Page 1

....

-,

TJ2-4861A

5.25

INCH

FLEXIBLE

DISK

DRIVE

MODEL

M4853

MAINTENANCE

MANUAL

MITSUBISHI

ELECTRIC

CO.,

LTD.

Page 2

4.

OPERATING

IHFOR.."'..'\TlON

4.1

1 Temperature/Humidity

Environment

There

but

work

is

no

when

operating

properly

Temperature

Humi dity

Range

problem in operating under

Range

•

Tempe,ra

Humidity

ture

Range

Range

out of following

or

Diskette

may

get

Range

Durino

Operatio~

+5°C -+43°C

20~ -80~

(DEW

LESS)

(Maximum

RH

wet

During Transportation

Cl

-40

C -

1% -95%

peri

odof

+62

RH

72

C1

C

with

damaged.

bulb

for

no

hours

normal

conditions,

Quring Nbn-ooeration

5: - 95:

(DEW

temp

maximum

29.4°C)

ped

condensation

office

Drive

LESS)

od

conditions

may

RH

of

72

hours

for

m~ximum

not

Z Dust

Be

extra

damage

4.2

1

Diskette

(Be

extra

Keep

magnetic

electrical

2

3

Do

not

Do

not bend media under

4 Return

storing

S

Do

not touch

alcohol.

Do

6

not expose

careful

to

head

Handling

careful

diskette

field.

appliances.)

bring

the

diskette

it.

of

or

diskette

of

media

(i.e.

any

ferro

or

attempt

diskette

dust

the

away

radio,

magnetic

any

to

storage

to

to

entering

unit

because

media.

following)

from

any

applian~e

tv,

motor/dynamo

materials

near

condition.

envelope

when

clean the disk media

head,

d~st

or

sunliyht.

it

may

which

and

the

may

other

diskette

transporting

surface

cause

generate

..

and

with

7

Do

a

not

soft

write

felt

anywhere

tip

pen.

except

on

the medial

label

and

only use

Page 3

FICLIRE

2

-3-

Page 4

5.

REGUlAR

MAINTENANCE

"Unit

environment

methods as visual

and

and

Time

rate

modification

condition,

life

can

be

or

excessive

affected

inspection,

regular

functional checks will

enable the discovery of

span between maintenance

of 8 hours a

is

day

needed.

so

perform mairtenance

5.1 Caution

1 During maintenance,

damaging head.

2

3

4

Make

When

sure

Do

not touch

bring

sure

put

off/on

power

any

power

switch

Ois~

ferro

sl/itch

P-inted

media

n~gnetic

by

damaged

operation".

cleaning/change

any

problem

is

calculated

in case of a

When

is

operating

onc~

be

careful

;s

off

Circ~it

"off"

to

surface or

materials

parts

So

keep

the

at

greater

at a normal

a

year.

of

dust

first

Board

protect

as a result

maintenance

of

damaged

unit

an

at

in

early

an

actual operation

rate,

entering

when

starting

(P.C.B.) Assy,

semiconductors

head

directly

near

it.

of

dusty

by

such

parts

good

condition

stage.

differences

environment

unit,

and

maintenance.

make

and

and

do

not

ICs.

5

6

7

When

be

Do

Avoid

because

using

careful

this

of

unit

write

not touch steEl

static

it

has

shock

bE-en

screws except wh(re

for

Read

mode

belt

or

ca

~ishandling

and

excessive force to

refull y adjusted.

specified

data only

do

not

in

this

to

protect

adjust

manual.

(when

related

head

Do

no

using

CE

data.

mechanism.

carriage

readjust

disk),

assembly

any

-4-

Page 5

5.2

Head

Cleaning

on

Field Applications

Head

cleaning

is

recommended

at

user's

sites,

especially

when

used

in severe environments, because the heads

may

accumulate

dust

in

the

air

and

mag~etic

coating material of the

disk,

causing chance

of

error

increase and/or

scratch

on

the disk

surface.

Recommended

sch:?dules

and

procedures are as follows:

1)

Cleaning Schedules

(1) Periodical cleaning using

wet

type cleaning

disk.

i.

Once

a mrnth for

normal

usage in

normal

environments.

ii.

Should

be

increased to about once a

week

when

used in severe environments such as dusty

area,

high humidity, high

and

low

extreme temperatures.

Low

temperature such as 5

to

10°C

(41

to 50°F)

under

hi~h

humidity

is

most

severe

for

diskettes.

iii.

Higher frequency

for

brand

new

drives

would

be

recommended.

for

about once a

week.

