Page 1

Installation plan

Heat pump dryer

PT 8203 SL WP

To avoid the risk of accidents or damage to the

machine, it is essential to read these instructions

before it is installed and used for the first time.

en - GB, IE

M.-Nr. 10 534 370

Page 2

2 PT 8203 SL WP

Page 3

Contents

Installation and planning notes..........................................................................................4

Installation requirements ....................................................................................................... 4

General operating conditions ................................................................................................ 4

Installation ............................................................................................................................. 4

Levelling the machine............................................................................................................ 5

Securing the dryer against slippage...................................................................................... 6

Guide to the machine ............................................................................................................ 6

Electrical connection ............................................................................................................. 7

Air intake vent........................................................................................................................ 8

Air outlet vent ........................................................................................................................ 8

Condensate drainage ............................................................................................................ 8

Accessories ........................................................................................................................... 9

Communication module XKM for RS232 interface ......................................................... 9

Technical drawings -dimensions in mm.........................................................................10

Dimensions.......................................................................................................................... 10

Installation ........................................................................................................................... 11

Set up .................................................................................................................................. 12

Technical data....................................................................................................................13

Electrical data...................................................................................................................... 13

Voltage variant 3N AC 400V, 50Hz............................................................................... 13

Condensate drainage .......................................................................................................... 13

Transport data ..................................................................................................................... 13

Installation data ................................................................................................................... 13

3

Page 4

Installation and planning notes

Installation requirements

The dryer must only be set up by a Miele authorised and trained

service technician or an authorised dealer.

This dryer must be installed in accordance with all relevant regula-

tions and standards. Local energy supplier regulations must also be

observed.

This dryer must only be operated in a room that has sufficient vent-

ilation and which is frost-free.

General operating conditions

This dryer is intended only for use in a commercial environment and

must only be operated indoors.

Permissible ambient temperature:2 °C to 43 °C

The electrical components of this dryer comply with safety standards IEC/DINEN60335-1 and DINEN50570.

