Page 1

GROUP 14

ENGINE COOLING

CONTENTS

14-1

GENERAL INFORMATION . . . . . . . . 14-2

SERVICE SPECIFICATIONS. . . . . . . 14-2

LUBRICANT. . . . . . . . . . . . . . . . . . . . 14-2

SEALANT. . . . . . . . . . . . . . . . . . . . . . 14-2

SPECIAL TOOLS. . . . . . . . . . . . . . . . 14-3

TROUBLESHOOTING . . . . . . . . . . . . 14-3

ON-VEHICLE SERVICE. . . . . . . . . . . 14-15

ENGINE COOLANT LEAK CHECK . . . . . . 14-15

RADIATOR CAP PRESSURE CHECK. . . . 14-15

ENGINE COOLANT REPLACEMENT . . . . 14-15

CONCENTRATION MEASUREMENT . . . . 14-16

FAN CONTROLLER CHECK . . . . . . . . . . . 14-16

FAN CONTROL RELAY CONTINUITY

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-17

COOLING FAN MOTOR CHECK . . . . . . . . 14-17

THERMOSTAT . . . . . . . . . . . . . . . . . . 14-18

REMOVAL AND INSTALLATION . . . . . . . . 14-18

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 14-19

WATER PUMP . . . . . . . . . . . . . . . . . . 14-20

REMOVAL AND INSTALLATION . . . . . . . . 14-20

WATER HOSE AND WATER PIPE . . 14-22

REMOVAL AND INSTALLATION . . . . . . . . 14-22

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 14-23

RADIATOR . . . . . . . . . . . . . . . . . . . . . 14-24

REMOVAL AND INSTALLATION . . . . . . . . 14-24

Page 2

14-2

ENGINE COOLING

GENERAL INFORMATION

GENERAL INFORMATION

M1141000100456

The cooling system is designed to keep every part of

the engine at appropriate temperature in whatever

condition the engine may be operated. The cooling

method is of the water-cooled, pressure forced circu

lation type in which the water pump pressurizes coolant and circulates it throughout the engine. If the

engine coolant temperature exceeds the prescribed

temperature, the thermostat opens to circulate the

Item Specification

Radiator Performance kJ/h 216,700

coolant through the radiator as well so that the heat

absorbed by the coolant may be radiated into the air.

The water pump is of the centrifugal type and is

-

driven by the drive belt from the crankshaft. The radi

ator is the corrugated fin, down flow type. The cooling fan is controlled by the fan controller and

engine-ECU depend on driving conditions.

SERVICE SPECIFICATIONS

M1141000300483

Item Standard value Limit

Radiator cap pressure kPa 93 − 123 Minimum 83

Range of coolant antifreeze concentration of radiator % 30 − 60 -

Fan controller input voltage V Ignition switch: "ON" Battery positive voltage -

-

Fan controller output voltage V A/C switch: "OFF" 1 or less -

A/C switch: "ON" Repeat steps 1) and 2).

1) 8.2 ± 2.6

2) Battery positive voltage

± 2.6

Thermostat Valve opening temperature of thermostat °C 80 ± 1.5 -

Full-opening temperature of thermostat °C 93 -

Valve lift mm 9.5 or more -

-

LUBRICANT

M1141000400424

Item Specified lubricant Quantity L

Engine coolant (including

reserve tank)

DIA QUEEN SUPER LONG LIFE COOLANT or equivalent 6.0

SEALANT

M1141000500658

Item Specified sealant Remark

Cylinder block drain plug 3M Nut Locking Part No.4171 or equivalent Drying sealant

Page 3

ENGINE COOLING

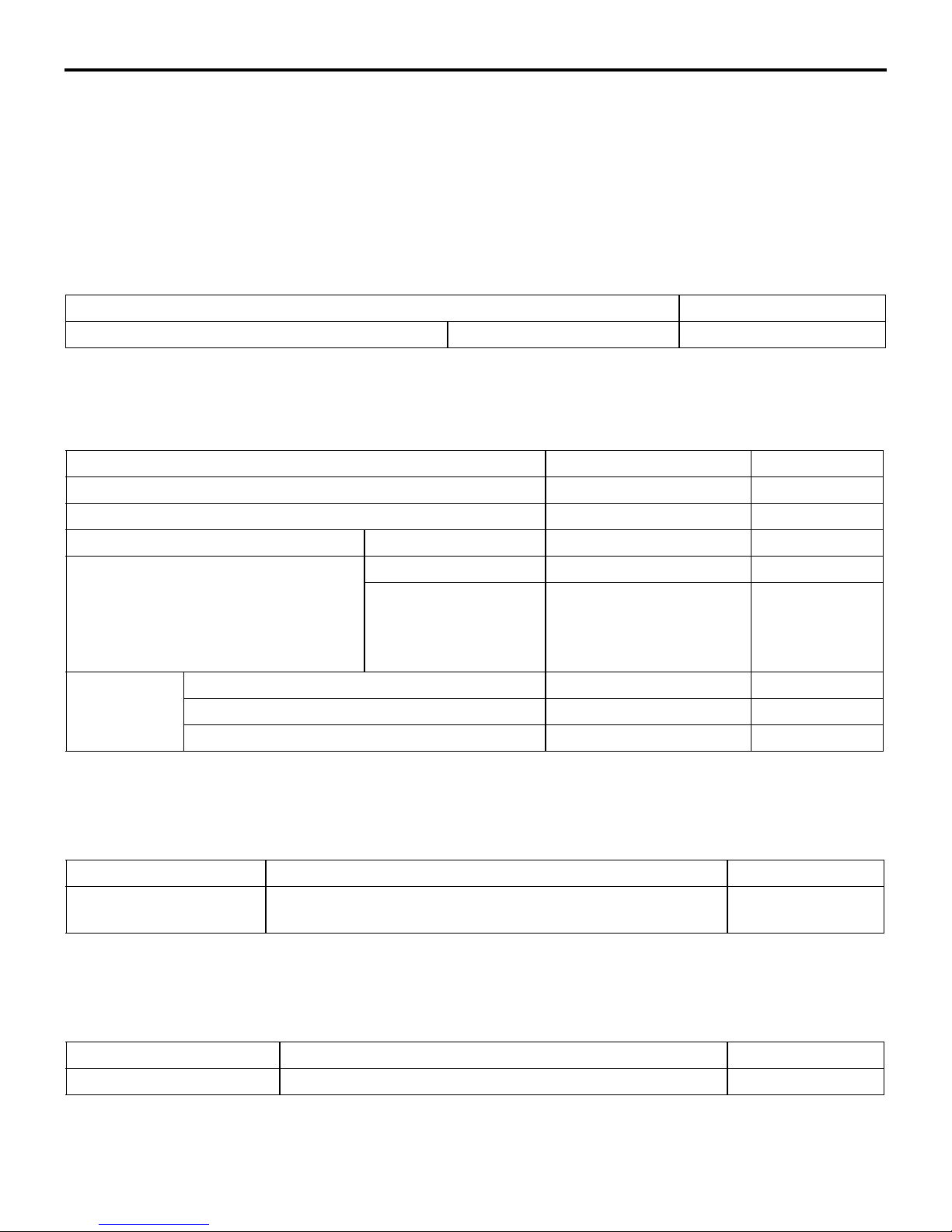

SPECIAL TOOLS

SPECIAL TOOLS

Tool Number Name Use

A

MB991223

A: MB991219

B: MB991220

C: MB991221

D: MB991222

B

C

Harness set

A: Check harness

B: LED harness

C: LED harness

adapter

D: Probe

Making voltage and

resistance measurement

during troubleshooting

A: Connector pin contact

B: Power circuit inspection

C: Power circuit inspection

D: Commercial tester

14-3

M1141000600592

pressure inspection

connection

D

DO NOT USE

MB991223

AZ

MB992006 Extra fine probe Making voltage and

MB992006

MB991871 LLC changer Coolant refilling

MB991871

TROUBLESHOOTING

INSPECTION CHART FOR TROUBLE

SYMPTOMS

Trouble symptom Inspection

Cooling fan does not operate 1

Cooling fan does not change speed or does not stop 2

M1141005600434

procedure No.

