Page 1

Body/equipment mounting directives

for CANTER EURO V (FB/FE)

Europe

'HFHPEHU 2010

Page 2

Mitsubishi Fuso Service

Body/equipment mounting directives

for Canter EURO V (FB/FE)

Europe

KAWASAKI, JAPAN

Page 3

Contents

10.Dec. 2010

1 Introduction

1.1 The aim of these directives 6

1.2 Conventions 8

1.3 Vehicle safety 9

1.4 Operational reliability 10

Accident prevention 11

1.5

2 General

2.1 Vehicle and model designations 12

2.2 Technical advice and contact persons 14

2.3 Issue of letter of no objection 15

2.4 Product safety 17

2.5 Mitsubishi three diamonds and Fuso emblem 19

2.6 Recycling of components 20

2.7 Quality system 21

3 Planning of bodies

3.1 Selecting the chassis 22

3.2 Vehicle modifications 23

3.3 Dimensions, weights, overall vehicle height 24

3.4 About vehicle body incline 28

3.5 Tyres 29

3.6 Bolted and welded connections 30

3.7 Soundproofing 32

3.8 Exhaust system 33

3.9 Maintenance and repairs 35

3.10 Special equipment 38

4 Technical threshold values for planning

4.1 Vehicle overhang and technical wheelbases 39

4.2 Weight distribution, CoG height, anti-roll bars 41

4.3 Steerability 42

4.4 Clearance for assemblies and cab 43

4.5 Wind deflectors 45

4.6 Governor and transmission power-take-off 48

Mitsubishi Fuso body/equipment mounting directives for Canter EURO V (FB/FE) Issue date: 27. Jan. 2010

! Only print out complete sections from the current versioni

2

Page 4

Contents

10.Dec. 2010

5 Damage prevention

5.1 Electrical system 55

5.2 Brake hoses/cables and lines 57

5.3 Mobile communications systems 58

5.4 Electromagnetic compatibility (EMC) 59

5.5 Welding work 60

5.6 Corrosion protection measures 62

5.7 Corrosion prevention in welding work 64

5.8 Bolted connections 65

5.9 Painting work 67

5.10 Leaf springs 68

5.11 Tilting the cab 69

5.12 Towing and tow-starting 70

5.13 Risk of fire 71

5.14 Storing and handing over the vehicle 72

6 Modifications to the basic vehicle

6.1 General 73

6.2 Chassis frame material 74

6.3 Drilling work on the vehicle frame 75

6.4 Welding work on the vehicle frame 77

6.5 Reinforcement on side rail 79

6.6 Brake systems 81

6.7 Modifications to the wheelbase 82

6.8 Frame modifications 83

6.9 Mounting equipment on the side rail 86

6.10 Cab 94

6.11 Seats and bench seat 95

6.12 Electrics/electronics 96

6.13 Installation of propeller shafts 103

7 Construction of bodies

7.1 General 104

7.2 Mounting frame 105

7.3 Mounting frame attachment 109

7.4 Clearance between chassis parts and bodies 111

7.5 Fuel tank 114

7.6 Blue Tec® system 116

8 Calculations

8.1 Axle load calculation 120

Mitsubishi Fuso body/equipment mounting directives for Canter EURO V (FB/FE) Issue date: 27. Jan. 2010

! Only print out complete sections from the current versioni

3

Page 5

Contents

10.Dec. 2010

9 Technical data

9.1 Vehicle performance list 122

9.2 Performance curve 123

9.3 Weight distribution table 158

9.4 Chassis cab drawings 201

9.5 Frame layout 245

9.6 Spring diagram 284

9.7 Lamp layout drawings 300

9.8 Power train 303

9.9 Maximum height of axle housing and tyre when bounding

307

9.10 Engine transmission assembly 309

9.11 Transmission power-take-off layout 310

9.12 Battery mounting layout 312

9.13 Fuel tank mounting layout 315

9.14 Blue Tec

9.15 Electrical wiring diagram 322

®

exhaust gas aftertreatment 318

Mitsubishi Fuso body/equipment mounting directives for Canter EURO V (FB/FE) Issue date: 27. Jan. 2010

! Only print out complete sections from the current versioni

4

Page 6

1Introduction

10.Dec. 2010

Mitsubishi Fuso Truck and Bus Corp., as the manufacturer of Mitsubishi Fuso vehicles, publishes this body/

equipment mounting directive to provide body manufacturers with important technical information about

the basic vehicle. This information must be observed

by the body manufacturer in the production of bodies

and equipment, fittings and modifications for

Mitsubishi Fuso vehicles.

Due to the large number of body manufacturers and

body types, Mitsubishi Fuso Truck and Bus Corp.

cannot take into account all the possible modifications to the vehicle, e.g. performance, stability, load

distribution, centre of gravity and handling characteristics, that may result from the design of attachments,

bodies, equipment or modifications. For this reason,

Mitsubishi Fuso Truck and Bus Corp. can accept no

body manufacturer liability for accidents or injuries

sustained as a result of such modifications to the vehicles if such modifications have a negative impact on

the overall vehicle. Accordingly, Mitsubishi Fuso Truck

and Bus Corp. will only assume liability as vehicle

manufacturer within the scope of the design, production and instruction services which it has performed

itself.

The body manufacturer is bound to ensure that its

bodies and equipment, fittings and modifications are

themselves not defective, nor capable of causing

defects or hazards to the overall vehicle. If this obligation is violated in any way, the body manufacturer shall

sume full product liability. The body/equipment

as

unting directives enable Mitsubishi Fuso Truck and

mo

Bus Corp. to instruct the body manufacturer about

important aspects that must be observed when

mounting its bodies and equipment, fittings and modifications.

These body/equipment mounting directives are

marily intended for the professional manufac

pri

of bodies, equipment, fittings and modifications for

our vehicles. As a result, these body / equipment

mounting directives assume that the body manufacturer has suitable background knowledge. If you intend

to mount attachments, bodies and equipment on or

carry out modifications to our vehicles, please be

aware that certain types of work (e.g. welding work on

load-bearing components) may only be carried out by

qualified personnel. This will avoid the risk of injury

while also ensuring that the degree of quality required

for the attachments, bodies, equipment and modifications is given.

turers

Mitsubishi Fuso body/equipment mounting directives for Canter EURO V (FB/FE) Issue date: 27. Jan. 2010

! Only print out complete sections from the current versioni

5

Page 7

1 Introduction

10.Dec. 2010

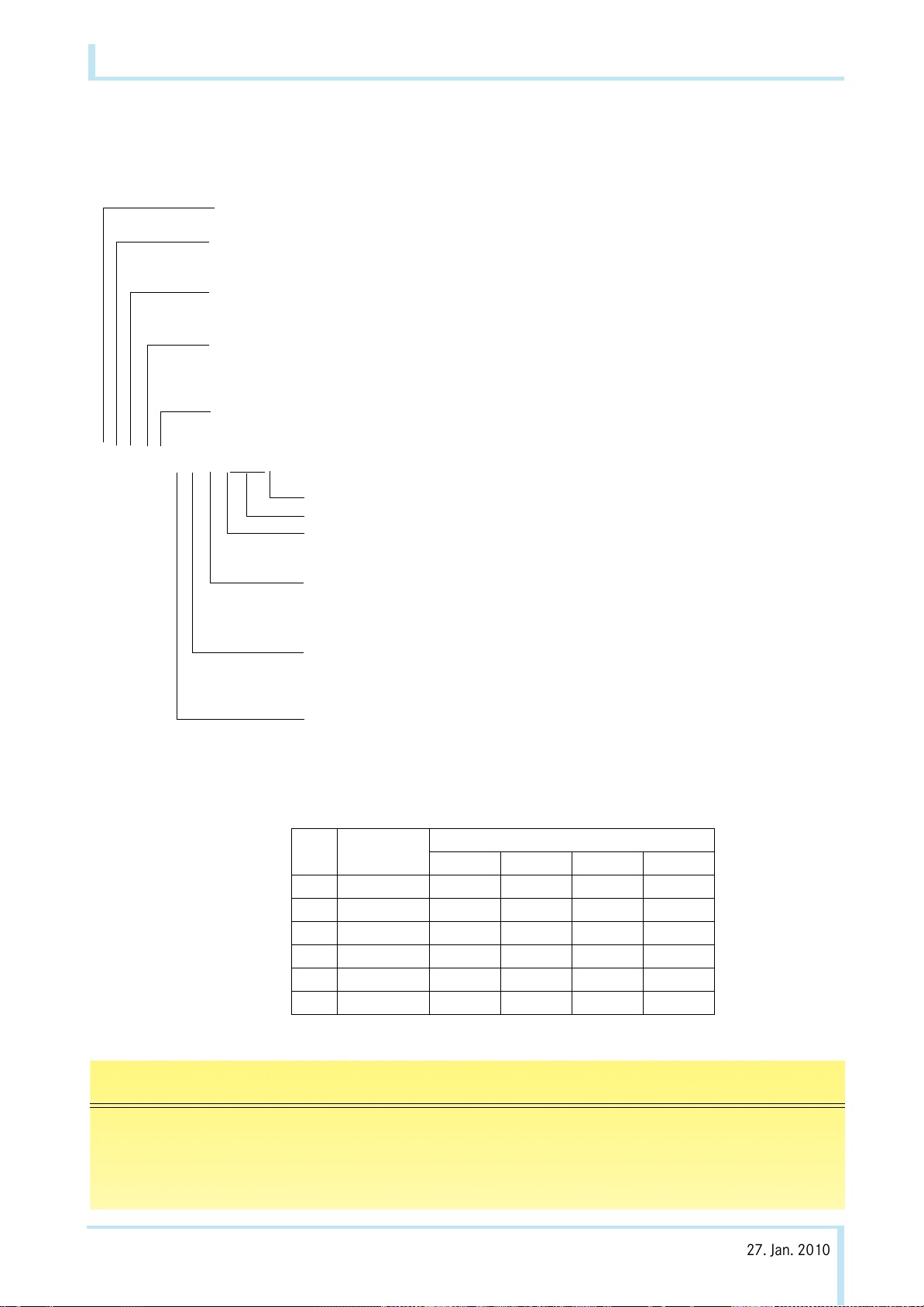

1.1 The aim of these directives

These directives serve as instructions for the manufacture of attachments, bodies, equipment and modification to other make bodies and major assemblies.

These directives are divided into 9 interlinked chapters to help you find the information you require more

quickly:

1.1 The aim of these directives

i

The index, in PDF format, is linked to help you find

the information you require quickly.

