Page 1

Installation instructions

Gas cooktops

To prevent the risk of accidents or damage to the appliance, it is

essential to read these instructions before it is installed and used for

the first time.

en-AU, NZ M.-Nr. 05 827 671

Page 2

This appliance can be used in countries other than those specified on the

appliance and in these operating and installation instructions. It is, however, set

up for connection to the gas and electricity supplies in the countries specified.

For trouble-free operation of the appliance, it is best to use it in the countries

specified for use.

For use in other countries, please contact Miele in your country.

Repairs and other work by unqualified persons could be dangerous.

Installation, maintenance work and repairs to electrical appliances must only be

carried out by a Miele approved service technician

Please stick the extra data plate for the appliance supplied with this

documentation near the appliance if the appliance markings are not visible after

installation.

2

Page 3

Contents

Safety instructions for installation....................................................................... 4

Safety distances .................................................................................................... 5

Installation notes ................................................................................................... 8

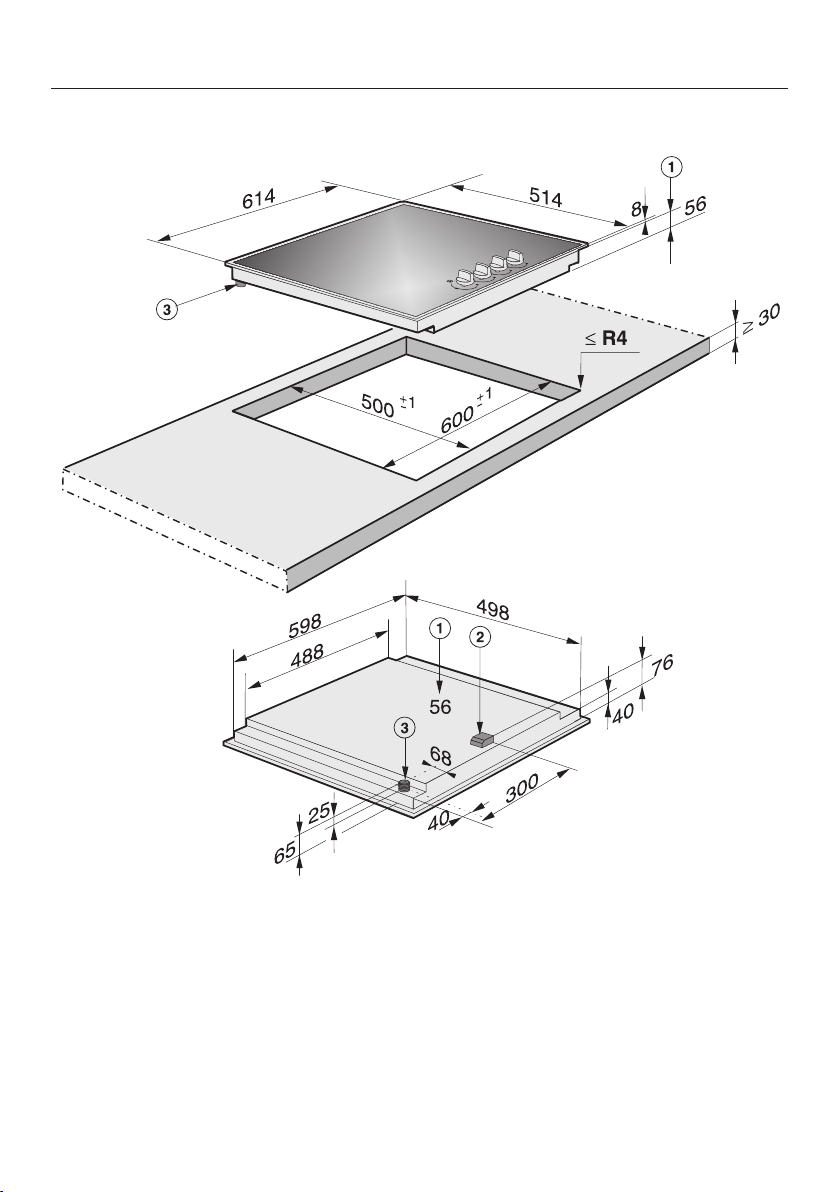

Detailed dimensions.............................................................................................. 9

Installation dimensions....................................................................................... 10

KM 360 / KM 362 .................................................................................................. 10

KM 360-1 / KM 362-1 ........................................................................................... 11

KM 361 G / KM 363 G........................................................................................... 12

Installation............................................................................................................ 13

Electrical connection ..........................................................................................15

Gas connection.................................................................................................... 16

Burner ratings...................................................................................................... 19

Conversion to another type of gas ....................................................................21

Jet table................................................................................................................. 21

Changing the jets .................................................................................................. 21

Changing the main jets.......................................................................................... 21

Changing the small jets......................................................................................... 23

Checking operation ............................................................................................... 24

Service.................................................................................................................. 25

Contact in case of fault ......................................................................................... 25

Data plate .............................................................................................................. 25

Warranty ................................................................................................................ 25

