Page 1

TECHNICAL INFORMATION

G600 & G800 Electronic Dishwashers

© 2003 Miele

Page 2

Technical Information

G600 & G800 Electronic Dishwashers

G600 & G800 Electronic Dishwashers – Table of Contents

1.0 Construction Design…………………………………………………………….8

1.1 Appliance Overview................................................ ……………………9

1.1.1 Appliance Overview – Typical Integrated Model....................... 9

1.1.2 Unit Overview – Typical Fully Integrated (VI) Model............... 10

1.2 Controls Overview .............................................................................11

1.3 Types of Dishwashers ........................................................................13

1.4 Technical Data....................................................................................14

1.4.1 Dishwasher Width................................................................... 14

1.4.2 Dishwasher Height ................................................................. 14

1.4.3 Summary of Dimensions......................................................... 15

1.4.4 Electrical Information.............................................................. 15

1.4.5 Hard Wire Electrical Connection............................................. 16

1.4.6 Plumbing Connection.............................................................. 16

1.4.6.1 Intake Connection..................................................... 16

1.4.6.2 Drain Connection...................................................... 16

1.5 Data Tag.............................................................................................17

1.6 Layout of Components........................................................................18

1.6.1 Novotronic and Touchtronic Series......................................... 18

1.6.2 Incognito Series...................................................................... 19

2.0 Installation (Refer to the Appliance Installation Manual)………………. 20

3.0 Commission and Operation………………………………………………….21

3.1 Door Handle and Door Lock (Novotronic & Touchtronic Series).........21

3.2 Closing the Dishwasher Door.............................................................21

3.3 Child Safety Lock................................................................................21

3.4 Water Softener ...................................................................................22

3.5 General Operation – Novotronic Series..............................................23

3.6 General Operation – Touchtronic Series ............................................23

3.7 General Operation – Incognito Series.................................................23

4.0 Description of Function……………………………………………………….24

4.1 Cabinet Construction..........................................................................24

4.2 Fan Assembly (Turbothermic Fan Equipped Models).........................24

4.2.1 PTC Release Element............................................................ 24

4.3 Combination Dispenser ......................................................................25

4.3.1 Construction ........................................................................... 25

4.3.2 Dispensing...............................................................................26

4.4 Heaters...............................................................................................27

4.4.1 Wash Cavity Heating Element............................................... 27

4.4.2 Flow Through Heater:............................................................ 28

2

Page 3

G600 & G800 Electronic Dishwashers

Technical Information

G600 & G800 Electronic Dishwashers – Table of Contents (continued)

4.4.2.1 Flow Through Heater Electrical Data........................ 28

4.5 Heater Circuit - Operation..................................................................29

4.6 Pulsed Heating - Operation................................................................30

4.7 Temperature Protection.....................................................................30

4.8 Static Drying ......................................................................................30

4.9 Spray Arms........................................................................................31

4.9.1 Spray Arms - Rotation Data.................................................. 31

4.10 Filter Assembly..................................................................................31

4.11 Water Intake – Technical Data ..........................................................32

4.12 WaterProof System ...........................................................................33

4.13 Flowmeter - Operation.......................................................................36

4.14 Water Intake......................................................................................37

4.15 Water Mixing......................................................................................38

4.15.1 Water Mixing - External Flowmeter...................................... 38

4.15.2 Water Mixing - Integrated Flowmeter................................... 39

4.15.3 Solenoid Valve - Operating (Plus Models Only).................. 41

4.16 Electronic Controlled Water Hardness...............................................42

4.17 Water Softener ..................................................................................43

4.17.1 Reactivation......................................................................... 44

4.17.2 Reactivation Cycles ............................................................. 45

4.18 Condenser Drying (UKT)...................................................................46

4.18.1 Operation............................................................................. 46

4.18.2 Technical Data..................................................................... 46

4.18.3 Control Valve ....................................................................... 48

4.19 Drain Pump, Circulation Pump ..........................................................49

4.20 Level Switch – Heater (Heater Pressure Switch)...............................49

4.21 Level Switch (Intake Overflow)..........................................................51

4.22 Temperature Sensor..........................................................................52

4.23 Top Solo Valve..................................................................................53

4.24 Turbidity Sensor (ECO Sensor).........................................................54

4.25 Electronic Unit - Power Outputs.........................................................55

4.25.1 Programming After Replacing the Electronic ....................... 56

4.25.2 Electronic Modes ................................................................. 56

5.0 Service and Maintenance……………………………………………………..57

5.1 Locking Plate - Adjustment................................................................57

5.2 Cabinet Seal - Replacement..............................................................57

5.3 Side Panel - Removal........................................................................58

5.4 Spring Bracket - Replacement ..........................................................59

5.5 Cover Plate - Removal .....................................................................60

5.6 Connecting Strip - Removal...............................................................61

5.7 Basket Support Rollers – Replacement.............................................62

5.8 Combination Dispenser - Removal....................................................64

5.9 Turbothermic Fan - Removal.............................................................65

3

Page 4

Technical Information

G600 & G800 Electronic Dishwashers

G600 & G800 Electronic Dishwashers – Table of Contents (continued)

5.10 Door Panel (Outer and Inner) - Removal...........................................66

5.11 Cable Holder - Removal ...................................................................67

5.12 Lock / Handle Assembly - Removal...................................................68

5.13 Door Hinge - Removal.......................................................................69

5.14 Door Tension - Adjustment................................................................70

5.15 Top Spray Arm - Removal.................................................................71

5.16 Middle Spray Arm - Removal.............................................................71

5.17 Bottom Spray Arm - Removal............................................................71

5.18 Top Spray Arm Feed Pipe - Removal................................................71

5.19 Middle Spray Arm Cover - Removal..................................................72

5.20 Middle Spray Arm Feed Pipe - Removal ...........................................72

5.21 Flow-Through Heater - Removal .......................................................73

5.22 Temperature Limiter - Replacement.................................................. 74

5.23 Microfine Filter – Exchange...............................................................75

5.24 WaterProof System (WPS) - Removal...............................................76

5.25 WaterProof System (WPS) Restrictor - Exchange.............................77

5.26 Water Inlet (Diverter) - Removal........................................................78

5.27 Water Softener – Operational Check.................................................79

5.28 Water Softener Assembly- Removal..................................................80

5.29 Drip Tray - Removal ..........................................................................80

5.30 Float Switch Housing - Removal........................................................80

5.31 Float Switch – Removal....................................................................81

5.32 Steam Condenser - Removal ............................................................82

5.33 Control Valve - Removal...................................................................83

5.34 Temperature Sensor (NTC) - Removal ............................................ 83

5.35 Circulation Pump (M6) - Removal...................................................... 84

5.36 Circulation Pump - Partition & Impeller Replacement........................85

5.37 Circulation Pump Housing - Exchange............................................ 86

5.38 Circulation Pump – Release with Tool...............................................86

5.39 Heater Level Switch – Removal.........................................................88

5.40 Drain Pump – Removal .....................................................................89

5.41 Top Solo Valve - Removal.................................................................90

5.42 Overflow Level Switch - Removal......................................................91

5.43 Sump - Removal................................................................................92

5.44 Turbidity Sensor - Calibration............................................................93

5.45 Turbidity Sensor - Removal...............................................................93

5.46 Fully Integrated (Vi) Control Panel - Removal ...................................94

5.47 Novotronic & Touchtronic Control Panel – Removal..........................95

5.48 Fixing Bracket – Removal..................................................................96

5.49 Heating Relay & Power Relay – Removal .........................................97

4

Page 5

G600 & G800 Electronic Dishwashers

Technical Information

G600 & G800 Electronic Dishwashers – Table of Contents (continued)

6.0 Fault Diagnosis……………………………………………………………….....98

6.1 General Information...........................................................................98

6.2 Programming and Service Mode - Features......................................98

6.2.1 Water Hardness Programming............................................ 98

6.2.2 Drying Options (As Applicable)........................................... 98

6.2.3 Water Intake Duration......................................................... 98

6.2.4 Buzzer (As Applicable)........................................................ 99

6.2.5 Fault Code (Retrieval)......................................................... 99

6.2.6 Increase Temperature......................................................... 99

6.2.7 With OR Without Water Softener........................................ 99

6.2.8 2nd Interim Rinse................................................................ 99

6.2.9 Width of Unit ..................................................................... 100

6.2.10 Flowmeter Count .............................................................. 100

6.2.11 Operating Hours ............................................................... 100

6.3 Programming / Service Modes – Access……………………………...100

6.4 Timing Charts – General Information ................................................101

6.5 Wiring Diagrams – General Information...........................................105

6.6 Timing Charts & Wire Diagrams ......................................................105

6.7 Fault Repair..................................................................................... 106

5

Page 6

Technical Information

G600 & G800 Electronic Dishwashers

G600 &G800 Electronic Dishwashers – List of Figures

1-1: Appliance Overview - Typical Integrated Model...................................9

1-2: Appliance Overview – Typical Fully Integrated (Vi) Model.................10

1-3: Pre-Finished Dishwasher...................................................................13

1-4: Integrated Dishwasher.......................................................................13

1-5: Fully Integrated..................................................................................13

1-6: Dishwasher Widths ............................................................................14

1-7: Dishwasher Heights...........................................................................14

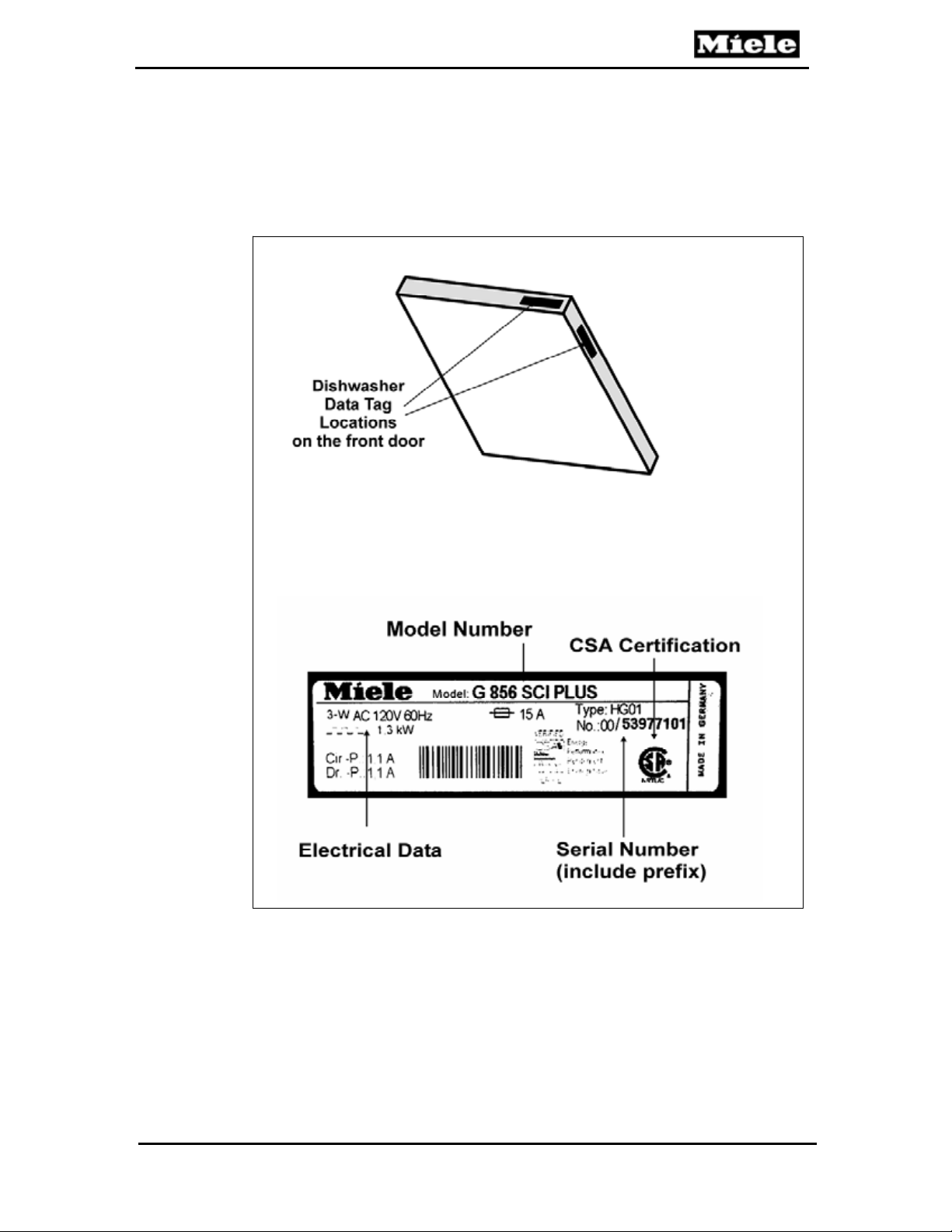

1-8: Data Tag Locations and Information..................................................17

