Page 1

Wheel Truing Stand

FT-1

instructions manual

(Ver.2.1 2014/6)

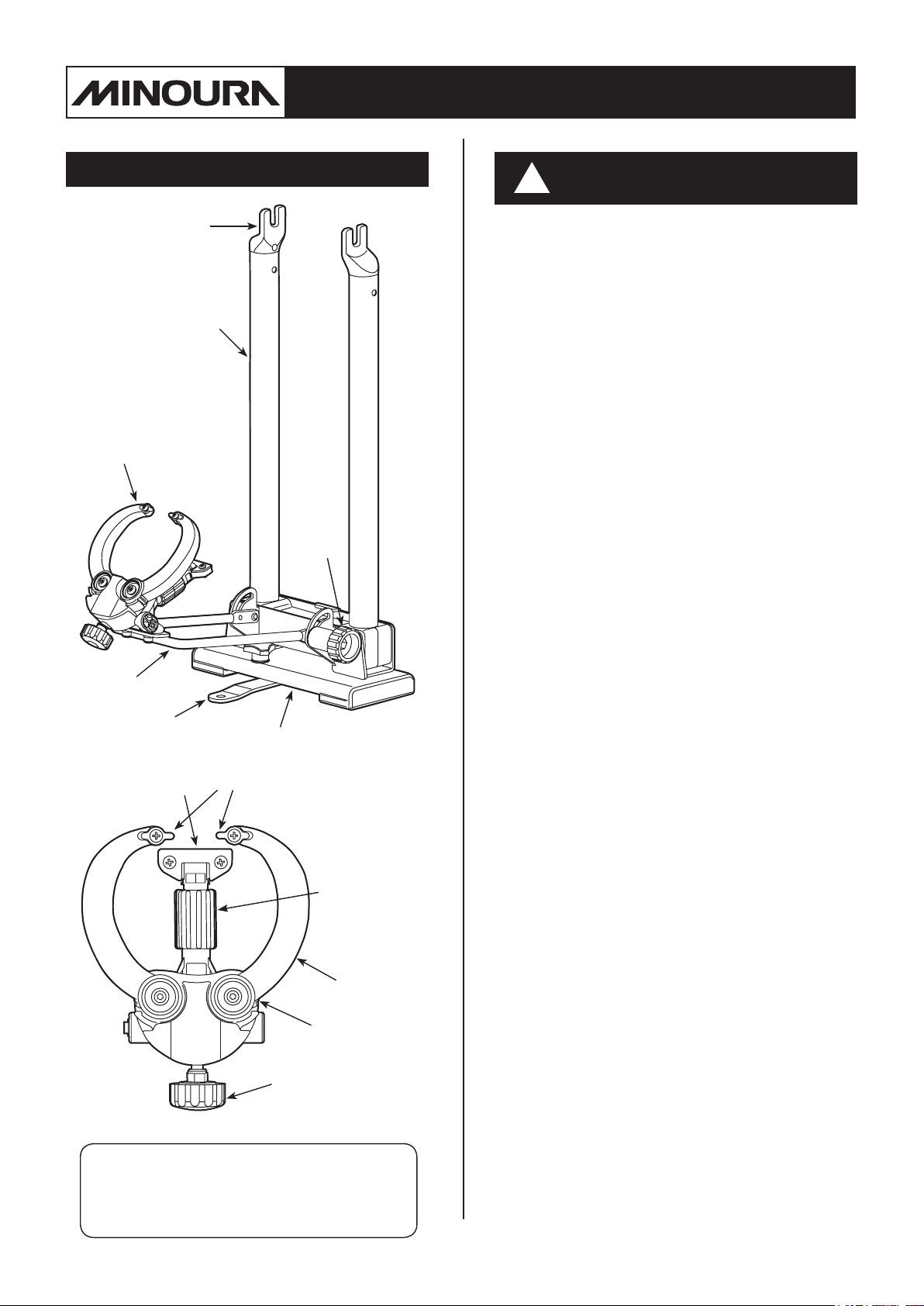

Components

Axle Holder

Pillar

Gauge Arm

Locking

Knob

Important Notes

!

