Option

Service Manual

EDH-5

C-403/C-404

FN-7/FN-115

Cover Inserter C

PK-3

ZK-2

TMG-2

Dual references may be used on the following:

Official Options name : Popular Options name

EDH-5 : RADF

C-403/C-404 : LT and LCT

FN-115 : FNS

FN-7 : FNS

Cover Inserte Cr : PI

PK-3 : PU

TMG-2 TU

ZK-2 : PZ

In-System Writer : ISW

EDH-5

RADF

RADF

CONTENTS

EDH-5

SAFETY AND IMPORTANT WARNING ITEMS

Refer to the Di850 service manual on page.......... S-1

1. OUTLINE

PRODUCT SPECIFICATIONS..................................1-1

CENTER CROSS-SECTIONAL DRAWING..............1-2

DRIVE SYSTEM DIAGRAM ......................................1-3

ORIGINAL CONVEYANCE PROCESS.....................1-4

[1] Single side original copy mode (large) .......1-5

[2] Single side original copy mode (small).......1-6

[3] Double side original copy mode (large)......1-7

[4] Double side original copy mode (small) .....1-8

[5] Mixed original copy mode...........................1-9

2. UNIT EXPLANATION

EXTERNAL SECTION...............................................2-1

[1] Composition ...............................................2-1

[2] Mechanisms ...............................................2-1

ORIGINAL FEED/CONVEYANCE/EXIT SECTION...2-2

[1] Composition ...............................................2-2

[2] Mechanisms ...............................................2-2

[3] Original Fe ed/Conveyance/Scan Control ...2-4

[4] Original Reversal and Conveyance

Control........................................................2-7

[5] Original Exit Control ...................................2-9

[6] Original Size Detection Control ................2-11

RADF

RADF

1

OUTLINE

RADF

RADF

PRODUCT SPECIFICATIONS

EDH-5

[1] Type

Type

Sheet-through type reversible DF

[2] Functions

Original size:

• Metric area

A3 / B4 / A4 / A4R / B5 / B5R / A5 / A5R

11 x 17 / 8.5 x 14 / F4

• Inch area

11 x 17 / 8.5 x 14 / 8.5 x 11 / 8.5 x 11R /

5.5 x 8.5 / 5.5 x 8.5R

A3 / B4 / A4 / B5 / B5R

• All sizes are detected automatically.

• Mixing of original sizes possible.

Original type:

Plain original

50 to 200 g/m

paper.

Special original

Original feed and conveyance ability may be

inferior to those of 50 to 130 g/m

lbs high quality original.

Only SDF mode single-sided passage allowed

for 131 to 200 g/m2 or 35 to 45 lbs thick original.

The following types of original cannot be used:

• OHP film

• Blueprint masters

• Label original

•Offset masters

• Bonded originals

Original curling:

10 mm maximum

2

or 14 to 45 lbs high quality

Original

2

or 14 to 35

Original read speed (copies per minute,

600dpi):

Mode Original size Feed speed

Single sided original A4/8.5x11 85

Double sided original A4/8.5x11 58

Original feed layout:

Face-up placement, centered, U-turn feed/

straight eject (large size/small size independent eject), reversal section placed at ejection

side.

Original image read position:

At the slit glass section

[3] Machine Data

Power source:

DC24 V / 5 V (supplied from the main unit)

Max. power consumption:

Less than 180 VA

Weigh t:

Approx. 21.5 kg

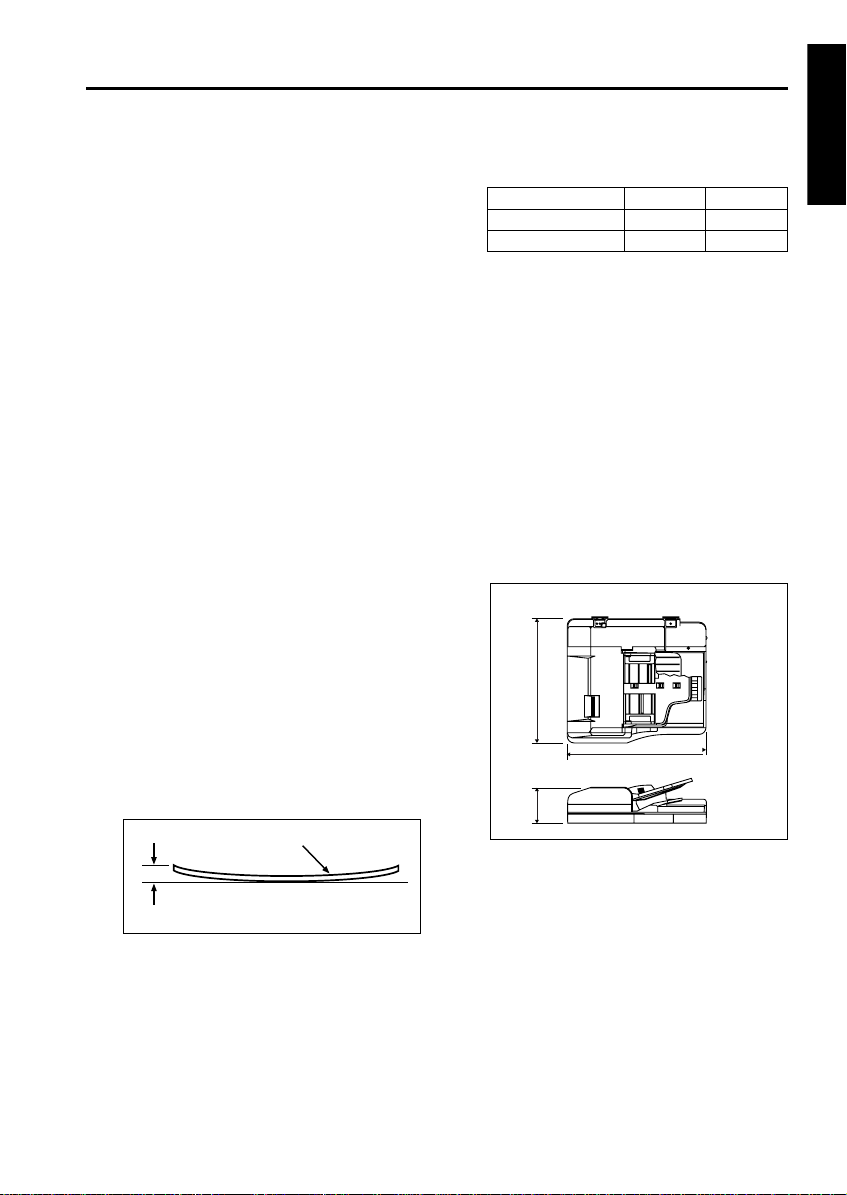

Machine dimensions:

570

650

170

RADF

Unit: mm

Amount of curl

Maximum number of stacked originals:

100 sheets maximum (80 g/m

2

or 22 lbs)

[4] Maintenance

Maintenance : Same as the main body

Service life : Same as the main body

[5] Operating Environment

Temperature:

10 to 30 °C (50 to 86 °F)

Humidity:

10 to 80 % RH

Note: The information herein may be subject to

change for improvement without notice.

