WORKSHOP MANUAL

EVOLUTION-IV

EVOLUTION-V

Pub. No. S9806CNCP9

General . . . . . . . . . . . . . . . . . . . . . . . .

00

EVOLUTION-IV

EVOLUTION-V

WORKSHOP MANUAL

FOREWORD

This Workshop Manual contains procedures for

service mechanics, including removal, disassembly,

inspection, adjustment, reassembly and

installation. Figures taken from registration

documents are given in metric units only. All other

figures are given in SI units with metric units in

brackets. Use the following manuals in combination

with this manual as required.

Engine . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Lubrication . . . . . . . . . . . . .

Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Cooling . . . . . . . . . . . . . . . . .

Intake and Exhaust . . . . . . . . . . . .

Engine Electrical . . . . . . . . . . . . . . .

Engine and Emission Control . . . .

Clutch . . . . . . . . . . . . . . . . . . . . . . . . .

Manual Transmission . . . . . . . . . . .

Front Axle . . . . . . . . . . . . . . . . . . . . . .

Rear Axle . . . . . . . . . . . . . . . . . . . . . .

Power Plant Mount . . . . . . . . . . . . . .

11

12

13

14

15

16

17

21

22

26

27

32

TECHNICAL INFORMATION MANUAL

N9806CNCP9

All information, illustrations and product

descriptions contained in this manual are current

as at the time of publication. We, however, reserve

the right to make changes at any time without prior

notice or obligation.

July 1998

Front Suspension . . . . . . . . . . . . . . .

Rear Suspension . . . . . . . . . . . . . . .

Service Brakes . . . . . . . . . . . . . . . . .

Parking Brakes . . . . . . . . . . . . . . . . .

Steering . . . . . . . . . . . . . . . . . . . . . . . .

Body . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exterior . . . . . . . . . . . . . . . . . . . . . . . .

Chassis Electrical . . . . . . . . . . . . . .

Electrical Wiring . . . . . . . . . . . . . . . .

33

34

35

36

37

42

51

54

ELECTRICAL

WIRING

CONTENTS

HOW TO READ THE WIRING DIAGRAMS A. . . . . . . . . . . . . . . . . . . . . .

ELECTRICAL WIRING (EVOLUTION-IV) B. . . . . . . . . . . . . . . . . . . . . . .

ELECTRICAL WIRING (EVOLUTION-V) C. . . . . . . . . . . . . . . . . . . . . . . .

NOTES

GENERAL

CONTENTS

MODELS 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

00-1

00-2

16 valves-intercooler

(4WD-5M/T)

controlled fuel

16

(4WD-5M/T)

MODELS

<LANCER EVOLUTION-IV>

GENERAL – Models

Model

code

E-CN9A SNDF ’97 RS 4G63 (2,000-DOHC –-W5M51

Class

code

SRGF ’97 GSR

Model

year

Grade Engine model Transmission

model

turbo)

<LANCER EVOLUTION-V>

Model

code

GF-CP9A SNDF ’98 EVOLUTION-V RS 4G63 (2,000-DOHC –

Class

code

SNGF ’98 EVOLUTION-V

Model

year

Grade Engine model Transmission

GSR

model

W5M51

valves-intercooler

turbo)

Applicable serial numbers

E-CN9A: CN9A – 0000001 Y

GF-CP9A: CP9A – 0000001 Y

Fuel supply

system

Electronically

injection (MPI)

Fuel supply

system

MPI

f

ENGINE

CONTENTS

11-1

SERVICE SPECIFICATIONS 2. . . . . . . . . . . . . .

SEALANTS 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SPECIAL TOOLS 2. . . . . . . . . . . . . . . . . . . . . . . .

ENGINE ADJUSTMENTS 4. . . . . . . . . . . . . . . . .

1. Drive Belt Tension Check 4. . . . . . . . . . . . . . .

2. Auto Tensioner Check 5. . . . . . . . . . . . . . . . . . .

3. Lash Adjuster Check 5. . . . . . . . . . . . . . . . . . . .

4. Lash Adjuster Replacement 7. . . . . . . . . . . . . .

5. Ignition Timing Check 7. . . . . . . . . . . . . . . . . . .

6. Idle Speed Check and Idle Mixture Check 7

7. Compression Pressure Check 7. . . . . . . . . . . .

8. Manifold Vacuum Check 8. . . . . . . . . . . . . . . . .

CRANKSHAFT PULLEY 9. . . . . . . . . . . . . . . . . .

CAMSHAFT AND CAMSHAFT

OIL SEAL 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OIL PAN 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CRANKSHAFT OIL SEAL 15. . . . . . . . . . . . . .

CYLINDER HEAD GASKET 17. . . . . . . . . . . .

TIMING BELT . . . . . . . . . . . . . . 21. . . .

ENGINE ASSEMBLY 32. . . . . . . . . . . . . . . . . . .

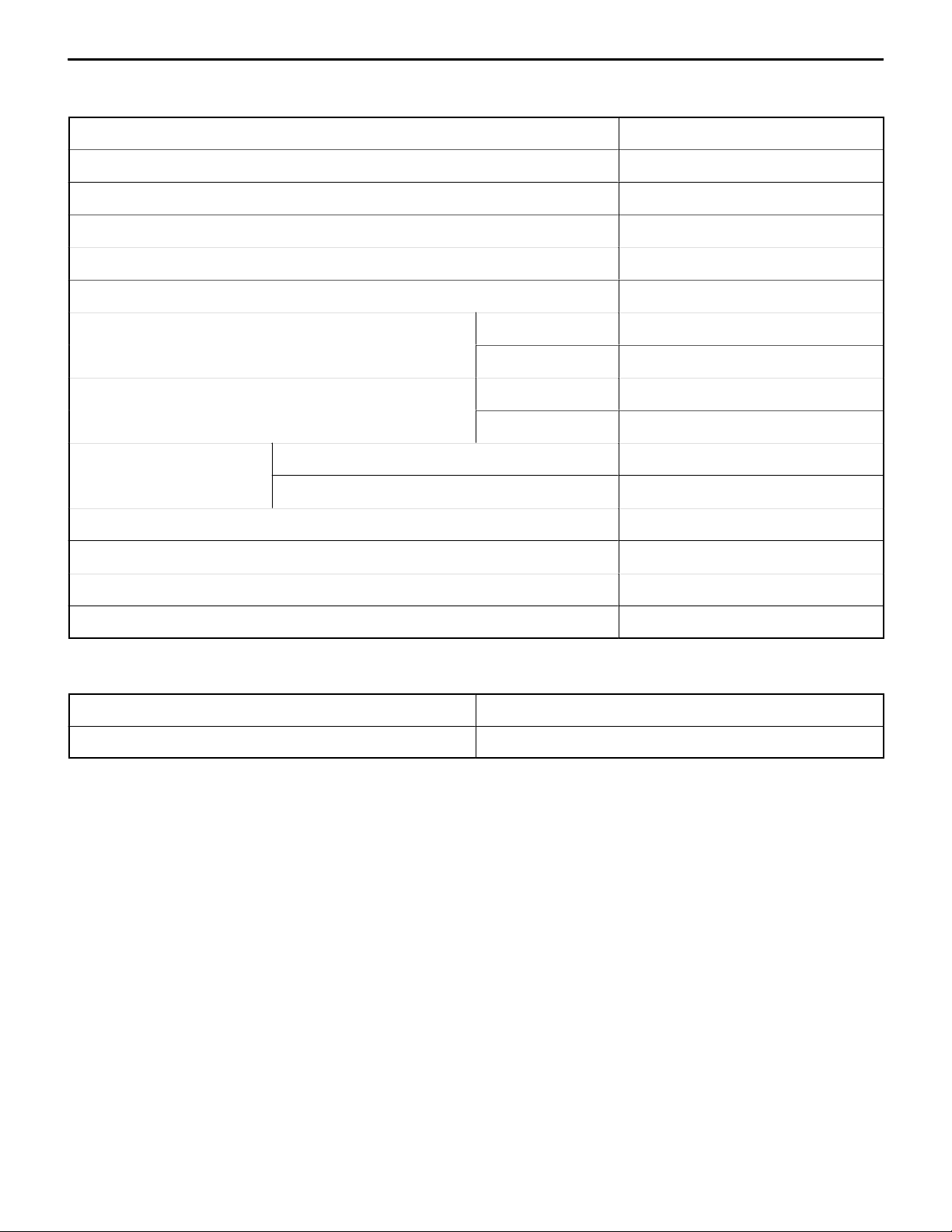

11-2

ENGINE – Service Specifications / Sealants / Special Tools

SERVICE SPECIFICATIONS

Items Standard value Limit

Basic ignition timing 5_ BTDC ± 3_ –

Ignition timing (at idle) Approx. 5_ BTDC –

Idle speed rpm 850 ± 50 –

CO contents % 0.6 or less –

HC contents ppm 300 or less –

Compression pressure kg/cm2 – rpm 11.5 – 250 Min. 9.7 – 250

Compression pressure difference of all cylinders kg/cm

Intake manifold vacuum kPa {mmHg} – Min. 55 {410}

Cylinder head bolt shank length mm – 99.4

2

– Max. 1.0

SEALANTS

Items Specified sealants

Rocker cover Semi-drying sealant: THREEBOND 1207D [MZ 100168] (containing 150 g)

Oil pan Semi-drying sealant: THREEBOND 1207F [MZ 100191] (containing 150 g)

NOTE:

Given in [ ] are MITSUBISHI GENUINE PART numbers.

