Page 1

For Internal Training

This document covers the functions for AG-150A software Ver. 1.20

Functions planned to be added in the later versions are not described.

Page 2

AG-

150

A

- Visualizing control -

C

entralized Remote Controller

I

ndividual Remote Controller

BACnet interface software

PAC-YG31CDA

Interface

(LM ADAPTER)

MITSUBISHI ELECTRIC's

CITYMULTI can be easily

connected to the building

management system through

BACnet .

LONW

ORKS

transmission line

BACnet transmission line

Ethernet

Ethernet

Integrated centralized

control software TG-2000A

System

Remote

Controller

Schedule

Timer

Remote

Controller

Simple

Remote

Controller

Wireless

Remote

Controller

PAR-F27MEA

PAR-FA32MA

PAC-SE51CRA

PAC-YT51CRB

PAR-FL32MA

PAR-21MAA

OUTDOOR UNIT

Y :PUHY

R2 :PURY

WY:PQHY

WR2:PQRY

S :PUMY

INDOOR UNIT

PLFY PCFY

PMFY PKFY

PEFY PFFY

Fresh Air Intake type

LGH GUF

A

ir-Conditioning

Control System

ON/OFF

Remote

Controller

PAC-YT40ANRAPAC-SF44SRA PAC-YT34STA

AG-150A

GB-50A

Group

Remote

Controller

PAC-SC30GRA

PAC-YG60MCA

PAC-YG66DCA

PAC-YG63MCA

AI Controller

DIDO Controller

PI Controller

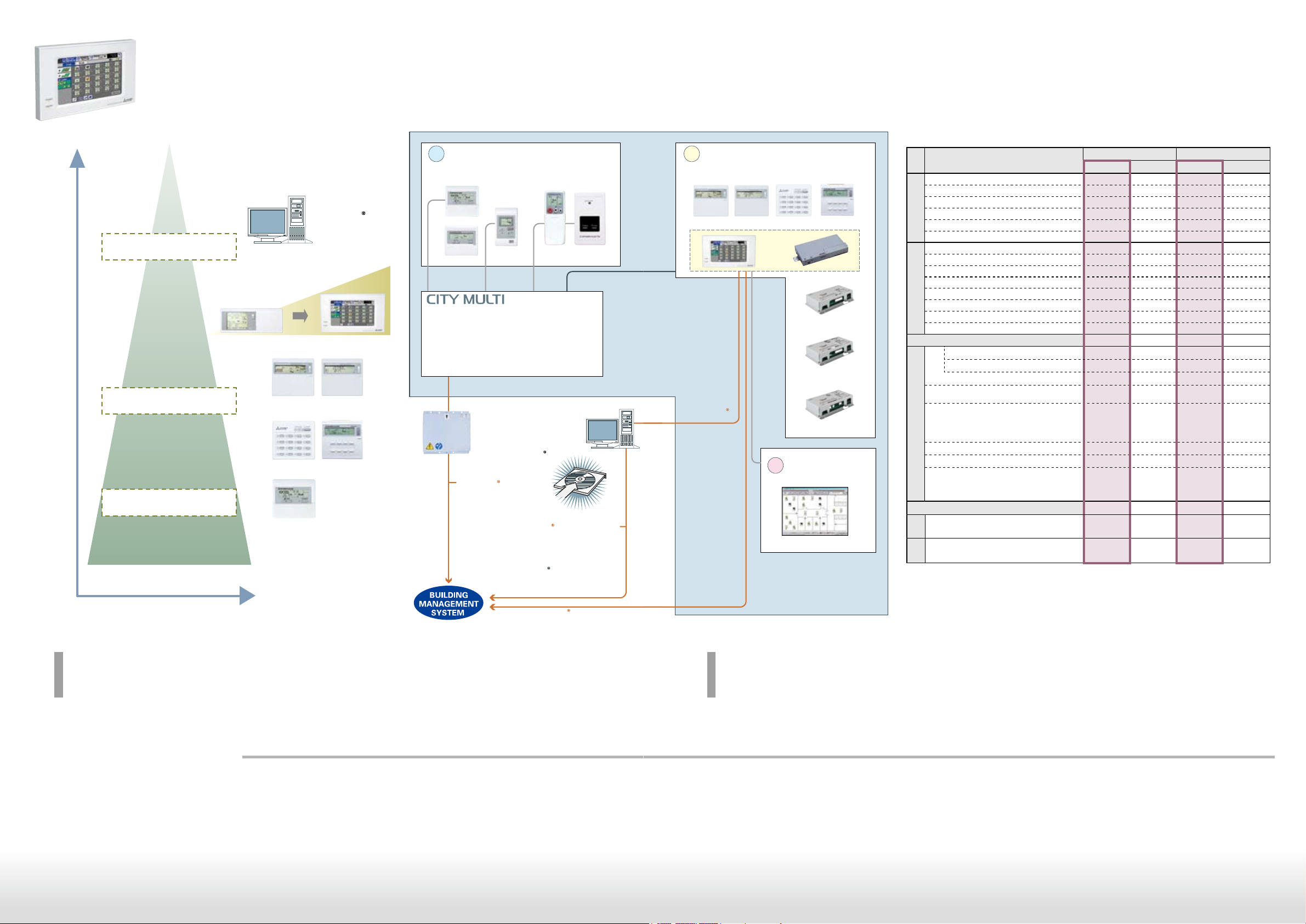

C

ontrollers are one of the most important and familiar devices in an air conditioning system. Not only

does it control to provide optimum air environment but supports operations to minimize running costs and

to preserve energy. Through studies and development, we’ve visualized a new system controller meeting

needs with versatile options.

–

Design your control with our new centralized controller; AG-150A.

With a new coloured touch panel, new functions, and continuation of all the current G-50A functions,

AG-150A visualizes its functions from basic control to advanced operations and bringing an ultimate

controller to reality.

We offer a wide range of air conditioner management to meet all requirements from the smallest and simplest

to the largest and most complex. Among those controllers, AG-150A centralized controller covers the

application ranges from middle to large sized buildings.

Contents

New design

. . . . . . . . . . .. . . . . . . . . . . . .. . . . . . . . . . .

3

Functions

. . . . . . . . . . .. . . . . . . . . . . . .. . . . . . . . . . .

4

System structure

. . . . . . . . . . .. . . . . . . . . . . . .. . . . . . . . . . .

1 5

Installation

. . . . . . . . . . .. . . . . . . . . . . . .. . . . . . . . . . .

1 7

Wiring

. . . . . . . . . . .. . . . . . . . . . . . .. . . . . . . . . . .

1 8

Q&A

. . . . . . . . . . .. . . . . . . . . . . . .. . . . . . . . . . .

