Page 1

Air-conditioner Control System

BM ADAPTER

Model: BAC-HD150 Instruction Book

Contents

Page

Safety precautions .................................................2

1. Introduction....................................................3

1.1 Applicable Model .................................3

1.2 Restrictions/Cautions........................... 4

2. System configurations ...................................5

2.1 Sample system configuration...............5

2.2 Group configurations ...........................6

3. Function specifications ..................................7

3.1 Basic Functions ...................................7

3.2 Communication protocol

specifications ....................................... 7

3.3 Objects.................................................8

3.4 Relations between objects and control

items .................................................... 9

3.5 Services .............................................10

3.6 Services per object ............................ 12

4. Setting for power-on for the first time .......... 13

4.1 Caution ..............................................13

4.2 Setting up after turning on the power

5. Starting up the BAC-HD150 ........................ 13

6. Switches and 7-segment LEDs ................... 14

7. On-site adjustment steps.............................16

Thoroughly read this instruction book before use

for the first time ..................................13

5.1 Starting up the BAC-HD150...............13

5.2 Restarting the BAC-HD150................13

5.3 Mode of BAC-HD150 .........................13

6.1 Swith and LED layout ........................14

6.2 Switch types.......................................14

6.3 LED types .......................................... 15

7.1 On-site adjustment flowchart ............. 16

7.2 Preparation for on-site adjustment.....17

7.3 Step - 1 Initial setting for air

conditioning system ........................... 18

7.4 Step - 2 Test run of air conditioning

system ...............................................19

7.5 Step - 3 Initial settings for the BAC-

HD150 related items ..........................20

7.6 Step - 4 Test run of BAC-HD150 ....... 21

to ensure safety. The users should keep this

manual for future reference and refer to it as

necessary.

BACnet™ is a registered trade mark of ASHRAE

(American Society of Heating, Refrigerating, and

Air-Conditioning Engineers, INC.).

Page 2

Safety precautions

Before using the BAC-HD150, read the Safety Precautions section carefully to ensure proper operation.

These safety precautions must be observed by anyone who operates the BAC-HD150.

Keep the Instruction Book and Installation Manual for future reference. Make sure both manuals are passed on to any

future air condition system users.

WARNING

of serious injury of death.

This symbol indicates that failure to follow the instructions exactly as stated poses the risk

This symbol indicates that failure to follow the instructions exactly as stated poses the risk

CAUTION

of injury or damage to the BAC-HD150.

WARNING

The unit must be installed by a dealer or technical

representative.

Improper installation by an unqualified person may result

in electric shock and fire.

Install in a location that is strong enough to

withstand the weight of the unit.

A weak installation area may cause the unit to fall down,

resulting in a personal injury.

Only use specified cables. Securely connect each

cable so that the weight of the cable is not applied to

the connectors.

Loose or improper connections may result in heat

generation or fire.

If any abnormality is noticed (e.g., burning smell), stop

the operation, turn off the power supply, and contact

your dealer or technical representative immediately.

Continuing the operation may result in damage to the

BAC-HD150, electric shock, or fire.

Ask your dealer or an authorized technician to move

or reinstall the BAC-HD150.

Improper installation may result in an electric shock or

fire.

BAC-HD150 must be disposed of properly.

Contact your dealer for proper disposal procedures.

Do not attempt to modify or repair the BAC-HD150.

Modification or improper repair may result in electric

shock or fire. Consult your dealer when repairs are

necessary.

Stop the operation immediately and notify your

dealer if the BAC-HD150 does not operate, or when

any abnormality is noticed.

Continuing the operation may result in damage to the

BAC-HD150 or fire.

CAUTION

Do not install the BAC-HD150 where there is a risk of

leaking flammable gas.

If the leaked gas accumulates around the BAC-HD150, it

may ignite and cause an explosion.

Do not wash the BAC-HD150 with water.

Doing so may cause an electric shock or malfunction.

Do not use the BAC-HD150 for specialized

applications.

This product is designed exclusively for use with the

MITSUBISHI ELECTRIC building air conditioning control

system. The use of this product for other purposes may

result in malfunctions.

Do not spray insect sprays or sprays with flammable

propellants to the BAC-HD150.

To avoid the risk of fire or explosion, do not place

flammable sprays near the BAC-HD150 or spray them

directly on the BAC-HD150.

Do not apply mechanical shock to BAC-HD 150.

Do not use the BAC-HD150 in an environment high in

oil, steam, or sulfuric gas.

These substances may have adverse effects on the

performance of the BAC-HD150 or damage its parts.

Operate the BAC-HD150 within the temperature range

specification.

The use of controller outside of its specification may

result in serious damage to the BAC-HD150. Be sure to

check the temperature range specification in the

Installation Manual.

Use a security device such as a VPN router when

connecting the BAC-HD150 to the Internet to prevent

unauthorized access.

If no security devices are installed, the operation settings

may be changed by an unauthorized person without the

knowledge of the user.

