MITEL GP2021IG, GP2021GQ1R, GP2021 Datasheet

The GP2021 is a 12 channel C/A code baseband

correlator for use in NAVSTAR GPS and GLONASS satellite

navigation receivers. The GP2021 complements the GP2015

and GP2010 C/A code RF downconverters available from

Mitel Semiconductor.

The GP2021 is compatible with most 16 bit and 32 bit

microprocessors, especially those from Motorola and Intel,

with additional on–chip support for the ARM60 32 bit RISC

processor. When the ARM60 is used, the on–chip memory

management functions allow implementation of a full GPS

receiver with minimal external logic.

The GP2021 allows individual channel de–activation, for

systems not requiring full 12 channel operation, to save power

and processor loading. Receiver power may be further

conserved by reducing the supply voltage to 2.2V under

battery backup. Although all system functions are disabled,

the 32.768kHz oscillator and Real Time Clock are maintained

for the microprocessor to estimate satellite visibility at power

on to reduce signal acquisition time.

A development system called the GPS Architect is

available as a basis for receiver design using the GP2021 and

associated products.

FEATURES

■ 12 Fully Independent Correlation Channels

■ 1PPS UTC Aligned Timing Output

■ On–Chip Dual UART and Real Time Clock

■ Compatible with most 16 and 32 bit Microprocessors

■ Memory Control Logic for ARM60 Microprocessor

■ Low Voltage, Low Current Power–Down Mode

■ Power Dissipation 150mW Typical

■ Compatible with GP2015 and GP2010 RF Front Ends

■ Battery Backup Voltage 2.2V (min)

