Operating and installation

instructions

Washing machine

To avoid the risk of accidents or damage to the machine, it is essen-

tial to read these instructions before it is installed and used for the

first time.

en-GB M.-Nr. 11 713 010

Contents

Caring for the environment .............................................................................. 6

Warning and safety instructions ...................................................................... 7

Operating the washing machine ...................................................................... 15

Control panel....................................................................................................... 15

Symbols on the control panel ............................................................................. 16

Symbols in the display ........................................................................................ 17

Sensor controls and touch display with sensor controls .................................... 18

Standard menu.................................................................................................... 18

Examples of how to operate the appliance......................................................... 19

Before using for the first time .......................................................................... 20

Washing environmentally and economically .................................................. 24

Detergent............................................................................................................. 24

1. Preparing the laundry.................................................................................... 25

2. Loading the washing machine ..................................................................... 26

3. Selecting a programme and settings .......................................................... 27

4. Adding detergent........................................................................................... 29

5. Starting the programme – end of the programme ..................................... 31

Delay start .......................................................................................................... 32

Programme chart .............................................................................................. 33

Special features in the programme sequence................................................ 35

Spinning .............................................................................................................. 35

Anti-crease .......................................................................................................... 35

Changing the programme sequence............................................................... 36

Changing a programme....................................................................................... 36

Cancelling a programme ..................................................................................... 36

Switching on the washing machine after an interruption to the power supply ... 36

Adding or removing laundry ................................................................................ 37

Detergent ........................................................................................................... 38

The correct detergent.......................................................................................... 38

Recommended detergents in accordance with Directive (EU) No.

1015/2010 ...................................................................................................... 38

2

Contents

Cleaning and care ............................................................................................. 39

Cleaning the casing and fascia panel ................................................................. 39

Cleaning the detergent drawer............................................................................ 39

Cleaning the drum, suds container and drainage system................................... 41

Cleaning the water inlet filters ............................................................................. 41

Problem solving guide ...................................................................................... 42

The wash programme does not start .................................................................. 42

Programme cancellation and error message....................................................... 43

A fault message appears in the display .............................................................. 44

An unsatisfactory wash result ............................................................................. 45

General problems................................................................................................ 46

The door will not open......................................................................................... 48

Opening the door in the event of a blocked drain outlet and/or power cut ........ 49

Miele Service ..................................................................................................... 51

Contact in case of malfunction ........................................................................... 51

EPREL database ................................................................................................. 51

Optional accessories........................................................................................... 51

Installation.......................................................................................................... 52

Front view............................................................................................................ 52

Rear view............................................................................................................. 53

Installation locations............................................................................................ 54

Installation notes ................................................................................................. 54

Transporting the washing machine to its installation site.................................... 55

Installation surface .............................................................................................. 56

Removal of transit bars ....................................................................................... 56

Fitting the transit bars ......................................................................................... 58

Levelling the washing machine ........................................................................... 59

Holding bracket for plinth .............................................................................. 60

External control equipment ................................................................................. 62

Payment system............................................................................................. 62

Water connection ................................................................................................ 63

Cold water connection .................................................................................. 63

Drainage .............................................................................................................. 64

Drain pump..................................................................................................... 64

Electrical connection ........................................................................................... 65

Technical data.................................................................................................... 67

Conformity declaration........................................................................................ 68

3

Contents

Consumption data............................................................................................. 69

Supervisor level ................................................................................................. 70

Code-based access ............................................................................................ 70

Changing the code.............................................................................................. 70

Opening the Supervisor level .............................................................................. 70

Exiting the Supervisor level ................................................................................. 70

Language............................................................................................................. 71

Brightness ........................................................................................................... 71

Clock display....................................................................................................... 71

Finish tone volume .............................................................................................. 71

Keypad tone volume ........................................................................................... 71

Welcome tone volume......................................................................................... 71

Fault alarm........................................................................................................... 71

Memory ............................................................................................................... 71

Anti-crease .......................................................................................................... 72

Suds cooling........................................................................................................ 72

"Display" switch-off status.................................................................................. 72

Delay start ........................................................................................................... 73

Programme name................................................................................................ 73

Visibility parameters ............................................................................................ 73

Pre-wash water ................................................................................................... 74

Main wash water ................................................................................................. 74

First rinse water................................................................................................... 74

Final rinse water .................................................................................................. 74

Low water pressure............................................................................................. 75

Water level Cottons............................................................................................. 75

Water level Minimum iron.................................................................................... 75

Cottons Pre-wash temp ...................................................................................... 75

Wash time Pre-wash ........................................................................................... 75

Wash time Cottons.............................................................................................. 76

Wash time Minimum iron..................................................................................... 76

Pre-rinse Cottons ................................................................................................ 76

Pre-rinse Minimum iron ....................................................................................... 76

Pre-wash Cottons/Min. iron ................................................................................ 76

Cottons rinses ..................................................................................................... 76

Min. iron rinses .................................................................................................... 76

Temp reduction.................................................................................................... 77

Auto load control................................................................................................. 77

COM module selection........................................................................................ 77

WiFi/LAN ............................................................................................................. 77

Network time ....................................................................................................... 78

4

Contents

Remote................................................................................................................ 78

RemoteUpdate .................................................................................................... 79

SmartGrid ............................................................................................................ 79

Alternating current............................................................................................... 79

Heating ................................................................................................................ 79

Legal information................................................................................................. 80

Copyrights and licences for operator and control software ........................... 80

Payment system.................................................................................................. 80

Settings for payment systems........................................................................ 80

Feedback signal to pay system...................................................................... 81

Payment system lock ..................................................................................... 81

FOC programmes........................................................................................... 82

Delete paid signal........................................................................................... 82

Debounce time ............................................................................................... 82

5

Caring for the environment

Disposal of the packing material

The packaging is designed to protect

the appliance from damage during

transportation. The packaging materials

used are selected from materials which

are environmentally friendly for disposal

and should be recycled.

Recycling the packaging reduces the

use of raw materials in the manufacturing process and also reduces the

amount of waste in landfill sites.

Disposing of your old appliance

Electrical and electronic appliances often contain valuable materials. They

also contain specific materials, compounds and components, which were

essential for their correct function and

safety. These could be hazardous to human health and to the environment if

disposed of with your domestic waste

or if handled incorrectly. Please do not,

therefore, dispose of your old appliance

with your household waste.

Please dispose of it at your local community waste collection / recycling

centre for electrical and electronic appliances, or contact your dealer or

Miele for advice. You are also responsible for deleting any personal data that

may be stored on the appliance being

disposed of. Please ensure that your

old appliance poses no risk to children

while being stored prior to disposal.

6

Warning and safety instructions

This washing machine complies with all current local and national

safety requirements. However, inappropriate use can lead to personal injury and damage to property.

Read the operating instructions carefully before using the washing

machine. They contain important information on safety, installation, use and maintenance. This prevents both personal injury and

damage to the washing machine.

In accordance with standard IEC60335-1, Miele expressly and

strongly advises that you read and follow the instructions in the

chapter on installing the washing machine as well as the safety instructions and warnings.

Miele cannot be held liable for damage caused by non-compliance

with these instructions.

Keep these operating instructions in a safe place and pass them

on to any future owner.

When instructing other people how to use the washing machine,

they must be made aware of these safety and warning instructions.

Appropriate use

The washing machine is only suitable for washing fabrics with a

care label stating that they are suitable for machine washing. Any

other applications may be dangerous. The manufacturer cannot be

held liable for damage resulting from incorrect or improper use or

operation of the machine.

This washing machine must be used as described in the operating

instructions and must be checked on a regular basis to make sure it

is functioning correctly. Maintenance must be carried out when necessary.

The washing machine is not suitable for outdoor use.

This washing machine may also be operated in public areas.

7

Warning and safety instructions

This washing machine can only be used by people with reduced

physical, sensory or mental capabilities, or lack of experience or

knowledge, if they are supervised whilst using it or have been shown

how to use it in a safe way and understand and recognise the consequences of incorrect operation.

Children under the age of 8 must not be allowed near the washing

machine unless they are constantly supervised.

Children over the age of 8 may only use the washing machine

without supervision if its operation has been clearly explained to

them and they are able to use it safely. Children must be able to understand and recognise the possible dangers caused by incorrect

operation.

Children may not carry out cleaning or maintenance on the wash-

ing machine unsupervised.

Always supervise any children in the vicinity of the washing ma-

chine. Never allow children to play with the washing machine.

8

Warning and safety instructions

Technical safety

Before setting up the washing machine, check it for any externally

visible damage. Do not set up or use a damaged washing machine.

The electrical safety of the washing machine can only be guaran-

teed when correctly earthed.

It is most important that this basic safety requirement is tested and

in case of any doubt the on-site wiring system should be inspected

by a qualified electrician.

Miele cannot be held liable for the consequences of an inadequate

earthing system.

Unauthorised repairs could result in unforeseen dangers for the

user, for which the manufacturer cannot accept liability. Repairs

should only be undertaken by a Miele approved service technician,

otherwise any subsequent damage will not be covered by the warranty.

Do not make any alterations to the machine, unless authorised to

do so by Miele.

The machine must be isolated from the electricity supply when

cleaning and maintaining the machine and in the event of a fault:

- switch off at the wall and disconnect the plug from the socket, or

- disconnect the fuse at the mains circuit board, or

- unscrew the on-site screw-in fuse.

See “Installation – Electrical connection”.

9

Warning and safety instructions

If the electrical connection cable is faulty it must only be replaced

by a Miele authorised service technician to protect the user from

danger.

The washing machine must only be connected to the on-site wa-

ter supply using a new hose kit. Old hoses must not be re-used.

Check the hose regularly for signs of wear. Replace it in good time to

avoid the risk of leaks and subsequent damage.

Faulty components must only be replaced by genuine Miele ori-

ginal spare parts. Miele can only guarantee the safety standards of

the machine when Miele replacement parts are used.

For reasons of safety, do not connect the machine to the mains

electricity supply by an extension lead, multi-socket adapter, or similar. These can overheat and are a fire hazard.

In the case of commercial use, all relevant national provisions and

regulations (DGUV in Germany) relating to accident insurance are applicable to this machine. It is recommended to carry out testing in

accordance with national regulations (e.g. the regulatory framework

described in DGUV100-500/Chapter 2.6/Section 4). The test book

required for the documentation is available from Miele.

The machine must not be used in a non-stationary location (e.g.

on a ship).

Please observe the instructions in “Installation” and “Technical

data”.