Installation

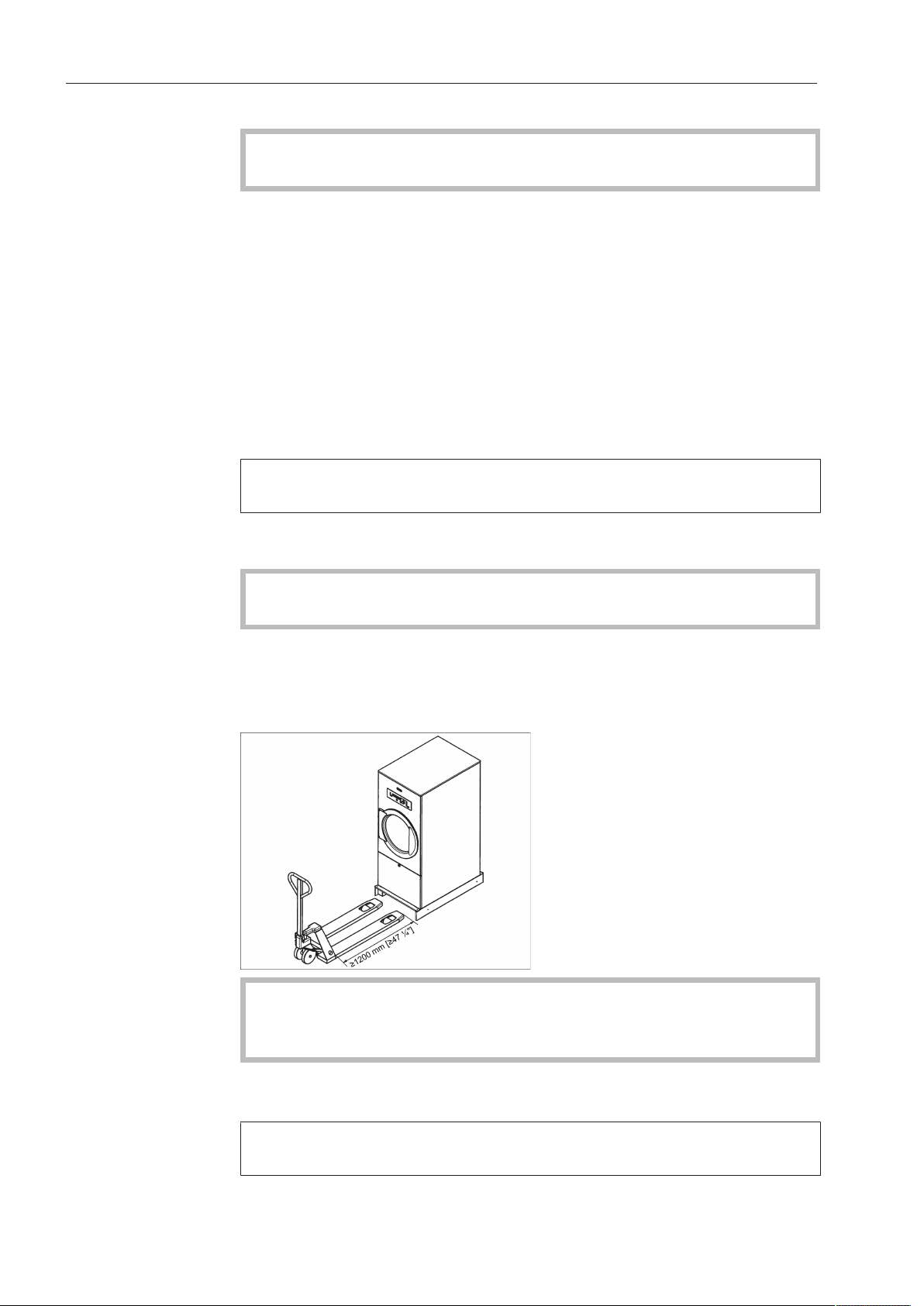

This dryer must only be transported with the transport safety

device fitted.

Transport the dryer to its installation site using a suitable pallet truck

and then remove the transport safety device. Keep this device in a

safe place for refitting should the dryer need to be moved in the future (e.g when moving to a new site).

When transporting the dryer be aware of its total height.

Be careful when transporting it on a pallet truck that it does not tip

up.

The dryer must be set up on a level and firm surface, with a minimum

load bearing capacity of2220 N.

The floor load created by the dryer is concentrated and transferred

to the installation footprint via the machine feet.

4 PT 8203 SL WP

Page 5

Installation and planning notes

To ensure easy access in the event of future servicing, please maintain a gap of at least 500 mm behind the dryer.

After setting up the dryer please let it stand for approx. 30 minutes

before using it for the first time. If the heat-pump unit was tilted by

an angle of 30° before the dryer was set up, or if it was subjected

to excessive movement, please let the dryer stand for 24hours before using it.

Otherwise the heat pump can suffer damage.

Levelling the machine

To ensure the dryer functions correctly and energy efficiently, it must

stand securely and evenly on the floor with all four feet. Any unevenness in the floor can be compensated for by adjusting the feet.

Loosen the counter nuts on the feet using a spanner.

With the assistance of a spirit level align the dryer horizontally and

vertically by adjusting the height of the feet.

After aligning the dryer tighten the counter nuts by turning them in a

clockwise direction with a spanner. This will prevent the feet from

adjusting themselves.

PT 8203 SL WP 5

Page 6

Installation and planning notes

Securing the dryer against slippage

The dryer can be secured to the floor by fitting the clamps supplied

over the feet.

Fittings supplied are for installation on a concrete floor. For other

types of flooring please purchase suitable fitting materials separately.

Guide to the machine

a

Control panel

with controls

b

Door

c

Fluff filter compartment cover

d

Air intake vent

e

Machine feet

Qty 4, adjustable

6 PT 8203 SL WP

f

Electrical connection

with cable gland

g

Communication module slot

for XKMRS232

Optional accessory

h

Condensate drainage

i

Air outlet vent

j

Data plate

Page 7

Installation and planning notes

Electrical connection

The electrical connection must be carried out by a qualified electrician who must ensure that all electrical work is carried out in accordance with applicable electrical regulations and standards (BS

7671 in the UK).

This dryer must be connected to an electrical mains supply that

complies with local and national regulations. Please also observe

your insurance and energy supplier's regulations as well as any health

and safety at work regulations.

The required voltage, power consumption and specifications for

external fusing are quoted on the data plate on the dryer. Ensure that

the supply voltage complies with the voltage quoted on the data plate

before connecting the dryer to the mains.