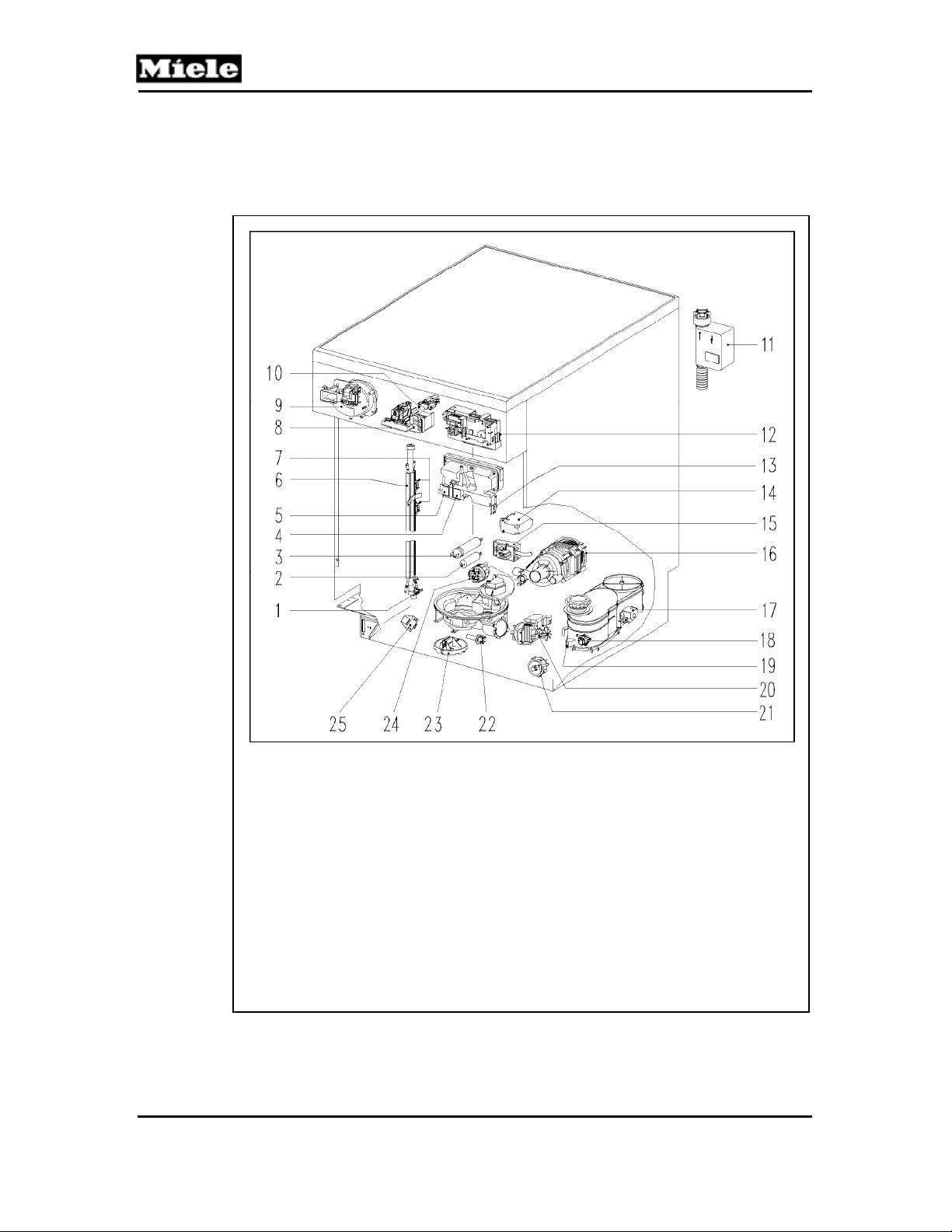

1-9: Component Overview – Novotronic & Touchtronic Series .................18

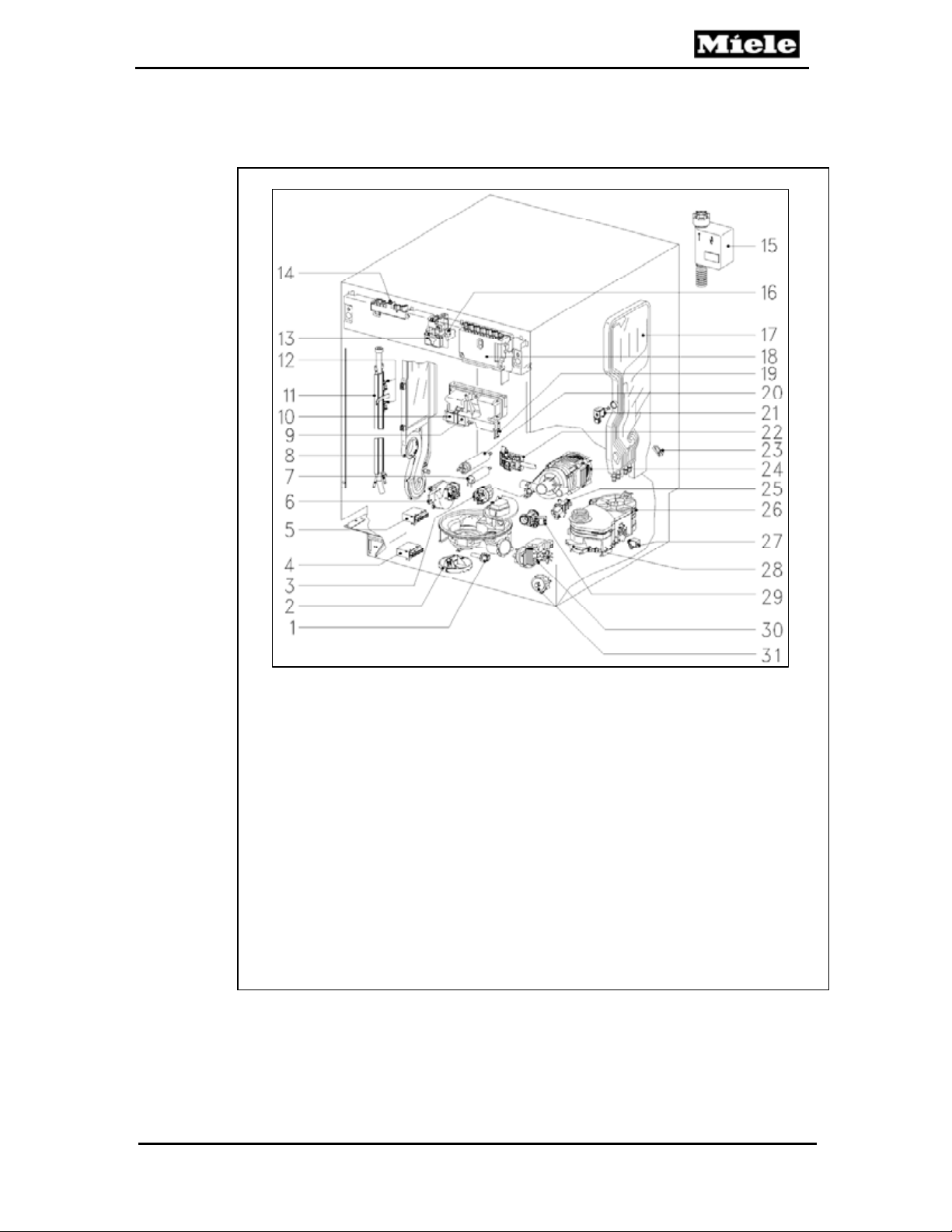

1-10: Component Overview – Incognito (Vi) Series ....................................19

4-1: Dispenser Assembly ..........................................................................25

4-2: Cavity Style Heater Element..............................................................27

4-4: Heater Circuit.....................................................................................29

4-5: Filter Assembly ..................................................................................31

4-6: WaterProof System Connection.........................................................33

4-7: Water Intake Circuit............................................................................35

4-8: Flowmeter Assembly Components (External Flowmeter Shown) ......36

4-9: Water Intake System Equipped With Integrated Flowmeter...............37

4-10: Water Hardness Selector...................................................................38

4-11: Water Path with Integrated Flowmeter...............................................39

4-12: Water Inlet Mixer................................................................................40

4-13: Water Hardness Mixer Solenoid ........................................................41

4-14: Water Softener...................................................................................43

4-15: Components for the Condenser Drying System.................................47

4-16: Control Valve .....................................................................................48

4-17: Heater Pressure Switch – Contact Positions and Current Paths........50

4-18: Water Intake / Level Switch Circuit.....................................................51

4-19: Circulation Pump & Top Solo Valve...................................................53

4-20: Turbidity Sensor (ECO Sensor) .........................................................54

5-1: Locking Plate .....................................................................................57

5-2: Seal Fitting Plan.................................................................................57

5-3: Side Panels and Cabinet....................................................................58

5-4: Side View, Door with Bracket............................................................. 59

5-5: Cover Plate........................................................................................60

5-6: Plinth area with Connecting Strip.......................................................61

5-7: Basket Guide .....................................................................................62

5-8: Bolt and Retaining Clip.......................................................................62

5-9: Basket Guide Stopper........................................................................63

5-10: Stopper removal.................................................................................63

6

Page 7

G600 & G800 Electronic Dishwashers

Technical Information

G600 &G800 Electronic Dishwashers – List of Figures (continued)

5-11: Exterior view of the Inner Door Panel.................................................64

5-12: Fan Removal...................................................................................... 65

5-13: Inner Door Panel Removal.................................................................66

5-14: Cable Holder Removal.......................................................................67

5-15: Lock Removal....................................................................................68

5-16: Hinge Removal ..................................................................................69

5-17: Door Tension Adjustment Screw........................................................70

5-18: Middle Spray Arm Cover Removal.....................................................72

5-19: Dishwasher with Flow-Through Heater..............................................73

5-20: Flow-Through Heater with Seal..........................................................74

5-21: Microfine Filter – Replacement ..........................................................75

5-22: Pressing and Locking the Filter Assembly. ........................................76

5-23: Tilting the Flow Restrictor...................................................................77

5-24: Removing the Flow Restrictor............................................................77

5-25: Water Inlet - Removal ........................................................................78

5-26: Float Switch Housing .........................................................................81

5-27: Steam Condenser Components......................................................... 82

5-28: Circulation Pump – Removal..............................................................84

5-29: Components within the Circulation Pump ..........................................85

5-30: Placing the Circulation Pump Tool into ..............................................86

5-31: Engaging the tool prongs into the Circulation Pumps Impellers.........86

5-32: Turning the Circulation Pump Tool.....................................................87

5-33: Heater Level Switch and Circulation Pump........................................88

5-34: Drain Pump - Replacement................................................................89

5-35: Circulation Pump with Top Solo Valve attached. ...............................90

5-36: Releasing the Overflow Level Switch from the Connecting Strip .......91

5-37: Self Tensioning Sump Clamp.............................................................92

5-38: Sump Clamp without the self tensioning;...........................................92

5-39: Fully Integrated (Vi) Control Panel.....................................................94

5-40: Control Panel (Novotronic and Touchtronic Dishwashers).................95

5-41: Removing the Fixing Bracket.............................................................96

7

Page 8

Technical Information

G600 & G800 Electronic Dishwashers

G600 &G800 Electronic Dishwashers – List of Tables

1-1: Summary of Dimensions......................................................................15

4-1: Detergent Quantity in Combination Dispensers...................................26

4-2: Rinse Aid Dispensing...........................................................................26

4-4: Flow Restrictor Data.............................................................................32

4-5: Water Inlet Mixer Data .........................................................................32

4-6: Reactivation Cycles Timing..................................................................45

4-7: Circulation and Drain Pump Data.........................................................49

4-8: NTC Sensor Resistance Values...........................................................52

4-9: Activation of Components....................................................................55

