Page 1

MELSEC iQ-F

FX5 User's Manual (Application)

Page 2

Page 3

SAFETY PRECAUTIONS

WARNING

Indicates that incorrect handling may cause hazardous conditions, resulting in

death or severe injury.

CAUTION

Indicates that incorrect handling may cause hazardous conditions, resulting in

minor or moderate injury or property damage.

(Read these precautions before use.)

Before using this product, please read this manual and the relevant manuals introduced in this manual carefully and pay

attention to safety in order to handle the product correctly.

This manual classifies the safety precautions into two categories: [ WARNING] and [ CAUTION].

Depending on the circumstances, procedures indicated by [ CAUTION] may also cause severe injury.

It is important to follow all precautions for personal safety.

Store this manual in a safe place so that it can be read whenever necessary. Always forward it to the end user.

[DESIGN PRECAUTIONS]

WARNING

● Make sure to set up the following safety circuits outside the PLC to ensure safe system operation

even during external power supply problems or PLC failure. Otherwise, malfunctions may cause

serious accidents.

- Most importantly, set up the following: an emergency stop circuit, a protection circuit, an interlock

circuit for opposite movements (such as forward vs. reverse rotation), and an interlock circuit to

prevent damage to the equipment at the upper and lower positioning limits.

- Note that when the CPU module detects an error, such as a watchdog timer error, during self-

diagnosis, all outputs are turned off. Also, when an error that cannot be detected by the CPU

module occurs in an input/output control block, output control may be disabled. External circuits

and mechanisms should be designed to ensure safe machine operation in such a case.

- Note that the output current of the 24 V DC service power supply varies depending on the model

and the absence/presence of extension modules. If an overload occurs, the voltage automatically

drops, inputs in the PLC are disabled, and all outputs are turned off. External circuits and

mechanisms should be designed to ensure safe machine operation in such a case.

- Note that when an error occurs in a relay or transistor of an output circuit, the output might stay on

or off. For output signals that may lead to serious accidents, external circuits and mechanisms

should be designed to ensure safe machine operation.

● Construct an interlock circuit in the program to ensure safe operation for the whole system when

executing control (for data change) of the PLC in operation.

Read the manual thoroughly and ensure complete safety before executing other controls (for program

change, parameter change, forced output and operation status change) of the PLC in operation.

Otherwise, the machine may be damaged and accidents may occur due to erroneous operations.

● In an output circuit, when a load current exceeding the current rating or an overcurrent caused by a

load short-circuit flows for a long time, it may cause smoke and fire. To prevent this, configure an

external safety circuit, such as a fuse.

● For the operating status of each station after a communication failure of the network, refer to relevant

manuals for the network. Incorrect output or malfunction may result in an accident.

1

Page 4

[DESIGN PRECAUTIONS]

CAUTION

● After the CPU module is powered on or is reset, the time taken to enter the RUN status varies

depending on the system configuration, parameter settings, and/or program size.

Design circuits so that the entire system will always operate safely, regardless of this variation in time.

[INSTALLATION PRECAUTIONS]

CAUTION

● Connect the expansion board and expansion adapter securely to their designated connectors. Loose

connections may cause malfunctions.

● Connect the extension cables, peripheral device cables, input/output cables and battery connecting

cable securely to their designated connectors. Loose connections may cause malfunctions.

● When using an SD memory card, insert it into the SD memory card slot. Check that it is inserted

completely. Poor contact may cause malfunction.

● Turn off the power to the PLC before attaching or detaching the following devices. Failure to do so

may cause device failures or malfunctions.

- Peripheral devices, expansion board and expansion adapter

- Extension modules, bus conversion module and connector conversion module

- Battery

[WIRING PRECAUTIONS]

CAUTION

● Do not bundle the power line, control line and communication cables together with or lay them close to

the main circuit, high-voltage line, load line or power line. As a guideline, lay the power line, control

line and connection cables at least 100 mm (3.94") away from the main circuit, high-voltage line, load

line or power line. Noise may cause malfunctions.

2

Page 5

[STARTUP AND MAINTENANCE PRECAUTIONS]

WARNING

● Do not touch any terminal while the PLC's power is on. Doing so may cause electric shock or

malfunctions.

● Before modifying the program in mid-operation, forcing output, running or stopping the PLC, read this

manual and the associated manuals carefully and ensure complete safety. An operation error may

damage the machinery or cause accidents.

● Do not change the program in the PLC from two or more peripheral equipment devices (such as an

engineering tool and a GOT) at the same time. Doing so may cause destruction or malfunction of the

PLC program.

● Use the battery for memory backup in conformance to the FX5 User's Manual (Hardware).

- Use the battery for the specified purpose only.

- Connect the battery correctly.

- Do not charge, disassemble, heat, put in fire, short-circuit, connect reversely, weld, swallow or

burn the battery, or apply excessive force (vibration, impact, drop, etc.) to the battery.

- Do not store or use the battery at high temperatures or expose to direct sunlight.

- Do not expose to water, bring near fire or touch liquid leakage or other contents directly.

Incorrect handling of the battery may cause excessive heat, bursting, ignition, liquid leakage or

deformation, and lead to injury, fire or failures and malfunction of facilities and other equipment.

[PRECAUTIONS IN OPERATION]

CAUTION

● Construct an interlock circuit in the program to ensure safe operation for the whole system when

executing control (for data change) of the PLC in operation. Read the manual thoroughly and ensure

complete safety before executing other controls (for program change, parameter change, forced

output and operation status change) to the PLC in operation. Otherwise, the machine may be

damaged and accidents may occur by erroneous operations.

3

Page 6

INTRODUCTION

This manual contains text, diagrams and explanations which will guide the reader in the correct installation, safe use and

operation of the FX5 Programmable Controllers and should be read and understood before attempting to install or use the

module.

Always forward it to the end user.

Regarding use of this product

• This product has been manufactured as a general-purpose part for general industries, and has not been designed or

manufactured to be incorporated in a device or system used in purposes related to human life.

• Before using the product for special purposes such as nuclear power, electric power, aerospace, medicine or passenger

movement vehicles, consult Mitsubishi Electric.

• This product has been manufactured under strict quality control. However when installing the product where major

accidents or losses could occur if the product fails, install appropriate backup or failsafe functions in the system.

Note

• If in doubt at any stage during the installation of the product, always consult a professional electrical engineer who is

qualified and trained in the local and national standards. If in doubt about the operation or use, please consult the nearest

Mitsubishi Electric representative.

• Since the examples indicated by this manual, technical bulletin, catalog, etc. are used as a reference, please use it after

confirming the function and safety of the equipment and system. Mitsubishi Electric will accept no responsibility for actual

use of the product based on these illustrative examples.

• This manual content, specification etc. may be changed without a notice for improvement.

• The information in this manual has been carefully checked and is believed to be accurate; however, if you notice a doubtful

point, an error, etc., please contact the nearest Mitsubishi Electric representative. When doing so, please provide the

manual number given at the end of this manual.

4

Page 7

MEMO

5

Page 8

CONTENTS

SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

RELEVANT MANUALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

TERMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

PART 1 PROGRAMMING

CHAPTER 1 PROGRAM EXECUTION 16

1.1 Scan Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Initial processing and initialization processing in RUN mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

I/O refresh . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Program operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

END processing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1.2 Scan Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Initial scan time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1.3 Program Execution Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1.4 Execution Type of Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Initial execution type program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Scan execution type program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Fixed scan execution type program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Event execution type program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Stand-by type program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

1.5 Program Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Subroutine program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Interrupt program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

CHAPTER 2 PROCESSING OF OPERATIONS ACCORDING TO CPU MODULE

OPERATI ON STATUS 35

CHAPTER 3 CPU MODULE MEMORY CONFIGURATION 37

3.1 Memory Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Memory configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3.2 Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

File type and storage destination memory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Executable file operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

PART 2 FUNCTIONS

CHAPTER 4 FUNCTION LIST 42

CHAPTER 5 SCAN MONITORING FUNCTION 44

5.1 Scan time monitoring time setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.2 Resetting of the watchdog timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.3 Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Watchdog timer reset when executing a program repeatedly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Scan time when the WDT instruction is used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6

Page 9

CHAPTER 6 CLOCK FUNCTION 46

6.1 Time Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Clock data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Changing the clock data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Reading clock data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.2 Setting Time Zone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

6.3 System clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Special relay used for system clock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Special register used for system clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

CHAPTER 7 ONLINE CHANGE 50

7.1 Online Ladder Block Change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Editable contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Range changeable in a single session . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Online ladder block change during the boot operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

CHAPTER 8 INTERRUPT FUNCTION 53

8.1 Multiple Interrupt Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Interrupt priority . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

CONTENTS

CHAPTER 9 PID CONTROL FUNCTION 55

9.1 Outline of Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

9.2 Basic Operation Expressions in PID Instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Basic operation expression for PID control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

9.3 How to Use PID Instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

9.4 Relationship Between Parameter Setting and Auto-Tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

When auto-tuning is not executed (parameter setting) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

When auto-tuning is executed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

9.5 Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

9.6 Details of Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Sampling time (s3). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Operation setting (S3)+1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Input filter constant (s3)+2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Proportional gain (s3)+3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Integral time (s3)+4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Differential gain (s3)+5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Differential time (s3)+6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Alarm output (s3)+24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

9.7 Auto-Tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Limit Cycle Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Step Response Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

9.8 Examples of Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

System configuration example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Program example 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Program example 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Program example 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Program example 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Program example 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

7

Page 10

CHAPTER 10 CONSTANT SCAN 84

10.1 Constant scan settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

CHAPTER 11 REMOTE OPERATION 86

11.1 Remote RUN/STOP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Applications of remote RUN/STOP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Operation during remote RUN/STOP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Method of execution of remote RUN/STOP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

11.2 Remote PAUSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Application of remote PAUSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Method of execution of remote PAUSE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

11.3 Remote RESET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Application of remote RESET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Enabling remote RESET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Method of execution of remote RESET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

11.4 Relationship Between Remote Operation and CPU Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

CHAPTER 12 DEVICE/LABEL MEMORY AREA SETTING 92

12.1 Default Capacity of Each Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

12.2 The Setting Range of the Capacity of Each Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

12.3 Device/Label Memory Area Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

12.4 Device Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Range of use of device points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

CHAPTER 13 INITIAL DEVICE VALUE SETTING 97

13.1 Setting Initial Device Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Setting initial device values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

13.2 Applicable Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

CHAPTER 14 LATCH FUNCTION 99

14.1 Types of Latch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

14.2 Device/label that can be Latched . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

14.3 Latch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Latch settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Setting latch on labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

14.4 Clearing of Data of the Latch Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

14.5 Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

CHAPTER 15 MEMORY CARD FUNCTION 103

15.1 SD Memory Card Forced Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

15.2 Boot Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

CHAPTER 16 DEVICE/LABEL ACCESS SERVICE PROCESSING SETTING 107

CHAPTER 17 RAS FUNCTIONS 109

8

17.1 Self-Diagnostics Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Self-diagnostics timing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Check method of error. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

CPU Module Operation Upon Error Detection Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Error Clear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Page 11

CHAPTER 18 SECURITY FUNCTIONS 113

CHAPTER 19 BUILT-IN I/O FUNCTION 114

19.1 High-speed Counter Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

High-speed counter function overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

High-speed counter function execution procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

High-speed counter specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Assignment for high-speed counters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

High-speed counter parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

High-speed counter (normal mode). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

High-speed counter (pulse density measurement mode) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

High-speed counter (rotational speed measurement mode) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

High-speed comparison table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Multiple point output, high-speed comparison tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Special relay list. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Special relay details. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Special registers list. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Special register details. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Special relays/special registers capable of high-speed transfers with the HCMOV instruction. . . . . . . . . . . . . 161

Precautions when using high-speed counters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

19.2 FX3-compatible high-speed counter function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

FX3-compatible high-speed counter function overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

How to start/stop the high-speed counter using the LC device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

The elements of the composition of the LC device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

The comparison between the UDCNTF instruction and HIOEN instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

Assignment for FX3-compatible high-speed counters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

FX3-compatible high-speed counter setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

FX3-compatible high-speed counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Special relay list. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Special relays/LC devices capable of high-speed transfers with the HCMOV instruction. . . . . . . . . . . . . . . . . 172

