Page 1

!

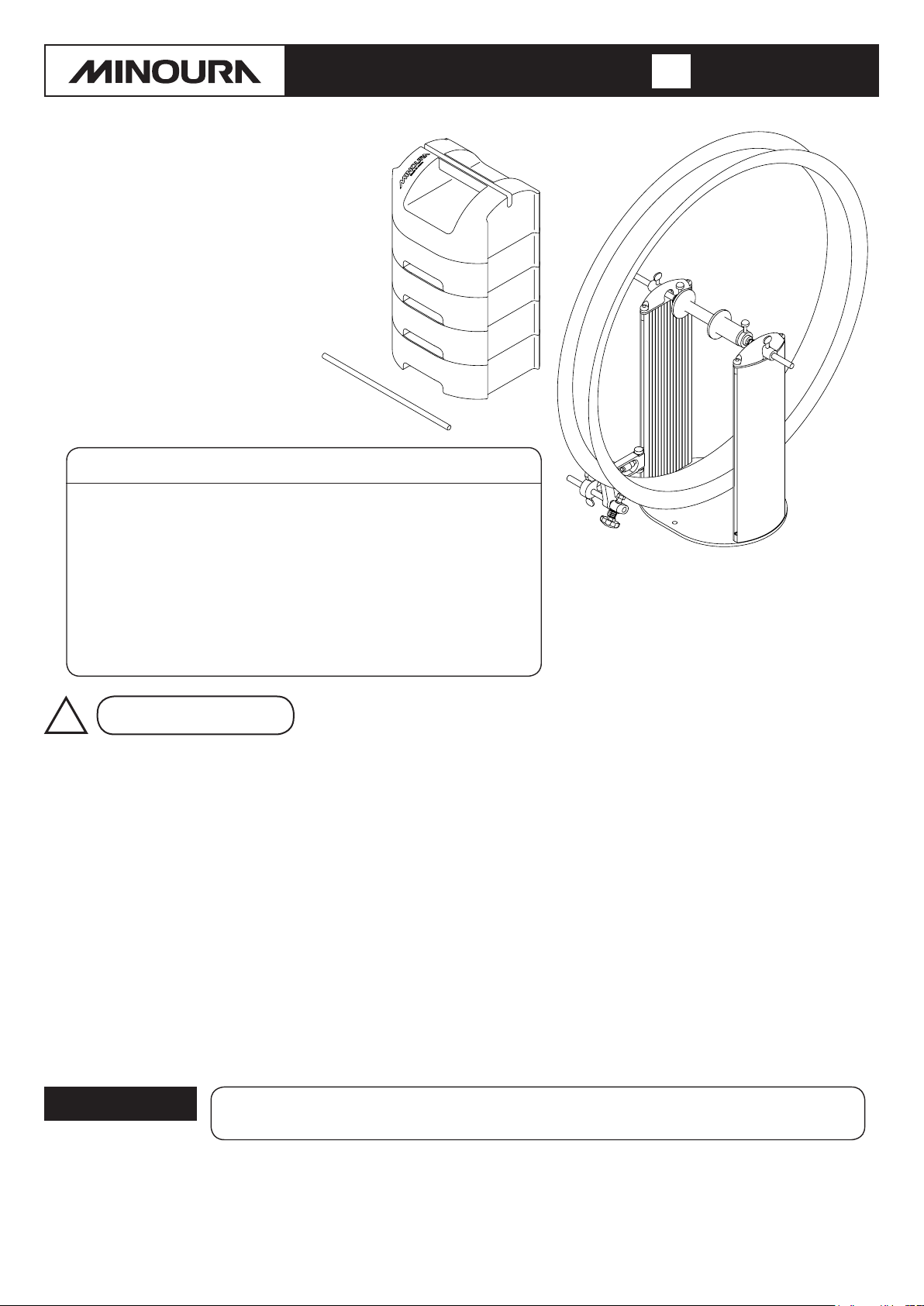

Bicycle Wheel Truing Stand

The FT-50W is the wider version of

the FT-50. This version offers tool

storage and a handy carrying handle

for easy transportation and storage.

Read this instruction manual

carefully before use.

Keep this manual in hand

while you use this product.

FT-50 W

instruction manual

(ver.1.0 2018/10)

Warranty Period :

Minoura offers 1-year limited warranty service to the original owner

of this product from the date of the purchase.

Any problems caused by the manufacturer's defect will be solved by

free repair or replacing the whole product or necessary parts.

However, any problems caused by user's misuse, unapproved

modification and disassembling, damage during use or shipping, or

expected natural wear will not be covered by this program.

