Page 1

ENG

GER

FRE

ITL

ESP

HARDWARE MANUAL

α

SIMPLE APPLICATION CONTROLLER

Page 2

α

Simple Application Controller

Foreword

• This manual contai ns text, diag r ams and explanati ons whic h wil l guid e the rea der in th e corre ct ins tal latio n,

safe use and operation of the α Series and should be read and understood before attempting to install or

use the unit.

ENG

• If in doubt at any stage during the installation of the

neer who is qualified and trained to the local and national standards. If in doubt about the operation or use

of the

• This manual is subject to change without notice.

Series pl ease consult the nearest Mitsubishi Electri c distributor.

α

Series always consult a professional electrical engi-

α

Page 3

α

Simple Application Controller

α

α

Simple Application Controller

αα

Hardware Manual

ENG

Manual number : JY992D74201

Manual revision : J

Date : April 2002

i

Page 4

α

Simple Application Controller

Guidelines for the safety of the user and protection of equipment

This manual is written to be use d by trained and co mpe tent per so nnel for instal latio n of this equ ipment as defi ned b y

the European directives for machinery, low voltage and EMC. A technician or engineer trained in the local and

ENG

national electrical st andard s sho uld pe rform all tasks associate d with th e el ectrical wiring of the

Throughout t his manual symbols a re used t o highli ght inform ation rela ting to th e user’s personal safety and prote c-

tion of the equipment. When any of these symbols are encountered, the associated note must be read and understood.

Symbols are:

1) The identified danger will cause physical and property damage.

2) The identified danger could cause physical and property damage.

• Under no circumstances will MITSUBISHI ELECTRIC be liable or responsible for any consequential damage that may arise as a

result of installation or use of this equipment.

• All example and diagrams shown in this manual are intended to aid understanding and do not guarantee operation. MITSUBISHI

ELECTRIC will accept no responsibility for actual use of this product based on these examples.

• Due to the great variety of possible applications for this equipment, the user must assess the suitability of this product for specific

applications.

• If the controller breaks for any reason, please have safety procedures in plac e to stop any connected equipment in a saf e manner.

• Do not replace electrical parts or try to repair an α Series product in any way.

Series controllers .

α

• Please dispose of the

Series product in accordance with local and national standards.

α

ii

Page 5

α

Simple Application Controller

Table of Contents

Guideline...................................................................................................................................ii

1. Introduction............................................................................................................1

2. Hardware Specification......................................................................................... 3

2.1 Available Models.......................................................................................................... 3

2.2 Power Supply Specification ........................................................ ................................. 4

2.3 Input Specification........................................................................................................ 6

2.4 Output Specification..................................................................................................... 8

2.5 General Specification................................................................................................... 9

3. Installation............................................................................................................11

3.1 DIN RAIL Mounting.................................................................................................... 11

3.2 Termination at Screw Terminals................................................................................ 11

3.3 Installation Mounting Notes........................................................................................ 12

ENG

iii

Page 6

α

Simple Application Controller

4. Wiring ...................................................................................................................15

4.1 Installation Wiring Notes............................................................................................ 15

4.2 Wire Size and Specifications .............................................................. ....................... 15

4.3 Power Supply............................................................................................................. 16

4.4 Recommended Power Input Wiring Diagram............................................................. 16

4.5 AC Input Wiring.......................................................................................................... 17

ENG

4.5.1 AC Input Wiring Diagr a m.......................... ......................................... .................. 17

4.6 Wiring Diagrams for the Sink/Source Terminals........................................................ 18

4.6.1 Source (“+” Common) Input Wiring Diagram....................................................... 1 8

4.6.2 Sink ("-" Common) Input Wiring Diagram............................................................ 18

4.7 Output Relay and Transistor Wiring........................................................................... 19

4.7.1 Relay Output Wiring Diagram (AC and/or DC).................................................... 19

4.7.2 Transistor Output (Source or “+” Common Only) Wiring Diagram ...................... 20

5.

6. How to Use

Series Terminal Layout....................................................................................21

αααα

Series Controllers - Getting Started ..........................................23

αααα

6.1 Connecting Two Blocks ................................................................... ...................... .... 23

6.2 Accessing Blocks ......................................................................................................24

6.3 Setting Function Block Parameters............................................. ..................... .......... 25

6.4 Exiting, Running, and Stopping the Program........................... ... .. ...................... ....... 25

iv

Page 7

α

Simple Application Controller

1. Introduction

The simple, friendly α Series has been designed for use around your home, office, factory.... anywhere that

requires a flexible supervisor y control function. Every module allows you to read signals and set outputs

according to particular conditions or time settings defined by you, the user. Plus the built-in programmable

display allows you to check the status of your system anytime.

Special features of the

• Direct (on-device) programming capability

• High current output capability

•Small size

• Easy access programming port

• EEPROM cassette program storage capability

α

Series system are:

Introduction 1

ENG

• Built-in Real Time Clock as standard

• Windows based programming package, AL-PCS/WIN-E

• Plus a full range of support documentation and Training packages

The

irrigation, doors, gates, simple secur ity systems, greenhouses, air fans, etc. The Real Time Clock can be

used as a power saving device to automatically turn the equipment On/Off at scheduled times.

Debug prog r ams c ar efully b efore installin g i n automate d e quipmen t. The

in life critical or fail safe applications.

Contact your dealer for more information.

Series is designed to be used in the following automatic applications: lighting, air conditioning,

α

Series is not design ed to b e u sed

α

1

Page 8

ENG

α

Simple Application Controller

Introduction 1

2

Page 9

α

Simple Application Controller

Hardware Specification 2

2.

Hardware

Specification

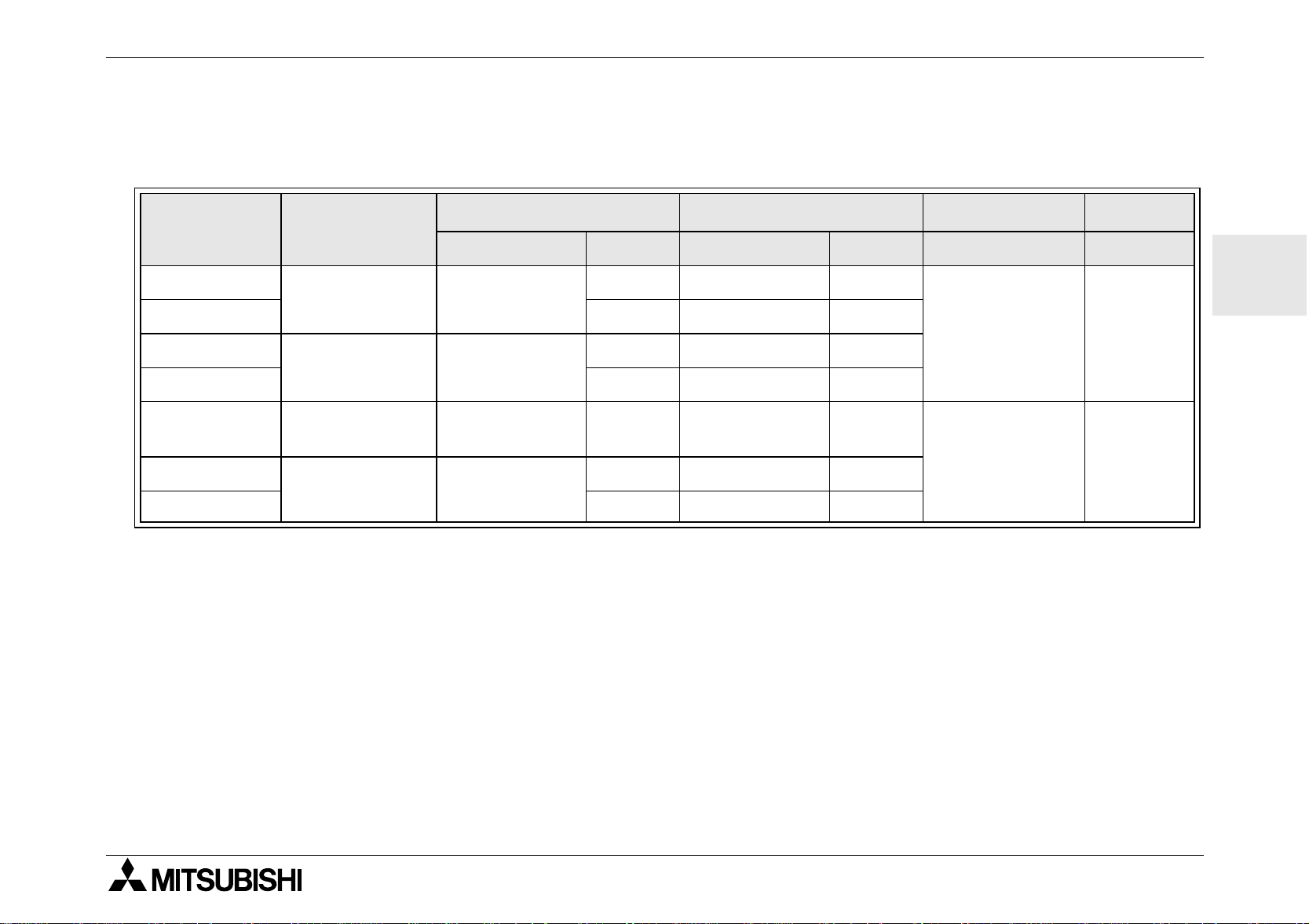

2.1 Available Models

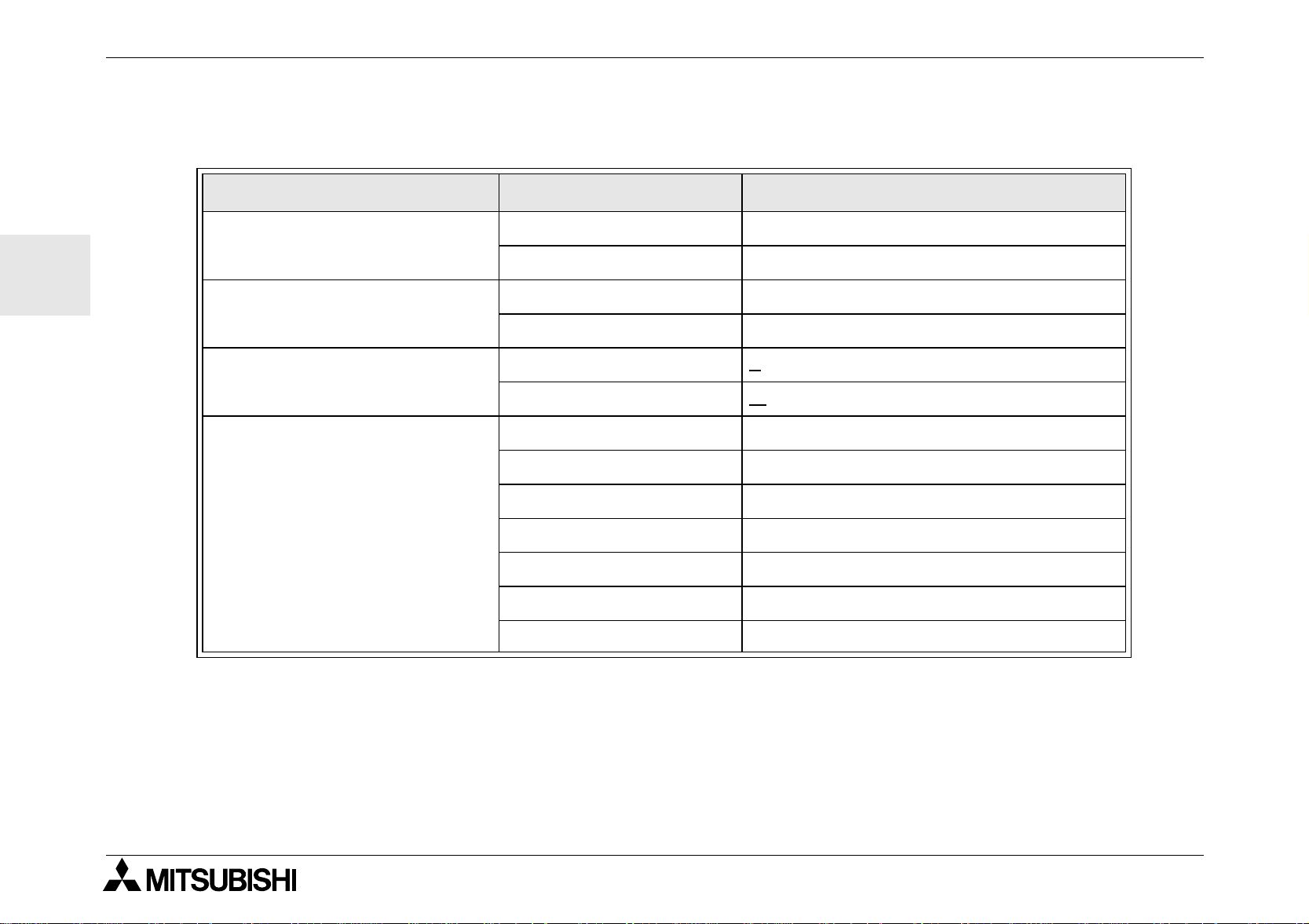

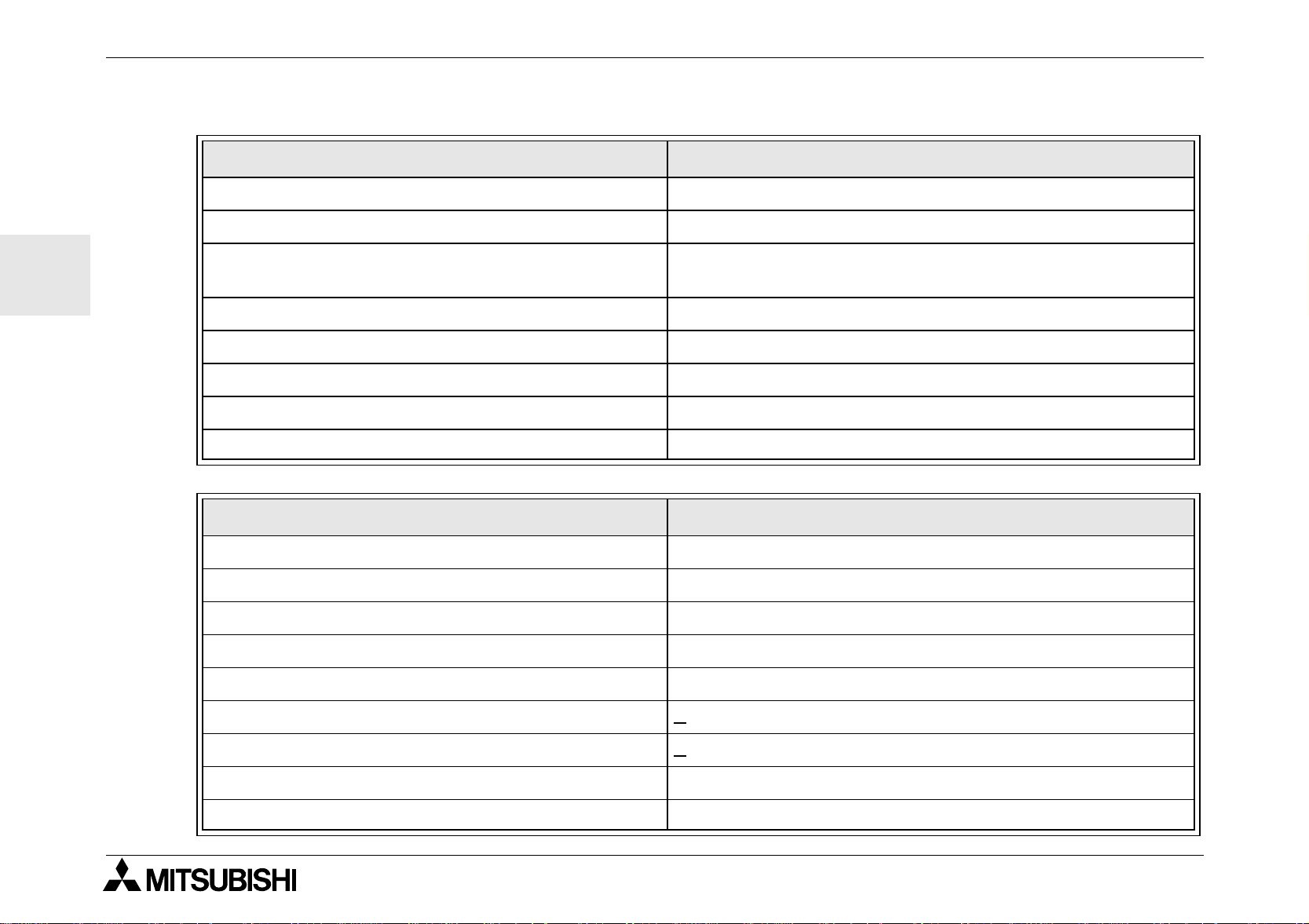

Table 2.1:Model Table

Input Output Dimensions Weight

Model Power Supply

Type Number Type Number mm (inches) kg (lbs)

AL-6MR-A

AL-10MR-A 6 RELAY 4

AL-10MR-D

AL-10MT-D 6 TRANSISTOR 4

AL-20MR-A

AL-20MR-D

AL-20MT-D 12 TRANSISTOR 8

* Without Special Connection Mo dules.

