Operating and Installation instructions

Gas hob

KM 405

KM 406

KM 416

To avoid the risk of accidents or

damage to the appliance it is

essential to read these

instructions before it is installed

or used for the first time.

-CNen

M.-Nr. 06 127 100

Contents

Description of the appliance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

KM 405. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

KM 406. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

KM 416. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Warning and Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Before using for the first time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

General notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Disposal of the packing material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Disposal of your old appliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Cleaning and heating up for the first time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Gas burner unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Switching on, Switching off, Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

KM 405 / KM 416 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

KM 406 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Using the gas hob . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Suitable pans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Safety cut-out. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Use during a power cut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Cleaning and care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Ceramic hob surface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Burners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Problem solving guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

After sales service, data plate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2

Contents

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Safety distance above appliances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Building-in dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

KM 405 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

KM 406 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

KM 416 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Worktop cut-out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Fitting the spacer bars and support brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Fixing the spacer bars . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Fixing the support brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Building in the gas hob . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Gas connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Town gas / LPG / Natural gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Conversion to another type of gas. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

KM 405. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Jet table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Changing the jets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

KM 406. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Jet table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Changing the jets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Check the first intake of air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

KM 416. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Jet table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Changing the jets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Check the first intake of air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

3

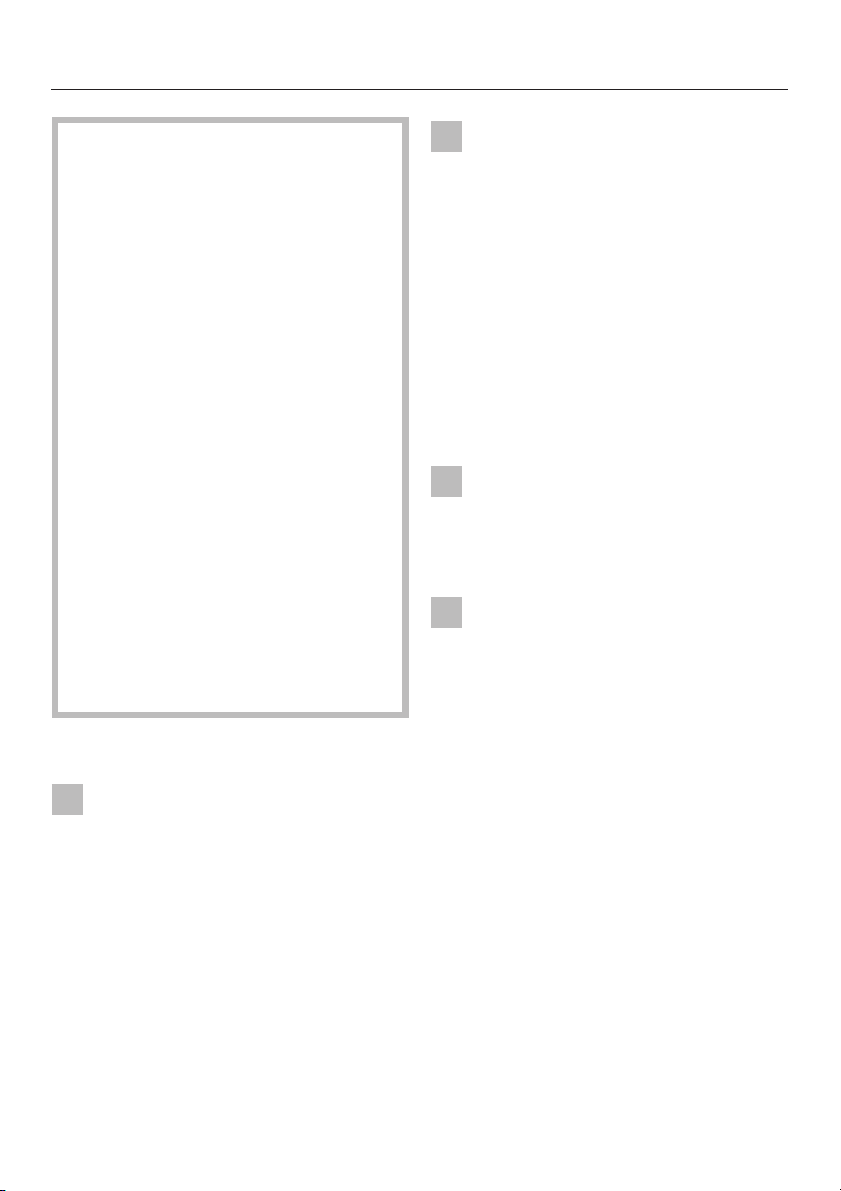

Description of the appliance

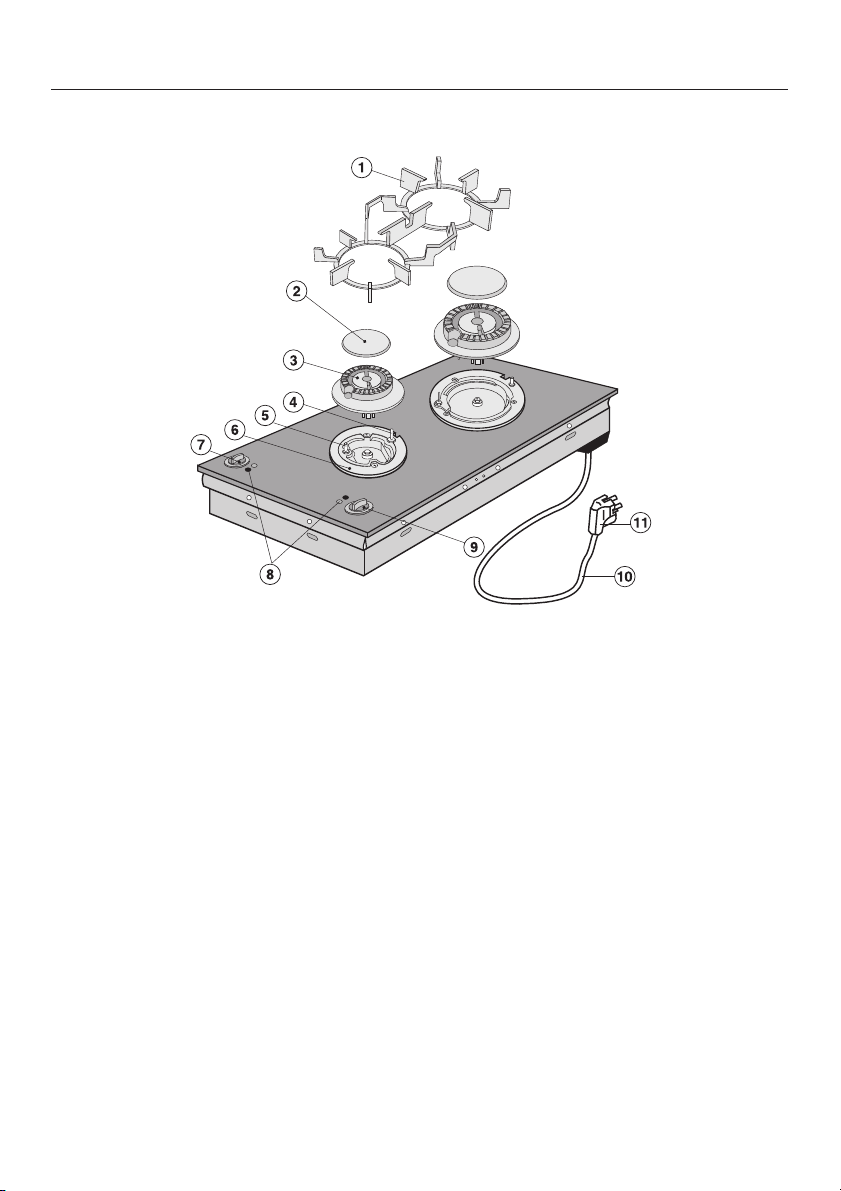

KM 405

a Pan support

b Burner cap

c Burner head

d Ignition safety device

e Ignitor

f Burner base

4

g Control knob for the

front burner

h Symbols to indicate which

cooking zone the control is for

i Control knob for the

back burner

j Mains connection cable

k Plug

Depending on country of destination,

the appliance may be supplied with

or without a plug. The plug shown is

for illustration only.

