Page 1

TRANSISTORIZED INVERTER

FR-C

500

INSTRUCTION MANUAL

INVERTER WITH BUILT-IN PLC FUNCTION

(plus COMMUNICATION COMPATIBILITY)

FR-C520-0.1K

to

3.7K

INSTALLATION AND

WIRING

OPERATION AND

CONTROL

INVERTER

FUNCTIONS

Chapter 1

Chapter 2

Chapter 3

PLC FUNCTION

CC-Link

COMMUNICATION

PROTECTIVE

FUNCTIONS

SPECIFICATIONS

Chapter 4

Chapter 5

Chapter 6

Chapter 7

Page 2

This instruction manual gives handling information and precautions for use of this

product.

Please forward this manual to the end user.

This section is specifically about safety matters

Do not attempt to install, operate, maintain or inspect the inverter until you have read

through this instruction manual and appended documents carefully and can use the

equipment correctly. Do not use the inverter until you have a full knowledge of the

equipment, safety information and instructions.

In this instruction manual, the safety instruction levels are classified into "WARNING"

and "CAUTION".

WARNING

CAUTION

Assumes that incorrect handling may cause hazardous

conditions, resulting in death or severe injury.

Assumes that incorrect handling may cause hazardous

conditions, resulting in medium or slight injury, or may cause

physical damage only.

Note that even the level may lead to a serious consequence

according to conditions. Please follow the instructions of both levels as they are

important to personnel safety.

1. Electric Shock Prevention

CAUTION

WARNING

While power is on or when the inverter is running, do not open the front cover. You

!!!!

may get an electric shock.

Do not run the inverter with the front cover removed. Otherwise, you may access

!!!!

the exposed high-voltage terminals or the charging part of the circuitry and get an

electric shock.

If power is off, do not remove the front cover except for wiring or periodic inspection.

!!!!

You may access the charged inverter circuits and get an electric shock.

Before starting wiring or inspection, switch power off, wait for more than at least 10

!!!!

minutes and check for the presence of any residual voltage with a meter, etc.

Earth (ground) the inverter in a class D or higher protective earthing (grounding)

!!!!

method.

Any person who is involved in the wiring or inspection of this equipment should be

!!!!

fully competent to do the work.

Always install the inverter before wiring. Otherwise, you may get an electric shock

!!!!

or be injured.

Operate the switches with dry hands to prevent an electric shock.

!!!!

Do not subject the cables to scratches, excessive stress, heavy loads or pinching.

!!!!

Otherwise, you may get an electric shock.

Do not change the cooling fan with power on. It is dangerous to c hange the cooling

!!!!

fan while power is on.

2. Fire Prevention

CAUTION

Mount the inverter on incombustible material. Mounting it to or near combustible

!!!!

material can cause a fire.

If the inverter has become faulty, switch off the inverter power. A continuous flow of

!!!!

large current could cause a fire.

Do not connect a resistor directly to the DC terminals P(+), N(+). This could cause a fire.

!!!!

A-1

Page 3

3. Injury Prevention

CAUTION

!

! Apply only the voltage specified in the instruction manual to each terminal to pre-

!!

vent damage, etc.

!

! Ensure that the cables are connected to the correct terminals. Otherwise, damage,

!!

etc. may occur.

!

! Always make sure that polarity is correct to prevent damage, etc.

!!

!

! While power is on or for some time after power-off, do not touch the inverter or

!!

brake resistor as they are hot and you may get burnt.

4. Additional instructions

Also note the following points to prevent an accidental failure, injury, electric shock, etc.:

(1) Transportation and installation

CAUTION

!

! When carrying products, use correct lifting gear to prevent injury.

!!

!

! Do not stack the inverter boxes higher than the number recommended.

!!

!

! Ensure that installation position and material can withstand the weight of the

!!

inverter. Install according to the information in the Instruction Manual.

!

! Do not operate if the inverter is damaged or has parts missing.

!!

!

! Do not hold the inverter by the front cover; it may fall off.

!!

!

! Do not stand or rest heavy objects on the inverter.

!!

!

! Check the inverter mounting orientation is correct.

!!

!

! Prevent screws, wire fragments or other conductive bodies, oil or other flammable

!!

substances from entering the inverter.

!

! Do not drop the inverter, or subject it to impact.

!!

!

! Use the inverter under the following environmental conditions:

!!

Ambient

temperature

Ambient

humidity

Storage

temperature

Ambience

Environment

Altitude,

vibration

*Temperatures applicable for a short time, e.g. in transit.

(2) Wiring

-10°C to +50°C (non-freezing)

90%RH or less (non-condensing)

-20°C to +65°C*

Indoors (free from corrosive gas, flammable gas, oil mist,

dust and dirt)

Max. 1000m above sea level

2

5.9m/s

{0.6G} or less (conforming to JIS C 0040)

CAUTION

!

! Do not fit capacitive equipment such as power factor correction capacitor, radio

!!

noise filter or surge suppressor to the output of the inverter.

!

! The connection orientation of the output cables U, V, W to the motor will affect the

!!

direction of rotation of the motor.

(3) Trial run

CAUTION

!

! Check all parameters, and ensure that the machine will not be damaged by a sud-

!!

den start-up.

A-2

Page 4

(4) Operation

WARNING

!

! The [STOP] key is valid only when the appropriate function setting has been made.

!!

Prepare an emergency stop switch separately.

!

! Make sure that the start signal is off before resetting the inverter alarm. A failure to

!!

do so may restart the motor suddenly.

!

! The load used should be a three-phase induction motor only. Connection of any

!!

other electrical equipment to the inverter output may damage the equipment.

!

! Do not modify the equipment.

!!

CAUTION

!

! The electronic overcurrent protection does not guarantee protection of the motor

!!

from overheating.

!

! Do not use a magnetic contactor on the inverter input for frequent starting/stopping

!!

of the inverter.

!

! Use a noise filter to reduce the effect of electromagnetic interference. Otherwise

!!

nearby electronic equipment may be affected.

!

! Take measures to suppress harmonics. Otherwise power harmonics from the

!!

inverter may heat/damage the power capacitor and generator.

!

! When parameter clear is performed, each parameter returns to the factory setting.

!!

Re-set the required parameters before starting operation.

!

! The inverter can be easily set for high-speed operation. Before changing its set-

!!

ting, fully examine the performances of the motor and machine.

!

! In addition to the inverter's holding function, install a holding device to ensure

!!

safety.

!

! Before running the inverter which had been stored for a long period, always per-

!!

form inspection and test operation.

(5) Emergency stop

CAUTION

!

! Provide a safety backup such as an emergency brake which will prevent the

!!

machine and equipment from hazardous conditions if the inverter fails.

(6) Maintenance, inspection and parts replacement

CAUTION

!

! Do not carry out a megger (insulation resistance) test on the control circuit of the

!!

inverter.

(7) Disposing of the inverter

CAUTION

!

! Treat as industrial waste.

!!

(8) General instructions

Many of the diagrams and drawings in this instruction manual show the inverter

without a cover, or partially open. Never operate the inverter in this status. Always

replace the cover and follow this instruction manual when operating the inverter.

A-3

Page 5

CONTENTS

1. INSTALLATION AND WIRING 1

1.1 Basic Config u ration............ .. ............................. ............... ...........2

1.2 Precautions for Use ....................................................................3

1.3 Installation of the Inverter............................................................3

1.4 Terminal Connection Diagram....................................................5

1.5 Wiring of the Power Supply and Motor........................................6

1.5.1 Description of the main circuit terminals....................................................... 6

1.5.2 Layout and wiring of the main circuit terminals............................................. 6

1.5.3 Cables, wiring lengths, crimping terminals, etc............................................. 6

1.6 Earthing (Grounding) Precautions...............................................7

1.7 Control Circuit .............................................................................8

1.7.1 Description of the control circuit terminals....................................................8

1.7.2 Layout and wiring of the control circuit terminals........................................ 10

1.7.3 Layout and wiring of the CC-Link terminals................................................ 11

1.7.4 Changing the control logic ..........................................................................12

1.7.5 RS-485 Connector......................................................................................14

1.7.6 Connection of the parameter unit (FR-PU04)............................................. 14

1.8 Input Terminals.........................................................................15

1.8.1 Run (start) and stop (STF, STR)................................................................. 15

1.8.2 External frequency selection (RH, RM, RL)................................................ 17

1.8.3 Control circuit common terminals (SD, SE) ................................................ 18

1.8.4 Signal inputs by contactless switches......................................................... 18

1.9 How to Use the Input Signals (Assigned Terminals RL, RM, RH,

STR, SQ) ..................................................................................19

1.9.1 Multi-speed setting (RL, RM, RH signals): Pr. 60 to Pr. 63, Pr. 65, Pr. 505

setting "0, 1, 2"............................................................................................19

1.9.2 Output shut-off (MRS signal): Pr. 60 to Pr. 63, Pr. 65, Pr. 505 setting "6".. 1 9

1.9.3 External thermal relay input: Pr. 60 to Pr. 63, Pr. 65, Pr. 505 setting "7".... 19

1.9.4 Reset signal: Pr. 60 to Pr. 63, Pr. 65, Pr. 505 setting "10".......................... 20

1.9.5 Start (forward rotation) signal: Pr. 65 setting "17".......................................20

1.9.6 Sequence start: Pr. 60 to Pr. 63, Pr. 65, Pr. 505 setting "50" ..................... 21

1.9.7 No function: Pr. 60 to Pr. 63, Pr. 65, Pr. 505 setting "9998" ....................... 21

1.9.8 Start (reverse rotation) signal: Pr. 63 setting "9999"...................................21

1.10 Peripheral Devices.............. .......................................... ............22

1.10.1 Peripheral device list................................................................................... 22

1.10.2 Leakage current and installation of earth (ground) leakage circuit breaker 22

1.10.3 Power-off and magnetic contactor (MC)..................................................... 26

1.10.4 Regarding the installation of the power factor improving reactor................ 27

1.10.5 Regarding noises and the installation of the noise filter..............................28

1.10.6 Power harmonics........................................................................................29

I

Page 6

1.10.7 Power harmonic suppression guideline.......................................................30

1.11 Connection of Stand-Alone Option Units...................................33

1.11.1 Connection of the conventional BU brake unit (option)...............................33

1.11.2 Connection of the FR-HC high power factor converter (option)..................33

1.11.3 Connection of the power regeneration common converter (FR-CV)...........34

1.12 Wiring of the Inverter and Personal Computer Using

GX Developer for RS-485 Communication ......................... ......35

1.13 Wiring fo r C C -L i n k C o m mu n i c a t io n ..... .. ... ............................ .....36

1.14 Wiring of the Inverter and Computer Using

RS-485 communication........................................................... ..38

1.15 Desi g n In f o rm a t io n ................... ................ ............................ .....40

2. OPERATION AND CONTROL 41

2.1 Parts Identification and Functions of the

Operation Panel ............................. ...........................................42

2.2 Operation Mode Switching........................................................42

2.3 Monitor Transition......................................................................43

2.4 Monitoring the Output Current...................................................43

2.5 Displaying the CC-Link Data (Station Number, Baudrate)........43

2.6 LED On/Off Operations .............................................................44

2.6.1 How to check the LED lamps for CC-Link

communication errors................................. ..... ...... ...... ................................45

CONTENTS

3. INVERTER FUNCTIONS 49

3.1 Function (Parameter) List..........................................................50

3.2 List of Parameters Classified by Purpose of Use......................55

3.3 Basic Functions.........................................................................56

3.3.1 Torque boost (Pr. 0)....................................................................................56

3.3.2 Maximum and minimum frequencies (Pr. 1, Pr. 2)......................................57

3.3.3 Base frequency (Pr. 3)................................................................................58

3.3.4 Multi-speed operation (Pr. 4, Pr. 5, Pr. 6)....................................................59

3.3.5 Acceleration/deceleration time (Pr. 7, Pr. 8)................................................60

3.3.6 Electronic thermal O/L relay (Pr. 9).............................................................61

3.3.7 DC injection brake (Pr. 10, Pr. 11, Pr. 12)...................................................61

3.3.8 Starting frequency (Pr. 13)..........................................................................62

3.3.9 key rotation direction selection (Pr. 17)...........................................63

3.3.10 Stall prevention function and current limit function

3.3.11 Start-time earth (ground) fault detection selection (Pr. 40) .........................66

3.4 Operation Panel Display Selection............................................67

RUN

(Pr. 21, Pr. 22).............................................................................................63

II

Page 7

3.4.1 Monitor display (Pr. 52)............................................... ...... ..... ..................... 67

3.5 I/O Terminal Function Selection................................................68

3.5.1 Input terminal function selection (Pr. 60, Pr. 61, Pr. 62,

Pr. 63, Pr. 65, Pr. 505)............................................................................... 68

3.5.2 Output terminal function selection (Pr. 64, Pr. 505)....................................69

3.6 Operation Selection Function Parameters................................70

3.6.1 Applied motor (Pr. 71).................................................................................70

3.6.2 PWM carrier frequency (Pr. 72).................................................................. 70

3.6.3 Reset selection/PU stop selection (Pr. 75) .................................................71

3.6.4 Cooling fan operation selection (Pr. 76)......................................................73

3.6.5 Parameter write disable selectio n (Pr. 77)........................ ..... ...... ...... ......... 74

3.6.6 Operation mode and command source (Pr. 79, Pr. 338,

Pr. 339, Pr. 340).......................................................................................... 75

3.7 Computer L in k Op e r a tio n S e tting.......................................... ....79

3.7.1 Communication settings (Pr. 331 to Pr. 337, Pr. 341)................................79

3.7.2 E2PROM write selection (Pr. 342).............................................................. 92

3.8 Parameter Unit (FR-PU04) Setting ...........................................93

3.8.1 Parameter display language selection (Pr. 145)......................................... 93

3.8.2 PU buzzer control (Pr. 990) ........................................................................93

3.8.3 PU contrast adjustment (Pr. 991)................................................................ 94

3.8.4 PU main display screen data selection (Pr. 992)........................................ 94

3.8.5 PU disconnection detection/PU setting lock (Pr. 993)................................95

4. PLC FUNCTION 97

4.1 System Configuration................................................................98

4.2 Prior to Sequence Program Creation................................. .. .....99

4.2.1 Precautions for sequence program creation............................................... 99

4.2.2 Usable main GX Developer functions......................................................... 99

4.2.3 Sequence program execution key ............................................................ 100

4.2.4 Sequence program write...........................................................................101

4.3 Function Block Diagram.............................. ...................... ......102

4.3.1 Setting list of built-in PLC function parameter........................................... 103

4.4 PLC Instructions......................................................................104

4.4.1 How to use the instruction list...................................................................104

4.4.2 PLC instruction list................................ ..... ...... .........................................106

4.5 Device Map ...... ... .. ............................ ............................. .........109

4.5.1 I/O device map..........................................................................................109

4.5.2 Internal relay (M) device map ...................................................................110

4.5.3 Data register (D) device map.................................................................... 110

4.5.4 Special relays....................... ..... ...... ...... ..... ............................................. ..112