3

Page 4

Safety instructions for installation

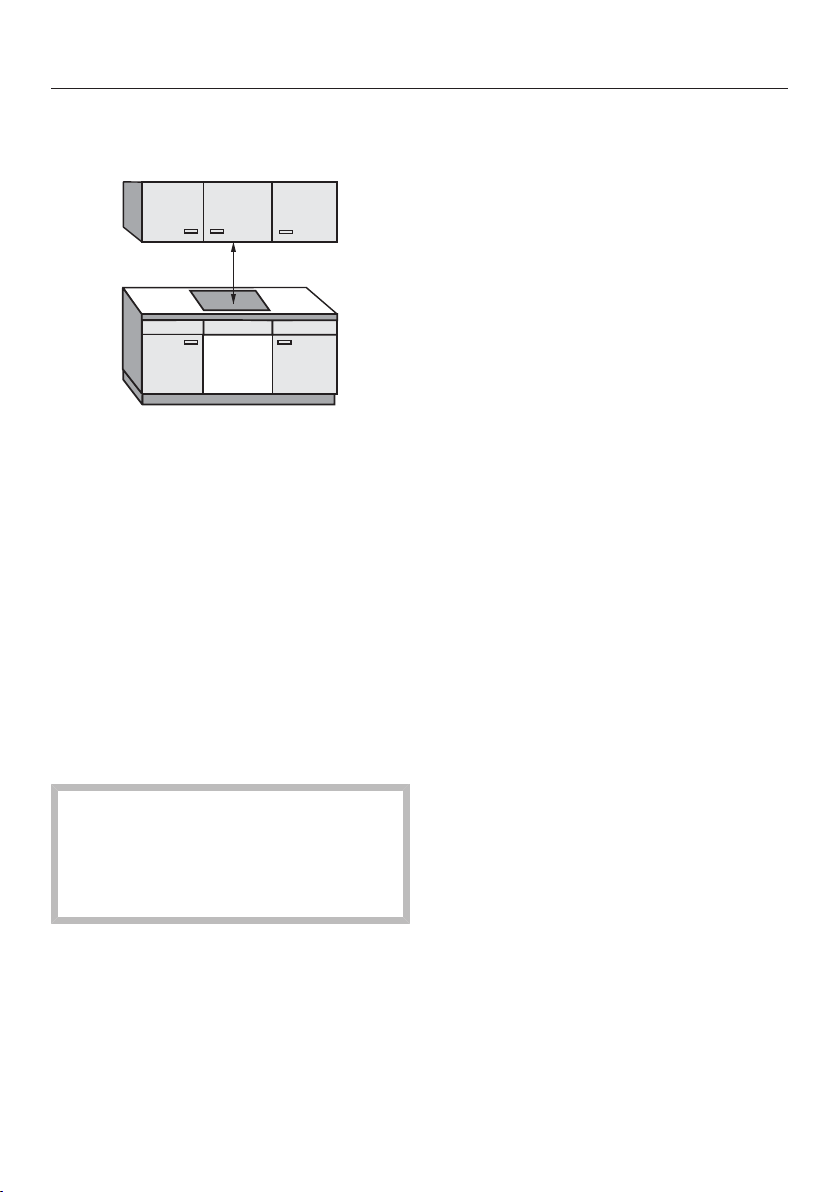

Damage from falling objects.

Take care not to damage the cooktop when fitting wall units or a rangehood

above it.

Fit the wall units and the rangehood before the cooktop.

The veneer or laminate coatings of worktops (or adjacent kitchen

units) must be treated with 100°C heat-resistant adhesive which will

not dissolve or distort. Any splashbacks must be of heat-resistant

material.

The cooktop must not be installed over a fridge, fridge-freezer,

freezer, dishwasher, washing machine, washer-dryer or tumble dryer.

A gas cooktop must not be installed directly next to a deep fat

fryer as the gas flames could ignite the fat in the fryer. It is essential

to maintain a distance of at least 300mm between these two

appliances.

When installing the cooktop, make sure that the gas hose and

electrical connection cable cannot come into contact with hot

appliance parts.

The electrical cable and any flexible gas connection pipes must be

installed in such a way so that they do not come into contact with

any moving kitchen parts (e.g. a drawer), and cannot become

trapped.

This cooktop is not suitable for installation and operation with

aftermarket lids or covers fitted.

This appliance must not be installed and operated in mobile

installations (e.g. on a ship).

Carefully observe the safety clearances listed on the following

pages.

All dimensions in this instruction booklet are given in mm.

4

Page 5

Safety distance above the cooktop

A minimum safety distance must be

maintained between the cooktop and

the rangehood above it. See the

rangehood manufacturer's operating

and installation instructions for details.

If the manufacturer's instructions are

not available for the rangehood, a

minimum safety distance as per AS/

NZS 5601.1 must be maintained.

Safety distances

For any flammable objects, e.g. utensil

rails, wall units etc., a minimum safety

distance of 600mm must be

maintained between these objects and

the highest part of the cooktop below.

When two or more appliances which

have different safety distances are

installed together below a

rangehood, you should observe the

greatest safety distance.

5

Page 6

Safety distances

Safety distances to the sides and back of the appliance

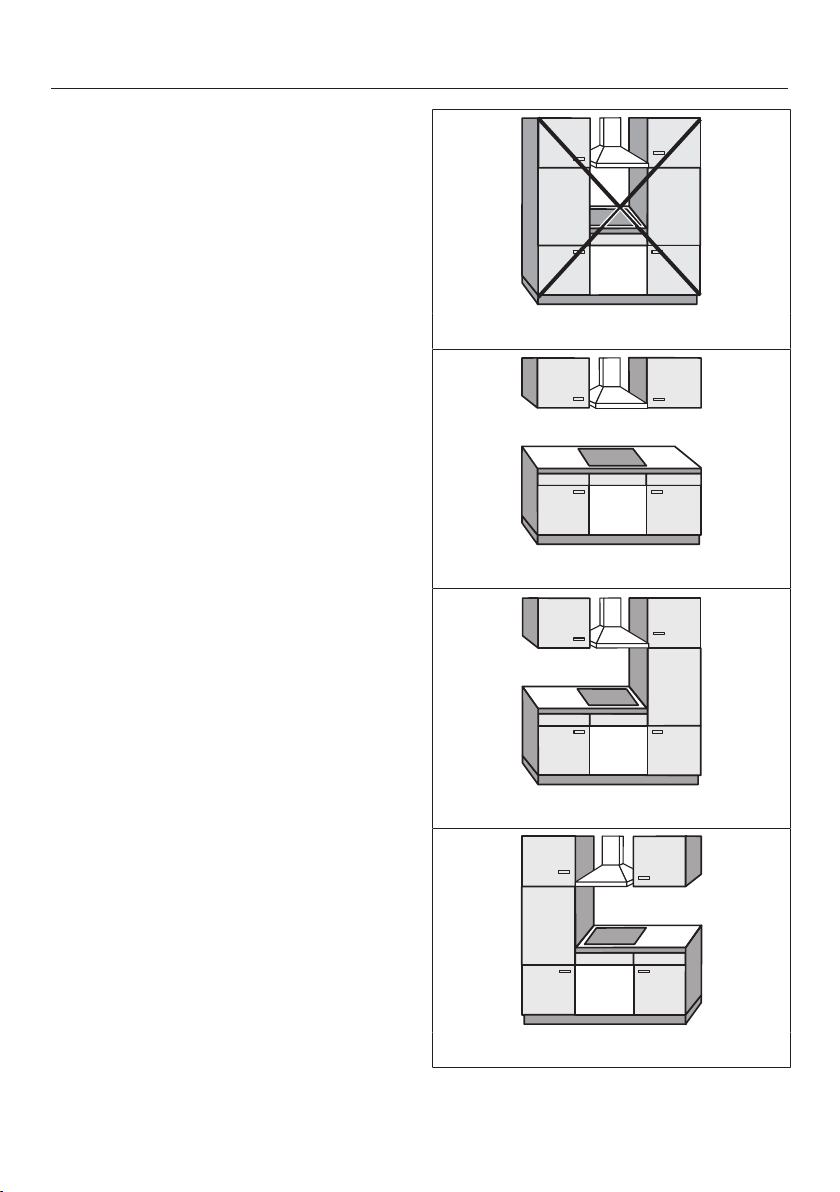

Ideally the appliance should be installed

with plenty of space on either side.