If the washing machine is equipped with an electrical plug con-

nection, it must be easily accessible after installation so that the machine can be disconnected from the electricity supply if necessary.

10

Warning and safety instructions

If the appliance is hard wired, an on-site all pole circuit breaker

must always be accessible to disconnect the washing machine from

the mains.

Reliable and safe operation of this washing machine can only be

assured if it has been correctly connected to the mains electricity

supply.

While the washing machine is under warranty, repairs should only

be undertaken by a Miele authorised service technician. Otherwise

the warranty will be invalidated.

Correct use

The maximum dry laundry weight is 7.0kg. The maximum recom-

mended loads for individual programmes are given in the Programme

chart.

Do not install your washing machine in a room where temperat-

ures below freezing may occur. Frozen hoses may burst or split. The

reliability of the electronic control unit may be impaired at temperatures below freezing point.

Before using the machine for the first time, check that the transit

bars at the rear of the washing machine have been removed (see “Installation – Removing transit bars”). During spinning, transit bars

which are still in place may result in damage to both the machine

and adjacent furniture or appliances.

Close the stopcock if the machine is to be left for any length of

time (e.g. while on holiday), especially if there is no floor drain (gully)

in the immediate vicinity.

11

Warning and safety instructions

Danger of flooding! If hooking the drain hose into a wash basin,

check that the water can drain off quickly enough to prevent the sink

from overflowing. Hook the hose over the edge and secure. If the

hose is unsecured, the force of the water flowing out of it can dislodge it from the basin.

Take care to ensure that foreign objects (e.g. nails, pins, coins, pa-

per clips) do not find their way into the machine with the laundry.

These may damage components of the machine (e.g. suds container, drum). Damaged components can damage the laundry.

If the correct amount of detergent is dispensed, the machine

should not need to be descaled. If, however, you do wish to descale

it, only use special non-corrosive descaling agents and strictly observe the instructions on the packaging. Special descaling agent is

available from your Miele dealer or from Miele Service. Strictly observe the instructions for the descaling agent.

For textiles that have been treated with solvent-based detergents,

always check whether they can be washed in a washing machine. To

check whether this is possible, refer to safety notes, information concerning the product's environmental properties, and other information.

Never use solvent based detergents, e.g. those containing ben-

zine, in this machine. Doing so may result in damage to component

parts and create toxic fumes. Risk of fire and explosion.

Benzine, petrol, paraffin, or any easily flammable liquid must not

be stored or used near the machine. Risk of fire and explosion

12

Warning and safety instructions

Only use dyes suitable for use in a washing machine. Always ob-

serve the manufacturer's instructions carefully.

Colour run and dye removers contain sulphur compounds which

can cause damage such as corrosion. Do not use these products in

this washing machine.

Avoid contact between stainless steel surfaces (front, lid, casing)

and liquid detergents or disinfecting agents which contain chlorine or

sodium hypochlorite. These agents can have a corrosive effect on

stainless steel. Aggressive vapours containing chlorine can also be

corrosive. Do not store open containers of these agents near the machine.

Do not use a pressure washer or hose to clean the washing ma-

chine.

It is particularly important to observe manufacturer's instructions

when using a combination of cleaning agents and special application

products. Products must only be used for applications approved by

the manufacturer to avoid any material damage or the occurrence of

strong chemical reactions.

If detergent has come into contact with the eyes, rinse out imme-

diately with plenty of lukewarm water. If detergent has accidentally

been ingested, seek medical advice immediately. People with damaged or sensitive skin should avoid contact with detergent.

When adding or removing laundry during the main wash, your skin

may come into contact with detergent, particularly if the detergent is

dispensed externally. Take care when placing your hands inside the

drum. If suds have come into contact with the skin, rinse off immediately with lukewarm water.

13

Warning and safety instructions

Accessories

Only use original Miele accessories. If other parts are used, war-

ranty, performance and product liability claims will be invalidated.

Miele tumble dryers and Miele washing machines can be installed

as a washer-dryer stack. This requires a Miele washer-dryer stacking

kit which can be purchased separately. Please ensure that the

washer-dryer connection kit is suitable for the Miele tumble dryer

and the Miele washing machine.

If installing the machine on a Miele plinth (available as an optional

accessory), please make sure you order the correct one for this

washing machine.

Miele will guarantee to supply functional spare parts for a min-

imum of 10years and up to 15years following the discontinuation of

your washing machine.

Miele cannot be held liable for damage caused by non-compliance

with these warning and safety instructions.

14

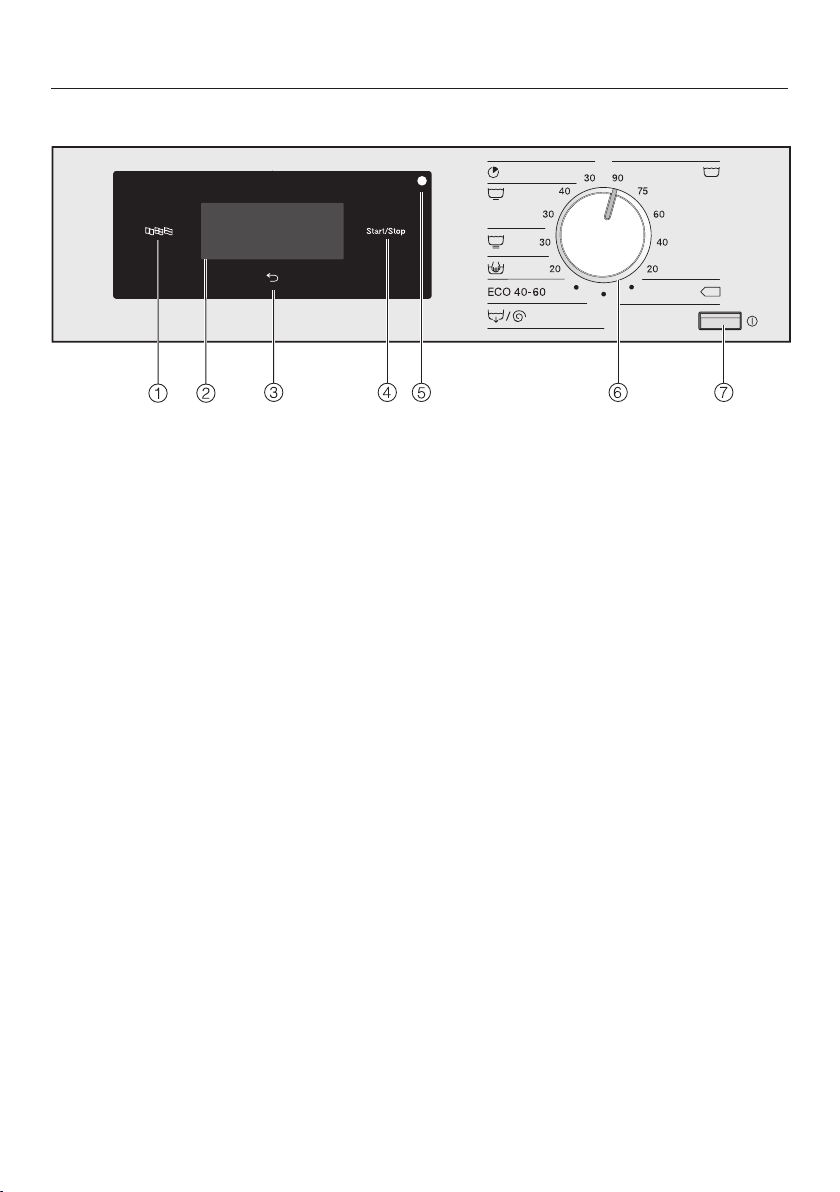

Control panel

Operating the washing machine

a

Language sensor control

For selecting the current user language.

The system language is displayed

again at the end of the programme.

b

Touch display with sensor controls

Displays the selected programme.

The programme settings are selected using the sensor controls in the

touch display.

c

Back sensor control

Takes you back one level in the

menu.

d

Start/Stop sensor control

Starts the selected programme and

cancels a programme once it has

started.

e

Optical interface

For the Customer Service Department.

f

Programme selector

For selecting the wash programme.

The programme selector can be

turned clockwise or anticlockwise.

g

button

For switching the washing machine

on and off.

The washing machine switches itself

off automatically to save energy. It is

switched off 15minutes after the

end of the programme/Anti-crease

phase, or after being switched on if

no further selection is made.

15

Operating the washing machine

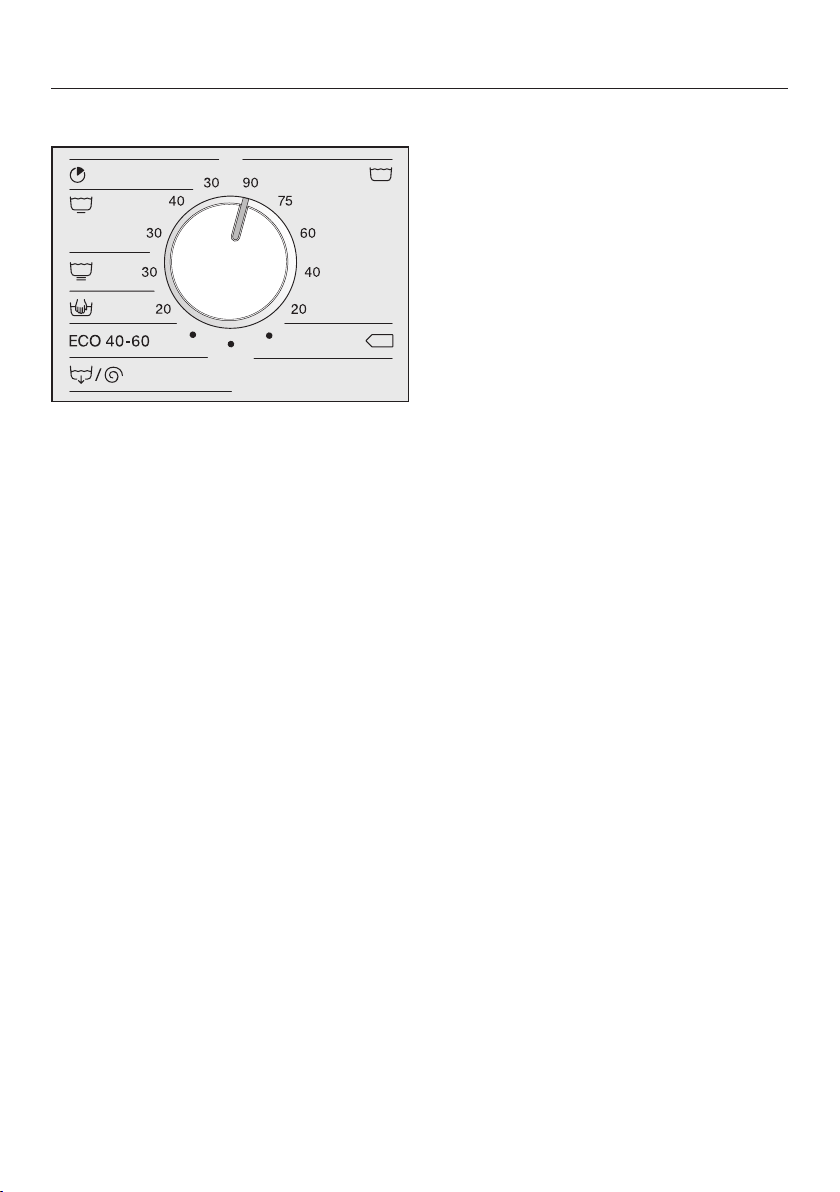

Symbols on the control panel

Cottons

Cottons /

Express

Minimum iron

Delicates

Woollens

ECO40-60 Cottons ECO40-60

/ Drain/Spin

16

Symbols in the display

Temperature: use the Temperaturesensor control to set the temperature

of the wash programme.

