Page 1

CNC

AC SERVO

SERVO ADJUSTMENT MANUAL

BNP-B2334B(ENG)

Page 2

1 PROLOGUE

1-1 Servo Adjustment ......................................................................1-2

1-1-1 Basic knowledge on machines...............................................................1-2

1-1-2 How to use a high-coder........................................................................1-3

1-1-3 D/A Output specifications for MDS-C1/CH-Vx .......................................1-4

1-1-4 D/A Output specifications for MDS-B-SVJ2...........................................1-6

1-1-5 Parameters Concerning with Acceleration/Deceleration Processing .....1-8

1-1

Page 3

1 PROLOGUE

1-1 Servo Adjustment

1-1-1 Basic knowledge on machines

It is important to have basic knowledge on machine characteristics. It is required to comprehend the

characteristics of the machine and set the appropriate parameters. Especially, the 2 items mentioned

below have to be fully understood.

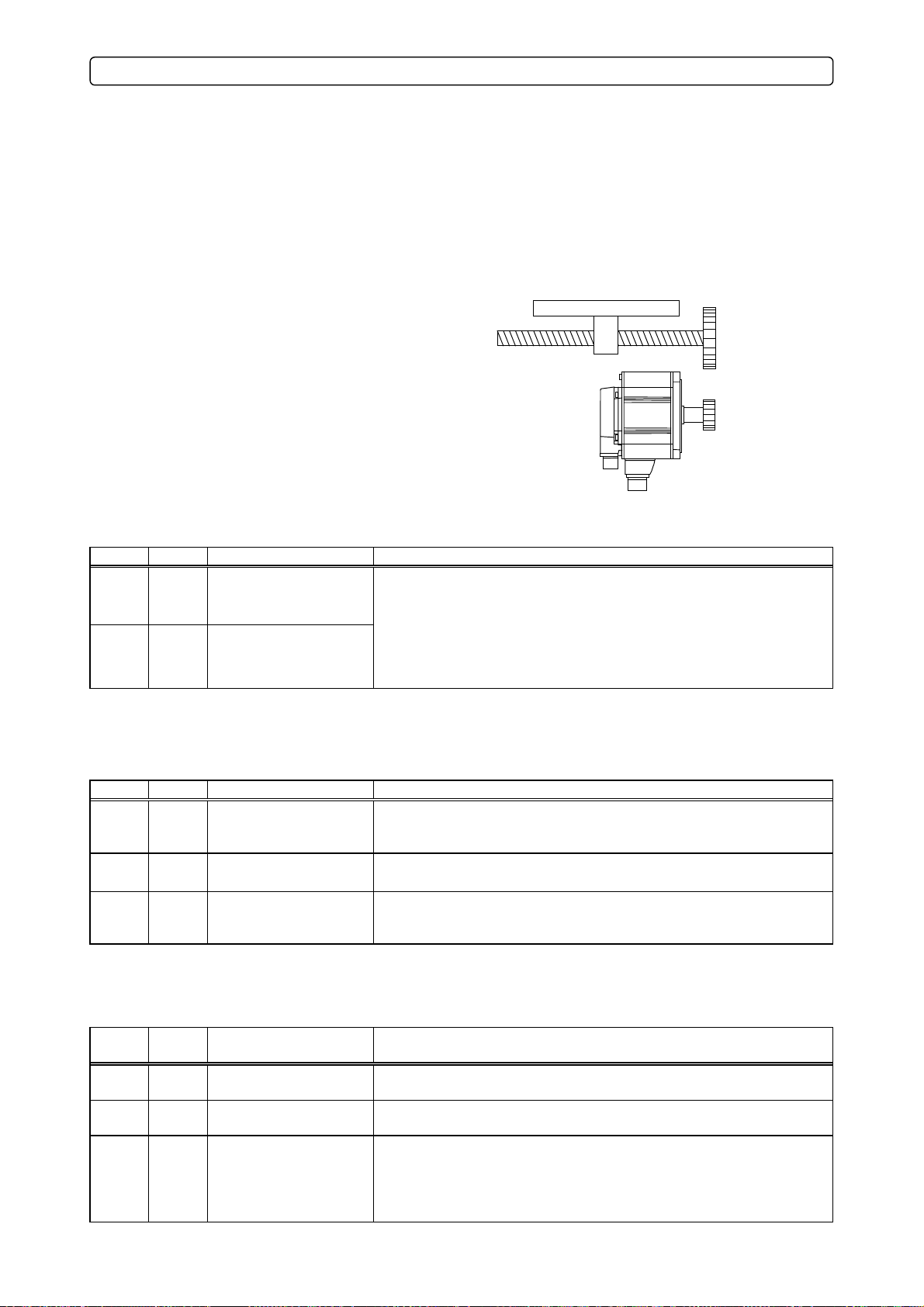

(1) Load inertia

Inertia is physical quantity to express load amount. In servo

control, load inertia converted into motor axis is more important

than load weight. Servo response is in proportion to speed loop

gain (VGN) and in inverse proportion to load inertia. It is

essential to know the load inertia amount when determining

appropriate VGN.

Servo response ∝

(Proportion)

Speed loop gain (VGN)

Load inertia

Load inertia

(2) Resonance frequency

All machines have a resonance point and the resonance of ball

screw is a serious problem for general machine tools.

Resonance has to be suppressed as it prevents VGN from being

raised.

Notch filter is installed on servo and it suppresses the resonance.

However, resonance frequency has to be set for each machine to

set parameters.

The clue to the efficient servo adjustment is recognizing

resonance frequency, suppressing resonance and raising VGN

as much as possible.

Vibration waveform

1-2

Page 4

1-1-2 How to use a high-coder

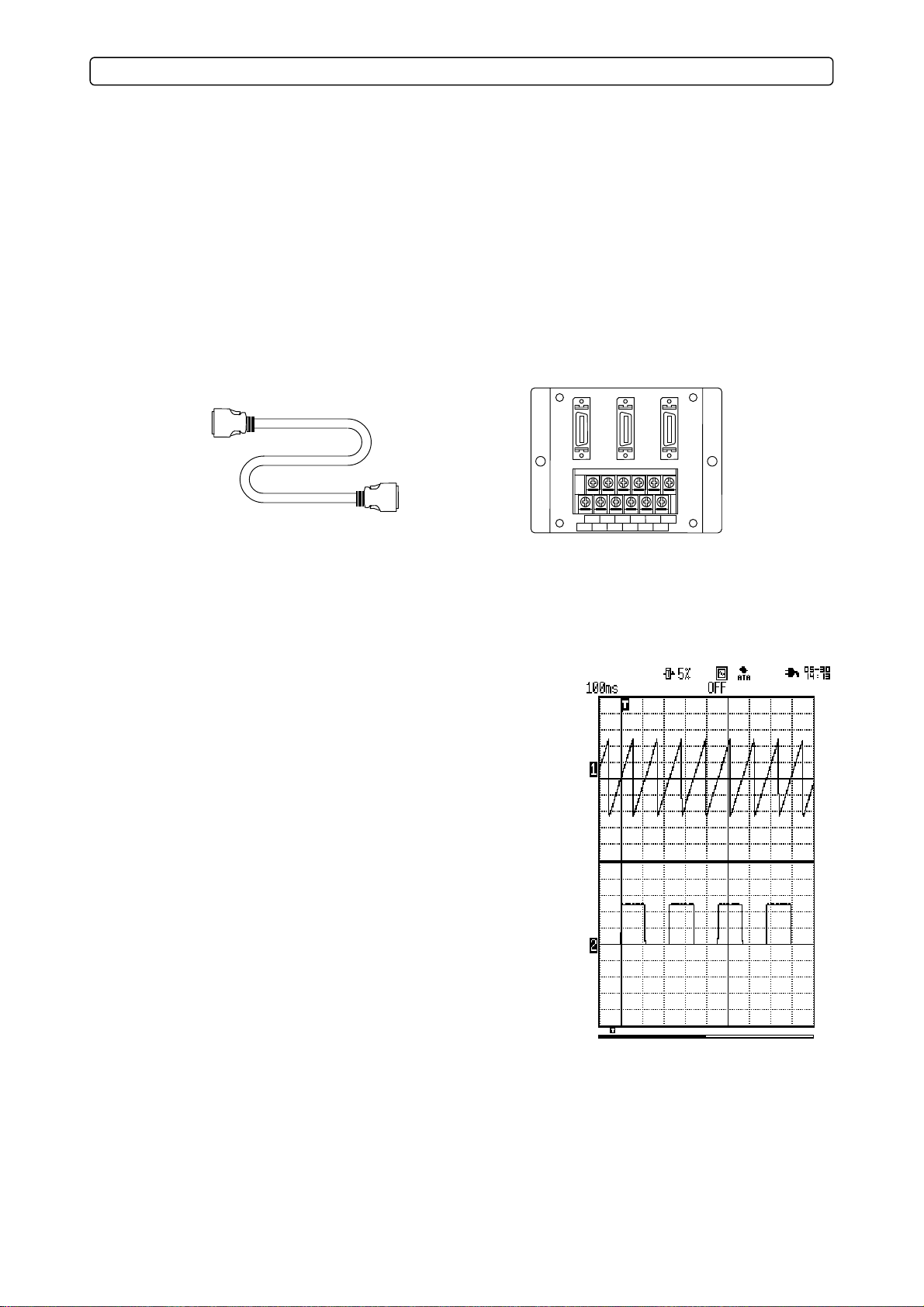

Before adjusting servo, it is required to understand the servo condition. Measure the D/A output

(analogue output) mounted on the servo drive unit with a high-coder etc. Get used to using a high-coder

before starting servo adjustment.

Prepare the cable SH21 (NC bus cable, etc.) and the tools shown below in advance. Relay terminal

(MR-J2CN3TM) is a tool designated for MDS-B-SVJ2 and MR-J2-CT. In case that DO output has already

been used, let the signal go through to encourage the D/A output by using a relay terminal as the D/A

output, contactor and DO output for break control shares the same connector.

SH21

(NC bus cable)

MR-J2CN3TM

(Relay terminal)

Have a look at the trial output in the display

when finished connecting high-coder. An

example of MDS-B-SVJ2 is shown the right.

Ch.1 Trial output of

saw-tooth wave

SV061=101

SV063=0

Ch.2. Trial output of

rectangular wave

SV062=102

SV064=0

Memory

Single

shot

Scroll

Waveform of MDS-B-SVJ2 trial output result

1-3

Page 5

1 PROLOGUE

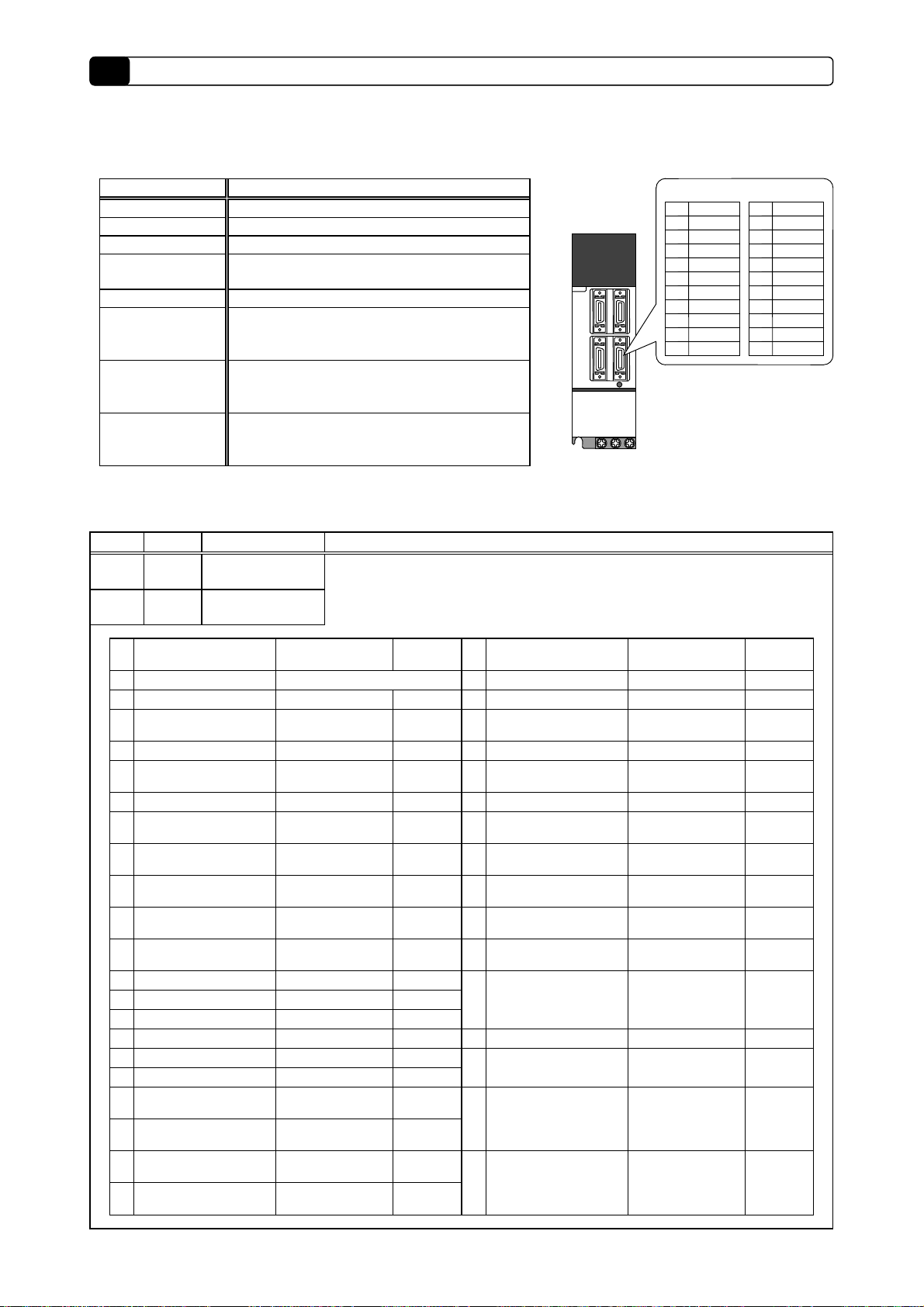

1-1-3 D/A Output specifications for MDS-C1/CH-Vx

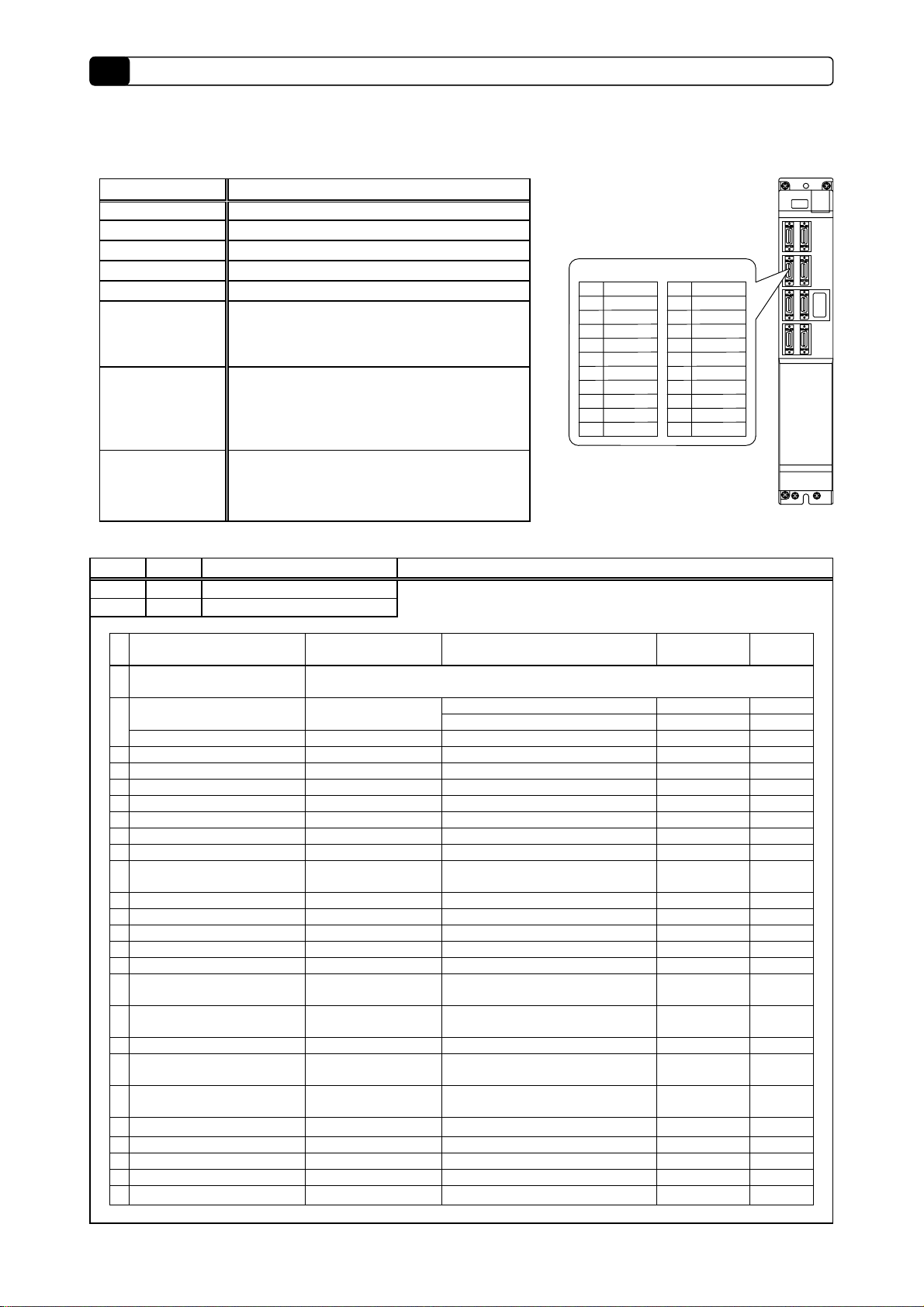

(1) D/A Output specifications

Item Explanation

No. of channels 2ch

Output cycle 888 µsec (minimum value)

Output precision 8bit

Output voltage

Output scale setting ±1/256 to ±128 times

Output pins

Function

Option

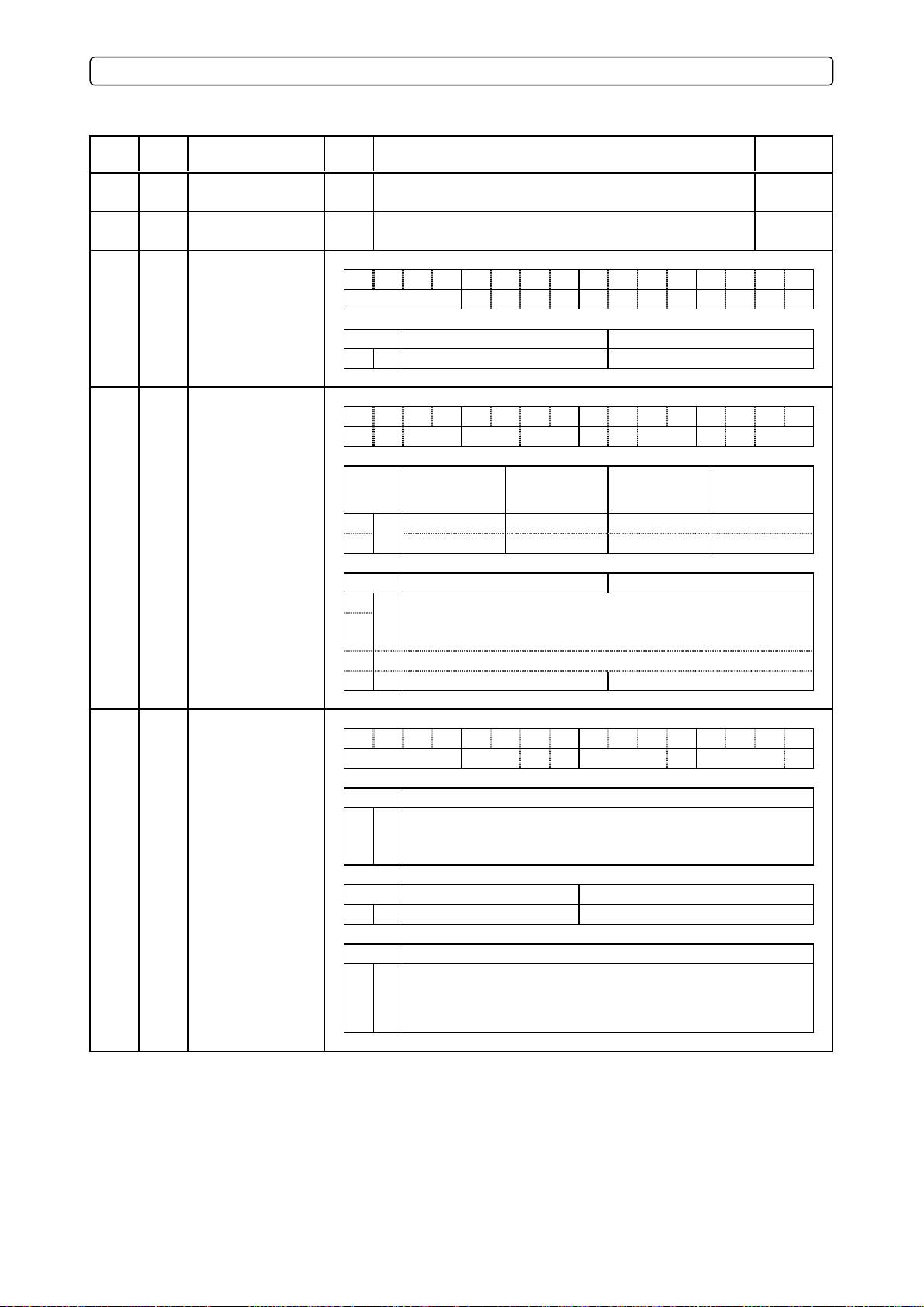

(2) Setting the output data

No. Abbrev Parameter name Explanation

SV061 DA1NO D/A output channel 1 data No. Input the No. of the data to be outputted to each data D/A output channel.

