FOREWORD

This service manual is written to familiarize you with the maintenance of your L-series Diesel Engine. If the engine is

carefully maintained, it will deliver a long productive life and efficient performance marked by power and economy.

Before attempting to inspect, disassemble, or repair the engine, read this manual carefully to learn more about the

engine and how to care for it properly. All descriptions, illustrations, specifications and serial numbers in this manual

are effective as of the date of printing of this manual.

The information contained in this manual applies to the engine model produced at the time of publication. It should

be noted that specifications and design may change due to improvements made thereafter.

What this manual covers

This service manual covers standard specifications for the L-series Mitsubishi Diesel Engine, and describes

• Specification

• Maintenance standard

• Adjustment

• Disassembly, inspection and repair

• Reassembly

In addition to the Summary of Manual Contents, a short summary of contents is found on the first page of each

group of the manual.

Operation and periodic maintenance are described in the Operation & Maintenance Manual, component parts and

ordering of service parts are described in the Parts Catalogue. Structure and function of the engine are described in

the various training manuals.

How to use this manual

1. Parts in illustrations are numbered to correspond with references to those numbers in the disassembly

sequence.

2. Items or conditions to be inspected during disassembly are enclosed in a box in the disassembled views:

3. Clogged oil hole

4. Maintenance standards for inspection and repair are described in text where they are relevant. For a quick

summary of maintenance standards, refer to group 9 of this manual.

5. Tightening torque under wet conditions is indicated as “(wet)” in text, drawings and tables. When so indicated as

(wet), apply engine oil to the threaded portion of the fastener. Unless indicated as such, the tightening torque is

to be assumed in the dry condition.

6. Measurements are based on the International System of Units (SI), and they are converted to the metric and

English system units in this manual based on the following conversion rates.

• Pressure 1 Mpa = 10.197 kgf/cm

• Torque N·m = 0.10197 kgf·m

• Force N = 0.10197 kgf

• Horsepower 1 kW = 1.341 HP = 1.3596 PS

2

Service Manual

Mitsubishi L-Series diesel engines

Version 08/2004

Copyright © 2004 MHI Equipment Europe B.V.

Service Manual Mitsubishi L-Series diesel engines

Version 08/2004

ENGLISH

1 / 155

WARNING SIGNS

The following safety related signs are used in this manual to emphasize important and critical instructions:

Indicates the most serious specific potential hazard which could result in

serious personal injury or death.

DANGER

Indicates a specific potential hazard which could result in personal injury.

WARNING

Indicates operating procedures, practices, etc. which could result in personal

CAUTION

injury or damage causing destruction to the engine. Some of the CAUTION

signs also indicate a specific potential hazard which could result in serious

personal injury or death.

Indicates procedures, conditions, etc. which are important to highlight.

NOTE

2 / 155

ENGLISH

Service Manual Mitsubishi L-Series diesel engines

Version 08/2004

TERMS USED IN THIS MANUAL

Before reading this manual, note that the following special terms are used in dimensional and other specifications.

Assembly standard

Indicates the dimension of a part, the dimension to be attained at the time of reassembly or the standard

performance. The value is rounded to the nearest number needed for inspection and is different from the design

value.

Repair limit

A part which has reached this limit must be repaired.

Service limit

A part which has reached this limit must be replaced.

Service Manual Mitsubishi L-Series diesel engines

Version 08/2004

ENGLISH

3 / 155

SUMMARY OF MANUAL CONTENTS

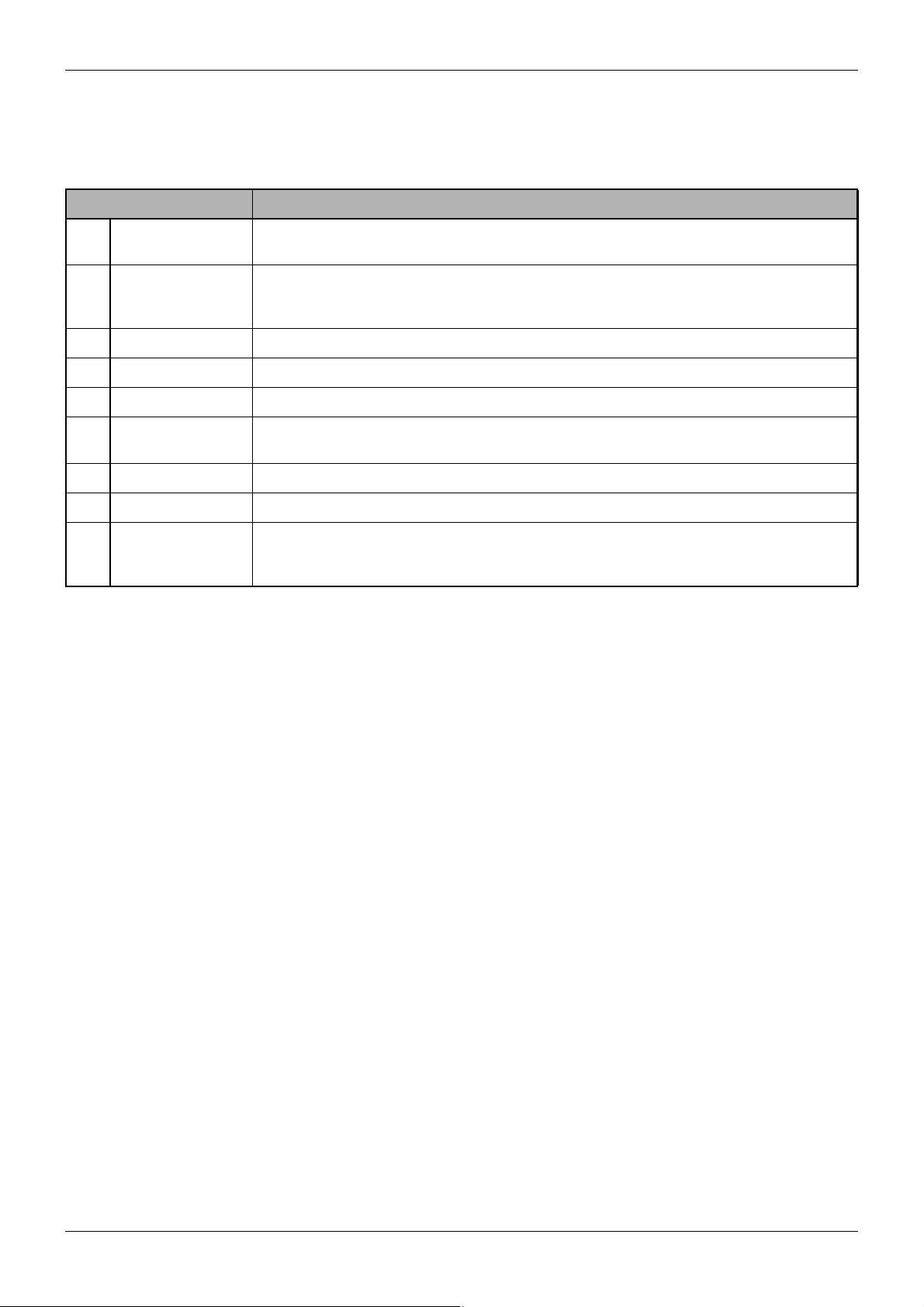

Section Contents

1. General Engine model and engine number, external views, features, engine specifications,

maintenance, troubleshooting

2. Engine main parts General, rocker arms and rocker shaft, cylinder head, valves and valve springs, inlet manifold

and exhaust manifold, gear case and oil pump, timing gear, camshaft (valve camshaft and

injection pump camshaft), piston and connecting rod, crankshaft, cylinder block

3. Lubrication system General, oil filter and oil pressure switch

4. Fuel system General, fuel injection pump, injection nozzle

5. Governor system General, torque spring

6. Cooling system General, fan and fan belt, water pump, thermostat, water temperature gauge unit and

thermoswitch

7. Air cleaner Air cleaner

8. Electrical system General, starter, alternator and dynamo, glow plug, key-off stop system, glow timer system

9. Service

specifications and

standard

Periodic service chart, specifications and standards, tightening torque chart and sealant chart,

special tools

Table 1 Sections in the service manual

4 / 155

ENGLISH

Service Manual Mitsubishi L-Series diesel engines

Version 08/2004

TABLE OF CONTENTS

TABLE OF CONTENTS

GENERAL

1 ENGINE MODEL AND ENGINE NUMBER........................................................................ 12

1.1 Model, classification and use ................................................................................................. 12

1.2 Engine model embossment and engine number stamp......................................................... 12

2 EXTERNAL VIEW ..................................................................................................................... 14

2.1 Engine L2............................................................................................................................... 14

2.2 Engine L3............................................................................................................................... 15

3FEATURES................................................................................................................................. 16

3.1 Aim of development ............................................................................................................... 16

3.2 Features of the new series..................................................................................................... 16

4 SPECIFICATIONS..................................................................................................................... 18

5 MAINTENANCE......................................................................................................................... 19

5.1 Engine oil and oil filter............................................................................................................ 19

5.2 Retightening the cylinder head bolts...................................................................................... 21

5.3 Adjusting the valve clearance ................................................................................................22

5.4 Adjusting the fan belt tension................................................................................................. 23

5.5 Bleeding air from the fuel system........................................................................................... 23

5.6 Replacing the fuel filter .......................................................................................................... 24

5.7 Checking and adjusting injection timing................................................................................. 26

5.8 Adjusting the engine speeds..................................................................................................27

5.9 Checking and adjustment of nozzles ..................................................................................... 28

6 TROUBLESHOOTING ............................................................................................................. 31

6.1 Hints on using the trouble-diagnosis chart............................................................................. 31

6.2 Hard starting .......................................................................................................................... 32

6.3 Knocking ................................................................................................................................ 33

6.4 Overheating ........................................................................................................................... 34

6.5 Black-smoky exhaust ............................................................................................................. 35

6.6 Unsteady idling ...................................................................................................................... 36

6.7 Low output ............................................................................................................................. 37

ENGINE MAIN PARTS

7GENERAL.................................................................................................................................... 40

7.1 Specifications......................................................................................................................... 40

7.2 Special Tools ......................................................................................................................... 41

8 ROCKER ARMS AND ROCKER SHAFT........................................................................... 42

8.1 Disassembly........................................................................................................................... 42

8.2 Removal and installation........................................................................................................ 43

8.3 Inspection............................................................................................................................... 43

9 CYLINDER HEAD ..................................................................................................................... 44

9.1 Disassembly........................................................................................................................... 44

9.2 Removal................................................................................................................................. 45

9.3 Inspection and Repair ............................................................................................................ 46

9.4 Replacement of valve guide...................................................................................................46

Service Manual Mitsubishi L-Series diesel engines

Version 08/2004

ENGLISH

5 / 155

TABLE OF CONTENTS

9.5 Repair of valve seat ............................................................................................................... 47

9.6 Installation.............................................................................................................................. 48

10 VALVES AND VALVE SPRINGS ......................................................................................... 49

10.1 Disassembly........................................................................................................................... 49

10.2 Removal................................................................................................................................. 50

10.3 Inspection and repair ............................................................................................................. 50

10.4 Installation.............................................................................................................................. 51

11 INLET MANIFOLD AND EXHAUST MANIFOLD............................................................. 52

11.1 Disassembly........................................................................................................................... 52

11.2 Inspection............................................................................................................................... 52

12 GEAR CASE AND OIL PUMP............................................................................................... 54

12.1 Disassembly........................................................................................................................... 54

12.2 Removal................................................................................................................................. 55

12.3 Inspection............................................................................................................................... 55

12.4 Replacement of front oil seal ................................................................................................. 56

12.5 Replacement of governor shaft bushings .............................................................................. 56

12.6 Inspection of governor system ...............................................................................................57

12.7 Disassembly and reassembly of governor levers .................................................................. 57

12.8 Installation of gear case assembly......................................................................................... 58

13 TIMING GEARS ......................................................................................................................... 59

13.1 Disassembly........................................................................................................................... 59

13.2 Removal................................................................................................................................. 60

13.3 Inspection............................................................................................................................... 60

13.4 Installation of timing gears ..................................................................................................... 61

14 CAMSHAFTS (VALVE AND INJECTION PUMP)............................................................ 62

14.1 Disassembly........................................................................................................................... 62

14.2 Removal of Valve Camshaft .................................................................................................. 63

14.3 Inspection............................................................................................................................... 64

14.4 Installation.............................................................................................................................. 65

15 PISTON AND CONNECTION ROD...................................................................................... 66

15.1 Disassembly........................................................................................................................... 66

15.2 Removal................................................................................................................................. 67

15.3 Inspection............................................................................................................................... 68

15.4 Installation.............................................................................................................................. 69

16 CRANKSHAFT........................................................................................................................... 73

16.1 Disassembly........................................................................................................................... 73

16.2 Removal................................................................................................................................. 74

16.3 Inspection............................................................................................................................... 74

16.4 Replacement of crankshaft rear oil seal................................................................................. 76

16.5 Installation.............................................................................................................................. 77

17 CYLINDER BLOCK .................................................................................................................. 78

17.1 Disassembly........................................................................................................................... 78

17.2 Inspection............................................................................................................................... 79

17.3 Reboring of cylinder ............................................................................................................... 79