Better

matchnirg between

head

and

medium

would

be

produced

by

a

10119

time use, as experienced.

(2)

When

frequent

errors

are

detected.

(Wet

or

dry type

may

be

Jsed.)

(3)

Whe.l

scratch(es)

are found

on

the

medium

surface.

(Wet

or

dry type

may

be

used.)

2)

Recommended

Head

Cleaning Material

(1)

Wet

type

Innovative

Computer

Products*,

Head

Cleaning Kit (or

equivalent).

*18360

Oxnard

Street,

Tarzana.

California

91356

(213)

996-4911/TWX

910-493-5964

(2)

Dr}

type

To

be

supplied

by

Mitsubishi

representatives.

No

substitutions

would

be

allowable unless accepted

by

fartory

test.

Page 6

5.3

Check

and

Adjustments

5.3.1 Diskette

rotational

cycle adjustments

1)

Equipment

CE

Tester

(Disk

Exerciser)

Scratch Diskette

Universal Counter

VR

Adjustment Driver

(Pot

Trimmer)

2)

Adjustment procedure

2)-1 Connect

CE

Tester to Drive then turn-on.

power

switch.

2)-2

Load

diskette

then turn-on motor with drive

select.

2)-3

Make

sure

HLMG

ON.

(Head

Loaded)

2)-4

Seek

to

TKOO.

2)-5

Connect

universal counter

to+INDEX

(interface

signal)

and

measure

rotational

cycle

rate.

2)-6 Adjust counter reading

until

it

comes

within

specifications

using

SPM

VR

(see Figure

4).

2)-7 After

this

adjustment,

Lock

VR

with white

paint.

3)

Test

specification

3)-1

Check:

±1.6%

(196.8 - 203.2ms)

3)-2 Adjust:

±1.0%

(198.0 - 202.0ms)

Page 7

'.

"

r

, "

.#-

,

-,'

-

'.

. "

'.

..

.

-

..

'"-

~

..

.......

198.0

...

202.0

"

r

+INOEX

I'

...

FfGURE

-7-

4

Page 8

5.3.2

TKOO

sensor position adjustment

1)

2)

Equi

pment

CE

Tester

(Disk

Exerciser)

Scratch Diskette

No.

1 plus screw

driver

Oscilloscope

Adjustment procedure

2)-1 Connect

and

2)-2

2)-3

2)-4

Turn-on motor

Repeat seek between

Observe

tr;gger

signal

2)-5

Loosen

within

the arrow

load

screw

3-4ms

CE

Tester

diskette.

waveform

CHl--step

CH2--TKOO

and

by

(see

to

and

select

(TKOO)

adjust

moving

figure).

Drive then turn-on

drive.

TKOO

at

(DC,

(DC

time

TKOO

and

TPBl

+)

)

in

(see Figure

02

using

until

the

direction

power

switch

5).

oscilloscope.

TPD15

TPEl

it

comes

to

of

5.3.3

3)

Note:

3)-1 Set step

3)-2

TROO

Connect

Turn

Insert

Recalibrate

Connect

Trigger

Source

2

±

TPBl

Step

TPBl

Make

Sensor

disk

on

motor

sure

Check

exerciser

Diskette

(Seek)

oscilloscope

Mode

CHI

volts/Div

lmsec./Div

should

out

should

be

to

TK02

be low .

rate

and

Auto

high

at

there

are

(Alternate

Select

to

TROO

probe

at

3ms

using

2 pulses

to

drive

drive

channel

TKOO

CE

tester.

on

step

signals.

Procedure--recommended)

I/DC

to

TPBl

-8-

Page 9

-'.

Trigger

.

(CH1)

TK

2-1-.0

t

1

11

I.·

(3ms)

TK

(k-1-2

11

~

·I~_--...I---

.,

3-4ms

FIGURE

5

Page 10

5.3.3

INDEX

sensor position adjustment

1)

Equipment

CE

Tester

CE

diskette

(DYMEK

502-10

STANDARD

DISKETTE)

No.

1 plus screw

driver

Oscilloscope

2)

Check

procedure

2)-1 Connect

CE

Tester to Drive

(set

power

off).

2)-2 Turn-on

power

switch

and

motor

on.

2)-3

Select

drive

and

load

CE

diskette

(close

clamp

door

slowly) .

2)-4

Read

timing of each

waveform

at

TPB9

+ TPBIOunder

read

model'TK02,

using oscilloscope. (See

figure.)