There may be a wall at the rear and a

tall unit or wall on one side (right or left).

On the other side, however, no tall unit

or wall should stand higher than the

appliance. Before installing the

appliance, check that the location

provides the required clearances from

combustible material and, if necessary,

provide protection to adjacent surfaces

as required by regulations.

Not allowed

Recommended

Not recommended

Not recommended

6

Page 7

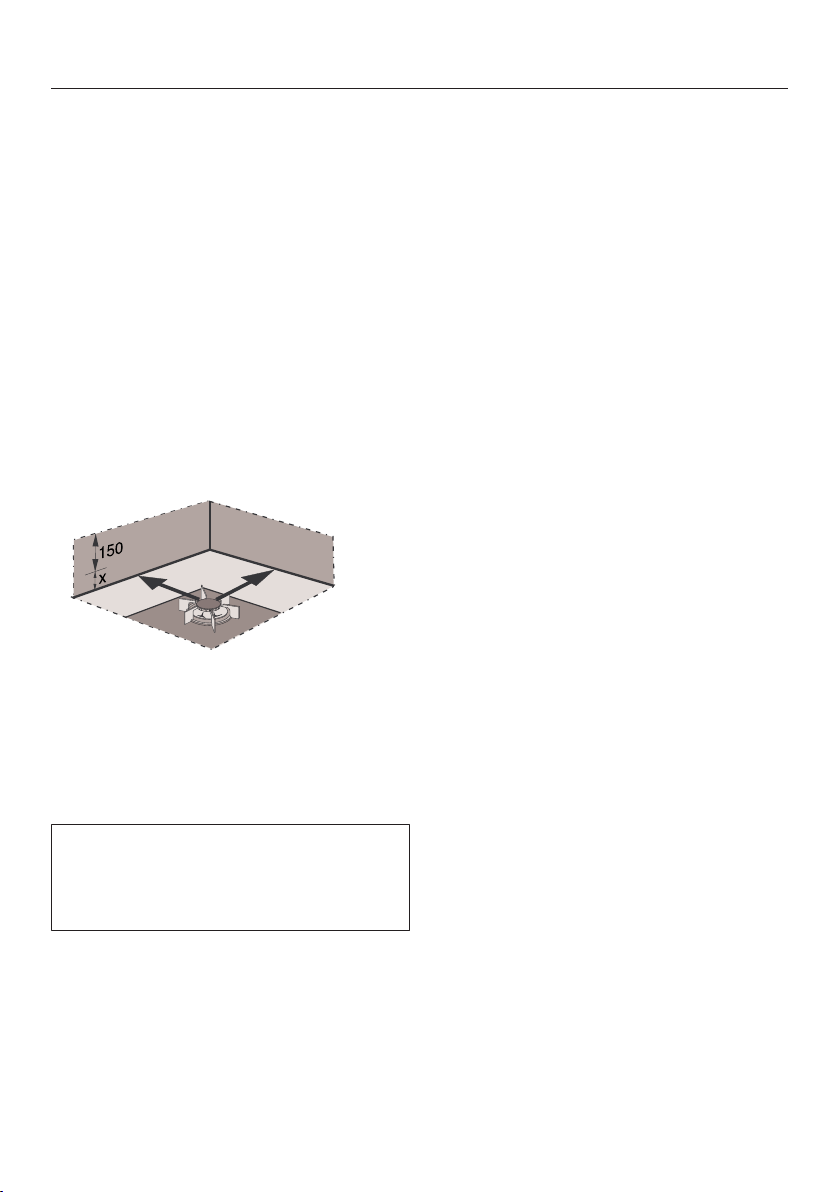

Safety distances

A gas appliance shall be installed such

that the surface temperature of any

nearby combustible surface* will not

exceed 65°C above ambient.

The minimum clearance from a

combustible surface shall be a 200mm

horizontal distance from the periphery

of any gas burner (AS/NZS 5601.1).

If that horizontal clearance is less than

200mm, that vertical surface must be

protected by a non-combustible

material for 150mm above the top of

the edge of the nearest burner for the

full dimension of the cooktop (depth,

width).

X Height from worktop surface to the

top of the edge of the burner

Clearance underneath the appliance

A minimum safety clearance of 30mm

must be provided underneath the

appliance.

Please note that clearance must also be

provided for the installation of the

flexible gas connection hose and mains

electrical cable if the appliance is to be

installed above a closed surface (e.g.

an oven).

The shown area indicates the protected

surface, which may be ceramic tiles or

other approved material.

*Combustible surface:

A material which will ignite and burn,

and includes material which has been

flameproofed.