2 1

Market size

Price/

Spec

PAC-YG31CDA

(BACnet IF)

or

TG-2000A

G-50A

AG-150A

SR

ST

ON/OFF

GR

MA ME R/C

Large scale

Small scale

Middle scale

Comparison between New

AG-150A

and Conventional

G-50A

AG-150A

SET SET

SET

G-50A AG-150A G-50A

WEBUnit

ON / OFF

� � �

Operation mode

� � �

Temperature setting

� � �

Fan speed

� � �

Air flow direction

� � �

Permit/ Prohibit local operation

� � �

ON / OFF

� � �

Operation mode

� � �

Temperature setting

� � �

Return air temp. (ambient temp)

� �

Error

� � �

Fan speed

� � �

Air flow direction

� � �

Filter sign

� � �

�

�

-

�

*1

Annual Schedule

Weekly Schedule

Optimized start-up control

Seasonal schedule

Today's Schedule

changing weekly or annual schedule

Day schedule can be changed without

Max.50 days schedule setting for 24 months

Time setting unit

1 min

OP

�

OP

�

OP

�

OP

�

OP

�

OP

�

�

�

�

10 min 1 min

No.of settings per day

24 6

24

Item:

ON / OFF, Operation mode,

Temp. setting, Permit / Prohibit local RC,

fan speed, air-flow direction

External

outputinput

ON / OFF, Error / Normal

� �

ON / OFF, Emergency stop

� �

�

�

�

�

�

�

�

�

�

�

�

�

�

�

-

-

-

-

-

OP

�

OP

�

OP

�

�

1 min

12

External

�

Operation

Floor layout ( from USB port)

MonitoringScheduling

�

NA

NA NA

NA NA

NA

(only ON/OFF,

RC prohibit)

exclude fan speed,

air flow direction

�

㧦Available

NA 㧦Not available

OP�

㧦Available with option. License registeration required.

SET : Available by changing the setting

*1 ON/OFF 3times/pattern. 3pattern+prohibit pattern/week.

Night setback

�

�

NA NA

C

entralized Remote Controller

Ethernet

Integrated centralized

control software TG-2000A

System

Remote

Controller

Schedule

Timer

A

ir-Conditioning

Control System

ON/OFF

Remote

Controller

PAC-YT40ANRAPAC-SF44SRA PAC-YT34STA

AG-150A

GB-50A

Group

Remote

Controller

PAC-SC30GRA

PAC-YG60MCA

PAC-YG66DCA

PAC-YG63MCA

AI Controller

DIDO Controller

PI Controller

C

ontrollers are one of the most important and familiar devices in an air conditioning system. Not only

does it control to provide optimum air environment but supports operations to minimize running costs and

to preserve energy. Through studies and development, we’ve visualized a new system controller meeting

needs with versatile options.

–

Design your control with our new centralized controller; AG-150A.

With a new coloured touch panel, new functions, and continuation of all the current G-50A functions,

AG-150A visualizes its functions from basic control to advanced operations and bringing an ultimate

controller to reality.

Installation

. . . . . . . . . . .. . . . . . . . . . . . .. . . . . . . . . . .

1 7

Wiring

. . . . . . . . . . .. . . . . . . . . . . . .. . . . . . . . . . .

1 8

Q&A

. . . . . . . . . . .. . . . . . . . . . . . .. . . . . . . . . . .

2 1

Comparison between New

AG-150A

and Conventional

G-50A

AG-150A

SET SET

SET

G-50A AG-150A G-50A

WEBUnit

ON / OFF

� � �

Operation mode

� � �

Temperature setting

� � �

Fan speed

� � �

Air flow direction

� � �

Permit/ Prohibit local operation

� � �

ON / OFF

� � �

Operation mode

� � �

Temperature setting

� � �

Return air temp. (ambient temp)

� �

Error

� � �

Fan speed

� � �

Air flow direction

� � �

Filter sign

� � �

�

�

-

�

*1

Annual Schedule

Weekly Schedule

Optimized start-up control

Seasonal schedule

Today's Schedule

changing weekly or annual schedule

Day schedule can be changed without

Max.50 days schedule setting for 24 months

Time setting unit

1 min

OP

�

OP

�

OP

�

OP

�

OP

�

OP

�

�

�

�

10 min 1 min

No.of settings per day

24 6

24

Item:

ON / OFF, Operation mode,

Temp. setting, Permit / Prohibit local RC,

fan speed, air-flow direction

External

outputinput

ON / OFF, Error / Normal

� �

ON / OFF, Emergency stop

� �

�

�

�

�

�

�

�

�

�

�

�

�

�

�

-

-

-

-

-

OP

�

OP

�

OP

�

�

1 min

12

External

�

Operation

Floor layout ( from USB port)

MonitoringScheduling

�

NA

NA NA

NA NA

NA

(only ON/OFF,

RC prohibit)

exclude fan speed,

air flow direction

�

㧦Available

NA 㧦Not available

OP�

㧦Available with option. License registeration required.

SET : Available by changing the setting

*1 ON/OFF 3times/pattern. 3pattern+prohibit pattern/week.

Night setback

�

�

NA NA

- 1 - - 2 -

Page 3

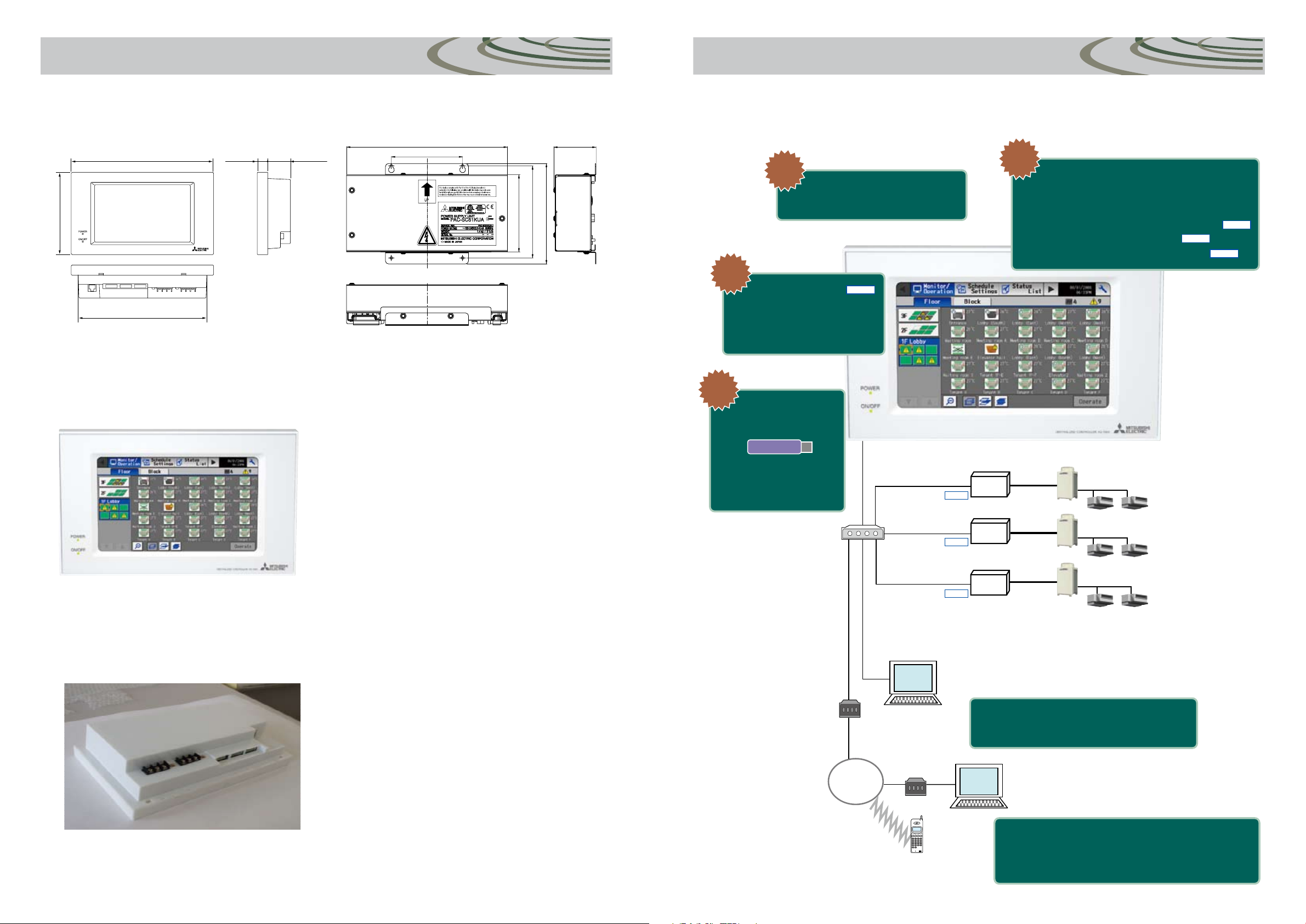

CENTRALIZED CONTROLLER AG-150A

185 (7-5/16)