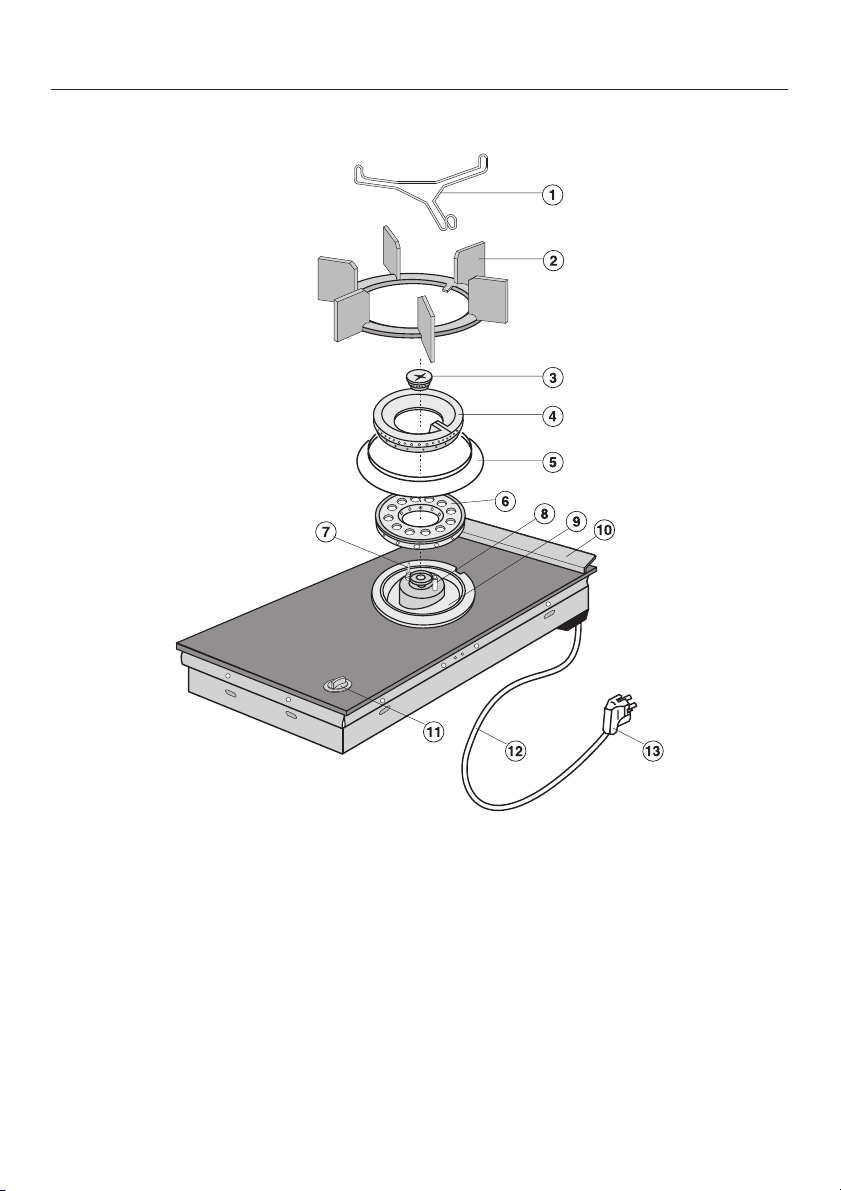

KM 406

Description of the appliance

a Trivet

b Pan support

c Small burner cap

d Large burner cap

e Burner collar ring

f Large burner cap base

g Ignition safety device

h Ignitor

i Burner base

j Air inlet with cover plate

k Control for burner

l Mains connection cable

m Plug

Depending on country of destination,

the appliance may be supplied with

or without a plug. The plug shown is

for illustration only.