Make absolutely sure that you observe the technical threshold values selected in Section 4 as

planning must be based on these values.

1Introduction

2General

3 Planning of bodies

4 Technical threshold values for planning

5 Damage prevention

6 Modifications to the basic vehicle

7 Construction of bodies

8Calculations

9Technical data

Appendix

Index

Section 6 "Modifications to the basic vehicle" and

Section 7 "Construction of bodies" represent the

main source of technical information contained in

these body/equipment mounting directives.

Mitsubishi Fuso body/equipment mounting directives for Canter EURO V (FB/FE) Issue date: 27. Jan. 2010

! Only print out complete sections from the current versioni

6

Page 8

1 Introduction

10.Dec. 2010

a Risk of accident

Before installing any attachments, special-purpose

bodies, equipment or carrying out any modifications to the basic vehicle and/or its assemblies,

you must read the relevant sections of the Owner’s

Handbook, as well as the operating and assembly

instructions issued by the manufacturer of the

accessories and items of optional equipment.

You could otherwise fail to recognise dangers,

which could result in injury to yourself or others.

The illustrations below explain the difference between

"Basic vehicle" and "Body":

1.1 The aim of these directives

The instructions listed herein must be observed in full

to maintain the operational reliability and road sa

of the chassis and for observance of material defect

claims.

Illustrations and schematic drawings are examples

nly and serve to explain the te

o

References to regulations, standards, directives etc.

are given in keywords and serve for information only.

Additional information is available from any

Mitsubishi Fuso Service Centre

Your

Mitsubishi Fuso Truck and Bus Corp.

xts and tables.

fety

Basic vehicle

Body

Mitsubishi Fuso body/equipment mounting directives for Canter EURO V (FB/FE) Issue date: 27. Jan. 2010

! Only print out complete sections from the current versioni

7

Page 9

1 Introduction

10.Dec. 2010

1.2 Conventions

The following conventions are used in these directives:

a Warning

A warning draws your attention to possible risks of

accident and injury to yourself and others.

H Environmental note

An environmental note gives you tips on the protection of the environment.

1.2 Conventions

!

A note draws your attention to possible hazards to

your vehicle.

i

A tip contains advice or further information you may

find useful.

page

This symbol indicates the page on which you will find

further information on the subject. These pages are

cross-linked in the PDF file.

Mitsubishi Fuso body/equipment mounting directives for Canter EURO V (FB/FE) Issue date: 27. Jan. 2010

! Only print out complete sections from the current versioni

8

Page 10

1 Introduction

10.Dec. 2010

1.3 Vehicle safety

1.3 Vehicle safety

a Risk of accident and injury

The use of parts, assemblies or conversion parts

and accessories which have not been approved

may jeopardise the safety of the vehicle.

Before installing any attachments, special-purpose

bodies, equipment or carrying out any modifications to the basic vehicle and/or its assemblies,

you must read the relevant sections of the Owner’s

Handbook, as well as the operating and assembly

instructions issued by the manufacturer of the

accessories and items of optional equipment.

You could otherwise fail to recognise dangers,

which could result in injury to yourself or others.

Official acceptance by public testing bodies or

official approval does not rule out safety hazards.

In many countries, parts that make ext

he vehicle can invalidate the general op

to t

permit. Specifically, this concerns parts which:

• change the vehicle type approved in the general

operating permit

• could endanger road users

• could adversely affect exhaust emissions or noise

levels

i

Make absolutely sure that you comply with national

registration regulations as attachments, bodies,

equipment on or modifications to the vehicle will

change the vehicle type approved and may

invalidate the general operating permit.

ensive changes

erating

Notes on vehicle safety

Mitsubishi Fuso recommends

using appropriate parts only for each particular vehicle

model.

Mitsubishi Fuso body/equipment mounting directives for Canter EURO V (FB/FE) Issue date: 27. Jan. 2010

! Only print out complete sections from the current versioni

9

Page 11

1 Introduction

10.Dec. 2010

1.4 Operational reliability

a Risk of accident

Before installing any attachments, special-purpose

bodies, equipment or carrying out any modifications to the basic vehicle and/or its assemblies,

you must read the relevant sections of the Owner’s

Handbook, as well as the operating and assembly

instructions issued by the manufacturer of the

accessories and items of optional equipment.

You could otherwise fail to recognise dangers,

which could result in injury to yourself or others.

Work incorrectly carried out on electronic components and their software could prevent this equipment from working correctly. Since the electronic

systems are networked, this might also affect

systems that have not been modified.

1.4 Operational reliability

Malfunctions in the electronic systems could seriously jeopardise the operating safety of the vehicle.

Mitsubishi Fuso body/equipment mounting directives for Canter EURO V (FB/FE) Issue date: 27. Jan. 2010

! Only print out complete sections from the current versioni

10

Page 12

1 Introduction

10.Dec. 2010

1.5 Accident prevention

The body, the attached or installed equipment and any

modifications must comply with the applicable laws

and ordinances as well as work safety or accident

prevention regulations, safety rules and accident

insurer leaflets.

All technical means shall be used to avoid operating

conditions that may be unsafe or liable to cause an

accident.

All national laws, directives and registration

equirements must be complied with.

r

1.5 Accident prevention

The manufact

ment or conversion or the device manufacturer is

respon

regulati

sible for compliance with these laws and

urer of the attachment, body, equip-

ons.

Mitsubishi Fuso body/equipment mounting directives for Canter EURO V (FB/FE) Issue date: 27. Jan. 2010

! Only print out complete sections from the current versioni

11

Page 13

2 General

10.Dec. 2010

2.1 Vehicle and model designations

2.1.1 Model coding system

Cab Style

2.1 Vehicle and model designations

F: Forward control

Drive System & Basic GVM

Development Order

Suspension Type

Engine Type

F E 8 4 S G 6 W L E A 1

B: 4 x 2, GVM 3.5 tons

E: 4 x 2, GVM 3.5 to 8.0 tons

7: Standard width cab

8: Wide cab (comfort cab)

3: Leaf spring, GVM 3.5 to 6.0 tons

4: Leaf spring, GVM 3.5 to 7.0 tons

5: Leaf spring, GVM 7.0 to 8.0 tons

S: 4P10

See following table *1.

Code Destination

Steering Wheel Location

Cab Type

Rear Tyre Arrangement

EA: Portugal (MFTE)

L: Left hand

R: Right hand

S: Single cab

W: Double cab

4: Double, tyre

6: Double, tyre

Z: Double, tyre

GVM 3.5 to 6.0 tons

GVM 6.0 to 8.0 tons

GVM 6.0 to 8.0 tons with wide frame

Wheelbase (mm)

*1

Engine Model Vehicle Model&Engine Output

1 4P10 0AT2 96kw 96kw 96kw

2 4P10 0AT3 107kw 107kw

3 4P10 0AT6 129kw

4 4P10 6AT2* 96kw 96kw 96kw

5 4P10 6AT3* 107kw 107kw

6 4P10 6AT6* 129kw

*: EEV (Enhanced Environmentally - friendly Vehicle) Compliant engine

B: 2300 to 2600

C: 2600 to 2900

D: 2900 to 3200

E: 3200 to 3500

FB7 FB8 FE7 FE8

F: 3500 to 3800

G: 3800 to 4100

H: 4100 to 4400

J: 4400 to 4700

i

In this document, vehicle model with the last model code of 1 and 4, 2 and 5, 3 and 6 are identical in the

vehicle specification except for the engine model type. There are no significant differences between the nonEEV compliant engine type (4P10-0AT2,3,6) with the EEV compliant engine type (4P10-6AT2,3,6) except as

otherwise noted.

Mitsubishi Fuso body/equipment mounting directives for Canter EURO V (FB/FE) Issue date: 27. Jan. 2010

! Only print out complete sections from the current versioni

12

Page 14

2 General

10.Dec. 2010

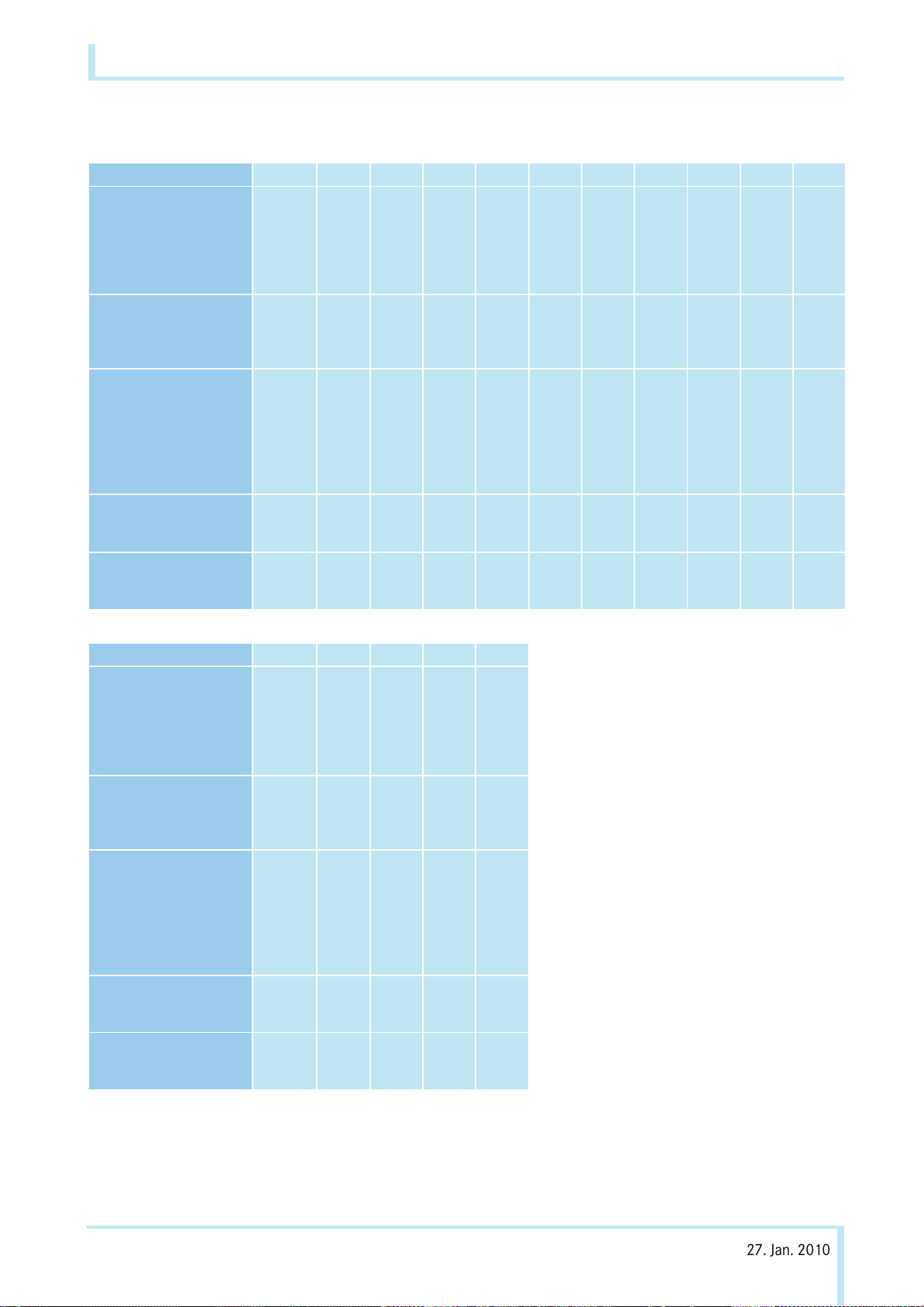

2.1.2 Vehicle and model designation

FB73 FB73 FB83 FB83 FB83 FE74 FE84 FE84 FE85 FE85

Engine Type

Number of Cylinders

Output (kW)