7

Page 8

Installation notes

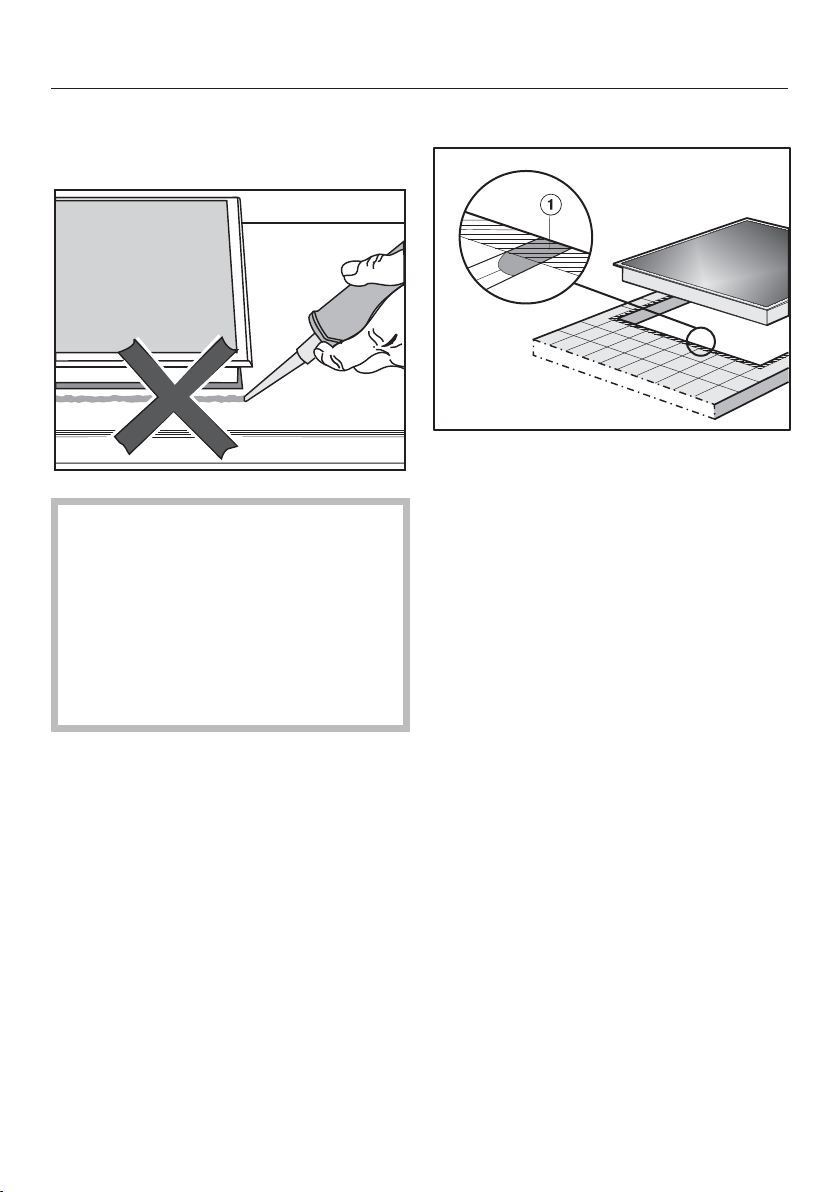

Seal between the cooktop and the worktop

Do not use sealant between the

cooktop and the worktop. This could

result in damage to the cooktop or

the worktop if the cooktop ever

needs to be removed for servicing.

The sealing strip under the edge of

the top part of the appliance

provides a sufficient seal for the

worktop.

Tiled worktop

Grout lines and the hatched area

underneath the cooktop frame must be

smooth and even. If they are not, the

cooktop will not sit flush with the

worktop and the sealing strip

underneath the cooktop will not provide

a good seal between the cooktop and

the worktop.

8

Page 9

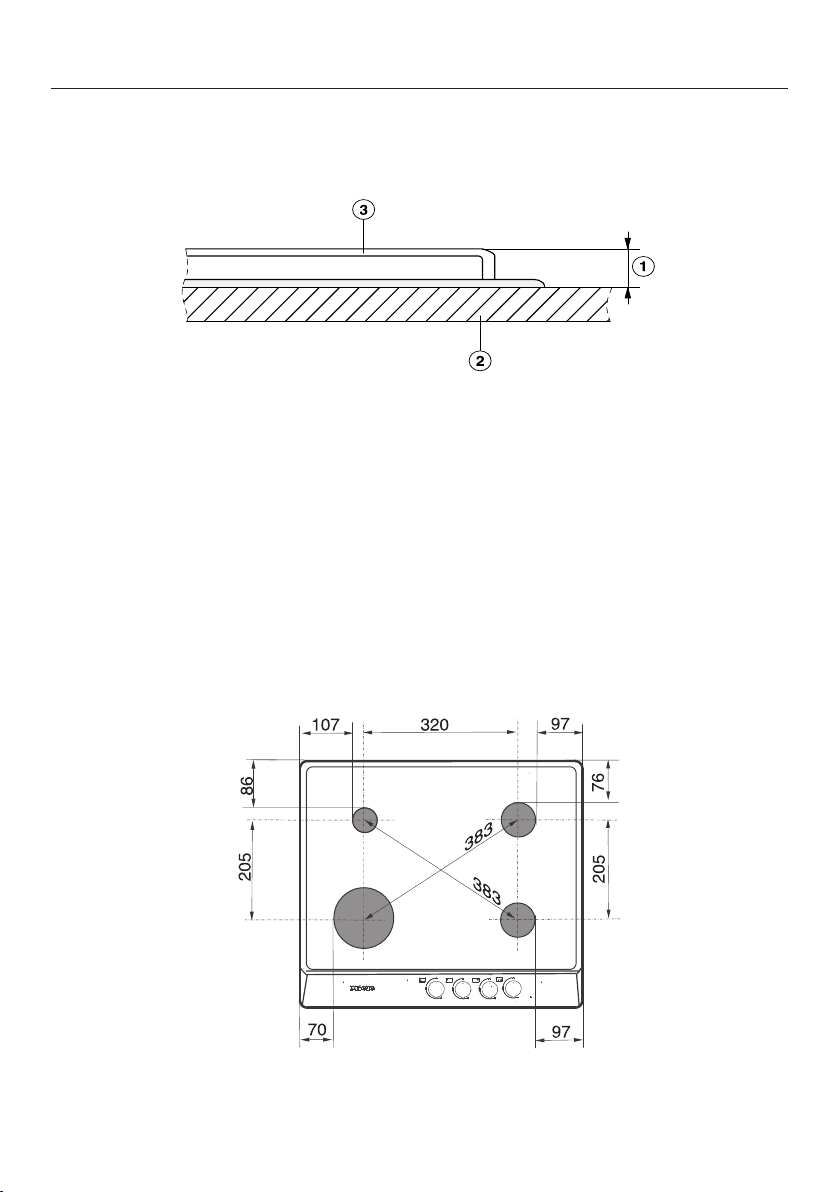

Detailed dimensions

Height of pan supports above the worktop surface

a

Vertical distance

b

Worktop surface

c

Pan support

The vertical distance from the top of the pan supports to the surface of the

worktop is 48mm.

