Page 1

CNC

C6/C64/C64T

PARAMETER MANUAL

BNP-B2267C(ENG)

Page 2

MELDAS and MELSEC are registered trademarks of Mitsubishi Electric Corporation.

Microsoft and Windows are a registered trademark of Microsoft Corporation in the United States and/or

other countries.

Other brands and product names throughout this manual are trademarks or registered trademarks of their

respective holders.

Page 3

Introduction

This manual is a guide of the parameters used with the CNC MELDAS C6/C64/C64T.

This manual is written on the assumption that all machine parameters of the MELDAS

C6/C64/C64T are provided. However, the CNC may not necessarily be provided with all

of the options. When the system is used, therefore, reference should be made to the

Specifications Manual issued by the machine maker.

Points to be observed when reading this manual

(1) This manual contains general descriptions as seen from the standpoint of NC

(numerical control) and thus refer to the Instruction Manual issued by the machine

maker for descriptions of individual machine tools.

The Instruction Manual issued by the machine maker takes precedence over this

manual when any mention of "restrictions", "usable states" or such details are

mentioned.

(2) As much information as possible on special procedures has been included in this

manual, and it may be considered that any procedures not mentioned cannot be

undertaken.

(3) Also refer to the following manuals.

• MELDAS C6/C64/C64T Instruction Manual........................................ BNP-B2259

• MELDAS C6/C64/C64T Programming Manual

(Machining center/Transfer machine system)........ BNP-B2260

• MELDAS C6/C64/C64T Programming Manual (Lathe system).......... BNP-B2264

• MELDAS AC Servo MDS-B-Vx Series Servo Parameter Manual....... BNP-A2993

• MELDAS AC Servo MDS-C1 Series Specification Manual................. BNP-C3000

CAUTION

For items described as "Restrictions" or "Usable State" in this manual, the Instruction

Manual issued by the machine maker takes precedence over this manual.

Items that are not described must be interpreted as "not possible ".

This manual is written on the assumption that all option functions are added. Refer to the

Specifications Manual issued by the mach i n e m a k e r before s t a r ting use .

Refer to the manuals issued by the machine manufacturer for each machine tool

explanation.

Some screens and functi ons m ay dif fer o r may not be usabl e depending on the NC system

version.

Page 4

Precautions for Safety

Always read the Specifications Manual issued by the machine maker, this manual, related

manuals and attached documents before installation, operation, programming,

maintenance or inspection to ensure correct use. Understand this numerical controller,

safety items and cautions before using the unit.

This manual ranks the safety precautions into "DANGER", "WARNING" and "CAUTION".

DANGER

WARNING

CAUTION

Note that even items ranked as " CAUTION", may lead to major results depending on

the situation.

In any case, important information that must always be observed is described.

When the user may be subject to imminent fatalities or major injuries

if handling is mistaken.

When the user may be subject to fatalities or major injuries if

handling is mistaken.

When the user may be subject to injuries or when physical damage

may occur if handling is mistaken.

Not applicable in this manual.

Not applicable in this manual.

1. Items related to product and manual

For items described as "Restrictions" or "Usable State" in this manual, the Instruction

Manual issued by the machine maker takes precedence over this manual.

Items that are not described must be interpreted as "not possible".

This manual is written on the assumption that all option functions are added. Refer to the

Specifications Manual issued by the machine maker before starting use.

Refer to the manuals issued by the machine manufacturer for each machine tool

explanation.

Some screens and functions may differ or may not be usable depending on the NC system

version.

DANGER

WARNING

CAUTION

Page 5

CAUTION

2. Items related to servo/spindle parameters

To change the control mode to the High-gain amp (MDS-B-V14/V24) mode after

replacement of the Standard amp (MDS-B-V1/V2), it is need to change the parameters

and to adjust the servo parameters to fit to the High-gain amp.

Mode change between the Standard amp mode and the High-gain amp mode is

actually performed when the power (200V) is turned ON. Thus, when changing some

parameters unique to each amp, an alarm “7F” occurs and requests to turn the power

ON again.

Note that the alarm “7F” may occur when the amp is mounted on the machine for the

first time.

When the alarm “7F” occurs, turn the power ON again.

The alarm “7F” may not occur at second turning ON or later unless the above-mentioned

parameters are changed.

With MDS-C1 series, only the serial encoder is applied as the motor end detector.

Thus, OHE/OHA type detector cannot be used as the motor end detector.

Do not make remarkable adjustments or changes of the parameters as the operation

may became unstable.

3. Items related to the other parameters

When setting the parameter (#6449/bit6, 7) not to check the overheat, the control unit

and the communication terminal may not be controlled because of overheat.

In such case, axis runaway may cause a machine breakage, an accident resulting in

injury or death, or device breakage.

To prevent the serious results, ordinarily set the parameters so that the overheat check

is valid.

Page 6

CONTENTS

1. Parameter Screens..................................................................................................................................1

2. Machining Parameters.............................................................................................................................3

2.1 Workpiece Coordinate Offset.........................................................................................................3

2.2 Process Parameters.......................................................................................................................4

2.3 Control Parameters........................................................................................................................6

2.4 Axis Parameters.............................................................................................................................7

2.5 Barrier Data....................................................................................................................................8

3. I/O Parameters.........................................................................................................................................9

3.1 Base Parameters............................................................................................................................9

3.2 I/O Device Parameters.................................................................................................................10

4. Setup Parameters..................................................................................................................................14

5. Base Specifications Parameters............................................................................................................15

6. Axis Specifications Parameters .............................................................................................................66

6.1 Axis Specifications Parameters....................................................................................................66

6.2 Zero Point Return Parameters.....................................................................................................73

6.3 Absolute Position Parameters......................................................................................................75

6.4 Axis Specifications Parameters 2.................................................................................................77

7. Servo Parameters..................................................................................................................................80

7.1 MDS-B-SVJ2................................................................................................................................82

7.2 MDS-C1-Vx High-gain (MDS-B-Vx4 Compatible)......................................................................108

7.3 MDS-C1-Vx Standard Specification (MDS-B-Vx Compatible)...................................................136

7.4 Supplement ................................................................................................................................166

7.4.1 D/A Output Specifications................................................................................................166

7.4.2 Electronic Gears..............................................................................................................172

7.4.3 Lost Motion Compensation..............................................................................................173

8. Spindle Parameters .........................................................................................................

8.1 Spindle Base Specifications Parameters...................................................................................174

8.2 MDS-B-SPJ2..............................................................................................................................181

8.3 MDS-B-SP/SPH, MDS-C1-SP/SPH...........................................................................................201

8.4 MDS-C1-SPM.............................................................................................................................234

8.5 Supplement ................................................................................................................................266

8.5.1 D/A Output Specifications................................................................................................266

9. Machine Error Compensation..............................................................................................................269

9.1 Function Outline.........................................................................................................................269

9.2 Setting Compensation Data.......................................................................................................273

9.3 Example in Using a Linear Axis as the Base Axis .....................................................................275

9.4 Example in Using a Rotation Axis as the Base Axis..................................................................277

10. PLC Constants...................................................................................................................................278

10.1 PLC Timer ................................................................................................................................278

10.2 PLC Counter.............................................................................................................................278

10.3 PLC Constants.........................................................................................................................279

10.4 PLC Bit Selection .....................................................................................................................280

11. Macro List...........................................................................................................................................283

12. Position Switch...................................................................................................................................284

12.1 Outline of Function...................................................................................................................284

12.2 Canceling the Position Switch..................................................................................................286

13. Indexing Axis Parameters................................................................................................... ................287

14. Indexing Axis Position Switch.............................................................................................................289

14.1 Outline of Function...................................................................................................................289

15. Indexing Axis Commands...................................................................................................................290

16. Auxiliary Axis Parameters..................................................................................................................291

