Page 1

art.nr. 722.392.20/T91701B

Operating instructions

Gas hob KM 326G

Conversion kit AH 102 C4U

Instructions pour l’utilisation

du dessus de cuisinière au gas KM 326G

Kit de conversion AH 102 C4U

Page 2

USA CDN

CDN

english page 1 - 27

operating instructions gashob KM 326G page 1 - 17

converting instructions converting kit AH 102 C4U page 18 - 27

français page 28 - 55

Instructions pour l’utilisation du dessus

de cuisinière au gas KM 326G page 28 - 45

Mode d'emploi du kit de conversion AH 102 C4U page 46 - 55

Page 3

1

* Do not store or use gasoline or

other flammable vapors and liquids

in the vicinity of this or any other

appliance.

* What to do if you smell gas

– Do not try to light any appliance.

– Do not touch any electrical

switch.

– Do not use any phone in your

building.

– Immediately call your gas supplier

using a neighbour’s phone. Follow

the gas supplier‘s instructions.

– If you cannot reach your gas

supplier, call the fire department.

* Installation and service must be

performed by a qualified installer,

service agency or the gas supplier.

Warning

If the information in this

manual is not followed

exactly, a fire or explosion

may result causing damage

to property, personal injury

or death.

Page 4

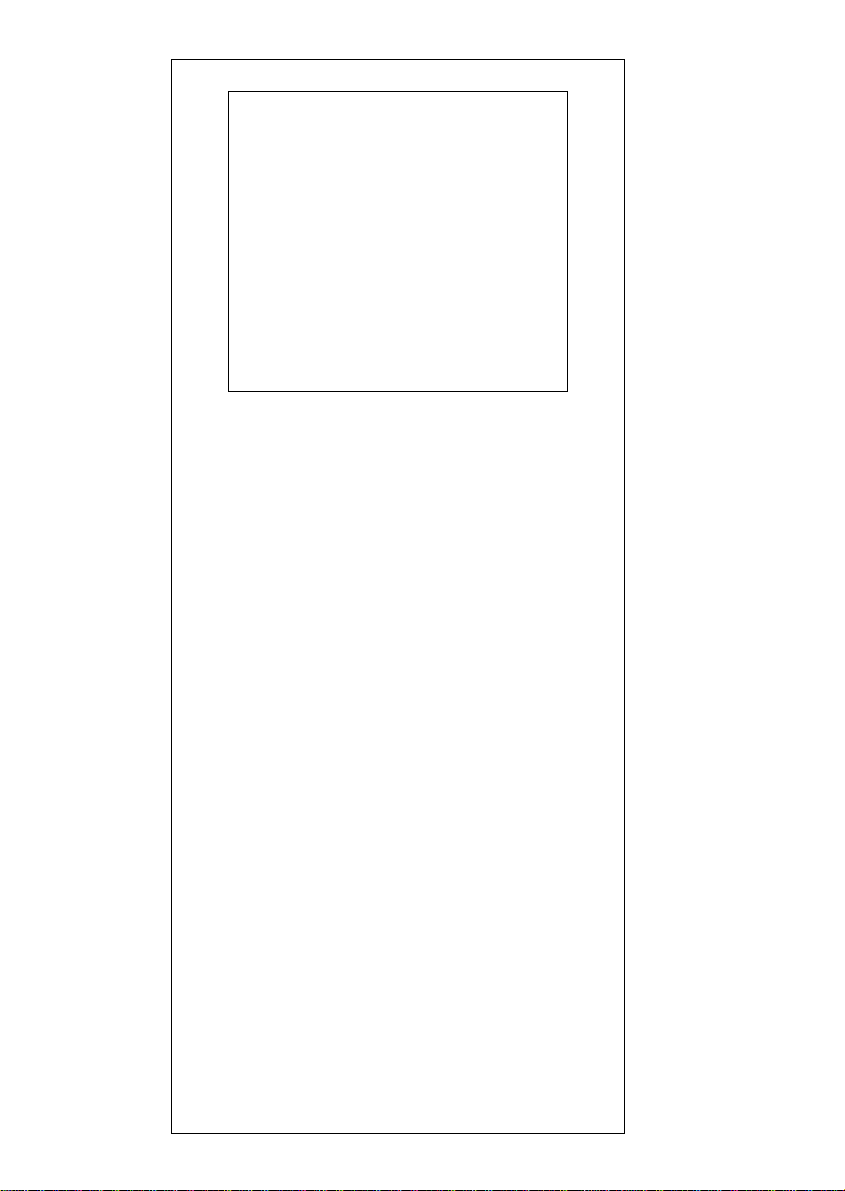

2 3

Marking

2-zone wok burner

rear left burner

front left burner

rear right burner

front right burner

General

1. control knobs with marking and

LED display

2. 2-zone high-speed wok burner

2.1 burner head

2.2 ignition

2.3 safety control

2.4 burner ring

2.5 burner cap

2.6 burner cap

2.7 pan support

2.8 trivet for 2-zone burner

3. super high-speed burner

4. high-speed burner

4.1 burner head

4.2 ignition

4.3 safety control

4.4 burner cap

5 pan support

6. super high-speed burner

7. high-speed burner

8. drip tray of heat resistant ceramic

1

2.

2.1

2.2/2.3

2.4

2.5

2.6

2.7

3

4

4.1

4.2/4.3

4.4

67

5

8

2.8

Page 5

Warning and safety instructions

1. Read all the instructions before using your

hob unit.

2. Use the unit only for its intended purpose.

3. Do not use the unit unless all parts are

properly in place according to the

installation and operating instructions.

4. Before servicing, disconnect the power

supply by removing the plug or switching off

the circuit breaker.

5. Never use the unit to warm or heat the

room.

6. When using an electrical socket near the

burners, make sure that the cable of the

appliance does not come into contact with

the burner of the unit.

7. Do not allow children to operate or play with

or near the unit.

8. Keep all play items stored away from the

unit to prevent injury to curious or playful

children.

9. Please remember that, in use, burners and

pot racks become hot; therefore ensure that

children do not touch them.

10. Do not store items on the unit when not in

use.