100 - 240V

AC~

24V DC

100 - 240V

AC~

24V DC

100 - 240V

AC~

24V DC

Sink/Source

100 - 240V

AC~

24V DC

Sink/Source

4RELAY 2

6RELAY 4

12 RELAY 8

12 RELAY 8

71.2 x 90 x 55

(2.80 x 3.54 x

2.17)

124.6 x 90 x 55

(4.91 x 3.54 x

2.17)

ENG

0.20

(0.44)

0.32

(0.70)*

3

Page 10

ENG

α

Simple Application Controller

2.2 Power Supply Specification

Table 2.2: Power Supply Specifications

Description Code Specification

Power Supply

Maximum Momentary Power

Failure

Hardware Specification 2

AL -***-A 100 - 240V AC~, +10% -15%, 50 - 60 Hz

AL-***-D 24V DC, +20% -15%

AL-***-A 10ms

AL-***-D 5ms

In-rush Current

Maximum Power Consumption

(without Special Connection

Modules)

240V AC~ (120V AC~) <

24 V DC <

AL-6MR-A, 264V AC~ 3.0 W

AL-10MR-A, 264V AC~ 4.0 W

AL-10MR-D, 28.8V DC 3.0 W

AL-10MT-D, 28.8V DC 2.0 W

AL-20MR-A, 264V AC~ 8.0 W

AL-20MR-D, 28.8V DC 7.0 W

AL-20MT-D, 28.8V DC 5.0 W

1.5 Amp (0.7 Amp)

7.0 Amp

4

Page 11

α

Simple Application Controller

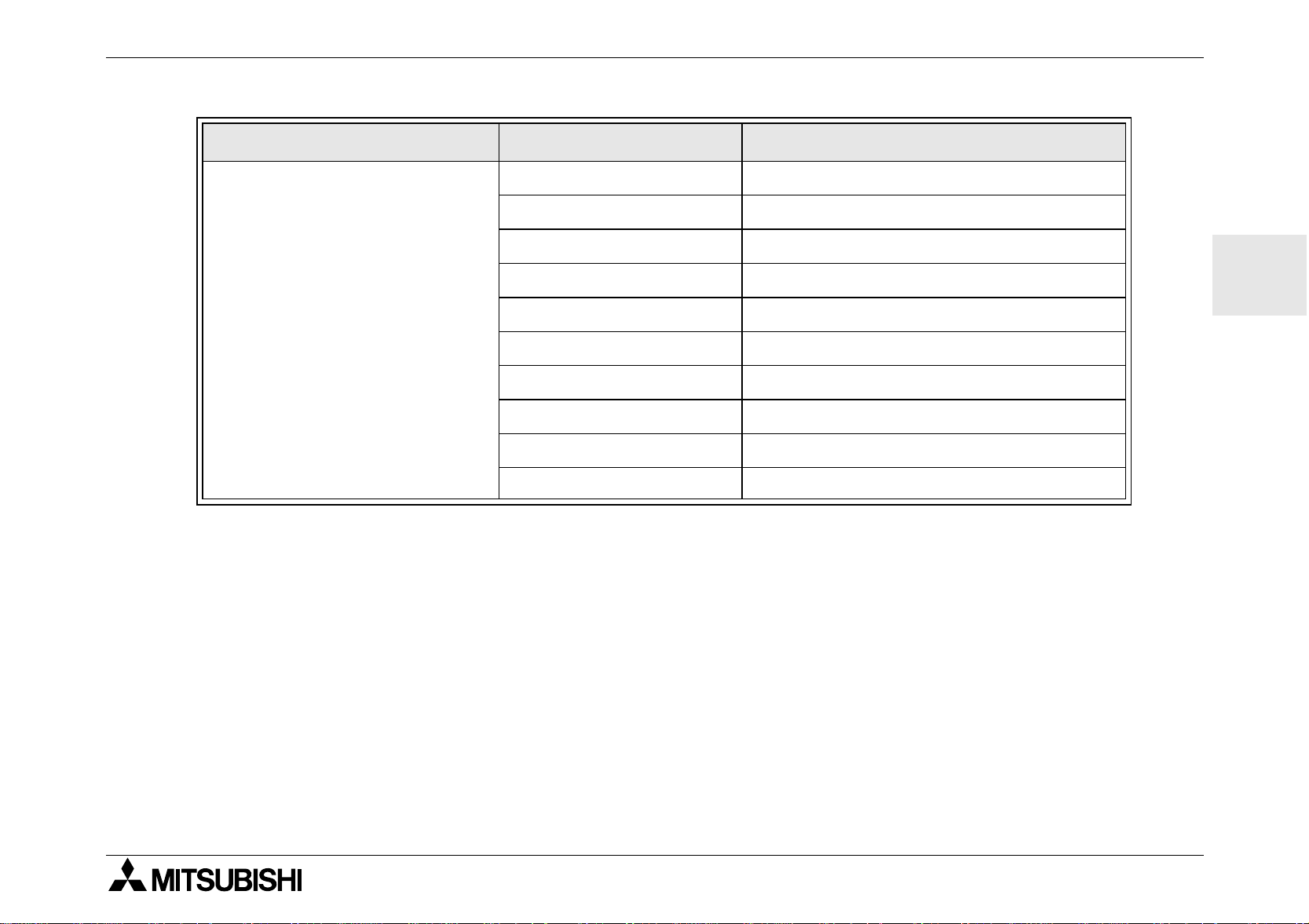

Table 2.2: Power Supply Specifications

Description Code Specification

Hardware Specification 2

AL-6MR-A, 240V AC~ I/O all On - 2.5 W, I/O all Off - 1.5 W

AL-6MR-A, 120V AC~ I/O all On - 2.0 W, I/O all Off - 1.2 W

AL-10MR-A, 240V AC~ I/O all On - 3.0 W, I/O all Off - 1.5 W

Typical Power Consumption

(without Special Connection

Modules)

AL-10MR-A, 120V AC~ I/O all On - 2.5 W, I/O all Off - 1.2 W

AL-10MR-D, 24V DC I/O all On - 2.0 W, I/O all Off - 0.3 W

AL-10MT-D, 24V DC I/O all On - 2.0 W, I/O all Off - 0.3 W

AL-20MR-A, 240V AC~ I/O all On - 5.0 W, I/O all Off - 1.5 W

AL-20MR-A, 120V AC~ I/O all On - 4.0 W, I/O all Off - 1.2 W

AL-20MR-D, 24V DC I/O all On - 5.0 W, I/O all Off - 0.3 W

AL-20MT-D, 24V DC I/O all On - 5.0 W, I/O all Off - 0.3 W

ENG

5

Page 12

α

Simple Application Controller

2.3 Input Specification

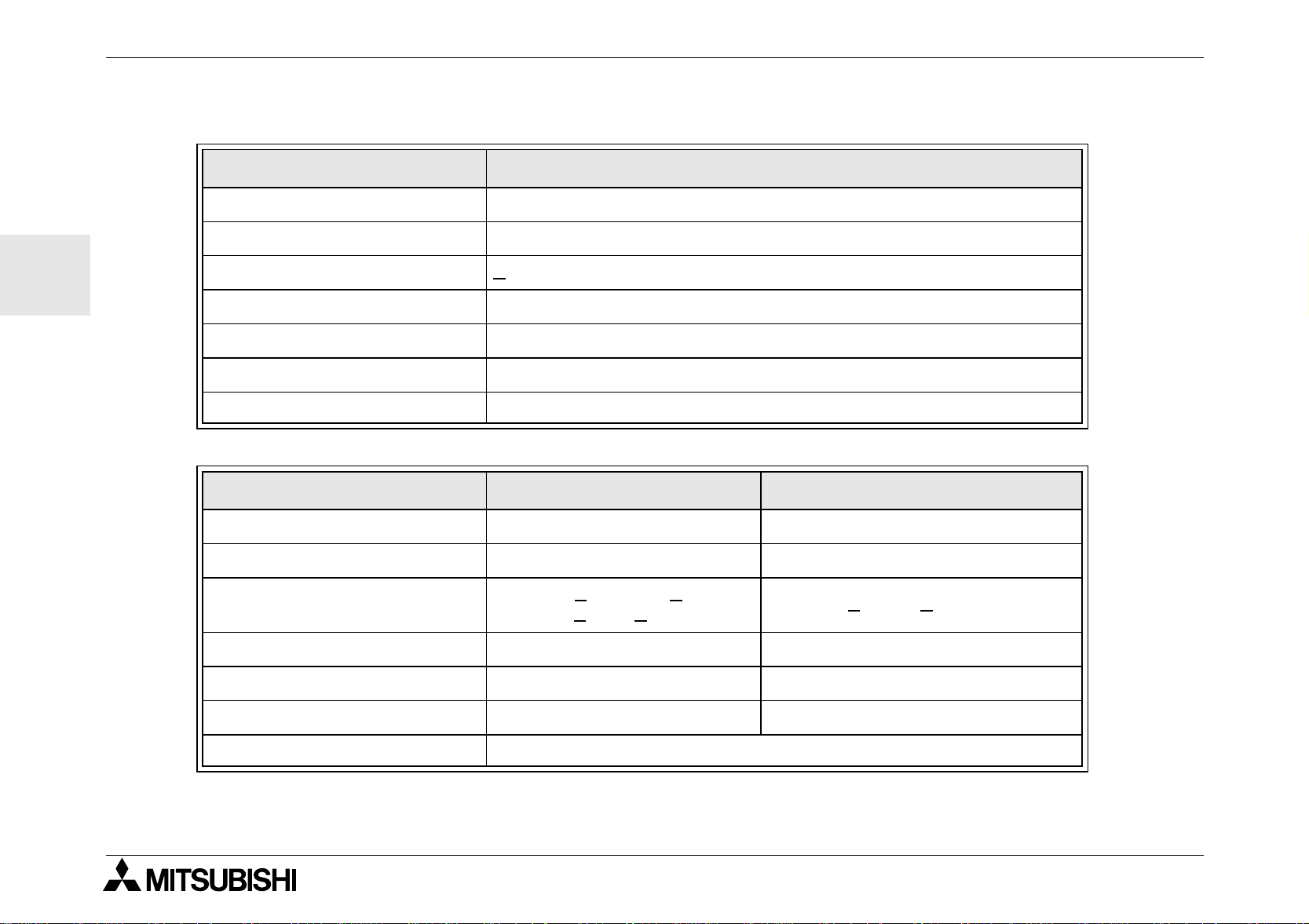

Table 2.3: AC Input Specifications

Description AC Inp ut Specific ation

Input Voltage 100 - 240V AC~, +10% -15%, 50 - 60 Hz

Input Current 0.24mA / 240V AC~, see Note 1

Hardware Specification 2

ENG

Input Impedance >

OFF to ON/ ON to OFF 80V/40V

Response Time ~ 50ms

Isolation Circuit None

Operation Indication Liquid Crystal Display

Table 2.4: DC Input Specifications

Description Sink (“-” Common) Source (“+ ” Common)

Input Voltage 24V DC +20% -15% 24V DC +20% -15%

Input Current 5.0 mA / 24V DC 5.0 mA / 24V DC

OFF to ON/ ON to OFF

Response Time (I01 - I08) 10 - 20 ms 10 - 20 ms

Response Time (I09 - I12) 20 - 40 ms 20 - 40 ms

Isolation Circuit None None

800 kOhms

Current: >

Voltage: <

4.3mA / < 1.1 mA

4V / > 18V

Vo ltage: > 18V / < 4V

Operation Indication Liquid Crystal Display

Note 1 - Current leakage from the sensors connected to the inputs might provide enough current to turn the

controller On. Do not use two wire sensors.

6

Page 13

α

Simple Application Controller

Table 2.5: Analog Input Specifications

Description Analog Input Specification

AL-10M*-D 6 Channels: I01 - I06

AL-20M*-D 8 Channels: I01 - I08

Analog Input Range 0 - 250

Hardware Specification 2

Resolution 10000/250 mv

Conversion Speed 10 ms

Input Voltage 0 - 10V DC

Input Impedance 150 kOhm or higher

Overall Accuracy +/- 5% (0.5V DC)

Offset Value = 0 at 0V DC

Offset/Gain

Temperatur e Drift +/- 3 LSB

Gain Value: 0 - 10V = 0 - 250

These default values can be changed in the Offset FB

ENG

7

Page 14

α

Simple Application Controller

2.4 Output Specification

Table 2.6:Relay Output Specifications

Description Relay Specification

Switched Voltage 250V AC~ or less, 30V DC or less

Max. Resistive Load (AL-6M ** or AL-10M**) 8A / common (10A/common for 110V AC~ outputs)

Hardware Specification 2

ENG

Contact Life Cycle / Re sistance Load

Minimum Load 50mW (10mA at 5V DC)

Max. Inductive Load 245 VA (1/3 hp)/ 125 VAC~, 367 VA (1/2 h p) / 250 VAC~

Response Time 10ms or less

Operation Indication Liquid Crystal Disp lay

Isolation Circuit By Relay

Table 2.7: Transistor Output Specifications (Source Type only)

Description Transistor Specification

Switched Voltage 5 - 24V DC (+20%, -5%)

Max. Resistive Load 1A / point (8 - 24V DC), 0.1A / point (5 - 8V DC)

Minimum Load 1.0mA

Max. Inductive Load 1A / 24V DC (24 W)

Max. Lamp Load 0.125 A / 24V DC (3.0 W)

100,000 Cycles at 8 Amps / 240V AC~ or 24V DC

30,000 Cycles at 10 Amps / 110V AC~

Response Time On/Off, Off/On (approx) <

Open Circuit Current Leakage <

Operation Indication Liquid Crystal Disp lay

Isolation Circuit None

1 ms

0.1mA / 24V DC

8

Page 15

α

Simple Application Controller

2.5 General Specification

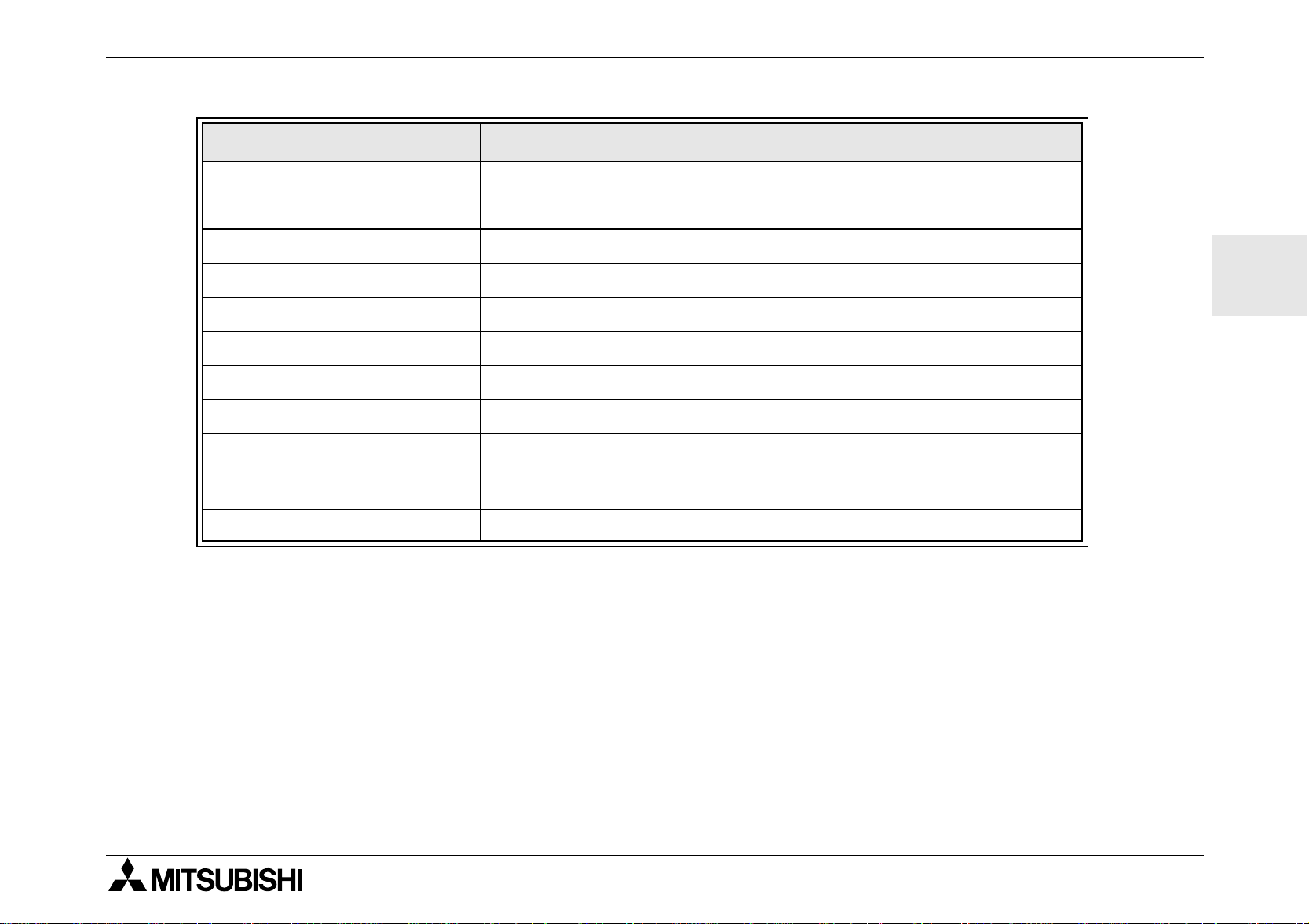

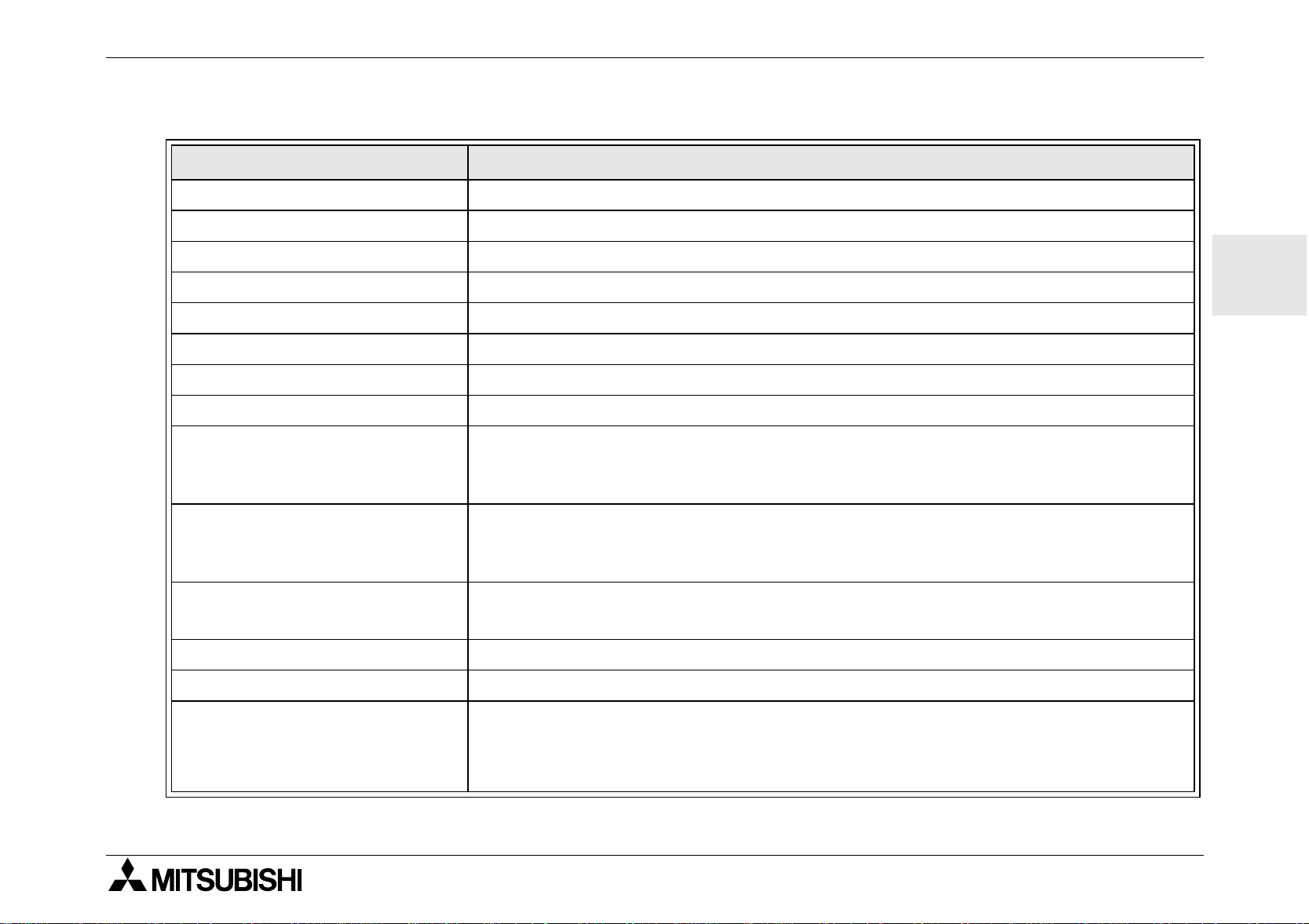

Table 2.8:Environmental and Electrical Specifications

Description Specification

Progra mming Method Function Bloc k

Program Capacity 64 Function Blocks or 1500 bytes

Program Storage Built in EEPROM (no battery backup required) or opt ion al EEPROM cassette

Device Backup 20 Days at 25°C (by capacitor)

RTC Backup 20 Days at 25°C (by capacitor)

RTC Accuracy 5 seconds / day

Operating Temperature 0 - 55 °C

Storage Temperature (-30) - 70 °C

Hardware Specification 2

ENG

Vibration Resistance - D irect

Mounting

Vibration Resi stan ce - DIN Rail

mounting

Shock Resistance

Noise Immunity 1000Vpp, 1 microsecond, 30 - 100 Hz, tested by noise simulator

Humidity 35 - 85% Relative Humidity, no condensation

Dielectric withstand voltage

Conforms to IEC 68-2-6; 10-57 Hz: 0.15 mm Constant Amplitude

57-150 Hz: 19.6 m/s

Sweep Count for X,Y,Z: 10 times (80 minutes in each direction)

Conforms to IEC 68-2-6; 10-57 Hz: 0.075 mm Constant Amplitude

57-150 Hz: 9.8 m/s

Sweep Count for X,Y,Z: 10 times (80 minutes in each direction)

2

Conforms to IEC 68-2-27: 147m/s

3 times in each direction X,Y, and Z

3750V AC > 1 min per EN60730-1 between the following points:

Power/Input Terminals and Relay Output Terminals

Relay Output Terminal and Relay Output Terminal

All Terminals and the DIN 43880 Control box or equivalent

Acceleration, Action Time: 11 ms

2

Acceleration

2

Acceleration

9

Page 16

ENG

α

Simple Application Controller

Table 2.8:Environmental and Electrical Specifications

Description Specification

Insulation Resistance

Type of Action EN 60730-1, Section 6.4.3 - Type 1C (Relay Output)

Type of Action EN 60730-1, Section 6.4.3 - Type 1Y (Transistor Output)

Software Class EN 60730-1, Section H6.18 - Class A

Construction of Control EN 60730-1, Section 6.15 - Incorporated Control

Whether the Control is electric EN 60730-1, Section H2.5.7 - Electric Control

Hardware Specification 2

7 Mohm at 500V DC per EN60730-1 between the following points:

Power/Input Terminals and Relay Output Terminals

Relay Output Terminal and Relay Output Terminal

All Terminals and the DIN 43880 Control box or equivalent

Safety Class

Pollution Control For use in normal pollution situations

Grounding None

Electrical Isolation Reinforced primary/secondary insulation

Operation Ambience To be free of corrosive gases. Dust should be minimal.