4.5.5 Special registers........................................ ...... ..... ....................................112

4.6 Inputs/Outputs.........................................................................114

III

Page 8

4.6.1 Input (X) assignment........................................................ ...... ...... .............114

4.6.2 Output (Y) assignment..............................................................................116

4.7 Inverter Status Monitoring, Special Registers for Control .......117

4.7.1 Data that can be read at all times..............................................................117

4.7.2 Data that are read by controlling (OFF to ON) the read command...........119

4.7.3 How to write data by controlling (OFF to ON) the write

command..................................................................................................121

4.7.4 Inverter operation status control................................................................126

4.7.5 Inverter parameter access error (D9150)..................................................128

4.7.6 Inverter status (D9151)..............................................................................128

4.8 Inverter Paramet er Read/Write Method .............................. ....129

4.8.1 Reading the inverter parameters...............................................................130

4.8.2 Writing the inverter parameters.................................................................132

4.9 User Area Read/Writ e Method.................... ...................... ......135

4.9.1 User parameter read/write method............................................................135

4.10 Debugging Mode Specifications..............................................136

4.11 Regi s te r D is p lay ..................... ............................. ....................13 7

4.12 Inverter Operation Lock Mode Setting.....................................138

5. CC-Link COMMUNICATION 139

5.1 System Configuration ..............................................................140

5.1.1 System configuration example..................................................................140

5.1.2 Regarding CC-Link Ver. 1.10....................................................................140

5.1.3 Function block diagram.............................................................................141

5.2 CC-Link Para m e t e rs.... .. ............................. ............................ .143

5.2.1 Setting of station number and baudrate (Pr. 503, Pr. 504)........................143

5.2.2 Regarding the operation mode..................................................................143

5.2.3 Operation at CC-Link communication error occurrence............................144

5.3 CC-Link I/O Sp e c if ic a tio n s ......... .. ............................. ..............145

5.4 Buffer Memory.........................................................................148

5.4.1 Remote output signals (Master module to inverter)..................................148

5.4.2 Remote input signals (Inverter to master module) ....................................149

5.4.3 Remote registers (Master module to inverter)...........................................150

5.4.4 Remote registers (Inverter to master module)...........................................151

CONTENTS

6. PROTECTIVE FUNCTIONS 153

6.1 Errors (Alarms)........................................................................154

6.1.1 Error (alarm) definitions.............................................................................155

6.1.2 To know the operating status at the occurrence of alarm

(Only when FR-PU04 is used)..................................................................161

6.1.3 Correspondences between digital and actual characters..........................161

IV

Page 9

6.1.4 Resetting the inverter................................................................................ 161

6.2 Troubleshooting......................................................................162

6.2.1 Motor remains stopped ............................................................................. 162

6.2.2 Motor rotates in opposite direction............................................................ 162

6.2.3 Speed greatly differs from the setting.......................................................163

6.2.4 Acceleration/deceleration is not smooth...................................................163

6.2.5 Motor current is large................................................................................ 163

6.2.6 Speed does not increase..........................................................................163

6.2.7 Speed varies during operation.................................................................. 163

6.2.8 Operation mode is not changed properly..................................................164

6.2.9 Operation mode is not switched to CC-Link operation mode.................... 164

6.2.10 Inverter cannot be started in CC-Link operation mode ............................. 164

6.2.11 Operation panel display is not provided.................................................... 164

6.2.12 Parameter write cannot be performed................................... ...... ...... ..... ..164

6.2.13 Motor produces annoying sound............................................................... 164

6.3 Precautions for Maintenance and Inspection..........................165

6.3.1 Precautions for maintenance and inspection............................................ 165

6.3.2 Check items.............................................................................................. 165

6.3.3 Periodic inspection.................................................................................... 165

6.3.4 Insulation resistance test usin g megger........... ..... ...... ...... ........................ 166

6.3.5 Pressure test........................................................................................... ..166

6.3.6 Daily and periodic inspection....................................................................167

6.3.7 Replacement of parts................................................................................171

6.3.8 Measurement of main circuit voltages, currents and powers....................174

7. SPECIFICATIONS 177

7.1 Ratings....................................................................................178

7.2 Common Specifications ..........................................................179

7.3 PLC Function Specificat ions...................................................180

7.4 CC-Link Inte r fa c e Sp e c if ic a tio n s... .. ................ ............... .........180

7.5 Outline Drawings.....................................................................181

APPENDICES 183

Appendix 1 Parameter Data Codes for Computer Link

Operation U si n g R S -485 Commun ic a tion......... .. .........184

Appendix 2 Instructions for Compliance with

the European Standards..............................................187

Appendix 3 Instructions for compliance with U.S. and Canadian

Electrical Codes...........................................................189

V

Page 10

1. INSTALLATION AND WIRING

This chapter explains the "installation and wiring" for use of this

product.

Always read the instructions before use.

1.1 Basic Configuration ............................................. 2

1.2 Precautions for Use ............................................. 3

1.3 Installation of the Inverter ................................... 3

1.4 Terminal Connection Diagram............................. 5

1.5 Wiring of the Power Supply and Motor .............. 6

1.6 Earthing (Grounding) Precautions ..................... 7

1.7 Contr o l C ircuit ...... ................ ............... ................. 8

1.8 Input Terminals..................................................... 15

1.9 How to Use the Input Signals (Assigned

Terminals RL, RM, RH, STR, SQ)

1.10 Peripheral Devices.................... .. ......................... 22

1.11 Connection of Stand-Alone Option Units .......... 33

1.12 Wiring of the Inverter and Personal Computer

Using GX Developer for RS-485 Communication

1.13 Wiring for CC-Link Communication.................... 36

1.14 Wiring of the Inverter and Computer Using RS485 communication

1.15 Design Information............................................... 40

<Trademarks>

• CC-Link is a registered trademark of CC-Link Partner

Association.

• Other company and product names herein are the trademarks

or registered trademarks of their respective owners.

......................................................

............................

19

35

38

Chapter 1

Chapter 2

Chapter 3

Chapter 4

Chapter 5

Chapter 6

Chapter 7

1

Page 11

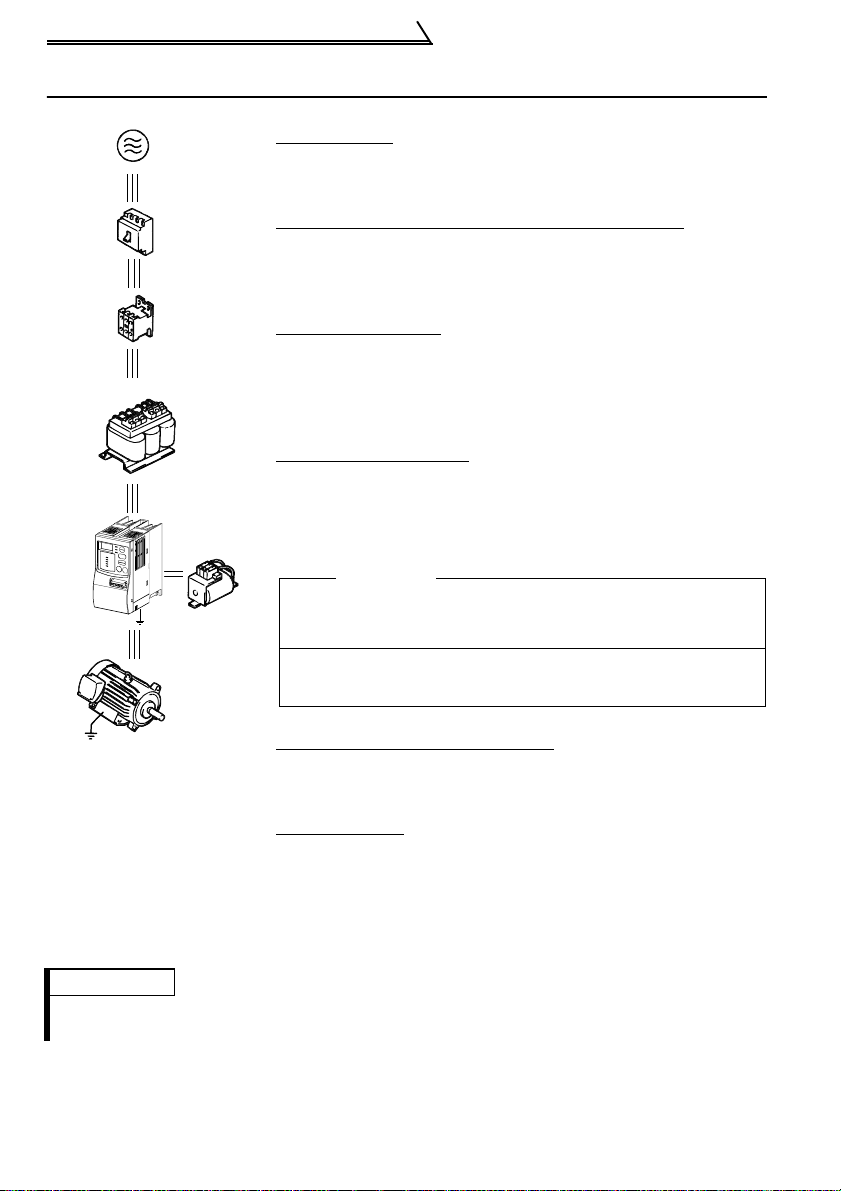

Basic Configuration

1.1 Basic Configuration

Power supply

Use within the permissible power supply specifications of the

inverter. (Refer to page 178.)

(NFB)

or

(ELB)

(MC)

AC reactor

(FR-BAL)

Earth

(Ground)

Earth (Ground)

DC reactor

(FR-BEL)

No-fuse breaker or earth leakage circuit breaker

The breaker must be selected carefully since an inrush current

flows in the inverter at power-on. (Refer to page 22.)

Magnetic contactor

Do not use this magn etic contacto r to start and stop th e inverter.

Doing so will cause the inverter life to be shorter. (Refer to page

22.)

Installation of reactors

The reactors must be used when the power factor is to be

improved or the inverter is installed near a large power supply

system (500kVA or more and w iring distance within 1 0m). Make

selection carefully. (Refer to page 22.)

Inverter

The inverter life is influenced by ambient temperature. The

ambient temperature should be as low as possible within the

permissible range. (Refer to page 4.)

Wrong wiring might lea d to damage of the inverter. The control

signal wires must be kept fully away from the main circuit to

protect them from noise. (Refer to page 5.)

Devices connected to the output

Do not connect a power factor correction capacitor, surge

suppressor or radio n oi se fi lter to the out put side.

Earth (Ground)

To prevent an electric shock, always earth (ground) the motor and

inverter.

For reduction of induction noise from the power line of the

inverter, it is recommended to wire the earth (ground) cable by

returning it to the earth (ground) terminal of the inverter.

(For details of noise reduction techniques, refer to pa ge 28.)

REMARKS

•When using t he P LC fu nc tion, refer to page 35 for wiring an d to page 98 for details.

•When using t he CC-Link function, refer to page 36 for wiring and to page 140 fo r de ta ils .

2

Page 12

Precautions for Use

1.2 Precautions for Use

Harmonic Suppression Guideline

The "harmonic suppression guideline for household appliances and general-purpose

products" issued by the Ministry of Economy, Trade and Industry (formerly Ministry of

International Trade and Industry) in September, 1994 applies to the FR-C500 series.

By installing the FR-BEL or FR-BAL power factor improving reactor, this product

complies with the "harmonic suppression techniques for transistorized inverters (input

current 20A or less)" established by the Japan Electrical Manufacturers' Association.

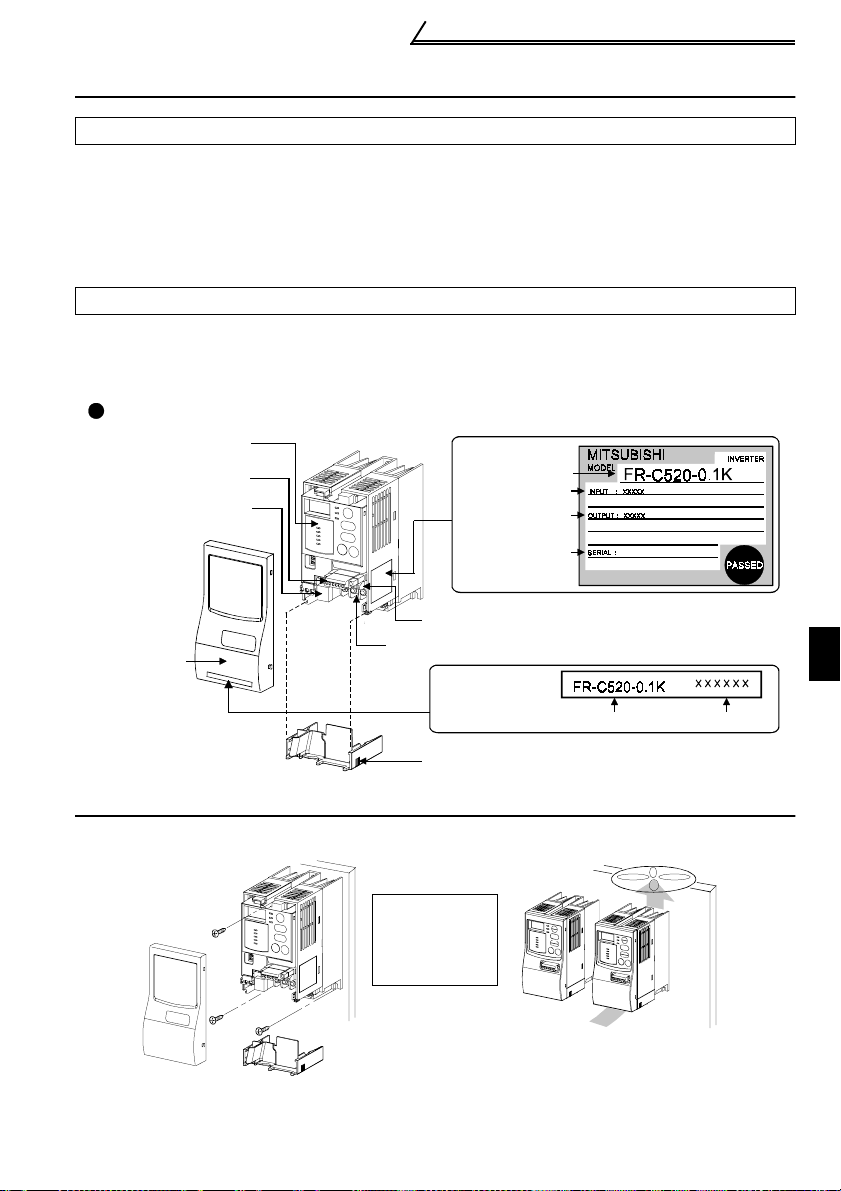

Product Checking and Parts Identification

Unpack the inverter and check the capacity plate on the front cover and the rating

plate on the inverter side face to ensure that the product agrees with your order and

the inverter is intact.

Part names and plates

Operation panel

CC-LINK connector

PU connector

(RS-485 connector)

Rating plate

Inverter type

Input rating

Output rating

Serial number

Control circuit terminal block

Front cover

Main circuit te rm inal block

Capacity plate

Wiring cove r

1.3 Installation of the Inverter

Enclosure surface mounting

Fix the front

cover and wiring

cover after

removing the m .