11. Do not let cooking grease or other

flammable materials accumulate on the unit.

12. Never leave the unit unattended when

cooking with oil or fat. Very hot oil can

cause fire.

13. Allow sufficient time for the unit to cool

before touching or exposing surface areas

to flammable materials.

14. If high settings are used, remain near the

hob in case of spitting grease or pans

boiling over, which may cause smoke.

15. Never use moist pot holders.

16. Use only certain containers suitable for

range-top service. Unsuitable containers

may break due to a sudden temperature

change.

17. Position the handle of the container towards

the centre of the range to minimize burns,

spillage and ignition of flammable materials.

18. Before removing pots and pans, be sure to

turn surface unit to “OFF”.

19. Always heat fat slowly, watching as it heats.

20. Use a deep fat thermometer to prevent

overheating.

21. When frying foods, make sure that the food

is as dry as possible to prevent moisture

from causing hot fat to bubble over.

22. When shallow or deep-fat frying, do not

overfill the pan with oil.

23. Do not use the hob if it is not connected to

the electricity mains or in the event of a

power cut. It is not safe under these

conditions.

Save the instructions.

Leave these instructions with the consumer.

Page 6

4 5

OFF

HI

LO

OFF

HI

LO

XLO

Important notes for the user

– Installation and maintenance should only be

carried out by a suitably qualified person

(licensed gas fitter in Canada).

– For safety reasons, this hob should only be

fitted as a built-in appliance.

– Please remember that the hob becomes hot,

not only around the burner, but also the

control panel. Therefore ensure that small

children do not touch the hob when it is being

used.

– When cooking or boiling in large pots or pans,

ensure that there is a minimum distance of

2˝ (50 mm) between the pot and a heatsensitive worktop.

After combustion, the hot gases flow

outwards under the base of the pot and may

consequently burn the edge of the worktop if

it is too close.

– Make sure there is a minimum distance of

5/8˝ (15 mm) between the pot or pan and the

control panel. Never place a pot on the

control panel.

– When using a cooker hood over the gas hob,

ensure that any burners in use are always

covered with a pot or frying pan. Otherwise,

parts of the cooker hood could be damaged

by the heat and/or flames.

– Note that potential hazards may exist with

overhead cabinets.

– Not to be used for space heating. This

instruction is based on safety considerations.

– When a gas cooking appliance is being used,

heat and moisture are produced in the area

where the appliance is situated. Make sure

that the area is sufficiently ventilated; open

natural ventilation openings or fit a

mechanical ventilator (extractor). When the

hob is used for longer periods, extra

ventilation may be needed, such as an open

window or a higher setting on the ventilator

(extractor).

Advice

– The safe and efficient use of this appliance

requires that it be regularly serviced by a

qualified technician; however, the frequency

of service will depend on usage. Once a year

should suffice.

Before starting check

Remove all packaging materials and labels

before using your hob.

Check:

– that the gas is on at the mains;

– that the plug is in the wall socket;

– that the pan supports are positioned correctly.

Page 7

Gas burners

If a burner blows out, the electronic ignition

automatically sparks all burners to relight the

flame.

The flame is lit by means of an electrical ignition

device. When the burner control is pressed and

turned, a high voltage flows into the electrode

by the burner. Sparks are created. A spark

ignites the gas to give a flame.

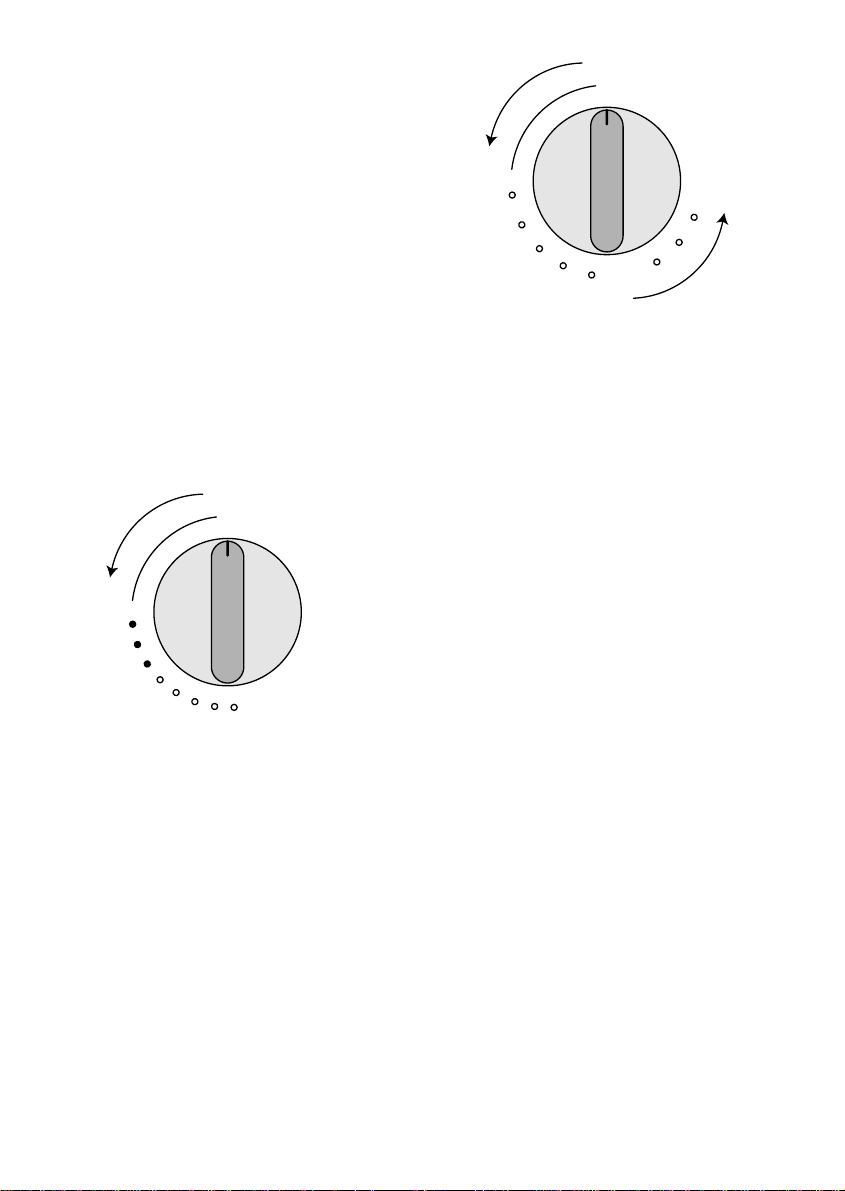

Lighting and adjusting

high-speed and super high-speed burners

A symbol above the control knob indicates

which burner is being operated.

