Mitsubishi MOTORS Lancer Evolution 2008 Repair Manual

2008

GROUP INDEX

MITSUBISHI

LANCER EVOLUTION

BODY

REPAIR MANUAL

FOREWORD

This manual has been prepared for the use of all

service mechanics engaged in the body repair service.

Body dimensions, welded panel replacement

procedures, body sealing application instructions, and

all the other information required to provide quick and

accurate body repair service are contained herein.

One especially important point is the welding method.

All of the vehicleís original strength and durability can

be maintained by following the welding procedures

contained in this manual.

Now that, in order to maximize the efficiency of the

repair work, first, both the extent of the damage and

the replacement parts that are needed must be

calculated accurately, and then the actual work must

be performed accurately and efficiently.

following also available, and should be used in

The

conjunction with this manual.

TECHNICAL INFORMATION MANUAL

MSSP-260B-2008

SERVICE MANUAL MSSP-206B-2008

PARTS CATALOG BUM6Y108A_

BODY CONSTRUCTION . . . . . . . . .

BODY DIMENSIONS . . . . . . . . . . . . .

WELDED PANEL REPLACEMENT. .

CORROSION PROTECTION . . . . . .

SYNTHETIC-RESIN PARTS . . . . . . .

BODY COLOR . . . . . . . . . . . . . . . . . .

BASE OF BODY REPAIR . . . . . . . . .

1

2

3

4

5

6

9

Mitsubishi Motors Corporation reserves the right to make changes in

design or to make additions to or improvements in its products without

imposing any obligations upon itself to install them on its products

previously manufactured.

©2007 Mitsubishi Motors Corporation

All Rights, Reserved

Printed in USA

MSSP-460B-2008

MANUAL DESCRIPTION

CONTENTS

The first page of this manual contains a table of contents which lists the name of vehicle models and groups

within each model.

TEXT

The vehicles to which the information in the text pertains are generally designated according to their body

classification. In some cases, other limiting designations such as model name, type of drive system, etc., are

given. If there are no such limiting designations, the information can be assumed to cover all models.

PAGE N U M BERS

Al pages are numbered consecutively within each model. The page number can be found on the upper left or

right of each page.

SECTION TITLES

The group titles and section titles can be found at the upper center of each page.

Page number

Group number

Group title

Section title

GROUP 1

BODY

CONSTRUCTION

CONTENTS

1-1

BODY COMPONENTS. . . . . . . . . . . . 1-2

BODY MAIN CROSS-SECTIONAL

VIEWS . . . . . . . . . . . . . . . . . . . . . . . . 1-4

MAINTENANCE, SERVICEABILITY . 1-6

BODY CONSTRUCTION

CHARACTERISTICS . . . . . . . . . . . . . 1-8

FRONT BODY. . . . . . . . . . . . . . . . . . . . . . . 1-8

SIDE BODY. . . . . . . . . . . . . . . . . . . . . . . . . 1-15

REAR BODY . . . . . . . . . . . . . . . . . . . . . . . . 1-17

ROOF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

UNDER BODY. . . . . . . . . . . . . . . . . . . . . . . 1-20

DOOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

SILENCER APPLICATION

LOCATIONS . . . . . . . . . . . . . . . . . . . . 1-25

FOAMING MATERIAL USAGE

LOCATIONS . . . . . . . . . . . . . . . . . . . . 1-26

STIFFENER AND DAMP SHEET

APPLICATION LOCATIONS . . . . . . . 1-27

THEFT PROTECTION . . . . . . . . . . . . 1-28

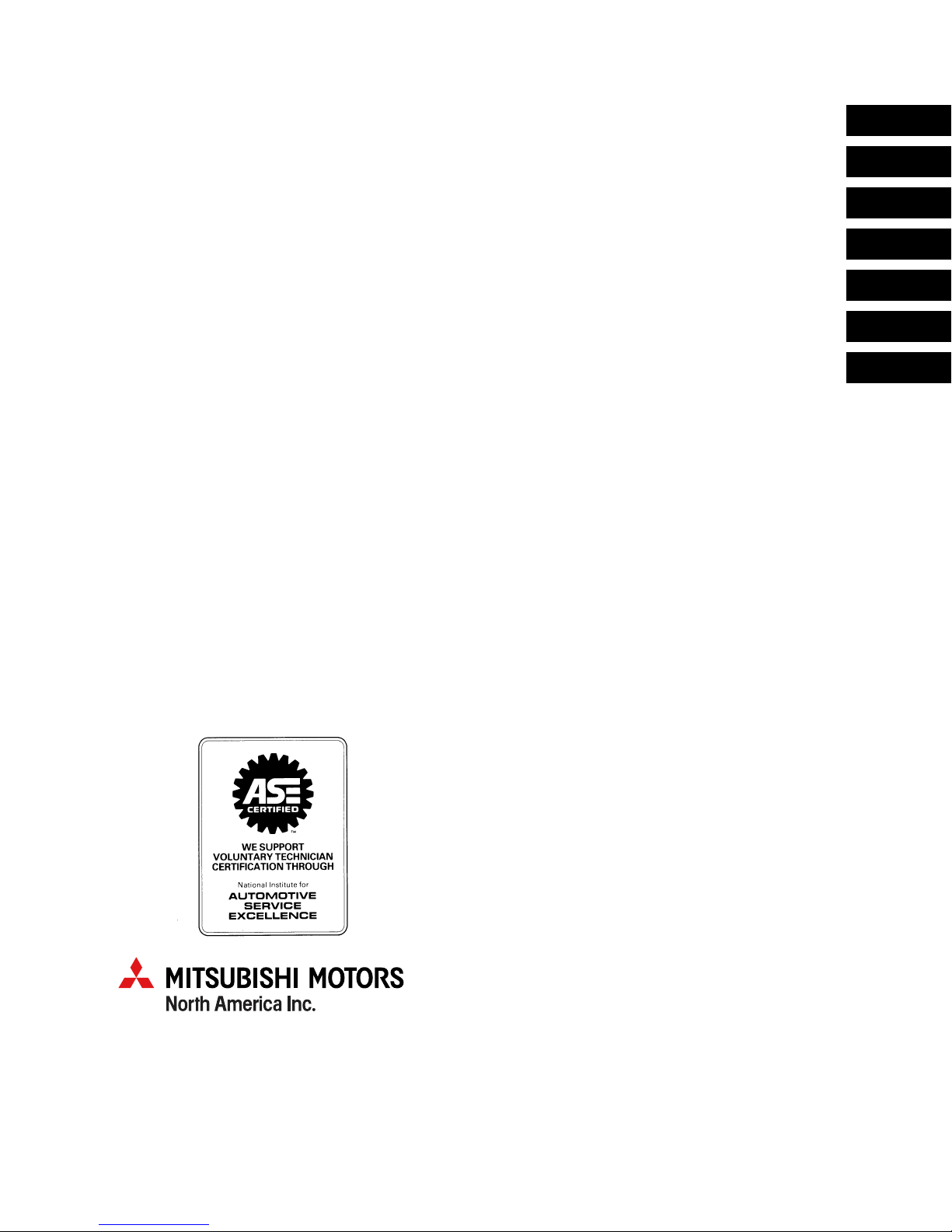

1-2

BODY CONSTRUCTION

BODY COMPONENTS

27

24

25

30

26

28

BODY COMPONENTS

37

36

29

35

32

31

79

80

33*

*

81

97*

34

99*

*

98

82

92

93

38

39

84

91

83

40

87

86

88

M4010001001309

85

89

90

11

13

12

23

10

9*

14

15

16

8

78

22

18

77

20

21

76

96

95*

94

74**

75**

47

43

70

48

19

*

17

60

73

72

59

71

50

56

54

4*

61*

57*

55

49

51

41

42

44

45

46

52*

58*

5

7

6

2

3

68

66

67

65

62

53

1

: Anti-corrosion steel panels

: High-tensile steel panels (*: Indicates 590MPa-high-tensile steel panels.)

69

(**: Indicates 980MPa-ultra-high-tensile steel panels.)