Protection IP 20

Certifications CE, UL/cUL

Attestation of Conformity TÜV (AL-10MT-D, AL-10MR-D)

Complies with

Liquid Crystal Display

II

UL 508

EN60730-1

EN61010-1

EN50081-1

EN50082-1

EN61000-6-2

Will display 4 lines of ten characters per line, Program Run On/Off mode,

Pas s w ord P rotect ion, Imag e Table, and Functio n Bloc ks during pr ogr ammi ng.

10

Page 17

α

Simple Application Controller

3. Installation

Installation 3

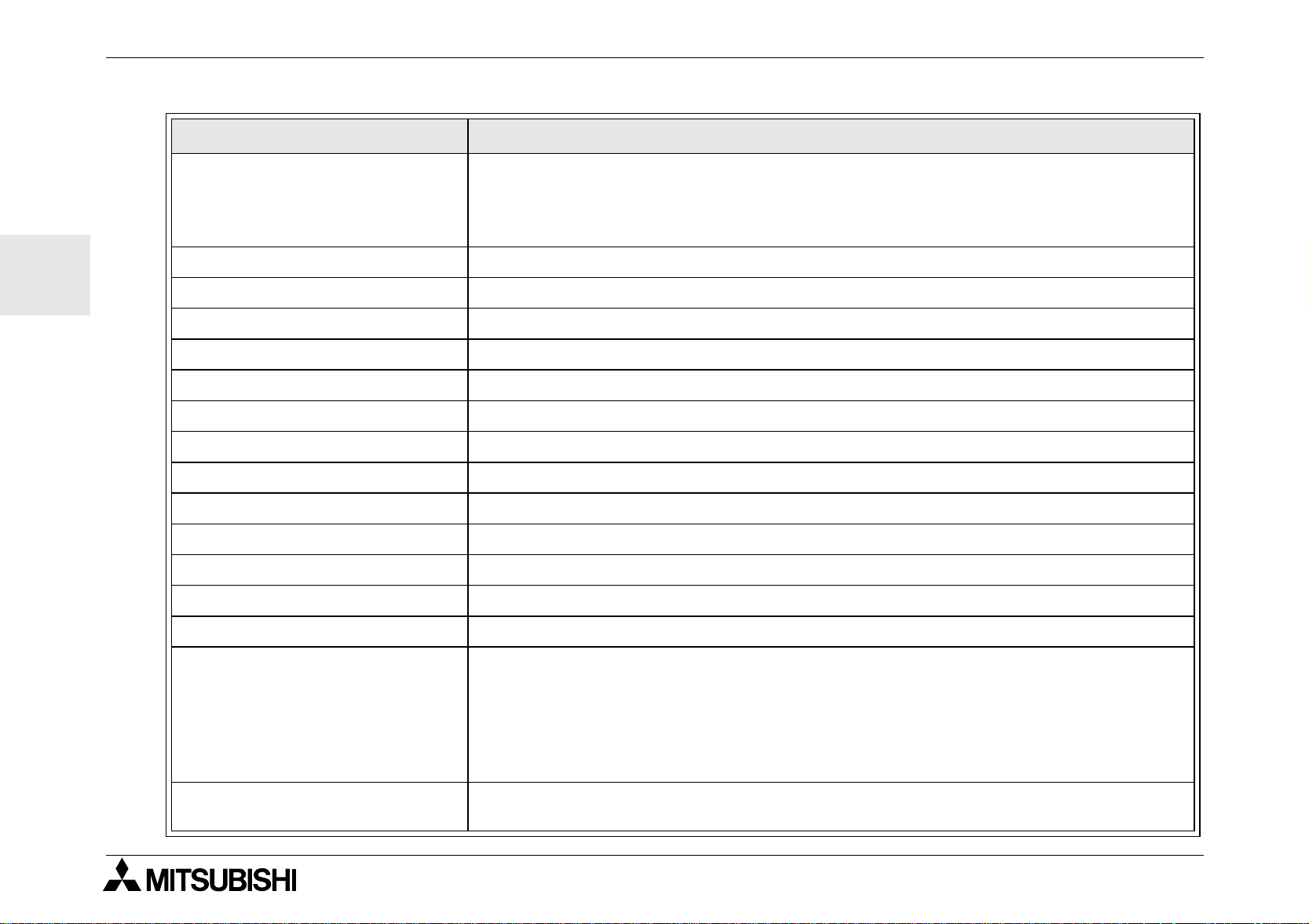

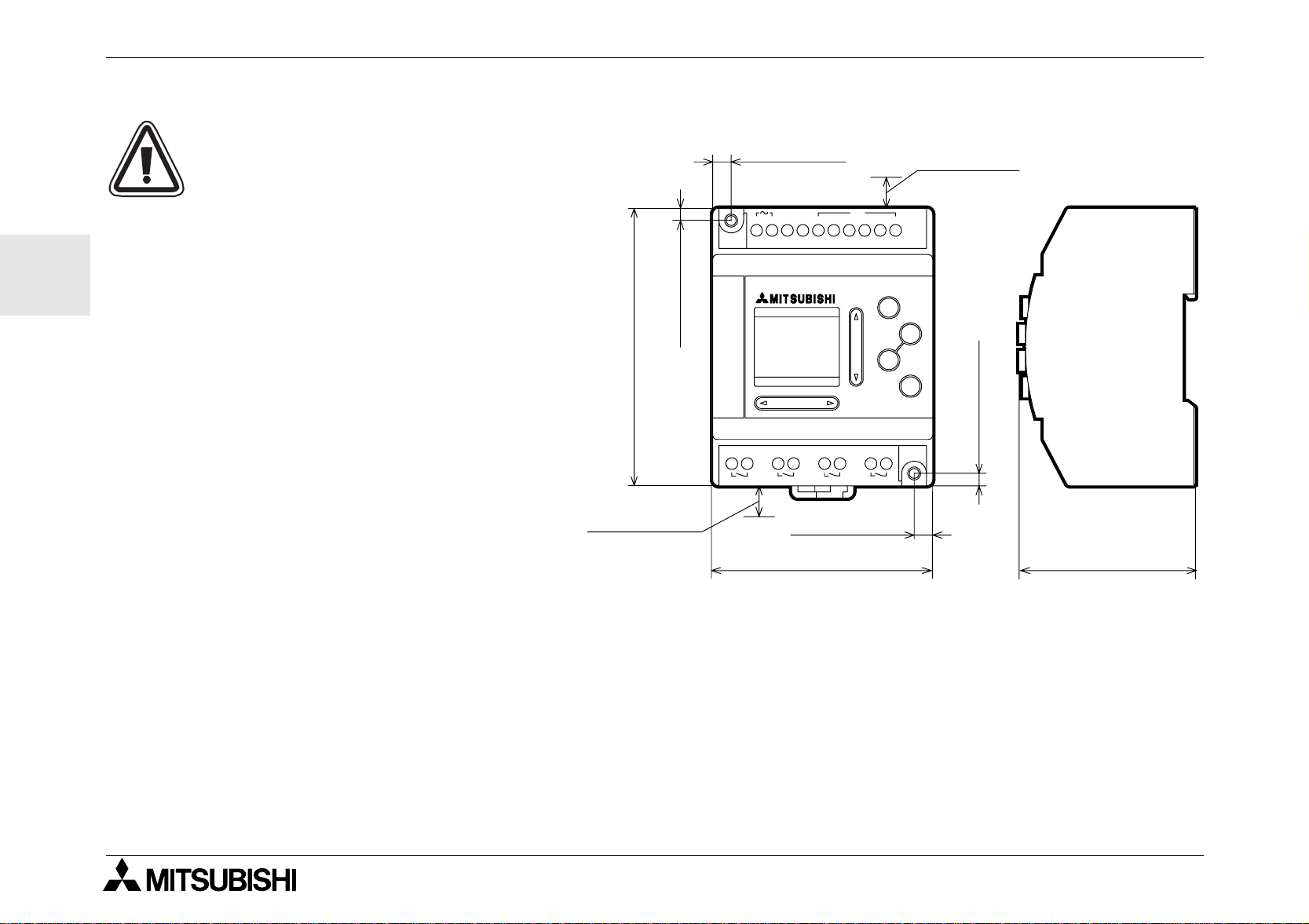

Tab le 3.1: Front Panel Layout

7

5

6

2

LN

POWER

AC 100-240V

OUT

1

3

~

1 2 3 4 5 6 7 8 9 10 11 12

4

Ref. Item Description

IN

1 DIN-RAIL Mounting clips

2 Mounting ho le, D ia. 4.2 mm

AC INPUT

ESC

3Power Terminals

4 Input Terminals

ENG

5 Liquid Crystal Display

6 Operation keys

OK

AL-20MR-A

RELAY OUTPUT

7 Output Terminals

3.1 DIN RAIL Mounting

Units can be snap mou nted t o 35mm DIN ra il (DIN

OUT

OUT

OUT

2

3

OUT

4

5

OUT

6

OUT

OUT

8

7

EN 50022). To release pull the spring loaded clips

away from the rail and sli de the unit off and up.

1

3.2 Termination at Screw Terminals

Cables terminati ng at a screw ter minal should be

fitted with insulated crimp terminals.

11

Page 18

α

Simple Application Controller

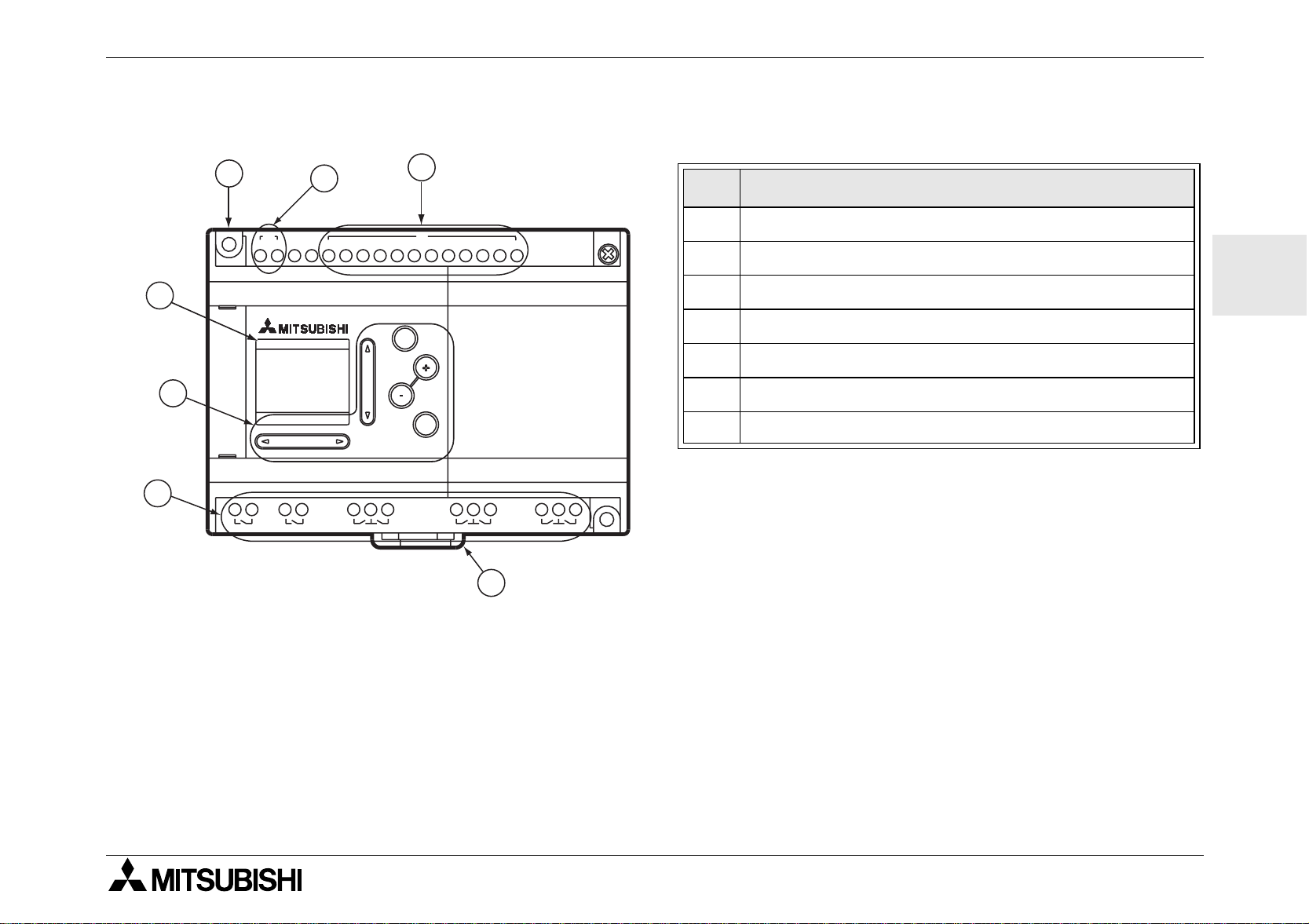

3.3 Installation Mounting Notes

Installation 3

ENG

The α Series’ safe design means the

user can install it almost anywhere but

the f ollowing points sho uld be taken into

consideration.

Do not install i n are as wit h: excessive or

conductive dust, corrosive or flammable

gas, moisture or rain , excessive heat,

regular impact shocks or excessive

vibration. Do not place in water or let

water leak onto the controller.

Do not allow debris to fall inside the unit

during installation.

Keep as far as possible from

high-voltage cables and power equipment.

The

Series Controller must be

α

installed in ca bin ets which are designed

for the assembly of devices complyin g

to DIN 43880 or in a control box.

4.0(0.16")

90.0(3.54")

10(0.39")*

6.0(0.24")

POWER

AC 100/240V

RELAY OUTPUT

OUT3 OUT4OUT2OUT1

6.0(0.24")

71.2(2.80")

IN

34215L6N

AC INPUT

10(0.39")*

ESC

+

-

OK

4.0(0.16")

55.0(2.17")

Use size M4 screws when mounting by screw holes.

The connectors must be covered to prevent injury from contact with “live” wires.

* Leave a minimum of 10mm of space for ventilation between the top and bottom edges of the

troller and the enclosure walls.

Series Con-

α

12

Page 19

α

Simple Application Controller

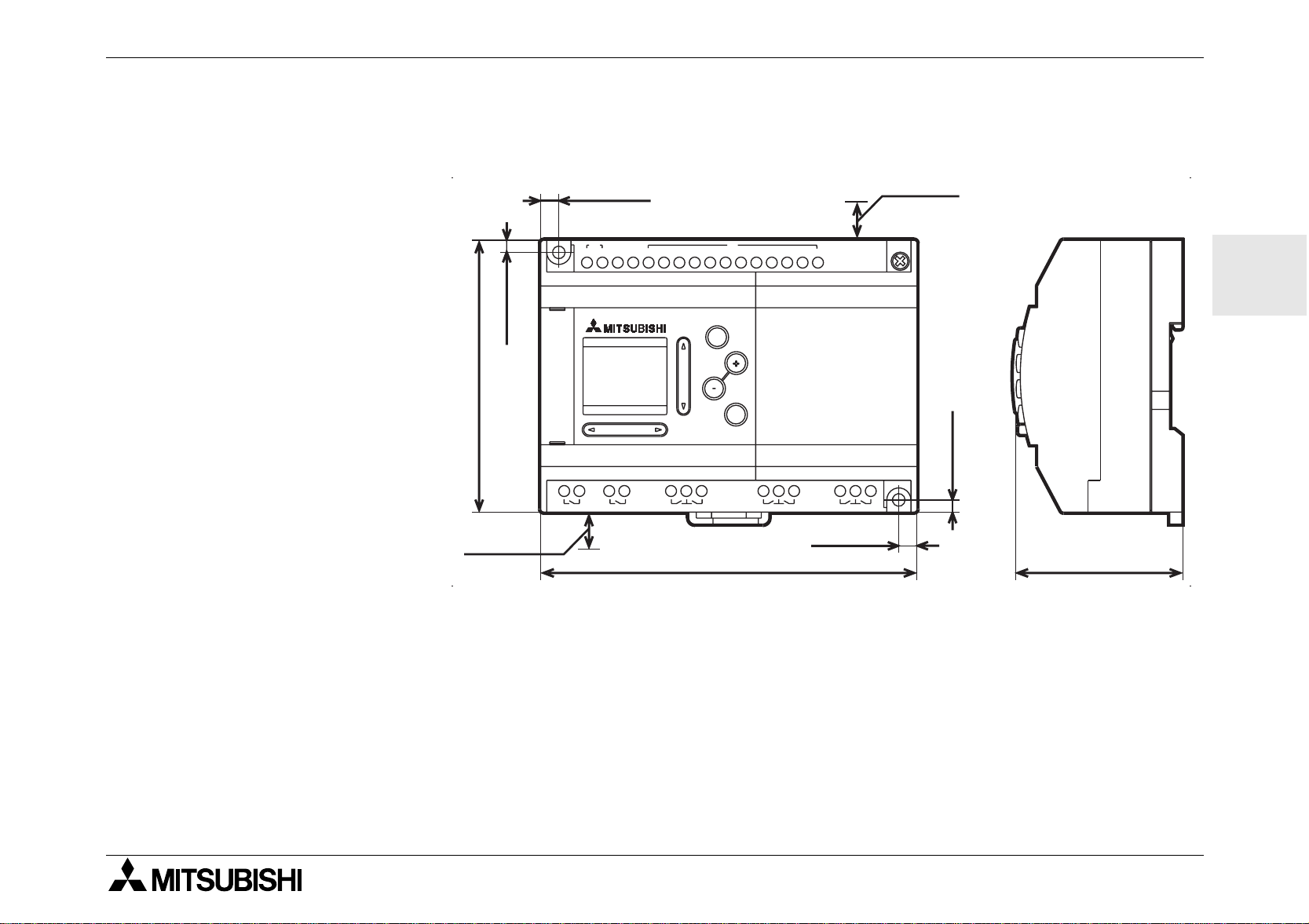

Do not disassemble the α Series controller. Ref er to the Memory Cassette Manual when ch anging th e Memory Cassette.