(rpm)

Maximum torque (Nm)

(rpm)

Cab

Transmission

Wheelbase (mm) 2500

Permissible axle load

and weight (kg)

Permissible total

gross weight of (kg)

combination

Standard

Wide

Double

2750

2950

3350

3850

4200

4470

Front

Rear

Total

4P10T2

L4

96

3500

300

1600

•

6S420

•

•

• •

1950

2700

3500

7000 7000 7000 7000 7000 9000 10000 10000 11000 11000

4P10T2

L4

96

3500

300

1600

4P10T2

L4

96

3500

300

1600

•

•

6S420•6S420

•

•

•

•

1950

2700

3500

1950

2700

3500

2.1 Vehicle and model designations

4P10T2

6S420•6S420•6S420•6S420

L4

96

3500

300

1600

•

•

•

1950

2700

3500

4P10T3

L4

107

3500

370

1600

•

•

•

•

1950

2700

3500

4P10T2

L4

96

3500

300

1600

•

•

•

2300

3800

5500

4P10T3

L4

107

3500

370

1600

•

•

• •

2500

4500

6500

4P10T3

L4

107

3500

370

1600

4P10T3

L4

107

3500

370

1600

•

•

6S420•6S420

•

•

•

•

•

2500

4500

6500

3100

5200

7500

4P10T3

L4

107

3500

370

1600

•

•

6S420

•

•

3100

5200

7500

Engine Type

Number of Cylinders

Output (kW)

(rpm)

Maximum torque (Nm)

(rpm)

Cab

Transmission

Wheelbase (mm) 2500

Permissible axle load

and weight (kg)

Permissible total

gross weight of (kg)

combination

Standard

Wide

Double

2750

2950

3350

3850

4200

4470

Front

Rear

Total

FE84 FE84 FE85 FE85

4P10T6

6S420

L4

129

3500

430

1600

•

•

•

4P10T6

L4

129

3500

430

1600

4P10T6

L4

129

3500

430

1600

•

•

6S420•6S420

•

•

•

•

4P10T6

L4

129

3500

430

1600

•

•

6S420

•

•

•

2640

4750

6500

10000 10000 11000 11000

2640

4750

6500

3100

5200

7500

3100

5200

7500

Mitsubishi Fuso body/equipment mounting directives for Canter EURO V (FB/FE) Issue date: 27. Jan. 2010

! Only print out complete sections from the current versioni

13

Page 15

2 General

10.Dec. 2010

2.2 Technical advice and contact persons

2.2 Technical advice and contact persons

The staff members of the Daimler development

department TP/EVM., the team responsible for

conversion/body manufacturers and the body/equipment mounting directive for the overall vehicle development of Mitsubishi Fuso vehicle, issue letter of

no objection for the Canter (FB/FE) and answe

technical and design-enginee

vehicle registration and damage as the representative

of Mitsubishi Fuso. The relevant members of staff can

be contacted at:

Europe and German contacts Responsibility

Telephone: +49 (0)7 11-17-4 30 34 Mitsubishi Fuso Canter

ring questions regarding

+49 (0)7 11-17-5 17 19 Team management, standards and procedures for

r

Mercedes-Benz Actros, Axor, Atego, Econic, Zetros

and Mitsubishi Fuso Canter series

Telefax: +49 (0)7 11-17-5 21 91

Postal address: Daimler AG

HPC (in-house post code) C 108

TP/EVM

D-70546 Stuttgart, Germany

Mitsubishi Fuso body/equipment mounting directives for Canter EURO V (FB/FE) Issue date: 27. Jan. 2010

! Only print out complete sections from the current versioni

14

Page 16

2 General

10.Dec. 2010

2.3 Issue of letter of no objection

2.3.1 Letter of no objection

2.3 Issue of letter of no objection

Mitsubishi Fuso Truck and Bus Corp. does not issue

body/equipment approval certificates f

manufactured by Mitsubishi Fuso Truck and Bus Corp.

These directives only supply important information

and technical specifications to body manufacturers

explaining how to handle the product. For this reason,

Mitsubishi Fuso Truck and Bus Corp. recommends

that all work on the basic vehicle and body be carried

out in compliance with the Mitsubishi Fuso body/

equipment mounting directives.

Mitsubishi Fuso Truck and Bus Corp. advises against

attachments, bodies, equipment and modifications

which:

• are not produced in accordance with Mitsubishi

uso Body/Equipment Mounting Directives

F

• exceed the permitted maxi

ight

we

• exceed the permissible axle loads

Mits

ubishi Fuso Truck and Bus Corp. issues a letter

of no objection voluntarily based on the follo

criteria:

Mitsubishi Fuso Truck and Bus Corp.'s assess

shall be based solely on the documents submitted by

the body manufacturer carrying out the modifications.

The assessment and the endorsement shall only cover

the expressly defined scopes and their basic compatibility with the designated chassis and its connection

points or, in the case of chassis modifications, the

basic feasibility of the design for the designated

chassis.

mum gross vehicle

or bodies not

wing

ment

The letter of no objection shall not refer to the

rall design of the body, its functions or its intended

ove

field of operation. No o

design, production and assembly are performed by the

body manufacturer carrying out the modifications in

accordance with the state of the art and in compliance

with the valid Mitsubishi Fuso body / equipment

Mounting Directives – unless deviations have been

endorsed in these directives. Nevertheless, the letter

of no objection shall not release the body

manufacturer carrying out the modifications from his

product liability or his obligation to perform his own

calculations, tests and trials on the overall vehicle in

order to ensure that the overall vehicle produced by

the company meets the required specifications for

operating and road safety and handling characteristics. Accordingly, it shall be the sole duty and responsibility of the body manufacturer to ensure the compatibility of his attachments, bodies, equipment and

odifications with the basic vehicle an

m

the operating and road safety of the vehicle.

All national laws, directives and registration

requirements must be complied with.

bjection shall only apply if

d to guarantee

Mitsubishi Fuso body/equipment mounting directives for Canter EURO V (FB/FE) Issue date: 27. Jan. 2010

! Only print out complete sections from the current versioni

15

Page 17

2 General

10.Dec. 2010

2.3 Issue of letter of no objection

2.3.2 Required documents

In individual cases, the body drawings may be

submitted to the department responsible before the

start of w

the following information:

• All deviations from Mitsubishi Fuso body/

• Complet

• Attachmen

• Vehicle operating conditions, e.g.

• Certificates ("e" mark, seat tensile strength test,

Submitting the required documentati

make queries on our part unnecessary and will speed

up the approv

ork Page 14. The drawings shall contain

quipment mounting directives.

e

e data on dimensions, weights and centre

ravity (weight certificates)

of g

t of body to the chassis

– on poor roads

– in very dusty conditions

– at high altitude

– at extremely high or low ambient temperatures

c.)

et

on in full will

al procedure.

2.3.3 Legal claim

• No legal claim can be made as to the issue of a

letter of no objection.

• Mitsubishi Fuso Truck and Bus Corp. reserves th

ght to refuse the issue of a letter of no

ri

objection due

and the knowledge gained from it, even if a similar

certificate was issued in the past.

• A letter of no objection may be restricted

individual vehicles.

to

• Subsequent issuan

bjection for vehicles

o

delivered can be refused.

The body manufacturer alone shall be responsible for:

• The functionality and compatibility of its bodies

and equipment, fittings and conversions with the

c vehicle

basi

• Operating and road safety

• All bodies and equipment, fittings, conversions and

alled parts

inst

to ongoing technical development

ce of a letter of no

alrea

dy comp

leted or

e

If complex calculations and/or vehicle tests are

necessary for the no objection check, all costs

incurred must be borne by the vehicle body/conversion manufacturer or its client. The extent of testing

required is defined by the relevant department of

Mitsubishi Fuso Truck Development Page 14.

Mitsubishi Fuso body/equipment mounting directives for Canter EURO V (FB/FE) Issue date: 27. Jan. 2010

! Only print out complete sections from the current versioni

16

Page 18

2 General

10.Dec. 2010

2.4 Product safety

2.4 Product safety

Both the vehicle manufacturer and the body manufacturer must always ensure that they introduce their

scopes into the market in a safe condition and that

third parties are not at risk of any safety hazard. If this

is not adhered to they may be subject to civil, criminal

and public law consequences. Every manufacturer is

liable for the products it manufactures.

From this, it follows that the vehicle body/conversion

anufacturer therefore also bears responsibility for

m

the following:

• the operating and road safety of the body

• the operating and road safety of parts and modifi-

tions

ca

• testing and maintaining th

afety of the vehicle after th

s

mounted (the body and/or equipment must not

have a negative effect on the driving, braking or

steering characteristics of the vehicle)

• influences of parts on or modifications to the

hassis

c

• consequential damage r

tachment, equipment or modification

at

•

consequential damage resulting from retrofitted

ectrical and electronic systems

el

• maintaini

of mo

after the body

springs, propeller shafts, steering, gearbox linkage,

etc.) even in the case of diagonal torsion between

the chassis and the bodies

ng the operational reliability and freedom

vement of all moving parts of the chassis

/equipment is mounted (e.g. axles,

e operating and handling

e body/equipment is

esulting from the body,

Mitsubishi Fuso body/equipment mounting directives for Canter EURO V (FB/FE) Issue date: 27. Jan. 2010

! Only print out complete sections from the current versioni

17

Page 19

2 General

10.Dec. 2010

2.4.1 Guarantee of traceability

Hazards in your implement/body which become

known after delivery may necessitate suppleme

measures in the market (customer notification, warnings, recalls). In order to make these measures as efficient as possible, your product must be traceable after

delivery.