Spin speed: use the Spin speedsensor control to set the spin speed of

the wash programme.

Pre-wash: use the Pre-washsensor control to select the Pre-washExtra

for a wash programme.

Rinse plus: use the Rinse plussensor control to add an extra rinse cycle

to a wash programme.

Further choices: use the Further choicessensor control to set further op-

tions.

Supervisor level: use the Supervisor levelsensor control to alter the

washing machine’s settings.

Delay start: use the Delay startsensor control to set the start time of a

wash programme...

...or the finish time

Operating the washing machine

...or the time until the programme starts.

17

Operating the washing machine

1600

Coloured items

60°C

h

0:59

1600

Cottons

2:59

h

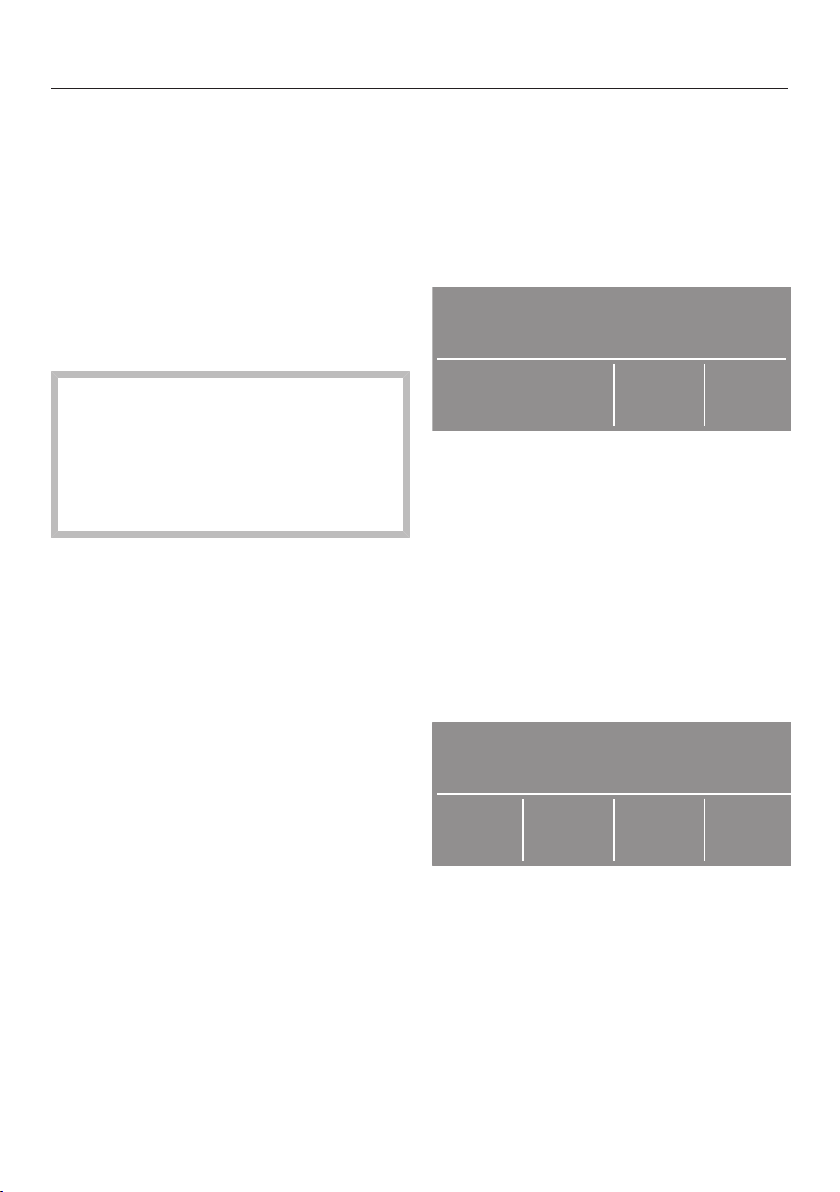

Sensor controls and touch display with sensor controls

The sensor controls , and

Start/Stop and the sensor controls in

the display respond to finger tip contact. Every touch of a sensor is confirmed with an audible tone. You can

adjust the volume of the keypad tone or

switch it off (see information on “Supervisor level”).

The control panel with sensor controls and the touch display can be

scratched by pointed or sharp objects, e.g. pens.

Only touch the display with your fingers.

Standard menu

The standard menu of a wash programme displays different values depending on the programme.

For programmes with a fixed temperature setting:

- Selected programme with the set

temperature

- Programme running time

- Spin speed set

- Selectable Extras

- Further available options and the settings on the Supervisor level

For programmes with a variable temperature setting:

18

- Selected programme

- Programme running time

- Temperature set

- Spin speed set

- Selectable Extras

- Further available options and the settings on the Supervisor level

Operating the washing machine

Language

deutsch

čeština

english

(AU)

dansk

Spin speed

800

1000

400

0

1200

1600

Finish

(today)

10

OK

25:

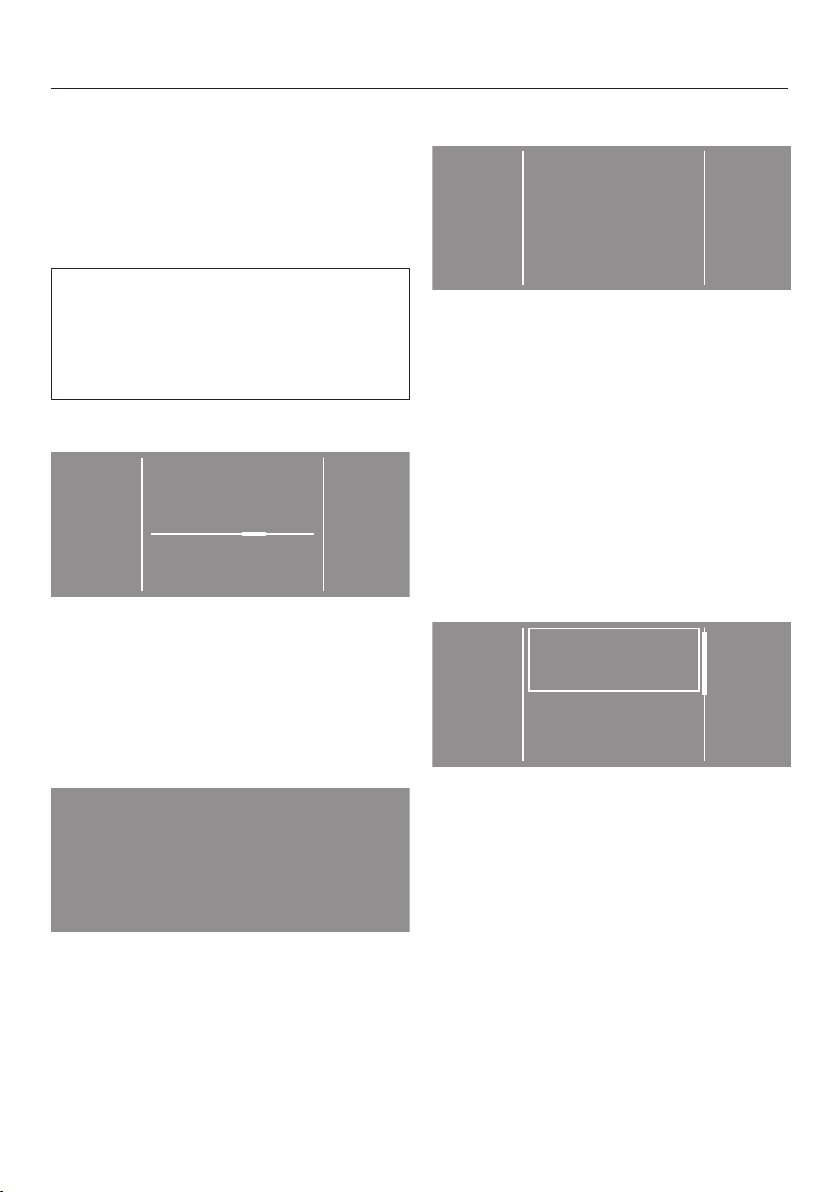

Examples of how to operate the appliance

Option lists

The andarrows on the right of the

display indicate that choices are available.

The list scrolls down when the

sensor is touched. The list scrolls up

when the sensor is touched.

The scroll bar indicates that further options follow.

The currently selected value is marked

with a frame.

Touch the required value to select it.

Setting numerical values

To change a numerical value, use the

andarrows above or below the

numbers you want to change.

Touch theandarrows and confirm

with the OK sensor.

Exiting a sub-menu

Select the Backsensor to exit a submenu.

If you select a value in a sub-menu, but

do not confirm with OK, you can discard this value by touching the

sensor.

Easy selection

If there are no arrows, the selection is

limited to the displayed values.

The currently selected value is marked

with a frame.

Touch the required value to select it.