....................174

Page 7

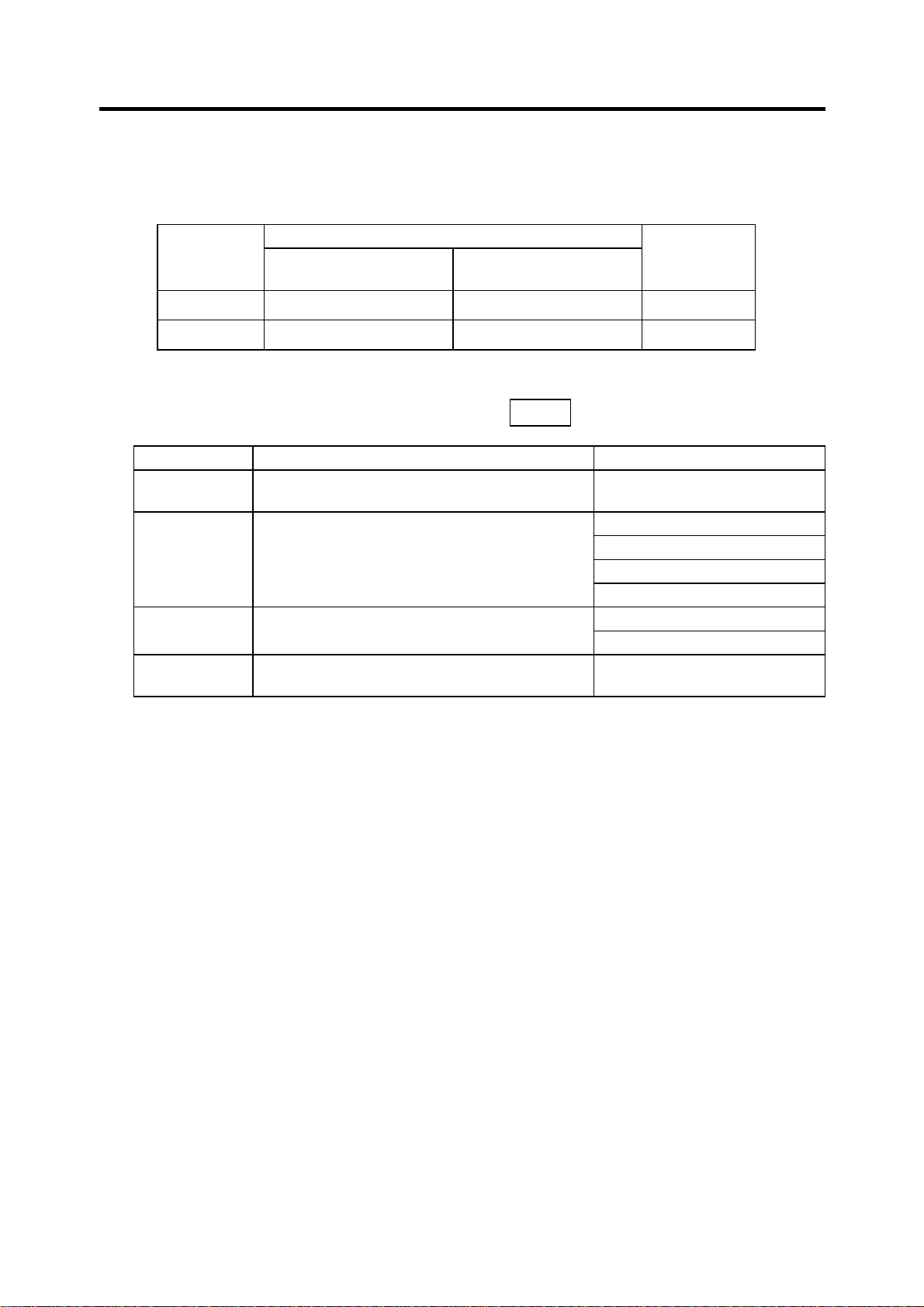

1. Parameter Screens

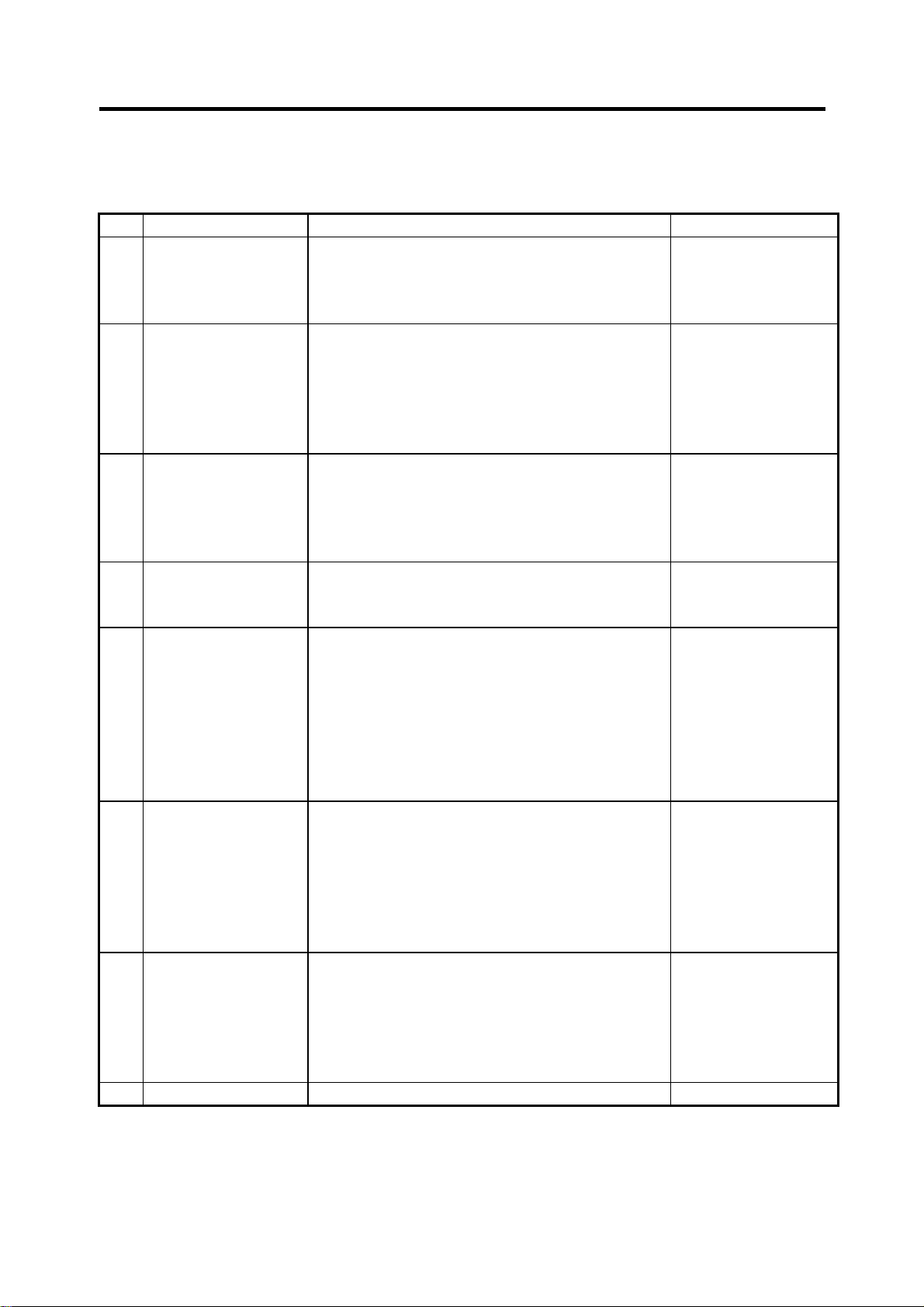

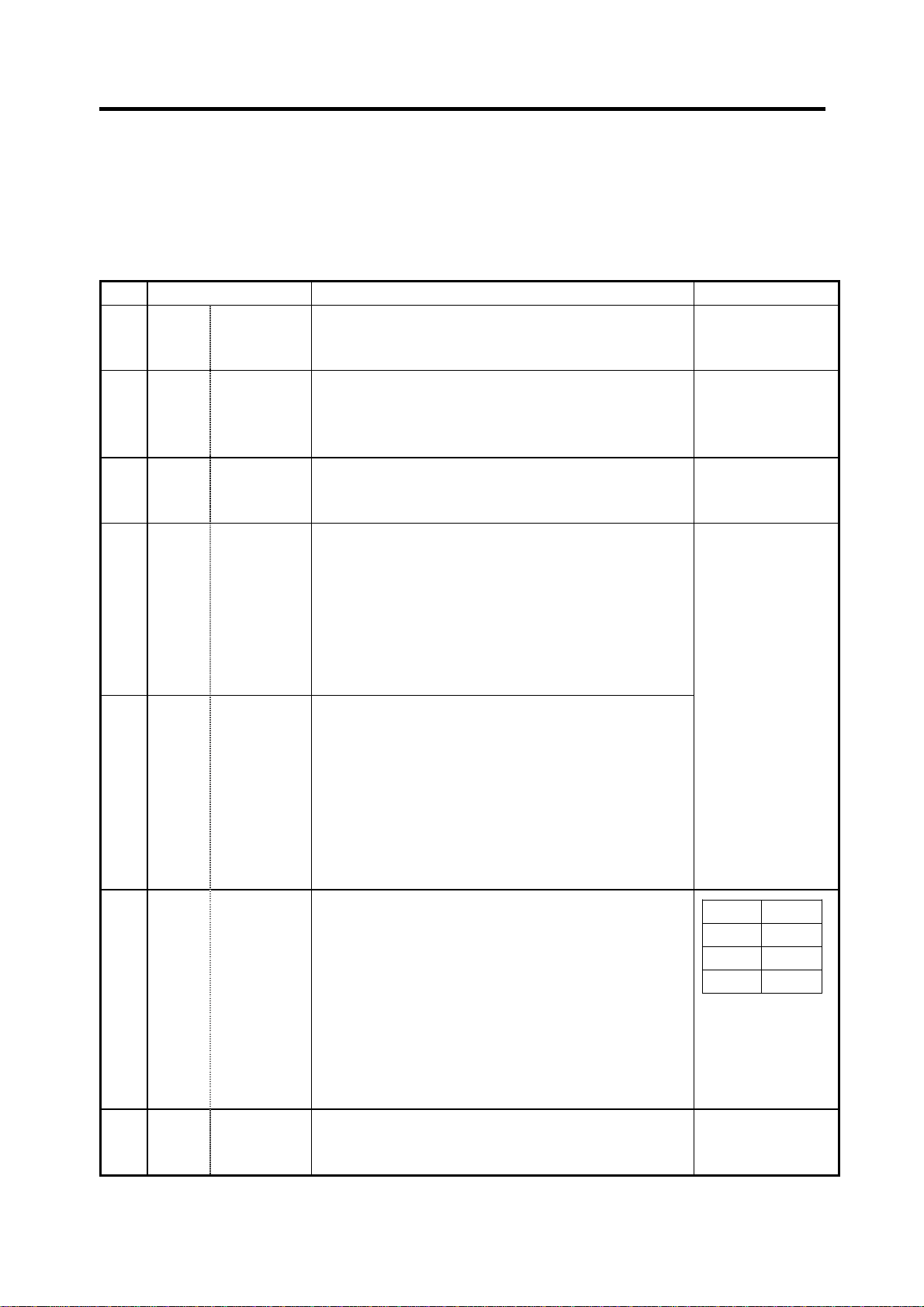

The parameter input setting units are as follow.

Input unit

"#1003 iunit"

B 0.001 mm 0.0001 inch 0.001°

C 0.0001 mm 0.00001 inch 0.0001°

(1) User parameters

The following menus can be selected when the key

Menu Details Reference Section

WORK

PROCESS

I/O PARAM

SETUP

Machine constant:mm

"#1040 M_inch"=0

The WORK OFFSET screen will open. 2.1 Workpiece Coordinate

The PROCESS PARAM screen will open.

The I/O PARAM screen will open.

The screen to set the setup parameters will

open.

1. Parameter Screens

Linear axis "#1017 rot"=0

Machine constant:inch

"#1040 M_inch"=1

TOOL

PARAM

Rotary axis

"#1017 rot"=1

is pressed.

Offset

2.2 Process Parameters

2.3 Control Parameters

2.4 Axis Parameters

2.5 Barrier Data

3.1 Base Parameters

3.2 I/O Device Parameters

4. Setup Parameters

1

Page 8

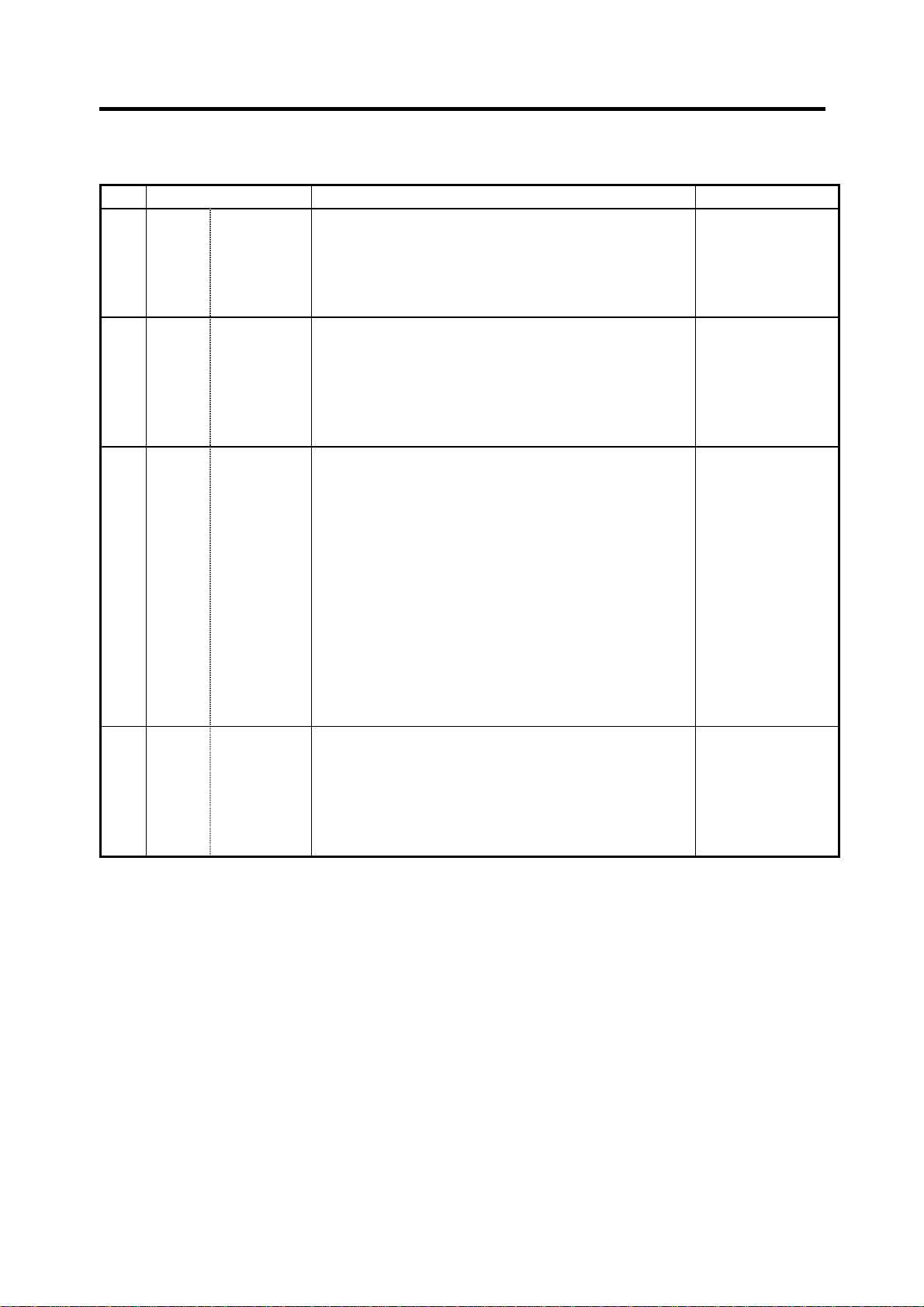

(2) Setup Parameters

The following menus can be selected when SETUP is selected. (Refer to the section "4. Setup

Parameters" for details.

Menu Details Reference Section

BASE

1. Parameter Screens

The BASE SPEC. PARAM screen will open. 5. Base Specifications

Parameters

AXIS SPEC

SERVO

SPINDLE

The AXIS SPEC PARAM screen will open. 6. Axis Specifications

The SERVO PARAM screen will open. 7. Servo Parameters

The SPINDLE BASE SPEC. PARAM screen will

open.

MC-ERR

PLC

MACRO

PSW

IDX-PRM

The MC-ERR. CMP. screen will open. 9. Machine Error

The PLC DATA screen will open. 10. PLC Constants

The MACRO FILE screen will open. 11. Macro List

The POSITION SWITCH screen will open. 12. Position Switch

The INDEXING AXIS PARAMETERS screen will

open.

IDX-PSW

The INDEXING AXIS POSITION SWITCH

screen will open.

IDX-CMD

The INDEXING AXIS COMMANDS screen will

open.

(3) The following menus can be selected when the key

ALARM

DIAGN

Parameters

8. Spindle Parameters

Compensation

13. Indexing Axis Parameters

14. Indexing Axis Position

Switch

15. Indexing Axis Commands

is pressed.