- 2 -

Page 3

1Introduction

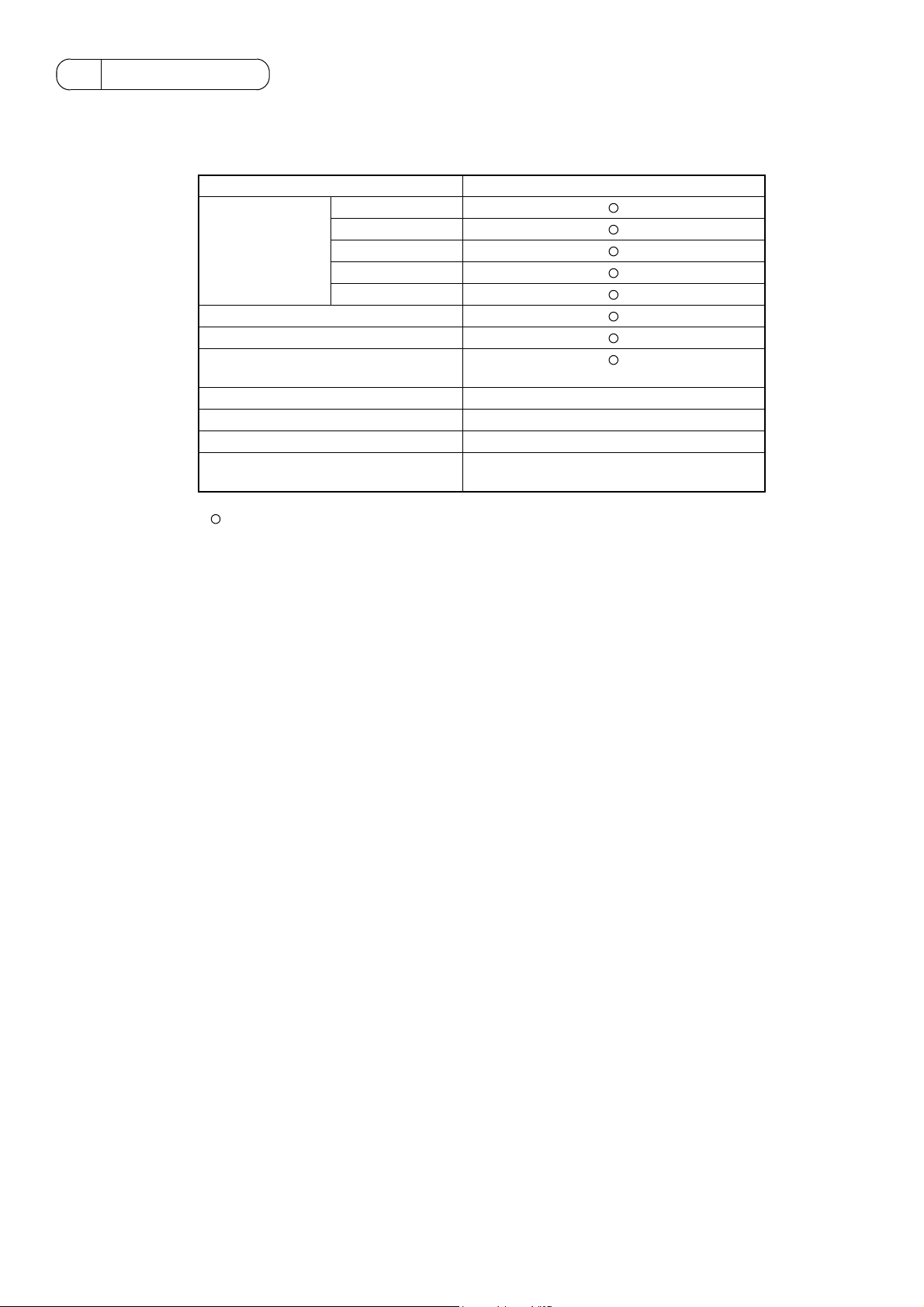

1.1 Applicable Model

BAC-HD150 have functions to monitor and operate air conditioning units (excl. certain models).

Table: Models and available functions

Model Function (Monitor/Operation)

S series

Y Series

CITY MULTI

LOSSNAY

OA Processing unit

R2 series

WY series

WR2 series

A-control unit (Mr Slim)

AK-control unit (Mr Slim) x

K-control unit x

Room air conditioner (RAC) x

Air To Water Booster unit/Air To Water

HEX unit

: Supported

X : Not supported

(Requires an adapter)

x

- 3 -

Page 4

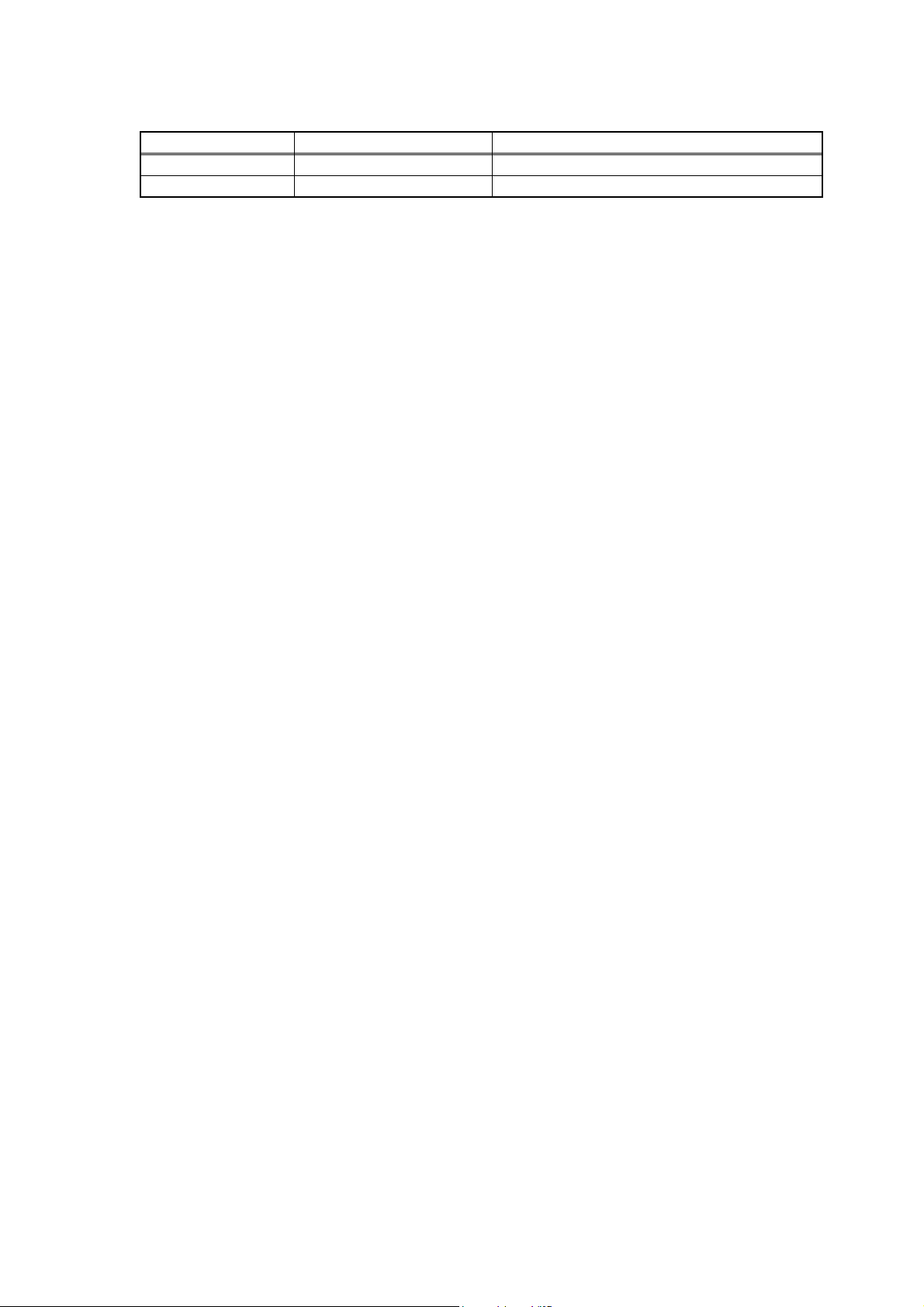

1.2 Restrictions/Cautions

Restrictions and Cautions for BAC-HD150 are as follows.

(1) Restrictions on the system configuration

Number of connectable units Notes

M-NET One line only

Indoor unit 50 units max./M-NET Includes all IC, AIC, LC, FU.

