Page 1

Installation recommendations

Washer-extractor

PW 6080 XL EL AV/LP

en - GB

3520

Mat. no. 07 580 680 / 07

Page 2

Miele & Cie. KG, Carl-Miele-Straße 29, 33332 Gütersloh, Germany

Manufacturer:

Malaysia

Miele Sdn Bhd

Suite 12-2, Level 12

Menara Sapura Kencana Petroleum

Solaris Dutamas No. 1, Jalan Dutamas 1

50480 Kuala Lumpur, Malaysia

Phone: +603-6209-0288

Fax: +603-6205-3768

Miele New Zealand Limited

IRD 98 463 631

8 College Hill

Freemans Bay, Auckland 1011, NZ

Tel: 0800 464 353

Internet: www.miele.com.au/professional

E-mail: info@miele-professional.com.au

New Zealand

Miele Pte. Ltd.

29 Media Circle, #11-04 ALICE@Mediapolis

Singapore 138565

Tel: +65 6735 1191, Fax: +65 6735 1161

E-Mail: info@miele.com.sg

Internet: www.miele.sg

Singapore

Miele (Pty) Ltd

63 Peter Place, Bryanston 2194

P.O. Box 69434, Bryanston 2021

Tel: (011) 875 9000, Fax: (011) 875 9035

E-mail: info@miele.co.za

Internet: www.miele.co.za

South Africa

Miele Appliances Ltd.

Showroom 1, Eiffel 1 Building

Sheikh Zayed Road, Umm Al Sheif

P.O. Box 114782 - Dubai

Tel. +971 4 3044 999, Fax. +971 4 3418 852

800-MIELE (64353)

E-Mail: info@miele.ae, Website: www.miele.ae

United Arab Emirates

United Kingdom

Miele Co. Ltd., Fairacres, Marcham Road

Abingdon, Oxon, OX14 1TW

Professional Sales, Tel: 0845 365 6608

E-mail: professional@miele.co.uk

Internet: www.miele.co.uk/professional

Miele Australia Pty. Ltd.

ACN 005 635 398, ABN 96 005 635 398

1 Gilbert Park Drive, Knoxfield, VIC 3180

Tel: 1300 731 411

Internet: www.miele.com.au/professional

E-mail: info@miele-professional.com.au

Australia

Miele Electrical Appliances Co., Ltd.

1-3 Floor, No. 82 Shi Men Yi Road

Jing' an District, 200040 Shanghai, PRC

Tel: +86 21 6157 3500, Fax: +86 21 6157 3511

E-mail: info@miele.cn, Internet: www.miele.cn

China Mainland

Miele (Hong Kong) Ltd.

41/F - 4101, Manhattan Place

23 Wang Tai Road, Kowloon Bay, Hong Kong

Tel: (852) 2610 1025, Fax: (852) 3579 1404

Email: customerservices@miele.com.hk

Website: www.miele.hk

Hong Kong, China

Miele India Pvt. Ltd.

Ground Floor, Copia Corporate Suites

Plot No. 9, Jasola, New Delhi - 110025

Tel: 011-46 900 000, Fax: 011-46 900 001

E-mail: customercare@miele.in, Internet: www.miele.in

India

Miele Ireland Ltd.

2024 Bianconi Ave., Citywest Business Campus, Dublin 24

Tel: (01) 461 07 10, Fax: (01) 461 07 97

E-Mail: info@miele.ie, Internet: www.miele.ie

Ireland

Mat. no. 07 580 680 / 07

It is essential to read the operating and installation instructions

before installing, commissioning or using the machine.

This avoids the risk of accidents or damage.

All rights reserved

2

Page 3

Page 4

Page 5

Page 6

Page 7

Technical Datasheet

Washer-extractor:

Heating:

PW 6080 AV/LP

Electric (EL)

Legend:

Circled, bold-type abbreviations:

Connection required

Abbreviations surrounded by broken circle:

Connection optional or required, depending on model

Optional extras:

UM

Miele plinth

UO 6008 (UO = Open plinth)

Height

mm

305

Width

mm

680

Depth

mm

679

UG 6008 (UG = Closed plinth)

Height

mm

305

Width

mm

692

Depth

mm

685

US 6008 (US = Plinth with drawer)

Height

mm

320

Width

mm

692

Depth

mm

685

BS

Concrete plinth

Concrete plinth (min. quality C12/15)

Recommended height

mm

300

Minimum height

mm

70

Recommended width

mm

≥700

Recommended depth

mm

≥700

It must be ensured that the om-site concrete plinth is

anchored to the floor!