LUBRICATION SYSTEM

6 / 155

ENGLISH

Service Manual Mitsubishi L-Series diesel engines

Version 08/2004

18 GENERAL.................................................................................................................................... 82

18.1 Specification........................................................................................................................... 82

18.2 Special tools........................................................................................................................... 82

19 OIL FILTER AND OIL PRESSURE SWITCH.................................................................... 83

19.1 Disassembly........................................................................................................................... 83

19.2 Removal and installation........................................................................................................ 84

19.3 Inspection............................................................................................................................... 84

FUEL SYSTEM

20 GENERAL.................................................................................................................................... 86

20.1 Specifications......................................................................................................................... 86

20.2 Disassembly........................................................................................................................... 88

21 FUEL INJECTION PUMP........................................................................................................ 89

21.1 Disassembly........................................................................................................................... 89

21.2 Inspecting the injection pump while operating the engine ..................................................... 90

21.3 Removal................................................................................................................................. 90

21.4 Disassembly........................................................................................................................... 90

21.5 Inspection............................................................................................................................... 91

21.6 Reassembly of plunger .......................................................................................................... 91

21.7 Reassembly of delivery valve ................................................................................................91

22 INJECTION NOZZLE ............................................................................................................... 92

22.1 Disassembly........................................................................................................................... 92

22.2 Removal................................................................................................................................. 92

22.3 Disassembly........................................................................................................................... 93

22.4 Inspection............................................................................................................................... 94

22.5 Assembly ............................................................................................................................... 94

22.6 Adjustment ............................................................................................................................. 94

22.7 Installation.............................................................................................................................. 95

GOVERNOR SYSTEM

23 GENERAL.................................................................................................................................... 98

23.1 Specification........................................................................................................................... 98

23.2 Disassembly........................................................................................................................... 99

24 TORQUE SPRING................................................................................................................... 100

24.1 Installation of torque spring set ............................................................................................ 100

24.2 Assembling the torque spring set......................................................................................... 100

24.3 Single spring type ................................................................................................................ 101

24.4 Inspection............................................................................................................................. 102

24.5 Removal and installation...................................................................................................... 103

COOLING SYSTEM

25 GENERAL.................................................................................................................................. 106

25.1 Specifications....................................................................................................................... 106

25.2 Disassembly......................................................................................................................... 107

26 FAN AND FAN BELT............................................................................................................. 108

26.1 Fan belt inspection............................................................................................................... 108

26.2 Fan inspection...................................................................................................................... 108

Service Manual Mitsubishi L-Series diesel engines

Version 08/2004

ENGLISH

7 / 155

27 WATER PUMP ......................................................................................................................... 109

27.1 Removal and installation...................................................................................................... 109

27.2 Inspection............................................................................................................................. 109

28 THERMOSTAT......................................................................................................................... 110

28.1 Removal and installation...................................................................................................... 110

28.2 Inspection............................................................................................................................. 110

29 WATER TEMPERATURE GAGE UNIT AND THERMOSWITCH.............................. 111

29.1 Inspection of water temperature gage unit........................................................................... 111

29.2 Inspection of thermoswitch .................................................................................................. 111

AIR CLEANER

30 AIR CLEANER ......................................................................................................................... 114

30.1 Disassembly......................................................................................................................... 114

30.2 Inspection............................................................................................................................. 115

ELECTRICAL SYSTEM

31 GENERAL.................................................................................................................................. 118

31.1 Specifications....................................................................................................................... 118

31.2 Wiring diagrams ................................................................................................................... 120

32 STARTER .................................................................................................................................. 122

32.1 Structure .............................................................................................................................. 122

32.2 Inspection (assembly) .......................................................................................................... 123

32.3 Disassembly......................................................................................................................... 125

32.4 Inspection............................................................................................................................. 126

32.5 Assembly and adjustment.................................................................................................... 128

33 ALTERNATOR AND DYNAMO........................................................................................... 129

33.1 Structure .............................................................................................................................. 129

33.2 Dynamo................................................................................................................................ 130

33.3 Inspection of the alternator (installed on the engine) ........................................................... 130

33.4 Output inspection ................................................................................................................. 131

33.5 Removal............................................................................................................................... 131

33.6 Disassembly of alternator .................................................................................................... 131

33.7 Inspection............................................................................................................................. 132

33.8 Installation............................................................................................................................ 135

33.9 Alternator and regulator ....................................................................................................... 135

34 GLOW PLUG ............................................................................................................................ 137

34.1 Removal............................................................................................................................... 137

34.2 Inspection............................................................................................................................. 137

34.3 Installation............................................................................................................................ 137

35 KEY-OFF STOP SYSTEM .................................................................................................... 138

35.1 General ................................................................................................................................ 138

35.2 Control timer unit.................................................................................................................. 138

35.3 Fuel cutoff solenoid (ETS type)............................................................................................ 138

35.4 Fuel cutoff solenoid (ETR type) ........................................................................................... 139

36 GLOW TIMER SYSTEM........................................................................................................ 141

36.1 General ................................................................................................................................ 141

8 / 155

ENGLISH

Service Manual Mitsubishi L-Series diesel engines

Version 08/2004

36.2 Glow timer............................................................................................................................ 141

36.3 Glow relay ............................................................................................................................ 141

SERVICE DATA

37 PERIODIC INSPECTION CHART....................................................................................... 144

37.1 Periodic service chart........................................................................................................... 144

38 SPECIFICATIONS AND MAINTENANCE STANDARDS............................................ 145

38.1 Engine Main Parts................................................................................................................ 145

38.2 Lubrication System .............................................................................................................. 148

38.3 Fuel System ......................................................................................................................... 148

38.4 Governor System ................................................................................................................. 149

38.5 Cooling System.................................................................................................................... 149

38.6 Electrical System ................................................................................................................. 150

39 TIGHTENING TORQUE CHART AND SEALANT CHART......................................... 152

39.1 Tightening Torque for Main Bolts......................................................................................... 152

39.2 Tightening Torque for Common Bolts and Nuts................................................................... 152

39.3 Tightening Torque for Common Plugs ................................................................................. 153

39.4 Sealant Chart ....................................................................................................................... 153

40 SPECIAL TOOLS .................................................................................................................... 154

Service Manual Mitsubishi L-Series diesel engines

Version 08/2004

ENGLISH

9 / 155

10 / 155

ENGLISH

Service Manual Mitsubishi L-Series diesel engines

Version 08/2004

GENERAL

Service Manual Mitsubishi L-Series diesel engines

Version 08/2004

ENGLISH

11 / 155

ENGINE MODEL AND ENGINE NUMBER GENERAL

GENERAL

1 ENGINE MODEL AND

ENGINE NUMBER

1.1 Model, classification and use

1.1.1 Engine model

Model Application Use

L2A 11,12 - For Agricultural

L2C

L2B 31, 32 - For Industrial

L3A

L3C 61, 62 - For Export only

L3E

Table 1 Engine model and usage

1.1.2 Engine model and application codes

L 3 C – 11 A

L – Name of series (L: Lightweight engine)

3 – Number of cylinders (2: two, 3: three)

C – Cylinder bore

• A: ø65, C: ø70,

• E: ø76

11 – Application

• 11: Agricultural, 31: Industrial,

• 61: For export only

A – Subdivision of specification

t

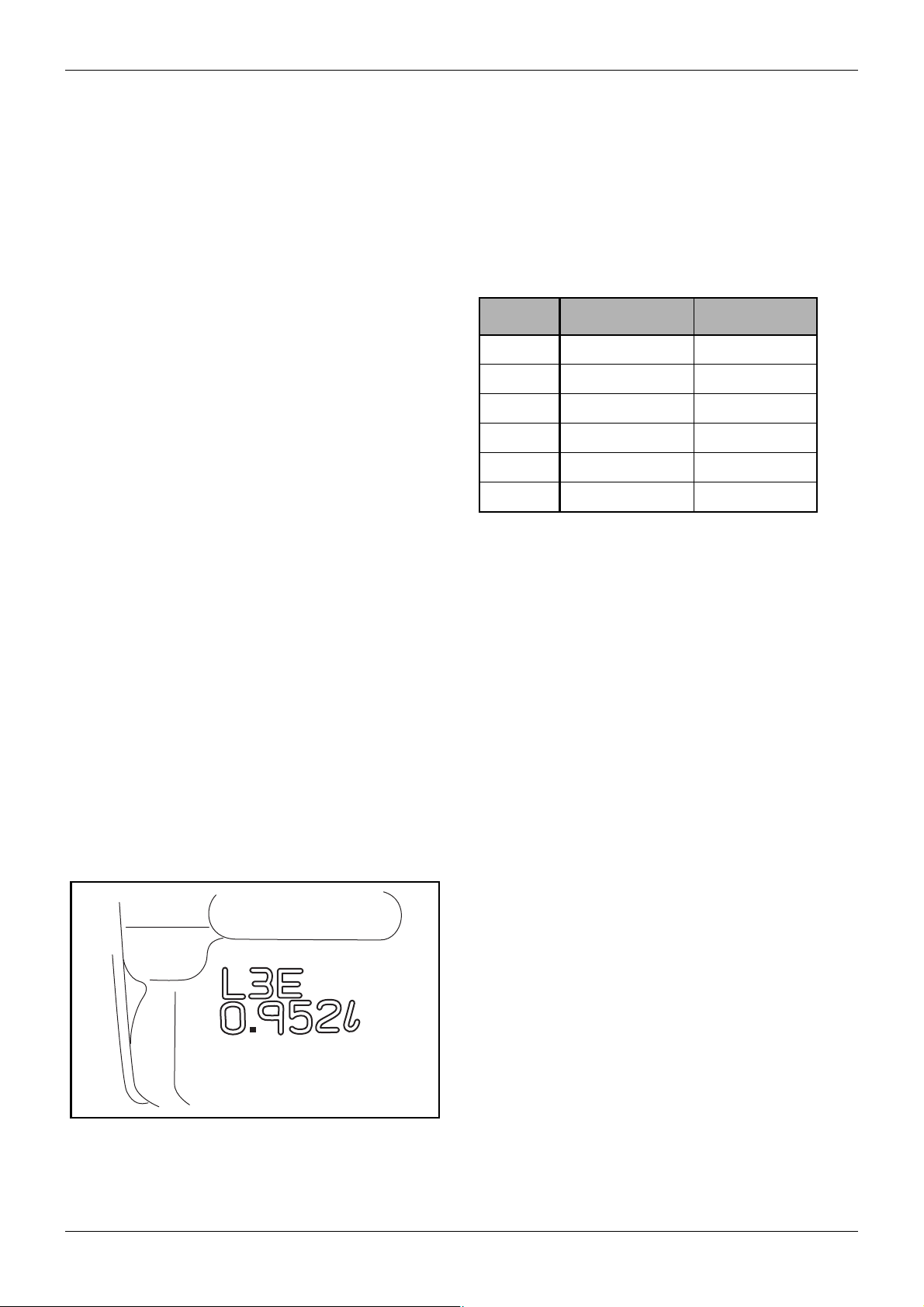

1.2 Engine model embossment and engine number stamp

1.2.1 Embossment of engine model and

cylinder volume

Figure 1 Engine model and cylinder volume

12 / 155

ENGLISH

The engine model and cylinder volume are embossed

on the side of injection pump mounting portion of the

cylinder block.