1-1

EDH-5

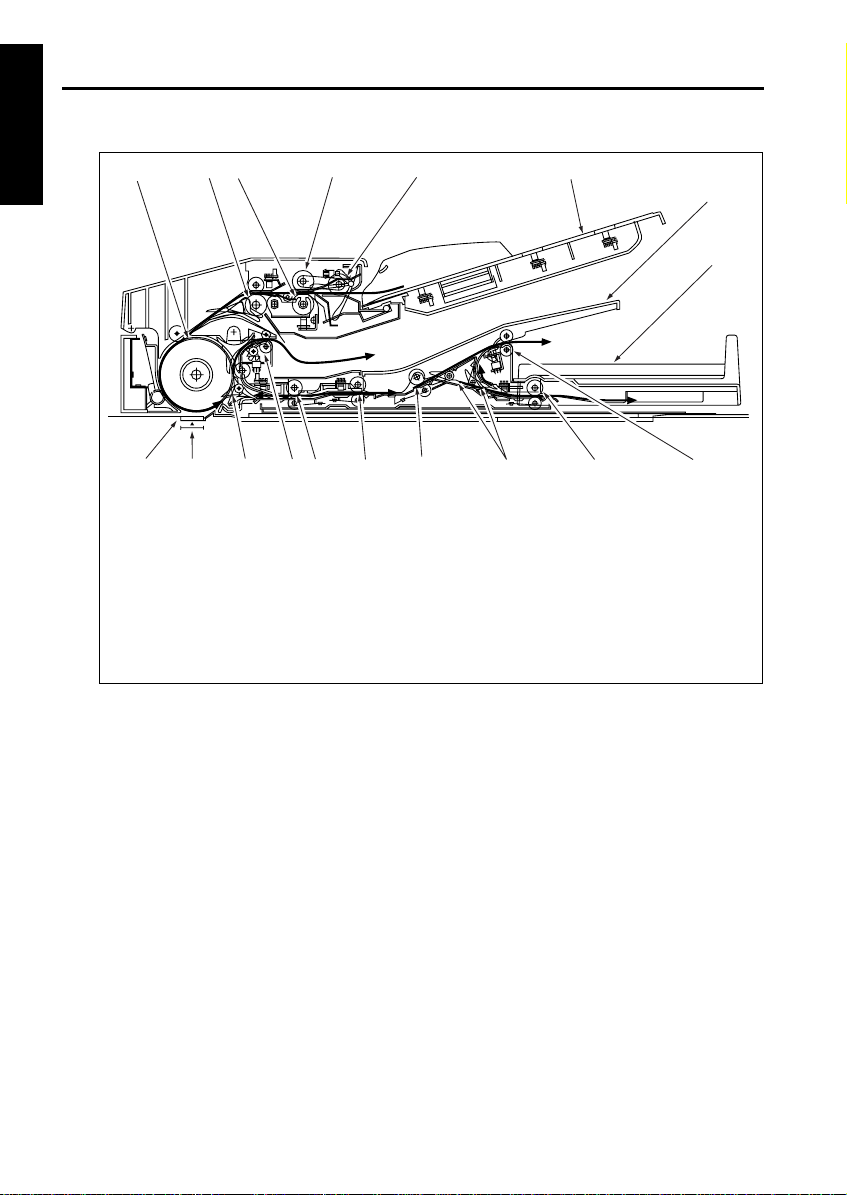

CENTER CROSS-SECTIONAL DRAWING

RADF

3

1

2

4

5

6

7

8

17

18

1. Original conveyance roller

2. Registration roller

3. Double feed prevention roller

4. Separation roller

5. Original feed roller

6. Original feed tray

7. Original exit tray (for large-size original)

8. Original exit section (for small-size original)

9. Original exit roller 2

15

14

16

13

12

11

10. Original exit reversal roller

11. Original exit gate

12. Reversal conveyance roller 2

13. Reversal conveyance roller 1

14. Reversal roller

15. Original exit roller 1

16. Flapper

17. Read position

18. Slit glass

10

9

1-2

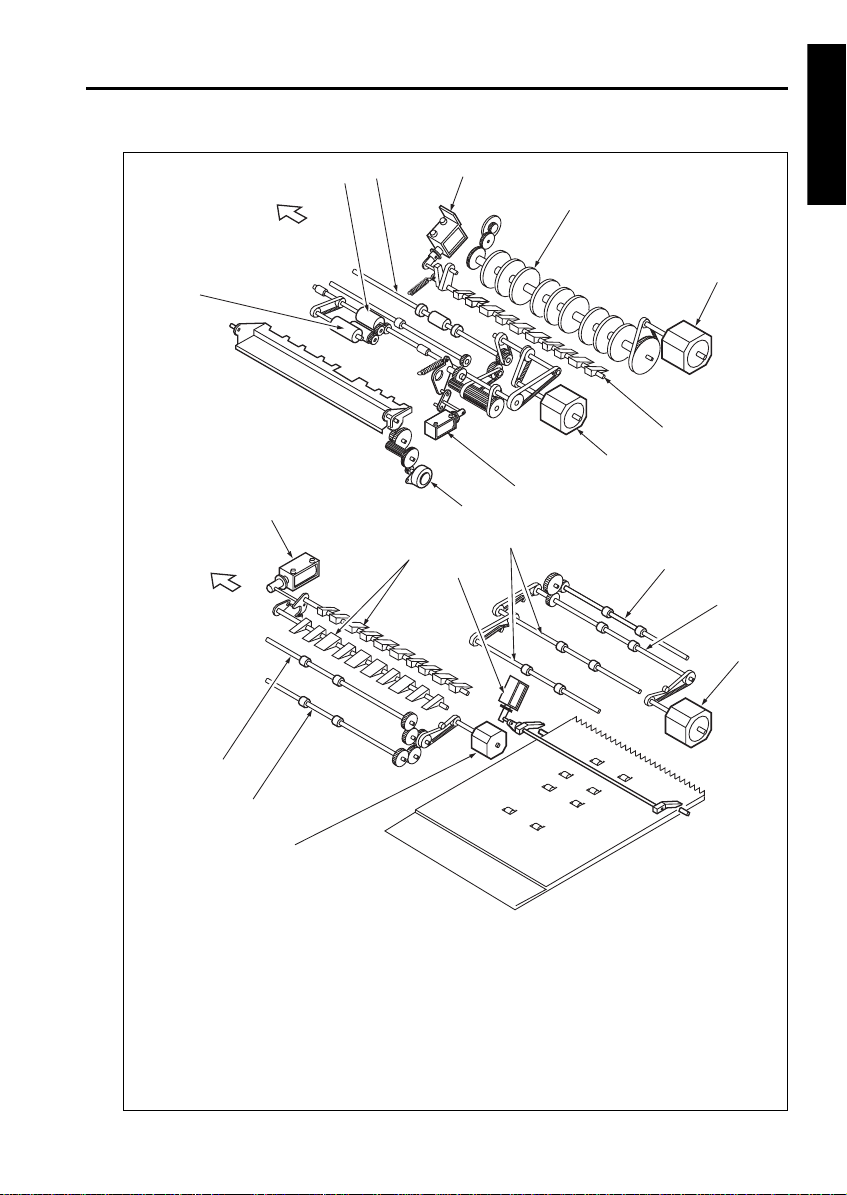

DRIVE SYSTEM DIAGRAM

2

FRONT

1

EDH-5

RADF

3

4

10

FRONT

5

6

7

8

11

20

19

18

9

12

14

13

15

16

17

1. Separation roller

2. Registration roller

3. Flapper drive SD (SD 301)

4. Original conveyance roller

5. Original conveyance motor (M301)

6. Flapper

7. Original feed motor (M302)

8. SDF switching SD (SD304)

9. Tray up/down drive motor (M303)

10. Original feed roller

11. Original exit gate SD (SD303)

12. Original exit gate

13. Pressure roller release SD (SD302)

14. Reversal conveyance roller

15. Original exit roller 1

16. Reversal roller

17. Original exit motor 1 (M304)

18. Original exit motor 2 (M305)

19. Original exit reversal roller

20. Original exit roller 2

1-3

EDH-5

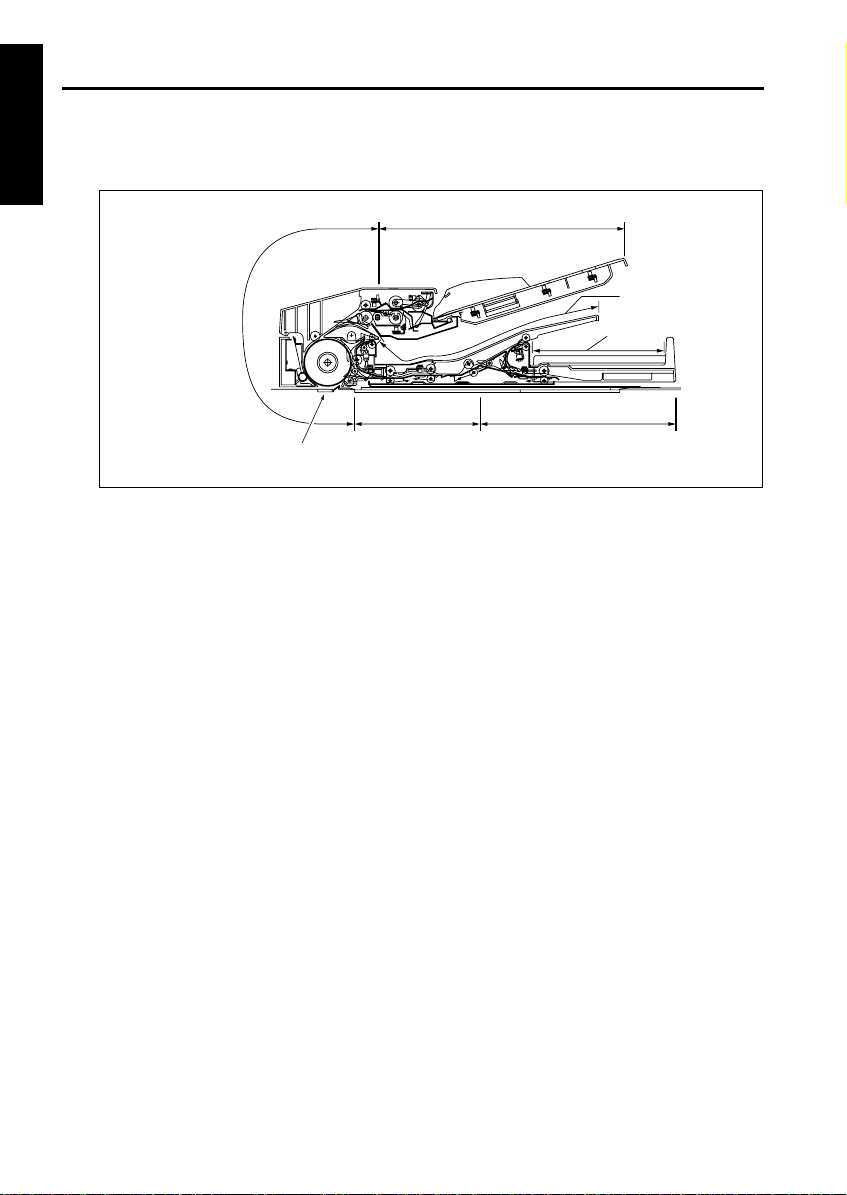

ORIGINAL CONVEYANCE PROCESS

RADF

The RADF consists of a original feed section, conveyance section, reversal section, original exit reversal section, original exit tray (large), and original exit tray (small).

Original feed section

Original exit tray

Conveyance section

Reversal section

Slit glass (Read section)

The original placed faced up on the original feed

tray is fed from the topmost original. The fed original is not conveyed to the original glass. Instead,

it is read when it passes the slit glass placed in

the conveyance path.

The RADF operation consists of (a) single side

original copy mode, (b) double side original copy

mode, (c) mixed original copy mode and Z fold

mode. Each has a different conveyance path.

The conveyance path also depends on the original size.

Original exit reversal section

Original exit tray (small)

1-4

EDH-5

)

)

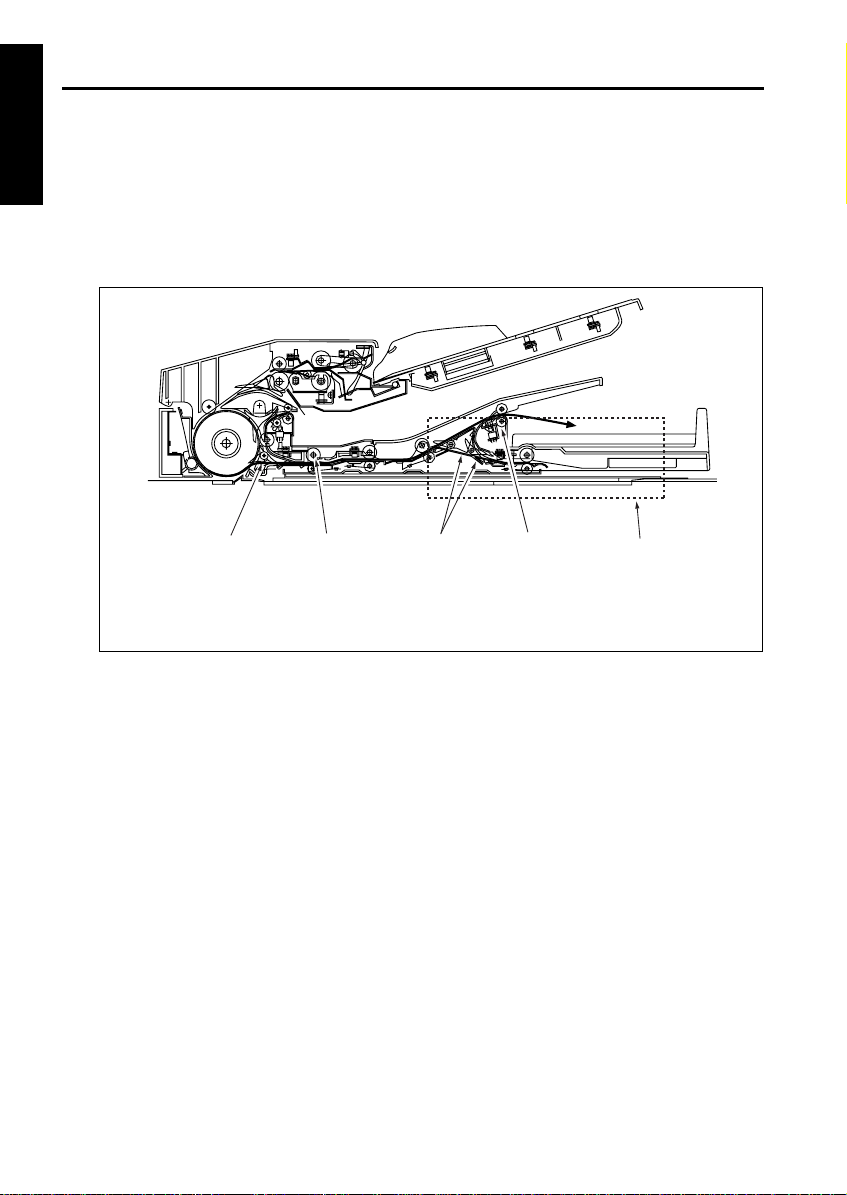

[1] Single side original copy mode (latge)

(single side to single side copy, single side to

double side copy)

The original set in the original feed tray is fed by

the original feed roller and separation roller until

PS306 (original registration detection) turns on.

1

1. Original registration detection PS (PS306

2. Separation roller

3. Original feed roller

4. Registration roller

When PS306 turns on, the registration roller prefeeds the original and original is rapidly conveyed

to the conveyance roller. The speed of the conveyance roller changes to scan speed at predefined interval after PS306 turns ON and feeds

the original over the slit glass.

At this point, if the next original is present, it is

pre-fed as soon as PS306 detects its leading

edge.

2

3

4

1

3

4

1. Next original

2. Original exit roller 1

3. Flapper

4. Slit glass

The original is read when it passes over the slit

glass. The original that has been read is conveyed along the circumference of the conveyance roller by the opening of the flapper, goes

through original exit roller 1, and is exited to the

original exit tray (large).

2

RADF

1

4

1. Original conveyance detection PS (PS308

2. Registration roller

3. Original conveyance roller

4. Slit glass

2

3

1-5

EDH-5

RADF

[2] Single side original copy mode (small)

(single side to single side copy, single side to double side copy)

The original feed and conveyance actions up to scanning are performed in the same manner as for single

side original copy mode (large). The original that has been scanned is fed to the original reversal unit by the

reversal roller because the flapper is closed and the paper exit path is blocked. The original fed to the reversal

unit passes through the original exit roller 2 and is exited to the original exit tray (small) since the original exit

gate is closed.

4

1. Original exit roller 2

2. Original exit gate

3

2

3. Reversal roller

4. Flapper

1

Original reversal section

1-6

EDH-5

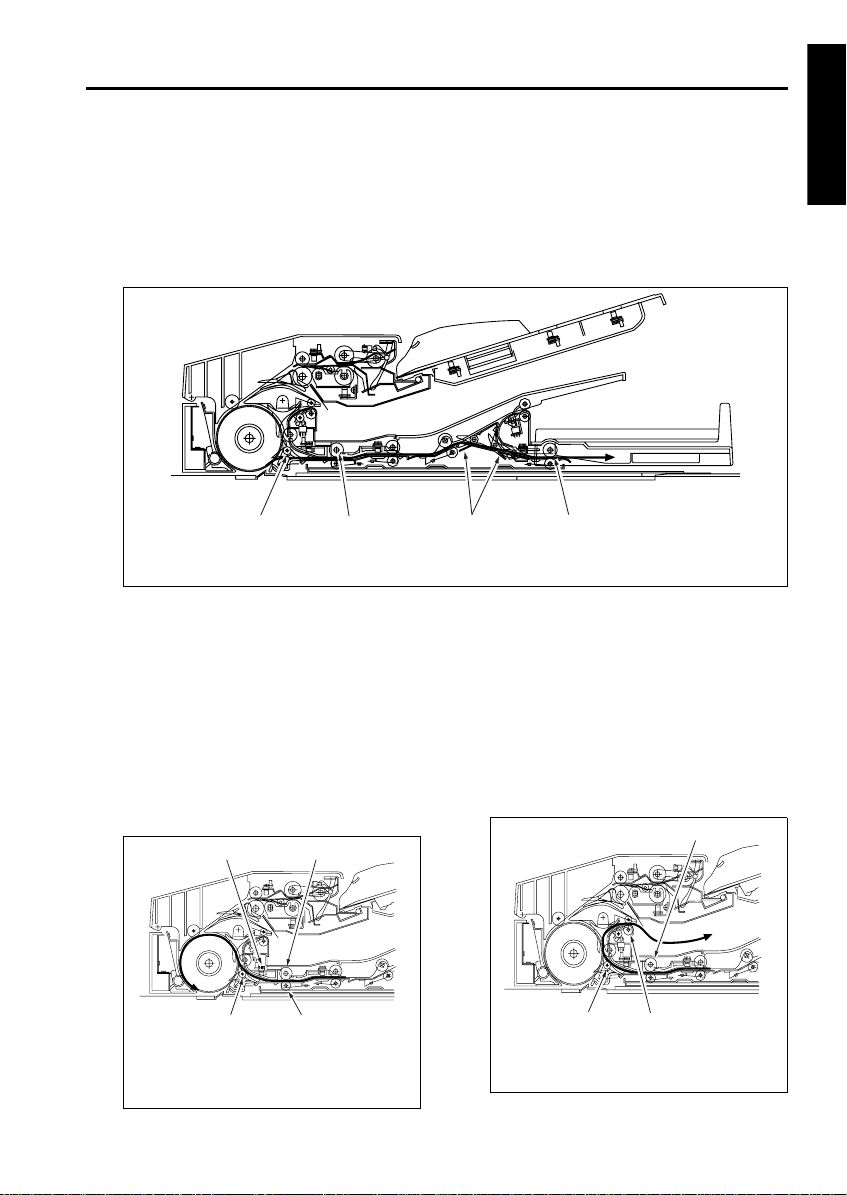

[3] Double side original copy mode (large)

(double side to single side copy, double side to double side copy)

The original conveyance action up to the start of scanning of the front side of the first double side original is

the same as for single side original copy mode (large). The original that has been scanned and read on the

front side is fed by the reversal roller to the reversal unit since the flapper is closed and the original exit path

is blocked. The original fed to the reversal unit does not fit in the reversal unit so the original exit gate opens

to feed it to the original exit reversal section.

4

1. Original exit reversal roller

2. Original exit gate

When the original reversal detection PS (PS309)

detects the trailing edge of the original and turns

off, the reversal roller changes direction and

feeds the original in the reversal section to the

conveyance roller. Since the original is passed

over the surface of the flapper, it is sent to the

conveyance roller with sides reversed. The original reaching the conveyance roller does not exit

the reversal roller so the pressure roller is

released. The conveyance roller feeds this original over the slit glass for scanning.

1

3

2

2

3. Reversal roller

4. Flapper

The original that has completed scanning of the

back side is fed inside the reversal unit once

again since the flapper is closed. When PS309

detects the trailing edge of the original and turns

off, the reversal roller changes direction and

feeds the original in the reversal unit to the conveyance roller. Since the flapper is now opened,

the original is fed along the flapper, passes

through original exit roller 1, and is exited to the

original exit tray (large).