– Push in the burner control knob and turn it to

the “HI” position. Ignition follows.

– Turn the control to the desired setting once

the burner is alight. The LED’s indicate the

position of the control knob.

You may set the knob at any position between

“HI” and “LO”.

2-zone super high-speed wok burner

Outer ring

– Push in the burner control knob and turn it to

the “HI” position. Ignition follows.

– Turn the control to the desired setting once

the burner is alight.

You may set the knob at any position between

“HI” and “LO”.

Inner ring

– Push in the burner control knob and turn it to

the “HI” position. Ignition follows.

– Turn the control to “LO” once the burner is

alight.

– Push in the burner control knob and turn it to

any position between “LO” and “XLO”.

OFF

HI

LO

OFF

HI

LO

XLO

Page 8

6 7

How to use gas burners

Place the pot over the pot support fitted above

the hob.

For small pots with a diameter of less then

7˝ (175 mm), the trivet must be used in

combination with the 2-zone wok burner.

Make sure the trivet is securely fixed to the pot

support.

Push the appropriate control knob, turn it

counter-clockwise to the setting “HI”.

If the burner fails to ignite, check that:

– the burner cap is positioned correctly;

– the burner is clean and dry.

To switch off the gas supply to the burner, turn

the control knob, in a clockwise direction, to the

“OFF” position.

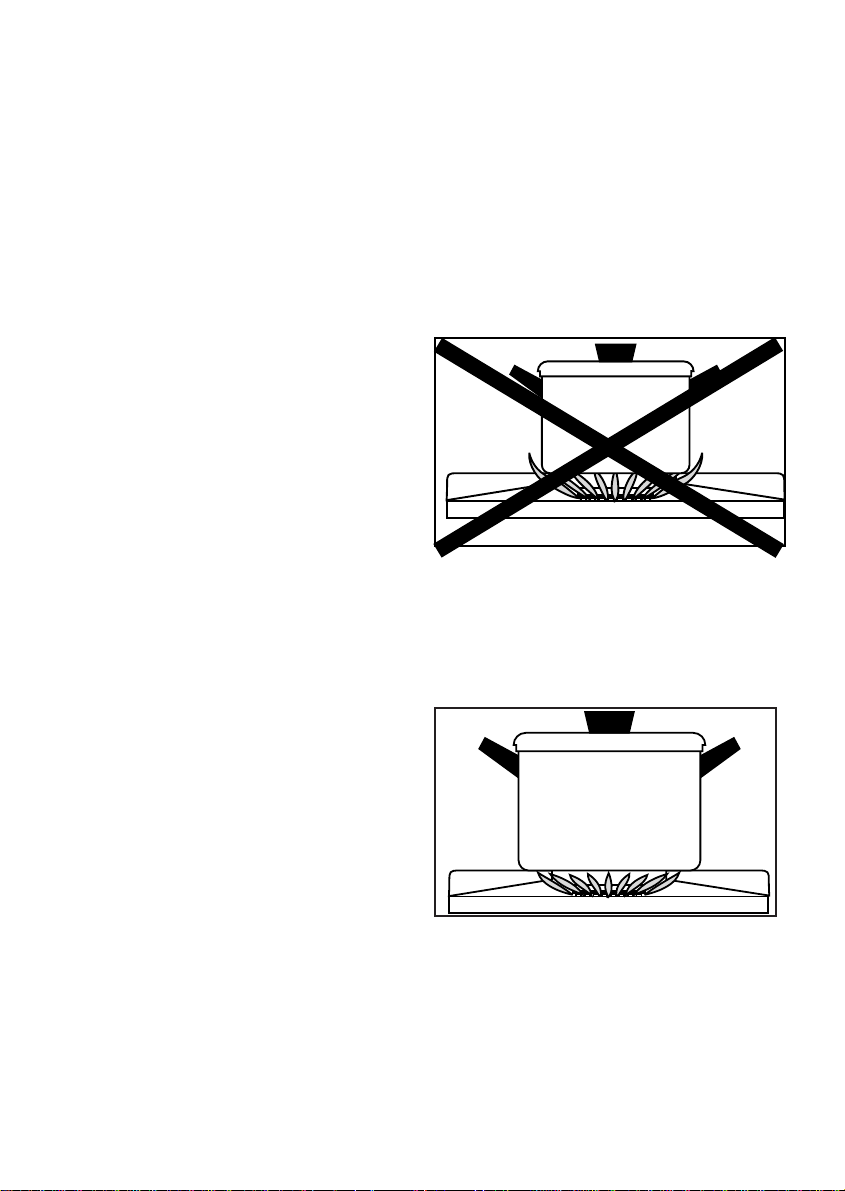

When cooking or boiling in large pots or pans,

ensure that there is a minimum distance of

2˝ (50 mm) between the pot and a heat-sensitive

worktop.

After combustion, the hot gases flow outwards

under the base of the pot and may consequently

burn the edge of the worktop if it is too close.

Make sure there is a minimum distance of

5/8˝ (15 mm) between the pot or pan and the

control panel. Never place a pot on the control

panel.

