Page 1

Page 2

Introduction

This manual covers the items required for installing, connecting and setting up the C80.

Read this manual thoroughly and understand the product's functions and performance before starting to use.

This manual is written on the assumption that all optional functions are added, but the actually delivered device may

not have all functions.

The unit names, cable names and various specifications are subject to change without notice. Please confirm these

before placing an order.

Be sure to keep this manual always at hand.

Notes on Reading This Manual

(1) This manual explains general parameters as viewed from the NC.

For information about each machine tool, refer to manuals issued from the machine tool builder.

If the descriptions relating to "restrictions" and "allowable conditions" conflict between this manual and the

machine tool builder's instruction manual, the later has priority over the former.

(2) This manual is intended to contain as much descriptions as possible even about special operations.

The operations to which no reference is made in this manual should be considered "impossible".

CAUTION

For items described as "Restrictions" or "Usable State" in this manual, the instruction manual issued by

the machine tool builder takes precedence over this manual.

Items that are not described in this manual must be interpreted as "not possible".

This manual is written on the assumption that all the applicable functions are included.

Some of them, however, may not be available for your NC system.

Refer to the specifications issued by the machine tool builder before use.

For information about each machine tool, refer to manuals issued from the machine tool builder.

Some screens and functions may differ depending on each NC system (or version), and some functions

may not be possible. Please confirm the specifications before starting to use.

Do not connect NC system to the Internet-connected network.

To maintain the safety of the NC system against unauthorized access from external devices via the

network, take appropriate measures.

Also refer to the manuals on "Manual List" as necessary.

Page 3

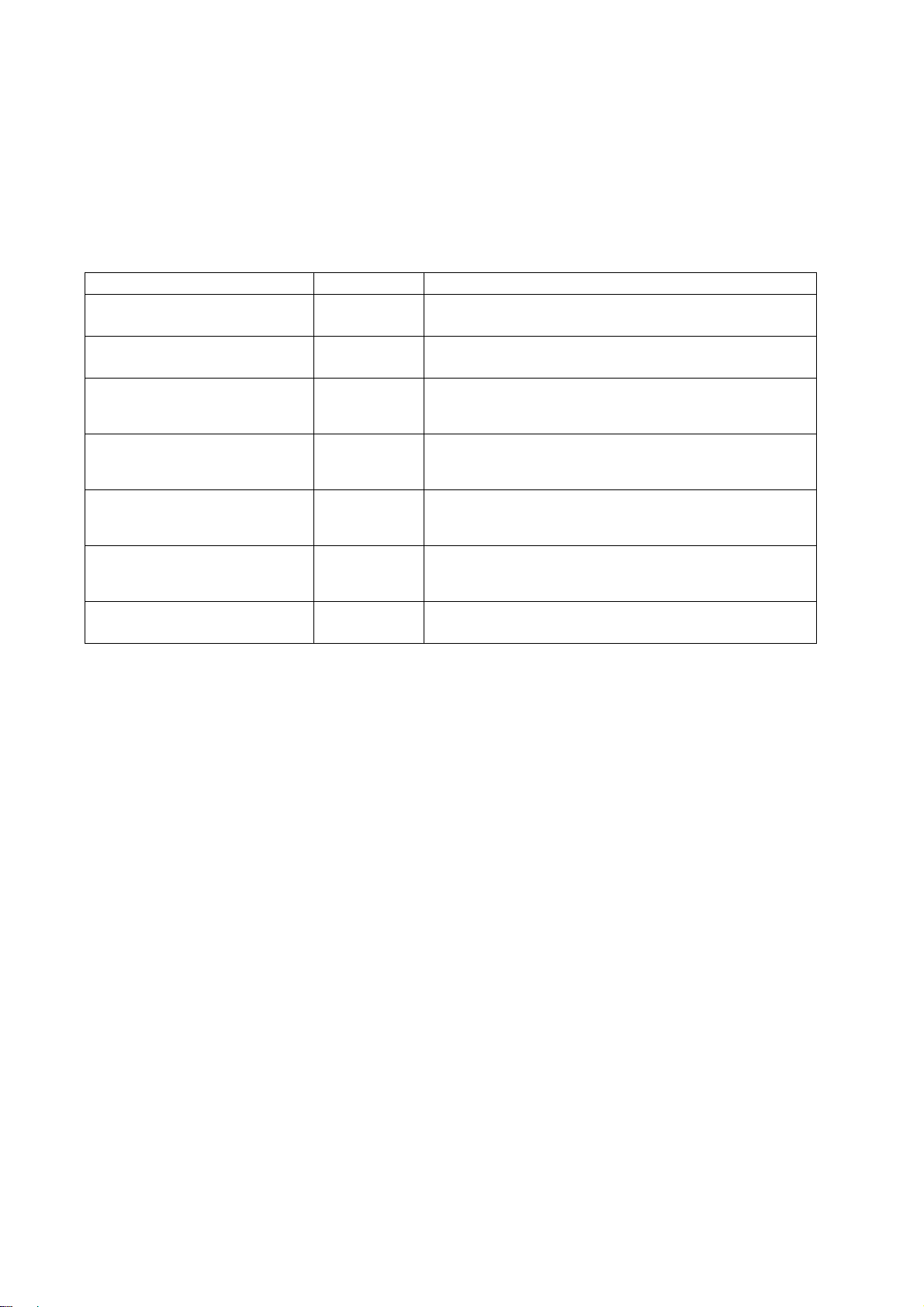

Manual List

Manuals related to M800/M80/E80/C80 Series are listed as follows.

These manuals are written on the assumption that all optional functions are added to the targeted model.

Some functions or screens may not be available depending on the machine or specifications set by MTB. (Confirm the

specifications before use.)

The manuals issued by MTB take precedence over these manuals.

Manual IB No. Purpose and Contents

M800/M80/E80 Series

Instruction Manual

C80 Series

Instruction Manual

M800/M80/E80/C80 Series

Programming Manual

(Lathe System) (1/2)

M800/M80/E80/C80 Series

Programming Manual

(Lathe System) (2/2)

M800/M80/E80/C80 Series

Programming Manual

(Machining Center System) (1/2)

M800/M80/E80/C80 Series

Programming Manual

(Machining Center System) (2/2)

M800/M80/E80/C80 Series

Alarm/Parameter Manual

IB-1501274

IB-1501453

IB-1501275

IB-1501276

IB-1501277

IB-1501278

IB-1501279

Operation guide for NC

Explanation for screen operation, etc.

Operation guide for NC

Explanation for screen operation, etc.

G code programming for lathe system

Basic functions, etc.

G code programming for lathe system

Functions for multi-part system, high-accuracy function, etc.

G code programming for machining center system

Basic functions, etc.

G code programming for machining center system

Functions for multi-part system, high-accuracy function, etc.

Alarms

Parameters

Page 4

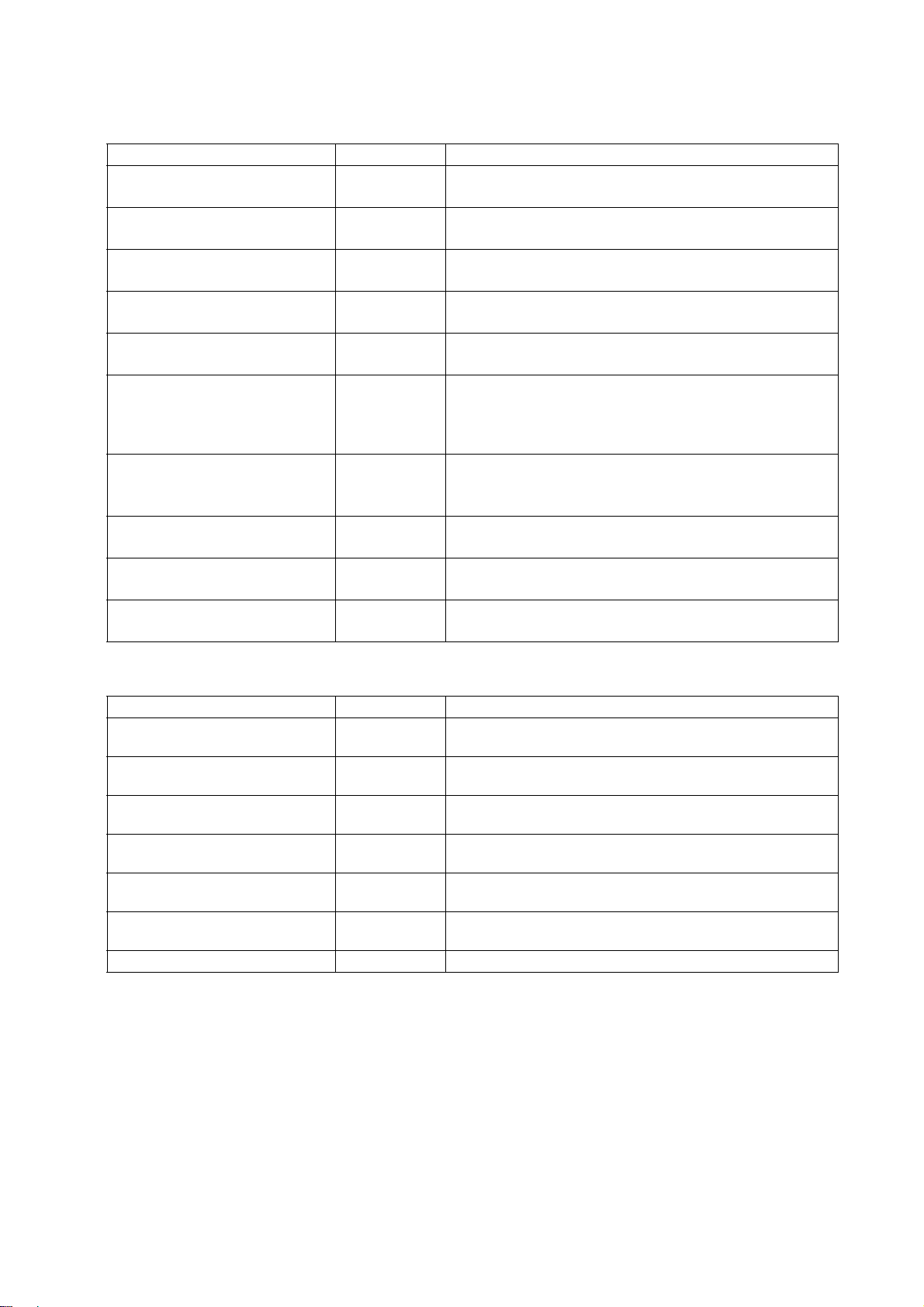

Manuals for MTBs (NC)

Manual IB No. Purpose and Contents

M800/M80/E80/C80 Series

Specifications Manual (Function)

M800/M80/E80/C80 Series

Specifications Manual (Hardware)

M800W/M80W Series

Connection and Setup Manual

M800S/M80/E80 Series

Connection and Setup Manual

C80 Series

Connection and Setup Manual

M800/M80/E80 Series

PLC Development Manual

M800/M80/E80 Series

PLC Programming Manual

M800/M80/E80/C80 Series

PLC Interface Manual

M800/M80/E80 Series

Maintenance Manual

C80 Series

Maintenance Manual

IB-1501505

IB-1501506

IB-1501268

IB-1501269

IB-1501452

IB-1501270

IB-1501271

IB-1501272

IB-1501273

IB-1501454

Model selection

Outline of various functions

Model selection

Specifications of hardware unit

Detailed specifications of hardware unit

Installation, connection, wiring, setup (startup/adjustment)

Detailed specifications of hardware unit

Installation, connection, wiring, setup (startup/adjustment)

Detailed specifications of hardware unit

Installation, connection, wiring, setup (startup/adjustment)

Electrical design

I/O relation (assignment, setting, connection), field network

Development environment (PLC on-board, peripheral

development environment), etc.