Distances from burner to the edge of the appliance

KM 362-1

9

Page 10

*INSTALLATION*

Installation dimensions

KM 360 / KM 362

a

Building-in depth

b

Mains connection box

c

Gas connection R½ - ISO7-1

10

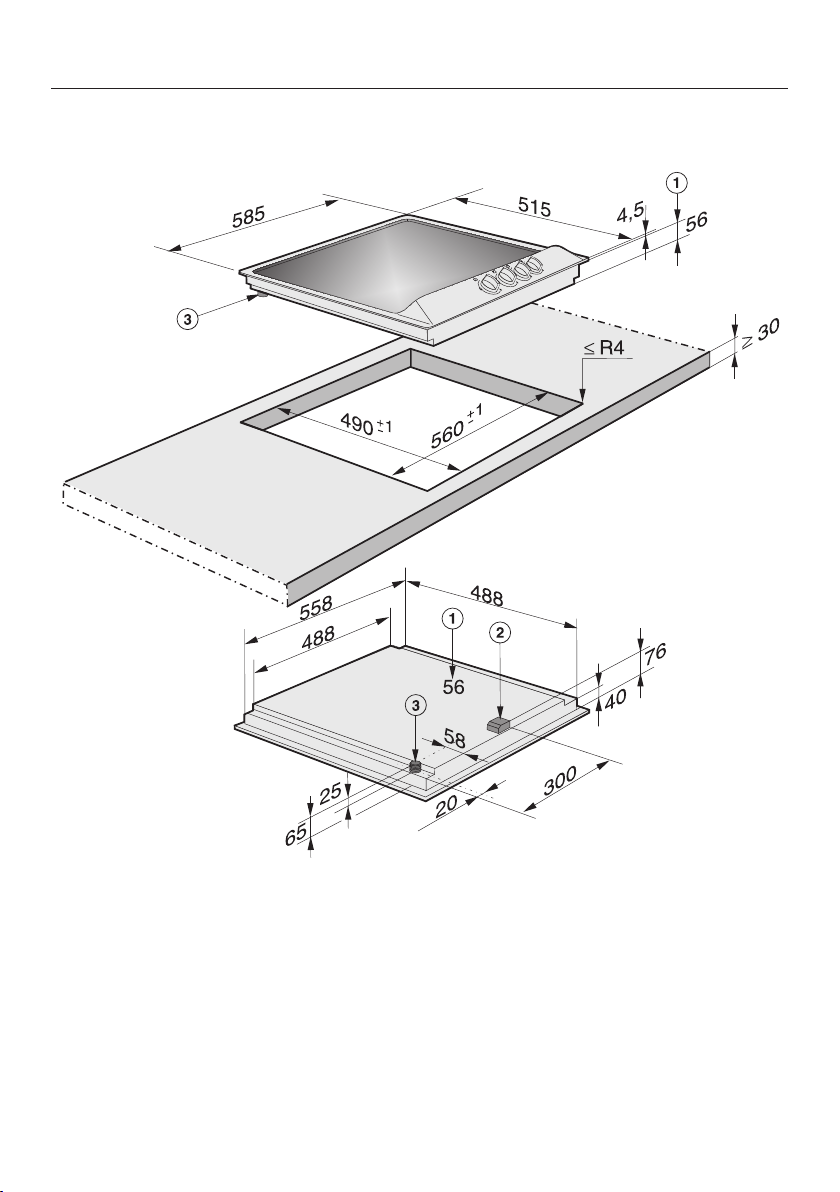

Page 11

*INSTALLATION*

KM 360-1 / KM 362-1

Installation dimensions

a

Building-in depth

b

Mains connection box

c

Gas connection R½ - ISO7-1

11

Page 12

*INSTALLATION*

Installation dimensions

KM 361 G / KM 363 G

a

Building-in depth

b

Mains connection box

c

Gas connection R½ - ISO7-1

12

Page 13

*INSTALLATION*

Installation

Preparing the worktop

Create the worktop cut-out as shown

in “Building-in dimensions”.

Remember to maintain the minimum

safety distances (see “Safety

distances”).

Seal the cut surfaces with a suitable

heat-resistant sealant to avoid

swelling caused by moisture. The

sealant must be temperatureresistant.

Make sure the sealant does not

come into contact with the top

surface of the worktop.

The sealing strip ensures that the

cooktop will sit securely in the cut-out

without slipping. Any gap between the

frame and worktop will become

smaller over time.

Installing the cooktop

Feed the mains connection cable

down through the worktop cut-out.

Place the cooktop centrally in the

cut-out. When doing this make sure

that the seal of the appliance sits

flush with the worktop on all sides.

This is important to ensure an

effective seal all round.

If the seal does not meet the worktop

correctly on the corners, the corner

radii (≤R4) can be carefully scribed to

suit.

Do not use any additional sealant

(e.g. silicone).

Connect the cooktop to the mains

electricity supply.

Connect the cooktop to the gas

supply (see “Gas connection”).

13

Page 14

*INSTALLATION*

Installation

Securing the cooktop

Secure the cooktop using the

brackets supplied.

Checking operation

After installing the cooktop, ignite all

burners to check that they are

operating correctly:

– The flame must not go out on the

lowest setting, or when the control is

turned quickly from the highest to the

lowest setting.

– On the highest setting, the flame

must have a distinctive and visible

core.

14

Page 15

*INSTALLATION*

Electrical connection

All electrical work must be carried out

by a suitably qualified and competent

person in strict accordance with current

local and national safety regulations.

Connection must be made via a

switched socket. This will make it easier

for service technicians should the

appliance need to be repaired. The

electrical socket must be easily

accessible after installation.

Danger of injury!

Miele cannot be held liable for

unauthorised installation,

maintenance and repair work as this

can be dangerous to users.

Miele cannot be held liable for

damage or injury caused by incorrect

installation, maintenance or repair

work, or by an inadequate or faulty

earthing system (e.g. electric shock).

If the plug has been removed or the

connection cable is not supplied with

a plug, the cooktop must be

connected to the mains supply by a

suitably qualified electrician.

If the appliance is to be hard-wired,

an additional means of

disconnection must be provided for

all poles in accordance with the

wiring rules. When switched off,

there must be an all-pole contact

gap of at least 3mm in the switch

(including switch, fuses and relays).

Connection data is shown on the

data plate. It must match the mains

electrical supply.

After installation, ensure that all

electrical components are shielded

and cannot be accessed by users.

Connection

AC 230 V, 50 Hz

The voltage and rated load are given on

the data plate. Please ensure these

match the household mains supply.

Residual current device

For extra safety, it is advisable to

protect the appliance with a suitable

residual current device (RCD) with a trip

range of 30 mA.

Replacing the mains connection cable

Risk of electric shock!

Incorrect connection to the electricity

supply may result in an electric

shock.

The mains connection cable must

only be replaced by a suitably

qualified and competent electrician

in accordance with current local and

national safety regulations.

If the mains cable needs to be replaced,

it must be replaced with a special

connection cable, type H05VV-F (PVC

insulated), available from Miele, by a

Miele authorised service technician or

suitably qualified and competent

electrician in order to avoid a hazard.

The connection data is given on the

data plate.

15

Page 16

Gas connection

Risk of explosion due to an

incorrect gas connection.

If the gas connection is carried out

incorrectly, it may result in gas

leakage.

Connection to the gas supply must

only be undertaken by an authorised

and registered gas installer in strict

accordance with current local and

national safety and building

regulations. The installer is

responsible for ensuring that the

appliance functions correctly when

installed.

Risk of explosion due to an

incorrect conversion.

If the conversion to another type of

gas is carried out incorrectly, it may

result in gas leakage.

Conversion from one type of gas to

another must only be undertaken by

an approved and registered gas

installer in strict accordance with

current local and national safety and

building regulations. The installer is

responsible for ensuring that the

appliance functions correctly when

installed.

