Page 1

New Vehicle Manual

Page 2

New Vehicle Manual

CONTENTS

LANCER

EVOLUTION VIII

MR

FOREWORD

This manual contains details of the main changes to

the 2004 model Lancer Evolution VIII MR. Only

differences to the current Lancer Evolution VIII are

included, so please use this manual in conjunction with

the related information specified on the next page.

This information relates to the current vehicle (February

2004). Since specifications will change, some of the

information contained here will inevitably be

superseded.

Note that SI units are used in this manual. Old units are

not shown alongside them.

(However, old units are used for some figures we have

taken from existing documents).

General..........................................

Engine ...........................................

Power Train...................................

Drive Control ................................

Body ..............................................

Exterior..........................................

Interior...........................................

0

1

2

3

4

5

6

Any opinions, requests, or questions concerning

this manual, should be written on the ‘Servicing

Comments Form’ at the end, and sent to us by

fax.

February 2004

MITSUBISHI MOT

OR CORPORATION

Equipment.....................................

Reference Materials .....................

There are no changes to the shaded chapter,

so it is not included at all in this manual.

7

8

This manual is printed on recycled paper

.

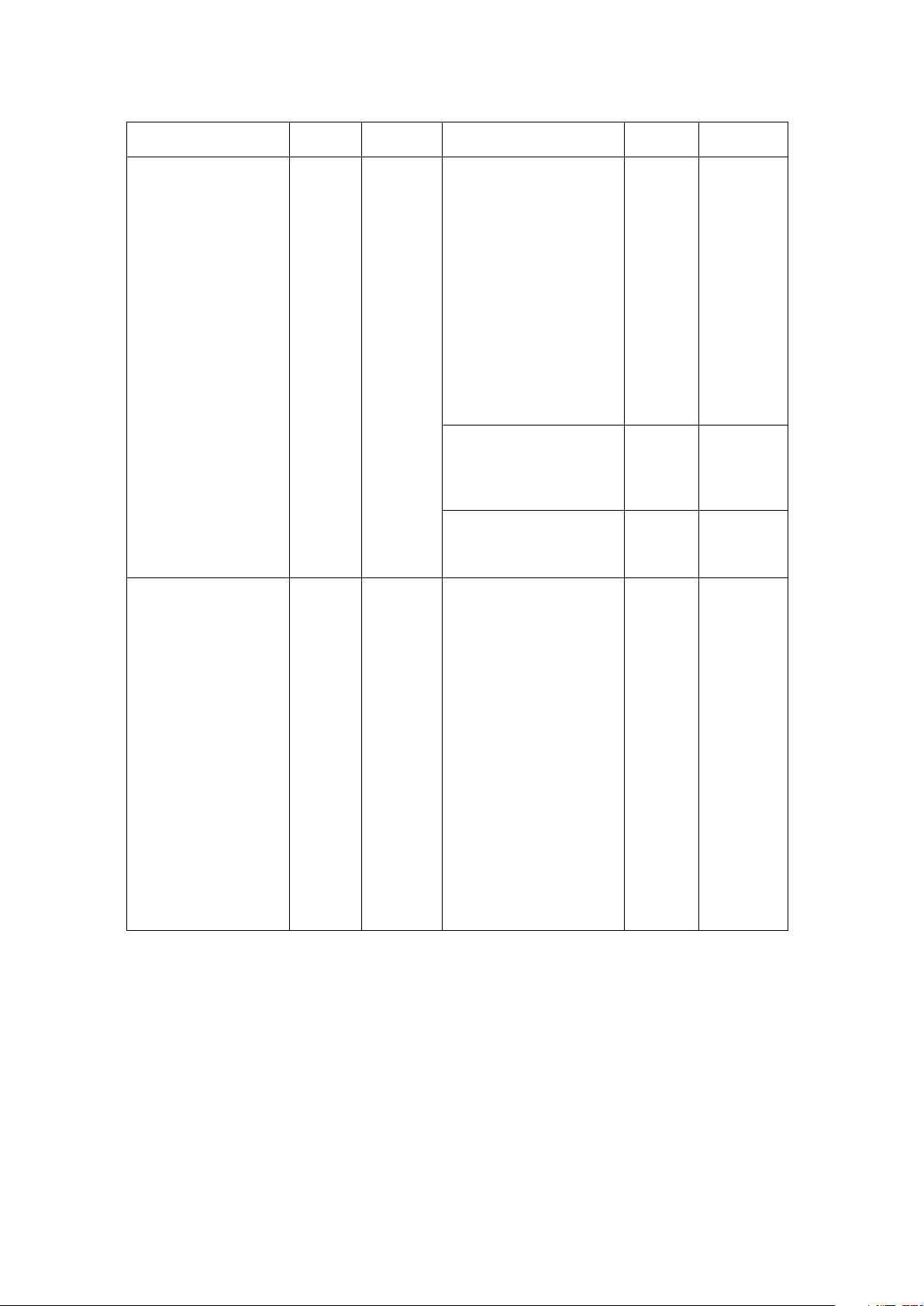

Page 3

Title

No.

Issue

Date

Title

No.

Issue Date

Body Manuals (Service

Manual)

• Mirage, Lancer

(supplement)

• Lancer Cedia

• Lancer Cedia

(supplement)

• Lancer Evolution VII

(supplement)

• Lancer Cedia

(supplement)

• Lancer Evolution VIII MR

(supplement)

1036F52

1036K50

1036K51

1036K52

1036K53

1036K54

Aug 1996

May 2000

July 2000

May 2001

Oct 2001

Feb 2004

Electrical Wiring Diagrams

Service Manual

• Lancer Evolution VIII

• Lancer Evolution VIII MR

(supplement)

1036K77

1036K80

Jan 2003

Feb 2004

New Vehicle Manuals

• Mirage, Lancer

• Mirage, Lancer

• Mirage, Lancer

• Mirage, Lancer

• Lancer

• Mirage, Lancer

• Lancer

• Lancer

• Lancer Cedia

• Lancer Cedia

• Lancer Evolution VII

• Lancer Cedia

• Lancer Cedia

• Lancer Evolution VII

• Lancer Cedia

• Lancer Evolution VIII

• Lancer

• Lancer

1036F30

1036F31

1036F32

1036F33

1036F34

1036F35

1036F36

1036F37

1036K30

1036K31

1036K32

1036K33

1036K34

1036K35

1036K36

1036K37

1036K38

1036K39

Oct 1995

Jan 1996

Aug 1996

Jul 1997

Jan 1998

Oct 1998

Jan 1999

Dec 1999

May 2000

July 2000

Jan 2001

May 2001

May 2001

Jan 2002

May 2002

Jan 2003

Feb 2003

Dec 2003

Engine Service Manual

• 4G6 Engine

• 4G6 Engine

(supplement)

1039G46

1039G63

Jan 2001

Jan 2003

Service Manuals

• Lancer Cedia

• Lancer Cedia

(supplement)

• Lancer Evolution VII

(supplement)

• Lancer Cedia

(supplement)

• Lancer Cedia

(supplement)

• Lancer Evolution VII

(supplement)

• Lancer Cedia

(supplement)

• Lancer Evolution VIII

(supplement)

• Lancer (supplement)

• Lancer (supplement)

• Lancer Evolution VIII

MR (supplement)

1036K00

1036K01

1036K02

1036K03

1036K04

1036K05

1036K06

1036K07

1036K08

1036K09

1036K10

May 2000

July 2000

Jan 2001

May 2001

Oct 2001

Jan 2002

May 2002

Jan 2003

Feb 2003

Dec 2003

Feb 2004

Transmission Service

Manual

• W5M51 Manual

Transmission

• W5M51 Manual

Transmission

(supplement)

