Page 1

Engine

Engine Model Cat®C7 ACERT™

Net Flywheel Power 140 kW 188 hp

Weights

General Forestry (HW) 31 226 kg 68,853 lb

Log Loader (U/U) 34 300 kg 75,698 lb

Log Loader (O/U) 34 484 kg 76,037 lb

• Operating weight with front linkage, without bucket

or grapple.

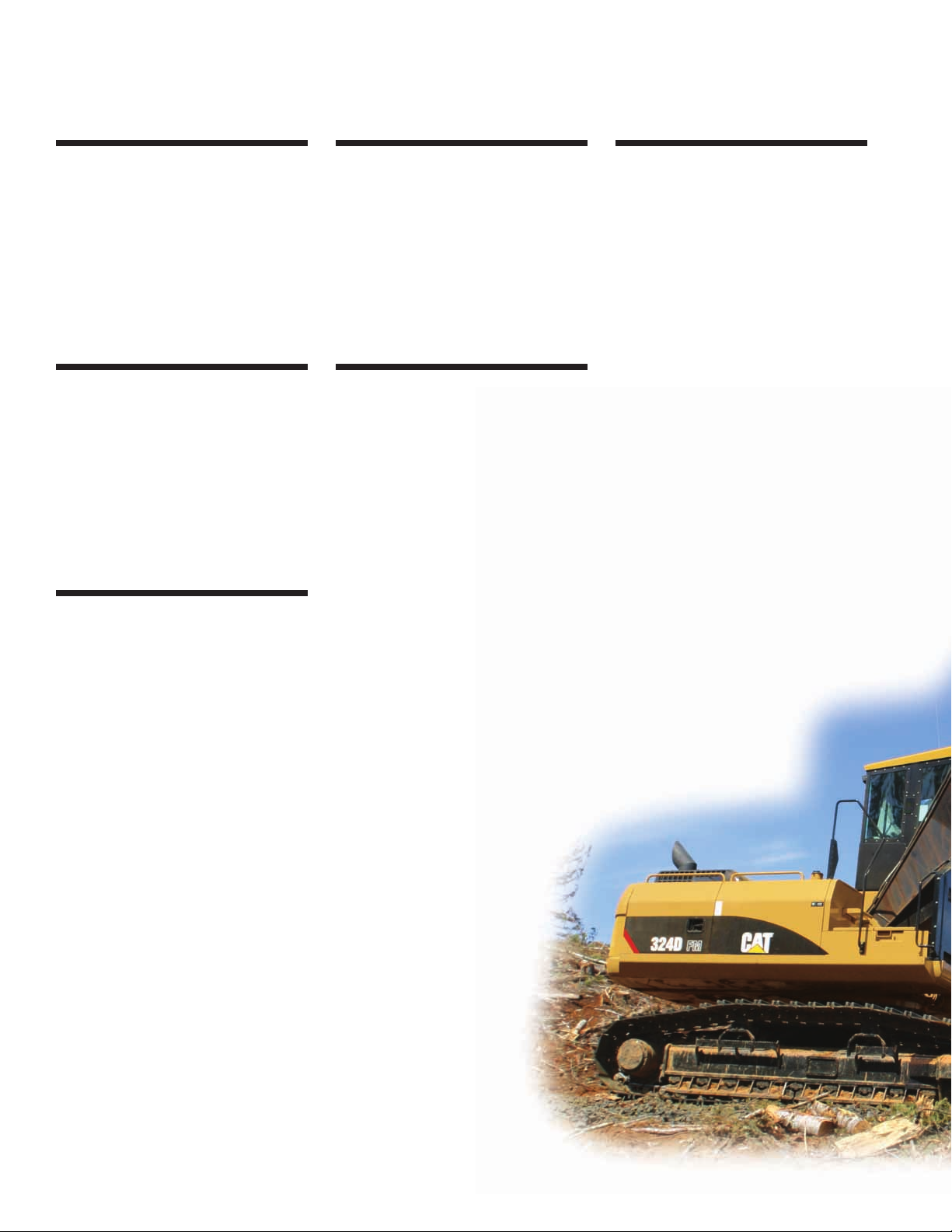

324D FM

Forest Machine

®

®

Page 2

2

324D FM Forest Machine

The D Series incorporates innovations for improved performance, rugged durability

and maximum productivity.

