Operating instructions

Rotary Ironer

Instrucciones de manejo

Planchadora

Instruções de utilização

Calandras

Bruksanvisning

Varmrulle HM 38-175

It is essential to read these

operating instructions before

installing or using the machine,

to avoid the risk of accident

or damage to the machine.

HM 38-205

QUVX

M.-Nr. 05 803 030

M.-Nr. 05803030 2

Contents

Page

Warning and safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Gas safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Caring for the environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Guide to the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

The controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Safety features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Type of fabric and preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Ironing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Pressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Safety features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Motor protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Insufficient air supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Insufficient gas supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Emergency release during a power cut . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Variations in equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Laundry return feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Belt feed-in . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Cleaning and care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Waxing the heater plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Aluminium heater plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Pick-off attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Ball bearings and gear box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Roller padding (steel wool) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Roller cloth cover, removing, replacing and washing . . . . . . . . . . . . . . . . . . . . . 18

Leaf-type roller padding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

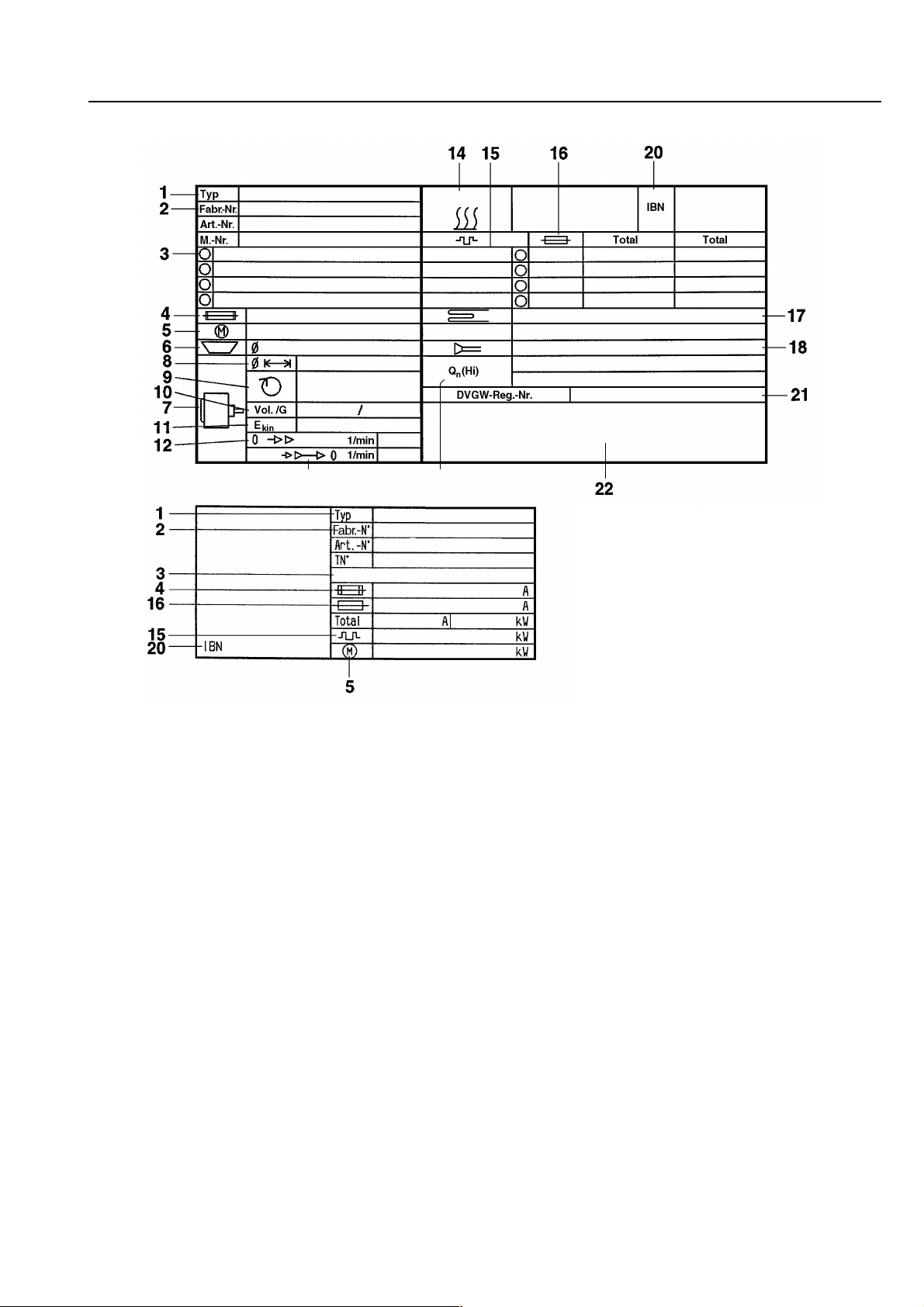

Symbols on the data plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Removing the transit fitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Gas connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Exhaust ducting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

The rotary iron must be installed by an

approved Service Technician or authorised

Service Dealer in accordance with local and

national safety regulations.

Página / Side

U Indice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

V Índice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

X Innhold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

3 M.-Nr. 05803030

Warning and safety instructions

Read the operating instructions before

using this machine for the first time. This

way you will avoid the risk of accidents and

damage to the machine.

Only iron materials with this ironer which

are suitable for machine ironing and

which were washed in water.

This machine must not be operated in the

same room as dry cleaning machines

which use solvents containing PERs or CFCs.

The ironer should only be used in a room

with a low relative humidity level.

Any removable outer panels must be back

in place, and all moving or electrical parts

shielded before the machine is switched on.

Do not damage, remove or bypass the

safety features, fixtures and control ele-

ments of the machine.

Do not use a machine with damaged controls or with damaged cables. These must

be repaired before it is used again.

Repairs to the machine should only be

undertaken by a suitably qualified trained

service engineer to ensure safety. Unauthorised repairs could be dangerous.

Never allow children to play on or near

the rotary ironer, or to operate it them-

selves.

When the ironer is heated up with the

heater plate in position, there is an acute

danger of burning, if the edge of the heater

plate is touched on the feed-out side.

When ironing double layered items do not

reach in between the layers to straighten

out the fabric. This is extremely dangerous as

you may not be able to extract your hands on

time. The same applies when ironing garments with pockets.

Ironers with belt-feed in:

Warning! Do not iron articles with

fringes/tassles, thin straps, ties etc. They

could cause the belt feed-in mechanism to fail

Always keep a fire extinguisher accessi-

ble in the rare event of textiles igniting.

Accessories

Accessory parts may only be fitted when

expressly approved by Miele. If other

parts are used, guarantee, performance and

product liability claims may be invalidated.

Faulty components must only be exchan-

ged for Miele original spare parts. Only

when these parts are fitted can the safety

standards of the machine be guaranteed.

The electrical safety of this appliance can

only be guaranteed when continuity is

complete between the appliance and an effective earthing system which complies with

local and national regulations. It is most important that this basic safety requirement is regularly tested by a qualified electrician.

The manufacturer can not be held respon-

sible for the consequences of an inadequate earthing system.

The machine is only completely isolated

from the electricity supply either when it is

switched off at the wall isolator or when the

mains fuse is withdrawn from the distribution

board.

M.-Nr. 05803030 4

Warning and safety instructions

Notes on the use of this machine

This ironer must be operated at all times

in accordance with the legal requirements

of the Health and Safety Acts.

Please allow only trained persons,

thoroughly familiar with the ironer, to work

at the feed-in. Always conform to local and

national regulations on minimum age requirements of operators.

Persons with especially slim fingers

should only work at the receiving side and

not at the feed-in.

When working with the ironer, always

wear close fitting clothes. Wide sleeves,

apron bands, ties or scarves could be taken

in by the roller. Also remove rings or bracelets

before starting to work.

Smooth out folds as far away as possible

from the feed-in on the feed-in table. Feed

pillow cases and duvet covers into the ironer

with the open part first. Do not take hold of

the corners from the inside. Do not take hold

of undershirt and apron straps from the inside.

Always check the proper setting of safety

devices. This way you will avoid the

danger of burns, squashed fingers and even

loss of hands.

Check daily whether the safety devices

function properly.

Make sure that the safety bars cannot be

bridged.

Before switching to reverse make sure

that nobody is endangered.

When using a gas heated system, make

sure that the ventilation of the work room

is sufficient.

Lubricate machine parts only when the

machine is shut off.

It is imperative that all local and national

safety regulations concerning the use of

this machine are observed.

5 M.-Nr. 05803030

Gas safety Caring for the environment

Safety precautions to take if you smell gas

(gas-heated ironers only).

(Natural gas usually has no smell of its own.

In the U.K. a smell is added by British Gas for

safety reasons).

If you smell gas you must act immediately.

Extinguish any flames.

Do not create any electrical sparks: e.g. do

not insert or withdraw any electrical plugs

or operate electrical switches such as

lights and door bells.

Do not enter a room with an open light

where there is the smell of gas.

Do not light cigarette lighters or matches.

Do not smoke.

Open all windows and doors.

Close any shut off valves at the gas con-

nection or mains supply immediately.

Shut off the gas-valve next to the machine.

Disposal of the packing material

The transport and protective packing has

been selected from materials which are environmentally friendly for disposal and can

normally be recycled.

Rather than just throwing these materials

away, please ensure they are offered for

recycling.

Disposal of your old machine

Old machines may contain material which can

be reclaimed or recycled. Please contact your

dealer, your local waste collection centre or

scrap merchant about potential recycling

schemes.

Ensure that the machine presents no danger

to children while being stored for disposal.

See the appropriate section in the Warning

and Safety instructions.

If all gas valves are closed but there is still

the smell of gas in the room you should call

your local gas supplier immediately.

Important: Before signing off any commissioning, maintenance, conversion or repair

work as finished, all gas pipework from the

manual isolating valve to the burner nozzles

must be checked for gas soundness.

Pay special attention to the test points on the

multifunction control, the connection pressure

monitor and the burner setting pressure.

The tests must be carried out with the burner

switched on and switched off.

All personnel working with this machine must

be fully trained in all aspects of its use and

safety.

Keep these instructions in a safe and

accessible place.

M.-Nr. 05803030 6

Guide to the machine

yx

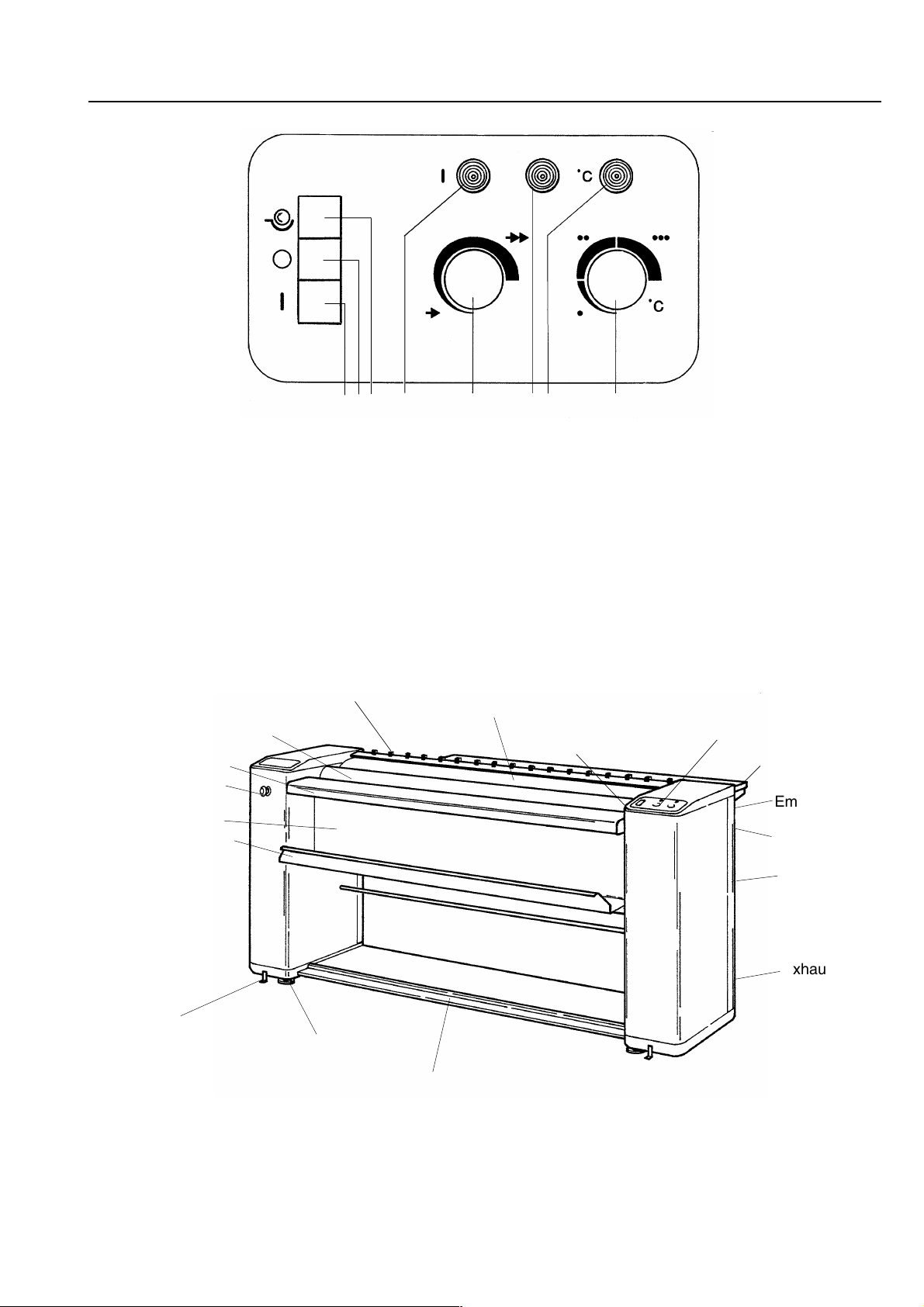

1 2 3 4 5 6 7 8

The controls

1 Button "I" On 5 Speed selector

2 Button "O" Off 6 Ignition fault indicator light yx*

3 Button "Ö Reverse run" 7 Temperature indicator light °C

4 In operation indicator light 8 Temperature selector

Pick-off band

Roller

Finger guard Control panel

Reset button*

Feed-in table Out tabling

Emergency stop

switch

Protective panel* switch

Laundry collector box Exhaust extraction

Fixing brackets (4)

Adjustable feet (4)

Foot control bar

*) only with gas heated rotary ironers

Emergency stop

Hand wheel

Exhaust pipe*

HM 38-175

7 M.-Nr. 05803030

Guide to the machine

The indicator lights

Pushbutton controls

Button "I" On

After pressing in button "I" the in-operation indicator light "I" and the temperature indicator

light "°C" come on.