resistance measurement

during troubleshooting

Reference page

P.14-4

P.14-10

Page 4

14-4

ENGINE COOLING

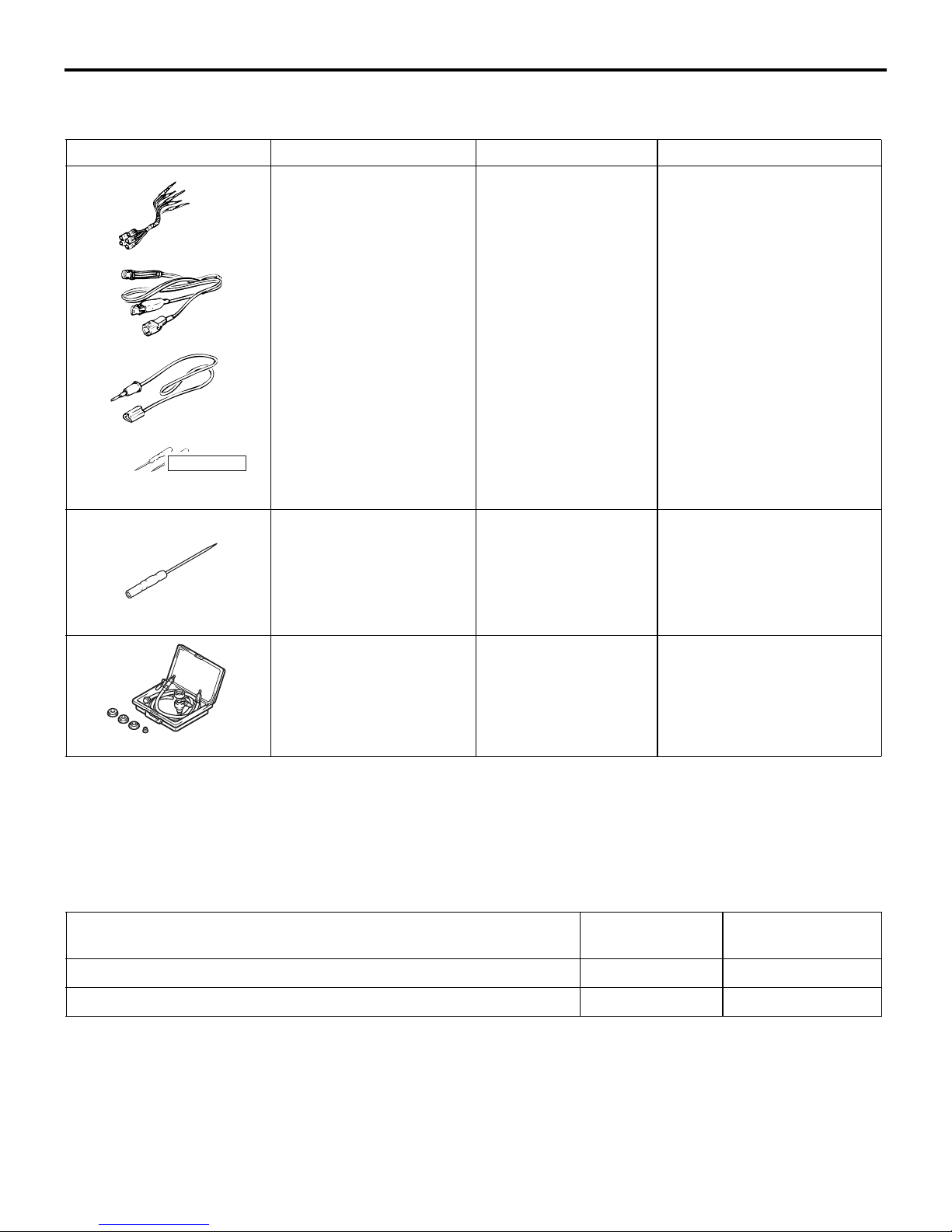

TROUBLESHOOTING

INSPECTION PROCEDURE FOR

TROUBLE SYMPTOMS

INSPECTION PROCEDURE 1: Cooling fan does not operate

Cooling fan drive circuit <L.H. drive vehicles>

INPUT SIGNAL

· A/C SWITCH

· ENGINE

COOLANT

TEMPERATURE

SENSOR

· VEHICLE SPEED

SENSOR

ENGINEECU

FUSIBLE

2

LINK

SMOOTHING

CIRCUIT

ENGINE

CONTROL

SYSTEM

ENGINE

CONTROL

RELAY

FAN

CONTROL

RELAY

INPUT SIGNAL

PROCESSING

TEMPERATURE

DETECTION

CURRENT

DETECTION

FAN CONTROLLER

Wire colour code

B : Black LG : Light green G : Green L : Blue W : White Y : Yellow SB : Sky blue

BR : Brown O : Orange GR : Grey R : Red P : Pink V : Violet PU : Purple

DRIVE

CIRCUIT

FIELD EFFECT

TRANSISTOR

CIRCUIT

RADIATOR

FAN

MOTOR

AC505138

AB

Page 5

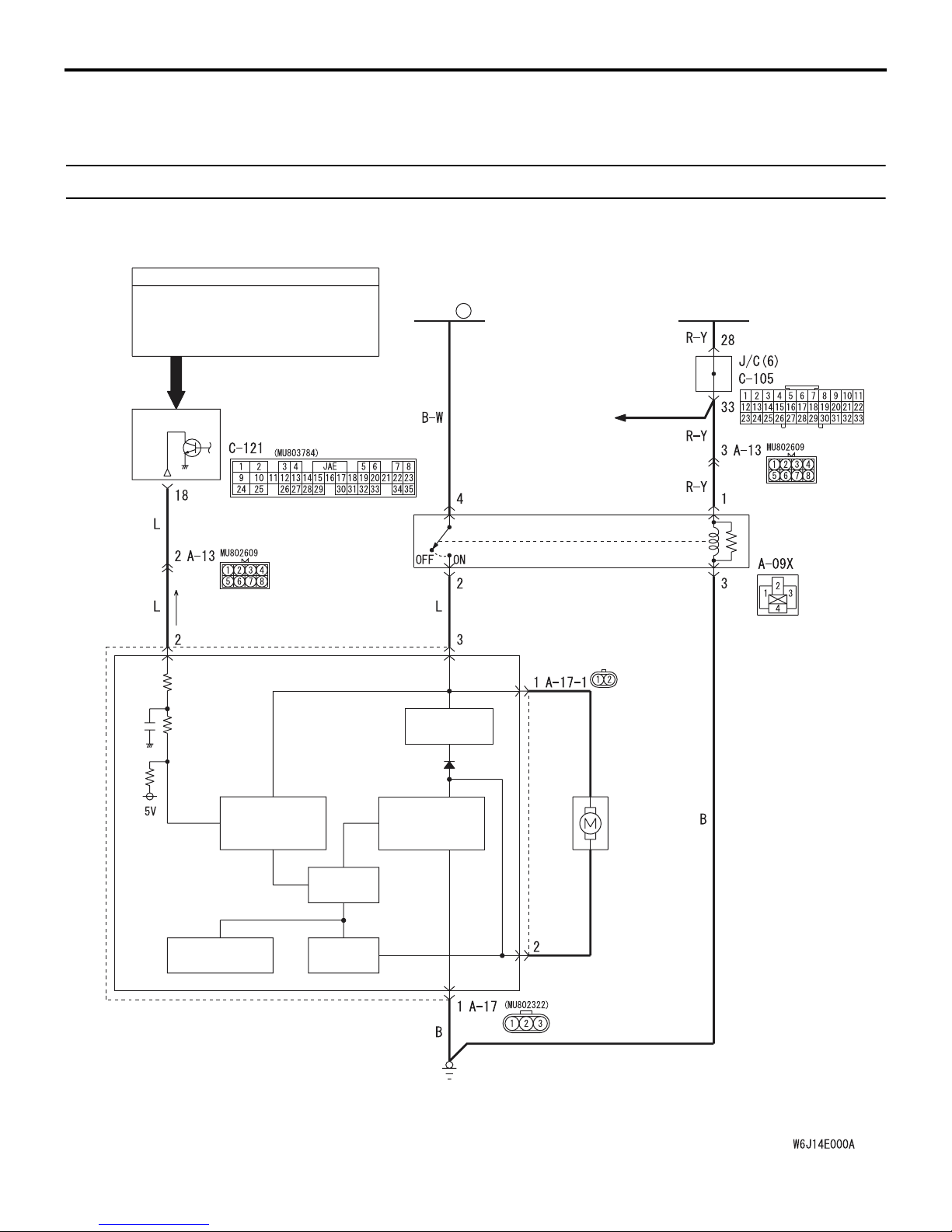

ENGINE COOLING

TROUBLESHOOTING

Cooling fan drive circuit <R.H. drive vehicles>

14-5

INPUT SIGNAL

· A/C SWITCH

· ENGINE

COOLANT

TEMPERATURE

SENSOR

· VEHICLE SPEED

SENSOR

ENGINEECU

FUSIBLE

2

LINK

SMOOTHING

CIRCUIT

ENGINE

CONTROL

SYSTEM

ENGINE

CONTROL

RELAY

FAN

CONTROL

RELAY

INPUT SIGNAL

PROCESSING

TEMPERATURE

DETECTION

DRIVE

CIRCUIT

CURRENT

DETECTION

FIELD EFFECT

TRANSISTOR

CIRCUIT

FAN CONTROLLER

Wire colour code

B : Black LG : Light green G : Green L : Blue W : White Y : Yellow SB : Sky blue

BR : Brown O : Orange GR : Grey R : Red P : Pink V : Violet PU : Purple

CIRCUIT OPERATION

• The fan controller is powered from fusible link

No.2.