• W6MAA Manual

Transmission

1039M17

1039M22

1039M23

Jan 2001

Jan 2003

Jan 2003

Related information

Page 4

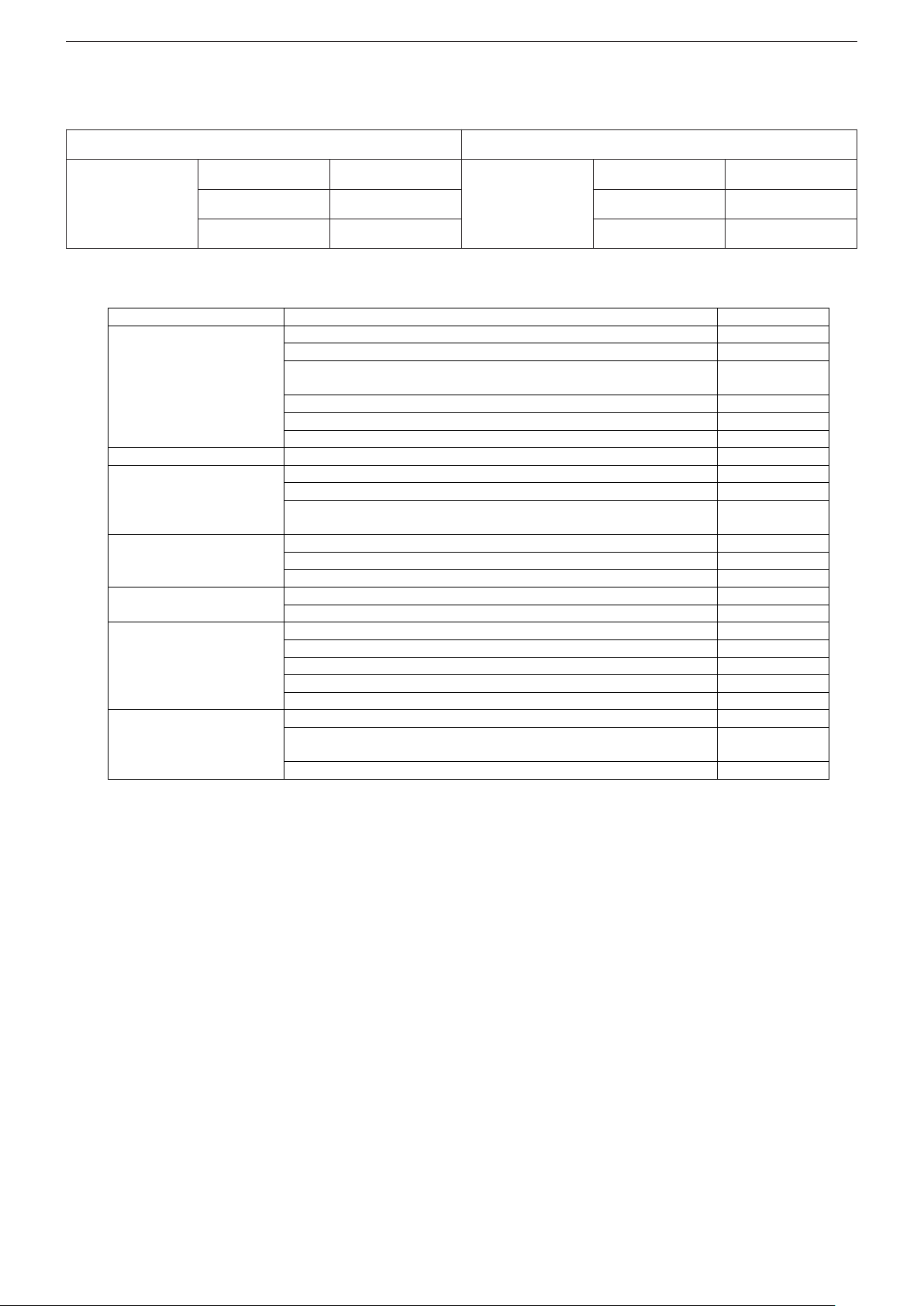

GENERAL – TECHNICAL FEATURES

SECTION 0

GENERAL

CONTENTS

00-1

Vehicle Identification..............................0-1

Implementation Code .............................0-1

Development Aims .................................0-1

Overview of Lancer Evolution VIII MR. 0-2

Model line-up

Model Version ’04 Model Grade Engine Model Transmission Fuel System

GH-CT9A SNDFZ

SJDFZ

SJGFZ

Note

¡ = Continued model

¡

¡

¡

RS

RS

GSR

4G63

(2 000 DOHC 16 valve

intercooler turbo)

W5M51 (4WD, 5M/T)

W6MAA (4WD, 6 M/T)

MPI

Applied vehicles

GH-CT9A: CT9A-0300001 ~

Development Aims

The launch of the Lancer Evolution VIII MR is the result of our pursuit of further advances and improvements based on the

Lancer Evolution VIII, with the aim of maintaining and strengthening the Mitsubishi Evolution brand.

Page 5

0-2

Section

Difference from Lancer Evolution VIII

Page

Change to cam profile (6 M/T)

1-5

Enlarged turbo nozzle diameter (6 M/T)

1-6

Adoption of tail pipe with built-in sound proofing in exhaust main

silencer (6 M/T)

1-7

Addition of wastegate solenoid valve (1 ‡ 2)

*1

1-8

Change to catalyst volume (2.0 l. ‡ 1.5 l.) (6 M/T)

-

Engine

Enlarged engine oil cooler

Power train

Change to super AYC differential

2-1

Installation of Bilstein shock absorbers

*2

3-1

Optional BBS 17-inch alloy wheels (new design)

3-1

Drive control

Black finish on spokes of Momo genuine leather steering wheel

(Type A) (GSR)

-

Aluminium used in roof panel and side door beams

4-1

Change to body colour

4-1

Body

Boot lid opener fitted as standard (RS)

Addition of Evolution MR logo

5-1

Exterior

Outer panel on rear spoiler and “Lancer” logo changed to dark grey

Ornamentation added to carbon finish instrument panel

Centre panel changed to black

Shift lever with special Lancer Evolution MR logo plate (6 M/T)

Door trim fabric changed

-

Interior

Recaro seat fabric changed to suede finish all-round (GSR)

Change to combination meter

7-1

Black outs on extensions of headlights (discharge) and rear

combination lamps

-

Equipment

Adoption of roof aerial (RS)

-

GENERAL – OVERVIEW OF THE LANCER EVOLUTION VIII MR

Overview of the Lancer Evolution VIII MR

Lancer Evolution VIII MR Lancer Evolution VIII

GH-CT9A SNDFZ RS (5M/T) GH-CT9A SNDFZ RS (5M/T)

SJDFZ RS (6M/T) SJDFZ RS (6M/T)

SJGFZ GSR SJGFZ GSR

Differences from the Lancer Evolution VIII

Notes:

*1

: The No.2 wastegate solenoid valve does not operate in vehicles with 5 M/T transmission.

*2

: Joint development of special shock absorbers for the Lancer Evolution VIII MR, with the German firm, Bilstein.

Page 6

ENGINE (4G6) – GENERAL

SECTION 1

ENGINE (4G6)

CONTENTS

1-1

General ....................................................1-1

1. Major Specifications....................................1-1

2. Engine Performance Curve.........................1-2

Base Engine (6 M/T) ...............................1-2

1. Cylinder head gasket...................................1-2

2. Pistons..........................................................1-3

3. Piston rings (2nd) ........................................1-3

4. Oil rings ........................................................1-4

5. Counterbalance shaft .................................1-4

6. Camshaft.......................................................1-5

Intake / Exhaust System (6 M/T)............1-6

1. Exhaust system ...........................................1-6

Control system (6 M/T)...........................1-8

1. Supercharging pressure control..............1-10

General

The 4G63-T/C engine fitted in the Lancer Evolution VIII MR is basically the same as the 4G63-T/C engine used in the Lancer

Evolution VIII.

The basic structure is the same in both the 6M/T (6-speed) and 5M/T (5-speed) versions, but the following improvements have

been made to the 6M/T version, in order to achieve higher performance.

• Adoption of 5-ply cylinder head gasket

• Addition of V-shaped groove in piston , and modified shape in cooling channel

• Reduced oil consumption by increasing tension in piston rings and reducing end-to-end gap

• Extra durability and reduced oil consumption by using new treatment on outer surface of oil ring side rail, and altering

thickness

• Lighter counterbalance shaft

• Increased output at high engine speeds by modifying intake cams

Major Specifications

Item 6 M/T 5M/T

Total Displacement cc 1997

Combustion chamber Pentroof type

Bore x stroke (mm) 85.0 x 88.0

Compression ratio 8.8

Camshaft arrangement DOHC-4 valve

Fuel Premium unleaded

Max. output (kW/rpm) 206/6500

Max. torque (Nm/rpm) 400/3500 392/3500

Fuel system Electronic controlled multipoint fuel injection

Ignition system Electronic controlled two-coil

Lash adjuster Equipped

Page 7

1-2

ENGINE (4G6) – GENERAL, BASE ENGINE (6 M/T)