Leave enough clearances and

provide cooling measures.

3

Inverter type

Mounting inside enclosure

When containing two or more

inverters, ins tall them in parallel

and provide cooling measures.

Serial number

1

INSTALLATION AND WIRING

Page 13

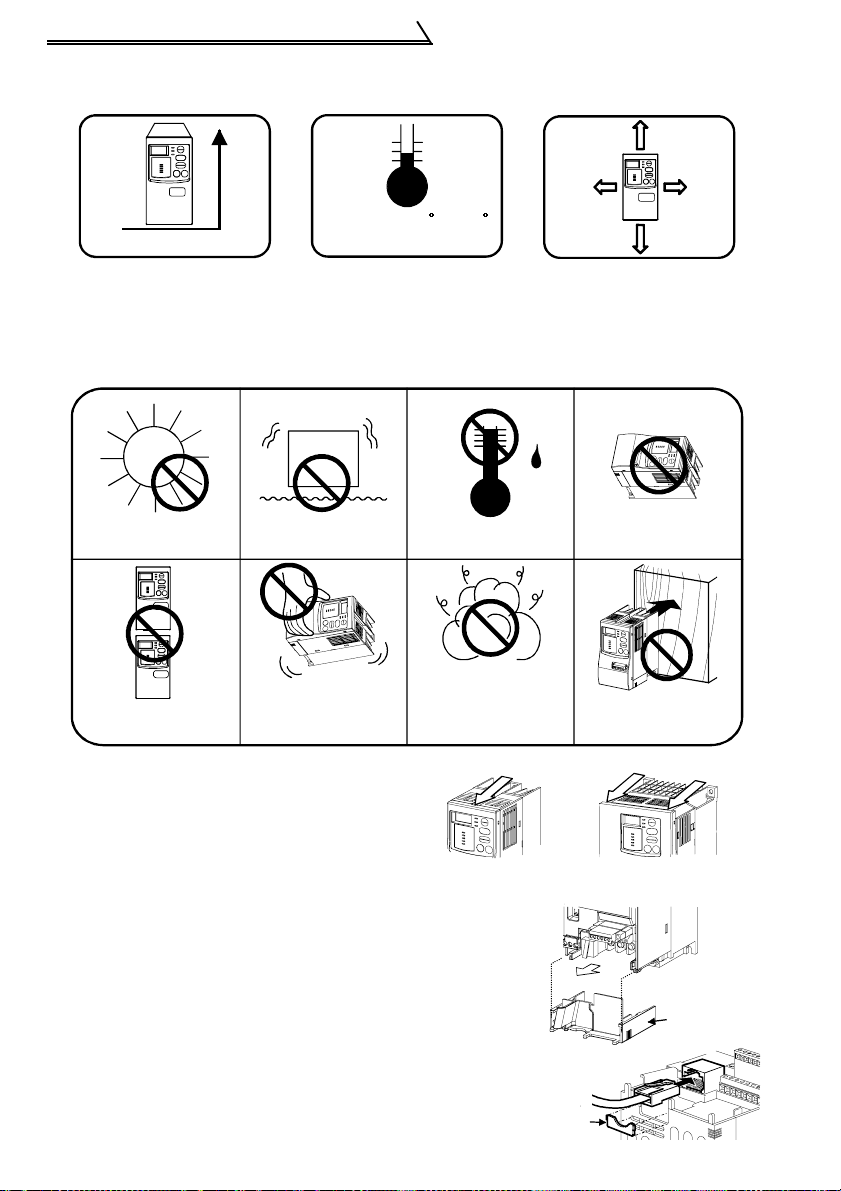

Installation of the Inverter

! Install the inverter under the following conditions:

Vertical mounting

Vertical

Ambient temperature and humidity

Temperature: -10 to 50

Humidity: 90%RH maximum

C C

Clearances

10cm or

more

1cm or

more

1cm or

more

10cm or

more

Clearances also necessary for

changing the cooling f an.

(1.5K or more)

! The inverter consists of precision mechanical and electronic parts. Never install or

handle it in any of the following conditions as doing so could cause an operation

fault or failure.

Direct sunlight

Vibration

(5.9m/s

2

max.)

High temperature,

high humidi ty

Oil mist,

Vertical mountin g (Wh en

mounted inside en closu re)

Transportation by

holding front cover

flammable gas,

corrosive gas,

fluff, dust, etc.

! Removal and reinstallation of the front

cover

Remove the front cover by pulling it

toward you in the direction of arrow.

To reinstall, match the cover to the inverter

front and in st all it straig ht.

FR-C520-0.1K to 0.75K FR-C520-1 .5K to 3.7K

! Removal and reinstallation of the wiring cover

The cover can be removed easily by pulling it toward

you.

To reinstall, fit the cover to th e in verter along the guides.

! Wiring of the RS-485 communication connector

When using the RS-485 connector to wire the cable, you

can cut off the lug of the wiring cover to wire it.

4

Horizontal placement

Mounting to

combustible material

Wiring

cover

Lug

Page 14

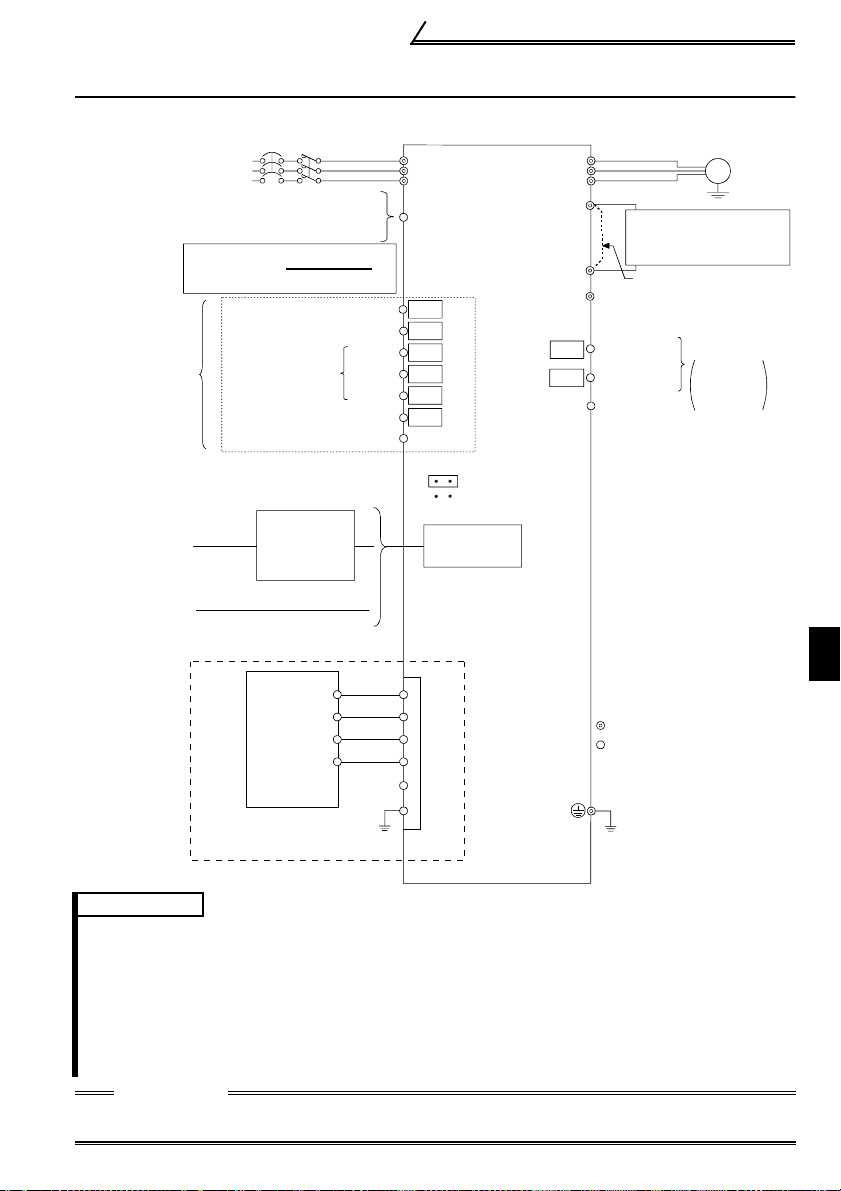

1.4 Terminal Connection Diagram

! Three-phase 200V power input

Three-phase AC

power supply

External transis tor common

24VDC power supply

Contact input common (source)

*2

Input terminals

Personal

computer

Parameter un it

(FR-PU04)

CC-Link co m m u nication signal s

NFB

MC

Be careful not to shor t

PC-SD.

Forward rotation start

Reverse rota tion start

Multi-speed

selection

Sequence start

High

Middle

Low

Contact input common

Control input signals

(No voltage input allowed)

*4

RS-232C

-RS-485

converter

R

S

T

PC

STF

STR

RH

RM

RL

SQ

SD

Inverter

*5

(X0)

(X1)

(X4)

(X3)

(X2)

(X5)

SINK

*1

SOURCE

PU connector

(RS-485)

(Y0)

(Y1)

Terminal Connection Diagram

U

V

W

P1

*5

RUN

ALM

SE

Power factor improving

DC reactor

(FR-BEL: Option)

P

N

Jumper: Remove

this jumper when

FR-BEL is connected.

Running

Alarm

output

Open

Output

terminals *3

collector

output common

Motor

IM

Earth

(Ground)

Open

collector

output

1

DA

DB

DG

SLD

DA

DB

DG

SLD

: Main circuit terminal

: Control circuit terminal

SLD

PLC CC-Link

FG

Earth (Ground)

master module

REMARKS

*1. You can change the control logic between sink and source logic. Refer to page 12 for details.

*2. The terminal functions cha nge with input terminal funct ion selection (Pr. 60 to Pr. 63, Pr.

65, Pr. 505). (Refer to page 68)

(RES, RL, RM, RH, MRS, OH, STR, STF, SQ signal, without function selection)

*3. The terminal functions change with out put terminal function selection (Pr. 64, Pr. 506).

(Refer to page 69.) (RUN, OL, ALM signal, without function selection)

*4. Only either the personal computer (e.g. GX Developer) or parameter unit can be

connected to the PU connector.

*5. For details of the I/O device, refer to page 109.

CAUTION

To prevent a malfunction due to noi se, keep the signal cables more t han 10cm away

from the power cables.

5

INSTALLATION AND WIRING

Page 15

Wiring of the Power Supply and Motor

1.5 Wiring of the Power Supply and Motor

1.5.1 Description of the main circuit terminals

Symbol T erminal Name Description

R/L1, S/L2, T/L3 Power input

U, V, W Inverter output

N/- DC voltage common

Power factor

P/+, P1

improving DC

reactor connection

Earth (Ground)

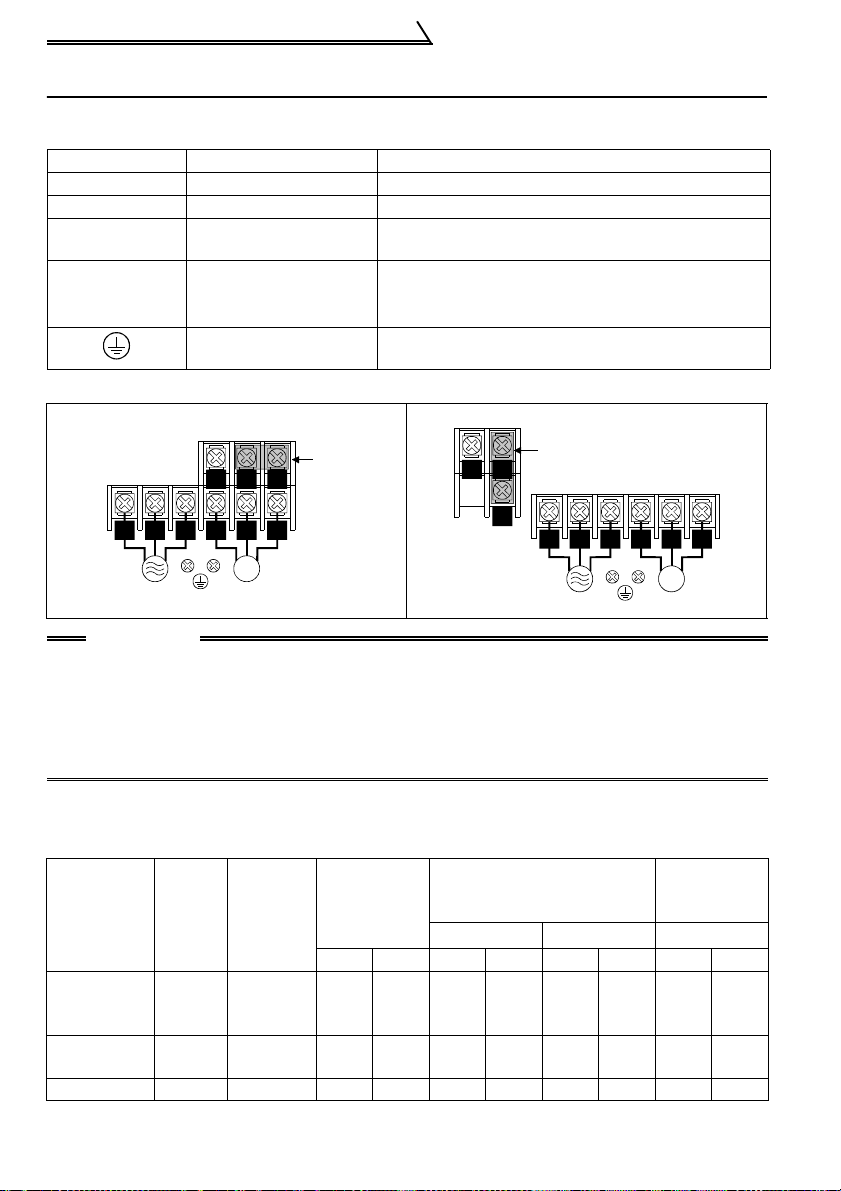

1.5.2 Layout and wiring of the main circuit terminals

FR-C520-0.1K, 0.2K, 0.4K, 0.75K

!

Connect to the commercial power supply.

Connect a three-ph ase squirrel-cage motor.

DC voltage common terminal. Not isolated from the

power supply and inv erter output.

Disconnect the jumper from t er m inal s P- P1 and

connect the optional po w er fac t or impr oving DC

reactor (FR-BEL).

For earthing (groundi ng) th e inverter chassis. Must

be earthed (grounded) .

FR-C520-1.5K, 2.2K, 3.7K

!

Jumper

P/+

P1

R/L1 S/L2 T/L3

Power supply

U V W

IM

Motor

R/L1 S/L2 T/L3

Power supply

P1

N/- P/+

U V W

IM

Motor

Jumper

N/-

CAUTION

•Always connect the power supply cables to R/L1, S/L2 and T/L3. Never

connect them to U, V and W since it will damage the inverter. (The phase

sequence need not be matched.)

•Connect the motor to U, V and W. When the forward rotation switch (signal) is

turned on at this time, the motor rotates in the counterclockwise direction as

viewed from the load shaft.