Right Wrong

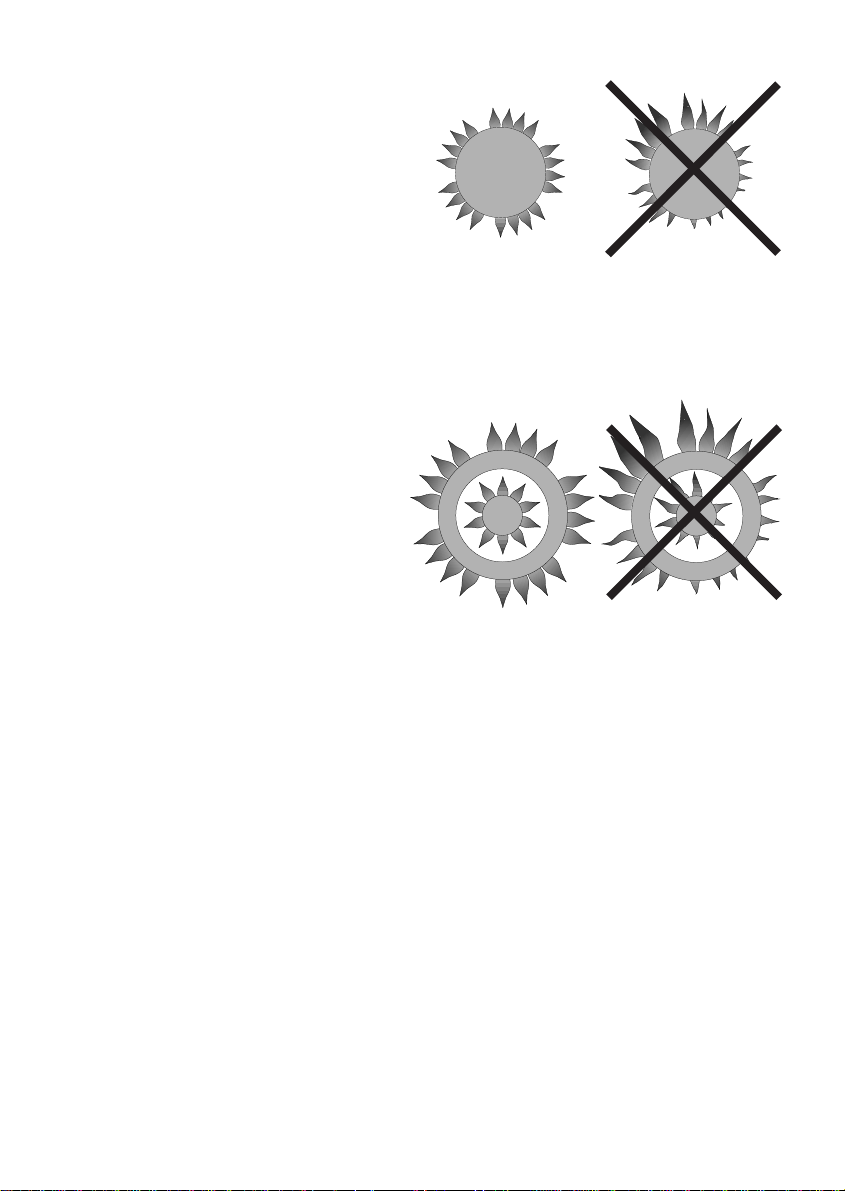

Check to ensure that the burner is burning

correctly. The flames should be blue and

uniform.

Right Wrong

If the flames are not uniform, check to ensure

that the burner cap is properly positioned on the

ring.

If the flames are irregular and yellow, check to

ensure that a pressure regulator has been

installed. Do not use the appliance and inform

the installer.

Page 9

Pans and pots

The heat from the burner is transferred via the

pan base. If the base is thick, the heat will take

longer to reach the contents, but the base will

have a more uniform temperature. Thin and light

pans will cause food to burn more easily.

To use the gas as efficiently as possible, it is

best to use a pan with a large diameter.

The tips of the flames are the hottest. If flames

escape around the sides of the pan, a great deal

of heat is lost.

Keeping the flame beneath the pan saves time

and gas and is the safest way to cook.

Cook with the lid on the pan. This can save on

energy by up to 50%.

Cooking in comfort

frying and pot-roasting

deep-frying and blanching

cooking large quantities

stir-frying

are best done on the super high-speed wok

burner.

stewing and steaming

cooking standard portions

making a roux

are best done on the high-speed burner.

The high-speed burner is ideal for preparing

portions for about 4 people.

making sauces

keeping food hot

cooking through/simmering

are best done on the inner ring of the 2-zone

burner.

At the “LO”position, this burner is large enough

to cook food through.

Wrong

Right

Page 10

8 9

Cleaning and maintenance

Before cleaning, be certain the burners are

turned off and the grates are cool.

In the event of boiling over, clean immediately,

to prevent the substance which has boiled over

from igniting.

Wiping the hob down regularly immediately after

use prevents dirt from burning on and resulting

in stains which are difficult to remove.

For cleaning, use a mixture of water and

detergent or all-purpose cleaner.

Stubborn stains on the appliance can be

removed with a non-abrasive cream or a soft

sponge.