Please read the enclosed warranty card for more details. And

Minoura strongly suggest to check out our web site regularly for the

latest update.

1 year

Important Notes

• FT-50W is a special tool for precisely maintaining the

bicycle wheel. Do not use this product for any other

purpose than instructed.

• Remove the quick release (Q/R) skewer from your

wheel before use.

• We recommend removing the tire from the wheel before

use.

• The max wheel hub width is 210mm that covers most

wide rims for fat bikes. Remove the spring from the right

side coupling axle when you mount a wide hub.

• Clamps on a standard 9mm Q/R using the side

couplings.

• 12mm or 15mm thru axle type hubs are also compatible.

Insert the supplied adapters in the hub hole for

mounting.

• Please note that a small amount of rim surface scratches

from the tips is normal. Especially on carbon or softer

metal wheels.

• Do not spin the wheel too fast. Rotate slowly.

• The verticality of the pillar is the most important matter

• Your wheels are critical to your riding safety. You assume

• Minoura is not responsible for any issues encountered

[In-Use Image with wide rim]

on FT-50W. Do not apply any shock or damage to the

pillars even while storing.

all responsibility for working on your wheels. Minoura

is not responsible for any issues that might arise from

truing your wheels. If you have doubts, please take your

wheels to a professional mechanic for service.

with your wheels after using the product. Make sure you

know what you're doing. If you have any doubts in your

abilities, consult a professional. Minoura is supplying

tool to do a job, but learning how to use this tool is your

responsibility.

Contact

If you have question or problem on this product, please contact the shop where you originally purchase this product or

the distributor in your country first. The distributor information can be found on our web site. Only when you cannot

obtain enough service from them, you can contact Minoura directly.

MINOURA JAPAN MINOURA NORTH AMERICAN TECH CENTER

(for ALL customers, including Canada) (for U.S. residents ONLY)

1197-1 Godo, Anpachi, Gifu 503-2305 Japan Mon - Fri, 9 am - 5 pm (PCT)