5

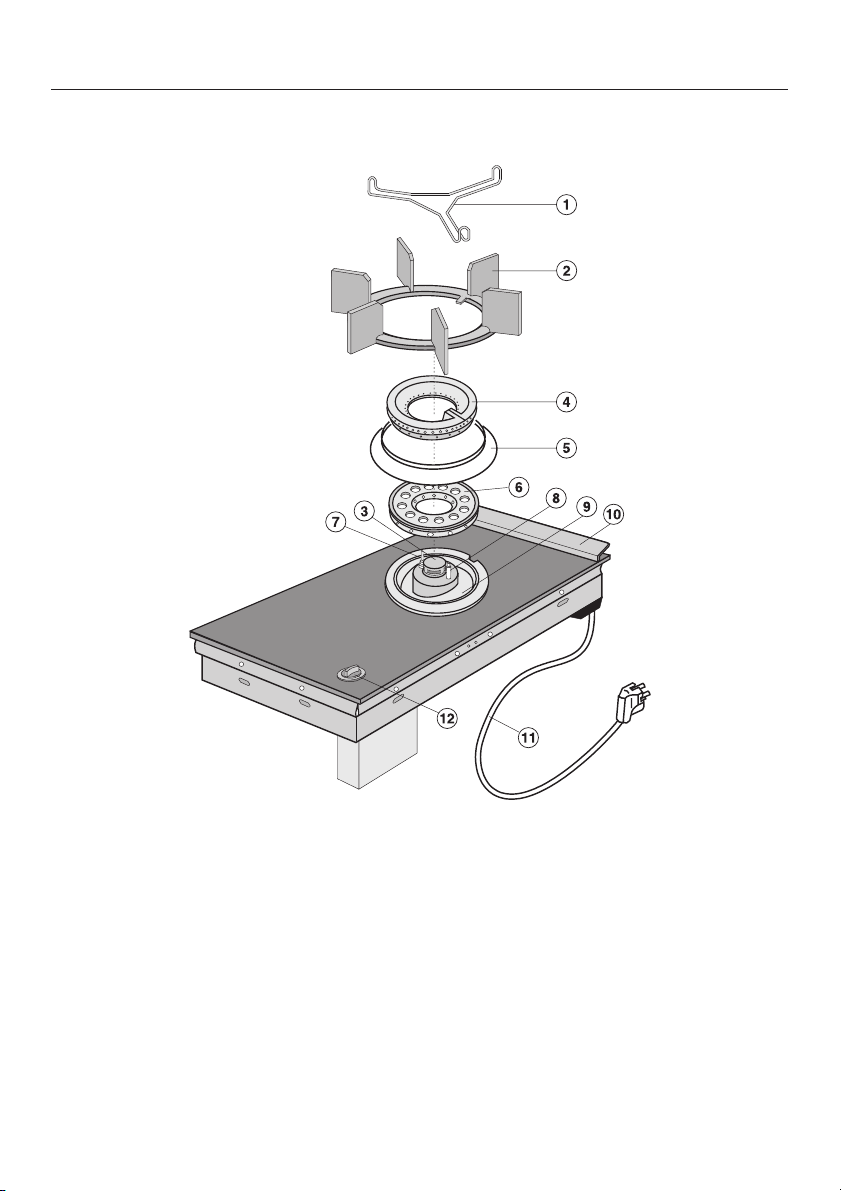

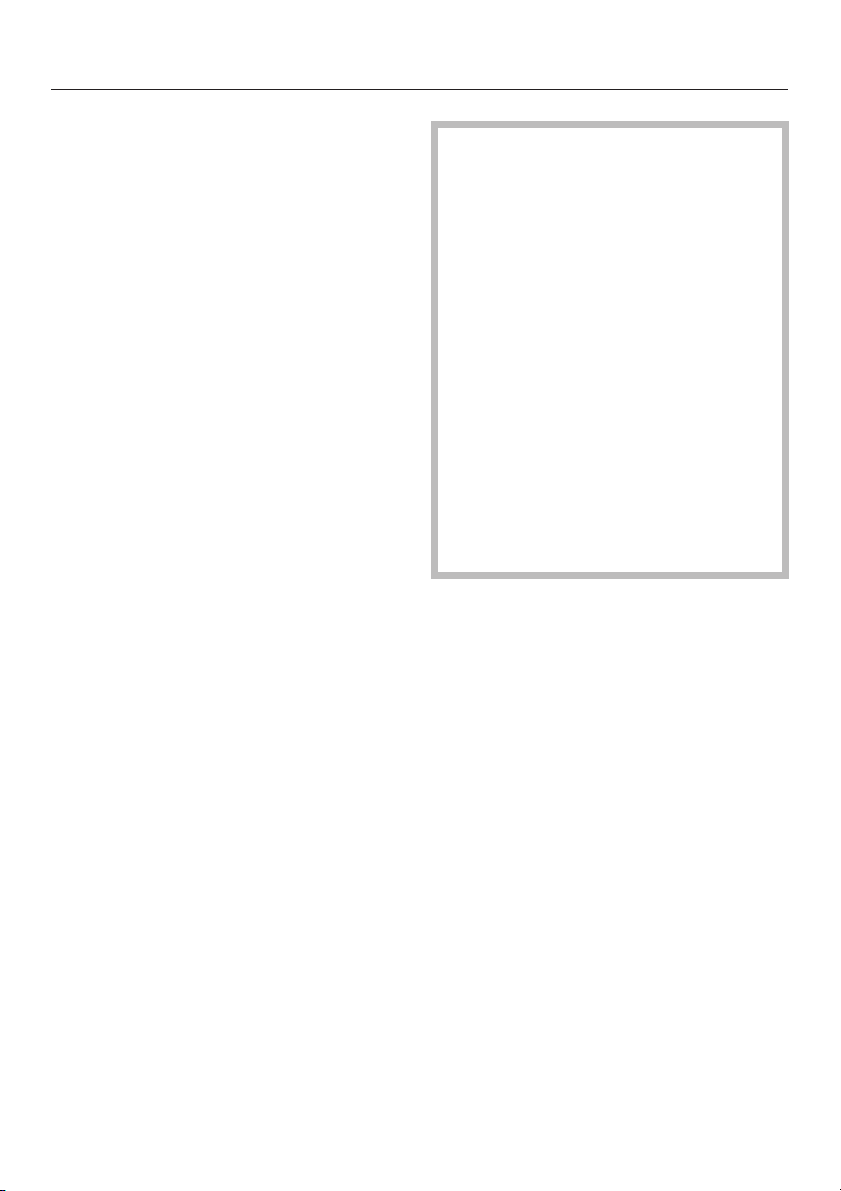

Description of the appliance

KM 416

a Trivet

b Pan support

c Air inlet cover for inner burner circle

d Large burner cap

e Burner collar ring

f Large burner cap base

g Ignition safety device

h Ignitor

6

i Burner base

j Air inlet with cover plate

k Cable for connection to electrical

supply approx. 3.5 ft (1.10m) long

(** See note on Contents page)

l Control for burner

Warning and Safety instructions

This appliance complies with all

relevant legal safety requirements.

Improper use of the appliance can,

however, present a risk of both

personal injury and material

damage.

Before installing and using the

appliance for the first time, read the

operating and installation

instructions carefully. They give

information on safety, on the

operation and care of the appliance.

This way you will avoid the risk of

accident and damage to the

appliance.

Do not let children access the

appliance or its controls. Supervise

its use by the elderly or infirm.

Keep these instructions in a safe

place for reference and pass them

on to any future user.

The electrical safety of this

appliance can only be guaranteed

when continuity is complete between

the appliance and an effective earthing

system.

It is imperative that this basic safety

requirement be tested and where there

is any doubt, the electrical system of

the house should be checked out by a

qualified electrician. The manufacturer

cannot be held liable for damage such

as electric shock caused by the lack or

inadequacy of an effective earthing

system.

Ensure that the gas pipe and

electrical cable are installed in

such a way that they do not touch any

parts of the appliance which become

hot. This could cause damage.

Do not connect the appliance to

the mains electricity supply by an

extension lead. Extension leads do not

guarantee the required safety of the

appliance.

Technical safety

The connection to the gas supply

must be carried out by a suitably

qualified and competent person in

accordance with local and national

safety regulations. If the appliance is

supplied without a plug, or if the plug is

removed the appliance must

additionally be installed and connected

by a suitably qualified and competent

electrician in strict accordance with

national and local regulations. The

manufacturer cannot be held liable for

damage caused by incorrect

installation or connection.

7

Warning and Safety instructions

Correct usage

For safety reasons the appliance

must only be operated after it has

been built in. This is necessary to

ensure that all electric components are

shielded.

This appliance is for domestic use

only, and is not intended for

commercial use.

Use this appliance for the

preparation of meals only. Any

other usage is at the owner’s risk and

could be dangerous. The manufacturer

can not be held liable for damage

caused by improper use or misuse of

the appliance.

Do not use the appliance to heat

up the room. The high temperature

could cause inflammable objects

nearby to catch fire.

Ensure the room in which the gas

hob is installed has sufficient

ventilation. In a small kitchen it may be

advisable to keep the door open if

using the hob for extended periods.

This appliance must not be set up

or operated in the open air.

Make sure all the components of

the gas burners have been

correctly assembled before switching

on.

Do not store any inflammable

objects near the gas hob.

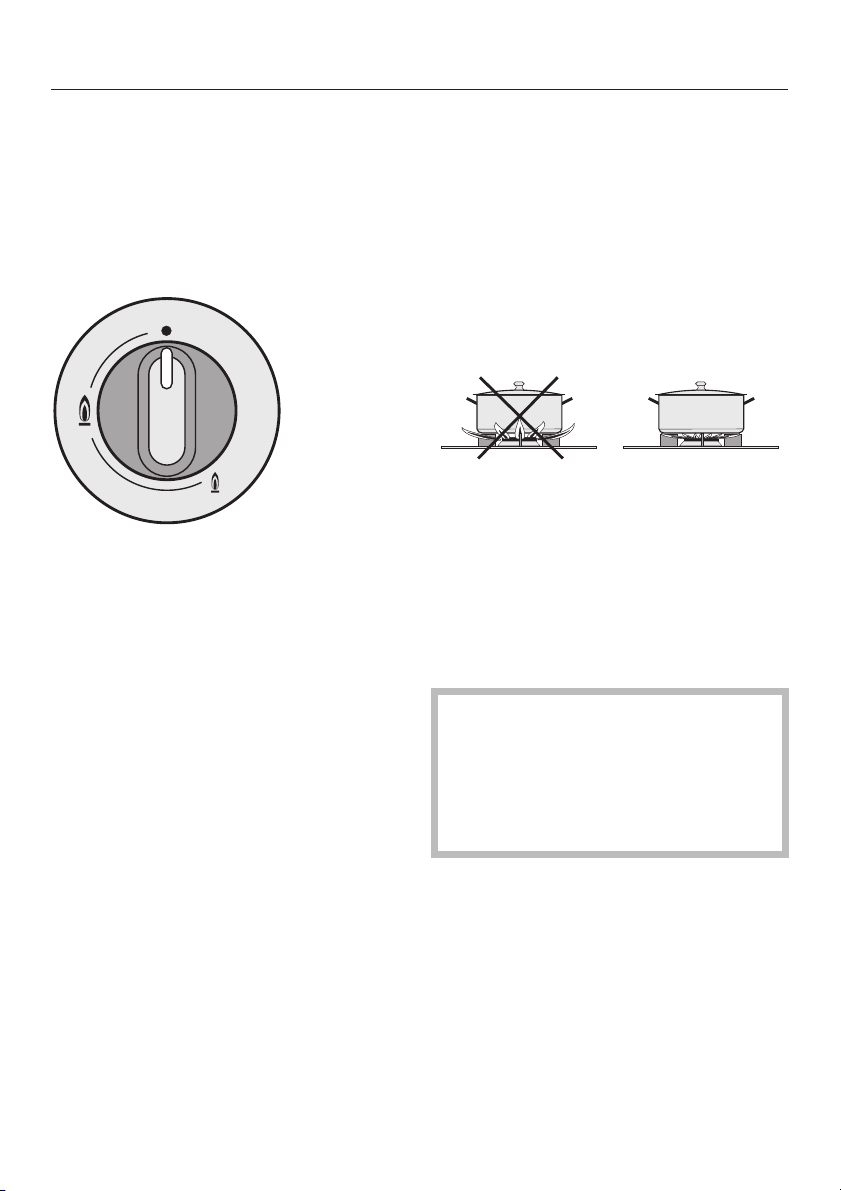

KM 405

Only use pans with a base

diameter of maximum 22 cm (front

burner) and 24 cm (rear burner) on this

hob. Using larger pans may cause the

flames to spread out to the sides and

damage or burn the worktop, wall

claddings or surrounding units.

