Page 1

Service Manual

SU-2/SU-3

Page 2

1. SAFETY PRECAUTIONS FOR INSPECTION AND SERVICE

• When performing inspection and service procedures, observe the following precautions

to prevent accidents and ensure utmost safety.

Depending on the model, some of the precautions given in the following do not apply.

✽

• Different markings are used to denote specific meanings as detailed below.

WARNING

• Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

CAUTION

• Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury. It may also be used to alert against unsafe practices.

• The following graphic symbols are used to give instructions that need to be observed.

Used to call the service technician attention to what is graphically represented

inside the marking (including a warning).

Used to prohibit the service technician from doing what is graphically represented

inside the marking.

Used to instruct the service technician to do what is graphically represented

inside the marking.

1-1. Warning

1. Always observe precautions.

• Parts requiring special attention in this product will include a label containing

the mark shown on the left plus precautionary notes. Be sure to observe the

precautions.

• Be sure to observe the “Safety Information” given in the Operator’s Manual.

WARNING

P-1

Page 3

WARNING

2. Before starting the procedures, be sure to unplug the power cord.

• This product contains a high-voltage unit and a circuit with a large current

capacity that may cause an electric shock or burn.

• The product also contains parts that can jerk suddenly and cause injury.

• If this product uses a laser, laser beam leakage may cause eye damage or

blindness.

3. Do not throw toner or the toner bottle into a fire.

• Do not throw toner or the Toner Bottle (Imaging Cartridge, Toner Cartridge) into

a fire. Toner expelled from the fire may cause burns.

4. Use the specified parts.

• For replacement parts, always use the genuine parts specified in the manufacturer’s parts manual. Installing a wrong or unauthorized part could cause

dielectric breakdown, overload, or undermine safety devices resulting in possible electric shock or fire.

• Replace a blown electrical fuse or thermal fuse with its corresponding genuine

part specified in the manufacturer’s parts manual. Installing a fuse of a different

make or rating could lead to a possible fire. If a thermal fuse blows frequently,

the temperature control system may have a problem and action must be taken

to eliminate the cause of the problem.

5. Handle the power cord with care and never use a multiple outlet.

• Do not break, crush or otherwise damage the power cord. Placing a heavy

object on the power cord, or pulling or bending it may damage it, resulting in a

possible fire or electric shock.

• Do not use a multiple outlet to which any other appliance or machine is connected.

• Be sure the power outlet meets or exceeds the specified capacity.

• Use only the power cord supplied in the package. If a power cord is not sup-

plied, only use the power cord and plug that is specified in POWER CORD

INSTRUCTION. Failure to use this cord could result in a fire or electrical shock.

• Use the power cord supplied in the package only for this machine and NEVER

use it for any other product. Failure to observe this precaution could result in a

fire or electrical shock.

6. Be careful with the high-voltage parts.

• A part marked with the symbol shown on the left carries a high voltage. Touching it could result in an electric shock or burn. Be sure to unplug the power cord

before servicing this part or the parts near it.

7. Do not work with wet hands.

• Do not unplug or plug in the power cord, or perform any kind of service or

inspection with wet hands. Doing so could result in an electric shock.

P-2

Page 4

WARNING

8. Do not touch a high-temperature part.

• A part marked with the symbol shown on the left and other parts such as the

exposure lamp and fusing roller can be very hot while the machine is energized. Touching them may result in a burn.

• Wait until these parts have cooled down before replacing them or any surrounding parts.

9. Maintain a grounded connection at all times.

• Connect the power cord to an electrical outlet that is equipped with a grounding

terminal.

10. Do not remodel the product.

• Modifying this product in a manner not authorized by the manufacturer may

result in a fire or electric shock. If this product uses a laser, laser beam leakage

may cause eye damage or blindness.

11. Restore all parts and harnesses to their original positions.

• To promote safety and prevent product damage, make sure the harnesses are

returned to their original positions and properly secured in their clamps and

saddles in order to avoid hot parts, high-voltage parts, sharp edges, or being

crushed.

• To promote safety, make sure that all tubing and other insulating materials are

returned to their original positions. Make sure that floating components

mounted on the circuit boards are at their correct distance and position off the

boards.

1-2. Caution

1. Precautions for Service Jobs.

• A star washer and spring washer, if used originally, must be reinstalled. Omitting them may result in contact failure which could cause an electric shock or

fire.

• When reassembling parts, make sure that the correct screws (size, type) are

used in the correct places. Using the wrong screw could lead to stripped

threads, poorly secured parts, poor insulating or grounding, and result in a malfunction, electric shock or injury.

• Take great care to avoid personal injury from possible burrs and sharp edges

on the parts, frames and chassis of the product.

• When moving the product or removing an option, use care not to injure your

back or allow your hands to be caught in mechanisms.

CAUTION

P-3

Page 5

CAUTION

2. Precautions for Servicing with Covers and Parts Removed.

• Wherever feasible, keep all parts and covers mounted when energizing the

product.

• If energizing the product with a cover removed is absolutely unavoidable, do

not touch any exposed live parts and use care not to allow your clothing to be

caught in the moving parts. Never leave a product in this condition unattended.

• Never place disassembled parts or a container of liquid on the product. Parts

falling into, or the liquid spilling inside, the mechanism could result in an electric

shock or fire.

• Never use a flammable spray near the product. This could result in a fire.

• Make sure the power cord is unplugged before removing or installing circuit

boards or plugging in or unplugging connectors.

• Always use the interlock switch actuating jig to actuate an interlock switch

when a cover is opened or removed. The use of folded paper or some other

object may damage the interlock switch mechanism, possibly resulting in an

electric shock, injury or blindness.

3. Precautions for the Working Environment.

• The product must be placed on a flat, level surface that is stable and secure.

• Never place this product or its parts on an unsteady or tilting workbench when

servicing.

• Provide good ventilation at regular intervals if a service job must be done in a

confined space for a long period of time.

• Avoid dusty locations and places exposed to oil or steam.

• Avoid working positions that may block the ventilation ports of the product.

4. Precautions for Handling Batteries. (Lithium, Nickel-Cadmium, etc.)

• Replace a rundown battery with the same type as specified in the manufacturer’s parts manual.

• Before installing a new battery, make sure of the correct polarity of the installation or the battery could burst.

• Dispose of used batteries according to the local regulations. Never dispose of

them at the user’s premises or attempt to try to discharge one.

5. Precautions for the Laser Beam. (Only for Products Employing a Laser)

• Removing the cover marked with the caution label could lead to possible exposure to the laser beam, resulting in eye damage or blindness. Be sure to

unplug the power cord before removing this cover.

• If removing this cover while the power is ON is unavoidable, be sure to wear

protective laser goggles that meet specifications.

• Make sure that no one enters the room when the machine is in this condition.

• When handling the laser unit, observe the “Precautions for Handling Laser

Equipment.”

6. Precautions for storing the toner or imaging cartridge.

• Be sure to keep the toner or imaging cartridge out of the reach of children.

Licking the imaging cartridge or ingesting its contents is harmful to your health.

P-4

Page 6

1-3. Used Batteries Precautions

ALL Areas

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type recommended by the manufacturer.

Dispose of used batteries according to the manufacturer’s instructions.

Germany

Explosionsgefahr bei unsachgemäßem Austausch der Batterie.

Ersatz nur durch denselben oder einen vom Hersteller empfohlenen gleichwertigen Typ.

Entsorgung gebrauchter Batterien nach Angaben des Herstellers.

France

Il y a danger d’explosion s’il y a remplacement incorrect de la batterie.

Remplacer uniquement avec une batterie du même type ou d’un type équivalent recommandé par le constructeur.

Mettre au rebut les batteries usagées conformément aux instructions du fabricant.

CAUTION

VORSICHT!

AT TE N T IO N

Denmark

Lithiumbatteri - Eksplosionsfare ved fejlagtig håndtering.

Udskiftning må kun ske med batteri af samme fabrikat og type.

Levér det brugte batteri tilbage til leverandøren.

Finland, Sweden

Paristo voi r äjähtää, jos se on virheellisesti asennettu.

Vaihda paristo ainoastaan laitevalmistajan suosittelemaan tyyppiin.

Hävitä käytetty paristo valmistajan ohjeiden mukaisesti.

Explosionsfara vid felaktigt batteribyte.

Använd samma batterityp eller en ekvivalent typ som rekommenderas av apparattillverkaren.

Kassera använt batteri enligt fabrikantens instruktion.

Norway

Eksplosjonsfare ved feilaktig skifte av batteri.

Benytt samme batteritype eller en tilsvarende type anbefalt av apparatfabrikanten.

Brukte batterier kasseres i henhold til fabrikantens instruksjoner.

ADVARSEL!

VAR OlTUS

VARNING

ADVARSEL

P-5

Page 7

1-4. Other Precautions

• When handling circuit boards, observe the “HANDLING of PWBs”.

• The PC Drum is a very delicate component. Observe the precautions given in “HAN-

DLING OF THE PC DRUM” because mishandling may result in serious image problems.

• Note that replacement of a circuit board may call for readjustments or resetting of partic-

ular items, or software installation.

1-5. Precautions for Service

• When performing inspection and service procedures, observe the following precautions

to prevent mishandling of the machine and its parts.

Depending on the model, some of the precautions given in the following do not apply.

✽

1. Precautions Before Service

• When the user is using a word processor or personal computer from a wall outlet of the

same line, take necessary steps to prevent the circuit breaker from opening due to overloads.

• Never disturb the LAN by breaking or making a network connection, altering termination,

installing or removing networking hardware or software, or shutting down networked

devices without the knowledge and express permission of the network administrator or

the shop supervisor.

2. How to Use this Book

DIS/REASSEMBLY, ADJUSTMENT

• To reassemble the product, reverse the order of disassembly unless otherwise specified.

TROUBLESHOOTING

• If a component on a PWB or any other functional unit including a motor is defective, the

text only instructs you to replace the whole PWB or functional unit and does not give troubleshooting procedures applicable within the defective unit.

• All troubleshooting procedures contained herein assume that there are no breaks in the

harnesses and cords and all connectors are plugged into the right positions.

• The procedures preclude possible malfunctions due to noise and other external causes.

3. Precautions for Service

• Keep all disassembled parts in good order and keep tools under control so that none will

be lost or damaged.

• After completing a service job, perform a safety check. Make sure that all parts, wiring

and screws are returned to their original positions.

• Do not pull out the toner hopper while the toner bottle is turning. This could result in a

damaged motor or locking mechanism.

• If the product is to be run with the front door open, make sure that the toner hopper is in

the locked position.

• Do not use an air gun or vacuum cleaner for cleaning the ATDC Sensor and other sensors, as they can cause electrostatic destruction. Use a blower brush and cloth. If a unit

containing these sensors is to be cleaned, first remove the sensors from the unit.

P-6

Page 8

4. Precautions for Dis/Reassembly

• Be sure to unplug the copier from the outlet before attempting to service the copier.

• The basic rule is not to operate the copier anytime during disassembly. If it is absolutely

necessary to run the copier with its covers removed, use care not to allow your clothing to

be caught in revolving parts such as the timing belt and gears.

• Before attempting to replace parts and unplug connectors, make sure that the power

cord of the copier has been unplugged from the wall outlet.

• Be sure to use the Interlock Switch Actuating Jig whenever it is necessary to actuate the

Interlock Switch with the covers left open or removed.

• While the product is energized, do not unplug or plug connectors into the circuit boards

or harnesses.

• Never use flammable sprays near the copier.

• A used battery should be disposed of according to the local regulations and never be dis-

carded casually or left unattended at the user’s premises.

• When reassembling parts, make sure that the correct screws (size, type) and toothed

washer are used in the correct places.