APPLICATIONS

■ GPS Navigation Systems

■ High Integrity Combined GPS–GLONASS Receivers

■ GPS Geodetic Receivers

■ Time Transfer Receivers

ORDERING INFORMATION

GP2021/IG/GQ1R

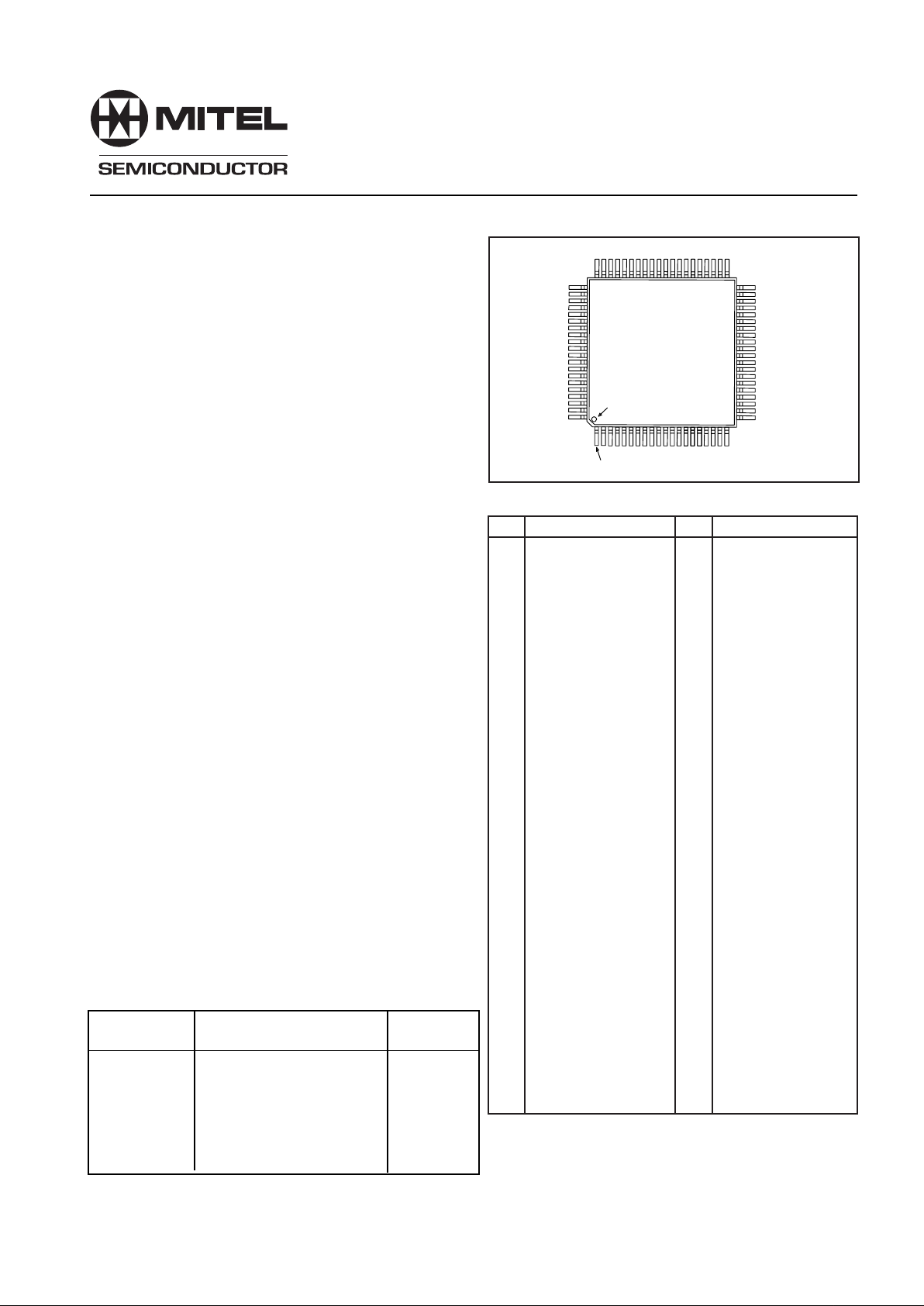

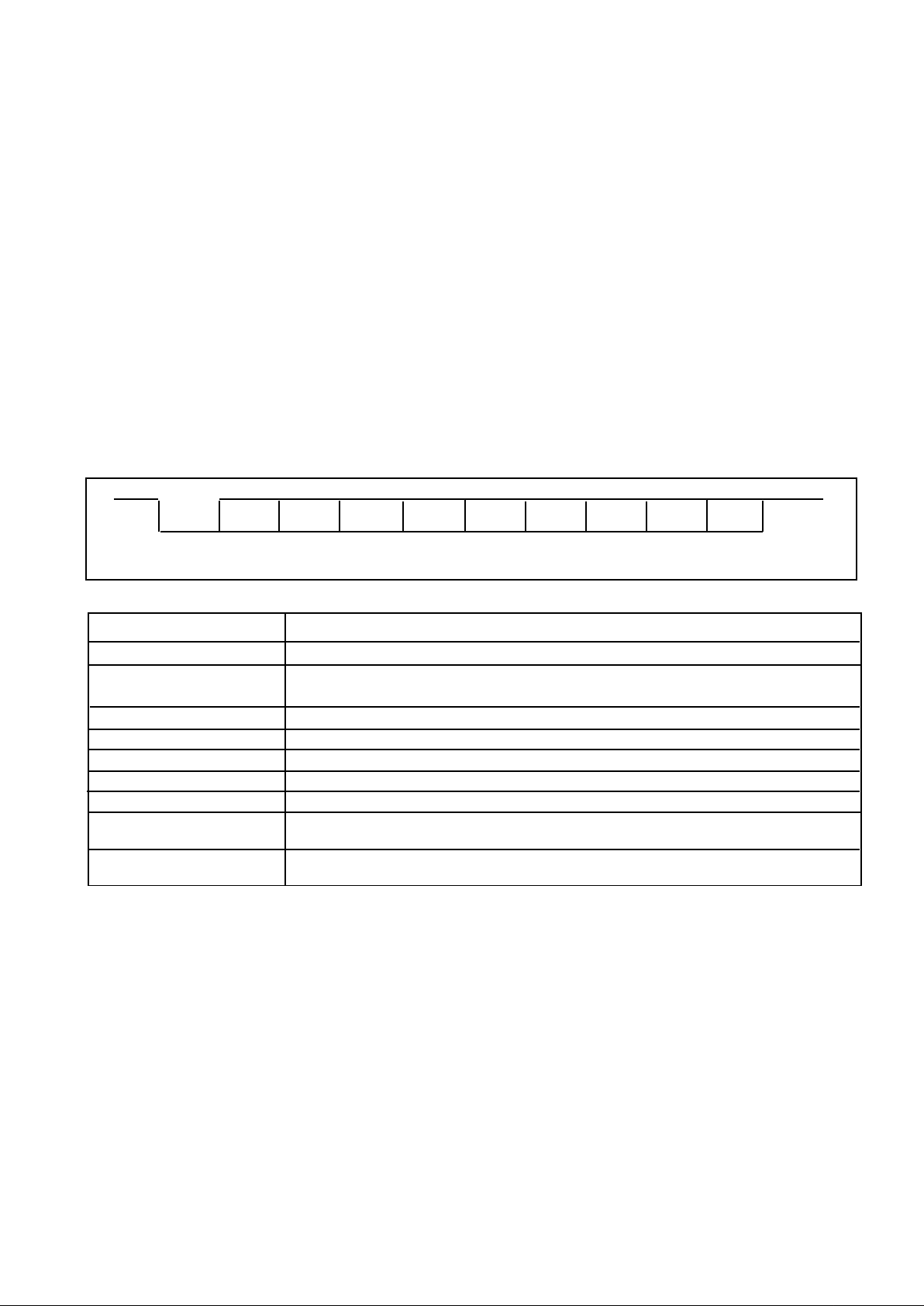

Fig.1 Pin connections - top view

GQ80

GP2021

PIN 1

PIN 1 IDENT

PIN

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

DESCRIPTION

MULTI_FN_IO

POWER _GOOD

NRESET_OP

NARMSYS

XIN

XOUT

TXA

TXB

RXA

RXB

NROM / NC

NEEPROM / NC

NSPARE_CS / NC

V

DD

V

SS

NRAM / BC

NW0 / NC

NW1 / NC

NW2 / NC

NW3 / NC

NRD / NC

ARM_ALE / NC

DBE / NC

ACCUM_INT

MEAS_INT

NBW / WRPROG

NMREQ / DISCIP2

NOPC / NINTELMOT

NRW / DISCIP3

MCLK / NC

ABORT / MICRO_CLK

DISCIO

A22 / READ

VDD

VSS

A21 / NCS

A20 / WREN

A9

A8

A7

DESCRIPTION

A6

A5

A4

A3

A2

A1 / ALE_IP

A0 / NRESET_IP

D0

D1

D2

D3

D4

D5

D6

V

DD

V

SS

D7

D8

D9

D10

D11

D12

D13

D14

D15

PLL_LOCK

VDD

DISCOP

V

SS

CLK_T

CLK_I

V

SS

SAMPCLK

V

DD

NBRAM / DISCIP4

SIGN0

MAG1

SIGN1

MAG1

DISCIP1

PIN

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

DS4077 - 2.6 July 1996

GP2021

GPS 12 channel Correlator

Advance Information

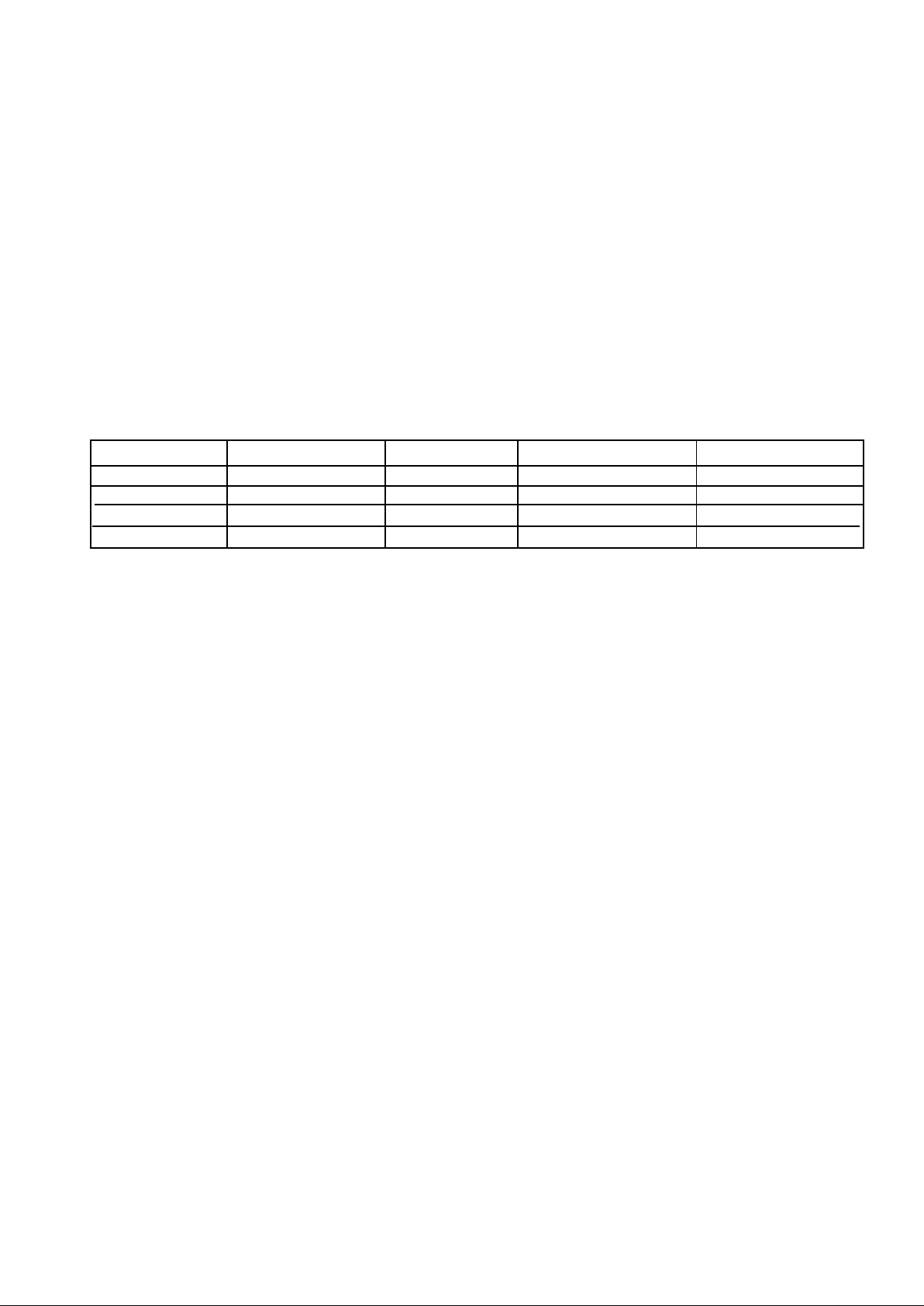

RELATED PRODUCTS

PART DESCRIPTION DATASHEET

REFERENCE

GP2015 GPS Receiver RF Front End DS4374

– TQFP 48 package

GP2010 GlPS Receiver RF Front End DS4056

– PQFP 44 package

DW9255 35.42MHz SAW Filter DS3861

P60ARM 32 bit RISC Microprocessor DS3553

GPS Architect GPS 12 Channel DS4004

Receiver Development System

2

GP2021

TABLE OF CONTENTS

HEADING PAGE

TYPICAL GPS RECEIVER 4

PIN DESCRIPTION 4

Differences between Real and Complex_Input Mode 7

FUNCTIONAL DESCRIPTION 7

12 CHANNEL CORRELATOR 8

Clock Generator 8

Timebase Generator 8

Status Registers 9

Sample Latches 9

Address Decoder 9

Bus Interface 9

TRACKING MODULES 9

Carrier DCO 9

Code DCO 9

Carrier Cycle Counter 9

C/A Code Generator 9

Source Selector 10

Carrier Mixers 10

Code Mixers 10

Accumulate and Dump 10

Code Phase Counter 10

Code Slew Counter 10

Epoch Counter 11

PERIPHERAL FUNCTIONS 11

Dual UART 11

Receiver 11

Transmitter 11

Reset 11

Channel Loopback 12

Real Time Clock (RTC) and Watchdog 12

Power and Reset Control 12

Power Down Mode 12

Hardware Reset Generation 13

System Error Status Register 13

Discrete I/O 14

Digital System Test Interface 15

MICROPROCESSOR INTERFACE 15

General Interface Timing 15

Write Cycle to Read Cycle Timings 15

Write Cycle to Write Cycle Timings 15

Notes about Interface Timing Constraints 15

ARM System Mode 17

Address Map 17

Control Signals 17

ARM System Timing 17

Wait State Generation 17

Debug (Abort) Function 20

Standard Interface Mode 20

Control Signals 21

Motorola Style Interface 21

Intel 80186 Style Interface 21

Intel 486 Style Interface 21

Reset 21

Register Addressing 21

CONTROLLING THE GP2021 22

Search Operation 22

Carrier DCO Programming 22

Code DCO Programming 22

Code Generator Programming 22

Reading the Accumulated Data 22

Search on Other Code Phases 22

Data Bit Synchronisation 22

Reading the Measurement Data 22

Preset Mode 23

3

GP2021

Interrupts 23

Signal Path Delay (Introduced by Hardware Signal Processing) 23

Integrated Carrier Phase Measurement 23

Timemark Generation 24

GP2021 Register Map 25

Correlator Registers 26

Tracking Channel Registers 27

ACCUM_STATUS_A 28

ACCUM_STATUS_B 28

ACCUM_STATUS_C 28

CHx_ACCUM_RESET 29

CHx_CARRIER_CYCLE_COUNTER 29

CHx_CARRIER_CYCLE_HIGH 29

CHx_CARRIER_DCO_INCR_HIGH 29

CHx_CARRIER_DCO_PHASE 29

CHx_CODE_DCO_INCR_HIGH 30

CHx_CODE_DCO_PHASE 30

CHx_CODE_DCO_PRESET_PHASE 30

CHx_CODE_PHASE 30

CHx_CODE_SLEW 30

CHx_EPOCH_CHECK 31

CHx_EPOCH 31

CHx_EPOCH_COUNT_LOAD 31

CHx_I_TRACK, CHx_Q_TRACK, CHx_I_PROMPT,CHx_Q_PROMPT 31

CHx_SATCNTL 31

MEAS_STATUS_A 33

MULTI_CHANNEL_SELECT 33

PROG_ACCUM_INT 33

PROG_TIC_HIGH, PROG_TIC_LOW 34

RESET_CONTROL 34

STATUS 35

SYSTEM_SETUP 35

TEST_CONTROL 35

TIMEMARK_CONTROL 36

X_DCO_INCR_HIGH 37

Peripheral Functions Registers 37

Real Time Clock and Watchdog 37

RTC_LS, RTC_2ND, RTC_MS 37

CLOCK_RESET 37

WATCHDOG_RESET 37

DUART 38

CONFIG_A, CONFIG_B 38

STATUS_A, STATUS_B 38

RESET_A, RESET_B 38

TX_DATA_A, TX_DATA_B, RX_DATA_A, RX_DATA_B 38

TX_RATE_A, TX_RATE_B 39

System Control 39

WAIT_STATE 39

SYSTEM_CONFIG 39

SYSTEM_ERROR_STATUS 39

CHIP_REVISION 39

DATA_RETENT 40

General Control 40

IO_CONFIG 40

TEST_CONFIG 41

DATA_BUS_TEST 41

ABSOLUTE MAXIMUM RATINGS 41

Electrostatic Discharge Protection (ESD) 41

Crystal Specification 41

ELECTRICAL CHARACTERISTICS 42

PIN TYPES 44

TIMING CHARACTERISTICS 47

PACKAGE DETAILS 64

DETAILED DESCRIPTION OF REGISTERS 25

4

GP2021

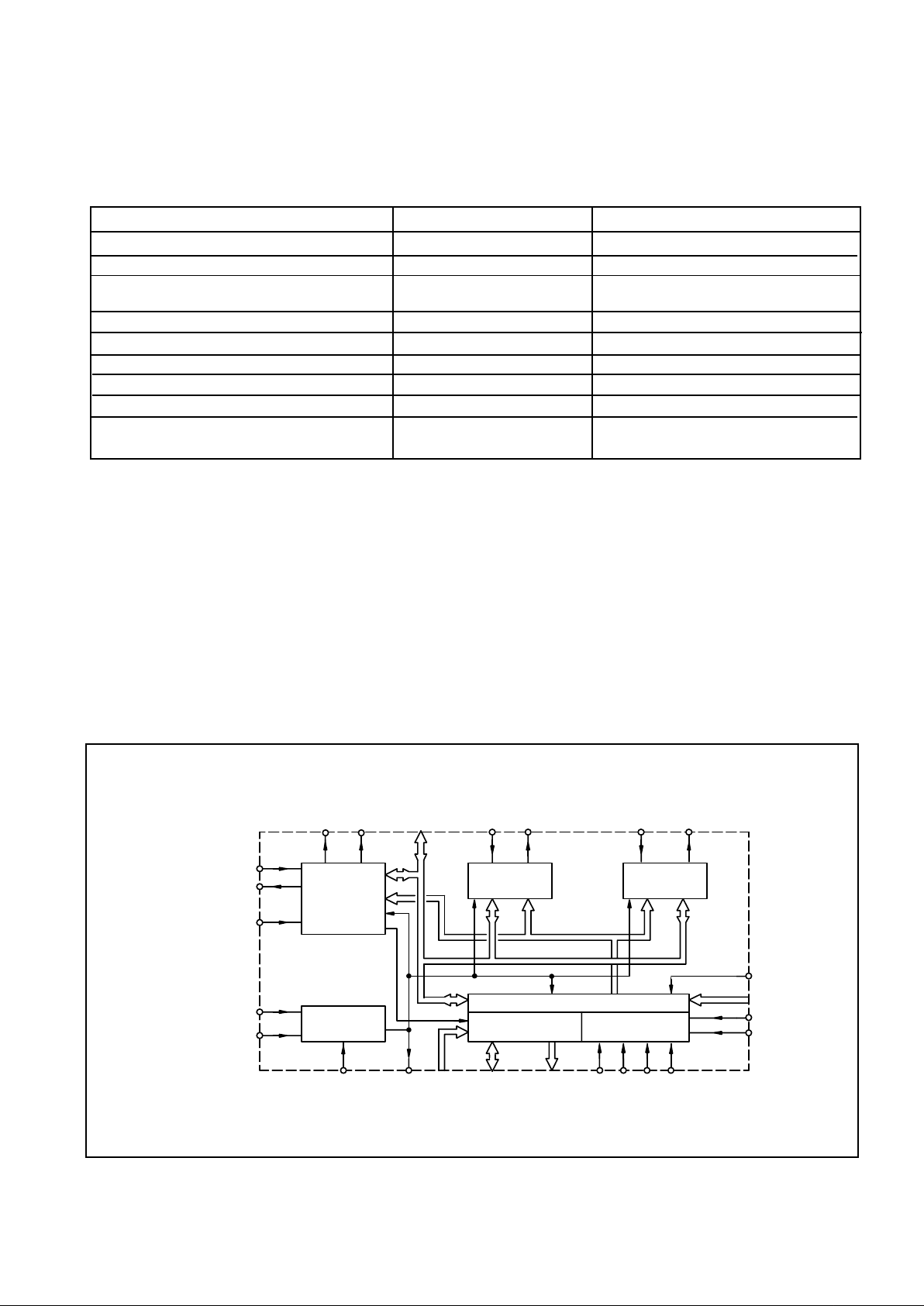

TYPICAL GPS RECEIVER

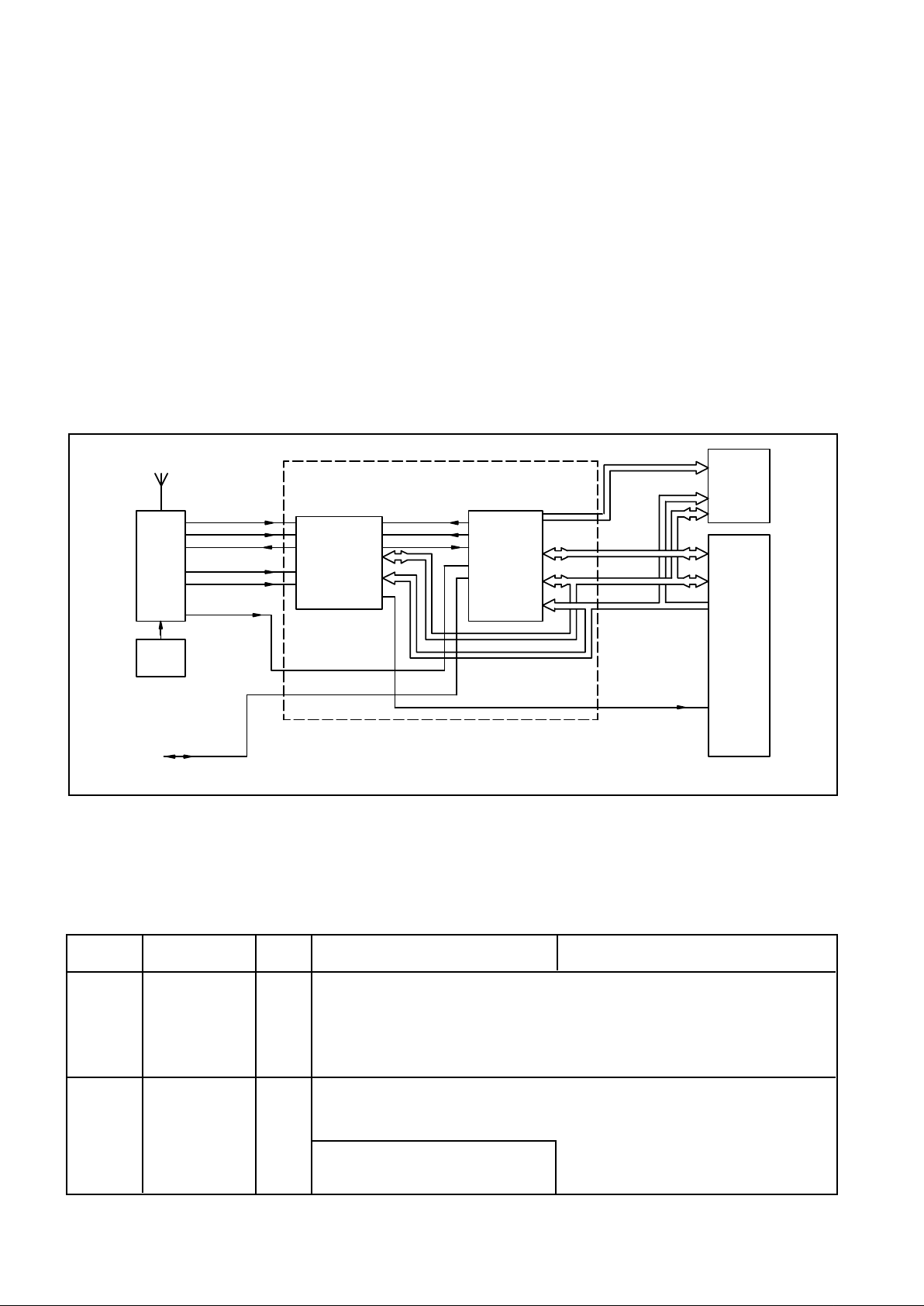

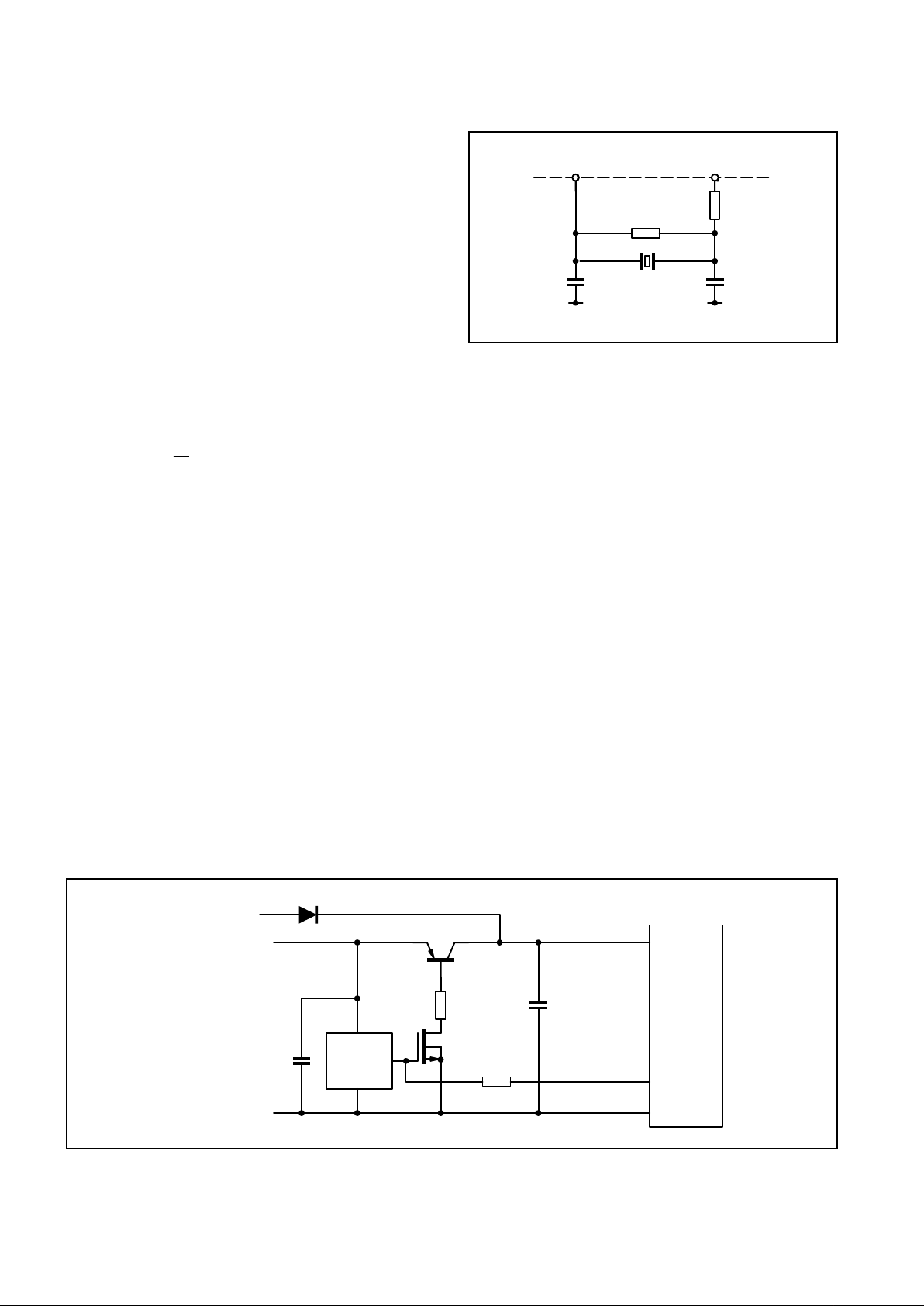

Fig. 2 shows a typical GPS receiver employing a GP2010

RF front–end, a GP2021 correlator and an ARM60 32 bit RISC

microprocessor.

