Page 1

CNC

C6/C64

PLC PROGRAMMING MANUAL

(Ladder Section with MELSEC Tool)

BNP-B2309D(ENG)

Page 2

MELSEC and MELDAS are the registered trademarks of Mitsubishi Electric Corporation.

Microsoft, Windows and Microsoft Windows NT are the registered trademarks of Microsoft Corporation in

the United States and/or other countries.

Other company and product names herein may be the trademarks or registered trademarks of their

respective owners.

Page 3

Introduction

These specifications are the programming manual used when creating the sequence

program with the PLC development software, or Mitsubishi Electric Co.’s integrated FA

software MELSOFT series (GX Developer).

The PLC (Programmable Logic Controller) is largely divided into the basic commands,

function commands and exclusive commands, and ample command types are available.

The commands can be used according to the purpose and application such as the PLC

support function used when supporting the user PLCs.

In addition to the explanation of commands and functions, the environment to develop the

user PLC using GX Developer, especially the usage unique to MELDAS, is described.

CAUTION

For items described as "Restrictions" or "Usable State" in this manual, the instruction

manual issued by the machine manufacturer takes precedence over this manual.

An effort has been made to describe special handling of this machine, but items that are

not described must be interpreted as "not possible".

This manual is written on the assumption that all option functions are added. Refer to the

specifications issued by the machine manufacturer before starting use.

Refer to the Instruction Manual issued by each machine manufacturer for details on each

machine tool.

Some screens and functions may differ or some functions may not be usable depending

on the NC version.

Refer to the related operation manuals for details of GX Developer and GX Converter

usage.

[Documents relating to MELDAS C6/C64]

MELDAS C6/C64/C64T PLC Interface Manual................................. BNP-B2261

MELDAS C6/C64 Network Manual.................................................... BNP-B2373

i

Page 4

Precautions for Safety

Always read the specifications issued by the machine manufacturer, this manual, related

manuals and attached documents before installation, operation, programming,

maintenance or inspection to ensure correct use.

Understand this numerical controller, safety items and cautions before using the unit.

This manual ranks the safety precautions into "DANGER", "WARNING" and "CAUTION".

DANGER

WARNING

CAUTION

Note that even items ranked as " CAUTION", may lead to major results depending

When there is a great risk that the user could be subject to

fatalities or serious injuries if handling is mistaken.

When the user could be subject to fatalities or serious injuries

if handling is mistaken.

When the user could be subject to injuries or when physical

damage could occur if handling is mistaken.

on the situation. In any case, important information that must always be observed is

described.

DANGER

Not applicable in this manual.

WARNING

Not applicable in this manual.

CAUTION

1. Items related to product and manual

For items described as "Restrictions" or "Usable State" in this manual, the instruction

manual issued by the machine manufacturer takes precedence over this manual.

An effort has been made to describe special handling of this machine, but items that are

not described must be interpreted as "not possible".

This manual is written on the assumption that all option functions are added. Refer to

the specifications issued by the machine manufacturer before starting use.

Refer to the Instruction Manual issued by each machine manufacturer for details on

each machine tool.

Some screens and functions may differ or some functions may not be usable

depending on the NC version.

2. Items related to start up and maintenance

Read this manual carefully and confirm the safety enough before executing the

operation of the program change, forced output, RUN, STOP, etc. during operation.

Operation mistakes may cause damage of the machine and accidents.

ii

Page 5

3. Items related to program development

Always observe the cautions before development to develop a program.

If the data transferred does not follow the file name rule, the CNC will mistake it for

another data, resulting in unexpected operation, e.g. PLC program erasure.

Do not read a sequence program on which a conversion error occurred into the GX

Developer. The file may include unexpected contents to result an illegal operation.

When an error occurred at GX Developer On-line function, the error message may not

explain exactly the state in the CNC side.

Always refer to the error list.

When initializing PLC data storage area is performed, all sequence programs and

messages currently stored in the CNC will be erased. Do not use this operation other

than when the error cannot be solved.

CAUTION

iii

Page 6

Contents

1. PLC Development Environment Using GX Developer ..........................................................1

1.1 Function ...............................................................................................................................1

1.1.1 Development Environment Configuration...................................................................1

1.1.2 Software Configuration ...............................................................................................1

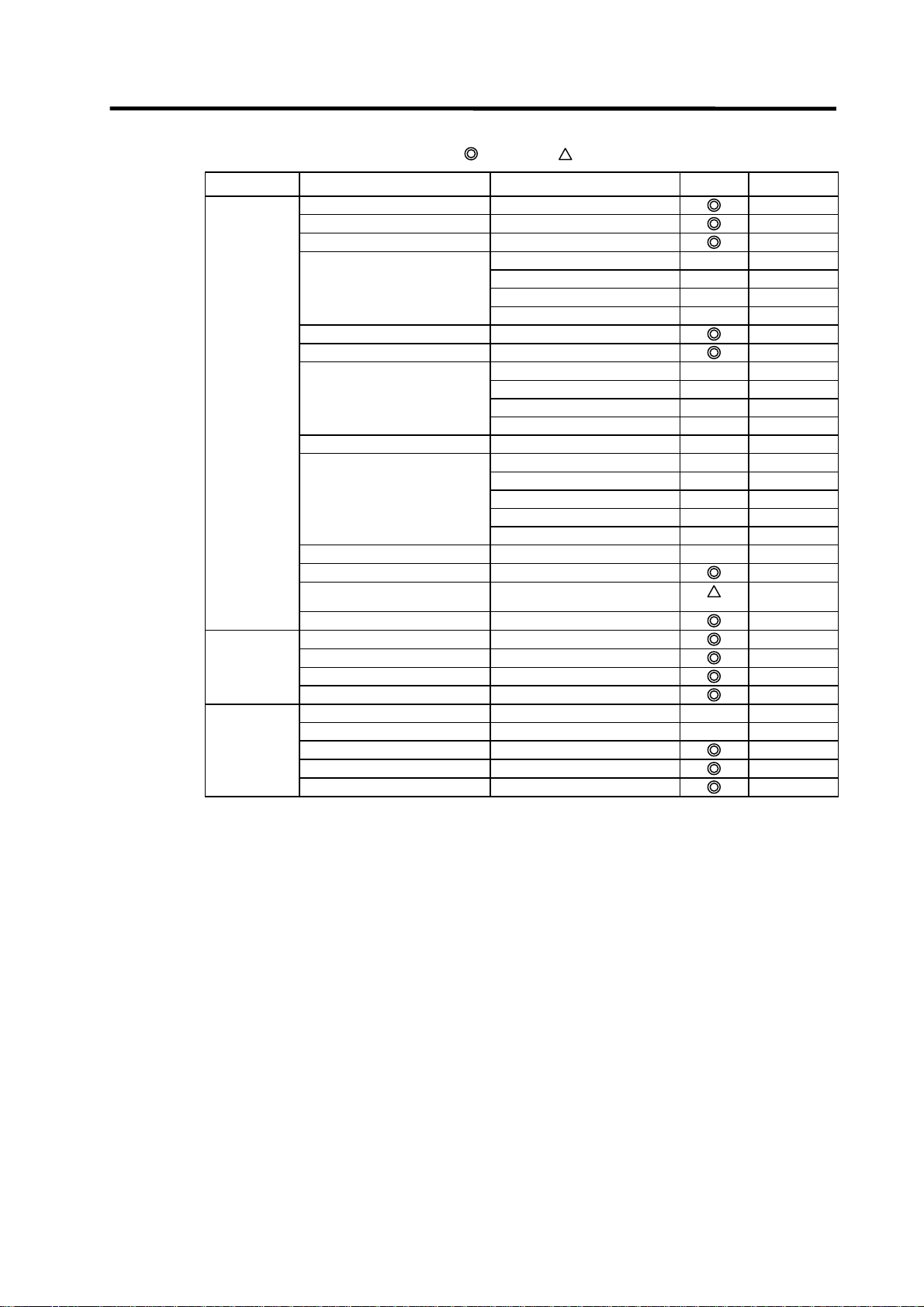

1.1.3 GX Developer Functions Supported by C64 Series...................................................3

1.1.3.1 Function Support Conditions (general section)..............................................3

1.1.3.2 Function Support Conditions (on-line section)...............................................7

1.2 Setup..................................................................................................................................10

1.2.1 Installing the Tools....................................................................................................10

1.2.2 Connecting the Serial Cable.....................................................................................10

1.3 Developing PLC Programs................................................................................................11

1.3.1 Precautions before Development .............................................................................11

1.3.2 Creating a New Program ..........................................................................................13

1.3.3 Specifying the Connection Target.............................................................................14

1.3.4 Starting/Stopping the PLC of the CNC .....................................................................16

1.3.5 Writing the PLC Program to the CNC.......................................................................17

1.3.6 Reading the PLC Program from the CNC ................................................................20

1.3.7 Verifying the PLC Programs .....................................................................................21

1.3.8 Monitoring the PLC Program ....................................................................................22

1.3.9 Diverting the PLC program that was developed using PLC4B.................................23

1.4 Creating PLC Message Data.............................................................................................27

1.4.1 Development Procedure...........................................................................................27

1.4.2 Message Data Description Method...........................................................................29

1.4.3 Converting Data into GX Developer Format.............................................................34

1.4.4 Entering/Editing Data Using GX Developer..............................................................36

1.4.5 Writing to the CNC....................................................................................................39

1.4.6 Reading and Verifying from the CNC .......................................................................39

1.5 Creating Device Comments...............................................................................................41

1.5.1 Development Procedure...........................................................................................41

1.5.2 Description Method for Indirect Entry .......................................................................42

1.5.3 Converting Comment Data into GX Developer Data................................................43

1.5.4 Writing Comment Data to the CNC...........................................................................45

1.6 PLC4B PLC Development Environment (M500) and Differences ....................................46

1.6.1 Development Tools, etc............................................................................................46

1.6.2 PLC Commands........................................................................................................47

1.7 Error Status........................................................................................................................49

1.8 Initializing for PLC Data Storage Area...............................................................................51

1.8.1 Operation procedure.................................................................................................51

2. PLC Processing Program.......................................................................................................52

2.1 PLC Processing Program Level and Operation................................................................52

2.1.1 High-speed processing program and main processing program.............................52

2.1.2 Cautions on high-speed processing programming...................................................53

2.2 Multi-Programming Function..............................................................................................54

2.2.1 Program Registration Numbers................................................................................54

2.2.2 Program Execution Order.........................................................................................54

2.2.3 Precautions ...............................................................................................................54

2.3 User Memory Area Configuration......................................................................................54

3. Input/Output Signals ...............................................................................................................55

3.1 Input/Output Signal Types and Processing.......................................................................55

3.2 Handling of Input Signals Designated for High-Speed Input.............................................56

iv

Page 7

3.3 High-Speed Input/output Designation Method..................................................................57

4. Parameters ...............................................................................................................................58

4.1 PLC Constants...................................................................................................................58

4.2 Bit Selection Parameters...................................................................................................59

5. Explanation of Devices ...........................................................................................................63

5.1 Devices and Device Numbers...........................................................................................63

5.2 Device List..........................................................................................................................63

5.3 Detailed Explanation of Devices........................................................................................64

5.3.1 Input/output X, Y ........................................................................................................64

5.3.2 Internal Relays M and F, Latch Relay L....................................................................65

5.3.3 Special Relays SM....................................................................................................65

5.3.4 Link Relay B, Link Register W ..................................................................................66

5.3.5 Special Relay for Link SB, Special Register for Link SW.........................................66

5.3.6 Timer T......................................................................................................................67

5.3.7 Counter C..................................................................................................................71

5.3.8 Data Register D.........................................................................................................74

5.3.9 File Register R...........................................................................................................75

5.3.10 Special Register SD................................................................................................76

5.3.11 Index Register Z......................................................................................................76

5.3.12 Nesting N.................................................................................................................77

5.3.13 Pointer P..................................................................................................................77

5.3.14 Decimal Constant K................................................................................................78

5.3.15 Hexadecimal Constant H........................................................................................78

6. Explanation of Commands.....................................................................................................79

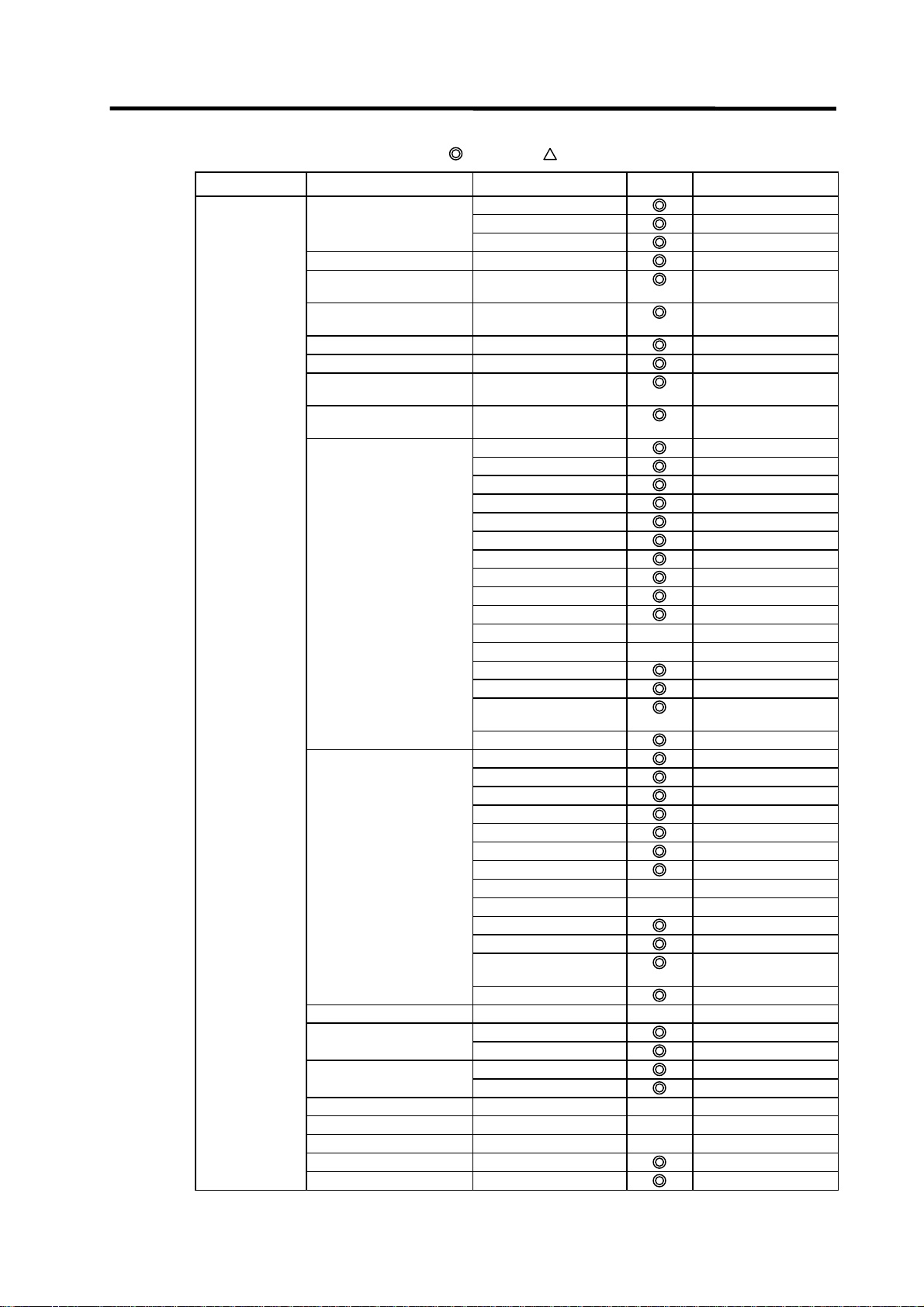

6.1 Command List....................................................................................................................79

