Page 1

BODY

42-1

CONTENTS

HOOD 3..............................

FENDER 4............................

SEALANT 4...............................

FENDER 5................................

FUEL FILLER DOOR 7................

WINDOW GLASS 10..................

ADHESIVE 10............................

SPECIAL TOOLS 10......................

WINDOW REPAIR 10.....................

WINDSHIELD 13..........................

QUARTER WINDOW GLASS 16...........

SIDE WINDOW GLASS 19................

SLIDE DOOR WINDOW GLASS 20........

TAILGATE WINDOW GLASS 22...........

42109000324

TROUBLESHOOTING 25..................

ON-VEHICLE SERVICE 31................

Door Fit Adjustment 31......................

Door Window Glass Adjustment 31...........

Adjustment and Replacement When

There is a Malfunction of the Power

Windows 32................................

Power Window Safety Mechanism

Check 32...................................

Door Outside Handle Play Check 33..........

Power Window Operation Current

Inspection 33...............................

Circuit Breaker (Incorporated in the Power

Window Motor) Inspection 33.................

Door Inside Handle Play Check and

Adjustment 34..............................

DOOR ASSEMBLY 35.....................

DOOR TRIM AND WATERPROOF

FILM 37..................................

DOOR 24.............................

SERVICE SPECIFICATIONS 24............

SEALANT 24.............................

SPECIAL TOOLS 24......................

DOOR GLASS AND REGULATOR 43......

DOOR HANDLE AND LATCH 49..........

WINDOW GLASS RUNCHANNEL AND

DOOR OPENING WEATHERSTRIP 51.....

CONTINUED ON NEXT PAGE

Page 2

42-2

SLIDE DOOR 52.......................

SERVICE SPECIFICATIONS 52............

SEALANT 52.............................

SPECIAL TOOLS 52......................

ON-VEHICLE SERVICE 53................

Door Fit Adjustment 53......................

Door Outside Handle Play Check and

Adjustment 54..............................

Door Inside Handle Play Check and

Adjustment 54..............................

SLIDE DOOR ASSEMBLY 55..............

SLIDE DOOR TRIM AND WATERPROOF

FILM 59..................................

SLIDE DOOR HANDLE AND LATCH 60...

SLIDE DOOR WEATHERSTRIP 61.........

TAILGATE 62.........................

SERVICE SPECIFICATION 62.............

SEALANT 62.............................

SPECIAL TOOLS 62......................

TROUBLESHOOTING 63..................

TAILGATE ASSEMBLY 64.................

TAILGATE TRIM AND WATERPROOF

FILM 67..................................

TAILGATE HANDLE AND LATCH 69.......

KEYLESS ENTRY SYSTEM 70..........

SPECIAL TOOL 70.......................

TROUBLESHOOTING 70..................

ON-VEHICLE SERVICE 74................

How to Replace a Battery of the

Transmitter 74..............................

Secret Code Registration Method 74...........

KEYLESS ENTRY SYSTEM 76............

SUNROOF 77.........................

SERVICE SPECIFICATION 77.............

TROUBLESHOOTING 77..................

ON-VEHICLE SERVICE 81................

Water Test 81...............................

Sunroof Fit Adjustment 81...................

SUNROOF 82............................

ON-VEHICLE SERVICE 63................

Tailgate Fit Adjustment 63...................

Tailgate Handle Free Play Check 63..........

Page 3

BODY -

Hood

42-3

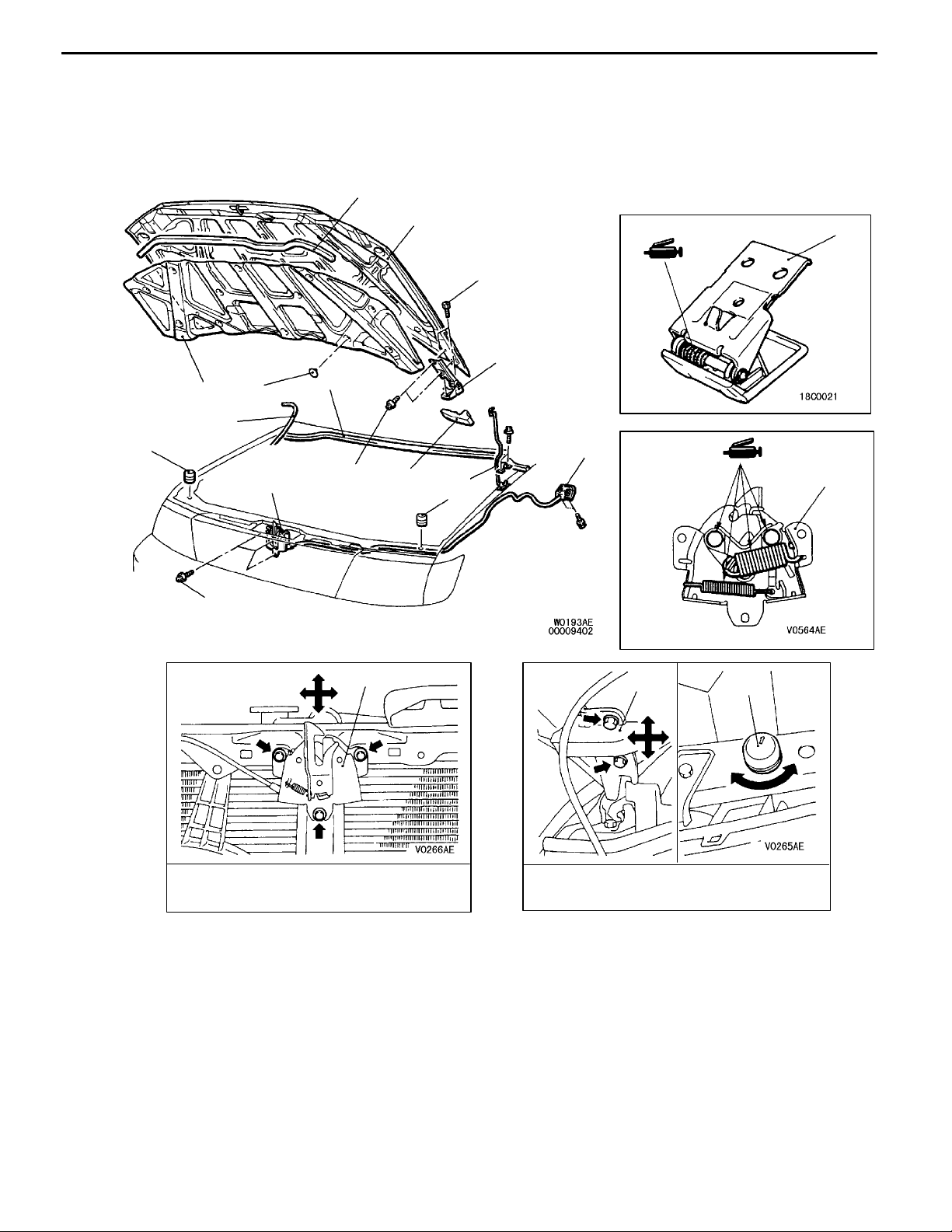

HOOD 42100160045

REMOVAL AND INSTALLATION

3

11

1

22 Nm

12

5

4

2

10

6

9

22 Nm

13

7

1

9

6

9Nm

9

Adjustment of hood step and

hood striker linkage

1. Hood lock release handle

2. Hood weatherstrip

3. Front hood weatherstrip

4. Clip

5. Hood insulator

6. Bumper

7. Hood support rod

Hood lock release cable removal

steps

8. Hood lock release cable

13

Adjustment of clearance around

hood and height

Hood latch removal steps

D Radiator grille (Refer to GROUP 51.)

9. Hood latch

Hood and hood hinge removal steps

10. Washer hose connection

1 1. Hood

12. Hood hinge

13. Hood side weatherstrip

6

Page 4

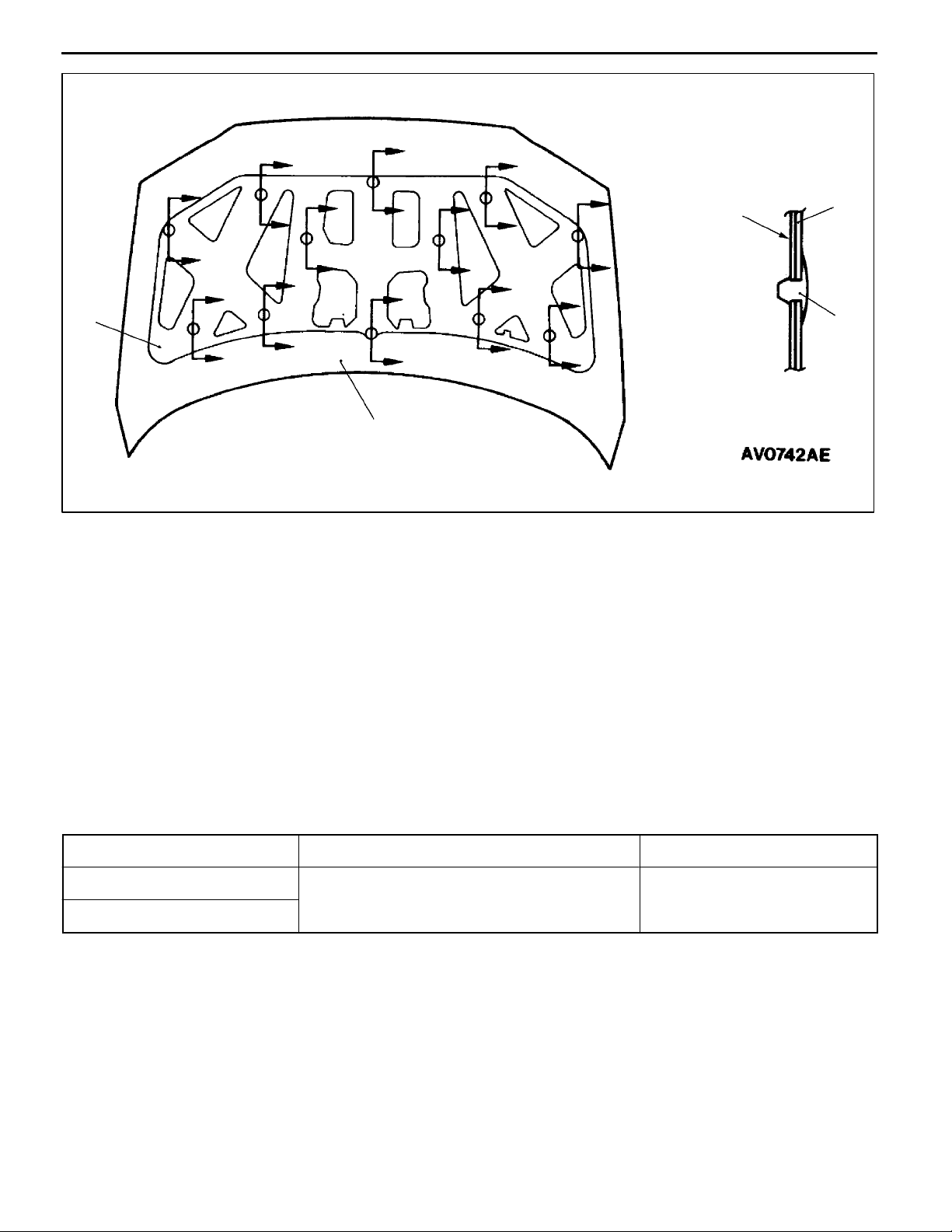

42-4

Clip positions

BODY -

Hood/Fender

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

5

A

A

A

A

A

Section A - A

Hood inner

panel

5

4

11

FENDER 42100050137

SEALANT

Item Specified sealant Remark

Splash shield 3M ATD Part No. 8625 or equivalent Ribbon sealer

Fender

Page 5

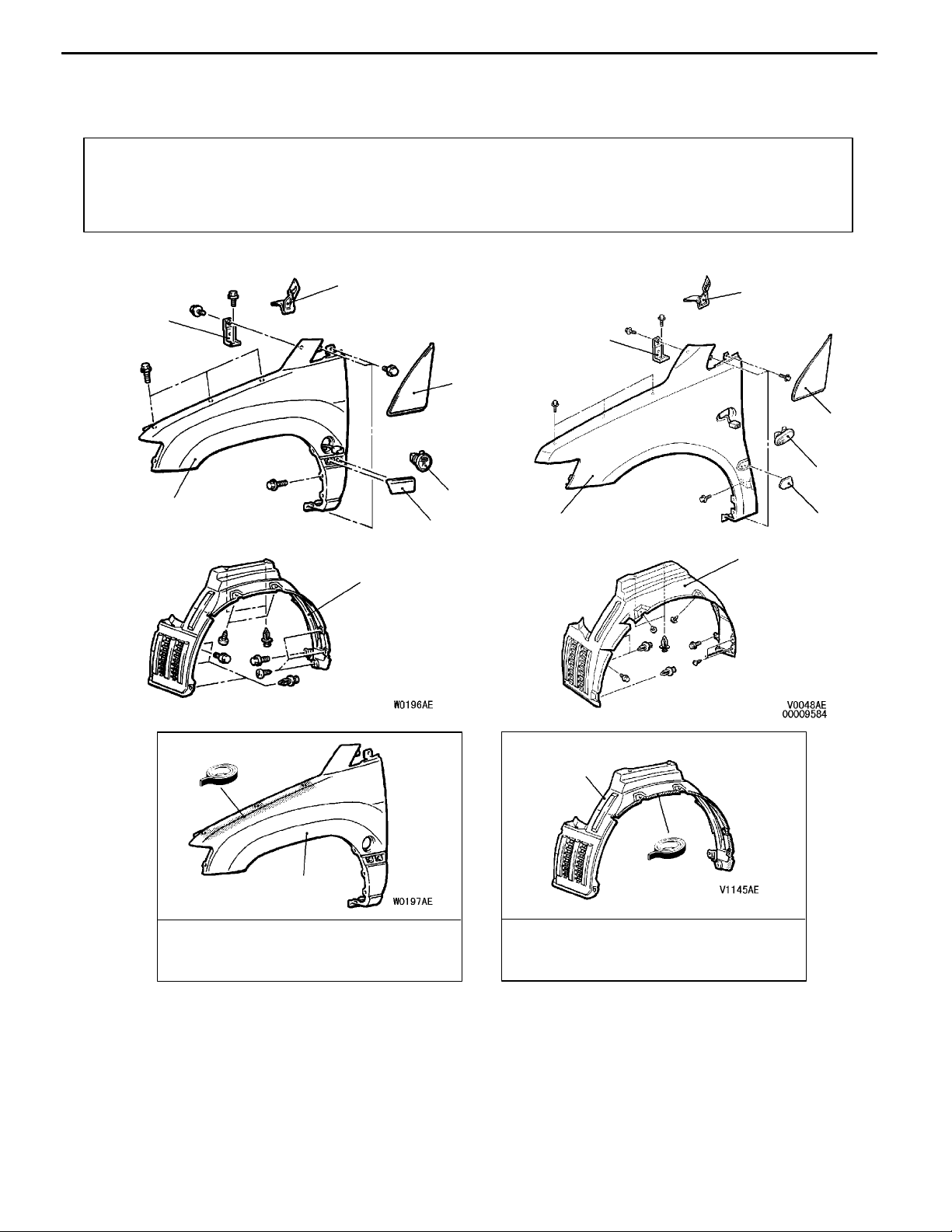

BODY -

Fender

42-5

FENDER

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operation

D Front Bumper Removal and Installation

(Refer to GROUP 51.)

D Headlamp Removal and Installation

(Refer to GROUP 54.)

<SPACE RUNNER>

1

7

5

42100190204

D Side Sill Cover Removal and Installation (Refer to

GROUP 51 - Aero Parts.)

D Hood Removal and Installation (Refer to P.42-3.)

<SPACE WAGON>

1

7

2

2

4

4

6

5

6

3

5

Sealant:

3M ATD Part No. 8625 or

equivalent

3

3

Sealant:

3M ATD Part No. 8625 or

equivalent

AA""AA

Removal steps

1. Front fender cover

2. Delta garnish

(Refer to GROUP 51 - Garnish.)

3. Splash shield

4. Side turn signal lamp

5. Fender

6. Side moulting

(Refer to GROUP 51 - Mouldings.)