19

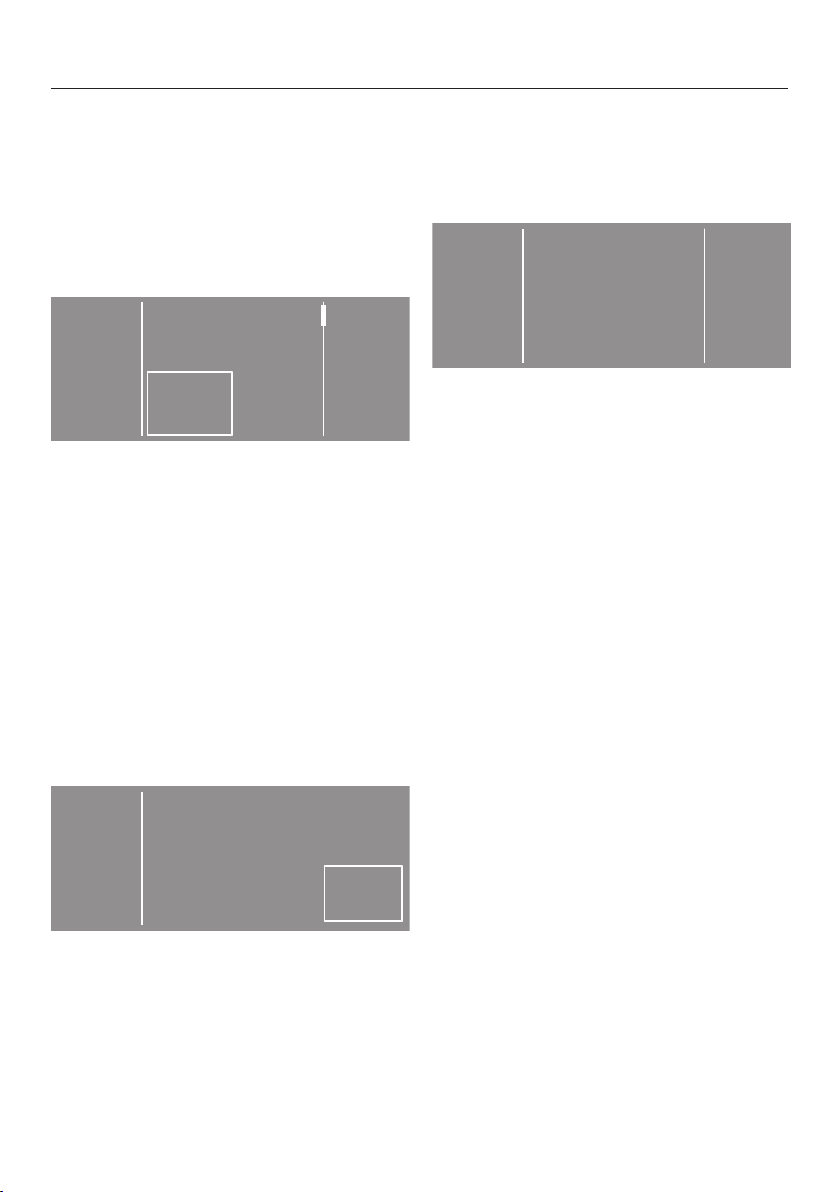

Before using for the first time

Language

deutsch

čeština

english

(AU)

dansk

Damage resulting from incorrect

installation and connection.

Installing and connecting the wash-

ing machine incorrectly will cause

serious property damage.

See “Installation”.

Emptying the drum

A swivel elbow for the drain hose and/

or assembly material may be stored in

the drum.

When commissioning the washing

machine for the first time, you will

have to define settings for daily use

of the appliance. Some settings can

only be configured during the initial

commissioning process. After that,

they must be changed by Miele Service.

Complete the initial commissioning

process.

These settings are also described under

“Supervisor level”.

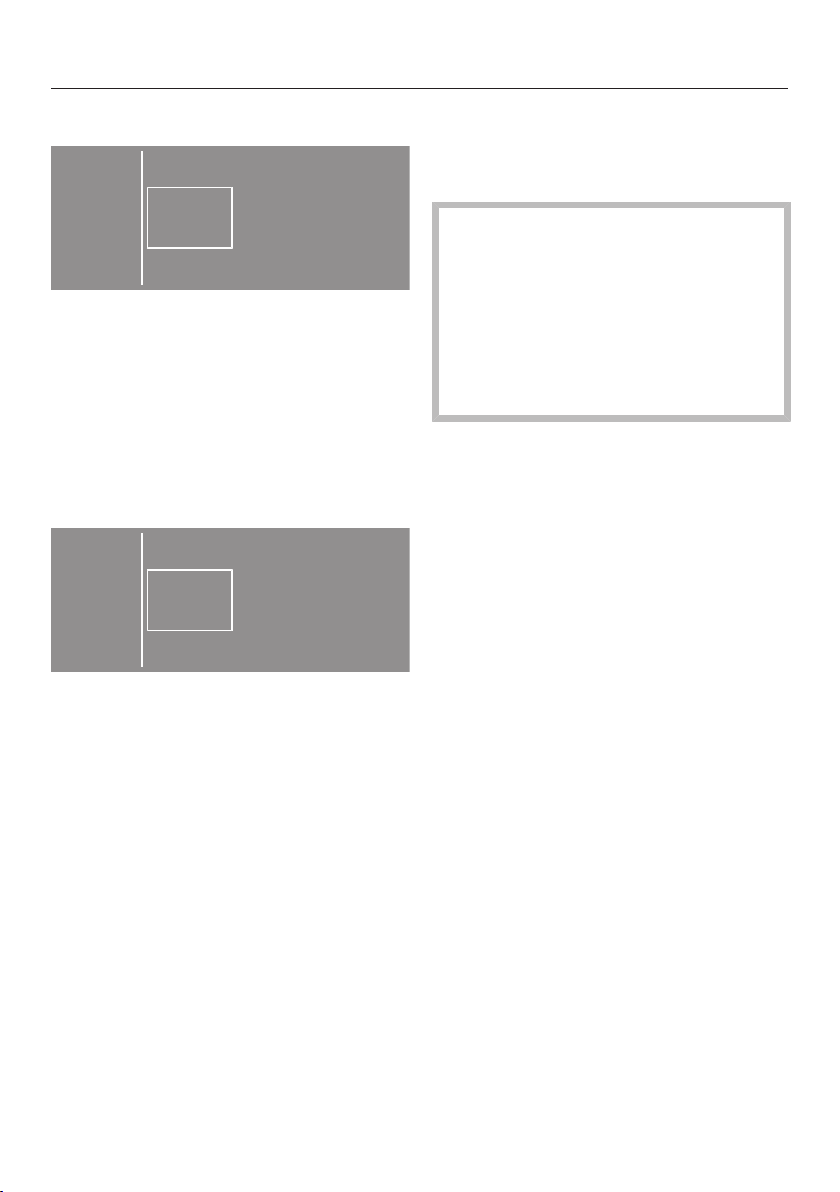

Setting the language

You will be asked to select the language

you require for the display. You can

change the language at any time (see

“Language” under “Supervisor level”).

Pull open the door.

Remove the swivel elbow and as-

sembly material.

Shut the door with a gentle swing.

Switching on the washing machine

Press the control.

The welcome screen will light up.

20

Touch the orsensor until the

language you want appears in the

display.

Touch the sensor for the language

you want.

The selected language is marked with a

frame and the display will change to

next setting.

Before using for the first time

Brightness

–

70

OK

+

%

Yes No

Should the clock display not

be shown?

Time

12

OK

05:

Payment

system

No payment

system

Programme

control

Reference to external appliances

A reference to external hardware appears.

Confirm with the OKsensor control.

Connect the XCI box or adapter before

initial commissioning. The washing

machine must be disconnected from

the mains. Then start the commissioning process.

Setting the display brightness

Set the brightness you want with the

– and + sensors and confirm your selection with the OKsensor.

The display will change to the next setting.

Setting the time of day

Use the andsensors to enter the

time and confirm your entry with the

OKsensor.

The display will change to the next setting.

Setting up a payment system

If you wish to set up a payment system,

read “Payment system” under “Supervisor level”.

If you do not wish to set up a payment

system, you can skip this stage.

Confirm time request

Touch the yes or nosensor.

If you select yes, the system will skip

the Clock displaysetting.

If you select no, the display will switch

to the Clock displaysetting.

Touch the No payment systemsensor.

The display will change to the next setting.

21

Before using for the first time

Pre-wash

water

Cold Hot

Main wash

water

Cold Hot

Select pre-wash water

Touch the coldsensor if the washing

machine is only connected to a cold

water supply, or touch hotif the

washing machine is connected to

cold and hot water.

The display will change to the next setting.

Select main wash water

Touch the coldsensor if the washing

machine is only connected to a cold

water supply, or touch hotif the

washing machine is connected to

cold and hot water.

Removing the transit bars

The display will remind you to remove

the transit bars.

Damage resulting from failure to

remove the transit bars.

Failure to remove the transit bars can

result in damage to the washing machine and to adjacent furniture or appliances.

Remove the transit bars as described

in “Installation and connection”.

Confirm that the transit bars have

been removed with the OKsensor.

Continue setting up as described in the Operating Instructionsappears in the dis-

play.

Confirm the message with the

OKsensor.

Further information will appear on the

display.

22

Completing the commissioning

1600

Coloured items

60°C

h

0:59

process

To complete commissioning, the Cottons 60°Cprogramme must be run

without laundry and without detergent.

If the power is interrupted prior to the

start of the first wash programme (e.g.

if the machine is switched off with the

sensor control), the initial commissioning process can be completed

again.

Once a wash programme has been

running for over 20minutes, the initial

commissioning process does not have

to be performed again.

Open the stopcock.

Turn the programme selector

toCottons 60°C.

Before using for the first time

Touch the Start/Stopsensor control.

When the programme has finished, your

machine is ready for use.

23

Washing environmentally and economically

Energy and water consumption

- To get the most out of your machine,

load the maximum dry load size for

the wash programme you are using.

This will keep the energy and water

consumption to a minimum in relation

to the size of the load.

- Programmes that are more efficient

with regard to energy and water consumption generally have a longer

programme running time. By extending the programme running time, the

wash temperature that is actually

reached can be reduced while still

providing the same wash results.

For example, the ECO40-60 programme has a longer running time

than the Cottons40°C or 60°C programme. The ECO40-60 programme

is more efficient in terms of energy

and water consumption.

- Use the Express programme for

small, lightly soiled loads.

- Modern detergents make it possible

to wash laundry at lower temperatures (e.g. 20°C). Using lower temperature settings will save energy.

Detergent

- Do not exceed the amounts of detergent recommended by the manufacturer on the packaging.

- Adjust the dosage to the degree of

soiling of the laundry.