TSB Revision

64

*

63**

AB700971

AB

BODY CONSTRUCTION

BODY COMPONENTS

1-3

1. Front bumper reinforcement

2. Headlight support panel upper

3. Front body frame to side sill brace

4. Front sidemember rear

5. Front inner sidemember

6. Headlight support panel

7. Front sidemember plate

8. Front outer sidemember

9. Front sidemember extension

10. Front fender gusset

11. Headlight support panel upper

12. Front fender shield

13. Fender shield frame upper outer

14. Fender shield frame upper inner

15. Spring house panel

16. Dash panel crossmember upper

17. Dash panel crossmember lower

18. Dash panel

19. Brake pedal support reinforcement

20. Cowl top panel

21. Brake pedal support bracket

22. Front deck crossmember

23. Hood panel inner

24. Hood panel outer

25. Front door side door beam

26. Front door panel inner

27. Front door panel outer

28. Rear door side door beam

29. Rear door panel inner

30. Rear door panel outer

31. Roof rail front lower

32. Roof rail front upper

33. Roof bow center lower <Vehicles without sunroof

(aluminum panel)>

34. Roof bow center upper <Vehicles without sunroof

(aluminum panel)>

35. Roof rail rear

36. Roof panel

37. Roof panel reinforcement <Vehicles with sunroof

(steel panel)>

38. Rear shelf panel

39. Trunk lid panel inner

40. Trunk lid panel outer

41. Fuel filler door panel (Left side)

42. Rear bumper reinforcement

43. Rear bumper reinforcement

44. Rear end panel outer

45. Rear end panel inner

46. Rear bumper side bracket

47. Rear seatback bracket lower

48. Rear floor

49. Rear floor rear end crossmember

50. Rear floor crossmember

51. Rear floor side panel

52. Rear floor sidemember extension

53. Rear floor sidemember lower

54. Rear seat under floor

55. Rear seat belt reinforcement (Left side)

56. Rear seat belt reinforcement (Right side)

57. Rear floor extension

58. Rear floor rear seat under crossmember

59. Front floor crossmember rear

60. Front floor backbone reinforcement

61. Front floor crossmember front

62. Front floor

63. Front floor side sill inner

64. Front floor sidemember

65. Front floor crossmember rear center

66. Front floor crossmember front

67. Front fender

68. Headlight support panel lower

69. Radiator bracket lower

70. Side outer panel

71. Front fender bracket

72. Upper frame to front pillar brace

73. Front deck frame upper outer

74. Side sill reinforcement outer front

75. Side sill reinforcement outer rear

76. Side sill inner support front

77. Front pillar lower reinforcement

78. Front pillar inner lower

79. Front pillar inner center

80. Front upper inner pillar

81. Roof side rail inner

82. Rear seatback brace

83. Rear wheel house panel inner

84. Rear wheel house panel front lower outer

85. Quarter panel lower inner (Left side)

86. Quarter panel inner

87. Quarter panel extension inner

88. Quarter panel extension lower outer

89. Quarter panel extension outer

90. Rear combination light housing panel

91. Rear pillar reinforcement

92. Roof side rail reinforcement rear

93. Rear pillar reinforcement lower

94. Center pillar reinforcement

95. Rear door hinge reinforcement

96. Rear door hinge reinforcement support

97. Roof side rail reinforcement

98. Center pillar inner lower

99. Center pillar inner upper

TSB Revision

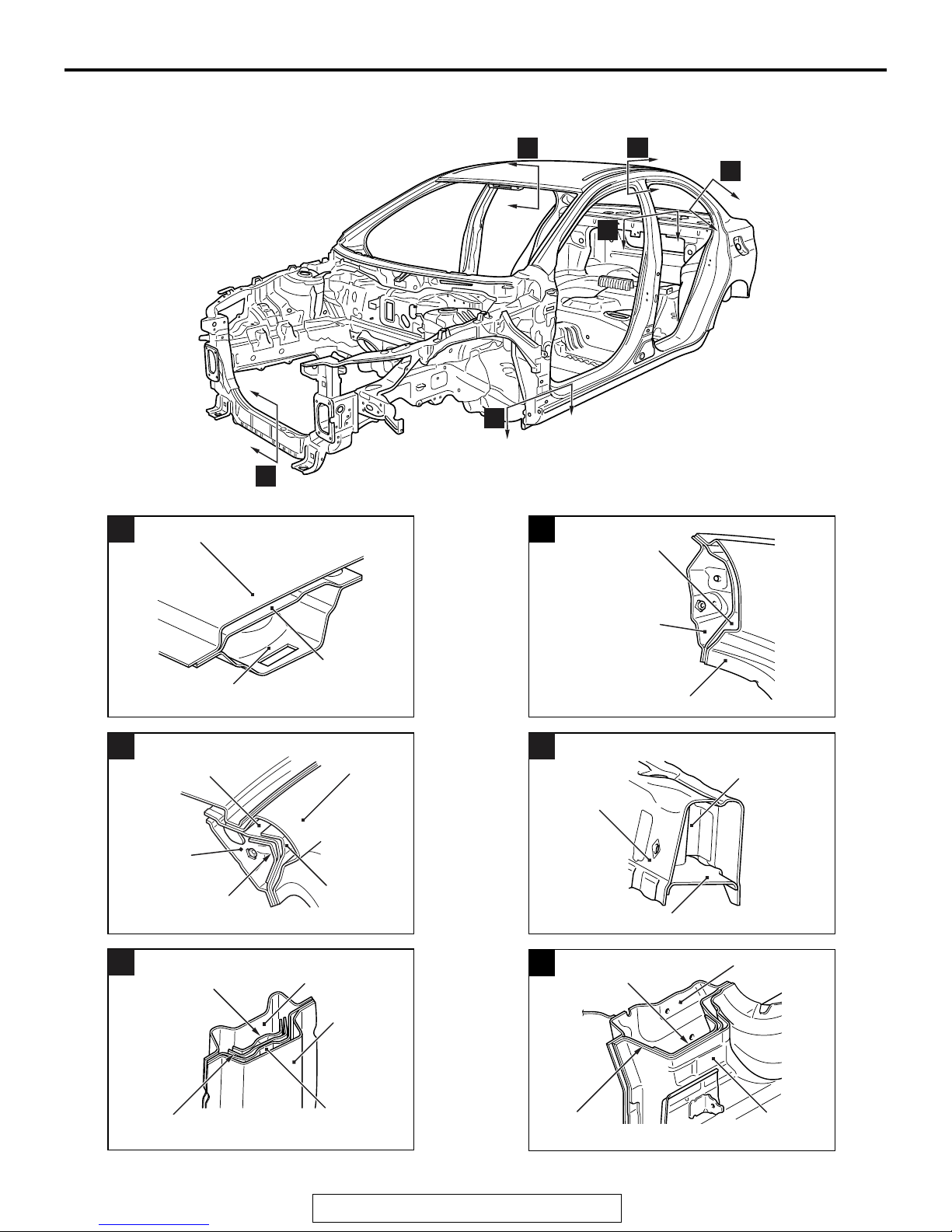

1-4

BODY CONSTRUCTION

BODY MAIN CROSS-SECTIONAL VIEWS

BODY MAIN CROSS-SECTIONAL VIEWS

M4010002001067

A

F

E

A

Roof panel

Roof side rail

D

reinforcement rear

B

D

C

AB700285

AB

B

Roof side

rail inner

Rear door hinge

C

reinforcement

support

Roof rail

front lower

Roof side rail

reinforcement

front

Roof side

rail support

Roof rail

front upper

AB601100

Side outer

panel

Center pillar

reinforcement

AB700969

Center pillar

inner upper

Side outer

panel

AC

AB

Roof side

rail inner

E

Front end

crossmember

upper

Front end

crossmember lower

Front door hinge

F

reinforcement lower

Side outer panel

AB700536

Front end

crossmember

bulkhead

AB601099

Front pillar

inner lower

AB

AC

Rear door hinge

reinforcement

Center pillar

reinforcement

AB601102

AC

TSB Revision

Front pillar

reinforcement lower

Side outer

panel

AB700537

AB

BODY CONSTRUCTION

BODY MAIN CROSS-SECTIONAL VIEWS

H

G

1-5

G

Side outer

panel

H

Roof side rail

reinforcement

front

Roof rail rear

I

Roof panel

J

Front upper

inner pillar

AB602354

AB601108

AC

AB

K

L

J

Side sill

AB700286

Rear floor

side sill

inner

AB

reinforcement

outer rear

Front floor

side sill

Side outer panel

Rear pillar

K

reinforcement

lower

inner

AB700539

AB

Rear wheel

house panel

inner

Side outer

panel

Quarter

inner

panel

Quarter panel extension

lower outer

AB700540

AB

I

Side sill

reinforcement

outer front

Side outer

panel

Front pillar

inner lower

Side sill inner

support front

AB700538

AB

TSB Revision

L

Rear end

panel inner

Rear bumper

reinforcement

Rear end

panel outer

AB601110

AC

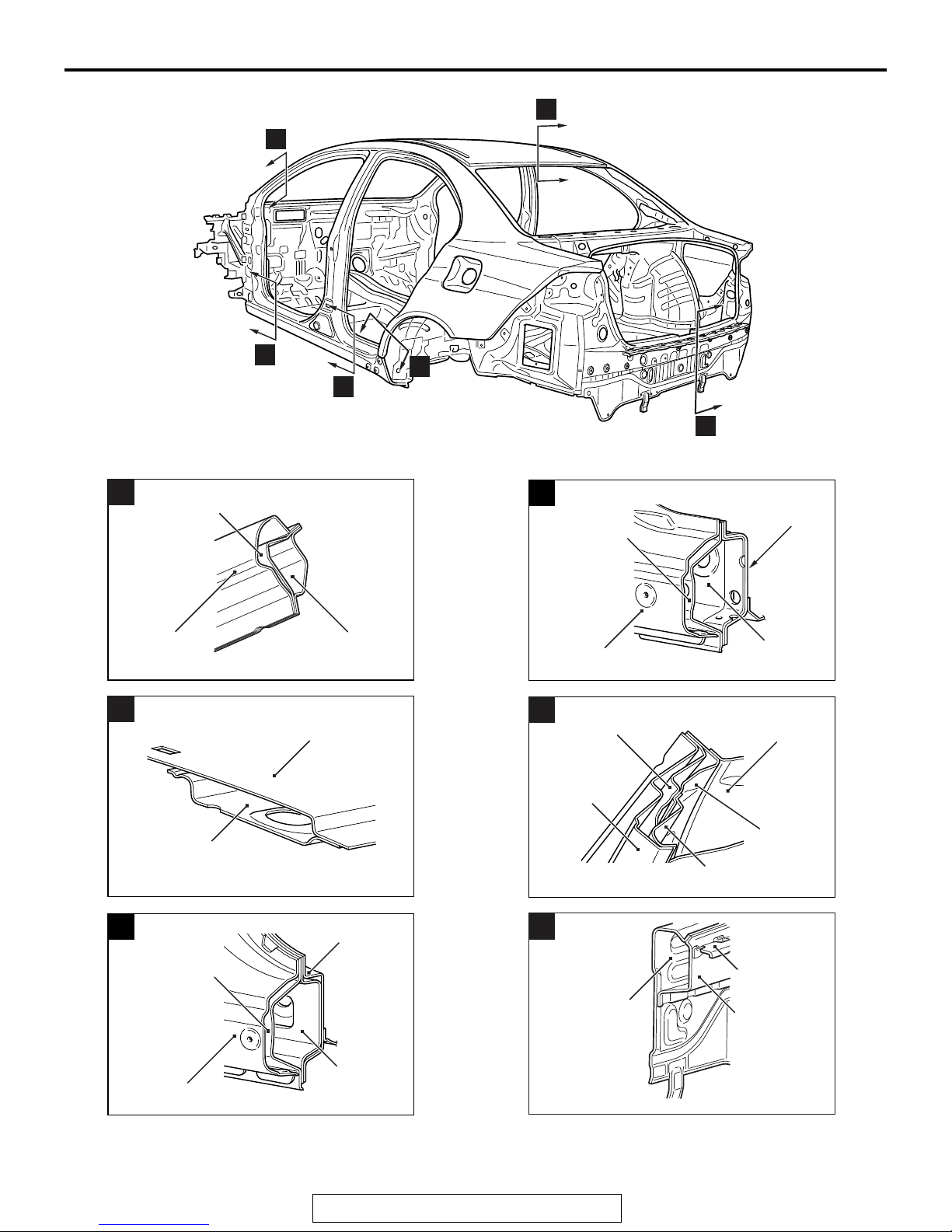

1-6

BODY CONSTRUCTION

MAINTENANCE, SERVICEABILITY

MAINTENANCE, SERVICEABILITY

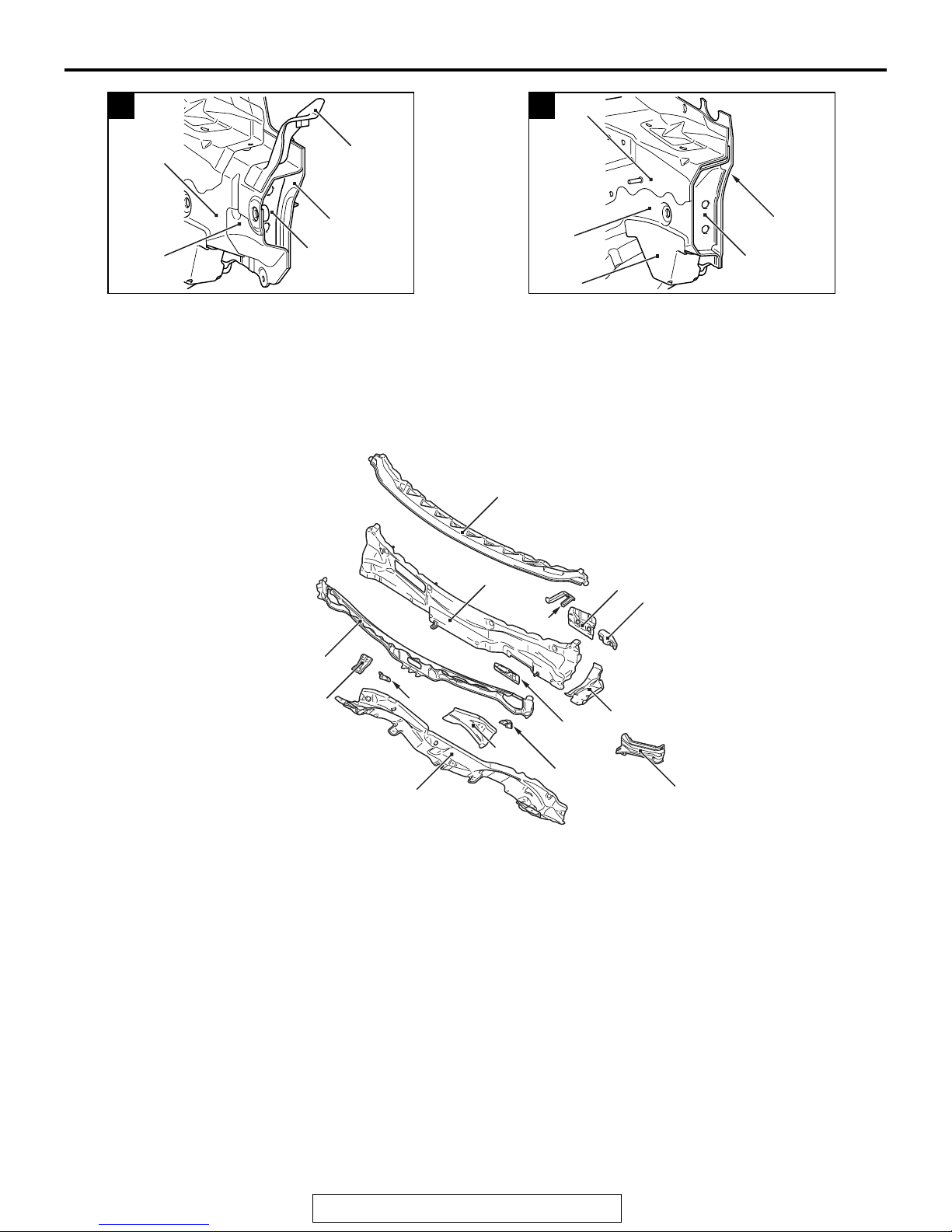

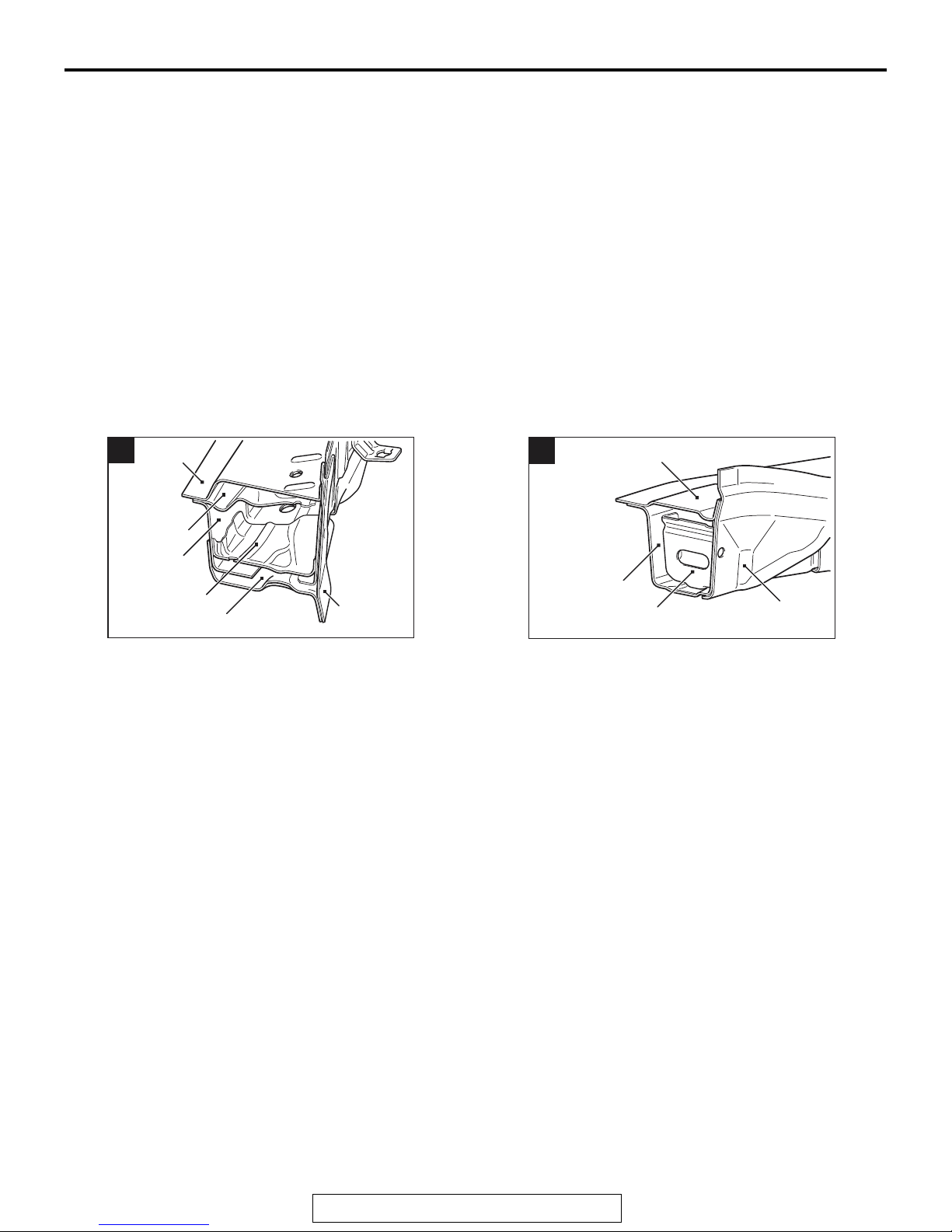

FENDER SHIELD

A positioning hole, lug, and notch have been added

on the front end upper bar side, front upper frame

inner, upper frame extension inner, front side mem

ber brace upper and dash panel to improve assembling workability during panel replacement.

-

M4010003000948

TSB Revision

AB700964

AB

BODY CONSTRUCTION

MAINTENANCE, SERVICEABILITY

SIDE STRUCTURE

A panel positioning notch has been added on the

door opening to improve assembling workability

when replacing the panel.

1-7

SIDE OUTER PANEL

The extra parts are supplied in 4 different cut forms

as a result of employing the integrated side-frame

side outer panel.