For safety and stability use only

pans with a minimum base

diameter of 12 cm (front burner) and 14

cm (rear burner).

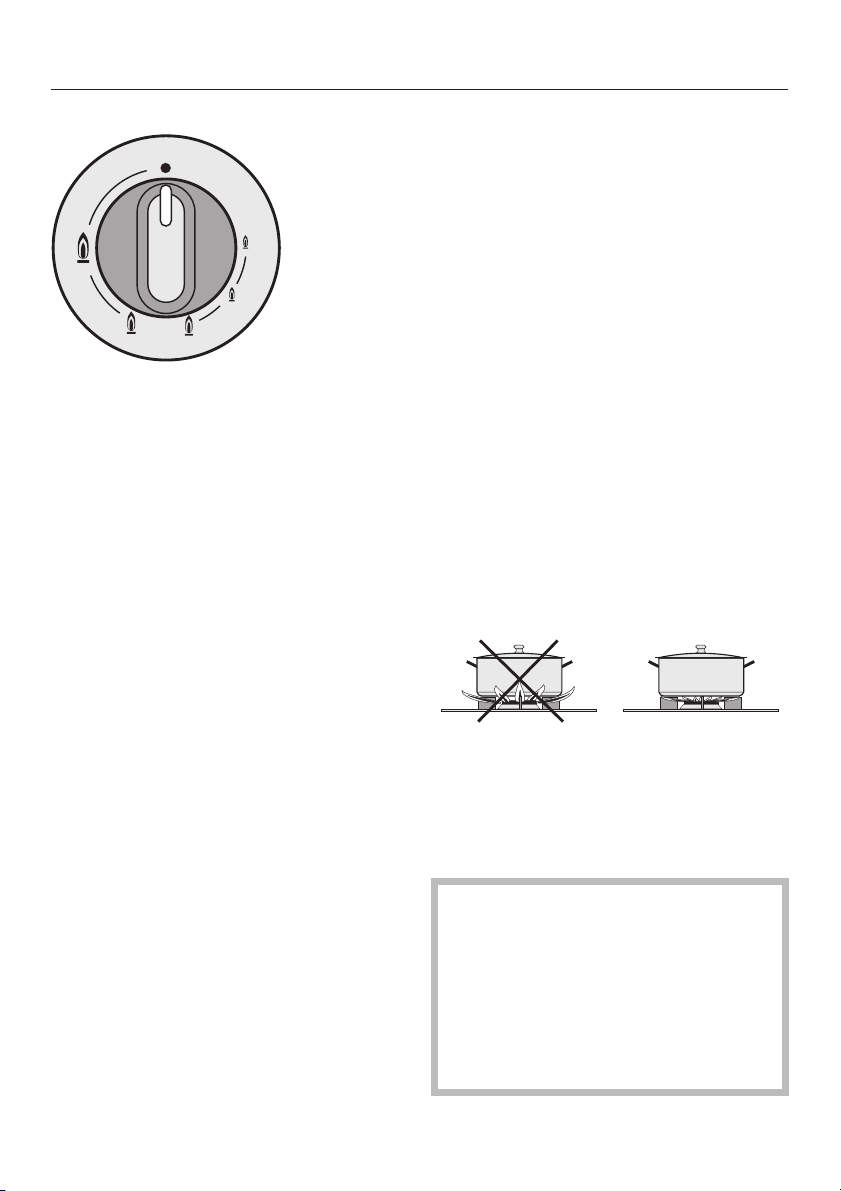

KM 406 / KM 416

Ensure that the air inlet is never

covered over with a cloth or

anything else.

Only use woks or pans with a base

diameter between 16 cm and

maximum 28 cm on this hob. Using

larger pans may cause the flames to

spread out to the sides and damage or

burn the worktop, wall claddings or

surrounding units.

For safety and stability use the

trivet for pans with a base diameter

of less than 16 cm.

When using a cooker hood over

the gas hob, ensure that any

burners in use are always covered with

a pan. Otherwise flames could be

drawn up by the suction of the cooker

hood, parts of which could then be

damaged or even set on fire.

8

Warning and Safety instructions

Protecting the appliance from

damage

Do not drop anything on the

ceramic surface of the hob. Even a

light object such as a salt cellar could

cause damage in certain

circumstances.

Unless the pan manufacturer

states that you can do so, you

should never use pans with thin bases

on this hob and you should never heat

up an empty pan. Otherwise the hob

could get damaged.

Under no circumstances use a

steam cleaning appliance to clean

the gas hob. Pressurised steam could

cause permanent damage to the

surface and to components, for which

the manufacturer cannot accept

responsibility.

In countries which may be subject

to infestation by cockroaches or

other vermin, pay particular attention to

keeping the appliance and its

surroundings in a clean condition at all

times. Any damage which might be

caused by cockroaches or other vermin

will not be covered by the appliance

guarantee.

Protection from burning

Do not let small children use the

appliance or touch it during

operation. The burner support, trivet,

burners and also the ceramic surfaces

around the burners heat up and remain

hot for quite a while after the appliance

has been switched off. Danger of

burning. Do not touch them until they

have cooled down. The use of oven

gloves is recommended.

Do not store anything which might

arouse a child’s interest in storage

areas above or next to the hob.

Otherwise they could be tempted into

climbing onto the appliance with the

risk of burning themselves.

Use heat-resistant pot holders or

gloves when handling hot pots and

pans. Ensure that the pot holders do

not come into contact with the flames.

Do not use large cloths, tea towels or

similar as the ends could touch the

flames and catch fire. Take care not to

let pot holders or gloves get damp or

wet, as this causes heat to transfer

through the material quicker with the

risk of burning yourself.

To prevent the risk of children

reaching pan handles and pulling

pans over with the danger of burning or

scalding themselves be sure to turn

pan handles inwards and out of their

reach. Special hob guards are available

from good retail outlets as additional

protection.

9

Warning and Safety instructions

Do not heat up unopened tins of

food on the hob as pressure will

build up in the tin and it can explode.

This could result in injury or damage.

Do not use the hob as a resting

place for anything else. If the hob

was switched on inadvertently, or if it

was still hot the article could begin to

melt or catch fire.

Remove splashes of fat and other

food debris from the surface as

soon as possible. These are a fire

hazard.

Do not cover the hob with a cloth,

household foils or other similar

objects. This could lead to danger of

the article catching fire, if the hob were

to be switched on inadvertently.

Never leave the hob unattended

when cooking with oil or fats as

these are fire hazards if overheated.

Overheated fat could catch fire and

even set the cooker hood on fire.

Do not flambé under a cooker

hood. Otherwise flames could be

drawn up by the suction of the cooker

hood, parts of which could then be

damaged or even set on fire.

Ensure that the flames from the

burner does not spread out

beyond the base and up the sides of

the pan.

Spray canisters, aerosols and other

inflammable substances should not

be stored in a drawer under the hob if

there is no shelf separating the drawer

from the hob. If cutlery inserts are to be

placed in the drawer these must be

made of a suitable heat-resistant

material.

If oil or fat does catch fire despite

this do not attempt to put out the

flames with water. Use a suitable fire

blanket or fire extinguisher.

10

Warning and Safety instructions

With a damaged appliance

In the event of damage or a defect,

switch off the appliance immedi

ately. Turn off the gas supply tap, and

disconnect completely from the

electricity supply. Contact the Service

department.

Ensure that the appliance is

disconnected from the electricity

supply before any servicing or repair

work.

Any breakages or cracks in the

ceramic surface of the hob are

defects and must be treated as such.

Repairs to the gas and electrical

components of this appliance must

only be carried out by a suitably

qualified person. Repairs by

unauthorised personnel could be

dangerous. On no account open the

outer casing of the appliance.

While the appliance is under

guarantee repairs should only be

undertaken by a service engineer

authorised by the manufacturer.

Otherwise the guarantee is invalidated.

11

Warning and Safety instructions

Further safety notes

When using an electric socket near

the hob, care should be taken that

the cable of the electrical appliance

does not come into contact with the gas

flames or the hot parts of the hob. The

insulation on the cable could become

damaged, giving rise to an electric

shock hazard.