6.1.1 Basic Commands......................................................................................................79

6.1.2 Function Commands.................................................................................................81

6.1.3 Exclusive Commands 1 ............................................................................................94

6.1.4 Exclusive Commands 2 ............................................................................................95

6.2 Command Formats............................................................................................................96

6.2.1 How to Read the Command Table ...........................................................................96

6.2.2 No. of Steps...............................................................................................................97

6.2.3 END Command.........................................................................................................98

6.2.4 Index Qualification.....................................................................................................98

6.2.5 Digit Designation.....................................................................................................100

7. Basic Commands (LD, LDI, AND, ANI, OR, ORI, ANB, ORB .....)......................................103

8. Function Commands (=, >, <, +, –, *, /, BCD, BIN, MOV .....)..............................................145

9. Exclusive Commands 1 ........................................................................................................303

10. Exclusive Commands 2 ......................................................................................................334

10.1 ATC Exclusive Command..............................................................................................335

10.1.1 Outline of ATC Control..........................................................................................335

10.1.2 ATC Operation......................................................................................................335

10.1.3 Explanation of Terminology ..................................................................................335

10.1.4 Relationship between Tool Registration Screen and Magazines.........................336

10.1.5 Use of ATC and ROT Commands........................................................................337

10.1.6 Basic Format of ATC Exclusive Command ..........................................................338

10.1.7 Command List.......................................................................................................339

10.1.8 Control Data Buffer Contents................................................................................339

10.1.9 File Register (R Register) Assignment and Parameters......................................340

10.1.10 Details of Each Command..................................................................................342

10.1.11 Precautions for Using ATC Exclusive Instructions.............................................351

v

Page 8

10.1.12 Examples of Tool Registration Screen...............................................................351

10.1.13 Display of Spindle Tool and Standby Tool..........................................................353

10.2 S.ROT Commands ........................................................................................................354

10.2.1 Command List.......................................................................................................354

10.3 Tool Life Management Exclusive Command.................................................................360

10.3.1 Tool Life Management System.............................................................................360

10.3.2 Tool Command System ........................................................................................360

10.3.3 Spare Tool Selection System ...............................................................................361

10.3.4 Interface ................................................................................................................361

10.3.5 User PLC Processing When the Tool Life Management Function Is Selected ...362

10.3.6 Examples of Tool Life Management Screen ........................................................370

10.4 DDB (Direct Data Bus) ... Asynchronous DDB..............................................................371

10.4.1 Basic Format of Command...................................................................................371

10.4.2 Basic Format of Control Data................................................................................371

10.5 External Search .............................................................................................................374

10.5.1 Function.................................................................................................................374

10.5.2 Interface ................................................................................................................374

10.5.3 Search Start Instruction ........................................................................................376

10.5.4 Timing Charts and Error Causes..........................................................................376

10.5.5 Sequence Program Example................................................................................378

11. PLC Help Function...............................................................................................................379

11.1 Alarm Message Display.................................................................................................380

11.1.1 Interface ................................................................................................................380

11.1.2 Message Creation.................................................................................................381

11.1.3 F or R Type Selection Parameter.........................................................................382

11.2 Operator Message Display............................................................................................383

11.2.1 Interface ................................................................................................................383

11.2.2 Operator Message Preparation ............................................................................384

11.2.3 Operator Message Display Validity Parameter ....................................................384

11.3 PLC Switches.................................................................................................................385

11.3.1 Explanation of Screen...........................................................................................385

11.3.2 Explanation of Operation ......................................................................................386

11.3.3 Signal Processing .................................................................................................387

11.3.4 Switch Name Preparation.....................................................................................391

11.4 Key Operation by User PLC..........................................................................................392

11.4.1 Key Data Flow.......................................................................................................392

11.4.2 Key Operations That Can Be Performed..............................................................392

11.4.3 Key Data Processing Timing ................................................................................393

11.4.4 Layout of Keys on Communication Terminal........................................................394

11.4.5 List of Key Codes..................................................................................................395

11.5 Load Meter Display........................................................................................................396

11.5.1 Interface ................................................................................................................396

11.6 External Machine Coordinate System Compensation ..................................................398

11.7 User PLC Version Display.............................................................................................399

11.7.1 Interface ................................................................................................................399

12. PLC Axis Control.................................................................................................................401

12.1 Outline............................................................................................................................401

12.2 Specifications.................................................................................................................401

12.2.1 Basic Specifications..............................................................................................401

12.2.2 Other Restrictions .................................................................................................402

12.3 PLC Interface.................................................................................................................403

12.3.1 S.DDBS Function Command................................................................................403

12.3.2 Control Information Data.......................................................................................404

12.3.3 Control Information Data Details...........................................................................405

12.3.3.1 Commands...............................................................................................405

12.3.3.2 Status........................................................................................................406

vi

Page 9

12.3.3.3 Alarm No...................................................................................................414

12.3.3.4 Control Signals (PLC axis control information data)................................415

12.3.3.5 Axis Designation.......................................................................................417

12.3.3.6 Operation Mode........................................................................................417

12.3.3.7 Feedrate...................................................................................................418

12.3.3.8 Movement Data........................................................................................418

12.3.3.9 Machine Position......................................................................................419

12.3.3.10 Remaining Distance...............................................................................419

12.3.4 Reference Point Return near Point Detection ......................................................420

12.3.5 Handle Feed Axis Selection..................................................................................421

Appendix 1. Example of Faulty Circuit....................................................................................422

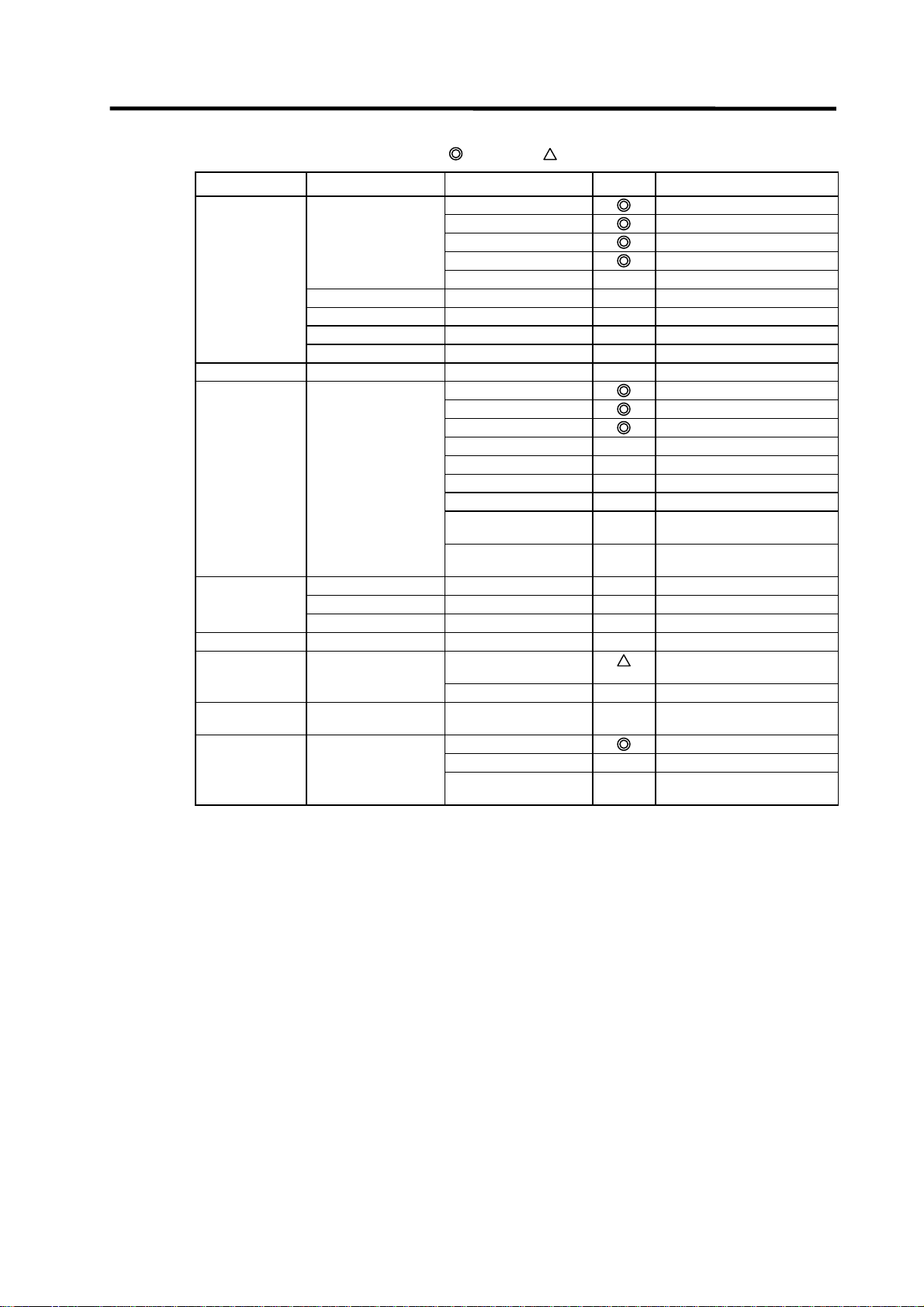

Appendix 2. MELSEC QnA Series Command Lists...............................................................423

2.1 Sequence Commands.....................................................................................................423

2.2 Basic Commands.............................................................................................................424

2.3 Application Commands....................................................................................................429

2.4 Exclusive Commands......................................................................................................432

Appendix 3. PLC Development Environment using GPPQ ..................................................433

3.1 System Configuration at PLC Development....................................................................433

3.2 Development Tool Function Outline................................................................................433

3.2.1 CNVQ (data conversion software package)...........................................................433

3.2.2 LNKQ (sequence ladder generating connection function software package)........433

3.2.3 GPPQ (SW2IVD/NX-GPPQ type GPP Function Software Package)....................434

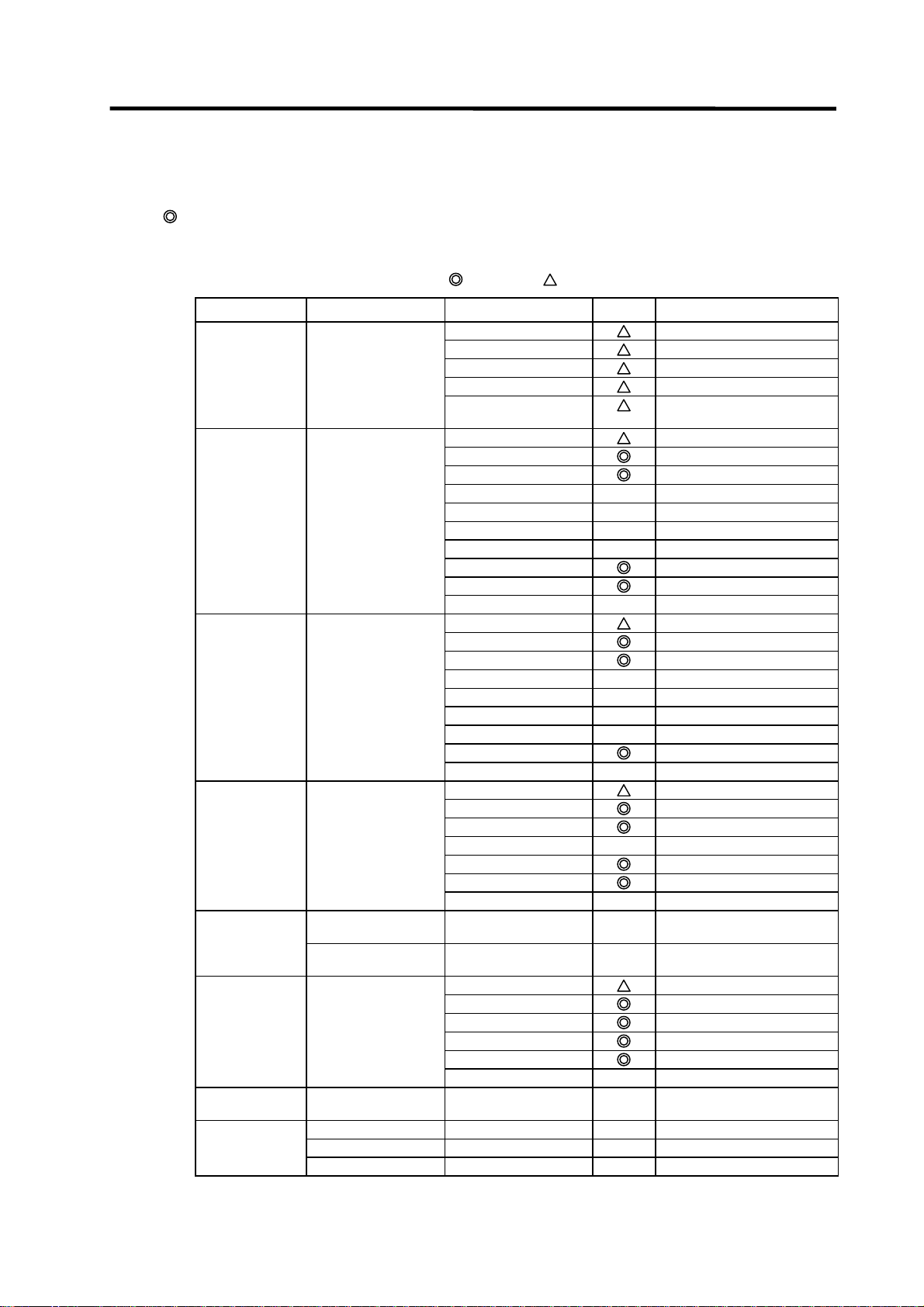

3.3 GPPQ Function Outline and Functions Supported by the C64 Series...........................435

3.3.1 Function Support Conditions (general section) ......................................................435

3.3.2 Function Support Conditions (on-line section)........................................................438

3.4 Setup Procedure..............................................................................................................444

3.4.1 Tool Setup Procedure.............................................................................................444

3.4.2 Connection Procedure............................................................................................444

3.5 PLC Program Development Procedure...........................................................................445

3.5.1 Precautions before Development ...........................................................................445

3.5.2 Ladder Transfer to the C64 Controller....................................................................446

3.5.3 Ladder Read from the C64 Controller.....................................................................448

3.5.4 Ladder Comparison with the C64 Controller ..........................................................449

3.6 PLC-Related Data Development Procedure...................................................................450

3.6.1 PLC Related Data File Names................................................................................450

3.6.2 Development Procedure.........................................................................................451

3.6.3 Message Data Description Method.........................................................................452

3.6.4 Conversion to GPPQ Data......................................................................................457

3.6.5 Operation with the GPPQ .......................................................................................459

3.6.6 Transfer to the Controller........................................................................................461

3.6.7 Reading and Comparing from the Controller..........................................................462

3.7 Differences From The M500 PLC Development Environment........................................464

3.7.1 PLC Commands......................................................................................................464

3.7.2 PLC Messages........................................................................................................466

vii

Page 10

1. PLC Development Environment Using GX Developer

1.1 Function

1. PLC Development Environment Using GX Developer

In the C64 Series, the user PLC development environment is supported using MELSEC PLC

development tool, which is Mitsubishi integrated FA software MELSOFT series (GX Developer).

