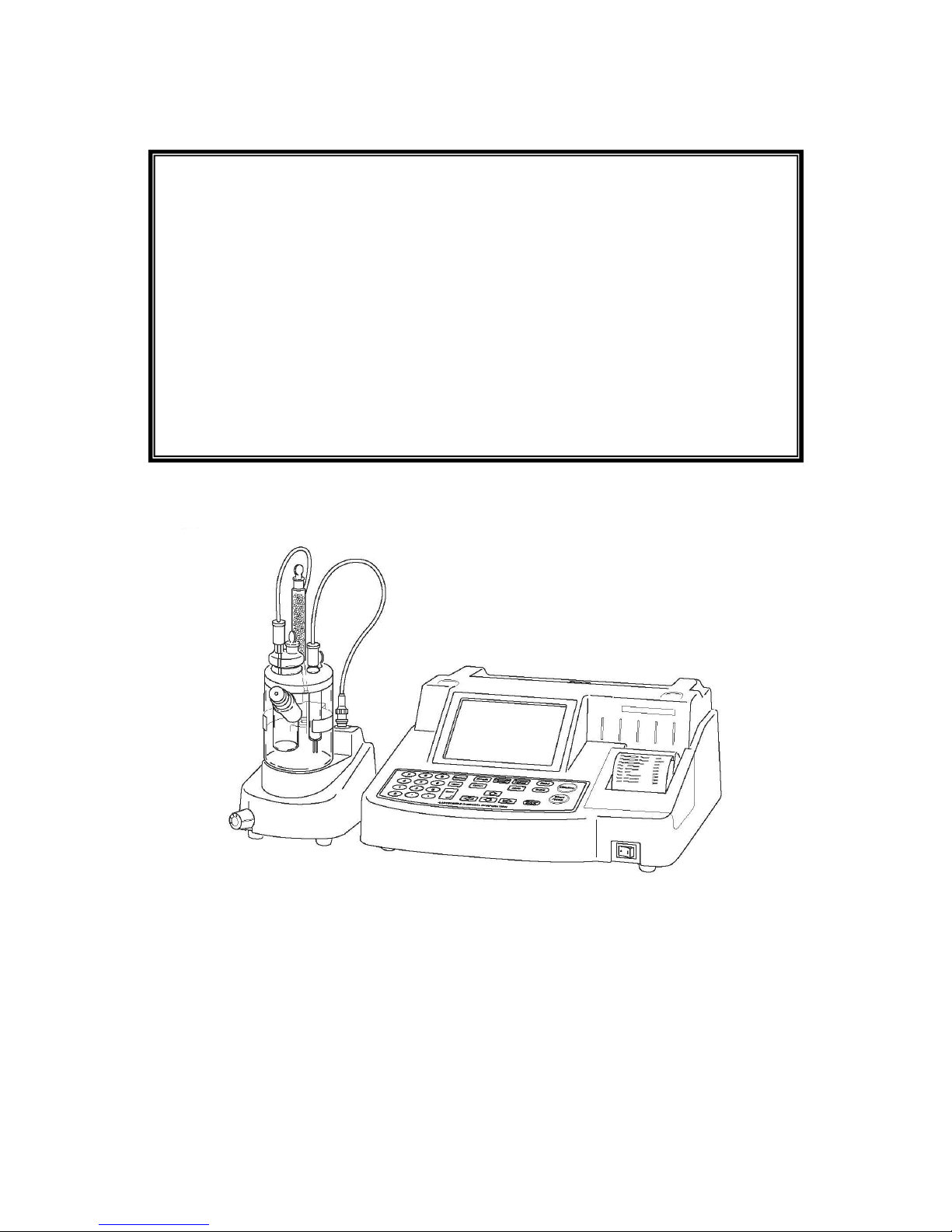

Mitsubishi CA-200 Instruction Manual

Control No. ZCAEMAE-00

MITSUBISHI CHEMICAL CORPORATION

TOKYO, JAPAN

Instruction Manual

For

Moisture Meter

(Coulometric Titration)

Model CA-200

DECLARATION OF CONFORMITY

Application of Council Directives :

EC Electromagnetic Compatibility Directive : 89/336/EEC

Electrical Equipment Designed for Use within Certain Voltage Limits : 73/23/EEC

Standard to which Conformity is Declared :

EN61000-6-3: 2001, EN61000-6-1: 2001, EN61010-1/A2 (1995)

Manufacturer’s Name : Mitsubishi Chemical Corporation

Manufacturer’s Address : 370, Enzo Chigasaki, Kanagawa, Japan

EU Office Address : Prinzenallee 13 40549 Duesseldorf Germany

Type of Equipment : Laboratory Equipment

Model Name : Moisture Meter Model CA-200

Beginning of Serial Number : E1M00016

Month and year of Manufacture : July, 2006

I, the undersigned, hereby declare that the equipment specified above

conforms to the above Directives and Standards.

Masanori Hirai

General Manager

CA-200 Introduction

1

Introduction

Thank you for your purchase of our Moisture Meter Model CA-200.

This unit measures trace (10μg to 100mg) of moisture in liquid, solid, and gas samples.

To use Model CA-200 correctly and safely, appoint supervisors and operators.

* “Sicapent” in this manual is a Merck’s registered trademark.

Before the use

You should read this instruction manual with care before the use of the moisture

meter.

Keep the manual at hand to read it soon if necessary. When the moisture meter is

rearranged, also rearrange the manual.

Follow the contents in this manual. When troubles or damages occur by neglecting

the contents in this manual, we do not guarantee the unit even within the term.

CA-200 IMPORTANT SAFEGUARDS AND PRECAUTIONS

1

IMPORTANT SAFEGUARDS AND PRECAUTIONS

WARNING

Place Model CA-200 at the place where temperature is 5 to 40 degrees Celsius and

humidity is under 80%. The placement except these conditions causes troubles.

WARNING

Ground a power cable ground line or a ground terminal surely.

By touching the metal of Model CA-200 without grounding, you can get an electric

shock.

WARNING

As it thunders, do not connect a power cable. Danger of an electric shock by lightning

CAUTION

Do not place things in front of Model CA-200. When things are placed, the power switch

of the unit can’t be turned off emergently and accidents can be caused.

CAUTION

Do not connect many cords into outlets. Danger of a fire by outlet overheat

CAUTION

Place Model CA-200 at the place free from water, humidity, dust, and oily smoke.

Danger of a fire, breakage, and an electric shock

WARNING

Model CA-200 is not explosion prevention, so do not place flammable material near

Model CA-200. The placement except these conditions causes a fire and

an explosion.

IMPORTANT SAFEGUARDS AND PRECAUTIONS CA-200

2

WARNING

After stopping the unit or at the parts change, repair, and inspection, pull off the main

power plug necessarily to avoid an electrical shock.

WARNING

Pull out a power plug while holding it not to disconnect or short-circuit in a plug or a

cord.

WARNING

Put on protective goggles and gloves necessarily when using reagents. Without putting

on them, skin disorder and blindness can be caused.

CAUTION

Do not impact exposed glass not to break it. Fragments and scatter cause accidents.

WARNING

Never disassemble or remodel the unit. Contact our distributors if necessary.

WARNING

When a trouble happens, immediately notify the fact to the person in charge and take an

emergency measure. If the cause is unclear or the problem is not solved, never restart the

unit.

CA-200 Table of Contents

1

Table of Contents

Section 1: Measurement Principle

1-1

Section 2: Installation and Assembly

2-1. Installation 2-1

2-1-1. Unpacking and contents check 2-1

2-1-2. Place for installation 2-5

2-1-3. Power supply 2-5

2-2. Assembly 2-6

2-2-1. Titration cell 2-6

2-2-2. Stirrer connection 2-7

2-2-3. Printer roll paper setting 2-8

Section 3: Names and Functions of Model CA-200

3-1. Main unit front 3-1

3-2. Main unit rear 3-2

3-3. Titration cell 3-3

3-4. Keypad 3-4

3-5. Display 3-6

3-5-1. 1 CH measurement indication 3-6

3-5-2. 1 CH menu indication 3-7

3-5-3. 2 CH measurement indication 3-8

3-5-4. 2 CH menu indication 3-9

3-6. Connection of optional units 3-10

3-6-1. CA-200 CH2 (channel 2) 3-10

3-6-2. KF-200 buret set 3-11

3-6-3. Moisture vaporizes 3-11

3-6-4. Electronic balance 3-11

3-6-5. Personal computer 3-11

3-6-6. Reagent supply and drain unit 3-11

3-6-7. Fritless cathode solution cell 3-11

Section 4: Measurement Preparation

4-1. Cautions 4-1

4-1-1. Caution in handling reagents 4-1

4-1-2. Caution in measurement 4-1

4-2. Titration cell preparation 4-2

Table of Contents CA-200

2

Section 5: Moisture Measurement Mode

5-1. Moisture measurement mode flow 5-1

5-2. Titration cell dehydration 5-3

5-3. File selection 5-4

5-3-1. File Composition 5-4

5-3-2. File selection 5-5

5-3-3. Multi-file selection 5-5

5-4. Parameters setting 5-6

5-4-1. Titration parameter setting 5-6

5-4-2. Titration parameters 5-6

5-4-3. Sample parameters setting 5-13

5-5. Sampling 5-17

5-5-1. Liquid sample sampling 5-17

5-5-2. Solid and powder sample sampling 5-19

5-5-3. Gaseous sample sampling 5-19

5-6. Measurement 5-20

5-6-1. Blank measurement 5-20

5-6-2. Recovery measurement 5-21

5-6-3. Sample measurement 5-21

5-7. Measurement end 5-21

Section 6: Function

6-1. Recalculation 6-2

6-1-1. Result list indication 6-2

6-1-2. Recalculation 6-3

6-2. Statistical calculation 6-3

6-2-1. Internal statistical calculation 6-4

6-2-2. External statistical calculation 6-4

6-3. Reagent consumption setting 6-5

6-4. File Setting 6-6

6-4-1. File protect setting 6-6

6-4-2. Multi file setting 6-7

6-4-3. Option formula setting 6-14

6-4-4. Option unit setting 6-14

6-5. Setting 6-15

6-5-1. Mode change 6-15

6-5-2. Calendar setting 6-16

6-5-3. Display setting 6-16

6-5-4. User management 6-16

6-5-5. Other details 6-19

6-5-6. Memory initialize 6-19

CA-200 Table of Contents

3

6-6. Communication setting 6-20

6-6-1. Balance setting 6-20

6-6-2. OPTION 1 setting 6-20

6-6-3. OPTION 2 setting 6-20

6-7. Validation 6-21

6-7-1. Hardware validation 6-21

6-7-2. Measurement validation 6-22

Section 7: Option

7-1. USB memory 7-1

7-1-1. Export 7-1

7-1-2. Import 7-3

7-1-3. Result format 7-4

7-2. Evac. unit 7-6

Section 8: Maintenance and Inspection

8-1. Inspection

8-1

8-1-1. Daily inspection 8-1

8-1-2. Regular inspection 8-2

8-2. Titration cell handling 8-3

8-2-1. Maintenance 8-3

8-2-2. Washing 8-4

8-3. Keeping of reagent for moisture measurement 8-5

8-3-1. Keeping 8-5

8-3-2. Caution in handling 8-5

8-3-3. Reagent change 8-5

Section 9: Troubleshooting

9-1. Help 9-1

9-2. Troubleshooting 9-2

9-3. Error messages 9-8

Section 10: Specifications

10-1

Section 11: Parts List

11-1. Titration cell 11-1

11-2. Sampler 11-3

11-3. Consumables 11-4

11-4. Option 11-4

11-5. Part pictures

11-5

Table of Contents CA-200

4

CA-200 Section 1: Measurement Principle

1-1

Section 1: Measurement Principle

Model CA-200 measures moisture by applying Karl Fischer reaction to coulometric titration.

In this coulometric titration, supply electrolytic solution mainly composed of iodide ions, sulfur

dioxide, and alcohol to a titration cell. Iodine for titration is internally generated by electrolysis.

