Installation plan

Washer-extractor

PW 6107 D

en - GB

06.15 M.-Nr. 10 303 250 / 01

2

M.-Nr. 10 303 250 / 01

Technical datasheet

Washer-extractor:

Heating type:

PW 6107

Steam (D)

Legend:

Circled, bold-type abbreviations:

Connection required

en - GB

Abbreviations surrounded by broken circle:

Connection optional or required, depending on model

UM

Miele plinth

UO 6010 (UO = open plinth)

Height

mm

144 Width

mm

780

Depth

mm

789

UG 6010 (UG = Box plinth)

Height

mm

144

Width

mm

800

Depth

mm

799

UO 6020 (UO = open plinth)

Height

mm

300

Width

mm

780

Depth

mm

789

UG 6010-30 (UG = Box plinth)

Height

mm

300

Width

mm

800

Depth

mm

799

BS

Concrete plinth

Recommended height

mm

150

Minimum height

mm

100

Plinth width min.

mm

950

Min. plinth depth

mm

910

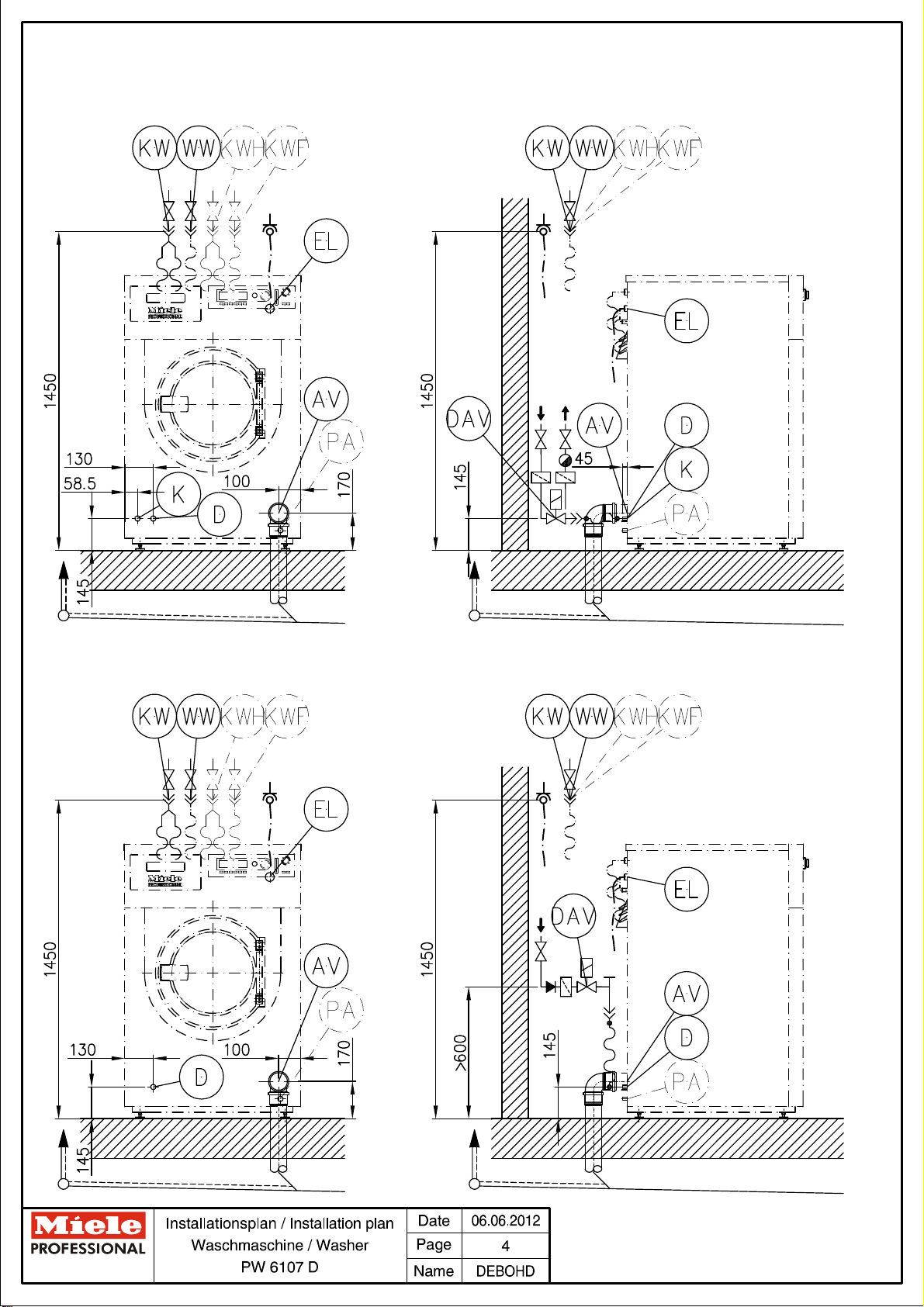

DAV

Steam

connection valve

The steam connection valve to regulate the steam supply

must be provided on site.