Panel positioning notch

AB201388

AB700289

AB

AB

Front outer pillar

Center outer pillar

Quarter panel outer

Front floor side sill outer

AB700613

AB

TSB Revision

1-8

BODY CONSTRUCTION

BODY CONSTRUCTION CHARACTERISTICS

BODY CONSTRUCTION CHARACTERISTICS

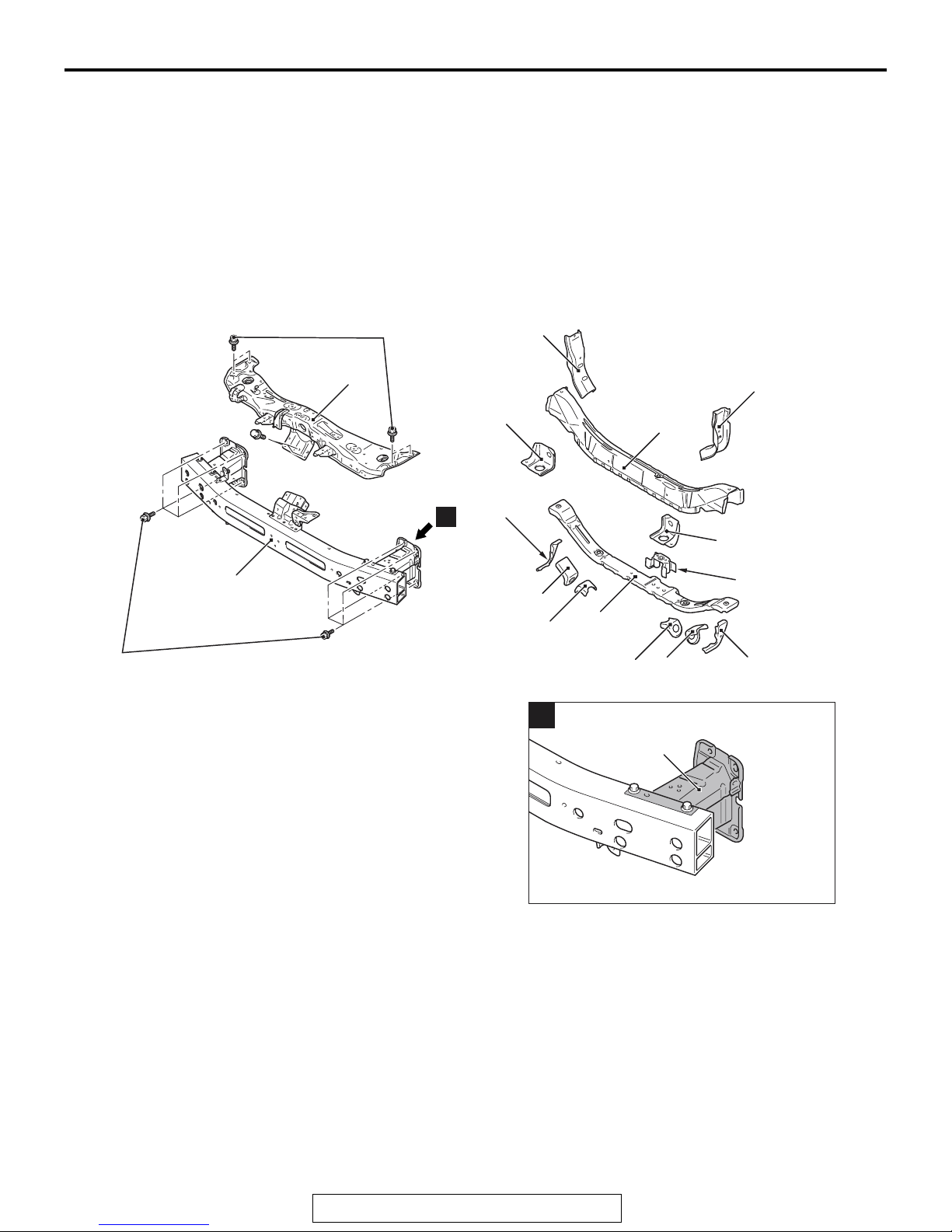

FRONT BODY

HEADLIGHT SUPPORT

• The crush box structure, which has an octagonal

cross-section at the front end of the front side

member, has been adopted. This structure can

effectively absorb energy upon frontal impact and

reduces the vehicle repair cost caused by a light

collision.

9.0 ± 2.0 N·m

80 ± 17 in-lb

2

M4010010001200

• The bolt-on headlight support panel upper is

used to improve maintainability.

-

• An aluminum front bumper reinforcement has

been adopted to improve the body rigidity, han

-

dling stability, and riding comfort.

3

3

5

A

7

4

5

1

20 ± 5 N·m

15 ± 3 ft-lb

1. Front bumper reinforcement

2. Headlight support panel upper

3. Front end crossmember gusset

4. Front end crossmember upper

5. Radiator bracket lower A

6. Front end crossmember bulkhead

7. Radiator bracket lower B

8. Shipping hook front

9. Shipping reinforcement front

10. Front end crossmember lower

6

8

10

9

8

9

A

Crush box

The crush box structure has been changed to

straight type with an octagon cross-section so that

the structure can effectively absorb energy from the

impact at the time of collision.

7

AB701123

AB700911

AB

AB

TSB Revision

BODY CONSTRUCTION

BODY CONSTRUCTION CHARACTERISTICS

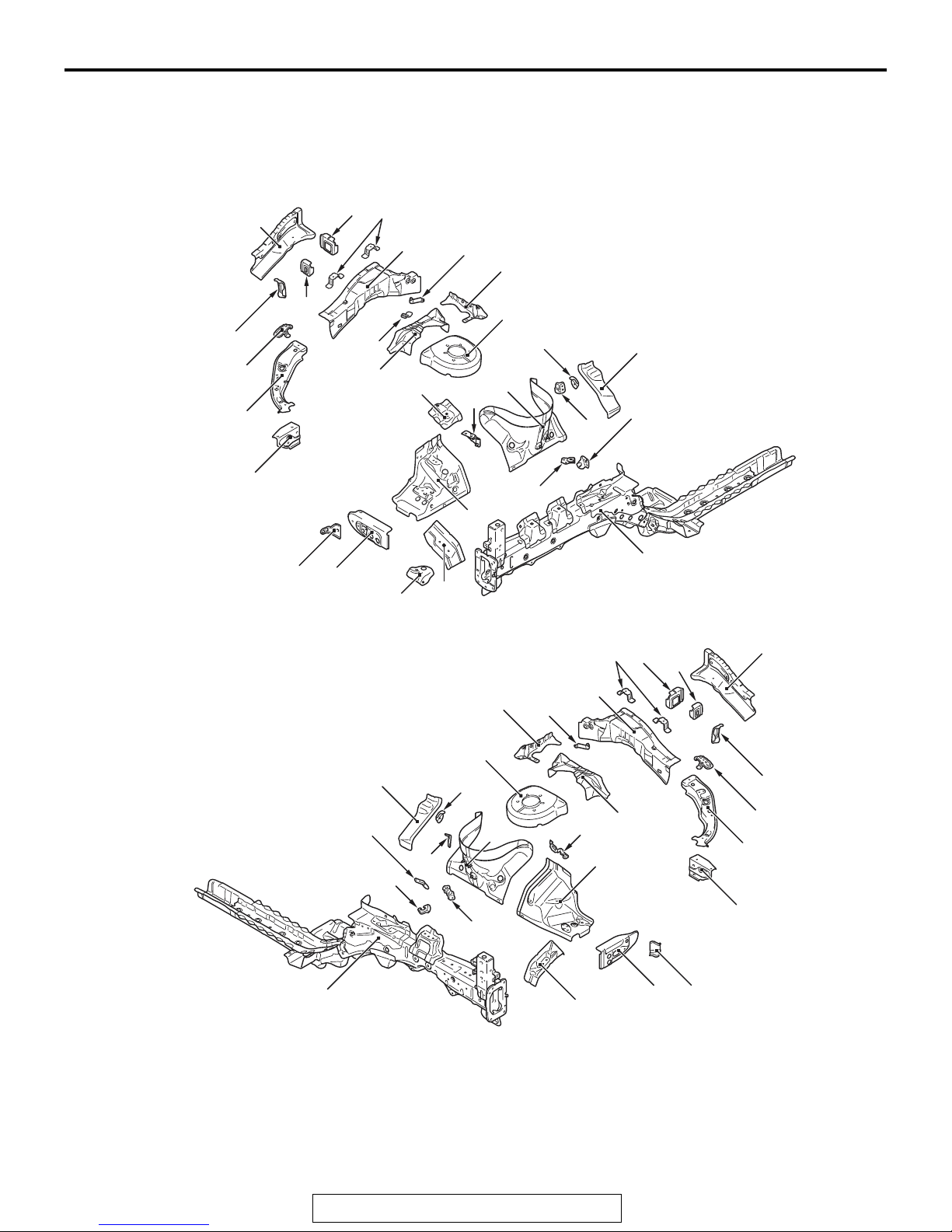

FENDER SHIELD

The padding structure of the front fender bracket has

been adopted to efficiently absorb energy upon

impact by the crushable structure and improve the

pedestrian protection capability.

7

(Right side)

5

8

9

1-9

10

12

(Left side)

6

4

3

11

13

22

2

21

14

20

16

15

18

17

1

19

23

28

27

26

24

25

12

10

8

7

6

9

5

AB700410

AB

14

15

16

4

28

31

32

30

TSB Revision

29

20

33

34

23

13

26

27

3

2

1

AB700409

AB

1-10

BODY CONSTRUCTION

BODY CONSTRUCTION CHARACTERISTICS

1. Upper side bar front

2. Front end upper bar side

3. Front fender bracket

4. Upper frame bulkhead front

5. Fender shield frame upper outer

6. Upper frame bulkhead center

7. Upper frame bulkhead rear

8. Front fender bracket

9. Front upper frame inner

10. Upper frame inner plate

11. Harness bracket

12. Spring house corner gusset

13. Spring house bracket reinforcement

14. Spring house bracket front

15. Spring house panel rear

16. Spring house reinforcement rear

17. Horn bracket

18. Spring house harness bracket

19. Suction hose bracket

20. Spring house panel

21. Power steering reservoir tank bracket

22. Engine mounting bracket upper

23. Front fender shield

24. Engine mounting gusset

25. Condense tank reinforcement

26. Fender gusset

27. Front fender bracket

28. Front sidemember

29. Engine control module bracket

30. Clutch tube bracket <M/T>

31. Harness bracket front

32. Harness bracket rear

33. Relay box bracket

34. Transaxle mounting gusset

TSB Revision

BODY CONSTRUCTION

BODY CONSTRUCTION CHARACTERISTICS

1-11

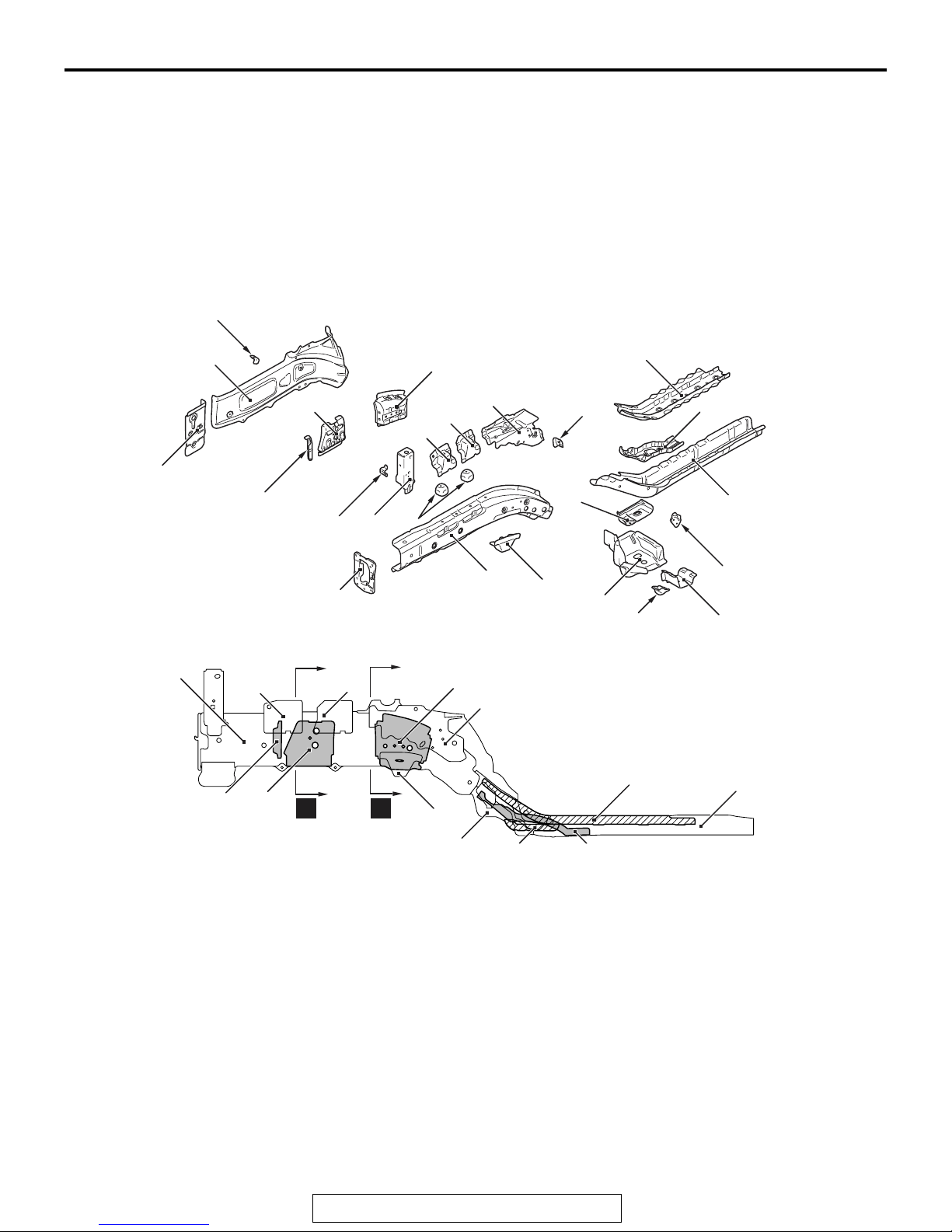

FRONT SIDEMEMBER REINFORCEMENT

• The front sidemember structure has been

changed to a straight frame structure with an

octagon cross section that efficiently absorbs

energy from the impact at the time of collision.

• The front sidemember is supported in three directions by the dash crossmember center, dash

crossmember lower and front sidemember rear in

order to improve the frontal collision characteris

tics, and increase the vehicle body rigidity.

(Right side)

1*

3

2

16

17

22

21

15

20

19

18

• The 590-MPa class high tensile strength steel

panels have been adopted for the front sidemem

ber extension, front sidemember rear bulkhead

and front sidemember rear to improve the body

rigidity.