1

1

RADF

4

1. Original reversal detection PS (PS309)

2. Reversal roller

3. Pressure roller

4. Flapper

3

1-7

3

1. Reversal roller

2. Original exit roller 1

3. Flapper

2

EDH-5

RADF

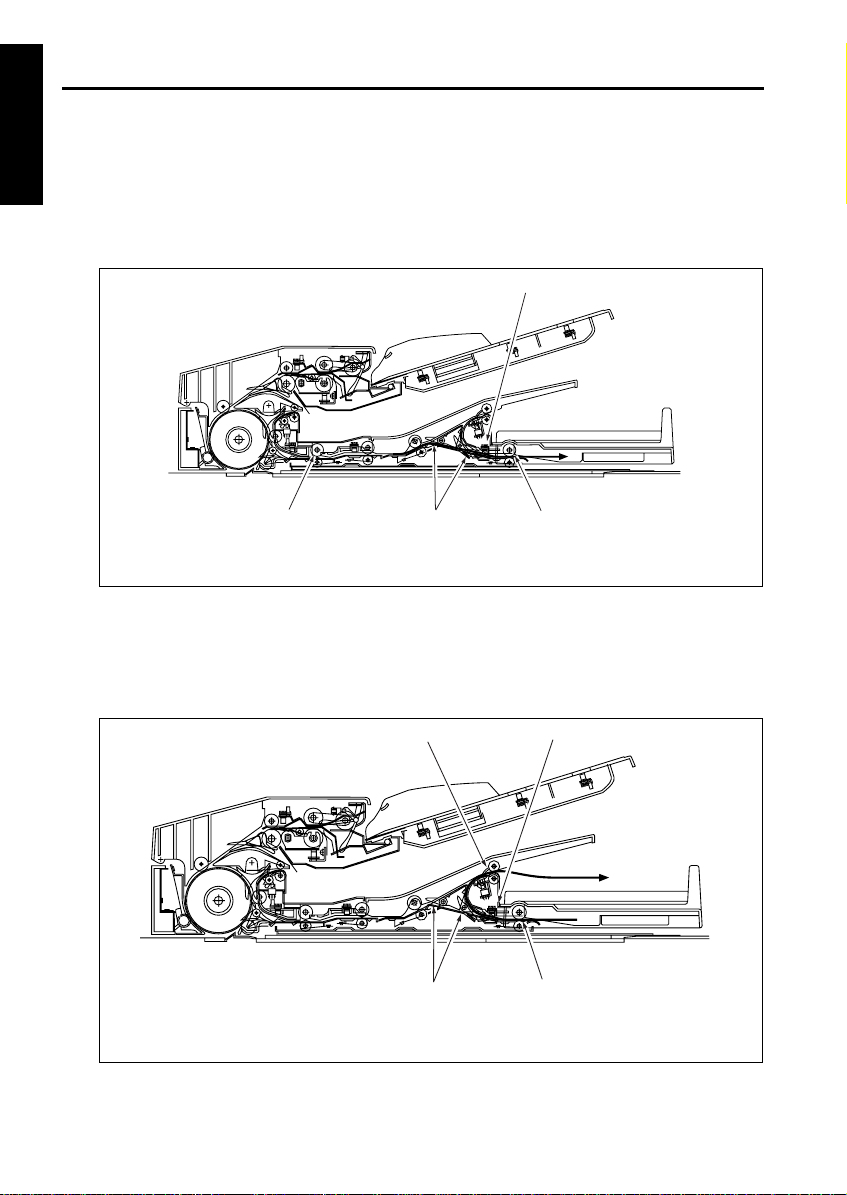

[4] Double side original copy mode (small)

(double side to single side copy, double side to double side copy)

The original conveyance action up to the start of scanning of the back side is the same as double side original

copy mode (large). The original that has been scanned and read on the back side is fed by the reversal roller

to the reversal section since the flapper is closed and the original exit path is blocked. Then the original exit

gate opens and the original is fed to the original exit reversal section.

1

4

1. Original exit reverse detection PS (PS313)

2. Original exit reversal roller

When PS313 (original exit reverse detection) detects the trailing edge of the original and turns off, the original

exit reversal roller changes direction and feeds the original to the original exit gate. Since the original exit

gate is closed, the original passes over the original exit gate and is exited from the original exit roller 2 to the

original exit section (small) with sides reversed.

1. Original exit roller 2

2. Original exit reverse detection PS (PS313)

3

3. Original exit gate

4. Reversal roller

1

4

3. Original exit reversal roller

4. Original exit gate

2

3

2

1-8

EDH-5

[5] Mixed original copy mode

The mixed original copy mode supports both the

same series originals and different series originals. However, since the size of the original in the

conveyance direction is determined by the ON

interval of PS306, size detection is performed

prior to scanning.

The subsequent operations are the same as

other copy modes.

For details on size detection, refer to section [6]

Original Size Detection Control in section 2.

UNIT EXPLANATION.

RADF

1-9

RADF

2

UNIT EXPLANATION

RADF

RADF

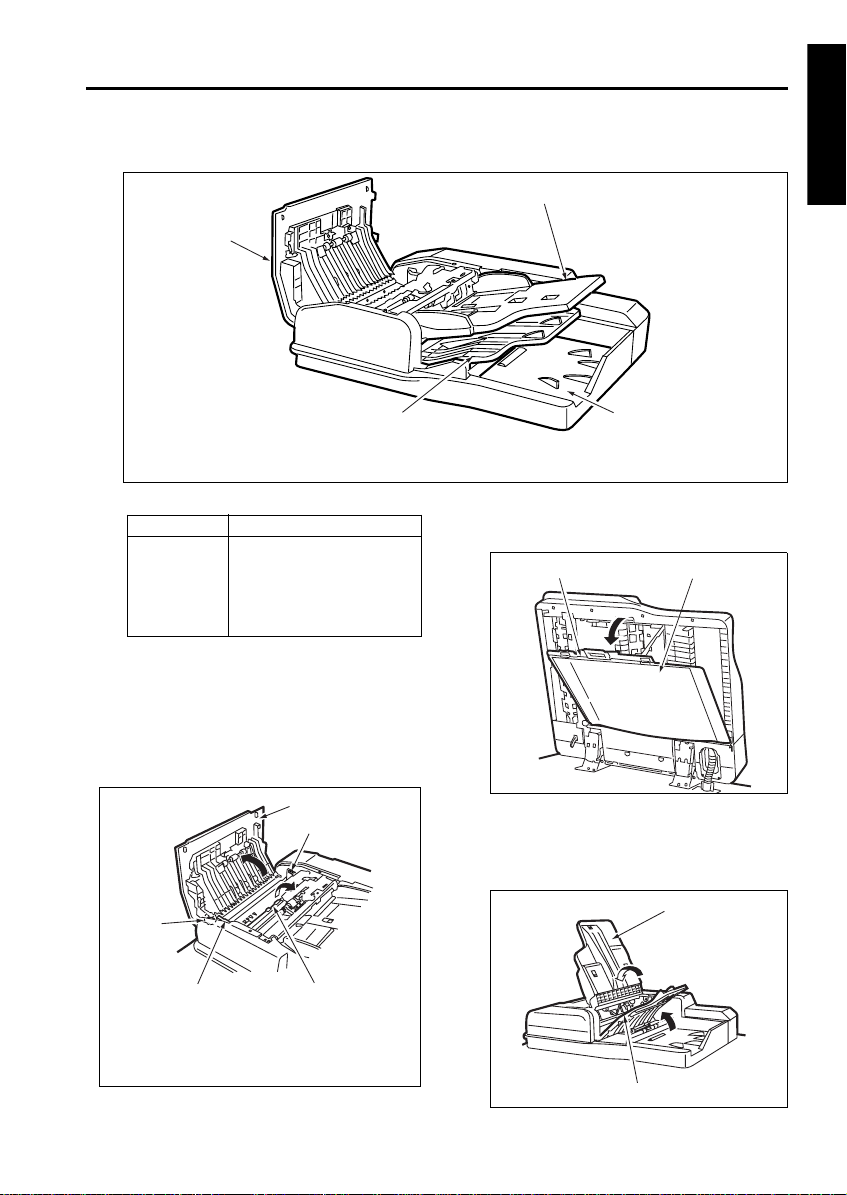

EXTERNAL SECTION

EDH-5

[1] Composition

4

1. Original feed tray

2. Original exit section (for small-size original)

[2] Mechanism

Mechanism Method

Jam removal *1Jam access cover

Jammed original release knob

Original conveyance guide

open/close lever

Platen guide

*1 Jam removal

If an original jam occurs during original feed,

open the Jam access cover and the original conveyance guide by releasing the original conveyance guide open/close lever, then turn the

jammed original release knob to remove the

jammed original.

1

2

4

RADF

1

3

3. Original exit tray (for large-size original

4. Jam access cover

If an original jam occurs during original reversal

operation, open the platen guide to remove the

jammed original .

Lock

If an original jam occurs during original exit, open

the original feed tray and original exit tray (for

large-size original) to remove the jammed original.

2

Platen guide

Original feed tray

2

1. Jam access cover

2. Original conveyance guide open/close lever

3. Original conveyance guide

4. Jammed original release knob

3

Original exit tray (for large-size original)

2-1

EDH-5

ORIGINAL FEED / CONVEYANCE / EXIT SECTION

RADF

[1] Composition

3

1. Original exit gate solenoid (SD303)

2. Pressure roller release solenoid (SD302)

3. Flapper drive solenoid (SD301)

4. Original feed tray

5. Jam access cover

1

2

[2] Mechanism

Mechanism System

Original feed Original feed roller

Double feed prevention

Original conveyance Original conveyance roller

Original conveyance

path selection *1

Original reverse and

feed *2

Original exit path

selection *3

Double feed prevention roller

Separation roller

Flapper

Reversal roller pressure

Reversal roller rotation

Gate 1

Gate 2

4

10

9

8

6. Original conveyance motor (M301)

7. SDF switching solenoid (SD304)

8. Original feed motor (M302)

9. Original exit motor 1 (M304)

10. Original exit motor 2 (M305)

*1 Original conveyance path selection

In the two-sided copy mode, the original conveyance path selected after completion of scanning

differs depending on whether the image on the

front surface is to be printed or the image on the

back surface is to be printed. A flapper is used

to switch between these original conveyance

paths. The flapper drive solenoid (SD301) is

turned on/off to switch between the reversal section and the original exit section.

FRONT

7

5

6

Flapper drive SD

(SD301)

2-2

Flapper

EDH-5

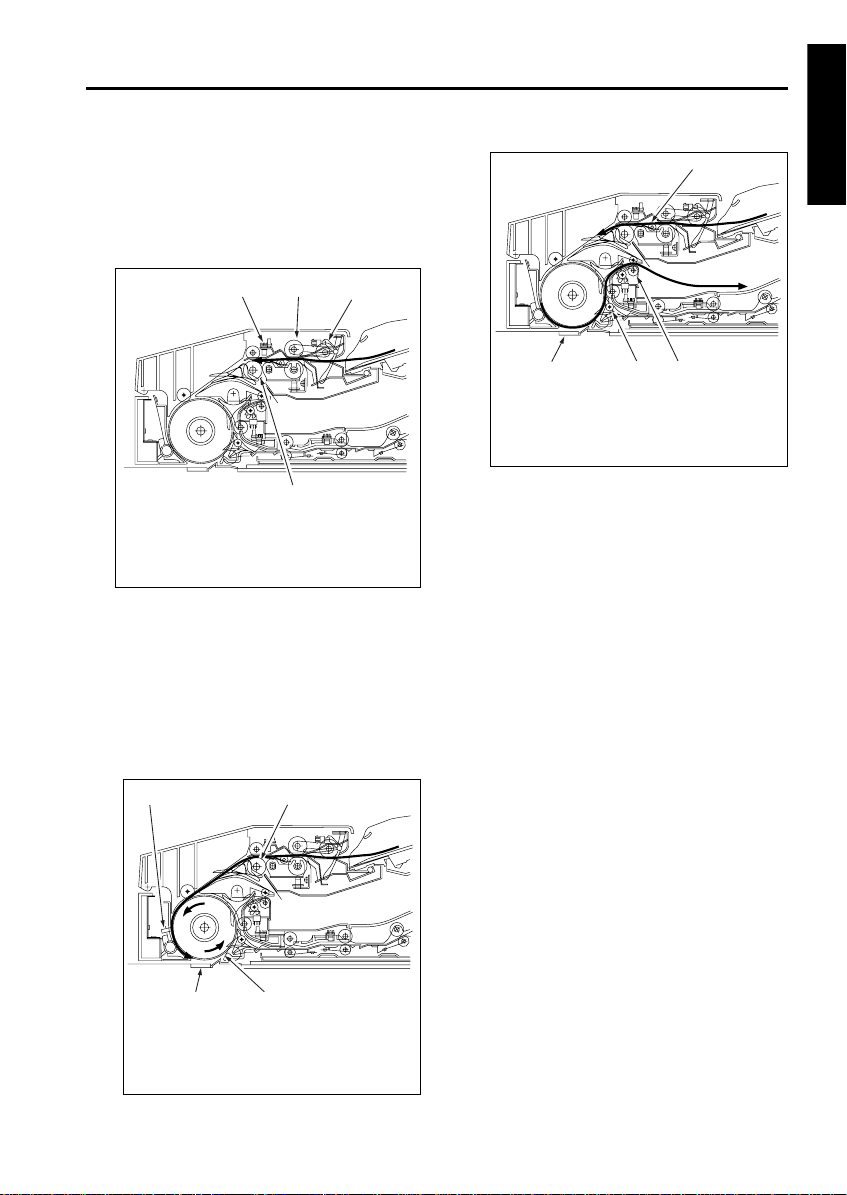

*2 Reversed original feed

In the double-side copy mode, the original fed to

the reversal section is fed back by pressing the

the pressure roller against the reversal roller.

The pressure roller is driven by the pressure

roller release solenoid (SD302).

Pressure roller release solenoid (SD302)

Pressure roller

FRONT

*3 Original exit path switching

Large-size one-side and two-side originals are

exited to the original exit tray (for large-size original). On the other hand, small-size one-side and

two-side originals are exited to the original exit

section (for small-size original) through the reversal section. The small-size two-side original fed

to the reversal section is reversed and exited to

the small size original exit section. The original

exit path switching to which the original is exited

is performed by the gate 1 and gate 2, driven by

the on/off contol of the original exit gate solenoid

(SD303).