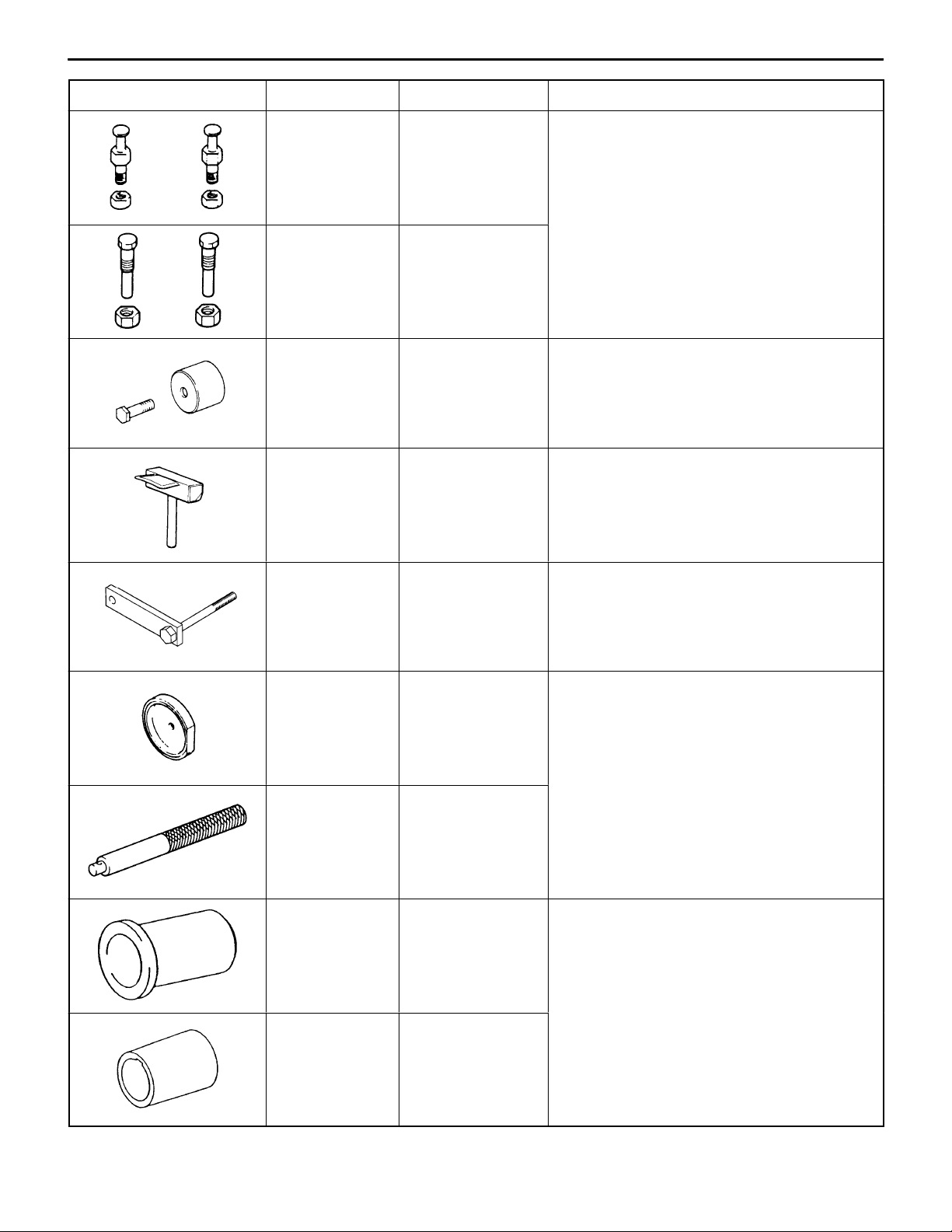

SPECIAL TOOLS

Tool Number Name Use

MD998782 Valve lifter set Replacing the lash adjuster

MB990767 End yoke holder D Holding the crankshaft pulley

D Holding the camshaft sprocket

Tool UseNameNumber

ENGINE – Special Tools

11-3

MD998719 Crankshaft pulley

holder pin

MD998715 Pulley holder pin

MD998713 Camshaft oil seal

installer

MD998727 Oil pan remover Removing the oil pan

D Holding the crankshaft pulley

D Holding the camshaft sprocket

Pressfitting the camshaft oil seal

MD998781 Flywheel stopper Securing the flywheel or drive plate

MD998776 Crankshaft rear oil

seal installer

MB990938 Handle

MD998382 Crankshaft front oil

seal installer

Pressfitting the crankshaft rear oil seal

Installing the crankshaft front oil seal

MD998285 Crankshaft front oil

seal guide

11-4

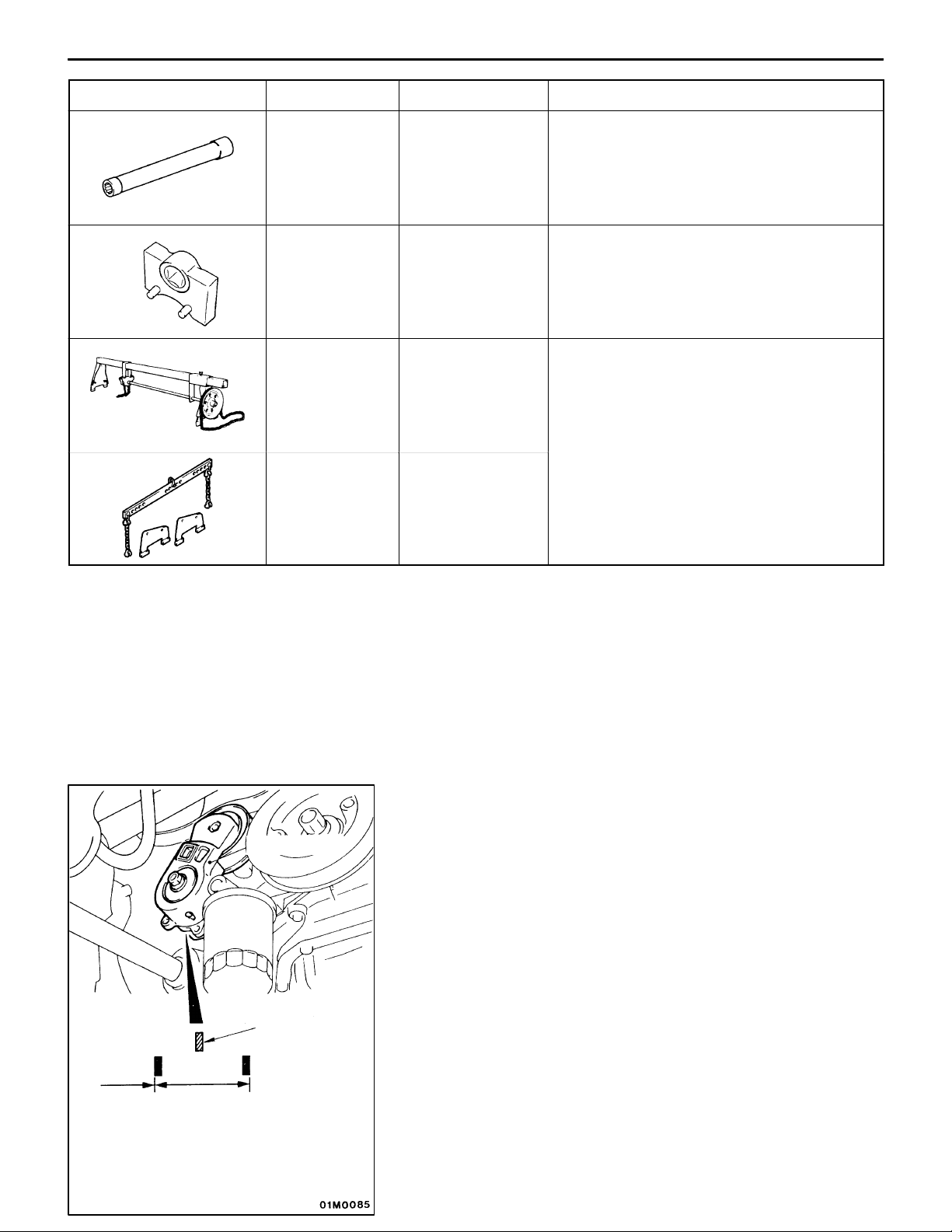

Tool UseNameNumber

ENGINE – Special Tools / Engine Adjustments

MB991654 Cylinder head bolt

wrench

MD998767 Tensioner pulley

socket wrench

Recommended

tool MZ203826

by Anzen

Jidosha or

MZ203827 by

Banzai

MD991453 Engine hanger

Engine lifter Supporting the engine assembly during

assembly

Removing and reinstalling the cylinder head

bolt

Timing belt tension adjustment

removal and installation of the transmission

ENGINE ADJUSTMENTS

Auto tensioner

Indicator mark

B

A

1. DRIVE BELT TENSION CHECK

NOTE

Use of the auto tensioner eliminates the need for belt tension

adjustment. Check that the indicator mark on the auto

tensioner is in the range of A shown.

If it is outside the specified range (i.e., in range of B shown),

replace the drive belt.

(For the removal and installation of the drive belt, refer to

P.11-9.)

Good

Tool mounting hole

MAX

MIN

High-pressure

chamber

ENGINE – Engine Adjustments

2. AUTO TENSIONER CHECK

(1) Stop the engine from the idle speed and check that the

belt rests within the auto tensioner pulley width.

(2) Remove the drive belt.

(For the removal of the drive belt, refer to P.11-9.)

(3) Fit a spinner handle or similar tool into the tool mounting

hole of the auto tensioner and turn the tensioner clockwise

and counterclockwise to ensure that it does not bind.

(4) If step (1) or (3), or both, have been checked abnormally,

replace the auto tensioner.

(5) Reinstall the drive belt.

3. LASH ADJUSTER CHECK

NOTE

If an unusual knocking noise can be heard immediately after

the engine has started or while it is running and if that is

probably attributable to the lash adjuster, make the following

checks.

(1) Check the engine oil and add or change oil as necessary.

NOTE

(1) If the engine oil level is low, air is taken in through

the oil screen, entering the oil passage.

(2) If the oil level is too high, the cranks agitate oil causing

oil to trap a large amount of air.

(3) Air does not easily separate from a deteriorated oil

that can contain an increased amount of air.

When air trapped in oil for these reasons gets into the

high-pressure chamber of the lash adjuster, the air in

the high-pressure chamber is compressed to shrink the

lash adjuster excessively while the valve is opening,

resulting in an unusual noise occurring. This is the same

symptom developing when the valve clearance is adjusted

to an excessive value.

The problem in this case is gone when air is released

from the lash adjuster.

(2) Start the engine and carry out several cycles (10 or less)

of mild racing*.

If the noise is gone after racing, it indicates that air has

been released from the high-pressure chamber of the

lash adjuster, restoring the lash adjuster to normal

operating conditions.

*: Gradually (extending over a 30-sec. period) increase

the engine speed from idle speed to 3,000 r/min and

then reduce it down to the idle speed gradually

(extending over a 30-sec. period).

11-5

NOTE

(1) If the vehicle is parked on a slope for a long time,

the amount of oil in the lash adjuster will decrease,

causing air to get into the high-pressure chamber

when the engine is started.

(2) After the vehicle has been parked for a long time,

oil drains out of the oil passage and it takes a long

time for the oil to reach the lash adjuster. This can

cause air to get into the high-pressure chamber.

11-6

ENGINE – Engine Adjustments

Timing belt side

AA B B

ABAB

(3) If the noise is not eliminated by racing, follow these steps

to check the lash adjuster.

a. Stop the engine.

b. Bring no. 1 cylinder to TDC on the compression stroke.

c. Push the rocker arms indicated by arrow A on the

left to see if they go down.

d. Slowly turn the crankshaft clockwise 360_.

e. Perform the same step as step c for rocker arms

indicated by arrow B.

f. Push the part of the rocker arm which contacts the

top of the lash adjuster. If the rocker arm can be

easily moved down to the bottom, the lash adjuster

is defective, requiring replacement.

When the lash adjuster is replaced, be sure first to

bleed the lash adjuster of air before installation. Then,

perform steps a through e to ensure that no abnormal

symptoms are noted.

NOTE

(1) The leak-down test is an effective means to

accurately determine if the lash adjuster is

operational or not.

(2) For the leak-down test and bleeding procedures,

refer to ENGINE WORKSHOP MANUAL.

If the rocker arm is felt binding and cannot be

pushed downward as you push it, the lash adjuster

is operational. Check for other possible causes

for the noise.

MD998782

MD998782

(4) Lash adjuster replacement

Caution

From the cylinder from which the lash adjuster is

to be removed, turn the crankshaft to lower the piston,

as the valve contacts the piston when pushed down.

A rocker arm cannot be removed if it is lifted by the

cam. If this is the case, turn the crankshaft so that

the arm is not lifted.

a. Using the special tool, push the valve downward to

remove the roller rocker arm.

b. Remove the lash adjuster from the cylinder head.

c. Mount a brandnew lash adjuster which has been bled

of air in the cylinder head.

d. Using the special tool, lower the valve and install

the roller rocker arm.

NOTE

To mount the roller rocker arm, first place the pivot

side of the rocker arm on the lash adjuster, then push

down the valve; next, place the slipper side of the

rocker arm on the valve system side.

ENGINE – Engine Adjustments

4. LASH ADJUSTER REPLACEMENT

Refer to (4) of the preceding paragraph.

5. IGNITION TIMING CHECK

Check that ignition timing is at the standard value.

Standard value: approx. 5_BTDC

NOTE

Ignition timing is variable within about ±7_, even under normal

operating.

11-7

Crank angle

sensor connector

6. IDLE SPEED CHECK AND IDLE MIXTURE CHECK

(1) Run the engine at 2,000 to 3,000 r/min for 2 minutes.

(2) Check the CO and HC contents at idle.

Standard value

CO contents: 0.6% or less

HC contents: 300 ppm or less

7. COMPRESSION PRESSURE CHECK

(1) Before inspection, check that the engine oil, starter and

battery are normal. In addition, set the vehicle to the

pre-inspection condition.

(2) Remove all of the spark plugs.

(3) Disconnect the crank angle sensor connector.

NOTE

Doing this will prevent the engine-ECU from carrying out

ignition and fuel injection.

(4) Cover the spark plug hole with a shop towel etc., and

after the engine has been cranked, check that no foreign

material is adhering to the shop towel.

Caution

(1) Keep away from the spark plug hole when

cranking.

(2) If compression is measured with water, oil, fuel,

etc., that has come from cracks inside the cylinder,

these materials will become heated and will gush

out from the spark plug hole, which is dangerous.

11-8

Compression gauge

ENGINE – Engine Adjustments

(5) Set compression gauge to one of the spark plug holes.

(6) Crank the engine with the throttle valve fully open and

measure the compression pressure.