-

4

23

11

24

5

*

*

6

-

14

*: Indicates 590MPa-high-tensile steel panels.

13

21

16

15

1. Front sidemember extension

2. Front sidemember outer

3. Front brake hose bracket

4. Front sidemember reinforcement rear lower

5. Front sidemember rear bulkhead

6. Front sidemember rear

7. Height sensor bracket

8. Dash crossmember extension lower

9. I plate bracket

10. Front body frame to side sill brace

11. Tie down reinforcement front

12. Front suspension crossmember bracket front

22

A

B

12

13

12

10

9

17

23

4

10

11

13. Front sidemember inner

14. Front sidemember plate

15. Front sidemember bulkhead front

16. Engine mounting bulkhead

17. Front suspension crossmember bulkhead

18. Headlight bracket lower

19. Headlight support panel

20. Engine mounting reinforcement

21. Engine mounting bracket front

22. Engine mounting bracket rear

23. Front sidemember brace upper

24. Front sidemember reinforcement rear

5

7

8

AB700925

AB

6

AB700929

AC

TSB Revision

1-12

BODY CONSTRUCTION

BODY CONSTRUCTION CHARACTERISTICS

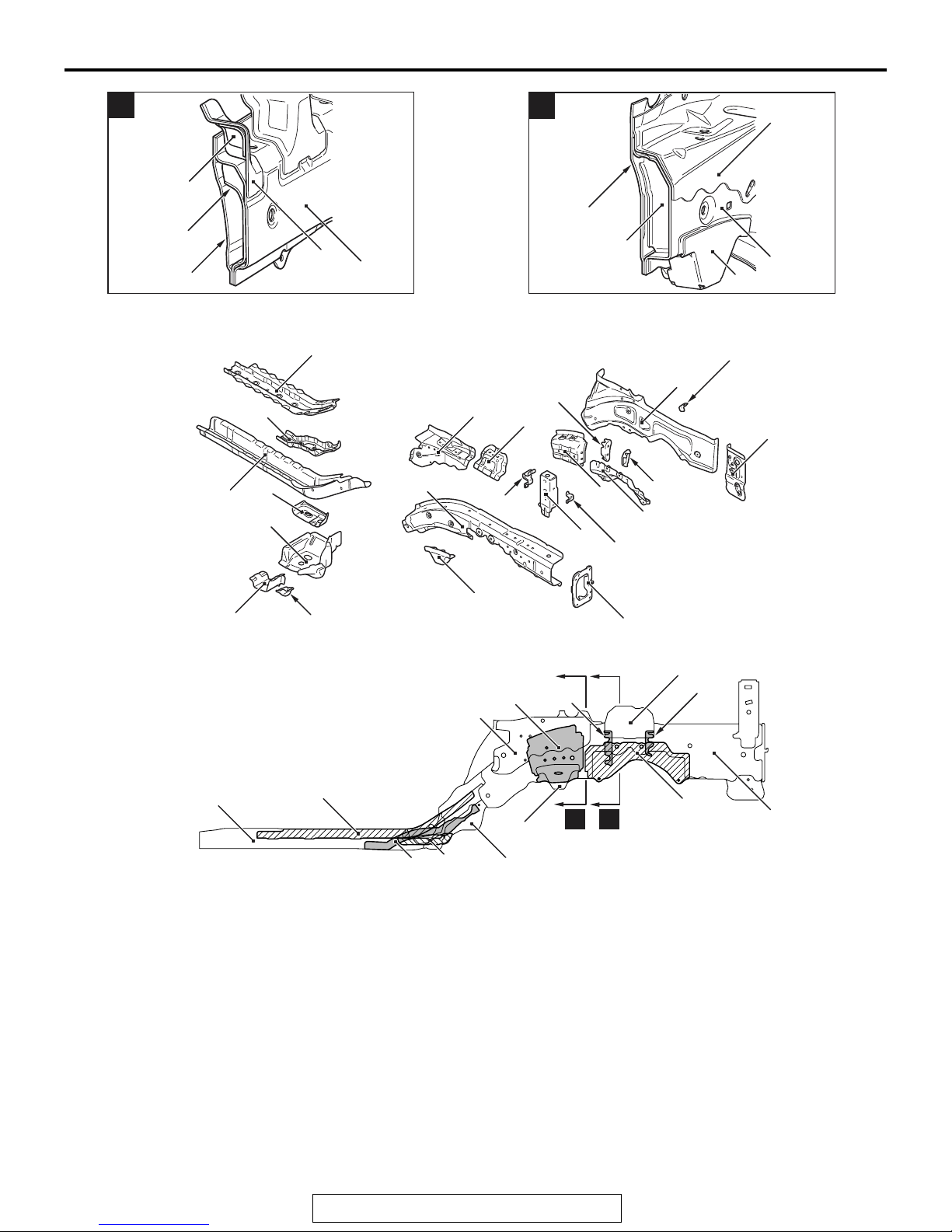

A

(Left side)

20

16

2

B

23

2

21

7

13

AB602309

AD

17

12

9

13

AB602310

AD

8

20

6

*

4

5

*

13

3

14

16

15

17

19

18

22

21

10

*

2

*: Indicates 590MPa-high-tensile steel panels.

5

1. I plate bracket

2. Dash crossmember extension lower

3. Front body frame to side sill brace

4. Tie down reinforcement front

5. Front sidemember rear

6. Front sidemember rear bulkhead

7. Front sidemember reinforcement rear lower

8. Front sidemember outer

9. Front brake hose bracket

10. Front sidemember extension

11. Front sidemember plate

1

7

12

11

AB700920

AB

15

19

20

21

14

B

A

12

4

6

3

12. Front suspension crossmember bracket front

13. Front sidemember inner

14. Front sidemember brace upper

15. Transaxle mounting bracket

16. Connector bracket

17. Headlight support panel

18. Headlight bracket lower

19. Front suspension crossmember bulkhead

20. Transaxle mounting bulkhead rear

21. Transaxle mounting bulkhead front

22. Front sidemember reinforcement

22

13

AB700931

AC

TSB Revision

BODY CONSTRUCTION

BODY CONSTRUCTION CHARACTERISTICS

1-13

A

13

15

8

22

20

AB700583

AC

FRONT DECK

• The impact absorbing opening on the cowl top

outer reinforcement upper has been added to effi

ciently absorb energy upon impact and improve

the pedestrian protection capability.

B

14

13

8

19

12

• Rigidity was heightened and driving stability was

improved by bonding the fender shield frame

-

upper outer and front pillar by the upper frame to

front pillar brace.

AB700584

6

AC

4

3

1. Cowl top panel lower

2. Wiper B bracket

3. Cowl top stay bracket rear

4. Cowl top outer reinforcement upper

5. Cowl top panel inner

6. Cowl top panel outer

7. Deck crossmember stay bracket

5

8

9

7

2

10

11

13

12

1

8. Brake pedal support bracket

9. Clutch pedal support bracket <M/T>

10. Upper frame extension inner

11. Brake pedal support reinforcement

12. Front fender bracket

13. Cowl top outer reinforcement lower

14. Upper frame to front pillar brace

14

AB602289

AC

TSB Revision

1-14

BODY CONSTRUCTION CHARACTERISTICS

BODY CONSTRUCTION

DASH PANEL

The 590-MPa class high tensile strength steel panels

have been adopted for the dash crossmember cen

ter, dash crossmember extension, dash panel reinforcement and dash crossmember side to improve

the body rigidity.

-

3*

2

*: Indicates 590MPa-high-tensile steel panels.

1. Brake tube bracket

2. Harness bracket

3. Dash crossmember center

4. Dash crossmember extension

5. Canister bracket

6. Dash heat protector bracket

7. Dash panel

8. Backbone reinforcement front

7

9

12*

6

8

10

11

13

5

4*

1

15

14*

16

AB700934

9. Dash panel lower

10. Accelerator pedal bracket

11. Steering shaft bracket

12. Dash panel reinforcement

13. Clutch pedal reinforcement lower <M/T>

14. Dash crossmember side

15. Dash crossmember lower bulkhead

16. Dash crossmember lower

AB

TSB Revision

BODY CONSTRUCTION

BODY CONSTRUCTION CHARACTERISTICS

1-15

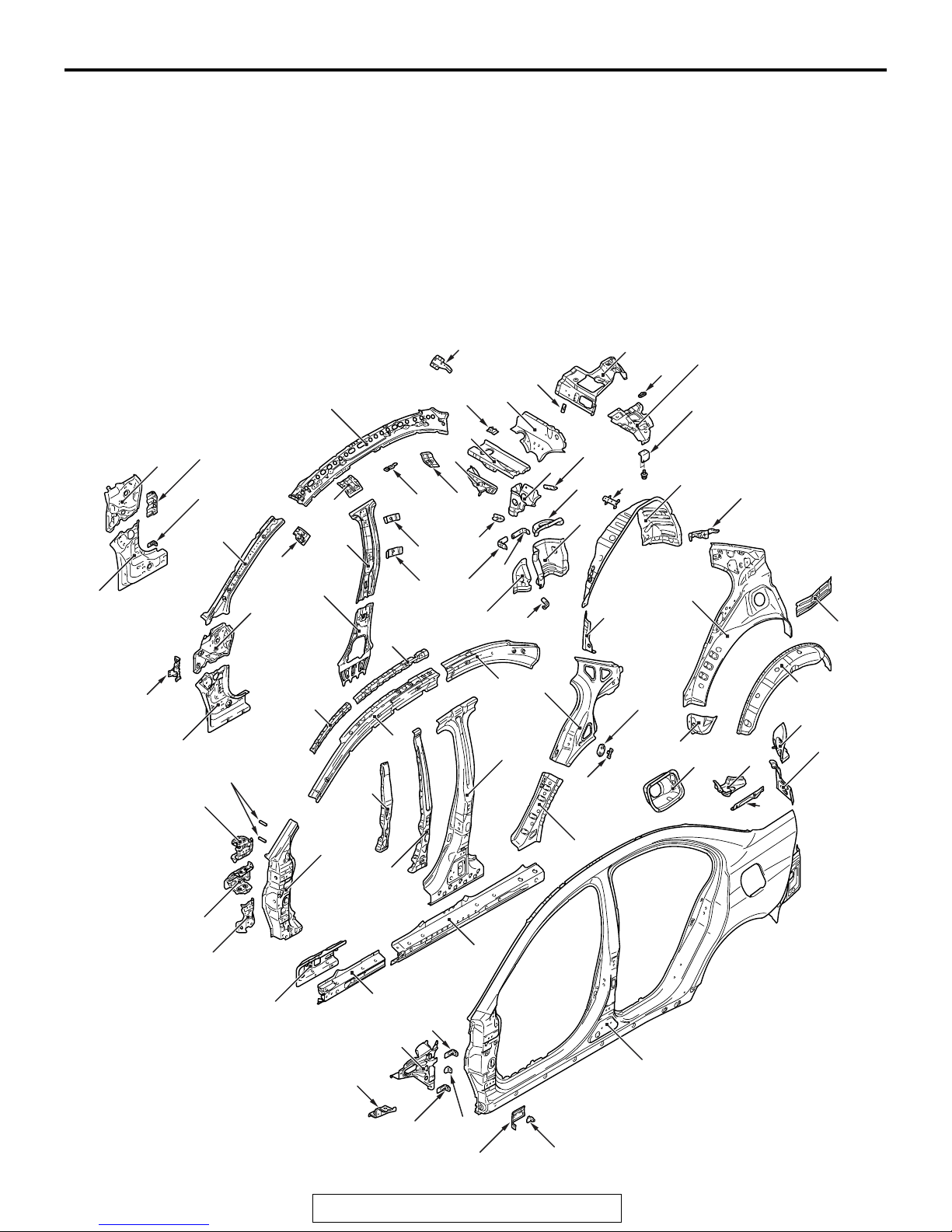

SIDE BODY

SIDE STRUCTURE

• The 590-MPa class high tensile strength steel

panels or 980-MPa class ultra high tensile

strength steel panels have been adopted for the

front pillar, center pillar, side sill, and roof side rail

to improve the body rigidity.

• Rigidity was heightened and driving stability was

improved by bonding the roof bow and roof rail

and the roof side rail inner by the roof rail exten

sion.

15*

5

2

4

12

6*

8*

11

1

2

7

13

10

9

64*

-

25

14

• A rear shelf lower brace is used to connect the

spring house middle panel and rear shelf upper

brace, so that the body rigidity, handling stability,

and riding comfort are improved.

• The number of the spot welding points at the door

opening has been increased to heighten the body

rigidity and to improve handling stability.

16

23

21

22

17

19

18

20

24

28

27

29

35

36

38

34

26

30

31

32

37

33

40

M4010011001087

39

3

63*

1

62

66

61

58

67*

60

59

57

56**

54

*: Indicates 590MPa-high-tensile steel panels.

