Page 1

Operating Instructions

Industrial cleaner

IR 6001

To prevent accidents

and machine damage,

read these

instructions before

installation or use. M.-Nr. 04 271 821

UV

Page 2

Table of Contents

Guide to the machine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

IMPORTANT SAFETY INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

IMPORTANT SAFETY INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . Center pages

Description of the machine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

MCU-control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

First Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Setting the water hardness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Loading and unloading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Adding detergent. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Venting the dispensing systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Altering the temperature and drying time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Key switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Turning on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Program sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Interrupting a program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Turning off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Applications Electronics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Applications Metal Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Applications Optics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Applications Particle Decontamination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Reactivating the water softener . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Serial interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Cleaning and Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Drying unit: Cleaning and Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Correcting minor faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Help to protect our environment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

2

Page 3

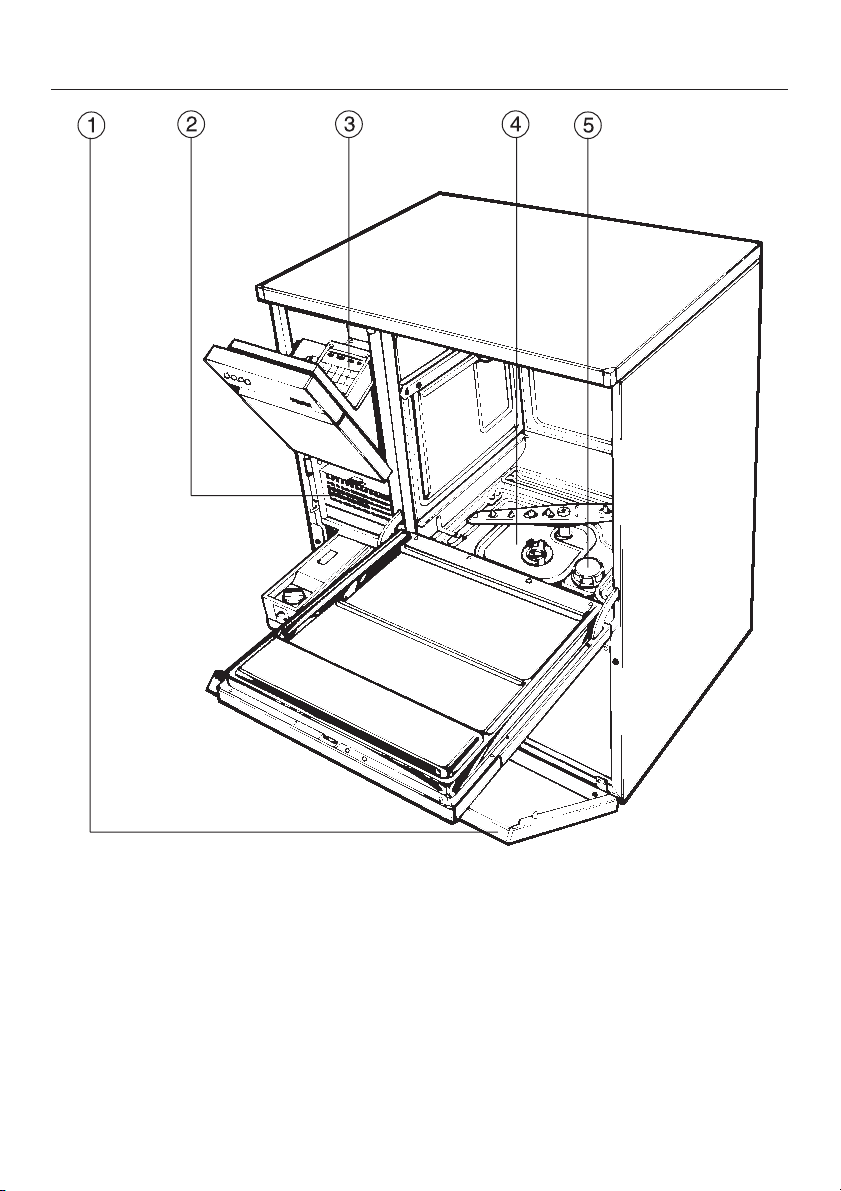

Guide to the machine

a Service Panel

b TA Drying unit

c MCU

d Filter combination

e Reactivation socket for salt

container (water softener)