Original exit gate solenoid (SD303)

Original exit gate

FRONT

RADF

2-3

EDH-5

RADF

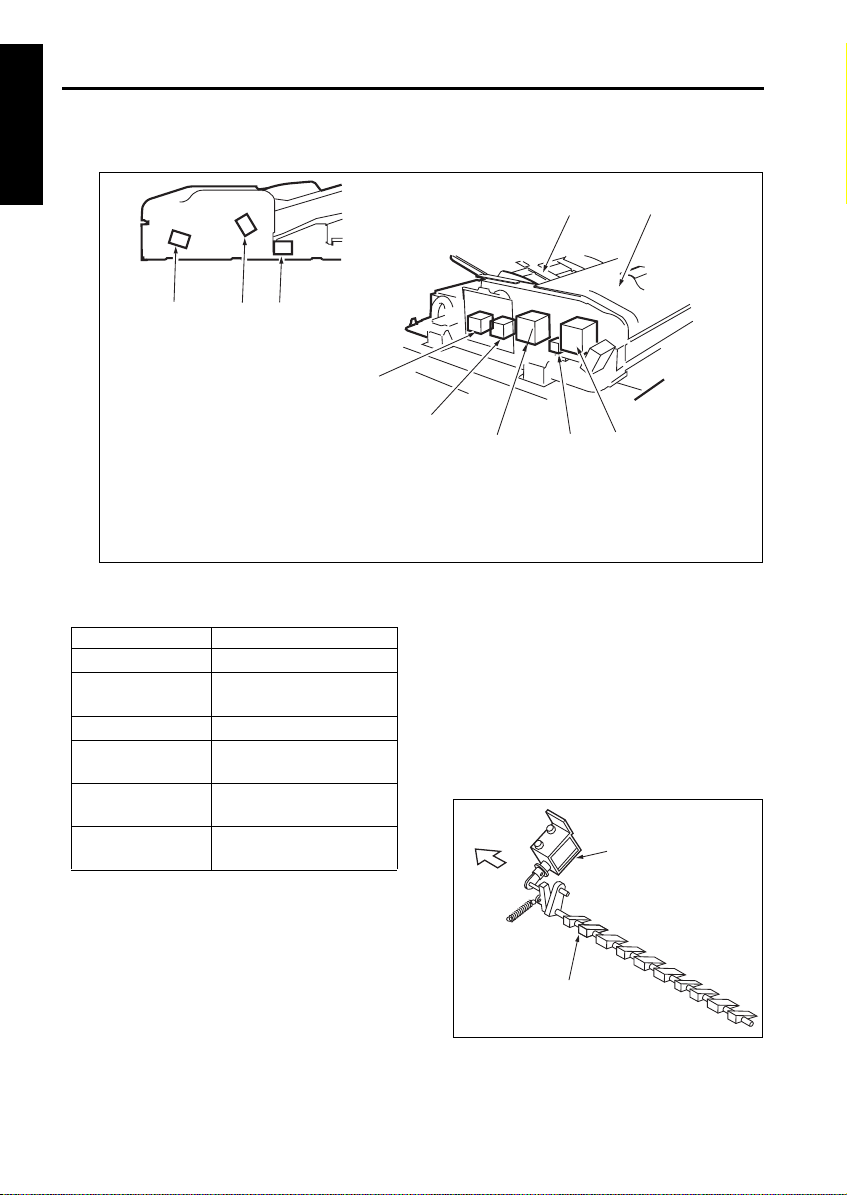

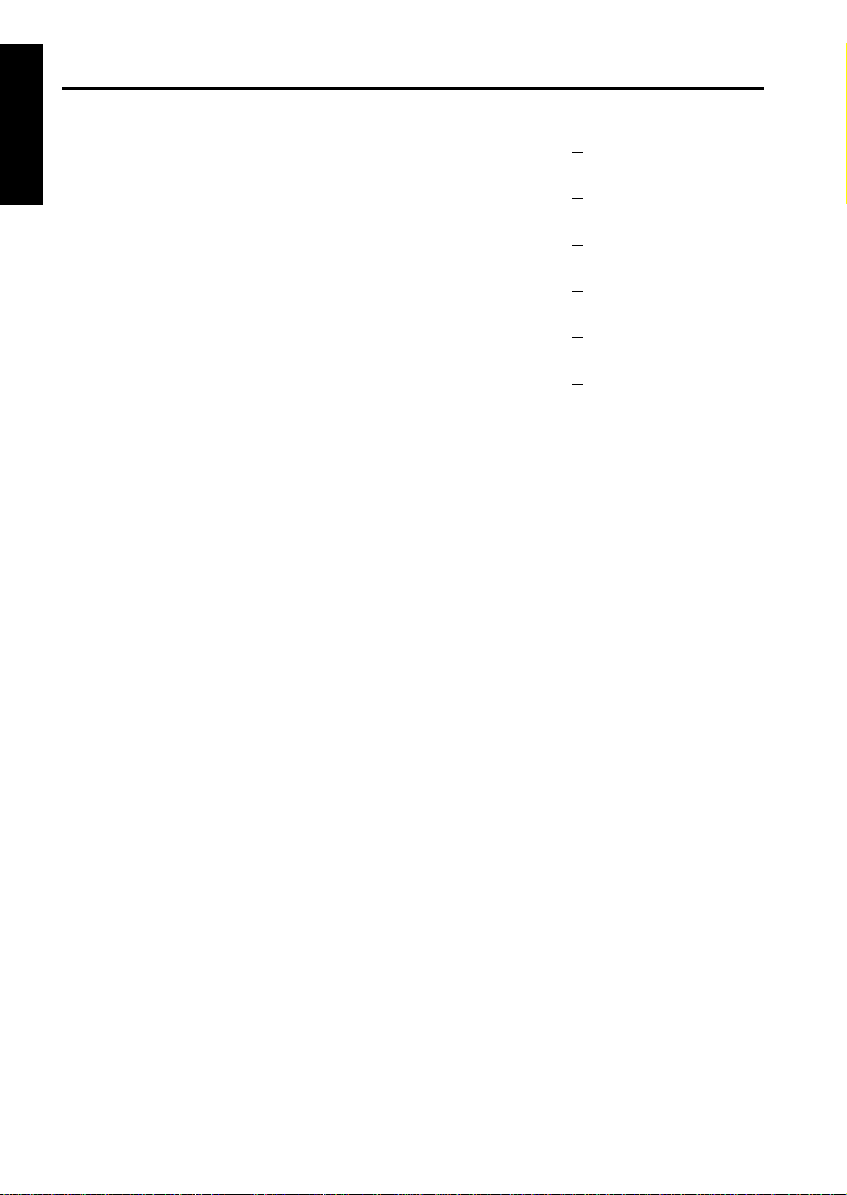

[3] Original Feed / Conveyance / Scan Control

PS312 PS311 PS308 PS301 PS316 PS315 PS305 PS306

MS301

5VDC

PS312

PS312 LED CONT

5VDC

SGND

PGND

24VDC

5VDC

PS311

PS311 LED CONT

DF VALID

DF CTS

DF DTR

DF RXD

DF RTS

DF TXD

DF DSR

5VDC

PS308

PS308 LED CONT

SD304

PS301

24VDC

SD304 DRIVE

MAIN BODY

riginal feed is performed by the original feed

roller and separation roller driven by M302 (original feed). Original conveyance is performed by

the original conveyance roller driven by M301

(original conveyance).

M301 and M302 are controlled by DFCB (RADF

control board).

1. Operation

a. Sensor activation at power ON

When SW1 (main) is ON, a sensitivity adjustment for PS306 (original registration detection),

PS308 (original conveyance detection), PS311

(original skew detection 1) and PS312 (original

skew detection 2) are performed. However,

automatic adjustment is not performed when the

RADF jam access cover is opened and MS301

(cover open/close MS) is OFF or when there is

original inside the RADF.

SGND

5VDC

SGND

PS316

5VDC

5VDC

PS315

SGND

5VDC

PS305

SGND

DFCB

PGND

FM301 LD

FM301 DRIVE

M302 DRIVE B

M302 DRIVE B

M302 DRIVE A

M302 DRIVE A

24VDC

24VDC

24VDC

24VDC

M301 DRIVE A

M301 DRIVE A

M301 DRIVE B

M301 DRIVE B

FM301 M302 M301 M303

b. Pressing original against roller

(1) First original

When a control signal is received from the main

body, M303 (tray up/down drive) turns forward to

raise the original feed tray. By this moment, the

original is raised and pressed against the original

feed roller.

After PS315 (tray upper limit detection) turns

ON, M303 stops after a predefined interval and

leaves the original feed tray raised in standby

state.

After M302 feeds the first original, M303 rotates

backward after a predefined time has elapsed

since it stopped, lowering the original feed tray,

and the pressure on the originals is released.

M303 continues to rotate backward for a predefined interval and then stops and remains in

standby state. At this point the original feed tray

waits without lowering to the bottom.

(2) Second and subsequent originals

When PS308 (original conveyance detection)

detects the leading edge of the first original and

turns ON, M303 that was in standby turns forward to raise the original feed tray and presses

the original against the original feed roller.

Subsequent operations are the same as for the

first original.

5VDC

PS306

PS306 LED CONT

M303 DRIVE B

M303 DRIVE B

M303 DRIVE A

MS301

M303 DRIVE A

24VDC

24VDC

24VDC

2-4

EDH-5

c. Original feed

M302 drives the original feed roller and separation roller.

When a control signal from the main body is

received, M302 rotates forward at low speed,

stops, and goes into standby.

When the original feed tray is raised and PS315

turns ON, M302 turns backward after a predefined interval to start original feed operation.

Then, when PS306 (original registration detection) detects the leading edge of the original and

turns ON, M302 switches to high speed forward

after a predefined interval to complete the original feed operation. After completing original feed

at high speed forward, M302 returns to low

speed forward and stops and goes into standby

when PS308 (original conveyance detection)

turns ON.

d. Original conveyance operation

When feeding the first original, M302 transports

the original to the conveyance roller by continuing to rotate at high and low speed.

During this time, M301 (original conveyance)

starts rotating forward at low speed at predefined

time after PS306 turns ON. The original reached

to the conveyance roller is then conveyed to the

scan position.

After starting conveyance of the first original,

M301 continues to rotate forward at low speed

until the last original is scanned.

e. Scan operation

The original is passed over the slit glass of the

optics unit by the low speed forward rotation of

M301 and read (scanned). While the original is

being scanned, original feed and conveyance

operations continue, triggered by the turning ON

of PS308.

f. Original mis-centering detection control

PS311 (original skew detection 1) and PS312

(original skew detection 2) are provided to detect

the inclined leading edge of the original during

conveyance.

PS311 and PS312 are placed at the front and

back of the pre-scan conveyance path and determine the inclination of the original by measuring

the difference in interval at which the leading

edge of the original turns these switches ON. A

skewed image caused by original inclination is

corrected through image processing so that the

image on the original is copied to a copy paper as

it is on the original.

g. SDF (Single Document Feeder) control

When SDF mode is selected, SD304 (SDF

switching SD) cut the drive force to the double

feed prevention roller to facilitate original feeding.

(1) ON timing

At the start of original feed

(2) OFF timing

When PS306 turns OFF

h. FM301 (ADF fan) operation

FM301 is used to cool M301 so that M301 does

not overheat during operation.

(1) ON timing

At the start of original feed

(2) OFF timing

When original ejection completed.

i. Jammed original ejection control

Upon receiving a control signal from the main

body, M301 rotates at high speed forward,

attempting to eject a jammed original in the

RADF.

2. Signals

a. Input signal

(1) MS301 (MS301 to DFCB)

Jam access cover open/close detection signal.

[L]: Cover opened

[H]: Cover closed

(2) PS301 (PS301 to DFCB)

RADF open/close detection signal.

[L]: RADF closed

[H]: RADF opened

(3) PS305 (PS305 to DFCB)

No original on original feed tray detection signal.

[L]: Original present

[H]: No original

(4) PS306 (PS306 to DFCB)

Original feed over original conveyance roller

detection signal.

[L]: Original present

[H]: No original

(5) PS308 (PS308 to DFCB)

Pre-scan position original detection signal.

[L]: Original present

[H]: No original

RADF

2-5

EDH-5

RADF

(6) PS311 (PS311 to DFCB)

Front side original skew detection signal.

[L]: Original present

[H]: No original

(7) PS312 (PS312 to DFCB)

Rear side original skew detection signal.

[L]: Original present

[H]: No original

(8) PS315 (PS315 to DFCB)

Original feed tray upper limit detection signal.

[L]: Tray at upper limit

[H]: Tray not at upper limit

(9) PS316 (PS316 to DFCB)

Original feed tray lower limit detection signal.

[L]: Tray at lower limit

[H]: Tray not at lower limit

(10) FM301 LD (FM301 to DFCB)

Goes [L] when FM301 reaches predefined

speed.

(11) DF TXD (MAIN BODY to DFCB)

Serial data for transmitting main body PRCB

operating status to RADF.

(12) DF RTS (MAIN BODY to DFCB)

Send the Request To Send signal from main

body PRCB to RADF.

(13) DF DSR (MAIN BODY to DFCB)

Send the Data Set Ready signal from main body

PRCB to RADF.

b. Output signals

(1) PS306 LED CONT (DFCB to PS306)

Reflective sensor PS306 LED ON/OFF control

signal.

[L]: PS306 LED ON

[H]: PS306 LED OFF

(2) PS308 LED CONT (DFCB to PS308)

Reflective sensor PS308 LED ON/OFF control

signal.

[L]: PS308 LED ON

[H]: PS308 LED OFF

(3) PS311 LED CONT (DFCB to PS311)

Reflective sensor PS311 LED ON/OFF control

signal.

[L]: PS311 LED ON

[H]: PS311 LED OFF

(4) PS312 LED CONT (DFCB to PS312)

Reflective sensor PS312 LED ON/OFF control

signal.

[L]: PS312 LED ON

[H]: PS312 LED OFF

(5) M301 DRIVE (DFCB to M301)

M301 A phase drive signal.

(6) M301 DRIVE (DFCB to M301)

M301 B phase drive signal.

(7) M302 DRIVE (DFCB to M302)

M302 A phase drive signal.

(8) M302 DRIVE (DFCB to M302)

M302 B phase drive signal.

(9) M303 DRIVE (DFCB to M303)

M303 A phase drive signal.

(10) M303 DRIVE (DFCB to M303)

M303 B phase drive signal.

(11) FM301 DRIVE (DFCB to FM301)

FM301 ON/OFF drive signal.

[L]: FM301 ON

[H]: FM301 OFF

(12) DF TXD (DFCB to MAIN BODY)

Serial data for transmitting RADF operating status to main body PRCB.

(13) DF DTR (DFCB to MAIN BODY)

Send the Data Terminal Ready signal from

RADF to main body PRCB.

(14) DF CTS (DFCB to MAIN BODY)

Send the Clear To Send signal from RADF to

main body PRCB.

(15) DF VALID (DFCB to MAIN BODY)

Image forming start signal.

