Page 1

2003

Body Repair

Return to Main Menu

GROUP INDEX

MITSUBISHI

LANCER

EVOLUTION VIII

TECHNICAL

INFORMATION

MANUAL

FOREWORD

This manual has been prepared as an introduction to

the specifications, features, construction, functions,

and other areas of the new 2003 LANCER EVOLUTION VIII. It includes Technical Information and Body

Repair Service. The Body Repair sections immediately follow Group 55 - Heater, Air Conditioning and Ventilation.

Please read this manual carefully so that it will be of

assistance for your service and sales activities. Please

note the following service manuals are also available

and should be used in conjunction with this manual.

General . . . . . . . . . . . . . . . . . . . . . . .

Engine . . . . . . . . . . . . . . . . . . . . . . . .

Lubrication . . . . . . . . . . . . . . . . . . . .

Fuel . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Cooling . . . . . . . . . . . . . . . . .

Intake and Exhaust . . . . . . . . . . . . . .

Engine Electrical. . . . . . . . . . . . . . . .

Engine and Emission Control . . . . .

Clutch. . . . . . . . . . . . . . . . . . . . . . . . .

Manual Transaxle . . . . . . . . . . . . . . .

Propeller Shaft . . . . . . . . . . . . . . . . .

Front Axle . . . . . . . . . . . . . . . . . . . . .

00

11

12

13

14

15

16

17

21

22

25

26

SERVICE MANUAL MSSP-206B-2003

PARTS CATALOG BUM6K103A

No part of this publication may be reproduced, stored in any retrieval

system of transmitted, in any form or by any means, including but not

limited to electronic, mechanical photocopying, recording or otherwise,

without the prior written permission of Mitsubishi Motors Corporation.

!2003 Mitsubishi Motors Corporation

All Rights, Reserved

Printed in USA

MSSP-260B-2003

Rear Axle . . . . . . . . . . . . . . . . . . . . . .

Wheel and Tire . . . . . . . . . . . . . . . . .

Power Plant Mount . . . . . . . . . . . . . .

Front Suspension . . . . . . . . . . . . . . .

Rear Suspension . . . . . . . . . . . . . . .

Service Brakes . . . . . . . . . . . . . . . . .

Parking Brakes . . . . . . . . . . . . . . . . .

Steering . . . . . . . . . . . . . . . . . . . . . . .

Body. . . . . . . . . . . . . . . . . . . . . . . . . .

Exterior . . . . . . . . . . . . . . . . . . . . . . .

Interior and Supplemental

General . . . . . . . . . . . . . . . . . . . . . . .

Restraint System (SRS) . . . . . . . . . .

Chassis Electrical . . . . . . . . . . . . . . .

Heater, Air Conditioning

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

and Ventilation . . . . . . . . . . . . . . . . .

27

31

32

33

34

35

36

37

42

51

52

54

55

Page 2

GROUP 52B

SUPPLEMENTAL

RESTRAINT

SYSTEM (SRS)

CONTENTS

52B-1

GENERAL DESCRIPTION. . . . . . . . . 52B-2

SYSTEM OPERATION. . . . . . . . . . . . 52B-7

SRS-ECU . . . . . . . . . . . . . . . . . . . . . . 52B-10

Page 3

52B-2

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

GENERAL DESCRIPTION

GENERAL DESCRIPTION

M2521000100132

CAUTION

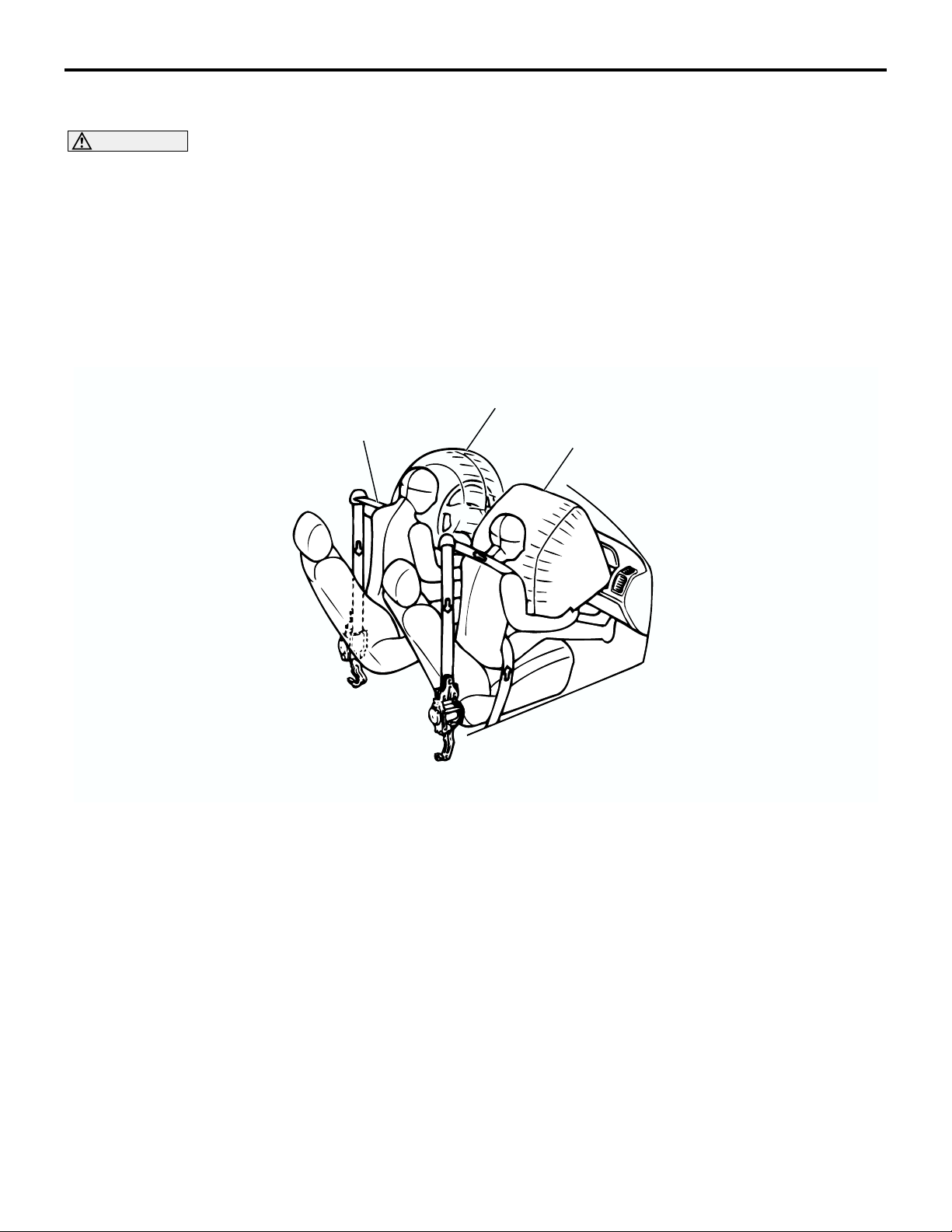

• Driver and front passenger air bags and seat belt pre-tensioners deploy and operate in all head-on

collisions that exceed the threshold to activate the SRS system.

• The specific value is the equivalent impact when a vehicle collides against a concrete (fixed) wall

at approximately 25 km/h (16 mph) or more.

• The SRS and pre-tensioner may not work under the following conditions:

• A head-on collision is less than the specific value.

• A vehicle collides on its rear end.

• A vehicle rolls over or is in a similar position.

DRIVER'S AIR BAG

SEAT BELT PRE-TENSIONER

PASSENGER'S

(FRONT) AIR BAG

Driverís and front passengerís air bags and seat

belts with pre-tensioner are standard, increasing the

passive safety level.

.

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

The SRS is designed to supplement the front seat

belts. It eliminates or reduces or injury to the front

passenger(s) by deploying air bag(s) in case of a

head-on collision.

.

AC211587

AB

SEAT BELT WITH PRE-TENSIONER

The seat belts with pre-tensioner work simultaneously with the SRS. The pre-tensioner takes up

seat belt slack immediately when a collision takes

place by that restraining the front passengers sooner

than the SRS. This prevents the passengers from

moving forwards.

Page 4

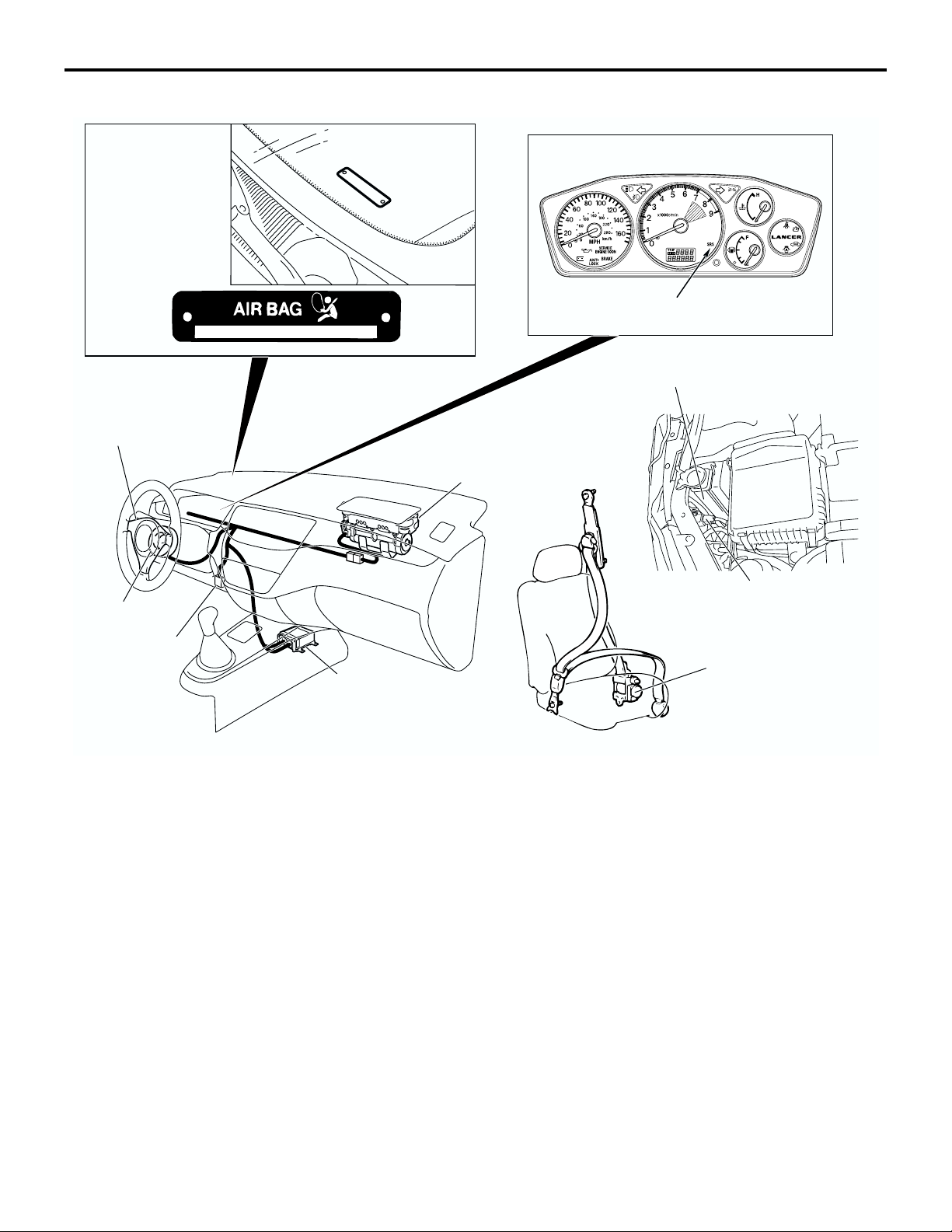

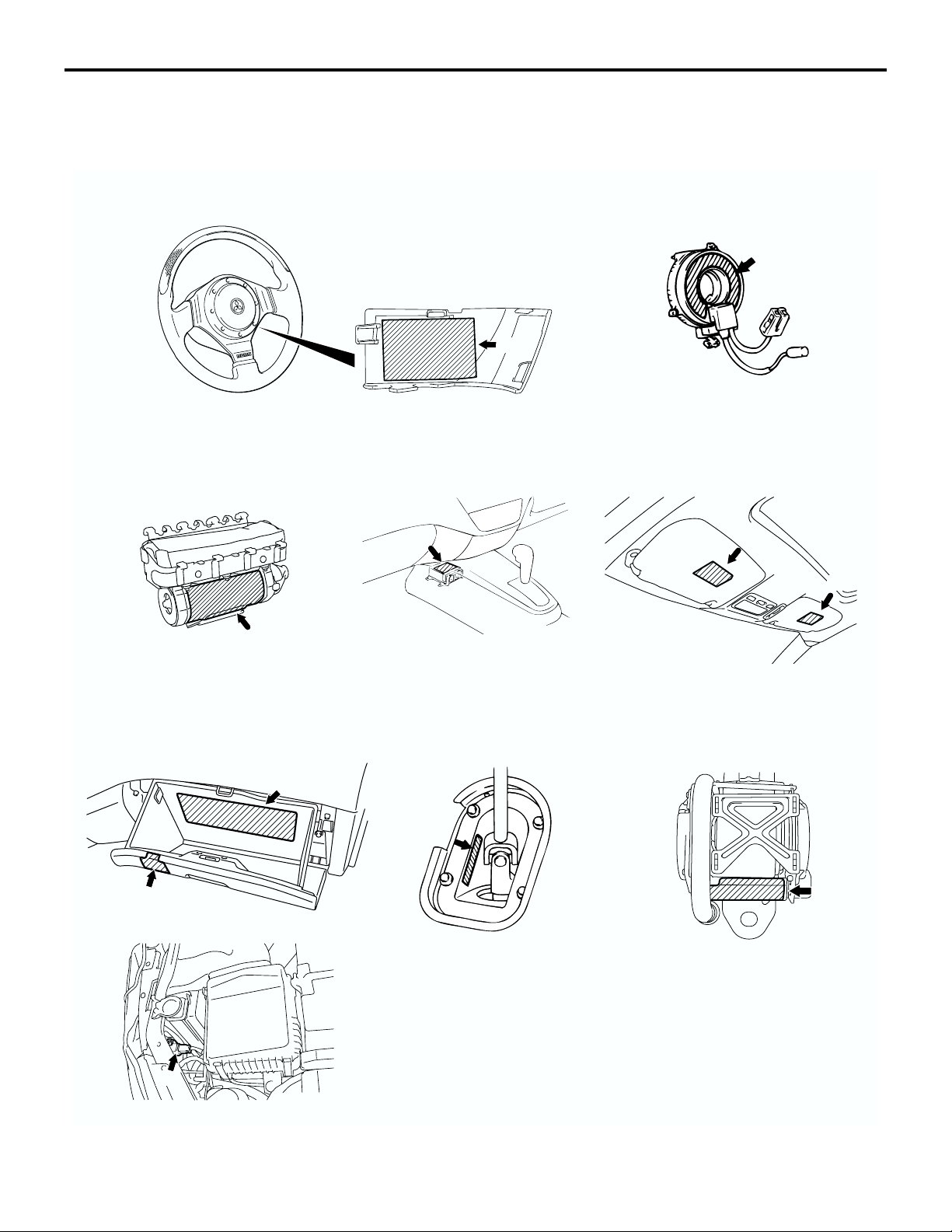

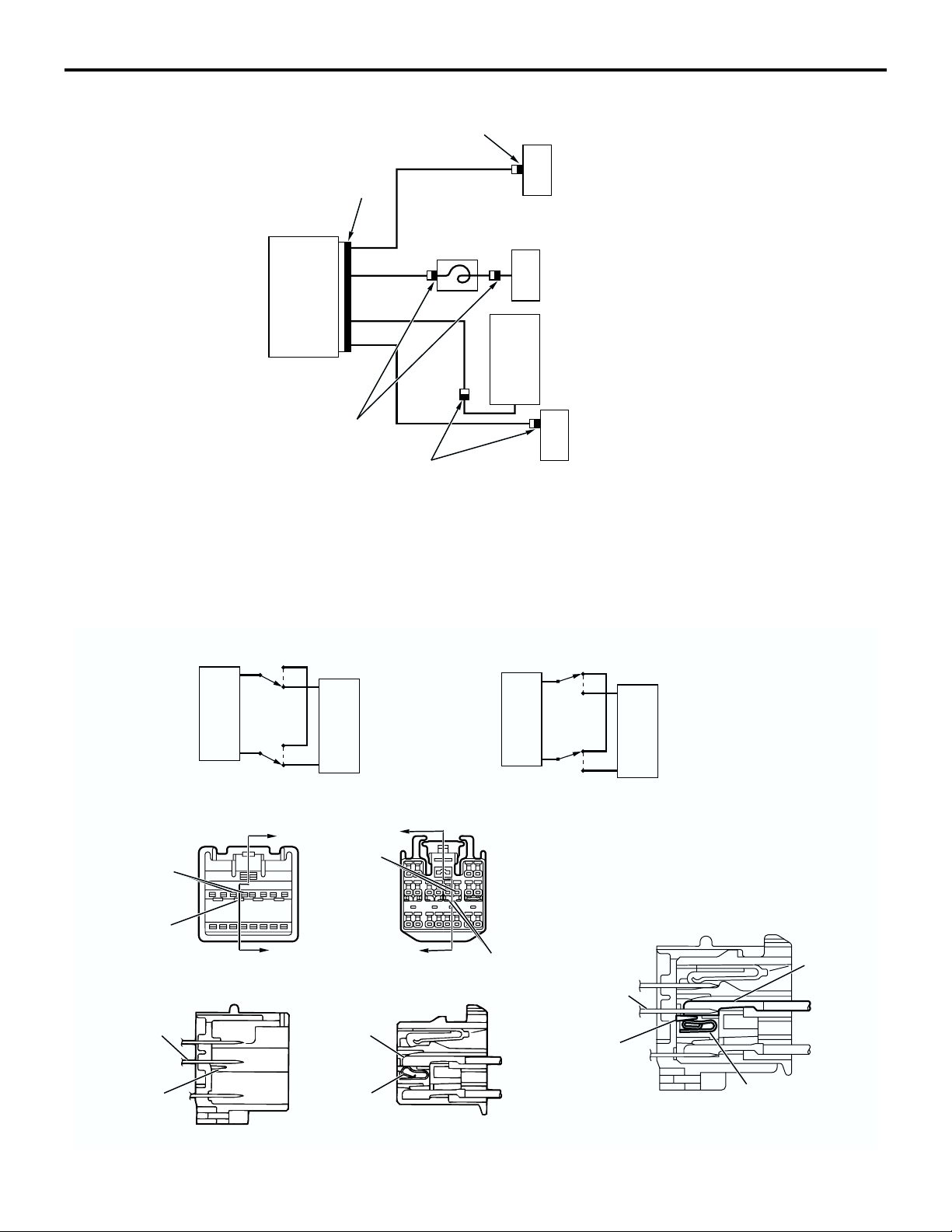

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

CONSTRUCTION DIAGRAM

VEHICLES

IDENTIFICATION

CODE CHART

PLATE

DRIVER'S AIR

BAG MODULE

GENERAL DESCRIPTION

PASSENGER'S (FRONT)

AIR BAG MODULE

52B-3

SRS WARNING LIGHT

RADIATOR

CLOCK SPRING

DATA LINK

CONNECTOR

(FOR SCAN

TOOL)

SRS-ECU

The SRS and seat belt tightening systems consist of

driverís/passenger air bag modules, SRS-ECU, two

front impact sensors, SRS warning light, clock

spring, and seat belt pre-tensioner. Air bags are

located in the center of the steering wheel and above

the glove box. Each air bag has a safing folded air

bag and an inflators the system and has a safing G

sensor and an analogue G sensor. On all air bag

modules, the inflator does not contain sodium azide.