3

Page 4

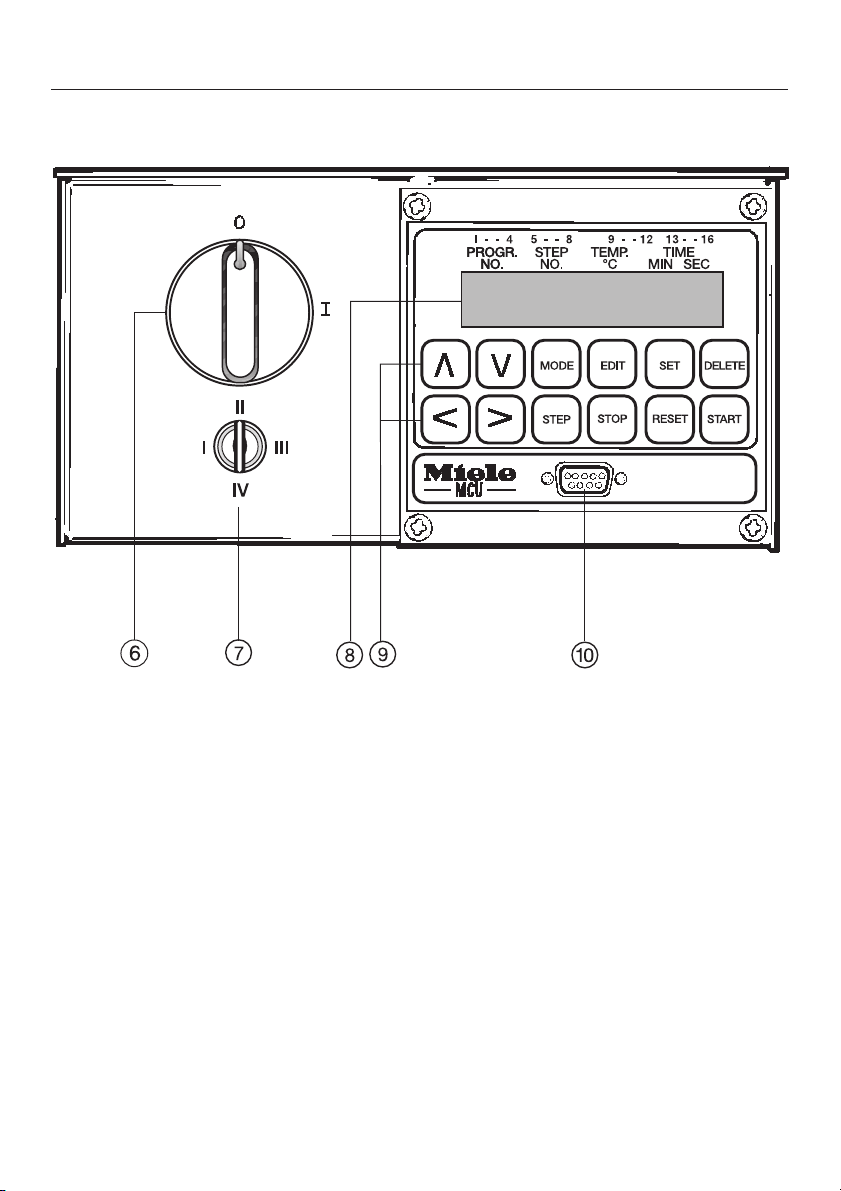

Guide to the machine

MCU

f Main power switch

g Key switch

h Display field

i Operating control pad

j Serial interface

4

Page 5

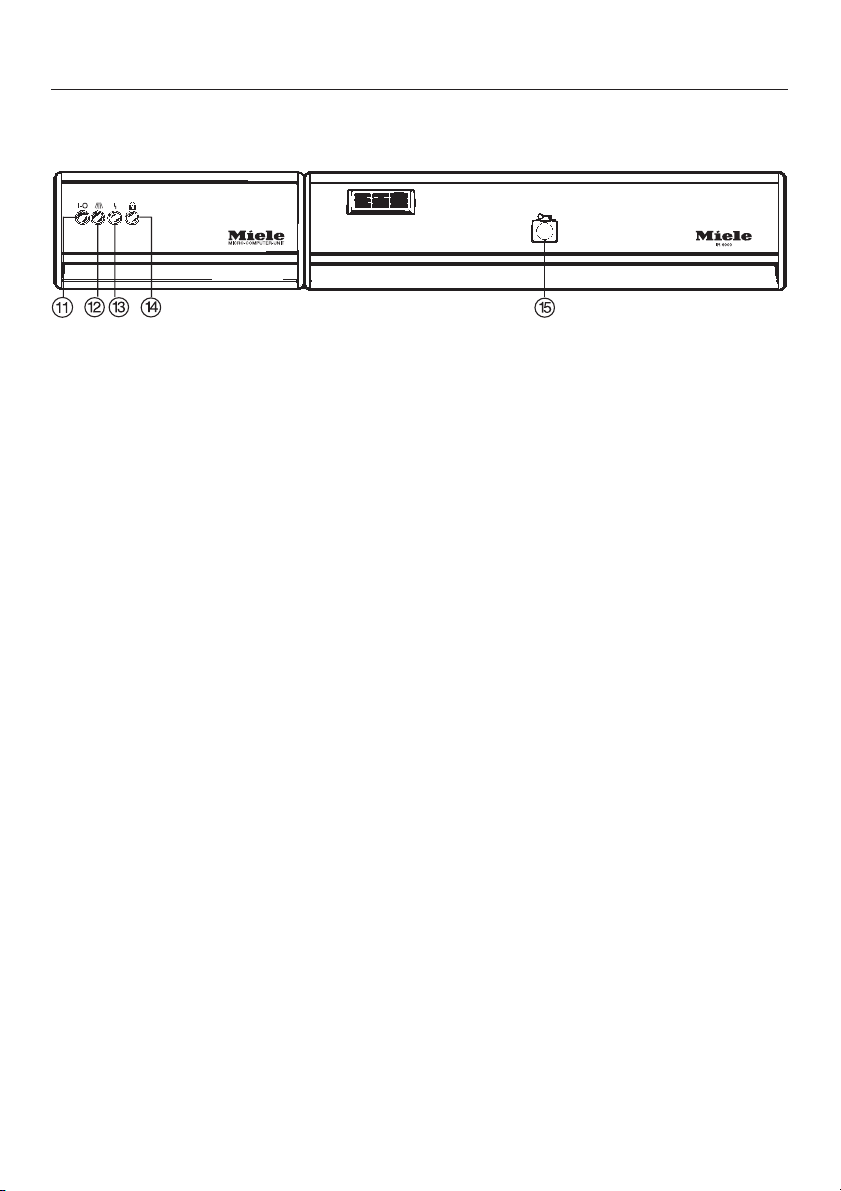

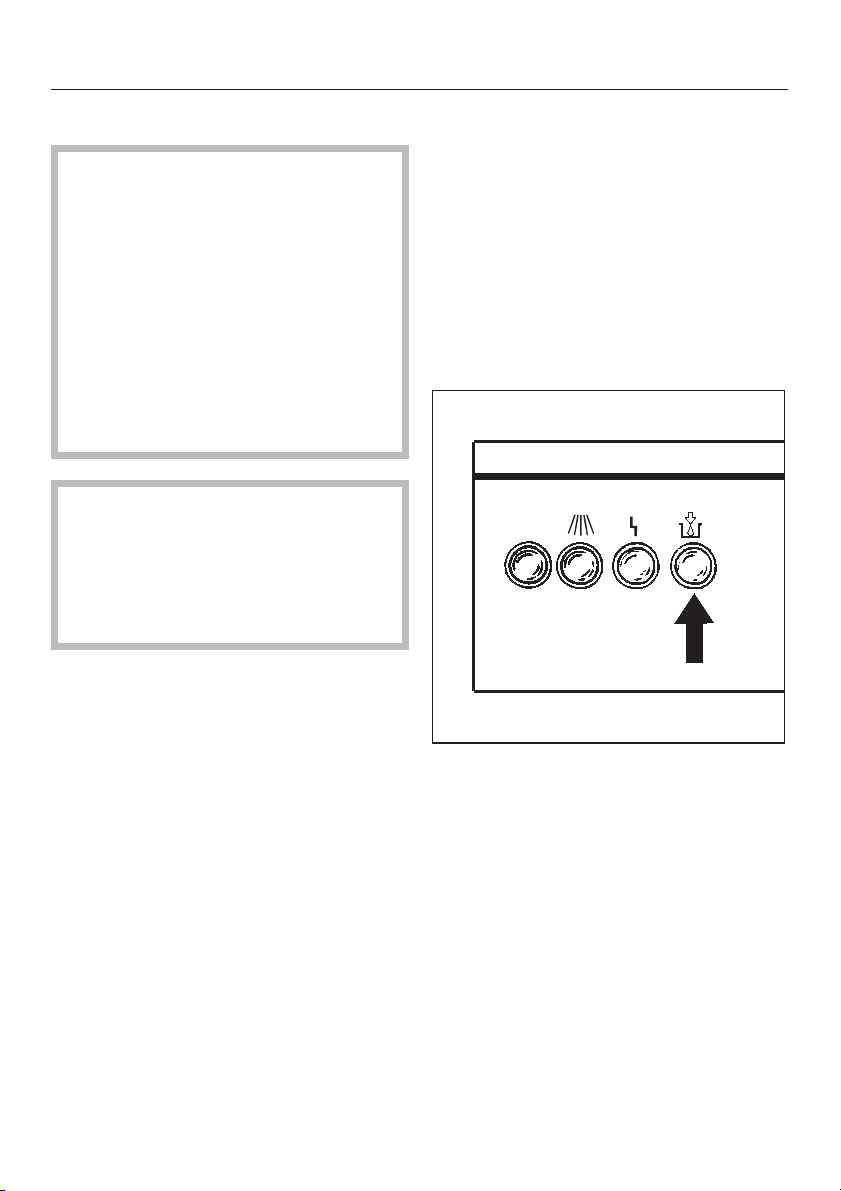

Control indicators

k "On/Off" indicator light

l "In operation" indicator light

m "Fault-Error" indicator light

n "DOS dispenser level" indicator light

o Door release

Guide to the machine

5

Page 6

IMPORTANT SAFETY INSTRUCTIONS

When using an electrical appliance, basic precautions should alwas be followed,

including the following:

READ ALL INSTRUCTIONS BEFORE

USING THE APPLIANCE

Before any maintenance or repair

WARNING -

The manufacturer cannot accept re

sponsibility for damage caused when

the appliance is not used according

to the instructions, or for uses other

than those for which it was intended.

This machine is designed for com-

mercial use and for specialized applications only, as described in these

Operating Instructions. Using it for purposes other than those for which it is

designed could cause damage or injury.

The manufacturer cannot be held responsible for any damage caused by

improper use.

Keep these instructions in a safe place

for future reference.

Please pay attention to the following

notes to maintain safe procedures.

-

work is undertaken, the machine

must be unplugged or disconnected

from the main power supply or the cir

cuit breaker.

A damaged machine is dangerous.

Turn off the power immediately and

call an authorized Miele Service technician.

Unauthorized personnel should not

be allowed access to the machine

or its controls.

Take care when handling liquids

such as detergents, wetting

agents, or neutralizing agents. These

may contain irritant or corrosive ingredients, acids or alkalis. Never use any or

ganic solvent, as the danger of an ex

plosion exists.

Follow all safety instructions. Wear

protective gloves and goggles.

-

-

-

Dot not install the machine in an

area where a danger of explosion

may be present.

The machine should be installed,

repaired and maintained by an au

thorized Miele Service technician. Re

pairs by unqualified persons could be

dangerous.