• Turing wheels is done at your risk. Minoura

is not liable for any damage that may be

caused by improper use of the stand.

Wrong wheel adjustment may cause poor

brake performance or spoil bike stability.

You can use FT-1 only when you accept

this caution. And Minoura will understand

you accept this caution when you start

using FT-1.

• Only use the FT-1 to true bicycle wheels

and for no other purpose.

• FT-1 will work with 9mm quick release

skewers and xed nut axels, too.

15mm / 20mm thru axle can be used when

using optional adapters. Any other size

thru axle will not t to FT-1.

Gauge

Stay

Anti-Rolling Leg

Vertical-Shaking

Gauge

Body

Side-Shaking Gauge

Vertical Gauge

Adjust Knob

Arm

Arm Lock

Side Gauge

Adjust Knob

(Fig. A)

(Fig. B)

• Both pillars are constructed to move

together. This helps to readjust the gauge

position when changing to a different hub.

This is NOT an "Auto-Centering" feature.

You must use a wheel dishing tool to

check wheel symmetry.

• When mounting a wide hub and tightening

the skewer, the wheel may not seat

correctly because the axle holders are

angled.

Push down the wheel to set it in the deep-

est position on the Axle Holder when you

tighten the quick release skewer.

• You will use only one Side Shaking Gauge

when checking the wheel. Widely open and

lock the gauge arm which you don't use.

When you need to order replacement parts,

refer the schemastics on the last page then

order it with the correct part number or part

name.

- 1 -

Page 2

Side Shaking Gauge

Side Shaking Gauge is for checking the horizontal

movement of the wheel.

The purpose of this job is making the distance

(gap) between the rim surface and the brake shoe

equal on all around the wheel in order to expect

greater brake performance.

This job can be accomplished with the tire on or

off the wheel.

Set the wheel on the stand and position the tip of

the Side Shaking Gauge 1 - 2mm away from the

rim surface (do not touch). (see Fig. C)

Rotate the wheel slowly (do not spin fast) and look

at the clearance between the rim surface and the

gauge tip. The gap will change vary and when the

rotating wheel comes in contact with the gauge,

you will hear a scratching sound.