The front impact sensor is assembled on the headlight support panel to monitor collision upon frontal

impact. The warning light on the instrument panel

indicates the operational status of the SRS. A clock

spring is installed in the steering column.

FRONT IMPACT SENSOR

SEAT BELT WITH

PRE-TENSIONER

AC211592

AB

The SRS-ECU detects the impact produced at the

time of a collision from the safing and analog G sensors and supplies squib ignition current to the air bag

modules.

The SRS-ECU has the following functions:

This triggers the air bag modules.

• Power supply backup function (backup condenser) that deploys or operates the air bag module and seat belt pretensioner within specific

period, in case of power failure upon impact.

• Voltage raising function (DC-DC converter circuit).

• Diagnostic test mode to improve safety and reliability.

Page 5

52B-4

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

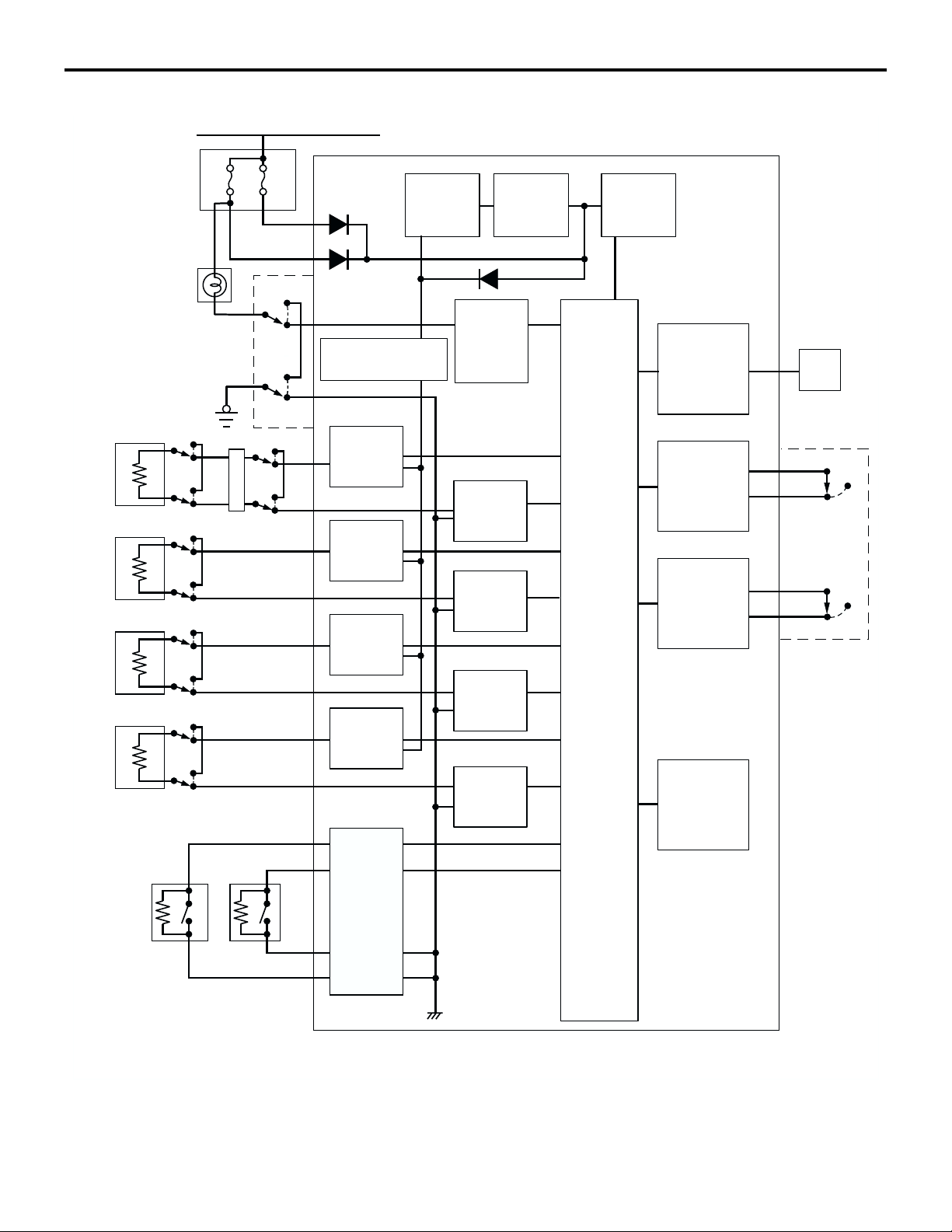

SRS SYSTEM CIRCUIT DIAGRAM

IGNITION SWITCH (IG1)

No.3

No.2

7.5A

7.5A

COMBINATION

METER (SRS

WARNING LIGHT)

CONNECTOR LOCK

SWITCH*

DRIVER'S

AIR BAG

MODULE

OFF

ON

OFF

PASSENGER'S

(FRONT) AIR BAG

MODULE

SEAT BELT

PRE-TENSIONER

(LH)

SEAT BELT

PRE-TENSIONER

(RH)

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

CONNCTOR LOCK

SWITCH*

CLOCK SPRING

CONNECTOR

LOCK SWITCH*

CONNECTOR

LOCK SWITCH*

CONNECTOR

LOCK SWITCH*

OFF

ON

OFF

ON

OFF

ON

OFF

ON

FRONT AIR BAG

SAFING

G-SENSOR

AIR BAG

DRIVE

CIRCUIT

AIR BAG

DRIVE

CIRCUIT

AIR BAG

DRIVE

CIRCUIT

AIR BAG

DRIVE

CIRCUIT

GENERAL DESCRIPTION

BACK UP

CAPACITOR

DC-DC

CONVERTER

WARNING

LIGHT

DRIVE

CIRCUIT

AIR BAG

DRIVE

CIRCUIT

AIR BAG

DRIVE

CIRCUIT

AIR BAG

DRIVE

CIRCUIT

AIR BAG

DRIVE

CIRCUIT

MICRO

PROCESSOR

POWER

SOURCE

CIRCUIT FOR

SIDE-AIRBAG

SCAN TOOL

INTERFACE

CIRCUIT

CONNECTOR

LOCK

DETECTION

CIRCUIT

CONNECTOR

LOCK

DETECTION

CIRCUIT

FRONT AIR

BAG

ANALOG

G-SENSOR

DATA LINK

CONNECTOR

(FOR SCAN

TOOL)

OFF

ON

OFF

ON

CONNECTOR

LOCK SWITCH*

(LH) (RH)

FRONT IMPACT

SENSOR

NOTE

*: CONNECTOR LOCKED: ON

CONNECTOR UNLOCKED: OFF

FRONT

IMPACT

SENSOR

INTERFACE

CIRCUIT

AC211582

AB

Page 6

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

GENERAL DESCRIPTION

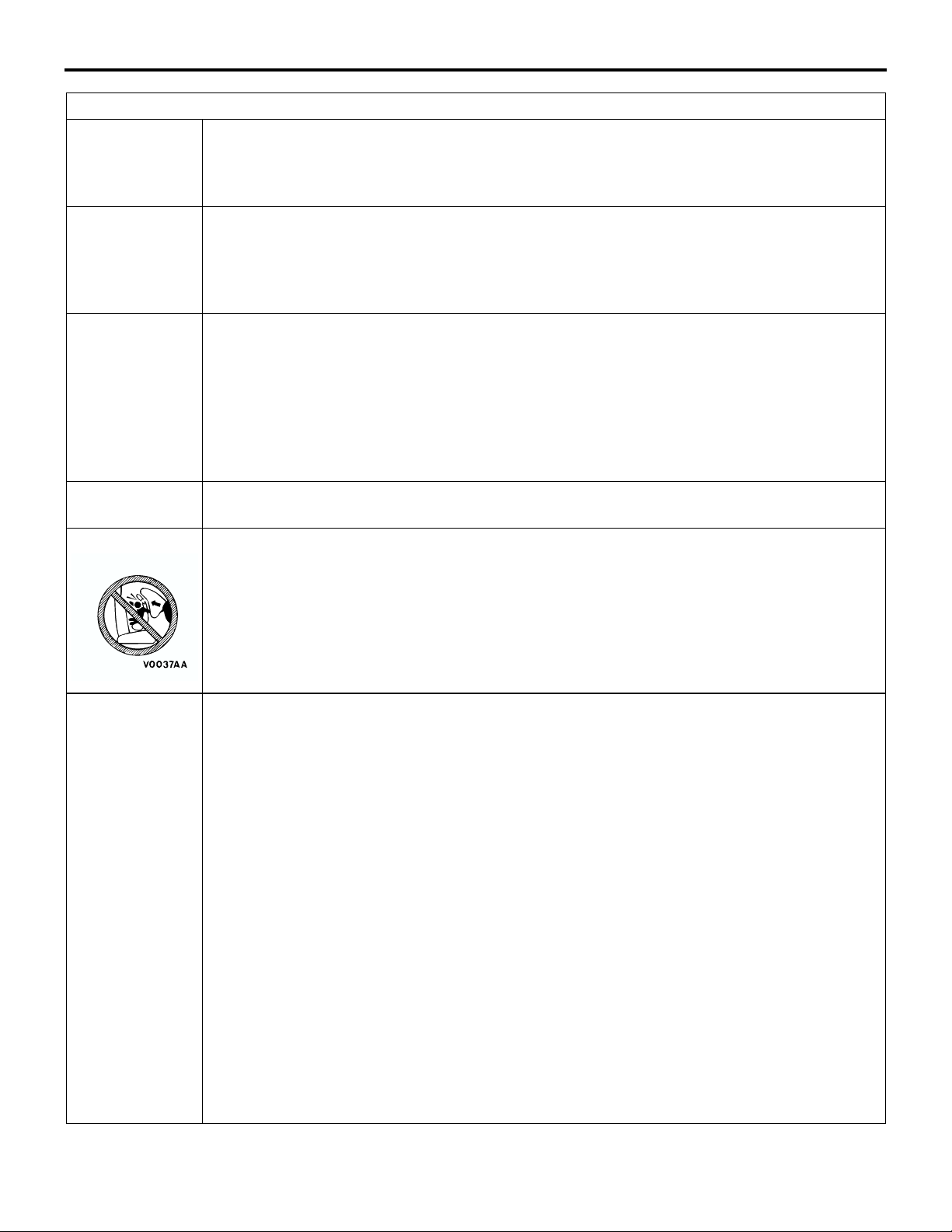

CAUTION LABELS

Labels to indicate cautions regarding the handling

and the services of SRS air bag air attached on the

position shown in the following illustration.

52B-5

PASSENGER'S (FRONT)

AIR BAG MODULE

C

COVER

D

A

SRS-ECU

CLOCK SPRING

B

SUN VISOR

E

E

GLOVE BOX

G

FRONT IMPACT SENSOR

J

SEAT BELT WITH

STEERING JOINT COVER

F

H

PRE-TENSIONER

(DRIVER'S AND FRONT

PASSENGER'S SEATBELT)

I

AC211604

AB

Page 7

52B-6

LABEL CONTENTS

AWARNING: SRS

BEFORE REPLACING STEERING WHEEL, READ SERVICE MANUAL. THIS AIR BAG

MODULE CANNOT BE REPAIRED.

DO NOT DISASSEMBLE OR TAMPER.

BCAUTION: SRS CLOCK SPRING

THIS IS NOT A REPAIRABLE PART. IF DEFECTIVE, REPLACE ENTIRE UNIT

ACCORDING TO THE SERVICE MANUAL INSTRUCTIONS. TO RE-CENTER: ROTATE

CLOCKWISE UNTIL TIGHT. THEN ROTATE IN OPPOSITE DIRECTION ROUGHLY 3

TURNS AND ALIGN ARROWS >><<.

CWARNING FLAMMABLE/EXPLOSIVE SRS AIR BAG MODULE

TO AVOID SERIOUS INJURY:

• DO NOT REPAIR, DISASSEMBLE OR TAMPER.

• AVOID C ONTA CT WIT H F LAM E OR ELECTRICITY.

• DO NOT DIAGNOSIS/USE NO TEST EQUIPMENT OR PROBES.

• STORE BELOW 200°F (93°C).

• BEFORE DOING ANY WORK INVOLVING MODULE, READ SERVICE MANUAL

FOR IMPORTANT FURTHER DATA.

DCAUTION:

DO NOT DISASSEMBLE OR DROP. IF DEFECT REFER TO SERVICE MANUAL.

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

GENERAL DESCRIPTION

EWARNING

DEATH or SERIOUS INJURY can occur

• Children 12 and under can be killed by the air bag.

• The BACK SEAT is the SAFEST place for children.

• NEVER put a rear-facing child seat in the front.

• Sit as far back as possible from the air bag.

• ALWAYS use SEAT BELTS and CHILD RESTRAINTS.

FAIR BAG SYSTEM INFORMATION

THIS VEHICLE HAS AN AIR BAG SYSTEM WHICH WILL SUPPLEMENT THE SEAT

BELT IN CERTAIN FRONTAL COLLISIONS. THE AIR BAG IS NOT A SUBSTITUTE FOR

THE SEAT BELT IN ANY TYPE OF COLLISION. THE DRIVER AND ALL OTHER

OCCUPANTS SHOULD WEAR SEAT BELTS AT ALL TIME.

WARNING!

IF THE "SRS" WARNING LIGHT DOES NOT ILLUMINATE FOR SEVERAL SECONDS

WHEN IGNITION KEY IS TURNED TO "ON" OR THE ENGINE IS STARTED, OR IF THE

WARNING LIGHT STAYS ON WHILE DRIVING, TAKE THE VEHICLE TO YOUR

NEAREST AUTHORIZED DEALER IMMEDIATELY. ALSO, IF VEHICLE'S FRONT END

IS DAMAGED OR IF THE AIR BAG HAS DEPLOYED, TAKE THE VEHICLE FOR

SERVICE IMMEDIATELY.

THE AIR BAG SYSTEM MUST BE INSPECTED BY AN AUTHORIZED DEALER TEN

YEARS AFTER THE VEHICLE MANUFACTURE DATE SHOWN ON THE

CERTIFICATION LABEL LOCATED ON THE LEFT FRONT DOOR-LATCH POST OR

DOOR FRAME.

READ THE "SRS" SECTION OF YOUR OWNER'S MANUAL BEFORE DRIVING FOR

IMPORTANT INFORMATION ABOUT OPERATION AND SERVICE OF THE AIR BAG

SYSTEM.

WHEN YOU ARE GOING TO DISCARD YOUR GAS GENERATOR OR VEHICLE,

PLEASE SEE YOUR DEALER.

Page 8

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

SYSTEM OPERATION

LABEL CONTENTS

GWARNING

CHILDREN CAN BE KILLED OR INJURED BY PASSENGER AIR BAG. THE BACK

SEAT IS THE SAFEST PLACE FOR CHILDREN 12 AND UNDER. MAKE SURE ALL

CHILDREN USE SEAT BELTS OR CHILD SEAT. NOT TO BE REMOVED EXCEPT BY

OWNER.

HCAUTION: SRS

FIX STRG. WHEEL AT TIRES STRAIGHT AHEAD BEFORE GEARBOX REMOVAL.

OTHERWISE, MAY DAMAGE SRS CLOCK SPRING MAKING SRS SYSTEM IN

OPERATIVE. RISKING SERIOUS DRIVER INJURY.

IDANGER SEAT BELT PRETENSIONER

CAUTION THIS ASSEMBLY CONTAINS AN EXPLOSIVE INITIATOR

FLAMMABLE MATERIAL

TO PREVENT PERSONAL INJURY

• DO NOT IMPACT, DISMANTLE OR INSTALL IT INTO ANOTHER VEHICLE.

• SERVICE OR DISPOSE OF IT AS DIRECTED IN THE REPAIR MANUAL.

JCAUTION:

DO NOT DISASSEMBLE OR DROP.

52B-7

SYSTEM OPERATION

A passengerís (front) air bag module and clock

spring are the same as OUTLANDER.

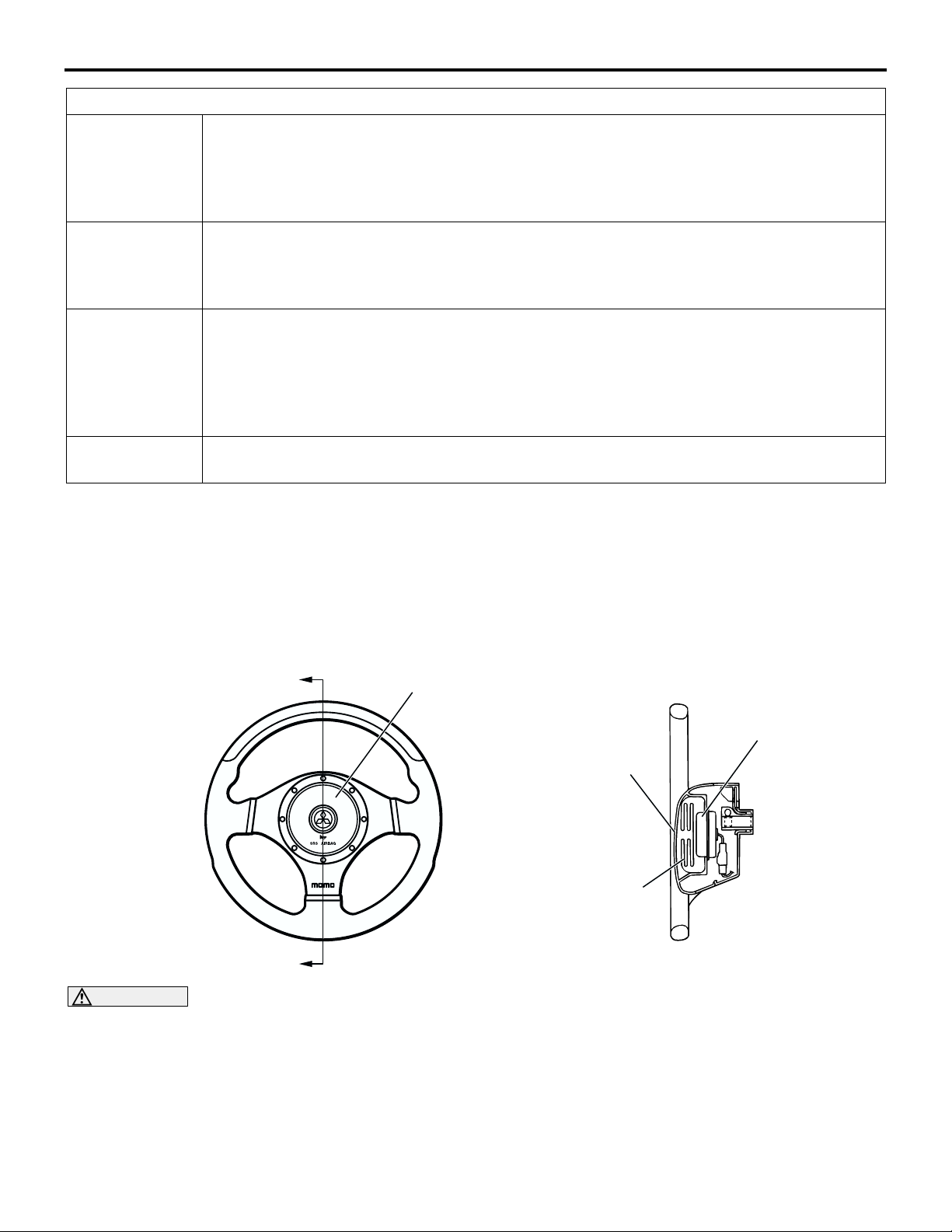

DRIVERíS AIR BAG MODULE

A

A

CAUTION

Never disassemble the air bag module.