Symbol IC: Indoor unit; AIC: A control indoor unit;

LC: LOSSNAY; FU: OA Processing unit

(2) Supports for errors

• It is recommended to recover the system immediately when errors related to air conditioning are displayed on the building

management system.

(3) Operation during power failure

• When BAC-HD150 needs to be operated during power failure, a power backup device such as UPS (Uninterruptible Power

Supply) is recommended to be installed.

(4) Functions

• Due to continuing improvement, specifications are subject to change without notice.

- 4 -

Page 5

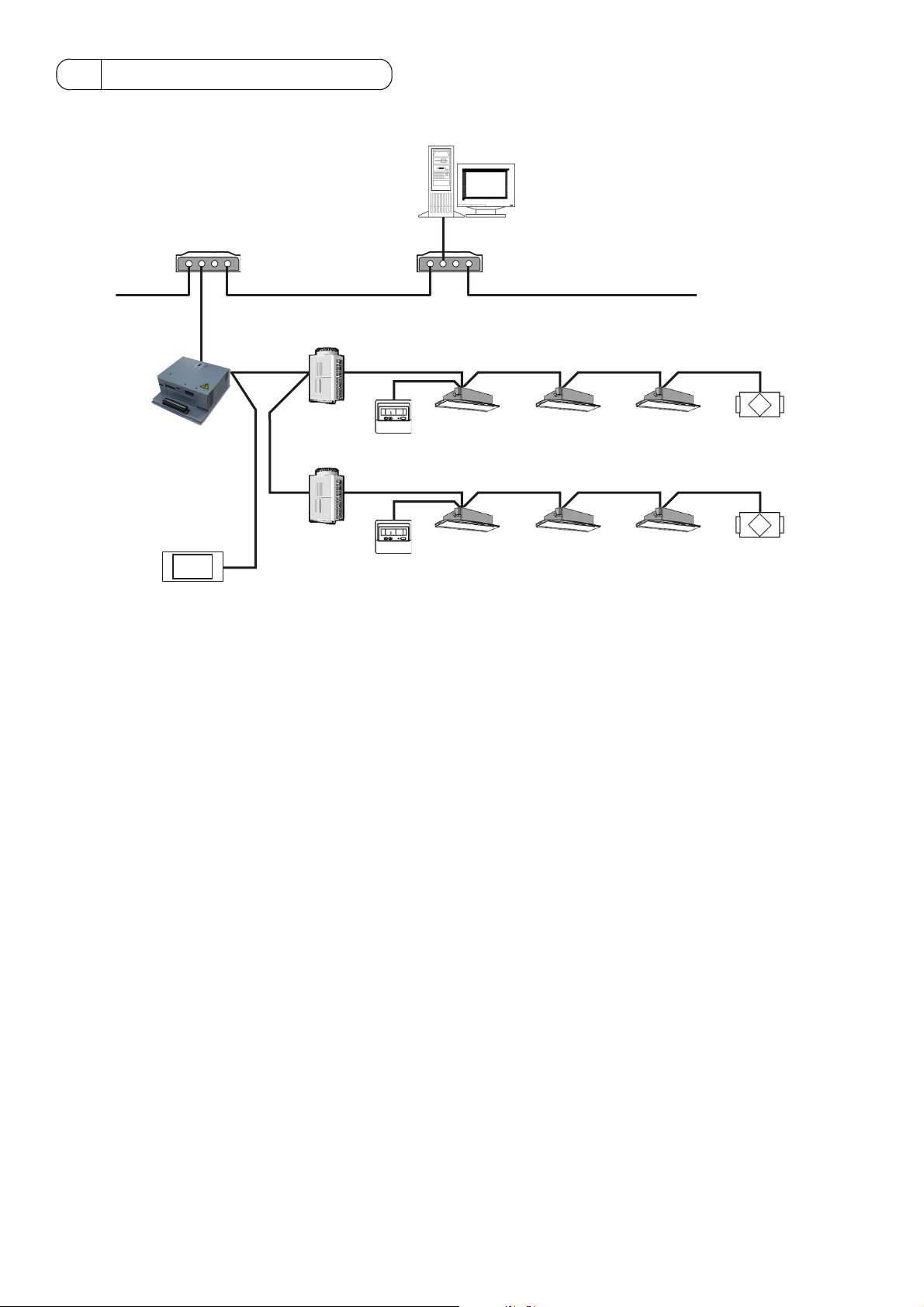

2 System configurations

㩷

㩷

2.1 Sample system configuration

HUB

BACnet

BACnet

M-NET

㩷

㩷

㩷

Outdoor unit

㩷

BAC-HD150

Outdoor unit

System remote controller

M-NET: Mitsubishi Electric air conditioning control line

ME remote controller

ME remote controller

Building Management System

HUB

M-NET

Indoor unit LOSSNAY

M-NET

Indoor unit LOSSNAY

HUB: Switching HUB

- 5 -

Page 6

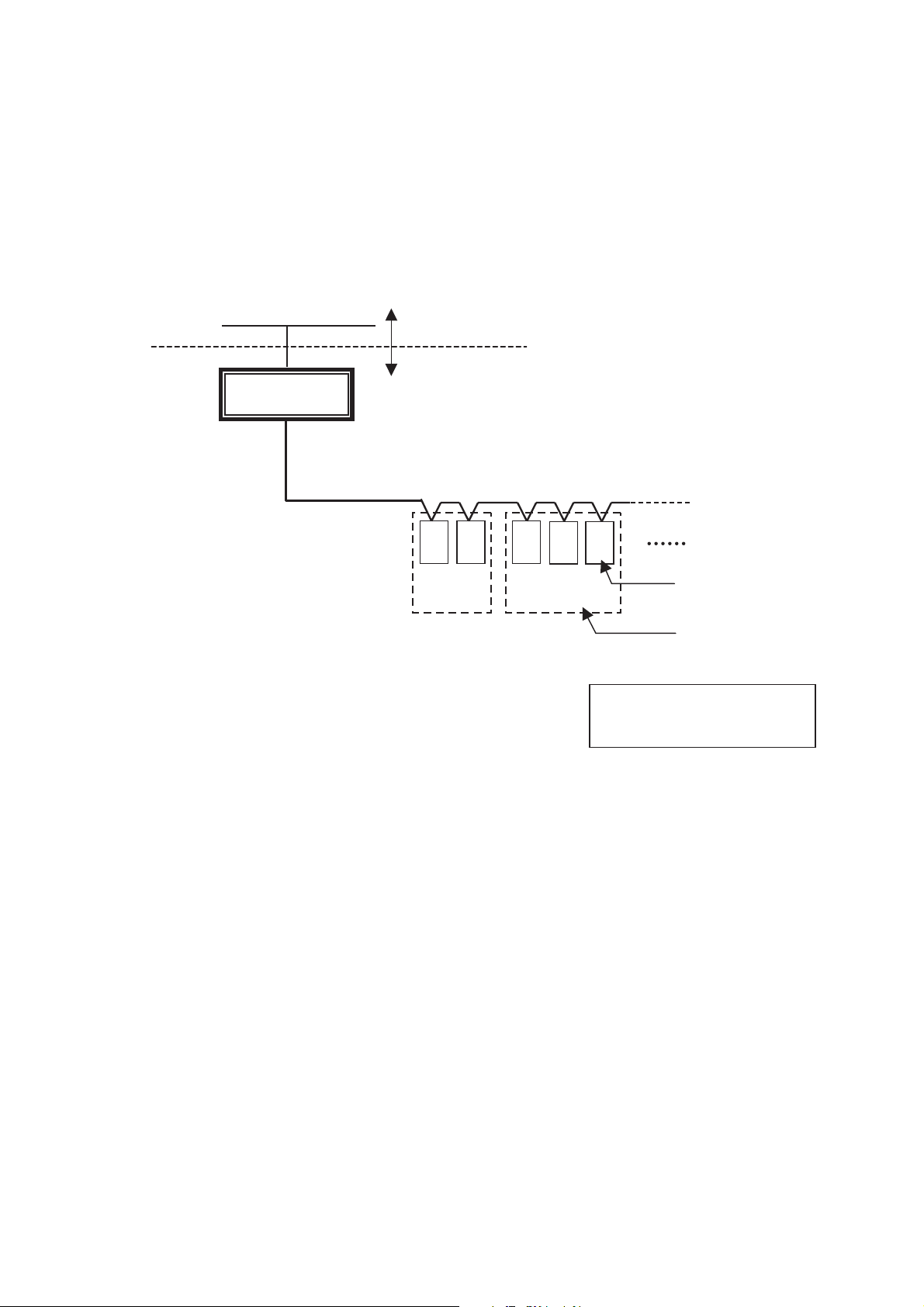

2.2 Group configurations

BACnet controls each group.

BACnet contol hierarchy consists of M-NET number + Group number + Member number.

Refer to “3.4 Relations between objects and control items” for member number details.

(1) M-NET number

Fixed to 01

(2) Group number

Multiple indoor units (IC) can be controlled as a target group. Group number range: 1-50

(3) Member number

Corresponds to Monitor/Operation items of air conditioners

㩷

㩷

㩷

㩷

BACnet

BAC-HD150

Building Management System

Air conditioning system

㩷

㩷

㩷

M-NET

㩷

㩷

㩷

㩷

㩷

㩷

IC01IC

02

Group

IC

03

IC04IC

Group

No.01 No.03

05

㩷㩷

Unit address

Group number

㩷

㩷

㩷

㩷

Outdoor units, remote

controllers, and etc. are omitted

in this drawing.

㩷

- 6 -

Page 7

3 Function specifications

3.1 Basic Functions