SV062 DA2NO D/A output channel 2 data No.

0V to 2.5V to +5V

CN9 connector

MO1 = pin 9

MO2 = pin 19

GND = pin 1, 11

Phase current feed back output function

L-axis U-phase current FB : pin 7

L-axis V-phase current FB : pin 17

M-axis U-phase current FB : pin 6

M-axis V-phase current FB : pin 16

A drive unit with 2 axes (MDS-C1/CH-V2) also has 2

channels for D/A output. Therefore, set the output

data of the axis (SV061,62), which is not observed,

to “-1”.

Pin

10

Signal

1

2

3

4

5

6

MUIFB

LUIFB

7

8

MO1

9

CN9 connector

LG

Pin

11

12

13

14

15

16

17

18

20

Signal

LG

MVIFB

LVIFB

MO2 19

No. Output data Standard output unit

-1 D/A output non-selected

13 (in case of 2000r/min) 1000r/min / V 3.55ms

ch1: Speed feedback r/min

0

For an Amp. with 2 axes (MDS-C1/CH-V2). Set for the parameter of the axis which is not

used.

Standard setting value of output scale

(Setting values in SV063, SV064)

9 (in case of 3000r/min) 1500r/min / V 3.55ms

Standard

output unit

Output

cycle

ch2: Current command Stall% 131 Stall 100% / V

1 Current command Stall% 131 Stall 100% / V 3.55ms

2 –

3 Current feedback Stall% 131 Stall 100% / V 3.55ms

4 –

5 –

6 Position droop NC display unit / 2 328 (When the display unit=1µm) 10µm / 0.5V 3.55ms

7 –

8 Feedrate (F∆T)

(NC display unit / 2)

/ communication cycle

55 (When 1µm,3.5ms)

1000(mm/min)

/ 0.5V

3.55ms

9 –

10 Position command NC display unit / 2 328 (When the display unit=1µm) 10µm / 0.5V 3.55ms

11 –

12 Position feedback NC display unit / 2 328 (When the display unit=1µm) 10µm / 0.5V 3.55ms

13 –

Collision detection estimated

14

torque

Collision detection

15

disturbance torque

Stall% 131 Stall 100% / V 3.55ms

Stall% 131 Stall 100% / V 3.55ms

Current command

64

(High-speed)

Current feedback

65

(High-speed)

77 Estimated disturbance torque Internal unit 8 (adjustment required)

Internal unit 8 (adjustment required)

Internal unit 8 (adjustment required)

–

–

–

888µs

888µs

888µs

125Saw-tooth wave test output 0V to 5V 0 (256) Cycle: 227.5ms 888µs

126Rectangular wave test output 0V to 5V 0 (256) Cycle: 1.7ms 888µs

1272.5V (data 0) test output 2.5V 0 (256)

–

888µs

1-4

Page 6

(3) Setting the output scale

Usually, the standard setting value is set for the output scale (SV063, SV064). When “0” is set, the output

will be made as well as when “256” is set.

DATA ×

(Example) When outputting the current FB with 100%/V–stall (SV061=3, SV063=131)

100 ×

No. Abbrev. Parameter name Explanation Normal setting range

SV063 DA1MPY D/A output channel 1

SV064 DA2MPY D/A output channel 2

SV063 5 [V]

256

131 5

256

output scale

output scale

×

×

256 (8bit)

256

The standard setting value is specified usually.

(When “0” is set, the output will be made as well as when “256”

is set)

+ 2.5 [V] (offset) = Output voltage [V]

+ 2.5 = 3.499 [V]

-32768 to 32767

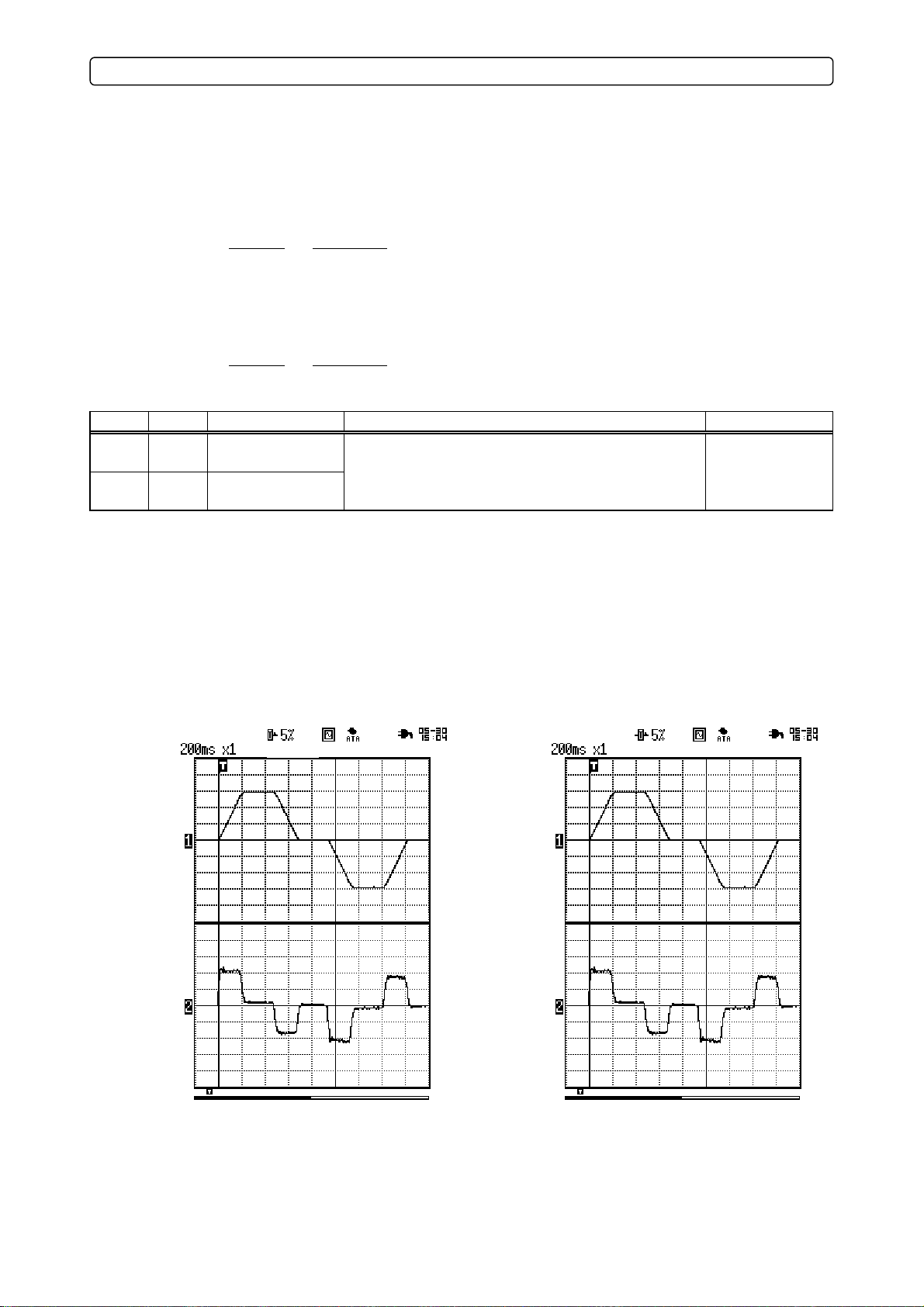

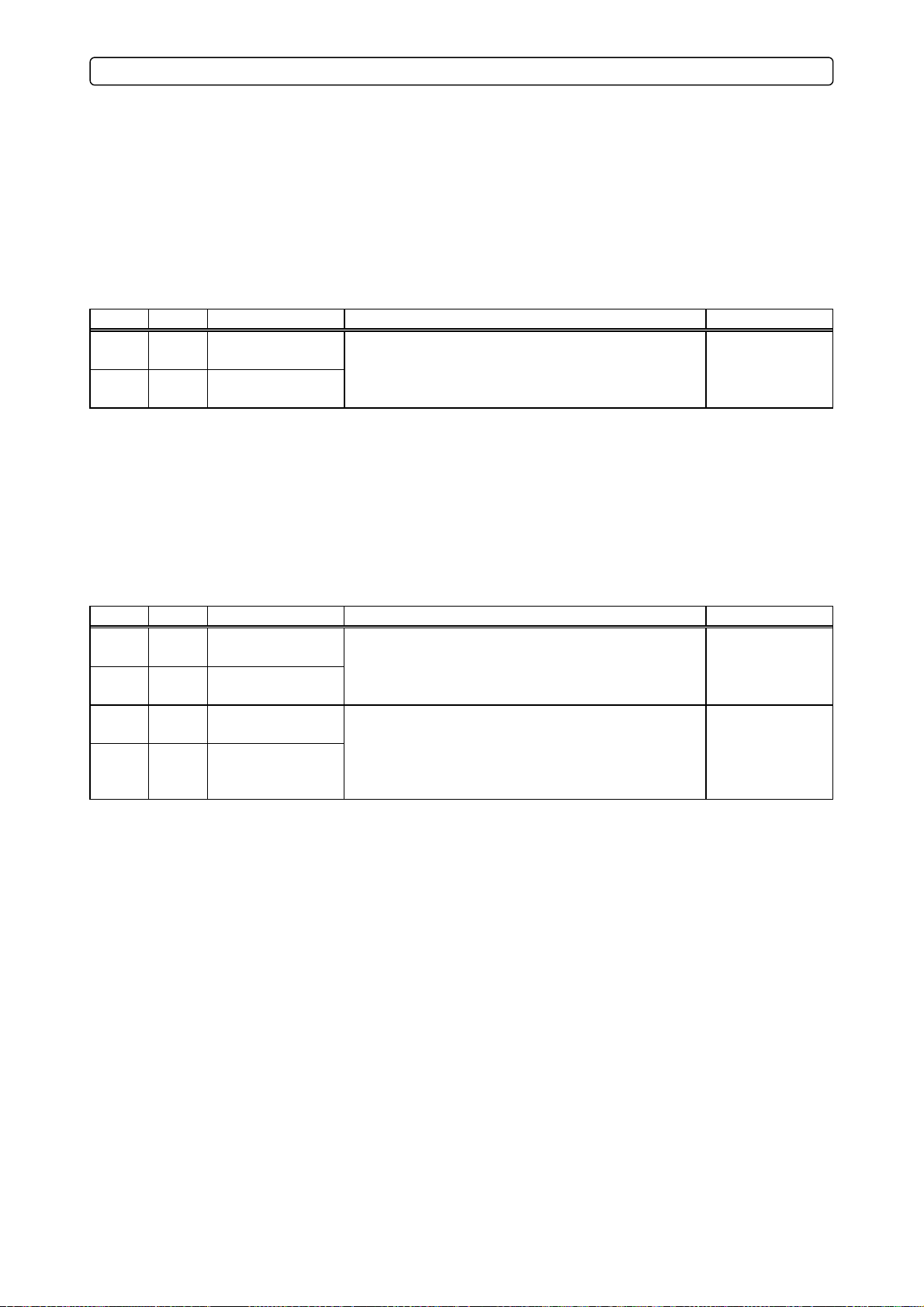

(4) Output voltage range and offset

The output voltage range for MDS-C1/CH-Vx series is different from MDS-B-SVJ2 series. When using

MDS-C1/CH-Vx series, adjust the zero level on Hi-coder side because of 2.5V offset voltage. (When the

data is “0”, 2.5V)

Memory

+5 [V]

Single

shot

Scroll

+10 [V]

Memory

Single

shot

Scroll

ch1 waveform

+2.5 [V]

ch.1 waveform

0 [V]

0 [V]

+5 [V]

-10 [V]

+10 [V]

ch.2 waveform

+2.5 [V]

ch.2 waveform

0 [V]

0 [V]

-10 [V]

Output waveform of MDS-C1/CH-Vx

Output waveform of MDS-B-SVJ2

1-5

Page 7

1 PROLOGUE

1-1-4 D/A Output specifications for MDS-B-SVJ2

(1) D/A output specifications

Item Explanation

No. of channels 2ch

Output cycle 888µsec (min. value)

Output precision 8bit

Output voltage

range

-10V to 0 to +10V

Output scale setting ±1/256 to ±128 times

CN3 connector MO1 = pin 4

Output pins

MO2 = pin 14

GND = pin 1, 11

Offset amount adjustment function

Function

Output clamp function

Low path filter function

Relay terminal: MR-J2CN3TM

Option

Connect from the CN3 connector using the SH21

cable as a lead-in wire.

(2) Setting the output data

No. Abbrev Parameter name Explanation

SV061 DA1NO D/A output

channel 1 data No.

SV062 DA2NO D/A output

channel 2 data No.

No. Output data

0 0V test output For offset am ount adjustment

1 Speed feedback 1000r/min / 2V 888µsec 21 Motor load level 100% / 5V 113.7ms

2 Current feedback

3 Speed command 1000r/min / 2V 888µsec 23 Regenerative load level 100% / 5V 910.2ms

4 Current command

5 V-phase current value 10A / V 888µsec 25 Speed cumulative item – 888µsec

6 W-phase current-value 10A / V 888µsec 26 Cycle counter

Estimated disturbance

7

torque

Collision detection

8

disturbance torque

9 Positio n f e e dbac k ( s t roke ) 100mm / V 3.55ms 29

10 P o s i t i o n fee d b a ck (p u l s e ) 10µm / V 3.55ms 30

11 Position droop mm / V 3.55ms 31

12 Position droop (×10) 100µm / V 3.55ms to –

13 Position droop (×100) 10µm / V 3.55ms 99

14 Feedrate (F∆T) 10000(mm/min) / V 888µsec 100 5V test output

15 Feedrate (F∆T × 10) 1000(mm/min) / V 888µsec

16 Model position droop mm / V 3.55ms

Model position droop

17

(×10)

Model position droop

18

(×100)

q-axis current

19

cumulative value

d-axis current

20

cumulative value

Input the No. of the data to be outputted to each D/A output channel.

(Channel No.9, 10, 29 and 30 correspond to C1 and subsequent versions of software.)

(Channel No.8 and 28 correspond to C3 and subsequent versions of software)

Standard

output unit

Rated(stall)

100% / 2V

Rated(stall)

100% / 2V

Output

cycle

No. Output data

888µsec 22 Amplifier load level 100% / 5V 113.7ms

888µsec 24 PN bus wire voltage 50V / V (1/50) 888µsec

0-5V (Regardless

of resolution)

Rated(stall)

100% / 2V

Rated(stall)

100% / 2V

888µsec 27

888µsec 28

Excessive error

detection amount

Collision detection

estimated torque

Rated (stall)

Position command

(stroke)

Position command

(pulse)

Saw-tooth wave test

101

100µm / V 3.55ms

10µm / V 3.55ms

– 888µsec

– 888µsec

output

Rectangular wave test

102

output

103

Setting prohibited

to

Cycle: 113.7ms

Cycle: 227.5ms

CN3 Connector

Pin

Signal

1

LG

2

SG

3

MO1

4

COM

5

6

7

8

9

VDD

10

Standard

output unit

mm / V 3.55ms

100% / 2V

100mm / V 3.55ms

10µm / V 3.55ms

-5 to 5V

0 to 5V

Pin

Signal

11

12

13

14

15

16

17

18

19

20

EMGX

Output

cycle

888µsec

888µsec

888µsec

888µsec

LG

MBR

MO2

MC

1-6

Page 8

(3) Setting the output scale

This is set when an output is to be made with a unit other than the standard output unit.

(Example 1) When SV061 = 5, SV063 = 2560

The V-phase current value will be output with 1 A/V unit to D/A output ch.1.

(Example 2) When SV063 = 11, SV064 = 128

The position droop will be output with a 2mm/Vunit to D/A output ch.2.

No. Abbrev. Parameter name Explanation Normal setting range

SV063 DA1MPY D/A output channel 1

output scale

SV064 DA2MPY D/A output channel 2

output scale

When “0” is set, the output will be made with the standard

output unit. To change the output unit, set a value other than 0.

The scale is set with a 1/256 unit. When 256 is set, the unit

will be the same as the standard output.

(4) Setting the offset amount

This is used when the zero level of the output voltage is to be finely adjusted. The output scale when the

data No. is “0” will be the offset amount. After setting the offset, set the data No. to a value other than “0”,

and do not set it to “0” again. Because the offset amount is saved in the drive unit memory, it does not

need to be set again when the drive unit power is turned ON next.

-32768 to 32767

No. Abbrev. Parameter name Explanation Normal setting range

SV061 DA1NO D/A output channel 1

data No.

SV062 DA2NO D/A output channel 2

data No.

SV063 DA1MPY D/A output channel 1

offset amount

SV064 DA2MPY D/A output channel 2

offset amount

Set “0”.

After setting the offset amount in SV063 and SV064, change

the data No. to a value other than “0”.

The amount can be set with the output precision unit.

Observe the output value and set so that the output value is 0V.

Because the offset amount is saved in the drive unit memory, it

does not need to be set again when the drive unit power is

turned ON next.