Connection to a supply voltage other than the one quoted on the

data plate can lead to functional faults and damage the dryer.

If more than one voltage is quoted on the data plate, the dryer can

be converted for connection to the voltages stated.

Conversion to a different voltage must only be carried out by a Miele

Service engineer or by an authorised Service Dealer. The wiring instructions given on the wiring diagram must be followed.

This dryer can either be hard-wired or connected via a plug and

socket that complies with IEC60309-1.

For hard-wired machines connection should be made via a suitable

mains switch with all-pole isolation which, when in the off position,

ensures a 3 mm gap between all open contacts. These include circuit breakers, fuses and relays (IEC/EN60947).

If the mains supply cannot be permanently disconnected, the isolator

switch (including plug and socket) must be safeguarded against being switched on either unintentionally or without authorisation.

Tip: We recommend connection to the power supply via a suitable IP

44 plug and socket which must be easily accessible for servicing and

maintenance work after the machine has been installed. An electrical

safety test must be carried out after installation and after any service

work.

If it is necessary to install a residual current device (RCD) in ac-

cordance with the local regulations, a residual current device type A

can be used.

Equipotential bonding with a good contact connection should be

carried out in accordance with local and national installation regulations. Equipotential bonding with a leakage current of >10mA should

be carried out. Accessories required for equipotential bonding (washers and nuts) are not supplied with the machine.

PT 8203 SL WP 7

Page 8

Installation and planning notes

Air intake vent

Air intake for the condenser is via an air intake vent at the front of

the dryer. Air is taken from the room in which the dryer is installed.

A fluff filter is located in the air intake vent in the dryer. This must be

regularly cleaned by hand.

The air intake vent must be kept clear. It must not be covered.

Air outlet vent

Because the heat-pump dryer operates with a closed air circuit, separate exhaust ducting is not required.

The warm air expelled from the machine as a result of cooling down

the heat-exchanger warms the room air. It is essential to ensure the

room has adequate ventilation, e.g. by providing ventilation openings

that cannot be closed whilst the machine is in use. Insufficient ventilation in the room increases the time required for drying, which in turn

will increase the amount of energy required for the drying process.

The ventilation openings must, on no account, be closed or

blocked by objects.

Condensate drainage

The heat-pump in this dryer operates on the principle of condensation. A separate floor drain must be provided in the installation room

for condensate from the drying process.

The condensate drainage point is located at the back of the heatpump dryer. The condensate must be drained via a downwards pointing DN30 pipe to the floor drain.

Ensure that condensate cannot backflow into the dryer. A non-return valve, available as an optional accessory, can be fitted if necessary.

Any condensate that gets back into the machine can cause damage.

8 PT 8203 SL WP

Page 9

Installation and planning notes

Accessories

Accessory or spare parts may only be connected or built-in to this

machine if they are expressly approved for such use by Miele.

If non-Miele parts are used, guarantee, performance and product liability claims may be invalidated.

Communication

module XKM for

RS232 interface

The serial interface RS-232 can be retrofitted to the dryer via an

XKMRS232 (optional accessory available from Miele). This communication module must only be used with MieleProfessionalmachines

that are fitted with an appropriate slot for the module.

The data interface provided via communication module

XKMRS232 complies with SELV (Safety Extra Low Voltage) in accordance with EN60950.

Appliances connected to this interface must also be SELV compliant.

Communication module XKMRS232 is supplied with a connection

cable and a D-sub-connector.

PT 8203 SL WP 9

Page 10

Technical drawings -dimensions in mm

1074

Dimensions

10 PT 8203 SL WP

Page 11

Installation

50

618 90

1700

200

500

>100

254

200

1700

Technical drawings -dimensions in mm

a

Electrical connection

b

Condensate drainage

PT 8203 SL WP 11

Page 12

Technical drawings -dimensions in mm

3

3

3

Set up

c

Anchoring point (optional)