44.7

(1-13/16)

25.6

(1-1/16)

300 (11-13/16)

272 (10-3/4)

TB2,TB3

TB1

271(10-

11

/16

)

90(3-

9

/16

)

155

(

6-

1

/

8

)

130

(

5-

1

/

8

)

169

(

6-

11

/16

)

72(2-

7

/8

)

T

Unit: mm (in)

Expansion controller

Expansion controller

Expansion controller

Web/TG-2000A

Remote monitoring PC

(with VPN function)

*1 AG-150A software needs

to be upgraded.

Router

Internet

VPN Router

Switching HUB

Controllable units

expanded to 50~150

NEW

Function3

P.9

CSV output of initial

setting, charge, user

info data

Function4

P.10

Optimum control setting

Seasonal scheduling function

Sliding temperature functions *

1

Night setback function *

1

Optimized start-up function *

1

NEW

Function2 P.7~8

Operation on Touch Panel

NEW

Function1

P.5~6

Control of Air-conditioners from PC

Function5 P.11~13

Monitor/operation from remote site.

Error mail on service person’s cell phone.

Function6 P.14

NEW

Apr 09

Apr 09

Apr 09

Apr 09

Dec 08

Dec 08

Dec 08

New design

Functions

Dimension

●

AG-150A Power Supply Unit PAC-SC51KUA

Backlight color liquid crystal display

●

Easy to see and control.

n

Able to identify whether a unit is ON or OFF from a

n

distance.

Switches ON when touched or in operation

n

First touch turns ON the backlight, followed by

operation touch.

Turns OFF when there is no operation for 10mins

n

Turns ON during unit malfunction (Alarm, Error)

n

when the backlight is OFF.

The need for control is paramount in order to optimize the performance of any air conditioning system.

AG-150A offers a wide range of control functions designed to do just this.

For further information on each function, refer to the pages indicated.

Back Structure

●

Easy installation

n

Ways to install-wall embedded/wall mounting

n

*For further information, refer to page 17

- 3 - - 4 -

Page 4

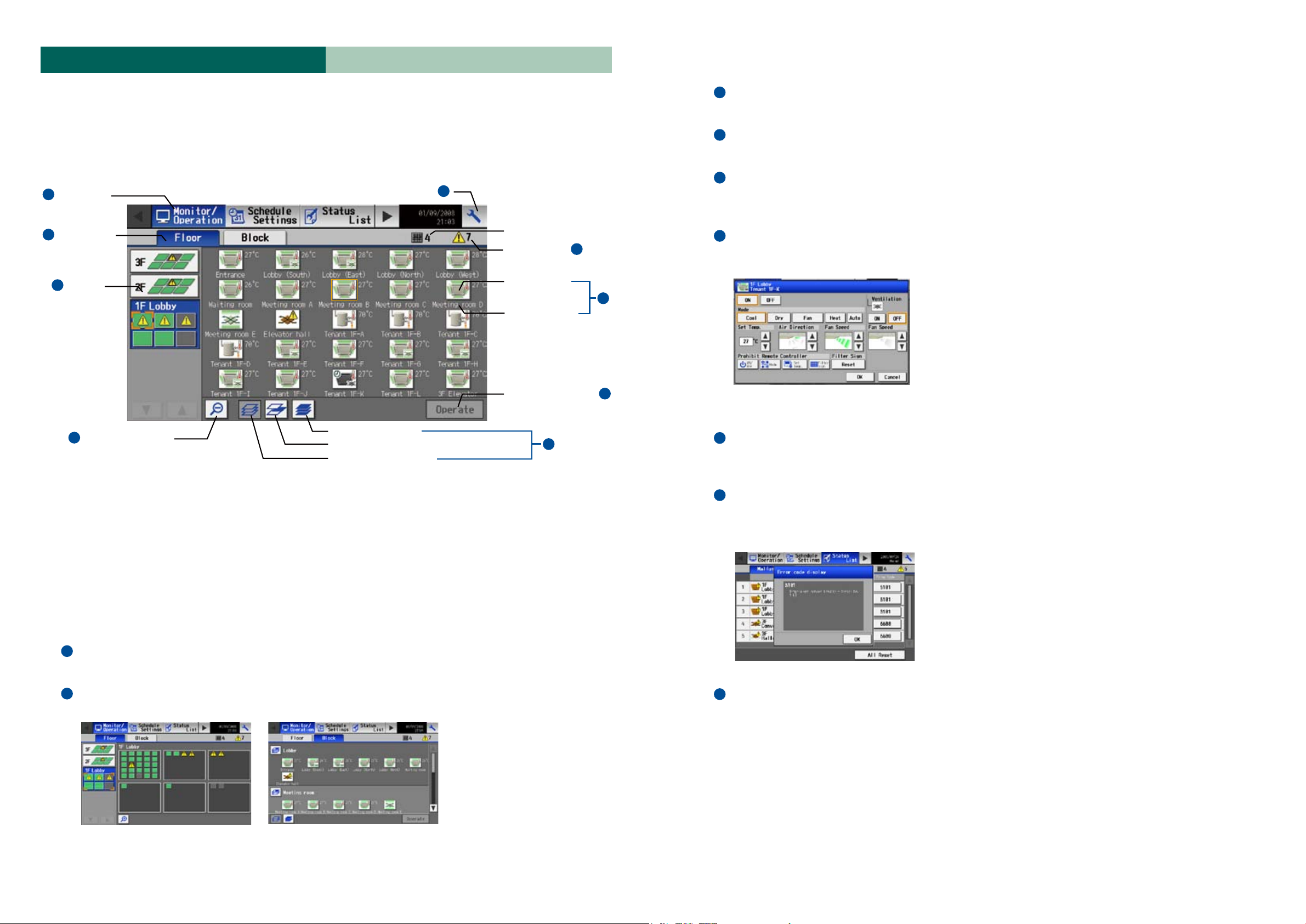

Function1

1

2

3

4

7

6

5

8

9

Menu bar

Sub menu

Floorswitching

button

Zoom-out button

Select-all button

Select-all-groups-on-the-floor button

Deselect-all button

Operation button

Group icon

Number of

malfunctioning unit

Filter sign

Setting change button

Group name

Operation on Touch Panel

●

The new colour touch panel is the ultimate function AG-150A offers which enables easy to monitor and

operate with just touching the panel with your ngers.

Here are the functions available on the colour touch panel.

3

Floor-switching button

Select the oor to monitor or operate. Floors to be displayed can be selected.

4

Zoom-out button

Display size can be reduced. Floors to be displayed can be selected.

5

Select-all button/Select-all-groups-on-the-oor button/Deselect-all button

Touching each unit with your index nger can select units or if the setting applies to multiple units,

it is also possible to select all units by oor or system and cancel the selection.