0 to 102

-10 to 10

1-7

Page 9

1 PROLOGUE

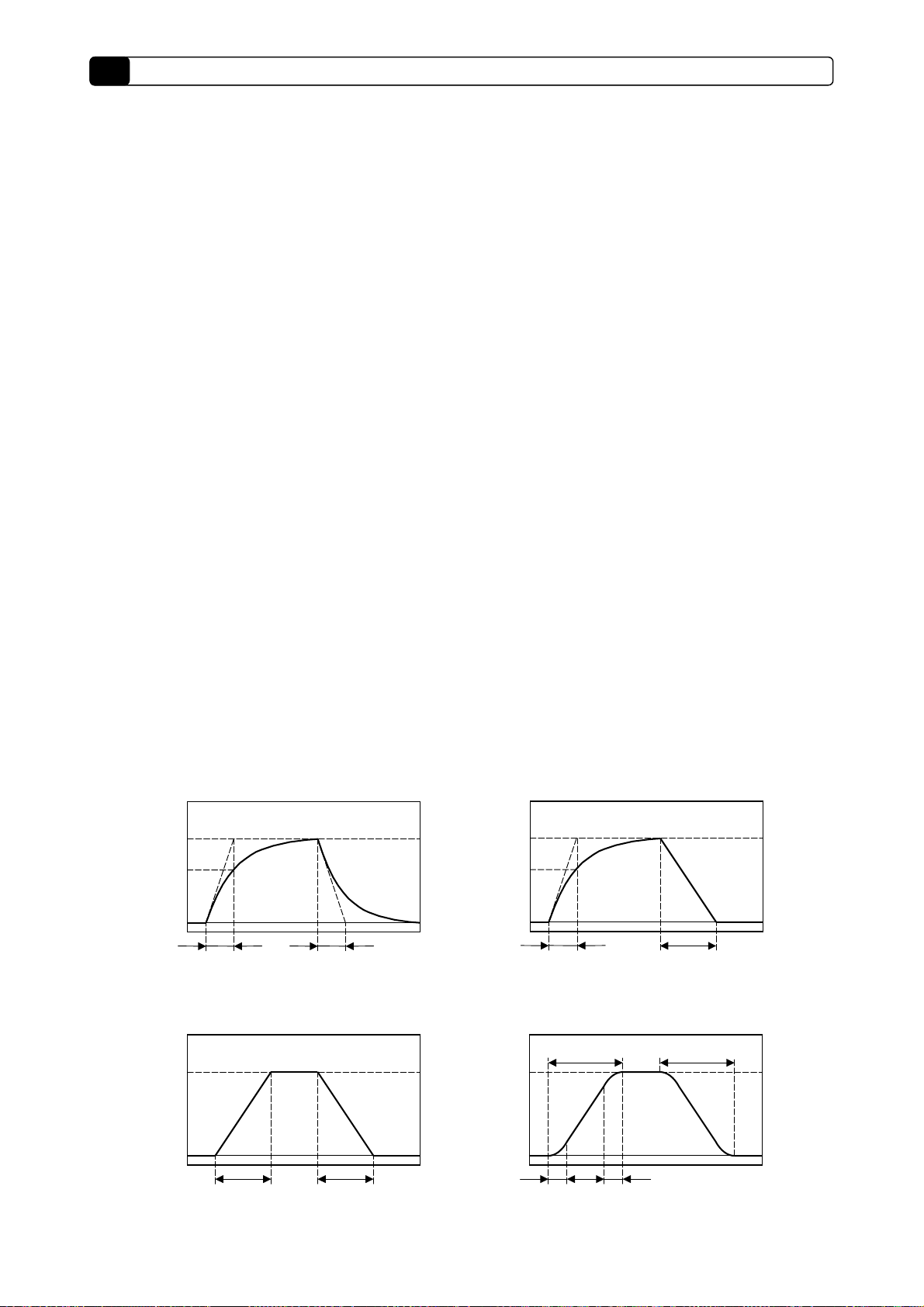

1-1-5 Parameters Concerning with Acceleration/Deceleration Processing

As for acceleration/deceleration control with NC, there are 4 types of processing. The setting of

acceleration/deceleration time constant is based on “constant time”, which means that the inclination

changes in accordance with the speed. (cf. constant inclination)

(1) Exponential (primary delay) acceleration/deceleration

Acceleration/deceleration is made according to exponential function. This acceleration/deceleration

control has been used for a long time as the way it is controlled is very simple. However, it takes longer

time to complete positioning and it is not used for rapid traverse feed any more. This is occasionally used

for cutting feed.

(2) Exponential acceleration - linear deceleration

This acceleration/deceleration control enabled to shorten the time to complete positioning by improving the

exponential acceleration/deceleration control.

(3) Linear acceleration/deceleration

This acceleration/deceleration control is most commonly used. Comparing with exponential acceleration/

deceleration control, the motor torque output is more ideal and the time to complete positioning can be

reduced. This acceleration/deceleration control requires the memory capacity, therefore, it was limited

when using conventional NC though the present NC has been relieved from such a limitation. Use linear

acceleration/deceleration for rapid traverse feed. Use also for the cutting feed.

(4) S-pattern (Soft) acceleration/deceleration

Use this acceleration/deceleration control in case that the shock at the start of acceleration when using

linear acceleration/deceleration, or in case that the torque output efficiency is not good enough as the

acceleration/deceleration torque is not constant (the protrusion can be observed in the torque waveform) i n

the axis with a large inertia (acceleration/deceleration time constant ≥300ms). However, this

acceleration/deceleration type cannot be used for the cutting feed in interpolation axis because the

synchronization between axes is not available.

F

0.632 X F

0

Gt1

(2) Exponential acceleration-linear deceleration

GtL+Gt1

F

2XGt1

GtL+Gt1

0.632 X F

F

0

Gt1

(1) Exponential (primary delay)

acceleration/deceleration

F

Gt1

0

GtL

(3) Linear acceleration/deceleration

GtL

1-8

0

GtL Gt1/2

Gt1/2

(4) S-pattern (Soft) acceleration/deceleration

Page 10

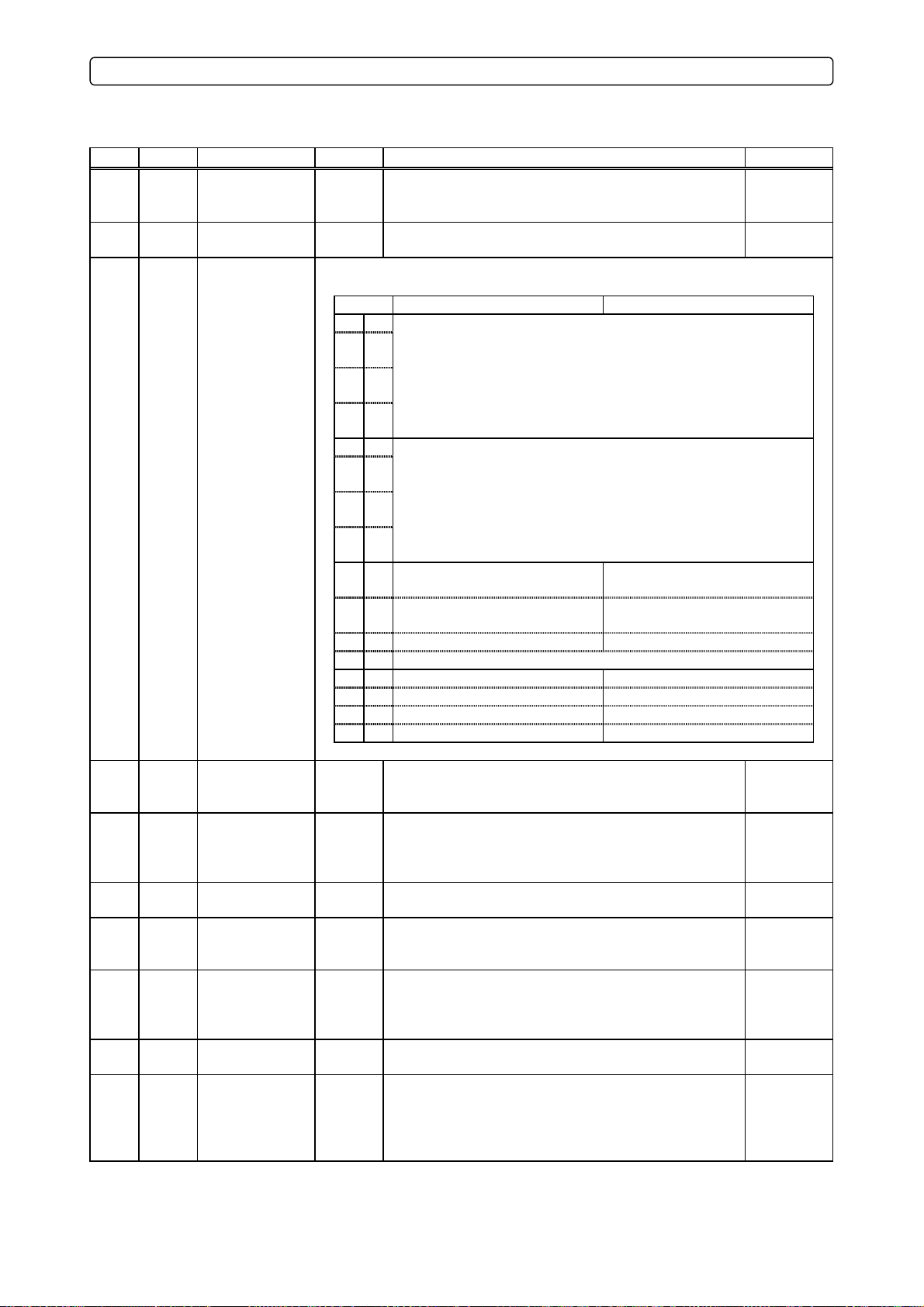

Axis specification parameters (M60S series) concerning with acceleration/deceleration control.

M60S Abbrev. Parameter name Unit Explanation Setting range

#2001 rapid Rapid traverse

rate

#2002 clamp Cutting feed

clamp speed

#2003 smgst Acceleration/

deceleration mode

#2004 G0tL G0 time constant

(linear)

#2005 G0t1 G0 time constant

(exponential)

#2006 G0t2 Not used. 0

mm/min Set rapid traverse rate for each axis.

The setting value has to be less than the maximum spindle

speed of the motor.

mm/min Set the cutting feed (G1 feed) clamp speed.

The programmed speed is restricted by this parameter.

Designate modes for acceleration/deceleration (smoothing) control;

bit Meaning when “0” is set. Meaning when “1” is set.

0 LR 1: Linear acceleration/deceleration

1 R1

2

3 R3

4 LC 1: Linear acceleration/deceleration

5 C1

6

7 C3

8 OT1

9 OT2

10 OT3 (Speed loop step stop)

11 (Note) Set this parameter(bit8-10) with a limit switch (H/W).

12

13

14

15

Set “0” in bits with no particular description.

ms Set time constant for linear control with G0 feed (rapid traverse)

ms Set the exponential time constant with G0 feed (rapid traverse)

Set the G0 feed (rapid traverse)

acceleration/deceleration type.

Set the G1 feed (cutting feed)

Acceleration/deceleration type.

Stroke end stop time constant

G0tl

Stroke end stop type: linear

deceleration

acceleration/deceleration, or time constant at the 1st step of

S-pattern acceleration/deceleration control

acceleration/deceleration, exponential acceleration-linear

deceleration time constant, or time constant at the 2nd step of

S-pattern time constant.

2: Exponential (primary delay)

acceleration/deceleration

8: Exponential acceleration, linear

deceleration

F: S-pattern (soft)

acceleration/deceleration

2: Exponential (primary delay)

acceleration/deceleration

8: Exponential acceleration, linear

deceleration

F: S-pattern (soft)

acceleration/deceleration

Stroke end stop time constant

G0tl×2

Position loop step stop

1 to 999,999

1 to 999,999

1 to 4000

1 to 5000

#2007 G1tL G1 time constant

(linear)

#2008 G1t1 G1 time constant

(exponential)

#2009 G1t2 ms Not used 0

#2013

#2014

OT–

OT+

Soft limit I –

Soft limit I +

ms Set time constant for linear control with G1 (cutting feed)

acceleration/deceleration, or time constant at the 1st step of

S-pattern time constant.

ms Set the exponential time constant with G1 feed (cutting feed)

acceleration/deceleration, exponential acceleration-linear

deceleration time constant, or time constant at the 2nd step of

S-pattern time constant.

mm These set the soft limit area with zero point of basic machine

coordinate system as reference point. When the inputted value

exceeds this parameter, the machine cannot move. When

#2013 is set to the same value as #2014 except for “0”, this

function is disabled. (For maker setup)

1 to 4000

1 to 5000

-99999.999

to

99999.999

1-9

Page 11

2 MDS-C1/CH-Vx ADJUSTMENT PROCEDURES

2-1 Setting Initial Parameters .....................................................2-3

2-1-1 Setting the gear ratio .............................................................................2-3

2-1-2 Setting detector specifications...............................................................2-3

2-1-3 Confirming the machine specifications value.........................................2-3

2-2 Gain Adjustment ...................................................................2-4

2-2-1 Preparation before operation.................................................................2-4

2-2-2 Measuring the inertia rate......................................................................2-6

2-2-3 Determining the standard speed loop gain ............................................2-7

2-2-4 Explanation of notch filter ......................................................................2-8

2-2-5 Adjusting the speed loop gain..............................................................2-12

2-2-6 Adjusting the position droop waveform................................................2-14

2-3 Adjusting Acceleration/Deceleration Time Constant...........2-20

2-3-1 Rapid traverse feed (G0 feed) .............................................................2-20

2-3-2 Cutting feed (G1).................................................................................2-21

2-4 Initial Adjustment for the Servo Functions..........................2-22

2-4-1 Standard settings for the lost motion compensation ............................2-22

2-4-2 Excessive error width detection...........................................................2-23

2-4-3 Vertical axis drop prevention control....................................................2-24

2-5 Procedures for Adjusting Each Functions................................2-28

2-5-1 Disturbance observer function.............................................................2-28

2-5-2 Overshooting compensation................................................................2-30

2-5-3 Collision detection function..................................................................2-34

2-5-4 Voltage non–sensitive zone (Td) compensation ..................................2-38

2-6 Full Closed System..................................................................2-39

2-6-1 Basic knowledge..................................................................................2-39

2-6-2 Speed loop delay compensation..........................................................2-42

2-6-3 Dual feedback control..........................................................................2-44

2-7 MDS-C1/CH-Vx Parameter List...............................................2-46

2-1

Page 12

2 MDS-C1/CH-Vx ADJUSTMENT PROCEDURES

A

Prepare the following manuals when adjusting the MDS-C1-Vx Series (200V series) and MDS-CH-Vx

Series (400V series) servo parameters in accordance with this manual.

“MDS-C1 SERIES SPECIFICATIONS MANUAL” BNP-C3000 “MDS-CH SERIES SPECIFICATIONS AND

INSTRUCTION MANUAL ” BNP-C3016

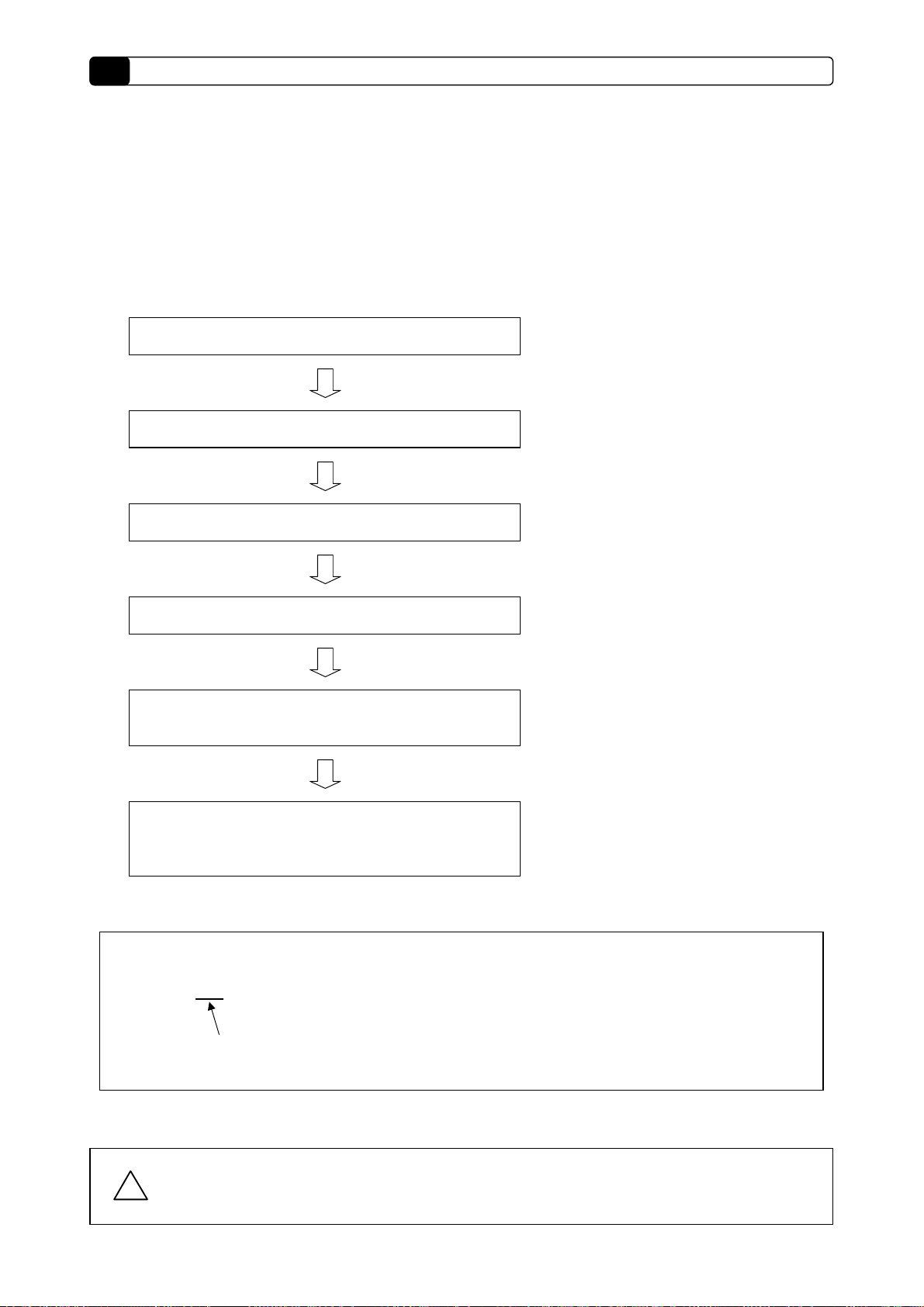

When adjusting the servo for the first time (primary adjustment), set and adjust the following items in order

from 2-1 to 2-4. “2-5 Procedures for adjusting each function” are set and adjusted only when required.

2-1 Setting initial parameters

2-2 Gain adjustment

2-3 Adjusting acceleration/deceleration time constant

s for the primary adjustment,

set and adjust the items in order

from 2-1 to 2-4.

2-4 Initial adjustment for the servo functions

In this manual, [Normal setting range] of parameters are shown instead of [Setting range]. [Normal

setting range] means the range of the values used in actual parameter adjustment (though [Setting range]

means the range of values that does not cause an error).

<Example of parameter explanation>

No. Abbrev. Parameter name Explanation

SV008 VIA Speed loop leading

compensation

“1364” is set as a standard. ”1900” is set as a standard during SHG

control. Adjust in increments of approx. 100 at a time.

Normal

setting range

700 to 2500

CAUTION

!

This manual explains only in case of high gain mode of MDS-C1-Vx.

2-2

Page 13

2-1 Setting Initial Parameters

Input the setting values listed in the "Standard Parameter list per motor" in the specifications manual for

the initial parameters before adjusting the servo. If a wrong value is input, the initial parameter error

(ALM37) will occur. In this case, the parameter number causing an error is displayed on the NC screen.

Some parameters are determined by the machine specification and they are explained below.