- The heater plate heats up Once the required temperature is reached the

temperature indicator light "°C" goes out.

When the "I" button is pressed again the

heater plate will move into position and the

roller starts.

Button "O" Off

This button is used to switch the machine off

and withdraw the heater plate.

In operation indicator light "I"

The in operation indicator light "I" comes on

when the "I" button is pressed in.

Temperature indicator light "°C"

The temperature indicator light comes on

while the machine is heating up, and it goes

out once the required temperature has been

reached.

Gas heated rotary ironers

Indicator light "yx" ignition fault

(and faults in the exhaust ducting)

This lights up if there is an ignition fault, or if

there is insufficient under-pressure in the exhaust system (exhaust ducting blocked).

Button "Ö " Reverse run

Reversing is only used to change the roller

covering or replace the padding. First switch

off the machine, the heater plate will then withdraw. Now press the "Ö " Reverse run button

- the roller will only run in reverse as long as

this button is pushed in.

M.-Nr. 05803030 8

Re-set switch "yx"(on the inside of the right

hand column, below the feed-in table)

When an ignition fault occurs, the re-set

switch can be activated after waiting for at

least one minute. If an ignition fault occurs

frequently call the Service department.

Guide to the machine

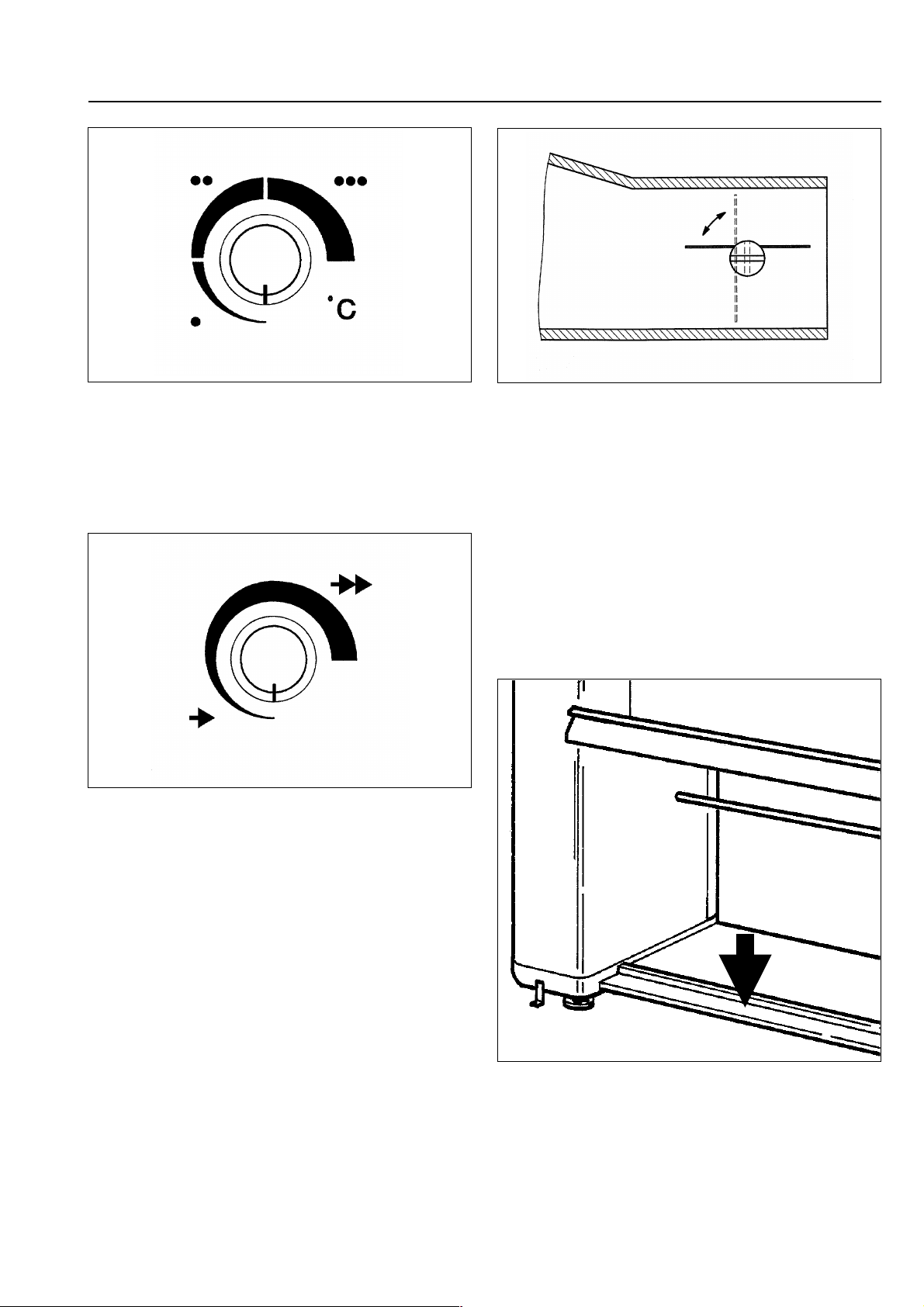

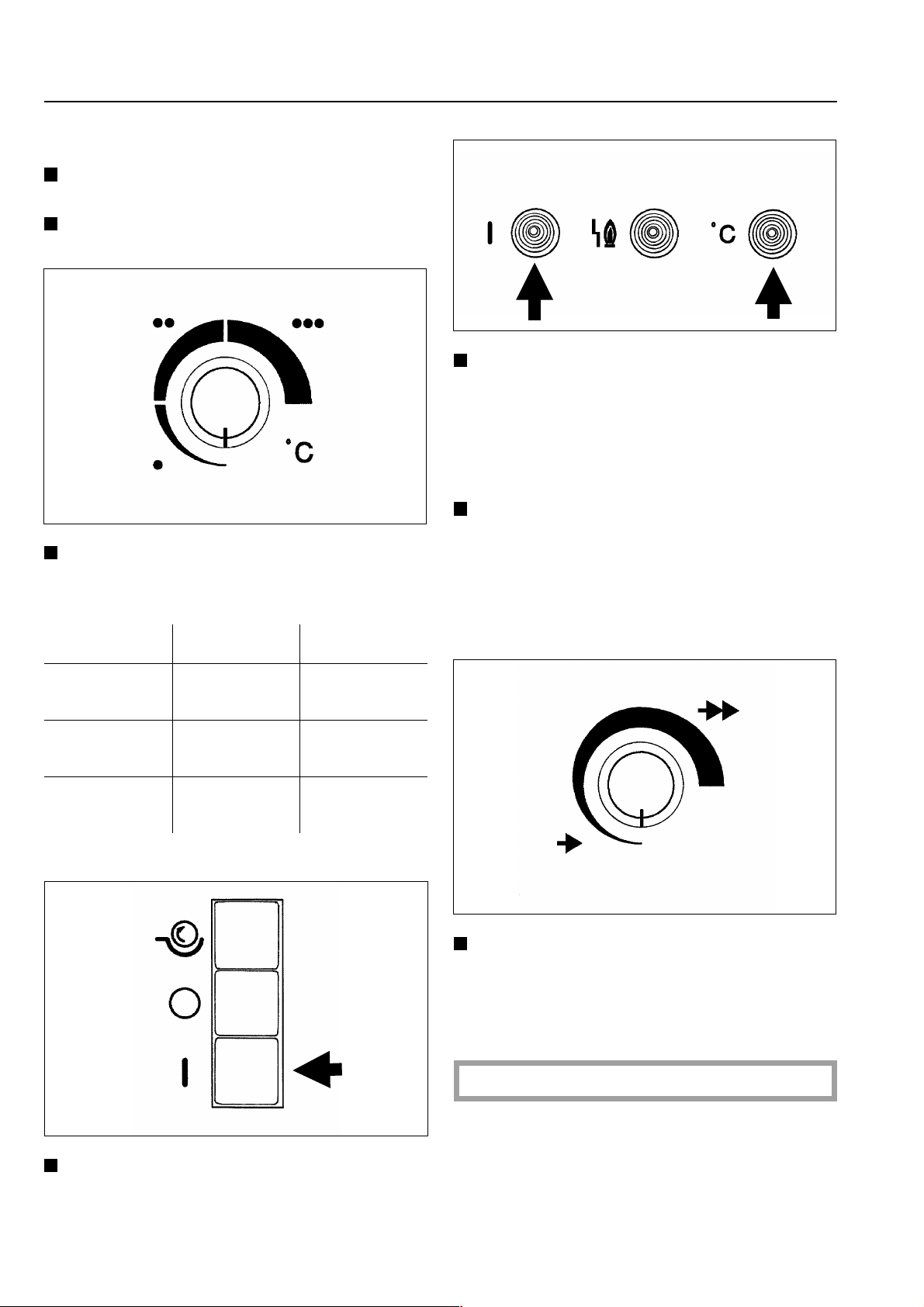

Temperature selector

ß = low temperature

ßß = medium temperature

ßßß = high temperature

Speed selector

The air volume is highest at the initial position

of the adjusting screw (see drawing), and can

be reduced by turning it through 90°.

The ideal throttle setting is when the roller

dries adequately with the lowest air flow volume, and no water spots appear on the roller

covering or on the items being ironed.

If the air throughput at the vapour exhaust is

too high, the roller will cool down too quickly,

resulting in a less efficient ironing process.

The roller speed is increased by turning the

speed selector clockwise and reduced by

turning it anti-clockwise.

Throttle valve - vapour exhaust

(only with electric heated rotary ironers)

A throttle valve has been installed in the va-

pour exhaust, whereby the air volume flowing

through the roller covering can be reduced.

Foot control bar

Functions:

not activated - ironing setting

activated - pressing setting

9 M.-Nr. 05803030

Guide to the machine

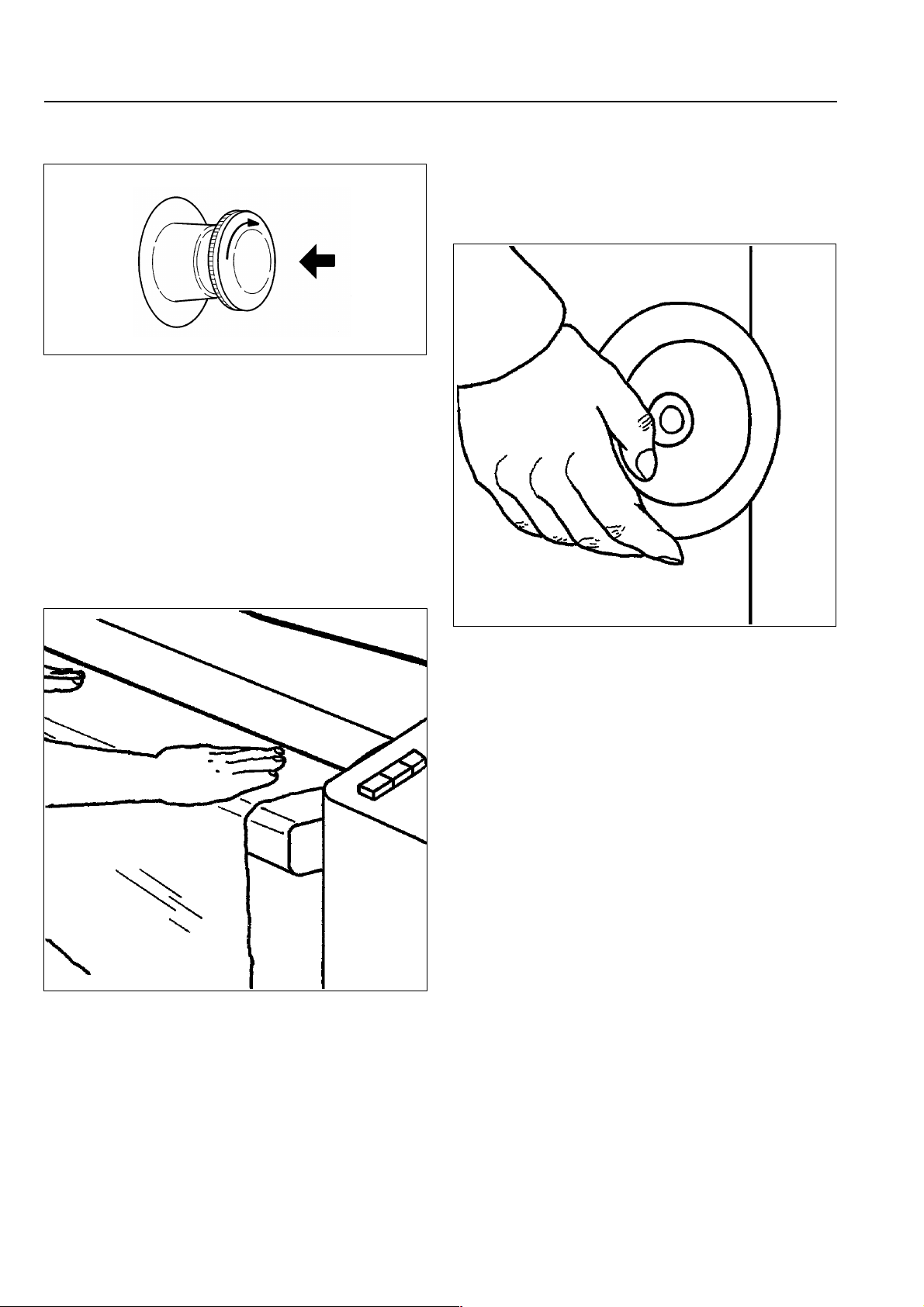

Safety features

Emergency stop switch

(at the front of the left hand column and at the

rear of the right hand column)

Immediately the emergency stop switch is

pushed in the roller stops and the heater plate

is withdrawn downwards.