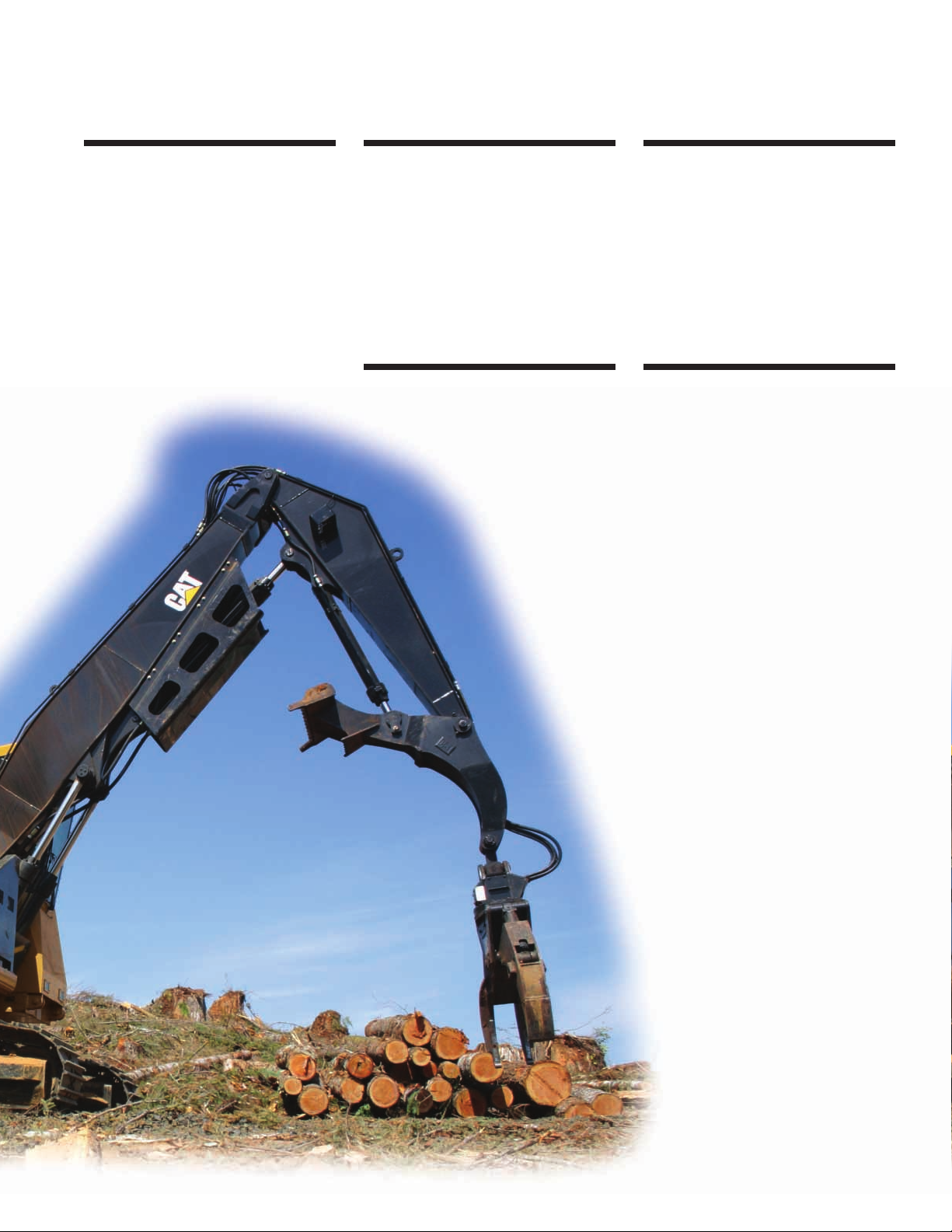

Caterpillar®Grapples

Cat®Log Loading Grapples combined

with Cat Forest Machines make the

324D FM flexible, versatile and efficient

enough, allowing you to maximize

productivity on your forestry job. pg. 12

Versatility

Designed and purpose-built to meet

diverse forestry applications, the

324D FM can help improve productivity

in various forestry and millyard

applications. pg. 11

Operator Comfort

Spacious purpose built forestry cab with

excellent sightlines to the work area

with 8 lights and all scratch resistant

polycarbonate windows. pg. 6

Hydraulics

Forest Machine hydraulic systems

are designed to provide reliability,

outstanding controllability and proven

performance in various forestry

applications. pg. 5

Power Train

The Cat®C7 with ACERT™ Technology

gives the 324D FM exceptional power

and fuel efficiency unmatched in the

industry. The C7 meets U.S. EPA Tier 3

emissions requirements. pg. 4

Customer Focus

Down time is minimized by the utilization

of a worldwide computer network that

can help find in-stock parts and minimize

your down time. Your Cat dealer can

also offer a wide range of other services

that can be set up to meet your equipment

needs. The dealer will help choose the

plan that can cover everything from

machine and attachment selection to

replacement. pg. 15

Page 3

✔ New Feature

3

Serviceability

The new FM cooling package provides

easy access to all radiator cores for

faster cleanouts. Regularly scheduled

maintenance extends machine service

life and lowers overall operating costs.

pg. 14

Owning and Operating Costs

Proven fuel efficiency combined with

easier access and extended service

intervals maximize uptime, reduce

operating costs and maximize

productivity. pg. 13

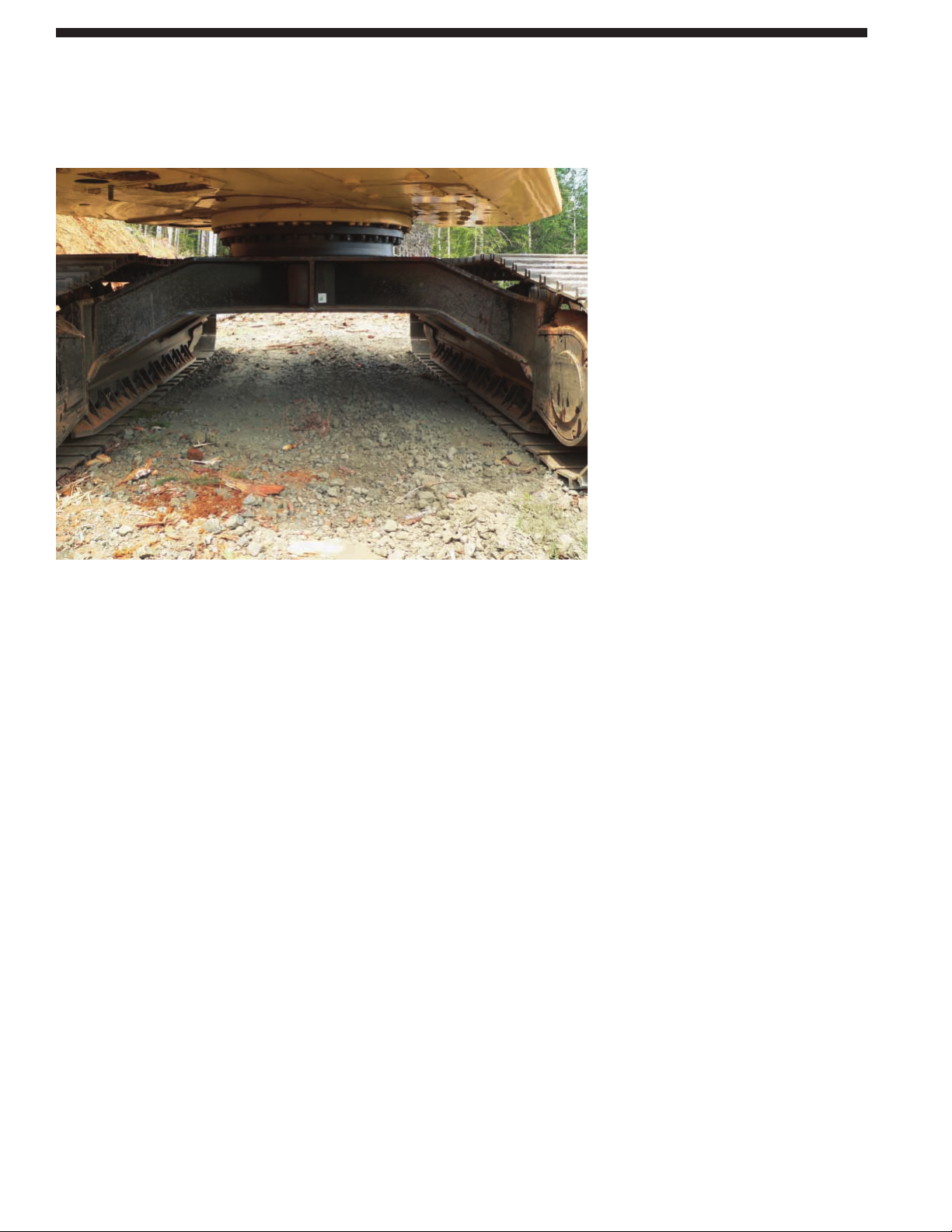

Undercarriage

Heavy Duty link assemblies provide

toughness and durability. The FM track

will maximize undercarriage life and

minimize operating costs. pg. 10

Guarding

Factory forestry cab guarding, shoe

support guards and heavy-duty access

doors help extend component life,

reduces downtime and helps to protect

your forestry machine investment. pg. 9

Structures

Purpose-built carbody design uses the

most advanced manufacturing processes,

ensuring durability and reliability in the

most rugged forestry applications. pg. 8

Page 4

Cat C7 ACERT™. The Cat®C7 with

ACERT™ Technology gives the

324D FM exceptional power and fuel

efficiency unmatched in the industry.

The C7 meets U.S. EPA Tier 3 emissions

requirements. The forestry designed

hydraulics give the 324D FM exceptional

power, efficiency and controllability

unequaled in the industry for consistently

high performance in all forestry

applications.

Performance. The 324D FM is equipped

with the C7 ACERT engine, which

provides 12% more horsepower as

compared to the 3126B ATAAC

HEUI™ engine.