**: Indicates 980MPa-ultra-high-tensile steel panels.

65*

53

52

52

51

55**

50

69

68

70

49

72

73

71

48

41

47

45

46

42

43

44

AB700954

AB

TSB Revision

1-16

BODY CONSTRUCTION

BODY CONSTRUCTION CHARACTERISTICS

1. Front pillar inner lower

2. Front pillar inner center

3. Hood opener bracket (Left side)

4. Cowl side trim bracket (Right side)

5. Deck crossmember bracket (Right side)

6. Front upper inner pillar

7. Center pillar inner lower

8. Center pillar inner upper

9. Center pillar seat belt reinforcement lower

10. Center pillar seat belt reinforcement upper

11. Roof rail front extension

12. Roof rail center extension <Vehicles without sunroof

(aluminum panel)>

13. Bracket C <Vehicles with sunroof (steel panel)>

14. Roof rail rear extension

15. Roof side rail inner

16. Harness bracket (Right side)

17. Rear shelf upper brace

18. Rear seat belt reinforcement

19. Nut plate <Vehicles with subwoofer>

20. Subwoofer upper bracket <Vehicles with subwoofer>

21. Rear seat hook A

22. Rear seatback brace rear

23. Rear seatback plate reinforcement

24. Rear seatback brace bulkhead

25. Rear seatback brace front

26. Rear spring house reinforcement upper front

27. Rear shelf lower brace

28. Rear spring house reinforcement upper rear

29. Rear spring house bracket

30. Trunk trim bracket

31. Washer tank center bracket (Left side)

32. Spring house middle front panel (Left side)

33. Filler pipe mounting bracket (Left side)

34. Spring house middle panel

35. Harness bracket (Left side)

36. Rear wheel house panel inner

37. Rear wheel house panel front lower outer

38. Curtain air bag bracket

39. Quarter panel lower inner (Left side)

40. Quarter inner panel

41. Quarter panel extension inner

42. Quarter panel extension lower outer

43. Rear combination light housing

44. Quarter corner panel

45. Quarter outer upper extension

46. Quarter outer upper side extension

47. Fuel filler neck bracket (Left side)

48. Side outer panel

49. Fender bracket

50. Fender bracket lower

51. Front fender bracket

52. Cowl side trim bracket

53. Front upper outer frame rear

54. Upper frame outer reinforcement

55. Side sill reinforcement outer rear

56. Side sill reinforcement outer front

57. Side sill inner support front

58. Front pillar reinforcement lower

59. Front door hinge reinforcement lower

60. Front pillar reinforcement center bulkhead

61. Front door hinge reinforcement upper

62. Deck support pipe (Left side)

63. Front pillar support

64. Roof side rail support

65. Roof side rail reinforcement front

66. Rear door hinge reinforcement support

67. Rear door hinge reinforcement

68. Center pillar reinforcement

69. Roof side rail reinforcement rear

70. Rear pillar reinforcement

71. Flap gate striker reinforcement

72. Nut plate

73. Rear pillar reinforcement lower

TSB Revision

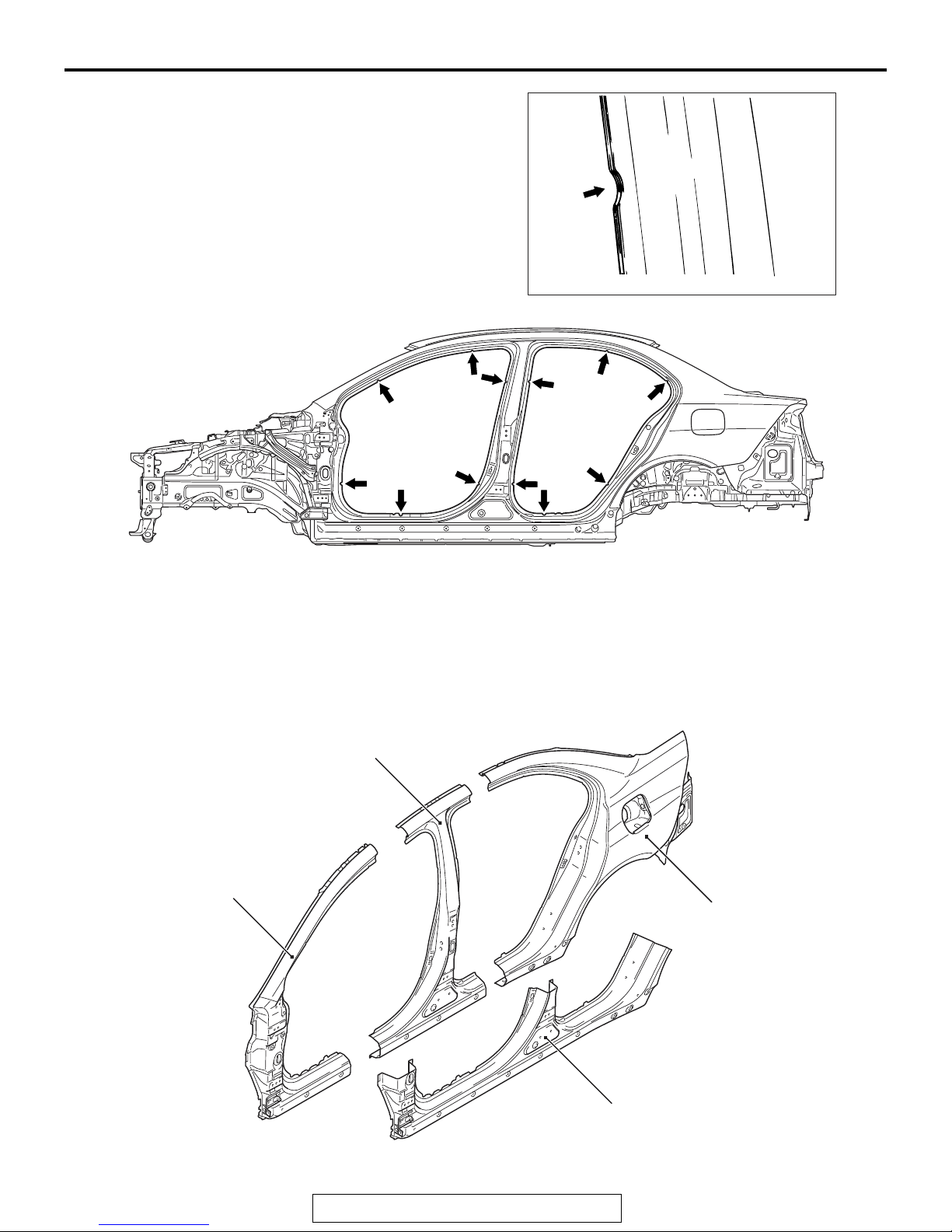

BODY CONSTRUCTION

BODY CONSTRUCTION CHARACTERISTICS

SIDE STRUCTURE REINFORCEMENT

The ring structure of the side structure reinforcement

has been adopted to improve the collision characteristics and the rigidity of the whole vehicle.