6

Operation button

After selecting a unit, when you click a unit or this operation button, the display will appear to specify

setting.

Operation by touching with index nger

In order to change operation status, just touch the icon with index nger and an orange box appears around

the unit icon indicating the selected unit.

Multi-language, total of 8

Language can be selected from the following.

Japanese/English/French/German/Spanish/Italian/Russian/Chinese (*English/Spanish only in Ver. 1.01~1.03)

1

Menu bar

“Monitor/Operation”, “Schedule Settings”, “Status List”, “Log” can be selected.

2

Sub menu

Change display between by oors or by block.

Operation screen

7

Group icon/Group name

Each unit and its status are displayed and visible on the touch panel giving the information wanted in

a glance.

8

Number of malfunctioning unit

To check what kind of error has occurred in the system, click on the yellow exclamation mark at the upper

right corner and the malfunction list appears. To check details, click on [error code] number and a screen

explaining the error will appear.

9

Setting change button

Initial setting can be changed.

Floor layout screen

Block display screen

- 5 - - 6 -

Page 5

36°C/97°F

35°C/95°F

34°C/93°F

33°C/91°F

32°C/89°F

31°C/88°F

30°C/87°F

29°C/85°F

28°C/83°F

27°C/81°F

26°C/79°F

25°C/77°F

24°C/75°F

23°C/73°F

Max. slide

temperature

range

No control

+1㷄 control

+2㷄 control

+3㷄 control

+4㷄 control

�

�

�

�

+1㷄 control

(+1.5㷄 or

above)

+2㷄 control

(+4.5㷄 or

above)

+3㷄 control

(+6.5㷄 or

above)

+4㷄 control

(+7.5㷄 or

above)

Temperature

AG-150A

IC

M-NET

M-NET

M-NET

adapter

A Control

AI Controller

OC

PSU

Set slide temp

Outdoor Temp.

Outdoor

temperature is

measured by

AI controller.

Time

�

�

�

�

� �

㪪㪼㫋㩷㫋㪼㫄㫇㪼㫉㪸㫋㫌㫉㪼㩷㫆㪽㩷㪸㩷

㪾㫉㫆㫌㫇㩷㫎㫀㫋㪿㩷㪸㩷㪤㪸㫏㪅㩷

㫊㫃㫀㪻㪼㩷㫋㪼㫄㫇㪼㫉㪸㫋㫌㫉㪼㩷㫉㪸㫅㪾㪼㩷

㫆㪽㩷㪲㪂㪉°C㪴

㪪㪼㫋㩷㫋㪼㫄㫇㪼㫉㪸㫋㫌㫉㪼㩷㪹㪼㪽㫆㫉㪼㩷㫀㫅㫋㪼㫉㫃㫆㪺㫂

㪪㪼㫋㩷㫋㪼㫄㫇㪼㫉㪸㫋㫌㫉㪼㩷㫆㪽㩷㪸㩷

㪾㫉㫆㫌㫇㩷㫎㫀㫋㪿㩷㪸㩷㪤㪸㫏㪅㩷

㫊㫃㫀㪻㪼㩷㫋㪼㫄㫇㪼㫉㪸㫋㫌㫉㪼㩷㫉㪸㫅㪾㪼㩷

㫆㪽㩷㪲㪂㪋°C㪴

㪦㫌㫋㪻㫆㫆㫉㩷㫋㪼㫄㫇㪼㫉㪸㫋㫌㫉㪼

*Max. slide temperature range can be selected for each group from below.

[No control] [+1°C] [+2°C] [+3°C] [+4°C]

� Control

( ) Difference between the outdoor temperature and original set temperature

Function2

AG-150A

IC

M-NET

M-NET

M-NET

adapter

A Control

OC

PSU

Weekly sc hedule 1

Group 1

<

09:00

12:00

13:00

Group 2

䇼ᦐᣣ䇽

09:00 ㆇォ䇭27㷄

12:00 ᱛ

13:00 ㆇォ

䋺

<

09:00

12:00

13:00

Group 3

<Mon>

09:00 ON Heat 27C

12:00 OFF

13:00 ON

Weekly sc hedule 1

Group 1

<

09:00

12:00

13:00

Group 2

䇼ᦐᣣ䇽

09:00 ㆇォ䇭27㷄

12:00 ᱛ

13:00 ㆇォ

䋺

<

09:00

12:00

13:00

Group 3

<Mon>

09:00 ON Heat 27C

12:00 OFF

13:00 ON

Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec

Schedule 2

Schedule 1 Schedule 1

Weekly sc hedule 2

Group 1

<

09:00

12:00

13:00

Group 2

䇼ᦐᣣ䇽

09:00 ㆇォ䇭27㷄

12:00 ᱛ

13:00 ㆇォ

䋺

<

09:00

12:00

13:00

Group 3

<Mon>

09:00 ON Cool 24C

12:00 OFF

13:00 ON

Weekly sc hedule 2

Group 1

<

09:00

12:00

13:00

Group 2

䇼ᦐᣣ䇽

09:00 ㆇォ䇭27㷄

12:00 ᱛ

13:00 ㆇォ

䋺

<

09:00

12:00

13:00

Group 3

<Mon>

09:00 ON Cool 24C

12:00 OFF

13:00 ON

Change

automatically

Change

automatically

Set seasonal

scheduling

Liquid crystal display

Stop time

18:00

22°C/71°F

14°C/57°F

Indoor temp

䇼Condition1䇽[Indoor temp䌝 [<][14°C/57°F]

䇼Operation1䇽[ON] 䌛HEAT䌝[14°C/57°F]

14°C/57°F

Target time

09:00

Change to [22°C/71°F]

indoor temperature

䇼

Condition 2䇽AG-150A study result

䇼Operation 2䇽[ON]䌛HEAT䌝[22°C/71°F]

ON 22°C/71°F

OFF

ON 14°C/57°F ON 22°C/71°F

Start time is changed at the

most suitable time

[ON][14°C/57°F]

AG-150A

IC

M-NET

M-NET

M-NET

adapter

A Control

KA Converter

K Control

OC

PSU

OFF 14°C/57°F

22°C/71°F

14°C/57°F

Target time

09:00

Change to [22°C/71°F]

indoor temperature

ޣCondition 2ޤAG-150A study result

ޣOperation 2ޤ[ON]㨇HEAT㨉[22°C/71°F]

ON 22°C/71°F

Start time is changed

at the most suitable time

AG-150A

IC

M-NET

M-NET

M-NET

adapter

A Control

OC

PSU

Setting night setback

Stop time

18:00

Stop time

8:00

ON 21°C/69°FON 22°C/71°F OFFOFF ON Heating 14°C/57°FON Cooling 28°C/83°F

21°C/69°F

14°C/57°F

28°C/83°F

22°C/71°F

(Lower limit temp)

(Upper limit temp)

Indoor temp

䇼Condition 1ޤ[Indoor temp.] [<][14°C/57°F]

䇼Operation 1䇽[ON] [HEAT][14°C/57°F]

[ON]{HEAT}[14°C/57°F][ON]{COOL}[28°C/83°F]

[Winter][Summer]

Indoor temp

ޣCondition1ޤ[Indoor temp] [>] [28°C/83°F]

ޣOperation1ޤ[ON] [COOL][28°C/83°F]

Liquid crystal display

Setting time zone of control

Setting minimum and

maximum temp.