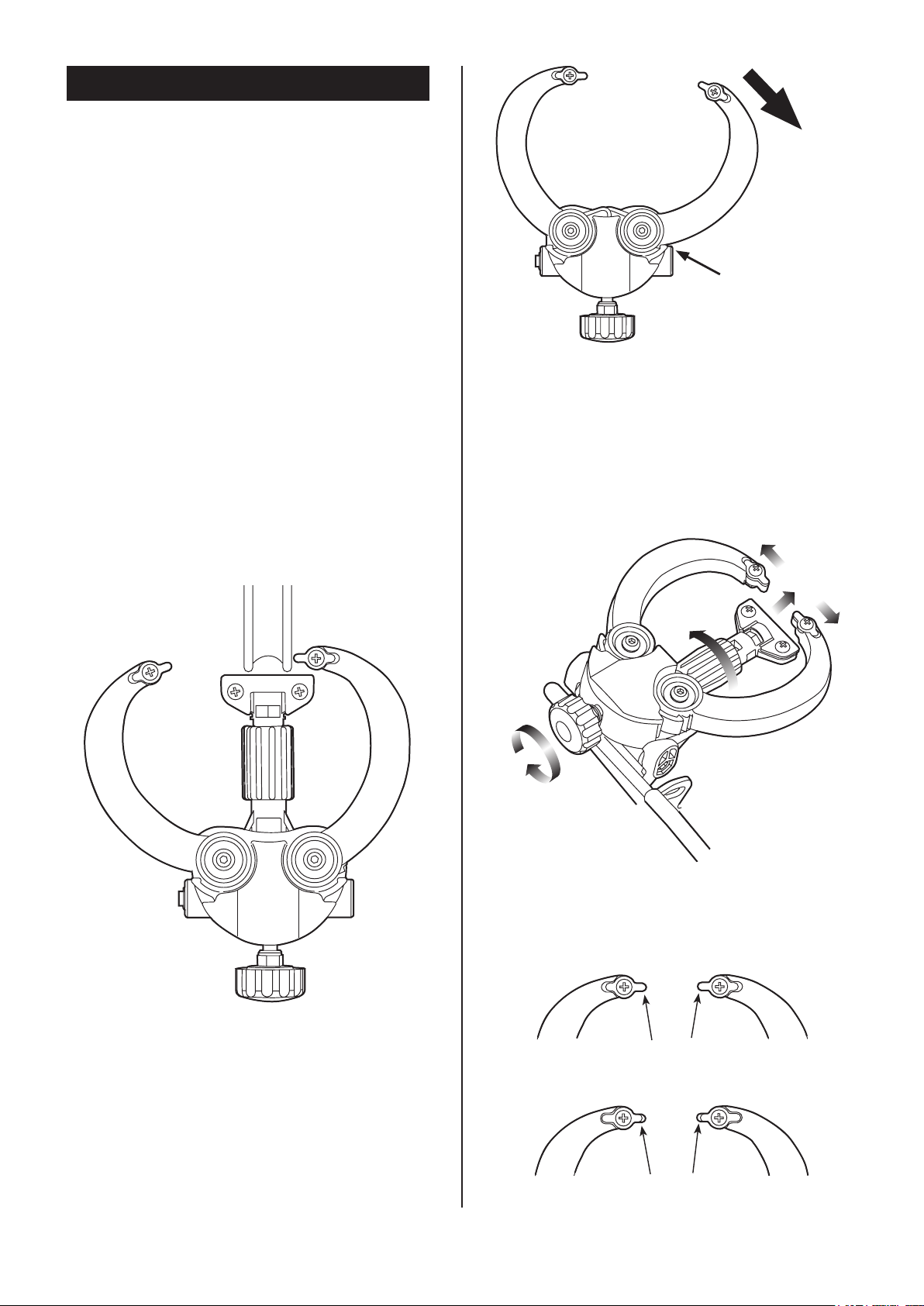

Widely open the

arm until it's caught

by the locking ratch

(Fig. D)

The side shaking gauge arm can be locked in

widely open position.

Hold the arm and move open. When the arm is

caught by the locking ratch, you will feel click.

This is the locking position. (see Fig. D)

Do not force to open more.

To close the arm, push it inward.

Turn the nipples to make this gap equal on all

around the wheel.

(Fig. C)

(Fig. E)

Turn the Side Gauge Adjust Knob, then both

arms move together. If the arm is in locked

position, it won't move even you turn the knob.

In case that you see the wheel from right hand side

to true the wheel.

On side shaking truing job, you use either right

or left side gauge. You will not use both gauges at

once.

Depends on your dominant eye, use the gauge

arm on your favorite side.

Fig.C shows then case you are dexitral.

- 2 -

Metal Rim Position

(metal tip is projected)

Carbon Rim Position

(metal tip is retracted)

(Fig. F)

Page 3

Turing wheels means the gauge has to touch the

rim and this may cause some light scratching.

the rotating wheel comes in contact with the

gauge, you will hear a scratching sound.

If you use an expensive carbon rim and you don't

want to scratch it, flip the metal piece on the Side

Shaking Gauge. In this position, only the plastic

arm body contacts the rim and it won't damage

the rim. (see Fig. F)

The contact sound between the tool and rim will

become fainter and more difficult to hear.

Turn the nipples to make this gap equal on all

around the wheel.