6

-

-

Page 7

IMPORTANT SAFETY INSTRUCTIONS

The water in the machine must not

be used as drinking water.

Do not sit or lean on the open door,

or rest objects on it. This could

cause the machine to tip and be dam

aged.

Be careful when sorting items with

sharp pointed ends. Position them

in the machine so that you do not hurt

yourself or create a danger for other

operators.

When using this machine at tem

peratures between 158 °F and

203 °F (70 °C and 95 °C) be especially

careful not to scald or burn yourself.

Baskets and inserts must first cool

down. Any water which may remain in

containers will be very hot and should

be emptied into the wash cabinet.

At the end of the drying cycle open

the door to allow the wash load

and inserts to cool down.

Do not touch the heating elements

during or directly after the end of a

program. You could burn yourself.

Never use a hose or steam cleaner

on or near the machine.

When disposing of an old machine,

first make it unusable. Disconnect

the power cord and cut off the plug. For

environmental and safety reasons en

sure the machine is completely drained

of any residual water and cleaning

agent. Make the door lock inoperative,

so that children cannot accidentally

shut themselves in.

-

-

-

The following points should be ob

served to avoid damage to the

IR 6001 and the loads being cleaned.

Use only cleaning agents formu

lated for special processes and

approved by Miele for use with this ma

chine. Use of unsuitable cleaning

agents could adversely affect the load

or the machine. See the enclosed pam

phlet for recommended detergents.

When a chemical additive is rec

ommended, the manufacturer of

the machine takes no responsibility for

the effect of the chemical on the mate

rial of the items being cleaned. Please

be aware of changes in formulation,

storage conditions, concentrations,

etc., which may not be publicized by

the chemical producer, can have a negative effect on the cleaning result.

The machine is designed for oper-

ation with water and cleaning

agents only. Organic solvents must not

be used in the machine, as the danger

of explosion exists under certain cir

cumstances. Although this is not the

case with all organic solvents, other

problems could arise with their use, for

example damage to rubber and syn

thetic materials.

-

-

-

-

-

-

-

-

7

Page 8

IMPORTANT SAFETY INSTRUCTIONS

In critical applications where strin

gent requirements have to be met,

it is strongly recommended that all pro

cess parameters, such as cleaning

agent or quality of water, are discussed

with the Miele Application Technology

specialists.

If the clean objects are subject to

particularly stringent requirements

(e.g. chemical analysis, industrial pro

cesses), a regular quality control test

should be carried out by the user to en

sure that required standards of cleanli

ness are being achieved.

Do not allow any remains of acids,

solvents, or chloride solutions to

get into the wash cabinet. Similarly,

avoid any materials with a corrosive effect. Their presence as compounds in

any solvents should be minimal (especially those in hazard class A1).

To avoid corrosion, ensure that so-

lutions or steam containing acid

salts do not come into contact with the

outer steel casing of the machine.

Do not use any cleaning agent

which adheres to file dust or filings.

Depending on the type and shape of

the file dust, this could damage the cir

culation pump, or cause contact corro

sion.

-

-

-

-

-

Empty any containers before load

ing them into the IR 6001.

Use special inserts in accordance

with the instructions provided.

Waste water must be discharged in

accordance with national and local

water regulations. Consult your local

water authority. Where discharge is in

direct, ensure that the waterborne resi

dues do not exceed statutory limits.

Only equipment made or autho

rized by Miele should be con

nected to this machine. Consult Miele

on the type and application of such

equipment.

SAVE THESE

INSTRUCTIONS

A second set of Safety Instructions

suitable for posting can be found in

the centerfold.

-

-

-

-

-

-

-

8

Page 9

Description of the machine

Applications

The Industrial Cleaner is designed for

specialized sectors of industrial high

technology production, where a consis

tently high standard of cleaning is re

quired, and where the structure of the

items to be cleaned may be complex.

Areas of application are:

Electronics, such as circuit boards

–

and solder frames

Metal cleaning

–

Optics

–

– Particle decontamination

-

Cleaning process

The Industrial Cleaner works on the

principle of fresh water circulation. The

bath time for cleaning and rinsing is

approx. 20-30 minutes. Drying is effected by means of an integrated drying unit. A period of 15 to 45 minutes

must be added to the above time to

thoroughly dry the batch, depending on

the heat retention capacity of the items

in the load and the amount of water re

maining.

-

Water recycling

The IR 6001 comes equipped with a

two stage drainage system, and a

pump to bring rinse water back into the

machine, enabling it to be re-used.

Rinse water which is still quite clean, for

example from the final rinse, can be di

rected into an external holding tank and

be fed back into the machine for the fol

lowing pre-wash or main wash cycle.

The holding tank does not come with

the machine, and must be supplied

on-site. The water from the pre-wash

and main wash is normally discharged

into the waste water system, or into an

effluent treatment plant. The separate

booklet "MCU Program Summary" explains how to program this feature.

-

-

The machine can be programmed, and

a variety of baskets and inserts used,

depending on specific needs.

Special cleaning programs can be writ

ten for individual applications.

-

9

Page 10

Description of the machine

MCU-control

The Industrial Cleaner is controlled by a

micro computer unit. This ensures

maintenance of wash process stan

dards by displaying the current stage of

the process, or an error message if

there is a fault.

The controls can be programmed for a

range of individual applications; for ex

ample, time, temperature, water quality,

dispensing to various liquid detergents

and additives. This enables the user to

adapt the process to individual require

ments. With a large memory capacity,

up to 64 different programs can be

stored and the selected according to

the load to be cleaned. Different keys

are used with the key switch to restrict

access to the operating and programming options.

The control unit has two serial interfaces to allow wash parameters to be

monitored or documented through the

use of a printer or PC (not supplied).

Should your needs change, or the machine be needed for other applications,

different programs can be designed

with the help of Miele.

-

-

-

10

Page 11

First Use

Setting the water hardness

Before using the machine for the first

time the regeneration parameters must

be set by the service technician ac

cording to the local water hardness

level (see MCU operating and program

ming manual).

The local water authority can advise

you of the water hardness in the area.

-

Loading and unloading

Press the door release button and, at

^

the same time, grasp the grip rail and

open the door.

^ Load the items into their respective

baskets and inserts.

See pages on the individual applications for details on loading the machine.

Automatic coupling

The machine is supplied as standard

with an automatic spring-loaded coupling for either the upper basket or a

mobile unit.

Make sure the spring loaded cou

pling engages correctly when a bas

ket, injector or mobile unit is inserted

into the machine, it should be

higher than the water inlet in the roof

of the cabinet. If it is not, adjust the

adapter by:

-

-

3

/8"

Loosening the lock ring.

^

3

Pushing up the adapter (

^

than the water connection inlet) and

re-tightening the lock ring.

-

Removing the upper basket

When the lower basket is being used

alone for large items such as solder

frames, the large spray arm supplied

with the machine should be attached

the water inlet on the roof of the cabi

net.

Remove the upper basket by pulling

^

it forward to the stop position, lifting it

up to the front, and then out of the

wash cabinet.

^ Unscrew the small upper spray arm

retainer and remove the small upper

spray arm.

^ Install the large upper spray arm with

its threaded spindle flange.

Important

Please note that only top baskets,

mobile units or injector nozzle

should be coupled without a spray

arm.

For other applications the small

spray arm should be re-installed.

/8" higher

-

11

Page 12

First Use

Adding detergent

Only use cleaning agents formulated

for special processes and approved

by Miele for use with this machine.

Use of unsuitable cleaning agents

could adversely affect the load or

the machine. Please see the en

closed pamphlet for a list of tested

and recommended cleaning agents

and additives. If you have questions

regarding the suitability of a deter

gent, please contact the Miele Appli

cations Department.

Exercise caution when handling

,

liquid additives. These can contain

irritant or corrosive ingredients.

Take care to ensure that necessary

safety precautions are observed.

Wear protective goggles and gloves

The IR 6001 comes standard with 3

DOS pumps for automatic dispensing

of liquid additives:

-

-

Filling the containers with liquid ad

ditive

The IR 6001 has suction tubes for use

with the external detergent containers.