Installation 3

4.0(0.16")

90.0(3.54")

10(0.39")*

6.0(0.24")

~

LN

POWER

AC 100-240V

OUT

OUT

1

1 2 3 4 5 6 7 8 9 10 11 12

OUT

2

3

IN

AC INPUT

ESC

OK

AL-20MR-A

RELAY OUTPUT

OUT

4

124.6(4.91")

10(0.39")*

ENG

4.0(0.16")

OUT

5

OUT

6

6.0(0.24")

OUT

8

OUT

7

55.0(2.17")

13

Page 20

ENG

α

Simple Application Controller

Installation 3

14

Page 21

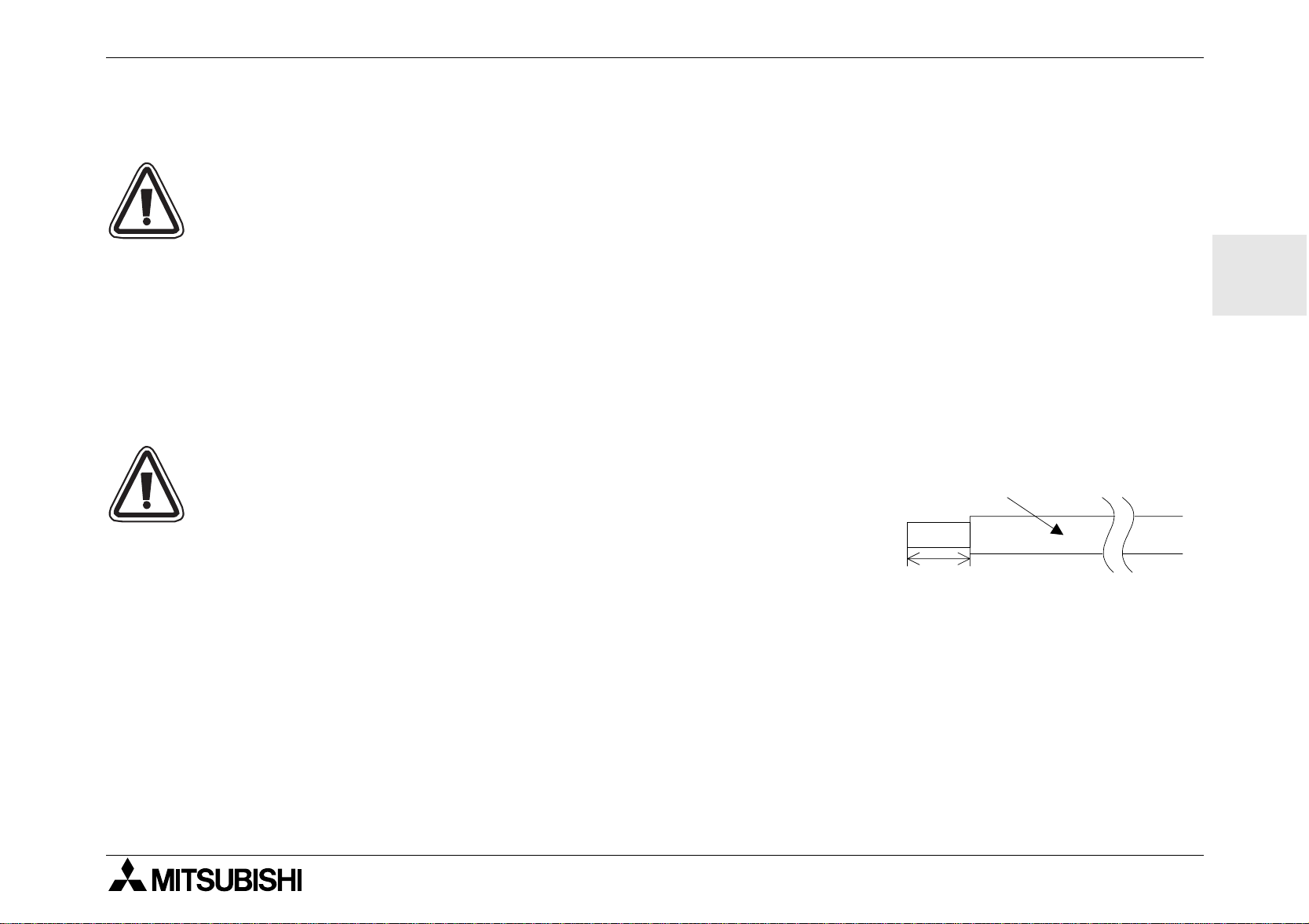

α

7mm(0.276") ± 0.5mm(0.02")

26 -12 AWG

Simple Application Controller

4. Wiring

4.1 Installation Wiring Notes

The wiring of α Series has been designed to be safe and easy. A technician or engineer trained in the local

Wiring 4

and national electrical standards should perform all tasks associated with the electrical wiring of the

controllers. Turn off the Power before performing any wiring operations.

• Input and output cables should not be run through the same multicore cable or share the same wire.

• Do not lay input/output cables near high voltage power cables.

Allow for voltage drop and noise interference with input/output lines used over an extended distance. Please

use wire that is properly sized for the current load.

4.2 Wire Size and Specifications

Wire the Inputs and Outpu ts using 26 - 12 AWG wire (0.13 mm2 - 3.31

2

mm

). Strip the wire to a length of 7 +- 0.5 mm (0.250 - 0.300 inches).

Please unscrew the terminal to its widest position before inserting a wire.

Insert the wire completely into the terminal to ensure that a proper connection can be made. Insert the wire into the terminal and tighten enough

to keep the wire from pulling free. To avoid damaging the wire, do not

exceed a maximum torque of 0.5 N⋅m. Please do not use tin, solder, or

any other substance on the stripped wire that might cause the wire strand

to break.

Series

α

ENG

The terminals will accept a 3mm flathead screwdriver.

15

Page 22

ENG

α

Simple Application Controller

4.3 Power Supply

When wiring AC supplies the “Live” cable should be connected to the “L” ter minal and the “Neutral” cable

should be connected to the “N” terminal. Do NOT connect the “Live” wire to the “N” terminal, the user might

receive a dangerous shock on powerup.

When wiring DC supplies the “positive” cable should be connected to the "+" terminal and the negative cable

should be connected to the “-” terminal. On no account should the power supply terminals be connected to

any other terminal on the unit. DC Power Supply units should be capable of providing 4 Amperes of current

to the controller.

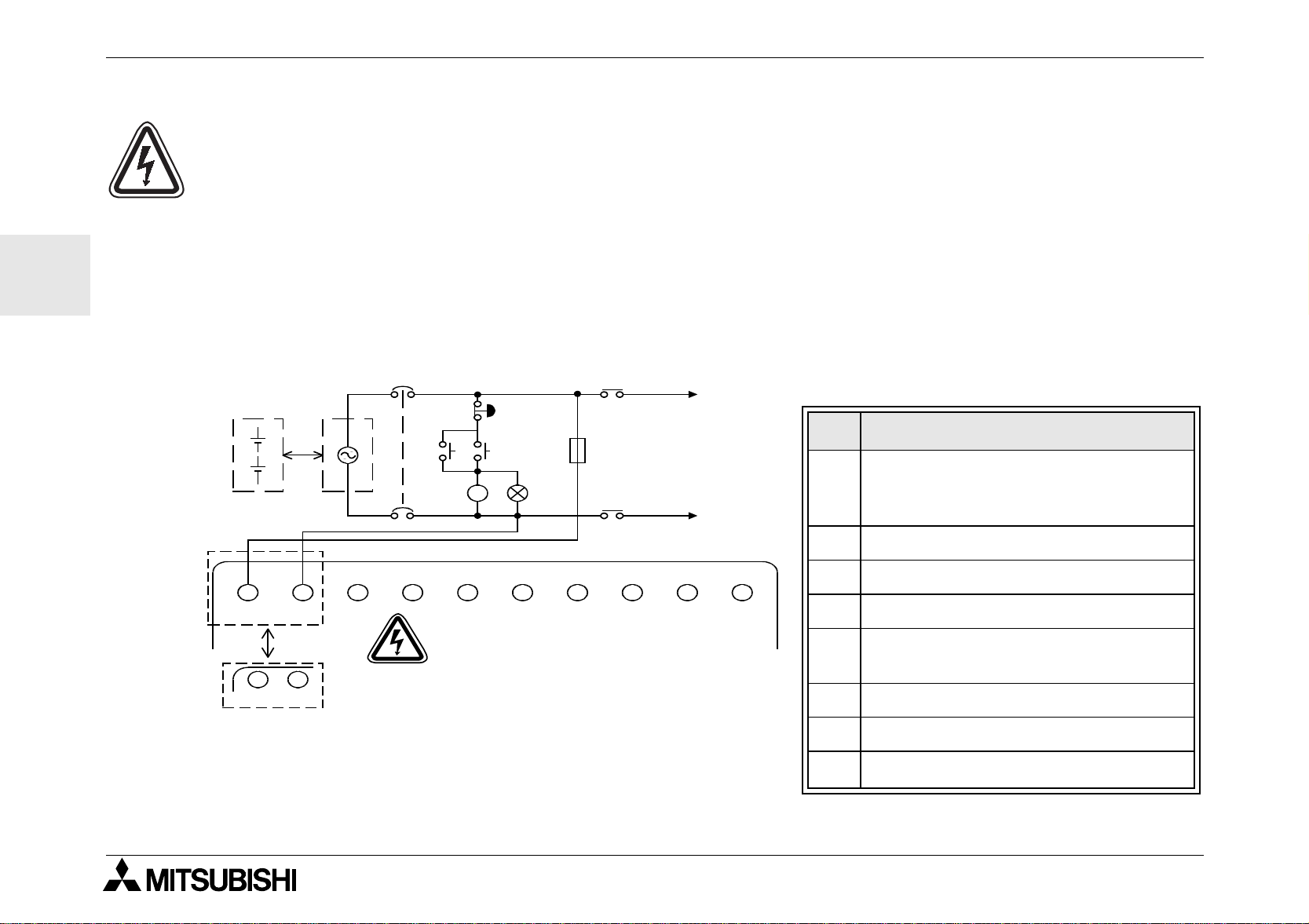

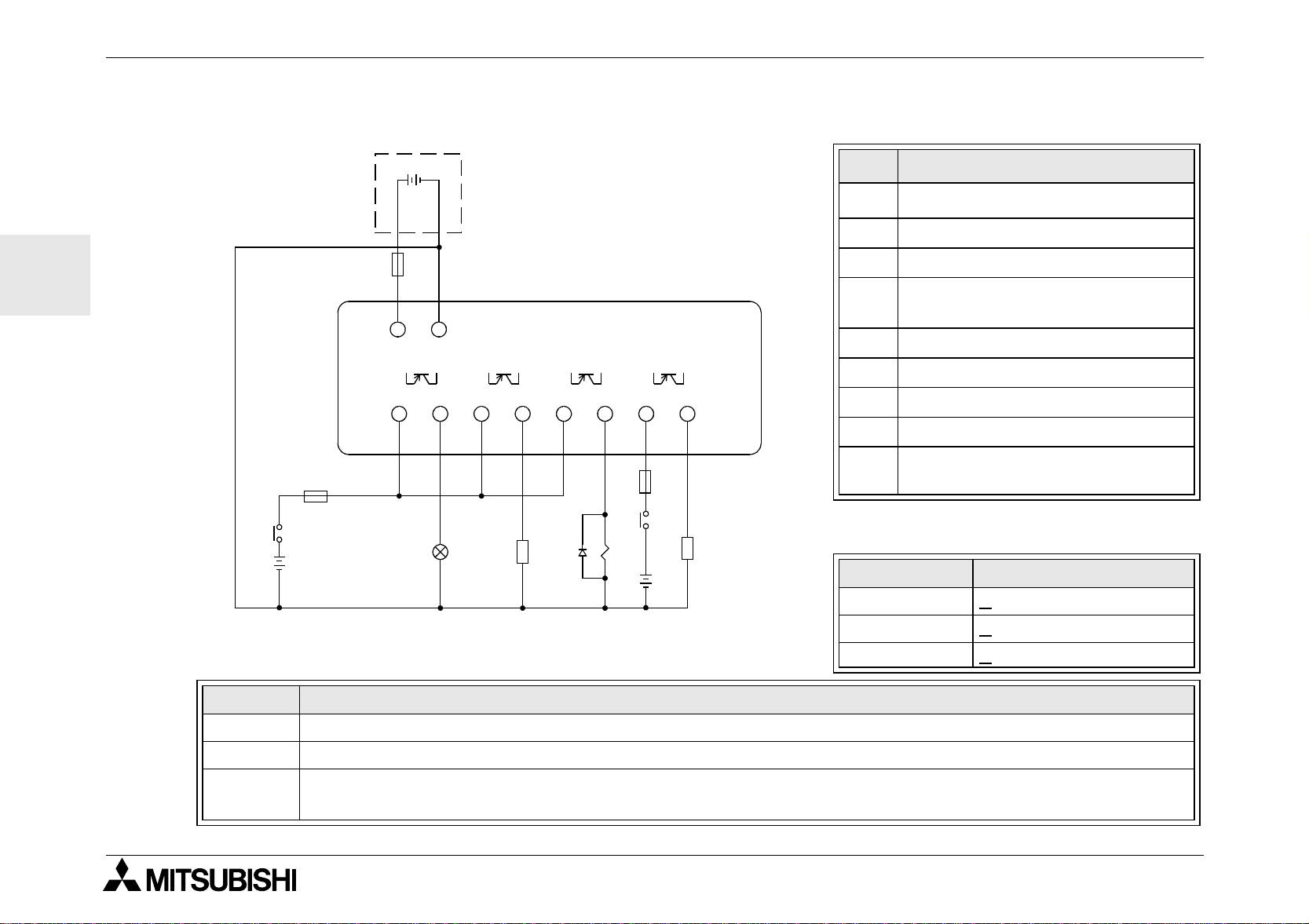

4.4 Recommended Power Input Wiring Diagram

%

MC

&

(

MC

+

−

!"

L

MC

N

MC

#

Start

$

Wiring 4

Table 4.1:Recommended Power Wiring

Ref. Item Description

Power Supply: AC~:100-240V

1

50-60Hz

DC: 24V

2 Circuit Isolation Device

LN

+−

'

"L" and "N" terminals are not

reversible.

3 Emergency Stop

4 Power On Pilot Indicator

5

Circuit protection device - limit to

1.0 Amps

6 Power Supply for AC loads

7 Magnetic Switch Contact

8

Base Unit

α

16

Page 23

α

Simple Application Controller

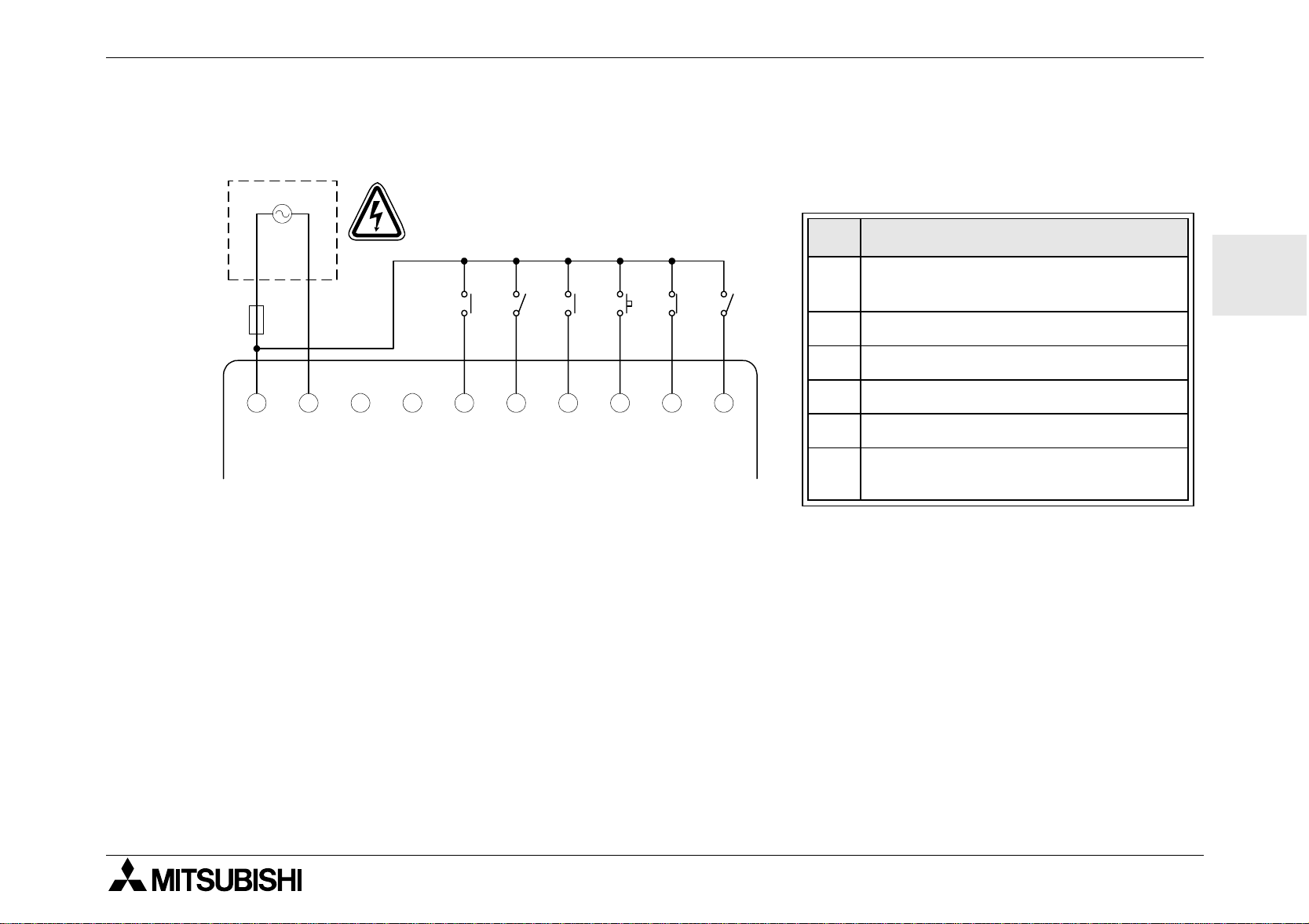

4.5 AC Input Wiring

4.5.1 AC Input Wiring Diagram

Wiring 4

!

LN

"L" and "N" terminals are not

reversible.