* Karl Fischer reaction

Water reacts with iodine and sulfur dioxide in base and alcohol.

H2O + I2 + SO2 + ROH + 3Base 2Base • HI + Base.....HSO4R (1)

* Coulometric titration

Iodine is generated from iodine ions by electrolysis in the anode solution containing iodine ions.

2I - - 2e I

2··········································································································································

(2)

When iodine generated by the reaction of the formula (2) is consumed according to the formula

(1), the consumption of iodine is detected by a detector electrode and iodine is generated again

from an anode by electrolysis according to the formula (2). The generated iodine is proportional to

electric quantity by “Faraday’s law”.

From the formula (1), the ratio of reaction of H2O and I2 is 1 : 1.

Therefore, 1 mol (18g) of water corresponds to 2×96500 coulombs and 1mg of water

corresponds to 10.72 coulombs.

Based on the above principle, moisture content is calculated from the electricity for electrolysis.

Section 1: Measurement Principle CA-200

2-2

CA-200 Section 2: Installation and Assembly

2-1

Section 2: Installation and Assembly

2-1. Installation

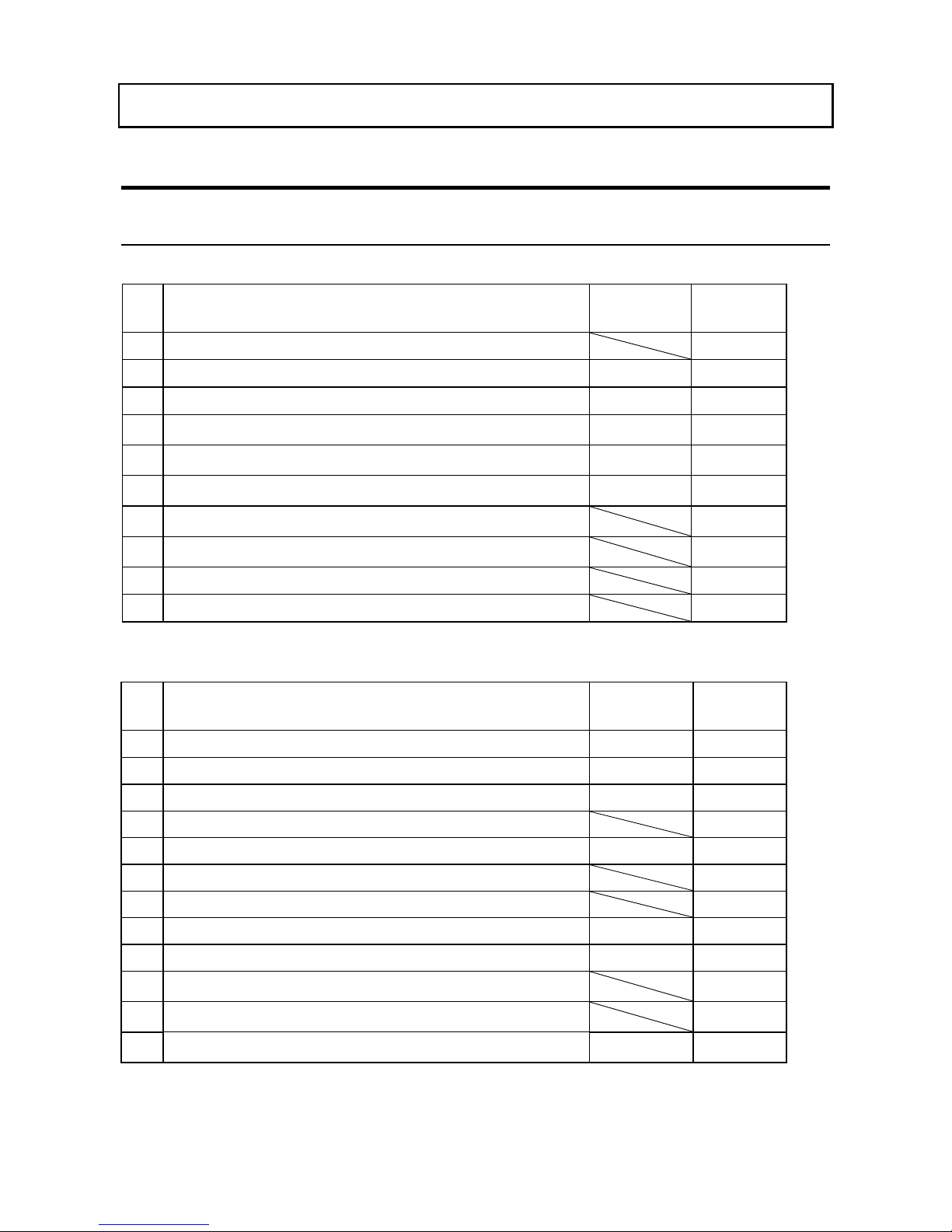

2-1-1. Unpacking and contents check

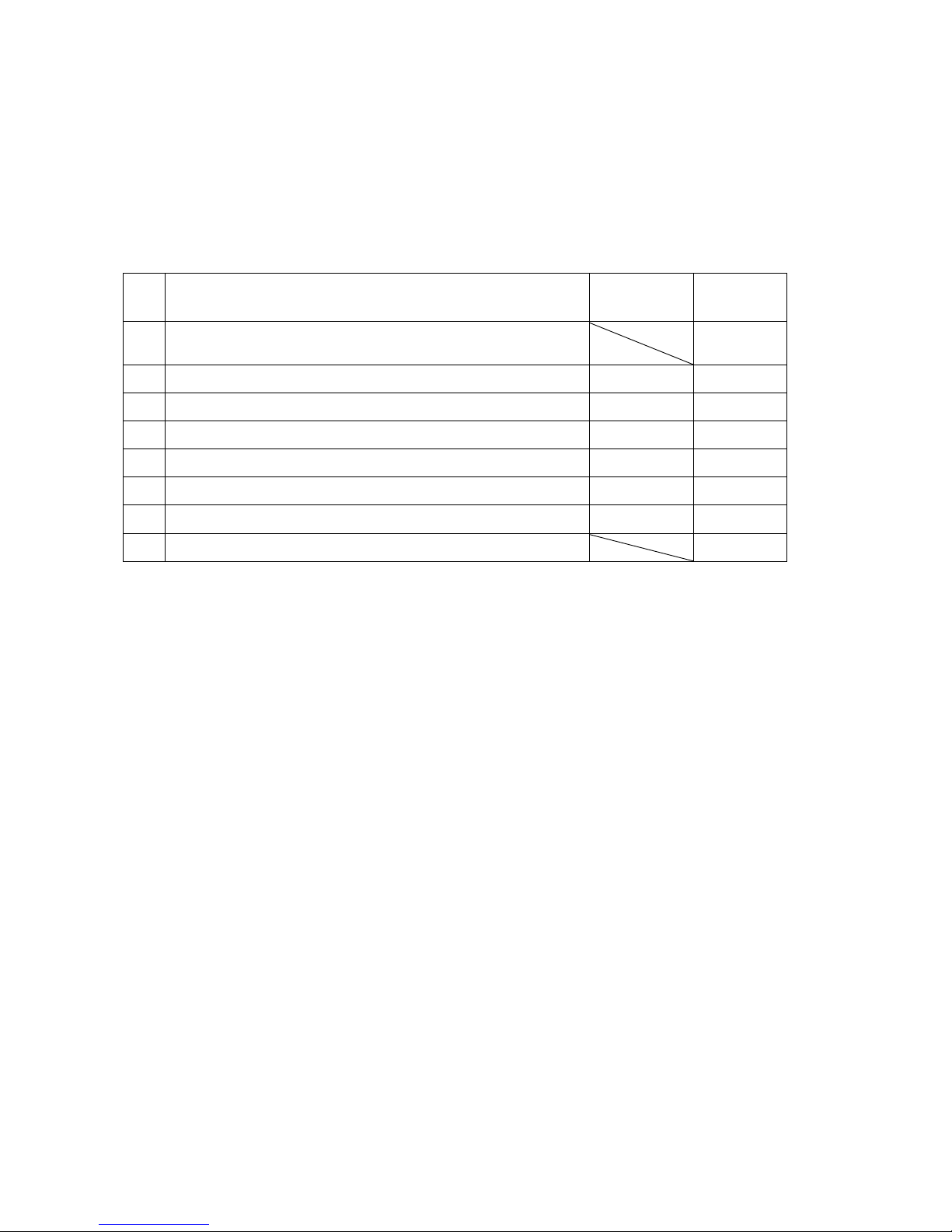

Packing box A: 1 set

No.

Part names Part

numbers

Quantity

1

CA-200 unit

1 set

2

CA-200 stirrer

CAESTR

1 set

3

Fuse 2.5A φ5.2/20 midget slow-blow

FU25MS

2 pcs/set

4

Printer roll paper

PRIPR4

1 set

5

Rubber packing φ10/2 t

CAMGPC

100 pcs/set

6

Silicon rubber chip small 10/10/5 t

CAMSIG

50 pcs/set

7

Grease 3g

1 set

8

Silica gel 100g

1 set

9

Cotton ball

50 pcs/set

10

Stirrer number sticker

1 pc

Packing box B: 1 set

No.

Part names Part

numbers

Quantity

11 Generator solution cell without a drain port CAMGC4

1 set

12 Detection electrode (BNC) CAMDEB 1 pc

13 Cathode solution cell (with a sealing plug, BNC) CA20CE 1 set

14

Sealing plug long φ12/12L 1 pc

15

Drying tube large (with a plug) CAM011 1 set

16

Stirrer bar φ35L 1 pc

17

Sample injection plug 1 pc

18

Polyethylene funnel (L) KF1050 1 pc

19

Polyethylene funnel (S) CARTS 1 pc

20

Pipette (For discharge) 1 pc

21

Lock-type syringe 1ml (with a needle) 1 set

22

Drain bottle 500ml (washing bottle-type) CAEVBL 1 pc

Section 2: Installation and Assembly CA-200

2-2

Packing box C: 1 set

No.

Part names Part

numbers

Quantity

23 CA-200 instruction manual (this manual) ZCAEMAE

1 pc

24 Balance interface specifications ZCAEBIE

1 pc

25 Power cable (100/ 120 or 230/ 240V) CAM085

1 pc

26 2P-3P converting plug (120V only) CAM083

1 pc

27 Check solution P (100ml)

1 pc

For 2 channels specifications, the following attachments are added to the above packing boxes A, B, C.