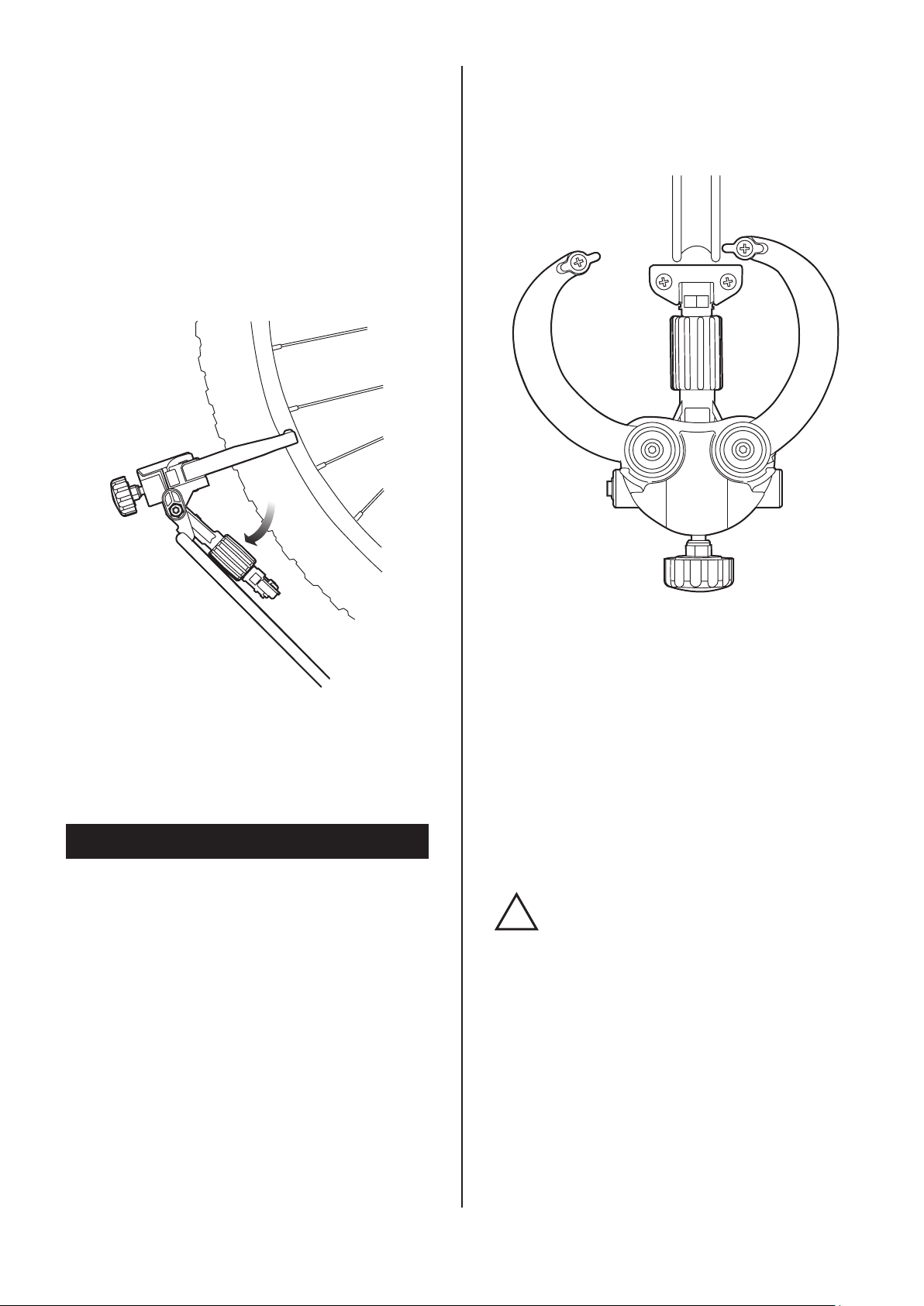

(Fig. H)

(Fig. G)

The angle of the gauge arm should be set as deep

as possible. (see Fig. G)

If the Vertical Shaking Gauge touch the tire, fold

it down or remove the tire.

Vertical Shaking Gauge

Vertical Shaking Gauge is for checking the vertical

movement of the wheel.

The purpose of this job is making the wheel

concentric circle to make the riding smoother.