&

LN 123

#

"

456

INPUTS

$

%

Table 4.2: AC Input Typical Wiring

Ref. Item Description

1

2 AC Power Terminals

3 Unused Terminals

4 Input Terminals

5 Digital Input Switches

6

AC Po wer Sup ply, 100 - 240V AC~

50 - 60 Hz

Circuit Protection Device - Limit to

1.0 Amps

ENG

17

Page 24

α

Simple Application Controller

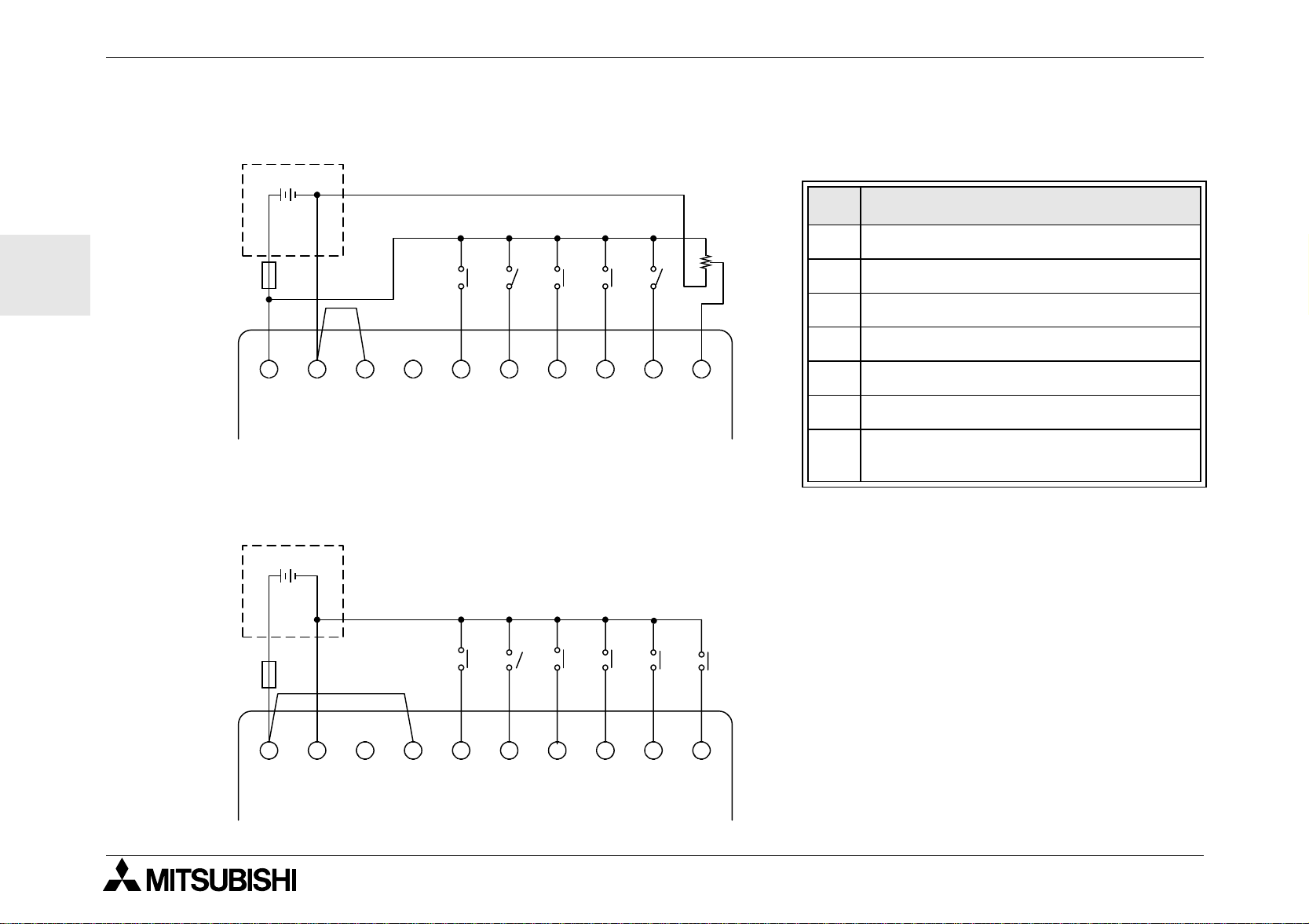

4.6 Wiring Diagrams for the Sink/Source Terminals

4.6.1 Source (“+” Common) Input Wiring Diagram

!

+−

Wiring 4

Table 4.3: Sink/Source Input Wiring

Ref. Item Description

ENG

(

+−

"

(A) (B)

#

123

INPUTS

456

$

4.6.2 Sink ("-" Common) Input Wiring Diagram

!

+−

(

%

%

&

1 DC Service Supply, 24V DC

2 DC Power Terminals

3 Sink/Source Input Wiring Terminals

4 Input Terminals

5 Sensor Input Switches

6 Analog Input

7

Circuit Protection Device - Limit to

1.0 Amps

+−

(A) (B) 1 2 3

"#

INPUTS

$

456

18

Page 25

α

Simple Application Controller

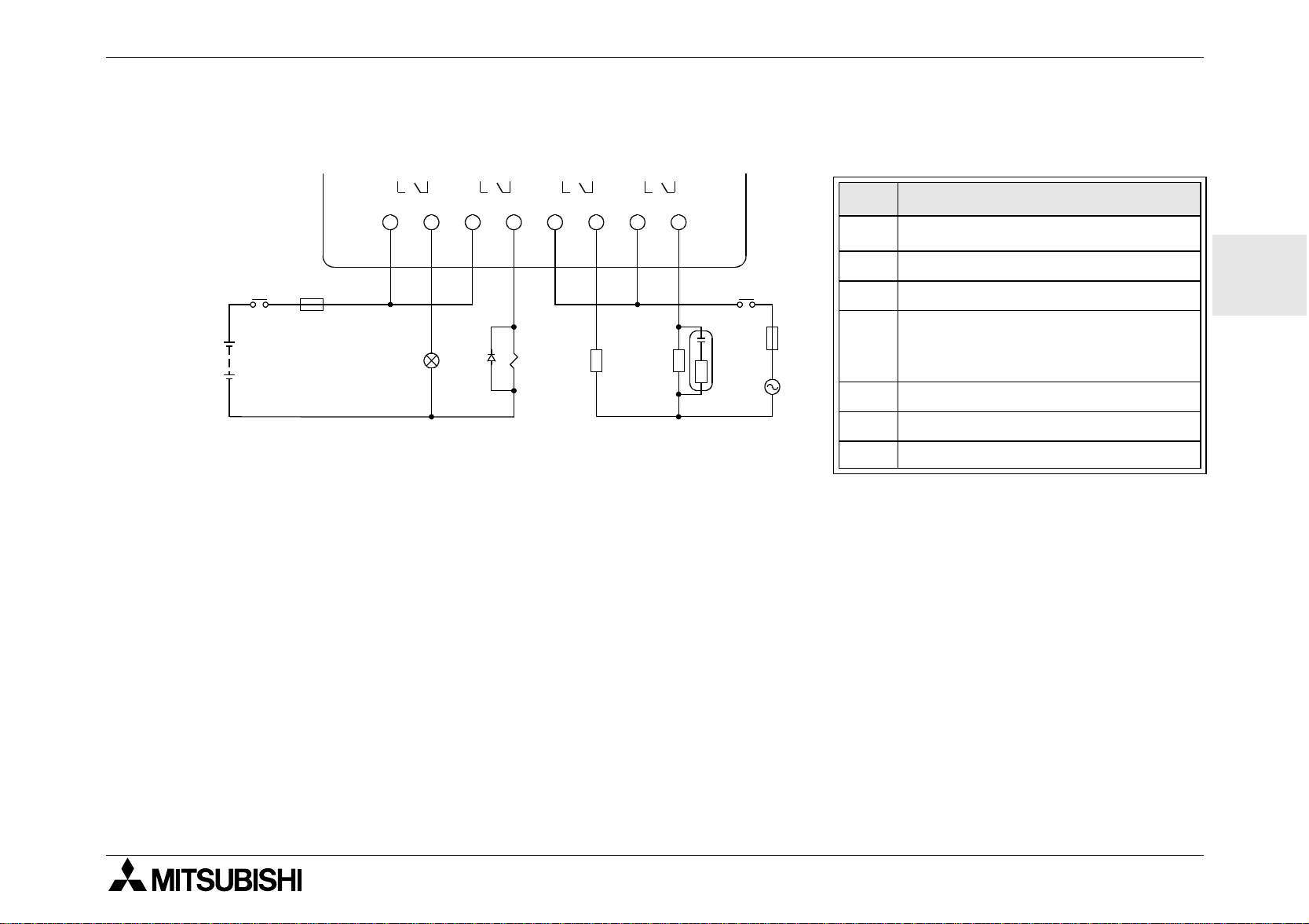

4.7 Output Relay and Transistor Wiring

4.7.1 Relay Output Wiring Diagram (AC and/or DC)

"!

OUT1

OUT2 OUT3 OUT4

Wiring 4

Table 4.4: Relay Output Wiring

Ref. Item Description

&

1

2 Mutually exclusive outputs

%

+

$

##

%

$

(

3 Output Devices

4

5 Emergency Stop

6 DC Power Supply

7 AC Power Supply

Base Unit

α

Circuit Protection Device - Limit

to 10 Amps per every four output terminals used.

ENG

19

Page 26

α

Simple Application Controller

4.7.2 Transistor Output (Source or “+” Common Only) Wiring Diagram

Table 4.5: Transistor Output Wiring

Wiring 4

ENG

%

&

'

+−

Ref. Item Description

1

Base Unit

α

2 Output Terminals

)

(

+−

OUT1

!

"

OUT2 OUT3 OUT4

3 Output Devices

Circuit Protection D evice - See

4

Table 4.6 for Specifications

5 Emergency Stop

6 DC Power Supply for output

7Power Terminal

8 DC Power Supply, 24V DC

Circuit Protection Device

9

- Limit to 1.0 Amps

Table 4.6: Tran si stor Output Circuit

Protection Table

Circui t V oltage Circuit Protection (Fuse)

%

&

$

#

+

$

+

#

#

5 Vo lt < 0.3 Amps per Circuit

12 Volt <

24 Volt <

Volt Output Terminal Notes

2.0 Amps per Circuit

2.0 Amps per Circuit

5 Each circuit can contain from on e output ter m inal up to every output te rminal.

12-24 Each circuit can contain from one output terminal up to every output terminal.

Using any combination of 5 Volt, 12 Volt, and 24 Volt outputs can be accomplished on the same

5,12,24

Series Controller if separate circuits are used for each voltage level.

α

20

Page 27

α

LN 1234

OUT1

AL-10MR-A

OUT2

IN

56

OUT3

OUT4

+−

(B)

1234

OUT1

AL-10MT-D

OUT2

IN

56

OUT3 OUT4

(A)

Simple Application Controller

Series Terminal Layout 5

αααα

5.

αααα

Series Terminal Layout

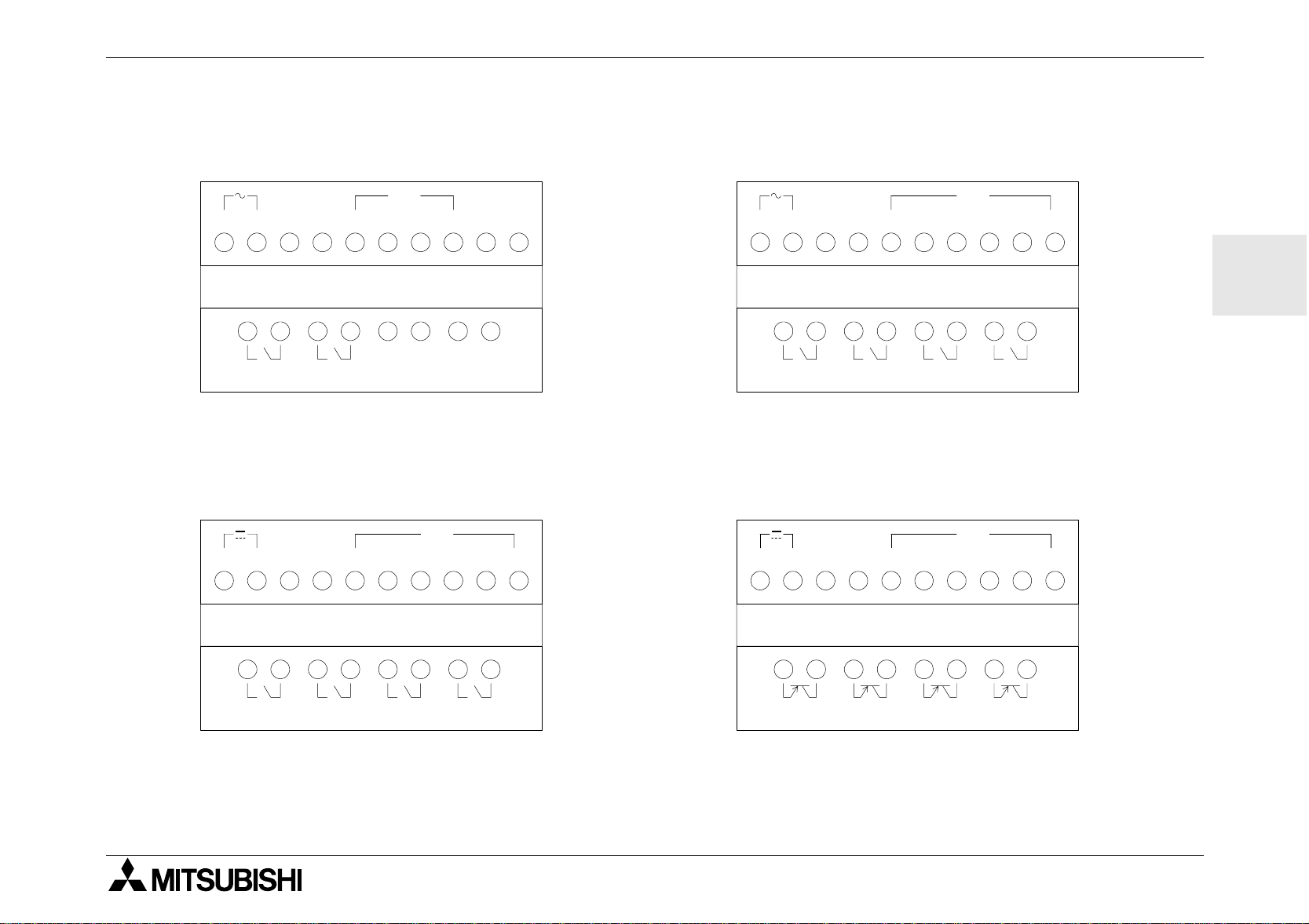

AL-6MR-A, AC Input, Relay Output AL-10MR-A, AC Input, Relay Output

IN

LN 1234

AL-6MR-A

OUT1

OUT2

AL-10MR-D, DC Input, Relay Output AL-10MT-D, DC Input, Transistor Output

IN

+−

(A) (B)

1234

56

ENG

AL-10MR-D

OUT1

OUT2

OUT3

OUT4

21

Page 28

ENG

α

Simple Application Controller

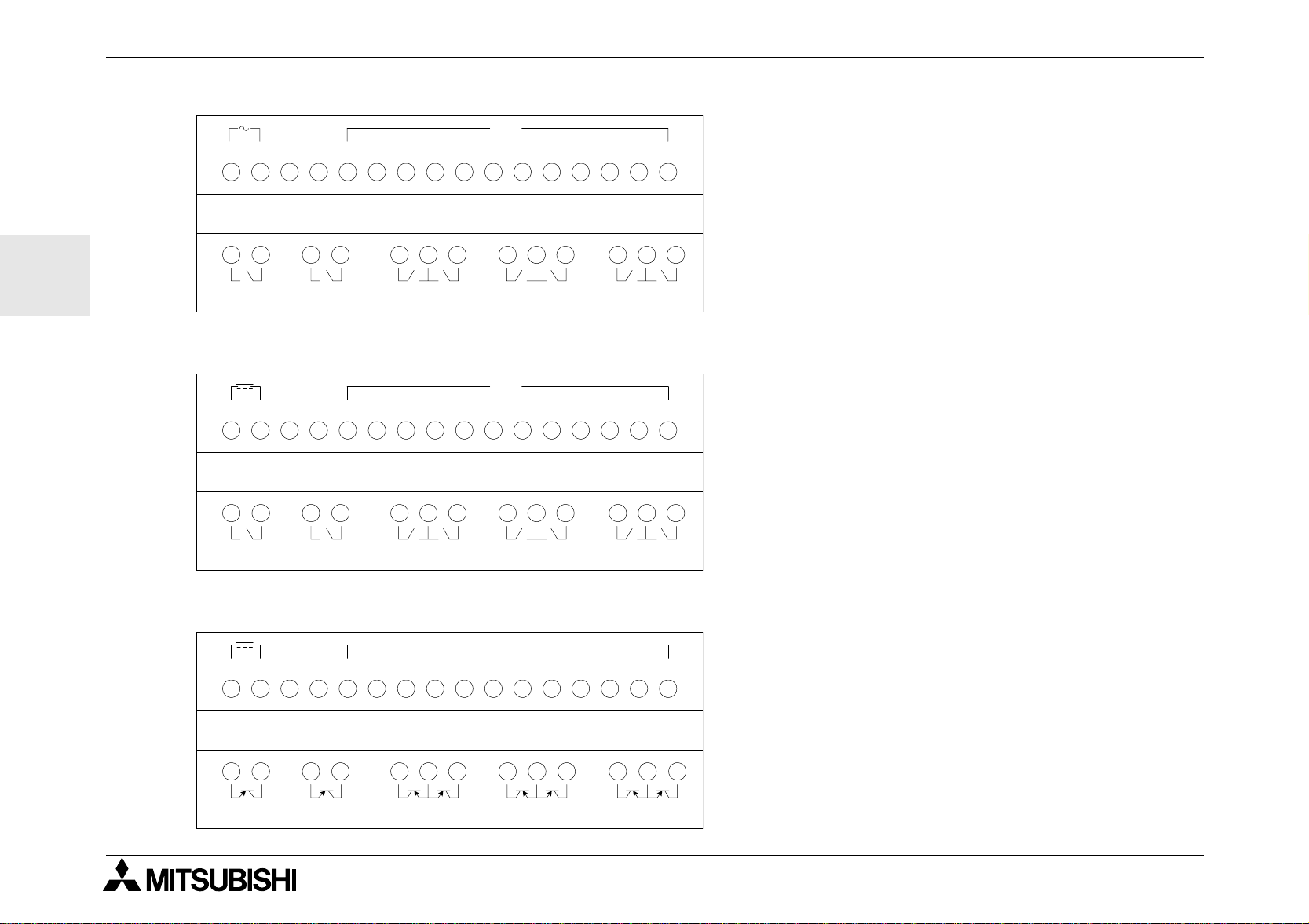

AL-20MR-A, AC Input, Relay Output

LN

AL-20MR-A

OUT1

OUT2 OUT3 OUT5 OUT7OUT4 OUT6 OUT8

AL-20MR-D, DC Input, Relay Output

-

+

AL-20MR-D

(A) (B)

IN

IN

Series Terminal Layout 5

αααα

121112345678910

121112345678910

OUT1

OUT2 OUT3 OUT5 OUT7OUT4 OUT6 OUT8

AL-20MT-D, DC Input, Transistor Output

IN

-

+

AL-20MT-D

OUT1 OUT2

(A) (B)

OUT3 OUT5 OUT7OUT4 OUT6 OUT8

121112345678910

22

Page 29

α

0 1

I n

0 1

A d d F B

O 0 1

C o n n e c t

Simple Application Controller

How to Use

Series Controllers - Getting Started 6

αααα

6. How to Use

Series controllers use Function Block Programming. In this style of programming, Function Blocks are con-

α

nected together to b uild a prog r am. Ther e are f iv e types o f b loc ks that can be pl aced in y our prog r am: Syst em

nputs, front panel Keys, System M bits, Function Block s, and System Outputs.

I

A screen showing the date, time, and image table (input and output status) will show when the controller is

turned On. Hit any key to proceed to the To p Menu. Enter the ProgEdit mode with the OK key to begin programming.