Electrical design

Sequence programming

PLC support functions, etc.

Electrical design

Interface signals between NC and PLC

Cleaning and replacement for each unit

Other items related to maintenance

Cleaning and replacement for each unit

Other items related to maintenance

Manuals for MTBs (drive section)

Manual IB No. Contents

MDS-E/EH Series

Specifications Manual

MDS-E/EH Series

Instruction Manual

MDS-EJ/EJH Series

Specifications Manual

MDS-EJ/EJH Series

Instruction Manual

MDS-EM/EMH Series

Specifications Manual

MDS-EM/EMH Series

Instruction Manual

DATA BOOK IB-1501252 Specifications of servo drive unit, spindle drive unit, motor, etc.

IB-1501226 Specifications for power supply regeneration type

IB-1501229 Instruction for power supply regeneration type

IB-1501232 Specifications for regenerative resistor type

1235 Instruction for regenerative resistor type

IB-150

IB-1501238

IB-1501241 Instruction for multi-hybrid, power supply regeneration type

Specifications for multi-hybrid, power supply regeneration

type

Page 5

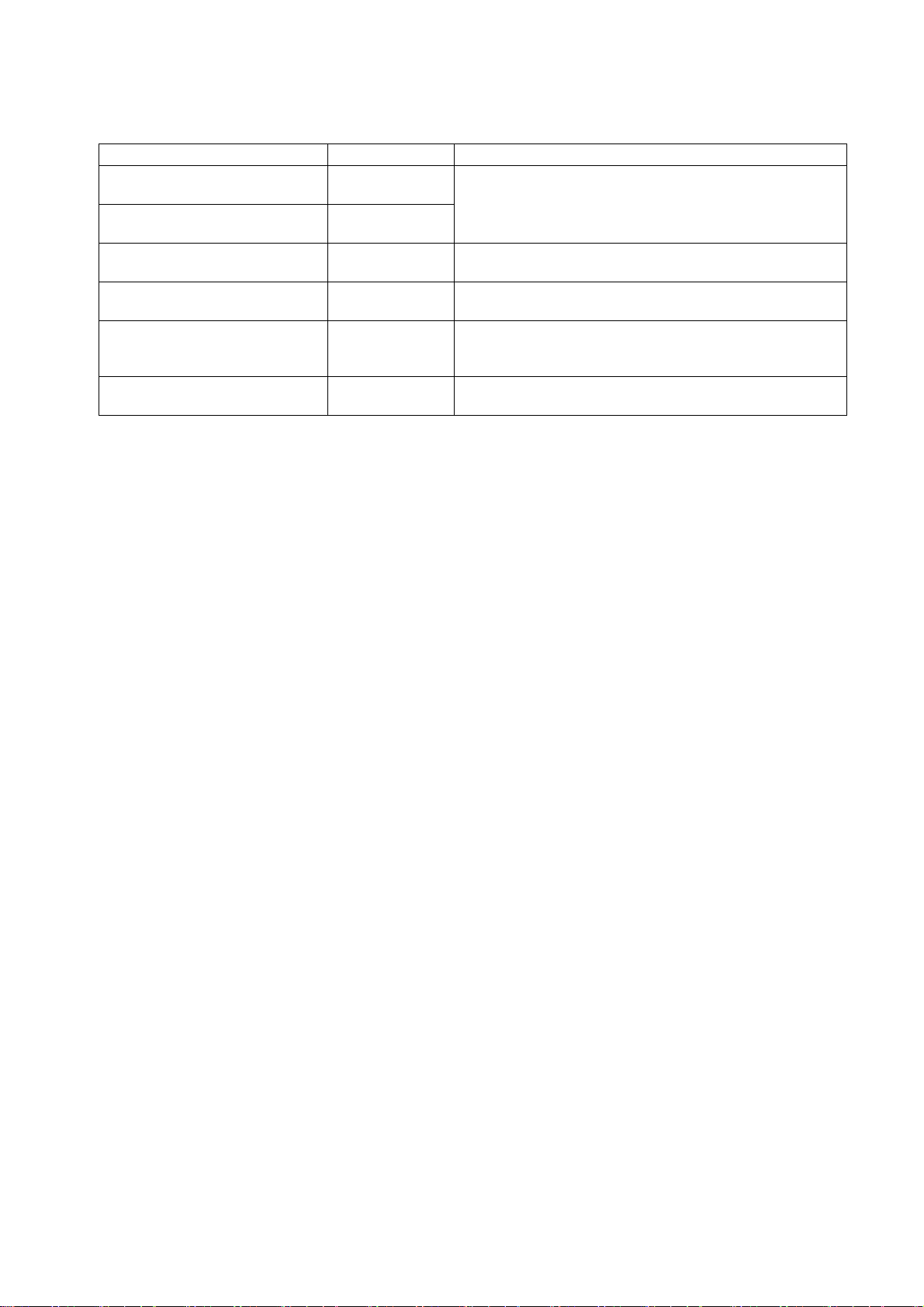

Manuals for MTBs (Others)

Manual No. Purpose and Contents

GOT2000 Series User’s Manual

(Hardware)

GOT2000 Series User’s Manual

(Utility)

GOT2000 Series User’s Manual

(Monitor)

GOT2000 Series Connection

Manual (Mitsubishi Electric

Products)

GT Designer3 (GOT2000) Screen

Design Manual

■ For M800/M80/E80 Series

Manual No. Purpose and Contents

GOT2000/GOT1000 Series CC-Link

Communication Unit User's Manual

GX Developer Version 8 Operating

Manual (Startup)

GX Developer Version 8 Operating

Manual

GX Converter Version 1 Operating

Manual

MELSEC-Q CC-Link System Master/

Local Module User’s Manual

GOT2000 Series Connection

Manual (Non-Mitsubishi Electric

Products 1)

GOT2000 Series Connection

Manual (Non-Mitsubishi Electric

Products 2)

GOT2000 Series Connection

Manual (Microcomputers, MODBUS/

Fieldbus Products, Peripherals)

GT SoftGOT2000 Version1

Operating Manual

SH-081194

SH-081195

SH-081196 Outline of each monitor function of GOTs

SH-081197

SH-081220

IB-0800351

SH-080372E

SH-080373E

IB-0800004E

SH-080394E

SH-081198ENG

SH-081199ENG

SH-081200ENG

SH-081201ENG

Outline of hardware such as part names, external dimensions,

installation, wiring, maintenance, etc. of GOTs

Outline of utilities such as screen display setting, operation

method, etc. of GOTs

Outline of connection types and connection method between

GOT and Mitsubishi Electric connection devices

Outline of screen design method using screen creation

software GT Designer3

Explanation for handling CC-Link communication unit (for

GOT2000 series/GOT1000 series)

Explanation for system configuration, installation, etc. of PLC

development tool GX Developer

Explanation for operations using PLC development tool GX

Developer

Explanation for operations using data conversion tool GX

Converter

Explanation for system configuration, installation, wiring, etc.

of master/local modules for CC-Link system

Explanation for connection types and connection method

between GOT and other company's devices

Explanation for connection types and connection method

between GOT and microcomputers, MODBUS/fieldbus

products, peripherals

Explanation for system configuration,

and operation method of monitoring software GT

SoftGOT2000

screen configuration

■ For C80 Series

Manual No. Purpose and Contents

MELSEC iQ-R Module Configuration

Manual

MELSEC iQ-R CPU Module User’s

Manual (Startup)

MELSEC iQ-R CPU Module User’s

Manual (Application)

QCPU User’s Manual (Hardware

Design, Maintenance and

Inspection)

GX Works3 Operating Manual SH-081215 Outline of functions, programming, etc.

SH-081262

SH-081263

SH-081264

SH-080483

Outline of system configuration, specifications, installation,

wiring, maintenance, etc.

Outline of specifications, procedures before operation,

troubleshooting, etc. for CPU module

Outline of memory, functions, devices, parameters, etc. for

CPU module

Outline of specifications, necessary knowledge to configure

the system and maintenance-related descriptions for Q series

CPU module, etc.

Page 6

Reference Manual for MTBs

Manual No. Purpose and Contents

M800/M80 Series Smart safety

observation Specification manual

C80 Series Smart safety observation

Specification manual

M800/M80 Series CC-Link (Master/

Local) Specification manual

M800/M80 Series PROFIBUS-DP

Specification manual

M800/M80 Series Interactive cycle

insertion (Customization)

Specification manual

M800/M80 Series EtherNet/IP

Specifications manual

BNP-C3072-022

Explanation for smart safety observation function

BNP-C3077-022

BNP-C3072-089 Explanation for CC-Link

BNP-C3072-118 Explanation for PROFIBUS-DP communication function

BNP-C3072-121-

0003

BNP-C3072-263 Explanation for EtherNet/IP

Explanation for interactive cycle insertion

Page 7

Page 8

Precautions for Safety

Always read this manual and enclosed documents before installation, operation, maintenance and inspection to

ensure correct usage. Thoroughly understand the basics, safety information and precautions of the devices before

using.

This manual classifies the safety precautions into "DANGER", "WARNING" and "CAUTION".