Menu Details Reference Section

AUX-PRM

The AUX-PARA screen will open. 16. Auxiliary Axis Parameter

2

Page 9

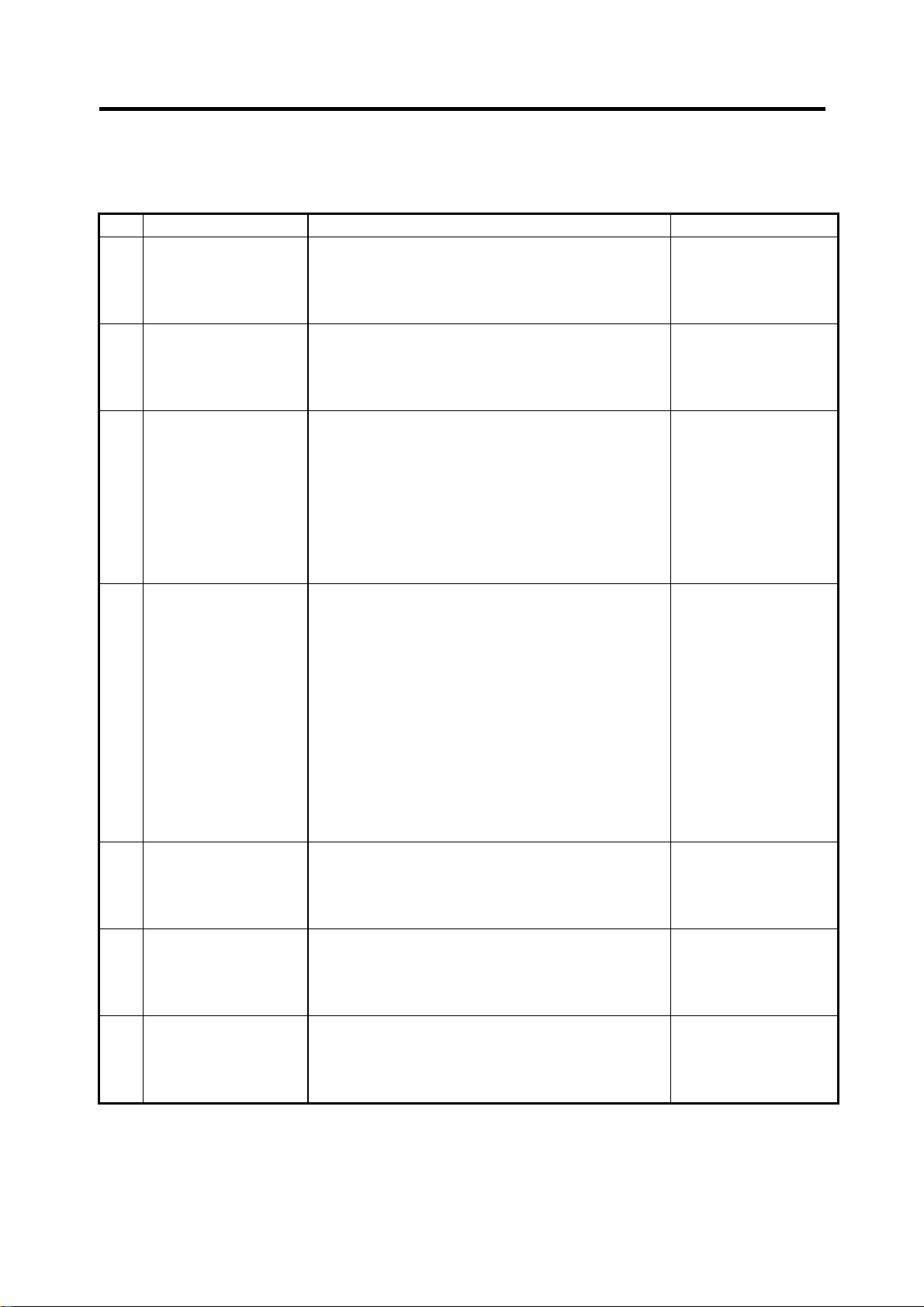

2. Machining Parameters

2.1 Workpiece Coordinate Offset

2. Machining Parameters

2.1 Workpiece Coordinate Offset

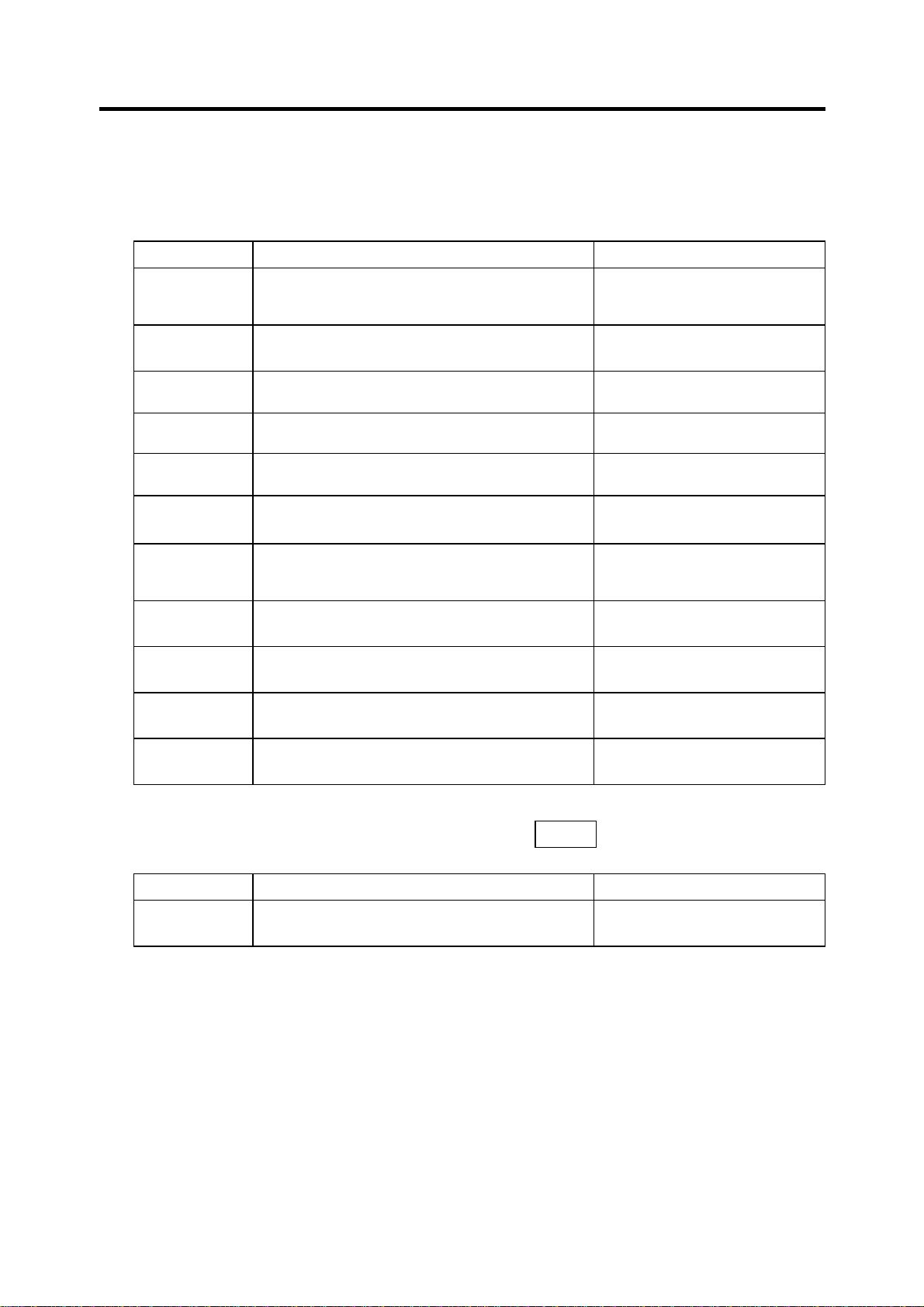

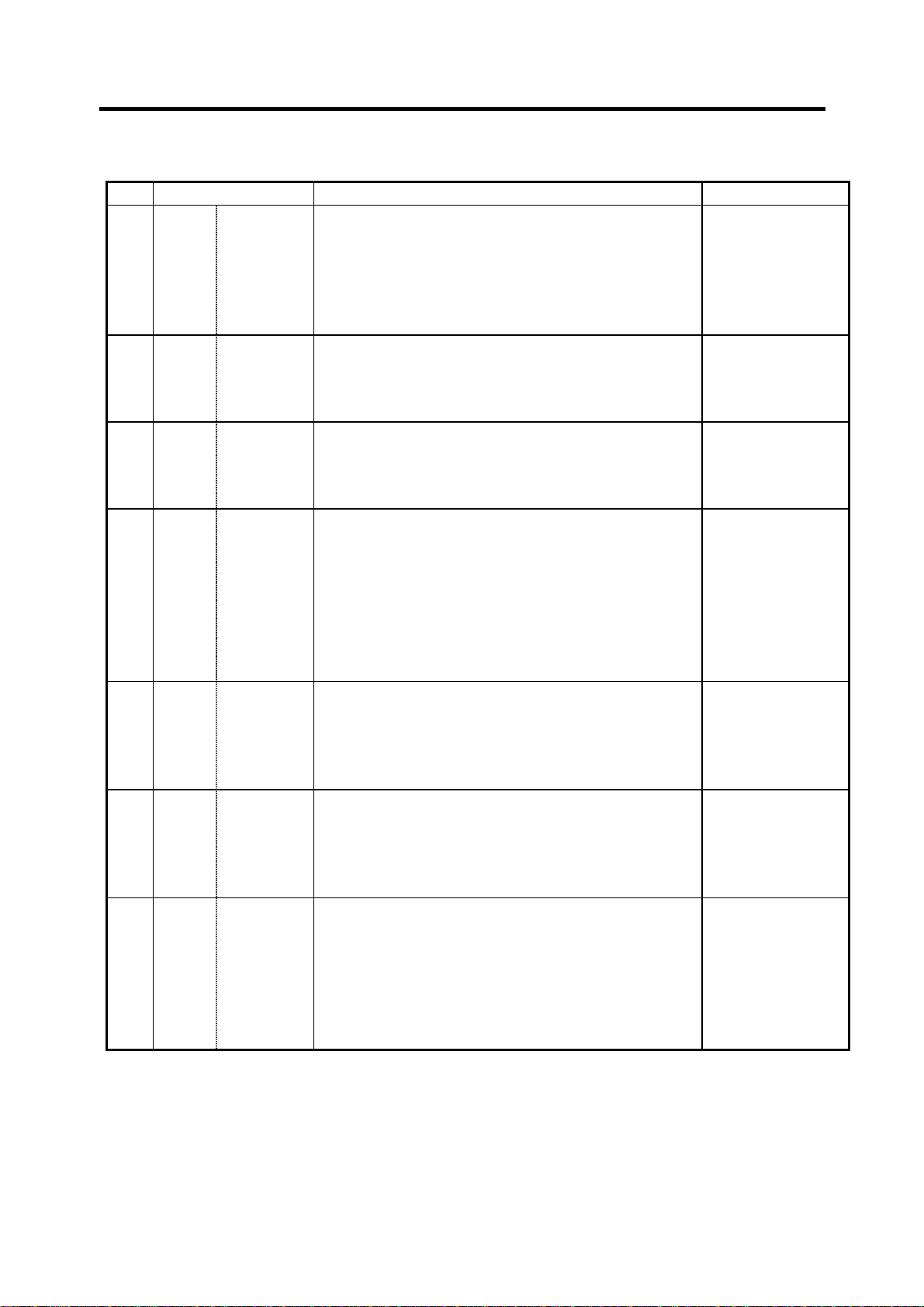

# Parameter Explanation Setting range (unit)

54 G54 offset

55 G55 offset

Set the workpiece coordinate system and external

workpiece coordinate offset values from G54 to G59.

The workpiece coordinate system offset data can

be set as an absolute value or incremental value.

±99999.999 (mm)

56 G56 offset

57 G57 offset

58 G58 offset

59 G59 offset

60 EXT offset

G55

workpiece

coordinate

system

Basic machine

coordinate system

W2

G54

workpiece

coordinate

system

W1

M

External

(EXT)

offset

R

Reference

point

3

Page 10

2. Machining Parameters

2.2 Process Parameters

2.2 Process Parameters

<WRK COUNT> (No. of workpieces machined)

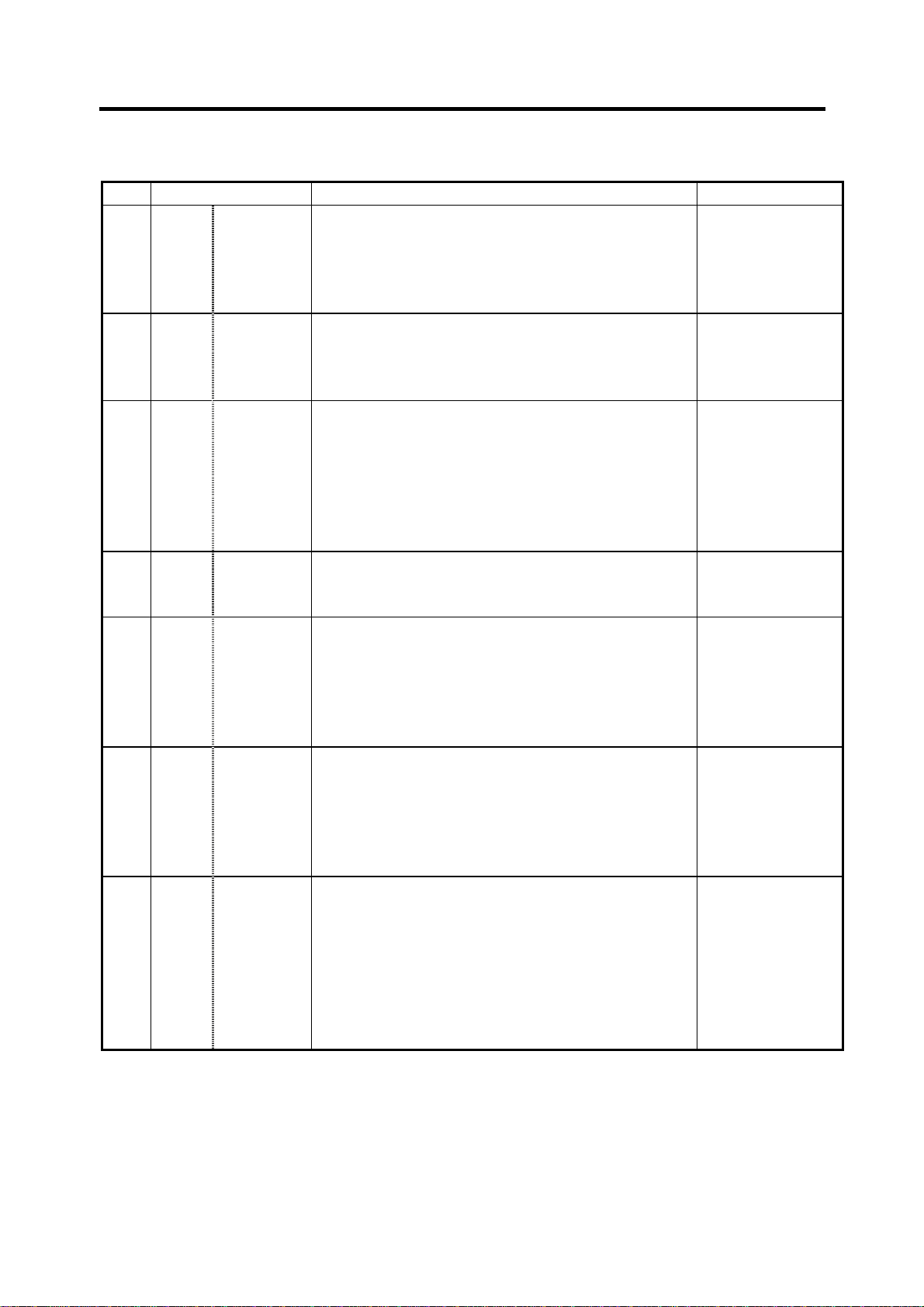

# Item Contents Setting range (unit)

8001 WRK COUNT M Set the M code that counts the No. of workpiece

repeated machining.

The No. will not be counted when set to 0.

8002 WRK COUNT The current machining No. is displayed. Set the

initial value.

8003 WRK LIMIT Set the maximum No. of workpieces machined.

A signal is output to PLC when the No. of machining

times is counted to this limit.

<AUTO TLM> (Automatic tool length measurement)

# Item Contents Setting range (unit)

8004 SPEED Set the feedrate during automatic tool length

measurement.

8005 ZONE r Set the distance between the measurement position

and deceleration start point.

8006 ZONE d Set the tolerable zone of the measurement position.

If the sensor signal turns on in front of d before the

measurement position‚ or if the signal does not turn

on after d is passed‚ an alarm will occur.

<AUTO CORNER OVR> (Automatic corner override)

# Item Contents Setting range (unit)

8007 OVERRIDE Set the override value for automatic corner override. 0 to 100 (%)

8008 MAX ANGLE Set the max. corner opening angle where deceler-

ation should start automatically.

If the angle is larger than this value‚ deceleration will

not start.

8009 DSC. ZONE Set the position where deceleration starts at the

corner.

Designate at which length point before the corner

deceleration should start.

<T-TIP OFFSET> (Wear data input)

# Item Contents Setting range (unit)

8010 ABS. MAX.

(For L system only)

8011 INC. MAX.

(For L system only)

Set the max. value when inputting the tool wear

compensation amount.

A value exceeding this setting value cannot be set.

Set the max. value for when inputting the tool wear

offset amount in the addition mode.

0 to 99

0 to 999999

0 to 999999

1 to 1000000

(mm/min)

0 to 99999.999 (mm)

0 to 99999.999 (mm)

0 to 180 (degrees)

0 to 99999.999 (mm)

0 to 99.999 (mm)

0 to 99.999 (mm)

4

Page 11

2. Machining Parameters

2.2 Process Parameters

<FIXED C.> (Fixed cycle)

# Item Contents Setting range (unit)

8012 G73 n

(For M system only)

8013 G83 n Set the return amount for G83 (deep hole drilling

8014 CDZ-VALE

(For L system only)

8015 CDZ-ANGLE

(For L system only)

8016 G71 MINIMUM

(For L system only)

8017 DELTA-D

(For L system only)

8018 G84/G74 return

(For M system only)

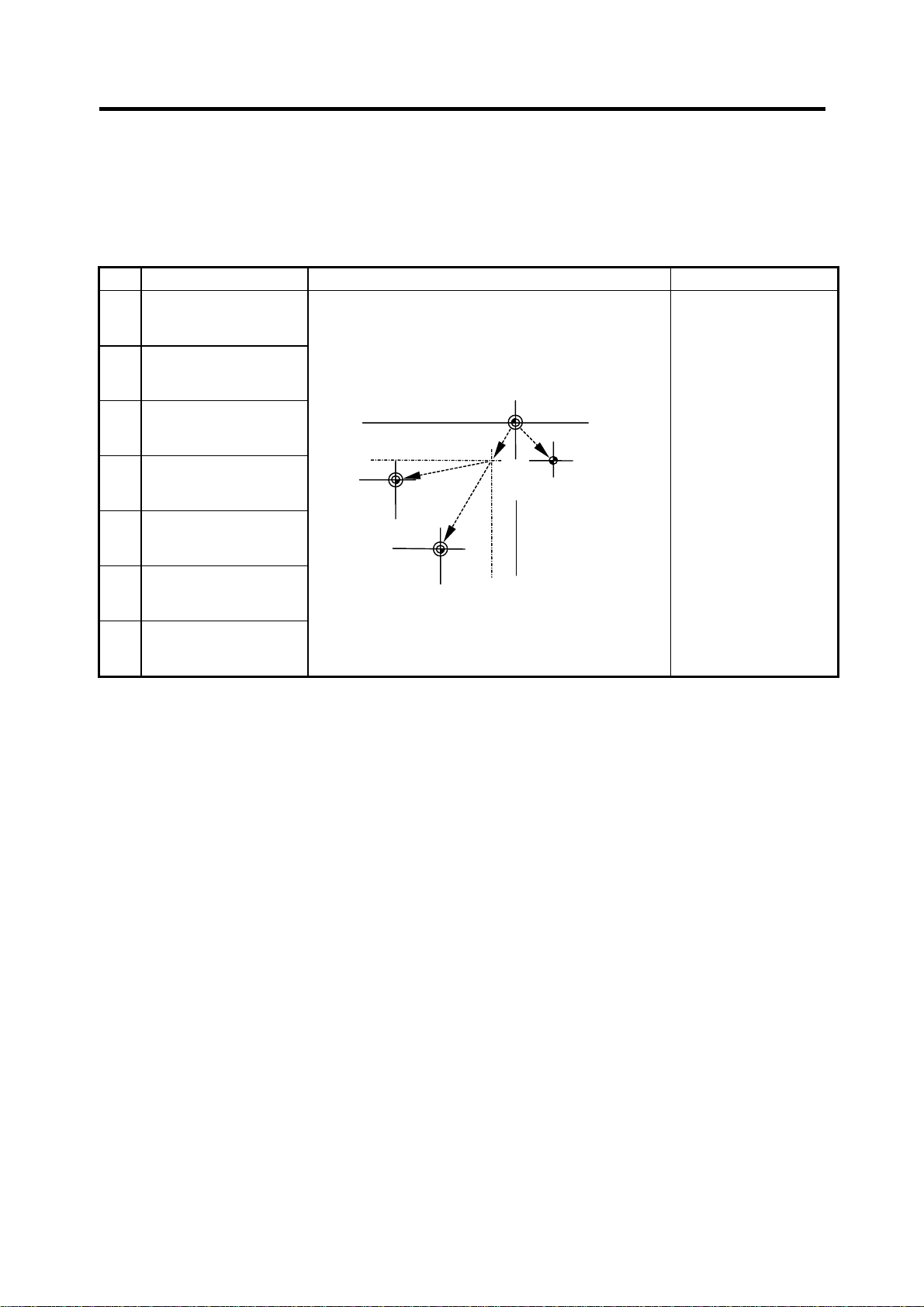

<PRECISION> (High precision control)

# Item Contents Setting range (unit)

8019 R COMP Set up a compensation factor for reducing a control

8020 DCC ANGLE Set up the minimum value of an angle (external

Set the return amount for G73 (step cycle). 0 to 99999.999 (mm)

0 to 99999.999 (mm)

cycle).