αααα

Series Controllers - Getting Started

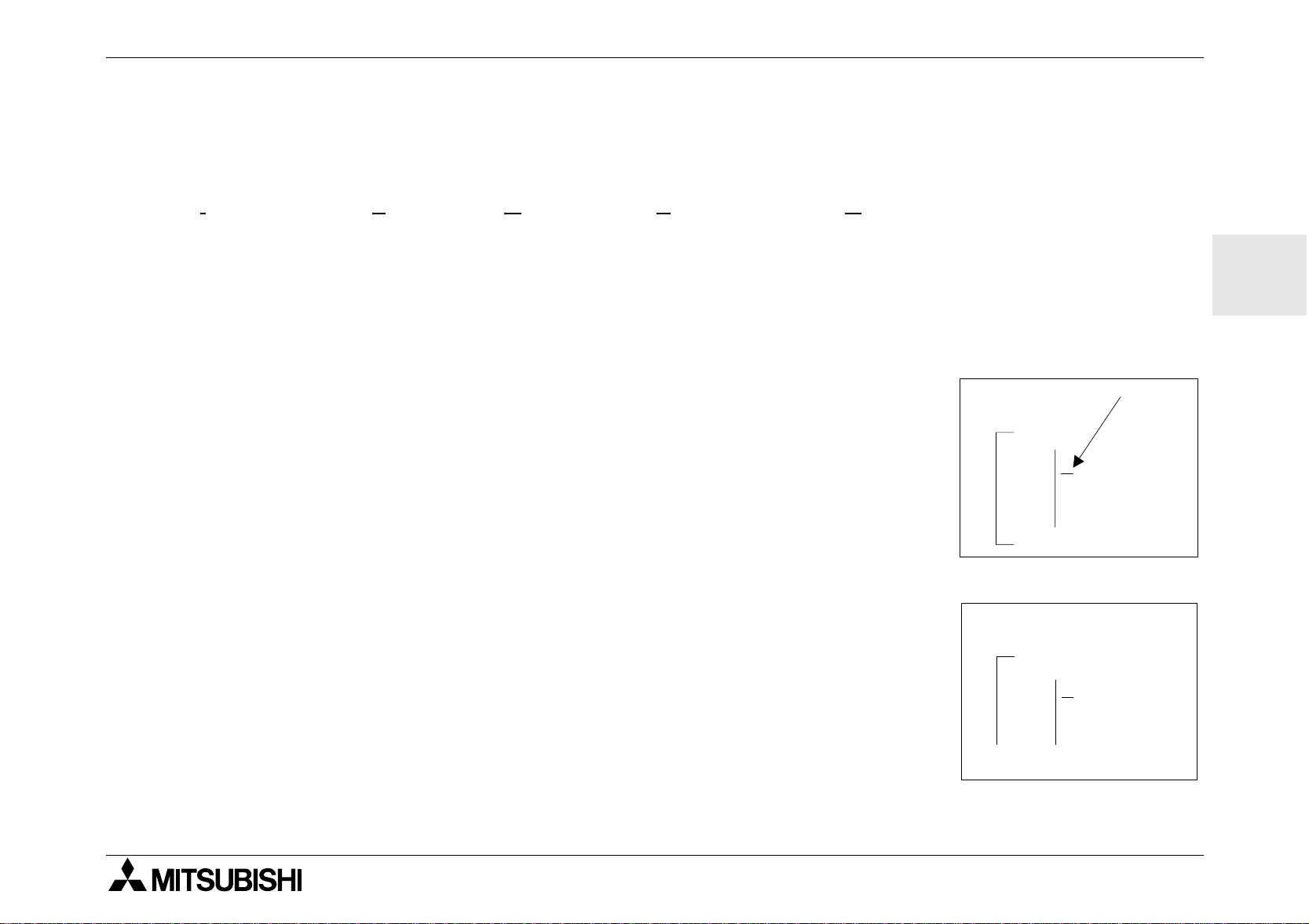

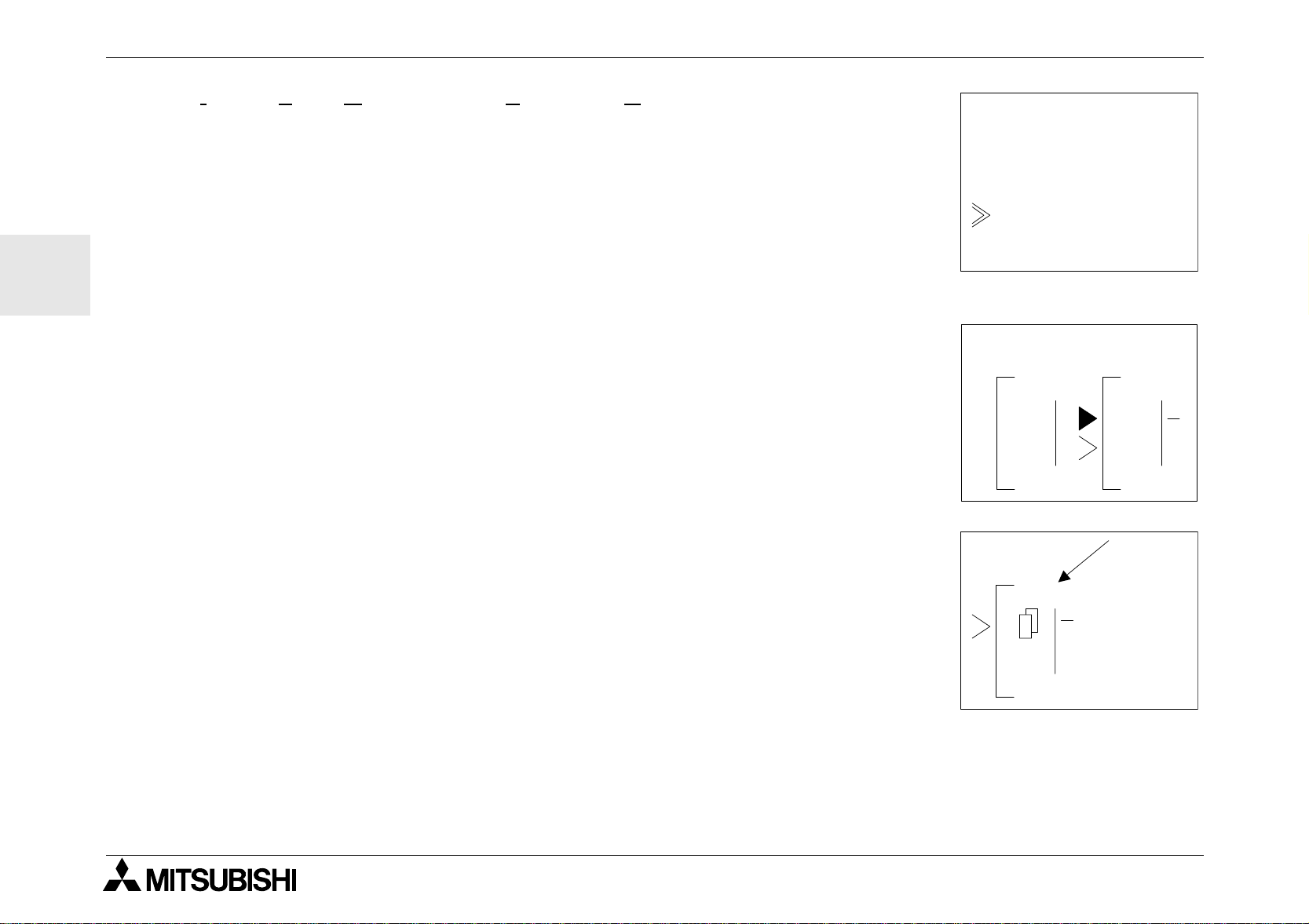

6.1 Connecting Two Blocks

Function Blocks (FB) are connected by joining an output pin to an unused input

pin. The arrow is pointing to the output pin. The out pu t pin is always shown on

the right side of the function blocks. Unused Input pins are shown as “>” while

used input pins show as a solid triangles. Press the right arrow button to move

the screen to the r ight until the output pin is flashing. U se the “+” key to connect or “add” a FB. The “-” key will disconnect two devices.

ENG

Press the “+” key. The FB options available for connection appear on the right

of the screen. Use the U p and Down arrows to move to the desired device to

add. The curren t cho ice will be blinking. A “Connect” prompt will app ear on the

top or bottom of the screen. Choose the desired connecting block with the OK

key

23

Page 30

ENG

Hourm eter

Pulse

F B S e l e c t

Tim e S W

AND

01 01

OUT

0 3

F L

α

Simple Application Controller

Inputs, Keys, M bits, Function Blocks, and Outputs will automatically show

whenever they can be connected. Function Blocks must be added durin g the

course of progr ammin g.

To add a new FB, select AddFB. The AddFB menu will show the list of twentytwo function blocks (see function block descriptions at the end of this chapter).

Choose the appropriate block with the OK key.

Choose an open (“>”) input pin and ent er OK. The “connect” p rompt should

disappear from the screen - the two function blocks are now connected!

Output pins can be connected to multiple input pins but input pins can have

only one connection.

How to Use

Series Controllers - Getting Started 6

αααα

6.2 Accessing Blocks

When the FB number is flashing, use the “+” and “-” keys to scroll through adjacently numbered blocks.

Ex. Input number 0 3 flashi ng on the d isplay. Pressing the “+” ke y will move the

screen to Input number 04. Inputs, Outputs, Keys, and Memory bits can be

accessed in this manner.

Function Blocks will perform the same operation but will scroll only through the

Function Blocks that have been added to the program.

24

Page 31

α

t = 0 . 0 s

O n T i m e

B 0 3 : F L

T = 0 . 0 s

E d i t M e n u

E x i t

P r o g S i z e

J u m p

N e w F B

M n e m o n i c

T o p M e n u

C l o c k S e t

R u n

P r o g E d i t

P r o g C l e a r

O t h e r s

. . .

L A N G U A G E

Simple Application Controller

6.3 Setting Function Block Parameters

Some Function Bloc ks ha ve parameters that ne ed to be set. Thes e parame ters

include Time (T), elapsed time (t), Set Repetitions (N), actual repetitions (n),

Set/Re set Priority a n d more.

Use the arrow keys to move to the FB. When the FB number is flashing, enter

OK twice to enter the FB Setup mode. Adjust the options to fit the program

requirements (refer to Key Operations Table 6.1). Enter all the necessary data

on each screen before using the OK button to accept.

Some FB have multipl e o pti on screens available. Use the ESC key to mo ve to a high er s c r ee n without saving

the contents to system memory. When finished entering data, use the ESC button to return to higher screen

levels until the main programming screen is shown again.

6.4 Exiting, Running, and Stopping the Program

Use the ESC button to ente r the Edit Menu (the ES C button might have to be

pressed more than once) and use the Exit option to leave ProgEdit.

How to Use

Series Controllers - Getting Started 6

αααα

ENG

Use the Run option to begin th e prog r am. Confi rm with OK. When the prog r am

is running the front screen is shown with the time, date, and image table.

Press any key to enter the Top Menu where the Stop option i s locate d. Enter

this option to Stop the program and confirm with OK.

Other options that can be selected include:

ClockSet - Set the Real Time Clock.

Language - Choose English, Japanese, German, French, Italian, or Spanish

25

Page 32

α

Simple Application Controller

ProgClear - Deletes everything in program memory, programs and data!

Others - Gives more Options for a Version Check, Password Protection, Summer Time Change Schedule,

Modem Initiali za tion, and Menu Key opera tion.

Table 6.1:Key Number and Basic Operation

How to Use

Series Controllers - Getting Started 6

αααα

ENG

Key

number

K01 OK: acceptance of data entry, menu options, program choices

K02 ESC: cancel current operation, move to higher screen or menu

K03 "+": connect function blocks, move to higher numbered blocks, increment values

K04 “-”: disconnect function blocks, move to lower numbered blocks, decrement values

K05 Up ( ): scroll to higher number numbered items (keys, FB, Inputs, Outputs, etc.)

K06

K07

K08

Table 6.2: Function Block Description

Function Block Byte Description

AND 19 Output On when all Inputs are On, Unused inputs considered On

Down ( ): scroll to lower numbered items (keys, FB, Inputs, Outputs, etc.)

Right ( ): move to the right on the LCD display, FB program or Jump command

Left ( ): move to the left on the LCD display, FB program or Jump command

Main Key Function

OR 19 Output On when at least one input On, Unused inputs considered Off

XOR 13 Exclusive OR; Output On when only One of Two Inputs is On

NAND 19 Not AND; Output Off only when all Inputs On, Unused inputs considered On

26

Page 33

α

Simple Application Controller

Table 6.2: Function Block Description

Function Block Byte Description

How to Use

Series Controllers - Getting Started 6

αααα

NOR 19

NOT 10 Inverts a signal; changes an Off to an On and vice versa

BOOLEAN * Logic equation using AND, OR, XOR, and NOT

SET/RESET 14 Latch a relay in SET or RESET position, give Set or Reset priority

DELAY 19 Delay a signal on the Rising, Falling, or both Edges

ONE SHOT 17 Send a single pulse; Time or Input signal based, Reset pin available

PULSE 10 Send a Pulse on the Rising, Falling, or both Edges

FLICKER 19 Send a pulse train; On/Off times, rep etitio ns , d ura tion, or conti nu ous ope ra tion

ALT 13 Output altern ates turning On or Off with each input pulse

COUNTER 16 Count upwards on pu lses, can reset at an input value or sig nal

U/D COUNTER 22 Up and Down Counter with Preset Input and Clear functions

COMPARE 17 Compare two values for <,>,=,<=,>=,<> (Analog, Direct Set, or FB values)

TIME SWITCH * Use the RTC to turn output On/Off; Calendar or weekly schedule

OFFSET GAIN 22 Manipulate Analog Values; y = A/B*x + C; Set High and Low Limit Values

Not OR; Output Off when at least one Input is On, Unused inputs considered

Off

ENG

DISPLAY * Display Messages or Data on the LCD display

ZONE COMPARE 20 Compare a value to a range of values (Analog, Direct Set, or FB values)

SCHMITT TRIGGER 19 Turn an Input On at the High Value and Off at the Low Value (or vice versa)

HOUR METER 19 Records the accumulated time an Output or Input signal has been ON

System Outputs 10 Controls External Devices through Relays and Transistors.

*Number of bytes varies with input data.

27

Page 34

ENG

α

Simple Application Controller

How to Use

Series Controllers - Getting Started 6

αααα

28

Page 35

HARDWARE-HANDBUCH

GER

α

-

Steuerung

Page 36

GER

α

-Steuerung

Vorwort

• Dieses Handbuc h enhält Texte, Abbildungen und Erläuterungen zur korrekten Installation und Bedienung

• Wenn während der Installation Fragen auftreten, ziehen Sie auf jeden Fall eine Elektrofachkraft zu Rate,

• Dieses Handbuch wird vorbehaltlich etwaiger Änderungen herausgegeben. Änderungen könn en ohne

der α-Steuerung. Vor der Installation und dem Einsatz des Gerätes muß dieses Handbuch gelesen

werden. Die Inhalte müssen verstanden sein.

die mit den lokalen und nationalen elektrotechnischen Bestimmungen vertraut ist. Setzen Sie sich mit dem

nächstliegenden Händler von MITSUBISHI ELECTRIC in Verbindung, wenn Sie Unterstützung bei der

Bedienung oder Anwendung der

Hinweis vorgenommen werden.

-Steuerung benötigen.

α

Page 37

α

-Steuerung

α

α

αα

Hardware-Handbuch

-Steuerung

GER

Nummer : JY992D74201

Revision : J

Datum :04/2002

i

Page 38

α

-Steuerung

GER

Sicherheitsrichtlinien für den Anwender und Schutzmaßnahmen für die

• Dieses Handbuch wurde für geschultes und kompetentes Personal erstellt. Die Qualifizierung wird durch die

europäischen Richtlinien für Maschinen, Niederspannungen und EMV definiert. Die Verdrahtungsarbeiten an

der

nischen Bestimmungen vert raut ist, durchgeführt werden. In diesem Handbuch werden zur Hervorhebung

von bestimmten Informationen verschiedene Symbole verwendet. Hiermit erhält das Bedienpersonal alle notwendigen Hinweise zu den Sicherheits- und Schutzmaßnahmen. Bei jedem Auftreten der Symbole muß der

zugehörige Hinweis gelesen werden. Die angegebene Information muß verstanden sein.

-Steuerung dürfen nur von einer Elektrofachkraft, die mit den lokalen und nationalen elektrotech-

α

1) Bezeichnet eine unmittelbar drohende Gefahr, die zu einem Personen- oder

Sachschaden führen kann.

2) Bezeichnet eine möglicherweise auftretende Gefahr, die zu einem Personen- oder

Sachschaden führen kann.

αααα

-Steuerung

• MITSUBISHI ELECTRIC übernimmt unter keinen Umständen die Haftung oder Verantwortung für einen Schaden, der aus einer

unsachgemäßen Installation oder Anwendung der Geräte oder des Zubehörs entstanden ist.

• Alle Beispiele und Abbildungen in diesem Handbuch dienen nur als Hilfe zum Verstehen des Textes. Für die Richtigkeit der

dargestellten Bedienvorgänge kann keine Gewährleistung übernommen werden. MITSUBISHI ELECTRIC über nimmt keine Verantwortung für eine Produktanwendung, die sich auf die dargestellten Beispiele bezieht.

• Aufgrund der großen Anzahl von verschiedenen Anwendungsmöglichkeiten dieser Geräte müssen Sie die Anpassung für Ihren

speziellen Anwendungsfall selbst vornehmen.

• Wenn die Steuerung ausfallen sollte, müssen entsprechende Sicherheitseinrichtungen dafür sorgen, daß die angeschlossene

Peripherie angehalten wird.

• Versuchen Sie niemals die α -Steuerung zu reparieren oder elektrische Teile auszutauschen.

• Beachten Sie bei der Installation und dem Einsatz der α -Steuerung die lokalen und nationalen Normen.

ii

Page 39

α

-Steuerung

Inhaltsverzeichnis

Sicherheitsrichtlinien................................................................................................................. ii

1. Einleitung............................................................................................................... 1

2. Technische Daten.................................................................................................. 3

2.1 Verfügbare Modelle...................................................................................................... 3

2.2 Spannungsversorgung................................................................................................. 4

2.3 Eingänge...................................................................................................................... 6

2.4 Ausgänge .................................................................................................................... 8

2.5 Umgebungsbedingungen............................................................................................. 9

3. Installation............................................................................................................11

3.1 DIN-Schienen-Montage ............................................................................................. 11

GER

3.2 Schraubklemmenanschluß ........................................................................................ 11

3.3 Installationshinweise.................................................................................................. 12

iii

Page 40

α

-Steuerung

4. Verdrahtung.........................................................................................................15

4.1 Hinweise zur Installationsverdrahtung....................................................................... 15

4.2 Kabelgröße und Spezifikation en................................................................................ 15

4.3 Spannungsversorgung............................................................................................... 16

4.4 Empfohlene Verdra htung der Spannungsversorgung................................................ 16

4.5 Verdrahtung der AC-Eingänge................................................................................... 17

4.5.1 Verdrahtung der AC-Eingänge............................................................................ 17

4.6 Verdrahtung der Sink-/Source-Eingänge................................................................... 18

4.6.1 Source-Eingangsverdrahtung (plusschaltend) .................................................... 18

GER

4.6.2 Sink-Eingangsverdrahtung (minusschaltend)...................................................... 18

4.7 Relais-/Transistor-Ausgangsverdrahtung .................................................................. 19

4.7.1 Relais-Ausgangsverdrahtung (AC und/oder DC) ................................................ 19

4.7.2 Transistor-Ausgangsverdrahtung (nur Source - plusschaltend).......................... 20

5. Klemmenbelegungen..........................................................................................21

6. Einstieg in die Programmierung........................................................................23

6.1 Verbinden von zwei Blöcken......................................................................................23

6.2 Bearbeitung von Blöcken .......................................................................................... 24

6.3 Einstellung der Funktionsblockparameter.................................................................. 25

6.4 Verlassen, Starten und Stoppen des Programms.......................................... ............ 26

iv

Page 41

α-Steuerung

1. Einleitung

Die α-Steuerung ist ausgesprochen einfach zu bedienen und prädestinier t für alle möglichen Schalt-,

Steuerungs- und Überwachungsaufgaben rund um Ihr Haus, Ihr Büro, Ihre Fabrik, ... eigentlich überall.