This manual explains system configurations user PLC development environment using GX

Developer, mainly usage specific to MELDAS.

1.1 Function

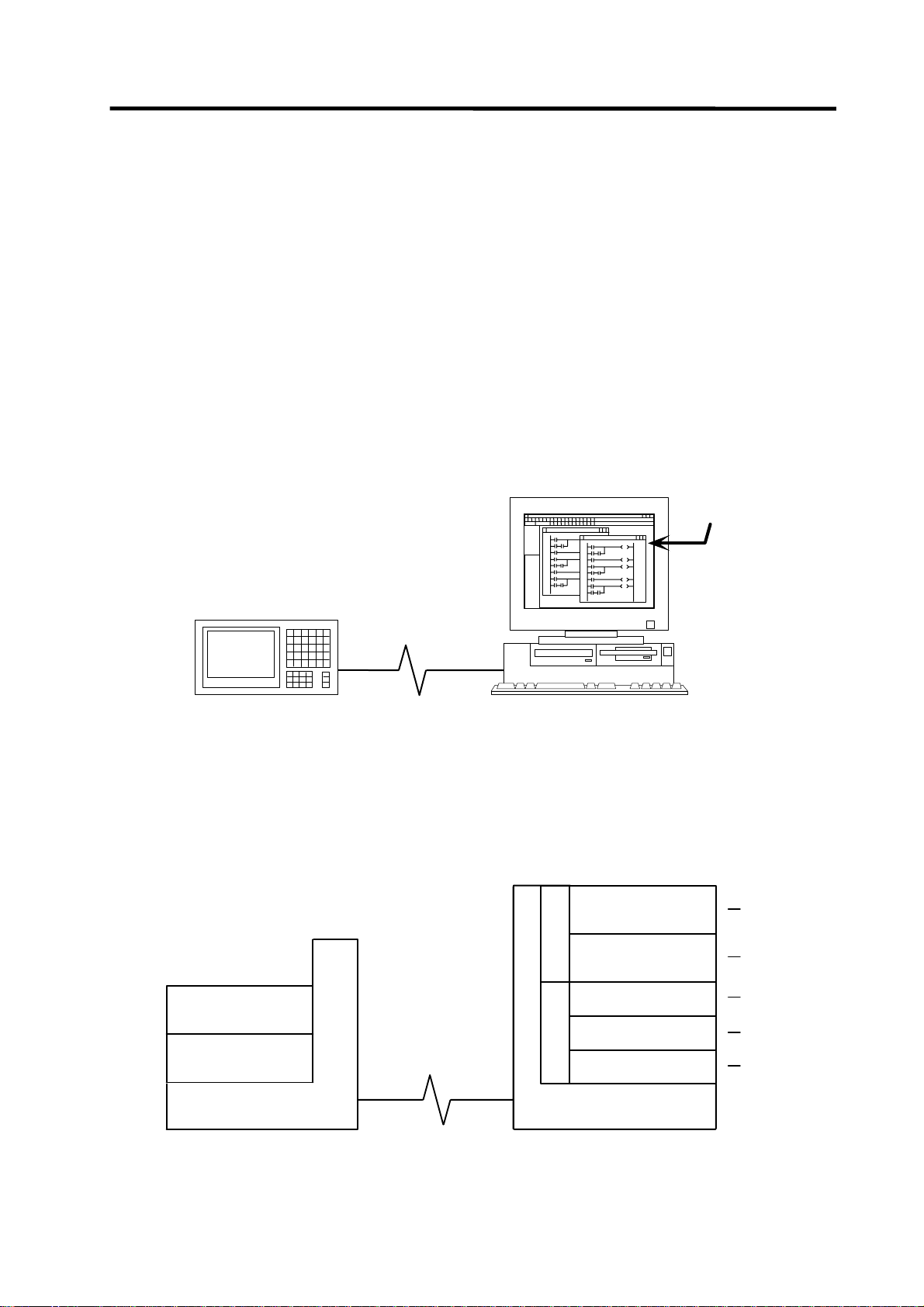

1.1.1 Development Environment Configuration

Most of the development works can be done by connecting the IBM PC/AT compatible machine and

a CNC unit by an RS-232C cable or RS-422 cable and by executing the tools on the personal

computer.

IBM PC/AT-compatible machine

(CD drive is required)

GX Developer

(GPPW)

CNC controller

System configuration using GX Developer

1.1.2 Software Configuration

PLC onbo ard

QnA simulator

CNC controller

RS-232C cable,

RS-422 cable

or Ethernet cable

RS-232C cable,

RS-422 cable

or E thernet cable

PLC development tool

C

s

for MELSEC

t

E

c

GX Developer

S

u

L

d

Data conversion

o

E

r

p

M

package for MELSEC

GX Converter

List output converter

S

s

t

A

c

D

u

L

d

o

E

r

p

M

PCNV6L

Comment converter

CLST6M

Ladder list converter

CLST6L

IBM PC/AT

Compatibl e machine

(1)

(2)

(3)

(4)

(5)

- 1 -

Page 11

1. PLC Development Environment Using GX Developer

1.1 Function

(1) GX Developer (PLC development software package for Windows)

GX Developer is a programming software package (model name: SW7D5C-GPPW) designed

for Mitsubishi Electric's MELSEC series programmable logic cont rollers. The conventional

function corresponding to MELDAS PLC development S/W (PLC4B) has been reinforced, and,

furthermore, that is a strong tool added the monitoring function by way of RS-232C. Note that

some functions specific to the "MELSEC series" may not be unavailable.

For MELDAS series ladder development, we recommend you to use GX Developer Version 4

(SW4D5C-GPPW) or later. For function details, refer to the operating manual supplied.

The DOS version "GPPQ" (SW2IVD/NX-GPPQ GPP function software package) of this

package is also usable. Refer to "Appendix3. Operation Method Using GPPQ" for details.

(2) GX Converter (Data conversion software package for Windows)

The GX Converter is a tool that carries out file conversion of GX Developer data files and the

following:

• Ladder list files and comment text files output by the CLIST6L

• Alarms and operator messages created by the text editor

• Data files of commercially available spreadsheet software, word processors and editors

This tool is add-on tool of the GX Developer, thus, start GX Converter from the GX Developer’s

menu.

This tool is a software package for MELSEC. GX Converter needs to be used with the versions

following GX Developer Version 3 (SW3D5C-GPPW). Refer to the enclosed Operating Manual

for function details.

The DOS version "CNVQ" (SW0IVD/NX-CNVQ data conversion software package) of this tool

can also be used. Refer to "Appendix 3. Operation Methods Using GPPQ" for details.

(3) PCNV6L (List output converter)

This tool outputs a MELDAS specification ladder printing image with cross information into the

text format from the GX Developer specification ladder list and comment data. Refer to the

instruction manual for function details.

This tool works on the DOS of Windows.

(4) CLST6M (Device comment converter)

This tool outputs the contact/coil comment data of a user PLC ladder developed using PLC4B

into the text format of the GX Developer specifications. The comment data developed using

PLC4B can be used with GX Developer by using GX Converter to further convert the

conversion results of this tool. Refer to the instruction manual for function details.

This tool works on the DOS of Windows.

(5) CLST6L (Ladder list converter)

This tool converts the user PLC ladder list data developed using PLC4B, and outputs the data

in a ladder list format. The user PLC ladder developed using PLC4B can be used with the GX

Developer by using the GX Converter to further convert the conversion results of this tool. Refer

to the instruction manual for function details.

This tool works on the DOS of Windows.

- 2 -

Page 12

1. PLC Development Environment Using GX Developer

1.1 Function

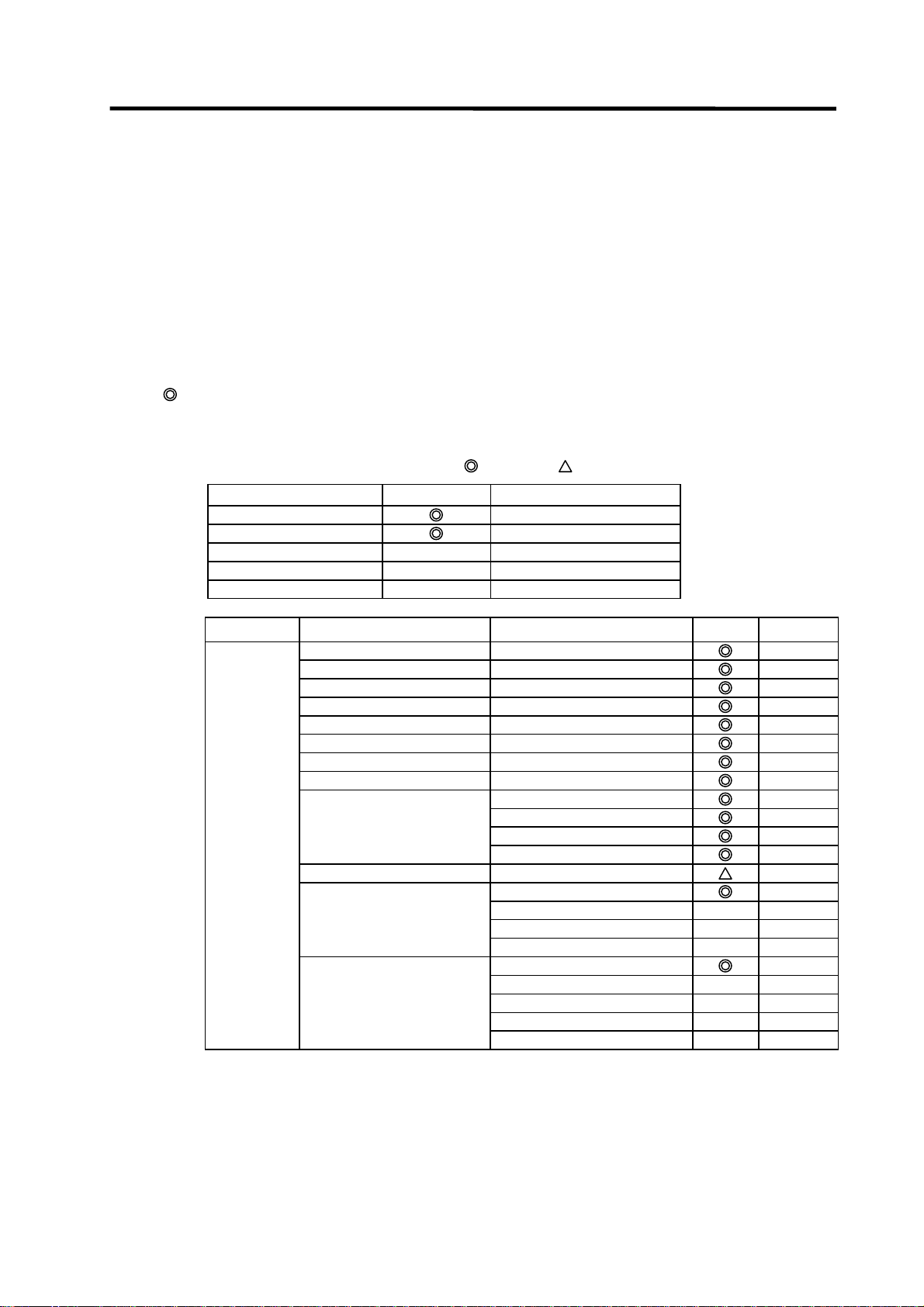

1.1.3 GX Developer Functions Supported by C64 Series

The GX Developer functions explained here are those supported by the C64 Series in the "off-line

functions" operated with the GX Developer independently and "on-line functions" carried out

connected to the CNC controller.

Refer to the enclosed Operating Manual for details of respective functions.

Refer to "Appendix 3. Operation Methods Using GPPQ" for the GPPQ-specific functions and

operations when the DOS version "GPPQ" (SW2IVD/NX-GPPQ GPP function software package) is

used.

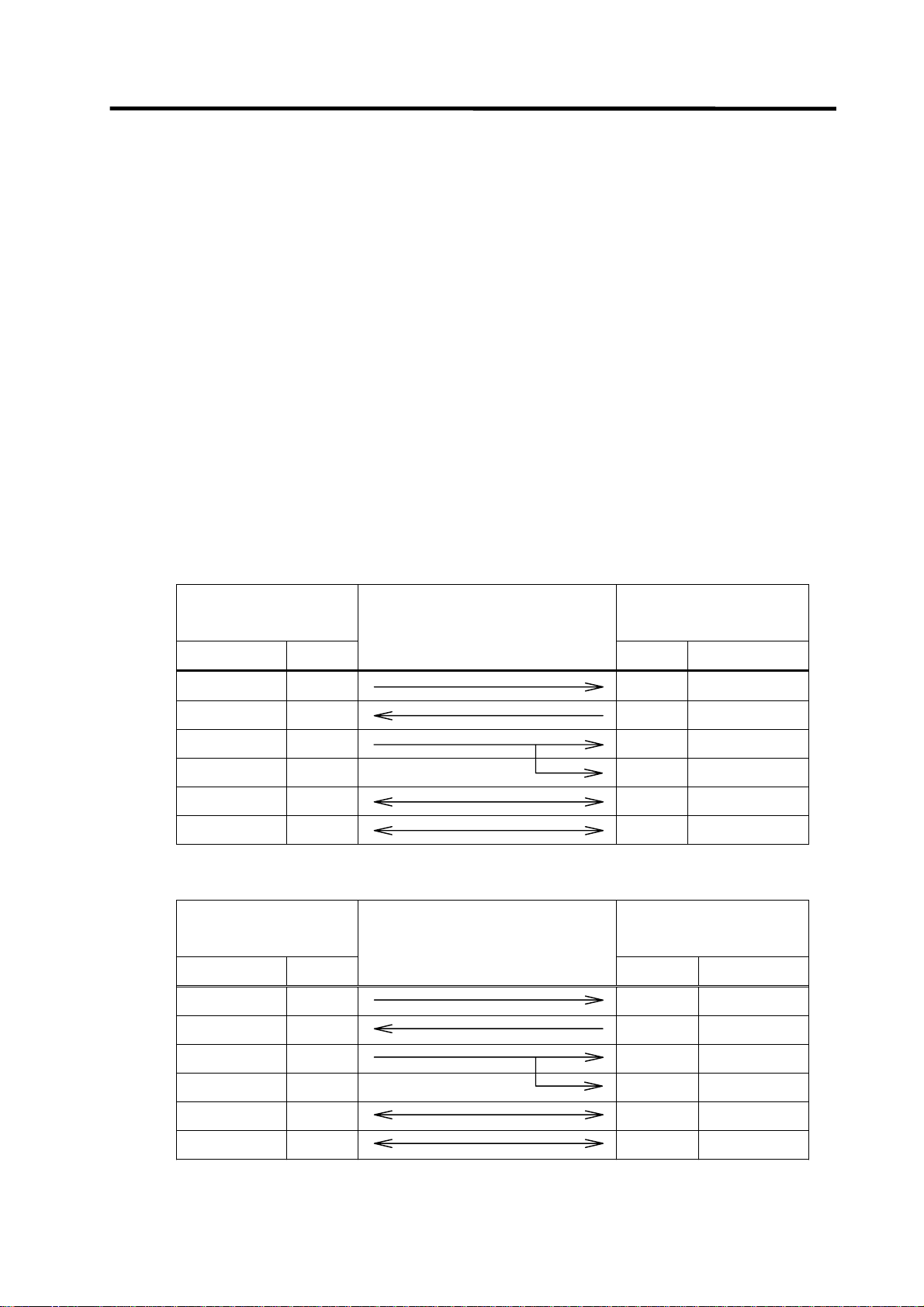

1.1.3.1 Function Support Conditions (general section)

The following shows a list of GX Developer outline functions supported by the C64 Series.

