Minipack-torre S.p.A.

Via Provinciale, 54 - 24044 Dalmine (BG) - Italy

Tel. (035) 563525 – Fax (035) 564945

E-mail: info@minipack-torre.it

IT ISTRUZIONI PER L’INSTALLAZIONE, L’USO E LA MANUTENZIONE

EN INSTALLATION, OPERATION AND MAINTENANCE

DE INSTALLATIONS-, GEBRAUCHS- UND WARTUNGSANLEITUNG

FR INSTRUCTIONS POUR L’INSTALLATION, L’EMPLOI ET L’ENTRETIEN

ES INSTRUCCIONES PARA LA INSTALACION, USO Y MANTENIMENTO

SV BRUKSANVISNINGAR, MONTERINGSINSTRUKTIONER OCH UNDERHÅLLSFÖRESKRIFTER

PT INSTRUÇÕES PARA A INSTALAÇÃO, O USO E A MANUTENÇÃO

IT MACCHINA CONFEZIONATRICE SOTTOVUOTO

EN VACUUM PACKING MACHINE

DE VAKUUMMASCHINE

FR MACHINE CONFECTIONNEUSE SOUS-VIDE

ES MÁQUINA DE ENVASADO AL VACÍO

SV VAKUUMFÖRPACKNINGSMASKIN

PT MÁQUINA CONFECCIONADORA SOB VÁCUO

http://www.minipack-torre.it

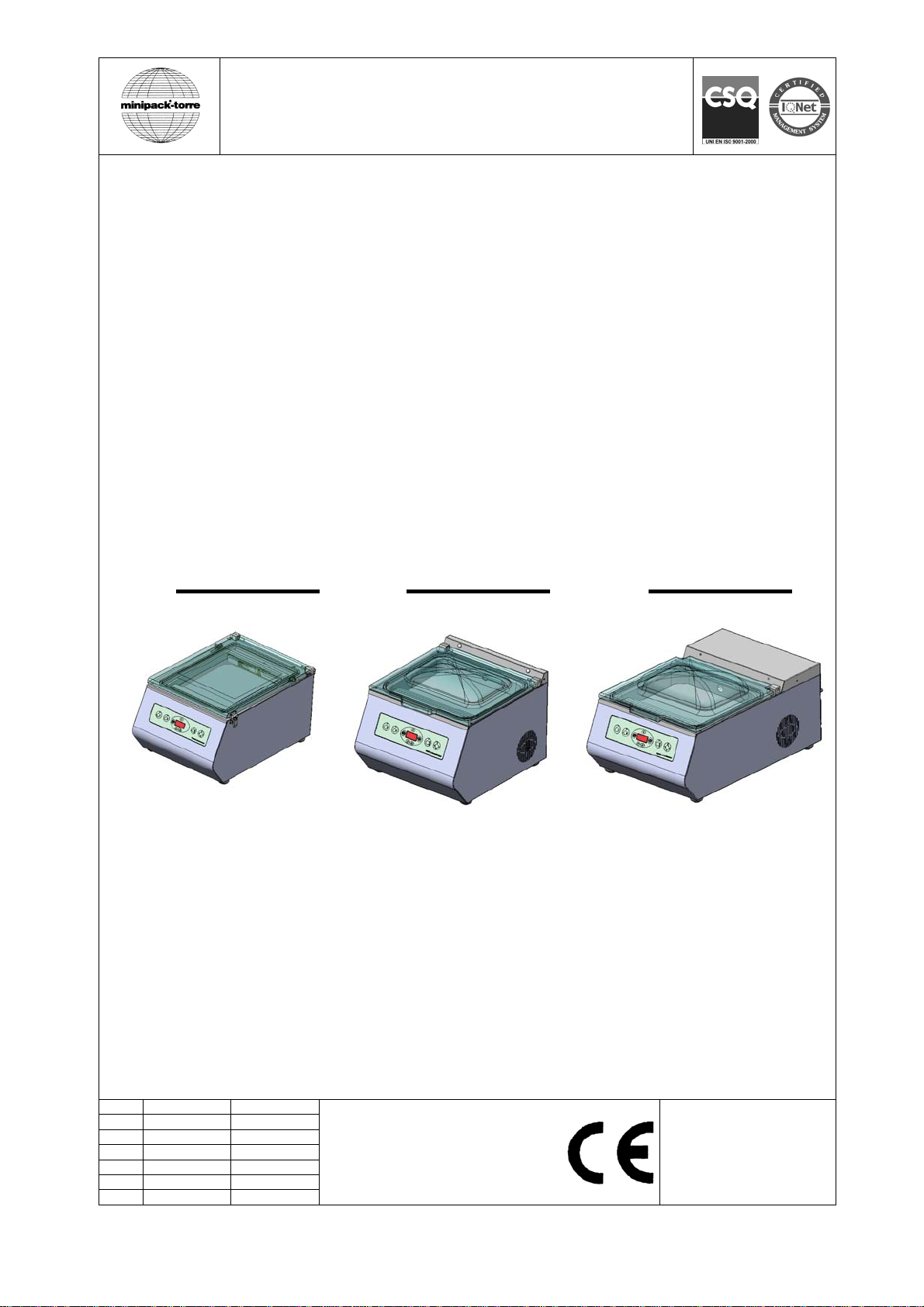

mod. MV26 X mod. MV31 X mod. MV35 X

6m³

IT LEGGERE ATTENTAMENTE QUESTE ISTRUZIONI PRIMA DI USARE LA MACCHINA

EN BEFORE USING THE MACHINE PLEASE CAREFULLY READ THE INSTRUCTIONS

DE BITTE LESEN SIE DIESE ANLEITUNG GENAU DURCH, BEVOR SIE DIE MASCHINE BENÜTZEN

FR PRIERE DE LIRE ATTENTIVEMENT CE MANUEL D’INSTRUCTIONS AVANT D’UTILISER LA MACHINE

ES LEER ATENTAMENTE ESTE MANUAL ANTES DE USAR LA MÁQUINA

SV DENNA HANDBOK SKA NOGA LÄSAS IGENOM INNAN MASKINEN TAS I BRUK

PT ANTES DE USAR A MÁQUINA LER CUIDADOSAMENTE ESTE MANUAL

IT Italiano Pagina 01

EN English Page 15

DE Deutsch Seite 29

FR Français Page 43

ES Español Página 57

SV Svenska Sida 71

PT Português Página 85

6m³

10m³

DOC. N.FM111150

REV. 03

ED. 10.2013

…

…

.