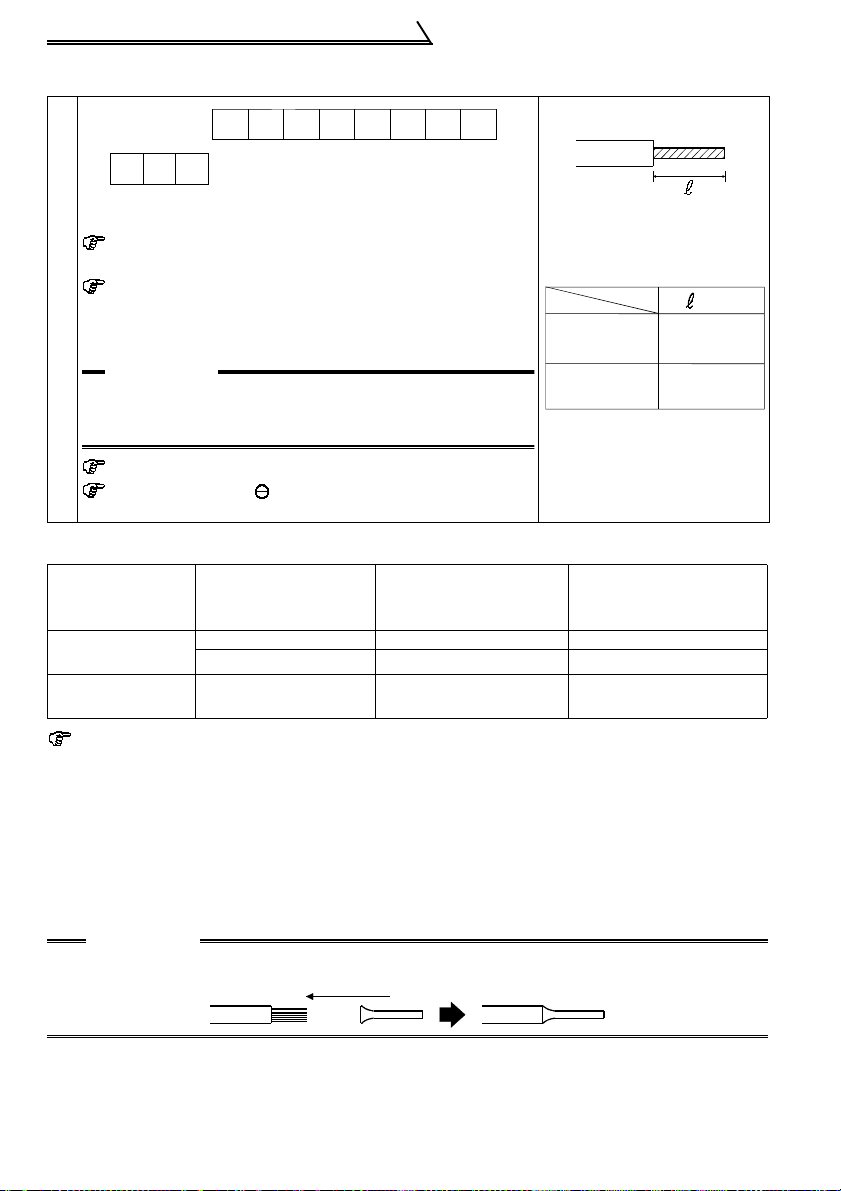

1.5.3 Cables, wiring lengths, crimping terminals, etc.

The following selection example assumes the wiring length of 20m.

1) FR-C520-0.1K to 3.7K

PVC

mm

Cables

2

AWG

Applicable

Inverter Type

FR-C520-

0.1K to

0.75K

FR-C520-

1.5K, 2.2K

FRC520-3.7K M4 1.5 5.5-4 5.5-4 3.5 3.5 12 12 4 2.5

Terminal

Screw

Tightening

Torque

Size

M3.5 1.2 2-3.5 2-3.5 2 2 14 14 2.5 2.5

M4 1.5 2-4 2-4 2 2 14 14 2.5 2.5

N•m

Crimping

Terminals

R, S, T U, V , WR, S, T U, V, W R, S, T U, V, WR, S, T U, V, W

Insulated

Cables

2

mm

6

Page 16

Earthing (Grounding) Precautions

! Wiring length

100m maximum

CAUTION

•When the wiring length of the 0.1K or 0.2K is 30m or more, use the carrier

frequency at 1kHz.

•If the inverter-to-motor wiring distance is long, the motor torque will decrease

due to a voltage drop in the main circuit cables especially at low frequency

output. Use thick cables for wiring to make a voltage drop less than 2%.

1.6 Earthing (Grounding) Precautions

! Leakage currents flow in the inverter. To prevent an electric shock, the inverter and

motor must be earthed (grounded). (Class D earthing (grounding), earthing

maximum)

(grounding) resistance 100

! Use the dedicated earth (ground) terminal to earth (ground) the inverter. (Do not use

the screw in the casing, chassis, etc.)

Use a tin plated* crimping terminal to connect the earth (ground) cable. When

tightening the screw, be careful not to damage the threads.

*Plating should not include zinc.

! Use the thickest possible earth (ground) cable. Use the cable whose size is equal to

or greater than that indicated below, and minimize the cable length. The earthing

(grounding) point should be as near as possible to the inverter.

Motor Capacity

2.2kW or less 2(2.5)

3.7kW 3.5(4)

For use as a product compliant with the Low Voltage Directive, use PVC cable

whose size is indicated within parentheses.

! Earth (Ground) the motor on the inverter side using one cable of the 4-core cable.

Ω

2

(Unit: mm

Earth (Ground) Cable Size

200V class

)

1

CAUTION

If the inverter is run in the low acoustic noise mode, more leakage currents flow due to

fast switching operations than in the non-low acoustic noise mode. Always use the

inverter and motor after earthing (grounding) them. When earthing (grounding) the

inverter, always use its earth (ground) terminal.

7

INSTALLATION AND WIRING

Page 17

Control Circuit

1.7 Control Circuit

1.7.1 Description of the control circuit terminals

Symbol

STF

STR

RH

RM

RL

Contact input

SQ

SD

Input signals

(*1)

PC

(*1)

ALM

RUN

Open collector

Output signals

SE

Terminal

Name

Forward

rotation

start

Reverse

rotation

start

Multispeed

selection

Sequence

start

Contact

input

common

(sink)

External

transistor

common

24VDC

power

supply

Contact

input

common

(source)

Alarm

output

Inverter

running

Open

collector

common

Description

Turn on the STF signal

to start forward rotation

and turn it off to stop.

Turn on the STR signal

to start reverse rotation

and turn it off to stop.

You can select mu lti pl e speeds (three

speeds).

Turn on the SQ signal to execute the

built-in PLC function. (RUN state of

the PLC) Turn off the SQ signal to stop

the built-in PLC function. (S TOP stat e

of the PLC)

Common terminal for contact i nputs (terminals STF,

STR, RH, RM, RL, SQ).

Isolated from terminal SE .

When connecting the transistor output (open collector

output) of a programm able controller (PLC), etc.,

connect the positive external power supply for

transistor output to this terminal to prevent a

malfunction due to un desirable current.

It can be used as a 24V 0.1A DC power output across

PC-SD terminals.

Acts as the common terminal of the contact input

signals when sourc e l ogi c is selected.

Low when the inverte r prot ective

function is activated a nd H i gh wh en

the inverter is not in error. (*2)

Low when the inverte r ou tp ut

frequency is the starti ng f re quency or

higher (factory-set to 0. 5H z and

changeable), and H ig h du ring stop or

DC injection brake op eration. (*2)

Common terminal for inverter running terminal RUN.

Isolated from terminal SD.

A stop

command is

given if STF

and STR

signals turn

on at the

same time.

The terminal

functions

change with

input terminal

function

selection (Pr.

60 to Pr. 63,

Pr. 65, Pr.

505). (*3)

The terminal

functions

change with

output

terminal

function

selection (Pr.

64, Pr. 506).

(*4)

Rating

Specifications

Input resistance

4.7kΩ

Open-time

voltage

21 to 27VDC

Short-time

current

4 to 6mADC

Controll ed by

open collector

output or 0V

contact signal

—

Voltage range

18 to 26VDC

Permissible load

current

0.1A

Permissible load

24VDC 0.1A

Permissible load

24VDC 0.1A

—

8

Page 18

Control Circuit

Symbol

—

Terminal

Name

RS-485

connector

Description

• Compliant standard: EIA Sta nda rd RS-485

• Transmission form: Multidrop li nk system

• Communication speed: Maximum 19200bps

• Overall distance: 500m

Rating

Specifications

—

Communication

*1. D o not connect terminals SD and PC each other or to the ground.

For sink logic (fa ct or y setting), terminal SD acts as the commo n terminal of contact in put.

For source logic, terminal PC acts as the comm on terminal of contact input. (Refer to

page 12 for the way to switch between them.)

*2. Low indicates that the open collector ou tput transistor is on (conducts). High indicates

that the transistor is off (does not conduct).

*3. RL, RM, RH, MRS, OH , RES, STF, STR, SQ signal, without function sele ction (Refer to

page 68 for input terminal function selection.)

*4. R UN, OL, ALM signal, without function selection (Refer to page 69 for output ter minal

function selection .)

1

INSTALLATION AND WIRING

9

Page 19

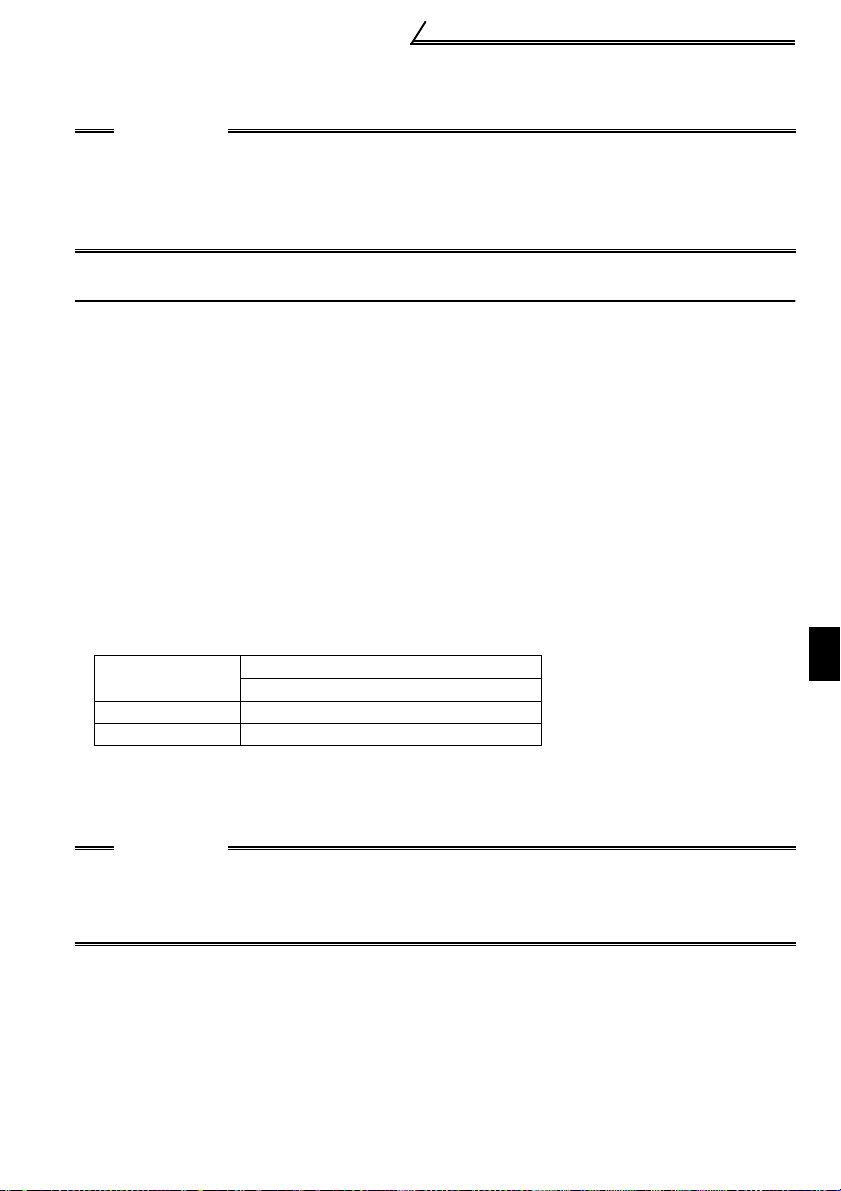

Control Circuit

1.7.2 Layout and wiring of the control circuit terminals

STR RL RM RH SQ RUNALMSTF

SD PC

Loosen the terminal scr ew and insert the cable into the

terminal.

Sc re w size : M3 (SD, PC, S E te rmina ls ),

Tightening torque: 0.5N•m to 0.6N•m (SD, PC, SE

SE

M 2 (o the r th a n on th e left)

ter minals )

0.22N•m to 0.25N•m (other than the

above)

CAUTION

Undertightening can cause cable disconnection or

malfunction. Overtightening can ca use a short circuit

Control circuit terminal block

or malfunction due to damage to the screw or unit.

Cable size : 0. 3mm2 to 0.75mm

Screwdriver: Small screwdriver

*Information on bar te rmi nals

Introduced products (as of April, '02): Phoenix Contact Co., Ltd.

T erminal Screw

Size

M3 (SD, PC, SE

terminals)

M2 (other than

above)

Bar terminal crimping tool : CRI M PFO X ZA3 (Phoenix Contac t Co., Lt d.)

(Tip thickness: 0.4mm/tip width: 2.5mm)

Bar Terminal Model

(With insulating

sleeve)

Al 0.5-6WH A 0.5-6 0.3 to 0.5

Al 0.75-6GY A 0.75-6 0.5 to 0.75

Al 0.5-6WH A 0.5-6 0.3 to 0.5

2

Bar Terminal Model

(Without insulating

sleeve)

Cable stripping size

Wire the stripped cable after

twisting it to preven t it from

becoming loose.

In addition, do not solder it. *

(mm)

SD, PC, SE

terminals

Other than

the above

6

5

Wire Size (m m2)

1)Terminals SD and SE are common terminals of the I/O signals. Do not earth

(ground) these common terminals.

2)Use shielded o r twisted cables for conne ction to the control circuit te rminals and run

them away fr om the main and po wer ci rcuits (inclu ding t he 200V rela y seque nce ci rcuit ).

3)The input signals to the control circuit are micro currents. When contacts are

required, use two or more parallel micro signal contacts or a twin contact to prevent

a contact fault.

CAUTION

When using the bar terminal (wi thout insulating sleeve), use care so that the twisted

wires do not come out.