5. Precautions for Circuit Inspection

• Never create a closed circuit across connector pins except those specified in the text and

on the printed circuit.

• When creating a closed circuit and measuring a voltage across connector pins specified

in the text, be sure to use the GND wire.

6. Handling of PWBs

During Transportation/Storage

• During transportation or when in storage, new P.W. Boards must not be indiscriminately

removed from their protective conductive bags.

• Do not store or place P.W. Boards in a location exposed to direct sunlight and high temperature.

• When it becomes absolutely necessary to remove a Board from its conductive bag or

case, always place it on its conductive mat in an area as free as possible from static electricity.

• Do not touch the pins of the ICs with your bare hands.

• Protect the PWBs from any external force so that they are not bent or damaged.

During Inspection/Replacement

• Avoid checking the IC directly with a multimeter; use connectors on the Board.

• Never create a closed circuit across IC pins with a metal tool.

• Before unplugging connectors from the P.W. Boards, make sure that the power cord has

been unplugged from the outlet.

• When removing a Board from its conductive bag or conductive case, do not touch the

pins of the ICs or the printed pattern. Place it in position by holding only the edges of the

Board.

• When touching the PWB, wear a wrist strap and connect its cord to a securely grounded

place whenever possible. If you cannot wear a wrist strap, touch a metal part to discharge static electricity before touching the PWB.

• Note that replacement of a PWB may call for readjustments or resetting of particular

items.

7. Handling of Other Parts

• The magnet roller generates a strong magnetic field. Do not bring it near a watch, floppy

disk, magnetic card, or CRT tube.

P-7

Page 9

8. Handling of the PC Drum

Only for Products Not Employing an Imaging Cartridge.

✽

During Transportation/Storage

• Use the specified carton whenever moving or storing the PC Drum.

• The storage temperature is in the range between –20°C and +40°C.

• In summer, avoid leaving the PC Drum in a car for a long time.

Handling

• Ensure that the correct PC Drum is used.

• Whenever the PC Drum has been removed from the copier, store it in its carton or protect

it with a Drum Cloth.

• The PC Drum exhibits greatest light fatigue after being exposed to strong light over an

extended period of time. Never, therefore, expose it to direct sunlight.

• Use care not to contaminate the surface of the PC Drum with oil-base solvent, fingerprints, and other foreign matter.

• Do not scratch the surface of the PC Drum.

• Do not apply chemicals to the surface of the PC Drum.

• Do not attempt to wipe clean the surface of the PC Drum.

If, however, the surface is contaminated with fingerprints, clean it using the following procedure.

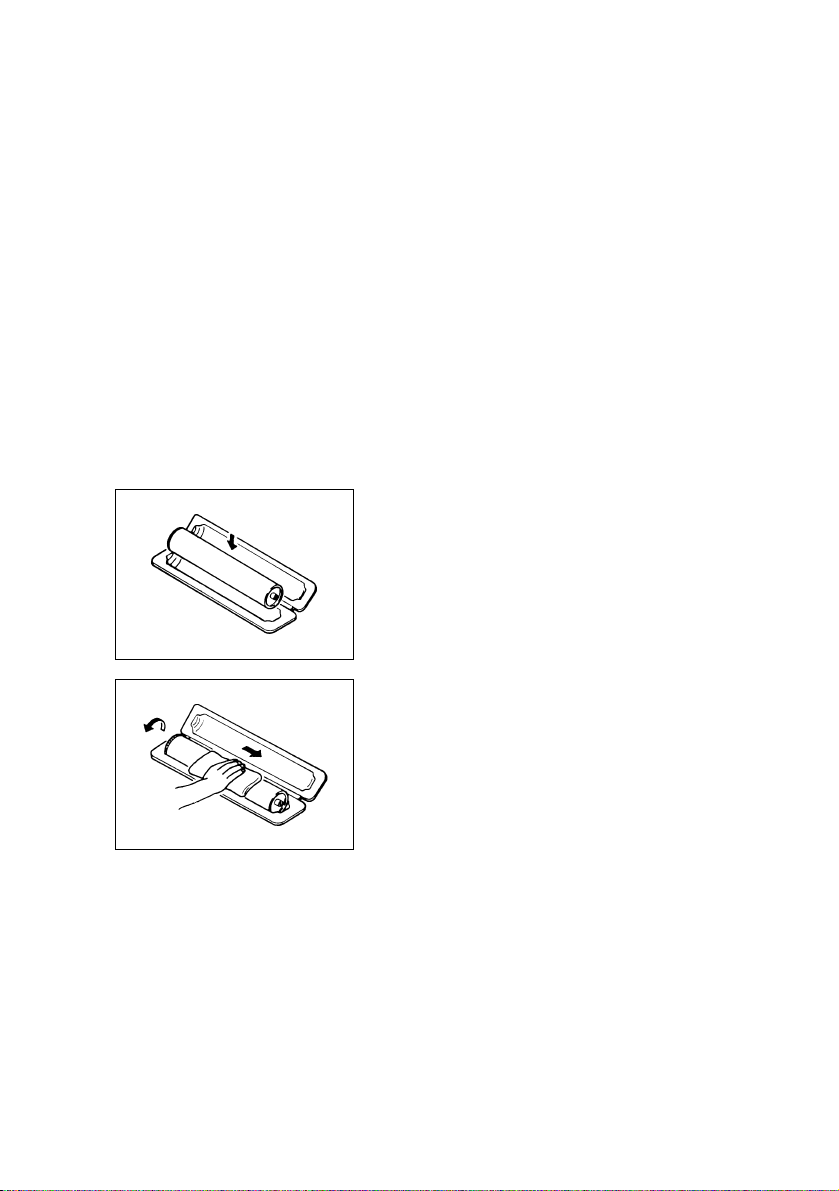

A. Place the PC Drum into one half of its carton.

1076D001

1076D002

B. Gently wipe the residual toner off the surface of the

PC Drum with a dry, Dust-Free Cotton Pad.

• Turn the PC Drum so that the area of its surface on

which the line of toner left by the Cleaning Blade is

present is facing straight up. Wipe the surface in one

continuous movement from the rear edge of the PC

Drum to the front edge and off the surface of the PC

Drum.

• Turn the PC Drum slightly and wipe the newly

exposed surface area with a CLEAN face of the

Dust-Free Cotton Pad. Repeat this procedure until

the entire surface of the PC Drum has been thoroughly cleaned.

At this time, always use a CLEAN face of the dry

✽

Dust-Free Cotton Pad until no toner is evident on the

face of the Pad after wiping.

P-8

Page 10

C. Soak a small amount of either ethyl alcohol or iso-

propyl alcohol into a clean, unused Dust-Free Cotton Pad which has been folded over into quarters.

Now, wipe the surface of the PC Drum in one continuous movement from its rear edge to its front

edge and off its surface one to two times.

Never move the Pad back and forth.

✽

1076D003

D. Using the SAME face of the Pad, repeat the proce-

dure explained in the latter half of step 3 until the

entire surface of the PC Drum has been wiped.

Always OVERLAP the areas when wiping. Two

complete turns of the PC Drum would be appropriate for cleaning.

1076D004

NOTES

• Even when the PC Drum is only locally dirtied, wipe the entire surface.

• Do not expose the PC Drum to direct sunlight. Clean it as quickly as possible even under

interior illumination.

• If dirt remains after cleaning, repeat the entire procedure from the beginning one more

time.

9. Handling of the Imaging Cartridge and Print Unit

Only for Products Employing an Imaging Cartridge and Print Unit.

✽

During Transportation/Storage

• The storage temperature is in the range between –20 °C and +40 °C.

• In summer, avoid leaving the Imaging Cartridge and Print Unit in a car for a long time.

Handling

• Store the Imaging Cartridge and Print Unit in a place that is not exposed to direct sunlight.

Precautionary Information on the PC Drum Inside the Imaging Cartridge and Print Unit.

• Use care not to contaminate the surface of the PC Drum with oil-base solvent, fingerprints, and other foreign matter.

• Do not scratch the surface of the PC Drum.

• Do not attempt to wipe clean the surface of the PC Drum.

P-9

Page 11

Page 12

CONTENTS

1. SAFETY PRECAUTIONS FOR INSPECTION AND SERVICE .......................P-1

1-1. Warning ....................................................................................................P-1

1-2. Caution .....................................................................................................P-3

1-3. Used Batteries Precautions ......................................................................P-5

1-4. Other Precautions ....................................................................................P-6

1-5. Precautions for Service ............................................................................P-6

GENERAL

1. OVERVIEW AND SPECIFICATIONS ..............................................................M-1

1-1. Difference between functions available on different models ....................M-1

1-2. Scan to E-mail ..........................................................................................M-2

1-3. Scan to Server (FTP) ...............................................................................M-3

1-4. Scan to PC (FTP) .....................................................................................M-5

1-5. Scan to HDD ............................................................................................M-6

1-6. Scan to PC (SMTP) ..................................................................................M-7

1-7. Internet Fax ..............................................................................................M-9

1-8. IP Address Fax (LAN-FAX) ......................................................................M-11

1-9. IP Scanner ...............................................................................................M-12

1-10.Distribution of Fax Documents .................................................................M-14

1-11.Direct Fax Transmission ..........................................................................M-15

1-12.PageScope Light ......................................................................................M-17

1-13.Overview of Attached Utilities ..................................................................M-18

(1) “Network FAX” Operating Environment (Reference) .......................M-18

2. RESTRICTIONS AND PRECAUTIONS FOR USING NETWORK A

PPLICATIONS .................................................................................................M-19

2-1. Precautions when using Network Applications ........................................M-19

2-2. Functions that cannot use Network Applications .....................................M-19

(1) Fax functions that can not be used. .................................................M-19

(2) Fax functions that can be used. .......................................................M-19

(3) Precautions for using IP Scanner ....................................................M-20

(4) Using a modem or terminal adapter .................................................M-20

3. FUNCTIONAL OVERVIEW OF CARDS USED ...............................................M-21

3-1. CLAN Card ...............................................................................................M-21

(1) Overview ..........................................................................................M-21

(2) Functions .........................................................................................M-21

(3) LED Indicators .................................................................................M-21

(4) Block Diagram ..................................................................................M-22

Page 13

DIS/REASSEMBLY, ADJUSTMENT

1. EQUIPMENT SETUP .......................................................................................D-1

1-1. Connection ...............................................................................................D-1

2. DISASSEMBLY / REASSEMBLY ....................................................................D-2

2-1. Detaching Parts ........................................................................................D-2

(1) Removing the main cover ................................................................D-2

(2) Removing the CLAN Board ..............................................................D-4

(3) Removing Expansion (Printer / Network Scan /

Internet Fax & Network Scan) Board ...............................................D-6

(4) Removing the function expansion hard disk kit ................................D-7

(5) Removing the function expansion hard disk power supply

circuit board D-8

2-2. Confirmation when Reassembling ...........................................................D-9

(1) Confirm operation of the Printer Controller. .....................................D-9

(2) Confirm operation of the Network Scan kit /

Internet Fax & Network Scan kit. .....................................................D-9

DISPLAYS / SETTINGS

1. TOUCH PANEL DISPLAY CONFIRMATION ...................................................S-1

1-1. Printer unit / Network interface card .........................................................S-1

1-2. Network scanner kit / Network interface kit ..............................................S-2

2. SPECIFICATION PARAMETERS ....................................................................S-3

2-1. Required specification parameters for each model ..................................S-3

(1) Explanation of specification parameters ..........................................S-3

(2) Network Specifications List ..............................................................S-5

3. SOFTWARE SWITCHES .................................................................................S-7

3-1. Software switches that can be changed by users (diagram). ...................S-7

3-2. Table of Default Values ............................................................................S-13