…

.

…

TRANSLATION OF THE

ORIGINAL INSTRUCTIONS

Index EN

Chapter 1. Description Page

1.1. Preface..….….…………………….……………………………………………….…… 16

1.2. Performances of packaging machine.........…….……………………………….…

1.3. Technical data of the machine……………………………....…………………….…. 16

Chapter 2. Pouches features

2.1. Pouches to use.....................................……......………………………………….… 18

Chapter 3. Machine usage conditions

3.1. Items that may be packaged……………………………………………………….…. 18

3.2. Items not to be packed….........................……..……………………………….….

Chapter 4. Safety standards

4.1. Warnings...............................................…….....…………………………………..…18

4.2. Description of safety stickers……………………………………………………….… 20

4.3. Individual protection devices………………………………………………………….. 20

Chapter 5. Machine installation

5.1. Transport and positioning.................…….........…………………………….………. 20

5.2. Environmental conditions.........................…….…………………………….………. 20

5.3. Users…………………..............................……..…………………………….………. 21

5.3.1. Loading the oil in the pump…………………………………………………… 21

5.3.2. Electrical connections..............................……..……………………….….…21

5.3.3. Gas connections..............................…………...…………………………..... 21

Chapter 6. Machine adjustment and setting up

6.1. Adjustment...............................................……..……………………………………. 22

6.1.1. Control panel…………………………………………………………………… 22

6.1.2. Switching the machine on…………………………………………………….. 22

6.1.3. Selecting the programs and setting up the parameters……………………

6.1.4. Packaging………………………………………………………………………. 24

6.1.5. Alarm messages…..…………………………………………………………… 24

Chapter 7. Ordinary maintenance

7.1. Precautions for ordinary maintenance interventions……………………………….. 25

7.2. Cleaning of the sealing bar….………………………………………………………

7.3. Replacement of the Teflon and the sealing blade..………………………………....25

7.4. Replacement of the cover gasket…………………………………………………….

7.5. Cleaning machine…………..………………………………………………………......26

7.6. Vacuum pump maintenance…………………………………………………………

7.7. Problem solving………………………………………………………………………… 26

7.8. Wiring diagram.……………………………………………………………………….... 27

7.9. Pneumatic diagram ……………………………………………………………….……27

7.10. Disassembling, demolition and elimination of residuals………………………….... 28

Chapter 8. Guarantee

8.1. Certificate of guarantee...............................….………………………………….….. 28

8.2. Guarantee conditions..................................…………………………………….……28

CE declaration of conformity......................…………………………………………..99

16

18

22

25

25

26

15

Chapter 1. Description EN

1.1. Preface

This manual has been drawn up in compliance with the UNI 10893 standard dated July 2000. It is meant for all users in

order to enable them to use the machine correctly. Keep it in a place which can be easily accessed in the proximity of the

machine and which is known to all users. This manual is an integral part of the machine for safety reasons. We wish to

specify the symbols in use here below in order to improve their understanding.

All reproduction rights of this manual are reserved to the manufacturer. Partial or complete reproduction is forbidden as

provided by the law. Descriptions and pictures provided in this manual are not binding. Therefore the manufacturer,

reserves the right to make any change considered necessary. This manual cannot be transferred for viewing to third

parties without authorisation in writing from the manufacturing company.

1.2. Performances of packaging machine

This machine represents what the modern technology of vacuum-packing may express at its best. It is flexible, easily

programmable and cheap. It is intended to vacuum-pack foodstuffs by removing oxygen as well as any chemical and

biological pollutant present in the environment. To attain the vacuum level you wish, just program the machine in order to

remove almost all the air contained in the packet. Your product will preserve its organoleptic features, colour, taste,

flavour and nutritive value for a long time.

1.3. Technical data of the machine

ATTENTION:

Accident prevention rules for the operator. This warning indicates the presence of dangers which can

injure the person operating on the machine.

ATTENTION:

Hot parts. Shows the danger of burning, thus involving the risk of a serious accident for the exposed

person.

WARNING:

It indicates the possibility of damaging the machine and/or its components.