A, A

B, B

A, A

B, B

A, A

B, B

2-6

EDH-5

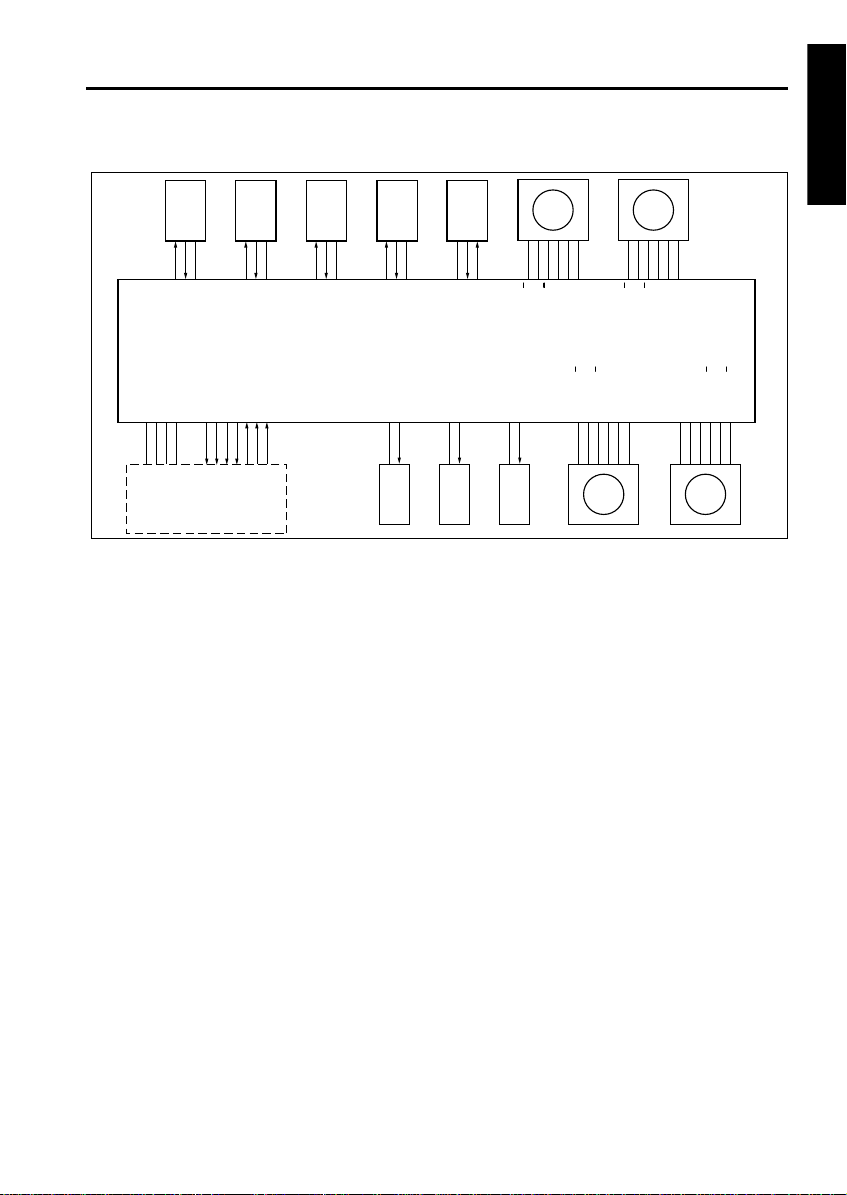

[4] Original Reversal and Conveyance Control

PS308 PS309 PS304 PS306

5VDC

PS308

PS308 LED CONT

5VDC

SGND

PGND

24VDC

MAIN BODY

In two side copy mode, an original that has been

scanned on the front side is conveyed to the original reversal section to be reversed and then rescanned.

At entrance to the original reversal section, there

is a flapper to switch the original conveyance

path. The flapper is driven by SD301 (flapper

drive). The reversal roller, which reverses and

conveys front-side-scanned original to the original reversal section and feeds that original to the

scan section again, is driven by M304 (original

exit 1). The original reversal roller which conveys

original to the original reversal section is driven

by M305 (original exit 2). When reversing and

feeding large originals, the pressure roller is

released by SD302 (pressure roller release).

M304, M305, SD301, and SD302 are controlled

by DFCB (RADF control board).

DF VALID

DF CTS

PS309

PS309 LED CONT

DF DTR

DF RXD

DF RTS

DF DSR

5VDC

DF TXD

5VDC

PS304

PS304 LED CONT

5VDC

PS306

PS306 LED CONT

DFCB

24VDC

SD301 DRIVE

SD301 SD302 SD303

PS313

5VDC

PS313

PS313 LED CONT

24VDC

SD302 DRIVE

M305 DRIVE B

M305 DRIVE B

24VDC

SD303 DRIVE

24VDC

24VDC

M305 DRIVE A

M305 DRIVE A

M302 DRIVE B

M304M305

24VDC

24VDC

M304 DRIVE B

M304 DRIVE B

M304 DRIVE A

M304 DRIVE A

M302 DRIVE B

M302 DRIVE A

M302 DRIVE A

24VDC

24VDC

24VDC

24VDC

M301 DRIVE A

M302 M301

M301 DRIVE A

M301 DRIVE B

M301 DRIVE B

MS) is OFF or when there is original inside the

RADF.

b. Original conveyance path switching/reversal

and original feed operation

(1) Small size original

SD301 is always OFF and the flapper is closed.

Therefore, the scanned original, whether it is single side or double side, is conveyed to the reversal section by M304 rotating at low speed

forward.

When copying the back side of a double-side

original, at predefined interval after PS309 (original reversal detection) detects the trailing edge

of original and turns OFF, M304 rotates backward at low speed and then at high speed to

reverse and feed the original. The reversed original is conveyed through the flapper and the

guides to the conveyance roller.

RADF

1. Operation

a. Sensor activation during power ON

When SW1 (main) is turned ON, a sensitivity

adjustment for PS309 (original reversal detection) and PS313 (original exit reverse detection)

are performed. However, automatic adjustment

is not performed when the RADF jam access

cover is opened and MS301 (cover open/close

2-7

EDH-5

RADF

(2) Large size original

The scanned-single side original is conveyed to

the original exit tray (large) by the original conveyance roller since SD301 is ON and the flapper

is opened.

In the case of large double-side original, the original is conveyed to the reversal section when

SD301 turns OFF after scanning the front side of

a double-side original . The original reaching the

reversal section does not fit in the reversal section so it is fed to the large-size original exit tray

side by the large original reversal roller, which is

driven by M305 (original exit 2). During this time,

SD303 (original exit gate) turns ON and the original exit gate is closed.

The original conveyed to the reversal section is

reversed and fed to the scan section again in the

same manner as small originals. Since the original reaching the conveyance roller does not exit

the reversal roller, SD302 is turned ON at predefined interval after high speed backward rotation of M304 to release the pressure roller for the

reversal roller. This enables original conveyance

using the conveyance roller. SD302 turns OFF

when it detects an image scan complete signal

from the main unit.

c. Two side original next original feed operation

(1) Small size original

During front-side scanning of two-side original,

the original feed of the next one is started by the

rotation of M302 (original feed) when PS306

(original registration detection) detects the trailing edge of the previous original and turns OFF.

The next original stops and waits in standby at

predefined interval after the turning ON of PS306

by its own leading edge.

When the back side of the first original is

scanned and PS308 (original conveyance detection) turns ON, M302 turns ON after a predefined

interval to resume original feed to scan the front

side of the next original. Thereafter, the same

operation is repeated.

(2) Large size original

During front-side scanning of double-side original, the original feed of the next original is started

when PS306 (original registration detection)

detects the trailing edge of the previous original

and turns OFF. The next original stops and waits

in standby at predefined interval after the turning

ON of PS306 by its own leading edge.

During ejection of previous original by reverse

and exit operation, when PS309 (original reversal detection) detects the trailing edge of the previous original and turns OFF, M302 turns ON

after a predefined interval to resume original

feeding to scan the front side of the next original.

Thereafter, the same operation is repeated.

Note: See [5] Original Exit Control for informa-

d. Jammed original ejction control

tion on reverse and exit operation.

Upon receiving a control signal from the main

unit, M304 and M305 rotate at high speed forward, attempting to eject a jammed original in the

RADF.

2. Signals

a. Input signals

(1) PS304 (PS304 to DFCB)

Reversal section original detection signal.

[L]: Original present

[H]: No original

(2) PS309 (PS309 to DFCB)

Reversal section entrance original detection signal.

[L]: Original present

[H]: No original

(3) PS313 (PS313 to DFCB)

Original ejection reversal section original detection signal.

[L]: Original present

[H]: No original

b. Output signal

(1) M304 DRIVE (DFCB to M304)

M304 A phase drive signal.

(2) M304 DRIVE (DFCB to M304)

M304 B phase drive signal.

(3) M305 DRIVE (DFCB to M305)

M305 A phase drive signal.

(4) M305 DRIVE (DFCB to M305)

M305 B phase drive signal.

A, A

B, B

A, A

B, B

2-8

EDH-5

[5] Original Exit Control

PS307 PS309 PS304

5VDC

SGND

PS307

5VDC

SGND

The ejection destination of the original that has

been scanned depends on the size of original.

The original exit roller 1 which conveys the original to the original exit tray (large) is driven by

M304 (original exit 1). The original exit roller 2

which conveys the original to the original exit

section (small) is driven by M305 (original exit 2).

The flapper which switches the original exit path

and the original exit gate are driven by SD301

(flapper drive) and SD303 (original exit gate)

respectively.

M304, M305, SD301, and SD303 are controlled

by DFCB (RADF control board).

1. Operation

a. Small size original exit operation

(1) Single-side original

Scanned original is conveyed to the reversal section since SD301 is OFF and the flapper is

closed.

Original conveyed to the reversal section is conveyed to the original exit gate by the reversal

roller which is driven by M304. During this time,

M304 drives the conveyance roller with low

speed forward rotation.

The original is conveyed to the original exit roller

2 since SD303 is OFF and the original exit gate

is opened. M305 drives the original exit roller 2

with low speed forward rotation and ejects the

PGND

24VDC

MAIN BODY

5VDC

PS309

PS309 LED CONT

DF VALID

DF CTS

DF DTR

DF RXD

DF RTS

DF DSR

5VDC

PS304

PS304 LED CONT

DF TXD

PS314 PS313

5VDC

5VDC

SGND

PS314

DFCB

PS313

PS313 LED CONT

24VDC

SD301 DRIVE

SD301 SD302 SD303

M305 M304

24VDC

24VDC

SD302 DRIVE

M305 DRIVE B

M305 DRIVE B

M305 DRIVE A

M305 DRIVE A

24VDC

SD303 DRIVE

24VDC

24VDC

M304 DRIVE B

M304 DRIVE B

M304 DRIVE A

24VDC

M301 DRIVE A

M301 DRIVE A

M301 DRIVE B

M301

24VDC

24VDC

M304 DRIVE A

M301 DRIVE B

original to the original exit section (small) with the

original surface facing down.

(2) Two-side original

A original that has been scanned on the back

side is conveyed to the original exit gate in the

same manner as single-side original. During this

time, SD303 is ON and the original exit gate is

closed. Therefore, the original is passed through

the original exit reversal roller, which is driven by

the low speed forward rotation of M305, and conveyed to the original exit reversal section.

M305 turns OFF when PS313 ( original exit

reverse detection) is turned OFF by the conveyed original. When SD303 turns OFF and the

original exit gate opens, M305 starts high speed

backward rotation after a predefined interval and

reverses the direction of the conveyed original.

Since the original exit gate is opened, the original

is conveyed to the original exit section (small)

rather than returning to the reversal section.

As a result, the two-side original is ejected with

the front side facing down.

RADF

2-9

EDH-5

RADF

b. Large size original ejection operation

(1) Single-side original

The scanned original is conveyed to the original

exit roller 1 by the conveyance roller since SD301

is ON and the flapper is opened. The original exit

roller 1 is driven by the low speed forward rotation

of M304 and the original is ejected to the original

exit tray (large) with the copy surface facing

down.

(2) Two-side original

The original that has been scanned on the back

side is conveyed to the reversal section since

SD301 is OFF and the flapper is closed.

When PS309 (original reversal detection)

detects the trailing edge of conveyed original,

SD301 (flapper drive SD) is turned ON and the

flapper is opened. Then, M304 (original exit 1)

rotates backward and the original is ejected to

the original exit tray (large size original) since the

flapper is open.

2. Signals

a. Input signals

(1) PS307 (PS307 to DFCB)

Original exit tray (large) entrance original detection signal.

[L]: Original present

[H]: No original

(2) PS314 (PS314 to DFCB)

Original exit section (small) entrance original

detection signal.

[L]: Original present

[H]: No original

2-10

EDH-5

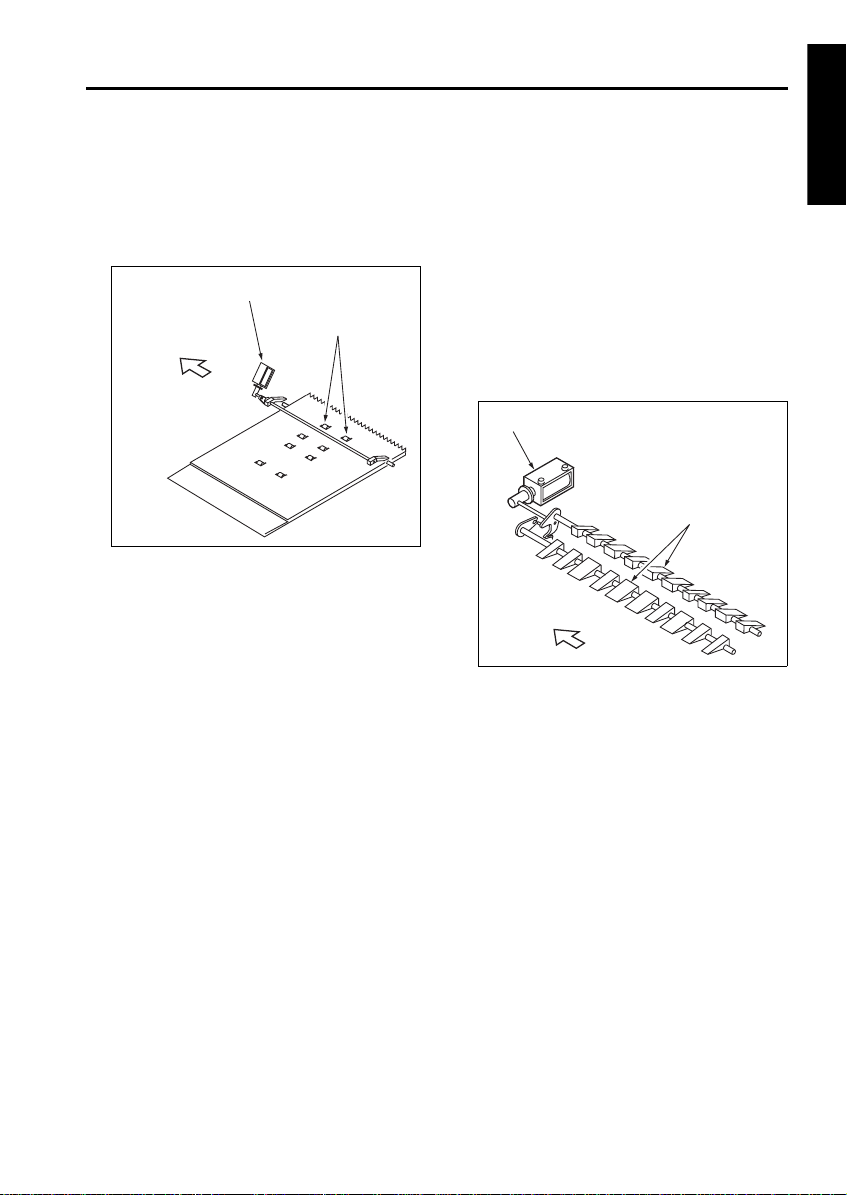

[6] Original Size Detection Control

PS317 PS308 PS306

5VDC

SGND

PS317

5VDC

SGND

PGND

24VDC

MAIN BODY

The size of the original placed in the original feed

tray is detected by PS302 (original size detection

1), PS303 (original size detection 2), and VR301

(original size detection).

PS302, PS303, and VR301 are controlled by

DFCB (RADF control board) through PTBD (tray

drive board). DFCB contains a non-volatile

memory for storing data such as timing data and

original size detection threshold.

1. Operation

a. Normal copy mode

DFCB detects the original size from the combination of the following signals:

(1) Drum axis direction size detection

A guide plate is connected to VR301 and the

resistance vary with the position of the guide

plate. This is used to determined the vertical

dimension of the original.