Mit jedem Modul können Sie Signa le lesen und Ausgänge setzen, und zwar genau nach den Bedin gungen

und Zeitvo rga ben, d ie Sie festgel egt ha be n. Natürlich k önnen Sie den aktuellen Zustand des Systems auf der

Anzeige jederzeit ablesen.

Einleitung 1

Besonderheiten der

• Programmierung direkt am Gerät

• Hohe Ausgangsstromschaltle istung

• Kleine Abmessungen

• Programmierschnittstelle direkt auf dem Gerät

• EEPROM-Kassetten für die Programmspeicherung

• Integrierte Echtzeituhr als Standard

• Windows-Programmiersoftware AL-PCS/WIN-E

• Ausführliche Dokumentation und Lernpakete

Die

Bewässerung, Türen, Tore, einfache Alarmanlagen, Gewächshäuser, Belüftungsanlagen usw. Die integrier te

Echtzeituhr kann als stromsparende Komponente verwendet werden, da sie die Anlage zu vorher festgelegten Zeiten ein- und ausschalten kann.

-Steuerung ist für die folgenden automatischen Anwendungen konstruiert: Beleuchtung, Klimaanlagen,

α

-Steuerung:

α

GER

Testen Sie die Programme sorgfältig, bevor Sie sie in automatisierten Einr ichtungen installieren. Die

-Steuerung wurde nicht für lebenserhaltende oder selbstüberwachende Anwendungen entwickelt.

α

Bitte wenden Sie sich an Ihren Händler, dort erhalten Sie detaillierte Informationen zu diesem Produkt.

1

Page 42

GER

α

-Steuerung

Einleitung 1

2

Page 43

α-Steuerung

2. Technische Daten

2.1 Verfügbare Modelle

Tabelle 2.1: Typenbeschreibung

Technische Daten 2

Modell

AL-6MR-A

AL-10MR-A 6 RELAIS 4

AL-10MR-D

AL-10MT-D 6 TRANSISTOR 4

AL-20MR-A

AL-20MR-D

AL-20MT-D 12 TRANSISTOR 8

*Ohne Sonderfunktionsmodule.

Spannungs-

versorgung

100 - 240 V

AC~

24 V DC

100 - 240 V

AC~

24 V DC

100 - 240 V

Sink/Source

100 - 240 V

Sink/Source

Eingänge Ausgänge Abmessungen Gewicht

Typ Anzahl Typ Anzahl mm kg

4 RELAIS 2

AC~

24 V DC

AC~

24 V DC

6 RELAIS 4

12 RELAIS 8

12 RELAIS 8

71,2 x 90 x 55 0,2

GER

124,6 x 90 x 55 0,32*

3

Page 44

α

-Steuerung

2.2 Spannungsversorgung

Tabelle 2.2: Spannungsversorgung

Beschreibung Modell Technische Daten

Spannungsversorgung

Technische Daten 2

AL -***-A 100 - 240V AC~, +10% -15%, 50 - 60 Hz

AL-***-D 24 V DC, +20% -15%

GER

max. zulässige

Spannungsausfallzeit

Stromspitzenwerte

Max. Leistungsauf nahme

(ohne Sonderfunktionsmodule)

AL-***-A 10 ms

AL-***-D 5 ms

240 V AC~ (120 V AC~) <

24 V DC <

AL-6MR-A, 264 V AC~ 3,0 W

AL-10MR-A, 264 V AC~ 4,0 W

AL-10MR-D, 28,8 V DC 3,0 W

AL-10MT-D , 28,8 V DC 2,0 W

AL-10MR-A, 264 V AC~ 8,0 W

AL-20MR-D, 28,8 V DC 7,0 W

AL-20MT-D , 28,8 V DC 5,0 W

1,5 A (0,7 A)

7,0 A

4

Page 45

α-Steuerung

Tabelle 2.2: Spannungsversorgung

Beschreibung Modell Technische Daten

Technische Daten 2

AL-6MR-A, 240 V A C~ Alle E/A ein - 2,5 W, alle E/A aus - 1,5 W

AL-6MR-A, 120 V A C~ Alle E/A ein - 2,0 W, alle E/A aus - 1,2 W

AL-10MR-A, 240 V AC~ Alle E/A ein - 3,0 W, alle E/A aus - 1,5 W

AL-10MR-A, 120 V AC~ Alle E/A ein - 2,5 W, alle E/A aus - 1,2 W

Typ. Lei stungsaufnahme

(ohne Sonderfunktionsmodule)

AL-10MR-D, 24 V DC Alle E/A ein - 2,0 W, alle E/A aus - 0,3 W

AL-10MT-D , 24 V DC Alle E/A ein - 2,0 W, alle E/A aus - 0,3 W

AL-20MR-A, 240 V AC~ Alle E/A ein - 5,0 W, alle E/A aus - 1,5 W

AL-20MR-A, 120 V AC~ Alle E/A ein - 4,0 W, alle E/A aus - 1,2 W

AL-20MR-D, 24 V DC Alle E/A ein - 5,0 W, alle E/A aus - 0,3 W

AL-20MT-D , 24 V DC Alle E/A ein - 5,0 W, alle E/A aus - 0,3 W

GER

5

Page 46

α

-Steuerung

2.3 Eingänge

Tabelle 2.3: Technische Daten der AC-Eingänge

Beschreibung Technische Daten

Eingangsspannung 100-240 V AC~, +10% -15%, 50 - 60 Hz

Eingangsstrom 0,24mA / 240V AC~, Siehe Hinweis 1*

Technische Daten 2

GER

Eingangsimpedanz >

AUS->EIN/EIN->AUS 80 V / 40 V

Ansprechzeit ~ 50 ms

Schaltkreisisolation keine

Betriebsanzeige LCD-Anzeige

Tabelle 2.4: Technische Daten der DC-Eingänge

Beschreibung Sink (“-” Common) Source (“+ ” Common )

Eingangssp annung 24 V DC +20% -15% 24 V DC +20% -15%

Eingangsstrom 5,0 mA / 24V DC 5, 0 mA / 24V DC

AUS->EIN/EIN->AUS

Ansprechzeit (I01 - I08) 10 - 20 ms 10 - 20 ms

Ansprechzeit (I09 - I12) 20 - 40 ms 20 - 40 ms

Schaltkreisisolation keine keine

800 kOhm

Strom: >

Spannung: <

4,3mA / < 1,1 mA

4 V / > 18 V

Spannung: > 18V / < 4V

Betriebsanzeige LCD-Anzeige

*Hinweis 1: St romableitunge n von den an die Ei ngäng e angeschl ossenen S ensoren k önnten genug Strom

liefern, um die Steuerung einzuschalten. Keine Zweileiter-Sensoren verwenden.

6

Page 47

α-Steuerung

Tabelle 2.5: Technische Daten der Analogeingänge

Beschreibung Technische Daten

AL-10M*-D 6 Kanäle: I01 - I06

AL-20M*-D 8 Kanäle: I01 - I08

Technische Daten 2

Analogeingangsbereich

Auflösung 10000/250 mv

Wandler-

geschwindigkeit

Eingangsspannung 0 - 10 V DC

Eingangsimpedanz 150 kOhm oder höher

Genauigkeit +/- 5% (0,5 V DC)

Offset/Gain

Temperaturabweichung

0 - 250

10 ms

Offset-Wert = 0 bei 0 V DC

Gain-Wert: 0 - 10V = 0 - 250

Diese voreingestellten Werte können im Funktionsblock

Offset geänder t werden.

+/- 3 LSB

GER

7

Page 48

α

-Steuerung

2.4 Ausgänge

Tabelle 2.6: Technische Daten der Relais-Ausgänge

Beschreibung Technische Daten

Einschalts pannung 250 V AC~ oder weniger, 30 V DC oder weniger

Technische Daten 2

GER

Max. Widerstandslast

Lebenszyklus / ohmsche Last

Minimale Last 50 mW (10 mA bei 5 V DC)

Max. induktive Last 245 VA (1/3 hp) / 125 VAC~, 367 VA (1/2 hp) / 250 VAC~

Ansprechzeit

Betriebsanzeige LCD-Anzeige

Schaltkreisisolation über Relais

Tabelle 2.7: Technische Daten der Transistor-Ausgänge (nur Source-Typ)

Beschreibung Technische Daten

Einschalts pannung 5 - 24 V DC

Max. Widerstandslast

Minimale Last 1,0 mA

Max. induktive Last 1 A / 24 V DC (24 W)

8A / gemeinsam (10A / gemeinsam fur Ausgänge 110V AC~

)

100000 Zyklen bei 8 A / 240 V AC~ oder 24 V DC

30000 Zyklen bei 10 A / 110 V AC~

10 ms oder weniger

1A / Klemme (8 - 24 V DC),

0,1A / Klemme (5 - 8V DC)

Max. Lampenlast 0,125 A / 24 V DC (3,0 W)

Ansprechzeit Ein/Aus, Aus/Ein (circa) <

Leckstrom <

Betriebsanzeige LCD-Anzeige

Schaltkreisisolation keine

1 ms

0,1 mA / 24 V DC

8

Page 49

α-Steuerung

2.5 Umgebungsbedingungen

Tabelle 2.8: Umgebungsbedingungen

Beschreibung Technische Daten

Programmiermethode Funktionsblock-Methode

Programmkapazität 64 Funktionsblöcke oder 1500 Bytes

Programmspeicherung EEPROM (keine Batterie erforderlich) oder optionale EEPROM-Kassette

Technische Daten 2

Operandensicherung,

Echtzeituhr-Backup

Genauigkeit Echtzeituhr 5 s/Tag

Betriebstemperatur 0 - 55 °C

Lagertemperatur (-30) - 70 °C

Vibrationsfestigkeit

Direkte Montage

Vibrationsfestigkeit

DIN-Schienen-Montage

Stoßfestigkeit

Störspannungsfestigkeit 1000Vpp, 1 Mikrosek., 30 - 100 Hz, getestet mit Störspannungssimulator

Luftfeuchtigkeit 35 - 85% Relative Luftfeuchtigkeit, keine Kondensation

Spannungsfestigkeit

20 Tage bei 25°C (Kondensator)

entspricht IEC 68-2-6; 10-57 Hz: 0,15 mm Konstante Amplitude

57-150 Hz: 19,6 m/s

Ablenkzyklus X,Y,Z: 10 x (80 min. in alle 3 Richtungen)

entsprich t IEC 68-2-6; 10-57 Hz: 0,075 mm Konstante Amplitude

57-150 Hz: 9,8 m/s

Ablenkzyklus für X,Y,Z: 10 x (80 min. in alle 3 Richtungen)

entsprich t IEC 68-2-27: 147m/s

3 x in alle 3 Richtungen X,Y und Z

3750 V AC > 1 min nach EN60730-1 zwischen den folgenden Klemmen:

Spannungs-/Eingangsklemmen und Relais-Ausgangsklemmen

Relais-Ausgangsklemme und Relais-Ausgangsklemme

Alle Klemmen und der Steuerkasten (DIN 43880) oder ähnliches

2

Beschleunigung

2

Beschleunigung

2

Beschleunigung, Aktionszeit: 11 ms

GER

9

Page 50

GER

α

-Steuerung

Tabelle 2.8: Umgebungsbedingungen

Isolationswiderstand

Wirkungsweise Table 2.9:EN 60730-1, Abschnitt 6.4.3 - Typ 1C (Relais-Ausgänge)

Wirkungsweise EN 60730-1, Abschnitt 6.4.3 - Typ 1T (Transistor-Ausgänge)

Software-Klasse EN 60730-1, Abschnitt H6.18 - Klasse A

Konstruktionsart EN 60730-1, Abschnitt 6.15 - eingebautes Gerät

Konstruktionsart (elektronisch) EN 60730-1, Abschnitt H2.5.7 - elektronisches Gerät

Technische Daten 2

Beschreibung Technische Daten

7 MOhm at 500V DC nach EN60730-1 zwischen den folgenden Klemmen:

Spannungs-/Eingangsklemmen und Relais-Ausgangsklemmen

Relais-Ausgangsklemme und Relais-Ausgangsklemme

Alle Klemmen und der Steuerkasten (DIN 43880) oder ähnliches

Sicherheitsklasse

Verschmutzungsgrad normale Umgebungsbedingungen

Erdung keine

Elektrische Isolation Verstärkte Primär- und Sekundärisolation

Umgebungsbedingungen Umgebungen mit aggressiven Gasen meiden, staubfrei aufstellen

Schutzklasse IP 20

Zertifizierungen CE, UL/cUL

Kornformitätsbescheinigung TÜV (AL-10MT-D, AL-10MR-D)

Tests

LCD-Anzeige

II

UL 508

EN60730-1

EN61010-1

EN50081-1

EN50082-1

EN61000-6-2

4 Zeilen mit je 10 Zeichen, Run-Modus, Passwortschutz, Statustabelle und

Funktionsblock-Übersicht während der Programmierung

10

Page 51

α-Steuerung

3. Installation

Installation 3

Tabelle 3.1: Gerätebeschrei bung

7

5

6

2

LN

POWER

AC 100-240V

OUT

1

3

~

1 2 3 4 5 6 7 8 9 10 11 12

4

Nr. Beschreibung

IN

1 DIN-Schienen-Montagekl emmen

2 Montagebohrung, Durchm. 4,2 mm

AC INPUT

ESC

3 Spannungsklemmen

4 Eingangsklemmen

5 LCD-Anzeige

GER

6 Bedientasten

OUT

OK

AL-20MR-A

RELAY OUTPUT

OUT

OUT

2

3

OUT

4

5

OUT

6

OUT

OUT

8

7

1

7 Ausgangsk l e mmen

3.1 DIN-Schienen-Montage

Die Geräte können auf einer DIN-Schiene 35 mm

(DIN EN 50022) montiert werden. Zur Demontage

des Gerätes heben Sie d i e Schnellbefestigung mit

einem Schraubendreher ab, und nehmen Sie das

Gerät von der Schiene.

3.2 Schraubklemmenanschluß

Für den Kabe lanschluß sind an der α-Steueru ng

Schraubklemmen vorgesehen.

11

Page 52

α

-Steuerung

3.3 Installationshinweise

Installation 3

GER

Die α-Steuerung ist so konzipiert, daß

sie nahezu überall eingesetzt werden

kann.

Die Geräte dürfen den folgenden

Umgebungsbedingungen jedoch nicht

ausgesetzt werden: Umgebungen mit

einem hohen Grad an leitfähigen

Stäuben, Korrosion, entzündbaren

Gasen, Nebel, Rege n, direkte Sonnenbestrahlung, große Hitze, starke

Schockwellen und Vibrationen. Stellen

Sie das Gerät nicht ins Wasser, und

achten Sie darauf, daß kein Wasser in

das Gerät dringt. Achten Sie da rauf,

daß keine Fremdkörper in das Gerät

gelangen.

Montieren Sie das Gerät möglichst weit

entfernt von Hochspannungskabeln und

Stromgeräten.

4,0

90,0

10,0*

All units in mm

6,0

POWER

AC 100/240V

AC INPUT

RELAY OUTPUT

OUT3 OUT4OUT2OUT1

71,2

IN

34215L6N

6,0

10,0*

ESC

+

-

OK

4,0

55,0

Die

-Steuerung kann in einen Schaltschrank nach DIN 43880 oder einen Steuerkasten eingebaut werden

α

Verwenden Sie bei der Montage immer M4-Schrauben.

Die Verbindungen müssen abgedeckt werden, um Stromberührung zu vermeiden.

* Lassen Sie einen Minimalabstand von 10 mm zur Lüftung zwischen Ober- und Unterrand der

und den umgebenden Wänden.

12

-Steuerung

α

Page 53

α-Steuerung

-Steuerung nicht demontieren. Hinweise, die beim Austausch der Speicherkassette zu beachten sind, fin-

α

den Sie im Handbuch Speicherkassette.

Installation 3

4.0(0.16")

90.0(3.54")

10(0.39")*

6.0(0.24")

~

LN

POWER

AC 100-240V

OUT

OUT

1

1 2 3 4 5 6 7 8 9 10 11 12

OUT

2

3

IN

AC INPUT

ESC

OK

AL-20MR-A

RELAY OUTPUT

OUT

4

124.6(4.91")

10(0.39")*

GER

4.0(0.16")

OUT

5

OUT

6

6.0(0.24")

OUT

8

OUT

7

55.0(2.17")

13

Page 54

GER

α

-Steuerung

Installation 3

14

Page 55

α-Steuerung

7mm ± 0,5mm

26 -12 AWG

4. Verdrahtung

4.1 Hinweise zur Installationsverdrahtung

Tie Verdrahtung der α-Steuerung ist denkba r einfach. Nur speziell ausgebildetes Personal darf die elektrische Verdrahtung der Geräte vornehmen. Sollten Sie spezialisierte Unterstützung brauchen, wenden Sie

sich an eine anerkannt ausgebildete Elektrofachkraft, die mit den lokalen und nationalen Sicherheitsstandards der Automatisierungstechnik vertraut ist. Stromversorgung abschalten, bevor Sie mit der Verdrahtung

beginnen.

• Die Ein- und Ausgangskabel dürfen nicht durch das gleiche Multikernkabel oder den gleichen Kabel-

baum verlegt werden.

Verdrahtung 4

4.2 Kabelgröße und Spezifikationen

• Die Ein- und Ausgangskabel dürfen nicht in der Nähe von Hoc hs pa nnungsleitungen verlegt werden.

Berücksichtigen Sie Spannungsabfälle und Stör ungen, wenn die Einga ngs- und Ausgangssignalkabel über

große Entfernungen geführt werden. Stel len Sie sicher, daß für die Kabel die r ichtige n Kabelgrößen verwendet werden.

Verwenden Sie für die Eingänge und Ausgänge Kabel mit einem Aderquerschnitt von 0,13 mm

Kabelenden auf eine Länge von 7 ± 0,5 mm. Öffnen Sie die

Schraubklemme, bevor Sie ein Kabel einstecken. Stecken Sie das Kabelende komplett in die Schraubklemme, damit eine störu ngsfreie Verbindung gewährleistet ist. Ziehen Sie die Schraubklemme wieder so fest an,

daß das Kabel nicht herausgezogen werden kann. Damit das Kabel nicht

beschädigt wird, darf das Anzugsmoment von 0,5 N⋅m nicht überschritten

werden. Verwenden Sie weder Zinn noch Lötmetall oder ähnliche Substanzen auf dem isolierten Kabelende,

dadurch kann das Kabel beschädigt werden.

Für die Senkkopfschrauben der Klemmen einen 3mm Schraubendreher verwenden.

2

- 3,31 mm2 (26-12 AWG). Isolieren Sie die

GER

15

Page 56

GER

α

-Steuerung

4.3 Spannungsversorgung

Beim Anschluß einer Wechselspannung (AC) muß der L-Leiter an die L-Klemme und der N-Leiter an die NKlemme angeschlossen werden. Der L-Leiter darf niemals mit dem N-Leiter verbunden werden, dies könnte

für den Benutzer beim Einschalten des Gerätes zu einem gefährlichen Schock führen.