Always ensure that food is

sufficiently cooked or reheated.

Some foods may contain micro

organisms which are only destroyed by

thorough cooking, therefore when

cooking or reheating foods, e.g. poultry,

select a longer cooking or reheating

time.

Do not use plastic or aluminium foil

containers. These melt at higher

temperatures and could damage the

ceramic surface. Fire hazard.

Before disposing of an old

appliance, ensure that

disconnection from the gas supply is

made by a suitably competent person.

Switch off at the mains electricity

supply. Cut off and render any plug

useless. Cut off the cable directly

behind the appliance to prevent

misuse. Ensure that the appliance

presents no danger to children while

being stored for disposal.

12

General notes

A data plate for your appliance is

supplied with this documentation. It

should be stuck into the space

provided at the end of the instruction

book. The address of the nearest Ser

vice Department is given on the back

page.

Before using for the first time

-

13

Before using for the first time

Disposal of the packing

material

The transport and protective packing

has been selected from materials which

are environmentally friendly for disposal

and can normally be recycled.

Ensure that any plastic wrappings,

bags etc. are disposed of safely and

kept out of the reach of babies and

young children. Danger of suffocation!

Rather than just throwing these

materials away, please ensure that they

are offered for recycling.

Disposal of your old appliance

Old appliances contain materials which

can be reclaimed or recycled. Please

contact your dealer, your local waste

collection centre or scrap merchant

about potential recycling schemes.

Before disposing of an old

appliance, ensure that

disconnection from the gas supply is

made by a suitably qualified and

competent person. Switch off at the

mains electricity supply. Cut off and

render any plug useless. Cut off the

cable directly behind the appliance

to prevent misuse. This should be

done by a competent person.

Ensure that the appliance presents

no danger to children while being

stored for disposal.

The manufacturer cannot be held

liable for damage caused by

non-compliance with these safety

instructions.

14

Before using for the first time

Cleaning and heating up for

the first time

Before using for the first time clean the

hob and all removable parts as follows:

The removable parts of the gas

^

burner assembly can be washed in a

mild solution of water and

washing-up liquid. Wipe dry and

reassemble in the correct order (see

"Cleaning and care").

Clean the ceramic surface with a

^

damp cloth only, and then wipe dry.

Do not use washing up liquid on the

ceramic surface as it can leave a

blue sheen on the surface which

may be difficult to remove.

Metal components have a protective

coating which may give off a slight

smell when the hob is heated up for the

first time. The smell and any vapours

will dissipate after a short time and do

not indicate a faulty connection or

appliance.

15

Gas burner unit

Switching on, Switching off,

Controls

The control knob is used to switch on

the burner and regulate the strength of

the flame.

KM 405 / KM 416

ß the gas supply is turned off

& strong flame

/ weak flame

Switching on:

Control the flame so that it does not

spread out beyond the sides of the

pan. As the outer part of the flame is

much hotter than the centre, the tips of

the flames should stay beneath the pan

base. Flame tips which extend beyond

the sides of the pan merely warm up

the air in the room and can also

damage pan handles and increase the

danger of burning.

Switching off:

^ Turn the knob clockwise until the ß

position is reached.

This stops the flow of gas and the flame

goes out.

^ Press in the control and then turn

anti-clockwise to the large flame

symbol.

^

When the flame ignites, keep the

control pressed in for 8-10 seconds,

and then let it go.

If the flame goes out, repeat the

procedure, keeping the control knob

pressed in for a few extra seconds.

^

With the knob no longer pressed in

you can continue turning it towards

the small flame symbol.

16

Remember: Turn anti-clockwise to

switch on, turn clockwise to switch

off.

The control knob cannot be turned

anti-clockwise from the small flame

symbol to the "ß" position.

Gas burner unit

KM 406

ß gas is turned off

* strongest flame

outer and inner rings both produce

high flames

& (2x)strong flame

outer flame ring burns on low,

inner flame ring burns on high

+ low flame

inner flame ring burns on high

/ very low flame

inner flame ring burns on low

resistance. Briefly press to turn past

the resistance. Then without pressing

it in turn the control to the required

setting.

To turn the heat up from a low to a

^

high setting, turn the control

clockwise until there is a resistance.

Briefly press to turn past the

resistance. Then without pressing it in

turn the control to the required

setting.

Control the flame so that it does not

spread out beyond the sides of the

pan. As the outer part of the flame is

much hotter than the centre, the tips of

the flames should stay beneath the pan

base. Flame tips which extend beyond

the sides of the pan merely warm up

the air in the room and can also

damage pan handles and increase the

danger of burning.

Switching on:

^

Press in the control and then turn

anti-clockwise to the large flame

symbol.

^

When the flame ignites, keep the

control pressed in for 8-10 seconds,

and then let it go.

If the flame goes out, repeat the

procedure, keeping the control knob

pressed in for a few extra seconds.

To regulate the burner setting:

^

To turn the heat down from a high to

a low setting turn the control

anti-clockwise until there is a

Switching off:

^

Turn the control clockwise until "ß" is

reached.

This stops the flow of gas and the flame

goes out.

Remember: Turn anti-clockwise to

switch on, turn clockwise to switch

off.

Stop when you feel a resistance. Do

not try to force the control further.

The control cannot be turned

anti-clockwise from the small flame

symbol to the "ß" position.

17

Using the gas hob

Suitable pans

Any heat-resistant pans can be used on

a gas burner.

Pan bases do not need to be even for

cooking, (in contrast with those used on

an electric hob). Through the spreading

action of the flame, heat reaches all

parts of the base.

Thick pan bases reduce the risk of food

overheating in places, as heat is better

distributed.

Thin pan bases conduct heat to the

food inside more quickly than thicker

ones. However as the heat is not evenly

distributed over the pan base there is a

danger that food may heat up unevenly.

Stir the food frequently.

Pan size

The simple rule: a large pan for the

large flame, a small pan for the small

flame.

Wide, shallow pans are preferable to

narrow, tall ones. They heat up more

quickly as there is room for more flame

under the base.

KM 405

The base diameter of the pan should

–

not exceed 22 cm for the front burner

and 24 cm for the rear burner.

Using larger pans may cause the

flames to spread out to the sides and

damage or burn the worktop, wall

claddings or surrounding units.

For safety and stability, please use

–

pans with a minimum base diameter

of 12 cm for the front burner and 14

cm for the rear burner.

KM 406 / KM 416

– The base diameter of the pan or wok

should not exceed 28 cm.

Using larger pans may cause the

flames to spread out to the sides and

damage or burn the worktop, wall

claddings or surrounding units.

– For safety and stability, please use

the trivet for pans with a base

diameter less than 16 cm.

When using smaller pans you should

always turn the hob control to the

lowest setting. If it is too high flames

can lick up the sides of the pan!

18

Using the gas hob

Safety cut-out

This appliance is fitted with an electric

ignition safety device which cuts off the

supply of gas to a burner if the flame

goes out, for example if food has boiled

over, or if there was a sudden draught.

To use the hob again, turn the knob

^

clockwise until the ß position is

reached and switch on as normal.

The safety cut-out operates

independently from the electricity

supply. This means that it is still active

when the hob is used during a power

cut (see "Use during a power cut").

Use during a power cut

If there is an interruption to the

electricity supply the gas can be

ignited with a match:

Press in the relevant control knob and

^

turn it anti-clockwise to the large gas

symbol.

Hold the control pressed in and light

^

the gas at the burner with a match.

Keep the control knob pressed in for

^

a further 8-10 seconds and then

release it.

19

Cleaning and care

Under no circumstances use a

steam cleaner to clean this

appliance. Pressurised steam could

cause permanent damage to the

surface and to components for

which the manufacturer cannot

accept liability.

Do not use any sharp objects which

could damage the seal between the

ceramic surface and the

surrounding frame and between the

frame and the worktop.

Never use aggressive or abrasive

cleaning agents, e.g. grill and oven

sprays, stain or rust removers,

scouring agents or abrasive

sponges.

Do not use washing up liquid on the

ceramic surface as it can leave a

blue sheen on the surface which

may be difficult to remove.

Ceramic hob surface

The ceramic surface should be cleaned

regularly, preferably after each use.

Before cleaning, allow the hob to cool

down. Once it has cooled down, wipe

soiling off using a damp cloth. Stubborn

soiling is best removed with a shielded

scraper blade.