(2) Original feed direction size detection

The horizontal dimension of the original is

detected with the ON/OFF combination of

PS302 and PS303.

PS315

DF VALID

DF CTS

5VDC

PS308

PS308 LED CONT

DF DTR

DF RXD

DF TXD

DF RTS

DF DSR

5VDC

PS306

PS306 LED CONT

24VDC

24VDC

M301 DRIVE A

M301

PS302 PS303 VR301

5VDC

SGND

PS302

PTBD

5VDC

5VDC

PS303

SGND

PS303

PS302

VR301

SGND

DFCB

M301 DRIVE A

M301 DRIVE B

M301 DRIVE B

b. Mixed copy mode original size detection

Size detection during mixed copy mode is performed as follows:

(1) Drum axis direction size detection

The vertical dimension of the largest original is

determined by the position of the guide plate.

(2) The ON interval of PS306 (original registration

detection) after the original passes the registration roller is used to determine the horizontal

dimension of each original.

5VDC

VR301

RADF

SGND

2-11

EDH-5

RADF

(3) Original feed direction size detection

When the original is fed, M301 (original conveyance) turns forward and conveys the original to

the original exit tray (large). M301 continues to

rotate forward until PS306 detects the trailing

edge of the original and turns OFF. At this point,

the ON interval of PS306 is used to detect the

size of original in the feed direction.

1

1

2

4

1. Registration roller

2. PS 306 (Originalregistration detection)

3. Original conveyance roller

4. PS308 (Original conveyance detection)

After a predefined interval since PS306 turns

OFF, M301 changes direction and returns the

leading edge of the original conveyed to the original exit section to the scan wait position. The

trailing edge of the returned original is conveyed

to the original exit tray (large) due to the shape of

the conveyance guide plate.

The backward rotation of M301 stops at predefined interval after PS308 (original conveyance detection) detects the leading edge of the

original and turns OFF.

3

3

1. Scan stanby position

2. Original conveyance roller

3. PS 308 (Original conveyance detection)

Thereafter, read operation (scan) is performed in

the same manner as normal mode.

The size detection of the second and subsequent originals differ for single-side mode and

two-side mode.

• Single-side mode: After scanning of the previous original starts

• Two-side mode: When scanning of the back

side of the previous original starts

2

Second original

First original

2-12

EDH-5

c. Allowed size combination

( : Same size, : Same series, : Different

series, X: Mixing prohibited, -: Not supported)

Reference original (maximum-size

original detectable with guide plate)

A3 A4 B4 B5

A3

A4

B4

B5

A4R

A5

B5R

XX -

A5R

XXXXXXX -

B6R

XXXXXXX

A4RA5B5R A5R B6R

-------

-------

-----

-----

---

---

2. Signals

a. Input signals

(1) PS302 (PS302 to PTBD to DFCB)

Original horizontal dimension detection signal

[L]: Original present

[H]: No original

(2) PS303 (PS303 to PTBD to DFCB)

Original horizontal dimension detection signal

[L]: Original present

[H]: No original

(3) VR301 (VR301 to PTBD to DFCB)

Original vertical dimension detection signal

(4) PS317 (PS317 to DFCB to MAIN BODY)

Original size detection timing signal during

platen mode

Original size is detected when this signal

changes from [H] to [L].

RADF

2-13

RADF

C-403/C-404

LCT

LCT

CONTENTS

C-403/C-404

SAFETY AND IMPORTANT WARNING ITEMS

Refer to the Di850 service manual on page.......... S-1

1. OUTLINE

PRODUCT SPECIFICATIONS..................................1-1

CENTER CROSS-SECTIONAL DRAWING..............1-2

DRIVE SYSTEM DRAWING......................................1-3

[1] Paper feed drive section.............................1-3

[2] Stacked paper up/down wire drive

section........................................................1-4

2. UNIT EXPLANATION

PAPER FEED SECTION...........................................2-1

[1] Composition ...............................................2-1

[2] Mechanisms ...............................................2-1

[3] First paper feed control ..............................2-3

[4] Up/down plate drive control........................2-5

[5] Remaining paper detection/No paper

detection control.........................................2-6

LCT

LCT

1

OUTLINE

LCT

LCT

PRODUCT SPECIFICATIONS

C-403/C-404

[1] Type

Type:

Side mount type large volume paper feed tray

[2] Functions

Standard size paper :

A4LCT

• Metric area

A4 / B5 / 8.5 x 11

Wide paper (314 x 223 mm max.)

• Inch area

8.5 x 11 / A4

Wide paper (314 x 223 mm max.)

A3LCT

• Metric area

A3 / B4 / A4 / A4R / F4

11 x 17 / 8.5 x 14 / 8.5 x 11 / 8.5 x 11R

Wide paper (314 x 459 mm max.)

• Inch area

11 x 17 / 8.5 x 14 / 8.5 x 11 / 8.5 x 11R

A3 / B4 / A4 / A4R / F4

Wide paper (314 x 459 mm max.)

Maximum quantity:

4000 sheets (80 g/m

2

or 20lbs)

[3] Machine Data

Power source

24V DC/5V (supplied from the main body),

AC27.3V

Max. power consumption

A4LCT Max. 82 W

A3LCT Max. 100 W

Weight

A4LCT Approx. 30 kg

A3LCT Approx. 42 kg

Machine dimensions

A4LCT 430(W) x 639(D) x 690(H) mm

A3LCT 670(W) x 639(D) x 695(H) mm

[4] Maintenance

Maintenance:

Same as the main body

Machine life:

Same as the main body

[5] Operating Environment

Temperature:

10 to 30 °C (50 to 86 °F)

Humidity:

10 to 80 %RH

Note: The information herein may be subject to

change for improvement without notice.

LCT

1-1

C-403/C-404

CENTER CROSS-SECTIONAL DRAWING

LCT

1

7

1. Conveyance roller

2. Feed roller

3. Paper feed roller

4. Top cover

2

3

5. Up/down wire (the other side wire as well)

6. Up/down plate

7. Double feed prevention roller

4

5

6

1-2

DRIVE SYSTEM DRAWING

[1] Paper feed drive section

1

FRONT

4

C-403/C-404

2

LCT

3

6

5

7

FRONT

10

1. LT First paper feed SD (SD100)

2. Feed roller

3. Paper feed roller

4. Conveyance roller

5. LT First paper feed MC (MC 102)

1-3

9

8

6. LT paper feed motor (M101)

7. LT feed drive MC (MC101)

8. Paper feed roller

9. Feed roller

10. Double feed prevention roller

C-403/C-404

[2] Stacked paper up/down wire drive section

a. A4LCT

Up/down plate

LCT

LT up/down motor (M100)

FRONT

Up/down shaft

1-4

b. A3LCT

C-403/C-404

Up/down plate

LCT

LT up/down motor (M100)

FRONT

Up/down shaft

1-5

LCT

2

UNIT EXPLANATION

LCT

LCT

PAPER FEED SECTION

[1] Composition

2

1

3

C-403/C-404

9

8

7

10

11

LCT

6

5

1. LT paper feed motor (M101)

2. LT feed MC (MC101)

3. LT first paper feed MC (MC102)

4. Up/down wire (the other side wire as well)

5. Remaining paper detection gear

6. LT up/down motor (M100)

7. LT first paper feed SD (SD100)

[2] Mechanisms

Mechanism Method

Paper lifting *1 Wire drive

Paper feed Paper feed roller

No paper detection

Remaining paper

detection *2

Paper conveyance Roller conveyance

*1 Paper lifting

a. Up/down plate lifting drive operation

The up/down plate is lifted with the up/down

wires. When the top cover closes, LT up/down

motor (M100) rotates and the up/down plate connected to the up/down wires rises.

Photo sensor (PS108)

+actuator

Remaining paper detection gear+ photo sensor

(PS102, PS103, PS104,

PS105)

4

8. Paper dust removing brush

9. Conveyance roller

10. LT feed PS (PS106)

11. LT first paper feed PS (PS107)

12. Up/down plate

13. LT tray down drive switch (SW 100)

b. Up/down plate down drive operation

The up/down plate automatically lowers by 120

mm when the top cover is opened.

Subsequently, it is lowered by 120 mm each time

LT tray down drive switch (SW100) is pressed.

*2 Remaining paper detection

The LCT is equipped with a remaining paper

detection gear which rotates together with LT up/

down motor (M100) driving the up/down plate.

The remaining paper detection gear has an actuator to turn ON/OFF LT remaining paper detection PS1 (PS102), LT remaining paper detection

PS2 (PS103), LT remaining paper detection PS3

(PS104), and LT remaining paper detection PS4

(PS105).

13

12

2-1

C-403/C-404

LCT

Each sensor is turned ON/OFF according to the

rotating position of the remaining paper detection gear and since this is linked with the up/down

position of the up/down plate, the remaining

paper quantity in the LCT can be determined by

monitoring the ON/OFF of each sensor. The

remaining paper quantity detected with the four

sensors is displayed on the main body display.

a. A4LCT

8

(PS102)

(PS103)

(PS104)

(PS105)

2

7

3

4

5

6

1

1. LT up/down motor (M100)

2. Actuator

3. LT remaining paper detection PS1

4. LT remaining paper detection PS2

5. LT remaining paper detection PS3

6. LT remaining paper detection PS4

7. Remaining paper detection gear

8. Gear for M100

b. A3LCT

2

1

7

6

1. LT remaining paper detection PS1

(PS102)

2. LT remaining paper detection PS2

(PS103)

3. LT remaining paper detection PS3

(PS104)

4. Gear for M100

5. LT remaining paper detection PS4

(PS105)

6. Remaining paper detection gear

7. Gear for M100LT remaining paper

8. Actuator

3

4

5

2-2

C-403/C-404

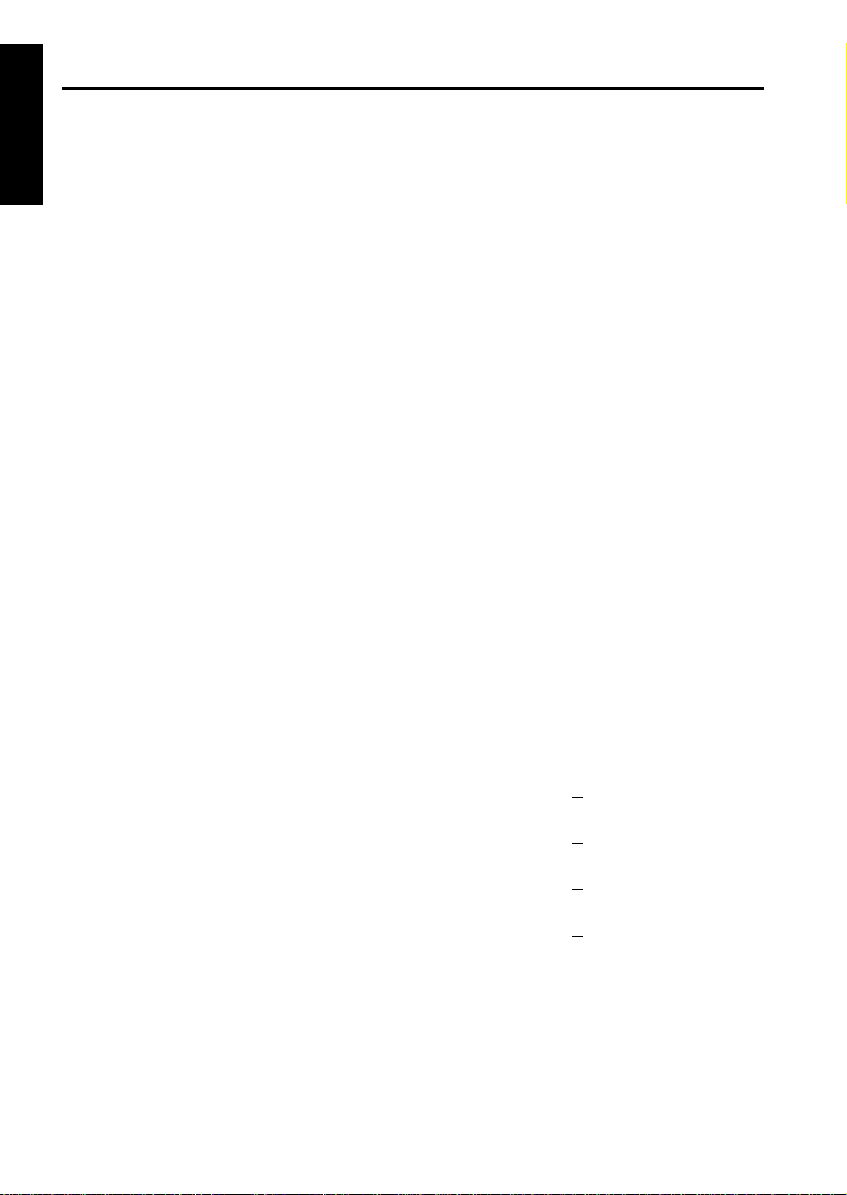

[3] First paper feed control

UPOP_PS

S_GND

CONV_PS

S_GND

PR_PS

SIDOP_PS

CONT

CONT

CONT

5V

5V

24V

24V

24V

LT DB

HTR101

MAIN BODY

24V

PGND

5V

SGND

IO_DTXD

IO_UCLK

LCT_LATCH

IO_DCLK

ERR_OUT4

IO_URXD

ACK4

REQ4

The first paper is fed by the paper feed roller and

the feed roller driven by M101(LT paper feed) via

MC101(LT feed MC). The paper feed roller and

feed roller touche the paper when SD100 (LT first

feed) is ON, feeding the paper to the conveyance

roller. Then, SD100 (LT first paper feed) turns

OFF to release the paper feed roller and feed

roller from the paper. The conveyance roller is

also driven by M101, by turning ON MC102 (LT

first feed MC), paper is fed to the main body.

The related signals are: PS100 (LT top cover

open/close detection), PS106 (LT feed), PS107

(LT first feed), and PS110 (LT jam access door

open/close detection).

PS100

PS106

PS107

PS110

MC101

MC102

SD100

1. Operation

a. First paper feed timing

(1) Start of first paper feed

At predefined interval after the START button is

pressed.

(2) Start of second and subsequent papers

When PS106 (LT feed) is turned OFF by the preceding paper.

(3) OFF timing

When the main body M7 (paper exit) turns OFF.

b. Interlock

The power supply line of M101 (LT paper feed) is

equipped with MS101 (LT interlock/1) and

MS102 (LT interlock/2). When the top cover is

opened, MS101 turns OFF, and when the jam

access door is opened MS102 turns OFF,

thereby cutting off the power supply to M101.

Furthermore, the top cover is equipped with

PS100 (LT top cover open/close detection) and

the jam access door is equipped with PS110 (LT

jam access door open/close detection) and

when either of these doors is opened during

paper feed, the M101 drive signal is turned OFF

to stop the paper feed operation.

c. Internal heater

The LCT is equipped with HTR101 (LT internal

heater) to protect the paper from humidity.