2-1-1 Setting the gear ratio

Input the ratio of gear tooth. When initial parameter

error (ALM37) –error parameter number 101– occurs,

reconsider the specification as electric gear must be

overflowing.

When the machine specification is “rack and pinion”,

π is included in the deceleration ratio. In this case, the

accurate positioning is impossible to be made.

Express the π with a rough fractional number when

calculating the gear ratio.

No. Abbrev Parameter name Explanation

SV001

SV002 PC2 Machine side gear ratio

PC1 Motor side gear ratio

Calculate the reducible number of each gear tooth and set the result.

When PC1 < PC2, deceleration is set.

In case that π is included as well as “rack and pinion”, the accurate positioning is

impossible to be made as π is calculated into a rough fractional number when

calculating the gear ratio.

For accurate positioning, the full-closed loop control using a linear scale is

required.

PC2=Machine side

gear ratio

PC1=Motor side

gear

ratio

2-1-2 Setting detector specifications

When using the linear scale, refer to the linear scale instruction manual, and set the parameters correctly.

No. Abbrev Parameter name Explanation

SV019 RNG1 Position detector resolution

SV020 RNG2 Speed detector resolution

SV025 MTYP Motor/detector type

For semi-closed loop (using the detector at the motor end only), set the same

value as SV020.

For full-closed loop, set in accordance with the linear scale specification.

Set the motor detector resolution with kp/rev (1000 pulse/1 rotation) unit.

The 2 high-order digits have to be set in accordance with the specification of the

detector at the motor end and linear scale.

Refer to the "2-7 List of MDS-C1/CH-Vx Parameters" in addition.

2-1-3 Confirming the machine specifications value

Confirm the following machine specifications value to be set in axis specification parameters.

M60S

Series

#2001 rapid Rapid traverse rate Set the rapid traverse rate.

#2002 clamp Cutting feed clamp speed Specify the maximum speed of the cutting feedrate.

#2003 smgst Acceleration/deceleration

Abbrev. Parameter name Explanation

Confirm the maximum rotation speed of the motor.

Even though the feedrate for G01 exceeds this value, clamped with this speed.

Set in accordance with machine specifications. In machine tools, rapid traverse

mode

feed is generally set to “Linear acceleration/deceleration” mode and cutting feed

is generally set to “Exponent acceleration/deceleration” mode. S-pattern (soft)

acceleration/deceleration function is occasionally used for the machine with a

large inertia.

2-3

Page 14

2 MDS-C1/CH-Vx ADJUSTMENT PROCEDURES

A

2-2 Gain Adjustment

2-2-1 Preparation before operation

(1) Confirming the safety

The servo is ready to be operated when the initial parameter settings are completed. Confirm the safety

by checking the following items before operation.

Cancel the emergency stop and make READY ON.

Confirm the axis movement by using a manual pulse generator.

Is any alarm occurring?

re there any vibration or strange sound?

Is the load too large? (Is the current too large?)

Confirm the soft limit movement by using a manual pulse generator.

Does the axis stop before hitting the machine?

Confirm the soft limit (over travel) protection.

Make a program taking account of axis movement range.

Make a program taking account of soft limit position.

(Refer to the sample program.)

Specify the single block operation and set the rapid traverse

override to less than 25%.

Move slowly at first confirming the program.

Move axis forward and backward by memory operation (program

operation). If there is no problem, cancel the single block and

raise the override up to 100% gradually.

If the acceleration current is too large, make

acceleration/deceleration time constant longer.

If there is more than 100% of acceleration current,

that will be enough.

(Sample program of rapid traverse feed for reciprocating operation.)

G28 X0; X axis zero return

N01 G90 G0 X-200.

G4 X1.0; Dwell for 1 second. (1-second pause) Use “X” even for Y axis and Z axis.

G0 X0; Make X axis move to X=0 by rapid traverse feed.

G4 X1.0; Dwell for 1 second. (1-second pause) Use “X” even for Y axis and Z axis.

GOTO 01 Back to “N01”

; Move X axis to X= -200 with rapid traverse feed by absolute position command (the line N01).

Make sure not collide.

No “.” means 200µm,

do not fail to add “.”.

Do not fail to confirm the soft limit movement (over travel) to prevent collision.

CAUTION

!

Be careful of the position of other axes and pay attention when the cutter has

already mounted as the collision possibly occurs before the soft limit.

2-4

Page 15

r

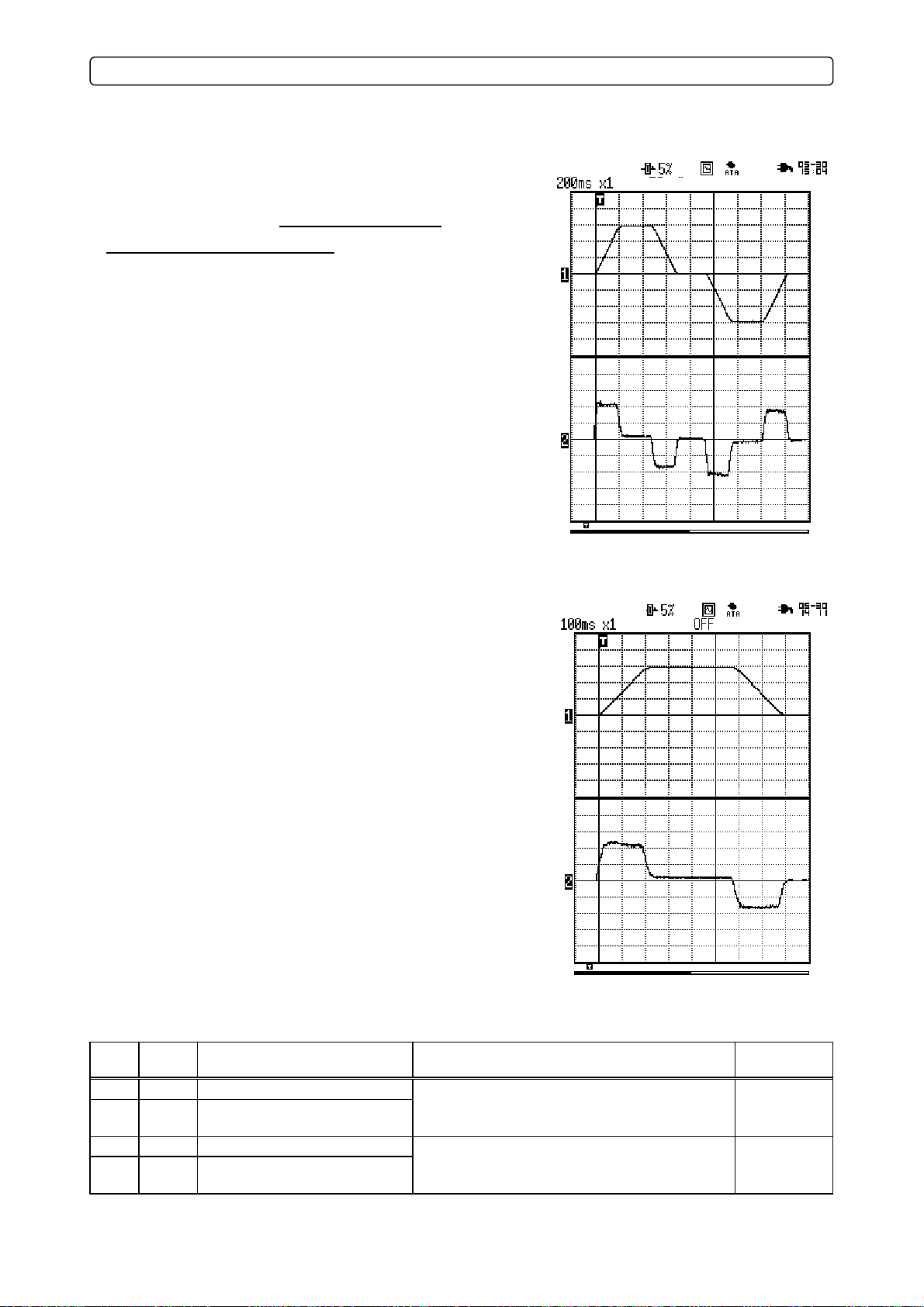

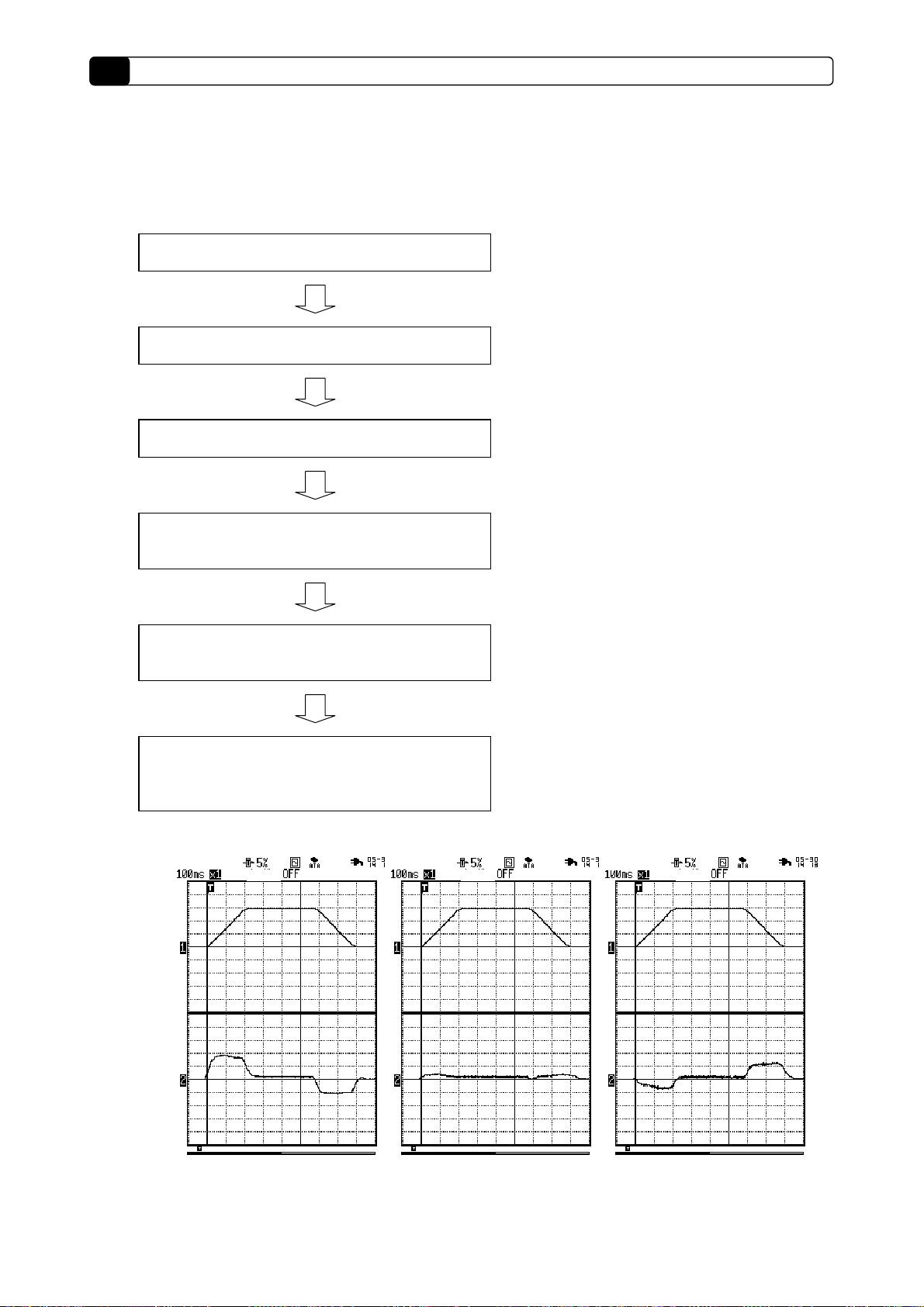

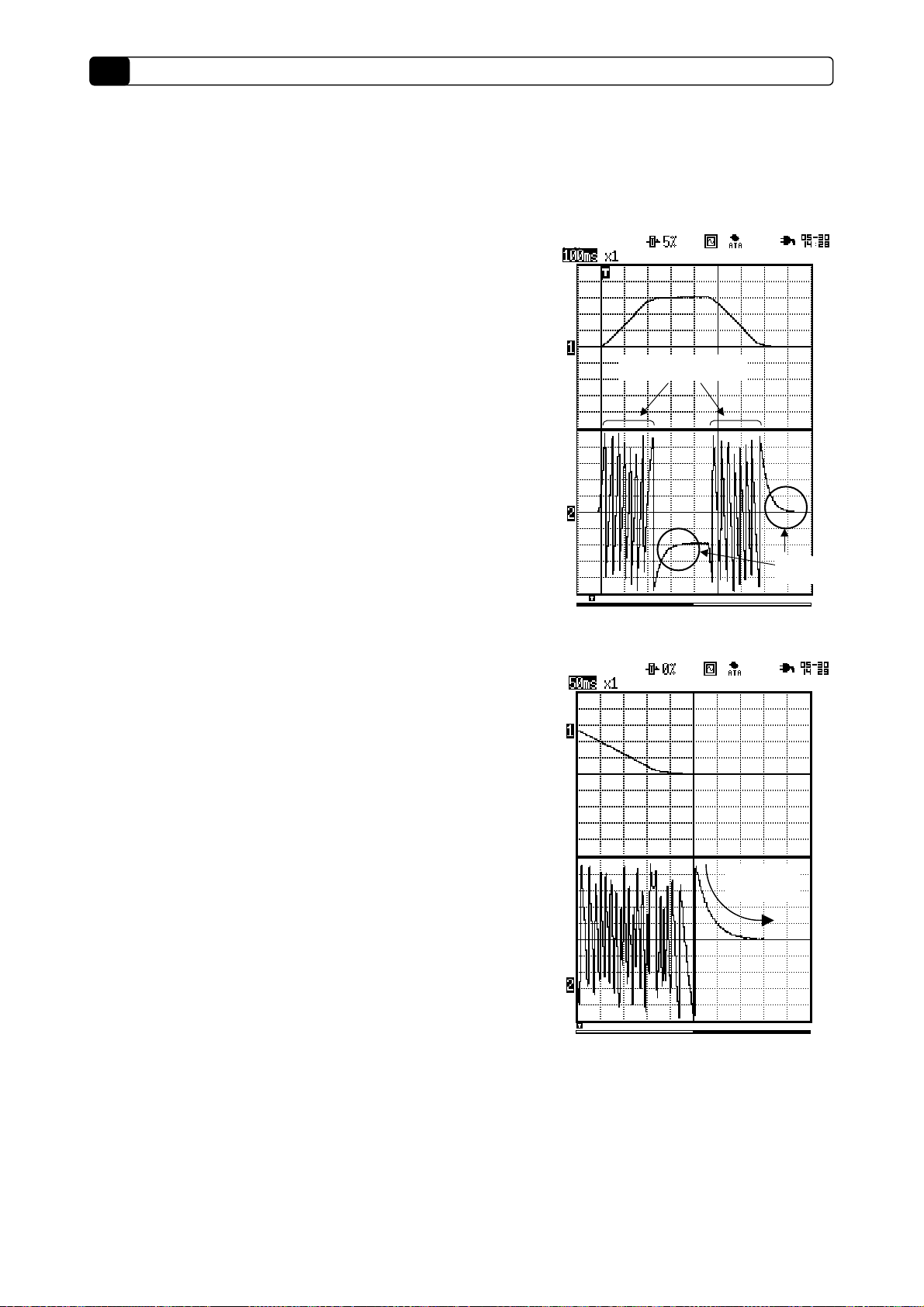

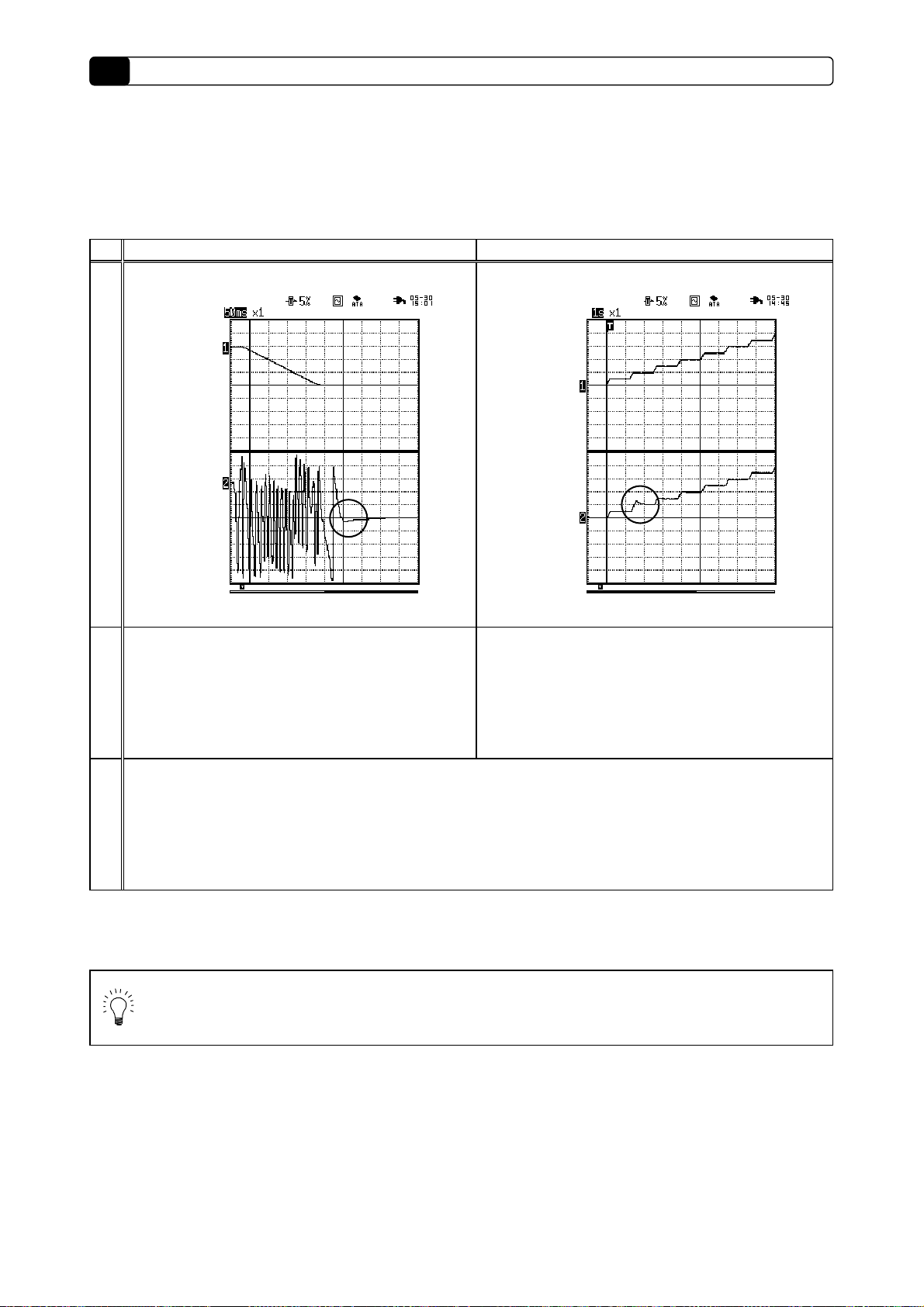

(2) Confirming the acceleration/deceleration waveform with a Hi-coder

Measure speed FB waveform and current

waveform during acceleration/deceleration after

connecting a Hi-coder. Zero level adjustment

on Hi-coder side is required to obtain the

waveform shown right because of 2.5V offset.