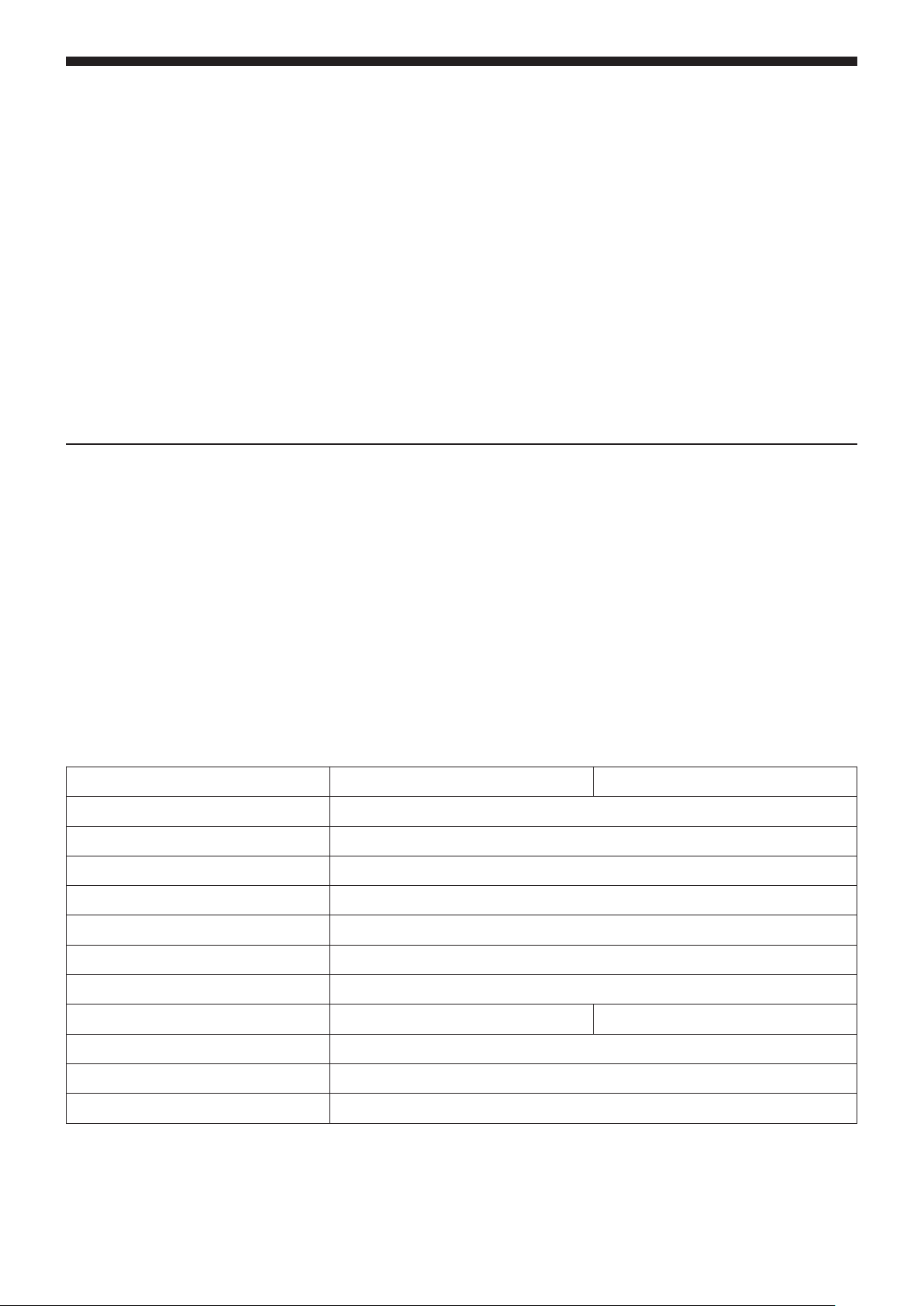

2. Engine performance curve (6 M/T)

Shaft output (kW)

Base Engine (6 M/T)

Shaft torque (N•m)

Engine r.p.m.

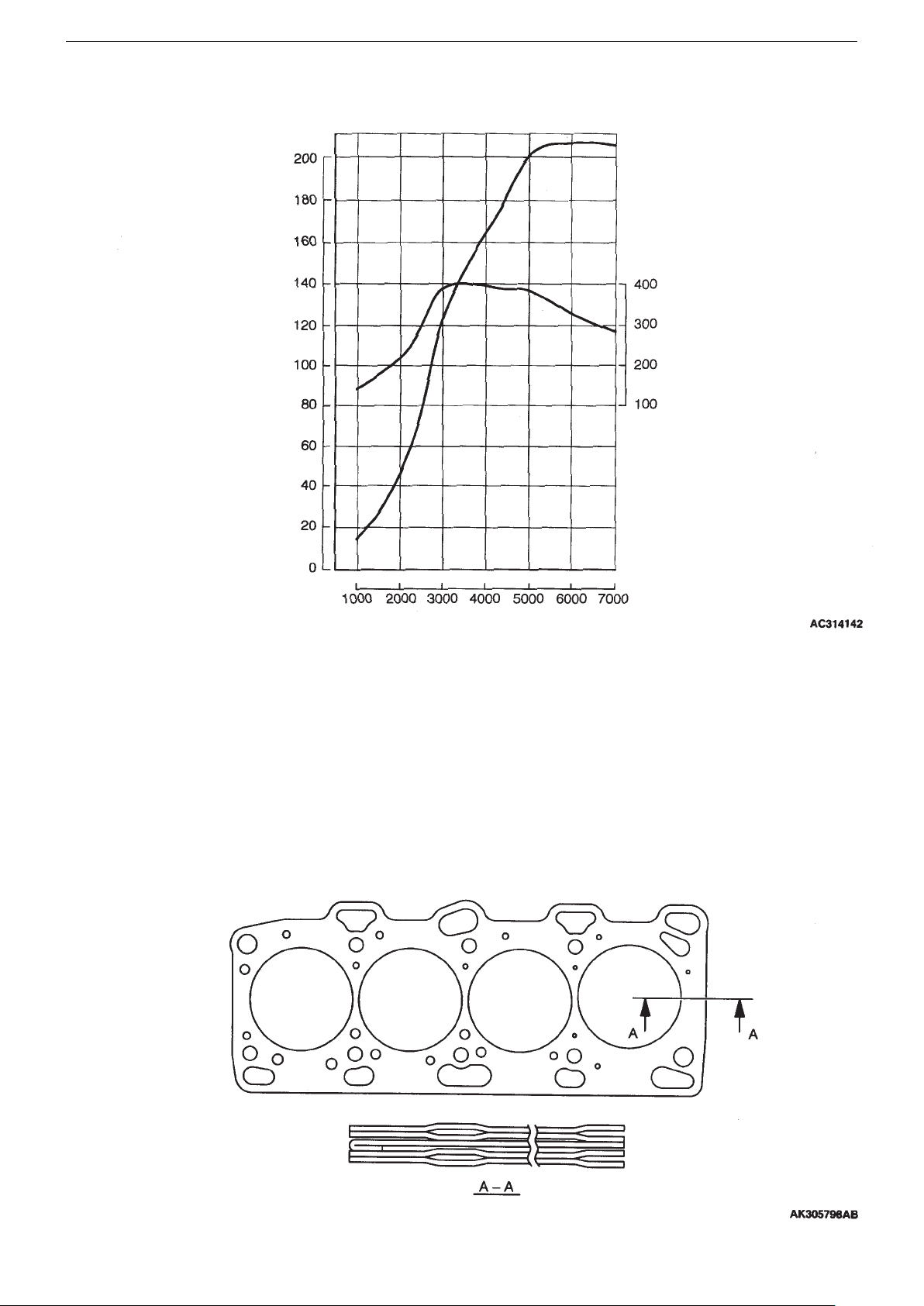

1. Cylinder head gasket

5-ply metal gasket has been introduced, in order to improve sealing properties.

A

Page 8

ENGINE (4G6) – BASE ENGINE (6 M/T)

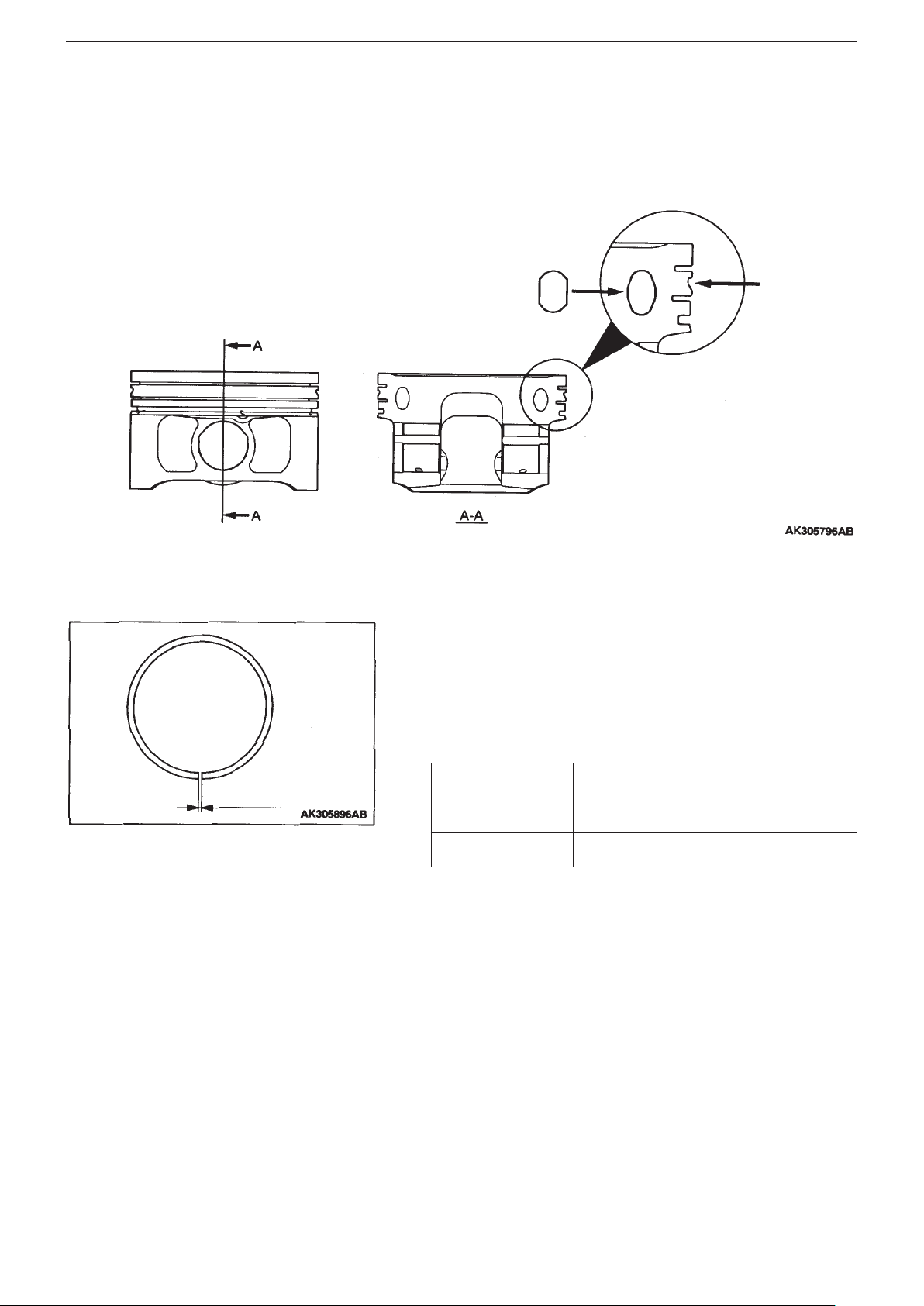

2. Pistons

• Addition of V-shaped groove.