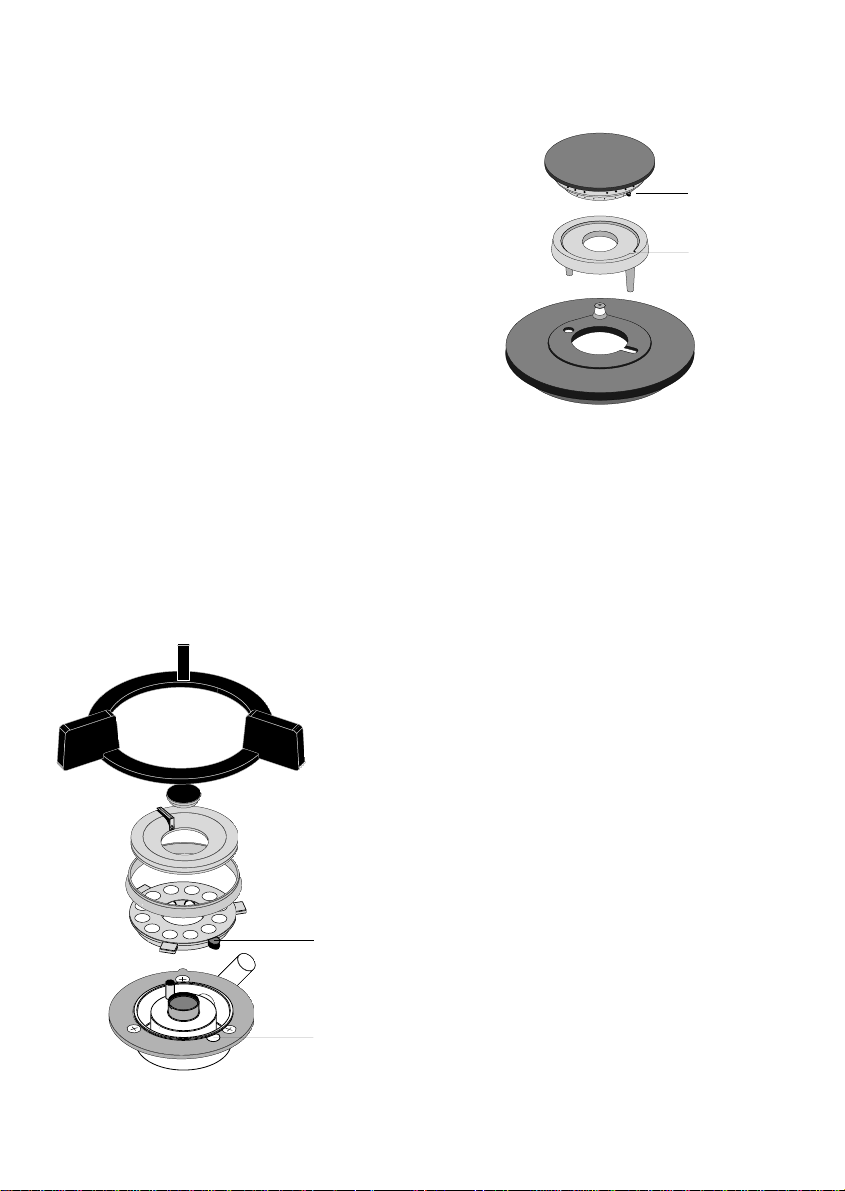

2-zone high-speed wok burner

Super high-speed burner/ high-speed burner

The burners can be taken apart for cleaning and

put back together as the diagram shows.

Do not submerge hot burner caps in cold water.

The quick change in temperature may damage

the enamel.

Important:

The burners must only be lit when they are

correctly fitted together, otherwise the ignition

device could be damaged.

Avoid using too much water when cleaning the

burners. Do not use scouring powder or other

aggressive cleaning agents.

Keep the appliance and vicinity clear and free

from combustible materials, gasoline and other

flammable vapors and liquids.

From time to time, the electrodes should be

wiped with a well wrung-out cloth and dried

with a clean cloth.

tab

indentation

tab

indentation

tab

indentation

Page 11

Disposal of packaging and

appliance

The packaging of the appliance is recyclable. It

is made up of:

– cardboard

– polyethylene film (PE)

– CFC-free polystyrene (PS rigid foam)

Please dispose of these materials in a

responsible way in accordance with the

regulations of your local authority.

Your local authority will also be able to give you

information about disposing of disused

household appliances in a responsible way.

Cleaning and maintenance

(cont.)

After cleaning always dry the burners and the

electrodes, otherwise the flame will not ignite.

When using a cooker hood over the hob, ensure

that any burners in use are always covered with

a pan. Otherwise flames could be drawn up by

the suction of the cooker hood, parts of which

could then be damaged.

Page 12

10 11

5-point gas re-ignitor

120 Vac/60 Hz/3 VA

spark/sense

re-ignition

earth

N

A

SW1

SW2

SW3

SW4

SW5

S1

S2

S3

S4

S5

120V/60HZ

main connecting board

L

N

TWO ZONE

WOK BURNER

12-leds

com

S1

LED

com

S1

LED

9-leds

com

S1

LED

9-leds

9-leds

com

S1

LED

com

S1

LED

9-leds

FRONT RIGHT

BACK RIGHT

BACK LEFT

FRONTLEFT

Problem

Burner does not burn well

Ignition sparks but burner

does not ignite

Ignition does not spark

Cause

– Burner dirty or moist

– Not suitable for type of gas

– Burner dirty or moist

– Burner cap not aligned

properly

– The appliance has not yet

been plugged in properly

– Ignition is defective

Solution

– Clean and/or dry the burner

– Check identification plate

and if necessary have the

appliance adapted

– Clean and/or dry the burner

– Position the cap properly

onto the ring

– Plug in the appliance

properly

– Phone the Miele Service

Department

If your appliance does not operate as desired,

first check if you can solve the problem yourself

by using the table above. There is often a simple

reason for the problem.

Repairs to the gas and electrical components of

this appliance must only be carried out by a

suitably qualified person (licensed gas fitter in

Canada).

Repairs by unauthorised personnel could be

dangerous and are not covered by the

guarantee.

In the event of any fault on this appliance,

please contact:

– your Miele dealer or

– the Miele Service Department,

the address of which is shown on the back

page.

Please quote the model and serial number of

your appliance. You will find both on the data

plate located on the underside of the appliance.

Troubleshooting

Page 13

Electrical circuit diagram

5-point gas re-ignitor

120 Vac/60 Hz/3 VA

spark/sense

re-ignition

earth

N

A

SW1

SW2

SW3

SW4

SW5

S1

S2

S3

S4

S5

120V/60HZ

main connecting board

L

N

TWO ZONE

WOK BURNER

12-leds

com

S1

LED

com

S1

LED

9-leds

com

S1

LED

9-leds

9-leds

com

S1

LED

com

S1

LED

9-leds

FRONT RIGHT

BACK RIGHT

BACK LEFT

FRONTLEFT

Page 14

12 13

Gas connection

These appliances must be installed with a

separate shut-off valve and a gas pressure

regulator.

Both shut-off valve and pressure regulator must

be easily accessible to the consumer.

The shut-off valve is solely intended to be used

to shut off the gas supply.

This appliance and its individual shut-off valve

must be disconnected from the gas supply

piping system during any pressure testing of that

system.

The hob comes equipped for natural gas.

You should find out details about the type of gas

and calorific value from your Gas Utility and

compare this information with the type of gas

quoted on the data plate.

Before using the appliance, check the

connection with a soapy solution for leaks.