Roof side rail reinforcement rear

Roof side rail reinforcement front

1-17

Rear pillar reinforcement

Rear pillar reinforcement lower

Front pillar

reinforcement lower

REAR BODY

REAR DECK

Side sill reinforcement outer rear

Center pillar reinforcement

Side sill reinforcement outer front

AB700608

M4010012000764

AB

3

4

2

1

18 ± 7 N·m

13 ± 5 ft-lb

1. Washer tank bracket upper

2. Rear seat hook A

3. Rear shelf panel

4. Rear shelf reinforcement

TSB Revision

6

7

5. Seat belt reinforcement center

6. Rear shelf extension

7. Rear seatback reinforcement

5

AB700406

AB

1-18

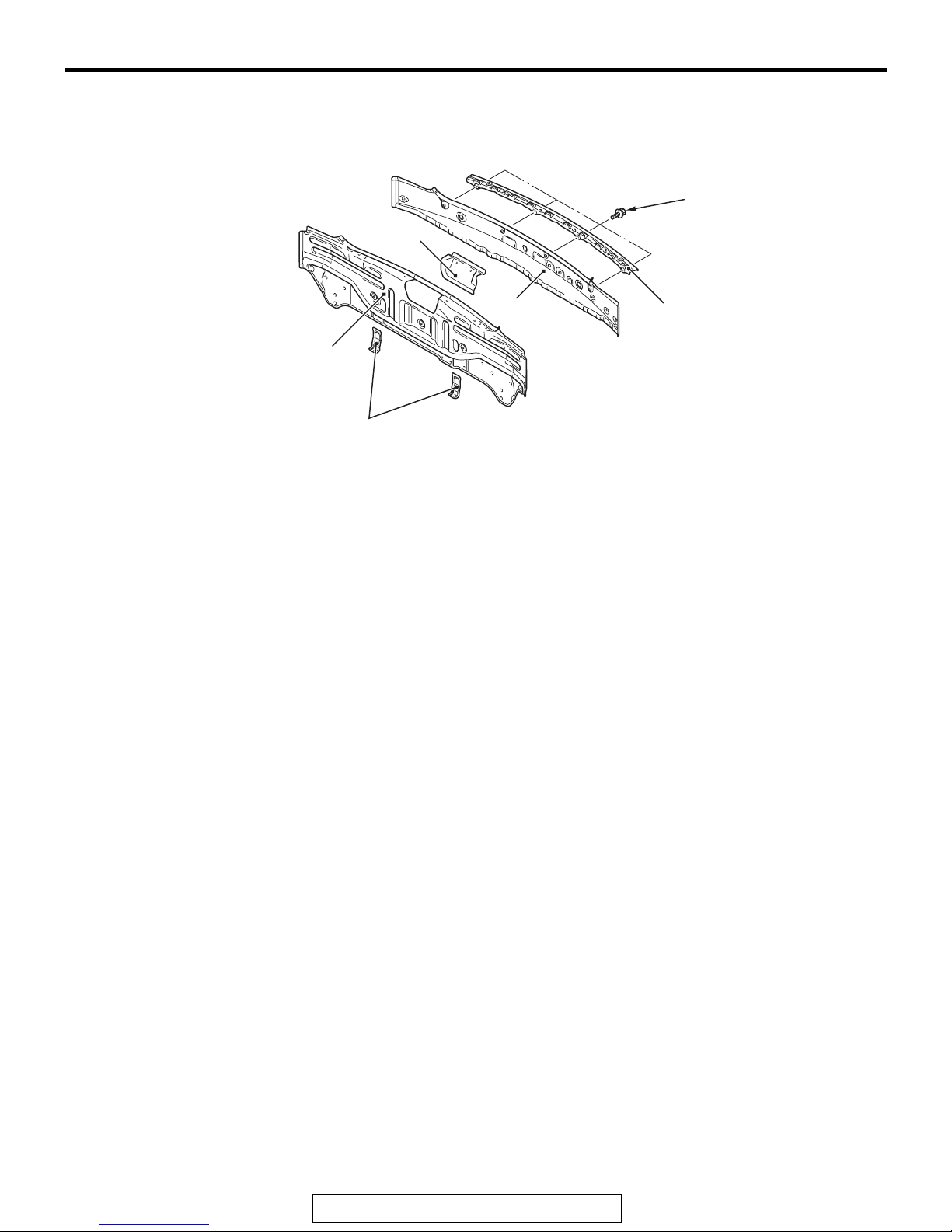

REAR END PANEL

BODY CONSTRUCTION

BODY CONSTRUCTION CHARACTERISTICS

5.0 ± 1.0 N·m

44 ± 9 in-lb

3

2

1

1. Rear bumper side bracket

2. Rear end panel inner

3. Trunk lid striker reinforcement

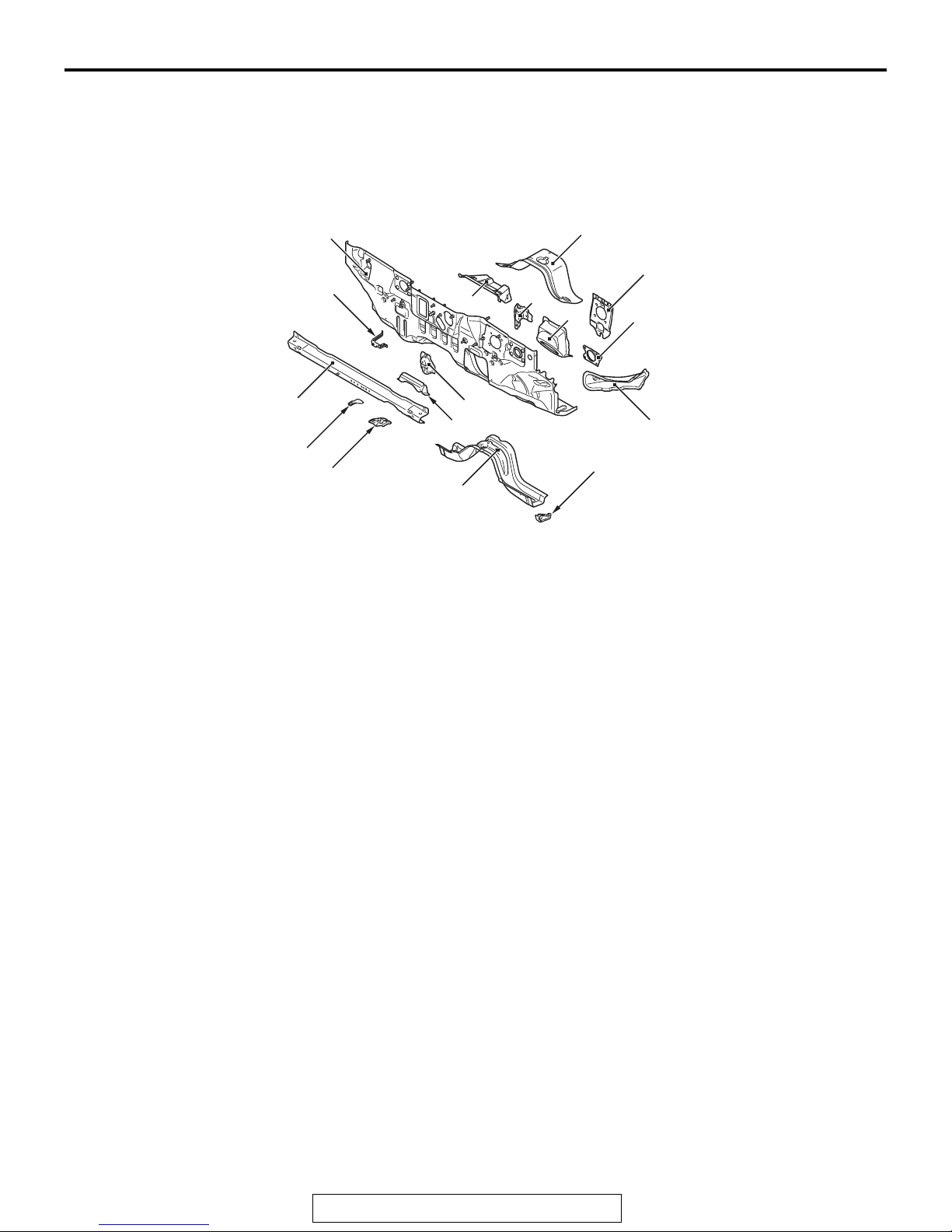

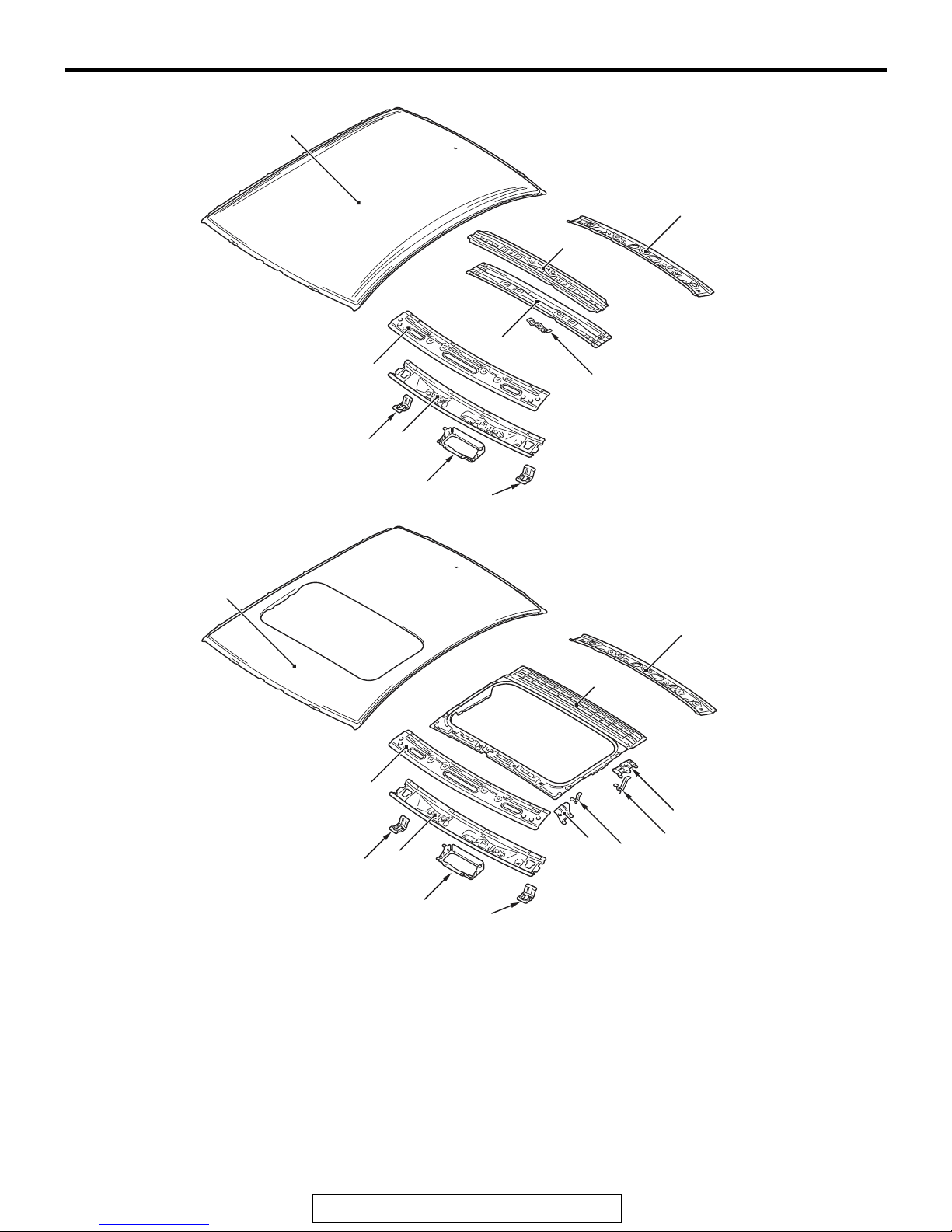

ROOF

• An aluminum roof panel has been adopted to

improve lightweightness for greater handling sta

bility. <Vehicles without sunroof (aluminum

panel)>

• The closed section structure has been adopted

for the roof rail front and the roof bow center to

heighten body rigidity, improve handling stability

and riding comfort, and to reduce vibration and

noise.

4

4. Rear end panel outer

5. Rear bumper reinforcement

5

• The 590-MPa class high tensile strength steel

-

panel has been adopted for the roof bow center

lower to improve the body rigidity. <Vehicles with

out sunroof (aluminum panel)>

AB700570

M4010013001306

AB

-

TSB Revision

BODY CONSTRUCTION CHARACTERISTICS

<Vehicles without sunroof (aluminum panel)>

5

1

BODY CONSTRUCTION

8*

4

3

1-19

6

7

9

*: Indicates 590MPa-high-tensile steel panels.

<Vehicles with sunroof (steel panel)>

5

1. Sunvisor bracket

2. Reading light bracket

3. Roof rail front lower

4. Roof rail front upper

5. Roof panel

6. Roof rail rear

7. Roof bow center upper

2

1

AB700936

AB

6

10

4

11

13

12

AB700863

AE

3

1

2

1

8. Roof bow center lower

9. Dome light bracket

10. Roof panel reinforcement

11. Set rear bracket

12. Bracket A

13. Bracket B

14. Set front bracket

14

TSB Revision

1-20

BODY CONSTRUCTION

BODY CONSTRUCTION CHARACTERISTICS

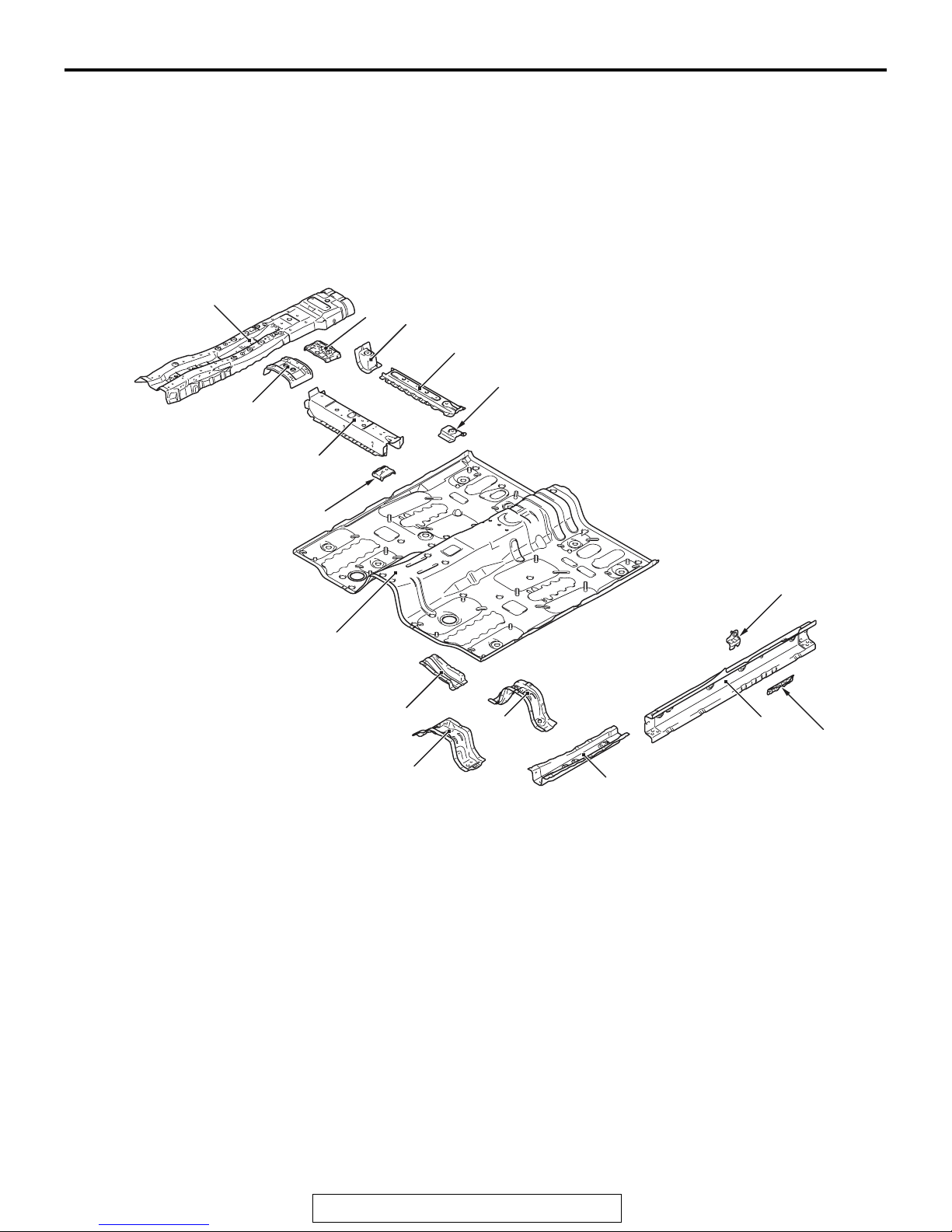

UNDER BODY

FRONT FLOOR

The 590-MPa class high tensile strength steel panels

have been adopted for the front floor crossmember

front and front floor sidemember, and the 980-MPa

class ultra high tensile strength steel panels for the

front floor side sill inner, to improve the body rigidity.

5

4

3

*

2

6

7

M4010014001202

8

9

1

16

*: Indicates 590MPa-high-tensile steel panels.

**: Indicates 980MPa-ultra-high-tensile steel panels.

1. Front floor

2. Front floor crossmember front reinforcement

3. Front floor crossmember front

4. Parking brake lever reinforcement

5. Backbone reinforcement

6. Parking brake cable reinforcement

7. Seat center bracket rear

8. Front floor crossmember rear

15

10

14

12

**

11

13

*

9. Seat side bracket rear

10. Seat belt reinforcement

11. Front floor side sill inner center reinforcement

12. Front floor side sill inner

13. Front floor sidemember

14. Front floor crossmember rear center

15. Front floor crossmember front

16. Front floor reinforcement lower (Right side)

AB700937

AB

TSB Revision

BODY CONSTRUCTION

BODY CONSTRUCTION CHARACTERISTICS

1-21

REAR FLOOR

• The 590-MPa class high tensile strength steel

panels have been adopted for the rear floor

extension and rear seat crossmember to improve

the body rigidity.

7

5

6

4

2

1*

• The rear floor rear end crossmember has been

straightened to heighten body rigidity, improve

handling stability and riding comfort, and to

reduce vibration and noise.

8

3

9

16

*: Indicates 590MPa-high-tensile steel panels.

1. Rear floor extension

2. Rear seat under floor

3. Rear floor pan rear

4. Rear seatback bracket lower

5. Rear floor crossmember upper

6. Battery bracket rear floor front

7. Battery bracket rear floor

8. Spare tire bracket

9. Rear floor rear end crossmember

15*

14

13

11

10

11

12

17

16

10. Rear floor crossmember front

11. Fuel tank rear bracket

12. Rear seat belt reinforcement (Left side)

13. Rear seat belt reinforcement (Right side)

14. Rear seat crossmember bulkhead inner

15. Rear seat crossmember

16. Sidemember front floor extension

17. Rear floor sidemember

AB700404

AB

TSB Revision

1-22

BODY CONSTRUCTION CHARACTERISTICS

BODY CONSTRUCTION

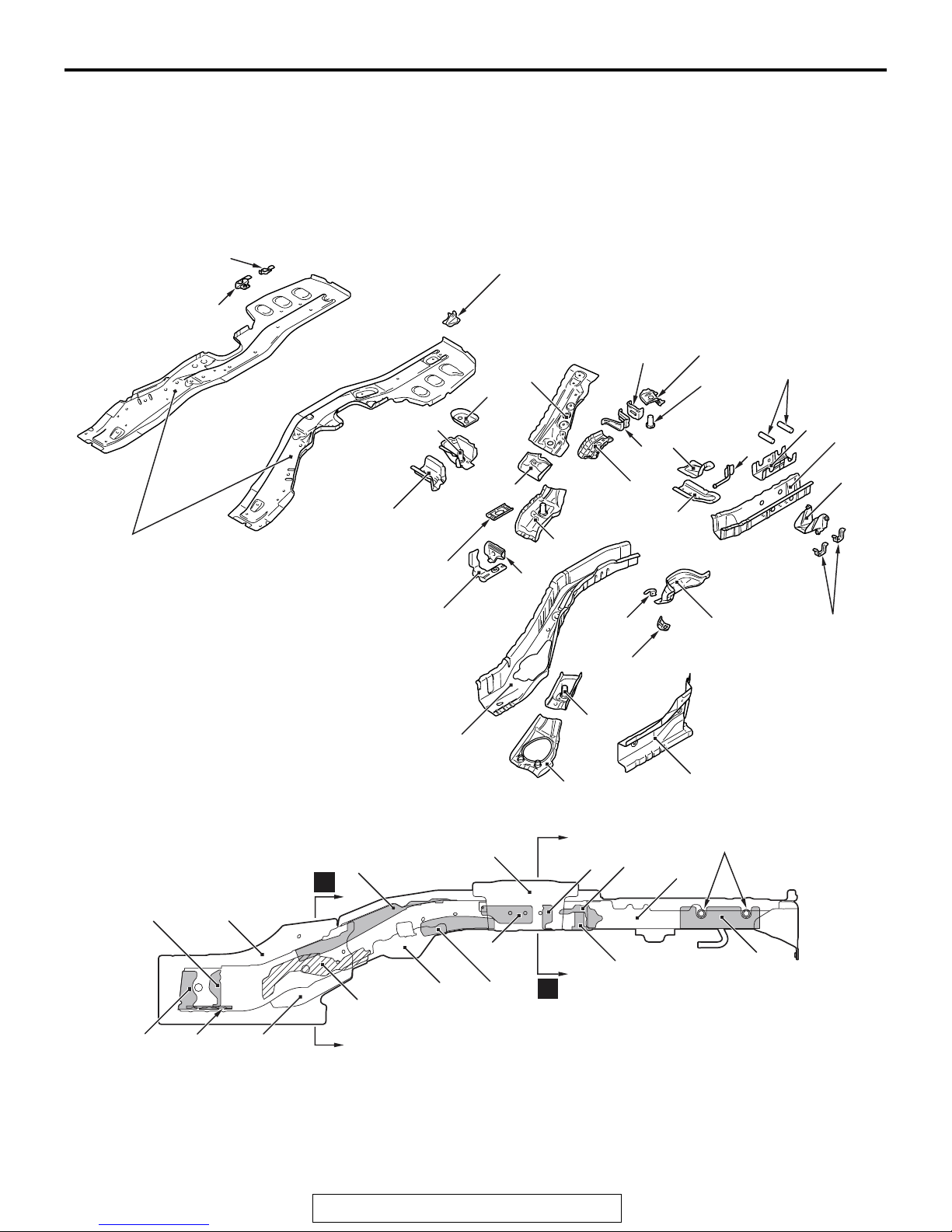

REAR FLOOR SIDEMEMBER

REINFORCEMENT

The 590-MPa class high tensile strength steel panels

have been adopted for the rear floor sidemember

reinforcement, rear floor sidemember extension, rear

floor side sill inner and rear floor sidemember bulk

head to improve the body rigidity.

-

33

2

32

29

6*

30

31

10

5

4

7

28

9

11

12*

13

16

27

8

15

14

26

3

1

23

25

24*

22

17

*: Indicates 590MPa-high-tensile steel panels.