RADIATOR

FAN

MOTOR

AC505139

AB

• The engine-ECU judges the required revolution

speed of cooling fan motor using the input signals

transmitted from A/C switch, vehicle speed sen

sor and engine coolant temperature sensor. The

engine-ECU activates the fan controller to drive

the cooling fan motor.

-

Page 6

14-6

ENGINE COOLING

TROUBLESHOOTING

TECHNICAL DESCRIPTION

• The cause could be a malfunction of the fan controller power supply or earth circuit.

• The cause could also be a malfunction of the fan

controller or the engine-ECU.

TROUBLESHOOTING HINTS

• Malfunction of fusible link

• Malfunction of fan control relay

• Malfunction of cooling fan motor

• Malfunction of fan controller

• Malfunction of engine-ECU

• Damaged wiring harness or connector

DIAGNOSIS

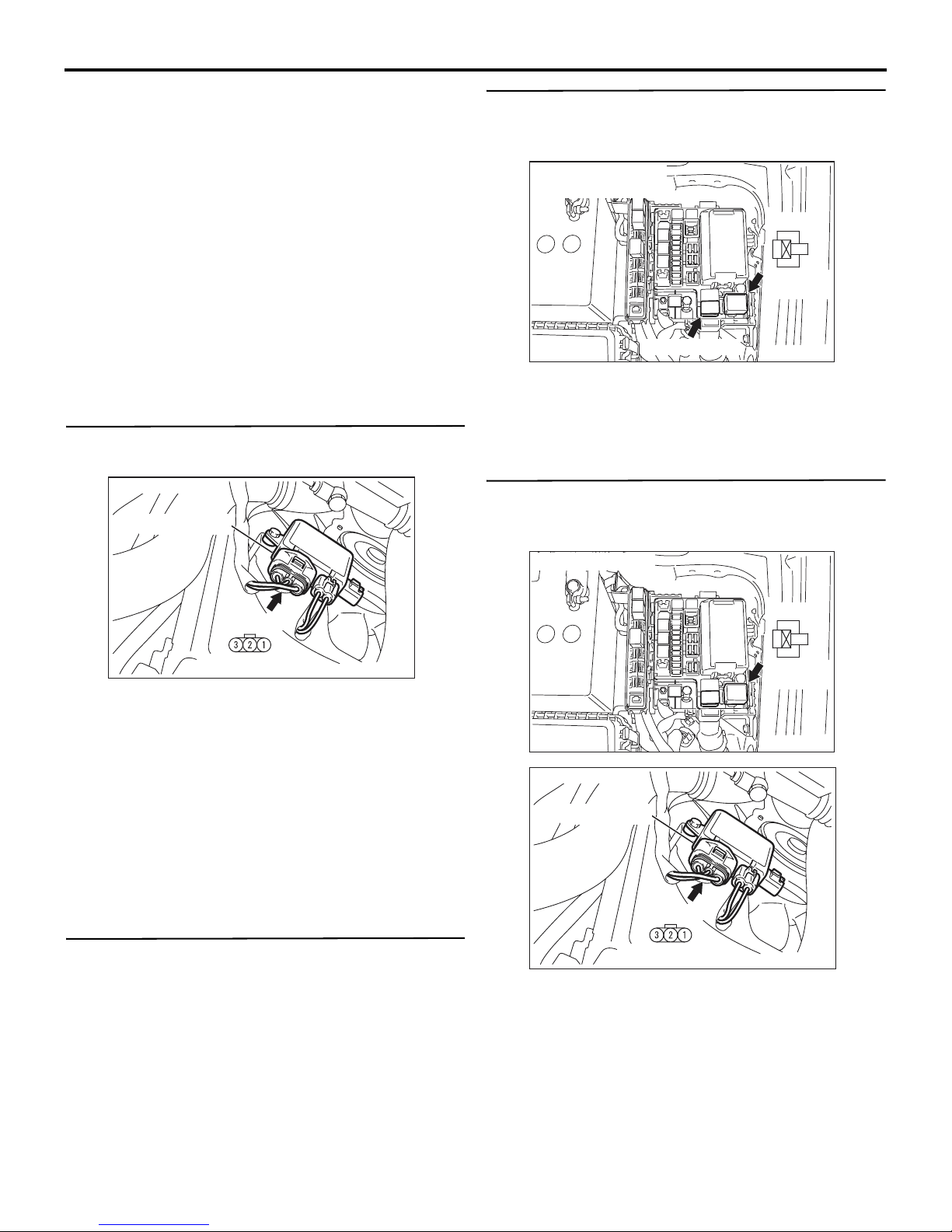

STEP 1. Check the circuit at fan controller

connector A-17 terminal 3.

Connector: A-17

Fan controller

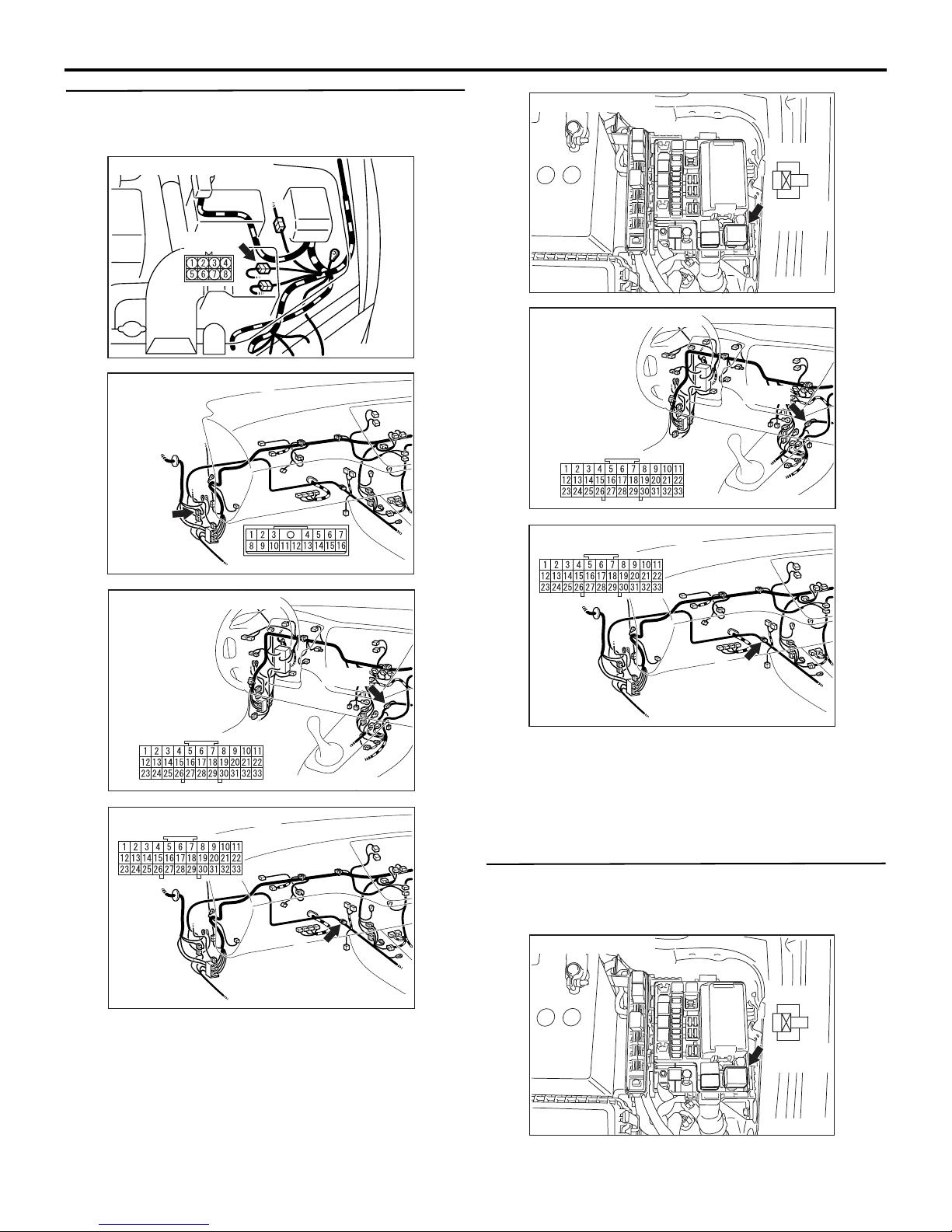

STEP 3. Check for harness damage between

fusible link No.2 and fan control relay connector

A-09X terminal 4.

Fusible link (2) And

Connector: A-09X

A-09X

3

2

4

1

Relay box

side

Fusible link (2)

AC310900

AC

Q: Are the harness wires between fusible link No.2

and fan control relay connector A-09X damaged?

YES : Repair or replace them, then go to Step 13.

NO : Go to Step 4.