The driverís air bag module is incorporated into the

3-spoke steering wheel. The driverís air bag module

is an assembly part consisting of air bag, module

cover, inflator, and its their fasteners. It is installed

into the steering wheel. The air bag is made from

AIR BAG MODULE

M2521001000116

SECTION A - A

INFLATOR

MODULE COVER

AIR BAG

AC211615

AB

nylon and inflates by the gas generating from the

inflator. As a driver is being pressed to the air bag, it

deflates discharging gas from two vents at the rear of

the air bag to reduce the shock from the impact. An

inflator that does not contain sodium azide is used.

Page 9

52B-8

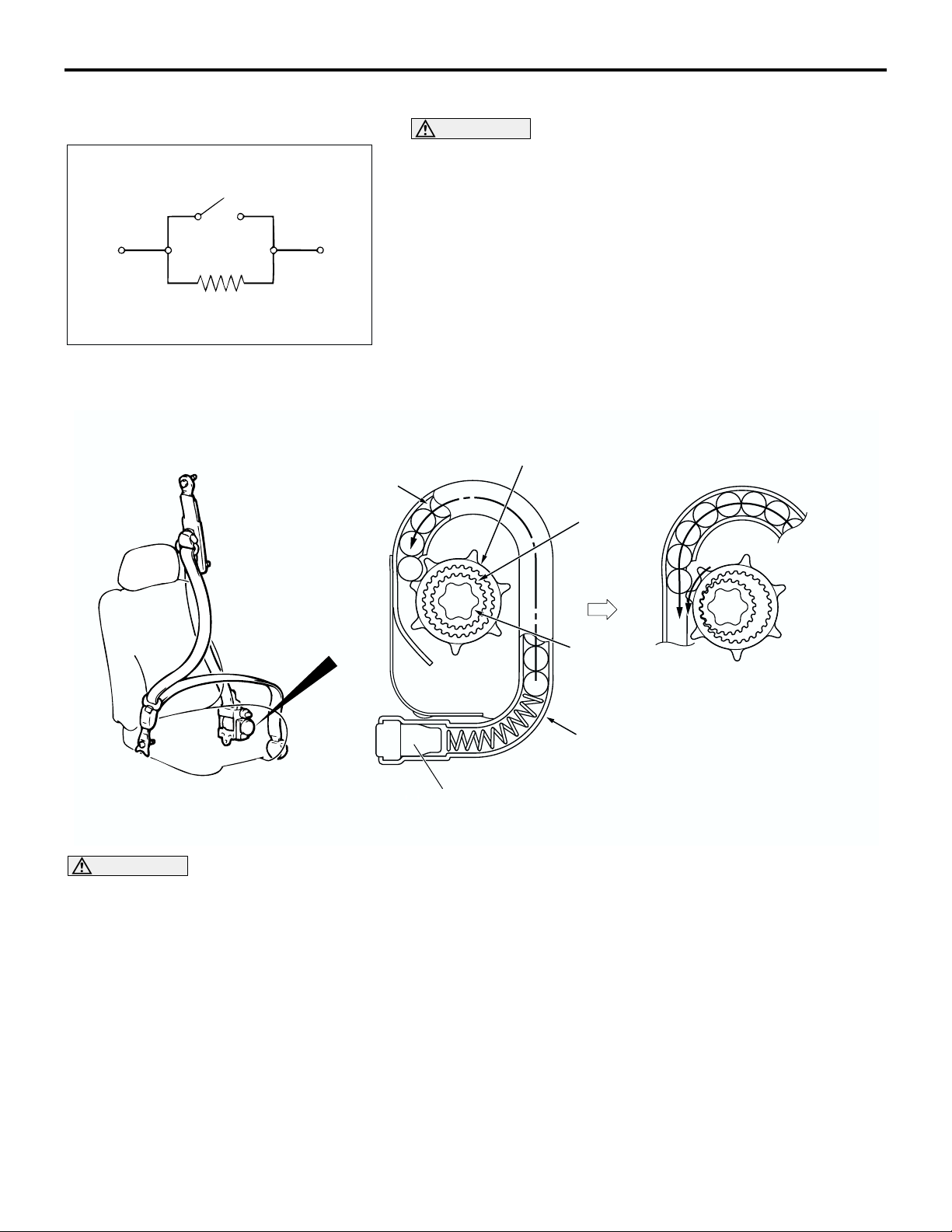

SENSOR INTERNAL CIRCUIT

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

SYSTEM OPERATION

FRONT IMPACT SENSOR

CAUTION

Never disassemble the front impact sensor.

The front impact sensor is installed in the radiator support

panel. In a collision, the contact in the front impact sensor turns

ON and an output signal is send to the SRS-ECU. A resistor is

connected to the front impact sensor in parallel with the contact

for fault diagnosis.

AC206958

AC

SEAT BELT WITH PRE-TENSIONER

BALL

RING GEAR

PINION

SPOOL

PIPE

GAS GENERANT

CAUTION

Never disassemble the seat belt with pre-tensioner.

The seatbelt incorporating the pretensioner automatically winds the seatbelt upon front impact to reduce

forward shifting of the passenger.

The seat belt pre-tensioner is built into the driver's

and passenger's front seat belt retractor.

AC101663

AE

Upon front impact the pretensioner ignites the gas

generator and emits gas with the SRS-ECU signal

when the front impact sensor, attached to the front of

the body, detects an impact that exceeds the permissible limit. The gas pressure shifts the ball in the pipe

and the balls comes in contact with the protrusion of

the ring gear, The ball is inserted in the ring gear and

then interlocked with the pinion. The ring gear rotation forces the pinion to turn the spool toward the belt

wind direction to wind the webbing.

Page 10

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

SYSTEM OPERATION

SRS AIR BAG SPECIAL CONNECTOR

A

CLOCK

SPRING

SRS-ECU

A

A

To en han ce th e Sys te mís r el iabi li ty, a c on nec to r lo ck

switch is integrated into the SRS-ECU connector, the

air bag module connectors, the clock spring connector, the seat belt pretensioner connectors (black connector "A" shown in the illustration above).

52B-9

A

SEAT BELT WITH

PRE-TENSIONER

(DRIVER'S SIDE)

DRIVER'S AIR BAG MODULE

PASSENGER'S (FRONT)

AIR BAG MODULE

SEAT BELT WITH

PRE-TENSIONER

(FRONT PASSENGER'S

SIDE)

AC103223

AF

SQUIB CIRCUIT CONNECTOR LOCK SWITCH

CONNECTOR CONNECTED

SQUIB

<CONNECTOR SHORTING MECHANISM (E.G. SRS-ECU CONNECTOR)>

ECU-SIDE CONNECTOR

TERMINAL

(MALE)

PARTITION

PANEL

SECTION A - A

TERMINAL

(MALE)

OFF

ON

OFF

ON

A

A

SRS-ECU

WIRING HARNESS-SIDE CONNECTOR

TERMINAL

(FEMALE)

TERMINAL

(FEMALE)

B

CONNECTOR DISCONNECTED

SQUIB

B

SECTION B - B

SHORT SPRING

OFF

ON

OFF

ON

TERMINAL

(MALE)

PARTITION

PANEL

SRS-ECU

CONNECTOR CONNECTED

TERMINAL

(FEMALE)

PARTITION

PANEL

SHORT

SPRING

SHORT SPRING

AC006197

AH

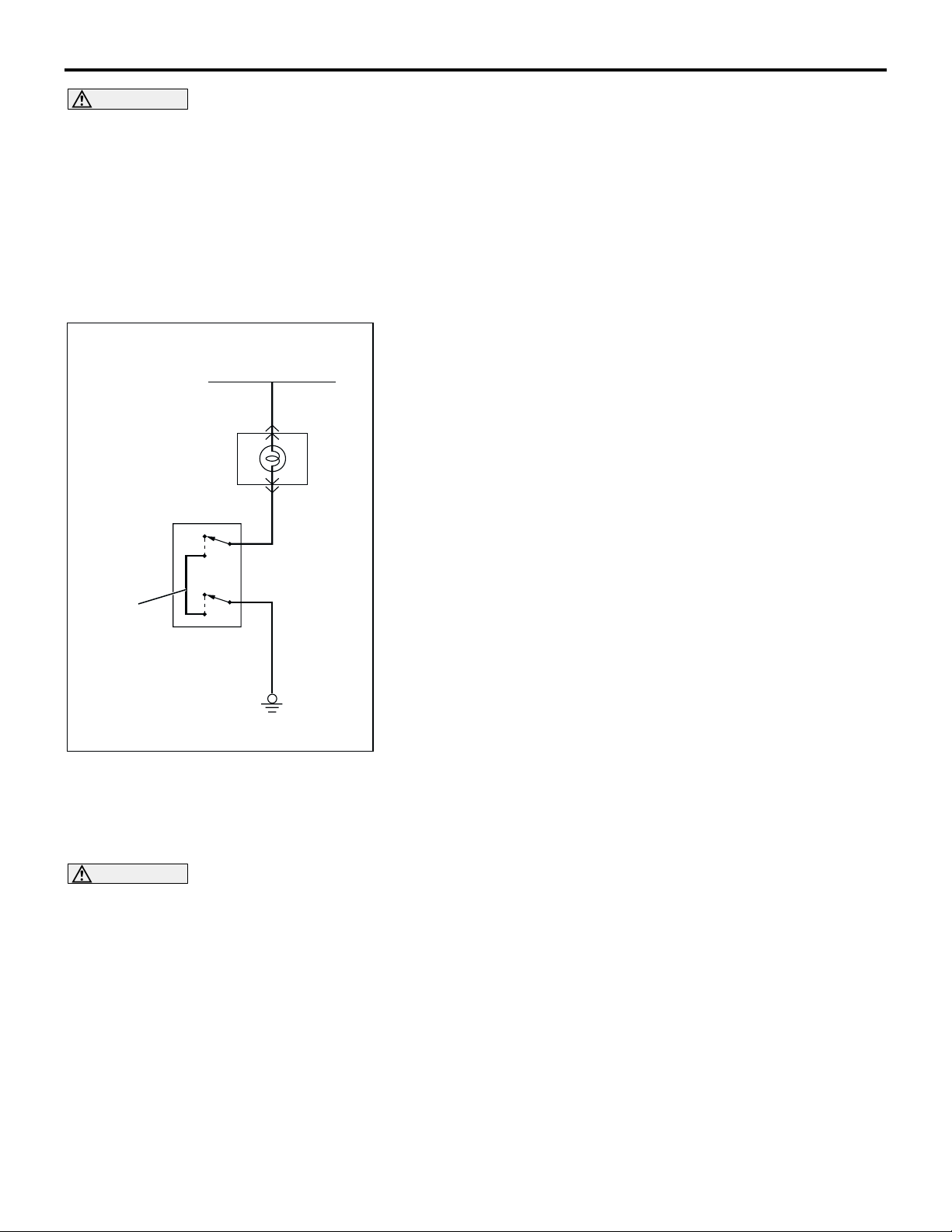

Page 11

52B-10

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

SRS-ECU

CAUTION

When the connector is disconnected, there will

be short circuit between the terminals. This is not

a fault.

WARNING LIGHT CIRCUIT CONNECTOR LOCK

SWITCH

The switch is a mechanism that shorts the power supply termi-

IGNITION

SWITCH (IG1)

SRS WARNING

LIGHT

SRS-ECU HARNESS-SIDE

CONNECTOR

ON

nal to the ground terminal automatically in the warning light circuit, when the connector is disconnected. Its structure is similar

to the squib circuit connector shorting mechanism.

The switch is a mechanism that shorts the power

supply terminal to the ground terminal automatically

in the air bag squib circuit when the connector is disconnected. A "short" spring is integrated inside the

connector. This spring prevents static electricity from

flowing to the squib by shorting the power supply terminal to the ground terminal (i.e. there is no potential

difference between the two terminals).

CONNECTOR

LOCK SWITCH*

SHORT

SPRING

NOTE

*: CONNECTOR LOCKED: ON

CONNECTOR UNLOCKED: OFF

OFF

ON

OFF

AC006203

AB

SRS-ECU

CAUTION

Never disassemble the SRS-ECU.

The SRS-ECU incorporates an analog G-sensor and

safing G-sensor for frontal collisions and a safing Gsensor for side collisions. In frontal collisions, the

driverís and passengerís (front) air bags deploy and

the seat belt pre-tensioners are activated only when

both the analog and safing G-sensors detect simultaneously a collision-induced G of a level exceeding

the threshold as in the case with the conventional

system. In the case of side collisions, the side-airbag

on the side subjected to an impact deploys if the side

impact sensor and the SRS-ECUís safing G-sensor

detect simultaneously a lateral G of forces above the

predetermined level.

M2521007000095

The SRS-ECU is provided with the following capabilities:

• Backup power supply in case of power failure in

collisions

• Boosting function in case of battery voltage drop

• Self-diagnosis function to avoid systemís opera-

tion errors and improve its reliability

DIAGNOSTIC FUNCTION

The SRS-ECU has the following functions to make

system checking using the scan tool easy.

• Diagnostic trouble code output

• Service data output

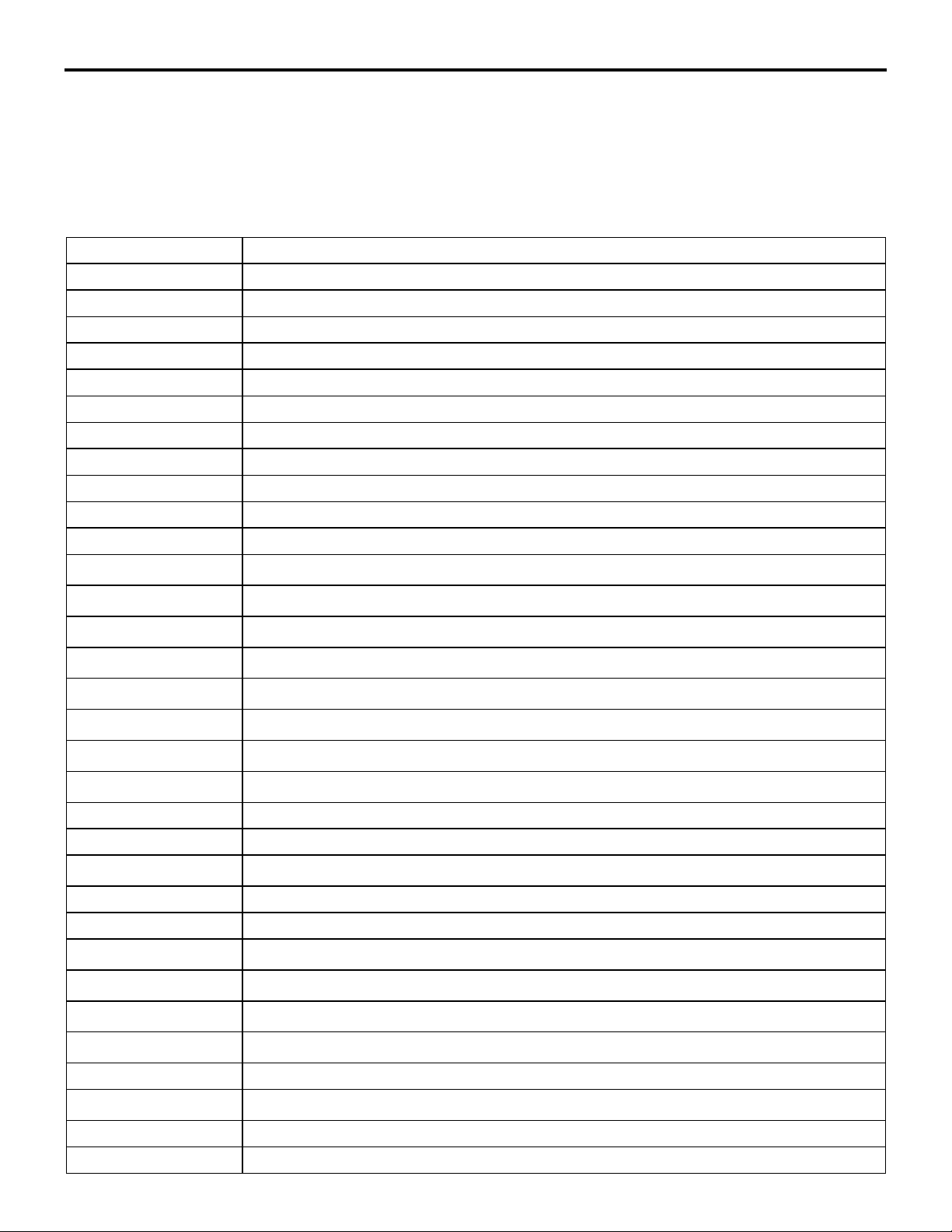

Page 12

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

SRS-ECU

DIAGNOSTIC TROUBLE CODE OUTPUT

The SRS-ECU diagnoses the following items and

stores a diagnostic trouble code in the non-volatile

memory (EEPROM*

Therefore, the memory is not deleted after a battery

terminal is disconnected, (The diagnostic trouble

code memory can be deleted by the scan tool.)

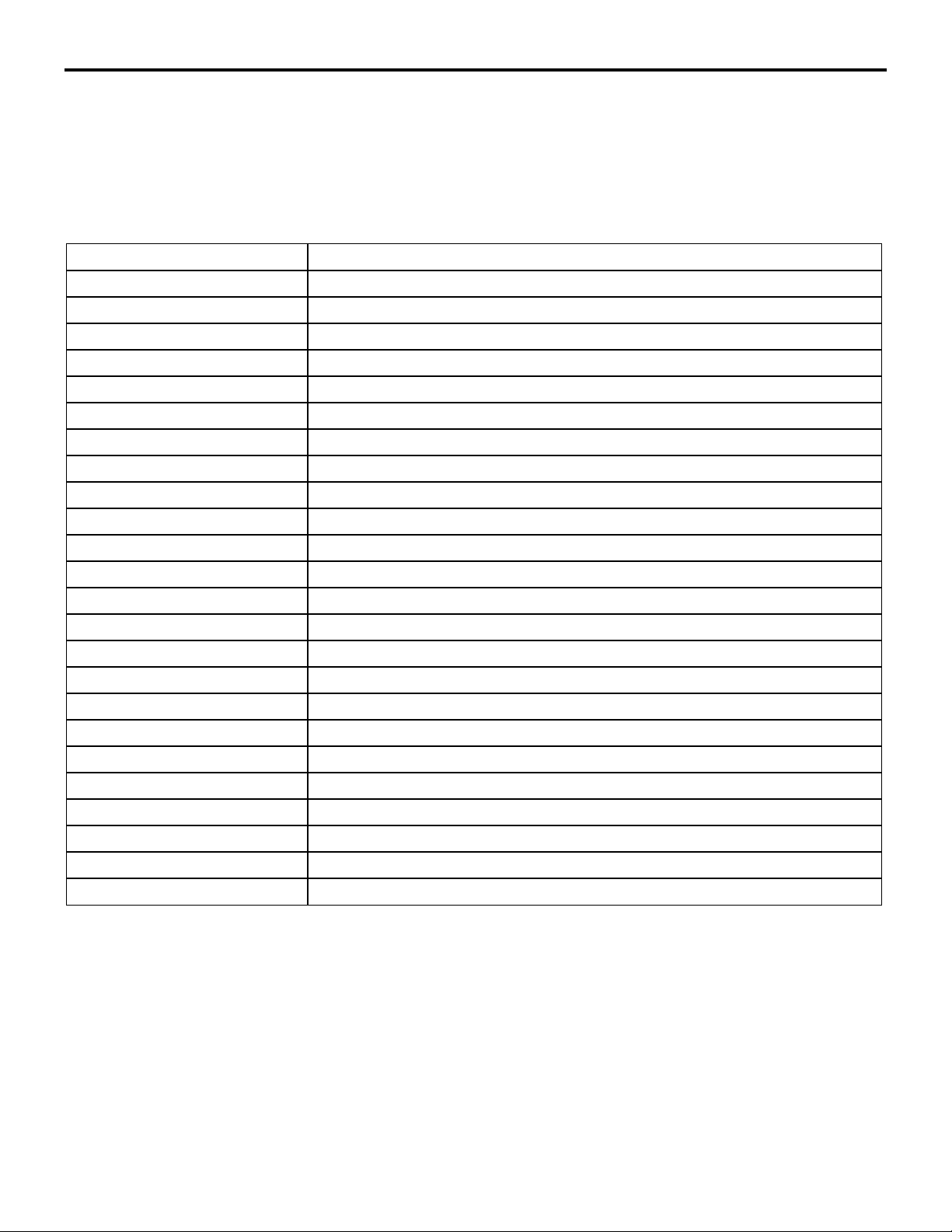

CODE NO. MAJOR CONTENTS OF DIAGNOSTICS

1A Front impact sensor (LH) short-circuited

1B Front impact sensor (LH) open-circuited

1C Front impact sensor (LH) short-circuited to power supply

1D Front impact sensor (LH) short-circuited to ground

2A Front impact sensor (RH) short-circuited

2B Front impact sensor (RH) open-circuited

2C Front impact sensor (RH) short-circuited to power supply

2D Front impact sensor (RH) short-circuited to ground

14 Analog G-sensor malfunction

1

) when a problem is detected.