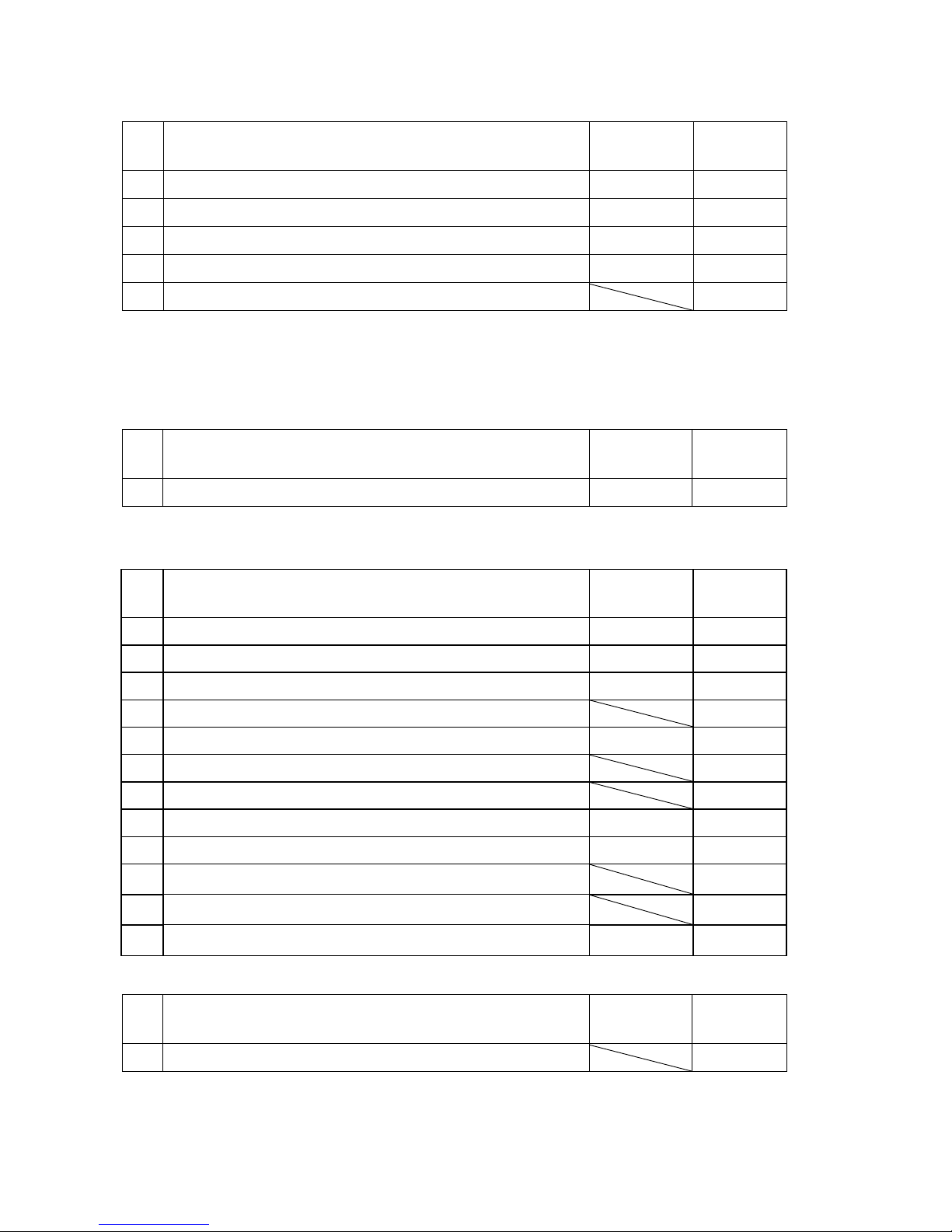

1. Coulometric-method- Coulometric method

Attachment added to Packing box A

No

.

Part names Part

numbers

Quantity

28 CA-200 stirrer CAESTR

1 set

One set of packing box B is added to be two sets.

No.

Part names Part

numbers

Quantity

29 Generator solution cell without a drain port CAMGC4

1 set

30 Detection electrode (BNC) CAMDEB 1 pc

31 Cathode solution cell CA20CE 1 set

32 Sealing plug long φ12/12L 1 pc

33 Drying tube large (with a plug) CAM011 1 set

34 Stirrer bar φ35L 1 pc

35 Sample injection plug 1 pc

36 Polyethylene funnel (L) KF1050 1 pc

37 Polyethylene funnel (S) CARTS 1 pc

38

Pipette (discharge) 1 pc

39

Lock-type syringe 1ml (with a needle) 1 set

40

Drain bottle 500ml (washing bottle-type) CAEVBL 1 pc

Attachment added to Packing box C

No

.

Part names Part

numbers

Quantity

41 Check solution P

1 pc

CA-200 Section 2: Installation and Assembly

2-3

2. Coulometric-method- Volumetric method

Attachment added to Packing box A

No.

Part names Part

numbers

Quantity

42

KF-200 stirrer

KFESTR

1 sets

One set of the following packing box is added.

No.

Part names Part

numbers

Quantity

43 Titration flask body A-2 type (without a drain port) KFA202

1 set

44 Titration flask cap (with an O-ring) KF7FCP

1 set

45 Titration flask cap screw KF10N1

3pcs/set

46

Detection electrode (BNC) KF7DTE

1 pc

47

Sealing plug long φ12/12L

1 pc

48

Sealing plugφ12/12L

CAMBLS

2 pcs/set

49

Drying tube with a three-way cock KF1006

1 set

50

Stirrer bar φ30L

1 pc

51

Sample injection plug

1 set

52

Polyethylene funnel (L) KF1050

1 pc

53

Lock-typesyringe 2ml (with a needle)

1 set

54

Drain bottle 500ml (washing bottle-type) CAEVBL

1 pc

Attachment added to Packing box C

No.

Part names Part

numbers

Quantity

55 KF-200 instruction manual ZKFEMAE

1 pc

One set of Packing box D is added.

No.

Part names Part

numbers

Quantity

56

KF-200 buret drive

(a protective cover, a holder, a tray)

1 set

57 Syringe buret, 10ml KFEBS7

1 set

58 Valve line set φ3 KF7TB9

1 set

59 Buret nozzle φ3M7 KF5BNZ

1 pc

60 Buret nozzle holder

1 pc

61 Reagent bottle cap kit (with a desiccant tube) GTCPK5

1 set

62 Dropper bottle small (for titer determination)

1 set

63 Drive signal cable (single) KF8CB1

1 set

64 Buret number sticker

1 pc

Section 2: Installation and Assembly CA-200

2-4

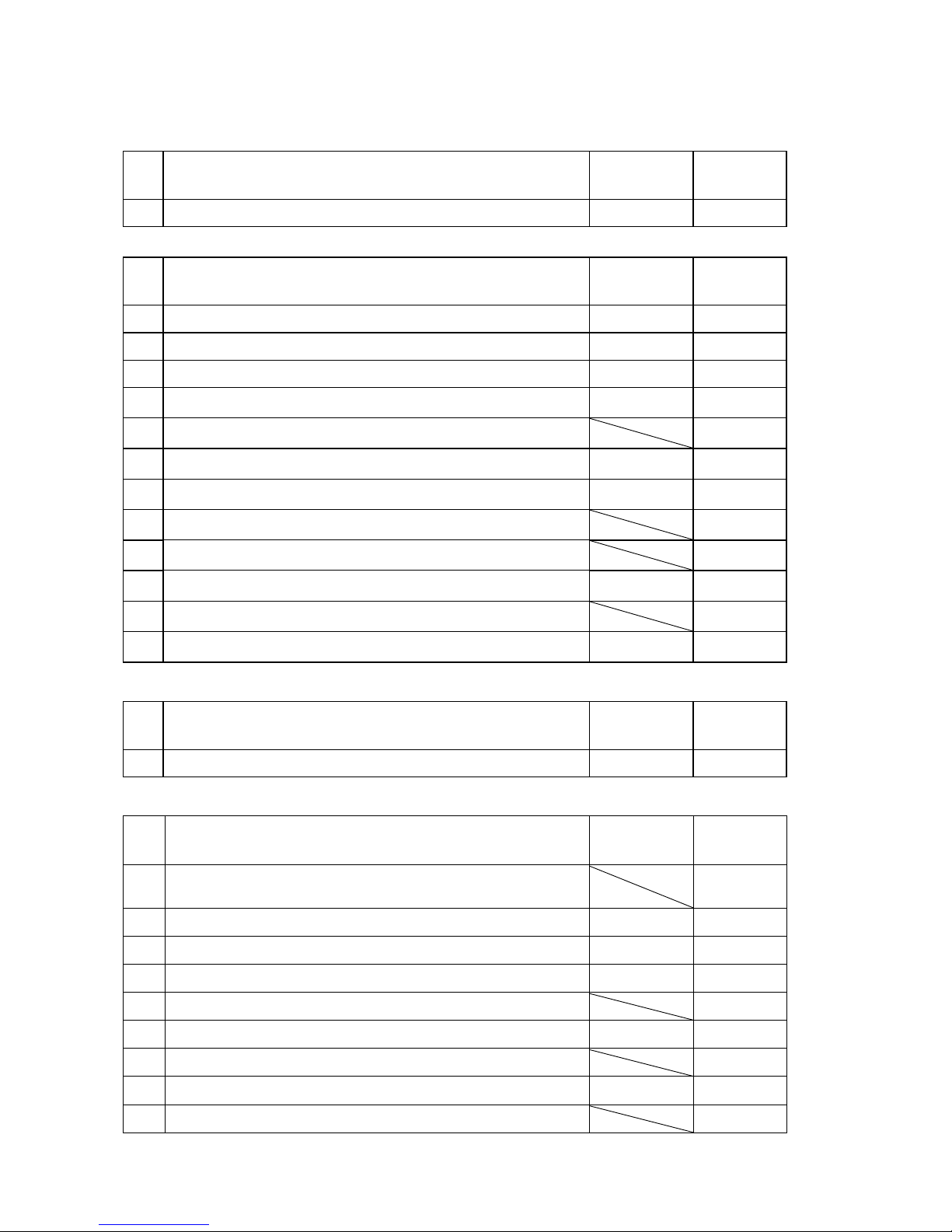

3. Coulometric-method- Volumetric method (Double)

The following attachments are added to Coulometric method - Volumetric method (Single).

One set of packing box D is added to be two sets.

* A drive signal cable (double) is attached and a dropper bottle small is not attached.

No.

Part names Part

numbers

Quantity

65

KF-200 buret drive

(a protective cover, a holder, a tray)

1 set

66 Syringe buret, 10ml KFEBS7

1 set

67 Valve line set φ3 KF7TB9

1 set

68 Buret nozzle φ3M7 KF5BNZ

1 pc

69 Buret nozzle holder KF6NZ1

1 pc

70 Reagent bottle cap kit (with a desiccant tube) GTCPK5

1 set

71 Drive signal cable (double) KF8CB1

1 set

72 Buret number sticker

1 pc

CA-200 Section 2: Installation and Assembly

2-5

2-1-2. Place for installation

(1) No large temperature changes, corrosive gas, dust, vapor, and direct sunlight

(2) The temperature should be 5 to 40 degrees Celsius and humidity should be under 80% without dew

drop.

(3) No electric and magnetic fields influence

POINT

Temperature change makes detection potential unstable and analysis accuracy

low. Direct sunlight causes liberation of iodine and analysis values are low.

2-1-3. Power supply

Connect a power cable apart from other units (large motors, dryers etc.) which generate noise.

In addition, connect it at the place where power change is within ±10%.

Use a 3P outlet with a ground or a 2P-3P adapter to ground firmly.

WARNING

If you touch the chassis metal part when an earth terminal is not grounded

completely, you get a shock.

Section 2: Installation and Assembly CA-200

2-6

2-2. Assembly

2-2-1. Titration cell

Remove each part of a titration cell and spread lightly contacting parts with attached exclusive grease.

Put cotton balls and silica gel into a drying tube.

POINT

Necessarily use exclusive grease. Particularly when moisture adsorbs to the ceramic

septum of a cathode solution cell, much time is required until the widow condition

indication is stable. After leaving a cell in the air for a long time, dry it with a dryer and

assemble it.

(1) Put a titration cell to a stirrer stand so that a sample injection plug is at the front.

(2) Insert the BNC connector 1 of a detection electrode into the right connection jack (green). Insert

the BNC connector 2 of a cathode solution cell into the left connection jack (blue). Turn the cell

right to fix it.

