milling control axis.

• The external mirror image and

parameter mirror image were turned

ON simultaneously.

• Measurement of an axis that had not

returned to the reference point was

attempted during manual tool length

measurement 2.

• The designated tool number was not

within the number of tool sets during

manual tool length measurement 2.

• Measurement of two or more axes

was attempted simultaneously during

manual tool length measurement 2.

• The measured axis was not the tool

offset target axis.

• Measurement without designating

the sensor No. was attempted during

manual tool length measurement 2.

1.1 Operation Errors (M01)

• Check the program.

• Check the program.

• Check the program.

• Check the mirror image signal in the

PLC Interface.

• Check the Axis parameter mirror

image.

• Check the program.

• Carry out reference point return

before measuring.

• Designate a tool number within the

number of tool sets.

• Check the axis to be measured.

• Confirm the sensor No. designated

for the parameter manual tool length

measurement 2.

I - 11

Page 26

1. Errors During Operation

Error

No.

1117 Inclined ctrl

1118 G170/G171

1119 Inclined ctrl

1120 Disapprove

Message Details Remedy

manual mode

ilgl

cood not

changed

axis illegal

coordinate

conver

• Automatic dogless, manual

reference point return, manual feed

or a manual mode other than handle

was selected in the actual axis mode.

• Incremental feed, manual skip or

automatic dogless was selected

during the orthogonal mode.

• Automatic handle interruption was

selected during manual-automatic

simultaneous operation.

• The G170/G171 coordinate

changeover command was issued

during start point designation wait,

end point designation wait,

miscellaneous function output during

axis movement wait, or during

superimposition/synchronous/

peripheral axis synchronous control.

• A cross command, arbitrary axis

exchange command or

superimposition/synchronous/

peripheral axis synchronous control

command was issued to an inclined

master axis or inclined axis.

• A synchronous tap command tap axis

was commanded for an inclined axis.

• The hypothetical coordinate

coordinates cannot be set when the

hypothetical coordinate setting

command is issued.

1.1 Operation Errors (M01)

• Check the ladder circuit.

• Check the machining program.

• Check the machining program.

Check whether the hypothetical

coordinate target axis is in any of the

following states. Remove the cause if

found.

• Hypothetical coordinate target axis is

related to control axis synchronous

control, control axis superimposition

control, arbitrary axis

superimposition control, peripheral

axis synchronous control or

synchronous control during axis

movement.

• The other axis in the set of

hypothetical coordinate target axes

is in the automatic/ manual machine

lock state.

• The hypothetical coordinate target

axis is in the servo OFF state.

• The hypothetical coordinate target

axis has been removed.

• The hypothetical coordinate target

axis has not completed reference

point return.

• The hypothetical coordinate target

axis is in the automatic handle

interrupt mode or manual/automatic

simultaneous mode.

• The hypothetical coordinate target

axis is in the constant torque control

or proportional torque pressing

control state.

I - 12

Page 27

1. Errors During Operation

Error

No.

1121 Invalid during

1122 Disapprove

Message Details Remedy

coord conver

chage TDO

mode

• A command that can be issued only

in the hypothetical coordinate cancel

state was issued while setting the

hypothetical coordinates.

• The tool axis direction tool length

offset cannot be set when the tool

axis direction tool length offset is

commanded.

1.1 Operation Errors (M01)

One of the following commands was

issued to the hypothetical coordinate

target axis while setting the

hypothetical coordinates. Remove the

cause.

• Manual mode (jog, incremental,

handle)

The hypothetical coordinate target

axis making up the set exist in

separate part systems

Select the feed axis simultaneously

for the two hypothetical coordinate

target axes

• Manual random feed

• Manual reference point return

• Absolute position establish

• Automatic/manual machine lock

Machine lock signal ON for only one

of the hypothetical coordinate target

axes

• Automatic handle interrupt

• Manual/automatic simultaneous

• Control axis synchronous control

command (G125)

• Control axis superimposition control

command (G126)

• Random superimposition control

command (G156)

• Peripheral axis synchronization

command

• Servo OFF signal OFF

• Axis removal signal ON

• Constant torque control

• Proportional torque pressing control

• Tap restract control

Check whether the axis targeted for

tool axis direction tool length offset is

in the following state, and remove the

cause.

• The axis targeted for tool axis

direction tool length offset is not in

the command system.

• The axis targeted for tool axis

direction tool length offset is in

control axis synchronous control,

control axis superimposition control

or synchronous control during axis

movement.

• One or two of the axes targeted for

tool axis direction tool length offset is

in the machine lock state.

• The axis targeted for tool axis

direction tool length offset is in the

servo OFF state.

• The axis targeted for tool axis

direction tool length offset is

removed.

• The axis targeted for tool axis

direction tool length offset has not

completed reference point return.

I - 13

Page 28

1. Errors During Operation

Error

No.

1123 Cmnd invalid

Message Details Remedy

during TDO

mode

• A command that can be issued only

when tool axis direction tool length

offset is canceled was commanded

during the tool length direction tool

length offset mode.

1.1 Operation Errors (M01)

One of the following commands was

issued to the axis targeted for tool axis

direction tool length offset during the

tool axis direction tool length offset

modal. Cancel the tool axis direction

tool length offset modal, or remove the

cause.

• Manual reference point return

• When the automatic machine lock

signal has not been selected for

even one of the axes targeted for

machine lock tool axis direction tool

length offset

• Cross machining command (G110)

• Manual skip

• Manual tool length measurement I, II

• Tool retract return

• When the servo OFF signal has not

been selected for even one of the

axes targeted for servo OFF tool axis

direction tool length offset

• When the axis removal signal has

not been selected for even one of the

axes targeted for axis removal tool

axis direction tool length offset

• Control axis synchronous control

command (G125)

• Control axis superimposition control

command (G126)

• Synchronous control command

during axis movement (G128)

