Page 1

MELSEC L-Series

Programmable Logic Controllers

User's Manual

Art. no.: 286236

11 05 2015

Version A

CANopen쏐 Module

ME3CAN1-L

INDUSTRIAL AUTOMATION

Version check

Page 2

Page 3

About this Manual

The texts, illustrations, diagrams and examples in this manual are provided for

information purposes only. They are intended as aids to help explain the

installation, operation, programming and use of the programmable controllers

of the Mitsubishi MELSEC-L series.

If you have any questions about the installation and operation of any of the

products described in this manual please contact your local sales office or

distributor (see back cover).

You can find the latest information and answers to frequently asked

questions on our website at

https://eu3a.mitsubishielec

tric.com.

MITSUBISHI ELECTRIC EUROPE BV reserves the right to make changes to this

manual or the technical specifications of its products at any time without notice.

© 2014

MITSUBISHI ELECTRIC EUROPE B.V.

Page 4

Page 5

Version Changes / Additions / Corrections

A 05/2015 pdp-dk First edition

CANopen쏐 Module

ME3CAN1-L

User's Manual

Art.-no.: 286236

Page 6

Page 7

Safety Guidelines

For use by qualified staff only

This manual is only intended for use by properly trained and qualified electrical technicians who are

fully acquainted with the relevant automation technology safety standards. All work with the hardware descr

ing of the equipment, may only be performed by trained electrical technicians with approved qualifications who are fully acquainted with all the applicable automation technology safety standards

and regulations. Any operations or modifications to the hardware and/or software of our products

specifically described in this manual may only be performed by authorised Mitsubishi Electric staff.

Proper use of the products

The programmable logic controllers of the MELSEC-L series are only intended for the specific applications explicitly described in this manual. All parameters and settings specified in this manual must

be obser

in strict compliance with the relevant safety standards. Unqualified modification of the hardware or

software or failure to observe the warnings on the products and in this manual may result in serious

personal injury and/or damage to property. Only peripherals and expansion equipment specifically

recommended and approved by Mitsubishi Electric may be used with the programmable logic controllers of the MELSEC-L series.

All and any other uses or application of the products shall be deemed to be improper.

Relevant safety regulations

ibed, including system design, installation, configuration, maintenance, service and test-

ved. The produc

ts described have all been designed, manufactured, tested and documented

not

m

b

All safety and accident prevention regulations relevant to your specific application must be obser

in the system design, installation, configuration, maintenance, servicing and testing of these products. The installation should be carried out in accordance to applicable local and national standards.

Safety warnings in this manual

In this manual warnings that are relevant for safety are identified as follows:

DANGER:

Failure to observe the safety warnings identified with this symbol ca

hazards for the user.

WARNING:

Failure to observe the safety warnings identified with this symbol can result in damage to the

equipment or other property.

n result in health and injury

ed

v

MELSEC-L Series – CANopen Module ME3CAN1-L I

Page 8

m

General safety information and precautions

The following safety precautions are intended as a general guideline for using PLC systems together

with other equipment. These precautions must always be observed in the design, installation and

operation of all control systems.

DANGER:

● Observe all safety and accident prevention regulations applicable to your specific application. Always disconnect all power supplies before performing installation and wiring work

or opening any of the assemblies, components and devices.

● Assemblies, components and devices must always be installed in a shockproof housing fitted

with a proper cover and fuses or circuit breakers.

● Devices with a permanent connection to the mains power supply must be integrated in the

building installations with an all-pole disconnection switch and a suitable fuse.

● Check power cables and lines connected to the equipment regularly for breaks and insulation

damage. If cable damage is found immediately disconnect the equipment and the cables

from the power supply and replace the defective cabling.

● Before using the equipment for the first time check that the power supply rating matches that

of the local mains power.

● Take appropriate steps to ensure that cable damage or core breaks in the signal lines cannot

cause undefined states in the equipment.

●

You are responsible for taking the necessary precautions to ensure that programs interrupted

by brownouts and power failures can be restarted properly and safely. In particular, you must

ensure that dangerous conditions cannot occur under any circumstances, even for brief

periods.

● EMERGENCY OFF facilities conforming to EN 60204/IEC 204 and VDE 0113 must remain fully

operative at all times and in all PLC operating modes. The EMERGENCY OFF facility reset

function must be designed so that it cannot ever cause an uncontrolled or undefined restart.

● You must implement both hardware and software safety precautions to prevent the possibility of undefined control system states caused by signal line cable or core breaks.

● When using modules always ensure that all electrical and mechanical specifications and

requirements are observed exactly.

II

Page 9

Symbols used in the Manual

Use of notes

Notes concerning important information are marked separately and are displayed as follows:

NOTE Note text

Use of examples

Examples are marked separately and are displayed as follows:

Example Example text

The end of an example is marked with the following symbol:

se of numbering in the figures

U

Numbering within the figures is displayed by white numbers within black cir

a table following it using the same number, e.g.:

Use of handling instructions

Handling instructions are steps that must be carried out in their exact sequence during startup, operation, maintenance and similar operations.

They are numbered consecutively (black numbers in white circles):

Text.

Text.

Text.

Use of footnotes in tables

Instructions in tables are explained in footnotes underneath the tables (in superscript). There is a footnote character at the appropriate position in the table (in superscript).

If there are several footnotes for one table then these are numbered consecutively underneath the

table (black numbers in white circle, in superscript):

Text

Text

Text

cles and is explained in

Writing conventions and guidance notes

Keys or key-combinations are indicated in square brackets, such as [Enter], [Shift] or [Ctrl]. Menu

names of the menu bar, of the drop-down menus, options of a dialogue screen and buttons are indicated in italic bold letters, such as the drop down menu New in the Project menu or the option Serial

USB in the "Transfer Setup Connection" screen.

Registration

● CiA and CANopen are registered Community Trademarks of CAN in Automation e.V.

● The company name and the product name to be

trademarks or trademarks of each company.

MELSEC-L Series – CANopen Module ME3CAN1-L III

described in this manual are the registered

Page 10

IV

Page 11

Contents

Contents

1 Overview

1.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.2 Features of the ME3CAN1-L . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.3 Abbreviations and Generic Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

2 System Configuration

2.1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2.2 Applicable Systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2.3 How to Check the Function Version and Serial No. of the Modules . . . . . . . . . . . . . . . . . . . . .2-2

2.4 System Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

3 Detailed Description of the Module

3.1 Part Names. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.1.1 Indicator LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

3.1.2 Signal Layout of the Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

3.2 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

3.2.1 External Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

3.3 I/O Signals for the Programmable Controller CPU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

3.3.1 List of I/O signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

3.3.2 Details of I/O signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

3.4 Buffer Memory Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

3.4.1 Buffer Memory Assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

3.5 Buffer Memory Details: CANopen

Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

3.5.1 Data Exchange Control (Un\G20) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

3.5.2 Function Mode (Un\G21). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

3.5.3 Save/Restore Configuration (Un\G22) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

3.5.4 Baud Rate (Un\G24). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

3.5.5 Communication Status (Un\G25) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

3.5.6 Node Address (Un\G27). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

3.5.7 Error state (Un\G29) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

3.5.8 CAN transmission error counter (Un\G35) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

MELSEC-L Series – CANopen Module ME3CAN1-L V

Page 12

Contents

3.5.9 CAN reception error counter (Un\G36). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

3.5.10 Buffer memory setting error display (Un\G39, Un\G40). . . . . . . . . . . . . . . . . . . . . . 3-19

3.5.11 Time stamp (Un\G50–Un\G59) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

3.5.12 NMT Start all Nodes delay (Un\G70) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

3.5.13 SDO Time out (Un\G71) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

3.5.14 NMT Error Clear Node (Un\G400) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

3.5.15 NMT Error Control Status (Un\G401–Un\G527). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

3.5.16 NMT State (Un\G601–Un\G727) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

3.5.17 Emergency Message Buffer (Un\G750–Un\G859) . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

3.5.18 Command Interface (Un\G1000–Un\G1066) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

3.5.19 RPDO (Un\G10000–Un\G11023), TPDO (Un\G13000–Un\G14023) . . . . . . . . . . . 3-26

3.6 Buffer Memory Details: Layer 2 Message Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-32

3.6.1 Message Slot specific error code list (Un\G5001–Un\G5042). . . . . . . . . . . . . . . . . 3-32

3.6.2 Pre-defined Layer 2 message configuration (Un\G6000–Un\G6167) . . . . . . . . . 3-33

3.6.2.1 Pre-defined Layer 2 transmit messages 34

3.6.2.2 Pre-defined Layer 2 receive messages 36

3.6.3 Layer 2 RTR flags (Un\G8350–Un\G8352) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-38

3.6.4 Message transmit trigger flags (Un\G8400–Un\G8402) . . . . . . . . . . . . . . . . . . . . . . 3-39

3.6.5 PLC RUN>STOP messages (Un\G8450–Un\G8477) . . . . . . . . . . . . . . . . . . . . . . . . . . 3-40

3.6.6 Receive/Transmit Process Data (Un\G10000–Un\G10293) . . . . . . . . . . . . . . . . . . . 3-41

3.6.7 CIF (command interface): Sending Layer 2 Message. . . . . . . . . . . . . . . . . . . . . . . . . 3-43

4Functions

4.1 Function Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 Function Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

4.3 Object Dictionary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.4 Command Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

4.5 Data Type Definition Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

4.6 Communication Profile Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

4.6.1 CAN-ID / COB-ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

4.6.2 Error Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

4.6.3 Pre-defined error field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

4.6.4 SDO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

4.6.5 RPDO / TPDO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

4.6.6 SYNC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-26

4.6.7 Node guarding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

MELSEC-L Series – CANopen Module ME3CAN1-L VI

Page 13

Contents

4.6.8 Heartbeat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-29

4.6.9 TIME . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

4.6.10 Store parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-31

4.6.11 Restore default parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-31

4.6.12 EMCY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-32

4.7 Error Behavior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-34

4.8 Network Management. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-35

4.8.1 CANopen

4.8.2 Boot-Up protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-36

4.8.3 NMT protocol (node control) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-37

4.8.4 NMT slave identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-37

4.8.5 NMT master start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-38

4.8.6 NMT slave start-up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-42

4.8.7 NMT boot-up / Error event handling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-46

boot-up procedure and NMT states. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-35

4.8.8 Request NMT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-47

4.8.9 Request node guarding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-48

4.8.10 Flying master. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-48

4.8.11 Layer Setting Services (LSS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-52

4.8.12 Configuration manager . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-53

4.9 Device Profile CiA

5 Command Interface

5.1 SDO Request . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

5.1.1 CIF SDO read access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.1.2 CIF Multi SDO read access. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

5.1.3 CIF SDO write access. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

5.1.4 CIF Multi SDO write access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

5.2 Send an Emergency Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

5.3 Display Current Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

-405 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-55

5.4 Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-9

5.4.1 Unknown command used. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-9

5.4.2 Command or parameter change while CIF was busy . . . . . . . . . . . . . . . . . . . . . . . . . .5-9

5.4.3 Clear/Reset the "CIF was busy" error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-9

5.4.4 SDO Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

5.4.5 Bus OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

5.4.6 Device in wrong state. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

MELSEC-L Series – CANopen Module ME3CAN1-L VII

Page 14

Contents

6 Setup and Procedures before Operation

6.1 Implementation and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

6.1.1 Handling Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.2 Procedures before Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6.3 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

6.3.1 Wiring Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

6.3.2 CAN bus wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-4

6.4 Start-up Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

6.4.1 CANopen

6.4.2 11 bit/29 bit CAN-ID Layer 2 Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-6

7 Programming

405 mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-6

7.1 CANopen PDO Communication using Function Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.1.1 System configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

7.1.2 Local Label setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

7.1.3 Program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-5

7.2 Layer 2 Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-21

7.2.1 Layer 2 communication using function blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-21

7.2.2 Layer 2 communication without function blocks. . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-30

8Troubleshooting

8.1 Error Processing and Recovery Method. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8.1.1 Preliminary check by LED status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8.1.2 Detailed error check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-2

8.2 Error Code and Error Message Summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-4

8.2.1 EMCY Emergency error codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-4

8.2.2 EMCY Manufacturer specific error codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-5

VIII

8.2.3 SDO Access abort codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-5

Index

Page 15

Introduction Overview

1 Overview

This User's Manual describes the specifications, handling and programming methods for the

CANopen Module ME3CAN1-L (hereinafter referred to as the ME3CAN1-L) which is used with the

programmable controllers of the MELSEC-L series.

Before using the ME3CAN1-L, please read this manual and the relevant manuals carefully and develop

familiarity with the functions and performance of the MELSEC-L series programmable controller to

handle the product correctly.

1.1 Introduction

The ME3CAN1-L is a network module of the MELSEC-L series. It is used to connect a MELSEC-L series

PLC system to CANopen and CAN Layer 2 networks. CAN (Controller Area Network) is a serial bus sys-

tem especially for networking devices as well as sensors and actuators.

1.2 Features of the ME3CAN1-L

D-sub connector for connection to CAN

The connection to the CANopen network is made via a D-sub 9-pin connec

CiA-303-1 V1.8.

Various bit rates

● Pre-defined (according to CANopen standard):

10 k

bps, 20 kbps, 50 kbps, 100 kbps, 125 kb

CANopen services according to CiA-301 V4.2

● 256 TPDO (1024 word write)

The Process Data Objec

(the consumers) which subscribed to it. The Transmit PDO (TPDO) is used to send input data of

the node.