A single front end may be used, since all GPS satellites use

the same L1 frequency of 1575.42 MHz. However, in order to

achieve better sky coverage, it is sometimes desirable to use

more than one antenna. In this case, separate front ends will

be needed.

The RF section, GP2010, performs down conversion of

the L1 signal for digital baseband processing. The resultant

signal is then correlated in the GP2021 with an internally

generated replica of the satellite code to be received.

Individual codes for each channel may be selected

independently to enable acquisition and tracking of up to 12

different satellites simultaneously

The results of the correlations form the accumulated data

and are transferred to the microprocessor to give the

broadcast satellite data (the ’Navigation Message’) and to

control the software signal tracking loops.

The GP2021 can be interfaced to one of two styles of front

end. In Real_Input mode, the front end supplies either a 1

(sign) or 2 (sign and magnitude) bit signal to either the

SIGN0/MAG0 or SIGN1/MAG1 inputs of the GP2021.

Alteratively, in Real_Input mode, 2 separate front ends can be

connected to a single GP2021 and selected under software

control. The GP2015 and GP2010 are Real_Input mode front

ends.

In Complex_Input mode, the front end is required to supply

In–phase (I) and Quadrature (Q) signals to the SIGN0/MAG0

and SIGN1/MAG1 inputs respectively. Hence, only a single

front end can be used with each GP2021 in Complex_Input

mode.

GP2010

SIGN

MAG

SAMPCLK

CLK_T

CLK_I

PLL_LOCK

10MHz

TCXO

TX/RX

SERIAL

COMMS PORT

ACCUM_INT,MEAS_INT

12

CHANNEL

CORRELATOR

WREN

READ

MICRO_CLK PERIPHERAL

FUNCTIONS

MEMORY

CONTROL

MEMORY

CONTROL

DATA

ADDR

ARM60

GP2021

L1

ANTENNA

Fig. 2 Block diagram of typical ARM based receiver

PIN DESCRIPTION

All V SS and V DD pins must be connected in order to ensure reliable operation. Any unused inputs must be tied High or Low.

The Table below describes the pin functions in Real_Input mode and assumes a master clock input frequency of 40MHz.

Those pins whose functions differ in Complex_Input mode are described at the end of the table.

Note that those pin names containing a ‘/’ have dual functionality between ARM System and Standard Interface modes. The

Pin mnemonic for ARM System mode always precedes the ‘/’.

Pin No Signal Name Type Description ARM System Mode Description Standard Interface

Mode

15, 35, V SS - Ground Pin

56, 69,

72

14, 34, V DD + Power supply to device.

55, 67,

74

1 MULTI_FN_IO I/O Multi–function input / output. Its function is configured by the IO_CONFIG register.

After a GP2021 reset it acts as the Digital System Test Enable input. It can also

be configured as a discrete output, or a discrete input if certain conditions are met.

Can be configured as the TRIGGER

input to the DEBUG block in ARM

System mode.

5

GP2021

Pin No Signal Name Type Description ARM System Mode Description Standard Interface

Mode

2 POWER_GOOD I Power Monitor input. High for normal operation. Low forces the GP2021 into

Power Down mode.

3 NRESET_OP O System Reset output (Active Low). Lasts for 4 MICRO_CLK cycles after all reset

conditions have cleared.

4 NARMSYS I Processor Mode Selection input. When Low, this input selects ARM System

mode. When High, Standard Interface mode is selected.

5 XIN I Crystal input connection to Real Time Clock.

6 XOUT O Crystal output connection from Real Time Clock.

7 TXA O Transmit Data output from Channel A of the Dual UART.

8 TXB O Transmit Data output from Channel B of the Dual UART.

9 RXA 1 Receive Data input to Channel A of the Dual UART. This pin acts as a master clock

input in Digital System Test mode.

10 RXB I Receive Data input to Channel B of the Dual UART. This pin acts as the Real Time

Clock reset in Digital System Test mode.

11 NROM / NC O ROM Chip Select output (Active Low). Unused output. (Do not connect.)

12 NEEPROM / NC O EEPROM Chip Select output (Active Low) Unused output. (Do not connect.)

13 NSPARE_CS / NC O Spare Chip Select output (Active Low). Unused output. (Do not connect.)

16 NRAM / NC O RAM Chip Select output (Active Low). Unused output. (Do not connect.)

17 NW0 / NC O Byte 0 Write Strobe output (Active Low). Unused output. (Do not connect.)

18 NW1 / NC O Byte 1 Write Strobe output (Active Low). Unused output. (Do not connect.)

19 NW2 / NC O Byte 2 Write Strobe output (Active Low). Unused output. (Do not connect.)

20 NW3 / NC O Byte 3 Write Strobe output (Active Low). Unused output. (Do not connect.)

21 NRD / NC O Read Data Strobe output (Active Low). Unused output. (Do not connect.)

22 ARM_ALE / NC O ALE output to the microprocessor Unused output. (Do not connect.)

(Active High). Controls the transparent

latches at the microprocessor address

outputs.

23 DBE / NC O Data Bus Enable output to the Unused output. (Do not connect.)

microprocessor. When Low, places the

microprocessor data bus drivers in a

high impedance state.

24 ACCUM_INT O A free running interrupt to the microprocessor. It allows control of data transfer

between the accumulators in the correlator and the microprocessor. It is active

Low when configured for ARM System mode or Motorola mode and is active High

in Intel mode.

25 MEAS_INT O An interrupt to the microprocessor. It allows control of measurement data transfer

between the correlator and the microprocessor. It is active Low when configured

for ARM System mode or Motorola mode and is active High in Intel mode.

26 NBW / WRPROG I Byte/Word input from the Write–Read Program input. In Intel

microprocessor. Low indicates a byte mode, High selects 486 style

transfer, and High a word transfer. interface and Low 186 style.

Unused in Motorola mode

27 NMREQ / DISCIP2 I Memory Request input from the Multi–purpose discrete input.

microprocessor. Low indicates that the

microprocessor requires a memory

access during the following cycle.

28 NOPC / NINTELMOT I Opcode fetch input from the High selects Motorola mode and

microprocessor. Low indicates that an Low Intel mode.

instruction is being fetched and High

that data is being transferred.

29 NRW / DISCIP3 I Read/Write Select input from the Multi–purpose discrete input.

microprocessor. Low indicates a read

cycle and High a write cycle.

30 MCLK / NC O Microprocessor Clock output Unused output. (Do not connect.)

(nominally 20MHz). Its phases can be

stretched under control of the

Microprocessor Interface.

6

GP2021

Pin No Signal Name Type Description ARM System Mode Description Standard Interface

Mode

31 ABORT/ MICRO_CLK O Abort output to the microprocessor. 20MHz Clock output. Provides a

Generates a valid ARM Data Abort 20MHz clock with a 1:1

sequence, triggered by a rising edge mark-to-space ratio

at MULTI_FN_IO if this function is

enabled.

32 DISCIO I/O Multi–purpose discrete input / output. After a GP2021 reset it is

configured as an input.

33 A22 / READ I Address input from the microprocessor. Read input from the

A<22:20> are decoded to select the microprocessor. In Intel mode

address space partitioning. it is the active Low read strobe.

In Motorola mode it is the Read

(High)/Write (Low) select line.

36 A21 / NCS I Address input from the microprocessor. GP2021 Chip Select input

A<22:20> are decoded to select the (Active Low).

address space partitioning.

37 A20 / WREN I Address input from the microprocessor Write–Read Strobe input from

A<22:20> are decoded to select the the microprocessor. In Intel

address space partitioning. mode it is the active Low write

strobe. In Motorola mode it is

the active High Write-Read

strobe.

38 – 45 A<9:2> I Address Inputs <9:2> from the microprocessor. These allow register

selection.

46 A1 / ALE_IP I Address input 1 from the Address Latch Enable input

microprocessor. A<1:0> are decoded from microprocessor (Active

to provide individual byte write High)

selection via NW<3:0>.

47 A0 / NRESET_IP I Address input 0 from the Reset input (Active Low).

microprocessor. A<1:0> are decoded

to provide individual byte write

selection via NW<3:0>.

48– 54, D<0:15> I/O Bidirectional data bus.

57–65

66 PLL_LOCK I PLL Lock Indicator input from RF section. When High this signa

indicates that the PLL within the RF section is in lock and the master

clock inputs have stabilised.

68 DISCOP O Multi–purpose discrete output.

70 CLK_T I Master clock input (40MHz).

71 CLK_I I Inverted Master clock input.

73 SAMPCLK O Sample Clock output to the front end. Provides a 5.714MHz clock with a

4:3 mark–to–space ratio.

75 NBRAM / DISCIP4 I Battery Backed RAM select input. Multi–purpose discrete input.

Defines the state of the NRAM output in

Power Down mode.

76 SIGN0 I SIGN0 input from the RF section.

77 MAG0 I MAG0 input from the RF section.

78 SIGN1 I SIGN1 input from a second, optional, RF section.

79 MAG1 I MAG1 input from a second, optional, RF section.

80 DISCIP1 I Multi–purpose discrete input.

7

GP2021

Difference between Real and Complex_Input

Mode

The input mode is selected by theFRONT_END_MODE bit

in the SYSTEM_SETUP register. It defaults to Real_Input

mode at power up. The differences between Real and

Complex input mode are summarised in the following table.

Description Real_Input mode Complex_Input mode

Recommended Master clock frequency 40MHz 35MHz

GP2021 internal clocking

1

± 7 ÷ 6

MICRO_CLK 2 output frequency 20MHz 17.5MHz

mark : space 1:1 1:1

Pin No 76 SIGN 0 SIGN_I

Pin No 77 MAG 0 MAG_I

Pin No 78 SIGN 1 SIGN_Q

Pin No 79 MAG 1 MAG_Q

Input Signal Sampling Rate 5.714MHz 5.833MHz

SAMPCLK output frequency 5.714MHz Not available

mark : space 4:3 (held Low)

)

Notes. 1 The GP2021 interrupt and TIC timebase dividers are clocked by this resulting clock.

2 The MCLK output is derived from this signal. In ARM mode the phases of MCLK are stretched by the

Microprocessor Interface block.