Select the stopper with the appropriate

thread (depending on the size of the

container). The suction tube length can

be adjusted (see note supplied).

When the containers are full, the DOS

level indicator light v goes out.

-

I-O

-

–

DOS 10/30 injector pump for dis

pensing acid additives. Dispensing

capacity is 10 ml/30 secs (channel

9).

–

2 DOS 60/30 injector pumps for dis

pensing liquid cleaning agent. Dis

pensing capacity is 60 ml/30 secs

(channels 6 and 8).

12

The containers for liquid cleaning

agents must be filled or the DOS level

indicator light v will stay on.

If a dispensing system is not used, the

service technician should remove the

plug connection for this system, to pre

vent the DOS indicator light from stay

ing on.

-

-

Page 13

The containers should not be al

lowed to empty completely and

should be filled regularly, otherwise

the first wash cycle after refilling will

take place without detergent.

The internal dispenser pump hoses

are subject to wear and should be

replaced as preventative mainte

nance every 12 to 18 months.

-

-

First Use

Venting the dispensing

systems

Before using the machine for the first

time, the air has to be expelled from the

dispensing system.

This should also be done if the con

tainer has not been refilled in time and

the despensing system was allowed to

empty completely.

Close the door.

^

Set the key switch to position II.

^

Turn the main switch to I.

^

^ Select program 14 (DOS-FILL/

DOS-FUELL) using the key pads O

or M. "14 DOS-FILL" (or DOS-FUELL)

appears in the display field.

^ Press the START key pad.

^ Repeat the program serveral times if

necessary.

-

Altering the temperature and

drying time

The temperatures for cleaning and dry

ing, as well as the drying times, are

strored for each program (see program

summary supplied).

To change the stored values:

^

Turn the key switch to setting II.

^

Turn the main swich to I.

^

Select the program (see Turning on).

-

13

Page 14

First Use

Altering temperature T1, from 201 °F

to 185 °F (94 °C to 85 °C) (example)

Touch pad

P XXX T1 094

U XXX T1 094

O XXX T1 093

O XXX T1 092

O XXX T1 085

S XXX T1 085

S XXX PROGRAM NAME

Display

XXX PROGRAM NAME

Altering the TA drying temperature

from 194 °F to 176 °F (90 °C to 80 °C)

(example).

Touch pad

P XXX T1 094

P XXX T2 070

P XXX TA 090

U XXX TA 090

N XXX TA 090

O XXX TA 08

S XXX TA 080

S XXX PROGRAM NAME

_ = number flashes

Display

XXX PROGRAM NAME

0

_ = number flashes

XXX = program number selected

Altering the T2 temperature

Start by pressing the touch pad P

twice, then proceed as for temperature

T1.

Note:

Header parameters which have not

been programmed do not appear in the

display.

14

XXX = program number selected

Page 15

Altering the ZA drying time from

30 min to 40 min. (example).

First Use

Touch pad

P XXX T1 094

P XXX T2 070

P XXX TA 090

P XXX ZA 030

U XXX ZA 031

M XXX ZA 031

M XXX ZA 032

M XXX ZA 040

Display

XXX PROGRAM NAME

S XXX ZA 040

S XXX PROGRAM NAME

_ = number flashes

XXX = program number selected

15

Page 16

Operation

Key switch

The following choices can be selected

with the four position key switch, using

the three keys provided:

I = fixed program

(key can be removed)

II = free program selection

III = programing

(see operating and programming

manual).

IV = service mode

(see operating and programming

manual).

A

B

Turning on

1. Free program selection

Key switch setting: II.

^

Turn main switch to I (on).

^

Select program with keys O or M:

^

The program description appears in the

display field.

1 Wafer chip. . . . . . . . . . WAFER-CHIP

2 Semiconductors . . . . . HALBLEITER

3 Solder frames . . . . . . LOETRAHMEN

4 PCB Rosin. . . . . . . . . . . . . . LEI-KOL

5 PCB water . . . . . . . . . . LEI-WASSER

6 Metal . . . . . . . . . . . . . . . . . . METALL

7 PCB oil. . . . . . . . . . . . . . . . . LEI-OEL

10 Fill . . . . . . . . . . . . . . . . . . . FUELLEN

11 Empty . . . . . . . . . . . . . . ENTLEEREN

12 PREFILTER TA *) . . . GROBFILTER *)

The slot in the keyhole (A) points to the

switch position selected (B).

Three keys are supplied, numbered

separately 1, 2 and 3:

Key 1 for switch settings I, II

Key 2 for switch settings I, II, III

Key 3 for switch settings I, II, III, IV

16

13 S-FILTER ta *). . . . . . . FEINFILTER *)

14 DOS-FILL . . . . . . . . . . . DOS-FUELL

15 REGENERATE . . . . . . REGENERIER

*) Only visible when using swich setting

III or IV.

For detailed information on the pro

grams see the supplied program sum

mary.

^

Press the START touch pad.

If the selected program is desired as a

fixed program

^

Turn the key switch to position I.

The key can then be withdrawn.

, it can be stored:

-

-

Page 17

Operation

2. Starting a fixed program

Key switch to position I.

^

Turn main switch to I (On).

^

The pre-selected program appears in

the display field.

Press the START touch pad.

^

The l in operation indicator light co

mes on to show that the machine is run

ning a program.

Note:

If several programs are required as

fixed programs, (i.e. switchable with

key setting I), consult the programming

manual under PROG-SELECTION.

The program parameters (codetext)

can be read off the display without activating any further functions:

00 6 0 0 3 0 0 7 8 1 5 1 0

12 34

1. Program number

-

Program sequence

After starting, the program proceeds

automatically. It is finished when the in

operation light l goes out.

y The Fault-Error indicator light

will come on if the system has been in

terrupted during operation.

-

The cause of the interruption is shown

in the display field as an error mes

sage.

The following error messages are possi

ble:

ERR DOOR

The door has been opened during the

wash program.

ERR INFLOW

Water intake has been impeded (closed

valve, clogged filters, etc.)

ERR DRAIN

Water is not draining freely (kinked

hose, sewer blockage, etc.)

ERR TEMP

Temperature not reached in prescribed

time. Call Miele Technical Service Dept.

-

-

-

2. Current program step

3. Current temperature

4. Remaining step time in minutes and

seconds

Touch the MODE pad to see the current

program segment, (pre-wash, main

wash, interim rinse, final rinse, drying)

or the Codetext.

ERR T-SENSOR

Defective sensor. Call Miele Technical

Service Dept.

ERR PUMP-PRG

Programming fault: several pumps were

activated simultaneously in one pro

gram step.

ERR KEY

Defective key switch. Call Miele Techni

cal Service Dept.

-

17

-

Page 18

Operation

ERR WATER-PRG

Programming fault: more than one

water inlet valve has been activated in

one program step, or an inlet valve has

not been activated in combination with

the circulation pump.

ERR WATERINF

Water inflow time is insufficient. In

crease the ADD-WATER time in the sys

tem parameters.

ERR BATTERY

Change the lithium battery within 4

weeks after this message.

^ If possible, reset the fault and start

the program again.

When the following operating mes-

sages appear in the display, the appropriate action must be taken:

GROBFILTER (PREFILTER)

Change the coarse filter in the drying

unit (see page on drying unit maintenance). Then reset the filter display

message.

^

Key switch position III or IV.

^

Use touch pad O or M to select pro

gram 12 GROBFILTER (Coarse filter).

^

Press the START button.

FEINFILTER (HEPA-Filter)

Call the Miele Technical Service Dept to

change the particle filter in the TA dry

ing unit. (See page on drying unit main

tenance.)

REGENERIER (REGENERATE)

-

-

Interrupting a program

Once a program has been started, it

should only be interrupted in an emer

gency or if the items are moving about

noisily due to incorrect loading.

The machine must be turned off, the

water drained from the wash cabinet

and the program re-started.

Turn the main switch to 0 (off).

^

Wait 5 seconds, the turn the main

^

switch to I (on).