I - 14

Page 29

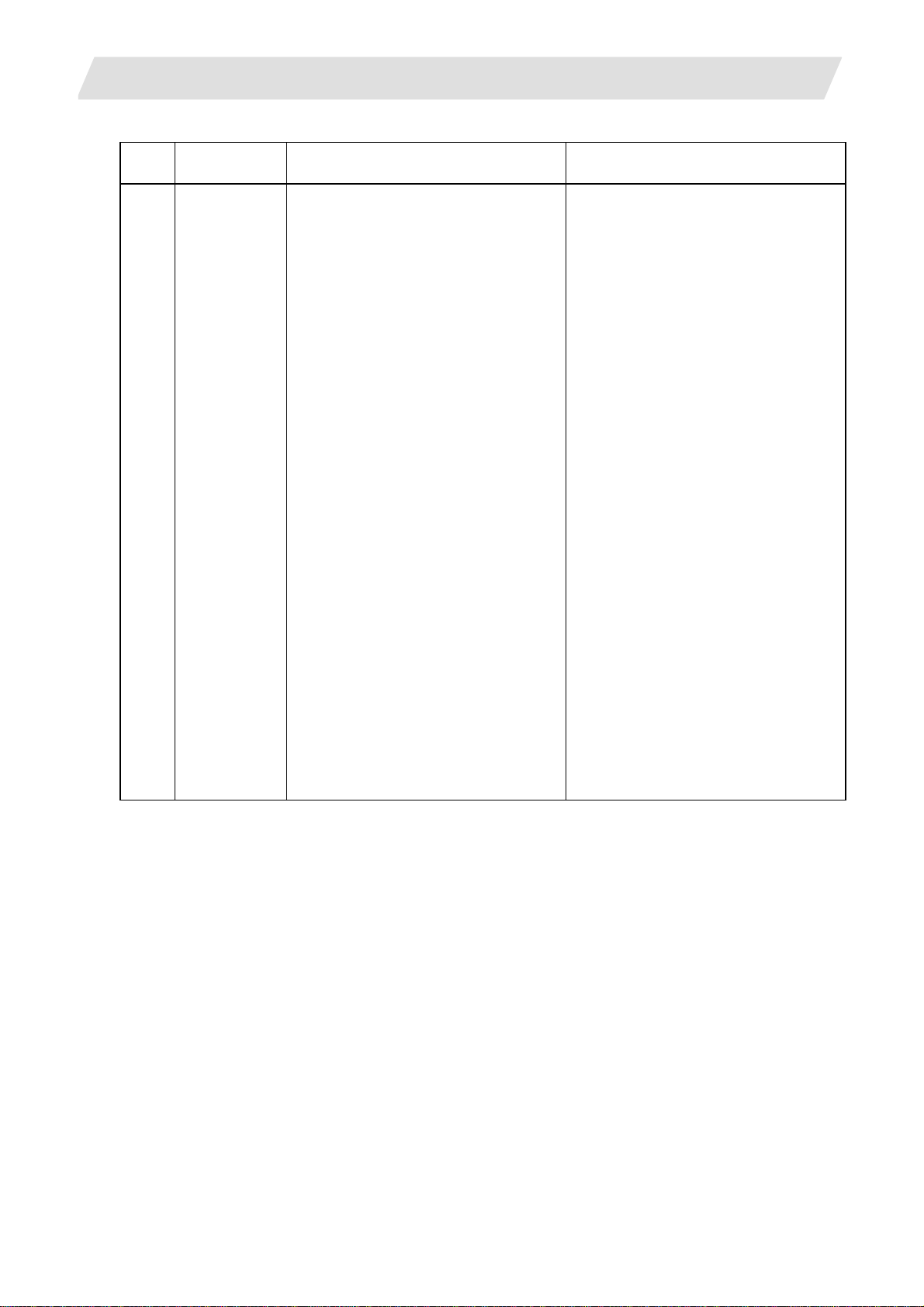

1. Errors During Operation

Error

No.

1125 Program

Message

restart

impossible

Details Remedy

• The program restart mode signal

was turned ON when one of the part

systems was in automatic startup.

• The program restart mode signal

was turned ON during the spindle

synchronization, the tool-spindle

synchronization mode, the spindle

superimposition mode, the

synchronous tap mode or the tap

cycle mode.

• The program restart mode signal

was turned ON during reverse run of

program check.

• The program restart mode signal

was turned ON during subsystem

operation.

• The program restart mode signal

was turned ON in the next block

when G28, G30 or G27 was

commanded at the head of the main

program.

• The program restart signal was

turned ON in the subprogram’s head

block when subprogram call is

commanded at the head of the main

program.

• The program restart mode signal

was turned ON in the head block of

the main program.

• The program restart mode signal

was turned ON during automatic

handle interrupt or manual/automatic

simultaneous mode.

• The program restart mode signal

was turned ON during MDI operation

or PLC interrupt operation.

• During the program restart mode,

the MDI operation mode or PLC

interrupt operation mode was

selected before turning the restart

mode interrupt signal was turned

OFF.

• All axes did not return to the restart

position during automatic operation

after the program restart mode.

• The program restart mode signal

was turned ON while waiting for

synchronization during automatic

operation after the program restart

mode.

• The program restart mode signal

was turned ON when simultaneous

blocks are being executed.

1.1 Operation Errors (M01)

• Turn the program restart mode signal

ON when none of the part systems

are in automatic startup.

• Turn the program restart mode

signal ON in a mode other than the

spindle synchronization, the

tool-spindle synchronization mode,

the spindle superimposition mode,

the synchronous tap mode or the tap

cycle mode.

• Turn the program restart mode signal

ON with program check forward run in

a block that exceeds the reverse run

start block.

• Turn the program restart mode

signal ON during operation other

than subsystem operation.

• When G28, G30 or G27 is

commanded at the head of the main

program, turn the program restart

mode signal ON in the next or

following block.

• If subprogram call is commanded at

the head of the main program, turn

the program restart mode signal ON

after the head block of the

subprogram.

• Turn the program restart mode

signal ON in a block after the main

program's head block.

• Turn the program restart mode signal

ON in a mode other than the

automatic handle interrupt or manual/

automatic simultaneous mode.

• Turn the program restart mode signal

ON during a mode other than MDI

operation or PLC interrupt operation.

• Select the MDI operation mode or

PLC interrupt operation mode after

turning the restart mode interrupt

signal ON.

• Return all axes to the restart

position.

• Turn the program restart mode

signal ON after the synchronization

wait state is completed.

• Turn ON the program restart mode

signal after the completion of G184

command.

I - 15

Page 30

1. Errors During Operation

Error

No.

1126 Sync. Tap

1131 Illegal Ope

1132 In HSPRGM

1133 Axis change

1134

1135

1200 GB SP

1201 G182 timeout • G181 command having the same

Message Details Remedy

speed param

illegal

mode in

HSPRGM

conversion

invalid in

HSPRGM

Phase Z not

passed in

spindle

synchronizati

on

Spindle

synchronizati

on cancel

error

sync:R-pnt

posn illegal

• The synchronous tap cycle was

commanded in the following state.

(1) When the tap speed setting for the

first step was 0 or not within the

setting range.

(2) The setting value of a step is bigger

than the value of a bigger step, or

the setting value of a step is smaller

than the value of a smaller step.

(Except for "0" setting.)

• When executing the execution type

data's machine tool builder macro,

change over to the manual mode

was selected (mode changeover,

manual/automatic simultaneous,

handle interrupt), or MDI interrupt or

PLC interrupt was selected.

• Automatic operation was started

during a machine tool builder macro

conversion process.

• An arbitrary axis exchange

command was issued in an axis

change invalid state while executing

execution type data.

• The phase Z of the basic or

synchronous spindle has not been

passed, when the spindle

synchronization control signal was

turned ON.

• Spindle synchronization cancel

command was issued while C axis

was moving under spindle

synchronization C axis control.

• The target axis was exchanged upon

issuance of the arbitrary axis

exchange command during

interference avoidance G0 speed

control.

• Interference avoidance G0 speed

control was executed during

superimposition or synchronization.

Control axis superimposition was

executed during interference

avoidance G0 speed control.

identification No. as G182 command

was not executed within set timeout

time.

1.1 Operation Errors (M01)

• Check the details set for the tap

speed parameters.

• This alarm is canceled by resetting.

When the manual mode is selected,

turn the manual mode OFF to reset

the alarm.

• This alarm is canceled by resetting.

Start automatic operation after the

machine tool builder macro

conversion is completed.

• Review the execution type data

program.

• Check the ladder program.

• To cancel this operation error, stop

the C axis, and then, command the

spindle synchronization cancel in C

axis's stop state.