Then apply a proprietary cleaning

agent for ceramic surfaces using a soft

cloth or kitchen paper towel. This way

any limescale deposits, caused for

example by water boiling over, are

removed.

Finally wipe the hob surface with a

damp cloth and then dry it with a clean

soft cloth.

Note that some cleaning agents contain

a protective additive designed to

prevent water marks and smears

adhering to the surface.

The ceramic surface can be cleaned

using a proprietary cleaner for

ceramic surfaces. Follow the

manufacturer’s instructions on the

packaging.

Do not let the ignitor in the burner

get wet. If it gets wet it will not spark.

After cleaning the ceramic surface it

must be thoroughly dried with a soft

cloth to prevent a build up of

limescale deposits.

20

Cleaning and care

Burners

The burners can be dismantled for

cleaning once they have cooled down.

Proceed as follows:

Take off all the removable parts of the

^

burner and wash in a solution of hot

water and washing-up liquid. Then

dry them all thoroughly. Make sure

that the flame holes are clean and

completely dry.

The surface of the burner cover will

gradually become more matt with time.

This is quite normal and will not affect

the operation of the hob.

Wipe the fixed parts of the burner

^

base with a damp cloth and dry

afterwards.

Gently wipe the ignitor and the

^

ignition safety device with a well

wrung-out cloth and wipe dry with a

clean cloth.

21

Cleaning and care

KM 405 Re-assemble the burner as follows:

(see illustration):

Make sure that all the locating tabs

^

and notches line up exactly. Place

the burner head c on to the burner

base f so that the ignitor and the

ignition safety control extend through

their respective holes in the burner

head. The burner head must click

into place correctly.

Replace the burner cap b ensuring

^

that the locating tabs fit into the

notches in the burner head.

Make sure that the parts of the burner

are re-assembled in the correct order

after cleaning.

Important:

1. Do not mix up the top and bottom.

2. The locating lugs must fit exactly

into the notches.

22

Cleaning and care

KM 406 Re-assemble the burner as follows:

(see illustration):

Fit the large burner cap base on to

^

the burner base a.

Fit the burner collar ring.

^

Fit the large burner cap on the large

^

burner cap base b.

Fit the small burner cap.

^

Put the pan support in place c.

^

Put the trivet in place if required.

^

Make sure that the parts of the burner

are re-assembled in the correct order

after cleaning.

Important:

1. Do not mix up the top and bottom.

2. The locating lugs must fit exactly into

the notches.

23

Cleaning and care

KM 416 Re-assemble the burner as follows :

(see illustration):

Fit the large burner cap base on to

^

the burner base a.

Fit the burner collar ring e.

^

Put the large burner cap on the large

^

burner cap base b.

Put the pan support in place c.

^

Put the trivet in place if required.

^

Make sure that the parts of the burner

are re-assembled in the correct order

after cleaning.

Important:

1. Do not mix up the top and bottom.

2. The locating lugs must fit exactly

into the notches.

24

Repairs to the gas and electrical

components of this appliance must

only be carried out by a suitably

qualified and competent person to

ensure safety. Unauthorised repairs

could be dangerous.

However, some minor problems can be

resolved as follows:

What to do if ...

Problem solving guide

... the gas flame goes out after being

lit

Check whether the burner cover is

correctly assembled.

... the ignitor on the burner does not

spark?

Check whether food deposits have

lodged themselves between the ignitor

and the burner cover.

Carefully remove any soiling. Do not let

the ignitor get wet.

... the burner does not ignite after

several attempts

Check whether

– The burner is correctly assembled.

– The gas supply tap is turned on.

– The burner is dry and clean.

– The flame slits are clean and

unblocked.

–

The mains fuse has blown. If this is

the case, call an electrician or the

Service Department. (The gas can

be lit with a match). (See "Use during

a power cut").

... the flame suddenly looks different

Check whether the burner is correctly

assembled.

25

After sales service, data plate

In the event of any faults which you cannot remedy yourself, please contact

Your Miele Dealer

–

or

The Miele Service Department (see address on back cover).

–

When contacting the Service Department, please quote the model and serial

number of your appliance. These are given on the data plate.

Space in which to stick the extra data plate supplied with the appliance. Ensure

that the model number is the same as the one on the front of these operating

instructions.

Please note that telephone calls may be monitored and recorded to improve

our service.

26

Safety instructions

Fit wall units and cooker hood before

fitting the gas hob, to avoid

damaging the hob.

Installation

The room in which the gas hob is

installed must be at least 20 m

size with a door or window in it which

can be opened to the outside air.

The veneer or laminate coatings of

worktops (or adjacent kitchen

units) must be treated with 100°C

heat-resistant adhesive which will not

dissolve or distort.

Any backmoulds must be of heat

resistant material.

Ideally the hobs should be installed

with plenty of space on either side.

There may be a wall at the rear and wall

or tall units at one side. On the other

side however, no unit or divider should

stand higher than the hob.

Due to the heat radiated by the hob

and to allow cooking fumes to

dissipate it is essential that a

minimum safety distance a is

maintained between the worktop

cut-out and adjacent furniture, e.g. a

tall unit, as follows:

100 mm with KM 405

250 mm with KM 406 / 416.

There must be a minimum safety

distance of 50 mm between the hob

and a back wall.

3

in

recommended

not recommended

not allowed

27

Installation

An electric fryer must not be

installed next to a gas hob, as the

gas flames could ignite the fat in the

fryer.

It is essential to maintain a distance of

at least 288 mm between these two

appliances.

These appliances must not be

installed over a dishwasher,

washing machine, tumble dryer,

refrigerator or freezer. The high

temperatures radiated by hobs could

damage the appliance below.

This equipment is not designed for

maritime use or for use in mobile

installations such as caravans, aircraft

etc. However it may be suitable for

such usage subject to a risk

assessment of the installation being

carried out by a suitably qualified

engineer.

Spray canisters, aerosols and other

inflammable substances must not

be stored in a drawer under the hob.

Cutlery inserts must be heat-resistant.

Safety distance above appliances

A minimum safety distance b must be

maintained between the hob and the

cooker hood above it. See the

manufacturer’s operating and

installation instructions for details. For

any flammable objects, e.g utensil rails,

wall units etc. a minimum safety

distance of at least 760 mm should be

maintained between it and the hob

below.

When two or more appliances are

installed together below a cooker

hood, e.g. a ceramic combiset and

a gas wok combiset, which have

different safety distances given in

their installation instructions you

should select the greater distance of

the two.

28

All dimensions in this instruction booklet

are given in mm.

Keep these instructions in a safe place

and pass them on to any future owner

of the appliance.

Building-in dimensions

KM 405

Installation

a Support bracket

b Building in height plus 3 mm for fixing screw

c Front

d Building in height - Mains connection box

e Gas connection

29

Installation

KM 406

a Support bracket

b Building in height plus 3 mm for fixing screw

30

KM 416

Installation

a Support bracket

31

Installation

Worktop cut-out

Number

of

appliances

Worktop cut-out

Depth

in mm

± 1 mm

Width

(= Dim. B)

in mm

± 1 mm

Dimensions 7 mm and 11 mm are the

space taken up by the frame of the

appliance on the worktop.

^ Make a cut-out for the hob in the

worktop, paying attention to the

appliance height. See "Building-in

dimensions".

Dimension "B" applies to a combination

of appliances and is shown on the

chart.

^

There must be a minimum safety

distance of 50 mm between the hob

and the back wall and 100 mm

distance from a side wall to the right

or left of the hob ( 250 mm for

KM 406, KM 416).

(See "Warning and Safety

instructions")

1

2

3

4

5

6

7

500

500

500

500

500

500

500

266

554

842

1130

1418

1706

1994

Important:

The maximum tolerance for the worktop

cut-out must not exceed ±1 mm.

When building in several combiset

appliances a spacer bar must be

fitted between each unit. See "Fitting

the spacer bars and support

brackets".

^

Seal the cut surfaces with a suitable

sealant to avoid swelling caused by

moisture.

The materials used must be heat

resistant.

32

Fitting the spacer bars and

support brackets

Installation

a Support brackets

b Spacer bars

Installation of several appliances

The illustration above shows an

example of a worktop cut-out with

spacer bars b and support brackets a

for 3 appliances.

