Page 1

CNC

64

CONNECTION MANUAL

BNP-B2203D(ENG)

Page 2

MELDASMAGIC is a registered trademark of Mitsubishi Electric Corporation.

Microsoft and MS-DOS are registered trademarks of Microsoft Corporation U.S.A.

Windows is a registered trademark of Microsoft Corporation U.S.A.

IBM is a registered trademark of International Business Machines Corporation U.S.A.

Other company and product names are trademarks or registered trademarks of the

respective companies.

i

Page 3

Introduction

This manual is the MELDASMAGIC64 Connection Manual.

MELDASMAGIC64 installation and connection methods are explained centered on the NC Card.

Refer to the materials below for explanations concerning functions.

MELDASMAGIC64 Setup Instruction Manual................................................................................ BNP-B2191

MELDASMAGIC64 Maintenance Manual...................................................................................... BNP-B2207

MELDAS AC Servo and Spindle MDS-A/B Series Specifications Manual..................................... BNP-B3759

MELDAS AC Servo and Spindle MDS-C1 Series Specifications Manual...................................... BNP-C3000

MELDAS AC Servo and Spindle MDS-CH Series Specifications Manual.....................................BNP-C3016

MELDAS AC Servo MDS-B-SVJ2 Series Specification Manual....................................................BNP-B3937

MELDAS AC Servo MDS-B-SPJ2 Series Specification Manual....................................................BNP-B2164

General items

(1) Read this manual carefully before using MELDASMAGIC64. Please have a full understanding of

product functions and performance, and use this product correctly.

(2) All efforts possible have been made to describe any special handling in this manual. Items not

described in this manual must be interpreted as "Not Possible".

(3) When the details described in this instruction manual change, the sub-No. of the cover page instruction

manual No. (*, A, B) will be changed.

(4) The details described in this manual may change without notice. Mitsubishi may not be held respo nsible

for errors in the contents described.

About MELDASMAGIC64

(1) MELDASMAGIC64 includes the ISA NC Card compatible with the ISA bus, and the PCI NC Card

compatible with the PCI bus. Either card can be selected. The user can structure a custom-made NC

unit by inserting the NC Card supplied from Mitsubishi into the selected personal computer's expansion

slot (ISA bus or PCI bus).

NC Card

ISA NC Card PCI NC Card

(ISA bus specifications)

HR621

HR623

(2) The NC Card supplied by Mitsubishi realizes the equivalent environmental resistance (ambient

temperature, noise resistance and vibration resistance) as conventional NC units. However, some

environmental resistance equivalent to conventional NC units is not always guaranteed regarding

personal computers presumed to be normally used in an office. Therefore, when selecting a personal

computer, study this manual well and select an appropriate model responding to the required uses and

applications. When required, execute the appropriate countermeasures.

(PCI bus specifications)

FCU6-HR655

ii

Page 4

(3) Take care to the working environment when using MELDASMAGIC64.

Working environment

PCI NC Card ISA NC Card

Applicable personal

computer

Compatible OS

• Windows 98SE

• Windows 2000

• Windows XP

• For Windows 95

IBM PC/AT or compatible machine

• Windows 95

• Windows 98

• Windows 98SE

• Windows NT Workstation 4.0

Pentium 100MHz or faster (Pentium 150MHz or faster recommended)

CPU

• For Windows 98, Windows 98SE, Windows NT Workstation 4.0

Pentium 200MHz or faster (Pentium 233MHz or faster recommended)

• For Windows 2000, Windows XP

Pentium 300MHz or faster

• For Windows 95, Windows 98

16MB or larger (24MB or larger recommended)

• For Windows 98SE, Windows NT Workstation 4.0

Memory

24MB or larger (32MB or larger recommended)

• For Windows 2000

64MB or larger (128MB or larger recommended)

• For Windows XP

128MB or larger

Hard disk 20MB or more open space recommended

Floppy disk One 3.5-type 1.44MB drive

Expansion slot

Electric

characteristics

+3.3V (*1) 0.2A or more

+5.0V 2.5A or more

PCI bus (PCI bus Standards 2.0 or

higher)

+12.0V 0.7A or more 0.5A or more

Power drop characteristics

Time for +5.0V power voltage to drop from +4.5V to +4.0V when the

power is turned OFF takes 1ms or more.

ISA bus

(*1) When using the PCI NC Card, always use a personal computer that supplies +3.3V power to the PCI

bus.

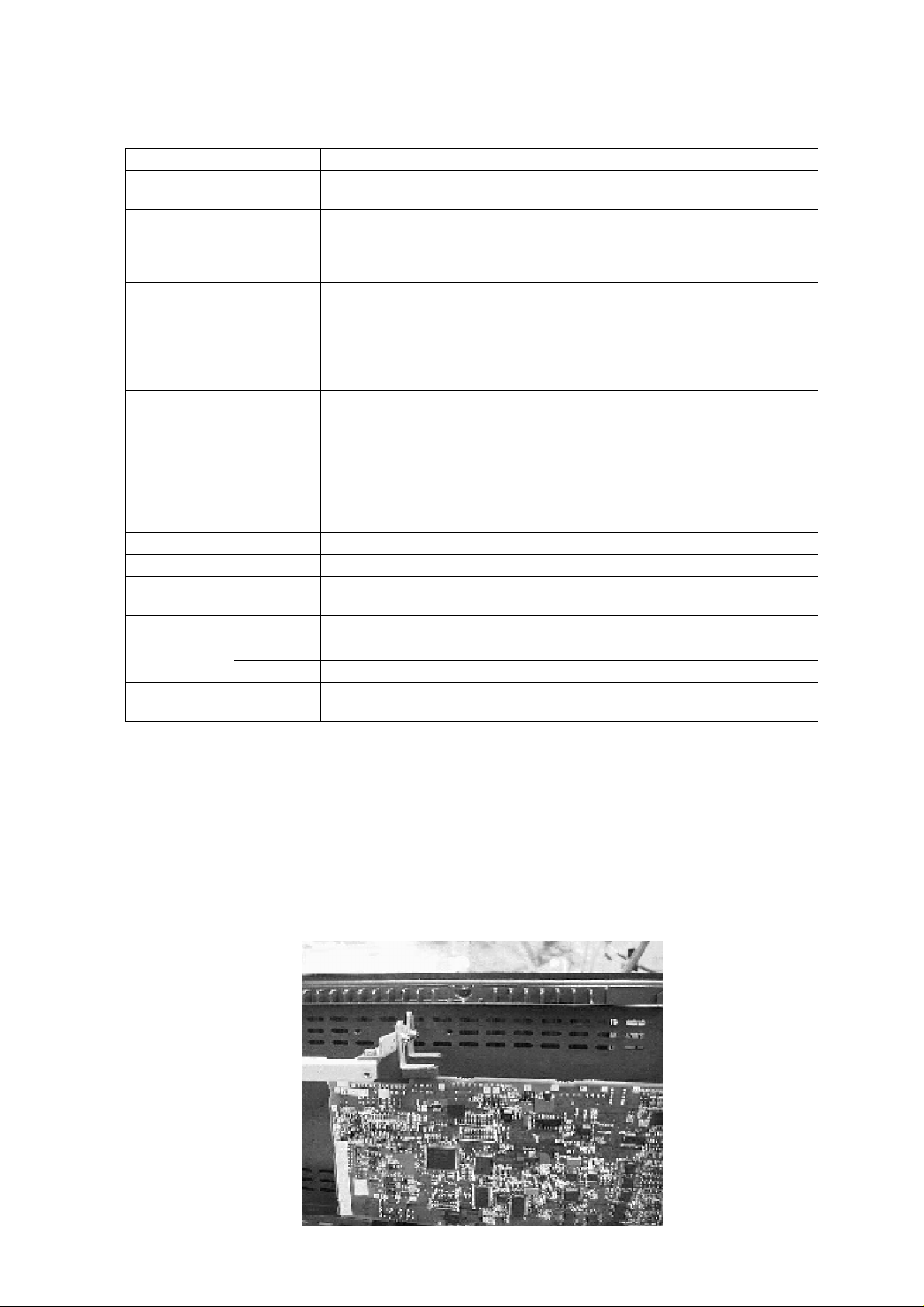

(4) Heat radiation-countermeasures for personal computer

A rise in the personal computer's internal temperature could cause NC Card damage or malfunction.

Select a personal computer with a fan for circulating the heat in the personal computer, or a personal

computer to which a fan can be mounted.

(5) Personal computer vibration

If the expansion slot on the personal computer vibrates greatly, a connector co nnection fault could occu r

and result in incorrect operations. Select a personal computer with a fitting for fixing the NC Card, or a

personal computer that can be fixed.

<Fixing example>

iii

Page 5

Precautions for Safety

Always read the specifications issued by the machine maker, this manual, related manuals

and enclosed documents before starting installation, operation, programming, maintenance

or inspection to ensure correct usage. Thoroughly understand the basics, safety information

and precautions of this numerical controller before using the unit.

This manual ranks the safety precautions into "DANGER", "WARNING" and "CAUTION".

DANGER

WARNING

CAUTION

Note that even if the items is ranked as "

serious results. Important information is described in all cases, so please observe the items.

When there is a great risk that the user could be subject to

fatalities or serious injuries if handling is mistaken.

When the user could be subject to fatalities or serious injuries

if handling is mistaken.

When the user could be subject to injuries or when physical

damage

CAUTION

", incorrect handling could lead to

DANGER

Not applicable in this manual.

1. Items related to prevention of electric shocks

WARNING

Do not open the front cover while the power is ON or during operation. Failure to observe this could result

in electric shocks.

Do not operate the device with the front cover removed. The high voltage terminals and charged sections

will be exposed, and could result in electric shocks.

Do not remove the front cover even when the power is OFF except for wiring work or periodic

inspections. The controller and servo drive unit are charged internally and could result in electric shocks.

Always wait at least 15 minutes after turning the power OFF and check the voltage with a tester, etc.,

before starting wiring work or inspections. Failure to observe this could result in electric shocks.

Ground the 200V Series input controller, servo drive unit and servomotor with Class C or higher

protective grounding, and the 400V Series input with Class D or higher protective grounding.

All wiring work and inspections must be carried out by a qualified electrician.

Wire the controller, servo drive unit and servomotor after installation. Failure to observe this could result

in electric shocks.

Do not operate the switches with wet hands, as this may lead to electric shocks.

Do not damage, apply excessive stress, place heavy things on or sandwich the cables, as this may lead

to electric shocks.

iv

Page 6

2. Items related to prevention of fires

CAUTION

Install the controller, servo drive unit, servomotor and regenerative resistor on non-combustible material.

Installation directly on or near combustible materials coul d result in fires.

If trouble occurs in the servo drive unit, shut off the power at the servo drive unit's input power side. Fires

could result if large current continues to flow.

When using the regenerative resistor, shut off the power with an error signal. The regenerative resistor

could abnormally overheat and cause fires due to a regenerative transistor fault, etc.

Incorrect wiring or connections could damage the device.

3. Items related to prevention of damage

CAUTION

Do not apply voltages other than those indicated in the Controller Connection Manual or Specifications

Manual for Servo Drive Unit. Failure to observe this could lead to rupture, or damage, etc.

Do not mistake the terminal connections. Failure to observe this could lead to rupture, or damage, etc.

Do not mistake the polarity (+, –). Failure to observe this could lead to rupture, or damage, etc.

Persons wearing medical devices, such as pacemakers, must not be near this unit. The medical device

could be affected by electromagnetic waves.

The servo drive unit fins, regenerative resistor and servomotor , et c., will be hot durin g operation an d for a

while after operation is stopped. Touching these sections could result in burns.

v

Page 7

4. General Precautions

Always observe the following precautions. Incorrect handling could result in faults, injuries, or electric shocks,

etc.

(1) Transportation and installation

CAUTION

Correctly transport the product according to its weight.

Use servomotor's suspension bolts only to transport the se rvomotor.

Do not use suspension bolts of the servomotor on the machine to transport the machine.

Do not stack products above the indicated limit.

Do not hold cables, shaft or detector when transporting the servomotor.

Do not suspend or hold the controller or servo drive unit by the connected wires or cables when transporting.

Do not hold the front cover when transporting the controller or servo drive unit. The device could drop.

When installing, always observe the installation direction and install on a place which can withstand the

weight.

Do not get on the product, or place heavy objects on it.

Provide the specified distance between the controller, servo drive unit and inner surface of the control

panel and between other devices.

Do not install or operate a controller, servo drive unit or servomotor that is damaged or that has missing

parts.

Take care not to cut hands on the heat radiating fins or metal edges.

Do not block the intake/outtake ports of the servomotor with cooling fan.

Do not allow conductive foreign matter such as screws or metal chips or combustible foreign matter such

as oil enter the controller, servo drive unit or servomotor.

The controller, servo drive unit and servomotor are precision devices so do not drop or apply strong

impacts on them.

Do not install the controller operation board where it may be subject to cutting oil.

vi

Page 8

(2) Wiring

CAUTION

Correctly wire this product. Failure to do so could result in servomotor runaway, etc.

Do not install a phase advancing capacitor, surge absorber or radio noise filter on the output side of the

servo drive unit.

Correctly connect the output side (terminals U, V, W). The servomotor will not operate if incorrectly

connected.

Do not directly connect a commercial power supply to the servomotor. Failure to observe this could lead

to faults.

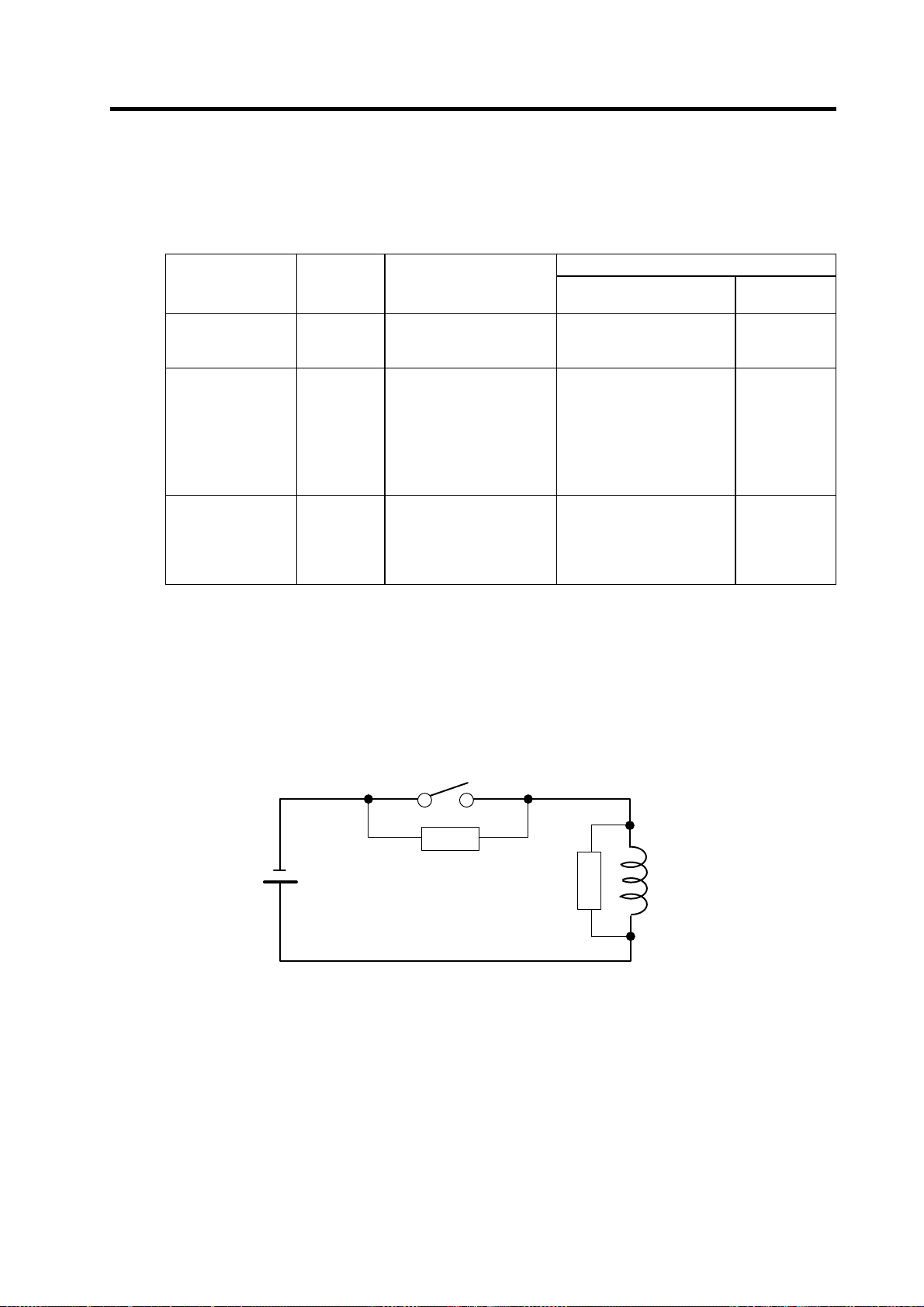

When using an inductive load such as relays, always connect a diode in parallel to the load as a noise

measure.