3-3. Changing Software Switch Settings .........................................................S-15

(1) Opening the settings screen from Tech. Rep. Mode .......................S-15

(2) Opening the settings screen from Maintenance Mode ....................S-15

(3) Opening the PC printer software switch settings screen .................S-16

3-4. Software Switch Functions .......................................................................S-17

(1) Table of printer / scanner / network function software switches ......S-17

Page 14

TROUBLESHOOTING

1. ALARM DISPLAY .............................................................................................T-1

2. TRANSMISSION RESULTS ERROR CODES ................................................T-2

2-1. Scan to Server (FTP) Transmissions .......................................................T-2

2-2. Scan to PC (FTP) Transmissions .............................................................T-2

2-3. Scan to HDD Transmissions ....................................................................T-3

2-4. URL notification (with Scan to Server (FTP) and

Scan to HDD transmissions) ....................................................................T-3

2-5. Internet Fax Transmissions / Scan to E-mail Transmissions ...................T-3

2-6. Internet Fax Reception .............................................................................T-4

2-7. Scan to PC (SMTP) Transmissions .........................................................T-5

2-8. IP Scanner ...............................................................................................T-6

2-9. Direct Fax Transmission (Gateway transmissions) ..................................T-7

3. TROUBLESHOOTING FUNCTIONS ...............................................................T-8

3-1. Internet fax Transmissions / Scan to E-mail Transmissions ....................T-8

3-2. IP Address Fax Reception .......................................................................T-8

3-3. Internet Fax Reception .............................................................................T-9

3-4. Distribution of Fax Documents .................................................................T-10

3-5. Scan to PC (SMTP) Transmission ...........................................................T-11

3-6. IP Scanner ...............................................................................................T-11

3-7. Direct Fax Transmission (Gateway transmission) ....................................T-14

3-8. PageScope Light ......................................................................................T-15

3-9. Other (Network Functions) .......................................................................T-16

3-10.Reference: “Network FAX” .......................................................................T-16

(1) “Network FAX” Fax Transmission ....................................................T-16

(2) “Network FAX” .................................................................................T-18

Page 15

Page 16

GENERAL

Page 17

Page 18

1. Overview and Specifications

• The following is an overview of the functions of network scanners and network interfaces:

• For details and requirements, referred to the “electronic manual” in the manual.

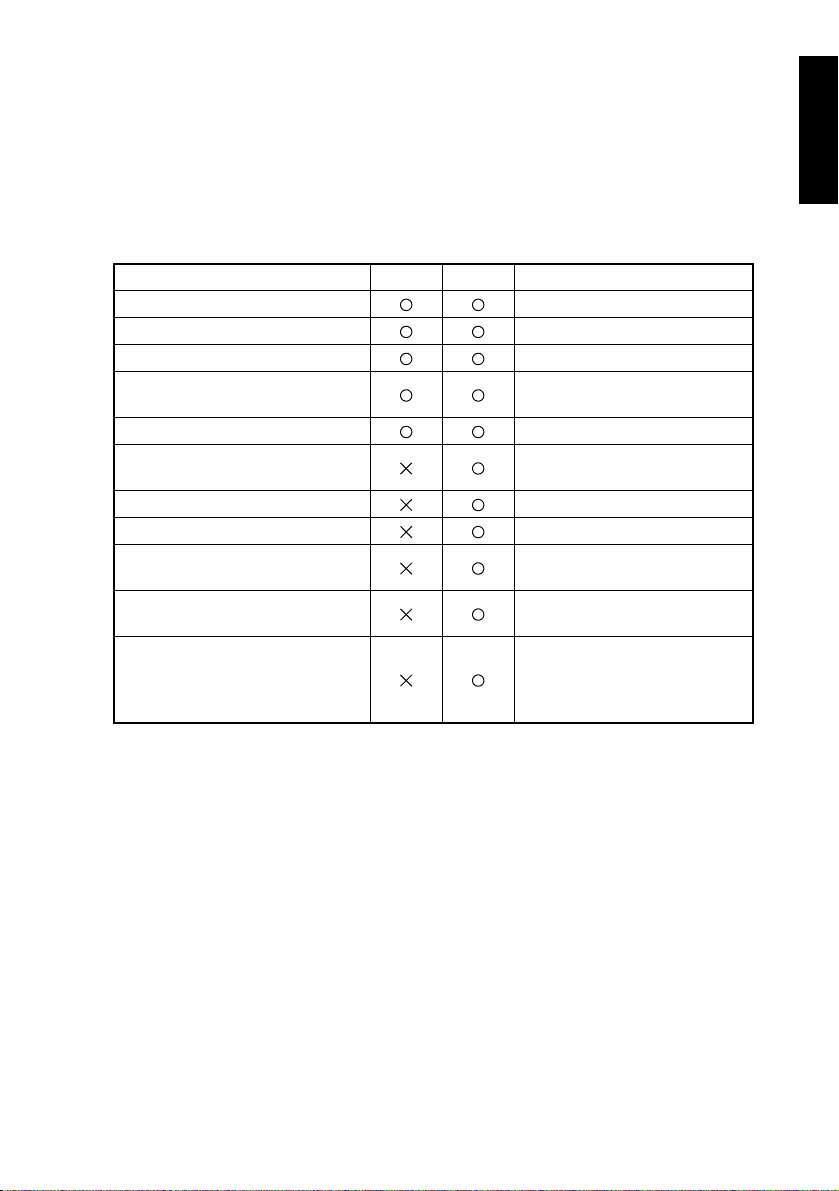

1-1. Difference between functions available on different models

• Depending on model, the functions that can be used differ, and are as follows.

SU-2: Network Scan Kit

SU-3: Internet Fax & Network Scan Kit

Function Name SU-2 SU-3 Remarks

Scan to E-Mail

Scan to Server (FTP)

Scan to PC (FTP)

Scan to HDD

PageScope Light

Scan to PC (SMTP)

Internet fax

IP Address Fax

IP Scanner

Transmission from fax document

Direct fax

The function expansion hard

disk kit is required

Uses IP Scanner /Image

Receiver

Uses IP Scanner /Image

Receiver

When the device is Di2010f/

Di2510f/Di3010f/Di3510f

When the device is Di2010f/

Di2510f/Di3010f/Di3510f

Uses Network Fax transmission

(EX Lite Edition)

M-1

Page 19

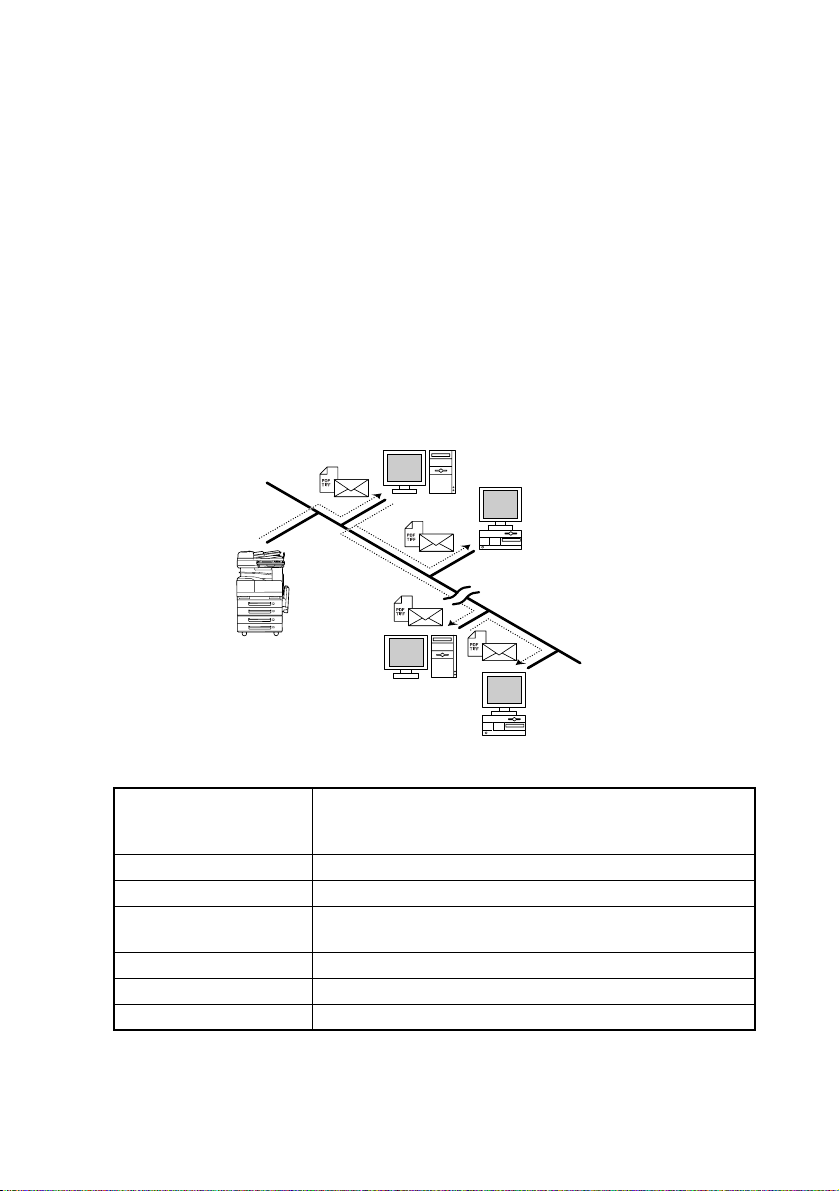

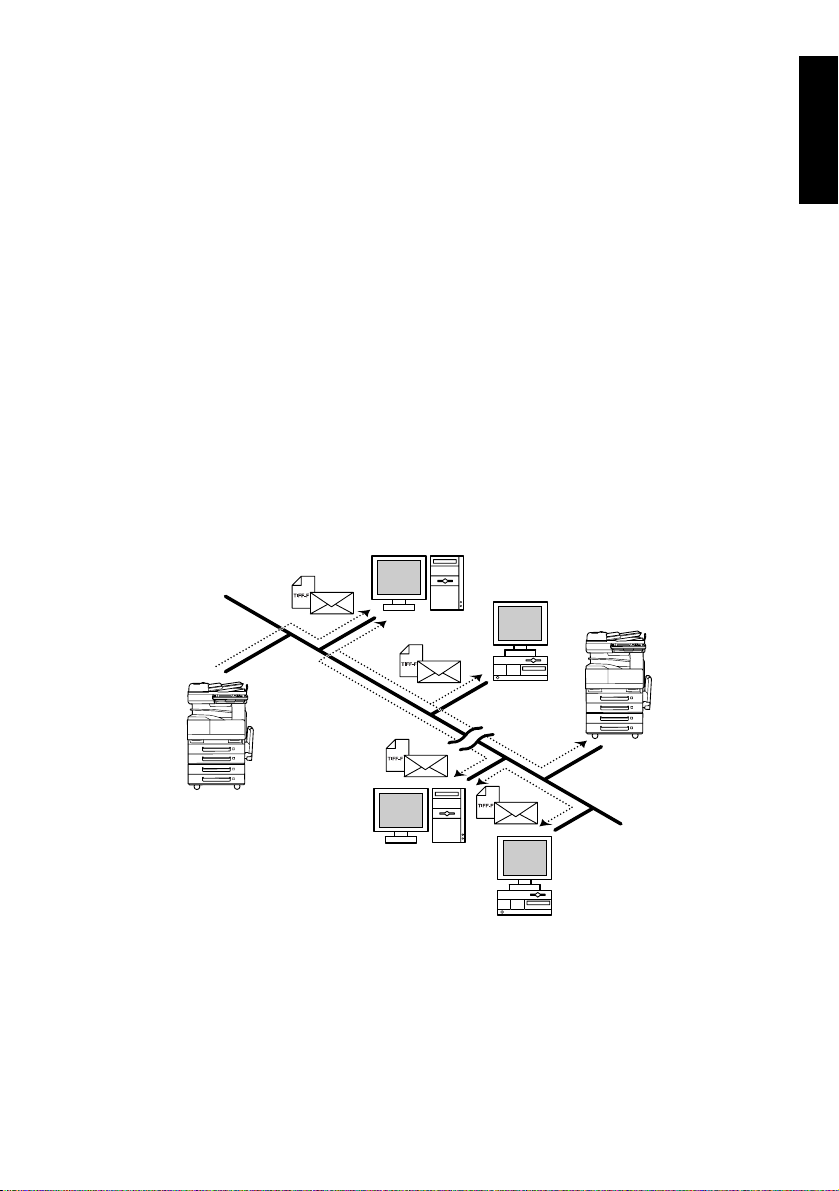

1-2. Scan to E-mail

Attaches the scanned document image data to e-mail, and transmits it to a PC.