The following valves can be ordered separately as electric

steam valves or as pneumatic steam valves.

Electric steam valve (ELD 01)

Regulatable steam pressure

kPa

200 - 1000

Connection gauge

Inch

½"

Voltage

V

1N AC 230

Frequency

Hz

50 - 60

Pneumatic steam valve (PND)

Regulatable steam pressure

kPa

0 - 1000

Connection gauge

Inch

½"

Supply point and pneumatic valve controls must be provided

on site.

Options / Accessories:

Technisches Datenblatt / Technical datasheet: PW 6107 D

Datum / Date: 24.04.2013 Seite / Page: 7

Electrical

connection

1. Standard voltage (standard version)

V 3N AC 380 - 415

Frequency

Hz

50 - 60 Connected load

kW

2.3

Fuse rating

A 3 × 16

Connection cable, min. gauge

mm²

5 × 1.5

Connection cable not supplied (to be ordered

separately)

Variations in the following countries:

1. Standard voltage (standard version)

V 3 AC 220 - 240

Frequency

Hz

60 Connected load

kW

2.3

Fuse rating

A 3 × 15

Connection cable, min. gauge

mm²

4 × 1.5

Connection cable not supplied (to be ordered

separately)

Alternative voltage (convertible)

V 3 AC 208

Frequency

Hz

60

Connected load

kW

2.3

Fuse rating

A 3 × 15

Connection cable, min. gauge

mm²

4 × 1.5

Connection cable not supplied (to be ordered

separately)

The electrical connection may only be made to an electrical

system provided in accordance with all appropriate local and

national legislation and regulations. In addition, all regulations

of the appropriate utility supply companies and standards

relating to safety, and all applicable valid regulations and

technical standards must be complied with!

Electrical connection is the responsibility of a qualified

electrician.

The machine can be either hard-wired or connected via a

socket in compliance with IEC 60309-1. Wall socket or mains

isolator must be accessible after installation.

It is always recommended to make electrical connection via a

plug and socket so that electrical safety checks, e.g. during

repair or service work, can be carried out easily.

If it is necessary to install a residual current device (RCD) in

accordance with the local regulations, a residual current

device type B must be used.

Equipotential

bonding

Connection with male thread

mm

10 × 35

for washers and nuts

M

10

Fasteners such as washers and nuts are not provided.

If necessary, equipotential bonding with good galvanic

contact must be guaranteed in compliance with all applicable

local and national installation codes.

Steam

connection

Steam pressure (Low pressure steam)

kPa

50

Direct

Boiling point

°C

120

Mass flow (max. delivery)

kg/h

31

Heater rating

kW

18

Steam pressure (high-pressure steam)

kPa

50 - 400

Boiling point

°C

152

Mass flow (max. delivery)

kg/h

47

Heater rating

kW

27

On-site threaded union

Inch

½" female thread

Steam valve, filter, non-return valve and steam shut-off valve

must be provided on site.

The steam valve should be installed in such a way as to

prevent any wash liquor from the machine from flowing back

into the valve.

Machine connections:

Technisches Datenblatt / Technical datasheet: PW 6107 D

Datum / Date: 24.04.2013 Seite / Page: 8

Steam

connection

Steam pressure

kPa

400 - 1000

Indirect

Boiling point

°C

152 - 184

Mass flow (max. delivery)

kg/h

67

Heater rating

kW

37

On-site threaded union

Inch

½" female thread

Steam valve, filter, non-return valve and steam shut-off valve

must be provided on site.

Steam valve supply lead length

mm

500

The supply lead for the electric steam valve is included.

The steam valve should be installed close to the steam

connection.

Installation instructions for steam-heated washer-extractors

apply throughout.

Condensate

connection

On-site threaded union

Inch

½" female thread

A shut-off device and condensate trap must be provided on

site.

The condensate separator must be installed such that when

the system is not operating, the heater bank is completely

emptied. This means that no condensate may remain in the

heater bank.