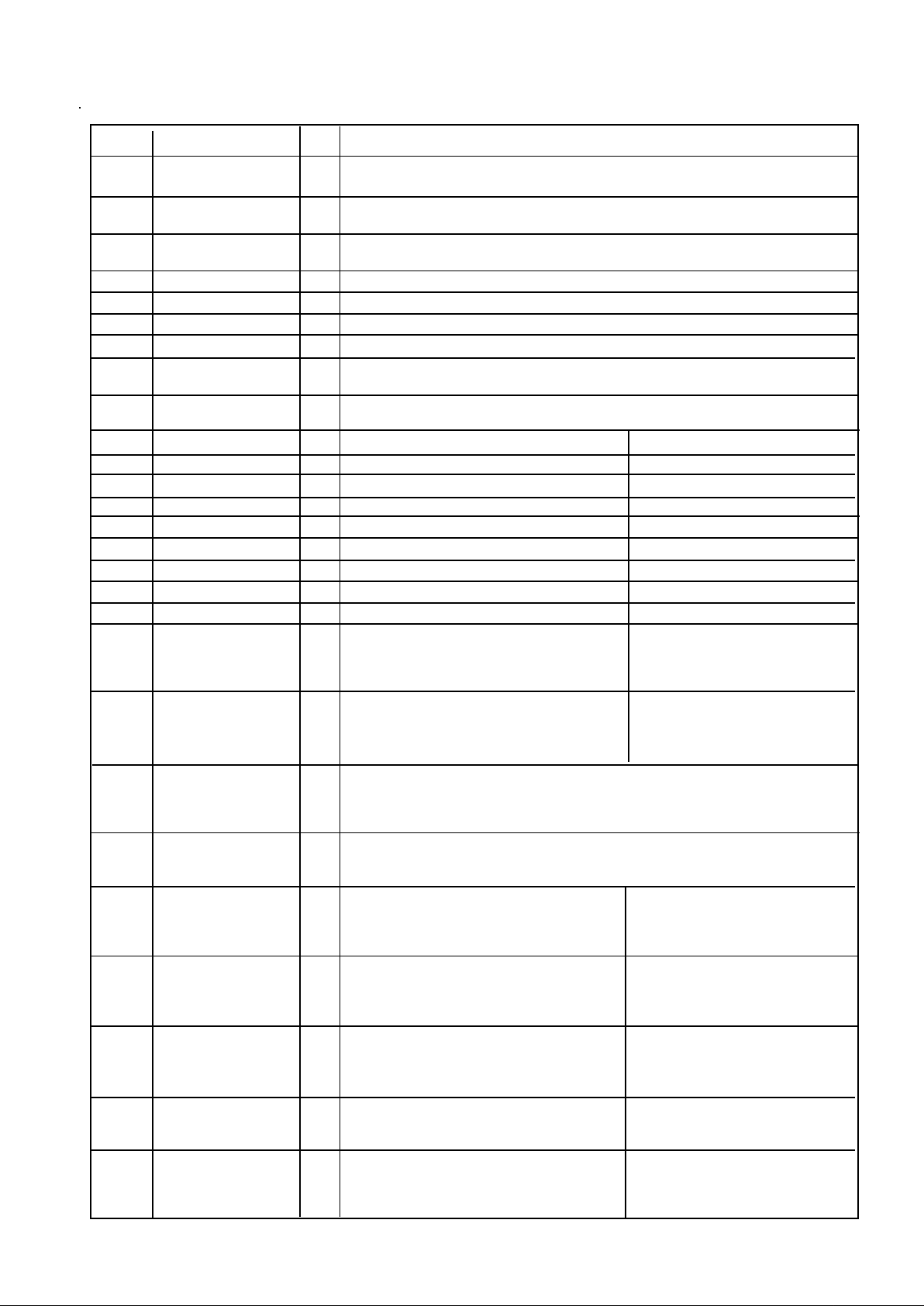

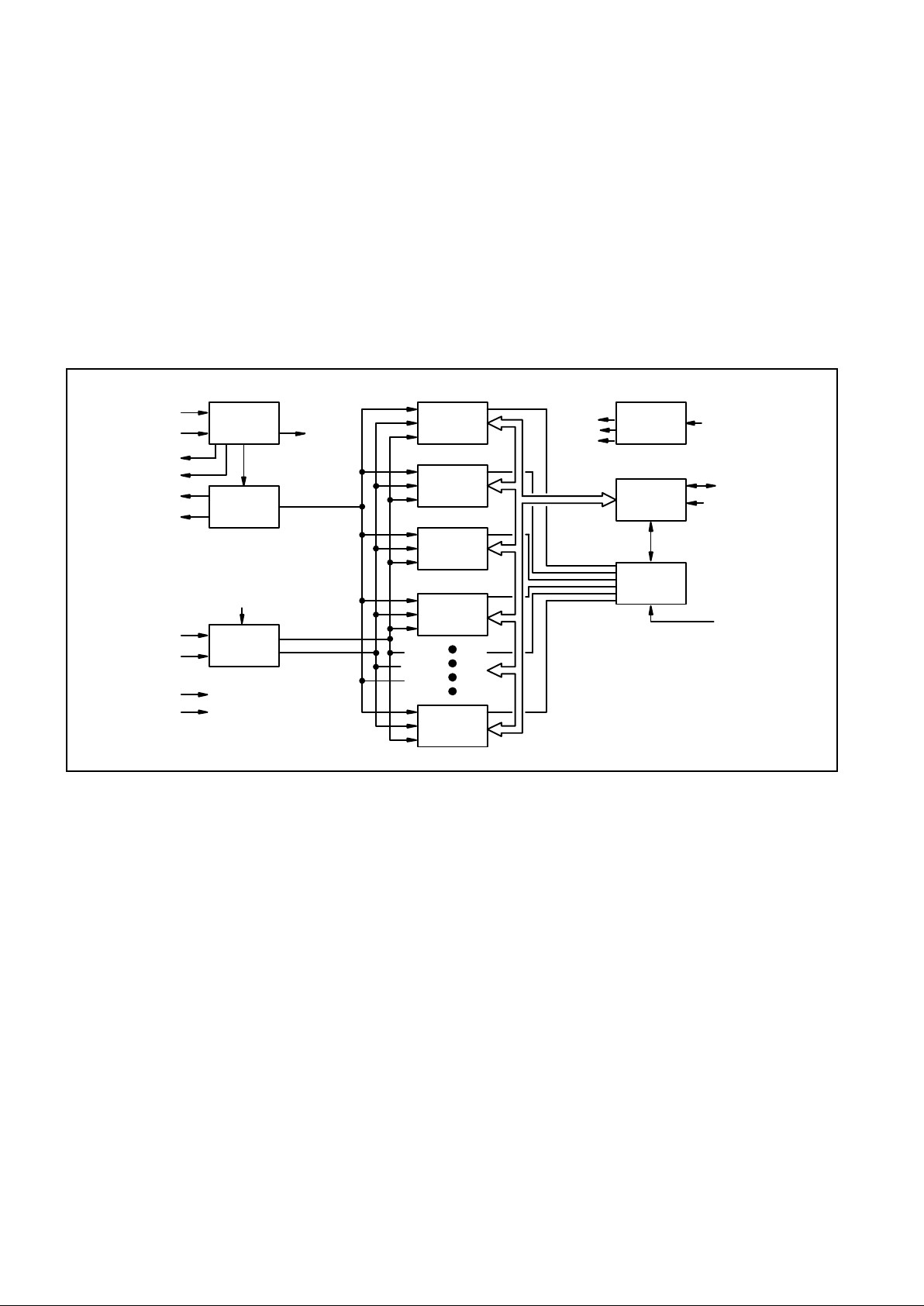

FUNCTIONAL DESCRIPTION

The GP2021 incorporates a 12 Channel GPS Correlator,

together with microprocessor support functions including a

Dual UART, a Real Time Clock and Memory Control Logic for

the ARM60 microprocessor. It can be configured for either

ARM System mode or Standard Interface mode. A block

diagram of the GP2021 is shown in Fig. 3.

Whilst in ARM System mode the Memory Control Logic

allows an ARM60 microprocessor to interface with the

Correlator, Real Time Clock, Dual UART and a variety of

memory devices (i.e.

SRAM, EPROM, Flash and EEPROM), without the need for

external glue logic.

In Standard Interface mode the GP2021 allows most 16

and 32 bit microprocessors to interface with the Correlator,

Real Time Clock and Dual UART. More specifically, this mode

allows the interface to be configured for either Intel or Motorola

style microprocessor interfaces.

In the functional description which follows the correlator is

described first, followed by the peripheral functions.

MEAS_INT

D<15:0>

RXA, RXB

TXA, TXB

XIN

XOUT

SIGN, MAG

SAMPCLK

CLK_T

, CLK_I

POWER_GOOD

PLL_LOCK

MICRO_CLK

NRESET_IP

NRESET_OP

A<22:20>

ARM60

INTERFACE

MEMORY

INTERFACE

ALE_IP

NCS

WREN

READ

NARMSYS

A<9:0>

NINTELMOT

WRPROG

12 CHANNEL

CORRELATOR

GPS

POWER &

RESET

CONTROL

DUAL

UART

REAL

– TIME

CLOCK

CONTROL

BUS

DATA

BUS

MICROPROCESSOR INTERF

ACE

ARM SYSTEM

STANDARD

INTERFACE

ACCUM_INT

Fig. 3 : GP2021 block diagram

8

GP2021

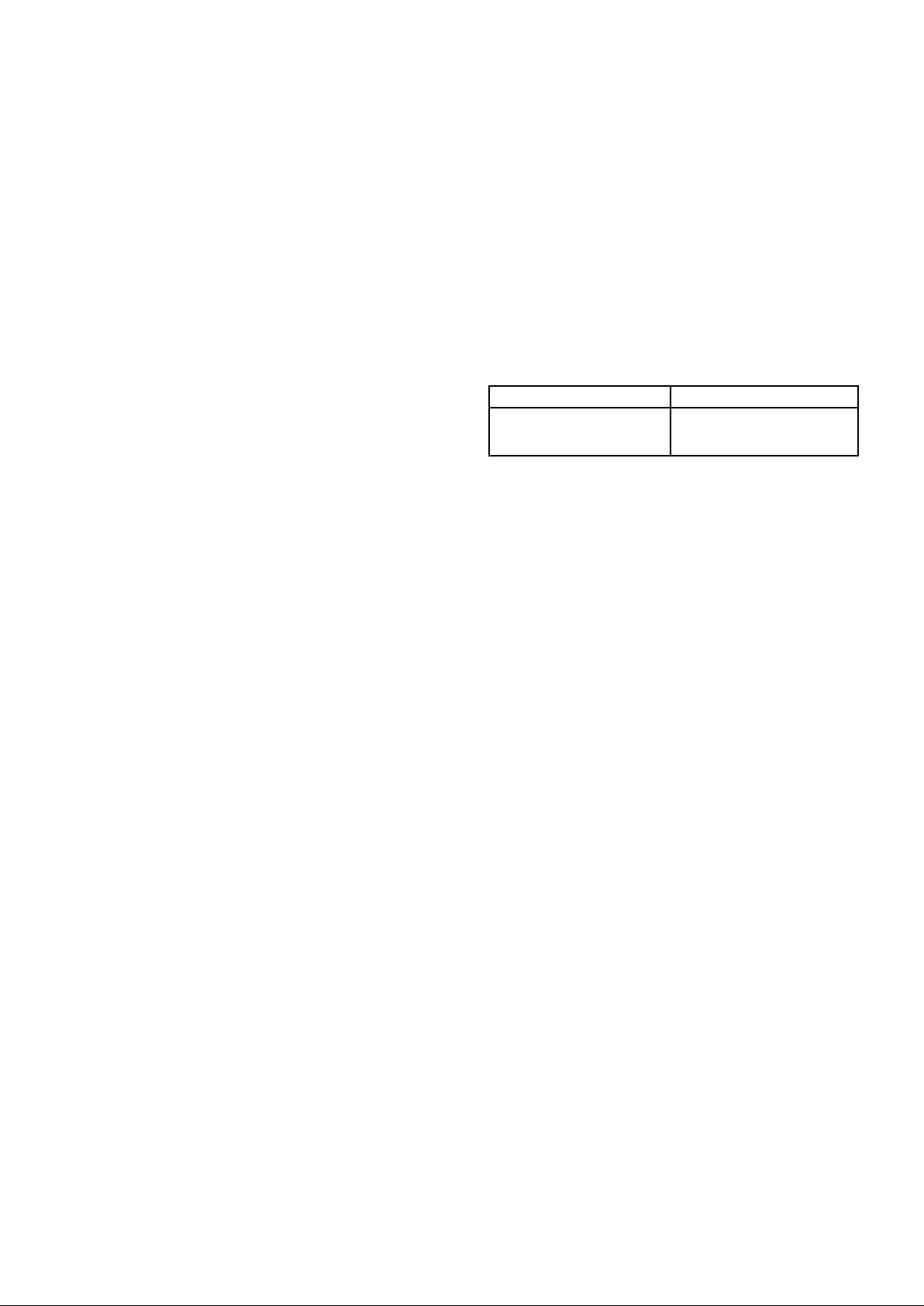

12 CHANNEL CORRELATOR

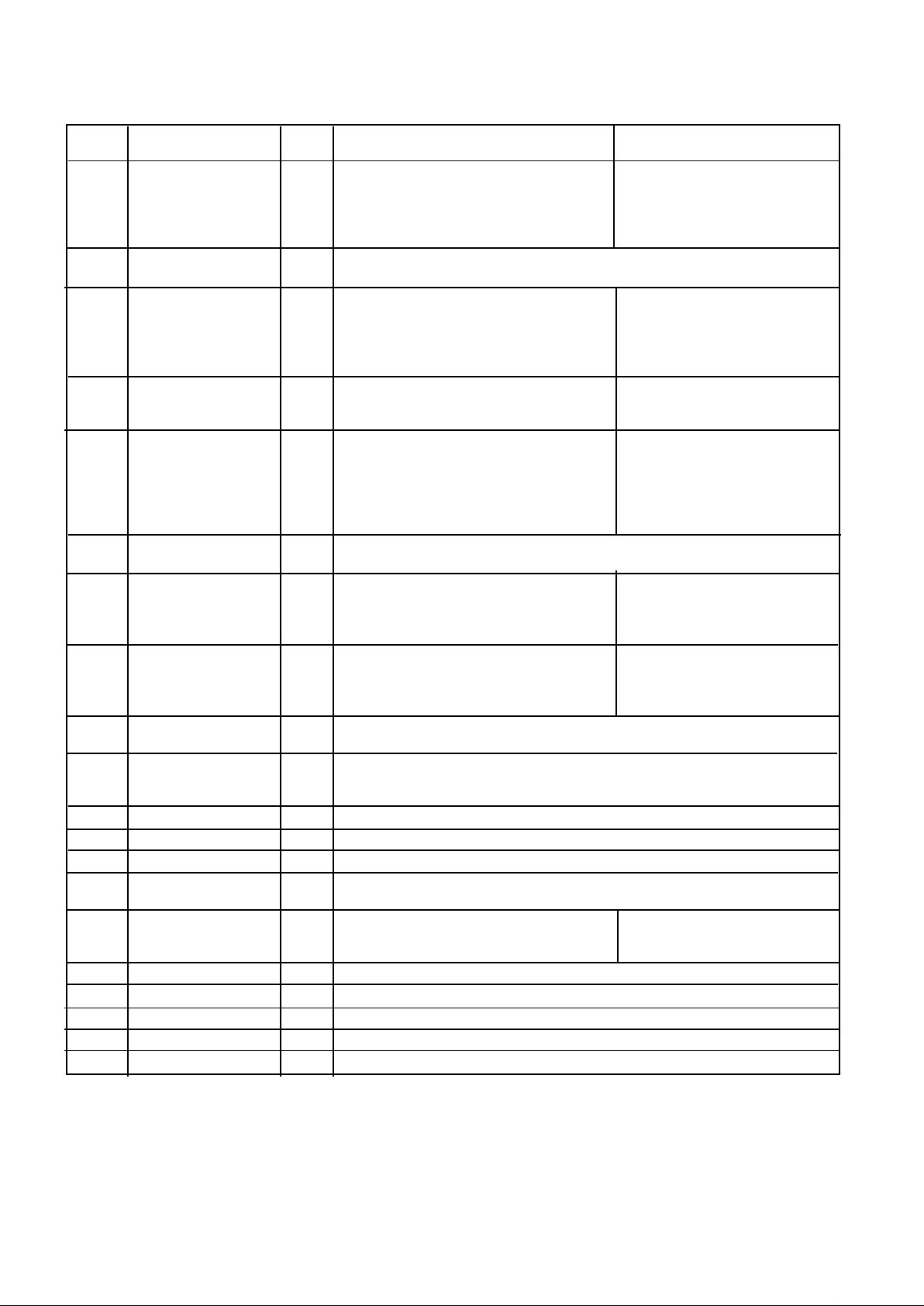

Fig. 4 shows a block diagram of the correlator. It consists

of the following blocks:

Clock Generator

The Clock Generator block divides the frequency of the

master clock CLK_T/CLK_I by 6 or 7 to give the internal multi–

phase set of clocks. When in Real_Input mode CLK_T/CLK_I

will normally be a 40MHz clock, which is divided by 7. When

in Complex_Input mode it will normally be at 35MHz which is

divided by 6. The SAMPCLK pin is an output giving a 4:3

mark–to–space ratio clock at 40 MHz / 7 (= 5·714MHz) in

Real_Input Mode.

The Clock Generator also produces the MICRO_CLK

signal at half the master clock frequency (20 MHz for

Real_Input mode, 17.5 MHz for Complex_Input mode) with a

1:1 mark–to–space ratio. This signal is output on the

MICRO_CLK pin in Standard Interface mode. However, its

main purpose is that of a synchronising clock to the memory

control logic in ARM System Mode and it is from this that the

processor clock output, MCLK, is derived.

Timebase Generator

The Timebase Generator produces 4 important timing

signals: ACCUM_INT, TIC, MEAS_INT and TIMEMARK.

ACCUM_INT is an interrupt provided to control data transfer

between the correlator accumulators and the microprocessor.

It may be detected by means of the ACCUM_INT output or by

reading the ACCUM_STATUS_A register (where bit 15 is a

flag indicating that ACCUM_INT has occurred since the

previous read of this register). ACCUM_INT is cleared by

reading ACCUM_STATUS_A.

After power–up this interrupt occurs every 505.05µs. Its

period can subsequently be changed in one of 3 ways:

1) toggling the FRONT_END_MODE bit of the

SYSTEM_SETUP register,

2) toggling the INTERRUPT_PERIOD bit of the

SYSTEM_SETUP register, or

3) writing directly to the PROG_ACCUM_INT register.

See section ‘‘Detailed Description of Registers” on page 25 for

more information.

TIC is an internal signal with a default period of

99999.90µs. It is used to latch measurement data (Epoch

count, Code phase, Code DCO phase, Carrier DCO phase

Fig. 4 Correlator block diagram

and Carrier cycle count) of all 12 channels at the same instant.

Its period can subsequently be changed, by writing to the

PROG_TIC_HIGH and PROG_TIC_LOW registers, or

toggling the FRONT_END_MODE bit of the

SYSTEM_SETUP register.

MEAS_INT is a signal derived from the TIC counter. It may

be used by the microprocessor as a software module

switching interrupt either by using the MEAS_INT output or by

reading the ACCUM_STATUS_B or MEAS_STATUS_A

register. MEAS_INT is activated at each TIC and 50 ms before

each TIC so long as the TIC period is greater than 50 ms. If the

TIC period is less than 50 ms, MEAS_INT is activated only at

each TIC. It is cleared by reading either the

ACCUM_STATUS_B or MEAS_STATUS_A register,

depending upon the MEAS_INT_SOURCE bit of the

SYSTEM_SETUP register.