- Reduce the amount of detergent with

smaller loads (approx. ⅓ less than

the amount recommended can be

used when washing a half load).

Information about subsequent tumble drying

The spin speed selected affects the residual moisture in the laundry and the

sound emissions of the washing machine.

The higher the spin speed, the lower

the residual moisture in the laundry.

However, the sound emissions of the

washing machine will increase.

Select the highest possible spin speed

for the wash programme to save energy

in the subsequent tumble dryer cycle.

- Washing at low temperatures and/or

using liquid detergents can cause

bacteria and odours to build up in the

washing machine. To maintain the

hygiene of the washing machine,

carry out a hot wash above 60°C at

regular intervals.

24

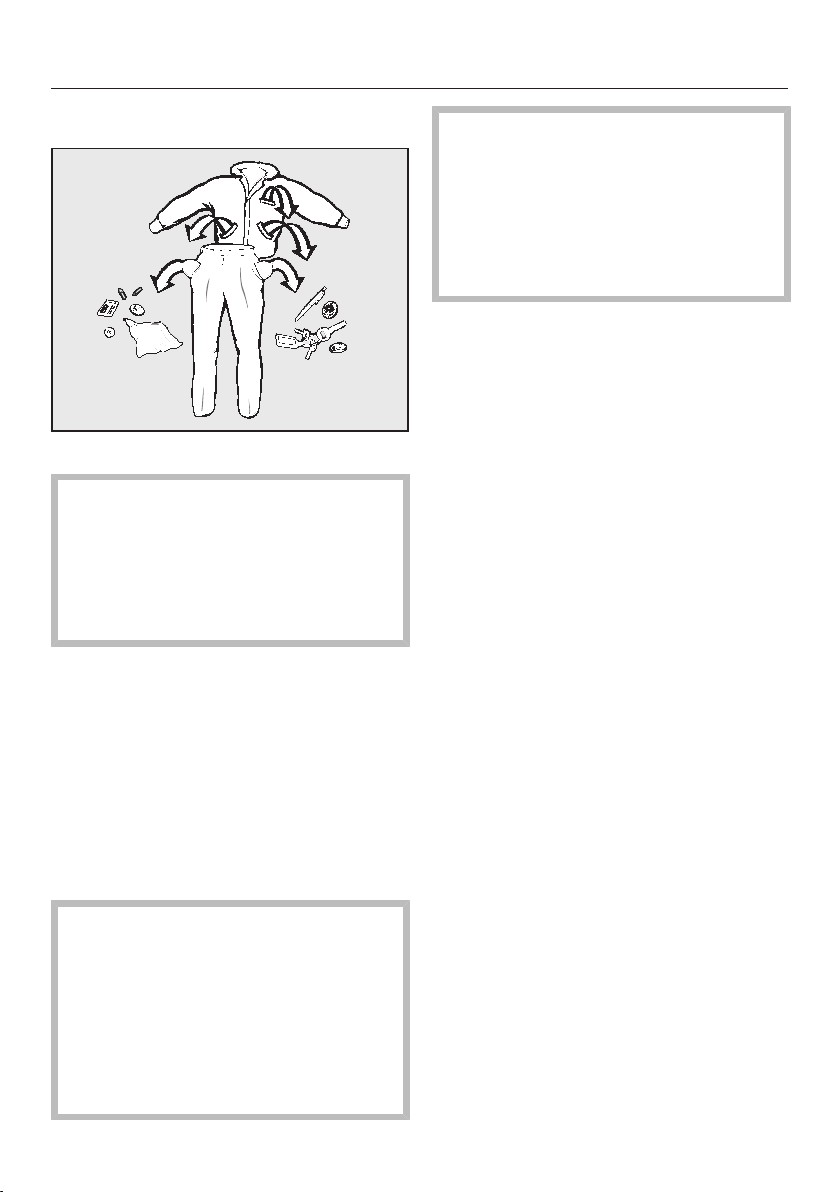

1. Preparing the laundry

Emptying pockets

Empty all pockets.

Damage due to foreign objects.

Nails, coins, paper clips, and so on

can cause damage to garments and

components in the machine.

Check the laundry before washing

and remove any foreign objects.

Sorting the laundry

Sort the laundry according to colour

and the garment care label.

Pre-treating stains

Badly soiled areas and stains should

be cleaned as soon as possible.

Spillages should be carefully dabbed

off using a soft, colourfast cloth.

Risk of explosion due to solvent-

based detergents.

When using solvent-based deter-

gents, an explosive mixture may develop.

Never use solvent-based detergents

in the washing machine.

General tips

- Do not machine wash items which

are specified by the manufacturer as

not washable on the care label ().

- Curtains: remove rollers and lead

weights or place in a laundry bag.

- Sew in or remove any loose underwiring in bras.

- Turn garments inside out, if recommended by the manufacturer.

- Zip up or close any jackets with Velcro or hook and eye fastenings before

washing.

- Fasten duvet covers and pillow cases

to prevent small items from becoming

rolled up inside them.

- Please refer to the Programme chart

for more tips and tricks.

Damage due to solvent-based

detergents.

Detergents containing benzine, stain

remover, etc., can damage plastic

parts.

When pre-treating textiles, make sure

that any plastic parts do not come

into contact with the detergent.

25

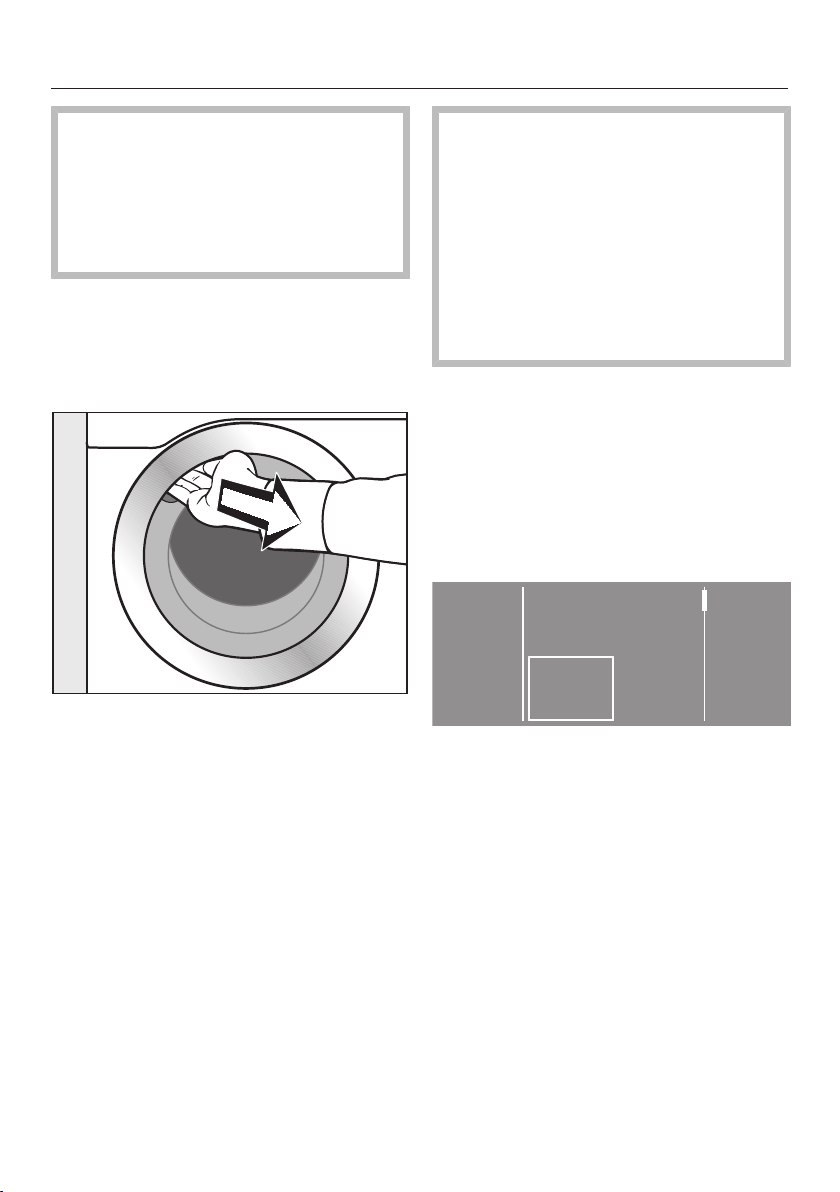

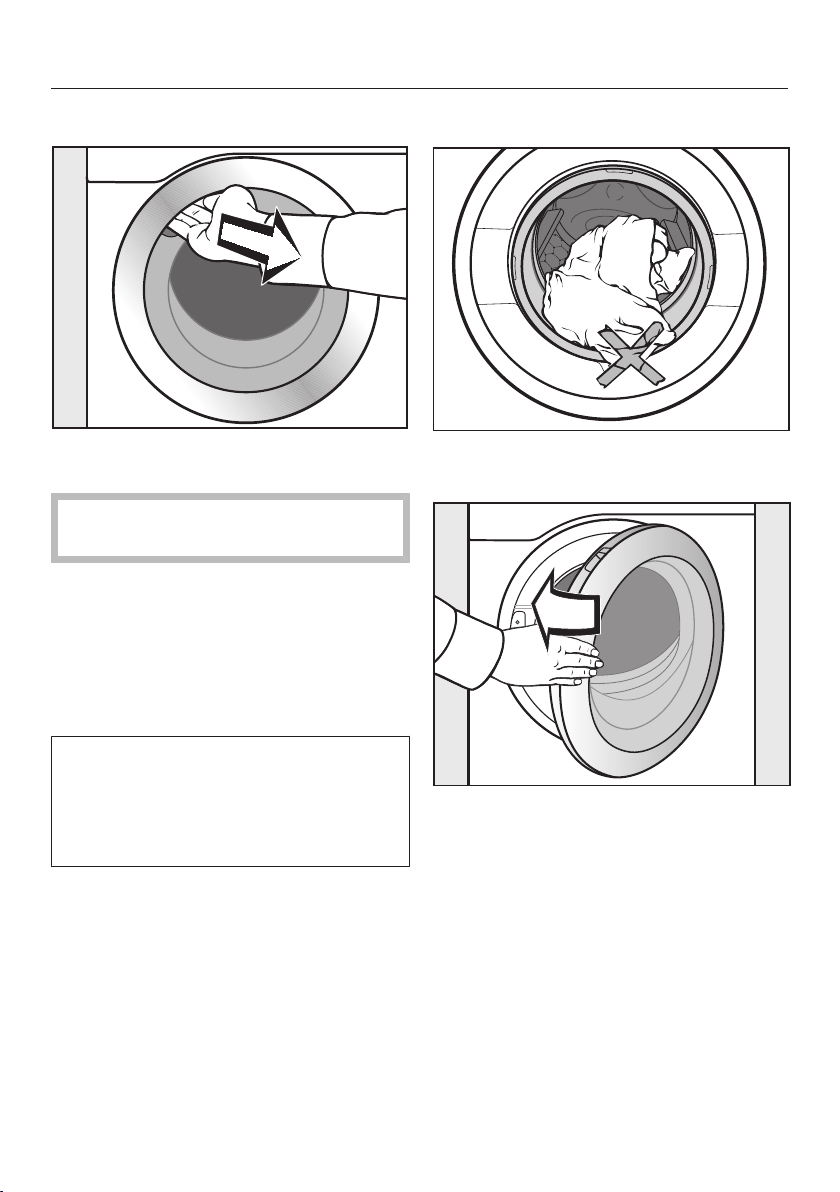

2. Loading the washing machine

Opening the door

Reach under the door grip and pull

the door open.