Service Manual Mitsubishi L-Series diesel engines

Version 08/2004

GENERAL

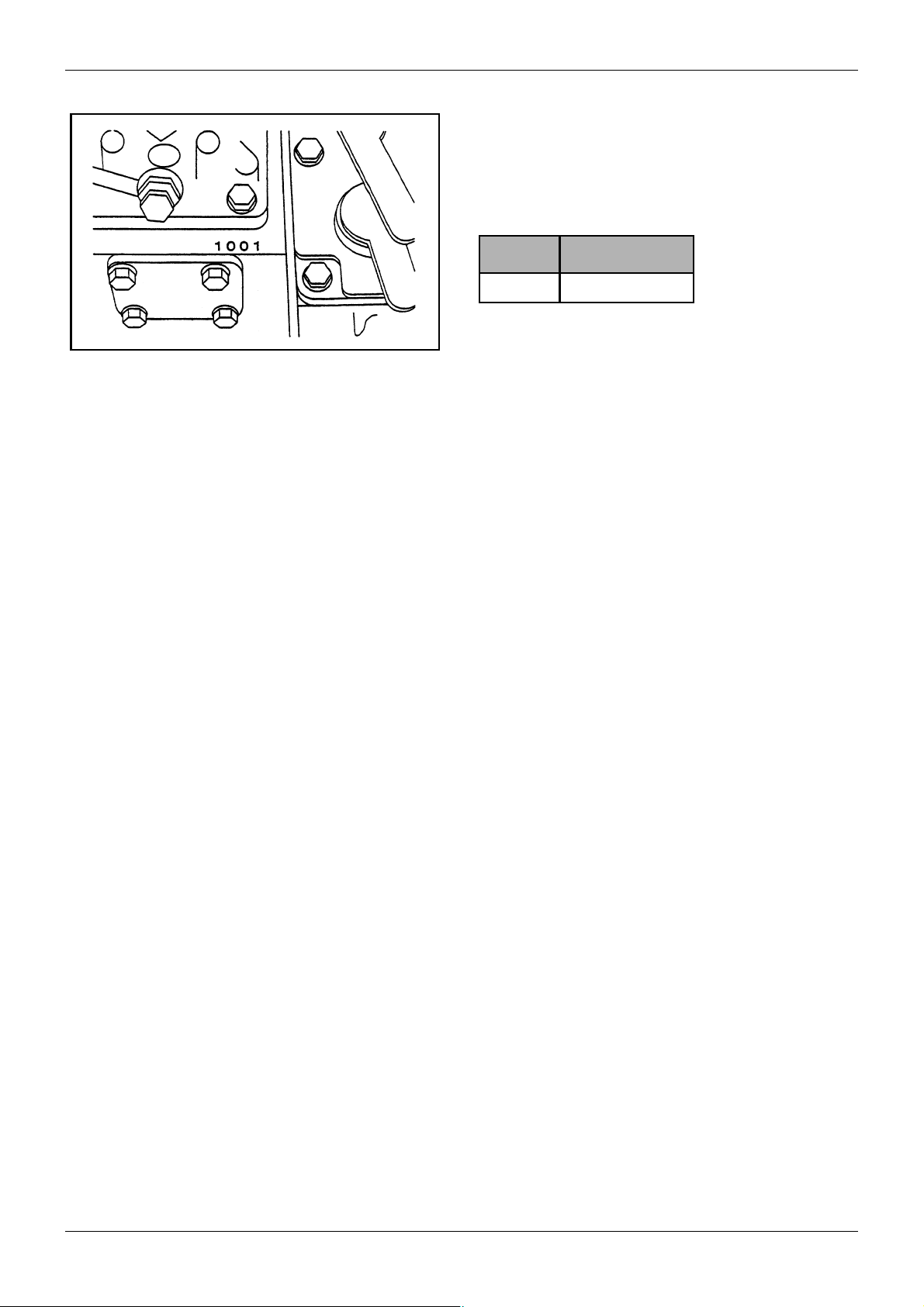

Figure 2 Engine number

ENGINE MODEL AND ENGINE NUMBER

1.2.2 Engine number stamp

The engine number is stamped on the injection pump

mounting portion of the cylinder block (on the upper

side of the tie rod cover). It is a serial number beginning

with 1001 shown as below.

Number Engine model

1001 - (ALL models)

Table 2 Engine number stamp

Service Manual Mitsubishi L-Series diesel engines

Version 08/2004

ENGLISH

13 / 155

EXTERNAL VIEW GENERAL

GENERAL

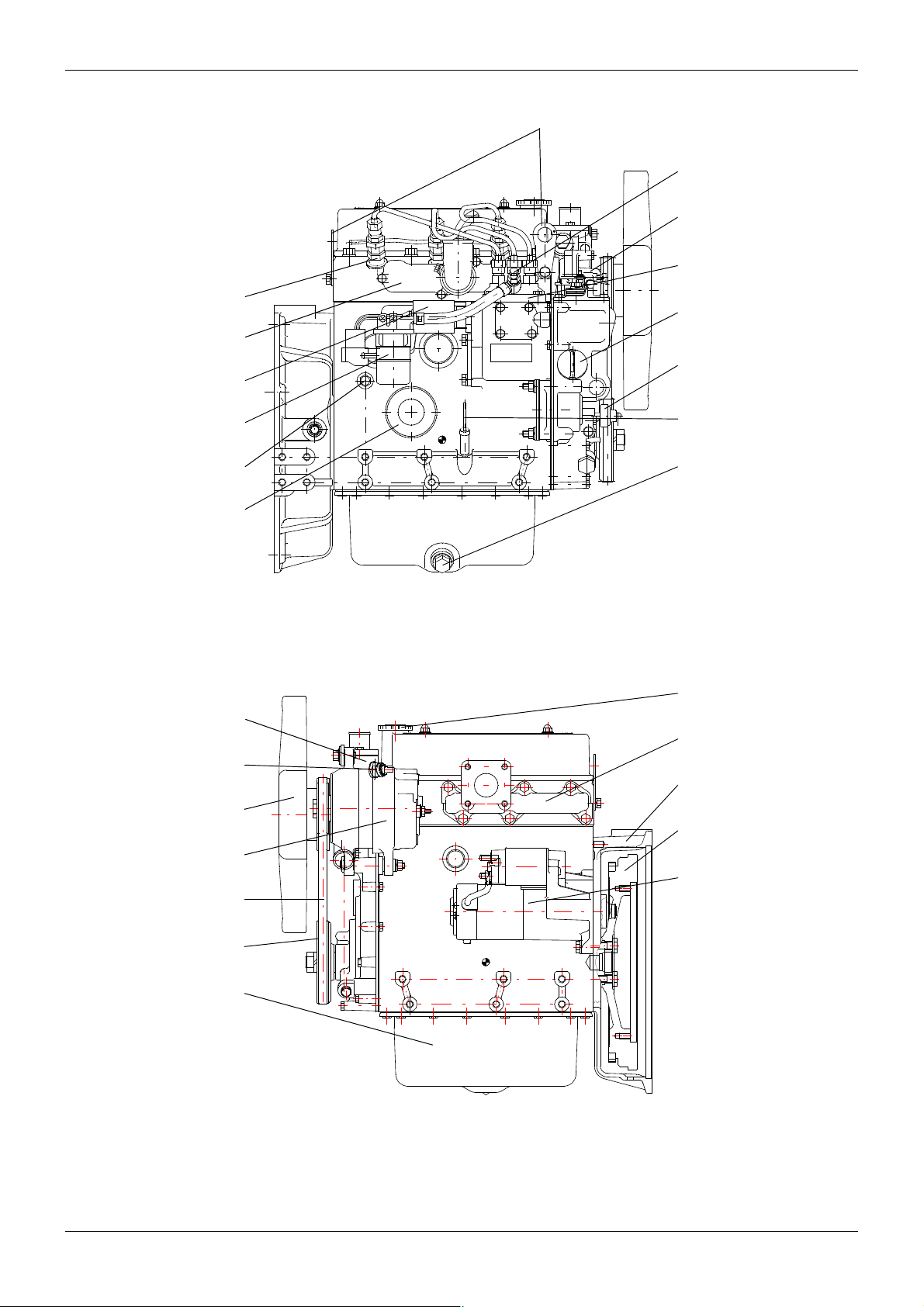

2 EXTERNAL VIEW

2.1 Engine L2

Engine hangers

Air vent screw

Water pump

Fuel injection pump

Fuel injector

Air inlet cover

Stop solenoid

Fuel filter

Side oil filler

Coolant drain plug

Oil pressure switch

Oil filter

REAR

Thermostat housing

Thermoswitch

Alternator

Fan

V-b elt

Dipstick

Oil drain plug

FRONT

RIGHT SIDE VIEW

Top oil filler

Exhaust manifold

Flywheel housing

Flywheel

Starter

14 / 155

Crankshaft pulley

Oil pan

FRONT

LEFT SIDE VIEW

ENGLISH

REAR

Service Manual Mitsubishi L-Series diesel engines

Version 08/2004

GENERAL

EXTERNAL VIEW

2.2 Engine L3

Fuel injector

Air inlet cover

Stop solenoid

Fuel filter

Coolant drain plug

Oil filter

REAR

Engine hangers

Air vent screw

Water pump

Fuel injection pump

Side oil filler

Oil pressure switch

Dipstick

Oil drain plug

FRONT

Thermostat housing

Thermoswitch

Fan

Alternator

V-belt

Crankshaft pulley

Oil pan

RIGHT SIDE VIEW

Top oil filler

Exhaust manifold

Flywheel housing

Flywheel

Starter

FRONT

Service Manual Mitsubishi L-Series diesel engines

Version 08/2004

LEFT SIDE VIEW

ENGLISH

REAR

15 / 155

FEATURES GENERAL

GENERAL

3FEATURES

3.1 Aim of development

The L-series designs are compact, lightweight engines

suitable for superseding gasoline engines to power

lawn mowers, vehicles, etc. The high-speed (3600 min

1

continuous) engines are also available for generators,

welders, and marine use. The L series are the smallest

and the lightest water-cooled diesel engines in the

world.

3.2 Features of the new series

3.2.1 Small and lightweight engine

The new L-series are 10 to 20% lighter in weight and

15 to 20% smaller in contour volume than the same

class of competitor’s engines.

-

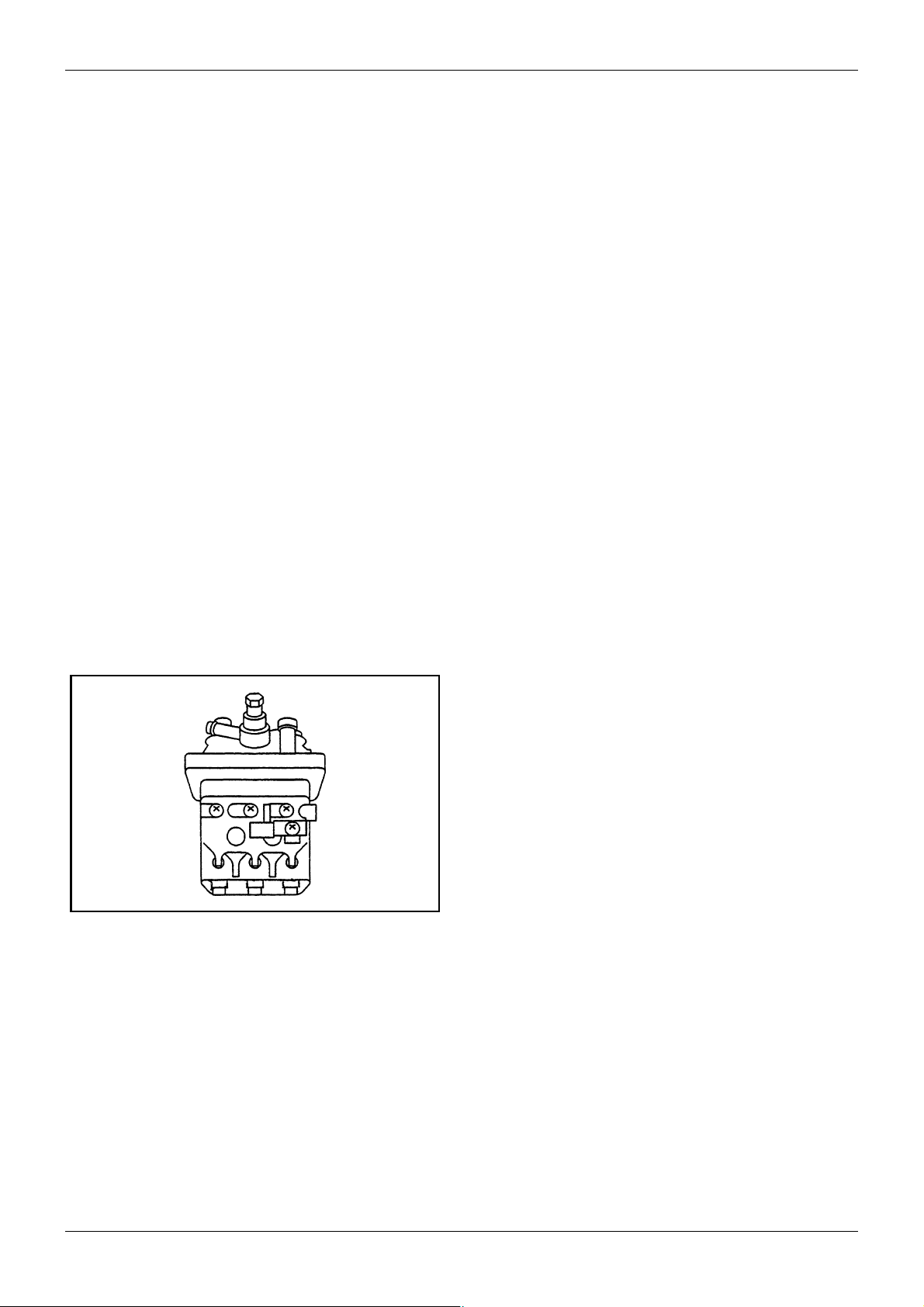

Figure 3 Injection pump

3.2.2 Low noise and economical fuel

consumption

Low noise and economical fuel consumption are

attained by the well designed cylinder block

construction (having curved side faces), the rearranged

combustion chambers, and the compacted fuel

injection system.

3.2.3 Easy starting

The engine can be started instantly only by keeping the

starting switch key in the ON position for about 6

seconds to feed electric current to the glow plugs

automatically (For engines with the automatic glow plug

system). The new governor mechanism also

contributes to easy engine start, by increasing the

amount of fuel injection and delaying injection timing,

without moving the throttle lever to the “full throttle”

position.