DRAIN is displayed if there is water in

the machine (the water is then pumped

away).

OR the program parameters are displayed with a flashing step time (no

water in the machine).

^ Key switch position II.

^ Press the RESET touch pad.

^ Open the door and arrange the items

properly.

^

Shut the door.

^

Start the program again.

-

Turning off

On completion of the program the ON

indicator light l goes out. If the ma

chine is not to be used again:

^

Turn the main switch to 0 (off). This

disconnects the machine from the

main power supply.

^

Turn off the faucets (water supply).

-

-

Replenish the water softener with salt

(see Reactivating water softener).

18

Page 19

Electronics

Populated circuit boards and solder

frames require cleaning that takes into

account product specifications and the

soldering processes used.

Circuit boards

Circuit boards can be cleaned of resin

residues in the machine. The results

depend on the type of flux used. For in

dividual application, Miele recommends

consultation with cleaning technology

advisors. Cleaning is generally per

formed with tenside additives (0.5 -

0.7% at 149 °F - 167 °F (65 °C - 75 °C)).

The wash/rinse process consists of several stages and purified ion-free water

is used throughout (DI-water).

For surface mount or hybrid technology,

the use of water soluble soft solder

paste is recommended. A high standard of cleaning can then be achieved

by using water and variable temperature washes. This also applies to integrated circuit boards. The time for a

cleaning program is approx. 30 minutes

for the wash phase and 40 - 50 minutes

for the drying phase, depending on the

structural complexity and volume of the

load.

-

Applications Electronics

-

Top basket O 500-10

Baskets designed for circuit boards are

made of plastic coated stainless steel.

These are the O 500-10 top basket and

U 500-10 bottom basket, which to

gether can hold 73 PCBs.

-

Bottom basket U 500-10

19

Page 20

Applications Electronics

Solder frames

Depending on the type of soil, an alka

line cleaning agent at a low concentra

tion of 0.3 - 0.5%, a neutralization agent

or wetting agent (0.1%), is used.

With aluminum solder frames, using

de-ionized water (either throughout or

in the final rinse, depending on quality

standard required) reduces the risk of

damage to the material, which may be

adversely affected by non-purified

water after prolonged use.

Example:

W 16

8 solder frames (L 1811/16" x

29

/32" x D 131/32") (L 475 mm x

W 430 mm x D 45 - 50 mm) can be

cleaned and dried in the machine

within 30 minutes if operated with a hot

water intake of 149 °F (65 °C).

Sample configuration:

Lower basket U 874 with E 500 insert.

-

Insert E 500

20

Page 21

Applications Electronics

Application,

Material/

Soiling

Program P 004

Wash

temperature

T1 (°C)

Wash

temperature

T2 (°C)

Cleaning agent

Concentration

for use

Neutralizer

Concentration

for use

Notes a second

1)

circuit

boards

flux with

resin

LEI-KOL

65 - 75 65 - 75 75

65 65 - 75 65 - 75 65 - 75

1)

neutral,

with tensides

2)

0.5 - 0.7 %

2)

cleaning

agent may be

necessary

circuit

boards

water soluble

flux

P 005

LEI-WASSER

where foam

occurs use

silicone-free

anti-foaming

agent

solder

frames

flux with

resin

P 003

LOETRAHMEN

3 - 10 minutes

alkaline,

with silica

0.5 %

anti-foam

additive

required

slightly acidic,

citric or

phosphoric

acid base

0.1 - 0.15 %

do not use neutralizers if susceptible steel

items are cleaned on the frames

(Delete Step 11), and set T2 to 65 °C.

solder

frames

water soluble

flux

P 003

LOETRAHMEN

65 - 75

alkaline,

with silica

0.5 %

anti-foam

additive not

always required

slightly acidic,

citric or

phosphoric

acid base

0.1 - 0.15 %

1) Characteristics of cleaning and neutralizing agents are given, not product names.

2) Concentration for use = percentage of the chemical additive in the wash water solution

Water requirement / wash cycle = approximately 15 liters, e.g.:

0.1 % = 0.5 fl.oz. (15 ml) or 15 g amount to be dispensed

0.3 % = 1.6 fl.oz. (45 ml) or 45 g amount to be dispensed

0.5 % = 2.6 fl.oz. (75 ml) or 75 g amount to be dispensed

0.7 % = 3.7 fl.oz. (105 ml) or 105 g amount to be dispensed

21

Page 22

Applications Metal Cleaning

Cleaning metal

The machine can be used for cleaning

products requiring degreasing, removal

of dust or polishing/grinding paste, or

pre-treatment before painting or galva

nizing.

Cleaning agents and wash parameters

can be selected according to the prop

erties of the iron, steel or non-ferrous

metal. A test wash is advisable with pol

ishing/grinding pastes to identify the

most suitable cleaning processes.

-

-

-

A final rinse with de-ionized water is of

ten necessary, especially with non-ferrous metals, to achieve the cleaning result required.

Make sure that no file dust or

,

other fillings, (from drilling, milling

etc), especially from iron based materials, are introduced into the machine.

The upper basket O-188 and lower

basket U 874 are recommended as a

basic basket set for the machine.

-

22

Page 23

IMPORTANT SAFETY INSTRUCTIONS

To the person responsible for the machine:

Make this pull-out with the Warning and Safety Instructions available to any op

^

erators of the machine. Place it near the machine, where it can be seen.

Ensure that operators know and understand these Warning and Safety Instruc

^

tions, and observe them in use.

When using an electrical appliance, basic precautions should always be followed,

including the following:

READ ALL INSTRUCTIONS BEFORE

USING THE APPLIANCE

Please pay attention to the following

WARNING -

The manufacturer cannot accept responsibility for damage caused when

the appliance is not used according

to the instructions, or for uses other

than those for which it was intended.

This machine is designed for com-

mercial use and for specialized applications only, as described in these

Operating Instructions. Using it for pur

poses other than those for which it is

designed could cause damage or in

jury.

The manufacturer cannot be held re

sponsible for any damage caused by

improper use.

Keep these instructions in a safe place

for future reference.

notes to maintain safe procedures.

Dot not install the machine in an

area where a danger of explosion

may be present.

The machine should be installed,

repaired and maintained by an authorized Miele Service technician. Repairs by unqualified persons could be

dangerous.

-

-

-

Before any maintenance or repair

work is undertaken, the machine

must be unplugged or disconnected

from the main power supply or the cir

cuit breaker.

A damaged machine is dangerous.

Turn off the power immediately and

call an authorized Miele Service techni

cian.

-

-

-

-

1

Page 24

IMPORTANT SAFETY INSTRUCTIONS

Unauthorized personnel should not

be allowed access to the machine

or its controls.

Take care when handling liquids

such as detergents, wetting

agents, or neutralizing agents. These

may contain irritant or corrosive ingredi

ents, acids or alkalis. Never use any or

ganic solvent, as the danger of an ex

plosion exists.

Follow all safety instructions. Wear

protective gloves and goggles.

The water in the machine must not

be used as drinking water.

Do not sit or lean on the open door,

or rest objects on it. This could

cause the machine to tip and be damaged.

Be careful when sorting items with

sharp pointed ends. Position them

in the machine so that you do not hurt

yourself or create a danger for other

operators.

-

When using this machine at tem

peratures between 158 °F and

203 °F (70 °C and 95 °C) be especially

careful not to scald or burn yourself.

Baskets and inserts must first cool

down. Any water which may remain in

containers will be very hot and should

be emptied into the wash cabinet.

At the end of the drying cycle open

the door to allow the wash load

and inserts to cool down.

Do not touch the heating elements

during or directly after the end of a

program. You could burn yourself.

Never use a hose or steam cleaner

on or near the machine.

When disposing of an old machine,

first make it unusable. Disconnect

the power cord and cut off the plug. For

environmental and safety reasons ensure the machine is completely drained

of any residual water and cleaning

agent. Make the door lock inoperative,

so that children cannot accidentally

shut themselves in.