Check the drum for foreign objects

before loading it with laundry.

Unfold the laundry and load loosely

into the drum.

Mixing both large and small items gives

better wash results and also helps to

distribute the load evenly during spinning.

Closing the door

Make sure that no items are caught

between the door and the seal.

The most efficient use of energy and

water is achieved when a full load is

washed. However, do not overload as

this reduces cleaning efficiency and

causes creasing.

26

Shut the door with a gentle swing.

3. Selecting a programme and settings

Spin speed

800

1000

400

0

1200

1600

Switching on the washing machine

Press the control.

Selecting a programme

Turn the programme selector to the

required programme.

The selected programme will be shown

in the display. The display will then

change to the standard menu for that

programme.

Selecting a temperature

You can alter the preset temperature of

certain programmes.

Touch the Temperaturesensor con-

trol.

Select the desired temperature.

The selected temperature is marked

with a frame.

Selecting the spin speed

You can alter the preset spin speed.

Touch the Spin speedsensor.

The following will appear in the display:

Select the spin speed you want.

The selected spin speed is marked with

a frame.

27

3. Selecting a programme and settings

Further

choices

Finish at

Supervisor level

Selecting Extras

You can select Extras for a wash programme.

Selecting Pre-wash

The Pre-wash Extra is offered for

certain programmes.

For laundry that is heavily soiled.

Coarse soiling is loosened and removed

before the main wash.

Touch the sensor control.

Pre-wash is activated.

Selecting Rinse plus

The Rinse plus Extra is offered for

certain programmes.

An extra rinse is carried out to achieve a

better wash result.

Touch the sensor control.

Rinse plus is activated.

Selecting further options

You can select a delay start period or

change the settings of the washing machine.

Touch the Further choicessensor

control.

The following will appear in the display:

Select the option you want.

The display will change to the submenu for that option.

Delay start is not possible for some

programmes.

28

4. Adding detergent

You can use any detergent that is suitable for washing machines.

Detergent dispensing

Please follow the detergent manufacturer's instructions in relation to

dosage.

Adding too much detergent will lead

to excessive foaming.

Avoid adding excess detergent.

The amount to dispense will depend on:

- the amount of laundry

- the amount of soiling in the laundry

- the water hardness

Hardness

range

I (soft) 0-1.5 0-8.4

II (medium) 1.5-2.5 8.4-14

III (hard) above 2.5 above 14

Check with your local water supplier if

you do not know the water hardness in

your area.

Hardness

inmmol/l

Degree of

German hardness

°dH

Adding detergent

Pull out the detergent drawer and add

detergent to the compartments.

Detergent for the pre-wash (di-

vide the total recommended

amount as follows: ⅓ to compartment and ⅔ to compartment)

Detergent for the main wash

Fabric conditioner or liquid

starch

For disinfection programmes, the

andcompartments can be

filled with detergent for the main wash

if you have not selected pre-wash.

29

4. Adding detergent

Automatic dispensing of fabric softener or liquid starch

Add fabric conditioner or liquid starch

to the compartment. Do not ex-

ceed the maximum level mark.

This will be automatically dispensed in

the final rinse. At the end of the wash

programme a small amount of water remains in the compartment.

Tip: If starching frequently, thoroughly

clean the detergent drawer, especially

the siphon tube, regularly.

Dye removers and dyes

Damage due to colour run/dye

removers.

Colour run and dye removers can

cause corrosion in the washing machine.

Do not use colour run or dye removers in this washing machine.

Only use dyes suitable for use in a

washing machine. The manufacturer's

instructions on the packaging must be

observed.

30

5. Starting the programme – end of the programme

Payment system

If your machine is connected to a payment system, the amount of payment

required will appear in the display.

Do not cancel the programme once it

has started. Depending on the settings, money may be lost in the payment system.

Starting the programme

The programme can be started as soon

as the Start/Stopsensor is flashing on

and off.

Touch the Start/Stopsensor.

The door will lock (symbol) and the

programme will start.

If a delay start period has been selected, this will appear in the display.

Once the delay start period has elapsed

(if applied), the programme duration will

appear in the display; otherwise, the

duration will appear straight away. The

programme sequence is also shown in

the display.

End of programme

The door remains locked during the

anti-crease phase. However, the washing machine door can be unlocked at

any time by touching the Start/Stop

sensor.

Unloading the drum

Pull open the door.

Remove the laundry.

Items left in the drum could discolour

other items in the next wash or become discoloured themselves.

Remove all items from the drum.

Tip: Touch the sensor to display the

set temperature, spin speed and any

set Extras.

Check the door seal for any foreign

objects.

Tip: Leave the door slightly open to allow the drum to dry.

Switch the washing machine off with

the button.

Tip: Leave the detergent drawer slightly

open to allow it to dry.

31

Delay start

Add laundry

Cancel

programme

Start programme

immediately

The Delay start function can be used to

set the time until the programme starts

or the programme finish time (see

“Delay start” under “Supervisor level”).

Selecting the Delay start function

Touch the Further choicessensor

control.

Select the Finish at, Start at or

Start inoption.

Use the andsensors to enter the

hours and minutes and confirm your

entry with the OKsensor.

The minutes entry moves to the next

“full quarter of an hour” and can then

be adjusted in 15-minute increments.

Starting Delay start

Touch the Start/Stopsensor.

The door will lock and the time until the

programme starts will appear in the display.

Cancelling or changing Delay start

Touch the Start/Stopsensor.

The following will appear in the display:

Touch the Start programme immedi-

atelysensor.

The wash programmes starts immediately.

or

Touch the Cancel programmesensor.

The programme start is cancelled and

the Start/Stopbutton flashes on and

off.

32

Programme chart

Cottons 20°C to 90°C Max. load 7.0kg

Use for Cotton, linen and mixed fibre textiles

Tip - Select the temperature according to the instructions on the care

label, the detergent, the type of soiling and the hygiene requirements.

- For dark-coloured fabric, use a colour detergent or liquid detergent.

1600rpm Extras: Pre-wash Rinses: 1–5*

Cottons / Max. load 7.0kg

Items Normally soiled cotton garments

Tip - These settings are the most efficient in terms of energy and wa-

ter consumption for washing cottons.

- With, the wash temperature reached is below 60°C.

1600rpm Extras: Pre-wash Rinses: 2

The test programme conforms to EN60456 and energy labelling to Directive1061/2010.

Express 30°C Max. load3.5kg

Use for Cotton garments that have hardly been worn or are only very

lightly soiled

1400rpm Extras: Rinse plus Rinses: 1

Minimum iron 30°C to 40°C Max. load 3.5kg

Use for Synthetic and mixed fibre textiles as well as easy care cotton

Tip - Reduce the final spin speed for fabric that creases easily.

1200rpm Extras: Pre-wash Rinses: 2–4*

*You can alter the number of rinses carried out via the Supervisor level.

33

Programme chart

Delicates 30°C Max. load 2.5kg

Use for Delicate garments made from synthetic fibres, mixed fibres and

viscose

Tip - Deselect the final spin speed for fabric that creases easily.

600rpm Extras: Pre-wash Rinses: 2

Woollens 20°C Max. load 2.5kg

Use for Machine-washable woollens and woollen blends

Tip - Use detergent formulated for delicates/woollens.

1200rpm Rinses: 2

ECO40-60 Max. load 7.0kg

Items Normally soiled cotton garments

Tip - A laundry load consisting of mixed cottons that are intended for

washing at 40°C or 60°C can be washed in the same wash

cycle.

- This programme is the most efficient in terms of energy and water consumption for washing cottons.

1600rpm Rinses: 2

/Drain/Spin Max. load7.0kg

Tip - Make sure you select the appropriate spin speed.

- Select the Rinse plusExtra for an additional rinse.

- Drain only: select 0rpm for the spin speed.

1600rpm Extras: Rinse plus

34

Special features in the programme sequence

Spinning

Final spin speed

When a programme is selected, the

maximum spin speed for this wash programme is shown in the display.

You can reduce the final spin speed.

However, you cannot select a final spin

speed higher than that shown in the

chart.

Interim spin

There is a spin cycle after the main

wash and between the rinses. A reduction in the final spin speed will also reduce the interim spin speed as appropriate.

Omitting the interim spin and the final spin

Select the programme setting Spin

speed 0.

After the last rinse, the water will be

pumped away and the anti-crease

phase will switch on.

Anti-crease

At the end of the programme, the drum

continues to turn at intervals for up to

30minutes to help prevent creasing.

The washing machine can be opened at

any time.

There is no anti-crease phase at the

end of some programmes.

35

Changing the programme sequence

A programme cannot be cancelled or

changed when operating a payment

system.

If the washing machine is switched off

during active programme operation,

the standby function does not switch

the washing machine off completely

after 15minutes. Safety functions

continue to be active because there

may still be water inside the drum.

Changing a programme

After the start of a programme, it is no

longer possible to select a different programme.

You will need to cancel the current programme before you can select a new

one.

Programme cannot be changedappears

in the display if the programme selector has been moved. The text disappears when the programme selector

is set to the original programme.

Cancelling a programme

You can cancel a wash programme at

any time after it has started.

Touch the Start/Stopsensor control.

Select Cancel programme.

If you want to select a different programme:

Close the door.

Select the programme you want.

Add detergent to the detergent

drawer.

Touch the Start/Stopsensor control.

The new programme will begin.