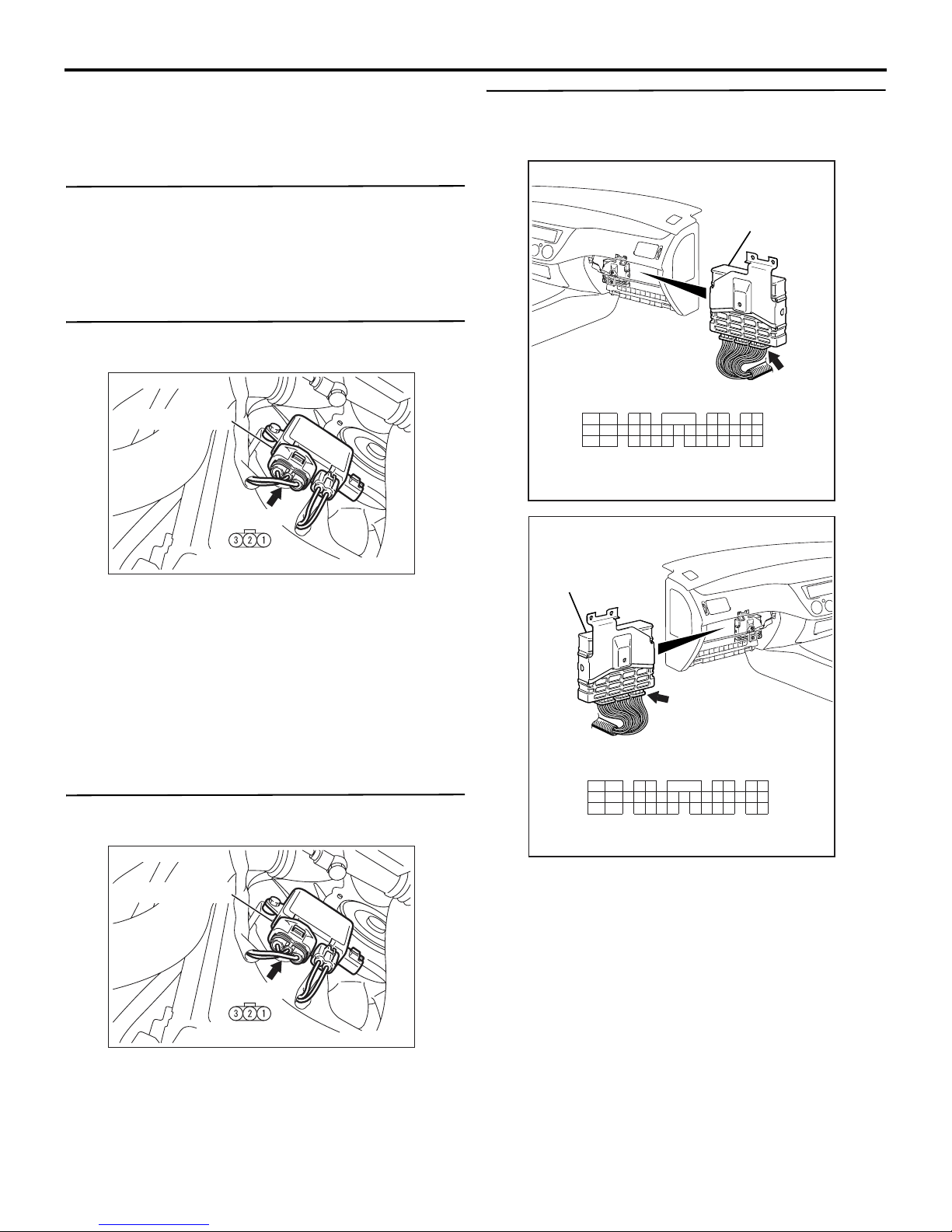

STEP 4. Check for harness damage between fan

control relay connector A-09X terminal 2 and fan

controller connector A-17 terminal 3.

A-17 (GR)

Component side

AC210859

AD

(1) Disconnect fan controller connector A-17, and

measure at the harness side connector.

(2) Measure the voltage between terminal No.3 and

earth.

• When the ignition switch is turned to the "ON"

position, voltage should measure battery pos

itive voltage.

Q: Is the voltage battery positive voltage when the

ignition switch is turned to the "ON" position?

YES : Go to Step 7.

NO : Go to Step 2.

STEP 2. Check the fan control relay.

Refer to P.14-17.

Q: Is the fan control relay in good condition?

YES : Go to Step 3.

NO : Replace it, then go to Step 1.

Connector: A-09X

A-09X

3

4

1

Relay box

side

AC310900

Connector: A-17

-

Fan controller

A-17 (GR)

Component side

Q: Are the harness wires between fan control relay

connector A-09X terminal 2 and fan controller

connector A-17 terminal 3 damaged?

YES : Repair or replace them, then go to Step 13.

NO : Go to Step 5.

AC210859

2

AB

AD

Page 7

ENGINE COOLING

TROUBLESHOOTING

14-7

STEP 5. Check for harness damage between J/C

(6) C-105 and fan control relay connector A-09X.

NOTE:

Connector: A-13 <LHD>

A-13 (B)

AC210877

Connector: C-31 <RHD>

C-31

AC

Connector: A-09X

Connector: C-105 <LHD>

Connector: C-105 <RHD>

A-09X

4

Relay box

side

AC310900

C-105

AC310901

3

2

1

AB

AB

AC310903

AB

Connector: C-105 <LHD>

C-105

AC310901

AB

Connector: C-105 <RHD>

C-105

AC310902

AB

After inspecting intermediate connector A-13 <LHD>

terminal 3, intermediate connector C-31 <RHD> ter

minal 12 and J/C (6) C-105 terminal 28, 33 inspect

the wires. If intermediate connector A-13 <LHD>,

C-31<RHD> and J/C (6) C-105 are damaged, repair

or replace them. Refer to GROUP 00, How to Use

Troubleshooting/Inspection Service Points

P.00-5.

C-105

AC310902

AB

Q: Are the harness wires between J/C (6) C-105

terminal 28 and fan control relay connector A-09X

terminal 1 damaged?

YES : Repair or replace them, then go to Step 13.

NO : Go to Step 6.

STEP 6. Check for harness damage between fan

control relay connector A-09X terminal 3 and

earth.

Connector: A-09X

A-09X

3

2

4

1

Relay box

side

AC310900

AB

Page 8

14-8

ENGINE COOLING

TROUBLESHOOTING

Q: Are the harness wires between fan control relay

connector A-09X terminal 3 and earth damaged?

YES : Repair or replace them, then go to Step 13.

NO : Go to Step 7.

STEP 7. Check the cooling fan motor.

Refer to P.14-17.

Q: Is the cooling fan motor in good condition?

YES : Go to Step 8.

NO : Replace it, then go to Step 13.

STEP 8. Check the circuit at fan controller

connector A-17 terminal 1.

Connector: A-17

Fan controller

A-17 (GR)

STEP 10. Measure the output circuit voltage at

engine-ECU connector C-121 terminal 18 by

backprobing.

Connector: C-121 <LHD>

Engine-ECU

C-121 (GR)

1924

10

11312

24

25

Connector: C-121 <RHD>

JAE

16

13

1415

26

1718

2829

27

3031

Harness side

6205

19 21

3332

8237

22

35

34

AC505254

AB

Component side

AC210859

AD

(1) Disconnect fan controller connector A-17, and

measure at the harness side connector.

(2) Measure the resistance between terminal No.1

and earth.

• The resistance should measure less than 2

ohms.

Q: Is the resistance less than 2 ohms?

YES : Go to Step 10.

NO : Go to Step 9.

STEP 9. Check the harness wire between fan

controller connector A-17 and earth.

Connector: A-17

Fan controller

A-17 (GR)

Engine-ECU

C-121 (GR)

1924

10

11312

24

25

JAE

16

13

1415

26

2829

27

1718

3031

6205

19 21

3332

8237

22

35

34

Harness side

AC505255

AB

(1) Do not disconnect engine-ECU connector C-121.

(2) Start the engine and allow it to idle.

(3) Turn the A/C switch to the "ON" position.

(4) Measure the voltage between terminal No.18 and

earth by backprobing.

• The voltage should measure 0.7 volt or more

when the cooling fan is operating.

Component side

Q: Are the harness wires between fan controller

connector A-17 and earth damaged?

YES : Repair or replace them, then go to Step 13.

NO : Go to Step 10.

AC210859

AD

Q: Is the voltage 0.7 volt or more when the cooling fan

is operating?

YES : Go to Step 12.

NO : Go to Step 11.

Page 9

ENGINE COOLING

TROUBLESHOOTING

14-9

STEP 11. Check the harness wire between

engine-ECU connector C-121 and fan controller

connector A-17.

NOTE:

Connector: A-13 <LHD>

A-13 (B)

AC210877

Connector: C-31 <RHD>

C-31

AC

Connector: C-121 <LHD>

56

3233 30

31

JAE

161819 1720

15

29

42

78

222123

34

35

Component side

Connector: C-121 <RHD>

Engine-ECU

Engine-ECU

3

11 10121314

24

262827 25

C-121 (GR)

1

9

AC505254

AC

AC310903

AB

If intermediate connector A-13 <LHD> terminal 2 and

intermediate connector C-31 <RHD> terminal 14 is

damaged, repair or replace it. Refer to GROUP 00,

How to Use Troubleshooting/Inspection Service

Points

P.00-5.