A

23

18

20

24

22

6

25

19

21

15

28

27

19

20

18*

AB700942

AB

10

30

29

31

B

12

11

AB700587

AB700953

AC

TSB Revision

BODY CONSTRUCTION

BODY CONSTRUCTION CHARACTERISTICS

1-23

1. Rear floor side panel

2. Rear bumper beam reinforcement

3. Rear floor crossmember extension rear

4. Rear suspension bracket center

5. Rear suspension center reinforcement

6. Rear floor sidemember reinforcement

7. Rear floor crossmember extension rear upper

8. Rear floor crossmember extension rear

9. Muffler hanger rear

10. Shipping pipe

11. Shipping bracket reinforcement

12. Rear floor sidemember extension

13. Rear bumper support

14. Canister bracket (Left side)

15. Rear spring house panel lower

16. ABS sensor bracket

17. Brake hose bracket

A

1

6

18. Rear floor side sill inner

19. Rear suspension bracket front

20. Trailing arm bracket lower

21. Rear floor sidemember lower

22. Rear floor sidemember extension front

23. Rear tie down plate

24. Rear floor sidemember bulkhead

25. Trailing arm bracket

26. Trailing arm bulkhead

27. Rear floor sidemember rear reinforcement

28. Rear suspension center bulkhead

29. Rear floor sidemember bulkhead rear

30. Rear suspension bracket rear

31. Pipe nut

32. Hydraulic unit bracket front (Right side)

33. Hydraulic unit bracket rear (Right side)

B

1

21

25

20

18

AB700589

AC

21

29

15

AB700588

AB

TSB Revision

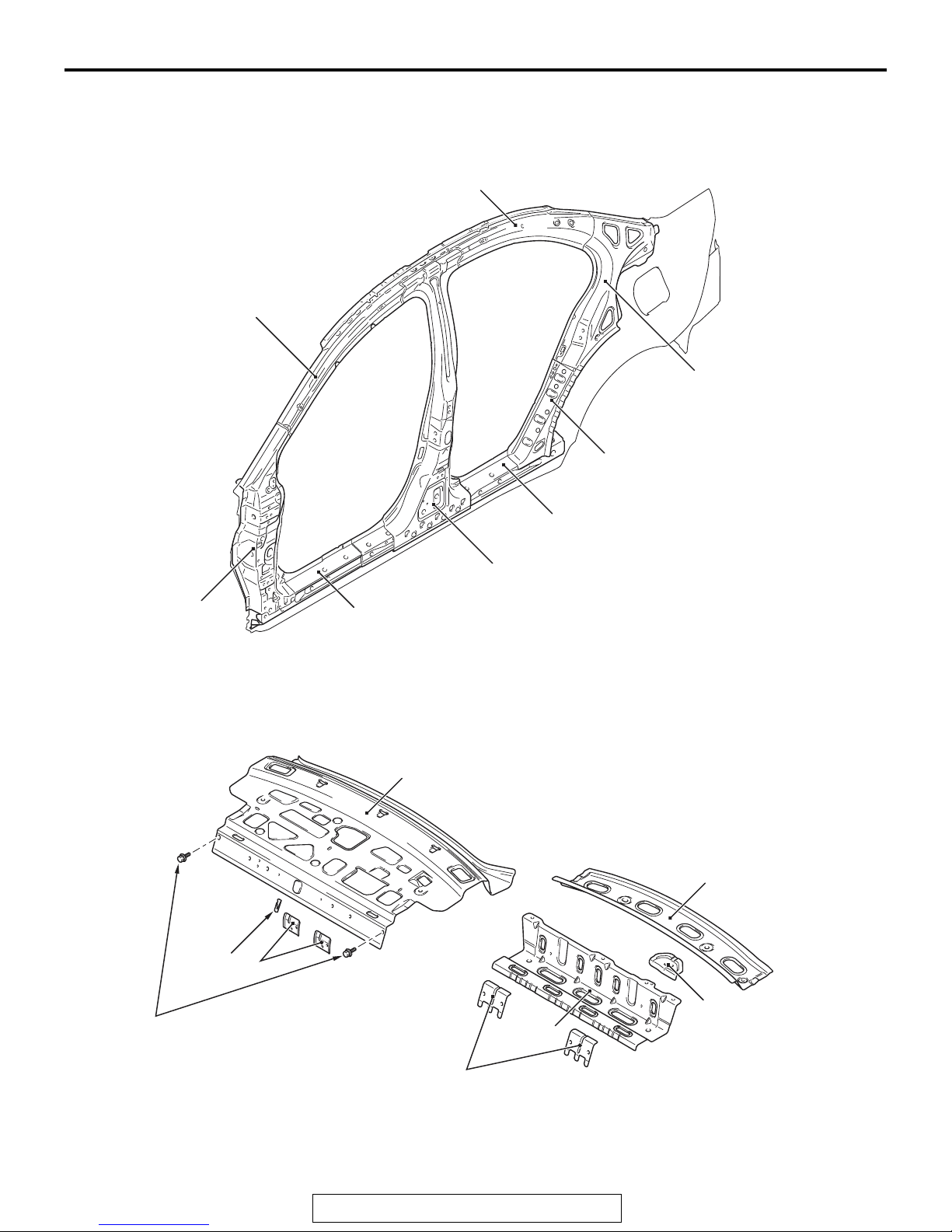

1-24

BODY CONSTRUCTION

BODY CONSTRUCTION CHARACTERISTICS

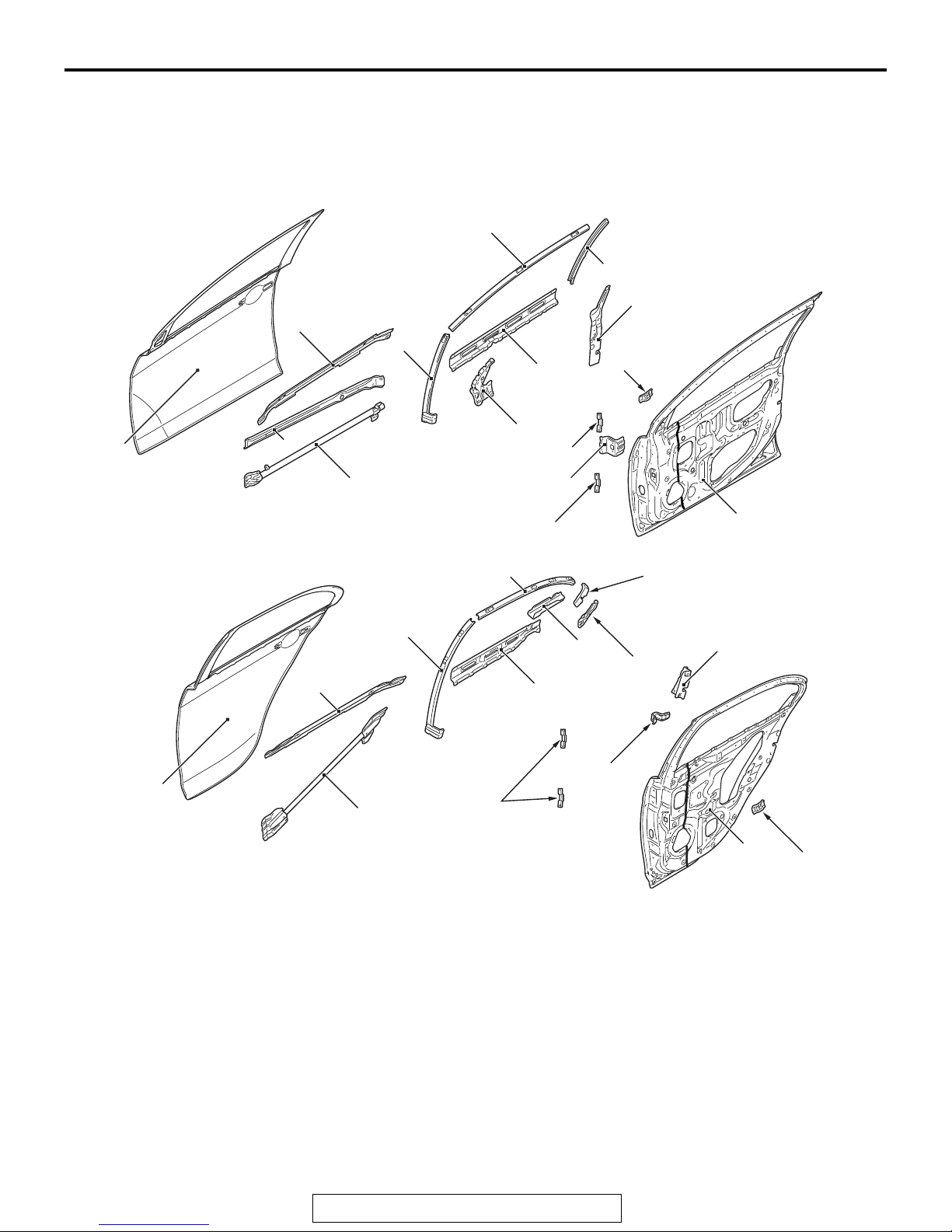

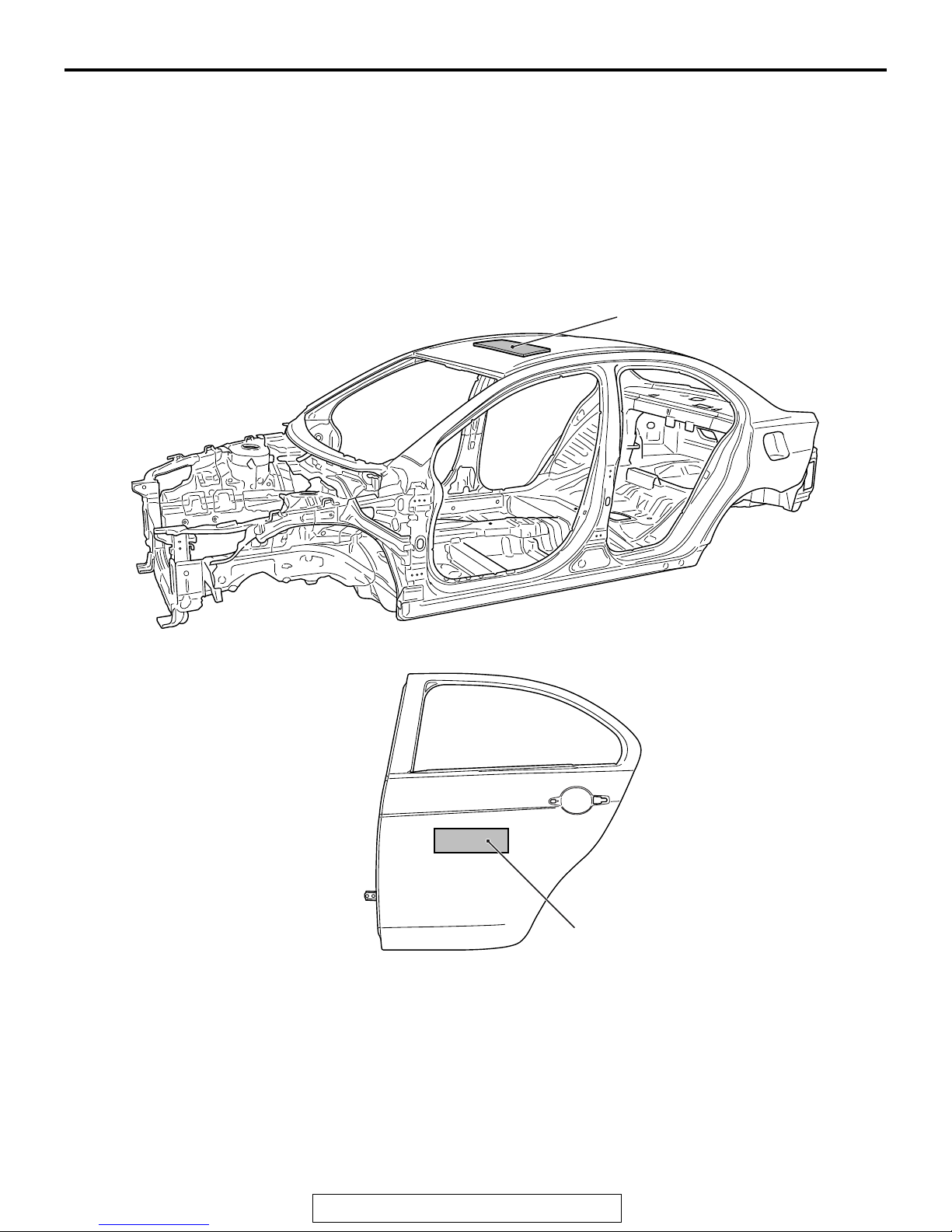

DOOR

An uneven thickness steel sheet* has been used for

the front and rear door panel inners to make the forward part of the vehicle thicker for reduction in vehicle weight and higher rigidity.

(Front door)

2

5

1

(Rear door)

3

4

M4010015000893

NOTE: *: A steel sheet of varying thickness that is

welded into one steel sheet.