Automatic Engine Speed Control.

The two-stage, one-touch control

maximizes fuel efficiency and reduces

sound levels.

ADEM™ A4 Engine Controller.

The ADEM A4 electronic control module

manages fuel delivery to get the best

performance per liter of fuel used.

The engine management system provides

flexible fuel mapping, allowing the

engine to respond quickly to varying

application needs. It tracks engine and

machine conditions while keeping the

engine operating at peak efficiency.

Electronic Control Module.

The Electronic Control Module (ECM)

works as the “brain” of the engine’s

control system, responding quickly to

operating variables to maximize engine

efficiency. Fully integrated with sensors

in the engine’s fuel, air, coolant, and

exhaust systems, the ECM stores and

relays information on conditions such as

RPM, fuel consumption, and diagnostic

information.

Fuel Delivery. The Cat C7 ACERT

features electronic controls that govern

the fuel injection system. Multiple

injection fuel delivery involves a high

degree of precision. Precisely shaping

the combustion cycle lowers combustion

chamber temperatures, generating

fewer emissions and optimizing fuel

combustion. This translates into more

work output for your fuel cost.

Cooling System. The cooling fan

is directly driven from the engine.

An optional programmable reversible

fan allows for radiator blowout, to

increase service intervals and to maintain

engine operational temperatures.

The optimum fan speed is calculated

based on the target engine speed, coolant

temperature, hydraulic oil temperature

and actual fan speed. The Cat C7 ACERT

delivered a completely new layout that

separates the cooling system from the

engine compartment.

Air Cleaner. The radial seal air filter

features a double-layered filter core for

more efficient filtration and is located in

a compartment behind the cab. A warning

is displayed on the monitor when dust

accumulates above a preset level.

Noise Reduction Technologies.

The engine mounts are rubber-isolating

mounts matched with the engine package.

Further noise reduction has been achieved

through design changes to the isolated

top cover, oil pan, multiple injection

strategy, insulated timing cover, sculpted

crankcase and gear train refinements.

4

Power Train

The Cat®C7 has exceptional power and fuel efficiency unmatched in the industry

for consistently high performance in both forestry and millyard applications.

Page 5

Component Layout. The 324D FM

hydraulic system and component

locations have been designed to provide

a high level of system efficiency.

The main pumps, control valves and

hydraulic tank are located close together

to allow for shorter tubes and lines

between components that reduce friction

loss and pressure drops in the lines.

The layout further provides greater

operator comfort by placing the radiator

on the cab side of the upper structure.

This allows incoming air to enter the

engine compartment from the operator

side and hot air and corresponding

engine sound to exit on the opposite

side away from the operator. This reduces

engine compartment heat and sound

being transmitted to the operator.

Pilot System. The pilot pump is

independent from the main pumps and

controls the front linkage, swing and

travel operations.

Hydraulic Cross Sensing System.

The hydraulic cross sensing system

improves productivity with faster

implement speeds and quicker, stronger

pivot turns.

Boom and Stick Regeneration Circuit.

Boom and stick regeneration circuit

saves energy during boom-down and

stick-in operation which increases

efficiency, reduces cycle times and

pressure loss for higher productivity,

lower operating costs and increased

fuel efficiency.

Fine Swing Control. Standard fine swing

control cushions start and stop for better

implement control.

Controllability. The hydraulic system

offers precise control to the 324D FM

reducing operator fatigue, improving

operator effectiveness and efficiency,

which ultimately translates into

enhanced performance.

Auxiliary hydraulic Valve. The auxiliary

valve is standard on the 324D FM.

Control Circuits are available as

attachments, allowing for operation

of high and medium pressure tools

such as grapples.

Hydraulic Cylinder Snubbers. Snubbers

are located at the rod-end of the boom

cylinders and both ends of the stick

cylinders to cushion shocks, reduce

sound and increase cylinder life,

increasing uptime and productivity.

5

Hydraulics

Cat®hydraulics provide the power and control needed for a variety of applications.

Page 6

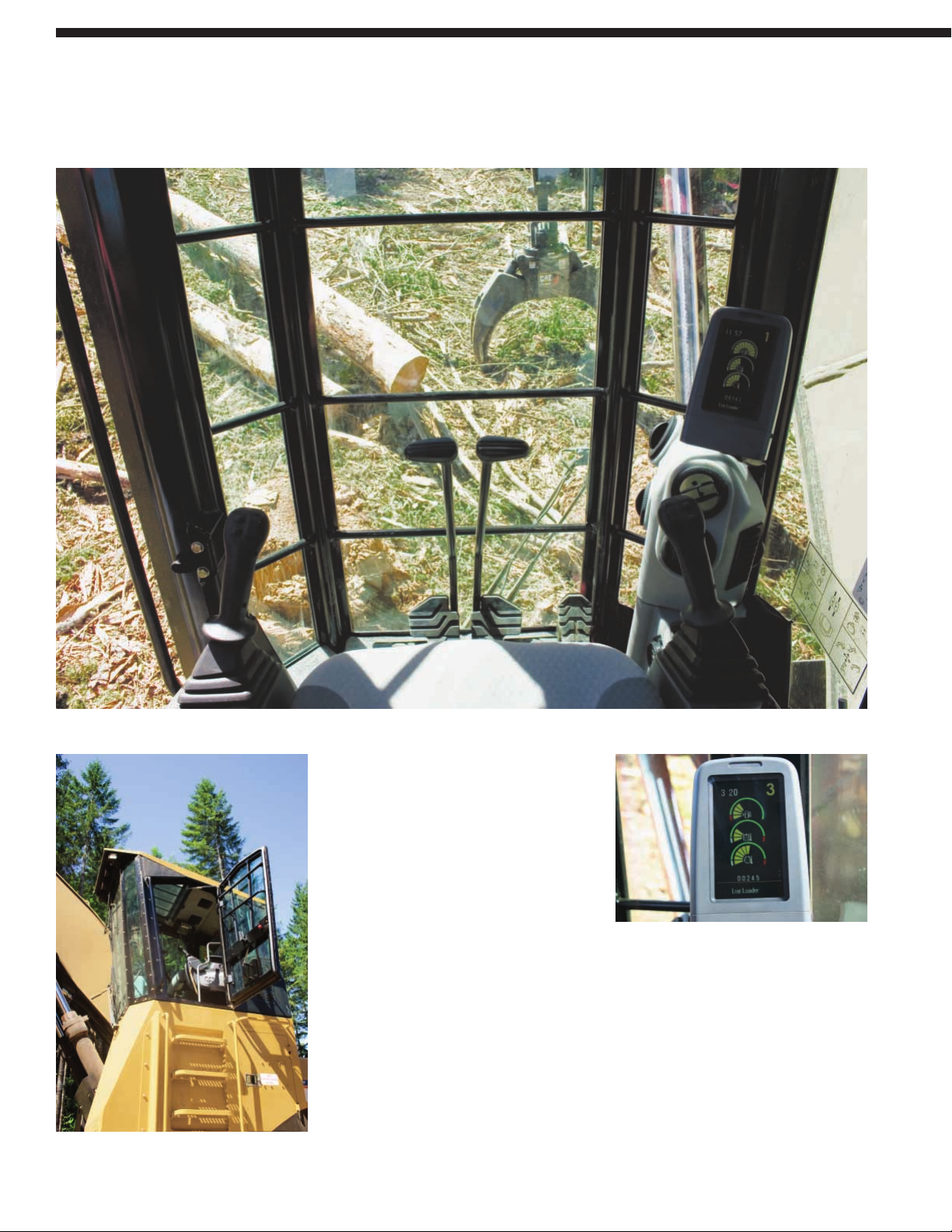

Operator Station. The workstation

is spacious, quiet and comfortable,

assuring high productivity during a

long work day. Controls, joysticks and

an ergonomically designed seat reduces

operator fatigue.

