Page 1

22B-0-1

MANUAL

TRANSMISSION

F5M41, F5M42, W5M42

CONTENTS

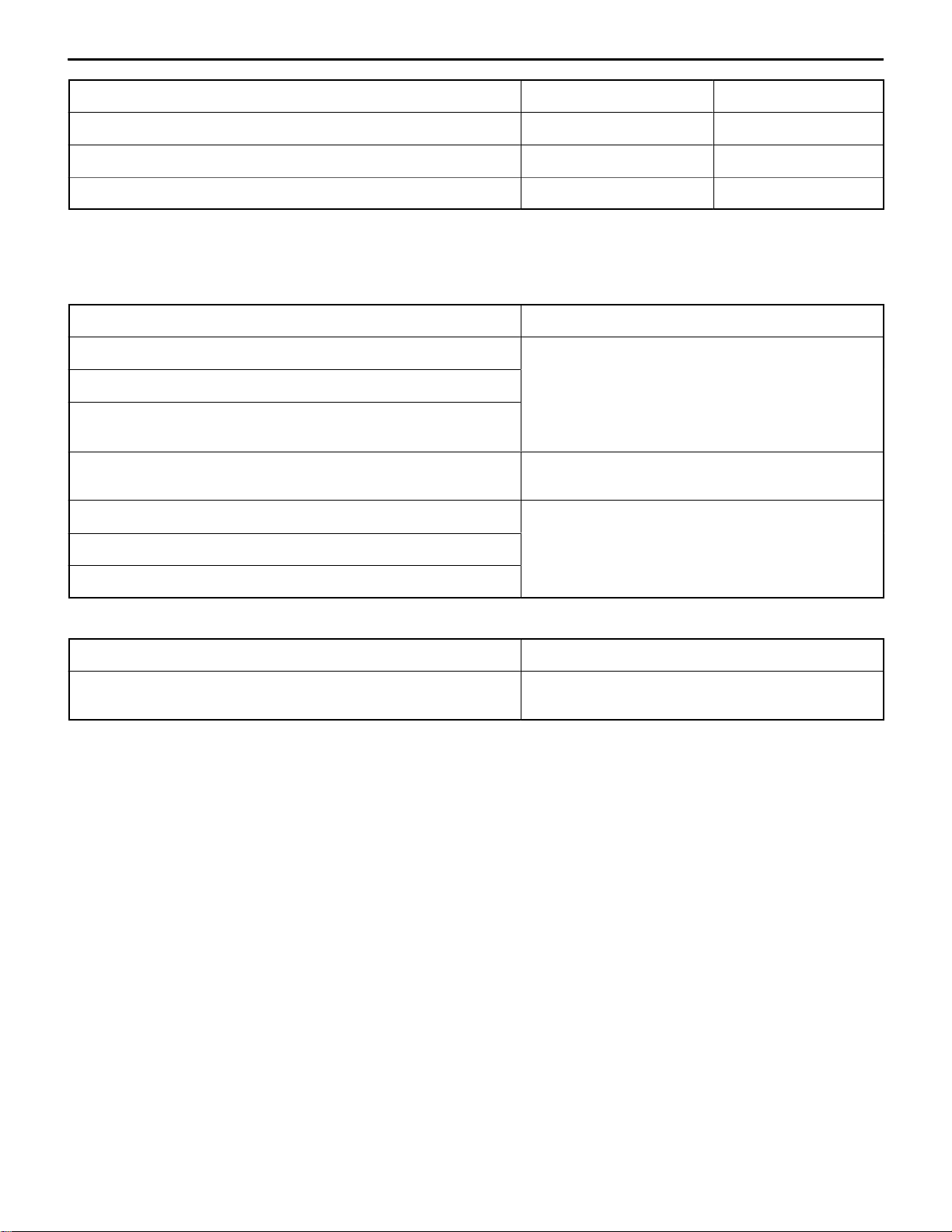

GENERAL INFORMATION 22B-0-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1. SPECIFICATIONS 22B-1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRANSMISSION MODEL TABLE 22B-1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GEAR RATIO TABLE 22B-1-2f. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SERVICE SPECIFICATIONS 22B-1-2f. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SEALANTS AND ADHESIVES 22B-1-2g. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LUBRICANTS 22B-1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SNAP RINGS, SPACERS AND THRUST PLATE

ADJUSTMENT 22B-1-4

TORQUE SPECIFICATIONS 22B-1-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. SPECIAL TOOLS 22B-2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. TRANSMISSION <F5M41> 22B-3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. TRANSMISSION <F5M42, W5M42> 22B-4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5. INPUT SHAFT <F5M41> 22B-5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6. INPUT SHAFT <F5M42, W5M42> 22B-6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7. OUTPUT SHAFT <F5M41> 22B-7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8. OUTPUT SHAFT <F5M42, W5M42> 22B-8-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9. REVERSE IDLER GEAR <F5M42, W5M42> 22B-9-1. . . . . . . . . . . . . . . . . . . . . .

10. SPEEDOMETER GEAR 22B-10-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11. SELECT LEVER 22B-11-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12. CONTROL HOUSING 22B-12-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13. CLUTCH HOUSING 22B-13-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14. TRANSMISSION CASE 22B-14-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15. DIFFERENTIAL <F5M41, F5M42>,