C-121 (GR)

6

3233 30

JAE

15

161819 1720

29

42

3

11 10121314

262827 25

1

9

24

5

31

78

222123

34

35

Component side

AC505255

AC

Connector: A-17

Fan controller

A-17 (GR)

Component side

AC210859

AD

Q: Are the harness wires between engine-ECU

connector C-121 terminal 18 and fan controller

connector A-17 terminal 2 damaged?

YES : Repair or replace them, then go to Step 13.

NO : Go to Step 12.

Page 10

14-10

ENGINE COOLING

TROUBLESHOOTING

STEP 12. Check the fan controller at engine-ECU

connector C-121.

Connector: C-121 <LHD>

Engine-ECU

C-121 (GR)

1924

10

11312

24

25

Connector: C-121 <RHD>

JAE

16

13

1415

26

1718

2829

27

3031

Harness side

6205

19 21

3332

8237

22

35

34

AC505254

AB

(2) Pull out terminal No.18.

(3) Turn the ignition switch to the "ON" position.

Q: Does the cooling fan motor operate?

YES : Replace the engine-ECU. Then go to Step

.

13

NO : Replace the fan controller. Then go to Step

.

13

STEP 13. Check the symptoms.

Q: Does the cooling fan operate correctly?

YES : The procedure is complete.

NO : Return to Step 1.

Engine-ECU

C-121 (GR)

1924

10

11312

24

25

JAE

16

13

1415

26

2829

27

1718

3031

6205

19 21

3332

8237

22

35

34

Harness side

AC505255

AB

(1) Do not disconnect engine-ECU connector C-121.

INSPECTION PROCEDURE 2: Cooling fan does not change speed or does not stop

NOTE: If the engine coolant temperature reaches 110°C or higher, the cooling fan control runs the cooling fan

for up to 5 minutes even after the ignition switch is turned to the "LOCK" (OFF) position (the fan stops its rota

tion when the engine coolant temperature decreases to 110°C or lower).

COOLING FAN DRIVE CIRCUIT

Refer to P.14-4.

CIRCUIT OPERATION

• The fan controller is powered from fusible link

No.2.

• The engine-ECU judges the required revolution

speed of cooling fan motor using the input signals

transmitted from A/C switch, vehicle speed sen

sor and engine coolant temperature sensor. The

engine-ECU activates the fan controller to drive

the cooling fan motor.

-

-

Page 11

ENGINE COOLING

TROUBLESHOOTING

14-11

TECHNICAL DESCRIPTION

• The fan controller has variable control of the cooling fan motor speed using signals transmitted

from the engine-ECU.

TROUBLESHOOTING HINTS

• Malfunction of fan control relay

• Malfunction of fan controller

• Malfunction of engine-ECU

DIAGNOSIS

STEP 1. Check the fan control relay.

Refer to P.14-17.

Q: Is the fan control relay in good condition?

YES : Go to Step 2.

NO : Replace the part, then go to Step 8.

STEP 2. Check the harness wire between fan

control relay connector A-09X terminal 2 and fan

controller connector A-17 terminal 3.

STEP 3. Measure the output circuit voltage at

engine-ECU connector C-121 terminal 18 by

backprobing.

Connector: C-121 <LHD>

Engine-ECU

C-121 (GR)

1924

10

11312

24

25

Connector: C-121 <RHD>

JAE

16

13

1415

26

1718

2829

27

3031

Harness side

6205

19 21

3332

8237

22

35

34

AC505254

AB

Connector: A-09X

A-09X

3

2

4

1

Relay box

side

AC310900

AB

Connector: A-17

Fan controller

A-17 (GR)

Component side

AC210859

AD

Q: Are the harness wire between fan control relay

connector A-09X and fan controller connector A-17

damaged?

YES : Repair or replace the part, then go to Step

6

.

NO : Go to Step 3.

Engine-ECU

C-121 (GR)

1924

10

11312

24

25

JAE

16

13

1415

26

2829

27

1718

3031

6205

19 21

3332

8237

22

35

34

Harness side

AC505255

AB

(1) Do not disconnect engine-ECU connector C-121.

(2) Start the engine and allow it to idle.

(3) Measure the voltage between terminal No.18 and

earth by backprobing.

• The voltage should measure less than 0.3 volt

when the cooling fan is not operating.

Q: Is the voltage less than 0.3 volt when the cooling

fan is not operating?

YES : Go to Step 6.

NO : Go to Step 4.

Page 12

14-12

ENGINE COOLING

TROUBLESHOOTING

STEP 4. Measure the output circuit voltage at

engine-ECU connector C-121 terminal 18 by

backprobing.

Connector: C-121 <LHD>

Engine-ECU

C-121 (GR)

1924

10

11312

24

25

Connector: C-121 <RHD>

JAE

16

13

1415

26

1718

2829

27

3031

Harness side

6205

19 21

3332

8237

22

35

34

AC505254

AB

(2) Start the engine and allow it to idle.

(3) Turn the A/C switch to the "ON" position.

(4) Measure the voltage between terminal No.18 and

earth by backprobing.

• The voltage should measure 0.7 volt or more

when the cooling fan is operating.

Q: Is the voltage 0.7 volt or more when the cooling fan

is operating?

YES : Go to Step 6.

NO : Go to Step 5.

Engine-ECU

C-121 (GR)

1924

10

11312

24

25

JAE

16

13

1415

26

2829

27

1718

3031

6205

19 21

3332

8237

22

35

34

Harness side

AC505255

AB

(1) Do not disconnect engine-ECU connector C-121.

Page 13

ENGINE COOLING

TROUBLESHOOTING

14-13

STEP 5. Check the harness wire between

engine-ECU connector C-121 and fan controller

connector A-17.

NOTE:

Connector: A-13 <LHD>

A-13 (B)

AC210877

Connector: C-31 <RHD>

C-31

AC

Connector: C-121 <LHD>

56

3233 30

31

JAE

161819 1720

15

29

42

78

222123

34

35

Component side

Connector: C-121 <RHD>

Engine-ECU

Engine-ECU

3

11 10121314

24

262827 25

C-121 (GR)

1

9

AC505254

AC

AC310903

AB

If intermediate connector A-13 <LHD> terminal 2 and

intermediate connector C-31 <RHD> terminal 14 is

damaged, repair or replace it. Refer to GROUP 00,

How to Use Troubleshooting/Inspection Service

Points

P.00-5.

C-121 (GR)

6

3233 30

JAE

15

161819 1720

29

42

3

11 10121314

262827 25

1

9

24

5

31

78

222123

34

35

Component side

AC505255

AC

Connector: A-17

Fan controller

A-17 (GR)

Component side

AC210859

AD

Q: Are the harness wires between engine-ECU

connector C-121 terminal 18 and fan controller

connector A-17 terminal 2 damaged?

YES : Repair or replace them, then go to Step 8.

NO : Go to Step 6.

Page 14

14-14

ENGINE COOLING

TROUBLESHOOTING

STEP 6. Check the fan controller at engine-ECU

connector C-121.

Connector: C-121 <LHD>

Engine-ECU

C-121 (GR)

1924

10

11312

24

25

Connector: C-121 <RHD>

JAE

16

13

1415

26

1718

2829

27

3031

Harness side

6205

19 21

3332

8237

22

35

34

AC505254

AB

STEP 7. Check the fan controller at engine-ECU

connector C-121.

Connector: C-121 <LHD>

Engine-ECU

C-121 (GR)

1924

10

11312

24

25

Connector: C-121 <RHD>

JAE

16

13

1415

26

1718

2829

27

3031

Harness side

6205

19 21

3332

8237

22

35

34

AC505254

AB

Engine-ECU

C-121 (GR)

1924

10

11312

24

25

JAE

16

13

1415

26

2829

27

1718

3031

6205

19 21

3332

8237

22

35

34

Harness side

AC505255

AB

(1) Do not disconnect engine-ECU connector C-121.

(2) Pull out terminal No.18.

(3) Turn the ignition switch to the "ON" position.

Q: Does the cooling fan motor operate?

YES : Replace the engine-ECU. Then go to Step

8

.

NO : Go to Step 7.

Engine-ECU

C-121 (GR)

1924

10

11312

24

25

JAE

16

13

1415

26

2829

27

1718

3031

6205

19 21

3332

8237

22

35

34

Harness side

AC505255

AB

(1) Disconnect engine-ECU connector C-121.

(2) Pull out terminal No.18.

(3) Connect terminal No.18 to the body earth.

(4) Turn the ignition switch to the "ON" position.

Q: Does the cooling fan motor stop running?

YES : Replace the engine-ECU. Then go to Step

.

8

NO : Replace the fan controller. Then go to Step

8

.

STEP 8. Check the symptoms.

Q: Does the cooling fan operate correctly?