You must remove the tire from the wheel when

doing this job.

Raise up the Vertical Shaking Gauge Arm (and

extend the arm length by turning the center barrel

type knob if necessary) to position the tip 1 - 2mm

away from the rim edge (do not touch). (see Fig. H)

The gauge arm angle against the rim should be as

deeply as possible.

Turing wheels means the gauge has to touch the

rim and this may cause some light scratching.

If you use an expensive carbon rim and you don't

want to scratch it, remove the metal bracket from

the Vertical Shaking Gauge and only the plastic

part contacts the rim.

Be sure the contacting sound will have to become

very small and difficult to listen.

If the Vertical Shaing Gauge has been

!

twisted by some reason, it will contact

only either edge of the rim.

Even in this condition, you can

continue the wheel truing job without

any problem, but if you want to have

the gauge contacts both edges at

once, twist the gauge.

Rotate the wheel slowly (do not spin fast) and

look at the clearance between the rim edge and

the gauge tip. The gap will change vary and when

- 3 -

Page 4

How To Fold Down

Pillars

To open or close the pillars, hold them with both

hands and move at once.

If you move just one side pillar or push or pull

the pillar to different direction, your FT-1 should

be deformed.

This will cause a serious problem that FT-1 no

longer holds the wheel in proper angle and you

cannot expect correct result from wheel truing job.

(Fig. I)

FT-1 is completely foldable for easier transportation and compact storage.

To fold down, follow the steps;

1. Shut the Side Gauge as narrow as possible.

(if you don't want to change the gauge

clearance, you can leave it in current position)

2. Close the pillars by pushing inward from both

sides at same time.

3. Loosen the Lock Knob.

4. Fold the gauges

Pillars.

5. Tighten the Lock Knob.

6. Turn the Anti-Rolling Leg to store under the

body, then tighten the triangle head knob bolt.

Be careful not to pinch your ngers

!

between the body and stay.

Do not try to store the gauge bet-

!

ween the pillars.

If strong sideward shock is applied,

the plastic gauges should be broken.

downward

and push toward the

About Anti-Rolling Leg

Steps of Wheel Truing Job

Usually, wheel truing job is done with the

following steps.

Different job step may force you to re-adjust

the point you already done and it will take time

longer.

You need to think about the jobs totally. You

should not focus on just one point.

1. Vertical shaking adjustment

↓

2. Side shaking adjustment

↓

3. Wheel symmetry check & Off-set

adjustment

↓

4. Spoke tension adjustment

You need to have a long fuse. Wheel truing job is

quite difficult for beginners and you should not

expect right result from just one action.

If you feel that you cannot finish it by yourself, it's

highly recommended to ask to a professional or

well-skilled mechanics.

Some shaking on the wheel is not problem for

your daily use, but be careful about the spoke

tension. Bad adjustment will cause serious

accident.

You will see a retractable leg underneath the FT-1

body. This is for preventing the rolling down

problem due to the worse balance when a wheel sits

on the stand.

The hole on the leg is xing FT-1 on your workbench

with a screw.

To retract the leg, loosen the triangle knob bolt, ip

out the leg, then tighten the knob again.

- 4 -

Page 5

About Offset Wheel Setting

How To Fix Vertical Movement

At rst, you should understand that you should

x the vertical movement prior to the horizontal

movement, especially on the rear wheel because of

its unique wheel system named

Offset Wheel

Tensioning the front wheel is much easier than

the rear. Rear wheel tensioning requires Offset

Tensioning.

The rear wheel has a different spoke angle pattern

when looking at it from behind. (see Fig. J)

A rear hub is not symmetrical to the wheel. Flanges

can be far from center. Because the rear hub must

have extra space for the set of transmission gears,

you will need to true using Offset Tensioning.

"Offset"

.

(Fig. J)

The vertical movement within 3 mm may not

cause any troubles. But if you want to be it as zero

as possible for smoother ride, you should try the

following process again and again.

