Page 1

Installation plan

Washer-extractor

PW 6107 EL

en - GB

10.11 M.-Nr. 09 270 450 / 01

Page 2

2

M.-Nr. 09 270 450 / 01

Page 3

Page 4

Page 5

Page 6

Page 7

Page 8

Technical Datasheet

Washer-extractor:

Heating:

PW 6107

Electric (EL)

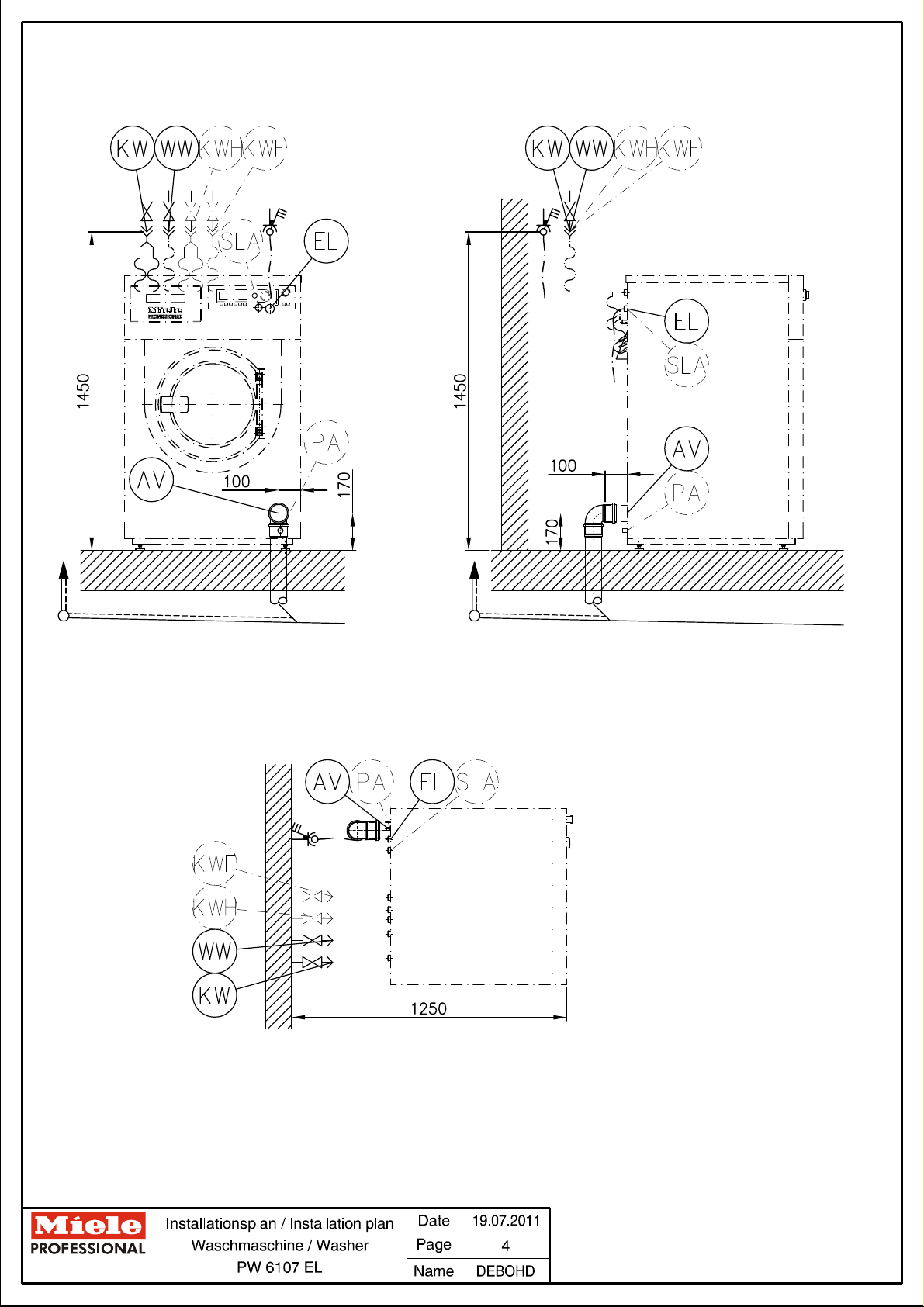

Legend:

Solid circle around symbol:

Connection mandatory

en-GB

Broken circle around symbol:

Connection optional or as required

UM

Miele plinth

UO 6010 (UO = Open plinth)

Height

mm

144

Width

mm

780

Depth

mm

789

UG 6010 (UG = Box plinth)

Height

mm

144

Width

mm

800

Depth

mm

799

UO 6010-30 (UO = Open plinth)

Height

mm

300

Width

mm

780

Depth

mm

789

UG 6010-30 (UG = Box plinth)

Height

mm

300

Width

mm

800

Depth

mm

799

BS

Concrete plinth

Recommended height

mm

150

Minimum height

mm

100 Min. plinth width

mm

950

Min. plinth depth

mm

910

WI

Weighing

system

Model version with integrated weighing system

OS

Offshore

Special offshore version

Electrical

connection

1. Standard voltage (as supplied)

V

3N AC 380 - 415

Frequency

Hz

50 - 60 Rated load

kW

11 Fuse rating

A

3 × 16

Connection cable, min. cross-section

mm²

5 × 2.5

Connection cable (not supplied)

Country variations:

1. Standard voltage (as supplied)

V

3 AC 220 - 240

Frequency

Hz

50 - 60

Rated load

kW

11

Fuse rating

A

3 × 25

Connection cable, min. cross-section

mm²

4 ×4

Connection cable (not supplied)

Optional extras:

Machine connections:

Technisches Datenblatt / Technical datasheet: PW 6107 EL

Datum / Date: 12.10.2011 Seite / Page: 8

Page 9

1. Standard voltage (as supplied)

V

3 AC 220 - 240

Frequency

Hz

50 - 60 Rated load

kW

11

Fuse rating

A

3 × 25

Connection cable, min. cross-section

mm²

4 × 4.0

Connection cable (not supplied)

Alternative voltage (convertible)

V

3 AC 208

Frequency

Hz

60 Rated load

kW

9.5

Fuse rating

A

3 × 25

Connection cable, min. cross-section

mm²

4 × 4

Connection cable (not supplied)

Non-standard voltages:

OS 440

Standard voltage (as supplied)

V

3 AC 440

Frequency

Hz

60 Rated load

kW

11

Fuse rating

A

3 × 16

Connection cable, min. cross-section

mm²

4 × 2.5

Connection cable (not supplied)

Electrical connection must comply with national legislation, guidelines and ordinances as well as local

regulations. Guidelines issued by power utilities and

insurance companies, occupation safety regulations

and general good practices also apply.

Connection should only be performed by a qualified

person with suitable training.

The machine can be hard-wired or installed with a

plug connection according to IEC 60309-1. A wall

socket or mains isolator must be accessible after

installation.

A plug and socket connection is recommended to

facilitate accessibility for electrical safety tests.

If an earth-leakage circuit breaker (RCD) is required

by local regulations, a Type B device (sensitive to all

types of current) should be installed.

Equi-potential

bonding

Sleeve with external thread

mm

10 × 35

for washer and nut

M

10

Fitting such as washers and nuts are only supplied

with the OS machine version.

If necessary, equipotential bonding with good galvanic contact must be provided in accordance with all

appropriate national and local regulations.

Peak-load

cut-off

Connection voltage for control signals

V

AC 230

Connection cable, min. cross-section

mm²

5 × 1.5

Connection cable (not supplied)

Miele recommends the use of a flexible supply lead

and an additional cut-off switch. The switch should be

visible and accessible after installation.

Technisches Datenblatt / Technical datasheet: PW 6107 EL

Datum / Date: 12.10.2011 Seite / Page: 9

Page 10

Cold water

Soft water

Min. water pressure/flow pressure

kPa

100

Max. water pressure/flow pressure

kPa

1000

Max. throughput

l/min

26

Max. throughput (if hot or raw water supply is not

available)

l/min

42

2 inlet hoses with ¾" threaded union including Ypiece (¾" / 1") included.

On-site connection thread according to DIN 44 991

Inch

1" external thread

Length of inlet hose

mm

1500

Average water requirements for standard programme

(60°C Cottons) for cold, hot and raw water connections.

l/h

Approx. 76

Additional requirements if hot water supply is not

available.

If connected to grey water supply, subtract cold water

(soft) volume.