(Items to be checked)

1) Voltage output level (ch.1, ch.2)

2) Zero level (ch.1, ch.2)

3) Output polarity of the current FB

Make sure that the hi-code data is reliable as the

rest of the servo adjustment procedures which

will be done later depend on this Hi-coder data.

When measuring repeatedly, set the trigger for

starting Hi-coder measurement at the start of

speed FB. When measuring the data later,

change the data of ch.2 only and leave ch.1 at

speed FB, so that the measurement is always

executed at the same timing. Set the timing of

the measurement, and the data can be

compared easily in case that the operation

conditions including parameters are changed.

The waveforms shown in this manual are

measured at one acceleration/deceleration as

the reciprocating operation includes the same

waveform which has different polarity. In case

of the waveform shown the right, the trigger level

is set as follows;

ch.1: 100mV ↑direction

Speed FB

[500 r/min/div]

SV061 = 0

SV063 = 13

Current FB

[50 %/div]

SV062 = 3

SV064 = 131

Speed FB

[500 r/min/div]

SV061 = 0

SV063 = 13

Current FB

[50 %/div]

SV062 = 3

SV064 = 131

Memory

Memory

Single

Scroll

shot

Acceleration/deceleration waveform of

reciprocating operation

Single

shot

Cursor

Determine the measuring timing

by setting the trigge

No. Abbrev. Parameter name Explanation

SV061 DA1NO D/A output channel 1 data No.

SV062 DA2NO D/A output channel 2 data No.

SV063 DA1MPY D/A output channel 1 output scale

SV064 DA2MPY D/A output channel 2 output scale

The data No. to be output each D/A output channel is

output.

The output will be made with a standard output unit

normally. The scale is set with a 1/256 unit. Refer to

“1-2-3 D/A Output Specifications for MDS-C1/CH-Vx ”.

2-5

Normal

setting range

-1 to 12,

64, 65, 77,

125 to 127

-32768

to 32767

Page 16

2 MDS-C1/CH-Vx ADJUSTMENT PROCEDURES

(

)

A

f

A

2-2-2 Measuring the inertia rate

Measure the load inertia by using the disturbance observer function of a servo drive unit to determine the

standard speed loop gain (standard VGN). Set the measured load inertia rate in the servo parameter

SV037.

Measure the unbalance torque and set it in SV032.

In case of horizontal axis, set “SV032=0”.

In case of vertical axis, refer to “2-4-1 (1) unbalance torque

and frictional torque ”.

Speed FB

SV061 = 0

Set “SV037=100”, “SV043=600” and “SV044=0”.

Set “SV061=0”, “SV062=77”, “SV063=13”, and “SV064=8”.

ccelerate/decelerate and then adjust the output scale o

ch.2.

Change SV037 during acceleration/deceleration so that the

estimated disturbance torque becomes flat.

Designate the load inertia scale as the value of SV037 at

which the estimated disturbance torque becomes the

flattest.

Memory Single

shot

Cursor

Memory

Single

shot

Cursor

No need to compensate the disturbance observer itself.

Therefore, set gain (SV044) to “0”.

Output the estimated disturbance torque to D/A output

ch.2.

In case that 3000r/min is specified, set SV063 to “9”.

djust the output scale (SV064) so that the disturbance

torque waveform in case of SV037=100 becomes as

shown below.

(Adjust so that the inertia rate can be judged.)

Make a program taking account of the soft limit position.

(Refer to the sample program.)

The load inertia rate of the following example including the

motor itself is JL = 3.4 x JM.

(Set SV043 back to “0” and take a note of SV037.)

Memory

Single

shot

Cursor

Estimated

disturbance

torque

SV062 = 77

SV037 = 100

(Too low)

SV037 = 340

(Optimum)

SV037 = 500

(Too high)

2-6

Page 17

A

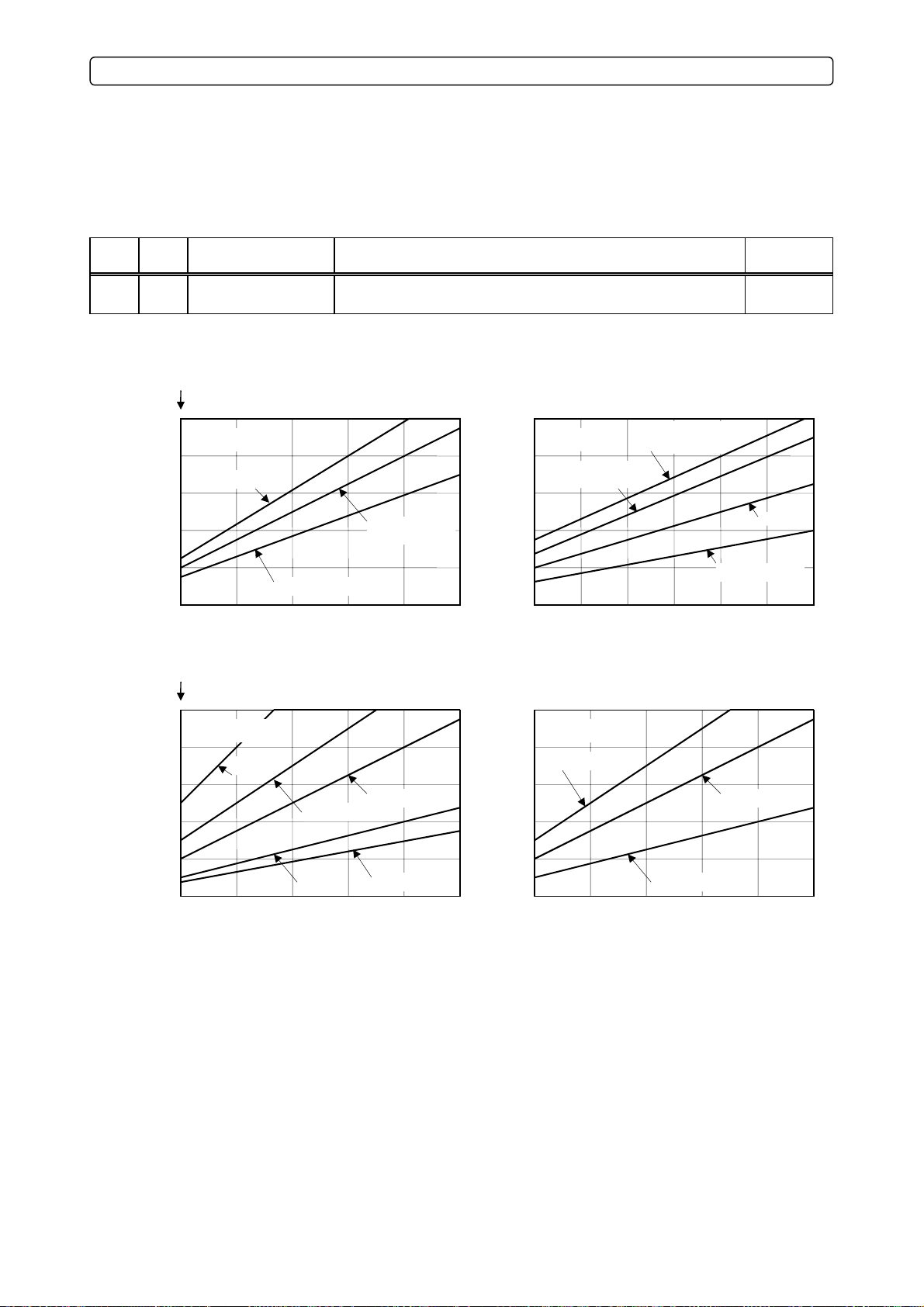

2-2-3 Determining the standard speed loop gain

The standard speed loop gain (standard VGN) is determined referring to the respective load inertia rate in

the following table. If the standard VGN is set as it is, vibration would occur in most models; so at this point,

keep this value in mind as the target value for adjusting the gain.

No. Abbrev. Parameter name Explanation

SV005 VGN1 Speed loop gain 1 Determine the standard setting value by measuring load inertia scale

and referring to the graph below.

Standard

VGN

Standard

VGN

Motor only

500

<HC>

400

HC353 to HC703

300

200

100

0

100

200

HC52 to HC152

300

HC202 to HC902

HC53 to HC203

400

Load inertia scale (%) SV037 setting value

Motor only

500

<HC-H>

400

HC-H1502

300

200

100

0

100

200

HC-H902, 1102

300

HC-H202 to 702

HC-H102, 152HC-H52

400

Load inertia scale (%) SV037 setting value

500

500

600

600

500

<HAN>

400

HA80N/100N/900N

43N to HA103N

H

300

200

100

0

100

150

HA200N to HA700N

HA203N to HA703N

250

200

300

Load inertia scale (%) SV037 setting value

500

<HC-H>

400

HC-H903, 1103

300

200

100

0

100

200

HC-H52 to 153

300

400

Load inertia scale (%) SV037 setting value

HA053 to HA33N

HC-H203 to 703

Normal

setting range

100 to 400

HA40N

350

500

400

600

2-7

Page 18

2 MDS-C1/CH-Vx ADJUSTMENT PROCEDURES

2-2-4 Explanation of notch filter

Machine resonance occurs when the speed loop gain is increased to improve the control accuracy. The

machine resonance is a phenomenon that occurs when the servo's speed loop control acts on the

machine's specific frequency (characteristic resonance frequency). When adjusting the speed loop gain, a

notch filter must be set to suppress this machine resonance (vibra tion) resulting in an in crease of vibration.

The notch filter functions to suppress the servo response at the set frequency, and thereby suppress the

occurrence of vibration. Always understand the methods of setting the notch filter before adjusting the

speed loop gain. Refer to section "2-2-5 Adjusting the speed loop gain" for details on setting the notch

filter.

(1) Notch filter specifications

Mainly the following two notch filters are used with the MDS-C1/CH-Vx series.

MDS-C1/CH-Vx filters

Frequency range Frequency settings Depth compensation settings

Notch filter 1 100Hz to 2250Hz SV038 SV033.bit1 to 3

Notch filter 2 100Hz to 2250Hz SV046 SV033.bit5 to 7

The operation frequency parameter can be set in 1Hz increments, but the internal control will function at

the frequency shown below which is the closest to the setting value. Set the setting frequency shown

below in the parameter when adjusting the notch filter.

The depth compensation is a function that sets the notch filter at a low frequency. A stable notch filter can

be set even at a low frequency. Usually, the standard value that matches the setting frequency is set as

shown below.

Setting frequency and standard filter depth for notch filter 1 and 2

Setting frequency Standard filter depth Setting frequency Standard filter depth Setting frequency Standard filter depth

2250Hz 0 562Hz 0 281Hz 4

1800Hz 0 529Hz 0 250Hz 4

1500Hz 0 500Hz 0 225Hz 4

1285Hz 0 474Hz 0 204Hz 4

1125Hz 0 450Hz 0 187Hz 8

1000Hz 0 429Hz 0 173Hz 8

900Hz 0 409Hz 0 160Hz 8

818Hz 0 391Hz 4 150Hz 8

750Hz 0 375Hz 4 132Hz 8

692Hz 0 346Hz 4 125Hz 8

642Hz 0 321Hz 4 112Hz 8

600Hz 0 300Hz 4 100Hz C

(Note) The depth compensation setting above shows a HEX setting value when the bit0 or bit4 setting is 0.

bit

SV033

setting

When

bit0, 4 = 0

When

bit0, 4 = 0

F E D C B A 9 8 7 6 5 4 3 2 1 0

* *

Does not change Does not change 0, 4, 8, C 0, 4, 8, C

Does not change Does not change 1, 5, 9, D 1, 5, 9, D

Notch filter 2

depth

compensation

*

Notch filter 2

depth

compensation

*

2-8

Page 19

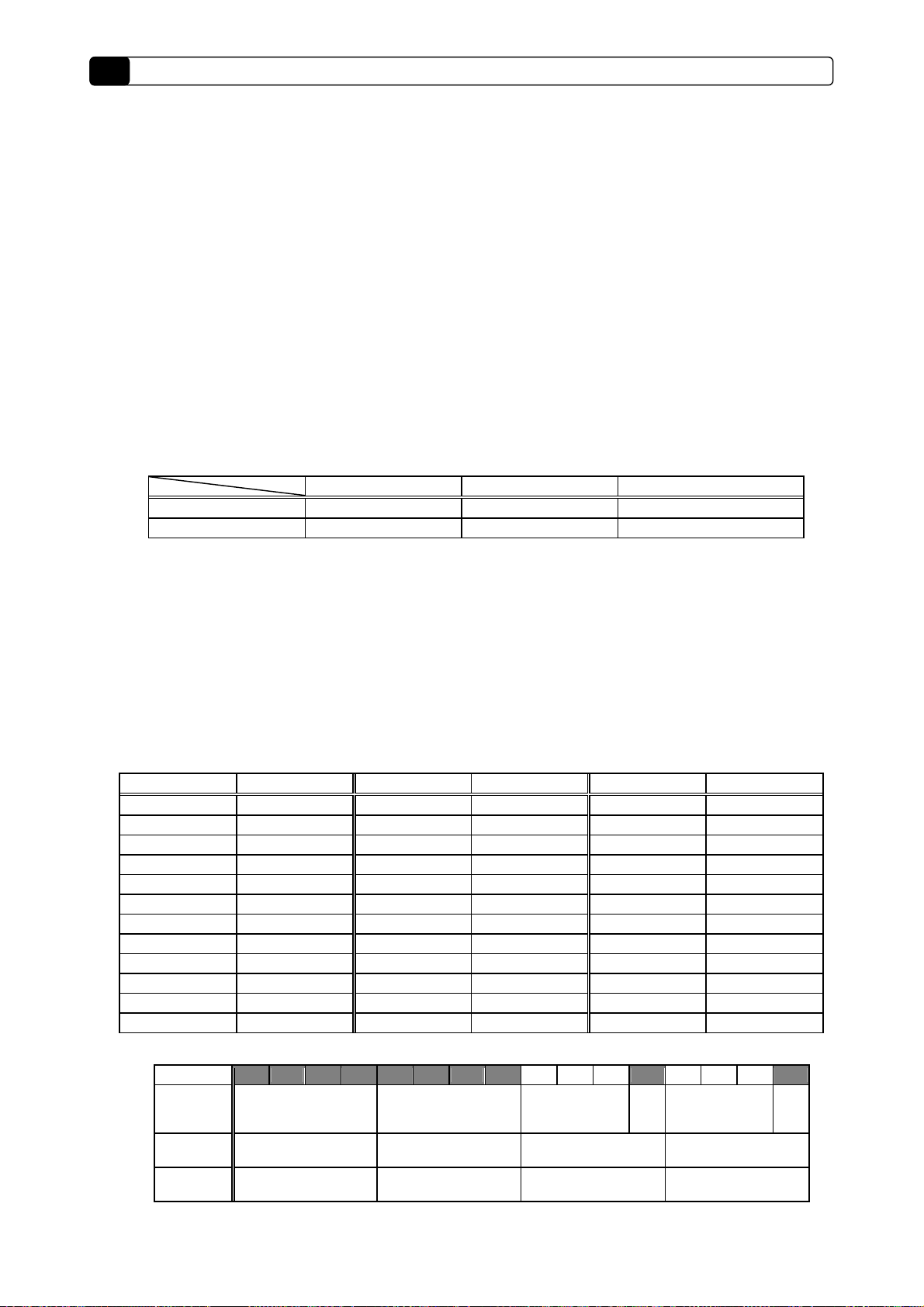

(2) Measuring the resonance frequency

The resonance frequency must be measured before

setting the notch filter frequency. To measure, gradually

increase the speed loop gain to generate vibration, and

measure the current waveform with a Hi-corder.

The phase current feedback output function is used to

measure the resonance frequency of the

MDS-C1/CH-Vx. (Refer to the following table) Output

the U-phase current feedback to Ch. 1 of the Hi-corder,

and the V-phase feedback to Ch. 2 as shown on the

right. Then measure the two phase current feedbacks

simultaneously. Depending on the motor rotation angle,

there may be cases where vibration cannot be

measured at either one of the current phases; however,

if measuring the two phases simultaneously, the

U-phase

current FB

V-phase

current FB

Memory

Single

shot

Scroll

7 wave length/30ms: 7÷0.03=233Hz

vibration can always be measured.

Once the resonance frequency has been measured,

Measuring vibration frequency (233Hz)

(Measure manually when vibration occurs.)

immediately apply emergency stop and stop the

vibration.

To calculate the vibration frequency, select an easy-to-view range in the Hi-corder grid, and calculate the

number of waves generated in one second. (The unit is [Hz] at this time.)

Phase current feedback output function (CN9)

MDS-C1/CH-V1 MDS-C1/CH-V2 Signal Output pin GND pin

L axis L axis (No. 1 axis)

M axis (No. 2 axis)

U-phase current FB 7 pins

V-phase current FB 17 pins

U-phase current FB 6 pins

V-phase current FB 16 pins

1, 11 pins

(Common for each

signal)

1. Measure the Y-phase current feedback and V-phase current feedback

simultaneously so that the measurement can be completed without being affected

by the motor angle.

POINT

2. The phase current feedback is used, so when the motor is rotating, a SIN wave that

is 4-fold the speed (for HC motor) can be measured.

3. If a "squeak" is heard at the instant when acceleration/deceleration is started, the

machine is vibrating at a high frequency exceeding 700Hz. The 750Hz or 1125Hz

filter is effective in this case.

!

CAUTION

When generating resonance, make sure that the speed loop gain is not increased

too far resulting in a large vibration. After measuring the resonance frequency,

immediately apply emergency stop to stop the vibration. The machine or servo

amplifier could fail if vibration is generated for a long time.

2-9

Page 20

2 MDS-C1/CH-Vx ADJUSTMENT PROCEDURES

(3) Setting the notch filter frequency

After measuring the resonance frequency, refer to the "Setting frequency and standard filter depth for

notch filter 1 and 2". Select the setting frequency larger than but closest to the resonance frequency and

set the parameter. Set the depth compensation parameter to the standard filter depth that matches the

frequency.

In the example of measurement on the previous page, the measured resonance frequency is 233Hz. Thus,

set the following:

Filter setting frequency = 250Hz, Filter depth = 4

The notch filter easily becomes unstable when a low frequency is set. Even when set,

POINT

Basically, all resonance can be removed by setting the notch filter. The MDS-C1/CH-Vx series has the

following functions in addition to the notch filter. Use those as necessary.

only the resonance frequency may change (the vibration tone changes), and the

resonance may not be completely removed. If the state is unstable, try using a higher

frequency.

(4) Jitter compensation

Jitter compensation is effective to eliminate the vibration occurring when the axis motor whose backlash is

comparatively large or whose linear movement object is heavy stops rotating. Set from 1 pulse by turn

and confirm how it works.

Jitter compensation is effective only in case that the vibration occurs due to the backlash, thus, it does not

work when the vibration is caused by other factors. (Even when set, only the vibration tone changes.) If

the jitter compensation is not effective, remove the vibration with the notch filter.

Jitter compensation

Parameter setting

SV027. bit4 0 1 0 1

SV027. bit5 0 0 1 1

No jitter

compensation

Compensation 1

pulse

Compensation 2

pulses

Compensation 3

pulses

(5) Other filters

The notch filter 3 with an operation frequency fixed at 1125Hz, and the speed feedback filter fixed at

2250Hz are the other notch filters available. The usage methods are the same as notch filter 1 and 2. Set

them as necessary such as when treating with the third frequency.

Other MDS-C1/CH-Vx filters

Frequency range Frequency settings Depth compensation settings

Notch filter 3 1125 Hz fixed SV033. bit4 None

Speed feedback filter 2250 Hz fixed SV017. bit3 None

2-10

Page 21

Parameter settings related to resonance removing filter

No. Abbrev. Parameter name Unit Explanation

SV038 FHz1 Notch filter frequency 1 Hz Set the resonance frequency to be suppressed. (Valid at 36 or more.)