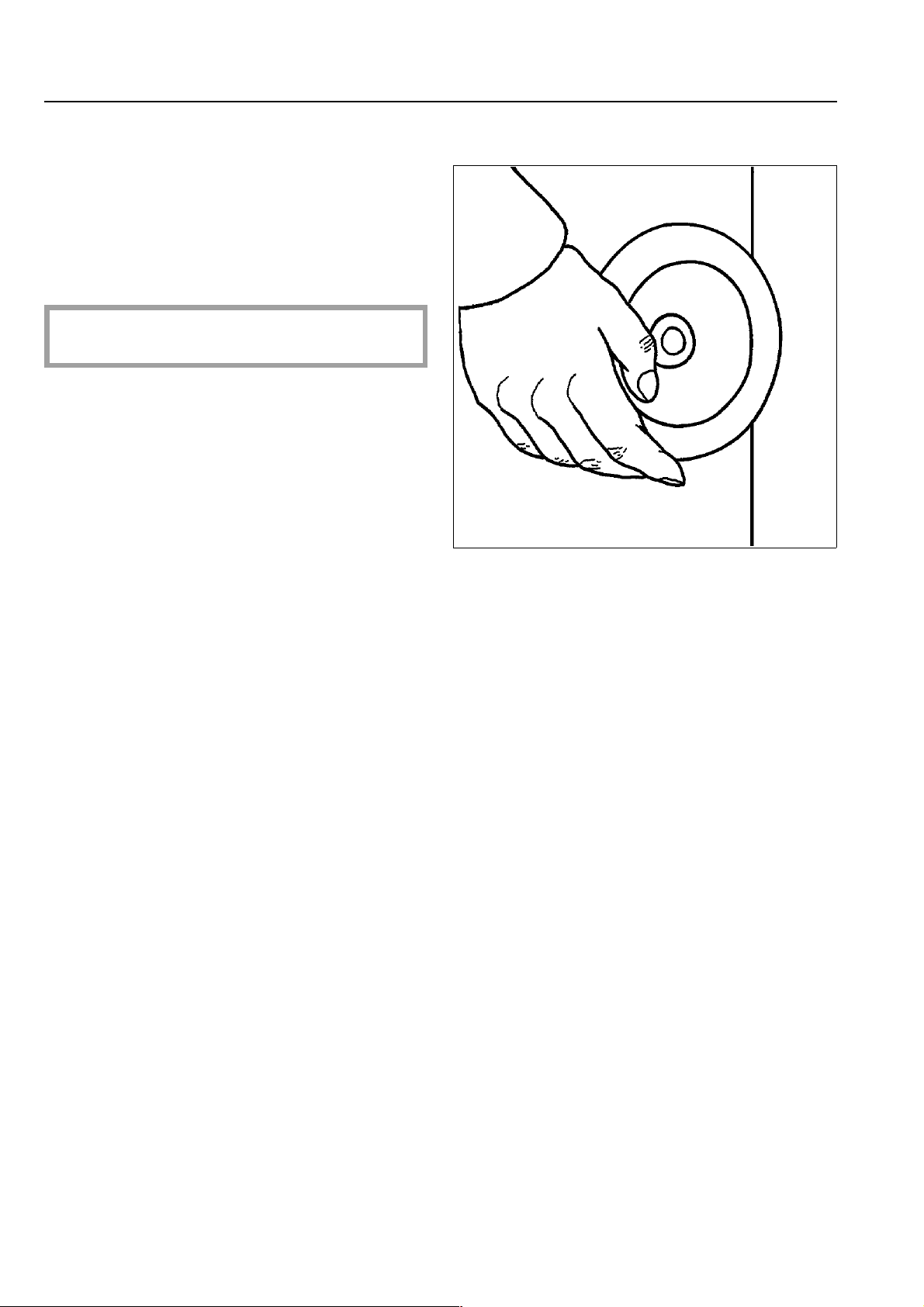

To reset the emergency stop switch after it

has been used, turn the ribbed disc clockwise.

The finger guard is a safety feature which

must be checked daily for proper functioning before the machine is used.

Finger guard

If the fingers slip between the laundry feed in

table and the finger guard the roller will stop

immediately and the heater plate is withdrawn

downwards. The finger guard does not work if

the roller is running in reverse.

If the finger guard has been activated, the machine can only be restarted by pushing in

button "I".

Hand wheel (at the rear of the right hand

column)

The hand wheel is used to release the heater

plate from the stationary roller in the event of

a power cut. Turn the handwheel anti-clockwise to lower the heater plate from the roller

and clockwise to raise it to the roller.

The machine must be disconnected from

the mains supply. (Switch off at the isolator or mains fuse box).

M.-Nr. 05803030 10

Operation

Condition of linen

For a good finish the ideal residual moisture

level lies between 25% - 40%.

If the laundry is rinsed with hot water in the

final rinse, the residual heat in the laundry,

together with the reduced residual moisture

content, will lead to shorter processing times

and save energy.

Laundry with a synthetic fibre content

greater than 50% (e.g. Dralon) must not be

ironed as the high temperatures would

melt the fibres.

Laundry with a lower synthetic content can

be ironed at a low temperature.

Preparing the flatwork

A cloth should be placed over zips, metal buttons and hooks to protect the heater plate

during ironing.

Metal and plastic buckles and very bulky

buttons should not be passed through the

ironer.

Note!

Clean the flatwork ironer before using for

the first time by passing through a cloth

along the entire length of the trough.

Before starting to iron laundry should be

sorted according to size and type of fabric.

First iron articles made from:

perlon, nylon etc.

(

ß - low temperature)

then iron:

woollens and silks

ßß - medium temperature)

(

then iron:

cottons and linen fabrics

(ßßß - high temperature)

To switch back to ironing at a lower temperature reduce the temperature setting and then

wait for it to cool down sufficiently, i.e. when

the temperature indicator light "°C" comes on

again.

Starched laundry should be ironed last to prevent any starch residues on the heater plate

from affecting other items of laundry.

Check the function of the Finger Guard

The finger guard is a safety feature which

must be checked daily for proper functioning before the machine is used.

If fingers slip between the laundry feed in

table and the finger guard the roller must stop

immediately and the heater plate withdraw

from the roller.

The finger guard does not work if the roller is

running in reverse.

If the finger guard has been activated, the

machine can only be restarted by pushing

in button "I".

Items with buttons should be passed through

the ironer with the buttons facing into the roller padding. If they face upwards there is a

danger of them being damaged or torn off

when the item is passed through the ironer.

11 M.-Nr. 05803030

Operation

Ironing

Switch on the electricity supply to the

machine (on site)

Open the gas stopcock (on site)

Select the temperature according to the

type of fabric

The in operation "I" indicator light and the

temperature indicator light "°C" come on,

and the heater plate starts to heat up.

As soon as the desired temperature has

been achieved, the temperature indicator

light "°C" goes out.

Press button "I" once more.

The heater plate moves up to the roller and

the roller rotates. Allow the roller to rotate

for approx. 5 minutes, so that the temperature of the heater plate and of the roller

equalize.

Fibres Symbol Temperature

Perlon /

artificial silk

Silk/wool ● ● medium

Cottons/linen ● ● ● high

● low

temperature

temperature

temperature

Set the required roller speed.

Check the function of the Finger Guard

Switch the machine on by pressing

button "I".

M.-Nr. 05803030 12

Operation

Pressing is stopped by raising your foot off

the foot control bar.

Freshly ironed laundry can be very hot

when it comes off the ironer. Wear gloves

to protect your hands.

In pauses between ironing, withdraw the

heater plate and reduce the temperature.

Pick-off attachment

The pick-off attachment is used for picking

laundry off the roller. Laundry no longer

needs to be removed manually from the roller.

Start ironing by feeding laundry pieces in

by the feed-in table.

Smooth items from the middle outwards towards the edges.

Do not restrict ironing of smaller articles to

any one part of the roller. Make use of the

whole roller width.

If one of the pick-off spring lifters is dislocated

by a piece of laundry it should be manually

pushed back into position.

After ironing

After ironing use the residual heat on the heater plate to iron out the remaining moisture in

the roller covering (approx. 5 mins).

Press the "O" button to switch the machine

off.

Close the gas stopcock (on site).

Switch the machine off at the mains

isolator.

Allow freshly ironed laundry to cool down

before packing it or stacking it to prevent

the risk of very hot laundry igniting and

causing a fire.

Press the foot control bar down for pressing.

The roller does not rotate during pressing.

13 M.-Nr. 05803030

Safety features

Motor protection

If the winding is heated excessively due to

overload the motor is switched off automatically by a winding thermostat. The heater

plate is lowered. Switch the ironer on again

only after it has had time to cool down by

pressing button "I".

Avoid unnecessarily running the ironer

without passing laundry through it.

Do not restrict ironing of smaller articles to

any one part of the roller. Make use of the

whole roller width.

This way an equal amount of heat is obtained

from the heater plate and energy is saved.

The roller is also protected from uneven use.

Safety feature for insufficient air supply*

When there is insufficent air supply to the

machine the heating is automatically switched

off, and the "Ignition fault" indicator light

comes on.

It is only possible to iron cold after a few

minutes.

Emergency release during a power cut

There is a handwheel at the rear of the right

hand column which can be operated manually

to release the roller from the hot heater plate

in the event of a power cut. Isolate the machine from the electricity supply. Turn the

handwheel anti-clockwise to lower the heater

plate from the roller. During normal operation

the wheel turns as the heater plate is brought

into position or withdrawn.

Check whether the exhaust system is clear.

If there is nothing wrong with the exhaust sy-

stem call the Service department.

Safety feature for insufficient gas supply*

When the gas stopcock is turned off or the

gas supply pressure is low, the rotary iron can

not be switched on. If the gas supply pressure

is reduced during operation, the machine switches off automatically and the heater plate is

withdrawn.

When the gas supply pressure has been reestablished, the machine can be switched on

again by pressing the "I" button.

If this fault recurs the on-site gas supply

system must be checked by an accredited

gas engineer, (Corgi registered in the UK).

*) only with gas heated rotary ironers

M.-Nr. 05803030 14

Variations in equipment

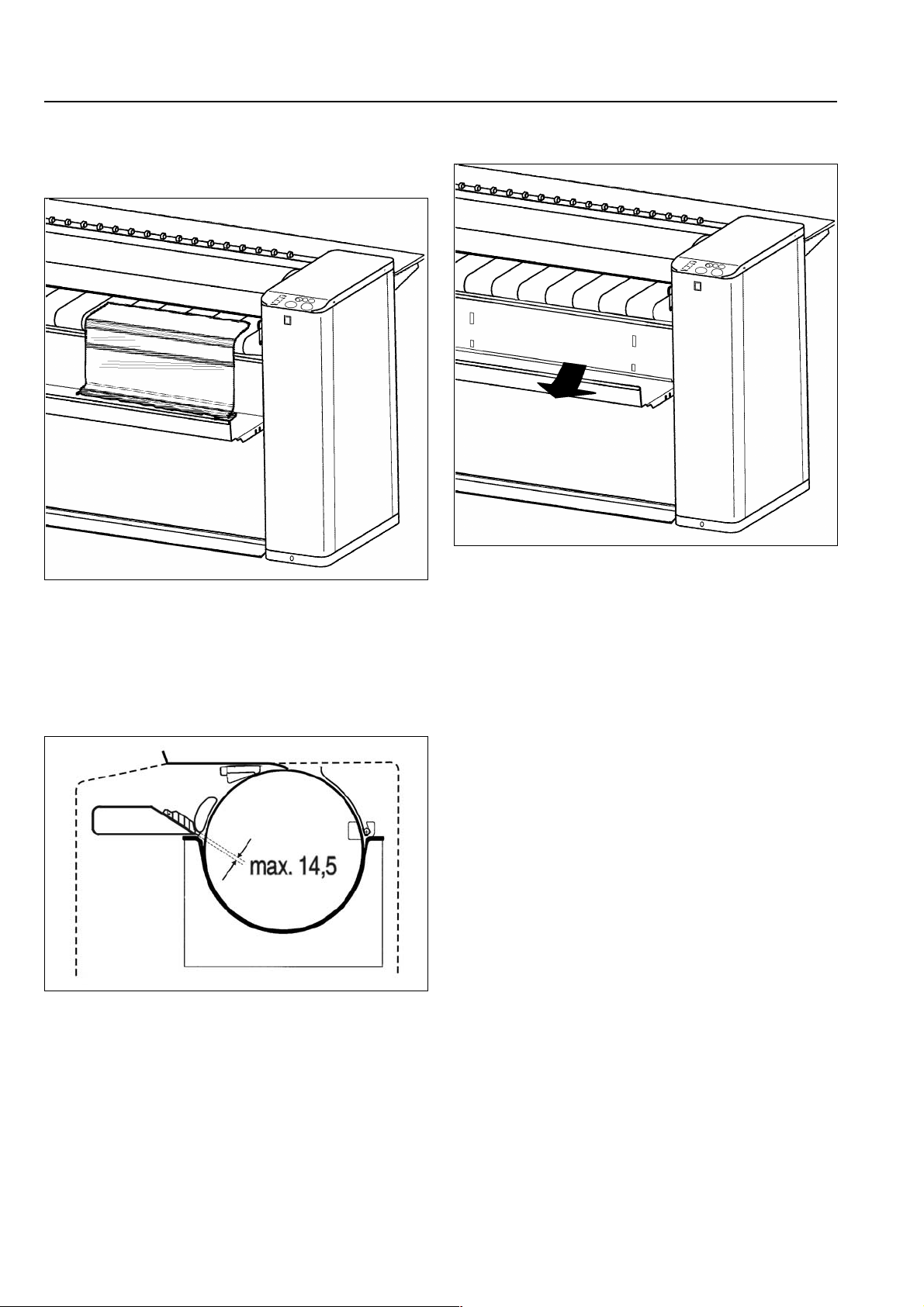

Laundry return feed

Laundry return feed enables ironed laundry to

be taken off the machine at the feed-in. No

extra personnel are required for taking

laundry off the machine. For this mode of

operation only the ironer can be positioned

close to a wall, (allow space for servicing).