FRONT DIFFERENTIAL <W5M42> 22B-15-1

16. CENTER DIFFERENTIAL <W5M42> 22B-16-1. . . . . . . . . . . . . . . . . . . . . . . . . .

17. TRANSFER <W5M42> 22B-17-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

E

Mar . 2002Mitsubishi Motors Corporation Revised

PWEE9508-I

Page 2

22B-0-2

NOTES

Page 3

MANUAL TRANSMISSION (E-W) -

General Information

GENERAL INFORMATION

F5M41 <Types with single synchronizer ring for 2nd gear>

22B-0-3

67

2

1

3

5

4

8

9

10

15

1214 13

11

TFM0809

1. Reverse gear meshing noise prevention device

<Models with reverse brake>

2. 5th-reverse speed synchronizer hub

3. 5th speed gear

4. 4th speed gear

5. 3rd-4th speed synchronizer hub

6. 3rd speed gear

7. Transmission case

E

July 1999Mitsubishi Motors Corporation Revised

PWEE9508-F

8. Clutch housing

9. Release bearing retainer

10. Input shaft

11. Differential

12. 1st speed gear

13. 1st-2nd speed synchronizer hub

14. 2nd speed gear

15. Output shaft

Page 4

22B-0-4

MANUAL TRANSMISSION (E-W) -

General Information

F5M41 <Types with double synchronizer ring for 2nd gear>

12

34

6

7

8

5

9

10

15

1214 13

11

1. Reverse gear meshing noise prevention device

2. 5th-reverse speed synchronizer hub

3. 5th speed gear

4. 4th speed gear

5. 3rd-4th speed synchronizer hub

6. 3rd speed gear

7. Transmission case

E

July 1999Mitsubishi Motors Corporation Revised

PWEE9508-F

8. Clutch housing

9. Release bearing retainer

10. Input shaft

11. Differential

12. 1st speed gear

13. 1st-2nd speed synchronizer hub

14. 2nd speed gear

15. Output shaft

Page 5

MANUAL TRANSMISSION (E–W) – General Information

22B-0-4a

F5M41 <Types with single synchronizer ring for 2nd gear and synchronizer lever

for 5th gear>

1234

5

6

7

8

9

14

13

12

11

10

1. 5th-reverse speed synchronizer hub

2. 5th speed gear

3. 4th speed gear

4. 3rd-4th speed synchronizer hub

5. 3rd speed gear

6. Transmission case

7. Clutch housing

E

Dec. 2000Mitsubishi Motors Corporation Added

PWEE9508-H

8. Release bearing retainer

9. Input shaft

10. Differential

11. 1st speed gear

12. 1st-2nd speed synchronizer hub

13. 2nd speed gear

14. Output shaft

Page 6

22B-0-4b

MANUAL TRANSMISSION (E–W) – General Information

Intentionally blank

E

Dec. 2000Mitsubishi Motors Corporation Added

PWEE9508-H

Page 7

MANUAL TRANSMISSION (E-W) -

General Information

22B-0-5

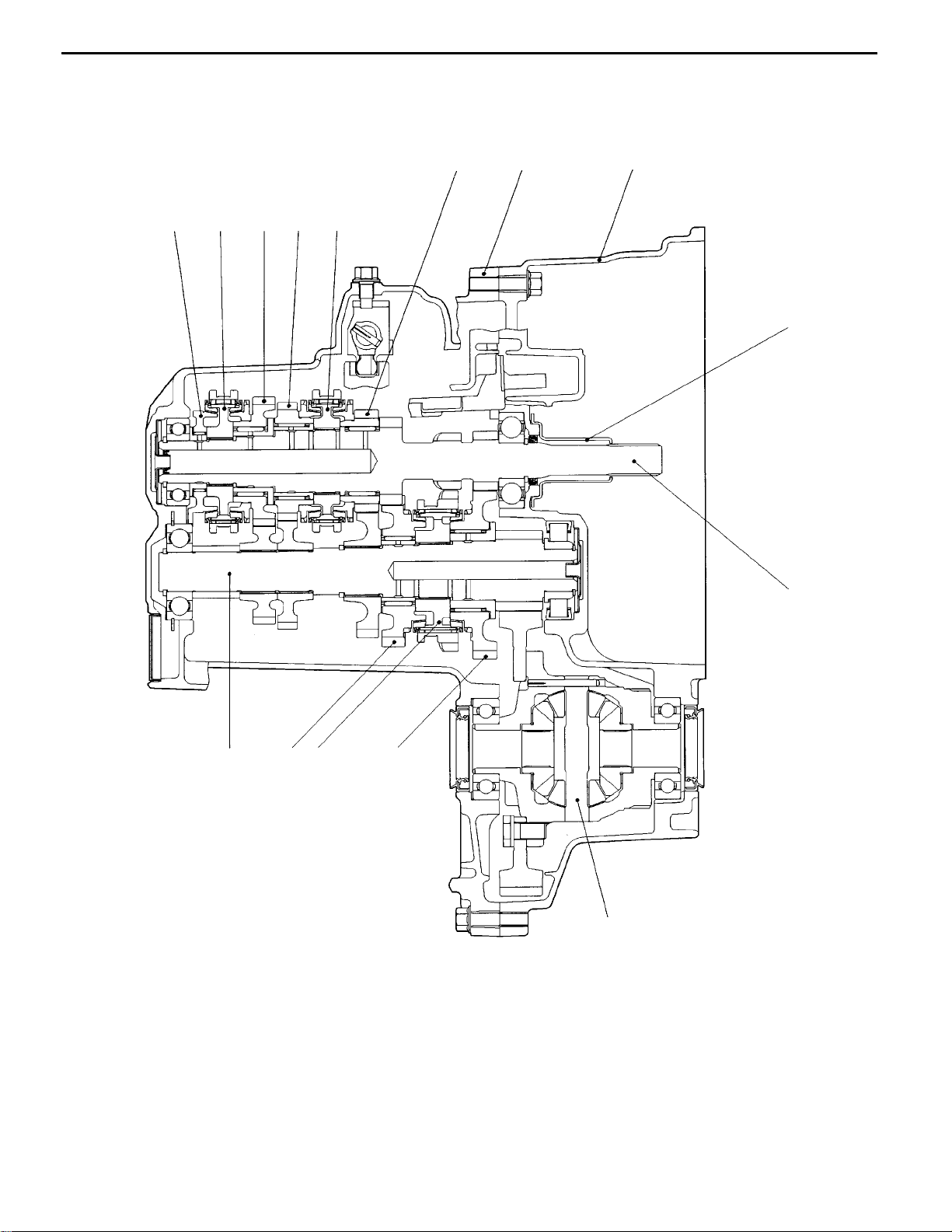

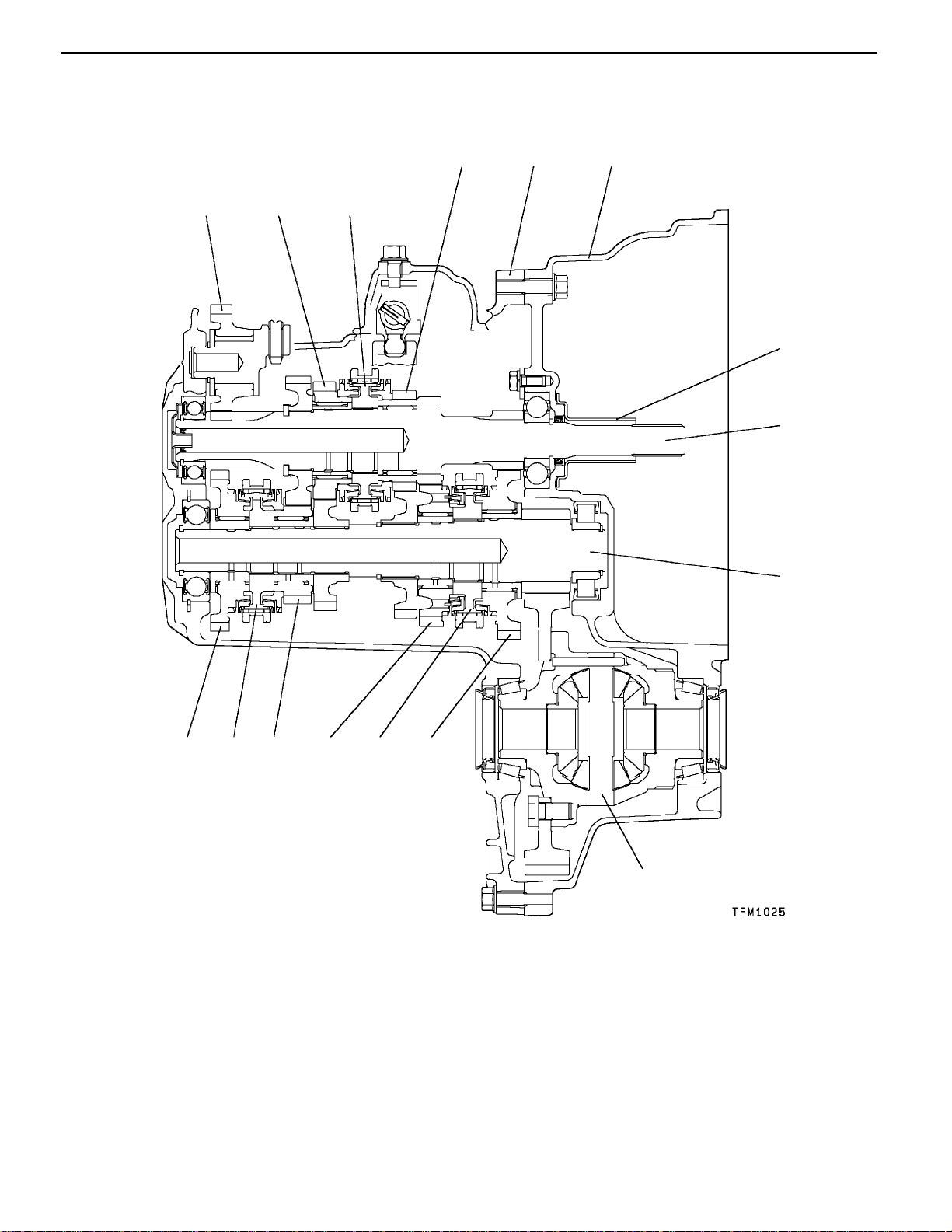

F5M42

<Types with single synchronizer ring for 1st gear and double synchronizer ring

for 2nd gear>

4

1

2

3

5

6

7

8

9

111214 131516

10

1. Reverse idler gear

2. 4th speed gear

3. 3rd-4th speed synchronizer hub

4. 3rd speed gear

5. Transmission case

6. Clutch housing

7. Release bearing retainer

8. Input shaft

E

July 1999Mitsubishi Motors Corporation Revised

PWEE9508-F

9. Output shaft

10. Differential

11. 1st speed gear

12. 1st-2nd speed synchronizer hub

13. 2nd speed gear

14. 5th speed gear

15. 5th-reverse speed synchronizer hub

16. Reverse gear

Page 8

22B-0-6

MANUAL TRANSMISSION (E-W) -

General Information

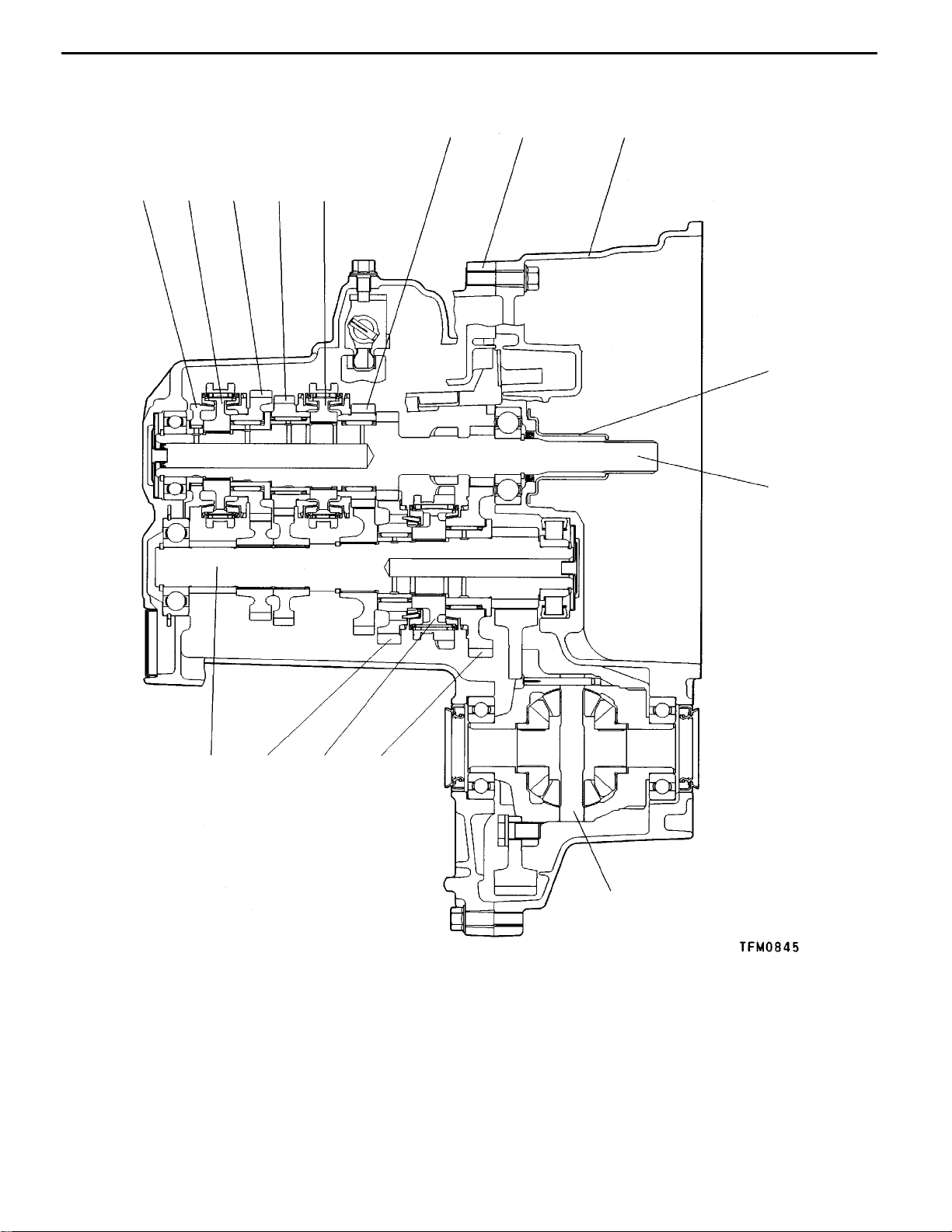

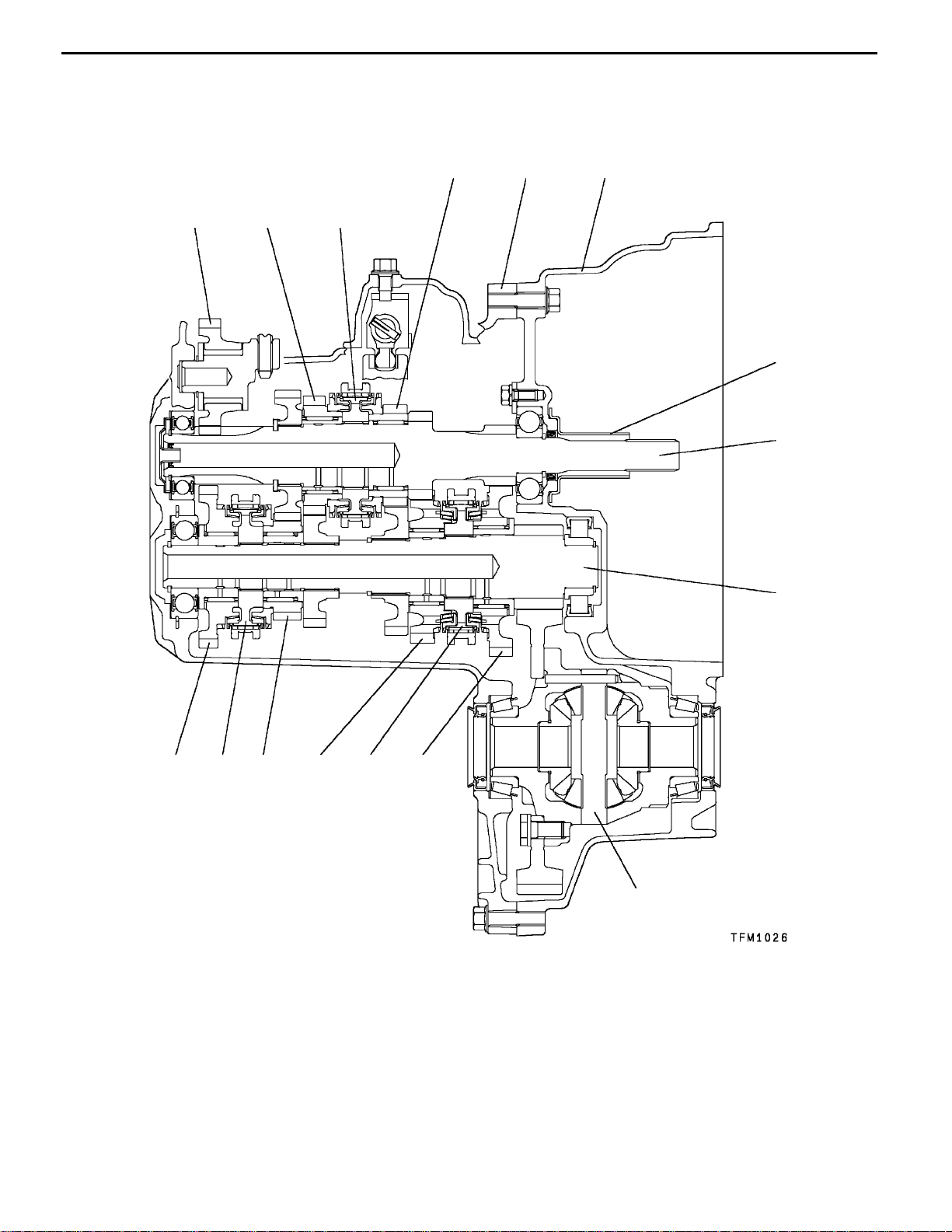

F5M42

<Types with double synchronizer ring for both 1st and 2nd gears, types with

double synchronizer ring for 1st gear and triple synchronizer ring for 2nd gear>

4

1

2

3

5

6

7

8

9

16

15

14

13

1112

10

1. Reverse idler gear

2. 4th speed gear

3. 3rd-4th speed synchronizer hub

4. 3rd speed gear

5. Transmission case

6. Clutch housing

7. Release bearing retainer

8. Input shaft

E

July 1999Mitsubishi Motors Corporation Revised

PWEE9508-F

9. Output shaft

10. Differential

11. 1st speed gear

12. 1st-2nd speed synchronizer hub

13. 2nd speed gear

14. 5th speed gear

15. 5th-reverse speed synchronizer hub

16. Reverse gear

Page 9

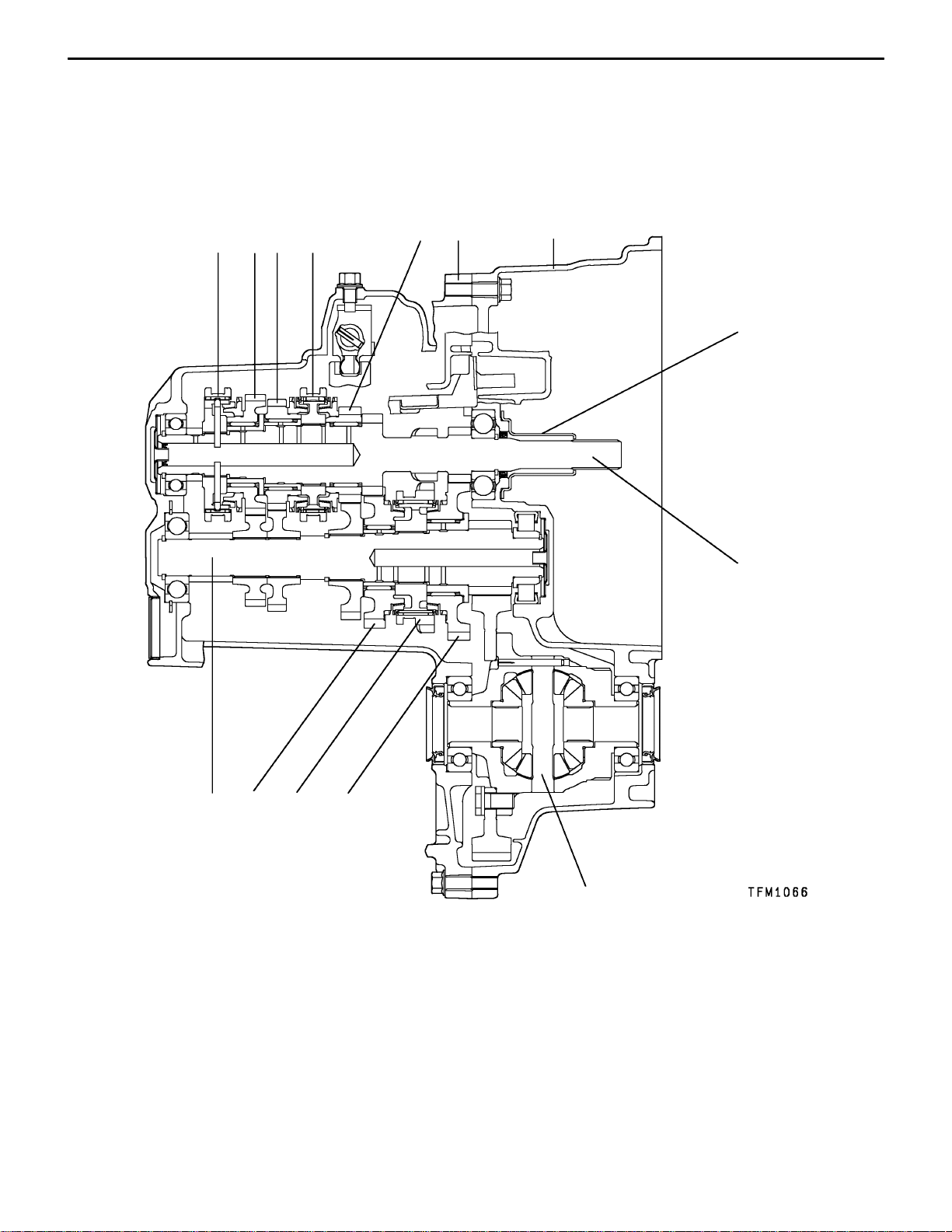

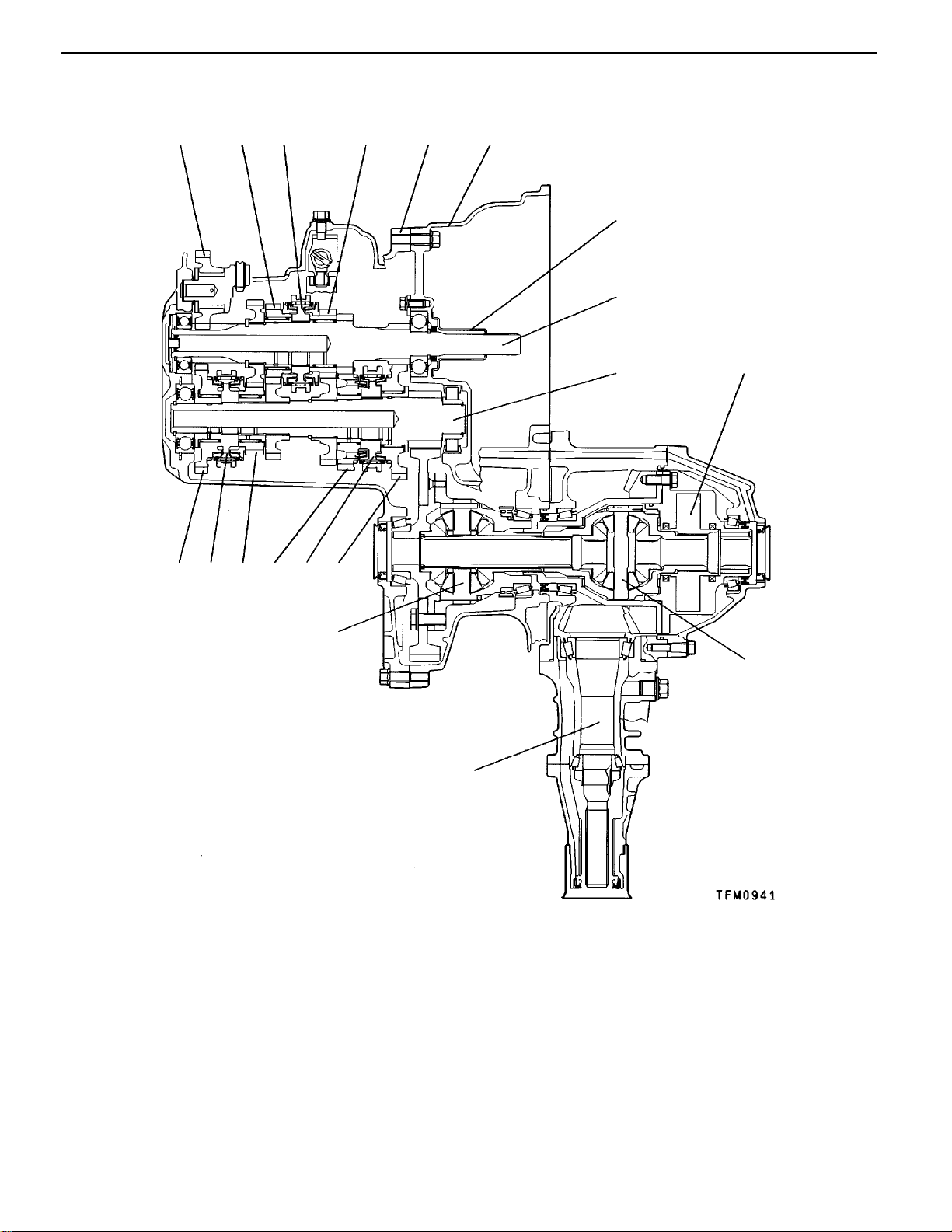

W5M42

MANUAL TRANSMISSION (E-W) -

General Information

22B-0-7

1

2

3

4

56

7

8

9

16

171819

15

14

10

13

1. Reverse idler gear

2. 4th speed gear

3. 3rd-4th speed synchronizer hub

4. 3rd speed gear

5. Transmission case

6. Clutch housing

7. Release bearing retainer

8. Input shaft

9. Output shaft

10. Viscous coupling

11

12

11. Front differential

12. Transfer driven gear

13. Center differential

14. 1st speed gear

15. 1st-2nd speed synchronizer hub

16. 2nd speed gear

17. 5th speed gear

18. 5th-reverse speed synchronizer hub

19. Reverse gear

E

Jun. 1998Mitsubishi Motors Corporation Added

PWEE9508-E

Page 10

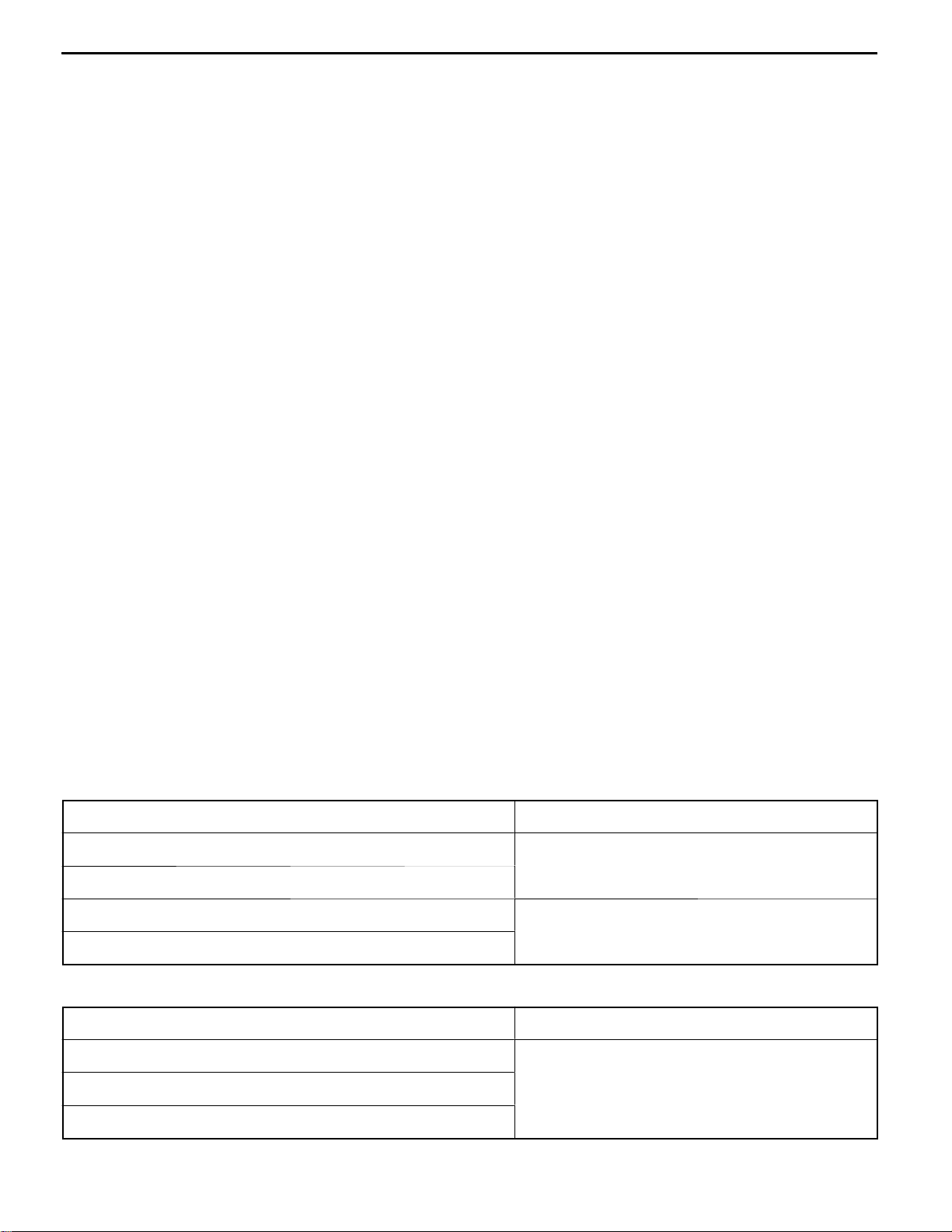

MANUAL TRANSMISSION (E–W) – Specifications

1. SPECIFICATIONS

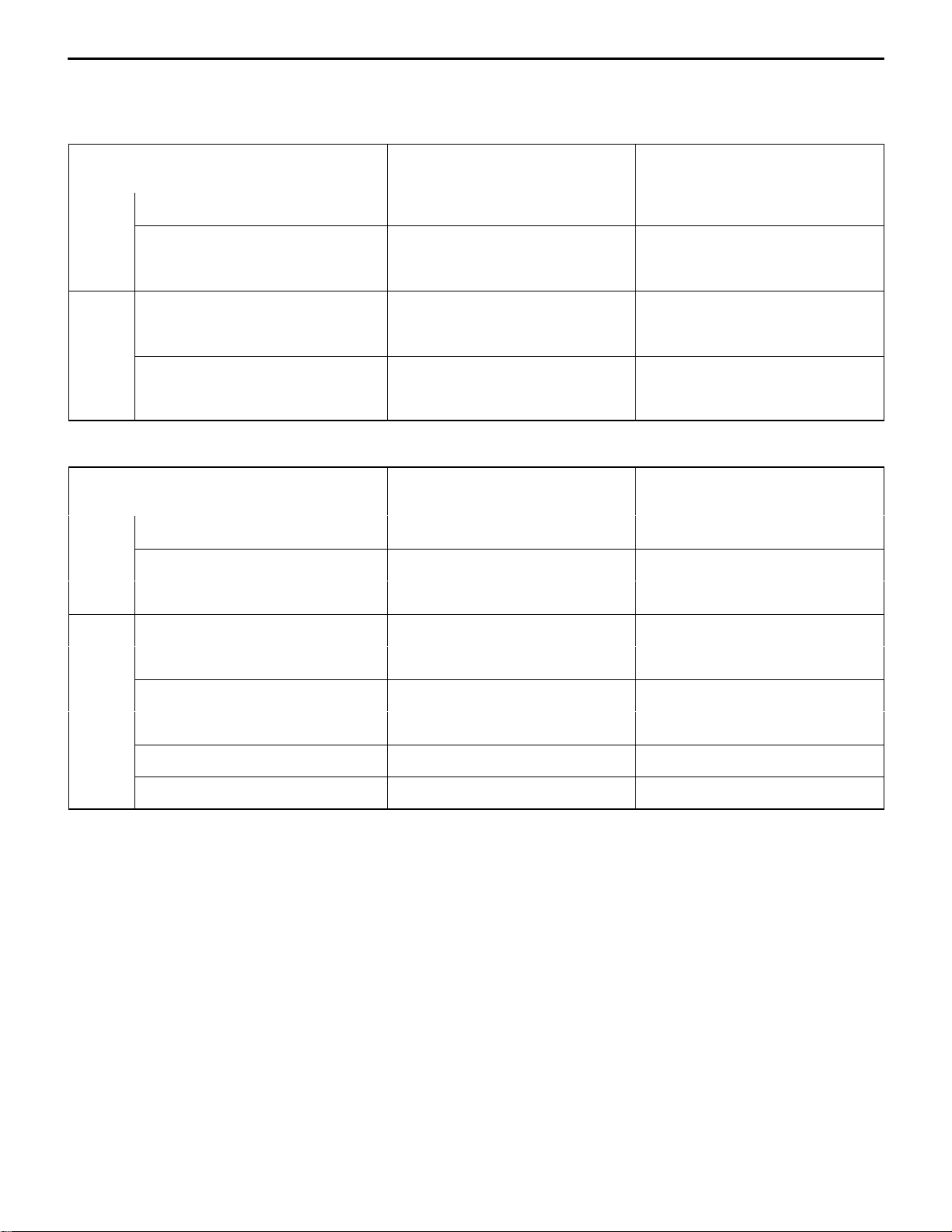

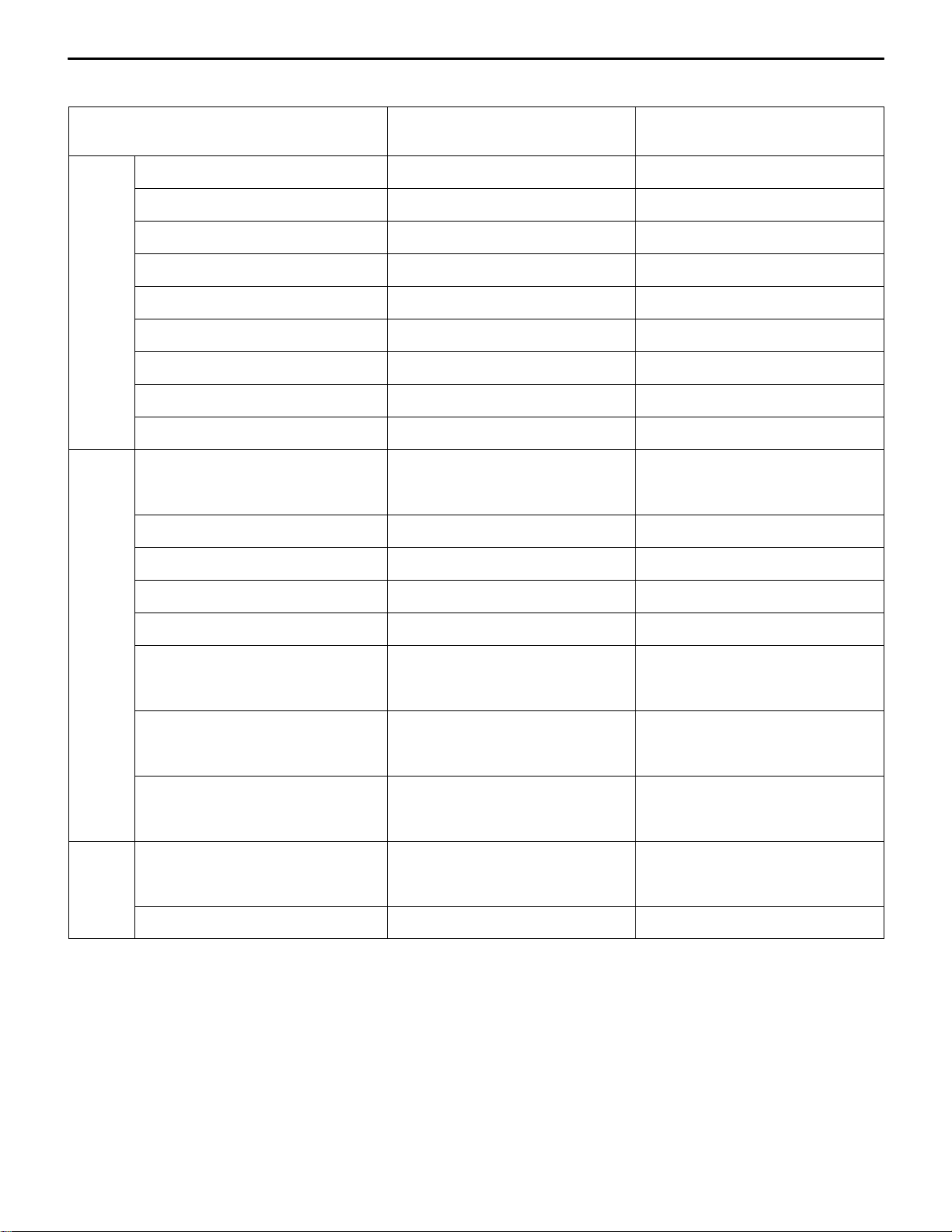

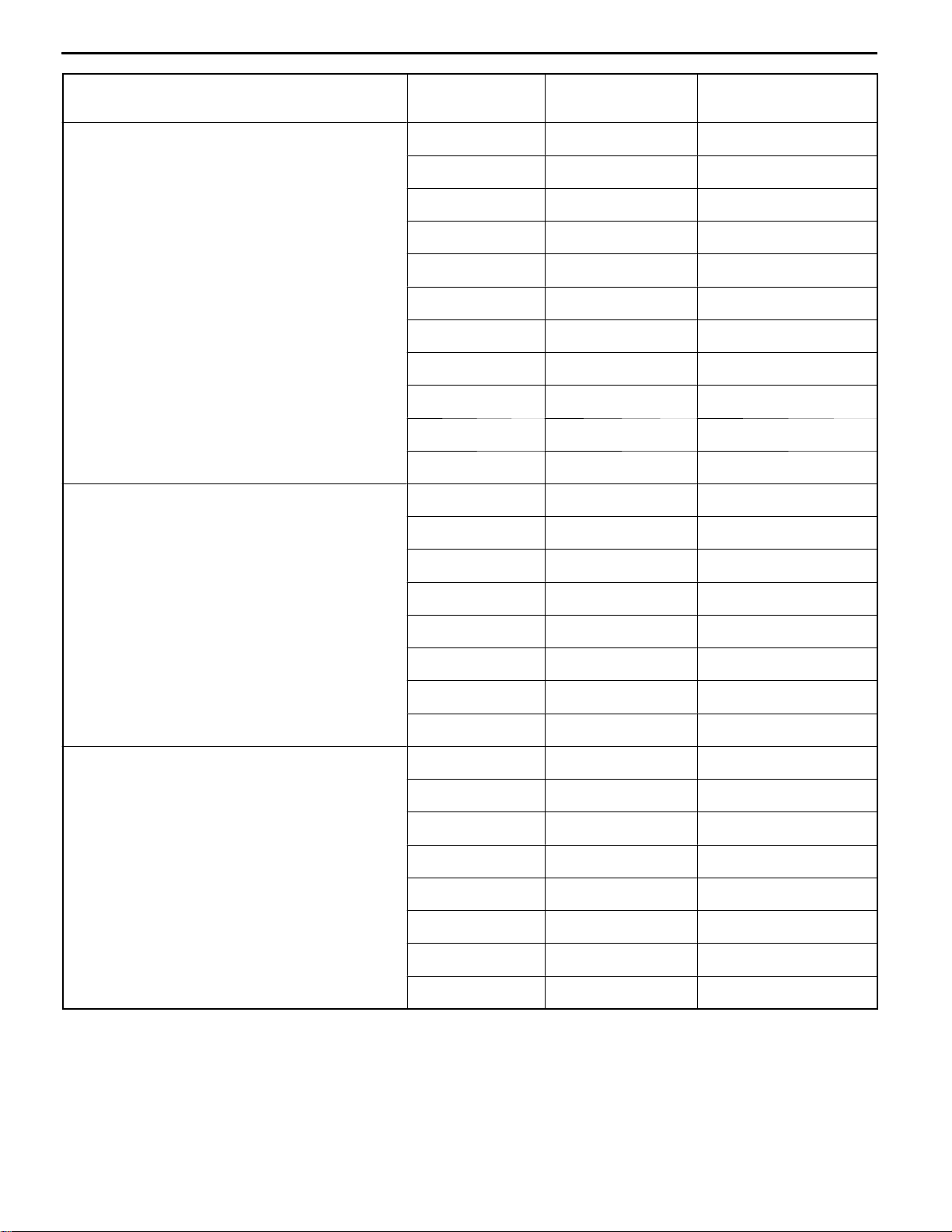

TRANSMISSION MODEL TABLE – MODEL 1996

22B-1-1

Transmission model Gear ratio Speedometer

gear ratio

EUR F5M41-1-B8A1 B 31/36 3.454 CJ4A 4G92-MVV

F5M41-1-F8A1 A 31/36 3.714 CJ4A, CK4A 4G92-MPI

F5M41-1-R8A A 31/36 4.052 CJ1A, CK1A 4G13

EXP F5M41-1-F8A1 A 31/36 3.714 CJ4A, CK4A 4G92-MPI

F5M41-1-R8A A 31/36 4.052 CJ1A, CK1A 4G13

F5M41-1-R8A A 31/36 4.052 CJ2A, CK2A 4G15

F5M42-1-Y8A C 31/36 4.625 CK4A 4G92-MIVEC