For this purpose and to enable the Federal Office for

Motor Vehicles' Central Vehicle Register (ZFZR) or

comparable registers abroad to be used for determining which owners are affected, we advise you to

promptly file the serial number/identification number

of your equipment/add-on part linked to the vehicle

identification number for the truck in your databases.

Similarly, it is also advisable to store the addresses of

your customers for this purpose and to grant subsequent purchasers the opportunity to register.

ntary

2.4 Product safety

Mitsubishi Fuso body/equipment mounting directives for Canter EURO V (FB/FE) Issue date: 27. Jan. 2010

! Only print out complete sections from the current versioni

18

Page 20

2 General

10.Dec. 2010

2.5 Mitsubishi three diamonds and Fuso emblem

2.5 Mitsubishi three diamonds and Fuso emblem

The Mitsubishi three diamonds and Fuso emblem are

owned or controlled by MITSUBISHI FUSO.

They must not be removed or affixed in another position.

Mitsubishi three diamonds and Fuso emblems

supplied separately must be attached at the points

specified by MITSUBISHI FUSO.

Overall appearance of the overall vehicle

If the vehicle fails to comply with the appearance and

quality standards as required by

and Bus Corp., the trademarks such as the Mitsubishi

three diamonds and Fuso emblem must be removed.

Third-party trademarks

Mitsubishi Fuso Truck

• may not be affixed next to MITSUBISHI FUSO

trademarks

Binding ruling

The Mitsubishi Fuso Brand Trademark Directive

governs the use of trademarks

on integrated bodies mounted on FB/FE chassis.

Mitsubishi Fuso Truck and Bus Corp. reserves the right

to prohibit the body manufacturer from using Mitsubishi Fuso trademarks in the event of any violations to

this body/equipment mounting directive, including

the trademark directive.

• If you have any question, contact the department

sponsible Page 14.

re

by body manufacturers

Mitsubishi Fuso body/equipment mounting directives for Canter EURO V (FB/FE) Issue date: 27. Jan. 2010

! Only print out complete sections from the current versioni

19

Page 21

2 General

10.Dec. 2010

2.6 Recycling of components

H Environmental note

When planning attachments, bodies, equipment

and modifications, and with regard to the legal

requirements according to EU Directive

2000/53/EC, the following principles for environmentally-compatible design and material selection

shall be taken into account.

Materials with risk potential, such as halogen additives, heavy metals, asbestos, CFCs and CHCs, are to

be avoided.

• It is preferable to use materials which permit

recycling and closed material cycl

• Materials and production processes are to be

lected such that only low quantities of waste are

se

g

enerated during production and that this waste

can be easily recycled.

• Plastics are to be used only where they provide

dvantages in terms of cost, function

a

• In the case of plastics, and composite materials in

articular, only compatible substanc

p

material family are to be used.

es.

or weight.

es within one

2.6 Recycling of components

• For components which are relevant to recycling,

the number of different types of plastics used must

kept to a minimum.

be

• It must be assessed whether a component can be

de from recycled material or with recycle

ma

elements.

• It must be ensured that components can be

smantled easily for recycling, e.g. by snap

di

connect

These components should generally be easily

accessible and should permit the use of standard

tools.

• Service products must be capable of being

rem

resp

• Wherever possible, components should not be

pa

used instead.

• Components in areas at risk from accidents must

be

tolerant, repairable and easy to replace.

• All plastic parts are to be marked in accordance

w

• EU Directive 2000/53/EC must be complied with.

ions or predetermined breaking points.

oved simply and in an environmentally

onsible manner by means of drain plugs, etc.

inted or coated; coloured plastic

designed in such a way that they are dama

ith VDA code of practice 260, e.g. "

parts are to be

PPGF30R".

d

ge-

Mitsubishi Fuso body/equipment mounting directives for Canter EURO V (FB/FE) Issue date: 27. Jan. 2010

! Only print out complete sections from the current versioni

20

Page 22

2 General

10.Dec. 2010

2.7 Quality system

World-wide competition, increased quality standards

demanded by the customer from the product as a

whole, national and international product liability laws,

new organisational forms and rising cost pressures

make efficient quality assurance systems a necessity

in all sectors of the automotive industry.

For the reasons quoted above, Mitsubishi Fuso Truck

and Bus Corp. urgently advises body manufacturers to

set up a quality management system with the following minimum requirements:

• Does the quality management system clearly

fine responsibility and aut

de

• Is there a description of processes/workflows?

• Are the contracts checked/is the feasibility of

constru

• Are product checks on the basis of specifie

nstructions carried out?

i

• What provisi

pr

• Are the inspection results documented

ar

• Do all employees concerned have cu

p

• Is t

• Is there a system for labelling materials/parts?

• Are quality assurance measures carried out at

sup

ction checked?

ons are made for the handling of faulty

oducts?

chived?

roof of the qualification required?

he test equipment systematically monitored?

pliers?

hority?

d

and

rrently valid

2.7 Quality system

Mitsubishi Fuso body/equipment mounting directives for Canter EURO V (FB/FE) Issue date: 27. Jan. 2010

! Only print out complete sections from the current versioni

21

Page 23

3 Planning of bodies

10.Dec. 2010

3.1 Selecting the chassis

3.1 Selecting the chassis

!

When planning attachments, bodies, equipment or

modification work, the selected vehicle must be

checked to verify whether it fulfils the necessary

requirements.

In order to ensure safe operation of the vehicle, it is

essential to choose the chassis and equipment carefully in accordance with the intended use.

Along with the selection of the correct vehicle version,

the required series and special equi

•Wheelbase

• Engine/gearbox

• Power take-offs

•Axle ratio

• Position of the centre of gravity

• Legal registration requirements

(e.g. underride guard)

• Permissible and technical gross vehicle weight

should be taken into consideration and be appropriate

for the intended use.

pment such as

!

Observe the Model. The axle designation or the load

capacity of the tyres has only limited relevance to

the gross weight of the vehicle.

i

The non-availability of a vehicle version may be an

indication that the vehicle is not suitable for the

intended application.

i

Mitsubishi Fuso body/equipment mounting directives for Canter EURO V (FB/FE) Issue date: 27. Jan. 2010

! Only print out complete sections from the current version

22

Page 24

3 Planning of bodies

10.Dec. 2010

3.2 Vehicle modifications

a Risk of accident

Do not carry out any modifications to major assemblies (steering, brake system etc.). Any modifications to the steering and the brake system may

result in these systems malfunctioning and ultimately failing. The driver could lose control of the

vehicle and cause an accident.

Alterations to the basic vehicle are permitted only

within the framework of the procedures described

in this body/equipment mounting directive.

3.2 Vehicle modifications

Standard production vehicles comply ex factory with

EU Directives and national regulations

The vehicles must still comply with EC Directives or

national regulations after modifications have been

carried out.

The body manufacturer must inform the officially

recognised approval authority or inspector of any

modifications to the chassis when the vehicle is

inspected. If necessary, present a letter of no

objection from Mitsubishi Fuso Truck and Bus Corp.

(e.g. drawing with approval note) or the applicable

body/equipment mounting directive.

Following all work on the brake system, i.e. even if

merely disassembling parts, a complete check (operation, effectiveness and visibility) of the entire brake

system must be performed.

i

Mitsubishi Fuso body/equipment mounting directives for Canter EURO V (FB/FE) Issue date: 27. Jan. 2010

! Only print out complete sections from the current version

23

Page 25

3 Planning of bodies

10.Dec. 2010

Please note the minimum weight of the vehicle

including body which is specified in the

homologation documents.

3.3 Dimensions, weights, overall vehicle height

3.3 Dimensions, weights, overall vehicle height

a Risk of accident

The vehicle tyre load capacity may not be exceeded

by overloading the vehicle beyond its specified

gross vehicle weight. The tyres could overheat and

suffer damage. This could cause you to lose control

of the vehicle and cause an accident with possible

injury to yourself and others.

Information on the permissible axle loads can be

found on the vehicle model plate.

All legal provisions governing the permissible

vehicle height must be taken into account when

planning bodies. In the Federal Republic of

Germany the permissible vehicle height is limited to

max. 4 m. In other countries (and if the vehicle is

operated on international services), comply with all

the relevant national regulations.

i

Information about changes in weight is available

from the department responsible page 14.

Dimensions and weight details can be found in the

drawings and technical data. They are based on a

vehicle that is fitted with standard equipment. Weight

tolerances of ±3% in production must be taken into

consideration (2003/19/EC).

The permissible axle loads and the maximum permissible gross vehicle weight specified in the technical

data may not be exceeded.