For more than 3 appliances, repeat

dimension 288 mm.

The worktop cut-out dimensions for

several appliances are shown in the

table on the previous page.

c Gap between spacer bar and

worktop.

d Drilling for a granite worktop.

^

Fix the spacer bars b and the

support brackets a supplied to the

positions indicated. See "Fixing the

spacer bars" and "Fixing the support

brackets".

33

Installation

Fixing the spacer bars

d

c

The spacer bar is only required when

combined with another appliance.

^ Position the spacer bars b in the

positions shown in "Fitting the spacer

bars and support brackets" so they

are flush with the top edge of the

cut-out and secure using the

3.5 x 25 mm screws supplied.

Granite worktops

With granite worktops the spacer bars

b must be positioned and secured with

strong double-sided adhesive tape. In

addition, coat the edges with silicone

and fill in the gap c.

The screws are not required for granite

tops.

^

Then fill in the gap c between the

bars and the worktop with silicone

from the tube supplied.

34

Installation

Fixing the support brackets

^ Position the two support brackets

supplied a in the positions shown in

"Fitting the spacer bars and support

brackets" so they are flush with the

top edge of the cut-out and secure

using the 3.5 x 25 mm screws

supplied. 2 screws are needed to

secure each support bracket.

The thickness of the worktop will

determine which drill hole is used.

Granite worktops

On a granite worktop a hole must be

drilled d at the position indicated to

secure each support bracket.

Using a piece of strong, double-

^

sided adhesive tape position the

support brackets supplied a at the

positions indicated flush with the top

edge of the worktop and secure each

bracket with one screw in hole d as

shown.

Building in the gas hob

^ Place the gas hob in the prepared

cut-out.

^ Feed the electricity connection cable

through the cut-out and connect.

^ Make the gas connection.

(see relevant section).

^

Secure the gas hob from below

through the middle elongated hole b

in each support bracket using the

two screws supplied. Carefully adjust

the hob if necessary.

35

Installation

Sealant

Under no circumstances should

sealant find its way between the

frame of the top part of the hob and

the worktop.

This could cause difficulties if the

hob ever needs to be taken out for

servicing, (possibly leading to

damage to the frame and worktop).

The sealing strip under the edge of

the top part of the hob provides a

sufficient seal for the worktop.

36

Installation

Electrical connection

All electrical work should be carried

out by a suitably qualified and

competent person in strict

accordance with national and local

safety regulations.

Installation, repairs and other work

by unqualified persons could be

dangerous. The manufacturer

cannot be held responsible for

unauthorised work.

Ensure power is not supplied to the

appliance while installation or repair

work is being carried out.

The appliance must only be

operated when built-in. This is to

ensure that all electrical parts are

shielded. Live parts must not be

exposed.

Do not connect the appliance to the

mains electricity supply by an

extension lead. These do not

guarantee the required safety of the

appliance.

Connection should be made via a

suitable isolator or a double pole fused

spur connection unit or fused plug and

switched socket (rated load up to 3 kW)

which complies with national and local

safety regulations and the on/off switch

should be easily accessible after the

appliance has been built in.

When switched off there must be an

all-pole contact gap of 3 mm in the

isolator switch (including switch, fuses

and relays).

For extra safety it is advisable to install

a residual current device (RCD) with a

trip current of 30 mA.

If the socket is not accessible after

installation (depending on country) an

additional means of disconnection must

be provided for all poles.

Important

This appliance is supplied for

connection to a single phase 220-240 V

50 Hz supply with a 3-core cable.

The wires in the mains lead are

coloured in accordance with the

following code:

After the appliance has been built in,

a check must be made that all

electrical parts are shielded.

The voltage and rated load are given

on the data plate. Ensure that these

match the household mains supply.

Green/yellow = earth

Blue = neutral

Brown = live

WARNING

THIS APPLIANCE MUST BE

EARTHED

37

Installation

If the appliance is connected via a

fused plug and switched socket the

colours of the wires in the mains lead of

this appliance may not correspond with

the coloured markings identifying the

terminals in your plug. If this is the

case, proceed as follows:

The wire which is coloured green and

^

yellow must be connected to the

terminal in the plug which is marked

with the letter E or by the earth

symbol z or coloured green or

green and yellow.

The wire which is coloured blue must

^

be connected to the terminal which is

marked with the letter N or coloured

black.

^ The wire which is coloured brown

must be connected to the terminal

which is marked with the letter L

(GB / IRL / ZA) or A (AUS / NZ) or

coloured red.

Non-rewireable plugs (BS 1363)

If this appliance is fitted with a

non-rewireable plug, the following

information applies:

If the socket outlets are not suitable for

the plug supplied with this product, it

must be cut off and an appropriate plug

fitted.

The fuse carrier and the fuse should be

removed from the old plug and

disposed of. The plug cut from the

flexible cord should then be disposed

of and on no account be inserted into

any socket elsewhere in the house

(electric shock hazard).

The fuse cover must be re-fitted when

changing the fuse, and if the fuse cover

is lost, the plug must not be used until a

suitable replacement is obtained. The

colour of the correct replacement cover

is that of the coloured insert in the base

of the plug, or the colour that is

embossed in words in the base of the

plug (as applicable to the design of the

plug fitted).

Replacement fuses should be ASTA

approved to BS 1362. Replacement

fuses and fuse covers may be

purchased from your local electrical

supplier, or Miele Service agent.

Important

The electrical safety of this appliance

can only be guaranteed when

continuity is complete between the

appliance and an effective earthing

system, which complies with local and

national regulations. It is most important

that this basic safety requirement is

tested by a qualified electrician. The

manufacturer cannot be held liable for

the consequences of an inadequate

earthing system such as an electric

shock.

The manufacturer cannot be held liable

for damage which is the direct or

indirect result of incorrect installation or

connection.

38

Installation

Ensure power is not restored to th

appliance while installation work is

being carried out.

Disconnection from the power supply

will depend on the isolator, according to

country e.g.:

Safety fuse:

–

Completely remove the fuse links

from the fuse carrier.

or

Safety cut-outs (screw type):

–

Press the (red) test button until the

black centre button pops out.

or:

– Built-in safety cut-outs

(MCBs at least type B or C):

Set rocker from 1 (On) to 0 (Off)

or:

– FI-Safety-switch (RCD):

Set main switch from 1 (On) to 0 (Off)

or press the test button.

Technical Data

Fusing:

See data plate

For appliances up to 3 kW 13 amps

For appliance above 3 kW 20 amps

If the cable needs to be changed select

either

type H 05 RR-F (rubber insulated) or

type H 05 W-F (PVC-insulated)

See data plate for connection data.

39

Installation

Gas connection

Connection to the gas supply, or

conversion from one type of gas to

another should only be undertaken

by an approved and registered gas

installer in strict accordance with

local and national safety regulations.

Every appliance should have its own

isolating valve.

Check with your local gas supplier

about the type of gas, and compare

this information with the type of gas

quoted on the hob data plate.

The gas installation must be made in

such a way that the isolating valve is

visible and easily accessible after

the appliance has been built in.

The installer is responsible for

ensuring that the appliance

functions correctly when installed.

Connection

Conversion to another type of gas is

described under the relevant Section.

The gas connection must be installed

so that connection can be made either

from inside or outside the kitchen unit,

and the isolating valve must be easily

accessible and visible (by opening one

of the kitchen unit doors, if necessary).

A test for possible leakages must be

carried out after installation.

The relevant building regulations must

also be observed.

Safety regulations demand that a

pressure test nipple is installed near

a gas hob to allow an engineer to

test the pressure, following

servicing.

All gas hobs come set for connection to

either natural gas or LPG or Towngas.

Check suitability in your country with

your dealer or agent.

Depending on country a set of jets for

conversion to liquid gas may be

included with the hob.

40

Installation

Town gas / LPG / Natural gas

An appropriate rigid or flexible

^

connection and isolating valve must

be installed for final connection.

The gas connection must be so sited

^

that it is not adversely heated when

the appliance is in operation.

In particular ensure that hot gas

exhaust cannot touch the gas hose or

appliance connections.

After installing the appliance the gas

burners have to be set for local

conditions.