Final gear ratio Vehicle model Engine model

TRANSMISSION MODEL TABLE – MODEL 1997

Transmission model Gear ratio Speedometer

gear ratio

EUR F5M42-1-F7N D 30/36 3.722 EA2A, EA2W 4G63

F5M42-2-F6N2 F 29/36 3.722 EA5A, EA5W 6A13

F5M42-2-F6N5 E 29/36 3.722 EA6A, EA6W 4D68

Final gear ratio Vehicle model Engine model

EXP F5M42-1-F6N4 D 29/36 3.722 EA2A 4G63-MPI

F5M42-1-F7N D 30/36 3.722 EA2A 4G63-MPI

F5M42-1-R6N2 D 29/36 4.058 EA1A 4G93

F5M42-1-R6N3 D 29/36 4.058 EA2A 4G63-CARB

F5M42-2-F6N2 F 29/36 3.722 EA5A 6A13

F5M42-2-V6N D 29/36 4.312 EA4A 6A12

E

Dec. 2000Mitsubishi Motors Corporation Revised

PWEE9508-H

Page 11

22B-1-2

MANUAL TRANSMISSION (E–W) – Specifications

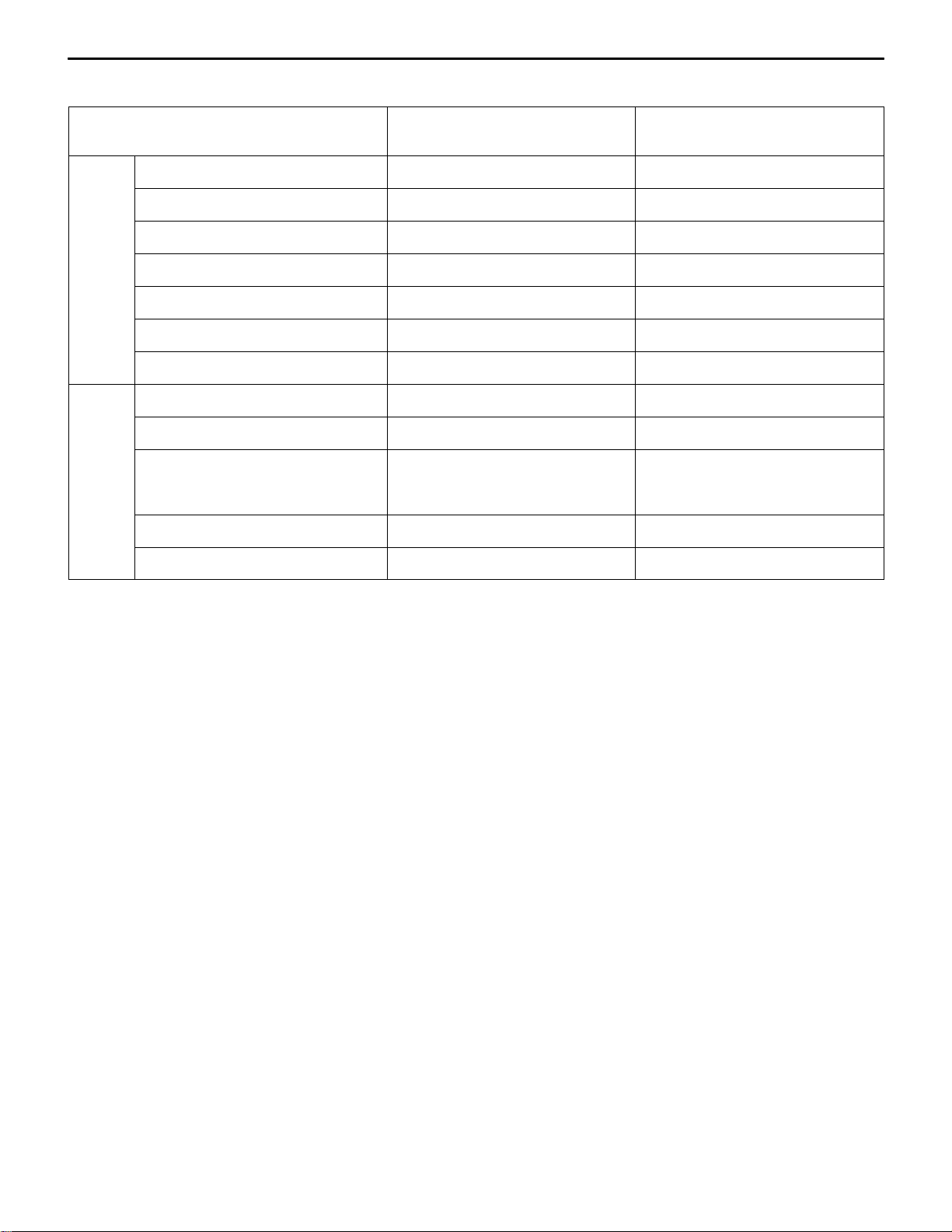

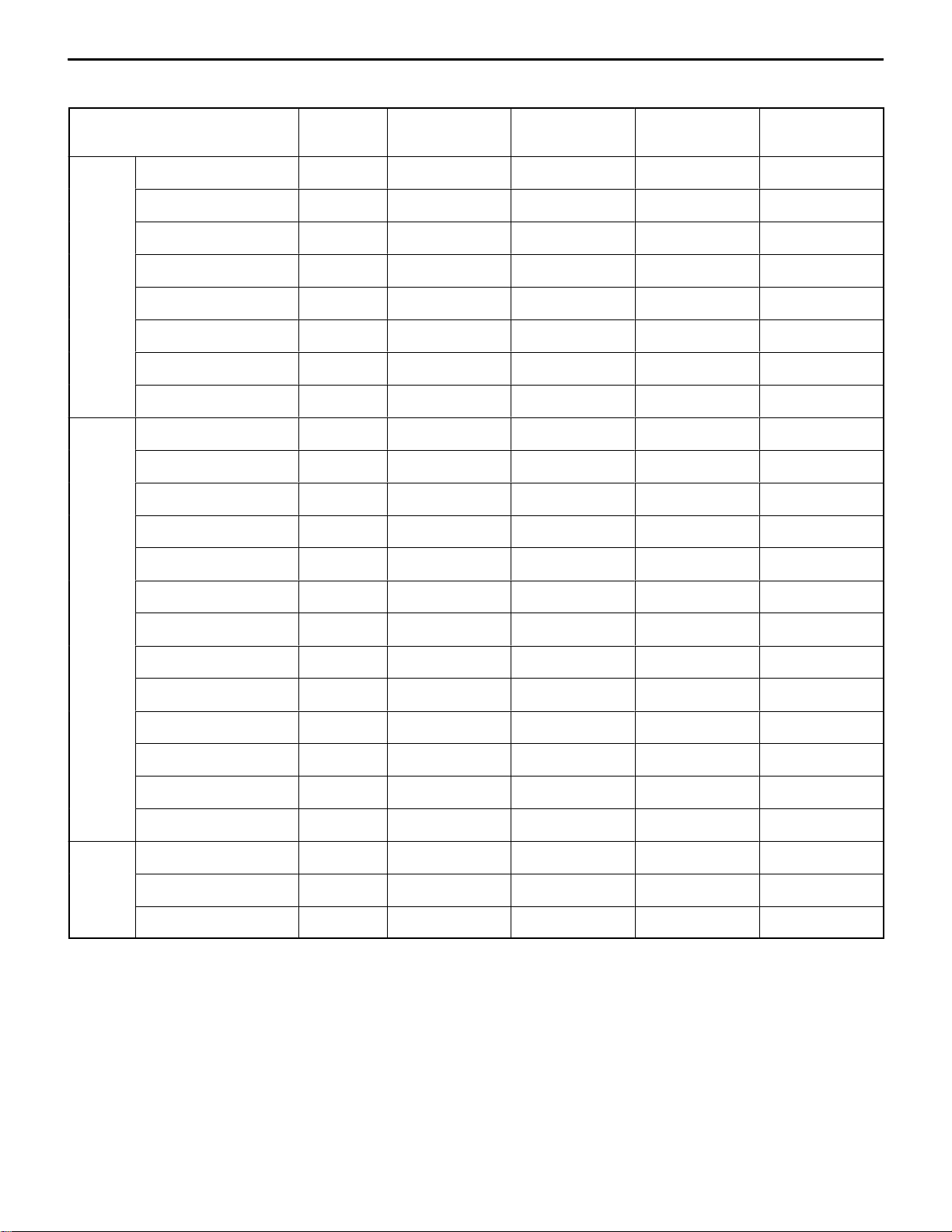

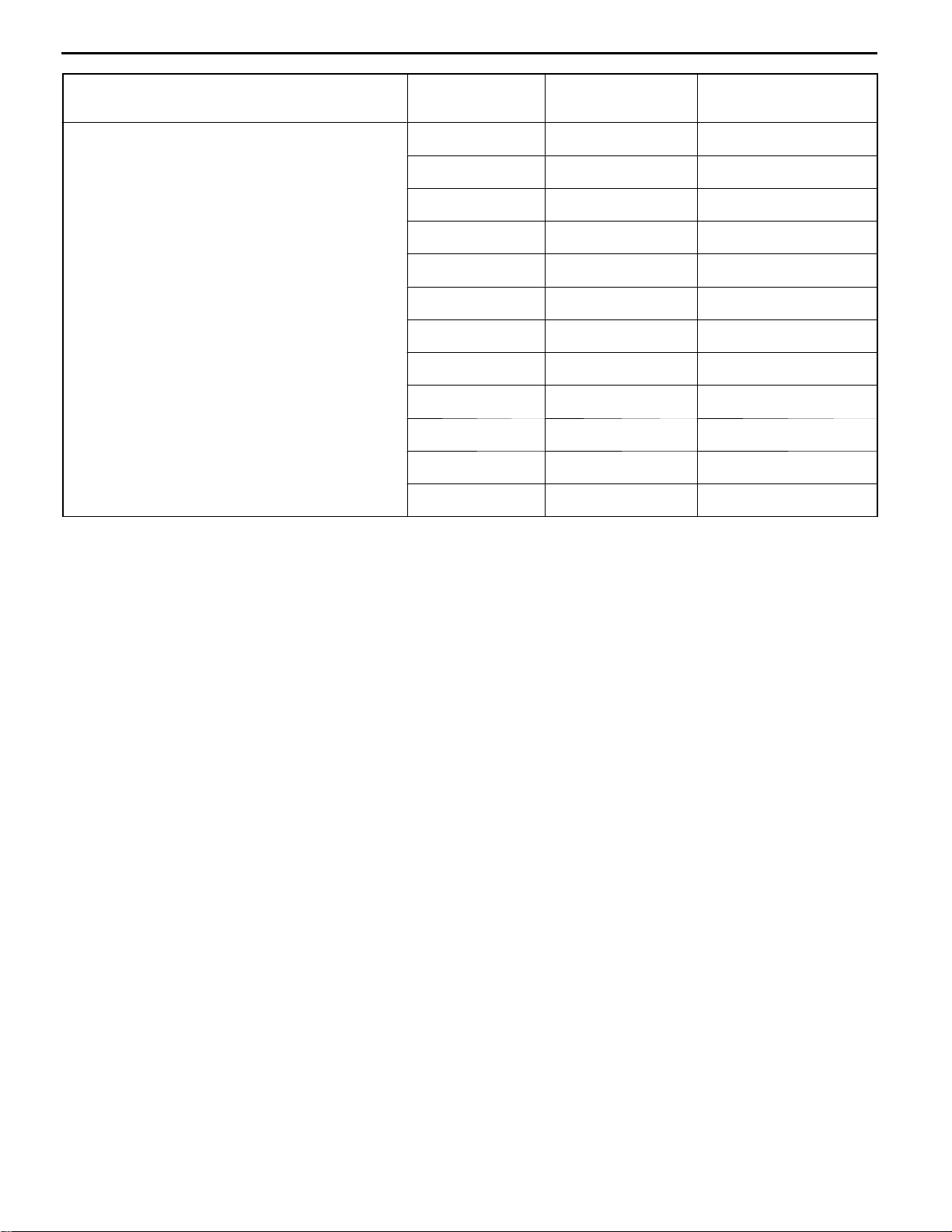

TRANSMISSION MODEL TABLE – MODEL 1998

Transmission model Gear ratio Speedometer

gear ratio

EUR F5M41-1-B8A2 B 31/36 3.454 CJ4A 4G92

F5M41-1-F8A5 A 31/36 3.714 CJ4A 4G92

F5M41-1-R8A1 A 31/36 4.052 CK1A, CJ1A 4G13

F5M42-2-F7N2 D 30/36 3.722 EA2A, EA2W 4G63

F5M42-1-F8A4 G 31/36 3.722 DA2A 4G93-GDI

F5M42-2-F6NA E 29/36 3.722 EA6A, EA6W 4D68

F5M42-2-F6N7 F 29/36 3.722 EA5A, EA5W 6A13

EXP F5M41-1-F8A5 A 31/36 3.714 CJ4A, CK4A 4G92

F5M41-1-R8A1 A 31/36 4.052 CJ1A, CK1A 4G13

F5M41-1-R8A1 A 31/36 4.052 CJ2A, CK2A 4G15

F5M42-1-R6N6 D 29/36 4.058 EA1A 4G93

F5M42-1–F6N9 D 29/36 3.722 EA2A 4G63

F5M42-2-R6N8 E 29/36 4.058 EA6A 4D68

Final gear ratio Vehicle model Engine model

E

Dec. 2000Mitsubishi Motors Corporation Revised

PWEE9508-H

Page 12

MANUAL TRANSMISSION (E–W) – Specifications

TRANSMISSION MODEL TABLE – MODEL 1999

22B-1-2a

Transmission model Gear ratio Speedometer

gear ratio

EUR F5M42-1-V5A4 D 28/36 4.312 N61W 4G93-GDI

F5M42-2-R5A3 G 28/36 4.058 N84W 4G64-GDI

W5M42-1-V5A1 H 28/36 4.352 N94W 4G64-GDI

F5M42-1-F8A4 G 31/36 3.722 DA2A 4G93-GDI

F5M42-2-F7N2 D 30/36 3.722 EA2A, EA2W 4G93

F5M42-2-F6NC G 29/36 3.722 EA3A, EA3W 4G64-GDI

F5M42-2-F6N7 F 29/36 3.722 EA5A, EA5W 6A13

F5M42-2-F6NA E 29/36 3.722 EA6A, EA6W 4D65

EXP F5M42-1-R6N6 D 29/36 4.058 EA1A 4G93

F5M42-1-R6N7 D 29/36 4.058 EA2A 4G63

F5M42-1-F6N9 D 29/36 3.722 EA2A 4G63

F5M42-1-F7N1 D 30/36 3.722 EA2A 4G63

F5M42-2-V6N1 D 29/36 4.312 EA4A 6A12-MIVEC

Final gear ratio Vehicle model Engine model

F5M42-2-F6N7 F 29/36 3.722 EA5A 6A13

F5M42-2-R6N8 E 29/36 4.058 EA6A 4D56

F5M42-2-R5A2 D 28/36 4.058 N84W 4G64

MMAL F5M41-1-F8A5 A 31/36 3.714 CJ2A, CK2A 4G15

F5M42-1-F8A7 F 31/36 3.722 CJ5A, CK5A 4G93

F5M42-2-R5A2 D 28/36 4.058 N84W 4G64

E

Dec. 2000Mitsubishi Motors Corporation Revised

PWEE9508-H

Page 13

22B-1-2b

MANUAL TRANSMISSION (E–W) – Specifications

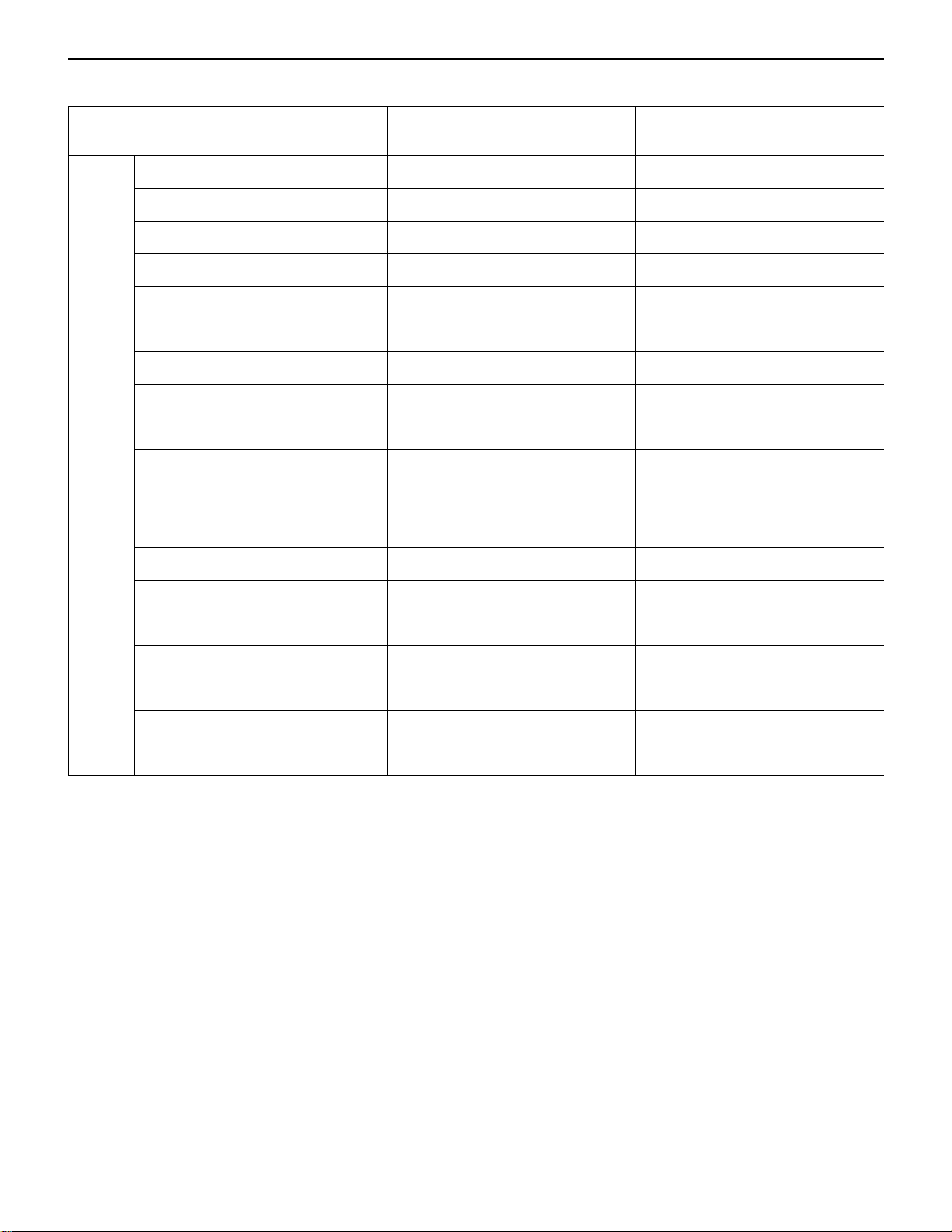

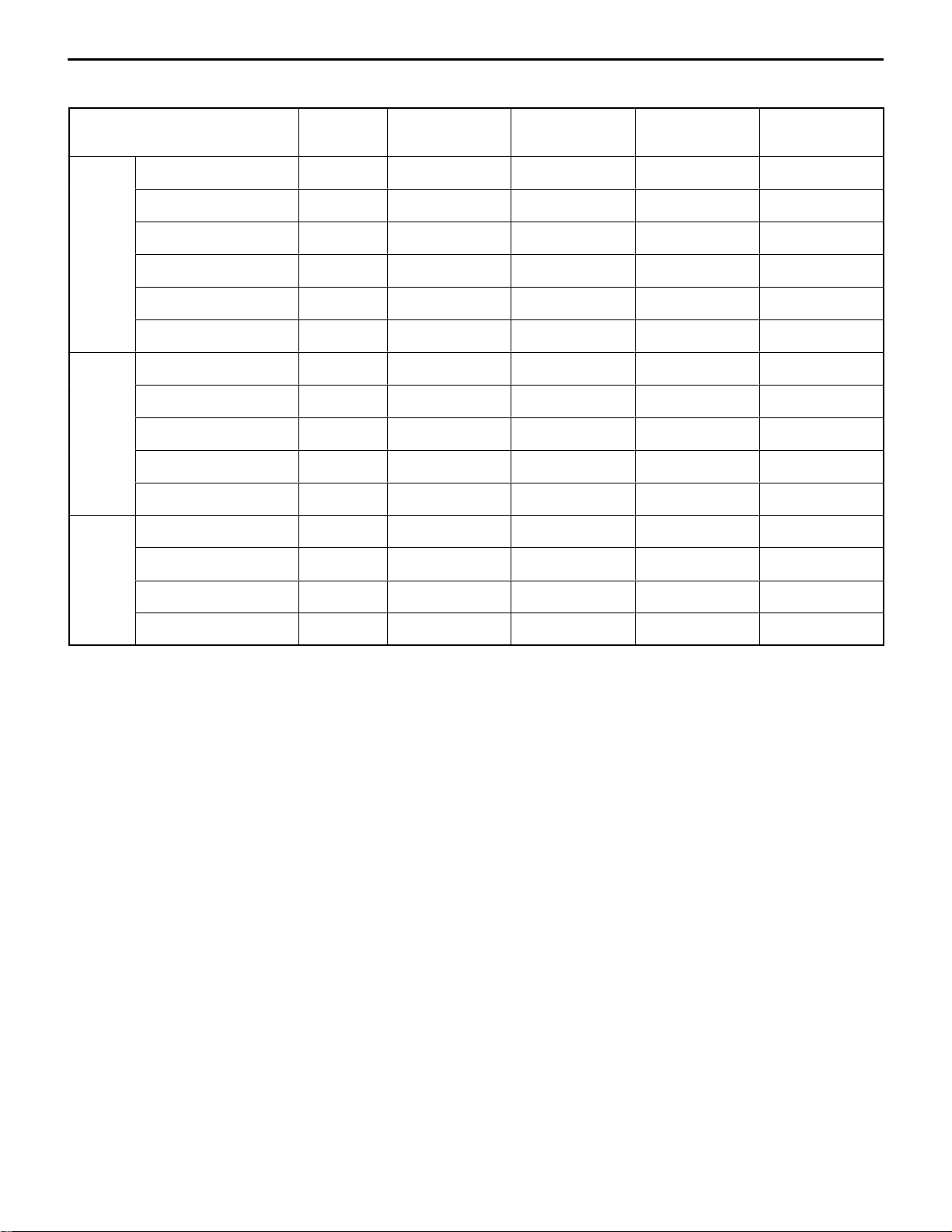

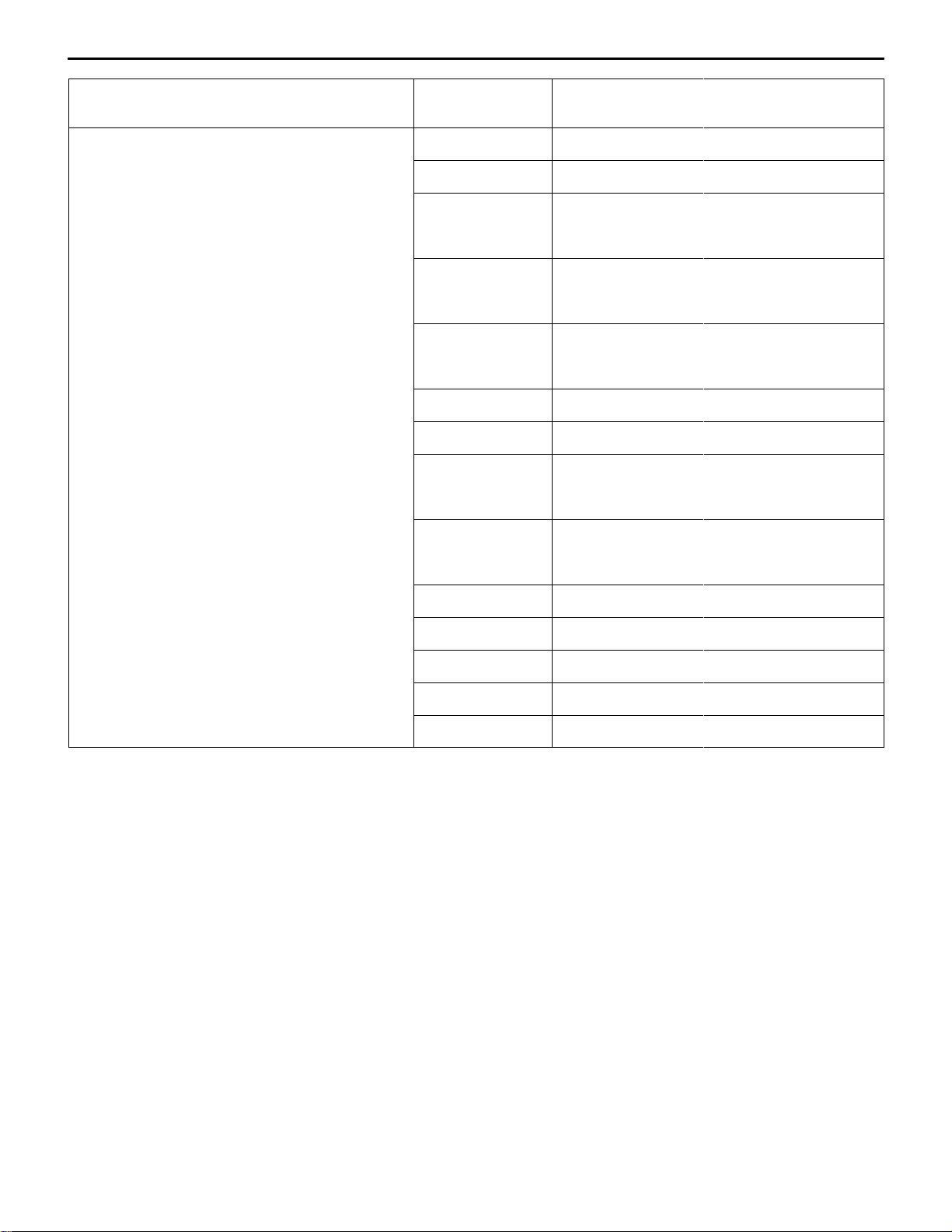

TRANSMISSION MODEL TABLE – MODEL 2000

Transmission model Gear ratio Speedometer

gear ratio

EUR F5M41-1-R8A1 A 31/36 4.052 CJ1A 4G13

F5M41-1-F8A5 A 31/36 3.714 CJ4A 4G92

F5M41-1-B8A2 B 31/36 3.454 CJ4A 4G92-MVV

F5M42-1-R7A2 G 30/36 4.058 DA2A 4G93-GDI

F5M42-1-V5A4 D 28/36 4.312 N61W 4G93-GDI

F5M42-2-R5A3 G 28/36 4.058 N64W, N84W 4G64-GDI

W5M42-1-V5A1 H 28/36 4.352 N94W 4G64-GDI

EXP F5M41-1-R8A1 A 31/36 4.052 CJ1A, CK1A 4G13

F5M41-1-F8A5 A 31/36 3.714 CJ4A, CK4A 4G92

F5M42-1-R6N6 D 29/36 4.058 EA1A 4G93

F5M42-1-R6N7 D 29/36 4.058 EA2A 4G63

F5M42-1-F6N9 D 29/36 3.722 EA2A, EA2W 4G63

F5M42-2-F6N7 F 29/36 3.722 EA5A 6A13

Final gear ratio Vehicle model Engine model

F5M42-2-R5A2 D 28/36 4.058 N84W 4G64

MMAL F5M42-2-R5A2 D 28/36 4.058 N84W 4G64

E

Dec. 2000Mitsubishi Motors Corporation Revised

PWEE9508-H

Page 14

MANUAL TRANSMISSION (E–W) – Specifications

TRANSMISSION MODEL TABLE – MODEL 2001

22B-1-2c

Transmission model Gear ratio Speedometer

gear ratio

EUR F5M41-1-R8A1 A 31/36 4.052 CJ1A 4G13

F5M41-1-F8A5 A 31/36 3.714 CJ4A 4G92

F5M42-1-F8AC I 31/36 3.722 DG5A 4G93

F5M42-1-R7A2 G 30/36 4.058 DA2A 4G93

F5M42-2-F7N2 D 30/36 3.722 EA2A, W 4G63

F5M42-2-F6NC G 29/36 3.722 EA3A, W 4G64

F5M42-2-F6N7 F 29/36 3.722 EA5A, W 6A13

F5M42-2-V5A D 28/36 4.312 N63W 4G63

F5M42-2-R5A3 G 28/36 4.058 N64W 4G64

EXP F5M41-1-R8A1 A 31/36 4.052 CJ1A, CJ2A 4G13, 4G15

F5M41-1-R7B A 30/36 4.052 CS1A, CS3A 4G13, 4G18

F5M41-1-R8B A 31/36 4.052 CS1A, CS3A 4G13, 4G18

F5M41-1-F8A5 A 31/36 3.714 CJ4A 4G92

Final gear ratio Vehicle model Engine model

F5M42-1-F6N9 D 29/36 3.722 EA2W 4G63

F5M42-1-F7N1 D 30/36 3.722 EA2W 4G63

F5M42-1-R6N6 D 29/36 4.058 EA1A 4G93

F5M42-2-R6N7 D 29/36 4.058 EA2A 4G63

F5M42-1-F6N9 D 29/36 3.722 EA2A 4G63

F5M42-2-F6N7 F 29/36 3.722 EA5A 6A13

F5M42-2-R6N8 E 29/36 4.058 EA6A 4D68

F5M42-2-R5A2 D 28/36 4.058 N84W 4G64

MMAL F5M41-1-F8A5 A 31/36 3.714 CJ2A, CK2A 4G15

F5M42-1-F8A7 F 31/36 3.722 CJ5A, CK5A 4G93

F5M42-2-R5A2 D 28/36 4.058 N84W 4G64

E

Dec. 2000Mitsubishi Motors Corporation Revised

PWEE9508-H

Page 15

22B-1-2d

MANUAL TRANSMISSION (E–W) – Specifications

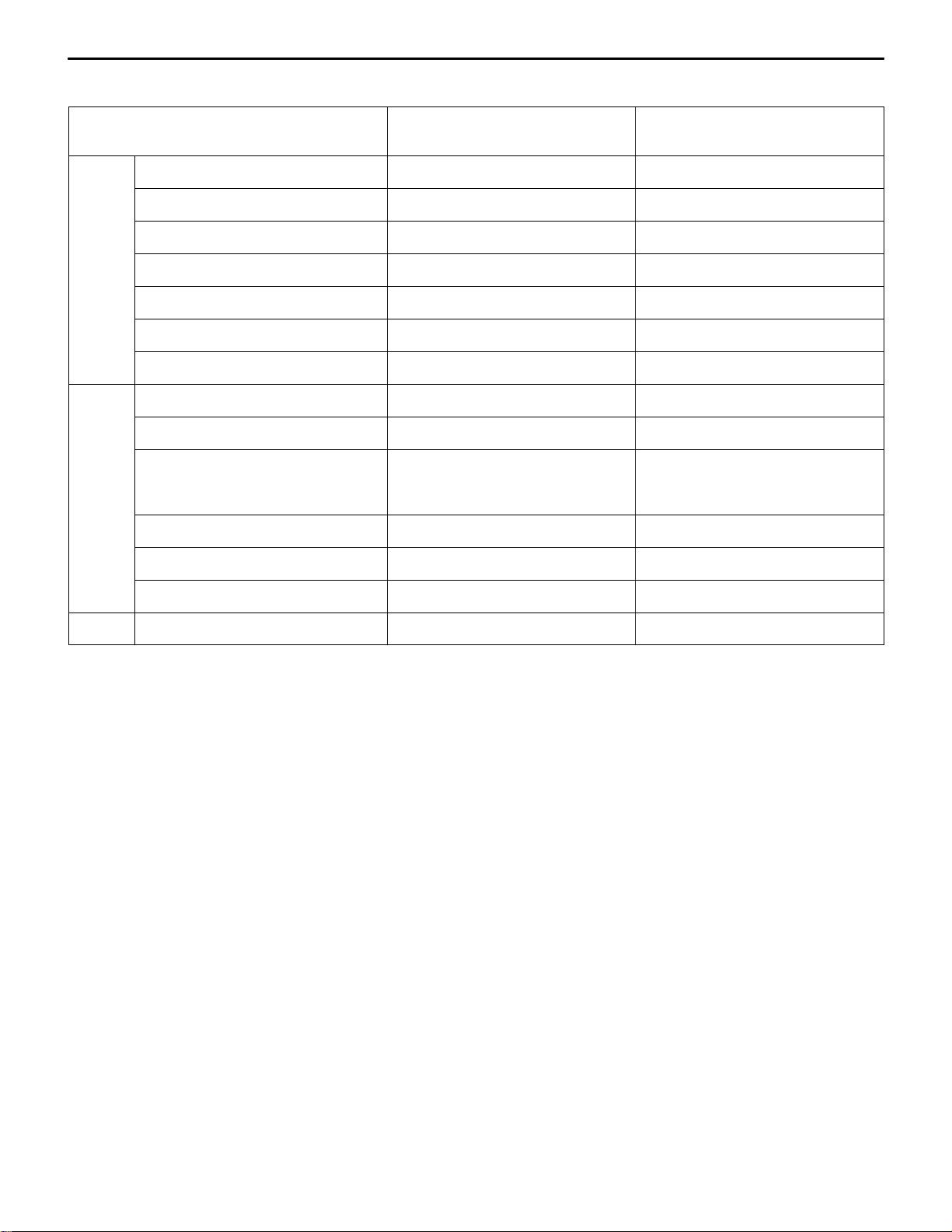

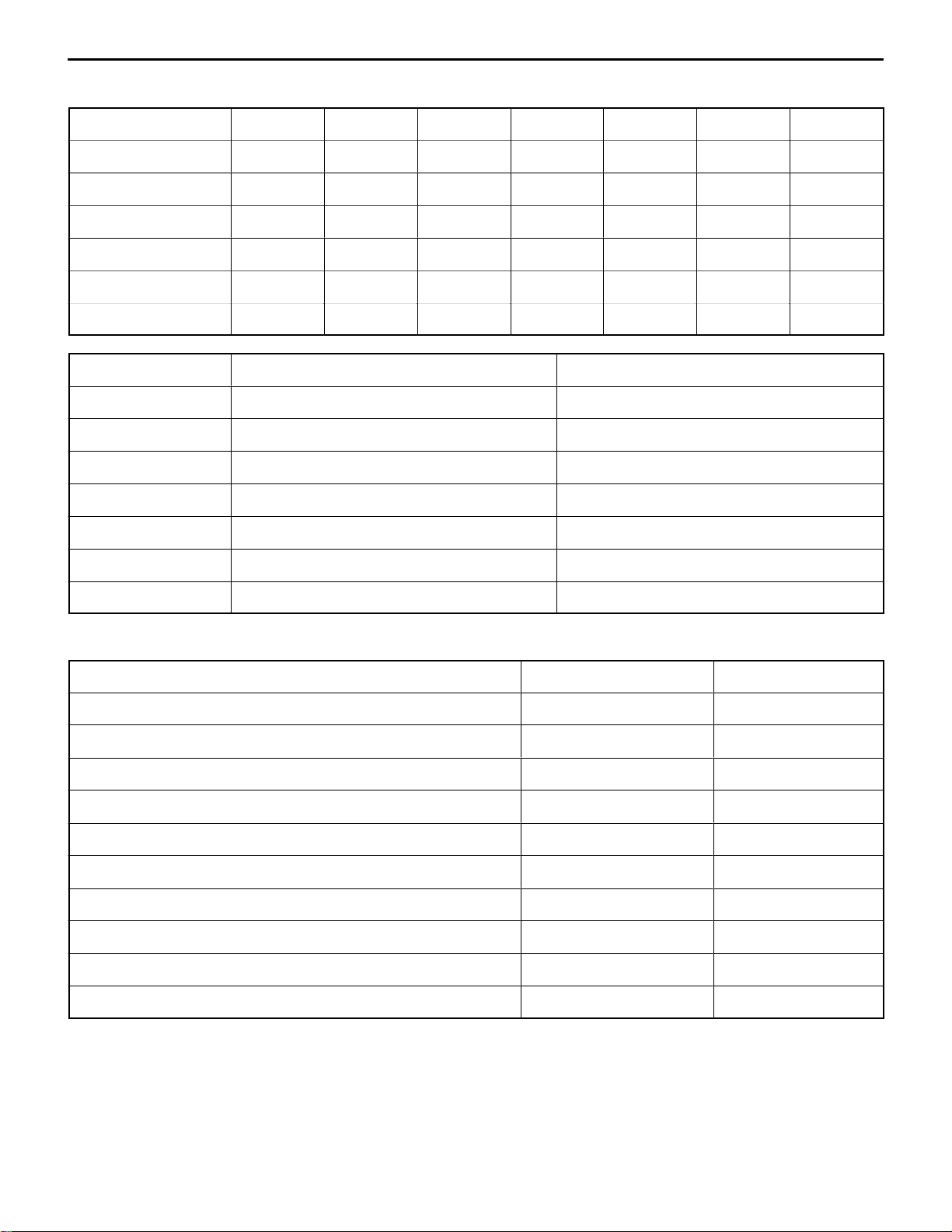

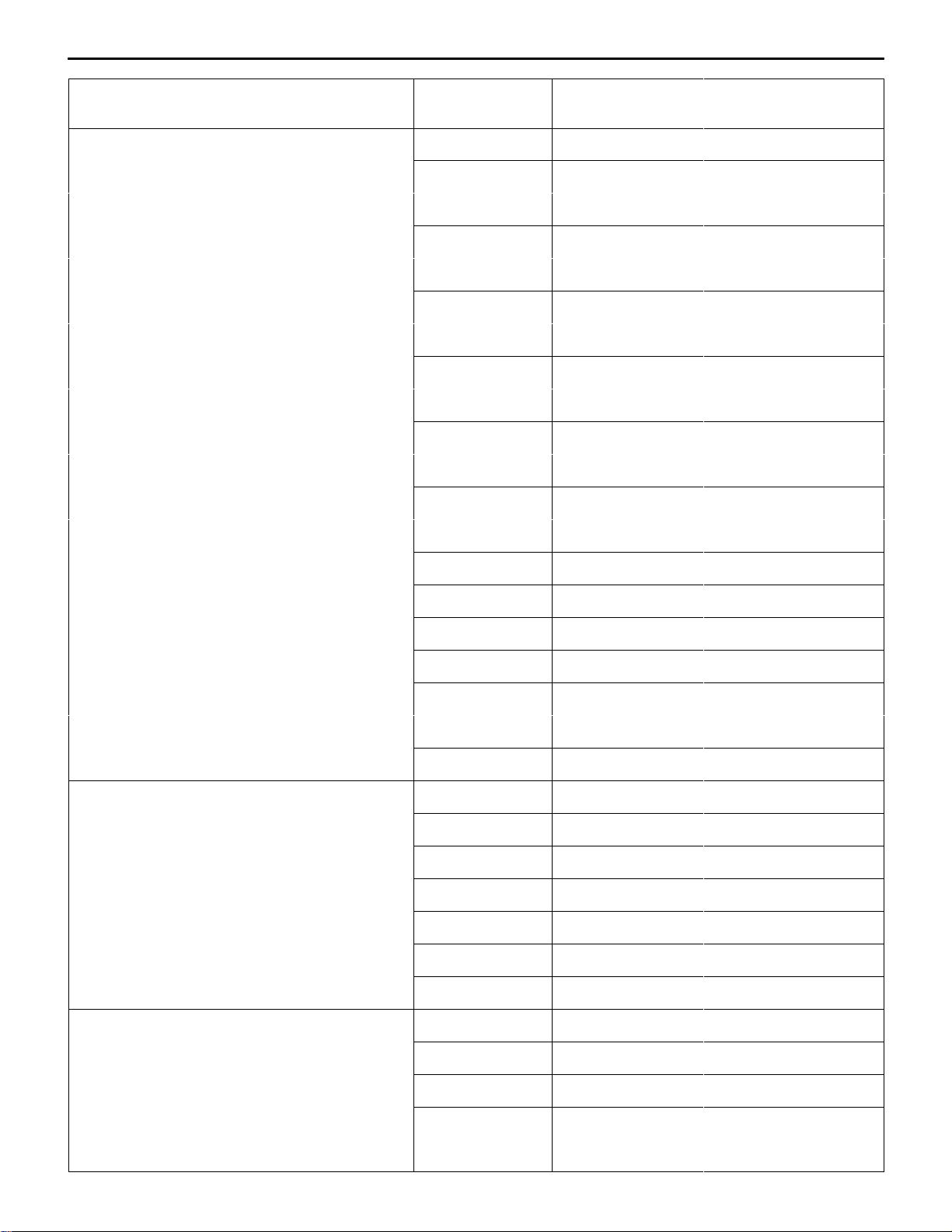

TRANSMISSION MODEL TABLE – MODEL 2002

Transmission model Gear ratio Speedometer

gear ratio

EUR F5M41-1-R8A1 A 31/36 4.052 CJ1A 4G13

F5M41-1-F8A5 A 31/36 3.714 CJ4A 4G92