● 256 RPDO (1024 word read)

The Receive PDO (RPDO) is used to receive output data.

● SDO ser

The Ser

can be used to set network parameters and also to initiate CANopen functionality.

● SYNC serv

vice

vice Data Object can be used to read/write data to the Object

ice

t (PDO) is sent by a node (the producer) and will be received by other nodes

ps, 250 kbps, 500 kbps, 800 kbps, 1 Mbps

tor according to

Dictionary. This command

The SYNC service provides the basic network synchronization mechanism.

● TIME ser

The TIME ser

may use the TIME object to adjust their own time

● EMCY object

Emergency objects are triggered by the occurrence of a CANopen device internal error situation

and are transmitted from an emergency producer on the CANopen device.

MELSEC-L Series – CANopen Module ME3CAN1-L 1 – 1

vice

vice provides a simple network clock. CANopen devices that operate a local clock

base to that of the time stamp object producer.

service

Page 16

Overview Features of the ME3CAN1-L

C

● Network management (NMT)

– General NMT services

– Boot-up Message

– Node guarding Master/Slave

– Heartbeat Consumer/Producer

CANopen services according to CiA-302 V4.1

T master

● NM

The network management provides services for controlling the network behavior of CANopen

devices as defined in CiA

NMT slaves are controlled by ser

● Flying master

-301 and CiA-302. All CANopen devices of a network referred to as

vices provided by an NMT master.

The flying master mechanism provides services for a hot stand-by NMT master within a C

network.

● Configuration manager

The Configur

pen network.

CANo

● SYNC producer

The SYNC producer broadcasts the SYNC object. The SYNC serv

synchronization mechanism.

Layer Setting Services master (LSS) according to the Standard CiA-305 V2.2

It is necessary to set the baud rate and node number of the C

devices, e.g. devices with high IP protection like rotary encoders, waterproof sensor, etc. don't have

DIP-switches for these setting. Such devices must be configured by CAN using this LSS.

CANopen device profiles according to CiA-405 V2.0

Interface and Device Profile CiA-405 V2.0 for IEC 61131-3 Progr

cation with other Device Profiles (e.g. encoder CiA-406, motion/ drives CiA-402, etc.).

Setting back up in non-volatile memory

The following setting values will be backed up in the Flash-ROM:

– Setting values stored in the buffer memory;

ation manager provides mechanisms for configuration of CANopen devices in a

ice provides the basic network

ANopen devices. But some CANopen

mmable Devices allows communi-

a

ANopen

1 – 2

– Module configuration stored in the Object Dictionary;

– Setting values of Concise Device Setting File (CDCF).

CAN layer 2 communication

Besides the CANopen mode, the ME3CAN1-L can be swit

and be set up so that it can be used for the customer's own CAN based communication protocol.

ched to CAN layer 2 communication mode,

MITSUBISHI ELECTRI

Page 17

Abbreviations and Generic Terms Overview

1.3 Abbreviations and Generic Terms

Unless otherwise specified, this manual uses the following generic terms and abbreviations to

describe the CANopen Module ME3CAN1-L.

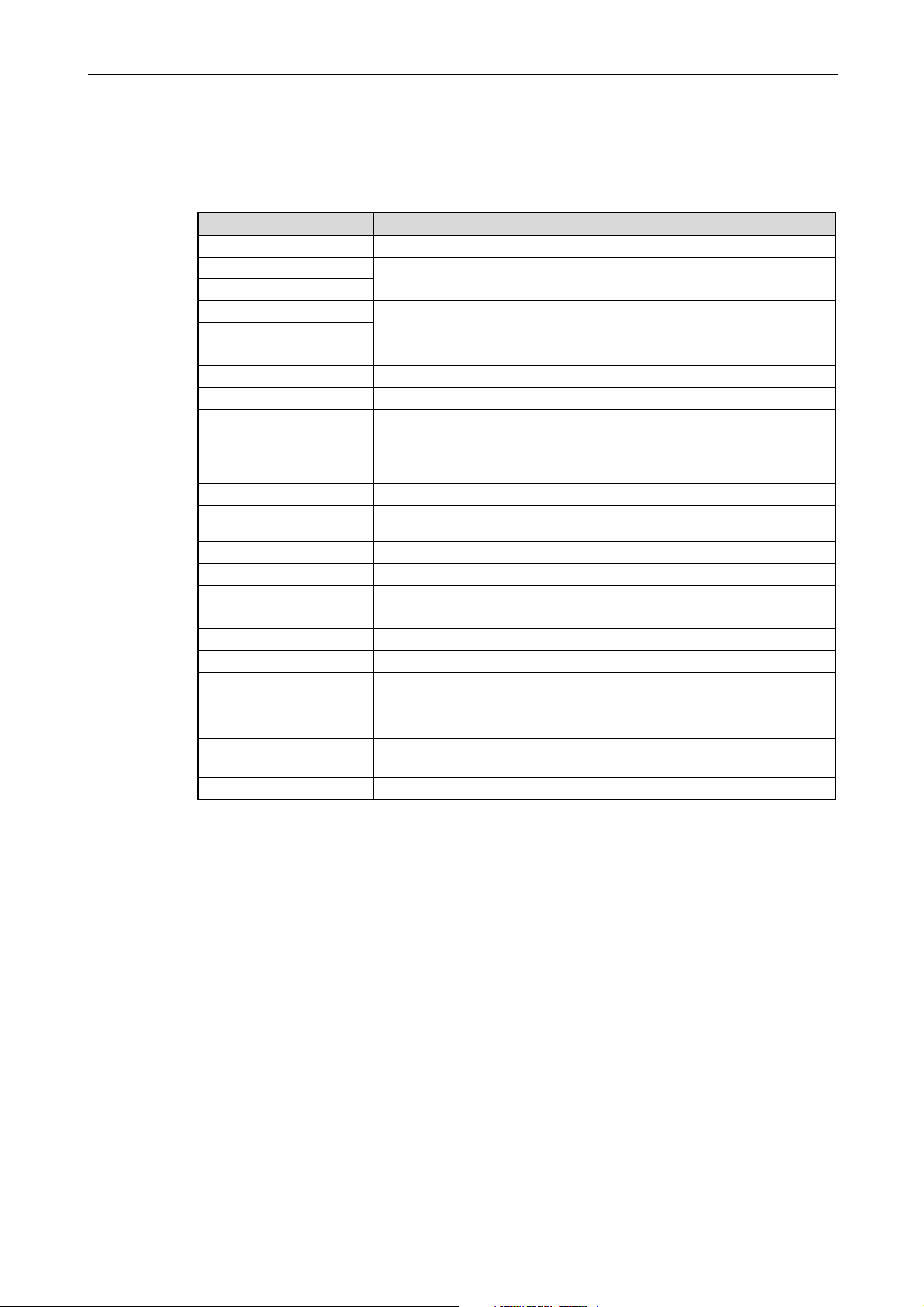

General term / Abbreviation Description

ME3CAN1-L Abbreviation for the CANopen Module ME3CAN1-L.

MELSEC-L CPU

LCPU

PLC CPU

CPU module

GX Works2 Generic product name for the programming and configuration software GX Works2.

CAN Controller Area Network

CANopen CAN based higher-layer protocol

CiA

RPDO Receive Process Data Objects are data read from other nodes via the CAN bus.

TPDO Transmit Process Data Objects are data send to other nodes via the CAN bus.

CIF

SDO Service Data Object

SYNC Synchronization object

EMCY Emergency object

NMT Network management

LSS Layer Setting Services

RTR Remote transmission request

OD

COB-ID

CDCF Concise Device Setting File

Generic term for L series CPU modules, e.g. L02CPU, L02CPU-P, L26CPU-BT and

L26CPU-PBT, etc.

Generic term for programmable controller.

CAN in Automation

Non-profit organization for standardization of CAN protocols. The CiA Members

develop specifications which are published as CiA specifications. (http://can-cia.org/)

Command interface; used to access the Object Dictionary of the local node or a network

node.

Object dictionary

The object dictionary is an array of variables with a 16-bit index. Additionally, each varia-

ble can have an 8-bit subindex. The variables can be used to configure the device and

reflect its environment, i.e. contain measurement data.

Communication object identifier

Identifier that contains the CAN-ID and additional control bits.

Tab. 1-1: Abbreviations and general terms

MELSEC-L Series – CANopen Module ME3CAN1-L 1 – 3

Page 18

Abbreviations and Generic Terms Overview

MELSEC-L Series – CANopen Module ME3CAN1-L 1 – 4

Page 19

Overview System Configuration

Terminating

resistor

Terminating

resistor

CANopen Node

CANopen

Node

CANopen Node

(ME3CAN1-L)

CANopen Node

(ME3CAN1-L)

CAN bus network

Terminating

resistor

Terminating

resistor

CANopen Node

CANopen Node

CANopen Node

(ME3CAN1-L)

CC-Link IE Field Master/Local Module

(QJ71GF11-T2)

CC-Link IE Field

CANopen Module (ME3CAN1-L)

CC-Link IE Field Head module (LJ72GF15-T2)

CAN bus network

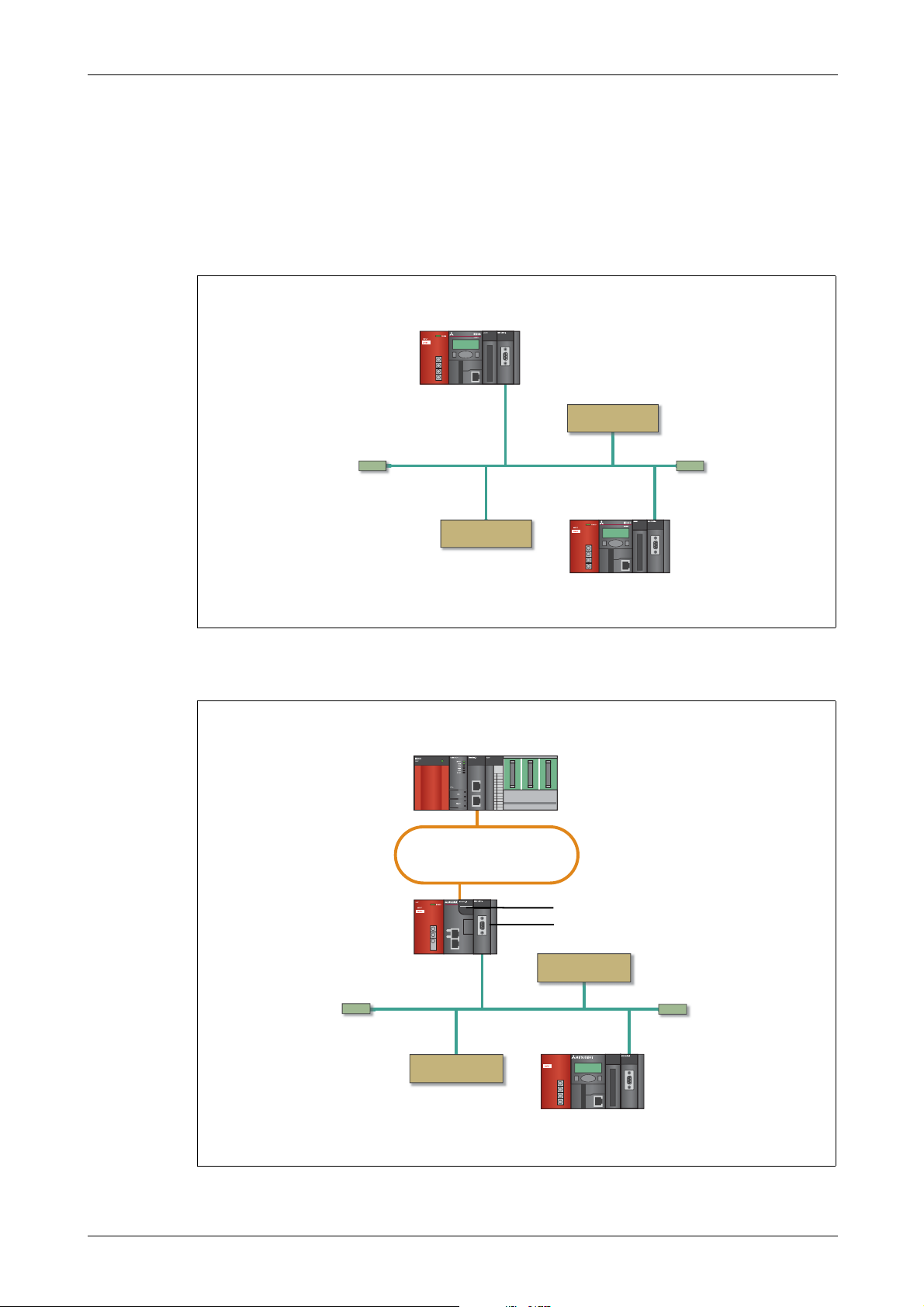

2 System Configuration

2.1 Overview

The ME3CAN1-L can be connected to a CPU module, an extension module or a CC-Link IE Field network head module of the MELSEC-L series.