Set “0” when the filter is not be used.

SV046 FHz2 Notch filter frequency 2 Hz Set the resonance frequency to be suppressed. (Valid at 36 or more.)

Set “0” when the filter is not to be used.

SV017 SPEC*

mtr drva drvu mpt mp abs vdir fdir vfb qro dfbx fdir2

<Start speed feedback f ilter> Eliminate the high frequency vibration of a motor and a det ector.

bit Meaning when “0” is set Meaning when “1” is set

3 vfb Speed FB filter stop Speed FB filter start (2250Hz fixed)

SV027 SSF1

aflt Zrn2 afse ovs lmc omr zrn3 vfct upc vcnt

<Start jitter compensation> Eliminate the vibration while the motor is stopping.

4 0 1 0 1

5

<Active adaptive filter>

bit Meaning when “0” is set Meaning when “1” is set

C Raise the sensitivity of the adaptive filter.

E zrn2 Set to “1”

F aflt Adaptive filter stopped Adaptive filter activated

SV033 SSF2

dos dis nfd2 nf3 nfd1 zck

<Depth compensation for the notch filter 1>

bit Explanation

<Activate notch filter 3> Eliminate the high frequency vibration.

bit Meaning when “0” is set Meaning when “1” is set

4 nf3 Notch filter 3 stopped Notch filter 3 stopped (fixed to1125Hz)

<Depth compensation for notch filter 2>

bit Explanation

Servo specification

selection

Servo function

selection 1

Servo function

selection 2

F EDCBA98765 4 3 2 10

F EDCBA98765 4 3 2 10

bit

vfct

afse

D

F EDCBA98765 4 3 2 10

1

to 3 nfd1

5

to 7 nfd2

No jitter

compensation

0 0 1 1

00: Standard sensitivity 11: high-sensitivity of vibration detector

(Set 2 bit at the same time.)

When bit0 (zck) = 0 (Standard), set the first digit of SV033 to even

numbers such as 0, 2, 4…A, C, and E. 0 is the deepest. The higher

the setting value is, the shallower the filter is.

Set the same as the depth compensation for notch filter 1.

Set shallowly to make control stable and prevent other vibrations apart

from the filter frequency though the effective vibration elimination can

not be expected.

Pulse of

compensation

type1

Pulse of

compensation

type2

compensation

Normal

setting range

150 to 1125

150 to 1125

Pulse of

type3

2-11

Page 22

2 MDS-C1/CH-Vx ADJUSTMENT PROCEDURES

q

(

2-2-5 Adjusting the speed loop gain

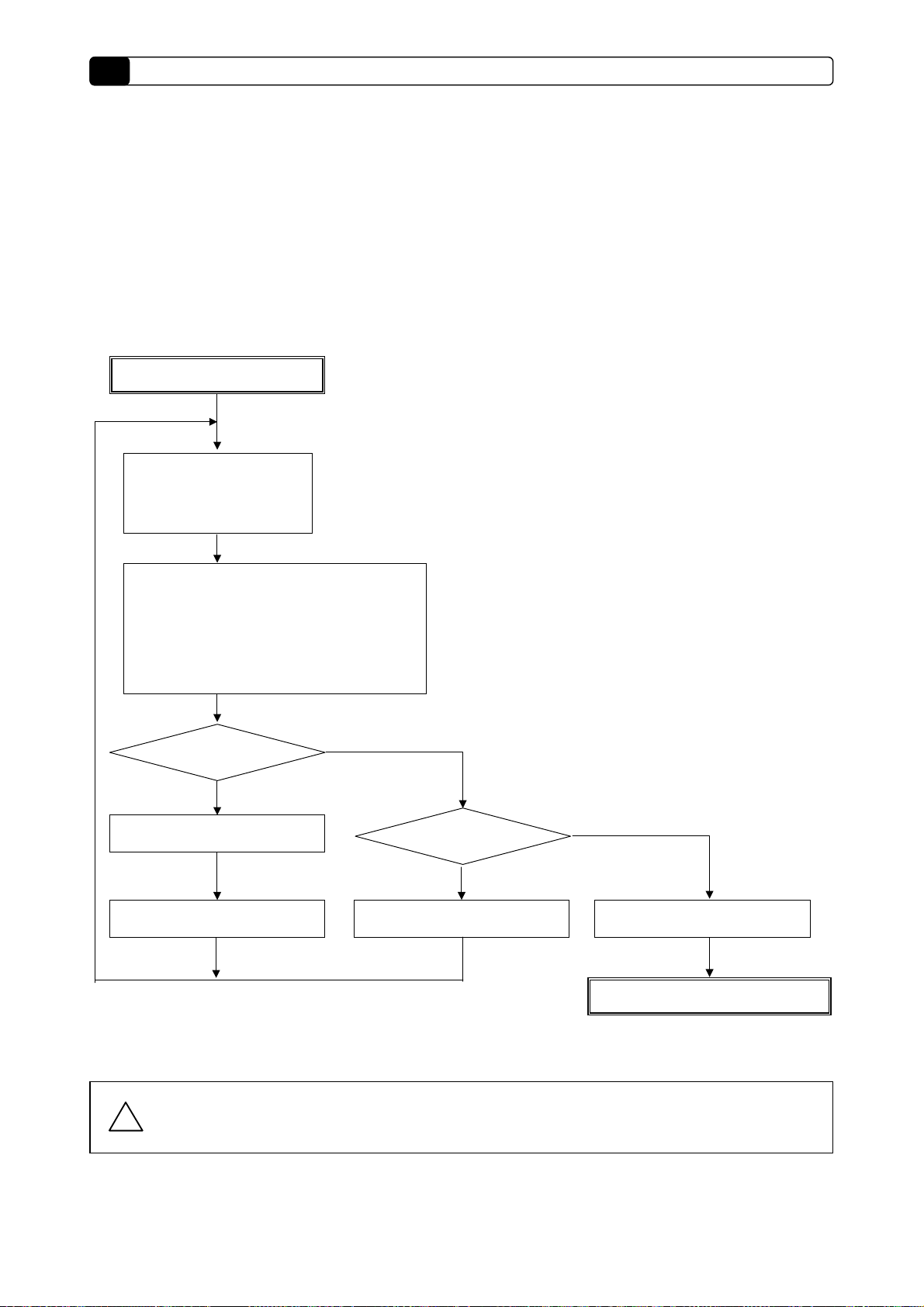

The speed loop gain (SV005) is gradually increased from the state where reson ance does not occur. Once

resonance starts, set the notch filter to remove the resonance. Next, increase the speed loop gain while

removing the vibration with the notch filter, and adjust the speed loop gain targeting the standard VGN

determined from the load inertia. A 30% margin must be secured to ultimately set the standard VGN value,

so set a standard VGN x 1.3 value and confirm that resonance does not occur.

If the resonance cannot be eliminated even when the notch filter is set, the speed loop gain setting will be

limited. Set a value 30% lower than the maximum value at which resonance does not occur.

START speed loop gain adjustment.

Set the standard VGN for the

isolated motor (load inertia

scale 100%) for the speed

loop gain (VGN1: SV005).

Start at state where there is no vibration.

Refer to section "2-2-3 Determining the

standard speed loop gain".

Confirm the vibration by operating the items below.

• Rapid traverse feed (RAPID)

• Change override

• Operate with a manual pulse generator

• Change the axis position

(Or change the table position)

Does vibration occur?

NO

YES

Measure the resonance frequency

with Hi-corder.

Set notch filter to measured

resonance fre

uency.

SV005 ≥ 1.3 × standard VGN1?

NO

Increase the speed loop gain

SV005) by 10 to 20%.

YES

Secure a 30% margin.

Set the speed loop gain (SV005) to

standard VGN.

Speed loop gain adjustment is completed.

Do not set the notch filters to the frequency where vibration does not occur as a

CAUTION

!

means of insurance. Setting many notch filters does not necessarily guarantee a

better effect.

2-12

Page 23

(

)

1. The final SV005 (VGN1) setting value is 70% of the maximum value at which

machine resonance does not occur. If the resonance is suppressed and the SV005

setting is increased by using a vibration suppression function, such as a notch filter,

POINT

<<Reference material>>

Machine resonance is not the only vibration that occurs at the servo shaft. Types of vibration that occur at

the servo shaft are listed below.

Types of

vibration

Machine

resonance

Hunting

Isolated

machine

vibration

Delay in servo

control response

The speed loop PI

gain (VGN, VIA) is

unbalanced

Insufficient

machine rigidity

the servo can be adjusted easier later on.

2. If the vibration is caused by resonance (mutual action of servo control and machine

characteristics), the vibration can always be stopped by lowering SV005 (VGN1). If

the vibration does not change even when SV005 is lowered, there may be a

problem in the machine. The notch filter is not effective when there is a problem i n

the machine.

Cause

Vibration

frequency

150Hz to 1kHz

Several Hz

10 to 20Hz

Measures Explanation

• Set the notch filter

• Lower VGN1 (SV005)

• Lower VIA (SV008)

• Raise VGN1 (SV005)

• Use the disturbance observer

• Lower PGN1 (SV003)

• Use S-pattern (soft)

acceleration/deceleration

There may be several resonance points.

The vibration can always be stopped by

lowering VGN1.

Visually apparent that the shaft vibrates

during acceleration, or the shaft trembles

when stopped.

The machine vibrates due to impact during

acceleration/deceleration. A "clonk" sound

may be heard during acceleration.

Judging the type of vibration

Is a vibration sound heard?

YES

sound heard only during acceleration/

Set standard VGN1 for isolated

motor in speed loop gain (SV005).

Is a vibration

deceleration?

YES

Is a vibration sound heard?

YES

Isolated machine vibration

NO

NO

Set standard VGN1 for isolated

motor in speed loop gain (SV005).

Does vibration occur?

NO

Machine resonance

NO

NO

YES

Is the frequency low, and

vibration visible?

Hunting

Vibration other than servo system.

Vibration of oil pump, etc.

YES

2-13

Page 24

2 MDS-C1/CH-Vx ADJUSTMENT PROCEDURES

2-2-6 Adjusting the position droop waveform

After adjusting the filter and determining the optimal speed loop gain (VGN1), adjust the speed loop

leading compensation (VIA) and position loop gain (PGN) observing the position droop waveform.

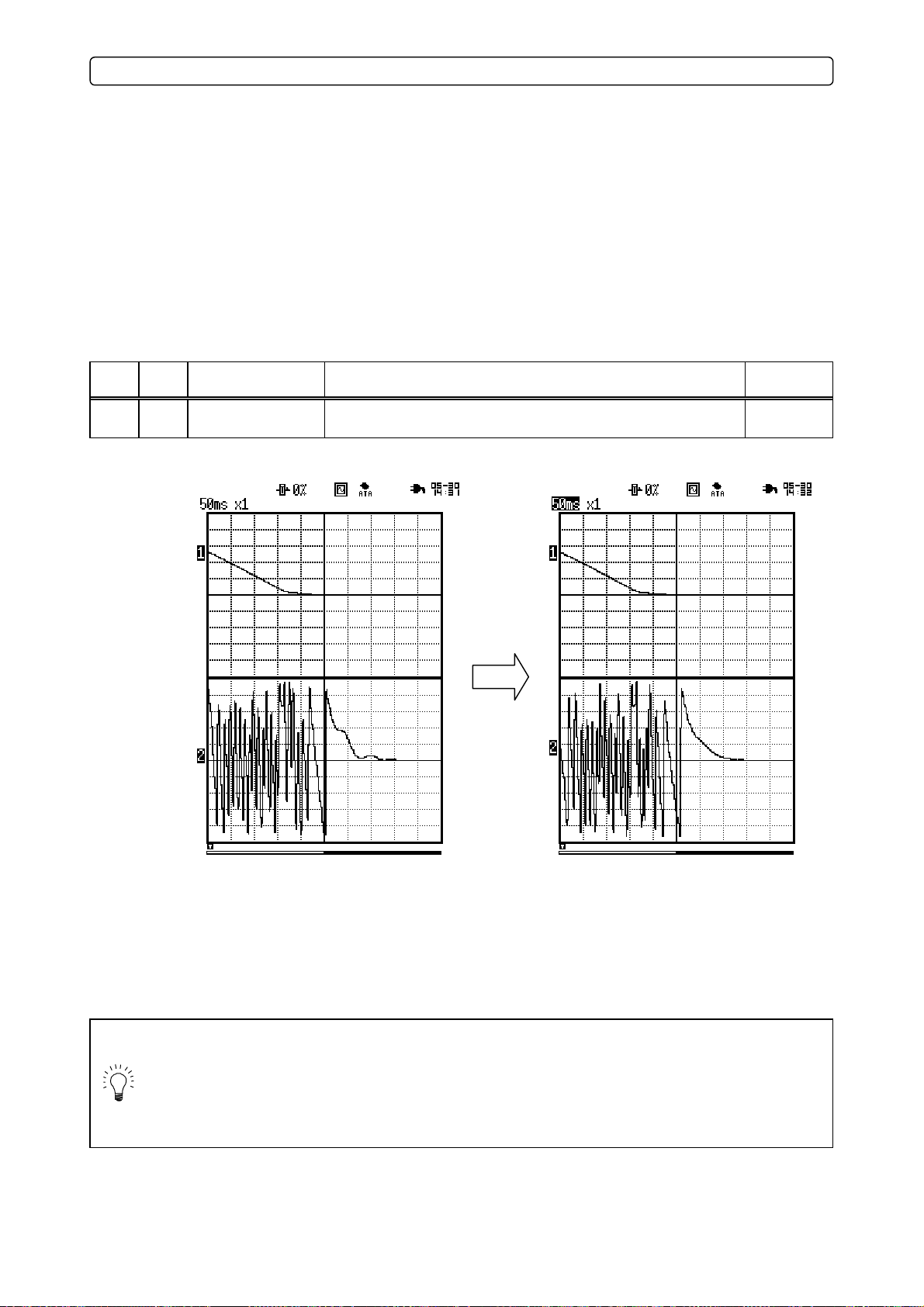

(1) Measuring the position droop

During rapid traverse feed, position droop takes a

few millimeters. However, the unit of the

waveform to be observed is “µm” and the

Memory

Single

shot

Scroll

overflowing waveform is displayed on the Hi-coder.

Before adjusting, make the waveform as shown

right appear on the Hi-coder.

Smooth convergence is the most important thing

about position droop waveform. The position

droop have to converge smoothly when the speed

becomes constant or when positioning is

completed and position droop becomes “0”. Both

of the waveforms enclosed with circles can be used

for gain adjustment, however, the waveform at

when positioning is completed is normally used

because it enables to confirm the overshooting at

the same time when adjusting servo.

It is necessary to confirm that the waveform of the

positioning converges smoothly (approaches to

“0”) at the range of 10µm/0.5V because accurate

control is required for the feed axis of machine

tools.

Speed FB

[500 r/min/div]

SV061 = 0

SV063 = 13

Position droop

[100 µm/div]

SV062 = 6

SV064 = 33

Speed FB

[500 r/min/div]

SV061 = 0

SV063 = 13

Memory

Overflowing range

Position droop waveform

Single

shot

Scroll

Confirm

here

Converge

smoothly

Position droop

[10 µm/div]

SV062 = 6

SV064 = 328

Confirm the waveform

when positioning is completed

2-14

Page 25

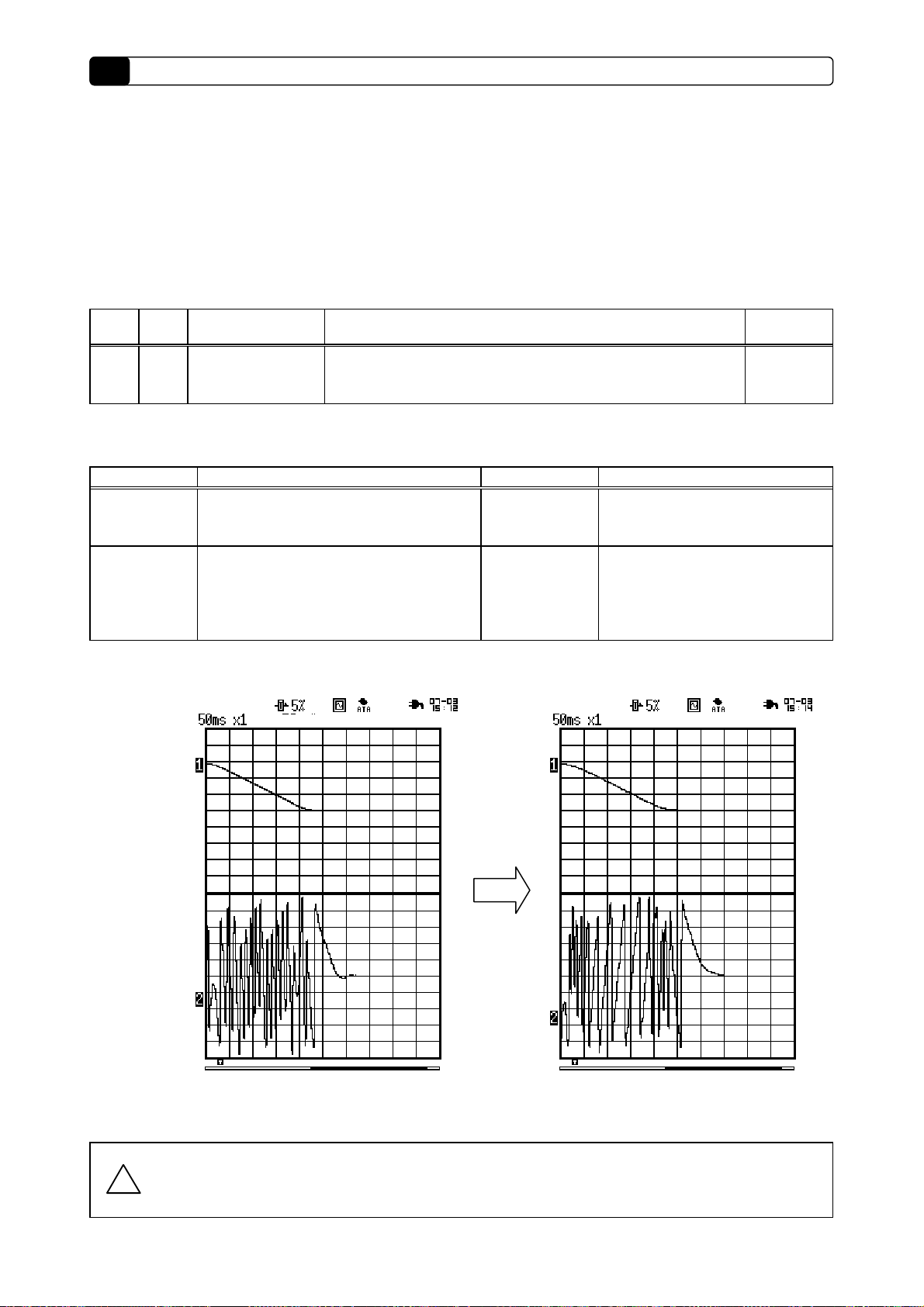

(2) Adjusting speed loop leading compensation

There may be no problem when used at a normal load inertia scale. However, if used at a load inertia scale

exceeding 500% with an insufficient speed loop gain (SV005) set, the position droop waveform may

vibrate just before the motor stops. If the speed loop gain is small, and the shaft has relatively low wear,

the motor may repeatedly reciprocate just before stopping resulting in hunting.

If vibration of the position droop is not improved much even when the position loop gain (SV003) is lowe red,

the leading compensation (SV008) value set for the proportional gain (SV005) is too large, so lower SV008

by approx. 100.