TIMEMARK is also derived from TIC and may be output on

one of the discrete output pins. This signal is intended to be

used as an accurate 1 Pulse Per Second timing reference,

aligned to UTC (Universal Time Co–ordinated system), with a

pulse width of 1ms.

TIMEMARK has two methods of operation but in both

TRACKING

MODULE

CHANNEL 0

TRACKING

MODULE

CHANNEL 1

TRACKING

MODULE

CHANNEL 2

TRACKING

MODULE

CHANNEL 3

TRACKING

MODULE

CHANNEL 11

REGISTER

SELECTS

ADDRESS

DECODER

A<9:2>

32 BIT BUS

D<15:0>

CONTROL

BUS

INTERFACE

STATUS

REGISTERS

SYSTEM STATUS

MULTI–

PHASE

CLOCKS

CLOCK

GENERATOR

CLK_T

CLK_I

SAMPCLK

MICRO_CLK

MEAS_INT

ACCUM_INT

TIMEBASE

GENERATOR

TIC

INTERNAL

SAMPCLK

LATCHED

SIGN0 & MAG0

LATCHED

SIGN1 & MAG1

SAMPLE

LATCH

SIGN0 &

MAG0

SIGN1 &

MAG1

V

DD

POWER SUPPLY

V

SS

BITS

9

GP2021

cases TIMEMARK rising edges are generated co–incident

with the rising edges of TIC. Therefore, for TIMEMARK to be

aligned with UTC, TIC must be aligned with UTC. This is done

by modifying the TIC period for a single TIC cycle, then setting

it back to its original value, thus slewing the phase of TIC.

TIMEMARK may be generated by setting the

TIMEMARK_ARM bit in the TIMEMARK_CONTROL register,

in which case the next TIC will generate a rising edge at

TIMEMARK and clear the TIMEMARK_ARM bit. Alternatively

TIMEMARK may be generated as a programmable integer

number of TIC’s, again under the control of the

TIMEMARK_CONTROL register.

Status Registers

There are four status registers (ACCUM_STATUS_A, _B,

_C and MEAS_STATUS_A). These contain flags associated

with the accumulated and measurement data held on each of

the 12 channels. Some system level status bits also appear in

these registers.

Sample Latches

The Sample Latches synchronise data from the front end

to the internal SAMPCLK. In Real_Input mode the down

converted satellite signal can be sampled at the output of the

front end by SAMPCLK. This data is then input to the GP2021

as 2 bit data on either the SIGN0, MAG0, or SIGN1, MAG1

inputs, where it is re–sampled at the next rising edge of

SAMPCLK. These signals are then distributed to the 12

tracking modules.

When a GP2015 or GP2010 front end is used, the data

represents a band–limited signal at an IF centered on

4.309MHz. Sampling at 5.714MHz aliases it to an IF of

1.405MHz.

In Complex_Input mode, the down converted satellite

signal is applied direct to the GP2021 at its SIGN0, MAG0,

SIGN1, MAG1 inputs, which act as In–Phase Sign, In–Phase

Magnitude, Quadrature Sign and Quadrature Magnitude

respectively. These signals are sampled at 5.833MHz within

the correlator and then passed to the tracking modules.

Address Decoder

The Address Decoder performs address decoding for the

correlator.

Bus Interface

The Bus Interface controls the transfer of data between the

external 16 bit wide data bus and the internal 32 bit data bus.

Apart from the code and carrier DCO increment values, all

data transfers are 16 bits wide. Write operations to the code

and carrier DCO’s are 32 bit data transfers, in which the High

16 bit word must be written immediately before the low 16 bit

word. Note that the write cycle to write cycle delay of 300 ns

referred to in the Microprocessor Interface does not apply

between the first and second write cycles for 32 bit DCO data

transfers. For further information see the Microprocessor

Interface section.

TRACKING MODULES

The Tracking Modules are 12 identical signal tracking

channels numbered CH0 to CH11, each with the block

diagram shown in Fig 5. These blocks generate the data used

to track the satellite signals. There is no overwrite protection

mechanism on this data. For further information see the

section on CONTROLLING THE GP2021.

Each Tracking Channel can be individually programmed to

operate in either Update or Preset mode. Update mode is the

normal mode of operation. Preset mode is a special mode of

operation where writes to certain registers are delayed until

the next TIC to allow synchronisation of registers and

presetting of the code DCO phase. For further information see

the Preset Mode section in the Detailed Operation of the

GP2021.

The individual sub–blocks in the tracking modules are:

Carrier DCO

The Carrier DCO, which is clocked at the SAMPCLK

frequency, is used to synthesise the digital local oscillator

signal required to bring the input signal to baseband in the

mixer block, and must be adjusted away from its nominal value

to allow for Doppler shift and reference frequency error.

When used with the GP2015/GP2010 the nominal

frequency of this signal is 1·405396825 MHz (with a resolution

of 42.57475 MHz) and is set by loading the 26 bit register

CHx_CARRIER_DCO_INCR. This very fine resolution is

needed so that the DCO will stay in phase with the satellite

signal for an adequate time. The Carrier DCO Phase cannot

be directly set, but must be adjusted by altering the frequency.

The Carrier DCO outputs are 4 level, 8 phase sinusoidals

with the following sequences over one cycle:

As the clock to the DCO is normally less than 8 times the

output frequency, not all phases are generated in every cycle.

With a typical clock frequency of 5·714 MHz and an output

frequency of 1·405 MHz there are only around 4 phases per

cycle. These will slide through the cycle as time progresses to

cover all values.

Code DCO

The Code DCO is similar to the Carrier DCO block. It is also

clocked at the SAMPCLK frequency and synthesises the

oscillator required to drive the code generator at twice the

required chipping rate. The nominal frequency of the output is

2·046 MHz, to give a chip rate of 1·023 MHz and is set by

loading the 25 bit register CHx_CODE_DCO_INCR.

It is programmed with a resolution of 85·14949 mHz when

used with a GP2015/GP2010 front end. The very fine

resolution is again needed to keep the DCO in phase with the

satellite signal. The Code DCO Phase can only be set to the

exact satellite phase in Preset mode. In Update mode, it must

be aligned with the satellite phase by adjusting its frequency.

Carrier Cycle Counter

The Carrier Cycle Counter is 20 bits long, and keeps a

count of the number of cycles of the Carrier DCO between

TIC’s. This is not needed for a basic navigation system but

may be used to measure the range change (delta–range) to

each satellite between TIC’s. The delta ranges can be used to

smooth the code pseudo–ranges. For finer detail the Carrier

DCO phase may also be read at each TIC to give the fractional

part of the cycle count or delta–range.

C/A Code Generator

The C/A Code Generator generates the selected Gold

code for a GPS satellite (1 to 32), a ground transmitter

(pseudolite, 33 to 37), an INMARSAT–GIC satellite (201 to

211) or a GLONASS satellite. A Gold code is selected by

writing a specific pattern of 10 bits, as listed in the section

‘Detailed Description of Registers’, to the CHx_SATCNTL

register, or by setting the GPS_NGLON bit to Low for the

GLONASS code. Two outputs are generated to give both a

PROMPT and a TRACKING signal. The TRACKING signal

can be set to one of four modes: EARLY (one half chip before

the PROMPT signal), LATE (one half chip behind),

DITHERED (toggled between EARLY and LATE every 20ms)

or EARLY–MINUS–LATE (the signed difference).

The output code is a sequence of +1’s and –1’s for all code

types except EARLY–MINUS–LATE where the result can also

Destination Arm

I

LO

Q

LO

Sequence

–1+1+2+2+1–1–2–2

+2+2+1–1–2–2–1+1

Table 1 Carrier DCO outputs

10

GP2021

be a 0. To avoid having an unused LSB in the accumulators,

the values in EARLY–MINUS–LATE mode are halved from

the +2, 0, –2 that results from the calculation (+1 or –1) – (+1

or –1) to +1, 0, –1. This must be considered when choosing

thresholds in the software, as the correlation results will be

exactly half of the values otherwise expected.

At the end of every code sequence (1023 chips in GPS

mode or 511 chips in GLONASS mode) a DUMP signal is

generated to latch the Accumulated Data for use by the signal

tracking software. Each channel is latched separately, as the

satellite signals are not received in phase with each other.

Source Selector

In Real_Input mode the Source Selector selects which

input signal pair to use (SIGN0/MAG0 or SIGN1/MAG1). In

Complex_Input mode SIGN0/MAG0 are passed to the In–

phase arm and SIGN1/MAG1 to the Quadrature arm. The data

is treated as having the values shown in Table 2 below (in both

modes):

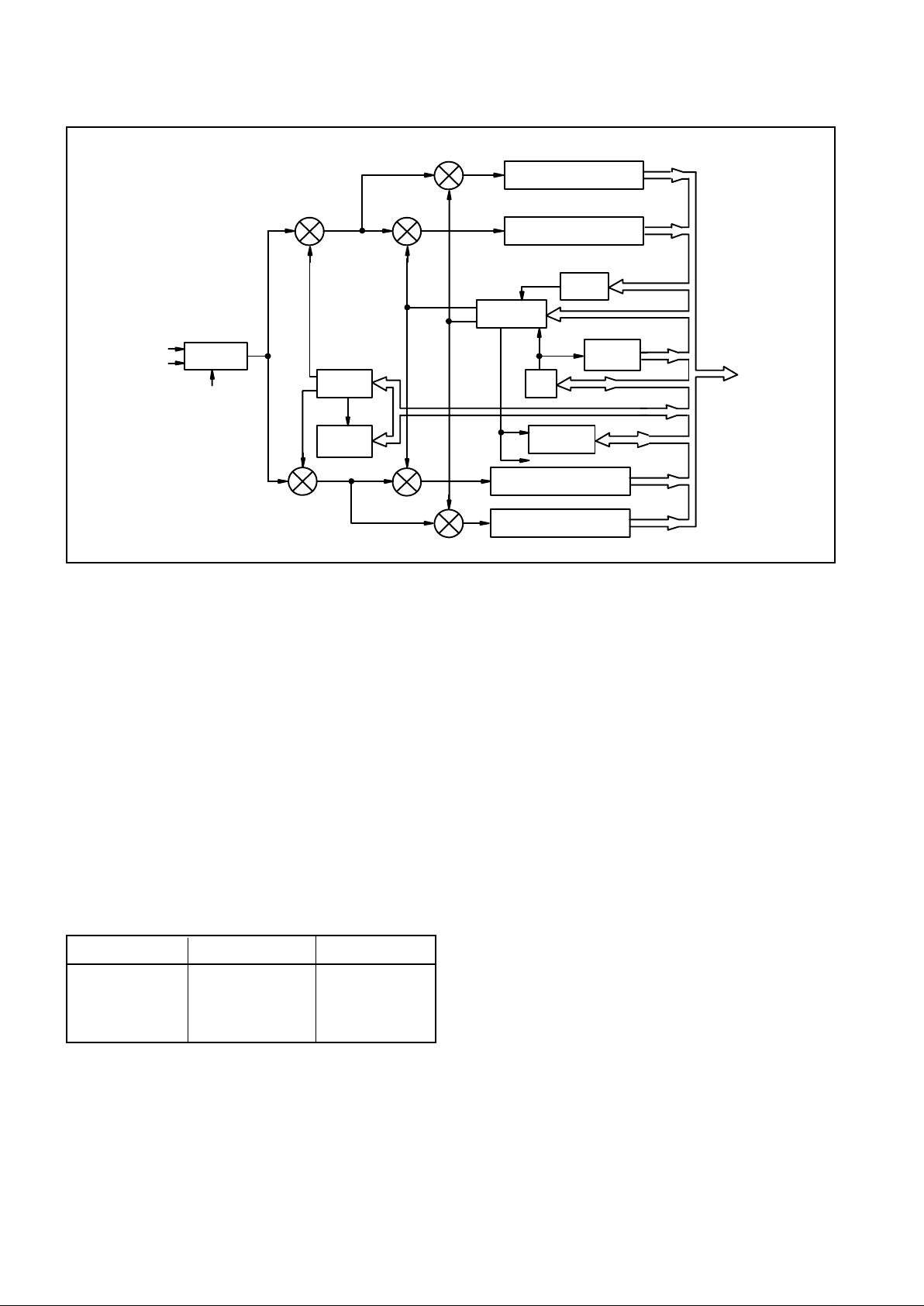

Carrier Mixers

The Carrier Mixers multiply the digital input signal by the

Carrier DCO digital local oscillator to generate a signal at

baseband. In Real_Input mode both I and Q Carrier DCO

phases are directed to the appropriate mixers. In

Complex_Input mode a single In–Phase Carrier DCO output

is used in both mixers since the input signal is already in I and

16 BIT ACCUMULATE

AND DUMP – Q_TRACKING

16 BIT ACCUMULATE

AND DUMP – Q_PROMPT

CODE

SLEW

C/A CODE

GENERATOR

CODE

PHASE

COUNTER

CODE

DCO

EPOCH

COUNTERS

DUMP

ACCUMS, CODE PHASE, ETC

16 BIT ACCUMULATE

AND DUMP – I_PROMPT

16 BIT ACCUMULATE

AND DUMP – I_TRACKING

CARRIER

CYCLE

COUNTER

CARRIER

DCO

I

1,

2

SOURCE

SELECTOR

SIGN 0

AND

MAG 0

SIGN 1

AND

MAG 1

SELECT

SOURCE

AND

SELECT

MODE

IN AND OUT

DATA

BUSSES

CODE

MIXER

CARRIER

MIXER

1, 2,

3, 6

3

LO

Q

LO

I

LO

1

1, 0

OR

1,

Fig.5 Tracking Module block diagram

Sig

0

0

1

1

Mag

1

0

0

1

Value

-3

-1

+1

+3

Table 2 SIGN/MAG values

Q form. The mixing of the Carrier DCO outputs with the input

signal produces a baseband signal which can have the values

±1, ±2, ±3 and ±6.

Code Mixers

The Code Mixers multiply the I and Q baseband signals

from the Carrier Mixers with both the PROMPT and

TRACKING local replica codes to produce 4 separate

correlation results. The correlation results are passed to the

Accumulate and Dump blocks for integration.

Accumulate and Dump

The Accumulate and Dump blocks integrate the Mixer

outputs over a complete code period of nominally 1ms.

There are 4 separate 16 bit accumulators for each channel.

These represent the correlation of the I and Q signals with the

PROMPT and TRACKING codes, over the integration period.

There is no overwrite protection mechanism on these

registers so the data must be read before the next DUMP.

Code Phase Counter

The Code Phase Counter counts the number of half–chips

of generated code and stores this value in the

CHx_CODE_PHASE register on each TIC.

Code Slew Counter

The Code Slew Counter is used to slew the generated code

by a number of half chips in the range 0 to 2047. In Update

mode the slew occurs following the next DUMP. In preset

mode it occurs at the next TIC. All slew operations are relative

to the current code phase. The Code Slew counter must be

written to each time a slew is required.

During the slewing process the accumulators for the

channel being slewed are inhibited so that the first result is

valid. If a slew is written while a channel is disabled it will occur

as soon as the channel is enabled.

