Minoura TRUE-PRO owners Manual

Wheel Truing Stand

!

TRUE-PRO

instructions manual

Axle Holder

Pillar

Gauge

Stay

Leg

Lock Knob

Thank you for choosing the MINOURA

.

PRO

This portable wheel truing stand features our

convenient AUTO CENTERING system. ACS

allows you to perform almost every procedure

needed in building a wheel without the need for an

additional dishing tool.

Also, newly designed gauges that check vertical and

horizontal movement of the wheel are intuitive and

easy to use.

TRUE-PRO folds down completely for easy transport and storage.

Please read this instructions manual carefully before

use and keep handy at all times for future references.

Body

TRUE-

Components

Vertical Gauge

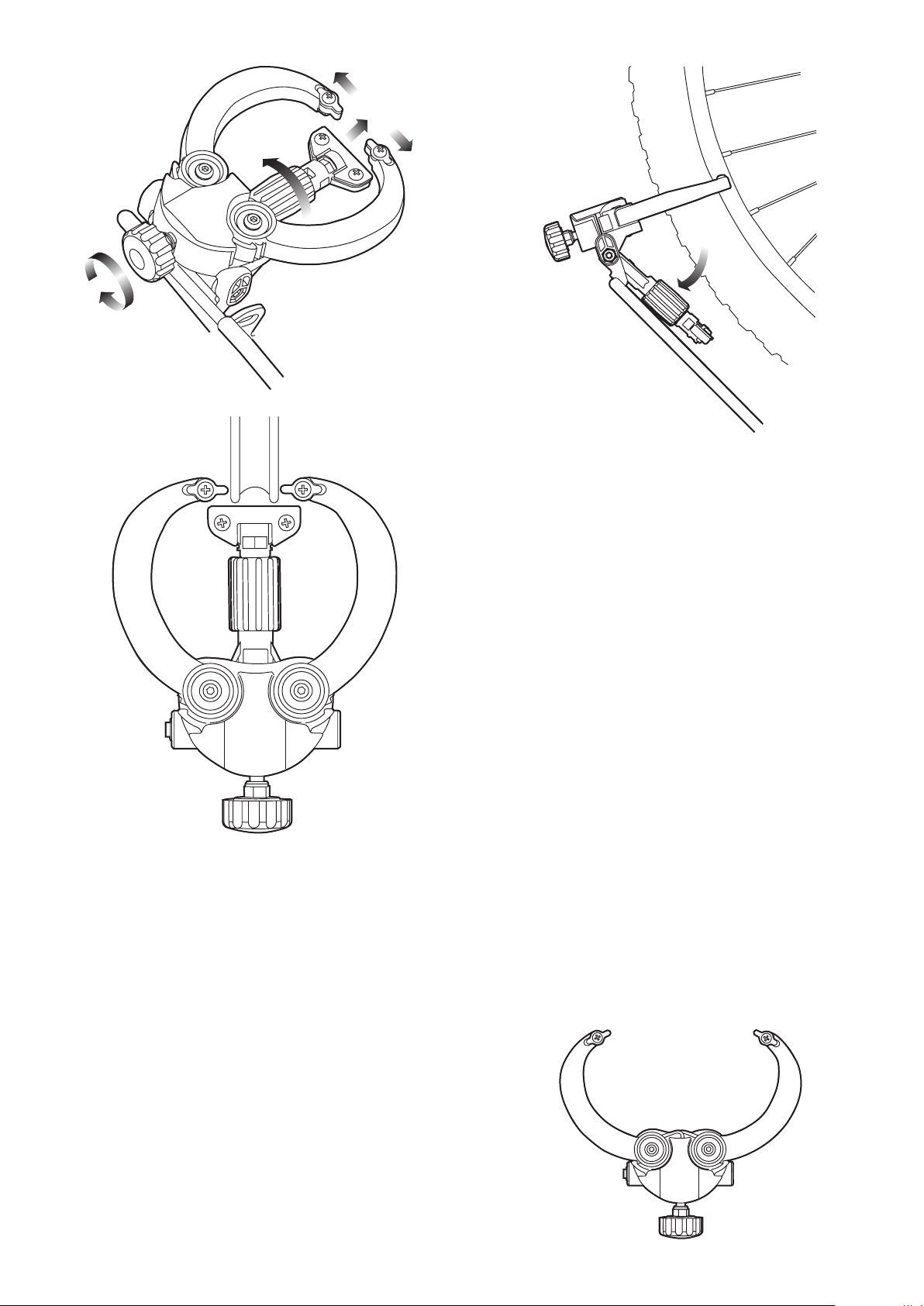

• PILLARS

Both right and left side Pillars are connected in the

Body so they will move together at the same time.