YES : The procedure is complete.

NO : Return to Step 1.

Page 15

ENGINE COOLING

ON-VEHICLE SERVICE

ON-VEHICLE SERVICE

14-15

ENGINE COOLANT LEAK CHECK

M1141001000388

WARNING

When pressure testing the cooling system,

slowly release cooling system pressure to

avoid getting burned by hot coolant.

CAUTION

• Be sure to completely clean away any moisture from the places checked.

• When the tester is taken out, be careful not to

spill any coolant.

•

Be careful when installing and removing the

tester and when testing not to deform the

filler neck of the radiator.

Cap adapter

Adapter

Minimum limit: 83 kPa

Standard value: 93 − 123 kPa

3. Replace the radiator cap if the reading does not

remain at or above the minimum limit.

ENGINE COOLANT REPLACEMENT

M1141001200553

1. Remove the under cover (Refer to GROUP 51,

Front Bumper

WARNING

When removing the radiator cap, use care to

avoid contact with hot coolant or steam.

Place a shop towel over the cap and turn the

cap anti-clockwise a little to let the pressure

escape through the vinyl tube. After relieving

the steam pressure, remove the cap by

slowly turning it anti-clockwise.

2. Drain the water from the radiator, heater core and

engine after unplugging the radiator drain plug

and removing the radiator cap.

P.51-2).

ACX01844

AB

1. Check that the coolant level is up to the filler neck.

Install a radiator tester and apply 160 kPa

pressure, and then check for leakage from the

radiator hose or connections.

2. If there is leakage, repair or replace the

appropriate part.

RADIATOR CAP PRESSURE CHECK

M1141001300453

NOTE: Be sure that the cap is clean before testing.

Rust or other foreign material on the cap seal will

cause an improper reading.

Cap adapter

AC211643 AB

1. Use a cap adapter to attach the cap to the tester.

2. Increase the pressure until the indicator of the

gauge stops moving.

Water inlet pipe

44 ± 5 N·m

AC210639

AB

3. Drain the water in the water jacket by unplugging

the drain plug of the cylinder block.

4. Remove the reserve tank and drain the coolant.

5. Drain the cooling water then clean the path of the

cooling water by injecting water into the radiator

from the radiator cap area.

Page 16

14-16

ENGINE COOLING

ON-VEHICLE SERVICE

6. Apply the designated sealant to the screw area of

the cylinder block drain plug, and then tighten to

the standard torque.

Specified sealant: 3M Nut Locking Part

No.4171 or equivalent

Tightening torque: 44 ± 5 N⋅m

7. Securely tighten the drain plug of the radiator.

8. Assemble the reserve tank.

CAUTION

Do not use alcohol or methanol anti-freeze or any

engine coolants mixed with alcohol or methanol

anti-freeze. The use of an improper anti-freeze

can cause corrosion of the aluminium compo

-

nents.

MB991871

Air hose

AC210658

AB

9. By referring to the section on coolant, select an

appropriate concentration for safe operating

temperature within the range of 30 to 60 %. Use

special tool LLC changer (MB991871) to refill the

coolant. A convenient mixture is a 50 % water and

50 % antifreeze solution (freezing point:

−31°C).

Recommended antifreeze: DIA QUEEN SUPER

LONG LIFE COOLANT or equivalent

Quantity: 6.0 L

NOTE: For how to use the special tool, refer to its

manufacturer’s instructions.

10.Reinstall the radiator cap.

11.Start the engine and let it warm up until the

thermostat opens.

12.Repeatedly revving the engine up to 3,000 r/min

several times, then stop the engine.

13.Remove the radiator cap after the engine has

become cold, and pour in coolant up to the brim.

Reinstall the cap.

CAUTION

Do not overfill the reserve tank.

14.Add coolant to the reserve tank between the

"FULL" and "LOW" mark if necessary.

15.Install the under cover (Refer to GROUP 51,

Front Bumper

P.51-2).

CONCENTRATION MEASUREMENT

M1141001100448

Measure the temperature and specific gravity of the

engine coolant to check the antifreeze concentration.

Standard value: 30 − 60 % (allowable concen-

tration range)

Recommended antifreeze: DIA QUEEN SUPER

LONG LIFE COOLANT or equivalent

CAUTION

If the concentration of the anti-freeze is below 30

%, the anti-corrosion property will be adversely

affected. In addition, if the concentration is

above 60 %, both the anti-freezing and engine

cooling properties will decrease, affecting the

engine adversely. For these reasons, be sure to

maintain the concentration level within the speci

fied range.

FAN CONTROLLER CHECK

M1141006100238

1. Remove the centre under cover (Refer to GROUP

51, Front Bumper

Fan controller

connector:

Component

side

23 1

2. Disconnect the fan controller connector.

3. Turn the ignition switch to the "ON" position, and

measure the voltage between the harness-side

connector terminals.

Standard value: Battery positive voltage

4. Turn the ignition switch to the "LOCK" (OFF)

position, and connect the fan controller connector.

P.51-2).

Fan controller

AC210945

AB

-

Page 17

Fan controller

MB991222

Circuit tester

Cooling fan motor

connector:

Harness side

ENGINE COOLING

ON-VEHICLE SERVICE

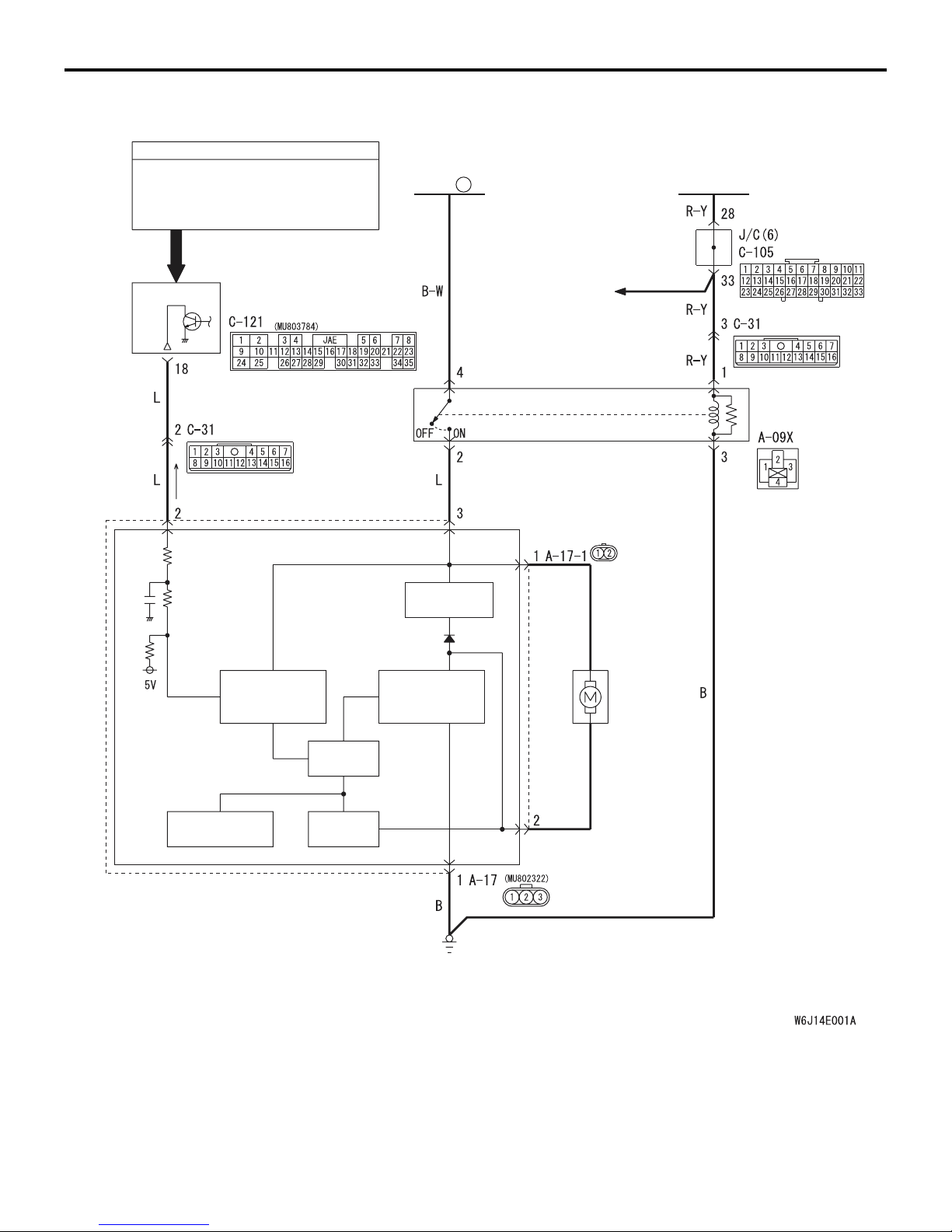

FAN CONTROL RELAY CONTINUITY

CHECK

Battery

14-17

M1141006200354

AC210667

AB

5. Insert special tool probe (MB991222) at the back

of the cooling fan motor connector.