6

7

8

9

11

10

12

13

14

AB602334

AB

19

12

23

16

15

1. Front door panel outer

2. Front door beltline outer reinforcement

3. Front door outer stiffener

4. Front door side door beam

5. Front door window front sash

6. Front door window upper sash

7. Front door window rear sash

8. Front door latch reinforcement

9. Front door beltline inner reinforcement

10. Front door mirror reinforcement

11. Front door inside handle bracket

12. Nut plate

13. Front door checker reinforcement

14. Front door panel inner

17

18

21

24

22

20

25

12

27

15. Rear door panel outer

16. Rear door beltline outer reinforcement

17. Rear door side door beam

18. Rear door window front sash

19. Rear door window upper sash

20. Rear door beltline inner reinforcement

21. Rear door beltline bracket

22. Rear door sash reinforcement

23. Rear door stat corner bracket

24. Rear door latch reinforcement

25. Rear door window sash lower bracket

26. Rear door inside handle bracket

27. Rear door panel inner

26

AB700413

AB

TSB Revision

BODY CONSTRUCTION

SILENCER APPLICATION LOCATIONS

1-25

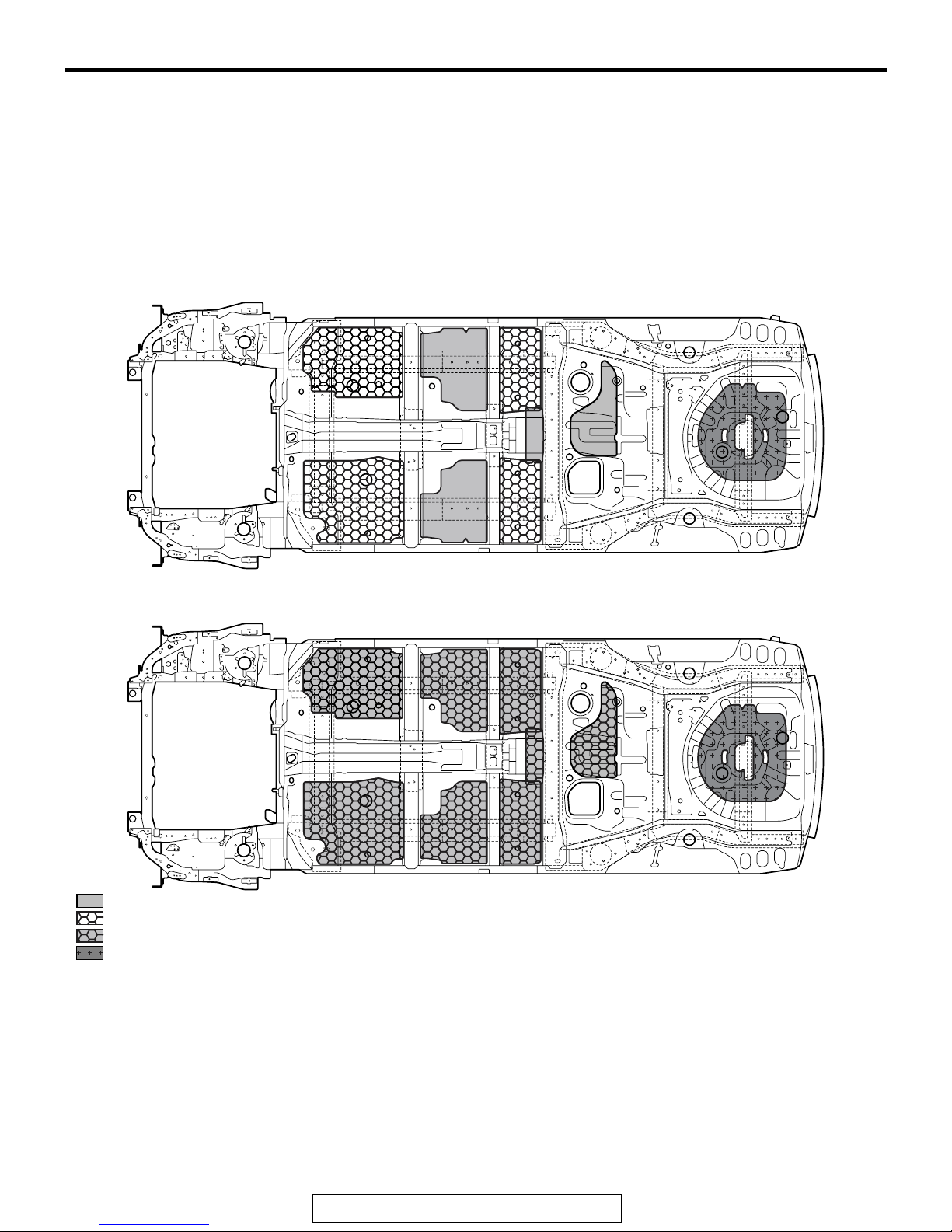

SILENCER APPLICATION LOCATIONS

A silencer (MD-12, RSS and melting sheet) has been

affixed on the upper surface of the floor for vibration

damping.

NOTE: .

•

MD-12 is a high performance sheet composed of

asphalt applied with mica and thermosetting resin

for improving anti-vibration performance.

<GSR>

M4010005001271

•

RSS (Rubber Special Sheet) is a product name

of Nihon Tokushu Toryo Co., Ltd. The product

features the same performance as a steel sheet

sandwich type and refers to a heat cured resin

sheet that is molded into a sheet with a uniform

thickness. It contains degenerating resin and filler

with asphalt and rubber as the main contents.

<MR>

: 1.6 mm (

: 1.6 mm (

: 3.2 mm (

: 1.6 mm (

[

Place three 1.6 mm (

0.063 in)

0.063 in)

0.126 in)

0.063 in)

thick melting sheet

thick MD-12 [Place a 1.6 mm (

thick MD-12 [Place two 1.6 mm (

thick melting sheet and 2.0 mm (

0.063 in)

melting sheet one on top of the next.

0.063 in)

0.063 in)

0.079 in)

NOTE: [ ] indicates the number of melting sheets that

are used for repair.

melting sheet.

melting sheet one on top of another.

thick RSS

]

]

AB700568

AB700568

]

AB700569

AB

AB

TSB Revision

1-26

BODY CONSTRUCTION

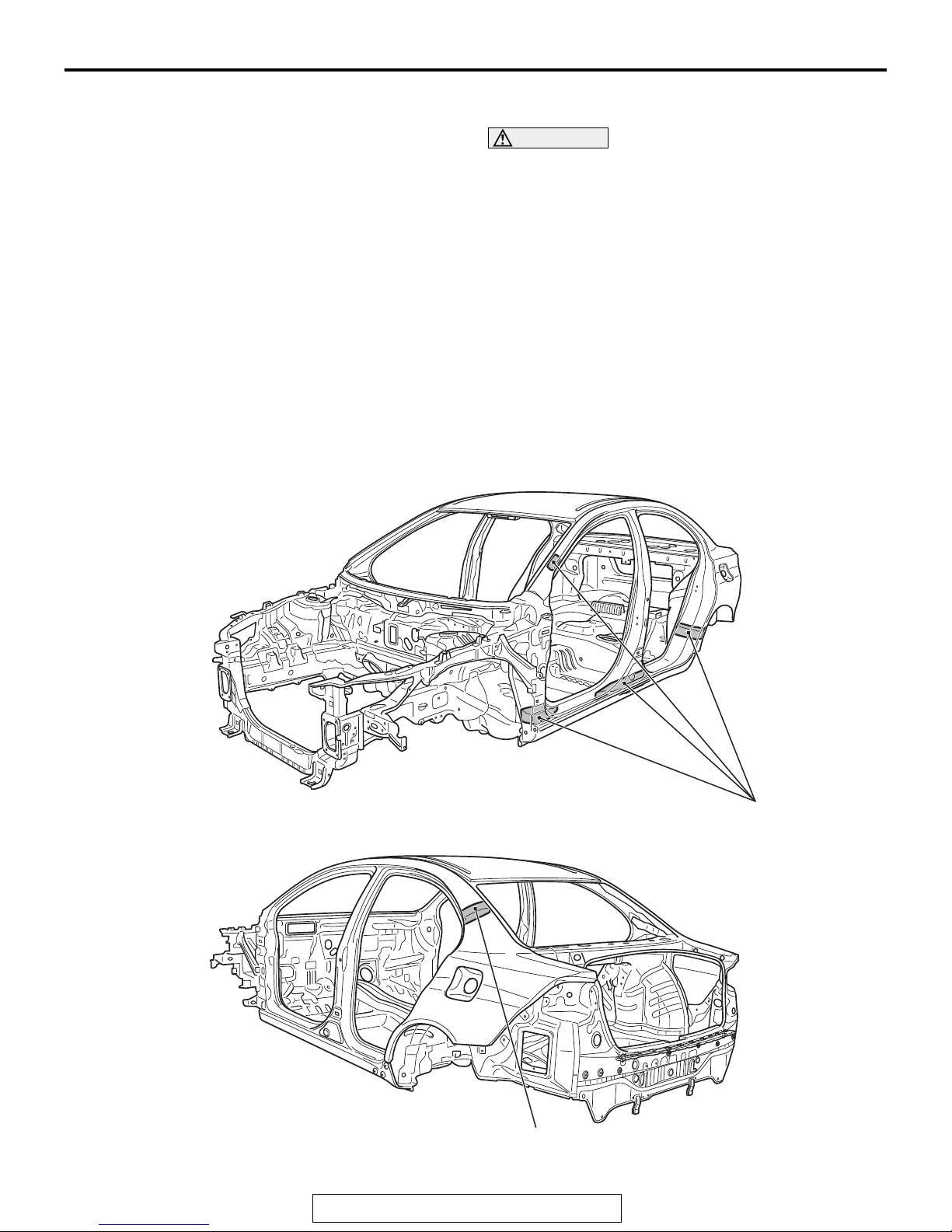

FOAMING MATERIAL USAGE LOCATIONS

FOAMING MATERIAL USAGE LOCATIONS

The sound dampening foam material have been

adopted to the upper and lower sections of the front

pillar, center pillar lower section, rear pillar and wheel

house arch inside to shield from external noise.

M4010006000163

CAUTION

The sound dampening foam material may burn

when heated. Always observe the following

instructions:

• Never use a gas burner to burn the areas

where sound dampening foam material is

used.

• When cutting the parts which are provided

with sound dampening foam material, ensure

to use tools (air saw, etc.) that do not gener

ate fire.

• If there are residual sound dampening foam

material remaining on the cut section (body

side), remove the sound dampening foam

material from periphery of the welding area

before welding work.

-

TSB Revision

Sound dampening foam material

Sound dampening foam material

AB700801

AB

BODY CONSTRUCTION

STIFFENER AND DAMP SHEET APPLICATION LOCATIONS

1-27

STIFFENER AND DAMP SHEET APPLICATION LOCATIONS

M4010001400263

A damp sheet (roof insulator) <Vehicles without sunroof (aluminum panel)> on the inner side of the roof

panel and a stiffener on the inner side of the rear

door panel outer have been adopted for higher sur

face rigidity.

-

NOTE: .

•

The main contents of a stiffener are epoxy resin.

It comes in a sheet form and contains a mixture

of glass fiber and filler, and cures (stiffens) when

heated.

•

No spare part of the stiffener for repair is available in the field. If the stiffener is damaged,

replace it together with the panel.

Damp sheet (roof insulator)

AB700461

(Rear door)

Stiffener

AB700893

AB700892

AB

AB

TSB Revision

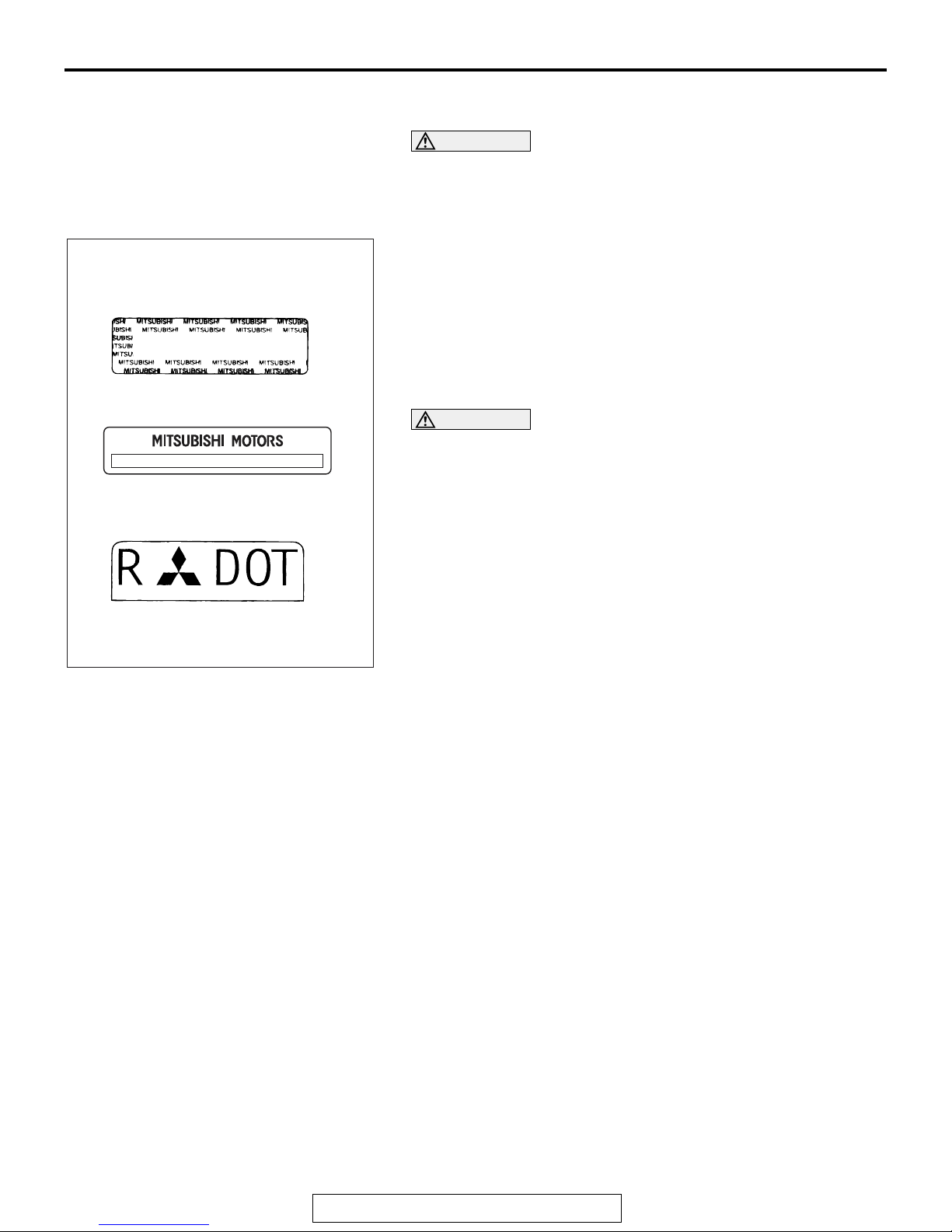

1-28

BODY CONSTRUCTION

THEFT PROTECTION

Theft protection plate and label

For original parts

For replacement parts

THEFT PROTECTION

CAUTION

When replacing a part that has the theft protection plate,

label or stamp on it, be sure that the part has either A or B

shown in the figure. It is illegal if both A and B are

attached, or neither A nor B is attached.

In order to protect against theft, a Vehicle Identification Number

(VIN) is attached as a plate or label to the following major parts

of the engine, transaxle and main outer panels: Engine cylinder

block, Transaxle housing, Front fender, Hood, Trunk lid,

Bumpers, Side outer panel, Doors. In addition, a theft-protec

tion label is attached to replacement parts for main outer panels. The same data is stamped into replacement parts for the

engine and the transaxle.

CAUTION

Cautions regarding panel repairs:

• When repainting original parts, do so after first masking

the theft-protection label. After painting, be sure to peel

off the masking tape.

• The theft-protection label for replacement parts is covered by masking tape, so such parts can be painted as

is. The masking tape should be removed after painting

is finished.

• The theft-protection label should not be removed from

original parts or replacement parts.

M4010017000145

-

AC704152

.

AB

TSB Revision

Loading...

Loading...