When using a capacitive load such as a lamp, always connect a protective resistor serially to the load to

suppress rush currents.

Do not mistake the direction of the surge absorption diode installed on the DC relay for the control output

signal. The signal will not be output due to fault and the protective circuit, such as emergency stop, will be

disabled.

Do not connect or disconnect the connection cables between each unit while the power is ON.

Securely

dislocation during operation.

Always treat the shield cables indicated in this manual with grounding measures such as cable clamps.

Separate

Use wires and cables having a wire diameter, heat resistance level and bending capacity that match the

system.

Ground the device according to the requirements of the country where the device is to be used.

Wire the heat radiating fins and wires so that they do no contact.

(3) Adjustments

Check and adjust each parameter before staring o peration . Unpredic table operations c ould occu r depend ing

on the machine.

Do not make marked adjustments or changes as the operation could become unstable.

the signal wire from the drive line/power line when wiring.

the cable connector fixing screw or fixing mechanism. Insufficient fixing could result in

tighten

CAUTION

vii

Page 9

(4) Usage methods

CAUTION

Install an external emergency stop circuit so that the operation can be stopped and the power turns OFF

immediately. A contactor, etc., must be used in addition to the shutoff function in the controller.

Turn OFF the power immediately if any smoke, abnormal noise or odor is generated from the controller,

servo drive unit or servomotor.

Only a qualified technician may disassemble or repair this product.

Do not modify this product.

Use a noise filter, etc., to reduce the effect of electromagnetic disturbances. Electronic devices used near

the servo drive unit could be affected by the electromagnetic disturbances.

Use the controller, servo drive unit, servomotor and regenerative resistor in the designated combination.

Failure to observe this could result in fires or faults.

The brakes (magnetic brakes) assembled in the servomotor are used for holding, and must not be used

for normal braking.

There may be cases when the magnetic brakes cannot hold the state because of the life or machine

structure (when ball screw and servomotor are coupled via a timing belt, etc.). Install a stopping device on

the machine side so that safety can be ensured.

After maintenance or inspection, always carry out a trial operation before starting actual operation.

Do not move the machine's movable range during automatic operation. Do not place hands, feet or face

near the spindle during rotation.

Use the power (input voltage, input frequency, tolerable instantaneous power failure time) under the power

specification conditions given in the Specifications.

Turn the NC Card's power ON before turning the base I/O unit's power ON.

If the base I/O unit's power is turned ON first, the current will be led to the NC Card from the connection

cable. This will prevent the personal computer or the cards in the personal computer from starting up

properly .

(5) Measures during a fault

CAUTION

If a hazardous situation could arise during a power failure or product fault, use the servomotor with

magnetic brakes or provide an external brake mechanism for holding purposes.

Use a double circuit structure for the magnetic brake's operation circuit so that the brakes will activate

even when the external emergency stop signal is issued.

If an alarm occurs, remove the cause, and secure surrounding safety before resetting the alarm and

restarting operation.

The machine could suddenly restart when power is restored after an instantaneous power failure. Do not

near the machine in this case. (Design the machine so that operator safety can be ensured even if the

machine restarts.)

viii

Page 10

(6) Maintenance, inspection and part replacement

CAUTION

The electrolytic capacitor's capacity will drop due to deterioration. To prevent secondary damage due to

capacitor's faults, Mitsubishi recommends replacing the electrolytic capacitor after approx. five years

when used in a general environment. Contact the Service Center or Service Station for replacements.

Do not perform a megger test (insulation resistance measurement) during inspection.

Save the machining programs, tool data and parameters with an input/output device before replacing the

battery.

Do not short-circuit, charge, overheat, incinerate or disassemble the battery.

The hard disk unit has a service life, and must be replaced when the life is reached.

Always back up the customer's data stored on the hard disk u nit. The customer's data stored on the hard

disk unit cannot be guaranteed.

(7) Disposal

CAUTION

Handle this product as general industrial waste. Note that some of the MDS Series products use alternate

Freon. These corresponding models must not be handled as general industrial waste and must always be

returned to the Service Center or Service Station. (Corresponding models have heat radiating fins on the

back of the unit.)

Do not disassemble the controller, servo drive unit or servomotor parts.

Collect and dispose of the spent batteries according to local laws.

(8) General precautions

CAUTION

To explain the details, drawings given in this instruction manual, etc., may show the unit with the cover or

safety partition removed. When operating the product, always install the cover or partitions at their original

position, and operate as indicated in the instruction manual, etc.

ix

Page 11

CONTENTS

1. Outline.................................................................................................................................. 1

2. Configuration ...................................................................................................................... 2

2.1 System Configuration..................................................................................................... 2

2.2 List of Configuration Units.............................................................................................. 3

3. Installation........................................................................................................................... 5

3.1 General Specifications ................................................................................................... 5

3.2 General System Diagram............................................................................................... 6

3.3 Installation...................................................................................................................... 8

3.3.1 Installation Direction and Spacing........................................................................... 8

3.3.2 Prevention of Foreign Matter Entry......................................................................... 9

3.3.3 Heat Radiation Countermeasures .......................................................................... 10

3.3.4 Noise Countermeasures......................................................................................... 12

4. NC Card Connection........................................................................................................... 15

4.1 NC Card Connection System Diagram........................................................................... 15

4.2 NC Card Part Names ..................................................................................................... 16

4.2.1 Names of HR621 Card Parts.................................................................................. 16

4.2.2 Names of HR623 Card Parts.................................................................................. 17

4.2.3 Names of FCU6-HR655 Unit Parts......................................................................... 18

4.3 Control Unit Connector Pin Assignment......................................................................... 19

4.4 ISA NC Card Mounting................................................................................................... 23

4.4.1 Before Mounting the ISA NC Card.......................................................................... 23

4.4.2 ISA NC Card Mounting Procedure.......................................................................... 24

4.5 PCI NC Card Mounting................................................................................................... 27

4.5.1 Before Mounting the PCI NC Card ......................................................................... 27

4.5.2 PCI NC Card Mounting Procedure ......................................................................... 28

5. Base I/O Unit Connection................................................................................................... 31

5.1 Base I/O Unit Outline ..................................................................................................... 31

5.2 Base I/O Connection System Drawing........................................................................... 32

5.3 Base I/O Unit Part Names.............................................................................................. 33

5.4 Base I/O Unit Connector Pin Assignment....................................................................... 35

5.5 Base I/O Unit Input/Output Specifications...................................................................... 38

5.5.1 Rotary Switch Settings ........................................................................................... 38

5.5.2 RIO1 Terminator..................................................................................................... 38

5.5.3 CF31, CF32 Input Circuit........................................................................................ 39

5.5.4 CF33, CF34 Output Circuit..................................................................................... 39

5.5.5 Specifications of ADD ON PCB Connected to CR31.............................................. 39

5.5.6 Connection of Base I/O Unit Power Supply............................................................ 40

5.5.7 Examples of DI/DO Connection.............................................................................. 41

5.5.8 Connection of Servo Drive Unit.............................................................................. 42

5.5.9 Connection of Spindle Encoder.............................................................................. 42

5.5.10 Connection of Sensor Signal................................................................................ 43

6. Relay Card Connection....................................................................................................... 44

6.1 Relay Card Outline......................................................................................................... 44

6.2 Relay Card Connection System Diagram....................................................................... 44

6.3 Relay Card Part Names ................................................................................................. 45

6.4 Relay Card Connector Pin Assignment.......................................................................... 46

6.5 Relay Card Input/Output Specifications.......................................................................... 48

6.5.1 Relay Card Power Connection............................................................................... 48

6.5.2 Emergency Stop Connection.................................................................................. 48

6.5.3 Connection of Spindle Encoder.............................................................................. 49

6.5.4 Manual Pulse Generator Connection ..................................................................... 49

6.5.5 RS-232C Device Connection.................................................................................. 49

6.6 Installation on the Base I/O Unit..................................................................................... 50

x

Page 12

7. Remote I/O Unit Connection .............................................................................................. 51

7.1 Outline of Remote I/O Unit............................................................................................. 51

7.2 Names of Each Remote I/O Unit Section....................................................................... 52

7.3 Connection of Remote I/O Power................................................................................... 53

7.4 Outline of Digital Signal Input Circuit.............................................................................. 54

7.5 Outline of Digital Signal Output Circuit........................................................................... 56

7.6 Outline of Analog Signal Output Circuit .......................................................................... 57

7.7 Outline of Analog Signal Input Circuit............................................................................. 58

7.8 Connection of FCUA-DX10*/13*/14* Unit and Machine Control Signal.......................... 59

7.9 Connection of FCUA-DX11* Unit and Machine Control Signal....................................... 61

7.10 Connection of FCUA-DX12* Unit and Machine Control Signal..................................... 63

7.11 Connection of FCUA-DX13* Unit and Handle .............................................................. 65

7.12 Outline of FCUA-DX13* Unit Pulse Input Circuit .......................................................... 66

7.13 Connection of FCUA-DX14* Unit and Analog Input/Output Signal............................... 67

7.14 Setting of Channel No. when Using Multiple Remote I/O Units.................................... 68

7.15 Remote I/O Unit Input/Output Signal Cables................................................................ 70

Appendix 1 Outline Drawings ................................................................................................ 71

Appendix 1.1 ISA NC Card Outline Drawing (HR621)....................................................... 71

Appendix 1.2 ISA NC Card Outline Drawing (HR623)....................................................... 71

Appendix 1.3 PCI NC Card Outline Drawing (FCU6-HR655) ............................................ 72

Appendix 1.4 Base I/O Unit Outline Drawing..................................................................... 73

Appendix 1.5 Relay Card (independent installation) Outline Drawing ............................... 74

Appendix 1.6 Base I/O Unit + Relay Card (add-on) Outline Drawing................................. 75

Appendix 1.7 Remote I/O Unit Outline Drawing................................................................. 76

Appendix 1.8 Manual Pulse Generator (HD60) Outline Drawing....................................... 77

Appendix 1.9 Spindle Encoder (OSE-1024-3-15-68) Outline Drawing............................... 78

Appendix 1.10 Grounding Plate and Clamp Fitting Outline Drawings.................................. 79

Appendix 2 Cable Manufacturing Drawings ......................................................................... 80

Appendix 2.1 SH21 cable (Servo drive unit)...................................................................... 82

Appendix 2.2 SH41 cable (Remote I/O unit)...................................................................... 83

Appendix 2.3 R031 cable (Analog signal input/output)...................................................... 84

Appendix 2.4 R041 cable (Manual pulse generator).......................................................... 85

Appendix 2.5 R042 cable (Manual pulse generator).......................................................... 86

Appendix 2.6 R211 cable (Remote I/O unit) ..................................................................... 87

Appendix 2.7 R220 cable (+24VDC input)......................................................................... 88

Appendix 2.8 R300 cable (Machine input/output).............................................................. 89

Appendix 2.9 R301 cable (Machine input/output).............................................................. 90

Appendix 2.10 F010 cable (NC Card).................................................................................. 91

Appendix 2.11 F011 cable (NC Card).................................................................................. 92

Appendix 2.12 F020 cable (Manual pulse generator) ........................................................ 93

Appendix 2.13 F021 cable (Manual pulse generator) ........................................................ 94

Appendix 2.14 F022 cable (Manual pulse generator) ........................................................ 95

Appendix 2.15 F040 cable (Spindle encoder)...................................................................... 96

Appendix 2.16 F041 cable (Spindle encoder)...................................................................... 97

Appendix 2.17 F070 cable (+24VDC input) ......................................................................... 98

Appendix 2.18 F390 cable (RS232C).................................................................................. 99

Appendix 2.19 ENC-SP1 cable (Spindle drive unit) ........................................................... 100

Appendix 2.20 Table of Connector Sets ............................................................................. 101

Appendix 3 Parts for EMC Measures..................................................................................... 102

Appendix 3.1 Shield Clamp Fitting..................................................................................... 102

Appendix 3.2 Ferrite Core.................................................................................................. 103

Appendix 3.3 Surge Protector............................................................................................ 104

Appendix 3.4 Selection of Stabilized Power Supply........................................................... 107

xi

Page 13

1. Outline

1. Outline

This manual explains MELDASMAGIC64 installation and connection methods centered on the NC

Card.

By installing this NC Card in a personal computer expansion slot (ISA bus or PCI bus), and connecting

a servo drive unit, servomotor, etc., a custom-made NC unit can be constructed.

This manual assumes that all functions are added, but the actually delivered device may not have all

functions.

Refer to the following documents for explanations on the functions.

MELDASMAGIC64 Setup Instruction Manual........................................................................ BNP-B2191

MELDASMAGIC64 Maintenance Manual..............................................................................BNP-B2207

MELDAS AC Servo and Spindle MDS-A/B Series Specifications Manual ............................BNP-B3759

MELDAS AC Servo and Spindle MDS-C1 Series Specifications Manual.............................. BNP-C3000

MELDAS AC Servo and Spindle MDS-CH Series Specifications Manual.............................BNP-C3016

MELDAS AC Servo MDS-B-SVJ2 Series Specification Manual............................................ BNP-B3937

MELDAS AC Servo MDS-B-SPJ2 Series Specification Manual............................................ BNP-B2164