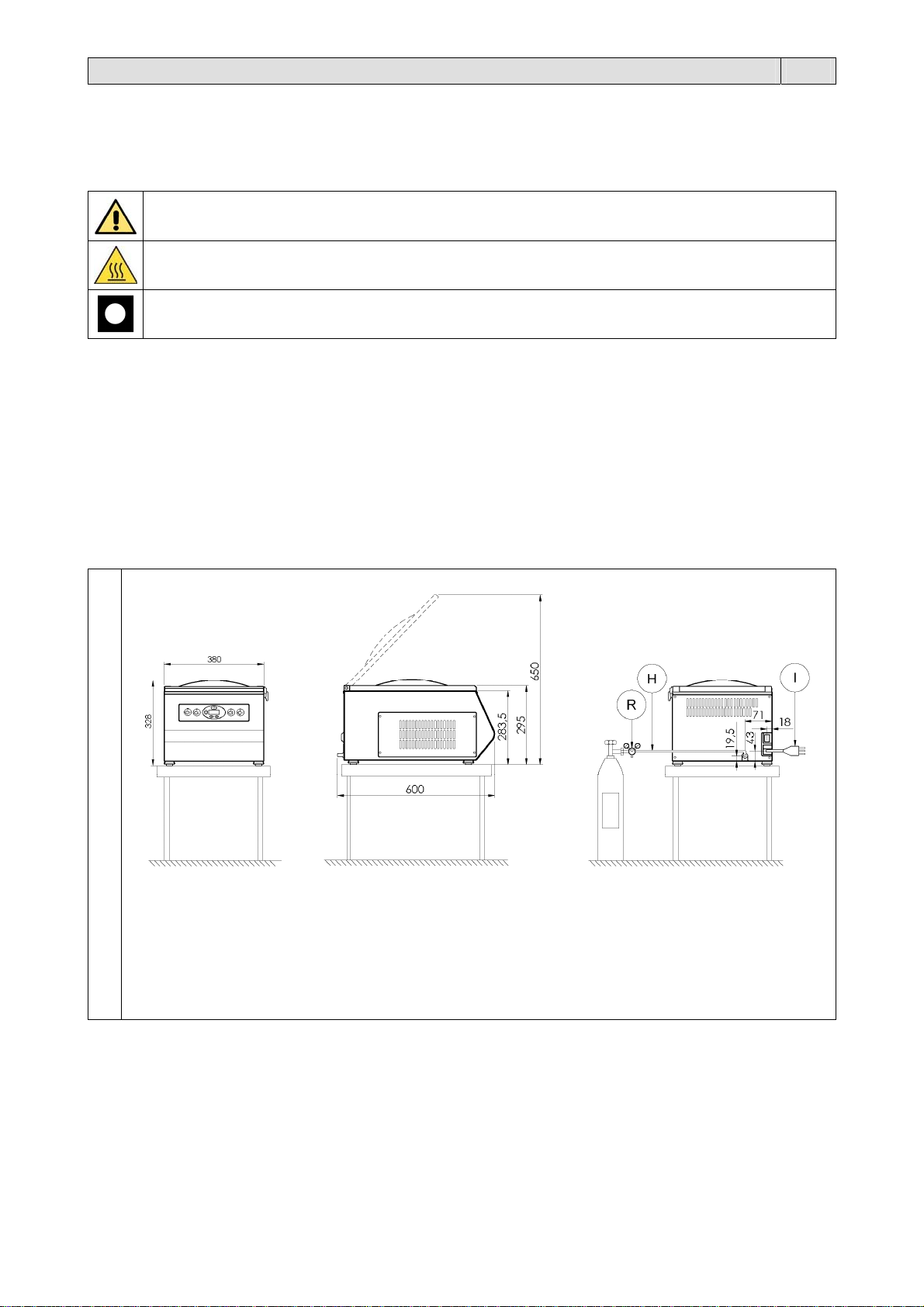

MV26 X

Package weight and sizes

Width = 700 mm Length = 510 mm Height = 440 mm Weight = 39 Kg

Machine weight

Weight = 34 Kg

Vacuum pump = 6m³

I = Electrical connections; H = Gas connection; R = Gas pressure reducer.