The technical data can be found in the vehicle documents or on the vehicle model plate.

i

Mitsubishi Fuso body/equipment mounting directives for Canter EURO V (FB/FE) Issue date: 27. Jan. 2010

! Only print out complete sections from the current version

24

Page 26

3 Planning of bodies

DRIVER SIDE

PASSENGER SIDE

10.Dec. 2010

DRIVER SIDE

DRIVER SIDE

DRIVER SIDE

DRIVER SIDE

DRIVER SIDE

DRIVER SIDE

PASSENGER SIDE

PASSENGER SIDE

PASSENGER SIDE

PASSENGER SIDE

PASSENGER SIDE

PASSENGER SIDE

3.3 Dimensions, weights, overall vehicle height

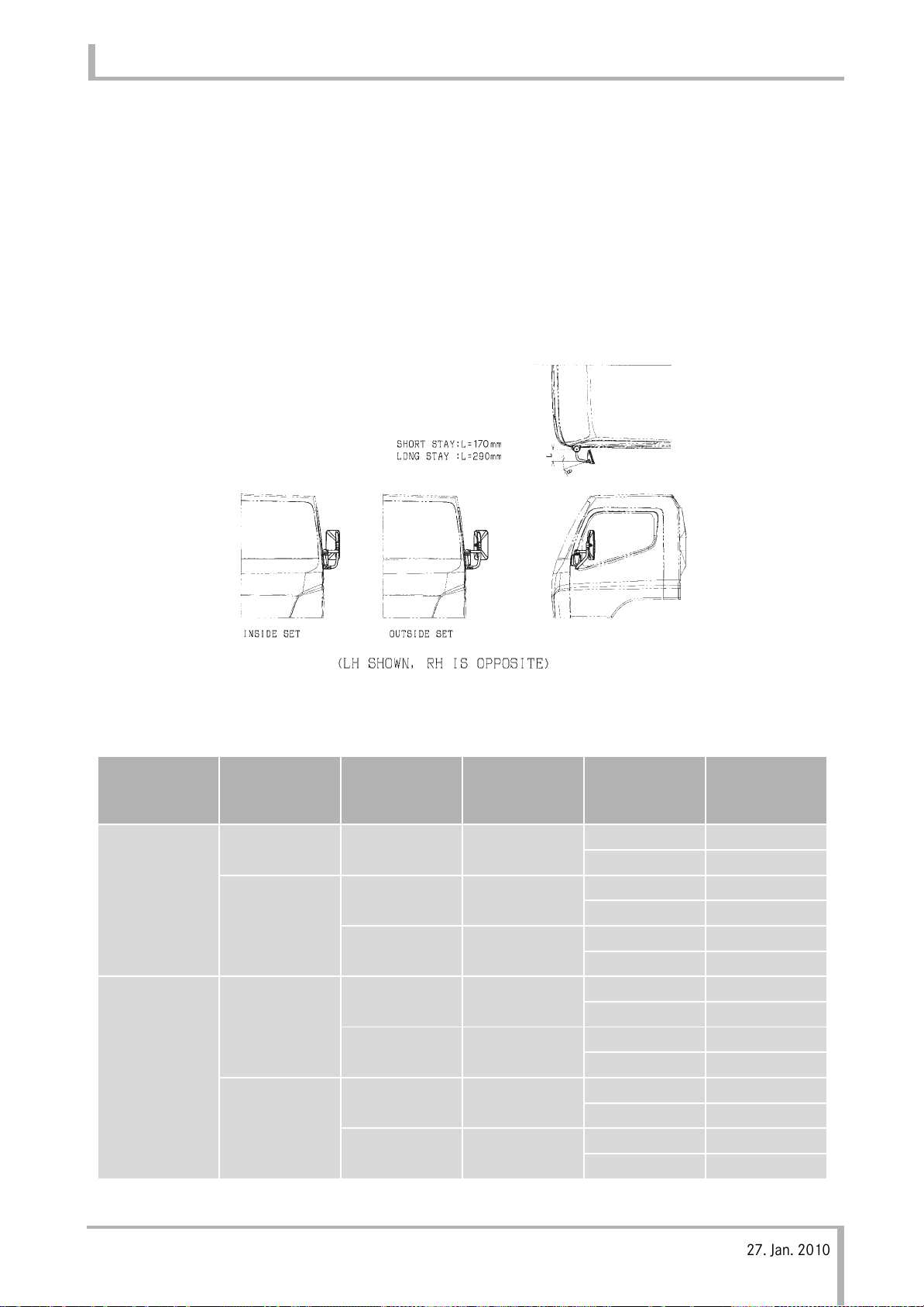

3.3.1 Maximum Rear Body Width

There is a limitation on rear body width for outside

Mirror and Lamps.

Outside mirror

The position of outside mirror for wide cabin must be

set according to the width of rear body as shown in

Fig. 1.

(The mirror is mounted on the inside position until the rear body is assembled.)

MODEL

(CABIN

WIDTH)

FB7

FE7

STD

FB8

FE8

WIDE

Fig. 1

STAY LENGTH MIRROR SET REAR BODY

WIDTH

(mm)

SHORT OUTSIDE SET 1870 to 2000 17.5°

LONG INSIDE SET 2000 to 2100 18.0°

OUTSIDE SET 2100 to 2200 19.0°

SHORT INSIDE SET 2000 to 2150 16.0°

OUTSIDE SET 2150 to 2280 17.5°

LONG INSIDE SET 2280 to 2400 18.5°

OUTSIDE SET 2400 to 2550 21.0°

SET ANGLE θ

31.0°

30.0°

31.5°

31.5°

33.5°

32.0°

34.0°

i

Mitsubishi Fuso body/equipment mounting directives for Canter EURO V (FB/FE) Issue date: 27. Jan. 2010

! Only print out complete sections from the current version

25

Page 27

3 Planning of bodies

10.Dec. 2010

3.3 Dimensions, weights, overall vehicle height

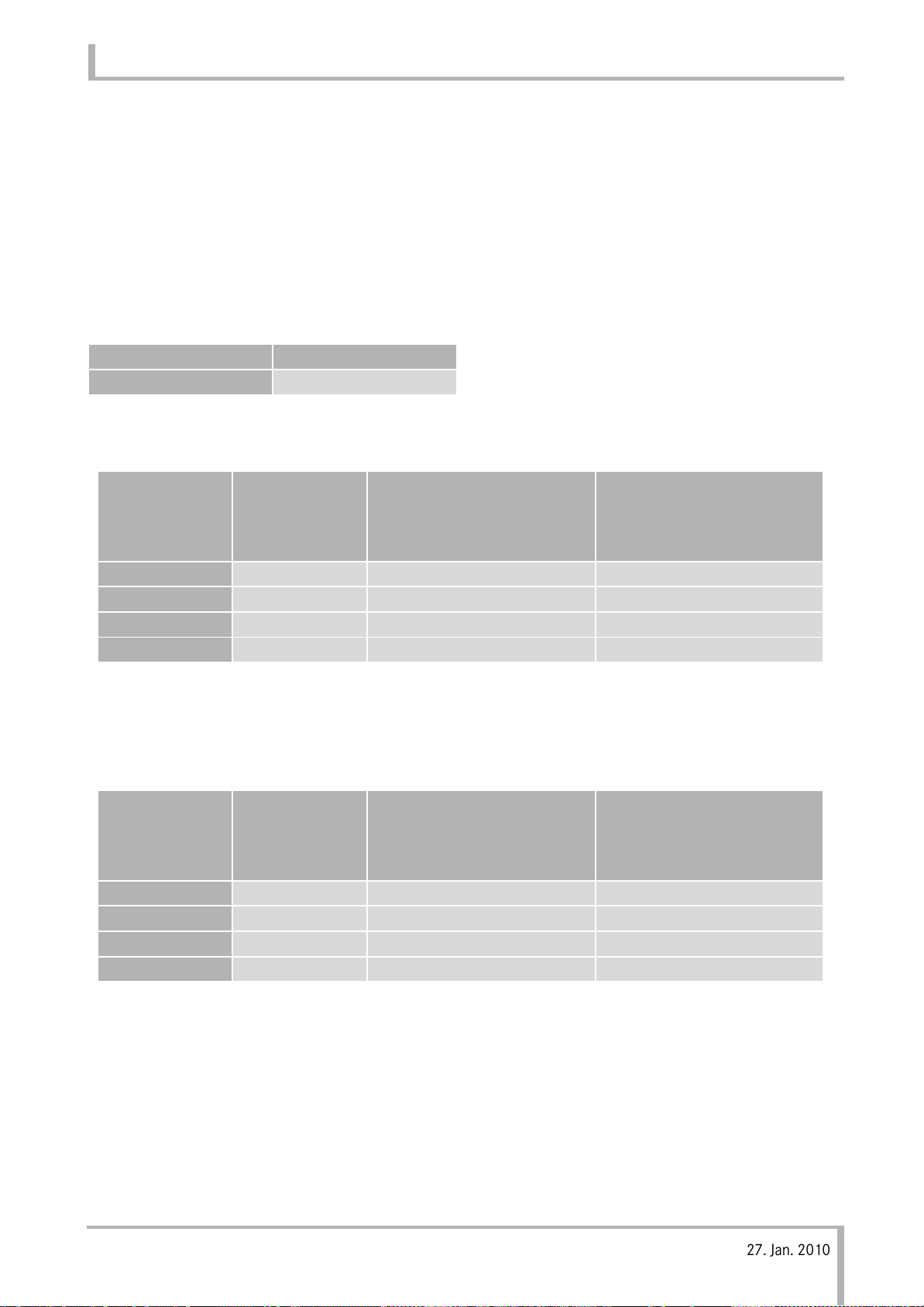

Lamps

Maximum rear body width is divided into the following

3 cases by the rear bumper in which rear combination

lamp

is installed.

When you add side direction indicator lamp, change

flasher relay to the followings and use 21watt bulb of

side direction indicator lamp.

Flasher relay

Type Parts No.

12 V MK542356

• When using no rear bumper

In case additional

MODEL Normal

FB7 / FE7 1900mm 2100mm 2200*mm

FB7-W 2070mm 2100mm 2200*mm

FB8 / FE8 2220mm 2550*mm –

FB8-W / FE8-W 2390mm 2550*mm –

*)Limited by outside mirror

• When using the rear bumper with vehicle resistration N1

(Without coupling de

MODEL Normal

FB7 / FE7 1900mm 2100mm 2200*mm

FB7-W 2070mm 2100mm 2200*mm

FB8 / FE8 2220mm 2340***mm –

FB8-W / FE8-W 2340**mm 2340***mm –

vice)

Side direction indicator

lamp on rear body sides

In case additional

Side direction indicator

lamp on rear body sides

In case additional

Side direction indicator

lamp and End outline marker lamp on rear body sides

In case additional

Side direction indicator

lamp and End outline marker lamp on rear body sides

*) Limited by outside mirror

**) Limited by rear bumper

When you mount wider rear body, change the location of rear combination lamp to rear body.

In that case, maximum rear body width is 2390mm

***)Limited by rear bumper

When you mount wider rear body, change the location of rear combination lamp to rear body.