8

Page 9

G600 & G800 Electronic Dishwashers

Technical Information

1.0 Construction and Design

1.1 Appliance Overview

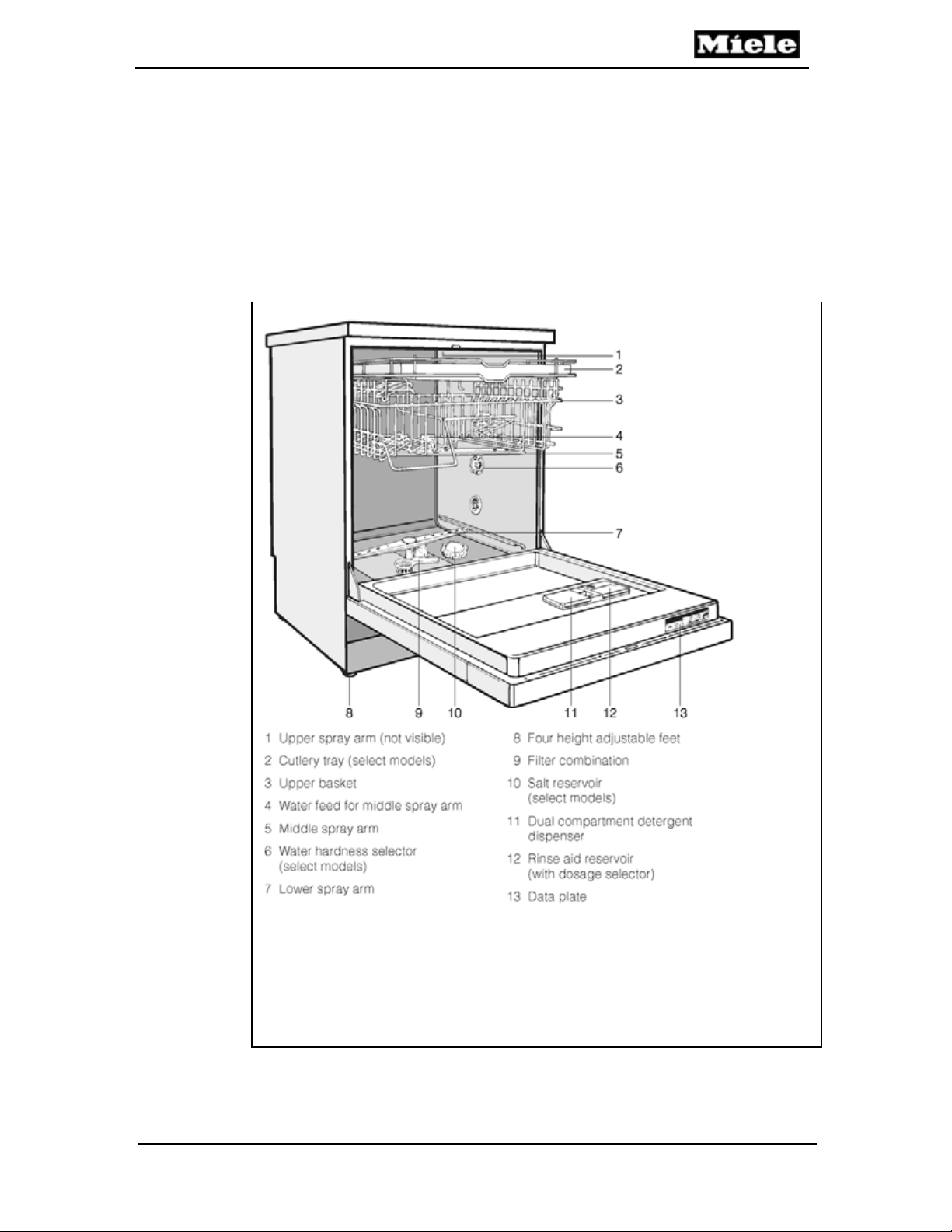

1.1.1 Appliance Overview – Typical Integrated Model

Figure 1-1: Appliance Overview - Typical Integrated Model

9

Page 10

Technical Information

G600 & G800 Electronic Dishwashers

1.1.2 Unit Overview – Typical Fully Integrated Model

Figure 1-2: Appliance Overview – Typical Fully Integrated (Vi) Model

10

Page 11

G600 & G800 Electronic Dishwashers

1.2 Controls Overview

Miele dishwashers are currently categorized into three (3) product

series, based on the type of controls.

Novotronic

Each Novotronic model dishwasher can be operated with a single

knob. Surface mounted design technology (SMD) allows Miele

Novotronic components to be extremely durable and reliable. These

controls are capable of performing hundreds of tasks which cannot be

handled by mechanical components.

Technical Information

Touchtronic

This new series of Miele dishwashers is operated by pushing a single

button -- no separate temperature or drying selections -- just turn the

machine on, pick a program and Miele does the rest. All models now

include a Pots and Pans program and a Water Management System,

designed to maximize cleaning results and optimize water and energy

conservation.

11

Page 12

Technical Information

Incognito

The Incognito (fully integrated) series dishwashers have the program

controls located on the top edge of the door; and are accessed while

the door is open. Neither seen nor heard, the Miele Incognito Series

OCI (Optical Cycle Indicator) you to see the progress of the

dishwasher cycle by way of a red light, which is steady or flashing

depending on the status of the cycle.

G600 & G800 Electronic Dishwashers

12

Page 13

G600 & G800 Electronic Dishwashers

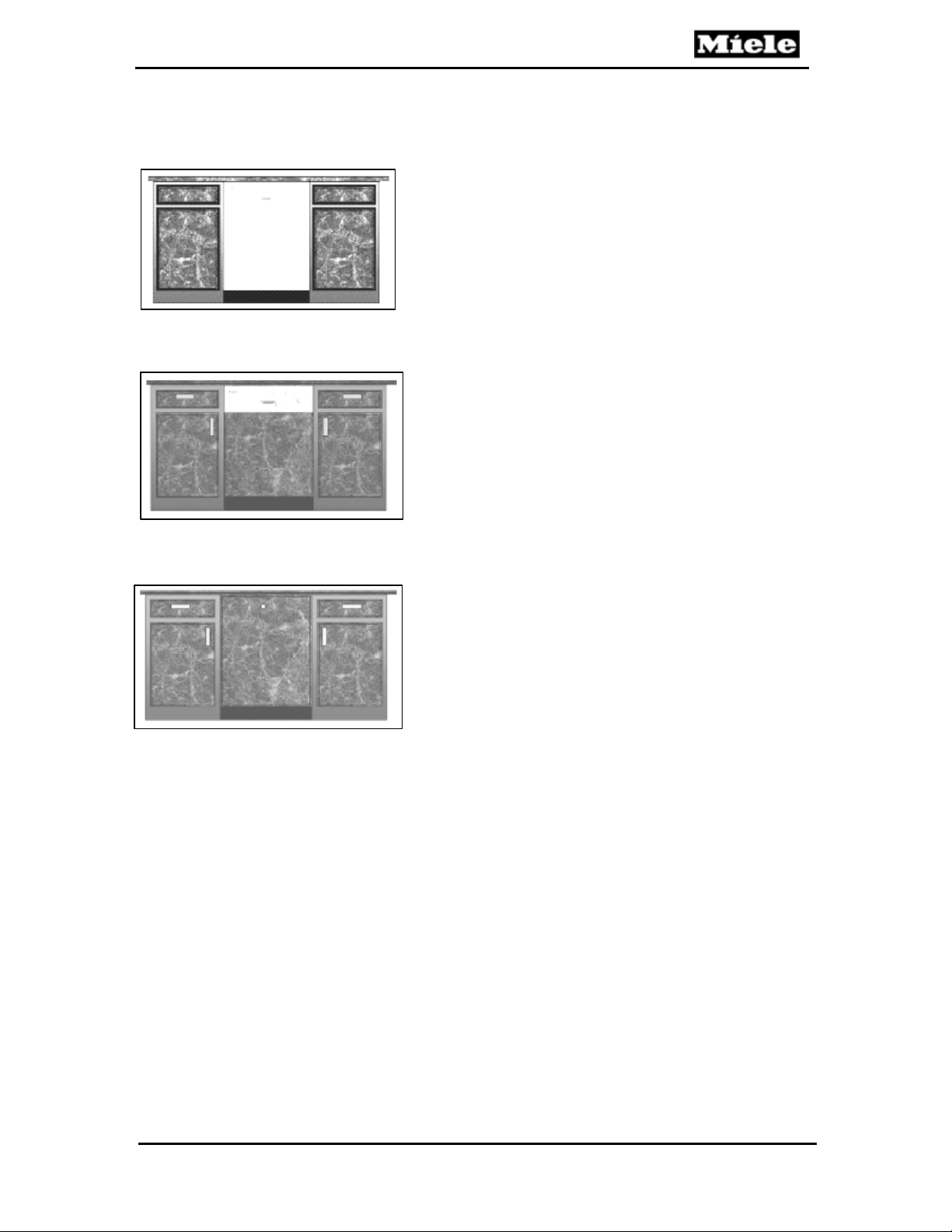

1.3 Types of Dishwashers

Pre-Finished: The pre-finished construction

consist of a pre-assembled door panel and control

panel; making it an ideal replacement unit.

Available in white, black or stainless steel.

Figure 1-3: Pre-Finished Dishwasher

Integrated: This type of dishwasher is shipped

with a separate control panel, and optional GDU

(door) panel. Every Integrated dishwasher ships

with a bracket for installing a custom cabinet

panel. The use of separate components allows for

a truly customized installation.

Figure1-4: Integrated Dishwasher

Fully Integrated: Fully Integrated (Incognito)

Dishwashers are designed to blend into the

surrounding cabinetry. The operator controls are

only available when door is opened. Each

dishwasher is shipped with a bracket for securing

a custom cabinet panel. An optional Miele

stainless steel SCVi panel is also available.

Figure 1-5: Fully Integrated

Technical Information

13

Page 14

Technical Information

G600 & G800 Electronic Dishwashers

1.4 Technical Data

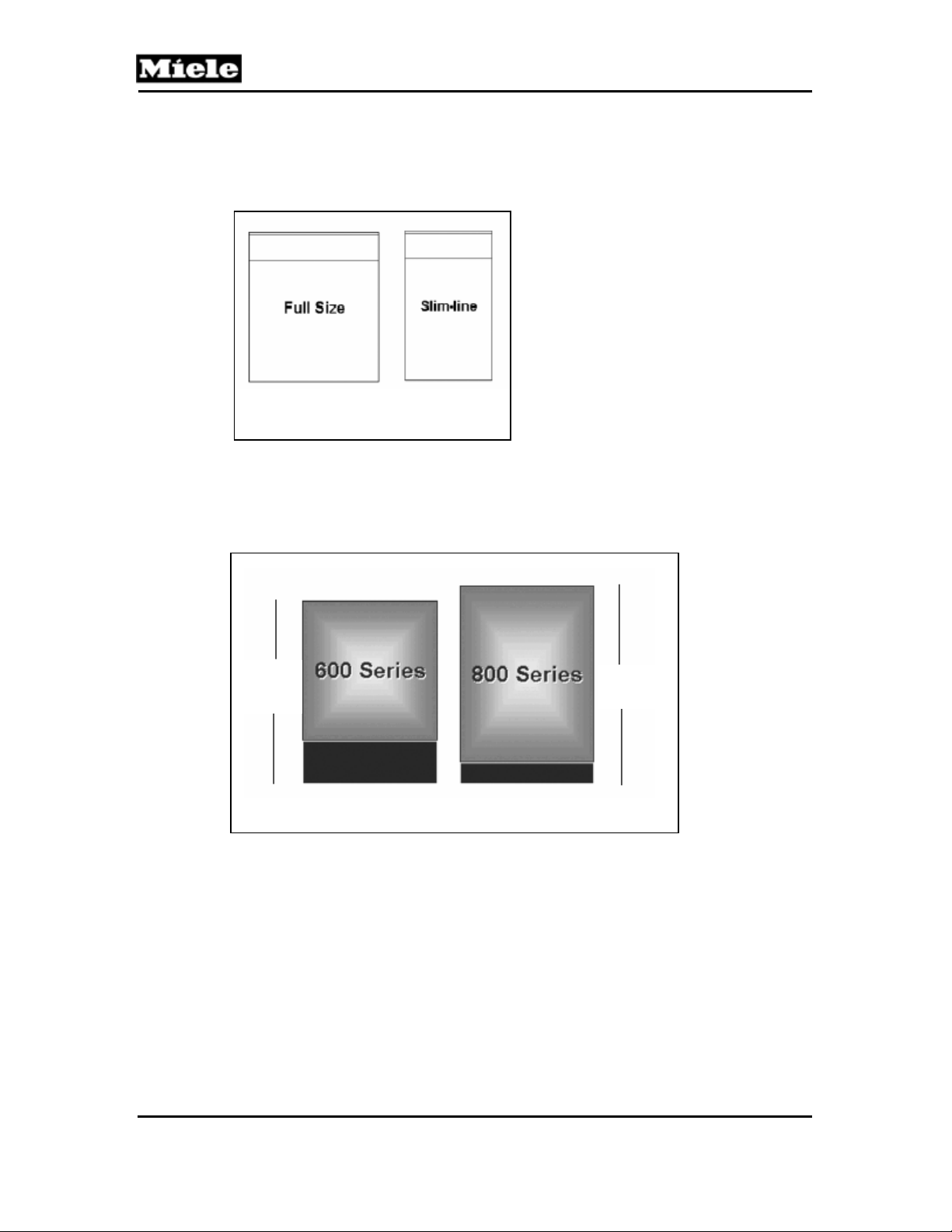

1.4.1 Dishwasher Width – Fullsize / Slimline

23 ½ in. 17 ½ in.