1

Page 14

2. Configuration

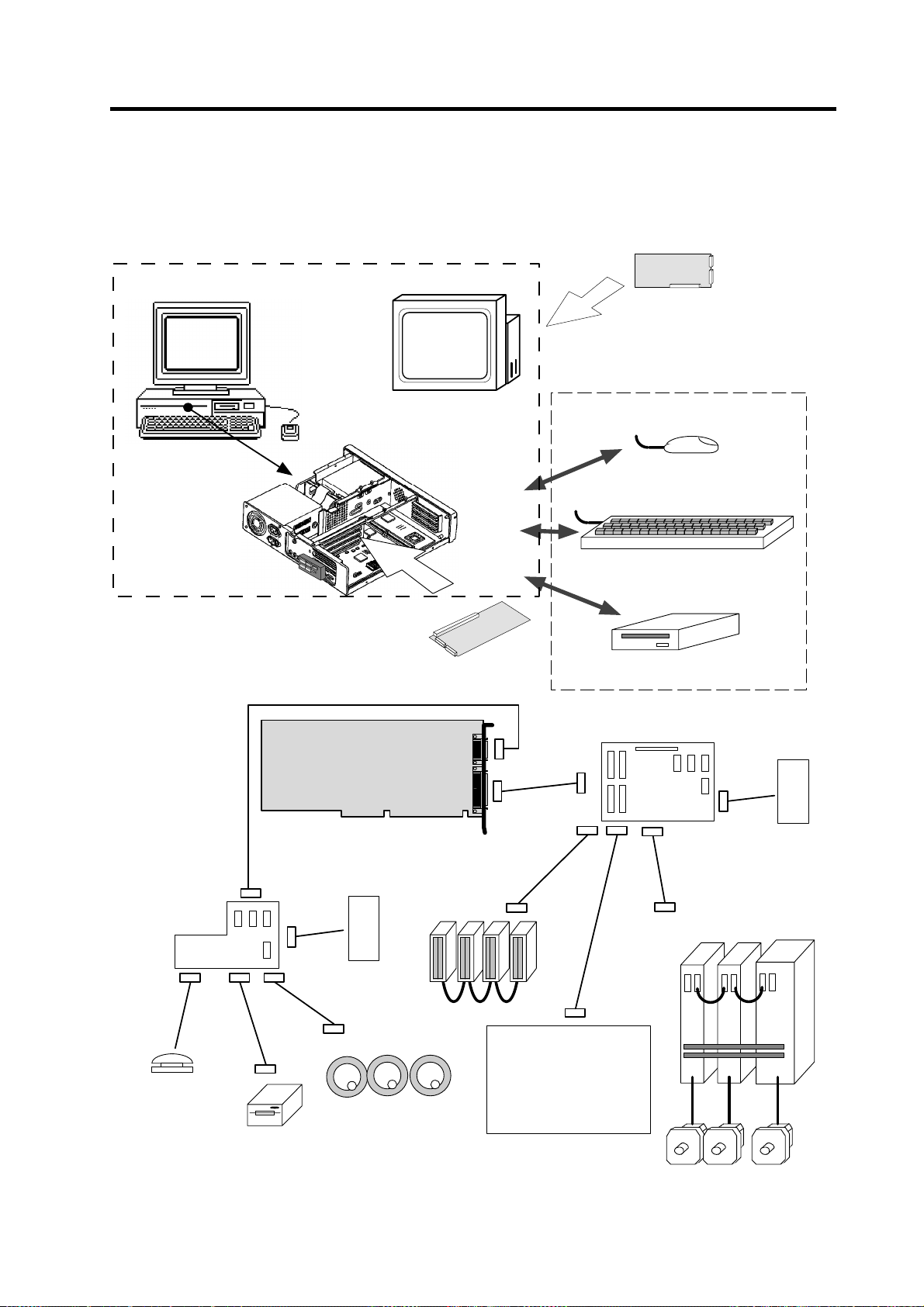

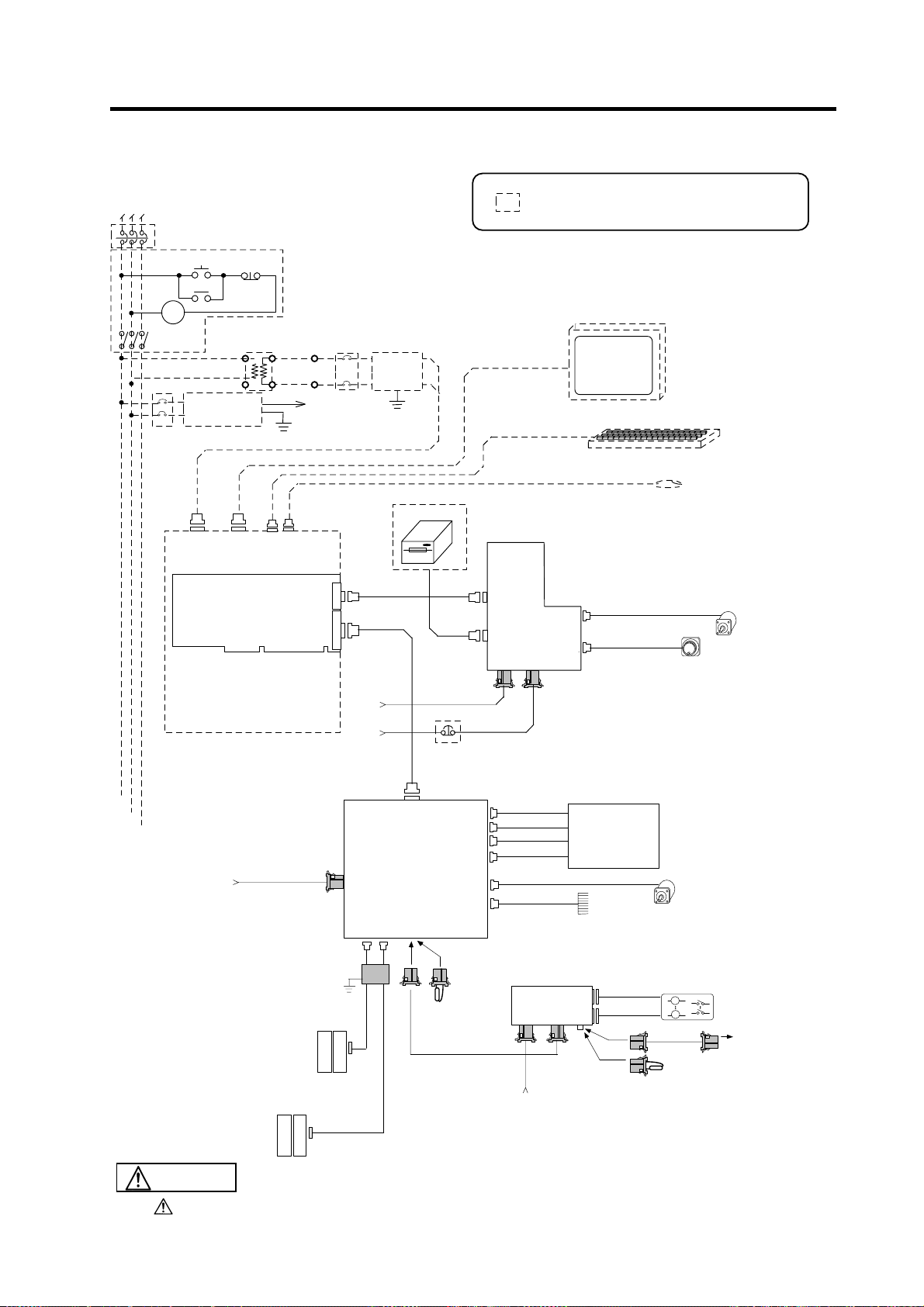

2.1 System Configuration

Prepared by machine tool manufacturer

2. Configuration

2.1 System Configuration

Desktop personal computer

or

ISA NC Card HR621/HR623

PCI NC Card FCU6-HR655

Panel computer

A

C

C

N

R

D

F010 cable

NC CARD

Prepared by machine tool manufacturer

Mouse

Keyb o ard

Floppy disk drive

Base I/O unit

(FCU6-DX2**, 3**, 4**)

External power

(24VDC supply)

F070 cable

(R220 cab l e )

Relay card

(HR682)

F070 cable

(R220 ca bl e )

External emergency

stop switch

F011 cable

Externalpo wer

(24VDC supply)

F070 cable

(R220 cable)

F020/F021/F022

cable

Manual pulse generator

#2

#1

RS-232C device

(Note) Only the DC code (X ON/OFF)

metho d ha n dshake is p o ssi b le

#3

SH41 cabl e

(R211 cab l e )

Re mo te I/ O unit

2

R300/R301

cable

Machine electric cabinet

SH21 cable

Servo drive unit/

spindle drive unit

Servomotor/spindle motor

MDS-B-V1/V2

MDS-C1-V1/V2

MDS-B-SVJ2

MDS-B-SP

MDS-B-SPJ2

MR-J2-CT

Page 15

2. Configuration

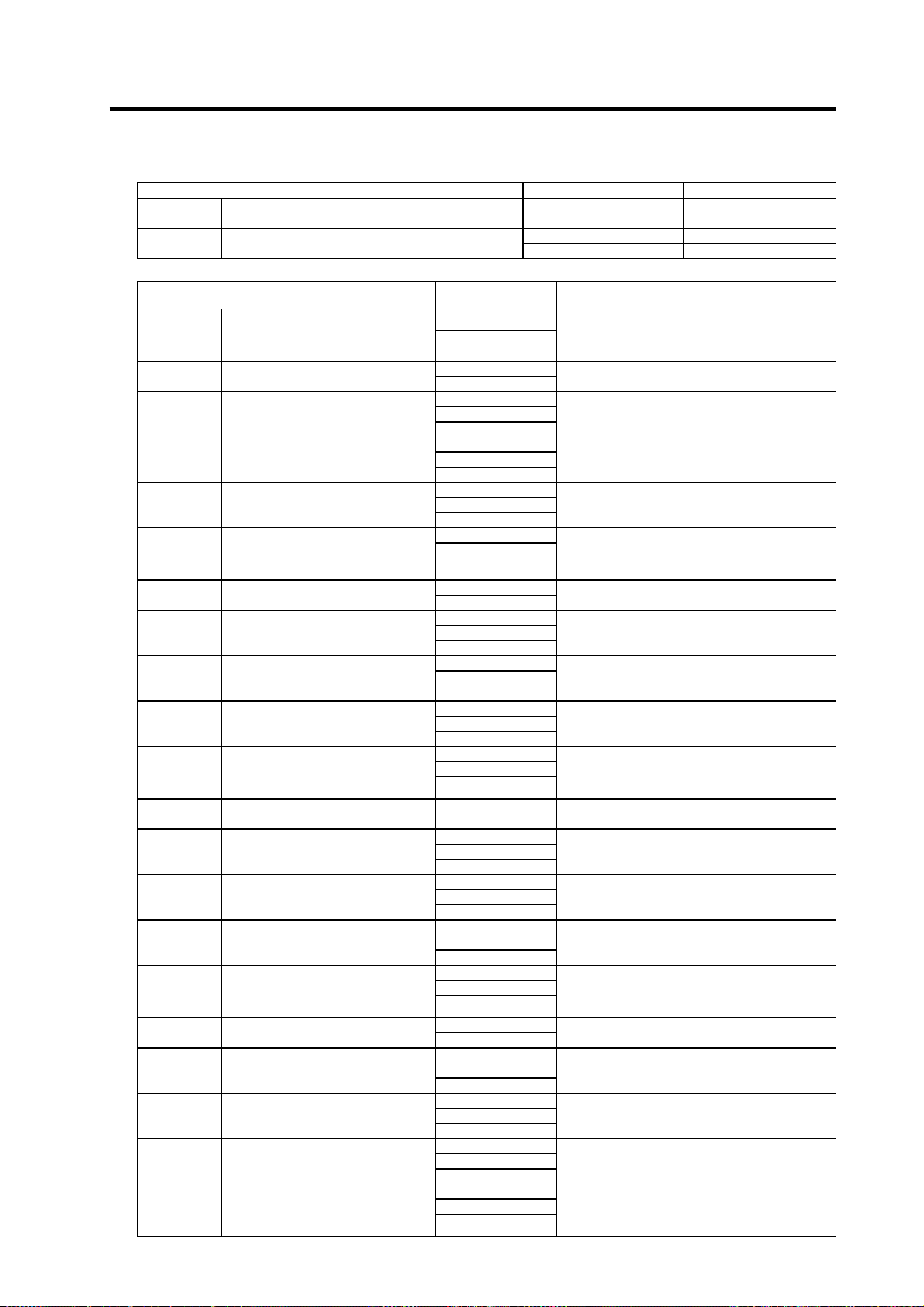

2.2 List of Configuration Units

2.2 List of Configuration Units

1. NC Card

HR621 NC Card installed in an ISA bus personal computer HR621 CPU PCB

HR623 NC Card installed in an ISA bus personal computer HR623 CPU PCB

2. I/O unit (1)

emergency stop switch input I/F

RS-232C uses only the DC code (X

ON/OFF) method handshake.

With servo, RIO, SKIP, ENC I/F

FCU6-DX310 DI (sink/source)/DO (sink) = 80/64

FCU6-DX320 DI (sink/source)/DO (sink) = 80/64

FCU6-DX330 DI (sink/source)/DO (sink) = 48/48

FCU6-DX340 DI (sink/source)/DO (sink) = 48/48

FCU6-DX410 DI (sink/source)/DO (sink) = 96/80

FCU6-DX420 DI (sink/source)/DO (sink) = 96/80

FCU6-DX430 DI (sink/source)/DO (sink) = 64/64

FCU6-DX440 DI (sink/source)/DO (sink) = 64/64

FCU6-DX311 DI (sink/source)/DO (source) = 80/64

FCU6-DX321 DI (sink/source)/DO (source) = 80/64

FCU6-DX331 DI (sink/source)/DO (source) = 48/48

FCU6-DX341 DI (sink/source)/DO (source) = 48/48

FCU6-DX411 DI (sink/source)/DO (source) = 96/80

FCU6-DX421 DI (sink/source)/DO (source) = 96/80

FCU6-DX431 DI (sink/source)/DO (source) = 64/64

FCU6-DX441 DI (sink/source)/DO (source) = 64/64

With servo, RIO, SKIP, ENC I/F

With servo, RIO, SKIP, ENC I/F

Analog output 1 point

With servo, RIO, SKIP, ENC I/F

Manual pulse 2ch

With servo, RIO, SKIP, ENC I/F

Analog input 4 points, analog output

1 point

With servo, RIO, SKIP, ENC I/F

With servo, RIO, SKIP, ENC I/F

With servo, RIO, SKIP, ENC I/F

Analog output 1 point

With servo, RIO, SKIP, ENC I/F

Manual pulse 2ch

With servo, RIO, SKIP, ENC I/F

Analog input 4 points, analog output

1 point

With servo, RIO, SKIP, ENC I/F

With servo, RIO, SKIP, ENC I/F

With servo, RIO, SKIP, ENC I/F

Analog output 1 point

With servo, RIO, SKIP, ENC I/F

Manual pulse 2ch

With servo, RIO, SKIP, ENC I/F

Analog input 4 points, analog output

1 point

With servo, RIO, SKIP, ENC I/F

With servo, RIO, SKIP, ENC I/F

With servo, RIO, SKIP, ENC I/F

Analog output 1 point

With servo, RIO, SKIP, ENC I/F

Manual pulse 2ch

With servo, RIO, SKIP, ENC I/F

Analog input 4 points, analog output

1 point

Type Configuration elements Details

HR183 CPU PCB FCU6-HR655 NC Card instal led in an PCI bus personal computer

HR655 I/F PCB

Type

Configuration

elements

HR682 HR682 HANDLE, ENC, RS-232C,

HR325 FCU6-DX210 DI (sink/source)/DO (sink) = 48/48

Aluminum die cast

HR325

RX323-1

Aluminum die cast

HR325

RX323

Aluminum die cast

HR325

RX331

Aluminum die cast

HR325

RX341

Aluminum die cast

HR327 FCU6-DX220 DI (sink/source)/DO (sink) = 64/64

Aluminum die cast

HR327

RX323-1

Aluminum die cast

HR327

RX323

Aluminum die cast

HR327

RX331

Aluminum die cast

HR327

RX341

Aluminum die cast

HR335 FCU6-DX211 DI (sink/source)/DO (source) = 48/48

Aluminum die cast

HR335

RX324-1

Aluminum die cast

HR335

RX324

Aluminum die cast

HR335

RX331

Aluminum die cast

HR335

RX341

Aluminum die cast

HR337 FCU6-DX221 DI (sink/source)/DO (source) = 64/64

Aluminum die cast

HR337

RX324-1

Aluminum die cast

HR337

RX324

Aluminum die cast

HR337

RX331

Aluminum die cast

HR337

RX341

Aluminum die cast

With metal spacers. Add-on to FCU6-DX2**

possible.