11

GP2021

Epoch Counter

The Epoch Counters keep track of the number of code

periods over a 1 second interval. This is represented by a 5 bit

word for the number of 1 ms integration periods (0 to 19), plus

a 6 bit word containing the number of 20 ms counts (0 to 49).

The Epoch Counters can be pre–loaded to synchronise them

to the data stream coming from the satellite. This value will be

transferred immediately to the counter when in Update mode,

or after the next TIC if in PRESET Mode.

The Epoch Counter values are latched on each TIC into the

CHx_EPOCH register. In addition the instantaneous values

are available from the CHx_EPOCH_CHECK register.

PERIPHERAL FUNCTIONS

The following section describes the Dual UART, Real

Time Clock and Watchdog, Power and Reset Control and

Discrete I/O blocks.

Dual UART

A Dual UART is included for serial communications. It has

2 identical blocks, UART_A and UART_B, each containing

separate transmit and receive channels. The parity and

separate transmit and receive baud rate can be configured

independently for each UART. Each uses a polled processor

interface and each transmit and receive channel has an 8 byte

deep FIFO.

For further information on the UART registers refer to the

Detailed Description of Registers and the GP2021 Register

Map.

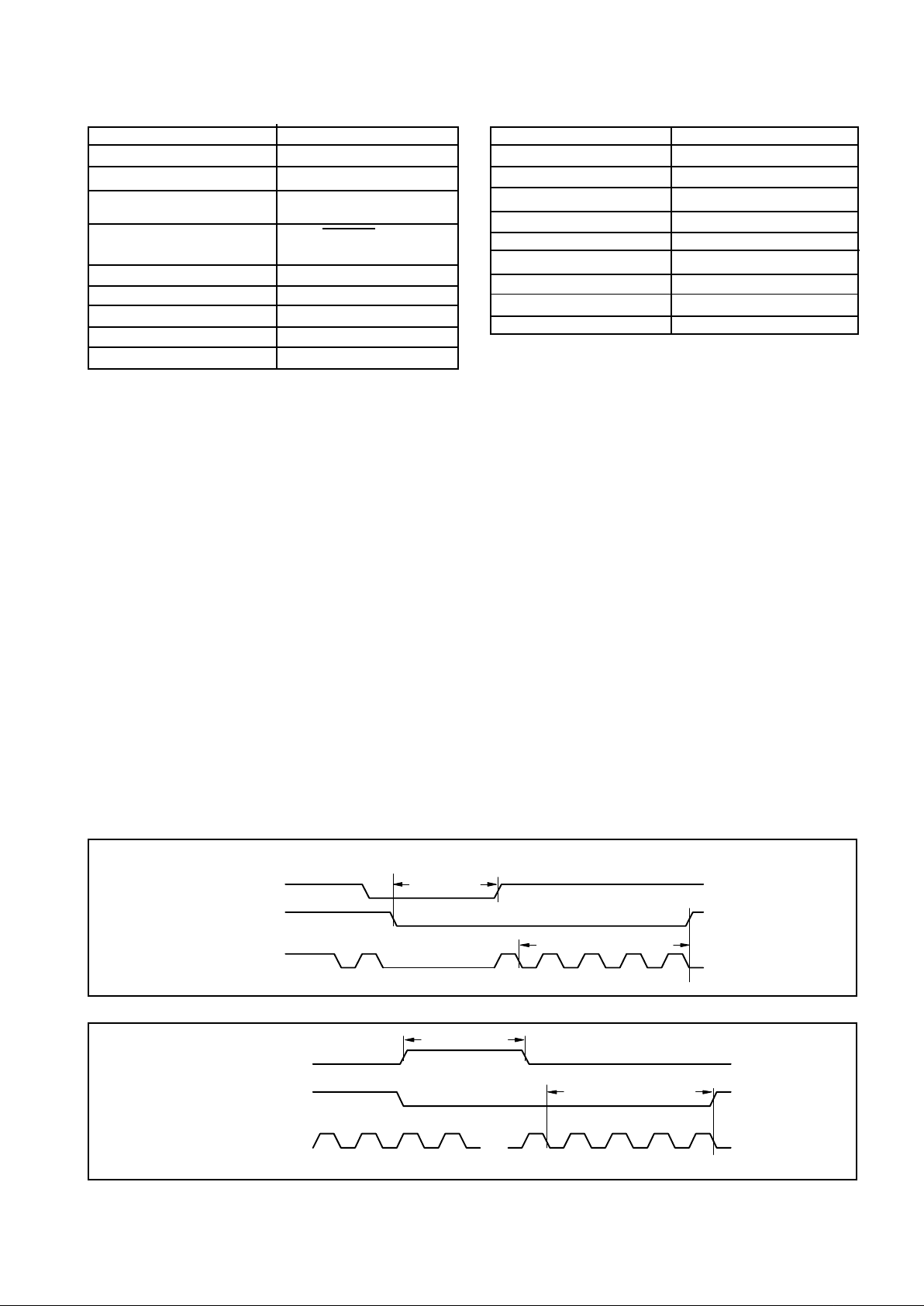

A typical serial data stream is shown in Fig. 6. The Parity

bit is optional and if no parity is selected the time slot for it is

removed from the data stream and the Stop bit follows

immediately after the last data bit in both transmit and receive

directions. Note that the LSB is always preceded by a Start bit.

Table 3 shows possible UART configurations.

Last

Start D8 D9 D10 D11 D12

D13 D14

D15

P

Stop

First

LSB MSB Parity

(optional)

Fig. 6 Serial Data waveform

Parameter Value

Start bits 1 bit Low

Data bits 8 bits Logic 0 = Low

Logic 1 = High

Stop bits 1 bit High

Parity Odd/Even/None

Flow control None

Transmit FIFO depth 8 bytes

Receive FIFO depth 8 bytes

FIFO speed Transmit FIFO write rate and Receive FIFO read rate maximum is one byte per 230ns.

The maximum buffer through delay is 2 µ s.

Data rate 300, 600,1.2k, 2.4k, 4.8k, 9.6k, 19.2k, 38.4k and 76.8k baud. Transmit and Receive

rates individu-ally configured.

Table 3 UART Functionality

Receiver

The incoming data streams on RXA, RXB are sampled by

a clock at nominally 20 times the data rate, to search for an

incoming Start bit. Once the receiver is synchronised to the

data stream, each data bit is sampled only at its nominal centre

to avoid errors due to slow or noisy bit edges. The receiver will

resynchronise to each Start bit to prevent the accumulation of

phase errors.

Only valid data (having correct Start, Stop and Parity bits)

will be stored in the receiver FIFO. If a received word contains

a parity or framing (Start/Stop bit) error, the appropriate flag bit

will be set in the status register. If too many valid data words

are received for the FIFO to hold, the excess will not be written

into the FIFO, and an Overflow bit will be set in the status

register. When receiving a continuous transmission, the Start

bit of one word will follow immediately after the Stop bit of the

preceding word. At lower word rates, a High is expected

between words. The receiver will accept data with a baud rate

error of up to ±1%.

Transmitter

Data is transmitted on pins TXA and TXB. In continuous

transmission, the Start bit of one word will follow immediately

after the Stop bit of the preceding word. At lower word rates,

a High is sent between words.

If too many data words are written by the microprocessor

to the UART for the transmitter FIFO to hold, the excess will not

be stored. The UART will resume normal operation as soon as

space becomes available. To avoid data loss, the software

should limit the transmit data rate by either: keeping track of

the number of bytes sent and the time to transmit them, or

should read the Status register and stop writing when the Full

bit is set.

12

GP2021

Reset

It is possible for the software to reset either UART

independently via the RESET_CHx registers. A hardware

reset affects both UARTs. During a UART reset, the contents

of all Control, and Status registers will be cleared. In addition

the Transmit and Receive FIFO’s will be emptied and the TX

outputs will be held Low.

Channel Loopback

For system test purposes, a loopback facility is provided

for each channel, controlled by the Configuration registers. In

loopback, the TX output is set High.

Real Time Clock (RTC) and Watchdog

This block consists of a 32.768kHz crystal oscillator, a

fixed divider, a 24 bit counter, a Watchdog function and three

8 bit data registers. XIN and XOUT are the crystal in and

crystal out connections to the oscillator circuit. A recommended crystal oscillator circuit is shown in Fig. 7. When the

Real Time Clock SSis not being used, XIN must be tied Low.

The first divider is a fixed divide by 32768 giving a 1 Hz

output. The counter then counts seconds, giving a maximum

time of 194 days. The time is output in three 8 bit registers with

the data being latched when a read is performed to the LS

register (The register holding the least significant byte of the

clock data). On reaching its maximum count, the count is

frozen (i.e. all 1’s), until being reset.

In Power Down mode the Real Time Clock continues to

run, but access to the data registers is not allowed. When

normal power is restored, the software can determine the

elapsed time whilst in Power Down mode, thereby assisting in

estimating the current position of GPS satellites and so

reducingTime–To–First–Fix.

The Watchdog generates a System Reset (see Power And

Reset Control) if the Watchdog Reset address has not been

written to for a period of approximately 2s. The watchdog

function is inhibited whilst in Power Down mode and can be

disabled via a bit in the System Configuration register.The

software is able to reset the Real Time Clock and Watchdog

via the Clock Reset and Watchdog Reset registers

respectively. In addition the watchdog is reset during a System

Reset.

For further information on the registers refer to the section

Detailed Description of Registers.

Power and Reset Control

This block performs 2 functions: Power Control and

System

Reset Generation

Power Down Mode

In order to allow power conservation within a battery

backup system, the GP2021 provides a Power Down mode,

in which the supply voltage may drop to a minimum of 2.2V,

thereby minimising the supply current. In this mode all

functions within the GP2021 are disabled except for the Real

Time Clock.

The GP2021 is placed in Power Down mode by taking the

POWER_GOOD pin Low. In ARM System mode with the

NBRAM pin held Low, the initiation of Power Down mode is

delayed until just after a falling edge of MICRO_CLK so as not

to corrupt battery backed RAM. Fig. 8 shows a suggested

circuit implementation. Table 4 shows output logic levels in

Power Down mode.

In Power Down mode all inputs and I/Os except

POWER_GOOD and XIN are internally switched to known

logic levels to prevent extraneous switching from causing

excessive power consumption, and may therefore be left

floating. All the I/O pins (D<15:0>, MULTI_FN_IO and

DISCIO) have their output drivers driven to the High

Impedance state.

XIN

XOUT

22pF22pF

CRYSTAL

10M

V

SS

V

SS

680k

32.768kHz

Fig. 7 Recommended Crystal Oscillator Circuit

BATTERY

SUPPLY

D1

SUPPLY+5V

C1

VOLTAGE

SENSOR

GP2021

POWER_GOOD

C2

V

DD

T2

R1

R2

T1

V

SS

V

SS

Fig. 8 : Suggested Battery Backup Configuration

13

GP2021

Pin Name Logic Level

NW<3:0> / NC Low

NRD / NC Low

NRAM Low

(standard interface mode)

NRAM NB RAM

(ARM system mode)

NROM / NC High Impedance

NSPARE_CS/NC High Impedance

NEEPROM / NC High Impedance

TXA,TXB Low

ACCUM_INT High Impedance

Pin Name Logic Level

MEAS_INT High Impedance

A

BORT / MICRO_CLK Low

MCLK / NC Low

ARM_ALE / NC Low

DBE / NC Low

NRESET_OP Low

DISCOP High Impedance

SAMPCLK Low

XOUT Active

Table 4 : Output Logic Levels in Power Down Mode

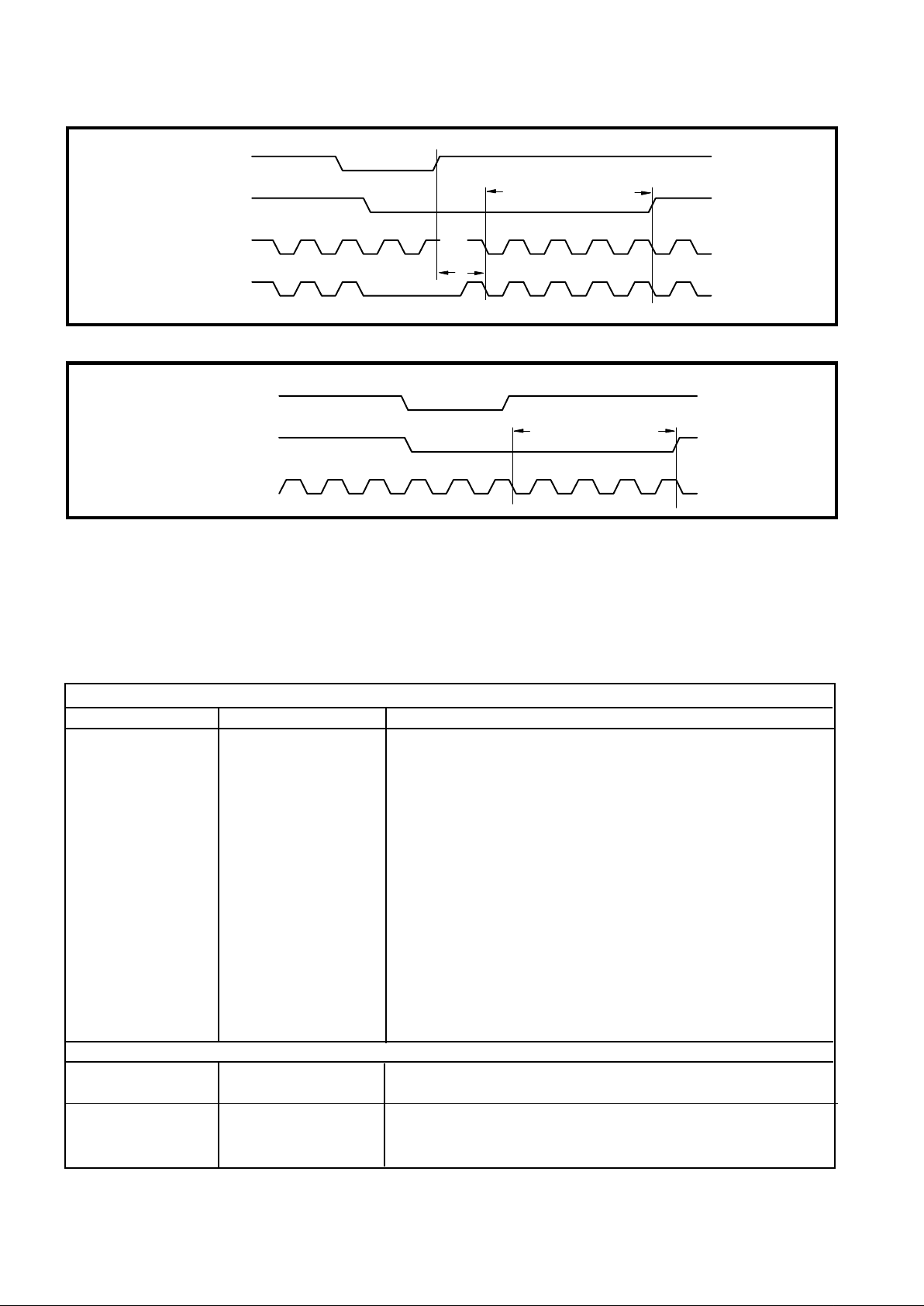

Hardware Reset Generation

The manner in which a hardware reset occurs depends on

whether the GP2021 is in ARM System mode or Standard

Interface mode. During a hardware reset, the NRESET_OP

pin is taken Low and the reset signal is applied within the

GP2021 to all blocks except the Real Time Clock.