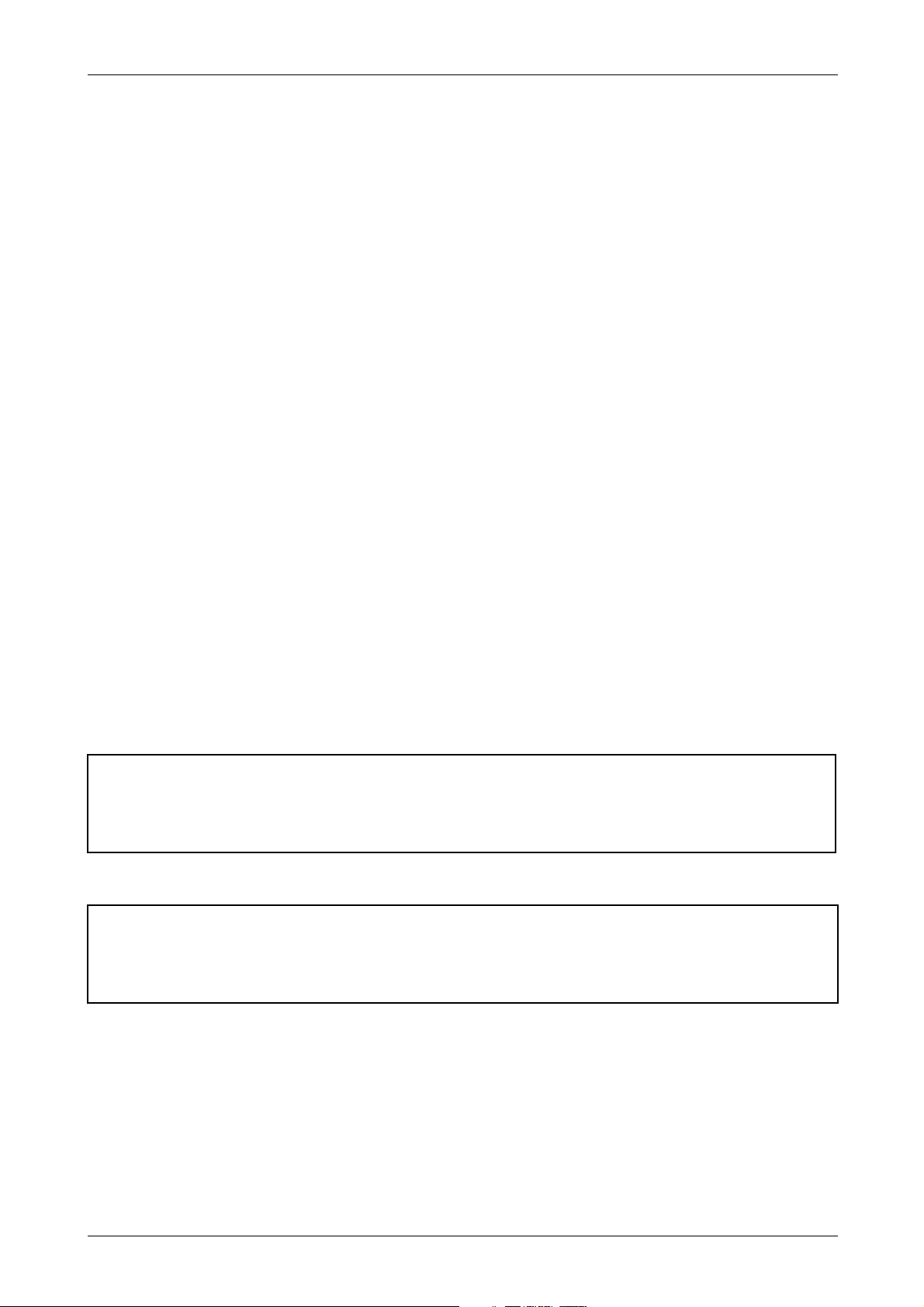

Fig. 2-1:

L63P

MITSUBISHI

MITSUBISHI

L63P

ME3CAN1-L connected to a LCPU directly

MITSUBISHI

MELSEC-L Series – CANopen Module ME3CAN1-L 2 – 1

Fig. 2-2:

L02CPU

L02CPU

L02CPU

L02CPU

L02CPU

L02CPU

L02CPU

L02CPU

L02CPU

L02CPU

L02CPU

L02CPU

L02CPU

L02CPU

L02CPU

L02CPU

L63P

L63P

L63P

L63P

L63P

L63P

L63P

L63P

L63P

L63P

L63P

L63P

L63P

L63P

L63P

L63P

L63P

INPUT

INPUT

INPUT

INPUT

INPUT

INPUT

INPUT

INPUT

INPUT

INPUT

INPUT

INPUT

INPUT

INPUT

INPUT

INPUT

INPUT

24VDC

24VDC

24VDC

24VDC

24VDC

24VDC

24VDC

24VDC

24VDC

24VDC

24VDC

24VDC

24VDC

24VDC

24VDC

24VDC

24VDC

L02CPU

MITSUBISHI

MITSUBISHI

MITSUBISHI

MITSUBISHI

MITSUBISHI

MITSUBISHI

MITSUBISHI

MITSUBISHI

MITSUBISHI

MITSUBISHI

MITSUBISHI

MITSUBISHI

MITSUBISHI

MITSUBISHI

MITSUBISHI

MITSUBISHI

MITSUBISHI

POWER

POWER

POWER

POWER

POWER

POWER

POWER

POWER

POWER

POWER

POWER

POWER

POWER

POWER

POWER

POWER

POWER

L6DSPU

L6DSPU

L6DSPU

L6DSPU

L6DSPU

L6DSPU

L6DSPU

L6DSPU

L6DSPU

L6DSPU

L6DSPU

L6DSPU

L6DSPU

L6DSPU

L6DSPU

L6DSPU

L6DSPU

ME3CAN1-L connected to a CC-Link IE Field head module

Page 20

System Configuration Applicable Systems

C

Serial number

(first 5 digits)

Function

version

Model name

2.2 Applicable Systems

For the number of connectable modules and the compatible software version, refer to the following.

● MELSEC-L CPU Module User's M

● MELSEC-L CC

Restrictions when the ME3CAN1-L is connected to a head module

No special restriction is applied for the ME3CAN1-L.

-Link IE Field Network Head Module User's Manual

anual (Hardware Design, Maintenance and Inspection)

2.3 How to Check the Function Version and Serial No. of the Modules

The serial No. and function version can be checked on the label attached to the right side of the

module.

Using the programming software GX Works2, the serial No. and the function version can be checked

while the PLC is operating.

From the Diagnostics menu select System Monitor and then select Product Information List.

2 – 2

Fig. 2-3:

Product Information List for a PLC with a ME3CAN1-L

MITSUBISHI ELECTRI

Page 21

System Equipment System Configuration

Terminating

resistor

Terminating

resistor

CANopen Node

CANopen Node

MELSEC-L series PLC

with ME3CAN1-L

Configuration by FBs

in GX Works2

Repeater

USB cable

CAN bus network

Import

EDS file

Terminating

resistor

Terminating

resistor

CAN bus network

MELSEC-L series PLC

with ME3CAN1-L

3rd party

configuration tool

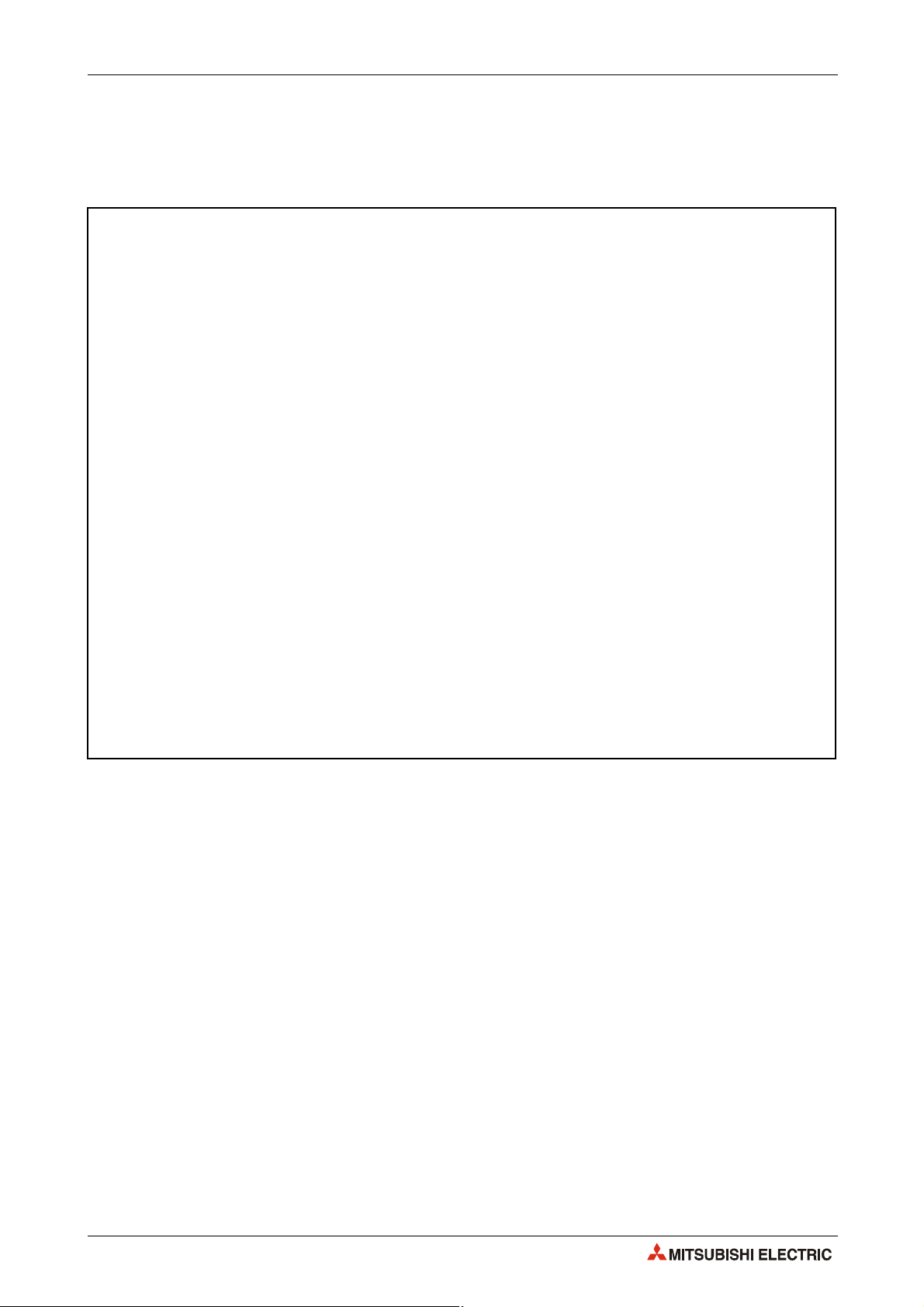

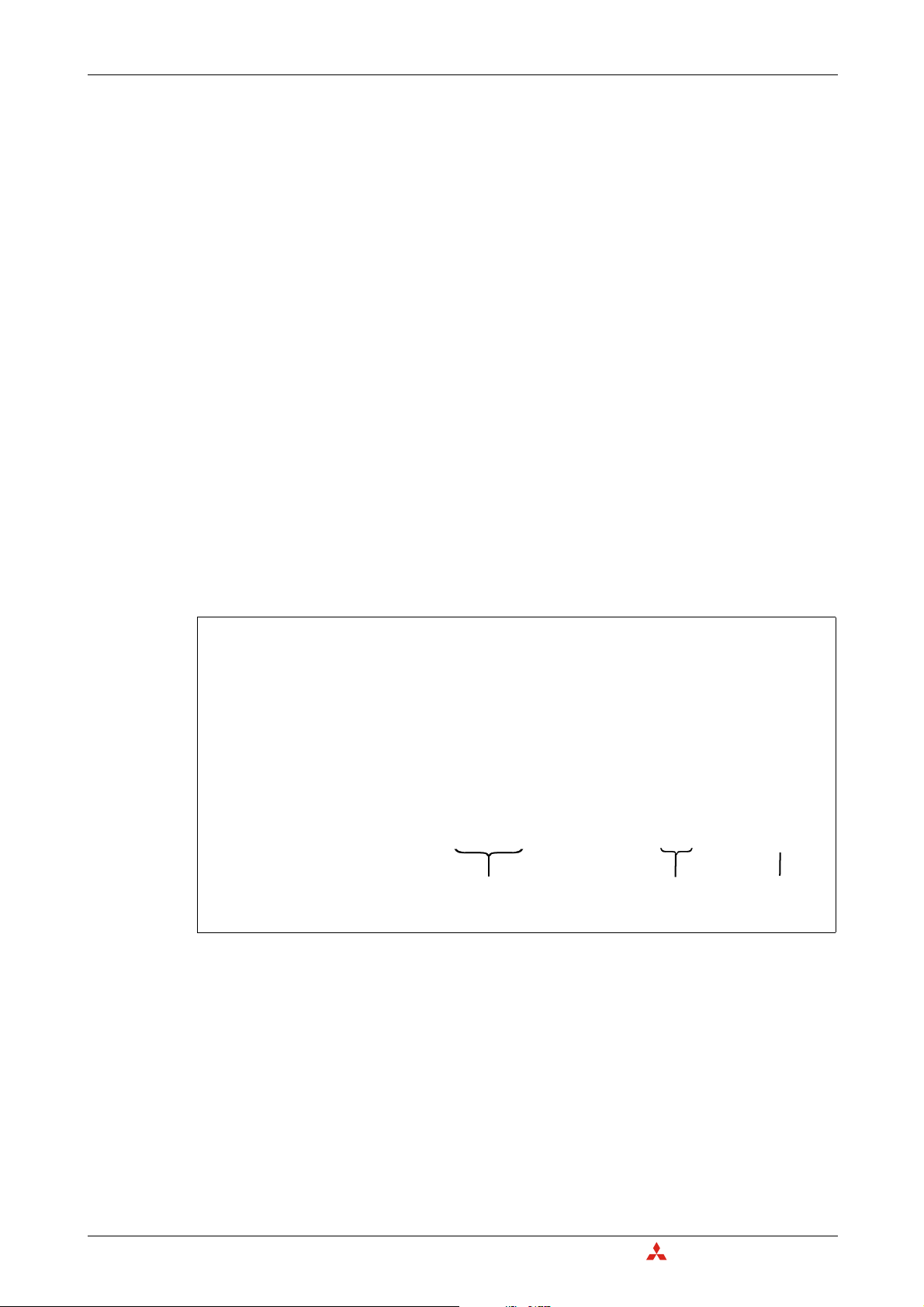

2.4 System Equipment

ME2PNR2-L

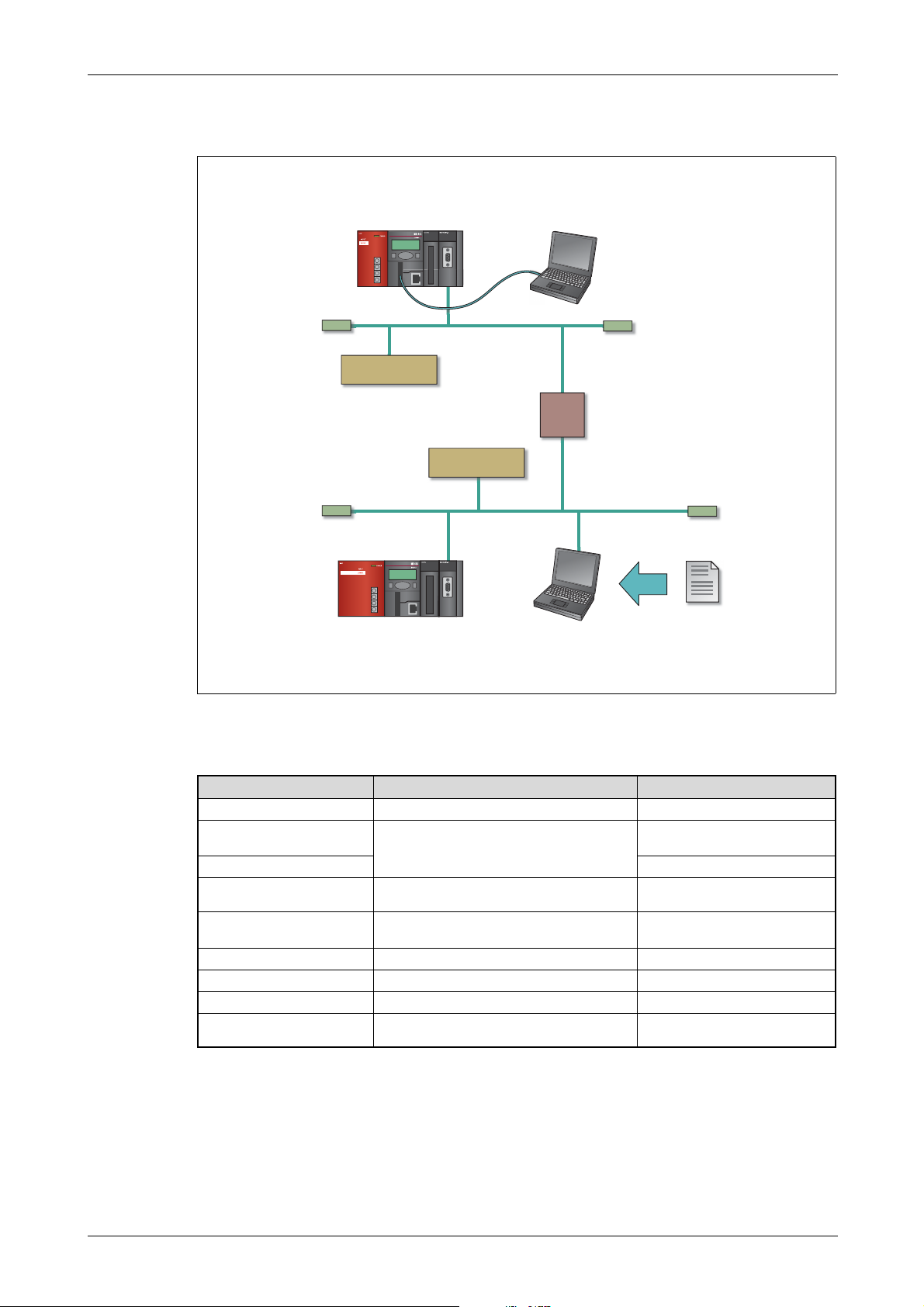

Fig. 2-4:

Product Description Note

ME3CAN1-L

Configuration tool integrated in

GX Works2

3rd party configuration tool —

D-sub connector

Terminating resistor

CAN bus network cable

CANopen node

Repeater

EDS file

Tab 2-1: System Equipment

Example for a system configuration with ME3CAN1-L

Module for CAN communication

Used to configure ME3CAN1-L (and CANopen

network)

Connector to connect ME3CAN1-L to the CAN

network

Resistor to terminate the CAN network. It is integrated in some D-sub connector.

Communication cable for CAN network

CANopen node from other manufacturer

Repeater for CAN network

Electronic data sheet (EDS) to describe the module. Used for 3rd party configuration tool.

—

—

—

Resistors are required to terminate

the CAN network at both ends.

—

—

—

—

MELSEC-L Series – CANopen Module ME3CAN1-L 2 – 3

Page 22

System Configuration System Equipment

C

2 – 4

MITSUBISHI ELECTRI

Page 23

Part Names Detailed Description of the Module

3 Detailed Description of the Module

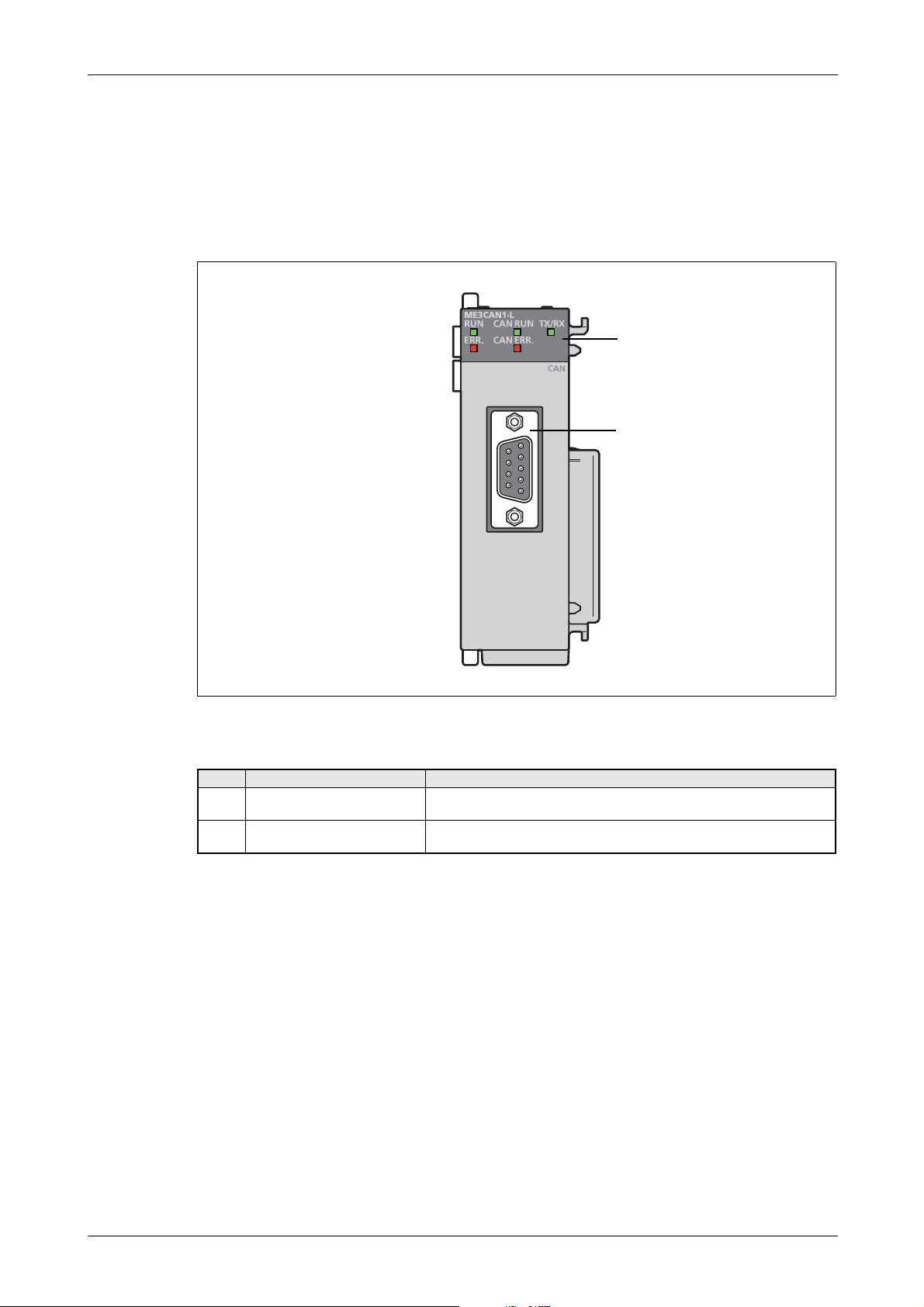

3.1 Part Names

This section explains the names of the components for the ME3CAN1-L.

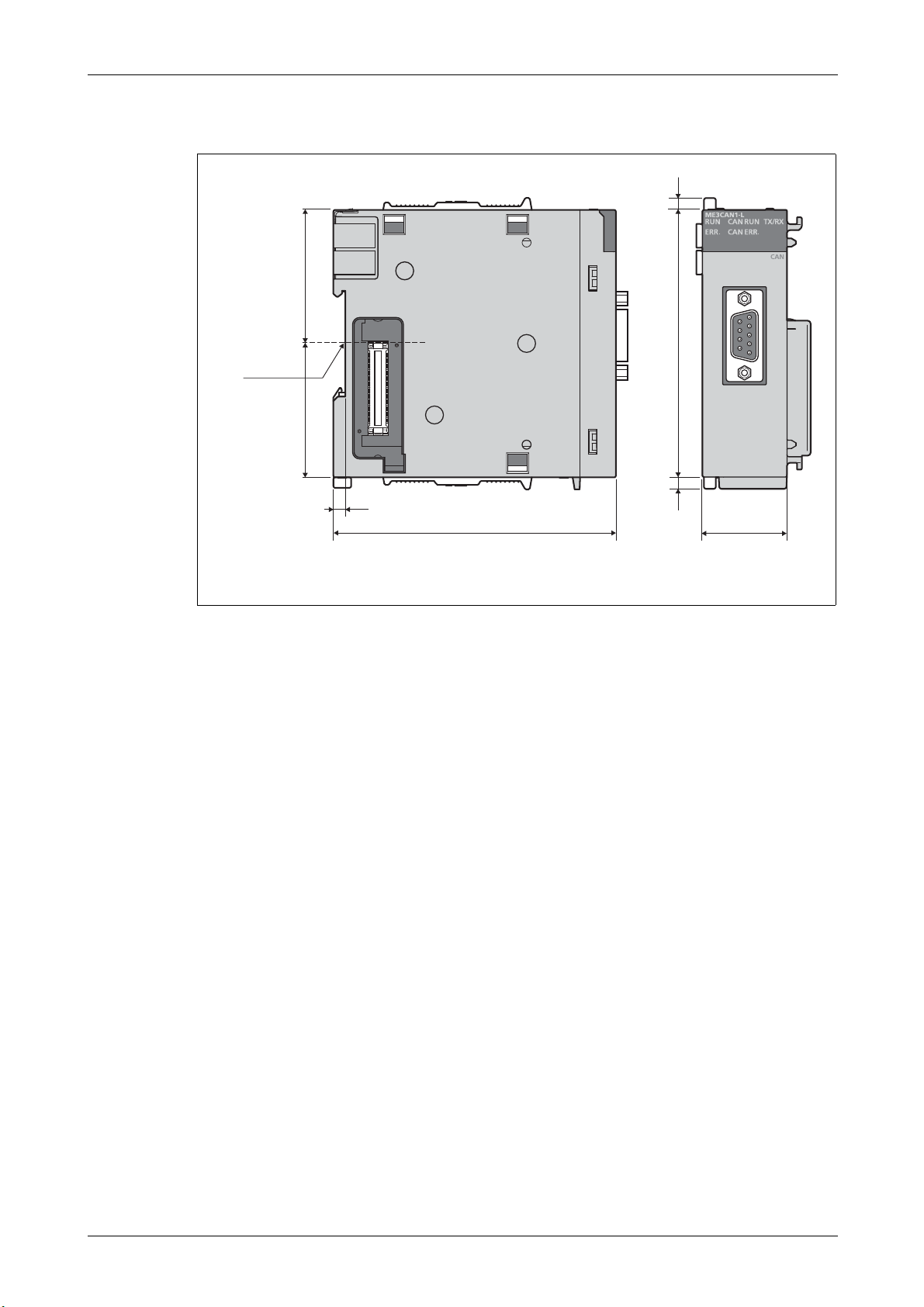

Fig. 3-1: Names of parts

No. Name Description

ed to indicate the status of the ME3CAN1-L.