Beim Anschluß einer Gleichspannung (DC) muß der positive Leiter an die (+)-Klemme und der negative

Leiter an die (-)-Klemme angeschlossen werden. Der Anschluß der Spannungsversorgung darf auf keinen

F all an einer anderen Klemme des Gerätes erfolgen. Gleichstromversorgungseinheiten sollten die Steuerung

mit 4A versorgen können.

4.4 Empfohlene Verdrahtung der Spannungsversorgung

Verdrahtung 4

+

−

L

N

LN

'

+−

!"

MC

%

MC

MC

#

Start

$

(

MC

Die Klemmen L und N

duerfen nicht v ert aus c h t

werden.

&

Tabelle 4.1:

Nr. Beschreibung

Spannungsversorgung:

1

2 Schaltkreis-Schutzgerät

3 NOT-AUS-Schalter

4 Anzeige für Spannung EIN

5 Überlastschutz max. Strom: 1,0 A

6 Spannungsversorgung für AC-Last

7 Magnetschalterkontakt

8

AC~: 10 0-240 V

50-60 Hz

DC: 24 V

α

Spannung

-Steuerung

sversorgung

16

Page 57

α-Steuerung

4.5 Verdrahtung der AC-Eingänge

4.5.1 Verdrahtung der AC-Eingänge

Verdrahtung 4

!

LN

Die Klemmen L und N duerfen

nicht vertauscht werden.

&

LN 123

#

"

INPUTS

$

%

456

Tabelle 4.2: AC-Eingänge

Nr. Beschreibung

Spannungsversorgung:

1

2 AC-Spannungsklemmen

3 Nicht verwendete Klemmen

4 Eingan gsklemmen

5 Digitaleingänge

6 Überlastschutz max. Strom: 1,0 A

100 - 240 V AC~

50 - 60 Hz

GER

17

Page 58

α

-Steuerung

4.6 Verdrahtung der Sink-/Source-Eingänge

4.6.1 Source-Eingangsverdrahtung (plusschalt end)

!

+−

Verdrahtung 4

Tabelle 4.3: Sink-/Source-Eingänge

Nr. Beschreibung

GER

%

(

+−

"

(A) (B)

#

123

INPUTS

456

$

4.6.2 Sink-Eingangsverdrahtung (minusschalt end)

!

+−

%

(

&

1

2 DC-Spannungsklemmen

3 Sink-/Source-Eingangsklemmen

4 Eingan gsklemmen

5 Sensor-Eingangsklemmen

6 Analogeingang

7 Überlastschutz max. Strom: 1,0 A

DC-Spannungsversorgung:

24 V DC

+−

(A) (B) 1 2 3

"#

INPUTS

$

456

18

Page 59

α-Steuerung

4.7 Relais-/Transistor-Ausgangsverdrahtung

4.7.1 Relais-Ausgangsverdrahtung (AC und/oder DC)

"!

OUT1

OUT2 OUT3 OUT4

Verdrahtung 4

Table 4.4: Relais-Ausgänge

Nr. Beschreibung

&

%

$

1

2

%

-Steuerung

α

Sich gegenseitig

ausschließende Ausgänge

3 Ausgangsgeräte

+

##

$

(

4

Sicherung:

10 A für jeweils 4 Ausgangsklemmen zum Schutz des SPS-

GER

Ausgangsschaltkreises.

5 NOT-AUS-Schalter

6 DC-Spannung

7 AC-Spannung

19

Page 60

α

-Steuerung

4.7.2 Transistor-Ausgangsverdrahtung (nur Source - plusschaltend)

+−

'

Verdrahtung 4

Tabelle 4.5: Transistor-Ausgänge

Nr. Beschreibung

GER

%

&

1

-Steuerung

α

2 Ausgangsklemmen

)

(

+−

OUT1

!

"

OUT2 OUT3 OUT4

3 Ausgangsgeräte

Schaltkreis-Schutzgerät

4

(siehe Tabelle 4.6)

5 NOT-AUS-Schalter

DC-Spannungsversorgung

6

für Ausgänge

7 Spannungsklemmen

8 DC-Spannung 24 V DC

%

&

$

+

Tabelle 4.6: Schaltkreis-Schutz für

#

SchaltkreisSpannung

$

+

#

#

Überlastschutz max. Strom: 1,0 A

9

Transistor-Ausgänge

Schaltkreis-Schutz

(Sicherung)

5 Vo lt < 0,3 A (Schaltkreis)

12 Volt <

2,0 A (Schaltkreis)

24 Volt <

Volt Hinweise zur Ausgangsklemme

2,0 A (Schaltkreis)

5 Alle Ausgangsklemmen können in einem Schaltkreis verdrahtet werden.

12-24 Alle Ausgangsklemmen können in einem Schaltkreis verdrahtet werden.

5,12,24 Für jeden der drei Spannungsbereiche muß ein separater Schaltkreis realisiert werden.

20

Page 61

α-Steuerung

LN 1234

OUT1

AL-10MR-A

OUT2

IN

56

OUT3

OUT4

+−

(B)

1234

OUT1

AL-10MT-D

OUT2

IN

56

OUT3 OUT4

(A)

5. Klemmenbelegungen

AL-6MR-A, AC-Eingang, Relais-Ausgang AL-10MR-A, AC-Eingang, Relais-Ausgang

IN

LN 1234

AL-6MR-A

Klemmenbelegungen 5

OUT1

AL-10MR-D, DC-Eingang, Relais-Ausgang AL-10MT-D, DC-Eingang, Transistor-Ausgang

+−

AL-10MR-D

OUT1

OUT2

(A) (B)

OUT2

IN

1234

OUT3

OUT4

GER

56

21

Page 62

α

-Steuerung

AL-20MR-A, AC-Eingang, Relais-Ausgang

LN

AL-20MR-A

Klemmenbelegungen 5

IN

121112345678910

GER

OUT1

OUT2 OUT3 OUT5 OUT7OUT4 OUT6 OUT8

AL-20MR-D, DC-Eingang, Relais-Ausgang

IN

-

+

AL-20MR-D

OUT1

(A) (B)

OUT2 OUT3 OUT5 OUT7OUT4 OUT6 OUT8

AL-20MT-D, DC-Eingang, Transistor-Ausgang

IN

-

+

AL-20MT-D

(A) (B)

121112345678910

121112345678910

OUT1 OUT2

OUT3 OUT5 OUT7OUT4 OUT6 OUT8

22

Page 63

α-Steuerung

0 1

I n

0 1

A d d F B

O 0 1

V e r b E r s t e l

6. Einstieg in die Programmierung

Einstieg in die Programmie ru ng 6

Die

Funktionsblöcke miteinander verbunden und bilden dadurch ein Programm. Sie haben die Auswahl zwischen

fünf Funktionsblöcken: Systemeingänge, Funktionstasten der Modulvorderseite, Systemspeicher-Bits, Funktionsblöcke und Systemausgänge.

Beim Einschalten der CPU erscheint ein Eröffnungsbildschirm, in dem Datum, Uhrzeit und Statustabelle (Eingangs- und Ausgangsstatus) angezeigt werden. Betätigen Sie eine beliebige Taste, um in das Hauptmenü zu

gelangen. Star ten Sie den Programmediti er-Modus durch Betätigung der OK-Tas te, um mit der Programmierung zu beginnen.

-Steuerung arbeitet mit der Funktion sblock -Pro g rammierung. In dieser Art der Programmierung werden

α

6.1 Verbinden von zwei Blöcken

Funktionsblöcke (FB) werden miteinander verbunden, indem man einen Ausgangspin mit einem freien Eingangspin verbindet. Der Pfeil zeigt in Richtung

des Ausgangspins. Der Ausgangspin befindet sich immer auf der rechten Seite

des Funktionsblocks. Freie Eingangspins sind mit einem „>“ gekennzeichnet,

wohingegen belegte Eingangspins mit einem gefüllten Dreieck dargestellt werden. Betätigen Sie die rechte Curso r taste, um das Bildschir mfenster nach

rechts zu verschieben, bis der Ausgangspin blinkt. Betätigen Sie die Tast e „+“

zur Herstellung einer Verbindung mit einem Funktionsblock. Die Taste „-“ dient

zum Trennen zweier Operanden.

GER

Betätigen Sie di e Taste „+“. Die FB-Optionen, die für eine Verbindung zur Verfü-

gung stehen, werden im rechten Teil des Bildschirms angezeigt. Über die Cursortasten HOCH und RUNTER wählen Sie ei nen hinz uzuf ügenden Op er anden.

Die aktuelle Auswahl wird blinkend dargestellt. Die Anzeige „VerbErstell“

erscheint im oberen oder unteren Bereich des Bildschirms. Wählen Sie den

gewünschten Verbindungsblock über die OK-Ta ste

23

Page 64

GER

Hourm eter

Pulse

F B - A u s w a h l

Tim e S W

AND

01 01

OUT

0 3

F L

α

-Steuerung

Eingänge, Tasten, Speicher-Bits, Funktionsblöcke und Ausgän ge zeigen

automatisch an, ob Sie verbunden werden können. Funktionsblöcke m üss e n

während der Programmierung hinzugefügt werden.

Zum Hinzufügen eines neuen FBs, wählen Sie „Neuer FB“. Das Menü „Neuer

FB“ zeigt eine Liste mit 22 Fu nktionsblöcken (siehe auch die Erläuter ung der

Funktionsblöcke am Ende dieses Kapitels). Wählen Sie d en gewünschten

Funktionsblock über die OK-Taste.

Wählen Sie einen freien („>“) Eingangspin, und betätigen Sie OK. Die Anzeige

„VerbErstell“ sollte am Bildschirm erlöschen – die beiden Funktionsblöcke s i nd

nun miteinander verbunden!

Ausgangspins können mit mehreren Eingangspins verbunden werden.

Eingangspins können jedoch nur jeweils eine Verbindung haben.

Einstieg in die Programmie ru ng 6

6.2 Bearbeitung von Blöcken

Wenn di e F B-Adr esse blinkt, können Sie über die Tasten „+“ und „-“ zu weiteren

Blöcken in aufsteigender oder abfallender Reihenfolge scrollen.

Beispiel: Die Eingangsadresse 03 blinkt in der Anzeige. Durch Betätigung der

Taste „+“ können Sie den Bildschir m zur Eingangsadresse 04 scrollen.

Eingänge, Ausgänge, Tasten und Speicher-Bits können so angesprochen werden.

Sie können über die gl ei che Vorgehens w eis e auc h die Funk tions b l öcke ansprechen, aber nur die im Programm verwendeten Funktionsblöcke.

24

Page 65

α-Steuerung

t = 0 . 0 s

E i n - Z e i t

B 0 3 : F L

T = 0 . 0 s

6.3 Einstellung der Funktionsblockparameter

Einige Funktionsblöcke ve rf ügen über Parameter, die eingestellt werden müs-

sen. Zu diesen Parametern gehören die Zeit (T), die abgelaufene Zeit (t), die

Sollzahl-Wiederholungen (N), die Istzahl-Wiederholungen (n), die Setzen/

Rücksetzen-Priorität und weitere.

Wählen Sie einen FB über die Cursortasten. Wenn die FB-Adresse blinkt,

betätigen Sie zweimal OK, um in den FB-Einstellmodus zu gelangen. Stellen

Sie die Optionen entsprechend der Programmerfordernisse ein (siehe auch

Tabelle 6.1). Geben Sie alle erforderlichen Optione n ei n, und b estäti ge n Sie mi t

OK.

Einige FB verfügen über mehrere Menüseiten. Verwenden Sie die ESC-Taste, um auf eine höhere Menüseite

zu gelangen, ohne den Inhalt in den Systemspeicher zu speichern. Wenn Sie die Dateneingabe abgeschlossen haben, betätigen Sie die ESC-Taste so oft, bis Sie in das Haupt-Programmiermenü zurückge kehrt sind.

Einstieg in die Programmie ru ng 6

GER

25

Page 66

GER

Edit ier en

Verlassen

ProgGr.

Sprung

Neue r FB

Mnem onic

Hauptm enue

UhrSetzen

R u n

Edit ier en

PrgLoesch

Weitere

L A N G U A G E

α

-Steuerung

6.4 Verlassen, Starten und Stoppen des Programms

Betätigen Sie die ESC-Taste, um das Editiermenü aufzurufen (unter

Umständen muß di e ESC-Taste dazu mehrf ach be tätigt w erden) , und v erlas sen

Sie das Editi ermenü über die Option „Verlassen“.

Über den Menüpunkt „Run“ start en Sie d as Pr ogramm. Bestäti gen S ie mit OK.

Während das Programm abgearbeitet wird, zeigt der Monitor die Uhrzeit, das

Datum und die Statustabelle.

Zum Aufruf des Hauptmenüs, in dem der Stopp-Befehl angeboten wird, betäti-

gen Sie eine beliebige Taste. Wählen Sie diesen Befehl zum Stoppen des Programms, und bestätigen Sie mit OK.

Einstieg in die Programmie ru ng 6

Weitere Menüpunkte sind:

„Uhr setzen“ - Einstellung der Echtzeituhr

„LANGUAGE“ (Sprache) - Wählen Sie Englisch, Japanisch, Deutsch, Französisch, Italienisch oder Spanisch

„Prg Loesch“ - Löscht den gesamten Programmspeicher, Programme und Daten!

„Weitere“ - Bietet weitere Optionen zur Versionsprüfung, Passwortvergabe, Umstellung auf Sommerzeit,

Modeminitialisierung und Menütastenbetrieb.

26

Page 67

α-Steuerung

Tabelle 6.1: Tastennummern und Hauptfunktionen

Einstieg in die Programmie ru ng 6

Tasten-

nummer

K01 OK: Bestätigung bei Dateneingabe, Menüoptionen oder Programmwahl

K02

K03

K04

K05 Hoch (G): Nach oben scrollen (Tasten, FB, Eingänge, Ausgänge, etc.)

K06 Runter (H): Nach unten scrollen (Tasten, FB, Eingänge, Ausgänge, etc.)

K07

K08

ESC: Abbruch des aktuellen Vorgangs, Wechsel zu einer höheren Bildschir manzeige oder

einem höheren Menü

„+“: Verbinden von zwei Funktionsblöcken, Wechsel zu höheren Prog rammblöcken,

Vergrößern von Werten

„-“: Trennen von zwei Funktionsblöcken, Wechsel zu niedrigeren Programmblöcken,

Verringern von Werten

Rechts (E): Auf der LCD-Anzeige, im FB-Programm oder bei einem Sprungbefehl nach

rechts scrollen

Links (F): Auf der LCD-Anzeige, im FB-Programm oder bei einem Sprungbefehl nach links

scrollen

Tasten-Hauptfunktion

GER

27

Page 68

α

-Steuerung

Tabelle 6.2: Funktionsblöcke

Einstieg in die Programmie ru ng 6

Funktionsblock Byte Beschreibung

GER

AND 19

OR 19

XOR 13 Exclusive OR; Ausgang EIN, wenn einer von zwei Eingängen EIN i s t

NAND 19

NOR 19

NOT 10 Invertierung eines Signals, Wechsel von EIN nach AUS und umgekehrt

BOOLEAN * Logische Anweisung mit AND, OR, XOR und NOT

SET/RESET 14

DELAY 19 Verzögerung eines Signals bei st eigender/fallender Flanke oder bei beiden

ONE SHOT 17

PULSE 10 Senden eines Signals bei steigender/fallender Flanke oder bei beiden

Ausgang EIN, wenn alle Eingänge EIN sind, freie Eingänge werden wie

EIN verarbeitet

Ausgang EIN, wenn mindestens ein Eingang EIN ist, freie Eingänge

werden wie AUS verarbeitet

Not AND; Ausgang AUS, wenn alle Eingänge EIN sind, freie Eingänge

werden wie EIN verarbeitet

Not OR; Ausgang AUS, wenn mindestens ein Eingang EIN ist,

freie Eingänge werden wie AUS verarbeitet

Erzwungenes Setzen oder Rücksetzen eines Merkers, Zuweisen eine r

Priorität für Setzen oder Rücksetzen

Senden eines einzelnen Impulses; in Anhängigkeit von Zeit oder Signal,

Rücksetz-Pin kann verwendet werden

FLICKER 19

ALTERNATE 13 Der Ausgang wechselt zwischen EIN und AUS mit jedem Eingangsimpuls

COUNTER 16 Aufwärts-Impulszähler, Rücksetzen über Sollwert oder Signal

U/D Counter TBD Aufwärts- und Abwärts-Zähler mit Sollwert-Eingab e und Löschfunktion

Senden einer Impulskette; EIN/AUS-Zeiten, Wiederholung, Dauer oder

kontinuierlicher Betrieb

28

Page 69

α-Steuerung

Tabelle 6.2: Funktionsblöcke

Funktionsblock Byte Beschreibung

Einstieg in die Programmie ru ng 6

COMPARE 17

TIME SW *

OFFSET 22

DISPLAY * Anzeige von Kommentaren oder Daten auf der LCD-Anzeige

ZONE CMP 20

SCHMITT 19

HOUR METER 19

System Outputs 10 Steuerung externer Operanden über Relais oder Transistoren

*Die Anzahl der Bytes hängt von den Eingangsdaten ab.

Vergleic h zweier Werte über <, >, =, <=, >=, <>

(Analogwerte, direkt gesetzte Istwerte oder FB-Werte)

Verwendung der Echtzeituhr zum Setzen/Rücksetzen eines Ausgangs;

kalendarische oder wöchentliche Steuerung

Manipulation analoger Wer te; y = A / B * x + C; oberen und unteren

Grenzwert setzen

Einen Wert mit ei nem Wertebereich vergleichen

(Analogwerte, direkt gesetzte Istwerte oder FB-Werte)

Setzen eines Eingangs bei einem oberen Schwellwert und Zurücksetzen

bei einem unteren Schwellwert (oder umgekehr t)

Aufzeichnung der akkumulierten Dauer, die ein Ausgangs- oder

Eingangssignal gesetzt ist

GER

29

Page 70

GER

α

-Steuerung

Einstieg in die Programmie ru ng 6

30

Page 71

MANUEL DU MATÉRIEL

FRE

BLOC LOGIQUE

α

Page 72

FRE

Bloc logique α

Préface

• Le présent manual contient des textes, des illustrations et des applications pour une installation et une

utilisation correctes du bloc logique α. L’utilisateur doit le lire et avoir compris son contenu avant d’installer

ou d’utliliser l’appareil.

• Si lors de l’installation des incertitudes persistent, n’hesitez pas à consulter un électricien compétent,

qualifié et for m é à l’utilisation des normes électriques locales et nationales. Contactez le représentant le

plus proche de MITSUBISHI ELECTRIC si la manipulation ou l’utilisation des blocs lo giques

des problèmes.

• Le présent manual est publié sous réserve de modification s. Ce s modifications peuvent être apportées

sans avis préalable.

vous pose

α

Page 73

Bloc logique α

Bloc logique

α

α

αα

Manuel du matériel

No. du manuel:JY992D74201

Indice :J

Date :04/2002

FRE

i

Page 74

Bloc logique

α

FRE

Directives de sécurité pour l’utilisateur et mesures de protection pour le bloc logique

Ce manuel a été conçu p our un personnel formé et qu alifié. La qualification est définie par les directives

européennes pour machines, basses tensions et CEM. Seul un élect ricien compétent, qualifié et formé à l’utilisation

des normes électriques locales et nationales doit effectuer les travaux de câblage du bloc logique

lise différents symboles pour la mise en évidence de certaines informations. Ceci permet de transmettre aux opéra-