-

2

Page 25

IMPORTANT SAFETY INSTRUCTIONS

The following points should be ob

served to avoid damage to the

IR 6001 and the loads being cleaned.

Use only cleaning agents formu

lated for special processes and

approved by Miele for use with this ma

chine. Use of unsuitable cleaning

agents could adversely affect the load

or the machine. See the enclosed pam

phlet for recommended detergents.

When a chemical additive is rec

ommended, the manufacturer of

the machine takes no responsibility for

the effect of the chemical on the mate

rial of the items being cleaned. Please

be aware of changes in formulation,

storage conditions, concentrations,

etc., which may not be publicized by

the chemical producer, can have a negative effect on the cleaning result.

The machine is designed for oper-

ation with water and cleaning

agents only. Organic solvents must not

be used in the machine, as the danger

of explosion exists under certain cir

cumstances. Although this is not the

case with all organic solvents, other

problems could arise with their use, for

example damage to rubber and syn

thetic materials.

-

-

-

-

-

-

In critical applications where strin

gent requirements have to be met,

it is strongly recommended that all pro

cess parameters, such as cleaning

agent or quality of water, are discussed

with the Miele Application Technology

specialists.

If the clean objects are subject to

-

particularly stringent requirements

(e.g. chemical analysis, industrial pro

cesses), a regular quality control test

should be carried out by the user to en

sure that required standards of cleanli

ness are being achieved.

Do not allow any remains of acids,

solvents, or chloride solutions to

get into the wash cabinet. Similarly,

avoid any materials with a corrosive effect. Their presence as compounds in

any solvents should be minimal (especially those in hazard class A1).

To avoid corrosion, ensure that so-

lutions or steam containing acid

salts do not come into contact with the

outer steel casing of the machine.

Do not use any cleaning agent

which adheres to file dust or filings.

Depending on the type and shape of

the file dust, this could damage the cir

culation pump, or cause contact corro

sion.

-

-

-

-

-

-

-

3

Page 26

IMPORTANT SAFETY INSTRUCTIONS

Empty any containers before load

ing them into the IR 6001.

Use special inserts in accordance

with the instructions provided.

Waste water must be discharged in

accordance with national and local

water regulations. Consult your local

water authority. Where discharge is in

direct, ensure that the waterborne resi

dues do not exceed statutory limits.

Only equipment made or autho

rized by Miele should be con

nected to this machine. Consult Miele

on the type and application of such

equipment.

-

-

SAVE THESE

INSTRUCTIONS

-

-

-

4

Page 27

Applications Metal Cleaning

Application

Material/

Soiling

Program P 006 METALL or

Wash

temperature

T1 (°C)

Wash

temperature

T2 (°C)

Cleaning

1)

agent

Concentration

for use

Neutralizer

Concentration

for use

Notes If a neutralizer is needed, select P 006, delete Step 5 (P 006),

stainless

steel

oil, grease,

particles etc.

P 007 LEI-OEL

65 - 75

(2 - 10 min)

65 - 75 50 - 65 50 - 60 40 - 50

mildly alkaline, to

highly alkaline

2)

0.3 - 0.5 %

also possible:

alkaline with silica

and neutral

(see Aluminum)

0.3 - 0.5 %

1)

not always

necessary to

neutralize

with a phosphoric

acid product

when using

alkaline cleaner

2)

0.1 - 0.15 %

and add a Step (Channel 9 and 14) between Steps 11 and

12 (P 006).

If no neutralizer and only a small amount (0.3 %) of cleaning

agents is dispensed, select P 007.

If the cleaning agent is low-foam delete Step 4 (P 007).

Aluminum

oil, grease,

particles etc.

P 006 METALL or

P 007 LEI-OEL

55 - 70

(2 - 5 min)

neutral or alkaline

with silica

(3-5 ml) use

only alkaline

product with

silica

sometimes

necessary for

a citric acid

based neutralizer

when using

alkaline cleaner

with silica

0.1 - 0.15 %

bright metal,

eg. brass,

oil, grease,

particles etc.

P 006 METALL or

P 007 LEI-OEL

55 - 65

(2 - 5 min)

neutral to alkaline

0.3 - 0.5 %

not highly

alkaline

addition of

citric or phosphoric acid based

neutralizer often

brightens the

surface

0.1 - 0.15 %

non-stainless

steel

oil, grease,

particles etc.

P 007 LEI-OEL

60 - 75

(2 - 10 min)

alkaline to

highly alkaline

(pH > 10)

0.3 - 0.5 %

not mildly

alkaline or

neutral

no acid

neutralization

Dispense an an

ti-corrosion additive

during water intake

for interim rinse and

final rinse. Delete

Step 4 in P 007

-

1) Characteristics of cleaning and deneutralizing agents are given, not product names

2) Concentration for use = percentage of the chemical additive in the wash water solution

Water requirement / wash cycle = approximately 15 liters, e.g.:

0.1 % = 0.5 fl.oz. (15 ml) or 15 g amount to be dispensed

0.3 % = 1.6 fl.oz. (45 ml) or 45 g amount to be dispensed

0.5 % = 2.6 fl.oz. (75 ml) or 75 g amount to be dispensed

0.7 % = 3.7 fl.oz. (105 ml) or 105 g amount to be dispensed

23

Page 28

Applications Optics

Optics

In the production of optical items the

machine can be used for degreasing,

removing dust or polishing/grinding

paste, and giving a final rinse to clear

the items of residues. The quality of the

final rinse depends on the quality of the

water. With polishing pastes it is advis

able to investigate the suitability of the

cleaning process for the type of glass

ware being cleaned.

-

-

Insert E 118-10

24

Page 29

Applications Optics

Application

Material/Soiling

Program P 006 METALL or

Wash temperature

T1 (°C)

Wash temperature

T2 (°C)

Cleaning agent

Concentration

for use

Neutralizer

Concentration

for use

Notes If a neutralizer is needed, select P 006, delete Step 5 (P 006), add a Step

1) Characteristics of cleaning and neutralizing agents are given, not product names

2) Concentration for use = percentage of the chemical additive in the wash water solution.

Water requirement / wash cycle = approximately 15 liters, e.g.:

1)

2)

1)

2)

Optical Glass

Dust/particles etc.

P 007 LEI-OEL

60 - 75

50 - 60

mildly alkaline, alkaline

0.3 - 0.5 %

Neutralization with product containing phosphoric component sometimes

necessary

0.1 - 0.15 %

(Channel 9 and 14) between Steps 11 and 12 (P 006).

If no neutralizer and only a small amount (0.3 %) of cleaning agent is

dispensed, select P 007.

If the cleaning agent is low-foam delete Step 4 (P 007).

0.1 % = 0.5 fl.oz. (15 ml) or 15 g amount to be dispensed

0.3 % = 1.6 fl.oz. (45 ml) or 45 g amount to be dispensed

0.5 % = 2.6 fl.oz. (75 ml) or 75 g amount to be dispensed

0.7 % = 3.7 fl.oz. (105 ml) or 105 g amount to be dispensed

25

Page 30

Applications Particle Decontamination

Particle decontamination

The IR 6001 offers exceptional cleaning

results and is recommended for particle

decontamination of chip boxes, wafer

trays, drainers, fitting racks, computer

components etc. Decontamination is

accomplished with the addition of a

minimal amount of a special cleaning

agent in a purely aqueous system, with

out the addition of solvents. In these

applications the cleaning process is

carried out using de-ionized water

throughout the wash-program.

Miele offers a wide variety of inserts for

different applications, not all of which

can be shown here. Please contact

Miele for details of other inserts available.

-

26

Page 31

Reactivating the water softener

Before using the machine for the first

time, the MCU must be set by the servi

ce technician to reactivate the water

softener according to the local water

hardness level (see Operating and pro

gram manual). The local water authority

can advise you of the water hardness in

the area.

When, after a number of wash cycles,

the message REGENERIER (REGEN

ERATE) appears in the display, the

built-in water softener is depleted and

cannot supply any more soft water. It

must therefore be reactivated with re

generate salt immediately after the

program has ended.