52B-11

15 Safing G-sensor short-circuited (for frontal collision)

16 Safing G-sensor open-circuited (for frontal collision)

21*

22*

24*

25*

26*

27*

28*

29*

3

3

3

3

3

3

3

3

Driver's air bag squib short-circuited

Driver's air bag squib open-circuited

Passenger's (front) air bag squib short-circuited

Passenger's (front) air bag squib open-circuited

Driver's pre-tensioner squib short-circuited

Driver's pre-tensioner squib open-circuited

Passenger's (front) pre-tensioner squib short-circuited

Passenger's (front) pre-tensioner squib open-circuited

31 SRS-ECU capacitor circuit voltage too high

32 SRS-ECU capacitor circuit voltage too low

34*

2

SRS-ECU connector lock out of order

35 Ignition of the air bag completed

39 Air bag deployed simultaneously

41*

42*

43*

44*

2

2

2

2

Power supply voltage (IG1 (A) voltage) drops a0bnormally.

Power supply voltage (IG1 (B) voltage) drops abnormally.

SRS warning light circuit open-circuited

SRS warning light circuit malfunction

45 SRS-ECU non-volatile memory (EEPROM) and A/D converter system

46*

2

Incorrect SRS-ECU

51 Driver's air bag squib activating circuit short-circuited

52 Driver's air bag squib activating circuit open-circuited

Page 13

52B-12

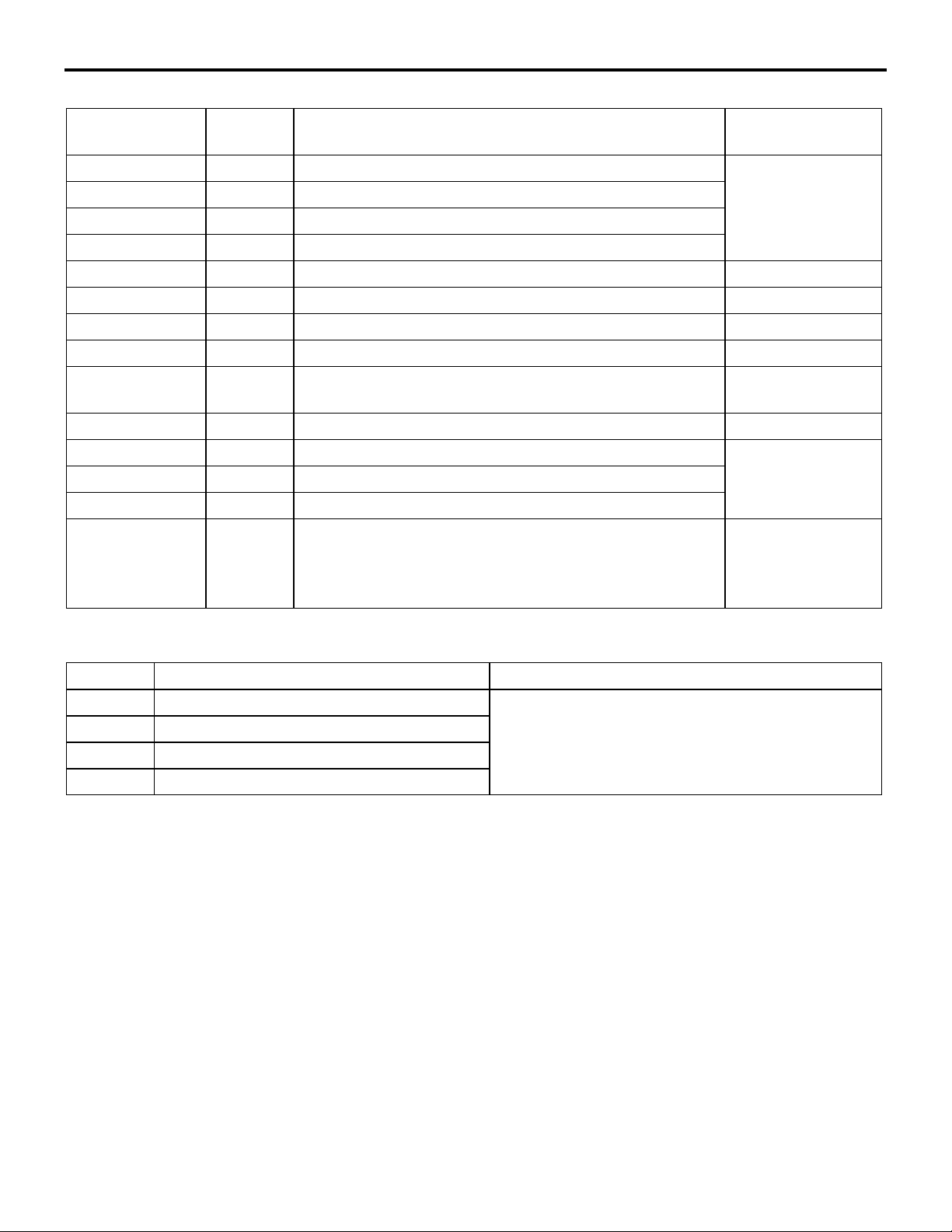

CODE NO. MAJOR CONTENTS OF DIAGNOSTICS

54 Passenger's (front) air bag squib activating circuit short-circuited

55 Passenger's (front) air bag squib activating circuit open-circuited

56 Driverís seat belt pre-tensioner (squib ignition drive circuit) system detected short

57 Driverís seat belt pre-tensioner (squib ignition drive circuit) system detected open

58 Passengerís seat belt pre-tensioner (squib ignition drive circuit) system detected

short

59 Passengerís seat belt pre-tensioner (squib ignition drive circuit) system detected

open

61 Driver's air bag squib drive circuit (power supply side) short-circuited

62 Driver's air bag squib drive circuit (ground side) short-circuited

64 Passenger's (front) air bag squib drive circuit (power supply side) short-circuited

65 Passenger's (front) air bag squib drive circuit (ground side) short-circuited

66 Driver's pre-tensioner squib (power supply side) short-circuited

67 Driver's pre-tensioner squib (ground side) short-circuited

68 Passenger's (front) pre-tensioner squib drive circuit (power supply side) short-

circuited

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

SRS-ECU

69 Passenger's (front) pre-tensioner squib drive circuit (ground side) short-circuited

NOTE: *1: Electrically Erasable Programmable ROM

2

: This diagnostic trouble code memory will be automatically cleared from the memory and the SRS warning

*

light will be switched off when the system returns to normal condition.

3

: The diagnostic trouble codes will remain in memory and the SRS warning light will be switched off if the

*

system returns to normal condition.

DATA LIST OUTPUT

When the SRS-ECU detects a problem, it stores a

diagnostic trouble code and the duration that the

problem has lasted in the non-voltage memory. In

addition, how often a diagnostic trouble code and

duration are cleared by the scan tool are stored in

the non-volatile memory as a reference for service

work. This data can be read by the scan tool.

No. DATA LIST ITEM APPLICABILITY

92 Number indicating how often the memory is cleared Maximum time to be stored: 250

days

93 How long a problem has lasted (How long from the

occurrence of the problem until the first air bag squib

ignition signal)

94 How long a problem has lasted (How long from the first

air bag squib igniting signal until now)

Maximum time to be stored: 9999

minutes (approximately seven

days)

Page 14

GROUP 36

PARKING BRAKE

CONTENTS

GENERAL INFORMATION . . . . . . . . 36-2

36-1

Page 15

36-2

PARK ING BR AKE

GENERAL INFORMATION

GENERAL INFORMATION

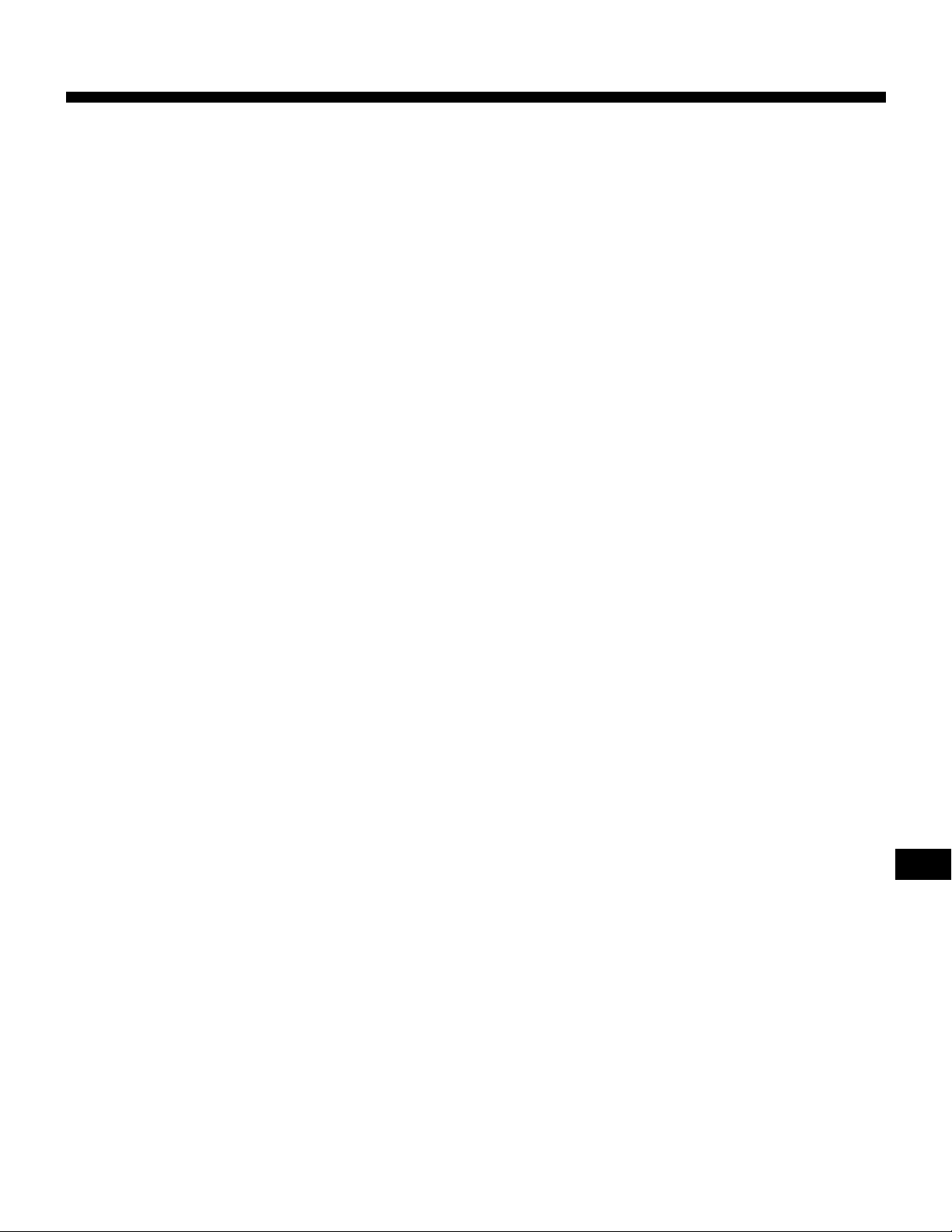

FEATURE

The parking brakes are a mechanical rear wheel

brake design and controlled by a lever.

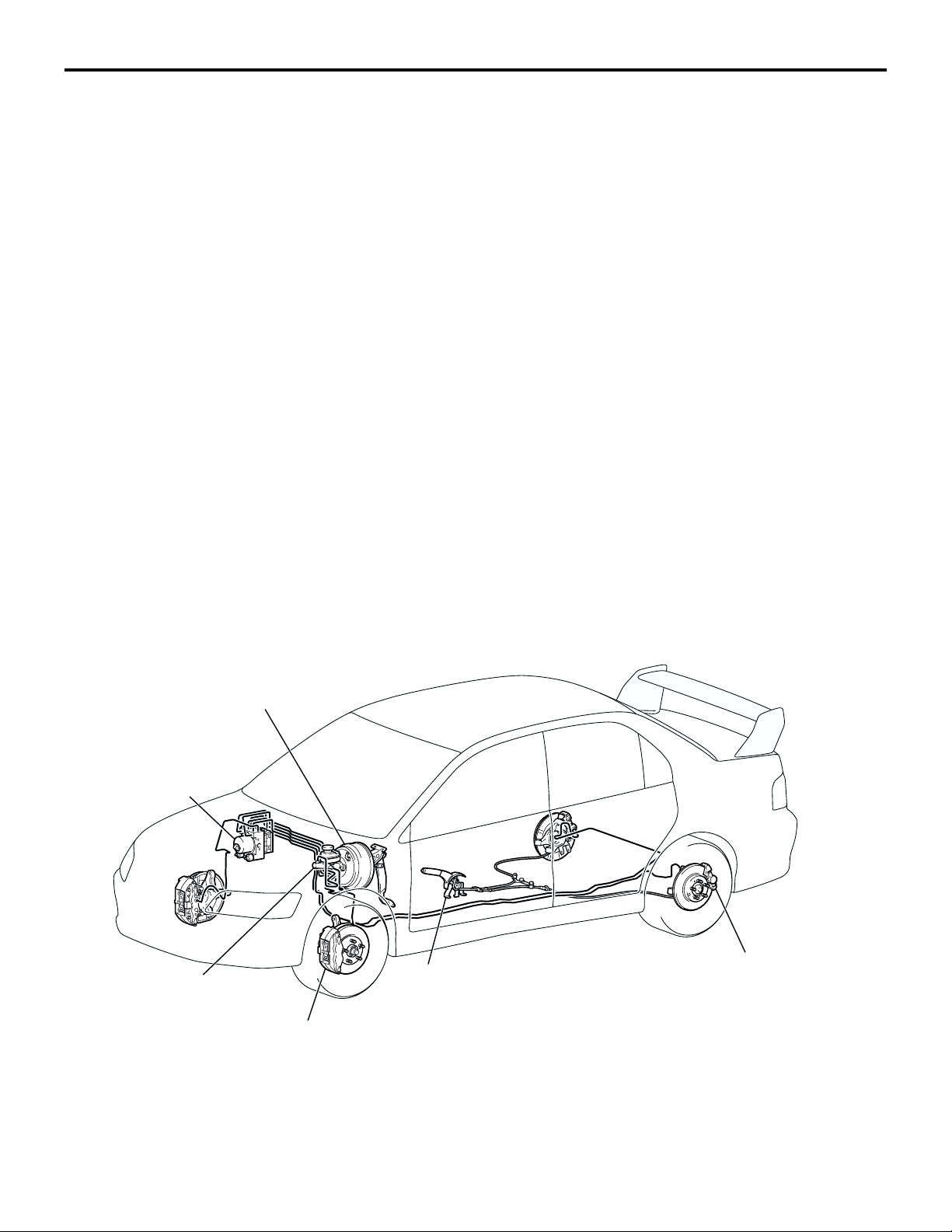

CONSTRUCTION DIAGRAM

M2360000100173

AC211553

AB

Page 16

GROUP 35B

FOUR-WHEEL

ANTI-LOCK BRAKE

SYSTEM (4ABS)

CONTENTS

35B-1

GENERAL DESCRIPTION. . . . . . . . . 35B-2

SENSORS . . . . . . . . . . . . . . . . . . . . . 35B-6

ACTUATORS . . . . . . . . . . . . . . . . . . . 35B-8

BRAKE MODULATOR (ABS-ECU) . . 35B-9

SYSTEM OPERATION . . . . . . . . . . . . 35B-10

Page 17

35B-2

FOUR-WHEEL ANTI-LOCK BRAKE SYSTEM (4ABS)

GENERAL DESCRIPTION

GENERAL DESCRIPTION

Top comp on ents such as Bremb o! brakes, EBD and

sports ABS improve braking power and braking stability.

SPORTS ABS

• 4-wheel independent control optimizes the brake

force to each wheel to achieve a balance of

improved braking force and braking stability.

• A steering angular velocity sensor was added to

monitor the steering angle status. Braking force is

altered in response to the steering status to

improve the quality of steering when braking in

corners.

• The steering angular velocity sensor, lateral Gsensor and longitudinal G-sensor accurately

monitor driving conditions and optimize ABS control to match the specific driving conditions.

M2351000100186

EBD (Electronic Brake-force Distribution

system)

• Rear brake power is electronically controlled to

optimize performance in accordance with road

and load conditions and to ensure optimal distribution of braking force between the front and rear

brakes.

• Rear brake fluid pressure control employs a

brake modulator hydraulic unit solenoid valve that

made it possible to eliminate the pressure control

valves (proportioning valves).

• Effective use of rear wheel brake force reduces

temperature build-up in the front brakes under

hard braking conditions.

• Independent control of the left and right rear

brakes when braking during cornering achieves a

balance of improved vehicle stability and braking

force.