Set the screw cut up amount for G76‚ 78 (thread

cutting cycle).

Set the screw cut up angle for G76‚ 78 (thread

cutting cycle).

Set the minimum cut amount for the final cutting in

G71‚ 72 (rough cutting cycle).

If the final cutting amount is smaller than this value‚

the final cut will not be performed.

Set the change amount to the command cut amount

D for G71‚ 72 (rough cutting cycle).

Each cut amount will be the value obtained by

adding or subtracting this value from command D‚

and thus‚ the amount can be changed each cut.

Set up return length m at a G84/G74 pecking tap

cycle.

(Note) Set 0 to specify a usual tap cycle.

error in the reduction of a corner roundness and

arch radius.

Indicates a maximum control error (mm) in

parentheses.

The larger the setup value, the smaller the

theoretical error will be. However, since the speed

at the corner goes down, the cycle time is extended.

angle) that should be assumed to be a corner.

When an inter-block angle (external angle) in highprecision mode is larger than the set value, it is

determined as a corner and the speed goes down to

sharpen the edge.

(Note) If “0” is set, it will be handled as 5 degrees.

The standard setting value is “0”.

If the set value is smaller than

θ

θ

, the speed goes down to

optimize the corner.

0 to 127

(0.1 lead)

0 to 89 (degrees)

0 to 99.999 (mm)

0 to 99.999 (mm)

0 to 99.999 (mm)

0 to 99 (%)

0 to 30 (degrees)

0: The angle will be 5

degrees.

5

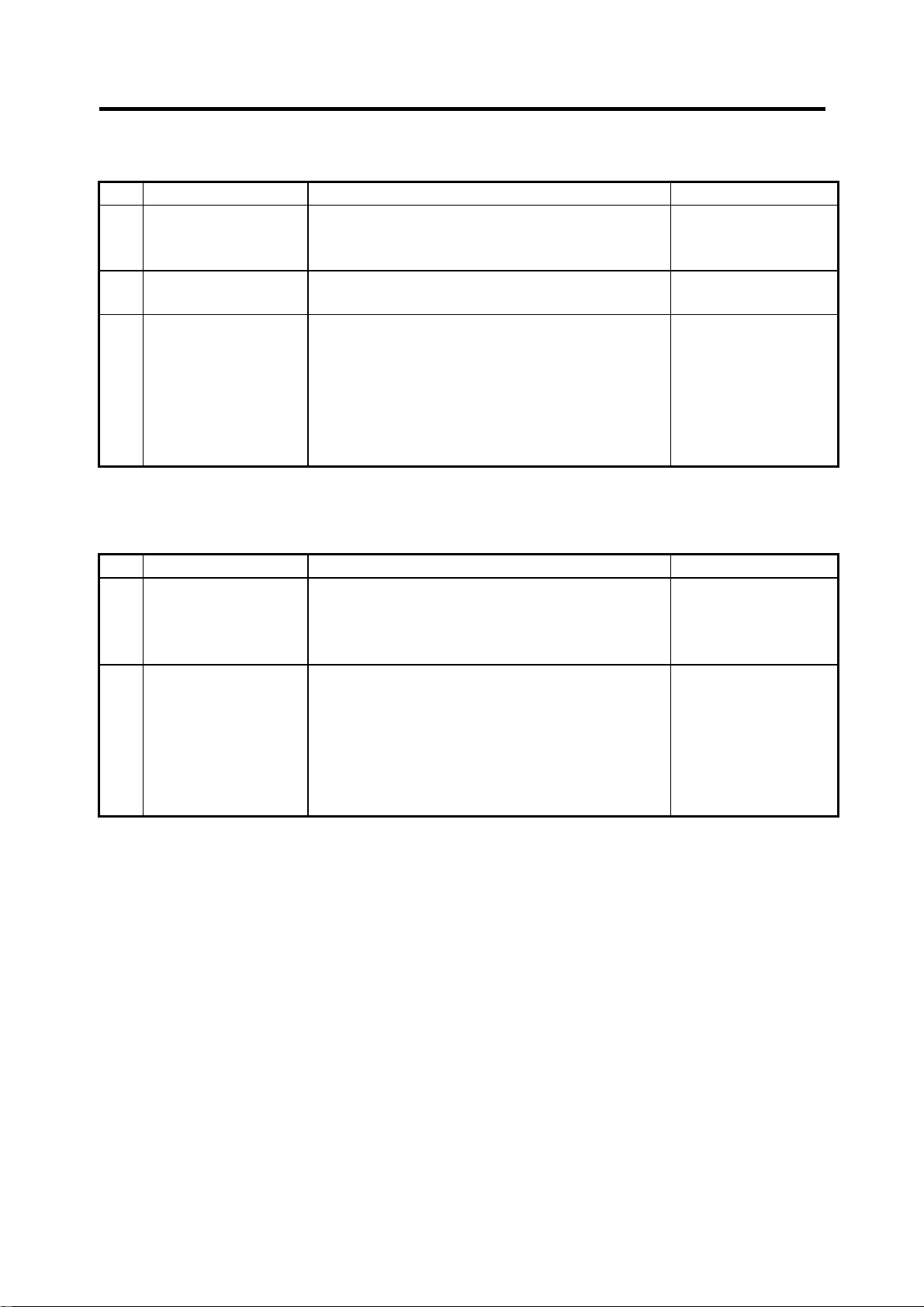

Page 12

2. Machining Parameters

2.3 Control Parameters

2.3 Control Parameters

# Item Contents Setting range (unit)

8101 MACRO SINGLE Select the control of the blocks where the user

macro command continues.

0: Do not stop while macro block continues.

1: Stop every block during signal block operation.

8102 COLL. ALM OFF Select the interference (bite) control to the

workpiece from the tool diameter during cutter

compensation and nose R offset.

0: An alarm is output and operation stops when

an interference is judged.

1: Changes the path to avoid interference.

8103 COLL. CHK OFF Select the interference (bite) control to the work

from the tool diameter during cutter compensation

and nose R offset.

0: Performs interference check

1: Does not perform interference check

8105 EDIT LOCK B Select the edit lock for program Nos. 8000 to 9999.

0: Program can be edited.

1: Editing of above program is prohibited.

8106 G46 NO REV-ERR

(For L system only)

8107 R COMPENSATION 0: In arc cutting mode, the machine moves to the

8108 R COMP Select Specify whether to perform arc radius error

8109 HOST LINK Not used. 0

Select the control for the compensation direction

reversal in G46 (nose R offset).

0: An alarm is output and operation stops when

the compensation direction is reversed (G41

→ G42‚ G42 → G41).

1: An alarm does not occur when the compensa-

tion direction is reversed‚ and the current

compensation direction is maintained.

inside because of a delay in servo response to

a command, making the arc smaller than the

command value.

1: In arc cutting mode, the machine compensates

the movement to the inside because of a delay

in servo response to a command

correction over all axes or axis by axis.

0: Perform correction over all axes.

1: Perform correction over axis by axis.

(Note) This parameter is effective only when

"#8107 R COMPENSATION" is 1.

0/1

0/1

0/1

0/1

0/1

0/1

0/1

6

Page 13

2. Machining Parameters

2.4 Axis Parameters

2.4 Axis Parameters

# Item Contents Setting range (unit)

8201 AX. RELEASE Select the function to remove the control axis from

the control target.

0: Control as normal

1: Remove from control target

8202 OT-CHECK OFF Select the stored stroke limit function set in #8204

and #8205.

0: Stored stroke limit valid

1: Stored stroke limit invalid

8203 OT-CHECK-CANCEL When the simple absolute position method ("#2049

type" is 9) is selected‚ the stored stroke limits I, II (or

IIB) and IB will be invalid until the first reference

point return is executed after the power is turned on.

0: Stored stroke limit II valid (according to #8202)

1: Stored stroke limit II invalid

(Note) This setting (#8203) affects all the stored

stroke limits.

8204 OT-CHECK-N Set the coordinates of the (–) direction in the

moveable range of the stored stroke limit II or the

lower limit coordinates of the prohibited range of

stored stroke limit IIB.

If the sign and value are the same as #8205 (other

than "0"), the stored stroke limit II (or IIB) will be

invalid.

If the stored stroke limit IIB function is selected, the

prohibited range will be between two points even

when #8204 and #8205 are set in reverse.

When II is selected, the entire range will be

prohibited.

8205 OT-CHECK-P Set the coordinates of the (+) direction in the

moveable range of the stored stroke limit II or the

upper limit coordinates of the prohibited range of

stored stroke limit IIB.

8206 TOOL CHG. P Set the coordinates of the tool change position for

G30. n (tool change position return).

Set with coordinates in the basic machine coordinate

system.

8207 G76/87 IGNR

(For M system only)

Select the shift operation at G76 (fine boring) and

G87 (back boring).

0: Shift effective

1: No shift

0/1

0/1

0/1

–99999.999 to

+99999.999 (mm)

–99999.999 to

+99999.999 (mm)

–99999.999 to

+99999.999 (mm)

0/1

7

Page 14

2. Machining Parameters

2.5 Barrier Data

# Item Contents Setting range (unit)

8208 G76/87 (–)

(For M system only)

8209 G60 SHIFT

(For M system only)

8210 OT INSIDE The stored stoke limit function set in #8204 and

Specify the shift direction at G76 and G87.

0: Shift to (+) direction

1: Shift to (–) direction

Set the last positioning direction and distance for a

G60 (uni-directional positioning) command.

#8205 prevents the machine from moving to the

inside or outside of the specified range.

0: Inhibits outside area.

(select stored stroke limit II.)

1: Inhibits inside area.

(select stored stroke limit II B.)

0/1

–99999.999 to

+99999.999 (mm)

0/1

2.5 Barrier Data

# Item Contents Setting range (unit)

8300 P0

(For L system only)

P1

8301

P2

8302

P3

8303

P4

8304

P5

8305

P6

8306

(For L system only)

Set the reference X-coordinates of the chuck and

the tail stock barrier.

Set the center coordinate (Radius value) of

workpiece by the basic machine coordinate system.

Set the area of the chuck and tail stock barrier.

(Radius value)

Set the coordinate value from the center of workpiece

for X-axis.

Set the coordinate value by basic machine

coordinate system for Z-axis.

–99999.999 to

+99999.999 (mm)

–99999.999 to

+99999.999 (mm)

8

Page 15

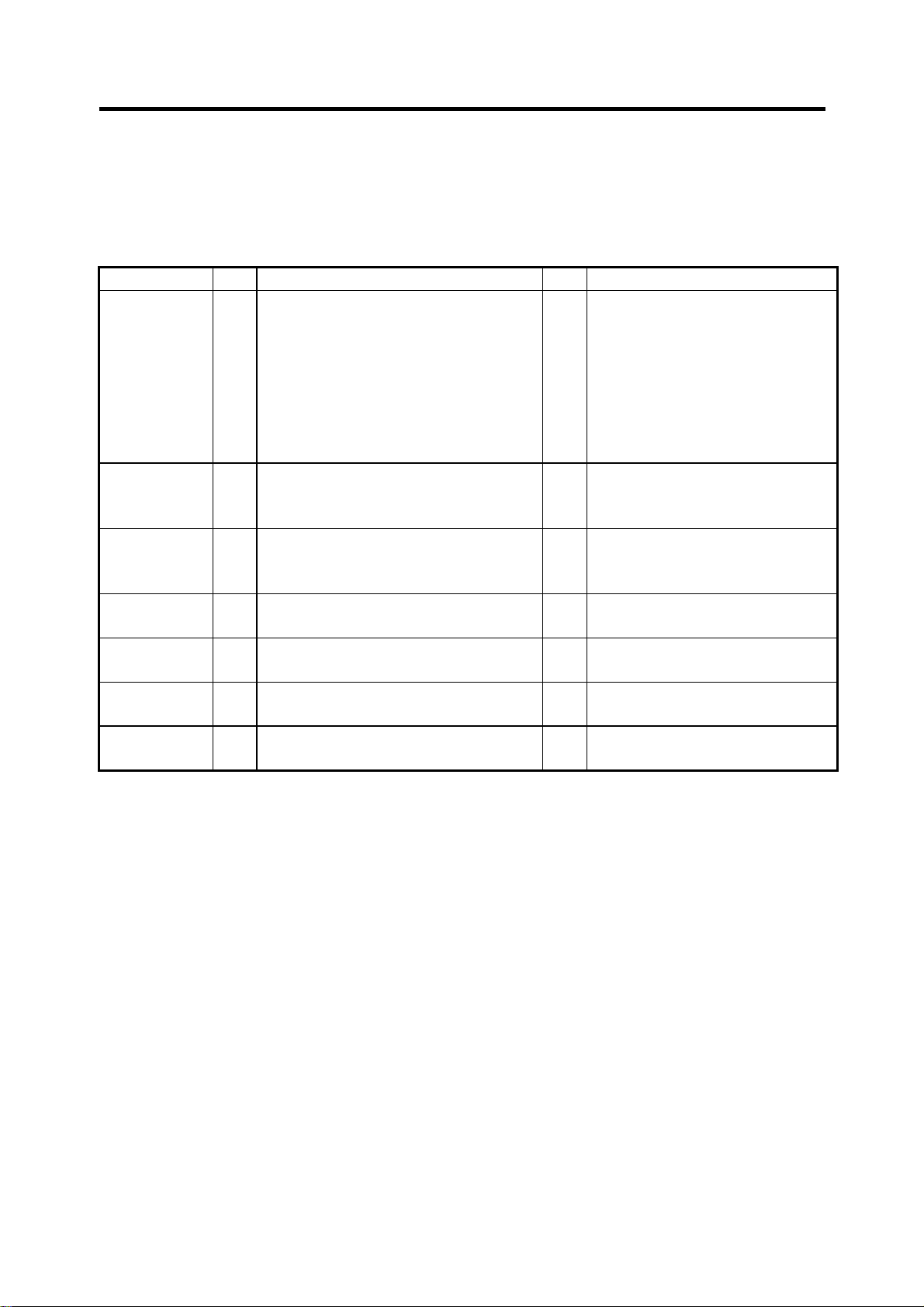

3. I/O Parameters

3.1 Base Parameters

3. I/O Parameters

3.1 Base Parameters

<I/O> # <PORT No.> # <DEV. No.> <DEV. NAME>

Specify the board No. to which the serial

input/output device is connected to each

application.