Never use a flame of any sort. The interior of

this appliance has been tested by the

manufacturer.

Pressure regulator

A pressure regulator is included with the

appliance.

After installing a gas shut-off valve in an easily

accessible location under the hob, install the

gas pressure regulator to the manifold pipe

using pipe dope on threads of the manifold pipe

(see also next page).

Electrical connection

The automatic ignition and the safety device

require connect ion to an A.C. single phase

120 V, 60 Hz supply. Fuse rating 6 A.

The appliances are factory equipped with a

power supply cord with molded three prong plug

– ready for connection to an electrically

grounded socket which complies with your local

electrical codes or with the National Electrical

Code ANSI/NFPA No. 70 for the USA or

Electrical Code Part I for Canada.

Ensure that the receptacle is positioned so that

it is easily accessible when the appliance is

built in.

Check that the data given on the data plate

under the appliance complies with the mains

voltage.

Warning:

This appliance must be grounded.

Do not cut or remove the grounding prong from

the plug.

Page 15

Warning

As shown in the above diagram, the regulator

included must be used when connecting the

Miele hob.

– Any pipe connections must be made using a

thread sealant approved for gas connections.

Failure to correctly install these items could

lead to a gas leak and subsequent explosion.

– Do not use any regulator unless it has been

supplied by Miele Appliances.

Connect the gas supply to the pressure

regulator using a 1/2” gas line connector

between the shut-off valve and the pressure

regulator. Flexible harmonica-type stainless

steel pipe is recommended.

For USA only

The gas connection must be made in

accordance with the local codes, or in absence

of local codes, with the National Fuel Gas Code

ANSI Z 223.1.

Gas pressures for USA

Natural gas

Max. supply pressure: 1/2 psi

Min. supply pressure: 5˝ water column

Liquid propane gas, after converting this

appliance with conversion kit number AH102 C4U.

Max. supply pressure: 1/2 psi

Min. supply pressure: 11˝ water column

Manifold pressure:

– natural gas 4˝ water column

– propane gas 10˝ water column

Page 16

14 15

35 7/16" (900 mm)

20

3/16"

(515 mm)

3"

(75 mm)

19 5/16"

(490 mm)

min. 3" (75 mm)

min. 1

3/4"

(45 mm)

33

7/8" (860 mm)

b. The appliance must be isolated from the gas

supply piping system by closing its individual

manual shut-off valve during any pressure

testing of the gas supply piping system at

test pressures equal to or less than 1/2 psi

(3.5 kPa).

Warning

The base of the hob will become hot. The gas

connection used must comply with the relevant

national and local regulations.

Important

When the gas hob has been installed, it is

essential to check the main cable is not in

contact with hot parts of the appliance,

otherwise temperature damage to the cable

could occur.

1)

Important

This appliance with the orifices as delivered for

natural gas or LP gas by the manufacturer is

suitable for use till 2000 feet. By installation

above 2000 feet contact your distributor or Miele

USA/Canada and ask for a replacement set with

orifices suitable for your altitude.

Change the orifices as written in the instructions

of the manual.

For Canada only

The gas connection must be made in

accordance with the local codes, or in absence

of local codes, with the current CAN/CA B 149.1

and .2 Inst.

Gas pressures for Canada

Manifold pressure:

– natural gas 4˝ water column

– liquid propane gas 10˝ water column

Nominal rating natural gas 4˝

1)

Burner high setting low setting

kW Btu/hr kW Btu/hr

high-speed burner 2.7 9200 0.35 1200

super high-speed burner 3.4 12000 0.45 1500

2-zone wok burner 4.0 14000 0.17 580

Nominal rating LP gas 10˝ with conversion kit

1)

Burner high setting low setting

kW Btu/hr kW Btu/hr

high-speed burner 2.0 7000 0.40 1300

super high-speed burner 2.7 9200 0.50 2000

2-zone wok burner 3.3 11200 0.18 600

Important

a. The appliance and its individual shut-off valve

must be disconnected from the gas supply

piping system during any pressure testing of

this system at test pressures in excess of

1/2 psi (3.5 kPa).

Page 17

There may be a wall at the rear and a wall or tall

units at one side. On the other side, however, no

unit or divider may stand higher than the hob.

Building-in dimensions

Prepare a cut-out in the worktop according to

the dimensions given in the diagram above.

35 7/16" (900 mm)

20

3/16"

(515 mm)

3"

(75 mm)

19 5/16"

(490 mm)

min. 3" (75 mm)

min. 1

3/4"

(45 mm)

33

7/8" (860 mm)

Page 18

16 17

burner box

glass shield

sealing tape

wooden block

worktop

Clearance above and around the appliance

min 33 1/4" (845 mm)

min 18"

(460 mm)

min 10"

(254 mm)

min 10"

(254 mm)

min 33 1/14"

(845 mm)

For safety reasons, ensure that the following

minimum clearences are provided:

– between adjacent combustible

construction 4” (100 mm).

– between appliance and rear wall 1

3/8”

(30 mm).

– between appliance and the overhead

combustible construction 33

1/4” (845 mm).

– between appliance and front edge of worktop

2

9/16” (65 mm).

– depth of overhead cabinets must not exceed

13” (330 mm).

– between combustible constructions and the

extended cooking surface 18” (460 mm).

Wall strips must be heat-resistant.

min. 10"

(254 mm)

not allowed

not advisable

recommended

Page 19

Building-in

1. Make the cut-out in the work surface. Ensure

that there is sufficient space allowed at the

sides and at the rear.

2. Attach the sealing strip to the underside of

the hob and the aeration profile.

3.*Connect the pressure regulator supplied at

the angle-joint, ensuring that they are

positioned correctly. (See also

“Gas Connection”.)

4. Place the hob in the cut-out. Check that the

air inlets at the back of the hob are clear.

5. Secure the hob in position. The brackets

clamp underneath the work surface.

6. Make the gas connection. Check the gas

connections with a soapy solution.

7. Put the plug in the socket (see "Electrical

Connection").

8. Test to check that the hob is operational.

* Undertray is positioned on work surface.

burner box

glass shield

sealing tape

wooden block

worktop

Page 20

WARNING

This conversion kit must be

installed by a qualified service

agency in accordance with the

manufacturer's instructions and all

applicable codes and requirements

of the authority having jurisdiction.