Illustration 2-1. Titration flask assembly

1

2

CA-200 Section 2: Installation and Assembly

2-7

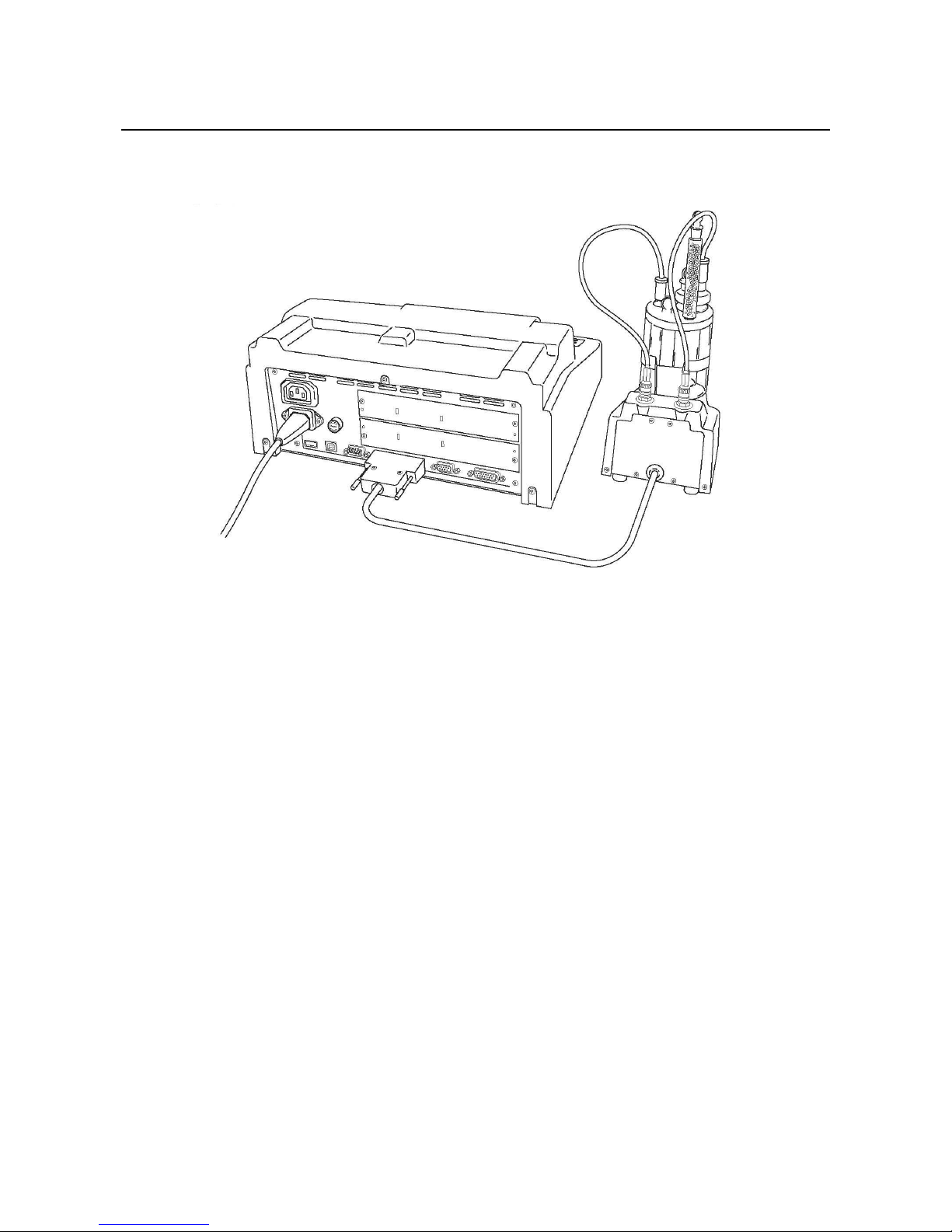

2-2-2. Stirrer connection

Connect a stirrer cable to “STIRRER 1” of the unit rear.

Illustration 2-2. Connection of a stirrer to the unit

* For 2 channels specifications, connect the second stirrer cable to CH2 board “STIRRER2”.

Section 2: Installation and Assembly CA-200

2-8

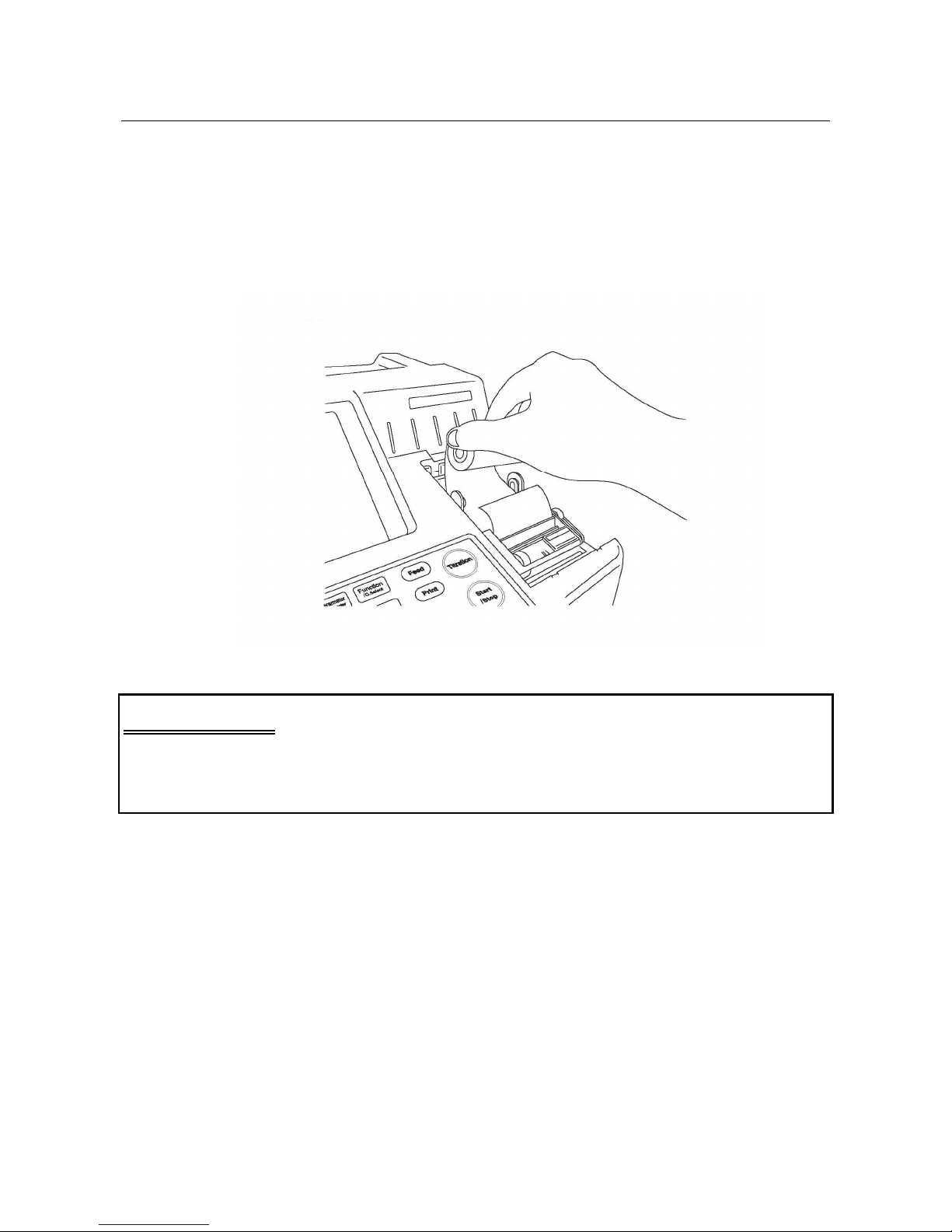

2-2-3. Printer roll paper setting

(1) Take off a printer cover. Do not take off it forcibly.

(2) Cut the end of printer paper in a perpendicular direction to the feed direction. Put the paper from a

roll paper inlet so that the back of paper faces to this side.

(3) Raise a lever, pass paper so that printing side is downside, and lower the lever.

(4) Pass roll paper through the cover and set the cover.

Illustration 2-3. Printer roll paper setting

CAUTION

After paper setting, set a printer cover necessarily.

The cutter of a printer cover is sharp.

Take care not to get hurt at the setting.

CA-200 Section 3: Names and Functions of Model CA-200

3-1

Section 3: Names and Functions of Model CA-200

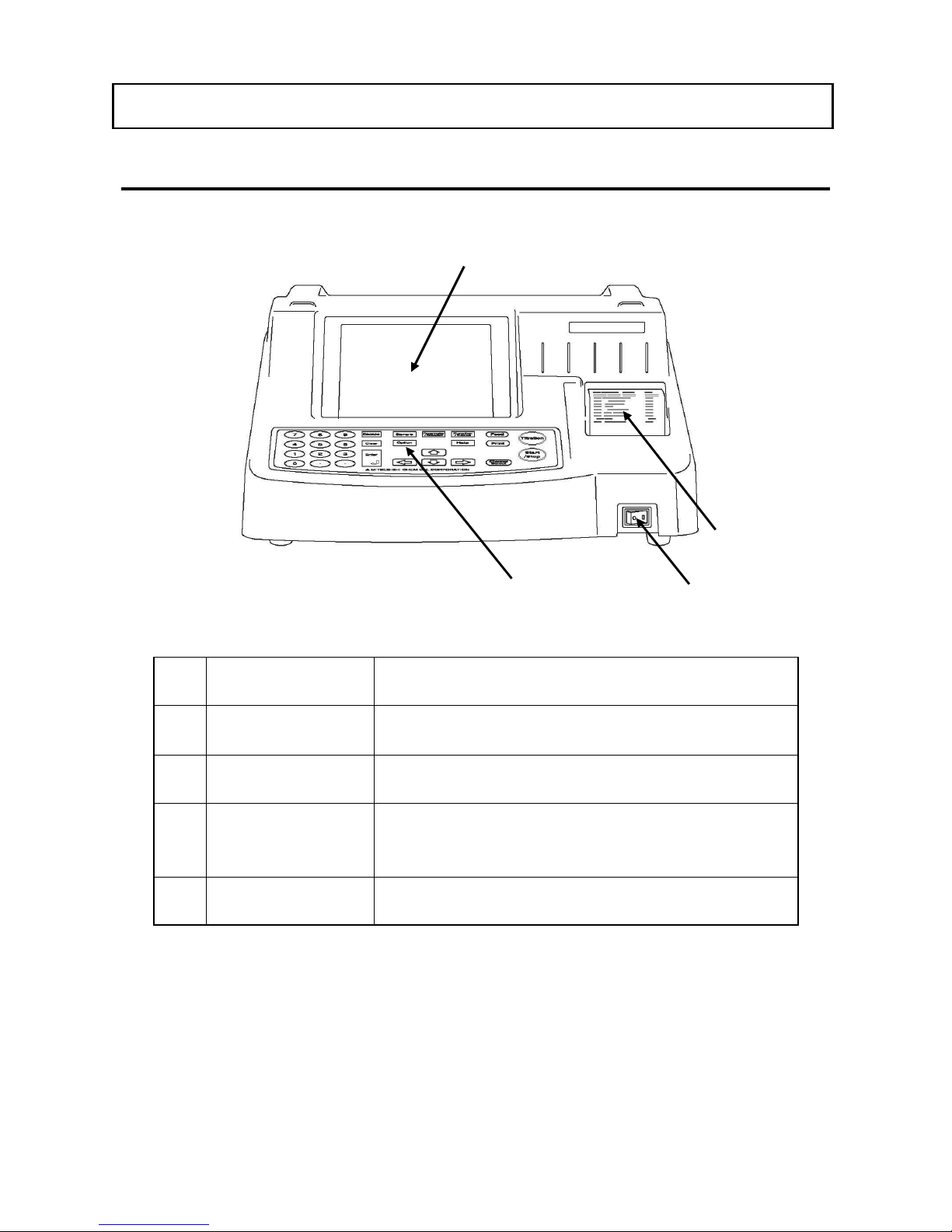

3-1. Main unit front

Illustration 3-1. Main unit front

No

.

Names Functions

1 Power switch

By pressing [|] side, power is on. By pressing [○] side,

power is off.

2 Display

It is 5.7 inches color LCD and displays setting and

operation information and error messages.

3 Keypad

For titration start, stop, and sample weight input

For keypad operation, display, and each input setting,

refer to 5. Moisture Measurement Mode.

4 Printer

Titration parameters, measurement result, and graphs are

printed.