A

mark indicates functions that can be used by the C64 Series. An r mark indicates that the

function cannot be used because it is related to "MELSEC Series" characteristic functions. The

function details during on-line are described in the next section.

List of general section functions (1)

Program type Support Remarks

Ladder

List

SFC

MELSAP-L

Function block

U

U

U

Function Menu Sub menu Support Remarks

Project New project

Open project

Close project

Save

Save as

Delete project

Verify

Copy

Edit Data New

Copy

Delete

Rename

Change PLC type

Import file Import from GPPQ format file

Import from GPPA format file

Import from FXGP[WIN] format file

Import from FXGP[DOS] format file

Export file Export to GPPQ format files

Export to GPPA format files

Export to FXGP[WIN] format file

Export to FXGP[DOS] format file

Export to TEXT ,CSV format file

: Possible,

: Limitedly possible, U : Not possible

U

U

U

U

U

U

Fixed Q4A

- 3 -

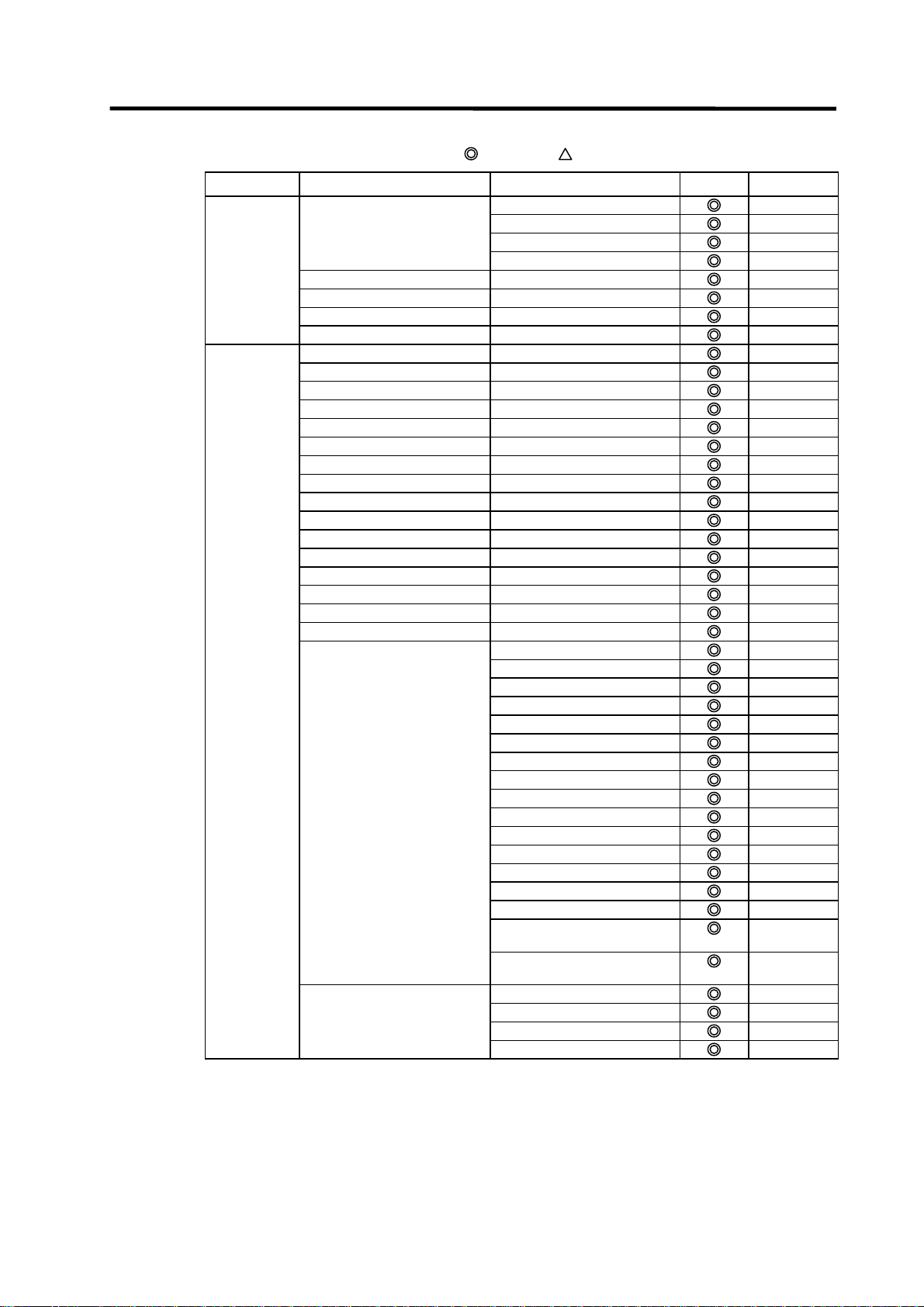

Page 13

1. PLC Development Environment Using GX Developer

1.1 Function

List of general section functions (2)

Function Menu Sub menu Support Remarks

(Project) Macro Registration macros

Macro utilize

Delete macros

Macro reference path

Printer setup

Print

Start new GX Developer session

Exit GX Developer

Edit Undo

Restore after ladder conversion

Cut

Copy

Paste

Insert line

Delete line

Insert row

Delete row

Insert NOP batch

Delete NOP batch

Draw line

Delete line

Change TC setting

Read mode

Write mode

Ladder symbol Open contact

Close contact

Open branch

Close branch

Coil

Application instruction

Vertical line

Horizontal line

Delete vertical line

Delete horizontal line

Rising pulse

Falling pulse

Rising pulse open branch

Falling pulse close branch

Invert operation results

Convert operation results to

Convert operation results to

Documentation Comment

Statement

Note

Statement/Note block edit

: Possible,

rising pulse

falling pulse

: Limitedly possible, U : Not possible

- 4 -

Page 14

1. PLC Development Environment Using GX Developer

1.1 Function

List of general section functions (3)

Function Menu Sub menu Support Remarks

Find/Replace Find device

Find instruction

Find step no.

Find character string

Find contact or coil

Replace device

Replace instruction

Change open/close contact

Replace character string

Change module start address

Replace statement/note type

Cross reference list

List of used devices

Convert Convert

Convert (All programs being

Convert (Online change)

View Comment

Online

Diagnostics PLC diagnostics

edited)

Statement

Note

Alias

Macro instruction format display

Comment format 4*8 characters

3*5 characters

Alias format display

Replace device name and

Toolbar

Status bar

Zoom 50%

75%

100%

150%

Auto

Project data list Specify

Instruction list

Elapsed time

Refer to "List of on-line section

functions"

Network diagnostics

Ethernet diagnostics

CC-Link diagnostics

System monitor

: Possible,

display

Arrange with device and display

Refer to "List of on-line section

functions"

: Limitedly possible, U : Not possible

U

U

U

U

U

U

- 5 -

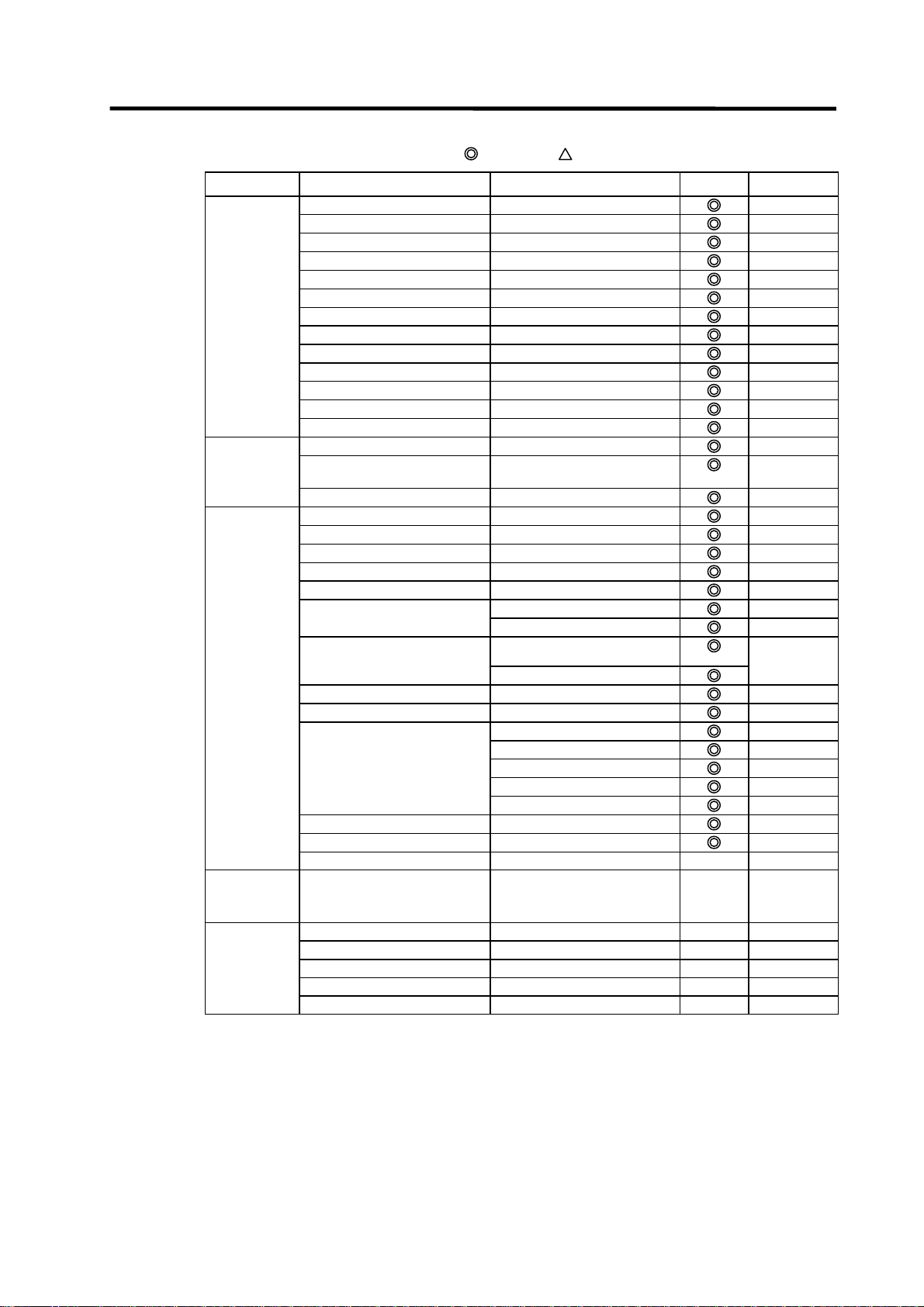

Page 15

1. PLC Development Environment Using GX Developer

1.1 Function

List of general section functions (4)

Function Menu Sub menu Support Remarks

Tools Check program

Merge data

Check parameter

Transfer ROM Read

Write

Verify

Write to file

Delete unused comments

Clear all parameters

IC memory card Read IC memory card

Write IC memory card

Read image data

Write image data

Start ladder logic test

Set TEL data Connection

Disconnection

TEL data

AT command

Call book

Intelligent function utility Utility list

Customize keys

Options

Create start-up setting file

Window Cascade

Tile vertically

Tile horizontally

Arrange icons

Help PLC error

Special relay/register

Key operation list

Product information

Connect to MELFANSweb

: Possible,

: Limitedly possible, U : Not possible

U

U

U

U

U

U

U

U

U

U

U

U

U

U

U

Partially

impossible

U

U

- 6 -

Page 16

1. PLC Development Environment Using GX Developer

1.1 Function

1.1.3.2 Function Support Conditions (on-line section)

The following shows a list of GX Developer on-line functions supported by the C64 Series.

A

mark indicates functions that can currently be used by the C64 Series. An r mark indicates

that the function cannot be used because it is related to "MELSEC Series" characteristic functions.

List of on-line section functions (1)

Menu Sub me nu Detailed function Support Remarks

Transfer setup PC side I/F

PLC side I/F

Other station

Network route

Co-existence network

Read from PLC Target memory

Title

File selection

Device data

Program

Common

Local

Refresh view

Free space volume

Create title

Write to PLC Target memory

Title

File selection

Device data

Program

Common

Local

Free space volume

Create title

Verify with PLC Target memory

Title

File selection

Program

Refresh view

Free space volume

Create title

Write to PLC

[Flash ROM]

Write to PLC

Delete PLC data Target memory

Title

File selection

Refresh view

Free space volume

Create title

Change PLC data

attributes

PLC user data Read PLC user data

Write PLC user data

Delete PLC user data

Write the program

memory to ROM

[Flash ROM]

: Possible,

route

: Limitedly possible, U : Not possible

Only for QnACPU

Only for internal memory

U

U

U

U

U

Only for internal memory

U

U

U

U

U

Only for internal memory

U

U

U

U

Only for internal memory

U

U

U

U

U

- 7 -

Page 17

1. PLC Development Environment Using GX Developer

1.1 Function

List of on-line section functions (2)

Menu Sub menu Detailed function Support Remarks

Monitor Monitor mode ON/OFF state

Scan time

PLC status

Monitor [Write mode]

Start monitor

[All windows]

Stop monitor

[All windows]

Start monitor

Stop monitor

Change current value

monitor [Decimal]

Change current value

monitor [Hexadecimal]

Device batch Device

Connect

Coil

Setting value

Current value

Monitor format : Bit & word

Monitor format : Bit

Monitor format : word

Display : 16bit integer

Display : 32bit integer

Display : Real number

Display : ASCII character

Value : DEC

Value : HEX

T/C set value Reference

Device test

Entry data monitor Device

ON/OFF/Current

Setting value

Connect

Coil

Display : 16bit integer

Display : 32bit integer

Display : Real number

Display : ASCII character

Value : DEC

Value : HEX

T/C setting value, Local

Device test

Buffer memory batch

Monitor condition setup Device

Step No.

Monitor stop condition setup Device

Step No.