F5M41-1-R8B A 31/36 4.052 CS3A 4G18

F5M42-1-F8AC I 31/36 3.722 DG5A 4G93

F5M42-1-R7A2 G 30/36 4.058 DA2A 4G93

F5M42-2-V5A D 28/36 4.312 N83W 4G63

F5M42-2-R5A3 G 28/36 4.058 N84W 4G64

W5M42-1-V5A1 H 28/36 4.352 N94W 4G64

EXP F5M41-1-F8A5 A 31/36 3.714 CJ4A 4G92

F5M41-1-R8A1 A 31/36 4.052 CJ1A, CJ2A 4G13, 4G15

F5M42-2-F6N7 F 29/36 3.722 EA5A 6A13

F5M42-1-R6N6 D 29/36 4.058 EA1A 4G93

F5M42-1-R6N7 D 29/36 4.058 EA2A 4G63

Final gear ratio Vehicle model Engine model

F5M42-1-F6N9 D 29/36 3.722 EA2A, W 4G63

F5M42-2-R6N8 E 29/36 4.058 EA6A 4D68

F5M41-1-R7B A 30/36 4.052 CS1A, CS3A 4G13, 4G18

F5M41-1-R8B A 31/36 4.052 CS1A, CS3A 4G13, 4G18

F5M41-1-V7B A 30/36 4.333 CS1A 4G13

F5M41-1-V8B1 A 31/36 4.333 CS1A 4G13

F5M42-1-R7A2 G 30/36 4.058 DA3A 4G93

F5M42-2-R5A2 D 28/36 4.058 N84W 4G64

MMAL F5M42-2-R5A2 D 28/36 4.058 N84W 4G64

F5M41-1-F8A5 A 31/36 3.714 CJ2A 4G15

F4M42-1-F8A7 F 31/36 3.722 CJ5A, CK5A 4G93

E

Mar . 2002Mitsubishi Motors Corporation Revised

PWEE9508-I

Page 16

MANUAL TRANSMISSION (E–W) – Specifications

TRANSMISSION MODEL TABLE – MODEL 2003

22B-1-2e

Transmission model Gear ratio Speedometer

gear ratio

EUR F5M41-1-F8A5 A 31/36 3.714 CJ4A 4G92

F5M41-1-R8A1 A 31/36 4.052 CJ1A 4G13

F5M42-2-V5A D 28/36 4.312 N83W 4G64

F5M42-2-R5A3 G 28/36 4.058 N84W 4G64

W5M42-1-V5A1 H 28/36 4.325 N94W 4G64

F5M42-1-R7A2 G 30/36 4.058 DA2A 4G93

EXP F5M41-1-F8A5 A 31/36 3.714 CJ4A 4G92

F5M41-1-R8A1 A 31/36 4.052 CJ1A, CJ2A 4G13, 4G15

F5M42-2-R5A2 D 28/36 4.058 N84W 4G64

F5M41-1-R7B1 A 30/36 4.052 CS1A, CS3A 4G13, 4G18

F5M41-1-R8B1 A 31/36 4.052 CS1A, CS3A 4G13, 4G18

MMAL F5M41-1-F8A5 A 31/36 3.714 CJ2A 4G15

F5M42-1-F8A7 F 31/36 3.722 CJ5A, CK5A 4G93

Final gear ratio Vehicle model Engine model

F5M42-2-R5A2 D 28/36 4.058 N84W 4G64

F5M42-1-F8B2 F 31/36 3.722 CS6A 4G93

E

Mar . 2002Mitsubishi Motors Corporation Revised

PWEE9508-I

Page 17

22B-1-2f

MANUAL TRANSMISSION (E–W) – Specifications

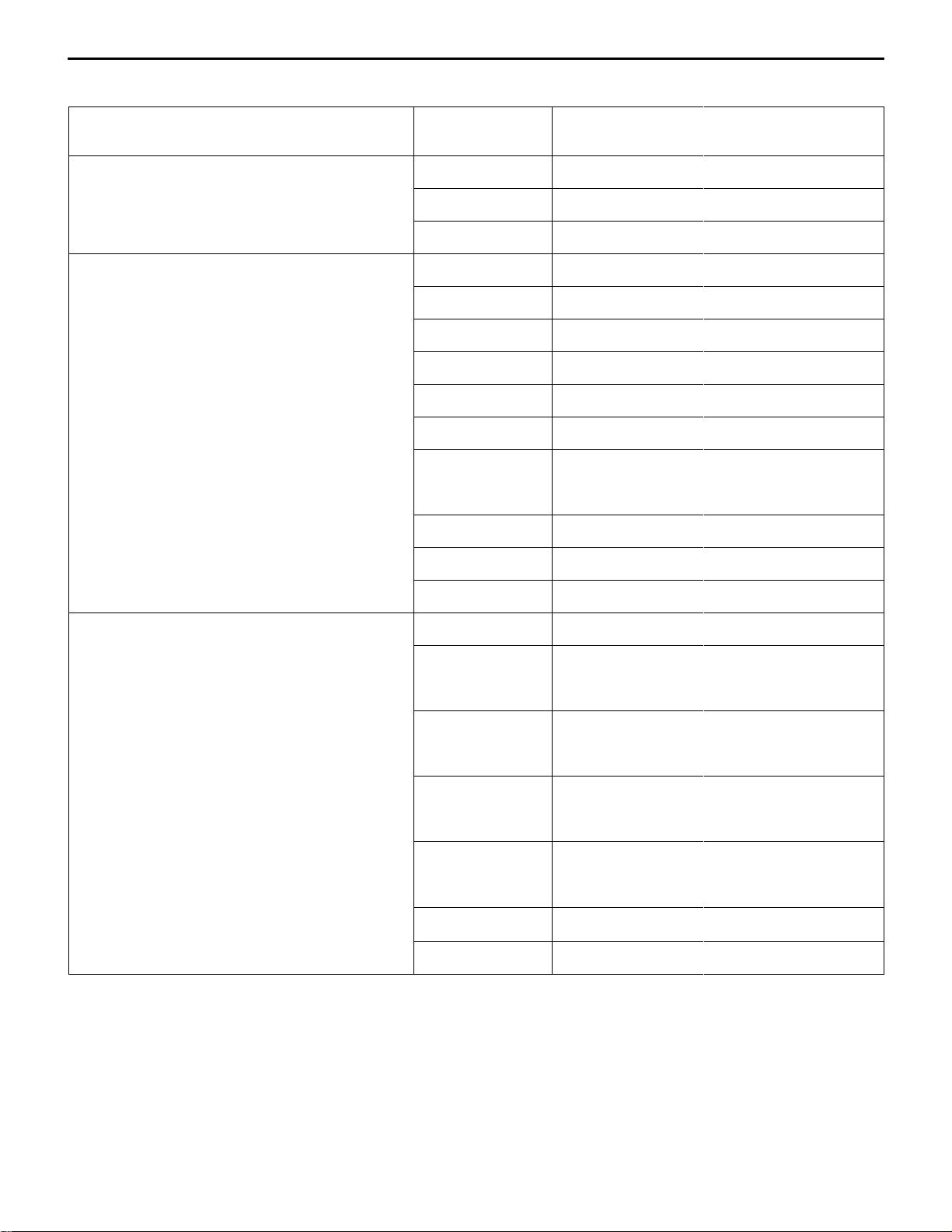

GEAR RATIO TABLE

A B C D E F G

1st 3.583 3.727 3.071 3.583 3.583 3.583 3.583

2nd 1.947 1.947 1.947 1.947 1.947 1.947 1.947

3rd 1.343 1.343 1.379 1.379 1.379 1.379 1.266

4th 0.976 0.976 1.030 1.030 1.030 1.030 0.970

5th 0.804 0.804 0.767 0.820 0.733 0.767 0.767

Reverse 3.416 3.416 3.363 3.363 3.363 3.363 3.363

H I

1st 3.583 3.583

2nd 1.947 1.947

3rd 1.266 1.266

4th 0.970 0.970

5th 0.767 0.820

Reverse 3.363 3.363

Transfer 0.3018 –

SERVICE SPECIFICATIONS

Items Allowable range Limit

Input shaft front bearing end play mm –0.01–0.12 –

Input shaft rear bearing end play <F5M41> mm –0.01–0.09 –

Input shaft rear bearing end play <F5M42, W5M42> mm –0.01–0.12 –

Input shaft 5th speed gear end play <F5M42, W5M42> mm –0.01–0.09 –

Output shaft front bearing end play mm –0.01–0.12 –

Output shaft rear bearing end play mm –0.01–0.09 –

Output shaft 3rd speed gear end play mm –0.01–0.09 –

Differential case end play <F5M41> mm 0.05–0.17 –

Differential case pinion backlash <F5M41, F5M42> mm 0–0.150 –

Differential case preload <F5M42> mm 0.05–0.11 –

NOTE: Standard play = 0 mm

E

Mar . 2002Mitsubishi Motors Corporation Revised

PWEE9508-I

Page 18

MANUAL TRANSMISSION (E–W) – Specifications

t

Items Allowable range Limit

Center differential case pinion backlash <W5M42> mm 0.025–0.150 –

Center differential case preload <W5M42> mm 0.05–0.11 –

Synchronizer ring back surface to gear clearance mm – 0.5

22B-1-2g

NOTE: Standard play = 0 mm

SEALANTS AND ADHESIVES

TRANSMISSION

Items Specified sealants and adhesives

Clutch housing–transmission case mating surface MITSUBISHI genuine sealant part No. MD997740

or equivalen

Control housing–transmission case mating surface

Under cover–transmission case mating surface

<F5M42, W5M42>

Air breather 3M SUPER WEATHERSTRIP No. 8001 or

equivalent

Differential drive gear bolt <F5M41, F5M42> 3M STUD Locking No. 4170 or equivalent

Center differential drive gear bolt <W5M42>

Front bearing retainer bolt (countersink head bolt) <F5M41>

TRANSFER

Item Specified sealant

Air breather 3M SUPER WEATHERSTRIP No. 8001 or

equivalent

E

Mar . 2002Mitsubishi Motors Corporation Added

PWEE9508-I

Page 19

22B-1-2h

MANUAL TRANSMISSION (E–W) – Specifications

Intentionally blank

E

Mar . 2002Mitsubishi Motors Corporation Added

PWEE9508-I

Page 20

MANUAL TRANSMISSION (E-W) -

Specifications

22B-1-3

FORM-IN-PLACE GASKET

The transmission has several areas where the form-in-place gasket (FIPG) is in use. To ensure that the

gasket fully serves its purpose, it is necessary to observe some precautions when applying the gasket.

Bead size, continuity and location are of paramount importance. Too thin a bead could cause leaks. Too

thick a bead, on the other hand, could be squeezed out of location, causing blocking or narrowing of

the fluid feed line. To eliminate the possibility of leaks from a joint, therefore, it is absolutely necessary

to apply the gasket evenly without a break, while observing the correct bead size.

Since the RTV hardens as it reacts with the moisture in the atmospheric air, it is normally used in the

metallic flange areas.

DISASSEMBLY

The parts assembled with the FIPG can be easily disassembled without use of a special method. In some