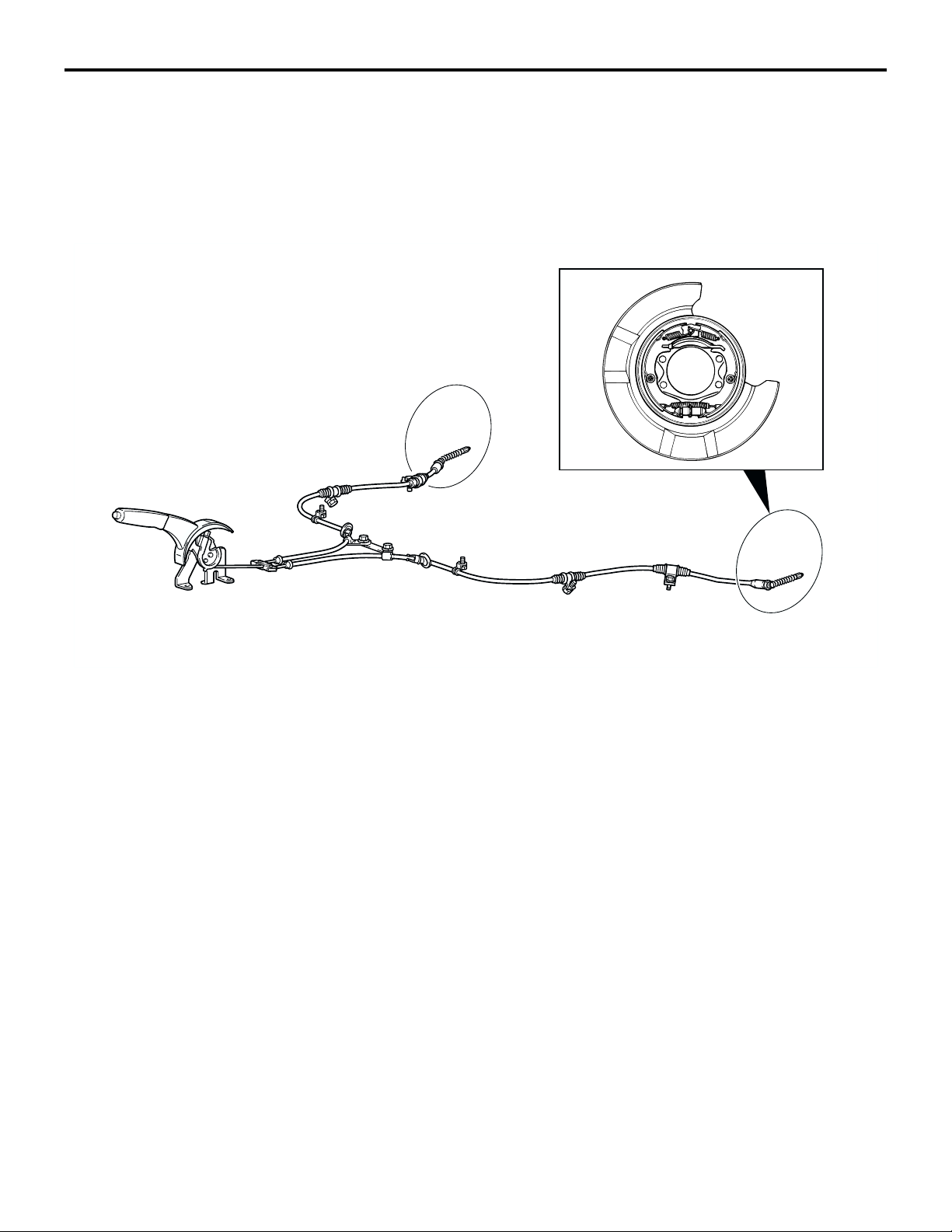

SPECIFICATIONS

ITEM LANCER EVOLUTION LANCER

ABS control method 4-sensor, 4-channel 4-sensor, 4-channel

No. of ABS rotor teeth Front 43 43

Rear 43 43

ABS sensor Type Magnet coil type Magnet coil type

Gap between sensor

and rotor mm (in)

Front 0.85 (0.033)

<Non-adjustable type>

Rear 0.60 (0.023)

<Non-adjustable type>

0.85 (0.033)

<Non-adjustable type>

0.89 (0.035)

<Non-adjustable type>

Page 18

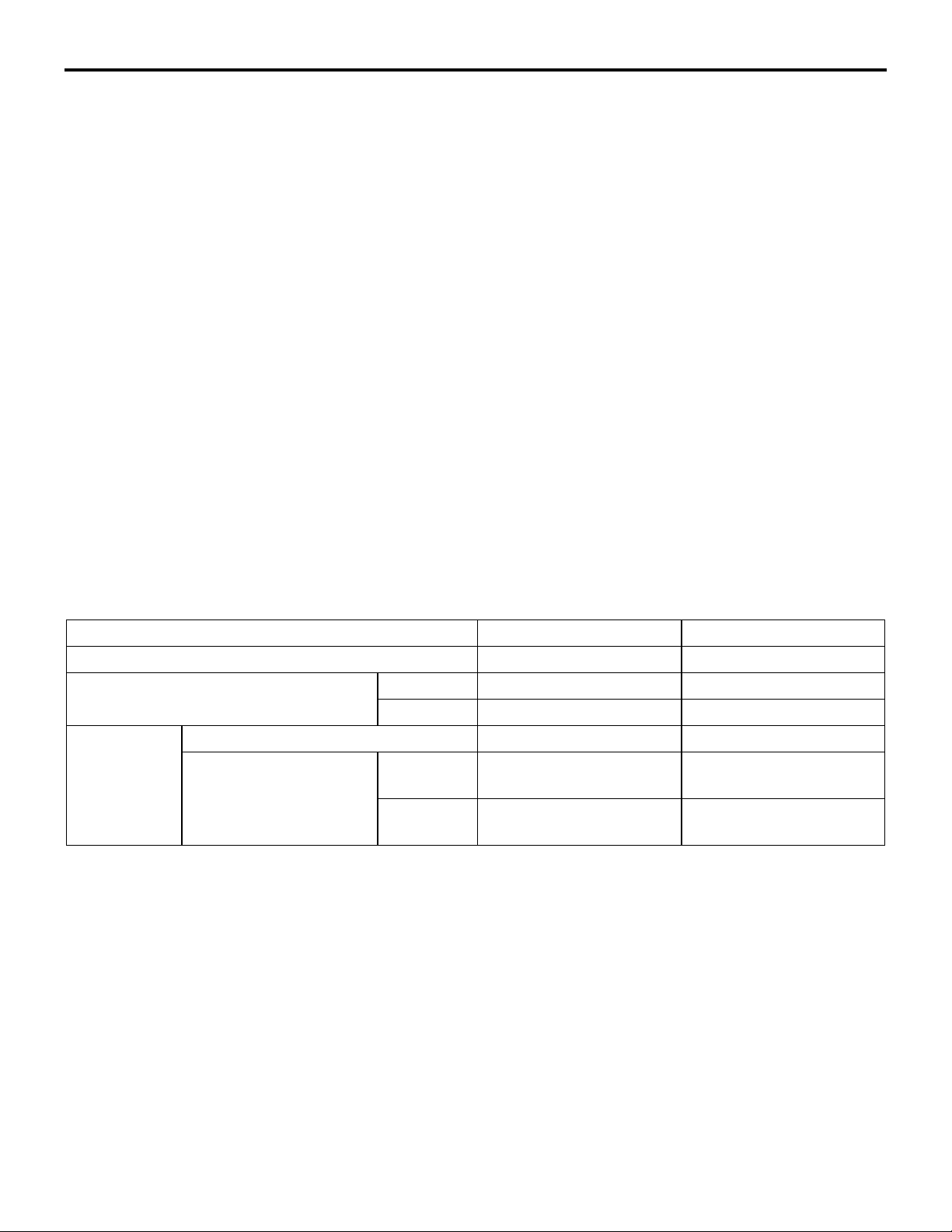

FOUR-WHEEL ANTI-LOCK BRAKE SYSTEM (4ABS)

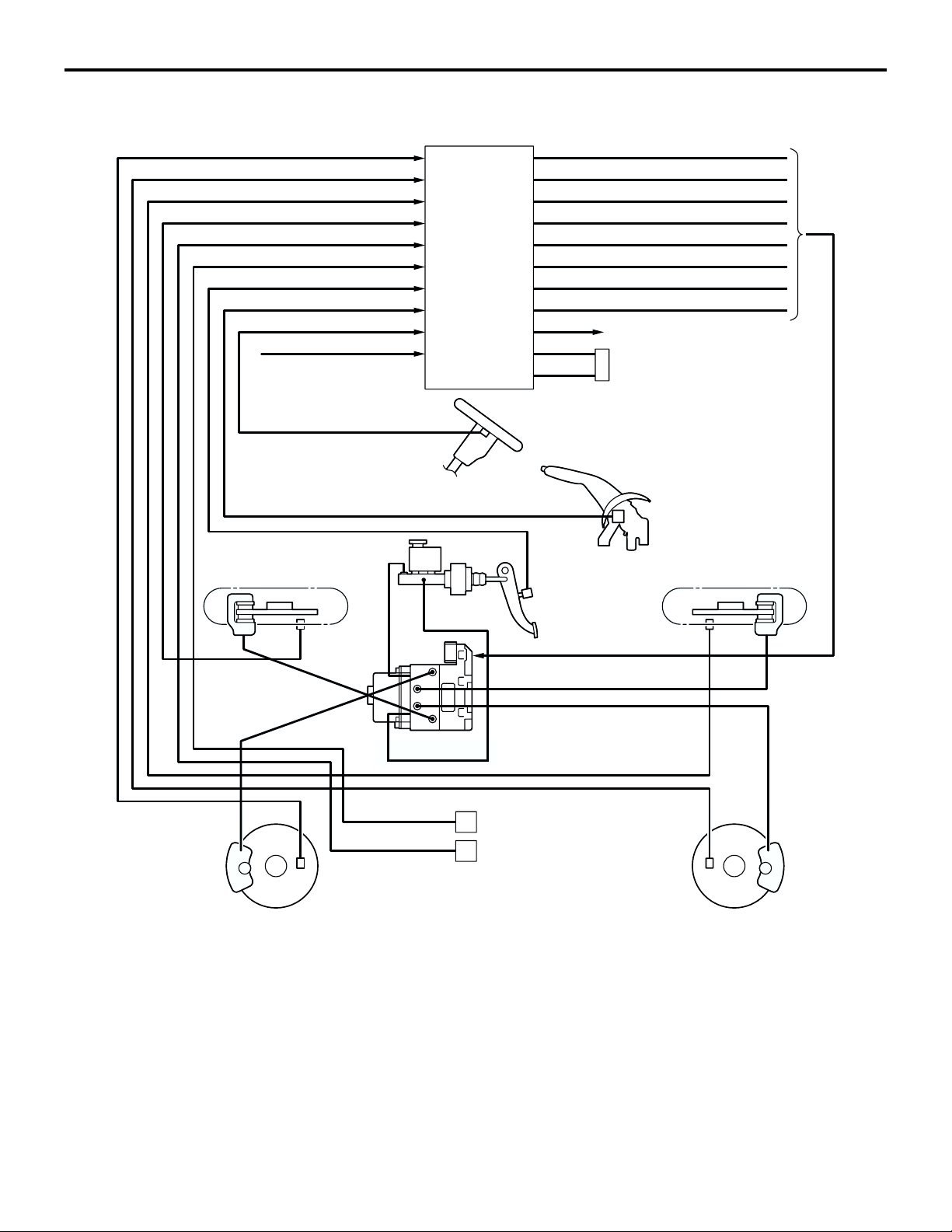

CONSTRUCTION DIAGRAM

GENERAL DESCRIPTION

6

4

35B-3

8

7, 10

9

AC209828

5

10067AU

2

3

1

1

AC211546

AB

NAME OF PART NO. OUTLINE OF FUNCTION

Sensor ABS sensor 1 Sends alternating current signals at frequencies which are proportional

to the rotation speeds of each wheel to the ABS-ECU.

Lateral G-sensor 2 Sends data on vehicleís rate of lateral acceleration to the ABS-ECU.

Longitudinal Gsensor

Steering angular

velocity sensor

3Sends data on vehicleís rate of longitudinal acceleration to the ABS-

ECU.

4Sends data on steering wheel angle to the ABS-ECU.

Indicates the ABS-ECU when steering wheel is in straight-ahead

position.

Stoplight switch 5 Sends a signal to the ABS-ECU to indicate whether the brake pedal is

depressed or not.

Parking brake

switch

6Sends a signal to the ABS-ECU to indicate whether the parking brake

lever is pulled or not.

Actuator Hydraulic unit 7 Drives the solenoid valves according to signals from the ABS-ECU in

order to control the brake hydraulic pressure for each wheel.

ABS warning

light

8Illuminates in response to signals from the ABS-ECU when a problem

develops in the system.

Data link connector 9 Outputs the diagnostic trouble codes and allows communication with

the scan tool.

Brake modulator (ABS-ECU) 10 Controls actuators (described above) based on the signals coming from

each sensor.

Controls the self-diagnosis and fail-safe functions.

Controls the diagnostic function (scan tool compatible).

Page 19

35B-4

FOUR-WHEEL ANTI-LOCK BRAKE SYSTEM (4ABS)

GENERAL DESCRIPTION

SYSTEM CONFIGURATION DIAGRAM

ABS SENSOR (FL)

ABS SENSOR (RL)

ABS SENSOR (RR)

ABS SENSOR (FR)

LONGITUDINAL G-SENSOR

LATERAL G-SENSOR

STOPLIGHT SWITCH

PARKING BRAKE SWITCH

STEERING ANGULAR VELOCITY SENSOR

ECU POWER SUPPLY

FRONT-RIGHT

WHEEL (FR)

ABS-ECU

FR SOLENOID VALVE (OUT)

FR SOLENOID VALVE (IN)

FL SOLENOID VALVE (OUT)

FL SOLENOID VALVE (IN)

RR SOLENOID VALVE (OUT)

RR SOLENOID VALVE (IN)

RL SOLENOID VALVE (OUT)

RL SOLENOID VALVE (IN)

ABS WARNING LIGHT

DATA LINK CONNECTOR

STEERING ANGULAR

VELOCITY SENSOR

PARKING

BRAKE

SWITCH

STOPLIGHT

SWITCH

REAR-RIGHT

WHEEL (RR)

FRONT-LEFT

WHEEL (FL)

ABS

SENSOR

ABS SENSOR

HYDRAULIC

UNIT

ABS SENSOR

LATERAL G-SENSOR

LONGITUDINAL G-SENSOR

ABS SENSOR

REAR-LEFT

WHEEL (RL)

10066AU

AC211547

AB

Page 20

FOUR-WHEEL ANTI-LOCK BRAKE SYSTEM (4ABS)

GENERAL DESCRIPTION

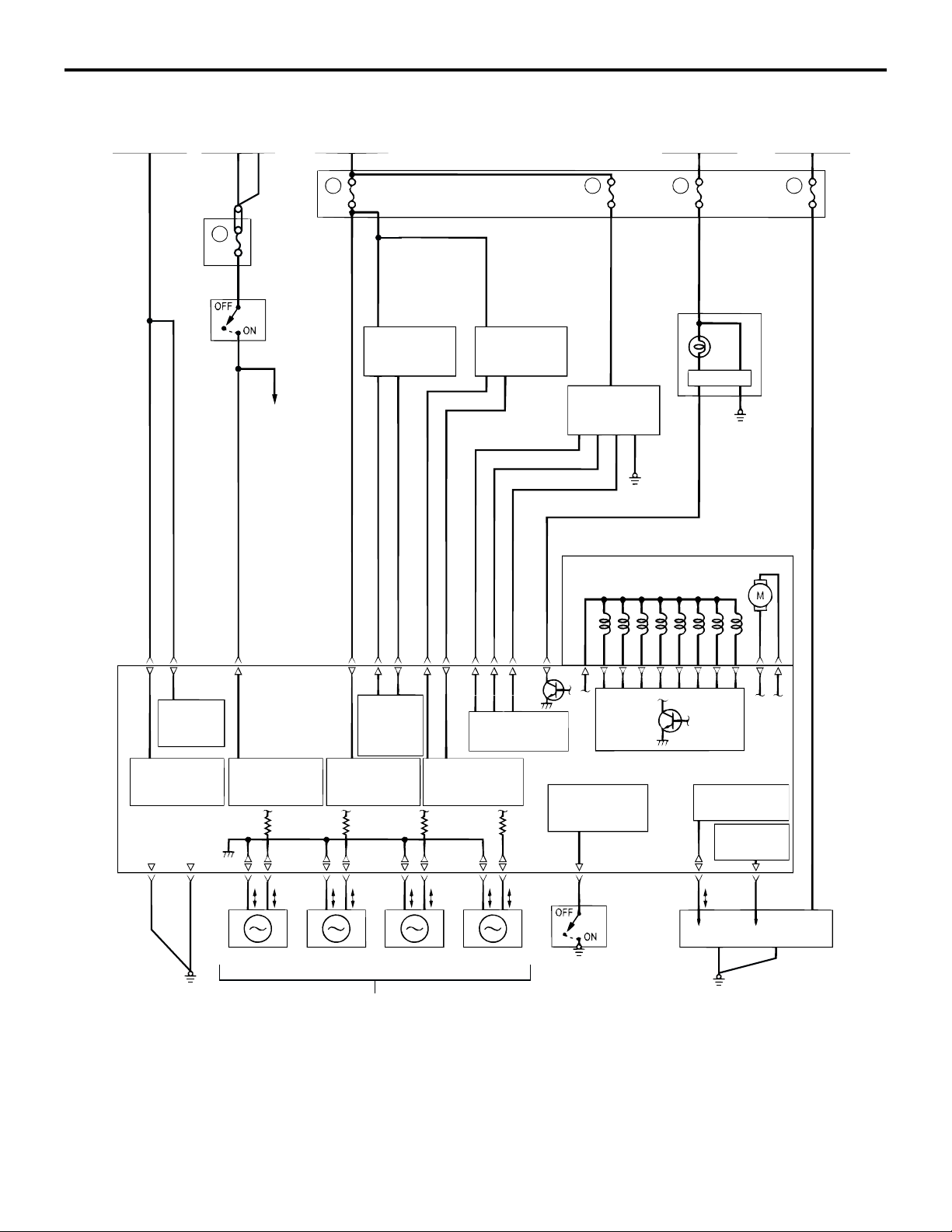

ABS ELECTRICAL CIRCUIT DIAGRAM

35B-5

FUSIBLE

LINK 3 BATTERY

10

15A

STOPLIGHT

IGNITION

SWITCH (IG2)

RELAY

BOX

STOPLIGHT

SWITCH

12

7.5A

LATERAL

G-SENSOR

JUNCTION BLOCK

LONGITUDINAL

G-SENSOR

IGNITION

SWITCH (IG1)

5

7.5A

STEERING

ANGULAR

VELOCITY

SENSOR

HYDRAULIC UNIT

SOLENOID VALVE

2

7.5A

COMBINATION

METER

ANTI

LOCK

MOTOR

FUSIBLE

LINK 1

15

15

15A

15A

ABS-ECU

MOTOR

POWER

SUPPLY

SOLENOID

VALVE POWER

SUPPLY

LATERAL

G-SENSOR

INPUT

STOPLIGHT

SWITCH

MONITOR

FL FR RL RR

(FL) (FR) (RL) (RR)