12 PT 8203 SL WP

Page 13

Technical data

Electrical data

Voltage variant 3N AC 400V, 50Hz

Voltage 3N AC 400 V

Frequency 50 Hz

Fuse rating 3 x 16 A

Total connected load 2,6 kW

Current draw 3 x 8,5 A

Connection cable, min. cross-section 5 x 2,5 mm²

Cable gland M25 x 1,5

Condensate drainage

External diameter 32 mm

Length (from the rear panel) 50 mm

Transport data

Packaging width 800 mm

Packaging height 1810 mm

Packaging depth 1180 mm

Volume 1651,8 l

Weight (gross) 213 kg

Installation data

Overall machine width 711 mm

Overall machine height 1800 mm

Overall machine depth 1075 mm

Casing width (without add-on components) 708 mm

Casing height (without add-on components) 1800 mm

Casing depth (without add-on components) 999 mm

Machine weight (net) 202 kg

Max. floor load in operation 2220 N

Minimum width of loading aperture (internal width) 725 mm

Recommended distance between front of machine and the wall 1500 mm

Average heat dissipation rate to installation site 650 W

Emission sound pressure level in accordance with EN ISO 11204 57 dB (A)

Noise power level in accordance with EN ISO 9614-2 71 dB (A)

PT 8203 SL WP 13

Page 14

Carl-Miele-Straße 29, 33332 Gütersloh, Germany

Miele & Cie. KG

Manufacturer:

Malaysia

Miele Sdn Bhd

Suite 12-2, Level 12

Menara Sapura Kencana Petroleum

Solaris Dutamas No. 1, Jalan Dutamas 1

50480 Kuala Lumpur, Malaysia

Phone: +603-6209-0288

Fax: +603-6205-3768

Miele New Zealand Limited

IRD 98 463 631

Level 2, 10 College Hill

Freemans Bay, Auckland 1011, NZ

Tel: 0800 464 353

Internet: www.miele-professional.com.au

E-mail: info@miele-professional.com.au

New Zealand

Miele Pte. Ltd.

163 Penang Road

# 04 - 03 Winsland House II

Singapore 238463

Tel: +65 6735 1191, Fax: +65 6735 1161

E-Mail: info@miele.com.sg

Internet: www.miele.sg

Singapore

Miele (Pty) Ltd

63 Peter Place, Bryanston 2194

P.O. Box 69434, Bryanston 2021

Tel: (011) 875 9000, Fax: (011) 875 9035

E-mail: info@miele.co.za

Internet: www.miele.co.za

South Africa

Miele Appliances Ltd.

Gold & Diamond Park

Office No. 217-6, Sheikh Zayed Road

P.O. Box 11 47 82 - Dubai

Tel: +971 4 3044 999, Fax: +971 4 3418 852

800-MIELE (64353)

E-Mail: info@miele.ae, Internet: www.miele.ae

United Arab Emirates

United Kingdom

Miele Co. Ltd.

Fairacres, Marcham Road

Abingdon, Oxon, OX14 1TW

Professional Sales, Tel: 0845 365 6608

E-mail: professional@miele.co.uk

Internet: www.miele-professional.co.uk

Miele Australia Pty. Ltd.

ACN 005 635 398

ABN 96 005 635 398

1 Gilbert Park Drive, Knoxfield, VIC 3180

Tel: 1300 731 411

Internet: www.miele-professional.com.au

E-mail: info@miele-professional.com.au

Australia

Miele (Shanghai) Trading Ltd.

1-3 Floor, No. 82 Shi Men Yi Road

Jing' an District, 200040 Shanghai, PRC

Tel: +86 21 6157 3500, Fax: +86 21 6157 3511

E-mail: info@miele.cn, Internet: www.miele.cn

China

41/F - 4101, Manhattan Place

23 Wang Tai Road

Kowloon Bay, Hong Kong

Tel: (852) 2610 1025, Fax: (852) 3579 1404

Email: customerservices@miele.com.hk

Website: www.miele.hk

Miele (Hong Kong) Limited

Miele India Pvt. Ltd.

Ground Floor, Copia Corporate Suites

Plot No. 9, Jasola

New Delhi - 110025

Tel: 011-46 900 000, Fax: 011-46 900 001

E-mail: customercare@miele.in, Internet: www.miele.in

India

Miele Ireland Ltd.

2024 Bianconi Avenue

Citywest Business Campus, Dublin 24

Tel: (01) 461 07 10, Fax: (01) 461 07 97

E-Mail: info@miele.ie, Internet: www.miele.ie

Ireland

Alteration rights reserved / Publication date: 2016 M.-Nr. 10 534 370 / 00

PT 8203 SL WP

Loading...

Loading...