16

Chapter 1. Description EN

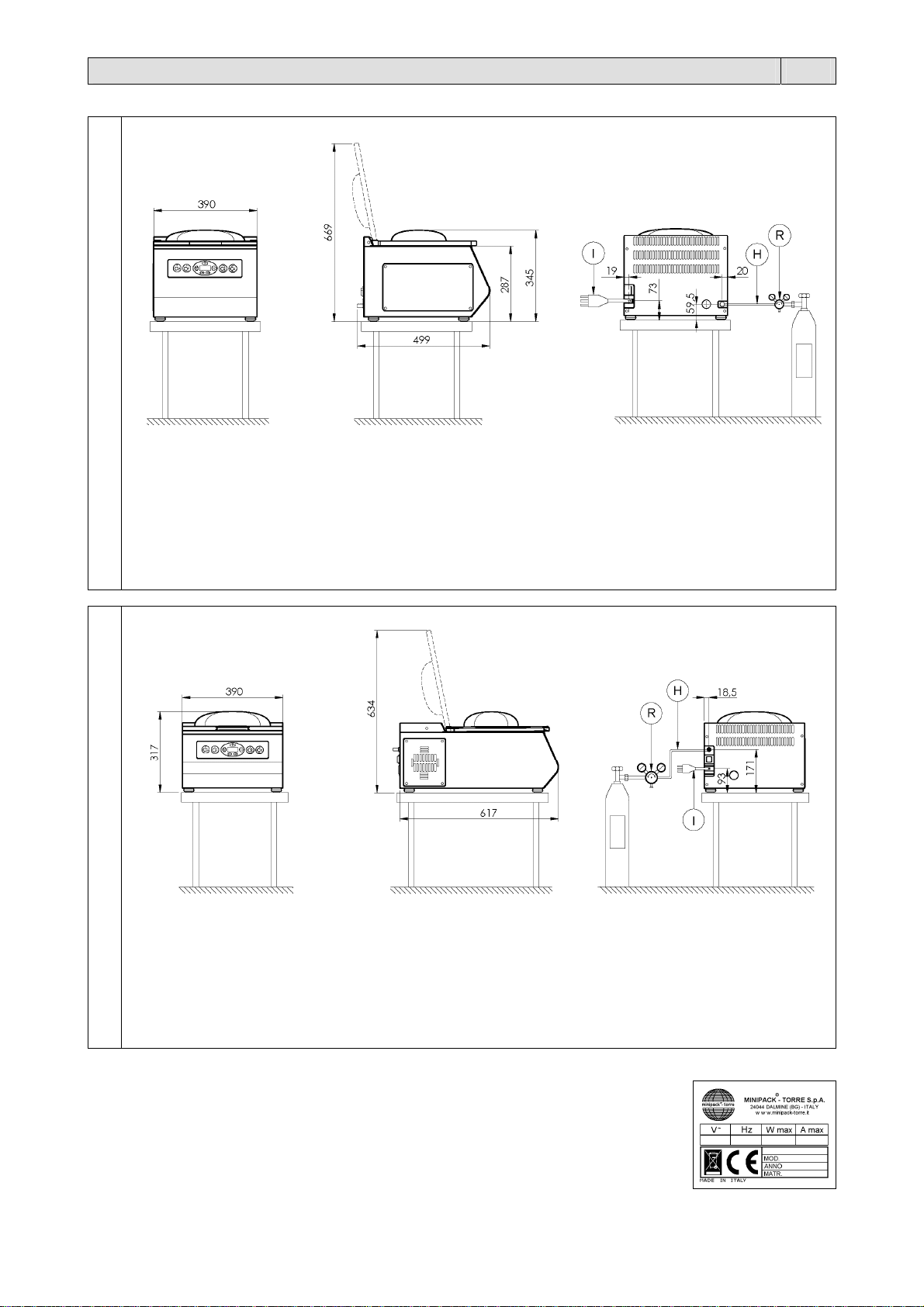

MV31 X

Package weight and sizes

Width = 610 mm Length = 520 mm Height = 420 mm Weight = 41 Kg

Machine weight

Weight = 37 Kg

Vacuum pump = 6m³

I = Electrical connections; H = Gas connection; R = Gas pressure reducer.

MV35 X

Package weight and sizes

Width = 710 mm Length = 460 mm Height = 485 mm Weight = 53 Kg

Machine weight

Weight = 45 Kg

Vacuum pump = 10m³

I = Electrical connections; H = Gas connection; R = Gas pressure reducer.

Electrical system

Voltage (V): see data on plate

Frequency (Hz): see data on plate

Maximum absorbed power (W): see data on plate

Maximum absorbed current (A): see data on plate

Note: When contacting the Manufacturer, always indicate the model and the serial number

specified on the plate on the rear part of the machine.

17

Chapter 2. Pouches features EN

2.1. Pouches to use

They may be of different thickness (85÷200µm) and shall be both airtight and gastight. Only food packaging pouches can

be used. The following table indicates the maximum dimensions of the pouches that can be used with the various

machine models.

Machine Pouch width open side Pouch length closed side

MV26X (front bar) 265mm 375mm

MV26X (front and rear bar) 265mm 325mm

MV31X (front bar) 305mm 265mm

MV35X (front bar) 305mm 265mm

The following table indicates the min/max temperature limits the pouches can undergo to.

Type of pouch Minimum temperature Maximum temperature

for cooking

for storage

It is recommended to refer to the technical and safety sheets of the pouches in use and to observe

the corresponding instructions!

-15°C +120°C for 30 minutes

-20°C +70°C for 2 hours; +100°C for 15 minutes.

Chapter 3. Machine usage conditions EN

3.1. Items that may be packaged

This machine can be used to pack the majority of foodstuffs, including: fruit, fish products, dairy products, meat,

delicatessen, oven ready products, gastronomic products, dried products, etc.

3.2. Items not to be packed

It is absolutely forbidden to pack the following products which might permanently damage the machine and harm operator:

Liquids of any type and density in fragile containers

Inflammable and explosive materials

Gas bottles under pressure or of any type

Bulk or volatile powders (unless a filter is assembled on the pump)

Any material and product which might in any way cause the user to be in a dangerous situation and

damage the machine.

Chapter 4. Safety standards EN

4.1. Warnings

It is extremely important to read this entire chapter as it contains important information regarding risks that personnel are

subject to in the event of incorrect use of the machine. These basic standards must be observed as well as specific

standards applicable in the country of installation.

The machine must be installed by trained and authorised technicians.

This machine is not intended for use by persons (including children) with reduced physical, sensory or mental

capabilities, or lack experience and knowledge, unless they have been given supervision or instruction concerning

use of the machine by a person responsible for their safety.

Children should be supervised to ensure that they do not play with the machine.

Keep children and animals away from the machine when running. Do not allow children to play with the pouches.

The machine must be used only for the purpose it was built for. Any other use shall be considered “improper” and

therefore dangerous.

Never allow unauthorised personnel to perform repairs or other operations on the machinery.

The operator must be familiar with all warnings related to the tasks in hand and always be informed by the head of

the site regarding risks.

Ensure that all clothing is tight fitting, with particular reference to cuffs or other loose clothing.

Ensure that all operating areas and transit zones are kept clear, clean and adequately lit at all times.

Eliminate all safety hazard conditions before using the machine and always notify the head personnel of any

malfunction.

18

Chapter 4. Safety standards EN

Never use the machine in the event of fault.

Never tamper with safety devices or circuits.

Never perform modifications on the machine without prior authorisation from the manufacturer.

If the supply cord is damaged, it must be replaced by a special cord or assembly available from the manufacturer or

its service agent.

The electrical enclosure must remain closed during operation.

Smoking is forbidden while the machine is operating!

Never performs maintenance and/or adjustments to the machine during operation. Guards may only be

disassembled by suitably trained and qualified maintenance engineers.

Never operate the machine without all guards fitted. Ensure correct position of all guards before resuming normal

operation.

If it is necessary to leave the machine unattended, switch it off by turning the main switch to the “0” (OFF) position!

The manufacturer declines all liability for damage or phisical injury caused by failure to observe safety standards.

THE MACHINE CAN NOT BE USED BY UNTRAINED PERSONNEL!

During work pay attention to all hot parts of the machine. The temperature they can reach is so high

that it can cause burns.

Never use gaseous mixtures in presence of oxygen in a percentage higher than the atmospheric one

(~ 19%).