Standard value

(at engine speed of 250 r/min): 11.5 kg/cm

Limit (at engine speed of 250 r/min): 9.7 kg/cm

2

2

(7) Measure the compression pressure for all the cylinders,

and check that the pressure differences of the cylinders

are below the limit.

Limit: Max. 1.0 kg/cm

2

(8) If there is a cylinder with compression or a compression

difference that is outside the limit, pour a small amount

of engine oil through the spark plug hole, and repeat

the operations in steps (5) through (7).

a. If the compression increases after oil is added, the

cause of the malfunction is a worn or damaged piston

ring and/or cylinder inner surface.

b. If the compression does not rise after oil is added,

the cause is a burnt or defective valve seat, or pressure

is leaking from the gasket.

(9) Connect the crank angle sensor connector.

(10)Install the spark plugs.

(11)Install the ignition coil and connect the ignition coil

connector.

(12)Erase the diagnosis codes by keeping the battery minus

(–) cable disconnected for more than 10 seconds.

NOTE

This will erase the diagnosis code resulting from the crank

angle sensor connector being disconnected.

Fuel pressure

regulator valve

Vacuum gauge

8. MANIFOLD VACUUM CHECK

(1) Before inspection, set the vehicle to the pre-inspection

condition.

(2) Connect a tachometer connector.

(3) Attach a three-way union to the vacuum hose between

the fuel pressure regulator valve and the intake manifold,

and connect a vacuum gauge.

(4) Start the engine and check that idle speed is within

standard value.

Standard value: 850 ± 50 r/min

5. Check the manifold vacuum at idling.

Limit: Min. 55 kPa {410 mmHg}

ENGINE – Crankshaft Pulley

CRANKSHAFT PULLEY

REMOVAL AND INSTALLATION

11-9

Pre-removal Operation

D Under Cover Removal

1

Post-installation Operation

D Drive Belt Tension Adjustment (Refer to P.11-4.)

D Under Cover Installation

25 {2.5}

2

Removal steps

AA" 1. Drive belt

2. Crankshaft pulley

Auto tensioner

Hole in arm

Hole in bracket

Unit: Nm {kgf@m}

REMOVAL SERVICE POINT

AA" DRIVE BELT REMOVAL

(1) Align the hole in the auto tensioner bracket with that

in the arm and insert a screwdriver into the holes.

(2) Remove the drive belt.

Phillips

screwdriver

11-10

ENGINE – Camshaft and Camshaft Oil Seal

CAMSHAFT AND CAMSHAFT OIL SEAL

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operation

(1) Engine Coolant Draining and Refilling

(2) Air Hose C Removal and Installation

(Refer to GROUP 15 – Intercooler.)

(3) Spark Plug Cable and Ignition Coil Assembly Removal

and Installation

4

6

2

10 {1.0}

14

15

(4) Air Pipe Removal and Installation

(Refer to GROUP 15 – Air Control Valve.)

(5) Timing Belt Removal and Installation

(Refer to P.11-21.)

9 {0.9}

1

5

3

3.4 {0.35}

20 {2.0}

7

22 {2.2}

8

12 – 15 {1.2 – 1.5}

9

10

Removal steps

1. Breather hose connection

2. PCV hose connection

3. Crank angle sensor bracket connection

4. Control harness connection

5. Rocker cover

6. Radiator upper hose connection

7. Cover

"EA 8. Cam position sensing cylinder

17 16

13

12

88 {9.0}

11

Unit: Nm {kgf@m}

9. Cam position sensor support

10. Semi-circular packing

AA""DA 11. Camshaft sprocket

"CA 12. Camshaft oil seal

"BA 13. Front cam cap

"BA 14. Rear cam cap

"BA 15. Cam cap

"AA 16. Camshaft (exhaust side)

"AA 17. Camshaft (intake side)

ENGINE – Camshaft and Camshaft Oil Seal

Grease and adhesive application points

11-11

26

10 mm

φ 3 mm

Semi-drying sealant:

THREEBOND 1207F

10 mm

Semi-drying sealant: THREEBOND 1207D

Semi-drying sealant: THREEBOND 1207D

10 mm

Timing belt side

Timing belt side

Lip

Engine oil

MB990767

MD998719

Camshaft sprocket side

Camshaft (exhaust side)

Slit

REMOVAL SERVICE POINT

AA" CAMSHAFT SPROCKET REMOVAL

INSTALLATION SERVICE POINTS

"AA CAMSHAFT INSTALLATION

(1) Apply engine oil to the cams and journals of the camshaft.

(2) Mount the camshaft on the cylinder head.

Caution

Make sure that the camshaft has a unique orientation

for installation, the intake side and exhaust side. The

exhaust camshaft has a slit in the rear end face.

11-12

Approx. 12_

Dowel pin

ENGINE – Camshaft and Camshaft Oil Seal

"BA CAM CAP / REAR CAP / FRONT CAM CAP

INSTALLATION

(1) Locate the camshaft dowel pins as illustrated.

Intake side

Exhaust side

(2) Temporarily tighten cam cap in two to three steps, then

torque it to specification.

Tightening torque: 20 Nm {2.0 kgf@m}

"CA CAMSHAFT OIL SEAL INSTALLATION

(1) Apply engine oil to the entire periphery of the oil seal

lip.

(2) Pressfit the oil seal as shown.

ID paint

MD998713

90_

Dowel pin

"DA CAMSHAFT SPROCKET INSTALLATION

As you did during removal, secure the camshaft sprocket

with the special tool and tighten bolt to specification.

Tightening torque: 88 Nm {9.0 kgf@m}

"EA CAM POSITION SENSING CYLINDER

Install the cam position sensing cylinder so that the ID paint

on the cam position sensing cylinder is 90_ with respect to

the camshaft dowel pin as shown.

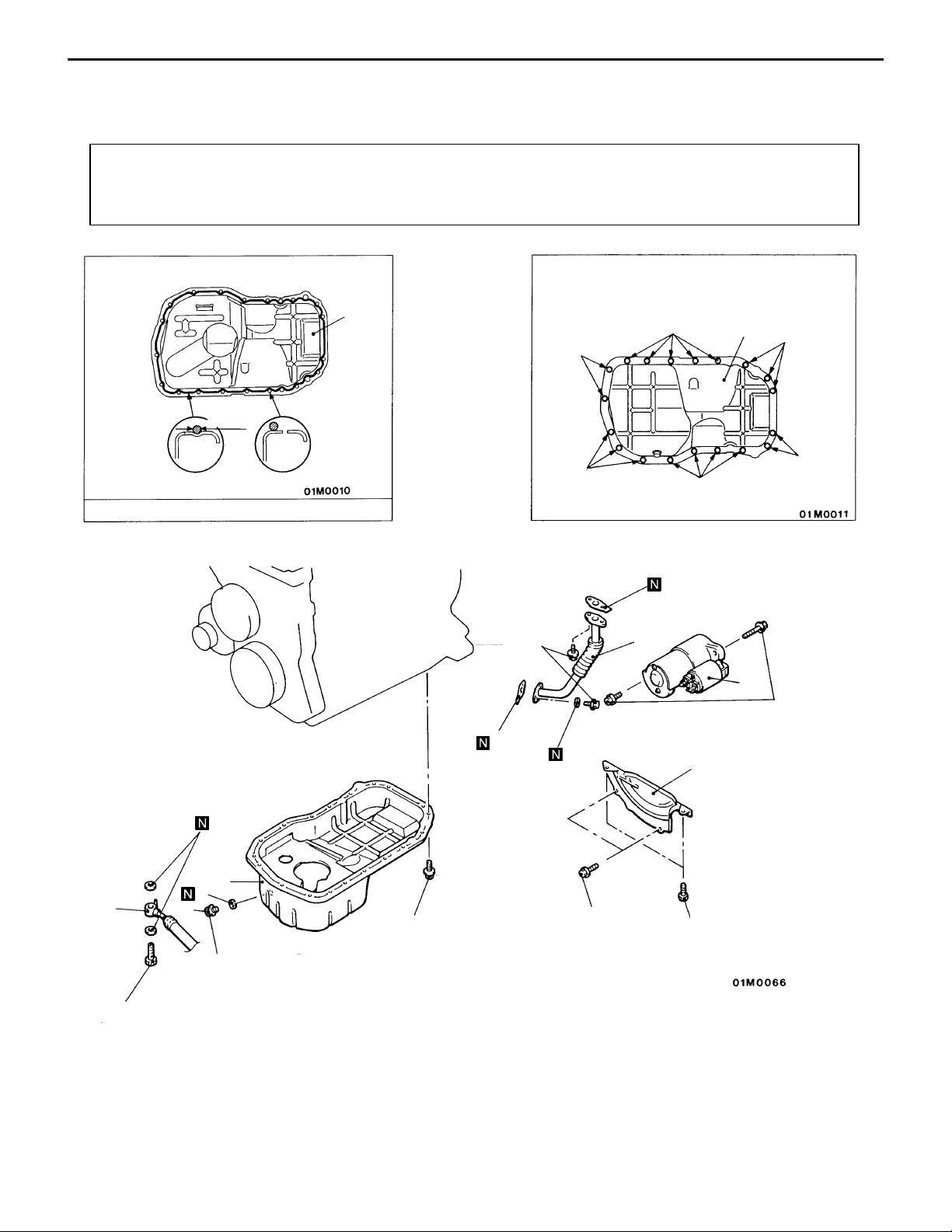

OIL PAN

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operation

(1) Under Cover Removal and Installation

(2) Front Exhaust Pipe Removal and Installation

(Refer to GROUP 15.)

ENGINE – Oil Pan

(3) Oil Level Gauge Removal and Installation

(4) Engine Oil Draining and Supplying

Identification of bolt location

11-13

8

φ 4 mm

Groove

Semi-drying sealant: THREEBOND 1207D

Bolt

hole

9 {0.9}

3

A

B

A: 6 × 8 mm

B: 6 × 10 mm

B

8

B

B

B

2

1

30 {3.1}

5

8

7

4

39 – 44 {4.0 – 4.5}

"BA 3. Oil return pipe gasket

6

39 {4.0}

Removal steps

1. Starter

2. Oil return pipe

4. Engine oil cooler return pipe

7 {0.7}

26 {2.6}

5. Bell housing cover

6. Drain plug

"AA 7. Drain plug gasket

AA" 8. Oil pan

Washer

assembled bolt

9 {0.9}

Flange bolt

10 {1.0}

Unit: Nm {kgf@m}

11-14

ENGINE – Oil Pan

MD998727

Drain plug gasket

MD998727

Printed portion

Oil pan side

REMOVAL SERVICE POINT

AA" OIL PAN REMOVAL

INSTALLATION SERVICE POINTS

"AA DRAIN PLUG GASKET INSTALLATION

Install the drain plug gasket in the direction so that it faces

as shown in the illustration.

"BA OIL RETURN PIPE GASKET INSTALLATION

Install the gasket with the printed portion toward the oil pan.

Gasket

ENGINE – Crankshaft Oil Seal

CRANKSHAFT OIL SEAL

REMOVAL AND INSTALLATION

11-15

4

127 – 137

{13.0 – 14.0}

5

3

2

1

Crankshaft front oil seal removal

steps

D Timing belt and timing belt B

(Refer to P.11-21.)

D Crank angle sensor

(Refer to GROUP 16.)

1. Crankshaft sprocket B

2. Key

"CA 3. Crankshaft front oil seal

3

Engine oil

Crankshaft rear oil seal removal

steps

D Transmission assembly

D Clutch cover and disc

AA""BA 4. Flywheel

"AA 5. Crankshaft rear oil seal

5

Unit: Nm {kgf@m}

11-16

ENGINE – Crankshaft Oil Seal

REMOVAL SERVICE POINT

AA" FLYWHEEL ASSEMBLY REMOVAL

Use the special tool to secure the flywheel assembly and

remove the bolts.

MD998781

Crankshaft

rear oil seal

MB990938

MB998776

Crankshaft

Oil seal

Crankshaft

INSTALLATION SERVICE POINTS

"AA CRANKSHAFT REAR OIL SEAL INSTALLATION

(1) Apply a small mount of engine oil to the entire

circumference of the oil seal lip.