Base PCB: DI (sink/source)/DO (sink) = 48/48

Add-on PCB: DI (sink/source)/DO (sink) = 32/16

Base PCB: DI (sink/source)/DO (sink) = 48/48

Add-on PCB: DI (sink/source)/DO (sink) = 32/16

Analog output 1 point

Base PCB: DI (sink/source)/DO (sink) = 48/48

Add-on PCB: Manual pulse generator 2ch

Base PCB: DI (sink/source)/DO (sink) = 48/48

Add-on PCB: Analog input 4 points,

analog output 1 point

Base PCB: DI (sink/source)/DO (sink) = 64/64

Add-on PCB: DI (sink/source)/DO (sink) = 32/16

Base PCB: DI (sink/source)/DO (sink) = 64/64

Add-on PCB: DI (sink/source)/DO (sink) = 32/16

Analog output 1 point

Base PCB: DI (sink/source)/DO (sink) = 64/64

Add-on PCB: Manual pulse generator 2ch

Base PCB: DI (sink/source)/DO (sink) = 64/64

Add-on PCB: Analog input 4 points,

analog output 1 point

Base PCB: DI (sink/source)/DO (source) = 48/48

Add-on PCB: DI (sink/source)/DO (source) =

32/16

Base PCB: DI (sink/source)/DO (source) = 48/48

Add-on PCB: DI (sink/source)/DO (source) =

32/16 Analog output 1 point

Base PCB: DI (sink/source)/DO (source) = 48/48

Add-on PCB: Manual pulse generator 2ch

Base PCB: DI (sink/source)/DO (source) = 48/48

Add-on PCB: Analog input 4 points,

analog output 1 point

Base PCB: DI (sink/source)/DO (source) = 64/64

Add-on PCB: DI (sink/source)/DO (source) =

32/16

Base PCB: DI (sink/source)/DO (source) = 64/64

Add-on PCB: DI (sink/source)/DO (source) =

32/16 Analog output 1 point

Base PCB: DI (sink/source)/DO (source) = 64/64

Add-on PCB: Manual pulse generator 2ch

Base PCB: DI (sink/source)/DO (source) = 64/64

Add-on PCB: Analog input 4 points,

analog output 1 point

Details

3

Page 16

2. Configuration

g

g

g

g

2.2 List of Configuration Units

2. I/O unit (2)

Type

RX323-1 DI (sink/source)/DO (sink)=32/16 RX323-1 Add-on PCB

RX323 DI (sink/source)/DO (sink)=32/16

Analog output 1 point

RX324-1 DI (sink/source)/DO

(source)=32/16

RX324 DI (sink/source)/DO

(source)=32/16

Analog output 1 point

RX331 Manual pulse generator 2ch RX331 Add-on PCB

RX341 Analog input 4 points,

Analog output 1 point

FCUA-DX100 DI (sink/source)/DO (sink)=32/32 RX311 Base PCB: DI (sink/source)/DO (sink)=32/32

Case

FCUA-DX110 DI (sink/source)/DO (sink)=64/48

FCUA-DX120 DI (sink/source)/DO (sink)=64/48

Analog output 1 point

FCUA-DX130 DI (sink/source)/DO (sink)=32/32

Manual pulse 2ch

FCUA-DX140 DI (sink/source)/DO (sink)=32/32

Analog input 4 points,

Analog output 1 point

DO (source)=32/32

FCUA-DX111 DI (sink/source)/

DO (source)=64/48

FCUA-DX121 DI (sink/source)/

DO (source)=64/48

Analog output 1 point

FCUA-DX131 DI (sink/source)/

DO (source)=32/32

Manual pulse 2ch

FCUA-DX141 DI (sink/source)/

DO (source)=32/32

Analog input 4 points,

Analog output 1 point

3. Peripheral devices

Type

HD60C Manual pulse generator Without MELDAS logo

HD60C-1 Manual pulse generator With MELDAS logo

Grounding plate D Grounding plate D set

Grounding plate E Grounding plate E set

4. Operation unit options

Type

FCU6-HR211 I/O branch plate HR211 card

FCU6-HR251 IC card interface HR251 card

Configuration

elements

RX323 Add-on PCB

RX324-1 Add-on PCB

RX324 Add-on PCB

RX341 Add-on PCB

RX311 Base PCB: DI (sink/source)/DO (sink)=32/32

RX321-1 Add-on PCB: DI (sink/source)/ DO (sink)=32/16

Case

RX311 Base PCB: DI (sink/source)/DO (sink)=32/32

RX321 Add-on PCB: DI (sink/source)/ DO (sink)=32/16

Case

RX311 Base PCB: DI (sink/source)/DO (sink)=32/32

RX331 Add-on PCB: Manual pulse generator 2ch

Case

RX311 Base PCB: DI (sink/source)/DO (sink)=32/32

RX341 Add-on PCB: Analog input 4 points,

analo

Case

RX312 Base PCB: DI (sink/source)/DO (source)=32/32FCUA-DX101 DI (sink/source)/

Case

RX312 Base PCB: DI (sink/source)/DO (source)=32/32

RX322-1 Add-on PCB: DI (sink/source)/ DO (source)=32/16

Case

RX312 Base PCB: DI (sink/source)/DO (source)=32/32

RX322 Add-on PCB: DI (sink/source)/ DO (source)=32/16

Case

RX312 Base PCB: DI (sink/source)/DO (source)=32/32

RX331 Add-on PCB: Manual pulse generator 2ch

Case

RX312 Base PCB: DI (sink/source)/DO (source)=32/32

RX341 Add-on PCB: Analog input 4 points,

analo

Case

Configuration

elements

Configuration

elements

Analo

Analo

Details

output 1 point

output 1 point

Details

Details

output 1 point

output 1 point

4

Page 17

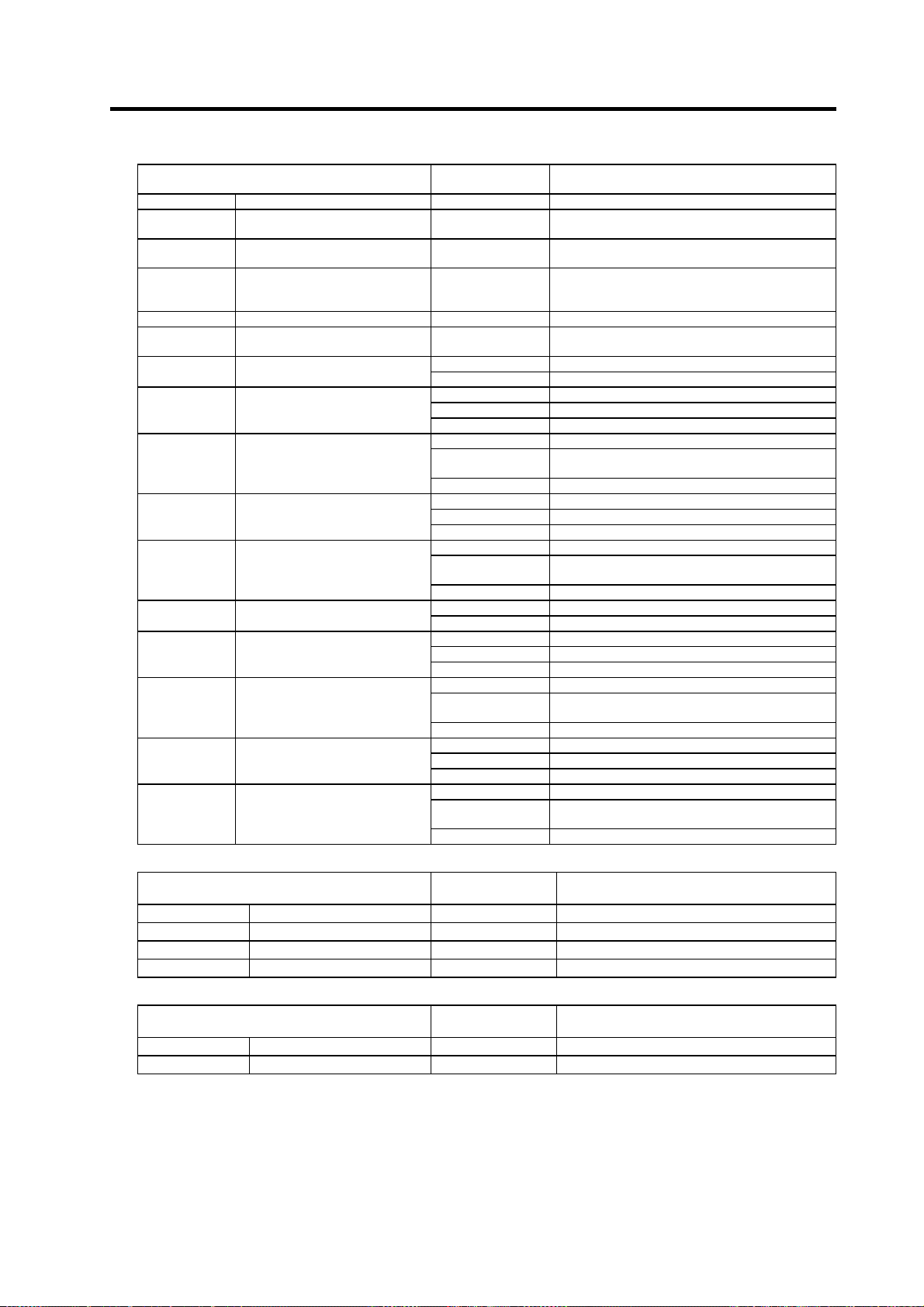

3. Installation

3.1 General Specifications

3. Installation

3.1 General Specifications

NC Card peripheral environment conditions

Type name HR621/HR623 FCU6-HR655 HR682

Unit name NC Card Relay card

Ambient

temperature

Ambient

humidity

General

Working atmosphere No corrosive gas or dust

specifications

Power voltage

consumption

Power specifications

Power drop characteristics Personal computer 5V: 4.5V

Heating value 19W 22W 12W

Unit size 248.9×107.6×20 (mm)

(*1) If these characteristics are not satisfied, the NC Card cannot back up the absolute position informati on of

the machine position when the power is turned OFF.

(*2) Excluding spacers

During operation 0~55°C

During storage -20~60°C

During operation 40~75% RH (with no dew condensation)

During storage 40~75% RH (with no dew condensation)

– 3.3VDC ± 5%

5VDC ± 2%

12VDC ± 2%

3.3V – 0.2A (max) –

Current

5V 2.5A (max) –

12V 0.5A (max) 0.7A (max) –

24V – 0.5A (max)

→4.0V is 1ms or more (*1)

174.63×106.68×21

(mm)

24VDC ± 5%

Ripple ± 5% (P-P)

–

115×156×30 (mm) (*2)

Environmental conditions in electric cabinet

Type name FCU6-DX210, FCU6-DX211 FCU6-DX220, FCU6-DX221

Unit name Base I/O unit

Ambient

temperature

Ambient

humidity

Vibration resistance 4.9m/s2 or less (during operation)

Shock resistance 29.4m/s2 or less (during operation)

Working atmosphere No corrosive gas or dust

General specifications

Power voltage

Power

Current consumption 5V 1A (max), 24V 3.6A (max) (*3) 5V 1A (max), 24V 4.8A (max) (*3)

specifications

Heating value 90W (*3) 110W (*3)

Mass 2.0kg

Unit size 220×168×35 (mm)

(*3) When all DO points are ON

During operation 0~55°C

During storage -20~60°C

During operation 45~75% RH (with no dew condensation)

During storage 45~80% RH (with no dew condensation)

24VDC ± 5%

Ripple ± 5% (P-P)

5

Page 18

3.2 General System Diagram

3.2 General System Diagram

RST

3-phase 200V-230VAC

No-f us e br eaker (N FB )

ON

MC

OFF

3. Installation

:

Machine t ool manu f act ur er

-prepared parts

MC

MC

No- f u s e br ak er

(NFB)

Perso nal com put er m ain un it

Transf ormer

200VAC: 100VAC

Stabilized

power s uppl y

NC Card

HR621/HR623/

FCU6-H R 655

(Note)

The pow er volta ge dep en ds

on the person a l c ompu t e r

specificat io ns.

FG

+24VDC

CF61

CF10

No-fu s e

braker

(NFB)

24VDC

24VDC

Noise

filter

FG

RS-232C devic e

F011

F010

F390

F070

(FCUA-R220)

Emer genc y st op swi tc h

Relay card

HR682

CF61

RS232C

DCIN EMG1

F070

(FCUA-R220)

Display u n i t

Keyboard

Pointin g devic e

(Note) Only the DC code (X ON /OF F) method

han dshake is possible for the RS-232C.

ENC#2

HANDLE

F040/F041

F020/F021/F022

Manu al pul s e gener ato r

(m ax. 3 chan n el s )

2nd s p i n dl e en c oder

R301

CF10

Base I/O unit

24VDC

F070

(FCUA-R220)

FCU6-DX2* *

(DX3**)

DCIN

(DX4**)

SV1

SV2

RIO1

Cable clamp

FG

NC servo/spi ndle drive un it

MDS- B-V1/ V 2

MDS-B-SVJ2

MDS-B-SP

MDS-B-SPJ2

MDS-C1-V1/V2

Auxiliary

axis

MR-J2-CT

CAUTION

Separate the signal wire from the drive line/power line when wiring.

SH21

SH21

CF31

CF32

CF33

CF34

ENC1

SKIP

RIO2

RIO

(for expansion)

Terminator

R-TM

SH41(FCUA-R211)

Note) The remote I/O u nit can be extended up to six stations.

Note that when an add-on PCB is mounted (DX3**, DX4**),

the remote I/O unit can be extended up to 5 stations.

DI

R301

DI

R301

DO

DO

R301

F040/F041

Remote I/O unit

FCUA-DX1**

DCIN RIO1

24VDC

RIO2

F070

(FCUA-R220)

Machine

electri c

cabinet

Sensor

contact,

max. 8 points

6

1st spindle

encoder

Machine control relay/contact

R

R

SH41

(FCUA-R211)