Hot water

(soft water)

Max. water intake temperature

°C

70

Min. water pressure/flow pressure

kPa

100

Max. water pressure/flow pressure

kPa

1000

Max. throughput

l/min

16

1 inlet hose with ¾" threaded union supplied.

On-site connection thread according to DIN 44 991

Inch

¾" external thread

Length of inlet hose

mm

1500

Average water requirements for standard programme

(60°C Cottons) for cold, hot and raw water connections.

l/h

Approx. 82

In the absence of a hot water supply, the hot water

hose should be connected to cold water!

Cold water

Raw water

Min. water pressure/flow pressure

kPa

100

Max. water pressure/flow pressure

kPa

1000

Max. throughput

l/min

32

2 inlet hoses with ¾" threaded union including Ypiece (¾" / 1") included (optional).

On-site connection thread according to DIN 44 991

Inch

1" external thread

Length of inlet hose

mm

1500

Average water requirements for standard programme

(60°C Cottons) for cold, hot and raw water connections.

l/h

Approx. 48

Cold water

Liquid

dispensing

Min. water pressure/flow pressure

kPa

100

Max. water pressure/flow pressure

kPa

1000

Max. throughput

l/min

5.5

1 inlet hose with ¾" threaded union included

(optional).

On-site connection thread according to DIN 44 991

Inch

¾" external thread

Length of inlet hose

mm

1500

Waste water

Drain valve

Max. water temperature

°C

95

Waste water connection on machine (ext. diameter)

mm

75 [DN 70]

Drain connection on site (int. diameter)

mm

75 [DN 70]

Max. transient throughput

l/min

200

Vented drainage required. If ventilation is insufficient,

fit Miele kit, Mat. no. 05238090.

Drain manifolds serving several machines must be of

sufficient cross-section.

Technisches Datenblatt / Technical datasheet: PW 6107 EL

Datum / Date: 12.10.2011 Seite / Page: 10

Page 11

Fasteners

Without plinth

The machine must be firmly anchored to the floor!

Anchor fittings included:

2 × angle brackets (from shipping lock)

2 × bolts DIN 571 (Ø × length)

mm

8 x 80

2 × rawl plugs (Ø × length)

mm

12 x 60

The floor must be solid and able to support the machine. The fittings included are suitable for a solid

concrete floor. Anchor bolts and fittings for other floor

types must be provided on site.

On concrete plinth

The machine must be firmly anchored to the floor!

Anchor fittings included:

2 × angle brackets (from shipping lock)

2 × bolts DIN 571 (Ø × length)

mm

8 x 80

2 × rawl plugs (Ø × length)

mm

12 x 60

The grade of concrete should be suitable for the load.

The plinth should be firmly anchored to the floor to

accommodate dynamic stress!

Miele plinth

The plinth must be firmly anchored to the floor!

Anchor fittings included with plinth:

4 × bolts DIN 571 (Ø × length)

mm

8 x 80

4 × rawl plugs (Ø × length)

mm

12 x 60

Both the machine and the plinth must be installed

according to the installation instructions provided.

Machine

version

WI

The machine must be firmly anchored to the floor!

Anchor fittings included:

4 × angled anchor brackets

4 × bolts DIN 571 (Ø × length)

mm

8 x 80

4 × rawl plugs (Ø × length)

mm

12 x 60

The floor must be solid and able to support the machine. The fittings included are suitable for a solid

concrete floor. Anchor bolts and fittings for other floor

types must be provided on site.

Machine

version

OS

The machine must be firmly anchored to the floor!

Fittings not supplied with machine.

Internal anchor thread

mm

12

Installation must comply with local requirements and

cater for on-site conditions. The machine is supplied

without feet to allow the interior thread to be used

with stay bolts.