A V-shaped groove has been formed in the second land, with a view to reducing oil consumption.

Modification of cooling channel.

•

The shape of the cooling channel, which recycles the oil, has been modified in order to improve recycling efficiency.

1-3

Modified shape of

cooling channel

V-shaped

groove added

3. Piston Rings (2nd)

To increase the tension in the piston rings, they have been changed

to ductile cast iron, from the standard cast iron used previously.

The end to end gap in the rings was also reduced.

These modifications are designed to reduce oil consumption.

End to end gap

Item Evolution VIII MR Evolution VIII

Tension 10.5 N 7.0 N

End to end gap 0.30 – 0.45 mm 0.35 – 0.50 mm

Page 9

1-4

ENGINE (4G6) – BASE ENGINE (6 M/T)

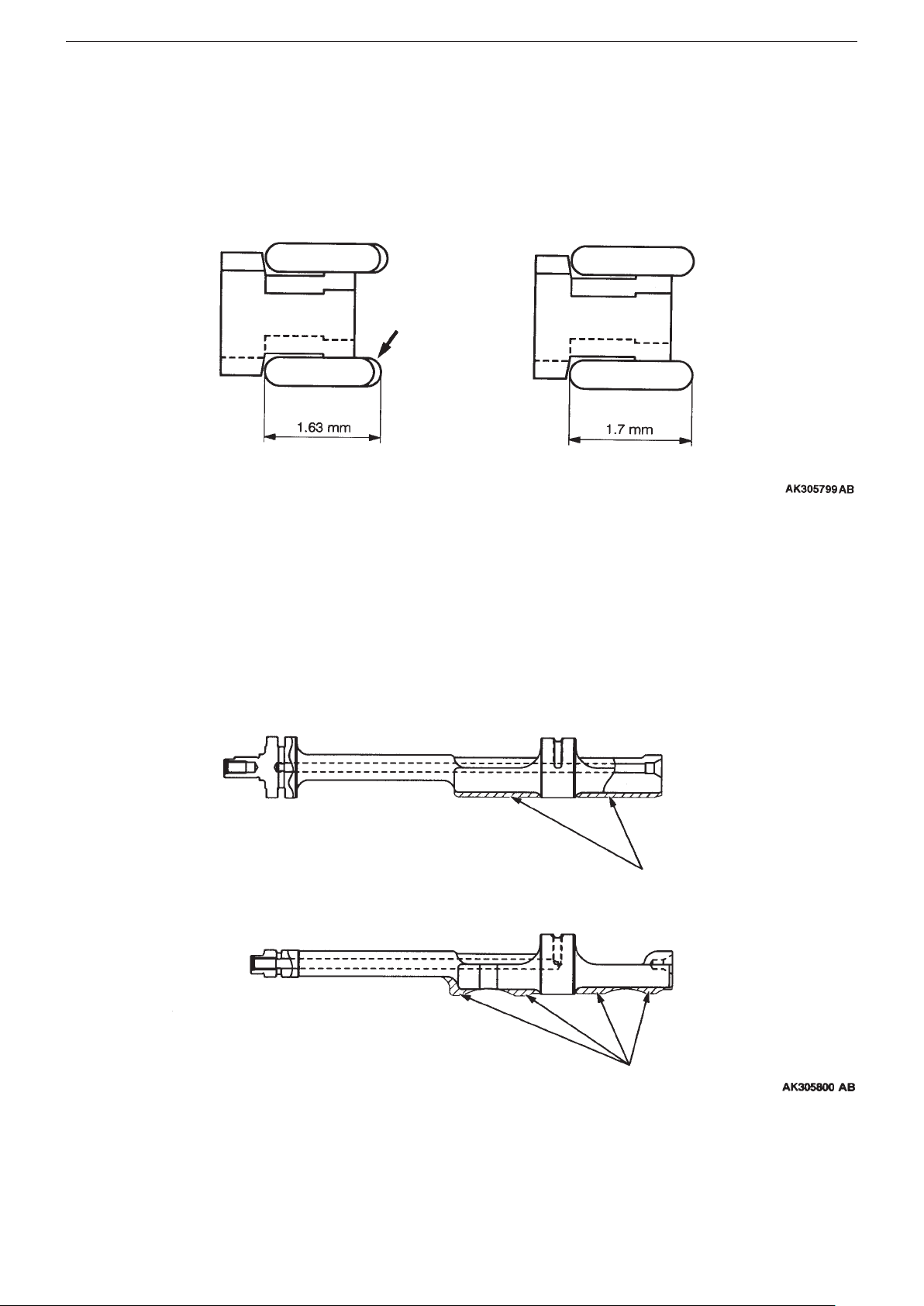

4. Oil Rings

The outer circumference of the side rail has been treated with chrome nitride. The thickness of the side rail has also been

reduced from 1.7 mm to 1.63 mm, with a view to increasing durability and reducing oil consumption.

(Evolution VII MR) (Evolution VIII)

Chrome nitride

5. Counterbalance shaft

The shape of the shaft was changed in order to reduce weight.

Counterbalance shaft (right)

Counterbalance shaft (left)

Thickness

reduced

Thickness

reduced

Page 10

ENGINE (4G6) – BASE ENGINE (6 M/T)

1-5

6. Camshaft

Output at high engine speeds has been improved by altering the cam profile of the intake camshaft, and optimizing the valve

timing.

Evolution VIII MR Evolution VIII

Cam height mm 35.96 35.79

Evolution VIII MR Evolution VIII

T.D.C (top dead centre) T.D.C (top dead centre)

Intake valve open

Intake valve

closed

B.D.C (Bottom dead centre) B.D.C (Bottom dead centre)

Exhaust

valve closed

Exhaust

valve open

Intake valve open

Intake valve

closed

Exhaust

valve closed

Exhaust

valve open

Page 11

1-6

ENGINE (4G6) – INTAKE / EXHAUST SYSTEM (6 M/T)

Intake / Exhaust System (6 M/T)

1. Exhaust system

1-1 Turbocharger

A large-nozzle 10.5T turbo has been adopted in order to improve mid to high-range torque. Optimum control of the

supercharging pressure has ensured good torque and response at medium engine speeds.

The positions of the turbine housing and the wastegate holes have also been changed to achieve smoother outflow and

increase low-speed torque. Along with these modifications, the wastegate valve has been changed from an oval to a circular

valve.

(Evolution VIII MR) (Evolution VIII)

Turbine housing

Wastegate holes

Turbine housing

Wastegate holes

Circular valve

Oval valve

Page 12

ENGINE (4G6) – INT

AKE / EXHAUST SYSTEM (6 M/T)

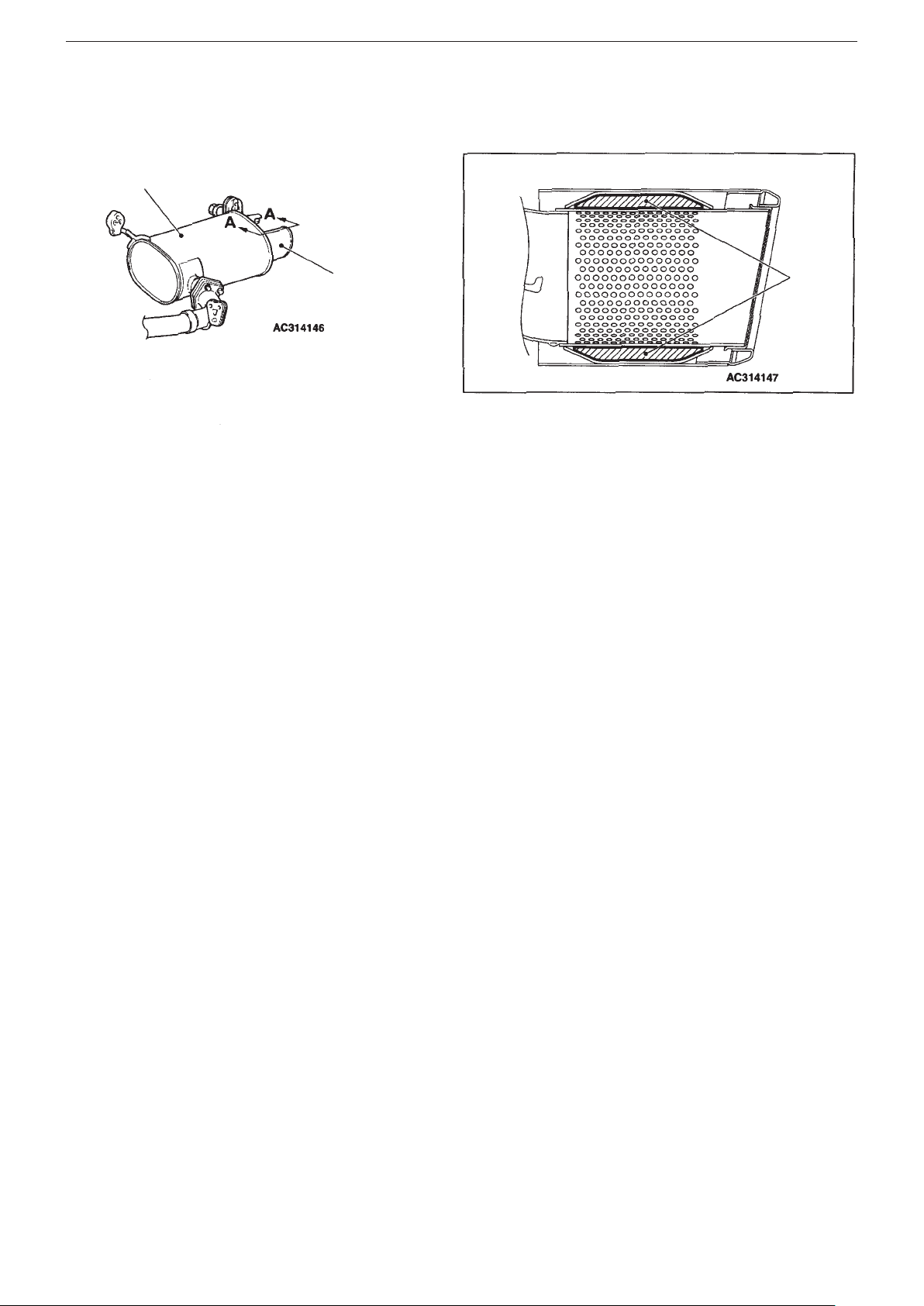

1-2 Exhaust silencer

A tailpipe with built-in sound-absorbing material has been adopted, in order to increase the silencing effect.