(2) Install the oil seal with the special tool as far as the

chamfered position of the oil seal case as shown in the

illustration.

"BA FLYWHEEL ASSEMBLY INSTALLATION

Use the special tool to hold the flywheel in the same manner

as removal, and install the bolt. Tighten the bolts to the

specification.

Tightening torque: 127 – 137 Nm {13.0 – 14.0 kgf@m}

"CA CRANKSHAFT FRONT OIL SEAL INSTALLATION

Apply a small amount of engine oil to the entire circumference

of the oil seal lip.

Pressfit the oil seal until it is flush with the chamfered end

of the oil pump case.

MD998382

MD998285

(Lubricate outer

circumference with oil)

ENGINE – Cylinder Head Gasket

CYLINDER HEAD GASKET

REMOVAL AND INSTALLATION

11-17

Pre-removal Operation

(1) Fuel Discharge Prevention

(2) Engine Oil Removal

(3) Strut Tower Bar Removal

(4) Timing Belt Removal (Refer to P.11-21.)

(5) Thermostat Case Assembly Removal

(Refer to GROUP 14 – Water Hose Pipe.)

(6) Front Exhaust Pipe Removal (Refer to GROUP 15.)

Delivery pipe

19

15

18

O-ring

Engine oil

16

18

10

17

8

9

Post-installation Operation

(1) Front Exhaust Pipe Installation

(Refer to GROUP 15.)

(2) Thermostat Case Assembly Installation

(Refer to GROUP 14 – Water Hose Pipe.)

(3) Engine Oil Filling

(4) Timing Belt Installation (Refer to P.11-21.)

(5) Strut Tower Bar Installation

(6) Accelerator Cable Adjustment

10 {1.0}

3 {0.3}

4

1

14

3

2

5 {0.5}

9 {0.9}

6

5

3

8

11

8

7

Removal steps

1. Center cover

2. Accelerator cable connection

3. Ignition coil connector

4. Ignition coil

5. Crank angle sensor connector

6. Crank angle sensor bracket connection

7. Brake booster vacuum hose connection

8. Vacuum hose connection

9. TPS connector

10. ISC motor connector

13

12

12 – 15 {1.2 – 1.5}

20

Unit: Nm {kgf@m}

11. Water hose connection

12. Oxygen sensor connector

13. Injector connector

14. Cam position sensor connector

15. Coolant temperature sensor connector

16. Water temperature gauge unit connector

17. Control harness

"DA 18. Fuel pipe pressure hose connection

19. Fuel return hose connection

20. Oil level gauge guide assembly

11-18

ENGINE – Cylinder Head Gasket

78 → 0 → 20 → +90_ → +90_

{8.0 → 0 → 2.0 → +90_ → +90_}

31

29

23

22

3.4 {0.35}

27

32

33

28

25

24

30

22 {2.2}

21

26

9 {0.9}

10 mm

30 {3.1}

22

10 mm

10 mm

9 {0.9}

Removal steps

21. PCV hose connection

22. Rocker cover

23. Semi-circular packing

24. Starter

25. Oil return pipe

"CA 26. Oil return pipe gasket

27. Vacuum tank/solenoid valve/vacuum

hose assembly

30 {3.1}

10 mm10 mm

23

Semi-drying sealant:

THREEBOND 1207D

28. Intake manifold stay

29. Heater hose connection

30. Alternator brace stay mounting bolt

AA""BA 31. Cylinder head bolt

32. Cylinder head assembly

"AA 33. Cylinder head gasket

22

Unit: Nm {kgf@m}

MB991654

ENGINE – Cylinder Head Gasket

REMOVAL SERVICE POINT

AA" CYLINDER HEAD BOLT REMOVAL

Loosen the bolts in 2 or 3 steps in order of the numbers

shown in the illustration, and remove the cylinder head

assembly.

11-19

Intake side

Exhaust side

Washer

A

Cylinder

head

Front of engine

Cylinder head bolt

(Engine

oil)

INSTALLATION SERVICE POINTS

"AA CYLINDER HEAD GASKET INSTALLATION

(1) Wipe off all oil and grease from the gasket mounting

surface.

(2) Install so that the shapes of the cylinder head holes match

the shapes of the respective cylinder head gasket holes.

"BA CYLINDER HEAD BOLT INSTALLATION

(1) When installing the cylinder head bolts, the length below

the head of the bolts should be within the limit.

If it is outside the limit, replace the bolts.

Limit (A): 99.4 mm

(2) Apply a small amount of engine oil to the thread section

and the washer of the cylinder head bolt.

11-20

MB991654

Intake side

Exhaust side

Front of engine

ENGINE – Cylinder Head Gasket

(3) Tighten the bolts by the following procedure.

Step Operation

1 Tighten to 78 Nm {8.0 kgf@m} in the order shown in the

illustration.

2 Fully loosen in the reverse order of that shown in the

illustration.

3 Tighten to 20 Nm {2.0 kgf@m} in the order shown in the

illustration.

4 Mark the head of the cylinder head bolt and cylinder head

by paint, then tighten 90_ of a turn in the order shown in

the illustration.

5 Tighten 90_ of a turn in the order shown in the illustration.

Check that the painted mark of the head bolt is lined up

with that of the cylinder head.

Caution

(1) Always make a tightening angle just 90_. If it is less

than 90_, the head bolt will be loosened.

(2) If it is more than 90_, remove the head bolt and repeat

the procedure from step 1.

Step 4

90_

Painted mark

Gasket

Step 5

Painted mark

Printed portion

90_

"CA OIL RETURN PIPE GASKET INSTALLATION

Install the gasket with the printed portion toward the oil pan.

"DA HIGH-PRESSURE FUEL HOSE INSTALLATION

(1) Apply a small amount of new engine oil to the O-ring,

then fit the O-ring in the delivery pipe.

Caution

Do not let any engine oil get into the delivery pipe.

(2) Check that the high pressure hose turns smoothly.

If the hose does not turn smoothly, the O-ring is probably

being clamped. Disconnect the high-pressure fuel hose

and check the O-ring for damage. After this, re-install

the hose to the delivery pipe and check that the hose

turns smoothly.

(3) Tighten the mounting bolts to the specification.

TIMING BELT

REMOVAL AND INSTALLATION

ENGINE – Timing Belt

11-21

11 {1.1}

2

9 {0.9}

25

5

1

49 {5.0}

12

118 {12.0}

3

19 {1.9}

6

24 {2.4}

13

45 {4.6}

24 {2.4}

8

11 {1.1}

23

49 {5.0}

18

17

3.5 {0.35}

21

7

22

26

11 {1.1}

27

30 {3.1}

4

15

24

88 {9.0}

48 {4.9}

AA""LA 5. Timing belt

"KA 6. Tensioner pulley

"JA 8. Auto tensioner

AB""IA 11. Oil pump sprocket

AC""HA 12. Crankshaft bolt

AD" 13. Crankshaft sprocket

9

Removal steps

1. Front upper cover

2. Front center cover

3. Front lower cover

4. Bracket

7. Tensioner arm

9. Idle pulley

10. Crankshaft position sensor

14. Sensing blade

54 {5.5}

11

14

16

28

20

19

9 {0.9}

AE""GA 16. Timing belt B

AF""FA 17. Counterbalance shaft sprocket

AG" 19. Crankshaft sprocket B

AH""AA 24. Camshaft sprocket bolt

10

49 {5.0}

15. Tensioner B

"EA 18. Spacer

20. Crankshaft key

"DA 21. Rocker cover

"CA 22. Semi-circular packing

"BA 23. Engine support bracket

25. Camshaft sprocket

26. Timing belt rear right cover

27. Timing belt rear left upper cover

28. Timing belt rear left lower cover

Unit: Nm {kgf@m}

11-22

Timing mark

ENGINE – Timing Belt

REMOVAL SERVICE POINTS

AA" TIMING BELT REMOVAL

(1) If the timing belt is to be reused, chalk an arrow mark

on the back surface of the belt so that the belt can be

reinstalled in the same direction.

(2) Place the exhaust camshaft sprocket in a position where

the timing mark for No. 1 cylinder is positioned about

one tooth before the top dead center of the compression

stroke.

Caution

The camshaft sprocket on the exhaust side can turn

very easily because of the valve spring tension. Use

care not to allow your fingers to get caught by the

sprocket.

(3) Loosen the lock nut of the tensioner pulley, then remove

the timing belt.

AB" OIL PUMP SPROCKET REMOVAL

(1) Remove the plug on the left side of cylinder block.

(2) Insert a screwdriver (shank diameter 8 mm) to block the

counterbalance shaft.

(3) Loosen the flange bolt.

(4) Remove the oil pump sprocket.

AC" CRANKSHAFT BOLT LOOSENING

AD" CRANKSHAFT SPROCKET REMOVAL

If it is difficult to remove the sprocket, use the special tool.

ENGINE – Timing Belt

AE" TIMING BELT “B” REMOVAL

Make an arrow mark on the back of the timing belt indicating

the direction of rotation so it may be reassembled in the

same direction if it is to be reused.

6EN1322

AF" COUNTERBALANCE SHAFT SPROCKET

REMOVAL

11-23

AG" CRANKSHAFT SPROCKET “B” REMOVAL

If it is difficult to remove the sprocket, use the special tool.

AH" CAMSHAFT SPROCKET BOLT LOOSENING

Use a wrench to hold the hexagonal part of the camshaft,

and then remove the camshaft sprocket mounting bolt.

INSPECTION

TIMING BELT

Replace belt if any of the following conditions exist.

(1) Hardening of back rubber.

Back side is glossy without resilience and leaves no indent

when pressed with fingernail.

11-24

ENGINE – Timing Belt

Peeling of

canvas

Cracks on rib root

Cracks

Tooth missing

Cracks

Cracks

on sides

(2) Cracks on rubber back.

(3) Cracks of canvas.

(4) Cracks on rib root.

(5) Cracks on belt sides.

(6) Abnormal wear of belt sides.

NOTE

The sides are normal if they are sharp as if cut by a

knife.

(7) Abnormal wear on teeth.

Initial stage:

Canvas on load side tooth flank worn (Fluffy canvas

fibers, rubber gone and color changed to white, and

unclear canvas texture)

Final stage:

Canvas on load side tooth flank worn down and rubber

exposed (tooth width reduced)

(8) Missing tooth.

12 mm

98 to 196 N {10 to 20 kgf}

Movement

6EN1033

AUTO TENSIONER

(1) Check the auto tensioner for possible leaks and replace

as necessary.

(2) Check the rod end for wear or damage and replace as

necessary.

(3) Measure the rod protrusion. If it is out of specification,

replace the auto tensioner.

Standard value: 12 mm

(4) Press the rod with a force of 98 – 196 N {10 – 20 kgf}

and measure its protrusion. If it is out of specification,

replace the auto tensioner.

Standard value: 1 mm or less

ENGINE – Timing Belt

INSTALLATION SERVICE POINTS

"AA CAMSHAFT SPROCKET BOLT TIGHTENING

Using a wrench, hold the camshaft at its hexagon and tighten

the bolt to the specification.

Caution

Locking the camshaft sprocket with a tool damages the

sprocket.

11-25

Apply sealant

"BA ENGINE SUPPORT BRACKET LEFT

INSTALLATION

Coat the bolts illustrated with sealant before tightening.

Specified sealant: THREEBOND 1207F or equivalent

"CA SEALANT APPLICATION ON SEMI-CIRCULAR

PACKING

Apply sealant to the areas indicated in the illustration.

Specified sealant: THREEBOND 1212D or equivalent

10 mm

Semi-circular

packing

Apply

sealant

10 mm

Cylinder head

11-26

10 mm

ENGINE – Timing Belt

"DA SEALANT APPLICATION ON ROCKER COVER

Apply sealant to the areas indicated in the illustration.

Specified sealant: THREEBOND 1212D or equivalent

10 mm

Apply sealant

10 mm

Apply sealant

Spacer

Chamfer

10 mm

Oil seal

Apply sealant

"EA SPACER INSTALLATION

(1) Apply very thin coat of oil to the outer periphery of the

spacer (oil seal contacting surface).