Switching on the washing machine after an interruption to

the power supply

If the washing machine is switched off

with the button during a wash programme, the programme will be interrupted.

Switch the washing machine back on

with the button.

Note the message in the display.

Touch the Start/Stopsensor.

The programme will also be interrupted

if power is interrupted by a power cut.

When power is resumed, confirm the

message in the display with OK.

Touch the Start/Stopsensor.

The programme continues.

The suds are pumped away. The programme is cancelled. The door lock is

released.

Pull open the door.

Remove the laundry.

36

Changing the programme sequence

Add laundry

Cancel

programme

Adding or removing laundry

You can add or remove items during the

first few minutes after the programme

has started.

Touch the Start/Stopsensor.

The following will appear in the display:

Touch the Add laundrysensor.

The programme will stop and the door

will unlock.

Risk of chemical burns from de-

tergent.

When adding or removing laundry,

your skin may come into contact

with detergent, particularly if the detergent is dispensed externally.

Take care when placing your hands

inside the drum.

If suds have come into contact with

the skin, rinse off immediately with

plenty of lukewarm water.

Once a programme has started successfully, the washing machine cannot

recognise any adjustment to the load.

For this reason, if laundry is added or

removed after the start of a programme, the machine will always

complete the programme cycle assuming a full load.

The door cannot be opened, if:

- The suds temperature is above 55°C.

The safety lock will remain activated if

the temperature in the drum is above

55°C. The lock will not deactivate until the temperature has dropped to below 55°C.

Pull open the door.

Add laundry or remove individual

items.

Close the door.

Touch the Start/Stopsensor.

The programme will continue.

37

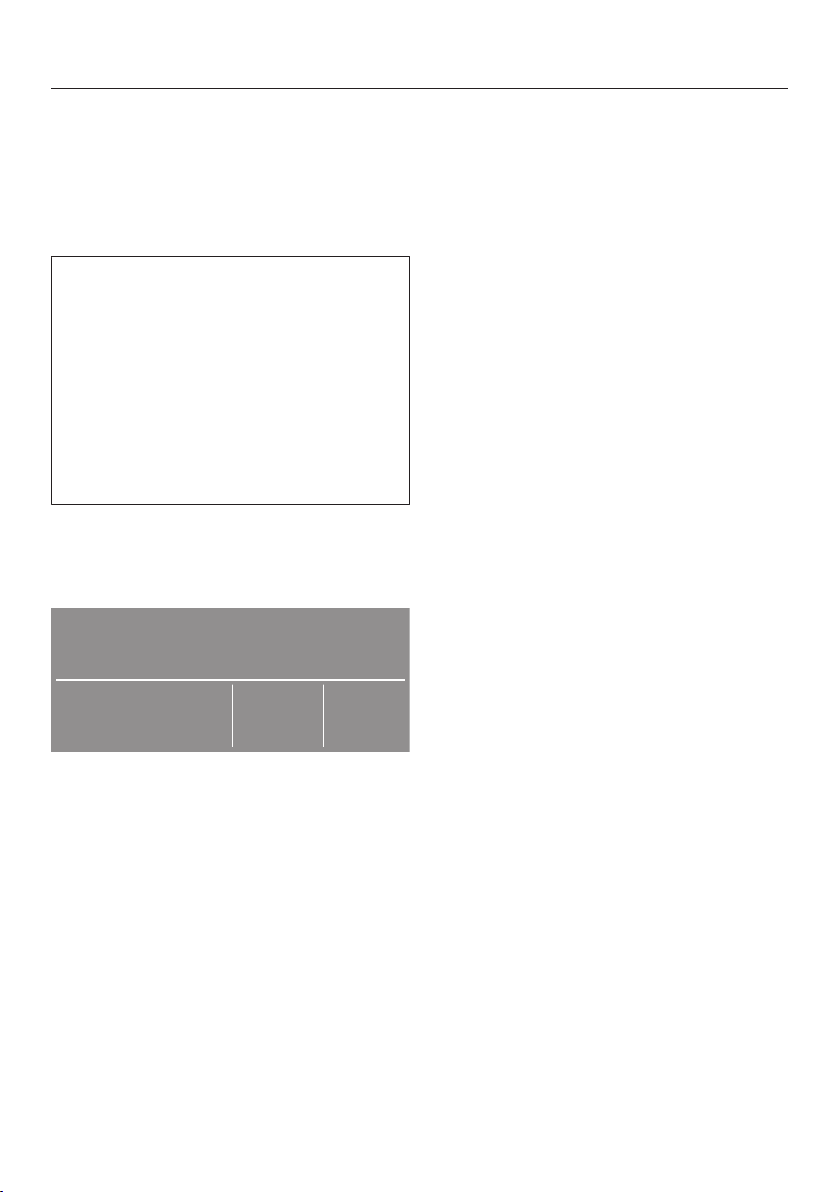

Detergent

The correct detergent

You can use any detergent that is suitable for washing machines. Instructions for

use and recommended amounts are given on the detergent packaging.

Recommended detergents in accordance with Directive (EU) No. 1015/2010

The recommendations apply to the temperature ranges given in the section “Programme chart”.

Universal Colour Delicates and

Special

woollens

detergent

Cottons – –

Cottons – –

Express –

1

– –

Minimum iron – – –

Delicates – – –

Woollens – –

ECO40-60 – –

Recommended

– Not recommended

1

Liquid detergent

38

Cleaning and care

Risk of electric shock.

Only ever perform cleaning and

maintenance work when the appliance is disconnected from the

power.

Disconnect the washing machine

from the mains electricity supply.

Cleaning the casing and fascia panel

Damage caused by detergents.

Solvent-based cleaning agents, abrasive cleaners, glass cleaners or

multi-purpose cleaning agents can

cause damage to plastic surfaces

and other parts.

Do not use any of these cleaning

agents.

Risk of damage due to ingress of

water.

The pressure of a water jet can

cause water to get into the washing

machine, resulting in damage to

components.

Do not spray the washing machine

with a water jet.

Cleaning the detergent drawer

Washing at low temperatures and the

use of liquid detergent can lead to a

build-up of mould and bacteria in the

detergent drawer.

For hygiene reasons, clean the entire

detergent drawer at regular intervals.

Pull out the detergent drawer until

resistance is felt. Press down the release button and at the same time

pull the drawer right out of the machine.

Clean the detergent drawer with

warm water.

Clean the casing and fascia panel

with a mild cleaning agent or soap

and water and dry both with a soft

cloth.

The drum and any other stainless

steel components can be cleaned using a suitable stainless-steel cleaning

agent.

39

Cleaning and care

Cleaning the siphon and the channel

Pull the siphon out of the compart-

ment .

Clean the siphon under warm running

water.

Refit the siphon.

Clean the fabric conditioner channel

using a brush and warm water.

Cleaning the detergent drawer

Use a bottle brush to remove deter-

gent residues and limescale from the

jets inside the detergent drawer.

Replace the detergent drawer.

Tip: Leave the detergent drawer slightly

open to allow it to dry.

40

Cleaning and care

Cleaning the drum, suds container and drainage system

The drum, suds container and drainage

system can be cleaned if necessary.

Start the Cottons90°C programme.

Add powder detergent to the

compartment in the detergent

drawer.

At the end of the programme, check

the inner drum and remove any

coarse residues.

Cleaning the water inlet filters

The washing machine has filters to protect the water intake valves. You should

inspect the filters approximately every

6months. Perform this check more often if there are frequent interruptions to

the external water supply.

Cleaning the filter in the water intake valve

Using pliers, carefully loosen the

ribbed plastic nut on the intake valve

and unscrew.

Use pointed pliers to withdraw the fil-

ter by the bar.

Clean the filter.

Reassemble in reverse order.

The filters are used to protect the

water intake valve.

The filters must be put back in place

after cleaning.

41

Problem solving guide

You are able to correct the majority of faults and problems that arise during day-today use without external assistance. You can save time and money in many cases,

as you do not need to call Miele Service.

The following tables are designed to help you to find the cause of a malfunction or

a fault and to resolve it.

The wash programme does not start

Problem Cause and remedy

The display remains

dark, and the Start/Stop

sensor control does not

light up or flash.

The following appears

in the display:

Door will not lock. Call Ser-

vice.

The programme does

not start when Spin has

been selected.

The display is dark and

the Start/Stop sensor

control is flashing

slowly.

There is no power to the machine.

Check whether the washing machine is switched

on.

Check whether the washing machine is connected

to the power supply.

Check whether the main fuse or circuit breaker has

tripped.

The washing machine has switched off automatically

to save energy.

Switch the washing machine back on with the

button.

The door is not closed properly. The door lock could

not engage.

Close the door again.

Start the programme again.

If the fault message appears again, contact Miele

Service.

You have not yet completed the initial commissioning

process.

Perform the Initial commissioning process as de-

scribed in these instructions.

The display has switched off automatically to save

energy.

Touch any of the controls. The display switches

back on.

42

Problem solving guide

Programme cancellation and error message

Problem Cause and remedy

Drainage fault. Clean

drain filter and pump.

Check the drain

hose.

Water intake fault.

Open stopcock.

Waterproof system

activated

Fault F . If restart

fails, call Service

The drain is blocked or restricted.

The drain hose has been fixed too high.

Clean the drain filter and the drain pump.

The maximum drain height is 1m.

The water inlet is blocked or restricted.

Check whether the stopcock has been properly

opened.

Check whether the inlet hose is kinked.

The water pressure is too low.

Switch on the Low water pressuresetting (see “Low

water pressure” under “Supervisor level”).

The filters in the water inlet are blocked.

Clean the filters (see “Cleaning the filters” under

“Cleaning and care”).

The water protection system has reacted.

Close the stopcock.

Call Miele Service.

There is a fault.

Disconnect the washing machine from the electri-

city supply.

Wait at least 2minutes before reconnecting the

washing machine to the electricity supply.

Switch the washing machine on again.

Start the programme again.

If the fault message appears again, contact Miele

Service.

43

Problem solving guide

A fault message appears in the display

1)

Problem Cause and remedy

Align machine. Laun-

dry not properly spun

The selected spin speed was not reached during the

final spin due to excessive imbalance.

Check that the washing machine is level.

Start the spin cycle again.

Machine is leaking

The washing machine or drain valve is leaking.

Close the stopcock.

Call Miele Service.

1

The messages will appear at the end of the programme and when the washing

machine is switched on and must be acknowledged with the OK sensor control.

44

An unsatisfactory wash result

Problem Cause and remedy

Liquid detergent does

not give the required

result.