Table 3-1. Main unit front

2

3

4

1

Section 3: Names and Functions of Model CA-200 CA-200

3-2

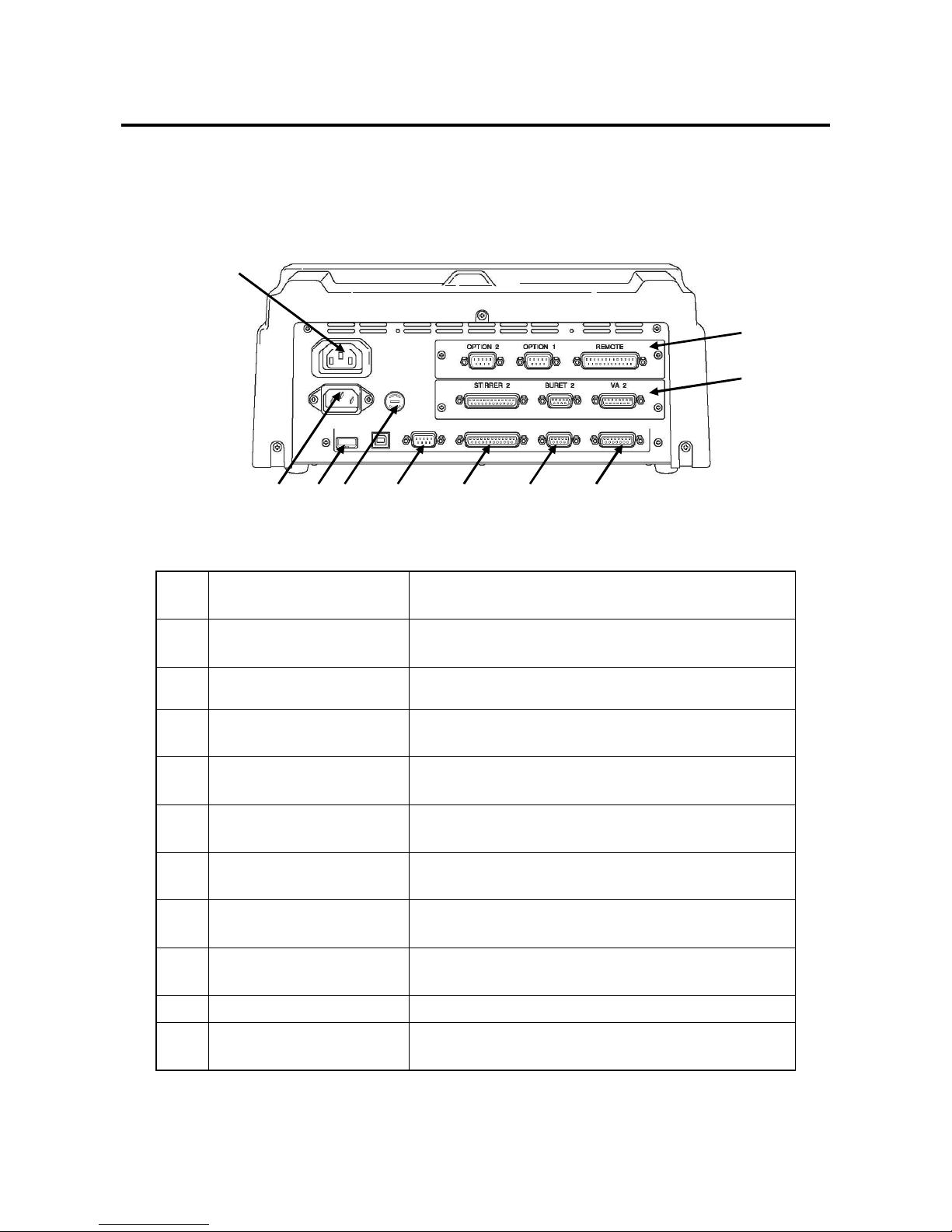

3-2. Main unit rear

No

.

Names Functions

1

Power cable connection

port

For connecting a power cable

2

Fuse holder

For setting a 2.5A fuse

Pull it with a flathead screwdriver.

3

VA power cable

connection port

For connecting a vaporizer power cable

4

Stirrer cable connection

port

For connecting a stirrer cable

5

VA signal connection

port

For connecting a vaporizer signal cable

6

USB memory

connection port

For connecting an USB memory

7

Balance signal

connection port

For connecting a balance signal cable

8

Buret signal connection

port

For connecting a KF-200 buret signal cable

9 CH2 board For 2 channels simultaneous measurement

10

Personal computer

interface board

For an external dot printer and RS-232C

communication

Table 3-2. Main unit rear

1 2

3

4 5 6

7 8

9

10

VA

POWER

a.c.

POWER

FUSE

2.5A

USB A USB B BALANCE STIRRER 1 BURET 1

VA 1

Illustration 3-2. Main unit rear

CA-200 Section 3: Names and Functions of Model CA-200

3-3

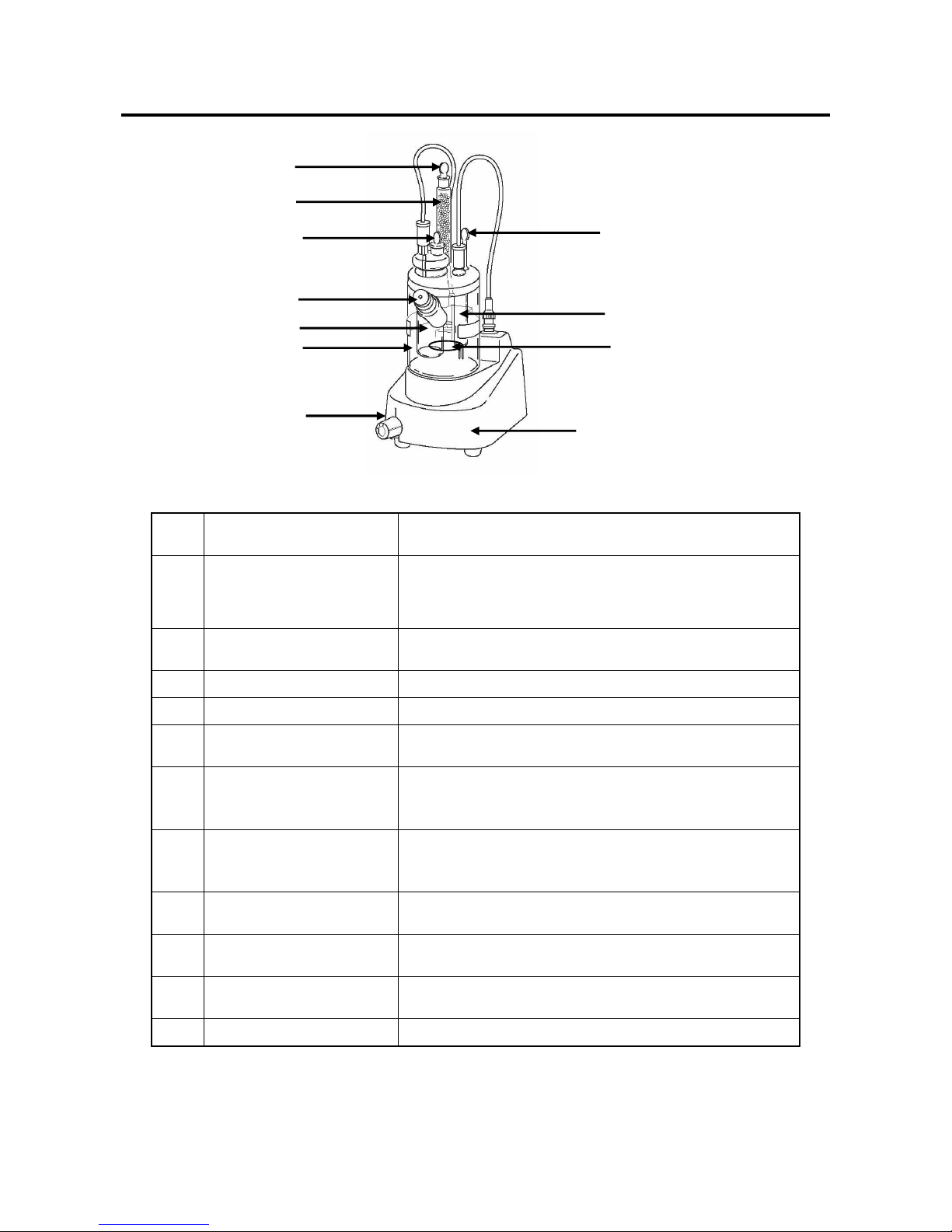

3-3. Titration cell

No

.

Names Functions

1 Speed adjustment knob

For adjusting stirrer bar rotation speed

Usually set it to “2 to 3”. By setting it to “0”, a stirrer

bar stops.

2 Stirrer bar 35L

For stirring evenly anode solution (generator

solution), samples, and iodine

3 Sample injection port For injecting liquid sample from here with a syringe

4 Generator solution cell For Karl Fischer reaction

5

Detection electrode

(BNC)

For potential detection

6

Sealing plug long

φ12/12L

Open a sealing plug and inject powdery and solid

samples. Moisture can be prevented from pouring into

a generator solution cell.

7

Drying tube plug

φ10/12L

(with ventilation)

With a gap to discharge gas at much sample injection,

8 Drying tube (Large)

For preventing moisture from pouring into a generator

solution cell

9

Sealing plug for

cathode solution cell

For preventing moisture from pouring into a cathode

solution cell

10

Cathode solution cell

(BNC)

For iodine generation from anode platinum mesh

11

Stirrer number Attach a stirrer number sticker.

Table 3-3. Titration cell

1

2

3

4

5

6

7

8

9

10

11

CH.1

Illustration 3-3. Titration cell

Section 3: Names and Functions of Model CA-200 CA-200

3-4

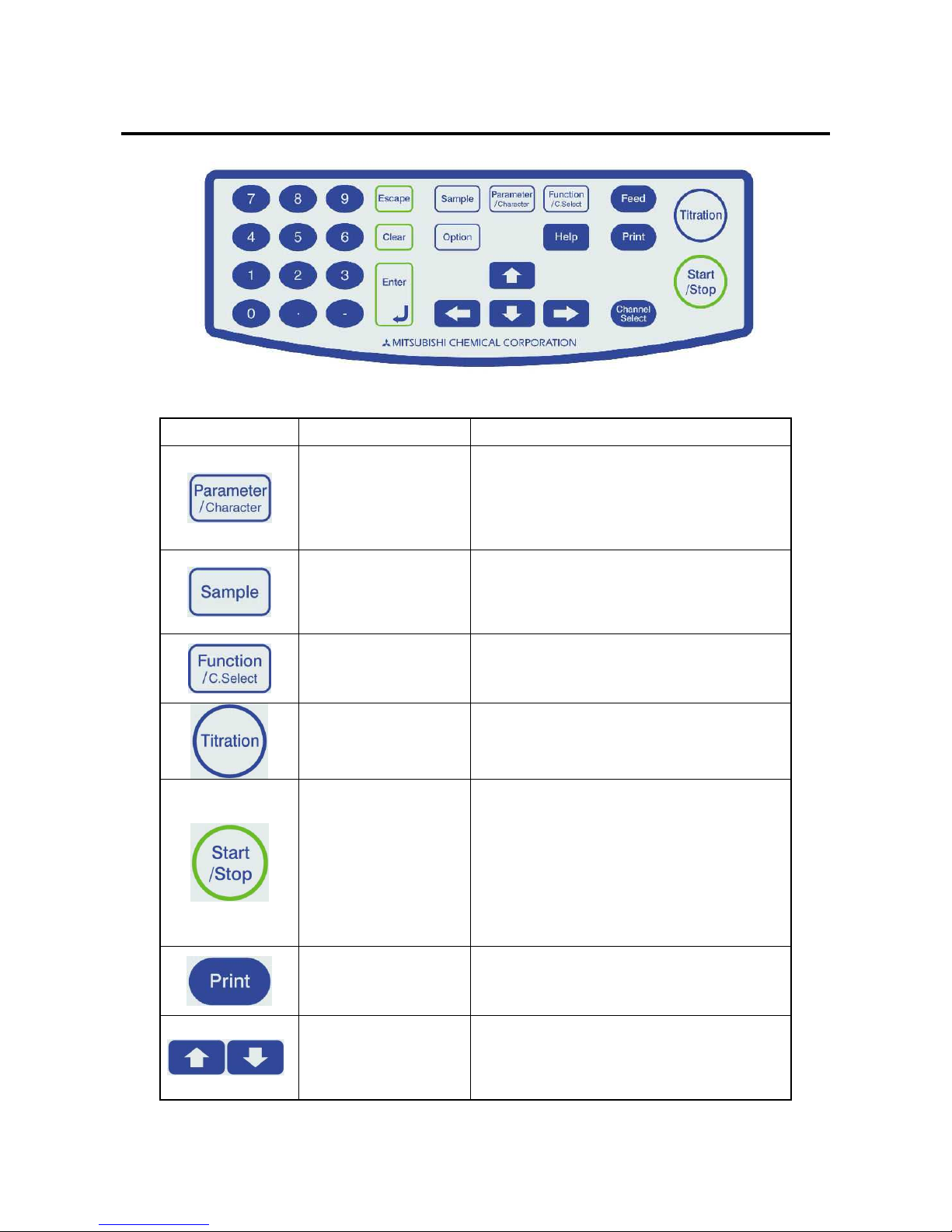

3-4. Keypad

Illustration 3-4. Keypad

Displays Names Functions

Parameter/Character

key

1. For parameter setting

Parameters can be set regularly and

changed during titration.