If the information in these

instructions is not followed exactly,

a fire, explosion or production of

carbon monoxide may result,

causing property damage, personal

injury or loss of life.

The qualified service agency is

responsible for the proper

installation of this kit.

The installation is not proper and

complete until the operation of the

converted appliance is checked as

specified in the manufacturer's

instructions supplied with the kit.

Page 21

Safety Instructions

Warning

This conversion kit must be installed by a

qualified service agency.

This conversion kit is for use with Miele gas hob

KM 326G only.

Conversion kit

type number AH 102 C4U

These conversion instructions are to be used

together with the operating and installation

instructions.

Right Wrong

Check to ensure that the burner is burning

correctly. The flames should be blue and uniform.

Right Wrong

If the flames are not uniform, check to ensure that

the burner cap is properly positioned on the ring.

If the flames are irregular and yellow, check to

ensure that a pressure regulator has been

installed. Do not use the appliance and inform

the installer.

Parts

This conversion kit includes the following parts:

Part ID number Number

Burner cap A 1

Injector wok burner

outer ring 090 1

Injector wok burner inner ring 007 1

Injector super high-speed

burner C 087 2

Injector high-speed burner B 075 2

Low flame screw outer

wok burner 054 1

Low flame screw inner

wok burner 025 1

Low flame screw burner C 040 2

Low flame screw burner B 036 2

Conversion instructions

Data plate LP gas 10” W.C.

Conversion data plate

This appliance is to be converted to Propane

10” W.C. (2.491 kPa) only.

Input ratings LP gas

1918

high speed burner . . . . . . . . . . . . . 7000 Btu/hr

super high speed burner . . . . . . . 9200 Btu/hr

wok burner inner ring . . . . . . . . . . 1125 Btu/hr

wok burner outer ring . . . . . . . . .11200 Btu/hr

Page 22

Remove the three screws securing the dual ring

wok burner. Remove the wok burner base plate.

Lift the ceramic tray from the hob.

Note

Each regulator shaft is equipped with a black

ring. This ring may cling to the rubber seal in the

ceramic tray. Check and remove the rings from

the rubber seals.

For future use

Save the orifices removed from the appliance

for future use. For converting this appliance

back to Natural gas, follow the instructions and

use the numbers in brackets (… ).

Igniter

The relationship between the igniter and the

main burners can't be changed. The relationship

in the case of LP gas and natural gas is identical.

The distance between the igniter and the high

speed burner and super high speed burner is

± 3.5 mm. For the two zone

high speed burner the

distance between the

igniter and the inner ring is

± 2.5 mm.

Conversion instructions

Caution

Before proceeding with the conversion, shut off

the gas supply to the appliance prior to

disconnecting the electrical power.

Disassembly

Shut off gas supply, disconnect the manifold

pipe, disconnect the electrical power. Remove

pan supports, burner heads and burner rings.

Remove control knobs.

In the event that the hob is built in, undo the

bracket clamps underneath the work surface.

Lift the hob on to the work surface.

Unscrew the venturis on the high-speed and

super high-speed burners using a 20 mm

wrench. Lift and remove the burner rings and

burner base plates. Disconnect the wires from

the ignition plugs. Keep the wire from dropping

into the undertray by inserting it in one of the

slots in the burner supports.

Remove the top five screws in the back of the

hob undertray.

(034)

007

(170)

090

(166)

087

(145)

075

087

(166)

075

(145)

054

(100)

025

(042)

036

(055)

040

(060)

036

(055)

040

(060)

(Natural gas)

LP gas

LP gas

(Natural gas)

Page 23

Pressure regulator conversion

The pressure regulator is located on the gas

supply pipe. Unscrew and remove the brass cap

in the centre of the regulator. This gas regulator

is only adjustable for 4" and 10" gas pressure.

There is a blue plastic pin on the inside of the

cap, marked "NAT" and "LP". Pull this pin from the

cap and insert it the other way round. Snap the

pin into the cap. The pin must be positioned as in

the drawing above. The regulator is now

adjusted for propane gas 10" WC. (For natural

gas 4", turn the pin back.) Screw the cap back on

the regulator. The pressure regulator is equipped

with a separate connection for pressure testing

purposes. Check gas pressure. Permitted

pressures: min. 11" WC (5" WC, natural gas), max.

1/2 psi.

High speed and super high speed burner

conversion

Unscrew and replace injectors on the highspeed and super high-speed burners. Replace

each injector separately. Refer to illustration

“Locations of injectors and minimum adjustment

screws” for screw locations.

2120

(034)

007

(170)

090

(166)

087

(145)

075

087

(166)

075

(145)

054

(100)

025

(042)

036

(055)

040

(060)

036

(055)

040

(060)

(Natural gas)

LP gas

LP gas

(Natural gas)

Locations of injectors and minimum adjustment screws

Page 24

gaspipe

injector

A

B

Wok burner outer ring conversion

Outer ring injector (B)

The wok burner outer ring injector is located on

the right hand side of the wok burner body (B).

1. Unscrew the screw holding the brass tube to

the left of the injector. Access this screw

from the rear. Slide the brass tube to the left,

but do not insert it into the aluminium tube all

the way.

2. Use a 10 mm wrench and unscrew the outer

ring injector. Support the aluminium gas pipe

feeding the injector by holding it down, while

turning the wrench. Unscrew the injector

and replace it with the injector marked 090

(170, natural gas).

Note

Outer ring airslot (B)

Adjust the air slot on the outer ring injector now.

The correct distance for the air slot (B) is 0.083".

Slide the brass tube to the prescribed distance

and tighten the holding screw at the rear of the

tube.

Wok burner inner ring conversion

Inner ring injector (A)

The inner ring injector is located on the left

hand side of the wok burner body (A).

A

B

A

B

A

B

Page 25

2322

1. First loosen the 8 mm ring securing the gas

feed pipe. Disconnect the gas pipe. The

actual injector is a thin metal cap mounted

between the two brass fittings attached to

the left of the wok burner body.