Be sure, in this case, you should tighten both side of

the nipples equally.

1.

You set the wheel on the FT-1 and see the Vertical

Gauge.

Put the tip of the Vretical Gauge close to the surface

of the rim.

2.

Rotate the wheel slowly, and check the vertical

movement. Do not spin fast.

3.

Attach tapes to two spokes; one is in the beginning

and another one is in the ending of vertical

movement.

4.

Make three (3) groups of spokes between your tape

markers as below;

If offset wheel, the torque works mostly only to

the right side (gear side) spokes. Because right side

spokes should be assembled more vertically than left

side.

Understand that right side spoke tension is more

important than left side spoke's one in this offset

assembling.

Well adjusted right side spokes can keep your wheel

stable in the future. Left side spoke tension is just a

help.

The nipple should not be loosened at any time.

Nipples are made from softer alloys or brass and are

prone to stripping easily.

You must use a correct spoke wrench

!

which ts the nipples perfectly,

especially when you use light alloy

nipples on your wheel.

If you use wrong size one, the nipple

will become round easily and you

cannot continue your work any more.

A

B

C

B

A

Group-A:

Group-B:

Group-C:

3 or less spokes in the beginning and in

the ending of vertical movement.

3 or less spokes between Group-A,

except for the center spoke.

The center 1 or 2 between the tapes.

5.

If the rim moves to outward, tighten both side

nipples.

- 5 -

(Fig. K)

Page 6

If the rim shakes inward, do NOT try to loosen the

nipples. Tighten both far side nipples.

This is because the nipples are made of soft material,

so its thread can be broken easily by loosening.

6.

Tighten the spokes as below;

• Group-B nipples = about 1/4 turns

• Group-C nipples = about 1/2 turns

Then check the vertical movement again with

rotating the wheel slowly.

If the wheel moves yet, continue the process again.

• Group-A nipples = about 1/8 turns

If you hear a strange sound or see

!

narrow metal "lines" or residue, your

nipple will fail soon.

Do NOT apply any lubricant to quiet

the sound. Put a new nipple on

immediately.

Group-A:

Group-B:

Group-C:

3 or less spokes in the beginning and in

the ending of horizontal movement.

3 or less spokes between Group-A,

except for the center spoke.

The center 1 or 2 between the tapes.

5.

If the rim moves to right, tighten the left side nipples.

Do NOT loosen the right side nipples.

This is because the nipples are made of soft material,

so its thread can be broken easily by loosening.

6.

Tighten the spokes as below;

• Group-B nipples = about 1/4 turns

• Group-C nipples = about 1/2 turns

Then check the horizontal movement again with

rotating the wheel slowly.

• Group-A nipples = about 1/8 turns

Do NOT tighten the spoke more

!

than 1/2 turns at one time. Wheel

truing must be done step by step.

Otherwise, you will loose the spoke

tension balance completely.

How To Fix Horizontal Movement

The horizontal movement within 2 mm may not

cause any troubles. But if you want to be it as zero

as possible for smoother ride, you should try the

following process again and again.

1.

You set the wheel on the FT-1 and see the Side

Gauges.

Put the tips of them close to the surface of the rim

side wall. Do not make them touch the rim.

2.

Rotate the wheel slowly, and check the horizontal

movement. Do not spin fast.

3.

Attach tapes to two spokes; one is in the beginning

and one is in the ending of horizontal movement.

If the wheel moves yet, continue the process again.

If you hear a strange sound or see

!

metal "lines" or residue, your nipple

will fail soon.

Do NOT apply any lubricant to quiet

the sound. Put a new nipple on

immediately.

Do NOT tighten the spoke more

!

than 1/2 turns at one time. Wheel

truing must be done step by step.

Otherwise, you will loose the spoke

tension balance completely.

There are several ways to true the

bike wheel, and there are many spoke

crossing patterns available depends on

the purpose on wheel.

Above is just one example and you don't

have to follow our way.

You should refer a bike maintenance

guidebook or ask to well-educated

mechanics to learn more effective

techniques.