6. Connect the special tool to the circuit tester.

7. Ensure that the A/C switch is off, and start the

engine and run it at idle.

8. Measure the voltage between the cooling fan

motor connector terminals.

Standard value: 1V or less

9. Turn the A/C switch to the "ON" position.

WARNING

Stay clear of the fan when the fan starts running.

10. Measure the voltage between the cooling fan

motor connector terminals while the fan is

running. The voltage should repeat the values 1)

and 2) below.

Standard value:

1) 8.2 ± 2.6 V

2) Battery positive voltage ± 2.6 V

11.If the voltage does not repeatedly change as

indicated, replace the fan controller.

12.Install the centre under cover (Refer to GROUP

51, Front Bumper

P.51-2).

4

2

3

1

AC210672

Continuity test

results

AB

Battery

voltage

2

13

4

Terminal No.to

be connected to

tester

Not applied 4 − 2 Open circuit

• Connect

4 − 2 Less than 2 ohms

terminal

No.1 and

battery

(+)

terminal.

• Connect

terminal

No.3 and

battery

−)

(

terminal.

COOLING FAN MOTOR CHECK

M1141007100134

1. Remove the centre under cover (Refer to GROUP

51, Front Bumper

P.51-2).

Page 18

14-18

ENGINE COOLING

THERMOSTAT

Cooling fan

motor

connector:

Component side

Cooling fan motor

AC210668

AB

2. Remove the cooling fan motor connector.

THERMOSTAT

REMOVAL AND INSTALLATION

M1141002400884

Pre-removal Operation

• Under Cover Removal (Refer to GROUP 51, Front

Bumper

• Engine Coolant Draining (Refer to P.14-15).

• Intake Air Duct Removal (Refer to GROUP 15, Air

Cleaner

• Air Hose E, Air Pipe C and Air Hose D Removal (Refer to

GROUP 15, Intercooler

P.51-2).

P.15-5).

P.15-6).

WARNING

Stay clear of the fan when the fan starts running.

3. Check to see that the fan motor of the radiator

turns when applying battery power between the

connector terminals of the cooling fan motor. Also

check to see that there is no abnormal sound

coming from the cooling fan motor at this time.

4. If the cooling fan motor is defective, replace it.

5. Install the centre under cover (Refer to GROUP

51, Front Bumper

Post-installation Operation

• Air Hose E, Air Pipe C and Air Hose D Installation (Refer

to GROUP 15, Intercooler

• Intake Air Duct Installation (Refer to GROUP 15, Air

Cleaner

• Engine Coolant Refilling (Refer to P.14-15).

• Under Cover Installation (Refer to GROUP 51, Front

Bumper

P.15-5).

P.51-2).

P.51-2).

P.15-6).

10 ± 1 N·m

5

6

7

8

4

5.0 ± 1.0 N·m

11 ± 1 N·m

2

1

11 ± 1 N·m

3

Removal steps

1. Accelerator cable connection <LH

drive vehicles>

2. Control wiring harness connection

<<A>> >>B<<

AC504958

Removal steps (Continued)

3. Vacuum hose and pipe assembly

4. Radiator upper hose connection

5. Wiring harness clamp

AB

Page 19

ENGINE COOLING

THERMOSTAT

14-19

Removal steps (Continued)

6. Harness bracket

7. Water outlet fitting

>>A<<

8. Thermostat

REMOVAL SERVICE POINT

<<A>> RADIATOR UPPER HOSE DISCON-

NECTION

Mating marks

AC200641AB

Make mating marks on the radiator hose and the

hose clamp. Disconnect the radiator hose.

INSTALLATION SERVICE POINTS

>>A<< THERMOSTAT INSTALLATION

1. Insert each hose as far as the projection of the

water outlet fitting.

2. Align the mating marks on the radiator hose and

hose clamp, and then connect the radiator hose.

INSPECTION

M1141002500494

THERMOSTAT CHECK

ACX00400

1. Immerse the thermostat in water, and heat the

water while stirring. Check the thermostat valve

opening temperature.

Standard value:

Valve opening temperature: 80 ± 1.5°C

CAUTION

Make absolutely sure that no oil is adhering to

the rubber ring of the thermostat. In addition, be

careful not to fold over or scratch the rubber ring

when inserting. If the rubber ring is damaged,

replace the thermostat.

Install the thermostat being careful not to fold over or

scratch the rubber ring.

>>B<< RADIATOR UPPER HOSE

CONNECTION

Projection

Water outlet fitting

Mating marks

AC200642

AB

Valve lift

ACX00401

AB

2. Check that the amount of valve lift is at the

standard value when the water is at the

full-opening temperature.

NOTE: Measure the valve height when the thermostat is fully closed, and use this measurement

to compare the valve height when the thermostat

is fully open.

Standard value:

Full-opening temperature: 93°C

Amount of valve lift: 9.5 mm or more

Page 20

14-20

ENGINE COOLING

WATER PUMP

WATER PUMP

REMOVAL AND INSTALLATION

M1141002701004

CAUTION

If the vehicle is equipped with the Brembo™ disc brake, during maintenance, take care not to contact

the caliper with tools or parts, because the caliper paint will be scratched.

Pre-removal Operation

• Under Cover Removal (Refer to GROUP 51, Front

Bumper

• Engine Coolant Draining (Refer to P.14-15).

• Timing Belt Tensioner Adjuster Removal (Refer to

GROUP 11A, Timing Belt

P.51-2).

24 ± 4 N·m

20 ± 2 N·m

P.11A-36).

22 ± 4 N·m

N

4

1

Post-installation Operation

• Timing Tensioner Adjuster Belt Installation (Refer to

GROUP 11A, Timing Belt

• Engine Coolant Refilling (Refer to P.14-15).

• Under Cover Installation (Refer to GROUP 51, Front

Bumper

P.51-2).

P.11A-36).

23 ± 3 N·m

14 ± 1 N·m

2

Removal steps

1. Alternator brace

2. Water pump

Bolt specifications

8 × 60

N

3

8 × 22

8 × 14

2

8 × 55

8 × 22

Nominal diameter × Nominal length mm

AC406755

>>A<<

AC504976

Removal steps (Continued)

3. Water pump gasket

4. O-ring

AB

Page 21

ENGINE COOLING

WATER PUMP

14-21

INSTALLATION SERVICE POINT

>>A<< O-RING INSTALLATION

CAUTION

Do not let the O-ring get contaminated with

grease or engine oil.

Water pump

O-ring

Water inlet pipe

AC103005

AC

Fit an O-ring into the O-ring groove located at the

end of the water inlet pipe and apply water to the

O-ring or the inside of the mounting surface of the

water pump for insertion.

Page 22

14-22

ENGINE COOLING

WATER HOSE AND WATER PIPE

WATER HOSE AND WATER PIPE

REMOVAL AND INSTALLATION

M1141003301076

Pre-removal Operation

• Under Cover Removal (Refer to GROUP 51, Front

Bumper

• Engine Coolant Draining (Refer to P.14-15).

• Battery and Battery Tray Removal

• Air Cleaner Assembly Removal (Refer to GROUP 15, Air

Cleaner

• Turbocharger Bypass Valve Assembly, Air By-pass Hose,

Air Hose E, Air Pipe C and Air Hose D Removal (Refer to

GROUP 15, Intercooler

• Thermostat Removal (Refer to P.14-18).

11

N

P.51-2).

P.15-5).

P.15-6).

12

13

13 ± 2 N·m

9

16

Post-installation Operation

• Thermostat Installation (Refer to P.14-18).

• Turbocharger Bypass Valve Assembly, Air By-pass Hose,

• Air Cleaner Assembly Installation (Refer to GROUP 15,

• Battery and Battery Tray Installation

• Engine Coolant Refilling (Refer to P.14-15).

• Under Cover Installation (Refer to GROUP 51, Front

N

10

5.0 ± 1.0 N·m

Air Hose E, Air Pipe C and Air Hose D Installation (Refer

to GROUP 15, Intercooler

Air Cleaner

Bumper

P.15-5).

P.51-2).

P.15-6).

11 ± 1 N·m

2

8

4

6

1

23 ± 4 N·m

3

<<A>> >>C<<

>>A<<

15

10 ± 1 N·m

Removal steps

1. Wiring harness clamp

2. Harness bracket

3. Engine coolant temperature gauge

unit connector

4. Engine coolant temperature

sensor connector

5. Water feed hose

6. Thermostat case assembly

7. Thermostat case gasket

8. Radiator lower hose connection

9. Detonation sensor connection

10. O-ring

11. Water feed hose

42 ± 7 N·m

19

20

N

>>B<<

>>A<<

7

N

14

5

10 ± 1 N·m

17

42 ± 7 N·m

N

18

AC504959

Removal steps (Continued)

12. Water return hose

13. Heater hose connection

14. Water return hose

15. Water inlet pipe

16. O-ring

17. Turbocharger water feed pipe

18. Gaskets

Turbocharger and exhaust fitting

•

assembly (Refer to GROUP 15,

Exhaust Manifold and

Turbocharger

19. Turbocharger water return pipe

20. Gaskets

P.15-10).