Structural diagram

1-7

Main exhaust

silencer

Tailpipe

(with built-in soundabsorbing material)

Cross-section

A–A

Soundabsorbing

material

Page 13

1-8

ENGINE (4G6) – GENERAL, BASE ENGINE (6 M/T)

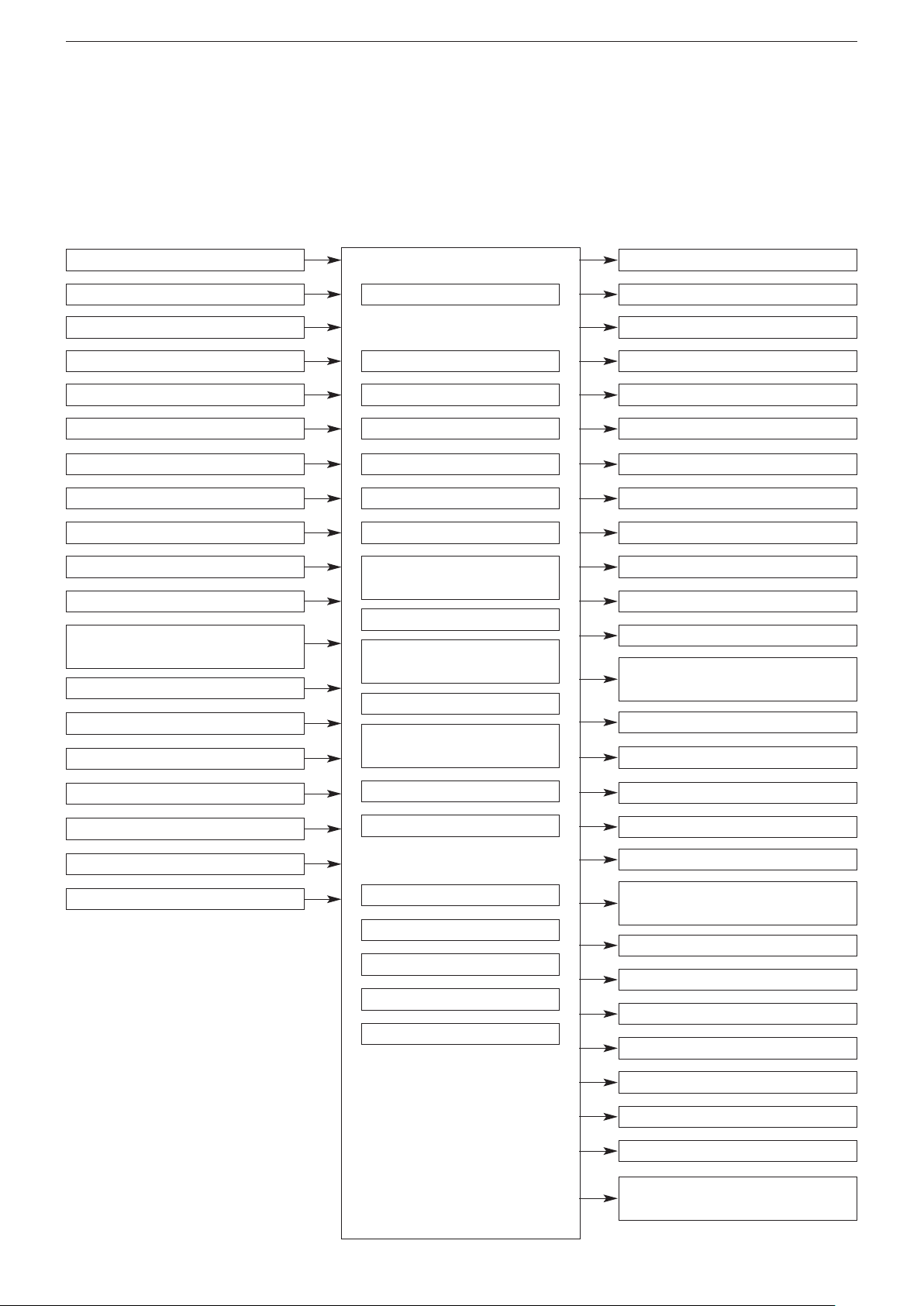

Control system (6M/T)

The following changes have been made, based on the control system in the 4G63-DOHC-T/C engine fitted in the current

Lancer Evolution VIII.

* Addition of wastegate solenoid valve (1 valve –> 2 valves)

System Block Diagram

Air flow sensor (AFS)

Air temperature sensor

Atmospheric pressure sensor

Water temperature sensor

Throttle position sensor (TPS)

A/C switch

A/C load signal

Cam position sensor

Crank angle sensor

Alternator FR terminal

Vehicle speed sensor

Power steering fluid pressure

switch

Knock sensor

Intercooler water spray (auto)

Intercooler water spray (manual)

Engine ECU

Fuel injection control

Idle speed control (ISC)

Ignition timing control

Engine control relay control

Fuel pump relay control

A/C relay control

Fan motor control (radiator)

Fan relay control (A/C

condenser)

Alternator control

Air flow sensor filter reset

control

Fuel pressure control

Supercharging pressure

control

No. 1 indicator

No. 2 indicator

No. 3 indicator

No. 4 indicator

ISC servo (stepper motor)

Ignition coil A (No.1 – No.4)

Ignition coil B (No.2 – No.3)

Engine control relay

Fuel pump relay 2

Fuel pump relay 3

A/C relay

Fan controller (radiator fan)

Fan motor relay (HI, LOW)

(A/C condenser)

Alternator G terminal

Air flow sensor

O

sensor

2

Ignition switch –IG

Ignition switch –ST

Power supply

Secondary air control

Intercooler water spay control

Engine warning light control

O

sensor heater control

2

Purge control

Diagnosis output

RAM data transmission

Fuel pressure control valve

No. 1 wastegate solenoid valve

No. 2 wastegate solenoid valve

Secondary air control solenoid

valve

Intercooler water spray relay

Intercooler water spray lamp

achometer

T

Engine warning lights

O

sensor heater

2

Purge control solenoid valve

Diagnosis output terminal

Diagnosis output terminal (for

-II)