HTR101 is directly controlled by the main body

PRCB (printer control board) rather than by the

LTDB (LT drive board).

LCT

2-3

C-403/C-404

2. Signals

a. Input signals

(1) UPOP_PS (PS100 to LTDB)

Top cover open/close detection signal

[L]: Cover opened

[H]: Cover closed

(2) CONV_PS (PS106 to LTDB)

Conveyance roller exit paper detection signal

[L]: Paper detected

LCT

[H]: Paper not detected

(3) PR_PS (PS107 to LTDB)

Conveyance roller entrance (pre-registration

position) paper detection signal

[L]: Paper detected

[H]: Paper not detected

(4) SIDOP_PS (PS110 to LTDB)

Jam access door open/close detection signal

[L]: Door opened

[H]: Door closed

(5) LCTM_EM (M101 to LTDB)

M101 rotation error detection signal

[L]: M101 rotating

[H]: M101 not rotating

(6) IO_DTXD (MAIN BODY to LTDB)

Serial data to transmit main body PRCB (printer

control board) operating status to LTDB

(7) LCT_LATCH (MAIN BODY to LTDB)

IO_DTXD signal latch signal

(8) IO_DCLK (MAIN BODY to LTDB)

IO_DTXD signal clock signal

(9) ERR_OUT4 (MAIN BODY to LTDB)

Signal to notify LTDB (LT drive board) when there

is error in the main body

(10) ACK4 (MAIN BODY to LTDB)

Serial data transmission enable signal from LCT

to main body PRCB (printer control board)

b. Output signals

(1) CONT (LTDB to MC101)

MC101 (LT feed MC) ON/OFF drive signal

[L]: MC101 ON

[H]: MC101 OFF

(2) CONT (LTDB to MC102)

MC102 (LT first paper feed MC) ON/OFF drive

signal

[L]: MC102 ON

[H]: MC102 OFF

(3) CONT (LTDB to SD100)

SD100 ( LT first paper feed) ON/OFF drive signal

[L]: SD100 ON

[H]: SD100 OFF

(4) LCTM_CONT (LTDB to M101)

M101 (LT paper feed) ON/OFF control signal

[L]: M101 ON

[H]: M101 OFF

(5) IO_URXD (LTDB to MAIN BODY)

Serial data to transmit the LTDB (LT drive board)

operating status to main body PRCB

(6) IO_UCLK (LTDB to MAIN BODY)

IO_URXD signal clock signal

(7) REQ4 (LTDB to MAIN BODY)

Serial data send request signal from LCT to main

body PRCB

(8) LCTM_CLK (M101 to LTDB)

M101 (LT paper feed) rotational speed control

clock signal

(9) LCTM_F/R (M101 to LTDB)

M101 (LT paper feed) rotational direction indication signal

This machine always indicates [H]: normal rotation.

2-4

C-403/C-404

[4] Up/down plate drive control

LT D B

PGND

SGND

IO_DTXD

IO_UCLK

LCT_LATCH

IO_DCLK

ERR_OUT4

IO_URXD

ACK4

REQ4

24V

5V

MAIN BODY

When the top cover opens or closes, M100 (LT

up/down motor) rotates forward or backward to

move the up/down plate up or down. The up/

down plate descends by 120 mm each time

SW100 (LT tray down drive) is pressed while the

top cover is opened.

The related signals are PS100 (LT top cover

open/close detection), PS101 (LT lower limit

detection), and PS109 (LT upper limit detection).

1. Operation

a. Up/down plate descend timing

(1) ON timing

When the top cover is opened and PS100 (LT top

cover open/close detection) is turned OFF, M100

rotates backward to lower the up/down plate.

When SW100 (LT tray down drive) turns ON by

pressing, M100 rotates backward to move the

up/down plate down.

(2) OFF timing

M100 turns OFF at predefined interval after

PS100 turns OFF or SW100 turns ON. This in

turn lowers the up/down plate by 120 mm.

(3) Others

The up/down plate descends by 120 mm each

time SW100 is pressed until PS101 turns ON to

indicate the bottom limit of the up/down plate.

UPOP_PS

S_GND

S_GND

DW_SW

UP_PS

S_GND

5V

5V

SIG

5V

D1

D2

PS100

PS101

SW100

PS109

M100

b. Up/down plate ascend timing

(1) ON timing

When the top cover is closed and PS100 (LT top

cover open/close detection) is turned ON, M100

(LT UP/DOWN) rotates forward to raise the up/

down plate.

(2) OFF timing

When the up/down plate rises and PS109 (LT

upper limit detection) turns ON to indicate the

detection of the topmost paper, M100 (LT UP/

DOWN) turns OFF and stops the up/down plate.

The up/down plate also stops when the top cover

is opened and PS100 (LT top cover open/ close

detection) turns OFF.

2. Signals

a. Input signals

(1) SIG (PS101 to LTDB)

Up/down plate lower limit detection signal

[L]: Up/down plate not at lower limit

[H]: Up/down plate at lower limit

(2) UP_PS (PS109 to LTDB)

Up/down plate upper limit detection signal

[L]: Up/down plate not at upper limit

[H]: Up/down plate at upper limit

(3) DW_SW (SW100 to LTDB)

SW100 (LT tray down switch) ON/OFF detection

signal

[L]: SW100 ON

[H]: SW100 OFF

b. Output signal

(1) D1, 2 (LTDB to M100)

M100 (LT UP/DOWN) drive signal

These signals switches the direction of the drive

current to control the rotation direction of M100.

LCT

2-5

C-403/C-404

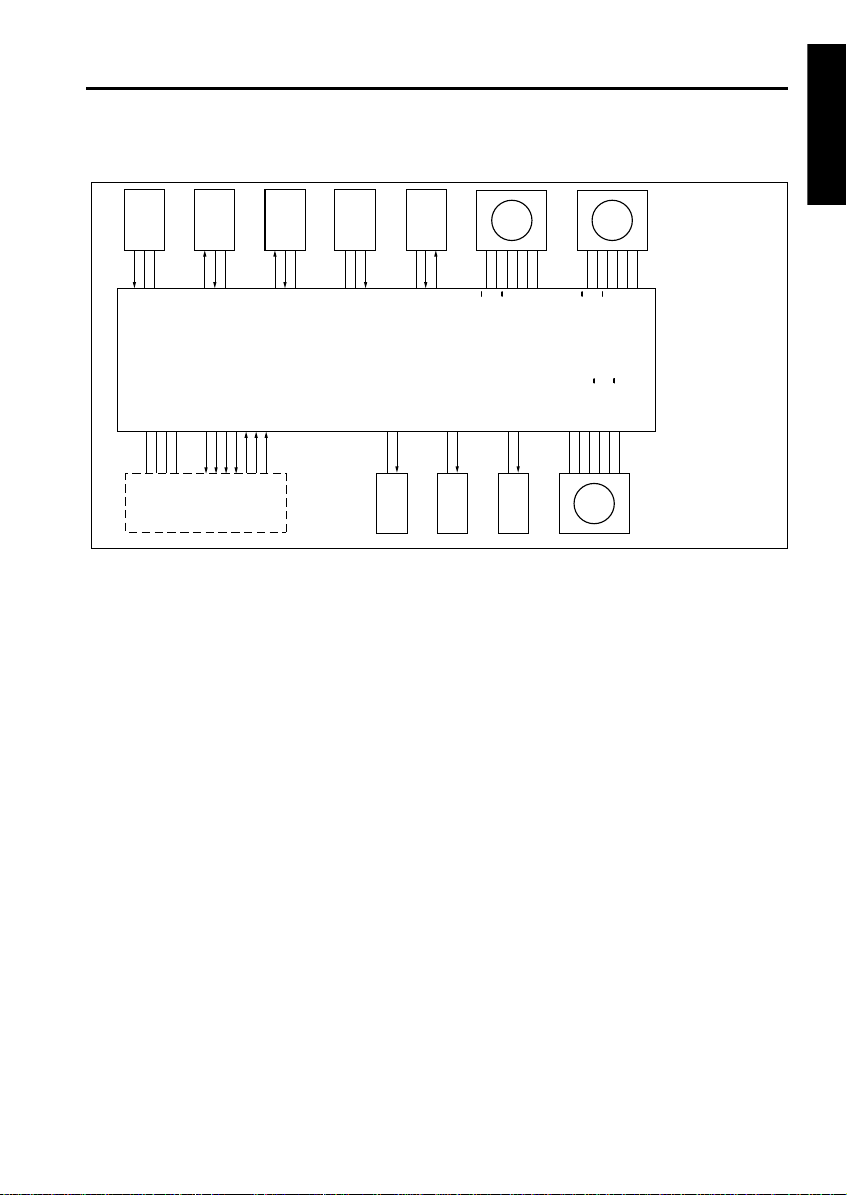

[5] Remaining paper detection/No paper

detection control

LT D B

LCT

PGND

SGND

IO_DTXD

IO_UCLK

LCT_LATCH

IO_DCLK

ERR_OUT4

IO_URXD

ACK4

REQ4

24V

5V

MAIN BODY

The remaining paper quantity is detected by

PS102 (LT remaining paper detection 1), PS103

(LT remaining paper detection 2), PS104 (LT

remaining paper detection 3), and PS105 (LT

remaining paper detection 4) and no paper

detection is made by PS108 (LT no paper detection).

The signals detected by these sensors are controlled by LTDB (LT drive board) and displayed on

the main body display.

1. Operation

a. Remaining paper detection control

The remaining paper quantity is determined from

the ON/OFF combination of sensors PS102 (LT

remaining paper detection 1), PS103 (LT remaining paper detection 2), PS104 (LT remaining

paper detection 3), and PS105 (LT remaining

paper detection 4) which detect the rotational

position of M100 (LT UP/DOWN) that is driving

the up/down plate. Each sensor turns ON or

OFF according to the position of the remaining

paper detection gear which is linked with the

rotation of M100.

The remaining paper quantity is detectable at

eight levels, but it is displayed on the main body

display as five levels.

S_GND

S_GND

S_GND

S_GND

0_PS

S_GND

5V

SIG

5V

SIG

5V

SIG

5V

SIG

5V

D1

D2

PS102

PS103

PS104

PS105

PS108

M100

<Remaining paper quantity and display>

Stacked

paper

quantity

PS102 PS103 PS104 PS105

Remaining

paper quantity

display

0 to 700 OFF OFF OFF OFF 1 flashing

701 to 1200 ON OFF OFF OFF 1 on

1201 to 1700 ON ON OFF OFF 2 on

1701 to 2200 ON ON ON OFF 2 on

2201 to 2700 ON ON ON ON 3 on

2701 to 3200 OFF ON ON ON 3 on

3201 to 3700 OFF OFF ON ON 4 on

3701 or more OFF OFF OFF ON 4 on

Caution:The remaining paper quantity is indicated on

the control panel with four horizontal bars.

Stacked paper quantity differs depending on

the thickness of the paper.

b. No paper detection control

When there is no more paper inside the LCT,

PS108 (LT no paper detection) turns ON and a

message is displayed on the main body display.

2. Signals

a. Input signals

(1) SIG (PS102 to LTDB)

Remaining paper detection gear rotational position detection signal

[L]: PS102 OFF

[H]: PS102 ON

(2) SIG (PS103 to LTDB)

Remaining paper detection gear rotational position detection signal

[L]: PS103 OFF

[H]: PS103 ON

(3) SIG (PS104 to LTDB)

Remaining paper detection gear rotational position detection signal

[L]: PS104 OFF

[H]: PS104 ON

(4) SIG (PS105 to LTDB)

Remaining paper detection gear rotational position detection signal

[L]: PS105 OFF

[H]: PS105 ON

(5) 0_PS (PS108 to LTDB)

LCT no paper detection signal

[L]: No paper

[H]: Paper present

2-6

FN-7/FN-115

FNS

FNS

CONTENTS

FN-7/FN-115

SAFETY AND IMPORTANT WARNING ITEMS

Refer to the Di850 service manual on page.......... S-1

1. OUTLINE

PRODUCT SPECIFICATIONS..................................1-1

CENTER CROSS-SECTIONAL DRAWING..............1-3

DRIVE SYSTEM DIAGRAM ......................................1-4

[1] Paper Conveyance Drive ...........................1-4

[2] Stacker Drive..............................................1-5

[3] Folding Drive (FN-7 only) ...........................1-6

PAPER CONVEYANCE PROCESS..........................1-7

[1] Paper Conveyance Process.......................1-7

[2] Non-Sort Mode ...........................................1-8

[3] Sort, Group Mode .......................................1-9

[4] Sub-tray Mode..........................................1-10

[5] Staple Mode .............................................1-11

[6] Booklet Mode (FN-7 only) ........................1-13

2. UNIT EXPLANATION

EXTERNAL SECTION...............................................2-1

[1] Composition ...............................................2-1

[2] Mechanisms ...............................................2-1

CONVEYANCE SECTION.........................................2-2

[1] Composition ...............................................2-2

[2] Mechanisms ...............................................2-3

[3] M1 (FNS Conveyance) Control ..................2-7

[4] Gate Control ...............................................2-9

[5] M13 (Stacker Entrance) Control...............2-11

[6] M5 (Alignment Plate/Upper) Control ........2-13

[7] M15 (Alignment Plate/Lower) Control

(FN-7 only) ...............................................2-14

[8] M2 (Roller Shift) Control...........................2-15

[9] M7 (Paper Exit Roller) Control .................2-16

[10] SD4 (Paper Exit Opening) Control...........2-18

[11] M8 (Paper Exit Opening) Control .............2-19

STAPLER UNIT.......................................................2-20

[1] Composition .............................................2-20

[2] Mechanisms .............................................2-21

[3] Stapler Control .........................................2-25

MAIN TRAY UNIT....................................................2-29

[1] Composition .............................................2-29

[2] Mechanisms .............................................2-29

[3] Main Tray Up/Down Control.....................2-29

FOLDING UNIT (FN-7 ONLY).................................2-31

[1] Composition .............................................2-31

[2] Mechanisms .............................................2-32

[3] Folding-Unit Control .................................2-33

FNS

FNS

1

OUTLINE

FNS

FNS

PRODUCT SPECIFICATIONS

FN-7/FN-115

[1] Type

FN-115:

Finishing device implementing offset collation

(sort,group), stapling, and sub-tray eject

FN-7:

Finishing device implementing offset collation(sort,group), stapling, sub-tray eject (booklet), stapling-and-folding, and folding

[2] Functions

Type of Paper: Same as the main body

Paper Size :

FN-7/115

Non-

Sort/

group

Staple

sort

A3

B4

F4

A4R

A/B

A4

stan-

B5R

dards

B5

A5R

A5

B6R

11 x 17

8.5 x 14

8.5 x

By

11R

inch

8.5 x 11

5.5 x

8.5R

5.5 x 8.5

Wide

paper

Paper Stacking Capacity (80 g/m

Sub-tray exit mode:

Maximum 200 sheets (same-size sheets only)

Non-Staple, Sort, and Group modes:

Maximum 1500 sheets

(A3, B4, F4, 11 x 17, 8.5 x 14)

Maximum 3000 sheets

(A4, A4R, B5, B5R, 8.5 x 11, 8.5 x 11R)

Maximum 500 sheets

(A5, A5R, B6R, 5.5 x 8.5, 5.5 x 8.5R)

FN-7

only

Sub-

Book-

tray

2

or 20 lbs):

Staple Mode:

Maximum 1000 sheets(same size sheets only)

Main-Tray Capacity

* : FN-7 only

Original pages

A3, 11 x 17,

A5, 5.5 x 8.5

Other paper

types

2 to 9 50 stacks 100 stacks

10 to 20 50 stacks 50 stacks

21 to 30 30 stacks 30 stacks

31 to 40 25 stacks 25 stacks

41 to 50 20 stacks 20 stacks

51 to 60 — 15 stacks *

let

61 to 100 — 10 stacks *

Booklet Mode (FN-7 only):

• Stapling-and-folding

20 booklets of 5 folded sheets each

(20 pages/ booklet; eq. to 400 pages).