16 / 155

ENGLISH

Service Manual Mitsubishi L-Series diesel engines

Version 08/2004

GENERAL

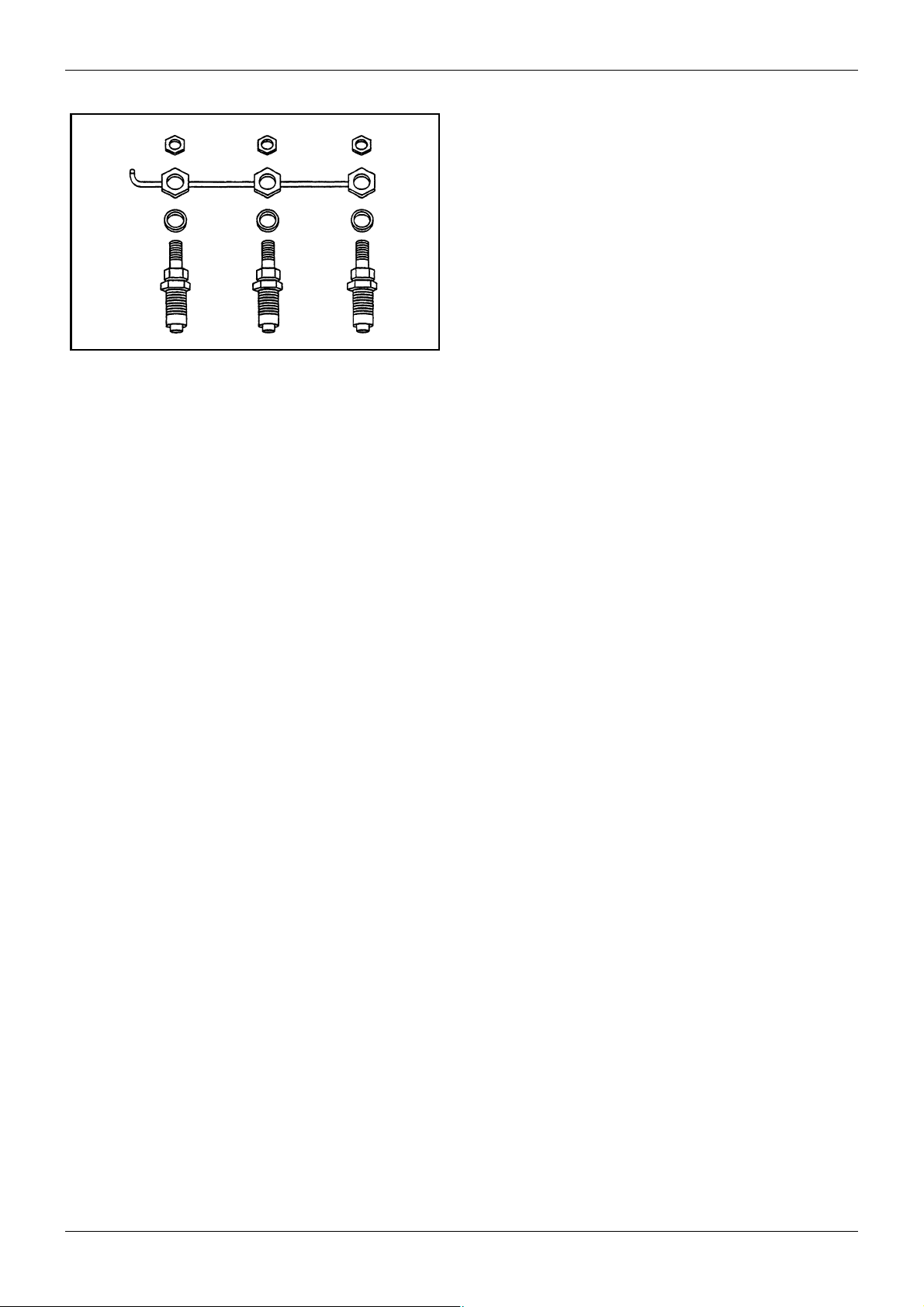

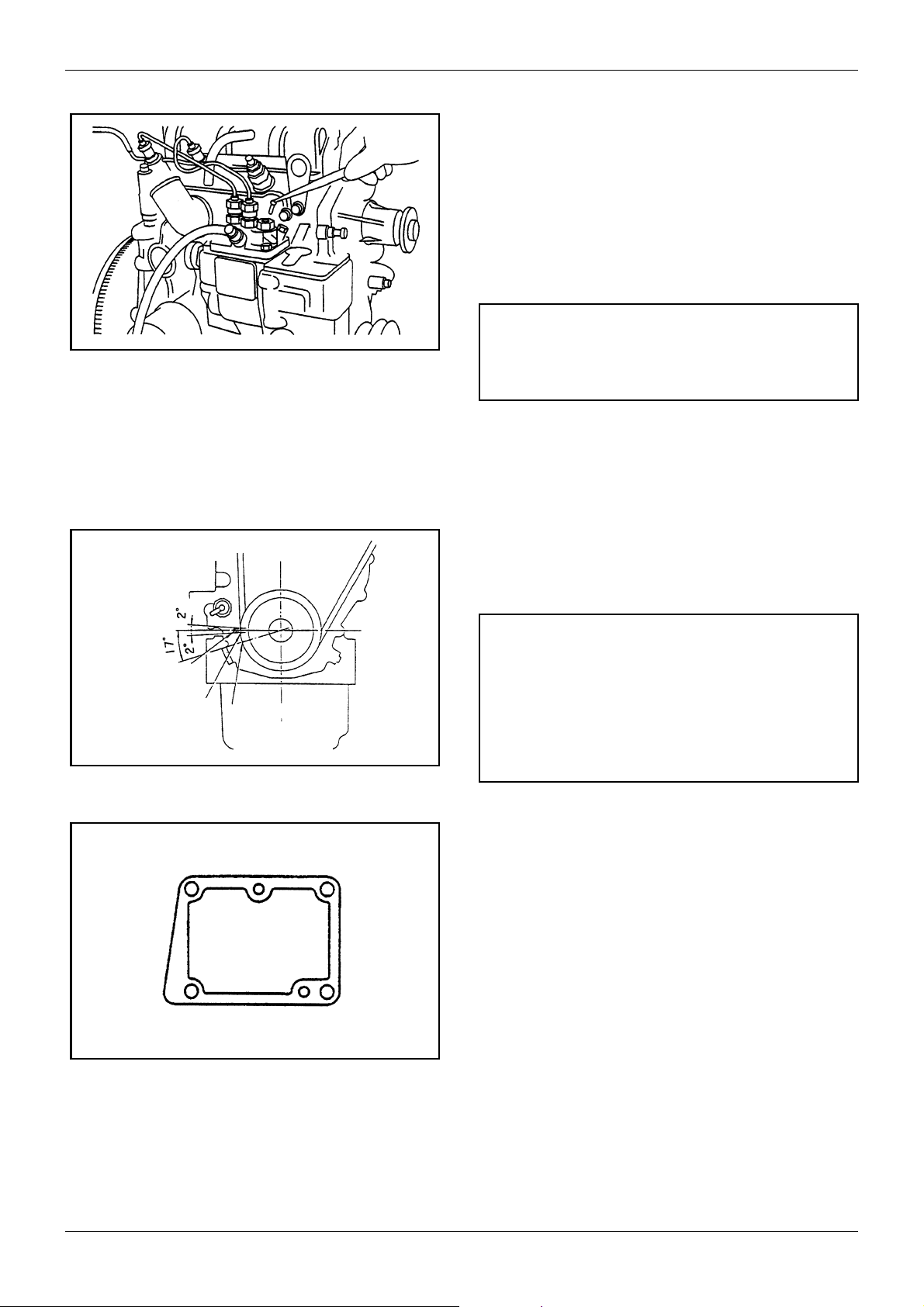

Figure 4 Nozzle holders and return pipe

FEATURES

3.2.4 Multipurpose engine

The L-series engine can be equipped with various

kinds of optional devices.

Ex.

• Key-OFF stop system (Fuel cutoff valve)

• Torque spring

• Manual stop lever

Service Manual Mitsubishi L-Series diesel engines

Version 08/2004

ENGLISH

17 / 155

SPECIFICATIONS GENERAL

GENERAL

4 SPECIFICATIONS

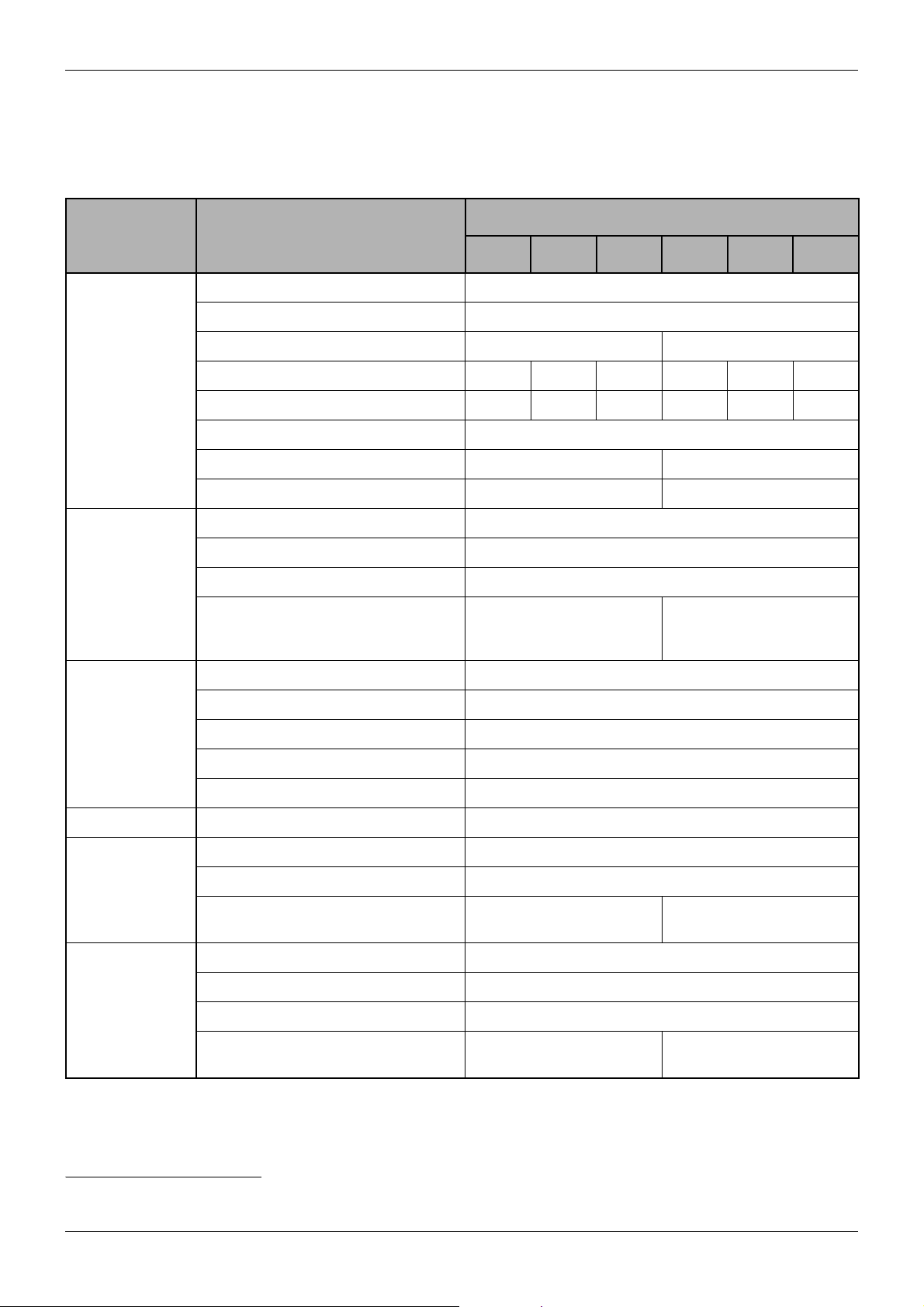

System Item

Type 4-cycle, water-cooled, vertical, overhead valve, diesel engine

Combustion chamber Swirl chamber type

No. of cylinders 2 3

ENGINE

PROPER

LUBRICATING

SYSTEM

Bore x Stroke (mm) 65x70 70x70 76x70 65x70 70x70 76x70

Total displacement (l ) 0.464 0.538 0.635 0.696 0.808 0.952

Compression ratio 23

Firing order 1 - 2 1 - 3 - 2

Dry weight (kg) 61 75

Lubricating method Forced lubrication

Oil pump Gear type

Oil filter Paper element type

Oil capacity:

FULL level/EMPTY level (l )

(Exclusive of oil filter capacity 0.5 l )

1

Model

L2A L2C L2E L3A L3C L3E

2.4/1.4 3.0/1.5 or 3.6/1.8 or 4.8/3.0

Fuel injection pump Bosch type NC

Nozzle Throttle type

FUEL SYSTEM

INTAKE SYSTEM Air cleaner Paper-element type or Oil-bath type

COOLING

SYSTEM

ELECTRICAL

SYSTEM

Fuel injection pressure 140 kgf/cm

Fuel to be used Diesel fuel; see chapter 7

Governor Centrifugal weight type

Cooling method Forced circulation of water

Water pump Centrifugal type

Coolant capacity (l)

(Engine proper only)

Starter (V - kW) Solenoid shift type (12-1.2 or 12-1.6 or 12-1.7)

Alternator (V - A) AC generator (12-40)

Glow plug Sheathed type

Battery

(capacity depends on application)

12V, 45 Ah or more 12V, 60 Ah or more

1.2 1.8

2

(1,991 psi) [13,729 kPa]