10

Page 20

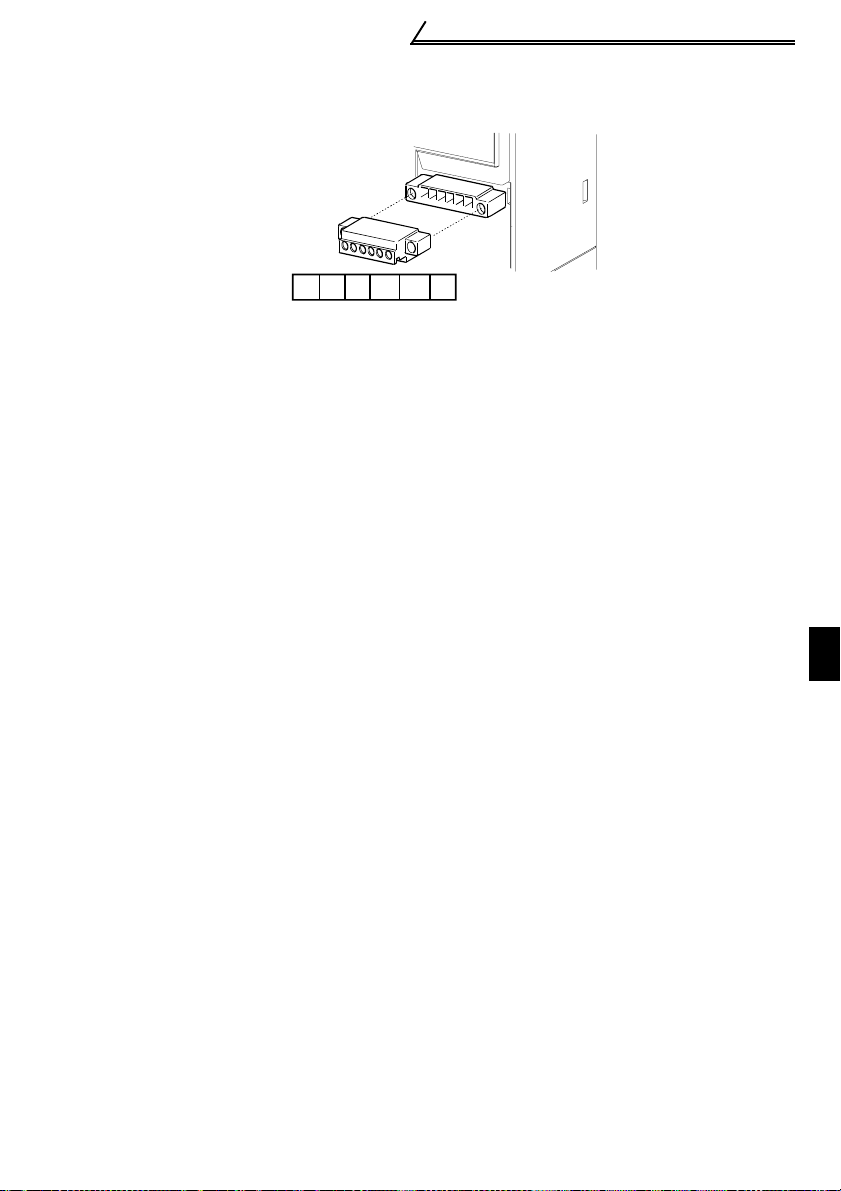

1.7.3 Layout and wiring of the CC-Link terminals

The terminal block is laid out as shown below.

erminal screw size: M2.5

Control Circuit

Refer to page 36 for details.

DA DB DG

SLD

SLD FG

1

INSTALLATION AND WIRING

11

Page 21

Control Circuit

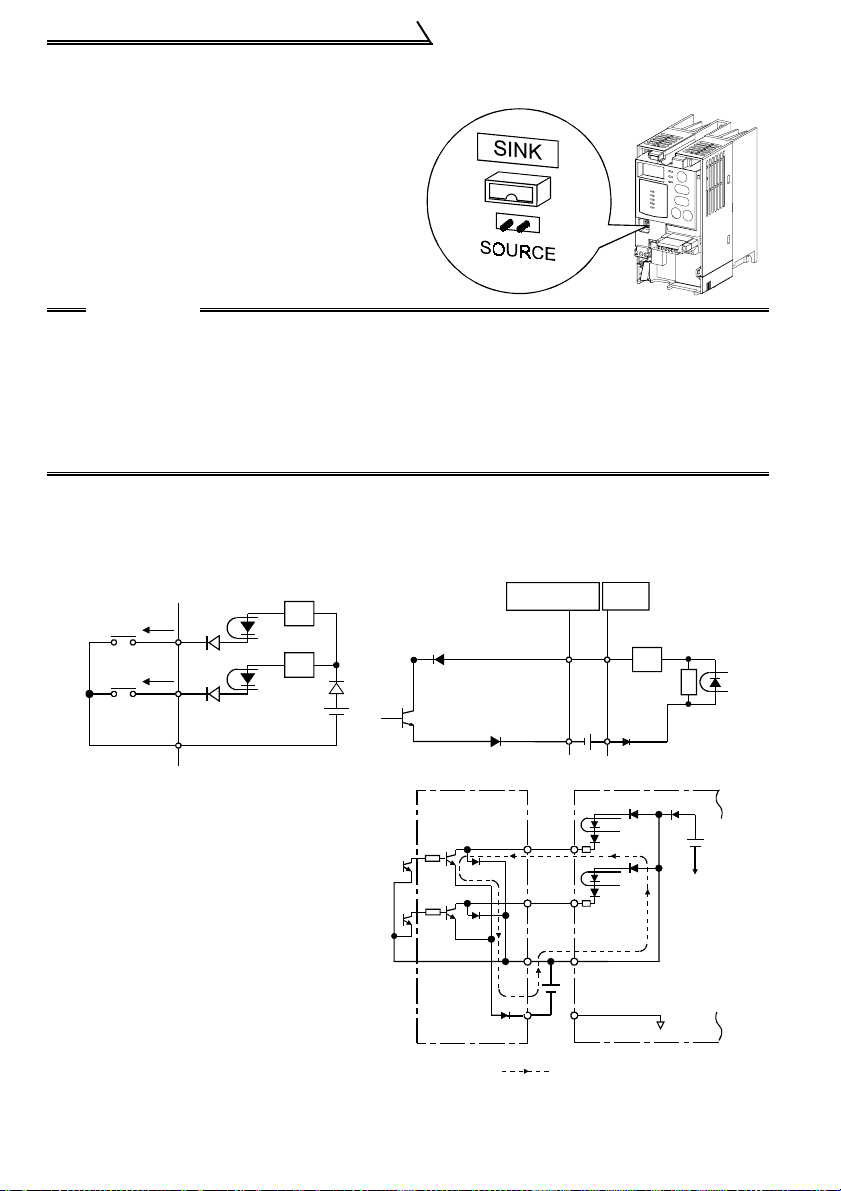

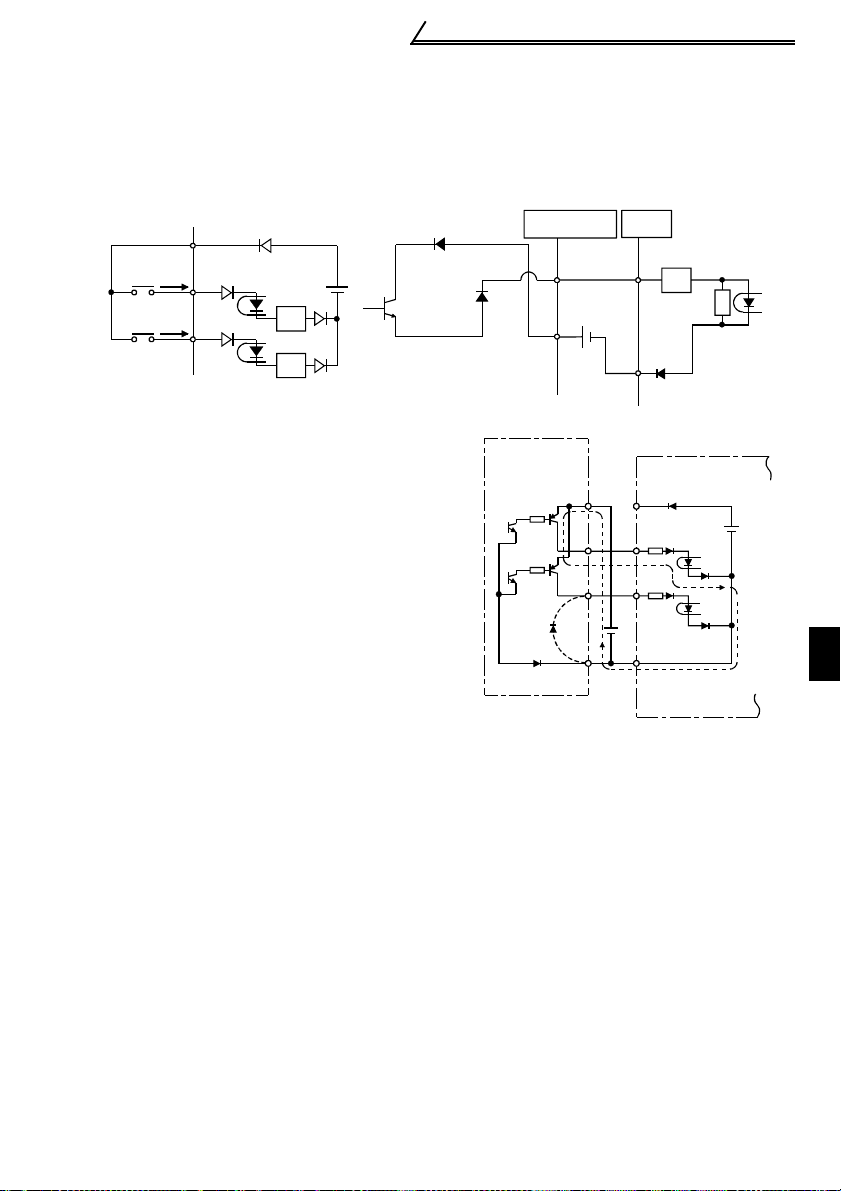

1.7.4 Changing the control logic

The input signals are set to sink logic.

To change the control logic, the jumper

connector must be moved to the other

position.

! Change the jumper connector position

using tweezers, a pair of long-nose pliers,

etc. Change the jumper connector position

before switching power on.

CAUTION

•Make sure that the front cover is installed securely.

•The front cover is fitted with the capacity plate and the inverter unit with the

rating plate. Since these plates have the same serial numbers, always replace

the removed cover onto the original inverter.

•The sink-source logic change-over connector must be fitted in only one of

those positions. If it is fitted in both p ositions at the same time, the inverter

may be damaged.

1) Sink logic type

•In this logic, a signal switches on when a current flows out of the corresponding

signal input terminal.

Terminal SD is common to the contact input signals. Terminal SE is common to the

open collector output signals.

Power

supply

STF

STR

R

Inverter

RUN

R

AX40

1

R

R

SD

•Connecting a positive external power

supply for transistor output to terminal

PC prevents a malfunction caused by

an undesirable current. (Do not

connect terminal SD of the inverter

with terminal 0V of the external power

supply. When using terminals PC-SD

as a 24VDC power supply, do not

install an external power supply in

parallel with the inverter. Doing so may

cause a malfunction in the inverter due

to an undesirable current.)

AY40 transistor

output module

12

1

2

9

9

10

SE

24VDC

STF

STR

24VDC

Current flow

9

Inverter

24VDC

(SD)

PC

SD

Page 22

Control Circuit

2) Source logic type

•In this logic, a signal switches on when a current flows into the corresponding signal

input terminal.

Terminal PC is common to the contact input signals. For the open collector output

signals, terminal SE is a positive external power supply terminal.

PC

Power

supply

STF

STR

R

R

•Connecting the 0V terminal of the external

power supply for transistor output to terminal

SD prevents a malfunction caused by an

undesirable current.

Inverter

RUN

SE

24VDC

AY80 transistor

output module

10

AX80

1

R

R

9

Inverter

9

1

2

24VDC

PC

STF

STR

SD

24VDC

(SD)

1

13

INSTALLATION AND WIRING

Page 23

Control Circuit

1.7.5 RS-485 Connector

<RS-485 connector pin layout>

View A of the inverter (receptacle

side)

8) to 1)

View A

CAUTION

1. Do not plug the connector to a computer LAN board, fax modem socket,

telephone modular connector, etc. As they are different in electrical

specifications, the inverter may be damaged.

2.Pins 2 and 8 (P5S) ar e provided for th e parameter unit power supply. Do not

use them for any other purpose or when making parallel connectio n by RS485 communication.

3.Refer to page 79 for the communication parameters.

REMARKS

•The PU connector (PS-485) automatically recognizes whether the FR-PU04 or RS-485

communication is connected.

•Refer to page 38 for wiring of the inverter and computer using user program for RS-485

communication.

•Refer to page 35 for wiring of the inverter and personal computer using GX Developer for RS485 communication.

View A

1) SG

2) P5S

3) RDA

4) SDB

5) SDA

6) RDB

7) SG

8) P5S

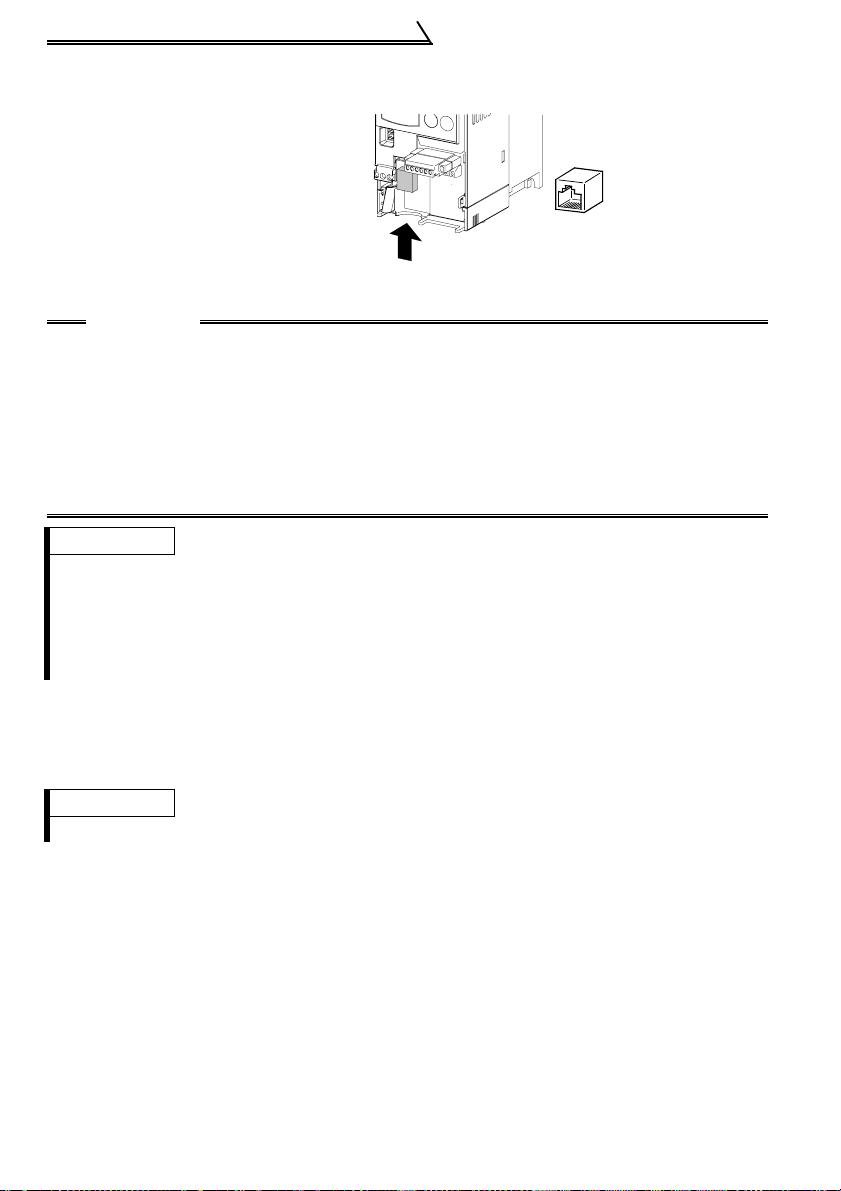

1.7.6 Connection of the parameter unit (FR- PU04 )

Use the FR-CB2 parameter unit connection cable.