Indicator LEDs

CAN interface connector

(D-sub 9-pin male connec

tor)

Us

For a detailed description, please refer to section 3.1.1.

This connector connects the communication cable to the ME3CAN1-L.

For details, refer to section 3.1.2.

Tab. 3-1: Description of the LEDs and the connector of the ME3CAN1-L

MELSEC-L Series – CANopen Module ME3CAN1-L 3 – 1

Page 24

Detailed Description of the Module Part Names

3.1.1 Indicator LEDs

The LEDs are arranged in two groups:

● General LEDs are arranged on the left side.

● LEDs for CAN communication are arranged on the right side.

Fig. 3-2:

Indicator LEDs of the ME3CAN1-L

LED Color Status Description

RUN Green

ERR. Red

CAN RUN Green

CAN ERR Red

TX/RX Green

ON Normally operating

OFF Hardware error (watchdog timer error) or power failure

ON An module error has occurred.

OFF Normally operating

ON

FLICKERING* LSS services in progress.

BLINKING* CANopen쏐 mode: The device is in CANopen state Pre-operational.

SINGLE FLASH* The device is in CANopen쏐 state Stopped.

OFF Layer 2 mode: The device is in Layer 2 offline mode.

ON

FLICKERING* LSS Services in progress.

BLINKING* General error

DOUBLE FLASH*

SINGLE FLASH* Warning limit reached.

OFF No error

ON Module is transmitting/receiving CAN message

OFF Module is not transmitting/receiving CAN message

앫 CANopen쏐 mode: The device is in CANopen쏐 state Operational.

앫 Layer 2 mode: The device is in Layer 2 online mode.

앫 The CAN controller is Bus-OFF-state.

앫 The CAN controller has too many transmission errors.

Error control event

A NMT guarding failure (NMT-Slave or NMT-Master) or a heartbeat fail-

ure (heartbeat consumer) has occurred.

3 – 2

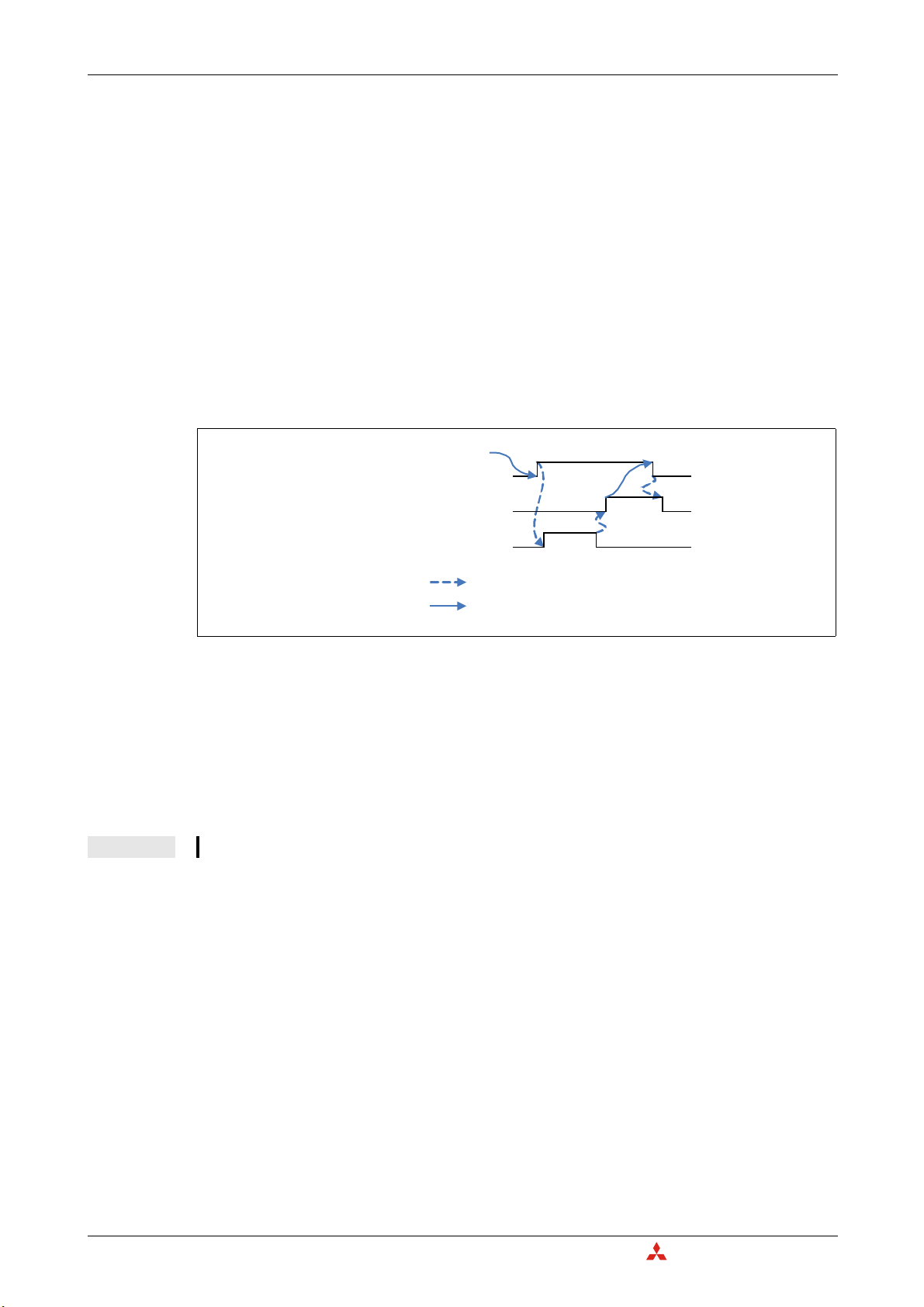

Tab. 3-2: Indicator LEDs

* The LEDs CAN RUN and CAN ERR have four kinds of flicker states (according to CiA쏐-303-3 V1.4): single flash, double flash,

blinking, and flickering. These LEDs flicker as follows.

SINGLE FLASH

0.2 s 1 s

DOUBLE FLASH

0.2 s 1 s0.2 s 0.2 s

BLINKING

0.2 s 0.2 s

FLICKERING

0.1 s

Page 25

Part Names Detailed Description of the Module

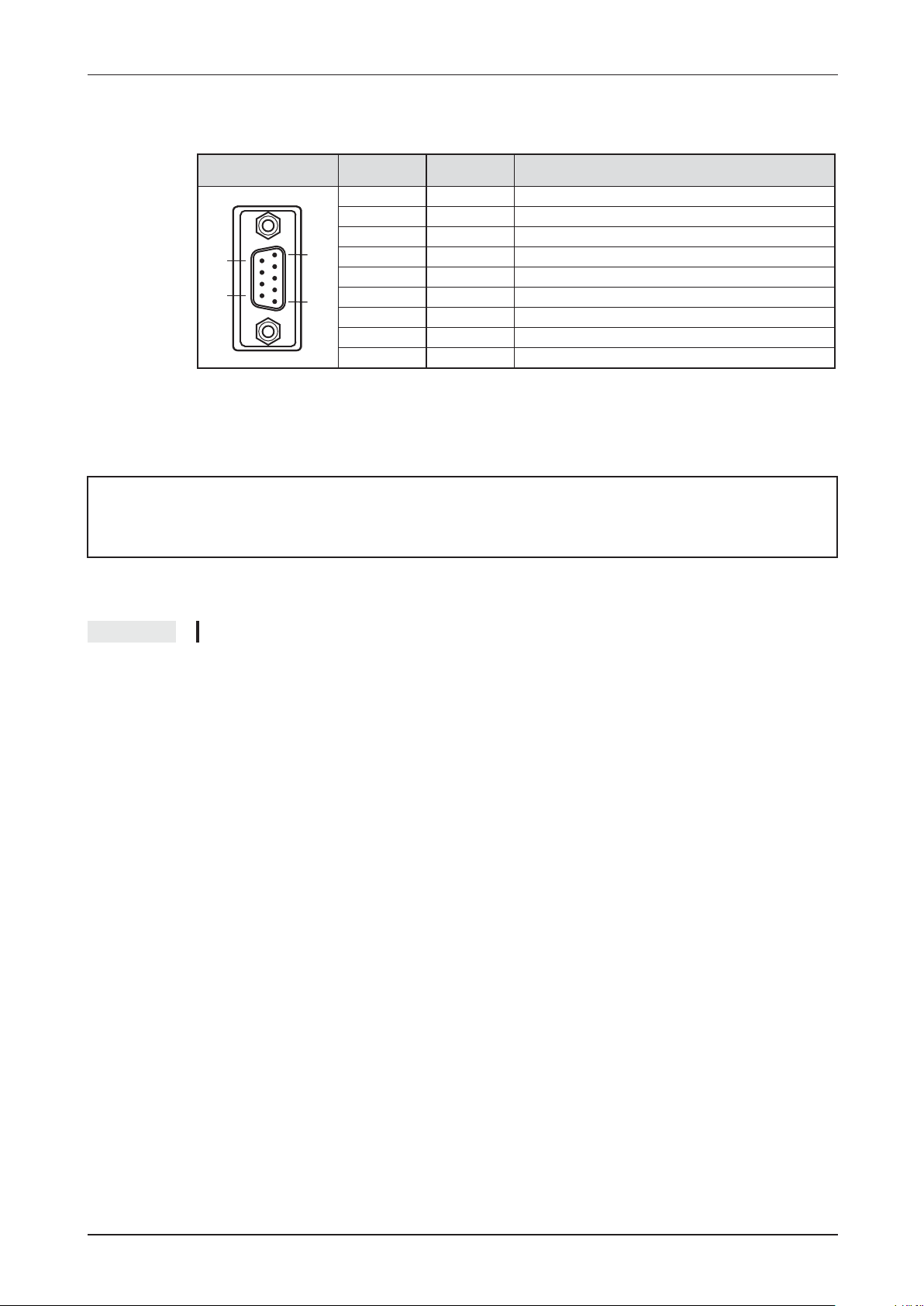

3.1.2 Signal Layout of the Connector

E

CANopen쏐 interface

connector

6

.

.

.

9

1

.

.

.

.

5

Pin no. Signal Description

1 — Reserved

2 CAN_L CAN_L bus line (dominant low)

3 CAN_GND CAN ground

4 — Reserved

5 CAN_SHLD CAN shield

6 — Reserved

7 CAN_H CAN_H Bus line (dominant high)

8 — Reserved

9 — Reserved

Tab. 3-3: Pin assignments of the CAN interface connector (D-sub 9-pin male connector) on the

ME3CAN1-L

WARNING:

Leave the "reserved" pins unconnected.

NOTE An inch screw thread (#4-40UNC) is used to fix the connector to the ME3CAN1-L.

For the wiring of the CANopen쏐 module ME3CAN1-L please refer to section 6.3.2.