DANGER

When the user could be subject to imminent fatalities or serious injuries if handling is mistaken.

WARNING

When the user could be subject to fatalities or serious injuries if handling is mistaken.

CAUTION

When the user could be subject to injuries or the property could be damaged if handling is mistaken.

Note that the items under " CAUTION" could lead to serious consequences as well depending on the situation.

All the items are important and must always be observed.

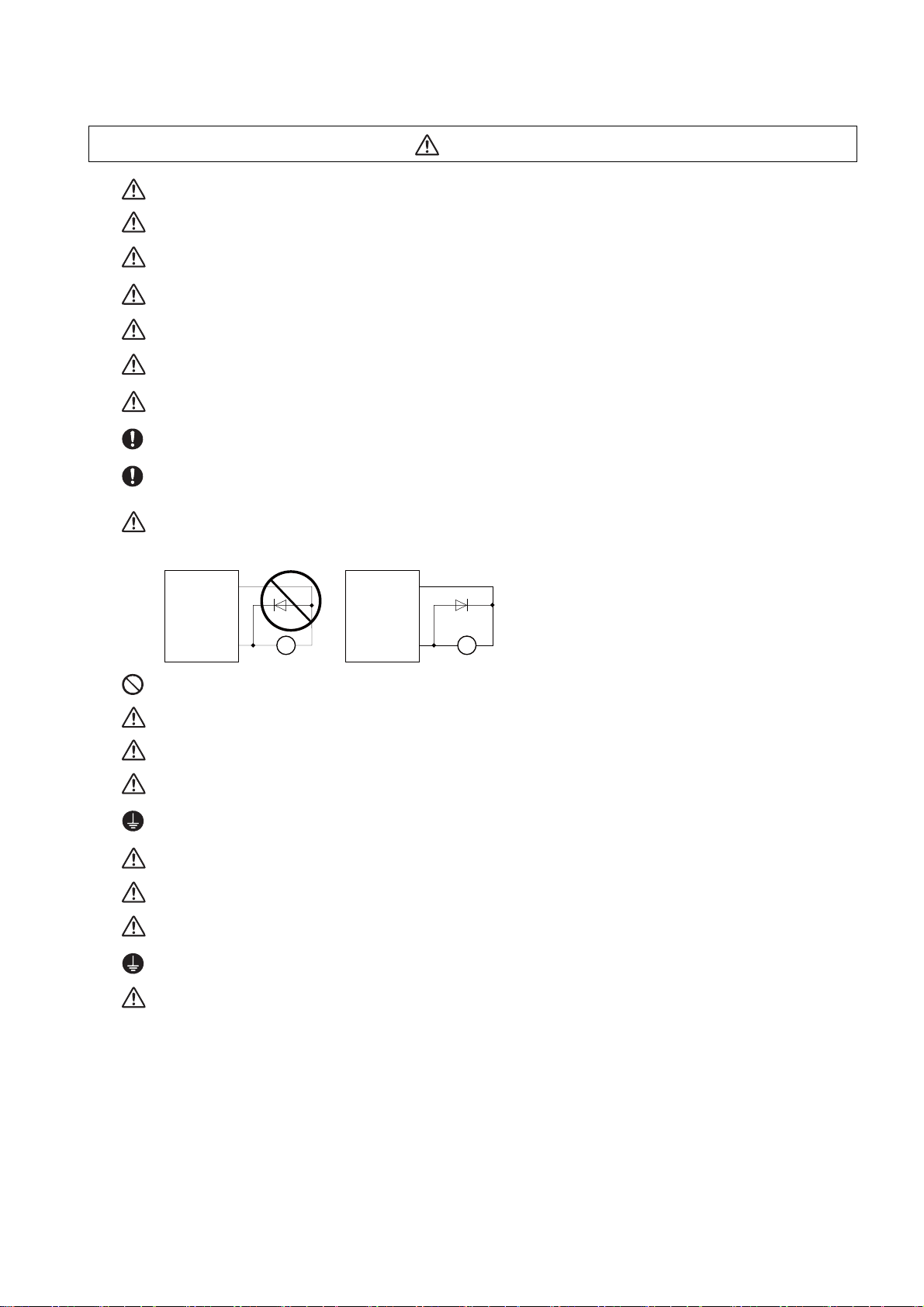

The following sings indicate prohibition and compulsory.

This sign indicates prohibited behavior (must not do).

For example, indicates "Keep fire away".

This sign indicated a thing that is pompously (must do).

For example, indicates "it must be grounded".

The meaning of each pictorial sing is as follows.

CAUTION

Prohibited

CAUTION rotated

Disassembly is

prohibited

object

CAUTION HOT

KEEP FIRE AWAY General instruction

Danger Electric shock

risk

Danger explosive

Earth ground

Page 9

For Safe Use

Mitsubishi CNC is designed and manufactured solely for applications to machine tools to be used for industrial

purposes.

Do not use this product in any applications other than those specified above, especially those which are

substantially influential on the public interest or which are expected to have significant influence on human lives or

properties.

1. Items related to prevention of electric shocks

Do not open or remove the front cover while the power is ON or during operation. The high voltage

terminals and charged sections will be exposed, and this could result in electric shocks.

Do not remove the front cover even when the power is OFF, except for the wiring works or periodic

inspections. The inside of the controller and drive unit are charged, and this could result in electric shocks.

Always wait at least 15 minutes after turning the power OFF. Then, check the voltage with a tester, etc.,

before wiring works, inspections or connecting with peripheral devices. Failure to observe this could result

in electric shocks.

Earth ground the controller, drive unit and motor according to the local laws. (In Japan, ground the 200V

Series input products with Class C or higher protective grounding and the 400V Series input with Class D

or higher protective grounding.)

All wiring works, maintenance and inspections must be carried out by a qualified technician. Failure to

observe this could result in electric shocks. Contact your nearby Service Center or Service Station for

replacing parts and servicing.

Wire the controller, drive unit and motor after installation. Failure to observe this could result in electric

shocks.

WARNING

Do not operate the switches with wet hands. Failure to observe this could result in electric shocks.

Do not damage, apply excessive stress, place heavy things on or sandwich the cables. Failure to observe

this could result in electric shocks.

Insulate the power lead using a fixed terminal block. Failure to observe this could result in electric shocks.

Completely turn off the all lines of the power supply externally before wiring. Not completely turning off all

power could result in electric shock or damage to the product.

When turning on the power supply or operating the module after wiring, be sure that the module's terminal

covers are correctly attached.

Not attaching the terminal cover could result in electric shock.

Page 10

2. Items related to prevention of fire

CAUTION

Install the controller, drive unit, motor and regenerative resistor on non-combustible material. Installation

directly on or near combustible materials could result in fires.

If any malfunction in the unit is observed, shut off the power at the unit’s power supply side. Continuous

flow of large current could result in fires.

Install an appropriate no fuse breaker (NFB) and contactor (MC) on the power input section of the drive unit

and configure the sequence that shuts the power off upon drive unit’s emergency stop or alarm.

When a breaker is shared for multiple power supply units, the breaker may not function upon short-circuit

failure in a small capacity unit. Do not share a breaker for multiple units as this is dangerous.

Incorrect wiring and connections could cause the devices to damage or burn.

3. Items related to prevention of bodily injury or property damage

DANGER

When transporting or installing a built-in IPM spindle or linear servomotor, be careful so that your hand or

property will not be trapped in the motors or other metal objects. Also keep the devices with low magnetic

tolerance away from the product.

CAUTION

Do not apply voltages to the connectors or terminals other than voltages indicated in the connection and

setup manual for the controller or specifications manual for the drive unit. Failure to observe this could

cause bursting, damage, etc.

Incorrect connections could cause the devices to rupture or damage, etc. Always connect the cables to the

indicated connectors or terminals.

Incorrect polarity (+ -) could cause the devices to rupture or damage, etc.

Persons wearing medical devices, such as pacemakers, must stay away from this unit. The

electromagnetic waves could adversely affect the medical devices.

Fins on the rear of the unit, regenerative resistor and motor, etc., will be hot during operation and for a while

after the power has been turned OFF. Do not touch or place the parts and cables, etc. close to these

sections. Failure to observe this could result in burns.

Do not ent er the ma chine’s movable range during automatic operation. Keep your hands, feet or face away

from the spindle during rotation.

Page 11

4. General precautions

Always follow the precautions below. Incorrect handling could result in faults, injuries or electric shocks, etc.

(1) Items related to product and manual

CAUTION

For items described as "Restrictions" or "Usable State" in this manual, the instruction manual issued by

the machine tool builder takes precedence over this manual.

Items that are not described in this manual must be interpreted as "not possible".

This manual is written on the assumption that all the applicable functions are included.

Some of them, however, may not be available for your NC system.

Refer to the specifications issued by the machine tool builder before use.

For information about each machine tool, refer to manuals issued from the machine tool builder.

Some screens and functions may differ depending on each NC system (or version), and some functions

may not be possible. Please confirm the specifications before starting to use.

Do not connect NC system to the Internet-connected network.

To maintain the safety of the NC system against unauthorized access from external devices via the

network, take appropriate measures.

(2) Transportation and installation

CAUTION

Correctly transport the products according to the mass.

Do not stack the products exceeding the indicated limit.

Do not hold the cables, shaft or detector when transporting the motor.

Do not transport the controller or drive unit by suspending or holding the connected wires or cables.

Do not hold the front cover when transporting the unit, or the front cover could come off, causing the unit

to drop.

Install on a non-combustible place where the unit's or motor's mass can be withstood according to the

instruction manual.

The motor does not have a complete water-proof (oil-proof) structure. Do not allow oil or water to contact

or enter the motor. Prevent the cutting chips from being accumulated on the motor as they easily soak up

oil.

When installing the motor facing upwards, take measures on the machine side so that gear oil, etc., will not

enter the motor shaft.

Do not remove the detector from the motor. (The detector installation screw is treated with sealing.)

Do not allow foreign matters, especially, conductive foreign matters such as screws or metal chips, or

combustible foreign matters such as oil, to enter the controller, drive unit or motor. Failure to observe this

could result in rupture or damage.

Do not get on the product or place heavy objects on it.

Provide prescribed distance between the controller/drive unit and inner surface of the control panel/other

devices.

Do not install or operate the controller, drive unit or motor that is damaged or has missing parts.

Page 12

CAUTION

Take care not to cut hands, etc. with the heat radiating fins or metal edges.

Do not block the intake/outtake ports of the motor with the cooling fan.

Install the controller’s display section and operation board section on the spot where cutting oil will not

reach.