Similar to when sending an Internet fax, a paper document can be easily sent via e-mail at

the push of a button.

• The document to be transmitted is attached to MIME format e-mail as either a TIFF-F format or PDF format image file, and then transmitted. In order to view the image that has

been received by the PC, e-mail software that supports the MIME format, and software

that can display either TIFF-F or PDF format image files needs to be installed.

• TIFF-F format images can be viewed using the TIFF Viewer, installed as standard on

Windows.

• PDF format images can be viewed using Acrobat Reader, included as a utility.

• A network environment that includes a mail server is required.

• The device needs to be connected to the LAN, and configured as part of the network.

STEP 1: Indicate transmission to a user PC in the same way as transmitting a fax.

STEP 2: Store the scanned image on the mail server.

STEP 3: Use e-mail software to import the scanned image that is on the mail server.

Mail server

Client computer

Intranet

Internet

Mail server

Specifications

Communications protocol

Transmitted document size A4, B4, A3

Resolution 200 × 100dpi, 200 × 200dpi, 400 × 400dpi, 600 × 600dpi

Data format

Coding method MH, MMR

Compatible circuits Ethernet LAN (100BASE-TX, 10BASE-T connection)

Destination registration Registered PC mail addresses: Maximum 540

E-mail transmission: SMTP (IETF RFC2821 and RFC2822)

procedure

TCP/IP transmission

E-mail format: MIME

Attachment format: TIFF-F, PDF

Client computer

M-2

Page 20

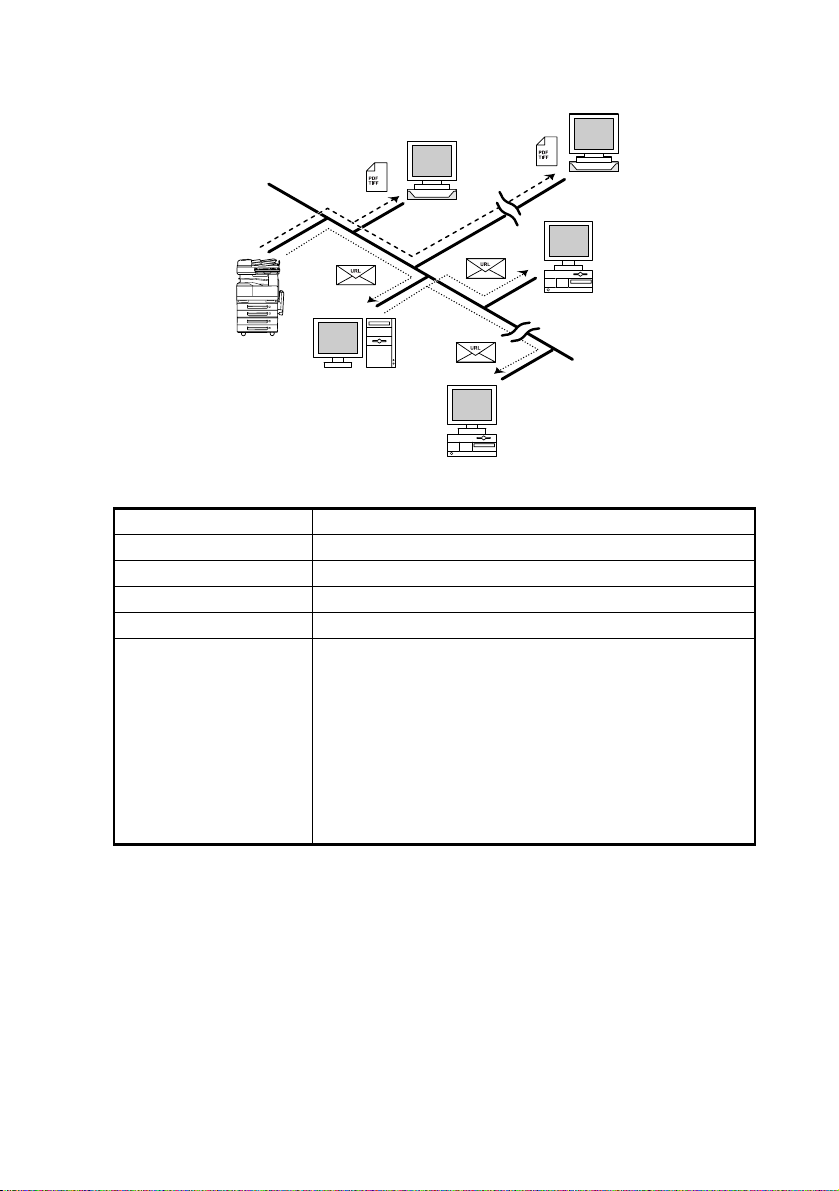

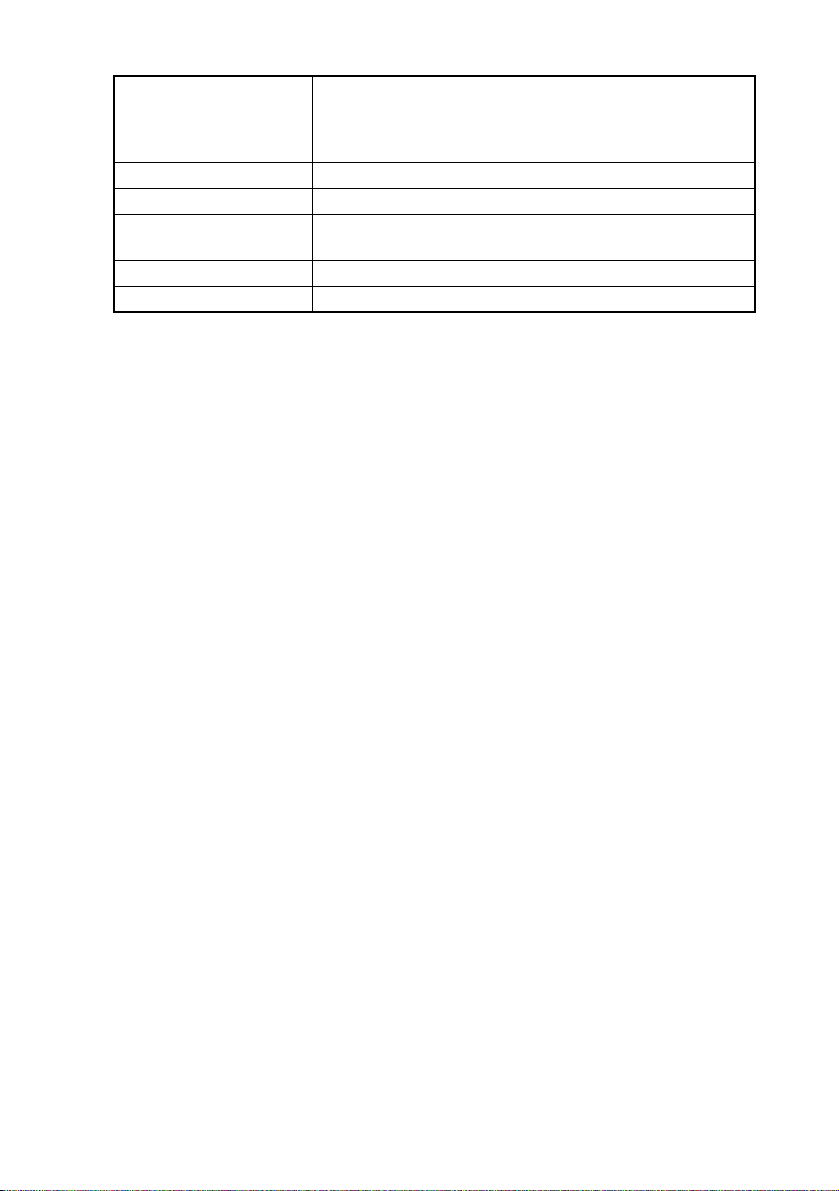

1-3. Scan to Server (FTP)

• Scan data can be uploaded as TIFF or PDF files to a specified directory on an FTP

server.

• In order to view the image that has been received by the PC, software that can display

either TIFF-F or PDF format image files needs to be installed.

• TIFF-F format images can be viewed using the TIFF Viewer, installed as standard on

Windows.

• PDF format images can be viewed using Acrobat Reader, included as a utility.

• A network environment that includes an FTP server is required.

• An FTP server on the Internet can be accessed through a proxy server.

• A maximum of five FTP servers can be registered, and a maximum of five directories can

be set up on each FTP server.

• The device needs to be connected to the LAN, and configured as part of the network.

FTP server

Intranet

Internet

M-3

Page 21

• With the “URL Report” function, a notification of the URL where the scan data is saved

can be sent by e-mail. (If the “URL Report” function is used, a mail server is required.)

FTP server

Internet

Intranet

Internet

Mail server

Client computer

Specifications

Communications protocol FTP, TCP/IP transmission

Resolution 200 × 100dpi, 200 × 200dpi, 400 × 400dpi, 600 × 600dpi

Data format TIFF, PDF

Coding method MH, MMR

Compatible circuits Ethernet LAN (100BASE-TX, 10BASE-T connection)

When registering one-touch keys, select the destination FTP

server and the directory. The FTP server and directory must

have been registered in advance using the network settings

screen.

Destination registration

A maximum of five FTP servers can be registered, and a

maximum of five directories can be registered on each FTP

server.

If all directories will be registered on the same FTP server,

then a maximum of 25 directories can be registered on that

single server.