cases, however, the sealant between the joined surfaces may have to be broken by lightly striking with

a mallet or similar tool. A flat and thin gasket scraper may be lightly hammered in between the joined

surfaces. In this case, however, care must be taken to prevent damage to the joined surfaces.

Surface Preparation

Thoroughly remove all substances deposited on the gasket application surfaces, using a gasket scraper

or wire brush. Check to ensure that the surfaces to which the FIPG is to be applied is flat. Make sure

that there are no oils, greases and foreign substances deposited on the application surfaces. Do not forget

to remove the old sealant remaining in the bolt holes.

FORM-IN-PLACE GASKET APPLICATION

When assembling parts with the FIPG, you must observe some precautions, but the procedures is very

simple as in the case of a conventional precut gasket.

Applied FIPG bead should be of the specified size and without breaks. Also be sure to encircle the bolt

hole circumference with a completely continuous bead. The FIPG can be wiped away unless it is hardened.

While the FIPG is still moist (in less than 15 minutes), mount the parts in position. When the parts are

mounted, make sure that the gasket is applied to the required area only. In addition, do not apply any

oil or water to the sealing locations or start the engine until a sufficient amount of time (about one hour)

has passed after installation is completed.

The FIPG application procedure may vary on different areas. Observe the procedure described in the

text when applying the FIPG.

LUBRICANTS

TRANSMISSION

Items Specified lubricants

Drive shaft oil seal lip area Hypoid gear oil SAE 75W-85W conforming to API

classification GL-4 or higher

Control shaft oil seal lip area

Input shaft oil seal lip area MITSUBISHI genuine grease part No. 0101011 or

equivalent

Select lever shoe

TRANSFER

Items Specified lubricants

Drive shaft oil seal lip area Hypoid gear oil SAE 75W-85W conforming to API

classification GL-4 or higher

Front differential oil seal lip area

Each O-ring

E

Jun. 1998Mitsubishi Motors Corporation Revised

PWEE9508-E

Page 21

22B-1-4

(For adjustment o input sha t ront bearing end

(For adjustment o input sha t rear bearing end

(For adjustment of output shaft rear bearing end

(For adjustment o input sha t 5th speed gear

(For adjustment o output sha t ront bearing end

(For adjustment o input sha t rear bearing end

MANUAL TRANSMISSION (E–W) – Specifications

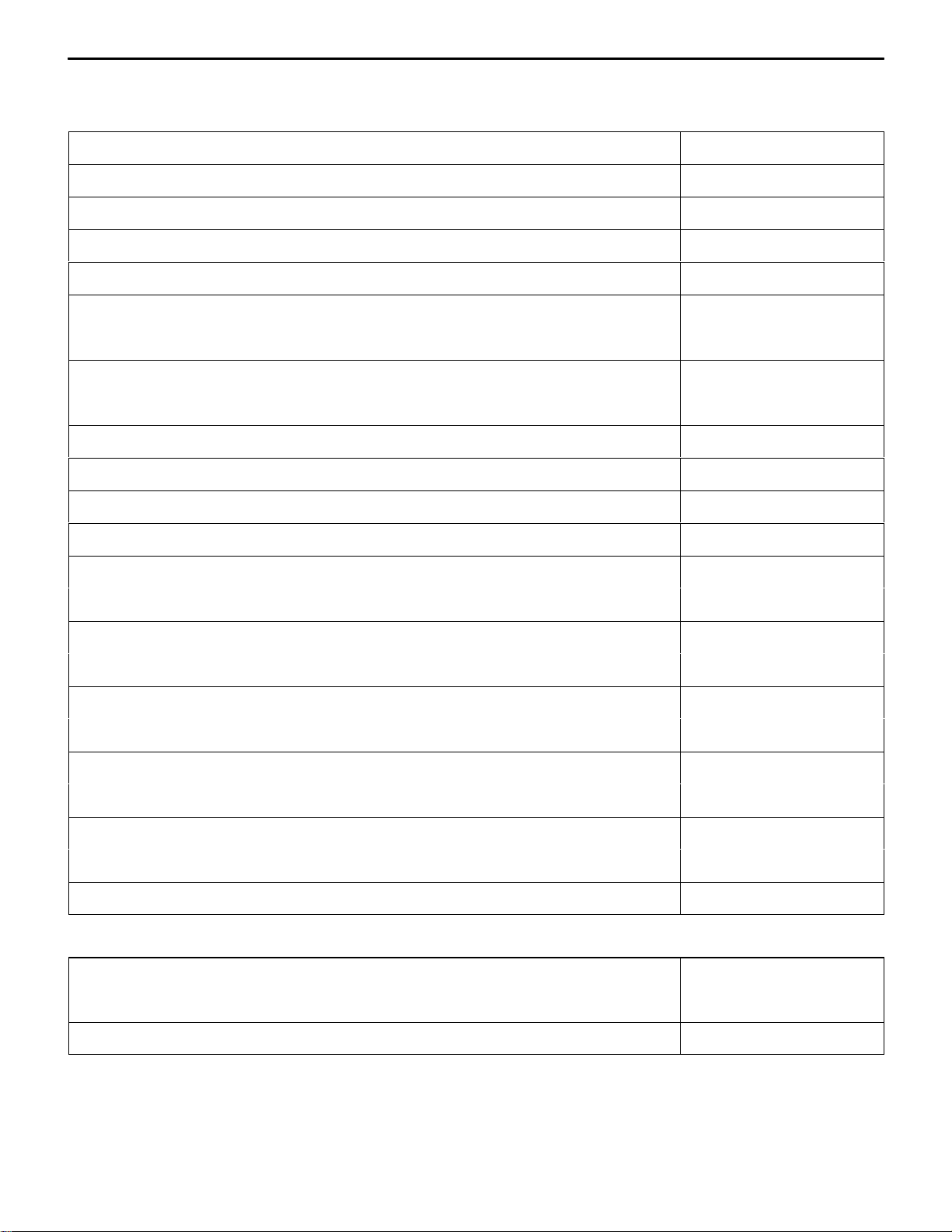

SNAP RINGS, SPACERS AND THRUST PLATE ADJUSTMENT

Part name Thickness mm Identification

symbol

Snap ring

f

play)

Snap ring

f

play ....F5M41)

f

play ....F5M42, W5M42)

f

f

f

f

2.24 None MD706537

2.31 Blue MD706538

2.38 Brown MD706539

2.31 Black (2) MD747149

2.35 None MD746561

2.39 Blue MD746562

2.43 Brown MD746563

2.47 Green MD746564

2.51 White MD746565

2.55 Yellow MD746566

2.59 Black MD746567

2.63 Orange MD746568

2.67 Blue MD746569

Part No.

2.71 Brown MD746570

Thrust plate: F5M42, W5M42

f

end play)

Snap ring

f

play)

f

play ....F5M42, W5M42) 1.59 Yellow (2) MD746710

f

f

f

f

2.82 0 MD748015

2.86 2 MD748016

2.90 3 MD748017

2.94 5 MD748018

2.98 6 MD748019

3.02 7 MD748020

3.06 8 MD748021

3.10 9 MD748022

1.43 Green (2) MD746708

1.51 White (2) MD746709

E

Dec. 2000Mitsubishi Motors Corporation Revised

PWEE9508-H

Page 22

MANUAL TRANSMISSION (E-W) -

Specifications

22B-1-5

Part name Part No.Identification

Snap ring: F5M41 2.31 Black (2) MD748800

(For adjustment of output shaft rear bearing end

play)

Snap ring: F5M41 2.81 Green MD748782

(For adjustment of output shaft 3rd speed gear

end play)

Thickness mm

symbol

2.35 None MD748801

2.39 Blue MD748802

2.43 Brown MD748803

2.47 Green MD748804

2.51 White MD748805

2.55 Yellow MD748806

2.59 Black MD748807

2.63 Orange MD748808

2.67 Blue MD748809

2.71 Brown MD748810

2.85 White MD748783

2.89 Yellow MD748784

2.93 Black MD748785

2.97 Orange MD748786

3.01 Red MD748787

3.05 Pink MD748788

3.09 Blue MD748789

Snap ring: F5M42, W5M42 2.81 Green MD745799

(For adjustment of output shaft 3rd speed gear

end play)

2.85 White MD745800

2.89 Yellow MD745801

2.93 Black MD745802

2.97 Orange MD745803

3.01 Red MD745804

3.05 Pink MD745805

3.09 Blue MD745806

E

July 1999Mitsubishi Motors Corporation Revised

PWEE9508-F

Page 23

22B-1-6

MANUAL TRANSMISSION (E-W) -

Specifications

Part name Part No.Identification

Spacer: F5M41 0.77 77 MD754476

(For adjustment of differential case end play)

Thickness mm

symbol

0.86 86 MD720938

0.95 95 MD720941

1.04 04 MD720944

1.13 D MD700270

1.22 G MD700271

1.31 E MD706574

1.40 None MD706573

1.49 C MD706572

1.58 B MD706571

1.67 A MD706570

1.76 F MD706575

E

July 1999Mitsubishi Motors Corporation Revised

PWEE9508-F

Page 24

MANUAL TRANSMISSION (E–W) – Specifications

(For adjustment o di erential case preload)

22B-1-7

Part name Thickness mm Identification

symbol

Spacer: F5M42

f

ff

0.71 71 MD754475

0.74 74 MD727660

0.77 77 MD754476

0.80 80 MD727661

0.83 83 MD720937

0.86 86 MD720938

0.89 89 MD720939

0.92 92 MD720940

0.95 95 MD720941

0.98 98 MD720942

1.01 01 MD720943

1.04 04 MD720944

1.07 07 MD720945

Part No.