• Check the machining program.

• Check the machining program.

• Check the parameter (#8061).

I - 16

Page 31

1. Errors During Operation

Error

No.

1210

1215

1216

9089

9097

9098 Position

9099 Position

Message Details Remedy

Axis

exchange

disabled

during time

constant

switching

High-speed

simple

program

check:

Workpiece

position error

High-speed

simple

program

check:

Machine

position error

Spindle

command

supervising

error

Position

supervising

error 3

supervising

error 1

supervising

error 2

• Cross machining command (G110)

or arbitrary axis exchange control

command (G140/G141) was issued

to an axis that was under G1 time

constant switching.

• When reset signal is input while

high-speed simple program check's

coodinate position check enable

signal is ON, the workpiece

coordinate position is different from

the position at the start of the

machining program.

• When reset signal is input while

high-speed simple program check's

coodinate position check enable

signal is ON, the machine coordinate

position is different from the position

at the start of the machining

program.

• The command to the spindle drive

unit failed to be normally output

when spindle control related

command was executed.

• The difference of the previous

cycle's feedback position and the

current cycle's feedback position

exceeded the tolerable range.

• A positional deviation occurred.

• The data for the program analysis

process and interpolation process

did not match, causing a positional

deviation.

• A positional deviation occurred.

• The data for the interpolation process

and acceleration/deceleration

process did not match, causing a

positional deviation.

• A positional deviation occurred.

1.1 Operation Errors (M01)

• Cancel the cutting feed time

constant switching, and then issue

cross machining command (G110)

or arbitrary axis exchange control

command (G140/G141).

• Check the machining program.

• Check the machining program.

• This error can be cancelled by NC

reset.

• Contact the Service Center.

• Contact the Service Center.

• Contact the Service Center.

• Contact the Service Center.

I - 17

Page 32

1. Errors During Operation

(2) Class: M02 Message: Absolute position restore required

1.1 Operation Errors (M01)

M02 Abs posn return required again

Details Remedy

The operation mode was changed to the

reference point return mode while in the retract

return mode.

(3) Class: M03 Message: Interference check alarm

M03 Interfere alarm (command)

Details Remedy

The issued command caused an interference

between two devices such as tool turrets.

(4) Class: M04 Message: Interference area alarm

• Select an operation mode other than the reference

point return mode.

• Release the alarm by a reset operation.

• To move the interfering device further in the

interfering direction, invalidate an interference check

before doing it.

• Refer to the instruction manual issued by the

machine manufacturer for the procedure to invalidate

an interference check.

M04 Interfere alarm (present area)

Details Remedy

Two interfering devices such as tool turrets

entered an interference area.

(5) Class: M05 Message: Interference data undefined

M05 Interference data undefined 0001

Details Remedy

Interference data is not defined. • Enabling the interference check III mode was

• Invalidate an interference check, and then move the

devices.

• Refer to the instruction manual issued by the

machine manufacturer for the procedure to invalidate

an interference check.

attempted while the interference definition data has

not been set. Set the interfering object's definition,

and then issue interference data enable command.