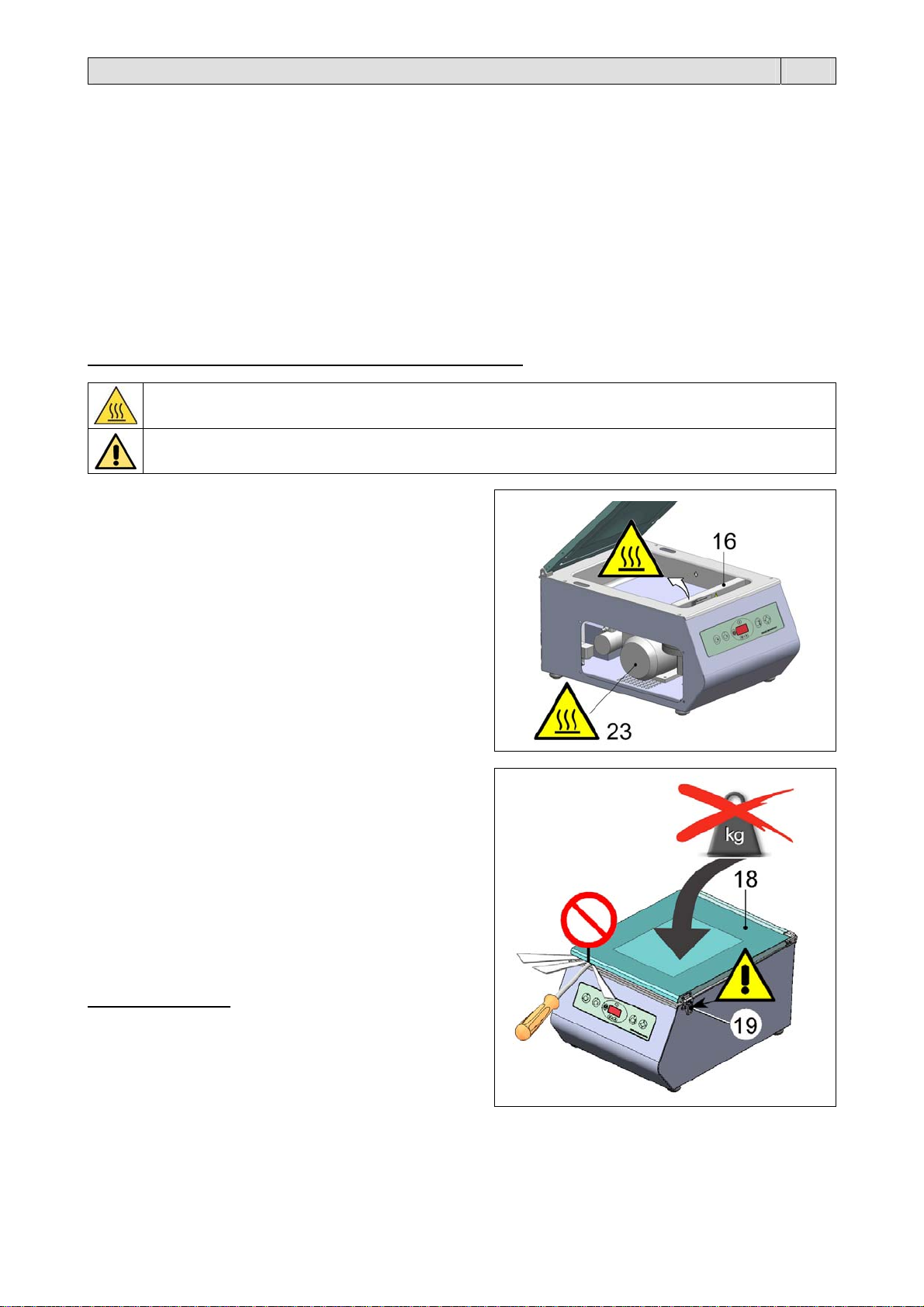

Do not touch the sealing blade (16) immediately after sealing.

Danger of burns due to hot blade.

Do not seal if the sealing wire is broken.

Replace it immediately.

Do not touch the vacuum pump (23) just after a working cycle.

Possibility of burning due to the high temperature the pump

may reach.

In case of a power failure during a working cycle when the

cover is closed, do not use any tool in order to force its opening.

Wait for the power supply to be restored.

Do not place any weight on the cover (18)!

Prevent any object from falling on the cover!

This can compromise the integrity, causing cracks or damage.

Do not proceed with packaging if the cover has cracks or is

broken.

Replace it immediately.

For mod. MV26 X only.

Before any working cycle make sure that the closing hook (19)

will not prevent the operator from closing the cover correctly.

Possibility of breaking the cover.

19

Chapter 4. Safety standards EN

4.2. Description of safety stickers

The following safety stickers feature on the machine:

On the power input.

ATTENTION! Periodically check the correct insulation of the power cable and the integrity of the

socket. During machine operation, the inspection panels to the electric system must be correctly

fitted.

On the sealing bars positioned inside the tank

On the vacuum pump positioned inside the machine.

ATTENTION! Hot members. It shows the danger of burning, thus involving the risk of a serious

accident for the exposed person.

On the sealing bars positioned inside the tank

ATTENTION! Indicates the danger of burns with risk of accident in case of

contact with the hot surface of the sealing bar.

On the Plexiglas lid.

ATTENTION! Indicates how to clean the lid to prevent damaging it and reducing

its transparency or strength.

4.3. Individual protection devices

Wear safety shoes that protect feet from impacts, crushing and compression while moving or handling the

machine.

Wear safety gloves that protect the hands from crushing and mechanical hazards and while moving or

handling the machine.

Wear safety gloves that protect the hands against cutting risks while changing the sealing blades.

Wear safety gloves that protect the hands against the specific risks associated with the materials to be

packed (mechanical, chemical) and against coming into contact with the high temperatures present on the

seals and/or sealing bars (up to 100°C).

Wear safety gloves that prevent the hands from coming into contact with foodstuffs when

packaging them.

Chapter 5. Machine installation EN

5.1. Transport and positioning

When transporting and positioning the machine, it is recommended to handle it with great care!

Neither overturn nor tilt the machine! Oil might come out of the pump and damage the machine.

Cut the strap with scissors make sure you protect your eyes by wearing glasses and withdraw the cardboard. Cut the

strap fastening the machine to the pallet.

5.2. Environmental conditions

Lift the machine and place it on the working surface. Make sure the machine is placed in a proper environment

Leave a minimal space of 0,5m around the machine so that not to obstruct air outlets.

Working environmental conditions:

Temperature from + 5°C to + 40°C.

Relative humidity from 30% to 90%, without condensation.