There are 3 sources of hardware resets common to both

ARM System and Standard Interface modes, with an

additional source in Standard Interface mode:

POWER_GOOD: A hardware reset will occur if this pin is

taken Low, as shown in Fig. 9. The purpose of this input is to

detect a power failure. If the NBRAM pin is held Low in ARM

System mode, the internal Power Down mode is not entered

until about 6ns after the falling edge of MICRO_CLK,

otherwise it is entered immediately. This allows for RAM write

cycles to complete sensibly when Battery Backed–Up RAM is

used, with no corruption of RAM data.

Watchdog: An expiry of the watchdog will result in a

hardware reset as shown in Fig. 10. This reset will clear the

watchdog whose time–out period is 2–3 seconds.

PLL_LOCK: The PLL_LOCK pin is used to indicate (when

High),that the phase locked loop in the RF front end, which

generates the master clock, is in lock. This signal is filtered

within the GP2021 and the reset state associated with it is only

de–activated if the PLL_LOCK input has been high for

approximately 50 ms as shown in Fig. 11.

NRESET_IP: In addition to the 3 reset sources described

above, an active Low NRESET_IP pin is available in Standard

Interface mode if the system resets are to be generated

externally. Fig. 12 shows a NRESET_IP generated reset.

Note that the NRESET_OP pin will go High 4 MICRO_CLK

cycles after all hardware reset sources have cleared. This

fulfills the reset requirements of the ARM60 microprocessor.

For information on the state of the registers following a

hardware reset refer to the Detailed Description of Registers

section.

System Error Status Register

This allows the software to determine whether the source

of a hardware reset was from a power failure, a PLL_LOCK

failure, watchdog timeout or from an external reset in Standard

Interface mode. For further information refer to the Detailed

Description of Registers section.

MICRO_CLK/

NRESET_OP

POWER_GOOD

4 CYCLES

MCLK

Power Down Mode

Fig. 9 : POWER_GOOD Hardware Reset Generation (NARMSYS = ‘0’, NBRAM =‘0’)

MICRO_CLK/

NRESET_OP

WATCHDOG

122 s

4 CYCLES

MCLK

Fig. 10 : Watchdog Hardware Reset Genera-

14

GP2021

PLL_LOCK

NRESET_OP

MICRO_CLK

4 CYCLES

MCLK

50ms

NRESET_IP

NRESET_OP

MICRO_CLK

4 CYCLES

Fig. 11 : PLL_LOCK Hardware Reset Generation

Fig. 12 : NRESET_IP Hardware Reset Generation

Discrete I/O

The GP2021 contains a number of pins which may be used

as discrete inputs or discrete outputs for general purpose

system monitoring and control applications. The actual pins

which may be used for each function vary according to the

application and the interface mode of the GP2021.Table 5

shows a list of possible discrete inputs and outputs and the

modes in which they may be used. The level on all discrete

inputs can be read from the IO_CONFIG register. The status

of the DISCIP pin may also be read from

ACCUM_STATUS_B. The discrete outputs are controlled via

either the SYSTEM_SETUP or IO_CONFIG registers.

Discrete Inputs

Pin Name Read Location Conditions for use as Discrete Input

NRW/DISCIP3 IO_CONFIG Standard Interface mode.

NOPC/NINTELMOT IO_CONFIG ARM System mode (debug disabled).

NMREQ/DISCIP2 IO_CONFIG Standard Interface mode.

NBW/WRPROG IO_CONFIG Motorola mode only.

DISCIO IO_CONFIG DISCIO configured as discrete Input.

NBRAM/DISCIP4 IO_CONFIG Standard Interface Mode.

MULTI_FN_IO IO_CONFIG MULTI_FN_IO configured as discrete input.

SIGN0, MAG0 IO_CONFIG Single real input mode (GP2010 or GP2015) front end using

SIGN0, MAG0.

SIGN1, MAG1 IO_CONFIG Single real input mode (GP2010 or GP2015) front end using

SIGN1, MAG1.

DISCIP1 IO_CONFIG Always available – dedicated Discrete Input.

ACCUM_STATUS_B

RXA IO_CONFIG UART Channel A not used.

RXB IO_CONFIG UART Channel B not used.

Discrete Outputs

Pin Name Configuration Possible Outputs

Location

DISCOP SYSTEM_SET_UP High, Low, CH0 Dump, TIMEMARK, 100kHz Square Wave, Scan Out.

DISCIO IO_CONFIG High, Low, TIMEMARK, 100kHz Square Wave.

MULTI_FN_IO IO_CONFIG High, Low, TIMEMARK, 100kHz Square Wave.

Table 5 : Discrete Input/Output Configuration

15

GP2021

Digital System Test Interface

The GP2021 contains a Digital System Test mode to allow

testing of the digital section of the system board. Provided that

the MULTI_FN_IO pin is High, this mode is enabled

subsequent to a hardware reset or a write of specific data to

the IO_CONFIG register. The enabling of Digital System Test

mode has 3 effects:

(1) The master clock inputs, CLK_T and CLK_I, are

replaced by the signal on the RXA pin. This allows the GP2021

to be clocked synchronously with the board tester which is

relevant in ARM System mode where the GP2021 produces

the main processor clock to the ARM60.

(2) The RXB pin becomes the active High RTC Reset

input. This is mainly intended for factory testing of the

GP2021, allowing the RTC to be reset on power up, but may

also be used to disable the RTC and Watchdog circuits in this

mode.

(3) The PLL_LOCK input and its associated 50ms delay as

a reset source is overridden. This removes the dependency

on the presence of the front end circuit.

MICROPROCESSOR INTERFACE

The Microprocessor Interface of the GP2021 is compatible

with most 16 and 32 bit microprocessors. It can be configured

for either ARM System mode or Standard Interface mode by

means of the NARMSYS pin.

In Standard Interface mode, two mode control pins

NINTELMOT and WRPROG are provided. NINTELMOT

selects between Intel and Motorola style interfaces, with

WRPROG selecting either Intel i486 or 80186 style interfaces.

See Table 6 for more details.

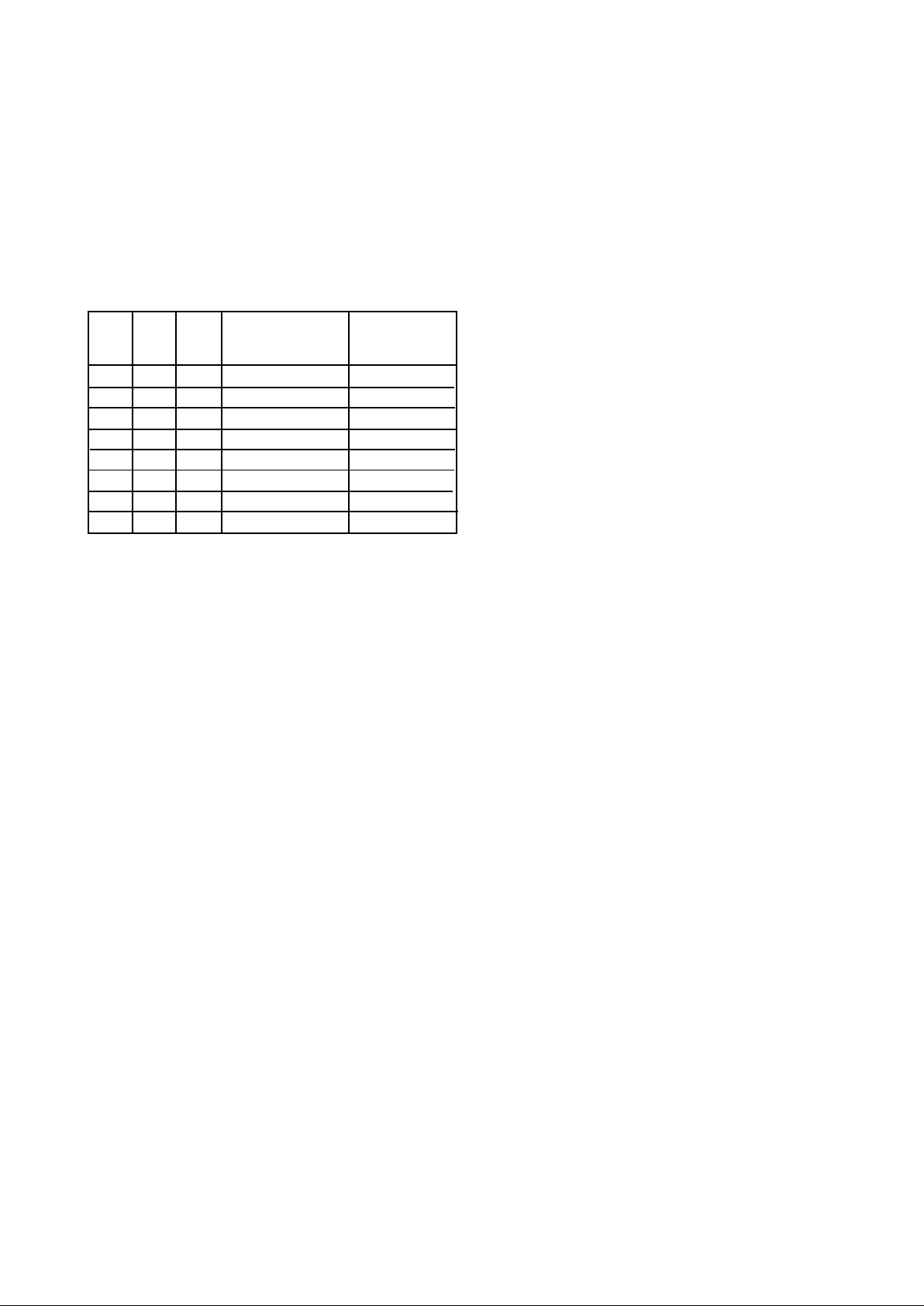

NARMSYS NINTELMOT WRPROG Mode Processor

0 x x ARM System ARM60

1 1 x Standard Interface Motorola style

1 0 0 Standard Interface Intel 80186 style

1 0 1 Standard Interface Intel 486 style

Table 6 Microprocessor Interface Configuration.

General Interface Timing

In addition to the detailed timings associated with

individual read and write cycles ( see Electrical Characteristics

section), the internal architecture of the correlator also

imposes limits on cycle to cycle timings (in particular write to

write cycle and write to read cycle). For a simple

microprocessor interface, it must be ensured that no attempts

are made to access the correlator for the 300ns following the

end of a correlator write cycle in Real_Input mode, or 314ns in

Complex_Input mode. However, if the controlling software is

to be allowed to write rapidly to the correlator (e.g. block

writes), then a more complex bus interface (which inserts wait

states) will be required. Note that this limitation only applies

after correlator writes, not peripheral function writes, and also

does not apply to writes to the correlator X_DCO_INCR_HIGH

address.

The correlator section of the GP2021 uses a multi–phase

clock internally, and the correlator registers load on specific

clock phases. At the end of a write cycle, the falling edge of the

internal write strobe latches both the relevant address and

data bits. This data is then loaded from the internal data bus

to the relevant register at some time during the following 300ns

for Real_Input mode or 314ns for Complex_Input mode. A

write cycle to the Correlator with no writes in the preceding

300ns (314ns) may be performed immediately, so long as the

detailed signal timings are met. However, subsequent read or

write cycles to the Correlator after this write cycle may need to

be delayed if they would modify the internal address or data

lines. Correlator read cycles with no write cycles in the

preceding 300ns (314ns) are self–contained, and do not delay

subsequent cycles. An isolated read cycle requires only

sufficient wait states to meet the detailed signal timings.

Write Cycle To Read Cycle Timings

As described previously, the internal write cycle of the

Correlator takes 300ns (314ns). Only once the write cycle is

complete will the correlator address decoders switch to

decoding the current address. The correlator uses a pre–

charged internal data out bus and hence the decoded address

lines must be stable before the internal bus drivers are

enabled (when the read strobe goes high). Consequently, the

read strobe must be held Low until some time after the end of

the 300ns (314ns) internal write cycle, to allow sufficient

internal address setup time. For the exact timing requirements

see the Electrical Characteristics Section.

Write Cycle To Write Cycle Timings

The internal write cycle of the correlator takes 300ns

(314ns) after the falling edge of the write strobe. During this

time the write internal address and data busses (latched by

write) must not be modified. If a second write follows the first,

the second write cycle must be delayed such that it ends no

earlier than 300ns (314ns) after the end of the previous write.

The ‘end’ being a falling edge on the internal write strobe. The

specific interface signal timings must also be met.

Notes about Interface Timing Constraints

It should also be noted that these timings need only be met

for correlator accesses, not support function accesses, since

these utilise self–contained write cycles and are not clocked

by the multi–phase clocks. In addition, writes to the Correlator

register X_DCO_INCR_HIGH need not incur subsequent

delays since writes to this location do not instigate an internal

write cycle. A write to this address must always be followed by

a write to either a CHX_CARRIER_DCO_INCR_LOW or a

CHX_CODE_DCO_INCR_LOW register and it is this second

associated write which instigates the internal write cycle.

In ARM System mode all these timing requirements are

handled by the internal memory manager.

16

GP2021

WREN

READ

NCS

A<9:2>

D<15:0>

Read Read

Read

Write

Delayed W

rite

Delayed Read

NOTE: OP

and IP

are with respect to the GP2021. OP denotes a GP2021 Output, IP

denotes a processor output.

OP OP IP OP OPIP

300ns (314ns) 300ns (314ns)

Fig.13 Correlator Bus Timing - Write to Write and Write to Read Timings

ARM60

GP2021

Memory

NRAM

NROM

NEEPROM

NSPARE_CS

NW<3:0>

NRD

D<15:0>

A<9:2>

A<19:10>

DBE

ARM_ALE

MCLK

NRW

NMREQ

NBW

D<15:0>

A<9:2>

A<22:20>,

A<1:0>

NOPC

ABORT

A<19:10>

(NRESET_OP

,

ACCUM_INT and MEAS_INT not shown)

Fig.14 ARM System Mode

Note that the exact number of wait states which need to be

inserted after a correlator write is not fixed. If the processor

were to perform a correlator write then spend 400ns

accessing a different peripheral, subsequent correlator reads

and writes would incur no additional delay. It is anticipated

that correlator wait states will be generated by either one or

two external counters, preset on the falling edge of a correlator

write, and which then count down to zero. Only once the

counter has reached zero may the next correlator access

either complete (write) or start (read).