Program monitor list

Interrupt program monitor list

Scan time measurement

Entry ladder monitor

Delete all entry ladder

: Possible,

program

label Reference program

: Limitedly possible, U : Not possible

U

U

U

U

U

U

U

U

- 8 -

Page 18

1. PLC Development Environment Using GX Developer

1.1 Function

List of on-line section functions (3)

Menu Sub me nu Detailed function Support Remarks

Debug Device test FORCE ON

FORCE OFF

Toggle force

Device

Buffer memory U

Debug

Skip execution

Partial execution

Step execution

Trace

Remote operation PLC status

RUN

STOP

PAUSE

Latch clear

STEP-RUN

Reset

Operation during RUN,

Specify execution

Keyword setup Register

Delete

Disable

Clear PLC memory

Format PLC

memory

Format

Arrange PLC

memory

Set time Date / time

Day of week

Specify execution

Target memory

: Possible,

STEP-RUN

destination

destination

: Limitedly possible, U : Not possible

U

U

U

U

U

U

U

U

U

U

U

U

U

U

U

For only internal RAM

U

U

U

U

- 9 -

Page 19

1. PLC Development Environment Using GX Developer

1.2 Setup

1.2 Setup

1.2.1 Installing the Tools

In the C64 Series PLC development environment, it is assumed that the various tools are u se d on

an IBM PC/AT compatible machine. Prepare each tool so that it is IBM PC/AT compatible machine.

Refer to the enclosed Operating Manual for the setup and start procedures of each tool.

1.2.2 Connecting the Serial Cable

As for the serial port connected with the CNC, refer to the MELDAS C6/C64/C64T Connection and

Maintenance Manual (BNP-B2255).

(1) RS-232C connection

Between the IBM PC/AT compatible machine that uses GX Developer and the CNC controller,

use an RS-232C serial cable equivalent to the one shown below in the RS-232C connection

diagram.

(Note) The cables given in the connection diagrams of the GX Developer Operating Manual

cannot be used.

As for the CNC side, setting for GPPW communication is not necessary.

(a) When connecting with C64 controller directly

NC side (TERMINAL)

Personal computer side

Cable connection and

(20-pin half-pitch)

(9-pin D-SUB)

signal direction

Signal name Pin No.

Pin No. Signal name

SD 6 2 RD

RD 16 3 SD

ER(DTR) 18 6 DR(DSR)

8 CS(CTS)

GND 1 1 GND

GND 11 5 GND

(b) When connecting with C64 controller using the intermediate cable dedicated to C64

NC side (TERMINAL)

Personal computer side

Cable connection and

(25-pin D-SUB)

(9-pin D-SUB)

signal direction

Signal name Pin No.

Pin No. Signal name

SD 2 2 RD

RD 3 3 SD

ER(DTR) 20 6 DR(DSR)

8 CS(CTS)

GND 1 1 GND

GND 7 5 GND

- 10 -

Page 20

1. PLC Development Environment Using GX Developer

1.2 Setup

(2) RS-422 connection

MELSEC-dedicated cable can be used to connect with C64 controller.

Refer to the GX Developer Operating Manual for details.

(3) Ethernet connection

For the connection using Ethernet, the Ethernet card (FCU6-EX875) must be mounted to the

extension slot on the control unit.

Connect the Ethernet cable to the modular jack on the Ethernet card.

1.3 Developing PLC Programs

1.3.1 Precautions before Development

Pay careful attention to the following items before developing PLC programs using the GX

Developer.

(1) PC type selection

The PLC type must be set when newly creating programs, etc. Select the following CPU type when

requested to select the PLC type with the GX Developer. An error will occur during transfer of the

PLC program to the CNC if another PLC type is selected.

Select "Q4A" for CPU type.

(2) Device setting

Do not set the devices when developing the PLC program for the CNC. Develop the program with

the device settings (No. of points, etc.) left at their default values applied when GX Developer was

started. The PLC program cannot be transferred to the CNC normally when it is developed with

settings other than the default values.

Do not set the devices.

(3) PLC commands

MELSEC-specific PLC commands cannot be used in the PLC program development for the CNC.

Refer to “6.1 Command List Table” and confirm the useable commands.

The format, etc., are changed with some commands. Refer to "1.5 PLC4B PLC Development

Environment and Differences" for details.

MELSEC-specific PLC commands cannot be used.

(4) Label at the beginning of ladder program

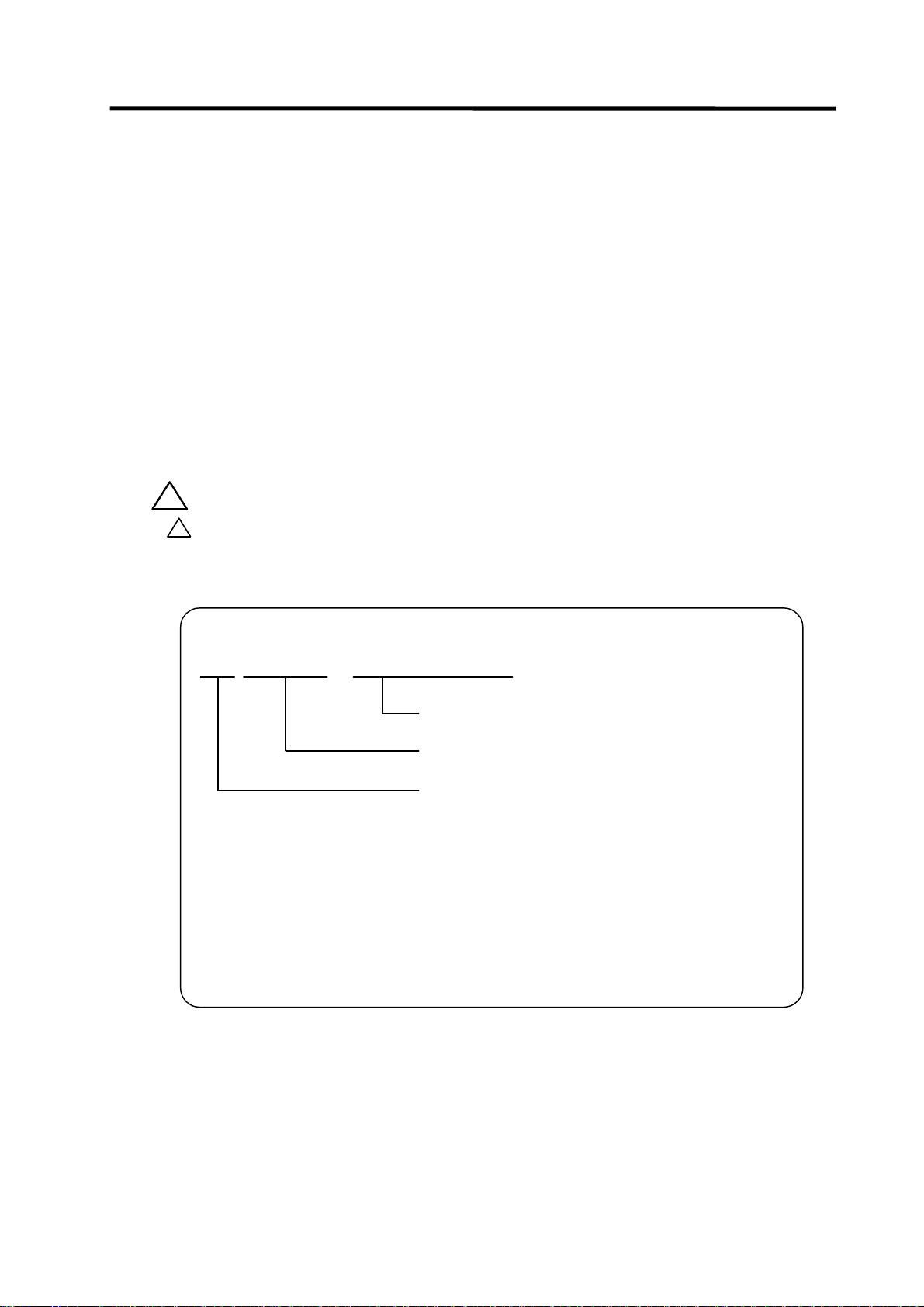

In a MELDAS PLC program, a processing unit is differentiated by specifying a reserved label

number at the beginning of processing. There are the following different processing units.

P251, P360 to 368 : PLC high-speed processing program starting label

P252, P370 to 378 : PLC main processing program starting label

Even if only the PLC main processing is to be performed, do not omit but describe the above label

at the beginning of a PLC program. Unless the label is described, normal RUN cannot be performed.

Specify a label at the beginning of a PLC program.

- 11 -

Page 21

1. PLC Development Environment Using GX Developer

1.3 Developing PLC Programs

(5) Statements and notes

GX Developer allows a PLC program to be commented (with interlinear statements and notes).

They are available in two types: integrated and peripheral.

Integrated type : Can be downloaded together with a ladder program to the CNC

controller.

Peripheral type : Cannot be downloaded.

The integrated type cannot be used with the C64 series. If it is used, a PLC program cannot be

transferred to the CNC properly.

Do not use integrated type interlinear statements and notes.

Create the message data as the integrated type statement.

(6) File name

Inside the C64 series, PLC-related data are controlled and stored in the following categories.

Therefore, they are also developed in the same categories.

!

CAUTION

!

If the data transferred does not follow the following file name rule, the NC will

mistake it for another data, resulting in unexpected operation, e.g. PLC

program erasure.

File name rule

M1

(Note) File name that is not permitted.

xxxx.

When data is transferred by GX Developer, its data type is distinguished by the file name.

An extension indicates a file type, and the first two characters denote a data type and a language

type.

File name can be specified within eight characters including data classification and language

classification freely with the exception of the extension.

The following characters at the head of file name are reserved for CNC side.

Do not use the file name of these characters combination.

Data classification

Language classification

WPG or WCD

Extensions .... Automatically attached with the GX Developer

(expresses file classification)

Random file name .... User free designation

Dataclassification and languag eclassification

(M1:Message 1st languag e )

: "M", "C", "H" (alphabet)

: "0" to "9" (number)

.... userfixed

designation

- 12 -

Page 22

1. PLC Development Environment Using GX Developer

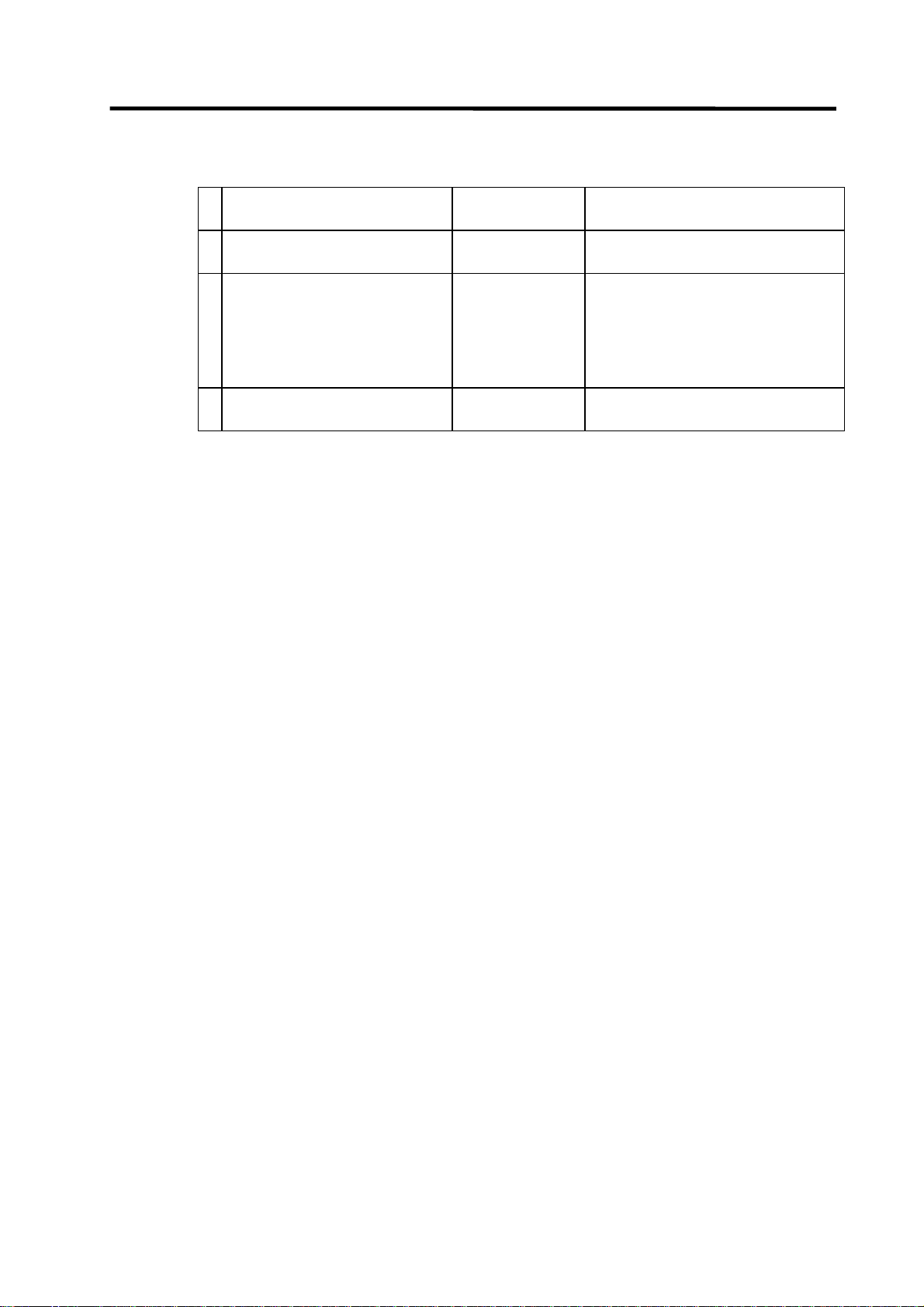

1.3 Developing PLC Programs

List of PLC-related data

Related data classification

12 PLC program (ladder)

PLC program comment

3 Message 1st language M1xxxx.WPG Message 1st language data such

4 Message 2nd language M2xxxx.WPG Same as above

(a) PLC program (ladder)

• PLC program developed using GX Developer.

• Only one file can be stored in the NC.

(b) PLC program comment

• Program comment for GX Developer display

• Only one file can be stored in the NC with the same file name as the PLC program.

• A device comment (32 characters) and a device name (10 characters) can be defined for each

device.

• Stored mainly when it is read to GX Developer and used as a comment.

(c) Message 1st language and (4) 2nd language

• Alarm message/operator message/PLC switch/comment message data.

• One 1st language file and one 2nd language file can be stored in the NC.

• The messages can be handled and edited as "integrated type interlinear statements" by GX

Developer.

• The maximum message length and the number of messages can be specified for each

message type.

1.3.2 Creating a New Program

Create a new program using GX Developer.

Refer to the GX Developer's operation manual for details of usage.

File name

(GX Developer)

zzzzzz.WPG

zzzzzz.WCD

Remarks

PLC ladder code

Comment data for GX Developer

as alarm messages/

operator messages/

PLC switches/

tool registration comment/

load meter comment

(2nd language data)

- 13 -

Page 23

1. PLC Development Environment Using GX Developer

1.3 Developing PLC Programs

1.3.3 Specifying the Connection Target

You must specify the connection target before performing on-line operations from GX Developer to

the CNC.

(1) Operation procedure

Perform the following operation from GX Developer to start the setting screen.

[Online] → [Transfer setup]

Set only the following items. Leave the other items unchanged from the initial values.