Group unit

Optimum control setting

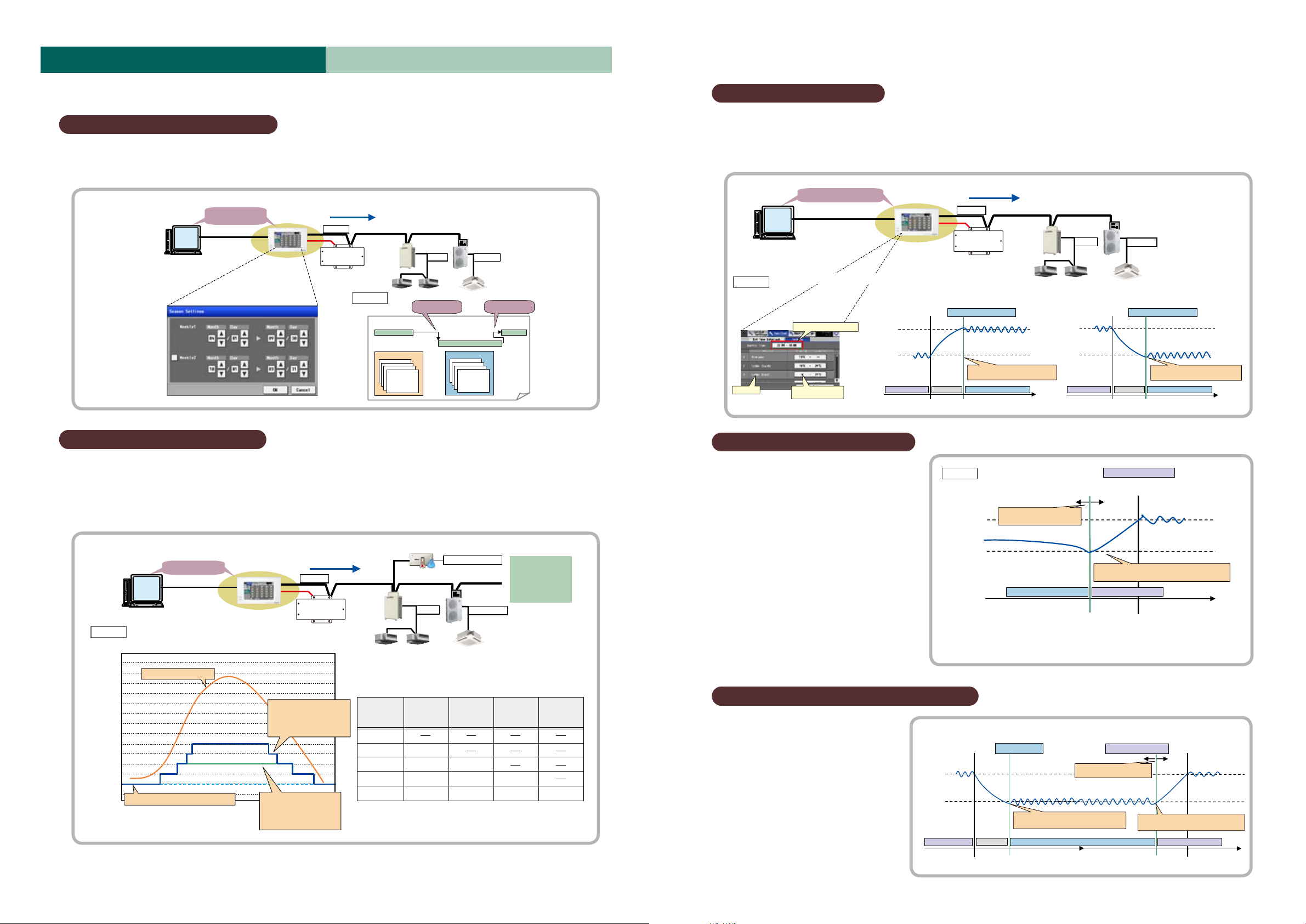

●

Seasonal scheduling function

With a seasonal scheduling, it is possible to set weekly schedule by seasons. 2 patterns of weekly schedule

(Weekly1, Weekly2) and day/month to apply that schedule can be set which automatically shifts when it

reaches the scheduled day of the year.

IMAGE

Night setback Function

In night setback function, indoor temperature is maintained to a set temperature. This prevents frost

formation in the winter. When the temperature goes below a specic value, the unit starts in HEAT mode

at low temp. Since the units only start at HEAT mode when it goes below a specic temperature, it is very

effective for energy saving. (Conventional methods:units only start at a decided time set by schedule)

IMAGE

Sliding Temperature control

In this interlock function, the outdoor temperature is used to slide the set temperature of a room.

This prevents a person from getting a shock (sick) of sudden change in temperature when they enter a

building from being outside. Also this process is very effective for energy saving.

This function enables to set different max. slide temperature range per group in accordance to the change in

outdoor temperature.

IMAGE

- 7 - - 8 -

Optimized Start-up control

W i t h this s t a r t up f u n c t i o n , pre

operation will be performed to bring

IMAGE

the te m p eratu r e to t he s p e cified

temper ature at the spe cif i ed time

providing optimum air environment all

year around.

For example, when it is set as 22°C/71°F

heating at 9:00, operation will start

at 8:45 -15min before 9:00, and will

achieve 22°C/71°F at 9:00. AG-150A

will decide when pre-cooling should

start 30 minutes before the target time

based on set/room temp and data of

the past days (when units were turned

<Logic>

30 minutes before the target time, AG-150A studies the set temp, room

temp, and data of the past days (when units were turned ON for optimized

start-up) and decides when to start the units.

ON for optimized start-up control).

Setback + Optimized start-up control

When combining the two functions

t o g e t h e r, a hi g h l y ef f e c ti v e

temperature control is possible.

For example, setback is set at 14

°C/57°F, unit will start its heating

o p er a t i o n w h e n t h e i n d oo r

temperature goes below 14°C/57°F.

Simultaneously, if the optimized

star t-up control targets 22°C/71°F

at 9:00, AG-150A will decide when

pre-heating should start and obtain

the desire d tem per ature at the

required time.

Page 6

Max.50

units

Max.50

units

Max.150 units

AG-150A

IC

M-NET

M-NET

OC

M-NET

adapter

A Control

M-NET

M-NET

Max.50

units

LAN

PSU

(PAC-SC51KUA)

(100BASE-TX)

IC

M-NET

OC

M-NET

adapter

A Control

IC

M-NET

OC

M-NET

adapter

A Control

Expansion

Controller

PAC-YG50ECA

Expansion

Controller

PAC-YG50ECA

Expansion

Controller

PAC-YG50ECA

Central Control PC

(TG-2000A)

Function3

Controller

TG2000

G-50A

AG-150A

Connectable maximum no. of units

2000 units

50 units

150* units

1 Backup of Initial setting Data

AG-150A

USB memory

2009/M

Dec 08

3 Restoring of Initial setting Data

2 Processing of charge parameter

data on PC

USB memory

USB memory

PC for processing data

AG-150A

*Proportional division calculation is processed with PC.

4 Initial setting on PC

PC for initial setting

Special SW

*The data from a design tool can be edited.

USB memory

AG-150A

AG-150A

Function4

Controllable units expanded

●

TENTATIVE

Maximum of 50 units

Include indoor units, LOSSNAY, DIDO (contacts), PI and AI controller.

*DIDO has 6 contact points. 1 contact point is counted as 1 indoor unit.

*Only 5 PI controllers can be connected to 1 AG-150A.