If this cannot be done immediately and

further batches have been washed, the

reactivation process must be carried

out twice in succession.

For each reactivation program you will

need:

-

-

The salt container must only be

,

filled with salt!

Filling the salt container with any

thing but salt, such as detergent,

could cause pressure to build in the

salt container resulting in harm

(chemical burns, physical injury) to

the operator.

To fill the salt container

-

– 4.4 lbs. (2 kg) reactivation salt (gran-

ule size must be 1-4 mm).

–

The plastic salt container supplied as

standard equipment with the ma

chine.

Please note

Never use rock salt as the dirt parti

cles it contains will block the water

softener unit.

Reactivation salt with granules

smaller than 1 mm or larger than

4 mm must not be used.

-

-

^

Unscrew and remove the filter insert

from the salt container.

^

Fill the salt container with granular

salt and replace the filter insert.

27

Page 32

Reactivating the water softener

To insert salt container

Remove the bottom basket from the

^

wash cabinet.

^ Unscrew the plastic cap in the base

of the wash cabinet.

Close the door.

^

Turn on the faucets (water supply).

^

Select program 15 REGENERIER

^

(Regenerate/Reactivate). See "Turn

ing on".

The reactivation program proceeds au

tomatically and is finished when the l

indicator light goes out.

Then:

Turn off the machine.

^

Open the door and remove the salt

^

container.

^ Replace the plastic cap on the

socket at the bottom of the wash cabinet.

^ Replace the lower basket.

^ Rinse the salt container and filter in-

sert under running water.

^ Turn off faucets (water supply).

-

-

^

Place the salt container on the reacti

vation socket and screw firmly into

place.

28

The water pressure must be al least

36 psi.

If the flow pressure is below 36 psi,

salt residues may be left in the salt

container. If this is the case, the

REGENERIER program must be run

again.

-

Page 33

Serial interfaces

The serial interfaces are RS 232 com

patible.

The interface enables data transfer be

tween the MCU and an EPSON com

patible printer or IBM compatible PC.

The MCU offers the following timed

printout options:

Date and machine number,

–

Program start (with program number,

–

step number),

Program end,

–

Confirmation that programmed tem

–

perature has been reached, and any

applicable Code-texts,

– Temperature,

– All faults (with parameters, where

given),

– All manual interventions.

At older MCU Versions (until version

S2.05 inkl.) the use of the interfaces is

not permitted.

,

Use ONLY the interface cable

provided by MIELE, as some of the

contact points on the MCU interface

are non-standard RS 232. An unap

proved cable could damage the

MCU and peripheral equipment.

-

The following connection cables are

-

available from Miele:

-

-

-

45 ft. (15 m) connection cable for

–

short-term connection between the

MCU front interface and a PC or

printer.

45 ft. (15 m) connection cable for

–

long-term connection between the

MCU rear (internal) interface and a

PC or printer.

6 ft. (2 m) connection cable for

–

short-term connection between the

MCU front interface and a PC.

When connecting a printer or PC to the

MCU please note the following points:

– When installing the machine take the

dimensions of the printer or PC into

account.

– After removing the interface cable,

replace the black cap on the interface socket.

The function PRINT must be selected in

the system parameters SERIAL-MODE/

FUNCTION, for the report printer to be

activated. At the same time the Baud

rate (transfer speed) of the printer must

be set on the MCU.

The following baud rates are possible:

1200, 2400, 4800, 9600, 19200.

29

Page 34

Serial interfaces

Preparing the MCU for report

printout

1. Set the baud rate (transfer speed)

of the printer

Turn the key switch to position III or IV.

Touch pad

W PROGRAMMING

M SYSTEMPARAMETER

W CTEXT SPECIALS

MM SERIAL MODE

W BAUDRATE nnn

U BAUDRATE nnn

Display

ZZZ PROGRAM NAME

2. Select communication type

"PRINT" (printer connection)

Touch pad

a)

M FUNCTION PROG

U FUNCTION PROG

M FUNCTION PRINT

S FUNCTION PRINT

T ZZZ PROGRAM NAME

b)

or alternatively if "PRINT" has already

been set:

M FUNCTION PRINT

T ZZZ PROGRAM NAME

Display

BAUDRATE XXX

O

..

..

..

O BAUDRATE XXX

S BAUDRATE XXX

30

___ = number sequence flashes

XXX = baud rate to be set

ZZZ = program number selected

nnn = stored baud rate

Page 35

Consult the supplier on the availability

of dedicated PC programs. (Programs

listed below may be universally obtain

able).

MCU-Protokoll-Manager (Report

printout manager

This program can be used to record

and store report data, load from a data

carrier, and print from an Epson com

patible or HP-LaserJet printer.

MCU-programming software

In addition to programming through the

MCU keyboard, was programs can be

created on a PC, stored, and transferred to the MCU.

-

Serial interfaces

-

31

Page 36

Cleaning and Care

Cleaning the filters in the wash

cabinet

The wash water passes through a four

filter combination in the base of the

wash cabinet which consists of:

Coarse filter

–

Fine filter

–

Flat filter

–

Micro-fine filter

–

It is important that the filters are kept

clean (otherwise the water overflow sys

tem cannot function reliably).

The filter combination has been designed so that most of the soil is collected in the coarse filter.

The coarse filter should be inspected

and, if necessary, cleaned after every

program.

,

Glass fragments, needles,

pieces of wire etc. may have collected in this filter, and could cause

injuries.

Cleaning the coarse filter

-

^ Press the two tabs inwards and re-

move the filter.

^ Clean the filter.

^ Replace the filter and press until it

clicks into place.

Fine filter

The filer filter is located under the

coarse filter. It will trap very small items

that are not caught in the coarse filter.

Whenever the coarse filter is cleaned,

the fine filter should be removed and in

spected.

-

32

^

To remove, lift out the fine filter and

clean.

^

Replace the filter by inserting it into

the center of the micro-fine filter.

Page 37

Cleaning the flat and microfine filters

Remove the coarse and fine filters.

^

^ To unscrew the micro-fine filter, take

hold of the two tabs, turn twice in a

counter-clockwise direction and remove together with the flat filter.

Cleaning and Care

^ Clean all the filters.

^ Replace the filter combination se-

curely in the reverse order in which it

was removed.

,

The machine must not be used

without all the filters in place!

33

Page 38

Cleaning and Care

Cleaning the water inlet filters

Two filters incorporated into the water

inlet system protect the valves from

particles that may be in the water sup

ply. The filters must be cleaned when

dirty, or insufficient water flows into the

wash cabinet.

Turn off the water valves.

^

Disconnect the inlet hoses.

^

Remove the filter housing from the

^

water valve.

Remove the filer insert (1) from the

^

housing and clean or replace, if necessary. Clean the filter located in the

hose connector (2).

-

2

^ Reinstall the filters. Connect the

hoses and turn on the valves to test

for leaks.

A third filter is located in the solenoid

valve and should only be cleaned or

replaced by an authorized technician.

1

34

Page 39

Changing the coarse filter

The coarse filter should be changed

when dirty or after approximately 100

operating hours ("GROBFILTER" ap

pears in the MCU control display).

^ Pull the top of the inlet grill out, then

lift up, off of the retainers, and remove.

-

Drying unit: Cleaning and Care

^ Change the coarse filter.

The smooth side of the filter should

face the rear.

^ Position the perforated plate at the

base and press into place at the top.

The edges should face forward.

^ On replacing the inlet grill, it should

click into place.

^

Take out the perforated plate.

Exchanging the HEPA particle

filter

This filter should be replaced every 500

hours, or when "FEINFILTER" is dis

played.

,

This filter should only be

changed by an authorized Service

technician.

Reproducible operation of the machine

can only be achieved if original Miele

HEPA particle filters are used.

-

35

Page 40

Correcting minor faults

Repairs should only be under

,

taken by an authorized technician.

Heater limiter

The IR 6001 is equipped with a thermal

breaker which shuts off the heating ele

ments if the machine overheats. The

breaker reset can be found on the

right-hand side behind the service

panel.