7. Fender bracket

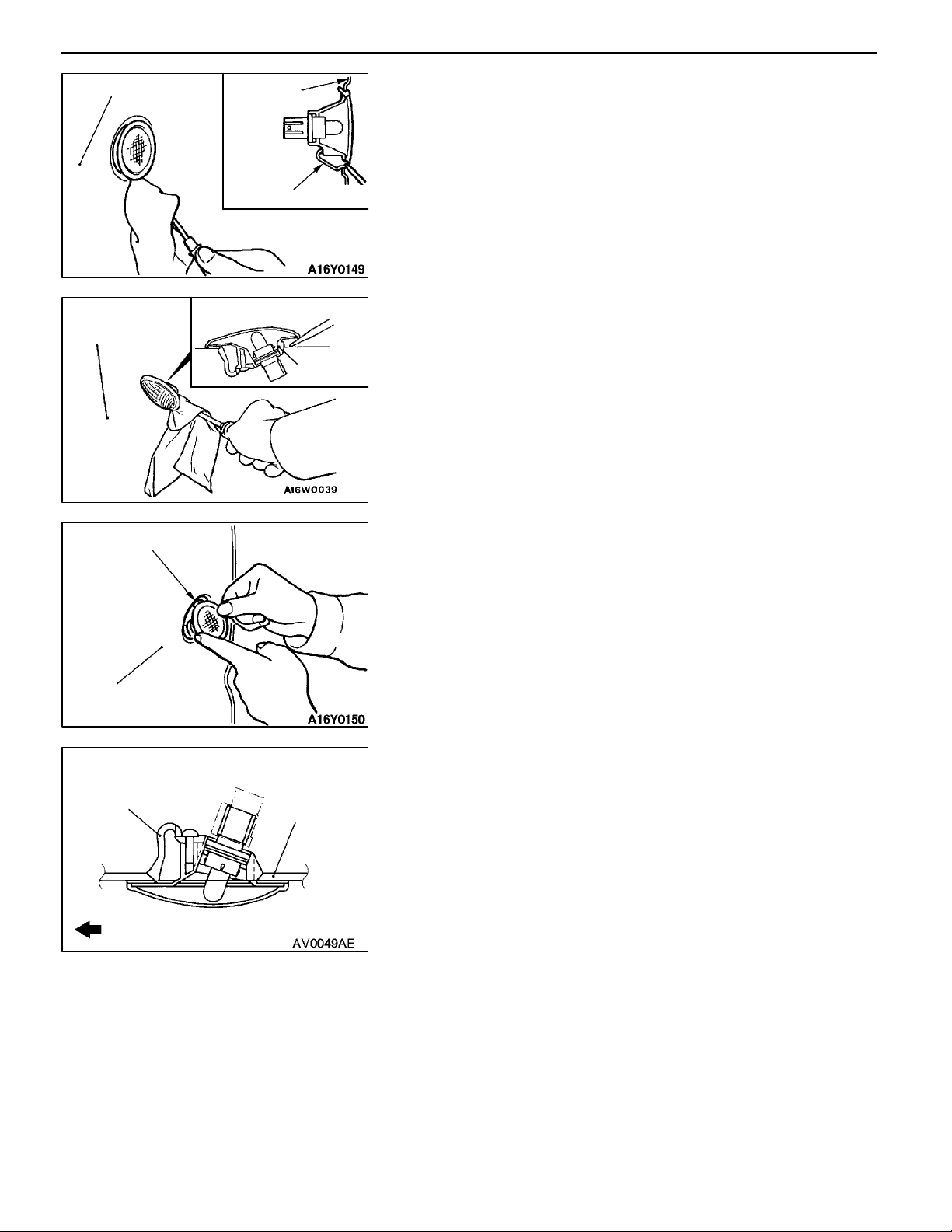

Page 6

42-6

BODY -

Fender

Fender

Fender

Lock

Fender

Hook

Lock

REMOVAL SERVICE POINT

AA"

<SPACE RUNNER>

Use a flat-tipped screwdriver to disengage the hook from

the fender, and then remove the side turn signal lamp.

<SPACE WAGON>

Use a flat-tipped screwdriver to disengage the lock from the

fender, and then remove the side turn signal lamp.

SIDE TURN SIGNAL LAMP REMOVAL

INSTALLATION SERVICE POINT

"AA

<SPACE RUNNER>

1. Put the lock in fender.

2. Push the side turn signal lamp toward the fender until

SIDE TURN SIGNAL LAMP INSTALLATION

the hook is caught in fender.

Fender

Hook

Front of vehicle

<SPACE WAGON>

Insert the hook into the fender panel, and then install the

side turn signal lamp.

Fender

Page 7

BODY -

Fuel Filler Door

42-7

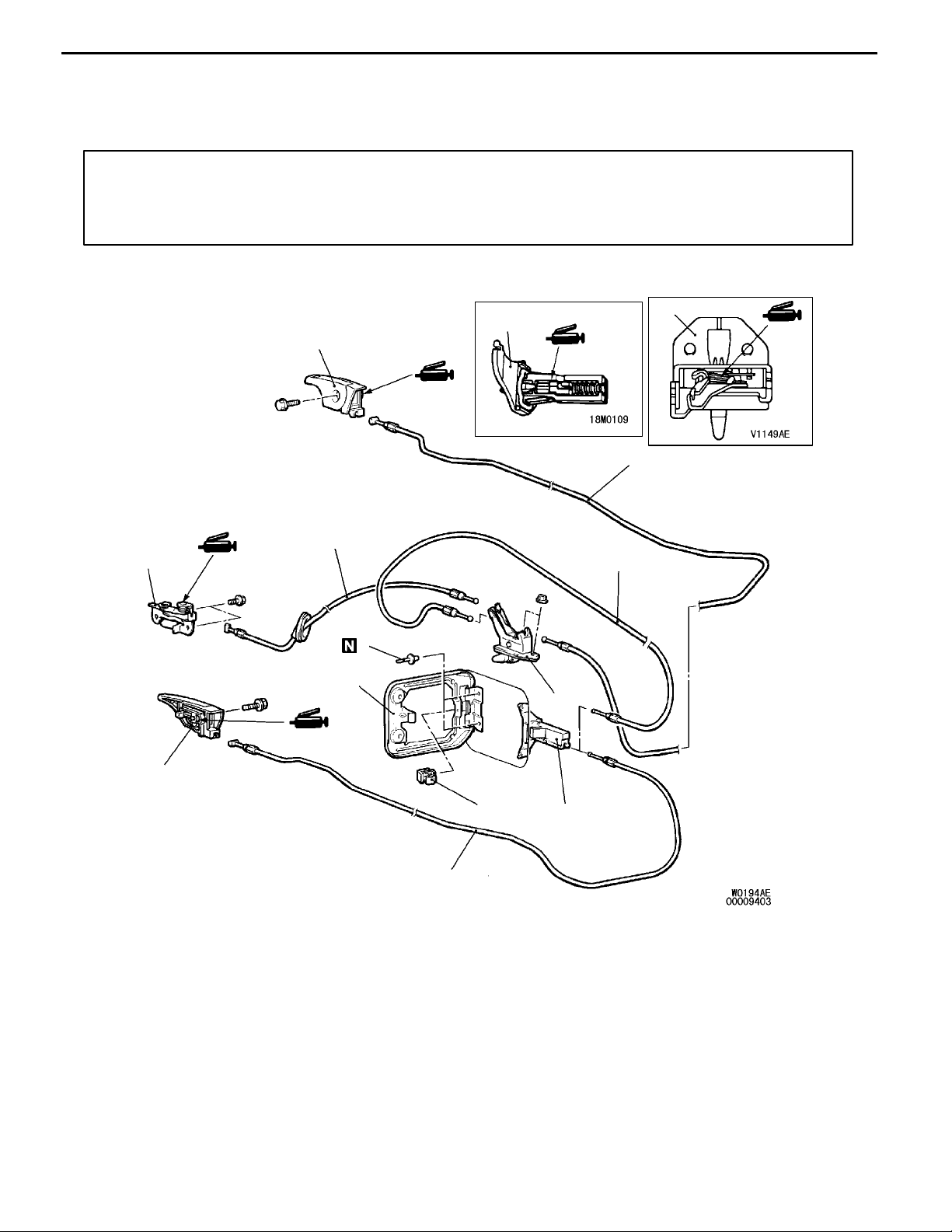

FUEL FILLER DOOR 42100250346

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operation

D Front Seat (driver’s side), Rear Seat Removal and

Installation (Refer to GROUP 52A.)

D Front Scuff Plate (driver’s side), Rear Scuff Plate

(driver’s side), Center Pillar Lower Trim (driver’s side),

<SPACE RUNNER>

Quarter Lower Trim (driver’s side) Removal an d

Installation (Refer to GROUP 52A.)

<R.H. drive vehicles>

10

<L.H. drive vehicles>

7

8

9

4

5

6

1

2

8

AA""AA

9

Removal steps

1. Rivet

2. Fuel filler door panel assembly

3. Clip

4. Fuel filler door lock release cable

5. Fuel filler door safety cable

6. Fuel filler door lock release cable

3

7

4

7. Fuel filler door hook assembly

8. Fuel filler door safety lever

assembly

9. Fuel filler door lock release handle

10. Fuel filler door safety stopper

assembly

Page 8

42-8

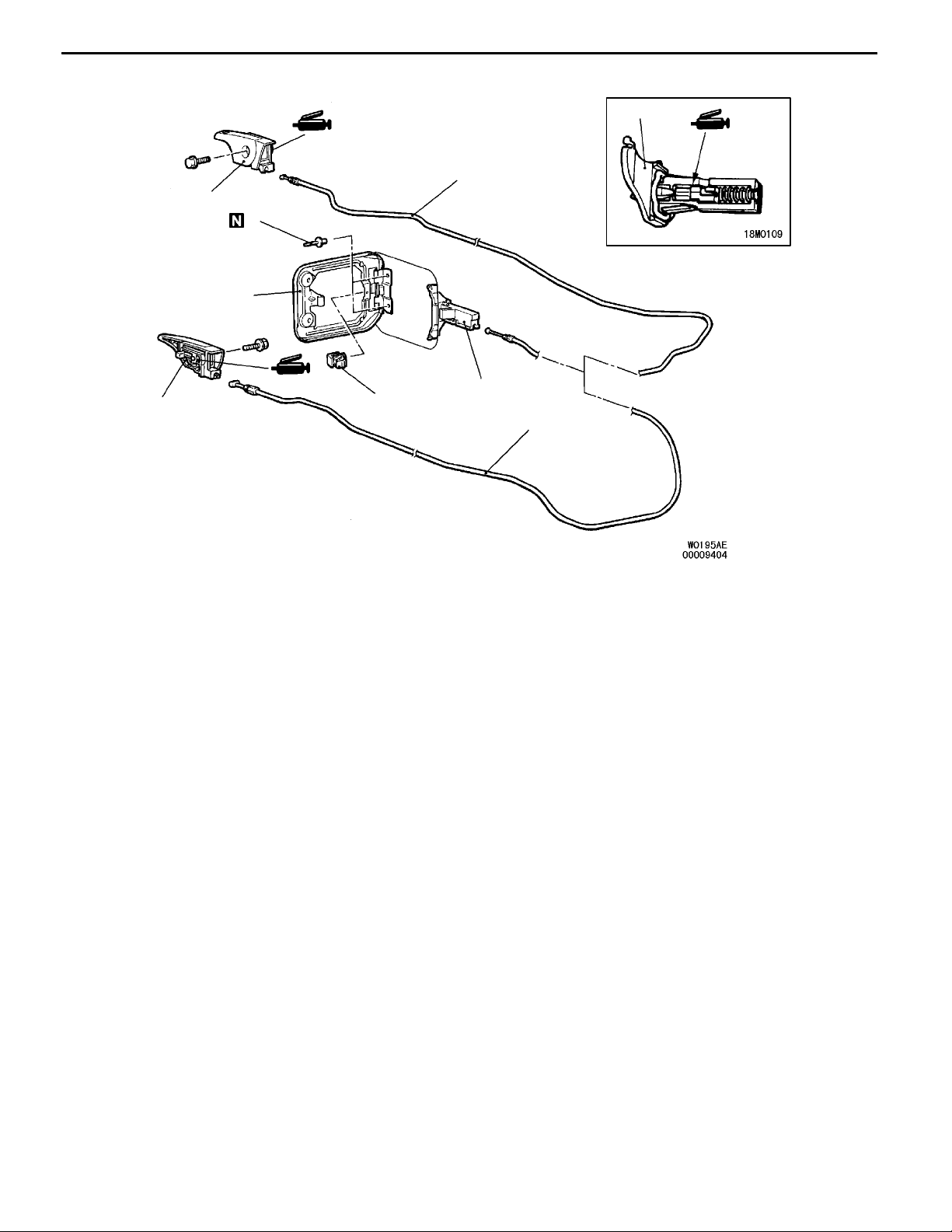

<SPACE WAGON>

<R.H. drive vehicles>

<L.H. drive vehicles>

BODY -

Fuel Filler Door

4

6

5

1

2

5

Removal steps

AA""AA 1. Rivet

2. Fuel filler door panel assembly

3. Clip

3

4

6

4. Fuel filler door hook assembly

5. Lid lock release handle

6. Fuel filler door lock release cable

Page 9

Fuel filler

door panel

assembly

Rivet

Drill

BODY -

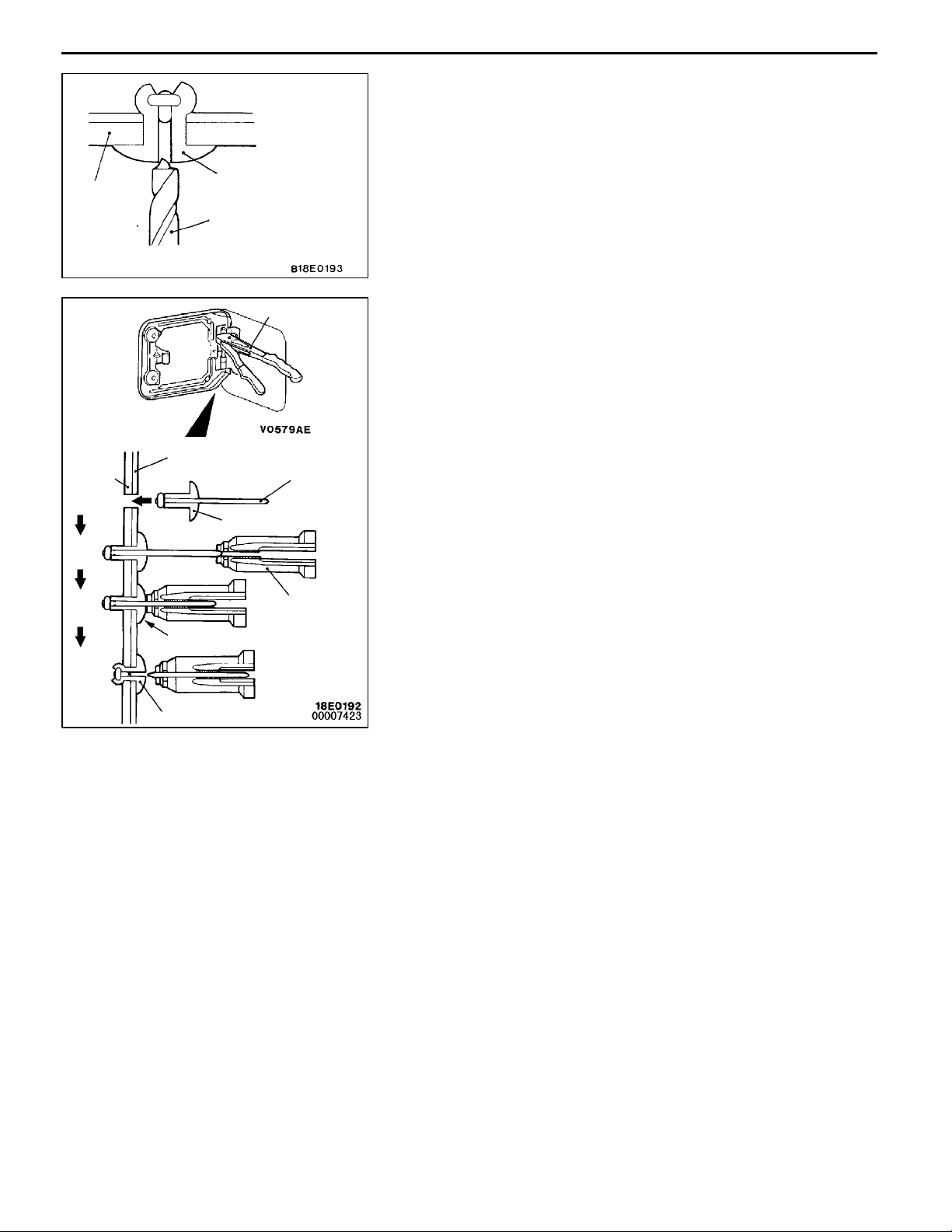

REMOVAL SERVICE POINT

AA"

Use a drill (Ø4.0 - 5.5 mm) to break the rivet by drilling

a hole, and then remove the rivet.

Fuel Filler Door

RIVET REMOVAL

42-9

Body

panel

1

2

3

4

Fuel filler door

panel assembly

Rivet

Flange surface

Rivet

Riveter

A

Riveter

INSTALLATION SERVICE POINT

"AA

Use a riveter shown to install th e rivet by the following

procedure:

1. Insert the rivet into the body panel and fuel filler door

2. Insert “A” of the rivet into the riveter.

3. Pressing the flange surface of the rivet with the riveter,

4. The thinnest point of “A” is cut and the rivet is held in

RIVET INSTALLATION

panel assembly.

move the handle of the riveter.

the position.