Figure 1-6: Dishwasher Widths

1.4.2 Dishwasher Height – 600 / 800 Series

32 1/4

to

34 7/8”

33 1/8

to 35”

Figure 1-7: Dishwasher Heights

14

Page 15

G600 & G800 Electronic Dishwashers

1.4.3 Summary of Dimensions

Technical Information

FULLSIZE G600 Series G800 Series

Height 32 ¼” - 34

Width of Machine 23

Width of Opening 23

1

/

” 23

2

5

/

” 23

8

7

/8” 33 1/

Depth 22 ½” 22 ½”

Depth w/ door open 45 ½” 47 ½”

SLIMLINE G600 Series G800 Series

Height 32 ¼” - 34

Width of Machine 17 ½” 17 ½”

Width of Opening 17 ¾ “ 17 ¾”

Depth 22 ½” 22 ½”

Depth w/ door open 45 ½” 47 ½”

7

/8” 331/

Table 1-1: Summary of Dimensions

1.4.4 Electrical Information

Power Requirements: 120 VAC, 60 Hz

Rated Load: 12.5 A / 1500 W (typical)

Circuit breaker: 15 AMPS

The appliance is equipped with a 4 ft power cord and molded

NEMA 515 plug; for connection to a NEMA 5-15R receptacle

(120VAC, 15 Amp, 3 prong, grounded outlet).

It is recommended that the power outlet for the appliance be

installed on the wall (within the cabinets), adjacent to under counter

space where the appliance is installed.

Ensure the cabinets contain no rough edges that could damage the

power cord or drain hose. If metal cabinets are used, ensure a

rubber grommet is installed around the opening.

Always exercise care when sliding the dishwasher in or out, to

prevent damaging the power cord and / or hoses.

”- 35”

8

1

/

”

2

5

/

”

8

” - 35”

8

15

Page 16

Technical Information

G600 & G800 Electronic Dishwashers

1.4.5 Hard Wire Electrical Connection

Connections: L1 (Black) to L on terminal block, N (White) to N on

terminal block, GND To ground connector.

Hard wiring the dishwasher should only be done if required by

electrical code.

Do not cut the plug off the power supply cord / plug and connect it

directly to the house wiring under any circumstances. This voids the

warranty.

For hard wiring, the power cord must be removed from the

appliance by disconnecting the cord from the terminal box located

at the lower left front of the dishwasher, behind the Toekick and

Service Panel. Pass the permanent power supply cable through the

strain relief and secure it directly to the terminal box.

THIS APPLIANCE MUST BE GROUNDED

1.4.6 Plumbing Connection

1.4.6.1 Intake Connection

The appliance is equipped with a five (5) foot long Double WaterProof

System Intake Hose; equipped with a ¾ inch female hose connection;

for connection to a ¾ inch male hose thread water supply valve.

1.4.6.2 Drain Connection

The appliance is equipped with a five (5) foot long Drain Hose for

connection to a ¾ inch drain nipple.

16

Page 17

G600 & G800 Electronic Dishwashers

1.5 Data Tag

The Data Tag is located on the top edge of the door or on the right side

edge of the door (fully integrated models) - as shown.

Figure 1-8: Data Tag Locations and Information

Technical Information

ETL Certification –OR-

17

Page 18

Technical Information

G600 & G800 Electronic Dishwashers

1.6 Layout of Components

1.6.1 Novotronic and Touchtronic Series

1 Temperature Limiter 90°C, 3F2. (before 8/99)

2 Interference Suppression Capacitor, Z2

3 Capacitor - Circulation Pump, C6

4 Rinse Aid Dispenser, Y50

5 Detergent Dispensert, Y51

6 Flow Through Heater, R1

7 Temperature Limiter 150°C, 1F2 and 2F2

8 Door Switch, S24

9 Fan M2 & PTC Release Element Y56

10 On / Off Switch, S2

11 WaterProof System (WPS), Y2

12 Electronic

13 Reed Switch - Rinse Aid, B8/1

14 Relay - Heating, 1K1/1

15 Terminal Block, X3/1

16 Circulation Pump, M6

17 Water Softener Valve, Y38/1

18 Flow Meter, B3/4

19 Reed Switch – Salt Float, B8/2

20 Drain Pump, M8

21 Level Switch - Overflow, B1/2

22 Temperature Sensor, R30

23 Float Switch, B8/3

24 Level Switch - Heating, B1/10

25 Transformer, T1

Figure 1-9: Component Overview – Novotronic & Touchtronic Series

18

Page 19

G600 & G800 Electronic Dishwashers

1.6.2 Incognito Series

Technical Information

Figure 1-10: Component Overview – Incognito (Vi) Series

1 Temperature Sensor, R30

2 Float Switch, B8/3

3 Level Switch - Heating, B1/10

4 Relay - Mains, 1K1/6

5 Relay - Heating, 1K1/1

6 Fan, M2

7 Interference Suppression Capacitor, Z2

8 Steam Condenser (not all models)

9 Rinse Aid Dispenser, Y50

10 Detergent Dispenser, Y51

11 Flow Through Heater, R1

12 Temperature Limiter, 1F2 and 2F2

13 Switch - Door Contact, S24

14 Electronic

15 WaterProof System (WPS), Y2

16 Door Switch, S5

17 Water Intake Mixer

18 Electronic

19 Reed Switch - Rinse Aid, B8/1

20 Capacitor - Circulation Pump, C6

21 Water Control Valve, Y5

22 Terminal Block, X3/1

23 Flow Meter, B3/4

24 Circulation Pump, M6

25 Condenser Control Valve, Y6 (if equip. w #8)

26 Water Softener (Resin Tank)

27 Water Softener Valve, Y38/1

28 Reed Switch - Reactivation Salt Indicator, B8/2

29 Circulation Valve, Y27

30 Drain Pump, M8

31 Level Switch - Overflow, B1/2

19

Page 20

Technical Information

2.0 Installation

Refer to the Appliance Installation Manual.

G600 & G800 Electronic Dishwashers

20

Page 21

G600 & G800 Electronic Dishwashers

3.0 Commission and Operation

3.1 Door Handle and Door Lock

(Novotronic and Touchtronic Series)

Press the release catch inside the Door Grip.

Note

If the door is opened during operation, the dishwasher will stop

running. Once the door is closed the program will restart.

Technical Information

3.2 Closing the Dishwasher Door

1. Push the baskets in.

2. Lift the door and push it closed until it locks into the closed

position.

3.3 Child Safety Lock

Horizontal:

the door is locked

Vertical:

the door can be opened

21

Page 22

Technical Information

3.4 Water Softener

If your tap water hardness is above 8 grains per gallon (140 ppm), the

water should be softened.

A Water Hardness Test Strip is used to determine the water hardness.

If the Water Softener is needed:

The dishwasher must be programmed to “with Water Softener”

(ON).

The Water Softener reservoir is filled with softener salt.

The water hardness level is programmed into the dishwasher

electronic.

If the Water Softener is not needed:

The dishwasher must be programmed to “without Water

Softener” (OFF); however the hardness level is not programmed

into the electronic

Salt is not needed and should not be installed.

G600 & G800 Electronic Dishwashers

Water Softener Salt

Only use water softener salt specially formulated for dishwashers.

Other salts may contain insoluble additives that impair the Water

Softener. The proper salt can be purchased from the Miele Technical

Service Department.

To add salt:

1. Remove the Lower Basket.

2. Unscrew and remove the Salt Reservoir Cap located on the

3. If this is the first time salt is installed; add 2 quarts water.

4. Place a funnel over the Salt Reservoir. Carefully fill with salt.

5. Clean any excess salt from the threads of the reservoir

6. Run the "Rinse & Hold" program to remove any traces of salt

floor of the Wash Cabinet.

Note

The Salt Reservoir holds approximately 4.5 lbs (2 kg) of

salt.

opening; and screw the cap on firmly.

from inside the Wash Cabinet.

22

Page 23

G600 & G800 Electronic Dishwashers

Technical Information

3.5 General Operation – Novotronic Series

1. Make sure the Spray Arms are not blocked.

2. Close the door.

3. Turn on the dishwasher. The "Start" Indicator will flash.

4. Select a wash program by turning the Program Selector to the left

or right.

5. Press the "Start" button.

3.6 General Operation – Touchtronic Series

1. Make sure the Spray Arms are not blocked.

2. Close the door.

3. Turn on the dishwasher. The "Start/Stop" Indicator will flash

and a Program Indicator will light.

4. Select a wash program using the Program Selection Buttons. The

Selected Program Indicator will light.

5. Select "Top Solo" if desired.

6. Press the "Start/Stop" button.

3.7 General Operation – Incognito Series

1. Open the door.

2. Make sure the Spray Arms are not blocked.

3. Turn on the dishwasher using the "On" button.

4. Select a wash program using the Program Selection Buttons.

The Selected Program Indicator will light.

5. Close the door. The Optic Indicator illuminates and the program

begins.

Note

For specific program details and further information on operating the

dishwasher refer to the model specific Operating Manual.

23

Page 24

Technical Information

G600 & G800 Electronic Dishwashers

4.0 Description of Function

4.1 Cabinet Construction

The inner cabinet is constructed of stainless steel (1.4301) welded

onto four (4) vertical U-section sub-frames. The cabinet is sound and

heat-insulated with bitumen and/or mineral wool matting.

4.2

Fan Assembly

(Units equipped with Turbothermic Fan)

The fan assembly consists of the Fan Motor (M2) and a PTC Release

Element (Y56), which opens the air outlet flap. The 120VAC fan

operates in the drying stage, after a brief delay. The PTC Release

Element is activated, and the Air Outlet Flap is partially opened. A

bypass channel behind the air outlet is also opened and ensures that

the moist air from the cabinet is mixed with dry air from the door

interior. This measure prevents condensation from developing. After

about a minute, the electronic switches off the Release Element,

however the Air Outlet Flap remains partially open. After a few minutes

the Release Element is activated again, which completely opens the

Air Outlet Flap. The fan operates constantly throughout this period

until the program ends.. The Air Outlet Flap remains open at program

end and closes when the dishwasher door is opened.

4.2.1 PTC Release Element

(Units equipped with Turbothermic Fan)

When 120VAC is applied to the Release Element, the PTC Resistor

heats a small grease-filled capsule. As the grease expands it pushes a

piston upward and slides the Air Outlet Flap to a partially open

position. When the Release Element is activated the second time, the

piston slides the Air Outlet Flap to a fully open position.

24

Page 25

G600 & G800 Electronic Dishwashers

4.3 Combination Dispenser

4.3.1 Construction

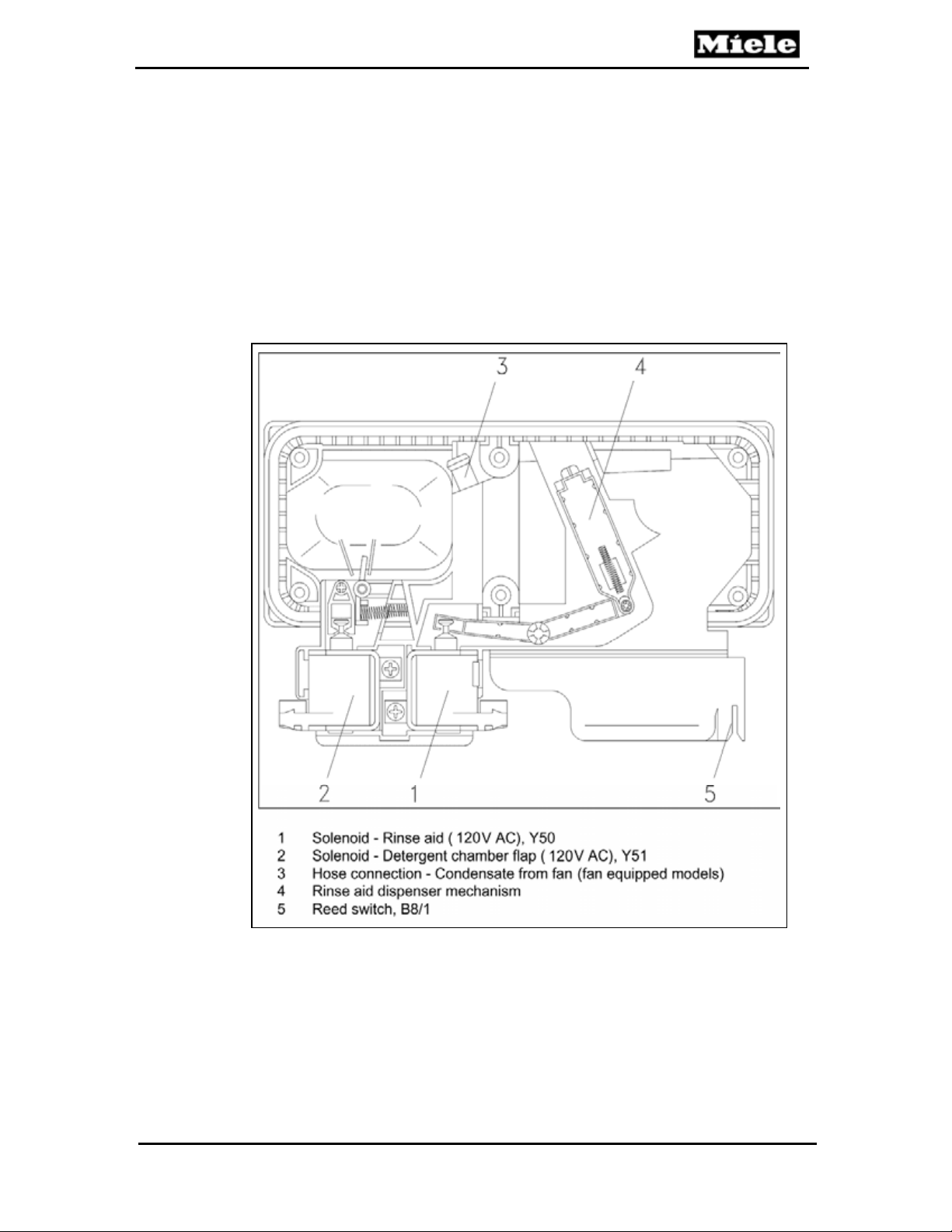

Two individual solenoids control detergent and rinse aid dispensing.