Precautions when using FX3-compatible high-speed counters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

19.3 Pulse Width Measurement Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Pulse width measurement function overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Pulse width measurement specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Pulse measurement function execution procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Pulse width measurement parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

List of special relays/special registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Details of special relays/special registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Cautions when using the pulse width measurement function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Examples of program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

19.4 Pulse Catch Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Outline of pulse catch function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Specifications of pulse catch function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Pulse catch function execution procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Pulse catch parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Operation of pulse catch function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

Cautions when using the pulse catch function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

19.5 FX3-Compatible Pulse Catch Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

Outline of FX3-compatible pulse catch function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

Specifications of FX3-compatible pulse catch function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

CONTENTS

9

Page 12

FX3-compatible pulse catch function execution procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

FX3-compatible pulse catch parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Operation of FX3-compatible pulse catch function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

Cautions when using the FX3-compatible pulse catch function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

19.6 General-purpose Input Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

Outline of general-purpose input functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

Specifications of general-purpose inputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

General-purpose input function parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

19.7 PWM Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Outline of PWM output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

PWM output specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

PWM output function execution procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

PWM output parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

List of Special relays/special registers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

Details of special relays/special registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

Cautions when using the PWM function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

Examples of program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

CHAPTER 20 BUILT-IN ANALOG FUNCTION 201

20.1 Function Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

20.2 Analog Input/Output Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Analog input specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Analog output specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

List of analog input functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

List of analog output functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

PART 3 DEVICES/LABELS

CHAPTER 21 DEVICES 204

21.1 List of Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

21.2 User Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

Input (X). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

Output (Y) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

Internal relay (M) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

Latch relay (L) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

Link relay (B) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

Annunciator (F) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

Link special relay (SB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

Step relay (S). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

Timer (T/ST) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Counter (C/LC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

Data register (D) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

Link register (W) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

Link special register (SW) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

21.3 System Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

Special relay (SM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

Special register (SD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

21.4 Module Access Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

Specification method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

Processing speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

10

Page 13

21.5 Index Registers (Z/LZ). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

Types of index registers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

Index register setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

21.6 File Register (R) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

21.7 Nesting (N) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

21.8 Pointer (P) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

Global pointers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

Label assignment pointers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

21.9 Interrupt Pointer (I) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

Interrupt causes of the interrupt pointer numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

The priority for the interrupt pointer numbers and interrupt factors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

21.10 Constant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Decimal constant (K) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Hexadecimal constant (H) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Real constant (E). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Character string constant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

CHAPTER 22 LABELS 222

APPENDIX 224

Appendix 1 Special Relay List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

Appendix 2 Special Register List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

Appendix 3 Error Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

Error code system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

Operation when an error occurs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

How to clear errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 275

List of error codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 275

Appendix 4 Parameter List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 291

System parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 291

CPU parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 291

Module parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 292

Memory card parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 297

CONTENTS

INDEX 298

REVISIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .300

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .301

TRADEMARKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .302

11

Page 14

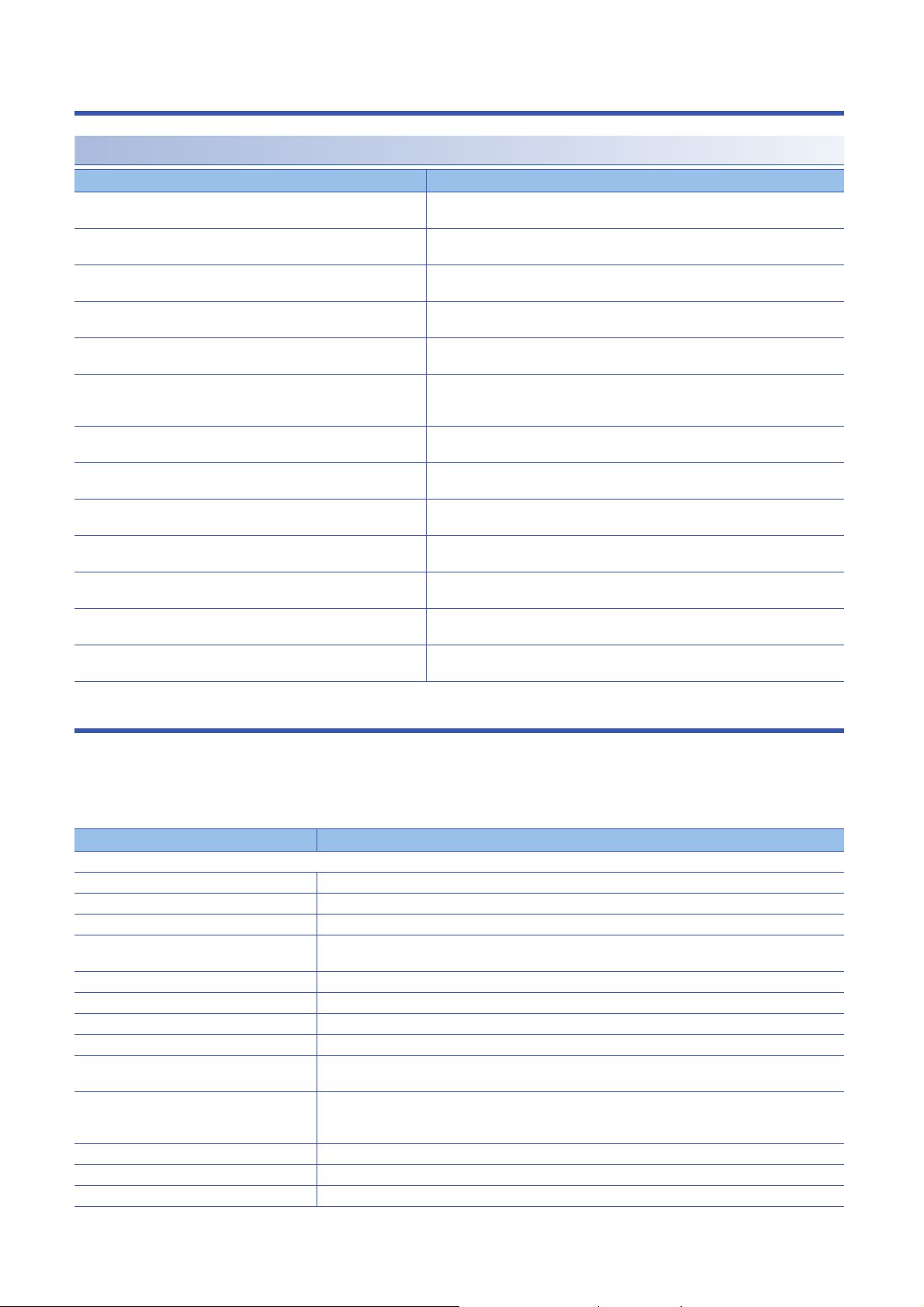

RELEVANT MANUALS

User's manuals for the applicable modules

Manual name <manual number> Description

MELSEC iQ-F FX5 User's Manual (Startup)

<JY997D58201>

MELSEC iQ-F FX5U User's Manual (Hardware)

<JY997D55301>

MELSEC iQ-F FX5UC User's Manual (Hardware)

<JY997D61401>

MELSEC iQ-F FX5 User's Manual (Application)

<JY997D55401> (This manual)

MELSEC iQ-F FX5 Programming Manual (Program Design)

<JY997D55701>

MELSEC iQ-F FX5 Programming Manual (Instructions, Standard

Functions/Function Blocks)

<JY997D55801>

MELSEC iQ-F FX5 User's Manual (Serial Communication)

<JY997D55901>

MELSEC iQ-F FX5 User's Manual (MODBUS Communication)

<JY997D56101>

MELSEC iQ-F FX5 User's Manual (Ethernet Communication)

<JY997D56201>

MELSEC iQ-F FX5 User's Manual (SLMP)

<JY997D56001>

MELSEC iQ-F FX5 User's Manual (Positioning Control)

<JY997D56301>

MELSEC iQ-F FX5 User's Manual (Analog Control)

<JY997D60501>

GX Works3 Operating Manual

<SH-081215ENG>

Performance specifications, procedures before operation, and troubleshooting of the

CPU module.

Describes the details of hardware of the FX5U CPU module, including input/output

specifications, wiring, installation, and maintenance.

Describes the details of hardware of the FX5UC CPU module, including input/output

specifications, wiring, installation, and maintenance.

Describes basic knowledge required for program design, functions of the CPU

module, devices/labels, and parameters.

Describes specifications of ladders, ST, FBD/LD, and other programs and labels.

Describes specifications of instructions and functions that can be used in programs.

Describes N:N network, MELSEC Communication protocol, inverter communication,

non-protocol communication, and predefined protocol support.

Describes MODBUS serial communication.

Describes the functions of the built-in Ethernet port communication function.

Explains methods for the device that is communicating with the CPU module by

SLMP to read and write the data of the CPU module.

Describes the built-in positioning function.

Describes the analog function.

System configuration, parameter settings, and online operations of GX Works3.

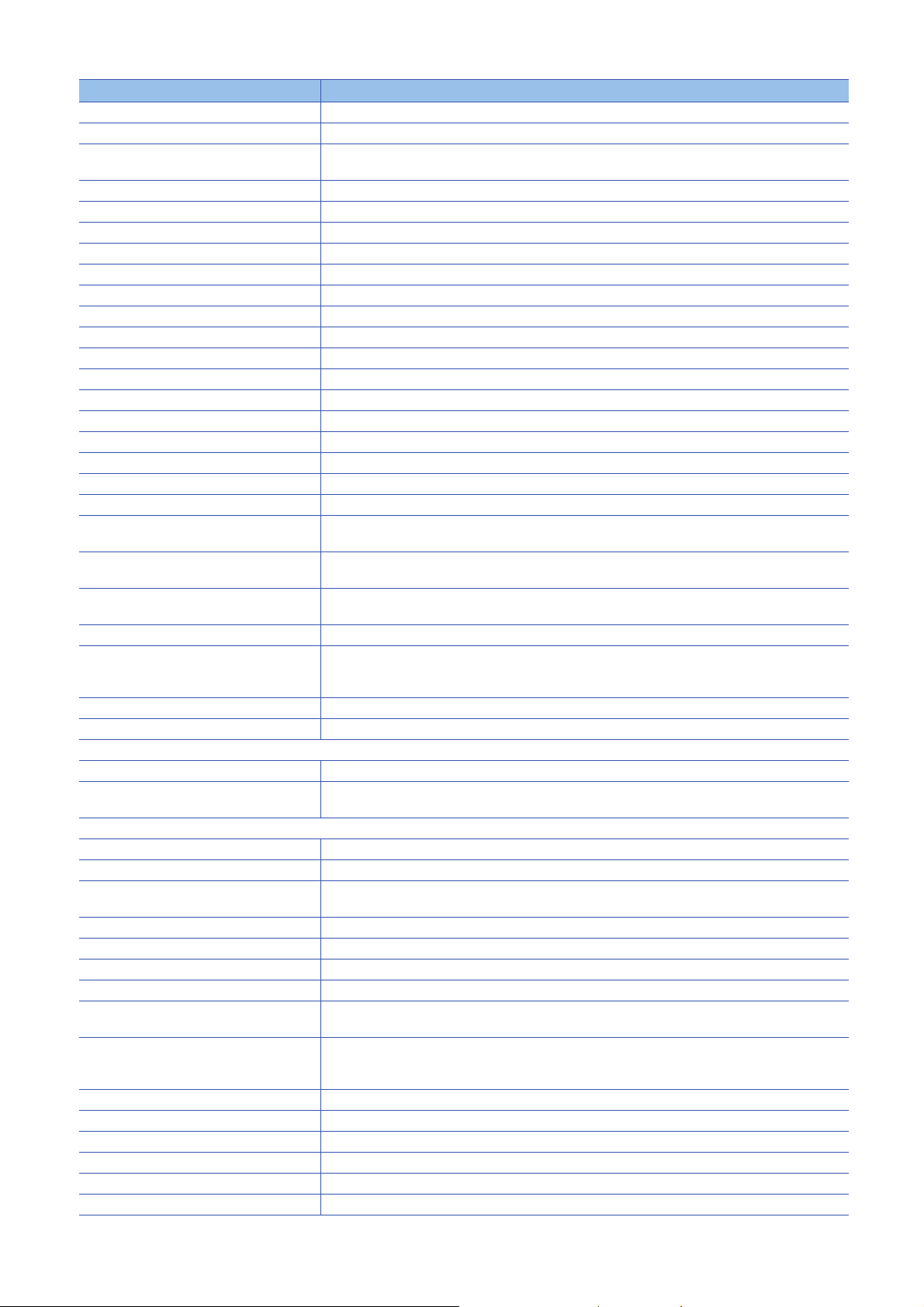

TERMS

Unless otherwise specified, this manual uses the following terms.