Page 10

42-10

BODY -

Window Glass

WINDOW GLASS 42200050161

ADHESIVE

Items Specified adhesive

Windshield 3M ATD Part No. 8609 Super Fast Urethane Auto Glass

Sealant or equivalent

Quarter window glass

Slide door window glass

Tailgate window glass

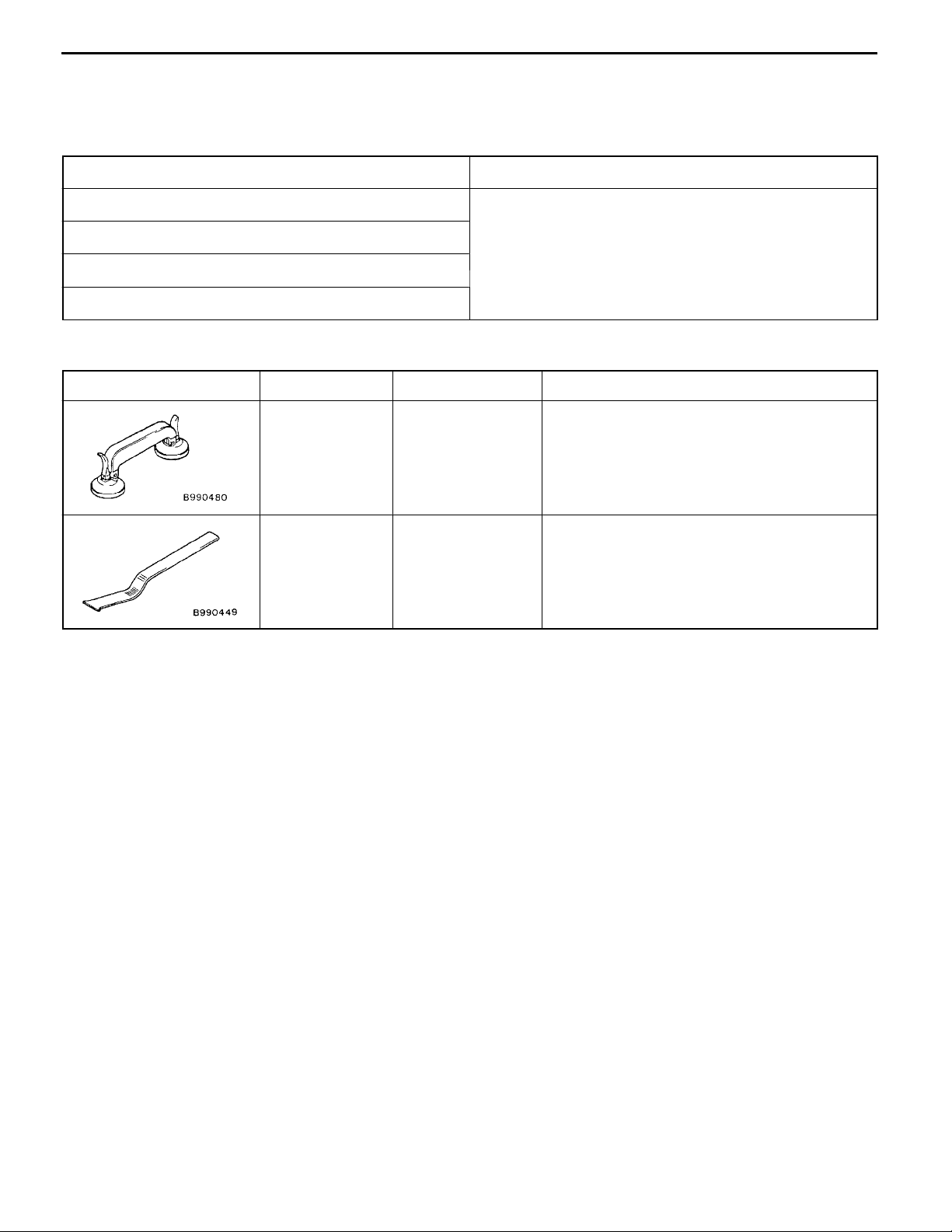

SPECIAL TOOLS

Tool Number Name Use

MB990480 Glass holder Removal and installation of windshield

MB990449 Window moulding

remover

WINDOW REPAIR

The following glass sections are installed by means of a liquid

urethane adhesive method.

Windshield

D

Quarter window glass

D

Slide door window glass

D

Tailgate window glass

D

42200060164

Removal of roof drip moulding

42200560114

Page 11

BODY -

Window Glass

42-11

ITEMS NEEDED

Name Remarks

Adhesive 3M ATD Part No. 8609 Super Fast Urethane Auto Glass Sealant or

equivalent

Primer 3M ATD Part No. 8608 Super Fast Urethane Primer or equivalent

Spacers Available as service part

Anti-rust solvent

(or Tectyl 506T...Valvoline Oil Company)

Isopropyl alcohol For grease removal from bonded surface

Steel piano wire Dia. ´ length...0.6mm ´ 1m For cutting adhesive

Adhesive gun For pressing-out adhesive

NOTE

The TEROSON 127.37V auto window sealer kit can also be used. If using the TEROSON 127.37V auto window

sealer kit, follow the instructions in the manual included with the kit.

For rust prevention

HANDLING OF AUTO WINDOW SEALER

Keep the sealant in a cool place, not exposed to the direct

rays of the sun. Do not place any heavy article on the sealant

nor press it, otherwise it will become deformed. Avoid storing

the sealant for more than 6 months, because it will lose its

sealing effect.

BODY PINCH-WELD FLANGE SERVICING.

Before servicing the body pinch-weld flange, remove old

adhesive completely. If the flange requires painting, bake

it after painting is completed.

Page 12

42-12

WORKING PROCESS

BODY -

Window glass installation procedure

Window Glass

Body side

Cleaning of adhesion surface

Cut off the residual adhesive until the

thickness is less than 2 mm. Clean the

adhesion surface with isopropyl alcohol,

and let dry for 3 minutes or more.

Attaching of clip

Attach the clip to set the positions for

the glass to be installed.

Application of primer

Apply to the adhesion surface of the

body and let dry for 3 minutes or more.

Window glass side

Reusing the glass Replacing the glass

Cleaning of adhesion surface

Completely cut off all of the residual

adhesive. Clean the adhesion surface

with isopropyl alcohol, and let dry for

3 minutes or more.

Gluing of window spacer and glass stoppers

Glue the window spacer along the standard position on the glass outer circumference. Install

the glass stoppers to the specified positions.

Application of primer

Apply sufficient primer evenly to the adhesion surface so that there is no patchiness. After

application, let dry for 3 to 30 minutes.

Application of adhesive

Within 30 minutes after applying the primer, apply the adhesive evenly all the way around

the inside edge of the glass.

Cleaning of adhesion surface

Clean off any dirt adhering to the adhesion surface with isopropyl alcohol, and

let dry for 3 minutes or more.

Installing the glass

After applying the adhesive, lightly press the glass evenly so that it adheres

completely.

Cleaning

After removing any adhesive that is sticking out or adhering to the body or

glass with a spatula, etc., clean off with isopropyl alcohol.

Checking for water leaks

Carry out a shower test to check that no water will leak through.

Page 13

BODY -

Window Glass

42-13

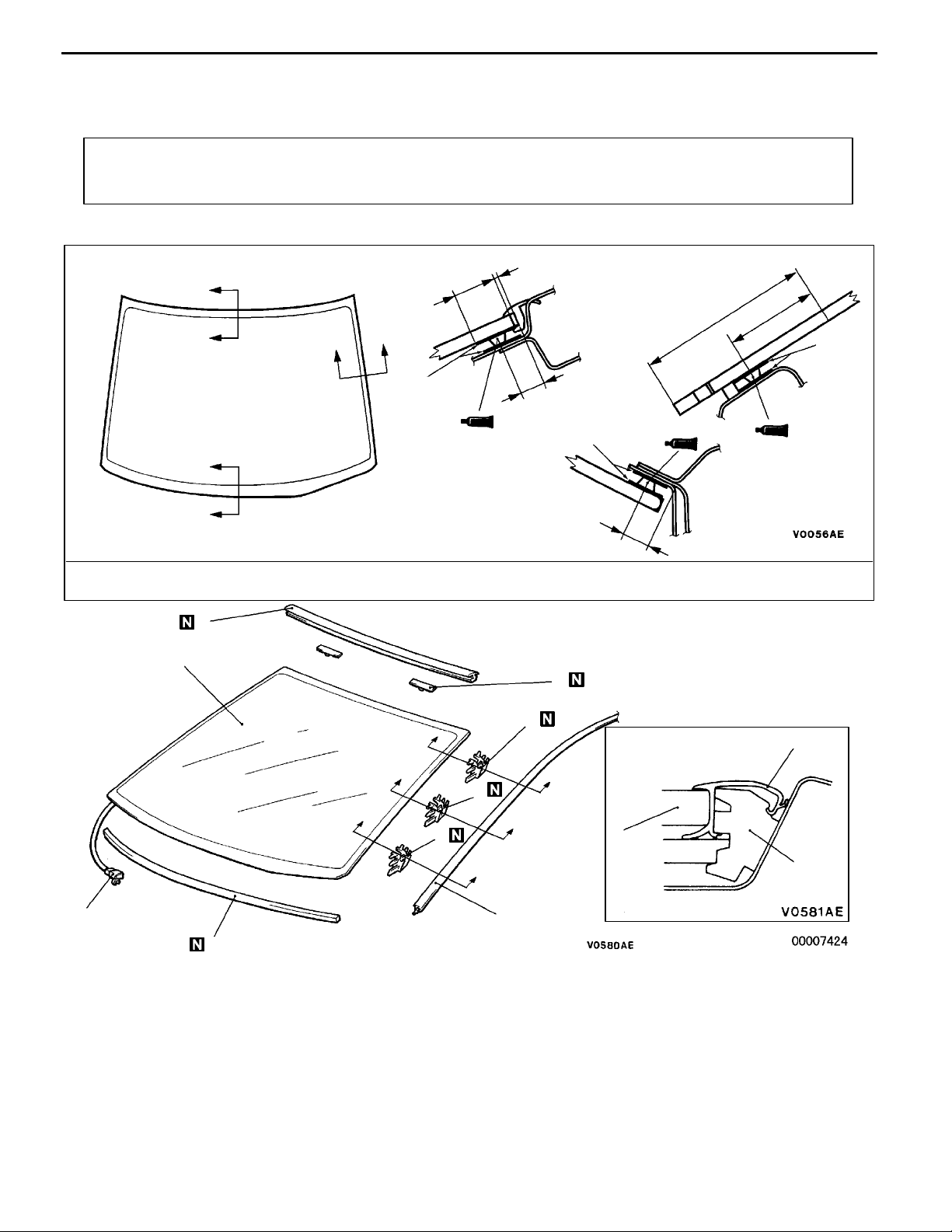

WINDSHIELD

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operation

D Front Pillar Trim Removal and Installation

(Refer to GROUP 52A.)

Section A - A

A

A

B

B

C

C

Primer

D Headlining Removal and Installation

2

16

9

Section C - C

Section B - B

Primer

61

42200100378

mm

37

Primer

11

Adhesive: 3M ATD Part No. 8609 Super Fast Urethane Auto Glass Sealant or equivalent

6

3

4

7

D

D

8

D

D

D

9

D

1

2

Section D - D

3

5

2

7, 8, 9

AA"

Removal steps

1. Wiper deicer <Vehicle for cold

climate region>

2. Roof drip moulding (Refer to

GROUP 51 - Moulding.)

D

Front deck garnish

(Refer to GROUP 51 - Windshield

Wiper and Washer.)

AB""AA

"AA

"AA

"AA

3. Windshield

4. Glass stopper

5. Window spacer

6. Windshield upper moulding

7. Drip moulding clip A

8. Drip moulding clip B

9. Drip moulding clip C

Page 14

42-14

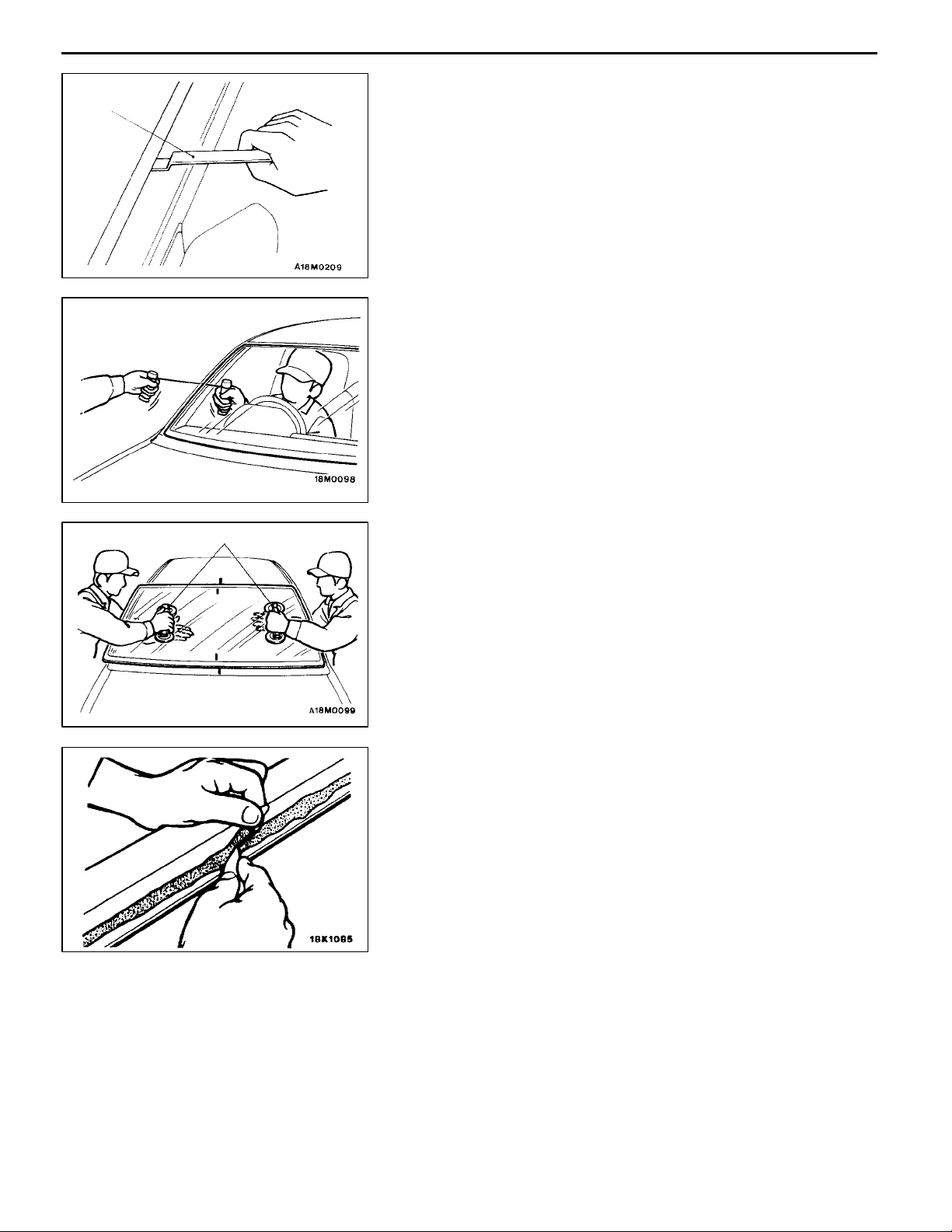

MB990449

BODY -

REMOVAL SERVICE POINTS

AA"

Use the special tool to lever out the moulding.

Caution

If the moulding has become warped, it should not be

reused.