Cold water

(softened water)

Min. water pressure/flow pressure

kPa

100

Max. water pressure/flow pressure

kPa

1000

Flow rate, max.

l/min

26

Max. throughput (if hot and raw water supply is not available)

l/min

42

2 connection hoses with ¾" threaded union incl. Y-piece

(¾" / 1") supplied.

On-site threaded union in accordance with DIN 44991 (flat

sealing)

Inch

1" male thread

Connection hose length

mm

1500

Average water consumption in standard programme (60°

Cottons) when connected to cold, hot and raw water supplies.

l/h

Approx. 76

In the absence of a hot water supply, add sufficient water to

reach the required amount.

If connecting to raw water, subtract water requirement from

cold water.

Hot water

(softened water)

Max. water intake temperature

°C

70

Min. water pressure/flow pressure

kPa

100

Max. water pressure/flow pressure

kPa

1000

Max. flow rate

l/min

16

1 inlet hose with ¾" threaded union provided.

On-site threaded union in accordance with DIN 44991 (flat

sealing)

Inch

¾" male thread

Connection hose length

mm

1500

Average water consumption in standard programme (60°

Cottons) when connected to cold, hot and raw water supplies.

l/h

Approx. 82

If no hot water supply available, connect hot water hose to

cold water supply!

Cold water

Raw water

Min. water pressure/flow pressure

kPa

100

Max. water pressure/flow pressure

kPa

1000

Flow rate, max.

l/min

32

2 connection hoses with ¾" threaded union including Y-piece

(¾" / 1") included in optional kit.

On-site threaded union in accordance with DIN 44991 (flat

sealing)

Inch

1" male thread

Connection hose length

mm

1500

Average water consumption in standard programme (60°

Cottons) when connected to cold, hot and raw water supplies.

l/h

Approx. 48

Technisches Datenblatt / Technical datasheet: PW 6107 D

Datum / Date: 24.04.2013 Seite / Page: 9

Cold water

Liquid dispensing

Min. water pressure/flow pressure

kPa

100

Max. water pressure/flow pressure

kPa

1000

Flow rate, max.

l/min

5.5

1 supply hose with ¾" threaded union included in optional kit.

On-site threaded union in accordance with DIN 44991 (flat

sealing)

Inch

¾" male thread

Connection hose length

mm

1500

Waste water

Drain valve

Max. water temperature

°C

95

Machine-side drain connection (ext. diameter)

mm

75 [DN 70]

On-site drain connection (int. diameter)

mm

75 [DN 70

connection]

Max. transient flow rate

l/min

200

Vented collector line required; if insufficient venting, use Miele

installation kit, Mat. no. 05238090.

When several machines are connected, ensure that the

manifold is of a sufficient diameter.

Securing of

machine

Without plinth

The machine must be adequately anchored to the floor!

Fastening material included with unit:

2 × angled brackets (from transport strut)

2 × wood screws DIN 571 (Ø × length)

mm

8 x 80

2 × rawl plugs (Ø × length)

mm

12 x 60

The installation surface must be sufficiently stable and solid.

The fastening material provided is designed for securing the

machine to a concrete floor only. Fasteners for other floor

types must be provided on site.

On concrete plinth

The machine must be adequately anchored to the floor!

Fastening material included with unit:

2 × angled brackets (from transport strut)

2 × wood screws DIN 571 (Ø × length)

mm

8 x 80

2 × rawl plugs (Ø × length)

mm

12 x 60

The quality of the concrete and its strength must be assessed

according to the machine load. A secure joint between a

concrete plinth and the floor must be guaranteed.

Miele plinth

A plinth must be securely bolted to the floor!

Fasteners included with plinth

4 × wood screws DIN 571 (Ø × length)

mm

8 x 80

4 × rawl plugs (Ø × length)

mm

12 x 60

Installation of machine and plinth must be in accordance with

the installation instructions provided.