Fax +81-584-27-7505 Phone 1-510-538-8599 / Fax 1-510-538-5899

minoura@minoura.jp / www.minoura.jp support@minourausa.com

Made in Japan

Page 2

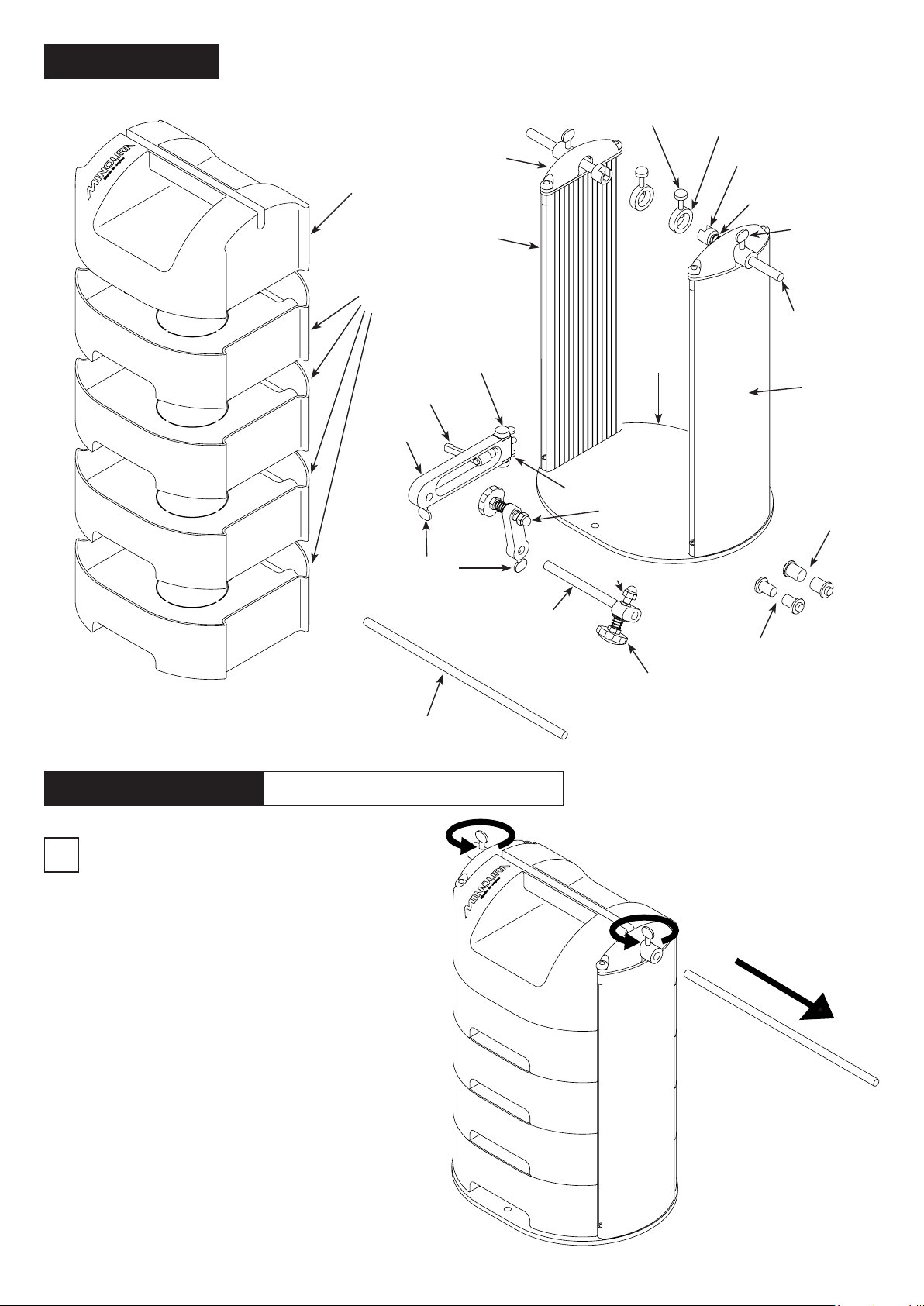

Schematics

(In this manual, we are explaining with the gauge mounted on the left side.

Of course, it can be set on the right side too.)

Tool Box

Top Cover

Tool Box +

Cushion Pad

(4 sets)

Lever Bolt

Gauge Base

Top Cover

Left Pillar

Metal Knob Bolt

Metal Knob Bolt

Base

Plate

Mounting

Bracket

Horizontal

Shaking

Gauge

Coupling

Guide Ring

Coupling

Spring

(Right side only)

Buttery Bolt

Coupling

Shaft

Right Pillar

15mm Thru

Axle Adapter

(Large)

How To Assemble

Gently place the FT-50W on your work

1

bench.

Required Tool :

Loosen the butterfly bolts on top of the

pillars, then the rod can be removed.

(Fig. A)

If removal is difficult, we suggest using a

pen to help push the rod through.

Buttery Bolt

Tool Box Fixing Rod

5mm Hex Wrench

Gauge Shaft

Vertical Shaking Gauge

Plastic Knob Bolt

12mm Thru

Axle Adapter

(Small)

- 2 -

(Fig. A)