BAC-HD150 has functions that communication from an air conditioning system is protocol converted to BACnet

communication, that command from a Building Management System is converted and transmitted to an air conditioning

system, and that air conditioning system status data is collected and the status change is detected. BAC-HD150 also collects

data on air conditioning units operation status and transmits the data upon request from the building management system.

Refer to “3.4 Relations between objects and control items” for control item of BAC-HD150.

3.2 Communication protocol specifications

(1) General descriptions of protocol

BACnet/IP which applied to ANSI/ASHRAE 135-2004 correspondingly on UDP/IP of Ethernet is used.

Ethernet header IP header UDP header BVLL header NPCI APDU

Ethernet is a registered trademark of Fuji Xerox, Inc.

(2) Ethernet header

Physical layer: Ethernet

Transmission medium: 10BASE-T

(3) IP header

Class C private address is recommended. (*1) Subnet Mask: 255.255.255.0

*1: Recommended value (range): [192.168.1.1] - [192.168.254.254]

Do not use [192.168.0.0] and [192.168.255.255] as a device address.

(4) UDP header

The default UDP port of unicast and broadcasting is set to 47808 (0xBAC0).

(5) BVLL header (BVLL: BACnet Virtual Link Layer)

BVLC type (1 octet) Fixed to 0x81 (BVLL against BACnet/IP)

BVLC function (1 octet) Unicast 0x0A

Broadcast 0x0B

BVLC length (2 octets) Variable (BVLL header (4 octets) + NPCI data length + APDU data length)

(Typical examples are listed above. Refer to ANSI/ASHRAE 135-2004 for details.)

(6) NPCI (NPCI: Network Layer Protocol Control Information)

Version (1 octet) Fixed to 0x01

Control (1 octet) Response is received. 0x04

No response 0x00

(Typical examples are listed above. Refer to ANSI/ASHRAE 135-2004 for details.)

(7) APDU (APDU: Application Layer Protocol Data Unit)

Data: 1024 octets or less

(Refer to ANSI/ASHRAE 135-2004 for details.)