The controller, drive unit and motor are precision devices, so do not drop or apply thumping vibration and

strong impacts on them.

Store and use the units according to the environment conditions indicated in each specifications manual.

When disinfectants or insecticides must be used to treat wood packaging materials, always use methods

other than fumigation (for example, apply heat treatment at the minimum wood core temperature of 56 °C

for a minimum duration of 30 minutes (ISPM No. 15 (2009))).

If products such as units are directly fumigated or packed with fumigated wooden materials, halogen

substances (including fluorine, chlorine, bromine and iodine) contained in fumes may contribute to the

erosion of the capacitors. When exporting the products, make sure to comply with the laws and regulations

of each country.

Do not use the products in conjunction with any components that contain halogenated flame retardants

(bromine, etc). Failure to observe this may cause the erosion of the capacitors.

Securely fix the motor to the machine. The motor could come off during operation if insecurely fixed.

Always install the motor with reduction gear in the designated direction. Failure to observe this could result

in oil leaks.

Always install a cover, etc., over the shaft so that the rotary section of the motor cannot be touched during

motor rotation.

When installing a coupling to the servomotor shaft end, do not apply impacts by hammering, etc. The

detector could be damaged.

Use a flexible coupling when connecting with a ball screw, etc., and keep the shaft core deviation smaller

than the tolerable radial load of the shaft.

Do not use a rigid coupling as an excessive bending load will be applied on the shaft and could cause the

shaft to break.

Do not apply a load exceeding the tolerable level onto the motor shaft. The shaft or bearing could be

damaged.

Before using this product after a long period of storage, please contact the Mitsubishi Service Station or

Service Center.

Following the UN recommendations, battery units and batteries should be transported based on the

international regulations such as those determined by International Civil Aviation Organization (ICAO),

International Air Transport Association (IATA), International Maritime Organization (IMO) and U.S.

Department of Transportation (DOT).

Due to ventilation problems, do not install the base units vertically or horizontally when C80 is mounted on

a board, etc.

Install the basic base on a flat surface. Unevenness or warping of the surface can apply undue force to

printed circuit boards and lead to operation failures.

Avoid installing the base units close to a vibration source, such as a large electromagnetic contactor or nofuse breaker. Install them on a separate panel or at a safe distance.

To limit the effects of reflected noise and heat, leave 100mm(3.94inch) or more clearance to instruments

fitted in front of CNC CPU (on the rear of the door). Similarly, leave 50mm(1.97inch) or more clearance

between instruments and the left and right sides of the basic b

ase.

Page 13

(3) Items related to wiring

RA

RA

COM COM

Control

output

signal

Drive unit

Control

output

signal

Drive unit

(24VDC) (24VDC)

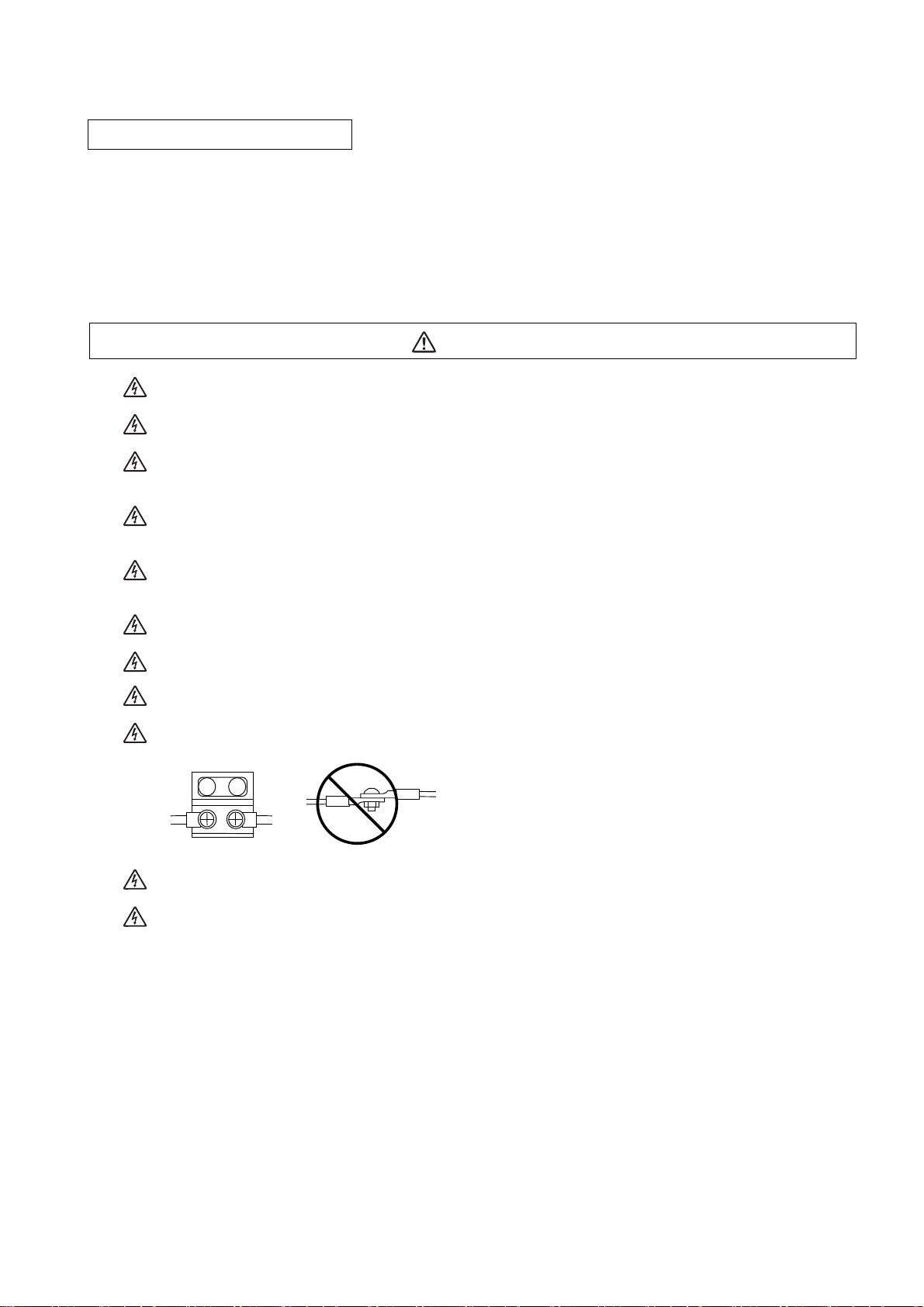

CAUTION

Correctly wire this product. Failure to observe this could result in motor runaway, etc.

Incorrect terminal connections could cause the devices to rupture or damage, etc.

Do not install a phase advancing capacitor, surge absorber or radio noise filter on the output side of the

drive unit.

Correctly connect the output side (terminal U, V, W). The motor will not run properly if incorrectly

connected.

Always install an AC reactor per each power supply unit.

Always install an appropriate breaker per each power supply unit. A breaker cannot be shared for multiple

power supply units.

Do not directly connect a commercial power supply to the motor. Failure to observe this could result in

faults.

When using an inductive load such as relays, always connect a diode in parallel to the load as a noise

countermeasure.

When using a capacitive load such as a lamp, always connect a protective resistor serially to the load to

suppress rush currents.

Do not mistake the direction of the surge absorption diode to be installed on the DC relay for the control

output signal. If mistaken, the signal will not be output due to fault in the drive unit, and consequently the

protective circuit, such as emergency stop, could be disabled.

Do not connect or disconnect the cables between units while the power is ON.

Do not connect or disconnect the PCBs while the power is ON.

Do not pull the cables when connecting/disconnecting them.

Securely tighten the cable connector fixing screw or fixing mechanism. The motor could come off during

operation if insecurely fixed.

Always treat the shield cables indicated in the Connection Manual with grounding measures such as cable

clamps.

Separate the signal wire from the drive line or power line when wiring.

Carry out wiring so that there is no possibility of short circuit between wires, nor of dangerous state.

Use wires and cables whose wire diameter, heat resistance level and bending capacity are compatible with

the system.

Ground the device according to the requirements of the country where the device is to be used.

Wire the heat radiating fins and wires so that they do not contact.