• indicates a variable portion used to collectively call multiple models or versions.

(Example) FX5U-32MR/ES, FX5U-32MT/ES FX5U-32M/ES

• For details on the FX3 devices that can be connected with the FX5, refer to FX5 User’s Manual (Hardware).

Ter ms Description

■Devices

FX5 Generic term for FX5U and FX5UC PLCs

FX3 Generic term for FX3S, FX3G, FX3GC, FX3U, and FX3UC PLCs

FX5 CPU module Generic term for FX5U CPU module and FX5UC CPU module

FX5U CPU module Generic term for FX5U-32MR/ES, FX5U-32MT/ES, FX5U-32MT/ESS, FX5U-64MR/ES, FX5U-64MT/ES,

FX5UC CPU module Generic term for FX5UC-32MT/D and FX5UC-32MT/DSS

Extension module Generic term for FX5 extension modules and FX3 function modules

• FX5 extension module Generic term for I/O modules, FX5 extension power supply module, and FX5 intelligent function module

• FX3 extension module Generic term for FX3 extension power supply module and FX3 intelligent function module

Extension module (extension cable type) Input modules (extension cable type), Output modules (extension cable type), Bus conversion module

Extension module (extension connector type) Input modules (extension connector type), Output modules (extension connector type), Input/output

I/O module Generic term for input modules, output modules, Input/output modules, and powered input/output modules

Input module Generic term for Input modules (extension cable type) and Input modules (extension connector type)

• Input module (extension cable type) Generic term for FX5-8EX/ES and FX5-16EX/ES

FX5U-64MT/ESS, FX5U-80MR/ES, FX5U-80MT/ES, and FX5U-80MT/ESS

(extension cable type), and Intelligent function modules

modules, Bus conversion module (extension connector type), and Connector conversion module (extension

connector type)

12

Page 15

Term s Description

• Input module (extension connector type) Generic term for FX5-C32EX/D and FX5-C32EX/DS

Output module Generic term for output modules (extension cable type) and output modules (extension connector type)

• Output module (extension cable type) Generic term for FX5-8EYR/ES, FX5-8EYT/ES, FX5-8EYT/ESS, FX5-16EYR/ES, FX5-16EYT/ES, and

FX5-16EYT/ESS

• Output module (extension connector type) Generic term for FX5-C32EYT/D and FX5-C32EYT/DSS

Input/output modules Generic term for FX5-C32ET/D and FX5-C32ET/DSS

Powered input/output module Generic term for FX5-32ER/ES, FX5-32ET/ES, and FX5-32ET/ESS

Extension power supply module Generic term for FX5 extension power supply module and FX3 extension power supply module

• FX5 extension power supply module Different name for FX5-1PSU-5V

• FX3 extension power supply module Different name for FX3U-1PSU-5V

Intelligent module The abbreviation for intelligent function modules

Intelligent function module Generic term for FX5 intelligent function modules and FX3 intelligent function modules

• FX5 intelligent function module Generic term for FX5 intelligent function modules

• FX3 intelligent function module Different name for FX3 special function blocks

Simple motion module Different name for FX5-40SSC-S

Expansion board Generic term for board for FX5U CPU module

• Communication board Generic term for FX5-232-BD, FX5-485-BD, and FX5-422-BD-GOT

Expansion adapter Generic term for adapter for FX5 CPU module

• Communication adapter Generic term for FX5-232ADP and FX5-485ADP

• Analog adapter Generic term for FX5-4AD-ADP and FX5-4DA-ADP

Bus conversion module Generic term for Bus conversion module (extension cable type) and Bus conversion module (extension

connector type)

• Bus conversion module (extension cable

type)

• Bus conversion module (extension connector

type)

Battery Different name for FX3U-32BL

SD memory card Generic term for NZ1MEM-2GBSD, NZ1MEM-4GBSD, L1MEM-2GBSD and L1MEM-4GBSD SD memory

Peripheral device Generic term for engineering tools and GOTs

GOT Generic term for Mitsubishi Graphic Operation Terminal GOT1000 and GOT2000 series

■Software packages

Engineering tool The product name of the software package for the MELSEC programmable controllers

GX Works3 The product name of the software package, SWnDND-GXW3, for the MELSEC programmable controllers

■Manuals

User's manual Generic term for separate manuals

• User's manual (Startup) Abbreviation of MELSEC iQ-F FX5 User's Manual (Startup)

• FX5 User's manual (Hardware) Generic term for MELSEC iQ-F FX5U User's Manual (Hardware) and MELSEC iQ-F FX5UC User's Manual

• FX5U User's manual (Hardware) Abbreviation of MELSEC iQ-F FX5U User's Manual (Hardware)

• FX5UC User's manual (Hardware) Abbreviation of MELSEC iQ-F FX5UC User's Manual (Hardware)

• User's manual (Application) Abbreviation of MELSEC iQ-F FX5 User's Manual (Application)

Programming manual (Program Design) Abbreviation of MELSEC iQ-F FX5 Programming Manual (Program Design)

Programming manual (Instructions, Standard

Functions/Function Blocks)

Communication manual Generic term for MELSEC iQ-F FX5 User's Manual (Serial Communication), MELSEC iQ-F FX5 User's

• Serial communication manual Abbreviation of MELSEC iQ-F FX5 User's Manual (Serial Communication)

• MODBUS communication manual Abbreviation of MELSEC iQ-F FX5 User's Manual (MODBUS Communication)

• Ethernet communication manual Abbreviation of MELSEC iQ-F FX5 User's Manual (Ethernet Communication)

• SLMP manual Abbreviation of MELSEC iQ-F FX5 User's Manual (SLMP)

Positioning manual Abbreviation of MELSEC iQ-F FX5 User's Manual (Positioning Control)

Analog manual Abbreviation of MELSEC iQ-F FX5 User's Manual (Analog Control)

Different name for FX5-CNV-BUS

Different name for FX5-CNV-BUSC

cards

Abbreviation of Secure Digital Memory Card. Device that stores data using flash memory.

(The 'n' represents a version.)

(Hardware)

Abbreviation of MELSEC iQ-F FX5 Programming Manual (Instructions, Standard Functions/Function Blocks)

Manual (MODBUS Communication), MELSEC iQ-F FX5 User's Manual (Ethernet Communication), and

MELSEC iQ-F FX5 User's Manual (SLMP)

13

Page 16

MEMO

14

Page 17

PART 1 PROGRAMMING

This part consists of the following chapters.