FTP server

Client computer

M-4

Page 22

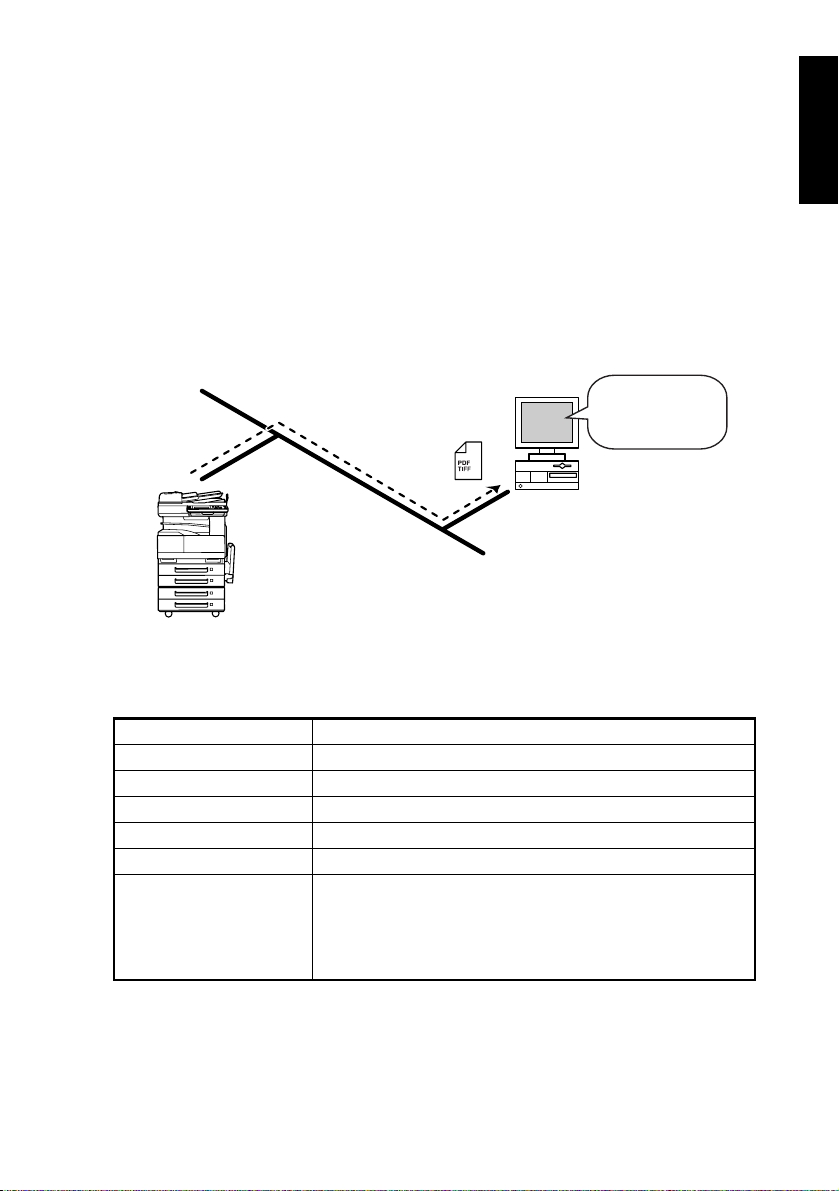

1-4. Scan to PC (FTP)

• Scan data can be sent as TIFF or PDF files to client computers using FTP.

• In order to view the image that has been received by the PC, software that can display

either TIFF-F or PDF format image files needs to be installed.

• TIFF-F format images can be viewed using the TIFF Viewer, installed as standard on

Windows.

• PDF format images can be viewed using Acrobat Reader, included as a utility.

• The FTP server application must be running on the client computers.

• The forwarding destination on the client computer is the root folder specified with the FTP

server application. This setting cannot be specified from the copier's control panel or

from PageScope Light.

• The device needs to be connected to the LAN, and configured as part of the network.

FTP Server

application

Client computer

Intranet

Specifications

Communications protocol FTP, TCP/IP transmission

Resolution 200 × 100dpi, 200 × 200dpi, 400 × 400dpi, 600 × 600dpi

Data format TIFF, PDF

Coding method MH, MMR

Compatible circuits Ethernet LAN (100BASE-TX, 10BASE-T connection)

Destination registration Register one-touch keys with destination PC IP address.

The FTP server application must be running on the

destination PC.

Remarks

In Scan to PC (FTP) transmission, access to the FTP server

is “anonymous”. Transmission of data to FTP servers that do

not allow anonymous users is not possible.

M-5

Page 23

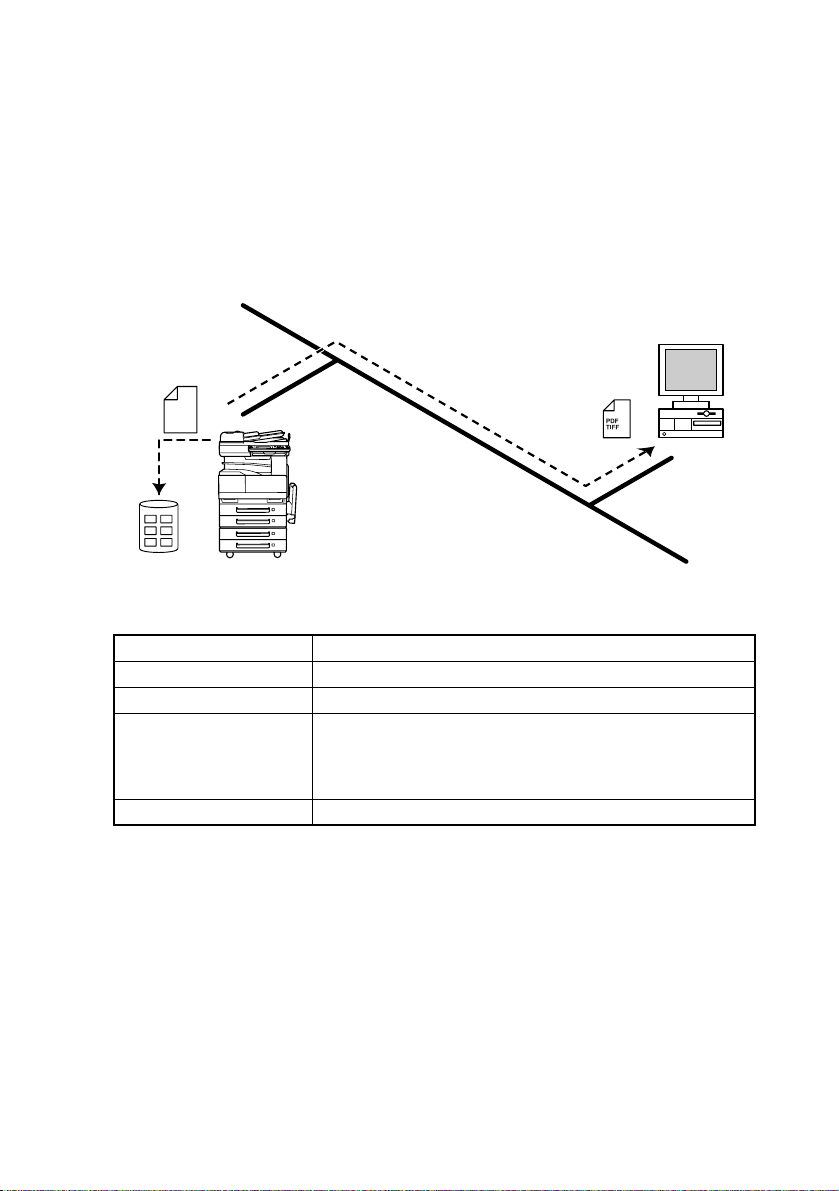

1-5. Scan to HDD

• Scan data is saved on the copier's hard disk as TIFF or PDF files.

• In order to view the image that has been received by the PC, software that can display

either TIFF-F or PDF format image files needs to be installed.

• TIFF-F format images can be viewed using the TIFF Viewer, installed as standard on

Windows.

• PDF format images can be viewed using Acrobat Reader, included as a utility.

• With the “URL Report” function, a notification of the URL where the scan data is saved

can be sent by e-mail. (If the “URL Report” function is used, a mail server is required.)

• The device needs to be connected to the LAN, and configured as part of the network.

Client computer

Scan

data

Intranet

Specifications

Resolution 200 × 100dpi, 200 × 200dpi, 400 × 400dpi, 600 × 600dpi

Data format TIFF, PDF

Coding method MH, MMR

When registering one-touch keys, select the mail box to save

Destination registration

Remarks Loading of data takes place from PageScope Light.

to. A mail box must have been created in advance using

PageScope Light. A maximum of 115 user boxes can be

created.

M-6

Page 24

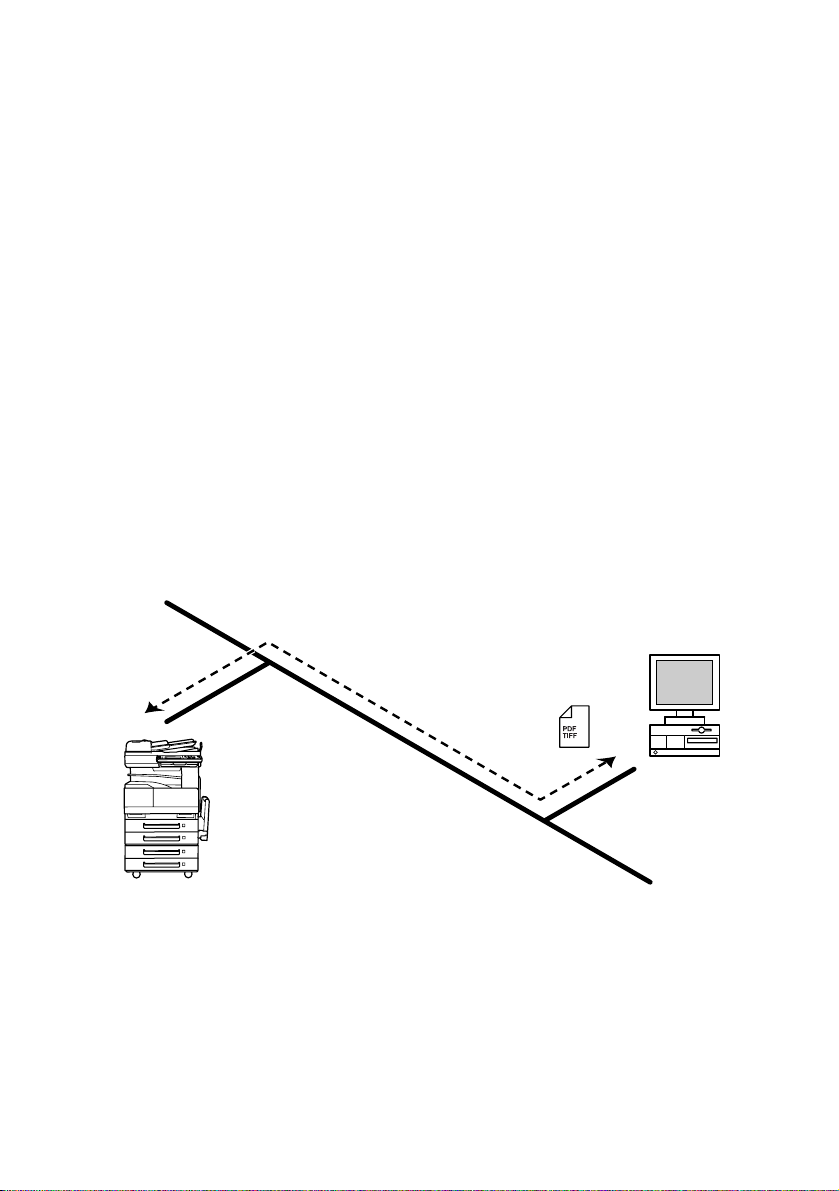

1-6. Scan to PC (SMTP)

Transmits scanned document images and data to your own PC and stores it in a previously

specified folder.

Even in an environment that does not use mail service, a paper document can be saved as

an electronic file simply by using a one touch key.

To do this, it is necessary to register in advance the IP address or host name of the filing

computer, on the device using the one touch key. On PCs, it is necessary to specify the filing location folder, using the IP Scanner included as a utility. In addition, it is possible to use

the IP scanner configurations in order to use a one touch key to create, and save to a folder.

• The document to be transmitted is transmitted as either a TIFF-F format or PDF format

image file. In order to view the image that has been received by the PC, software that can

display either TIFF-F or PDF format image files needs to be installed.

• TIFF-F format images can be viewed using the TIFF Viewer, installed as standard on

Windows.

• PDF format images can be viewed using Acrobat Reader, included as a utility.

• In order to save the image that has been received by the PC, the enclosed utilities IP

Scanner and Image Receiver are required.

• If there is a DHCP server on the network, this function may not operate correctly since IP

addresses are automatically distributed to each computer. In this case, specify a fixed IP

address for the computer or use IP Scanner.