*Depending on the model, indoor units may be counted as 2 or more units.

Maximum of 150 units

AG-150A software needs to be upgraded and Expansion controller (PAC-YG50ECA) is required.

Power supply for M-NET is included in the Expansion controller.

April 2009

USB Memory

●

AG-150A has a USB memory slot. Data can be extracted or restored incase there is a fault or resetting a

system.

Note : Please use the following USB memory.

Manufacturer : Sandisk, model : SDCZ6-2048-J65RB, 2G Byte

Manufacturer : Kingston, model : DT400/2GBFE, 2G Byte

* We are planning to add brands and models of USB memory in the future.

*Up to 50 units per Expansion controller, up to 3 expansion controllers

- 9 - - 10 -

Page 7

Function5

LAN

(100BASE-TX)

Central Control PC

(AG-150A WEB)

Switching

HUB

AG-150A

IC

M-NET

M-NET

M-NET

adapter

A Control

OC

Watt hour meter

PI Controller

PSU

PAC-SC51KUA

AG-150A WEB control/monitor

LAN

(100BASE-TX)

Central Control PC

(TG-2000A)

Switching

HUB

AG-150A

IC

M-NET

M-NET

M-NET

adapter

A Control

OC

Watt hour meter

PI Controller

PSU

PAC-SC51KUA

TG-2000A software control/monitor

TG-2000A software (Central control PC)

control/monitor

AG-150A WEB (Monitoring PC)

control/ monitor

General description

Daily/ Weekly1/

Weekly2/Annual

schedule

Apportioned

Electricity

Calculation (charge

data)

Maximum of 1 AG-150Aޓ(50 units) can be

controlled/monitored. Total of 254 AG-150A

and monitoring PC can be connected to one

LAN system. Screen-display is per AG-150A.

Av ailable f ro m

Dec. 2008

Maximum of 40 AG-150A (2000 units) can

be screen-displayed to control/monitor.

For ap p ort ion ed e lec tri cit y ca lcu l at i on,

TG-2000ASoftware is required.

Screen-display

is per AG-150A.

Maximum of 50

u n it s ca n be

displayed.

O p e ra t i o n o f

maximum 2000

u n it s c a n b e

displayed.

License registration required

(Weekly1 schedule license unnecessary)

License registration required

*1.Units include indoor units, LOSSNAY, DIDO, PI and AI controller. DIDO has 6 contact points. (1 con tact po int is

counted as 1 unit.) Large capacity indoor units are counted as 2 or 3 indoor units.

Units that can be scheduled: Indoor units, general equipmentޓ(Schedules can be copied)

� �

Energy saving/Peak

cut control

General equipment

control

Block display

Floor plan display

Indoor unit/genera l

equipment operation

display

For peak cut control, PI controller is required for electricity monitoring method.

� �

� �

PI controller required.

NA

License registration required

(Energy management license)

License registration required

(Energy management license)

License registration required

(Energy management license)

License registration required

(Energy management license)

(DIDO controller required) (DIDO controller required)

�

Accumulated

operation time

NA

�

Control of Air conditioner from PC

●

There are two ways to monitor air conditioner through a personal computer (PC).

One is from AG-150A WEB (Monitoring PC) and another with a TG-2000A (Central control PC).

*In both cases, control/monitor in a private network.

1) AG-150A WEB

Without special software, air conditioners can be controlled over a PC by just connecting a LAN and

registering WEB license. Units can be controlled collectively or in groups, and by blocks or floors. Also,

setting of annual schedule is possible with a license.

Number of AG-150A controlled/monitored per screen: 1 AG-150A (max. of 50 indoor units)

Comparison between AG-150A WEB and TG-2000A control/monitoring

●

2) TG-2000A

With TG-2000A software, up to 2000 indoor units can be controlled/monitored.

Compared to the AG-150A WEB, air conditioner layout by room and oor can be displayed and all AG-150A

in one system will be shown enabling easy control/monitoring.

*For AG-150A, a new version TG-2000A (Ver 5.50 or later) is required and a current version cannot be used.

- 11 - - 12 -

Page 8

TG-2000A software (Central control PC)

control/monitor

AG-150A WEB (Monitoring PC)

control/ monitor

All floor plan display

Co ntrol le r Displ ay

(DIDO controller)

In case floor in divided into four sections.Floor and section display only.

Click general equipment icon for operation

screen.

Click general equipment icon for operation

screen.

P r e s e n t v a l u e o f

measurement can be

d i s p l a y e d f r o m

[Measurement list].

ޓ

T r e n d g r a p h

(e lectricit y only) c an

b e d i splayed from

[ T o o l ] - [ G r a p h

display].

P r e s e n t v a l u e o f

measurement can be

d i s p l a y e d f r o m

[ M a i n t e n a n c e o f

charge data] - [Present

volume monitor].

Trend g rap h can b e

displayed from [Tool] [Graph display].

Measurement

ޓ

monitoring

(PI controller)

Measurement

Monitoring

(AI controller)

P r e s en t t e m p. a n d

hum id ity is in dic at ed

above the AI controller

icon on the floor plan.

Trend graph can be displayed from [Tool] [Graph display].

Present temp. and humidity can be seen from

[Measurement list].

Measuremen t c a n b e

displayed

from [Trend

graph].

NA

Function6

SSL authentication function

Global IP address

ADSL modem

ADSL modem

VPN router

VPN router

LAN

Internet

Web browser

Encrypted data

Internet connection

●

Enables control and monitor multiple properties from a remote location

n

Notication by e-mail to mobile phone or PC

n

.

Do not directly connect AG -150A to the Internet.

Note :

.

Use a security device such as a VPN router when connecting the AG -150A to the Internet to prevent unauthorized access.

.

To activate SSL functions use https://h.h.h.h/administrator.html

IP address of AG-150A

Remote monitoring

Monitoring and controlling on PC at desk or even in

remote buildings

AG-150A

No need to check every controller when turning ON/OFF

AG-150A

Error e-mail

Reports are provided to the designated e-mail addresses in the events of troubles.

Quick restoration is possible by understanding the causes of trouble in advance.

I can check the causes

of trouble without asking

customers.

AG-150A

AG-150A

AG-150A

It is convenient.

AG-150A

AG-150A

- 13 - - 14 -

Page 9

� External input: select A, B or C (on Network setting screen or on Initial setting web)

A

B

C

Level input

Pulse input

Emergency STOP

ON/OFF

ON/OFF/Prohibit local operate/Permit local operate

� External output

One or more IC: ON

One or more IC: Malfunction

ON signal output

Malfunction signal output

Max.50

units

Max.50

units

Max.150 units

AG-150A

IC

M-NET

M-NET

OC

M-NET

adapter

A Control

M-NET

M-NET

Max.50

units

LAN

PSU

(PAC-SC51KUA)

(100BASE-TX)

IC

M-NET

OC

M-NET

adapter

A Control

IC

M-NET

OC

M-NET

adapter

A Control

Expansion

Controller

PAC-YG50ECA

Expansion

Controller

PAC-YG50ECA

Expansion

Controller

PAC-YG50ECA

Central Control PC

(TG-2000A)

System structure

24VDC

Web function by PC

TG-2000A

100-240VAC

50Hz/60Hz

M-NET

to Air Conditioner

Switching HUB

PLC

LAN

Power supply

PAC-SC51KUA

Expansion

controller

Expansion

controller

Expansion

controller

April 2009 version

In case of 50 units or less

USB memory

In case of 51 units or more (Up to 150 units)

LED Lamp

POWER

ON/OFF

Z1

Y2

Y1

X2

X1

Z2

Remote monitoring

PC

Router

Service company

/Sales office

Router

Internet

Mobile phone of

service person

Switching

HUB

Switching

HUB

Switching

HUB

LAN

(100BASE-TX)

Central Control PC

(TG-2000A)

Monitoring PC

AG-150A WEB

AG-150A

IC

M-NET

M-NET

M-NET

adapter

A Control

OC

AG-150A

DIDO Controller

General Equipment

Temp/Humidity sensor

Watt hour meter

AI Controller

PI Controller

PSU

PAC-SC51KUA

with VPN with VPN

Note:New version (ver5.50

or later) of TG-2000A is

required for AG-150A.