1 PROGRAM EXECUTION

2 PROCESSING OF OPERATIONS ACCORDING TO CPU MODULE OPERATION STATUS

3 CPU MODULE MEMORY CONFIGURATION

PART 1

15

Page 18

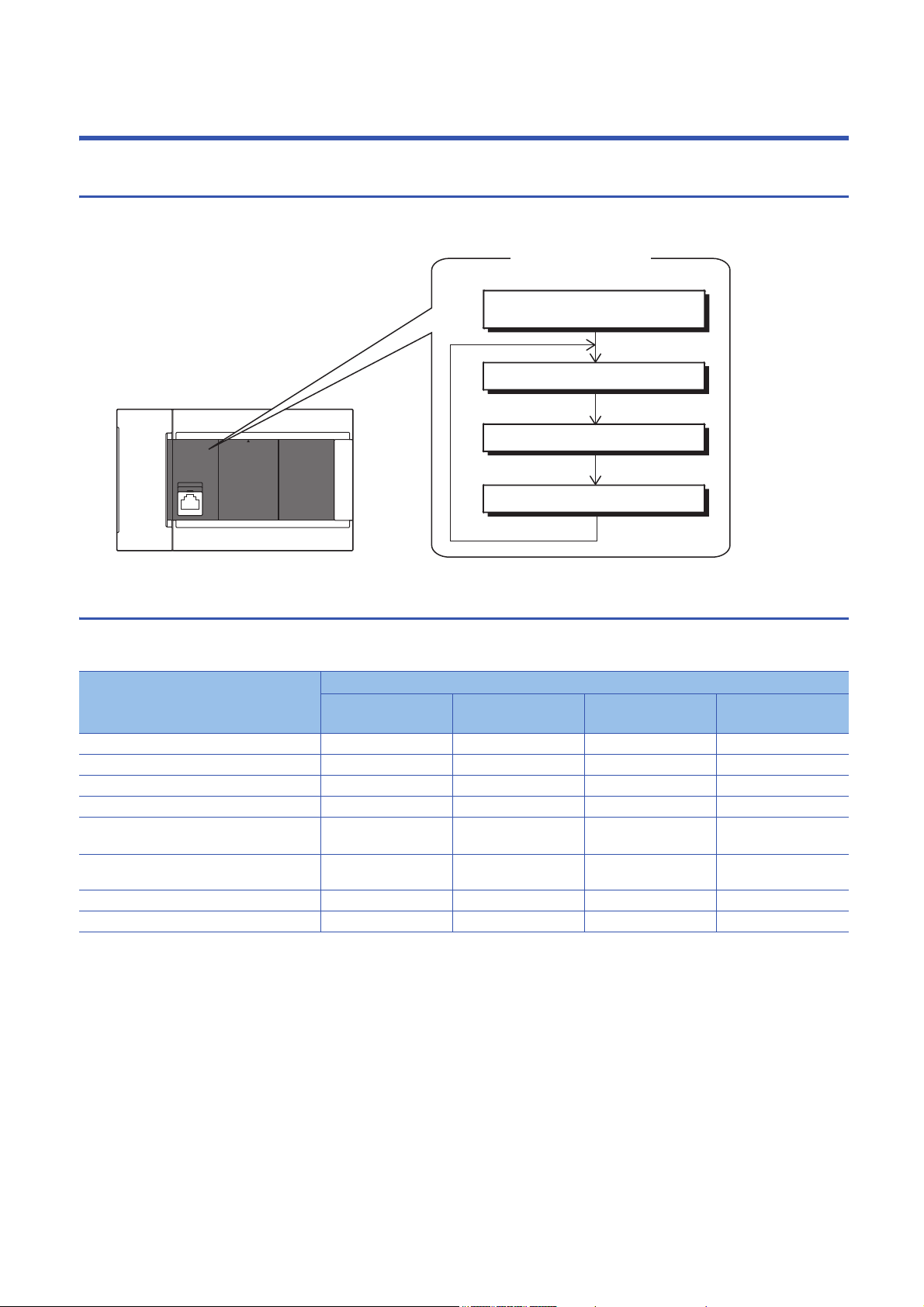

1 PROGRAM EXECUTION

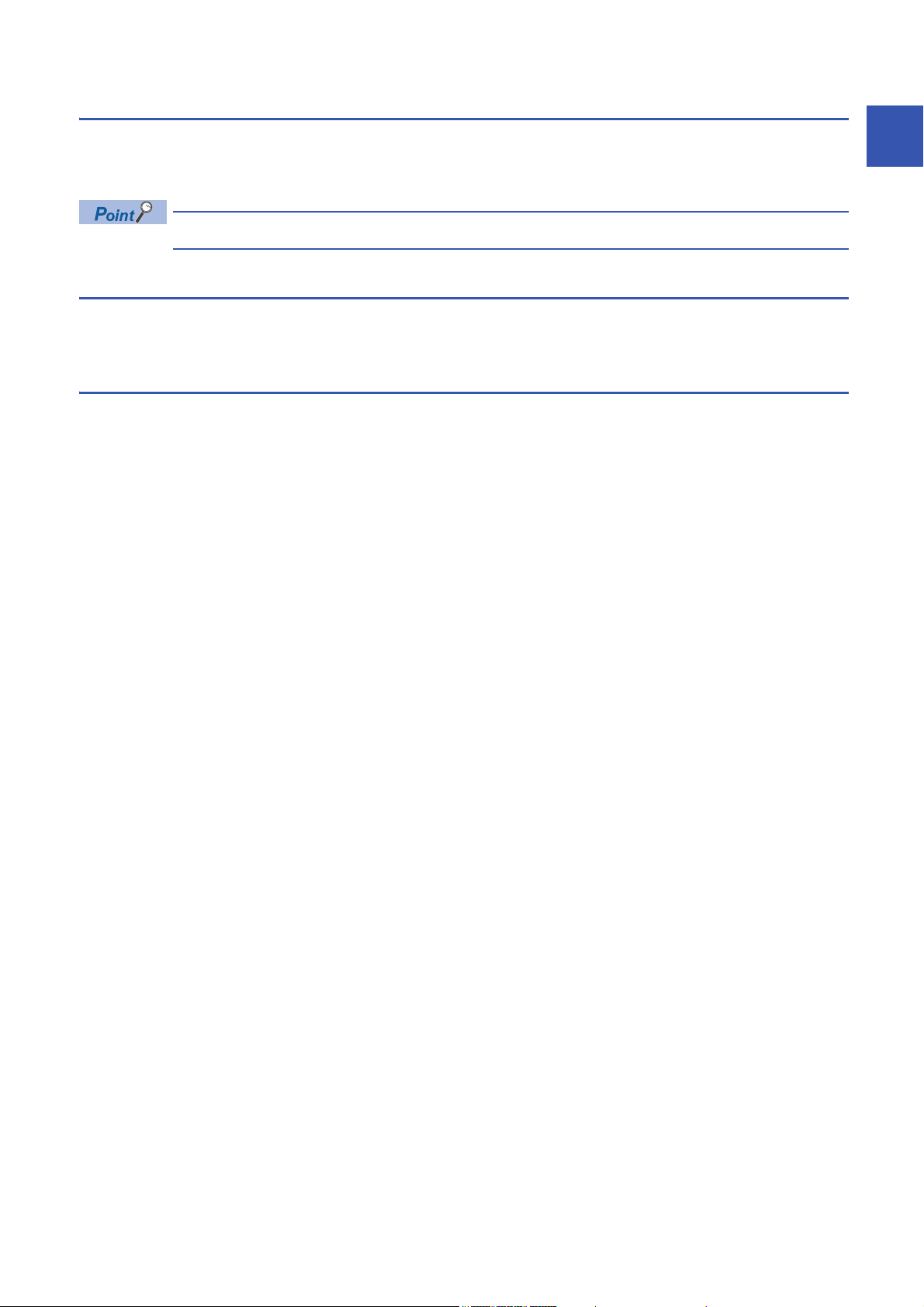

Inside the CPU module

Scan configuration

Program operations

END processing

Initial processing/RUN time

initialization processing

I/O refresh

1.1 Scan Configuration

The configuration of the scan of the CPU module is explained below.

Initial processing and initialization processing in RUN mode

Initial processing according to CPU module status and initialization processing in the RUN status are explained below.

: Execute, : Do not execute

Processing item CPU module status

At power ON At reset STOPRUN after

write to PLC

Initialization of input/output module

Boot from SD memory card

CPU parameter check

System parameter check

Initialization of device/label outside latch range

(bit device: OFF, word device: 0)

Assignment of I/O numbers of input/output

module

Setting of module parameters

Setting of device

*1 Indicates an instance of power OFFON or setting to RUN status without a reset after modifying parameters or program in STOP

status.

*1

At STOPRUN

16

1 PROGRAM EXECUTION

1.1 Scan Configuration

Page 19

I/O refresh

Execute I/O refresh before starting program operations.

• Input ON/OFF data input from input module/intelligent function module to CPU module

• Output ON/OFF data input from CPU module to output module/intelligent function module

When executing constant scan, I/O refresh is executed after the constant scan waiting time ends.

Program operations

Step 0 of each program up to the END/FEND instruction is executed according to program settings. This program is called the

"main routine." Main routine programs can be divided into subroutines. (Page 29 Subroutine program)

END processing

END processing involves the following processes:

• Refreshing of network modules

• Refreshing of intelligent function modules

• Instruction termination processing

• Device/label access service processing

• Resetting of the watchdog timer

• Self-diagnostic processing

• Setting of values to special relays/special registers (set timing: when END processing is executed)

1

1 PROGRAM EXECUTION

1.1 Scan Configuration

17

Page 20

1.2 Scan Time

I/O refresh

Program operations

END processing

RUN time

Scan time

RUN time initialization processing*1

The CPU module repeats the following processing. The scan time is the sum total of each process and execution time.

*1 This process is included in the initial scan time.

Initial scan time

This refers to the initial scan time when the CPU module is in the RUN mode.

How to check the initial scan time

The initial scan time can be checked by the following information:

• Value stored in SD518 (initial scan time (ms)), SD519 (initial scan time (s))

• Program list monitor (GX Works3 Operating Manual)

Monitoring the initial scan time

The initial scan time is monitored by the initial scan time execution monitor time. (5 SCAN MONITORING FUNCTION)

■Initial scan time execution monitor time precautions

• Set an initial execution monitor time longer then the execution time of the initial scan time. An error occurs when the initial

scan time exceeds the set initial execution monitor time.

• The measurement error margin of the initial scan execution monitor time is 10 ms. For example, if the initial execution

monitor time (t) is set to 100 ms, an error occurs in the initial scan time in the range 100 ms < t < 110 ms range.

1 PROGRAM EXECUTION

18

1.2 Scan Time

Page 21

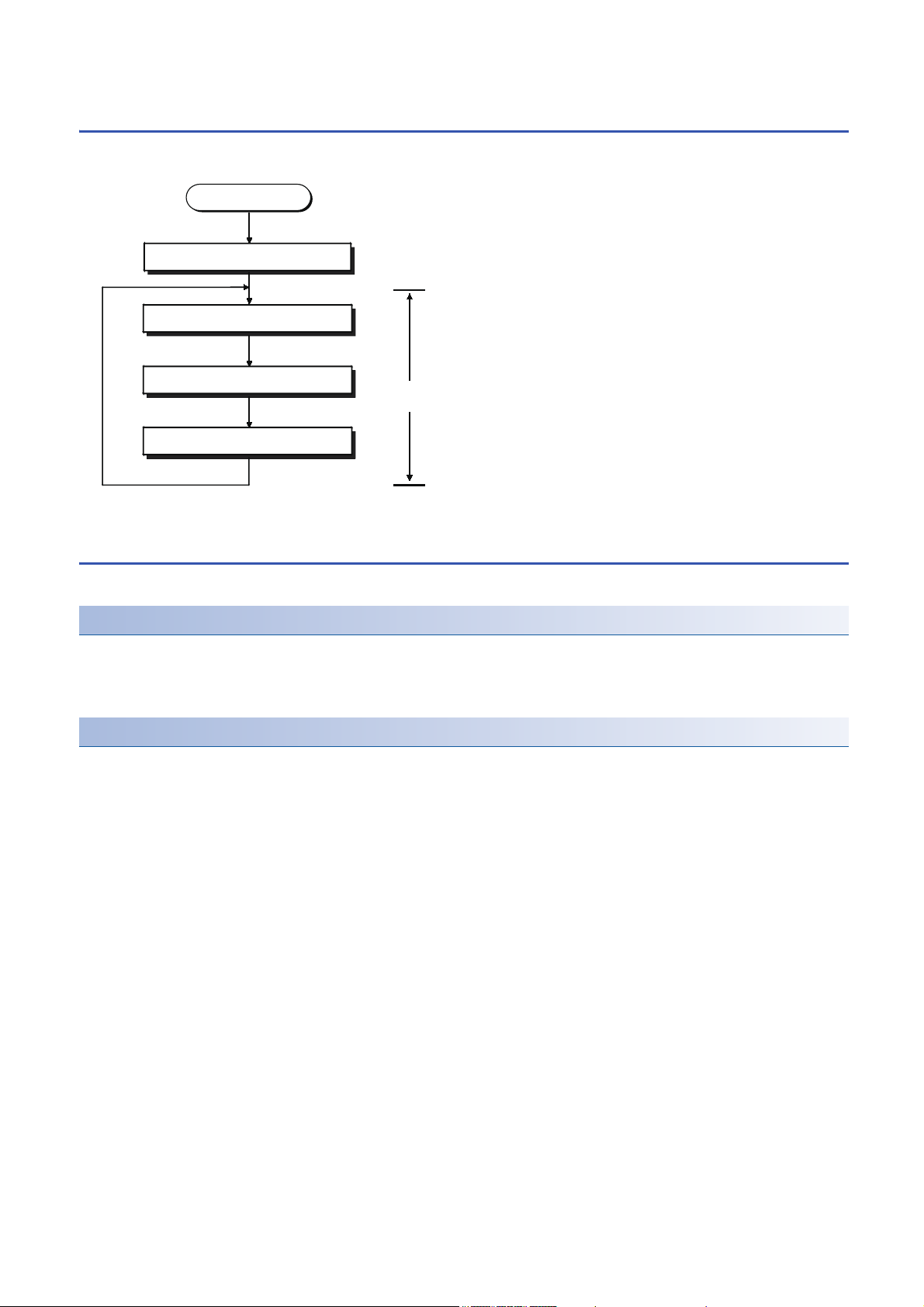

1.3 Program Execution Sequence

STOP/PAUSE→RUN

END processing

Initial execution

type program

Scan execution

type program

Event execution

type program

Fixed scan

execution type

program

Standby type

program

Exists

Does not exist

Does an initial

execution type

program exist?

When the CPU module enters the RUN status, the programs are executed successively according to the execution type of the

programs and execution order setting.

1

When the execution type of the programs is the same, the programs are executed in the order in which the

execution order was set.

1 PROGRAM EXECUTION

1.3 Program Execution Sequence

19

Page 22

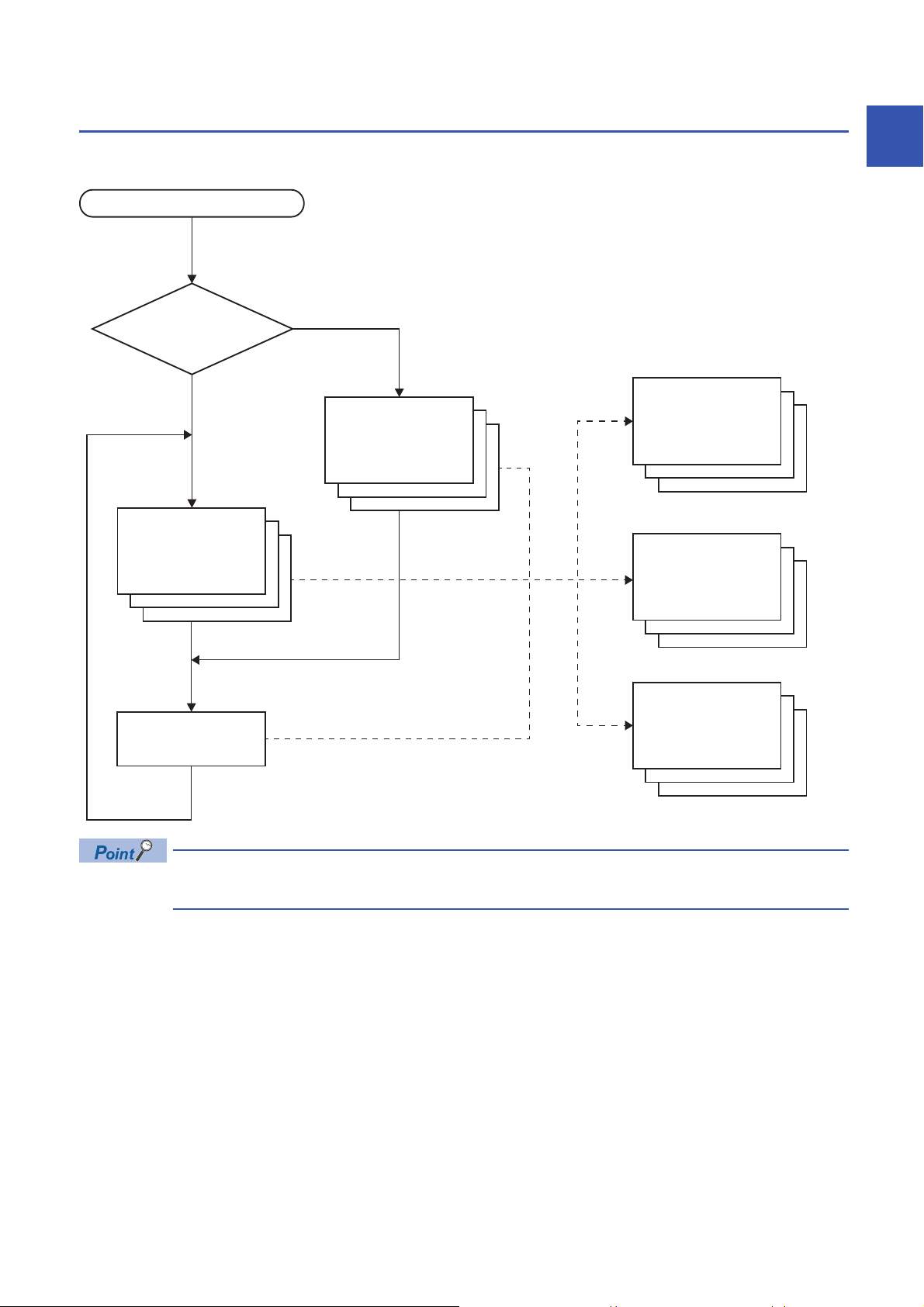

1.4 Execution Type of Program

Ex.