4.

Make three (3) groups of spokes between your tape

markers as below;

- 6 -

Page 7

Limited Warranty Policy

For More Information...

Minoura offers -year limited warranty on this product

under the following conditions;

1. Only the original user who purchased this FT-1 in brandnew and unopened condition at an authorized Minoura

dealer, authorized internet retailer or authorized mail order

house (hereafter "Original User") is covered under the

Minoura Warranty Service Program (hereafter "Warranty

Service").

2. Any used or new FT-1, either purchased or given

through a shop, internet auction site or person-to-person

will NOT be covered under Warranty Service, except under

special circumstances to be determined by Minoura.

3. Original User must keep the original sales reciept and

must present a photocopy of the reciept together with a

claim report to obtain Warranty Service.

4. The warranty period shall start from the date of

purchase. If the reciept is not presented, Minoura reserves

the right to extend or deny Warranty Service.

5. All warranties will be void if the FT-1 is damaged due

to user's abuse, disassembly, unauthorized alteration or

midication, or used in any way not intended as described

in the instructions manual.

* When you need help, please contact

the shop rst where you purchased FT-1.

MINOURA Japan Headquarters

(for ALL customers)

1197-1 Godo, Anpachi, Gifu 503-2305 Japan

Phone: +81-584-27-3131

Fax: +81-584-27-7505

Email: minoura@minoura.jp

URL: www.minourausa.com

MINOURA North America

(for U.S. residents only)

California, U.S.A.

Phone: 1-510-538-8599

Fax: 1-510-538-5899

Email: support@minourausa.com

** For countries not listed, please see

our web site at www.minoura.jp to

nd the Minoura distributor in your

country and contact them for service.

Made in Japan

6. Only issues caused by manufacturer's defects will be

covered to all users at Minoura's expense. The period

expires in a maximum of 7 years after the last production.

7. Minoura may offer paid service for in or out of warranty

products that may include, but is not limited to, repair,

replacement and shipping expenses.

For more detailed information, refer both the

attached "MINOURA LIMITED WARRANTY

POLICY" card and our web site (http://www.

minourausa.com).

Web can offer you the latest and more correct

information.

- 7 -

Page 8

FT-1 Schematics

Screw M4x12

TG-6

TG-7

Cap Bolt M5x25

TG-1

Tapping Screw M3.5x12

TG-9

TG-8

M5 Flat Washer

TG-5

Screw M4x10

FF-5

TG-3

TG-4

TG-2

M5 Spring Washer

Cap Bolt M5x10

PARTS CODE

FF-1: FT-1 Main Body

FF-2: Base End Cap

FF-3: Anti-Rolling Leg

FF-4: Triangle Knob Bolt

FF-5: Axle Holder

TF-4: Lock Knob

TG-1: Gauge Body

TG-2: Vertical Gauge

TG-3: Vertical Gauge Plate

TG-4: Arm (Right)

TG-5: Arm (Left)

TG-6: Side Gauge Plate

TG-7: Upper Cover

TG-8: Spring (Right, Silver)

TG-9: Spring (Left, Black)

FF-2

FF-4

FF-3

TF-4

FF-1

FF-2

Tapping Screw M5x10

Page 9

FCG-310

This is the instructions for the tools contained in the

FCG-310

wheels between 18" and 27"/700c (applicable rim diameter : 335mm – 655mm).

NW-300

Please read this instructions manual carefully before use to understand how you will do on your bicycle wheel.

is the tool to check if the wheel is exactly symmetrical for better ride. You can use FCG-310 on most size of

is the spoke nipple wrench for twisting nipples on 14G/15G spokes.

FT-1 Combo

&

NW-300

kit.

instructions manual

(Ver.1.1 2014/6)

Knob Bolt

<FCG-310>

IMPORTANT NOTES

FCG-310 is the measuring gauge for bicycle wheel only. Do not use it for any other purpose than

!

!

!

!

instructed.