The gas connection must be

installed so that connection can be

made either from inside or outside

the kitchen furniture unit. Every

appliance must have its own

isolating valve. The isolating valve

must be easily accessible and visible

(by opening the cabinet door if

necessary).

Check with your local gas supplier

about the type of gas supplied and

compare this information with the

type of gas quoted on the

appliance's data plate.

The cooktop is not connected to an

exhaust flue.

When installing and connecting the

appliance, please observe the

relevant regulations and ensure it has

adequate ventilation once installed.

The gas connection must be made in

accordance with national and local

regulations.

Special provisions of the local gas

supplier as well as building

regulations must also be observed.

Risk of heat damage.

Gas connections, gas hoses or pipes

and mains connection cables can be

damaged if exposed to heat from the

cooktop.

After installation make sure that

neither the gas hose/pipe nor the

mains cable can come into contact

with hot parts of the appliance and

that the gas hose/pipe and

connections on the cooktop cannot

come into contact with hot exhaust

fumes.

16

Page 17

Gas connection

Risk of explosion due to

damaged gas hoses and pipes.

Gas can leak from damaged flexible

gas hoses.

Attach flexible gas hoses in such a

way that the hose assembly is not

exposed to high temperatures

exceeding the maximum

recommended by the hose

manufacturer, subjected to strain,

kinking, permanent deformation or

damage by vermin.

Connect the cooktop to the gas

supply in accordance with national

and local regulations. Check the gas

connection for any leaks.

The gas pressure must be set by an

approved gas fitter and a full

operational test and a test for

possible leakages must be carried

out by the gas fitter after installation.

Depending on country of destination,

this appliance is set up for connection

to natural gas or ULPG. See adhesive

label on the appliance:

– G = NG (natural gas)

– LP = ULPG (Propane/Butane)

Depending on country of destination,

jets are supplied for conversion to a

different type of gas. If the appropriate

jets have not been supplied with the

appliance, you will need to contact

Miele. Conversion to another type of

gas is described in the section

“Conversion to another type of gas”.

Connecting the cooktop

The cooktop is supplied with a ¹/₂"

threaded gas connection. There are two

connection options:

– Fixed connection.

– Flexible hose class B or D which

complies with AS/NZS1869 and

must be certified. The minimum inner

diameter(Ø) must be 10mm and the

maximum length 1200mm.

Risk of explosion due to gas

leakage.

Unsuitable sealant will not ensure the

required leak protection for

connections.

Ensure that a suitable sealant is

used.

17

Page 18

Gas connection

a

b

~ 60

a

Setting the gas pressure

The gas pressure must be set by the

authorised gas fitter as shown on the

data plate:

Natural gas 1.0 kPa

ULPG (Propane/Butane) 2.75 kPa

The gas pressure must be set with the

largest burner operating at maximum

setting.

For ULPG models

For natural gas models

The gas regulator is only included with

appliances which are set up for

connection to natural gas. The

regulator must be connected directly

to the appliance.

a

Pressure Test Point

Loosen the screw in the test point

until it is free in its housing. The

screw is retained in this position.

a

Connection R¹/₂" with test point

b

Connection R¹/₂" with test point and

90° angle

When using a 90° angle the buildingin depth will increase to the depth of

the elbow used.

18

Connect the hose from the pressure

gauge.

Reassemble one of the large burners,

turn on the gas and manually light the

burners.

Disconnect the hose from the

pressure gauge and screw in the test

point screw.

For natural gas models: Connect the

gas regulator directly to the

appliance.

Page 19

Burner ratings

Nominal ratings for KM 360 / KM 360-1 / KM 361

Burner Gas type Highest setting Lowest setting

MJ/h MJ/h

Auxiliary burner NG

ULPG

Normal burner NG

ULPG

Fast burner NG

ULPG

Total NG

ULPG

3.85

3.60

5.85

6.35

10.35

9.68

25.90

25.98

0.70

0.41

1.10

0.97

1.70

1.65

Nominal ratings for KM 362 / KM 362-1

Burner Gas type Highest setting Lowest setting

MJ/h MJ/h

Auxiliary burner NG

ULPG

Normal burner NG

ULPG

Wok burner NG

ULPG

Total NG

ULPG

3.85

3.60

5.85

6.35

14.40

14.40

29.95

30.70

0.70

0.41

1.10

0.97

5.74

5.58

19

Page 20

Burner ratings

Nominal ratings for KM 363

Burner Gas type Highest setting Lowest setting

MJ/h MJ/h

Auxiliary burner NG

ULPG

Normal burner NG

ULPG

Fast burner NG

ULPG

Total NG

ULPG

3.85

3.60

5.85

6.35

10.35

9.68

20.05

19.63

0.70

0.41

1.10

0.97

1.70

1.65

20

Page 21

*INSTALLATION*

Conversion to another type of gas

Risk of explosion due to an

incorrect conversion.

If the conversion to another type of

gas is carried out incorrectly, it may

result in gas leakage.

Conversion from one type of gas to

another must only be undertaken by

an authorised and registered gas

installer in strict accordance with

current local and national safety and

building regulations. The installer is

responsible for ensuring that the

appliance functions correctly when

installed. Disconnect the cooktop

from the electricity supply and turn

off the gas supply.

Jet table

The jet markings refer to a ¹/₁₀₀mm

bore diameter.

Burner

Main jet Small jet

Natural gas

Auxiliary 0.90 0.42

Normal 1.10 0.52

Fast 1.50 0.60

Wok burner 1.70/0.70 1.30 (1A)

ULPG

Auxiliary 0.52 0.23

Normal 0.70 0.32

Fast 0.87 0.40

Wok burner 1.00/0.37 0.68

When converting to another type of

gas, both the main and small jets

need to be changed.