MUT

Page 14

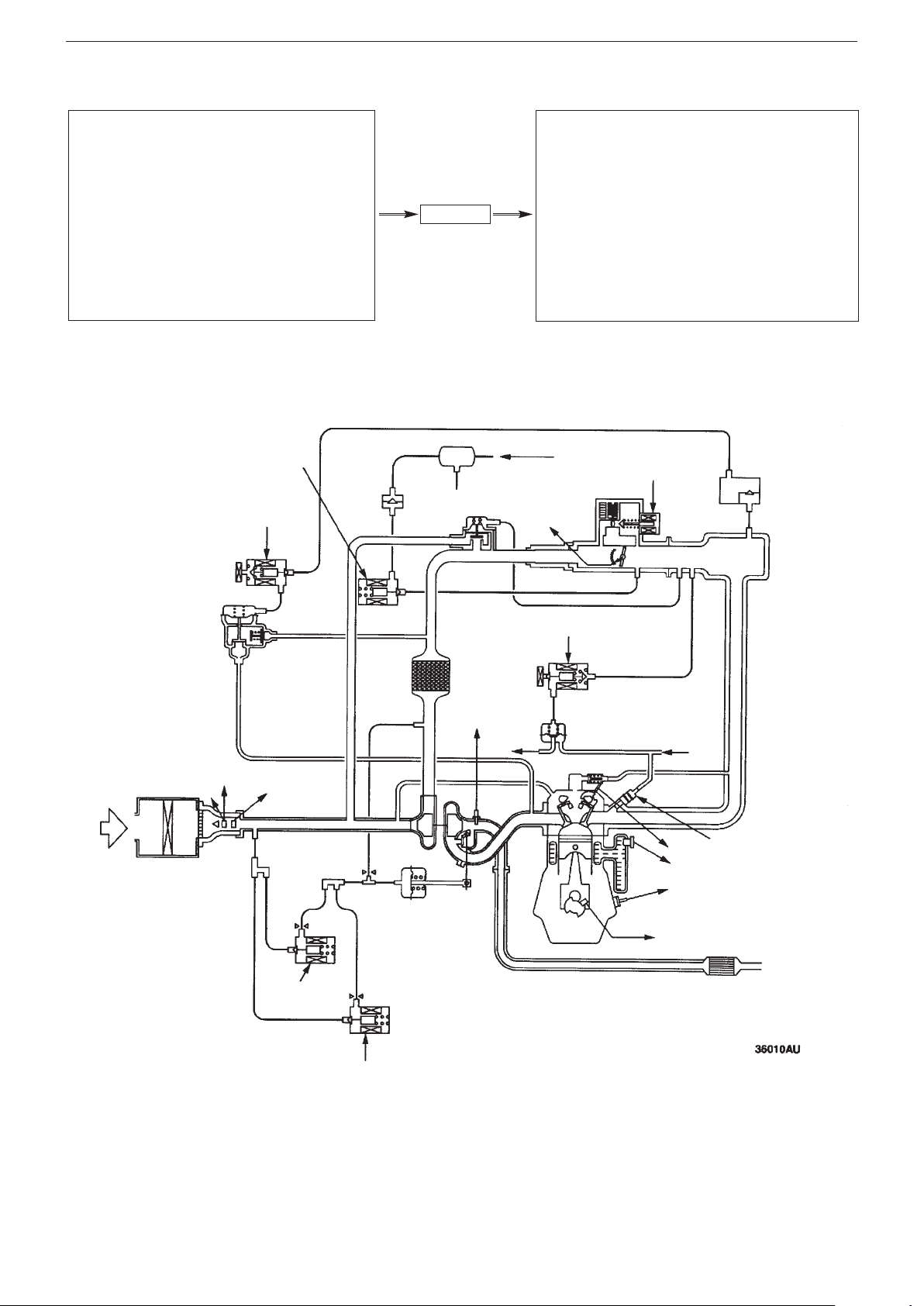

Control system diagram

ENGINE (4G6) – GENERAL, BASE ENGINE (6 M/T)

1-9

★1. O2 sensor

Air flow sensor

★2.

Air intake sensor

★3.

Throttle position

★4.

sensor

★5. Cam position sensor

★6. Crack angle sensor

Atmospheric pressure

★7.

sensor

ater temperature

★8. W

sensor

★9. Knock sensor

Power supply

•

Ignition switch IG

•

Ignition switch ST

•

Vehicle speed sensor

•

• A/C switch

A/C load signal

•

Power steering fluid

•

pressure switch

Alternator FR signal

•

Intercooler water spray

•

switch (auto)

Intercooler water spray

•

switch (manual)

✩6. Purge control

solenoid valve

✩7. Secondary air

control solenoid valve

Check

valve

Engine ECU

Canister

By-pass

valve

✩1. Injector

✩2. ISC servo (stepper

motor)

✩3. Fuel pressure control

solenoid valve

✩4. No.1 wastegate solenoid

valve

✩5. No.2 wastegate solenoid

valve

✩6. Purge control solenoid

valve

✩7. Secondary air control

solenoid valve

From fuel tank

✩2. ISC servo

Throttle

★4.

position

sensor

Engine control relay

•

Fuel pump relay 2, 3

•

A/C relay

•

Ignition coil

•

• Fan controller

Condenser fan relay (HI)

•

Condenser fan relay

•

(LOW)

Engine warning lamp

•

Diagnosis output

•

Alternator G terminal

•

Intercooler water spray

•

relay

Intercooler water spray

•

lamp

Vacuum

tank

Air

intake

Secondary

air valve

★2. Air flow sensor

Atmospheric pressure

★7.

sensor

★3.

sensor

✩4. No.1

wastegate

solenoid valve

Air intake

astegate actuator

W

★1. O

control solenoid valve

sensor

2

To fuel

tank

✩3. Fuel pressure

Fuel pressure

regulator

From fuel

pump

✩1. Injector

Cam position sensor

★5.

★8.Water temperature sensor

★9.Knock sensor

Crack angle sensor

Catalytic converter

✩5. No.2 wastegate

solenoid valve

Only operates on 6M/T

Page 15

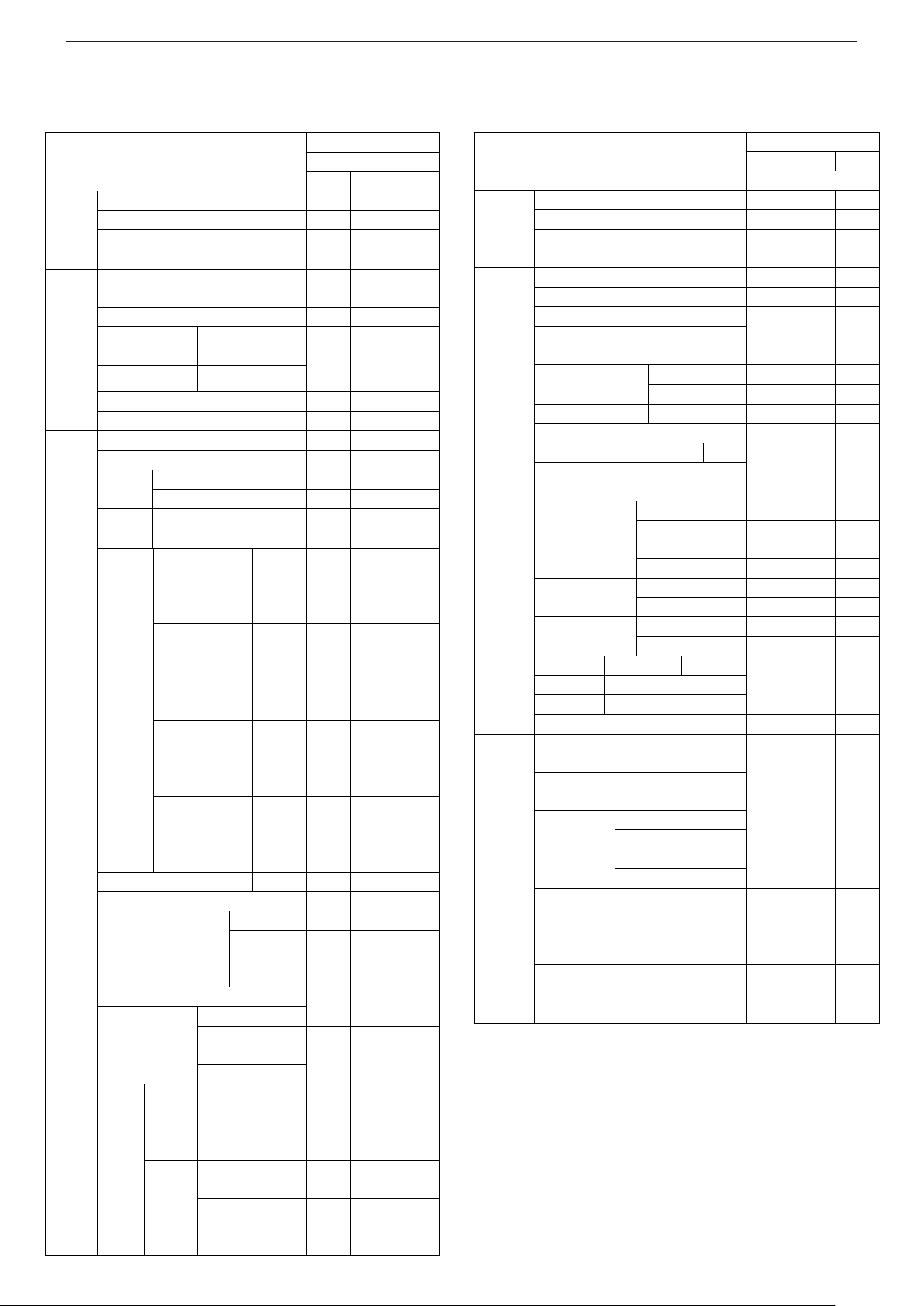

1-10

ENGINE (4G6) – CONTROL SYSTEM (6 M/T)

1. Supercharging pressure control

The maximum torque has been increased, compared to the 4G63-DOHC-T/C engine in the current Lancer Evolution VIII, by

installing an additional wastegate solenoid valve (increased from 1 to 2 valves).

Air flow

sensor

Crank angle

sensor

Knock

sensor

Battery

Secondary air

control solenoid

valve

Secondary

air valve

Ignition

switch

Air

intake

No. 1

wastegate

solenoid

valve

No. 2 wastegate

solenoid valve

Vacuum tank

Bypass valve

Intercooler

Turbocharger

Wastegate

actuator

Engine

ECU

By adding a parallel No.2 wastegate solenoid valve to the previous system, provides extra relief capacity for the pressure

applied to the wastegate actuator thus increasing the range of supercharging pressure..

The engine ECU raises the supercharging pressure even further, thus raising the maximum torque, by driving the No.2

wastegate solenoid valve when the engine approaches maximum torque.

The No.1 wastegate solenoid valve is essentially controlled in the same way as previously

.

Page 16

Power Train – Differential

SECTION 2

POWER TRAIN

CONTENTS

Differential ..............................................2-1

Differential

2-1

The following changes have been made to the Super

• Reduced weight: The weight of the differential has been reduced by building the clutch case from aluminium, rather than

steel, and partially revising the thickness of the clutch discs.

• Improved strength and durability: Strength and durability have been raised by adopting special high-strength steel for the

hypoid gears (pinion gear and drive gear), instead of the cast steel used previously.

• Improved control when ABS is operating: Revisions to the communications with the ABS-ECU and the control procedure

during ABS operation, as well as active ACD/AYC control in high friction road surfaces, such as circuits, have led to

increased steerability and stability.