Page 14

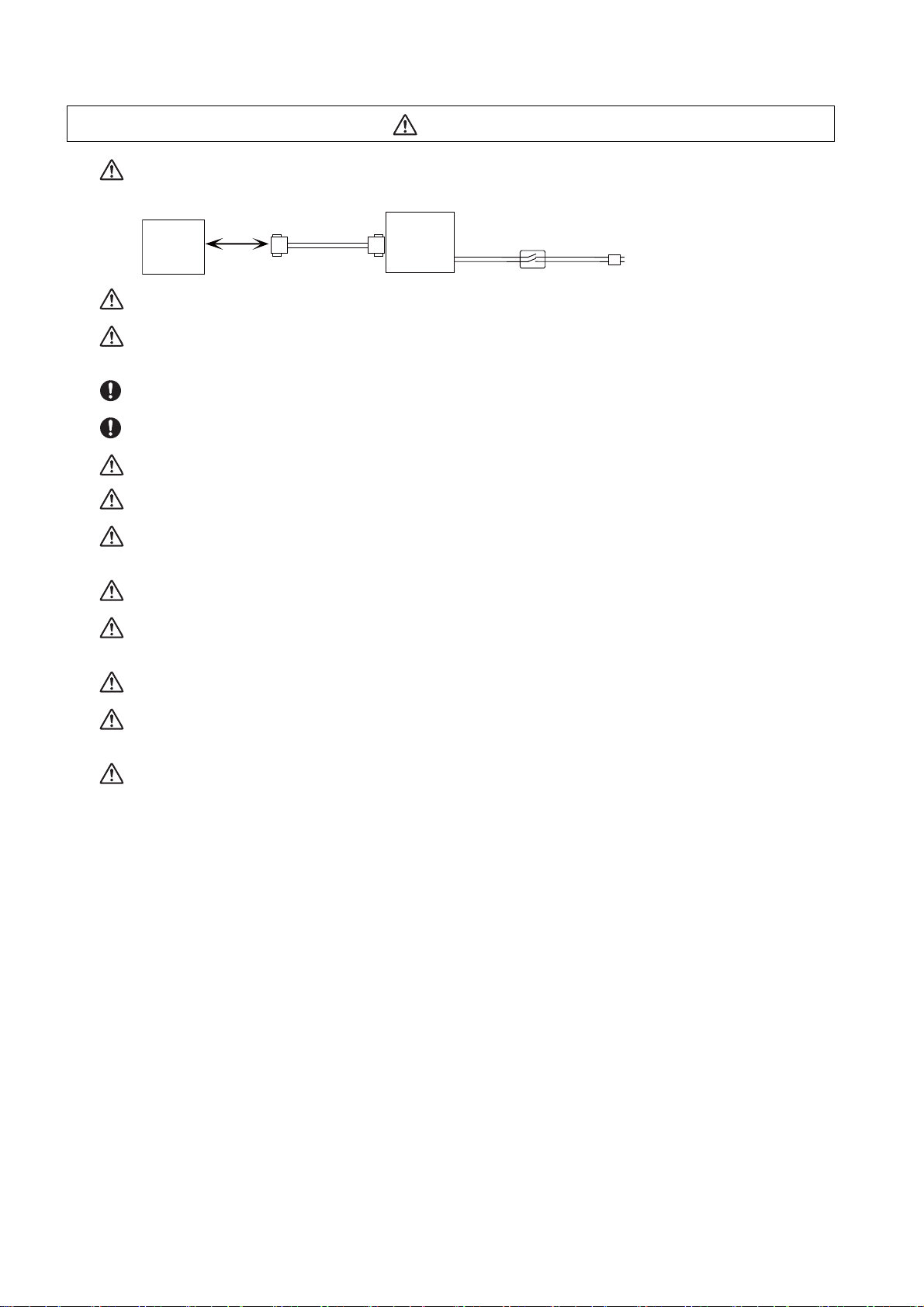

CAUTION

When using the RS-232C device as a peripheral device, caution must be paid for connector connection/

disconnection. Always use a double-OFF type AC power supply switch on the device side, and connect/

disconnect the connector with the AC power supply on the device side OFF.

NC unit

Device

RS-232C

Switch

AC socket

Using a stabilized power supply without overcurrent protection may cause the unit's failure due to

miswiring of 24V.

12V, 5V, and 3.3V output from connectors are to supply the power for dedicated peripheral devices. Do not

use for other equipment to supply the power since we do not guarantee the NC operation by voltage down

or noise sneaking.

When using an inductive load such as a relay, always connect a diode in parallel to the load to prevent a

counter-electromotive force.

When the rush current exceeds the maximum output current, always connect a protective resistor serially

to the load to suppress rush currents.

The wires from the surge absorber should be connected without extensions.

Be sure to ground the earth terminal FG and LG. Not doing so could result in electric shock or operation

failure. (Ground resistance: 100Ω or less)

When wiring in the unit, be sure that it is done correctly by checking the product's rated voltage and the

terminal layout. Connecting a power supply that is different from the rating or incorrectly wiring the product

could result in fire or damage.

External connections shall be crimped or pressure welded with the specified tools, or correctly soldered.

Imperfect connections could result in short circuit, fire, or operation failure.

Tighten the terminal screws within the specified torque range. If the terminal screws are loose, it could

result in short circuit, fire, or operation failure. Tightening the terminal screws too far may cause damages

to the screws and/or the module, resulting in drop, short circuit, or operation failure.

Be sure there are no foreign matters such as sawdust or wiring debris inside the module. Such debris could

cause fire, damage, or operation failure.

The module has an ingress prevention label on its top to prevent foreign matter, such as wiring debris, from

entering the module during wiring. Do not remove this label during wiring. Before starting system

operation, be sure to remove this label because of heat dissipation.

When connecting to a personal computer and a unit with the USB interface, an electric shock or a unit

failure may occur.

Operate these correctly according to the manual of a unit and a personal computer.

Observe the following cautions when a personal computer in an AC power supply is used.

(1) For a personal computer that uses a 3-pin power plug or power plug with a ground lead type, make sure

to use a plug socket including a ground input electrode or ground the earth lead, respectively.

And, ensure to ground a personal computer and a unit. (Ground resistance: 100Ω or less)

(2) For a personal computer that uses a 2-pin power plug without ground lead, make sure to connect the

unit to the personal computer according to the following procedures. And, it is recommended to supply the

same power supply line to a personal computer and the unit.

(a) Pull out the power plug of the personal computer from the AC outlet.

(b) Confirm that the power plug of the personal computer has been pulled out from the AC outlet, and

connect USB cables, the extension cable or the bus connection cable of a GOT.

(c) Insert the power plug of the personal computer into the AC outlet.

Page 15

(4) Set up

WARNING

Do not cancel the emergency stop before confirming the basic operation.

Always set the stroke end and stroke limit. Failure to set this could result in collision with the machine end.

CAUTION

If the descriptions relating to the "restrictions" and "allowable conditions" conflict between this manual

and the machine tool builder's instruction manual. the latter has priority over the former.

The operations to which no reference is made in this manual should be considered "impossible".

This manual is written on the assumption that all the applicable functions are included.

Some of them, however, may not be available for your NC system.

Refer to the specifications issued by the machine tool builder before use.

Some screens and functions may differ depending on each NC system (or version), and some functions

may not be possible. Please confirm the specifications before starting to use.

If the battery low warning is issued, save the machining programs, tool data and parameters in an input/

output device, and then replace the battery. When the battery alarm is issued, the machining programs,

tool data and parameters may have been destroyed. Replace the battery and then reload the data.

Do not adjust the spindle when possible risks associated with adjustment procedures are not thoroughly

taken into consideration.

Be careful when touching spindle's rotating section, or your hand may be caught in or cut.

It is dangerous to restore the backup data of other machine when the absolute position is established

because the zero point will be established with the absolute position of the linear axis rewritten, thus the

zero point position is off the right position.

Initialize the zero point again.

Restoration by SRAM data is available only if the rotary axis motor has not rotated in a same direction

30,000 times or more since the acquisition of the data.

Otherwise, the zero point of the rotary axis will change by turning the power OFF and ON after writing the

SRAM data, which will cause danger. Make sure the zero point is not off the right position.

The use of this method should be limited to when necessary, such as when replacing an NC unit, and

requires enough safety confirmation before executing.

(5) Operation and adjustments

CAUTION

If the operation start position is set in a block which is in the middle of the program and the program is

started, the program before the set block is not executed. Please confirm that G and F modal and

coordinate values are appropriate. If there are coordinate system shift commands or M, S, T and B

commands before the block set as the start position, carry out the required commands using the MDI, etc.

If the program is run from the set block without carrying out these operations, there is a danger of

interference with the machine or of machine operation at an unexpected speed, which may result in

breakage of tools or machine tool or may cause damage to the operators.

Under the constant surface speed control (during G96 modal), if the axis targeted for the constant surface

speed control moves toward the spindle center, the spindle rotation speed will increase and may exceed

the allowable speed of the workpiece or chuck, etc. In this case, the workpiece, etc. may jump out during

machining, which may result in breakage of tools or machine tool or may cause damage to the operators.

Check and adjust programs and each parameter before starting operation. Failure to observe this could

result in unpredictable operations depending on the machine.

Do not make drastic adjustments or changes in the parameters as the operation could become unstable.

In the explanation on bits, set all bits not used, including blank bits, to "0".

Page 16

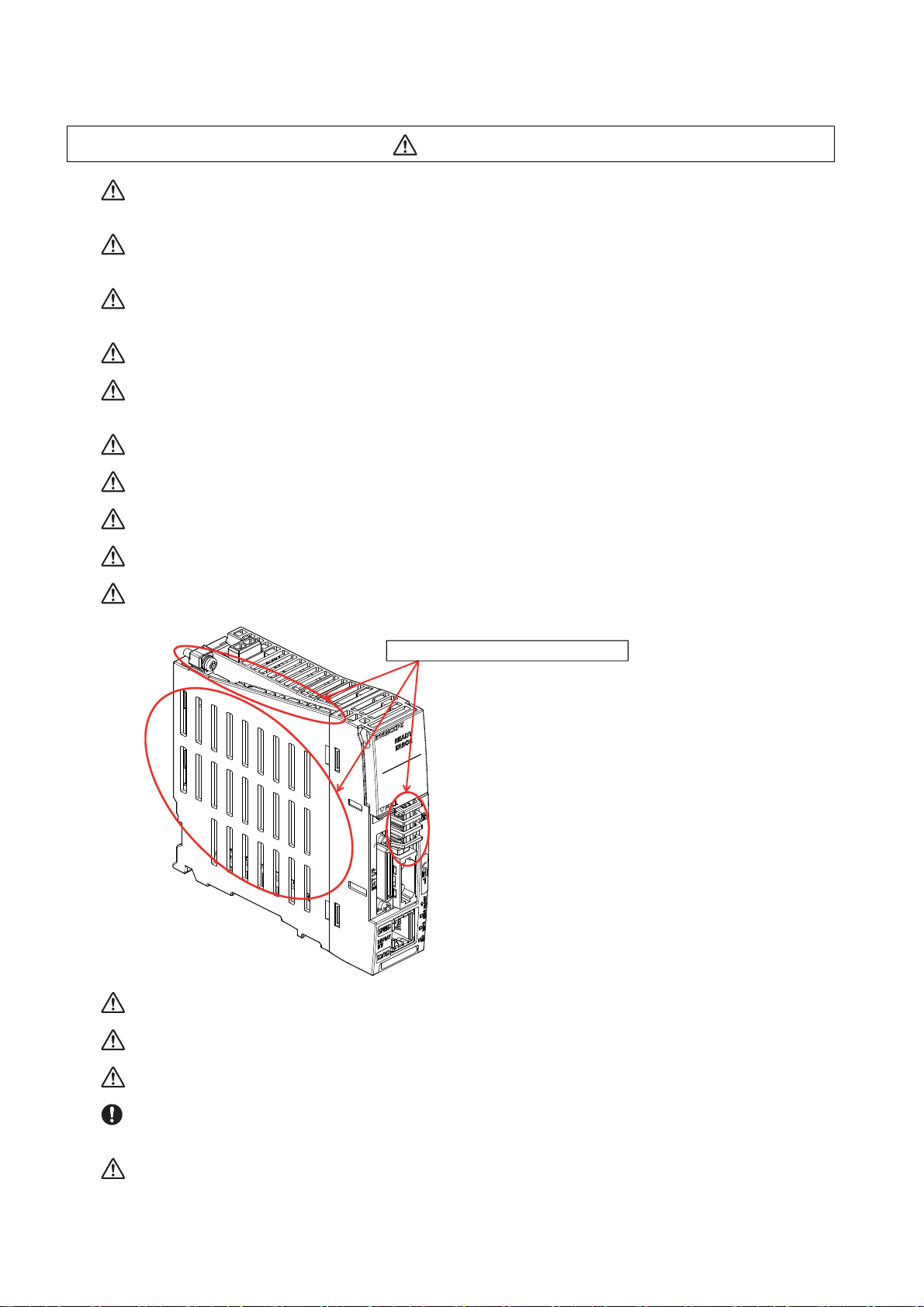

(6) Usage

The metal part becomes the high temperature.