The Rinse Aid Reservoir has a capacity of about 130 ml. When the

Rinse Aid level drops to about 25 ml. the Magnetic Float activates a

Reed Switch on the edge of the dispenser and the Rinse Aid LED

illuminates.

Technical Information

Figure 4-1: Dispenser Assembly

25

Page 26

Technical Information

4.3.2 Dispensing

During the main wash, the Detergent Solenoid (Y51) is energized

(120VAC), to open the Detergent Dispenser Flap. The water jet from

the Middle Spray Arm flushes detergent out of the dispenser.

G600 & G800 Electronic Dishwashers

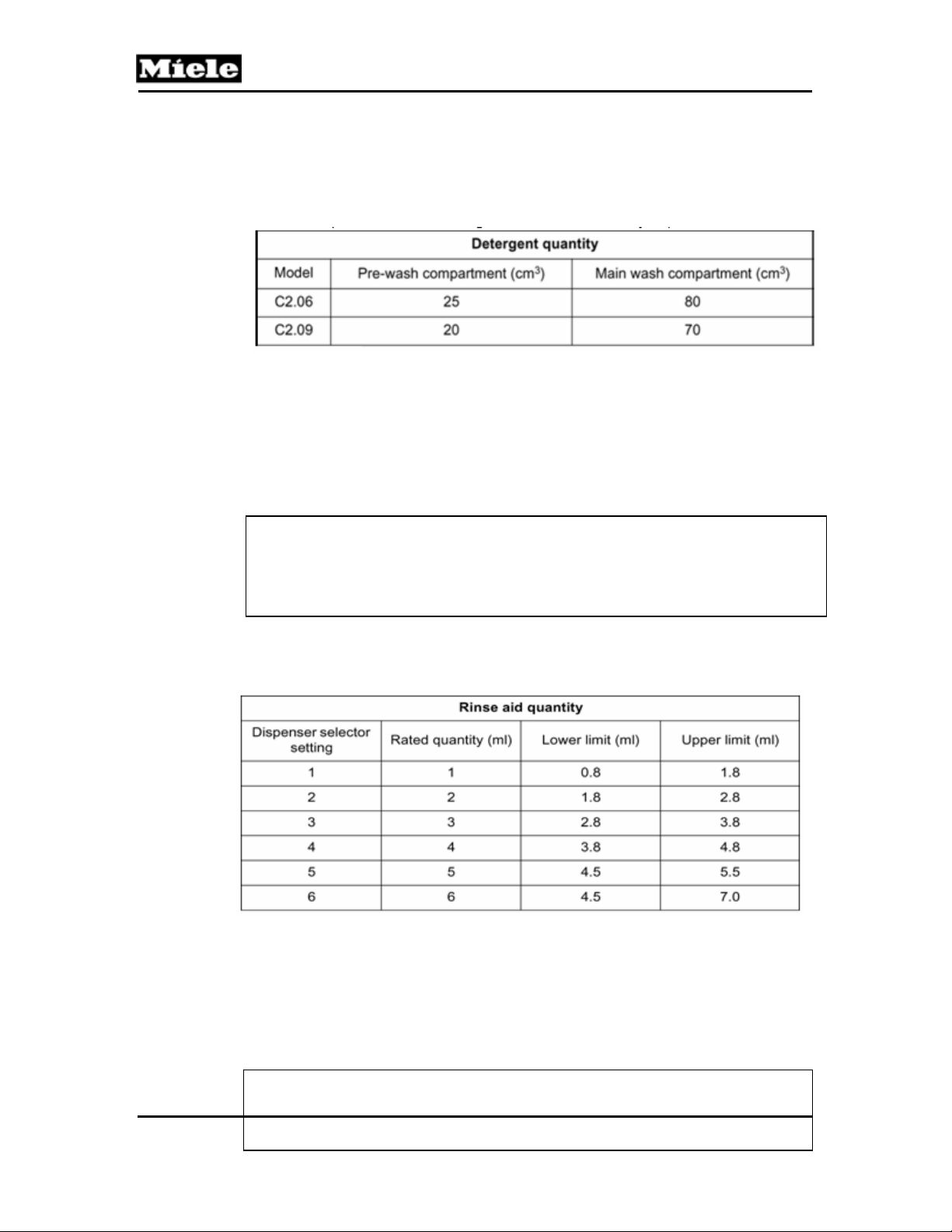

Table 4-1: Detergent quantity in Combination Dispensers C2.06 and C2.09.

During the final rinse the Rinse Aid Solenoid (Y50) is energized

(120VAC), to open the dispenser chamber and allow Rinse Aid to be

dispensed into the cabinet.

Note

The Rinse Aid only flows from the reservoir into the dispenser chamber

when the front door is fully opened at the end of a program.

The quantity taken into the dispenser chamber depends on the

dispenser selector setting.

Table 4-2: Rinse Aid Dispensing (Combination Dispensers C2.06 and C2.09).

When the Rinse Aid Light turns on, an additional 2 to 5 dispensings (at

setting 2) remain available.

26

Page 27

G600 & G800 Electronic Dishwashers

Note

To allow proper filling of the Rinse Aid Dispenser; Rinse Aid should

only be added with the door in the fully open position.

4.4 Heaters

During the main wash and final rinse portions of a wash cycle, the

water is heated to the programs specified temperature before

advancing to the next step in the program (i.e.Thermal Stop).

The water is heated using one of two systems:

4.4.1 Wash Cavity Heating Element

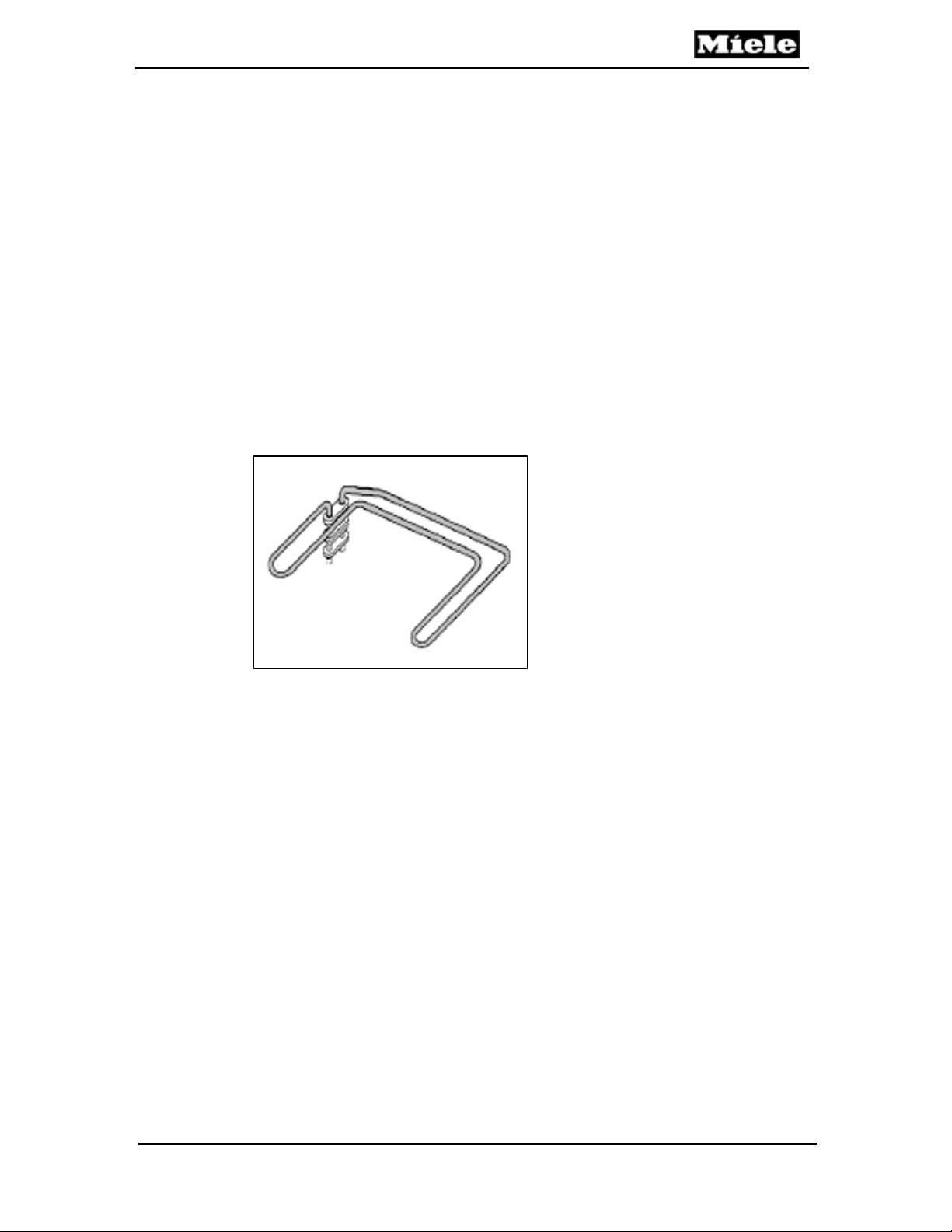

Figure 4-2: Cavity Style Heater Element

The Heating Element is mounted just off the floor of the wash cavity.

When powered (120 VAC) the element radiates heat thereby heating

the surrounding and circulating water. The temperature of

the water is monitored by the Temperature Sensor, mounted in the

Sump.

Heating Element switching is performed by the electronic via a Relay.

The relay (when energized) closes contacts to provide the Heater

Element with 120VAC. A Temperature Limiter mounted with the

element provides protection by opening up the circuit should the

temperature become to high.

Technical Information

27

Page 28

Technical Information

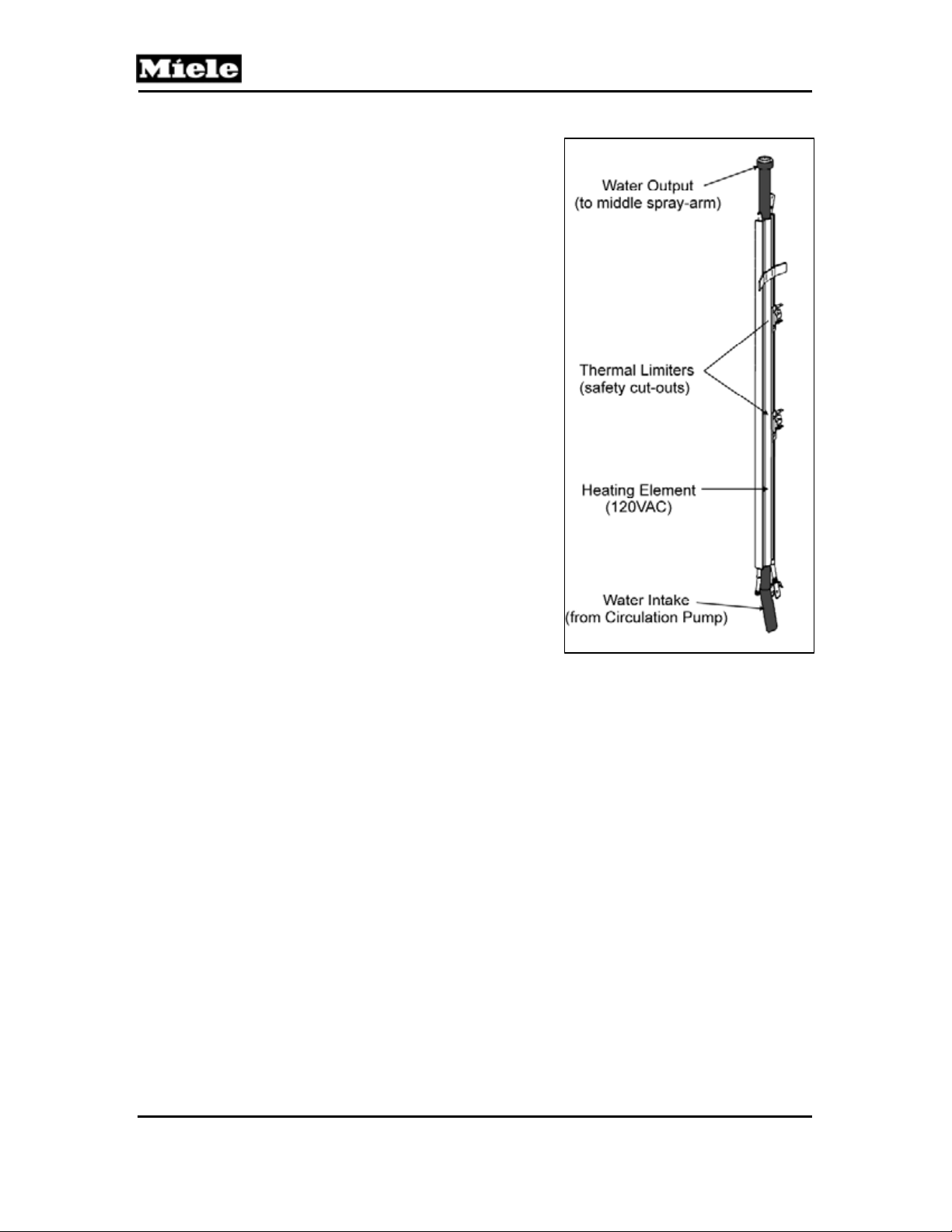

4.4.2 Flow Through Heater:

The Flow Through Heater

Assembly is mounted on the (left

side) exterior of the wash cabinet.