Structural Diagram

Hypoid gears

AYC differential.

Clutch case

Clutch discs

Page 17

3-1

DRIVE CONTROL – Front suspension, Rear suspension, Wheels, Tyres

SECTION 3

DRIVE CONTROL

CONTENTS

Front suspension....................................3-1

Wheels and Tyres ...................................3-1

Rear suspension.....................................3-1

Front suspension

Road-holding has been improved by the adoption of Bilstein shock absorbers.

(GRS: Standard; RS: Optional)

Notes :

* Bilstein are one of the world’s leading manufacturers of shock absorbers, and their products are used in racing vehicles

worldwide.

Rear suspension

• Road-holding has been improved by the adoption of Bilstein shock absorbers.

(GRS: Standard; RS: Optional)

• The specifications of the coil springs have been changed. (GSR)

Specifications

Item Lancer Evolution VIII MR GSR Lancer Evolution VIII GSR

Wire diameter mm 12

verage diameter mm

A

Free length mm 277 287

88

←

←

Wheels and Tyres

BBS lightweight forged alloy wheels are provided as an option,

which reduces the unsprung weight. Fitting these BBS lightweight

wheels allows the Bilstein shock absorbers to display their full

range of performance.

Note:

See “Section 8 Main Equipment” for detailed specifications.

Page 18

BODY – MAIN BODY

SECTION 4

BODY

CONTENTS

4-1

Main Body................................................4-1

Body Panels .....................................................4-1

Paintwork.................................................4-1

Body colour chart ............................................4-1

Main Body

Body Panels

Vehicle weight has been reduced by using aluminium for the roof panels and the side door beams, in addition to the bonnet

panel and front wing panels, as previously.

: Parts made from aluminium

Paintwork

Body colour chart

Colour name

(Former name)

Cool Silver Metallic CL A31 CMA10031 Aluminium M Kansai Paint

Medium Purplish Grey Mica ES A39 CMA10039 Aluminium +

Solid White (Scotia White) 2E W83 AC10983 –– S Kansai Paint

Solid Red (Palma Red) JW P85 AC11185 –– S Kansai Paint

Note :

• The maintenance code is only for the top coat. S = Solid; M = Metallic; 2P = 2-coat pearl

• The name of the paint manufacturer is the name of the manufacturer of the paint used at the time of production.

Colour

symbol

Colour

code

Colour (paint)

number

Coating ingredient Maintenance

symbol

2P Nippon Paint

interference mica

Name of paint

manufacturer

Page 19

5-1

EXTERIOR – MARKINGS

SECTION 5

EXTERIOR

CONTENTS

Markings ..................................................5-3

Markings

An Evolution MR logo has been added.

Evolution MR logo

Page 20

EQUIPMENT – COMBINATION METER

SECTION 7

EQUIPMENT

CONTENTS

Combination meter.................................7-1

Combination meter

7-1

The combination meter has been changed as illustrated below

(Lancer Evolution VIII MR) (Lancer Evolution VIII)

Marking changed

.

Page 21

8-1

GH-CT9A

Item

SNDFZ

SJDFZ

SJGFZ

Classification No.È

079, 080, 085, 086,

091, 092, 097, 098

083, 084, 089,

090, 095, 096,

099~102

105, 106, 109,

110, 113, 114,

117, 118

119

Vehicle length mm

4490

Vehicle width mm

1770

Vehicle height mm

1450

Wheelbase mm

2625

Front

1500

1515

¨

¨

Dimensions

Track mm

Rear

1500

1515

¨

¨

Weight

See weight chart

Left

50˚

Performance

Max.

angle of

stability

Right

50˚

Wheel alignment

Front 2 drive – Rear 2 drive

Front

Other

Tyre

size

Rear

205/65R15 94H

235/45ZR17

¨

¨

REFERENCE MATERIAL – MAIN SPECIFICATIONS

SECTION 8

REFERENCE MATERIAL

CONTENTS

Main specifications.................................8-1

Detailed specifications...........................8-4

Main equipment ......................................8-6

Cold climate specifications ...................8-8

Main Specifications

These Main Specifications are based on submitted data, and may therefore differ from the actual equipment.

The ★ symbol indicates specifications which have changed from the previous model.

Vehicle name and model Mitsubishi GH-CT9A

Chassis name and type Mitsubishi CT9A

Manufacturer Mitsubishi Motor Corporation

Category Normal

Use Passenger

Body shape Saloon

Engine type 4G63

Capacity cc 1997

GH-CT9A

Note :

See Weight Chart for relationships between classification numbers and equipment.

Page 22

Weight Chart

GH-CT9A

Item

SNDFZ

Classification No. È

079

080

(A)

083

(B,D,W)

084

(A,B,D,W)

085

086 (A)

Front axle

weight

800

810¨830

810

820

Rear axle

weight

510¨530¨510

¨

Vehicle

weight kg È

Total

1310

1320

1350

1360

1320

1330

Number of passengers

5

Front axle

weight

900

910¨930

910

920

Rear axle

weight

685¨705¨685

¨

Weight

Gross

vehicle

weight kg È

Total

1585

1595

1625

1635

1595

1605

GH-CT9A

Item

SNDFZ

Classification No. È

089

(B,D,W)

090

(A,B,D,W)

091

092

(A)

095

(B,D,W)

096

(A,B,D,W)

Front axle

weight

830

840

800

810¨830

Rear axle

weight

530¨520¨540

¨

Vehicle

weight kg È

Total

1360

1370

1320

1330

1360

1370

Number of passengers

5

Front axle

weight

930

940

900

910¨930

Rear axle

weight

705¨695¨715

¨

Weight

Gross

vehicle

weight kg È

Total

1635

1645

1595

1605

1635

1645

GH-CT9A

Item

SNDFZ

Classification No. È

097

098 (A)

099

(W)

100

(A,W)

101

(B,D,W)

102

(A,B,D,W)

Front axle

weight

810

820¨830¨840

Rear axle

weight

520¨530¨540

¨

Vehicle

weight kg È

Total

1330

1340

1350

1360

1370

1380

Number of passengers

5

Front axle

weight

910

920¨930¨940

Rear axle

weight

695¨705¨715

¨

Weight

Gross

vehicle

weight kg È

Total

1605

1615

1625

1635

1645

1655

REFERENCE MA

TERIAL – MAIN SPECIFICATIONS

8-2

Page 23

8-3

GH-CT9A

Item

SJDFZ

Classification No. È

105

(B,D,W)

106

(A,B,D,W)

109

(B,D,W)

110

(A,B,D,W)

113

(B,D,W)

Front axle

weight

830

840¨850

830

Rear axle

weight

530

¨¨¨

540

Vehicle weight

kg

È

Total

1360

1370

¨

1380

1370

Number of passengers

5

Front axle

weight

930

940¨950

930

Rear axle

weight

705

¨¨¨

715

Weight

Gross vehicle

weight kg È

Total

1635

1645

¨

1655

1645

GH-CT9A

Item

SJDFZ

SJGFZ

Classification No. È

114

(A,B,D,W)

117 (B,D,W)

118

(A,B,D,W)

119

(A,B,D,W)

Front axle

weight

840¨850

860

Rear axle

weight

540

¨¨¨

Vehicle weight

kg È

Total

1380

¨

1390

1400

Number of passengers

5

Front axle

weight

940¨950

960

Rear axle

weight

715

¨

¨

715

Weight

Gross vehicle

weight kg È

Total

1655

¨

1665

1675

REFERENCE MATERIAL – MAIN SPECIFICATIONS

Notes :

The symbols after the Classification Numbers indicate the following equipment.

A: Air conditioning B: ABS D: ACD (Active Centre Differential) W: 17-inch wheels

Page 24

REFERENCE MA

GH-CT9A

Item

SNDFZ

SJDFZ

SJGFZ

Minimum ground clearance m

0.140

¨

¨

Max. speed (estimated) km/h

180

¨

¨

Fuel consumption km/l (10/15 mode)

9.6

9.7

¨

Braking distance m (initial speed in

km/h) È

49 (100)

[Vehicle with

15-" brakes]

43 (100)

[Vehicle with

17" brakes]

¨

¨

Performance

Min. turning radius m

5.9

¨

¨

Bore x stroke mm

85.0 X 88.0

¨

¨

Compression ratio

8.8 (Unleaded

Premium)

¨

¨

Max. output net [k/W r.p.m.]

206 / 6500

(net)

¨

¨

Max. torque N•m/rpm.

392 / 3500

(net)

400 / 3500

(net) È

¨

Open

BTDC 21˚

BTDC 17˚

È

¨

Intake

Closed

ABDC 59˚

ABCD 63˚

È

¨

Open

BBDC 58˚

¨

¨

Engine

Valve or

port timing

Exhaust

Closed

ATDC 18˚

¨

¨

Fuel tank capacity (litres)

50

¨

55

Type and performance of ignition

equipment

Electronic:

-20˚~ 45˚

¨

¨

Type of spark plugs

IGR7A,

IGR7A-G,

S22PR-A7,

VW22PR-DA7

¨

¨

Battery capacity Ah

34 (5), 48 (5)

or 52 (5)

¨

¨

Electrical

Equipment

Alternator output V-A

12 – 58, 90,

100 or 105

¨

¨

TERIAL – MAIN SPECIFICATIONS / DETAILED SPECIFICATIONS

Detailed Specifications

8-4

These Detailed Specifications are based on submitted data, and may therefore dif

The

★ symbol indicates specifications which have changed from the previous model.

fer from the actual equipment.