Then position the laundry return feed to direct

laundry to the rear. Laundry is guided to the

ironer table.

If the ironing cloth cover is to be changed or

the roller needs more padding the lifter

springs need to be individually taken off the

pick-off strip.

The laundry return feed directs laundry back

to the front of the machine on to an ironing

shelf located above the finger guard.

If laundry is to be fed to the ironing table at

the rear allow adequate space for installation.

Fold the laundry guide back on to the laundry

table before starting.

15 M.-Nr. 05803030

Variations in equipment

Belt feed-in

This makes feeding in of laundry easier.

Items of laundry are placed parallel to the roller at the front of the feed-in table on the belt,

smoothed out and fed into the roller.

Feed-in table adjustment range

Protective panel

If laundry is fed incorrectly through the belt

feed-in it can be extracted by pulling the protective panel forwards.

The laundry can then be pulled out of the gap

between the laundry collector box and the protective panel using a suitable non-metallic

tool.

The feed-in table has a max. adjustment

range of 14.5 mm.

M.-Nr. 05803030 16

Cleaning and care

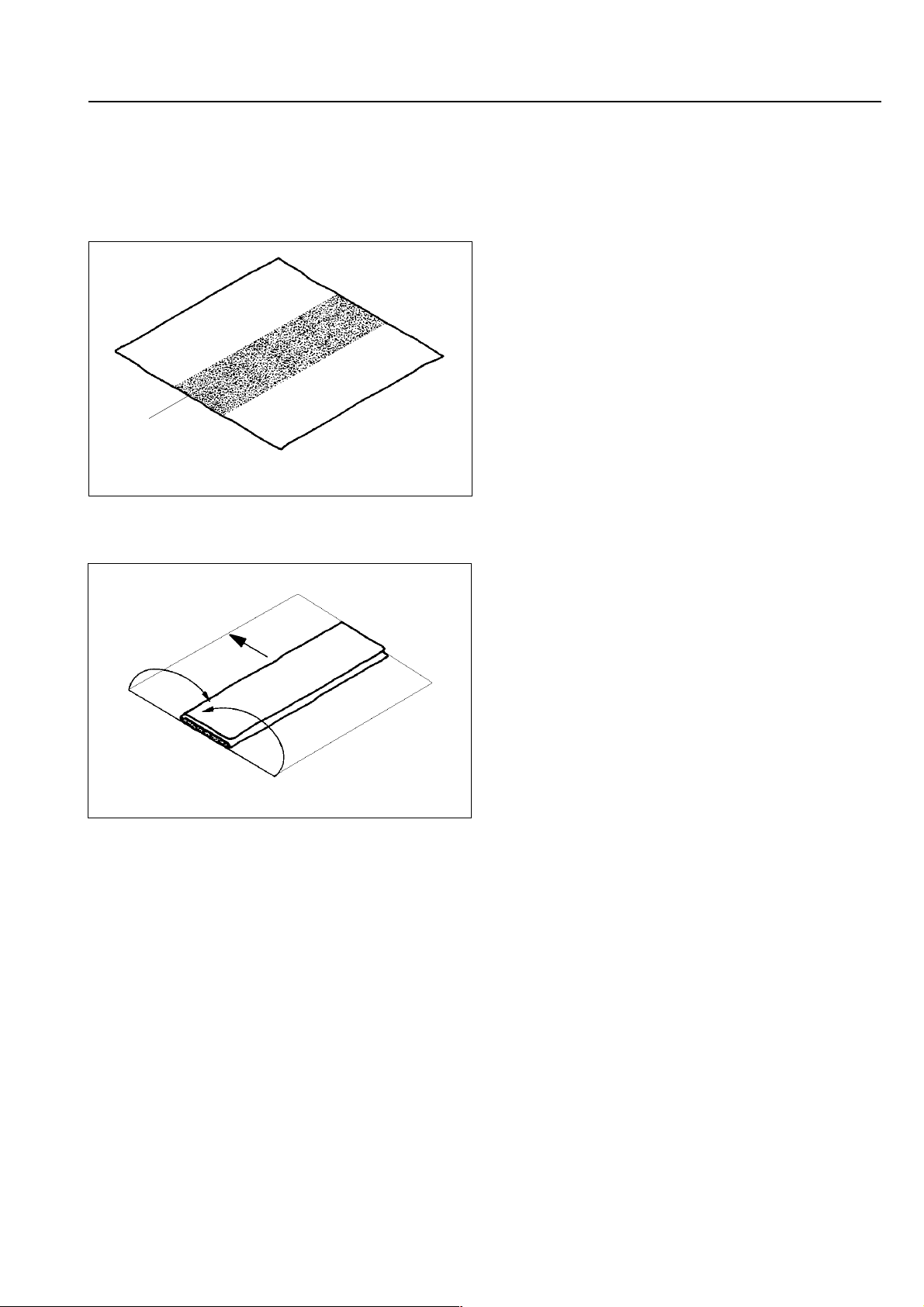

Waxing the heater plate

To maintain the smooth surface of the heater

plate it should be waxed on a regular basis

with an ironer waxing cloth.

Wax

Sprinkle the special wax into the centre of a

thin piece of cloth.

Aluminium heater plate

Limescale deposits and starch residues can

be removed from the heater plate using a suitable proprietary cleaning agent. Do not use

abrasive cleaning agents or abrasive cleaning

cloths.

Pick-off attachment

If you want to clean the lifter springs or the roller covering, re-cover the roller or to iron for a

short period without using the pick-off

attachment, this attachment can be raised

upright.

The tips of the pick-off lifter springs need to

be cleaned occasionally to remove the buildup of residues such as starch. Regular cleaning ensures smooth operation.

Direction of feed

Fold over the ends, then run through the

ironer as if it were a piece of washing. Keep

the folded ends of the cloth towards the roller.

Feed the cloth into the machine repeatedly,

moving along the whole width of the roller

from left to right.

For waxing or cleaning the heater plate select

the ● ● ● temperature setting and the slowest

roller speed.

Ball bearings and gear box

Ball bearings and gear box are greased for

many years of use.

The machine must be switched off for lubrication.

Disconnect the machine from the mains

before lubricating.

There is a danger of burning when removable

outer panels are not in place.

After maintenance work any removable outer

panels must be back in place, and all moving

or electrical parts shielded before the

machine is switched on.

A special cloth for cleaning and special wax

can also be ordered from the Miele Spare

Parts Department.

17 M.-Nr. 05803030

Cleaning and care

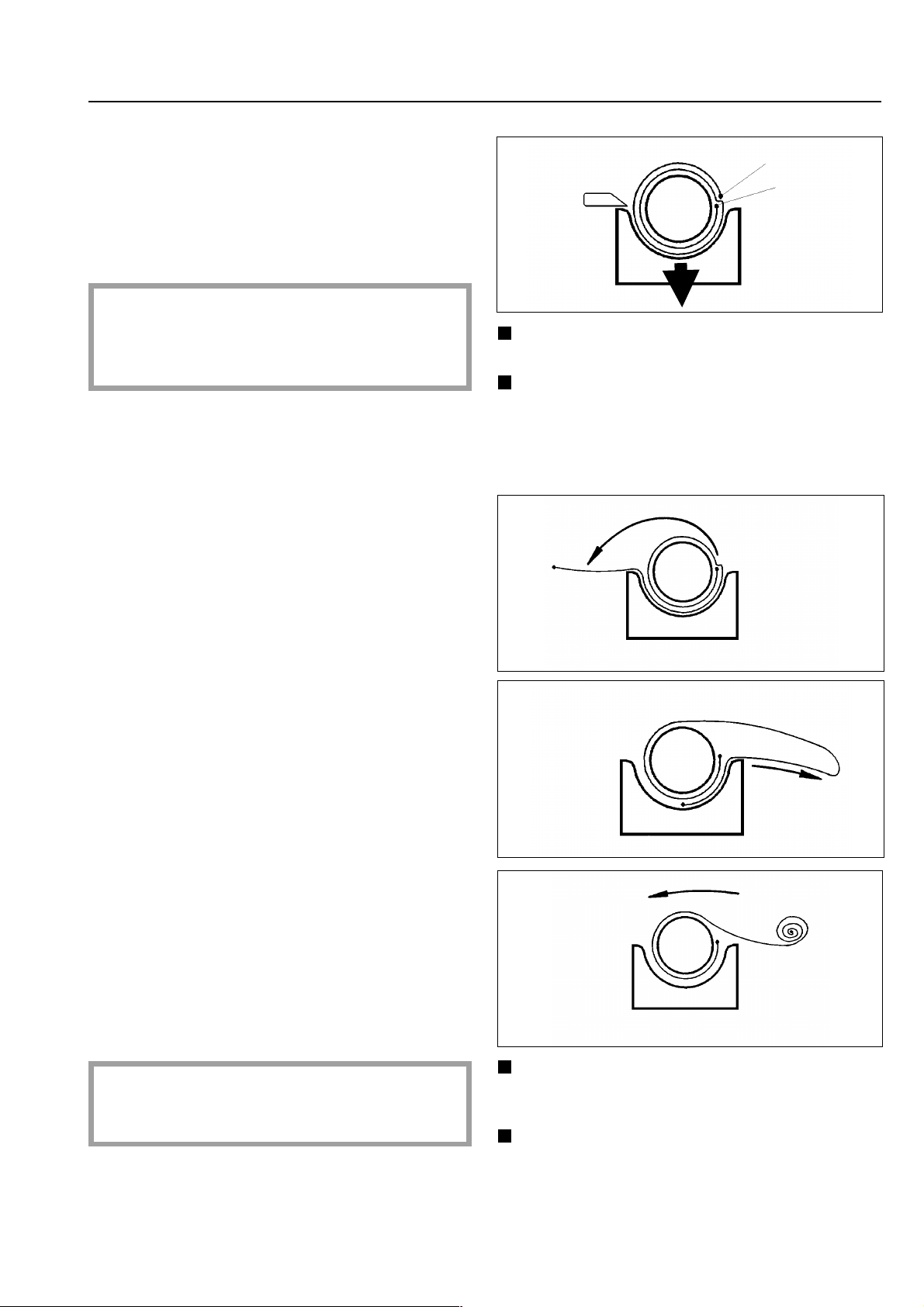

Removing the ironing cloth roller cover

Before removing the ironing cover (for cleaning or renewal) let the heater plate cool

down.

The end of the ironing cover must be visible

at the top of the roller.

Switch the machine off at the mains and raise

the pick-off attachment.

Loosen the side ties and lay the end of the

ironing cover over the feed in table or to the

back of the ironer.

Press the "Reverse run" Ö button and carefully remove the ironing cover.

Roller padding (steel wool)

Renewal or rewinding of the steel wool roller

padding should only be carried out by a Miele

authorised service engineer.

To avoid the danger of injury protective

gloves should be worn whilst renewing the

roller padding.

Replacing the ironing cloth roller cover

Do not wash the new cloth roller cover

before use.

Heat the roller up and in the pressed on position lay the new cloth on to the roller following

the direction of the arrow on the steel wool

covering. The front edge of the cloth should

be brushed out with a steel brush and fed in.

Let the roller run for approx. 5-10 mins, then

trim off any overlapping strands and comb

them out as done at the front edge of the

cloth.

HM 38-175/205 max. 1158 mm circumference

(with cloth)

Washing an ironing cloth

Ironing cloths which have slight discolouration

should, if possible, not be washed (yellowing

is normal). Heavily soiled cloths should be

washed in a Cottons 95 °C programme, spun

and put back on while still damp.

The following steel wool covering dimensions

should be maintained:

HM 38-175/205 max. 1138 mm circumference

(without cloth)

Remove any particles of steel wool that may

have fallen on the heater plate.