When the gas hob has been

installed it is essential to check that

neither the gas hose nor the

electricity cable is in contact with hot

parts of the appliance or hot gas

exhaust, otherwise heat damage to

the hose and cable could occur.

41

Conversion to another type of gas

KM 405

When converting to another type of

gas, the main jets and the small jets

of all burners must be changed.

Nominal rating at high setting

Gas type kW

Normal

burner

Fast

burner

Total

output

Town gas

LPG 28 mbar

Natural gas

Town gas

LPG 28 mbar

Natural gas

Town gas

LPG 28 mbar

Natural gas

1.40

1.40/102g/h

1.10

2.40

2.40/175g/h

2.30

3.80

3.8/277g/h

3.40

Jet table

Main

jet

Ø

Town gas

Normal burner

Fast burner

LPG 28 mbar

Normal burner

Fast burner

Natural gas

Normal burner

Fast burner

The jet markings refer to 1/100 mm of

the jet diameter.

1.85

2.75

0.65

0.85

1.00

1.29

Low

setting

jet

Ø

0.74

0.88

0.27

0.36

0.42

0.54

Nominal rating at low setting

Gas type kW

Normal

burner

Fast

burner

Screw in the new jets according to the

following table.

42

Town gas

LPG 28 mbar

Natural gas

Town gas

LPG 28 mbar

Natural gas

0.34

0.30

0.30

0.46

0.50

0.50

Conversion to another type of gas

Changing the jets

Disconnect the gas hob from the

electricity supply by switching off at

the socket and withdrawing the plug

or by removing the mains fuse.

Changing the main jets

Changing the small jets

^ Guide a screwdriver through the

holes in the the lower casing of the

hob and loosen the small jets f.

^ Pull the jets out with a pair of pointed

pliers.

^ Put in the new jets with a pair of

pointed pliers.

^

Take off the pan support, the burner

cover b and the burner head d.

^

Using an SW7 socket spanner

unscrew the main jet e.

^

Change the main jet.

^

Reassemble the burner head and

burner cover in the correct order.

^

Secure the new jets with a

screwdriver.

^

Finally secure the jets against

inadvertent loosening with sealing

wax.

At low setting the flame must not

extinguish, even when tthe control

switch is turned fast from "High" to

"Low" setting.

At "High" setting the flame must burn

with a clearly visible core.

43

Conversion to another type of gas

KM 406

When converting to another type of

gas, the main jets and the small jets

of all burners must be changed.

Nominal rating at high setting

Gas type KW

Natural gas

LPG 28 mbar

Nominal rating at low setting

Gas type KW

Natural gas

LPG 28 mbar

5.00

4.50 / 328 g/h

0.25

0.25

Jet table

Main jet

Ø

Natural gas 1.70 0.88 / 0.40

LPG 28 mbar 1.12 0.52 / 0.23

The jet markings refer to 1/100 mm of

the jet diameter.

Low

setting jet

Ø

Nr. 34

Nr. 7

Screw in the new jets according to the

following table.

44

Conversion to another type of gas

Changing the jets

Disconnect the gas hob from the

electricity supply by switching off at

the socket and withdrawing the plug

or by removing the mains fuse.

c

d

e

f

g

^

Take off the pan support, small

burner cap b, large burner cap c,

burner collar ring d and the large

burner cap base e.

^

Use a (T20) Torx screwdriver to

unscrew the 3 Torx screws f (M4).

^ Pull the control knob for the gas

burner upwards and off.

^ Use a (T20) Torx screwdriver to

unscrew the 4 Torx screws g (M4) in

the lower part of the hob housing.

^ Lift off the top part of the hob keeping

it level.

45

Conversion to another type of gas

Changing the main jet

^ Use an SW 10 socket spanner to

loosen the main jet from its holder, by

turning anti-clockwise. At the same

time use an SW 13 spanner to

counterhold.

^ Screw in the new main jets, once

again using the spanner to

counterhold.

Changing the small jets

a Small jet with smaller jet diameter

(e.g. for liquid gas: 0.23).

b Small jet with larger jet diameter

(e.g. for liquid gas: 0.52).

^ Using a small screwdriver, unscrew

both small jets in the gas fitting.

^

Pull the jets out with a pair of pointed

pliers.

46

^

Select the jets as shown in the table

and fit, reversing the procedure, and

secure.

Conversion to another type of gas

Changing the jet for the inner burner

d jet disc (main jet for the inner burner)

e air sleeve

f air vent

Remove screw c from fitting b with

^

an SW8 spanner and use an SW12

spanner to counterhold.

Then remove the screw fitting b from

^

a with an SW12 spanner and use

another SW12 spanner to

counterhold.

Take out the jet disc d held in a and

^

replace with the correct jet disc (see

jet table).

Move air sleeve e to adjust the two

^

air vents f to the opening illustrated

(2 mm).

Assemble the removed parts in the

reverse order and check for leaks by

operating the burner without the upper

part of the hob in place (use a match to

ignite the flame).

47

Conversion to another type of gas

Check the first intake of air

a Securing screw

b Air sleeve

Gap X must measure:

6,5 mm for Natural gas

11 mm for LPG

If this is not the case, loosen the

^

securing screw, re-position the air

sleeve and then tighten the securing

screw.

Finally secure the jets against

^

inadvertent loosening with sealing

wax.

Re-assemble the hob in the reverse

^

order.

The flame must not go out in the lowest

setting, or when the control is turned

quickly from a high to a low setting.

In the highest setting the flame must

have a distinctive and visible core.

48

Conversion to another type of gas

KM 416

When converting to another type of

gas, the main jets and the small jets

of all burners must be changed.

Nominal rating at high setting

Gas type KW

Natural gas

Town gas

LPG 28 mbar

Nominal rating at low setting

Gas type KW

Natural gas

Town gas

LPG 28 mbar

4.20

4.60

3.00 / 220 g/h

1.50

0.62

1.25

Jet table

Main jet

Ø

Natural gas 1.55 1.00

Town gas 3.80 1.00

LPG 28 mbar 0.96 0.58

The jet markings refer to 1/100 mm of

^

the jet diameter.

Low

setting jet

Ø

Screw in the new jets according to the

following table.

49

Conversion to another type of gas

Changing the jets

Disconnect the gas hob from the

electricity supply by switching off at

the socket and withdrawing the plug

or by removing the mains fuse.

^ Pull the control knob for the gas

burner upwards and off.

^ Use a (T20) Torx screwdriver to

unscrew the 4 Torx screws g (M4) in

the lower part of the hob housing.

^ Lift off the top part of the hob keeping

it level.

^

Take off the pan support, small

cap b, large burner cap c, burner

collar ring d and the large burner

cap base e.

^

Use a (T20) Torx screwdriver to

unscrew the 3 Torx screws f (M4).

50

Conversion to another type of gas

Changing the main jet

^ Use a SW 10 socket spanner to

loosen the main jet from its holder, by

turning anti-clockwise. At the same

time use an SW 13 spanner to

counterhold.

Changing the small jets

a Low setting jet

^ Using a small screwdriver, unscrew

both small jets in the gas fitting.

^ Pull the jets out with a pair of pointed

pliers.

^ Select the jets as shown in the table

and fit, reversing the procedure, and

secure.

^

Screw in the new main jets, once

again using the spanner to

counterhold.

51

Conversion to another type of gas

Check the first intake of air

a Securing screw

b Air sleeve

Gap X must measure:

6,2 mm for Natural gas

8 mm for Town gas

5,5 mm for LPG

If this is not the case, loosen the

^

securing screw, re-position the air

sleeve and then tighten the securing

screw.

Finally secure the jets against

^

inadvertent loosening with sealing

wax.

Re-assemble the hob in the reverse

^

order.

The flame must not go out in the lowest

setting, or when the control is turned

quickly from a high to a low setting.

In the highest setting the flame must

have a distinctive and visible core.

525354

55

Miele Beijing Rep. Office

3W Suite 512, Oriental Plaza

1 East Chang An Ave.

Dong Cheng District

0073

8

,P

RC

eijing

1

Tel.: +86 10 8515 1919

Fax:+861085181797

100738

: +86 10 8515 1919

: +86 10 8518 1797

3

5-12

1

Alteration rights reserved / 07

37

M.-Nr. 06 127 100 / 05

Loading...

Loading...