DATA IN 9001 Specify the port for inputting the data

such as machine program and

parameters.

DATA OUT 9003 Specify the port for outputting the data

such as machine program and

parameters.

TAPE MODE 9005 Specify the input port for running with

the tape mode.

MACRO

PRINT

PLC IN/OUT 9009 Specify the port for inputting/outputting

REMOTE

PROG IN

9007 Specify the output port for the user

macro DPRINT command.

various data with PLC.

9011 Not used. 9012 Not used.

Set the input/output device No. for

each application.

The device Nos. are 0 to 4 and

correspond to the input/output

device parameters.

The device name set in the

input/output device parameter is

also displayed for identification.

9002 Specify the No. of the device that

inputs the data.

9004 Specify the No. of the device that

outputs the data.

9006 Specify the No. of the device to be

run with the tape mode.

9008 Specify the No. of the device for the

DPRINT command.

9010 Specify the No. of the device for the

PLC input/output.

9

Page 16

3. I/O Parameters

3.2 I/O Device Parameters

3.2 I/O Device Parameters

Parameters for up to five types of input/output devices can be set in DEV <0> to <4>.

(Note) The parameters are set for each device.

9101 ~ Set the same settings for device 0.

9201 ~ Set the same settings for device 1.

9301 ~ Set the same settings for device 2.

9401 ~ Set the same settings for device 3.

9501 ~ Set the same settings for device 4.

# Item Contents Setting range (unit)

9101

9201

9301

9401

9501

9102

9202

9302

9402

9502

9103

9203

9303

9403

9503

9104

9204

9304

9404

9504

9105

9205

9305

9405

9505

9106

9206

9306

9406

9506

DEVICE NAME 0

DEVICE NAME 1

DEVICE NAME 2

DEVICE NAME 3

DEVICE NAME 4

BAUD RATE Set the serial communication speed. 1: 9600 (bps)

STOP BIT Set the stop bit length used in the start-stop system. 1: 1 (bit)

PARITY CHECK Specify whether to add the parity check bit to the

EVEN PARITY Specify the odd or even parity when it is added to

CHR. LENGTH Set the length of the data bit. 0: 5 (bit)

Set the device name corresponding to the device

No.

Set a simple name for quick identification.

data during communication.

the data.

Use alphabet

characters‚ numerals

and symbols to set a

name within 3

characters.

2: 4800

3: 2400

4: 1200

5: 600

6: 300

7: 150

2: 1.5

3: 2

0: Parity bit not added

1: Parity bit added

0: Odd parity

1: Even parity

1: 6

2: 7

3: 8

10

Page 17

3. I/O Parameters

3.2 I/O Device Parameters

# Item Contents Setting range (unit)

9107

TERMINATOR TYPE The code to terminate data reading can be selected. 0 and 3: EOR

9207

1 and 2: EOB or EOR

9307

9407

9507

9108

HAND SHAKE Specify the transmission control method.

9208

9308

The method will be no procedure if a value except 1

to 3 is set.

9408

9508

1: RTS/CTS method

(This method can

be used only for

SIO2.)

2: No procedure (No

handshaking)

3: DC code method

DC CODE PARITY Specify the DC code when the DC code method is

9109

9209

selected.

9309

9409

0: No parity to DC

code (DC3 = 13H)

1: DC code with parity

(DC3 = 93H)

9509

DC2/DC4 OUTPUT Specify the DC code handling when outputting data

9111

9211

to the output device.

9311

9411

9511

CR OUTPUT Specify whether to insert the <CR> code just before

9112

9212

the EOB (L/F) code during output.

DC2 / DC4

0: None / None

1: Yes / None

2: None / Yes

3: Yes / Yes

0: Do not add

1: Add

9312

9412

9512

EIA Output In data output mode, select the ISO or EIA code for

9113

9213

9313

9413

data output.

In data input mode, the ISO and EIA codes are

identified automatically.

0: ISO code output

1: EIA code output

9513

FEED CHR. Specify the length of the tape feed to be output at

9114

9214

the start and end of the data during tape output.

0 to 999 (characters)

9314

9414

9514

PARITY V Specify whether to check the parity of the No. of

9115

9215

9315

9415

characters in block during data input.

The No. of characters is factory-set so that the

check is valid at all times.

0: Do not perform

parity V check

1: Perform parity V

check

9515

11

Page 18

3. I/O Parameters

3.2 I/O Device Parameters

# Item Contents Setting range (unit)

9116

TIME-OUT (s) Set the time out time to detect an interruption in

9216

9316

9416

9516

communication.

The time out is not checked when 0 is set, so the

waiting time will be infinite.

The screens cannot be changed during the waiting

time.

0 to 30 (s)

Set this time to 10 as the standard.

DR OFF Specify whether to check the DR data at the data

9117

9217

input/output.

0: DR valid

1: DR invalid

9317

9417

9517

DATA ASC II 0: Output in ISO/EIA code (Depends on whether

9118

9218

9318

9418

#9113, #9213, #9313, #9413, or #9513 EIA

output parameter is set up)

1: Output in ASC II code

0/1

9518

INPUT FORM Specify the mode for input (collation).

9119

9219

9319

9419

9519

EIA CODE [ When outputting with the EIA codes, special ISO

9121

9221

9321

9421

9521

0: Standard input (Data from the very first EOB is

handled as significant information.)

1: EOBs following the first EOB of the input data

are skipped until data other than EOB is input.

codes not included in EIA can be output with

alternate codes.

For each special code, designate a code (as a

hexadecimal) that is not duplicated with existing EIA

codes.

0/1

0 to FF (hexadecimal)

(Continued on the next page.)

]

9122

9222

9322

9422

9522

9123

#

9223

9323

9423

9523

9124

∗

9224

9324

9424

9524

12

Page 19

3. I/O Parameters

3.2 I/O Device Parameters

# Item Contents Setting range (unit)

9125

=

(Continued from the previous page.)

9225

9325

9425

9525

:

9126

9226

9326

9426

9526

9127

$

9227

9327

9427

9527

!

9128

9228

9328

9428

9528

13

Page 20

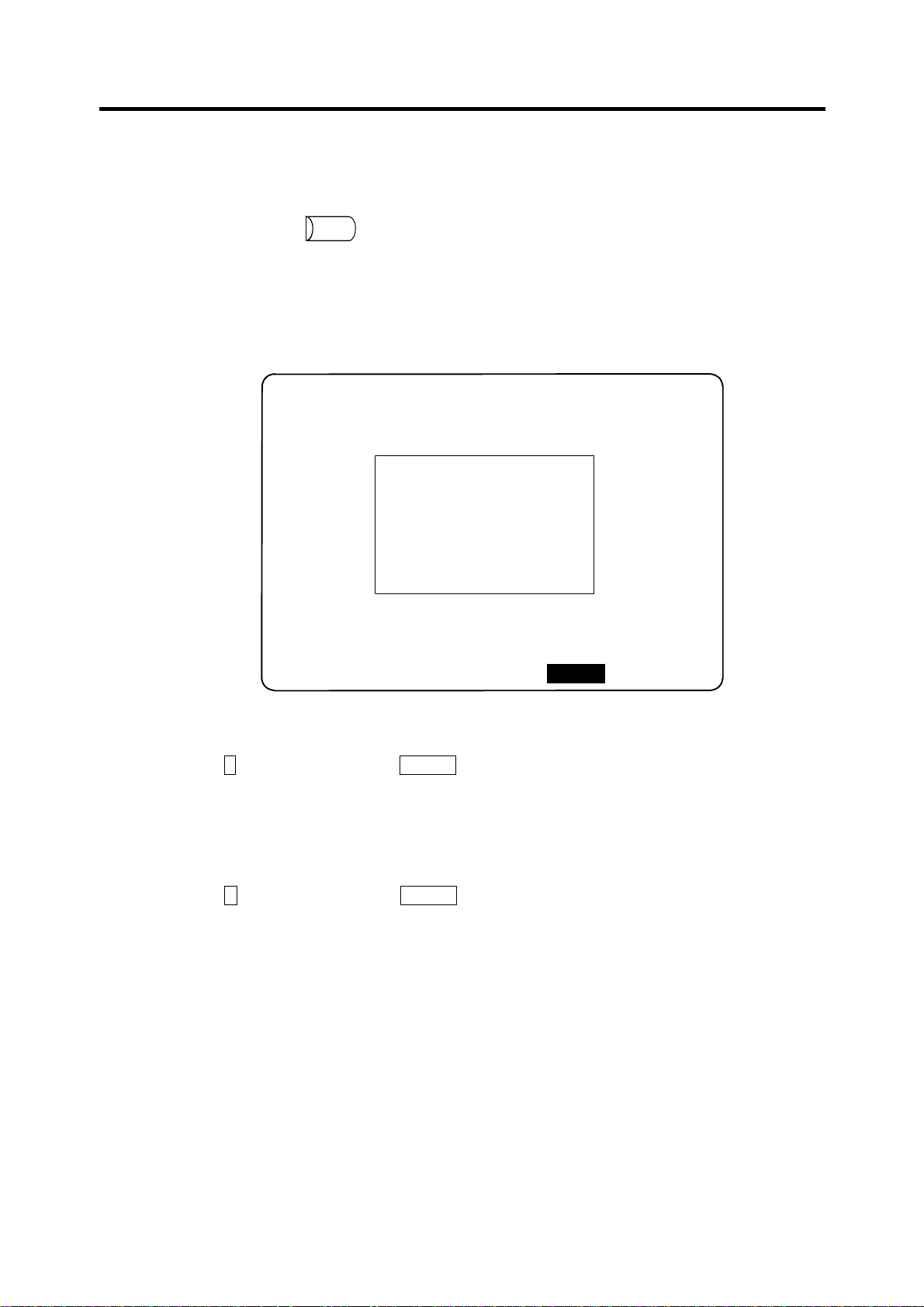

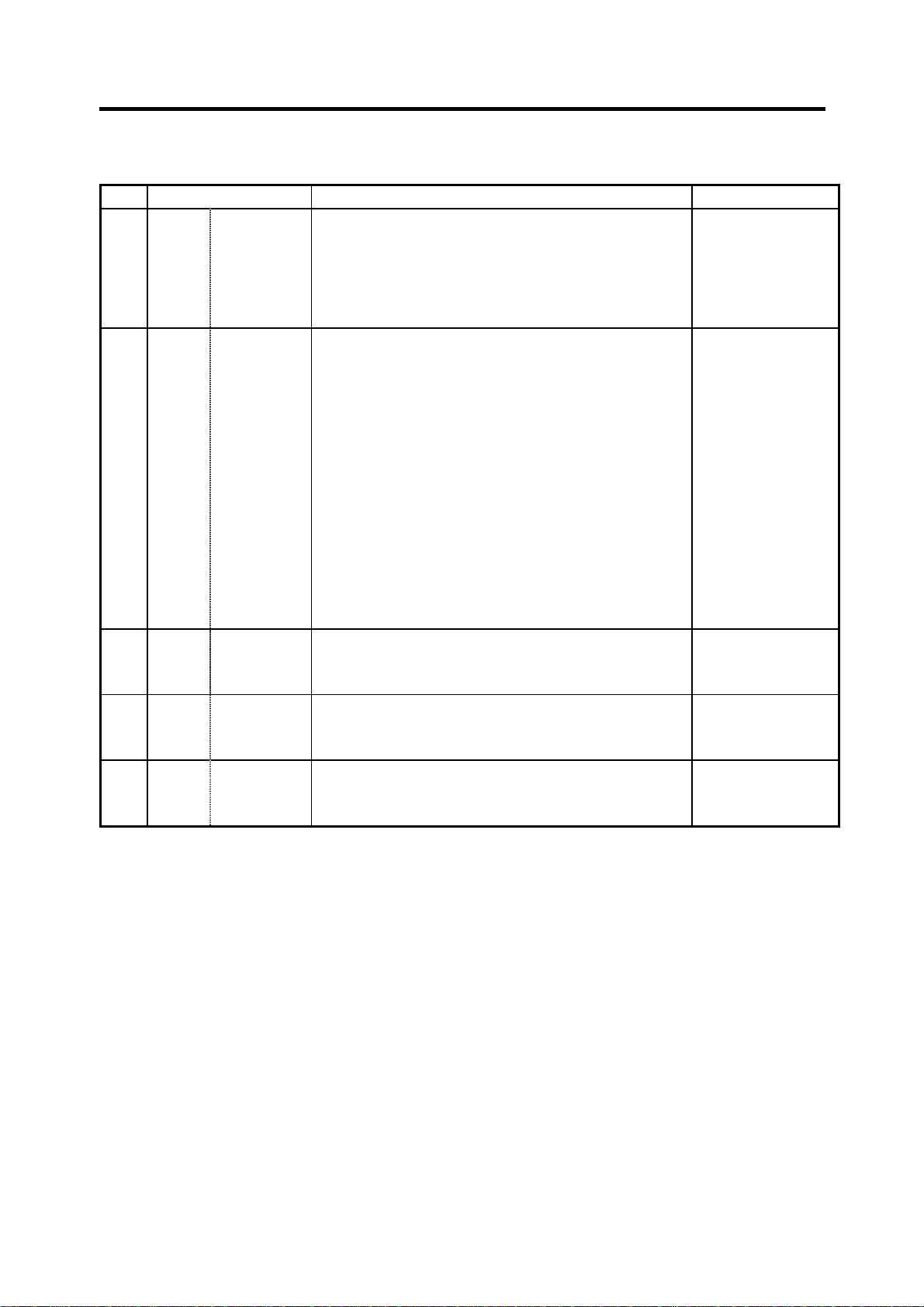

4. Setup Parameters

4. Setup Parameters

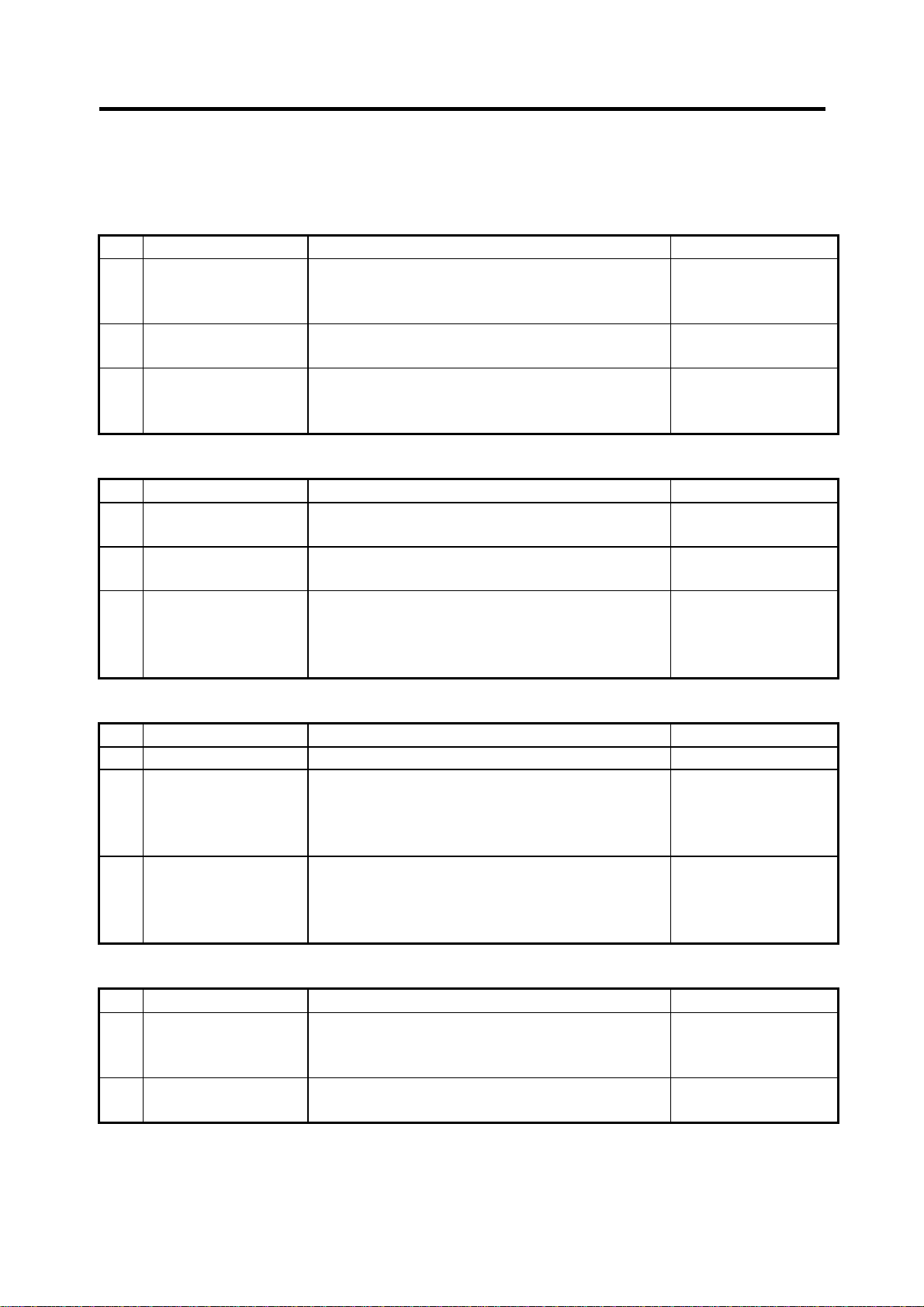

Pressing the menu key

SETUP

displays the OPEN SETUP PARAM screen.