Pre-Start Check. Prior to starting the

machine, the system will check for low

fluid levels for the engine oil, hydraulic

oil and engine coolant and warn the

operator through the monitor in the

event display area.

Monitor. The monitor is a full color

400 234 pixels Liquid Crystal

Display (LCD) graphic display.

The monitor angle can be adjusted to

minimize sun glare and has the capability

of displaying information 27 different

languages.

6

The purpose built forestry cab interior layout maximizes operator space, provides

exceptional comfort, provides excellent sightlines and reduces operator fatigue.

Operator Comfort

Page 7

Gage Display. Three analog gauges,

fuel level, hydraulic oil temperature

and coolant temperature, are displayed

in this area.

Event Display. Machine information is

displayed in this area with the icon and

language.

Multi-Information Display. This area

is reserved for displaying various

information which is convenient for the

operator. The “Cat” logo is displayed

when no information is available to be

displayed.

Seat. Seat provides a variety of

adjustments to suit the operator’s size

and weight including fore/aft, height and

weight. Wide adjustable armrests and a

retractable seat belt are also included.

Joystick Control. Joystick controls have

low lever effort and are designed to

match the operator’s natural wrist and

arm position. The operator can operate

joystick controls with an arm on the

armrest and the horizontal and vertical

strokes have been designed to reduce

operator fatigue. Exclusive proportional

control and push buttons are

programmable to operator personal

preferences, allowing maximum

productivity.

Hydraulic Activation Control Lever.

For added safety, this lever must be

in the operate position to activate the

machine control functions.

Console. Redesigned consoles feature

a simple, functional design to reduce

operator fatigue, ease of switch operation

and excellent visibility.

Skylight. An enlarged skylight with

sunshade provides excellent upwards

visibility.

Viewing. Cab design optimizes post

structures, and scratch-resistant

polycarbonate window placement to

provide excellent operator visibility

to front, sides and rear. Forestry cab

is designed with heavy-duty guarding,

meeting FOPS/OPS/FOGS/TOPS

and CB requirements.

7

Page 8

Rugged main frame design

maximizes durability.

• Outer frame utilizes curved side

rails, which are di-formed for

excellent uniformity and strength.

• Box-section channels improve upper

frame rigidity under the cab.

• Inverted U-channels span the width

of the main frame and are formed,

rather than fabricated, for superior

strength and reduced weight.

• Boom tower and main rails are

constructed of solid, high-tensile

strength, steel plates.

• Boom foot and engine mount areas

are reinforced for additional strength.

• Sheet metal supporting structure is

improved by integrating the mounting

into the upper frame structure.

Carbody Design. Advanced, reinforced,

purpose-built carbody design stands

up in the toughest forest applications.

Carbody Structure. Wide, tall, and thick

carbody structure provides operating

stability and durability while improving

operation’s effectiveness.

• Upper structure weight and stresses

are distributed evenly across the

full length of the track roller frame.

• Smooth transitions and long welds

help reduce stresses at the carbodyto-roller frame junctions for

excellent durability.

• Robot welding helps ensure

consistent, high-quality welds

throughout the manufacturing

process.

8

Structures

Purpose-built forest applications with reinforced carbody, rugged swing bearing,

heavy doors and extra guarding.

Page 9

Shoe Support Guards. Standard full

length track shoe support guards help

protect rollers and provide increased

rigidity to track links in rough underfoot

conditions.

Factory Forestry Cab. Caterpillar factory

forestry designed and built FOPS cab

has options for windshield guard and

window guards to meet local guarding

requirements. The right side and rear

windows are made from impact

resistant polycarbonate.

Heavy-Duty Access Doors. Heavy-duty

access doors are standard on the

324D FM and are made from 6 mm

(0.24 in), high-strength, low alloy steel.

Positive locking latch stays closed in

forestry applications. Hinges have larger

diameter pins over standard doors.

The smooth door profile enhances

machine appearance.

9

Guarding

Caterpillar guarding protects your forestry machine investment.

Page 10

Heavy-Duty Top Rollers. Track rollers

with dual supports replace carrier rollers

to assure superior endurance.

Heavy-Duty Track Rollers. Heavy-duty

track rollers stand up to the toughest

forest applications. Features include

greater sealability, higher resistance to

deformation and greater load carrying

capacity.

Heavy-Duty Grease Lubricated Track.

The 325 HD Track Link with 203 mm

(8 inch) pitch and 8 bottom rollers is

standard on the 324D FM.

1) Grease Lubricated Track.

• Extends internal bushing wear life

• Reduces noise

• Provides more usable horsepower

because of decreased internal friction

• Reduces chance for frozen

track joints

2) 10% Larger Bushing Diameter.

• Extends external bushing wear life

3) Greased Pin and Larger Bushing

Combined.

• Extends system life

• Reduces sprocket wear because

the system stays matched longer

• Improves balance in component

wear life

4) 15% Increase in Link Height

• Increases link wear life

5) 36% Wider Bushing Strap

• Improves bushing-to-link retention

6) Unique Pin Retention System

• Locks the pin to the link

10

Undercarriage

Durable undercarriage absorbs stresses and provides excellent stability.

Page 11

The Caterpillar Log Loader is Purpose

Built. The Caterpillar log loader is

purpose built for forest applications.

Completely assembled, heel-type log

loaders (including grapple) are available

from the factory.

The Caterpillar Heel-Type Loader

Arrangements. The Caterpillar heel-type

loader arrangements fit a wide variety

of log handling and loading applications

in the woods and millyards. Heel booms

are especially well-suited for use with

large diameter saw logs and tree

length loads.

Caterpillar Roadbuilders. Caterpillar

Roadbuilders can be equipped with

buckets, thumbs, clamshells and

clearing grapples to fit a wide range

of forest road jobs.

Applications Include. Moving rightof-way logs, stumping, pioneering,

stripping organic material, excavating

shot rock, truck loading, back sloping,

ditching, finish grading and slash piling.

The Caterpillar 324D FM Delimber

Carrier. The Caterpillar delimber

carrier can be fit with a variety of

AEM delimbers.

11

Versatility

A wide selection of Forest Machine configurations meet diverse forestry applications

and improve your productivity.

Page 12

Cat 360 Degree Continuous Rotating

Log Loader Grapples. Cat 360 Degree

Continuous Rotating Log Loading

Grapples for Forestry Machines are

high capacity tools, built for endurance

in high-volume logging applications.