Trigger:

EXT -+INDEX

(DC,

+) (TPD14)

Signal:

CHI -TPB9

(AC)

lOOrn\t/Div

CH2 -TPBIO

(AC,INV)

Add

SO-"(s/Div

2)-5

Specification

Check:

200±200

~s

at

TK02

Sici~

n

200 ±30 0 -"'(

sat

TK

0 2

Siee

1

Adjust:

200±100

~s

at

TK02

Side

0

LUO±200

~s

at

TK02

Side

1

*Check

=

make

sure

reading

falls

within

this

spec.

Adjust

=

if

reading

is

out

of

~check~

spec.,

adjust

to

within

spec.

indicated

here.

Tric;c;er

r

fINOEX

(TPD14)

(SOus)

Signal

(TPB9+10)

\~urs'!;

waveforal.)

•

•

To2

FIGURE

6

PCA.

set

screw

Page 11

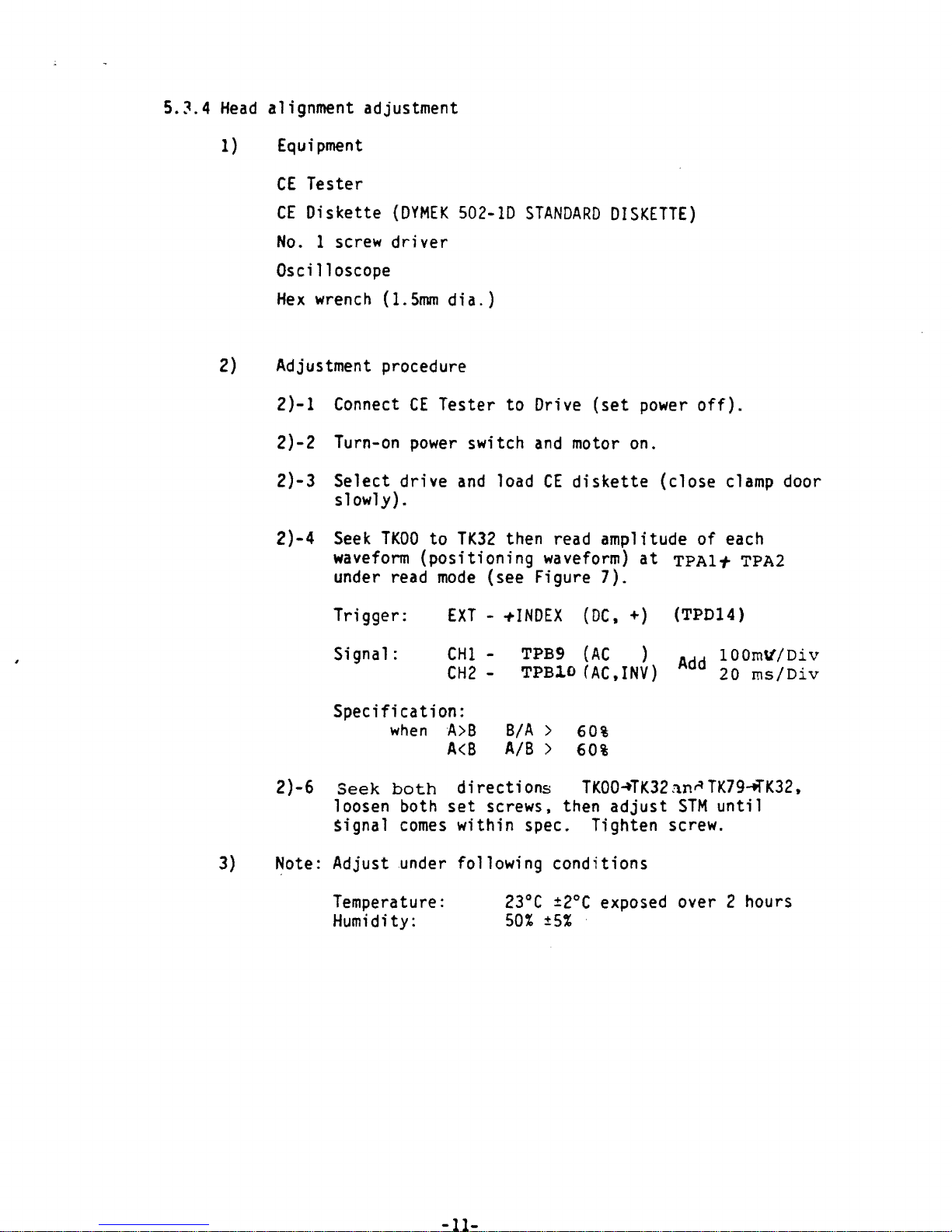

5.~.4

Head

alignment adjustment

1)

2)

Equi

pment

CE

Tester

CE

Diskette

No.