REMARKS

Refer to page 93 for the pa ra m et er s re la te d to parameter unit setting.

""

14

Page 24

Input Terminal s

1.8 Input Terminals

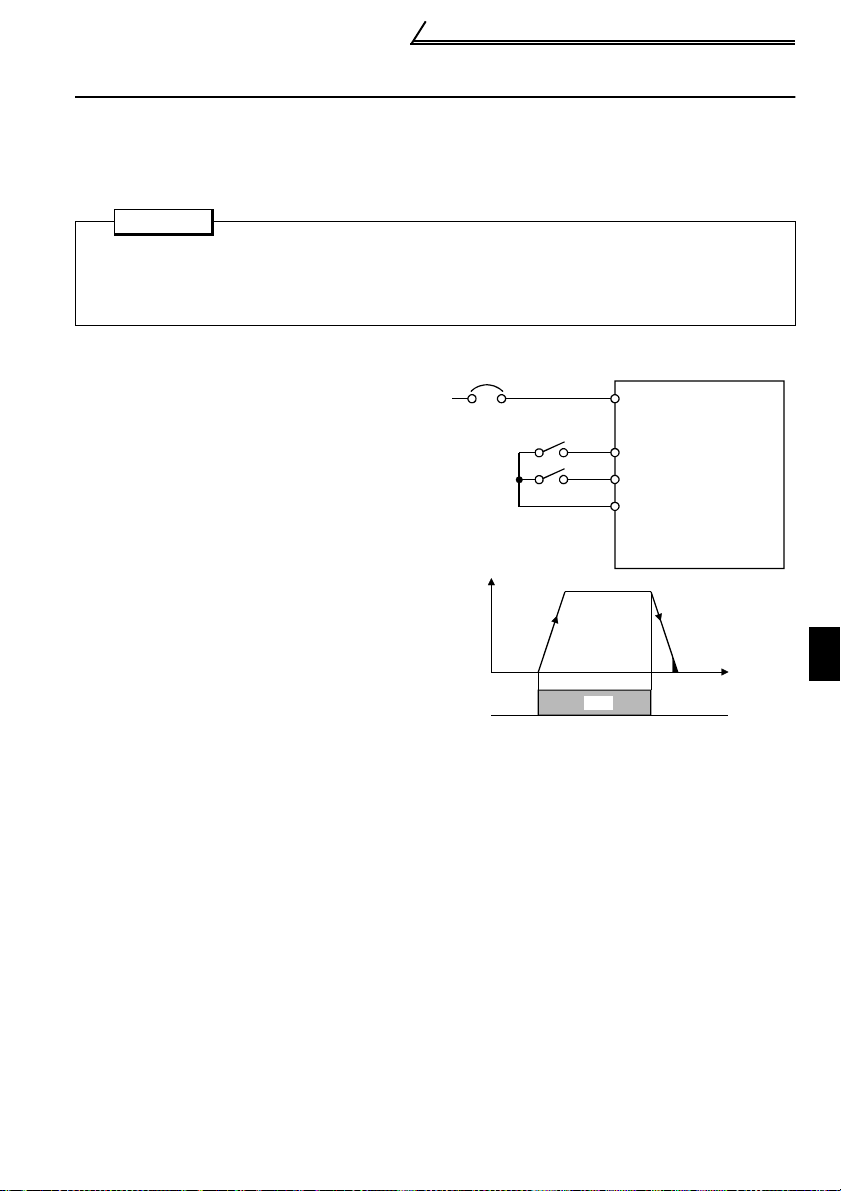

1.8.1 Run (start) and stop (STF, STR)

To start and stop the motor, first switch on the input power supply of the inverter

(switch on the magnetic contactor, if any, in the input circuit during preparation for

operation), then start the motor with the forward or reverse rotation start signal.

POINT

With "1" factory-set in Pr. 507 "inverter operation lock mode setting", the start

signal is not enabled unless the SQ signal is on.

Set "0" in Pr. 507 when performing inverter operation only.

(Refer to page 138 for Pr. 507.)

(1) STF, STR

A connection is shown on the right.

1) The forward/reverse rotation signal is

used as both the start and stop signals.

Switch on either of the forward and

reverse rotation signals to start the

motor in the corresponding direction.

Switch on both or switch off the start

signal during operation to decelerate

the inverter to a stop.

2) The frequency setting signal may be

given by setting the required values in

Pr. 4 to Pr. 6 "three-speed setting"

(high, middle, low speeds), by setting

using a sequence l adder, or by setting

from CC-Link. (For three-speed

operation, refer to page 1 7. )

3) After the start s ignal has been i nput, the inverter starts operatin g when the fre quency s etting

signal reaches or exce eds the "starting frequency " set in Pr. 13 (factory-set to 0.5 H z) .

If the motor load torque is large or the "torq ue boos t" set in Pr. 0 is small, the inverter may be

overloaded due to insu fficient t or que.

If the "minimum frequency" set in Pr. 2 (factory setting = 0Hz) is 6Hz, for example, merely

entering the start signal causes the running frequency to reach the minimum frequency of 6Hz

according to the "acceleration time" set in Pr. 7.

4) To stop the motor, operate the DC injection brake for the period of "DC injection brake

operation time" set in Pr. 11 (factory setting = 0.5s) at not more than the DC injectio n brake

operation frequenc y or at not mo re th an 0. 5Hz.

To disable the DC injection brake function, set 0 in either of Pr. 11 "DC injection brake

operation time" and Pr. 12 "DC injection brak e voltage".

In this case, the motor is coated to a stop at not more than the frequency set in Pr. 10 "DC

injection brake op eration frequency " (0 to 120Hz va riable) or at no t more than 0.5Hz (when

the DC injection brake is not operated).

5) If the reverse rot ation signal is i nput during forwar d rotation or the f orward rotation s ignal is

input during reverse rotation, the inverter is decel erated and then switched to the opposite

output polarity without going through the stop mode.

Power

supply

NFB

Forward

rotation star t

Reverse

rotation start

Output frequency

Across STF-SD

(STR)

Connection Example

15

Inverter

R,S,T

STF (Pr.65="17")

STR (Pr.63= " 99 99")

SD

ON

Time

1

INSTALLATION AND WIRING

Page 25

Input Termi na ls

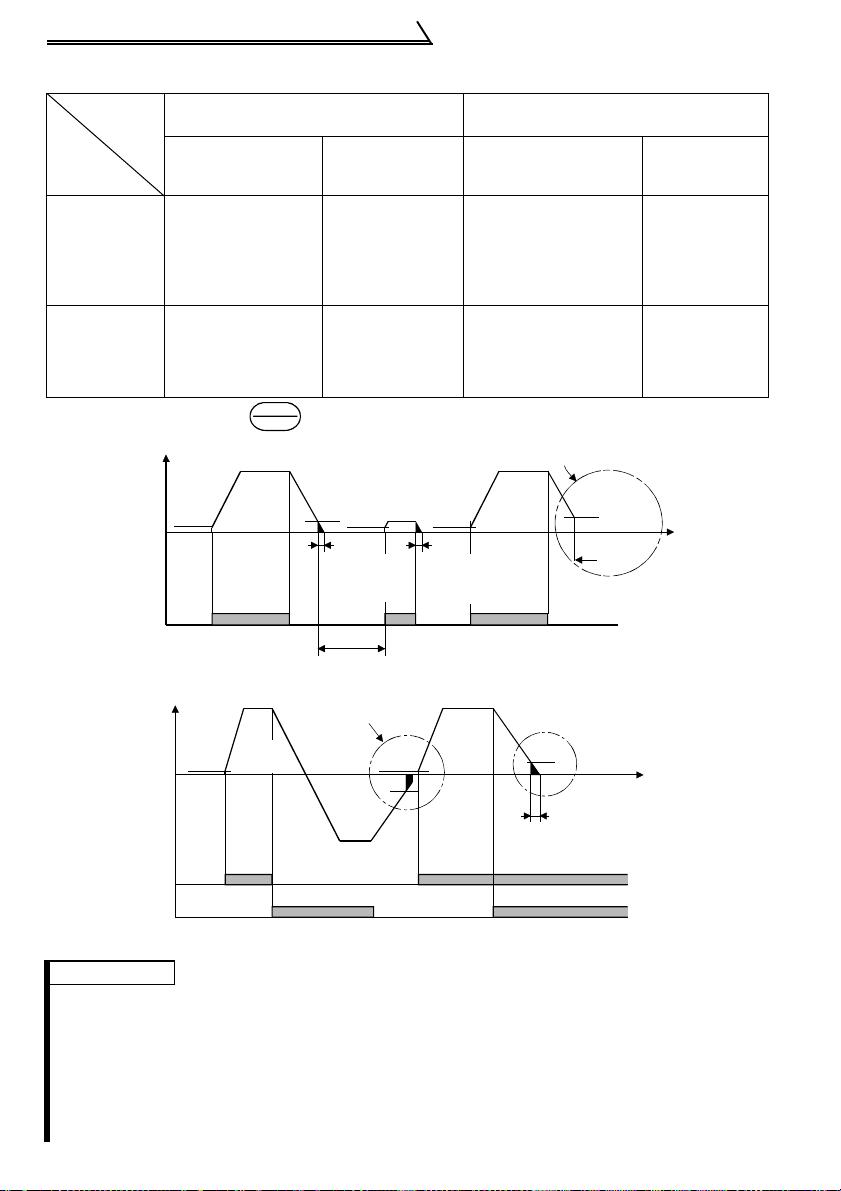

DC Injection Brake and Coasting to Stop

Operation

Mode

DC

Injection

Brake

disconnected (*1)

DC injection brake

DC injection

brake

enabled

operated at not

more than "DC

injection brake

operation frequ ency"

set in Pr. 10

Coasted to a sto p at

DC injection

brake

disabled

not more than "DC

injection brake

operation frequ ency"

set in Pr. 10

*1: Also stopped by the key. Refer to page 71.

Starting frequency

Pr. 13

(*1)

0.5Hz

Output frequency

Start

signal

terminal

Across STF-SD

Across STR-SD

Output frequency

Start

signal

terminal

Across

STF-SD

Across

STR-SD

Forward-Reverse Rotation Switch-Over Timing Chart

External Operation

Pr. 79= "0", "2", "3"

Te rmina ls STF

(STR)-SD

Set frequency

changed to 0Hz

DC injection brake

DC injection

brake operated at

0.5Hz or less.

operated at not more

than "DC injection

brake opera t ion

frequency" set in Pr. 10

Coasted to a stop at

Coasted to a stop

at 0.5Hz or less.

not more than "DC

injection brake

operation frequency"

set in Pr. 10

STOP

RESET

DC injection brake enabl e d DC injection brake d isabled

ON

DC injection brake

operation

frequency Pr. 10

3Hz

0.5Hz

0.5s

DC injection

brake operation

time Pr. 11 (*3)

ON

(*2)

0.5Hz

0.5s

DC injection

brake operation

time Pr. 11 (*3)

Start/Stop Timing Chart

Starting

frequency

Pr.13

(*1)

0.5Hz

Start signal switched on while

DC injection brake is being

operated

Forward

rotation

ON

ON ON

3Hz

Reverse

rotation

0.5Hz

ON

Forward

rotation

PU Operation

Pr. 79= "0", "1", "4"

Set frequency

Stop key

changed to

DC injection

brake operated

at 0.5Hz or less.

Coasted to a

stop at 0.5Hz or

less.

DC injection brake not operated

(*4)

3Hz

Coasted to

a stop

ON

DC injection brake operation

(*4)

frequency Pr. 10

DC injection brake

3Hz

enabled

Time

Time

0.5s

DC injection brake operation

time Pr. 11 (*3)

0Hz

REMARKS

*1. The "st ar ting frequency" in Pr. 13 (factory-set to 0.5Hz) may be set between 0 and 60Hz.

*2. If the nex t start signal is giv en durin g DC injec tio n brake operati on, the D C inject ion brake

is disabled and restart is made.

*3. The "DC injection brake operation time" i n Pr . 1 1 ( factory-set to 0.5s) may be set between 0 and 10s.

*4. The frequency at which the motor is coas ted to a stop is not more t han the "DC injection

brake operation frequency" set in Pr. 10 (factory setting = 3Hz; may be set b et w een 0 and

120Hz) or not more than 0.5Hz.

*5. The "starting frequency" in Pr. 13, "DC injection brake operation time" in Pr. 11 and "DC

injection brake operati on f re quency" in Pr. 10 are the factory-set values.

16

Page 26

Input Terminal s

S

M

s

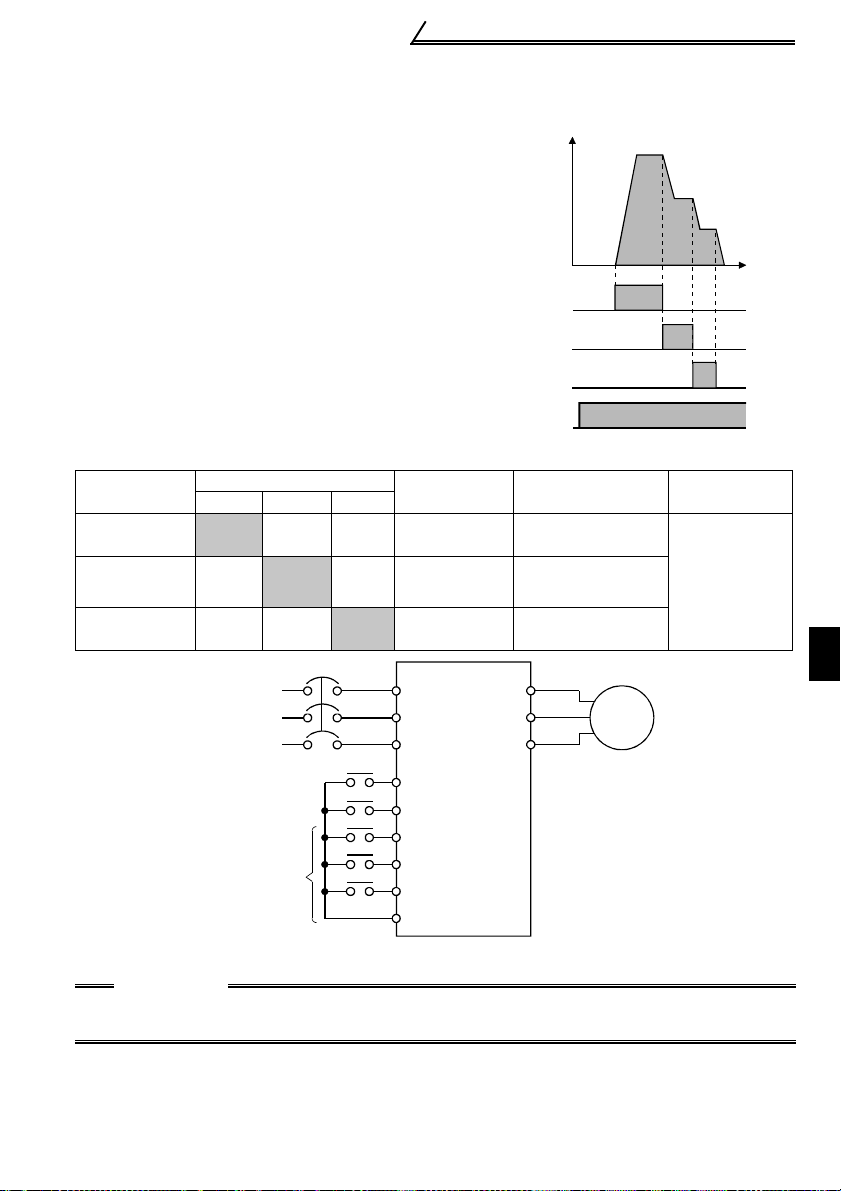

1.8.2 External frequency selection (RH, RM, RL)

Up to three speeds may be selected for an

external command start according to the

combination of connecting the multi-speed select

terminals RH, RM and RL-SD, and multi-speed

operation can be performed as shown on the

right by shorting the start signal terminal STF

(STR)-SD.