ECU

POWER

SUPPLY

STEERING ANGULAR

VELOCITY SENSOR

INPUT

ABS SENSOR

LATERAL

G-SENSOR

INPUT

PARKING BRAKE

SWITCH MONITOR

PARKING

BRAKE

SWITCH

COMMUNICATION

LINE

CONTROL

LINE

DATA LINK

CONNECTOR

AC211548

AB

Page 21

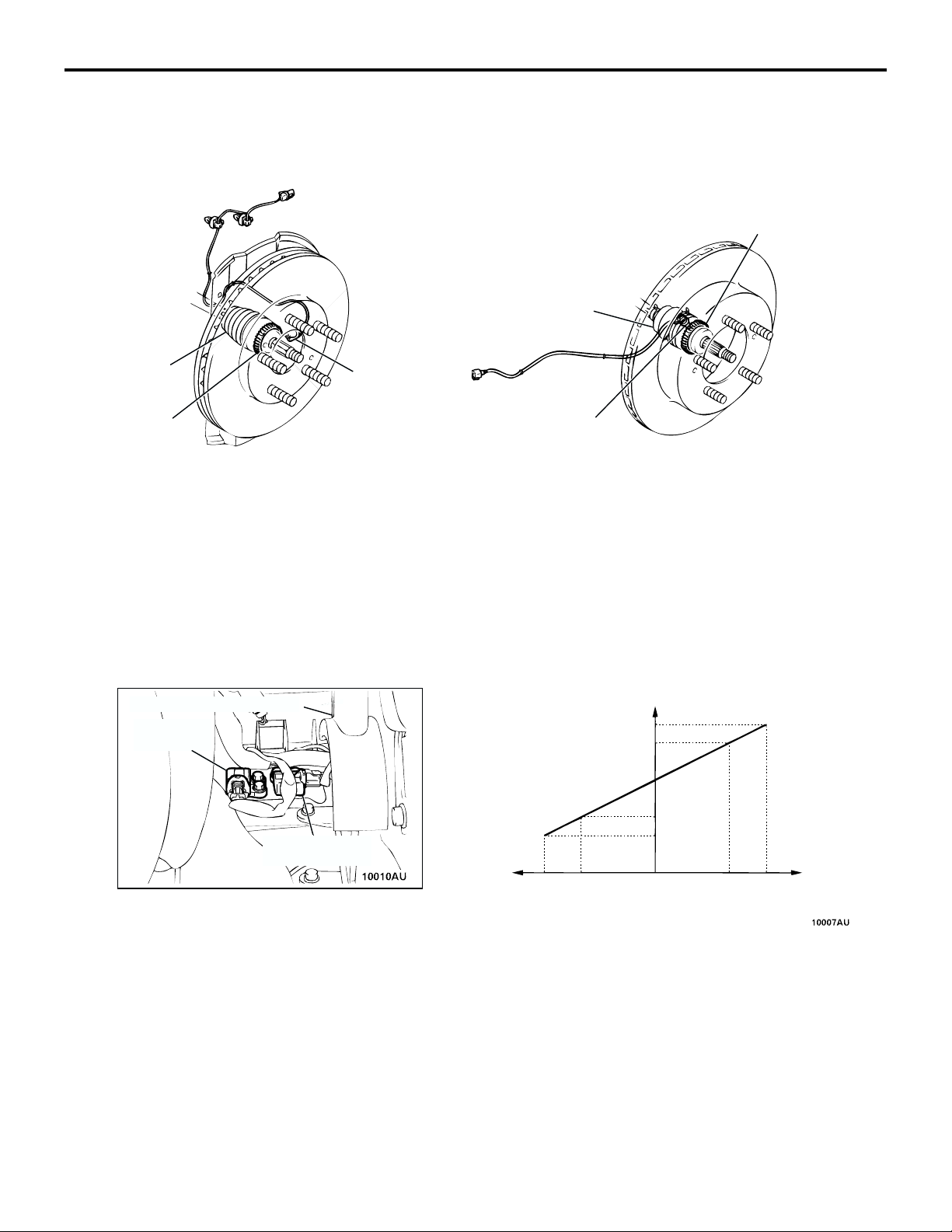

35B-6

FOUR-WHEEL ANTI-LOCK BRAKE SYSTEM (4ABS)

SENSORS

SENSORS

ABS SENSOR

FRONT

DRIVESHAFT

ABS SPEED

SENSOR

ABS ROTOR

The ABS sensors consist of fixed ABS speed sensors and the ABS rotors that rotate at the same

speed as the wheels, that output alternating current

signals at frequencies which are proportional to the

wheel speed.

M2351001000137

REAR

ABS ROTOR

DRIVESHAFT

ABS SPEED

SENSOR

AC211549

AB

• The ABS rotors (43 teeth) are installed to the

drive shafts, and the ABS speed sensors are

installed to knuckles.

• The gap between the ABS rotors and the ABS

speed sensors are non-adjustable at both the

front and rear to improve serviceability.

LATERAL G-SENSOR/LONGITUDINAL G-SENSOR

G-SENSOR OUTPUT CHARACTERISTICS

PARKING BRAKE LEVER

LATERAL

G-SENSOR

LONGITUDINAL

G-SENSOR

ACCELERATION

SPEED (G)

The longitudinal G-sensor detects the acceleration in

the lateral direction of the vehicle, and are basically

the same as those used conventionally. The lateral

G-sensor is used for detecting the acceleration along

the sides of the vehicle by changing the installing

direction by 90 degree angle. The same sensor as

the longitudinal G-sensor is used.

OUTPUT VOLTAGE (V)

4.0

3.5

2.5

1.5

1.0

0 1.01.0 1.51.5

DECELERATION

SPEED (G)

AC211550

AB

Page 22

FOUR-WHEEL ANTI-LOCK BRAKE SYSTEM (4ABS)

SENSORS

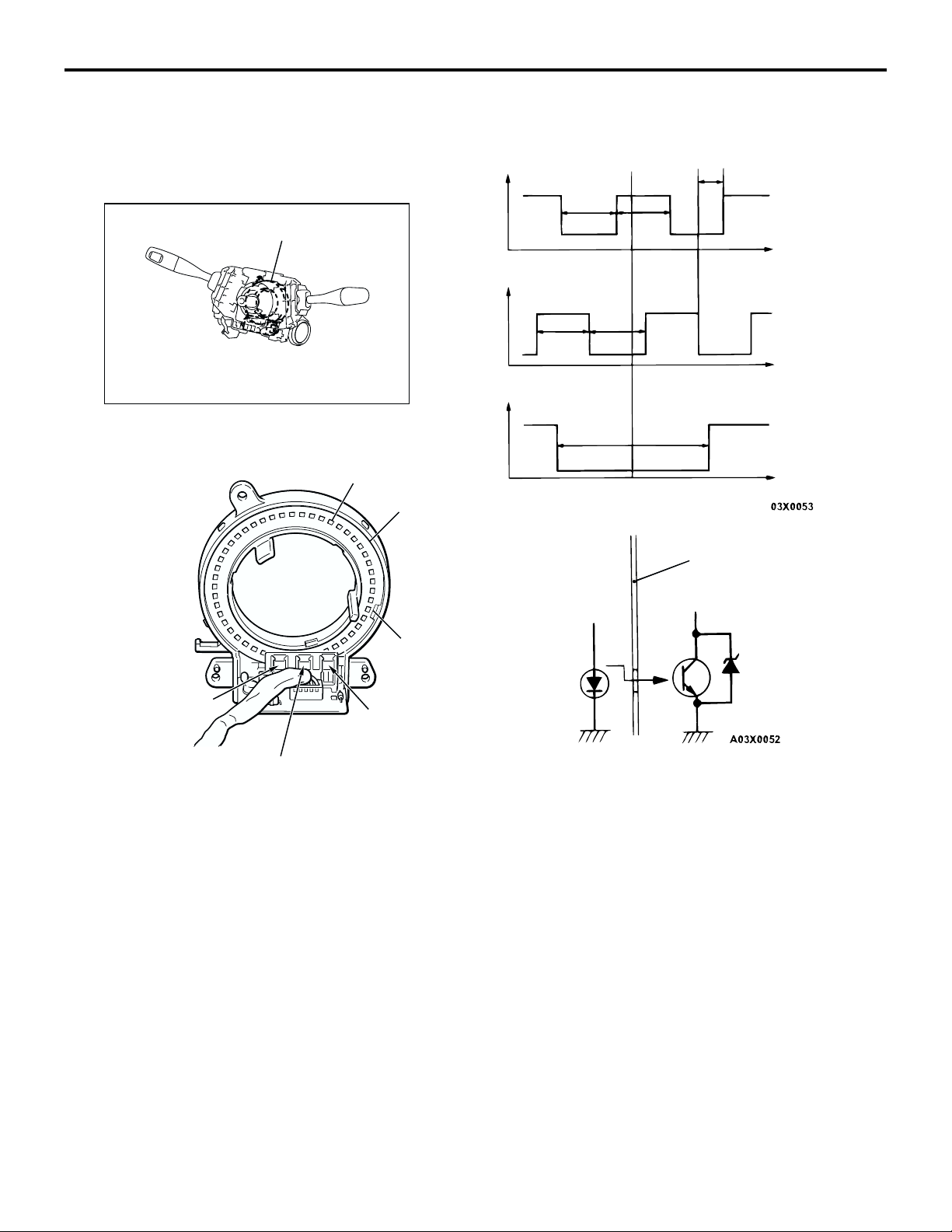

STEERING ANGULAR VELOCITY SENSOR

35B-7

OUTPUT WAVEFORM OF EACH PHOTOINTERRUPTOR

STEERING ANGULAR

VELOCITY SENSOR

Y2057AU

SLIT

SLIT PLATE

ST-1

ST-2

ST-N

V

HLHLH

L

V

H

L

V

H

L

4˚ 4˚4˚ 4˚

4˚ 4˚

11˚

2˚

θ

θθ

θ

SLIT PLATE

NEUTRAL POSITION

DETECTION SLIT

PHOTOINTERRUPTOR

(ST-2)

PHOTOINTERRUPTOR

(ST-1)

PHOTOINTERRUPTOR

(ST-N)

10091AU

The steering angular velocity sensor is installed at

the steering column, and is used to output steer

angles to the ABS-ECU as signals. It is composed of

the slit plate which rotates according to the movements of the steering wheel and a three-set photointerruptor. The slit plate and photointerruptors have a

sealed integrated structure to prevent the invasion of

foreign particles as well as misoperations by external

light. To detect malfunctions of the sensor output circuit, it is equipped with a zener diode for detecting

disconnections parallel to the photo-transistor. The

ZENER DIODE (FOR

DISCONNECTION

DETECTION)

LIGHT-EMITTING

DIODE

PHOTO-TRANSISTOR

AC211551

AB

ABS-ECU calculates the steering angle by reading

the signals of the steering angular velocity sensor

after every certain period of time and calculating the

total of the ST-1 signal and ST-2 signal. The steering

angle is obtained by taking the neutral position (ST-N

output is L center) as 0 degree angle, and if there are

changes, the steering angle is added with 2 degree

angle for right and -2 degree angle for left. The output of the photointerruptor becomes L (low) when

light passes through and H (high) when obstructed.

Page 23

35B-8

FOUR-WHEEL ANTI-LOCK BRAKE SYSTEM (4ABS)

ACTUATORS

STOPLIGHT SWITCH

This switch turns on when the brake pedal is

depressed, and turns off when the brake pedal is

released. The ABS-ECU detects whether the stoplight switch is on or off by means of fluctuations in

voltage (ON: system voltage; OFF: Approximately 0

V). This data is used for ABS control.

ACTUATORS

ABS WARNING LIGHT

The ABS-ECU controls the power transistor in ABS-ECU to

turn on and causes the ABS warning light to illuminate in the

following cases:

• During initial check when the ignition switch is at the "ON"

position (for approximately three seconds)

• When a problem develops in the ABS/EBD system

• Poor ABS-ECU connector connection

ABS WARNING LIGHT

AC211552

AB

PARKING BRAKE SWITCH

This switch turns on when the parking brake lever is

pulled, and turns off when the parking brake lever is

released. The ABS-ECU detects whether the parking

brake switch is on or off by means of fluctuations in

voltage (ON: less than 1 volt; OFF: system voltage).

This data is used for ABS control.

M2351002000099

HYDRAULIC UNIT

The hydraulic unit is basically the same as that of the LANCER.

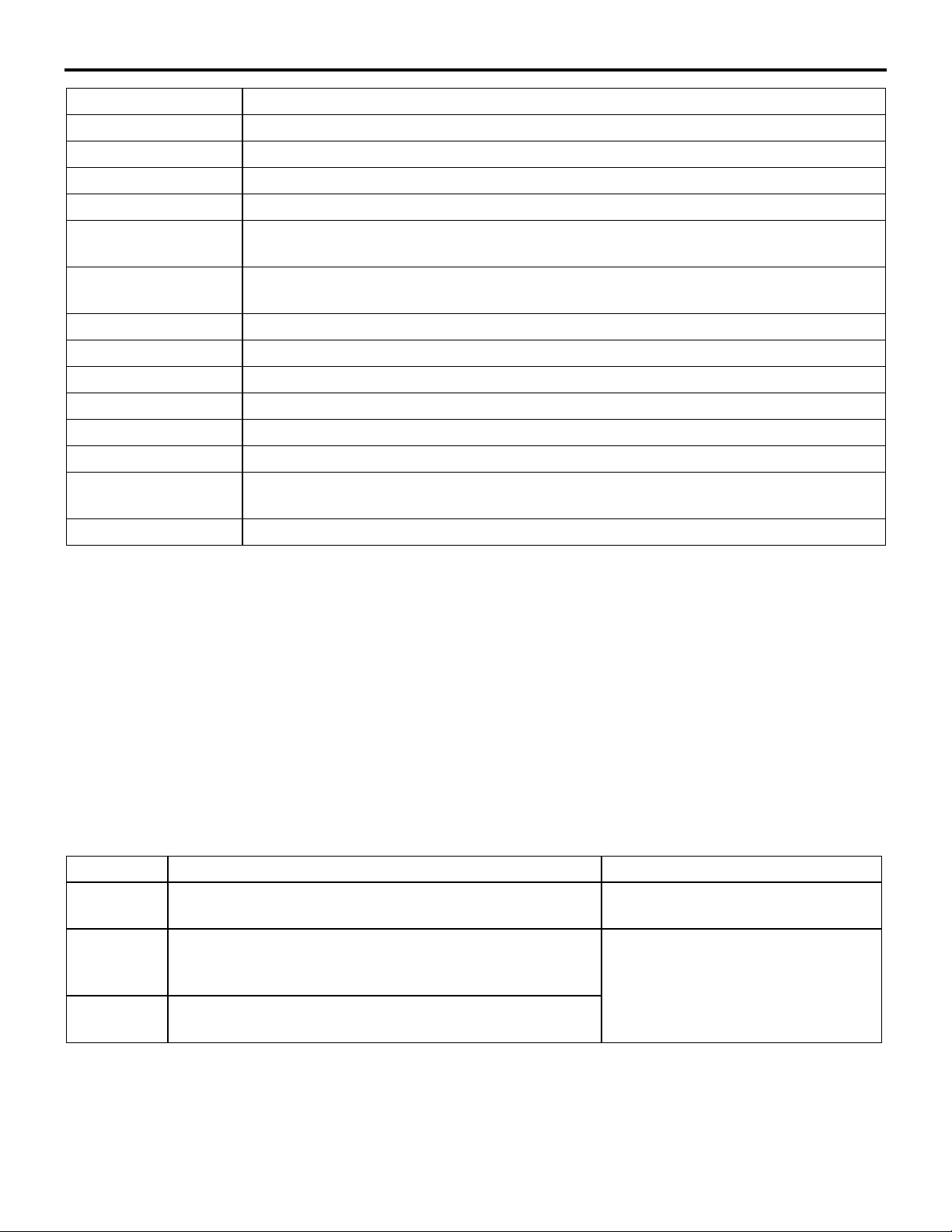

Page 24

FOUR-WHEEL ANTI-LOCK BRAKE SYSTEM (4ABS)

BRAKE MODULATOR (ABS-ECU)

35B-9

BRAKE MODULATOR (ABS-ECU)

The ABS-ECU is basically the same as that of the

LANCER except the followings:

DIAGNOSTIC FUNCTIONS

.

DIAGNOSTIC TROUBLE CODE OUTPUT

DTC ITEM

11 Ope n cir cuit or shor t-ci rcuit in ABS senso r (F R)

12 Open circuit or short-circuit in ABS sensor (FL)

13 Open circuit or short-circuit in ABS sensor (RR)

14 Open circuit or short-circuit in ABS sensor (RL)

16 Abnormal drop or rise in ABS-ECU power supply voltage

21 ABS sensor (FR) system

22 ABS sensor (FL) system

23 ABS sensor (RR) system

24 ABS sensor (RL) system

32 Longitudinal G-sensor system

41 Solenoid valve (FR) system

M2351003000144

42 Solenoid valve (FL) system

43 Solenoid valve (RR) system

44 Solenoid valve (RL) system

51 Valve relay ON problem

52 Valve relay OFF problem

53 Motor relay OFF problem

54 Motor relay ON problem

55 Motor system

63 ABS-ECU abnormality

71 Lateral G-sensor system

81 Steering angular velocity sensor (ST-1) system

82 Steering angular velocity sensor (ST-2) system

83 Steering angular velocity sensor (ST-N) system

.

Page 25

35B-10

FOUR-WHEEL ANTI-LOCK BRAKE SYSTEM (4ABS)

SYSTEM OPERATION

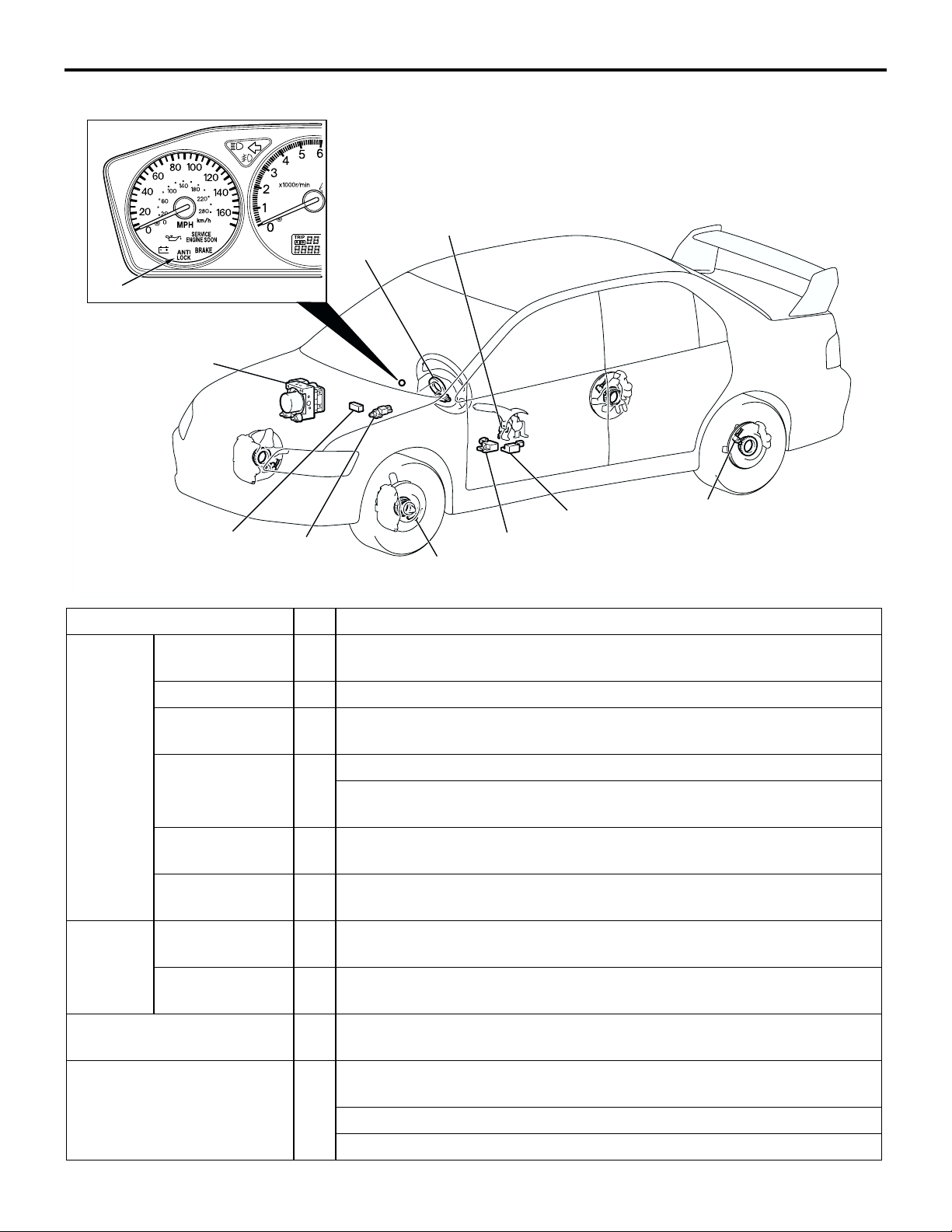

SERVICE DATA OUTPUT

SCAN TOOL

DISPLAY

ITEM NO. CHECK ITEM DISPLAY TEXT

OR UNIT

FR SNSR 11 Front-right ABS sensor km/h or mph

FL SNSR 12 Front-left ABS sensor

RR SNSR 13 Rear-right ABS sensor

RL SNSR 14 Rear-left ABS sensor

BATT. VOLTAGE 21 ABS-ECU power supply voltage V

29 Parking brake switch ON/OFF

32 Longitudinal G-sensor V

STOPLIGHT SW 36 Stoplight switch ON/OFF

37 Steering angular velocity sensor straight ahead position

ON/OFF

memory

71 Lateral G-sensor V

74 Steering angular velocity sensor (ST-N) OFF/ON

75 Steering angular velocity sensor (ST-1)

76 Steering angular velocity sensor (ST-2)

86 Steering angle

° or OFF (when the

steering angle is

straight ahead

position)

.