Page 3

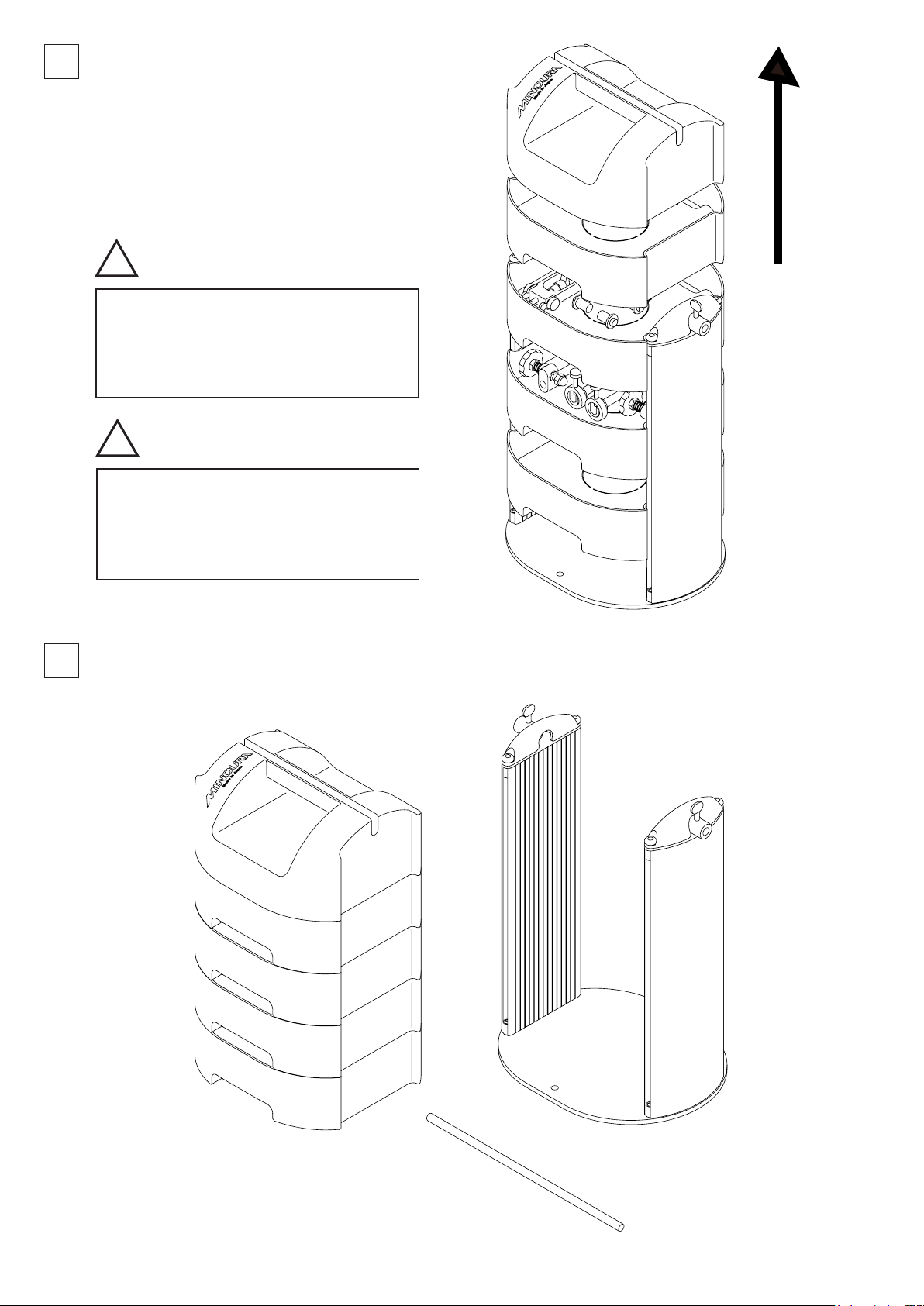

There is a total of four tool boxes stacked on

!

!

2

top of each other. They can be removed by

lifting them upward. (Fig. B)

You will see all necessary parts and adapters

in the boxes.

Also you can use this space for storing your

own parts and tools.

The boxes are not connected.

You need to pull them out one by

one, or grab the bottom box to lift

all boxes up together.

You must stack every box tightly as

the bottom rib is completely hidden

in the lower box, otherwise the xing

rod cannot be set in the last step.

After removal of all boxes, you will install the gauges

3

and coupling shafts onto the body.

(Fig. B)

(Fig. C)

- 3 -

Page 4

4

!

All 4 boxes are exactly the same.

To store a lubricant can or long tools such

as a spanner or screwdriver, cut the center

section of the cushion pad to make a hole,

and put the tool into the hole.

Please note that it's difcult to repair

the cushion if you modify it. Think

carefully before cutting the cushion

about your future needs.

Tool BoxCushion Pad

(Fig. D)

5

TIPS:

(Fig. E) (Fig. F)

Coupling Shafts,

Vertical & Horizontal Shaking Gauge

Install the coupling shafts on top of the pillars, and

set the coupling ring on each coupling.

The body is symmetric and the coupling shafts are

exactly the same.

We are installing the spring on the rigjt side coupling

in this manual. Of course, setting on left side is no

problem.

Insert a coupling shaft in the spring and set in the

hole on the right side pillar. Tighten the butterfly bolt

temporarily. (Fig. G)

On the left side, the coupling shaft doesn't have a

spring.

About Lever Bolt

Gauge Base,

Thru Axle Adapters (12mm & 15mm)

The lever bolt has a spring inside between the

threaded bolt and the lever. You are free to set

the lever at any angle as you want by pulling the

lever while turning.

To fix the gauge base, turn the lever to tighten,

pull the lever to get back to the previous angle,

and repeat the steps to tighten more.

- 4 -

(Fig. G)

Page 5

Install the gauges to the pillar rail.

!

!

6

Remove the mounting brackets from the gauge base, and put it into the pillar rail (Fig. H).

Flip the bracket vertical to insert (Fig. I), and flip horizontal back to hold (Fig. J).

1 2 3

(Fig. H)

Sandwich the gauge base with the brackets

7

from top and bottom, and screw the metal

knob bolts to mount.

The gauge base will be held in position by

screwing the inside

lever bolt which

pushes toward the

wall.

You will change the

gauge position

later, so you don't

need to tighten the

lever bolt so firmly

yet.