2. The name input window is indicated at

name input.

Sample key

For sample parameter setting

It can be set regularly.

If required mass is not set, input is waited

after titration.

Function/ C. Select

key

1. For each function selection

2. Unavailable during measurement.

Titration key

1. For setting titration to ON or OFF

2. For suspending titration and returning

to the initial titration window

Start/Stop key

1. For starting moisture measurement and

ending it forcibly

2. For canceling operations during

dehydration waiting, delay, purge,

pre-baking, and cooling to proceed to

the next step

3. For stopping KF-200 piston up and

down (at buret manual operation)

Print key

1. For printing statistical calculation

result, file contents, and data

2. Unavailable during titration

UP and Down arrow

keys

1. For transferring to items and

selecting characters

2. For KF-200 piston up and down

(at buret manual operation)

Table 3-4. Keypad

CA-200 Section 3: Names and Functions of Model CA-200

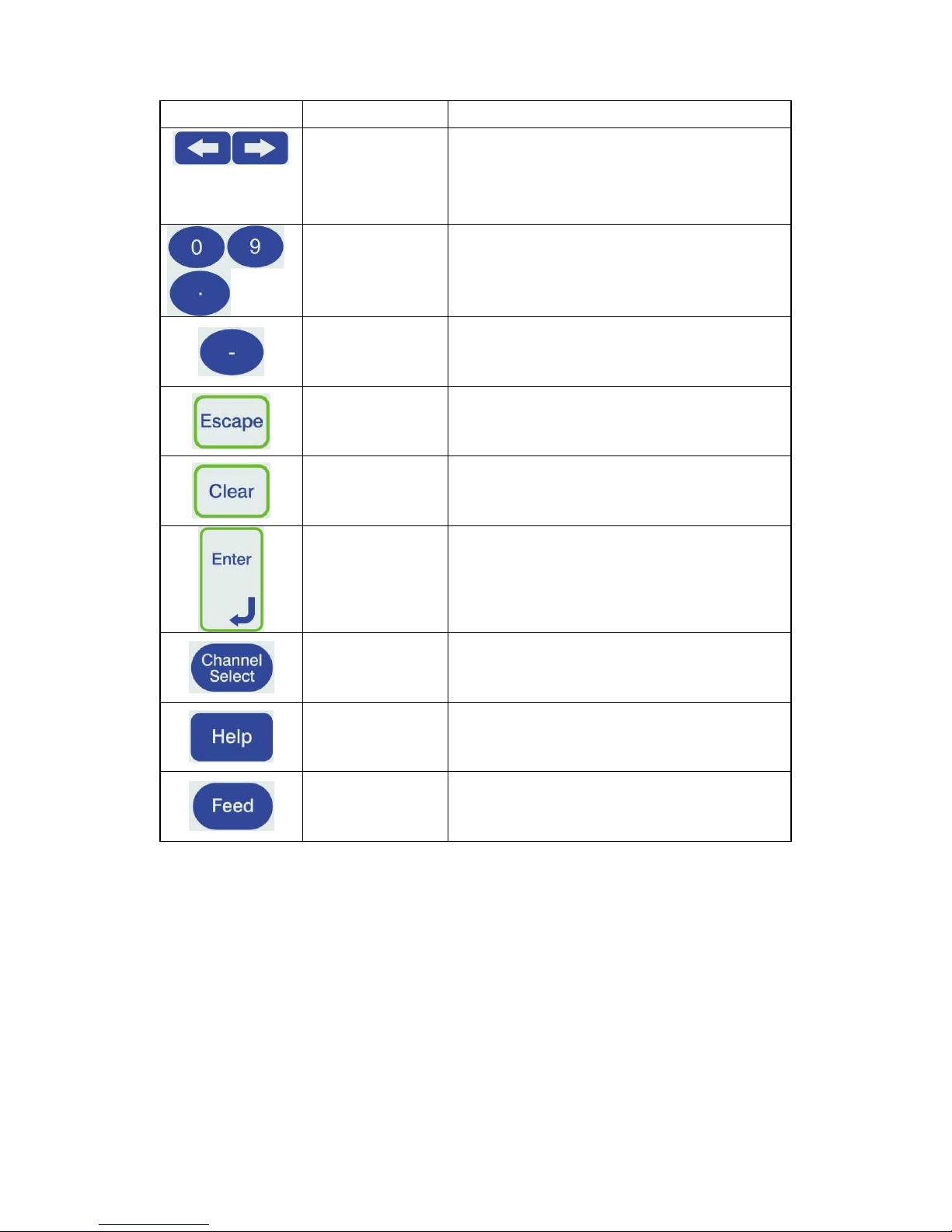

3-5

Displays Names Functions

Left and right

arrow keys

1. For changing parameters and selecting

characters

2. For KF-200 valve selection

(at buret manual operation)

Number keys

1. For menu selection, titration and sample

parameter input

2. For sample size decimal points

Bar key

For name input.

Escape key

1. For suspending the setting.

2. For returning to the previous window

Clear key

For deleting the right indication from the

cursor position

Enter key

For determining contents and menus

Channel Select

key

Available when a 2CH board is installed

In channel selection, it beeps once for CH1

and it beeps twice for CH2.

Help key

The help window is displayed to search

troubleshooting information.

Feed key

For paper feed

Unavailable during printing

Table 3-4. Keypad

Section 3: Names and Functions of Model CA-200 CA-200

3-6

3-5. Display

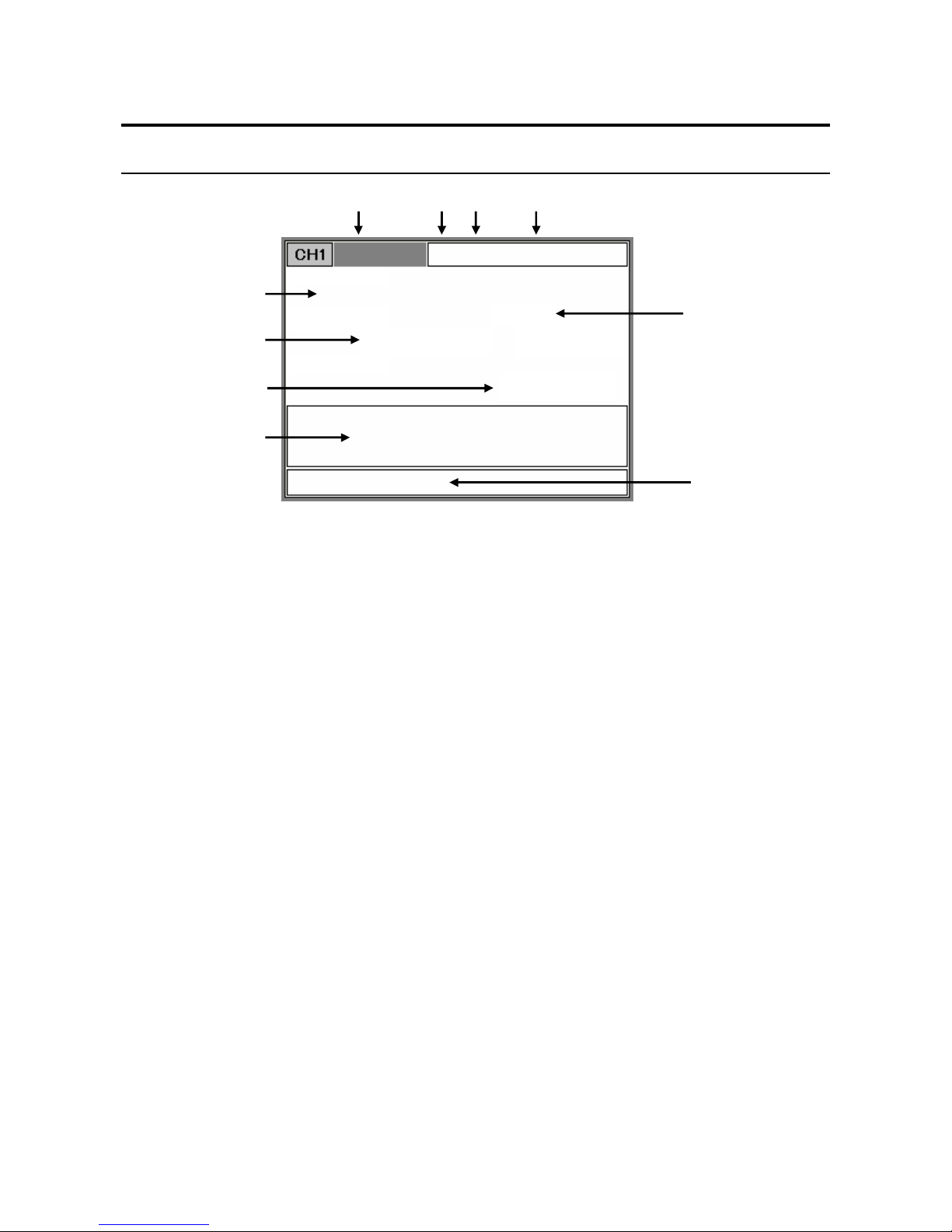

3-5-1. 1 CH measurement indication

1. Condition: Current conditions

Standby : When electrolysis is OFF

Conditioning 1 : At electrode conditioning

Conditioning 2 : Waiting for detection electrode stability

Wait : When titration speed is over 0.5 μgH2O/sec

(Measurement can’t be started.)

Ready : When titration speed is under 0.3 μgH2O/sec at the speed decrease

When titration speed is under 0.5 μgH2O/sec at the speed increase

Stable : When titration speed is under 0.1 μgH2O/sec

Delay : Waiting for delay: Set it at water vaporizer use.

Titration

2. File number: Selected numbers

3. Measurement number: 1 is added every measurement.

It is “1” automatically at power supply or file change.

4. Sample name: Up to 13 characters of a set name are indicated.

5. Time: Passed time (except delay time) from titration start

6. Titration speed: Titration speed (μgH2O/sec) is indicated by values.

7. Moisture: Moisture integrated value (μgH2O/sec) from titration start

8. Measurement result: Measurement values and units

9. B.G.: The passing time from measurement start (except delay time) is indicated.

1 2 3 4

ppm

5

6

7

8

00:11

F01-01 Sample A

134

4458.1

Press Titration key.

Time

Titration speed

Moisture

B.G

Stable

10

1234 μg

9

1.34 μg/s

0.01μg/s

CA-200 Section 3: Names and Functions of Model CA-200

3-7

10. Instructions: Operation guidance and contents description

“W” and “w” of weight result from a balance are indicated.