When an initial execution type program is used

Program A

Program B

Control by one program

Initial execution type program

Scan execution

type program

One program can be divided into initial execution

type and scan execution type program.

Processing performed

only once

Processing performed

in every scan

1st scan 2nd scan 3rd scan

STOP/PAUSE→RUN

END processing

Initial execution type program A

Initial execution type program B

Scan execution type program

Initial execution type program C

0 END

0 END

0

0

END

0END 0END

Initial scan time is the sum of the execution time of initial execution type programs

and the END processing time.

Set the program execution conditions.

Initial execution type program

This program type is executed only once when the CPU module changes from the STOP/PAUSE to the RUN status. This

program type is used for programs, that do not need to be executed from the next scan once they are executed, like initial

processing on an intelligent function module.

Also, the execution time of initial execution type programs is the same as the initial scan time.

When multiple initial execution type programs are executed, the execution time of the initial execution type programs

becomes the time until execution of all initial execution type programs is completed.

Precautions

The precautions for initial execution type programs are explained below.

■Restrictions in programming

With initial execution type programs, do not use instructions that require several scans to complete execution (instructions for

which completion devices exist).

e.g. RBFM and WBFM instructions

20

1 PROGRAM EXECUTION

1.4 Execution Type of Program

Page 23

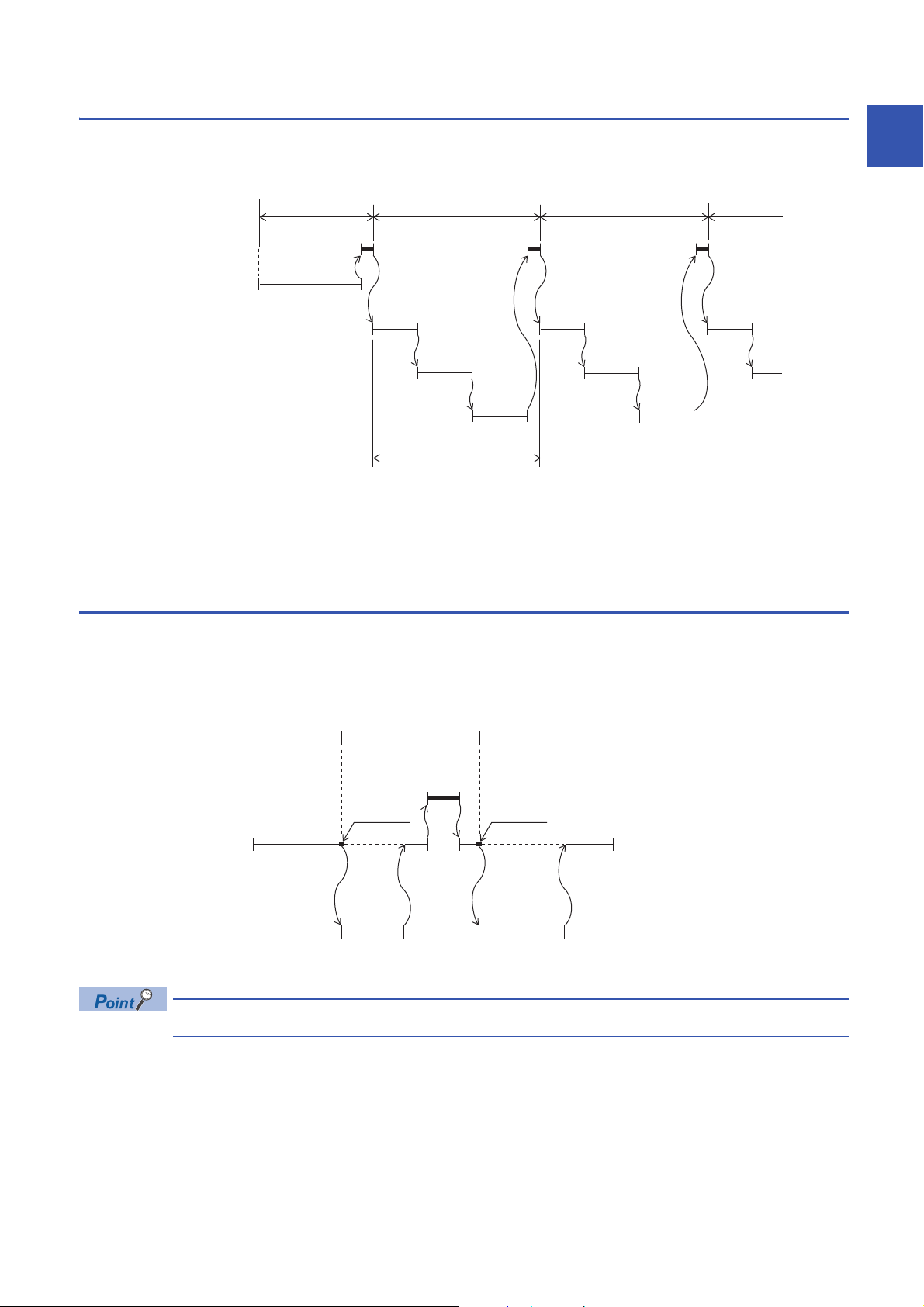

Scan execution type program

1st scan 2nd scan 3rd scan 4th scan

STOP/PAUSE→RUN

END processing

Initial execution type program

Scan execution type program A

Scan execution type program C

Scan execution type program B

Scan time

0 END

0 END

0 END

0 END

0 END

END

0 END

0

Fixed scan interval

END processing

Scan execution type program

Fixed scan execution type program

Condition

established

Condition

established

This program type is executed only once per scan from the scan following the scan where an initial execution type program

was executed.

When multiple scan execution type programs are executed, the execution time of the scan execution type programs becomes

the time until execution of all scan execution type programs is completed. Note, however, that when an program/event

execution type program is executed before a scan execution type program is completed, the execution time of these

programs is included in the scan time.

1

Fixed scan execution type program

An interrupt program which is executed at a specified time interval. Different from the normal interrupt program, this type of

program does not require interrupt pointer (I) and IRET instruction to be written (pointer is assigned by parameter). Execution

is performed by program file basis.

You can use 4 files of fixed scan execution type programs at the maximum.

To execute a fixed scan execution type program, the EI instruction must be used to enable interrupts.

1 PROGRAM EXECUTION

1.4 Execution Type of Program

21

Page 24

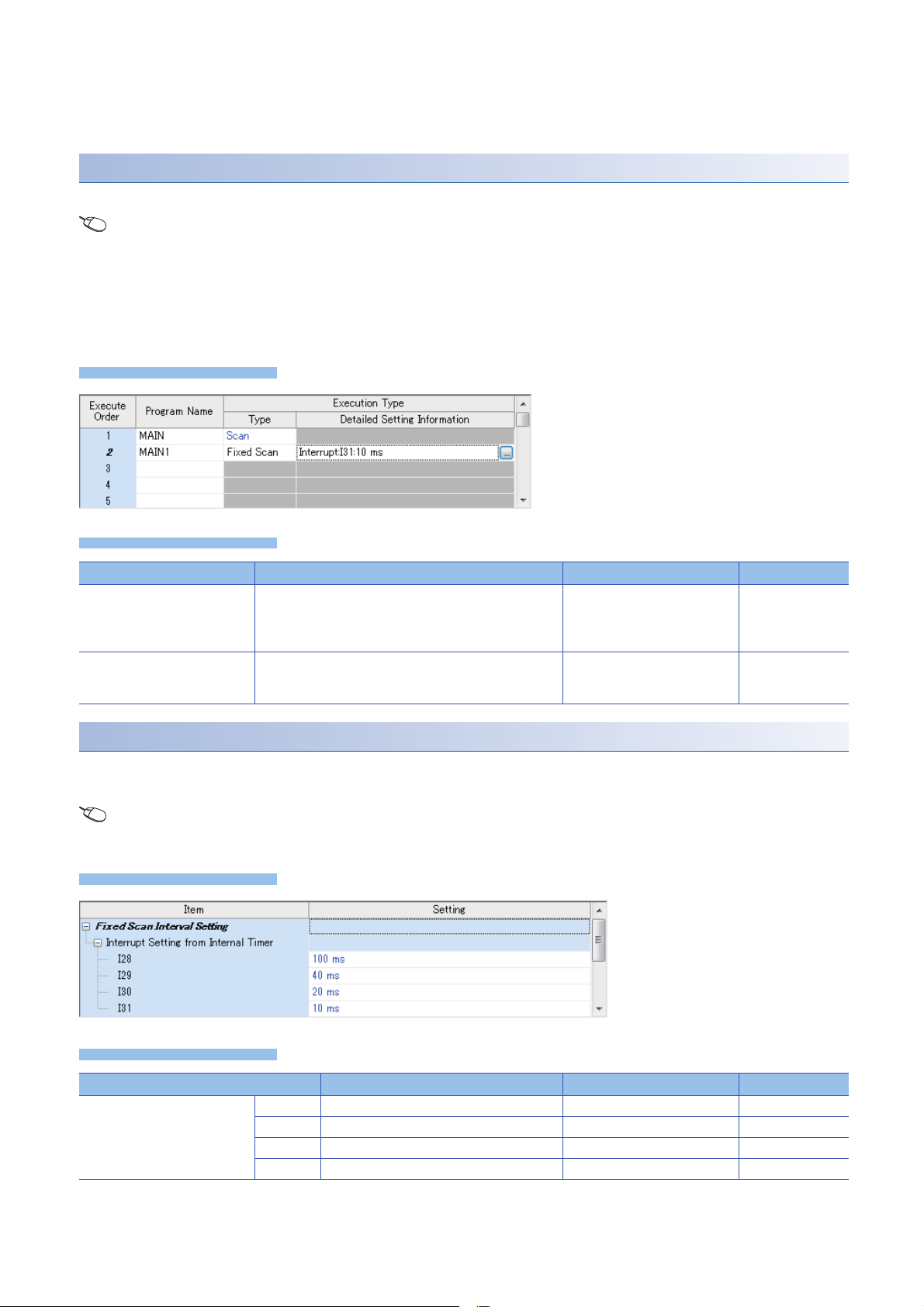

Make the following settings for fixed scan execution type program in CPU parameter.

Window

Displayed items

Window

Displayed items

• Interrupt pointer setting (Interrupt from internal timer: I28 to I31)

• Fixed scan interval setting

Interrupt pointer setting

The interrupt pointer (Interrupt from internal timer: I28 to I31) assigned to a fixed scan execution type program is set up.

Navigation window [Parameter] [FX5UCPU] [CPU Parameter] "Program Setting" "Program Setting"

"Detailed Setting" "Detailed Setting Information"

1. Open program setting screen.

2. Set type as fixed scan.

3. Specify interrupt pointer.

Item Description Setting range Default

Interrupt Pointer Set the interrupt pointer which is assigned to fixed scan

execution type program.

Specified Time Intervals Fixed scan interval setting value is displayed.