Output frequency (Hz)

Speeds (frequencies) may be specified as

desired as listed below using Pr. 4 to Pr. 6.

RH

RM

RL

TF(STR)

Multi-Speed Setting

Speed

Speed 1

(high speed)

Speed 2

(middle

Speed 3

(low speed)

Terminal Input

RH-SD RM-SD RL-SD

Parameter

ON OFF OFF Pr.4

OFF

OFF OFF

Power

supply

ON OFF Pr.5

Forward

rotation

Reverse

rotation

ulti-speed

election

ON Pr.6

R

S

T

STF

STR

RH

RM

RL

SD

Inverter

Set Frequency

0 to 120Hz

0 to 120Hz

0 to 120Hz

U

V

W

Multi-Speed Operation Connection Example

CAUTION

For three-speed setting, selection of two or more speeds sets the frequency of the lower

speed signal.

Range

Motor

Speed 1

(high speed)

Speed 2

(middle speed)

Speed 3

(low speed)

Time

ON

ON

ON

ON

Reference

Page

59

IM

1

INSTALLATION AND WIRING

17

Page 27

Input Termi na ls

1.8.3 Control circuit common terminals (SD, SE)

Terminals SD and SE are both common terminals (0V) for I/O terminals and are

isolated from each other.

Terminal SD is a common terminal for the contact input terminals (STF, STR, RH, RM,

RL, SQ).

Terminal SE is a common terminal for the open collector output terminals (RUN, ALM).

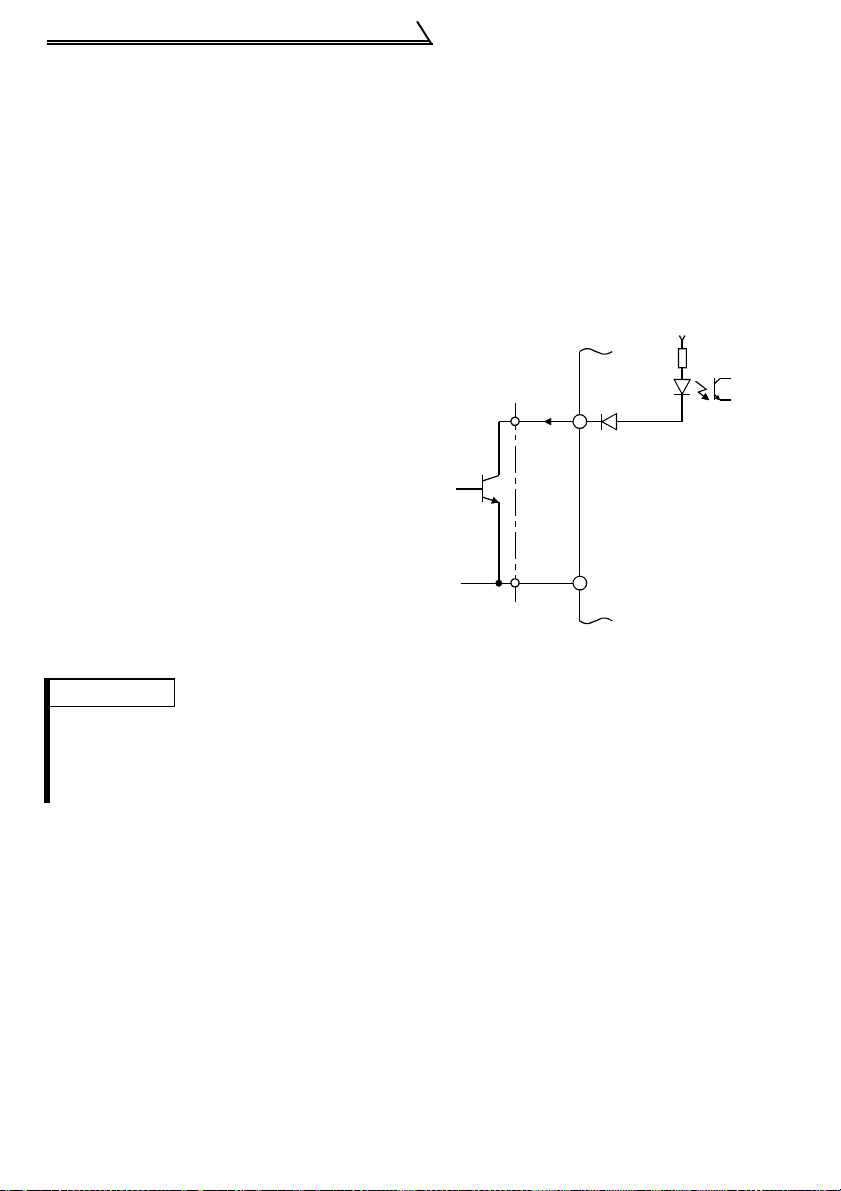

1.8.4 Signal inputs by contactless switches

If a transistor is used instead of a contacted

switch as shown on the right, the input

+24V

signals of the inverter can control terminals

STF, STR, RH, RM, RL, SQ.

STF, etc.

Inverter

SD

External Signal Input

by Transistor

REMARKS

•When using an external transistor connected with the external power supply, use terminal PC

to prevent a malfunction from occurring due to a leakage current. (Refer to page 12.)

•Note that an SSR (solid-state relay) has a relatively large leakage current at OFF time and it

may be accidentally input to the inverter.

18

Page 28

How to Use the Input Signals (Assigned Terminals

A

(

RL, RM, RH, STR, SQ)

1. 9 How to Use the Input Signals (Assigned T erminals RL, RM, RH, STR, SQ)

These terminals can be

changed in function by

setting Pr. 60 to Pr . 63, Pr . 65,

Pr. 505.

Pr. 60 "RL terminal function selection"

Pr. 61 "RM terminal function selection"

Pr. 62 "RH terminal function selection"

Pr. 63 "STR terminal function selection"

Page 68

Pr. 65 "STF terminal function selection"

Pr. 505 "SQ terminal function selection"

1.9.1 Multi-speed setting (RL, RM, RH signals):

Pr. 505 setting

"0, 1, 2"

Pr. 60 to Pr. 63, Pr. 65,

• By entering frequency commands into the RL, RM and RH signals and turning on/off

the corresponding signals, you can perform multi-speed operation (three speeds).

(For details, refer to page 17.)

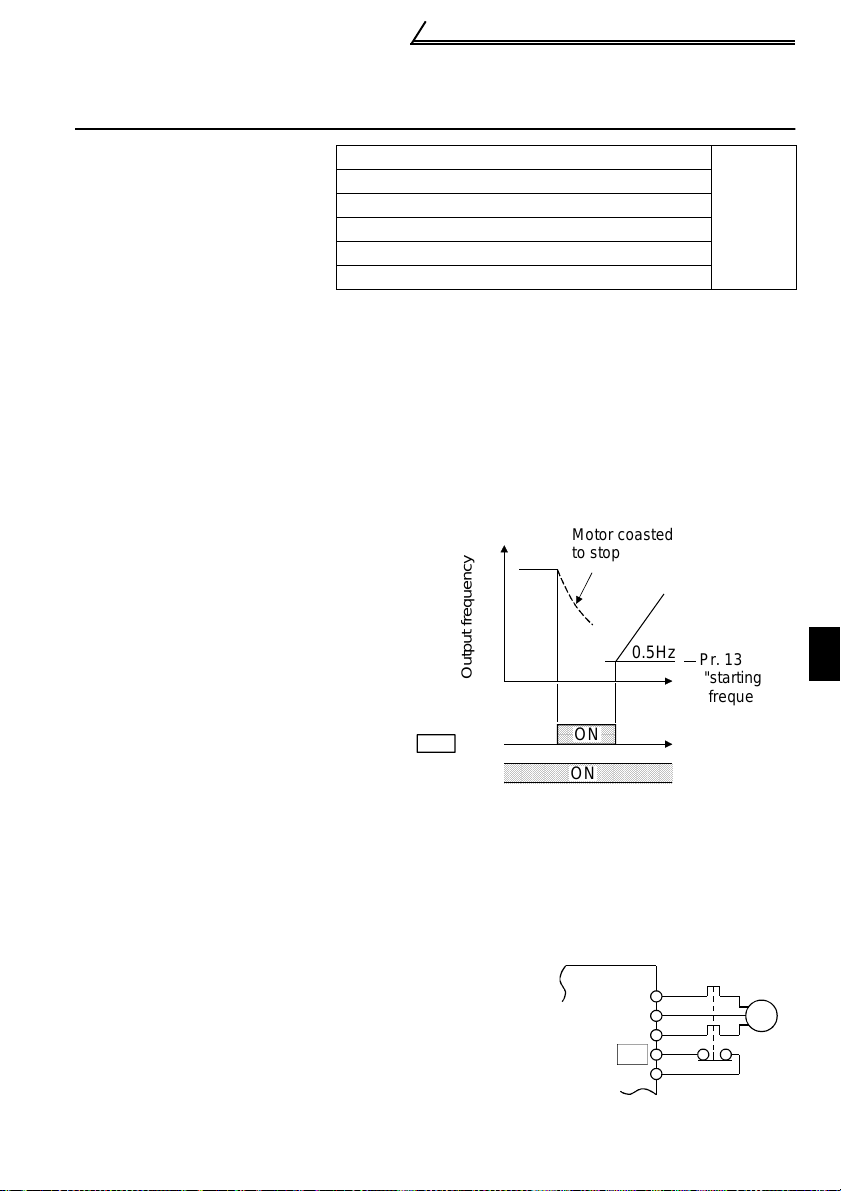

1.9.2 Output shut-off (MRS signal):

Pr. 60 to Pr. 63, Pr. 65, Pr. 505 setting

"6"

Short the output stop terminal MRS-SD during inverter output to cause the inverter to

immediately stop the output. Open terminals MRS-SD to resume operation in about

10ms. Terminal MRS may be used as described below:

(1) To stop the motor by

mechanical brake (e.g.

Motor coasted

to stop

electromagnetic brake)

Terminals MRS-SD must be

shorted when the mechanical

brake is operated and be opened

before motor restart.

(2) To provide interlock to disable

operation by the inverter

After MRS-SD have been shorted,

the inverter cannot be operated if

the start signal is given to the

inverter.

Across

MRS -SD

cross STF

STR)-SD

Output frequency

ON

ON

0.5Hz

Pr. 13

"starting

frequency"

(3) To coast the motor to stop

The motor is decelerated according to the preset deceleration time and is stopped

by operating the DC injection brake at 3Hz or less. By using terminal MRS, the

motor is coasted to a stop.

1.9.3 External thermal relay input:

Pr. 60 to Pr. 63, Pr. 65, Pr. 505 setting

"7"

1

INSTALLATION AND WIRING

When the external thermal relay or thermal relay built in

the motor (e.g. thermal protector) is actuated, the

inverter output is shut off and an alarm signal is given to

keep the motor stopped to protect the motor from

overheat. If the thermal relay contact is reset, the motor

is not restarted unless the reset terminal RES-SD are

shorted for more than 0.1s and then opened or power-on

reset is performed.

Inverter

OH

SD

U

V

W

Thermal relay

Motor

IM

The function may therefore be used as an external

emergency stop signal input.

19

Page 29

How to Use the Input Signals (Assigned Terminals

A

(

RL, RM, RH, STR, SQ)

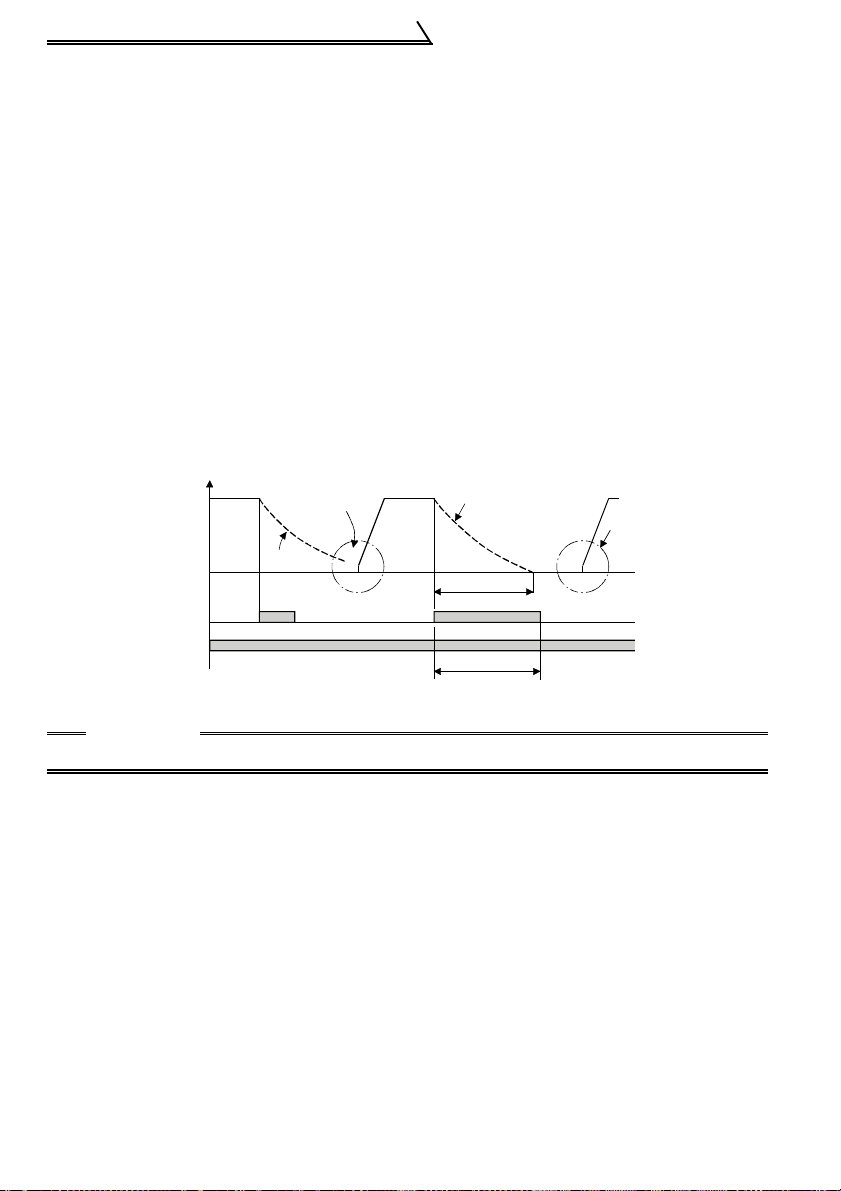

1.9.4 Reset signal:

Pr. 60 to Pr. 63, Pr. 65, Pr. 505 setting

"10"

Used to reset the alarm stop state established when the inverter's protective function

is activated. The reset signal immediately sets the control circuit to the initial (cold)

status, e.g. initializes the electronic overcurrent protection circuit. It shuts off the

inverter output at the same time. During reset, the inverter output is kept shut off. To

give this reset input, short terminals RES-SD for more than 0.1s. When the shorting

time is long, the operation panel or parameter unit displays the initial screen, which is

not a fault.