Gauge Base

8

Lever Bolt

Mounting

Bracket

Metal Knob Bolt

Horizontal Shaking

Gauge

(Fig. I) (Fig. J)

There is some clearance between the

bracket and the rail. That means the

gauge base may not be xed in exactly

the right angle to the pillar. Even if it's a

little slanted, it's no problem.

Screwing the lever bolt will pull the

gauge base against the pillar and holds

the gauge base solidly.

However, tightening excessively will

(Fig. K)

cause damage to the alloy rail tips and

may cause the unit to not work properly.

Do not over tighten the bolt.

Insert the side shaking

gauge unit to the gauge

shaft. (Fig. L)

9

Then insert the shaft to the

gauge base. (Fig, M)

The gauge position will

be adjusted later after

mounting the exact wheel.

We suggest you to put a

mark on the pillar to set

the gauge in right position

again easily.

Vertical Shaking

Gauge

(Fig. L)

(Fig. M)

- 5 -

10

Assembly completed. (Fig. N)

(Fig. N)

Page 6

How To Mount Wheel

!

9mm Quick Release Skewer Hub 12mm / 15mm Thru Axle Hub

Remove the Q/R.

Install with the hub

ONLY.

Conrm if the wheel

is set exactly vertical

without any backlash.

Thru Axle Adapter

(supplied)

(Fig. O)

Twist the couplings as the open side faces top, and set the wheel as both side couplings clamp the hub.

After clamping, tighten the butterfly bolt on the top cover to fix the position. (Fig. O)

It's crucial that each hub end sits in the deepest position in the coupling that makes both right and left

ends are set in the same height. This is critical in order to expect the correct result. For this purpose,

you should tighten the metal knob bolt on the coupling guide ring to push down and hold the hub axle.

In case of thru axle hub, insert the supplied adapter in the hub hole before mounting. (Fig. P)

(Fig. P)

TIPS!

Make sure there is a spring in the right side couping shaft. The spring helps push the hub towards the

clamp for a better fit.

Temporarily hold the right side coupling as the spring is compressed, place the wheel, and set the left

side coupling position. This means even if you loosen the metal knob bolt on the right side coupling,

it still continues pushing the hub.

This is also good to know if the wheel is finished symmetrically by flipping the wheel while retracting

the right side coupling only (do not move the left side coupling).

It's almost the same as when you use a dishing tool.

- 6 -

Page 7

X

How To True The Wheel

Adjust both the side coupling shaft lengths equally in order to get the wheel in the center of the stand as

closely as possible. Tighten the left side butterfly bolt firmly and tighten the right side bolt gently.

At first, loosen the butterfly bolt on the gauge base to set the vertical shaking gauge to the rim edge as close

as possible.

(Make sure you remove the tire from your wheel when checking vertical shaking.)

Next, set the horizontal shaking gauge as close as possible to the rim wall.

Tighten every butterfly bolt and metal knob bolt to fix the positions.

You should check the horizontal shaking at the area where the brake shoe touches the rim. This area is

resistant to scratching.

If your rim has a shallow wall like disc brake rims, it may be difficult to keep the rim from being scratched.

Carefully choose the right areas for contact.

If the wheel has a tire and it has contacted with the gauge or shaft, or the gauge tip cannot reach the rim,

you need to remove the tire from the rim.

Rotate the wheel slowly, and try to listen for small scratching sounds that the gauge touches the rim surface.

If the contact is too hard, turn the plastic knob bolt counter-clockwise to retract the gauge.

Adjust the gauge position so it sometimes touches the rim, not often. As the job proceeds, you need to

change the gauge position closer and closer, and in the final stage, you will see the gap between the gauge

and the rim visually, and you won't hear any more scratching sounds.

Here both side

couplings are set in

the correct position

and the wheel is

perfectly vertical.

Here the hub end

height is different

and you can see the

wheel is slanted.

(Fig. Q)

(Fig. R)

- 7 -

Page 8

If you hear the scratching sound, it means the rim has been deformed toward the gauge.

Loosen or tighten the spoke nipples to adjust the rim shape to a perfect disc.

Continue checking the gap between the gauge and the rim carefully, and when there are no more

sounds during rotations, the adjustment is complete.

In the side shaking adjustment, you should sometimes attach the Dishing Tool to know if the wheel

is symmetric.

Direct Mounting

You can fix the FT-50W to your work bench

directly with M8 bolts if you need a more solid

base. (Fig. S)

The hole pitch is 190mm.

Optional Item

The vertical and horizontal shaking gauge can be upgraded to a micro meter.

This allows you to distinguish the wheel shaking in the level of 0.1mm.

(Fig. S)

- 8 -

Loading...

Loading...