Current TG-2000A cannot

be used.

Up to 5 can be connected

to 1 AG-150A

Note : Use a security device such as a VPN router when connecting the

AG-150A to the Internet to prevent unauthorized access.

System structure

●

1. Management of 50 or less units

same as current system

AG-150A can control up to maximum of 50 units

Units: include indoor units, LOSSNAY, DIDO (contacts), PI and AI controller.

*DIDO has 6 contact points. 1 contact point is counted as 1 indoor unit.

*Only 5 PI controllers can be connected to 1 AG-150A.

*Depending on the model, indoor units may be counted as 2 or more units.

When 50 or less units have to be controlled, AG-150A is connected directly to M-NET (as conventional

G-50A).

- 15 - - 16 -

2. Management of 51 or more units

Apr.2009

When managing 51 or more units, EXPANSION CONTROLLER (EC) is required.

*Connection between AG-150A and EC is done using LAN cable (Ethernet)

*50 units can be connected to 1 EC.

*3EC can be connected to 1 AG-150A through Switching HUB.

Page 10

Electric box (PAC-YG83UTB;

sold separately)

Inner wall

A

G-150A

Building structure

60 mm

(2-3/8 in)

minimum

M4 rounded

screw (supplied)

Wall

A

G-150A

Wall

M4 roundhead

screw (supplied)

Wall

A

G-150A

PAC-YG81TB (sold

separately) is required

mount installations.

Seal with putty

M4 roundhead

screw (supplied

with the PACYG81TB)

Wall

A

G-150A

PAC-YG85KTB (sold

separately) is required

in wall mount

installation with both

the controller and a

power supply unit.

Power supply unit

(PAC-SC51KUA; sold

separately)

M4 roundhead screw

(supplied with

PAC-YG85KTB).

Screws (supplied with

PAC-YG85KTB)

FGV+V- 2NC1NCSBA

24VDCM-NET

A B S V+ V- FG

M-NET Output

CN1 CN2

TB2 TB3

24VDC

Power supply unit (PAC-SC51KUA)

Centralized controller

(AG-150A)

Outdoor unit

Cable Clamp

M-NET transmission line

(Centralized control line)

DC power supply line (24VDC) *Polarized

* Use a ring terminal to connect to the terminal block

Back of controller

DC power supply line

(Polarity)

Shield

M-NET transmission

A, B line (Non-Polarity)

50 m (164 ft) or less

Function earthing

(ground) line

DC power supply

line (Polarity)

Power supply unit

Installation

Wiring

Installation Method

●

1) Embedding AG-150A in the wall

To embed AG-150A in the wall, A and

B type installation plate (supplied with

AG-150A) is required.

2) Wall-Embedded installation with an electric box

Emb e ddi n g AG -150A on

t h e w a l l a n d m o u n t i n g

it t o el e c t r ic b o x (PA C YG83UTB).

Electric box is separately

sold optional part.

Option:

Electric box

(PAC-YG83UTB)

DC Power Supply and M-NET Transmission Line

●

There are two ways to connect AG-150A and Power Supply Unit PAC-SC51KUA.

1. Connection via terminal block

The DC power cable and M-NET transmission line can be connected with a terminal block as the gure

shown below.

3) Wall-mounting AG-150A

To install AG -150A on the

wall, M ounting at tachment

B t ype ( PAC -YG 81T B) is

required.

Option:

Mounting attachment

B type (PAC-YG81TB)

4) Installing AG-150A and PSU inside the mounting attachment on the wall

- 17 - - 18 -

Mounting attac hment A type

(PAC -YG 85KTB) is requir ed

when installing AG -150A and

PSU on the wall.

Option:

Mounting attachment A type

(PAC-YG85KTB)

Page 11

Power supply unit (PAC-SC51KUA)

Centralized controller

(AG-150A)

M-NET transmission

line (Centralized

controll line)

DC power supply line

(24VDC) *Polarized

M-NET transmission line (Centralized control line)

DC power supply line (24VDC)

*Polarized

2. Connection via connector

1) Maximum length of M-NET transmission line:

1 L1+L2+L3+ 5+ 1+ 2 ( 3) 500m (1640 ft)

2 L1+L2+L3+ 5+ 4 500m (1640 ft)

3 L1+L2+L4+ 6+ 7 ( 8) 500m (1640 ft)

4 2 ( 3) + 1+ 5+L3+L4+ 6+ 7 ( 8) 500m (1640 ft)

5 4+ 5+L3+L4+ 6+ 7 ( 8) 500m (1640 ft)

2) Maximum power feeding length for the indoor control line:

1 5+ 1+ 2 ( 3) 200m (656 ft)

2 5+ 4 200m (656 ft)

3 6+ 7 ( 8) 200m (656 ft)

3) Maximum power feeding length for the centralized control line:

1 L1 200m (656 ft)*

2 L2 +L3 (L4) 200m (656 ft)

All electric work must be performed according to local regulations.

Improper electrical work may result in electric shock or fire.

Be sure to shut off the power source of the unit and all other units to be connected to

the power supply unit before wiring.

Do not connect AC power line to M-NET and POWER (24VDC) terminal blocks of

AG-150A. Otherwise, the unit may fail.

D1 (24VDC) < 50m/164ft if connected via terminal

- The cable for M-NET is not connected to AG-150A

AG-150A

M-NET

PSU

LAN

100m/328ft

100m/328ft

100m/328ft

100m/328ft 100m/328ft

50m/164ft

100m/328ft

200m/656ft

200m/656ft

D1

Switching

HUB

Expansion

controller

Wiring length is same as

conventional system

PAC-YG50ECA

Expansion

controller

PAC-YG50ECA

Expansion

controller

PAC-YG50ECA

M-NET remote controller

M-NET transmission line(Centralized control line)

M-NET transmission line (Indoor control line)

AG-150A

DC Power supply

(24VDC)

L1 L2

L4

L3

PAC-SC51KUA

1

3

M-NET remote controller

2

7

6

Length:

max. 50m (164 ft)

5

8

4

CN40 CN41

*To supply power to the M-NET

line from PAC-SC51KUA,

connect the power jumper on

outdoor unit to CN41.

Outdoor unit

ON OFF

PSU

Note : If the remote control cable ( 4, 8) does not exceed 10m (32 ft) in length, the length for 4, 8 may not

need to be added to the total length.

Wiring Length

●

When installing AG-150A with mounting attachment A type (PAC-YG85KTB) (optional), DC power cable and

M-NET transmission line is connectable via connector using a cable supplied with PAC-YG85KTB.

1. Management of 50 units

Allowable length of M-NET Transmission Lines and its system conguration are follows.