M.-Nr. 05803030 18

Cleaning and care

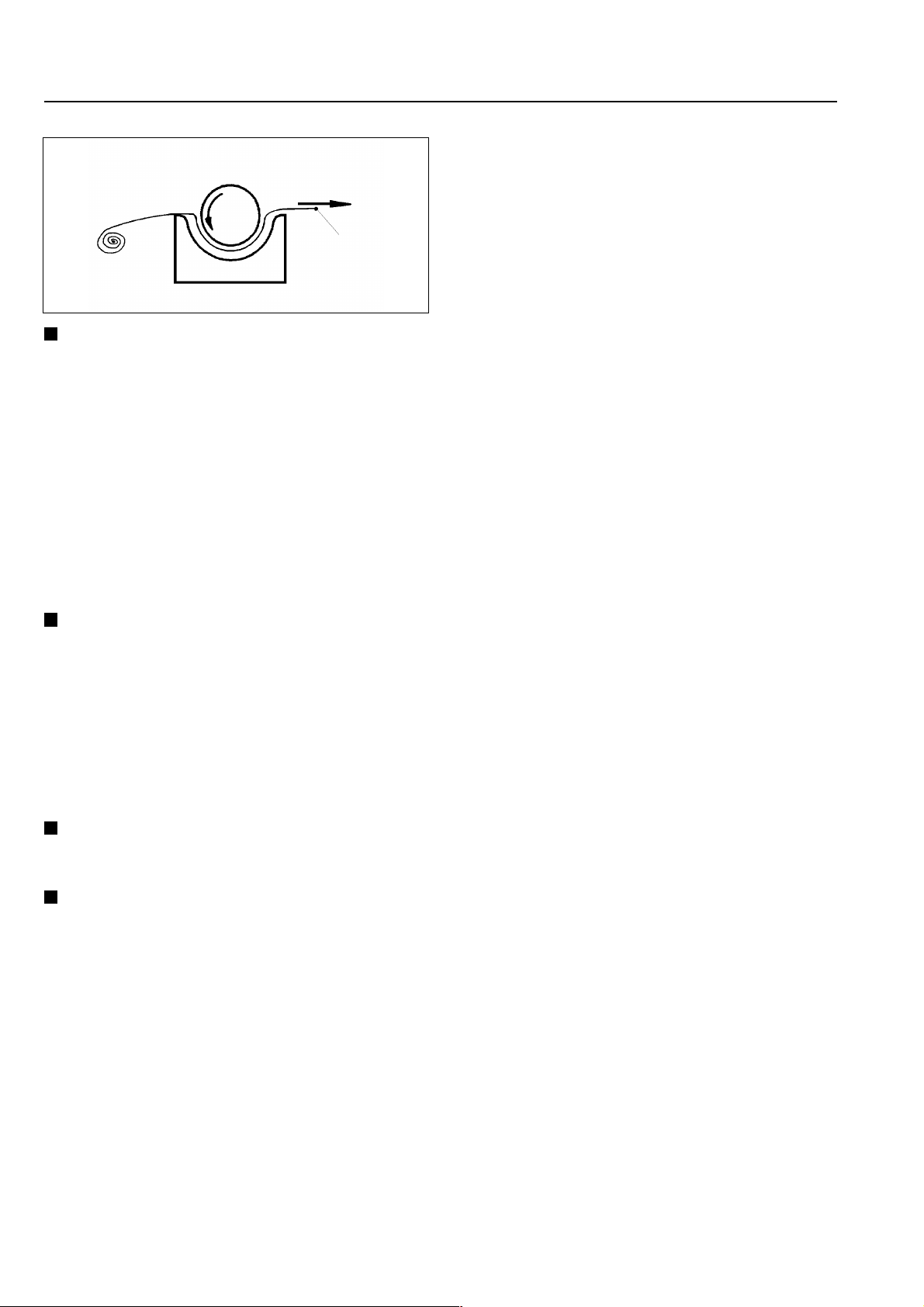

Leaf-type roller padding

To ensure smooth functioning of the ironer

and high capacity ironing, low servicing and

long life the laminated leaf-type padding

should have the specially made ironer roller

cloth cover fitted.

Note: Only iron articles up to max. 3 mm

thick. Thick knobbly fabrics, high buttons,

curtain weights etc. could damage the leaftype padding.

After commissioning

It is advisable approx. 40 operating hours

after commissioning to cut back the overlap of

the ironing cover which has occured through

stretching to about 20 mm overlap and then

to brush out about 15 mm of this using a wire

brush. This is to avoid damp streaks and

shadowing. The roller covering must be the

same thickness along the whole length of the

roller and fit firmly up to the heater plate.

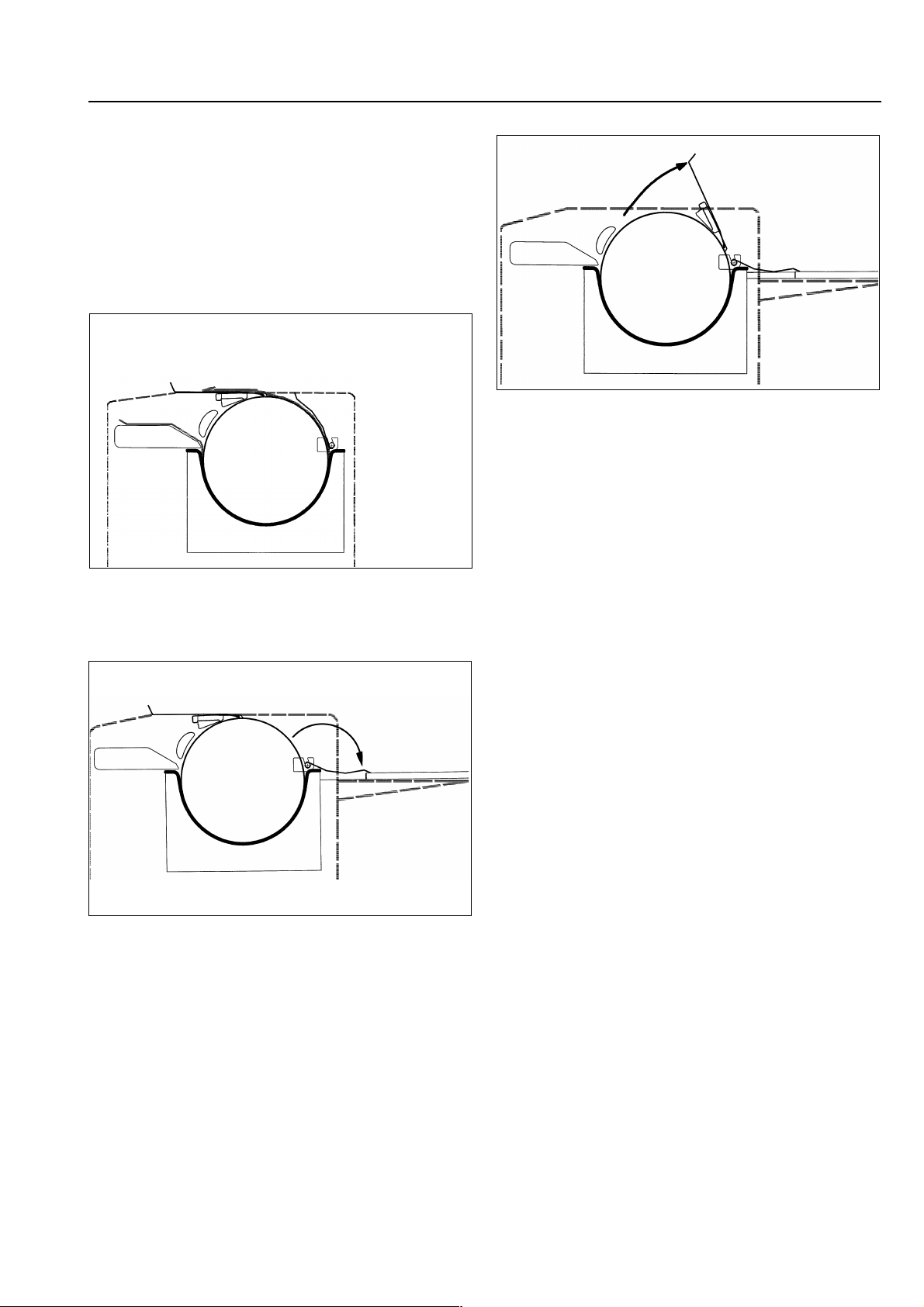

Cloth end

Laundry

feed-in

Switch the machine off, the heater plate

withdraws.

When removing and replacing the ironing

cloth cover the hand wheel should be

turned in an anti-clockwise direction as far

as it will go, so that the heater plate drops

right down and cannot rise up again.

Cloth leading edge

Phase 1

Washing the ironing roller cloth cover

Washing will restore the ironing cover to a softer and more elastic condition, which

absorbs moisture better, and clear the wax

deposits. It should, however, be washed as

infrequently as possible in a Cottons 95 °C

programme. The cover should be completely

alkali free after the last rinse. Do not treat with

solvent or spin too strongly, to avoid the danger of creasing.

Removing the ironing cover on rollers with

leaf-type padding

If a new ironing cover is being fitted it

should first be washed in a Cottons 95 °C

programme.

Phase 2

Phase 3

Phase 4

Raise the laundry pick-off attachment.

Remove the cloth cover as shown in

phases 2 to 4.

When removing pull slowly and carefully

away from the grippers on the leaf-type

padding.

19 M.-Nr. 05803030

Cleaning and care

Discoloration of the ironer cloth

Some discoloration of the ironer cloth from

light to dark brown is normal.

Cloth leading

edge

Phase 5

Switch the machine on, set to the slowest

speed and let the ironing cloth cover run

through as shown in phase 5.

Fitting the ironing cloth cover on a roller

with leaf-type padding

The ironing cover should be wound back on

when still damp.

A double layer is wound on to the roller in one

operation. Do not tuck in the cloth at the ends

of the roller.

Place the cloth in position. Ensure that the

hand wheel is turned as far as it will go in

an anti-clockwise direction, so that the

heater plate is lowered and cannot rise up

again. Switch the machine on and feed it in

following the laundry feed direction using a

low roller speed setting until it lies smooth

and flat. This is to ensure that the heater

plate does not get damaged by the grippers on the leaf-type padding.

To avoid the cloth turning black:

- always use the complete width of the roller.

- space out smaller items and do not always

place them in the same place.

- in pauses between ironing, withdraw the

heater plate or trough and reduce the

temperature.

Switch the machine off and turn the hand

wheel in a clockwise direction about 4

times to raise the heater plate.

Switch the machine on and the heater

plate will raise up completely. Let the roller

rotate slowly. The ironing cloth cover must

have no creases in it. Let the roller rotate

for about 5 minutes.

M.-Nr. 05803030 20

Symbols on the data plate

1 Machine type

2 Machine number/ (year of manufacture)*

3 Voltage/frequency

4 Control fusing

5 Drive motor

6 Plate diameter/Plate qty.*

7 Drum data*

8 Drum diameter/Drum depth*

9 Spin speeds*

10 Drum volume/Laundry dry weight*

11 Kinetic Energy*

12 Top running time*

13 Braking time*

14 Heating

15 Electric heating

16 Fusing (to be installed on site)

17 Steam heating indirect*

18 Steam heating direct*

19 Gas heating

20 Commissioning date

21 Water registrationDVGW- test cert (Water)*

22 Field for CE test symbol...(Product ID-No./

Gas)

*)does not apply to this machine

In the event of any faults please contact your

Miele authorised Service Dealer or the nearest Miele Service Department.

When contacting the Service Department,

please quote the Model and Serial number

(Fabr.-N°) of your machine, both of which are

shown on the data plate.

When ordering spare parts from the Spare

Parts Department please quote the Model

and Serial number (Fabr.-N°) of your machine.

Only use Spare Parts approved by the

manufacturer.

Noise emission

HM 38-205 gas 74.1 dB

registered on the "A" scale.

(measured in Germany in accordance with

DIN (IEC) 45 635, machine noise regulations

3.GSGV p 1.1a).

21 M.-Nr. 05803030

Installation

The rotary ironer may only be commissioned by the Miele Service Department or

a Miele authorised Dealer.

This machine must not be installed in the

same room as dry cleaning machines using

perchlorethylene (PER) or Chlorofluorocarbons (CFCs). On combustion, the escaping

vapours are decomposed to form hydrochloric

acid which can result in dangerous consequences.

Transportation to installation site

The machine should be transported on its

wooden base to the site where it will be installed. Only then should it be taken off the

wooden base.

Lifting points for lifting gear such as straps

and hooks are located underneath the side

base frames of the machine stands near the

feet.

When setting up the machine leave at least

400 mm space each side of the machine so

that the side panels are accessible.

Removing the transit fitting.

Remove the transit fitting at the rear of the machine. This is not applicable to gas-heated rotary ironers.