CAUTION

Use C80 in an environment that meets the general specifications contained in this manual. Using C80 in an

environment outside the range of the general specifications could result in electric shock, fire, operation

failure, and damage to or deterioration of the product.

When mounting the module, be sure to insert the module fixing hook on the module's bottom into the

module fixing hole on the base unit. Incorrect mounting could cause an operation failure or a damage/drop

of the unit.

Hold down the module loading lever at the module bottom and securely insert the fixing hook into the fixing

hole in the base unit. Install the module with the module fixing hole as a supporting point. Incorrect

mounting could cause an operation failure or a damage/drop of the unit.

Be sure to fix all the modules with screws to prevent them from dropping. The fixing screws (M3 x 12) are

to be prepared by user.

Tighten the screw in the specified torque range. Under tightening may cause a drop, short circuit or

operation failure. Over tightening may cause a drop, short circuit or operation failure due to damage to the

screw or module.

Be sure to install the extension cable to connectors of the basic base unit correctly. After installation,

check them for looseness. Poor connections could cause an input or output failure.

Completely turn off all lines of external power supply used in the system before loading or unloading the

module. Not doing so could result in electric shock or damage to the product.

Do not mount/dismount the modules or base over 50 times. Mounting/dismounting over 50 times may

cause an operation failure.

Do not directly touch the module's conductive parts or electronic parts. Touching these parts could cause

an operation failure or give damage to the module.

Do not touch the radiating fin of the CNC CPU module while an electric current is supplied or in a short

while after the power OFF. Touching the fin may cause burns. Take care when removing the unit.

When removing the unit, always remove the fixing screws and then take the fixing hook out from the fixing

hole. Incorrect removal will damage the module fixing hook.

When the module fixing screws are used, remove the screws first and module from the base unit. Failure

to do so may damage the module.

The module surface temperature may be high immediately after power-off. When the module is removed,

pay attention to the burn injury.

Install an external emergency stop circuit so that the operation can be stopped and the power turns OFF

immediately when unforeseen situation occurs. A contactor, etc., is required in addition to the shutoff

function mounted in the controller.

Turn OFF the power immediately if any smoke, abnormal noise or odor is generated from the controller,

drive unit or motor.

Page 17

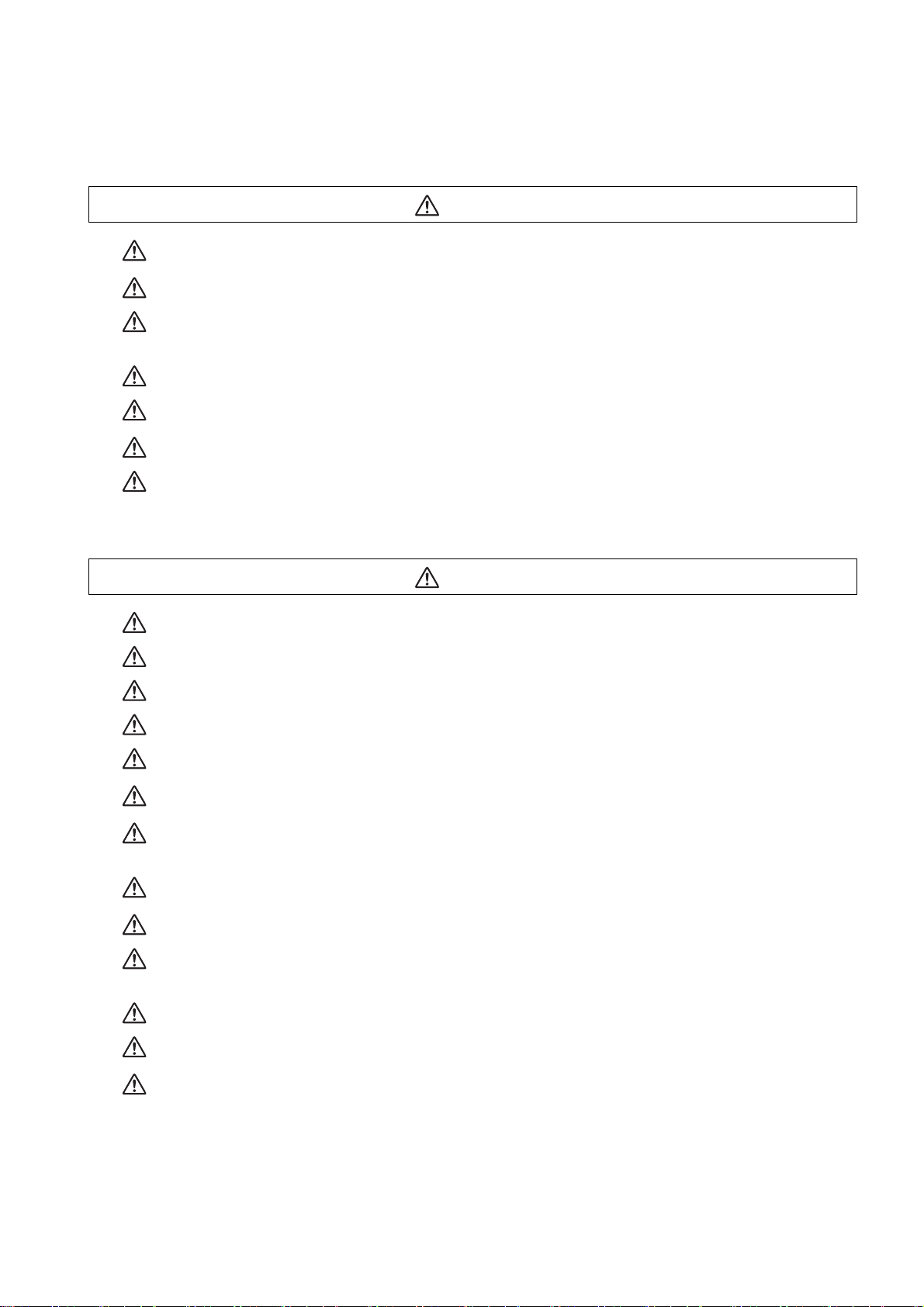

CAUTION

MBR EMG

Motor

Electromagnetic

brake

Shut off with motor

brake control output

Shut off with CNC brake

control PLC output

24VDC

Only a qualified technician may disassemble or repair this product.

Do not alter.

Use a noise filter, etc. to reduce the effect of electromagnetic disturbances in the case where

electromagnetic disturbances could adversely affect the electronic devices used near the drive unit.

Use the drive unit, motor and each regenerative resistor with the designated combination. Failure to

observe this could result in fires or faults.

The combination of the motor and drive unit that can be used is determined. Be sure to check the models

of motor and drive unit before test operation.

The brakes (electromagnetic brakes) mounted in the servomotor are used for the purpose of holding, and

must not be used for normal braking. Also, do not run the motor with the motor brake applied. Motor brake

is used for the purpose of holding.

For the system running via a timing belt, install a brake on the machine side so that safety can be ensured.

Be sure to confirm SERVO OFF (or READY OFF) when applying the electromagnetic brake. Also, be sure

to confirm SERVO ON prior to releasing the brake.

When using the DC OFF type electromagnetic brake, be sure to install a surge absorber on the brake

terminal.

Do not connect or disconnect the cannon plug while the electromagnetic brake’s power is ON. The cannon

plug pins could be damaged by sparks.

After changing programs/parameters, or after maintenance/inspection, always carry out a test operation

before starting actual operation.

Use the power that are complied with the power specification conditions (input voltage, input frequency,

tolerable instantaneous power failure time) indicated in each specifications manual.

When making detector cables, do not mistake connection. Failure to observe this could result in

malfunction, runaway or fire.

(7) Troubleshooting

Use a motor with electromagnetic brakes or

establish an external brake mechanism for

the purpose of holding; this serves as

countermeasures for possible hazardous

situation caused by power failure or

product fault.

Use a double circuit structure for the

electromagnetic brake's operation circuit

so that the brakes will activate even when

the external emergency stop signal is

issued.

The machine could suddenly restart when the power is restored after an instantaneous power failure, so

stay away from the machine. (Design the machine so that the operator safety can be ensured even if the

machine restarts.)

To secure the absolute position, do not shut off the servo drive unit’s control power supply when its battery

voltage drops (warning 9F) in the servo drive unit side.

If the battery voltage drop warning alarm occurs in the controller side, make sure to back up the machining

programs, tool data and parameters, etc. with the input/output device before replacing the battery.

Depending on the level of voltage drop, memory loss could have happened. In that case, reload all the data

backed up before the alarm occurrence.

CAUTION

Page 18

(8) Maintenance, inspection and part replacement

CAUTION

Periodically back up the programs, tool data and parameters to avoid potential data loss. Also, back up

those data before maintenance and inspections.

The electrolytic capacitor’s capacity will drop due to deterioration. To prevent secondary damage due to

capacitor’s faults, Mitsubishi recommends the electrolytic capacitor to be replaced approx. every five

years even when used in a normal environment. Contact the Service Center or Service Station for

replacements.

Do not perform a megger test (insulation resistance measurement) during inspection.

Do not replace parts or devices while the power is ON.

Do not short-circuit, charge, overheat, incinerate or disassemble the battery.

Be careful not to break the heat radiating fins during maintenance or replacement.

(9) Disposal

CAUTION

Take the batteries, etc., off from the controller, drive unit and motor, and dispose of them as general

industrial wastes.

Do not alter or disassemble controller, drive unit, or motor.

Collect and dispose of the spent batteries according to the local laws.

(10) General precautions

To explain the details, drawings given in the instruction manual, etc., may show the unit with the cover

or safety partition removed. When operating the product, always place the cover or partitions back to

their original position, and operate as indicated in the instruction manual, etc.

Page 19

Page 20

Treatment of waste

The following two laws will apply when disposing of this product. Considerations must be made to each law.

The following laws are in effect in Japan. Thus, when using this product overseas, the local laws will have a

priority. If necessary, indicate or notify these laws to the final user of the product.