Window Glass

ROOF DRIP MOULDING REMOVAL

MB990480

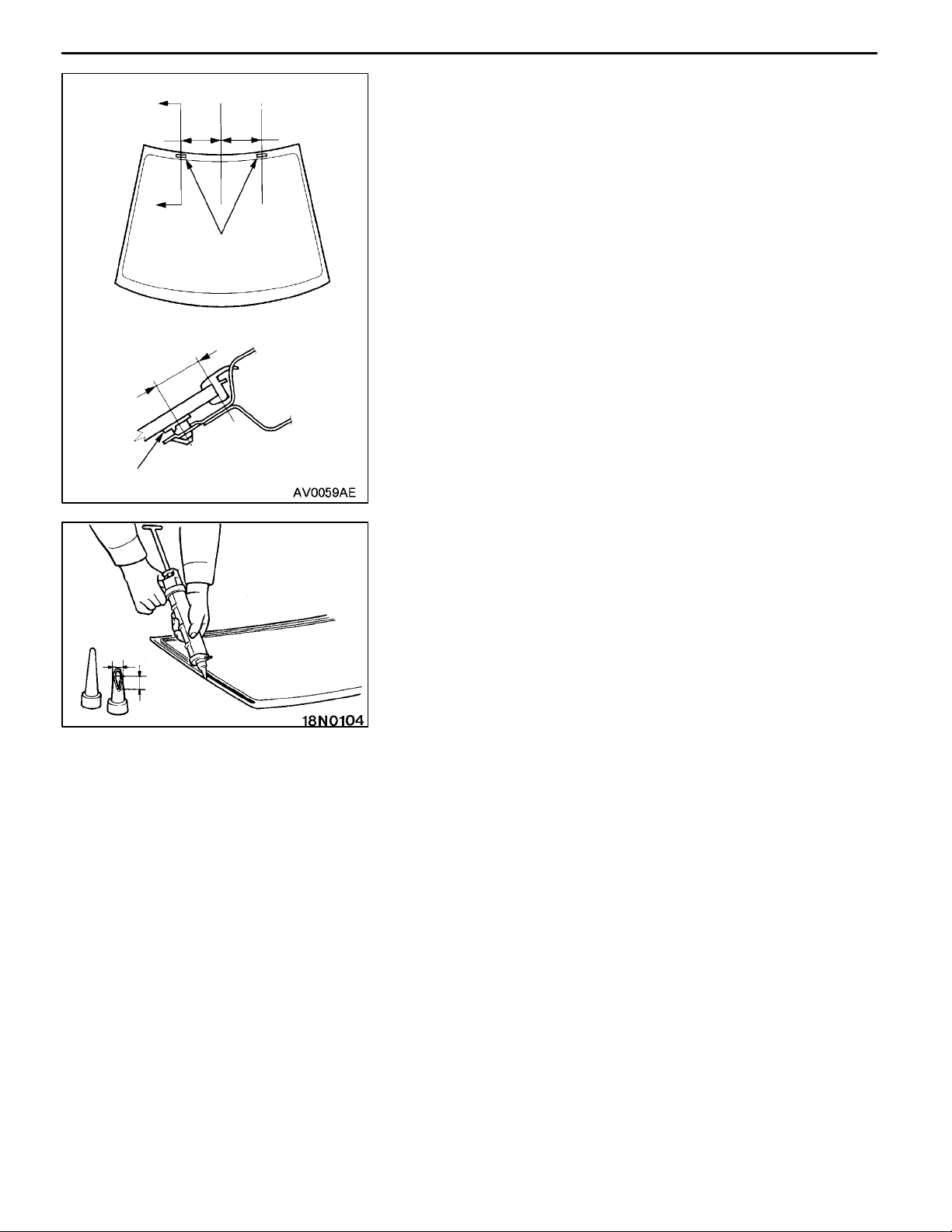

AB"

1. In order to protect the body (paint surface), apply cloth

2. Using a sharp-point drill, make hole in the windshield

3. Pass the piano wire from the inside of the vehicle through

4. Pull the piano wire alternately from the inside and outside

5. Make mating marks on the windshield and body.

6. Use the special tool to remove the windshield.

7. Use a knife to cut away the remaining adhesive so that

8. Finish the flange surfaces so that they are smooth.

WINDSHIELD REMOVAL

tape to all body areas around the installed windshield.

adhesive.

the hole.

along the windshield to cut the adhesive.

Caution

Do not let the piano wire touch the edge of the

windshield.

the thickness is within 2 mm around the entire

circumference of the body flange.

Caution

(1) Be careful not to remove more adhesive than is

necessary.

(2) Be careful also not to damage the paintwork on

the body surface with the knife. If the paintwork

is damaged, repair the damaged area with repair

paint or anti-rust agent.

9. When reusing the windshield, remove the adhesive still

adhering to the windshield, and clean with isopropyl

alcohol.

10. Clean the body side in the same way.

Caution

Let the cleaned places stand for 3 minutes or more,

and carry out the next procedures after they have

dried. Also, do not touch any surface that has been

cleaned.

Page 15

BODY -

Window Glass

42-15

A

300 mm

A

Section A - A

19.6 mm

Glass stopper

10 mm

15 mm

Centre

Glass stopper

300 mm

INSTALLATION SERVICE POINTS

"AA

1. When replacing the windshield, temporarily set the

2. Use isopropyl alcohol to degrease the inside and outside

3. Soak a sponge in the primer, and apply evenly to the

4. Apply the primer, and then let it dry for 3 to 30 minutes.

5. Install the windshield upper moulding to the windshield.

6. Place the window spacer to the windshield so that it

7. Install the glass stopper to the shown dimension.

8. Fill a sealant g u n with adhesive. Then apply the adhesive

9. After applying the adhesive, align the mating marks on

10. Use a spatula or the like to remove any excessive

11. Try not to move the vehicle until the adhesive sets. Wait

WINDSHIELD UPPER MOULDING/WINDOW

SPACER/GLASS STOPPER/WINDSHIELD

INSTALLATION

windshield against the body, and place a mating mark

on the windshield and body.

of the windshield and the body flanges.

windshield and the body in the specified places.

Caution

(1) The primer strengthens the adhesive, so be sure

to apply it evenly around the entire circumference.

However, a too thick application will weaken the

adhesive.

(2) Do not touch the coated surface.

inclines toward t he windshield and its right and left

clearances are equal. Then install the spacer firmly so

that it is not adrift.

evenly around the windshield within 30 minutes after

applying the primer.

NOTE

Cut the tip of the sealant gun nozzle into a V shape

to simplify adhesive application.

the windshield and the body, and then press the windshield

gently to seat it.

adhesive. Then clean the surface with isopropyl alcohol.

Install the roof drip moulding before the adhesive hardens.

30 minutes or more, and then test for water leakage.

Caution

(1) Do not move the vehicle unless absolutely

necessary.

(2) When testing for water leakage, do not pinch the

end of the hose to spray the water.

Page 16

42-16

BODY -

Window Glass

QUARTER WINDOW GLASS

REMOVAL AND INSTALLATION

<SPACE RUNNER>

Pre-removal and Post-installation Operation

D Quarter Upper Trim Removal and Installation

(Refer to GROUP 52A.)

Section A - A

B

B

C

C

A

A

D

D

Section C - C

Primer

Primer

D Headlining Removal and Installation

Section B - B

57

Section D - D

42200250196

mm

14.5

Primer

Primer

14.5

14.5

Adhesive: 3M ATD Part No. 8609 Super Fast Urethane Auto Glass Sealant or equivalent

1

3

2

Section E - E

4

4

E

E

3

E

E

5

2

AA""AA

AA""AA

AA""AA

Removal steps

1. Quarter window dam

2. Quarter window glass

3. Quarter window garnish

"AA

4. Clip A

5. Spacer

Page 17

BODY -

<SPACE WAGON>

Pre-removal and Post-installation Operation

D Quarter Upper Trim, Retractor Trim and Belt Line Trim

Removal and Installation (Refer to GROUP 52A.)

Window Glass

D Headlining Removal and Installation

42-17

Section A - A

Section B - B

14.5

B

B

A

A

D

D

C

C

Section C - C

55

Primer

Section D - D

Primer

14.5

Adhesive: 3M ATD Part No. 8609 Super Fast Urethane Auto Glass Sealant or equivalent

2

1

Section E - E

6

mm

Primer

Primer

14.5

AA""AA

AA""AA

5

E

E

E

E

6

Removal steps

1. Harness connector

2. Quarter window dam

3. Quarter window glass

3

Section F - F

F

F

View G

4

AA""AA

View G

For left window glass

"AA

5

3

3

4

4

For right

window glass

4. Clip B

5. Quarter window garnish

6. Clip A

Page 18

42-18

BODY -

REMOVAL SERVICE POINT

AA"

<SPACE RUNNER>

Removal procedure is same as for the windshield except

for the service points mentioned below. (Refer to P.42-14.)

(1) Break a clip A to remove it.

(2) If the quarter window glass or quarter window garnish

<SPACE WAGON>

Removal procedure is same as for the windshield except

for the service points mentioned below. (Refer to P.42-14.)

(1) Break the clip A to remove it.

(2) Use pliers to pinch the clip B behind the quarter window

(3) If the quarter window glass or quarter window garnish

Window Glass

QUARTER WINDOW DAM/QUARTER WINDOW

GLASS/QUARTER WINDOW GARNISH REMOVAL

is re-used, make the positioning mark on it before removing

in order to re-install it correctly.

garnish to remove it.

is re-used, make the positioning mark on it before removing

in order to re-install it correctly.

Position A

Position B

Positioning

mark

INSTALLATION SERVICE POINT

"AA

Installation procedure is same as for the windshield except

for the service points mentioned below. (Refer to P.42-14.)

If the quarter window glass or quarter window garnish is

re-used, install it by the following procedure:

1. If t he quarter window garnish is re-used, cut away the

2. If the quarter window glass is re-used and the clip B

3. If the quarter window glass is re-used, eliminate the clip

4. Assemble the quarter window glass and quarter window

QUARTER WINDOW GARNISH/CLIP A/QUARTER

WINDOW GLASS/QUARTER WINDOW DAM

INSTALLATION

remaining clips at positions A and B, and clean up the

clip surface .

NOTE

If the quarter window garnish is re-used, you made the

positioning mark, therefore you may eliminate the clips.

had been broken, make the positioning mark as shown

in the illustration before eliminating the clip B, in order

to install new clip B correctly.

B which was broken, and then attach new clip B at the

marked position by using the double-sided tape. Clips

B for left window glass and right window glass differ in

shape, therefore confirm its shape before attaching.

garnish temporarily, and note their contact surfaces.

Page 19

BODY -

5. Disassemble the quarter window glass and quarter

6. If the quarter window garnish is re-used, apply a butyl

7. If the quarter window garnish is re-used, apply an adhesive

8. Install the quarter window glass and quarter window

Window Glass

42-19

window garnish, and degrease that contact surfaces in the

same manner as for the windshield. Apply primer and

adhesive to the contact surfaces, and then assemble

them.

tape to the clip fixing bosses on the quarter window garnish

at positions A and B, in order to prevent the noise.

tape to the clip holes on the body panel at positions

A and B, in order to prevent water from penetrating.

garnish to the body, and use a gummed tape, etc. to

fix them until the adhesive hardens.

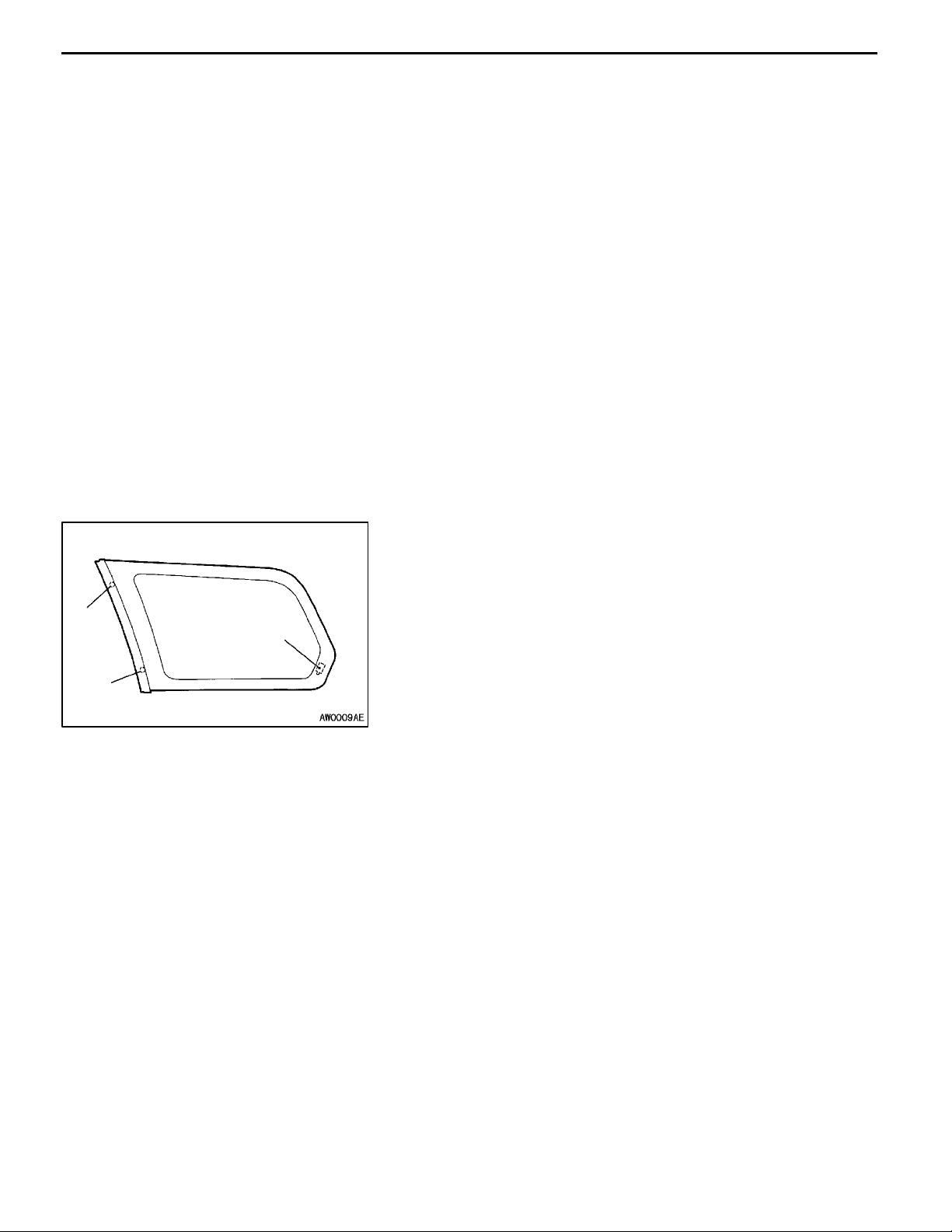

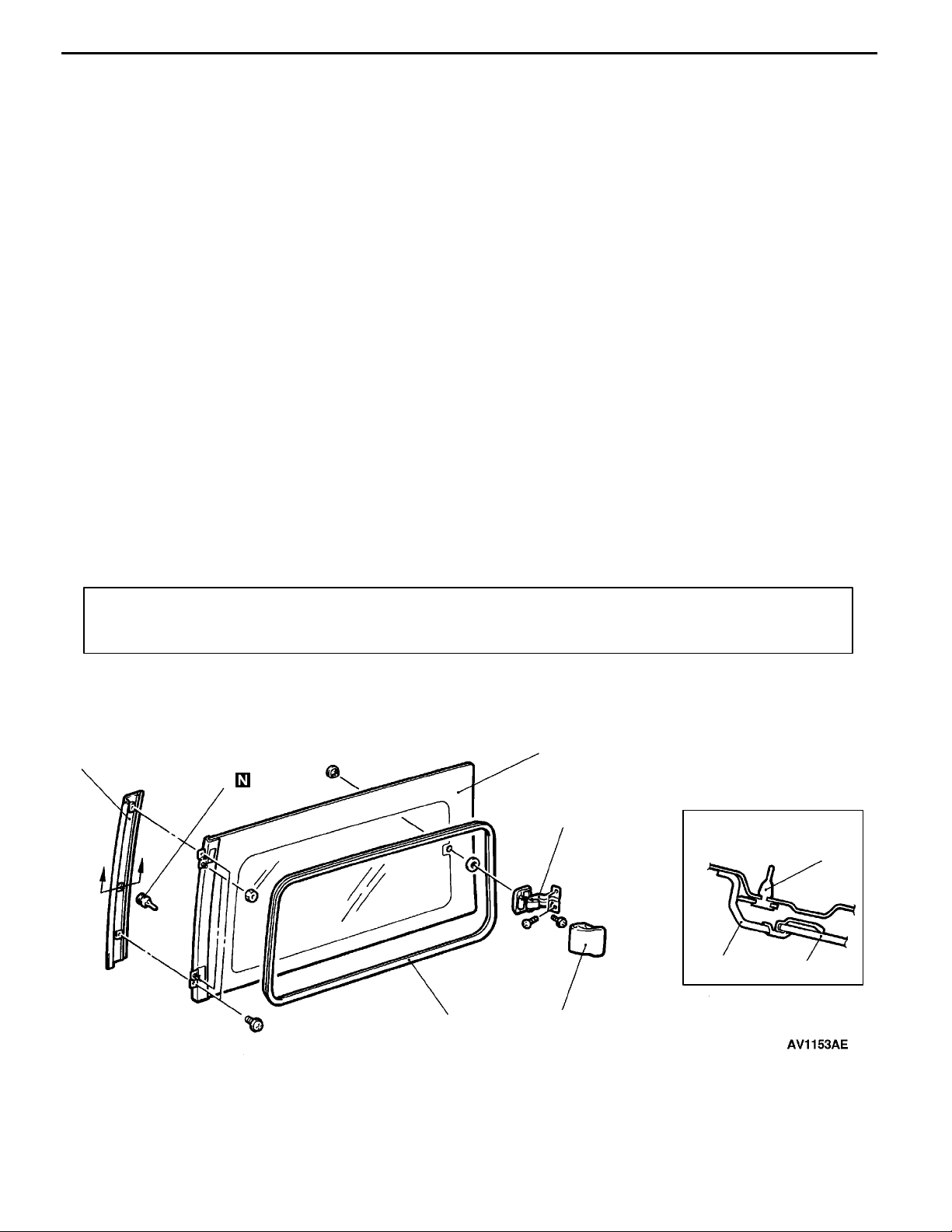

SIDE WINDOW GLASS <SPACE RUNNER>

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operation

Quarter Upper Trim Removal and Installation

D

(Refer to GROUP 52A.)