• Folding

33 booklets of 3 folded sheets each

FNS

(12 pages/ booklet; eq. to 396 pages)

Paper curling: 10mm or less

Amount of curl

Paper (5 sheets)

Booklet-mode folding level (FN-7 only):

Height of folding

Original

pages

0 to 5

6 to 10

11 to 20

A3, 11 x 17

25mm or

less

50mm or

less

Not

specified*

(80 g/m2 or 20 lbs)

B4,

8.5 x 14

25mm or

less

50mm or

less

Not

specified*

A4R,

8.5 x 11R

25mm or

less

Not

specified*

Not

specified*

* The height of folding may be larger after exit,

although the booklet must be folded with ease

manually.

Amount of sort offsetting:

30 mm (after sorting and grouping)

1-1

FN-7/FN-115

[3] Staple Mode

Number of sheets to be stapled:

FN-115:

50 sheets maximum (the length in the paper

feed direction is 400 mm or more)

100 sheets maximum (except for paper mentioned above in parentheses)

* The height must be 10 mm or less when using

80g/m2 or 20 lbs quality paper.50 sheets or

less (the height must be 5mm or less when

using 80g/m

FN-7:

50 sheets maximum

* The height must be 5 mm or less when using

80g/m2 or 20 lbs quality paper.

Staple position:

* : adjustment possible

FNS

A 9.0 ± 3 mm * 8.5 ± 3 mm *

B 9.0 ± 3 mm 8.5 ± 3 mm

C 82.5 ± 3 mm 82.5 ± 3 mm

D 9.0 ± 3 mm * 8.5 ± 3 mm *

E 15.0 ± 3 mm 8.5 ± 3 mm

2

or 20lbs quality paper)

FN-115 FN-7

[4] Booklet Mode (FN-7 only)

Stapling-and-fold:

Maximum 20 sheets (80 g/m

Maximum 19 sheets (80 g/m

+ 1 sh eet ( 200 g /m

Folding:

Maximum 3 sheets (80 g/m

2

2

2

2

or 20 lbs paper)

[5] Option

Cover Inserter B:

(Cover sheet feeder)

[6] Machine Specifications

Power source:

24 V, 5 VDC (supplied from the main body)

Maximum power consumption:

100 VA

Weight:

FN-115: Approx. 65 kg

FN-7: Approx. 80 kg

External Dimensions:

656

85

781

367

or 20 lbs paper)

or 20 lbs paper)

or 45 lbs paper)

1151

1095

Single staple

(rear)

Booklet mode (stitch-and-fold, FN-7 only)

Staple capacity: 5000 staples/cartridge

Binding Staples:

A

Binding staples 100 sheets 50 sheets

Two staples

FN-115 FN-7

A 13.5 mm 12.0 mm *

B

B 13.2 mm 8.0 mm

Single

staple

(front)

(Unit : mm)

[7] Maintenance

Maintenance procedures:

Same as the main body

Service life:

Same as the main body

[8] Operating Environment

Temperature:

10 to 30 °C (50 to 86 °F)

Humidity:

10 to 80 % RH

Note: The information herein may be subject to

change for improvement without notice.

1-2

CROSS SECTION DIAGRAM

4

1

2

14

13

3

FN-7/FN-115

5

6

7

8

9

FNS

10

11

12

1. Main tray

2. Paper exit unit

3. Shift unit

4. Sub-tray

5. Gate

6. Sub-tray gate

7. By-pass gate

Area within dotted lines: FN-7 only.

8. Flat-stapling stopper

9. Stapler unit

10. Stapling and folding stopper

11. Folding unit

12. Folding stopper

13. Booklet tray

14. Stacker unit

1-3

FN-7/FN-115

DRIVE SYSTEM DIAGRAM

[1] Paper Conveyance Drive

1

2

3

4

13

12

11

5

6

FNS

10

9

8

1. Sub-tray paper exit roller (B)

2. Sub-tray paper exit roller (C)

3. Sub-tray paper exit roller (A)

4. Nip paper exit roller

5. Paper exit roller

6. Paper exit roller motor (M7)

7. Intermediate conveyance roller

7

8. FNS conveyance motor (M1)

9. Conveyance roller (A)

10. Conveyance roller (B)

11. Conveyance roller (C)

12. Conveyance roller (D)

13. Conveyance slide shaft

1-4

[2] Stacker Drive

(FN-115)

(FN-7)

9

8

7

6

1. Nip paper exit roller

2. Paper exit roller

3. Paper exit roller motor (M7)

4. Coupling

5. Stacker entrance motor (M13)

9

1

5

6. Swivel roller

7. Stacker entrance roller

8. Paper exit belts

9. Paper exit arms

1

2

4

2

FN-7/FN-115

3

FNS

3

8

7

6

1. Nip paper exit roller

2. Paper exit roller

3. Paper exit roller motor (M7)

4. Coupling

5. Stacker entrance motor (M13)

4

5

6. Paper exit arms

7. Swivel roller

8. Stacker entrance roller

9. Paper exit belts

1-5

FN-7/FN-115

[3] Folding Drive (FN-7 only)

7

6

FNS

1. Pressure roller (A)

2. Pressure roller (B)

3. Folding conveyancebelts

4. Folding conveyance motor (M20)

5. Folding knife motor (M19)

9

8

5

4

1

2

3

6. Folding knife

7. Folding conveyance roller

8. Folding roller (A)

9. Folding roller (B)

1-6

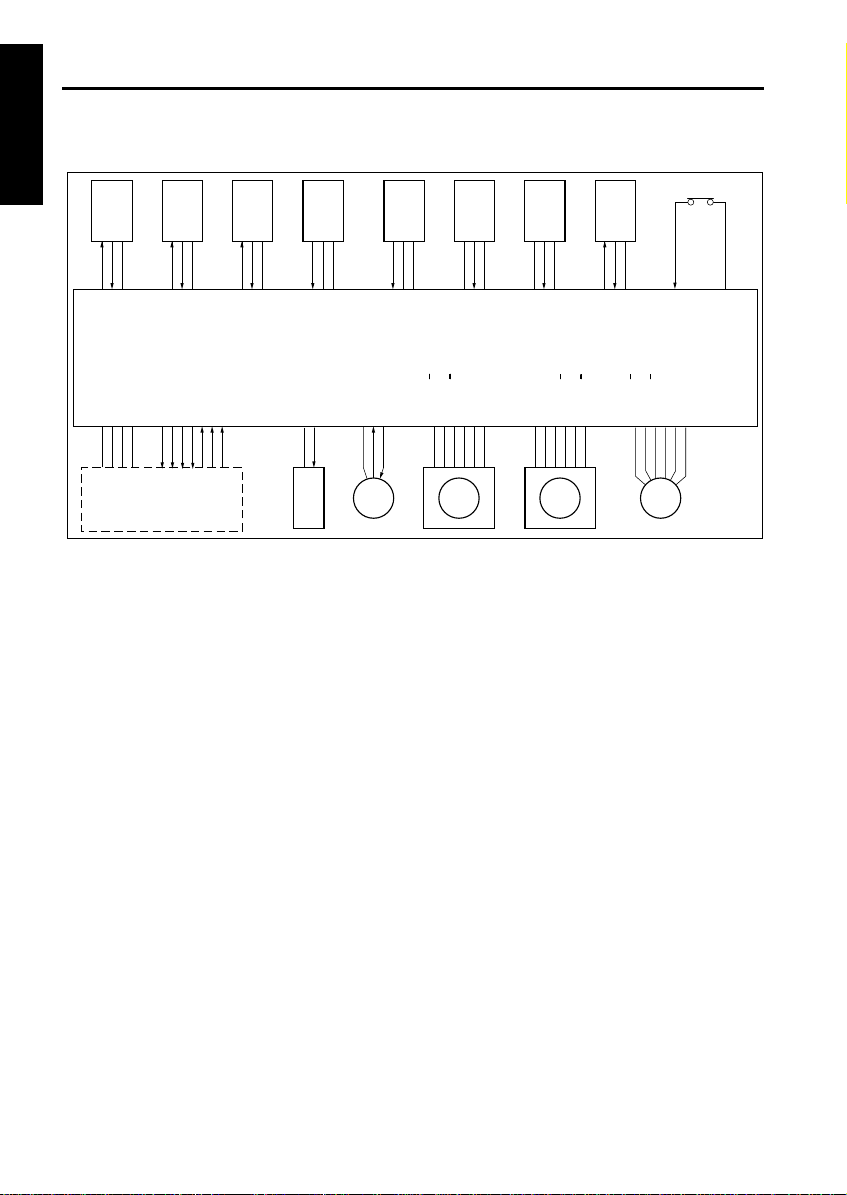

PAPER CONVEYANCE PROCESS

[1] Paper Conveyance Process

The FNS (finisher) provides four paper paths, as shown in the diagram below.

Face-up and face-down inversion is handled by at the main-body side by the main body’s exit page inverter.

Non-SortMode

Sub-tray

Main tray

FN-7/FN-115

FNS

Booklet tray

Paper conveyance path Finishing mode

1

2

3

4

Non-sort, Sort, Group modes

Sub-tray mode

Staple mode

Booklet mode (FN-7 only)

1-7

FN-7/FN-115

[2] Non-Sprt Mode

Exit to main tray

A paper exited from the main body is conveyed and exited to the main tray.

1

8

7

FNS

1. Gate

2. Sub-tray gate

3. Co nveyance roller (B)

4. Co nveyance roller (A)

6

5. C onveyance roller (C)

6. C onveyance roller (D)

7. Paper exit roller

8. Main tray

2

3

4

5

1-8

FN-7/FN-115

[3] Sort, and Group Modes

Exit to main tray

Paper exited from the main body is conveyed and exited to the main tray. This mode has an off-set function

that allows each page of the even-numbered sets to be exited with the paper shifted 30mm to the rear..

Off-set- Function

(1) The odd-numbered pages are exited to the main tray with the image side face down.

(2) The even-numbered pages are shifted 30mm to the rear by the conveyance slide shaft of the shift unit and

then exited to the main tray.

30mm

1

2

10

9

3

8

7

4

5

6

FNS

1. Shift unit

2. Conveyance slide shaft

3. Gate

4. Sub-tray gate

5. C onveyance roller (B)

6. Conveya nce rol ler (A)

7. Conveyance roller (C)

8. Conveya nce rol ler (D)

9. Paper exit roller

10. Main tray

1-9

FN-7/FN-115

[4] Sub-tray Mode

The sub-tray gate opens. Paper exited from the main body is conveyed and exited to the sub-tray.

7

6

1

5

FNS

1. Sub-tray paper exit roller (C)

2. Sub-tray gate

3. Conveyance roller (B)

5. Sub-tray paper exit roller (A)

6. Sub-tray paper exit roller (B)

7. Sub-tray

2

3

4

4. Conveyance roller (A)

1-10

[5] Staple Mode

(1) The gate switches to the staple mode.

(2) For A4R paper and above, the paper exit opening opens.

(3) The first set of paper is conveyed and stacked.

1) The stacker section roller sends the paper to the flat-stapling stopper and the paper is lined up in the

length wise direction.

2) The upper alignment plate lines up paper in the widthwise direction.

3) Paper is stapled.

4) The first set is conveyed by the paper exit arm and exited to the main tray.

FN-7/FN-115

3

1

F

i

r

s

t

s

t

a

p

l

e

d

s

e

t

2

4

5

6

FNS

7

16

15

8

9

14

10

11

13

12

1. Paper exit opening

2. Intermediate conveyance roller

3. Gate

4. Conveyance roller (C)

5. Sub-tray gate

6. Conveyance roller (B)

7. Conveyance roller (A)

8. By-pass gate

9. Stacker entrance roller

10. Swivel roller

11. Flat-stapling stopper

12. Paper exit arm

13. Stapler unit

14. Paper exit belt

15. Alignment plate upper

16. Main tray

1-11

FN-7/FN-115

(4) The second and subsequent sets of paper are conveyed and stacked.

1) The first page stops in the stacker entrance with the by-pass gate opened. The stacker entrance roller stops

to wait for the previous stack to be exited.

2) The by-pass gate is closed and the second page is stacked on top of the first.

3) Once the previous stack has exited, the stack entrance roller rotates and the first and second pages are

simultaneously sent to the stacker.

* The above steps (1) to (3) are for paper to a maximum of A4 size.

4) The stacker section roller sends the paper to the flat-stapling stopper and the paper is lined up in the length

wise direction.

5) The upper alignment plate lines up paper in the widthwise direction.

6) When all paper is conveyed to the stacker, the paper is stapled.

7) The second and subsequent sets are conveyed by the paper exit arm and the paper is exited to the main

tray.

3

FNS

1

F

i

r

s

t

s

t

a

p

l

e

d

s

e

t

2

4

5

6

7

18

17

16

8

9

10

11

15

14

1. Paper exit opening

2. Intermediate conveyance roller

3. Gate

4. Conveyance roller (C)

5. Sub-tray gate

6. Conveyance roller (B)

7. Conveyance roller (A)

8. By-pass gate

9. First sheet

10. Stacker entrance roller

11. Swivel roller

12. Flat-stapling stopper

13. Paper exit arm

14. Stapler unit

15. Paper exit belt

16. Second sheet

17. Alignment plate upper

18. Main tray

12

13

1-12

FN-7/FN-115

[6] Booklet Mode (FN-7 only)

(1) The gate switches to the staple mode.

(2) The paper exit opening opens.

(3) The paper is conveyed and stacked.

(4) The stacker section roller sends the paper to the stapling-and-folding stopper and the paper is lined up in the

lengthwise direction.

(5) The upper and lower alignment plate lines up paper in the widthwise direction.

(6) If stapling-and-folding has been selected, staple the stack.

(7) Release the stapling-and-folding stopper and convey the stack to the folding unit by the paper exit belt.