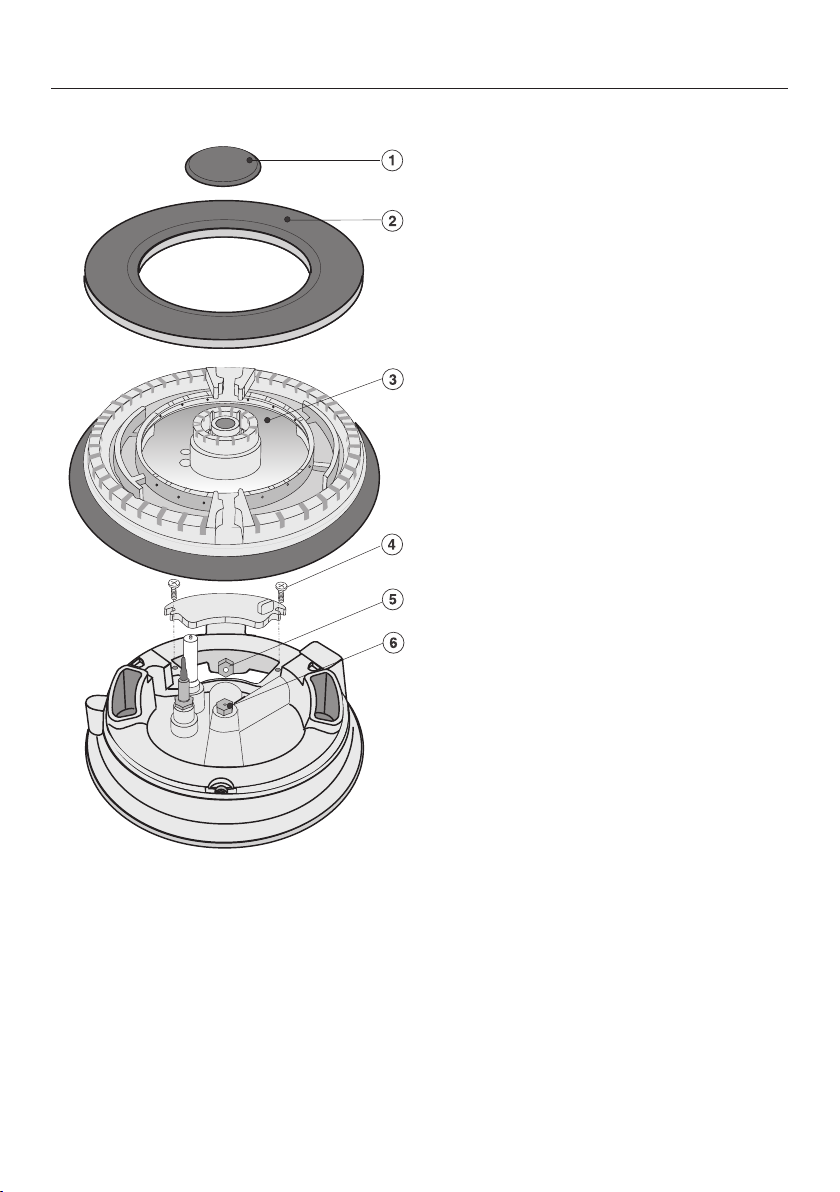

Changing the main jets

Auxiliary, normal and fast burners

Remove the pan support, burner

cap and burner head.

Using an M7 socket spanner,

unscrew the main jet.

Fit the correct jets securely (see jet

table).

Secure the jets against inadvertent

loosening with sealing wax.

Changing the jets

Disconnect the cooktop from the

electricity supply and turn off the gas

supply.

21

Page 22

*INSTALLATION*

Conversion to another type of gas

Wok burner

Fit the correct jets securely (see jet

table).

Secure the jets against inadvertent

loosening with sealing wax.

Remove the burner cap, burner

ring and burner head.

Undo the screws and remove the

cover plate.

Using a socket spanner or flat

spanner (M7), unscrew the main

jets(larger diameter) and

(smaller diameter).

22

Page 23

*INSTALLATION*

a

b

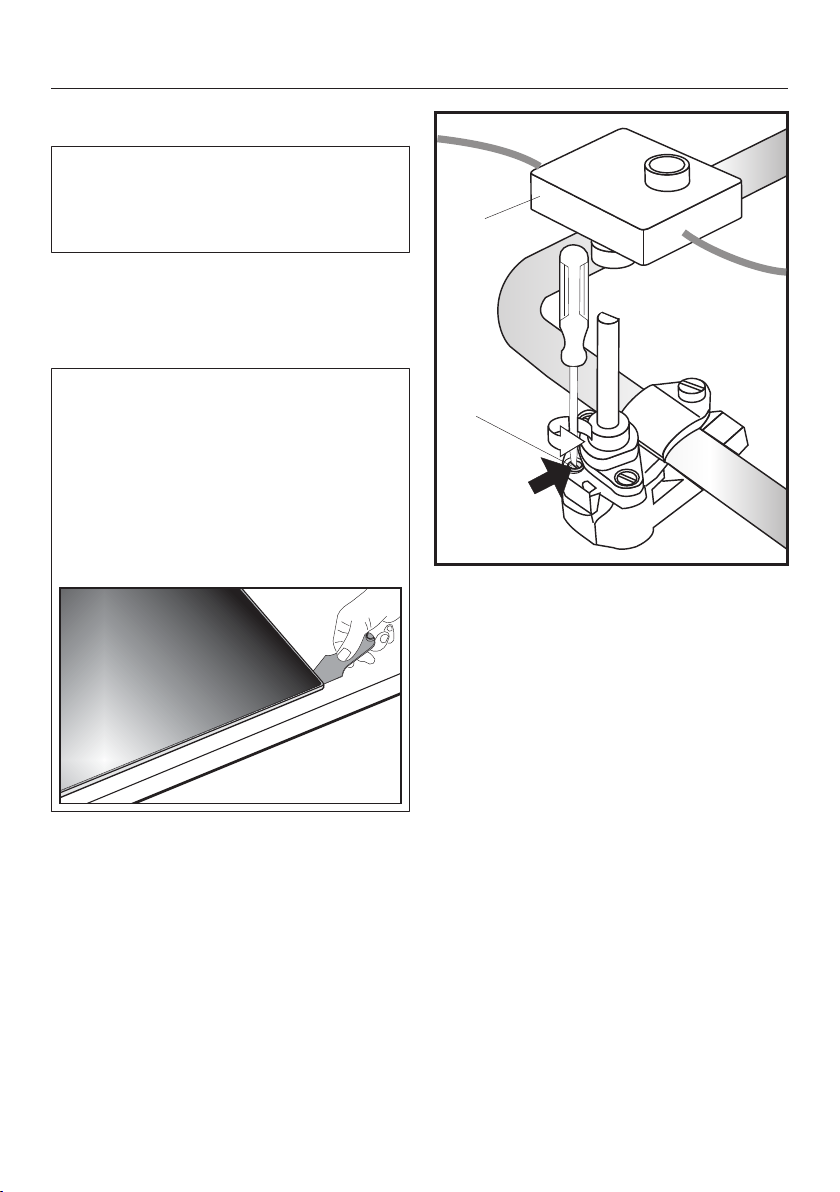

Changing the small jets

To change the jets, the burner fixing

screws must first be loosened and the

upper section of the appliance

removed.

Pull the control knobs off.

Remove the burner components.