The lighting of the operation room shall comply with the laws in force in the country where the machine is installed.

However, it shall be uniform and provide for good visibility in order to safeguard the operator’s safety and health.

MACHINE SAFETY FACTOR = IP20

THE AERIAL NOISE MADE BY THE MACHINE IS LOWER THAN 70 dB(A)

without any inflammable and explosive materials or gas. The machine may only be installed on smooth, flat non-

inflammable surfaces.

20

Chapter 5. Machine installation EN

5.3. Users

5.3.1. Loading the oil in the pump

If the pump has no oil, to load, fully use the provided bottle.

The oil loading operation must be carried out by trained and

authorised technical personnel.

To access inside the machine, remove the side panel (MV26X) or

rear panel (MV31X, MV35X), using a screw driver to remove the

fixing screws.

Remove the cap to load oil (21) using the provided wrench and fill the

oil tank following the instructions indicated in the pump user manual

attached to the machine.

(20) Oil discharge plug

(21) Oil filling plug

(22) Oil inspection plug

MV26 X

MV31 X

MV35 X

5.3.2. Electrical connections

OBSERVE HEALTH AND SAFETY REGULATIONS!

If the machine is not equipped with the power supply plug, use a plug that is suitable for the

voltage and amperage values described by the rating plate and that can comply with the

rules in force in the installation country.

GROUNDING OF THE UNIT IS OBLIGATORY!

Before executing electrical connections, make sure the mains voltage matches the one on

the plate on machine rear and that the ground contact complies with the safety rules in

force. In case of doubts about the mains voltage, contact the local public supply Company.

Insert the plug on the cable from machine electrical cabinet in a mains power supply socket

that can be reached easily by the operator.

5.3.3. Gas connections

When carrying out packaging operations in modified atmospheres, use specific gas for food package in compliance with

the rules in force about food additives in the country where the machine is used.

The gas, which consists of a mixture of nitrogen, carbon dioxide and, more rarely, oxygen and other gases, is a “made to

measure” gaseous mixture, depending on the product to be packaged.

Never use gaseous mixtures in presence of oxygen in a percentage higher than the atmospheric

one (~ 19%).

Connect gas attachment, in case the machine is equipped with such a device, to the gas cylinder through the proper

tube (H) (see chapter 1.3.).

Pressure of gas plant has to be set on about 2 atm., bearing in mind the max. working pressure is 4 atm.

If the pressure is not correct, act on the knob of the pressure reducer (R) (see chapter 1.3.).

21

V

V

Chapter 6. Machine adjustment and setting up EN

6.1. Adjustment

6.1.1. Control panel

The machine is fitted with a control panel, from which all programming and operation functions can be set.

3 Start button (models MV31 X and MV35 X

only)

4 Selection button

5 Display. Displays selected functions and

relative settings

6 Button “INCREASE”. Increases set

function values

7 Button “DECREASE”. Reduces set

function values

8 Stop button

9 Led for vacuum and extra vacuum

function

10 Led for gas function

11 Led for sealing function

12 Led for air re-immission function

6.1.2. Switching the machine on

Set the main switch, located on the rear of the machine, to ON. As soon as the board has been switched on, display will

show the software version, then the last program being executed (P1÷P9).

6.1.3. Selecting the programs and setting up the parameters

To select the program number, just press the buttons (6) and (7).

Press button (4) to enter scheduling of the program shown at the moment. By pressing again button (4), all parameters fo

the selected program will appear one after the other. Push buttons (6) and (7) to increase or decrease the value of the

parameter shown. Parameters are stored when, while running a program, the number of the program itself will appear

on the display.

The machine has 9 selectable programs.

Programmes P1÷P8 are composed by 4 modifiable variables (vacuum, extravacuum, gas, sealing).

Program P9, “External Vacuum”, can be ran only on models equipped with a tank set for this type of packaging.

It consists of only 2 variables that can be modified (vacuum and extra-vacuum).

It is the program to be used for removing air from container surfaces that can be closed hermetically.

These containers must be connected using an intake tube to the pick-up fitting placed inside the tank.

To start the program, press Start (3), for models MV31 X and MV35 X. Press Stop (8) for model MV26 X. The cover

must always be open.

TABLE OF PARAMETERS ACCORDING TO PROGRAMMES

ariable P1÷P8

acuum

(values expressed in %)

Min. = 0,0

Max. = 99,9

Recommended = 99,9

Extravacuum

(values expressed in seconds)

Gas

(values expressed in %)

Min. = 0,0

Max. = 30,0

Min. = 0,0

Max. = 60,0

Recommended = never exceed 40%

Sealing

(values expressed in seconds)

Min. = 0,0

Max. = 4,0

Recommended = 1,3÷1,5

All packaging machines are tested at works. The parameters set at works generally prove to be fit for use.

P9

(External Vacuum)

Min. = 0,0

Max. = 99,9

Recommended = 99,9

Min. = 0,0

Max. = 30,0

not settable

not settable

22

V

V

Chapter 6. Machine adjustment and setting up EN

1) VACUUM

It is possible to set a value from 0 to 99,9%. The recommended vacuum percentage is 99,9%.

For other settings refer to the attached table.

Scheduling of vacuum parameter is signaled through LED (9).

Food

Meat

Cheese

Grated cheese

Fruit

Jam and cream

Soups

Sandwiches

Pasta

Fish, shellfish

Sausages

cured meats

egetables

Fresh vegetables (salad, tomatoes)

2) EXTRAVACUUM

If the vacuum value is set to 99.9%, press button (4) to program the EXTRAVACUUM parameter indicated by the letter

E in the last digit on the display.

This value can be set to between 0 and 30 seconds. This the length of time that the pump continues to extract air from

the hood after the machine has reached the programmed maximum vacuum level. This function is useful for porous

products where it is particularly difficult to extract the air (e.g. meat).

Note: if the programmed VACUUM value is less than 99.9%, the EXTRAVACUUM function is not displayed, and the

system proceeds to the subsequent parameter (GAS).