You should hold both Pillars with both hands when

opening or closing them.

• AXLE HOLDER

Axle Holder can adjust its angle to keep parallel at

any width to t hubs properly. (see Fig. A)

It is crucial to set the wheel into the deepest position

of the Axle Holder by pushing down the wheel when

setting up the wheel on True-Pro to get better result.

If one side has been lifted up due to bad installation,

the wheel won't be symmetrical.

Side Gauge

Vertical Gauge

Adjust Knob

Arm

Arm Lock

Side Gauge

Adjust Knob

Important Notes

• Do NOT use True-Pro for any purpose other

than instructed such as display stand or

indoor trainer.

• This Auto-Centering system is not 100%

perfect so we recommend you to use a

wheel dishing tool together for much more

precise adjustment.

• Setting wheel in the correct position is

crucial. Push down the wheel to set it in

the deepest position on the Axle Holder

when you tighten the quick release skewer.

- 1 -

(Fig. A)

How to Operate

Checking Position

Foldable Vertical

Gauge

(Fig. B)

(Fig. D)

The metal tip on the Vertical Gauge can be removed

by loosening two screws if you don't wish to scratch

the soft carbon rim surface.

However, we recommend you keep the metal tip in

contact at all times.

(Fig. C)

• VERTICAL GAUGE

Vertical gauge is for checking the vertical movement

of the wheel. When the rotating wheel comes in

contact with the Vertical gauge, you will hear a

scratching sound.

To adjust the gauge position, rotate the Vertical

Gauge Adjust Knob. (see Fig. B)

• SIDE GAUGE

Side gauge checks for horizontal movement. Spin

your wheel and

a scratching sound.

hear

To adjust the opening of Side Gauge, rotate Side

Gauge Adjust Knob, then both Arms will move

together at the same time. (see Fig. B)

Side Gauge should be positioned 1 - 2 mm away

from the rim side wall. (see Fig. C)

If the movement is so heavy, you should place the

gauge farther, then set it closer gradually as the

adustment is being done.

If you already set the best opening size of the Side

Gauge to your rim but the wheel has a tire, you can

open the Arm manually for quicker installation.

To do so, hold the Arm then open it until it is locked

at the widest position. (see Fig. E)

Vertical Gauge should be positioned 1 - 2 mm away

from the rim. (see Fig. C)

If the movement is so heavy, you should place the

gauge farther, then set it closer gradually as the

adustment is being done.

If you mount a wheel with tire for just checking the

horizontal movement, you can fold down the Vertical

Gauge manually. (see Fig. D)

(Fig. E)

- 2 -

The metal tip of the side gauge can be retracted by

!

turning the screw and tip if you worry about damage

to the side of your rim. However, some contact must

be maintained so you can hear if the wheel needs

adjusting.

Normal Position

(metal tip is projected)