Symptoms:

The water in the wash cabinet does not

heat up; the program cycle takes too

long, or the fault message F TEMP is

displayed.

Overheating can occur if large items

cover the heater elements preventing

them from transfering heat to the water.

It can also occur if the filters in the

wash chamber are blocked, or too little

water has been taken into the wash

chamber.

-

Remedy:

Isolate and correct the cause of the

^

problem.

Clean the filters in the water inlet.

^

Reset the heater by:

-

Removing the service panel and

^

Pressing the blue reset button on the

^

heater limiter.

The Miele Technical Service

,

Dept. should be called if the thermal

breaker trips again.

USA: 1-800-999-1360

CDN: 1-800-565-6435

36

Page 41

Installation

This machine must be con

,

nected to the water supply in accor

-

dance with all national and local

plumbing codes!

Faucets and drain connections should

be situated as close to the machine as

possible, and be easily accessible. The

cold and hot water supply flow pressure

should be between 36 and 145 psi (2.5

and 10.0 bar). The machine is supplied

with 4 connection hoses 5 ft. (1.5 m)

long with

3

/4" (19 mm) female hose

thread ends. Do not shorten the hoses!

Where flow pressure is between 5 and

36 psi (0.3 and 2.5 bar), fill time may be

extended by reprogramming the machine. The machine cannot be operated with an inflow pressure of less

than 5 psi (0.3 bar).

Requirements (refer to IR 6001 MCU

Installation Diagram for corresponding

numbers):

1. Cold water connection:

1

One

/2" (13 mm) cold water supply line

with a standard

3

/4" (19 mm) male hose

thread faucet is needed. The cold water

supply hose is marked with blue tape.

2. Hot water connection:

1

One

/2" (13 mm) hot water supply line

with a standard

3

/4" (19 mm) male hose

thread faucet is needed. The water

temperature must not exceed 150 °F

(65 °C) (recommended: 140 °F / 60 °C).

The hot water supply hose is marked

with red tape.

This hose may also be connected to a

cold water supply, if hot water is not

available.

3. DI water connection:

1

One

/2" (13 mm) de-ionized water sup

ply line with a standard

3

/4" (19 mm)

male hose thread faucet is needed.

Flow pressure should be between 25

and 145 psi (1.5 and 10.0 bar). Where

flow pressure is between 5 and 25 psi

(0.3 and 1.5 bar), fill time may be ex

tended by reprogramming the machine.

The machine cannot be operated con

ventionally with an inflow pressure of

less than 5 psi (0.3 bar). In this case

the installation of an optional DI pump

is required. The DI water supply hose is

marked with green tape.

This hose may also be connected to a

cold water supply, if DI water is not

available, and where the local water

hardness does not exceed 100 ppm

CaCO

.

3

4. Tank water connection:

The machine has a 1" (25 mm) connection socket. A connection hose from the

holding tank to the machine is not sup

plied as standard. This connection

hose must be installed from the bottom

of the tank to the machine, with a down

ward gradient, and should not be

looped or inclined (see item 4 on en

closed diagram). Minimum height for

the supply connection is 14" (35 cm).

-

-

37

Page 42

Installation

5. Drain connection to the sewage

system:

The machine comes equipped with a

flexible drain hose

7

/8" (22 mm) internal

diameter, 5 ft. (1.5 m) long, with appro

priate hose clamps. It can be con

nected to a drain pipe or a 1

1

/4" (32

-

mm) minimum diameter stand pipe. The

drain pipe must be able to accept a

flow volume of 13.2 gal/min. (50 l/min.).

Do not decrease the diameter of the

drain connection at any point to less

3

than

/4" (19 mm).

This hose must not be shortened. An in

crease in length up to 13 ft. (4 m) is

possible using a

7

/8" (22 mm) internal

diameter hose (available through Miele

Technical Service). Maximum drain

height is 3 ft. (1 m).

6. Drain connection to the holding

tank:

The machine comes equipped with a

flexible drain hose

7

/8" (22 mm) internal

diameter, 5 ft. (1.5 m) long, for connec

tion to a holding tank.

7. Electrical connection:

All electrical connections must

,

be made by a qualified electrician

and meet all national and local

codes.

The machine comes equipped for con

nection to a three phase power supply:

Three phase 208 V AC

–

6.6 kW connected load

–

20 A circuit breaker per phase

–

A dedicated three phase line incorpo

rating the appropriate circuit breakers

(specified above) should be situated

near the appliance. The machine comes supplied with a 6-foot 4 X 12 AWG

cord (without a plug), that may be hardwired into an appropriate electrical box,

or plugged in via the use of a 3 pole, 4

wire grounding plug and receptacle

(NEMA type L15-20R and L15-20P are

recommended).

-

-

-

This hose must not be shortened. An in

crease in length up to 13 ft. (4 m) is

possible using

7

/8" (22 mm) internal di

ameter hose (available through Miele

Technical Service). Do not decrease he

internal diameter of the drain connec

tion at any point to less than

3

/4"

-

(19 mm).

Maximum drain height is 3 ft. (1 m).

38

-

-

Page 43

Installation

8. Vent connection:

The machine is equipped with a venting

socket at the rear. It must be connected

to a vent pipe to be provided on-site.

The vent must be able to accept a mini

mum volume of 3,530 cfm

(100 m³/min.). Using an adapter it is

possible to obtain venting up to 15 ft.

(5 m) in length with HT pipe (HT - able

to withstand high temperatures), 2

3

/4"

(70 mm) internal diameter. Deduct a

nominal 20" (50 cm) from the maximum

length for each bend. Where several

machines are installed, each one must

be connected individually as described

above to the main ducting. The main

duct must have a minimum diameter of

4" (100 mm), and work with

underpressure.

9. Connection to cleaning agent containers:

The connection hoses for the three integrated DOS dispenser pumps can be

directed through the rear to either side

of the machine. Maximum distance of

the agent containers is 43" (107.5 cm)

to the left, or 15" (37.5 cm) to the right.

10. Holding tank (not supplied with

the machine):

An external holding tank is not supplied

with the machine, but must be provided

-

on-site if required. The tank should be

positioned to the left of the machine

(viewed from the front). If the user

wishes to connect a holding tank to the

machine, the following conditions have

to be met:

The water level in the tank must not

–

rinse above 37

1

/4" (950 mm), mea

sured from the base level of the ma

chine in position. The tank must be

provided with an unrestricted overflow at this height. There must still be

a capacity of 5

1

/2gal. (20 l) in the

tank above this level.

– The drain outlet from the holding tank

must be situated at least 13

(350 mm) high, measured from the

base level of the machine in position.

The connection hose must be laid so

that there is an uninterrupted downward gradient from the holding tank

to the connection on the machine.

–

The holding tank must be vented.

-

-

3

/4"

–

There is no inlet filter in line with the

suds recycling pump. It is the re

sponsibility of the user to take suit

able steps (e. g. using a lid) to en

sure that no impurities enter the

holding tank. If this is not possible, a

filter should be installed in the hold

ing tank at the outlet connection.

The holding tank and its connection

hose must be provided on site.

-

-

-

-

39

Page 44

Help to protect our environment

Disposal of the packing mate

rial

The transport and protective packing

materials are environmentally friendly

for disposal and can normally be recy

cled. Please recycle.

Disposal of an old appliance

-

Old appliances contain materials that

may be recyclable. Please contact your

local recycling authority about potential

recycling, before disposing of the appli

ance. See also the section under

"Warning and Safety instructions".

When disposing an old machine,

,

first make it unusable. Disconnect or

cut off the plug and cable. For envi

ronmental and safety reasons en

sure the machine is completely

drained of any residual water and

cleaning agent. (Observe safety regulations and wear safety goggles

and gloves). Make the door lock inoperative, so that children cannot

accidentally shut themselves in. The

simplest way to do this is to remove

the locking pin (2 philips screws

above the door). Make appropriate

arrangements for the safe disposal

of the machine).

-

-

-

404142

Page 45

Page 46

Page 47

43

Page 48

Alteration rights reserved / 000 2101

Loading...

Loading...