Terminato r

R-TM

To the next

remote

I/O unit

Page 19

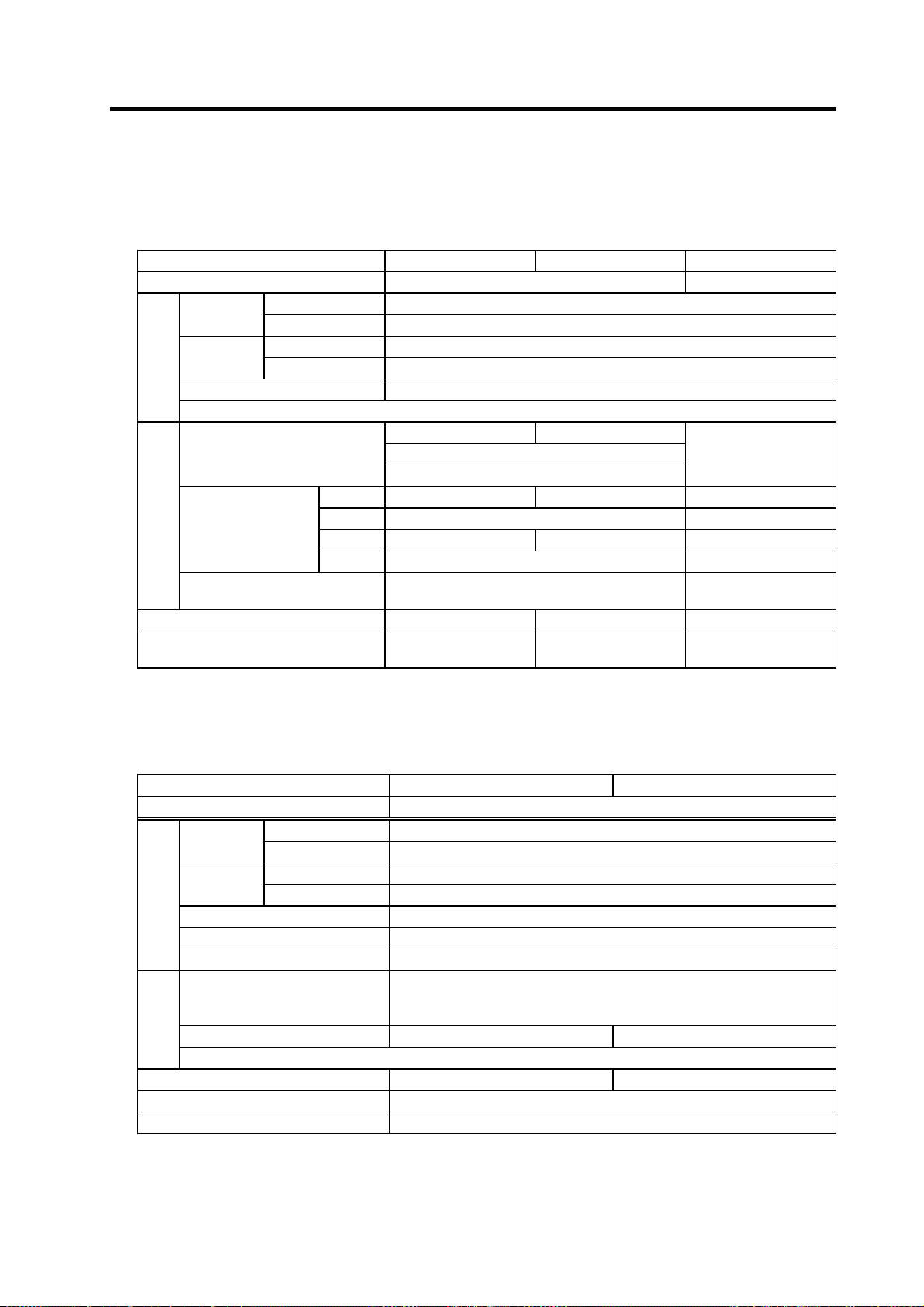

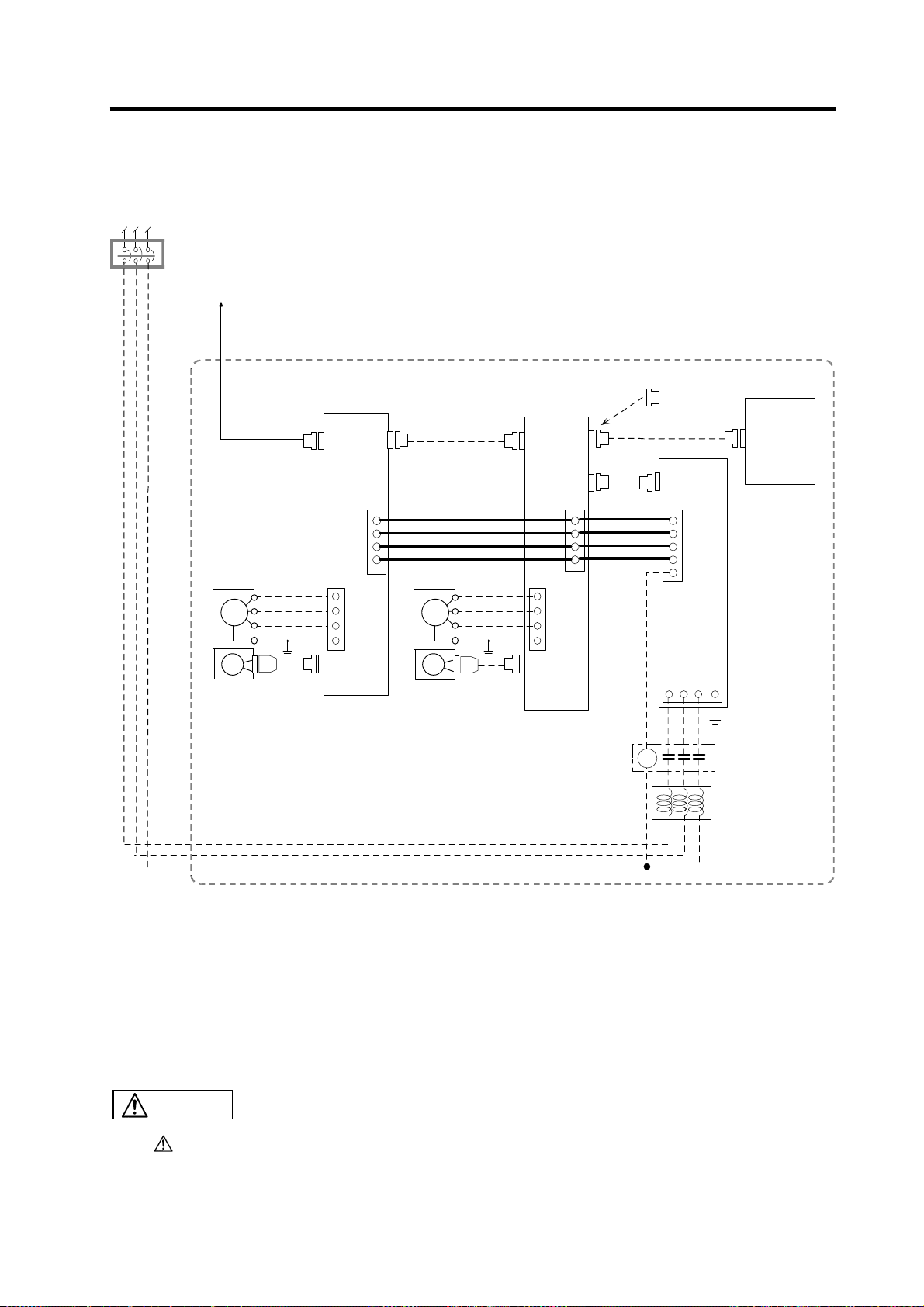

3. Installation

3.2 General System Diagram

Example of connection when using V1/V2 in the drive section

RST

Connection to base I/O unit

SV1 and SV2

Note (1)

SH21 cable

AC servomotor

SM

PG

Motor end detector

Servo drive un i t

MDS- B/ C1 Ser i es

CN1A

CN1B

P

N

R0

S0

AC servomotor

U

V

W

E

CN2

Motor end detector

Note (2)

SH21 cable

SM

PG

Servo drive unit

MDS - B/C 1 Ser i es

CN1B

CN1A

CN4

U

V

W

E

CN2

Terminator

A-TM

SH21 cable

CN4

P

N

R0

S0

MC1

Power

supply unit

RSTE

MC

Batter y

unit

MDS-A-BT-4 (4 axes)

MDS-A-BT-2 (2 axes)

B-AL

(Note) (1) Drive section connections differ according to the configuration of the servo drive unit and

motor used.

(2) When connecting the spindle drive unit, set the axis No. to the value after the last servo

axis.

(3) Connect the last axis (the axis to be connected to the battery unit) to the power supply unit.

(4) When using a terminator, connect to the last axis.

(5) Always wire the control unit's signal wire away from the drive section's drive lines/power

lines.

CAUTION

Separate the signal wire from the drive line/power line when wiring.

7

Page 20

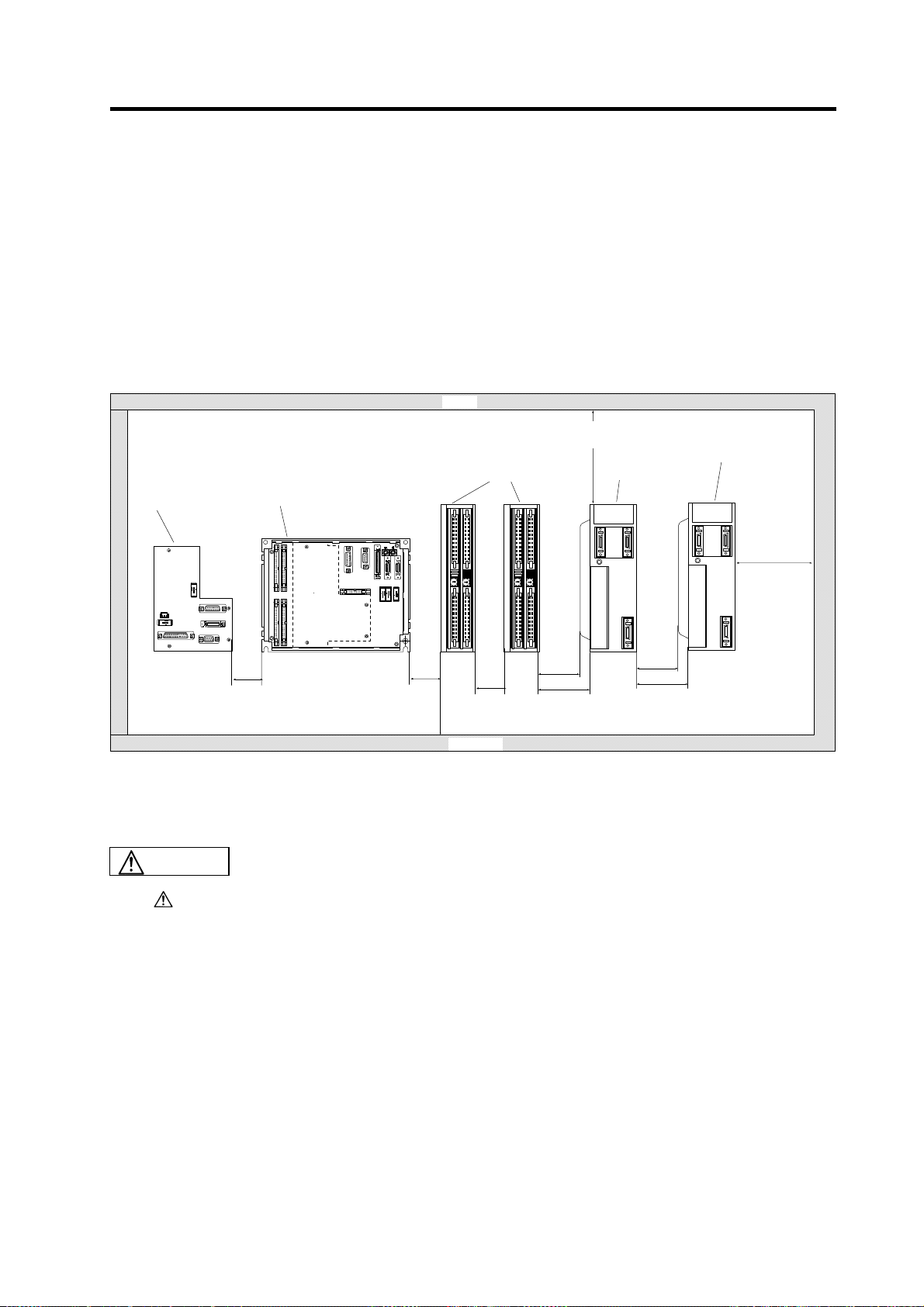

3. Installation

3.3 Installation

3.3 Installation

3.3.1 Installation Direction and Spacing

Each unit is installed in a sealed structure electric cabinet as a principle. Observe the following points

when installing into the electric cabinet.

(1) Install each unit vertically, so that it is visible from the front.

(2) Consider the heat radiation and wiring of each unit. Refer to the following drawing, and secure

space for ventilation.

(3) Install the personal computer main unit paying particular attention to the specification conditions of

the selected personal computer.

Top

100mm or more

Remote I/O unit

(heat radiation space)

Servo drive unit

Spindle drive unit

Relay card

EMG2

EMG1

RS232C

DCIN

HANDLE

CF61

ENC#2

Base I/O u nit

10mm or more

CF31 CF32

MITSUB I SHI

0 0

ENC1

SKIP

SV2

CF10

SV1

CR31

CF34CF33

RI02

DCIN

RI01

10mm

or more

150mm or more

(heat r ad iat io n an d

wiring spac e)

10mm or more

10mm

or more

15mm or more

(wiring space)

10mm

or more

15mm or more

(wiring space)

MITSUB I SHI

30mm or more

Bottom

(Note) The relay card can be added on to the base I/O unit. Refer to "6.6 Installation to the Base I/O

Unit" for the installation method when adding on.

CAUTION

Always observe the direction of installation.

8

Page 21

3. Installation

3.3 Installation

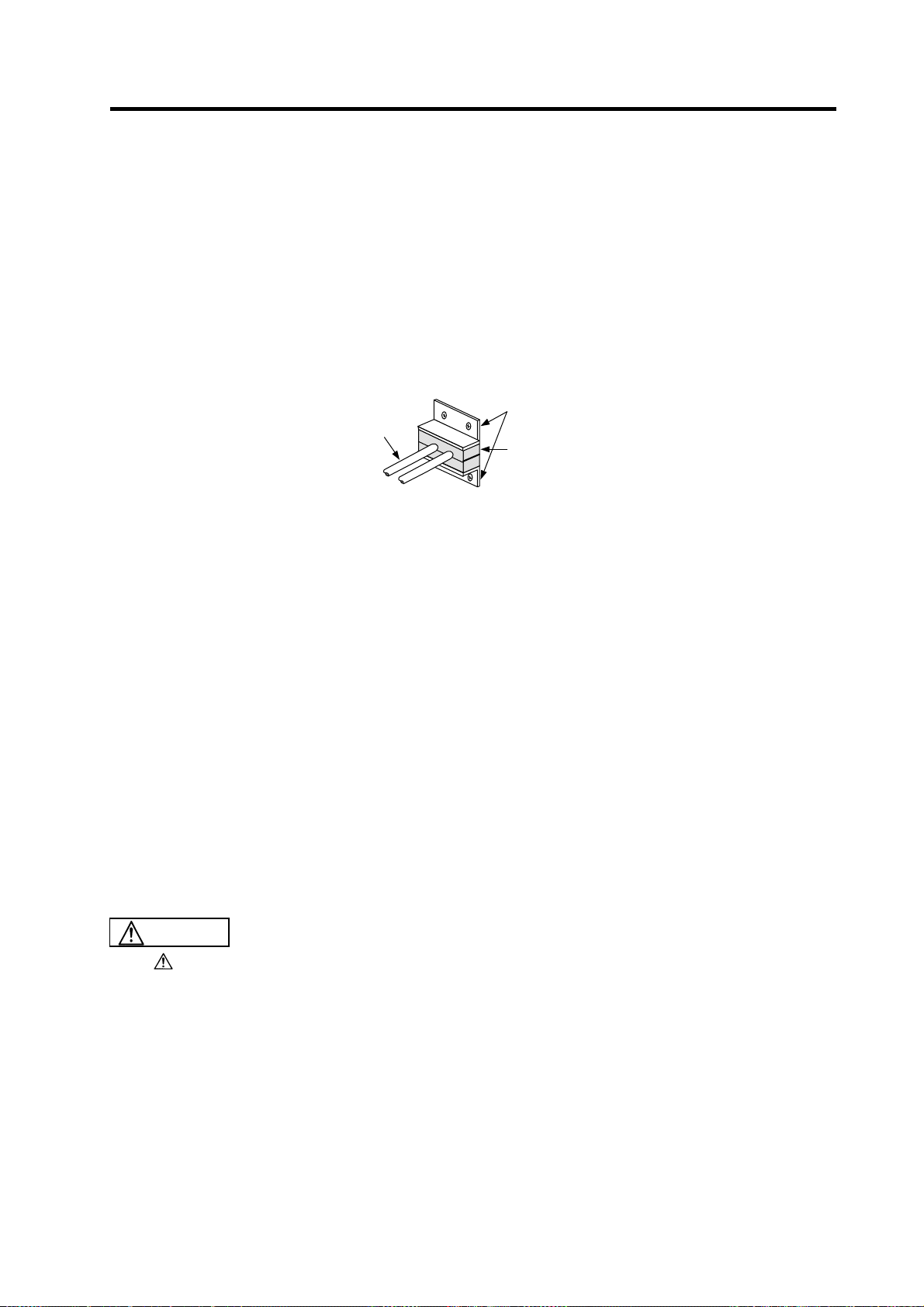

3.3.2 Prevention of Foreign Matter Entry

(1) The inside of each unit is densely mounted, and is sensitive to dust, etc. Always design a sealed

structure electric cabinet, and execute the following measures.

Carry out dust-proofing and oil-proofing measures such as sealing the cable inlets with pa cking.

Be particularly careful that outside air does not enter the electric cabinet through heat radiation

holes, etc.

Seal all gaps.

Securely install the door packing.

Always install packing around any back cover (when present).

Oil can easily accumulate in screw holes on top of the electric cabinet and penetrate into the

electric cabinet. Therefore, carry out special countermeasures such as using oil-proof packing.

Cable

Metal fittings

Pa cking

Cable inlet (example)

(2) After installing each unit, avoid any tool machining in the area surrounding those units. Cutting

chips, etc., may adhere to electronic parts and cause a failure.

(3) Design the electric cabinet so the internal temperature will rise no more than 10°C (target value

5°C or less) over the ambient temperature, and will stay within the temperature conditions of the

personal computer, NC Card, etc. (Refer to "3.3.3 Heat Radiation Countermeasures" for details.)

Use a panel cooler when required.

(4) The personal computer display unit may not operate normally due to external magnetic fields.