No. Abbrev. Parameter name Explanation

SV008 VIA Speed loop leading

compensation

1364 is set as a standard. 1900 is set as a standard during SHG control.

Adjust in increments of approx. 100.

Memory

Single

shot

Scroll

Memory

Speed FB

[500 r/min/div]

SV061 = 0

SV063 = 13

Lower SV008

Single

shot

Scroll

Normal

setting range

700 to 2500

Position droop

[10 µm/div]

SV062 = 6

SV064 = 328

POINT

Insufficient speed loop gain

After adjusting speed loop leading

compensation (SV008)

1. The vibration can be eliminated by lowering VIA (SV008); however, VIA only

adjusts the gain balance for the speed loop's PI control. As long as VGN1 (SV005)

is set lower than the standard value, high-accuracy control cannot be expecte d.

2. Disturbance observer can also suppress the vibration.

(Refer to “2-5-1 Disturbance observer”.)

2-15

Page 26

2 MDS-C1/CH-Vx ADJUSTMENT PROCEDURES

(3) Adjusting position loop gain

When raising the position loop gain, the responsiveness of the position and cutting accuracy is improved.

Setting time is shortened and the cycle time can also be reduced. However, be aware of the limit value

determined by the speed loop characteristics and machine characteristics.

The same position gain has to be set in both interpolation axes (the axes to perform synchronous control

with). Set the position loop gain of the all axes to the lowest limit value of all.

No. Abbrev. Parameter name Explanation

SV003 PGN1 Position loop gain 1 Set 33 as a standard. Adjust in increments of approx. 3. If PGN is

increased, cutting precision will be improved and the setting time will be

shortened.

Limit of the position loop gain

Limit of PGN Phenomenon Cause Remedy

Limit of

speed loop

characteristics

Limit of machine

characteristics

Position droop waveform vibrates during

positioning.

Overshooting occurs during positioning.

Machine vibrates or makes strange noise during

acceleration/deceleration.

When feeding with the maximum scale by a

pulse generator, machine vibrates or makes

strange noise.

Insufficient speed

loop gain (VGN1)

Insufficient

machine rigidity

Suppress the resonance more and raise

VGN. Use disturbance observer.

Use SHG control function.

Use S-pattern acceleration/deceleration

function when vibration occurs in rapid

traverse feed. (NC function)

Memory

Single

shot

Scroll

Memory

Single

shot

Scroll

Speed FB

[500 r/min/div]

SV061 = 0

SV063 = 13

Lower

PGN

Normal

setting range

18 to 70

Position droop

[10 µm/div]

SV062 = 6

SV064 = 328

CAUTION

!

After adjusting PGN (23SHG) PGN is too high (33SHG)

Set the same position loop gain (PGN) to all the interpolation axes.

(For the PGN of X, Y, Z axes, set the smallest value of the three to all of X, Y, Z axis.)

2-16

Page 27

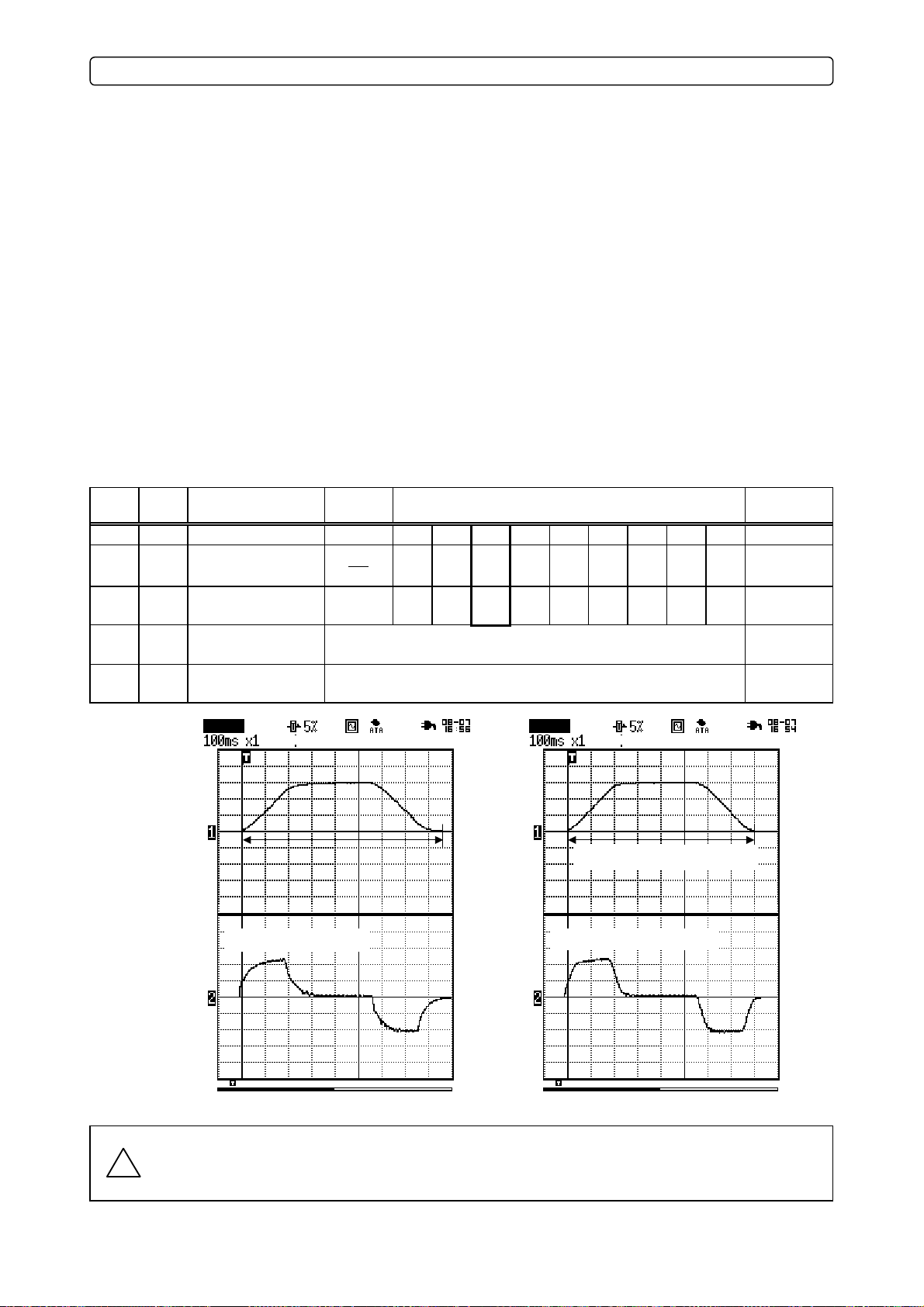

(4) SHG (Smooth High Gain) control

A high-response control and smooth control (reduced impact on machine) were conventionally conflicting

elements; however, SHG control enables the two elements to function simultaneously by controlling the

motor torque (current GB) with an ideal waveform during acceleration/deceleration.

Start the adjustment with PGN1=23 (hereinafter referred to as 23SHG) for the feed axis of a machine tool

at first. Try to adjust the SHG value so that it become as close to 47SHG as possible. If more than

33SHG can be set, this machine tool is a precision machine. If more than 23SHG can be set, the

machine tool precision is good enough. SHG control function is efficient for feed axes of machine tools (X

axis, Y axis or Z axis of the machining center etc.) to meet the demand of high-speed and high-accuracy

cutting.

When changing normal control to SHG control, start adjusting, by setting PGN1 to “1/2”. SHG control is

as effective as when PGN1 is doubled. SHG control also can shorten the cycle time as it reduces the

setting time.

No. Abbrev. Parameter name

SV003 PGN1 Position loop gain 1 1 18 21 23 26 33 38 47 60 70 18 to 70

SV004 PGN2 Position loop gain 2

SV057 SHGC SHG control gain

SV008 VIA Speed loop leading

compensation

SV015 FFC Acceleration feed

forward gain

Memory

Single

shot

Setting

ratio

8

3

6 108 126 140 160 187 225 281 360 420

Set 1900 as a standard for SHG control.

Set 100 as a standard for SHG control. 0 to 300

Scroll

48 56 62 70 86 102 125 160 186

Setting example

Memory

Single

shot

Scroll

Normal

setting range

48 to 186

108 to 420

700 to 2500

Speed FB

[500 r/min/div]

SV061 = 0

SV063 = 13

Current FB

[50%/div]

SV062 = 3

SV064 = 131

CAUTION

!

Little delay with fast positioning

Ideal acceleration waveform Torque is not constant

SHG control (PGN = 26SHG) Normal control (PGN = 26)

The SHG control is an optional function. Confirm if the option is set in the NC with a

System Specification Order List.

2-17

Page 28

2 MDS-C1/CH-Vx ADJUSTMENT PROCEDURES

(5) Confirming overshooting

Adjust to make overshooting amount become less than 1 µm.

Cause and remedy of overshooting

Speed FB

[500 r/min/div]

SV061 = 0

Waveforms

Position droop

[10 µm/div]

SV062 = 6

-Position loop gain is too high.

-Acceleration feed forward gain (SV015) is too high.

-Torsion of the machine system is too large.

If a machine has a torsion factor, overshooting is easily

Cause

caused as the axis is pushed to a stop when positioning.

-Lower the position loop gain

-When acceleration feed forward gain (SV015) is set to more than “100”, lower it.

-Try the speed loop delay compensation during full closed loop control (when using linear scale).

(Refer to [2-6-2 Speed loop delay compensation].)

Remedy

-If nothing has improved after lowering gain parameter, use overshooting compensation as the cause seems to be on machine

side. Overshooting can be resolved by 1% to 3% of compensation.

(Refer to “2-5-2 Overshooting compensation” in this manual.)

During rapid traverse feed During pulse feed

Memory

Single

shot

Scroll

Position

command

[20 µm/div]

SV061 = 10

Position FB

[20 µm/div]

SV062 = 12

-Position loop gain is too high.

-Friction of the machine system is too large.

If the machine static friction is too large, overshooting is easily

caused as a large torque is maintained when the machine

starts operation.

-If the general motion of the machine is unstable, possibly

caused by the machine-side problem.

Memory

Single

shot

Scroll

POINT

If more than “100” is set in acceleration feed forward gain (SV015) during SHG control,

overshooting will be caused easily.

2-18

Page 29

p

g

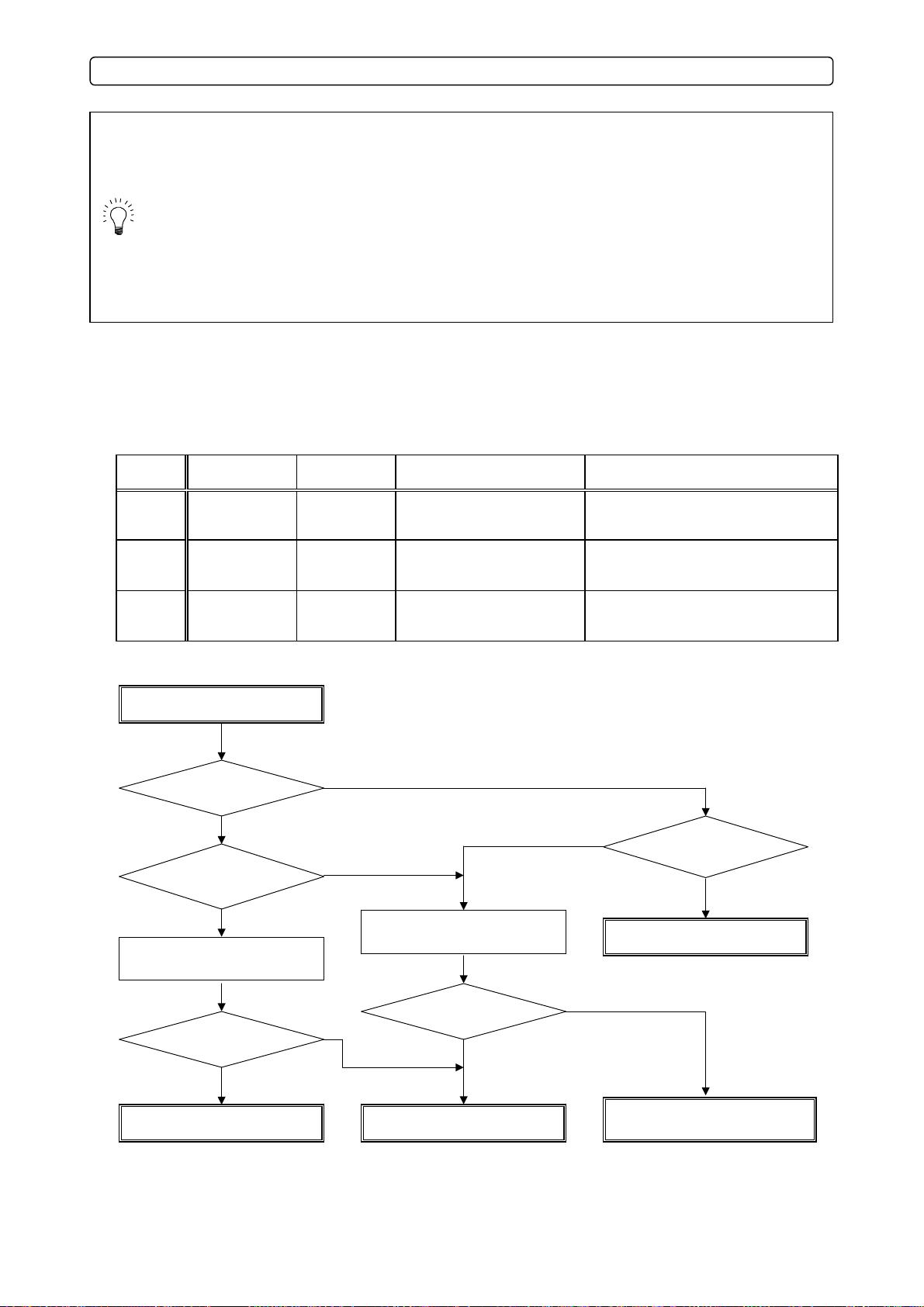

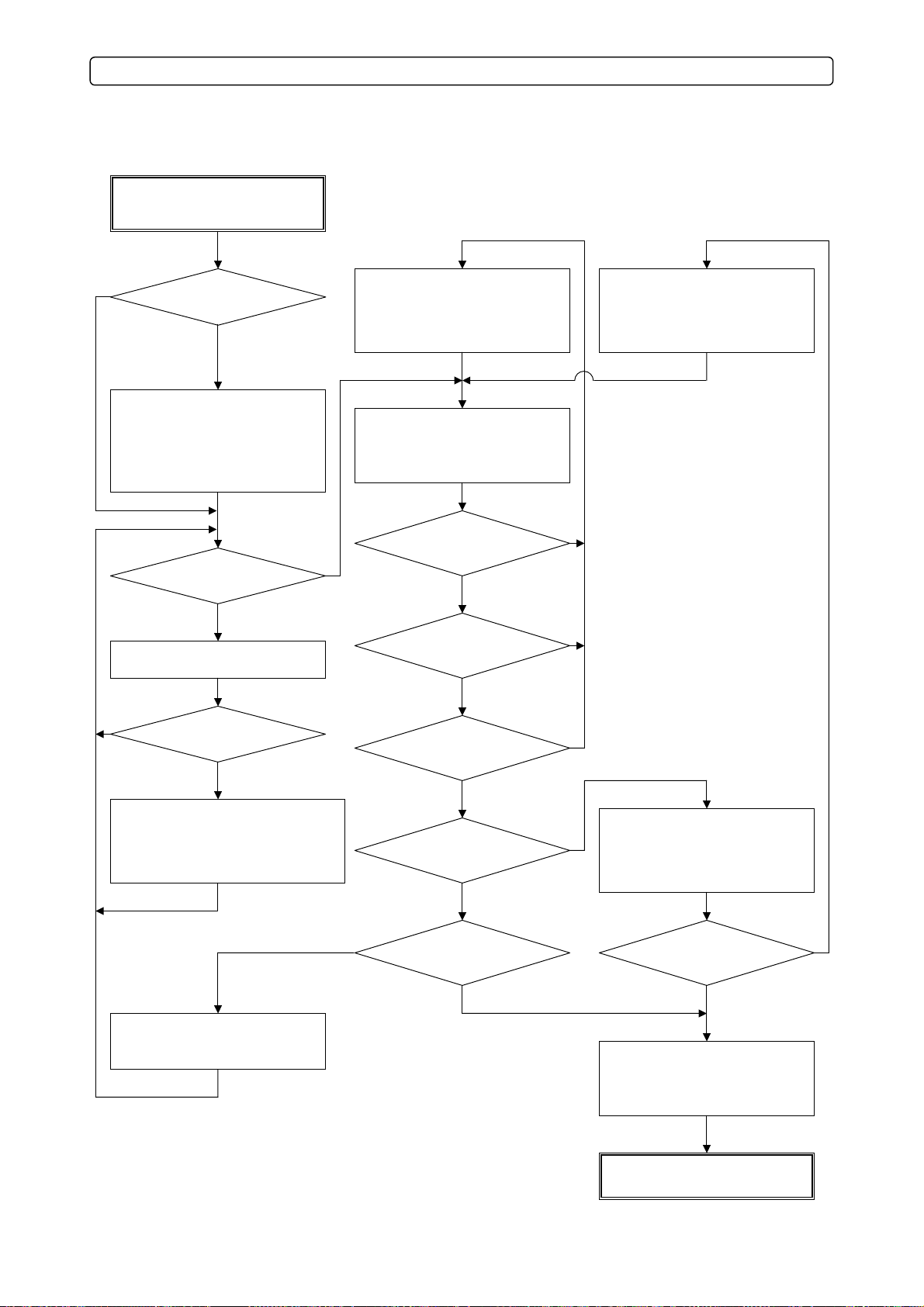

(6) Adjusting the position droop waveform

START position droop waveform

NO

Confirm that the

SHG control

function is o

Confirm the balance

in PI control.

YES

Set SV008 back to a standard value and;

lower SV003 by 3 during normal control.

lower the gain by 1 grade during SHG

control.

Set PGN1 to half of the current

value when start adjusting in SHG

control.

adjustment

SHG control?

YES

tioned.

Set SV003 = 23

SV004 = 62

SV057 = 140

SV008 = 1900

SV015 = 100

Does droop vibrate

when positioning?

YES

Lower SV008 by 100.

Has vibration suppressed?

NO

Confirm that the SHG control

function is optioned.

Lower SV003 by 3 during normal

control.

Lower the gain by 1 grade during

SHG control.

Perform rapid traverse reciprocating

operation or manual pulse feed with

maximum scale.

a

Is position droop waveform

NO

Confirm the speed

loop limit.

Does machine vibrate or

Confirm machine

limit.

YES YES

Using SHG control function?

overshootin

Does position droop

waveform vibrate?

make strange noise?

Has position loop gain

reached to its limit?

?

NO

NO

NO

YES

NO NO

YES

YES

YES

NO

Raise SV003 by 3 during normal

control.

Raise the gain by 1 grade during

SHG control.

PGN1 target value

-Feed axis of

the machine tool: 47SHG

(Determined by considering the

required precision.)

Does PGN have to be raised?

Determine the PGN limit value for

each axis and set the minimum value

in all axes. (The same value has to

be set in both interpolation axes.)

Position droop waveform adjustment

is completed.