GLL grapple legs are made of highstrength alloy steel with unique leg

profiles for maximum performance in

picking/sorting, bunching/loading or

shoveling applications. Large bunches

of stems or single large logs are easily

handled by the wide grapple opening

1524 mm (60 inch), while interlocking

legs close down to 127 mm (5 inch) for

picking and sorting. Cat grapples have

bolt-on access panels allowing for easy

serviceability and are backed by the

world-class Caterpillar Dealer Network.

360-Degree Continuous Rotation.

High torque hydraulic motor positions

the grapple precisely for rapid sorting

and loading.

Hydraulic Cylinders. Heavy-duty wall

construction delivers durability and

maximum closing power move the

maximum amount of wood per pass.

Legs. Built with high-strength alloy steel

for maximum durability. Optimized

profile performs equally well whether

sorting, bunching or shoveling.

Pin. Induction-hardened alloy pins float,

decreasing wear.

Serviceability. Bolt-on access panels

protect the grapples internal components,

while providing easy access. Long service

intervals and infield servicing result in

more uptime and lower operating costs.

12

Caterpillar Grapples

Caterpillar Forest Machines combined with Cat Log Loading Grapples mean optimal

performance, reliability and on-the-job productivity.

GLL Specifications/Dimensions

GLL52B GLL55B GLL60B

Weight (kg/lb) 1255/2,767 1291/2,840 1344/2,965

Width (mm/in) 1725/68 1765/70 1935/76

A Height, open (mm/in) 2134/84 2184/86 2261/89

B Height, closed (mm/in) 2159/85 2210/87 2286/90

C Maximum Opening (mm/in) 1321/52 1397/55 1524/60

D Minimum Opening (mm/in) 127/5 127/5 127/5

Rotation, continuous 360° 360° 360°

Rotation torque

at 1,200 psi (N·m/ft lb) 1153/850 1153/850 1153/850

Matching Guide

GLL52B GLL55B GLL60B

320 FM

324 FM

325 FM

330 FM

Provides optimum machine match.

Provides acceptable machine match.

Page 13

ACERT™ Technology Fuel Economy.

Based on Caterpillar testing, the fuel

economy of Cat engines with ACERT

technology is 3 to 5 percent better

than current competing technologies.

This fuel economy is directly related to

the complete combustion of fuel due to

the integration between the electronic

control that monitors conditions, the air

management system that controls air

volume and the fuel injection system

that delivers just the right amount of

fuel as needed.

Radiator Compartment. The radial air

filter has a double layered filter core for

more efficient filtration and is located

in a compartment behind the cab.

Easy access doors allows for easy,

faster cleanout minimizing down time.

Heavy-duty screen filters assembled

on the door keep debris away from

the radiator compartment, extending

service intervals.

13

Owning and Operating Costs

Caterpillar Forest Machines provide the best value for your forestry and millyard applications.

Page 14

Ground Level Service. The design and

layout of the 324D FM was made with

the service technician in mind. Many

service locations are easily accessible

at ground level allowing critical

maintenance to get done quickly

and efficiently.

Air Filter Compartment. The air filter

features a double-element construction

for superior cleaning efficiency. When the

air cleaner plugs, a warning is displayed

on the monitor screen inside the cab.

Pump Compartment. A service door

on the right side of the upper structure

allows ground-level access to the pump

and pilot filter.

Radiator Compartment. The left rear

service door allows easy access to the

engine radiator, oil cooler and air-to-air

aftercooler. A reserve tank and drain

cock are attached to the radiator for

simplified maintenance.

Grease Lubricated Track. Grease

lubricated seals protect the track link

and deliver long track pin and bushing

inner wear life.

Capsule Filter. The hydraulic return

filter, a capsule filter, is situated outside

the hydraulic tank. This filter prevents

contaminants from entering the system

when hydraulic oil is changed and

keeps the operation clean.

Fan Guard. Engine radiator fan is

completely enclosed by fine wire mesh,

reducing the risk of an accident.

Anti-Skid Plate. Anti-skid plate covers

top of storage box and upper structure

to prevent slipping during maintenance.

Diagnostics and Monitoring.

The 324D FM is equipped with S•O•S

SM

sampling ports and hydraulic test ports

for the hydraulic system, engine oil,

and for coolant. A test connection for

the Cat Electronic Technician (Cat ET)

service tool is located in the cab.

Extended Service Interval. 324D FM

service and maintenance intervals have

been extended to reduce machine

service time and increase machine

availability.

14

Serviceability

Simplified service and maintenance features save you time and money.

Page 15

15

Product Support. You will find nearly

all parts at our dealer parts counter.

Cat dealers utilize a worldwide computer

network to find in-stock parts to minimize

machine down time. Save money with

remanufactured components.

Machine Selection. Make detailed

comparisons of the machines you are

considering before you buy. What are the

job requirements, machine attachments

and operating hours? What production

is needed? Your Cat dealer can provide

recommendations.

Customer Support Agreements.

Cat dealers offer a variety of product

support agreements, and work with

customers to develop a plan the best

meets specific needs. These plans can

cover the entire machine, including

attachments, to help protect the

customer’s investment.

Operation. Improving operating

techniques can boost your profits.

Your Cat dealer has videotapes, literature

and other ideas to help you increase

productivity, and Caterpillar offers

certified operator training classes to

help maximize the return on your

investment.

Maintenance Services. Repair option

programs guarantee the cost of repairs

up front. Diagnostic programs such

as Scheduled Oil Sampling, Coolant

Sampling and Technical Analysis

help you avoid unscheduled repairs.

Replacement. Repair, rebuild, or replace?

Your Cat dealer can help you evaluate

the cost involved so you can make the

right choice.

Customer Focus

Caterpillar dealer services help you operate longer with lower costs.

Page 16

16

324D FM Forest Machine specifications

Hydraulic System

Main Implement System – 220 L/min 58.1 gal/min

Maximum Flow (2x)

Max. pressure – Implements 35 000 kPa 5,075 psi

Max. pressure – Travel 35 000 kPa 5,075 psi

Max. pressure – Swing 24 500 kPa 3,553 psi

Pilot System – Maximum flow 36 L/min 9.5 gal/min

Pilot System – Maximum pressure 3920 kPa 568 psi

Boom Cylinder – Bore 135 mm 5.3 in

Boom Cylinder – Stroke 1305 mm 51.4 in

Stick Cylinder – Bore 140 mm 5.5 in

Stick Cylinder – Stroke 1660 mm 65.4 in

Log Loader Linkage

Boom Cylinder – Bore 140 mm 5.5 in

Boom Cylinder – Stroke 1185 mm 46.7 in

Stick Cylinder – Bore 170 mm 6.7 in

Stick Cylinder – Stroke 1680 mm 66.1 in

Under/Under Heel Cylinder – Bore 130 mm 5.1 in

Under/Under Heel Cylinder – Stroke 1156 mm 45.5 in

Over/Under Heel Cylinder – Bore 150 mm 5.9 in

Over/Under Heel Cylinder – Stroke 1470 mm 57.9 in

Swing Mechanism

Swing Torque – General Forestry 73.4 kN·m 54,147 lb ft

Swing Speed – General Forestry 10 rpm

Excavator Linkage

CB1 Family Bucket Cylinder – Bore 130 mm 5.1 in

CB1 Family Bucket Cylinder – Stroke 1156 mm 45.5 in

Standards

Brakes SAE J1026 APR90

Cab/FOGS/OPS/TOPS/FOPS SAE J1356 FEB88 ISO 10262/

SAE J1084/ISO 8084/

OR-OSHA 437-007-0775/

WCB G602, G603, G604,

G608

Engine

Engine Model Cat®C7 ACERT™

Net Flywheel Power 140 kW 188 hp

ISO 9249 140 kW 188 hp

J1349 139 kW 186 hp

EEC 80/1269 140 kW 188 hp

Bore 110 mm 4.3 in

Stroke 127 mm 5 in

Displacement 7.2 L 440 in

3

• The 324D FM meets U.S. EPA Tier 3 and EU Stage IIIa

emissions requirements.