(2) Install the spacer with the chamfered end toward the

oil seal. Mounting in the reverse direction can damage

the oil seal lip.

"FA COUNTERBALANCE SHAFT SPROCKET

INSTALLATION

Timing

marks

Timing

marks

"GA TIMING BELT “B” INSTALLATION

(1) Align timing marks on the crankshaft sprocket “B” and

counterbalance shaft sprocket with the marks on the front

case respectively.

(2) Install the timing belt “B” on the crankshaft sprocket “B”

and counterbalance shaft sprocket. There should be no

slack on the tension side.

ENGINE – Timing Belt

11-27

Tensioner “B”

Center of

tensioner

pulley

Center

of bolt

T ension side

of timing belt

Timing belt “B”

(3) Make sure that the relationship between the tensioner

pulley center and the bolt center is as shown in the

illustration.

(4) Move the tensioner “B” in the direction of arrow while

lifting with a finger to give a sufficient tension to the tension

side of timing belt. In this condition, tighten bolt to secure

tensioner “B”. When the bolt is tightened, use care to

prevent shaft from turning together. If shaft is turned

together, belt will be overtensioned.

"HA CRANKSHAFT BOLT TIGHTENING

"IA OIL PUMP SPROCKET INSTALLATION

(1) Block the counterbalance shaft in the same way as at

the disassembly to prevent it from turning.

(2) Install the oil pump sprocket.

(3) Apply a proper amount of engine oil to the bearing surfaces

of the flange nuts.

(4) Tighten the flange nuts to the specified torque.

6EN0564

"JA AUTO TENSIONER INSTALLATION

(1) If the auto tensioner rod is in its fully extended position,

reset it as follows.

B

A

a. Clamp the auto-tensioner in the vise with soft jaws.

b. Push in the rod little by little with the vise until the

set hole A in the rod is aligned with the hole B in

the cylinder.

6AE0049

11-28

Holes in

tensioner

pulley

ENGINE – Timing Belt

c. Insert a wire (1.4 mm in diameter) into the set holes.

d. Unclamp the auto tensioner from the vise.

(2) Install the auto tensioner. Leave the wire installed in the

auto tensioner until the timing belt is installed.

6AE0050

"KA TENSIONER PULLEY INSTALLATION

Install the tensioner pulley as shown in the illustration.

6EN1323

Timing marks

Timing marks

"LA TIMING BELT INSTALLATION

(1) Place the exhaust side camshaft sprocket in a position

where its timing mark is one tooth offset from the timing

mark on the rocker cover in the counterclockwise direction.

NOTE

Even if the timing marks on the sprocket and the rocker

cover are brought into alignment, the exhaust camshaft

is forced back by the valve spring tension. It is stabilized

at a position one tooth before the timing mark.

(2) Align the timing mark on the intake side camshaft sprocket

with that on the rocker cover.

NOTE

Even if the timing marks on the sprocket and the cover

are brought into alignment, the intake camshaft is forced

to turn one tooth in the clockwise direction by the valve

spring tension and stabilized there.

(3) Place the timing mark on the crankshaft sprocket one

tooth this side from the mated timing mark as in the case

of the camshaft sprocket.

Timing marks

Plug

Screwdriver

ENGINE – Timing Belt

(4) Align the timing mark on the oil pump sprocket with its

mating mark.

(5) Remove the plug on the left side of the cylinder block

and insert a Phillips screwdriver (shank diameter 8 mm)

through the hole.

If it can be inserted as deep as 60 mm or more, the

timing marks are correctly aligned. If the inserted depth

is only 20 – 25 mm, turn the oil pump sprocket one turn

and realign timing marks. Then check to ensure that the

screwdriver can be inserted 60 mm or more.

(6) Remove the Phillips screwdriver. Place the oil pump

sprocket in a position where its timing mark is one tooth

offset from the mated timing mark in the counterclockwise

direction.

11-29

6EN1327

(7) Fit the timing belt over the exhaust side camshaft sprocket,

and secure it at the illustrated position using a paper

clip.

(8) Turn the intake side camshaft sprocket as shown to a

position where its timing mark is one tooth offset from

the mated timing mark in the counterclockwise direction.

Then, fit the timing belt over the sprocket and secure

it with a paper clip.

NOTE

The intake camshaft will be turned a little clockwise by

the valve spring tension and stabilized in position even

if the belt is clipped at one tooth offset position.

Timing marks

(9) Check to ensure that the timing marks on the intake

camshaft sprocket side are in alignment when the exhaust

camshaft sprocket is turned clockwise to align the timing

marks.

NOTE

The timing belt span between the intake and exhaust

sprockets will have 17 cogs.

11-30

Camshaft

sprocket

Crankshaft

sprocket

ENGINE – Timing Belt

(10)Fit the timing belt over the idler pulley, oil pump sprocket

and crankshaft sprocket in this order.

NOTE

Be careful that the belt does not become slack.

Oil pump

sprocket

(11)Fit the timing belt over the tensioner pulley.

NOTE

When fitting the timing belt over the tensioner pulley,

turn the intake side camshaft sprocket a little

counterclockwise, as this will facilitate the work.

Crankshaft

sprocket

MD998767

(12)Turn the crankshaft pulley a little in the illustrated direction

to pull up the timing belt at the idler pulley side.

(13)Check to ensure that the timing marks on the crankshaft

sprocket, oil pump sprocket and exhaust camshaft

sprocket are all offset one tooth from the corresponding

timing marks in the counterclockwise direction.

(14)Using the special tool, turn the tensioner pulley in the

illustrated direction to strain the timing belt. Then, secure

the tensioner temporarily by tightening the retaining bolt

lightly.

NOTE

There must be no slack in the timing belt between the

intake and exhaust camshafts.

(15)Turn the crankshaft to align the timing mark with the mark

for No. 1 cylinder top dead center in the compression

stroke.

(16)Set the special tool as shown and screw it in up to the

position where the wire inserted in the auto-tensioner

when installing it can be moved lightly.

MD998738

ENGINE – Timing Belt

11-31

MD998767

(17)Loosen the retaining bolt of the tensioner pulley.

Caution

Loosening the retaining bolt can cause the intake

and exhaust camshafts to turn, resulting in slackened

timing belt. Use care that the timing belt does not

come off the sprockets at this time.

(18)Pull up the slack of the timing belt by turning the tensioner

in illustrated direction using the special tool and a torque

wrench (0 – 5 Nm {0 – 0.5 kgf@m}).

(19)From this position, turn back the tensioner until the torque

wrench reading becomes 3.5 Nm {0.36 kgf@m}, then

secure it by tightening the retaining bolt.

(20)Remove the special tool attached in step (16).

(21)Rotate the crankshaft clockwise 2 turns. Then, leave it

intact 15 minutes.

(22)Check to see that the wire inserted when installing the

auto-tensioner can be pulled out lightly. If it can be pulled

out lightly, the timing belt is being tensioned properly.

If so, remove the wire. In addition, check that the rod

protrusion from the auto-tensioner meets the standard

value, which is also an indication of properly tensioned

timing belt.

Standard value: 3.8 – 4.5 mm

(23)If the wire cannot be removed with a light force, repeat

steps (16) through (21) until the proper belt tensioner

is obtained.

ENGINE – Engine Assembly

ENGINE ASSEMBLY

REMOVAL AND INSTALLATION

11-32

Pre-removal Operation

(1) Fuel Discharge Prevention

(2) Hood Removal

(3) Strut Tower Bar Removal

(4) Air Hose C Removal

(Refer to GROUP 15 – Intercooler.)

(5) Radiator Assembly Removal (Refer to GROUP 14.)

(6) Under Cover Removal

(7) Front Exhaust Pipe Removal (Refer to GROUP 15.)

Delivery pipe

17

O-ring

Engine oil

10 – 12

{1.0 – 1.2}

15

14

16

17

13

Post-installation Operation

(1) Front Exhaust Pipe Installation

(Refer to GROUP 15.)

(2) Under Cover Installation

(3) Radiator Assembly Installation

(Refer to GROUP 14.)

(4) Accelerator Cable Adjustment

(5) Air Hose C Installation

(Refer to GROUP 15 – Intercooler.)

(6) Strut Tower Bar Installation

(7) Hood Installation

10 – 12

{1.0 – 1.2}

1

12

5 {0.5}

8

8

9

3 {0.3}

2

18

6

4

5

7

Removal steps

1. Center cover

2. Accelerator cable

3. Brake booster vacuum hose

connection

4. Vacuum hose connection

5. Throttle position sensor connector

6. Idle speed control motor connector

7. Heater hose connection

8. Ignition coil connector

9. Crank angle sensor connector

10. Oxygen sensor connector

11

10

3

Unit: Nm {kgf@m}

11. Injector connector

12. Cam position sensor connector

13. Coolant temperature sensor connector

14. Coolant temperature gauge unit

connector

15. Vacuum pipe/hose assembly

16. Control harness

"CA 17. High-pressure fuel hose connection

18. Fuel return hose connection

11-33

ENGINE – Engine Assembly

39 {4.0}

19

26

27

29

20

9 {0.9}

12 {1.2}

28

57 {5.8}

22

22

21

25

24

23

19. Solenoid valve connector

20. Vacuum tank/solenoid valve/vacuum

hose assembly

21. Oil pressure switch connector

22. Alternator connector

D Drive belt tension inspection

(Refer to P.11-4.)

AA" 23. Drive belt

AB" 24. A/C compressor

AC" 25. Power steering oil pump

D Transmission assembly

98 {10.0}*

Unit: Nm {kgf@m}

26. A/C relay box

27. A/C receiver bracket mounting bolt

28. Oil pressure hose mounting bolt

AC""BA 29. Engine mount bracket

AE""AA 30. Engine assembly

Caution

Mounting locations marked by * should be

provisionally tightened, and then fully tightened after

placing the vehicle horizontally and loading the full

weight of the engine on the vehicle body.

Hole in arm

Phillips

screwdriver

Auto tensioner

Hole in bracket

ENGINE – Engine Assembly

REMOVAL SERVICE POINTS

AA" DRIVE BELT REMOVAL

(1) Align the hole in the auto tensioner bracket with that

in the arm and insert a screwdriver into the holes.

(2) Remove the drive belt.

11-34

MZ203826 or MZ203827

MB991453

AB" POWER STEERING OIL PUMP REMOVAL

Remove the power steering oil pump from the bracket with

the hose attached.

NOTE

Place the removed power steering oil pump in a place where

it will not be a hindrance when removing and installing the

engine assembly, and tie it with a cord.

AC" A/C COMPRESSOR REMOVAL

Disconnect the A/C compressor connector and remove the

compressor from the compressor bracket with the hose still

attached.

NOTE

Place the removed A/C compressor where it will not be a

hindrance when removing and installing the engine assembly,

and tie it with a cord.

AD" ENGINE MOUNT BRACKET REMOVAL

(1) Support the engine with a garage jack.

(2) Remove the special tools which was attached when the

transmission assembly was removed.

(3) Hold the engine assembly with a chain block or similar

tool.

(4) Place a garage jack against the engine oil pan with a

piece of wood in between, jack up the engine so that

the weight of the engine is no longer being applied to

the engine mount bracket, and then remove the engine

mount bracket.

11-35

ENGINE – Engine Assembly

AE" ENGINE ASSEMBLY REMOVAL

After checking that all cables, hoses and harness connectors,

etc., are disconnected from the engine, lift the chain block

slowly to remove the engine assembly upward from the engine

compartment.

INSTALLATION SERVICE POINTS

"AA ENGINE ASSEMBLY INSTALLATION

Install the engine assembly, checking that the cables, hoses,

and harness connectors are not clamped.

MZ203826 or MZ203827

MB991453

"BA ENGINE MOUNT BRACKET INSTALLATION

(1) Place a garage jack against the engine oil pan with a

piece of wood in between, and install the engine mount

bracket while adjusting the position of the engine.

(2) Support the engine with the garage jack.

(3) Remove the chain block and support the engine assembly

with the special tools.

"CA HIGH-PRESSURE FUEL HOSE INSTALLATION

(1) Apply a small amount of new engine oil to the O-ring,

then fit the O-ring in the delivery pipe.

Caution

Do not let any engine oil get into the delivery pipe.