I - 18

Page 33

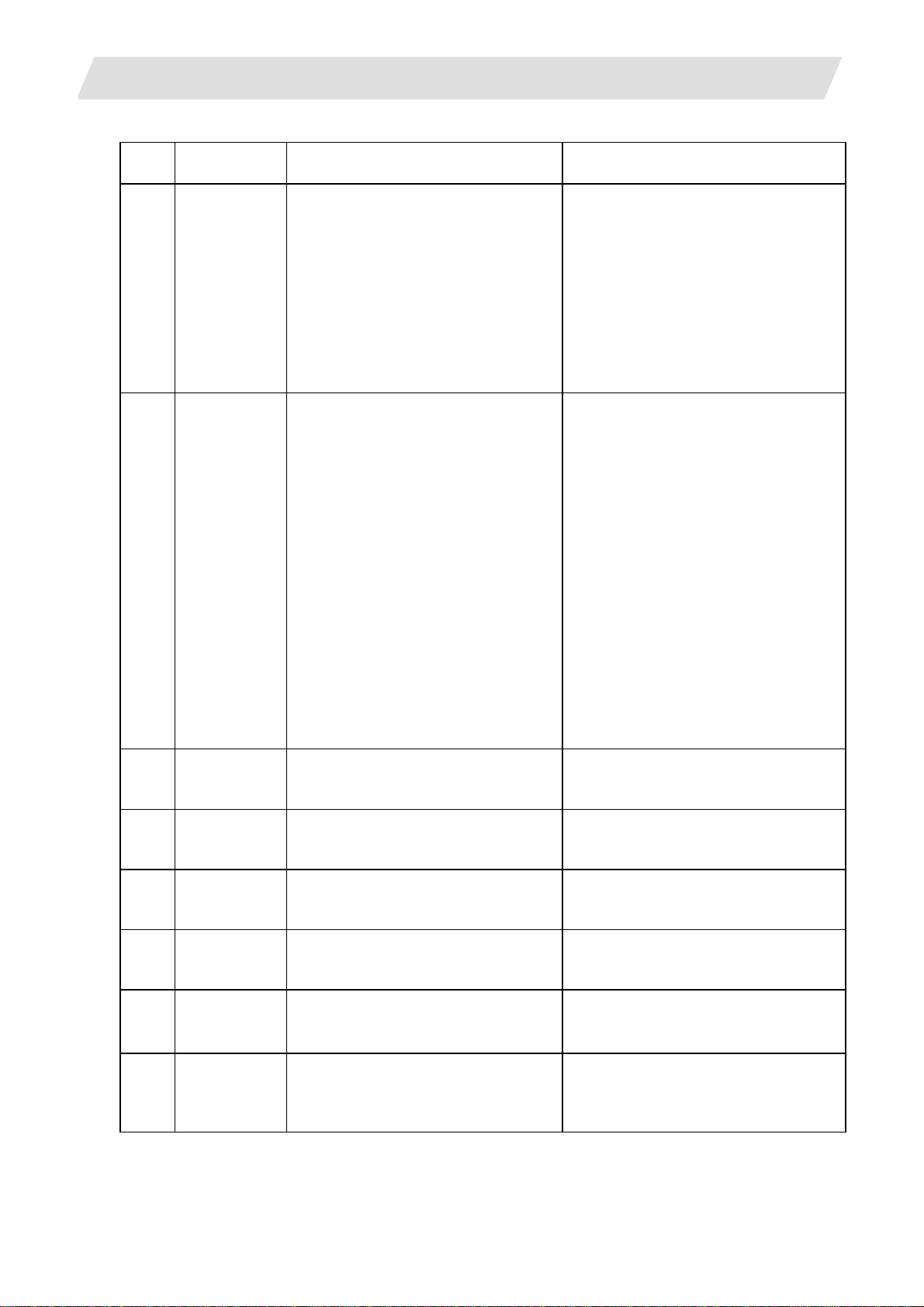

1. Errors During Operation

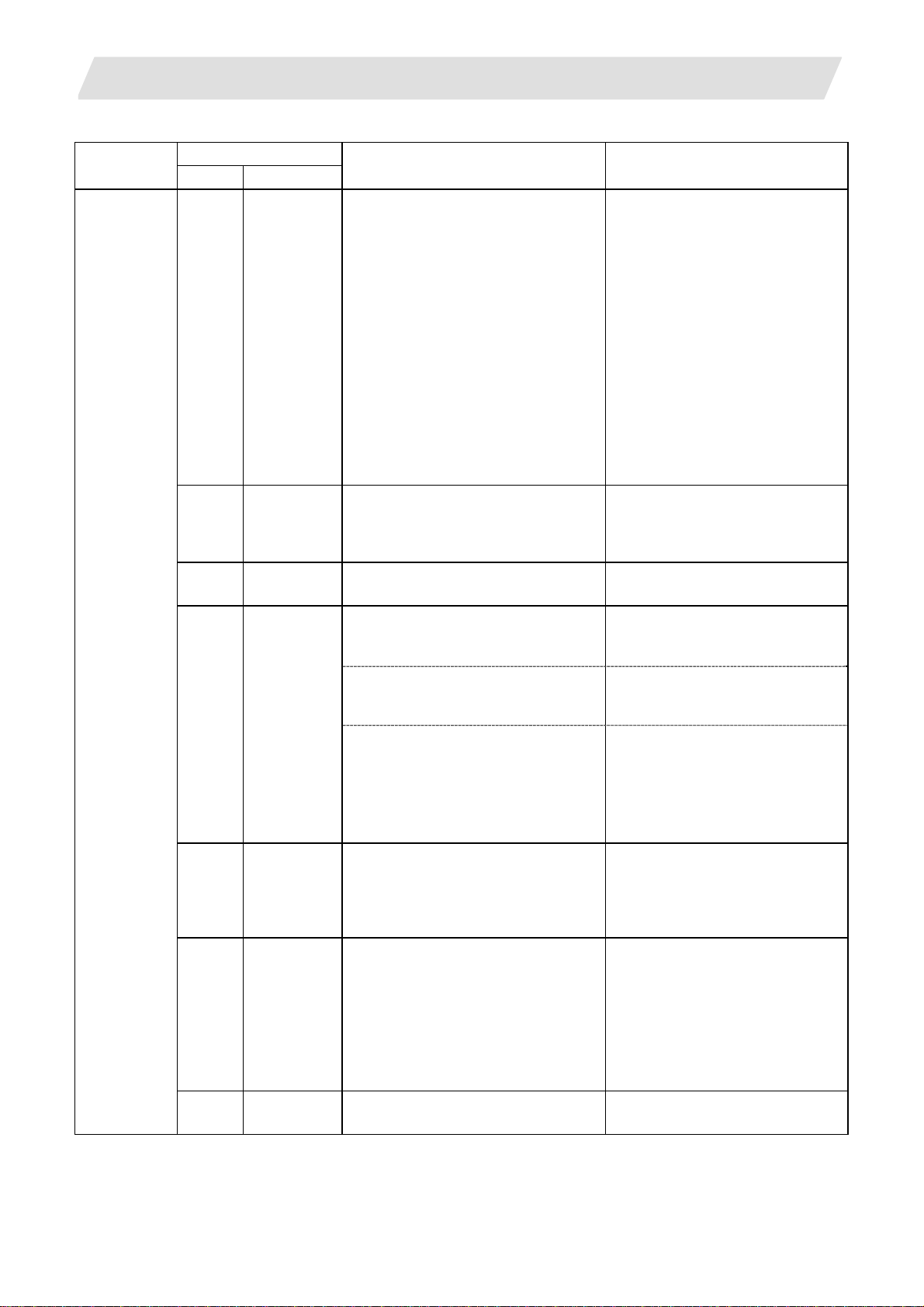

(6) Class: M06 Interfering object number illegal

1.1 Operation Errors (M01)

M06 Message

Error No. Interfering object definition No.

Error No. Message Details Remedy

0001

1001

1002

1003

2001

Interfering

object number

illegal

Interference

data error

Interference

data error

Interference

data error

Interference

data error

• The total number of

solids to be used as

interfering objects has

exceeded 32.

The interfering object

definition is incorrect.

• The interfering object

definition is incorrect.

• The interfering object

definition is incorrect.

• The interfering object

definition is incorrect.

Interfering object number illegal

• The total number of selected interfering

object definitions set in the system variable

and R register has exceeded 32. Check the

setting.

• A nonexistent axis (an axis that is not set in

the basic axis parameter (#1013 axname2))

is set in the interference object definition A.

Check the setting.

• I, J, K axes are set in the interfering object

definition A, although these axes don't

belong to the same part system. Check the

setting.

• A rotation angle is set to the interfering

object definition A, which has been defined

as a cylinder. Check the setting.

• 2 or more axes' rotation angles are set to the

interfering object definition A, which has

been defined as a cube. Check the setting.

• The interference model coordinate system

offset 1, which has been set in the system

variable and R register, is outside the setting

range. Check the setting.