4

5

A

A

Headlining Removal and Installation

D

3

42200250196

2

Section A - A

5

4

3

Removal steps

1. Link cover

2. Side window link assembly

3. Side window glass

6

1

4. Side window glass moulding

5. Clip

6. Side window weatherstrip

Page 20

42-20

BODY -

Window Glass

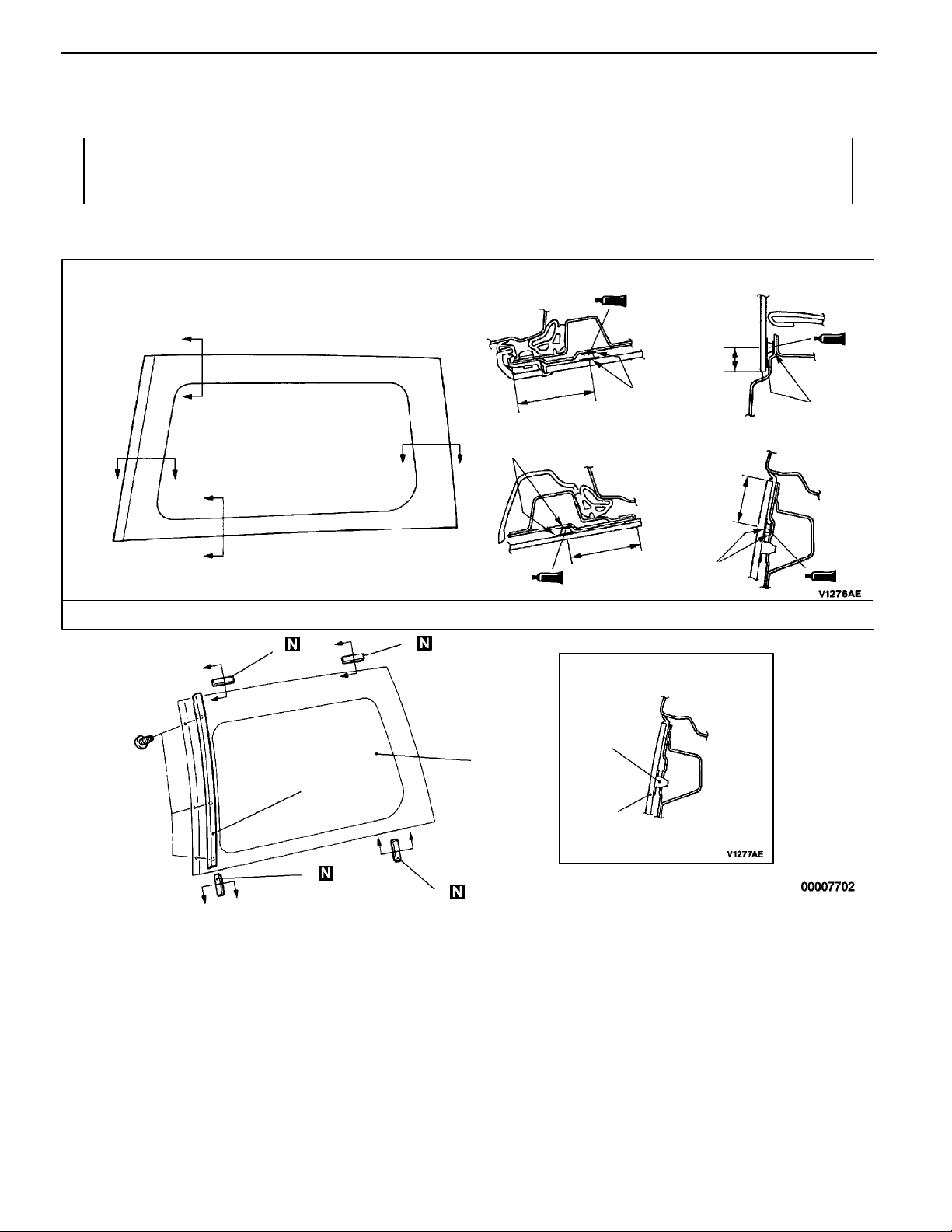

SLIDE DOOR WINDOW GLASS <SPACE RUNNER>

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operation

D Slide Door Sash Trim Removal and Installation

(Refer to P.42-59.)

D

D

A

A

B

CC

D Slide Door Upper Trim Removal and Installation

(Refer to P.42-59.)

Section A - A

51.0

Section C - C

Primer

Primer

Section D - D

Section B - B

15.5

31.0

42200250196

mm

Primer

B

46.5

Primer

Adhesive: 3M ATD Part No. 8609 Super Fast Urethane Auto Glass Sealant or equivalent

3

E

E

E

E

3

Section E - E

3

2

1

2

E

E

3

3

3. Glass stopper

AA""AA

E

E

Removal steps

1. Slide door window garnish

2. Slide door window glass assembly

Page 21

BODY -

REMOVAL SERVICE POINT

AA"

Remove the slide door window glass assembly in the same

manner as for the windshield, except th e glass stopper. (Refer

to P.42-14.)

INSTALLATION SERVICE POINT

"AA

Install the slide door window glass assembly in the same

manner as for the windshield, except th e glass stopper. (Refer

to P.42-15.)

Window Glass

SLIDE DOOR WINDOW GLASS ASSEMBLY

REMOVAL

SLIDE DOOR WINDOW GLASS ASSEMBLY

INSTALLATION

42-21

Page 22

42-22

BODY -

Window Glass

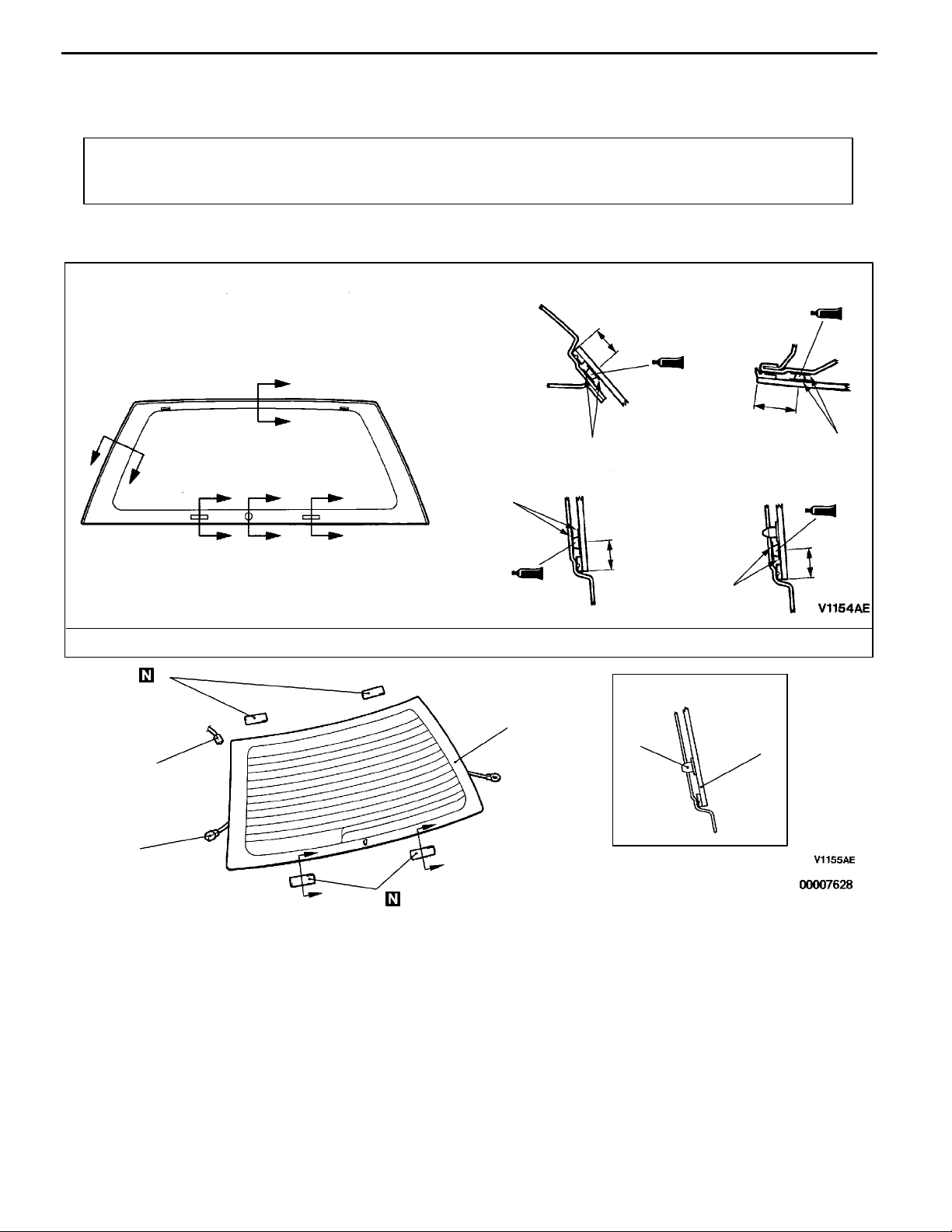

TAILGATE WINDOW GLASS

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operation

D Side Tailgate Trim, Lower Tailgate Trim Removal and

Installation (Refer to P.42-67.)

<SPACE RUNNER>

A

A

B

B

D

D

C

C

D

D

D Rear Wiper Removal and Installation

(Refer to GROUP 51.)

Section A - A

18.5

Primer

Section C - C

Primer

18.5

Section B - B

Section D - D

42200370243

mm

28.5

Primer

18.5

Primer

Adhesive: 3M ATD Part No. 8609 Super Fast Urethane Auto Glass Sealant or equivalent

5

Section E - E

3

4

2

E

1

Removal steps

1. Harness connector

2. Harness connector <Vehicles with

diversity antenna>

E

E

E

4

AA""AA

3. Tailgate window glass

4. Glass stopper

5. Dual-lock fastener

3

Page 23

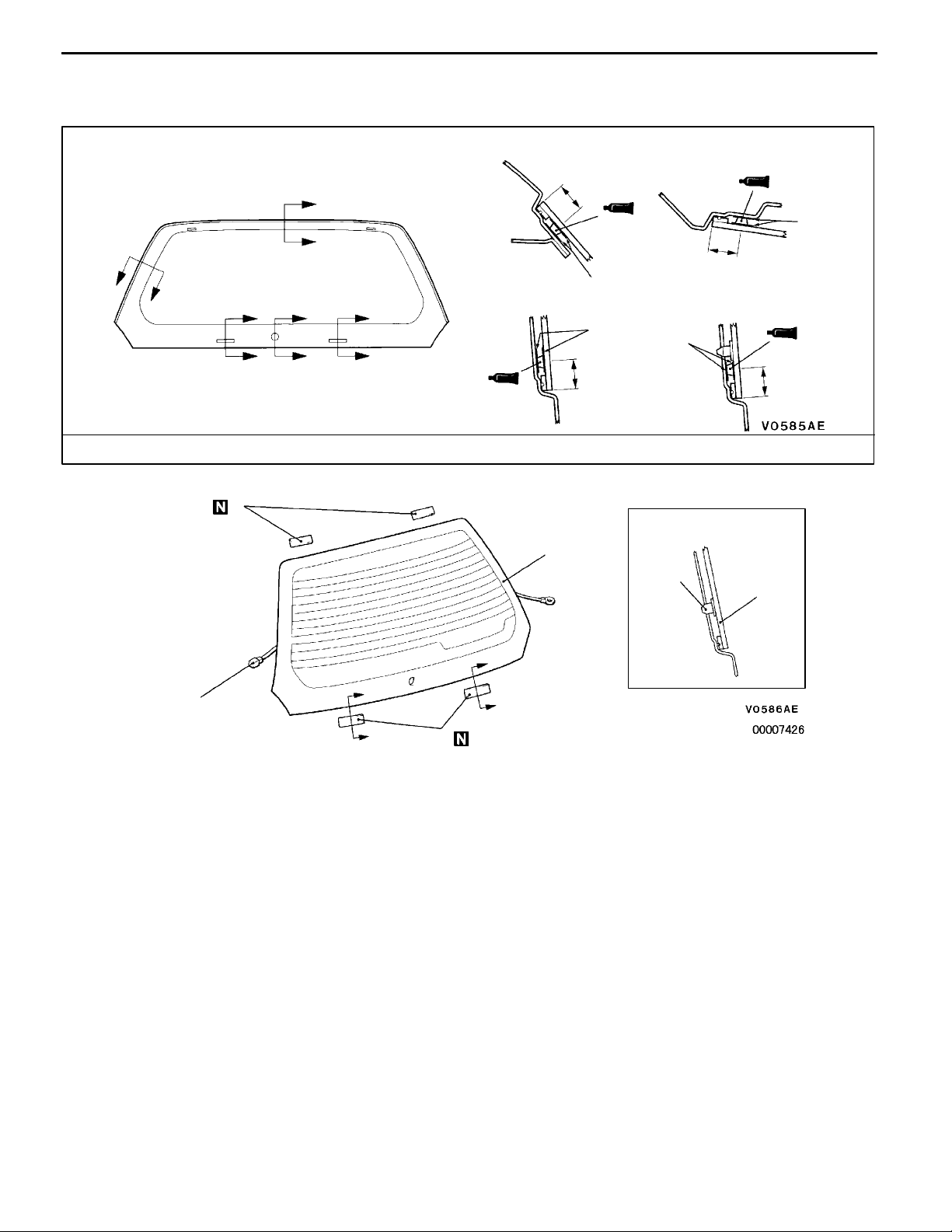

<SPACE WAGON>

BODY -

Window Glass

42-23

Section A - A

A

A

B

B

D

D

C

C

D

D

Section C - C

18.5

Primer

Primer

18.5

Section B - B

18.5

Section D - D

Primer

Adhesive: 3M ATD Part No. 8609 Super Fast Urethane Auto Glass Sealant or equivalent

3

Section E - E

2

3

mm

Primer

18.5

2

AA""AA

1

Removal steps

1. Harness connector

2. Tailgate window glass

3. Glass stopper

E

E

E

3

E

REMOVAL SERVICE POINT

AA"

Remove the tailgate window glass in the same manner as

for the windshield, except the glass stopper. (Refer to P.42-14.)

TAILGATE WINDOW GLASS REMOVAL

INSTALLATION SERVICE POINT

"AA

Install the tailgate window glass in the same manner as for

the windshield, except the glass stopper. (Refer to P.42-15.)