Technisches Datenblatt / Technical datasheet: PW 6107 EL

Datum / Date: 12.10.2011 Seite / Page: 11

Page 12

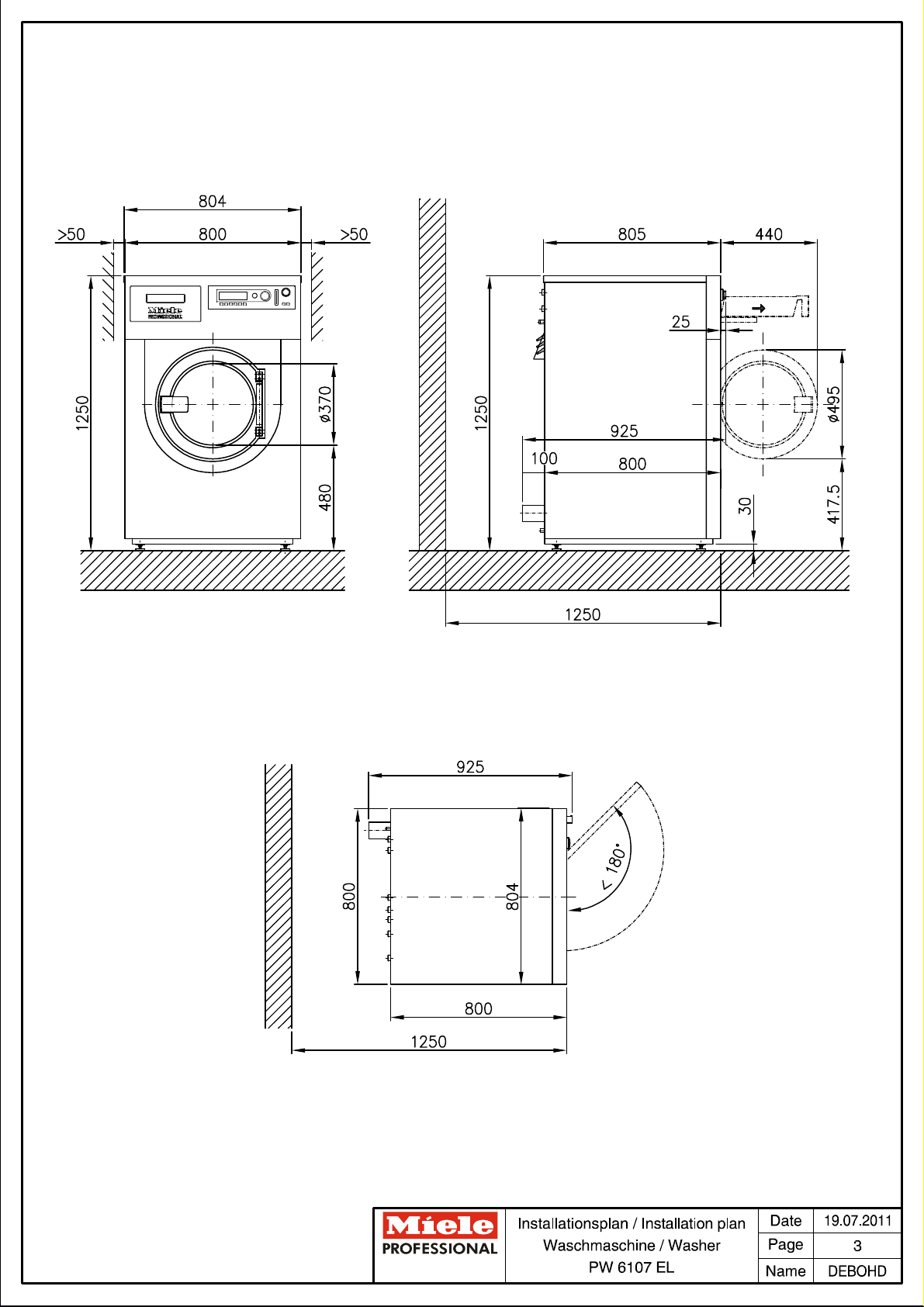

Machine data

Machine width

mm

804

Machine depth

mm

925

Machine height

mm

1250

Casing width

mm

800

Casing depth

mm

800

Min. access width to installation site

mm

810

Recommended rear wall gap (measured to front of

machine)

mm

1250

Minimum wall gap (measured to rear of machine lid)

mm

400

Net weight

kg

320

Dynamic floor load, max.

N

3931

Static floor load, max.

N

3483

Dynamic load, max.

N

448

Drum frequency, max.

Hz

20

Average heat dissipation

(dependent on ambient room temperature and programme selected)

W

1050

Sound pressure level (re 20 mPA),

workplace-related

(at distance of 1 m and height of 1.6 m)

dB (A)

66

Installation should only be carried out by authorised fitters in accordance with valid regulations!

Observe installation instructions when installing machine! All rights reserved! Dimensions in mm

Technisches Datenblatt / Technical datasheet: PW 6107 EL

Datum / Date: 12.10.2011 Seite / Page: 12

Loading...

Loading...