2-19

Page 30

2 MDS-C1/CH-Vx ADJUSTMENT PROCEDURES

2-3 Adjusting Acceleration/Deceleration Time Constant

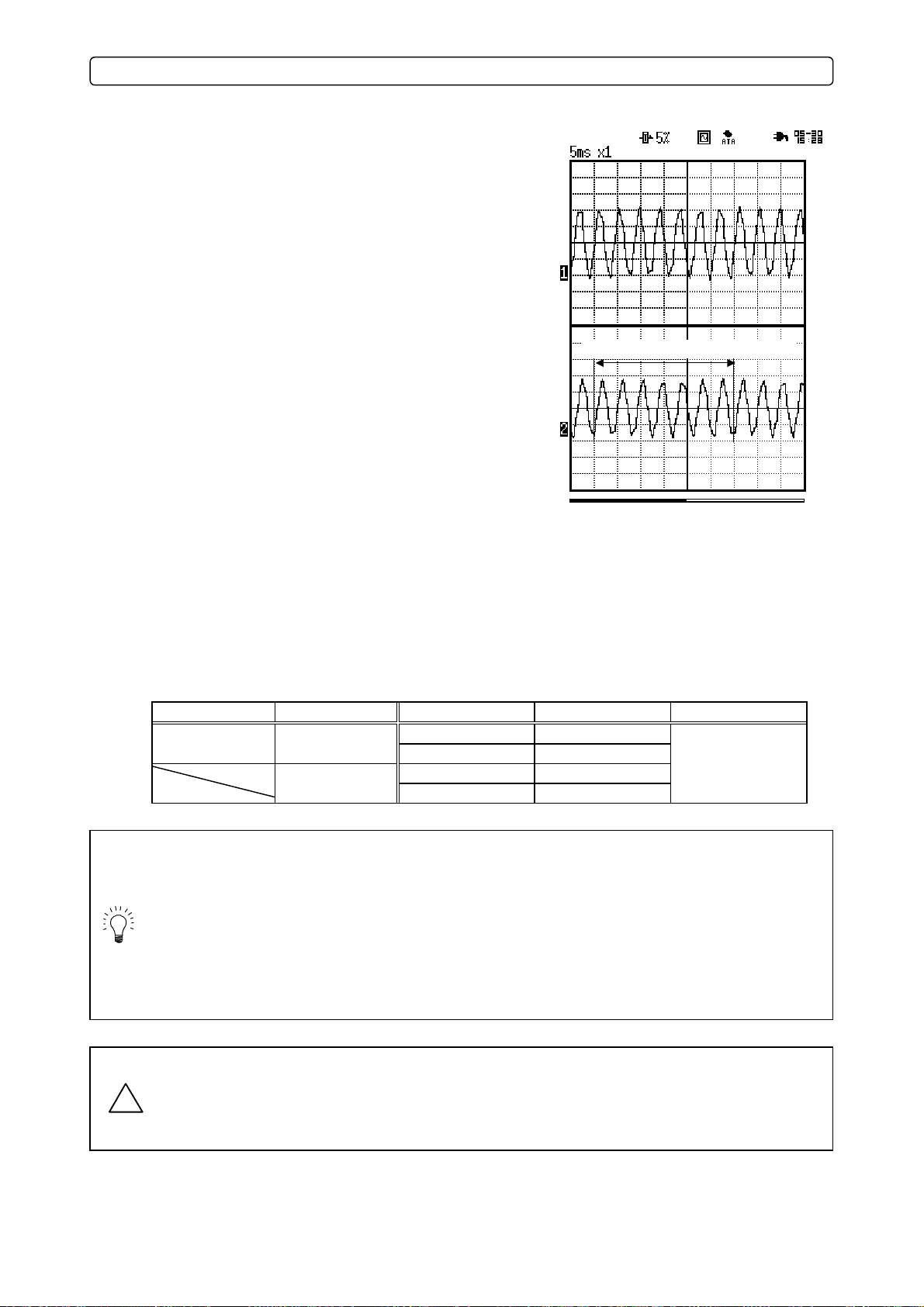

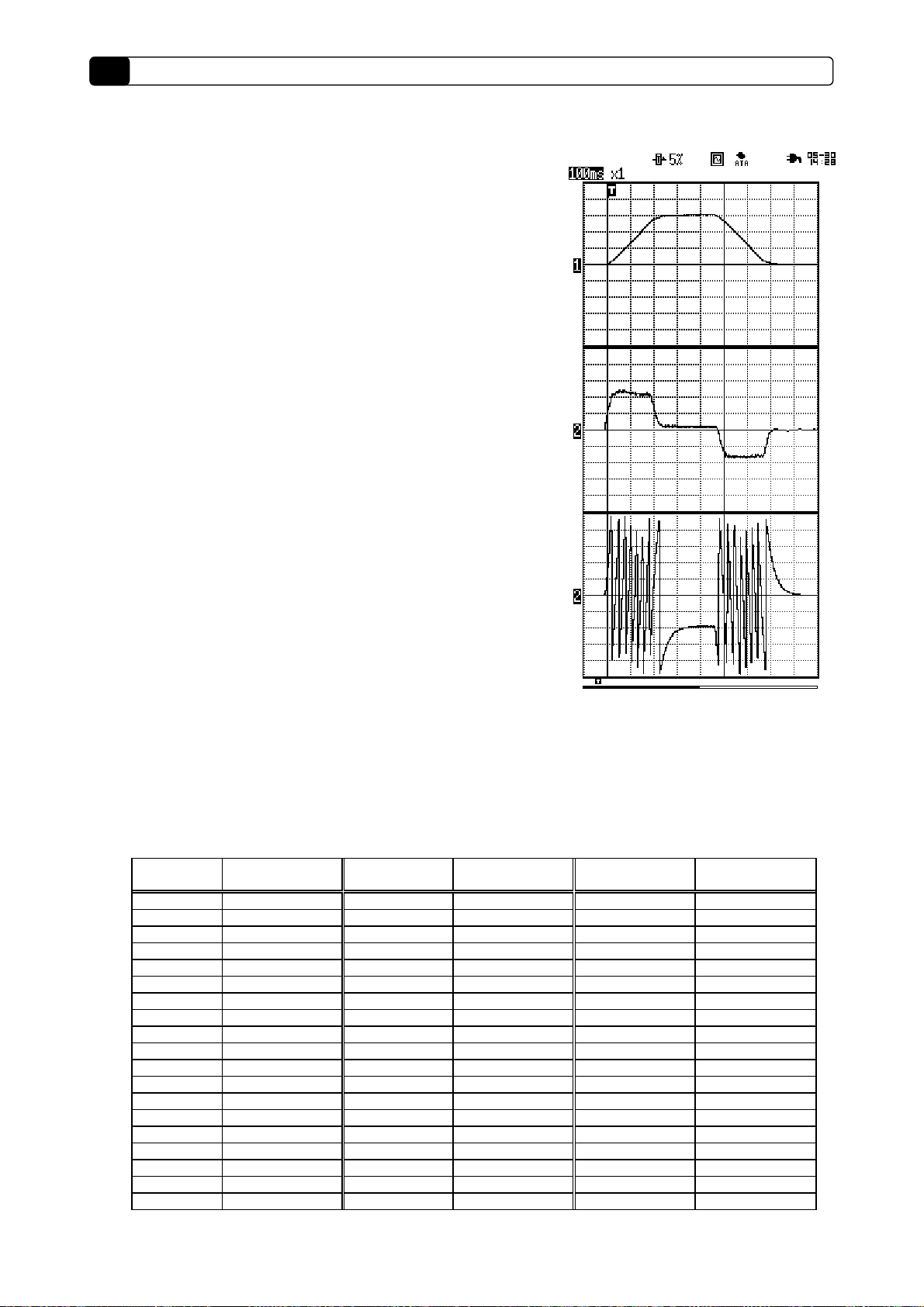

2-3-1 Rapid traverse feed (G0 feed)

For rapid traverse feed, linear acceleration/

deceleration function is normally used. Occasionally,

S-pattern (soft) acceleration/deceleration function is

used to ease the collision against machines.

(1) Confirm that the rapid traverse rate ≤ max.

rotation speed

Fist of all, confirm that the rapid traverse rate is less

than the maximum rotation speed of the servo motor.

(2) Adjust acceleration/deceleration time constant

by the maximum current command value

Perform the rapid traverse reciprocating operation

confirming in NC servo monitor screen and adjust

acceleration/deceleration time constant (with NC axis

specification parameter) so that the maximum current

command value during acceleration/deceleration

becomes less than the range of the table shown

below.

(Acceleration/deceleration time constant is not judged

by current FB but by current command)

Speed FB

[500 r/min/div]

SV061 = 0

Current FB

[50 %/div]

SV061 = 3

Position droop

[100 µm/div]

SV062 = 6

Memory

Single

shot

Scroll

(3) Confirm the rapid traverse feed

Waveforms during rapid traverse feed

Confirm: 1) if the machine does not vibrate or make strange noise.

2) if the waveforms during acceleration/deceleration are not disturbed when observing current

FB waveform and position droop waveform.

3) if the friction torque is normal.

4) 1) to 3) with the override changing.

Max. current command value when adjusting acceleration/deceleration time constant (MDS-C1/CH-Vx)

Motor type

HC52 Within 388% HA40N Within 400% HC-H52 Within 400%

HC102 Within 340% HA80N Within 365% HC-H102 Within 340%

HC152 Within 380% HA100N Within 260% HC-H152 Within 500%

HC202 Within 275% HA200N Within 225% HC-H202 Within 340%

HC352 Within 251% HA300N Within 200% HC-H352 Within 260%

HC452 Within 189% HA700N Within 205% HC-H452 Within 270%

HC702 Within 221% HA900N Within 220% HC-H702 Within 280%

HC902 Within 227% HC-H902 Within 215%

HA053N Within 240% HC-H1102 Within 200%

HC53 Within 264% HA13N Within 240% HC-H1502 Within 190%

HC103 Within 257% HA23N Within 230% HC-H53 Within 290%

HC153 Within 266% HA33N Within 230% HC-H103 Within 280%

HC203 Within 257% HA43N Within 295% HC-H153 Within 350%

HC353 Within 230% HA83N Within 275% HC-H203 Within 320%

HC453 Within 177% HA103N Within 245% HC-H353 Within 240%

HC703 Within 189% HA203N Within 210% HC-H453 Within 240%

HA303N Within 180% HC-H703 Within 195%

HA-LF11K2 Within 215% HA703N Within 180% HC-H903 Within 230%

HA-LF15K2 Within 240% HC-H1103 Within 190%

Max. current

command value

Motor type

Max. current

command value

Motor type

Max. current

command value

2-20

Page 31

2-3-2 Cutting feed (G1)

For cutting feed, exponent acceleration/deceleration function is normally used. S-pattern acceleration/

deceleration cannot be used as it disables synchronous interpolation.

(1) Reciprocating operation without dwell

During cutting feed, no confirmation of in-position is made before going on to the next step. Adjust the

acceleration/deceleration time constant during acceleration/deceleration by recip rocating operation without

dwell. Set the feedrate at the maximum (clamp: axis specification parameter) and confirm the maximum

current command during the turn without swell.

(Cutting feed reciprocating operation Sample program)

G28 X0; X axis zero return

N01 G90 G1 X-200. F8000

G1 X0; Turn without dwell and move to X=0 with F5000 cutting feed.

G4 X1.0; Dwell for a second. (Pause for a second) Use “X” even for Y axis and Z axis.

GOTO 01 Go back to the line N01.

Max. cutting feedrate

; Move X axis to X=-200 with F5000 cutting feed by absolute position command.

(2) Adjust acceleration/deceleration time constant by max. current command value

Confirm the maximum current command value in the servo monitor and adjust acceleration/deceleration

time constant (with NC axis specification parameter) so that the maximum current command value

becomes less than the range of the table shown in the chapter “2-3-1 Rapid traverse feed (G0)”.

(3) Set all the interpolation axes to the same value as the axis with the longest time constant

For example, set the same value for the cutting feed time constant of X axis, Y axis and Z axis in

machining center because interpolation control is required.

(4) Confirm the cutting feed

Confirm : 1) if the machine does not vibrate or make strange noise.

2) if the waveforms during acceleration/deceleration are not disturbed when observing current

FB waveform and position droop waveform.

3) 1) and 2) with the override changing.

POINT

Perform reciprocating operation without dwell when adjusting cutting feed (G1) time

constant.

!

CAUTION

1. Set the same value for the cutting feed time constant in both interpolation axes

and for the position loop gain (PGN).

2. For vertical axis, perform from downward stop to upward start without dwell and

confirm the current command.

2-21

Page 32

2 MDS-C1/CH-Vx ADJUSTMENT PROCEDURES

2-4 Initial Adjustment for the Servo Functions

2-4-1 Standard settings for the lost motion compensation

(1) Unbalance torque and frictional torque

As for the initial adjustment of lost motion compensation, set the standard compensation amount.

Measure the unbalance torque and the frictional torque to calculate the standard compensation amount.

During a stop, the static frictional torque may effect. Feed slowly by about F1000, measure the load

current in the servo monitor screen of NC and calculate by the following expression.

Unbalance torque =

(+ Feed load current%) + (– Feed load current%)

2

Frictional torque =

(+ Feed load current%) – (– Feed load current%)

2

Unbalance torque and frictional torque

Horizontal axis Unbalance axis

Lathe: Z axis

In machine tools

Unbalance torque 0

Frictional torque

Vertical machining center: X axis, Y axis

Horizontal machining center: X axis, Z axis etc.

The load torque when feeding by about F1000. The difference between load torque and unbalance

Lathe: X axis

Vertical machining center: Z axis

Horizontal machining center: Y axis etc.

The average of the load torque when feeding to

both + and – direction by about F1000.

torque when feeding by about F1000.

(2) Setting the standard compensation amount

As for lost motion compensation type, use type 2 (SV027.bit9). Set the unbalance torque in SV032 and

set the doubled frictional torque in SV016 as a standard compensation amount. (Set SV041 to “0”.) To

adjust the compensation amount more accurately, determine the value to be set in SV016 and SV041 by

measuring the roundness.

How to set the standard lost motion compensation amount

!

Setting item Parameter setting

(1) Start lost motion compensation type 2 SV027.bit9 = 1 (SV027.bit8 = 0)

(2) Unbalance torque setting SV032 = unbalance torque [%]

(3) Lost motion compensation standard amount SV016 = 2 x frictional torque [%] (SV041 = 0)

When using the disturbance observer, further adjustment by roundness

CAUTION

measurement is required because the lost motion compensation amount (SV016)

calculated as mentioned above will become over compensation.

2-22

Page 33

(Example)

In case that the load current% is -25% in + direction and -65% in – direction when performing JOG feed by about F1000,

Unbalance torque =

Therefore, set SV032 = -45, SV016 = 40.

No. Abbrev Parameter name Explanation

SV027 SSF1 Normally type 2 is used for the lost motion compensation.

F EDCBA98765 4 3 2 10

aflt zrn2 afse ovs lmc omr zrn3 vfct upc vcnt

bit Explanation

8 00: lost motion compensation stop 10: lost motion compensation type 2

9

Servo function

selection 1

No. Abbrev. Parameter name Unit Explanation

SV032 TOF Torque offset Stall% Set the unbalance torque am ount. -60 to 60

-25 + (-65)

2

= -45%

lmc

01: lost motion compensation type 1 11: Setting prohibited

Frictional torque =

-25 - (-65)

2

= 20%

Normal

setting range

SV016 LMC1 Lost motion

compensation 1

SV041 LMC2 Lost motion

compensation 2

Stall% Set “2 × (frictional torque)” as an initial value.

When using disturbance observer, further adjustment by

roundness measurement is required.

Stall% Set “0” as a standard (initial adjustment value).

When “0” is set, compensate the value set in SV016 in both +

and – direction.

2-4-2 Excessive error width detection

In most cases, no problem will occur with the standard setting values.

No. Abbrev. Parameter name Unit Explanation

SV023 OD1 Excessive error

detection width during

servo ON

SV026 OD2 Excessive error

detection width during

servo OFF

mm Calculate as follows by using rapid traverse rate and position

loop gain (PGN1). When “0” is set, the excessive error alarm

will not be detected.

<Standard setting value>

mm

OD1=OD2=

Rapid traverse rate (mm/min)

60 × PGN1

0 to 60

0 to 60

Normal

setting range

3 to 15

÷ 2 (mm)

(Round fractions off.)

2-23

Page 34

2 MDS-C1/CH-Vx ADJUSTMENT PROCEDURES

2-4-3 Vertical axis drop prevention control

Vertical axis drop prevention control is performed for the unbalance axis which equips a mot or brake. Set

the time to delay the servo ready OFF confirming the drop amount when an emergency stop occurs.

(1) Parameter settings

Set the 3 parameters (SV048, SV055 and SV056) at the same time to enable vertical axis drop prevention

control. For MDS-C1/CH-Vx series, set the parameters of the axes which does not perform the vertical

axis drop prevention control because the converter unit of MDS-C1 series are in common with other servo

axes and spindles. (Refer to “2-4-3(3) Parameter settings in each system” in this manual)

<How to set>

1) Adjust the vertical axis drop prevention time (SV048) and set the minimum value at which the axis

does not drop when the Emergency stop is inputted.

2) Set the same value as the adjusted vertical axis drop prevention time (SV048) for the max. gate off

delay time after emergency stop (SV055).

3) Set the same axis as the acceleration/deceleration time constant in the deceleration time constant at

emergency stop (SV056) is set for the axis that controls the drop prevention.

4) If the vertical axis is MDS-C1/CH-V2 (drive unit with 2 axes), set the servo parameter of the other axis.

SV048 = the same value as SV048 of the vertical axis

SV055 = the same value as SV055 of the vertical axis

SV056 = the sa m e v a l u e as ra p i d trav e r s e acce l erat i o n /dec e l erat i o n t i m e c o n s t a n t o f t h e i d e n tica l axi s

5) If the converter which supplies the PN power to the vertical axis is controlled by a spindle driv e unit, set

the spindle parameter SP033.bit15 = 1.

6) If the converter which supplies the PN converter to the vertical axis is controlled by the other servo

drive unit, set the servo parameters of the axis. (as mentioned in (4))

No. Abbrev. Parameter name Unit Explanation

SV048 EMGrt Vertical axis drop

prevention time

SV055 EMGx Max. Gate off delay

time after emergency

stop

SV056 EMGt Deceleration time

constant at emergency

stop

ms Increase the setting by 100 ms at a time and set the minimum

value where the axis does not drop.

ms Set the time from emergency stop input to compulsory ready OFF.

When performing vertical axis drop prevention control, set the

same value as SV048.

ms When performing vertical axis drop prevention control, set the

deceleration control. Set the same value as the rapid traverse

acceleration/deceleration time constant.

1. SV048 and SV055 are set individually in each axis. However, when using

MDS-C1/CH-V2 (drive unit with 2 axes), both axes are controlled at the same time

POINT

with the larger setting value of these 2 parameters.

2. This control will not function if an alarm for which dynamic brakes are set as the

stopping method occurs in an axis where the vertical axis drop prevention control is

being carried out.

3. A drop amount of several µm to 10µm) will rem ain due to the brake play.

Normal

setting range

0 to 300

0 to 300

0 to 300

!

CAUTION

When only SV048 and SV055 are set and SV056=0, machine will occasionally come

into collision because stopping method is changed from “decelerating to a stop” to

“Step s to a stop”.

2-24

Page 35

(2) Adjustment procedures for vertical axis drop prevention control

START adjusting for vertical axis drop control

Is servo converter controlled

by a spindle?

NO

YES

Set spindle parameter.

(SP033.bitF = 1)

(In case of 5) and 6) in the next chapter, set for

the converter control axis at the same time.)

Set SV048 = 100

Decrease SV048 by 100

Set the value as SV048 in SV055.

Cancel the emergency stop.

Input the emergency stop by checking the

coordinate position in NC screen.

Set SV056 to the same vale as rapid traverse

acceleration/deceleration time constant.

Confirm the drop amount.

MDS-C1/CH-V2 (drive unit with 2 axes)?

NO

YES

Has drop amount decreased?

YES

NO

Set SV048 and SV055 of the identical drive