TAILGATE WINDOW GLASS INSTALLATION

Page 24

42-24

BODY -

Door

DOOR 42300030168

SERVICE SPECIFICATIONS

Items Standard value

Door outside handle play mm Front <SPACE RUNNER> 2.1 or more

<SPACE WAGON> 1.9 or more

Rear 2.4 or more

Power window operating current A 5 ± 1 (for 14 -15 V power supply at 25_C)

Door inside handle play mm 5.3 or more

SEALANT

Items Specified sealant Remark

Waterproof film 3M ATD Part No. 8625 or equivalent Ribbon sealer

SPECIAL TOOLS

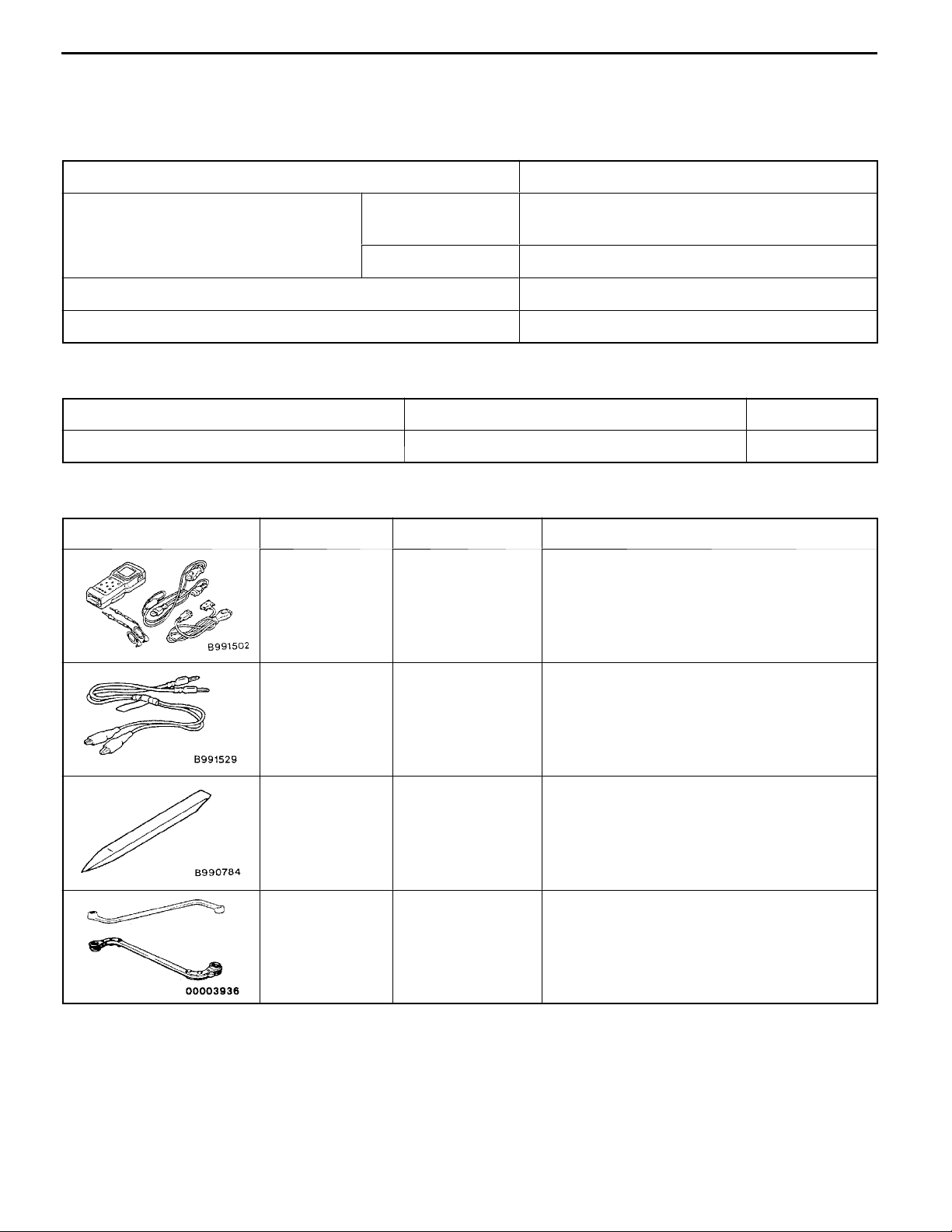

Tool Number Name Use

MB991502 MUT-II sub

assembly

MB991529 Diagnosis code

check harness

MB990784 Ornament remover Removal of door trim

ETACS-ECU input signal checking

ETACS-ECU input signal checking when

voltmeter is used

42300050065

42300060143

MB990900 or

MB991 164

Door adjusting

wrench

Adjustment of door fit

Page 25

BODY -

Door

42-25

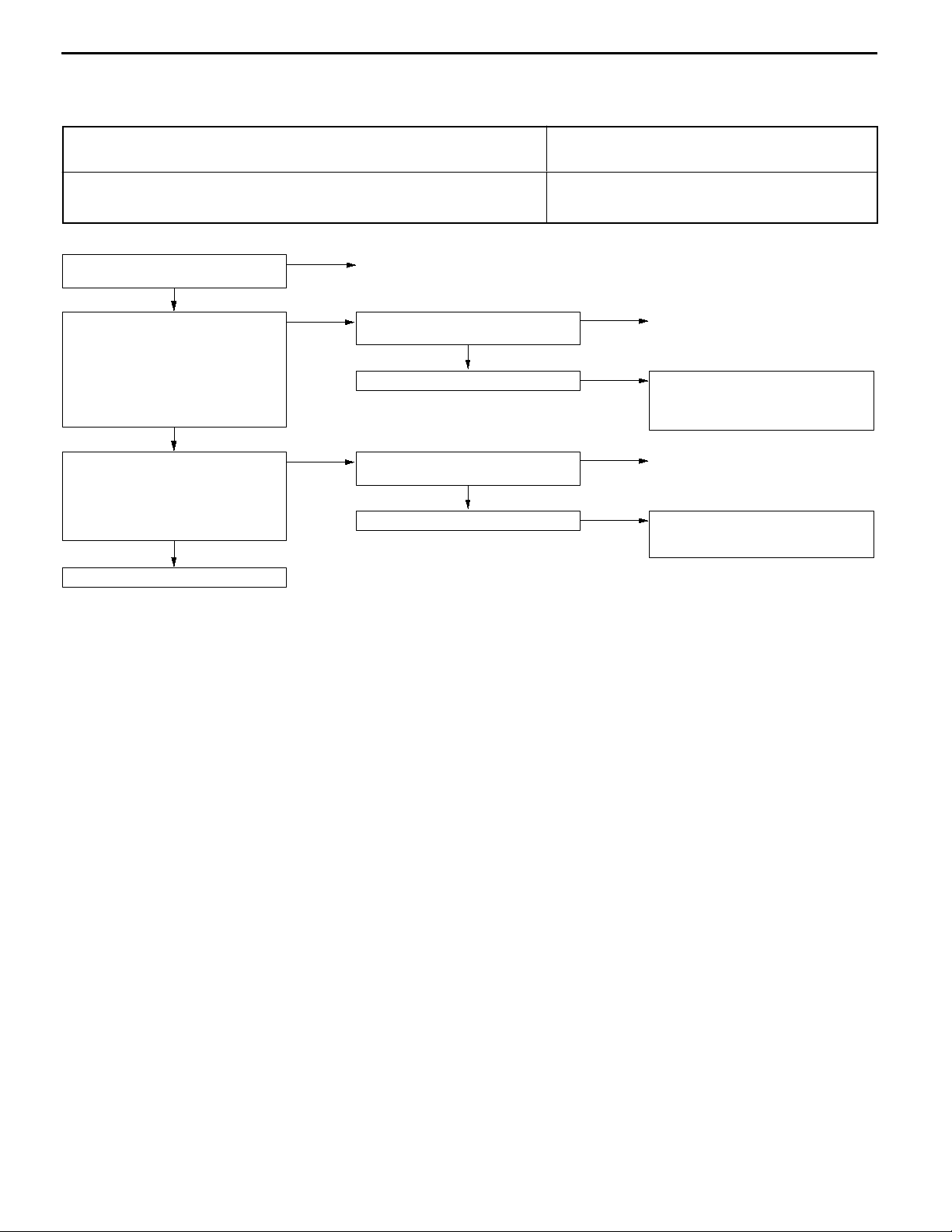

TROUBLESHOOTING

42300070238

DIAGNOSIS FUNCTION

INPUT SIGNAL INSPECTION POINTS <VEHICLES WITH ETACS-ECU>

1. Connect the MUT-II to the diagnosis connector. (Refer to GROUP 00 - How to Use

Troubleshooting/Inspection Service Points.)

2. If buzzer of the MUT-II sounds once when door lock actuator switch is operated (LOCK/UNLOCK),

the ETACS-ECU input signal for that switch circuit system is normal.

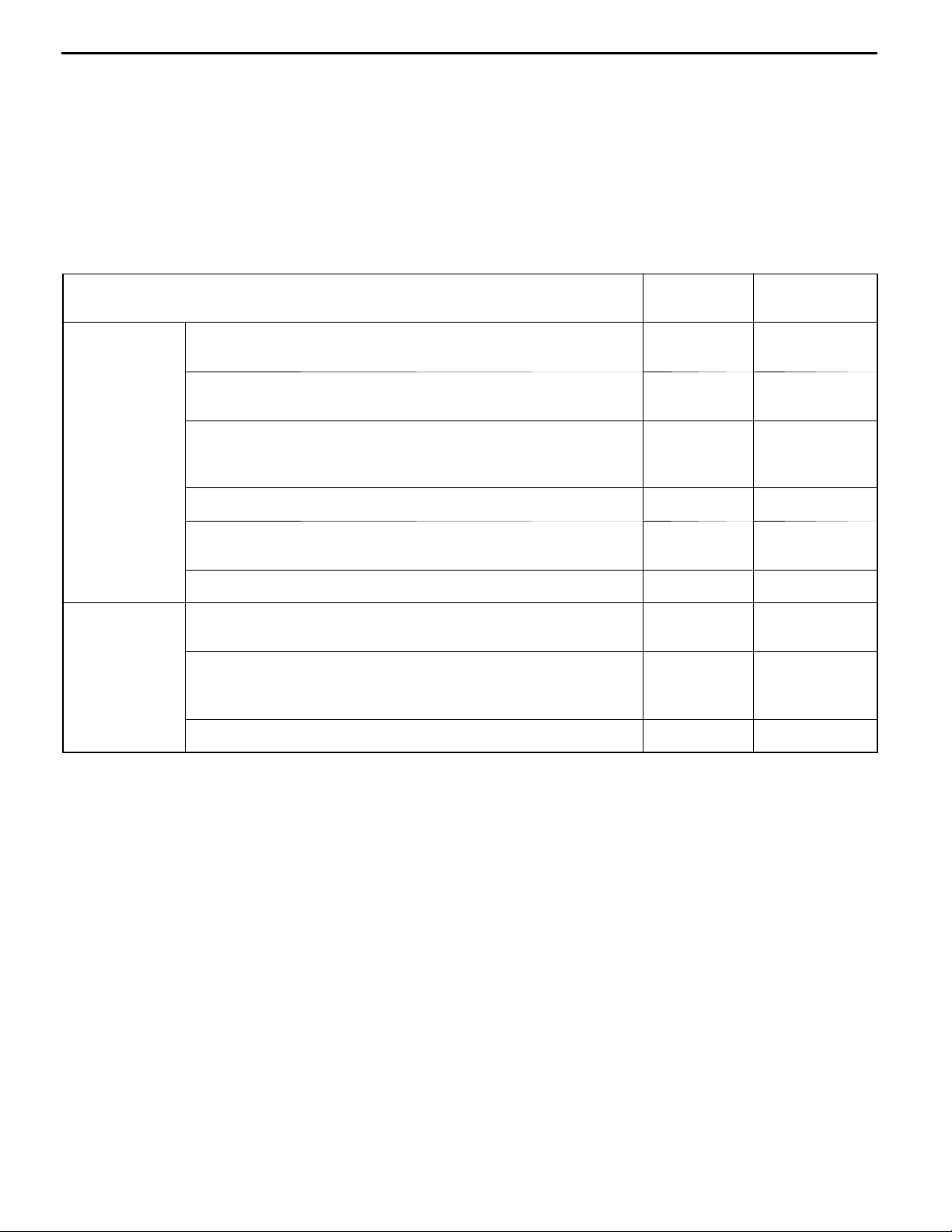

INSPECTION CHART FOR TROUBLE SYMPTOMS

Trouble symptom Inspection

procedure

Power windows The power windows cannot be operated by any of the power

window switches.

Driver’s side power window cannot be operated by the power

window main switch.

Passenger’s side power window cannot be operated by the power

window main switch. (However, it can be operated by the power

window sub-switch.)

When the glass is raised, it then lowers automatically. 4 42-28

The glass is not lowered when something is jammed in the

window.

1 42-26

2 42-27

3 42-28

5 42-28

Reference

page

42300700083

Door locking

mechanism

When the glass is fully raised, it then lowers automatically. 6 42-29

None of the door lock functions operate. (Keyless entry system

does not operate also.)

None of the doors lock or unlock when the driver’s side inside door

locking knob is operated (including by means of the door key).

(However, keyless entry system operates.)

Some doors do not lock or unlock. 9 42-30

7 42-29

8 42-30

Page 26

42-26

BODY -

Door

INSPECTION PROCEDURE FOR TROUBLE SYMPTOMS

Inspection Procedure 1

The power windows cannot be operated by any of the

power window switches.

The cause may be a malfunction of the power window relay, power window relay

drive circuit and of the ETACS-ECU.

Check the power window relay continuity. (Refer to P.42-48.)

OK

Measure at the junction block connector

B-89.

D Disconnect the connector and

measure at the harness side.

D Ignition switch: ON and OFF

D Voltage between 1 and body earth

OK:

System voltage (ON)

0 V (OFF)

OK

Measure at the ETACS-ECU connector

B-104.

D Disconnect the connector and

measure at the harness side.

D Voltage between 8 and body earth

OK:

System voltage

OK

Replace the ETACS-ECU.

NG

NG

NG

Replace

Check the following connectors:

B-66, B-103, B-101, B-89

OK

Check trouble symptoms.

Check the following connectors:

B-104, B-101

OK

Check trouble symptoms.

Probable cause

D Malfunction of power window relay

D Malfunction of ETACS-ECU

D Malfunction of wiring harness or connector

NG

NG

NG

NG

Repair

Check the harness wire between fusible

link No.6 and power window relay, between power window relay and junction

block, and repair if necessary.

Repair

Check the harness wire between power

window relay and ETACS-ECU, and repair if necessary.

Page 27

Inspection Procedure 2

BODY -

Door

42-27

Driver’s side power window cannot be operated by the

power window main switch.

The cause may be a malfunction of power window main switch, power window

motor-ECU, or open circuit or short circuit in the communication line between power

window main switch and power window motor-ECU.

Measure at the power window main

switch connector D-17*, D-05*

D Disconnect the connector and

measure at the harness side.

D Ignition switch: ON and OFF

D Voltage between 3 <SPACE

RUNNER> or 1 <SPACE WAGON>

and body earth

OK:

System voltage (ON)

D Continuity between 5 <SPACE

Measure at the power window motorECU connector D-04*, D-15*

D Disconnect the connector and

D Ignition switch: ON and OFF

D Voltage between 1 and body earth

D Continuity between 3 and body earth

Measure at the power window main

switch connector D-17*, D-05*

power window motor-ECU connector

D-04*, D-15*

D Disconnect the connector and

D Continuity between 3 <SPACE

Replace the power window main switch.

0 V (OFF)

RUNNER> or 3 <SPACE WAGON>

and body earth

OK:

Continuity

OK

measure at the harness side.

OK:

System voltage (ON)

0 V (OFF)

OK:

Continuity

OK

1

.

measure at the harness side.

RUNNER> or 1 <SPACE WAGON>

(power window main switch side)

and 2 (power window motor-ECU

side)

OK:

Continuity

OK

1

.

1

.

1

and the

NG

NG

NG

Check the following connectors:

B-89, B-26, D-17*, D-05*

Check trouble symptoms.

Check the following connectors:

D-04*, D-15*

Check trouble symptoms.

Check the following connectors:

D-04*, D-17*, D-05*

Check trouble symptoms.

1

, B-66, B-89

OK

OK

1

, D-15*

OK

1

Probable cause

D Malfunction of power window main switch

D Malfunction of power window motor-ECU

D Malfunction of wiring harness or connector

NG

NG

NG

NG

NG

1

NG

Repair

Check the harness wire between junction block and power window main

switch, between power window main

switch and earth, and repair if necessary.

Replace the power window main switch.

Repair

Check the harness wire between junction block and power window motorECU, and repair if necessary.

Replace the power window motor-ECU.

Repair

Check the harness wire between power

window main switch and power window

motor-ECU, and repair if necessary.

OK

OK

*: L.H. drive vehicles

1

: R.H. drive vehicles

*

Page 28

42-28

Inspection Procedure 3

BODY -

Door

Passenger’s side power window cannot be operated by

the power window main switch. (However, it can be

operated by the power window sub-switch.)

The cause may be open circuit or short circuit in the communication line between

power window main switch and passenger’s side power window motor-ECU, or a

malfunction of power window main switch.

Measure at the connector B-26.

D Ignition switch: ON and OFF

D Voltage between 31 and body earth

OK:

System voltage (ON)

0 V (OFF)

OK

Check the following connectors:

B-66, D-04*, D-15*

Check trouble symptoms.

*: L.H. drive vehicles

1

*

: R.H. drive vehicles

1

OK

NG

NG

NG

Check the following connectors:

B-26, D-17*, D-05*

Check trouble symptoms.

Repair

Check the harness wire between connector B-26 and passenger’s side power

window motor-ECU, and repair if necessary.

1

OK

Probable cause

D Malfunction of wiring harness or connector

D Malfunction of power window main switch

NG

NG

Repair

Check the harness wire between power

window main switch and connector

B-16, and repair if necessary.

OK

Replace the power window main switch.

Inspection Procedure 4

When the glass is raised, it then lowers automatically.

If the sliding resistance is too large when the glass is being raised, it is judged that

something is jammed in the window, and the window is lowered by approximately

150 mm.

NG

Check the power window drive circuit. (Refer to P.42-33.)

Drive current: 5 ± 1A

OK

Replace the power window motor-ECU.

Inspection Procedure 5

Theglassis notlowered when something isjammed in the

window.

The cause may be a malfunction of the revolution detection sensor in the power

window motor-ECU.