Setup is performed on another screen. (Page 22 Fixed

scan interval setting)

•I28

•I29

•I30

•I31

I31

Fixed scan interval setting

Sets the fixed scan interval setting of the fixed scan execution type program. (It is the same as setting for interrupt from

internal timer.)

Navigation window [Parameter] [FX5UCPU] [CPU Parameter] "Interrupt Settings" "Fixed Scan Interval

Setting"

Item Description Setting range Default

Interrupt Setting from Internal

Timer

22

1 PROGRAM EXECUTION

1.4 Execution Type of Program

I28 Sets the execution interval of I28. 1 to 60000 ms (1 ms units) 100 ms

I29 Sets the execution interval of I29. 1 to 60000 ms (1 ms units) 40 ms

I30 Sets the execution interval of I30. 1 to 60000 ms (1 ms units) 20 ms

I31 Sets the execution interval of I31. 1 to 60000 ms (1 ms units) 10 ms

Page 25

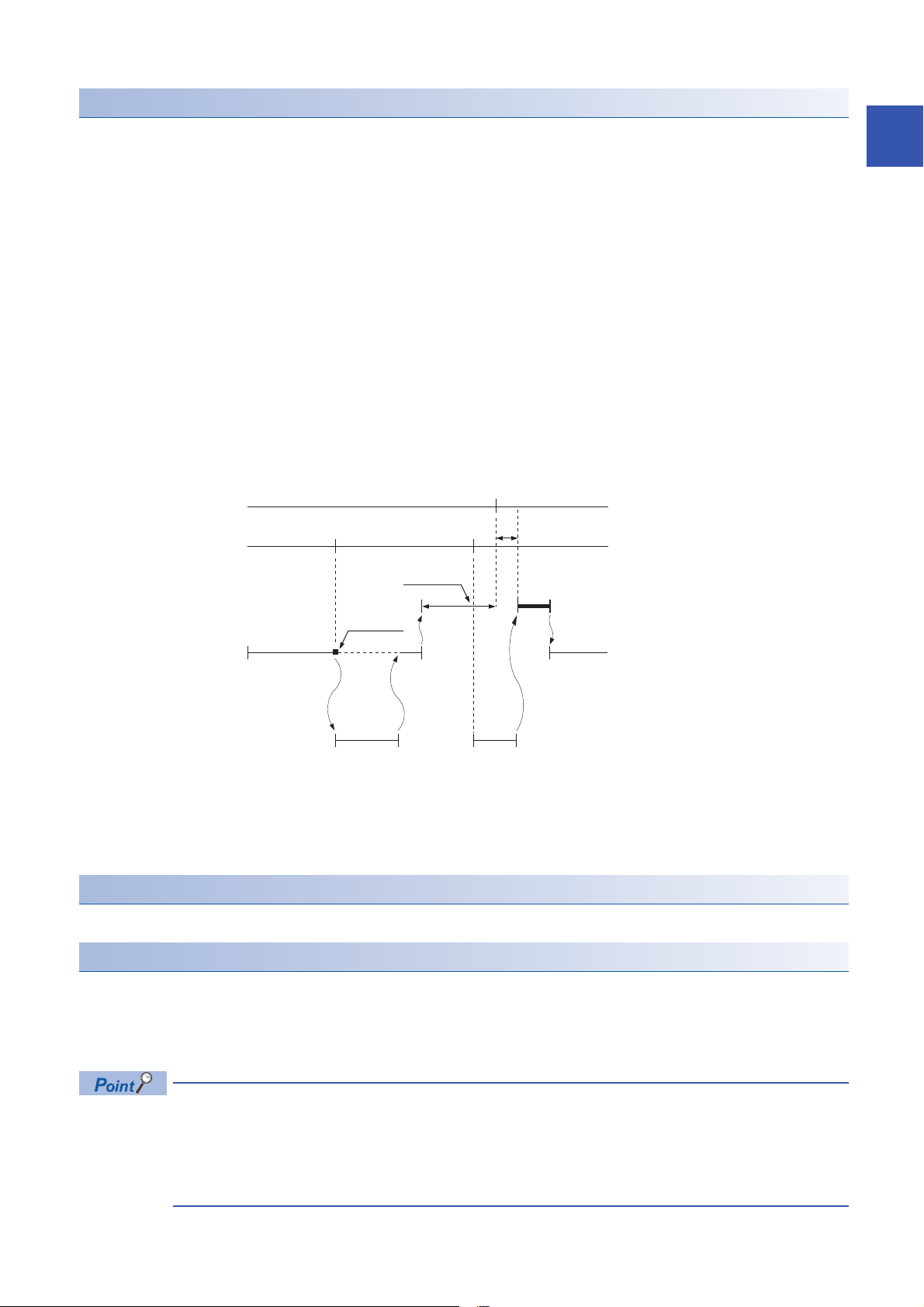

Action when the execution condition is satisfied

Fixed scan interval

END processing

Scan execution type program

Fixed scan execution type program

Condition

established

Constant scan

*1

Waiting time

Performs the following action.

■If the execution condition is satisfied before the interrupt is enabled by the EI instruction

The program enters the waiting status and is executed when the interrupt is enabled. Note that if the execution condition for

this fixed scan execution type program is satisfied more than once during the waiting status, the program is executed only

once when the interrupt is enabled.

■When there are two or more fixed scan execution type programs

When the specified time intervals expire in the same timing, the programs are executed in order according to the priority (I31

> I30 > I29 > I28) of the periodic interrupt pointer.

■If another or the same execution condition is satisfied while the fixed scan execution type

program is being executed

Operates according to the fixed scan execution mode setting.

■If the execution condition is satisfied while the interrupt is disabled by the system

Operates according to the fixed scan execution mode setting.

■When an interrupt is generated during a standby while executing constant scan

Executes the fixed scan execution type program.

1

*1 If processing does not finish during the waiting time, the scan time is extended.

■If another interrupt occurs while the fixed scan execution type program is being executed

If an interrupt program is triggered while the fixed scan execution type program is being executed, the program operates in

accordance with the interrupt priority.

Processing when the fixed scan execution type program starts

The same processing as when the interrupt program starts. (Page 34 Processing at startup of interrupt program)

Fixed scan execution mode

If execution condition for a fixed scan execution type program and fixed cycle interrupt (I28 to I31) based on the internal timer

of the CPU module is satisfied while interruption is disabled, the operation of the program execution after interruption

becomes allowed is specified. However, if execution condition is satisfied while interruption is set to be disabled because of a

DI instruction or the like, this is out of the scope of the fixed scan execution mode.

"Interrupts disabled" refers to the following:

• A program having an interrupt priority higher than or the same as the corresponding program is currently

being executed.

• The corresponding program is currently being executed.

• Program execution is currently at a part in which interrupts are disabled by the system.

1 PROGRAM EXECUTION

1.4 Execution Type of Program

23

Page 26

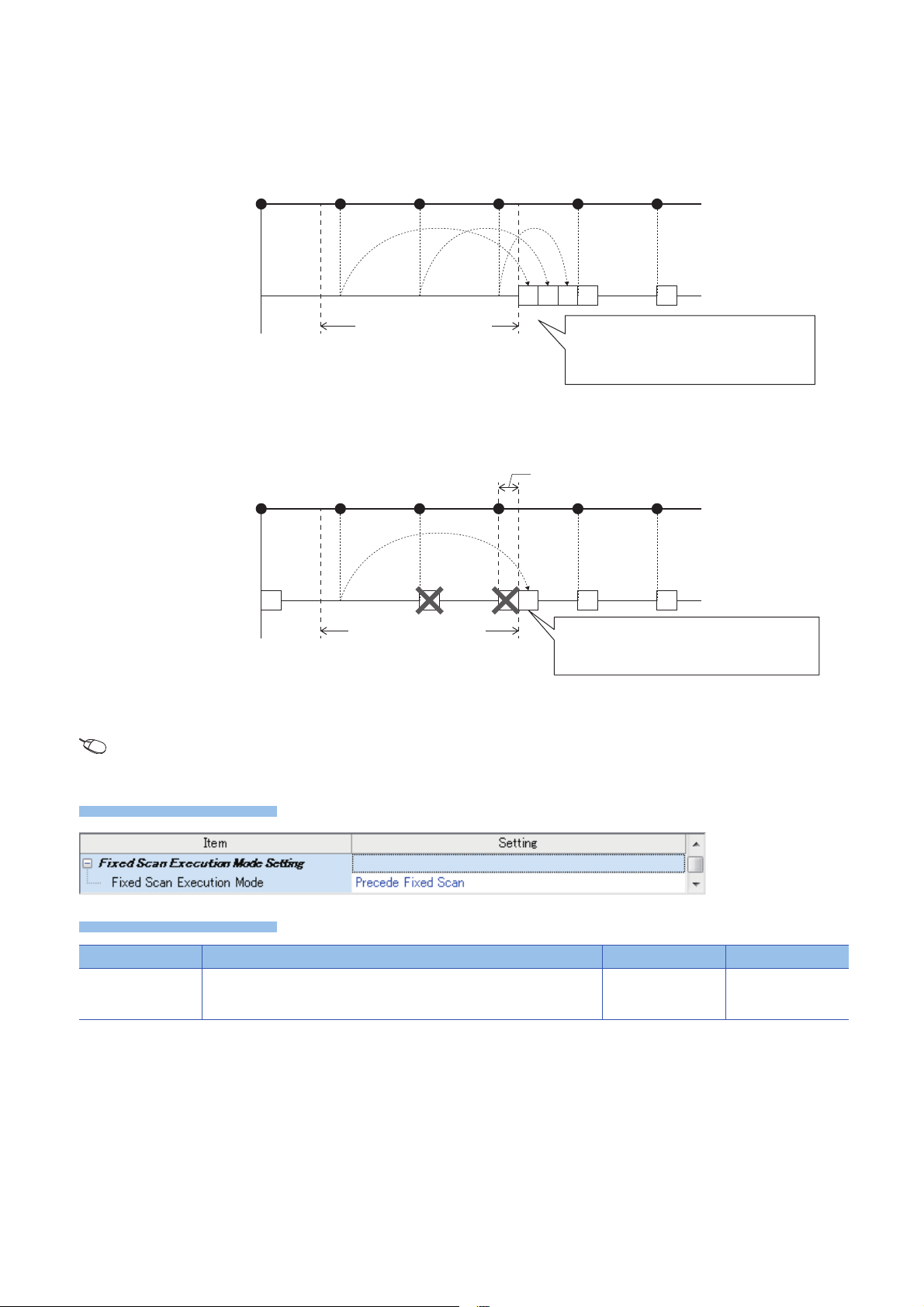

■Operation in the fixed scan execution mode

Window

Displayed items

[1]

Execution condition satisfied:

6 times

Cycle interval of TEISYU

"TEISYU"

(Fixed scan execution type program)

Number of executions:

6 times

All pending executions are executed and the

number of executions of the fixed scan is

guaranteed. (In the chart, three executions are

made immediately after interruption becomes

allowed [1]).

Section where interruptions

are disabled

Section where interruptions

are disabled

Execution condition satisfied:

6 times

Delay behind the cycle

Cycle interval of TEISYU

"TEISYU"

(Fixed scan execution type program)

Number of executions:

4 times

The program is executed once, and the fixed period

execution of the program is maintained. (Even if

execution condition was satisfied twice or more, only

one execution is made.)

This section describes the operation which can be performed in the fixed scan execution mode.

• Execution Count Takes Priority

The program is executed for all the pending number of executions so that it can be executed the same number of times as

execution condition was satisfied.

• Precede Fixed Scan

When the waiting for execution , one execution is made when interrupt becomes allowed. Even if execution condition was

satisfied twice or more, only one execution is performed.

■Fixed scan execution mode setting

Use the fixed scan execution mode setting.

Navigation window [Parameter] [FX5UCPU] [CPU Parameter] "Interrupt Settings" "Fixed Scan Execution

Mode Setting"

Item Description Setting range Default

Fixed Scan Execution

Mode

For Precede Fixed Scan, the periodicity of the program is maintained. For

Execution Count Takes Priority, the program is executed for all pending number

of executions.