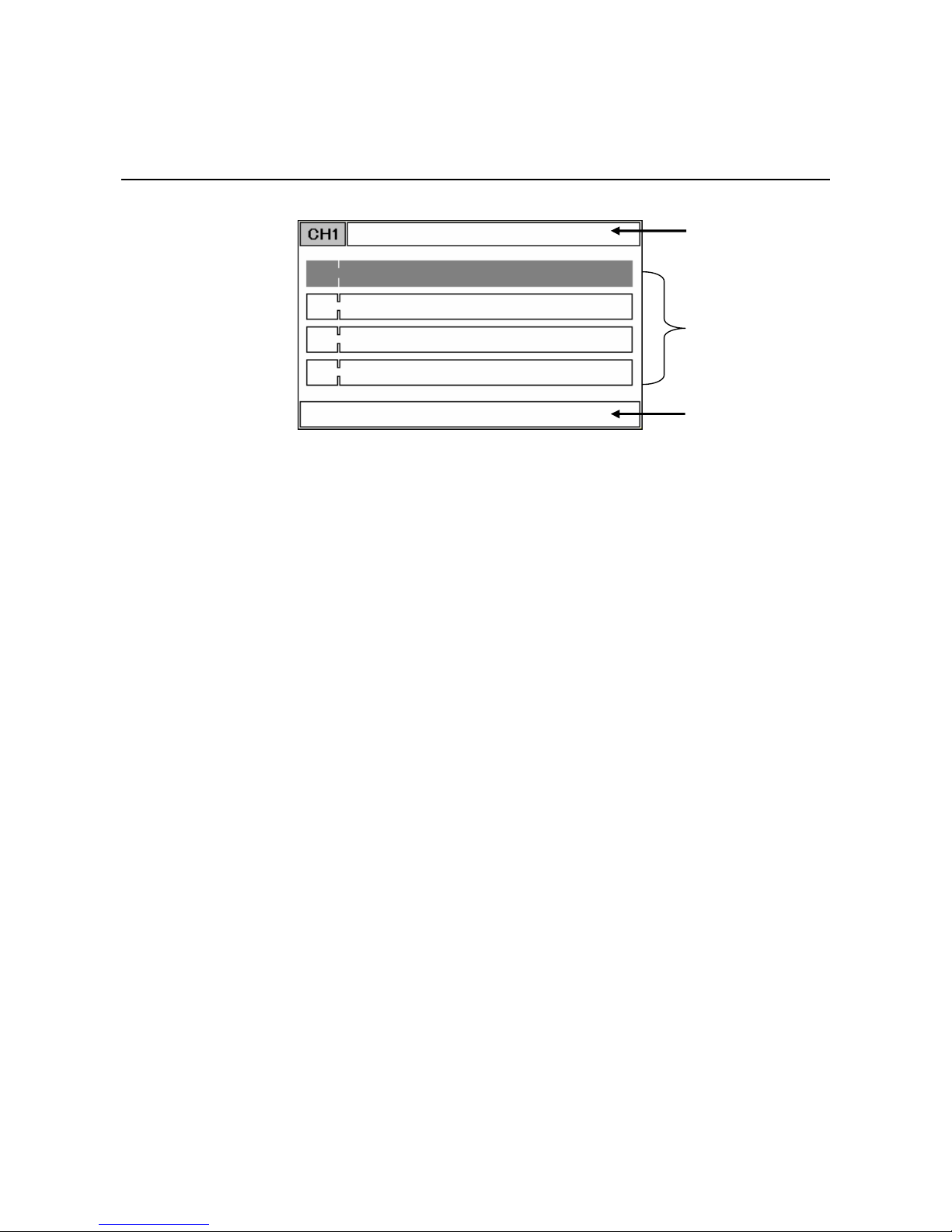

3-5-2. 1 CH menu indication

1. Title: Current menu contents

2. Menu items

3. Instructions: Operation guidance and contents description

Function menu

01 Recalculation

02 Statistical calculation

03 Reagent consumption

04 File setting

Select with ↑, ↓ and press Enter.

1

2

3

Section 3: Names and Functions of Model CA-200 CA-200

3-8

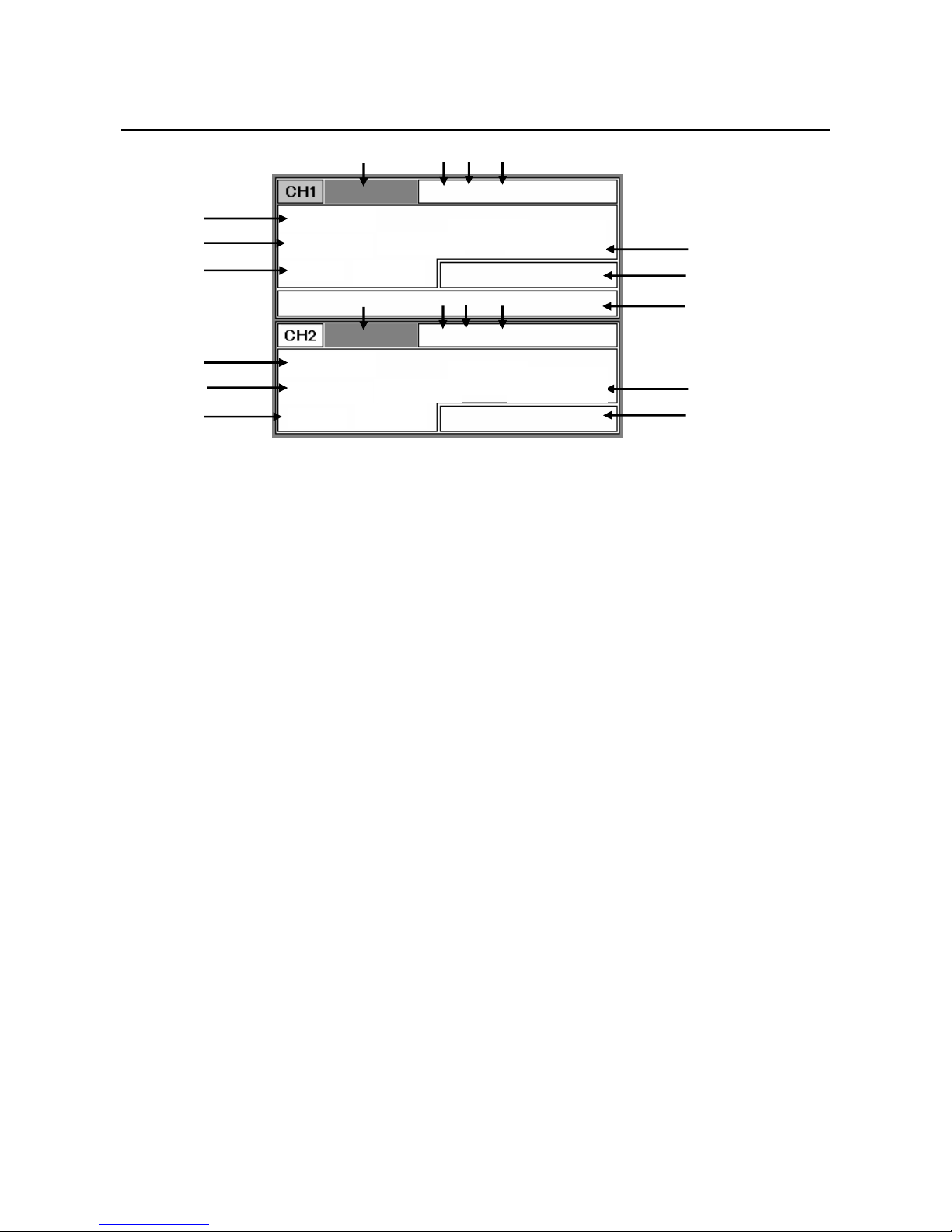

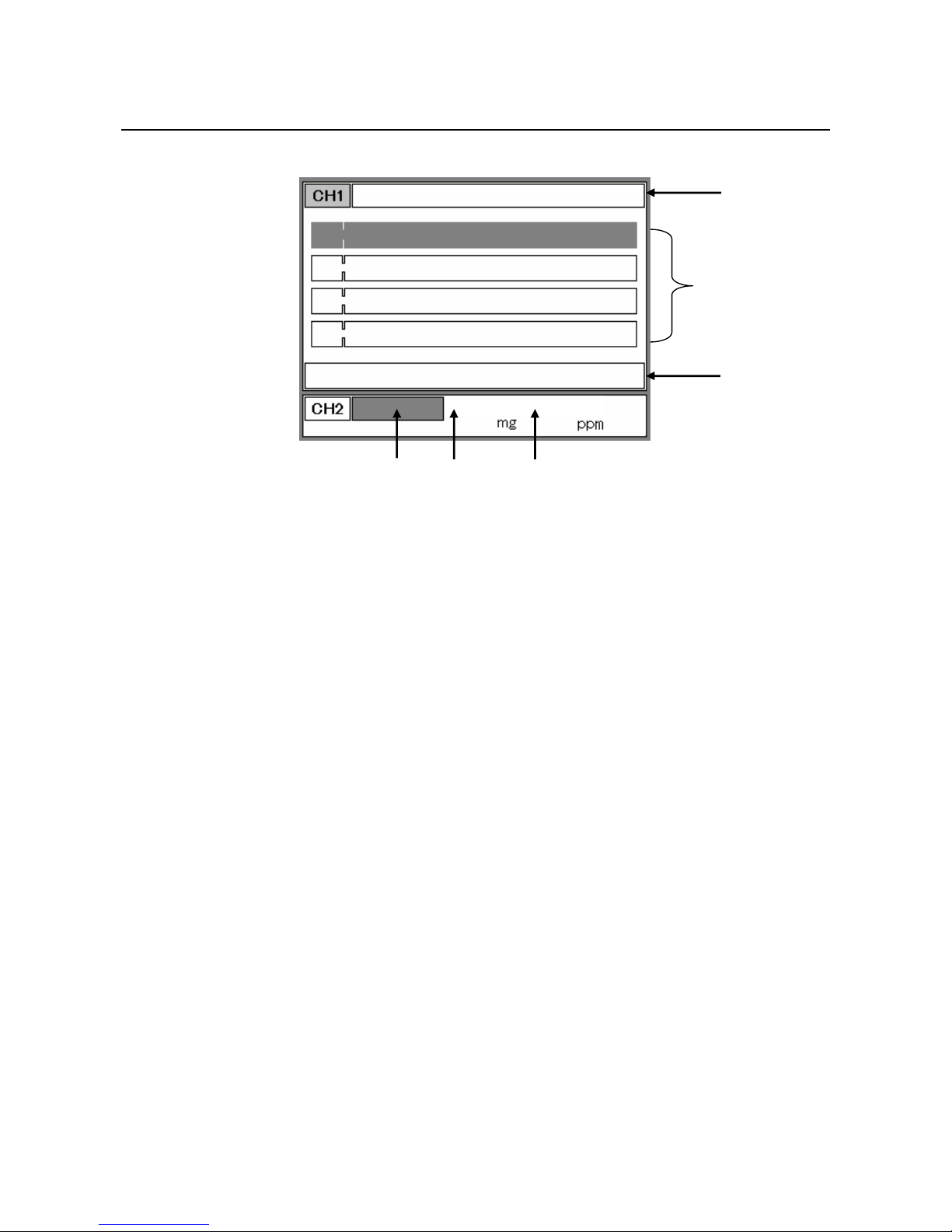

3-5-3. 2 CH measurement indication

1. 1CH condition: Current conditions

2. 1CH file number: Selected numbers

3. 1CH measurement number: 1 is added every measurement.

It is “1” automatically at power supply or file change.

4. 1CH sample name: Up to 13 characters of a set name are indicated.

5. 1CH Time: Passed time (except delay time) from titration start

6. 1CH Titration speed: Titration speed (μgH2O/sec) is indicated by values.

7. 1CH Moisture: Moisture integrated value (μgH2O) from titration start

8. 1CH B.G.: Titration speed (background) when pressing [titration] key is indicated.