2. Management of 51 or more units

- 19 - - 20 -

When managing 51 or more units, EXPANSION CONTROLLER (PAC-YG50ECA) (EC) is required.

Refer to the below for wiring restrictions.

* AG-150A is connected to Expansion controller (EC)

via LAN cable.

(LAN cable : Category 5 or above cable)

* The length of transmission line can be lengthened by adding switching HUB.

(Can not use Repeater HUB)

* There is no limitation in the number of cascade connection when using a switching HUB.

Recommended cascade connection is 3.

(In the case of 3 cascade, the maximum length between AG-150A and EC is 400m/1312ft.)

Precautions

●

Page 12

Q & A

AG-150A

IC

M-NET

M-NET

M-NET

adapter

A Control

OC

PSU

DIDO Controller

General Equipment

Temp./Humidity sensor

Watt hour meter

AI Controller

PI Controller

PAC-SC51KUA

How many units can be controlled by AG-150A?

Q1

50 units. But use of expansion controllers (EC) allows controlling maximum 150 units. 50 units can

be connected to 1 EC so max.3EC is required to control 150 units by AG-150A.

Controllable units include, indoor units, LOSSNAY, DIDO, PI and AI controller.

*DIDO has 6 contact points. 1 contact point is counted as 1 indoor unit.

*Only 5 PI controllers can be connected to 1 AG-150A.

*Depending on the model, indoor units may be counted as 2 or more units.

What happens when someone forgets the password of initial setting screen of AG-150A?

Q2

Contact your sales ofce. A special password will be released.

What happens when AG-150A is connected directly to the Internet?

Q3

AG-150A could be hacked. Please use a security device such as a VPN router when connecting

the AG-150A to Internet to prevent unauthorized access.

Is license required for weekly schedule?

Q4

Is it possible to connect AG-150A and G-50A in same system controlled by TG-2000A?

Q10

Yes. Use TG-2000A Ver.5.50 and above.

Can we use power supply unit PAC-SC50KUA with AG-150A?

Q11

No. Use PAC-SC51KUA.

24VDC power supply is required to drive AG-150A. Conventional G-50A used 12VDC to drive

controller and this 12VDC was supplied by PAC-SC50KUA. So since PAC-SC50KUA does not

supply 24VDC, it cannot be used with AG-150A.

Is it possible to put units in Refrigerant status check mode automatically?

Q12

No. You need to do it manually.

How many AG-150A can be connected to TG-2000A?

Q13

Same as conventional G-50A, 40 AG-150A can be connected to TG-2000A.

(Total of 2000 units can be connected to TG-2000A to be controlled/monitored.)

Q5

Q6

Q7

Q8

Q9

No. Weekly schedule is a standard function. License is required for seasonal (weekly1, weekly2),

yearly, daily schedule, and when connected to TG-2000A.

How does optimized start-up work?

AG-150A studies the set temp, room temp (return air temp) and the data of past days (at what conditions

the optimized start-up executed) and decides when to switch on the units.

What is the life span of backlight and color LCD?

Design life span is 13 years. To maintain long life, it is required to activate the automatic switch off

function of backlight. We also plan to have backlight as a service parts.

What happens when LCD of AG-150A is damaged?

There is no spare part for LCD. AG-150A needs to be changed.

Is it possible to connect AG-150A to current TG-2000A?

- 21 - - 22 -

No.You need TG-2000A Ver.5.50 and above to connect to AG-150A.

Since version of G-50A and AG-150A are different, new TG-2000A ver.5.50 and above is required.

Is it possible to send charge data by e-mail?

No. Use USB memory to extract charge parameter data.

Can PC be connected to AG-150A via USB port?

Q14

No. USB port is only for USB memory.

What kind of data is extractable with USB memory?

Q15

Initial settings and charge parameter.

Can any USB memory be used to extract data from AG-150A?

Q16

No. Specied USB memory should be used.

Manufacturer : SanDisk, model : SDCZ6-2048-J65RB, 2G Byte

Manufacturer : Kingston, model : DT400/2GBFE, 2G Byte

We are planning to add brands and models of USB memory in the future.

*

What’s the system conguration like when only 50 or less units are connected?

Q17

AG-150A is connected directly to

M-NET (same as the conventional

centralized controller G-50A.)

Page 13

Centralized controller

Other system controllers

AG-150A G-50A GB-50A

ON/OFF

remote controller

System controller, Schedule timer, Group

remote controller

1

-

1 5 10

Total number of ON/OFF remote controller

0 1 2 3 4 5

0 � � � � �

�

1 � � � �

2 � � � �

3 � � � �

4 � � �

5 � � �

6 � �

7 � �

8 �

Total number of System remote

controller, Schedule time,

Group remote controller

When connecting 1 AG-150A

9 �

Q18

Max.50

units

Max.50

units

Max.150 units

AG-150A

IC

M-NET

M-NET

OC

M-NET

adapter

A Control

M-NET

M-NET

Max.50

units

LAN

PSU

(PAC-SC51KUA)

(100BASE-TX)

IC

M-NET

OC

M-NET

adapter

A Control

IC

M-NET

OC

M-NET

adapter

A Control

Expansion

Controller

PAC-YG50ECA

Expansion

Controller

PAC-YG50ECA

Expansion

Controller

PAC-YG50ECA

Central Control PC

(TG-2000A)

What’s the system conguration like when more than 50 units are connected?

Q21

Where is the serial number for AG-150A indicated?

AG-150A connected to

M-NET via Expansion

Controller.

April 2009

How many AG-150A can be connected to 1 power supply unit (PAC-SC51KUA)?

Q19

One AG-150A can be connected.

Max.connectable number of controller when using PAC-SC51KUA

Serial number is indicated in two places. One on the packaging box and another can be seen at the

lower right corner when taking off the AG-150A cover.

What should be done if the touch panel has a poor reaction?

Q22

To adjust touch panel, go to the Initial setting, [Maintenance] and [Touch Panel Calibration] to bring

up the Touch Panel Calibration screen.

For further instruction, refer to the AG-150A Instruction Book.

Start calibration

button

Max. connectable number of controller when using PAC-SC51KUA

Q20

Is it possible to monitor and operate general equipments from AG-150A?

Yes. To connect general equipment use DIDO (PAC-YG66DCA)

- 23 - - 24 -

Page 14

- 25 -

Page 15

AG-

150

demonstration site

A

Access

http://wwwl1.mitsubishielectric.co.jp/wink_doc/wink_files/acr/menu/ag150/

from your PC.

Explanation

AG-150A unit

WEB

Installation image

This demonstration site covers the primary functions AG-150A possesses and gives users

fundamental experience of AG-150A.

FM 33568 / ISO 9001;2000

Certificate Number EC97J1227

The Air Conditioning & Refrigeration Systems Works acquired ISO 9001 certification under Series

9000 of the International Standard Organization (ISO) based on a review of Quality , management for

the production of refrigeration and air conditioning equipment.

ISO Authorization System

The ISO 9000 series is a plant authorization system relating to quality management as stipulated by

the ISO. ISO 9001 certifies quality management based on the "design, development, production,

installation and auxiliary services" for products built at an authorized plant.

The Air Conditioning & Refrigeration Systems Works acquired environmental management system

standard ISO 14001 certification.

The ISO 14000 series is a set of standards applying to environmental protection set by the

International Standard Organization (ISO).

ht tp :/ /G lo ba l. Mi ts ub is hi El ec tr ic .c om

MEE08K043

Specifications subject to change without notice

New publication effective Jan. 2009

Loading...

Loading...