ACTUATOR TEST

NO. ITEM PARTS TO BE ACTIVATED

01 Solenoid valve for front-left wheel Solenoid valves and pump motors in the hydraulic

02 Solenoid valve for front-right wheel

unit (simple inspection mode)

03 Solenoid valve for rear-left wheel

04 Solenoid valve for rear-right wheel

SYSTEM OPERATION

In terms of operation, the system is basically the

same as that of the LANCER.

M2351004000114

Page 26

GROUP 35

SERVICE BRAKES

CONTENTS

SERVICE BRAKES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35A

FOUR-WHEEL ANTI-LOCK BRAKE SYSTEM (4ABS) . . . . . . . 35B

35-1

Page 27

NOTES

Page 28

GROUP 35A

SERVICE BRAKES

CONTENTS

35A-1

GENERAL DESCRIPTION. . . . . . . . . 35A-2

MASTER CYLINDER . . . . . . . . . . . . . 35A-4

BRAKE BOOSTER ASSEMBLY . . . . 35A-4

FRONT DISC BRAKE. . . . . . . . . . . . . 35A-5

REAR DISC BRAKE . . . . . . . . . . . . . . 35A-6

Page 29

35A-2

SERVICE BRAKES

GENERAL DESCRIPTION

GENERAL DESCRIPTION

Top comp on ents such as Bremb o! brakes, EBD and

sports ABS improve braking power and braking stability.

FEATURES

.

Improved braking performance

1. A 8+9-inch tandem vacuum booster is utilized to

provide high braking force with a small pedal

depression force.

2. Brembo! 17-inch 4-pot front ventilated disc

brakes and Brembo! 16-inch 2-pot rear ventilated disc brakes are adopted to provide stable

braking force and improved braking feel.

.

Improved stability

1. Sports ABS (4-wheel anti-lock braking system) is

used to prevent slipping caused by the vehicle

wheels locking up in order to maintain an appropriate braking distance, and also to maintain a

stable vehicle posture and steering performance.

M2350000100183

2. Adoption of an electronic brake-force distribution

(EBD) makes it possible to maintain the maximum amount of braking force even when the

vehicle's load is unevenly distributed.

3. Front- and rear-wheel X-type brake line layout is

used.

4. Ventilated discs improve anti-fading performance.

.

Improved serviceability

1. A diagnosis function has been adopted for the

ABS system in order to make inspection easier.

2. An outer disc method separated hub and rotor is

featured to make removal and installation easier.

3. The master cylinder reservoir tank cap is colored

white to make identification easier.

4. The ABS-ECU and hydraulic unit are integrated

to make them more compact and light weight.

CONSTRUCTION DIAGRAM

BRAKE BOOSTER

ASSEMBLY

BRAKE MODULATOR

HYDRAULIC UNIT

(INTEGRATED WITH

THE ABS-ECU)

BRAKE MASTER

CYLINDER ASSEMBLY

FRONT DISC BRAKE

PARKING BRAKE

LEVER ASSEMBLY

10064AU

REAR DISC BRAKE

AC211387

AB

Page 30

SERVICE BRAKES

GENERAL DESCRIPTION

SPECIFICATIONS

ITEM SPECIFICATION

Master

cylinder

Type Tandem type

I.D. mm (in) 26.9 (1.06)

35A-3

Brake

booster

Rear wheel hydraulic control method Electronic brake-force distribution (EBD)

Front brakes Type 4-opposed piston, ventilated disc

Rear brakes Type 2-opposed piston, ventilated disc

Brake fluid DOT3 or DOT4

Type Vacuum type, tandem

Effective dia. of power cylinder

mm (in)

Boosting ratio 4.5 <Brake pedal depressing force: 230 N (51.7 lb)>

Disc effective dia × thickness

mm (in)

Wheel cylinder I.D. mm (in) 40.0 (1.58) × 2, 46.0 (1.81) × 2

Pad thickness mm (in) 10.0 (0.39)

Clearance adjustment Automatic

Disc effective dia × thickness

mm (in)

Wheel cylinder I.D. mm (in) 40.0 (1.58) × 2

Pad thickness mm (in) 9.0 (0.35)

Clearance adjustment Automatic

205 + 230 (8.07 + 9.06)

263 × 32 (10.4 × 1.3)

252 × 22 (9.9 × 0.9)

Page 31

35A-4

SERVICE BRAKES

MASTER CYLINDER

MASTER CYLINDER

MASTER CYLINDER BODY

SECONDARY PISTON ASSEMBLY

The master cylinder is a tandem-type, with a structure that emphasizes safety.

BRAKE FLUID RESERVOIR

PRIMARY PISTON ASSEMBLY

PISTON RETAINER

AE

AC005372

M2350001000145

BRAKE BOOSTER ASSEMBLY

FRONT DIAPHRAGM

PUSH ROD

DIAPHRAGM RETURN SPRING

A 8 + 9-inch tandem-type brake booster assembly

has been adopted.

REAR DIAPHRAGM

OPERATING ROD

ATMOSPHERIC CHAMBERS

M2350002000148

AC206215

AC

Page 32

SERVICE BRAKES

FRONT DISC BRAKE

35A-5

FRONT DISC BRAKE

FRONT OF VEHICLE

Brakes with the following specifications have been

adopted for the front brakes.

• Brembo! V7-Z4046 4-opposed-piston ventilated

discs

• An outer disc method in which the wheels and

discs are tightened together is used to improve

the ease of brake disc removal and installation.

DISC BRAKE NOMENCLATURE

M2350003000141

PADS

AC211388

AB

• The brake pads are equipped with mechanicaltype audible wear indicators to notify the driver

when the usage limit [2 mm (0.08 in)] is reached.

• Split fins adopted as the disc fins to improve cooling performance

NOTE: Brembo! is an italian brake component

maker whose name and products are well known in

the motorsports world.

V 7 – Z 40 46

2

1

34

AC211390

NO. ITEM CONTENT

1Brake disc type V: Ventilated

2Brake size

7: 17-inch

(Minimum applicable

disc wheel)

3No. of pistons Z: 4-piston (opposed

type)

4Piston size (rounded

to nearest integer)

40: φ40 mm (1.6 in)

46: φ46 mm (1.8 in)

Page 33

35A-6

SERVICE BRAKES

REAR DISC BRAKE

REAR DISC BRAKE

FRONT OF

VEHICLE

Brakes with the following specifications have been

adopted for the rear brakes.

• Brembo! V6-X40 2-opposed-piston ventilated

discs

• An outer disc method in which the wheels and

discs are tightened together is used to improve

the ease of brake disc removal and installation.

DISC BRAKE NOMENCLATURE

M2350004000155

PADS

AC211389

AB

• The brake pads are equipped with mechanicaltype audible wear indicators to notify the driver

when the usage limit [2 mm (0.08 in)] is reached.

• Split fins adopted as the disc fins to improve cooling performance

NOTE: Brembo! is an italian brake component

maker whose name and products are well known in

the motorsports world.

V6– X 40

2

1

34

AC211391

NO. ITEM CONTENT

1Brake disc type V: Ventilated

2Brake size

6: 16-inch

(Minimum applicable

disc wheel)

3No. of pistons X: 2-piston (opposed

type)

4Piston size (rounded

40: φ40 mm (1.6 in)

to nearest integer)

Page 34

GROUP 34

REAR SUSPENSION

CONTENTS

GENERAL DESCRIPTION. . . . . . . . . 34-2

34-1

Page 35

34-2

REAR SUSPENSION

GENERAL DESCRIPTION

GENERAL DESCRIPTION

A trailing arm type multi-link suspension is used for

the rear suspension. In contrast to the trailing arm

multi-link system used on the Lancer, the Lancer

Evolution uses a newly developed multi-link system

built on a double wishbone base to achieve superior

handling stability. Optimum design of the suspension

points and use of aluminum parts for the suspension

arms and crossmember reduces weight. In addition,

use of ball joints on the suspension arms reduce friction and creates a suspension system that exhibits

superior stroke characteristics that respond well

under all driving conditions.

STRUCTURE

1. The A-shape upper arm assembly mounted

inside the wheel combines with the three Ishaped arms including the trailing arm assembly

that runs in front-rear orientation with the vehicleís body, the lower arm assembly and the assist

link to support the knuckle.

2. Each arm uses a ball joint and pillow ball bushing

at the knuckle end and a pillow ball bushing at the

body end, and are mounted on the body via the

crossmember.

3. Alignment and suspension stroke, a wider track,

and optimization of roll center height improves

cornering response throughout the range from

initial response through to the cornering limit.

M2340000100137

COMPONENT CHARACTERISTICS

(COMPARED TO THE LANCER)

1. Suspension arm (made of forged aluminum)

• The trailing arm assembly, upper arm assembly, lower arm assembly and assist link are

made of forged aluminum to reduce weight

and increase rigidity.

• The knuckle mount and body-end mount for

the lower arm assembly use pillow ball bushings for high rigidity and reduce suspension

friction.

• The body-end mount for the assist link uses a

low-friction slide bushing.

2. Crossmember (made of forged aluminum)

• The crossmember is made of forged aluminum to reduce weight and increase rigidity.

3. Shock absorber, coil spring, stabilizer, bump rubber

• The shock absorber size was changed and

the rod diameter was increased to improve

stability during roll by increasing damping

response.

• Optimization of shock absorber damping,

spring rate, bump rubber characteristics and

bushing characteristics improves cornering

response throughout the range from initial

response through to the cornering limit.

Page 36

CONSTRUCTION DIAGRAM

COIL SPRING

REAR SUSPENSION

GENERAL DESCRIPTION

34-3

SHOCK ABSORBER

UPPER ARM ASSEMBLY

(FORGED ALUMINUM)

STABILIZER BAR LINK

ASSIST LINK

(FORGED ALUMINUM)

TRAILING ARM ASSEMBLY

(FORGED ALUMINUM)

ASSIST LINK

CONTROL BAR

CROSSMEMBER

(FORGED ALUMINUM)

DIFFERENTIAL SUPPORT

MEMBER

LOWER ARM ASSEMBLY

(FORGED ALUMINUM)

STABILIZER BAR

DIFFERENTIAL

SUPPORT ARM

AC211385

AB

SPECIFICATIONS

.

SUSPENSION SYSTEM

ITEM SPECIFICATION

Suspension method Trailing arm type multi-link

.

WHEEL ALIGNMENT

ITEM LANCER EVOLUTION LANCER

Camber

Toe -i n m m (in ) 3 (0 .12 ) 3 (0 .12 )

.

COIL SPRING

ITEM LANCER EVOLUTION LANCER

Wire diameter mm (in) 12 (0.5) 10 (0.4)

Average diameter mm (in) 88 (3.5) 90 (3.5)

Free length mm (in) 287 (11.3) 370 (14.6)

−1°00' −0°40'

Page 37

NOTES

Page 38

GROUP 33A

FRONT

SUSPENSION

CONTENTS

33A-1

GENERAL DESCRIPTION. . . . . . . . . 33A-2

LOWER ARM . . . . . . . . . . . . . . . . . . . 33A-4

STRUT ASSEMBLY . . . . . . . . . . . . . . 33A-5

Page 39

33A-2

FRONT SUSPENSION

GENERAL DESCRIPTION

GENERAL DESCRIPTION

A MacPherson strut independent suspension-type

suspension is used for the front suspension. Aggressive use of special components that include

Mitsubishi Motorís own inverted struts and forged

aluminum parts reduces weight to create a suspension that gives superior performance made with competition use in mind.

FEATURES (COMPARED TO THE

LANCER)

.

Inverted struts

Use of inverted struts ensures smooth shock

absorber action even during high speed cornering

that places high lateral G-force on the suspension.

.

Coil springs

The coil spring rate was optimized and highresponse spring material is used to achieve high

durability and reduce weight.

.

Lower arm assembly

Use of forged aluminum reduces load on the coil

springs and produces nimble suspension action. In

addition, outer casings and stoppers on the front

bushings (A-point) and pillow ball bushings in the

rear (G-point) improves the feeling of stiffness and

stroke. Increased size of the ball on the ball joints at

the knuckle connection (B-point) also improve reliability.

M2330000100147

.

Stabilizer

A change to pillow ball joints for the stabilizer link

improves stabilizer efficiency to deliver a high level of

stability.

.

Crossmember

A reinforcing bar (front axle crossmember bar) that

connects the left and right lower arm mounts (Apoints) increases lateral rigidity. This improves steering feel and adds extra stiffness when cornering.

.

Strut insulator

Input from the strut has been changed from a separation pattern to a unified one and the use of a metal

bearing achieves greater rigidity, durability, and lower

friction.

.

Alignment

A wider track and optimization of roll center height

improves cornering response throughout the range

from initial response through to the cornering limit.

Page 40

CONSTRUCTION DIAGRAM

STABILIZER LINK

(PILLOW BALL JOINT)

B-POINT

FRONT SUSPENSION

GENERAL DESCRIPTION

COIL SPRING

STABILIZER BAR

LOWER ARM BUSHING

(PILLOW BALL BUSHING)

33A-3

STRUT INSULATOR

STRUT

(INVERTED STRUT)

G-POINT

A-POINT

LOWER ARM ASSEMBLY

(FORGED ALUMINUM)

FRONT AXLE No.1

CROSSMEMBER

A-POINT

FRONT AXLE

CROSSMEMBER BAR

SPECIFICATIONS

.

SUSPENSION SYSTEM

ITEM SPECIFICATION

Suspension method MacPherson strut with coil springs

.

WHEEL ALIGNMENT

ITEM LANCER EVOLUTION LANCER

Camber -1°00' <Default factory setting>

(-2°00' adjustment possible)

Caster 3°55' 2°50'

Kingpin inclination 13°45' 12°35'

0°00'

AC211383

AB

Toe -i n m m (in ) 0 (0 ) 1 (0 .04 )

.

COIL SPRING

ITEM LANCER EVOLUTION LANCER (SPORT)

Wire diameter mm (in) 14 (0.6) 14 (0.6)

Average diameter mm (in) 155 (6.1) 160 (6.3)

Free length mm (in) 286 (11.3) 363 (14.3)

Page 41

33A-4

FRONT SUSPENSION

LOWER ARM

STOPPERS

FRONT OF VEHICLE

LOWER ARM

M2330002000050

LOWER ARM ASSEMBLY

PILLOW BALL BUSHING

ENLARGED BALL DIAMETER

Use of forged aluminum reduces load on the coil

springs and produces nimble suspension action. In

addition, outer casings and stoppers on the front

bushings and pillow ball bushings in the rear

improves the feeling of stiffness and stroke.

Increased size of the ball on the ball joints at the

knuckle connection also improve reliability.

AC211384

AB

Page 42

FRONT SUSPENSION

STRUT ASSEMBLY

33A-5

FRONT OF

VEHICLE

A

-1˚ CAMBER

SELECTED

STRUT ASSEMBLY

INVERTED

STRUT

KNUCKLE

ECCENTRIC BOLT

-1˚ CAMBER

SELECTED

A

-2˚ CAMBER

SELECTED

M2330001000079

SECTION A -A

-2˚ CAMBER

SELECTED

An inverted strut layout (with the cylinder at the top

and the piston at the bottom) is used. This layout

offers superior rigidity and consequently improved

camber stiffness. Further, either of two camber

angles can be selected in accordance with operating

conditions. The camber angle is determined by the

alignment of an eccentric bolt at the top of the joint

AC211392

AB

between the strut assembly and knuckle. Vehicles

leave the factory with a camber angle of -1 degree

angle selected. (An arrow on the eccentric bolt is

pointing toward the inside of the vehicle.) For a camber angle of -2 degree angle, the bolt must be positioned with its arrow pointing toward the outside of

the vehicle.

Page 43

NOTES

Page 44

GROUP 00

GENERAL

CONTENTS

00-1

HOW TO USE THIS MANUAL. . . . . . 00-2

TARGETS OF DEVELOPMENT . . . . 00-2

TECHNICAL FEATURES. . . . . . . . . . 00-3

EXTERIOR . . . . . . . . . . . . . . . . . . . . . . . . . 00-3

INTERIOR . . . . . . . . . . . . . . . . . . . . . . . . . . 00-4

BODY DIMENSIONS . . . . . . . . . . . . . . . . . 00-5

ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . 00-6

TRANSAXLE. . . . . . . . . . . . . . . . . . . . . . . . 00-6

SUSPENSION . . . . . . . . . . . . . . . . . . . . . . . 00-7

ACTIVE SAFETY. . . . . . . . . . . . . . . . . . . . . 00-8

PASSIVE SAFETY . . . . . . . . . . . . . . . . . . . 00-9

ENVIRONMENTAL PROTECTION . . . . . . . 00-10

SERVICEABILITY AND RELIABILITY . . . . 00-11

VEHICLE IDENTIFICATION . . . . . . . . 00-12

GENERAL DATA AND

SPECIFICATIONS . . . . . . . . . . . . . . . 00-13

Page 45

00-2

GENERAL

HOW TO USE THIS MANUAL

HOW TO USE THIS MANUAL

ABBREVIATIONS

The following abbreviations are used in this manual

for classification of model types:

MFI: Indicates multiport fuel injection, or engines

equipped with the multiport injection.

TARGETS OF DEVELOPMENT

Since the modelís introduction in 1992, Mitsubishi

Motors has continually evolved the Lancer Evolution

series through developments that reflect direct feedback from actual competition in motor sports events

around the world. This is highlighted by entry in the

M2000029000093

M/T: Indicates manual transaxle, or models equipped

with the manual transaxle.

AWD: Indicates 4-wheel-drive vehicles.

A/C: Indicates air conditioning.

M2000004000182

premier event, the WRC (World Rally Championship). The Lancer Evolution series continues to

prove its trademark speed and high performance by

taking the winnerís trophy time and again, including

four WRC titles.

Page 46

GENERAL

TECHNICAL FEATURES

TECHNICAL FEATURES

00-3

EXTERIOR

DESIGN FEATURES

4

1

3

2

M2000017000160

AC205386

6

5

AC205387

8

.

1. Large Three Diamond Mark

.

2. Front Bumper with Integrated Grille

.

3. Front Air Dam

The design strikes a continuous line with the bumper

for an integrated look.

.