In that case, maximum rear body width is

2550*mm

Mitsubishi Fuso body/equipment mounting directives for Canter EURO V (FB/FE) Issue date: 27. Jan. 2010

i

! Only print out complete sections from the current version

26

Page 28

3 Planning of bodies

10.Dec. 2010

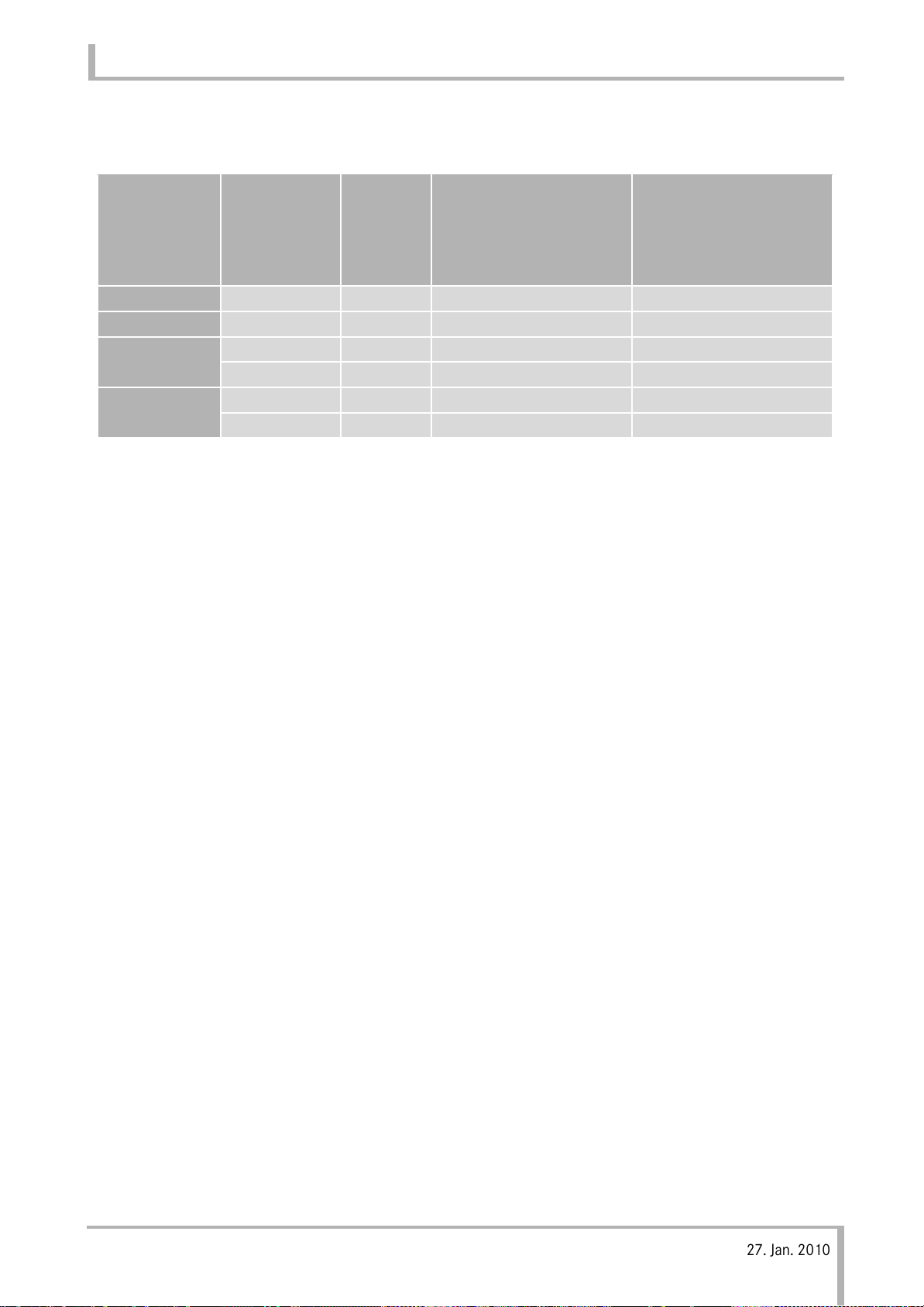

• When using the other rear bumper

3.3 Dimensions, weights, overall vehicle height

Rear

MODEL

FB7 / FE7 – 1900mm 2100mm 2200*mm

FB7-W – 2070mm 2100mm 2200*mm

FB8 / FE8

FB8-W / FE8-W

*) Limited by outside mirror

**) Limited by rear bumper

When you mount wider rear body, change the rear

combination lamp to outside set or the location of

rear combination lamp to rear body.

In that case, maximum rear body width is

2550*mm

combination

lamp

inside set 2220mm 2250**mm –

outside set 2220mm 2550*mm –

inside set 2250mm 2250**mm –

outside set 2390mm 2550*mm –

Normal

In case additional

Side direction indicator

lamp on rear body sides

In case additional

Side direction indicator

lamp and End outline

marker lamp on rear

body sides

i

Mitsubishi Fuso body/equipment mounting directives for Canter EURO V (FB/FE) Issue date: 27. Jan. 2010

! Only print out complete sections from the current version

27

Page 29

3 Planning of bodies

10.Dec. 2010

3.4 About vehicle body incline

• When mounting the rear body onto the chassis,

take care to evenly balance weight on the left and

right sides. If there is difference in weight between

the left and right sides, adjust by adding counterweights or spacers on the sub-frame.

Also, use the chassis height adjustment shims (4.5

m thickness) set on the f

m

Spacer Specification

ront and rear springs.

3.4 About vehicle body incline

Material

SS400(JIS G3101)

E275A(ISO 630)

S275JR/JO(EN10025)

SUP9(JIS G4801)

55Cr3(ISO683-14)

or equivalent

• The following are target reference values for tilting

the body of an assembled vehicle.

• Left-rig

|HfL - HfR|

|HrL - HrR|

• Front-back deviation

|(HfL - HfR) - (HrL - HrR)|

HfL: Centre height of headlamp (left side)

HfR: Centre height of headlamp (right side)

HrL: Lower height of rear end of body outer panel

HrR: Lower height of rear end of body outer panel

ht weight difference

≤ 20 mm

≤ 20 mm

(left side)

(right side)

Thickness

(mm)

4.5

≤ 20 mm

Finish

Painting for

rust

prevention

i

Mitsubishi Fuso body/equipment mounting directives for Canter EURO V (FB/FE) Issue date: 27. Jan. 2010

! Only print out complete sections from the current version

28

Page 30

3 Planning of bodies

10.Dec. 2010

3.5 Tyres

The body manufacturer must ensure that:

• the largest permissible tyres can be fitted.

• the distance between the tyre and the mudguard or

wheel housing is sufficient even when snow or a

skid chains are fitted, with the suspension fully

compressed (including any twist) (Adherence to

valid regulations).

• that the relevant information in the drawings is

rved.

obse

If the option of fitting snow and anti-skid chains

cannot be guaranteed, the operator should be

informed by the body manufacturer (operating instructions).

nti-

3.5 Tyres

a Risk of accident

Exceeding the specified tyre load-bearing capacity

or the permissible maximum tyre speed can lead to

tyre damage or failure. You can lose control of the

vehicle, cause an accident and injuries.

For this reason, only fit tyres of a type and size

approved for your vehicle and observe the tyre loadbearing capacity required for your vehicle. Observe

tyre speed index.

Comply with national regulations governing the

approval of tyres. These regulations may define a

specific type of tyre for your vehicle or may forbid the

use of certain tyre types which are approved in other

countries.

!

If you have other wheels fitted

• the brakes or components of the suspension

system could be damaged

• wheel and tyre clearance can no longer be

guaranteed

• the brakes or components of the suspension

system can no longer function correctly.

Mitsubishi Fuso body/equipment mounting directives for Canter EURO V (FB/FE) Issue date: 27. Jan. 2010

i

! Only print out complete sections from the current version

29

Page 31

3 Planning of bodies

10.Dec. 2010

3.6 Bolted and welded connections

3.6 Bolted and welded connections

3.6.1 Nuts and Bolts for Use on Frame

a Risk of accident

Do not modify any bolted connections that are relevant to safety, e.g. that are required for wheel alignment, steering or braking functions.

When unfastening bolted connections make sure

that, when work is complete, the connection again

corresponds with the original condition.

Welding work on the chassis/body may only be

carried out by trained personnel.

The body, the attached or installed equipment and

any modifications must comply with the applicable

laws and ordinances as well as work safety or accident prevention regulations, safety rules and accident insurer leaflets.

Pay attention to the following when removing nuts and

bolts used on a standard vehicle.

•Tar

get Locations

Nuts and bolts used for tightening frame crossmembers and side members (including nuts and

bolts used

together)

How to distinguish nuts and bolts

Bo

ut (6T) .... Identification at diagonal corner

N

• Handling of nuts and bolts

(a) Bolts that have been removed cannot be used

again. Tighten again using new bolts having th

same strength.

(b) Nuts and bolts must be tightened to the

foll

M10: 60 to 80 Nm

M12: 9

for tightening the fuel tank and battery

lt (8T) .... Identifying letter "8"

owing torques:

8 to 120 Nm

e

i

Further information on bolted and welded connections can be found in Section 5 "Damage prevention" page 60 and Section 6 "Modifications to

the basic vehicle" page 73.

• In particular, cross-members must be tightened

when bolts used for tightening cross-members

together are removed for moving the fuel tank and

battery.

i

Mitsubishi Fuso body/equipment mounting directives for Canter EURO V (FB/FE) Issue date: 27. Jan. 2010

! Only print out complete sections from the current version

30

Page 32

3 Planning of bodies

10.Dec. 2010

3.6.2 Welded connections

Welding work on the chassis/body may only be

carried out by trained personnel.

!

Parts which must not be welded:

• Assemblies such as the engine, gearbox, axles,

etc.

• The chassis frame (except frame modifications).

i

3.6 Bolted and welded connections

Further information on bolted and welded connections can be found in Section 5 "Damage prevention" page 60 and Section 6"Modifications to the

basic vehicle" page 73.

i

Mitsubishi Fuso body/equipment mounting directives for Canter EURO V (FB/FE) Issue date: 27. Jan. 2010

! Only print out complete sections from the current version

31

Page 33

3 Planning of bodies

10.Dec. 2010

3.7 Soundproofing

If modifications are carried out on any parts whose

operation produces noise, e.g.

•engine

• exhaust system

• air intake system

•tyres

• Noise absorbing cover, etc.

sound level measurements must be made.

3.7 Soundproofing

prevent modifications from ch

To

sound levels, it must be ensured that interior sound

levels are reduced when planning bodies.

• Noise-insulating parts fitted as standard must not

be removed or modified.

• The level of interior no

cted.

affe

i

Comply with all national regulations and directives.