• Precede Fixed Scan

• Execution Count

Takes Priority

Precede Fixed Scan

24

1 PROGRAM EXECUTION

1.4 Execution Type of Program

Page 27

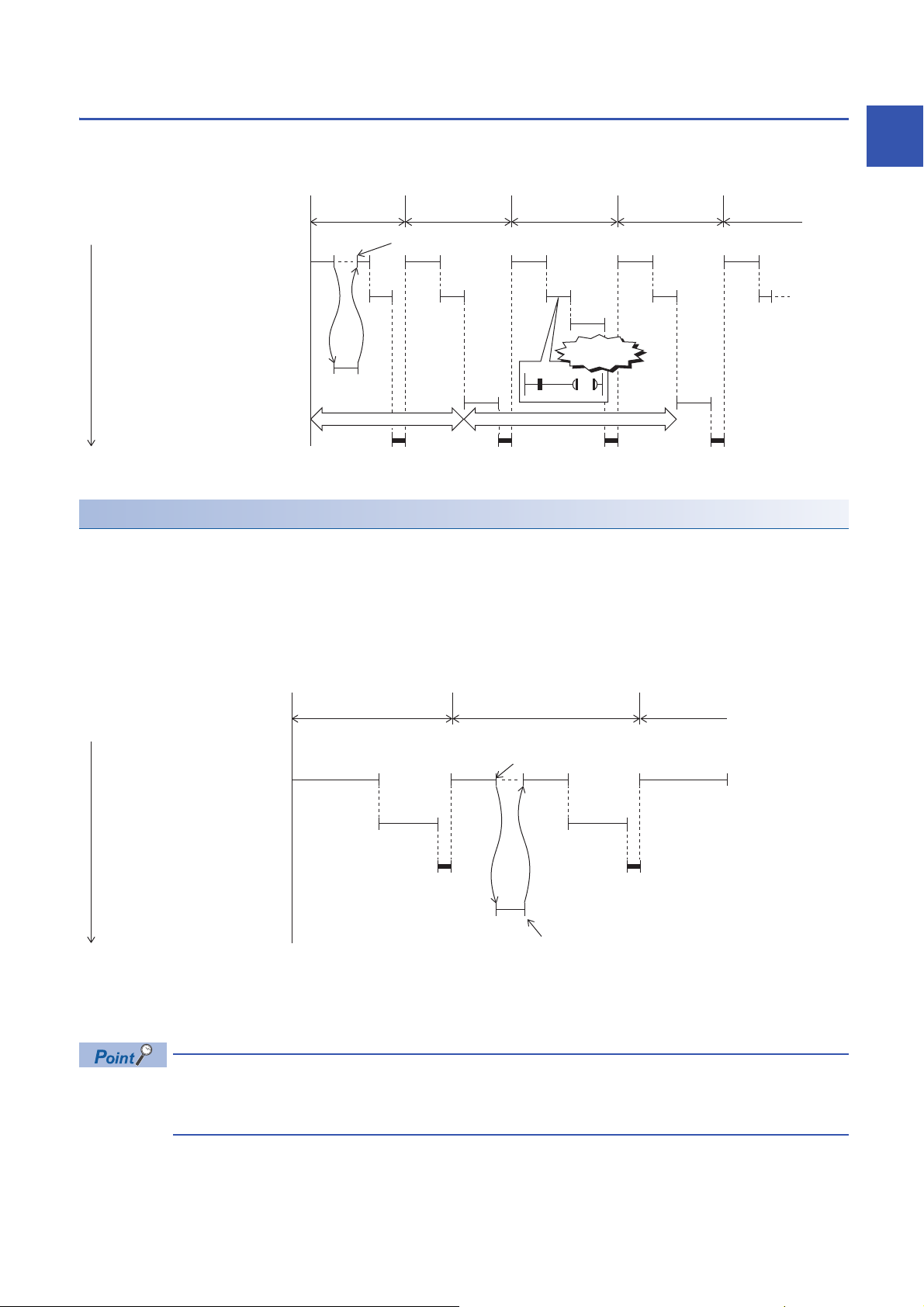

Event execution type program

Y50

M0

10 ms

*1

10 ms

*1

1st scan

I60 interrupt occurs

2nd scan 3rd scan 4th scan 5th scan

STOP/PAUSE→RUN

Scan execution type program A

END processing

Scan execution type program B

Execution order

Y50 turns ON

Event execution type program E

(Executed when 10 ms elapses)

Event execution type program D

(Executed when I60 interrupt occurs)

Event execution type program C

(Executed when Y50 turns ON)

(1)

1st scan

I60 interrupt occurs

2nd scan 3rd scan

STOP/PAUSE→RUN

Scan execution type program A

END processing

Scan execution type program B

Execution order

Event execution type program C

(Executed when I60 interrupt

occurs)

Execution of this program type is triggered by a user-specified event. (Page 25 Trigger type)

*1 Measurement of elapsed time is 10 ms or more because it is determined depending on the scan time.

Trigger type

Triggers for event execution type programs are explained below. (Page 27 Trigger setting)

■Generation of interrupt by interrupt pointer (I)

The program is executed once, immediately, when a specified interrupt cause is generated. An interrupt pointer label can be

appended by adding the FEND instruction to a different program, and the program description partitioned by the IRET

instruction can be turned into an exclusive program.

1

(1) Event execution type program C is executed immediately when the specified event is generated.

• Specifiable interrupt pointer (I)

Specifiable interrupt pointers are I0 to I15, I16 to I23, and I50 to I177.

Execution conditions for the event execution type program which is triggered by interrupt occurred by the

interrupt pointer (I) are the same as those for general interrupt programs. (Page 31 Operation when an

interrupt is generated)

1 PROGRAM EXECUTION

1.4 Execution Type of Program

25

Page 28

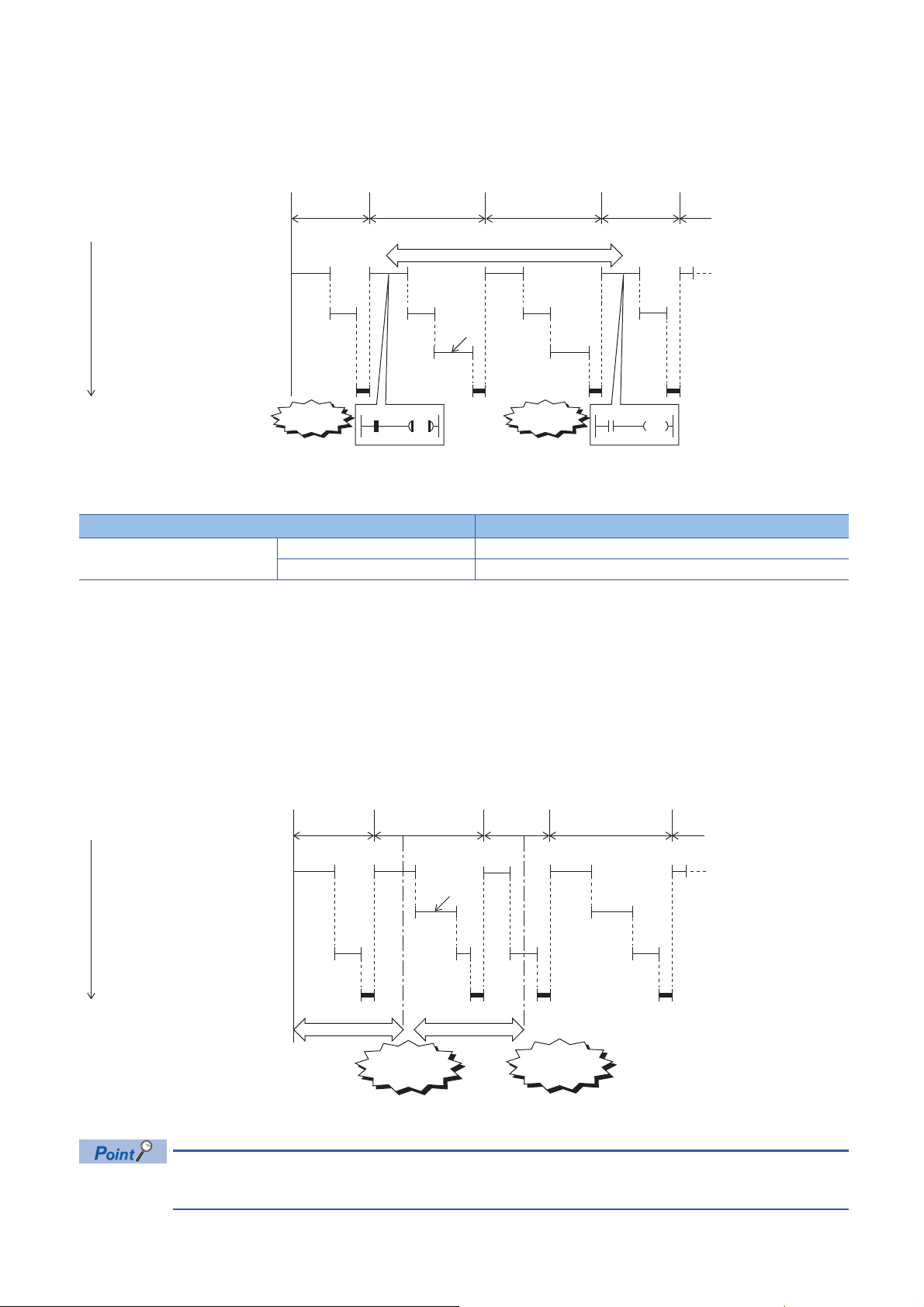

■Bit data ON (TRUE)

Y50

M0

Y50

M0

(1)

1st scan 2nd scan 3rd scan 4th scan

STOP/PAUSE→RUN

Scan execution type program A

END processing

Scan execution type program B

Execution order

Y50 is the ON interval

Y50 turns OFFY50 turns ON

Event execution type program C

(Executed when Y50 turns ON)

10 ms 10 ms

(1)

1st scan 2nd scan 3rd scan 4th scan

STOP/PAUSE→RUN

Scan execution type program A

END processing

Scan execution type program B

Execution order

Measurement interval

Event execution type program C

(Executed when 10 ms elapses)

Specified time 10

ms has passed

Specified time 10

ms has passed

When it is the turn of the corresponding program to be executed, the program is executed if the specified bit data is ON. This

eliminates the need for creating a program for monitoring triggers in a separate program.

(1) The program is executed if Y50 is ON when it is the turn of event execution type program C to be executed.

Applicable devices are as follows.

Item Description

*1

Device

Bit device X (DX), Y, M, L, F, SM, B, SB

Bit specification in word device D, SD, W, SW, R, U\G

*1 Indexed devices cannot be specified.

■Elapsed time

The program is executed once when it is the turn of the corresponding program to be executed first after the CPU module is

run and the specified time has elapsed. For second execution onwards, the time is re-calculated from the start of the previous

event execution type program. When it is the turn of the corresponding program to be executed first after specified time has

elapsed, program execution is repeated. Output (Y) currently used in the corresponding program and the current values of

timer (T) can be cleared at the next scan following execution of the corresponding program. This will not be always executing

an interrupt at a constant cycle but can be used when executing a specified program after a specified time has elapsed.

(1) When it is the turn of the first execution after the specified time has elapsed, event execution type program C is executed.

Output and timer current values are not cleared even when the program is set so that output and timer current

values are cleared, if the scan time is longer than the elapsed time set value.