- 7 -

Page 8

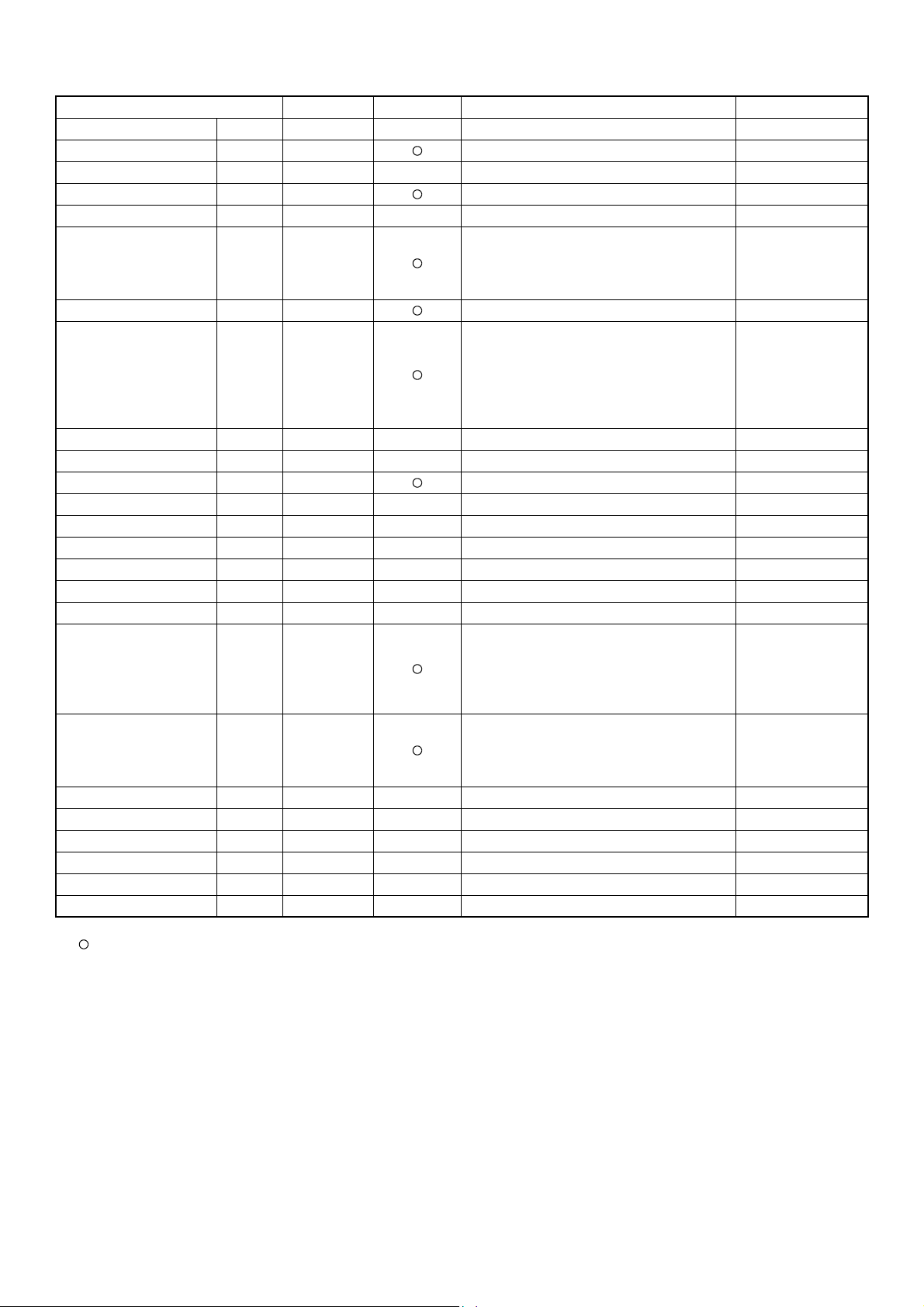

3.3 Objects

Supported object list is shown below.

Object type Abbreviation Support Control item Notes

Accumulator 23 −−

Analog Input 0 AI Room Temp

Analog Output 1 −−

Analog Value 2 AV Set Temp

Averaging 18 −−

On Off State

Binary Input 3 BI

Binary Output 4 BO On Off Setup

Binary Value 5 BV

Calendar 6 −−

Command 7 −−

Device 8 DEV Device object of BAC-HD150

Event Enrollment 9 −−

File 10 −−

Group 11 −−

Life Safety Point 21 −−

Life Safety Zone 22 −−

Loop 12 −−

Multi-state Input 13 MI

Multi-state Output 14 MO

Multi-state Value 19 −−

Notification Class 15 CLS −

Program 16 −−

Pulse Converter 24 −−

Schedule 17 −−

Trend Log 20 −−

Alarm Signal

Filter Sign

Communication State

Filter Sign Reset

Prohibition On Off

Prohibition Mode

Prohibition Filter Sign Reset

Prohibition Set Temperature

System Forced Off

Error Code

Operational Mode State

Fan Speed State

Air Direction State

Ventilation Mode State

Operational Mode Setup

Fan Speed Setup

Air Direction Setup

Ventilation Mode Setup

: Supported

− : Not supported

- 8 -

Page 9

3.4 Relations between objects and control items

Object ID consists of object type + instance number.

Instance number consists of M-NET number, air conditioner group number, and member number.

31 22 21 0

BACnet object type Instance number

BACnet object type : Refer to the object type as shown in the table below.

Instance number (6 digits in decimal notation) : 01

xx xx

Member number (01-99)

Group number (01-50, 99)

M-NET number (fixed to 01)

Unit

Text-1 Text-2 Text-3 Text-4 Text-5

Control item

Object

type

Instance

number

On Off Setup BO 01xx01 Stop Run

On Off State BI 01xx02 Stop Run

Alarm Signal BI 01xx03 Normal Error

01: Normal 06: Electronic

02: Other errors system error

Error Code MI 01xx04 Normal

03: Refrigeration 07: Sensor fault

system fault 08: Communication

04: Water system error error

05: Air system error 09: System error

Operational Mode Setup MO 01xx05 Cooling Heating Fan Auto Dry

Operational Mode State MI 01xx06 Cooling Heating Fan Auto Dry

Fan Speed Setup MO 01xx07 Low High Mid 2 Mid 1

Fan Speed State MI 01xx08 Low High Mid 2 Mid 1

Room Temp AI 01xx09 °F/°C

Set Temp AV 01xx10 °F/°C

Filter Sign BI 01xx11 OFF ON

Filter Sign Reset BV 01xx12 Reset Void

Prohibition On Off BV 01xx13 Permit Prohibit

Prohibition Mode BV 01xx14 Permit Prohibit

Prohibition Filter Sign Reset BV 01xx15 Permit Prohibit

Prohibition Set Temperature BV 01xx16 Permit Prohibit

Communication State BI 01xx20 Normal Error

System Forced Off BV

Air Direction Setup MO 01xx22

Air Direction State MI 01xx23

Ventilation Mode State MO 01xx35

Ventilation Mode Setup MI 01xx36

01xx21

019921

Reset Execute

Horizontal

Horizontal

Heat

exchange

Heat

exchange

Downblow

60%

Downblow

60%

Bypass Auto

Bypass Auto

Downblow

80%

Downblow

80%

Downblow

100%

Downblow

100%

Swing

Swing

NotesInactive Active

*1) *4)

*1)

*2) *4)

*2)

*3)

*3) *5)

*3)

*3)

*3) *4)

*3)

*1 : “Dry” can be used only when “use” is selected for the “Dry” setting. (“Dry” is not used for a default.)

Fan is used for a group whose attribute is LC.

*2 : “Mid 1/Mid 2” can be used only when “use” is selected for the “Mid 1/Mid 2” setting.

(“Mid 1/Mid 2” is not used for a default.)

Low< Mid 2< Mid 1< High

*3 : Initial value is returned for a group whose attribute is LC because the group is not a target item.

*4 : Different operation mode settings, fan speed settings, and airflow direction settings are available on different models.

*5 : Settable indoor preset temperature range varies in each operation mode.

• Cooling : 19-30 °C

• Heating : 17-28 °C

• Auto : 19-28 °C

• Dry : 19-30 °C

The settable range also varies with the models.

- 9 -

Page 10

3.5 Services

The following table shows the supported services.