AB

Page 23

ENGINE COOLING

WATER HOSE AND WATER PIPE

14-23

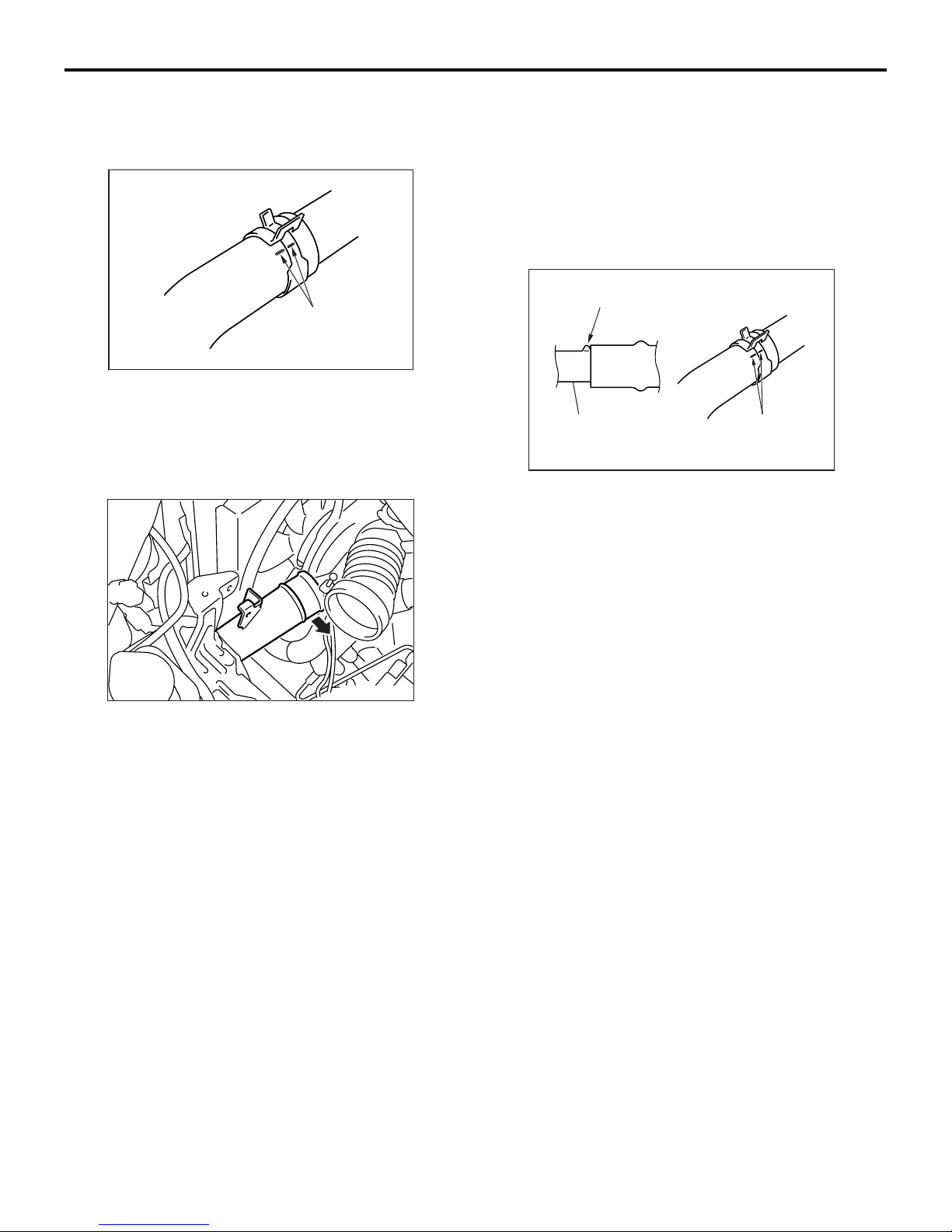

REMOVAL SERVICE POINT

<<A>> RADIATOR LOWER HOSE DIS-

CONNECTION

Mating marks

AC200641AB

Make mating marks on the radiator hose and the

hose clamp. Disconnect the radiator hose.

INSTALLATION SERVICE POINTS

>>A<< O-RING INSTALLATION

CAUTION

Do not let the O-ring get contaminated with

grease or engine oil.

Water pump

>>B<< WATER INLET PIPE

INSTALLATION

Temporarily install the water inlet pipe. After installing

the water outlet fitting and thermostat case assembly,

tighten the mounting bolt of the water inlet pipe to the

specified torque.

Tightening torque

M6 bolt: 5.0 ± 1.0 N⋅m

M8 bolt: 13 ± 2 N⋅m

>>C<< RADIATOR LOWER

HOSE/RADIATOR UPPER HOSE

CONNECTION

Projection

Water inlet pipe or

water outlet fitting

Mating

marks

AC200642

AD

O-ring

Water inlet pipe

AC103005

AC

Fit an O-ring into the O-ring groove located at the

end of the water inlet pipe and apply water to the

O-ring or the inside of the mounting surface of the

water pump for insertion.

1. Insert each hose as far as the projection of the

water inlet pipe or water outlet fitting.

2. Align the mating marks on the radiator hose and

hose clamp, and then connect the radiator hose.

INSPECTION

M1141003400360

WATER PIPE AND HOSE CHECK

Check the water pipe and hose for cracks, damage

and clogs. Replace them if necessary.

Page 24

14-24

ENGINE COOLING

RADIATOR

RADIATOR

REMOVAL AND INSTALLATION

M1141001501193

Pre-removal Operation

• Under Cover Removal (Refer to GROUP 51, Front

Bumper

• Engine Coolant Draining (Refer to P.14-15).

• Battery and Battery Tray Removal

• Air Cleaner Assembly Removal (Refer to GROUP 15, Air

Cleaner

• Air Hose E, Air Pipe C and Air Hose D Removal (Refer to

GROUP 15, Intercooler

P.51-2).

P.15-5).

12 ± 2 N·m

11

P.15-6).

12 ± 2 N·m

3

13

Post-installation Operation

• Air Hose E, Air Pipe C and Air Hose D Installation (Refer

11

to GROUP 15, Intercooler

• Air Cleaner Assembly Installation (Refer to GROUP 15,

Air Cleaner

• Battery and Battery Tray Installation

• Engine Coolant Refilling (Refer to P.14-15).

• Under Cover Installation (Refer to GROUP 51, Front

Bumper

P.15-5).

P.51-2).

5.0 ± 1.0 N·m

4

P.15-6).

6

7

9

5

5.0 ± 1.0 N·m

N

2

1

5.0 ± 1.0 N·m

8

<<A>> >>A<<

<<A>> >>A<<

<<B>>

14

10

12 ± 2 N·m

12

Radiator removal steps

1. Radiator drain plug

2. O-ring

3. Radiator cap

4. Reserve tank hose

5. Reserve tank

6. Reserve tank cap

7. Reserve tank hose

8. Reserve tank bracket

9. Radiator upper hose

10. Radiator lower hose

11. Upper insulator

12. Air pipe B mounting bolt

13. Radiator assembly

14. Lower insulator

14

3.5 ± 0.4 N·m

20

4.5 ± 0.4 N·m

19

<<B>>

22

16

5.4 ± 0.5 N·m

21

17

18

15

AC210706

Radiator removal steps

15. Fan controller connector

16. Fan controller, cooling fan motor,

fan and shroud assembly

Fan controller and cooling fan

motor removal steps

12. Air pipe B mounting bolt

15. Fan controller connector

17. Cooling fan motor connector

18. Fan controller

19. Cooling fan motor, fan and shroud

assembly

20. Cooling fan

21. Cooling fan motor

22. Cooling fan shroud

AC

Page 25

ENGINE COOLING

RADIATOR

14-25

REMOVAL SERVICE POINTS

<<A>> RADIATOR UPPER HOSE/RADIA-

TOR LOWER HOSE DISCONNECTION

Mating marks

AC200641AB

Make mating marks on the radiator hose and the

hose clamp. Disconnect the radiator hose.

<<B>> AIR PIPE B MOUNTING BOLT

REMOVAL

After removing the bolt, position air pipe B out of the

way so that the pipe does not interfere with the radia

tor assembly or the cooling fan motor, the fan and

shroud assembly.

INSTALLATION SERVICE POINT

>>A<< RADIATOR LOWER HOSE/RADIA-

TOR UPPER HOSE CONNECTION

Projection

Water inlet pipe,

water outlet fitting

or radiator

1. Insert each hose as far as the projection of the

water inlet pipe, water outlet fitting or radiator.

2. Align the mating marks on the radiator hose and

hose clamp, and then connect the radiator hose.

Mating marks

AC200642

AC

-

AC210705

Page 26

NOTES

Loading...

Loading...