The Flow Through Heater is

plumbed into the water path

between the Circulation Pump

Output and the Middle Spray Arm.

The Flow Through Heater Consist

of a Heater Element mounted

parallel to a metal tube that water

passes through when the

dishwasher is circulating.

As water flows through the metal

tube; the water is heated and exits

through the Middle Spray-Arm. As

the water falls to the bottom of the

wash cavity, it passes through the

filter and re-enters the Circulation

Pump - the process then repeats.

The Temperature Sensor monitors

the water temperature until the

programs specified temperature is

reached. Generally the water heats Figure 4-3: Flow Through Heater

about 20 per minute.

Heating Element switching is performed by the electronic via a Relay.

The relay (when energized) closes contacts to provide the Heater

Element with 120VAC. Two Temperature Limiters are mounted along

the element and provides protection by opening up the circuit should

the temperature become to high.

4.4.2.1

Flow Through Heater Electrical Data

120VAC

1.5kW

9.6 k.Ohms

G600 & G800 Electronic Dishwashers

28

Page 29

G600 & G800 Electronic Dishwashers

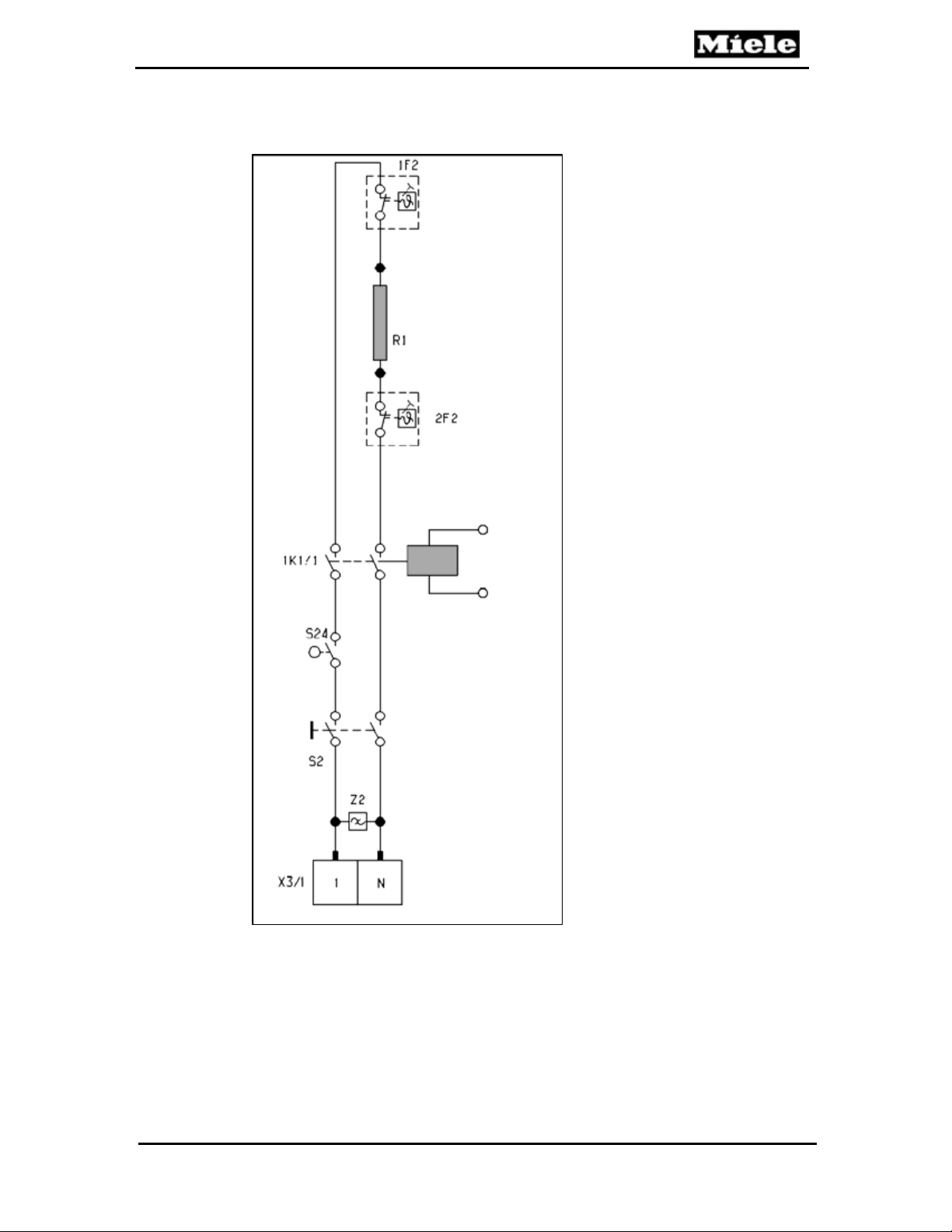

4.5 Heater Circuit - Operation

Technical Information

Figure 4-4: Heater Circuit

29

Page 30

Technical Information

4.6 Pulsed Heating - Operation

In certain programs the heating may be operated at full power until a

water temperature of 77°F is reached; then power is applied in pulses.

This extends the heating time and allows enzyme-containing

detergents to develop their full cleaning potential.

The pulsed heating operates as follows:

• 1 min heater element on.

• 1 min heater element off.

The number of pulse cycles is limited to a maximum of 11. If the

programs specified temperature has not been reached, the heating

resumes using full power. Once the programs temperature has been

reached, the electronic unit advances to the next step in the program.

If the temperature cannot be reached (i.e. heater failure) within a

specified time, the program will advance; and a heating fault is stored

in the electronic.

G600 & G800 Electronic Dishwashers

4.7 Temperature Protection

The Flow-through Heater uses two (2) Temperature Limiters (2F2)

mounted on the body of the Flow-Through Heater. The Temperature

Limiters are designed to open the circuit should the temperature

become too high. When the temperature falls, the Temperature

Limiters do not reset automatically and must be reset manually (via the

red button on the back of the device).

Additional protection is provided by the Electronic, which switches the

appliance off and stores an F4 fault code, should the temperature

exceed 194°F (90°C) – as determined by the Temperature Sensor.

4.8 Static Drying

The Static Drying System uses no electrical and / or mechanical

components to assist in drying. With this system the final rinse water is

heated to 154°F (68°C) (not the usual 150°F / 67°C). The dishwasher

cabinet is made of stainless steel; and conducts the heat generated

during the final rinse. As the final rinse ends this stored thermal energy

radiates and assists in the drying.

30

Page 31

G600 & G800 Electronic Dishwashers

4.9 Spray Arms

The circulation pump (M6) moves the wash water from the sump

through the Filter Assembly and to the Spray Arms. The water

pressure causes a propulsion effect causing the Spray Arms to rotate.

4.9.1 Spray Arms - Rotation Data

Top Spray Arm: 30 to 55 rpm

Middle Spr ay Arm: 16 to 40 rpm

Bottom Spray Arm: 24 to 50 rpm

4.10 Filter Assembly

Technical Information

1 Coarse Filter / Handle

2 Large Surface Area Fine Filter

3 Microfine ilter F

4 Filter cap

Figure 4-5: Filter Assembly

Circulating wash water is filtered via 2 parallel paths. A portion of the

water flows through the center opening of the Coarse Filter and

passes through the Microfine Filter. The remaining water passes

through the Large Surface Area Fine Filter. The Coarse Filter, is

attached to the Filter Combination Handle. If dispensed powder

31

Page 32

Technical Information

detergent should fall into the Microfine Filter, it remains on the Filter

Cap, where it can dissolve, instead of collecting in the drain outlet.

Foreign bodies which pass the Coarse Filter to the Microfine Filter

collect on the Filter Cap and so they don’t clog the drain outlet.

G600 & G800 Electronic Dishwashers

4.11 Water Intake – Technical Data

Table 4-3: WaterProof System Data

1: An optional 4.5 meter version can be installed.

Flow Restrictor - Data

Table 4-4: Flow Restrictor Data

(1) Standard with slimline models

(2) Standard with 60cm (fullsize) models

Water Inlet Mixer – Data

Green 4.1 (1) liters per minute

Grey 4.9 (2) liters per minute

White 5.25 liters per minute

Blue 6.0 liters per minute

Table 4-5: Water Inlet Mixer Data

32

Page 33

G600 & G800 Electronic Dishwashers

4.12 WaterProof System (WPS)

The Water Inlet Valve (Y2) consists of two (2) electro-mechanical

valves mounted within a waterproof box located at the water

connection (end of the water intake hose).

The valves are mounted in physically and electrically in series to

ensure that if one valve should fail (e.g. due to blockage caused by a

foreign body) the water flow will still be switched off by the other valve.

Figure 4-6: WaterProof System Connection

The water inlet system is protected by WPS (WaterProof System)

which uses an outer sleeve protecting the water inlet hose and valves.

In the event a valve or the hose should leak, the leaking water will flow

along the outer sleeve to the drip tray in the bottom of the unit. When a

quantity of water collects in the drip tray, the Float Switch (B8/3) is

actuated.

Technical Information

33

Page 34

Technical Information

With the Float Switch actuated; power that is normally distributed

throughout the appliance is re-directed to the Drain Pump. The Drain

Pump will continuously operate when the unit is turned on and the door

is closed. Normal operation and Program Selection is not possible

during this time.

Warning!

● If the WPS is replaced, always ensure the correct flow restrictor is

installed

● The WaterProof system only operates with the door closed and the

dishwasher switched on.

● To ensure optimal protection, the water connection should be at

least 20 cm higher than the floor on which the dishwasher is

standing.

● The connection hose must be routed so that no point is higher than

the connection housing.

For further details, refer to the model specific Operating and

Installation Manual.

G600 & G800 Electronic Dishwashers

34

Page 35

G600 & G800 Electronic Dishwashers

WaterProof System Circuit – normal operating position

WaterProof System Circuit – Float Switch B8/3 actuated

From water being present in the lower pan of the dishwasher.

B1/2 Level switch - Overflow

B8/3 Float switch - Overflow

M8 Drain pump

S2 Main switch (pushbutton switch)

S24 Door contact switch

Y2 Solenoid valve (2 off) - Water intake (WaterProof system)

Figure 4-7: Water Intake Circuit

Technical Information

35

Page 36

Technical Information

4.13 Flowmeter - Operation

The incoming water turns an impeller that contains a magnet located in

the Flow Meter Axle. As the impeller turns, an external Reed Switch is

switched on / off by the effect of the magnet. The electronic monitors

the number of pulses to determine the volume of incoming water.

Approximately 200 pulses = 1 liter.

G600 & G800 Electronic Dishwashers

1 Reed Switch

2 Housing

3 Magnet (could also be mounted directly on an impeller blade)

4 Impeller

5 Housing cap

Figure 4-8: Flowmeter Assembly Components (External Flowmeter Shown)

36

Page 37

G600 & G800 Electronic Dishwashers

4.14 Water Intake

If the water pressure is low, the electronic can be programmed to

increase the allotted intake duration from 2 minutes, to up to 4 minutes.

For further information refer to the section 6 Fault Diagnosis.