3) GAS

It is possible to set a value from 0 to 99%. Such a parameter cannot be higher than the vacuum one, otherwise you will

obtain an opposite function. Scheduling of gas parameter is signaled through LED (10). If the gas LED (10) is flashing,

it means the gas cylinder is not properly connected and machine will not start. Connect it properly.

Note: When scheduling a program “vac + gas”, the minimum residual vacuum percentage soon after gas immission

should be higher than 60%

Example: VAC 99,9%

GAS 40%

Residual vacuum (99,9 - 40)= 59,9%

4) SEALING

It is possible to set a value from 0 to 4 seconds. For the first working cycles it is recommendable to set a sealing time of

about 1,6 seconds and then lower it to prevent the teflon tape from burning. Scheduling of sealing time parameter is

signaled through LED (11).

The following table indicates the sealing time we recommend setting according to the type and thickness of the

pouches.

Type of pouch Pouch thickness (µm) Sealing time (seconds)

acuum

Recommended

99.9%

99.9%

35 - 50%

99.9%

99.9%

99.9%

60 - 70%

99.9%

99.9%

99.9%

99.9%

99.9%

35 - 50%

Smooth for cooking

Smooth for storage

Smooth made of aluminium

85 – 95 1,3 – 1,5

85 – 95 1,3 – 1,5

120 – 140 2,0 – 2,5

Bellow made of aluminium

(it can be packed only with

120 – 140 2,5 – 3,0

"sealing counterbar"; optional)

23

Chapter 6. Machine adjustment and setting up EN

6.1.4. Packaging

After selecting the program and setting the necessary variables, go ahead with packaging.

Place the product to be packaged inside the pouch.

Place the pouch inside the tank and on the sealing bar in a way as linear

as possible.

Try to prevent the pouch from wrinkling. Wrinkles might negatively affect

the hermetic seal formed by sealing. Pouches shall be at least 2cm

beyond the sealing.

If the “GAS” function is on, the pouch must be positioned with the strip

open on the gas nozzle on one side of the sealing bar.

Close the upper Plexiglas cover.

Model MV26 X: the packaging cycle starts when the cover is closed.

Models MV31 X and MV35 X: Once the cover has been closed, press

the Start button (3) to run the packaging

cycle.

Note: When the product dimensions allow, we recommend using some

tables (13) as shimming the product facilitates positioning the pouch in

relation to the sealing bar.

Moreover, it allows decreasing the volume of the tank (14) and, therefore,

the amount of air to be removed, speeding up the packaging cycle.

The packaging cycle is sub-divided into four phases:

1. Suction phase during which all the air contained inside the tank and

the pouch is sucked.

The LED is on (9).

2. Gas injection phase (if the machine is equipped with a gas plant).

The LED is on (10).

3. Sealing phase during which the packet is sealed.

The LED is on (11).

4. Air re-enter phase and subsequent opening of the cover.

The LED is on (12).

The tank will reach its atmospheric pressure and the upper cover will

open again.

Machine is ready for a new packing cycle.

If you press the Stop button (8), the machine will immediately stop sucking and automatically start sealing

the pouch. This function will be used to pack liquid and hot products which may start boiling during the

vacuum cycle.

6.1.5. Alarm messages

The electronic board detects a series of alarms that are indicated by the following messages, which appear on the

display (5):

OIL: Check the level and colour of the oil, as described in the pump manual.

To reset this alarm, press buttons (6) and (7) simultaneously.

OFF: The electronic board is blocked.

Contact the technical service department.

EAA: The machine did not generate the vacuum within the defined maximum time (90 seconds).

Check that the cover is closed correctly.

To reset this alarm, switch the machine off and on again.

FLA: The power supply voltage is low.

Contact the technical service department.

24

Chapter 7. Ordinary maintenance EN

7.1. Precautions for ordinary maintenance interventions

ORDINARY MAINTENANCE, MUST BE EXECUTED BY QUALIFIED STAFF APPROPRIATELY TRAINED.

7.2. Cleaning of the sealing bar

Use a dry cloth to remove any film residue on the sealing bar

(16).

Before any routine maintenance switch the machine off by acting on the main switch and remove

the plug from the mains socket.

Disconnect gas plant.

7.3. Replacement of the Teflon and the sealing blade

Before replacing Teflon and the sealing blade wait for the

machine to be properly cooled.

Remove the sealing bar (16) from its seat

Remove the Teflon adhesive tape

Unscrew the nuts fastening the blades to each end of the

sealing bar

Tighten the new blades. Make sure they are tout enough

before blocking them

Use the Teflon adhesive tape to cover the sealing blades

Place the sealing bar into its seat.

7.4. Replacement of the cover gasket

When the cover gasket (17) is worn out, replace it.

This will improve the efficiency of the machine and increase its

speed rate. Replacement is very easy. After having removed the

gasket which has worn out, clean its seat and insert the new

gasket in a linear way. Make sure its ends are joined. Leave no

opening which might prevent the product from being properly

vacuum-packed.

25

Chapter 7. Ordinary maintenance EN

7.5. Cleaning machine

To clean the Plexiglas cover (18), clean both the outer

and the inner side with water and soap only.

Never use detergents or solvents which might damage

the cover (18) and reduce its transparency as well as its

resistance.

Check the state of the cover on a regular basis, it must in good

condition, completely clean, and must not display any yellowing

or increase in opacity.

If any of the above defects are observed, replace the cover.

The Plexiglas cover must be replaced ever 10 years!

Use normal detergents for stainless steel to clean the case and the internal tank.

Do not use chlorine-based detergents (hydrochloric acid, sodium hypochlorite, etc.), even if diluted.

Do not use abrasive agents, metal wool or any abrasive sponge to clean the surfaces.

Do not use detergents for silver.

Do not clean the machine using water jet or vapour.

7.6. Vacuum pump maintenance

It is very important to regularly service the pump to ensure extended and correct operation.