In Germany, the EC Directive 70/157/EEC or

Article 49.3 of the German licensing regulations

(low-noise vehicles) must be observed.

ise must not be adversely

anging the vehicle's

i

Mitsubishi Fuso body/equipment mounting directives for Canter EURO V (FB/FE) Issue date: 27. Jan. 2010

! Only print out complete sections from the current version

32

Page 34

3 Planning of bodies

10.Dec. 2010

3.8 Exhaust system

3.8 Exhaust system

The exhaust system must not be modified.

If modification is unavoidable, consult with the department in charge of the measures page 14.

!

The original exhaust system mounting, by this we

mean the bracket components including framemounted castings, may not be modified. Modifications can lead to damage to the exhaust system.

3.8.1 Clearance between exhaust system parts

and other parts

• The exhaust pipe and exhaust gas purification

devices (Blue Tec

they are too close to or interfere with other chassis

parts, a serious accident like fire or damage by

melting could occur. Malfunction is also a possible

consequence. Secure sufficient clearance in

accordance with the standards page 112. If this

is impracticable, provide a heat shield plate to

nsure safety.

e

• Do not install th

e joint or fuel filter drain hose.

hos

Wooden and rubb

100 mm apart from the diesel particulate filter

than

(

DPF) integrated muffler and exhaust pipe. If this is

impracticable, provide a heat shielding plate

against to ensure safety.

a Risk of accident and injury

The tail pipe of a DPF-equipped vehicle can become

considerably hotter than that of a conventional

vehicle during automatic regeneration. Provide

sufficient clearance between the tail pipe and other

parts.

®

system) become so hot that if

e tail pipe under the fuel pipe, fuel

er body parts should be more

3.8.2 Exhaust gas purification devices (Blue

• Exhaust gas purification devices (Blue Tec

system) may be damaged by heavy impact against

their body or fall. When mounting, handle them

with sufficient care.

• To prevent the exhaust gas purification devices

ue Tec

(Bl

adversely affected, do not relocate the exhaust gas

purification devices (Blue Tec

temperature senor, differential pressure sensor,

lambda sensor and NOx sensor.

If temporary removal of these parts becomes

ine

these

pressure sensor hose properly, not in reverse, too

loose nor too tense. Also, securely clip hose joints

and make sure of gas-tightness.

• Exhaust gas purification devices and sensors are

riodically removed for maintenance. Install them

pe

so that

carried out without any problems.

3.8.3 Regeneration controlling DPF system

• The regeneration controlling DPF system can

maintain its full PM (particulate matter) remov

capability thanks to an automatic computer control

it employs to actively regenerate the filter (or

remove the collected PM by oxidation) and thus

prevent an overfilled ceramic filter.

Accumulated PM in DPF might not be able to be

rem

conditio

Please deal it according to the following when the

PF indicator lamp is on.

D

• Unless Engine cont

flashing or Engine control warning lamp

(amber) is on when this lamp is illuminated,

ontinue driving at a constant speed on the

c

highway.

This will remove particulate matter and

reg

• If the lamp comes on again within 30 minu

riving after it turned off, have the vehicle

d

inspec

distributor or dealer.

®

system) and sensors

Tec

®

®

system) and engine proper from being

®

system), exhaust

vitable during mounting, be sure to reinstall

parts in the original places. Connect the

removal and reinstallation work can be

oved automatically depending on use

ns (e.g. long PTO operation).

rol warning lamp (red) is

enerates DPF.

tes of

ted by an authorised Mitsubishi Fuso

ing

i

Mitsubishi Fuso body/equipment mounting directives for Canter EURO V (FB/FE) Issue date: 27. Jan. 2010

! Only print out complete sections from the current version

33

Page 35

3 Planning of bodies

10.Dec. 2010

• If engine control warning lamp (red) is flashing

or Engine control warning lamp (amber) is on

when this lamp is illuminated, have the vehicle

spected by an authorised Mitsubi

in

distributor or dealer as soon as possible.

3.8.4 Blue Tec® exhaust gas aftertreatment

Blue Tec

the exhaust gas.

Do not modify and transfer the following parts

because the performance of the system is deteriorated.

®

exhaust gas aftertreatment removes NOx in

shi Fuso

3.8 Exhaust system

• SCR muffler

•AdBlue

• Dosing module

• AdBlue hose

®

tank unit

!

The function of Blue Tec® exhaust gas aftertreatment can not work when the fuse of system is

blowout.

®

Blue Tec

of electric power to work the heating device for

freeze proofing in winter or cold region.

Don't take out the power supply for other electric

components from the fuse of Blue Tec

aftertreatment.

exhaust gas aftertreatment requires a lot

®

exhaust gas

i

Mitsubishi Fuso body/equipment mounting directives for Canter EURO V (FB/FE) Issue date: 27. Jan. 2010

! Only print out complete sections from the current version

34

Page 36

3 Planning of bodies

10.Dec. 2010

3.9 Maintenance and repairs

a Risk of accident and injury

Always have maintenance work performed at a

qualified specialist workshop possessing the

required expertise and tools in order to perform the

necessary work.

Mitsubishi Fuso recommends a Mitsubishi Fuso

Service Centre for this work.

3.9 Maintenance and repairs

• The Instruction Manual must be complied with and

supplemented as necessary.

• Stowage boxes must be fi

ps or removable rear panels.

fla

• The battery c

ntilated, with provision for air to ente

ve

• Check the condition and capacity of batteries and

ice them in accordance with the

serv

manufact

ompartment must be sufficiently

urer's specifications page 36.

tted with maintenance

r and exit.

It is absolutely essential that all safety-relevant

work and all work on safety-relevant systems is

performed by a qualified specialist workshop.

Before performing any maintenance work, always

read the technical documentation, such as the

Instruction Manual and the workshop information.

Always have all maintenance work performed at the

correct time. If this is not done, malfunctions or

failures may occur in systems that could be relevant

to safety. This could make you cause an accident,

which could result in injury to yourself or others.

Maintenance and repair of the vehicle should not be

made unnecessarily difficult by the body.

Maintenance points and major assemblies must be

easily accessible.

Any additional expenses arising from the body in

connection with warranty, maintenance or repair will

not be bo

3.9.1 Maintenance instructions

The following must be observed by the body manufacturer before delivery of the vehicle

• Due date of inspection

• The load sensing valve (LSV) must be set.

• Check the condition and capacity of batteries and

• Check the headlamp setting or have this checked

• Retigh

• Instruction Manual and directives for maintenance

• Mitsubishi Fuso recommends adapting to each

rne by Mitsubishi Fuso Truck and Bus Corp..

:

rvice them in accordance with the

se

manufacturer's specifications.

t a qualified specialist workshop.

a

ten the wheel nuts to the specified torque.

ttachments, bodies, installations or

of a

conversion

manufacturer, must be provided with the vehicle in

the language of the country of use.

individual body the scope of maintenance work

which has to be carried out on the body, coordinating it by means of the valid Mitsubishi Fuso

service systems. This applies both to the scope and

type of service work, and for determining the

service due dates for servicing intervals based on

time elapsed and distance covered.

s, which have been installed by the body

i

Mitsubishi Fuso body/equipment mounting directives for Canter EURO V (FB/FE) Issue date: 27. Jan. 2010

! Only print out complete sections from the current version

35

Page 37

3 Planning of bodies

10.Dec. 2010

3.9.2 Preparation for storing the vehicle

3.9 Maintenance and repairs

Maint

enance work on stored vehicles (in storage

for > 1 month):

!

For vehicle deliveries in winter (gritted roads). To

prevent surface damage, please clean the vehicle at

the earliest opportunity. Particular attention should

be paid to the gearbox housing and light-alloy

wheels.

Storage in an enclosed space:

• Clean the overall vehicle.

• Check the oil and coolant levels.

• Inflate the tyres to 0.5 bar above the specified

tyre pressures.

• Release the handbrake and chock the wheels.

• Disconnect the battery an

terminal

Storing the vehicle in the open (< 1 month):

s.

d grease battery lugs and

• Check the oil level once a month.

• Check the coola

• Check the tyre pressures once a month.

• Remove the battery.

Removing the vehicle from storage:

• Check the fluid levels in the vehicle.

• Correct the tyre pressures to the manufacturer's

ecifications.

sp

• Check the battery charg

• Clean the overall vehicle.

3.9.3 Battery maintenance and storage

To avoid damage to the battery, disconnect the

battery if the vehicle is to be imm

of longer than 1 week.

If the vehicle is immobilised for periods of longer than

1 month, remove the battery and store it in a dry place

at temperatures of between 0 °C to 30 °C.

Store the battery in an upright position.

The battery charge must be kept above

12.55 V at all times.

nt once a month.

e and install the battery.

obilised for a period

• Carry out the same procedure as for storing in an

enclosed space.

• Close all air inlets and set the heat

"Off".

Storing the vehicle in the open (> 1 month):

• Carry out the same procedure as for storing in an

enclosed space.

• Fold the windscre

ndscreen.

wi

• Close all air inlets and set the

Off".

"

• Remove the battery and stor

he manufacturer's specifications.

t

en wipers away from the

ing system to

heating system to

e it in accordance with

!

If the battery voltage drops below 12.1 V, the

battery is damaged and it will have to be replaced.

Leaving the vehicle parked up for long periods of

time can lead to battery damage. This can be

avoided by disconnecting the battery and storing it

appropriately.

i

Mitsubishi Fuso body/equipment mounting directives for Canter EURO V (FB/FE) Issue date: 27. Jan. 2010

! Only print out complete sections from the current version

36

Page 38

3.9.4 Work before handing over the modified

10.Dec. 2010

vehicle

The manufacturer must confirm the work and modifications carried out by making an entr

Booklet.

Checking the overall vehicle

Check the vehicle for perfect condition. All damage

must be repaired.

y in the Service

3.9 Maintenance and repairs

If it is not known how long a

hydraulic clutch operating system has been in storage,

the brake fluid must be renewed.

Checking the batteries:

Test the battery charge before handing over the

vehicle.

Checking the tyres

Before handing over the veh

are inflated to the specified p

tyres for damage. Damaged tyres must be replaced.

Checking wheel alignment

When equipment, attachments and bodies have been

mounted, it is recommended to have the toe setting

checked b

Fuso recommends a Mitsubishi Fuso Service Centre

for this work.

It is absolutely essential that all safety-relevant work

and all work on safety-relevant systems is performed

by a qualified specialist workshop.

y a qualified specialist workshop. Mitsubishi

vehicle equipped with a

icle, check that the tyres

ressure and check the

i

i

Further details are available from any

Mitsubishi Fuso Service Centre.