Page 25

8-5

GH-CT9A

Item

SNDFZ

SJDFZ

SJGFZ

1st2.785

2.909

¨

2nd1.950

1.944

¨

3rd1.444

1.434

¨

4th1.096

1.100

¨

5th0.825

0.868

¨

6th-

0.693

¨

Transmission

Gear ratio

Reverse

3.416

2.707

¨

Front

4.529

4.583

¨

Differential

Reduction

ratio

Rear

3.307

¨

¨

Power train

Transfer

Reduction

ratio

0.302

¨

¨

Main brake type

Hydraulic:

Front : Disc

Rear : Disc

¨

¨

Parking brake type

Mechanical

wheel brake

¨

¨

Front

MacPherson

¨

¨

Braking

system

Suspension

Rear

Multi-link

¨

¨

CO when

unloaded : %,

HC : ppm

CO: 0.1,

HC: 100

¨

¨

10/15 mode

g/km

CO: 0.67,

HC: 0.08,

NOx: 0.08

¨

¨

Emission

gas

suppression

equipment

Quantity or concentration

of exhaust gas

11 mode g/test

CO: 19.0,

HC: 2.20,

NOx: 1.40

¨

¨

REFERENCE MATERIAL – DETAILED SPECIFICATIONS

Page 26

Main Equipment

4WD

RS

GSR

Equipment

5M/T

6M/T

Aluminium turbo

l

l

r

Intercooler water spray system

lll

W/out Intercooler water spray system

r

r

Engine

Engine oil cooler

lll

5-speed manual (short stroke, high gear

ratio)

l

6-speed manual (short stroke)

l

l

Gear lever

Leather

Front LSD

Helical

Rear LSD

Mechanical

lll

l

Active Centre Differential (ACD)

lll

Power

Train

Active Yaw Control Differential (AYC)

r

l

l

Bilstein shock absorbers

r

r

l

Front strut tower bars

lll

205/65R15 94H

l

Tyres

235/45ZR17

r

l

l

T125/70D16

l

Spare

tyre

T125/70D17

r

l

l

Steel (5-hole)

(Offset : 46 mm)

(PCD:

114.3mm)

15-inch

¥ 6.0JJ

silver

l

17-inch

¥ 8.0JJ

r

l

l

Steel (5-hole)

(Offset : 38 mm)

(PCD:

114.3mm)

17-inch

¥ 8.0JJ

(BBS)

rrr

Steel (5-hole)

(Offset : 40 mm)

(PCD:

114.3mm)

4.0T•

16-inch

l

Wheel

Steel (5-hole)

(Offset : 30 mm)

(PCD:

114.3mm)

4.0T•

17-inch

r

l

l

Centre cap

Black

l

Power steering

lll

MOMO

l

l

Steering wheel (leather

type ; 3-spoke; airbag)

MOMO

(black

spokes)

r

r

l

Tilt steering mechanism

Full cover

lll

Release switch

(gloss)

Parking brake

lever

Leather grip

l

15-inch ventilated

disc

l

Front

17-inch ventilated

disc (BREMBO)

r

l

l

15-inch ventilated

disc (drum in)

l

Drive

Control

Brake

Rear

16-inch ventilated

disc (drum in)

(BREMBO)

r

l

l

4WD

RS

GSR

Equipment

5M/T

6M/T

4 ABS (sports ABS)

r

l

l

Pressure control valve (PCV)

l

Drive

Control

Electronic Brake Force Distribution

System (EBD)

r

l

l

Central door locking

r

r

l

Boot lid opener

lll

Fuel filler flap opener

Child protection

lll

Multimode keyless entry

l

Black

l

l

Outer door handles

Body colour

l

Inside door handles

Coloured

lll

Power windows with safety mechanisms

r

r

l

Windscreen (laminated glass)

Green

Front door windows (UV absorbing

glass)

lll

Green

l

l

Green, with sun

shade

l

Rear window

glass (with

heating element)

Privacy glass

r

Green

lll

Rear door

windows

Privacy glass

r

Green

lll

Rear static

windows

Privacy glass

r

Bonnet

Aluminium

Air outlet

Wing

Aluminium

Roof

Aluminium

lll

Body

Rear end crossbar

l

l

Exclusive

front bumper

Body colour

Exclusive

rear bumper

Body colour

Windscreen

Rear window

Pillar, roof

Mouldings

(black)

Belt line

lll

Manual type (black)

l

l

Door mirror

Electric stowable

remote control door

mirror (body colour)

l

Front air dam

Exclusive

extension

Rear air dam

lll

Exterior

Rear spoiler (large size)

lll

REFERENCE MA

TERIAL – MAIN EQUIPMENT

8-6

The “●” symbol indicates standard equipment, and the “r” symbol indicates a manufacturer

’s option. The equipment may change, depending on the time of manufacture.

Note:

In the wheel columns, “PCD” is an abbreviation of “Pitch

Circle Diameter”, referring to the diameter of the pitch circle

of the installation holes.

Page 27

8-7

4WD

RS

GSR

Equipment

5M/T

6M/T

Seat finish

Fabric

lll

Standard type

l

l

Recaro seat

r*1r

*1

l

Slide

Adjustment

mechanism

Reclining

lll

Front

Seat

Headrest

Low back bench seat (fixed)

l

l

High back bench seat (fixed)

Rear

Seat

Centre arm rest (with cup

holder)

l

2 ¥ 3-point with

ELR

With pre-tensioner

(driver’s seat &

front passenger

seat)

Front

Adjustable

seatbelt anchor

SRS

airbags

Rear

2 ¥ 3-point with

ELR / ALR + 1 ¥ 2-

point belt

lll

Driver’s seat

lll

SRS

airbags

Front passenger’s seat

r

r

l

Accessories box (1 DIN)

l

l

Parcel box (with lid)

l

Parcel

boxes

Coin box

Glove box

lll

Standard type

l

l

Large type

With lid

l

Shift boot ring

l

Front seat

lll

Ashtray

Rear seat

l

Floor

console

Cup holder (front seat)

lll

Centre panel (unique type)

l

l

2 DIN type

l

Headlining

Cloth

lll

Moulded type (soft)

Front door

trim

Door pocket (driver’s

seat, front passenger’s

seat)

Interior

Rear door

Moulded type (soft)

lll

4WD

RS

GSR

Equipment

5M/T

6M/T

Boot interior trim

Boot interior

floor carpet

Needle punch

l

¥ 1 (front passenger’s seat)

l

l

Retractable

assistance

straps

¥ 3 (front passenger’s seat,

rear seats)

l

Driver’s seat

lll

Front passenger’s seat

r

r

l

Ticket holder (driver’s seat)

lll

Sun

visors

Vanity mirror (with lid)

l

Internal

mirror

Day / night switchable

Interior

Foot rests

lll

44B20L

lll

Battery

55B24L

rrr

Halogen (low and

high beam)

l

l

Discharge (low

beam)

Halogen (high

beam)

Fog lamps

(halogen)

r

r

l

Position lights

lll

Automatic lights

l

Headlight levelling

r

r

l

Extension (black)

r

r

l

Rear combination

lights

(clear type *2)

lll

External

lights

Headlight

assembly

(Clear

type *2)

Extension (black)

r

r

l

High mount stop

light

Rear shelf mounting

(bulb type)

Front cabin lights (with map light)

lll

Rear cabin lights

lll

Interior

lights

Boot interior light

Combination meter

Special type

Electric type analogue

speedometer

Twin type trip meter

Tachometer

Water temperature

Meter

gauge

Fuel

lll

Fog lights

r

r

l

High beam

Turn signal and hazard lights

Equip-

ment

Indicator

lights

ACD

lll

Note :

*1

: 4-point seatbelt asymmetric type seat

*2

: Turn signal lamps coloured amber

REFERENCE MATERIAL – MAIN EQUIPMENT

Page 28

REFERENCE MA

4WD

RS

GSR

Equipment

5/MT

6/MT

ABS

r

l

l

SRS airbags

Fuel level

Parking brake

Charge

Brake fluid

Engine check

Warning

lights

Door not properly closed

Lighting monitor warning

Buzzer

Ignition key reminder warning

l

l

l

Fixed time

intermittent

l

l

Variable

intermittent

(speed-

sensitive)

l

Windscre

en wipers

2 speed

Mist spray

Equip-

ment

Windscreen washer (synchronized with

wiper, 4-jet)

lll

4WD

RS

GSR

Equipment

5/MT

6/MT

Rear

window

wiper /

washer

Fixed time intermittent,

synchronized with (R) gear

position

l

AM/FM tuner radio + MD player

+ DVD-MMCS (DVD navigation

Mitsubishi Multi-Communication

System)

r

Roof aerial

lll

Roof and window aerial (diversity

aerial)

r

W/out audio

lll

Audio

parts

6 speakers (2 DIN compatible)

r

*3

Digital clock

Immobiliser system

lll

Manual heater

Air conditioning kit

l

l

Equip-

ment

Air

conditioning

Fully automatic air

conditioning

l

4WD

RS

GSR

Equipment

5M/T

6M/T

Battery

Weather strip silicon coating

Rear seat heater duct

Cold Climate Specification label

rrr

Door mirrors with heating elements

r

TERIAL – MAIN EQUIPMENT, COLD CLIMATE SPECIFICATIONS

8-8

Notes:

*3

: Brackets for an aerial and radio are installed as standard.

Cold Climate Specifications

Loading...

Loading...