Service Initiate request Execute request

1. Alarm and Event Services

(1) Acknowlege Alarm Service −−

(2) Confirmed COV Notification Service −−

(3) Confirmed Event Notification Service −−

(4) Get Alarm Summary Service −−

(5) Get Enrollment Summary service −−

(6) Get Event Information Service −−

(7) Life Safety Operation Service −−

(8) Subscribe COV Service −−

(9) Subscribe COV Property Service −−

2. File Access Services

(1) Atomic Read File Service −−

(2) Atomic Write File Service −−

3. Object Access Services

(1) Add List Element Service −−

(2) Remove List Element Service −−

(3) Create Object Service −−

(4) Delete Object Service −−

(5) Read Property Service −

(6) Read Property Conditional Service −−

(7) Read Property Multiple Service −

(8) Read Range Service −−

(9) Write Property Service −

(10) Write Property Multiple Service −

4. Remote Device Management Services

(1) Device Communication Control Service −−

(2) Confirmed Private Transfer Service −−

(3) Confirmed Text Message Service −−

(4) Reinitialize Device Service −−

5. Virtual Terminal Services

(1) VT-Open Service −−

(2) VT-Close Service −−

(3) VT-Data Service6.Security Services −−

: Supported

− : Not supported

Initiate request: Provides services

Execute request: Receives and uses services

- 10 -

Page 11

Service Initiate request Execute request

6. Security Services

(1) Authenticate Service −−

(2) Request Key Service −−

7.Unconfirmed Services

(1)I-Am −

(2)I-Have −

(3)Unconfirmed COV Notification Service −−

(4)Unconfirmed Event Notification Service −−

(5)Unconfirmed Private Transfer Service −−

(6)Unconfirmed Text Message Service −−

(7)Time Synchronization Service −

(8)UTC Time Synchronization Service −−

(9)Who-Has −

(10)Who-Is −

: Supported

− : Not supported

Initiate request: Provides services

Execute request: Receives and uses services

- 11 -

Page 12

3.6 Services per object

The following table shows the supported service per object.

Object

Service

Read Property

Read Property Multiple

Write Property

Write Property Multiple

I-Am

I-Have

Time Synchronization

Who-Has

Who-Is

INIT

EXEC

INIT

EXEC

INIT

EXEC

INIT

EXEC

INIT

EXEC

INIT

EXEC

INIT

EXEC

INIT

EXEC

INIT

EXEC

Device

Input

Analog

Val ue

Analog

Input

Binary

Binary

Output

Val ue

Binary

Multi-State

Input

Multi-State

Notes

Output

INIT: Provides services

EXEC: Receives and uses services

: Supported

: Changeable using setting data

- 12 -

Page 13

4 Setting for power-on for the first time

4.1 Caution

BACnet LAN IP address for BAC-HD150 is set to “192.168.1.254” at factory setting.

The address may overlap one of the addresses that are assigned to other devices connected to BACnet. When turning on the

power for the first time after installation, turn on the power with the BACnet LAN cable with BAC-HD150 disconnected.

If an address overlaps any of the addresses that are assigned to other devices, BACnet communication cannot be performed

properly via BAC-HD150 or other devices.

Connect the LAN cable for BAC-HD150 to BACnet after IP address is set by using BAC-HD150 Setting Tool (abbreviated to

Setting Tool below).

4.2 Setting up after turning on the power for the first time

Make initial setting using Setting Tool after the power to BAC-HD150 is turned on.

Refer to the Instruction Book that came with Setting Tool for details about Initial Setting.

5 Starting up the BAC-HD150

5.1 Starting up the BAC-HD150

BAC-HD150 starts up when the power is turned on.

BACnet communication and M-NET communication are performed after startup.

5.2 Restarting the BAC-HD150

BAC-HD150 restarts when SW403 is pressed.

5.3 Mode of BAC-HD150

BAC-HD150 has “Online” mode and “Offline” mode.

“Online” mode is an operation mode to perform BACnet communication and M-NET communication.

“Offline” mode is a maintenance mode in which BACnet communication and M-NET communication are not performed.

It is the mode in which the Setting Tool can configure data settings to the BAC-HD150.

Mode change between “Online” and “Offline” are as follows.

• Startup by turning on

the power

• Restart by resetting

• Receiving “Change to Online mode request ”

from the Setting Tool.

Online mode

• Receiving “Change to Offline mode request ”

from the Setting Tool.

• “Change to Offline mode” by operating the

switch.

Offline mode

- 13 -

Page 14

6 Switches and 7-segment LEDs

6.1 Swith and LED layout

The layouts of the switches and LEDs on BAC-HD150 are shown below.

7-segment LED

Switch Board

TB3

M-NET Board

6.2 Switch types

(1) Dipswitches

SW601, SW602, SW603, and SW604 are available.

(The above switches are for future use.)

Main Board

TB1

Error LED

SW403

SW606,SW607

SW601

SW605

SW604

SW603

SW602

(2) Rotary switches

SW606 and SW607 are available.

(The above switches are for future use.)

(3) Push switches

SW403 and SW605 are available.

(SW403 is used to restart BAC-HD150, and SW605 is for future use.)

- 14 -

Page 15

6.3 LED types

(1) 7-segment LEDs

Each set of two vertically aligned lines in the 7-segment LEDs display the information that is summarized in the table below.

LD1 CPU status

LD2 (Undefined) −

LD3 BACnet communication status

LD4 Air conditioning unit errors

LD5 M-NET startup status

LD6 (Undefined) −

LD7 BACnetIF mode

LD8 BACnet communication service status

7segment LED

Lit : Normal

Unlit : Error

Lit : Error

Unlit : Normal

Lit : At least one indoor unit is in error.

Unlit : All indoor units are normal.

Lit : Initial setting has not been completed.

Unlit : Initial setting has been completed.

Blink: Initial setting in progress

Lit : Offline mode

Unlit : Online mode

Lit : Communication lock (setting other than Enable)

Unlit : Communication allowed (Enable)

LD2

LD1

(2) Error LED

The Error LED lights up when there is a BACnet communication error. It remains turned off when no errors are occurring.

LD3

LD4 LD5

LD6 LD7 LD8

- 15 -

Page 16

7 On-site adjustment steps

7.1 On-site adjustment flowchart

Generally, on-site adjustment is divided into four steps as follows. By following these steps, the cause of trouble can be solved

clearly and on-site adjustment can be identified efficiently.

It is recommended to follow the steps below.

Step - 1 Initial setting for air conditioning system

Make the setting for the BAC-HD150 system and air conditioning system group by using

Setting Tool.

Refer to the Instruction Book that came with the Setting Tool for BAC-HD150 system setting

and group setting for air conditioning system.

Step - 2 Test run of air conditioning system

Check that air conditioning units and controllers are system configured correctly and

operate properly. (Refer to the Installation Manual that came with each device for how to

perform test run.)

Step - 3 Initial settings for BAC-HD150 related items

Make the setting for the BAC-HD150 related items by using Setting Tool.

Refer to the Instruction Book that came with Setting Tool for setting related to BACnet.