• Net power advertised is the power available at the flywheel

when the engine is equipped with fan, air cleaner, muffler,

and alternator.

• No engine derating required below 2300 m (7500 ft) altitude.

Weights

General Forestry (HW) 31 226 kg 68,853 lb

Log Loader (U/U) 34 300 kg 75,698 lb

Log Loader (O/U) 34 484 kg 76,037 lb

• Operating weight with front linkage, without bucket or grapple.

Service Refill Capacities

Fuel Tank 520 L 137.4 gal

Fuel Tank – Optional Auxiliary 410 L 108.3 gal

Right Front

Optional Counterweight with 490 L 129.5 gal

Fuel Tank

Maximum Fuel with all 1420 L 375.2 gal

Optional Tanks

Cooling System 30 L 7.9 gal

Engine Oil 34 L 9 gal

Swing Drive 8 L 2.1 gal

Hydraulic System (including tank) 245 L 64.7 gal

Hydraulic Tank 145 L 38 gal

Final Drive (each) 8 L 2 gal

Drive

Maximum Travel Speed 5.7 km/h 3.5 mph

Maximum Drawbar Pull 259 kN 58,226 lb

Page 17

17

324D FM Forest Machine specifications

Dimensions

All dimensions are approximate.

4

1

2

6

7

4

2

324D FM General Forestry HW GF

1 Shipping height. (All risers with cab tilted) 3310 mm (10'10")

2 Boom height 3170 mm (10'5")

3 Overall height 4020 mm (13'2")

4 Shipping length 9880 mm (32'5")

5 Tail swing radius 2940 mm (9'8")

6 Length to centers of rollers 3780 mm (12'5")

7 Track length 4670 mm (15'4")

8 Ground clearance 710 mm (2'4")

9 Track gauge 2920 mm (9'7")

10 Transport width with 700 mm (27.5") shoes (DG) 3620 mm (11'11")

2

5

3

8

6

7

9

10

4

6

7

324D FM Log Loaders Under/Under Over/Under

1 Shipping height. (All risers with cab tilted) 3310 mm (10'10") 3310 mm (10'10")

2 Boom height 2780 mm (9'1") 2760 mm (9'1")

3 Overall height 4790 mm (15'9") 4790 mm (15'9")

4 Shipping length 14 080 mm (46'2") 14 990 mm (49'2")

5 Tail swing radius 2940 mm (9'8") 2940 mm (9'8")

6 Length to centers of rollers 3780 mm (12'5") 3780 mm (12'5")

7 Track length 4670 mm (15'4") 4670 mm (15'4")

8 Ground clearance 710 mm (2'4") 710 mm (2'4")

9 Track gauge 2920 mm (9'7") 2920 mm (9'7")

10 Transport width with 700 mm (27.5") shoes (DG) 3620 mm (11'11") 3620 mm (11'11")

Page 18

18

324D FM Forest Machine specifications

324D FM Working Ranges

Heel Boom (Under/Under, Over/Under), and Reach ranges

Feet

45

40

35

30

25

20

15

10

10

15

20

Heel Boom

(Under/Under)

Meters

14

13

12

11

10

9

8

7

6

5

4

3

2

5

1

0

0

1

5

2

3

4

5

6

1112 10 9

87654

3040 15202535 10 5 -50

321 -10

Meters

Feet

Feet

45

40

35

30

25

20

15

10

10

15

20

Meters

14

13

12

11

10

9

8

7

6

5

4

3

2

5

1

0

0

1

5

2

3

4

5

6

1112 10 9

Heel Boom

(Over/Under)

87654

3040 15202535 10 5 -50

321 -10

Meters

Feet

Feet

35

30

25

20

15

10

10

15

20

General Forestry

HW U/C, 5.9 m (19'4") Boom

with 2.95S Stick

Meters

10

9

8

7

6

5

4

3

2

5

1

0

0

1

5

2

3

4

5

6

7

01234567891011 -1

Meters

05101520253035 Feet

Page 19

19

324D FM Forest Machine specifications

324D FM LL Heel Boom Under/Under Lift Capacities

CONFIGURATION – 11.6 m (38') Boom/Stick/Heel Linkage,

SHOES – 700 mm (28") Double Grouser

Heavy Counterweight

Load

Point Over Over Over Over Over Over Over Over Over Over Over Over m

Height Front Side Front Side Front Side Front Side Front Side Front Side ft

10.5 m kg *8850 *8850 *7850 6800 *7600 5900 8.03

35.0 ft lb *19,400 *19,400 *17,250 14,350 *17,100 13,450 25.73

9.0 m kg *7500 7000 6550 5000 6000 4550 9.37

30.0 ft lb *18,650 *18,650 *16,400 14,950 13,900 10,550 13,500 10,200 30.38

7.5 m kg *8600 *8600 *7500 7000 *6600 5100 5100 3850 10.32

25.0 ft lb *18,750 *18,750 *16,350 15,050 14,200 10,850 11,400 8,550 33.65

6.0 m kg *9050 *9050 *7700 6900 6600 5050 5050 3800 4600 3450 10.98

20.0 ft lb *19,600 *19,600 *16,700 14,800 14,150 10,800 10,750 8,050 10,150 7,600 35.93

4.5 m kg *10 500 *10 500 *9700 9600 *8000 6700 6500 4950 5000 3750 4300 3200 11.41

15.0 ft lb *23,500 *23,500 *21,000 20,650 *17,350 14,350 13,950 10,600 10,700 8,050 9,500 7,050 37.39

3.0 m kg *10 400 9100 *8300 6400 6350 4800 4950 3700 *4100 3100 11.63

10.0 ft lb *22,450 19,550 *17,900 13,750 13,600 10,250 10,600 7,900 *9,100 6,800 38.14

1.5 m kg *10 750 8600 8150 6150 6200 4650 4850 3650 *3550 3050 11.65

5.0 ft lb *23,250 18,450 17,550 13,150 13,250 9,950 10,450 7,750 *7,850 6,750 38.22

Ground kg *10 200 *10 200 *10 450 8200 7950 5900 6050 4500 *4700 3550 *2900 *2900 11.47

Line lb *24,650 *24,650 *22,550 17,600 17,050 12,700 13,000 9,700 *9,850 7,650 *6,350 *6,350 37.63

–1.5 m kg *11 050 *11 050 *9300 7950 *7200 5750 *5450 4450 *3550 3550 *2550 *2550 10..97

–5.0 ft lb *25,900 *25,900 *20,100 17,150 *15,450 12,400 *11,600 9,550 *7,100 7,650 *5,550 *5,550 35.96

–3.0 m kg *9100 *9100 *7300 *7300 *5650 *5650 *3950 *3950 *3000 *3000 9.69

–10.0 ft lb *19,600 *19,600 *15,700 *15,700 11,950 11,950 *8,100 *8,100 *6,650 *6,650 31.57

4.5 m/15.0 ft 6.0 m/20.0 ft 7.5 m/25.0 ft 9.0 m/30.0 ft 10.5 m/35.0 ft

* Limited by hydraulic capacity rather than tipping load. The above loads are in compliance with hydraulic excavator lift capacity standard ISO 10567.