Table 3 Specifications

1 All specifications are subject to change without any prior notice.

18 / 155

ENGLISH

Service Manual Mitsubishi L-Series diesel engines

Version 08/2004

GENERAL

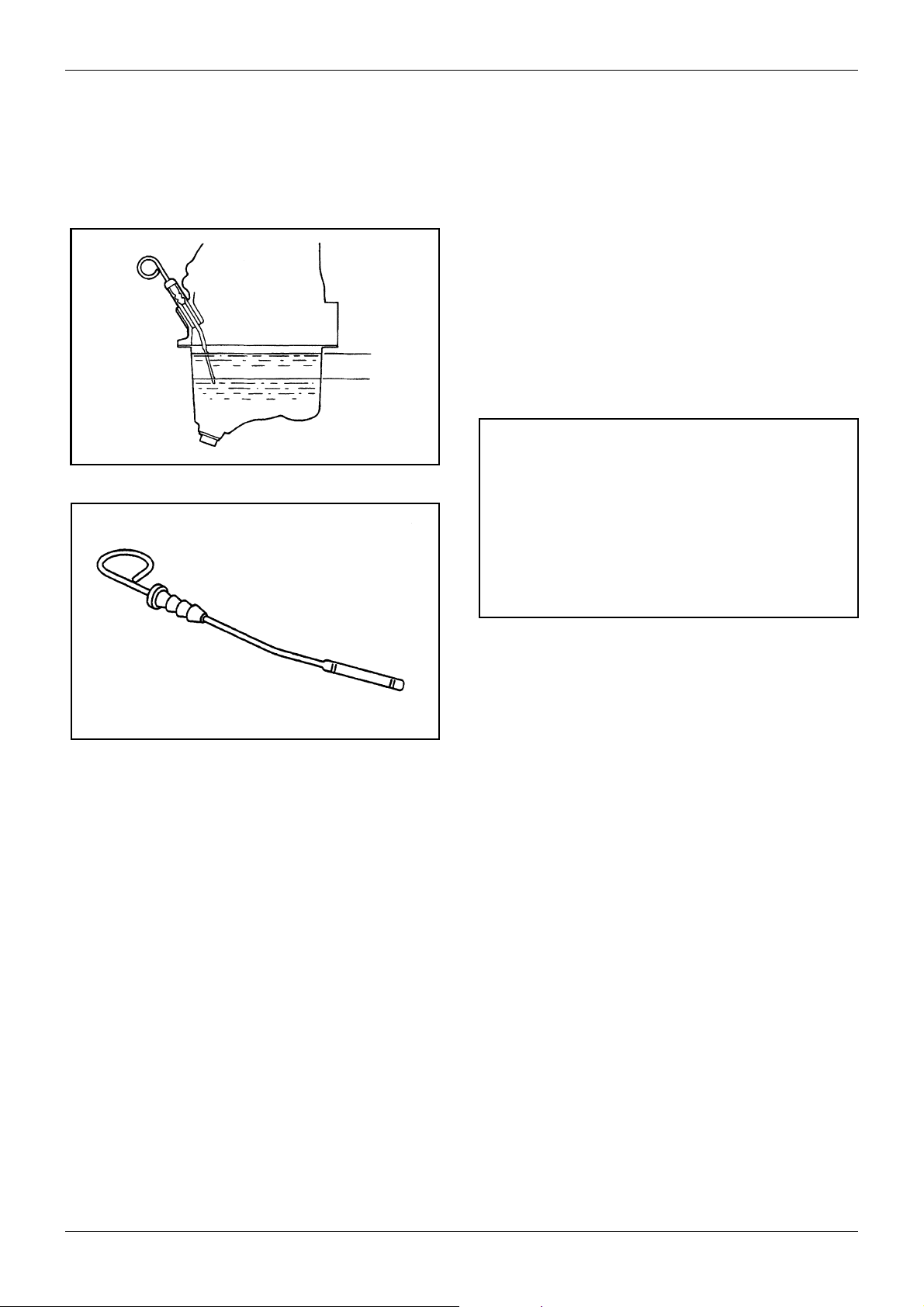

Figure 5 Checking oil level

MAINTENANCE

GENERAL

5 MAINTENANCE

5.1 Engine oil and oil filter

5.1.1 Checking and correcting the engine

oil level

Procedure

1. Place the engine horizontally.

2. Check the oil level with the oil level gage. If the oil

level has fallen to the lower limit, add oil up to the

upper limit.

3. Check the oil level before (everyday) operation of

the engine.

CAUTION

a. Whenever oil is added, check the oil level again

after waiting for about 1 minute.

b. When adding oil, use only the same engine oil as

used in the engine.

c. When checking the oil level in an engine which

has not been used for long time, check the oil

level again after running the engine for a few

minutes.

Figure 6 Oil level gage

5.1.2 Oil change intervals

Change the oil and the oil filter after initial 50 service

hour of a new engine and, thereafter, every 100 hours

of operation or once a year (whatever comes first).

Except generator application, 250 hours or once a year

(whatever comes first) can be applied for industrial and

marine application.

5.1.3 Engine oil to be used

Engine oil must conform to the API classification and

viscosity number specified in the table below.

Service Manual Mitsubishi L-Series diesel engines

Version 08/2004

ENGLISH

19 / 155

MAINTENANCE GENERAL

API

classification

Class CF

or CF-4

Atm. temperature Viscosity

Above 20°C [68°F] SAE30

5° to 20°C [41 to

68°F]

Below 5°C [41°F] SAE10W-30

All seasons SAE10W-30

SAE20

Table 4 API classification

5.1.4 Replacing the oil filter

When replacing the oil filter, use only the genuine

replacement filter.

Figure 7 Oil filter

5.1.5 Changing the oil

To change oil, first warm up the engine and remove the

drain plug to let oil drain completely. Put back the drain

plug and refill the oil pan with fresh engine oil through

the oil filler.

Tightening torque N·m (kgf·m) [lbf·ft]

Description Standard

Oil pan drain plug

tightening torque

Table 5 Tightening torque

Oil capacity (Upper

limit/Lower limit)

(excluding 0.5 l of

oil filter capacity)

1 [U.S.gal]

49.0 to 58.8 (5.0 to 6.0)

[36.17 to 43.40]

L2 L3

2.4/1.4

[0.6341/

0.3699]

Ordinary type 3.0/1.5

[0.7926/0.3963]

Deep type 3.6/1.8

[0.9511/0.4756] or

4.8/3.0 [1.2682/

0.7926]

20 / 155

ENGLISH

Table 6 Oil capacity

5.1.6 Replacing the oil filter

Procedure

1. Remove the oil filter with a filter wrench or the like.

Service Manual Mitsubishi L-Series diesel engines

Version 08/2004

GENERAL

MAINTENANCE

2. Thoroughly clean the filter mounting surface of the

filter bracket. Install the new filter with the O-ring

coated with engine oil and tighten securely by

hand.

Unit: N·m (kgf·m) [lbf·ft]

Tightening torque 10.8 to 12.7 (1.1 to 1.3) [7.96 to 9.40]

Table 7 Tightening torque

CAUTION

Be careful not to twist the O-ring.

3. Run the engine for several minutes and make sure

that no oil leaks.

4. After stopping the engine, check the oil level. If

necessary, add oil.

M10 bolt: 73.5 to 83.4 N·m (7.5 to 8.5 kgf·m)

[54.25 to 61.48 lbf·ft]

M8 bolt: 19.6 to 29.4 N·m (2.0 to 3.0 kgf·m)

[14.47 to 21.70 lbf·ft]

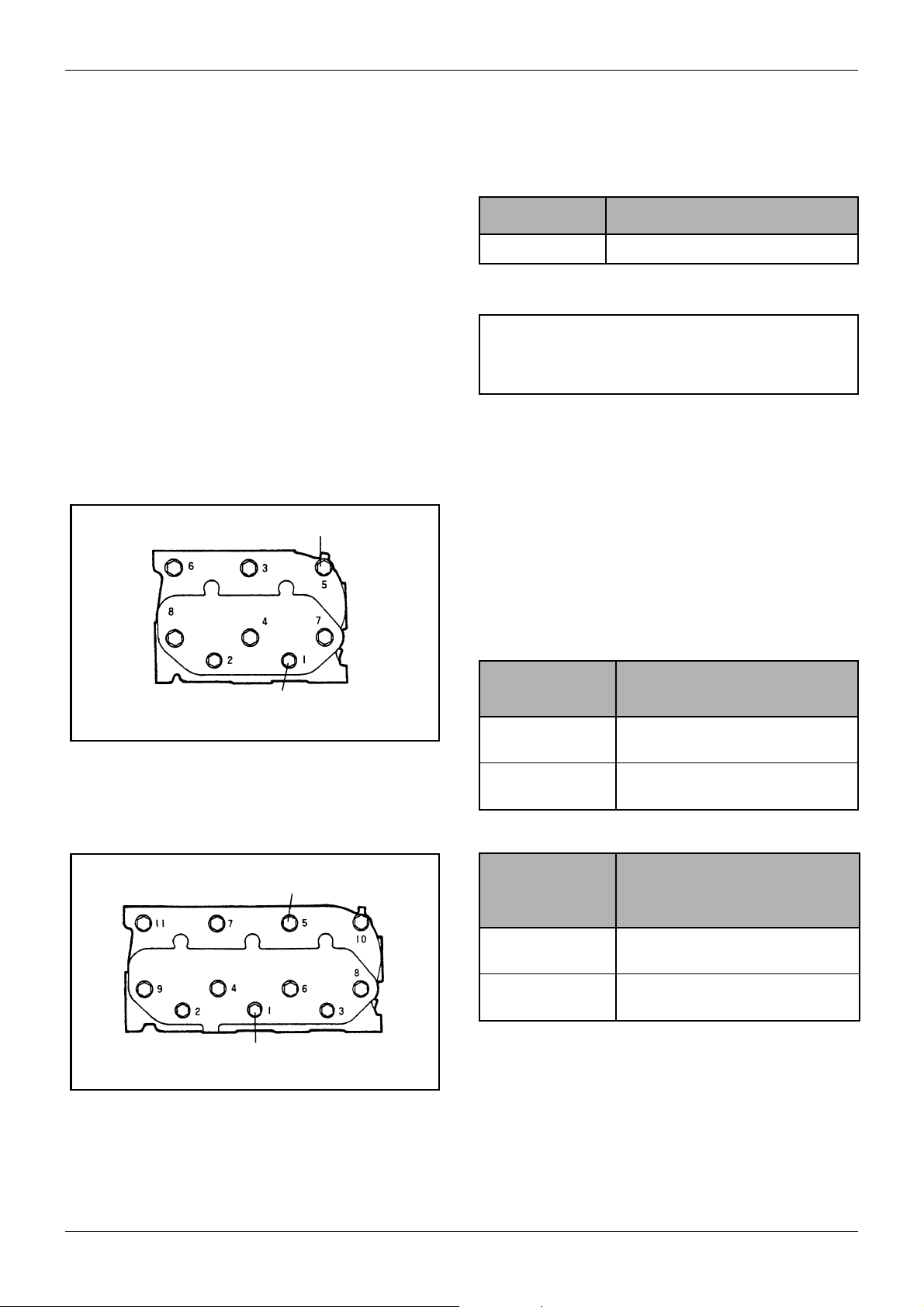

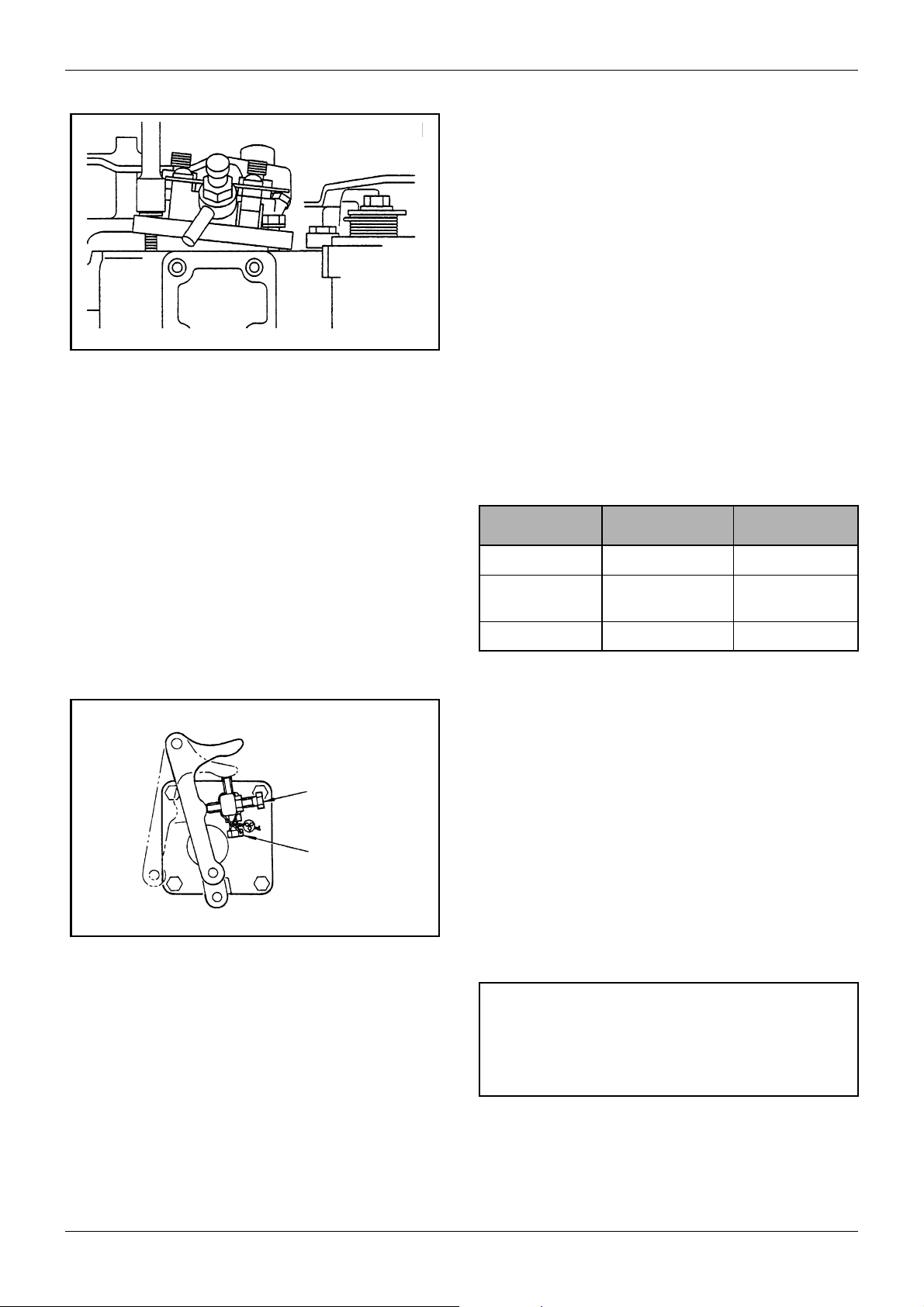

Figure 8 Cylinder head bolt tightening sequence

(L2)

M10 bolt: 73.5 to 83.4 N·m (7.5 to 8.5 kgf·m)

[54.25 to 61.48 lbf·ft]

5.2 Retightening the cylinder head

bolts

When retightening the cylinder head bolts, drain out

coolant, loosen the bolts slightly, and then retighten the

bolts to the specified torque in the numerical order

illustrated at right.