Mitsubishi Fuso body/equipment mounting directives for Canter EURO V (FB/FE) Issue date: 27. Jan. 2010

! Only print out complete sections from the current version

37

Page 39

3.10 Special equipment

Bracket for the second compressor (option code :

GC/CG6) is developped specially for the compressor

model CR2211L (Supplier: MITSUBISHI HEAVY

INDUSTRIES,LTD), and can be used only for the model

CR2211L.

10.Dec. 2010

a Risk of accident and injury

The use of parts, assemblies or conversion parts

and accessories which have not been approved

may jeopardise the safety of the vehicle.

Before installing any attachments, special-purpose

bodies, equipment or carrying out any modifications to the basic vehicle and/or its assemblies,

you must read the relevant sections of the vehicle

Instruction Manual, as well as the operating and

assembly instructions issued by the manufacturer

of the accessories and items of optional equipment.

You could otherwise fail to recognise dangers,

which could result in injury to yourself or others.

3.10 Special equipment

Mitsubishi Fuso recommends using equipment

available as option codes to adapt the vehicle to the

body optimally.

All code-specific special equipment is available from

your Mitsubishi Fuso Service Centre or from body

manufactur

Optional equipment (e.g. , auxiliary tanks, anti-roll

bars, etc.) or retrofitted equipment increases the

unladen weight of the vehicle.

When chassis are fitted with different springs or tyre

sizes, the frame height can change considerably in

both the laden and unladen state.

The actual vehicle weight and axle loads must be

determined by weighing before mounting.

Not all optional equipment can be installed in any

vehicle without problems. This applies, in particular,

for retrofitted equipment because the installation

space may already be occupied by other components

or the special equipment may require other components.

er advisors page 14.

i

Mitsubishi Fuso body/equipment mounting directives for Canter EURO V (FB/FE) Issue date: 27. Jan. 2010

! Only print out complete sections from the current version

38

Page 40

4 Technical threshold values for planning

10.Dec. 2010

4.1 Vehicle overhang and technical wheelbases

4.1 Vehicle overhang and technical wheelbases

a Risk of accident

The body must be designed in such a way that a

placing of excessive load weight at the rear is

prevented. It is important to comply with the points

listed below, otherwise the necessary steering and

braking forces for safe vehicle operation cannot be

transferred to the road.

• When calculating the length of the vehicle

overhang, always take into account the permissible

axle loads and the minimum front axle load.

• Comply with the minimum front axle load

page 42.

• Take the weight of special equipment into consideration when making calculations.

Mitsubishi Fuso body/equipment mounting directives for Canter EURO V (FB/FE) Issue date: 27. Jan. 2010

! Only print out complete sections from the current versioni

39

Page 41

4 Technical threshold values for planning

10.Dec. 2010

4.1 Vehicle overhang and technical wheelbases

4.1.1 Maximum vehicle overhangs

Maximum vehicle overhang

65% of wheelbase (Van body)

50% of wheelbase (Except Van body)

Van body: Body that does not accept load jutting out

in the rear of vehicle

Example: Van body, lorry, etc

i

All national laws, directives and registration

requirements must be complied with.

.

Mitsubishi Fuso body/equipment mounting directives for Canter EURO V (FB/FE) Issue date: 27. Jan. 2010

! Only print out complete sections from the current versioni

40

Page 42

4 Technical threshold values for planning

10.Dec. 2010

4.2 Weight distribution, CoG height, anti-roll bars

4.2 Weight distribution, CoG height, anti-roll bars

4.2.3 Stabilisers roll control

a Risk of accident

The body must be designed in such a way that a

placing of excessive load weight at the rear is

prevented. It is important to comply with the points

listed below, otherwise the necessary steering and

braking forces for safe vehicle operation cannot be

transferred to the road.

4.2.1 Weight distribution

Make sure that the vehicle you are building is correctly

equipped. Mitsubishi Fuso provides stabilisers for

different model series. Stabilising equipment is

required if the vehicle is used for extremely high loads.

If this equipment is unsuitable due to operating conditions (such as a need for off-road capability), the

mounting frame must be designed in a manner that

stabilises the overall vehicle in consultation with the

department responsible page 14.

Avoid one-sided weight distribution.

The wheel load (1/2 the axle load

by no more than 4%. Observe the tyre load capacity.

Example:

• Permissible axle load 5,000 kg

• Permissible wheel load distribution 2,600 kg to

2,400 kg

4.2.2 CoG height

For approval of the vehicle with body/implements

mounted, a calculation of the height o

gravity of the laden vehicle must be submitted in

accordance with EC Brakes Directive 71/320/EEC.

The calculation basis for permissible heights of centre

of gravity can be requested from the responsible

department page 14.

Mitsubishi Fuso cannot vouch for the handling,

braking and steering characteristics of vehicles with

attachments, installations or modifications for

payloads with unfavourable centres of gravity

(e.g. rear-mounted. overheight and side-mounted

loads). The vehicle body/equipment manufacturer/

converter is responsible for the safety of the vehicle in

the case of these bodies.

) may be exceeded

f the centre of

Mitsubishi Fuso body/equipment mounting directives for Canter EURO V (FB/FE) Issue date: 27. Jan. 2010

! Only print out complete sections from the current versioni

41

Page 43

4 Technical threshold values for planning

10.Dec. 2010

4.3 Steerability

a Risk of accident

The body must be designed in such a way that a

placing of excessive load weight at the rear is

prevented. The following points must be complied

with otherwise the steering and braking forces

necessary for safe driving cannot be transmitted.

To ensure sufficient vehicle steerability, the minimum

front axle load (25% of gross vehicle weight) must be

maintained under all load conditions. Consult the

department responsible in the event of any deviations

page 14.

4.3 Steerability

!

The permissible front axle load must not be

exceeded.

Observe the notes on product liability page 17.

Mitsubishi Fuso body/equipment mounting directives for Canter EURO V (FB/FE) Issue date: 27. Jan. 2010

! Only print out complete sections from the current versioni

42

Page 44

4 Technical threshold values for planning

10.Dec. 2010

4.4 Clearance for assemblies and cab

4.4 Clearance for assemblies and cab

Certain clearances must be maintained in order to

ensure the function and operational safety of assemblies.

Dimensional data in the tender drawings must be

observed.

i

Read and comply with the relevant sections of the

Instruction Manual.

4.4.1 Attachment above cab

• Observe the permissible centre of gravity location

nd the front axle load.

a

• Make sure that there is sufficient

page 241.

space for tilting.

Cab tilting range clearance

Mitsubishi Fuso body/equipment mounting directives for Canter EURO V (FB/FE) Issue date: 27. Jan. 2010

! Only print out complete sections from the current versioni

43

Page 45

4 Technical threshold values for planning

10.Dec. 2010

4.4 Clearance for assemblies and cab

4.4.2 Cab

• The distance between the cab and the body must

be keeped per layout drawings.

i

You can obtain tender drawings and technical data.

page 241.

Mitsubishi Fuso body/equipment mounting directives for Canter EURO V (FB/FE) Issue date: 27. Jan. 2010

! Only print out complete sections from the current versioni

44

Page 46

4 Technical threshold values for planning

10.Dec. 2010

4.5 Wind deflectors

4.5 Wind deflectors

4.5.1 Attaching the roof rack or drag foiler

Roof

• When attaching externally mounted parts such as

roof rack or drag foiler onto the roof, use the

exclusive mounting holes prov

ided on the roof.

• Prevent the weight of externally mounted parts

ttached to the roof from exce

a

eding 50 kg. (See

Figs. 1, 2 and 4.)

Cautions

• Use nickel-chrome plated stainless steel bolts and

washers.

• Take special care

coming scratched when attaching

be

to prevent the body from

externally

mounted parts.

• Insert packing between externally mounted parts

nd the body to prevent rusting. Use packing m

a

of EPDM rubber to prevent ozone cracking.

• After attaching externally mounted parts, coat the

tire periphery of the mounting bolts with sealer

en

• The top coat of paint must be applied to externally

unted parts before attaching to the roof. (See

mo

Fi

g. 3.)

7

ade

.

6

5

1

3

1

4

Fig. 1

2

3

2

1Section A-A

2Section B-B

380

4 Detail C

Mitsubishi Fuso body/equipment mounting directives for Canter EURO V (FB/FE) Issue date: 27. Jan. 2010

51408 (Standard cab)

1664 (Wide cab)

6 1436 (Standard cab)

1694 (Wide cab)

7500

! Only print out complete sections from the current versioni

45

Page 47

4 Technical threshold values for planning

10.Dec. 2010

4.5 Wind deflectors

2

1

(Shipped State)

DETAIL C (1)

A-A

3

7

4

6

8

5

B-B

(Shipped State)

DETAIL C (2)

114.5° (Standard cab)

16.5° (Wide cab)

232.5 (Standard cab)

31.0 (Wide cab)

3roof top

41408 (Standard cab)

1664 (Wide cab)

<Standard cab>

<Wide cab>

Fig. 2

512.0° (Standard cab)

14.5° (Wide cab)

621.5 (Standard cab)

34.5 (Wide cab)

7 roof top

8 1436 (Standard cab)

1694 (Wide cab)

Mitsubishi Fuso body/equipment mounting directives for Canter EURO V (FB/FE) Issue date: 27. Jan. 2010

! Only print out complete sections from the current versioni

46

Page 48

1 Use washer and bolt with plain washer

10.Dec. 2010

2 Coat periphery with sealer

3 Roof deck or drag foiler

4Rubber packing

4.5 Wind deflectors

1 Bolt and washer: Left/right total 8 places

(For roof deck or drag foiler)

Mitsubishi Fuso body/equipment mounting directives for Canter EURO V (FB/FE) Issue date: 27. Jan. 2010

! Only print out complete sections from the current versioni

47

Page 49

4.6 Governor and transmission power-take-off

10.Dec. 2010

4.6 Governor and transmission power-take-off

4.6.1 Governor

The electronically controlled governor (electronic governor) automatically switches to serve as special

ment governor at the time of PTO activation. Also, the cab back engine control (sensor-based) is provided for

use as engine control during PTO activation.

Engine

model

4P10 Electronically

Note. -

- *2 The accelerator pedal is inoperative as long as PTO is activated.

Governor

type

controlled

*1

The cab back engine control is not equipped in dump trucks.

Governor

& torque

Normal

engine

governor

Special

equipment

governor

Engine

control

– – Standard

Sensor-

based

Operation Applicable vehicle*

PTO-ON Specially

vehicle