(1) Requirements for "Law for Promotion of Effective Utilization of Resources"

(a) Recycle as much of this product as possible when finished with use.

(b) When recycling, often parts are sorted into steel scraps and electric parts, etc., and sold to scrap

contractors. Mitsubishi recommends sorting the product and selling the members to appropriate

contractors.

(2) Requirements for "Law for Treatment of Waste and Cleaning"

(a) Mitsubishi recommends recycling and selling the pr oduct when n o longer needed a ccording to item

(1) above. The user should make an effort to reduce waste in this manner.

(b) When disposing a product that cannot be resold, it shall be treated as a waste product.

(c) The treatment of industrial waste must be commissioned to a licensed industrial waste treatment

contractor, and appropriate measures, including a manifest co ntrol, must be taken.

(d) Batteries correspond to "primary batteries", and must be disposed of according to local disposal

laws.

Page 21

Page 22

Disposal

(Note) This symbol mark is for EU countries only.

This symbol mark is according to the directive 2006/66/EC Article 20 Information for endusers and Annex II.

Your MITSUBISHI ELECTRIC product is designed and manufactured with high quality materials and

components which can be recycled and/or reused.

This symbol means that batteries and accumulators, at their end-of-life, should be disposed of

separately from your household waste.

If a chemical symbol is printed beneath the symbol shown above, this chemical symbol means that the

battery or accumulator contains a heavy metal at a certain concentration. This will be indicated as

follows:

Hg: mercury (0,0005%), Cd: cadmium (0,002%), Pb: lead (0,004%)

In the European Union there are separate collection systems for used batteries and accumulators.

Please, dispose of batteries and accumulators correctly at your local community waste collection/

recycling centre.

Please, help us to conserve the environment we live in!

Page 23

Page 24

Trademarks

MELDAS, MELSEC, EZSocket, EZMotion, iQ Platform, MELSEC iQ-R, MELSOFT, GOT, CC-Link, CC-Link/LT,

CC-Link IE, CC-Link IE/field, EcoMonitorLight and SLMP are either trademarks or registered trademarks of

Mitsubishi Electric Corporation in Japan and/or other countries.

Ethernet is a registered trademark of Xerox Corporation in the United States and/or other countries.

Microsoft®, Windows®, SQL Server® and Access® are either trademarks or registered trademarks of Microsoft

Corporation in the United States and/or other countries.

SD logo and SDHC logo are either registered trademarks or trademarks of LLC.

UNIX is a registered trademark of The Open Group in the United States and/or other countries.

Intel® and Pentium® are either trademarks or registered trademarks of Intel Corporation in the United States and/or

other countries.

MODBUS® is either a trademark or a registered trademark of Schneider Electric USA, Inc. or the affiliated

companies in Japan and/or other countries.

EtherNet/IP is a trademark of Open DeviceNet Vendor Association,Inc.

PROFIBUS-DP and PROFINET are either trademarks of Profibus International.

Oracle® is a registered trademark of Oracle Corporation, the subsidiaries, or the affiliated companies in the United

States and /or other countries.

VNC is a registered trademark of RealVNC Ltd. in the United States and other countries.

Other company and product names that appear in this manual are trademarks or registered trademarks of the

respective companies.

Page 25

Page 26

本製品の取扱いについて

( 日本語 /Japanese)

本製品は工業用 ( クラス A) 電磁環境適合機器です。販売者あるいは使用者はこの点に注意し、住商業環境以外で

の使用をお願いいたします。

Handling of our product

(English)

This is a class A product. In a domestic environment this product may cause radio interference in which case the

user may be required to take adequate measures.

본 제품의 취급에 대해서

( 한국어 /Korean)

이 기기는 업무용 (A 급 ) 전자파적합기기로서 판매자 또는 사용자는 이 점을 주의하시기 바라며 가정외의 지역에

서 사용하는 것을 목적으로 합니다 .

Page 27

Page 28

Contents

1 System Basic Configuration ....................................................................................................................... 1

1.1 System Basic Configuration Drawing..................................................................................................... 2

2 General Connection Diagram...................................................................................................................... 3

3 List of Configuration.................................................................................................................................... 5

3.1 CNC Control Unit ................................................................................................................................... 6

3.2 GOT ..................................................................................................................................................... 16

3.2.1 GT27............................................................................................................................................ 16

3.2.2 GT25............................................................................................................................................ 18

3.3 Peripheral Device................................................................................................................................. 19

3.4 Dual Signal Module.............................................................................................................................. 19

3.5 List of Q Series Units (for RQ extension base unit) ............................................................................. 20

4 General Specifications .............................................................................................................................. 23

4.1 Installation Environment Conditions..................................................................................................... 24

4.2 Base Unit ............................................................................................................................................. 25

4.2.1 Basic Base Unit............................................................................................................................ 25

4.2.2 Extension Base Unit..................................................................................................................... 26

4.2.3 RQ Extension Base Unit .............................................................................................................. 28

4.3 Power Supply....................................................................................................................................... 29

4.3.1 R61P/R62P/R63P/R64P .............................................................................................................. 29

4.3.2 Q61P/Q63P/Q64PN..................................................................................................................... 33

4.4 PLC CPU ............................................................................................................................................. 38

4.5 CNC CPU Module................................................................................................................................ 43

4.6 Dual Signal Module.............................................................................................................................. 47

4.7 Signal Splitter....................................................................................................................................... 52

4.8 Manual Pulse Generator ...................................................................................................................... 54

4.8.1 5V Manual Pulse Generator (UFO-01-2Z9) ................................................................................. 54

4.8.2 12V Manual Pulse Generator (HD60C) ......................................................................................55

4.9 Recommended Terminal Block for Dual Signal Module ...................................................................... 55

4.10 GOT (Panel Cut Dimensions) ............................................................................................................ 56

5 Installation .................................................................................................................................................. 57

5.1 Module Installation ............................................................................................................................... 58

5.1.1 Precautions for Handling................................................................................................

Precautions for Installation of Basic Base Unit ............................................................................ 61

5.1.2

5.1.3 Module Installation and Removal................................................................................................. 63

5.1.4 Installation and Removal the Signal Splitter ................................................................................ 66

5.2 Calculating Heat Generation by C80 ................................................................................................... 68

6 Wiring and Connecting.............................................................................................................................. 71

6.1 Precautions .......................................................................................................................................... 72

6.1.1 Precautions for Power Supply Wiring .......................................................................................... 72

6.1.2 Precautions for Wiring of I/O Equipment...................................................................................... 73

6.1.3 Precautions for Grounding........................................................................................................... 73

6.1.4 Precautions for Using Optical Communication Cable.................................................................. 74

6.2 Wiring to the Power Supply Module..................................................................................................... 76

6.2.1 R61P/R62P/R63P/R64P .............................................................................................................. 76

6.2.2 Q61P/Q63P/Q64PN..................................................................................................................... 77

6.3 Connecting the Emergency Stop Signal .............................................................................................. 78

6.4 Connecting the GOT ............................................................................................................................ 79

6.5 Connecting the Drive Unit .................................................................................................................... 80

6.6 Connecting the Dual Signal Module..................................................................................................... 81

6.7 Connecting the Signal Splitter.............................................................................................................. 82

6.8 Connecting the Skip Signal (Sensor) ................................................................................................... 83

6.9 Connecting the Manual Pulse Generator............................................................................................. 84

.............. 58

Page 29

7 Cable ........................................................................................................................................................... 87

7.1 Symbols for Writing Cable Drawings.................................................................................................... 88

7.2 Cables for CNC CPU ........................................................................................................................... 89

7.2.1 F020/F021/F022 Cable ................................................................................................................ 89

7.2.2 G020/G021/G022 Cable .............................................................................................................. 90

7.2.3 H010 Cable .................................................................................................................................. 91

7.2.4 H101 Cable .................................................................................................................................. 92

7.2.5 H300 Cable .................................................................................................................................. 93

7.2.6 H310 Cable .................................................................................................................................. 94

7.2.7 H401 Cable .................................................................................................................................. 95

7.2.8 H501 Cable .................................................................................................................................. 95

7.2.9 J303 Cable................................................................................................................................... 96

7.3 Cable Relating to Drive Unit................................................................................................................. 97

7.3.1 Cable Wire and Assembly............................................................................................................ 97

7.3.2 CNP2E-1 Cable ........................................................................................................................... 98

7.3.3 CNP3EZ-2P/CNP3EZ-3P Cable .................................................................................................. 99

7.3.4 CNV2E-8P/CNV2E-9P Cable .................................................................................................... 100

7.3.5 CNV2E-D Cable......................................................................................................................... 101

7.3.6 CNV2E-HP Cable ...................................................................................................................... 102

7.3.7 DG30 Cable ............................................................................................................................... 103

7.3.8 G380 Cable................................................................................................................................ 104

7.3.9 J395 Cable................................................................................................................................. 105

7.3.10 J396 Cable............................................................................................................................... 106

7.3.11 MR-BKS1CBL-A1-H / MR-BKS1CBL-A2-H Cable................................................................... 107

7.3.12 MR-BT6V2CBL Cable.............................................................................................................. 107

7.3.13 MR-D05UDL3M-B Cable ......................................................................................................... 108

7.3.14 MR-PWS1CBL-A1-H / MR-PWS1CBL-A2-H Cable ................................................................. 108

7.3.15 SH21 Cable.............................................................................................................................. 109

8 Setup Outline............................................................................................................................................ 111

8.1 Flow of the Initial Setup...................................................................................................................... 112

9 GOT Initial Setup ...................................................................................................................................... 113

9.1 GT Designer3..................................................................................................................................... 114

9.1.1 Installing GT Designer3 ..................................

9.1.2 Making Communication Settings ............................................................................................... 115

9.1.2.1 Setting Ethernet Connection.............................................................................................. 115

9.1.3 Setting the Saving Destination Drive for Backup Data............................................................... 122

9.1.4 Setting Time on GOT ................................................................................................................. 124

9.1.5 Creating a GOT Screen ............................................................................................................. 126

9.1.5.1 Precautions for Device Settings......................................................................................... 126

9.1.5.2 Special Function Switch..................................................................................................... 127

9.1.6 Writing the Package Data to GOT ............................................................................................. 128

10 PLC CPU Initial Setup ............................................................................................................................ 133

10.1 GX Works3....................................................................................................................................... 134

10.1.1 Connecting the Devices Necessary for Setup ......................................................................... 134

10.1.2 Setting the Connection to GX Works3 ..................................................................................... 135

10.1.3 Setting Multi-CPU Parameters................................................................................................. 137

10.1.4 Writing the Created Parameters to the PLC ............................................................................ 148

11 CNC CPU Initial Setup ........................................................................................................................... 149

11.1 Initializing CNC CPU Internal Data (Clearing SRAM Data).............................................................. 150

11.1.1 Loss and Restoration of Absolute Position Data...................................................................... 151

11.2 Selecting NC System Type and Display Language ......................................................................... 153

11.3 Setting Multi-CPU Parameters ......................................................................................................... 155

11.4 Setting the Date and Time ............................................................................................................... 170

................................................................