(a) Setting for serial connection (RS-232C or RS-422)

• Personal computer side I/F : Serial

Serial port name COM1 or COM2

Baud rate 19.2Kbps

• PLC side IF : CPU unit

(b) Setting example for Ethernet connection

• Personal computer side I/F : Ethernet

Network No. 1

Station No. 1

• PLC side I/F : Ethernet unit

Network No. 1

Station No. 2

IP address (Address set by NC parameter)

Routing method Automatic conversion method

• CNC side IP address setting

#1926 IP address 192.182.1.2

#1927 Subnet mask 255.255.255.0

#1928 Gateway address 192.182.1.254

#1929 Port number 64758

# No. Parameter name Setting example

The local station’s IP address is set for the NC side.

The IP address set here is shared with the other Ethernet communication functions (GOT

connection, etc.).

(Note) The setting example above is for when the GX Developer is connected to the CNC.

To connect the GX Developer to the Ethernet or multiple hierarchical network of

MELSECNET/10, setting values will differ.

- 14 -

Page 24

1. PLC Development Environment Using GX Developer

1.3 Developing PLC Programs

• Setting the GX Developer Connection Destination

These parameters are used to set the GX Developer connection method. These

parameters are included in the GX Developer project data.

- 15 -

Page 25

1. PLC Development Environment Using GX Developer

1.3 Developing PLC Programs

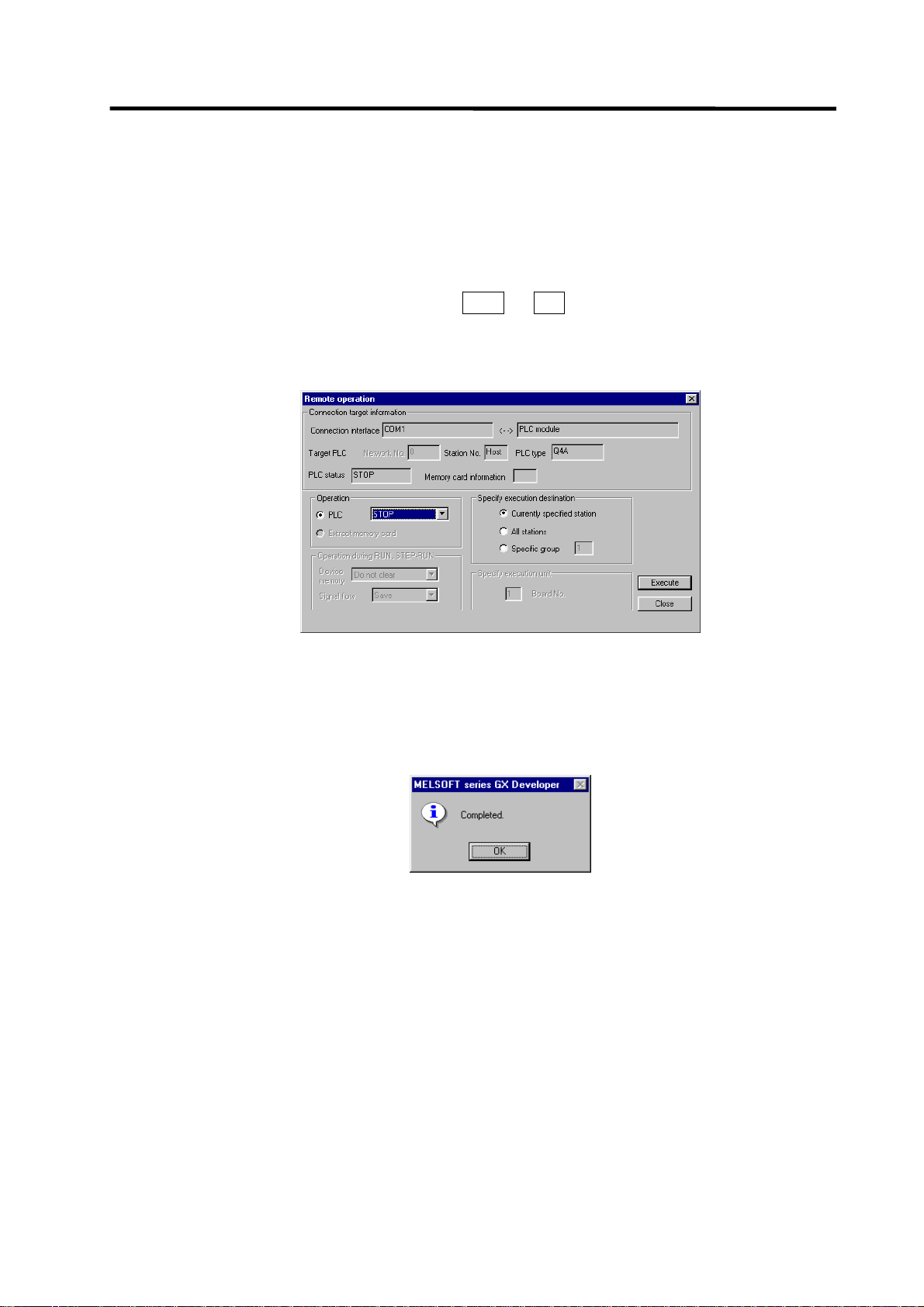

1.3.4 Starting/Stopping the PLC of the CNC

Before writing a ladder program, you must stop the PLC of the CNC.

(1) Operation procedure

Perform the following operation from GX Developer to start the operation screen.

[Online] → [Remote operation] or Alt + 6

On the following screen, set "STOP" or "RUN" in the [PLC] part under [Operation] and click

[Execute]. The current status is displayed in [PLC status] under [Connection target information].

(Note) The operation other than "RUN" or "STOP" can not be performed.

The operation is completed when the following dialog appears. Click [OK]. The status after

completion appears in [PLC status] on the remote operation screen displayed behind. If the status

does not change, check whether an alarm is displayed or not on the CNC side.

- 16 -

Page 26

1. PLC Development Environment Using GX Developer

1.3 Developing PLC Programs

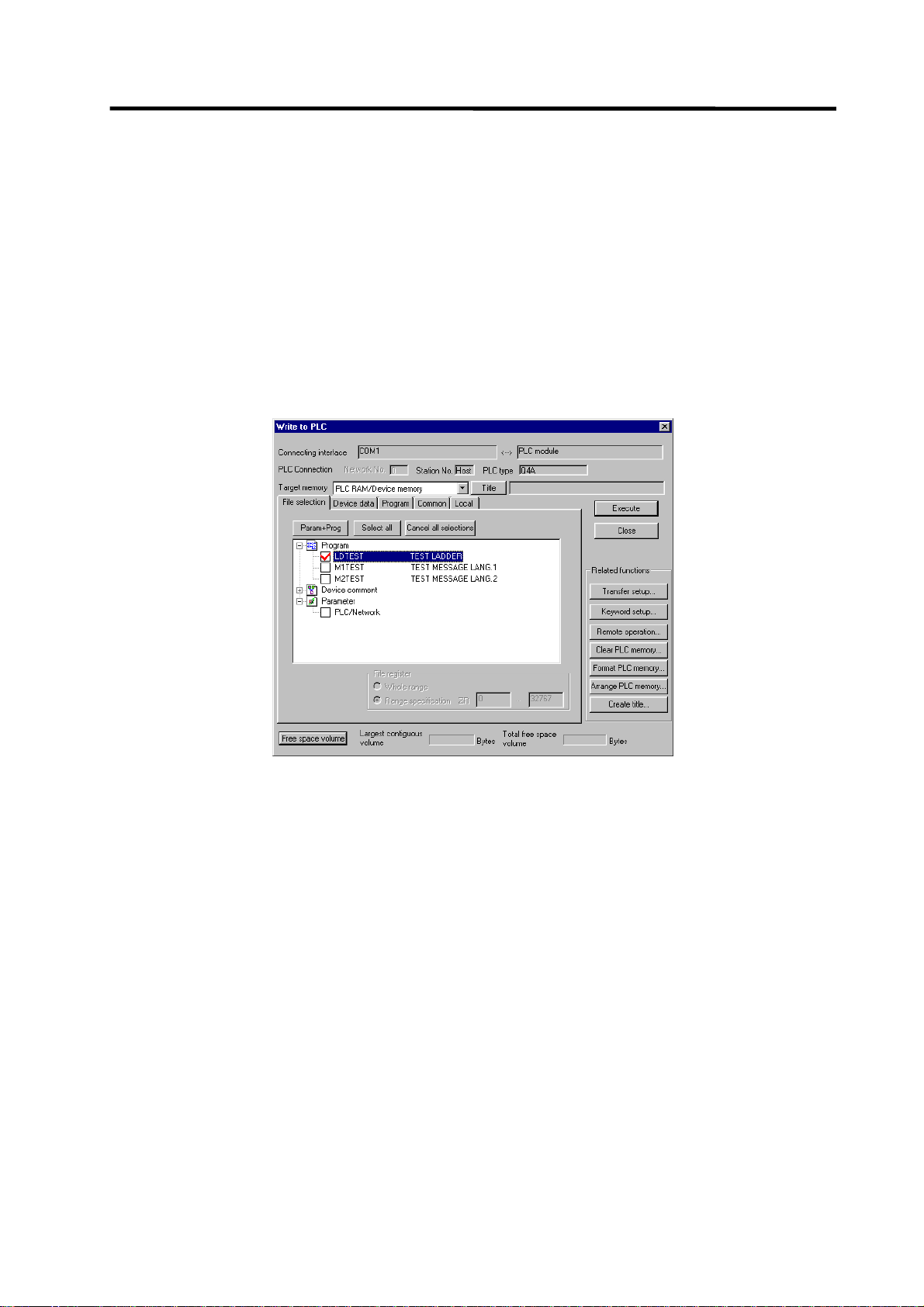

1.3.5 Writing the PLC Program to the CNC

The following indicates how to write ladders from GX Developer to the CNC (especially the

restrictions and C64 series-specific operations).

(1) Operation procedure

Perform the following operation from GX Developer to start the operation screen.

[Online] → [Write to PLC]

On the following screen, choose the ladder file to be written from the [File selection] tab and click

[Execute].

You can command RUN/STOP of the PLC using [Remote operation] under [Related functions].

(Note) As [Target memory], only [PLC RAM/Device memory] is valid.

Do not set the other tabs ([Device data], [Program], [Common], [Local]) than [File

selection].

- 17 -

Page 27

1. PLC Development Environment Using GX Developer

1.3 Developing PLC Programs

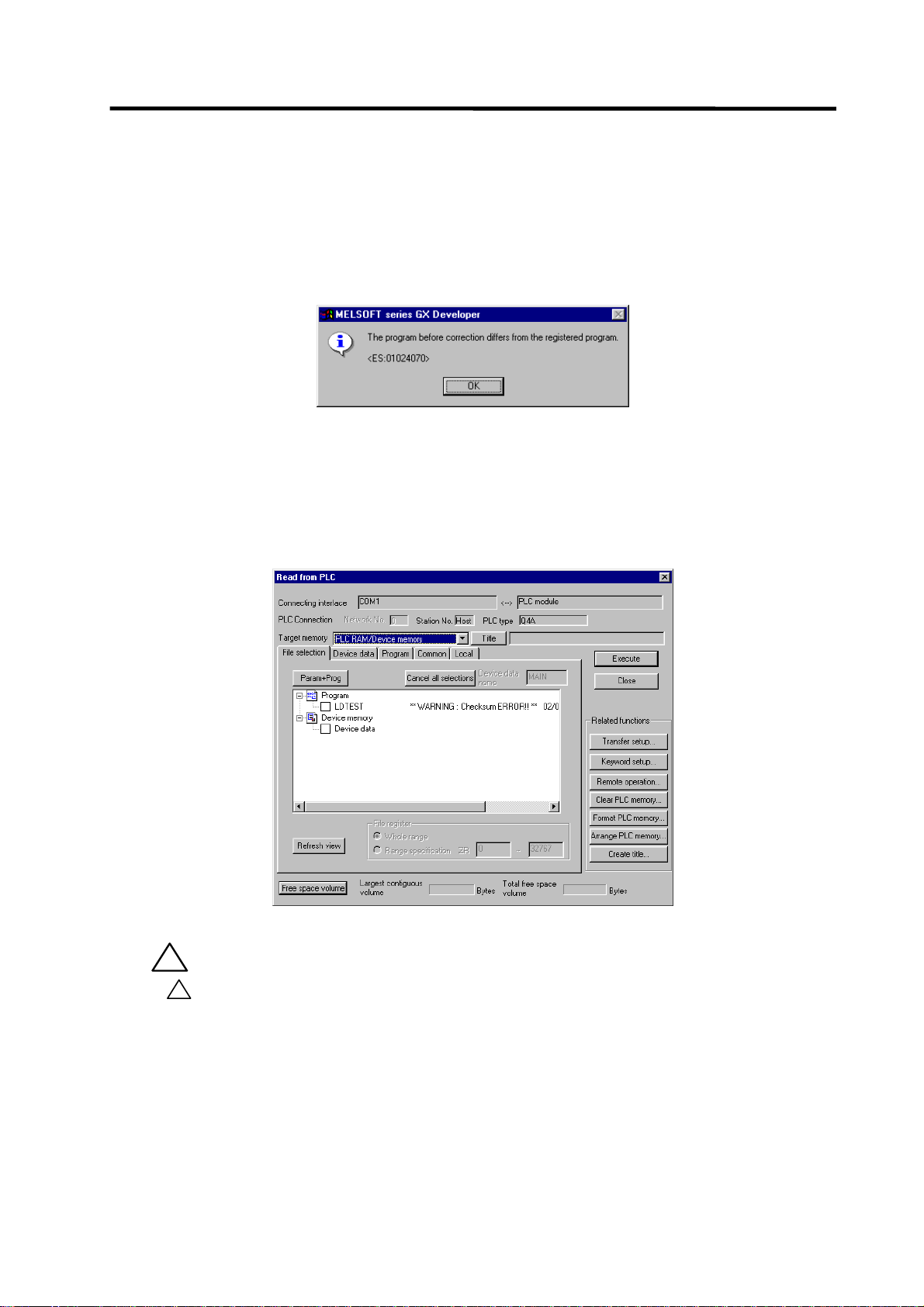

(2) Operation to be performed at write error

As soon as a ladder is written from GX Developer to the CNC, the CNC converts it into the CNCspecific ladder machine code. A conversion error occurs if any of the devices and command formats

not supported by the C64 series is used.

At a conversion error, the CNC side ladder machine code is converted into the [NOP code], the

ladder up to the last step is transferred, and the following dialog is then displayed on the GX

Developer screen.

When the file that resulted in a conversion error is displayed with the [File selection] tab of the

[Read from PLC] screen, the following warning appears in the title field.

“∗∗ WARNING Checksum ERROR!! ∗∗”

If you execute RUN the PLC as-is, an alarm occurs on the CNC side and the PLC does not RUN.

!

CAUTION

!

Do not read a sequence program on which a conversion error occurred into

the GX Developer.

The file may include unexpected contents to result an illegal operation.