Tightening

torque

M10 bolt 73.5 to 83.4 (7.5 to 8.5)

M8 bolt 19.6 to 29.4 (2.0 to 3.0)

Table 8 Tightening torque

Rocker stay

tightening

torque

M10 bolt 73.5 to 83.4 (7.5 to 8.5)

Unit: N·m (kgf·m) [lbf·ft]

[54.25 to 61.48]

[14.47 to 21.70]

Unit: N·m (kgf·m) [lbf·ft]

[54.25 to 61.48]

M8 bolt: 19.6 to 29.4 N·m (2.0 to 3.0 kgf·m)

[14.47 to 21.70 lbf·ft]

Figure 9 Cylinder head bolt tightening sequence

(L3)

Service Manual Mitsubishi L-Series diesel engines

Version 08/2004

Table 9 Rocker stay tightening torque

The rocker assembly (the rocker arms, shaft and stays)

is to be kept removed when the cylinder head bolts are

retightened.

ENGLISH

M8 bolt 19.6 to 29.4 (2.0 to 3.0)

[14.47 to 21.70]

21 / 155

MAINTENANCE GENERAL

5.3 Adjusting the valve clearance

CAUTION

Be sure to retighten the cylinder head bolts before

adjusting the valve clearance.

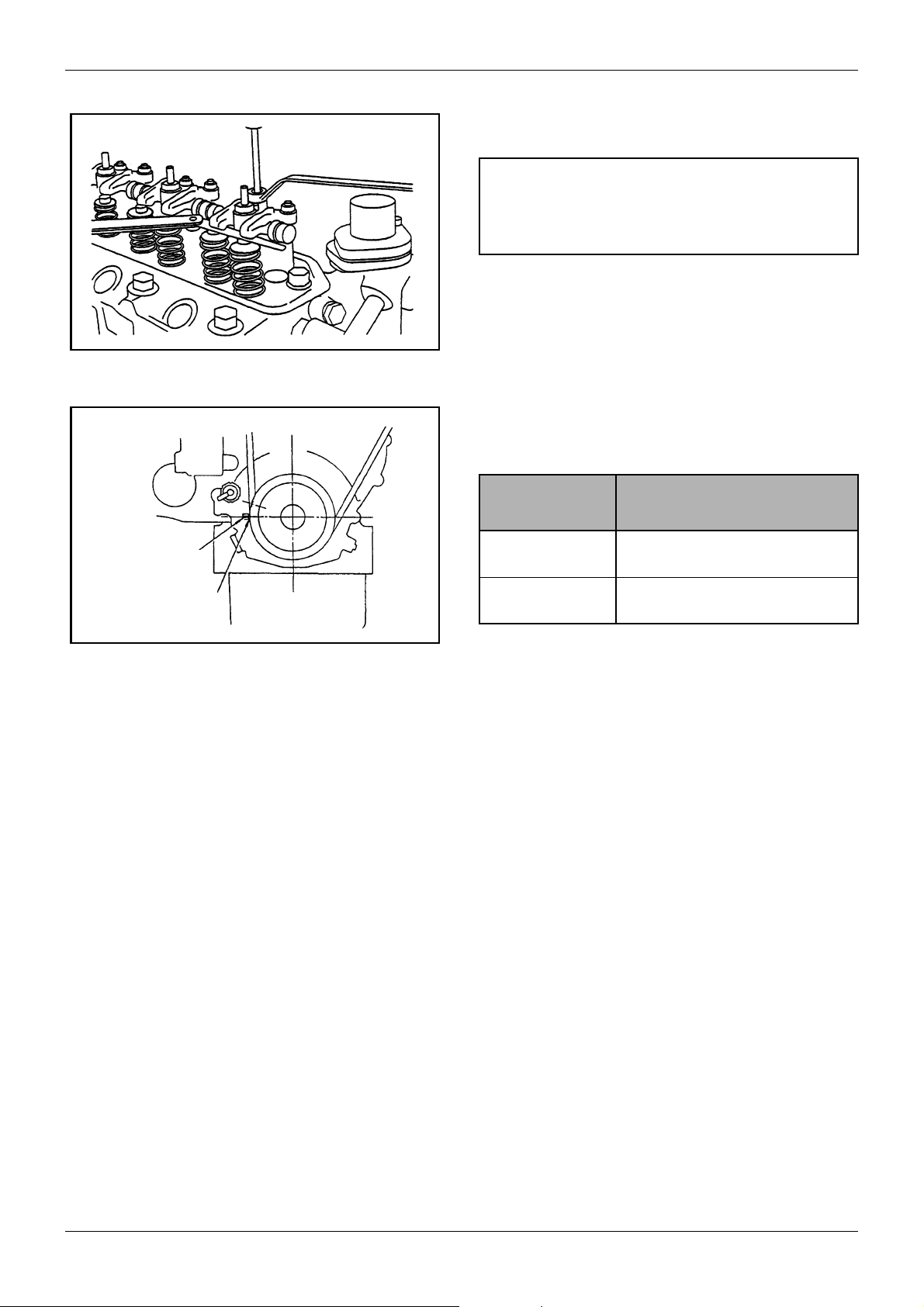

Figure 10 Adjusting valve clearance

Procedure

1. Set the cylinder to be adjusted to the top dead

center of compression stroke.

Mark on

gear case

TDC mark on

crankshaft pulley

Figure 11 Timing mark

Tightening

torque

M10 bolt 73.5 to 83.4 (7.5 to 8.5)

M8 bolt 19.6 to 29.4 (2.0 to 3.0)

Table 10 Tightening torque

2. The top dead center of compression stroke can be

obtained by aligning the TDC (Top Dead Center)

mark (notch) on the crankshaft pulley with the

mark on the gear case.

3. First align the TDC mark for the No. 1 cylinder.

Confirm that the valves do not move up and down

when the crankshaft is turned about 20° in normal

direction of rotation and in reverse direction.

4. When setting the top dead center for the No. 2

cylinder and that for the No. 3 cylinder, perform as

follows:

a L2 (Two-cylinder engine)

Turn the crankshaft 180° clockwise from TDC

(Top Dead Center) of the No. 1 cylinder, to set

the No. 2 cylinder TDC.

b L3 (Three-cylinder engine)

Turn the crankshaft 240° clockwise from TDC

of the No. 2 cylinder, to set the No. 3 cylinder

TDC. Further, turn the crankshaft 240°

clockwise from No. 3 cylinder TDC and

reconfirm the position of the No. 2 cylinder

TDC.

Unit: N·m (kgf·m) [lbf·ft]

[54.25 to 61.48]

[14.47 to 21.70]

22 / 155

ENGLISH

Service Manual Mitsubishi L-Series diesel engines

Version 08/2004

GENERAL

Approx: 10 mm

[0.3937 in.]

(98 N (10 kgf) [22 lbf]

of thumb force)

Figure 12 Adjusting fan belt tension

Figure 13 Fuel filter air bleeding

MAINTENANCE

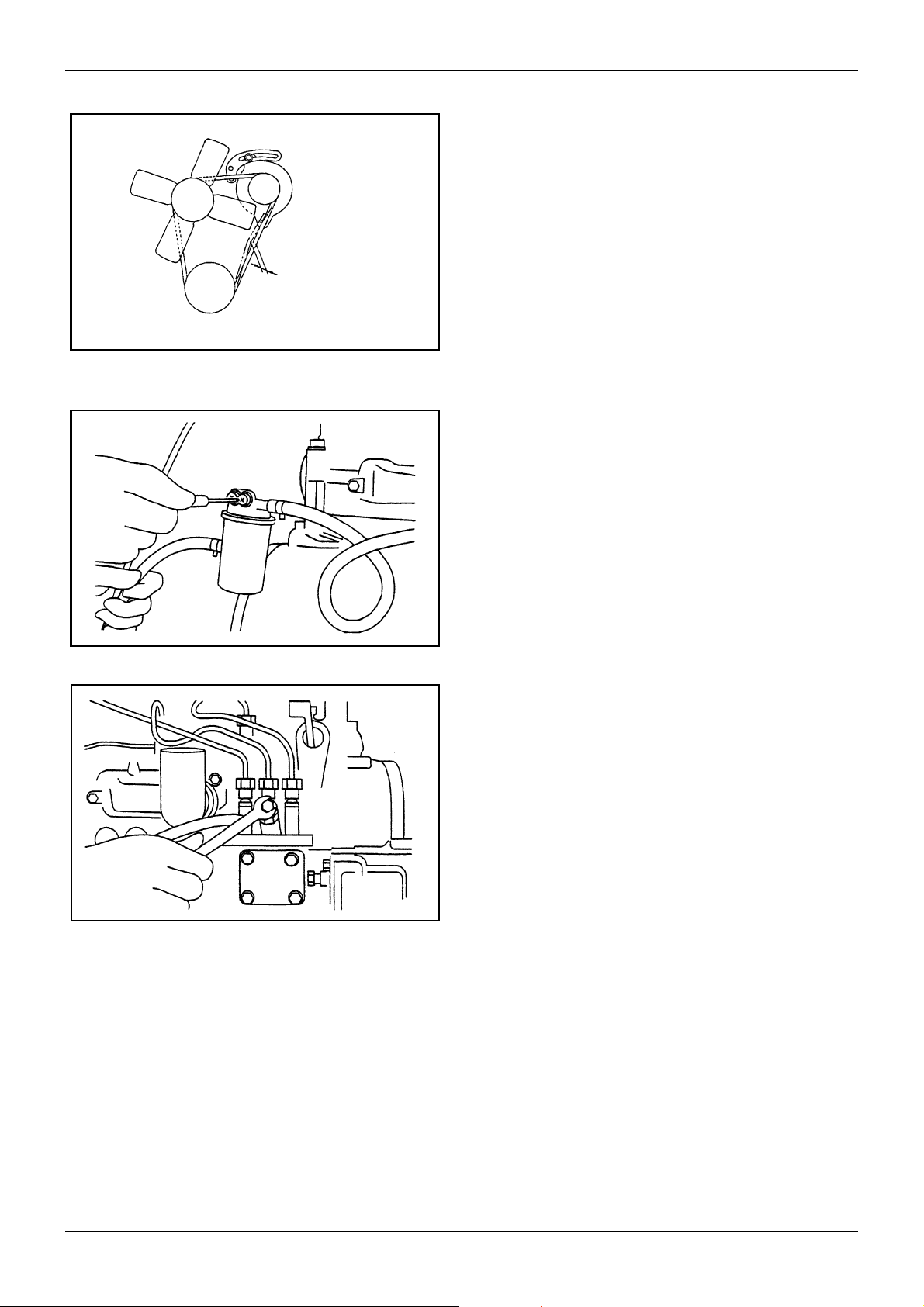

5.4 Adjusting the fan belt tension

To check if the belt tension is appropriate, press the

belt at a midpoint between the alternator pulley and

crankshaft pulley with your thumb, and check that the

amount of belt deflection is about 10 mm [0.3937 in.]

(about 98 N (10 kgf) [22 lbf]).

5.5 Bleeding air from the fuel system

Procedure

1. Loosen the air vent screw on the fuel filter.

2. For engine without feed pump, fuel flows down and

enters the fuel filter, wait for fuel to overflow from

the air vent screw. Then tighten the air vent screw.