........... 114

12 Setting Machine Parameters ................................................................................................................. 171

12.1 Setting the Parameters for the System Specifications ..................................................................... 172

Page 30

12.2 Setting the Parameters for the Machine Specifications ................................................................... 173

12.3 Setting Drive Unit MDS-E/EH Series ............................................................................................... 175

12.3.1 Setting the Rotary Switch......................................................................................................... 175

12.3.2 Setting DIP Switch ................................................................................................................... 176

12.4 Setting Drive Unit MDS-EM/EMH Series ......................................................................................... 177

12.4.1 Setting the Rotary Switch......................................................................................................... 177

12.5 Setting Drive Unit MDS-EJ/EJH Series............................................................................................ 178

12.5.1 Setting the Rotary Switch......................................................................................................... 178

12.5.2 Setting the DIP Switch ............................................................................................................. 179

12.6 Setting Up without Connecting to the Motor/Drive Units at the Startup of Drive Unit ...................... 180

12.7 Servo Simplified Adjustment ............................................................................................................ 181

12.7.1 First Measure Against Vibration............................................................................................... 181

12.7.2 NC Analyzer2........................................................................................................................... 182

13 Setting of Inter-CPU Features ............................................................................................................... 183

13.1 Setting to Share Handles between CNC CPU Modules .................................................................. 184

14 Setting the Position Detection System ................................................................................................ 185

14.1 Adjusting the Absolute Position Detection System ..........................................................................186

14.1.1 Basic Position Alignment Method I .......................................................................................... 188

14.1.2 Basic Position Alignment Method II ......................................................................................... 191

14.1.3 Machine End Stopper Method: Automatic Initialization............................................................ 193

14.1.4 Machine End Stopper Method: Manual Initialization................................................................ 197

14.1.5 Dog-type .................................................................................................................................. 200

14.1.6 Precautions Common for the Initilization Operation................................................................. 200

14.1.7 Precautions Common for the Dogless-type Absolute Position Detector.................................. 201

14.2 Adjustment of Reference Position Return in Relative Position Detection System ........................... 202

14.2.1 Dog-type Reference Position Return Operation ..................................................................... 202

14.2.2 Dog-type Reference Position Return Adjustment Procedures ................................................. 203

15 Setting the Tool Entry Prohibited Range ........................................................................................... 209

15.1 Stroke End (H/W OT)....................................................................................................................... 210

15.2 Stored Stroke Limit (S/W OT) .......................................................................................................... 211

15.2.1 Outline ..................................................................................................................................... 211

15.2.2 Stored Stroke Limit I ...................................

15.2.3 Stored Stroke Limit II ............................................................................................................... 215

15.2.4 Stored Stroke Limit IB .............................................................................................................. 217

15.2.5 Stored Stroke Limit IC.............................................................................................................. 218

15.2.6 Movable Range during Inclined Axis Control ........................................................................... 219

15.2.7 Stored Stroke Limit for Rotation Axis ....................................................................................... 220

15.2.8 Changing the Area for the Stored Stroke Limit I ...................................................................... 220

15.2.9 Precautions .............................................................................................................................. 221

16 Setting the Deceleration Check ............................................................................................................ 223

16.1 Function ........................................................................................................................................... 224

16.2 Deceleration Check Method............................................................................................................. 226

16.3 Deceleration Check for Opposite Direction Movement Reversal..................................................... 228

16.4 Parameter ........................................................................................................................................ 229

16.5 Relation with Other Functions.......................................................................................................... 231

16.6 Precautions ...................................................................................................................................... 232

17 Data Backup and Restoration ............................................................................................................... 233

17.1 Backup ............................................................................................................................................. 235

17.2 Restoration....................................................................................................................................... 237

................................................................

............. 214

18 Appx.1: Protection Setting .................................................................................................................... 239

18.1 Protect Setting Screen ..................................................................................................................... 240

18.2 Returning the Password to the Non-input State (Operation level 0 to 3) ......................................... 242

18.3 Changing the Operation Level to One of 4 to 6 ............................................................................... 242

18.4 Changing the Password................................................................................................................... 243

Page 31

18.5 Clearing the Password ..................................................................................................................... 244

18.6 Changing the Protection Level ......................................................................................................... 245

18.7 Saving the Protection Level Setting ................................................................................................. 245

19 Appx.2: EMC Installation Guidelines.................................................................................................... 247

19.1 Introduction ...................................................................................................................................... 248

19.2 EMC Directives ................................................................................................................................ 248

19.3 EMC Measures ................................................................................................................................ 249

19.4 Panel Structure ................................................................................................................................ 249

19.4.1 Measures for Control Panel Body ............................................................................................ 249

19.4.2 Measures for Door ................................................................................................................... 250

19.4.3 Measures for Power Supply..................................................................................................... 250

19.5 Measures for Wiring in Panel ........................................................................................................... 251

19.5.1 Precautions for Wiring in Panel................................................................................................ 251

19.5.2 Shield Treatment of Cables ..................................................................................................... 252

19.6 EMC Countermeasure Parts ............................................................................................................ 253

19.6.1 Shield Clamp Fitting................................................................................................................. 253

19.6.2 Ferrite Core.............................................................................................................................. 254

19.6.3 Surge Absorber........................................................................................................................ 256

19.6.4 Selection of Stabilized Power Supply ...................................................................................... 258

20 Appx.3: Restrictions for Lithium Batteries .......................................................................................... 259

20.1 Restriction for Packing ..................................................................................................................... 260

20.1.1 Target Products ....................................................................................................................... 260

20.1.2 Handling by User ..................................................................................................................... 261

20.1.3 Reference ................................................................................................................................ 261

20.2 Products Information Data Sheet (ER Battery) ................................................................................ 262

20.3 Forbiddance of Transporting Lithium Battery

by Passenger Aircraft Provided in the Code of Federal Regulation................................................. 264

20.4 California Code of Regulation "Best Management Practices for Perchlorate Materials" ................. 264

20.5 Restriction Related to EU Battery Directive ..................................................................................... 265

20.5.1 Important Notes ....................................................................................................................... 265

20.5.2 Information for End-user ...............................................................................................

........... 265

Appx.4: Precautions for Compliance to UL/c-UL Standards ............................................................. 267

21

Page 32

1

IB-1501452-C

1

System Basic Configuration

Page 33

C80 Series Connection and Setup Manual

1 System Basic Configuration

CNC CPU

R16NCCPU

RnCPU

LED

GT Designer3

GX Works3

NC Analyzer2

EMG

SKIP

MPG

GOT2000 Series

(SVGA, VGA)

SD card

Ethernet connection

PLC CPU

Rotary switch

Optical communication

Drive unit

1.1 System Basic Configuration Drawing

(Note) The supported versions of the GT Designer3 are as follows:

SVGA: Version 1.155M or later

VGA: Version 1.165X or later

GX Works3 Version 1.025B or later is required.

IB-1501452-C

2

Page 34

3

IB-1501452-C

2

General Connection Diagram

Page 35

C80 Series Connection and Setup Manual

2 General Connection Diagram

EMG

FG

RlO1

PLCIO

NCIO

RIO2

EMG DISPLAY I/F

MPG

CN1

EXT l/F

RlO

MPG#1

ACIN/DCIN

AC/DC

H300

H010

H401

H101

H501

H501

R16NCCPU

J303

FA-CBLxxFMV-M

R173SXY

MPG#3MPG#2

RlO1

PLCIO

NCIO

RIO2

R173SXY

RlO1

PLCIO

NCIO

RIO2

R173SXY

H501

SKIP

TU l/F

SW

MPG TERMINAL DCIN

H310

MPG#2

MPG#3

MPG#1

DClN

DClN

FA-TBS40P

FA-TBS40P

Machine I/O

/Operation panel

Manual Pulse Generator

Drive Units

Power

Unit

MELSEC iQ-R I/O Module

/ Intelligent Module

CPU Module

/ Network Module

UFO-01-2Z9 (5VDC)

(Note1)

cable

(Max:20m)

cable

(Max:0.5m)

cable

(Max:20m)

cable

Cable

cable

(Max:20m)

cable

(Max:5m)

Cable

G020 (5VDC, 1ch, Max:15m)

G021 (5VDC, 2ch, Max:15m)

G022 (5VDC, 3ch, Max:15m)

F020 (12VDC, 1ch, Max:45m)

F021 (12VDC, 2ch, Max:45m)

F022 (12VDC, 3ch, Max:45m)

Dotted lines indicate the sections prepared by the machine tool builder.

Used with connector. Cannot be used with cable H300 at the same time

Cable for terminal block

(Max:5m)

Terminal block type

24VDC

24VDC or

100 to 240VAC

Source Power

UFO-01-2Z9 (5VDC)

24VDC

Dual Signal Module

Terminal block type

24VDC

Display module

GOT2000 Series

HD60C (12VDC)

(Max:20m)

PLC

CPU

Module

CPU/

Net-

work

Module

#1

Dual

Signal

Module

CNCCPU

Module

Manual Pulse Generator 3CH

SKIP signals. 4 points (24VDC)

/ Manual Pulse Generator 2CH

Specifications including unit names, cable

names, and maximum lengths of cables are

subject to change without notice. Always

confirm these details before placing an order.

cable

24VDC or

100 to 240VAC

Basic

Base

CPU/

Net-

work

Module

#2

Dual

Signal

Module

Dual

Signal

Module

I/O

Module

#5

I/O

Module

#4

I/O

Module

#3

I/O

Module

#2

I/O

Module

#1

I/O

Module

#6

G380 (Max:30m, for wiring outside the panel)

J395 (Max:10m, for wiring outside the panel)

J396 (Max:10m, for wiring inside the panel)

cable

Signal splitter

FCU7-HN387

SKIP

signals. 4 points (24VDC)

cable

(Max:15m)

24VDC (Not used)

(12VDC) (Note1)

(Note 1) HD60C (12VDC) requires another power source 12VDC.