Step - 4 Test run of BAC-HD150

Check that operation status of air conditioning units appears correctly on the BMS and that

air conditioning units operate properly from the BMS control.

BMS: Building Management System

- 16 -

Page 17

㩷

㩷

Step-4

BAC-HD150

Step-1

Step-3

System remote controller

HUB

M-NET

BACnet

㩷

㩷

Outdoor unit

㩷

ME remote controller

Outdoor unit

ME remote controller

Building Management System

HUB

M-NET

Indoor unit LOSSNAY

M-NET

Indoor unit LOSSNAY

Step-2

7.2 Preparation for on-site adjustment

Have the following tools and documents ready before performing on-site adjustment and a test run.

Item Description Notes

Group configuration, IP address, Control item, and

etc.

Reference

Tools and parts

Air conditioning control system diagram

Instruction Book that came with BAC-HD150 (This document)

Instruction Book that came with Setting Tool

BAC-HD150 Installation Manual

Relevant air-conditioner and controller’s

Instructions Books and Installation Manuals

Miscellaneous BACnet device list

Computer For Setting Tool

USB memory For setting data backup

Installation CD for the Setting Tool Setup disk

HUB For connection to Setting Tool

LAN cable (straight cable) For connection to Setting Tool

General tools such as a driver

Tester Use to check wiring and voltage.

Miscellaneous

- 17 -

Page 18

7.3 Step - 1 Initial setting for air conditioning system

㩷

㩷

Make the initial settings for air conditioning system using Setting Tool.

Change LAN

connection

HUB

Building Management System

HUB

BACnet

㩷

Setting tool

Step-1

HUB

BAC-HD150

System remote controller

M-NET

㩷

㩷

Outdoor unit

㩷

ME remote controller

Outdoor unit

ME remote controller

M-NET

Indoor unit

M-NET

Indoor unit

(1) Installing the Setting Tool software

Install the Setting Tool program on a PC, and set the IP address. (Refer to the Instruction Book that came with Setting Tool for

installation and setting method.)

LOSSNAY

LOSSNAY

(2) Connecting the Setting Tool

To connect Setting Tool to BAC-HD150, disconnect LAN cable connecting to BACnet of BAC-HD150.

Use additional HUB to connect BAC-HD150 and Setting Tool.

To connect BAC-HD150 and the additional HUB, use LAN port (LAN1) connecting to BACnet.

(3) Data setting

Make the settings for the air conditioning system related items and IP address of BAC-HD150 by using Setting Tool.

The following table shows setting items. (Refer to the Instruction Book that came with Setting Tool for setting method.)

No. Main tab Sub tab Setting item

1

System Settings

2 M-NET All setting items

3

Group Settings

4 LOSSNAY All setting items

Basic System All setting items

Group All setting items

CAUTION

When IP address is duplicated, not only BAC-HD150 but also other equipments may malfunction in BACnet communication.

Check IP address of BAC-HD150 before setting.

BAC-HD150 and BACnet do not get connected in Step - 1 to 3, so the setting related to IP address in Step - 1 is not

necessary. IP address is set in Step - 1 just for the case they are connected accidentally.

- 18 -

Page 19

7.4 Step - 2 Test run of air conditioning system

Perform test run only on air conditioning system.

HUB

㩷

Setting tool

HUB

BAC-HD150

System remote controller

(1) Checking items before test run

Check that test run of air conditioning units is completed.

M-NET

BACnet

Outdoor unit

ME remote controller

Outdoor unit

ME remote controller

Building Management System

HUB

M-NET

Indoor unit

M-NET

Indoor unit

LOSSNAY

LOSSNAY

Step-2

(2) Turning on the power of all the air conditioning units and system controllers

Turn on the power of all the air conditioning units and system controllers.

(3) Restarting the BAC-HD150

Restarting the BAC-HD150, then it becomes [Online mode].

The setting data made in Step - 1 such as air conditioning system group is automatically sent from BAC-HD150 to air

conditioning system.

(It may take about 5 minutes for the setting.)

(4) Test run using system controller or remote controller

Perform test run using system controller or remote controller to check operation status of each unit.

* Refer to the Installation Manual that came with air conditioning unit and system controller for how to perform test run.

- 19 -

Page 20

7.5 Step - 3 Initial settings for the BAC-HD150 related items

㩷

㩷

Make the initial settings for BACnet using Setting Tool.

HUB

Building Management System

HUB

BACnet

㩷

Setting tool

Step-3

HUB

BAC-HD150

M-NET

㩷

㩷

Outdoor unit

㩷

ME remote controller

Outdoor unit

ME remote controller

M-NET

Indoor unit LOSSNAY

M-NET

Indoor unit LOSSNAY

System remote controller

(1) Data setting

Make the settings for BACnet using Setting Tool.

The following table shows setting items. (Refer to the Instruction Book that came with Setting Tool for setting method.)

No. Main tab Sub tab Setting item

1

2 Network and Device All setting items

BACnet Settings

3 Object All setting items

BACnet All setting items

4 Other All setting items

- 20 -

Page 21

7.6 Step - 4 Test run of BAC-HD150

㩷

㩷

Connect BMS and perform test run of air conditioning system.

Change LAN

HUB

connection

BACnet

㩷

Setting tool

HUB

BAC-HD150

M-NET

㩷

㩷

Outdoor unit

㩷

Outdoor unit

Step-4

System remote controller

(1) BACnet connection

Switch LAN connection of BAC-HD150 from Setting Tool to BACnet.

ME remote controller

ME remote controller

Building Management System

HUB

M-NET

Indoor unit

M-NET

Indoor unit

LOSSNAY

LOSSNAY

(2) Restarting the BAC-HD150

Restart BAC-HD150, then it becomes [Online mode].

(3) Test run items and method

Refer to the next page for test run items and method.

- 21 -

Page 22

On-site adjustment sheet for BACnet interface (proposal)

Check these items to use the system.

Group No. [ ]

Control item Object Status Steps Result

• Turn ON/OFF the specific group from BMS(*1).

On Off Setup BO_01xx01

On Off State BI_01xx02

Alarm Signal BI_01xx03

Error Code MI_01xx04

Operational Mode

Setup

Operational Mode

State

Fan Speed Setup MO_01xx07

Fan Speed State MI_01xx08

Room temp AI_01xx09 °C

Set Temp AV_01xx10 °C

Filter Sign BI_01xx11

Filter Sign Reset BV_01xx12

MO_01xx05

MI_01xx06

INACTIVE: Stop

ACTIVE: Run

INACTIVE: Stop

ACTIVE: Run

INACTIVE: Normal

ACTIVE: Error

01 : Normal

02 : Other errors

03 : Refrigeration fault

04 : Water error

05 : Air error

06 : Electronic error

07 : Sensor fault

08 :

09 : System error

01 : Cooling

02 : Heating

03 : Fan

04 : Auto

05 : Dry (*4)

01 : Cooling

02 : Heating

03 : Fan

05 : Dry (*4)

01 : Low

02 : High

03 : Mid 2 (*5)

05 : Mid 1 (*5)

01 : Low

02 : High

03 : Mid 2 (*5)

04 : Mid 1 (*5)

INACTIVE : OFF

ACTIVE : ON

INACTIVE : RESET

ACTIVE : Void

Communication error

After doing so, check that the operation status of the group

renews the condition using system controller or remote

controller.