• The device needs to be connected to the LAN, and configured as part of the network.

STEP 1: Program a one-touch key with the IP address of the computer receiving the data.

STEP 2: Using the same procedure for sending e-mail messages, specify that the data is

STEP 3: The sent scan data is received by the recipient computer.

STEP 4: The IP Scanner application converts the data to a TIFF or PDF file, then saves

to be sent to a computer.

the file in the specified folder.

Intranet

Client computer

M-7

Page 25

Specifications

Communications protocol TCP/IP transmission

Transmitted document size A4, B4, A3

Resolution (dpi) 200 × 100dpi, 200 × 200dpi, 400 × 400dpi, 600 × 600dpi

Data format TIFF-F, PDF

Coding method MH, MMR

Destination registration

Storage folder settings

Register the PC IP address

Maximum 540

Specify a directory on the PC. Below this, directories

specified by the PC may be created for each data item.

M-8

Page 26

1-7. Internet Fax

Scanned document image data is attached to an e-mail, and is sent to an Internet fax terminal through the Internet or an Intranet.

When sending, specify an e-mail address in the same way as specifying a telephone (fax)

number when sending a regular fax.

If the recipient is already specified with a one-touch key, transmission is easy with the single touch of a button.

• The document to be transmitted is attached to MIME format e-mail as a TIFF-F format

image file, and then transmitted.

• TIFF-F format images can be viewed using the TIFF Viewer, installed as standard on

Windows.

• Internet fax is totally different to a normal fax, which transmits through telephone lines, in

that there is no direct connection with the recipient. There are certain inherent limitations.

• When transmitting faxes using Internet fax, the sender can check reception results from

the recipient.

In addition, the sender can detect the reception capabilities of the recipient machine, and

transmit in accordance with those capabilities (the recipient must also have a machine

that is compatible with the full mode).

• The device needs to be connected to the LAN, and configured as part of the network.

STEP 1: Specify the e-mail address, and from the transmission display, transmit the Inter-

net fax.

STEP 2: Transmit the image to the recipient over an existing e-mail network.

STEP 3: Retrieve mail from the server, and receive the Internet fax.

Mail server

Client computer

Internet

fax terminal

Mail server

M-9

Intranet

Internet

Client computer

Page 27

Specifications

E-mail transmission: SMTP (IETF RFC2821 and RFC2822)

Communications protocol

Transmitted document size A4, B4, A3

Resolution (dpi) 200 × 100dpi, 200 × 200dpi, 400 × 400dpi, 600 × 600dpi

Data format

Coding method MH, MR, MMR

Compatible circuits Ethernet LAN (100BASE-TX, 10BASE-T connection)

TCP/IP transmission

E-mail reception: POP3(IETF RFC1725 and RFC1939)

TCP/IP transmission

E-mail format: MIME

Attachment format: TIFF-F

M-10

Page 28

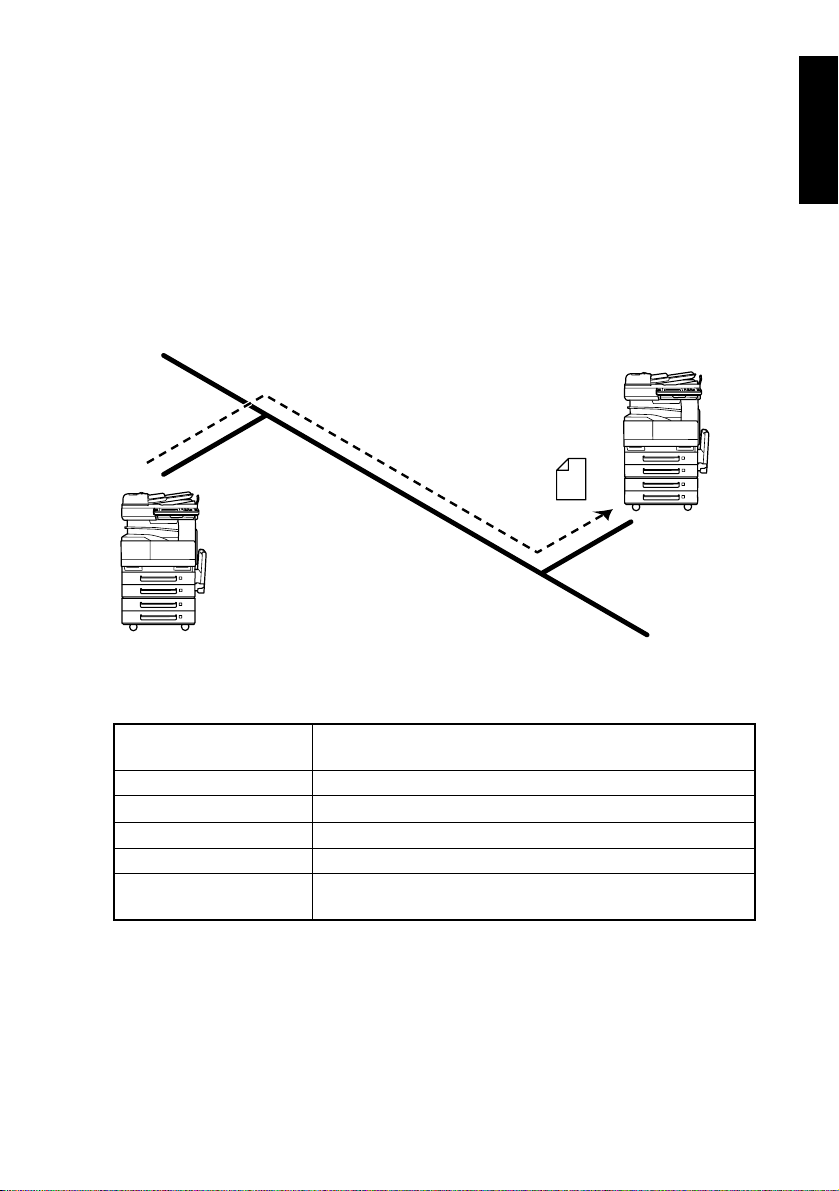

1-8. IP Address Fax (LAN-FAX)

Scan data is sent to a copier of the same type (Internet fax) through the Internet, without

passing though a mail server.

To do this, it is necessary to register in advance the IP address or host name of the recipient, in the device using the one touch key.

• The device needs to be connected to the LAN, and configured as part of the network.

STEP 1: Program a one-touch key with the IP address or host name of the recipient.

STEP 2: Specify the recipient using the one-touch key, and from the transmission display,

STEP 3: Retrieve the fax image (IP address fax transmission).

transmit IP address fax.

Internet fax terminal

(Same model as

this device)

Intranet

Specifications

Communications protocol

Transmitted document size A4, B4, A3

Resolution 200 × 100dpi, 200 × 200dpi, 400 × 400dpi, 600 × 600dpi

Data format TIFF-F

Coding method MH, MR, MMR

Destination registration

E-mail transmission: SMTP (IETF RFC2821 and RFC2822)

TCP/IP transmission

Register the destination IP address

Maximum 540

M-11

Page 29

1-9. IP Scanner

Scanned image data is sent to a client computer, where it is saved in a folder that is created

using the name of the scanner button.

After programming a button (Scan data destination and scan settings) from the client computer when scanning, a paper document can easily be saved as an electronic file with just

the touch of a button in the copier’s touch panel.

• The document to be transmitted is transmitted as either a TIFF-F format or PDF format

image file. In order to view the image that has been received by the PC, software that can

display either TIFF-F or PDF format image files needs to be installed.

• TIFF-F format images can be viewed using the TIFF Viewer, installed as standard on

Windows.

• PDF format images can be viewed using Acrobat Reader, included as a utility.

• In order to view the image that has been received by the PC, the enclosed utilities IP

Scanner and Image Receiver are required.

• This function can be used in a network without a LAN if a crossover cable is used to con-

nect the copier to a client computer. (Network settings are required.)

• The device needs to be connected to the LAN, and configured as part of the network. In

addition, the destination PC also needs to be connected to the LAN, and configured as

part of the network.

STEP 1: From the user’s PC, program a button (recipient of the scan data).

STEP 2: Press the programmed button to send the scan image.

STEP 3: The sent scan image is received by the recipient computer.

STEP 4: The IP Scanner application converts the data to an image file TIFF-F format),

then saves the file in the specified folder.

Client computer

M-12

Page 30

Specifications

Communications protocol TCP/IP transmission

Transmitted document size A4, B4, A3

Resolution (dpi) 200 × 200dpi, 400 × 400dpi, 600 × 600dpi

Data format TIFF-F, PDF

Coding method MH, MMR

Destination registration not required: automatically obtains

Destination registration

Storage folder settings

the OP address from the PC when scanning.

Button registration: A maximum of six scanner buttons on a

copier can be programmed.

Specify a directory on the PC. Below this, directories

specified by the PC may be created for each data item.

M-13

Page 31

1-10. Distribution of Fax Documents

Image data received from a fax machine on a common telephone line can be sent directly

to a computer or attached to an e-mail message.

The fax document can be received at your own computer.

Received fax documents can be classified as “F-Code”, “Reception Port” or “Public Document”, and the distribution destinations for each type of document can be specified.

• By specifying a one-touch key as a forwarding destination, fax documents can be sent as

TIFF or PDF image format files directly to computers, or as a TIFF image file directly as a

MIME e-mail attachment. In order to view the image that has been received by the PC,

software that can display either TIFF-F or PDF format image files needs to be installed.

Additionally, in order to transmit e-mail, MIME compliant e-mail software is required.

• TIFF-F format images can be viewed using the TIFF Viewer, installed as standard on

Windows.

• PDF format images can be viewed using Acrobat Reader, included as a utility.

• F codes are used in various other ways, such as a mailbox or a bulletin board.

When specifying F codes, we recommend managing numbers, such as by to classifying

the data by function, in order to prevent number duplication.

• When forwarding faxes by e-mail, a network environment that includes a mail server is

required.

• The device needs to be connected to the LAN, and configured as part of the network.

STEP 1: Use the Doc. Manage settings to classify and store the fax image.

STEP 2: The fax image is sent to the computer specified as the recipient.

STEP 3: The fax image is received by the recipient computer as an image file.

Facsimile

terminal

Specifications

Registering forwarding

destinations

communications

Facsimile

Telephone

line

Client computer

In account registration for this copier, specify the F-Code or

forwarding destination mail address.

M-14

Mail server

Page 32

1-11. Direct Fax Transmission

A document created in an application, such as word-processing software, can be faxed by

specifying the telephone (fax) number of the recipient, without first printing the document.

An e-mail address or a telephone (fax) number can be specified for the recipient.

• To carry out direct fax transmission, “Network FAX Transmission”, included as a utility is

required. Check the network environment, configure the network, and install “Network

FAX ”.

• In order to perform direct faxing operations using a mail server, the DNS settings must be

specified.

• The result of the completed fax transmission can be checked from the computer.

• The device needs to be connected to the LAN, and configured as part of the network.

STEP 1: Specify the fax number of the destination (specify the recipient after specifying

STEP 2: The image data is transmitted from the client computer or mail server.

STEP 3: The data received by the computer is sent to the specified fax number.

Client computer

printing from the application).

Mail server

Telephone

line

Facsimil e Facsimile

terminalcommunications

M-15

Page 33

Specifications

Sender FAX, E-Mail, iFAX

Transmitted document size A4, B4, A3

Resolution 200 × 200 dpi, 400 × 400 dpi

Coding method

Data exchange FAX data ← Conversion → BMP, TIFF data

Transmission quantity

Broadcast transmission Maximum 1500

Entries in phone book

Phone book search

functions

Management functions

FAX: MH

E-Mail/ iFAX: TIFF

Comments of maximum of approximately 700 single byte

characters can be input.