1 Input - Ion exchanger (softener)

2 Intake opening - Sump

3 Output - Ion exchanger (softener)

4 Water softener selector

5 Bypass - Water

6 Non-return device

7 Water reservoir

Figure 4-9: Water Intake System Equipped With Integrated Flowmeter

Technical Information

8 Water intake channel

9 Cabinet ventilation

10 WaterProof system (valve Y2)

11 Salt container

12 Solenoid valve Y38/1

13 Non-return valve

14 Ion exchanger

37

Page 38

Technical Information

G600 & G800 Electronic Dishwashers

4.15 Water Mixing

4.15.1 Water Mixing - External Flowmeter

Refer to figure 4-9.

The main water flows into the WaterProof system (Item 10), to the

Water Intake Assembly where it passes a Non-Return Device (Item 6).

The Non Return Valve prevents a reflux of water from the machine into

the supply should a vacuum develop in the system.

The water path is then divided at the bypass (Item 5), and up to 5% of

the water flows directly into the cabinet without passing through the

Water Softener. Depending on the Water Hardness Selector Setting

(Item 4), a proportion of the water flows directly into the cabinet via the

Cabinet Ventilation, (Item 9). The remaining water fills the reservoir in

the Water Inlet (Item 7), for later reactivation of the softener. When the

reservoir is full, water flows through the Ion Exchanger (Item 14), and

the intake opening in the sump (Item 2), to enter the cabinet.

Mains water mixing (External Flowmeter)

Figure 4-10: Water Hardness Selector

With correct programming and operation the water softener should

supply water with a hardness level < 4° in all wash programs. With

certain types of glass it may be necessary to set the wash water

hardness individually to avoid possible glass corrosion. Depending on

the water hardness, the selector at the Water Intake (Non Plus Models

Only) must be set to between 0 - 3. This sets the quantity of mains

water flowing directly into the cabinet without passing the Water

Softener. For details, see the model specific operating manual.

38

Page 39

G600 & G800 Electronic Dishwashers

Technical Information

4.15.2 Water Mixing - Integrated Flowmeter

1 Drain pump

2 Sump

3 Sump - Soft water intake

4 Water softener - Soft water outlet

5 Solenoid valve Y2 (WPS)

6 Water inlet mixer

7 Water inlet mixer intake and outlet

8 Control valve Y6 - Steam condenser

9 Solenoid valve Y38/1 (reactivation)

10 Salt container

11 Salt container intake

12 Non-return device

13 Water softener hard water intake

14 Ion exchanger

Figure 4-11: Water Path with Integrated Flowmeter

39

Page 40

Technical Information

Refer to the figure 4-12.

The water intake hose from the WaterProof System (WPS) is

connected to the Water Inlet Mixer (Item 6). Hard water flows through

the Integrated Flow Meter (Item 1), and into the Intake Channel (Item

3), to Solenoid Valve Y5 (Item 4).

1 Flow meter B3/4

2 Surrounding test channel, for production purposes only

3 Mains water intake channel

4 Solenoid valve Y5 (wash water hardness)

5 Valve pin

6 Ball valve

7 Water reservoir - Softener reactivation

8 Overflow

Figure 4-12: Water Inlet Mixer

G600 & G800 Electronic Dishwashers

9 Non-return device

10 Cabinet ventilation

11 Vent

12 Water intake - Soft water from water softener

13 Water outlet to sump

14 Water outlet from water reservoir for softener

15 Water outlet to softener

16 Water intake from WaterProof system (WPS)

40

Page 41

G600 & G800 Electronic Dishwashers

4.15.3

Solenoid Valve (Y5) - Operating (Plus Models Only)

Figure 4-13: Water Hardness Mixer Solenoid

Refer to figure 4-12.

With no voltage to Y5

The Valve Pin (Item 5) closes the channel for cabinet ventilation. The

non-softened water then flows behind the Valve Pin (Item 5.1), through

an opening in the Water Channel (Item 3.2). From here it flows

upwards to the Ball Valve (Item 6), where a small proportion of the

water passes through a small bypass in the Ball Valve to the Water

Reservoir (Item 7), for later use during softener reactivation.

Note

After softener reactivation, the reservoir is filled again by the time

the third water intake has taken place.

The majority of the water, blocked by the Ball Valve at the Water

Reservoir Inlet, flows through the Water Channel (Item 3.3), to the

Water Mixer Outlet and then to the Water Softener, (Item 5). After

passing through the Water Softener, the now soft water flows via the

Soft Water Intake (Item 12), back into the Water Inlet Mixer. It then

flows past the Non-Return Device (Item 9), into the Sump, (Item 13).

With voltage applied to Y5

The Valve Pin is drawn back and a portion of the hard water flows

through the hole into the channel (Item 3.1), via the Cabinet Ventilation

Port. This mixing of hard water with the soft water allows the wash

water hardness to be adjusted more precisely.

Technical Information

41

Page 42

Technical Information

G600 & G800 Electronic Dishwashers

4.16 Electronic Controlled Water Hardness (EGS)

To avoid possible glass corrosion, the wash water hardness level

should not exceed or fall below

45 ppm in programs with heating

71 ppm in program without heating

With water hardness below 286 ppm (in heating steps under 232 ppm)

the Solenoid Valve Y5 is activated to add a proportion of hard water to

the cabinet. The proportion added in this way is fixed and depends on

the mains water hardness level programmed into the electronic.

The EGS system is not active in all wash programs, however it can be

programmed if required. The additional function Top Solo has no

influence on the EGS system.

The EGS system is not active in the following cases:

● In programs Universal Plus 55°, Universal Plus 65° or Economy

(standard setting).

• If the programmed water hardness is above 286 ppm.

• In the program when the softener is being reactivated.

• When flushing the Water Softener after reactivation.

• If no Water Softener is fitted.

• If the function “Without Softener” has been programmed

Note

If a water softener is fitted but has been deactivated (programmed to

“without water softener”), then the incoming water flows directly into

the cabinet via the Solenoid Valve only. However a small quantity

(approximately 1 liter) of water still flows through the Water Softener

System to prevent mold from forming.

42

Page 43

G600 & G800 Electronic Dishwashers

4.17 Water Softener

The Water Softener consists of 2 compartments - a Salt Container and

an Ion Chamber. In addition it also has a mechanical Non-Return

Valve, a Solenoid Valve and a Reed Switch / Magnetic Float Switch.

Technical Information

1 Reed switch B8/2 - salt level float switch

2 Salt container

3 Water exit

4 Ion exchanger

5 Mains water intake on underside

6 Solenoid valve Y38/1 - Softener

7 Intake for water for reactivation from reservoir in water mixer

Figure 4-14: Water Softener

Incoming water flows through the Intake Assembly and into the Ion

Exchanger. When the water flows through the Softener, the calcium

and magnesium ions are exchanged for sodium ions which soften the

water. The softened water flows into the cabinet via a port in the Sump.

43

Page 44

Technical Information

G600 & G800 Electronic Dishwashers

4.17.1

Reactivation

The electronic unit activates the Softener Valve (Y38/1) and water from

the Water Intake Assembly flows into the Salt Container, where it

dissolves a quantity of salt to become a brine mixture.

The saturation point, above which the water cannot dissolve any more

salt, is approximately 40%. The brine then flows past a mechanical

Non-Return Valve into the Ion Exchanger and flushes the existing

water into the Sump. The built-in Non-Return Valve in the Softener

prevents the brine mixing with the incoming water during normal

operation.

The brine flushes the resin in the Ion Exchanger, and replaces the

retained calcium and magnesium ions, with sodium ions. At the next

program start, the incoming water flushes out the remaining brine and

hardness minerals before the actual dishwashing program begins.

44

Page 45

G600 & G800 Electronic Dishwashers

4.17.2 Reactivation Cycles

Number of Program sequences

Water Hardness

Parts per

Million

18 to 71 1 to 4.1 18 12

89 to 107 5.2 to 6.2 13 8

125 7.3 12 8

143 to 179 8.3 to 10.4 7 5

196 to 214 11.4 to 12.4 6 4

232 to 250 13.5 to 14.5 5 3

268 to 304 15.5 to 17.6 4 2

321 to 375 18.6 to 21.8 3 1

393 to 625 22.8 to 36.3 2 1

643 to

1250

Table 4-6: Reactivation Cycles Timing

Grains per

Gallon

37.3 to 72.5 1 1

before reactivation (Universal

Normal Water

Quantity

Technical Information

650C)

Increased

Water

Quantity

The salt in the Salt Container is sufficient for several reactivation

cycles as it is not dissolved all at once. As the quantity of salt in the

Salt Container reduces, the concentration of the brine decreases.

When a specific concentration is reached, the Float (containing a

magnet) activates the Float Switch. The Salt Indicator is then

illuminated to advise the operator the softener system needs salt

added.

The dishwasher operates with consumption-linked reactivation. After a

certain number of programs (Refer to Table 4-6), the Electronic

activates the Solenoid Valve (Y38/1) at the end of the Final Rinse

Cycle and starts the reactivation process. If several other programs are

operated between two Universal 65°C programs such as Economy, the

electronic unit calculates the probable quantity of water used and the

approximate number of equivalent Universal 65°C programs. Therefore

the figures provided in Table 4-6 can only be considered as a guide

only.

45

Page 46

Technical Information

4.18 Condenser Drying (UKT)

Does not apply to all dishwasher models

4.18.1 Operation

An air inlet port is located on the back / left area of the cavity ceiling.

An air duct is fitted to the port and attaches to the Condenser

Assembly.

During the Drying portion of a program, moist air within the cabinet is

drawn through the Condenser Assembly via the Condenser Fan (M2).

As the cabinet air passes the Cold Water Reservoir (inside the

condenser) water vapor forms and exits the condenser (as water) via

the port on the left wall of the cabinet.

The cooling bank within the Condenser Assembly utilizes water from

the intake / softening system controlled by the electronic via the

Condenser Control Valve (Y6).

4.18.2 Technical Data

Control valve (Y6) AC 120 Hz

Cold Water Reservoir 750 ml

G600 & G800 Electronic Dishwashers

46

Page 47

G600 & G800 Electronic Dishwashers

1 Water Control ValveY6 – (for Steam Condenser)

2 Fan M2

3 Vent / Water Port from condenser

4 Steam Condenser Assembly

5 Air Duct (Condenser Intake)

6 Water Intake Assembly

7 Solenoid Valve Y5 - Water hardness

8 Cabinet Vent / Water Port (un-softened)

9 Flow Meter B3/4

10 Reactivation Valve Y38

11 Water Softener Assembly

Figure 4-15: Components for the Condenser Drying System

Technical Information

47

Page 48

Technical Information

4.18.3 Control Valve

Refer to figure 4-15…

The Miele Circulation Condenser Drying System consists of a Steam

Condenser (Item 4), with Circulation Fan. The Steam Condenser

contains a Cold Water Reservoir over which an air duct passes and

moist air from the cabinet is passed through this air duct. The cold

water and the air duct are separated by a 0.5 mm thick membrane

which provides the condensing surface. The Fan (Item 2), takes in

moist air from the top of the cabinet (Item 5), and passes it over the

condensing surface where it is cooled then blows it back into the

cabinet via the opening in the lower area of the Side Panel (Item 3).

The water vapor that is condensed out during cooling flows down and

enters the cabinet via the opening in the lower area of the Side Panel.

Some vapor may condense out in the Fan and this flows out via a hole

in the bottom of the Fan Housing to the Drip Tray where it evaporates

Figure 4-16: Control Valve Y6

Refer to figure 4-16.

No voltage applied to Control Valve Y6

The path between positions 1 and 3 is always open so during every

water intake the Cold Water Reservoir in the Steam Condenser is filled

with water from the Water Softener. If the Reservoir is full, excess

water overflows at its top edge and flows down then enters the cabinet

via the opening in the lower area of the Side Panel.

Voltage applied to Control Valve Y6

If voltage is applied to the Control Valve during water intake stages,

the path between 1 and 2 is also open (this is marked with +K in the

Program Timing Chart). In this way soft water flows to the Water Mixer

and then into the cabinet.

G600 & G800 Electronic Dishwashers

1 Soft water from Water Softener

2 Soft water to Water Mixer

3 Soft water to Condenser Module

48

Page 49

G600 & G800 Electronic Dishwashers

4.19 Drain Pump, Circulation Pump

The Drain Pump (M8) is located below the cabinet and connects to the

right / front of the Sump. The Pump removes the wash water through

the Non-Return Valve and Drain Hose to the on-site drain. The Drain

Pump is controlled / powered by the electronic.

Note

If the on-site drain is below the level of the guides for the bottom

basket, the drain must be vented to prevent siphoning. See the

appropriate operating/ installation instructions or call Technical Support

for assistance.

During dishwashing, the Circulation Pump (M6) takes in the wash

water from the side of the Sump through the Microfine Filter and the

Large Surface Area Filter and pumps it to the Spray Arms. During

drainage, the Drain Pump removes water out from below the Microfine

Filter. This change of direction in the water flow assist in flushing out

any residues that may have been retained within the Filter. Water

passing through the Non-Return Valve and then to the on-site drain.