Inner ring injector

2. Two 12 mm wrenches are needed to

separate the fittings.

Use one 12 mm wrench to keep the righthand fitting in place, while using the other

12 mm wrench to loosen the left-hand fitting.

3. With the left fitting loosened, unscrew the

right-hand fitting from the wok burner body.

4. Holding them vertical, take both fittings

apart. The metal cap with the injector will

remain on top of the lower fitting. Replace

the injector cap with the injector cap marked

007 (034, natural gas) and put the two fittings

back together.

Warning

Make sure that the natural gas injector is

removed from the fitting when the propane gas

injector is installed.

5. Screw the assembled fittings back into the

wok burner body. Carefully tighten both

fittings. Do not overtighten.

6. Reattach the gas pipe and tighten the 8 mm

ring.

Note

Inner ring air slot (A)

Adjust the air slot on the inner ring injector now.

The slot is adjusted by shifting the metal clip

around the right-hand fitting. Move the clip to

obtain a full opening of the hole (A) in the fitting.

Reference table

gaspipe

injector

A

B

LP gas

adjustment

injector screw

high-speed burner 0.75 mm 0.36 mm

0.03” 0.014”

super high-speed burner 0.87 mm 0.40 mm

0.034” 0.016”

wok burner inner ring 0.50 mm 0.25 mm

0.02” 0.01”

wok burner outer ring 0.90 mm 0.54 mm

0.035” 0.021”

natural gas

adjustment

injector screw

high-speed burner 1.45 mm 0.55 mm

super high-speed burner 1.66 mm 0.60 mm

wok burner inner ring 0.60 mm 0.42 mm

wok burner outer ring 1.70 mm 1.00 mm

Page 26

Minimum adjustment screws

1. Lift and remove the small black ring if this is

still on the regulator shaft (see note in

"Disassembly").

2. Lift and remove the square black switches.

Do not disconnect the wires from the

switches or the light emitting diodes (LED).

The wok burner is equipped with two minimum

adjustment screws, one for each burner ring.

Note

Make sure you replace both minimum

adjustment screws. Put screw 054 (100, natural

gas) on the left, 025 (042, natural gas) on the

right.

Use a small screwdriver and replace each

screw individually.

3. Put the black switches with the light emitting

diodes back in place.

4. Attach the label 'This control has been

converted for use with propane gas' to the

top of the hob undertray. Attach it as close to

the controls as possible.

5. Fill in the conversion date label and attach

conversion kit identification label close to the

appliance's original identification plate.

Note

This concludes conversion. The hob can now be

reassembled.

Assembly

1. Check that the seals are fitted on the ceramic

tray. Put the ceramic tray on the hob. Make

sure it is correctly positioned on the undertray.

Put the black ring around the regulator shaft

as shown. Press the black rings into the seals.

Put the control knobs back.

2. Put the wok burner base plate back in place.

Fasten the three screws securing the wok

burner base plate.

3. Connect the wires to the ignition plugs. Put

the high-speed and super high-speed burner

base plates and burner rings back. Fasten

the high-speed and super high-speed

venturis using a 20 mm wrench.

(034)

007

(170)

090

(166)

087

(145)

075

087

(166)

075

(145)

054

(100)

025

(042)

036

(055)

040

(060)

036

(055)

040

(060)

(Natural gas)

Propane gas

Propane gas

(Natural gas)

Page 27

2524

Installing appliance

1. Install the appliance according to the

installation instructions.

2. Attach the moulding at the rear to the

undertray. Put the hob back in the work

surface and fasten the bracket clamps

underneath the work surface.

3. Set the gas pressure regulator to a new

pressure of 10” WC (4" WC, natural gas).

Check pressure (see page 21). Permitted

pressures: minimum 11” WC (5" WC, natural

gas), max. 1/2 psi.

4. Reconnect gas supply, reconnect the manifold

pipe, reconnect the electrical power.

5. Put the burner heads and pan supports in

place. Make sure the burner heads are

mounted the right way. Put the burner head

marked "A" on top of the wok burner.

Testing converted appliance

Note

This appliance has been internally tested for gas

leakages by the manufacturer.

Caution

Check converted hob for gas leaks. Check the

connection with a soapy solution. Never use a

flame of any sort.

Check that the hob functions normally:

Turn on the gas supply and plug in the power

supply cord.

Light each of the burners individually.

When the burner is at low setting, or when the

control knob is turned quickly from 'high' to 'low',

the flame should not go out.

When set at 'high', the gas flame must burn with

the center clearly visible.

(034)

007

(170)

090

(166)

087

(145)

075

087

(166)

075

(145)

054

(100)

025

(042)

036

(055)

040

(060)

036

(055)

040

(060)

(Natural gas)

Propane gas

Propane gas

(Natural gas)

Locations of injectors and minimum

adjustment screws

Page 28

Warranty and service

The warranty period is effective from the date of purchase of the appliance.

All malfunctions caused by installation errors, improper use or maintenance are excluded from the

guarantee.

Evidence of the date of purchase must be provided upon request, for example through a delivery slip

or sales receipt.

In the event of any fault with this appliance, please contact:

your Miele Dealer, or

the Miele Service Department, the address of which is shown on the back page.

When contacting the Service Department, please quote the Model and Serial numbers of your

appliance. You will find both on the data plate located on the underside of the appliance.

Page 29

Technical details

Model number: KM 326G

Gas source: see identification plate

Energy source: 120 V - 60 Hz

Overall wattage, electricity: 3 VA

Total burnerrate

Natural gas 56400 Btu/hr (16.2 kW)

Liquid propane gas 43600 Btu/hr (12.78 kW)

This appliance with the orifices as delivered for

natural gas or LP gas by the manufacturer is

suitable for use till 2000 feet. By installation

above 2000 feet contact your distributor or Miele

USA/Canada and ask for a replacement set with

orifices suitable for your altitude.

Change the orifices as written in the instructions

of the manual.

.

Page 30

art.nr. 722.392.20/T91701B

Page 31

art.nr. 722.392.20/T91701B

Page 32

Alteration rights reserved / 2503

This paper is made from cellulose bleached without the use of chlorine.

01

Loading...

Loading...