Per single phone book: Maximum 1000 entries (No limit on

number of phone books)

Search: search for “Paris”, and it searches for all items

containing “Paris”.

Search on Item: specify parameters and search.

Search on Group: select a group name and search.

Document storage: specify storage numbers for each

document box and warnings for transmission.

Nondelivered document management: resend nondelivered

documents

Trash: interim storage of documents discarded from

document boxes.

Headers: Registration of each document’s headers (30).

Creation of tables: Documents, nondelivered documents,

transmitted documents, documents in the trash.

M-16

Page 34

1-12. PageScope Light

PageScope Light is a utility for managing devices supported by the HTTP server integrated

into the printer/scanner controller.

Using a Web browser, PageScope Light can remotely control the printer/scanner controllers on the network.

For Administration

• Setting of fixed number of

device systems

• Understanding of usage

status

Specifications

Communications protocol TCP/IP, HTTP

Data format HTML

Windows 95/98/Me/NT4.0: Internet Explorer 4 or later

Netscape Navigator 4.73 or 7.0

Supported browsers

Windows 2000: Internet Explorer 5 or later

Netscape Navigator 7.0

Windows XP: Internet Explorer 6 or later

Netscape Navigator 7.0

Internet / Intranet

For Users

• Monitoring of usage status

• Display of communications

results

• Confirmation of alarm status

• One-touch key registration

LAN

M-17

Page 35

1-13. Overview of Attached Utilities

Network FAX transmission

IP Scanner

(1) “Network FAX” Operating Environment (Reference)

• For detailed operating restrictions, refer to the “Network FAX” user’s manual. (electronic

manual)

PC Type

CPU Pentium 133 MHz or higher

Memory

Hard disk free space

Supported operating

systems

Operation environment

Software that enables users to send faxes directly from

applications by specifying the telephone (fax) number, without

first printing the document.

IP Scanner functions and one-touch document scanning –

Software that enables users to IP address type functions.

Supported OS: Microsoft Windows 95 (English edition)

Microsoft Windows 98 (English edition)

Microsoft Windows Me (English edition)

Microsoft Windows NT4.0 (English edition)

Microsoft Windows 2000 (English edition)

Microsoft Windows XP (English edition)

PC/AT compatible machines.

(Limited to all officially supported Windows98/ Me/ NT4.0/

2000/ XP versions)

24 MB or more (48 MB recommended)

*IP Scanner: 32 MB or more (64 MB recommended)

64 MB or more (128 MB recommended) for Windows® XP or

Windows® 2000

50 MB or more

(More recommended for document management functions)

Microsoft Windows 98 (English edition)

Microsoft Windows Me (English edition)

Microsoft Windows NT4.0 (English edition)

Microsoft Windows 2000 (English edition)

Microsoft Windows XP (English edition)

A network environment that can be used by this computer or

a mail server.

M-18

Page 36

2. Restrictions and Precautions for using network

Applications

2-1. Precautions when using Network Applications

• Internet faxes and Scan to E-mail transmissions are sent and received with the help of a

mail server; they are not sent directly to the recipient or received directly from the sender.

In addition, as soon as transmission with the server is finished correctly, the transmission

is considered complete.

• If transmission from the mail server to the recipient is not possible for some reason, an email describing the error will be received from the server.

• For some reason, the e-mail describing the error may not be received. If confirmation of

the transmission is required, call the recipient after transmission to confirm reception.

• Since the privacy of transmissions through the Internet or an intranet is limited, we recommend sending important documents directly to the recipient through a common telephone line.

• Telephones on a LAN cannot be used.

• It may take some time for a transmission to be sent due to Internet/ intranet traffic.

• Depending on the mail servers, it may not be possible to send documents with a large

number of pages or a large amount of image data.

2-2. Functions that cannot use Network Applications

(1) Fax functions that can not be used.

• The following fax functions can be used by regular fax machines over a common telephone line, but can not be used with network applications.

Batch transmission Bulletin board registration Polling transmission

On-hook Real-time transmission

Confidential box Password transmission * Remote copying *

*: These items are specified on the panel, but are not functional.

Remote retrieval of bulletin

board

(2) Fax functions that can be used.

• The following fax functions can be used with network applications.

Image quality specification 2 in 1 Destination insert

Forward the received

Density specification 2-sided transmission

Non-reduction mode TX marker stamp (optional) Priority transmission

Scan area specification TSI Timer transmission

Time stamp

• Precautions on Mail Delivery of Fax Documents

facsimile documents

(Document Management)

M-19

Page 37

(3) Precautions for using IP Scanner

1. Using a dial-up router

• When using IP Scanner, ensure that the IP address of the main device is correctly specified.

Particular care is needed when using IP scanner on a network in which an a dial-up

router is used.

• If an incorrect IP address is specified in an environment where a dialup router is used,

the dial-up router may unnecessarily be dialed up.

In addition, depending on the network environment of the computer, the dial-up router

may be unnecessarily dialed up, regardless of whether the correct IP address was specified.

(4) Using a modem or terminal adapter

• If a computer with a built-in modem (or a computer connected to terminal adapter) is

used, they may be used to dial up.

If this occurs, select either “Never dial a connection” or “Dial whenever a network connection is not present” in the “Dial-up settings” group box on the Connections tab of the Internet Properties dialog box. For details, refer to the instruction manual for the operating

system.

M-20

Page 38

3. Functional Overview of Cards Used

Cards that can be used in the Network Scan / Internet Fax & Network Scan / Printer have

the following capabilities.

Card name Functional overview

CLAN card By connecting to the MFB3 card, network functions can be used.

Printer card

Network scan card

Internet Fax & Network

Scan card

3-1. CLAN Card

(1) Overview

• This circuit board comprises a network LAN interface and an extended PCI interface,

made up of a USB1.1b interface and PCI bus interface, in order that the copier can be

used as a PC printer.

• Network specifications (Ethernet): 10Base-T/100Base-TX

• Communications protocols: TCP/IP, SMTP, POP3, MIME, HTTP

• Connection method: Connection to CN7 on the MFB3 circuit board.

(2) Functions

1. USB1.1b interface

• The USB connector is used so the copier can be used as a PC printer.

2. Network LAN interface

• The network connector enables the copier to be used as a network scanner and network

printer.

3. Extended PCI interface

• Fitted with a PCI bus interface connector (specialized connector: 100pin) as a future

extended interface.

By connecting to the MFB3 card, printer functions can be used.

Pi3505e: 32MB, Pi3505e/PS:128MB capacity.

By connecting to the MFB3 card, network scanner functions can

be used. 128MB capacity.

By connecting to the MFB3 card, Internet Fax and Network Scan

functions can be used. 128MB capacity.

(3) LED Indicators

LED Condition Meaning

Lit The LAN is connected correctly

Data may be sent or received.

Green

Red

Off

Flashing Data is being sent or received.

Lit Operating at 100Mbps

Off Operating at 10Mbps

The copier has not been turned on.

The LAN is not connected correctly.

M-21

Page 39

(4) Block Diagram

MFB3 board

interface connector

100 pin

Address bus

Data bus

Europe

PCI bus

USB

controller

USB1.1b

LAN

controller

PCI bus interface for future expansion

Specialized 100 pin connector

Plus

trans-

former

USB connector

4 pin

Series B

LAN connector

8 pin

100base-T

M-22

Page 40

DIS/REASSEMBLY,

ADJUSTMENT

Page 41

Page 42

1. Equipment Setup

1-1. Connection

• Connection with phone lines and other devices is as follows.

Standard device

1

2

No. Name Connected to: Remarks

1 TEL PORT1 External telephone Standard

2 LINE PORT1 Telephone line (port 1) Standard

3 LINE PORT2 Telephone line (port 2) Option G3 multiport required

4 DC-IN

6 HAND SET Handset Option

7 LAN LAN cable connection Option

8 USB Printer connection Option

Optional power

connector

Left rear

Optional device

3

4

5

6

Option

7

4384D501AA

Cannot be used when FAX/

TEL switcher and handset

installed

FAX/TEL switcher and handset

required5 TEL External telephone Option

External interface kit required

8

Rear

D-1

Page 43

2. Disassembly / Reassembly

When carrying out disassembly and reassembly, refer to the copier and controller service

manuals.

NOTE

• Before commencing, confirm that the storage memory capacity is at 0%.

• If the memory storage capacity is not at 0%, either print out, or delete any data in the

memory.

2-1. Detaching Parts

When detaching parts from network scanners, network interfaces, or printers, follow the

procedure as follows:

(1) Removing the main cover

1. Remove the upper rear cover (3 screws).

NOTE

• When removing the cover, push in the ADF angledetecting lever.

• When fixing the cover, push the angle-detecting

sensor lever through the hole in the upper rear

4599U008AB

cover.

Cable connector

Cable clamp

I/F CLAN board

cover

4514U002AB

2. Remove the two cable connectors.

3. Removed the two cables from the cable of the

clamps.

4. Remove the interface CLAN board cover (6

screws).

D-2

Page 44

4599U009AB

4599U040AA

4599U036AA

5. Remove the rear cover (13 screws).

(When removing, lift the cover slightly.)

NOTE

When fixing the cover, use gold colored screws in the

six upper locations.

6. Remove the reinforcing plate (4 screws).

NOTE

Do not pinch the hard disk flat cable or power relay

harness.

7. Remove the connector attachment plate (1

screw).

4514U003AA

D-3

Page 45

(2) Removing the CLAN Board

CN4

4599U035AA

CN5

4599U034AA

1. When the function expansion hard disk kit is

removed, disconnect CN4 and CN5 from the

CLAN board.

D-4

Page 46

2. Remove the three screws.

The screws in ➁ can be accessed by opening the document cover, and reaching

✽

between the scanner.

The screws in ➂ also hold the CLAN finger.

Use a short screwdriver for screws in ➁ and ➂.

3. Remove the CLAN board.

CLAN circuit board

4514U007AB

➂

➀

➁

CLAN finger

C4514U008AA

When affixing the CLAN board, prior to this, make

✽

sure that the OPE cable is not covered by the connector for the CLAN circuit board.

4514U005AB

When affixing the CLAN board, push the two parts

✽

indicated with arrows and confirm that the connector is properly inserted (do not touch any soldered

areas).

4514U007AA

D-5

Page 47

(3) Removing Expansion (Printer / Network Scan / Internet Fax & Network Scan)

Board

CN3

Expansion 1 slot (CN4)

Expansion 2 slot (CN5)

4514U010AB

1. With the Di3510f, Di3010f, Di2510f or Di2010f,

disconnect the Ni-MH battery cable from CN3 on

the MFB3 circuit board (in order to prevent damage to the memory IC).

NOTE

Disconnect the Ni-MH battery cable from CN3 on the

MFB3 circuit board to stop power from being supplied to the expansion memory from the Ni-MH battery.

2. Remove the Printer Memory circuit board from

the expansion slot 1 (CN4) on the MFB3 circuit

board.

3. Remove the Network Scan circuit board and the

Internet Fax & Network Scan circuit board from

the expansion slot 2 (CN5) on the MFB3 circuit

board.

NOTE

• Do not touch the terminals of the Printer circuit

board with your bare hands.

• Check the installation direction (location of the

notch), and then firmly insert the circuit board until

it snaps into place.

With the Di3510f, Di3010f, Di2510f or Di2010f,

✽

reconnect the Ni-MH battery cable to CN3 on the

MFB3 circuit board.

NOTE

If the cable is not reconnected, there will be no

backup power in case of a power failure. Therefore,

be sure to reconnect the battery cable.

D-6

Page 48

(4) Removing the function expansion hard disk kit

1. Remove the upper rear cover, the rear cover, the

interface CLAN circuit board cover, the reinforcing plate, and the connector plate.