1.10 J MD710454

1.13 D MD700270

1.16 K MD710455

1.19 L MD710456

1.22 G MD700271

1.25 M MD710457

E

Dec. 2000Mitsubishi Motors Corporation Revised

PWEE9508-H

Page 25

22B-1-8

(For adjustment o center di erential case

(For adjustment o di erential case backlash)

(For adjustment o center di erential case pinion

MANUAL TRANSMISSION (E–W) – Specifications

Part name Part No.Identification

Spacer: W5M42

f

preload)

ff

Thickness mm

symbol

0.74 74 MD727660

0.77 77 MD745476

0.80 80 MD727661

0.83 83 MD720937

0.86 86 MD720938

0.89 89 MD720939

0.92 92 MD720940

0.95 95 MD720941

0.98 98 MD720942

1.01 01 MD720943

1.04 04 MD720944

1.07 07 MD720945

1.10 J MD710454

Spacer: F5M41, F5M42

f

ff

1.13 D MD700270

1.16 K MD710455

1.19 L MD710456

1.22 G MD700271

1.25 M MD710457

1.28 N MD710458

1.31 E MD706574

0.72 – 0.79 – MA180862

0.85 – 0.90 – MA180861

0.94 – 0.98 – MA180860

1.02 – 1.06 – MA180875

1.06 – 1.10 – MR581570

1.12 – 1.16 – MA180876

1.16 – 1.20 – MR581571

Spacer: W5M42

f

backlash)

E

ff

Dec. 2000Mitsubishi Motors Corporation Revised

0.48 – 0.55 – MD744236

0.56 – 0.65 – MD744235

0.66 – 0.73 – MD744234

0.74 – 0.81 – MD744233

0.82 – 0.89 – MD744232

PWEE9508-H

Page 26

MANUAL TRANSMISSION (E–W) – Specifications

TORQUE SPECIFICATIONS

TRANSMISSION

Items Nm

Under cover mounting bolt <F5M42, W5M42> 6.9

Interlock plate bolt 30

Clutch housing–transmission case mounting bolt 44

Clutch release bearing retainer mounting bolt 9.8

Control housing mounting bolt 18

Shift cable bracket mounting bolt 18

Speedometer gear mounting bolt 3.9

Stopper bracket mounting bolt 19

Select lever mounting bolt 18

Select lever mounting nut 11

22B-1-9

Center differential flange mounting screw <W5M42> 3.9

Center differential drive gear mounting bolt <W5M42> 132

Differential drive gear mounting bolt <F5M41, F5M42> 132

Back-up lamp switch 32

Front bearing retainer mounting bolt 18

Poppet spring 32

Restrict ball <F5M41> 32

Reverse idler gear shaft mounting bolt 48

Reverse shift lever mounting bolt <F5M41> 18

Roll stopper bracket mounting bolt 70

Oil temperature sensor <For GDI engine only> 22

Connector bracket mounting bolt <For GDI engine except DA2A> 18

Clutch fluid line bracket mounting bolt <DA2A only> 18

TRANSFER

Items Nm

Transfer cover mounting bolt 23

Transmission – transfer mounting bolt 69

E

Dec. 2000Mitsubishi Motors Corporation Revised

PWEE9508-H

Page 27

MANUAL TRANSMISSION (E-W) -

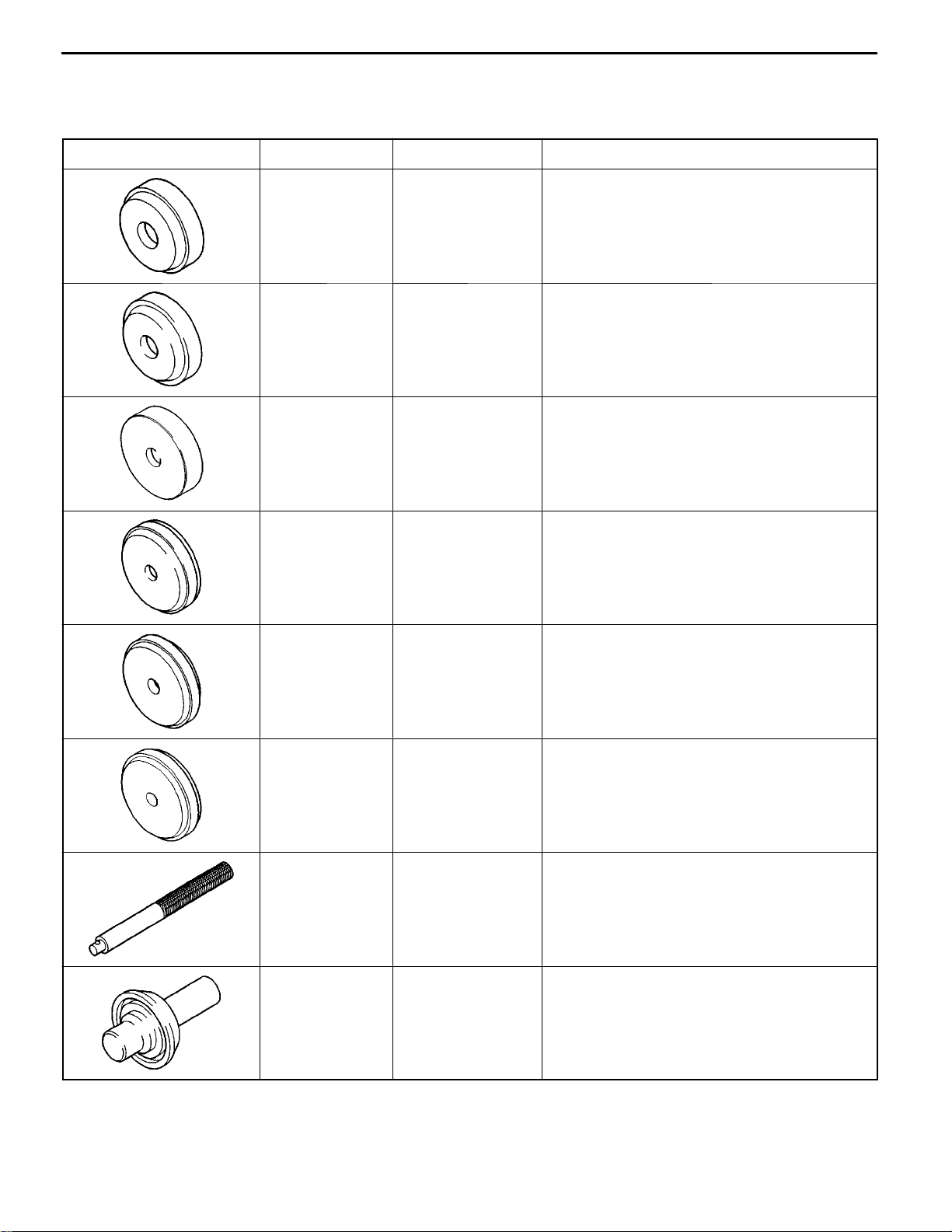

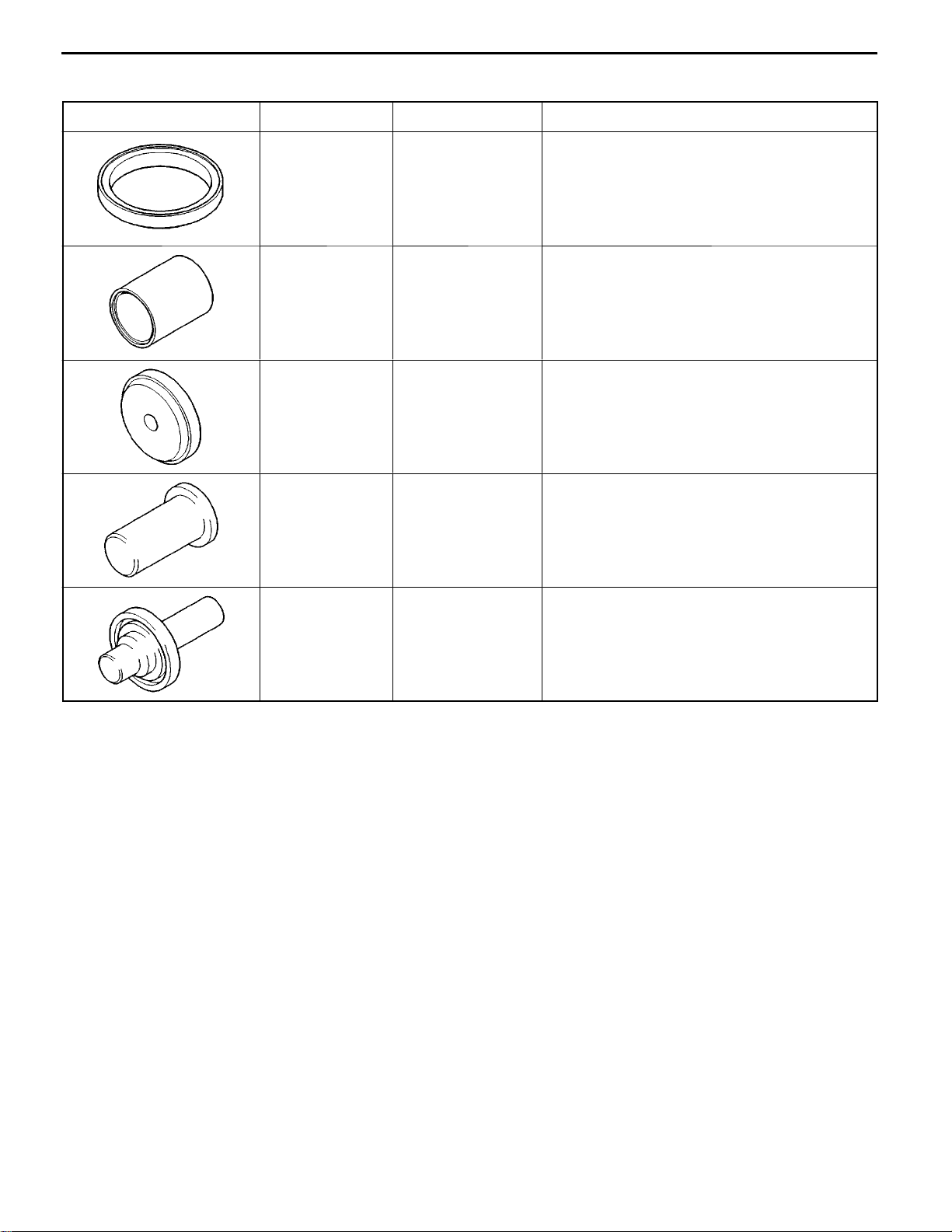

2. SPECIAL TOOLS

TRANSMISSION

Tool Number Name Use

MB990926 Installer adapter Installation of clutch housing input shaft oil seal

MB990927 Installer adapter Installation of sealing cap

MB990930 Installer adapter Removal of center differential taper roller

Special Tools

bearing <W5M42>

22B-2-1

MB990934 Installer adapter Installation of roller bearing outer race

MB990935 Installer adapter Installation of differential case taper roller

bearing outer race

MB990937 Installer adapter Installation of center differential taper roller

bearing <W5M42>

MB990938 Handle Use with Installer adapter

MD998325 Differential oil seal

installer

E

Jun. 1998Mitsubishi Motors Corporation Revised

PWEE9508-E

Installation of differential oil seal

<F5M41, F5M42>

Page 28

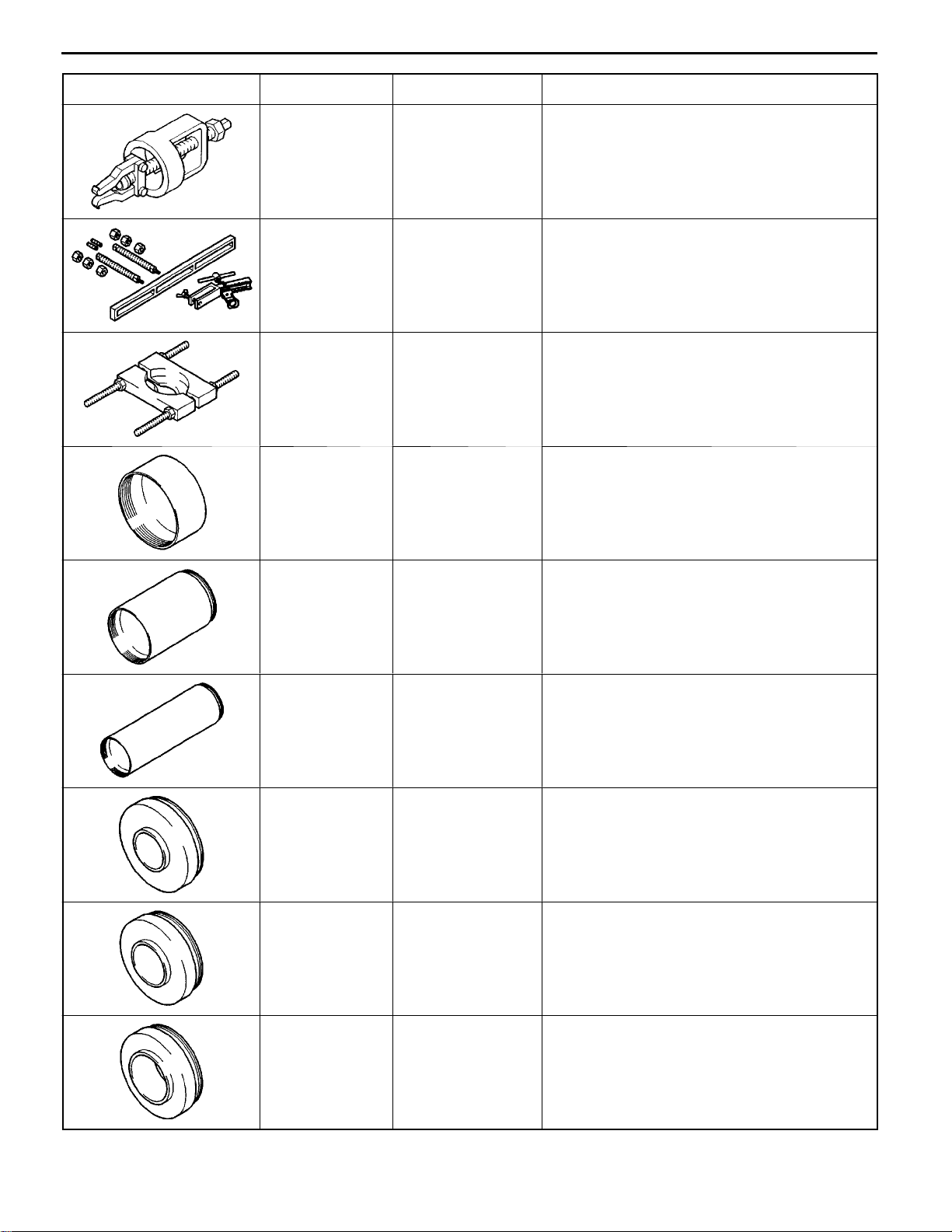

22B-2-2

Tool UseNameNumber

MANUAL TRANSMISSION (E-W) -

Special Tools

MD998346 Bearing outer race

remover

MD998772 Valve spring com-

pressor

MD998801 Bearing remover Installation and removal of gears, bearings and

MD998812 Installer cap Use with Installer and Installer adapter

Removal of roller bearing outer race

Removal of roller bearing outer race

sleeves

MD998813 Installer-100 Use with Installer cap and Installer adapter

MD998814 Installer-200 Use with Installer cap and Installer adapter

MD998816 Installer adapter

(30)

MD998817 Installer adapter

(34)

Installation of input shaft front bearing

<F5M42, W5M42>

Installation of input shaft front bearing

<F5M41>, output shaft rear bearing <F5M42,

W5M42>

MD998818 Installer adapter

(38)

E

Jun. 1998Mitsubishi Motors Corporation Revised

PWEE9508-E

Installation of input shaft rear bearing, roller

bearing inner race, reverse gear, needle roller

bearing, reverse gear bearing sleeve <F5M42,

W5M42> and reverse bearing sleeve

<F5M41>

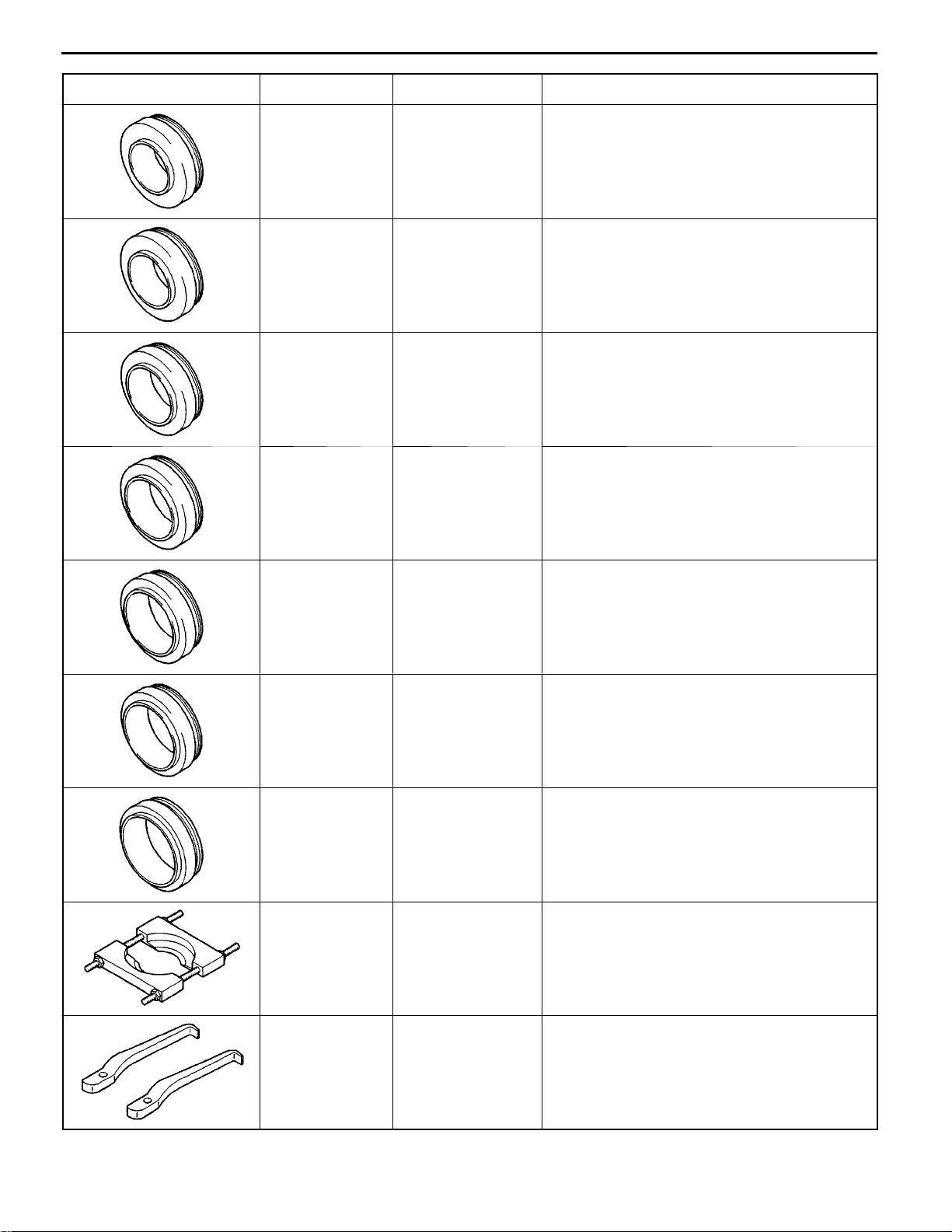

Page 29

MANUAL TRANSMISSION (E-W) -

Tool UseNameNumber

Special Tools

22B-2-3

MD998819 Installer adapter

(40)

MD998820 Installer adapter

(42)

MD998822 Installer adapter

(46)

MD998823 Installer adapter

(48)

Installation of 5th-reverse speed synchronizer

hub, differential case bearing, 4th speed gear

and 5th speed gear sleeve <F5M42, W5M42>

Installation of 5th speed gear sleeve, 2nd

speed gear sleeve <F5M41>

Installation of 1st speed gear sleeve,1st-2nd

speed synchronizer hub <F5M41>, 2nd speed

gear sleeve and 3rd speed gear <F5M42,

W5M42>

Installation of differential case taper roller

bearing inner race <F5M42, W5M42>

MD998824 Installer adapter

(50)

MD998825 Installer adapter

(52)

MD998826 Installer adapter

(54)

MD998917 Bearing remover Installation and removal of gears, bearings and

Installation of 4th speed gear sleeve and 5th

speed gear <F5M42, W5M42>

Installation of 1st-2nd speed synchronizer hub,

3rd-4th speed synchronizer hub and 1st speed

gear sleeve <F5M42, W5M42>

Installation of 3rd-4th speed synchronizer hub

<F5M41>

sleeves

MD999566 Claw Removal of differentialcase taper roller bearing

outer race <F5M42, W5M42>

E

Jun. 1998Mitsubishi Motors Corporation Revised

PWEE9508-E

Page 30

22B-2-4

MANUAL TRANSMISSION (E-W) -

TRANSFER

Tool Number Name Use

Special Tools

MB990887 Arm bush remover

and installer ring

MB990891 Arm bush remover

and installer base

MB990933 Installer adapter Installation of transfer cover oil seal

MD998304 Oil seal installer Installation of transfer extension housing oil

Installation of transfer oil seal

Installation of transfer oil seal

seal

MD998800 Oil seal installer Installation of transfer cover oil seal

E

Jun. 1998Mitsubishi Motors Corporation Added

PWEE9508-E

Page 31

MANUAL TRANSMISSION (E–W) – Transmission <F5M41>

3. TRANSMISSION <F5M41>

DISASSEMBLY AND REASSEMBLY

18 Nm

22B-3-1

32 Nm

5

70 Nm

3

3.9 Nm

2

4

8

9

6

10

11

7

70 Nm

1

1

Disassembly steps

1. Roll stopper bracket

2. Insulator washer <some model>

3. Shift cable bracket

"MA 4. Select lever

"LA 5. Speedometer gear

6. Back-up lamp switch

7. Gasket

8. Restrict ball

9. Gasket

10. Poppet spring

11. Gasket

Nov. 1995Mitsubishi Motors Corporation Added

E

E

Dec. 2000Mitsubishi Motors Corporation Revised

PWEE9508-A

PWEE9508-H

Page 32

22B-3-2

MANUAL TRANSMISSION (E–W) – Transmission <F5M41>

Apply gear oil to all

moving parts before

installation.