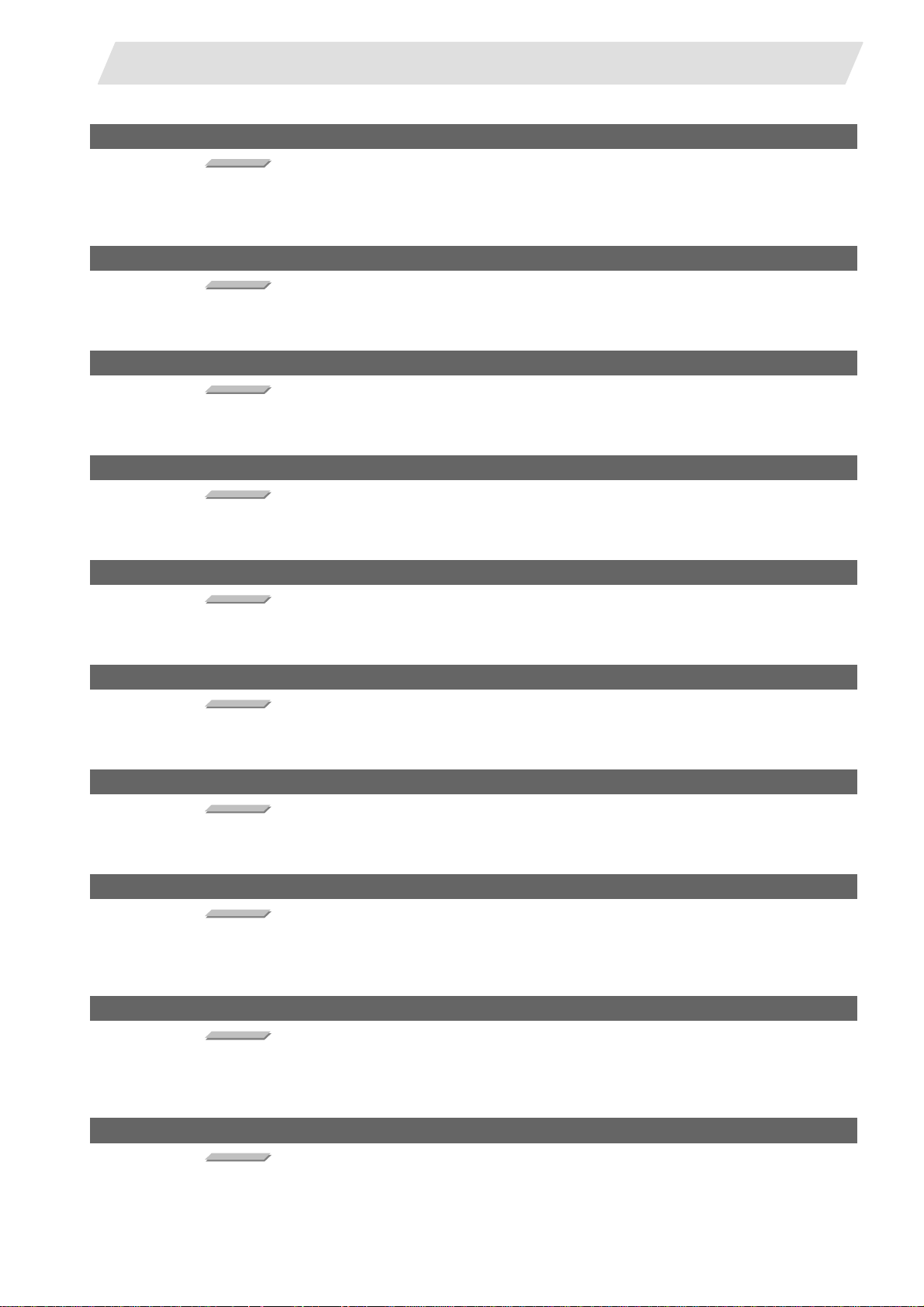

1.2 Operation Warning

(1) Class: m03 Message: Interference check warning

m03 Interference check warning

Interfering object definition No.

Details Remedy

The issued command caused more than one

interfering object to enter the interference

warning area.

• Interfering objects have intruded into the interference

warning area. If any operational problem is likely to

occur, stop the axis travel by stopping automatic

operation, cancelling the manual axis travel, or

inputting reset signal.

I - 19

Page 34

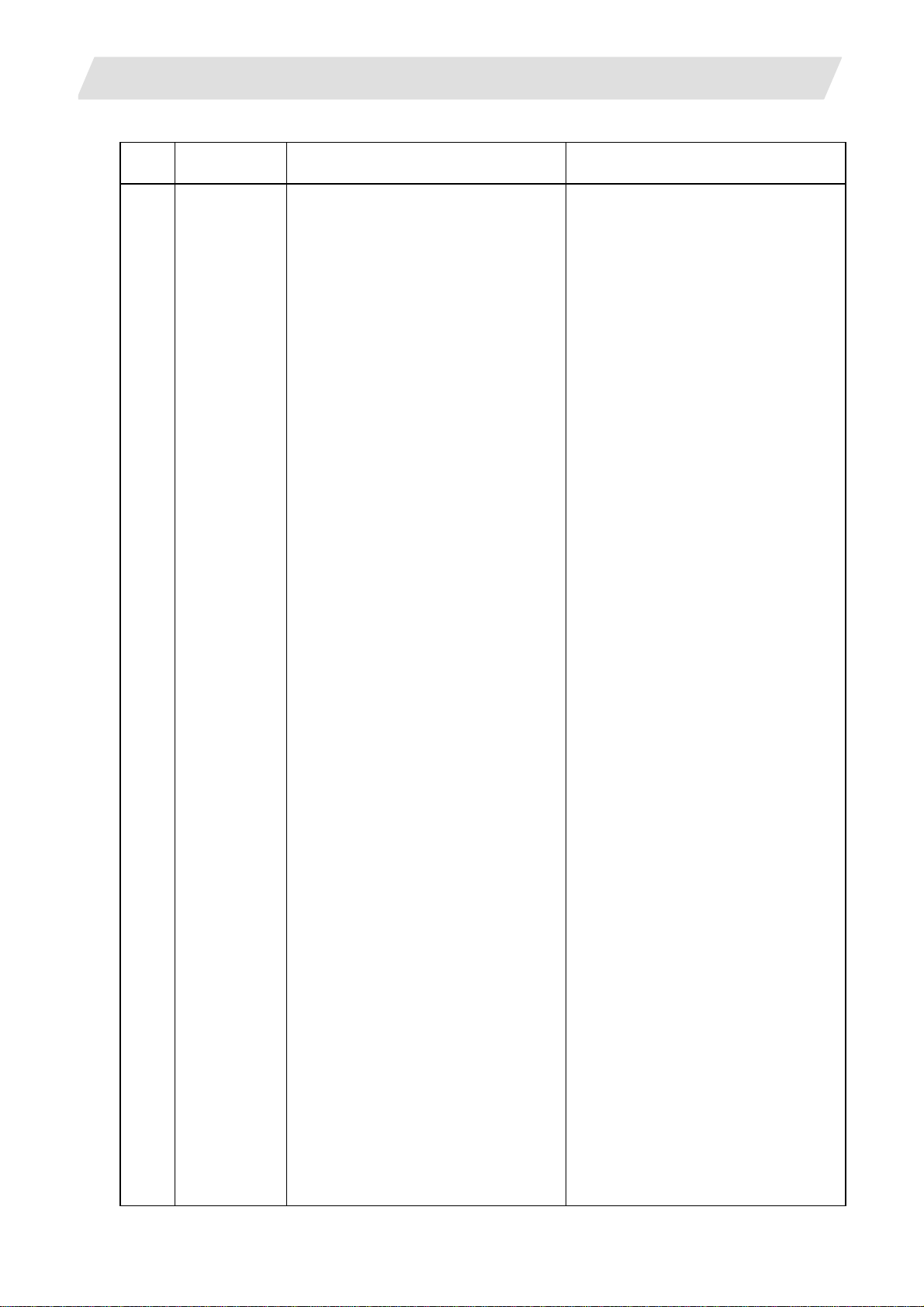

2. Stop Codes

2. Stop Codes

This code indicates that the NC has stopped for some reason.

T01 Message

Error

No.

0101 Axis in motion

0102 NC not ready

0103 Reset signal

0104 Auto

0105 H/W stroke

0106 S/W strok end

0107 No operation

0108 Operation

0109 Operation

0110 In buffer

0111 In program

Message Details Remedy

ON

operation

pause signal

ON

end axis

exists

axis exists

mode

mode

duplicated

mode

changed

correction

search

• Since one of the axes is in motion,

automatic start is not possible.

• Automatic start is not possible

because the NC ready signal is not

supplied.

• Automatic start is not possible

because the reset signal has been

input.

• The "FEED HOLD" switch on the

machine operation panel is ON

(valid).

• Automatic start is not possible

because one of the axes has

reached the stroke end.

• Automatic start is not possible

because one of the axes has

reached the stored stroke limit.

• The operation mode has not been

selected.

• Two or more operation modes have

been selected in error.

• A shift was made from one automatic

operation mode to another automatic

operation mode.

• Start is impossible because buffer is

being corrected.

• Automatic start is disabled because

operation search is being processed.

• Automatic start is disabled because

external search is being processed.

In this status, automatic operation start cannot be executed when an

attempt is made to execute it from the NC stop status.

The numbers given in the table can be referred to on the Alarm list

screen (Diagnosis group).

• Try automatic start again after all

axes have stopped.

• Another alarm has been issued and

the cause should be checked out

and remedy.

• Set the reset input signal to "OFF".

• Check for a failure in the reset switch.

• Check the sequence program.

• Check the "FEED HOLD" switch.