Technisches Datenblatt / Technical datasheet: PW 6107 D

Datum / Date: 24.04.2013 Seite / Page: 10

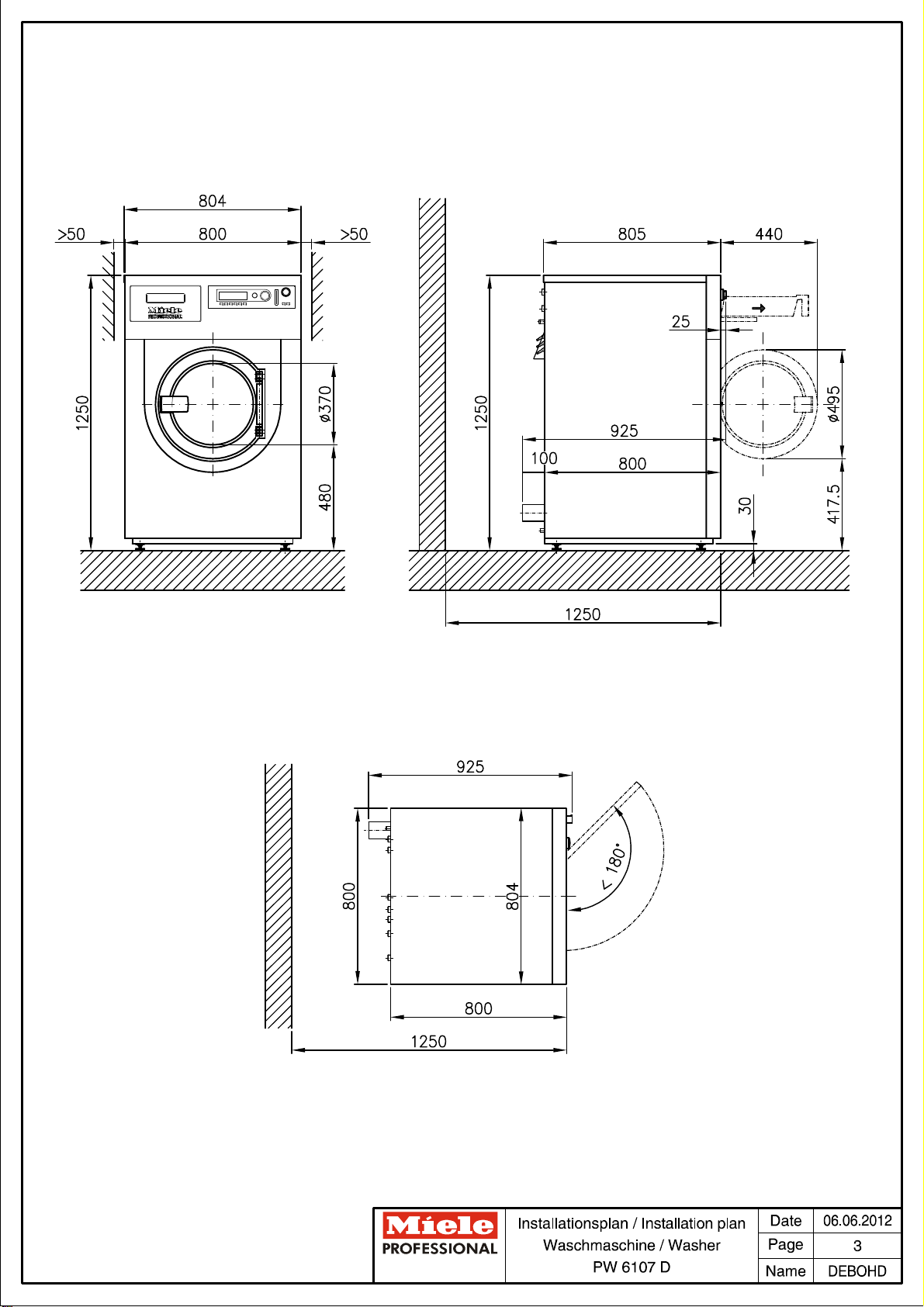

Machine data

Machine width

mm

804

Machine depth

mm

925

Machine height

mm

1250

Machine width

mm

800

Casing depth

mm

800

Min. access width

mm

810

Recommended distance from opposite wall (to front of

machine)

mm

1250

Min. wall gap (to rear edge of lid)

mm

400

Net weight

kg

320

Max. floor load in operation

N

3970

Max. static floor load

N

3522

Max dynamic floor load

N

448

Max. drum rotation frequency

Hz

20

Average heat dissipation to installation site

(depending on ambient temperature and programme

selected)

W

1050

Sound pressure level (re 20 mPA),

(distance 1 m and 1.6 m above floor)

dB(A)

66

Installation should only be performed by qualified fitters in accordance with valid regulations, relevant standards and health

and safety codes!

It is important to comply with installation instructions when installing machines! All rights reserved! Dimensions in mm.

Technisches Datenblatt / Technical datasheet: PW 6107 D

Datum / Date: 24.04.2013 Seite / Page: 11

Loading...

Loading...