White residues which

look like powder detergent are seen on dark

textiles after washing.

Textiles with particularly

greasy soiling are not

properly clean.

Liquid detergents usually contain no bleaching

agents. They do not remove fruit, coffee, and tea

stains.

Use a general purpose powder detergent contain-

ing a bleaching agent.

Pour stain removers into the drawer in the dis-

penser compartment and liquid detergent into a

dispenser ball.

Never put stain removers and liquid detergent to-

gether in the dispenser drawer.

The detergent contained compounds (zeolites) to aid

water softening which are not soluble in water. These

have ended up on the laundry.

Try to brush off the residues with a soft brush once

the laundry is dry.

In future, wash dark textiles using a detergent

which contains no zeolites. Liquid detergents usually contain no zeolites.

Select a programme with pre-wash. Use liquid de-

tergent for the pre-wash.

Continue to use universal powder detergent for the

main wash.

Problem solving guide

Grey, greasy particles

cling to washed laundry.

The use of heavy-duty detergent is recommended in

the main wash for very heavily soiled work clothing.

Please seek advice from the detergent manufacturer.

Insufficient amounts of detergent were used. The

laundry was heavily soiled with grease (oils, ointments).

Use more detergent or use liquid detergent with

this type of soiled laundry.

Before washing the next load, run a 60°C pro-

gramme with liquid detergent but without a load.

45

Problem solving guide

General problems

Problem Cause and remedy

The machine shakes

during the spin cycle.

Strange pump noises

can be heard.

Large amounts of detergent residue remain in

the detergent dispenser

drawer.

Fabric softener is not

completely dispensed

or too much water remains in the compartment.

The display is in a different language.

The laundry has not

been spun properly. The

laundry is still wet.

The machine feet are not level and not secured.

Level the machine and adjust the feet correctly.

This is not a fault. These slurping noises occur at

the start and end of a pump sequence as a normal

part of the operation.

The water pressure is too low.

Clean the filters in the water inlet.

Powder detergent used in conjunction with water

softeners tends to become sticky.

Clean the detergent dispenser drawer and, in fu-

ture, add detergent into the drawer first, and then

add the water softener.

The siphon tube is not correctly positioned or is

clogged.

Clean the siphon, see “Cleaning and care – Clean-

ing the detergent dispenser compartment”.

A different language has been selected.

Switch the washing machine off and on again.

The selected operator language appears in the display.

The operator language has been changed.

Select the language you require (see “Language”

under “Supervisor level”).

The machine detected a high level of imbalance during the final spin and reduced the spin speed automatically.

Include both large and small items in the load as

this will achieve better distribution.

46

Problem Cause and remedy

The drum remains stationary but the programme keeps running.

Switch the washing machine off and then back on

with the button.

Note the message in the display.

Touch the Start/Stopsensor control.

The drum continues to spin and the programme continues.

Problem solving guide

47

Problem solving guide

The door will not open

Problem Cause and remedy

The door cannot be

pulled open during a

programme.

Programme cancelled

appears in the display

at the end of a programme or after a programme has been cancelled.

The following appears

in the display:

Door lock jammed. Call

Service.

The door is locked during the wash programme.

Touch the Start/Stop sensor control.

Select Cancel programme or Add laundry.

The door will unlock and you will be able to pull it

open.

There is still water in the drum and the machine is unable to drain.

Clean the drainage system as described under

“Opening the door in the event of a blocked drain

outlet and/or power cut”.

To protect the user against scalding, the door cannot

be opened if the suds temperature is higher than

55°C.

Wait until the temperature in the drum has de-

creased and the message has gone out in the display.

The door lock has jammed.

Call Miele Service.

48

Problem solving guide

Opening the door in the event of a blocked drain outlet and/ or power cut

Risk of electric shock.

Only ever perform cleaning and

maintenance work when the appliance is disconnected from the

power.

Disconnect the washing machine

from the mains electricity supply.

Open the access panel to the drain

system.

Emptying the drum

....For machines with a drain pump

Place a suitable container under the

access flap.

Remove the drain filter, though not

completely.

Slowly unscrew the drain filter to let

the water out.

Tighten the drain filter back up again

if you need to interrupt the flow of

water.

Blocked drain outlet

If the drain outlet is blocked, there may

be a large quantity of water (max. 30l)

left behind in the washing machine.

Risk of scalding due to hot suds.

Escaping suds will be hot if laundry

has been washed at high temperatures.

Carefully allow all suds to drain off.

49

Problem solving guide

Cleaning the drain filter

Once the flow of water ceases:

Remove the drain filter completely.

Clean the drain filter thoroughly.

Water damage.

Water will escape from the machine

if you forget to replace the drain filter.

Replace the drain filter correctly and

tighten it securely.

Opening the door

Danger of injury due to rotating

drum.

Reaching into a moving drum is ex-

tremely dangerous.

Always make sure that the drum is

stationary before reaching in to remove laundry.

Check the drain pump impellers to

make sure they can rotate freely.

Remove any foreign objects (e.g. but-

tons, coins, etc.) and clean the interior.

Put the drain filter back in place and

secure it.

50

Use a screwdriver to unlock the door.

Pull open the door.

Miele Service

Made in xxx

Mod.: XXXxxx

M-Nr.: xxxxxxxx

Type: XXxx-X

Nr.:/ xxxxxxxxx

Contact in case of malfunction

In the event of any faults which you

cannot remedy yourself, please contact

your Miele Dealer or Miele Service.

Contact information for Miele Service

can be found at the end of this document.

Please quote the model and serial number of your appliance when contacting

Miele Service. This information can be

found on the data plate.

The data plate is found above the

porthole glass when the washing machine door is opened:

EPREL database

From 1 March 2021, information on energy labelling and ecodesign requirements will be available in the European

Product Database (EPREL). You can

find the product database at the following link https://eprel.ec.europa.eu/. You

will be asked to enter the model identifier.

The model identifier can be found on

the data plate.

Optional accessories

Optional spare parts and accessories

for this washing machine are available

from Miele.

51

*INSTALLATION*

Installation

Front view

a

Inlet hose (cold water)

b

Electrical connection

c

Control panel

d

Detergent drawer

52

e

Door

f

Access flap to drain filter and drain

pump

g

Height-adjustable feet

*INSTALLATION*

Installation

Rear view

a

Protruding lid for holding when moving the appliance

b

Electrical connection

c

Interface for communicating with external appliances

d

Drain hose

e

Water inlet hose (cold water)

f

Safety caps for transit bars

g

Transport clips for hoses

h

Holder for removed transit bars

53

*INSTALLATION*

1132

850

>1000

714

min. 300

1702

Installation

Installation locations

Side view

Washer-dryer stack

Installation on a plinth

The washing machine can be installed

on a steel plinth (open or closed, available as an optional Miele accessory) or

on a concrete plinth.

Injury can occur if the washing

machine has not been adequately

secured.

When installing the machine on a

plinth, there is the danger of the

washing machine falling off the plinth

during spinning.

Secure the washing machine using

the clamps supplied.

Installation notes

The distances between the machine

and the wall are recommendations to

help make it easier to carry out service

work. If installation space is limited,

the machine can also be pushed up

against the wall.

The washing machine can be installed

as a washer-dryer stack together with a

Miele tumble dryer. This requires a

Miele washer-dryer stacking kit which

can be purchased separately.

54

This washing machine is not suitable

for building under.

Risk of damage due to moisture

ingress.

Moisture can damage electrical com-

ponents.

Do not install the machine near or

directly above an open gully or floor

drain.

*INSTALLATION*

Installation

Transporting the washing machine to its installation site

Danger of injury from incorrect

transport.

If the washing machine tips up there

is a danger of injury to people and

damage to property.

Make sure the washing machine is

stable during transportation.

Transporting the washing machine with a sack truck

Transporting the washing machine to its installation site

The protruding lid at the back can be

used to hold the machine when transporting.

Danger of injury due to unsecure

lid.

The fixings at the back of the lid

could break as a result of external

forces. There is a danger of the lid

being pulled off when carrying the

machine.

Before carrying the machine, check

that the lid is secure where it protrudes at the back of the machine.

If transporting the washing machine

with a sack truck, make sure its left or

right side is resting on the truck.

Risk of damage from incorrect

transport.

The front or back of the washing ma-

chine may be damaged if the machine is transported with a sack

truck.

Always insert the sack truck under

one of the sides of the washing machine.

Carry the washing machine by the

front feet and by the lid where it protrudes at the back of the appliance.

55

*INSTALLATION*

Installation

Installation surface

A concrete floor is the most suitable installation surface, being far less prone

to vibration during the spin cycle than

wooden floorboards or a carpeted surface.

The machine must be level and se-

curely positioned.

To avoid vibrations during spinning,

the machine should not be installed

on soft floor coverings.

If installing on a wooden joist floor:

Install the machine on a plywood

base (at least 70x60x3cm). The

base should span several joists and

be bolted to the joists and not only to

the floorboards.

Tip: If possible, install the machine in a

corner of the room. This is usually the

most stable part of the floor.

Removal of transit bars

Removing the left-hand transit bar

Push the cover out and turn the

transit bar 90° using the open spanner supplied.

56

Pull out the transit bar.

*INSTALLATION*

Installation

Removing the right-hand transit bar

Push the cover out and turn the

transit bar 90° using the open spanner supplied.

Covering holes

Danger of injury from sharp

edges.

There is a danger of injury from

reaching into holes that are not

covered.

Cover the holes for the transit bars

after they have been removed.

Push the covers in firmly until they

engage in position.

Pull out the transit bar.

57

*INSTALLATION*

Installation

Securing the transit bars

Secure the transit bars to the back of

the washing machine.

Tip: Make sure that the holes are fit-

ted over the retainers .

Risk of damage from incorrect

transport.

The washing machine may become

damaged if moved without the transit

bars in place.

Keep the transit bars in a safe place.

Fit them again if the washing machine is to be moved (e.g. when

moving house).

Fitting the transit bars

Opening the covers

Press against the retainer with a

sharp object (a narrow screwdriver,

for example).

The cover opens.

Fitting the transit bars

To fit the bars, follow the instructions

for removing them in reverse order.

Tip: The bars will slide in more easily if

you lift the drum slightly.

58

*INSTALLATION*

Levelling the washing machine

The washing machine must stand perfectly level on all four feet to ensure

safe and proper operation.

Incorrect installation may increase electric and water consumption and may

cause the machine to move about.

Screwing out and adjusting the feet

The 4 adjustable screw feet are used for