FCG-310 is a precision tool so please handle it with care. Do not hit or bend the frame and gauge

plate.

Be careful not to pinch your ngers when openning or closing the FCG-310.

Insert the NW-300 fully to the nipple when tightening. Use exactly same size of wrench without any

wag to protect the nipple. The size indication is just for your reference.

Frame

Gauge Plate

Ratch

Rim Guide

Positioning Lib

<NW-300>

15G

14G

15G

14G

How To Use FCG-310

1.

2.

3.

4.

5.

To open the FCG-310, loosen the Knob Bolt then open the Frame with both hands.

Look for the grooves on the inside of the Ratches that fix the angle when the Frame is opened.

Extend until the grooves meet and lock into place by pushing them each other.

Turn the Gauge Plate counter-clockwise to locate the hole at the down end side.

Put the Gauge Plate on the flat groove on the outside of the Ratch.

Tighten the Knob Bolt, but you don't need to tighten it so firmly at this moment.

If the Gauge Plate doesn't t to the at

groove on the Ratch correctly, you won't

!

be able to measure properly. And also the

Gauge Plate will have to be bent.

Please be sure that the Gauge Plate cannot

be replaced.

Attach the FCG-310 to the wheel as shown in Fig. A.

While keeping both Rim Guides touching the rim, loosen the Knob Bolt to slide down

the Gauge Plate, then tighten the Knob Bolt firmly to record the triangle point.

(Fig. A)

At this moment, make sure the following points;

• Both Rim Guides touch the rim.

!

• The wheel axle is running through the hole on the Gauge Plate, and the Gauge Plate touches the

hub.

Page 10

6.

Flip over the wheel and attach the FCG-310 onto

the opposite side of the wheel. Do not change the

Gauge Plate position yet.

At this time, if all three points (both Rim Guides

and the tip of the Gauge Plate) touch each

appropriate position at once on both side of

the wheel (see Fig. B), your wheel is properly

assembled and adjusted.

But if either one of the Rim Guides or the Gauge

Plate doesn't touch the appropriate position (see

Fig. C), your wheel needs to be adjusted further.

If the Rim Guide doesn't touch the rim, the wheel

has been moved toward opposite side.

If the Gauge Plate doesn't touch the hub even

though both Rim Guides touch the rim, your wheel

has been moved backward.

Set the wheel on the wheel truing stand to adjust. To know how to adjust the wheel, refer the instructions manual

of the truing stand.

It is crucial to measure the wheel at several different points to get proper result.

!

Properly Adjusted

(Fig. B)

Wrong Adjsuted

(Fig. C)

Useful Additional Features

FCG-310 can be used on most wheels sized between 24" and 27"/700c in the standard position.

In addition, you can use it for the smaller wheel (18" or larger) and the wide (up tp 140mm) hub wheel which is used on

some DH, FR and city commuting bikes by changing the the Rim Guide position. (see Fig. D & E)

<To Measure Smaller Wheel>

Make both Rim Guides inward

<To Measure Wide Hub>

Step down both Rim Guides

(Fig. D)

The hole must be outward

(Fig. E)

How To Fold Down FCG-310

To fold down the FCG-310, 1) loosen the Knob Bolt fully,

2) separate the Ratches as if pulling outward on each other, 3) rotate

the Gauge Plate as the hole faces outward, then 4) fold the Frame.

Do not tighten the Knob Bolt while the hole of the Gauge

!

Plate is facing inward, otherwise the Gauge Plate will be bent.

Please be sure the Gauge Plate cannot be replaced.

How To Use NW-300

Insert the wrench of the NW-300 to the nipple fully to the bottom. Do not use any incorrect (wider) size wrench. Tighten

the nipple slowly. You must stop tightening after turning 1/2 rotation at once at widest. These are for protecting the

nipple from damage. Once the nipple is damaged, you won't be able to continue any work on wheel.

Do not continue using the NW-300 if its jaws don't t

!

your nipples. Use another nipple wrench.

(Fig. F)

Loading...

Loading...