9. 1CH Measurement result: Measurement values and units

10. 2CH condition: Current conditions

11. 2CH file number: Selected numbers

12. 2CH measurement number: 1 is added every measurement.

It is “1” automatically at power supply or file change.

13. 2CH sample name: Up to 13 characters of a set name are indicated.

14. 2CH Time: Passed time (except delay time) from titration start

15. 2CH Titration speed: Titration speed (μgH2O/sec) is indicated by values.

16. 2CH Moisture: Moisture integrated value (μgH2O) from titration start

17. 2CH B.G.: Titration speed (background) when pressing [titration] key is indicated.

18. 2CH Measurement result: Measurement values and units

19. 2CH instructions: Operation guidance and contents description

Weight result “W” and “w” from a balance are indicated.

1 2 3 4

5

KF

Time

00:12

4458μg

F01-01 Sample A

F01-01 Sample A

1234 ppm

1234 ppm

Moisture

Titration speed

Moisture

Time

12.23μg/s

00:12

00:12

Standby

Standby

8

9

19

7

6

10 11 12 13

14

16

15

17

18

001μg/s

0.01μg/s

Titration speed

12.23μg/s

4458μg

BG

BG

CA-200 Section 3: Names and Functions of Model CA-200

3-9

3-5-4. 2 CH menu indication

1. Title: Current menu contents

2. Menu items

3. Instructions: Operation guidance and contents description

4. 2CH condition: Current conditions

5. 2CH Moisture: Moisture integrated value (μgH2O) from measurement start

6. 2CH Result: Measurement values and units

Function menu

01 Recalculation

02 Statistical calculation

03 Reagent consumption

04 File setting

Select with ↑, ↓ and press Enter.

Standby

123 856

1

2

3

Moisture Result

4 5 6

Section 3: Names and Functions of Model CA-200 CA-200

3-10

3-6. Connection of optional units

CA-200 optional units are as follows. Buy them if necessary. Refer to each instruction manual for

details. By connecting various optional units, KF-200 application extends and efficiency improves.

3-6-1. CA-200 CH2 (channel 2)

CA-200 CH2 is useful when one more volumetric moisture meter is required.

By connecting a display, a keypad, and a printer, simultaneous measurement by 2 units is possible.

By pressing [Channel / Select] key, CH1 and CH2 display contents switch.

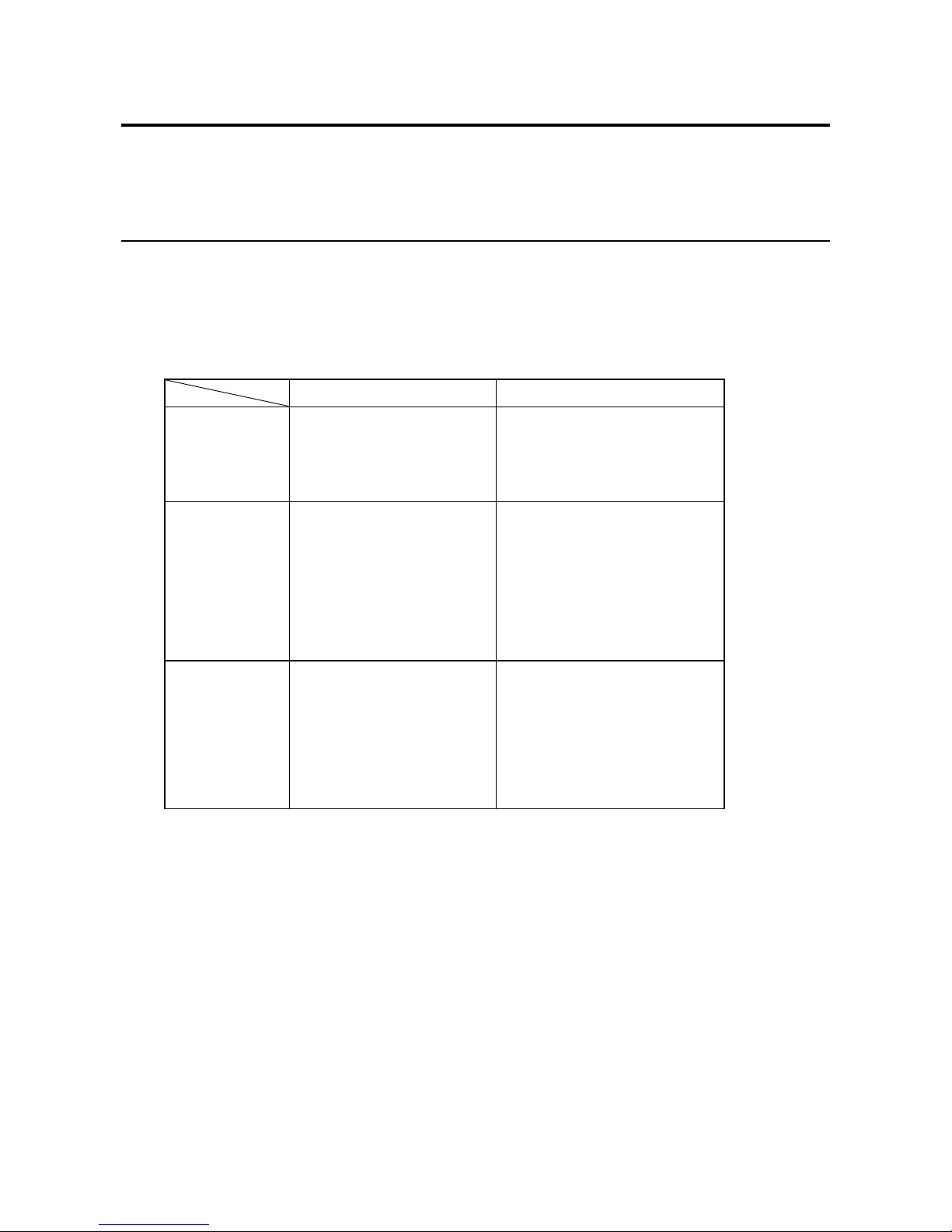

CH1 and CH2 available measurement modes and optional units are as follows.

CH1 CH2

Measurement

modes

CA-200 moisture

measurement mode

KF-200 moisture

measurement mode

CA-200 moisture

measurement mode

KF-200 moisture

measurement mode

Vaporizers VA-200*1

VA-210*1

VA-230

VA-124S

VA-121

VA-122

VA-200*1

VA-210*1

VA-230

VA-124S

VA-121

VA-122

Others Electronic balance

Personal computer

Reagent supply and drain

unit

(Valid only when KF-200

is used.)

Electronic balance*2

Personal computer

Reagent supply and drain

unit

(Valid only when KF-200 is

used.)

Table 3-5. Measurement modes and optional units

*1. VA-200 or VA-210 can be connected to one CA-200. To connect the second unit, purchase

an optional CA/KF200 expanded power unit.

*2. To input sample weight into CH2 side by an electric balance, purchase an optional cable with

a switch for CA/KF200 balance connection.

CA-200 Section 3: Names and Functions of Model CA-200

3-11

3-6-2. KF-200 buret set

By adding a KF-200 buret set, a moisture meter is changed to KF-200 of volumetric titration.

KF-200 is useful for the samples containing much water and insoluble to electrolytic solution.

Up to 4 burets can be connected.

* When using more than 3 burets, purchase an optional CA/KF200 addition power unit.

3-6-3. Moisture vaporizers

For samples insoluble to electrolysis solution and containing interfering substances, water vaporizers

are required. We offer the following water vaporizers for your needs.

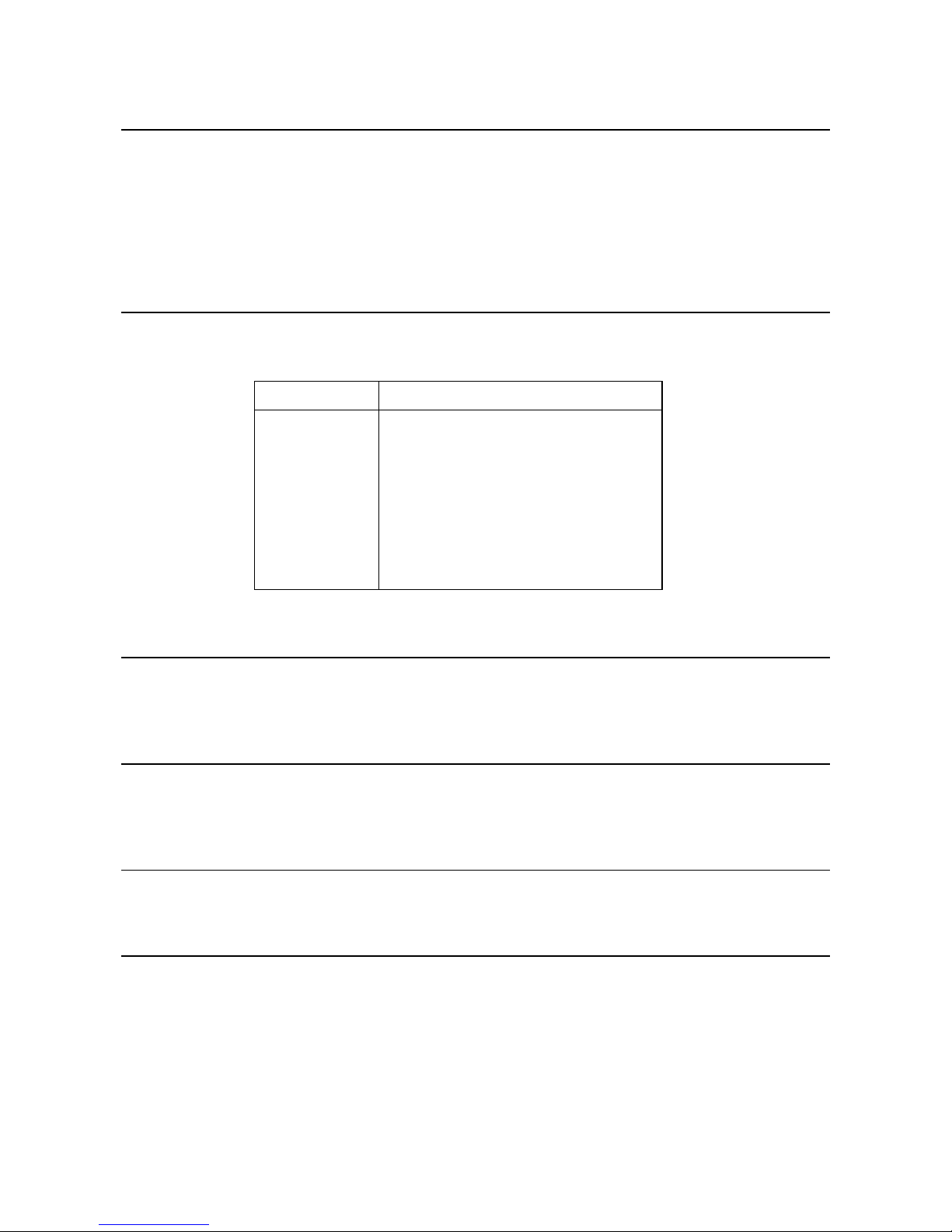

Names Purposes

VA-200

VA-210

VA-230

VA-124S

VA-121

VA-122

For general use

For lubricants

For general use, vial-type

For solid and powder samples

(Automatic sample changer)

For high temperature

For iron ore

Table 3-6. Water vaporizer list

3-6-4. Electronic balance

Weight can be automatically inputted by connecting an electronic balance.

For connection and interface tests, refer to balance interface specifications.

3-6-5. Personal computer

Data can be processed by connecting a personal computer.

For format setting and interface test, refer to computer interface specifications.

3-6-6. Reagent supply and drain unit

Dehydrating solvent is supplied and drained automatically at KF-200 use.

3-6-7. Fritless cathode solution cell

A fritless cathode solution cell is used for CA-200 moisture measurement mode.

Loading...

Loading...