(B contact)

• Check for a breakage in the feed

hold signal wire.

• Check the sequence program.

• If the stroke end has been reached

by the axis end, move the axis by

operating it manually.

• Check for a breakage in the stroke

end signal wire.

• Check for a failure in the stroke end

limit switch.

• Move the axis manually.

• Check the contents of the parameter

unless the axis end is at the stored

stroke end.

• Restart after selecting the operation

mode.

• Check for a breakage in the

automatic operation mode (memory,

MDI) signal wire.

• Check for a short-circuit in the mode

selection signal wire (memory, MDI).

• Check for a failure in the switch.

• Check the sequence program.

• Restart after selecting the operation

mode.

• Return to the original automatic

operation mode, and then restart.

• Bring the buffer correction to an end.

Or cancel it and then restart.

• Try automatic start again after the

search has finished.

I - 20

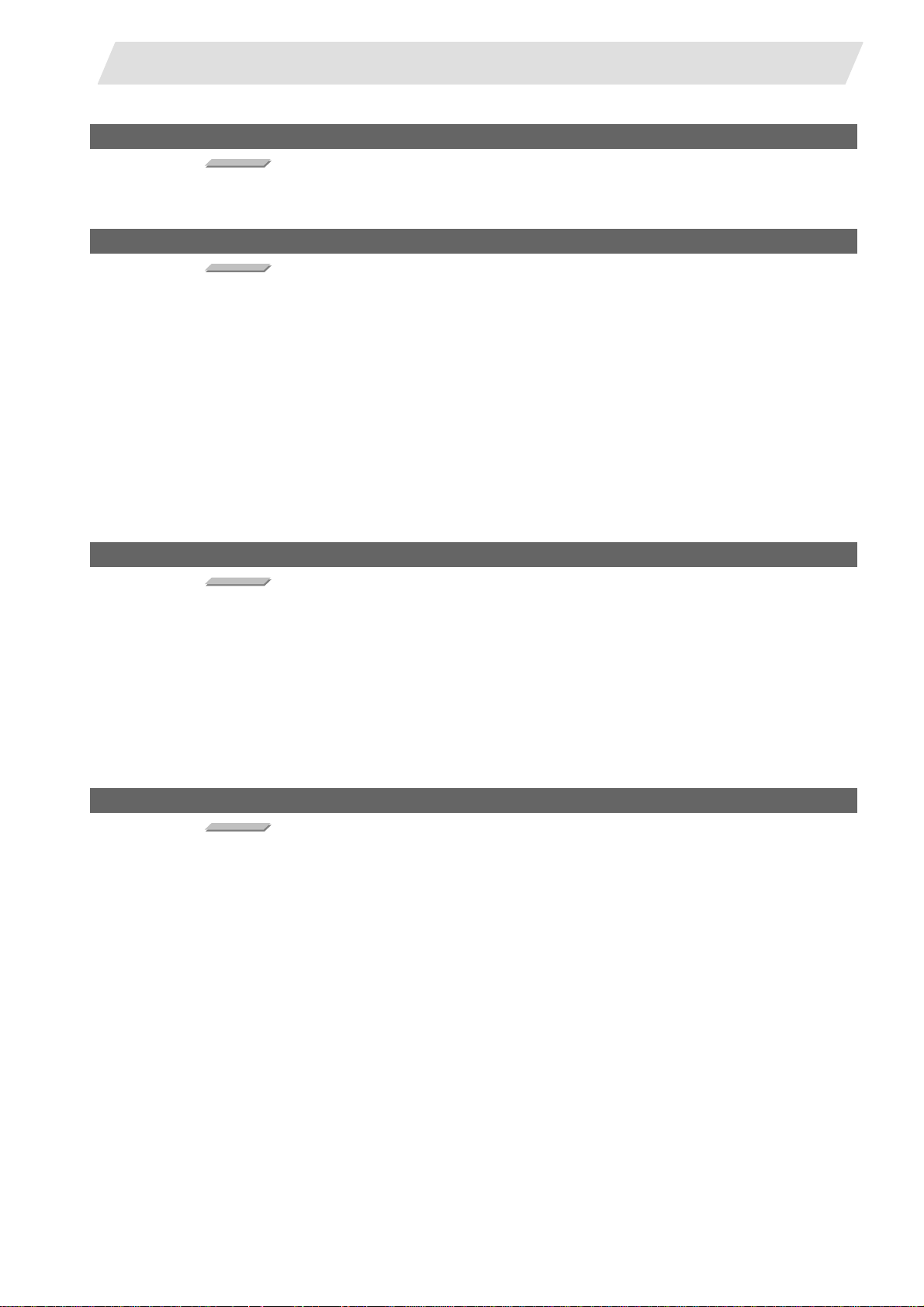

Page 35

2. Stop Codes

Error

No.

0114 Fixed cycle

0115 CNC

0116 Stat sgnl ON

0117 Restart point

0118 Program

0119 Reset signal

0120

0127

0138 In absolute

0139 In abs posn

0151 In prog check

0160 Memory

Message Details Remedy

• Register the fixed cycle subprogram

again.

• Refer to "Appendix 1. Fixed Cycle

Program" for the procedures.

• The temperature of the NC or

operation board has risen above the

specified temperature. Take cooling

measures. Turn OFF the NC power,

or lower the temperature with a

cooler, etc.

• Check the program.

• Check the user PLC.

• Return all axes to the restart position

before starting automatic operation.

• Turn the program restart mode

signal OFF, or turn the axis position

return mode signal OFF before

starting automatic operation.

• Input the NC reset signal before

starting automatic operation.

• Cancel Z08 File area alarm.

• Try automatic start after the tap

retract has finished.

• Start after the absolute position

detection alarm is released.

• Start after the zero point initialization

is complete.

• Put the program check function in

forward state and execute automatic

start.

• Delete or format the machining

program.

• Add the super option purchase point.

registered

illegal

overheat

in sub-sys

mode

ret. Not comp.

restart mode

not input

File area

illegal

Start disabled

during retract

position alarm

initial setting

backward

mode

capacity over

• The fixed cycle subprogram is not

correctly registered.

• NC operation cannot be started

because of a thermal warning (Z53

CNC overheat).

• An automatic start signal was input for

a system in the sub-system operation

mode before the subsystem was

started.

• When using the program restart

function, all axes have not returned

to the restart position.

• When using the program restart

function, the program restart mode

signal was turned ON or the axis

position return mode signal was

turned ON after the restart block was

stopped.

• When using the program restart

function, the NC reset signal was not

input after turning the program

restart mode signal OFF.

• Automatic start signal has been input

while Z08 file area alarm is

occurring.

• Automatic start is disabled because

tap retract is being carried out.

• A start signal was input during an

absolute position detection alarm.

• Start signal is input during zero point

initialization of absolute position

detection system.

• Automatic start is disabled because

the program check function is in

backward state.

• The super option is invalid. The

program memory capacity of the

machining program has been

exceeded.

I - 21

Page 36

2. Stop Codes

T02 Message

Error

No.

0201 H/W stroke

0202 S/W stroke

0203 Reset signal

0204 Auto

0205 Operation

0206 In

0215 Abs posn

The feed hold status has been established due to some condition or

other during automatic operation.

The numbers given in the table can be referred to on the Alarm list

screen (Diagnosis group).