- 18 -

Page 28

1. PLC Development Environment Using GX Developer

1.3 Developing PLC Programs

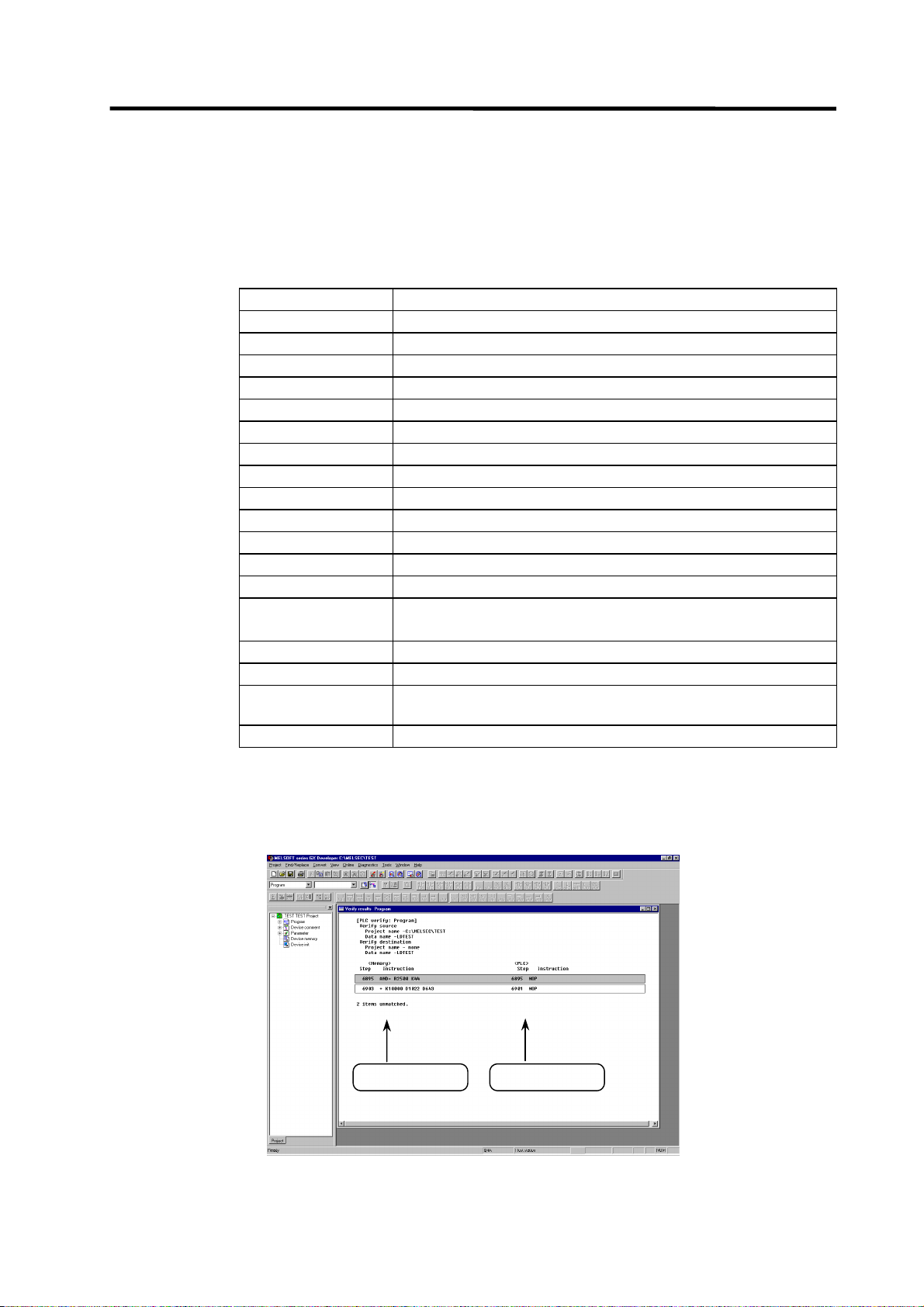

(3) How to confirm the error step number

At a conversion error, error information is stored to the special registers as below. Devicemonitoring these registers enables to find the error position.

SD30 : Error step No. where the error occurred.

SD31 : Cause of the error.

The error No. which occurred while writing from GX Developer to C64

SD31 value Cause of error

1 Command format error.

2 File already exists.

3 File to be read is not found.

4 Object code error.

5 File can not be opened.

6 File name is too long.

7 File name is illegal.

9 This is not a ladder or a message file.

10 Ladder code has been already changed.

20 Device No. exceeds the specification range.

21 Search was failed.

22 Device No. is illegal.

23 There is an error in the conversion table data.

24 Conversion can not be performed.

(Already converted with M500.)

25 Attribute code is illegal.

101 Warning : Device can not be converted.

102 Some of the designated digits can not be used in the ladder

sub-routine.

103 Designated index can not be used in the ladder sub-routine.

The [Verify with PLC] function can be used to confirm the error step. Executing verification with PLC

displays mismatches as in the following example. For details of the [Verify with PLC] function, refer

to "1.3.7 Verifying the PLC Programs".

<Memory> indicates the GX Developer side, and <PLC> the CNC side.

GX Developer side

CNC controller side

- 19 -

Page 29

1. PLC Development Environment Using GX Developer

1.3 Developing PLC Programs

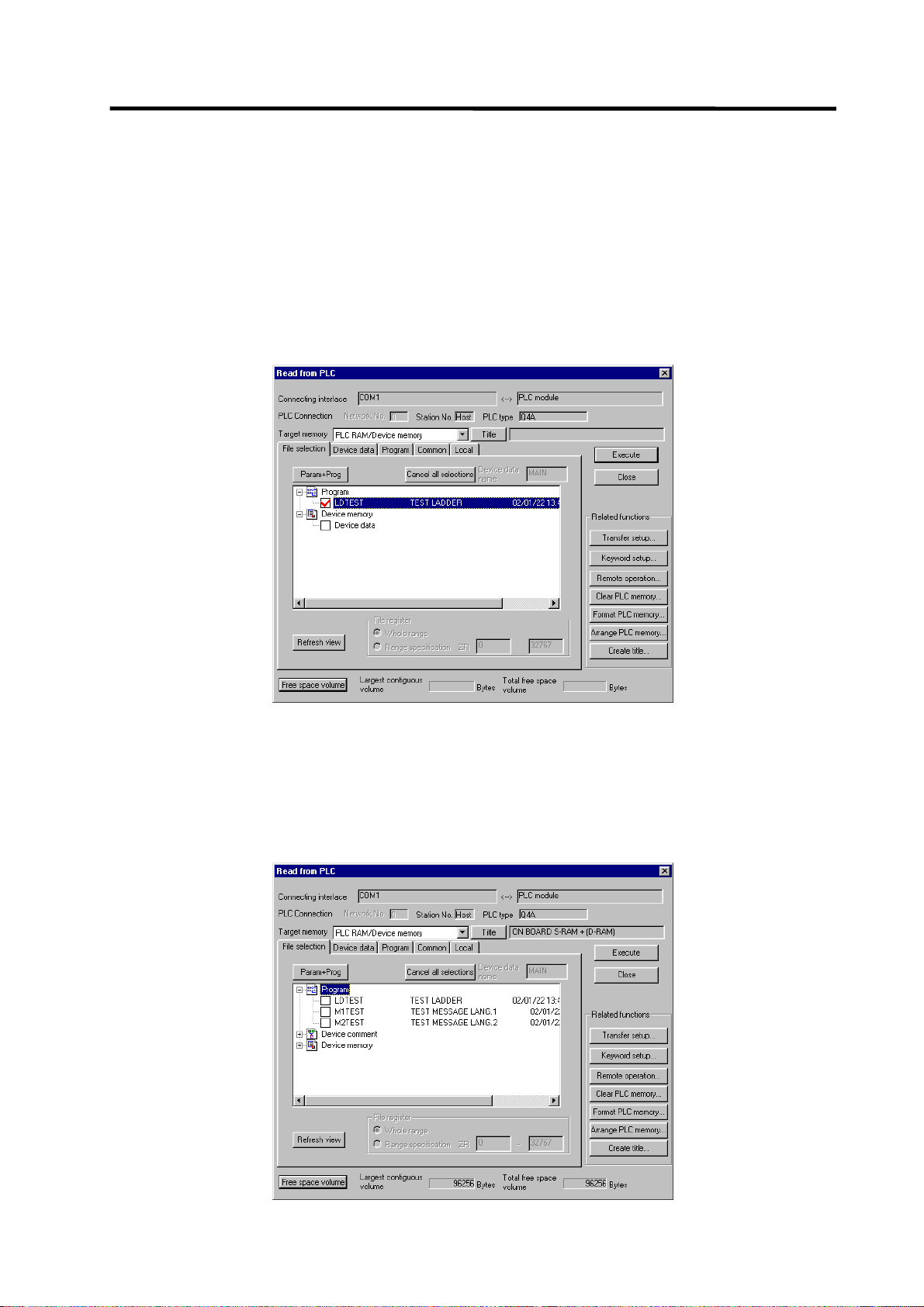

1.3.6 Reading the PLC Program from the CNC

The following indicates how to read a ladder from the CNC to GX Developer.

(1) Operation procedure

Perform the following operation from GX Developer to start the operation screen.

[Online] → [Read from PLC]

On the following screen, choose the ladder file to be read from the [File selection] tab, and click

[Execute].

(Note) As [Target memory], the fitted memory is valid.

Do not set the other tabs ([Device data], [Program], [Common], [Local]) than [File

selection].

The [Read from PLC] screen can also be used as a CNC side file listing function. Move the scroll

bar of the [File selection] tab to the right to display the write date and size of each file. Click [Free

space volume] to display the free area of the target memory.

- 20 -

Page 30

1. PLC Development Environment Using GX Developer

1.3 Developing PLC Programs

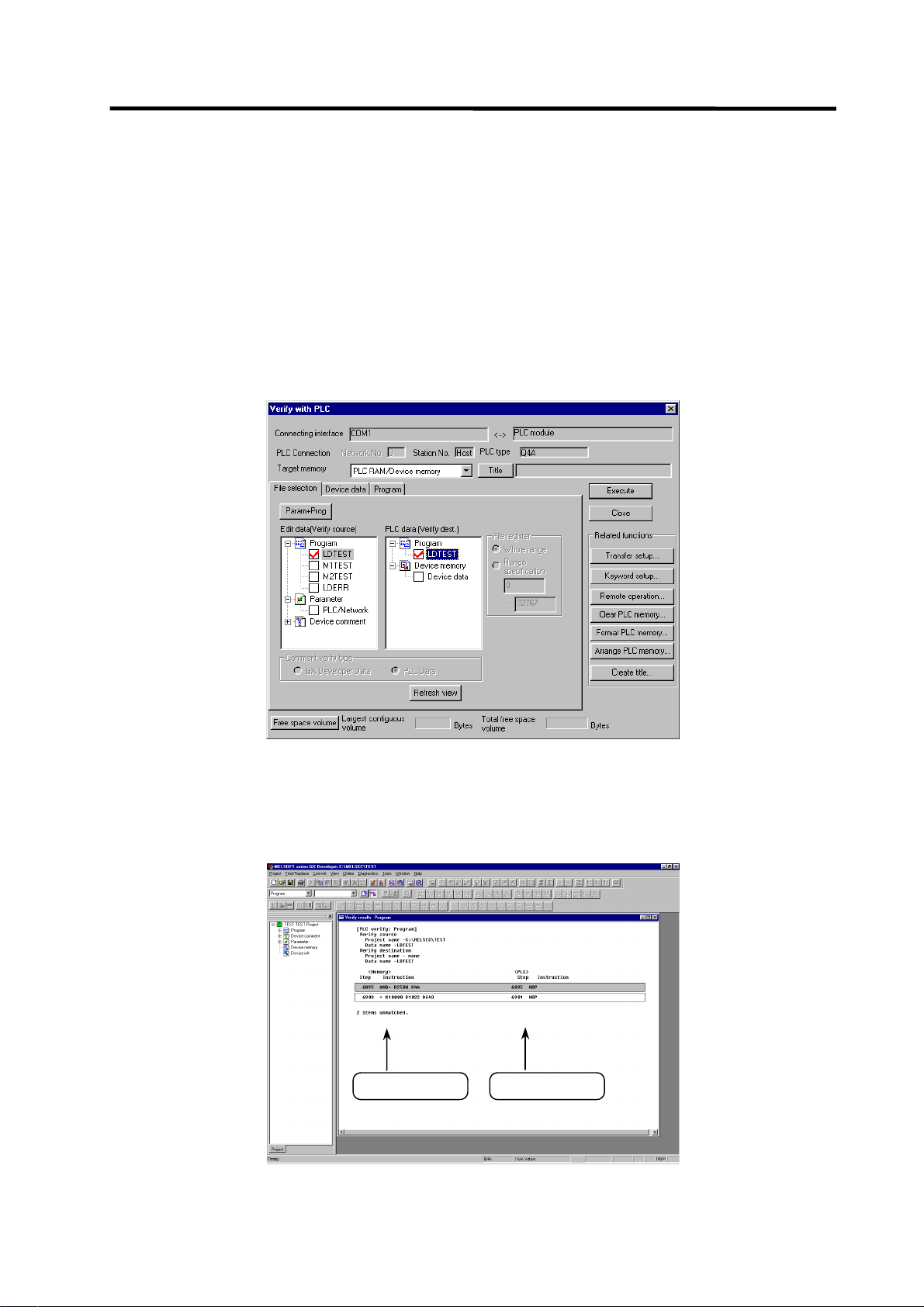

1.3.7 Verifying the PLC Programs

The following indicates how to verify ladders between the CNC and GX Developer.

(1) Operation procedure

Perform the following operation from GX Developer to start the operation screen.

[Online] → [Verify with PLC]

On the following screen, choose the ladder files to be verified with the [File selection] tab, and click

[Execute].

[Verify source] : GX Developer side [Verify dest] : CNC side

(Note) As [Target memory], the fitted memory is valid.

Do not set the other tab ([Program], [Device data]) than [File selection].

If verification mismatches occur, the following mismatch screen appears. Double-click the mismatch

to display the corresponding part of the GX Developer side file.

GX Developer side

CNC controller side

- 21 -

Page 31

1. PLC Development Environment Using GX Developer

1.3 Developing PLC Programs

1.3.8 Monitoring the PLC Program

There are no MELDAS-specific operations to monitor a PLC program. Refer to the GX Developer

operating manual for the operation methods. For usable functions, refer to "1.1.3.2 Function Support

Conditions (on-line section)". This section explains the operation procedure outline and precautions.

(1) Operation procedure

Perform the following operation from GX Developer to start monitoring.

(a) Display the ladder program to be monitored and move to the circuit part to be monitored.

(b) Perform the following operation to start monitoring.

[Online] → [Monitor] → [Monitor mode] or F3

(c) Perform the following operation to stop monitoring.

[Online] → [Monitor] → [Stop monitor] or Alt + F3

(Note) If the ladder program being run by the CNC diff ers from the one being displayed on GX

Developer, monitoring will not result in an error but will continue

.

- 22 -

Page 32

1. PLC Development Environment Using GX Developer

1.3 Developing PLC Programs

1.3.9 Diverting the PLC program that was developed using PLC4B

(Note) PLC4B and LIST4B can not be used with C64. This section describes the method to use

the ladder data on the C64 series system, however, the ladder data here must be created

with PLC4B of the former-model CNC.