For any maintenance operation, eg level and oil quality check, oil and filter replacement, cleaning, etc., comply with the

instructions indicated on the pump manual.

7.7. Problem solving

PROBLEM CAUSE SOLUTION

The pouch is not

sealed correctly

Final vacuum is poor

The cover does not

open

If the machine does not work properly after the above-mentioned checks, contact the assistance service

describing the detected defect.

The sealing time is not correct.

The cover gasket is dirty or worn.

The pouch is not placed correctly on the

sealing bar.

The sealing bar is worn (the Teflon

coating is burnt).

The blade placed under the Teflon of the

sealing bar is broken.

The set vacuum percentage is incorrect.

The cover gasket is dirty or worn.

The cover is not closed correctly.

No power supply.

Change the sealing time.

Clean or replace the cover gasket (contact

the Technical Assistance Service for a

replacement).

Position the pouch correctly.

Replace the sealing bar (contact the

Technical Assistance Service for a

replacement).

Replace the blade (contact the Technical

Assistance Service for a replacement).

Change the vacuum percentage.

Clean or replace the cover gasket (contact

the Technical Assistance Service for a

replacement).

Close the cover correctly.

Make sure that objects or dirt are not found

between the cover and tank.

Wait until the power supply is restored.

26

Chapter 7. Ordinary maintenance EN

7.8. Wiring diagram

MV26 X (230V / 120V ETL) (page 100).

B0 Limit switch

B1 Gas pressure switch

C1 Vacuum pump condenser

ER1/2 Sealing blade

K1 Power board

F1 Line fuse

F2 Line fuse

M1 Vacuum pump motor

Q1 Main switch

QV1 Air re-immission valve

QV2 Gas injection airvalve

QV3 Sealing airvalve

S1 Membrane keyboard

T1 Sealing transformer

X1 Power supply plug

MV31 X (230V / 120V ETL) – MV35 X (230V) (page 101).

B1 Gas pressure switch

C1 Vacuum pump condenser

ER1 Sealing blade

F1 Line fuse

F2 Line fuse

M1 Vacuum pump motor

Q1 Main switch

QV1 Air re-immission valve

QV2 Gas injection airvalve

QV3 Sealing airvalve

SK1 Electronic board

T1 Sealing transformer

X1 Power supply plug

MV35 X (120V ETL) (page 102).

B1 Gas pressure switch

C1 Vacuum pump condenser

ER1 Sealing blade

F1 Line fuse

F2 Line fuse

M1 Vacuum pump motor

Q1 Main switch

QF1 Magneto-thermal switch

QM1 Sealing blade contactor

QV1 Air re-immission valve

QV2 Gas injection airvalve

QV3 Sealing airvalve

SK1 Electronic board

T1 Sealing transformer

7.9. Pneumatic diagram (page 103).

CV Vacuum hood

UG Gas nozzles

BA Suction pipe union

QV1 Air re-immission valve

QV2 Gas injection airvalve

QV3 Sealing airvalve

B1 Gas pressure switch

BG Gas cylinder

MP Pneumatic membrane

M1 Vacuum pump motor

PV Vacuum pump

S Sensor

27

Chapter 7. Ordinary maintenance EN

7.10. Disassembling, demolition and elimination of residuals

ATTENTION!

All operations about disassembling and demolition must be done by qualified personnel with mechanical and

electrical expertise required to work in security conditions.

Proceed as follows:

disconnect machine from power mains

disconnect the machine from the gas system (if installed)

disassemble components

drain the oil from the pump.

All wastes must be treated, eliminated or recycled according to their classification and to the procedures in force

established by the laws in force in the country the equipment has been installed.

The symbol indicates that this product shall not be treated as household waste.

By assuring that the product will be properly disposed of, you will facilitate the prevention of potential

negative effects for the environment and the man’s health, which might be otherwise caused by the improper

waste treatment of this product.

For more detailed information about the recycling of this product, please contact the product seller or, as an

alternative, the after-sales service or the corresponding waste treatment service.

Chapter 8. Guarantee EN

8.1. Certificate of guarantee

The guarantee runs for 12 months after the installation date under the conditions set forth on the instruction manual.

Fill in the card with all data requested, tear out along the perforations and send in.

8.2. Guarantee conditions

The guarantee runs for 12 months and goes into force on the installation date of the machine. The guarantee covers free

replacement or repair of any parts due to defects arising from faulty material. The repairs or replacement are usually

carried out at the manufactures, with transport or workmanship at buyer’s charge. If the repair or replacement is carried

out at the buyer’s place, he shall bear the travelling, transfer and workmanship charges. Work under guarantee can be

carried out exclusively by the manufacturer or by the authorised dealer. In order to be entitled to repairs under the

guarantee, the faulty part must be sent for repair or replacement to the manufacturer or his authorised dealer. The return

of such repaired or replaced part will be considered to be the performance of the guarantee.

The guarantee is voided:

in case of failure to mail the CERTIFICATE OF GUARANTEE, duly filled in and signed, with in 20 days after the date

of purchase

in case of inappropriate installation, power supply, misuse and mishandling by unauthorised persons

in case of changes made to the machine without prior agreement in writing by the manufacturers

if the machine is no longer the property of the first buyer.

The manufacturer decline any responsibility for damage to persons or things in case of inappropriate

installation or connection to the power mains or omission of connection to earth or in case of any mishandling

of the machine.

The manufacturer undertake to carry out any variations and changes made necessary by technical and

operating requirements.

IN THE EVENT OF DISPUTES THE COURT OF BERGAMO (ITALY)

SHALL HAVE SOLE JURISDICTION.

28

7.8. Mod. MV26 X (230V / 120V ETL)

100

–

7.8. Mod. MV31 X (230V / 120V ETL)

MV35 X (230V)

101

7.8. Mod. MV35 X (120V ETL)

102

7.9.

Versione con 1 barra saldante / Version with 1 sealing bar

Versione con 2 barre saldanti / Version with 2 sealing bars

103

Loading...

Loading...