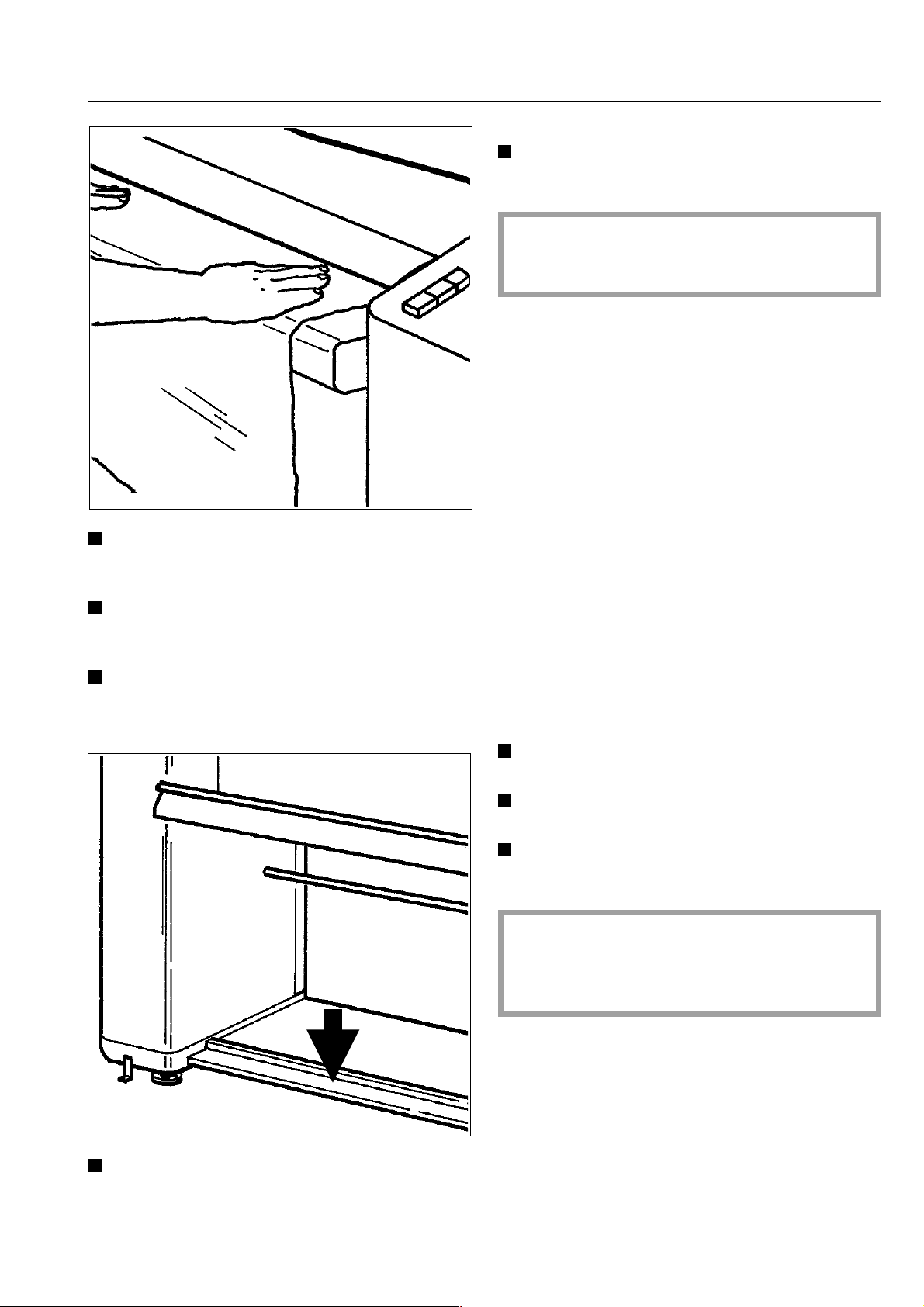

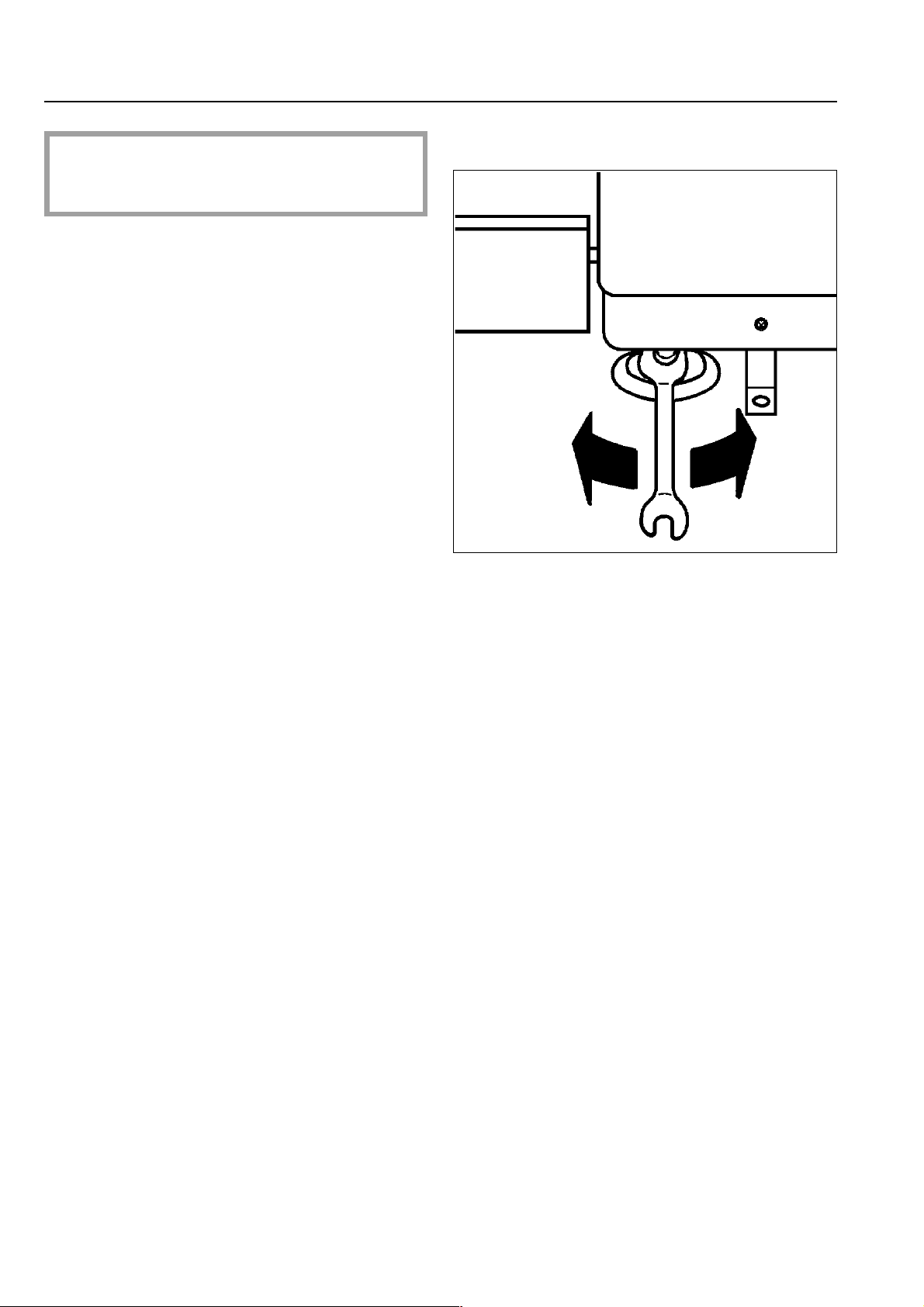

Levelling and securing the ironer

The machine must be level both lengthwise

and widthwise. Use a spirit level and adjust

the feet if necessary (use a SW = 19 mm

spanner).

When adjusting the feet loosen the locking

nuts on the fixing bracket, make the adjustment then tighten the locking nuts back

against the casing.

The ironer should be secured to the floor

using the screws and dowels supplied with

the machine. The holes for the dowels should

be drilled through the holes in the

fixing bracket, (see installation diagram). After

tightening the floor fixing bolts tighten the nuts

which fix the bracket to the machine base.

Attaching the out-tabling

The two support brackets for the out-tabling

on the inside of the end stands should be secured with the M 8 screws supplied.

The separately provided out-tabling is placed

on top of the brackets, levelled so that the

gap between the feed out edge of the roller

and the out-tabling is as small as possible,

and secured with the wood screws provided.

M.-Nr. 05803030 22

Electrical connection

The electrical connection may only be carried

out by a fully competent person in accordance with local and national safety regulations.

The machine is supplied ex works for AC 3N

50 Hz. See the data plate for details.

Connection to the electrical supply must be

carried out in accordance with the data

plate, wiring diagram and installation diagram.

The machine must be connected to a suitable

permanent on-site electricity supply.

WARNING

THIS APPLIANCE MUST BE EARTHED

The wiring diagram and control box are situated underneath the cover on the left hand

stand. The mains connection points are located in the control box.

Before connecting to the mains supply, use

the handwheel to lower the heater plate completely, and then raise it by 12 turns.

Connect the machine to the mains supply and

switch on the on-site mains switch.

If the phase connection is correct, the heater

plate will withdraw.

If the phase connection is incorrect the heater

plate moves into position and two phases

must be changed. Turn the handwheel 12

times to lower the heater plate and switch on

the on-site mains switch.

Once the basic temperature has been

reached raise the heater plate by pressing

button "I".

Exhaust ducting

Refer to calculation of air outlet, air inlet and

ventilation cross sections

The exhaust ducting to be installed on site,

must not be piped into any chimney which is

used by gas, solid fuel or oil fired boilers. It

must also be kept separate from any exhaust

system leading from a tumble dryer.

The warm, moist exhaust air should be discharged into the outside air by the shortest

possible route.

To ensure optimum flow, the ducting should

be laid with as few bends as practicable, and

airtight connections.

The connection point for the exhaust ducting

is situated at the rear of the right hand stand.

To prevent condensation from collecting in

ducting which slopes upwards, provide a condensate trap (3-5 mm diameter) at the lowest

point.

The exhaust ducting must have an internal

diameter of 60/70 mm.

Ensure that there is sufficient ventilation in

the room where the ironer is installed.

If the exhaust is piped into the outside air, the

end of the duct should be protected against

bad weather conditions.

An exhaust duct vented to the outside should

terminate in a freely exposed position and

must be so situated as to prevent the exhaust

from causing a nuisance.

After connecting the machine to the

electricity supply any removable outer panels must be back in place, and all moving

or electrical parts shielded before the

machine is switched on.

23 M.-Nr. 05803030

Gas connection

The gas connection may only be carried out

by a suitably qualified engineer (eg. Corgi in

the UK) in accordance with local and national

safety regulations.

The enclosed installation diagram and the

installation instructions for gas must be followed to ensure correct gas connection.

Check the adhesive label at the rear of the

machine for the gas type to which the

machine has been set at the factory.

When converting to liquid gas or another gas

type, a conversion kit is required, available

from the Miele Spare Parts Department, (give

the model and serial number of the machine

as well as the local gas connection pressure).

The installation instructions for gas heated

machines must be followed. Conversion may

only be carried out by suitably competent persons. Contact your nearest Miele Service Department or your Miele authorised Service

Dealer.

Do not attempt to undertake any repairs to

gas appliances yourself. Repairs must only

be carried out by suitably competent persons

to ensure safety, e. g. gas engineers must be

registered. Please consult the Miele Service

Department or a Miele authorised Service

Dealer.

Exhaust ducting

Please refer to the Installation drawing and instructions supplied.

The connection point for the exhaust ducting

is situated at the rear of the right hand stand.

On first commissioning there can be air in the

inlet pipe, with no ignition taking place in the

first safety period. In this case the ignition

fault light comes on, and the "Reset" button

must be pressed in.

This renewed start procedure can be repeated several times, until the air has been bled

and the burner flame burns.

Note:

If no flame signal appears during the safety

period, the valve shuts and the ignition is switched off, (malfunction cut-out with locking).

The "Ignition fault" indicator light comes on.

To unlock, press the Reset button.

After connecting the machine to the gas

supply any removable outer panels must

be back in place, and all moving or electrical parts shielded before the machine is

switched on.

M.-Nr. 05803030 24

25 M.-Nr. 05803030

M.-Nr. 05803030 26

Indice

Página

Advertencias concernientes a la seguridad . . . . . . . . . . . . . . . . . . . . . . . . 28

Su contribución a la protección del Medio Ambiente . . . . . . . . . . . . . . . . . . . 30

Descripción del aparato . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

– Elementos de mando . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

– Dispositivos de seguridad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Manejo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

– Características y preparación de la ropa . . . . . . . . . . . . . . . . . . . . . . . . . . 35

– Planchado . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

– Planchado a vapor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

– Después del planchado . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Generalidades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

– Corte de corriente durante el planchado . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Dotación especial (bajo pedido)/ Módulo-guía de retorno . . . . . . . . . . . . . . . . . 39

Dotación especial (bajo pedido)/ Cintas introductoras . . . . . . . . . . . . . . . . . . 40

Limpieza y mantenimiento . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

– Aplicación de cera a la teja . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

– Instrucciones para el rebobinado con lana de acero . . . . . . . . . . . . . . . . . . . . 42

– Bobinado elástico laminar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Símbolos de la placa de características . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Para el técnico . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

– Emplazamiento de la máquina . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

– Retirar el seguro de transporte . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

– Montaje de la mesa . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

– Conexión eléctrica . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

– Conexión a gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

– Conducción de salida de vaho . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

¡La planchadora se instalará exclusivamente

por un técnico autorizado!

27 M.-Nr. 05803030

Advertencias concernientes a la seguridad

Lea atentamente las "Instrucciones de manejo" antes de poner la planchadora en

servicio, para protegerse y evitar el deterioro de la máquina debido a un manejo

incorrecto.

Uso adecuado de la planchadora

Esta planchadora deberá utilizarse exclusivamente para tejidos lavados con agua y

aptos para el planchado mecánico.

Seguridad técnica

No se permite el emplazamiento de la

planchadora en una misma estancia con

máquinas de limpieza química que utilizan disolventes con percloroetileno o CFC.

La planchadora sólo deberá utilizarse en

estancias secas.

Utilizar la planchadora sólo con todos los

revestimientos montados y, por consiguiente, no existe riesgo alguno de poder llegar al

contacto con los elementos eléctricos o piezas

giratorias de la máquina.

No dañar, eliminar o descartar los disposi-

tivos de seguridad y elementos de mando

de la planchadora.

La planchadora sólo quedará desconectada

de la red eléctrica, cuando se haya extraído

la clavija de la base de enchufe o desactivado

el fusible de la instalación central del lugar de

emplazamiento.

Utilización

Nunca deberá permitirse que los niños

jueguen encima o cerca de la máquina o

que la manejen.

Con la planchadora caliente existe el ries-

go de quemarse, cuando se llegue al contacto con el borde de la teja en la salida de la

ropa.

Al planchar y alisar la ropa de varias capas,

no deberán introducirse las manos entre

las mismas. Existe el grave riesgo de no poder

apartar a tiempo las manos de la teja caliente.

Lo mismo rige para bolsillos que miran con la

parte abierta hacia la teja.

Sólo con entrada de correa:

No planche piezas de ropa con flecos, cintas finas o hilos. Existe el peligro de que

estos tejidos provoquen un fallo en el funcionamiento de la entrada de correa.

Tenga preparado un extintor para el caso

de que una prenda se pudiera inflamar.

Una planchadora con elementos de mando o conducciones eléctricas deterioradas

no deberá utilizarse antes de ser reparada.

Cualquier reparación de aparatos eléctricos

deberá llevarse a cabo exclusivamente por

personal autorizado. De lo contrario podrían

surgir riesgos considerables para el usuario.

Los componentes defectuosos únicamen-

te deben cambiarse por piezas de recambio originales Miele. Sólo en estas piezas

garantizamos que cumplen en todo su alcance las exigencias de seguridad que planteamos a todas nuestras máquinas.

La seguridad eléctrica del aparato tan

sólo está garantizada por una toma de tierra debidamente instalada. La comprobación

de este detalle por un técnico autorizado es

de suma importancia. Al fabricante no podrán

reclamarse daños y perjuicios, que sean consecuencia de la falta de una toma de tierra o

de su estado defectuoso.

¡Además ha de tenerse en cuenta cualquier

normativa de seguridad complementaria y

vigente al respecto!