3. For engine with the electromagnetic fuel pump,

turn the starting switch key to the ON position to

feed fuel to the fuel filter. Loosen the air vent screw

on the filter and, after bleeding air, tighten the air

vent screw.

4. Loosen the air vent screw on the fuel injection

pump to let air bleed from the fuel pipe and fuel

injection pump.

5. Air in the injection pipes and nozzles is driven out

automatically by cranking the engine.

Figure 14 Fuel injection pump air bleeding

Service Manual Mitsubishi L-Series diesel engines

Version 08/2004

ENGLISH

23 / 155

MAINTENANCE GENERAL

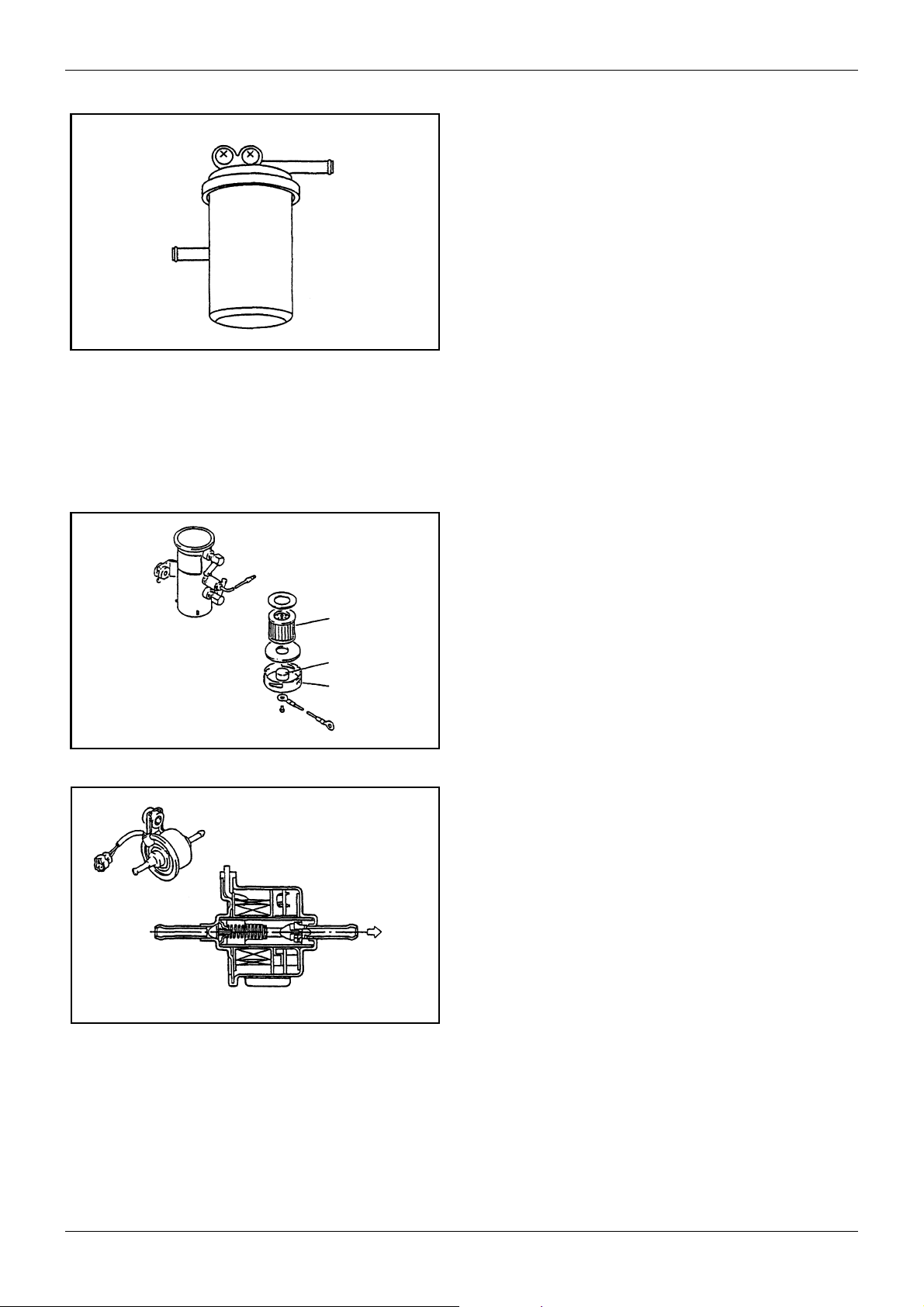

5.6 Replacing the fuel filter

5.6.1 Cartridge type

Replace the cartridge type filter as an assembly if

accumulation of dust or water is in its element. Regular

replacement interval is every 500 service hours of

engine operation. Check the filter every 100 service

hours and, if necessary, replace early.

5.6.2 Separate type filter with cock

Close the filter cock, remove the ring nut, and take out

Figure 15 Cartridge type filter

the element from the inside of filter. Clean or replace

the element.

5.6.3 Fuel pump

The following three types of fuel pumps are available.

Which type of pump is to be used for an engine

depends upon engine specification.

Filter

Magnet

Cover

Figure 16 Plunger type (common) fuel pump

1. Plunger type electromagnetic pump

The plunger-type pumps are classified as the common, large-sized pump having a filter element or

as the compact lightweight, low-priced pump without filter element. Regardless of classification,

check the plunger-type pump for normal function

and make sure that it does not leak fuel. Only on

the pump with filter element, remove the cover and

clean or replace the filter element.

Figure 17 Plunger type (compact) fuel pump

24 / 155

ENGLISH

Service Manual Mitsubishi L-Series diesel engines

Version 08/2004

GENERAL

Figure 18 Diaphragm type fuel pump

Adapter

Camshaft, fuel

injection pump

Fuel pump

Primer lever

MAINTENANCE

2. Diaphragm type electromagnetic pump

The diaphragm type electromagnetic pump should

not be disassembled. Like the compact plungertype pump mentioned above, check the pump for

functions and fuel leak.

3. Mechanical type fuel pump

This type of fuel pump is installed with an adapter

on the rear-end side of the fuel injection pump

camshaft. As the camshaft rotates, the fuel pump

cam pushes the tappet to actuate the diaphragm of

the fuel pump. This type of fuel pump is provided

with a priming lever to allow manual feed to fuel.

Check the fuel pump for normal function and make

sure that it does not leak fuel or make unusual

noise.

Pump type Delivery flow

Shut-off

pressure

Figure 19 Mechanical type fuel pump

Plunger type

(common)

Plunger type

(compact)

Diaphragm

type

Mechanical

type

0.9 l

[0.24 U.S.gal]/ min

or more

0.4 l

[0.11 U.S.gal]/ min

or more

0.37 l

[0.10 U.S.gal]/ min

or more

0.255 l

[0.06 U.S.gal]/ min

or more

0.03 MPa

(0.35 kgf/cm2)

[4.98 psi]

0.03 MPa

(0.35 kgf/cm

[4.98 psi]

0.01 MPa

(0.15 kgf/cm

[2.13 psi]

0.01 MPa

(0.15 kgf/cm

[2.13 psi]

2

)

2

)

2

)

Table 11 Fuel pumps at 12V (electromagnetic

pumps only) and at 20°C [68°F]

5.6.4 Draining water from the water

sedimentator

For engine provided with a water sedimentator, remove

the filter ring nut involved and take out the cup. Wipe off

water and dust accumulated in the cup.

Service Manual Mitsubishi L-Series diesel engines

Version 08/2004

ENGLISH

25 / 155

MAINTENANCE GENERAL

5.7 Checking and adjusting injection timing

To check and adjust injection timing, use the following

procedure:

1. Disconnect the No. 1 injection pipe.

2. Remove the No. 1 delivery valve from the injection

pump. Put back the valve holder only.

CAUTION

Figure 20 Removing delivery valve

Be sure to shut off the fuel feed before removing the

delivery valve.

3. Remove the tie-rod cover and disconnect the tie-

rod from the control rack.

4. Set the control rack to a midway position in the

working range.

5. Open the fuel feed pipe and make sure that fuel

flows from the delivery valve holder.

6. Turn the crankshaft in the direction of normal

rotation (clockwise) and find an instant that fuel

stops flowing from the delivery valve holder. This

instant is the real injection timing.

Mark on gear

case

IT mark on

pulley

Figure 21 Injection timing mark

Figure 22 Adjusting shim thickness

TDC mark

CAUTION

The standard injection timing differs with engine

specification and engine speed.

Check to see whether the real injection timing

coincides with the standard injection timing (whether

the IT mark on the crankshaft pulley aligns with the

mark on the gear case).

7. If they do not coincide with each other, adjust

thickness of the injection pump mounting shim.

Increasing or decreasing shim thickness by 0.1

mm [0.0039 in.] causes the real injection timing to

vary about 1°.

26 / 155

ENGLISH

Service Manual Mitsubishi L-Series diesel engines

Version 08/2004

GENERAL

Figure 23 Removing injection pump

MAINTENANCE

8. To remove the injection pump, first disconnect the

injection pipes and fuel feed pipe from the injection

pump. Then, remove the tie-rod cover and tie-rod.

Dismount the pump assembly. Reassembly

sequence of the pump is the reverse of

disassembly.

9. In the dusty place or when the engine is dirty,

removal of a delivery valve may cause dust to

enter into the injection pump. Under such

circumstances leave the delivery valve installed

and check injection timing using the following

procedure:

a Remove the tie-rod cover and disconnect the

tie-rod from the control rack.

b Set the control rack to a midway position in

the working range. Disconnect the injection

pipe from the No. 1 nozzle. Turn the

crankshaft gradually in the direction of normal

rotation until swelling of fuel is found at the

open end of the injection pipe. This instant is

the real injection timing, which will come

approx. 1° later than standard injection timing.

LOW-SPEED

set bolt

HIGH-SPEED

set bolt

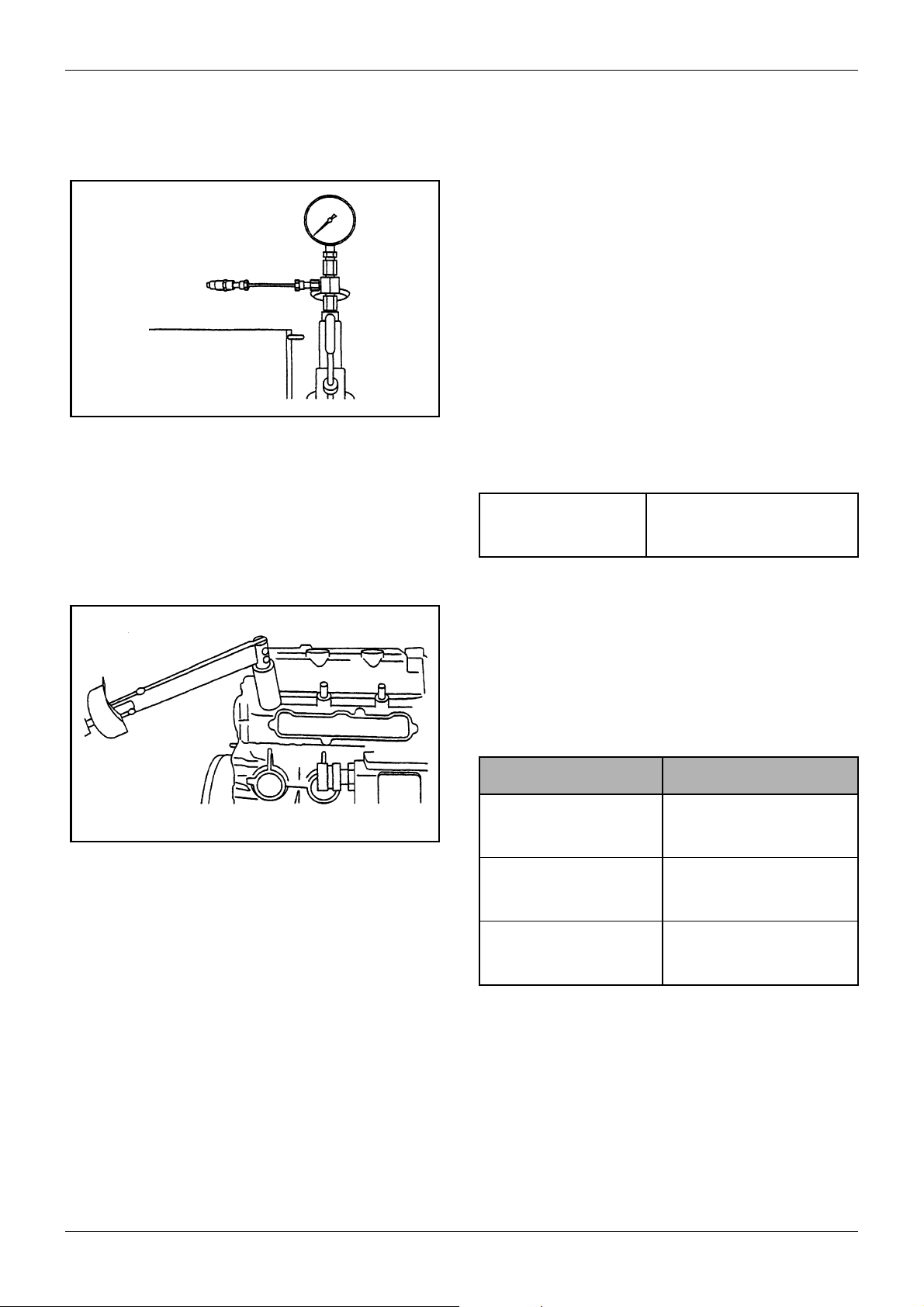

Figure 24 HIGH-SPEED and LOW-SPEED set bolts

1

min-

Less than 2000 BTDC 15° BTDC 15°

200 to less than

3600

3600 or more BTDC 19° BTDC 19°

Table 12 Standard injection timing

Model L2 Model L3

BTDC 17° BTDC 17°

5.8 Adjusting the engine speeds

To adjust engine speed, remove the cooling fan and

install the safety cover over the fan to reduce the risk of

injury.