MELSEC-L Series – CANopen쏐 Module ME3CAN1-L 3 – 3

Page 26

Detailed Description of the Module Specifications

C

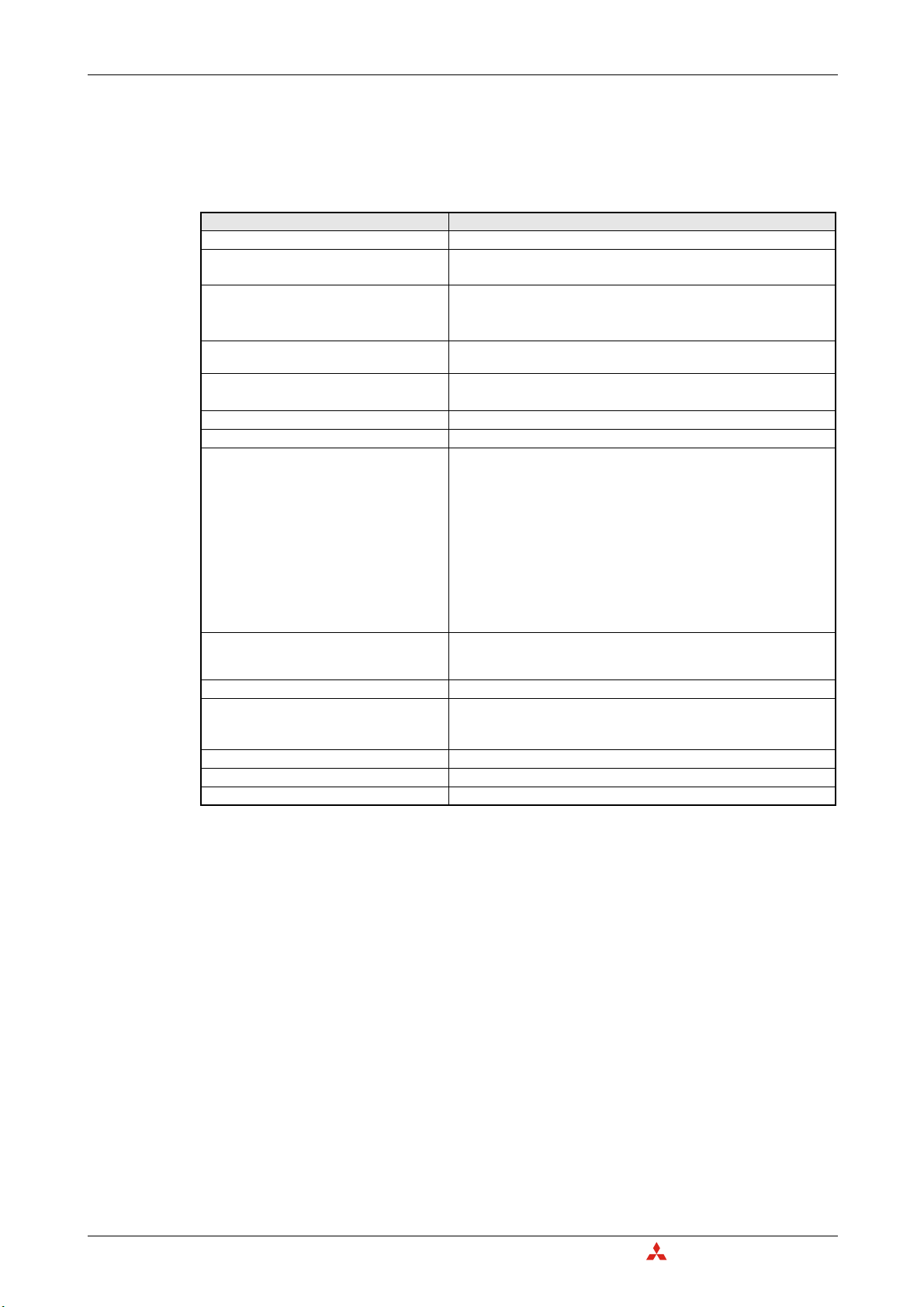

3.2 Specifications

The specifications for the ME3CAN1-L are shown in the following table. For general specifications,

refer to the operation manual for the CPU module being used.

Specification ME3CAN1-L

Transmission type CAN Bus network (RS-485, CSMA/CR)

Applicable functions

CANopen communication services according

to CiA standards

CANopen device and application profiles

according to CiA Standards

Remote Transmit Request (RTR)

Node number Selectable from 1 to 127

Communication method Acyclic, cyclic or event-driven

Supported transmission speed / maximum

bus length

Connection cable

Connection to CANopen network via 9-pin D-sub connector

Insulation method

Number of occupied I/O points 32 points (I/O assignment: Intelligent 32 points)

Internal current consumption (5 V DC) 0.39 A

Weight 0.14 kg

앫 CANopen Node

앫 CAN Layer 2 Node

앫 CiA-301 V4.2

앫 CiA-302 V4.1

앫 CiA-305 V2.2

Interface and Device Profile CiA-405 V2.0 for IEC 61131-3 Programmable

Devices

앫 Layer 2 mode: supported

앫 CANopen mode: not supported for PDO

The maximum bus length varies depending on the transmission speed.

앫 1 Mbps / 25 m

앫 800 kbps / 50 m

앫 500 kbps / 100 m

앫 250 kbps / 250 m

앫 125 kbps / 500 m

앫 100 kbps / 600 m

앫 50 kbps / 1,000 m

앫 20 kbps / 2,500 m

앫 10 kbps / 5,000 m

The cable should conform to ISO11898.

Recommended is a shielded 2x2 twisted pair cable with an impedance of

about 120 (refer to section 6.3.2).

앫 Photocouplers are used to insulate the CAN input from the PLC.

앫 A DC/DC converter is used to insulate the power supply from the CAN

input.

3 – 4

Tab. 3-4: Specifications of the ME3CAN1-L

MITSUBISHI ELECTRI

Page 27

Specifications Detailed Description of the Module

4

DIN rail center

45

Unit: mm

(45)

95

90

4

4

28.5

3.2.1 External Dimensions

Fig. 3-3: Dimensions of the ME3CAN1-L

MELSEC-L Series – CANopen Module ME3CAN1-L 3 – 5

Page 28

Detailed Description of the Module I/O Signals for the Programmable Controller CPU

C

3.3 I/O Signals for the Programmable Controller CPU

3.3.1 List of I/O signals

Note that the I/O numbers (X/Y) shown in this section and thereafter depend on the mounting position resp. on the start I/O number or head address of the ME3CAN1-L. This head address has to be

added to the shown I/O numbers.

For example, if the ME3CAN1-L occupies the range from X/Y040 to X/Y05F the head address is X/Y040.

However the least significant digit is omitted and the head address "n" in this case reads as "4". The "module ready" input (Xn0) will be X40 and the "EMCY message available" signal (X(n+1)1) will be X51.

Signal direction CPU Module ME3CAN1-L Signal direction CPU Module ME3CAN1-L

Device No. (Input) Signal name Device No. (Output) Signal name

Xn0 Module ready Yn0 Use prohibited

Xn1 Data exchange completed Yn1 Data exchange request

Xn2 Module restart completed Yn2 Module restart

Xn3

Xn4

Xn5

Xn6 Yn6

Xn7 Yn7

Xn8 Yn8

Xn9 Yn9

XnA YnA

XnB YnB

XnC YnC

XnD YnD

XnE YnE

XnF ME3CAN1-L error YnF ME3CAN1-L error clear request

X(n+1)0

X(n+1)1

X(n+1)2

X(n+1)3

X(n+1)4

X(n+1)6 Y(n+1)6

X(n+1)7 Command execution completed Y(n+1)7 Command execution request

X(n+1)8

X(n+1)9 Y(n+1)9

X(n+1)A Y(n+1)A

X(n+1)B Y(n+1)B

X(n+1)C Y(n+1)C

X(n+1)D Y(n+1)D

X(n+1)E Y(n+1)E

X(n+1)F

Module in Layer 2 online mode

(Layer 2 modes only)

Message transmit trigger completed

(Layer 2 modes only)

Use prohibited

NMT Error Control failure available

(CANopen mode only)

EMCY message available

(CANopen mode only)

Time stamp setting completed

(CANopen mode only)

Time stamp information is available in

buffer memory (CANopen mode

only)

Use prohibited

Use prohibited

Save configuration / restore factory

default completed

Yn3

Yn4

Yn5

Y(n+1)0

Y(n+1)1

Y(n+1)2

Y(n+1)3

Y(n+1)4

Y(n+1)8

Y(n+1)F

Layer 2 online mode request

(Layer 2 modes only)

Message transmit trigger request

(Layer 2 modes only)

Use prohibited

NMT Error Control failure clear

request (CANopen mode only)

EMCY message area clear request

(CANopen mode only)

Time stamp set request

(CANopen mode only)

Time stamp read request

(CANopen mode only)

Use prohibitedX(n+1)5 Y(n+1)5

Use prohibited

Save configuration / restore factory

default configuration request

Tab. 3-5: I/O signals of the ME3CAN1-L

NOTE The "Use prohibited" signals cannot be used by the user since they are for system use only.

If these are turned ON/OFF by the sequence program, the performance of the CANopen module

cannot be guaranteed.

3 – 6

MITSUBISHI ELECTRI

Page 29

I/O Signals for the Programmable Controller CPU Detailed Description of the Module

3.3.2 Details of I/O signals

Module ready signal (Xn0)

● This signal turns ON when the ME3CAN1-L is enabled for access from the CPU module.

● This signal turns OFF when the ME3CAN1-L is disabled for ac

module watchdog timer error or hardware fault.

Data exchange completed (Xn1), Data exchange request (Yn1)

● These signals are used to exchange data between the buffer memory of the ME3CAN1-L and the

CA

Nopen object dictionary/Layer 2 message buffer.

● To ensure that the ME3CAN1-L can handle the C

to set the data exchange request (Yn1) to ON after writing the data. The Data exchange completed

(Xn1) and Data exchange request (Yn1) signals control the internal buffer exchange and thereby

which data is transmitted from the PLC by PDO.

● PDO transmit data will only be sent to the CAN bus if the module is in NMT state Operational and

af

ter setting Yn1 to ON. As long as the reading of the previous data is not finished and a new data

exchange command has not been sent, data will not be overwritten by further PDO.

If the module is in NMT state Operational, the received PDO data from other nodes can be read

by the MELSEC-L series CPU by using a FROM instruction and the transmit PDO data can be written

to the module and sent to the network by using

signal (Xn1) will be turned ON when the data exchange between buffer memory and Object

Dictionary/Data exchange buffer is finished.

● Depending on the bits turned ON in the Data Exchange Control (Un\G20), OD data and/or EMCY

data will be ex

NOTE If Xn1 is turned ON and the module is not in CANopen state Pre-operational or Stopped, the PDO

data will be exchanged after going into Operational state.

changed.

ANopen data in a consistent way, it is necessary

a TO instruction. The data exchange completed

cess from the CPU module due to a

MELSEC-L Series – CANopen Module ME3CAN1-L 3 – 7

Page 30

Detailed Description of the Module I/O Signals for the Programmable Controller CPU

C

Performed by the ME3CAN1-L

Performed by the sequence program

Module restart request (Yn2)

Module restart completed (Xn2)

Module initialization state (Un\G25 bit 7)

OFF

OFF

ON

ON

OFF

ON

Module restart completed (Xn2), Module restart request (Yn2)

● A restart is necessary to activate the following new settings:

– Function mode (Un\G21), refer to section 3.5.2

– Baud rate (Un\G24), refer to section 3.5.4

– Node-ID (Un\G27), refer to section 3.5.6

– NMT master setting, refer to section 4.8.5.

All not saved settings will be lost.

● To restar

t the module

, please set the module restart request (Yn2) signal to ON. The module will

be set to initialization state as indicated by the Un\G25 bit 7 (refer to section 3.5.5). After the

module is restarted, the module restart completed (X

n2) will be set to ON. The module restart

request (Yn2) signal can be reset to OFF. Not setting this signal back to OFF will cause that the

module will be restarted again and again. The restart procedure will take approx. 6 seconds to

complete.

Fig. 3-4: Timing of the signals Xn2 and Yn2

Module in Layer 2 online mode (Xn3), L

● The Layer 2 online mode request signal (Yn3) must be set to ON to star

yer 2 online mode request (Yn3)

a

t data exchange with other

network nodes.

● The module in Layer 2 online mode signal (X

mode. The configuration of the module can only be changed while this signal is OFF..

NOTE In case a configuration buffer memory was changed during online mode, Un\G29 bit 5 is set to ON.

Message transmit trigger completed (Xn4), Message transmit trigger request (

● The transmission trigger of a message in Layer 2 mode which is set in Un\G8400 to Un\G8402

must be star

● The message transmit trigger completed signal (X

been written into the transmit buffer. Please refer also to section 3.6.4.

3 – 8

n3) will turn ON if the module can be set to online

ted with a message transmit trigger request (Yn4).

Yn4)

n4) will turn ON when all the messages have

MITSUBISHI ELECTRI

Page 31

I/O Signals for the Programmable Controller CPU Detailed Description of the Module

Performed by the ME3CAN1-L

Performed by the sequence program

Error (Un\G29)

ME3CAN1-L error (XnF)

ME3CAN1-L error clear request (YnF)

OFF

OFF

ON

ON

ON

OFF

ME3CAN1-L error (XnF), ME3CAN1-L error clear request (YnF)

● If one or more of the following bits in the buffer memory address Un\G29 (error state) are turned

ON, XnF will be turned ON: Bits 1, 2, 4, 5, 6, 8, or 15. Please refer to section 3.5.7.

● If XnF is turned ON, if necessary please take correct

ive action to remove the error cause and then

turn ON YnF to clear the error signals XnF and the bits in the error state (Un\G29).

● If a new error is generated while the ME3CAN1-L error clear request (

YnF) is ON, this will be cleared

automatically.

● After the ME3CAN1-L error clear request (YnF) is turned OFF

, the ME3CAN1-L will check for new

errors again.

Fig. 3-5: Timing of the signals XnF and YnF

NMT Error Control failure available (X(n+1)0), NMT Error Control failure clear request (Y(n+1)0)

● If there is at least one CANopen

NMT Error Control failure (at least one of the assigned NMT slaves

failed during NMT Error Control), the NMT error of CANopen node available (X(n+1)0) will turn

ON.

● How to clear the error of all nodes

H

To clear the error of all nodes, write 0000

to Un\G400 (this is the default setting of Un\G400) and

turn ON the Clear NMT Error Control failure request (Y(n+1)0). The NMT error control failures of

all nodes will be then cleared and the NMT Error Control failure available (X(n+1)0) will be turned

OFF.

● How to clear the error of a certain node

To clear the error of a node

failure clear request (

, write the node number to Un\G400 and turn ON NMT Error Control

Y(n+1)0). The NMT error control failures of this node will be cleared and if

there no other NMT error control failures the NMT Error Control failure available (X(n+1)0) will also

be turned OFF.