• Turn ON/OFF the specific group using system controller

or remote controller.

After doing so, check that the operation status of the group

renews the condition on BMS .

• Make an error on an air conditioning units of the specific

group.

After doing so, check that the warning signal of the group

turns to (ACTIVE) on BMS. (*2)

• Recover the error of the air conditioning units of the

specific group.

After doing so, check that the warning signal of the group

turns to (INACTIVE) on BMS.

• Disconnect M-NET transmission line that is connected to

BAC-HD150.

After doing so, check that the error code of all groups turns

to Communication error (08) on BMS. (*3)

• Connect M-NET transmission line to BAC-HD150.

After doing so, check that the error code of all groups turns

to Normal (01) on BMS.

(Do not perform this check when other errors occur.)

• Change operation mode of the specific group from BMS.

After doing so, check that the operation mode of the group

renews the mode using system controller or remote

controller.

• Change operation mode of the specific group using

system controller or remote controller.

After doing so, check that the operation mode of the group

renews the mode on BMS.

• Change fan speed of the specific group from BMS.

After doing so, check that the fun speed of the group

renews the speed using system controller or remote

controller.

• Change fun speed of the specific group using system

controller or remote controller.

After doing so, check that the fun speed of the group

renews the speed on BMS.

• Change intake air temperature and check if the display of

BMS and system controller/remote controller are the

same.

• Make a setting of set room temperature of the specific

group from BMS.

After doing so, check that the set room temperature of the

group renews the temperature using system controller or

remote controller.

• Change the set room temperature of the specific group

using system controller or remote controller.

After doing so, check that the set room temperature of the

group renews the temperature on BMS.

• Perform something to turn on the filter sign. (*2)

After doing so, check that the filter sign of the group turns to

ON(ACTIVE) on BMS.

• Reset the filter sign of the group that detects filter sign

[ON(ACTIVE)] from BMS. (*2)

After doing so, check that the filter sign of the group turns to

OFF(INACTIVE) on BMS.

- 22 -

Page 23

Control item Object Status Steps Result

• Prohibit the remote controller (ON/OFF) of the specific

group from BMS.

After doing so, check that the remote controller (ON/OFF) of

Prohibition On Off BV_01xx13

Prohibition Mode BV_01xx14

Prohibition Filter

Sign Reset

Prohibition Set

Temperature

Communication

State

System Forced Off

Air Direction Setup MO_01xx22

Air Direction State MI_01xx23

Ventilation Mode

Setup

Ventilation Mode

State

BV_01xx15

BV_01xx16

BI_01xx20

BV_01xx21

BV_019921

MO_01xx35

MI_01xx36

INACTIVE : Permit

ACTIVE : Prohibit

INACTIVE : Permit

ACTIVE : Prohibit

INACTIVE : Permit

ACTIVE : Prohibit

INACTIVE : Permit

ACTIVE : Prohibit

INACTIVE: Normal

ACTIVE: Error

INACTIVE: Reset

ACTIVE: Execute

01 : Horizontal

02 : Downblow 60%

03 : Downblow 80%

04 : Downblow 100%

05 : Swing

01 : Horizontal

02 : Downblow 60%

03 : Downblow 80%

04 : Downblow 100%

05 : Swing

01 : Heat exchange

02 : Bypass

03 : Auto

01 : Heat exchange

02 : Bypass

03 : Auto

the group turns to (ACTIVE) via the remote controller.

• Permit the remote controller (ON/OFF) of the specific

group from BMS.

After doing so, check that the remote controller (ON/OFF) of

the group turns to (INACTIVE) via the remote controller.

• Operation/checking object is the same as the steps of

remote controller (operation mode), but the checking

method is the same as the steps of remote controller (ON/

OFF).

• Operation/checking object is the same as the steps of

remote controller (filter sign reset), but the checking

method is the same as the steps of remote controller (ON/

OFF).

• Operation/checking object is the same as the steps of

remote controller (set temperature), but the checking

method is the same as the steps of remote controller (ON/

OFF).

• Disconnect M-NET transmission line which is connected

to BAC-HD150.

After doing so, check that the communication condition of all

groups turns to error (ACTIVE) on BMS. (*3)

• Connect M-NET transmission line to BAC-HD150.

After doing so, check that the error code of all groups turns

to Normal (INACTIVE) on BMS.

• Perform a forced stop of the system of the specific group

from BMS.

After doing so, check that the air conditioner stops on BMS.

• Change the air direction of the specific group from BMS.

After doing so, check that the air direction of the group

renews the direction using system controller or remote

controller.

• Change the air direction of the specific group using

system controller or remote controller.

After doing so, check that the air direction of the group

renews the direction on BMS.

• Change the LOSSNAY ventilation mode of the specific

group from BMS.

After doing so, check that the LOSSNAY ventilation mode of

the group renews the mode using system controller or

remote controller.

• Change the LOSSNAY ventilation mode of the specific

group using system controller or remote controller.

After doing so, check that the LOSSNAY ventilation mode of

the group renews the mode on BMS.

*1: BMS = Building Management System

*2: Consult a Mitsubishi personnel for the confirmation method.

*3: It can take up to five minutes for an error to be detected.

*4: “Dry” can be used only when “use” is selected for the “Dry” setting (“Dry” is not used for a default.)

*5: “Mid 1/Mid 2” can be used only when “use” is selected for the “Mid 1/Mid 2” setting. (“Mid 1/Mid 2” is not used for a default.)

- 23 -

Page 24

This product is designed and intended for use in the residential,

commercial and light-industrial environment.

The product at hand is

based on the following

EU regulations:

• Low Voltage Directive 2006/95/EC

• Electromagnetic Compatibility Directive,

2004/108/EC

Please be sure to put the contact address/telephone number on

this manual before handing it to the customer.

HEAD OFFICE: TOKYO BLDG. , 2-7-3, MARUNOUCHI, CHIYODA-KU, TOKYO 100-8310, JAPAN

Authorized representative in EU: MITSUBISHI ELECTRIC EUROPE B.V.

HARMAN HOUSE, 1 GEORGE STREET, UXBRIDGE, MIDDLESEX UB8 1QQ, U.K.

WT05542X01

WT05542X01

Printed in Japan

Printed in Japan

Recycled Paper

Recycled Paper

Loading...

Loading...