Separate magnetism producing sources (transformers, fans, magnetic switches, solenoid relays,

magnet stands, magnetic workpieces, power lines flowing a large current, etc.) from the display

unit by 200mm or more.

Note that the magnetism produced by these magnetism producing sources differs individually, and

will also differ according to the installation direction, etc. Therefore, the display unit may not

operate properly even when separated by 200mm or more from these sources. When determining

the layout of magnetism producing sources, also consider the direction, etc., of the magnetism

produced, and finally confirm by actual operation of the machine.

CAUTION

Make sure that conductive foreign matter (screws, metal pieces, etc.) and flammable

foreign matter (oil, etc.) does not enter inside any unit.

9

Page 22

3. Installation

3.3 Installation

3.3.3 Heat Radiation Countermeasures

In normal NC units, the electric cabinet thermal design is so the electric cabinet ambient temperature is

a 0 to 45°C usage condition, and the electric cabinet internal temperature rise is 10°C. However, these

conditions do not necessarily apply in MELDASMAGIC64.

This is because the operation of all Mitsubishi-supplied units, including the NC Card, is guaranteed up

to 55°C, but the operation of the personal computer is not necessarily guaranteed up to 55°C.

Thus, the electric cabinet ambient temperature must first be determined as shown below.

(1) Determine the electric cabinet ambient temperature T

.

a

Ex. 0 to 35°C

(2) Determine the internal temperature rise ∆T.

Ex. 5°C

(3) Select a personal computer.

When T

max. = 35°C and ∆T = 5°C, the personal computer must have a guaranteed operating

a

temperature of 40°C or more (45°C or more for a margin of safety).

(4) In this example, the average temperature in the electric cabinet will be 40°C or less according to

(1) and (2).

(Note) 1. When heat accumulates in upper areas, etc., of the unit, circulate the air inside the electric

cabinet using a circulation fan.

2. Use an electric cabinet cooler when required.

Use an electric cabinet cooler type that does not take outside air into the electric cabinet.

3. If the personal computer's heat builds up in the personal computer, circulate the air in the

personal computer with a fan.

Back fan

Front fan

NC card

10

Page 23

3. Installation

3.3 Installation

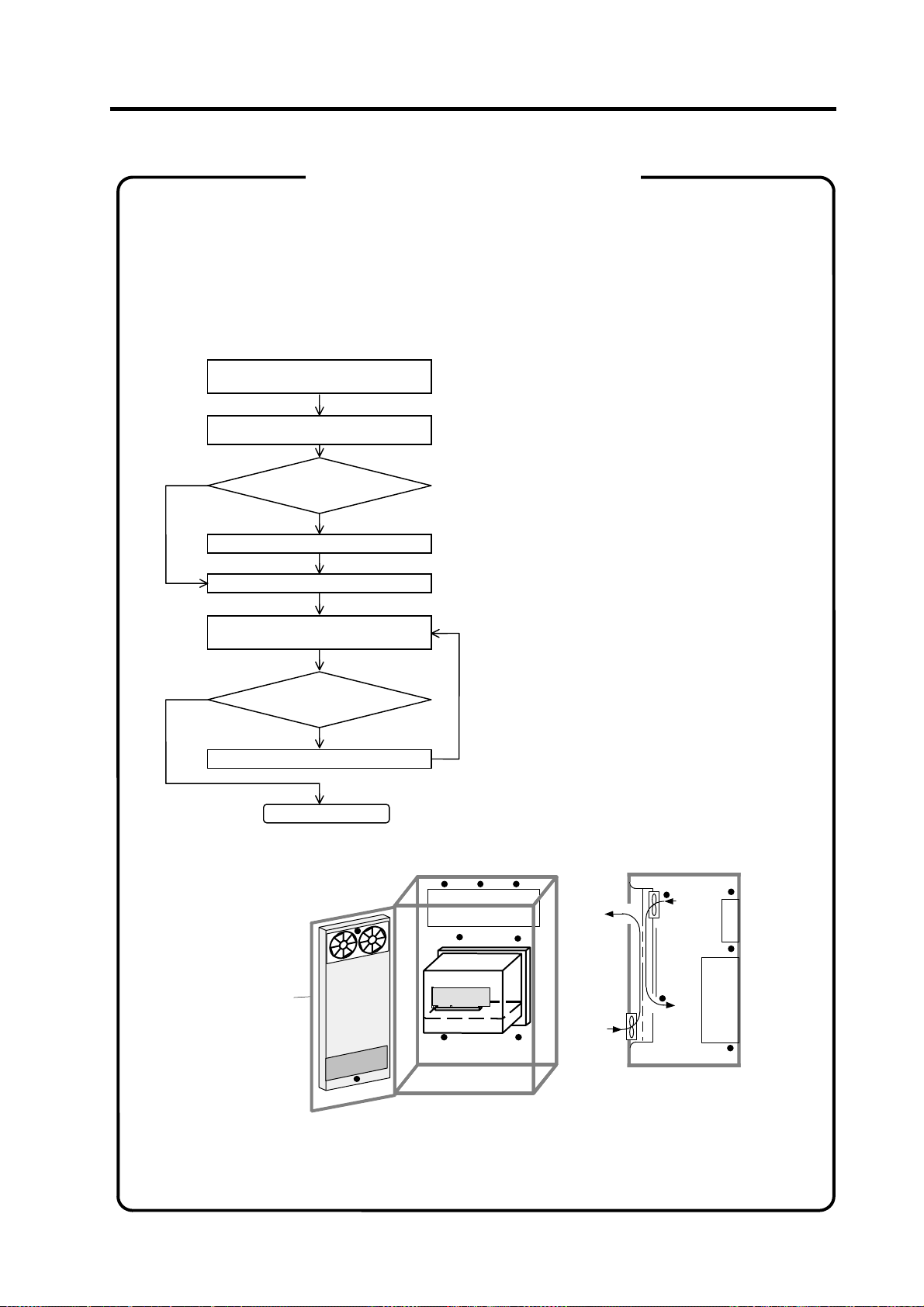

Please refer to following method for heat radiation countermeasures method.

Example of heat radiation countermeasures

<Hypothetical conditions>

(1) Electric cabinet ambient temperature : T

(2) Internal temperature rise value : ∆T

a

d

(The value for the conventional NC is 10°C, but this temperature must be set to 10°C or

less (target value 5°C) for the MELDASMAGIC64.)

(3) Average temperature in electric cabinet : T

Procedures for heat design and verification

+ ∆Td

a

<Supplement>

(1) Refer to "3.1 General Specifications" for the

Calculate total heat generation of

each mounted unit (W)

heat generated by each unit.

(2) Enclosed electric cabinet (thin steel plate)

cooling capacity calculation equation

W≤W1

Calculate electric cabinet’s

cooling capacity (W1)

Comparison of W and W1

W1 = U × A × ∆T

U : 6W/m2 × °C

with internal circulation fan

4W/m

without internal circulation fan

2

× °C

d

A : Effective heat radiation area (m2)

>

Selection of heat exchanger

(Area where heat can be radiated from

electric cabinet)

<Caution>

When calculating the effective heat

Mounting design

radiation area, do not include the parts that

contact other objects.

(3) Points of caution for heat radiation

Collection of internal temperature rise

distribution data

countermeasures when designing mounting

state

* Consider convection in electric cabinet

(eliminate heat spots)

≤

Evaluation

* Collect hot air at suction port in heat

exchanger panel.

(4) Evaluation standards for internal

Improvements

>

temperature rise distribution data

∆Tm (average value)

≤ ∆T

d

∆Tm max (maximum value) ≤ (∆Td + 5) °C

R (inconsistency ∆T

max - ∆Tm min) ≤ 6°C

m

(Evaluate existence of heat spots)

Completion

∆T

: Internal temperature rise

m

measurement value

Mounting example and introduction to temperature (∆T) measurement locations (reference)

: Temperature rise measurement

points (example)

Rela y p an el, e tc.

Internal

air flow

Heat exchang er

Air inlet

Air outlet

External

air flow

11

Page 24

3.3.4 Noise Countermeasures

(1) Connection of frame ground (FG)

The frame should basically be grounded at one earth point. When relaying through the grounding

plate in the middle of the connection route, separate the desktop personal comp uter/panel

personal computer from the remote I/O unit, and the base I/O unit from the servo drive unit/spindle

drive unit, etc.

The NC Card FG is connected to the personal computer electric cabinet with card installation met al

fittings.

Remote

I/O unit

3. Installation

3.3 Installation

Base I/O unit

HR682

Note 3

EMG2

EMG1

RS232C

DCIN

HANDLE

0 0

CF61

ENC#2

Desktop personal computer/

panel personal computer

Note 1

Spindle motor

Servomotor

Servo drive unit/spindle drive unit, etc.

Note 2

Note 2

Main gr ound

Note 1

Note 1: This is not required when directly connecting to the main ground.

Note 2: Connect the motor's grounding cable to the servo drive unit and spindle drive unit.

Note 3: A spacer is used when mounting the HR682 card on the base I/O unit, but when not mounting on the base

I/O unit, connect the card to the main ground using the FG terminal.

12

Page 25

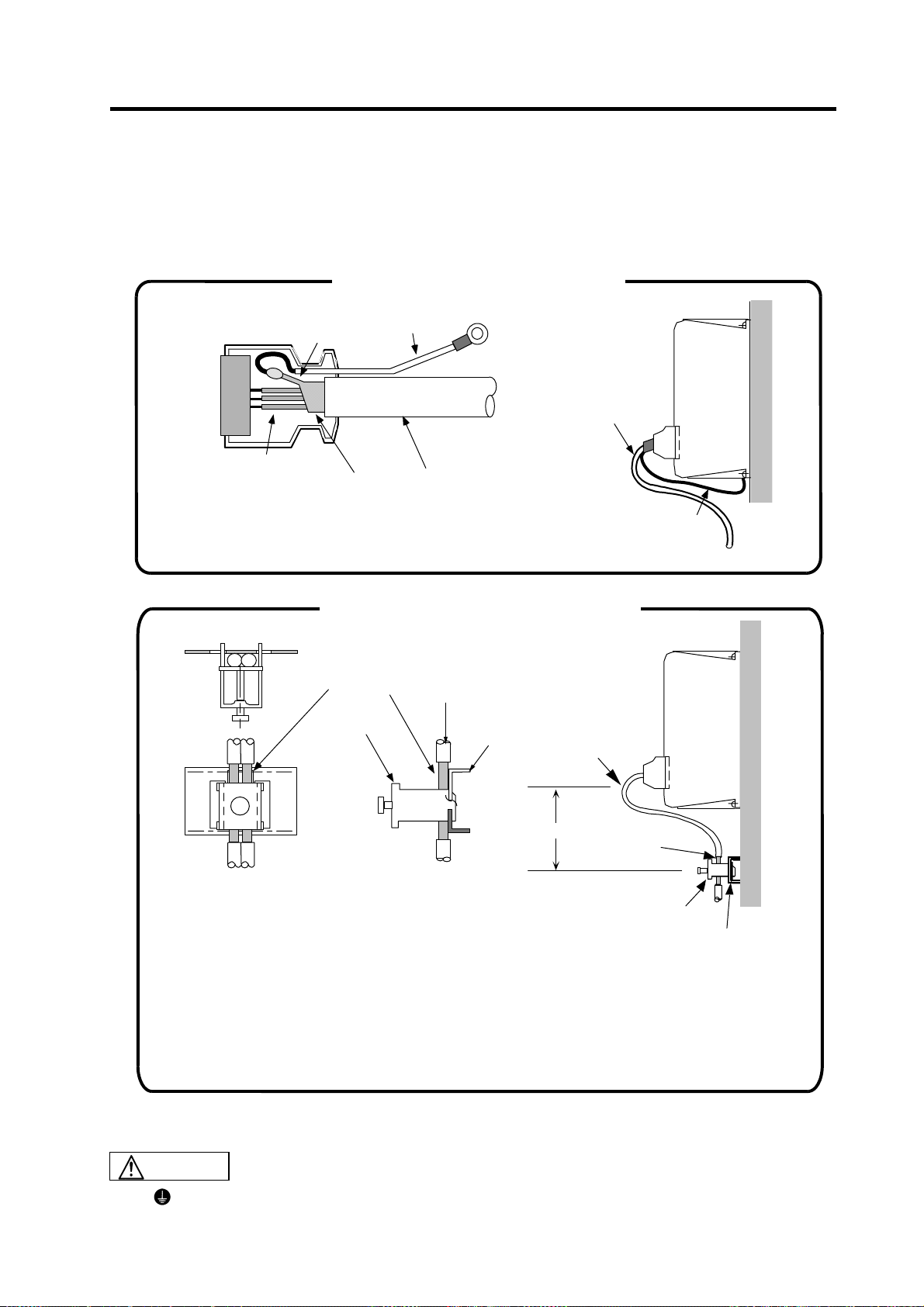

(2) Shield clamping of cables

The shield of the shield cable connected to the base I/O unit, servo drive unit and spindle drive unit

must be connected to the grounding plate to stabilize operation while preventing malfunctioning due to

noise.

The shield can be connected to the grounding plate with lead wires or clamp fittings. Refer to the

following drawings to treat the shield cable.

Example of lead wire treatment

Soldering

Signal wire

Caution

When soldering the grounding cable to the shield, if the soldered

section is close to the shield, the signal wire's sheath could melt

by the soldering heat resulting in a short-circuit.

Solder at a place 10 to 20mm away from the mesh section.

3. Installation

3.3 Installation

Example of connection with lead wire

Grounding cable

Shield

Cable

Cable

Example of connection with clamp fitting

Unit

Unit

Grounding

cable

Shield

Clamp fitting

(1) Peel part of the cable sheath and expose

the shield as shown in the drawing.

Press the exposed part against the grounding

plate with the cable clamp fittings.

(2) If the cable is thin, clamp several together

in a bunch.

(3) Use adequate force when tightening the cable

so that the wire material is not damaged.

(4) Connect each grounding plate together and

ground them at one point.

Cable

Grounding plate

Cable

Less than 0.8m

Shield

Clamp

fitting

Unit

Grounding

plate

When manufacturing the clamp fittings and grounding plate, refer to "Appendix 1.10 Grounding Plate

and Clamp Fitting Outline Drawings". These can also be ordered from Mitsubishi.

CAUTION

Execute ground treatment by cable clamps, etc., for the shielded cable indicated in this

instruction manual.

13

Page 26

3. Installation

3.3 Installation

Cables which require shield clamp with a connector cases are shown following table.

<Shield clamp method>

Fold the wire material shield over the sheath, and wrap copper foil tape over it. Connect the wrapped

copper foil tape to the connector case GND plate.

Treatment of cable ends

Connection origin

Connection

destination

Not required

Not required

Not required

Not required

Not required

Not required

Not required

Not required

Not required

Not required

Not required

Not required

Not required

Unit name

NC Card

(HR621/HR623/

FCU6-HR655)

Base I/O unit

(FCU6-DX2

∗∗)

4

Relay card

(HR682)

∗∗, 3∗∗,

Connector

name

CF10

CF61

CF10

SV1

SV2

ENC1

SKIP

PI01

PI02

CF61

ENC#2

HANDLE

RS232C

Connection destination

Base I/O unit

Relay card

NC Card

Servo drive unit

Servo drive unit

Spindle encoder

Skip

Remote I/O unit

Remote I/O unit

NC Card

Spindle encoder

Manual pulse generator

RS-232C (I/O device)

(Note)

(NC Card) Not required

(NC Card) Not required

(Base I/O unit) Not required

(Base I/O unit) Required

(Base I/O unit) Required

(Base I/O unit) Required

(Base I/O unit) Required

(Base I/O unit) Required

(Base I/O unit) Required

(Relay card) Not required

(Relay card) Required

(Relay card) Required

(Relay card) Required

(Note) RS-232C uses only the DC code (X ON/OFF) method handshake.

(3) Connecting Spark Killers

Connect a spark killer on the coil or relay contact in parallel for noise counterme asures.

Use spark killers which are 0.033~0.1µF, 10~120Ω.