Lift the top of the appliance off.

To lift out the stainless steel upper

section, lift it at the rear, slide

forwards and take it out.

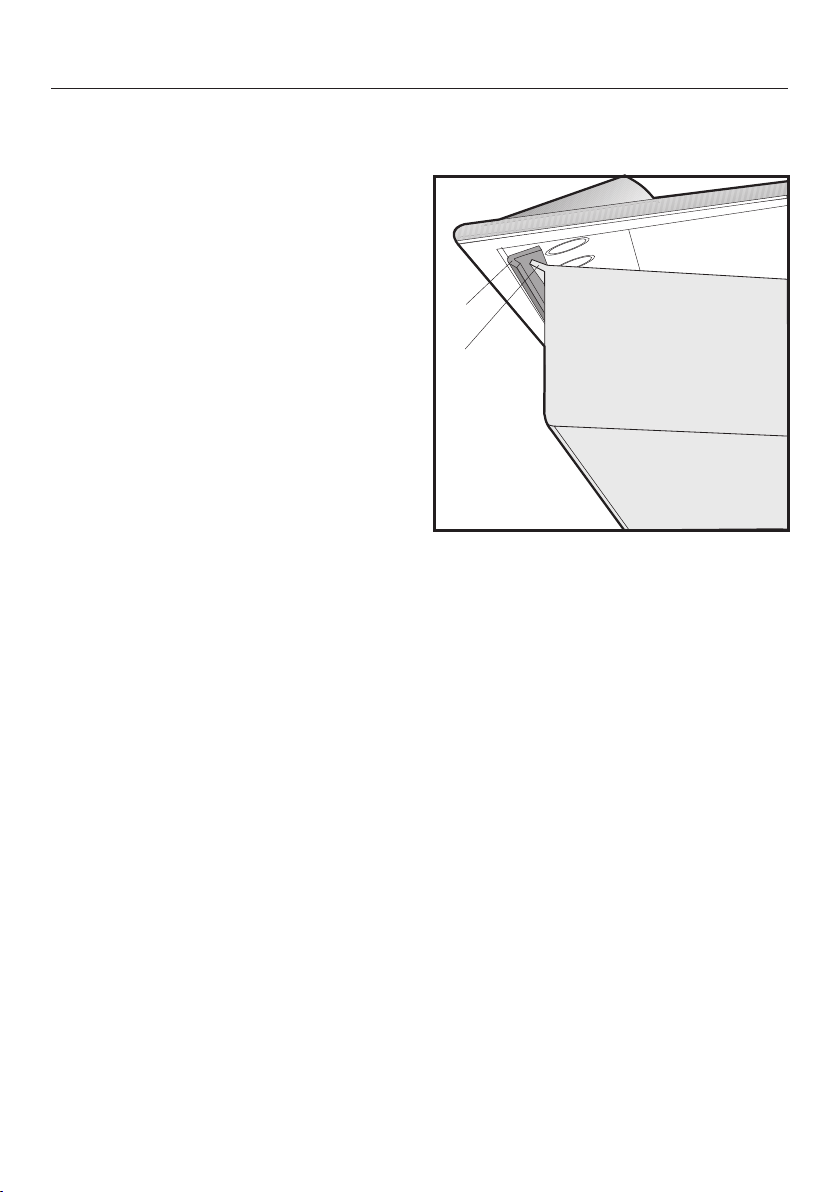

To remove the ceramic upper

section, insert the supplied tool at the

corner between the appliance frame

and the worktop, lift it up and take it

out.

Conversion to another type of gas

Remove the ignition switch.

Using a small screwdriver, unscrew

the small jet in the gas fitting.

Pull out the jet with a pair of pliers.

Fit the correct jets securely (see jet

table).

Secure the jets against inadvertent

loosening with sealing wax.

23

Page 24

*INSTALLATION*

a

b

Conversion to another type of gas

Checking operation

Check all gas fittings for leaks.

Reassemble the cooktop.

Ignite all burners to check that they

are operating correctly.

– The flame must not go out on the

lowest setting, or when the control is

turned quickly from the highest to the

lowest setting.

– On the highest setting, the flame

must have a distinctive and visible

core.

Adhere the label supplied with the

jets over the old label stating the type

of gas being used.

Refitting the stainless steel upper section

Position the upper section as shown

in the illustration.

Push it forwards first and then

backwards until the angle bracket

clicks into place underneath the

lip.

Then lower the upper section.

24

Page 25

Service

Contact in case of fault

In the event of any faults which you cannot remedy yourself, please contact Miele.

Contact information for Miele can be found at the end of this booklet.

Please quote the model and serial number of your appliance when contacting

Miele. This information can be found on the data plate.

Data plate

Adhere the extra data plate supplied with the appliance in the space below. Make

sure that the model number matches the one specified on the back cover of these

operating and installation instructions.

Warranty

The manufacturer's warranty for this appliance is 2years.

For further information, please refer to your warranty booklet.

25

Page 26

Page 27

Miele Experience Centre and

Head Office Melbourne:

1 Gilbert Park Drive

Knoxfield, VIC 3180

Miele Experience Centre South Melbourne:

206-210 Coventry Street

South Melbourne, VIC 3205

Miele Experience Centre and Office Sydney:

3 Skyline Place

Frenchs Forest, NSW 2086

Miele Experience Centre and Office Brisbane:

Tenancy 4C, 63 Skyring Terrace

Newstead, QLD 4006

Miele Experience Centre and Office Perth:

83-85 Sir Donald Bradman Drive

Hilton, SA 5033

Miele Experience Centre and Office Adelaide:

Miele Australia Pty. Ltd. Miele New Zealand Limited

Level 2, 10 College Hill

Freemans Bay, Auckland 1011

Miele Experience Centre

Auckland:

8 College Hill

Freemans Bay, Auckland 1011

Miele Global Headquarters

Germany

Miele & Cie. KG

Carl-Miele-Straße 29

33332 Gütersloh

Federal Republic of Germany

Head Office:

IRD 98 463 631

ACN 005 635 398

ABN 96 005 635 398

Miele Experience Centre Gold Coast:

131 Ferry Road

Southport, QLD 4215

Miele Experience Centre

Wellington:

183 Featherston Street

Wellington 6011

0800 464 353 (0800 4 MIELE)

www.miele.co.nz

205-207 Stirling Highway

Claremont, WA 6010

1300 464 353 (1300 4 MIELE)

www.miele.com.au

Page 28

KM360 / KM360-1 KM / KM361 / KM362 / KM362-1 /

KM363

M.-Nr. 05 827 671 / 05en-AU, NZ

Loading...

Loading...