Replace the power window motor-ECU.

Probable cause

D Incorrect window glass adjustment

D Glass slider is incorrectly installed or warped

Adjust the window glass. (Refer to P.42-31.)

Check trouble symptoms.

NG

Replace the window regulator assembly.

Probable cause

D Malfunction of power window motor-ECU

Page 29

Inspection Procedure 6

BODY -

Door

42-29

When the glass is fully raised, it then lowers

automatically.

When the window is within 15 mm of being fully closed, the limit switch turns off

to prevent the window from being lowered. However, the above problem can occur

if there is a malfunction of the limit switch in the power window motor-ECU.

Limit switch operation position adjustment (Refer to P.42-47.)

Check trouble symptoms.

NG

Replace the power window motor-ECU.

Inspection Procedure 7

None of the door lock functions operate. (Keyless entry

system does not operate also.)

The cause may be a malfunction of the ETACS-ECU power supply circuit system

or of the earth circuit system.

Measure at the junction block connector

B-104.

D Remove the ETACS-ECU and

measure at the junction block side.

D Voltage between 6 and body earth

OK:

System voltage

OK

Check the following connectors:

B-104, B-106, B-90

OK

Check trouble symptoms.

NG

NG

NG

Check the following connectors:

B-66, B-103, B-104

OK

Check trouble symptoms.

Repair

Check the harness wire between

ETACS-ECU and body earth.

OK

Probable cause

D Malfunction of the power window motor-ECU

Probable cause

D Malfunction of ETACS-ECU

D Malfunction of wiring harness or connector

NG

NG

NG

Repair

Check the harness wire between fusible

link No.5 and junction block, and repair

if necessary.

Repair

Replace the ETACS-ECU.

Page 30

42-30

Inspection Procedure 8

BODY -

Door

None of the doors lock or unlock when the driver’s-side

inside door locking knob is operated (including by means

of the door key). (However, keyless entry system

operates.)

The cause may be a malfunction of the door lock actuator switch, the ETACS-ECU

or of a wiring harness or connector.

MUT-IIPulse check

Front door lock actuator switch input

signal

OK:

The MUT-II buzzer sounds once

when the front door lock actuator

moves from the locked to the unlocked position, or from the unlocked to the locked position.

OK

Replace the ETACS-ECU.

*: L.H. drive vehicles

1

*

: R.H. drive vehicles

NG

Check the front door lock actuator.

(Refer to P.42-50.)

OK

Check the following connectors:

B-26, D-19*, D-08*

Check trouble symptoms.

1

, B-90, B-104, B-106

OK

Inspection Procedure 9

Probable cause

D Malfunction of front door lock actuator

D Malfunction of ETACS-ECU

D Malfunction of wiring harness or connector

NG

NG

NG

Replace

Repair

Check the harness wire between the

front door lock actuator and ETACSECU, between front door lock actuator

and the earth, and repair if necessary.

Some doors do not lock or unlock.

The cause may be a malfunction of the door lock actuator or tailgate lock actuator

or of a wiring harness or connector.

Check the door lock actuator of the door that does not operate

or the tailgate lock actuator. (Refer to P.42-50, 69.)

OK

Check the following connectors:

<SPACE RUNNER>

Front L.H.: D-19, B-26*, B-47*

Front R.H.: D-08, B-47*, B-26*

Rear: D-12*, D-23*

Tailgate: E-10, E-07, B-98, B-104

<SPACE WAGON>

Front L.H.: D-19, B-26*, B-47*

Front R.H.: D-08, B-47*, B-26*

Rear L.H.: D-23, B-98*, B-90*

Rear R.H.: D-12, B-90*, B-99*

Tailgate: E-10, E-07, B-98, B-104

Check trouble symptoms.

*: L.H. drive vehicles

1

*

: R.H. drive vehicles

1

, D-24, C-36, B-49, B-90, B-104

1

, B-90, B-104

1

, B-90, B-104

1

, B-90, B-104

1

, B-90, B-104

1

, C-19, B-104

1

, C-19, B-104

OK

NG

NG

NG

Replace

Repair

Check the harness between ETACS-ECU andthe door lock actuator

of the door that does not operate, between ETACS-ECU and tailgate

lock actuator, and repair if necessary.

Probable cause

D Malfunction of door lock actuator

D Malfunction of tailgate lock actuator

D Malfunction of wiring harness or connector

Page 31

BODY -

Door

42-31

MB990900 or

MB991164

Striker

Shim

ON-VEHICLE SERVICE

42300090166

DOOR FIT ADJUSTMENT

1. If the clearance between the door an d the vehicle body

is uneven, affix protective tape to the fender around the

hinge and to the edge of the door. Then use the special

tool to loosen the door hinge mounting bolts on the body,

and adjust the clearance around the door so that it

becomes even.

2. If the door and the body are not flush with each other,

use the special tool to loosen the door hinge mounting

bolts on the door. Then align the door.

Caution

Do not load more than 98 Nm on the special tool.

3. If the door opening and closing is heavy, adjust the

meshing of the striker and the door latch (in the longitudinal

direction) by adding shims to the striker and by moving

the striker up and down or to the left and right.

Front Rear

Adjusting

hole

Adjusting

hole

DOOR WINDOW GLASS ADJUSTMENT

42300100302

Check that the door glass moves securely along the door

glass runchannel when the window glass is fully raised and

fully lowered. If the glass does not move correctly, adjust

by the following procedure.

1. Remove the door trim and the waterproof film.

(Refer to P.42-37, 38, 39.)

2. Loosen the door glass mounting screw through the

adjusting hole with the door window glass fully closed,

and lower the door window glass slightly.

3. Close the door window glass fully again, and tighten the

door glass mounting screw securely through the adjusting

hole.

Page 32

42-32

BODY -

Door

Runchannel

Door

sash

Lower sash

ADJUSTMENT AND REPLACEMENT WHEN

THERE IS A MALFUNCTION OF THE POWER

WINDOWS

If th e window glass automatically starts moving downwards

at the wrong time while it is being raised, carry out the following

adjustment or replacement procedures.

1. Remove the door trim and waterproof film. (Refer to

P.42-37, 38, 39.)

2. Remove the window regulator assembly from the door

window glass, and then raise and lower the door window

glass by hand to check the operation force.

NOTE

Insert a cushion or similar object to prevent damage to

the glass if it should happen to fall down.

3. If the door window glass does not move up and down

smoothly, check or repair the following points.

D Check the installation condition of t h e runchannel.

D Repair the twisting in the door sash.

D Check the installation condition of the lower sash

or the center sash.

NOTE

The lower sash cannot normally be adjusted, but it may

be possible to adjust the sash span slightly within the

range allowed by manufacturing tolerances by pushing

the lower sash outwards while re-installing it.

4. If repair or adjustment is not possible, replace the door

assembly.

42900190109

POWER WINDOW SAFETY MECHANISM

CHECK

1. Place a wooden board with a thickness of approximately

10 mm as shown in the illustration, and then raise the

window glass.

2. Check that the window lowers by a distance of

approximately 150 mm when the window clamps the

wooden board. If this doesn’t happen, refer to

“Troubleshooting” (P.42-29).

42900100102

Page 33

BODY -

Door

42-33

Section A - A

DOOR OUTSIDE HANDLE PLAY CHECK

42300160164

1. Check that the door outside handle play is within the

standard value range.

A

Standard value (B):

Front door:

A

<SPACE RUNNER> 2.1 mm or more

<SPACE WAGON> 1.9 mm or more

Rear door: 2.4 mm or more

B

2. If the door outside handle play is not within the standard

value range, check the door outside handle or the door

latch assembly. Replace, if necessary.

POWER WINDOW OPERATION CURRENT

INSPECTION

1. Remove the power window fuse and connect a circuit

analyser as shown in the illustration.

2. When the power window switch is pulled to close the

window, a large amount of current flows at the time the

window starts to close and when it is fully closed, so

measure the operation current in the interval between

these two points.

42900110105

Standard value:

5±1 A (for 14 - 15 V power supply voltage at

25_C)

3. If the operation current is outside the standard value,

refer to “Troubleshooting” (P.42-29).

CIRCUIT BREAKER (INCORPORATED IN THE

POWER WINDOW MOTOR) INSPECTION

1. Pull the power window switch to fully close the window

glass, and keep pulling the switch for a further 10 seconds.

2. Release the power window switch and immediately press

it to open the window. The condition of the circuit breaker

is good if the power window glass starts to move

downwards within 60 seconds.

42900170134

Page 34

42-34

BODY -

Door

Section B - B

A

DOOR INSIDE HANDLE PLAY CHECK AND

ADJUSTMENT

B

B

1. Check that the door inside handle play is within the

standard value range.

Standard value (A): 5.3 mm or more

2. If the door inside handle play is outside the standard

value range, remove the door trim. (Refer to P.42-37,

38, 39.)

3. <Front door>

Disengage the rod from the clip on the inside handle,

and re-engage it to the clip to adjust the play.

<Rear door>

Loosen the inside handle mounting screws, and then

move the inside handle back and forth to adjust the play.

42300150260

Page 35

BODY -

Door

42-35

DOOR ASSEMBLY

REMOVAL AND INSTALLATION

Post-installation Operation

Door Adjustment (Refer to P.42-31.)

Front door

4, 5

26 Nm

42300220299

12 Nm

6

7

4

22 Nm

Rear door <SPACE WAGON>

8

9

3

1

5

2

12 Nm

6

4

22 Nm26 Nm

1

9

7

Door assembly removal steps

1. Harness connector

2. Door check connecting bolt

3. Door assembly

4. Door upper hinge

5. Door lower hinge

5

2

Striker removal steps

6. Striker

7. Striker shim

Door switch removal steps

8. Door switch cap

9. Door switch

3

8

Page 36

42-36

BODY -

Door

ON

Stroke

2

OFF

INSPECTION

42300600093

DOOR SWITCH CONTINUITY CHECK

Switch

1

position

Open (ON)

Depressed

(OFF)

Terminal No.

1 2

Page 37

BODY -

Door

42-37

DOOR TRIM AND WATERPROOF FILM

REMOVAL AND INSTALLATION

Front door <SPACE RUNNER>

10

11

9

12

Sealant:

3M ATD Part No. 8625 or equivalent

1

13

2

8

42300430272

13

6

Clip and tab positions

D

D

A

A

B

B

B

B

B

B

D

E

D

E

7

3

5

5

F

F

C

B

C

B

B

B

B

B

4

Section A - A

5

Door inner

panel

Section D - D

3

5

Section B - B

Clip

Section E - E

Door beltline

5

inner weatherstrip

Section C - C

5

Door inner

panel

Section F - F

3

5

3

B

B

B

B

B

B

5

5

AA"

AB"

Removal steps

1. Power window switch panel

2. Power window switch

3. Inside handle cover

4. Door lamp lens

5. Door trim

6. Front door grip

7. Power window switch cover

8. Grip bracket

9. Tweeter

10. Door trim bracket

11. Speaker

12. Power window switch bracket

13. Waterproof film

Page 38

42-38

Front door <SPACE WAGON>

BODY -

Door

10

6

7

8

Clip and tab positions

F

E

D

A

A

B

B

G

D

E

F

1

10

9

5

2

Sealant:

3M ATD Part No. 8625 or equivalent

3

4

Section A - A

5

C

G

C

B

B

B

B

B

B

Door inner panel

Section D - D

5

Clip

Section B - B

5

Clip

Section E - E Section F - F

5

Door beltline inner

weatherstrip

5

3

Section C - C

7

Door inner panel

5

B

AA"

AB"

3

BB

B

B

BB

B

B

B

Section G - G

3

5

Removal steps

1. Power window switch panel

2. Power window switch

3. Inside handle cover

4. Door lamp lens

5. Door trim

6. Tweeter

7. Door trim bracket

8. Speaker

9. Power window switch bracket

10. Waterproof film

3

3

5

5

Page 39

Rear door <SPACE WAGON>

BODY -

8

Door

Sealant:

3M ATD Part No. 8625 or equivalent

1

42-39

8

Clip and tab positions

D

D

D

A

C

C

D

A

C

C

C

C

7

6

2

4

5

3

Section A - A

Door inner panel

B

C

B

C

C

C

C

C

C

C

Section C - C

4

Section B - B

Door beltline inner weatherstrip

4

Door inner panel

Section D - D

AA"

AC"

AC"

C

C

C

C

Removal steps

1. Power window switch panel

2. Power window switch

3. Door lamp lens

4. Door trim

5. Inside handle cover

Clip

Door inner panel

4

7

6. Power window switch bracket

7. Door inside handle (Refer to

P.42-49.)

8. Waterproof film

5

Page 40

42-40

Power window switch panel

B

BODY -

Door

REMOVAL SERVICE POINT

AA"

B

<SPACE RUNNER>

Use the special tool to pry up the rear end of the power

window switch panel to remove it.

POWER WINDOW SWITCH PANEL REMOVAL

A

A

B

Section A - A

Power window switch panel

Door trim

Section B - B

Power window switch panel

Door trim Door trim

B

Page 41

BODY -

Door

42-41

Front

A

A

B

Rear

A

A

Section A - A

Door trim

Section B - B

Door trim

BB

B

Power window switch panel

B

B

Power window switch panel

Power window switch panel

B

B

B

B

B

B

<SPACE WAGON>

Use the special tool to pry up the rear end of the power

window switch panel to remove it.

Inside handle

Inside handle cover

Section A - A

Door trim

Inside

handle

Inside

handle

cover

cover

Door trim

B

A

A

Section B - B

B

Door trim

MB990784

Door trim

Inside

handle

cover

Door trim

AB"

INSIDE HANDLE COVER REMOVAL

1. Insert the special tool between the inside handle upper

end and the inside handle cover, and pry off the inside

handle cover from the upper tabs of the inside handle.

2. Insert the special tool between the inside handle lower

end and the inside handle cover, and pry off the inside

handle cover from the lower tabs of the inside handle.

3. Use the special tool to pry up the front end of the inside

handle cover to remove it.

Page 42

42-42

BODY -

Door

Inside handle

MB990784

Section A - A

Inside

handle

A

A

A

Inside handle cover

A

Inside

handle

cover

AC"

DOOR TRIM/INSIDE HANDLE COVER REMOVAL

<SPACE WAGON>

1. Insert the special tool between the inside handle upper

end and the inside handle cover, and pry off the inside

handle cover from the upper tabs of the inside handle.

2. Insert the special tool between the inside handle lower

end and the inside handle cover, and pry off the inside

handle cover from the lower tabs of the inside handle.

3. Remove the door trim.

4. Remove the inside handle cover from the door trim.

Page 43

BODY -

Door

42-43

DOOR GLASS AND REGULATOR

REMOVAL AND INSTALLATION

Pre-removal Operation

Door Trim and Waterproof Film Removal (Refer to

P.42-37, 38, 39.)

Front door

1

2

6

8

9

7

3

4

42900130378

Post-installation Operation

D Door Window Glass Adjustment (Refer to P.42-31.)

D Door Trim and Waterproof Film Installation (Refer

to P.42-37, 38, 39.)

Rear door <SPACE WAGON>

1

3

5

2

4

"BA

"AA

"AA

"BA

"AA

"AA

Front window regulator assembly

removal steps

1. Door window glass

2. Door window glass holder

3. Window regulator assembly

4. Power window motor

Rear window regulator assembly

removal steps

D

Window glass runchannel (Refer to

P.42-51.)

1. Door window glass

2. Door window glass holder

3. Window regulator assembly

4. Power window motor

5. Delta sash assembly

AA"

"AA

Stationary window glass removal

steps

D

Window glass runchannel (Refer to

P.42-51.)

1. Door window glass

6. Door center sash

7. Stationary window glass and weatherstrip assembly

8. Stationary window glass

9. Stationary window weatherstrip

Page 44

42-44

Door outer

opening

weatherstrip

Door center sash

BODY -

Door

REMOVAL SERVICE POINTS

AA"

1. Remove the door outer opening weatherstrip from the

2. Remove the door center sash mounting screws, and then

DOOR CENTER SASH REMOVAL

door center sash only.

remove the door center sash from the door panel.

INSTALLATION SERVICE POINTS

"AA

POWER WINDOW MOTOR AND WINDOW REGULATOR

ASSEMBLY INSTALLATION PROCEDURE

1. Connect the power window motor to the body-side harness

2. Continue to pull the power window switch until the power

3. Turn off the ignition switch, and then remove the power

POWER WINDOW MOTOR/WINDOW REGULATOR

ASSEMBLY INSTALLATION

connector, and then turn on the ignition switch.

window motor stops.

NOTE

Power window motor stops automatically and the limit

switch incorporated in the power window motor will be

reset.

Caution

Donot operate the power window motoruntil the glass

installation is finished.

window motor from the body-side harness connector.

Drum

Guide

Glass bracket

Square hole

Drive shaft

Rachet wrench

4. Align the power window motor drive shaft and the square

hole in the drum by the following procedure, while using

the guide and the opening in the motor housing as a

reference for the installation position.