4. Aluminum Hood

To cl ear ly ex pr ess t he Mi tsubi sh i d es ign i den ti ty

while also improving cooling performance, a kick-up

was added to the hood and the outlet was made

larger.

.

5. Smoked Headlight Exterior

The turn signal lights are amber, but the exterior lens

has a smoked finish.

.

7

9

AC210723

6. Rear Spoiler

Placing top priority on weight reduction, the rear

spoiler made of carbon fiber is used as a standard.

The vertical struts give the impression of speedy performance and the outer surfaces alone are painted to

the color key.

.

7. Rear Bumper

The design achieves a balance with that of the front

bumper while it remains simple and does not appear

to protrude or stand out.

.

8. Lancer and Evolution Mark

.

9. Rear Combination Light

The expression is designed to match that of the

headlights. The outer lens is clear, the turn signal

lights are amber, and the exterior section is smoked.

(Note that regulations in North America require the

front and rear turn signals to be clear.)

AC

Page 47

00-4

GENERAL

TECHNICAL FEATURES

INTERIOR

DESIGN FEATURES

1. Steering wheel

A MOMO leather-wrapped 3-spoke steering

wheel is used.

2. Meter panel

The driver-oriented meter panel has been

designed for easy visibility.

3. Center/instrument panel

M2000018000152

1

2

3

4

5

AC211416

It is vertically angled toward the front.

4. Separated center panel and floor console

5. Seats

High-back sport type RECARO seats are used in

the front, and a high-back bench seat is used for

the rear.

AB

Page 48

GENERAL

TECHNICAL FEATURES

00-5

BODY DIMENSIONS

5

3

11

8

10

12

9

4

1

6

7

2

M2000019000133

AC102003

AB

NO. ITEM DIMENSION NO. ITEM DIMENSION

1Overall length mm (in)4,535 (178.5) 7 Tread mm (in) Front1,515 (59.6)

2Overall width mm (in)1,770 (69.7) Rear1,515 (59.6)

3Overall height mm (in)1,450 (57.1) 8 Front leg space mm (in)930 (36.6)

9Rear leg space mm (in)785 (30.9)

4Wheel base mm (in) 2,625 (103.3) 10Total leg space mm (in)1,715 (67.5)

5Front overhang mm (in)930 (36.6) 11Hip point height

6Rear overhang mm (in)980 (38.6) 12 Rear335 (13.2)

mm (in)

Front 245 (9.6)

STORAGE SPACE

4

1

NO. ITEM DIMENSION NO. ITEM DIMENSION

1Trunk width mm (in)

980 (38.6) 4 Trunk opening mm (in) 430 (16.9)

(Distance between rear

wheelhouses)

2Trunk length mm (in) 840 (33.1) 5Ground-to-trunk opening

3Trunk height mm (in) 470 (18.5)

distance mm (in)

2

3

5

AC101532

AB

725 (28.6)

The trunk is at 430 liters (454.4 quart) (VDA), thanks

to the smaller rear wheel housings, specially

designed trunk lid hinges that are less intrusive, and

a redesigned rear suspension layout. A trunk-

through feature enables stowage of longer items.

Numerous storage spaces are conveniently located

throughout the vehicle.

Page 49

00-6

GENERAL

TECHNICAL FEATURES

MINIMUM TURNING RADIUS

NO. ITEM DIMENSION

1

2

3

4

AC005234

AB

ENGINE

2.0-litre 16-valve DOHC engine

The 4G63 2.0-liter engine is available with MFI.

1Effective turning radius mm (in) 5,900 (232.3)

2Minimum turning radius mm (in) 5,600 (220.5)

3Front overhang mm (in) 930 (36.6)

4Wheelbase mm (in) 2,625 (103.3)

M2000020000104

TRANSAXLE

MANUAL TRANSAXLE

5-speed manual transaxle is provided.

M2000021000107

Page 50

GENERAL

TECHNICAL FEATURES

00-7

SUSPENSION

STABILIZER LINK

(PILLOW BALL JOINT)

ASSIST LINK

(FORGED ALUMINUM)

LOWER ARM ASSEMBLY

(FORGED ALUMINUM)

UPPER ARM ASSEMBLY

(FORGED ALUMINUM)

STABILIZER

BAR LINK

M2000023000095

LOWER ARM BUSHING

(PILLOW BALL BUSHING)

STRUT INSULATOR

COIL SPRING

STABILIZER BAR

STRUT

(INVERTED STRUT)

FRONT AXLE No.1

CROSSMEMBER

FRONT AXLE

CROSSMEMBER BAR

CROSSMEMBER

(FORGED ALUMINUM)

DIFFERENTIAL SUPPORT

MEMBER

COIL SPRING

DIFFERENTIAL

SUPPORT ARM

SHOCK

ABSORBER

ASSIST LINK

CONTROL BAR

LOWER ARM ASSEMBLY

(FORGED ALUMINUM)

A MacPherson strut independent suspension is used

in front. Aggressive use of special components that

include Mitsubishi Motorís own inverted struts and

forged aluminum parts reduces weight. A trailing arm

type multi-link suspension is used in rear. In contrast

to the trailing arm multi-link system used on the

Lancer, the Lancer Evolution uses a newly devel-

TRAILING ARM ASSEMBLY

(FORGED ALUMINUM)

AC211449

AB

oped multi-link system built on a double wishbone

base for superior handling stability. Optimum design

of the suspension points and use of aluminum parts

for the suspension arms and crossmember reduces

weight to the limit. In addition, ball joints on the suspension arms reduce friction for superior performance under all driving conditions.

Page 51

00-8

GENERAL

TECHNICAL FEATURES

ACTIVE SAFETY

BRAKING SYSTEM

STEERING ANGULAR

VELOCITY SENSOR

HYDRAULIC UNIT

{INTEGRATED IN BRAKE

MODULATOR (ABS-ECU)}

DATA LINK

CONNECTOR

STOPLIGHT SWITCH

PARKING BRAKE SWITCH

ABS SENSOR

LATERAL G-SENSOR

LONGITUDINAL G-SENSOR

10067AU

ABS SENSOR

M2000031000090

AC211719

AB

Top comp on ents such as Bremb o! brakes, EBD and

sports ABS aim to improve braking power and braking stability.

SPORTS ABS

• 4-wheel independent control optimizes the brake

force to each wheel to achieve a balance of

improved braking force and braking stability.

• A steering angular velocity sensor monitors the

steering angle status. Braking force is altered in

response to the steering status to improve the

quality of steering when braking during cornering.

• The steering angular velocity sensor, lateral Gsensor and longitudinal G-sensor monitor driving

conditions and optimize ABS control to match the

specific driving conditions.

EBD (Electronic Brake-force Distribution

system)

• Rear brake power is electronically controlled to

optimize performance in accordance with road

and load conditions and to ensure optimal distribution of braking force between the front and rear

brakes.

• Rear brake fluid pressure control employs a

brake modulator hydraulic unit solenoid valve that

made it possible to eliminate the pressure control

valves (proportioning valves).

• Effective use of rear wheel brake force reduces

temperature build-up in the front brakes under

hard braking conditions.

• Independent control of the left and right rear

brakes when braking during cornering achieves a

balance of improved vehicle stability and braking

force.

Page 52

GENERAL

TECHNICAL FEATURES

00-9

PASSIVE SAFETY

SRS AIR BAGS

SEAT BELT PRE-TENSIONER

M2000032000093

DRIVER'S AIR BAG

PASSENGER'S

(FRONT) AIR BAG

Driverís and front passengerís air bags and seat

belts with pre-tensioner are standard.

.

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

The SRS is designed to supplement the front seat

belts. It eliminates or reduces injury to the driver and

front passengers by deploying air bag(s) in a headon collision.

.

AC211587

AB

SEAT BELT WITH PRE-TENSIONER

The seat belts with pre-tensioner work simultaneously with the SRS. The pre-tensioner takes up

seat slack immediately in a collision by restraining

the person before the air bags deploy. This prevents

the passengers from moving forward.

Page 53

00-10

BODY CONSTRUCTION

SIDE DOOR BEAM

GENERAL

TECHNICAL FEATURES

ENLARGED CROSS-SECTION

OF ROOF BOW

REINFORCED FRONT

PILLAR

ENLARGED CROSSSECTION AND

EXTENDED FRONT

SIDE MEMBER

The Lancer Evolution-VIII safety-enhanced body

structure comprises front and rear crushable zones

that absorb the impact energy of front and rear collisions. A deformation-resistant, highly rigid cabin

structure features strategic reinforcements plus a

large side-door beam.

ENVIRONMENTAL PROTECTION

Mitsubishi has given careful consideration to protection of natural resources and the environment in the

vehicle. Environmentally friendly features are shown

below.

ENLARGED CROSS-SECTION

OF SIDE SILL

ENLARGED CROSS-SECTION AND

MINIMIZED VERTICAL OFFSET OF

FRONT FLOOR MEMBER

ADDED DASH CROSSMEMBER

OTHER SAFETY FEATURES

• 3-point ELR seatbelts

• Front fog lights

• Child-protection rear door locks

• Child restraint fitting

REINFORCED CENTER

PILLAR

AC211731

M2000027000138

AB

Page 54

GENERAL

TECHNICAL FEATURES

Items Dealing with Environmental Protection

00-11

PREVENTION OF

ATMOS PHERI C

POLLUTION

Recycling Air cleaner case Application of recycled polypropylene material that

Reduction of

hazardous

substances

Air pollution

prevention

Weight reduction

(improve fuel

economy)

PART NAME MAI N DETA IL

contains recycled paper makes effective use of

resources and reduces weight.

Hood weatherstripping Use of a thermoplastic elastomer olefin material makes

Engine control vacuum

hose

Glass ceramic print No lead compounds.

Intake valve sheet No lead used as a lubricant.

Electropaint Lead-free compound used.

Fuel tank No lead-tin alloy coating.

Cylinder head gasket The metal reduces sheet thickness, which reduces the

Rear spoiler Use of carbon fiber reduces weight by 35 percent and

recycling easier.

crevice volume of the combustion chamber and

decreases the production of unburned hydrocarbons

(HC).

increases strength, so the spoiler is thinner and

aerodynamics are improved.

MAT construction

aluminum wheel.

Aluminum retainer Change to aluminum reduces weight by 55 percent.

Weight is reduced by 10 percent.

SERVICEABILITY AND RELIABILITY

MUT-III (Multi Use Tester-III)

Comprehensive improvements have been made to

the MUT-II, a tester for diagnosing problems with the

electronic control system. For easier servicing, the

newly developed MUT-III has greatly improved functions and is much easier to use. The MUT-III

expands the functions of the MUT-II in the following

ways:

1. Interactive Error Diagnosis

• In response to the nature of the problem, the

corresponding troubleshooting page from the

maintenance manual is retrieved.

• Service data is displayed, and from the actuator test screen, the page of the maintenance

manual is retrieved for a list of inspection reference values.

M2000028000131

2. Service Manual Viewer

• The new model guide and maintenance manual can be displayed on a PC monitor.

ENHANCED DIAGNOSIS SYSTEM

Diagnosis functions have been included for the following systems, so that it is possible to use the scan

tool to read the diagnosis codes and service data

and to carry out actuator tests. It is also possible to

read the diagnosis codes by the flashing of the warning light in some systems.

• MFI

• 4ABS

• SRS air bag

• Simplified Wiring System (SWS)

Page 55

00-12

GENERAL

VEHICLE IDENTIFICATION

JA3AH86F13U000001

1 2 3 4 5 6 7 8 9 10 11

VEHICLE IDENTIFICATION

.

VEHICLE IDENTIFICATION NUMBER LOCATION

The vehicle identification number (VIN) is located on a plate

attached to the left top side of the instrument panel.

AC100836

12

AC211419

AB

VEHICLE IDENTIFICATION CODE CHART PLATE

All vehicle identification numbers contain 17 digits. The vehicle

number is a code which tells country, make, vehicle type, etc.

NO. ITEM CONTENT

1Country J: Japan

2Make A: Mitsubishi

3Vehicle type 3: Passenger car

4Others A: Driver and passenger air bags

5Line H: LANCER AWD

M2000001000280

6Price class 8: Sports

7Body 6: 4-door sedan

8Engine F: 2.0L

9Check digits* 0, 1, 2, 3, -----------9, X

10 Model year 3: 2003 year

11 Plant U: Mizus him a

12 Serial number 000001 to 999999

NOTE: *: Check digit means a single number or letter used to

verify the accuracy of transcription of vehicle identification number.

VEHICLE IDENTIFICATION NUMBER LIST

.

Note that vehicle is certified as a 50-state emissions.

VIN (EXCEPT SEQUENCE

BRAND ENGINE

NUMBER)

JA3AH86F_3U MITSUBISHI LANCER

EVOLUTION-VIII

MODEL CODE

DISPLACEMENT

2.0L CT9ASNGFZL2M

Page 56

GENERAL

GENERAL DATA AND SPECIFICATIONS

00-13

GENERAL DATA AND SPECIFICATIONS

.

GENERAL SPECIFICATIONS

5

2

ITEM CT9A SNGFZL 2M

Vehicle

Overall length 1 4,535 (178.5)

dimension mm

(in)

Overall width 2 1,770 (69.7)

Overall height

(unladen)

Wheelbase 4 2,625 (103.3)

9

7418

31,450 (57.1)

M2000030000116

3

6

AC211823

AB

Tread-front 5 1,515 (59.6)

Tread-rear 6 1,515 (59.6)

Front overhang 7 930 (36.6)

Rear overhang 8 980 (38.6)

Minimum running

9140 (5.5)

ground clearance

Vehicle weight

Curb weight 1,506 (3,320)

kg (lb)

Gross vehicle weight

1,915 (4,222)

rating

Gross axle weight

1,030 (2,271)

rating-front

Gross axle weight

905 (1,995)

rating-rear

Seating capacity 5

Engine Model No. 4G63 T/C I/C

Piston displacement 2.0L

Transaxle Model No. W5M51

Type 5-speed forward, 1-speed reverse constant mesh

Fuel system Fuel supply system Electronic controlled multiport fuel injection

Page 57

NOTES

Page 58

GROUP 31

WHEEL AND TIRE

CONTENTS

GENERAL INFORMATION . . . . . . . . 31-2

31-1

Page 59

31-2

WHEEL AND TIRE

GENERAL INFORMATION

GENERAL INFORMATION

The following wheel and tire specifications have

been established.

SPECIFICATIONS

.

ITEM SPECIFICATION

Wheel Type Aluminum type

Size 17 × 8JJ

Amount of wheel offset mm (in) 38 (1.5)

Pitch circle diameter (PCD) mm

(in)

Tire Size P235/45R17 93W

Spare wheel Type Steel type

Size 17 × 4T

Amount of wheel offset mm (in) 30 (1.2)

Pitch circle diameter (PCD) mm

(in)

Spare tire Size T125/70D17 98M

114. 3 (4 .50)

114. 3 (4 .50)

M2310000100178

NOTE: PCD (Pitch Circle Diameter) indicates the pitch circle diameter of the wheel installation holes.

Page 60

GROUP 21

CLUTCH

CONTENTS

GENERAL DESCRIPTION. . . . . . . . . 21-2

21-1

Page 61

21-2

CLUTCH

GENERAL DESCRIPTION

GENERAL DESCRIPTION

The clutch is a dry single-disc, diaphragm type using

hydraulic controls.

SPECIFICATIONS

ITEM SPECIFICATION

Engine model 4G63-DOHC-Intercooler Turbocharger

Clutch disc type Dry single plate type

Clutch disc facing diameter OD x ID mm (in) 240 × 160 (9.4 × 6.3)

Clutch cover type Diaphragm spring type

Clutch cover setting load N (lb) 9,320 ± 750 (2,095 ± 169)

Control system Hydraulic type

Release cylinder I.D. mm (in) 20.64 (0.81)

Master cylinder I.D. mm (in) 15.87 (5/8)

Clutch fluid Brake fluid DOT 3 or DOT 4

CONSTRUCTION DIAGRAM

RESERVOIR HOSE

CLUTCH PEDAL ASSEMBLY

M2210000100063

CLUTCH PIPE

CLUTCH RELEASE

CYLINDER

CLUTCH HOSE

CLUTCH MASTER

CYLINDER

STOPPER

AC211157

AB

Page 62

GROUP 37

POWER STEERING

CONTENTS

37-1

GENERAL DESCRIPTION. . . . . . . . . 37-2

STEERING WHEEL . . . . . . . . . . . . . . 37-3

STEERING SHAFT AND COLUMN. . 37-4

OIL PUMP . . . . . . . . . . . . . . . . . . . . . . 37-6

STEERING GEAR. . . . . . . . . . . . . . . . 37-7

OIL RESERVOIR . . . . . . . . . . . . . . . . 37-8

Page 63

37-2

POWER STEERING

GENERAL DESCRIPTION

GENERAL DESCRIPTION

M2370000100129

FEATURES

Power steering has been adopted in all vehicles to

make the steering easier.

• MOMO leather-wrapped 3-spoke steering wheel

is used.

• The steering column has a shock-absorbing

mechanism and a tilt steering mechanism.

SPECIFICATIONS

ITEM SPECIFICATION

Steering wheel Type MOMO leather-wrapped 3-

Outside diameter mm (in) 365 (14.4)

Maximum number of turns 2.1

Steering column Column mechanism Shock absorbing

Power steering type Integral type

Oil pump Type vane pump

Basic discharge amount cm

• A rack and pinion steering gear provides steering

that feels more direct and for ample handling performance.

• An oil pump responsive to engine RPM is used,

which, with tuning for a rigid gear box mount, provides stable steering at high speeds.

• The separate oil reservoir is rubber-mounted.

spoke type

mechanism and Tilt steering

mechanism

3

/rev. (cu in/rev)

9.6 (0.59)

Relief pressure MPa (psi) 8.3− 9.0 (1,204−1,305)

Reservoir type Separate type (plastic)

Pressure switch Equipped

Steering gear Type Rack and pinion

Stroke ratio (Rack stroke/Steering wheel

Maximum turning radius)

Rack stroke mm (in) 146 (5.7)

Steering angle Inner wheel 32°

Outer wheel 27°

Power steering fluid Specified lubricants GENUINE MITSUBISHI

Quantity dm

3

(qt)

68.61

POWER STEERING FLUID

Approximately 1.0 (1.1)

Page 64

CONSTRUCTION DIAGRAM

OIL RESERVOIR

RETURN

HOSE

POWER STEERING

STEERING WHEEL

STEERING COLUMN

SHAFT ASSEMBLY

37-3

STEERING

WHEEL

SUCTION

HOSE

COOLER TUBE

ASSEMBLY

OIL PUMP

ASSEMBLY

PRESSURE HOSE

STEERING GEAR

ASSEMBLY

STEERING WHEEL

The steering wheel has the following features:

• It has 3-spoke-type MOMO leather-wrapped steering.

• It incorporates an airbag module to protect the driver in the

event of a frontal collision.

• The airbag module is equipped with an inflator that does not

contain sodium azide.

AC211250

M2370001000147

AB

AC211251

Page 65

37-4

POWER STEERING

STEERING SHAFT AND COLUMN

STEERING SHAFT AND COLUMN

TILT BRACKET(A)

TILT LEVER

SECTION A-A

SECTION B-B

TILT BRACKET(B)

B

B

RIVET

A

A

M2370002000128

STEERING

SHAFT

ASSEMBLY

ONEWAY

CAPSULE

The steering column allows drivers to sit in their preferred driving position, and the tilt steering wheel

offers easy access. In case of an accident, the following mechanisms improve driver safety.

AC209414

AC

• A collapsible intermediary shaft prevents the

steering column from entering the passenger

compartment during initial impact.