Utilización de accesorios

El montaje exterior o interior de accesorios

que puedan afectar el funcionamiento de

la maquina, tan sólo está permitido con la

expresa aprobación por parte de Miele. El

montaje o la incorporación de elementos de

procedencia ajena conllevaría la pérdida de

garantía y/o responsabilidad de producto por

parte del fabricante.

M.-Nr. 05803030 28

Advertencias concernientes a la seguridad

Normas para trabajar en planchadoras

En el lado de la introducción de ropa sólo

deberán emplearse operarios mayores de

17 años, que estén totalmente familiarizados

con el manejo de la planchadora.

El personal con dedos largos y finos debe-

rá operar en la salida de ropa, no en el

lado de la introducción de ropa.

Los operarios de la planchadora deberán

vestir prendas ceñidas. Las mangas anchas,

cintas de delantales y puntas de pañuelos podrían ser pilladas por el rodillo.

Antes de empezar a trabajar, quitarse sor-

tijas, brazaletes y similares.

No doblar la ropa inmediatamente delante

de la boca de admisión, sino a una distancia prudente en la tabla auxiliar. Cualquier tipo

de fundas (almohadas) deberá introducirse

comenzando con la parte abierta. No sujetar

las esquinas desde el interior. No enganchar

las manos en los tirantes de delantales o

prendas similares.

Medidas de seguridad en caso de olor

a gas (Exclusivamente para planchadoras

con calefacción a gas)

¡Apagar las llamas inmediatamente!

¡Abrir ventanas y puertas!

¡Seguidamente, cerrar el paso de gas al

contador o la llave de paso principal!

¡No entrar con llama viva en una habitación

donde huela a gas!

¡No encender cerillas/mecheros!

¡No fumar!

¡No producir chispas eléctricas (p. ej., sa-

cando enchufes eléctricos o accionando

interruptores / timbres)!

¡Cerrar la llave de paso de la toma de gas

de la planchadora (instalación en el lugar

de emplazamiento)!

En el caso de no dar con la causa del olor

a gas a pesar de hallarse cerrados todos

los pasos de gas de la instalación: avisar a

la compañía de abastecimiento de gas.

Siempre se ha de prestar atención al debi-

do funcionamiento de los dispositivos de

protección. Tan sólo así podrán prevenirse

lesiones graves, como contusiones, quemaduras o hasta la pérdida de manos.

¡Comprobar a diario la eficacia de los

dispositivos de protección!

Hay que procurar que sea prácticamente

imposible poder sobrepasar los listones

protectores.

Antes de conmutar al funcionamiento de

’marcha atrás’ hay que cerciorarse que

nadie corra peligro.

En caso de calefacción a gas ha de procu-

rarse la buena ventilación del lugar de trabajo.

¡Lubricar la máquina sólo cuando esté

parada!

¡Importante!

Al terminar los trabajos de puesta en servicio/

mantenimiento/modificación/reparación, siempre ha de comprobarse la estanqueidad de

todos los elementos conductores de gas (desde las llaves de paso hasta los quemadores),

¡prestando especial atención al manguito de

medición en la válvula de gas y en el quemador!

La comprobación ha de realizarse con el quemador encendido y apagado.

Las advertencias anteriores han de ponerse

en conocimiento de todo personal que trabaje

en la planchadora/calandra.

¡Conservar las presentes ’Instrucciones

de manejo!

29 M.-Nr. 05803030

Contribución a la protección medioambiental

Desestimación del embalaje/aparato inservible

El embalaje protege al aparato de daños durante el transporte. Los materiales de embalaje

se han seleccionado con criterios ecológicos

y en función de su posterior tratamiento en

plantas de reciclaje.

La devolución del embalaje al ciclo de reciclado

contribuye al ahorro de materias primas y reduce el aumento de residuos. Por tanto, dichos

materiales no deberán tirarse a la basura, sino

entregarse en un punto de recogida específica

¡Infórmese al respecto en su Ayuntamiento!

Desestimación de un aparato inservible

Cualquier aparato inservible lleva componentes

aprovechables que no tienen desperdicio y de

ningún modo deberán parar en el vertedero.

Infórmese en su Ayuntamiento y en un establecimiento de desguace de vehículos acerca

de las posibilidades de reciclaje.

Hasta el transporte al desguace ¡guarde la

máquina inservible fuera del alcance de los

niños!

M.-Nr. 05803030 30

Descripción del aparato

yx

12 3 4 5 6 7 8

1 Tecla “I" - conexión 5 Regulador de la velocidad del rodillo

2 Tecla “O" - desconexión 6 Piloto de control de anomalías "yx encendido"*

3 Tecla “Ö Marcha atrás” 7 Piloto de control de temperatura "°C"

4 Piloto de control de funcionamiento "I" 8 Selector de temperatura

Desprendedor de ropa

Rodillo

Listón protector de dedos Panel de mandos

Tecla de anulación*

Mesa entrada de ropa Tabla auxiliar

Parada de

emergencia Parada de

Chapa protectora* emergencia

Cajón recogida de ropa

Manivela

Volante

Tubo de salida

de gases

de combustión*

Sujeción/anclaje al suelo (4 )

Patas regulables (4)

Pedal de funcionamiento

*) Sólo planchadoras con calefacción a gas

HM 38-175

31 M.-Nr. 05803030

Descripción del aparato

Pilotos de control

Piloto de control de funcionamiento "I"

Elementos de mando

Tecla "I"

Al pulsar la tecla I se encienden los pilotos co-

rrespondientes a "Funcionamiento" I y "Tem-

peratura" °C.

–La teja se calienta.–

Al haber alcanzado la temperatura seleccionada, el piloto de control °C se apaga.

Pulsando la tecla I de nuevo, la teja se junta

con el rodillo que empieza a girar.

Tecla "O"

Pulsar la tecla para desconectar la planchado-

ra. La teja se separa del rodillo.

Tecla "Ö Marcha atrás"

La marcha atrás se selecciona tan sólo para

sustituir el paño de planchado o renovar el bobinado del rodillo.

Desconectar la máquina –la teja se separa–.

Pulsar "Ö Marcha atrás". El rodillo sólo gira

en marcha atrás, mientras que se mantenga

la tecla pulsada.

Se enciende después de pulsar la tecla I .

Piloto de control de temperatura "°C"

Se enciende durante el calentamiento y se

apaga, cuando se haya alcanzado la tempera-

tura seleccionada.

Planchadoras con calefacción a gas:

Piloto de control "y x Fallo de encendido"

Se enciende en caso de anomalía en el en-

cendido de la calefacción o en caso de una

depresión insuficiente en la conducción de sa-

lida de aire (obstrucción).

Tecla "y x Anulación" (en la columna dere-

cha, en la parte interior, debajo del tablero

de introducción)

La anomalía en el encendido se puede elimi-

nar como muy pronto transcurrido 1 minuto,

pulsando la tecla "Anulación". En caso de

producirse estas anomalías en el encendido

a menudo, se debe informar al Servicio Post-

venta.

M.-Nr. 05803030 32

Descripción del aparato

Selector de temperatura

Zona ● = temperatura baja

Zona ● ● = temperatura media

Zona ● ● ● = temperatura alta

Regulador de la velocidad del rodillo

Girando el mando hacia la derecha: mayor

velocidad,

girando hacia la izquierda: menor velocidad.

El máximo caudal de aire se da en la posición

inicial del tornillo de ajuste (véase fig.) y se irá

reduciendo a medida que se vaya girando hacia la posición de 90°.

La posición óptima de la trampilla se habrá

conseguido, cuando el rodillo se seque con

un caudal mínimo, no quedando manchas de

agua, ni en el revestimiento, ni en la ropa

planchada.

En el caso de una absorción excesiva, el rodillo se enfriaría demasiado, perjudicando el

efecto de planchado.

Trampilla reguladora de absorción de vaho

(sólo planchadoras con calefacción a

eléctrica)

El sistema de absorción de vaho lleva incorporada una trampilla reguladora que permite

reducir el caudal de aire que pasa por el revestimiento del rodillo.

33 M.-Nr. 05803030

Pedal de accionamiento

Funciones:

Pedal sin pisar Planchado

Pedal pisado Planchado a vapor

Descripción del aparato

Dispositivos de seguridad

Interruptor de emergencia (en la parte delantera de la columna izquierda y en la parte posterior de la columna derecha)

Al pulsar este interruptor, el rodillo se para

inmediatamente, separándose la teja. Un interruptor de emergencia activado se le restituye

en su función, girando el disco moleteado hacia la derecha.

El listón-protector de dedos es un disposi-

tivo de seguridad, cuya eficacia ha de com-

probarse a diario y con anterioridad a cada

uso de la planchadora.

Listón-protector de dedos

Si las puntas de los dedos fuesen a parar entre

la tabla auxiliar de introducción de la ropa y el

dispositivo protector de dedos, el rodillo pararía

inmediatamente, separándose la teja hacia

abajo. Cuando el rodillo gira al contrario del

planchado, el listón-protector no tiene función.

Tras el accionamiento del protector de dedos,

la máquina sólo podrá ponerse en marcha

pulsando la tecla I de nuevo.

Volante (en el lado posterior de la

columna derecha)

Sirve para separar manualmente la teja caliente

del rodillo parado en caso de un corte de co-

rriente. Girando en contra del sentido de las

agujas del reloj, la teja se separa bajando y,

girando en el sentido de las agujas del reloj,

a teja se junta con el rodillo.

¡La máquina siempre tiene que estar des-

conectada de la red eléctrica (desconectar

el interruptor principal de la instalación

del cliente)!

M.-Nr. 05803030 34

Manejo

Características y preparación de la ropa

Condición para un buen acabado de la ropa

es una humedad residual adecuada (entre un

25 y 40%).

Si se aclara la ropa en la lavadora utilizando

agua caliente en el último ciclo, se obtiene debido a la reducción de la humedad residual y

al calor de la ropa un tiempo más corto de

procesamiento y con ello, un ahorro de energía.

Los tejidos de mezcla, cuyo contenido en

fibras sintéticas supere el 50% (p. ej.,

dralón) no deberán plancharse, ya que la

materia sintética sometida a altas temperaturas se funde.

Los tejidos con una parte menor en fibras

sintéticas podrán plancharse a temperaturas bajas.

Preparación de la ropa

La preparación adecuada de la ropa es importante para un buen resultado de planchado y

la máxima rentabilidad. Conviene clasificarla

según tamaño y características.

Las cremalleras y botones/ganchos metálicos

deberán cubrirse con un paño, a fin de proteger la teja.

Los suplementos no termorresistentes y extremadamente sobresalientes (botones-perlas)

no deberán plancharse.

¡Comprobar la eficacia del dispositivo protector de dedos!

El listón protector de dedos es un dispositivo

de seguridad, cuya eficacia ha de comprobarse a diario y con anterioridad a cada

uso de la planchadora.

Al activar el dispositivo protector de dedos, el

rodillo tiene que pararse y la teja separarse

del mismo.

Cuando el rodillo gira al contrario del planchado, el listón-protector no tiene functión.

La restitución de la disposición de servicio se

consigue pulsando la tecla "I".

Proceder al planchado según la resistencia

térmica de la ropa:

perlón, nylón y similares (Zona ●)

Lana, Seda (Zona ●●)

Algodón, Lino (Zona ●●●)

Si fuera necesario bajar a un nivel de temperatura inferior, tendrá que esperarse a que se

encienda el piloto "Temperatura C°.

La ropa almidonada se planchará al final, para

evitar que las partículas de almidón adheridas

en la teja no perjudiquen las demás prendas.

Las piezas con botones se colocan con el

botón mirando hacia el rodillo. De lo contrario

correrían el riesgo de ser arrancados o destruidos al entrar en contacto con la teja.

35 M.-Nr. 05803030

Manejo

Planchado

Conectar el interruptor principal (del lugar

de emplazamiento).

Abrir la llave de paso de gas (del lugar de

emplazamiento).

Los pilotos de control para funcionamiento I

y temperatura °C se encienden y la teja se

calienta. Al apagarse el piloto °C se ha alcanzado el nivel de temperatura seleccionado.

Pulsar la tecla I de nuevo.

La teja se junta con el rodillo que gira. Dejar girar el rodillo durante aprox. 5 min.

para conseguir el reparto homogéneo de la

temperatura en teja y rodillo.

Seleccionar el nivel de temperatura de

acuerdo con las características de la ropa.

Tipo de tejido Símbolo Posición de

temperatura

Perlón/

Seda artificial

Seda/

Lana

Algodón/

Lino

●

● ●

● ● ●

baja

media

alta

Ajustar la velocidad de planchado deseada

mediante el correspondiente regulador.

¡Comprobar la eficacia del dispositivo protector de dedos!

Conectar la máquina, pulsando la tecla "I".

M.-Nr. 05803030 36

Manejo

Introducir la ropa preparada por encima de

la tabla auxiliar.

Al planchar, alisar la ropa desde el centro

hacia los extremos.

El planchado a vapor se termina, retirando

el pie del pedal.

La ropa planchada puede estar muy caliente cuando sale de la planchadora. Si es

preciso lleve guantes para proteger sus

manos.

En los descansos levantar la teja y reducir la

temperatura de la misma.

Desprendedor de ropa

Cuando la ropa sale expulsada del planchado,

el desprendedor se encarga de separarla del

rodillo. No es necesario hacerlo a mano.

Si alguna prenda provocara que se suelte un

resorte del desprendedor, se le devolverá a

su posición correcta, presionando con la

mano.

Las prendas pequeñas no deberán plancharse solamente en un punto del rodillo, sino

que conviene hacer uso de toda la anchura

del mismo, alternando.

Para planchar a vapor, pisar el pedal de

accionamiento.

- El rodillo se para.

Después del planchado

Una vez terminado el planchado y con

objeto de eliminar la humedad del revestimiento del rodillo, deberá seguirse planchando unos minutos con la calefacción

desconectada, aprovechando el calor

residual de la teja.

Desconectar la planchadora, pulsando la

tecla "O".