● If a new error is genera

ted while the NMT Error Control failure clear request (Y(n+1)0) is ON, this

will be cleared automatically.

● After the NMT Error Control failure Clear request (

Y(n+1)0) is turned OFF, the ME3CAN1-L will

check for new errors again.

● For more error details on NMT Error Control failure

, please refer to section 3.5.15.

MELSEC-L Series – CANopen Module ME3CAN1-L 3 – 9

Page 32

Detailed Description of the Module I/O Signals for the Programmable Controller CPU

C

Performed by the ME3CAN1-L

Performed by the sequence program

EMCY message available (X(n+1)1)

EMCY message area clear request (Y(n+1)1)

EMCY messages

OFF

OFF

ON

ON

No EMCY data

EMCY

data

available

No EMCY data (cleared)

EMCY message available (X(n+1)1), EMCY message area clear request (Y(n+1)1)

● If there is at least one CANopen emergency received (reception of an Emergency message from

at least one activated EMCY consumer objects), the EMCY message available (X(n+1)1) will turn

ON.

● To clear all EMCY messages,

turn ON the EMCY message area clear request (Y(n+1)1). All EMCY

messages will be then cleared and the EMCY message available (X(n+1)1) will be turned OFF.

● If a new EMCY message is received while the EMCY message area clear request (Y(n+1)1) is ON,

this will be cleared automatically.

● After the EMCY message area clear request (Y(n+1)1) is turned OFF

, the ME3CAN1-L will store the

newly received EMCY messages again.

For more error details, please refer to the sections 4.6.12 and 3.5.17.

Fi

g. 3-6: Ti

ming of the signals X(n+1)1 and Y(n+1)1

Time stamp setting completed (X(n+1)2), Time stamp set request (Y(n+1)2)

After setting the necessary time stamp information in Un\G50 to Un\G58, please turn ON the time

stamp set request (

A

fter the setting is finished, the time stamp setting completed signal (X(n+1)2) will be turned ON, and

Y(n+1)2).

the request signal can be turned OFF. When the ME3CAN1-L is the current network master and Producer, then the first time stamp will be sent.

Time stamp information is available in buffer memory (X(n+1)3), Time stamp read request

(

(n+1)3)

Y

To read the time stamp, please set the time stamp read request (Y(n+1)3) to ON.

The time stamp information will be stored in the buffer memory addresses Un\G50 to Un\G58 and the

time stamp information is available in buffer memory

(X(n+1)3) signal will be turned ON to indicate

that actual time stamp information is available.

Command 1 execution completed (X(n+1)7, Command 1 e

ecution request (Y(n+1)7)

x

● These signals are used for execution of Command Interface 1.

● After writing the necessary command par

ameter (refer to section 3.5.18), turn ON Y(n+1)7 to

execute the command. If the command execution is finished, X(n+1)7 will be turned ON.

3 – 10

MITSUBISHI ELECTRI

Page 33

I/O Signals for the Programmable Controller CPU Detailed Description of the Module

Save configuration/Restore factory default completed (X(n+1)F), Save configuration/Restore

factory default configuration request (Y(n+1)F)

These signals are used to execute the save configuration / restore factory default request. The request

must be specified in Un\G22 (Save/Restore Configuration, refer to sec

tion 3.5.3). After that the request

can be executed by setting Y(n+1)F to ON. When the request is completed, the corresponding bits in

Un\G22 will be cleared, and X(n+1)F will be turned ON.

NOTE

앫

If both bits Un\G22.0 and Un\G22.1 are set simultaneously the buffer memory and Flash ROM will

be reset to factory defaults.

앫

If only bit Un\G22.1 is set, factory default values are written to the configuration buffer memory

but not stored in Flash ROM. In order to store changes made to the configuration execute the

Save configuration request (Un\G22.0 then Y(n+1)F) after changing the configuration.

MELSEC-L Series – CANopen Module ME3CAN1-L 3 – 11

Page 34

Detailed Description of the Module Buffer Memory Overview

C

Bit

Buffer memory address

3.4 Buffer Memory Overview

The CANopen module has a memory range assigned as a buffer for temporary storage of data, such

as Received Process Data or CAN transmission error counter. The PLC CPU can access this buffer and

both read the stored values from it and write new values to it which the module can then process

(Transmit Process Data etc.).

Each buffer memory address consists of 16 bits.

Fig. 3-7: Assignments of bits to a buffer memory address

NOTE Do not write data in the "system areas" of the buffer memory. If data is written to any of the system

areas, the PLC system may not be operated properly. Some of the user areas contain partially system areas. Care must be taken when reading/writing to the buffer memory.

Also, do not write data (e.g. in a sequence program) to the buffer memory area where writing is

disabled. Doing so may cause malfunction.

The "Default" value indicated in the following tables is the initial value set af

or the PL

Instructions for data exchange with the buffer memory

Communication between the PLC CPU and the buffer memory of special function modules is per

formed with FROM and TO instructions.

The buffer memory of a special function module can also be accessed directly, e. g. with a MOV

instruction. The special function module addressed in this way can be mounted on a base unit or an

extension base unit but not in remote I/O stations.

Format of the device address: Un\Gn

– Un: Head address of the special function module

– Gn: Buffer memory address (decimal)

For example the device address U3\G11designates the buffer memory address 11 in the special function module with the head address 3 (X

In this User's Manual the latter form of addressing is used throughout.

For full documentation of all the instructions with examples please refer to the Programming Manual

for the MELSEC System Q and the L series.

C CPU is reset.

/Y30 to X/Y3F).

ter the power is turned on

-

NOTE As long as Un\G25 bit 7 is ON ("Module is in initialization state"), any write access to the buffer

3 – 12

memory is prohibited and will generate a Un\G29 bit 5 error. Refer to section 3.5.7.

MITSUBISHI ELECTRI

Page 35

Buffer Memory Overview Detailed Description of the Module

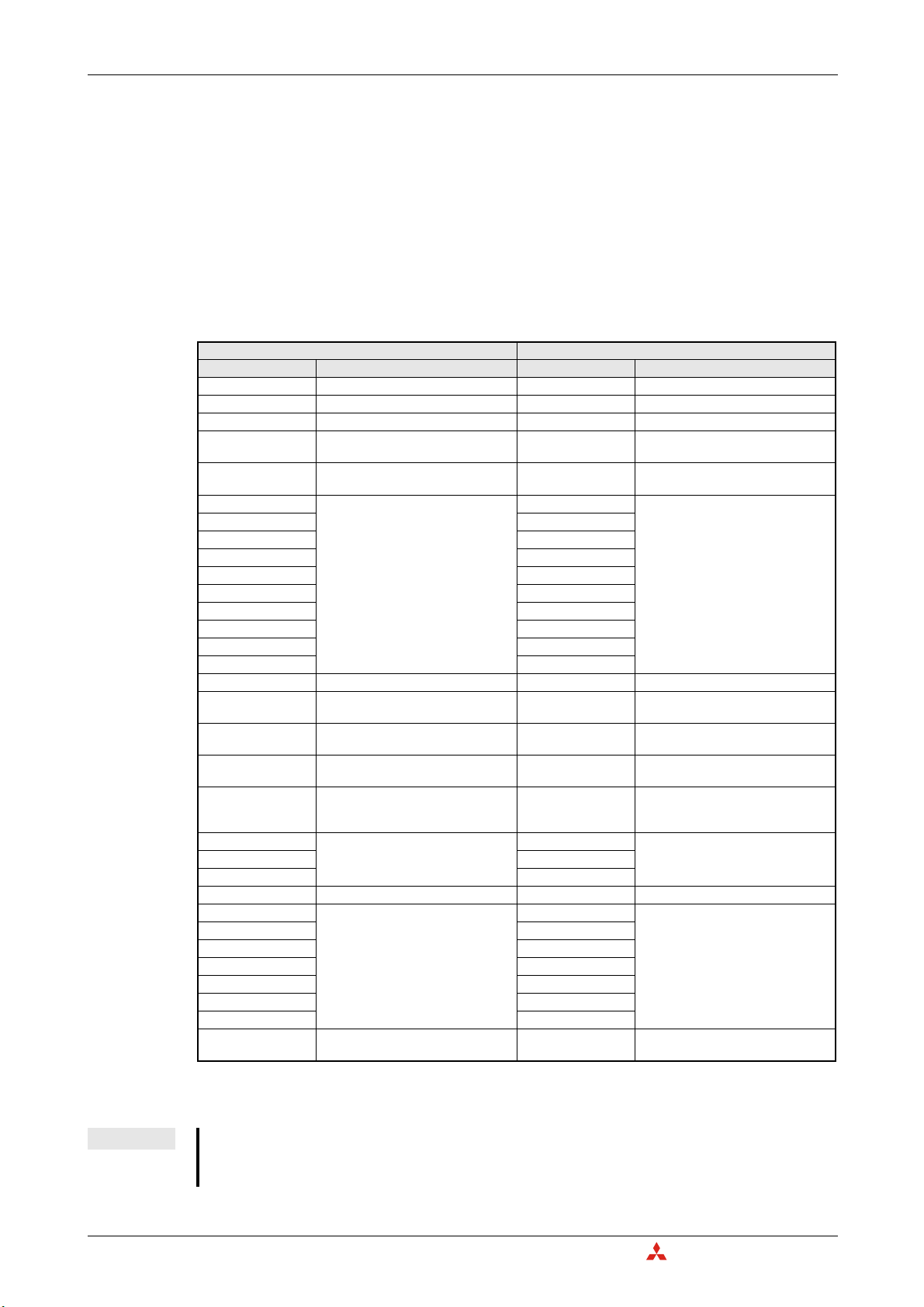

3.4.1 Buffer Memory Assignment

Address

(Decimal)

Description Default R/W

Stored to

Flash ROM

Reference

(Section)

0–19 System area — — — —

20 Data Exchange Control 0

H

R/W — 3.5.1

21 Function mode 405 R/W ✔ 3.5.2

22 Save/Restore Configuration 0

H

R/W — 3.5.3

23 System area — — — —

24 Baud Rate 250 R/W ✔ 3.5.4

25 Communication Status 80

H

R/W — 3.5.5

26 System area — — — —

27

Node Address

(CANopen modes only)

127 R/W ✔ 3.5.6

28 System area — — — —

29 Error Status 0

H

R/W — 3.5.7

30–34 System area — — — —

35 CAN transmission error counter 0

36 CAN reception error counter 0

H

H

R — 3.5.8

R — 3.5.9

Baud Rate display

37

Diagnose display for the current baud rate of the CAN

2500 R — —

Controller in multiples of 0.1kbps.

Sampling Point display

38

Diagnose Display for the current sampling point of

875 R — —

the CAN Controller in multiples of 0.1%.

39 Buffer memory setting error display 0

40

Buffer memory initialization/online mode write error

display

H

0

H

R—

R—

3.5.10

41–49 System area — — — —

50

Producer/consumer 1

51 Year 14

52 Month 8

53 Day 1

54 Hour 0

55 Minute 0

Time stamp

(CANopen modes

only)

R/W

—

3.5.11

56 Second 0

57 Day-of-the-week 5R

58 Transmission interval

0R/W

59 Daily correction (CANopen modes only) 0 R/W ✔

60–69 System area — — — —

70

71

NMT Start all Nodes delay

(CANopen modes only)

SDO Time out

(CANopen modes only)

500 R/W ✔ 3.5.12

500 R/W ✔ 3.5.13

72–399 System area — — —

400 NMT error clear node 0

401–527

NMT Error Control Status

(CANopen modes only)

H

0

H

R/W — 3.5.14

R/W — 3.5.15

528–600 System area — — — —

601–726

727 7F

NMT State

(CANopen modes only)

728–749 System area 0

750–859

EMCY Message Buffer

(CANopen modes only)

0

H

H

H

0

H

R — 3.5.16

— — —

— — 3.5.17

860–999 System area — — — —

1000–1066 Command Interface 0

H

R/W — 3.5.18

1067–5000 System area — — — —

5001–5042

Message Slot error code list

(Layer 2 function modes only)

0

H

R/W — 3.6.1

Tab. 3-6: Buffer memory assignment of the ME3CAN1-L

MELSEC-L Series – CANopen Module ME3CAN1-L 3 – 13

Page 36

Detailed Description of the Module Buffer Memory Overview

C

Address

(Decimal)

Description Default R/W

Stored to

Flash ROM

Reference

(Section)

5043–5999 System area — — — —

6000–8167

Pre-defined Layer 2 message configuration

(Layer 2 modes only)

—R/W ✔ 3.6.2

8168–8349 System area — — — —

8350–8352

Layer 2 RTR flags

(Layer 2 modes only)

0

H

R — 3.6.3

8353–8399 System area — — — —

8400–8402

Message transmit trigger flags

(Layer 2 modes only)

0

H

R/W — 3.6.4

8403–8449 System area — — — —

8450–8477

PLC RUN>STOP messages

(Layer 2 modes only)

0

H

R/W ✔ 3.6.5

8478–9999 System area — — — —

Layer 2 modes only

10000–10293 Receive / Transmit Process Data 0

H

R/W — 3.6.6

From 10294 System area — — — —

405 Mode only

10000–11023 Receive Process Data (RPDO) 0

H

R — 3.5.19

11024–12999 System area — — — —

13000–15047 Transmit Process Data (TPDO) 0

H

R/W — 3.5.19

From 15048 System area — — — —

Tab. 3-6: Buffer memory assignment of the ME3CAN1-L

Indicates whether reading from and writing to a sequence program are enabled.