The system’s basic parameters are normally hidden as setup parameters to prevent mistaken

operations and to simplify the display.

The setup parameters can be displayed and set by making a declaration to open the setup

parameters on this screen.

[OPEN SETUP PARAM]

Open the menu setup parameter?

*YES : "Y" "INPUT"

*NO : "N" "INPUT"

# ( )

PROCESSWORK

I/O PAR

SETUP

PARAM 3

MENU

1) Select the setup parameter.

Key-in Y in # ( )‚ and then press INPUT .

The basic specification parameter screen appears and the normally hidden setup parameter

menu will display.

The required menu can be selected to display and set the setup parameters.

2) Cancel the setup parameter selection.

Key-in N in # ( )‚ and then press INPUT .

The setup parameter menu will disappear.

(Note) The setup parameters are not displayed when the power is turned on.

Refer to "5. Base Specifications Parameters" and following for details on the setup parameters.

Be sure to turn off the power supply after selecting the setup parameter.

14

Page 21

5. Base Specifications Parameters

5. Base Specifications Parameters

After setting up the parameter (PR) listed in the table, turn off the NC power. To validate the

parameter, turn on the power again.

# Items Details

1001

(PR)

SYS_ON

Part system

validation

Specify the presence of the PLC axes and the 1st to

7th part systems with 1 or 0.

setup

1002

axisno Number of

(PR)

axes

Set No. of axes in each part system and the No. of PLC

axes.

Set so that the total of the NC axes and PLC axes is

less than the maximum number of controllable axes.

1003

iunit Input setup

(PR)

unit

Specify the input setting value for each part system

and the PLC axis. The parameter units will follow this

specification.

1013 axname Axis name Specify each axis’ name address with an alphabetic

character.

Use the characters X‚ Y‚ Z‚ U‚ V‚ W‚ A‚ B or C.

Do not specify the same address in one part system.

The same address can be specified as the other part

system.

The PLC address does not need to be set. (The axis

name is displayed as 1 and 2.)

1014 incax Increment

command

axis name

When specifying the program movement rate’s

absolute or incremental method with an address‚

specify the incremental command axis name address

with an alphabetic character.

The address that can be used is the same as "#1013

axname".

Specify an address that is different from that #1013.

Setting is not required if absolute/incremental command

with addresses is not performed ("#1076 Abslnc" = 0).

1015

cunit Command

(PR)

unit

Specify the minimum unit of the program movement

amount.

cunit Movement amount for movement command 1

10: 0.001 mm ( 1 µm)

100: 0.01 mm ( 10 µm)

1000: 0.1 mm (100 µm)

10000: 1.0 mm

If there is a decimal point in the movement command‚

the decimal point position will be handled as 1mm

regardless of this setting.

1016

iout Inch output Specify whether the machine system (ball screw pitch‚

(PR)

position detection unit) is an inch unit system or metric

unit system.

Setting range (unit)

0: Not used

1: Used

0 to 14

B: 1 µm

C: 0.1 µm

Axis addresses

such as X, Y, Z, U,

V, W, A, B, and C

100

1000

10000 1 mm

0: Metric unit

system

1: Inch unit system

10

1 µm

10 µm

100 µm

15

Page 22

5. Base Specifications Parameters

# Items Details

1017

rot Rotational

(PR)

axis

Specify whether the axis is a rotary axis or linear axis.

For the rotary axis‚ the position display will be 360

degrees‚ and the axis will return to 0 degrees.

If the position display is to be continuously displayed

even with the rotary axis‚ set the axis as a linear axis

1018

ccw Motor CCW Specify the direction of the motor rotation to the

(PR)

command direction.

0: Rotates clockwise (looking from motor shaft) with

the forward rotation command.

1: Rotates counterclockwise (looking from motor

shaft) with the forward rotation command.

1019

dia Diameter

(PR)

specification

axis

Specify whether the program movement amount is to

be commanded with the diameter dimension or as

movement amount.

When the movement amount is commanded with the

diameter dimensions‚ 5mm will be moved when the

command is a movement distance of 10mm.

The movement amount per pulse will also be halved

during manual pulse feed.

Among parameters concerning length‚ the tool length‚

the wear compensation amount and the workpiece

coordinate offset are displayed in diameter value when

diameter is specified‚ but other parameters are always

displayed in radius value.

1020

sp_ax Spindle

(PR)

Interpolation

Specify 1 when the NC control axis is used as the

spindle.

Setting range (unit)

0: Linear axis

1: Rotary axis

0: Rotates

clockwise

1: Rotates

counterclockwise

0: Command with

movement

amount

1: Command with

diameter

dimension

0: The NC control

axis is used as

the servo axis.

1: The NC control

axis is used as

the spindle.

16

Page 23

5. Base Specifications Parameters

# Items Details

1025 l_plane Initial plane

selection

Specify the plane to be selected when the power is

turned on or reset.

When 0 is specified, 1 is assumed (X-Y plane).

1026

1027

1028

base_l

base_J

base_K

Base axis I

Base axis J

Base axis K

Specify the basic axis address that composes the

plane.

Specify the axis address set in “#1013 axname”.

Set the axis name even when there is no need to

configure a plane, such as the case of 2-axis

specifications.

Normally‚ when X‚ Y and Z are specified respectively

for base_l‚_J‚_K‚ the following relation will be

established:

G17: X-Y

G18: Z-X

G19: Y-Z

Specify the desired address to set an axis address

other than the above.

1029 aux_I Flat axis I If there is an axis parallel to "#1026 base_l"‚ specify

that axis address.

1030 aux_J Flat axis J If there is an axis parallel to "#1027 base_J"‚ specify

that axis address.

1031 aux_K Flat axis K If there is an axis parallel to "#1028 base_K"‚ specify

that axis address.

Setting range (unit)

: X-Y plane (G17

1

command state)

2: Z-X plane (G18

command state)

3: Y-Z plane (G19

command state)

Control axis

addresses such as

X, Y, and Z

Control axis

addresses such as

X, Y, and Z

Control axis

addresses such as

X, Y, and Z

Control axis

addresses such as

X, Y, and Z

17

Page 24

5. Base Specifications Parameters

# Items Details

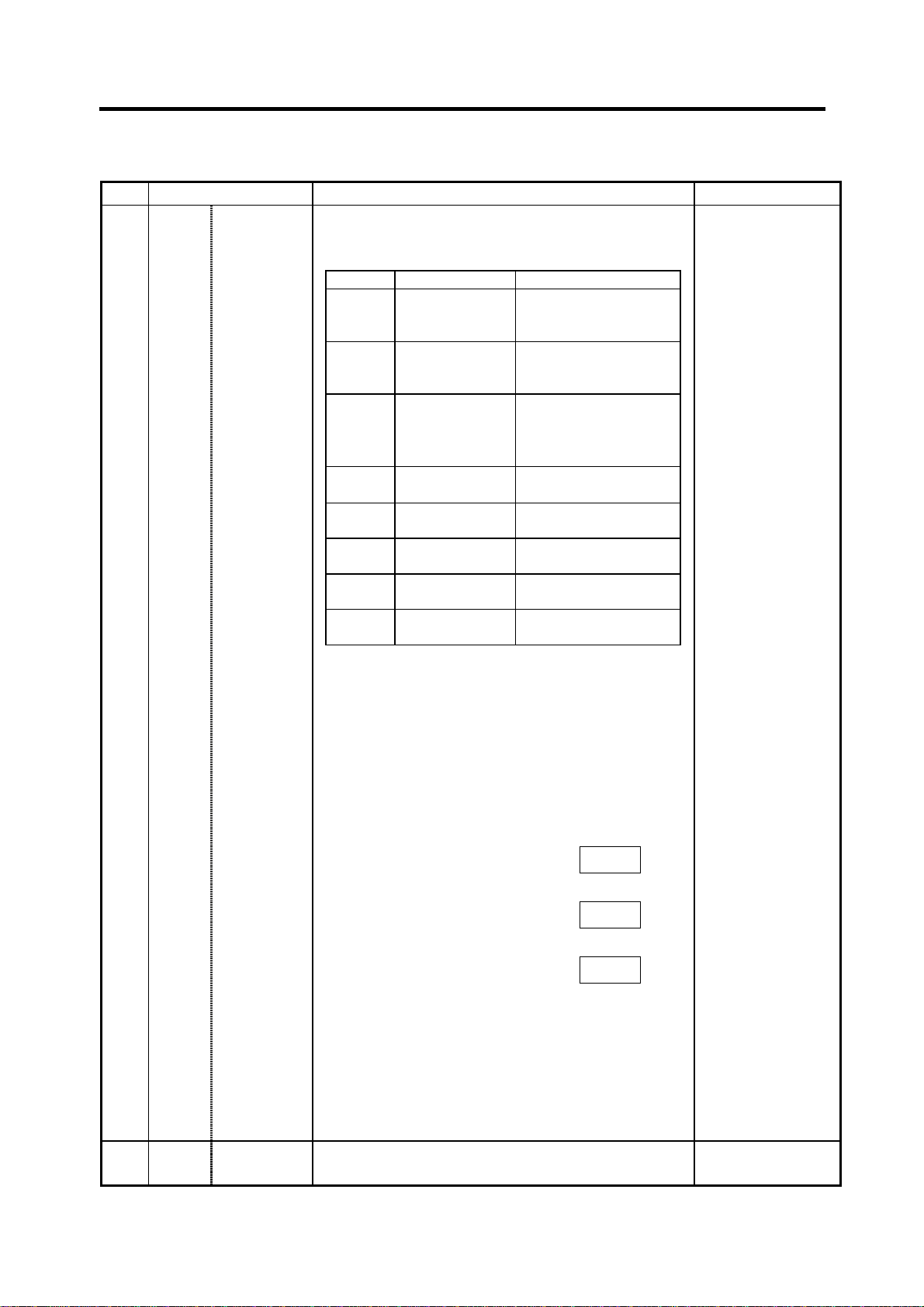

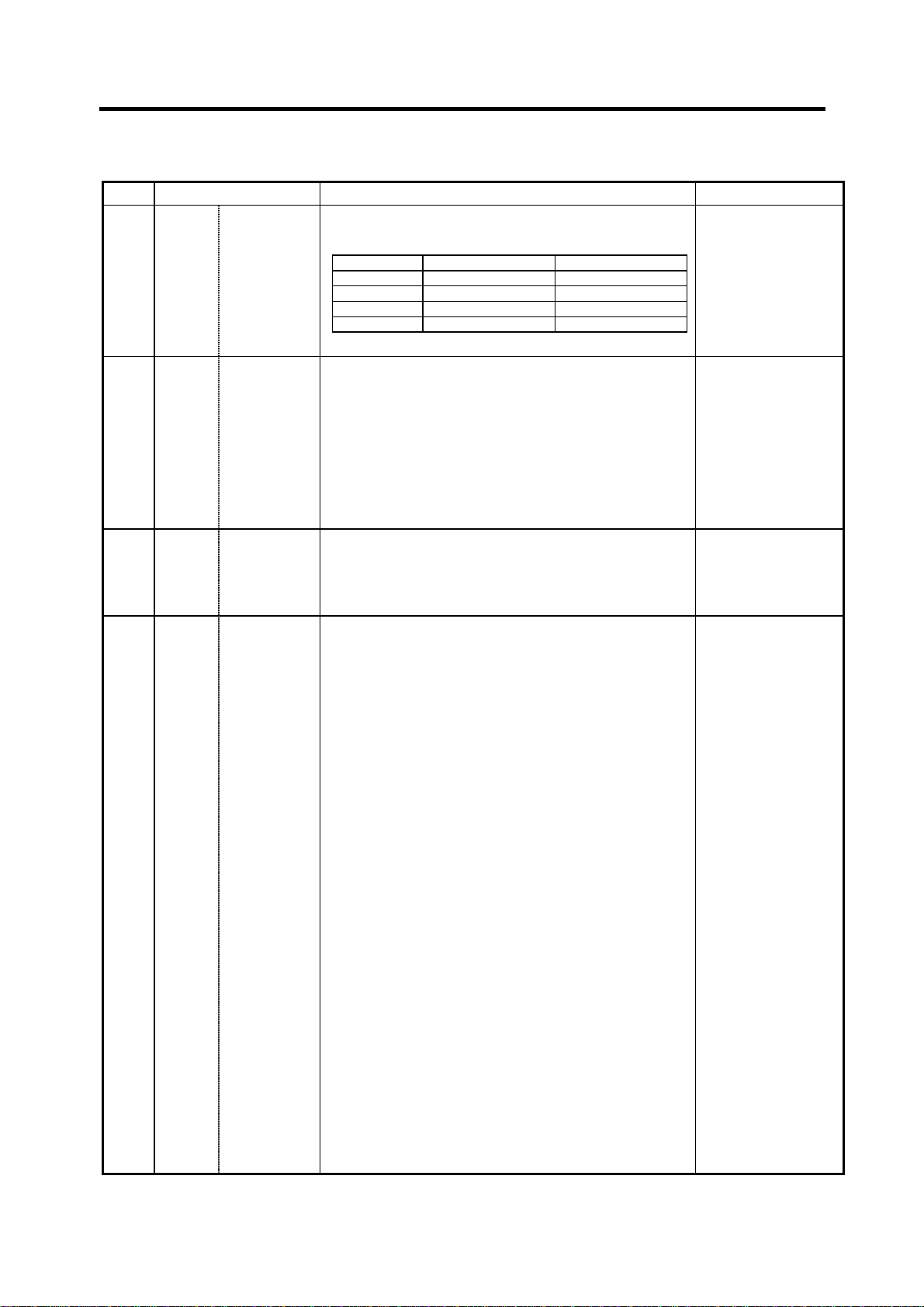

1037 cmdtyp Command

type

Specify the program G code series and compensation

type.

cmdtyp G code series Compensation type

1 System 1 (for M) Type A (one compensation

amount for one compensation number)

2 System 2 (for M) Type B (shape and wear

amounts for one compensation number)

System 2 (for L) Type C (two kinds of

3

System 3 (for L) Same as above

4

System 4

5

(for special L)

System 5

6

(for special L)

System 6

7

(for special L)

System 7

8

(for special L)

compensation amount of

shape and wear per

compensation No.)