Contact

SK

SK

E

Coil

14

Page 27

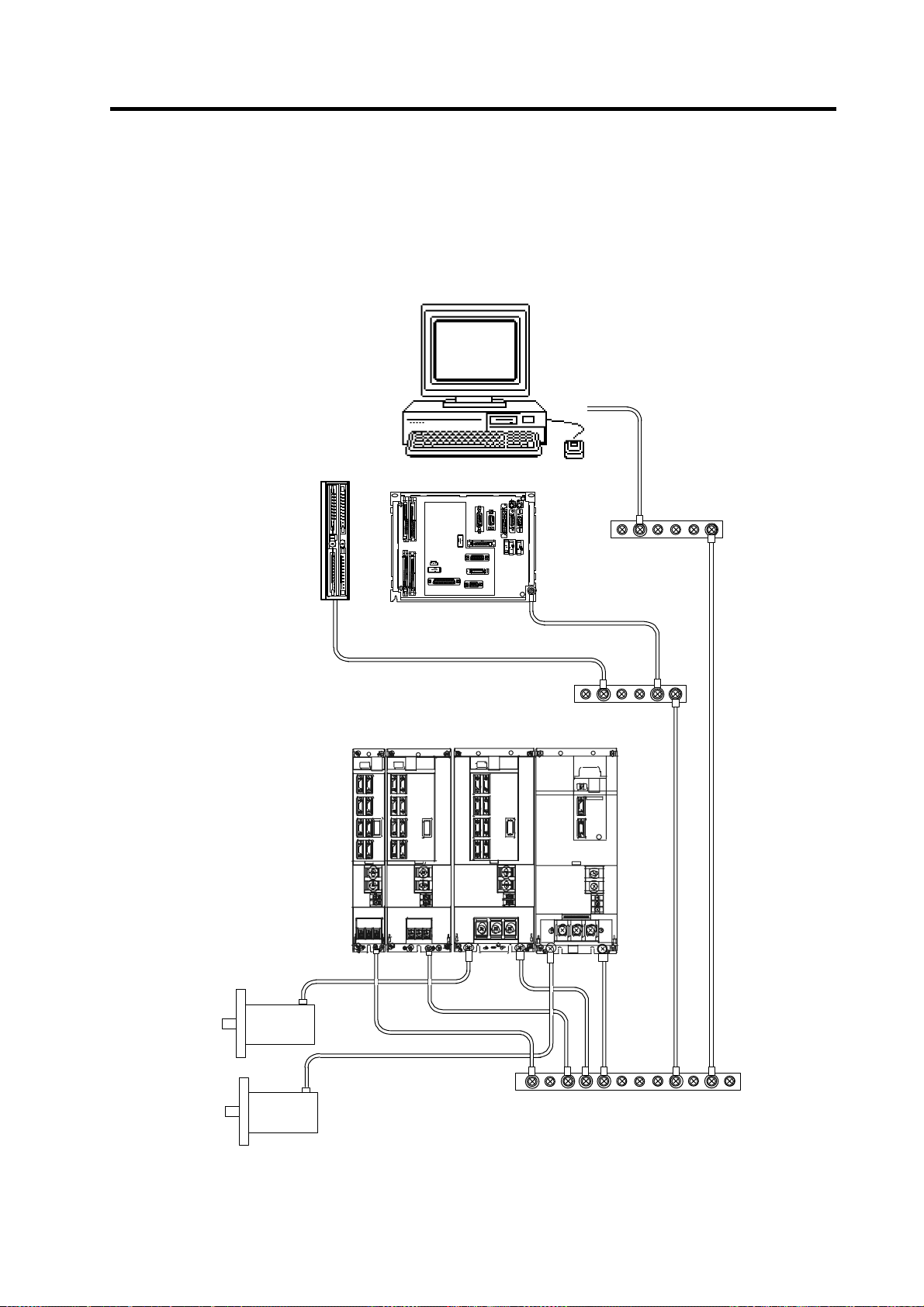

4. NC Card (HR621/HR623/FCU6-HR655) Connection

4.1 NC Card Connection System Diagram

4. NC Card (HR621/HR623/FCU6-HR655) Connection

4.1 NC Card Connection System Diagram

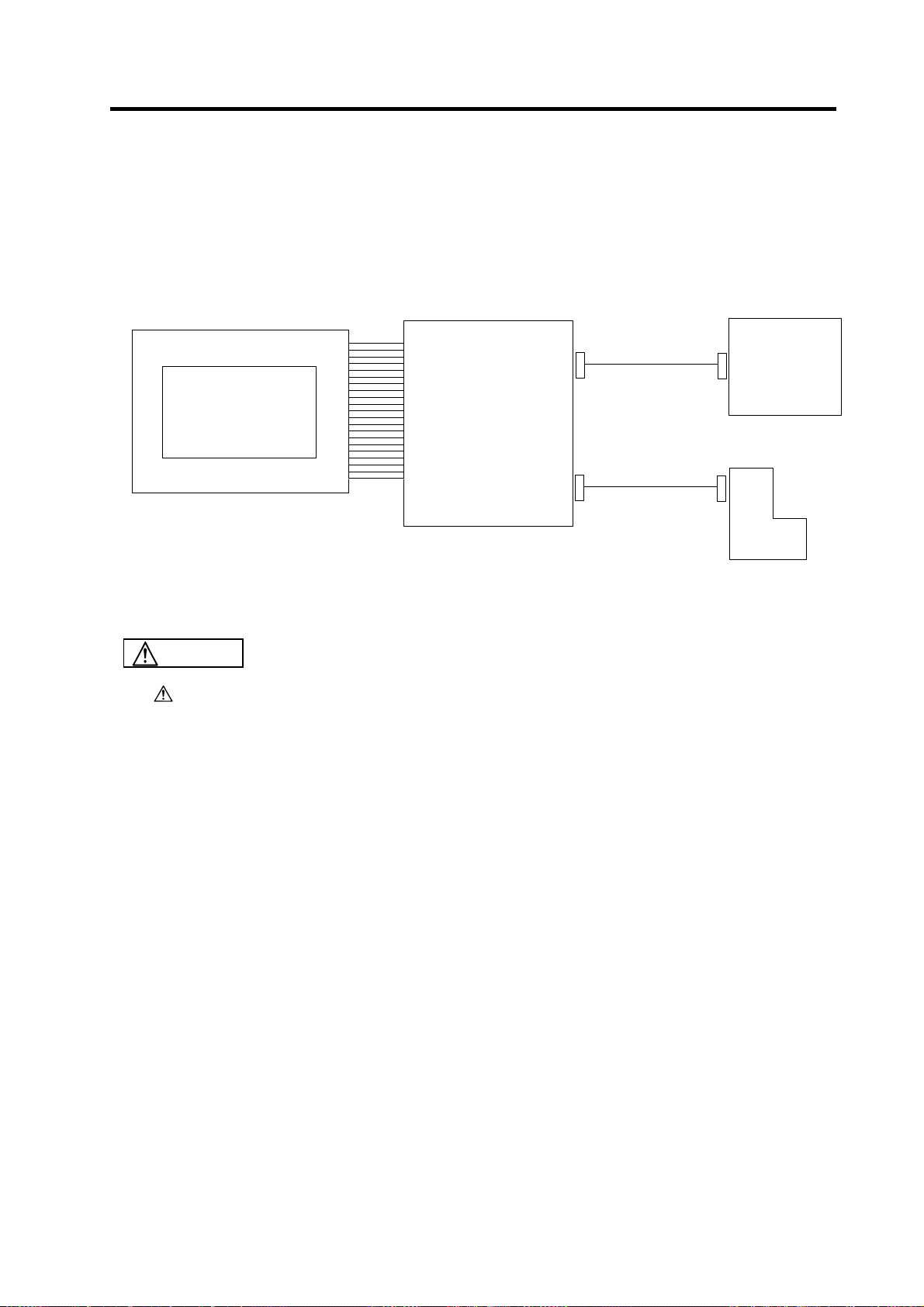

The NC Card is connected to the personal computer with the expansion slot (ISA bus or PCI bus). The

base I/O unit and relay card are connected with a cable.

Expansion slot

(ISA bus/PCI bus)

Base I/O unit

(FCU6-DX2**/3**/4**)

Personal computer

NC Card

(HR621/HR623/

FCU6-HR655)

CF10

CF61

F010 cable

CF10

Relay card

(HR682)

F011 cable

CF61

CAUTION

Turn the NC Card's power ON before turning the base I/O unit's power ON.

If the base I/O unit's power is turned ON first, the current will be led to the NC Card from

the connection cable. This will prevent the personal computer or the cards in the

personal computer from starting up properly.

15

Page 28

4. NC Card (HR621/HR623/FCU6-HR655) Connection

4.2 NC Card Part Names

4.2 NC Card Part Names

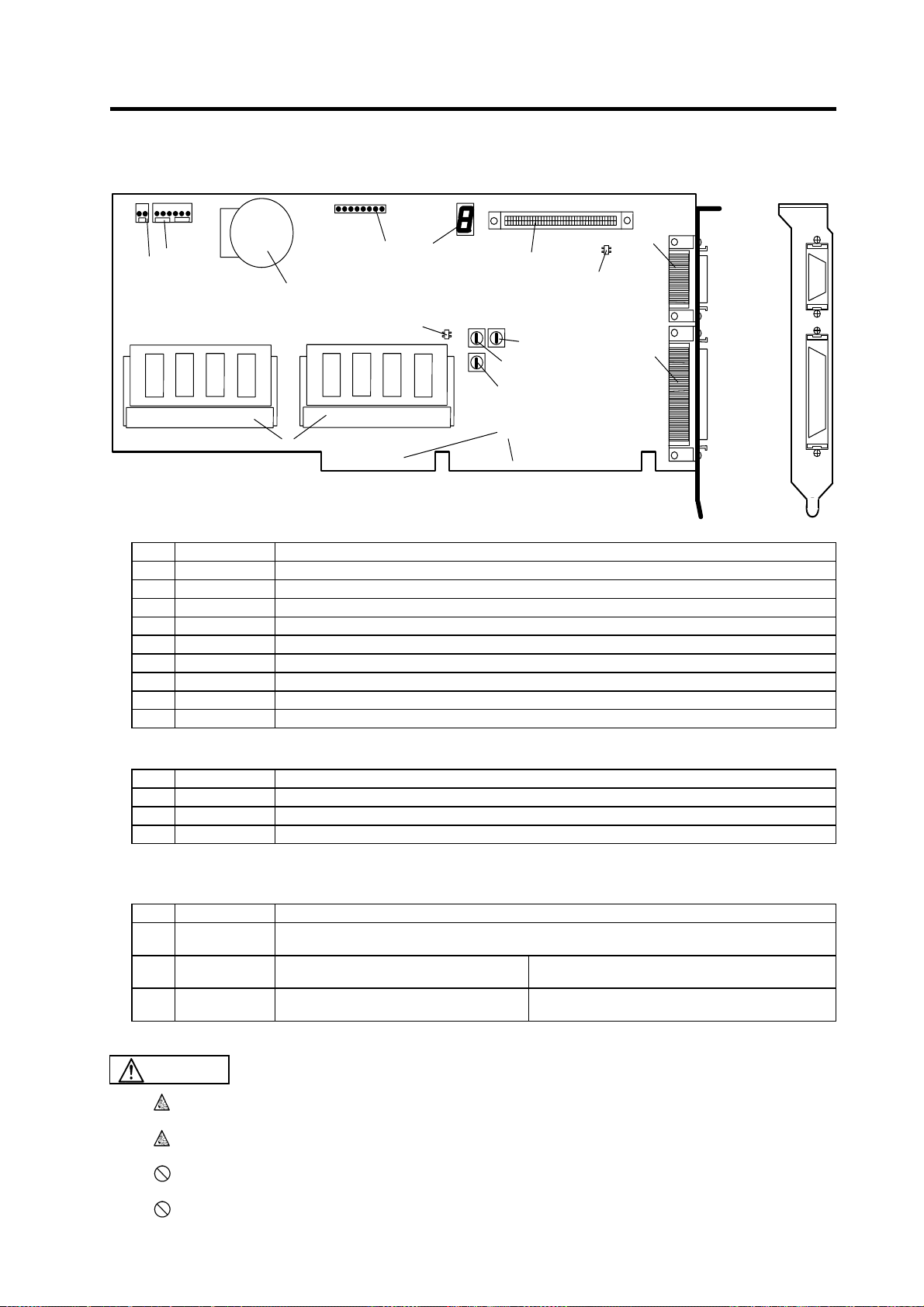

4.2.1 Names of HR621 Card Parts

CF62

BAT

(4)

(8)

TEST

(7)

S.O.DIMM2 S.O.DIMM1

(9)

ISP

(6)

(1 5)

(1 3)

RWDG

NCLED

DPADR IOPADR

IRQ

(12 )

(3)

(10 )

(5)

(1 1)

CIO

SEMG

(1 4)

(1)

CF61CF10

(2)

ISABUS ISABUS

List of connectors

No. Name Function details

(1) CF61 This is used in the connection with the relay card (HR682). An F011 cable is connected.

(2) CF10 This is used in the connection with the base I/O unit (DX2**, 3**, 4**). An F010 cable is connected.

(3) ISABUS This is connected to the personal computer expansion slot (ISA bus).

(4) BAT This is a battery holder. A Toshiba battery CR2450 is installed.

(5) CIO This is a connector for expansion.

(6) ISP Not used.

(7) TEST Not used.

(8) CF62 Not used.

(9) S.O. DIMM1, 2 This is the MAGIC 64 memory module connector. Do not remove the memory module.

List of rotary switches

No. Name Function details

(10) DPADR This is used in the address assignment setting of the personal computer expansion region.

(11) IOPADR This is used in the address assignment setting of the personal computer I/O port region.

(12) IRQ This is used in the level setting of the interrupt request signal to the personal computer CPU.

(Note) Refer to "4.4 ISA NC Card Mounting" for details on setting rotary switches.

LED list

No. Name Function details

(13) NCLED

(14) SEMG

(15) RWDG

This is the 7-segment LED for the NC status display. This LED changes when at startup, during

alarms, etc.

This is the chip LED for the NC system

emergency stop display.

This is the chip LED for the remote

communication watchdog display.

When lit (red) : System in emergency stop.

When not lit : Normal

When lit (red) : Watchdog alarm.

When not lit : Normal

CAUTION

Do not apply voltages on the connector other than those indicated in this manual. Doing

so may lead to destruction or damage.

Incorrect connections may damage the devices, so connect the cables to the specified

connectors.

Do not connect or disconnect the connection cables between each unit while the power

is ON.

Do not connect or disconnect any PCB while the power is ON.