They do not exceed 87% of hydraulic lifting capacity or 75% of tipping capacity.

Weight of all lifting accessories must be deducted from the above lifting capacities.

Load at

Maximum Reach

324D FM LL Heel Boom Over/Under Lift Capacities

CONFIGURATION – 12.2 m (40') Boom/Stick/Heel Linkage,

Heavy Counterweight

Load

Point Over Over Over Over Over Over Over Over Over Over Over Over Over Over Over Over m

Height Front Side Front Side Front Side Front Side Front Side Front Side Front Side Front Side ft

10.5 m kg *7450 7150 6700 5100 8.86

35.0 ft lb *16,350 15,150 *15,150 11,600 28.51

9.0 m kg *7200 *7200 *6500 5250 5400 4100 10.09

30.0 ft lb *15,750 *15,550 *14,150 11,100 12,100 9,150 32.76

7.5 m kg *7250 *7250 *6450 5250 5150 3900 4700 3500 10.98

25.0 ft lb *15,750 *15,550 *14,000 11,250 10,950 8,300 10,400 7,800 35.81

6.0 m kg *7450 7100 *6500 5200 5150 3900 4250 3200 11.60

20.0 ft lb *16,150 15,250 *14,100 11,100 11,050 8,350 9,400 7,000 37.95

4.5 m kg *9300 *9300 *7750 6850 6600 5050 5100 3850 4000 2950 4000 2950 12.01

15.0 ft lb *20,100 *20,100 *16,850 14,700 14,200 10,800 10,900 8,250 8,800 6,550 39.34

3.0 m kg *10 050 9300 *8100 6550 6400 4850 5000 3750 4000 2950 *3850 2850 12.21

10.0 ft lb *21,700 20,000 *17,550 13,800 13,800 10,450 10,700 8,050 8,550 6,300 8,500 6,300 40.06

1.5 m kg *10 550 8700 8250 6200 6200 4650 4900 3650 *3900 2950 *3350 2850 12.23

5.0 ft lb *22,800 18,700 17,700 13,300 13,350 10,000 10,500 7,800 *7,700 6,250 *7,400 6,250 40.13

Ground kg *13 000 12 650 *10 500 8200 7950 5900 6050 4500 4800 3550 *3000 2900 *2750 *2750 12.06

Line lb *31,050 27,150 *22,700 17,600 17,050 12,700 13,000 9,650 10,300 7,650 *6,050 *6,050 39.57

–1.5 m kg *11 500 *11 500 *9650 7850 *7450 5700 *5800 4400 *4250 3500 *2300 *2300 11.63

–5.0 ft lb *26,900 26,100 *20,900 16,900 *16,100 12,250 *12,400 9,450 *8,800 7,550 *5,050 *5,050 38.13

–3.0 m kg *6350 *6350 *10 250 *10 250 *8000 7750 *6200 5600 *4600 4350 *2750 *2750 *2600 *2600 10.57

–10.0 ft lb *14,500 *14,500 *22,100 *22,100 *17,200 16,650 *13,250 12,100 *9,650 9,350 *5,750 *5,750 34.51

–4.5 m kg *5500 *5500 *4150 *4150 *3800 *3800 7.88

15.0 ft lb *11,600 *11,600 *8,850 *8,850 24.65

–

* Limited by hydraulic capacity rather than tipping load. The above loads are in compliance with hydraulic excavator lift capacity standard ISO 10567.

They do not exceed 87% of hydraulic lifting capacity or 75% of tipping capacity.

Weight of all lifting accessories must be deducted from the above lifting capacities.

3.0 m/10.0 ft 4.5 m/15.0 ft 6.0 m/20.0 ft 7.5 m/25.0 ft 9.0 m/30.0 ft 10.5 m/35.0 ft 12.0 m/40.0 ft

SHOES – 700 mm (28") Double Grouser

Load at

Maximum Reach

Always refer to the appropriate Operation and Maintenance Manual for specific product information.

Page 20

20

324D FM Forest Machine specifications

324D FM GF Reach Boom Lift Capacities

CONFIGURATION – 5.9 m (19'4") Boom, 2.95 m (9'8") Stick,

SHOES – 700 mm (28") Double Grouser

Standard Counterweight

Load

Point Over Over Over Over Over Over Over Over Over Over m

Height Front Side Front Side Front Side Front Side Front Side ft

7.5 m kg *6650 *6650 *5450 *5450 6.67

25.0 ft lb *14,700 *14,700 *12,050 *12,050 21.56

6.0 m kg *6900 *6900 *5950 5950 *5250 *5250 7.67

20.0 ft lb *15,050 *15,050 *13,100 13,100 *11,600 *11,600 24.99

4.5 m kg *9200 *9200 *7750 *7750 *7000 *7000 *5300 *5300 8.27

15.0 ft lb *19,800 *19,800 *16,800 *16,800 *15,350 *15,350 *11,650 *11,650 27.06

3.0 m kg *11 650 *11 650 *8850 *8850 *7550 6950 *5550 *5550 8.57

10.0 ft lb *25,000 *25,000 *19,200 *19,200 *16,400 14,950 *12,150 *12,150 28.10

1.5 m kg *13 550 *13 550 *9900 9200 *8100 6800 *6000 5650 8.60

5.0 ft lb *29,250 *29,250 *21,450 19,850 *17,550 14,650 *13,150 12,450 28.20

Ground kg *6300 *6300 *14 300 13 600 *10 500 9000 *8400 6700 *6750 5800 8.35

Line lb *14,400 *14,400 *31,000 29,250 *22,800 19,400 *18,200 14,400 *14,850 12,800 27.40

–1.5 m kg *11 550 *11 550 *14 050 13 550 *10 550 8950 8250 6650 *7800 6350 7.81

–5.0 ft lb *26,150 *26,150 *30,500 29,150 *22,800 19,250 17,800 14,350 *17,200 13,950 25.58

–3.0 m kg *17 750 *17 750 *12 850 *12 850 *9700 9000 *8100 7500 6.90

–10.0 ft lb *38,400 *38,400 *27,800 *27,800 *20,850 19,400 *17,800 16,600 22.52

–4.5 m kg *10 100 *10 100 *8100 *8100 5.44

–15.0 ft lb *21, 500 *21, 500 *17,800 *17,800 17.55

* Limited by hydraulic capacity rather than tipping load. The above loads are in compliance with hydraulic excavator lift capacity standard ISO 10567.