Message Details Remedy

end axis

exists

end axis

exists

ON

operation

pause signal

ON

mode

changed

interference

mode

detect alarm

occurred

• An axis has reached the stored

stroke limit.

• An axis has reached the stored

stroke limit.

• The reset signal has been input.

• The "FEED HOLD" switch on the

machine operation board is ON

(valid).

• The mode changed from the

automatic operation mode to another

automatic operation mode.

• A command where two objects (tool

turrets, etc.) will interfere has been

issued.

• Two objects (tool turrets, etc.) have

entered the buffer area.

• Absolute position detection alarm

occurred.

• Using manual operations, move the

axis from the stroke end limit switch.

• The machining program must be

corrected.

• Using manual operations, move the

axis from the stroke end limit switch.

• The machining program must be

corrected.

• The position at which the program is

executed has returned to the head

and so automatic operation is

performed from the start point of the

machining program.

• Automatic operation can be resumed

by operating the CYCLE START

switch.

• Return to the original automatic

operation mode, and then restart.

• Release the alarm with reset.

• To move the interfering object in the

interfering direction, invalidate the

interference check first.

• Refer to the instruction manual issued

by the machine manufacturer for how

to invalidate the interference check.

• Release the absolute position

detection alarm.

I - 22

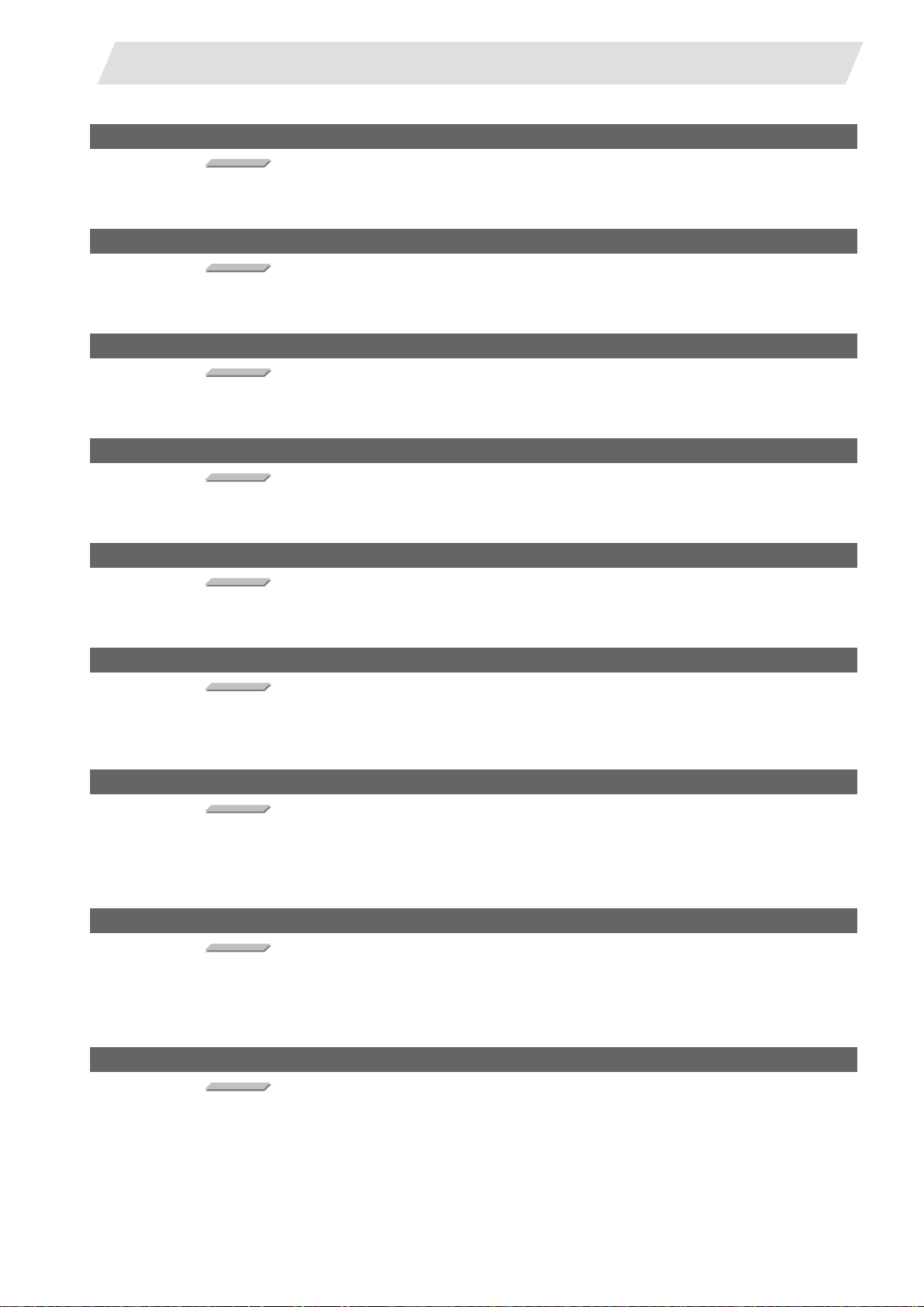

Page 37

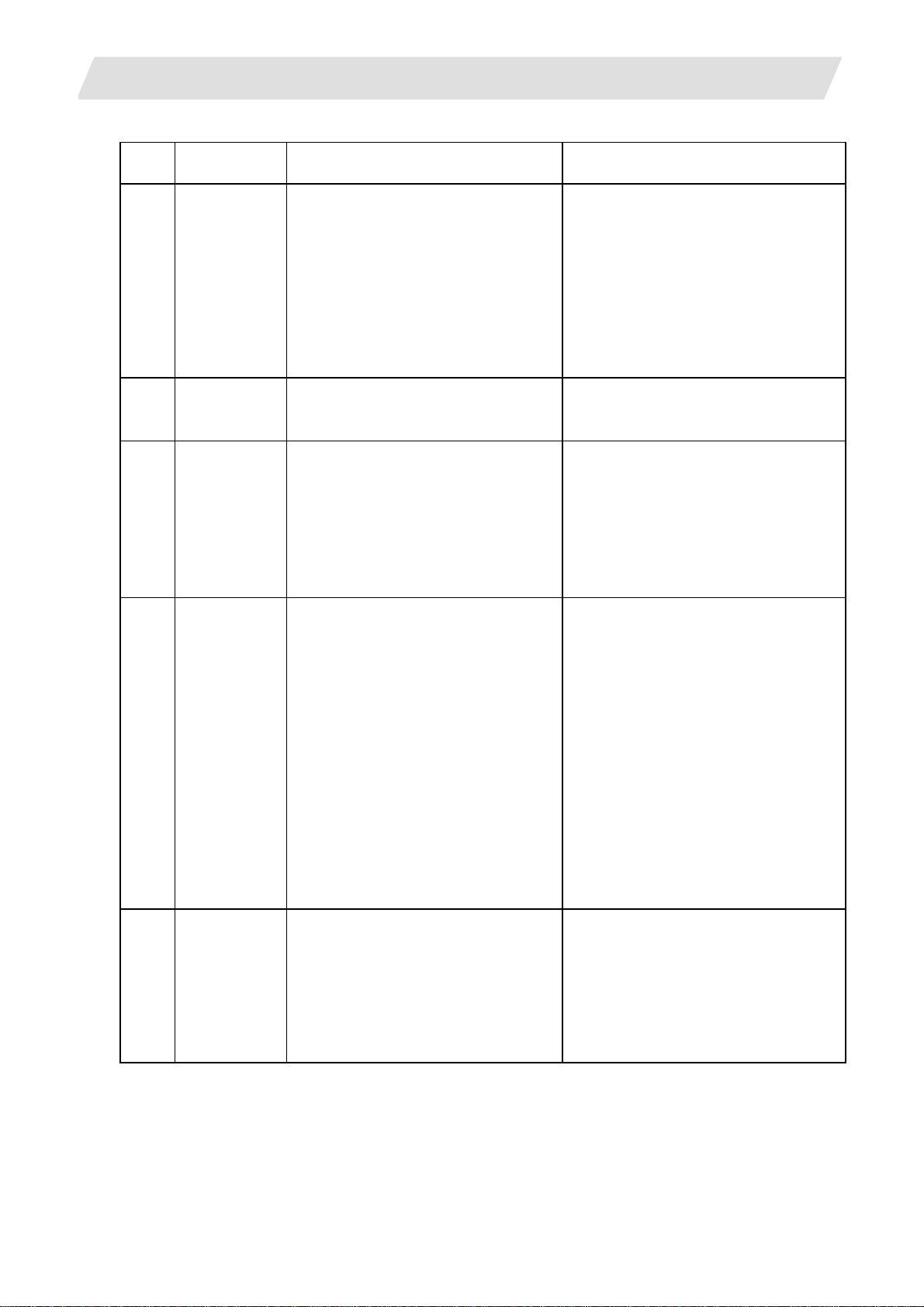

2. Stop Codes

T03 Message

Error

No.

0301 Single block

0302 Block stop

0303 Operation

0304 MDI interrupt

0305 Teaching

T04 Message

Error

No.

0401 Collation and

Operation stops after a single block in the program has executed

during automatic operation.

The numbers given in the table can be referred to on the Alarm list

screen (Diagnosis group).

Message Details Remedy

• Block stop occurred because the

stop signal

ON

cmnd in user

macro

mode

changed

completed

block

completed

Message Details Remedy

stop

"SINGLE BLOCK STOP" switch on

the machine operation panel was

ON.

• The block stop command was

specified in user macro program.

• The mode changed from the

automatic operation mode to another

automatic operation mode.

• The last block of MDI completed.

• The last block of PLC interrupt

completed.

• The block of the position control

command (G132) or position control

variable skip command (G133)

completed during teaching mode.

Collation and stop occurred during automatic operation.

• Collation and stop occurred.

• Automatic operation can be resumed

by setting the CYCLE START switch

to ON.

• Automatic operation can be resumed

by setting the CYCLE START switch

to ON.

• First return to the original automatic

mode and automatic operation can

be resumed by setting the CYCLE

START switch to ON.

• MDI operation can be resumed by

setting MDI again and setting the

CYCLE START switch to ON.

• Turn the CYCLE START switch to

ON to restart automatic operation.

• Turn the CYCLE START switch to

ON to restart automatic operation.

• Automatic operation can be resumed

by automatically starting.

I - 23

Page 38

3.Servo/Spindle Alarms

3. Servo/Spindle Alarms (S)

3.1 Servo Errors(s01/S03/S04)

3.1.1 MDS-D/DH Series

Servo alarms

S01 Insufficient voltage :PR 0010 (Axis name)

Details