CF61CF10

16

Page 29

4. NC Card (HR621/HR623/FCU6-HR655) Connection

4.2 NC Card Part Names

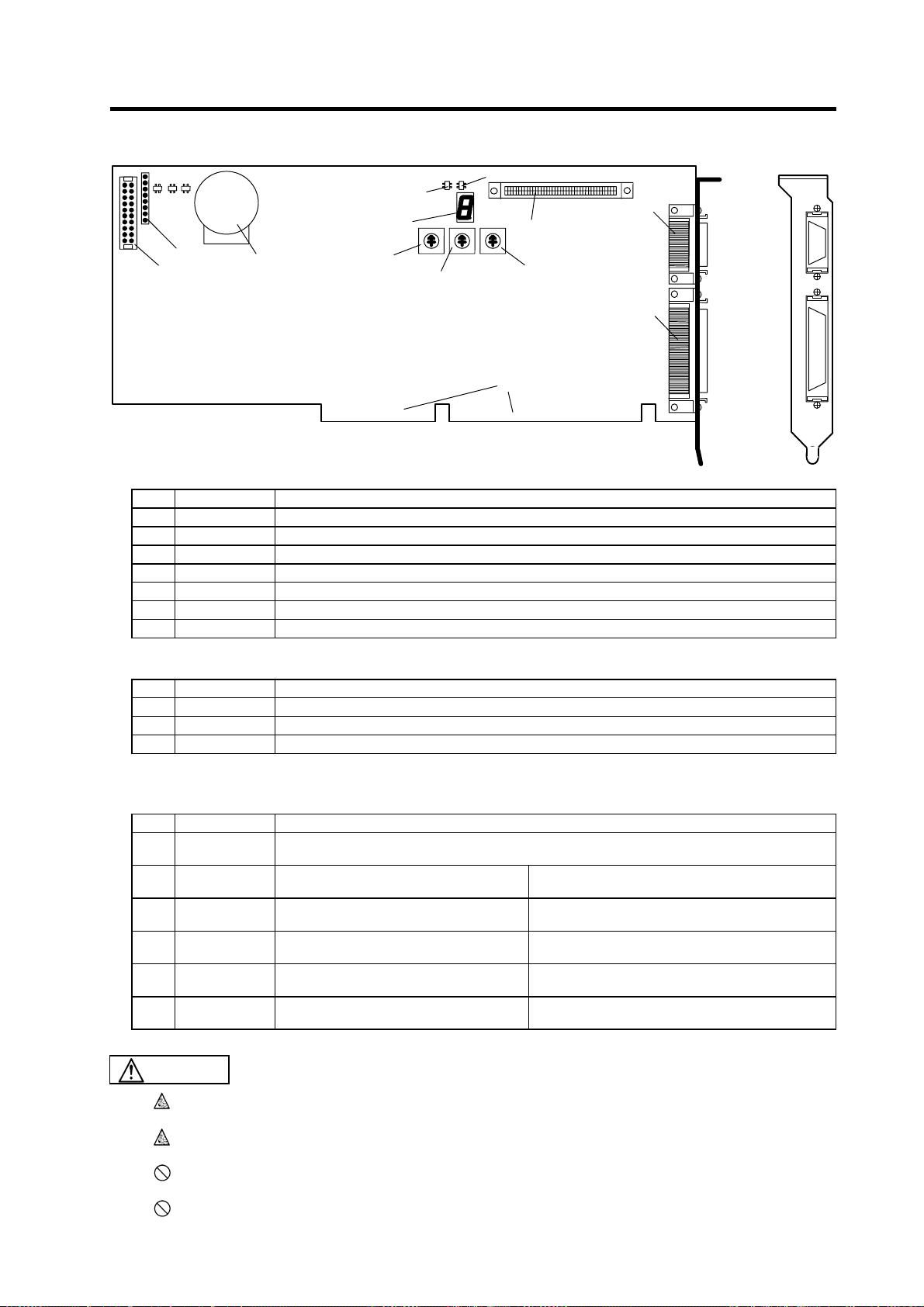

4.2.2 Names of HR623 Card Parts

(16)(17)(18)

BAT

3VALM

5VSALM

3VSALM

ISP

TEST

(7)

(6)

(4)

(12)

ISABUS ISABUS

(13)

(14)

SEMG

(11)

WDER

(15)

NCLD1

DPADRIOPADRIRQ

(3)

(5)

(10)

CIO

(1)

(2)

CF61CF10

CF61CF10

List of connectors

No. Name Function details

(1) CF61 This is used in the connection with the relay card (HR682). An F011 cable is connected.

(2) CF10 This is used in the connection with the base I/O unit (DX2**, 3**, 4**). An F010 cable is connected.

(3) ISABUS This is connected to the personal computer expansion slot (ISA bus).

(4) BAT This is a battery holder. A Toshiba battery CR2450 is installed.

(5) CIO This is a connector for expansion.

(6) ISP Not used.

(7) TEST Not used.

List of rotary switches

No. Name Function details

(10) DPADR This is used in the address assignment setting of the personal computer expansion region.

(11) IOPADR This is used in the address assignment setting of the personal computer I/O port region.

(12) IRQ This is used in the level setting of the interrupt request signal to the personal computer CPU.

(Note) Refer to "4.4 ISA NC Card Mounting" for details on setting rotary switches.

LED list

No. Name Function details

(13) NCLD1

(14) SEMG

(15) WDER

(16) 5VSALM

(17) 3VSALM

(18) 3VALM

This is the 7-segment LED for the NC status display. This LED changes when at startup, during

alarms, etc.

This is the chip LED for the NC system

emergency stop display.

This is the chip LED for the remote

communication watchdog display.

This is the chip LED for the circuit power

5VDC low alarm display.

This is the chip LED for the circuit power

3VDC low alarm display.

This is the chip LED for the circuit power

3VDC low alarm display.

When lit (red) : System in emergency stop.

When not lit : Normal

When lit (red) : Watchdog alarm.

When not lit : Normal

When lit (red) : 5VDC low

When not lit : Normal

When lit (red) : 3VDC low

When not lit : Normal

When lit (red) : 3VDC low

When not lit : Normal

CAUTION

Do not apply voltages on the connector other than those indicated in this manual. Doing

so may lead to destruction or damage.

Incorrect connections may damage the devices, so connect the cables to the specified

connectors.

Do not connect or disconnect the connection cables between each unit while the power

is ON.

Do not connect or disconnect any PCB while the power is ON.

17

Page 30

4. NC Card (HR621/HR623/FCU6-HR655) Connection

4.2 NC Card Part Names

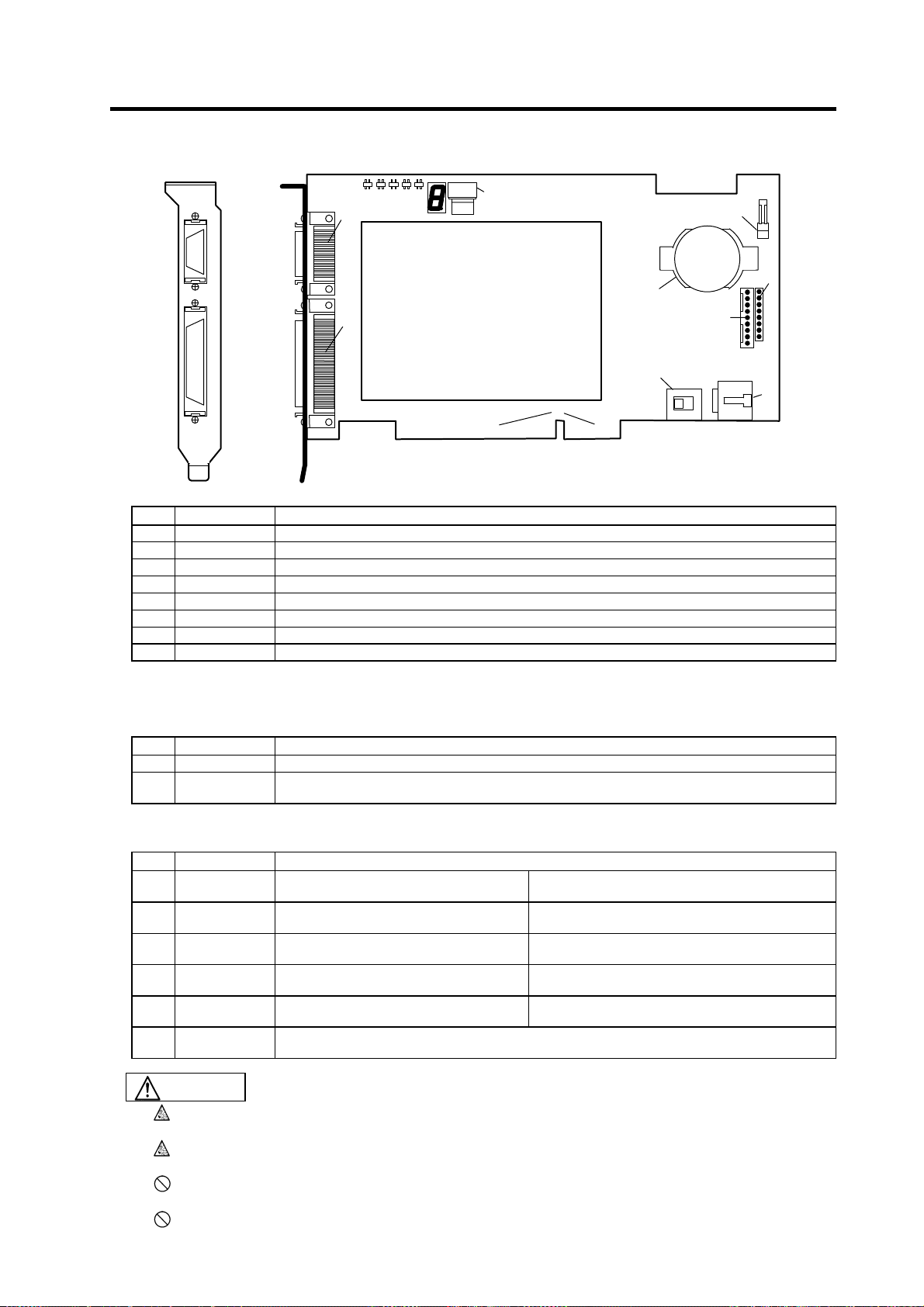

4.2.3 Names of FCU6-HR655 Unit Parts

(11)(12)(13)(14)(15)(16)

SEMG

(1)

CF61CF10

CF61

(2)

CF10

NCLD

WDER

3VALM

5VSALM

3VSALM

(9)

PCIBUS

(3)

PCIBUS

(4)

(10)

BAT

SW1

BAT

BAT

(7)

TEST

CF63

CF62

(5)

(8

)

ISP

(6)

List of connectors

No. Name Function details

(1) CF61 This is used in the connection with the relay card (HR682). An F011 cable is connected.

(2) CF10 This is used in the connection with the base I/O unit (DX2**, 3**, 4**). An F010 cable is connected.

(3) PCIBUS This is connected to the personal computer expansion slot (PCI bus).

(4) BAT This is a battery holder. A Toshiba battery CR2032 is installed.

(5) CF62 This is used to input AC FAIL from an external source. (Note 1)

(6) CF63 This is used to supply power from an external source. (Note 1)

(7) TEST Not used.

(8) ISP Not used.

(Note 1) When multiple FCU6-HR655 cards are inserted, the power supplied from the personal computer or panel compute r

may be insufficient. Supply the power from an external source to CF63 in this case. Input a FAIL signal to CF62 when

using an external power supply.

List of switches

No. Name Function details

(9) CDNO This is used to set the PCI NC Card's station No.

(10) SW1

(Note 2) Refer to "4.5 PCI NC Card Mounting" for details on setting rotary switches.

This sets the power supply method. Set "L" when supplying from the PCI bus, and set "M" when

supplying power to CF63 from an external power supply.

LED list

No. Name Function details

(11) SEMG

(12) WDER

(13) 5VSALM

(14) 3VSALM

(15) 3VALM

(16) NCLD

This is the chip LED for the NC system

emergency stop display.

This is the chip LED for the remote

communication watchdog display.

This is the chip LED for the circuit power

5VDC low alarm display.

This is the chip LED for the circuit power

3VDC low alarm display.

This is the chip LED for the circuit power

3VDC low alarm display.

This is the 7-segment LED for the NC status display. This LED changes when at startup, during

alarms, etc.

When lit (red) : System in emergency stop.

When not lit : Normal

When lit (red) : Watchdog alarm.

When not lit : Normal

When lit (red) : 5VDC low

When not lit : Normal

When lit (red) : 3VDC low

When not lit : Normal

When lit (red) : 3VDC low

When not lit : Normal

CAUTION

Do not apply voltages on the connector other than those indicated in this manual. Doing

so may lead to destruction or damage.

Incorrect connections may damage the devices, so connect the cables to the specified

connectors.

Do not connect or disconnect the connection cables between each unit while the power

is ON.

Do not connect or disconnect any PCB while the power is ON.

18

Page 31

4. NC Card (HR621/HR623/FCU6-HR655) Connection

4.3 NC Card Connector Pin Assignment

4.3 NC Card Connector Pin Assignment

Base I/O unit

CF10

25

50

<Cable side connector type>

Plug: 10150-6000EL

Shell: 10350-3210-000

Recommended manufacturer: Sumitomo 3M

Relay card

1

26

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

I/O

I/O

I

I

I

I

I

I

I

I

I

I

I

O

I

I

O

O

I

I

O

TXRX1

TXRX2

GND

SKIP1

SKIP2

SKIP3

SKIP4

SKIP5

SKIP6

SKIP7

SKIP8

GND

ENC1A

ENC1B

ENC1Z

GND

SVTXD2

SVALM2

SVRXD2

SVEMG2

GND

SVTXD1

SVALM1

SVRXD1

SVEMG1

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

I/O

I/O

I

I

I

I

I

I

I

I

I

I

I

O

I

I

O

O

I

I

O

TXRX1*

TXRX2*

GND

SKIP1*

SKIP2*

SKIP3*

SKIP4*

SKIP5*

SKIP6*

SKIP7*

SKIP8*

GND

ENC1A*

ENC1B*

ENC1Z*

GND

SVTXD2*

SVALM2*

SVRXD2*

SVEMG2*

GND

SVTXD1*

SVALM1*

SVRXD1*

SVEMG1*

RIO1

RIO2

SKIP

ENC1

SV2

SV1

(Note) I/O in the table is from the viewpoint of the

NC Card.

CF61

13

26

1

14

<Cable side connector type>

Plug: 10126-6000EL

Shell: 10326-3210-000

Recommended manufacturer: Sumitomo 3M

CAUTION

Do not apply voltages other than those indicated in this manual on the connector. Doing

so may lead to destruction or damage.

Incorrect connections may damage the devices, so connect the cables to the specified

connectors.

1

2

3

4

5

6

7

8

9

10

11

12

13

TD0

O

LED1

O

LED3

O

EMGIN

I

GND

HA1A

I

HA2A

I

HA3A

I

DR0

O

GND

EN2A

I

EN2B

I

EN2Z

I

14

15

16

17

18

19

20

21

22

23

24

25

26

I

RD0

O

LED2

O

EMGOUT*

I

EMGIN*

GND

I

HA1B

I

HA2B

I

HA3B

I

DC0

GND

I

EN2A*

I

EN2B*

I

EN2Z*

RS-232C

LED (for debugging)

Emergency stop

HANDLE

RS-232C

ENC#2

(Note) I/O in the table is from the viewpoint of the

NC Card.

19

Page 32

ISA bus (NC Card side)

4. NC Card (HR621/HR623/FCU6-HR655) Connection

4.3 NC Card Connector Pin Assignment

18C

(18D)

1C

(1D)

31A

(31B)

1A

(1B)

* Pin Nos. inside the ( ) are rear side pin Nos.

I

I

I

I

I

I

I

I

I

I

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

SBHE*

LA23

LA22

LA21

LA20

LA19

LA18

LA17

MEMR*

MEMW*

SD8

SD9

SD10

SD11

SD12

SD13

SD14

SD15

1D

2D

3D

4D

5D

6D

7D

8D

9D

10D

11D

12D

13D

14D

15D

16D

17D

18D

1C

2C

3C

4C

5C

6C

7C

8C

9C

10C

11C

12C

13C

14C

15C

16C

17C

18C

I

O

I

I

O

O

I

GND

RSTDRV

+5V

IRQ9

NC

NC

NC

NC

+12V

GND

NC

NC

IOW*

IOR*

NC

NC

NC

NC

NC

NC

IRQ7

NC

IRQ5

NC

NC

NC

NC

BALE

+5V

NC

GND

(Note) I/O in the table is from the viewpoint of the

NC Card.

1A

2A

3A

4A

5A

6A

7A

8A

9A

10A

11A

12A

13A

14A

15A

16A

17A

18A

19A

20A

21A

22A

23A

24A

25A

26A

27A

28A

29A

30A

31A

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

O

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

NC

SD7

SD6

SD5

SD4

SD3

SD2

SD1

SD0

IOCHRDY

AEN*

NC

NC

NC

SA16

SA15

SA14

SA13

SA12

SA11

SA10

SA9

SA8

SA7

SA6

SA5

SA4

SA3

SA2

SA1

SA0

1B

2B

3B

4B

5B

6B

7B

8B

9B

10B

11B

12B

13B

14B

15B

16B

17B

18B

19B

20B

21B

22B

23B

24B

25B

26B

27B

28B

29B

30B

31B

MEMCS16*

O

NC

IRQ10

O

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

+5V

NC

GND

20