1. The upper limit of engine speed can be adjusted

with the HIGH-SPEED stopper bolt. This stopper

bolt has been set properly and sealed in the

factory before shipping of the engine. Never

attempt to open the seal unless it is necessary.

2. The lower limit of engine speed can be adjusted

with the LOW-SPEED stopper bolt.

3. Never remove the sealing cap unless it is

necessary to adjust the torque spring set.

Service Manual Mitsubishi L-Series diesel engines

Version 08/2004

CAUTION

Warm up the engine (until coolant temperature rises

up to 60°C [140°F] or above) before adjusting engine

speeds.

4. During running of the engine for speed adjustment,

ENGLISH

check the engine for gas leak, water leak, oil leak

and fuel leak.

27 / 155

MAINTENANCE GENERAL

5. After adjustment, perform engine acceleration and

deceleration test to confirm that the engine is free

from hunting and smoking.

5.9 Checking and adjustment of nozzles

To check and adjust the injection nozzles, use the

following procedure:

5.9.1 Injection start pressure

1. Remove the nozzle assembly to be tested from the

cylinder head and set the nozzle on the nozzle

tester.

Perform air bleeding by moving the tester handle

up and down.

Figure 25 Testing injection start pressure

2. Operate the handle at a rate of one discharge a

second or more and read the gage pressure of fuel

injected from the nozzle.

H25 to 29 N m

(2.5 to 3.0 kgf m)

[18.08 to 21.70 lbf ft]

Figure 26 Installing nozzle assembly

Injection start pressure 13.7 MPa

+1.0

- 0

+10

(140 kgf/cm

- 0

+142

[1992 psi]

- 0

2

)

Table 13 Start pressure

3. If reading of gage pressure exceeds the specified

range, disassemble the nozzle and adjust by using

the adjusting shim.

Increasing or decreasing shim thickness by 0.1

mm [0.0039 in.] will cause injection pressure to

vary about 0.98 MPa (10 kgf/cm2) [142 psi].

4. When reassembling the nozzle, use the following

values of tightening torque:

Nozzle Tightening torque

Nozzle tightening (to

cylinder head) torque

Nozzle retaining nut

tightening torque

Nozzle union collar

tightening torque

49.0 to 58.8 N·m

(5.0 to 6.0 kgf·m )

[36.17 to 43.40 lbf·ft]

34.3 to 39.2 N·m

(3.5 to 4.0 kgf·m)

[25.32 to 28.93 lbf·ft]

25 to29 N·m

(2.5 to 3.0 kgf·m)

[18.08 to 21.70 lbf·ft]

28 / 155

ENGLISH

Table 14 Tightening torque

Service Manual Mitsubishi L-Series diesel engines

Version 08/2004

GENERAL

MAINTENANCE

5.9.2 Chattering test

Operate the tester handle at a speed of about one

stroke per second.

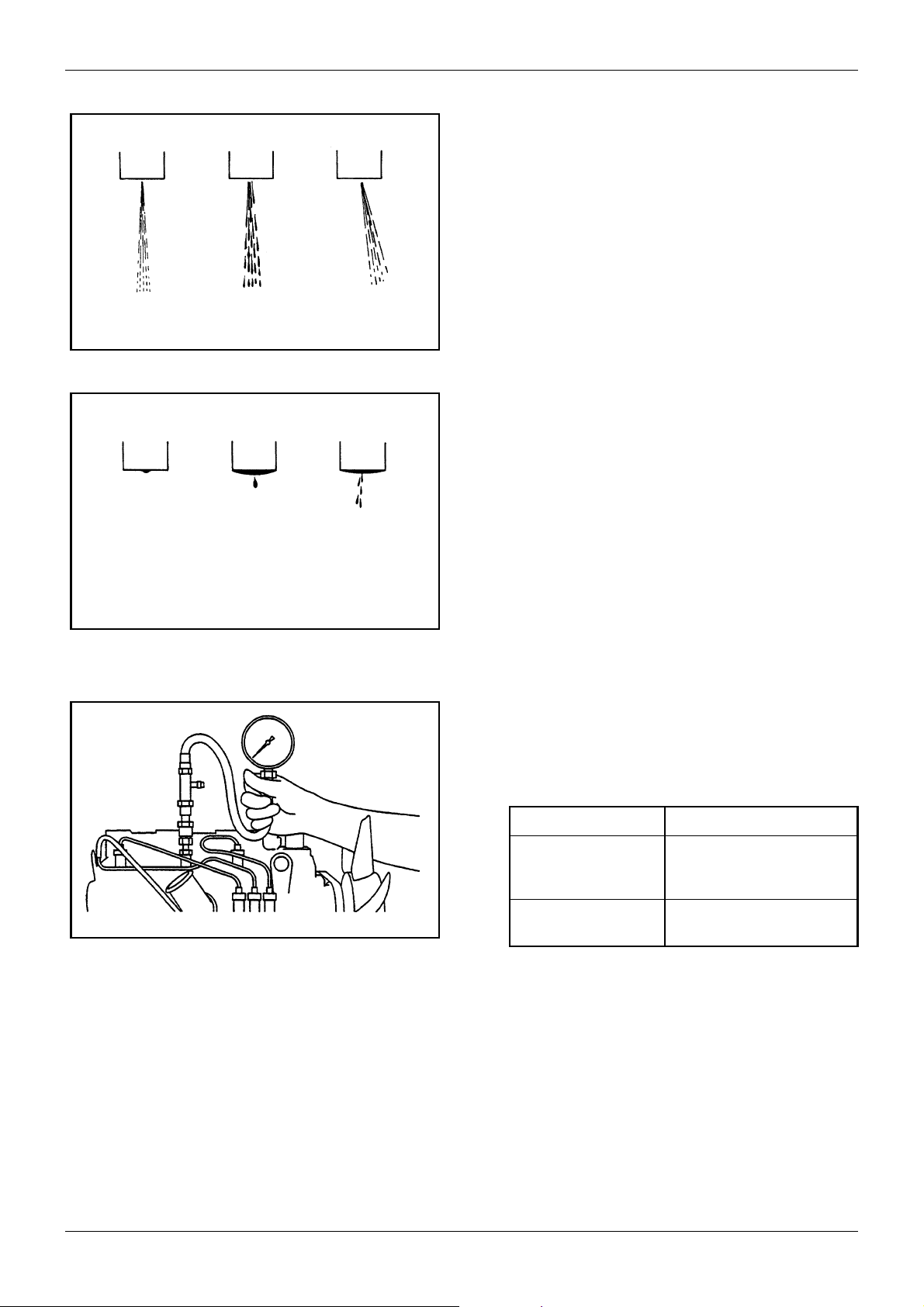

1. Needle valve oscillation

If the fuel spray shows good atomization, making

intermittent sounds, and oscillations of the needle

valve are transmitted to the handle, then the nozzle is considered as normal.

Good

Bad

Figure 27 Chattering test

Good

Bad

Figure 28 After-spilling

Bad

Bad

2. Shape of fuel spray

The nozzle should inject fuel spray straight in the

direction of its axis. A nozzle is defective if it does

not inject steadily or it injects fuel in several separate stripes.

A nozzle is defective if it spills fuel accumulated on

the bottom of the nozzle after chattering test. However, a very small drop of fuel remaining on the tip

of nozzle after chattering test may be regarded as

normal.

5.9.3 Injection Test

1. Operate the tester handle at a speed of 4 to 6

strokes per second.

2. A nozzle should inject fuel spray uniformly in the

shape of a cone.

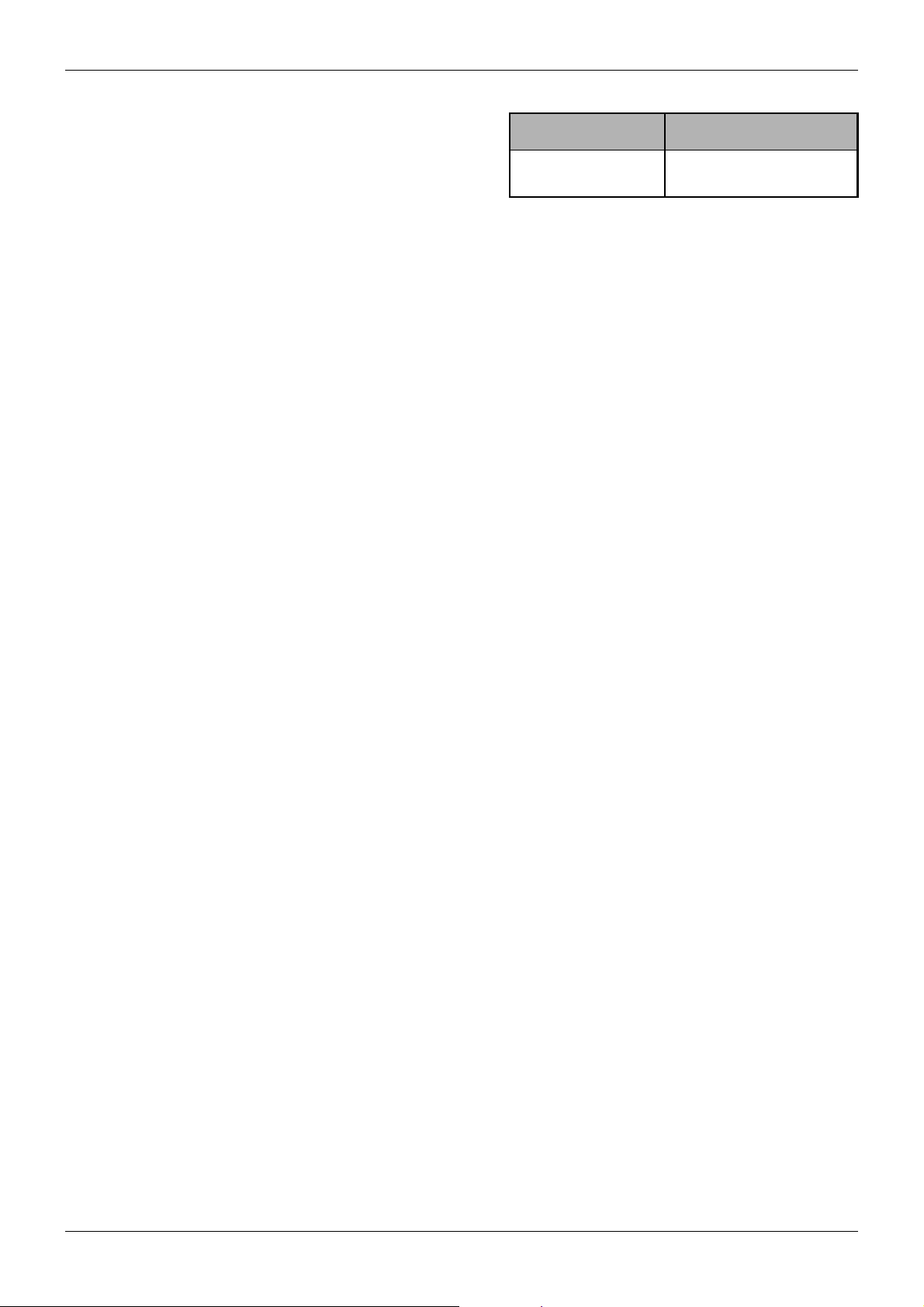

5.9.4 Checking the compression pressure

Make sure of the following:

1. The engine oil level, air cleaner, starting motor, and

battery are well-conditioned.

Figure 29 Testing compression pressure

Service Manual Mitsubishi L-Series diesel engines

Version 08/2004

2. Warm up the engine to the coolant temperature of

Measure the compression pressure using the following

procedure:

1. The following are the conditions to perform test.

2. Pull the stop lever to the “non-injection” position.

3. Remove the glow plug from the cylinder to be

ENGLISH

Engine speed 250 to 280 min

Compression

pressure

Pressure difference

between cylinders

2.84 to 3.14 Mpa

(29 to 32 kgf/cm2)

[413 to 455 psi]

0.29 MPa (3 kgf/cm

[43 psi] or less

-1

2

)

Table 15 Conditions to perform test

50°C [122°F] or more.

tested. Set the compression gage adapter to that

cylinder and install the gage.

29 / 155

MAINTENANCE GENERAL

Special tool name Part No.

Compression gage

adapter

ST332270

Table 16 Tools

4. Crank the engine with the starting motor until a

stable reading of the compression gage is

obtained.

5. After reading the gage, remove the compression

gage and adapter. Put back the glow plug.

6. Check all cylinders using the same procedure

described above.

30 / 155

ENGLISH

Service Manual Mitsubishi L-Series diesel engines

Version 08/2004

Loading...

Loading...