(2) Check that the high pressure hose turns smoothly.

If the hose does not turn smoothly, the O-ring is probably

being clamped. Disconnect the high-pressure fuel hose

and check the O-ring for damage. After this, re-install

the hose to the delivery pipe and check that the hose

turns smoothly.

(3) Tighten the mounting bolt to the specification.

ENGINE

LUBRICATION

CONTENTS

LUBRICANTS 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ENGINE OIL COOLER 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12-1

12-2

ENGINE LUBRICATION – Lubricants / Engine Oil Cooler

LUBRICANTS

Items Capacity dm3 {ȏ}

Engine oil Quantity in oil filter 0.3 {0.3}

Quantity in oil cooler 0.16 {0.16}

Total quantity 5.1 {5.1}

Brand DIA QUEEN MOTOR OIL (Grade SG or higher); or engine oil in

a can marked with ILSAC certification.

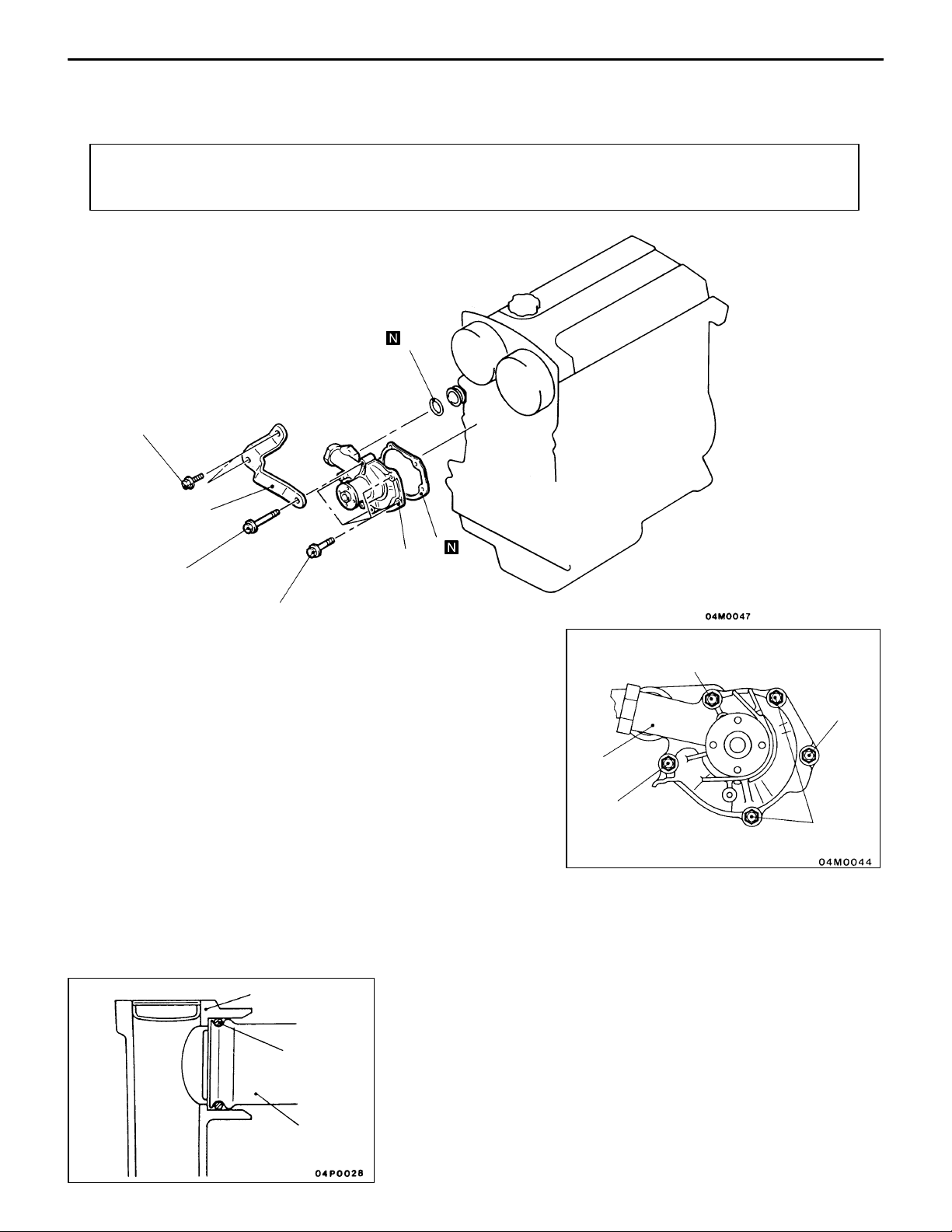

ENGINE OIL COOLER

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operation

(1) Engine Oil Removal and Refilling

(2) Front Bumper Removal and Installation

(Refer to GROUP 51.)

1

12 {1.2}

Removal steps

1. Engine oil cooler

"AA 2. Feed hose assembly

"AA 3. Return hose assembly

12 {1.2}

29 – 34

{3.0 – 3.5}

2

12 {1.2}

3

39 – 44

{4.0 – 4.5}

39 – 44

{4.0 – 4.5}

Unit: Nm {kgf@m}

INSTALLATION SERVICE POINT

"AA FEED HOSE ASSEMBLY / RETURN HOSE

Fit the hose joint positioning tab into the hole in oil cooler

to secure the hose assembly in position.

TSB Revision

ASSEMBLY INSTALLATION

FUEL

CONTENTS

13-1

MULTIPOINT INJECTION (MPI) 2. . . . . . .

GENERAL INFORMATION 2. . . . . . . . . . . . . . . .

SERVICE SPECIFICATIONS 3. . . . . . . . . . . . . .

SEALANT 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SPECIAL TOOLS 4. . . . . . . . . . . . . . . . . . . . . . . .

TROUBLESHOOTING 6. . . . . . . . . . . . . . . . . . . .

ON-VEHICLE SERVICE 30. . . . . . . . . . . . . . . .

1. Idle Position Switch and Throttle Position

Sensor (TPS) Adjustment 30. . . . . . . . . . . . .

2. Fixed SAS Adjustment 30. . . . . . . . . . . . . . . .

3. Basic Idle Speed Adjustment 30. . . . . . . . . .

4. Fuel Pressure Measurement 30. . . . . . . . . . .

5. MPI System Components Layout 31. . . . . .

6. Intake Air Temperature Sensor Check 32. .

7. Engine Coolant Temperature

Sensor Check 32. . . . . . . . . . . . . . . . . . . . . . . .

8. Oxygen Sensor Check 32. . . . . . . . . . . . . . . .

9. Injector Check 34. . . . . . . . . . . . . . . . . . . . . . .

10. Resistor Check 34. . . . . . . . . . . . . . . . . . . . . . .

11. Fuel Pump Relay No.2 Check 35. . . . . . . . .

12. Fuel Pump Resistor Check 35. . . . . . . . . . . .

INJECTOR 36. . . . . . . . . . . . . . . . . . . . . . . . . . . .

THROTTLE BODY 37. . . . . . . . . . . . . . . . . . . . .

13-2

MPI – General Information

MULTIPOINT INJECTION (MPI)

GENERAL INFORMATION

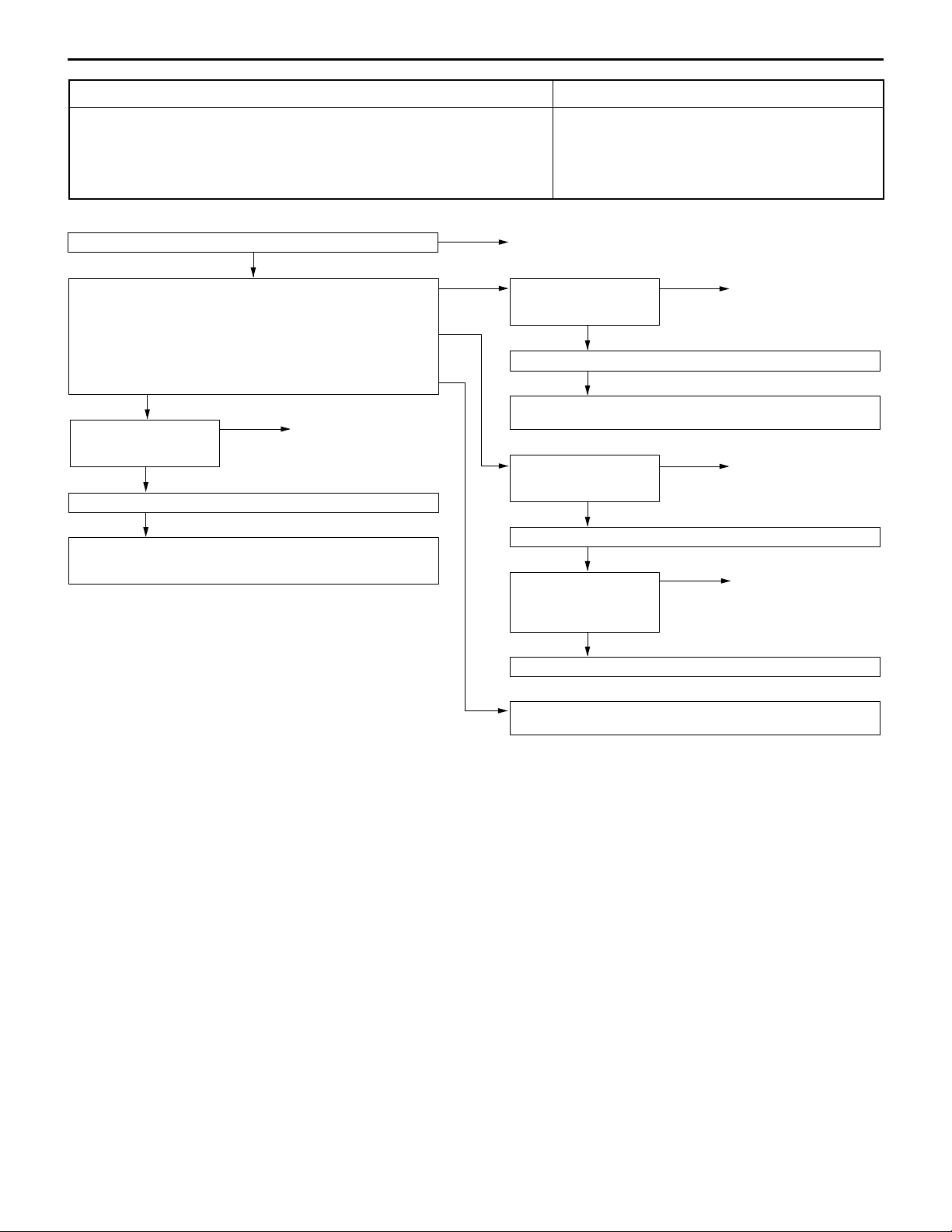

OMPI System Diagram

L1 Oxygen sensor

L2 Air flow sensor

L3 Intake air temperature sensor

L4 Throttle position sensor

L5 Idle switch

L6 Camshaft position sensor

L7 Crank angle sensor

L8 Barometric pressure sensor

L9 High temperature sensor

L10 Engine coolant temperature sensor

L11 Detonation sensor

D Power supply voltage

D Ignition switch-IG

D Ignition switch-ST

D Vehicle speed sensor

D A/C switch

D Power steering fluid pressure switch

D Alternator FR signal

l5 Secondary air

control solenoid

valve

Canister

Check valve

Engine ECU

From

fuel

tank

Throttle position

sensor (with a

built-in

idle

switch)

l1 Injector

l2 ISC servo

l3 Fuel pressure control valve

l4 Waste gate solenoid valve

l5 Secondary air control solenoid valve

D Control relay

D Fuel pump relay

D A/C relay

D Ignition coil

D Exhaust temperature warning lamp

D Engine warning lamp

D Diagnosis output

D Alternator G terminal

D Fan motor relay

D Tachometer

D Fuel pump relay No.2

l2 ISC servo

L4,

L5

Secondary

air valve

L8 Barometric

pressure sensor

L2 Air flow sensor

Air

L3

Intake air temperature sensor

l4 Waste gate

solenoid valve

L1 Oxygen sensor

Waste gate

actuator

To fuel

tank

Fuel

pressure

regulator

From

fuel

pump

L10 Coolant temperature sensor

L7 Crank angle sensor

L1 1 Detonation sensor

Catalytic converter

l3 Fuel pressure

control valve

L6 Camshaft position

sensor

l1 Injector

L9 High temperature

sensor

Given above is the MPI system diagram for EVOLUTION-IV. The MPI system for EVOLUTION-V is different

from this in the following point;

D Oxygen sensor with a heater is adopted.