R: Read enabled

W: Write enabled

Only in Layer 2 mode the contents of some buffer memory addresses is stored into the Flash-ROM (Refer to section 3.6.6).

3 – 14

MITSUBISHI ELECTRI

Page 37

Buffer Memory Details: CANopen Mode Detailed Description of the Module

3.5 Buffer Memory Details: CANopen Mode

3.5.1 Data Exchange Control (Un\G20)

This buffer memory address allows the control of the OD and EMCY data exchange.

Bit Description

0–7 Reserved

Only in CANopen modes: Data exchange mode setting (only OD data)

Bit = 0: No data exchange between buffer memory and CANopen object dictionary

Bit = 1: Activate data exchange between buffer memory and CANopen object dictionary

8

NOTES:

앫 The data will be also exchanged if this entire buffer memory address is set to 0 (default value).

앫 If the bit is set and the module is not in CANopen state Operational, the PDO data will be exchanged after

going into Operational state.

9–11 Reserved

Data exchange status (only EMCY data)

Bit = 0: No data exchange between Emergency Message buffer memories and EMCY Receive Buffer

Bit = 1: Exchange data between Emergency Message buffer memories and EMCY Receive Buffer

12

For more information please refer to section 3.5.17

NOTE:

앫 The data will be also exchanged if this entire buffer memory address is set to 0 (default value).

13–15 Reserved

Tab. 3-7: Assignment of the bits in buffer memory address Un\G20

3.5.2 Function Mode (Un\G21)

The ME3CAN1-L chooses the communication function corresponding to the function mode set in the

buffer memory address 21.The possible settings are shown in the following table:

Set value Function Mode Description

11 11 bit CAN-ID Layer 2 mode This mode supports the 11 bit CAN-ID Layer 2 Message.

29 29 bit CAN-ID Layer 2 mode This mode supports the 29 bit CAN-ID Layer 2 Message.

405 CANopen 405 mode

Other value —

Tab. 3-8: Function mode setting in buffer memory address Un\G21

The buffer memory setting needs to be stored by Un\G22 bit 0 and afterwards to be restar

to make the new settings effective (Refer to section 3.5.3 and section 3.3.2).

NOTE During a restart, all Object Dictionary (OD) settings will be deleted when the CANopen mode is

changed.

This mode supports the CANopen CiA 405 IEC 61131-3 Programmable Device Profile.

All other settings will generate an error (in this case bit 6 in Un\G29 is

set (Refer to section 3.5.7).

ted by Yn2

MELSEC-L Series – CANopen Module ME3CAN1-L 3 – 15

Page 38

Detailed Description of the Module Buffer Memory Details: CANopen Mode

C

3.5.3 Save/Restore Configuration (Un\G22)

This buffer memory specifies two bits that allow to restore the factory default configuration in the buffer memory and to store the buffer memory configuration into the Flash ROM. To execute the request,

please set Y(n+1)F to ON (refer to section 3.3.2).

Both bits will be reset automatically if the restore or save procedure is completed, and X(n+1)F will

turn ON.

Bit Description

0 Bit = 1:Save configuration to Flash ROM

1

Bit = 1: Restore factory default configuration (not saved to Flash ROM)

2–15 Reserved

Tab. 3-9: Assignment of the bits in buffer memory address Un\G22

NOTES

If both bit 0 and bit 1 are set simultaneously the buffer memory and Flash ROM will be reset to the

factory defaults.

If only bit 1 is set, factory default values are written to the configuration buffer memory but not

stored in the Flash ROM. In order to store changes made to the configuration buffer memory, set

Un\G22 bit 0 after changing the configuration.

3.5.4 Baud Rate (Un\G24)

In Un\G24 the baud rate is set. The current baud rate can be found in Un\G37.

Value in Un\G24 Baudrate

10

20

50

100

125

250

500

800

1000

10 kbps

20 kbps

50 kbps

100 kbps

125 kbps

250 kbps

500 kbps

800 kbps

1000 kbps

Tab. 3-10:

Settings for the baud rate

NOTES The baud rate must be equal for all nodes in the network.

The new value needs to be stored by Un\G22. Then Y(n+1)F has to be turned ON and the module

has to be restarted to make the new setting effective.

At low baud rates a too fast data exchange and/or high bus load can result in a transmission data

queue overflow error (bit 8 in Un\G29, refer to section 3.5.7).

3 – 16

MITSUBISHI ELECTRI

Page 39

Buffer Memory Details: CANopen Mode Detailed Description of the Module

3.5.5 Communication Status (Un\G25)

The buffer memory address Un\G25 displays the ME3CAN1-L communication status.

Bit Description

CANopen modes:

0

Bit = 0: Not in Operational State

Bit = 1: Operational State

Bit = 0: The error counter is below the warning level. (Refer to sections 3.5.8 and 3.5.9)

1

Bit = 1: The error counter of the CAN controller has reached the warning level.

2

3

Reserved

4

5

Bit = 0: No NMT Reset received.

Bit = 1: The CANopen Application was reset by an NMT Reset communication or NMT Reset Application com-

6

7

8

9

10

11 Reserved

12

13 Reserved

14

15

mand. All unsaved changes in the Object dictionary are lost and are set to factory default or to the former

stored value.

Write a 0 to reset the bit. (Refer to sections 4.8.8 and 4.6.10). The bit is set to 0 in the beginning of the reset process.

Module initialization state

Bit = 0: Module initialization finished

Bit = 1: Module is in initialization state

The module is initializing the internal data structures and the buffer memory.

While this bit is on, it is recommended to execute a read access to Un\G25 and Un\G29 only.

In case of a module restart request with Yn2 or over a CANopen NMT command this bit will be set.

This bit shall be monitored in the PLC program all the time to prohibit Un\G29 failures.

CANopen Network state

Bit 9 Bit 8 Description

00Stopped State

01Pre-operational State

10Operational State

11Reserved

Bit = 0: LSS Master routine inactive

Bit = 1: LSS Master routine active

This bit is only "1" when the LSS Master is searching and configuring LSS Slaves.

Bit = 0: No Time Stamp object received or bit is reset

Bit = 1: Time Stamp object received (Only if Consumer is set)

Write a 0 to reset the bit. (Refer to sections 4.6.9 and 3.5.11)

Bit = 0: NMT Start-up Master:

No Slave start-up in progress

Bit = 1: NMT Start-up Master: Slave start-up in progress (Refer to section 4.8.5)

Note:

This bit goes on during the NMT master/slave startup and any time when a NMT slave error occurs and the NMT

startup master tries to re-start the faulty NMT slave.

Bit = 0: Module works as NMT Slave

Bit = 1: Module works as NMT Master

Tab. 3-11: Assignment of the bits in buffer memory address Un\G25

3.5.6 Node Address (Un\G27)

The buffer memory address 27 sets the CANopen Node-ID. The setting value range is 1 to 127.

The buffer memory setting needs to be stored by Un\G22 bit 0 and afterwards to be restarted by Yn2

to make the new setting effective (Refer to section 3.5.3).

A setting out of the above range or a write access in Layer-2 function mode will generate a failure message in Un\G29 bit 6.

MELSEC-L Series – CANopen Module ME3CAN1-L 3 – 17

Page 40

Detailed Description of the Module Buffer Memory Details: CANopen Mode

C

3.5.7 Error state (Un\G29)

The following table shows the description of the error if a bit in the buffer memory address Un\G29 is

set.

Bit Error Description/Corrective action

0 Reserved

1 Hardware error

2 Reserved

3 The CAN controller is bus OFF.

4 FLASH memory error

Invalid write access in Layer 2

5

mode

6 Buffer memory setting error

7 Reserved

8 Internal data queue overflow

9

10

Reserved

11

12

13

14 CAN error passive state

Layer 2 Message Slot specific

15

error exists.

This bit can only be reset by switching the power OFF/ON.

Contact your Mitsubishi Electric representative.

The CAN controller has too many transmission errors (Refer to section 3.5.8).

Restart the Module (Refer to section 3.3.2).

Invalid data in the Flash memory might be caused by power loss during a write

operation to the Flash ROM.

If this bit is not cleared after a module restart (Yn2) or another power cycle, please

contact your Mitsubishi Electric representative.

Invalid write access to configuration buffer memory while in ONLINE/INIT mode.

Check user program, do not write into configuration buffer memory when mod-

ule is ONLINE.

In Un\G40 the buffer memory address where this failure occurred will be

displayed.

This bit is set if an attempt to write an invalid value into a buffer memory is

detected.

The target buffer memory address of the invalid write access is displayed in

Un\G39 (Refer to section 3.5.10). Check Un\G39 for buffer memory address and

correct set value to valid range.

Extreme bus load can cause the internal queues to overflow.

Decrease the bus load. At a low baud rate a too fast data exchange (refer to section 3.5.1) can overflow the CAN Transmit Buffer (Depends also on the bus-load of

the CAN).

This bit shows the CAN error active state/passive state.

Bit = 0: Error active state

Bit = 1: Error passive state

This bit will be reset automatically if the internal error counters return back below

128. (Refer to sections 3.5.8 and 3.5.9)

Check the Message Slot specific error code in Un\G5001–Un\G5584 (Refer to section 3.6.1).

3 – 18

Tab. 3-12: Assignment of the bits in buffer memory address Un\G29

Layer 2 modes: The configuration must not be changed when the module is set to ONLINE, before changing the configuration set Yn0 to OFF (configuration mode) and wait until Xn0 is OFF (module OFFLINE/INIT). The affec

buffer memories are Un\G10000 to Un\G10293, Un\G6000 to Un\G6167 and Un\G8400 to Un\G8402.

Any CANopen node will check all CAN messages on the bus for errors. Depending on the error state the action that the

node will take is different:

앫 In error ac

The node will ac

앫 In error passive state:

The node will not actively mark the frame as invalid to avoid bus disturbance if the node itself has an H/W problem.

tive state:

tively mark the frame as invalid.

ted configurations

If one or more of the bits 1, 4, 6, 8, or 15 in UN\G29 are set, XnF will be turned ON.

The bits 5 6, 8, and 15 are latched and it is necessary to set YnF to ON which will clear all latched error

bits in Un\G29. All other bits are reset automatically if the cause for the error is solved.

MITSUBISHI ELECTRI

Page 41

Buffer Memory Details: CANopen Mode Detailed Description of the Module

3.5.8 CAN transmission error counter (Un\G35)

The ME3CAN1-L stores the current value of the CAN transmit error counter. The displayed value range

is 0 to 256.

The counter counts 8 up if a transmission error is detected. For each transmission without error, the

counter counts 1 down.

Value in Un\G35 Description

0 to 127 Error active state

96 to 127 Warning level

128 to 255 Error passive state

256 Bus OFF state

NOTE

The warning level is also shown by bit 1 in Un\G25, error passive and Bus OFF are shown in

Un\G29.

3.5.9 CAN reception error counter (Un\G36)

The ME3CAN1-L stores the current value of the CAN reception error counter. The displayed value

range is 0 to 128 and 256.

The counter counts 8 up if a reception error is detected. For each reception without error, the counter

counts 1 down.

Value in Un\G36 Description

0 to 127 Error active state

96 to 127 Warning level

128 Error passive state

256 Bus OFF state

Tab. 3-13:

Meaning of the values for the transmission error

counter

Tab. 3-14:

Meaning of the values for the reception error

counter

NOTE

The warning level is also shown by bit 1 in Un\G25, error passive and Bus OFF are shown in

Un\G29.

3.5.10 Buffer memory setting error display (Un\G39, Un\G40)

Buffer memory setting error display (Un\G39)

Bit 6 of Un\G29 is set to ON if an attempt to write an invalid value into a buffer memory address is

ed. The content of Un\G39 shows the buffer memory address where this failure occurred. In

detect

case of a multiple write error, the first failure will be displayed. The buffer memory will be reset by setting YnF to ON.

Buffer memory initialization / online mode write error display (Un\G40)

If a write access is done while the module is in Layer 2 online mode or in initialization mode, bit 5 of

Un\G29 is set to "1" and Un\G40 indicates the buffer memory address, where this failure has occurred.

In case of a multiple write error, the first failure will be displayed. The buffer memory will be reset by

setting YnF to ON.

MELSEC-L Series – CANopen Module ME3CAN1-L 3 – 19

Page 42

Detailed Description of the Module Buffer Memory Details: CANopen Mode

C

3.5.11 Time stamp (Un\G50–Un\G59)

CANopen devices which operate a local clock may use the TIME object to adjust their own time base

to the time of the time stamp producer.

After each power up or restart the date and time are set to the default values and the counting is

stopped.

If the ME3CAN1-L is set to "consumer", the clock starts counting after receiving the first time stamp

object.

When the module is setup as "producer", the counter starts after setup of Un\G50 to Un\G58 and turning ON the Time stamp set request (Y(n+1)2) signal (refer to section 3.3.2). The time stamp will only be

produced if the ME3CAN1-L is active NMT Master and in CANopen state Operational or Pre-opera-

tional.

The lowest counting resolution of the time stamp object at the ME3CAN1-L is in seconds. If a time