Same as above

Same as above

Same as above

Same as above

Setting range (unit)

1 to 8

1038 plcsel Ladder

selection

There are some items in the specifications that can be

used or cannot be used according to the value set in

this parameter.

The file structure may also change depending on the

compensation data type.

Thus‚ after changing this parameter‚ initialize the

system with "#1060 SETUP".

# (1060) DATA ( 1) ( )

INPUT

↓

"BASE PARA SET? (Y/N)" : N

INPUT

↓

"FORMAT? (Y/N)" : Y

INPUT

↓

"SETUP COMPLETE"

(Note) The machining program is cleared with the

above operations. Back up necessary

machining programs in an external memory

before initializing.

Specify the PLC type. 0 to 2

18

Page 25

5. Base Specifications Parameters

# Items Details

1039 spinno Number of

spindles

Specify the existence of a spindle.

0: No spindle 4: Four spindles

1: One spindle 5: Five spindles

2: Two spindles 6: Six spindles

3: Three spindles 7: Seven spindles

1040

M_inch Constant

(PR)

1041

l_inch Initial state

(PR)

input (inch)

(inch)

Specify the parameter unit system for the position and

length.

Specify the unit system for the program movement

amount when the power is turned on or reset and for

position display.

1042

pcinch PLC axis

(PR)

command

Specify the unit system for the commands to the PLC

axis.

(inch)

1043 lang Select

language

displayed

Specify the display language.

0 : Japanese display

1 : English display

21: Polish display

(Note) If no character package is available for a

specified language, the screen is displayed in

English.

1044

auxno MR-J2-CT

(PR)

connections

Specify the number of MR-J2-CT axes connected.

As for C6/C64 system, up to 5 axes of MR-J2-CT can

be connected, thus, the setting range is 0 to 5.

(Note) Selection of inch and metric unit

When set value of "#1041 I_inch" is changed‚ the unit of length is changed after reset.

Among parameters concerning length‚ following items are not changed automatically‚ therefore

change the set values to agree with the new unit system when the unit system is changed.

Tool compensation amount

(Tool length compensation amount‚ tool wear compensation amount and tool tip compensation amount)

Workpiece coordinate offset

Machining parameter #8004 SPEED #8013 G83n #8052 PULL UP

#8005 ZONE r #8016 G71 MINIMUM #8053 G73U

#8006 ZONE d #8017 G71 DELTA-D #8054 W

#8009 DSC. ZONE #8018 G84/G74n #8056 G74 RETRACT

#8010 ABS. MAX. #8027 Toler-1 #8057 G76 LAST-D

#8011 INC. MAX. #8028 Toler-2

#8012 G73n #8051 G71 THICK

Axis parameter #8204 OT-CHECK-N

#8205 OT-CHECK-P

#8206 TOOL CHG.P

#8209 G60 Shift

Barrier data #8300 – #8306

Basic specification

parameter

#1084 RadErr

#8004 SPEED is 10 inches/min. unit for the inch system.

Setting range (unit)

0 to 7

0: Metric system

1: Inch system

0: Metric system

1: Inch system

0: Metric system

1: Inch system

0/1/21

0 to 7

19

Page 26

5. Base Specifications Parameters

N

# Items Details

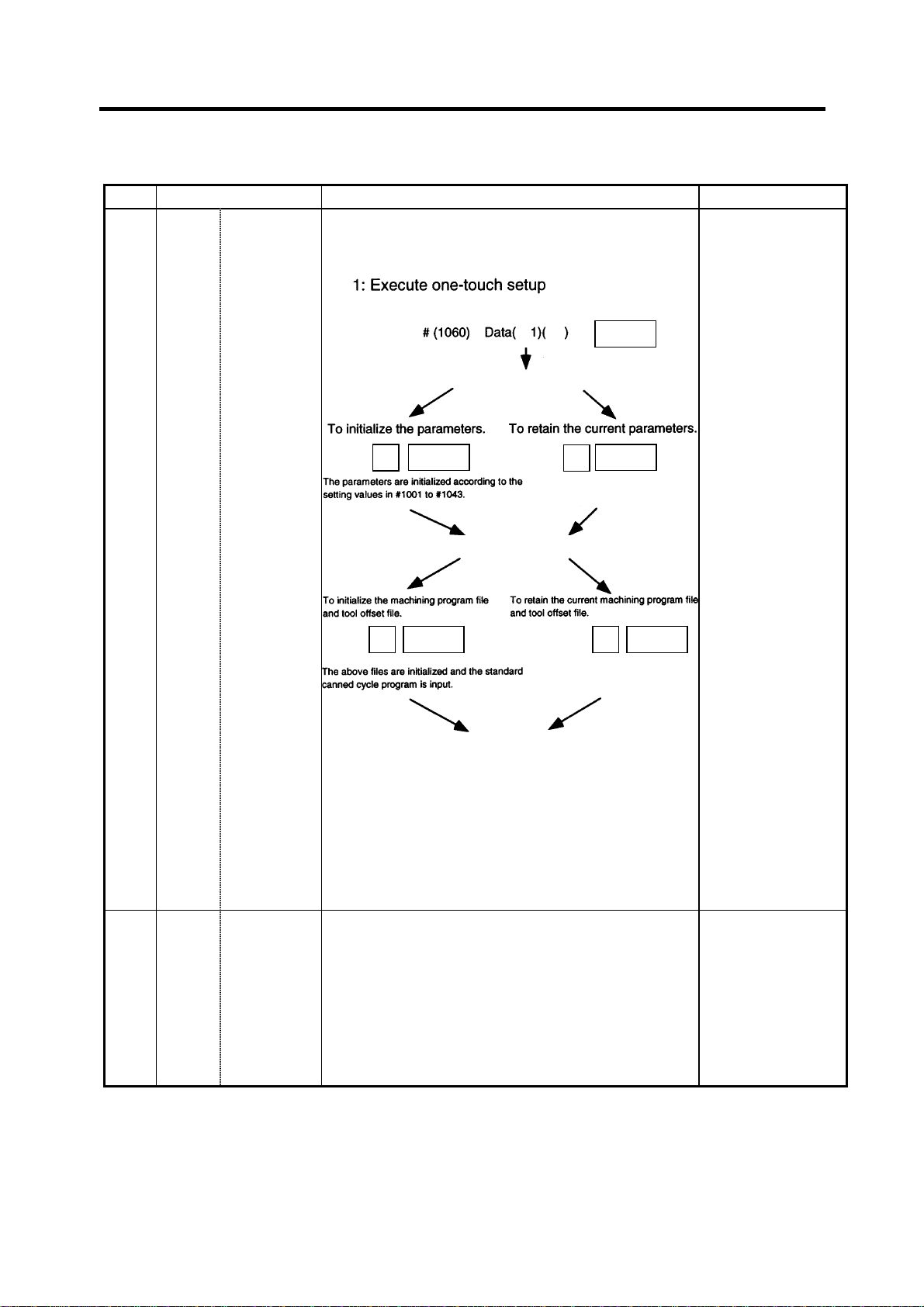

1060 SETUP Activate

setup

processing

Execute the functions required for initializing the

system.

“BASE PARA. SET? (Y/N)” is displayed.

Setting range (unit)

1

INPUT

1061

(PR)

intabs Manual ABS

updating

INPUT

Y

“FORMAT? (Y/N)” is displayed.

INPUT

Y

“SETUP COMPLETE” is displayed.

N

INPUT

INPUT

(Note) Most setup parameters will be initialized with

one-touch setup‚ so confirm the data before

executing.

This parameter will automatically be set to 0 when the

power is turned on.

Defines whether to update the absolute value data

during automatic handle interrupt.

This parameter is valid only when "#1145 l_abs" is set

to 1.

0: Does not update

(shift coordinates

by the amount of

the interruption)

1: Updates (same

coordinates as

when interrupt did

not occur will be

applied.)

20

Page 27

5. Base Specifications Parameters

# Items Details

1062 T_cmp Tool offset

function

Specify whether the tool length offset and wear

compensation is valid during T command execution.

Setting value Tool length offset Wear compensation

0 Valid Valid

1 Valid Invalid

2 Invalid Valid

3 Invalid Invalid

1063 mandog Manual

dog-type

The initial return to the reference point is performed

with dog-type return after the power is turned on‚ and

the coordinate system is established.

Specify the manual reference point return method

after the coordinate system is established with this

parameter.

(This setting is not required when using absolute

position detection.)

1064

(PR)

1065 JOG_H JOG

svof Error

correction

response

type

Specify whether to correct the error when the servo is

off.

Set up an improved JOG response type.

0: Conventional specification

The system is started and stopped by signals

via ladder without reference to external input

signals.

1: Type 1

The system is started up and stopped by

external signals.

2: Type 2

The system is started up and stopped by

performing the AND operation for external

signals and signals via ladder.

3: Type 3

The system is started up when signals via

ladder rise. It is stopped when external signals

and signals via ladder fall.

4: Type 4

Reference point return mode:

The system is started up and stopped by

signals via ladder without reference to

external input signals (conventional

specification).

Non-reference point return mode:

The system is started up and stopped by

performing AND for external signals and

signals via ladder (type 2).

Setting range (unit)

0 to 3

0: High speed

return

1: Dog-type

0: Does not

correct the error

1: Corrects the

error

0 to 4

21

Page 28

5. Base Specifications Parameters

# Items Details

JOG_HP

1066

Select JOG

activation

(+) device

Specify the number of the device that inputs +JOG

activation signals. The device type is specified by

"#1071 JOG_D". The effective range of set values vary

depending on the device type. A value outside of the

effective range is invalid if specified.

(Note) The setting range of this parameter has been

expanded on the software Ver.D0 and later.

JOG_HN

1067

Select JOG

activation

(−) device

Specify the number of the device that inputs -JOG

activation signals. The device type is specified by

"#1071 JOG_D". The effective range of set values vary

depending on the device type. A value outside of the

effective range is invalid if specified.

(Note) The setting range of this parameter has been

expanded on the software Ver.D0 and later.

1068

slavno Slave axis

(PR)

number

Specify the axis number of a slave axis to be

synchronized. The axis number is an NC number

excluding the spindle and PLC axis.

Two or more slave axes cannot be set up for one

master axis.

This parameter "slavno" cannot be set up for a slave axis.

A multiple part system cannot be set up so that the

relation between the master and slave axes extends

over a part system.

1069

no_dsp Axis with no

(PR)

counter

display

1070 axoff Axis

Set up an axis that displays no counter. This option is

valid on the counter display screen (e.g. POSITION

screen).

Define an axis that enables axis removal control. 0: Disables axis

removal

Setting range (unit)

X: 0000 to 03FF

(hexadecimal)

M: 0000 to 8191

(decimal)

X: 0000 to 03FF

(hexadecimal)

M: 0000 to 8191

(decimal)

0: No slave axis

1 to 6: First to

sixth axes

0: Displays the

counter

1: Does not

display the

counter.

removal.

1: Enables axis

removal

1071

(PR)

JOG_D

±JOG

activation

signal

device

name

Specify the number of the device that inputs ±JOG

activation signals.

0 : X device

1 or 2: M device

Set the JOG_HP (#1066) and JOG_HN (#1067)

parameters according to this device specification

parameter.

(Note) The setting range of #1066 and #1067

parameters has been expanded on the software

Ver.D0 and later.

22

0 to 2

Page 29

5. Base Specifications Parameters

# Items Details

1073 I_Absm Initial

absolute

Specify the absolute value/incremental value mode for

when the power is turned on or reset.

value

1074 l_Sync Initial

synchronous

feed

Specify the feedrate specification mode for when the

power is turned on or reset.

0: Asynchronous feed (feed per minute)

1: Synchronous feed (feed per rotation)

1075 I_G00 Initial G00 Specify the linear command mode for when the power

is turned on or reset.

0: Linear interpolation (G01 command state)

1: Positioning (G00 command state)

1076 Abslnc

(For L

system

only)

ABS/INC

address

The absolute value/incremental commands can be

issued by using the absolute value address and

incremental value address for the same axis.

0: Absolute/incremental with G command

1: Absolute/incremental with address code

(The "#1013 axname" address will be the

absolute value command‚ and "#1014 incax"

address will be the incremental value command)

1077 radius Incremental

command

for diameter

Specify if the diameter specification axis’ ("#1019 dia" is

set to 1) incremental value command uses the diameter

value or radius value

specification

axis

1078 Decpt2 Decimal

point type 2

Specify the unit of position commands that do not have

a decimal point.

0: The min. input command unit is used (follows

"#1015 cunit")

1: 1mm (or 1inch) unit is used

1079 F1digt Validate F1

digit

Specify whether to execute the F command with a

1-digit code command or with a direct numerical

command.

0: Direct numerical command (command feedrate

during feed per minute or rotation)

1: 1-digit code command (feedrate specified with

"#1185 spd_F1" to "#1189 F5")

Setting range (unit)

0: Incremental

value command

mode

1: Absolute value

command

mode

0: Asynchronous

feed

1: Synchronous

feed

0: Linear

interpolation

1: Positioning

0: Absolute/

incremental

with G

command

1: Absolute/

incremental

with address

code

0: Diameter value

1: Radius value

0: The min. input

command unit

is used

1: 1mm (or 1inch)

unit is used

0: Direct

numerical

command

1: 1-digit code

command

23

Page 30

5. Base Specifications Parameters

# Items Details

1080 Dril_Z

(For M

system

only)

Specify

boring axis

Specify a fixed-cycle boring axis.

0: Uses an axis perpendicular to the selected plane

as the boring axis.

1: Uses the Z axis as the boring axis regardless of

the selected plane.

1081

Gmac_P

Give priority

to G code

parameter

Specify the G code priority relationship during the

macro call with the G command.

0: G code used in system is priority

1: Registered G code for call out is priority

1082 Geomet

(For L

system

only)

Geometric Specify the validity of the geometric function.

As the designated address code is used exclusively for

geometric‚ if "A" or "C" is used for the axis address or

2nd miscellaneous command code‚ "A" that is the axis

address may be handled as the geometric’s angle

specification. Take special care to the setting of the

axis name‚ etc.‚ when using this function.

1084 RadErr Arc error Specify the tolerable error range when a deviation

occurs in the end point and center coordinate in the

circular command.

1085 G00Drn G00 dry run Specify whether to apply dry run (feed with manual

setting speed instead of command feedrate) to the G00

command.

0: Does not apply to G00 (moves at rapid traverse

feedrate)

1: Applies to G00 (moves at manual set feedrate)

1086 G0lntp G00 non-

interpolation

Specify the G00 movement path type

0: Moves linearly toward the end point (interpolation

type)

1: Moves to the end point of each axis at the rapid

traverse feedrate for each axis

(non-interpolation)

1087

G96_G0

Constant

surface

speed

control by

rapid

traverse

feed

Specify how to handle the cycle speed for the G00

command when using the constant surface speed

control function.

0: Calculates the cycle speed constantly even

during G00 movement.