D The diagnosis connector power supply circuit is different.

D The high temperature sensor is no longer used.

MPI – Service Specifications / Sealant

kPa {kgf/

2

}

SERVICE SPECIFICATIONS

Items Specifications

Basic ignition timing _BTDC 5 ± 3

Basic idle speed rpm 850 ± 50

Throttle position sensor adjusting voltage mV 400 – 1,000

Throttle position sensor resistance kΩ 3.5 – 6.5

ISC servo coil resistance (at 20_C) Ω 28 – 33

Intake air temperature sensor resistance kΩ At 20_C 2.3 – 3.0

At 80_C 0.30 – 0.42

Coolant temperature sensor resistance kΩ At 20_C 2.1 – 2.7

At 80_C 0.26 – 0.36

13-3

Fuel pressure

Injector coil resistance Ω 2 – 3

Amount of injector fuel leak drop/min 1 or less

Oxygen sensor output voltage 0.6 – 1.0

Fuel pressure control valve coil resistance (at 20_C) Ω 28 – 36

f

cm

2

When vacuum hose is connected 230 {2.35}

When vacuum hose is disconnected 289 – 309 {2.95 – 3.15}

SEALANT

Item Specified sealant

Coolant temperature sensor Drying sealant: HELMESEAL H-1M [0110513]

NOTE:

Given in [ ] are MITSUBISHI GENUINE PART numbers.

13-4

MPI – Special Tools

SPECIAL TOOLS

Tool Number Name Use

MB991348 Test harness set D Measurement of voltage during trouble-

shooting

D Inspection using an oscilloscope

MB991519 Alternator harness

connector

MB991536 TPS check

harness

MD998464 Test harness

(4-pin, square)

MD998463 Test harness

(6-pin, square)

Measurement of voltage during

troubleshooting

Adjustment of idle switch and throttle position

sensor (TPS)

Inspection of oxygen sensor

D Inspection of idle speed control servo

D Inspection using an oscilloscope

MD998478 Test harness

(3-pin, triangle)

MD998706 Injector test set Checking the spray condition of injectors

MD998741 Injector test

adaptor

MB991607 Injector test

harness

D Measurement of voltage during trouble-

shooting

D Inspection using an oscilloscope

Tool UseNameNumber

MD998746 Clip Checking the spray condition of injectors

MD998709 Adaptor hose Measurement of fuel pressure

MD998742 Hose adaptor

MB991637 Fuel pressure

MPI – Special Tools

gauge set

13-5

Red harness

White harness

MB991223 Inspection test

herness set

D Pin contact

pressure

inspection

harness

D Market tester

contact probe

(for general

connectors)

MB991529 Diagnostic trouble

code check harness

MB991709 Test harness D Measurement of voltage during trouble-

Measurement of terminal voltage

Reading of diagnosis codes

shooting

D Inspection using an oscilloscope

13-6

Engine warning lamp

(check engine lamp)

MPI – Troubleshooting

TROUBLESHOOTING

1. DIAGNOSIS FUNCTION

1-1 ENGINE WARNING LAMP (CHECK ENGINE LAMP)

If an abnormality occurs in any of the following items related

to the Multipoint Fuel Injection (MPI) system, the engine

warning lamp will illuminate.

If the lamp remains illuminated or if the lamp illuminates while

the engine is running, check the diagnosis code output.

Engine warning lamp inspection items

Engine-ECU

Air flow sensor (AFS)

Intake air temperature sensor

Throttle position sensor (TPS)

Engine coolant temperature sensor

Crank angle sensor

Camshaft position sensor

Barometric pressure sensor

Detonation sensor

Injector

Ignition coil, power transister

Misfire <Evolution-V only>

1-2 METHOD OF READING AND ERASING DIAGNOSIS

CODES

(1) Use the special tool to earth No.1 terminal (diagnosis

control terminal) of the diagnosis connector.

(2) To check ABS system, remove the valve relay.

NOTE

That is because the valve relay is off and the warning

lamp remains illuminated if there is a fault in the ABS

system.

(3) Turn off the ignition switch.

(4) Read out a diagnosis code by observing how the warning

lamp flashes.

Indication of diagnosis code by warning lamp

When the diagnosis code No.24 is output When no diagnosis code is output*

0.5 sec.

1.5 secs. 0.5 sec.

On

Off

Pause

time 3

secs.

Tens signal

Place

division

2 secs.

Units signal

On

Off

A03X0113

0.5 sec. <MPI, A/T>

0.25 sec. <ABS>

NOTE

*: Even if the ABS system is normal, removing the valve relay causes the diagnosis code No.52 to

be output.

MPI – Troubleshooting

13-7

1-3 ERASING DIAGNOSIS CODES

(1) Turn the ignition switch to OFF.

(2) After disconnecting the battery cable from the battery (–) terminal for 10 seconds or more, reconnect

the cable.

(3) After the engine has warmed up, run it at idle for about 15 minutes.

1-4 FAIL-SAFE FUNCTION REFERENCE TABLE

When the main sensor malfunctions are detected by the diagnosis function, the vehicle is controlled

by means of the pre-set control logic to maintain safe conditions for driving.

Malfunctioning item Control contents during malfunction

Air flow sensor (AFS) (1) Uses the throttle position sensor signal and engine speed signal (crank angle sensor

signal) to take reading of the basic injector drive time and basic ignition timing from

the pre-set mapping.

(2) Fixes the ISC servo in the appointed position so idle control is not performed.

Intake air temperature

sensor

Throttle position

sensor (TPS)

Engine coolant

temperature sensor

Camshaft position

sensor

Barometric pressure

sensor

Detonation sensor Switches the ignition timing from ignition timing for super petrol to ignition timing for standard

Ignition coil, power

transistor

Alternator FR terminal Does not control the output of the alternator according to an electrical load. (works as a

Misfire

(Evolution-V only)

Controls as if the intake air temperature is 25_C.

No increase in fuel injection amount during acceleration due to the throttle position sensor

signal.

Controls as if the engine coolant temperature is 80_C.

(This condition is maintained until the ignition switch is turned off even when the sensor signal

returns normal.)

(1) Injects fuel to all cylinders simultaneously for 4 seconds.

(However, after the ignition switch is turned to ON, the No. 1 cylinder top dead centre

is not detected at all.)

(2) Lets the fan motor (radiator and condensor) run at high speed.

Controls as if the barometric pressure is 101 kPa {760 mmHg}.

petrol.

Cuts off the fuel supply to cylinders with an abnormal ignition.

normal alternator)

Cuts off the fuel to the misfiring cylinder if a misfire that could damage the catalyst is detected.

13-8

MPI – Troubleshooting

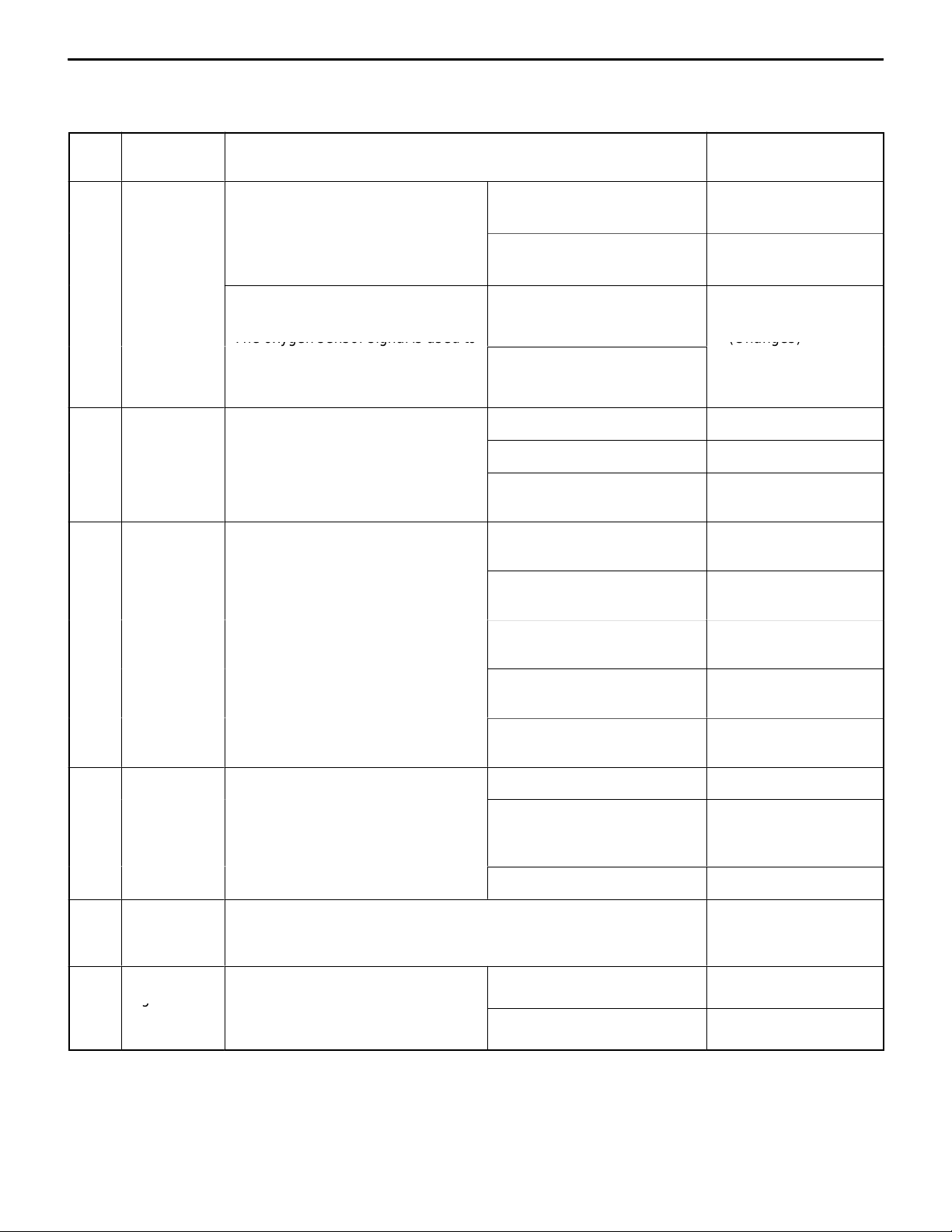

2. INSPECTION CHART FOR DIAGNOSIS CODES

Code No. Diagnosis item Reference page

12 Air flow sensor (AFS) system 13-8

13 Intake air temperature sensor system 13-9

14 Throttle position sensor (TPS) system 13-9

21 Engine coolant temperature sensor system 13-10

22 Crank angle sensor system 13-11

23 Camshaft position sensor system 13-11

24 Vehicle speed sensor system 13-12

25 Barometric pressure sensor system 13-13

31 Detonation sensor system 13-14

41 Injector system 13-14

44 Ignition coil and power transistor unit system 13-15

64 Alternator FR terminal system 13-16

3. INSPECTION PROCEDURE FOR DIAGNOSIS CODES

Code No. 12 Air flow sensor (AFS) system Probable cause

Range of Check

D Engine speed is 500 r/min or more.

Set conditions

D Sensor output frequency is 3 Hz or less for 4 seconds.

Measure at the air flow sensor connector A-25.

D Connect the connector. (Use

the test harness: MB991709)

1. Voltage between 3 and earth

(Engine: Idling)

OK: 2.2–3.2 V

2. Voltage between 7 and earth

OK: 0–1 V (Engine: idling)

6–9 V (2,000 r/min)

OK

Replace the engine-ECU.

1. NG

Check the air flow sensor circuit.

2. NG

Measure at the engine-ECU con-

nector B-59.

D Connect the connector.

D Voltage between 19 and earth

(Ignition switch: ON)

OK: 6–9 V

Check the following connector:

B-59

Check trouble symptom.