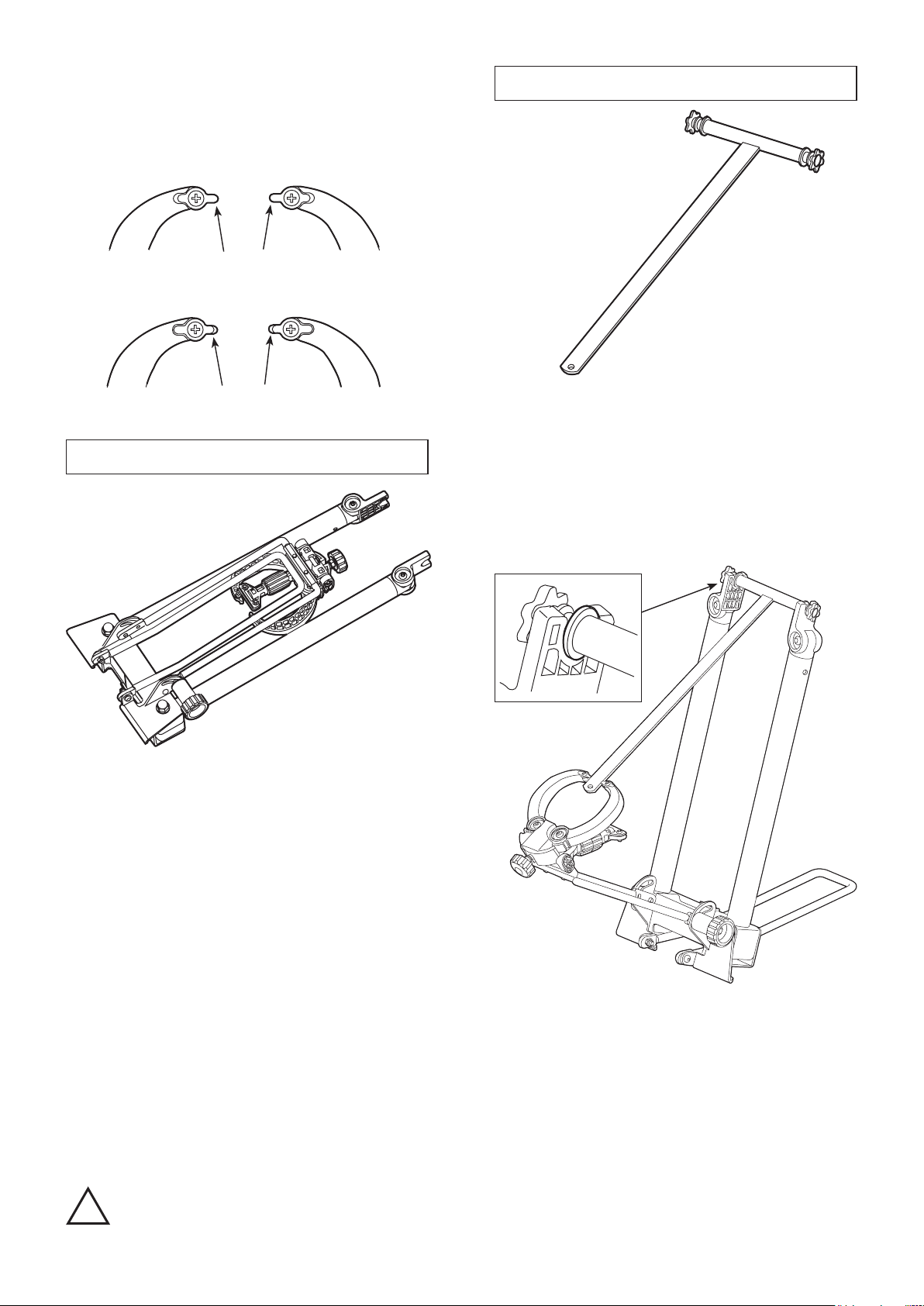

How To Use T-Gauge2

T-Gauge2

(Fig. H)

Carbon Position

(metal tip is retracted)

How To Fold Down

True-Pro is completely foldable for easier

transportation and compact storage.

To fold down, follow the steps;

(Fig. F)

(Fig. G)

The T-Gauge2 checks the position of your True-Pro

to make sure it is centered exactly so your wheel

should be able to be trued as symmetrically as

possible.

It's crucial to check the gauge position at the

point where you work on the actual wheel.

Also you should check regularly before using TruePro to avoid mistakes.

1. Shut the Side Gauge as narrow as possible.

2. Loosen the Lock Knob.

3. Open the Pillars slightly.

4. Fold the gauges downward and push toward the

Pillars.

5. Flip up the Leg until it touches the Gauge Stay.

6. Tighten the Lock Knob.

7. Close the Pillars until it touches the gauges.

Be careful not to pinch your ngers

between the body, stay and leg.

- 3 -

T-Gauge2 Setup

Position

T-Gauge2 should be installed on the Axle Holder as

deep as the case of wheel.

Loosen the knob nut, insert into the Axle Holders.

Make sure each metal washer is located inside of the

Axle Holder to keep the angle as vertical as possible.

While pushing down the T-Gauge2, tighten the knob

nut to x the position.

Put the Side Gauges close to the T-Gauge2, then shut

the Side Gauges by turining the adjust knob.

(Fig. I)

Loading...

Loading...