Electrical

connection

1. Standard voltage (as supplied)

V

3N AC 400

Frequency

Hz

50

Rated load

kW

8.2

Fuse rating

A

3 × 16

Connection cable cross-sectional area

mm²

5 × 1.5

Connection cable length

mm

2000

Connection cable without plug

(supplied as standard)

Country variations:

1. Standard voltage (as supplied)

V

1N AC 220 - 240

Frequency

Hz

50

Rated load

kW

5.05 – 6.0

Fuse rating

A

1 × 25

Connection cable cross-sectional area

mm²

3 × 2.5

Connection cable length

mm

2000

Connection cable without plug

(supplied as standard)

1. Standard voltage (as supplied)

V

3 AC 230

Frequency

Hz

50

Rated load

kW

8.2

Fuse rating

A

3 × 20

Connection cable cross-sectional area

mm²

4 × 2.5

Connection cable length

mm

2000

Connection cable without plug

(supplied as standard)

Machine connections:

Technisches Datenblatt / Technical datasheet: PW 6080 EL AV/LP

Datum / Date: 04.09.2015 Seite / Page: 7

Page 8

Non-standard voltages:

OS 440

1. Standard voltage (as supplied)

V

3 AC 440

Frequency

Hz

60

Rated load

kW

7.9

Fuse rating

A

3 × 16

Connection cable cross-sectional area

mm²

4 × 1.5

Connection cable length

mm

2000

Connection cable without plug

(supplied as standard)

Electrical connection must be in accordance with local and

national regulations.

Plug and socket connection in accordance with IEC/EN

60309 and IEC/EN 60947 recommended to facilitate

electrical safety tests.

If the machine is connected via a fixed connection, a multipole switch must be provided on site to ensure complete

isolation. Switches with a contact opening of more than 3 mm

should be used. Such switches are, e.g., LS switches, fuses

and contactors (IEC/EN 60947).

A wall socket or mains isolator must be visible and accessible

after installation.

A new connection, modification of an existing installation or

earth checking, including the determination of suitable fuse

rating, may only be carried out by a suitably qualified

electrician in accordance with all local and national

regulations.

Cold water

(soft water)

Min. flow pressure

kPa

100

Max. pressure

kPa

1000

Max. throughput

l/min

11

On-site connection thread according to DIN 44 991

Inch

¾" external thread

Length of connection hose

(parts supplied: 1 connection hose)

mm

1550

Water requirements (average for 60°C programme)

With standard connection (with hot water)

l/h

Approx. 70

If hot water supply is not available, a sufficient supply of cold

water must be ensured.

If connected to an alternative water supply (optional), subtract

cold water volume.

Hot water

(soft water)

Max. temperature

°C

70

Min. flow pressure

kPa

100

Max. pressure

kPa

1000

Max. throughput

l/min

11

On-site connection thread according to DIN 44 991

Inch

¾" external thread

Length of connection hose

(parts supplied: 1 connection hose)

mm

1550

Water requirements (average for 60°C programme)

l/h

Approx. 70

It is possible to connect the machine to a very hot water

supply with temperature from 70°C to max. 85°C. For this a

special connection hose is required. This special hose is

available from the Miele Spares Dept.

In addition, the Miele Service Dept. or an authorised dealer

must reprogram the machine accordingly.

If a hot water supply is not available, connect the hot water

hose to a cold water supply!

Technisches Datenblatt / Technical datasheet: PW 6080 EL AV/LP

Datum / Date: 04.09.2015 Seite / Page: 8

Page 9

Waste water

Model with dump

valve

Max. temperature

°C

Machine waste water connection (external diameter)

mm

On-site drain (internal diameter)

mm

95

Max. transient throughput

l/min

62

Vented drainage required. If ventilation is insufficient, fit Miele

kit, Mat. no. 05238090.

Drain manifolds serving several machines must be of

sufficient cross-section.

Drainage via

drain pump

Max. temperature

°C 95Drain hose (inner diameter)

mm

22 [DN 22]

On-site hose sleeve for drain hose

(inner diameter x length)

mm

22 × 30

Max. transient throughput

l/min

26

Max. head height (measured from base of unit)

mm

1000

Vented drainage required. If ventilation is insufficient, fit Miele

kit, Mat. no. 05238090. .

Drain manifolds serving several machines must be of

sufficient cross-section.

Fittings

(supplied)

Miele plinth UG/UO 6008

4 × fasteners (to secure machine to plinth)

4 × screws DIN 571 (Ø × length)

mm

8 × 65

4 × rawl plugs (Ø × length)

mm

12 × 60

Machine must be bolted to the floor!

Fixing materials for floating screed floor to be provided on site

Miele plinth US 6008

4 × fasteners (to secure machine to plinth)

4 × screws DIN 571 (Ø × length)

mm

6 × 50

4 × rawl plugs (Ø × length)

mm

8 × 40

Machine must be bolted to the floor!

Fixing materials for floating screed floor to be provided on site

On concrete plinth

2 × metal brackets

2 × screws DIN 571 (Ø × length)

mm

6 × 50

2 × rawl plugs (Ø × length)

mm

8 × 40

Machine must be bolted to the floor!