NG

OK

NG

OK

NG

D Malfunction of the air flow sensor

D Improper connector contact, open circuit or

short-circuited harness wire of the air flow sensor

D Malfunction of the engine-ECU

Check the following connector:

A-25

OK

Check trouble symptom.

NG

Repair

Replace the air flow sensor.

NG

Repair

Replace the engine-ECU.

MPI – Troubleshooting

Code No. 13 Intake air temperature sensor system Probable cause

Range of Check

D Ignition switch: ON

D Excluding 60 seconds after the ignition switch is turned to ON or immediately

after the engine starts.

Set conditions

D Sensor output voltage is 4.6 V or more (corresponding to an intake air temperature

of –45_C or less) for 4 seconds.

or

D Sensor output voltage is 0.2V or less (corresponding to an intake air temperature

of 125_C or more) for 4 seconds.

D Malfunction of the intake air temperature sensor

D Improper connector contact, open circuit or

short-circuited harness wire of the intake air

temperature sensor circuit

D Malfunction of the engine-ECU

13-9

Check the intake air temperature sensor. (Refer to P.13-32.)

OK

Measure at the air flow sensor connector A-25.

D Disconnect the connector, and

measure at the harness side.

D Voltage between 6 and earth

(Ignition switch: ON)

OK: 4.5–4.9 V

D Continuity between 5 and earth

OK: Continuity

OK

Check the following connector:

A-25

OK

Check trouble symptom.

NG

NG

NG

NG

Replace air flow sensor.

Check the following connector:

C-62

OK

Check trouble symptom.

NG

Check the harness wire between the

engine-ECU and the intake air temperature sensor connector.

OK

Repair

Replace the engine-ECU.

NG

NG

Repair

Repair

Code No. 14 Throttle position sensor (TPS) system Probable cause

Range of Check

D Ignition switch: ON

D Excluding 60 seconds after the ignition switch is turned to ON or immediately

after the engine starts.

Set conditions

D The sensor output voltage is 0.2 V or less for 4 seconds.

D Malfunction of the throttle position sensor

D Improper connector contact, open circuit or

short-circuited harness wire of the throttle position

sensor circuit

D Improper “ON” state of idle position switch

D Short circuit of the idle position switch signal line

D Malfunction of the engine-ECU

Check the throttle position sensor.

OK

Measure at the throttle position sensor

connector A-16.

D Disconnect the connector, and

measure at the harness side.

D Voltage between 1 and earth

(Ignition switch: ON)

OK: 4.8–5.2 V

D Continuity between 4 and earth

OK: Continuity

OK

Check the throttle position sensor output circuit.

NG

NG

Replace

Check the following connector:

B-62

OK

Check trouble symptom.

NG

Check the harness wire between the

engine-ECU and the throttle position

sensor connector.

OK

Replace the engine-ECU.

NG

NG

Repair

Repair

13-10

MPI – Troubleshooting

Code No. 21 Engine coolant temperature sensor system Probable cause

Range of Check

D Ignition switch: ON

D Excluding 60 seconds after the ignition switch is turned to ON or immediately

after the engine starts.

Set conditions

D Sensor output voltage is 4.6 V or more (corresponding to an engine coolant

temperature of –45_C or less) for 4 seconds.

or

D Sensor output voltage is 0.1 V or less (corresponding to an engine coolant

temperature of 140_C or more) for 4 seconds.

Range of Check

D Ignition switch: ON

D Engine speed is approx. 50 r/min or more

Set conditions

D The sensor output voltage increases from 1.6 V or less (corresponding to an

engine coolant temperature of 40_C or more) to 1.6 V or more (corresponding

to an engine coolant temperature of 40_C or less).

D After this, the sensor output voltage is 1.6 V or more for 5 minutes.

D Malfunction of the engine coolant temperature sensor

D Improper connector contact, open circuit or

short-circuited harness wire of the engine coolant

temperature sensor circuit

D Malfunction of the engine-ECU

Check the engine coolant temperature

sensor. (Refer to P.13-32.)

OK

Measure at the engine coolant temperature sensor connector A-38.

D Disconnect the connector, and

measure at the harness side.

D Voltage between 1 and earth

(Ignition switch: ON)

OK: 4.5–4.9 V

D Continuity between 2 and earth

OK: Continuity

OK

Check the following connector:

A-38

OK

Check trouble symptom.

NG

NG

NG

NG

Replace

Check the following connector:

B-62

OK

Check trouble symptom.

NG

Check the harness wire between the

engine-ECU and the engine coolant

temperature sensor connector.

OK

Repair

Replace the engine-ECU.

NG

NG

Repair

Repair

MPI – Troubleshooting

Code No. 22 Crank angle sensor system Probable cause

Range of Check

D Engine is cranking.

Set conditions

D Sensor output voltage does not change for 4 seconds (no pulse signal input.)

D Malfunction of the crank angle sensor

D Improper connector contact, open circuit or

short-circuited harness wire of the crank angle sensor

D Malfunction of the engine-ECU

13-11

Measure at the crank angle sensor connector A-51.

D Connect the connector. (Use the test harness: MD998478.)

D Voltage between 2 (black clip) and earth (Engine: cranking)

OK: 0.4–4.0 V

D Voltage between 2 (black clip) and earth (Engine: idling)

OK: 1.5–2.5 V

NG

Measure at the crank angle sensor connector A-51.

D Disconnect the connector, and measure at the harness side.

1. Voltage between 3 and earth (Ignition switch: ON)

OK: System voltage

2. Voltage between 2 and earth (Ignition switch: ON)

OK: 4.8–5.2 V

3. Continuity between 1 and earth

OK: Continuity

OK

Check the following connector: A-51

OK

Check trouble symptom.

NG

Replace the crank angle sensor.

NG

Repair

OK

1. NG

2. NG

3. NG

Replace the engine-ECU.

Check the harness wire between the crank angle sensor and the

control relay connector, and repair if necessary.

Check the following connector: B-62

OK

Check trouble symptom.

NG

Check the harness wire

between the engine-ECU and

the crank angle sensor

connector.

OK

Replace the engine-ECU.

Check the harness wire between the crank angle sensor and the

earth, and repair if necessary.

NG

NG

Repair

Repair

Code No. 23 Camshaft position sensor system Probable cause

Range of Check

D Ignition switch: ON

D Engine speed is approx. 50 r/min or more.

Set conditions

D Sensor output voltage does not change for 4 seconds (no pulse signal input.)

Measure at the camshaft position sensor connector A-97.

D Connect the connector.

D Voltage between 2 and earth (Engine: cranking)

OK: 0.4–3.0 V

D Voltage between 2 and earth (Engine: idling)

OK: 0.5–2.0 V

NG

Measure at the camshaft position sensor connector A-97.

D Disconnect the connector, and measure at the harness side.

1. Voltage between 3 and earth (Ignition switch: ON)

OK: System voltage

2. Voltage between 2 and earth (Ignition switch: ON)

OK: 4.8–5.2 V

3. Continuity between 1 and earth

OK: Continuity

OK

Check the following connector: A-97

OK

Check trouble symptom.

NG

Replace the camshaft position sensor.

NG

Repair

OK

1. NG

2. NG

3. NG

D Malfunction of the camshaft position sensor

D Improper connector contact, open circuit or

short-circuited harness wire of the camshaft position

sensor circuit

D Malfunction of the engine-ECU

Replace the engine-ECU.

Check the harness wire between the camshaft position sensor

and the control relay connector, and repair if necessary.

Check the following connector: B-62

OK

Check trouble symptom.

NG

Check the harness wire

between the engine-ECU and

the camshaft position sensor

connector.

OK

Replace the engine-ECU.

NG

NG

Repair

Repair

Check the harness wire between the camshaft position sensor

and the earth, and repair if necessary.

13-12

MPI – Troubleshooting

Code No. 24 Vehicles speed sensor system Probable cause

Range of check

D Ignition switch: ON

D Excluding 60 seconds after the ignition switch is turned to ON or immediately

after the engine starts.

D Idle position switch: OFF

D Engine speed is 3,000 r/min or more.

D Driving under high engine load conditions.

Set conditions

D Sensor output voltage does not change for 4 seconds (no pulse signal input).

D Malfunction of the vehicle speed sensor

D Improper connector contact, open circuit or

short-circuited harness wire of the vehicle speed

sensor circuit

D Malfunction of the engine-ECU

Check the vehicle speed sensor. (Refer to GROUP 54 – Combination Meters.)

OK

Measure at the vehicle speed sensor connector A-19.

D Disconnect the connector, and measure at the harness side.

1. Voltage between 1 and earth (Ignition switch: ON)

OK: System voltage

2. Voltage between 3 and earth (Ignition switch: ON)

OK: 4.8 – 5.2 V

3. Continuity between 2 and earth

OK: Continuity

OK

Check the following

connectors:

A-19, B-62

OK

Check trouble symptom.

NG

Check the harness wire

between the engine-ECU

and the vehicle speed

sensor connector.

OK

Replace the engine-ECU.

NG

NG

Repair

Repair

NG

1. NG

2. NG

3. NG

Replace

Check the following

connectors:

B-64, B-74, B-76

OK

Check trouble symptom.

NG

Check the harness wire

between the vehicle

speed sensor and ignition

switch connector.

OK

Check the ignition switch. (Refer to GROUP 54 – Ignition Switch.)

Check the following

connector:

B-62

OK

Check trouble symptom.

NG

Check the harness wire

between the engine-ECU

and the vehicle speed

sensor connector.

OK

Replace the engine-ECU.

NG

NG

NG

NG

Repair

Repair

Repair

Repair

Check the harness wire between the vehicle speed sensor and

the earth, and repair if necessary.

MPI – Troubleshooting

Code No. 25 Barometric pressure sensor system Probable cause

Range of Check

D Ignition switch: ON

D Excluding 60 seconds after the ignition switch is turned to ON or immediately

after the engine starts.

Set conditions

D Sensor output voltage is 4.5 V or more (corresponding to a barometric pressure

of 114 kPa {855 mmHg} or more) for 4 seconds.

or

D Sensor output voltage is 0.2 V or less (corresponding to a barometric pressure

of 53 kPa {40 mmHg} or less) for 4 seconds.

D Malfunction of the barometric pressure sensor

D Improper connector contact, open circuit or

short-circuited harness wire of the barometric pressure

sensor circuit

D Malfunction of the engine-ECU

13-13

Measure at the air flow sensor connector A-25.

D Connect the connector. (Use

the test harness: MB991709)

D Voltage between 2 and earth

(Ignition switch: ON)

OK: 3.7–4.3 V (Altitude: 0 m)

3.2–3.8 V

(Altitude: 1,200 m)

OK

Measure at the engine-ECU connector B-62.

D Connect the connector.

D Voltage between 85 and earth

(Ignition switch: ON)

OK: 3.7–4.3 V (Altitude: 0 m)

3.2–3.8 V

(Altitude: 1,200 m)

OK

Check the following connectors:

A-25, B-62

OK

NG

NG

NG

Measure at the air flow sensor connector A-25.

D Disconnect the connector , and

measure at the harness side.

D Voltage between 1 and earth

(Ignition switch: ON)

OK: 4.8–5.2 V

D Continuity between 5 and earth

OK: Continuity

OK

Check the following connector:

A-25

OK

Check trouble symptom.

Check the harness wire between

the engine-ECU and the barometric pressure sensor connector, and

repair if necessary.

Repair

NG

NG

NG

Check the following connector:

B-62

OK

Check trouble symptom.

NG

Check the harness wire between

the engine-ECU and the barometric pressure sensor connector.

OK

Repair

Replace the engine-ECU.

Check the harness wire between

the engine-ECU and the barometric pressure sensor connector.

OK

Replace the air flow sensor.

NG

NG

NG

Repair

Repair

Repair

Check trouble symptom.

NG

Replace the engine-ECU.

13-14

MPI – Troubleshooting

Code No.31 Detonation sensor system Probable cause

Range of Check

D Ignition switch: ON

D Excluding 60 seconds after the ignition switch is turned to ON or immediately

after the engine starts.

D Engine speed is approx. 5,000 r/min or more

Set conditions