Cerrar la llave de paso del gas (instalación

del lugar de emplazamiento).

Desactivar el interruptor principal (instalación

del lugar de emplazamiento).

Antes de embalar o apilar la ropa planchada,

ésta se debe enfriar lo suficientemente.

La ropa caliente podría autoinflamarse y

provocar un incendio.

37 M.-Nr. 05803030

Generalidades

Guardamotor

En caso de un calentamiento excesivo del bobinado del motor debido a la sobrecarga del

mismo, un termostato se encarga de desconectarlo automáticamente. La teja se separa

del rodillo. Tras el enfriamiento suficiente, la

planchadora tendrá que conectarse de nuevo,

pulsando la tecla I.

¡En todo caso deberá evitarse el funcionamiento innecesario de la planchadora sin

ropa!

No planchar las prendas pequeñas solamente

en un punto del rodillo, sino que conviene hacer

uso de toda la anchura del mismo, alternando.

Así se evita también un desgaste irregular del

bobinado.

Protección contra la falta de aire*

En caso de falta de aire la calefacción se desconecta automáticamente y se ilumina el piloto "Anomalía en el encendido". Después de

pocos minutos se puede planchar sólo en frío.

Se ha de comprobar si la conducción de salida

de gases de combustión está obstruida.

Si no se puede detectar ninguna anomalía en

la conducción de salida de gases de combustión, se debe informar al Servicio Post-venta.

Corte de corriente durante el planchado

En la parte posterior del montante derecho

se halla un volante que gira, cuando la teja se

junta con el rodillo. En caso de un corte de

corriente sirve también para poder separar la

teja del rodillo manualmente, girándolo en

sentido contrario de las agujas de reloj.

Protección contra la falta de gas*

En caso de que la llave de gas esté cerrada o

la presión de la red de gas sea excesivamente

baja, no se puede conectar la planchadora.

Si durante el funcionamiento la presión de la

red de gas bajase a unos valores inadmisibles,

la planchadora se desconecta automáticamente

y la teja baja. Pulsando la tecla "I" se puede

conectar la planchadora sólo, si se dispone

de la presión de gas necesaria.

En caso de que esta anomalía se produjese a

menudo, ha de avisarse a un técnico autorizado para que compruebe el sistema de conducción de gas del lugar de emplazamiento.

*) Sólo planchadoras con calefacción a gas

M.-Nr. 05803030 38

Dotación especial (bajo pedido)

Módulo-guía de retorno

Módulo-guía de retorno

El módulo-guía de retorno permite la instalación

de la máquina junto a la pared y el manejo por

una sola persona, que introduce y recoge la

ropa en el lado frontal.

El módulo-guía de retorno conduce la ropa

planchada hacia delante a una bandeja recogedora, que se encuentra encima del listón

protector de dedos.

Seguidamente se dobla el módulo-guía hacia

atrás. La ropa planchada será llevada a la tabla

receptora.

Para cambiar el paño de planchado o rebobinar

el rodillo se deben extraer las láminas elásticas

del desprendor de ropa una por una.

Si se desea que la ropa sea llevada a la tabla

receptora de la parte posterior, se coloca la

chapa-guía rebatible hacia atrás, mirando a la

tabla receptora.

39 M.-Nr. 05803030

Dotación especial (bajo pedido)

Cintas introductoras

Cintas introductoras

Las cintas introductoras facilitan la introducción de las prendas.

Colocar las prendas sobre las cintas al principio de la mesa, en paralelo al rodillo, alisarlas

y dejar que entren en la planchadora.

Ajuste de la mesa auxiliar

Chapa protectora

Es posible extraer la ropa que pudiera haber-

se introducido incorrectamente, mediante la

correa, desplazando hacia delante la chapa

protectora.

Empleando un dispositivo auxiliara decuado,

no metálico, extraer la prenda de ropa a tra-

vés de la ranura situada entre el cajón para

ropa y la chapa protectora.

La medida de ajuste de la mesa auxiliar es de

máx. 14,5 mm.

M.-Nr. 05803030 40

Limpieza y mantenimiento

Aplicación de cera a la teja

Con objeto de mantener la propiedad del fácil

deslizamiento, repasar la teja periódicamente

con un paño de cera especial para planchadoras.

Cera granulada

Impregnar de cera la tira central de un paño

fino.

Mantenimiento de la teja de aluminio

Cuando la teja presente residuos de cal o

almidón, podrán eliminarse con productos

limpiadores comunes. ¡No utilizar productos

abrasivos o paños especiales con papel de

lija incorporado!

Desprendedor de ropa

Siempre que se proceda a la limpieza de las

chapas elásticas de los desprendedores o del

paño de planchado, al rebobinado del rodillo

o se quiera prescindir del servicio de los desprendedores durante un tiempo breve, se los

colocará en posición vertical.

Tras el uso prolongado de la planchadora tendrá que procederse a la limpieza de las puntas de las chapas elásticas (deposiciones de

almidón, polvo y similares). Tan sólo así quedará garantizado su debido funcionamiento.

Sentido de introducción

Dóblense sus dos extremos e introdúzcase en

la planchadora como si se tratara de un prenda cualquiera. Ha de tenerse en cuenta, sin

embargo, que los extremos plegados han de

estar dirigidos hacia el rodillo.

El paño puede introducirse tanto por la derecha

como por la izquierda, pasando, en los espacios precisos, por todo el ancho del rodillo

dejando.

Tanto el encerado como la limpieza de la teja

deberán hacerse ajustando la temperatura a

● ● ● y reducir la velocidad a la mínima.

Cojinetes y engranaje

Tanto los cojinetes como el engranaje están

provistos del lubricante suficiente para un servicio de varios años.

¡Engrasar la máquina sólo, cuando esté parada y desconectada eléctricamente!

¡Con los revestimientos de la máquina quitados existe el riesgo de quemarse!

¡Una vez terminados los trabajos de mantenimiento han de volver a montarse los revestimientos de la máquina!

El paño y la cera se podrán adquirir a través

del Servicio Post-venta Miele o su distribuidor

Miele.

41 M.-Nr. 05803030

Limpieza y mantenimiento

Advertencias para el rebobinado del rodillo

con lana de acero

Quitar el paño de planchado

Antes de quitar el paño de planchado (en caso

de limpieza o sustitución), dejar enfriar la teja.

El borde final del paño tiene que quedar en la

parte superior del rodillo.

Desconectar la máquina y colocar el desprendedor de ropa en posición vertical.

En caso necesario, desatar las cintas a ambos

extremos y colocar el final del paño en la tabla

auxiliar o ponerlo hacia atrás.

Desconectar la máquina y colocar el desprendedor de ropa en posición vertical.

Pulsar la tecla "Ö Marcha atrás" y retirar

con cuidado el paño de planchado.

Bobinado

El rebobinado o la sustitución completa del

bobinado del rodillo con lana de acero deberá

realizarse exclusivamente por el personal autorizado del Servicio Post-venta.

Colocación del paño de planchado

No lavar un paño de planchado a estre-

nar.

Colocar el paño –con la máquina caliente y la

teja juntada al rodillo– en el sentido de la flecha

(flechas en el bobinado de lana de acero).

Peinar el canto del comienzo del paño con un

cepillo de alambre e ir enrollando el paño en

el rodillo.

Dejar girar el rodillo de 5 a 10 min., cortar la

tira sobrante y peinar el canto final del paño.

HM 38-175/205 Perímetro máx. 1158 mm

(con paño)

Lavado del paño

Cuando el paño muestra pequeños cambios

de color, a ser posible no lavarlo (el ponerse

amarillento es un fenómeno normal). Un paño

muy sucio se lavará apropiadamente en el

programa de ropa blanca a 95 °C, se centrifuga

y se vuelve a colocar húmedo.

Para este trabajo conviene ponerse guantes

protectores. ¡Riesgo de lesionarse!

Para el bobinado con lana de acero ha de

atenerse a la medida correspondiente:

HM 38-175/205 Perímetro máx.1138 mm

(sin paño)

Quitar los restos de lana de acero, que hayan

caído en la teja.

M.-Nr. 05803030 42

Limpieza y mantenimiento

Advertencias para el rodillo con bobinado

elástico laminar

Una de las condiciones más importantes para

el perfecto funcionamiento de la planchadora,

el rendimiento máximo y la larga duración del

bobinado sin necesidad de mantenimiento es

la utilización del paño de planchado, de fabricación especial para el bobinado elástico laminar, que mantiene su grosor.

Atención: Con este tipo de bobinado sólo

deberá plancharse ropa hasta 3 mm de

grosor. Las piezas más gruesas con elementos sobresalientes (botones altos, rodillos

de cortinas o similares) podrían causar

deterioros en el laminado elástico.

Tras la puesta en servicio

A las aprox. 40 horas de utilización de la máquina conviene recortar el sobrante del paño

de planchado (estirado debido al efecto del

planchado) a aprox. 20 mm. y peinar los últimos 15 mm. con un cepillo de alambre. Con

ello se impide la formación de franjas húmedas

y sombras de presión. El bobinado tiene que

presentar un grosor homogéneo a lo largo del

rodillo y adaptarse perfectamente a la teja.

Introducción

de ropa

Desconectar la máquina. La teja se separa

del rodillo.

Al quitar y poner el paño de planchado,

girar el volante en sentido contrario de las

agujas de reloj hasta el tope, a fin de que

la teja permanezca separada del rodillo.

Principio del paño

Final de

paño

Fase 1

Fase 2

Lavado del paño de planchado

Con el proceso de lavado se elimina la cera

que se ha quedado en el paño de planchado

y se devuelve a éste su característica elasticidad y capacidad hidroabsorbente. No obstante,

lavarlo con un programa de ropa blanca a 95°C

o darle la vuelta lo menos posible.

Después del último aclarado tienen que haberse

eliminado todos los residuos alcalinos.

¡No aclarar con aditivos! No centrifugarlo mucho, para evitar la formación de arrugas.

Quitar el paño de planchado del rodillo con

bobinado elástico laminar

Cuando se estrena un paño de planchado:

lavarlo antes con un programa de ropa

blanca a 95 °C.

Fase 3

Fase 4

Colocar los desprendedores de ropa en

posición vertical.

Quitar el paño, procediendo según las

figuras correspondientes a las fases 2 a 4.

Al quitar el paño, desprenderlo despacio y

cuidadosamente de las púas de sujeción

del bobinado elástico laminar.

43 M.-Nr. 05803030

Limpieza y mantenimiento

Principio del paño

Fase 5

Conectar la máquina con la menor velocidad

de giro y pasar el paño (véase la figura de

la fase 5).

Colocar el paño de planchado del rodillo

con bobinado elástico laminar

El paño deberá colocarse húmedo en el rodillo.

El paño se enrolla dos veces en el cilindro, no

debiendo remeterlo en los extremos del rodillo.

Decoloración del paño de planchado

Una coloración marrón del paño, incluso fuerte,

es normal.

La posibilidad de que el paño se ponga negro

se puede reducir de la forma siguiente:

- Aprovechar siempre toda la longitud del

rodillo.

- En caso de planchar prendas pequeñas,

utilizar la longitud del rodillo uniformemente y

no plancharlas siempre por el mismo sitio.

- En los descansos levantar la teja y reducir la

temperatura de la misma.

Colocar el paño. Comprobar que el volante

esté girado hasta el tope –en sentido contrario de las agujas de reloj– para que la

teja permanezca separada del rodillo.

Conectar la máquina con la menor velocidad

de giro y pasar el paño en el sentido del

planchado de ropa, hasta que una capa

quede sin pliegues y totalmente lisa. De

este modo las púas de sujeción del bobinado elástico laminar no deterioran la teja.

Desconectar la máquina y juntar la teja con

el rodillo, realizando con el volante 4 giros

completos en sentido de las agujas de reloj.

Conectar la máquina. La teja termina de

juntarse totalmente con el rodillo. Dejar

girar el rodillo despacio. El paño tiene que

quedar bien ajustado, sin formar pliegues.

A continuación, dejar girar el rodillo durante unos 5 minutos.

M.-Nr. 05803030 44

Símbolos en la placa de características

1 Modelo

2 Nº de máquina / Año de fabricación*

3 Tensión / Frecuencia

4 Fusible de maniobra

5 Motor de accionamiento

6 Diámetro de plato / Cantidad de platos*

7 Datos del tambor*

8 Diámetro de tambor / Profundidad de tambor*

9 Revoluciones de centrifugado*

10 Volumen de tambor / Peso de ropa seca*

11 Energía cinética*

12 Tiempo de arranque*

13 Tiempo de frenado*

14 Calefacción

15 Calefacción eléctrica

16 Fusible (instalación en el lugar de emplazamiento)

17 Calefacción a vapor indirecto*

18 Calefacción a vapor directo*

19 Calefacción a gas

20 Fecha de puesta en servicio

21 Homologaciones DVGW (agua)*

22 Espacio para homologaciones/CE-....

(Nº de identificación de producto/Gas)

*) no procede en caso de este modelo de planchadora

En caso de anomalía en el funcionamiento de

la máquina deberá dirigirse al Servicio Postventa de Miele.

El Servicio Post-venta precisa la indicación del

modelo y nº de máquina [Fabr.-Nº]. Ambos

datos se encuentran en la placa de características.

En caso de sustituciones deberán utilizarse exclusivamente repuestos de origen.

(también en este supuesto, el Servicio Postventa necesita saber el modelo y nº de máquina [Fabr.-Nº]).

Emisión de ruido

Nivel acústico según escala A:

HM 38-205 gas 74,1 dB

medido según DIN (IEC) 45 635

45 M.-Nr. 05803030

Para el técnico

La planchadora deberá ponerse en servicio

exclusivamente por personal autorizado del

Servicio Post-venta.

No se permite el emplazamiento de la máquina

en una misma estancia con máquinas de limpieza química que utilizan disolventes con

percloroetileno o CFC.

Los vapores liberados pueden transformarse

–debido a la formación de chispas en el electromotor de colector y consiguiente combustión–