1: Calculates the cycle speed at the block end point

in the G00 command.

command

Setting range (unit)

0/1

0/1

0: Invalid

1: Valid

0 to 1.000 (mm)

0/1

0/1

0/1

24

Page 31

5. Base Specifications Parameters

# Items Details

1088 G30SL Disable G30

soft limit

Specify how to handle the soft limit during G30 (2nd

reference point return) movement.

0: Soft limit valid during G30 movement

1: Soft limit invalid during G30 movement

1089 Cut_RT Short cut for

rotary axis

Specify how to handle the short cut control for the

rotary axis ("#1017 rot" is set to 1).

0: No short cut (move toward end point)

1: Uses short cut (when using the absolute value

command‚ move in the direction where the

movement amount will be 180 degrees or less)

1090 Lin_RT Linear

rotary axis

Specify how to handle a command for the rotary axis

that exceeds 360 degrees.

0: For absolute value commands that exceed 360

degrees‚ the value will be converted into a

remainder of 360 degrees and the axis will move.

Example: If the command is 420 degrees‚ the

applied value will be 60 degrees.

1: For absolute value commands that exceed 360

degrees‚ the axis will move in the same manner

as a linear axis.

Example: If the command is 420 degrees‚ the axis

will pass the 360 degree position and

will move to the 60 degree position.

1091 Mpoint Ignore

middle point

Specify now to handle the middle point during G28 and

G30 reference point return.

0: Moves to the reference point after passing the

middle point designated in the program.

1: Ignores the middle point designated in the

program and move straight to the reference point.

1092

Tchg _A

Replace

tools for

additional

axis

Specify the movement of the additional axis during tool

change position return.

0: The additional axis does not move with the tool

change position return command.

1: After returning the standard axis with the tool

change position return command‚ the additional

axis also returns to the tool change position.

1093 Wmvfin Waiting

method

between

part systems

Specify the method for waiting between part systems.

When the movement command is found in the wait

command ! block:

0: Waits before executing movement command

1: Waits after executing movement command

1094 Tl_SBK

(for L

system

only)

Select life

count for

single block

Select whether to count the data units to be used for a

single block when using the tool life management II

function (lathe system).

0: Does not count the data units.

1: Count the data units.

Setting range (unit)

0/1

0: No short cut

1: Use short cut

0/1

0/1

0/1

0/1

0/1

25

Page 32

5. Base Specifications Parameters

# Items Details

1095 T0tfof TF output Select how to handle TF for T00 command.

0: TF is output.

1: TF is not output

1096 T_Ltyp

(For L

system

only)

Tool life

management

type

1097 T1digt Tool wear

compensation

number

1-digit

command

Specify the tool life management type. 1: Life manage-

Specify the No. of digits in the tool wear compensation

No. in the T command.

0: The 2 high-order digits are the tool No.‚ and the 2

low-order digits are the wear compensation No.

1: The 3 high-order digits are the tool No.‚ and the 1

low-order digit is the wear compensation No.

This parameter will be fixed to 0 when tool life management II is selected.

1098 Tlno. Tool length

offset

number

Specify the No. of digits in the tool length offset No. in

the T command.

0: The 2 or 3 high-order digits are the tool No.

The 2 or 1 low-order digits are the tool length

offset and wear compensation Nos.

1: The 2 or 3 high-order digits are the tool No. and

tool length offset Nos.

The 2 or 1 low-order digits are the wear

compensation No.

1099 Treset Cancel tool

wear

compensation

amount

Specify how to handle tool compensation vector when

resetting system.

0: Clears the tool length and wear compensation

vectors when resetting.

1: Saves the tool length and wear compensation

vectors when resetting.

When the values are cleared‚ the compensation will

not be applied‚ so the axis will move the compensation

amount in the next compensation operation.

When the values are saved‚ the compensation will be

applied‚ so the axis will shift the differential amount of

the compensation amount in the next compensation

operation.

Setting range (unit)

0/1

ment type l

2: Life manage-

ment type ll

0/1

0/1

0: Clears

1: Saves

26

Page 33

5. Base Specifications Parameters

# Items Details

1100 Tmove Tool wear

compensation

Specify the period to perform tool length offset and

wear compensation.

0: Compensate when T command is executed.

1: Superimpose and compensate with the

movement command in the block where the T

command is located. If there is no movement

command in the same block‚ compensation will

be executed after the movement command is

superimposed in the next movement command

block.

2: Compensate when the T command is executed.

1: Superimpose and compensate a tool length

offset with the movement command in the same

block. If there is no movement command in the

same block, compensation will be executed after

the movement command is superimposed in the

next movement command block.

1101 Tabsmv Tool wear

compensation

method

Specify the type of movement command when "#1100

Tmove" is set to 1.

0: Compensate regardless of the movement

command type.

1: Compensate only at the movement command in

the absolute value command.

1102 tlm

(For L

system

only)

Manual tool

length

measuring

system

1103 T_life Validate life

Specify the measurement method for manual tool

measurement l.

0: Align tool with basic position

1: Input measurement results

Select the usage of the tool life management function. 0: Do not use.

management

1104

T_Com2

Tool

command

method 2

Select the command method for when "#1103 T_Life"

is set to 1.

0: Handle the program tool command as the group

No.

1: Handle the program tool command as the tool

No.

Setting range (unit)

0 to 2

0: Compensate

regardless of

the command

type.

1: Compensate

only with the

absolute value

command.

0: Basic position

method

1: Measured

value input

method

1: Perform tool life

management

control.

0/1

27

Page 34

5. Base Specifications Parameters

# Items Details

1105 T_Sel2 Tool

selection

method 2

Select the tool selection method for when "#1103

T_Life" is set to 1.

0: Select in order of registered No. from the tools

used in the same group.

1: Select the tool with the longest remaining life

from tools used in the same group and the

unused tools.

1106 Tcount

(For L

system

Life management count

Specify the function when address N is omitted when

inputting data (G10 L3 command) for tool life management function ll.

only)

1107 Tllfsc

(For L

system

only)

Split life

management

display

screen

Set up the number of groups to be displayed on the

tool life management II (lathe system) screen.

0: Displayed group count 1

1: Displayed group count 2

2: Displayed group count 4

1108 TlrectM

(For L

system

only)

1109

subs_M Validate

(PR)

Life management

re-count M

code

alternate M

Set up the M code for tool life management II (lathe

system) re-count.

Select the user macro interrupt with the substitute M

code.

code

1110 M96_M M96

alternate M

Specify an M code to replace M96 when "#1109

subs_M" is set to 1.

code

1111 M97_M M97

alternate M

Specify an M code to replace M97 when "#1109

subs_M" is set to 1.

code

1112

S_TRG Validate

(PR)

status trigger

system

Specify the validity conditions for the user macro

interrupt signal.

0: Valid when interrupt signal (UIT) turns off to on.

1: Valid when interrupt signal (UIT) is ON.

1113

INT_2 Validate

(PR)

interrupt

method type

2

Specify the movement after user macro interrupt

signal (UIT) input.

0: Execute interrupt program without waiting for

block being executed to end.

1: Execute interrupt program after completing block

being executed.

Setting range (unit)

0/1

0: Time specified

input

1: No. of times

specified input

0 to 2

0 to 99

0: Alternate M

code invalid

1: Alternate M

code valid

3 to 97

(excluding 30)

0: Valid when

interrupt signal

(UIT) turns off

to on.

1: Valid when

interrupt signal

(UIT) is ON.

0/1

28

Page 35

5. Base Specifications Parameters

# Items Details

1114 mcrint Macro

argument

initialization

Select whether to clear statements other than

specified arguments by macro call. Also, select

whether to clear local variables by power-on and

resetting.

0: Delete non-specified arguments by macro call.

1: Retain non-specified arguments by macro call.

2: Retain non-specified arguments by macro call

and clear local variables by power-on and

resetting.

1115 thwait Waiting for

thread cutting

Set the queue number during screw thread cutting

when the chamfering is not valid.

1116

G30SLM

Invalidate

soft limit

(manual

Enable this function when disabling the soft limit check

function from the second to the fourth reference point

return by manual operation.

operation)

1117 H_sens Handle

response

switch

Switch the handle response mode when feeding the

handle.

0: Standard handle response

1: High-speed handle response

1118 mirr_A

(For L

system

only)

Select how to

set up the

length of

tools on

facing turret

Select one of the following two methods.

0: Set up the current length of tools on facing turret.

1: Set up a value, assuming that the tools on facing

turret is in the same direction as that of those on

the base turret.

(double-turret

mirror image)

1119 Tmiron

(For L

system

only)

Select the

double-turret

mirror image

with T

Select whether to validate the double-turret mirror

image with the T command.

command

1120

TofVal Change

(PR)

macro

variable

Specify whether to change the macro variable (tool

offset) numbers for shape compensation and wear

compensation.

0: Do not change. (Conventional specifications)

1: Change the shape and wear compensation

variable numbers each for X, Z, and R.

Setting range (unit)

0/1/2

0 to 99 (Approx. 4

ms.)

Standard set value:

4

0: Enable soft limit

function.

1: Disable soft

limit function.

0/1

0/1

0: Invalid

1: Valid

0/1

29

Page 36

5. Base Specifications Parameters

# Items Details

1121 edlk_c Edit lock C Specify whether to prohibit editing of program Nos.

9000 to 9999.

1122

pglk_c Program

(PR)

display lock

The display and search of program Nos. 9000 to 9999

can be prohibited. Specify whether to prohibit display

and search.

0: Display and search is possible

1: Program details are not displayed

2: Program details are not displayed‚ and operation

search is prohibited.

The program details will not be displayed‚ but the

program No. and sequence No. will display in the

prohibited state.

1123 origin Origin zero

Select whether to use the origin zero function. 0: Use

inhibition

1124 ofsfix Fix tool wear

compensation

number

Specify whether to automatically increment the offset

No. by 1 with the input or to display the No. as it is in

the setting on the tool offset screen.

0: Increment the # No. by 1 when the input key is

pressed. (Same as general parameters)

1: # No. does not change even if input key is

pressed.

When making settings in sequence‚ 0 is handier.

When changing and setting repeatedly while adjusting

one offset value‚ 1 is handier

1125 real_f Actual

Specify the feedrate display on the monitor screen. 0: Command

feedrate

display

1126

1127

PB_G90

DPRINT

Not used. 0

DPRINT

alignment

Specify the alignment for printing out with the DPRINT

function.

0: No alignment‚ data is printed with left

justification.

1: Align the minimum digit and output.

Setting range (unit)

0: Editing

possible

1: Editing

prohibited

0 to 2

1: Do not use

0/1

speed

1: Real move-

ment feedrate

0/1

30

Page 37

5. Base Specifications Parameters

# Items Details

1128 RstVCI Clear

variables by

resetting

Specify how to handle the common variables when

resetting.

0: Common variables do not change after resetting.

1: The following common variables are cleared by

resetting:

During variable 100 sets specifications:

#100 to #149 are cleared.

During variable 200 or 300 sets specifications:

#100 to #199 are cleared.

1129 PwrVCl Clear

variables by

power-on

Specify how to handle the common variables when the

power is turned on.

0: The common variables are in the same state as

before turning the power off.

1: The following common variables are cleared

when the power is turned on.

During variable 100 sets specifications:

#100 to #149 are cleared.

During variable 200 or 300 sets specifications:

#100 to #199 are cleared.

1130 set_t Display

selected tool

number

Specify the tool command value display on the

POSITION screen.

0: T-modal value of program command is displayed.

1: Tool number sent from PLC is displayed.

1131

Fldcc Feed forward

(PR)

filter

Parameter to suppress acceleration changes with a

filter when starting acceleration or deceleration.

Specify the parameter in bits.

76543210

Feed forward filter

1132 CRT CRT

brightness

control

This parameter adjusts the brightness of the CRT

display unit.

–3: Highest luminance (Brightest state)

–3: Lowest luminance (Darkest state)

Adjust this parameter to an appropriate brightness

between –3 and 3.

The EL display unit does not have brightness

adjustment‚ so setting is not required.

Setting range (unit)

0/1

0/1

0/1

bit1: 7.1 (ms)

bit2: 14.2 (ms)

bit3: 28.4 (ms)

bit4: 56.8 (ms)

If bit 1 to bit 4 are

all 0 or two or more

bits of bit 1 to bit 4

are 1, 3.5 ms is set

up.

–3 to 3

31

Page 38

5. Base Specifications Parameters

# Items Details

1133 ofsmem Select how

to set up tool

wear

compensation screen

Select the number stored by previous setup when

selecting the tool wear compensation screen.

0: Does not display the number when selecting the

screen.

1: Displays the stored number when selecting the

screen.

1134 LCDneg LCD reverse

display

Specify 1 to reverse the display on the 10.4-type

monochrome LCD.

1135 unt_nm Unit name Set up a unit name.

Set up the unit name with 4 or less characters consisting

of both alphabets and numbers. If 0 is set up, the unit

name is not displayed.

1138 Pnosel Not used. 0

1139 edtype Edit type

selection

Set up an edit type.

0: Screen edit type (M50 or equivalent operation)

1: Screen edit type (The screen of EDIT or MDI is

changed automatically according to the selected

operation mode.)

2: Word edit type (The screen of EDIT or MDI is

changed automatically according to the selected

operation mode.)

1140 Mn100 M code

number

1141 Mn200 M code

number

1142 Mn300 M code

number

1143 Mn400 M code

number

1144 mdlkof MDI setup

First number of M code that corresponds to setup

number from 100 to 199.

First number of M code that corresponds to setup

number from 200 to 299.

First number of M code that corresponds to setup

number from 300 to 399.

First number of M code that corresponds to setup

number from 400 to 499.

Select whether to enable MDI setup in non-MDI mode. 0: Disable MDI

lock

Setting range (unit)

0/1

0: Normal display

1: Reverse display

4 or less characters

consisting of both

alphabets and

numbers

0/1/2

0 to 99999999

0 to 99999999

0 to 99999999

0 to 99999999

setup

1: Enable MDI

setup

32

Page 39

5. Base Specifications Parameters

# Items Details

1145 I_abs Manual ABS

parameter

Specify how to handle the absolute position data during

automatic handle interrupt.

0: Absolute position data is renewed if manual ABS

switch is on. Data is not renewed if switch is off.

1: Follows the intabs state when "#1061 intabs" is

valid.

1146 Sclamp Spindle

rotation

clamp

function

Specify how to handle the spindle rotation clamp

function with the G92S command.

0: G92S command is handled as a clamp command

only in the G96 state (during constant surface

speed control). G92S will be handled as normal S

command in G97 state (constant surface speed

OFF).

1: The S command in the same block as G92 is

constantly handled as a clamp command.

1147 smin_V Minimum

spindle

rotation

speed clamp

type

Specify the type of spindle min. rotation speed clamp

value.

0: Rotation speed setting

1: Output voltage coefficient setting

Set the "#3023 smini" parameter according to this type

setting.

1148 I_G611 Initial high

precision

Specify the default mode after power-on or resetting.

0: G64 (cutting mode)

1: G61.1 (high precision control mode)

1149 cireft Arc

deceleration speed

change

1150 F1dc0 G00 feed

forward filter

Specify whether to enable deceleration at the arc

entrance or exit.

0: Disable

1: Enable

This parameter is used to filter acceleration changes at

the start of rapid acceleration/deceleration. Specify

the filters in bit units.

7 6 5 4 3 2 1 0

G00 feed forward filter

Feed forward filter

G00 and G01 independent

0: Common 1: Independent

Setting range (unit)

0/1

0/1

0: Rotation speed

setting

1: Output voltage