24

18 Nm

27

44 Nm

25

26

14

18 Nm

15

30 Nm

12

13

18

19

17

16

48 Nm

Disassembly steps

12. Interlock plate bolt

13. Gasket

"KA 14. Control housing

15. Neutral return spring

"JA 16. Reverse idler gear shaft bolt

17. Gasket

AA""IA 18. Sealing cap

AB""HA 19. Transmission case

23

22

20

21

AC""GA 20. Reverse idler gear shaft

21. Reverse idler gear

22. Reverse shift lever shoe

23. Reverse shift lever

"FA 24. Oil guide

25. Magnet holder

26. Magnet

"EA 27. Spacer

TFM0719

E

E

Nov. 1995Mitsubishi Motors Corporation Added

Dec. 2000Mitsubishi Motors Corporation Revised

PWEE9508-A

PWEE9508-H

Page 33

MANUAL TRANSMISSION (E-W) -

Lubricate all internal

parts with gear oil during reassembly.

45

31

29

Transmission <F5M41>

30

32

41

22B-3-3

33

46

40

35

36

34

39

38

37

18 Nm

42

44

43

"DA

"DA

"DA

AD""CA

AD""CA

AD""CA

AD""CA

E

Disassembly steps

29. Spring pin

30. 1st-2nd speed shift rail

31. 1st-2nd speed shift fork

32. Spring pin

33. Spring pin

34. 5th speed shift rail

35. 5th speed shift fork

36. Reverse shift lug

37. Snap ring

Nov. 1995Mitsubishi Motors Corporation Added

AD""CA

AD""CA

AD""CA

AD""CA

AE""AA

AE""AA

PWEE9508-A

"BA

TFM0720

38. Reverse interlock rail

39. Steel ball

40. 3rd-4th speed shift rail

41. 3rd-4th speed shift fork

42. Front bearing retainer

43. Input shaft

44. Output shaft

45. Differential

46. Clutch housing

Page 34

22B-3-4

MANUAL TRANSMISSION (E-W) -

DISASSEMBLY SERVICE POINTS

Sealing cap

AA"

SEALING CAP REMOVAL

Transmission <F5M41>

Snap ring

3rd-4th speed synchronizer sleeve

Reverse shift lug

AB"

TRANSMISSION CASE REMOVAL

Expand the snap ring to remove it from the snap ring groove

of the ball bearing.

NOTE

Expansion of the snap ring causes the snap ring groove to

get out of position because of the output shaft’s own weight.

AC"

REVERSE IDLER GEAR SHAFT REMOVAL

Shift the 3rd-4th speed synchronizer sleeve toward the 4th

speed side.

AD"

3RD-4TH SPEED SHIFT RAIL / 3RD-4TH SPEED

SHIFT FORK / 5TH SPEED SHIFT FORK / SNAP

RING / REVERSE SHIFT LUG / 5TH SPEED

SHIFT RAIL / STEEL BALL / REVERSE

INTERLOCK RAIL REMOVAL

(1) While sliding the reverse shift lug in the direction shown,

remove the 5th speed shift fork, 5th speed shift rail, reverse

shift lug, snap ring, steel ball and reverse interlock rail.

E

3rd-4th

speed

shift rail

(2) While sliding the 3rd-4th speed shift rail in the direction

shown, remove it together with the shift fork.

Nov. 1995Mitsubishi Motors Corporation Added

PWEE9508-A

Page 35

Output shaft

MANUAL TRANSMISSION (E–W) – Transmission <F5M41>

AE" INPUT SHAFT / OUTPUT SHAFT REMOVAL

Remove the input and output shafts together.

Input shaft

22B-3-5

Solders

Detent

ADJUSTMENT BEFORE REASSEMBLY

SPACER SELECTION FOR DIFFERENTIAL CASE END

PLAY ADJUSTMENT

(1) Put solders (about 10 mm long, 1.6 mm in diameter) in

the illustrated positions of the transmission case and install

the differential.

(2) Install the clutch housing and tighten the bolts to the

specified torque.

(3) If the solders are not crushed, put larger diameter solders

and repeat Steps (1) and (2).

(4) Measure the thickness (T) of the crushed solder with a

micrometer and select a spacer according to the following

equation.

Spacer thickness:

(T – 0.05 mm) to (T – 0.17 mm)

REASSEMBLY SERVICE POINTS

"AA OUTPUT SHAFT / INPUT SHAFT INSTALLATION

<F5M41 with reverse brake>

While placing the reverse brake cone detent in the illustrated

position, install the input and output shafts together.

"BA FRONT BEARING RETAINER INSTALLATION

Apply a sealant to the front bearing retainer mounting bolts

(countersunk bolts only).

Specified sealant:

3M STUD Locking No. 4170 or equivalent

5 – 7 mm

2 – 3 mm

E

E

Nov. 1995Mitsubishi Motors Corporation Added

Dec. 2000Mitsubishi Motors Corporation Revised

PWEE9508-A

PWEE9508-H

Page 36

22B-3-6

MANUAL TRANSMISSION (E-W) -

Transmission <F5M41>

3rd-4th

speed

shift rail

5th

speed

shift rail

Reverse shift lug

Snap ring

3rd-4th

speed

shift

fork

5th speed shift fork

Reverse interlock

rail

Steel ball

(inside)

"CA

REVERSE INTERLOCK RAIL / STEEL BALL /

5TH SPEED SHIFT RAIL / REVERSE SHIFT LUG

/ SNAP RING / 5TH SPEED SHIFT FORK /

3RD-4TH SPEED SHIFT FORK / 3RD-4TH SPEED

SHIFT RAIL INSTALLATION

(1) Install the 3rd-4th shift rail and fork.

(2) Install the reverse interlock rail, steel ball, 5th speed shift

rail, 5th speed shift fork, reverse shift lug and snap ring

in the illustrated positions.

Reverse

shift lug

Snap ring

5th speed shift rail

Reverse

shift lug

Reverse

interlock rail

Steel ball

(3) While sliding the reverse shift lug in the direction shown,

install the 5th speed shift fork, 5th speed shift rail, reverse

shift lug, snap ring, steel ball and reverse interlock rail.

"DA

SPRING PIN INSTALLATION

E

Nov. 1995Mitsubishi Motors Corporation Added

PWEE9508-A

Page 37

MANUAL TRANSMISSION (E-W) -

Transmission <F5M41>

22B-3-7

Oil guide

"EA

SPACER INSTALLATION

Install the spacer selected in the section “ADJUSTMENT

BEFORE REASSEMBLY”.

"FA

"GA

OIL GUIDE INSTALLATION

REVERSE IDLER GEAR SHAFT INSTALLATION

(1) Shift the 3rd-4th speed synchronizer sleeve toward the

4th speed side.

3rd-4th speed synchronizer sleeve

Reverse

idler gear

shaft

(2) Face the threaded hole of the reverse idler gear shaft

toward the direction shown.

"HA

TRANSMISSION CASE INSTALLATION

(1) Apply a 1.5 mm bead of sealant to the illustrated positions

of the transmission case.

Specified sealant:

MITSUBISHI genuine sealant part No. MD997740

or equivalent

Caution

Squeeze out the sealant uniformly, while making sure

that it is not broken or excessively applied.

E

Nov. 1995Mitsubishi Motors Corporation Added

PWEE9508-A

Page 38

22B-3-8

Snap ring

MANUAL TRANSMISSION (E-W) -

(2) Install the transmission case and expand the snap ring.

(3) Tighten the transmission case mounting bolts to the

specified torque.

NOTE

Place the transmission upside down and let the snap ring

fit in the groove by taking advantage of the output shaft’s

own weight.

Transmission <F5M41>

MB990938

MB990927

Sealing cap

"IA

SEALING CAP INSTALLATION

Press-fit the sealingcap all the way up to the illustrated position.

"JA

REVERSE IDLER GEAR SHAFT BOLT

INSTALLATION

Using a screwdriver (8 mm in shaft diameter), center the bolt

hole.

"KA

CONTROL HOUSING INSTALLATION

Apply a 1.5 mm bead of sealant to the illustrated position

of the transmission case.

Specified sealant:

MITSUBISHI genuine sealant part No. MD997740 or

equivalent

Caution

Squeeze outthesealantuniformly, while making sure that

it is not broken or excessively applied.

E

Nov. 1995Mitsubishi Motors Corporation Added

PWEE9508-A

Page 39

MANUAL TRANSMISSION (E-W) -

Transmission <F5M41>

22B-3-9

O-ring

Control shaft

Select

lever

shoe

"LA

SPEEDOMETER GEAR INSTALLATION

Apply transmission oil to the O-ring of the speedometer gear.

Transmission oil:

Hypoid gear oil SAE 75W-85W conforming to API

classification GL-4 or higher

"MA

SELECT LEVER INSTALLATION

Apply grease to the control shaft sliding portion of the select

lever shoe.

Specified grease:

MITSUBISHI genuine grease part No. 0101011 or

equivalent

INSPECTION

BACK-UP LAMP SWITCH

Check for continuity between terminals.

Switch condition Continuity

Pressed Not exist

Released Exists

E

Nov. 1995Mitsubishi Motors Corporation Added

PWEE9508-A

Page 40

MANUAL TRANSMISSION (E–W) – Transmission <F5M42, W5M42>

4. TRANSMISSION <F5M42, W5M42>

DISASSEMBLY AND REASSEMBLY

18 Nm

22B-4-1

Apply gear oil to all

moving parts before

installation.

32 Nm

70 Nm

3

5

7

3.9 Nm

2

6

4

8

9

10

11

22 Nm

16

15

14

12

3

18 Nm

13

1

70 Nm

69 Nm

Disassembly steps

1. Transfer <W5M42>

2. O-ring <W5M42>

3. Roll stopper bracket

4. Insulator washer <some model>

5. Shift cable bracket

"KA 6. Select lever

"JA 7. Speedometer gear

8. Back-up lamp switch

9. Gasket

10. Poppet spring

11. Gasket

12. Connector bracket <For GDI engine except DA2A>

13. Clutch fluid line blacket <DA2A only>

14. Oil temperature sensor harness <For GDI engine only>

15. Oil temperature sensor <For GDI engine only>

16. Gasket <For GDI engine only>

E

Dec. 2000Mitsubishi Motors Corporation Revised

PWEE9508-H

TFM1069

Page 41

22B-4-2

Apply gear oil to all

moving parts before

installation.

MANUAL TRANSMISSION (E–W) – Transmission <F5M42, W5M42>

19

18 Nm

30 Nm

20

17

27

28

44 Nm

29

30

24

18

25

26

22

23

48 Nm

21

6.9 Nm

Disassembly steps

17. Interlock plate bolt

18. Gasket

"IA 19. Control housing

20. Neutral return spring

"HA 21. Under cover

22. Reverse idler gear shaft bolt

23. Gasket

24. Reverse idler gear

AA""GA 25. Sealing cap

AB""FA 26. Transmission case

"EA 27. Outer race

"DA 28. Spacer

29. Magnet holder

30. Magnet

E

Dec. 2000Mitsubishi Motors Corporation Revised

TFM0597

PWEE9508-H

Page 42

MANUAL TRANSMISSION (E-W) -

Apply gear oil to all

moving parts before

installation.

30

32

42

Transmission <F5M42, W5M42>

31

33

34

36

22B-4-3

38

43

35

41

39

37

18 Nm

40

Disassembly steps

"CA 30. Spring pin

31. 1st-2nd speed shift rail

32. 1st-2nd speed shift fork

"CA 33. Spring pin

"CA 34. Spring pin

AC""BA 35. 3rd-4th speed shift rail

AC""BA 36. 3rd-4th speed shift fork

AC""BA 37. 5th-reverse speed shift rail

AC""BA 38. 5th-reverse speed shift fork

39. Front bearing retainer

AD""AA 40. Input shaft

AD""AA 41. Output shaft

42. Differential

43. Clutch housing

E

Jun. 1998Mitsubishi Motors Corporation Revised

TFM0598

PWEE9508-E

Page 43

22B-4-4

MANUAL TRANSMISSION (E-W) -

DISASSEMBLY SERVICE POINTS

Sealing cap

AA"

Drive a screwdriver into the sealing cap at the center, then

pry off the sealing cap with the screwdriver.

SEALING CAP REMOVAL

Transmission <F5M42, W5M42>

Snap ring

5th-reverse

speed shift

fork

3rd-4th speed

shift rail

3rd-4th speed

shift fork

5th-reverse

speed shift rail

AB"

TRANSMISSION CASE REMOVAL

Expand the snap ring to remove it from the snap ring groove

of the ball bearing.

NOTE

Expansion of the snap ring causes the snap ring groove to

get out of position because of the output shaft’s own weight.

AC"

3RD-4TH SPEED SHIFT RAIL / 3RD-4TH SPEED

SHIFT FORK / 5TH-REVERSE SPEED SHIFT RAIL

/ 5TH-REVERSE SPEED SHIFT FORK REMOVAL

(1) Shift the 3rd-4th speed shift fork and 5th-reverse speed

shift fork in the direction shown.

(2) Slide the 3rd-4th speed shift rail and 5th-reverse speed

shift rail in the direction shown and remove them together

with the shift fork.

Output shaft

E

AD"

Input shaft

Jun. 1998Mitsubishi Motors Corporation Revised

Remove the input and output shafts together.

INPUT SHAFT / OUTPUT SHAFT REMOVAL

PWEE9508-E

Page 44

MANUAL TRANSMISSION (E-W) -

Transmission <F5M42, W5M42>

22B-4-5

Output shaft

Solders

Input shaft

ADJUSTMENT BEFORE REASSEMBLY

SPACER SELECTION FOR DIFFERENTIAL CASE

PRELOAD ADJUSTMENT

(1) Put solders (about 10 mm long, 1.6 mm in diameter) in

the illustrated positions of the transmission case and install

the bearing outer race and differential.

(2) Install the clutch housing and tighten the bolts to the

specified torque.

(3) If the solders are not crushed, put larger diameter solders

and repeat Steps (1) and (2).

(4) Measure the thickness (T) of the crushed solder with a

micrometer and select a spacer according to the following

equation.

Spacer thickness:

(T + 0.05 mm) to (T + 0.11 mm)

REASSEMBLY SERVICE POINTS

"AA

Install the input and output shafts together.

OUTPUT SHAFT / INPUT SHAFT INSTALLATION

5th-reverse

speed synchronizer sleeve

5th-reverse

speed shift

fork

E

3rd-4th

speed

synchronizer

sleeve

"BA

5TH-REVERSE SPEED SHIFT FORK /

5TH-REVERSE SPEED SHIFT RAIL / 3RD-4TH

SPEED SHIFT FORK / 3RD-4TH SPEED SHIFT

RAIL INSTALLATION

(1) Shift the 3rd-4th speed synchronizer sleeve and

5th-reverse speed synchronizer sleeve in the direction

shown.

(2) Install the 3rd-4th speed shift rail and fork and the

3rd-4th speed shift rail

3rd-4th speed shift fork

5th-reverse

speed shift rail

Jun. 1998Mitsubishi Motors Corporation Revised

5th-reverse speed shift rail and fork.

PWEE9508-E

Page 45

22B-4-6

3rd-4th speed

shift rail

MANUAL TRANSMISSION (E-W) -

(3) While fitting each shift fork in the sleeve, slide the shift

5th-reverse

speed shift rail

rails in the direction shown and install.

Transmission <F5M42, W5M42>

Shift rail

Spring pin

MB990938

Shift fork

Slit

2.5 mm

"CA

SPRING PIN INSTALLATION

Install the spring pin such that its slit may face in the axial

direction of the shift rail.

"DA

SPACER INSTALLATION

Install the spacer selected in the section “ADJUSTMENT

BEFORE REASSEMBLY”.

"EA

OUTER RACE INSTALLATION

Use th e special tools to install the outer race.

MB990935

E

"FA

TRANSMISSION CASE INSTALLATION

(1) Apply a 1.5 mm bead of sealant to the illustrated position

of the transmission case.

Specified sealant:

MITSUBISHI genuine sealant part No. MD997740

or equivalent

Caution

Squeeze out the sealant uniformly, while making sure

that it is not broken or excessively applied.

Jun. 1998Mitsubishi Motors Corporation Revised

PWEE9508-E

Page 46

Snap ring

MANUAL TRANSMISSION (E-W) -

(2) Install the transmission case and expand the snap ring.

(3) Tighten the transmission case to the specified torque.

NOTE

Place the transmission upside down a nd let the snap ring

fit in the groove by taking advantage of the output shaft’s

own weight.

Transmission <F5M42, W5M42>

22B-4-7

MB990938

MB990927

Sealing cap

"GA

SEALING CAP INSTALLATION

Press-fit the sealingcap all the way up to the illustrated position.

"HA

UNDER COVER INSTALLATION

Apply a 1.5 mm bead of sealant to the illustrated position

of the transmission case.

Specified sealant:

MITSUBISHI genuine sealant part No. MD997740 or

equivalent

Caution

Squeeze outthesealantuniformly, while making sure that

it is not broken or excessively applied.

"IA

CONTROL HOUSING INSTALLATION

Apply a 1.5 mm bead of sealant to the illustrated position

of the transmission case.

Specified sealant:

MITSUBISHI genuine sealant part No. MD997740 or

equivalent

Caution

Squeeze outthesealantuniformly, while making sure that

it is not broken or excessively applied.

E

Jun. 1998Mitsubishi Motors Corporation Revised

PWEE9508-E

Page 47

22B-4-8

MANUAL TRANSMISSION (E-W) -

Transmission <F5M42, W5M42>

O-ring

Control shaft

Select

lever shoe

"JA

SPEEDOMETER GEAR INSTALLATION

Apply transmission oil to the O-ring of the speedometer gear.

Transmission oil:

Hypoid gear oil SAE 75W-85W conforming to API

classification GL-4 or higher

"KA

SELECT LEVER INSTALLATION

Apply grease to the control shaft sliding portion of the select

lever shoe.

Specified grease:

MITSUBISHI genuine grease part No. 0101011 or

equivalent

Transmission oil

INSPECTION

BACK-UP LAMP SWITCH

(1) Check for continuity between terminals.

Switch condition Continuity

Pressed Not exist

Released Exists

(2) If the above requirements are not met, replace the back-up

lamp switch with a new one.

OIL TEMPERATURE SENSOR <For GDI engine only>

(1) Check for continuity between terminals.

Temperature (°C) Standard value (kW)

20 2.31 - 2.59

110 0.1451 - 0.1491

(2) If the standard value is not met, replace the oil temperature

sensor with a new one.

E

Jun. 1998Mitsubishi Motors Corporation Revised

PWEE9508-E

Page 48

MANUAL TRANSMISSION (E-W) -

Input Shaft <F5M41>

5. INPUT SHAFT <F5M41>

DISASSEMBLY AND REASSEMBLY <Models with reverse brake>

22B-5-1

Apply gear oil to all

moving parts before

installation.

27

25

29

13

28

24

22

23

21

20

15

17

19

16

18

1

2

4

5

6

7

3

25

26

14

13

Disassembly steps

"MA 1. Snap ring

AA""LA 2. Ball bearing

AB""KA 3. Reverse brake sleeve

4. Needle roller bearing

5. Reverse brake cone

6. Reverse brake ring

"DA 7. Synchronizer spring

"JA 8. Synchronizer sleeve

AC""IA 9. 5th-reverse speed synchronizer hub

10. Synchronizer ring

"DA 11. Synchronizer spring

12. 5th speed gear

13. Needle roller bearing

AD""HA 14. 5th speed gear sleeve

8

9

11

10

12

TFM0834

15. 4th speed gear

16. Needle roller bearing

AE""GA 17. 4th speed gear sleeve

18. Synchronizer ring

"DA 19. Synchronizer spring

"FA 20. Synchronizer sleeve

"EA 21. 3rd-4th speed synchronizer hub

22. Synchronizer ring

"DA 23. Synchronizer spring

24. 3rd speed gear

25. Needle roller bearing

"CA 26. Snap ring

AF""BA 27. Ball bearing

"AA 28. Oil seal

29. Input shaft

E

July 1999Mitsubishi Motors Corporation Revised

PWEE9508-F

Page 49

22B-5-2

MANUAL TRANSMISSION (E-W) -

Input Shaft <F5M41>

DISASSEMBLY AND REASSEMBLY <Except models with reverse brake>

14

Apply gear oil to all

moving parts before

installation.