2. Remove the connector from CN4 on the CLAN

circuit board.

4599U035AA

3. Remove the unit's relay from the wire harness.

NOTE

Harness types differ between the copier and the harness.

4599U041AA

4. Remove the mechanism circuit board cover (5

screws).

NOTE

Do not pinch the harness on the right of the mechanism circuit board cover.

4599U039AA

4599U023AC

5. Remove the flat cable from the hard disk.

When connecting the flat cable to the hard disk,

✽

connect with the ▼ as standard.

NOTE

• Connect so that the yellow wire on the flat cable is

at the left of the hard disk connector. (Up)

• The 4 terminals on the left of the hard disk are to

remain unused.

D-7

Page 49

6. Remove the hard disk from the mechanism circuit

board (4 screws).

When affixing the hard disk to the mechanism cir-

✽

cuit board, tighten until the bush at the back of the

mechanism circuit board cover is as in the figure.

4599U022AB

4599U038AB

(5) Removing the function expansion hard disk power supply circuit board

1. Remove the lower cover (4 screws).

NOTE

When fixing the hard disk, insert toothed washers

into the top right of the lower rear cover.

4348U018AC

2. Remove CN1 and CN2 from the connectors on

the power supply circuit board.

CN1

CN2

4599U013AB

4599U018AA

D-8

Page 50

3. Remove the power supply circuit board (4

screws).

4599U012AA

2-2. Confirmation when Reassembling

(1) Confirm operation of the Printer Controller.

Press <Utilities> on the operations panel, and confirm that “Printer Settings” is displayed at

the bottom left of the touch panel utility screen.

(2) Confirm operation of the Network Scan kit / Internet Fax & Network Scan kit.

Press <Utilities> on the operations panel, press “Management Administration”, “Manage-

ment Administration 2”, and “Network Settings”, and confirm that DNS settings is displayed.

When configuring network settings, it is necessary to restart the printer.

✽

D-9

Page 51

D-10

Page 52

DISPLAYS / SETTINGS

Page 53

Page 54

1. Touch Panel Display Confirmation

• Check the touch panel display settings as confirmation after service of this option.

• Where it is not displayed, repair the problem by refering to troubleshooting.

1-1. Printer unit / Network interface card

How to display confirmation of [Printer Settings].

1. Press the [Utility] key, and the Utility screen is displayed.

[Printer setting]

is displayed.

C4514P735CA

S-1

Page 55

1-2. Network scanner kit / Network interface kit

How to display confirmation of “Printer Settings”.

1. Press the [Utility] key, and the Utility screen is displayed.

2. Touch [Admin. Management].

3. Input the Administrator code, and press [OK].

4. Touch [Admin 2].

5. Check that the [Network Set] key is displayed.

[Network Set] is

Displayed.

C4514P704CA

6. Touch [Network Set], and check that [DNS Settings] is displayed.

[DNS Settings] are

displayed.

C4514P705CA

S-2

Page 56

2. Specification Parameters

• Network scanners and network interfaces have many specification and registration

parameters. These can all be specified by the user.

• Network specifications are to be carried out by the user's network administrator.

• For details on specification parameters, refer to the user manual.

2-1. Required specification parameters for each model

(1) Explanation of specification parameters

Specification Parameters Explanation

Basic Specifications

DHCP Specify whether an IP address is automatically assigned from a DHCP server, or

IP address Specify this copier’s IP address.

Subnet Mask Specify the subnet mask for the network to be connected.

Gateway Specify the default gateway address for the network to be connected.

Device Domain Name Specify this copier's domain name.

Network Port Settings Specify the network port transmission speed.

DNS Settings

DNS Settings Specify whether to use DNS (Domain Name System) functions.

Host Name Specify the DNS server host name.

Domain Name Specify the DNS server domain name.

DNS Server Address Specify the DNS server IP address.

Device Name

Device Name This device name is used as a part of the filename in Scan to E-mail transmission, Scan

SMTP settings <Transmission settings for Scan to E-mail and Internet fax transmissions (this is also

SMTP Server Address Specify the IP address or host name of the SMTP server.

E-mail Address Specify this copier's e-mail address.

POP3 Settings <Reception settings for Internet faxing>

POP3 Server Address Specify the POP3 server's IP address or host name.

POP3 User Name Specify the POP3 server’s login name (account name).

POP3 Password Specify the password to log into the POP3 server.

Automatic Mail Check Specify the interval to connect to the POP3 server and check for mail (Internet fax).

Specify Priority Compression

Level (mail mode)

Transmission Size

(upper limit)

Transmission Quality (limit) Specify the upper limit for transmission quality.

Encoding Format Specify the encoding format for transmitted scan data.

Specify Priority Compression

Level (scanner mode)

File Format Specify the file format for when transmitting scan data.

Encoding Format Specified the encoding format for when transmitting scan data.

Specifications for sending and receiving scans

Result Notification Specify whether to notify of reception of Internet faxes.

Print Received Document

Headers

whether a static IP address is specified.

Only specify when “specify IP” is selected for DHCP.

• Only specify when “specify IP” is selected for DHCP.

• Only specify when “specify IP” is selected for DHCP.

Specification required when sending a direct fax through a mail server.

• Only specify when “Use” is selected for DNS settings.

• Only specify when “Use” is selected for DNS settings.

• Only specify when “Use” is selected for DNS settings.

to Server transmission, Scan to PC transmission, Scan to HDD transmission, and

Internet fax transmission. In addition, it is also used in the Subject field of Internet fax

transmissions and scan to e-mail transmissions.

used in Scan to FTP and Scan to HDD URL acknowledgements)>

• The Host Name can only be specified when “Use” is selected for DNS settings.

<Specify the upper transmission size limit, upper transmission quality limit, and

encoding format for when transmitting internet fax and IP address fax.>

Specify the upper size limit for documents.

< Specify the file format and encoding format for when transmitting Scan to E-mail,

Scan to Server, Scan to PC (FTP), Scan to PC (SMTP), and Scan to HDD.

When printing received Internet faxes, specify whether to print the mail headers.

S-3

Page 57

Specification Parameters Explanation

Insert Text in Transmitted

Document

Gateway Transmission Specify whether there are direct fax transmission functions.

Subject Registration Register the subject when transmitting Internet faxes and Scan to E-mail transmissions.

Binary Split Settings Specify split settings for Internet fax, Scan to E-mail transmission

FTP Site Registration <Specification required when using Scan to Server (FTP)>

Proxy Specification <Specification required when connecting to an FTP server through a proxy ser ver. This

Proxy Server Specify the proxy server's IP address or host name.

Port Number Specify the proxy server's port number.

FTP Server Timeout Specify the FTP server connection timeout interval.

Frame Type Specification <Specify the frame type for when using PC printer functions, for when connected to a

Ping Used to check that the network (LAN connection) is correctly connected.

Specify whether to include an explanation that a file is attached in Internet faxes and

Scan to E-mail.

can only be specified in PageScope Light administrator mode>

NetWare server>

S-4

Page 58

(2) Network Specifications List

• This lists the required specification parameters for when using network interface functions

Function

Scan to

Scan to

Scan to

Server

E-mail

Specification

Parameters

Basic Specifications

DHCP

IP address

Subnet Mask

Default Gateway

Device Domain

Name

Network Port

Settings

DNS Settings

DNS Settings ——

Host Name ——

Domain Name ——

DNS Server

Address

Device Name

Device Name ————

SMTP Specifications

SMTP Server

Address

Por t Nu mbe r

E-mail Address

(FTP)

—————————

*1

*1

*1

Scan to

PC

(FTP)

PC

(SMTP)

——

——

——

Scan to

HDD

*1

*1

*1

IP

Internet

Scanner

Faxi ng

——

———

———

———

IP

address

Faxi ng

Delivery of

a document

received by

fax

Network

FAX

: Essential items : Available items : Required depending on environment

—: Unnecessary

S-5

Page 59

Function

Scan to

Scan to

Scan to

Server

E-mail

Specification

Parameters

POP3 Settings

POP3 Server

Address

Por t Nu mbe r

POP3 User

Name

POP3 Password

Automatic Mail

Check

Priority Compression Level

Mail Mode

Scanner Mode

Specifications for sending and receiving scans

Result Notifica-

tion

Print Received

Document

Headers

Insert Text in

Transmitted

Document

Gateway

Transmission

Subject

Registration

Split Settings

FTP Site Registration

FTP Site

Registration

Ping

Used to check that the network (LAN connection) is correctly connected.

*An SMTP server or POP3 server can be specified and a ping transmitted. In addition, an arbitrary IP address specified,

and a ping transmitted.

Frame Type Specification

Specify the frame type for when using PC printer functions, for when connected to a NetWare server.

PageScope Light Administrator Mode: [Network] > [FTP Server] > [FTP Specifications]

Proxy Server

Address

Proxy Port

Number

FTP Server

Timeout

(FTP)

—————— ———

—————— ———

—————— ———

—————— ———

—————— ———

—————— —

—————— ———

—————— ———

————— — —

—————————

————— ———

————— ———

— ————————

— ————————

— ————————

— ————————

PC

(FTP)

Scan to

PC

(SMTP)

Scan to

HDD

IP Scan-

Internet

ner

Faxi ng

—————

IP

address

Faxi ng

Delivery of

a document

received by

fax

Network

FAX

*1: When using the URL notification functions, mail transmission (SMTP) settings must be

configured.

S-6

Page 60

3. Software Switches

3-1. Software switches that can be changed by users (diagram).

Utility

User Set

User's Choice

Memory Recall (ON/OFF)

1/6

Mixed Original Detection (ON/OFF)

Language Selected for LCD (Japanese/English/French/ )

2/6

Original → Copy Default (1-Sided → 2-Sided/

2-Sided → 2-Sided/1-Sided → 1-Sided)

Auto Paper/Auto Size (Auto Paper/Auto Size/Manual)

Drawer Priority (Legal)

Special Paper (Normal/Nor for 2 Sided/Recycle/Special)

Multiple-in-1 and Booklet Copy Zoom (ON/OFF)

Energy Save Mode (1 to 240 Minutes: 15 Minutes)

3/6

Sleep Mode Setting (1 to 240 Minutes: 1 Minutes)

LCD Back-light OFF (1 to 240 Minutes)

Auto Panel Reset (No Reset/30 Sec./1 to 240 Minutes)

Plug-in Counter, ID key Reset (ON/OFF)

12

4/6

4-in-1 Copy Order ( / )

Density Priority (Auto/Manual)

(Text/Photo/Text+Photo)

Default Copy Output Levels (Lighter/Normal/Darker)

Printing Density (-2/-1/0/1/2)

Output Priority

(Non-Sort/Sort/Group/Corner Staple/2-Point Staple/Hole Punch)

(Corner Staple/2-Point Staple/Hole Punch are options)

Intelligent Sorting (ON/OFF)

5/6

Output Tray (Optional)

Received prints: (FAX/Network)

Copy and print: (PC print/Copy)

"Small" Originals (ON/OFF)

Scanner Dry

6/6

Priority Screen

Default Device Priority (Copy/FAX/Scanner/Auto)

Priority FAX Screen

(One-Touch/Search/10-key Dialing/Index)

Priority Device (Copier/Printer)

Density (ADF only) (mode 1/ mode 2)

13

34

24

MODE 400 Bit 7

MODE 400 Bit 6

MODE 401 Bit 7 - 4

MODE 402 Bit 7 - 5

MODE 402 Bit 4, 3

MODE 408 Bit 7 - 4

MODE 403 Bit 7

MODE 405 Bit 7 - 0

MODE 406 Bit 7 - 0

MODE 407 Bit 7 - 0

MODE 404 Bit 7 - 0

MODE 403 Bit 0