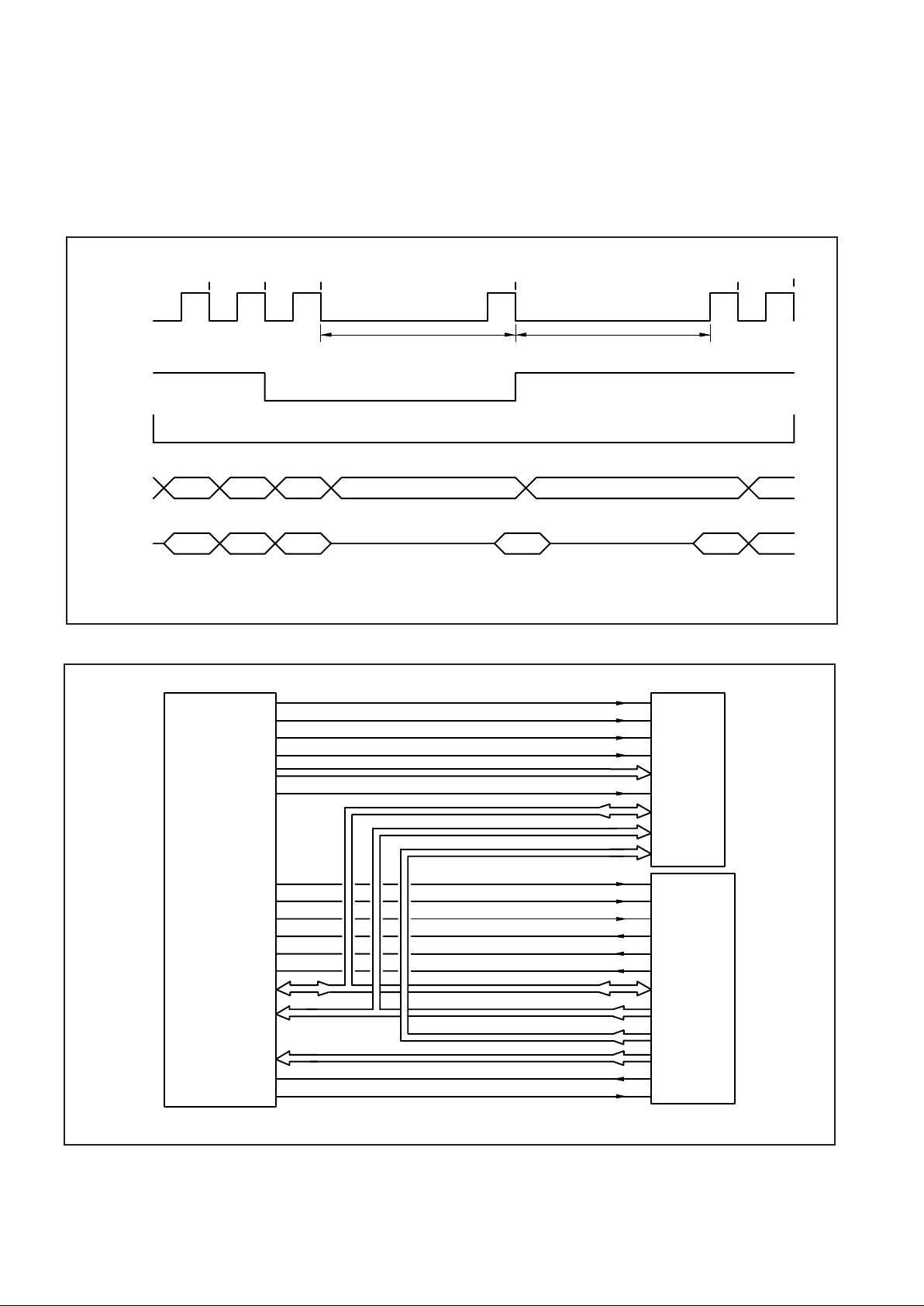

A series of correlator reads and writes are shown in Fig.13.

17

GP2021

ARM System Mode

ARM System Mode, as shown in Fig 14, allows the

GP2021 to be interfaced with an ARM60 microprocessor and

external memory devices (i.e RAM, ROM, EEPROM,

EPROM, Flash) without the need for external glue logic.

Address Map

Both the GP2021 and external memory devices are

memory mapped into 1 Mbyte segments by A<22:20> as

shown in Table 7.

Decoded

A22 A21 A20 Device selected output

pin

0 0 0 ROM NROM

0 0 1 RAM NRAM

0 1 0 Correlator

0 1 1 Support functions

1 0 0 EEPROM NEEPROM

1 0 1 User defined NSPARE_CS

1 1 0 Not Decoded

1 1 1 Not Decoded

Table 7 ARM system map

Control Signals

The GP2021 uses the ARM60 control signals NBW,

NMREQ and NRW to generate the processor clock MCLK and

the control signals ARM_ALE and DBE to match the timing

requirements of the various memory devices .

The memory interface is via the memory chip select lines

( NRAM, NEEPROM, NROM and NSPARE_CS) , the Read

line (NRD) and the byte write select outputs ( NW<3:0> ).

ARM System Timing

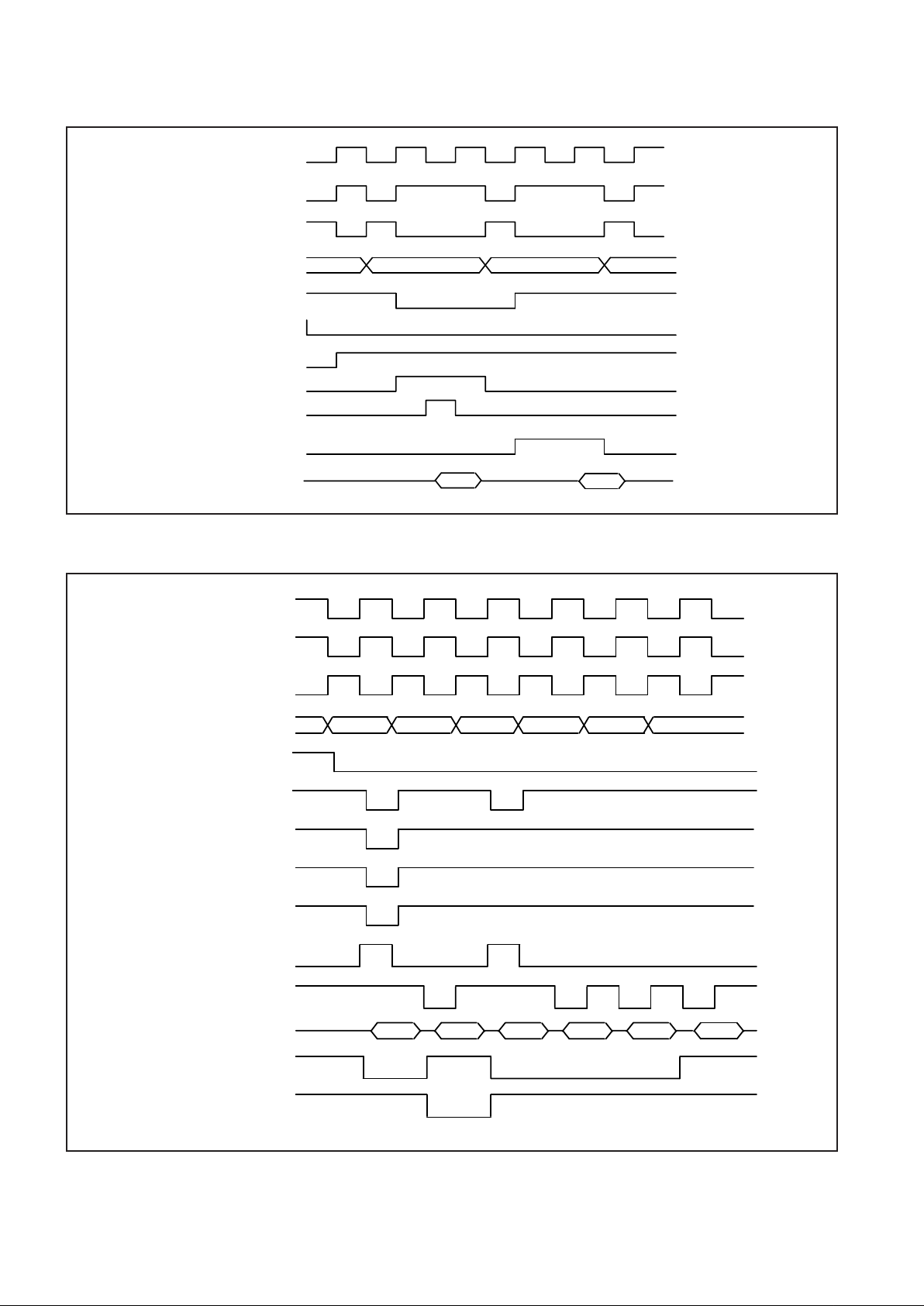

The GP2021 timing diagrams for each of the memory

interfaces ( EEPROM, RAM, ROM, SPARE), and ARM60

areshown in the section Electrical Characteristics.

Wait State Generation

To allow access to slow peripherals or memory, the clock

(MCLK) to the ARM60 microprocessor may be stretched in

either Phase 1 (Low) or Phase 2 (High), thus allowing wait

states to be introduced (where a wait state is defined as being

one MCLK period long).

The GP2021 introduces one wait state for accesses to the

Real Time Clock, Dual UART and System Control registers,

as shown in Fig 15. Correlator accesses, as shown in Fig 19

incur one wait state; subsequent accesses being prevented

from contravening the Correlator requirements (see

Correlator Functional Description) by adding several wait

states.

In order to ensure compatibility with variety of memory

devices, the ROM interface is programmable with between

one to three wait states, while the EEPROM and SPARE

interfaces can be programmed with between three to six wait

states via the Wait State Register. For further information on

the Wait State Register, refer to Detailed Description of

Registers. Read and write cycles for the RAM, EEPROM (or

Spare) and ROM interfaces are shown in Figs 16–18.

During a read cycle from Flash Memory, the output disable

to data bus release time, could be greater than 25 ns. Hence

in order to avoid bus contention, the nominal period of MCLK

is stretched by 25 ns during the following cycle.

The ARM60 is able to perform either byte or word ( 4 bytes

wide) writes to memory. All registers within the GP2021 are

word aligned, with only write accesses to external RAM being

either byte or word aligned. The signal NBW is used to indicate

either a byte or word write request, with A<1:0> performing

byte selection.

Decoding of NBW and A<1:0> is performed by the

Microprocessor Interface, with NW<3:0> being the byte write

select outputs to memory. During a word write all four of the

outputs NW<3:0> will be active.

Note that the register addresses for the Correlator and

Support Functions are as shown in the GP2021 Register Map.

18

GP2021

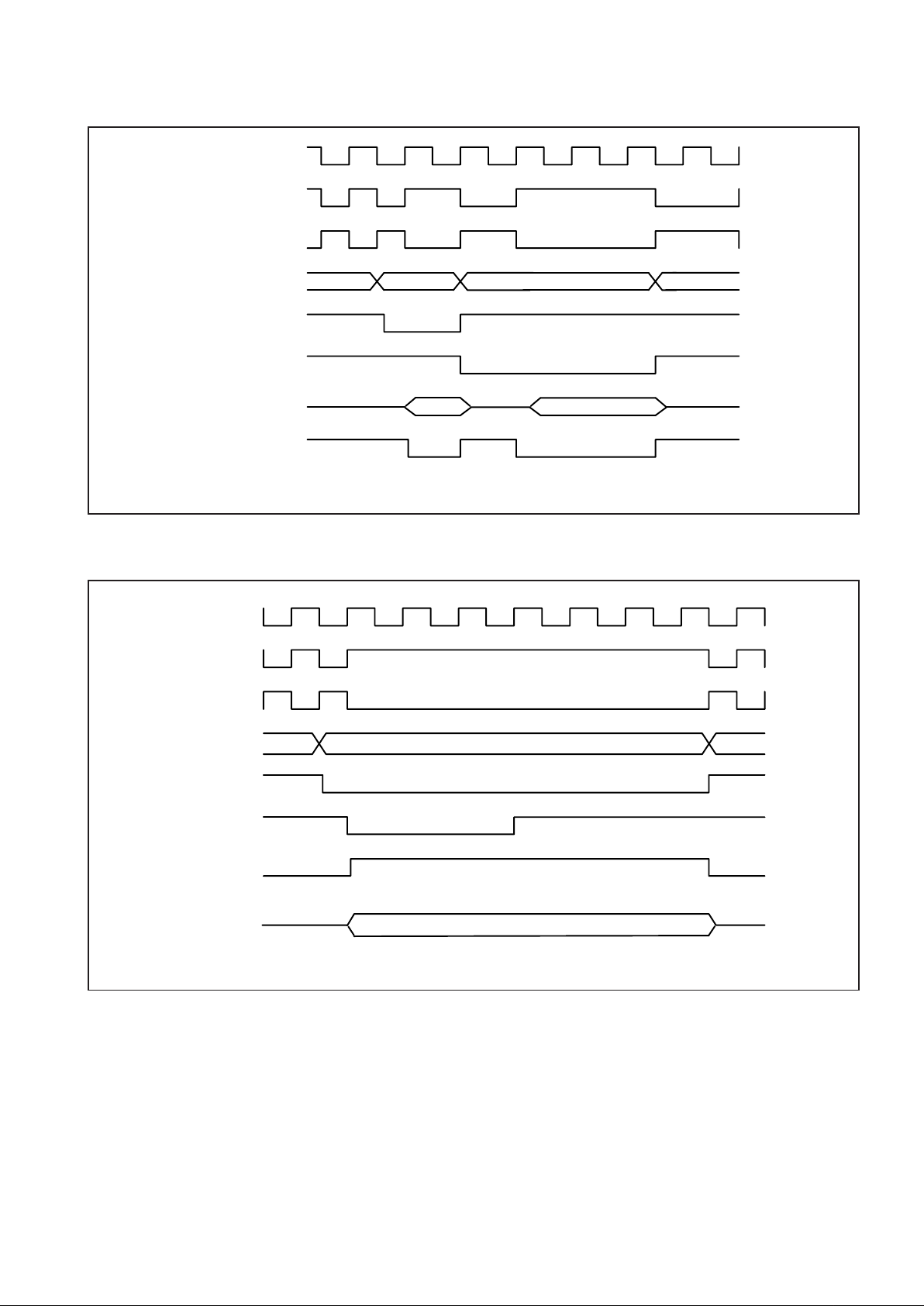

Fig.15 Peripheral functions write/read Cycle

Fig.16 RAM read/write Cycle

20MHz

INTERNAL

MCLK

ARM_ALE

NRW

NMREQ

NBW

DBE

INTERNAL

WRITE

INTERNAL

READ

D<15:0>

VALID

1 W

AIT ST

ATE

VALID

CLOCK

A<22:20>,

A<9:0>

MCLK

NOTE: This diagram assumes NMREQ is Low

.

20MHz

INTERNAL

ARM_ALE

NRAM

NW0

NW3

NW2

NW1

D<15:0>

DBE

NRD

NRW

NBW

VALID VALID VALID VALID VALID

CLOCK

A<22:20>,

A<9:2>

VALID

19

GP2021

Fig.17 ROM (1 wait state) and EEPROM/spare (2+1wait states) Read Cycles

MCLK

NOTE: NRW, NMREQ and DBE are assumed to be Low

20MHz

INTERNAL

CLOCK

ARM_ALE

NEEPROM

NROM

NRD

D<15:0>

A<22:20>,

A<9:0>

Fig.18 EEPROM (or Spare) Write Cycle

MCLK

NOTE: NBW and NR

W are assumed to be High for this cycle

20MHz

INTERNAL

CLOCK

ARM_ALE

A<22:20>,

A<9:0>

NEEPROM

NW<3:0>

DBE

D<15:0>

Loading...

Loading...