They do not exceed 87% of hydraulic lifting capacity or 75% of tipping capacity.

Weight of all lifting accessories must be deducted from the above lifting capacities.

Always refer to the appropriate Operation and Maintenance Manual for specific product information.

3.0 m/10.0 ft 4.5 m/15.0 ft 6.0 m/20.0 ft 7.5 m/25.0 ft

Load at

Maximum Reach

Forestry Grapples

Specification GLL 52 GLL 55 GLL 60

Part # 271-1533 271-1534 271-1535

For use with 320C FM, 324D FM 324D FM, 325D FM 325D FM, 330D FM

Rotation Continuous Continuous Continuous

Rotation torque 1153 N•m (850 ft-lb) 1153 N•m (850 ft-lb) 1153 N•m (850 ft-lb)

Max. Opening 1321 mm (52") 1397 mm (55") 1524 mm (60")

Min. Opening 126 mm (5") 126 mm (5") 126 mm (5")

Weight 1255 kg (2,767 lb) 1291 kg (2,840 lb) 1344 kg (2,965 lb)

Width 673 mm (26.5") 673 mm (26.5") 673 mm (26.5")

Height, open 2134 mm (84") 2184 mm (86") 2261 mm (89")

Page 21

21

324D FM Forest Machine specifications

Standard Equipment

Standard equipment may vary. Consult your Caterpillar dealer for details.

Power Train

Cat C7 with ACERT™ Technology U.S. EPA Tier 3

emissions compliant with 24-volt electric starting and

air intake heater

Automatic engine speed control with one touch low idle

Easy clean swing-out condenser

Easy clean swing out radiator

Muffler

Two speed auto-shift travel

Water separator in fuel line

Undercarriage

Hydraulic track adjusters

Track type undercarriage with grease lubricated seals

Idler and full-length track shoe support

Other Standard Equipment

Heavy-duty upper frame with catwalks, bottom guards,

heavy duty side doors

Core hydraulic lines and controls with standard main valves

on upper structures

Door locks, cap locks and Caterpillar one key security system

Automatic swing parking brake

Travel alarm

Counterweight with lifting eye

Right front corner guard

324D FM General Forestry Arrangement also includes:

Forestry cab, hydraulic tilt 457 mm (18 inch) riser

High-wide undercarriage

Heavy-Duty recoil springs

Heavy-Duty track roller frame

Heavy-Duty travel motor covers

Heavy-Duty swivel guard

Forestry Heavy-Duty upper frame with catwalk

Heavy-Duty bottom guard

Heavy-Duty side doors

Right front corner guard

Travel alarm

324D FM Log Loader Arrangement also includes:

Forestry cab

Hydraulic tilt 1219 mm (48 inch) riser

High-wide undercarriage

Heavy-Duty recoil springs

Heavy-Duty track roller frame

Heavy-Duty travel motor covers

Straight travel third pedal

Grapple/rotator hydraulic arrangement

Heavy-Duty swivel guard

Forestry Heavy-Duty upper frame with catwalk

Heavy-Duty bottom guard

Heavy-Duty side doors

Right front corner guard

Travel alarm

Electrical

80 Ampere alternator

4 Front working lights, cab top mounted

2 Front working lights, riser mounted

1 Left side working light, cab mounted

1 Rear working light, cab mounted

Horn

Operator Environment

Purpose built forestry cab with 8 lights and all scratch

resistant polycarbonate windows

Seat, four-way adjustable suspension seat with adjustable

armrest, retractable seat belt, headrest and lumbar support

Integrated seat, console and joystick type controls

Language display monitor with gauges

Warning information

• Filter/fluid change information

• working hour information

• machine condition

• error code and tool mode setting information

• start up level check for hydraulic oil, engine oil and

engine coolant

Full time clock on monitor (2 weeks)

Seat mounted joystick with extra functions for grapple

Fixed polycarbonate skylight with retractable sun shade

Interior lighting

Lower and upper windshield wipers and washer

Positive filtered ventilation, pressurized cab with bi-level air

conditioner, heater and defroster with manual control

Forced air fan

2 post mounted fresh air vents

Behind seat storage tray with tie down points

2 CB radio mounts

1 Fire extinguisher mount

1 Attachment computer control mount

Secondary roof exit openable from inside and outside

2 Coat hooks

Ashtray with lighter

Literature holder

Cup holder

Neutral lever for all controls

Travel control pedals with removable hand levers

Washable floor mat

Radio/CD player (12V)

1 Converter/2 sockets – 12V-10A power supply

Page 22

22

324D FM Forest Machine specifications

Optional Equipment

Optional equipment may vary. Consult your Caterpillar dealer for details.

Undercarriage (Track Shoes)

600 mm (24 in) Double Grouser Shoes with Trap Holes

700 mm (28 in) Heavy-Duty Double Grouser Shoes with

Trap Holes

800 mm (32 in) Heavy-Duty Triple Grouser Shoes with

Trap Holes

Electrical

Product Link (PL 321 SR)

General Optional Equipment

Auxiliary Pump Driver (for additional pump)

Right Front Corner Fuel Tank (additional 409 L – 108 gal)

Counterweight with Fuel Tank Adds (492 L – 130 gal)

Heavy Counterweight (additional 780 kg – 1,720 lb).

For General Forestry (Standard on Log Loader).

GLL and GLLS Family Grapples. For General Log Loader.

Front Linkage: For General Forestry

Reach Boom 5.9 m (19 ft 4 in)

Reach Stick 2.95 m (9 ft 8 in)

Bucket Linkage CB1 Family

Boom lowering Control Device

Front Linkage: For Log Loader

Over/Under Boom/Stick/Heel linkage 12.2 m (40 ft 0 in)

Under/Under Boom/Stick/Heel linkage 11.6 m (38 ft 0 in)

Stick Cylinder Guard

Hydraulic Arrangements: For General Forestry

Rotating Grapple (Standard on Log Loader)

Harvesting Head

Thumb

Auxiliary Hydraulic Lines: For General Forestry

Auxiliary lines HP& MP, Reach Boom

Auxiliary lines HP & MP, Reach Stick

Engine/Power Train

Auto Reverse Fan

Prefilter, air

Cold Weather Staring Aid

Extended Life Cooling with 50% concentration of

protection –34° C (–30º F)

Page 23

23

324D FM Forest Machine specifications

Notes

Page 24

For more complete information on Cat products, dealer services,

and industry solutions, visit us on the web at www.cat.com

© 2009 Caterpillar

All Rights Reserved

Printed in U.S.A.

Materials and specifications are subject to change without notice.

Featured machines in photos may include additional equipment.

See your Caterpillar dealer for available options.

CAT, CATERPILLAR, SAFETY.CAT.COM, ACERT, their respective logos, “Caterpillar Yellow”

and the POWER EDGE trade dress, as well as corporate and product identity used herein,

are trademarks of Caterpillar and may not be used without permission.

AEHQ5915-02 (1-09)

Replaces AEHQ5915-01

324D FM Forest Machine

R

Loading...

Loading...