17

19

18

20

21

15

16

22

23

13

12

21

11

25

10

2

24

9

5

7

1

3

4

6

8

9

Disassembly steps

"MA 1. Snap ring

AA""LA 2. Ball bearing

3. Collar

"JA 4. Synchronizer sleeve

AC""IA 5. 5th-reverse speed synchronizer hub

6. Synchronizer ring

"DA 7. Synchronizer spring

8. 5th speed gear

9. Needle roller bearing

AD""HA 10. 5th speed gear sleeve

11. 4th speed gear

12. Needle roller bearing

AE""GA 13. 4th speed gear sleeve

E

July 1999Mitsubishi Motors Corporation Revised

14. Synchronizer ring

"DA 15. Synchronizer spring

"FA 16. Synchronizer sleeve

"EA 17. 3rd-4th speed synchronizer hub

18. Synchronizer ring

"DA 19. Synchronizer spring

20. 3rd speed gear

21. Needle roller bearing

"CA 22. Snap ring

AF""BA 23. Ball bearing

"AA 24. Oil seal

25. Input shaft

PWEE9508-F

Page 50

MANUAL TRANSMISSION (E–W) – Input Shaft <F5M41>

DISASSEMBLY AND REASSEMBLY <Models with synchronizer lever>

14

Apply gear oil to all

moving parts before

installation.

17

19

18

20

21

15

16

22B-5-2a

22

23

13

12

21

11

25

10

2

24

5

9

7

1

3

4

6

8

9

Disassembly steps

"MA 1. Snap ring

AA""LA 2. Ball bearing

3. Collar

"JA 4. Synchronizer sleeve

AC""IA 5. 5th-reverse speed synchronizer hub

6. Synchronizer ring

7. Synchronizer lever

8. 5th speed gear

9. Needle roller bearing

AD""HA 10. 5th speed gear sleeve

11. 4th speed gear

12. Needle roller bearing

AE""GA 13. 4th speed gear sleeve

E

Dec. 2000Mitsubishi Motors Corporation Revised

14. Synchronizer ring

"DA 15. Synchronizer spring

"FA 16. Synchronizer sleeve

"EA 17. 3rd-4th speed synchronizer hub

18. Synchronizer ring

"DA 19. Synchronizer spring

20. 3rd speed gear

21. Needle roller bearing

"CA 22. Snap ring

AF""BA 23. Ball bearing

"AA 24. Oil seal

25. Input shaft

PWEE9508-H

Page 51

22B-5-2b

MD998801

MANUAL TRANSMISSION (E–W) – Input Shaft <F5M41>

DISASSEMBLY SERVICE POINTS

AA" BALL BEARING REMOVAL

MD998801

MD998917

MD998917

AB" REVERSE BRAKE SLEEVE REMOVAL

Mount a special tool on the 5th speed gear and remove the

reverse brake sleeve.

AC" 5TH-REVERSE SPEED SYNCHRONIZER HUB

REMOVAL

Mount a special tool on the 5th speed gear and remove the

5th-reverse synchronizer hub.

AD" 5TH SPEED GEAR SLEEVE REMOVAL

Mount a special tool on the 4th speed gear and remove the

5th speed gear sleeve.

E

MD998801

AE" 4TH SPEED GEAR SLEEVE REMOVAL

Mount a special tool on the 3rd speed gear and remove the

4th speed gear sleeve.

Dec. 2000Mitsubishi Motors Corporation Revised

PWEE9508-H

Page 52

MANUAL TRANSMISSION (E-W) -

Input Shaft <F5M41>

22B-5-3

MD998801

Oil seal

3.5 mm

MD998812

AF"

BALL BEARING REMOVAL

REASSEMBLY SERVICE POINTS

"AA

Drive in the oil seal all the way up to the illustrated dimension.

"BA

OIL SEAL INSTALLATION

BALL BEARING INSTALLATION

MD998801

Snap ring

MD998813

MD998817

"CA

SNAP RING INSTALLATION

Select and install a snap ring so that the input shaft front

bearing end play will have the standard value.

Standard value:

-0.01-0.12 mm

"DA

SYNCHRONIZER SPRING INSTALLATION

Install the synchronizer spring securely up to the illustrated

position of the synchronizer ring.

Synchronizer spring

E

Nov. 1995Mitsubishi Motors Corporation Added

PWEE9508-A

Page 53

22B-5-4

MANUAL TRANSMISSION (E-W) -

Input Shaft <F5M41>

Identification mark

MD998801

Identification

groove

Rear of

transmission

MD998812

MD998813

MD998826

"EA

3RD-4TH SPEED SYNCHRONIZER HUB

INSTALLATION

Install the 3rd-4th speed synchronizer hub in such a way that

it will be oriented in the direction shown.

Caution

Whenthe hubis installed,make surethat thesynchronizer

ring is not caught.

"FA

SYNCHRONIZER SLEEVE INSTALLATION

(1) Install the synchronizer sleeve in such a way that it will

be oriented in the direction shown.

MD998801

Synchronizer hub

Rear of

transmission

Synchronizer

sleeve

MD998812

MD998813

MD998824

(2) When the synchronizer sleeve is installed, make sure that

the deep groove portion of the synchronizer hub is aligned

with the projecting portion of the sleeve.

"GA

4TH SPEED GEAR SLEEVE INSTALLATION

E

Nov. 1995Mitsubishi Motors Corporation Added

PWEE9508-A

Page 54

MANUAL TRANSMISSION (E-W) -

Input Shaft <F5M41>

22B-5-5

MD998801

Identification mark

MD998812

MD998813

MD998820

Rear of

transmission

MD998812

MD998819

"HA

"IA

5TH SPEED GEAR SLEEVE INSTALLATION

5TH-REVERSE SPEED SYNCHRONIZER HUB

INSTALLATION

Install the 5th-reverse speed synchronizer hub in such a way

that it will be oriented in the direction shown.

Caution

Whenthe 5th-reverse speedsynchronizer hubis installed,

make sure that the synchronizer ring is not caught.

MD998801

Identification

groove

Rear of

transmission

Synchronizer

sleeve

"JA

SYNCHRONIZER SLEEVE INSTALLATION

(1) Install the synchronizer sleeve in such a way that it will

be oriented in the direction shown.

(2) When the synchronizer sleeve is installed, make sure that

the deep groove portion of the synchronizer hub is aligned

with the projecting portion of the sleeve.

Synchronizer hub

E

Nov. 1995Mitsubishi Motors Corporation Added

PWEE9508-A

Page 55

22B-5-6

MANUAL TRANSMISSION (E-W) -

Input Shaft <F5M41>

MD998801

MD998801

MD998812

MD998818

MD998812

MD998818

"KA

"LA

"MA

REVERSE BRAKE SLEEVE INSTALLATION

BALL BEARING INSTALLATION

SNAP RING INSTALLATION

Select and install a snap ring so that the input shaft rear

bearing end play will have the standard value.

Standard value:

-0.01-0.09 mm

INSPECTION

INPUT SHAFT

(1) Check theoutside diameter of theneedle bearingmounting

portion for damage, abnormal wear and seizure.

(2) Check the splines for damage and wear.

NEEDLE ROLLER BEARING

(1) Check to ensure that when the input shaft, sleeve and

gear are combined and made to rotate, they rotate

smoothly without noise.

(2) Check to ensure that the cage is not deformed.

E

Nov. 1995Mitsubishi Motors Corporation Added

PWEE9508-A

Page 56

MANUAL TRANSMISSION (E-W) -

SYNCHRONIZER RING

(1) Check to ensure that the clutch gear tooth surfaces are

not damaged and broken.

(2) Check to ensure that the cone inside diameter is not

damaged or worn and that the threads are not crushed.

Input Shaft <F5M41>

22B-5-7

A

Synchronizer ring Gear

(3) Press the synchronizer ring against the gear and check

clearance “A”. If “A” is less than the limit, replace.

Limit: 0.5 mm

SYNCHRONIZER SLEEVE AND HUB

(1) Check to ensure that when the synchronizer sleeve and

hub are combined and made to slide, they slide smoothly

without binding.

(2) Check to ensure that the front and rear ends of the sleeve

inside surface are not damaged.

SYNCHRONIZER SPRING

Check to ensure that the spring is not sagging, deformed

or broken.

SPEED GEARS

(1) Check to ensure that the helical and clutch gear tooth

surfaces are not damaged or worn.

(2) Check to ensure that the synchronizer cone surfaces are

not roughened, damaged or worn.

(3) Check to ensure that the gear inside diameter and front

and rear surfaces are not damaged and worn.

E

E

Nov. 1995Mitsubishi Motors Corporation Added

Jun. 2000Mitsubishi Motors Corporation Revised

PWEE9508-A

PWEE9508-G

Page 57

MANUAL TRANSMISSION (E-W) -

6. INPUT SHAFT <F5M42, W5M42>

DISASSEMBLY AND REASSEMBLY

Apply gear oil to all

moving parts before

installation.

15

16

Input Shaft <F5M42, W5M42>

9

10

11

12

14

13

22B-6-1

18

17

Disassembly steps

"LA 1. Snap ring

AA""KA 2. Ball bearing

"JA 3. Thrust plate stopper

"IA 4. Thrust plate

AB""HA 5. 5th speed gear

6. 4th speed gear

7. Needle roller bearing

AC""GA 8. 4th speed gear sleeve

9. Synchronizer ring

"DA 10. Synchronizer spring

16

20

19

6

7

8

"FA 11. Synchronizer sleeve

"EA 12. 3rd-4th speed synchronizer hub

13. Synchronizer ring

"DA 14. Synchronizer spring

15. 3rd speed gear

16. Needle roller bearing

"CA 17. Snap ring

AD""BA 18. Ball bearing

"AA 19. Oil seal

20. Input shaft

2

4

1

3

5

TFM0591

E

Jun. 1998Mitsubishi Motors Corporation Revised

PWEE9508-E

Page 58

22B-6-2

MANUAL TRANSMISSION (E-W) -

Input Shaft <F5M42, W5M42>

MD998801

MD998801

MD998801

DISASSEMBLY SERVICE POINTS

AA"

Use th e special tool to remove the ball bearing.

AB"

Use the special tool to remove the 5th speed gear.

AC"

Mount a special tool on the 3rd gear and remove the 4th

speed gear sleeve.

BALL BEARING REMOVAL

5TH SPEED GEAR REMOVAL

4TH SPEED GEAR SLEEVE REMOVAL

MD998801

E

Oil seal

AD"

BALL BEARING REMOVAL

Use th e special tool to remove the ball bearing.

REASSEMBLY SERVICE POINTS

3.5 mm

"AA

Drive in the oil seal all the way up to the illustrated dimension.

Jun. 1998Mitsubishi Motors Corporation Revised

OIL SEAL INSTALLATION

PWEE9508-E

Page 59

MANUAL TRANSMISSION (E-W) -

Input Shaft <F5M42, W5M42>

22B-6-3

MD998801

Snap ring

MD998812

MD998813

MD998816

"BA

BALL BEARING INSTALLATION

Use th e special tools to install the ball bearing.

"CA

SNAP RING INSTALLATION

Select and install a snap ring so that the input shaft front

bearing end play will have the standard value.

Standard value:

-0.01-0.12 mm

"DA

SYNCHRONIZER SPRING INSTALLATION

Install the synchronizer spring securely up to the illustrated

position of the synchronizer ring.

Synchronizer spring

Identification mark

MD998801

Rear of

transmission

MD998812

MD998813

MD998825

"EA

3RD-4TH SPEED SYNCHRONIZER HUB

INSTALLATION

Install the 3rd-4th speed synchronizer hub in such a way that

it will be oriented in the direction shown.

Caution

Whenthe hubis installed,make surethat thesynchronizer

ring is not caught.

E

Jun. 1998Mitsubishi Motors Corporation Revised

PWEE9508-E

Page 60

22B-6-4

MANUAL TRANSMISSION (E-W) -

Input Shaft <F5M42, W5M42>

Identification

groove

Synchronizer hub

Rear of transmission

Synchronizer sleeve

MD998812

"FA

SYNCHRONIZER SLEEVE INSTALLATION

(1) Install the synchronizer sleeve in such a way that it will

be oriented in the direction shown.

(2) When the synchronizer sleeve is installed, make sure that

the deep groove portion of the synchronizer hub is aligned

with the projecting portion of the sleeve.

"GA

4TH SPEED GEAR SLEEVE INSTALLATION

Use the special tools to install the 4th speed gear sleeve.

MD998801

MD998801

MD998813

MD998824

MD998812

MD998813

MD998824

"HA

5TH SPEED GEAR INSTALLATION

Use the special tools to install the 5th speed gear.

"IA

THRUST PLATE INSTALLATION

Select and install a thrust plate so that the input shaft 5th

speed gear end play will have the standard value.

Thrust plate

E

Standard value:

-0.01-0.09 mm

Jun. 1998Mitsubishi Motors Corporation Revised

PWEE9508-E

Page 61

MANUAL TRANSMISSION (E-W) -

Input Shaft <F5M42, W5M42>

22B-6-5

MD998801

Thrust plate stopper

Thrust plate

MD998812

MD998818

"JA

THRUST PLATE STOPPER INSTALLATION

When the thrust plate is installed, make sure that it is not

tilted.

"KA

BALL BEARING INSTALLATION

Use th e special tools to install the ball bearing.

"LA

SNAP RING INSTALLATION

Select and install a snap ring so that the input shaft rear

bearing end play will have the standard value.

Snap ring

Standard value:

-0.01-0.12 mm

INSPECTION

INPUT SHAFT

(1) Check theoutside diameter of theneedle bearingmounting

portion for damage, abnormal wear and seizure.

(2) Check the splines for damage and wear.

NEEDLE ROLLER BEARING

(1) Check to ensure that when the input shaft a n d gear are

combined and made to rotate, they rotate smoothly without

looseness and noise.

E

Jun. 1998Mitsubishi Motors Corporation Revised

PWEE9508-E

Page 62

22B-6-6

MANUAL TRANSMISSION (E-W) -

SYNCHRONIZER RING

(1) Check to ensure that the clutch gear tooth surfaces are

not damaged and broken.

(2) Check to ensure that the cone inside diameter is not

damaged or worn and that the threads are not crushed.

Input Shaft <F5M42, W5M42>

Synchronizer ring

A

(3) Press the synchronizer ring against the gear and check

clearance “A”. If “A” is less than the limit, replace.

Limit: 0.5 mm

Gear

SYNCHRONIZER SLEEVE AND HUB

(1) Check to ensure that when the synchronizer sleeve and

hub are combined and made to slide, they slide smoothly

without binding.

(2) Check to ensure that the front and rear ends of the sleeve

inside surface are not damaged.

SYNCHRONIZER SPRING

Check to ensure that the spring is not sagging, deformed

or broken.

SPEED GEARS

(1) Check to ensure that the helical and clutch gear tooth

surfaces are not damaged or worn.

(2) Check to ensure that the synchronizer cone surfaces are

not roughened, damaged or worn.

(3) Check to ensure that the gear inside diameter and front

and rear surfaces are not damaged and worn.

E

Jun. 2000Mitsubishi Motors Corporation Revised

PWEE9508-G

Page 63

MANUAL TRANSMISSION (E-W) -

Output Shaft <F5M41>

7. OUTPUT SHAFT <F5M41>

DISASSEMBLY AND REASSEMBLY

<Types with single synchronizer ring for 2nd gear>

Apply gear oil to all

moving parts before

installation.

19

22B-7-1

20

21

13

12

11

22

14

1

16

15

17

18

6

9

3

2

4

5

7

10

8

9

Disassembly steps

"JA 1. Snap ring

AA""IA 2. Ball bearing

3. Collar

4. 5th speed gear

5. 4th speed gear

"HA 6. Snap ring

7. 3rd speed gear

8. 2nd speed gear

9. Needle roller bearing

AB""GA 10. 2nd speed gear sleeve

11. Synchronizer ring

E

July 1999Mitsubishi Motors Corporation Revised

TFM0715

"DA 12. Synchronizer spring

"FA 13. Synchronizer sleeve

"EA 14. 1st-2nd speed synchronizer hub

15. Synchronizer ring

"DA 16. Synchronizer spring

17. 1st speed gear

18. Needle roller bearing

AC""CA 19. 1st speed gear sleeve

"BA 20. Snap ring

AD""AA 21. Roller bearing inner race

22. Output shaft

PWEE9508-F

Page 64

22B-7-2

MANUAL TRANSMISSION (E-W) -

Output Shaft <F5M41>

DISASSEMBLY AND REASSEMBLY

<Types with double synchronizer ring for 2nd gear>

Apply gear oil to all

moving parts before

installation.

21

22

15

23

13

11

12

24

16

1

18

17

19

20

6

9

3

2

4

5

7

10

8

9

14

Disassembly steps

"JA 1. Snap ring

AA""IA 2. Ball bearing

3. Collar

4. 5th speed gear

5. 4th speed gear

"HA 6. Snap ring

7. 3rd speed gear

8. 2nd speed gear

9. Needle roller bearing

AB""GA 10. 2nd speed gear sleeve

11. Inner synchronizer ring

12. Synchronizer cone

E

July 1999Mitsubishi Motors Corporation Revised

13. Outer synchronizer ring

"KA 14. Synchronizer spring

"FA 15. Synchronizer sleeve

"EA 16. 1st-2nd speed synchronizer hub

17. Synchronizer ring

"DA 18. Synchronizer spring

19. 1st speed gear

20. Needle roller bearing

AC""CA 21. 1st speed gear sleeve

"BA 22. Snap ring

AD""AA 23. Roller bearing inner race

24. Output shaft

PWEE9508-F

Page 65

MD998801

MANUAL TRANSMISSION (E-W) -

DISASSEMBLY SERVICE POINTS

AA"

BALL BEARING REMOVAL

Output Shaft <F5M41>

22B-7-2a

MD998917

MD998801

MD998917

Inner race

AB"

2ND SPEED GEAR SLEEVE REMOVAL

Mount a special tool on the synchronizer sleeve and remove

the 2nd speed gear sleeve.

AC"

AD"

1ST SPEED GEAR SLEEVE REMOVAL

ROLLER BEARING INNER RACE REMOVAL

E

MD998801

MD998812

MD998818

Inner

race

July 1999Mitsubishi Motors Corporation Added

REASSEMBLY SERVICE POINTS

"AA

ROLLER BEARING INNER RACE INSTALLATION

PWEE9508-F

Page 66

22B-7-2b

MANUAL TRANSMISSION (E-W) -

Output Shaft <F5M41>

Intentionally blank

E

July 1999Mitsubishi Motors Corporation Added

PWEE9508-F

Page 67

MANUAL TRANSMISSION (E-W) -

Output Shaft <F5M41>

22B-7-3

Snap ring

Sleeve

MD998812

MD998814

MD998822

"BA

SNAP RING INSTALLATION

Select and install a snap ring so that the output shaft front

bearing end play will have the standard value.

Standard value:

-0.01-0.12 mm

"CA

"DA

1ST SPEED GEAR SLEEVE INSTALLATION

SYNCHRONIZER SPRING INSTALLATION

Install the synchronizer spring securely up to the illustrated

position of the synchronizer ring.

Synchronizer spring

Identification mark

MD998812

MD998814

MD998822

Rear of transmission

"EA

1ST-2ND SPEED SYNCHRONIZER HUB

INSTALLATION

Install the 1st-2nd speed synchronizer hub in such a way

that it will be oriented in the direction shown.

Caution

Whenthe hubis installed,make surethat thesynchronizer

ring is not caught.

E

Nov. 1995Mitsubishi Motors Corporation Added

PWEE9508-A

Page 68

22B-7-4

MANUAL TRANSMISSION (E-W) -

Output Shaft <F5M41>

Rear of

transmission

Synchronizer sleeve

Synchronizer hub

MD998812

"FA

SYNCHRONIZER SLEEVE INSTALLATION

(1) Install the synchronizer sleeve in such a way that it will

be oriented in the direction shown.

(2) When the synchronizer sleeve is installed, make sure that

the deep groove portion of the synchronizer hub is aligned

with the projecting portion of the sleeve.

"GA

2ND SPEED GEAR SLEEVE INSTALLATION

Snap ring

MD998813

MD998812

MD998817

MD998820

"HA

SNAP RING INSTALLATION

Select and install a snap ring so that the output shaft 3rd

speed gear end play will have the standard value.

Standard value:

-0.01-0.09 mm

"IA

BALL BEARING INSTALLATION

E

Nov. 1995Mitsubishi Motors Corporation Added

PWEE9508-A

Page 69

MANUAL TRANSMISSION (E-W) -

Output Shaft <F5M41>

22B-7-5

Synchronizer

spring

"JA

SNAP RING INSTALLATION

Select and install a snap ring so that the output shaft rear

bearing end play will have the standard value.

Standard value:

-0.01-0.09 mm

"KA

SYNCHRONIZER SPRING INSTALLATION

Install the synchronizer spring securely inthe illustrated position

of t he outer synchronizer ring.

INSPECTION

OUTPUT SHAFT

Check the splines for damage and wear.

NEEDLE ROLLER BEARING

(1) Check to ensure that when the bearing sleeve and gear

are combined and made to rotate, they rotate smoothly

without looseness and noise.

(2) Check to ensure that the cage is not deformed.

SYNCHRONIZER RING

(1) Check to ensure that the clutch gear tooth surfaces are

not damaged and broken.

(2) Check to ensure that the cone inside diameter is not

damaged or worn and that the threads are not crushed.

E

E

Nov. 1995Mitsubishi Motors Corporation Added

July 1999Mitsubishi Motors Corporation Revised

PWEE9508-A

PWEE9508-F

Page 70

22B-7-6

MANUAL TRANSMISSION (E-W) -

Output Shaft <F5M41>

A

Synchronizer ring Gear

Gear

A

Outer ring

Cone

(3) Press the synchronizer ring against the gear and check

clearance “A”. If “A” is less than the limit, replace.

Limit: 0.5 mm

OUTER SYNCHRONIZER RING / INNER

SYNCHRONIZER RING / SYNCHRONIZER CONE

(1) Check to ensure that the clutch gear tooth surfaces and

cone surfaces are not damaged and broken.

(2) Install the outer ring, inner ring and cone, press them

against the gear, and check clearance “A”. If “A” is less

than the limit, replace.

Limit: 0.5 mm

Caution

When the outer ring, inner ring or cone has to be