Operation is enabled after terminals RES-SD are opened (after about 1s).

The reset terminal is used to reset the inverter alarm stop state. If the reset terminal is

shorted, then opened while the inverter is running, the motor may be restarted during

coasting (refer to the timing chart below) and the output may be shut off due to

overcurrent or overvoltage.

Setting either of "1" and "15" in reset selection Pr. 75 allows the accidental input of the

reset signal during operation to be ignored.

(For details, refer to page 71.)

When motor is restarted

Across

RES-SD

cross STF

STR)-SD

during coasting, inverter

activates current limit to

start acceleration.

Coasting

Output frequency (Hz)

ON

ON

Coasting to stop

(Indicates motor speed)

Ordinary

acceleration

Coasting time

ON

T

T: Should be long er than the time

of coasting to stop.

CAUTION

Frequent resetting will make electronic overcurrent protection invalid.

1.9.5 Start (forward rotation) signal:

Pr. 65 set ting

Turn the signal on or off to bring the motor to a forward rotation start or stop.

(Refer to page 15 for details.)

20

"17"

Page 30

How to Use the Input Signals (Assigned Terminals

RL, RM, RH, STR, SQ)

1.9.6 Sequence s t art:

Pr. 60 to Pr. 63, Pr. 65, Pr. 505 setti ng

"50"

Used to execute/stop (RUN/STOP) the built-in PLC function.

Short SQ-SD to execute (RUN) and open SQ-SD to stop (STOP).

Refer to page 100 for details.

1.9.7 No function:

Pr. 60 to Pr. 63, Pr. 65, Pr. 505 setting

"9998"

Disables the input terminal functions.

REMARKS

Refer to page 127 for the no function setting of the external terminal inputs in device D9149

"inverter operation sta tu s co nt ro l en able/disable setting".

1.9.8 Start (reverse rotation) signal:

Pr. 63 setting

"9999"

Turn the signal on or off to bring the motor to a reverse rotation start or stop.

(Refer to page 15 for details.)

1

21

INSTALLATION AND WIRING

Page 31

Peripheral Devices

1.10 Peripheral Devices

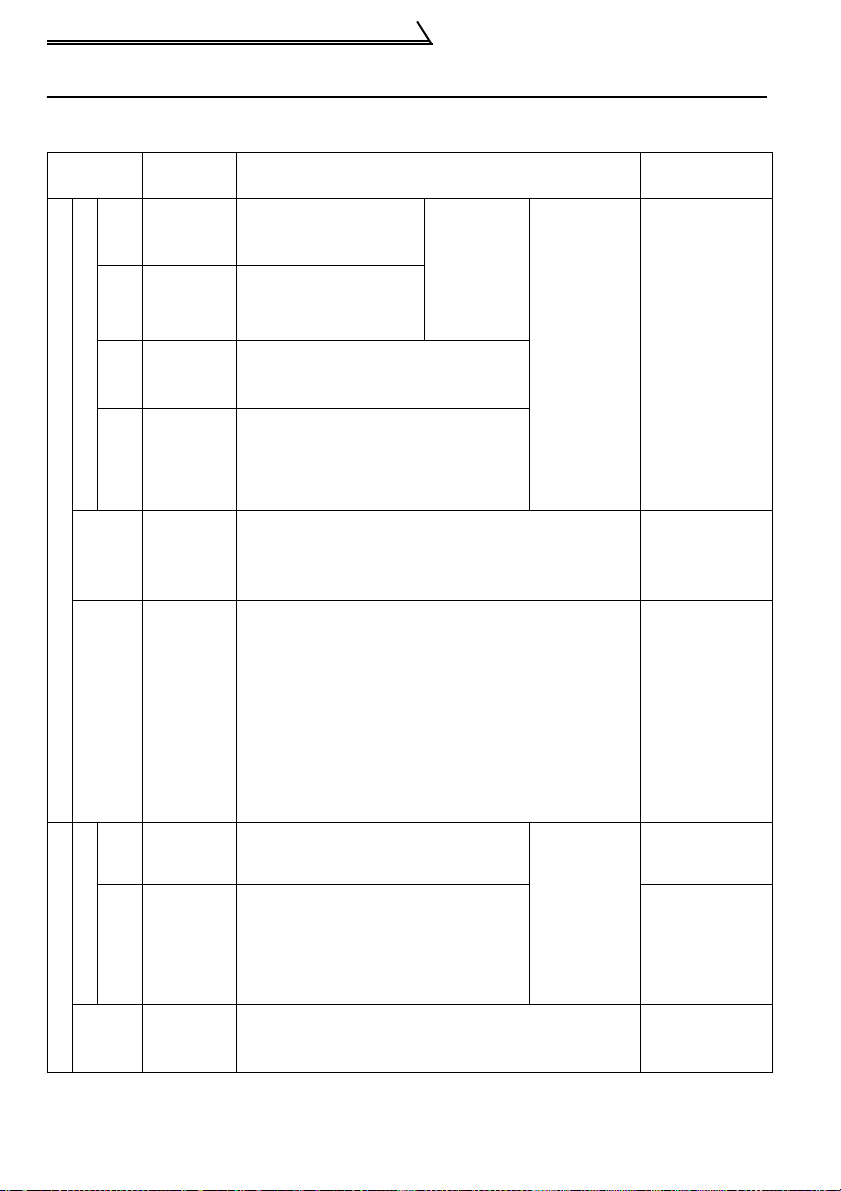

1.10.1 Peripheral device list

Selection of peripheral devices (Selection changes depending on

the power input specifications of the inverter.)

! FR-C520-0.1K to 3.7K

No-Fuse

Breaker (NFB

Motor

Output

(kW)

0.1

0.2

0.4

0.75

1.5

2.2

3.7

Inverter

Model

FR-C520-0.1K 30AF/5A

FR-C520-0.2K 30AF/5A

FR-C520-0.4K 30AF/5A FR-BAL-0.4K FR-BEL-0.4K S-N10 2 2

FR-C520-

0.75K

FR-C520-1.5K 30AF/15A FR-BAL-1.5K FR-BEL-1.5K S-N10 2 2

FR-C520-2.2K 30AF/20A FR-BAL-2.2K FR-BEL-2.2K S-N10 2 2

FR-C520-3.7K 30AF/30A FR-BAL-3.7K FR-BEL-3.7K

*1) or Earth

Leakage

Circuit

Breaker (ELB)

(*4)

30AF/10A FR-BAL-0.75K FR-BEL-0.75K S-N10 2 2

Power Factor

Improving AC

Reactor

FR-BAL-0.4K

(*3)

FR-BAL-0.4K

(*3)

Power Factor

Improving DC

Reactor

FR-BEL-0.4K

(*3)

FR-BEL-0.4K

(*3)

Magnetic

Contactor

(MC)

S-N10 2 2

S-N10 2 2

S-N20,

S-N21

*1. Choose the NFB type that meets the power supply capacity.

*2. The sizes of the cables assume t hat the wiring length is 20m.

*3. The power factor may be slight ly le ss.

*4. For ins tal la tions in the United States or Canada, select the UL/cUL-l ist ed breaker.

Cables (mm2)

(*2)

R, S, T

U, V,

3.5 3.5

W

REMARKS

Secondary side measuring in struments

If the wiring length between the inverter and motor is long, the measuring instruments and CT

may generate heat due to line-to-line leakage currents. Therefore, select the devices that have

sufficient current ratings.

1.10.2 Leakage current and installation of earth (ground) leakage circuit breaker

Due to static capacitances existing in the inverter I/O wiring and motor, leakage

currents flow through them. Since their values depend on the static capacitances,

carrier frequency, etc., take the following countermeasures.

(1) To-earth (ground) leakage currents

Leakage currents may flow not only into the inverter's own line but also into the

other line through the earth (ground) cable, etc. These leakage currents may

operate earth (ground) leakage circuit breakers and earth (ground) leakage

relays unnecessarily.

22

Page 32

Peripheral Devices

! Countermeasures

• If the carrier frequency setting is high, decrease the carrier frequency (Pr. 72) of

the inverter.

Note that motor noise increases.

• Using earth leakage circuit breakers designed fo r harmonic and surge s uppression

in the inverter's own line and other line, operation can be performed with the

carrier frequency kept high (with low noise).

(2) Line-to-line leakage currents

Harmonics of leakage

currents flowing in

static capacities

between the inverter

output cables may

operate the external

thermal relay

unnecessarily.

Power

supply

NFB

Inverter

Thermal relay

Line static capacitances

Line-to-Line Leakage Current Path

Motor

IM

! Countermeasures

• Use the electronic overcurrent protection of the inverter.

• Decrease the carrier frequency. Note that motor noise increases.

To ensure that the motor is protected against line-to-line leakage currents, it is

recommended to use a temperature sensor to directly detect motor temperature.

! Installation and selection of no-fuse breaker

On the power receiving side, install a no-fuse breaker (NFB) to protect the primary

wiring of the inverter. Which NFB to choose depends on the power supply side

power factor (which changes with the power supply voltage, output frequency and

load) of the inverter. Especially as the completely electromagnetic type NFB

changes in operational characteristic with harmonic currents, you need to choose

the one of a little larger capacity. (Check the data of the corresponding breaker.) For

the earth leakage circuit breaker, use our product designed for harmonic and surge

suppression. (Refer to page 25 for the recommended models.)

CAUTION

•Choose the NFB type according to the power supply capacity.

•To protect the motor from overheat, t he inverter h as protective fun ction s with

electronic thermal relay. However, when operating two or more motors with a

single inverter or running a multi-pole motor, for example, provide an

overcurrent relay (OCR) between the inverter and m otor. In this case, set the

electronic thermal relay of the inverter for 0A, and set the overcurrent relay for

1.0 time the current value at 50Hz on the motor rating plate, or 1.1 times the

current value at 60Hz, plus the line-to-line leakage current.

1

INSTALLATION AND WIRING

23

Page 33

Peripheral Devices

(3) Selecting the rated sensitivity current for the earth (ground) leakage

breaker

CAUTION

•On the power receiving side, install a no-fuse breaker (NFB) to protect the

primary wiring of the inverter. Selection of NFB depends on the power supply

side power factor (which changes with the power supply voltage, output

frequency and load) of the inverter. Especially as the completely

electromagnetic type NFB changes in operational characteristic with

harmonic currents, you need to choose th e one of a little larger cap acity. For

the earth (ground) leakage circuit breaker, use our product designed for

harmonic and surge suppression.

When using the earth (ground) leakage breaker with the inverter circuit, select its rated

sensitivity current as follows, independently of the PWM carrier frequency.

• Products designed for harmonic and surge suppression

Rated sensitivity current

(lg1+Ign+lg2+lgm)

≥10×

In

• General products

Rated sensitivity current

In

{lg1+Ign+3×(lg2+lgm)}

≥10×

Ig1, Ig2: Leakage currents of cable path during commercial power supply operation

Ign*: Leakage current of noise filter on inverter input side

Igm: Leakage current of motor during commercial power supply operation

Example of leakage current per 1km

in cable path during commercial

power supply operation when the

CV cable is routed in metal conduit

(200V 60Hz)

120

100

80

60

40

20

Leakage current (mA)

0

23.5

8142230386080

5.5

Cable size (mm2)

100

Leakage current example of

3-phase induction motor during

commercial power supply

operation (200V 60Hz)

2.0

1.0

0.7

0.5

0.3

0.2

Leakage current (mA)

150

0.1

1.5 3.7

2.2

Motor capacity (kW)

7.5 152211373055

5.5 18.5

45

<Example>

2

5m 2mm

2mm

Noise filter

NV

Inverter

Ig1 Ign Ig2 Igm

24

2

70m

3

IM

200V1.5kW

Page 34

Peripheral Devices

CAUTION

•The earth (ground) leakage circuit breaker should be installed to the

primary (power supply) side of the inverter.

•In the connection neutral point grounding system, the sensitivity current

becomes worse for earth (ground) faults in the inverter secondary side.

Hence, the protective earthing (grounding) of the load equipment should be

10ΩΩΩΩ or less.

•When the breaker is installed in the secondary side of the inverter, it may

be unnecessarily operated by harmonics if the effective value is less than

the rating.

In this case, do not install the breaker since the eddy current and

hysteresis loss increase and the temperature rises.

•General products indicate the following models: BV-C1, BC-V, NVB, NV-L,

NV-G2N, NV-G3NA, NV-2F, earth (ground) leakage relay (except NV-ZH) , NV

with single-phase, three-wire neutral conductor/open-phase protection

The other models are designed for harmo nic and su rge sup pression:NV-C/

NV-S/MN series, NV30-FA, NV50-FA, BV-C2, earth leakage alarm breaker,

NV-ZH

* Note the leakage current value of the noise filter installed on the inverter input side.

Product designed for

harmonic and surge

General product

suppression

Leakage current Ig1 (mA) 20×

Leakage current Ign (mA) 0 (without noise filter)

Leakage current Ig2 (mA)

Motor leakage current Igm (mA) 0.14

Total leakage current (mA) 1.66 4.78

Rated sensitivity cur r ent (mA)

≥Ig × 10)

(

×

20

30 100

5m

1000m

70m

1000m

=0.10

=1.40

1

25

INSTALLATION AND WIRING

Page 35

Peripheral Devices

1.10.3 Power-off and magnetic contactor (MC)

(1) Inverter's primary side magnetic contactor (MC)

On the inverter's primary side, it is recommended to provide an MC for the following

purposes (refer to page 22 for selection):

1)To release the inverter from the power supply when the inverter's protective function

is activated or when the drive is not functioning (e.g. emergency stop operation).

2)When the external terminal (terminal STF or STR) is used for operation, provide an

MC in the primary side to prevent an accident caused by an automatic restart made