26

1 PROGRAM EXECUTION

1.4 Execution Type of Program

Page 29

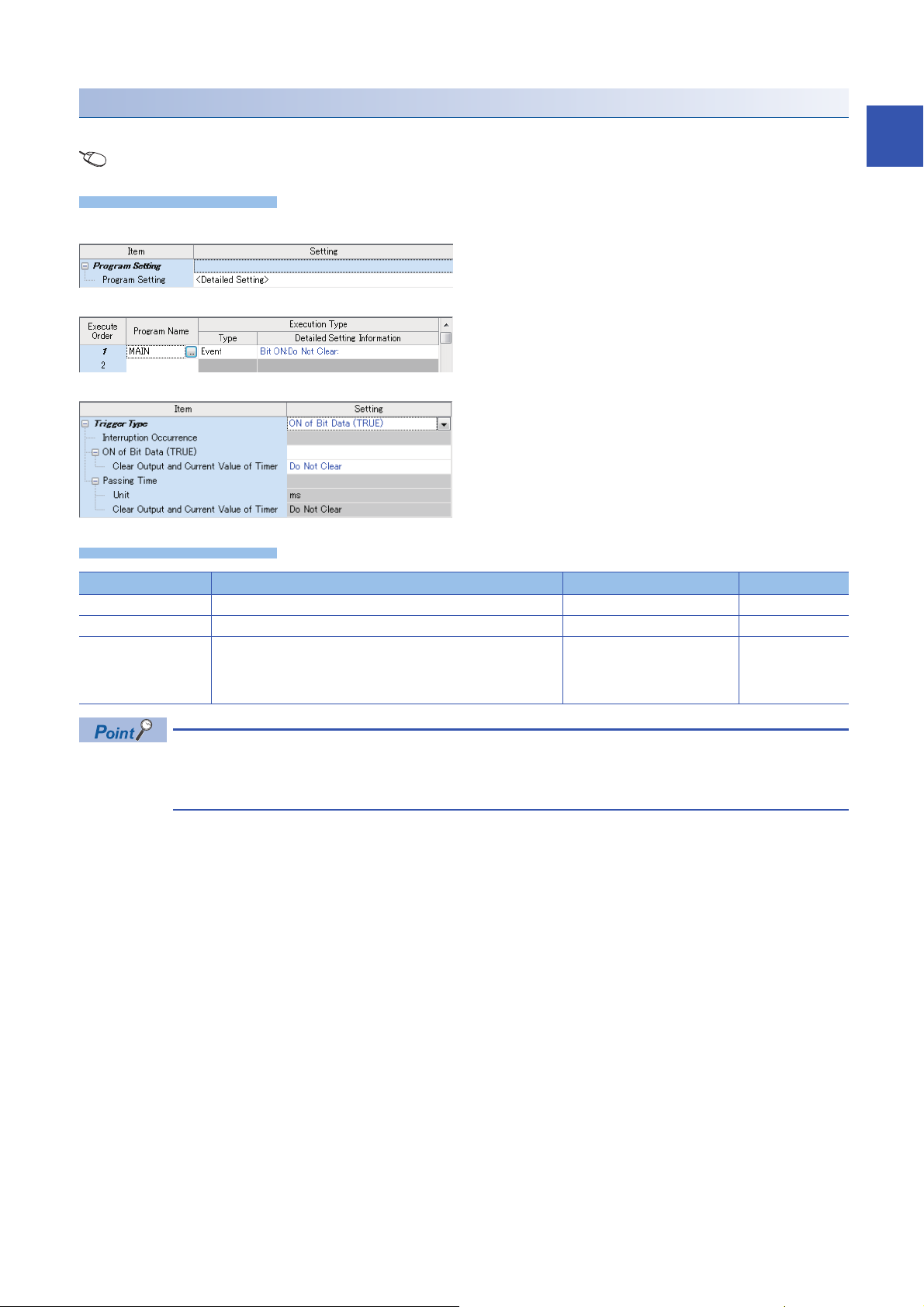

Trigger setting

Operating procedure

Displayed items

Use the event execution type detail setting.

Navigation window [Parameter] [FX5UCPU] [CPU Parameter] "Program Setting"

1

"Program Setting" window

"Detailed Setting" window

1. Click "Detailed Setting" on the Program Setting.

2. Select the program name and set the execution type to

"Event".

3. Click "Detailed Setting Information".

"Event Execution Type Detailed Setting" window

Item Description Setting range Default

Interruption Occurrence Sets the interrupt pointer used as the trigger. I0 to I23, I50 to I177

ON of Bit Data (TRUE) Sets the device used as the trigger. Page 26 Bit data ON (TRUE)

Passing Time Sets the elapsed time. • When "ms" is selected: 1 to

4. Set the trigger type to execute the event execution type

program.

65535 ms (in 1 ms units)

• When "s" is selected: 1 to

65535 s (in 1 s units)

When "Clear Output and Current Value of Timer" is enabled together with "ON of Bit Data (TRUE)" or

"Passing Time", the current values of the output (Y) and timer (T) of this program can be cleared at the first

execution turn of this program that comes after the trigger turns OFF.

1 PROGRAM EXECUTION

1.4 Execution Type of Program

27

Page 30

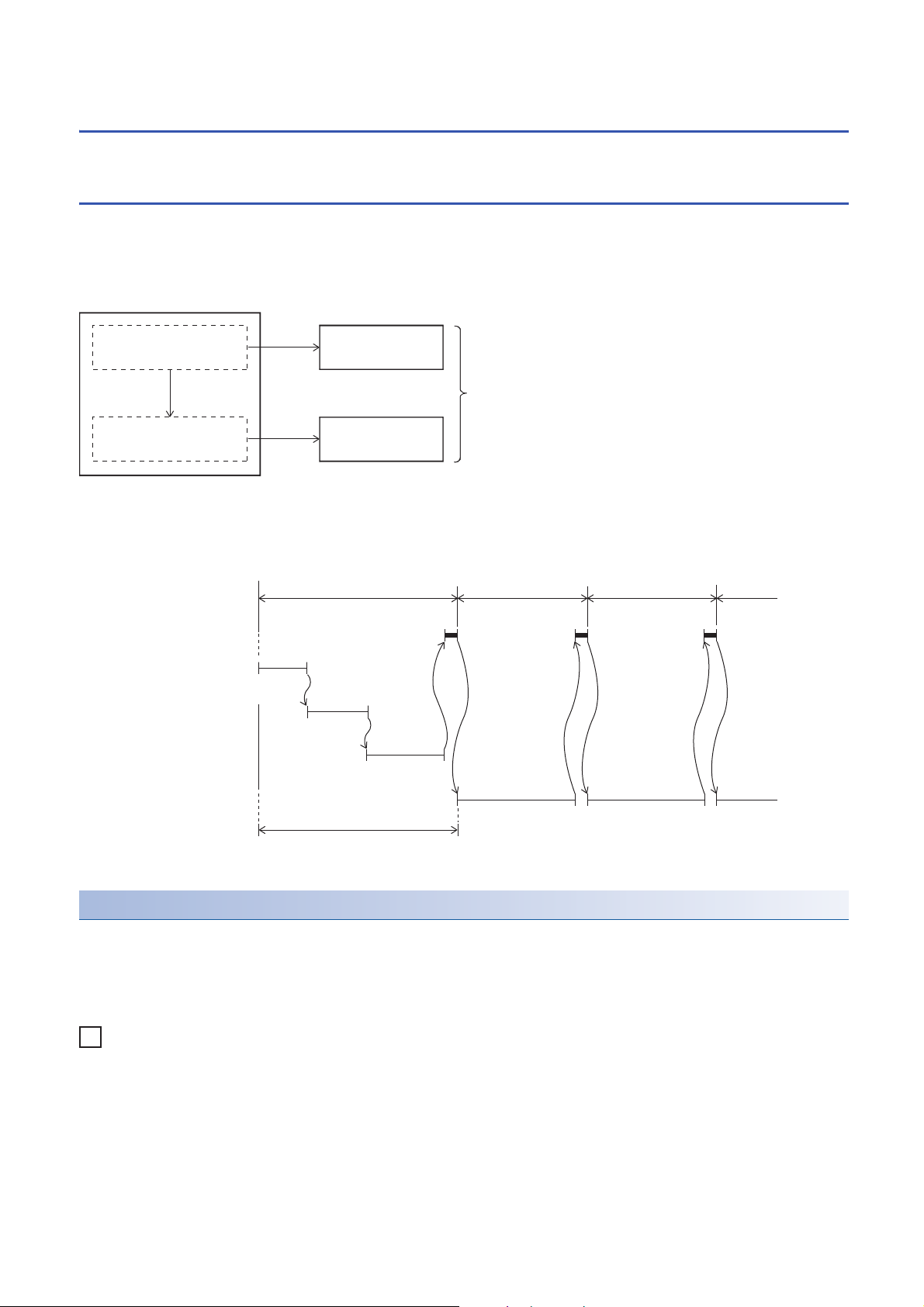

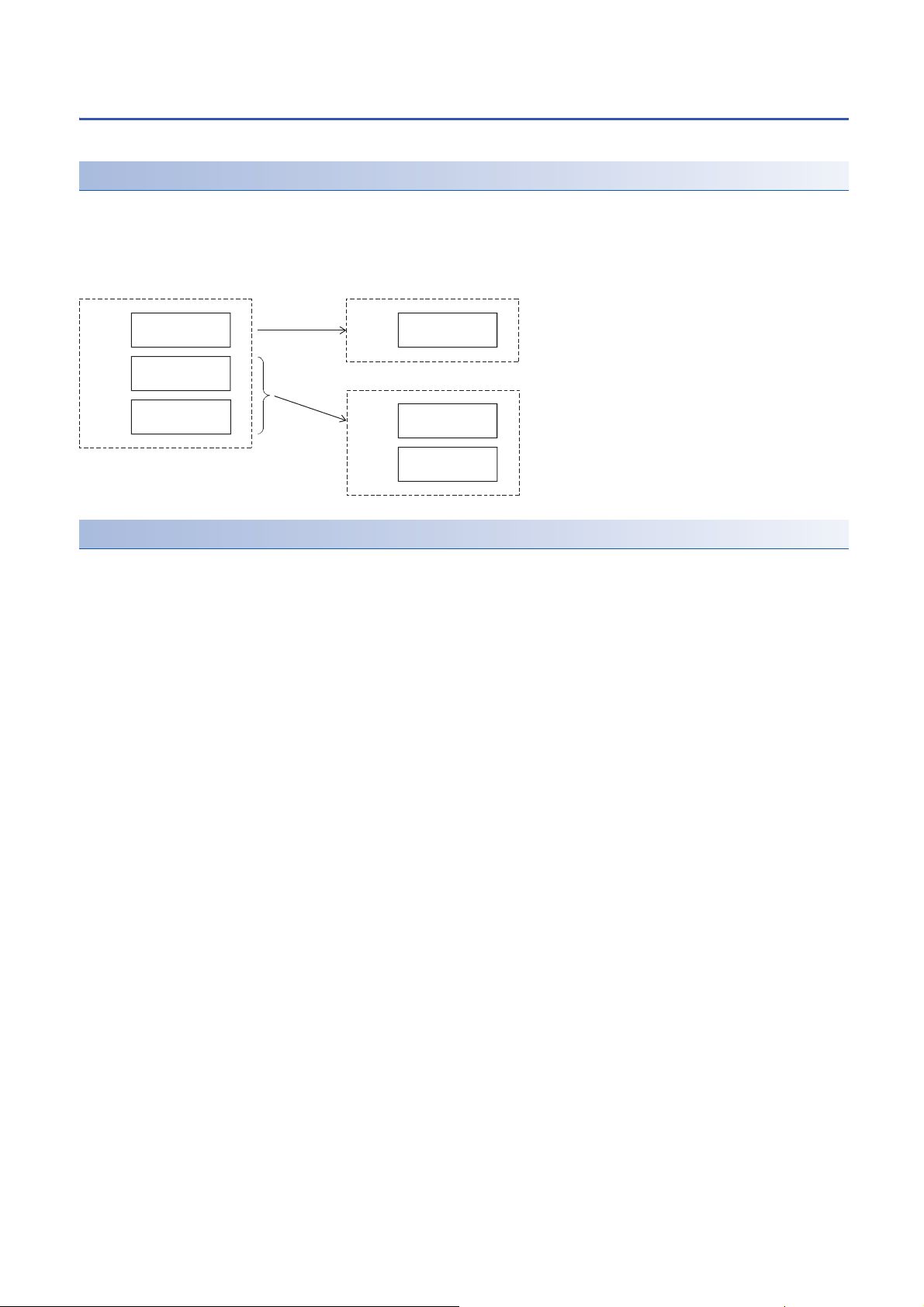

Stand-by type program

P100

I0

P100

I0

Scan execution type program Scan execution type program

Stand-by type program

Main routine

program

Subroutine

program

Interrupt

program

Main routine

program

Subroutine

program

Interrupt

program

This program is executed only when there is an execution request.

Saving programs in library

Subroutine programs or interrupt programs are saved as standby type programs so that they can be used when controlled

separately from the main routine program. Multiple subroutine programs and interrupt programs can be created in one

standby type program.