Guide

(1) Align the square hole with the drive shaft by sliding

the glass bracket (glass mounting section) or by

turning th e drum using a ratchet wrench (with a socket

diameter of 12.7 mm).

Page 45

Glass

bracket

Approx. 85 mm

BODY -

Door

42-45

(2) Turn the drum to position the glass bracket as shown

in the illustration. Support the drum and the guide with

your hand while turning the drum, otherwise the wires

may pull out of the drum.

(3) If the wires pull out of the drum, re-insert them by

following the drum and regulator wire installation

procedure.

5. Align the guide and the opening of the motor housing,

and slide the guide into the motor housing while holding

the guide and drum.

Metal cover

Drum

Square hole

Lowering wire

Guide

Slit

Spring A

Spring B

Lowering wire

Mounting

screw

Lifting

wire

Spring

6. Install the metal cover securely to the housing.

Caution

Make sure that the metal cover is installed securely

and does not move, in order to stop the drum from

vibrating. If the drum vibrates, the glass may not slide

up and down smoothly, or it may fall down.

DRUM AND REGULATOR WIRE INSTALLATION

PROCEDURE

1. Place the drum, guide and regulator on a work bench

as shown in the illustration.

(1) Place the drum so that the square hole is facing

upward.

(2) Place the guide so that the slits are facing upward.

(3) Place the regulator so that the glass bracket is facing

downward. Position the glass bracket so that glass

is in the fully-open position.

2. Pass the springs over the wires, and then install the

lowering wire to the guide first, followed by the lifting

wire. (The lifting wire should be on top of the lowering

wire.)

Lifting wire

Slit

Guide

Page 46

42-46

Narrowgauge wire

Slit

BODY -

Door

3. Use some narrow-gauge wire (approx. 0.5 mm diameter)

to compress the springs, and then tie the narrow-gauge

wires to the slits in the guide.

Lowering wire

Lifting wire

4. Insert the end of the lowering wire into the wire hole

at the bottom of the drum, and then wrap the wire securely

around the groove of the drum from the bottom so that

there is no slackness in the wire.

5. Install the lifting wire to the drum as follows:

(1) Insert the end of the lifting wire into the wire hole

at the top of the drum.

(2) Raise th e front of the drum until the drum is vertical,

and then position the lifting wire in the groove of

the drum.

Page 47

BODY -

(3) Return the drum to its original position while holding

6. After installing the power window motor assembly to the

window regulator assembly, cut and remove the wires

which are compressing the springs.

OPERATION CHECK

1. Install the window glass to the window regulator assembly.

Caution

(1) Do not operate the window regulator assembly

(2) Window glass safety mechanism does not operate

2. Close the window glass completely.

Door

the wires to make sure that they do not pull out.

before installing the window glass, otherwise the

limit switch will be set.

when the window glass is closed fully at first time.

42-47

NOTE

Closing t he window glass completely will finish the

adjustment of th e limit switch.

3. Check that the limit switch operates correctly.

"BA

1. Provisionally secure the door window glass to the window

2. After raising the door window glass as far as it will go,

DOOR WINDOW GRASS INSTALLATION

regulator assembly.

fully secure the door window glass to the window regulator

assembly.

Page 48

42-48

BODY -

Door

Power window relay

INSPECTION

POWER WINDOW RELAY CONTINUITY CHECK

Battery

voltage

Not applied

Applied

Terminal No.

1 3 4 5

42900180168

Page 49

BODY -

Door

42-49

DOOR HANDLE AND LATCH

REMOVAL AND INSTALLATION

Pre-removal Operation

Door Trim Removal (Refer to P.42-37, 38, 39.)

Front door

2

1

3

6Nm

Post-installation Operation

D Door Inside Handle Play Check (Refer to P.42-34.)

D Door Outside Handle Play Check (Refer to P.42-33.)

D Door Trim Installation (Refer to P.42-37, 38, 39.)

Rear door <SPACE WAGON>

7

1

42300460318

5

6Nm

5

8

4

Front door handle and door latch

assembly removal steps

1. Door inside handle

D

Waterproof film (Refer to P.42-37, 38,

39.)

2. Door outside handle

3. Door lock key cylinder assembly

4. Rear lower sash

5. Door latch assembly

8

6

Rear door handle and door latch

assembly removal steps

1. Door inside handle

D

Waterproof film (Refer to P.42-37, 38,

39.)

D

Door center sash

(Refer to P.42-43.)

5. Door latch assembly

6. Door lock actuator

7. Door outside handle

Door check removal

D

Waterproof film (Refer to P.42-37, 38,

39.)

8. Door check

Page 50

42-50

BODY -

BODY -

Door

Door

<Passenger’s side>

View A

<Driver’s side>

View B

<L.H.>

View A

Lock

Unlock

INSPECTION

FRONT DOOR LOCK ACTUATOR CHECK

Unlock

A

<Passenger’s side>

Rod position Terminal No. Rod operation

4 6

LOCK LOCK position ®

UNLOCK position

UNLOCK UNLOCK position ®

LOCK position

<Driver’s side>

Lock

B

Rod position Terminal No. Rod operation

1 2 3 4 6

LOCK LOCK position ®

UNLOCK position

UNLOCK UNLOCK position ®

LOCK position

LOCK

UNLOCK

REAR DOOR LOCK ACTUATOR CHECK

<L.H.>

42300610140

42300620129

<R.H.>

View B

Lock

Unlock

B

Lock

Unlock

Rod position

Terminal No.

Rod operation

2 3

LOCK LOCK position ®

UNLOCK position

A

UNLOCK UNLOCK position ®

LOCK position

<R.H.>

Rod position

LOCK LOCK position ®

UNLOCK UNLOCK position ®

Terminal No.

2 3

Rod operation

UNLOCK position

LOCK position

Page 51

BODY -

Door

WINDOW GLASS RUNCHANNEL AND DOOR OPENING WEATHERSTRIP

REMOVAL AND INSTALLATION

Front door Rear door <SPACE WAGON>

42-51

42300310248

5

4

3

5

3

2

2

1

1

4

: Section of clip : Section of clip

AA"

Door inner opening weatherstrip

removal steps

D

Scuff plate (Refer to GROUP 52A.)

D

Cowl side trim <Front door>

(Refer to GROUP 52A.)

D

Center pillar lower trim

(Refer to GROUP 52A.)

1. Door inner opening weatherstrip

Door outer opening weatherstrip

removal

2. Door outer opening weatherstrip

15 mm

4mm

8mm

Thickness

1mm

Door window glass runchannel

removal steps

3. Door window glass runchannel

4. Door window glass lower runchannel <Rear door>

Door beltline moulding removal

steps

D

Outside rear view mirror

(Refer to GROUP 51.)

5. Door beltline moulding

REMOVAL SERVICE POINT

AA"

Make a tool as shown in the illustration to remove the door

opening weatherstrip.

DOOR OUTER OPENING WEATHERSTRIP

REMOVAL

Page 52

42-52

BODY -

Slide Door

SLIDE DOOR <SPACE RUNNER>

SERVICE SPECIFICATIONS

Item Standard value

Door outside handle play mm 10.5 ± 1.5

Door inside handle play mm 14.2 ± 1.5

SEALANT

Item Specified sealant Remark

Waterproof film 3M ATD Part No. 8625 or equivalent Ribbon sealer

SPECIAL TOOLS

Tool Number Name Use

MB990784 Ornament remover Removal of the slide door trim

MB991223

A

B

C

D

A: MB991219

B: MB991220

C: MB991221

D: MB991222

Harness set

A: Test harness

B: LED harness

C: LED harness

adapter

D: probe

42400060030

Measurement of terminal voltage

A: Connector pin contact pressure inspection

B: Power circuit inspection

C: Power circuit inspection

D: Commercial tester connection

Page 53

BODY -

Slide Door

ON-VEHICLE SERVICE

42-53

Striker

Stopper A

DOOR FIT ADJUSTMENT

1. If the striker is not properly engaged with the latch, adjust

the door fit by moving the striker horizontally and vertically.

2. Check if the stopper touches the vehicle body properly

when the door is closed. If there is a problem, move

the stopper A horizontally and vertically to adjust.

3. Close the slide door. If the slide door is not flush with

the vehicle body or there is excessive or uneven clearance

between the door and body edges, follow the steps below:

Lower

roller arm

Upper

roller arm

Lowe roller

arm guide

Center roller

arm

Vertical adjustment

(1) Remove the slide door trim and waterproof film (Refer

to P.42-59.)

(2) Loosen the center roller arm and the lower roller arm

mounting bolts, and then move the center lower arm

and the lower roller arm up and down to adjust.

Inward and outward adjustment

(1) Loosen the upper roller arm and the lower roller arm

guide mounting bolts, and then move the upper roller

arm the lower roller arm guide inward a nd outward

to adjust.

Forward and backward adjustment

(1) Remove the slide door trim and waterproof film (Refer

to P.42-59.)

(2) Loosen the center roller arm mounting bolts, and then

insert shim(s) between the center roller arm and the

vehicle body to adjust.

Center roller arm

Page 54

42-54

BODY -

Slide Door

DOOR OUTSIDE HANDLE PLAY CHECK AND

ADJUSTMENT

AA

Standard value (A): 10.5±1.5 mm

If the shown distance is outside the standard value, adjust

the door outside handle play according to the following steps:

1. Remove the slide door trim an d waterproof film (Refer

to P.42-59.)

2. Using the clip securing the outside handle to the rod,

adjust the door outside handle play.

Section A-A

10.5

1.5 mm

±

DOOR INSIDE HANDLE PLAY CHECK AND

ADJUSTMENT

BB

Standard value (A): 14.2±1.5 mm

If the shown distance is outside the standard value, adjust

the door outside handle play according to the following steps:

1. Remove the slide door trim an d waterproof film (Refer

to P.42-59.)

2. Using the clip securing the inside handle to the rod, adjust

the door inside handle play.

Section B-B

14.2±1.5 mm

Page 55

SLIDE DOOR ASSEMBLY

REMOVAL AND INSTALLATION

Post-installation Operation

Slide door fit adjustment (Refer to P.42-53.)

6

BODY -

Slide Door

42-55

3

2

AA"

AA"

AB"

4

5

Slide door removal steps

D

Sash trim, front (Refer to P.42-59.)

D

Sash trim, rear (Refer to P.42-59.)

D

Trim, upper (Refer to P.42-59.)

1. Center roller arm cover A

2. Center roller arm cover B

3. Center roller arm safety bolt

D

Lower roller arm guide and cable

(Refer to P.42-57.)

4. Lower roller arm cover

5. Lower roller arm guide

D

Slide door rail cover (Refer to GROUP

52A.)

6. Slide door assembly

9

1

7

8

Lower rail removal steps

D

Slide door rail cover (Refer to GROUP

52A.)

6. Side door assembly

D

Fuel filler door safety cable connection

(Refer to P.42-7.)

7. Lower rail

8. Lower arm slider

9. Lower stopper

Page 56

42-56

BODY -

Slide Door

REMOVAL SERVICE POINT

AA"

Open the slide door, and then hold the door by operating

the fully closed locking mechanism. Then remove the lower

roller arm cover an d the lower roller arm guide.

LOWER ROLLER ARM COVER/LOWER ROLLER

ARM GUIDE REMOVAL

Notch at lower rail

Roller of lower

roller arm

AB"

Remove the slide door assembly according to the steps below:

1. Slide the door rearwards, and then disengage the upper

2. Hold the door by hand, disengage the lower roller arm

SLIDE DOOR REMOVAL

roller arm roller and the center roller arm roller from the

the rear end of the rail.

roller from the lower rail notch, and then remove the door.

Caution

Be careful not to damage the vehicle body or trims

when removing the slide door.

Page 57

BODY -

DISASSEMBLY AND REASSEMBLY

Slide Door

42-57

10

11

12

9

3

13

7

15

14

1

2

3

8

1

2

4

5

6

"AA 1. Stopper (A)

2. Shim

"AA 3. Stopper (B)

4. Door switch cap

5. Door switch

6. Lower roller arm

Slide door check disassembly

steps

7. Center rail

8. Door check cable

9. Slide door check

Upper rail disassembly steps

10. Upper rail

11. Upper stopper

Upper roller arm disassembly steps

12. Upper roller arm

13. Upper roller arm shim

Center roller arm disassembly

steps

14. Center roller arm

15. Center roller arm shim

Page 58

42-58

BODY -

Slide Door

Stopper (A)

Inside

of vehicle

Notch

2

ON

OFF

Stroke

Stopper (B)

INSTALLATION SERVICE POINT

"AA

STOPPER (B), (A) INSTALLATION

The notch on stopper (A) and the arrow mark on stopper

(B) should face the inside of the vehicle.

Inside

of vehicle

INSPECTION

DOOR SWITCH CONTINUITY CHECK

1

Switch position

Released (ON)

Depressed (OFF)

Terminal number

1 2

Page 59

BODY -

Slide Door

SLIDE DOOR TRIM AND WATERPROOF FILM

REMOVAL AND INSTALLATION

42-59

5

Section A - A

2

Section C - C

2

Section D - D

Clip

Clip

Section B - B

1, 2

Clip

6

Sealant:

3M ATD Part No. 8625 or equivalent

2

B

B

C

A

5

A

C

1

3

3, 4

Section E - E

Clip

Clip

3, 4

Removal steps

1. Sash trim, front

2. Sash trim, rear

3. Trim, upper

D

D

E

E

E

E

4

6

NOTE

: Plastic clips

: Metal clips

4. Trim, lower

5. Waterproof film, upper

6. Waterproof film, lower

Page 60

42-60

BODY -

Slide Door

SLIDE DOOR HANDLE AND LATCH

REMOVAL AND INSTALLATION

Post-installation operation

D Door outside handleplay check and adjustment (Refer

to P.42-54.)

6

D Door inside handle play check and adjustment (Refer

to P.42-54.)

5

7

9

8

10

3

14

15

13

12

11

Slide door inside handle removal

steps

D

Slide door trim, upper (Refer to

P.42-59.)

1. Slide door inside handle cover

2. Slide door inside handle

Slide door outside handle removal

steps

D

Slide door trim, upper (Refer to

P.42-59.)

1. Slide door inside handle cover

2. Slide door inside handle

D

Waterproof film, upper (Refer to

P.42-59.)

3. Slide door outside handle

Slide door latch removal steps

D

Slide door trim, upper and slide door

trim, lower (Refer to P.42-59.)

1. Slide door inside handle cover

2. Slide door inside handle

1

4

2

7

3

D

Waterproof film, upper (Refer to

P.42-59.)

4. Inside lock knob cover

5. Inside lock knob

6. Slide door lock link assembly

D

Waterproof film, lower (Refer to

P.42-59.)

7. Slide door latch assembly

8. Striker

9. Shim

"AA

10. Slide door child protection

11. Sub latch assembly

12. Striker

13. Shim

Contact switch removal steps

14. Contact switch (A)

D

Slide door trim upper, slide door trim

lower, waterproof film lower (Refer to

P.42-59.)

15. Contact switch (B)

Page 61

BODY -

Slide Door

INSTALLATION SERVICE POINTS

"AA

1. Move the child protection lever to “LOCK” position.

2. Hook the rod to the lever securely, and then install the

SLIDE DOOR CHILD PROTECTION

INSTALLATION

child protection to the door.

INSPECTION

42-61

SLIDE DOOR WEATHERSTRIP

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operation

Lower roller arm guide removal and installation (Refer

to P.42-55.)

Lock

position

LOCK LOCK position to UNLOCK

UNLOCK UNLOCK position to LOCK

Terminal number

2 3

Rod position

position

position

Slide door weatherstrip

Page 62

42-62

BODY -

Tailgate

TAILGATE 42400030031

SERVICE SPECIFICATION

Item Standard value

Tailgate handle free play mm 1.5 - 5.5

SEALANT

Item Specified sealant Remark

Waterproof film 3M ATD Part No. 8625 or equivalent Ribbon sealer

SPECIAL TOOLS

Tool Number Name Use

MB990784 Ornament remover Removal of the tailgate trim

MB991223

A

B

A: MB991219

B: MB991220

C: MB991221

D: MB991222

Harness set

A: Test harness

B: LED harness

C: LED harness

adapter

D: probe

Measurement of terminal voltage

A: Connector pin contact pressure inspection

B: Power circuit inspection

C: Power circuit inspection

D: Commercial tester connection

42400050044

42400060030

C

D

Page 63

BODY -

Tailgate

42-63

TROUBLESHOOTING

INSPECTION CHART FOR TROUBLE SYMPTOMS

Trouble symptom Reference page

Door lock mechanism does operate. 42-50

ON-VEHICLE SERVICE

TAILGATE FIT ADJUSTMENT

1. If the striker and the latch do not mesh properly, move

the striker forward or back or to the left or right to adjust.

2. If the clearance all the way around the tailgate is not

uniform when the tailgate is closed, adjust by moving