Fixing materials for floating screed floor to be provided on site

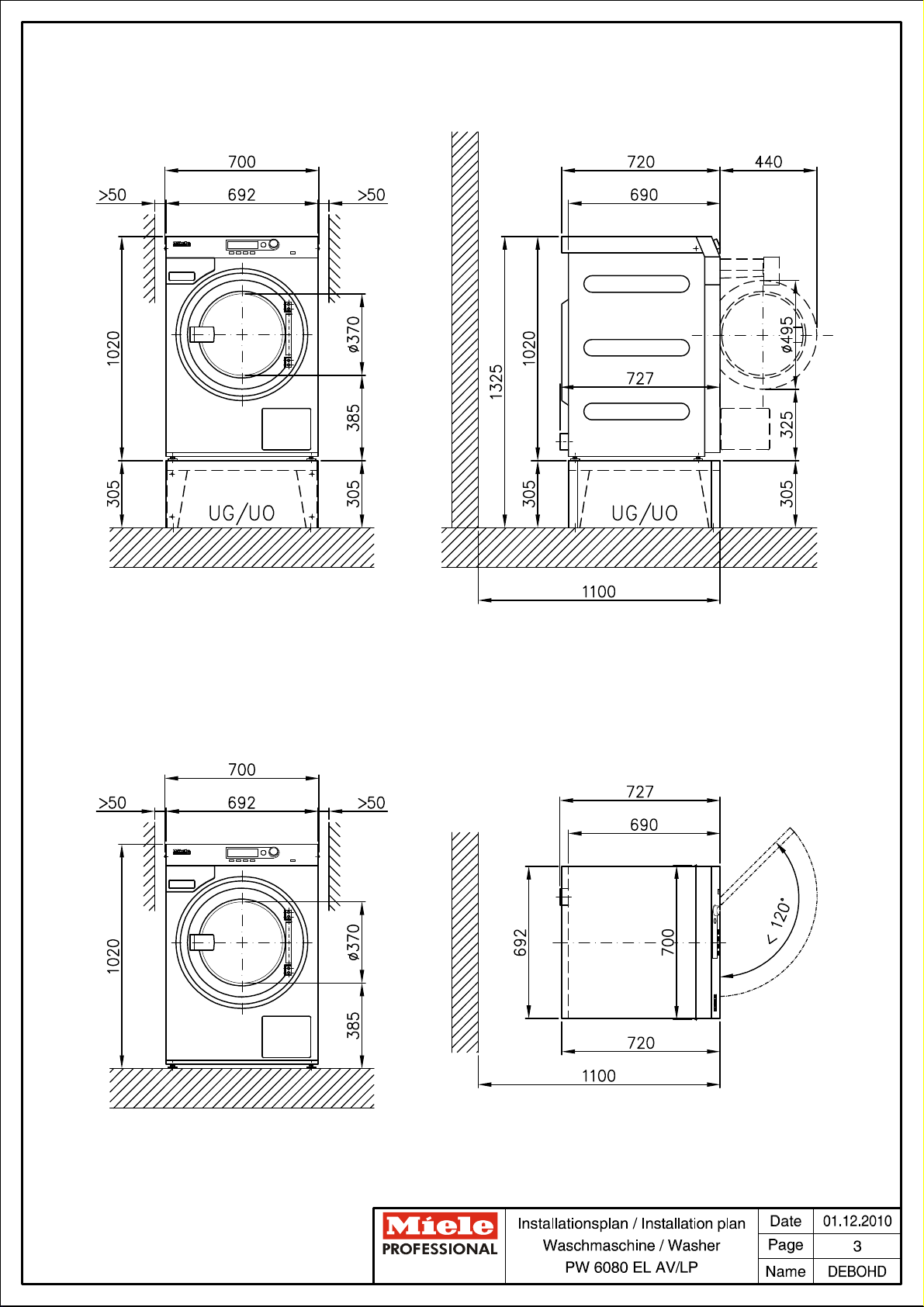

Machine data

Machine width

mm

700

Machine depth

mm

727

Machine height

mm

1020

Casing width

mm

692

Casing depth

mm

690

Min. access width to installation site

mm

720

Minimum rear wall gap (measured to front of machine)

mm

1100

Minimum wall gap (to front edge of machine)

With an installation with the minimum gap, additional work

may be required when service or repair work is necessary.

mm

900

kg

140

N

N

N

Hz

22

Sound pressure level (re 20 mPa),

(measured at a distance of 1 m from the machine and at a

height of 1.6 m)

dB (A)

<70

Installation should only be carried out by authorised fitters in accordance with valid regulations!

Observe installation instructions when installing machine! All rights reserved! Dimensions in mm

75 [DN 70]

75 [sleeve DN 70]

Net weight

Dynamic floor load, max.

Static floor load, max.

Dynamic load, max.

Drum frequency, max.

Technisches Datenblatt / Technical datasheet: PW 6080 EL AV/

LP Datum / Date: 09.05.2019 Seite / Page: 9

2330

1680

650

Loading...

Loading...