(1) Development procedure

IBM PC/A T comp atible mac hine

Creation

PLC4B/LIST4B

LIST4B

outpu t ladde r

list

zzzz.TX T

Ladder list for

CNC

zzzz. T X T

Ladder data

for CNC

zzzz.WPG

Ladder list conversion

CLST6L

List to ladder conversion

GX Converter

Editing (transfer)

GX Developer

(Note)

CNC controller

(a) Creation

The PLC program created for the old model is output in a list format.

(b) Conversion

Using CLST6L (ladder list converter), the output program is converted into a PLC program (list

format). Using GX Converter (data conversion software package), the list format program is

converted into the GX Developer data.

(c) Editing/transfer

The resultant program can be handled like a newly created PLC program.

Device

comment s

for CNC

zzzz. W CD

RS-232C, etc.

Messages

for CNC

M1xxx.WPG

- 23 -

Page 33

1. PLC Development Environment Using GX Developer

1.3 Developing PLC Programs

(2) Starting GX Converter and specifying the file to be converted

Perform the following operation from GX Developer to start GX Converter (read).

[Project] → [Import file] → [Import to TEXT ,CSV format file]

On the following screen, specify the file to be converted (LDTEST.TXT) and click [OK].

(3) Conversion format setting

Set the conversion format on the following data conversion wizard screen.

(a) Data conversion wizard 1/4

Choose [Original Data Type]-[Delimited] and [Data Type]-[List], and click [Next>].

- 24 -

Page 34

1. PLC Development Environment Using GX Developer

(b) Data conversion wizard 2/4

Choose [Delimiters]-[Tab] and click [Next>].

1.3 Developing PLC Programs

(c) Data conversion wizard 3/4

Choose to highlight the [Instr] column part in the [Data Preview] list and choose [Column Data

Format]-[Instruction].

- 25 -

Page 35

1. PLC Development Environment Using GX Developer

(d) Data conversion wizard 3/4

Further, choose to highlight the Argument column part in the [Data Preview] list and choose

[Column Data Format]-[I/O(Device)]. Click [Next>].

1.3 Developing PLC Programs

(e) Data conversion wizard 4/4

Set the program name used on GX Developer at [Data name] column and a ladder annotation

at [Title] column, and click [Finish].

(f) Completion

The setting is complete when the following completed dialog appears after the converting dialog.

Click [OK].

- 26 -

Page 36

1. PLC Development Environment Using GX Developer

1.4 Creating PLC-related Data

1.4 Creating PLC Message Data

This chapter explains a procedure for developing PLC-related data such as ala rm me ssages,

operator messages, and PLC switches.

1.4.1 Development Procedure

There are the following two methods as a general development procedure of message data.

1) Making conversion into GX Developer data using a general text editor or spreadsheet tool and

data conversion package.

(When there is a large volume of message data and you want to control them with a

commercially available tool, for example)

2) Entering messages directly from GX Developer

(When there is a small volume of message data or when addition or correction is to be made, for

example)

IBM PC/AT compatible machine

Creation

Spreadsheet tool

Text editor

CNC

message

M1 xxx.TXT

CNC

message

M1xxx.WPG

Conversion

GX Converter

Transfer (edit)

GX Developer

CNC controller

RS-232C, etc.

CNC device

commen t

zzzz.WCD

CNC

ladder

zzzz. W PG

- 27 -

Page 37

1. PLC Development Environment Using GX Developer

1.4 Creating PLC-related Data

(1) Using a general text editor

(a) Creation

The message data is described using a general text editor. The description method and format

will be described later.

(b) Conversion

The conversion from text data to GX Developer data is carried out using the "GX Converter

(data conversion software package)".

(c) Transfer

With the GX Developer, the message data is handled as a PLC program interlinear comment,

and can also be edited.

The message data is transferred to the CNC controller using the GX Developer, in the same

manner as the ladder program.

(2) Entering messages directly from GX Developer

(a) Creation

The message data is described directly from GX Developer. The message data is handled as a

PLC program interlinear comment by GX Developer. The description method and format will be

described later.

(b) Transfer

The message data is transferred from GX Developer to the CNC in the same manner as the

ladder program.

- 28 -

Page 38

1. PLC Development Environment Using GX Developer

1.4 Creating PLC-related Data

1.4.2 Message Data Description Method

The message data can be described as text data by a general text editor and also by commercially

available spreadsheet software in addition to the direct input with GX Developer.

(1) Description Format

Message data is classified into setting areas to store the setting for each message and message

areas to store message data. It is described in the following respective description format.

(a) Setting area

The message length and No. of messages are set for each message in the setting area. The

message data region secured by the CNC can be adjusted to the most efficient status using

these settings. The respective maximum values are set if nothing is set. (Refer to "(4)

Precautions" for the maximum values.)

(b) Message area

The message area is described using the following description format.

The description format cannot be abbreviated. Comma(,) and [CR] must be described, even the

message character string is blank.

Message classification Description format

Alarm message ;A, index No., data register No., message character string [CR]

Operator message ;O, index No., data register No., message character string [CR]

PLC switch ;P, switch No. message character string [CR]

Comment message ;M, device, device No., message character string [CR]

Message classification

code

Index No.

Switch No.

Data register No.

Device

Device No.

Message character string

Semicolon( ; )

Comma( , )

[CR]

;$, message classification code

A:Alarm message O:Operator message

P:PLC switch M:Comment message

: A one-byte alphabetic character expressing each message

classification

: One-byte number (0 to No. of messages in the setting area - 1)

: One-byte number (0 to No. of messages in the setting area - 1)

: One-byte number

: One-byte number (1 or 2)

: One-byte number (0 to 10)

: One-byte alphanumeric character, shift JIS Code 1 character,

No. of characters in the setting area message length.

Semicolons, commas, spaces and tabs can also be used. Note

that the tab at the head of the message character string is

ignored.

: Message data identification code

: Separator between each description (a comma only is used to

leave a message character string blank)

: Line feed code, (CR/LF) or (LF).

, maximum message length, No. of messages [CR]

- 29 -

Page 39

1. PLC Development Environment Using GX Developer

1.4 Creating PLC-related Data

(2) Description Method

The message data is described as text data by the following description format.

;# ladder ver1. '00.08.01

;$, A,32, 200

;$, 0, 40, 200

;$, P, 14, 32

;$, M, 60, 20

NOPLF

;A,0,0,Emergencystop

;A, 11, 1, Spindle alarm

:

:

NOPLF

:

:

NOPLF

:

:

NOPLF

;0, 1, 9000, MELDAS 600LADDER Ver1.0

;0, 20, 9000, BND-400W000-A0

:

:

NOPLF

;P, 1, Program restart

;P, 2, Automatic power OFF

:

:

NOPLF

;M,1,0,[Spindle]

;M,1,0,[Standby1]

:

:

END

... Comment

... Setting area

... Message area (alarm m essages)

... Page break code

... Messagearea(operator messages)

... Message area (PLC switches)

... Message area (comments)

... End code

(a) Comment

Statements having a semicolon (;) at the head of the line, in a different format than described in

"(1) Description format", are regarded as comments. These comments are handled as

comment data in the GX Developer also, but are erased during the transfer to the CNC

controller. An error will occur if there is no semicolon at the head of the line.

(b) Setting area

Each message is set here. This area must be described before the message are a of the

relevant message. That setting will be ignored if it is described in the middle of or after the

relevant message description.

(c) Message area

Collect similar messages in a group and describe them. There is no description order in the

respective messages, but the latter description is validated if there are descriptions with the

same factors (index No., etc.).

(d) Page break code

A page break code is described at one or more places approx. every 15 lines in the setting area

and message area. The message data may skip if there is no page break code.

- 30 -

Page 40

1. PLC Development Environment Using GX Developer

1.4 Creating PLC-related Data

(e) End code

An end code is described at the end of the description. Description after the end code are

ignored.

An error will occur if there is no end code.

(3) Details of comment message

The messages used for Tool registration screen and for load meter are defined as the comment

messages

Comment messages is described using the following format.

;M, device, device No., message character strings[CR]

(a) Tool registration message

Maximum 8 characters for a step, and up to 5 steps of messages can be created. Even if more

than 5 steps are created, the characters of first 5 steps are displayed.

[Description format]

;M, 1, 0, message character strings[CR]

(b) Load meter message

Maximum 40 characters for a step, and up to 7 steps of messages can be created.

• Message of 1st step is for the 1st part system.

• Message of 2nd step is for the 2nd part system.

• Message of 3rd step is for the 3rd part system.

: :

• Message of 7th step is for the 7th part system.

[Description format]

;M, 2, 0, message character strings[CR]

[Example]

NOPLF

;M,1,0,[Spindle]

;M,1,0,[Index 1]

NOPLF

;M,2,0,Spindle 1

;M,2,0,0 50 100

;M,2,0, %

;M,2,0,|_|_|_|_|_|_|_|_|_|_|_|

;M,2,0,Z- axis 1

;M,2,0,0 50 100

;M,2,0, %

Tool registration message(Up to 5steps)

Load meter message (1st part system)

Line 1 Left 10 characters displayed

Line 1 Right 30 characters displayed

Line 2 Left 10 characters (Only 3 of left valid)

Line 2 Right 30 characters displayed

Line 4 Left 10 characters displayed

Line 4 Right 30 characters displayed

Line 5 Left 10 characters (Only 3 of left valid)

Line 5 Right 30 characters displayed

;M,2,0,|_|_|_|_|_|_|_|_|_|_|_|

NOPLF

;M,2,0, Spindle 2

;M,2,0,0 50 100

;M,2,0, %

;M,2,0,|_|_|_|_|_|_|_|_|_|_|_|

;M,2,0, Z- axis 2

Load meter message (2nd part system)

;M,2,0,0 50 100

;M,2,0, %

;M,2,0,|_|_|_|_|_|_|_|_|_|_|_|

NOPLF

: : :

- 31 -

Page 41

5

(c) Load meter display

1. PLC Development Environment Using GX Developer

1.4 Creating PLC-related Data

40 characters

34 characters

1

Spindle 1 0

1 0 0

Z-axis 1 0

6 0

Indicates R942 value

(BIN 0 to 32767)

Indicates R944 value

(BIN 0 to 32767)

F E D C B A 9 8 7 6 5 4 3 2 1 0

10

%

%

|

|

_

|

|

_

Bar graph start position is fixed to

the 11th character of the left side

_

_

15

|

|

_

_

|

_

|

_

|

|

20

5 0

_

5 0

_

|

|

_

_

|

|

_

_

25

|

|

_

_

|

_

|

_

30

1 0 0

|

_

|

_

|

_

1 0 0

| |

_

Specify display length (No.

of characters) with R943

Specify display length (No.

of characters) with R945

35

|

_

Details

|

_

|

40

_

List of file registers (R) used for load meter display

Load meter 1

Numerical display

Bar graph display

Load meter 2

Numerical display

Bar graph display

For $1 For $2 For $3 For $4 For $5 For $6 For $7

R942 R1042 R1142 R1242 R1342 R1442 R1542

R943 R1043 R1143 R1243 R1343 R1443 R1543

R944 R1044 R1144 R1244 R1344 R1444 R1544

R945 R1045 R1145 R1245 R1345 R1445 R1545

(Note 1) Use $1 for models not having a part system.

No. of characters of whole bar graph

The length without highlight display

Load meter display valid

- 32 -

Page 42

1. PLC Development Environment Using GX Developer

1.4 Creating PLC-related Data

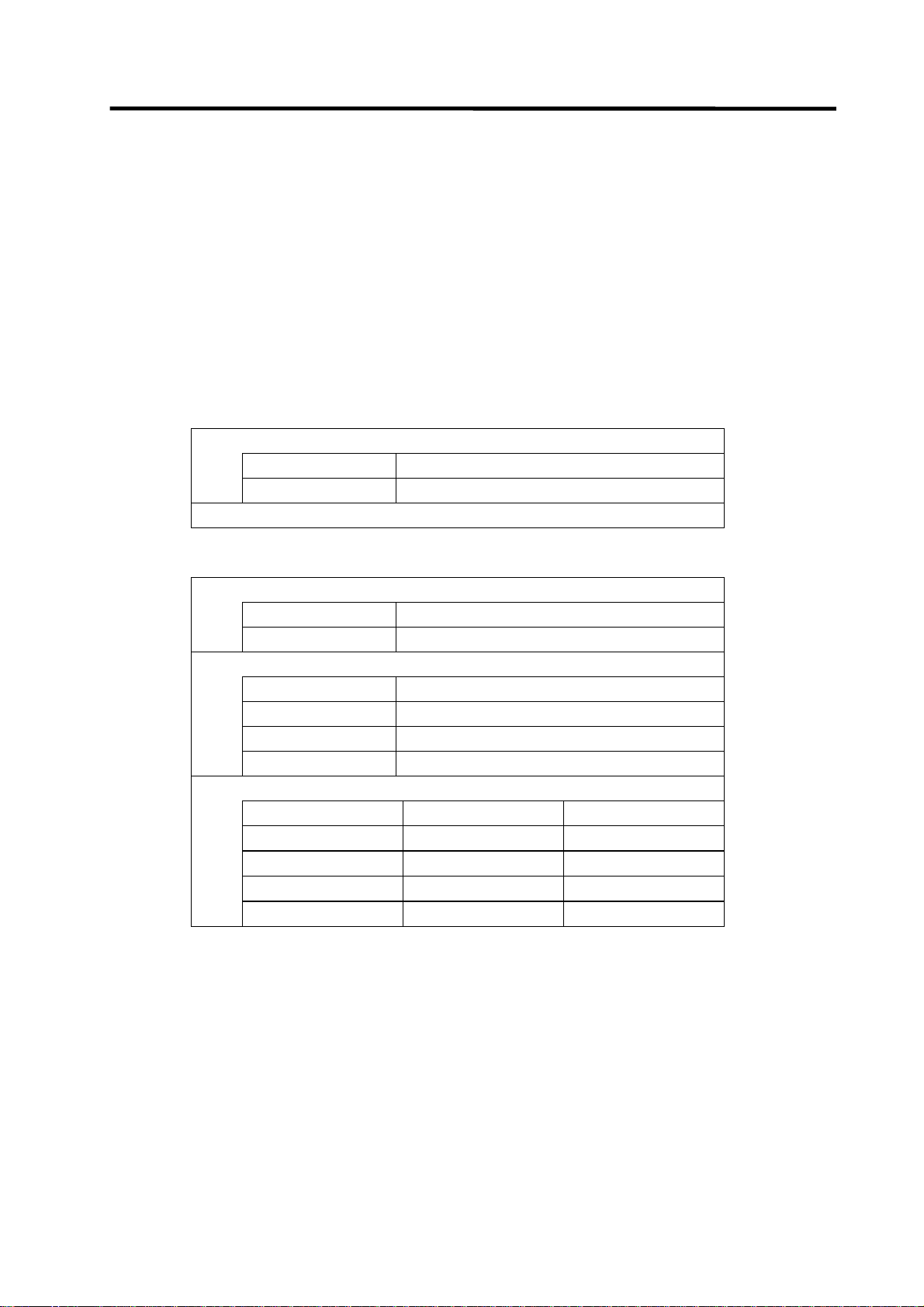

(4) Precautions

No. of characters, quantity limitations, handling of information other than settings, handling of

information other than format.

(a) Message data maximum value

Processing will be carried out with the following values considered as the maximum values if the

setting is not carried out in the setting area, or if the description position in the setting area is

illegal.

Message

classification

Max. message

length

Max. No. of

messages