A drop of bus voltage was detected in main circuit.

- Stop method:Dynamic stop

S01 Software processing error 1 :PR 0013 (Axis name)

Details

An error was detected for the software execution state.

- Stop method:Dynamic stop

S01 Init mag pole pos detect err :PR 0016 (Axis name)

Details

The initial magnetic pole position, detected in the initial magnetic pole position detection

control, is not reliable.

In the DC excitation function, this error will be detected when the servo ON has been set

before the magnetic pole shift amount is set while the absolute position detector is used.

- Stop method:Dynamic stop

S01 A/D converter error :PR 0017 (Axis name)

Details

A current feedback error was detected.

- Stop method:Dynamic stop

S01 Motor side dtc: Init commu err :PR 0018 (Axis name)

Details

An error was detected in the initial communication with the motor side detector.

- Stop method:Initial error

S01 Machine side dtc: Init comu er :PR 001A (Axis name)

Details

An error was detected in the initial communication with the machine side detector.

- Stop method:Initial error

I - 24

Page 39

3.Servo/Spindle Alarms

S01 Machine side dtc: Error 1 :PR 001B (Axis name)

Details

An error was detected by the detector connec te d to th e ma chin e s ide .

The error details are different according to the connected de tector.

- OSA17,OSE104,OSE105,OSA104,OSA105,OSA405,OSA166(MITSUBISHI)

Memoryalarm

- OSA18(MITSUBISHI)

CPU alarm

- MDS-B-HR(MITSUBISHI)

Memory error

- AT343, AT543(Mitutoyo)

Initialization error

- LC191M,LC491M,RCN723,RCN223, APE391M(HEIDENHAIN)

Initialization error

- MP scale, MPI scale (Mitsubishi Heavy Industries)

Installation accuracy fault

- Resetting methods :PR

(Note) A driver processes all reset types of alarms as 'PR'. However, 'AR' will be applied

according to the detector.

- Stop method :Dynamic stop

S01 Machine side dtc: Error 2 :PR 001C (Axis name)

Details

An error was detected by the detector connec te d to th e ma chin e s ide .

The error details are different according to the connected de tector.

- OSA17,OSE104,OSE105,OSA104,OSA105,OSA405,OSA166(MITSUBISHI)

LED alarm

- AT343, AT543(Mitutoyo)

EEPROM error

- LC191M,LC491M,RCN723,RCN223, APE391M(HEIDENHAIN)

EEPROM error

- Resetting methods :PR

(Note) A driver processes all reset types of alarms as 'PR'. However, 'AR' will be applied

according to the detector.

- Stop method :Dynamic stop

S01 Machine side dtc: Error 3 :PR 001D (Axis name)

Details

An error was detected by the detector connec te d to th e ma chin e s ide .

The error details are different according to the connected de tector.

- OSA17,OSE104,OSE105,OSA104,OSA105,OSA405,OSA166(MITSUBISHI)

Data alarm

- OSA18(MITSUBISHI)

Data alarm

- MDS-B-HR(MITSUBISHI)

Data error

- AT343, AT543(Mitutoyo)

Photoelectric type, static capacity type data mismatch

- LC191M,LC491M,RCN723,RCN223, APE391M(HEIDENHAIN)

Relative/absolute position data mismatch

- MP scale, MPI scale(Mitsubishi Heavy Industries)

Detection position deviance

- Resetting methods :PR

(Note) A driver processes all reset types of alarms as 'PR'. However, 'AR' will be applied

according to the detector.

- Stop method :Dynamic stop

I - 25

Page 40

3.Servo/Spindle Alarms

S01 Machine side dtc: Error 4 :PR 001E (Axis name)

Details

An error was detected by the detector connec te d to th e ma chin e s ide .

The error details are different according to the connected de tector.

- AT343, AT543(Mitutoyo)