A Bimetallic Switch is integrated in the Circulation Pump Motor

Windings and serves as a safety cut-off should the temperature

exceed 150°C (302°F). After a cooling-down phase, which can be

between 10 min - 1 hour the Switch resets automatically. If the Switch

is faulty, the Motor Assembly must be exchanged.

Technical Information

Type Voltage

Rated

Power

Table 4-7: Circulation and Drain Pump Data

Circulation

Pump

Drain

Pump

120 VAC 120 W 3.6 psi

120 VAC 65 W -

Pump

Pressure

Flow Rate

18.2

gallons /

minute

4.2 gallons

/ minute

Maximum

Head

Height

- -

39 inches 13 feet

Maximum

Hose

Length

(Meters)

4.20 Level Switch – Heater (Heater Pressure Switch)

The Level Switch – Heating (Heater Pressure Switch) (B1/10) is

located directly on the Circulation Pump and actuates when water is

present and circulating (producing pressure). The switch is monitored

by the Electronic and is electrically in series with the Heater Relay.

49

Page 50

Technical Information

If sufficient water and circulation is not present the switch is not

actuated; this keeps the Heater Relay circuit interrupted, the appliance

malfunctions and a fault is stored in the Electronic.

Should the switch be faulty and remain constantly actuated, the

appliance malfunctions and a fault is stored in the Electronic.

Figure 4-17: Heater Pressure Switch – Contact Positions and Current Paths

G600 & G800 Electronic Dishwashers

50

Page 51

G600 & G800 Electronic Dishwashers

4.21 Level Switch (Intake Overflow)

As an additional safety measure, the Overflow Level Switch (B1/2) is

electrically in series to the Water Inlet Valves (Y2). The Level Switch

interrupts power should the water level become to high inside the

cabinet.

Figure 4-18: Water Intake / Level Switch Circuit

Technical Information

51

Page 52

Technical Information

4.22 Temperature Sensor

The Temperature Sensor R30 (NTC resistor) is located in the bottom

area of the Sump. The Electronic Unit constantly monitors the water

temperature using the resistance value of the sensor. If the resistance

is less than 14.9 kilo-ohms ± 750 ohm at 68°, a fault is registered.

G600 & G800 Electronic Dishwashers

Table 4-8: NTC Sensor resistance values

52

Page 53

G600 & G800 Electronic Dishwashers

4.23 Top Solo Valve

Refer to figure 4-19.

If the Top Solo option is selected, water is directed to the Top and

Middle Spray Arms only. The Top Solo Valve (Y27) is located between

the Circulation Pump and the Sump within the plumbing circuit to the

Bottom Spray Arm. When Top Solo is selected an electromagnet (Item

3), releases a plastic ball in the water intake, wash and / or rinse

stages into the valve body (Item 2). This ball is now unlocked and the

water pressure pulls it free of the bottom part of the valve and presses

it against the output opening (Item 4). This almost completely closes

the channel to the Bottom Spray Arm. A bypass opening (a small

square cutout in the output opening) allows a minimal quantity of water

to flow to the Bottom Spray Arm so keeping the jets free of food

residue deposits.

Note

The Top Solo Valve is activated after 2.5 liters of water is present

inside the appliance.

Technical Information

1 – Intake Opening

2 – Valve Body

3 – Top Solo Solenoid

Figure 4-19: Circulation Pump; highlighting components for the Top Solo feature.

53

Page 54

Technical Information

G600 & G800 Electronic Dishwashers

4.24 Turbidity Sensor (ECO Sensor)

Certain model dishwashers are equipped with a Turbidity (ECO)

Sensor. The Sensor is comprised of a Phototransistor that emits a

beam of light through the water path. On the opposite side of the

sensor is a Photoelectric Switch (receiver). The amount of light

capable of passing through the water is based on the turbidity

(transparency) of the water. The amount of light received, effects the

current flow of the sensor, and is used by the Electronic to calculate

the condition of the water.

If clean water is present, the light flow is near 100%. As the water

becomes dirty the amount of light received is reduced.

During certain steps of the program (refer to the model specific Timing

Chart) the Sensor is monitored to determine the condition of the water.

Example

At the end of the Pre-Wash the water is checked via the Turbidity

Sensor. If the water is clean enough, the program will change by

eliminating the drain at the end of the Pre-Wash and fill at the

beginning of the Main Wash. The same water will continue to be used

to reduce water consumption.

If the Turbidity Sensor and electronic determine the water to be “dirty”.

Then the program will continue with a drain at the end of the PreWash, and a fill during the Main Wash.

1 5 V

2 Photoelectric Switch Line

3 Phototransistor Line

Figure 4-20: Turbidity Sensor (ECO Sensor)

54

Page 55

G600 & G800 Electronic Dishwashers

The sensor is located within the plumbing connection between the

Circulation Pump and Top Spray Arm. In order to compensate for

residues on the sensor and ageing of the optical system, the Turbidity

Sensor is re-calibrated automatically every time the dishwasher runs a

program (the steps on the Timing Chart are marked with a “T “). To

prevent residues drying on the sensor surface, the sensor remains in

water after the drainage cycle.

4.25 Electronic Unit - Power Outputs

The Electronic Unit controls all components within the dishwasher.

The activation of components requiring 120VAC power is handled by

Thyristors and Relays within the Electronic. The individual components

of the Electronic are not replaceable. Should the Electronic require

replacement; the Electronic is replaced as one assembled component.

Table 4-9: Activation of components

Technical Information

55

Page 56

Technical Information

G600 & G800 Electronic Dishwashers

4.25.1 Programming After Replacing the Electronic

In addition to Intake Duration and Water Softener Settings certain

dishwasher Electronics need to be programmed for the width of the

dishwasher (45 cm or 60 cm).

For further information refer to the model specific programming and

service mode(s) information.

4.25.2 Electronic Modes

The electronic modes are divided into 3 levels:

The Programming Mode

Service Mode 1

Service Mode 2

The Programming Mode is intended for user access. Service Mode 1

and Service Mode 2 are designed to be accessed only by qualified

service personnel.

Note - While in Service or Programming Modes…

If the dishwasher is switched off; or the door is opened the dishwas

her automatically exits the current mode and returns to the

operational mode.

56

Page 57

G600 & G800 Electronic Dishwashers

5.0 Service and Maintenance

5.1 Locking Plate - Adjustment

Figure 5-1: Locking Plate

1. Loosen the two Screws (Item 1).

2. Adjust the Locking Plate in the direction of the arrow as required

3. Tighten the Screws.

Technical Information

5.2 Cabinet Seal - Replacement

Figure 5-2: Seal Fitting Plan

Refer to figure 5-2.

1. Open the Door.

2. Remove the Old Seal.

3. Clean the groove around the cabinet.

4. Press the appropriate Sealing Compound, into the corners of the

Door Seal Groove.

5. Fit the new Seal in accordance with the figure 2; first at the ends

and corners of the groove. The Seal Lip should point inwards.

6. Press the mid points of the Seal on the edges (Item 3). Work

towards the corners and ends, press the Seal into its groove.

57

Page 58

Technical Information

5.3 Side Panel - Removal

Figure 5-3: Side Panels and Cabinet

Refer to figure 5-3

With the appliance removed from it’s installation location

2. Remove the raised head screws (Items 1 and 3).

3. Open the Door.

4. Remove the Raised Head Screws, (Item 2).

5. Remove the Side Panels.

G600 & G800 Electronic Dishwashers

Service Tip

When reinstalling the Side Covers; fit the bottom lip of the panel into

the edge of the Drip Tray.

58

Page 59

G600 & G800 Electronic Dishwashers

5.4 Spring Bracket - Replacement

Figure 5-4: Side View, Door with Bracket

1. Remove the Side Panels (5.3)

2. Fold up the Mineral Wool Matting (depending on model).

3. Hold the Spring with one hand and pull it down.

4. Release the Cable from the Bracket (Figure 5-4 – Item 3).

5. Unhook the Spring (Figure 5-4 – Item 1).

6. Remove the Raised Head Screws (Figure 5-4 – Item 2).

7. Remove the Bracket.

Caution

With the Springs removed from the Door; the Door has no tension.

Technical Information

59

Page 60

Technical Information

5.5 Cover Plate - Removal

Figure 5-5: Cover Plate

1. Remove the two Screws and the Plinth (Toekick).

2. Remove the Raised Head Screws, (Figure5-5 – Item 1).

3. Tilt the Cover Plate forwards slightly and lift its bottom edge out of

the Drip Tray.

4. Remove the Cover Plate.

Service Tip

When reinstalling the Side Covers; fit the bottom lip of the panel into

the edge of the Drip Tray.

G600 & G800 Electronic Dishwashers

60

Page 61

G600 & G800 Electronic Dishwashers

5.6 Connecting Strip - Removal

Figure 5-6: Plinth area with Connecting Strip

1. Remove the Cover Plate (5.5).

1. Remove the Raised Head and Countersunk Screws (Figure 5-6 –

Item 1).

2. Remove components from the Connecting Strip.

4. Remove the Connecting Strip.

Technical Information

61

Page 62

Technical Information

G600 & G800 Electronic Dishwashers

5.7 Basket Support Rollers – Replacement

Figure 5-7: Basket Guide

Warning!

Do not attempt to pry the Basket Guides free with a screwdriver; this

will result in irreversible damage to the cabinet walls.

1. Slide out the Basket Guide (Figure 5-7 – Item 1), until the Clip,

between the Bolt on the cabinet wall and the Basket Guide is

visible.

Figure 5-8: Bolt and Retaining Clip

62

Page 63

G600 & G800 Electronic Dishwashers

2. Insert a small screwdriver under the Clip between the Bolt on the

cabinet wall and the Basket Guide and remove the Clip upwards.

3. Remove the Basket Guide.

Figure 5-9: Basket Guide Stopper

4. Bend open the Holder Tag for the Rear Stopper in the direction

of the arrow (Figure 9 – Item 1).

Figure 5-10: Stopper removal

5. Remove the Rear Stopper in the direction of the arrow

(Figure 10 – Item 1).

6. Bend the other Holder Tag in the direction of the arrow

(Figure 10 – Item 2).

7. Remove the old Support Rollers.

8. Slide the Clips onto the new Support Rollers.

9. Insert 2 new Support Rollers in the Basket Guide.

10. Reinstall the Stopper.

11. Bend the Holder Tags back into position.

12. Reinstall the Clips on the 2 new Support Rollers. Align the Rollers

with the Bolts. Press the Basket Guide with the new Support

Rollers firmly onto the Bolts until the Rollers clip into place.

Technical Information

63

Page 64

Technical Information

G600 & G800 Electronic Dishwashers

5.8 Combination Dispenser - Removal

Figure 5-11: Exterior view of the Inner Door Panel

1. Remove the Outer Door Panel (5.10).

2. Disconnect all Electrical Plugs; and Hose – if fitted with a Fan.

Service Tip

To help avoid incorrect connection, the plug connection leads are of

different lengths.

3. Remove the Raised Head Screws (Figure 11 – Item 1).

4. Press the Retaining Clips downwards in the direction of the arrow

(Figure 11), and remove the Combination Dispenser Unit.

5. Fit a new Combination Dispenser Unit.

6. On models without a Fan, fit a stopper in the connection for the

Condensate Hose.

7. Check for proper operation.

64

Page 65

G600 & G800 Electronic Dishwashers

5.9 Turbothermic Fan - Removal

1. Remove the Outer Door Panel (5.10).

2. Remove the Control Panel.

3. Remove the Fixing Bracket. Components can remain on the Fixing

Bracket (i.e. Electronic Unit, Handle)

Figure 5-12: Fan Removal

4. Disconnect the Connection Plugs and the Drain Hose, to the

Combination Dispenser (Figure 5-12 - Item 2).

5. Open the Door.

6. Using needle-nose pliers, turn the Fan Cover (Filter) on the Door

Inner Panel in the direction of the arrow to release it from the

Bayonet Fitting.

7. Remove the Fan and Seal.

Service Tip

When refitting, insert the two lugs on the Fan in the

holes provided.

Technical Information

65

Page 66

Technical Information

G600 & G800 Electronic Dishwashers

5.10 Door Panel (Outer and Inner) - Removal

Note

This procedure does NOT apply to Pre-Finished models.

To Remove the Outer Door Panel

1. Remove the GDU or Custom Panel

2. Open the front door.

3. While supporting the Outer Door Panel; remove the six (6)

screws from the inside edge of the panel.

4. Lower the panel to remove.

To Remove the Inner Door Panel

1. Remove the Control Panel (5.47).

2. Remove the Fixing Bracket. Components can remain on the

Fixing Bracket (i.e. Electronic Unit, Handle) (5.48).

3. Remove the Insulated Matting between the Inner and Outer

Door Panels.

4. Remove the Dispenser (5.8).