1 screw

(DYMEK

502-10

driver

Oscilloscope

Hex

wrench

(1.5mm

dia.)

Adjustment procedure

2)-1

Connect

2)-2 Turn-on

2)-3 Select drive

1

owl

s

2)-4

Seek

waveform

under read

CE

Tester to Drive

power

y).

TKOO

to

(positioning

mode

and

TK32

switch

load

STANDARD

and

CE

DISKETTE)

(set

power

motor on.

diskette

(close

then read amplitude of each

waveform)

(see Figure

7).

at

TPA1+

off).

clamp

door

TPA2

3)

Trigger:

Signal:

Specification:

2)-6

Seek

loosen both

Signal

Note: Adjust

Temperature:

Humidity:

EXT -+INDEX

CHI

CH2

whenA>B

A<B

both

directions

set

comes

~nder

within spec. Tighten screw.

following conditions

(DC.

- TPB9

- TPBl.O

B/A

A/B >

(AC

(AC.INV)

>

60%

60%

TKOO-tTK32i'm~TK79""'K32.

screws, then

23°C

50%

±2°C

±5%

+)

(TPD14)

)

Add

100rn\l!Div

20

ms/Div

adjust

STM

until

exposed over 2 hours

-11-

Page 12

FIGURE

7

-12-

Page 13

5.3.5

Head

Azimuth

I)

Equi

pment

CE

Tester

CE

Diskette

Oscilloscope

2)

Check

procedure

2)-1 Connect

CE

Tester to Drive then turn-on

power

switch.

2)-2

Turn

on

motor.

2}-3

Select

drive

and

load

CE

diskette.

2)-4

Seek

to

TK68.

2)-5

Read

azimuth

waveform

using

oscilloscope.

Trigger:

EXT -+INDEX

(DC

+)

(TPD14)

Signal:

CHI

- TPB9 .

(AC)

Add

lOOm~/D~v

CH2

- TPBIC

(AC,INV)

±

Ims/DJ.v

2}-6 Acceptable

when

adjusted

waveform

within following

range

FIGURE

8

TPD14

____

~r--l~

____________________________

_

(INDEX)

0'

Azimuth

"Error

TPB9/TPBIO

----------~I_AJ~.

~1,B

I~!.C'!~.!

D:~.

------

(USE

DIFFERENTIAL

AMP)

--J

__

AZIMUTH

~±18'

115>AX

115

~

~

X

100

~

X

100

~

115

(-18 I )

(+

18

I )

Note:

A=B:

-12min

Specification=

±18min

C=D:

+12min

,

.,

Page 14

The

head's azimuth

sent to

In

the

an

latter

is

authorized

case,

all

NOTE

not

adjustable.

repair

previous adjustments should

center

It

or a

is

new

head

suggested

that

assembly

be

made

the drive

be

installed.

again.

•

be

-14-

Page 15

,,'

•

-j

-Il"~

Pl·

-~ "IX.

' ••00(

'.___

.....

-

--··'1"

:

-:::

ri

....

. .

-1

....

D •

"!o"

~IIO

'~----'-----""4~"

i

C"I(I

-:

t.O'

- -

1(.'''''

t_u

:..!J

;>--..:-

~;--------------~~~O

_____

•

;:)'01

.:

! !

+

1"1J

fll(,

.

~'j(;

0

/'

.-,

.

,

i

;

I;

...,

-

"'0

Iv

0

n

tv

~

U,;

f.-j

....;::

\.,.

,

"t.""-

"I

-

("T\

"3

'>

--;

n

-

"'l/l..

c

."

:s

~

t)O

V't

Lv

-ST[I'.I'I-

-"010.0111,"1-46

•

,.

US(

....

•

..

,

.,.,

,

-,.

1If"'~

t-t¥

"

"

'''~1J

:

•••.••

;

..

!>~

••••

!

crr--"

r""

"'.!l9

...

P.

....

..,

...

......

.JI

'"

·AA

-.UI

"",

-llfAOT

MOt'OII

ON

10010'1

ON

......c:wt'I'QII

,OIl

U!>£

."

U'So(

+"

GMO

ON

1.£0 "

~O

'S-S

,1'.1-

'S·~

'S',

..

Loading...

Loading...